Sony HCD-GNX780,HCD-GNX880 Service Manual

HCD-GNX780/GNX880

Mexican Model

SERVICE MANUAL

MiNi Hi-Fi COMPONENT SYSTEM

SPECIFICATIONS

Ver. 1.1 2006.09

– Continued on next page –

• HCD-GNX780/GNX880 is the Amplifier,

Disc player, tape deck and tuner

section in MHC-GNX780/GNX880.

Model Name Using Similar Mechanism HCD-GN880

CD CD Mechanism Type CDM74KF-F1BD84

Section Base Unit Name BU-F1BD84

Optical Pick-up Name KSM-215DCP/C2NP

TAPE Model Name Using Similar Mechanism HCD-GNX80

Section Tape Transport Mechanism Type CWN42FF601

Amplifier section

HCD-GNX880

The following are measured at AC 127 V, 60 Hz

Front/Surround speaker

DIN power output (rated) 180 + 180 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

225 + 225 watts

(6 ohms at 1 kHz, 10% THD)

Subwoofer

Continuous RMS power output (reference)

200 watts

(8 ohms at 100 Hz, 10% THD)

HCD-GNX780

The following are measured at AC 127 V, 60 Hz

Front speaker

DIN power output (rated) 210 + 210 watts

(4 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

285 + 285 watts

(4 ohms at 1 kHz, 10% THD)

Inputs

VIDEO/MD (AUDIO) IN (phono jacks):

voltage 250/450 mV,

impedance 47 kiloohms

TV (AUDIO) IN (phono jack): voltage 250 mV,

impedance 47 kiloohms

MIC (phone jack): sensitivity 1 mV,

impedance 10 kiloohms

Outputs

VIDEO OUT (phono jack): max. output level

1 Vp-p, unbalanced, Sync negative,

load impedance

75 ohms

PHONES (stereo mini jack): accepts headphones of 8 ohms or more

FRONT SPEAKER/SURROUND SPEAKER/

SUBWOOFER OUT: Use only the supplied speaker

Photo: HCD-GNX880

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

9-887-130-02

2006I02-1

© 2006.09

2

HCD-GNX780/GNX880

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

This appliance is classified as

a CLASS 1 LASER product.

