Sony HCD-GNZ5D Service manual

HCD-GNZ5D

SERVICE MANUAL

Ver. 1.1 2005. 12

• HCD-GNZ5D is the tuner, deck,

DVD and amplifier section in

MHC-GNZ5D.

DVD

Section

Tape Deck Model Name Using Similar Machanism HCD-GNZ7D/GNZ8D/GNZ9D

Section Tape Transport Mechanism Type CWM43FR601

Model Name Using Similar Mechanism HCD-GNZ7D/GNZ8D/GNZ9D

DVD Mechanism Type CDM74HF-DVBU101//C

Optical Pick-up Name KHM-310CAB/C2NP

E Model

Amplifier section

The following measured at AC 120, 220, 230 – 240 V,

50/60 Hz

Continuous RMS power output (reference)

50 + 50 watts

(6 ohms at 1 kHz, 10%

THD)

Inputs

MIC (phone jack): sensitivity 1 mV,

impedance 10 kilohms

Outputs

VIDEO OUT (phono jack):

max. output level

1 Vp-p, unbalanced, Sync

negative, load impedance

75 ohms

DIGITAL OPTICAL OUT (Square optical connector jack,

rear panel)

Wavelength 660 nm

PHONES (stereo mini jack):

accepts headphones of

8 ohms or more

FRONT SPEAKER: Use only the supplied

speaker SS-GNZ5D

SPECIFICATIONS

Disc player section

System Compact disc and digital

audio and video system

Laser Semiconductor laser

(DVD: λ=650 nm,

CD: λ=790 nm)

Emission duration:

continuous

Frequency response DVD (PCM 48 kHz):

2 Hz – 22 kHz (±1 dB)

CD: 2 Hz – 20 kHz (±1 dB)

Video color system format

NTSC, PAL

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassette

– Continued on next page –

9-879-821-02

2005L04-1

© 2005. 12

DVD DECK RECEIVER

Sony Corporation

Home Audio Division

Published by Sony Engineering Corporation

1

HCD-GNZ5D

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz (with the

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

Indian model: 220 – 240 V AC, 50/60 Hz

Thai model: 220 V AC, 50/60 Hz

Other models: 120 V, 220 V or 230 –

Power consumption 110 watts

Dimensions (w/h/d) (excl. speakers)

Mass (excl. speakers) Approx. 9 kg

Design and specifications are subject to change without

notice.

(50-kHz step)

interval set at 10 kHz)

531 – 1,602 kHz (with the

interval set at 9 kHz)

240 V AC, 50/60 Hz

Adjustable with voltage

selector

Approx. 280 × 326 × 365 mm

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

HCD-GNZ5D

Ver. 1.1

Notes on Chip Component Replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270°C during re-

pairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to about

350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky , less prone to flo w) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may also

be added to ordinary solder.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is

claassified as a CLASS 1

LASER product. This

label is located on the

rear exterior.

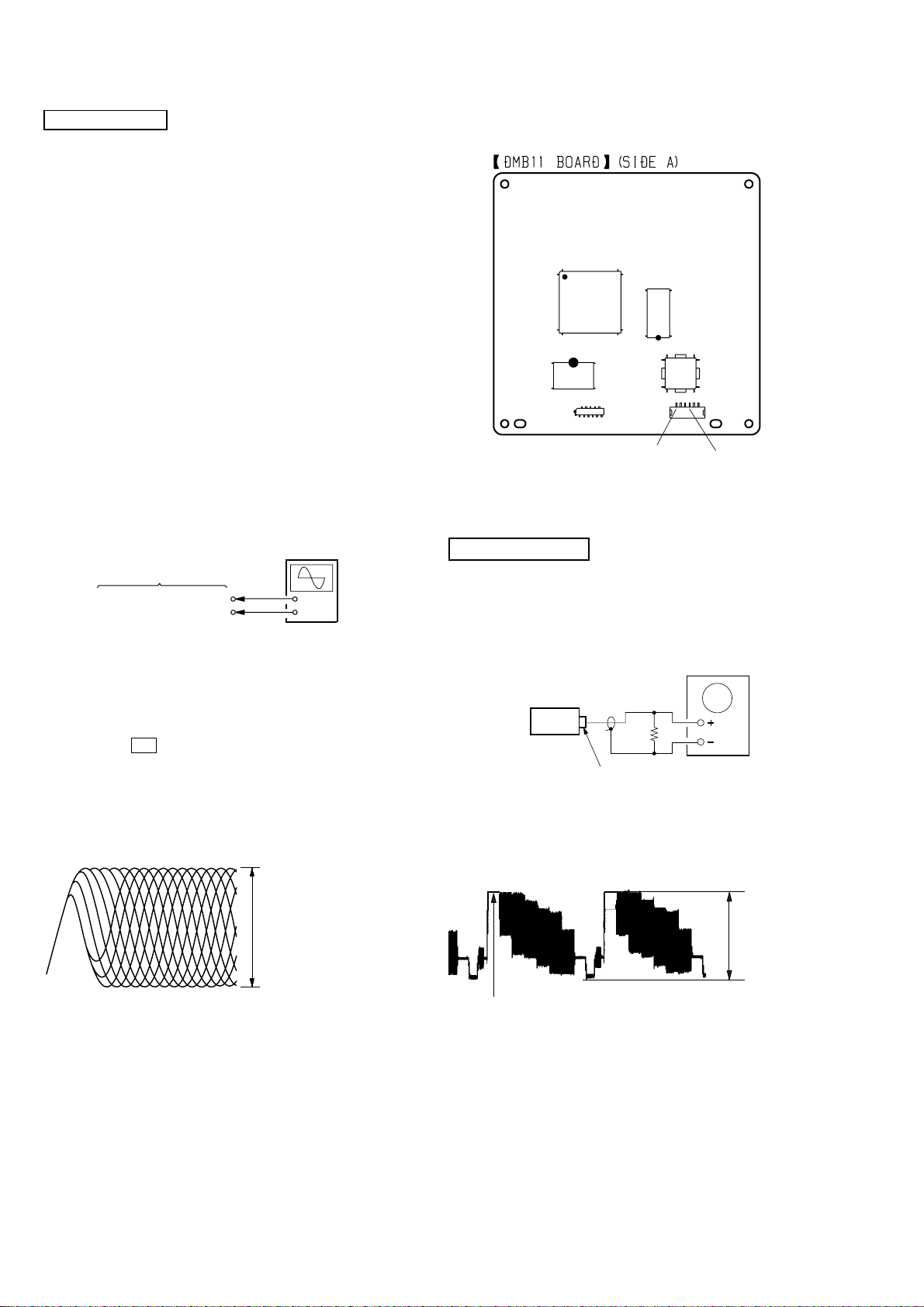

Note on DMB11 board replacement

New part of EEP ROM (IC103) on the DMB11 board cannot be

used. Therefore, if the mounted DMB11 board (A-1109-317-A, etc.)

is replaced, exchange new EEP R OM (IC103) with that used before

the replacement.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

3

HCD-GNZ5D

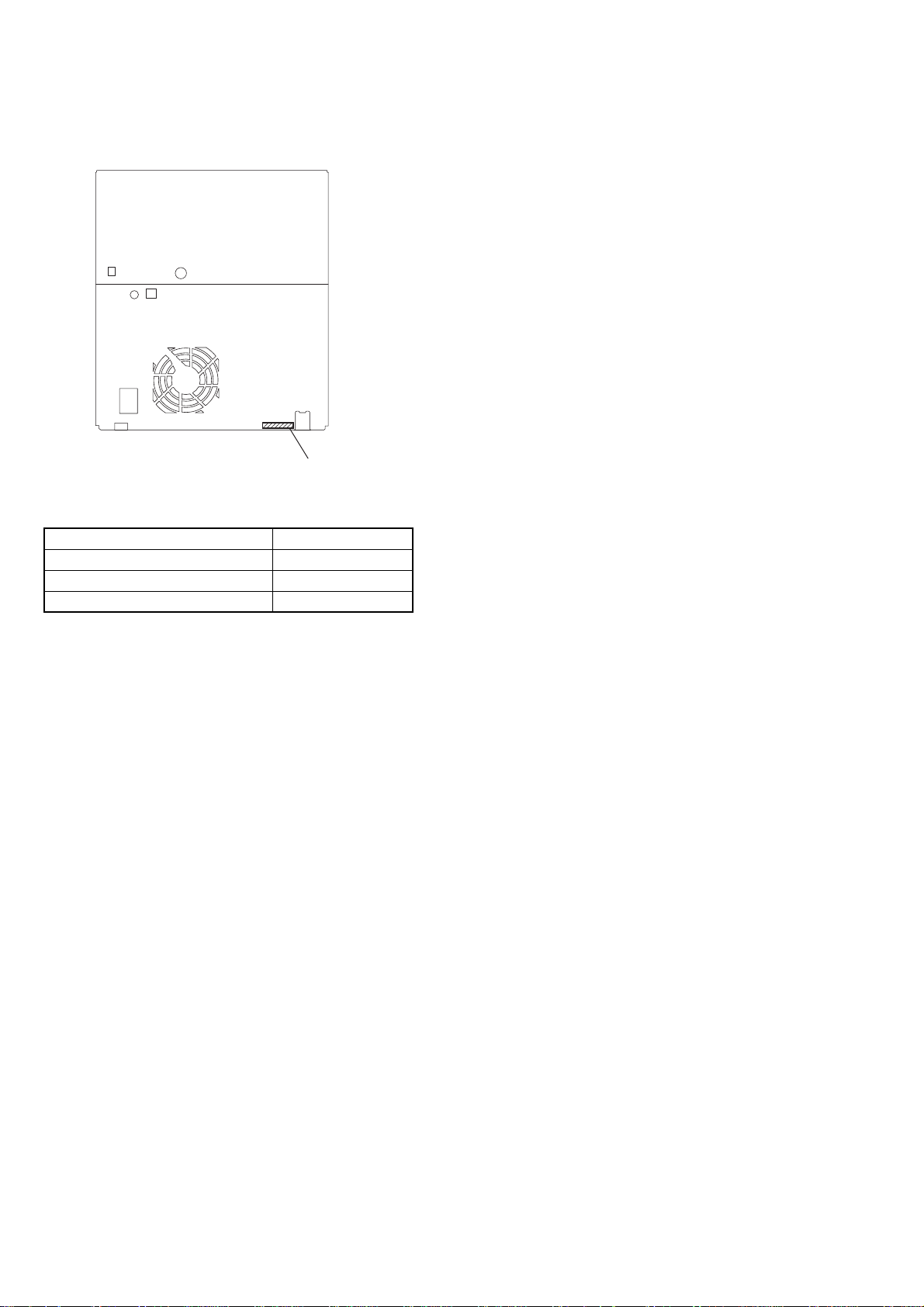

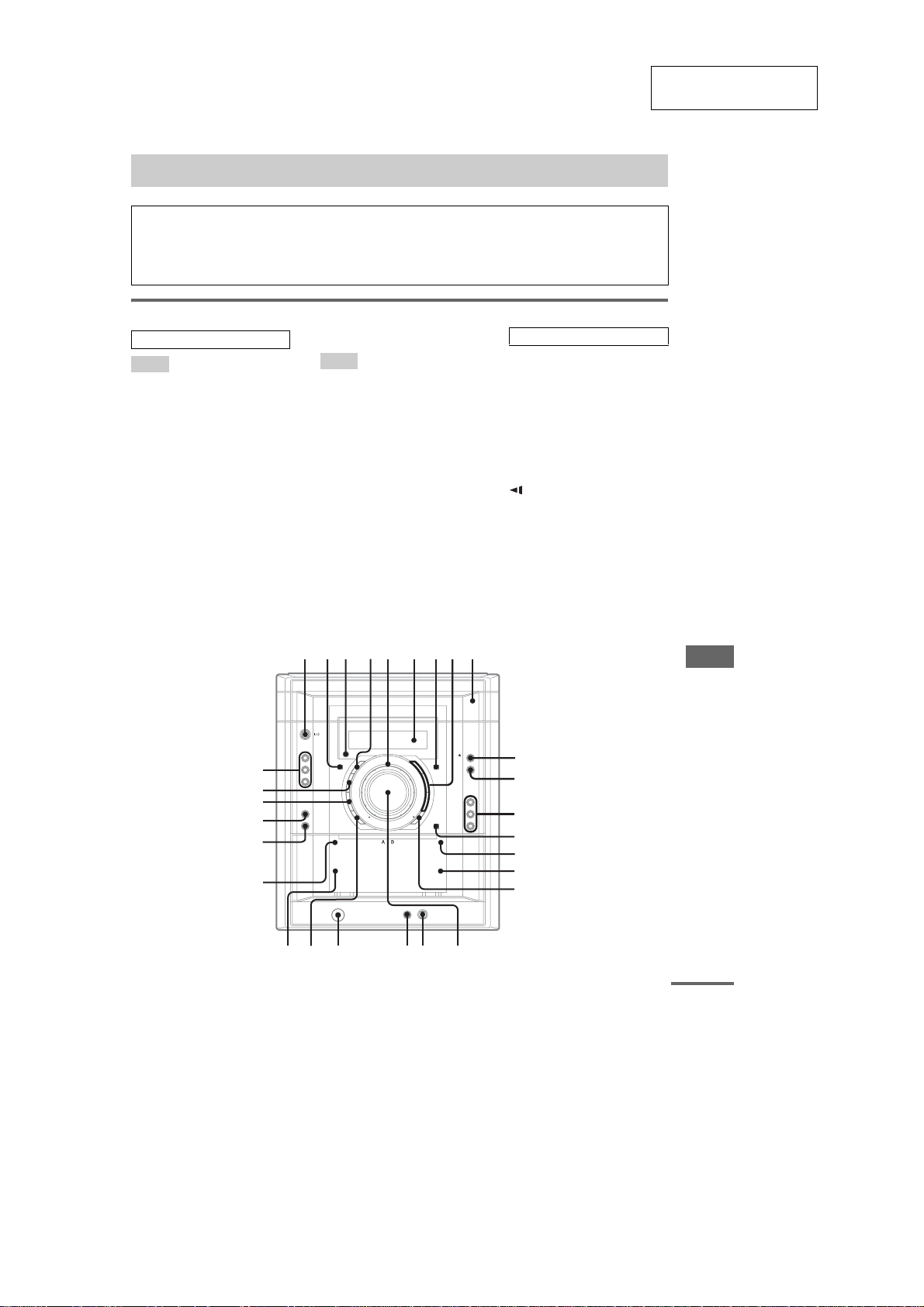

MODEL IDENTIFICATION

– BACK PANEL –

PARTS No.

MODEL PARTS No.

GNZ5D: PH 2-582-753-0s

GNZ5D: E3, E15 2-582-753-1s

GNZ5D: E12, E13 2-582-753-2s

• Abbreviation

E3 : 240 V AC area in E model

E12 : 220 – 240 V AC area in E model

E13 : 220 – 230 V AC area in E model

E15 : Iran model

PH : Philippine model

4

TABLE OF CONTENTS

HCD-GNZ5D

1. SERVICE NOTE

1-1. Service Position of CDM ....................................................6

1-2. Service Position of DMB11 Board, Video Board ............... 6

1-3. Service Position of TCM..................................................... 7

1-4. Service Position of Front AMP Board ................................7

2. GENERAL

Main Unit ................................................................................ 8

Remote Control ....................................................................... 9

3. DISASSEMBL Y

3-1. Case ................................................................................... 11

3-2. Loading Panel Assy........................................................... 11

3-3. Front Panel Section ...........................................................12

3-4. DVD Block Section........................................................... 12

3-5. Tape Mechanism Deck Section ......................................... 13

3-6. Panel Board ....................................................................... 13

3-7. Jack Board ......................................................................... 14

3-8. Back Panel Section............................................................ 14

3-9. Boards Section .................................................................. 15

3-10. Audio Board ...................................................................... 15

3-11. DVD Mechanism Block, Video Board, DMB11 Board .... 16

3-12. Pick-up Unit ......................................................................16

3-13. SW Board, Driver Board...................................................17

3-14. Sensor Board ..................................................................... 17

3-15. Motor (TB) Board .............................................................18

3-16. Motor (LD) Board ............................................................. 18

4. TEST MODE

4-1. General Description .......................................................... 20

4-2. Starting Test Mode ............................................................ 20

4-3. Drive Manual Operation.................................................... 20

4-4. Mirror Time Adjustment ................................................... 20

4-5. Executing IOP Measurement ............................................ 22

5. MECHANICAL ADJUSTMENTS............................... 23

6. ELECTRICAL ADJUSTMENTS................................. 24

7. DIAGRAMS

7-1. Circuit Boards Location ....................................................26

7-2. Block Diagram — RF/Servo Section — ........................... 27

7-3. Block Diagram — Video Section — ................................. 28

7-4. Block Diagram — Main Section —..................................29

7-5. Block Diagram — Function/Power Section —................. 30

7-6. Printed Wiring Boards — Driver Section —..................... 32

7-7. Schematic Diagram — Driver Section —......................... 33

7-8. Printed Wiring Board — DMB11 Section — ................... 34

7-9. Schematic Diagram — DMB11 Section (1/4) — .............36

7-10. Schematic Diagram — DMB11 Section (2/4) — .............37

7-11. Schematic Diagram — DMB11 Section (3/4) — .............38

7-12. Schematic Diagram — DMB11 Section (4/4) — .............39

7-13. Printed Wiring Boards — Audio Section — ..................... 40

7-14. Schematic Diagram — Audio Section (1/3) —................. 41

7-15. Schematic Diagram — Audio Section (2/3) —................. 42

7-16. Schematic Diagram — Audio Section (3/3) —................. 43

7-17. Printed Wiring Board — Video Section — ....................... 44

7-18. Schematic Diagram — Video Section —..........................45

7-19. Printed Wiring Board — Front AMP Section — ..............46

7-20. Schematic Diagram — Front AMP Section —.................47

7-21. Schematic Diagram — Panel Section (1/2) — ................. 48

7-22. Schematic Diagram — Panel Section (2/2) — ................. 49

7-23. Printed Wiring Boards — Panel Section — ...................... 50

7-24. Printed Wiring Board — Jack Section — ......................... 51

7-25. Schematic Diagram — Jack Section — ............................ 52

7-26. Schematic Diagram — Power Section — ......................... 53

7-27. Printed Wiring Board — Trans Section — ....................... 54

7-28. Printed Wiring Board — Sub Trans Section — ................55

8. EXPLODED VIEWS

8-1. Main Section ..................................................................... 64

8-2. Front Panel Section (1)...................................................... 65

8-3. Front Panel Section (2)...................................................... 66

8-4. Front Panel Section (3)...................................................... 67

8-5. DVD Block Section........................................................... 68

8-6. Chassis Section ................................................................. 69

8-7. Audio Board Section ......................................................... 70

8-8. DVD Mechanism Deck Section (1) .................................. 71

8-9. DVD Mechanism Deck Section (2) .................................. 72

9. ELECTRICAL PARTS LIST ........................................73

5

HCD-GNZ5D

A

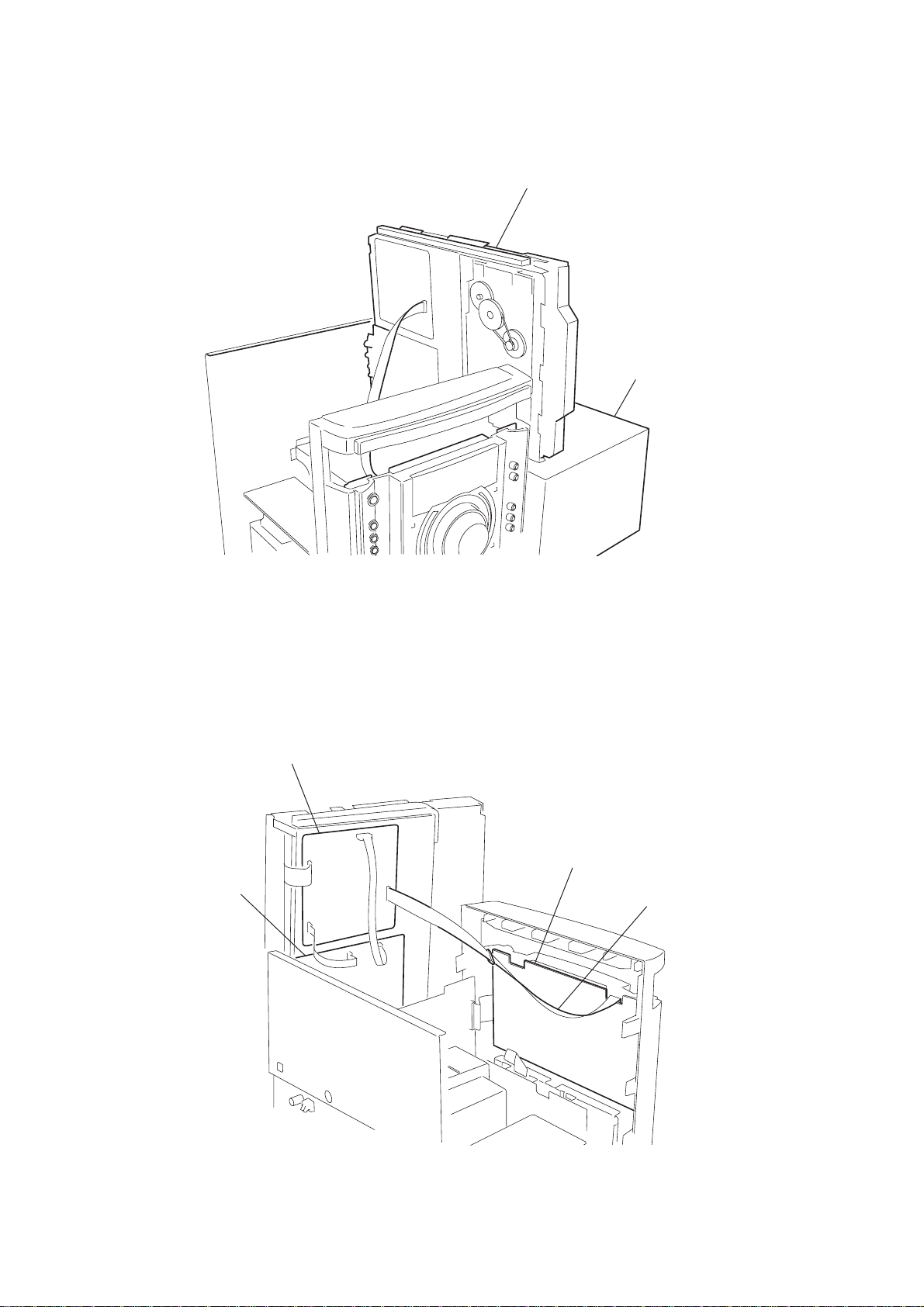

1-1. SERVICE POSITION OF CDM

SECTION 1

SERVICE NOTE

DVD mechanism block

stand

1-2. SERVICE POSITION OF DMB11 BOARD, VIDEO BOARD

DMB11 board

VIDEO board

PANEL board

J-2501-102-

6

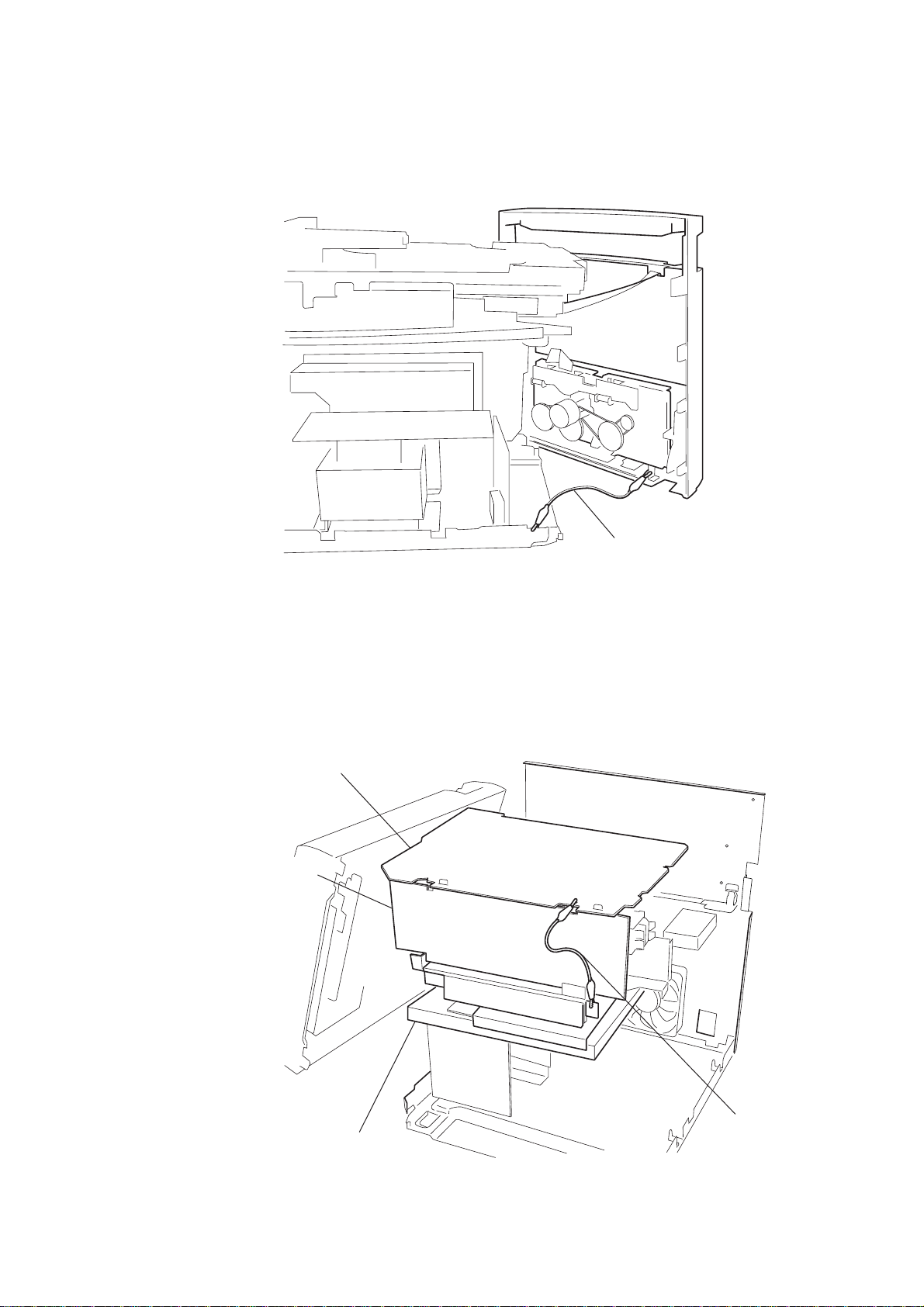

1-3. SERVICE POSITION OF TCM

earth is taken

n

HCD-GNZ5D

1-4. SERVICE POSITION OF FRONT AMP BOARD

AUDIO board

FRONT AMP board

insulating plate

earth is take

7

HCD-GNZ5D

List of button locations and reference pages

SECTION 2

GENERAL

This section is extracted

from instruction manual.