This label is located on the rear

exterior.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

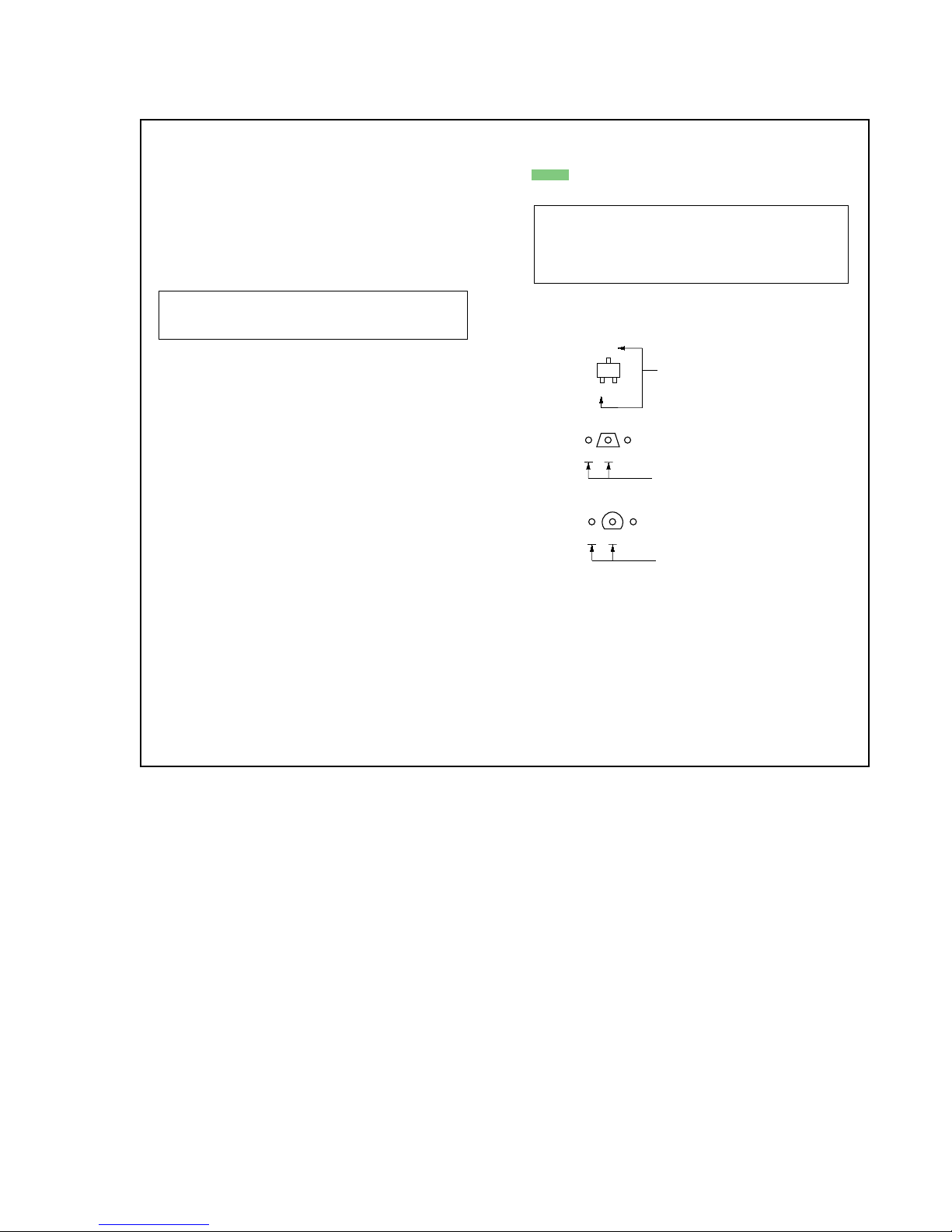

Unleaded solder

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Disc player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ=780 nm)

Emission duration: continuous

Laser Output Max. 44.6 µW*

* This output is the value measured at

a distance of 200 mm from the

objective lens surface on the Optical

Pick-up Block with 7 mm aperture.

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wave length 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

OPTICAL CD DIGITAL OUT

(Square optical connector jack, rear panel)

Wave length 660 nm

Output Level –18 dBm

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I tape

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz

(with the interval set at 10 kHz)

531 – 1,710 kHz

(with the interval set at 9 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements 127 V AC, 60Hz

Power consumption

MHC-GNX880 350 watts

MHC-GNX780 250 watts

Dimensions (w/h/d) (Approx.) 281 × 362 × 404.5 mm

Mass (Approx.)

HCD-GNX880 13.7 kg

HCD-GNX780 12.0 kg

Design and specifications are subject to change without notice.

3

HCD-GNX780/GNX880

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL

Locating the Controls ...................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Side Panel, Top Case ....................................................... 8

3-3. Loading Panel .................................................................. 8

3-4. Front Panel Assy.............................................................. 9

3-5. Tuner Pack ....................................................................... 9

3-6. Tape Mechanism Deck, MIC Board ................................ 10

3-7. CD-SW Board, PANEL Board ........................................ 10

3-8. FUNCTION Board, JOG Board ...................................... 11

3-9. CD Mechanism Deck ...................................................... 11

3-10. Back Panel ....................................................................... 12

3-11. PRIMARY Board, EFFECTOR Board ............................ 12

3-12. Power Amp PC Board Assy, MAIN Board ..................... 13

3-13. SURROUND Board, PA Board ....................................... 13

3-14. Power Transformer (T1200) ............................................ 14

3-15. CDG Board, DRIVER Board, SW Board ....................... 14

3-16. BD84 Board ..................................................................... 15

3-17. SENSOR Board ............................................................... 15

3-18. MOTOR (TB) Board ....................................................... 16