How to use this page

Use this page to find the location of buttons and other

parts of the system that are mentioned in the text.

Main unit

ALPHABETICAL ORDER

A — N

CD SYNC wg (38)

Deck A ws (37, 39)

Deck B qg (37, 38, 39, 46)

DIRECTION qd (37, 38, 39)

DISC 1 – 3 qs (12, 14, 38, 56)

DISC SKIP/EX-CHANGE qa (9,

11, 12, 14, 38)

Disc tray 9 (11)

DISPLAY 2 (47, 48, 56)

Display window 6

DVD wk (9, 38)

EQ BAND/MEMORY 4 (41)

GROOVE wh (40)

MIC jack ql (41)

MIC LEVEL qk (41)

O — Z

Operation Dial (lL) 5

(41)

PHONES jack w;

PRESET EQ wj (40, 41)

REC PAUSE/START wf (38, 39)

Remote sensor 3

SOUND FIELD 7 (40)

TAPE A/B wk (37, 38, 39)

TUNER/BAND wk (35, 36, 39)

TUNING + qh (35, 36)

TUNING – wa (35, 36)

VOLUME control qj (42)

4

3

5

1 2

Illustration number

r

TAPE A/B wk (37, 38, 39)

Name of button/part R e fer ence pag e

RR

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 36, 45, 56)

nN (play) 8 (11, 29, 37, 38)

X (pause) 8 (8, 11, 37)

x (stop) 8 (9, 11, 30, 37, 38, 56)

Z OPEN/CLOSE q; (11)

Z PUSH (deck B) (eject) qf

M (fast forward) qh (12, 37)

y (slow forward) qh (12)

m (rewind) wa (12, 37)

(slow rewind) wa (12)

Z PUSH (deck A) (eject) wd (37)

9

876

(37)

Additional Information

wk

wj

wh

wg

wf

wd

ws

nN

X

x

M y

M y

q;

qa

qs

qd

qf

qg

qh

qjqlqkw;wa

continued

67

GB

8

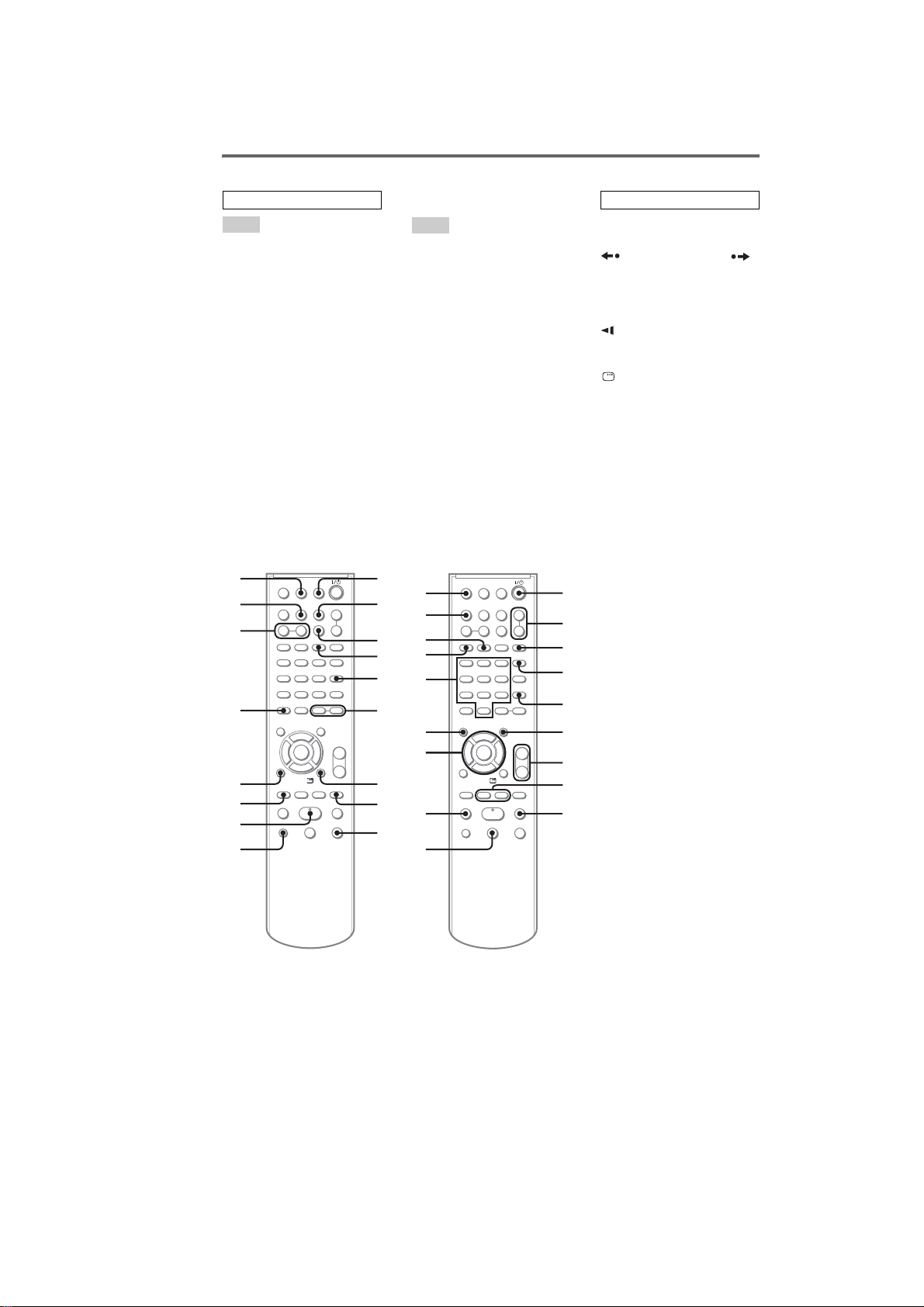

Remote control

HCD-GNZ5D

ALPHABETICAL ORDER

A — Q

ALBUM +/– wf (11, 50)

ANGLE 5 (34)

AUDIO 4 (25, 41)

CLEAR es (10, 14, 15, 16, 20,

23)

DISC SKIP w; (12, 14)

DISPLAY qj (47, 48)

ENTER qs (9, 13, 14, 16, 17, 19,

21, 23, 27, 35, 43, 45, 46, 56)

FM MODE ws (36)

FUNCTION +/– 2 (10, 11, 35,

36)

KARAOKE MODE qg (41)

KARAOKE PON qh (42)

MENU 6 (16, 18, 19, 21, 35)

Number buttons* qf (17, 31)

PICTURE NAVI 3 (20, 24)

PRESET + wh (36)

PRESET – e; (36)

eg

ef

ed

es

ea

e;

wl

+

++

2

O

.>

yxmM

–

#

+–

V

bB

+

v

–

C

c

z

z

<

<

y

H

X

wk

R — Z

REPEAT ws (15)

SLEEP qk (45)

SOUND FIELD wa (40)

SUBTITLE wd (34)

THEATRE SYNC ql (50)

TIMER MENU eg (9, 45, 46)

TIME/TEXT ef (47, 48)

TOP MENU qd (16)

TUNING + 9 (35, 36)

TUNING – qa (35, 36)

TV wk (50)

TV CH + wh (50)

TV CH – e; (50)

TV/VIDEO qk (50)

TV VOL +/–* 7 (50)

VOLUME +/–* 7 (45)

ql

qk

w;

wa

ws

wd

qj

qh

qg

qf

2

wf

qd

qs

O

wg

wh

qa

.>

mM

y

wj

q;

#

V

bB

v

C

c

z

z

<

<

H

Xx

BUTTON DESCRIPTIONS

?/1 (power)

1 (8, 45, 56)

TV ?/1 1 (50)

REPLAY/ADVANCE /

c STEP/STEP C 8 (12)

SLOW y 9 (12)

M (fast forward) 9 (12, 37)

X (pause) q; (11, 37)

SLOW qa (12)

m (rewind) qa (12, 37)

M/m/</, qs (9, 13, 26, 43, 45)

DISPLAY wg (13, 26, 49)

> (go forward) wh (11)

x (stop) wj (37)

. (go back) e; (11)

H (play)* wl (11, 29)

O RETURN ea (17)

-/-- es

KEY CONTROL

#/2

ed (42)

*The H, number 5 and

VOLUME + (TV VOL +)

buttons have tactil e dots. Use

the tactile dots as references

when operatihng the system.

1

+

2

–

3

4

5

+–

6

+

7

–

8

y

9

9

HCD-GNZ5D

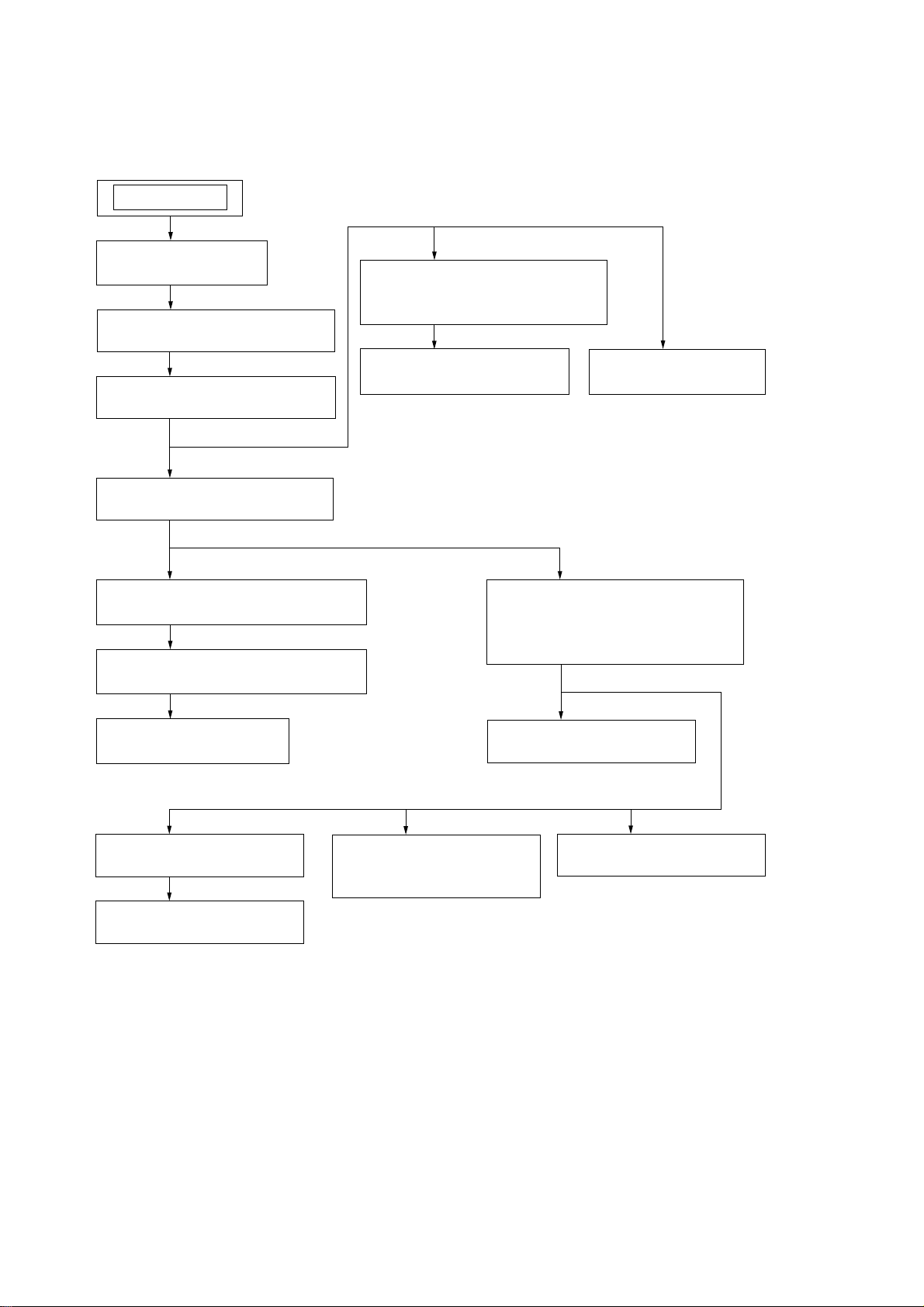

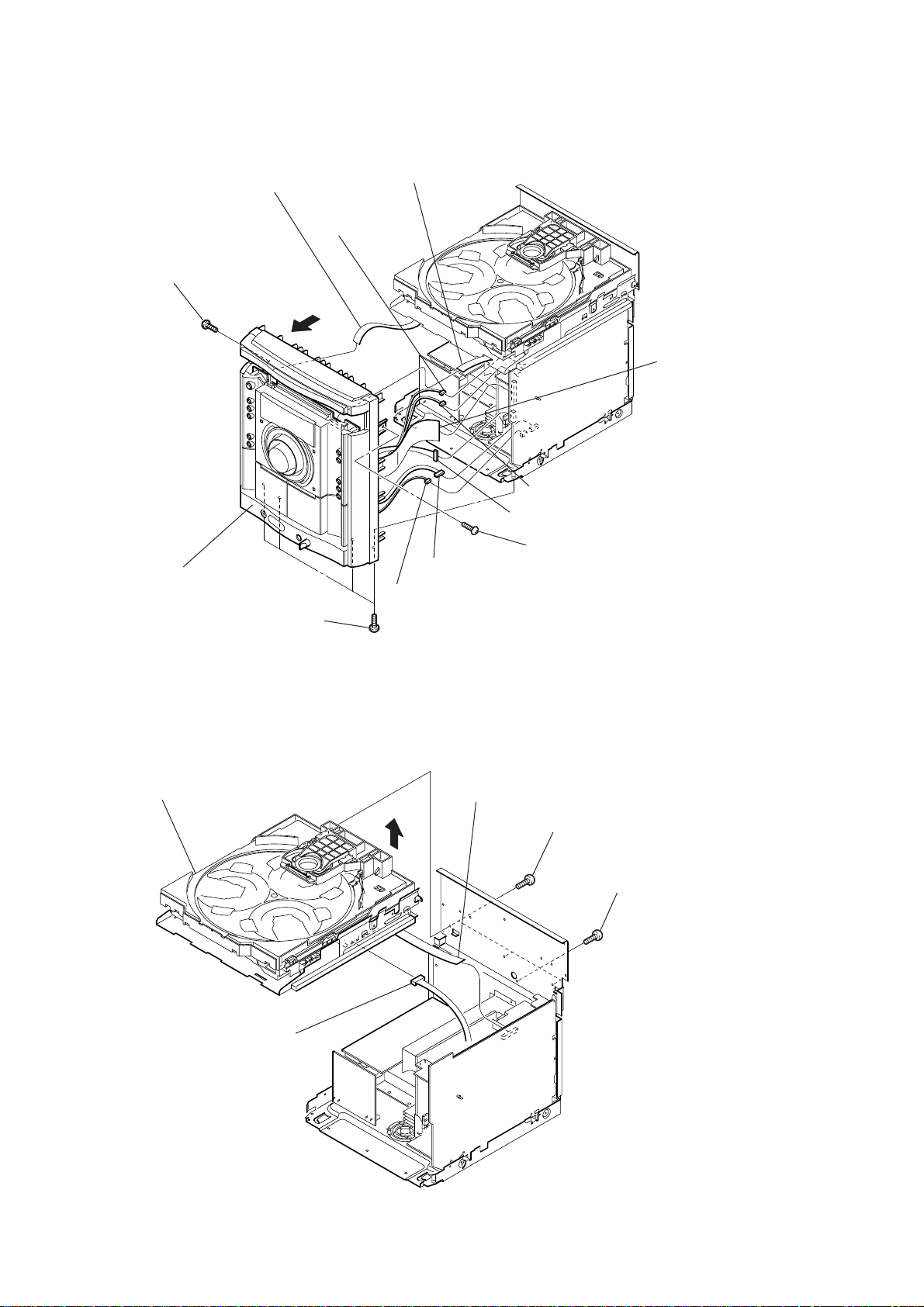

Note : Disassemble the unit in the order as shown below.

SET

3-1. CASE

(Page 11)

3-2. LOADING PANEL ASSY

(Page 11)

3-3. FRONT PANEL SECTION

(Page 12)

SECTION 3

DISASSEMBLY

3-5. TAPE MECHANISM DECK

SECTION

(Page 13)

3-7. JACK BOARD

(Page 14)

3-6. PANEL BOARD

(Page 13)

3-4. DVD BLOCK SECTION

(Page 12)

3-8. BACK PANEL SECTION

(Page 14)

3-9. BOARDS SECTION

(Page 15)

3-10. AUDIO BOARD

(Page 15)

3-15. MOTOR (TB) BOARD

(Page 18)

3-16. MOTOR (LD) BOARD

(Page 18)

3-13. SW BOARD,

DRIVER BOARD

(Page 17)

3-11. DVD MECHANISM BLOCK,

VIDEO BOARD,

DMB11 BOARD

(Page 16)

3-12. PICK-UP UNIT

(Page 16)

3-14. SENSOR BOARD

(Page 17)

10

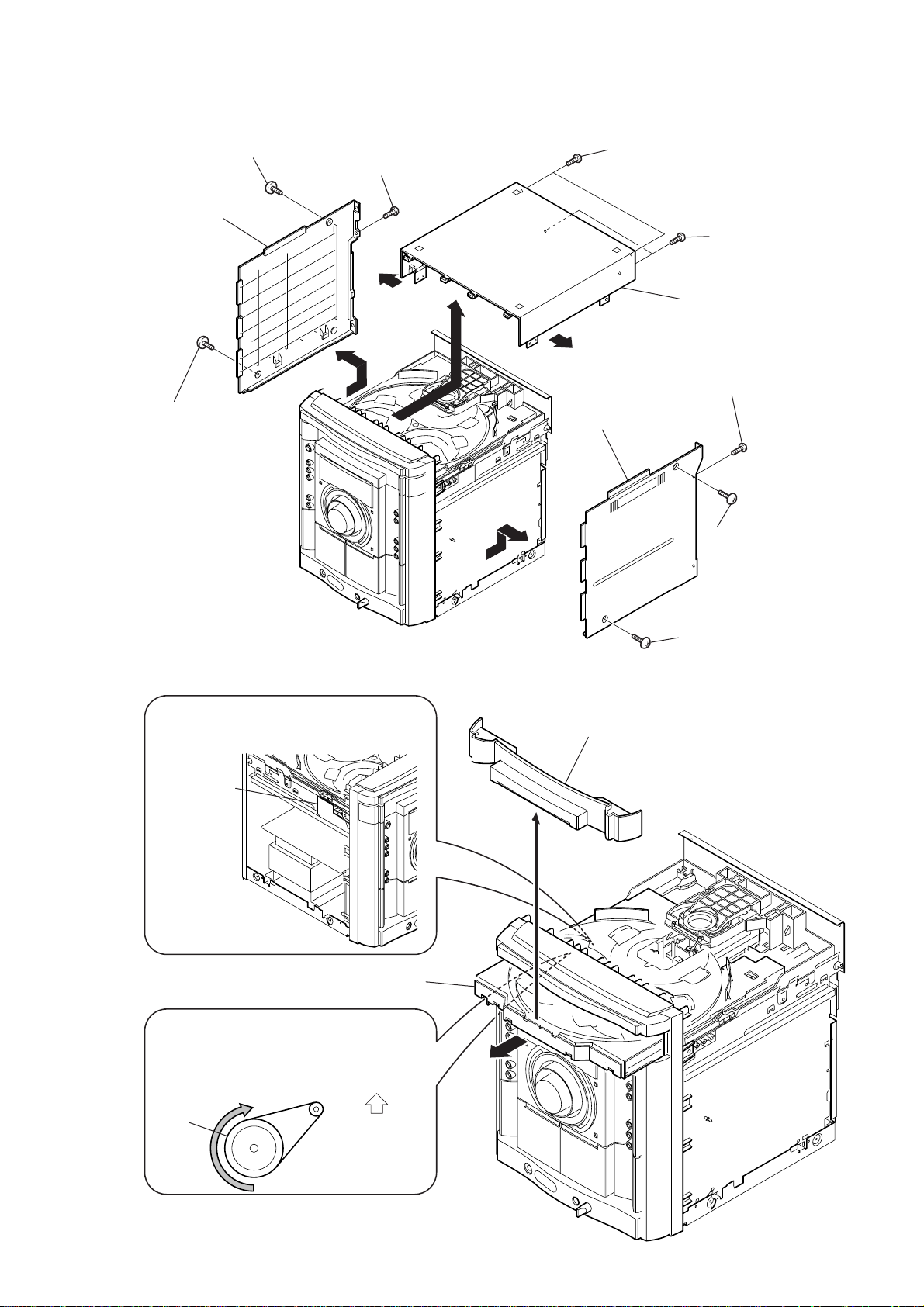

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE

6

0

case (side-R)

screw

(case 3 TP2)

8

screw

(+BVTT 3

qd

×

6)

qf

qa

two screws

(+BVTT 3

×

6)

qg

case (top)

HCD-GNZ5D

qs

two screws

(+BVTP 3

×

10)

7

screw

(case 3 TP2)

3-2. LOADING P ANEL ASSY

1

The DVD mechanism block has a cover.

So the pulley may not be rotated unless

the cover is opened.

cover (B-CDM)

9

4

qd

5

case (side-R)

5

loading panel assy

3

screw

(+BVTT 3

1

screw

(case 3 TP2)

2

screw

(case 3 TP2)

×

6)

3

Pull-out the disc tray.

CD mechanism deck (CDM74HF)

2

Turn the pulley to the direction of arrow.

Front panel side

pulley

4

11

HCD-GNZ5D

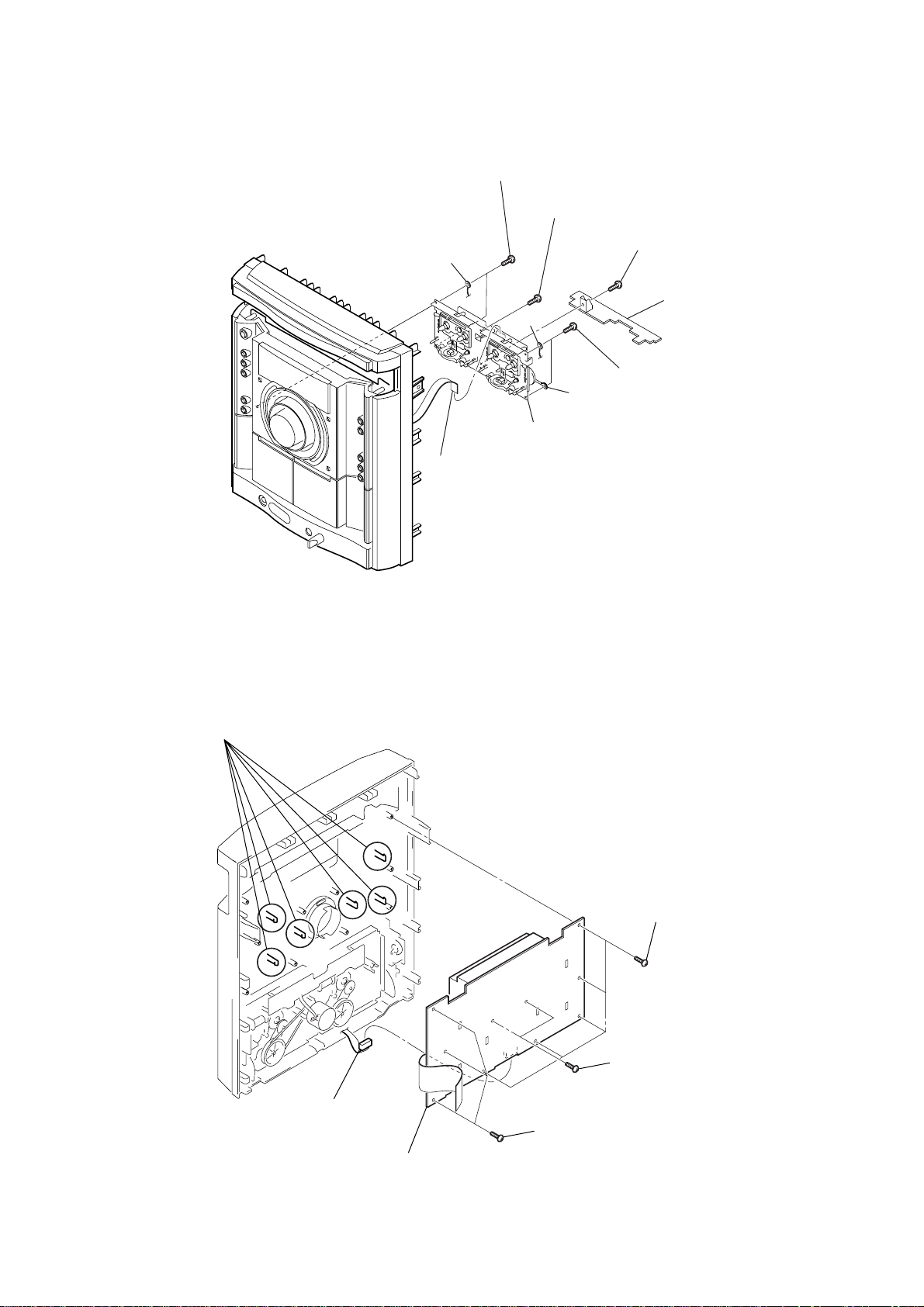

3-3. FRONT P ANEL SECTION

3

screw

(+BVTP 3

×

10)

1

CN005 (13 core)

6

8

CN755 (4P)

2

CN102 (13 core)

7

CN752 (27 core)

qd

front panel section

four screws (+BVTT 3

5

3-4. DVD BLOCK SECTION

6

DVD block section

9

CN203 (4P)

0

CN751 (10P)

4

screw

qa

CN602 (8P)

qs

CN601 (3P)

×

6)

3

4

(+BVTP 3

CN301 (17 core)

×

2

three

(+BVTT 3

screws

10)

×

6)

1

screw

(+BVTP 3

×

10)

12

5

CN851 (8P)

3-5. TAPE MECHANISM DECK SECTION

d

)

lug

1

connector

4

two

screws

(+BVTP 2.6 (3CR))

6

screw

(+BVTP 2.6 (3CR))

lug

clamp

7

tape mechanism deck

2

screw

(+BVTP 2.6 (3CR))

3

GUARD

5

two

screws

(+BVTP 2.6 (3CR))

boar

HCD-GNZ5D

3-6. P ANEL BOARD

4

six

claws

5

CN151 (7P)

6

PANEL board

3

three

(+BVTP 2.6 (3CR))

2

(+BVTP 2.6 (3CR))

screws

1

five

screws

(+BVTP 2.6 (3CR)

two

screws

13

HCD-GNZ5D

)