3-19. MOTOR (LD) Board ....................................................... 16

4. TEST MODE .............................................................. 17

5. MECHANICAL ADJUSTMENTS ....................... 21

6. ELECTRICAL ADJUSTMENTS

Deck section .................................................................... 21

CDG Section.................................................................... 22

7. DIAGRAMS

7-1. Block Diagram – CDG Section – ................................... 27

7-2. Block Diagram – Tape/Tuner Section – ......................... 28

7-3. Block Diagram – Main Section – ................................... 29

7-4. Block Diagram – AMP Section – ................................... 30

7-5. Block Diagram – Display/Power Section – .................... 31

7-6. Printed Wiring Board – BD84 Board – .......................... 32

7-7. Schematic Diagram – BD84 Board – ............................. 33

7-8. Printed Wiring Boards – CD Mechanism Sectiom – ...... 34

7-9. Schematic Diagram – CD Mechanism Section – ........... 35

7-10. Printed Wiring Board – MAIN Board – ......................... 36

7-11. Schematic Diagram – MAIN Board (1/3) – ................... 37

7-12. Schematic Diagram – MAIN Board (2/3) – ................... 38

7-13. Schematic Diagram – MAIN Board (3/3) – ................... 39

7-14. Printed Wiring Board – PANEL Board – ....................... 40

7-15. Schematic Diagram – PANEL Board – ........................... 41

7-16. Printed Wiring Boards

– CD-SW, JOG, MIC and FUNCTION Boards – ........... 42

7-17. Schematic Diagram

– CD-SW, JOG, MIC and FUNCTION Boards – ........... 43

7-18. Printed Wiring Board – PA Board – ............................... 44

7-19. Schematic Diagram – PA Board – .................................. 45

7-20. Printed Wiring Board – SURROUND Board – .............. 46

7-21. Schematic Diagram – SURROUND Board – ................. 47

7-22. Printed Wiring Board – EFFECTOR Board – ................ 48

7-23. Schematic Diagram – EFFECTOR Board – ................... 49

7-24. Printed Wiring Board – CDG Board – ........................... 50

7-25. Schematic Diagram – CDG Board – .............................. 51

7-26. Printed Wiring Boards – Power Section – ...................... 52

7-27. Schematic Diagram – Power Section – .......................... 53

7-28. IC Pin Function Description ............................................ 58