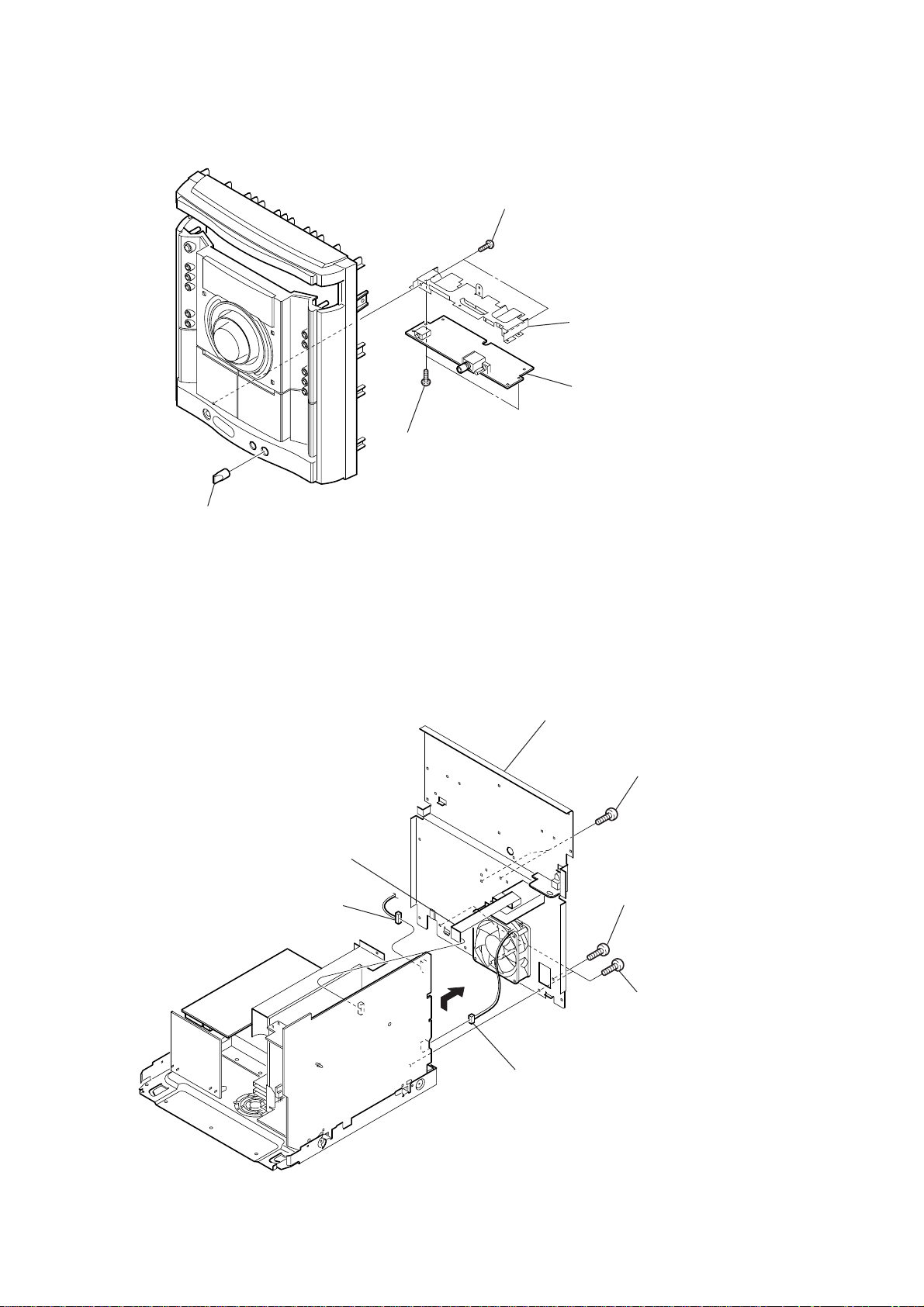

3-7. JACK BOARD

3

two screws

(+BVTT 3

2

two

screws

(+BVTP 2.6 (3CR))

×

6)

4

bracket (TC-JACK

5

JACK board

1

mic knob

3-8. BACK P ANEL SECTION

1

CN753 (9P)

2

CN306 (3P)

8

back panel section

3

two

screws

(+BVTT 3

4

screw

(+BVTP 3

×

×

10)

6)

14

6

7

CN754 (2P)

5

three

(+BVTT 3

screws

×

6)

3-9. BOARDS SECTION

)

d

2

CN914 (10P)

4

two

(+BV sumitite (B3))

5

two

screws

(+BV sumitite (B3))

1

CN915 (4P)

screws

6

boards section

3

(+BVTT 3

two

HCD-GNZ5D

screws

×

6

3-10. AUDIO BOARD

1

claw

2

AUDIO boar

CN201

CN202

15

HCD-GNZ5D

)

)

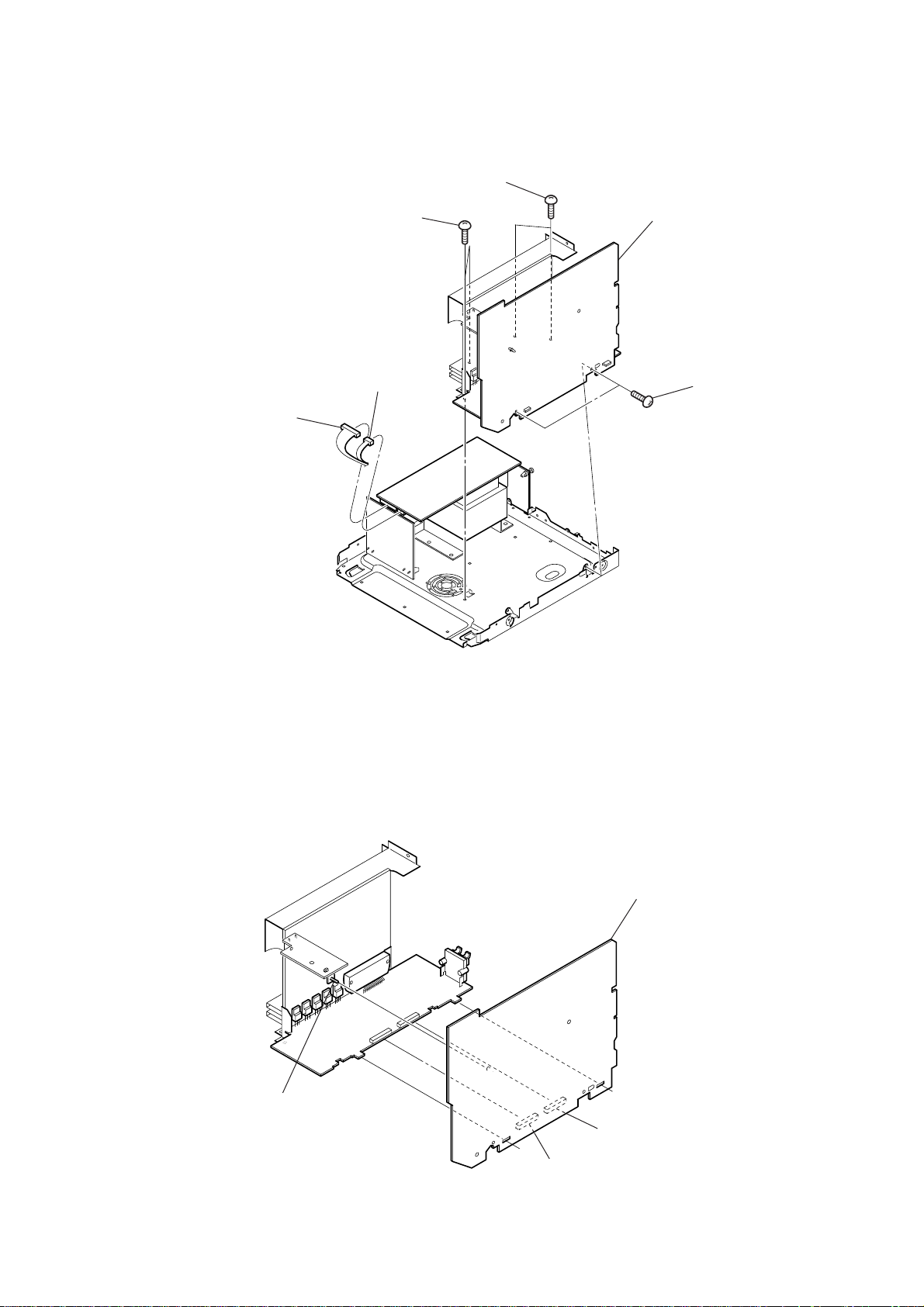

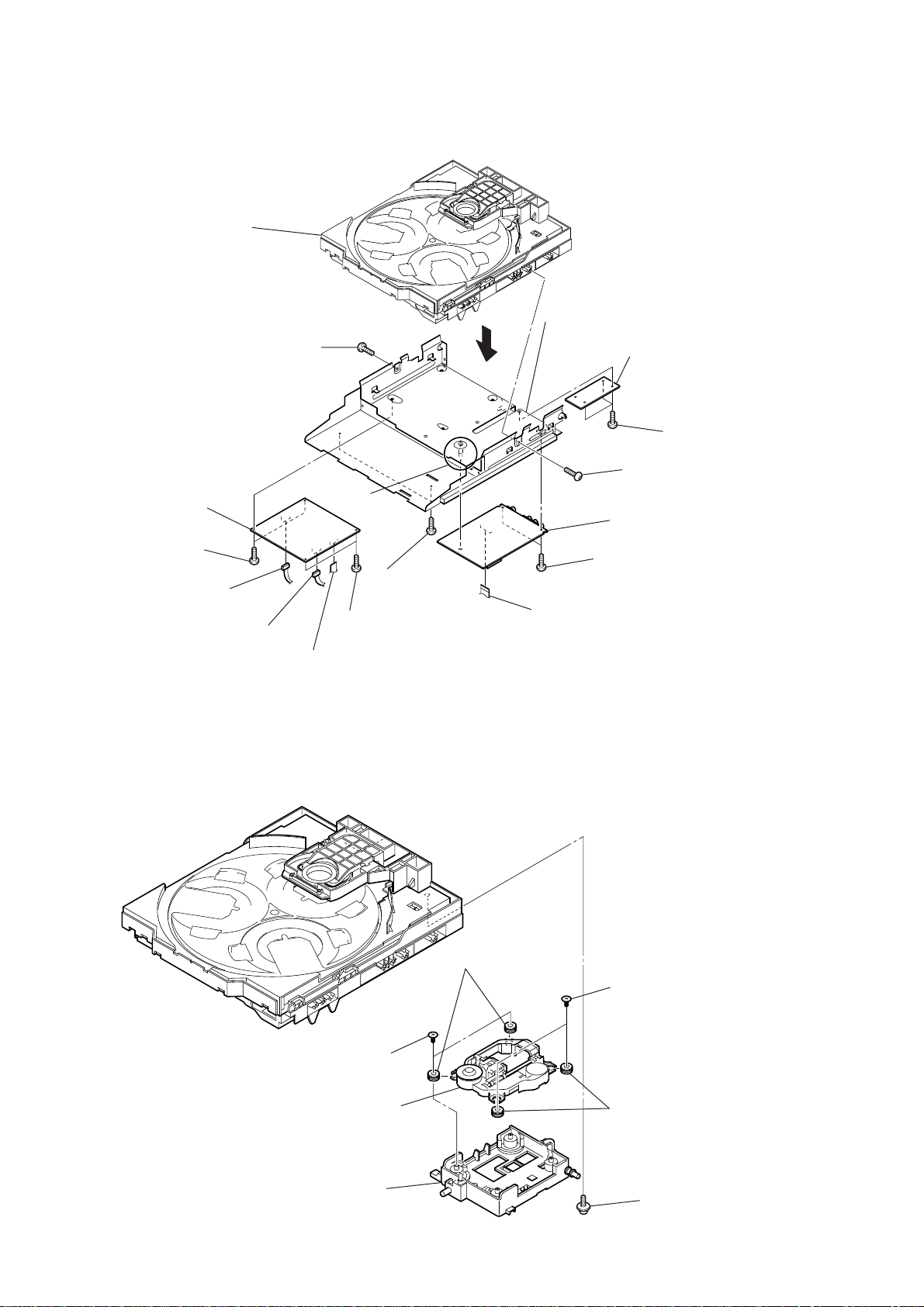

3-11. DVD MECHANISM BLOCK, VIDEO BOARD, DMB1 1 BOARD

qk

DVD mechanism block

qg

screw

qs

DMB11 board

qa

two

screws

(+BVTT 3

2

CN401 (5P)

×

6)

(+BVTP 3

8

CN201 (6P)

×

8)

4

0

(+BVTT 3

9

CN101 (24 core)

claw

two

qd

two

screws

(+BVTP 3

screws

×

6)

qh

×

8)

Note : Be short-circuited of the land of optical pick-up when CN101

is done in pulling out.

qj

bracket (DVD)

1

CN801 (5P)

7

REINFORCE (CDM) board

6

three

(+BVTT 3

qf

screw

(+BVTP 3

5

VIDEO board

3

two

screws

(+BVTT 3

×

×

6)

screws

8)

×

6

3-12. PICK-UP UNIT

3

two insulator screws

6

pick-up unit

7

holder (310)

5

two insulators

2

two insulator screws

4

two insulators

1

floating

(+PTPWH M2.6

screw

16

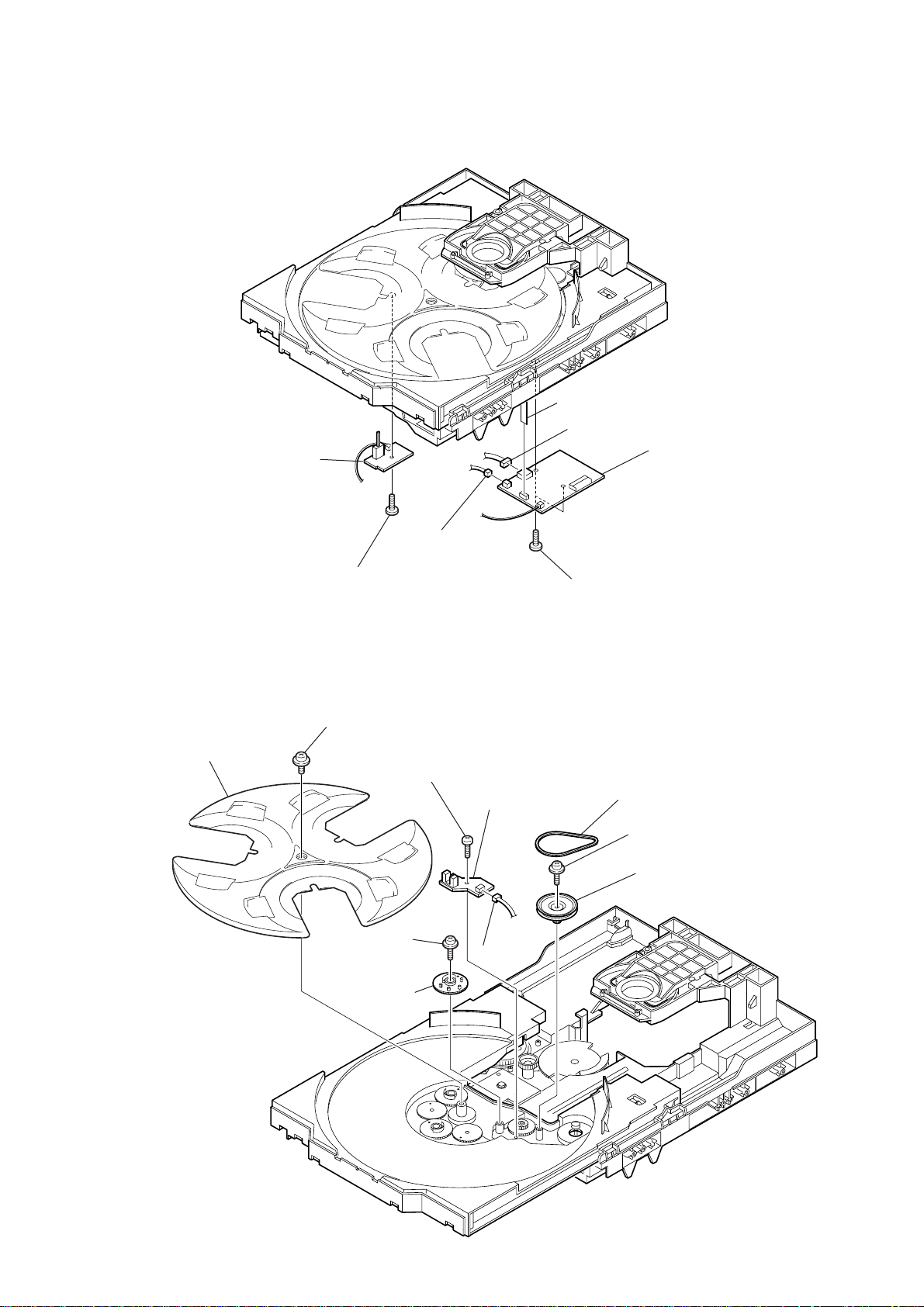

3-13. SW BOARD, DRIVER BOARD

d

2

SW board

7

CN702 (flat type)

4

CN703

6

DRIVER boar

HCD-GNZ5D

3-14. SENSOR BOARD

2

tray

1

screw

(+BTTP (M2.6))

1

floating

(+PTPWH M2.6)

6

floating

(+PTPWH M2.6)

screw

8

screw

(+BTTP (M2.6))

screw

3

CN704

0

9

SENSOR board

CN731

5

two

screws

(+BTTP (M2.6))

3

belt (table)

4

floating

(+PTPWH M2.6)

5

pulley (table)

screw

7

gear (geneva)

17

HCD-GNZ5D

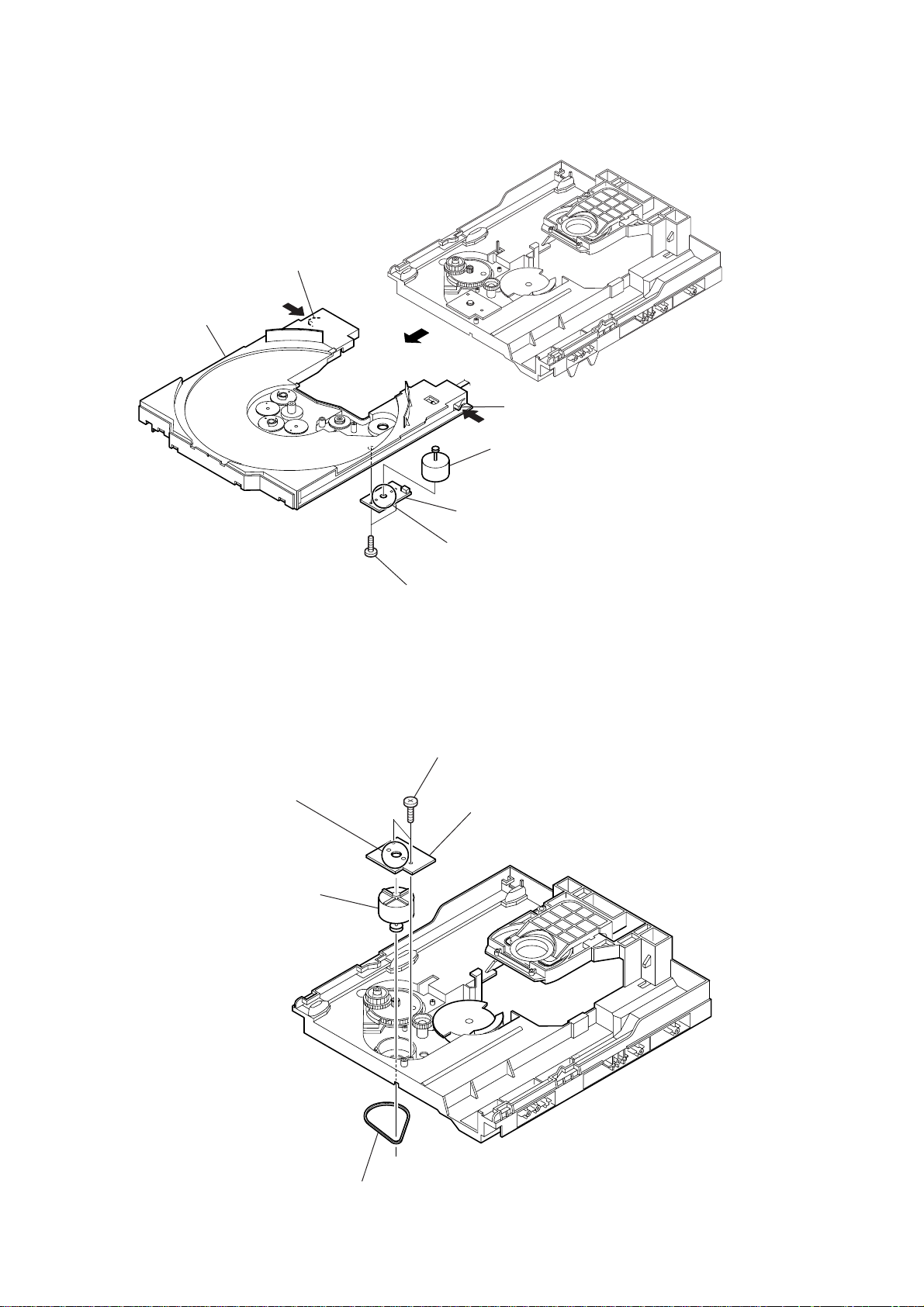

3-15. MOTOR (TB) BOARD

table assy

2

stopper

1

2

stopper

6

table motor assy (M741)

3-16. MOTOR (LD) BOARD

4

Remove the two solders of motor.

5

loading motor assy (M751)

4

MOTOR (TB) board

5

Remove the two solders of motor.

3

two

screws

(+BTTP (M2.6))

2

two

screws

(+BTTP (M2.6))

3

MOTOR (LD) board

18

1

belt (loading)

SECTION 4

TEST MODE

HCD-GNZ5D

[Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons of x , [DISPLAY] and [DISC 1]

simultaneously.

2. The message “COLD RESET” is displayed, and the set is reset.

[T uner Step Change]

•A step of AM channels can be changed o ver between 9 kHz and

10 kHz.

Procedure:

1. Press the `/1 button to turn the power ON, and set the function

to TUNER/BAND “AM”.

2. Press the `/1 button to turn the power OFF.

3. Press two buttons of [TUNING +] and `/1 simultaneously , and

the message changes to “AM 9 k STEP” or “AM 10 k STEP”,

and thus the channel step is changed over.

[Color System Change]

Procedure:

1. Press the

2. Press two buttons of X and `/1 simultaneously.

3. The message “COLOR NTSC” or “COLOR P AL” is displayed.

[Disc Tray Lock]

The disc tray lock function for the antitheft of a demonstration disc

in the store is equipped.

Setting Procedure :

1. Press the

2. Press two buttons of x and Z simultaneously for fiv e seconds.

3. The message “LOCKED” is displayed, and the tray is locked.

Releasing Procedure :

1. Press two buttons of

2. The message “UNLOCKED” is displayed, and the tray is

unlocked.

Note: When the message “LOCKED” is displayed, the tray lock is

[Panel T est Mode]

•This mode is used to check the fluorescent indicator tube, LEDs,

keyboard, volume and phones.

Enter The Panel Test Mode

Procedure:

1. Press three buttons of

neously.

2. LEDs and fluorescent indicator tube are all turned on.

Model Information

Procedure:

1. It puts it into the start of the panel test mode.

2. Press the [DIRECTION] button, the mode change model name

or destination display.

Key T est Mode

Procedure:

1. It puts it into the start of the panel test mode.

2. Press the Y button, the mode change key test mode.

`/1 button to turn the power ON.

?/1 button to turn the power ON.

x and Z simultaneously for f ive seconds.

not released by turning power ON/OFF with the ?/1 button.

x , [DISPLAY] and [DISC 2] simulta-

VACS Display

Procedure:

1. It puts it into the start of the panel test mode.

2. Press the

The message “VACS 0+0” is displayed.

Version Display

Procedure:

1. It puts it into the start of the panel test mode.

2. Press the [DIRECTION] button, the mode change version display .

Press the [DISPLAY] button, the mode c hange version or days is

displayed.

3. You can exit the Test Mode when you press three buttons of

[DISPLAY] and [DISC 2] simultaneously.

[Common Test Mode]

•This mode is used to check operations of the respective sections

of Amplifier and Tape.

Procedure:

•To enter MC Test Mode

1. Press the `/1 button to turn the power ON.

2. Press three buttons of x , [DISPLAY] and [DISC 3] simulta-

neously.

* Check of Amplifier

Initial settings: EQ , FLAT

• When you press the [EQ BAND/MEMORY] button, the message

“GEQ FLAT” is displayed, and the entire band of the graphic

equalizer is set to the center level.

• Whenever you press the [GROOVE] button, it toggles between

“VACS ON” and “VACS OFF” so that you can switch ON or

OFF of VACS.

*To return to normal mode again.

1. When you want to exit this mode, press the

2. The cold reset is enforced at the same time.

[DVD and CD Ship Mode (No Memory Clear)]

•This mode moves the position to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the

2. Press two buttons of x and [DISC SKIP] simultaneously.

3. After the “STANDBY” display blinks 15 times, the message

“LOCK” is displayed, and the DVD ship mode is set.

[DVD and CD Ship Mode (Memory Clear)]

•This mode moves the pickup to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the

2. Press three buttons of x , [DISPLAY] and [DIRECTION] simul-

taneously.

3. After the “STANDBY” display blinks 15 times, the message

“LOCK” is displayed, and the DVD ship mode is set.

X button, the mode change VACS display.

VACS , ON

`/1 button.

`/1 button to turn the power ON.

button to turn the power ON.

`/1

X ,

19

HCD-GNZ5D

Ver. 1.1

DVD SECTION

[TEST DISC LIST]

Be sure to use the DVD disc that matches the signal standards of

your region.

• CD

YEDS-18 (Part No.: 3-702-101-01)

PATD-012 (Part No.: 4-225-203-01)

• DVD SL (Single Layer)

NTSC : HLX-503 (Part No.: J-6090-069-A)

HLX-504 (Part No.: J-6090-088-A)

PAL : HLX-506 (Part No.: J-6090-077-A)

• DVD DL (Dual Layer)

NTSC : HLX-501 (Part No.: J-6090-071-A)

HLX-505 (Part No.: J-6090-089-A)

PAL : HLX-507 (Part No.: J-6090-078-A)

4-1. GENERAL DESCRIPTION

The Mirror Time and IOP measurement allows you to make

diagnosis and adjustment simply by using the remote commander

and monitor TV. The instructions, diagnosis results, etc. are given

on the on screen display (OSD).

The Mirror Time and IOP measurement is required is such events

where servicing a DVD-Player includes changing the Base Unit

(BU). For each new BU to be used with a certain MV-044 board,

Mirror Time and IOP measurement need to be carried out.

4-2. ST ARTING TEST MODE

Press three buttons

with the DVD player in standby mode.

The Test Mode starts, then the menu shown below will be

displayed on the TV screen.