8. EXPLODED VIEWS

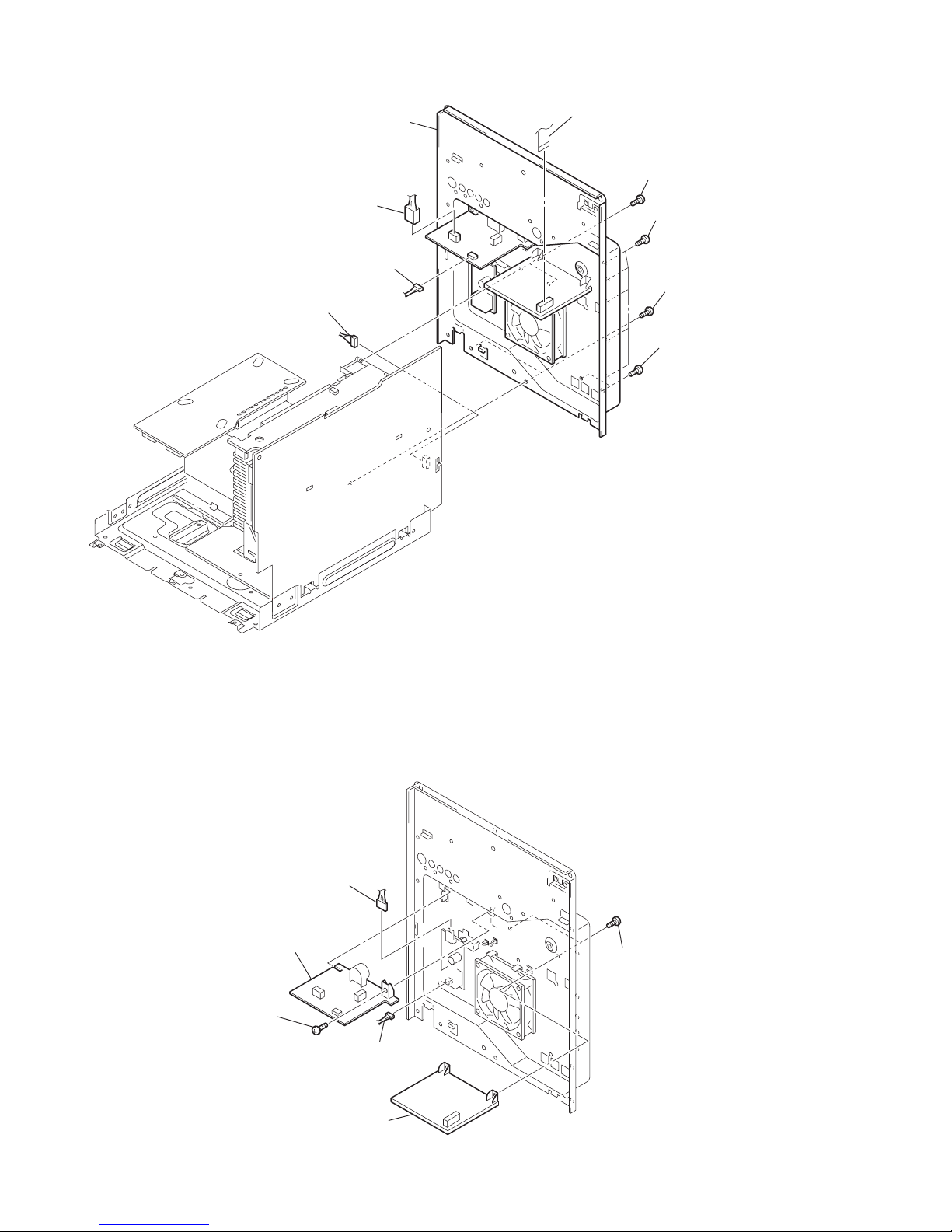

8-1. Case (Top), Back Panel Section ...................................... 64

8-2. Front Panel Section-1 ...................................................... 65