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

5. Video Level Adjustment

Model Name : GVLXD_XX

IF-con : V

Syscon : Ver.

x , A and [VOLUME +] simultaneously

Remocon Diagnosis Menu

er. xx.xx (xxxx)

x.xxx

4-4. MIRROR TIME ADJUSTMENT

To enter Mirror Time Adjustment, press 5 “R” button on the remote

commander. The screen will appear as below.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold:

4. Save to EEPROM

5. Default set MIRR time

[Open] Tray open [Close] Tray close

[0] Return to previous menu

There are five main commands in the Mirr time Adjust menu as

shown in the figure above. The functions of each command are

described in the following page.

1. CD MIRR time Check

This command checks the Mirror time value for CD disc.

2. DVD MIRR time Check

This command checks the Mirror time value for DVD disc.

3. Threshold

This command displays the threshold value between CD and DVD

mirror time.

4. Save to EEPROM

This command saves an adjusted mirror time value to the EEPR OM.

5. Default set MIRR time

This command will set CD and DVD mirror time to firmware def ault

value.

[Open] / [Close]

Pressing the A button controls the tray for disc change

during mirror time adjustment.

[0] Return to previous menu

Press 0 “R” button to return to previous menu.

4-4-1. EXECUTING MIRROR TIME ADJUSTMENT

In order to execute mirror time adjustment, the following standard

procedures must be followed.

The menu above is the Remocon Diagnosis Menu screen which

consists of six main function. At the bottom of the menu screen,

the model name and IF-con version. To enter Mirror Time

Adjustment menu, press button 2 “R” on the remote commander

to enter Drive Manual Operation menu. To exit from the Test Mode,

press the power button on the remote commander.

4-3. DRIVE MANUAL OPERATION

The Drive Manual Operation menu consists of five main

function. By pressing 2 “R” button on the remote commander in

the Remocon Diagnosis Menu, the screen will appear as below.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time Adjust

0. Return to Top Menu

20

(1) In standby mode, press three buttons x , A and [VOLUME +]

simultaneously.

(2) Select “2. Drive Manual Operation”.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History Check

4. Version information

5. Video Level Adjustment

Model : GVLXD_xx

IF-con : Ver. xx.xx (xxxx)

Syscon : Ver. x.xxx

HCD-GNZ5D

(3) Select “5. MIRR time Adjust”.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Mecha test mode

5. MIRR time Adjust

0. Return to Top Menu

(4) Select “5. Default set MIRR time”.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [Close] Tray close

[0] Return to previous menu

(5) Select “3. Threshold”.

(6) Confirm the number. If it is 7D, go to next step. If it is any

other value, return to step 4.

MIRR time Adjust Menu

(14) Confirm the same values are displayed. If it is not same,

return to step 7.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(15) Push A button to eject tray.

(16) Take out HLX-504 and insert Test Disc YEDS-18 into

tray.

(17) Push A button to close tray.

(18) Push “1. CD MIRR time check”.

(19) Wait for HEX number to display.

(20) Confirm the number, if YY is 5A ~ E8, proceed with next

step. If no, return to 15.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold: 7D

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [Close] Tray close

[0] Return to previous menu

(7) Push A button to eject tray.

(8) Insert Test Disc HLX-504 into tray.

(9) Push A button to close tray.

(10) Push “2. DVD MIRR time Check”.

(11) Wait for HEX number to display.

(12) Confirm the number, if XX is 28 ~ 70, proceed with next

step. If no, return to 8.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check: xx xx

3. Thereshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] tray open [close] Tray close

[0] Return to previous menu

1. CD MIRR time Check: yy YY

2. DVD MIRR time Check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(21) Push “4. Save to EEPROM”.

(22) Confirm the same values are displayed. If it is not the

same, return to step 15.

MIRR time Adjust Menu

1. CD MIRR time check: YY YY

2. DVD MIRR time check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(23) Push A button to eject tray.

(24) Remove Test Disc YEDS-18 from tray.

(25) Push A button to close tray.

(26) Press 0 “R” button to the Drive Manual Operation menu.

(13) Push “4. Save to EEPROM”.

(27) Press 0 “R” button to return to the Remocon Diagnosis

Menu.

(28) Press the

?/1 button to switch OFF set.

21

HCD-GNZ5D

4-5. EXECUTING IOP MEASUREMENT

In order to execute mirror time adjustment, the following standard

procedures must be followed.

(1) In standby mode, press three buttons x , A and

[VOLUME +] simultaneously.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History Check

4. Version information

5. Video Level Adjustment

Model : GVLXD XX

IF-con Ver : XX.XX (XXXX)

Syscon Ver : X.XX

(2) Select “2. Drive Manual Operation” by pressing the 2 “R”

button on the remote commander. The screen will appear as

below.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time adjust

0. Return to top Menu

(5) Wait until a hexadecimal number appear.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop. 5B:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Change Value

[0] Return to previous menu

(6) Convert each data from hexadecimal to decimal using

conversion table.

(7) Substract between these two values.

(8) If the remainder is smaller than 93 (decimal), then it is

OK. However if the value is higher than 93, then the BU

is defective and need to be change.

(9) Press RETURN “R” button to return back to previous menu.

(10) Press 0 “R” button to return to Top Menu and power OFF

the DVD Player.

(3) Select “3. Manual Adjustment” by pressing the 3 “R” b utton

on the remote commander. The screen will appear as below.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eg boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

o O Change Value

[RETURN] Return to previous menu

(4) Select Iop by pressing 6 “R” button on the remote commander .

22

SECTION 5

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be perfor med with the rated power

supply voltage unless otherwise noted.

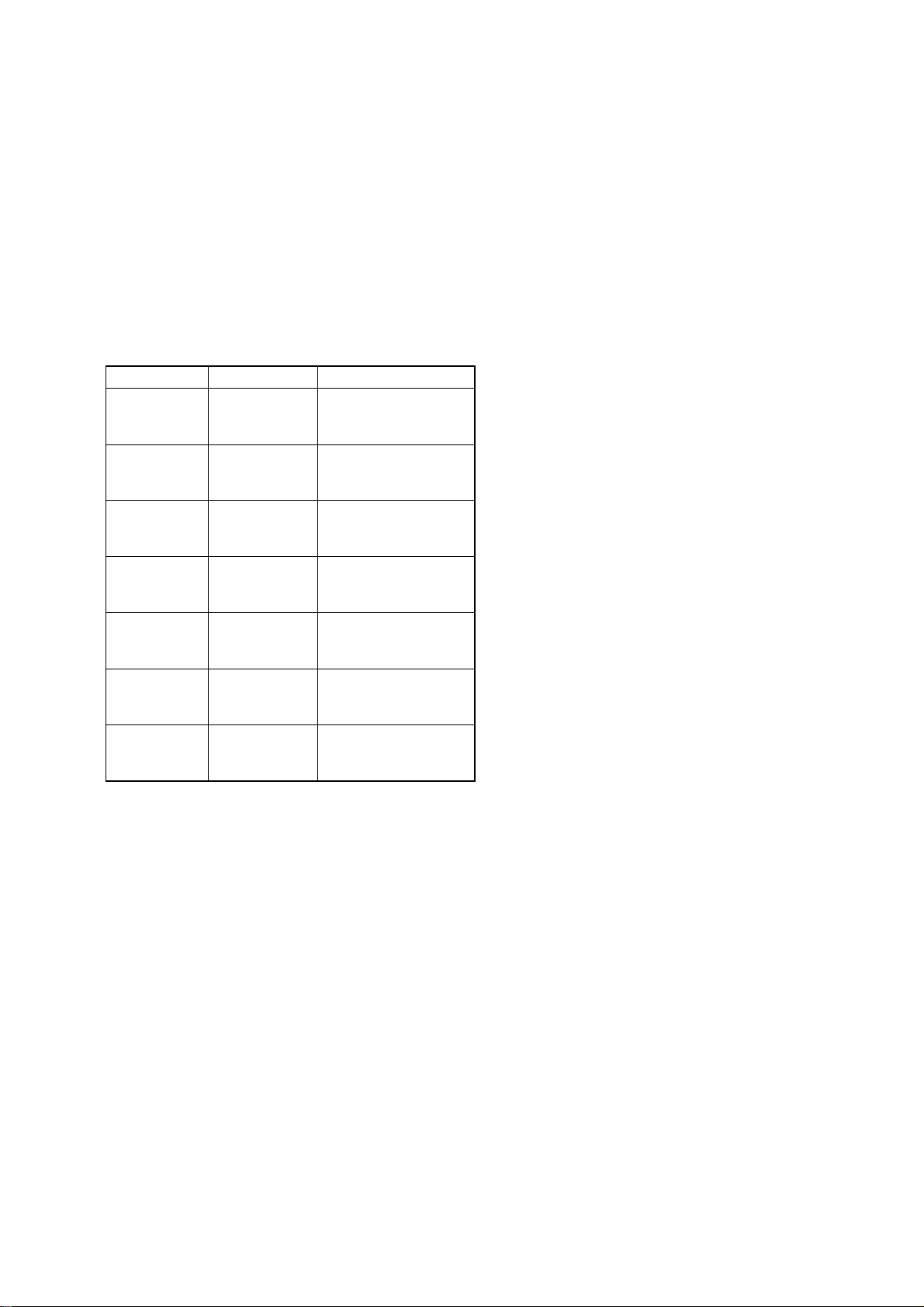

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

3.06 N • m to 6.96 N • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

3.06 N • m to 6.96 N • m

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

2 to 6 g • cm

(0.02 – 0.08 oz • inch)

6.96 N • m to 14.02 N • m

71 to 143 g • cm

(0.98 – 1.99 oz • inch)

9.80 N • m

100 g or more

(3.53 oz or more)

9.80 N • m

100 g or more

(3.53 oz or more)

HCD-GNZ5D

23

HCD-GNZ5D

)

Ver. 1.1

SECTION 6

ELECTRICAL ADJUSTMENTS

DVD SECTION

When the base unit is replaced, perform the adjustment and the

measurement as shown below in this order.

1) MIRROR TIME ADJUSTMENT (See page 20)

2) EXECUTING IOP MEASUREMENT (See page 22)

[TEST DISC LIST]

Be sure to use the DVD disc that matches the signal standards of

your region.

• CD

YEDS-18 (Part No.: 3-702-101-01)

PATD-012 (Part No.: 4-225-203-01)

• DVD SL (Single Layer)

NTSC : HLX-503 (Part No.: J-6090-069-A)

HLX-504 (Part No.: J-6090-088-A)

PAL : HLX-506 (Part No.: J-6090-077-A)

• DVD DL (Dual Layer)

NTSC : HLX-501 (Part No.: J-6090-071-A)

HLX-505 (Part No.: J-6090-089-A)

PAL : HLX-507 (Part No.: J-6090-078-A)

[RFMON Level Check]

Connection:

oscilloscope

DMB11 board

CN105 pin 6 (RFMON)

CN105 pin

3

(GND)

+

–

Checking Location: DMB10 board (Side A)

IC104

IC102

CN105

IC201

6

1

CN105 pin 3 (GND

IC101

CN106

CN105 pin 6 (RFMON)

VIDEO SECTION

Video Level Check (VIDEO BOARD)

Purpose

This adjustment is made to satisfy the NTSC standard, and if not

adjusted correctly, the brightness will be too large or small.

Procedure:

1. Connect an oscilloscope to CN105 pin 6 (RFMON) and

CN105 pin 3 (GND) on the DMB11 board.

2. Turn the power on.

3. Set the test disc (refer to the TEST DISC LIST) on the tray

and press H button to playback.

4. Confirm that oscilloscope waveform is clear and check

RFMON signal level is correct or not.

Note: A clear RFMON signal wa veform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RFMON signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 0.58 ± 1.23 Vp-p (DVD)

0.57 ± 1.1 Vp-p (CD)

oscilloscope

Ω

75

set

J801

VIDEO OUTPUT

Procedure:

1. Connect oscilloscope to VIDEO output.

2. Load a DVD reference disc playback.

3. Check the video signal level is 1.00±0.07Vp-p.

(WHITE 100%)

1.00 ± 0.07 Vp-p

24

HCD-GNZ5D

r

e

Ver. 1.1

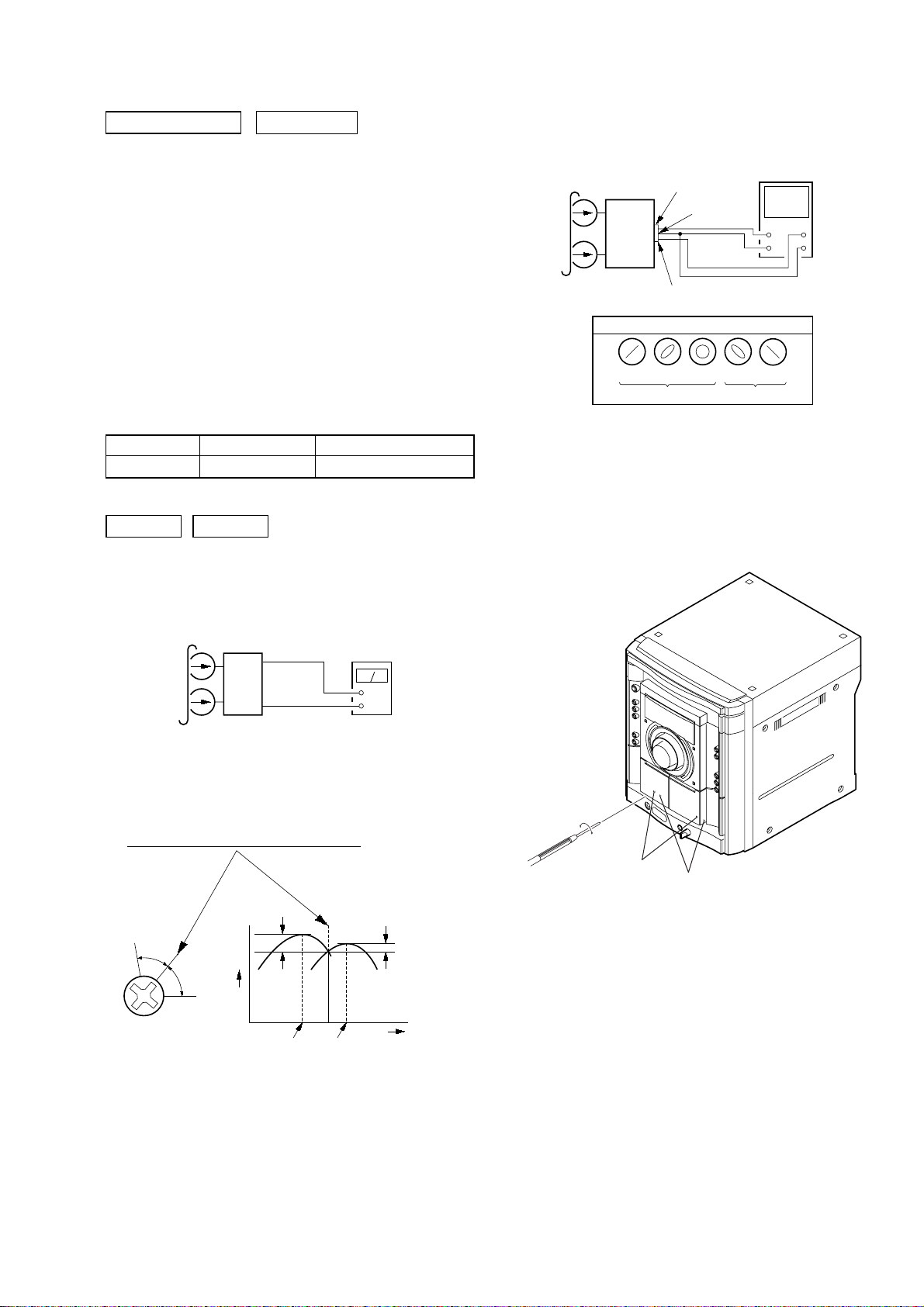

DECK SECTION

0 dB=0.775 V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

•Test Tape

Tape Signal Used for

P-4-A063 6.3 kHz, –10 dB Azimuth Adjustment

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

test tape

P-4-A063

(6.3 kHz, –10 dB)

AUDIO board

IC201

Pin 28 (L-CH)

Pin 37 (R-CH)

level mete

3. Mode: Playback

test tape

P-4-A063

(6.3 kHz, –10 dB)

L-CH

AUDIO

board

IC201

R-CH

waveform of oscilloscope

in phase 45°90°135°180

pin 28

pin 38

L

R

pin 37

good

oscilloscop

V

wrong

H

°

4. After the adjustments, apply suitable locking compound to the

pats adjusted.

Adjustment Location: Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

set

AUDIO board

IC201

Pin 38 (GND)

+

–

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

screw

position

L-CH

peak

screw

position

R-CH

peak

reverse

forward

25

HCD-GNZ5D

d

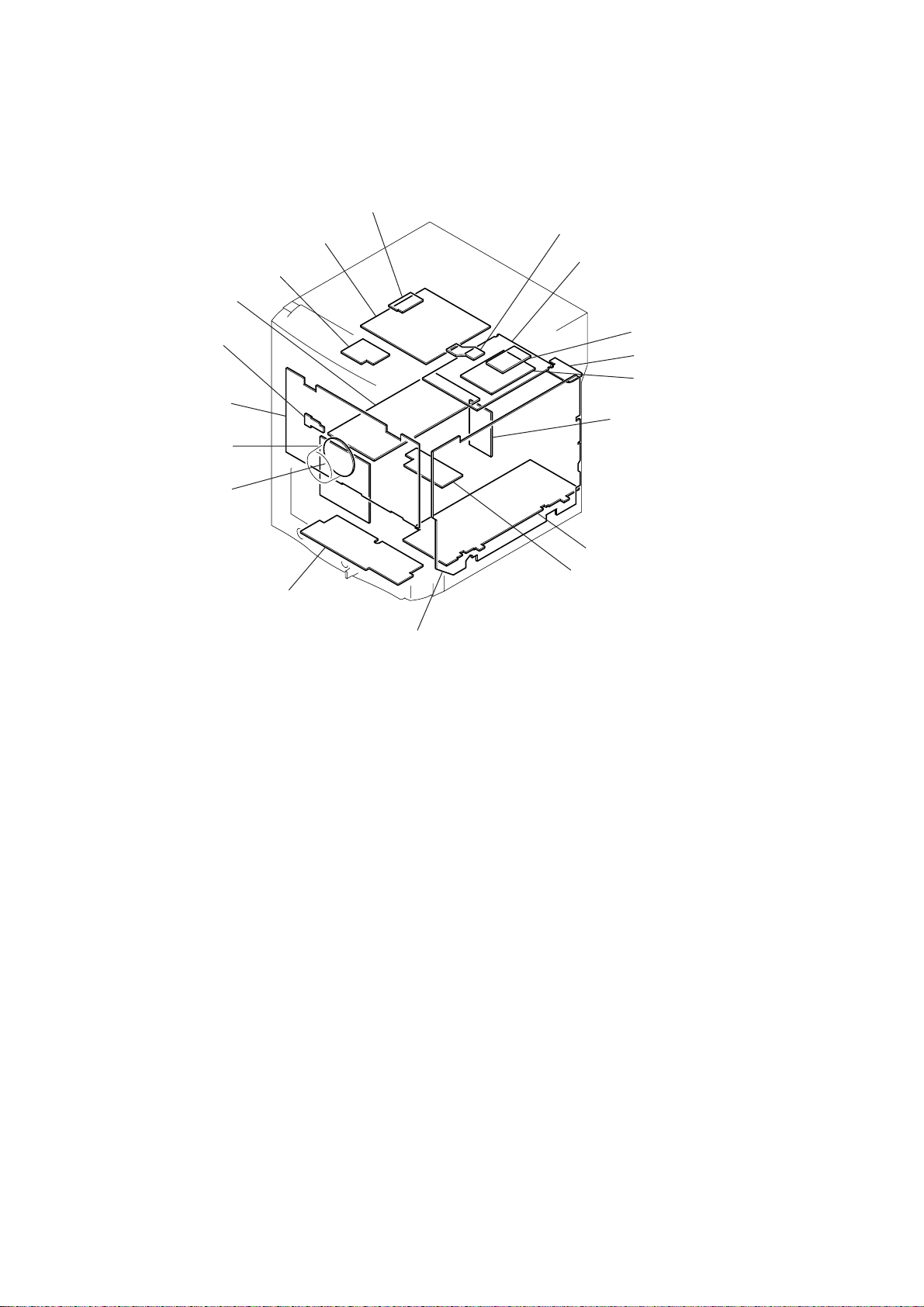

7-1. CIRCUIT BOARDS LOCATION

DMB11 board

MOTOR (LD) board

TRANS board

SECTION 7

DIAGRAMS

SW board

SENSOR board

VIDEO board

SIRCS board

PANEL board

SUB TRANS board

STREAM board

MOTOR (TB) boar

OPTICAL board

DRIVER board

POWER SWITCHING

FRONT AMP board

LEAD PIN board

JACK board

AUDIO board

26

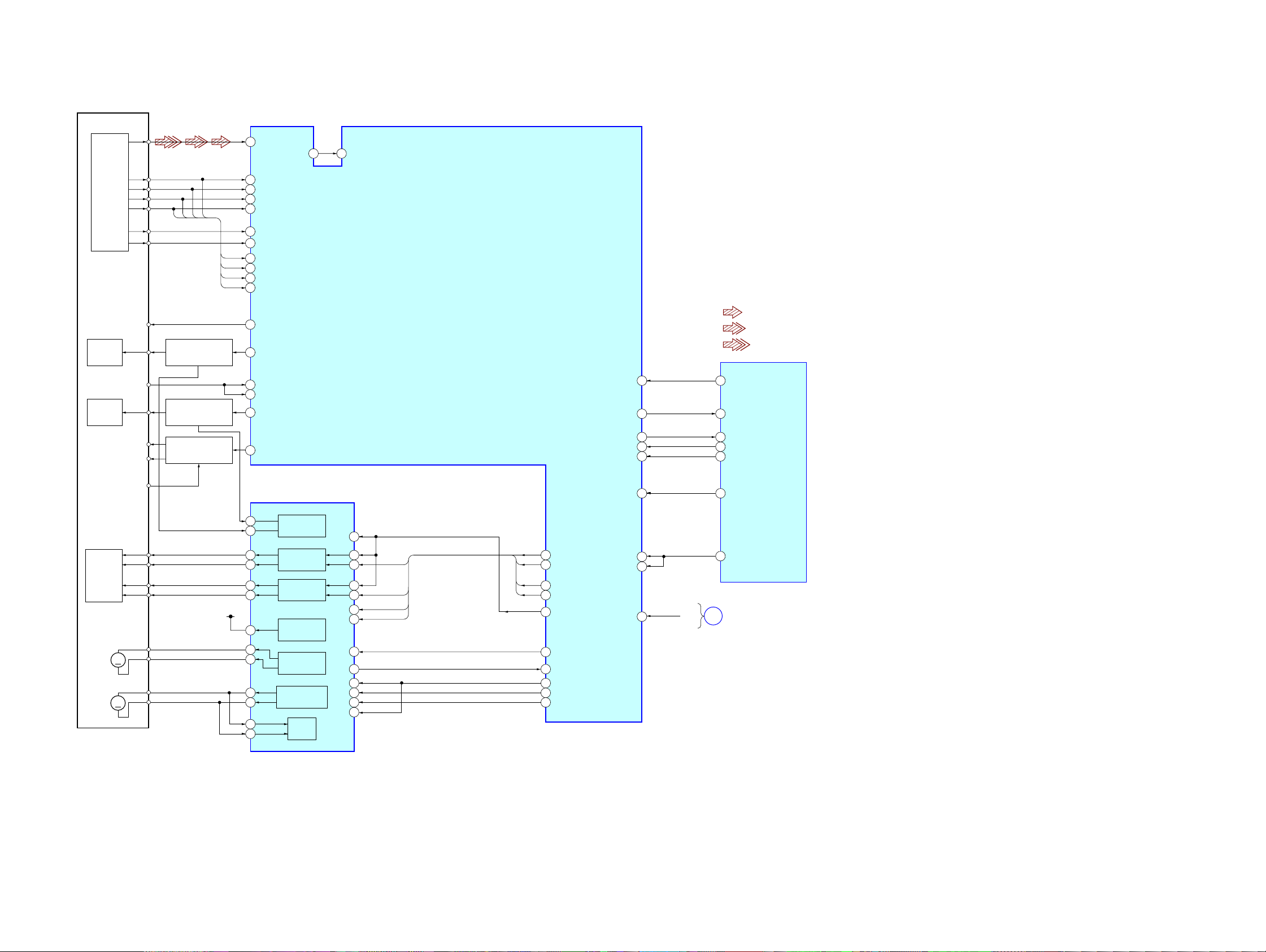

7-2. BLOCK DIAGRAM — RF/SERVO SECTION —

HCD-GNZ5D

DETECTOR

OPTICAL PICK-UP

BLOCK

LIMIT

LASER

CD LD

DIODE

(FOR CD)

LASER

DVD LD

DIODE

(FOR DVD)

WR650

VR780

RF

A

B

C

D

F

E

D

CBA

DVDRFIP

6

2

DVDA

3

DVDB

4

DVDC

5

DVDD

19

TPI

18

TNI

A

8

NA

B

9

NB

C

10

MC

D

11

MD

OSP

252 253

OSN

CD/DVD RF AMP,

FOCUS/TRACKING ERROR AMP

DVD SYSTEM PROCESSOR

DIGITAL SERVO PROCESSOR

IC102(1/2)

• Signal Path

: CD PLAY

176

LI M SW

Q102 (1/2)

AUTOMATIC POWER

CONTROL (FOR CD)

PD

Q102 (2/2)

AUTOMATIC POWER

CONTROL (FOR DVD)

Q101, Q103

VOLUME CONTROL

23

LD01

110

20

MD12

MD11

21

LD02

22

MSW

50

PRST

IFCK

IFSDO

IFSDI

XIFCS

99

98

101

100

23

29

28

27

30

: DVD PLAY

: SACD PLAY

MTK_XRST

MTK_CLK

MTK_IN

MTK_OUT

MTK_CS

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

SLED

SPINDLE

MSW

FCS+

FCS–

TRK+

TRK–

SL–

SL+

MM

SP+

SP–

MM

FOCUS/TRACKING COIL DRIVER,

SPINDLE, SLED MOTOR DRIVER

42

41

36 48

37 1

35 3

34 4

VCC

32

30

29

27

28

46

47

IC201

BUFFER

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

BUFFER

105

IFBSY

43

10

13

V1P4

FOO

TRO

FMO

DMO

V1P4

FMO

FOO

DMO

TRO

38

FMO

42

FOO

37

DMO

41

TRO

V REFO

30

KRMOD/HSYNC

MIC/VSYNC

MREQ

207

114

205

MIC

A

24

87

SECTION

MTK BUSY

KARAOKE/

MTK-REQ

MAIN

SYSTEM

CONTROL

IC101(1/3)

(Page 29)

40

45

19

20

22

21

40

47

211

210

170

IOPMON

SPFG

MUTE123

MUTE

TSDM

HCD-GNZ5D

27 27

Loading...

Loading...