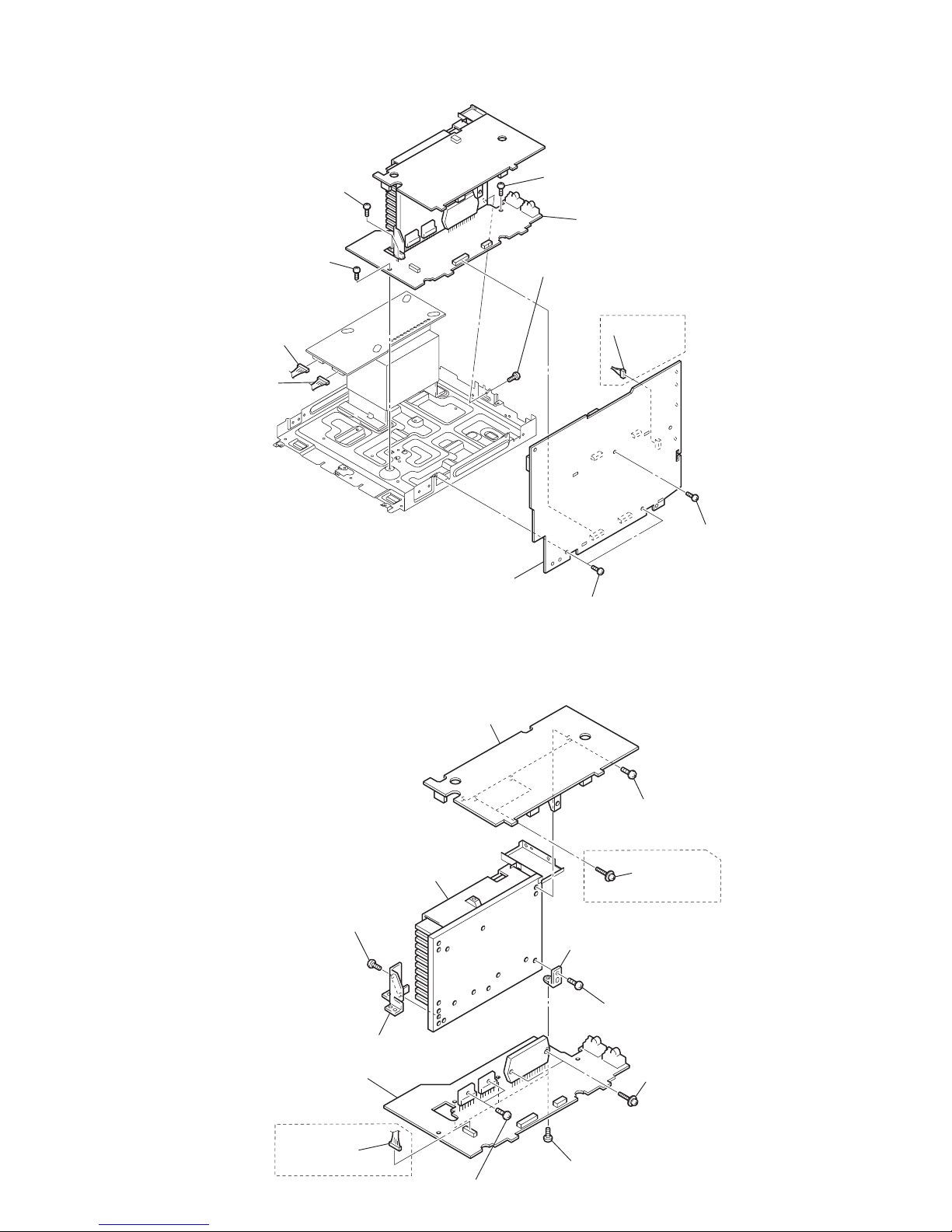

8-3. Front Panel Section-2 ...................................................... 66

8-4. Chassis Section ................................................................ 67

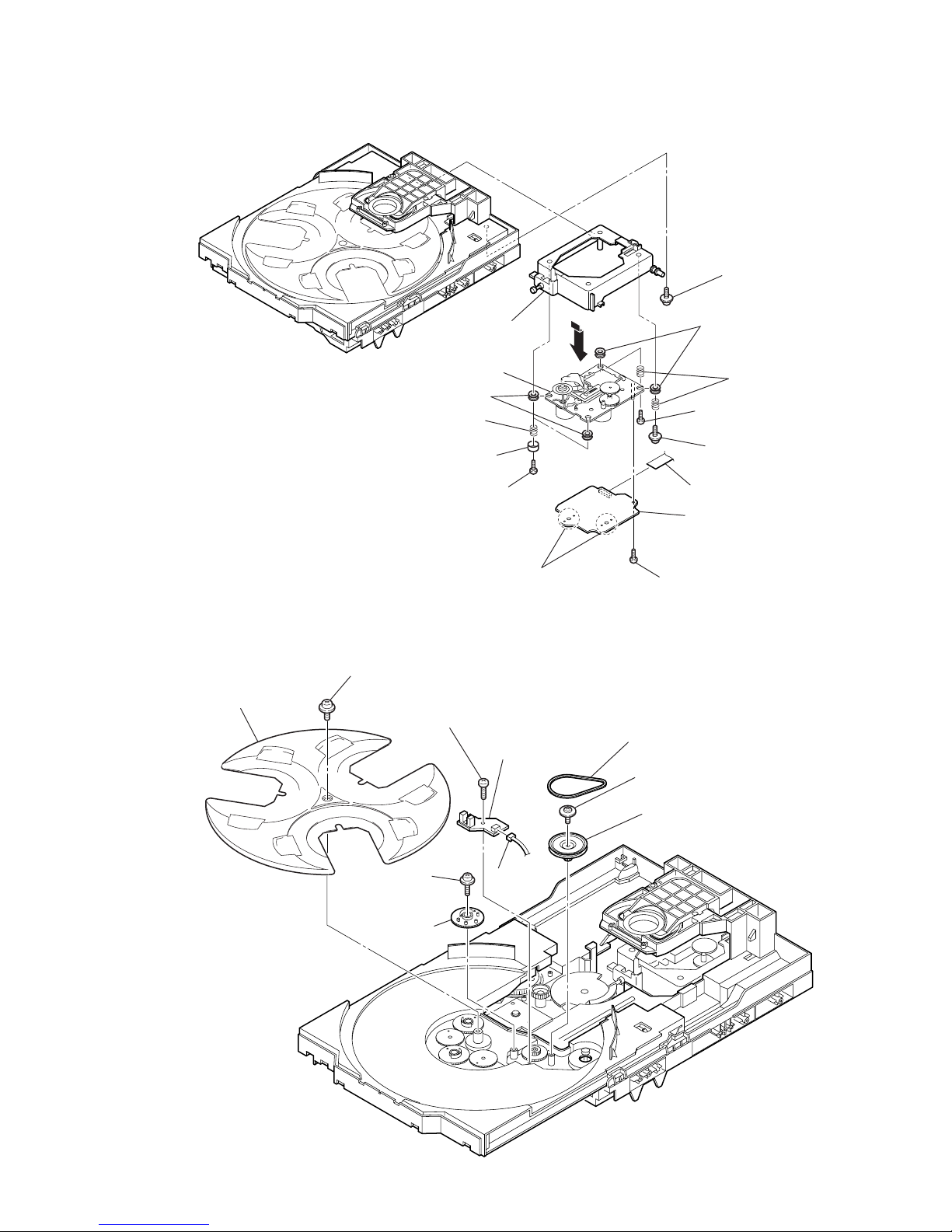

8-5. CD Mechanism Deck Section-1

(CDM74KF-F1BD84) ..................................................... 68

8-6. CD Mechanism Deck Section-2

(CDM74KF-F1BD84) ..................................................... 69

9. ELECTRICAL PARTS LIST ................................ 70

4

HCD-GNX780/GNX880

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

5

HCD-GNX780/GNX880

SECTION 2

GENERAL

This section is extracted

from instruction manual.

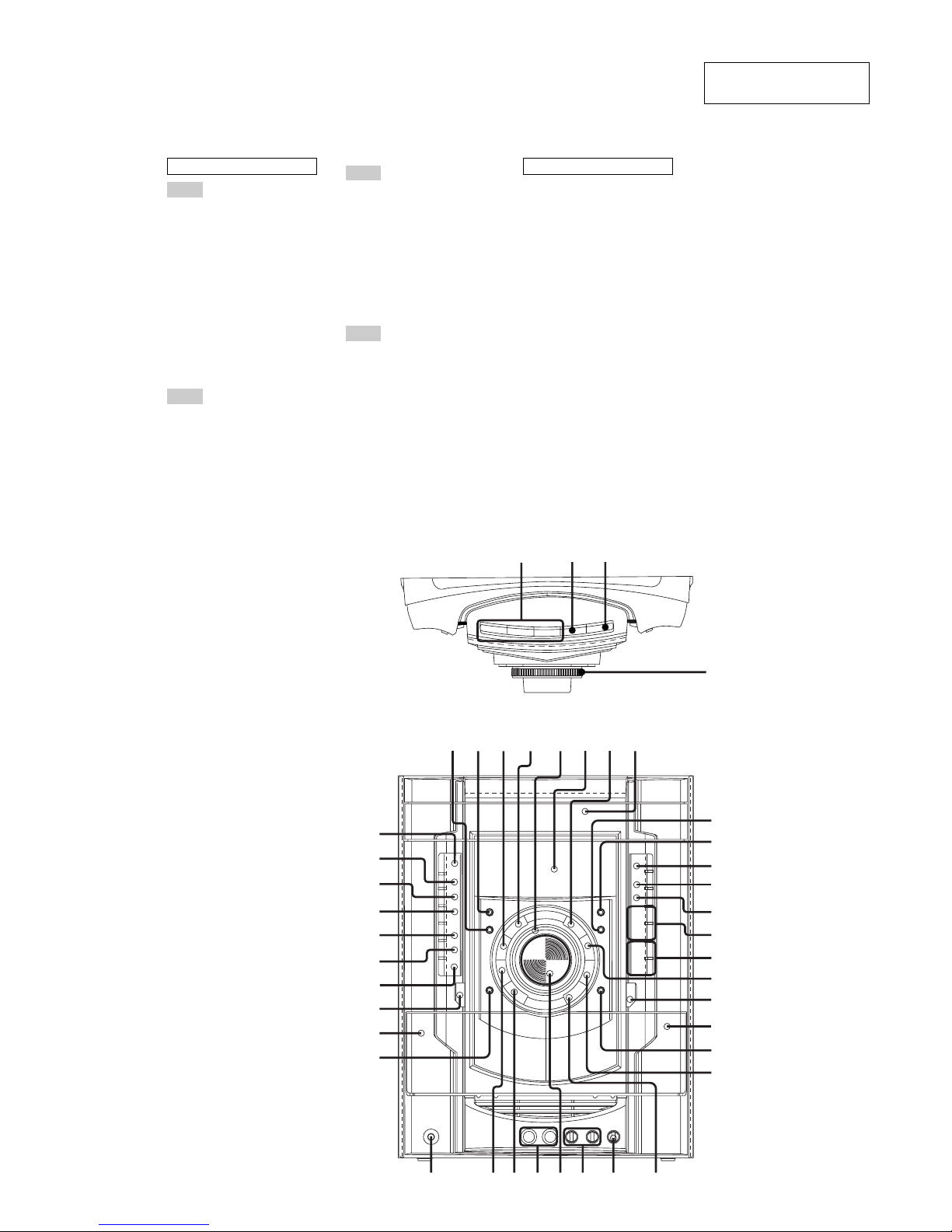

LOCATING THE CONTROLS

Main unit

ALBUM +/– ql

AMP MENU ed

CD r;

CD SYNC qf

Deck A ef

Deck B ws

DELAY ea

DIRECTION wd

DISC 1 ~ 3 1

Disc tray qs

DISPLAY 6

Display q;

ECHO LEVEL wh

ENTER wg

EQ BAND wf

EX-CHANGE/DISC SKIP 2

FLANGER 7

GROOVE w;

ILLUMINATION 5

IR Receptor ra

KARAOKE wd

MASTER VOLUME wk

MIC 1/2 (jack) wl

MIC 1/2 LEVEL wj

MP3 BOOSTER qa

OPEN/CLOSE 3

OPERATION DIAL 4

PHONES (jack) es

Power illuminator 9

REC PAUSE/START qd

SOUND FLASH e;

SURROUND

1)

8

SURR SPEAKER MODE

2)

8

TAPE A/B ek

Tape lid ws ef

TUNER/BAND el

TUNING +/– qk

TV ej

VIDEO/MD eh

?/1 (power) rs

Z OPEN/CLOSE 3

N (play) qg

>/. (forward/go

backward) qk

M/m (fast forward/rewind)

ql

X (pause) qh

x (stop) qj

A Z (Eject A) eg

B Z (Eject B) wa

1)

For MHC-GNX780

2)

For MHC-GNX880

ALPHABETICAL ORDER

A – D

E – L

M – R

S – Z

SYMBOLS

Top Panel

Front Panel

2

4

1

3

56

78 9q;qaqs

qd

qf

qg

qh

qj

qk

ql

w;

wa

ws

wg

wf

wd

whwjwkwle;eaes

ed

ef

eg

eh

ej

ek

el

r;

ra

rs

6

HCD-GNX780/GNX880

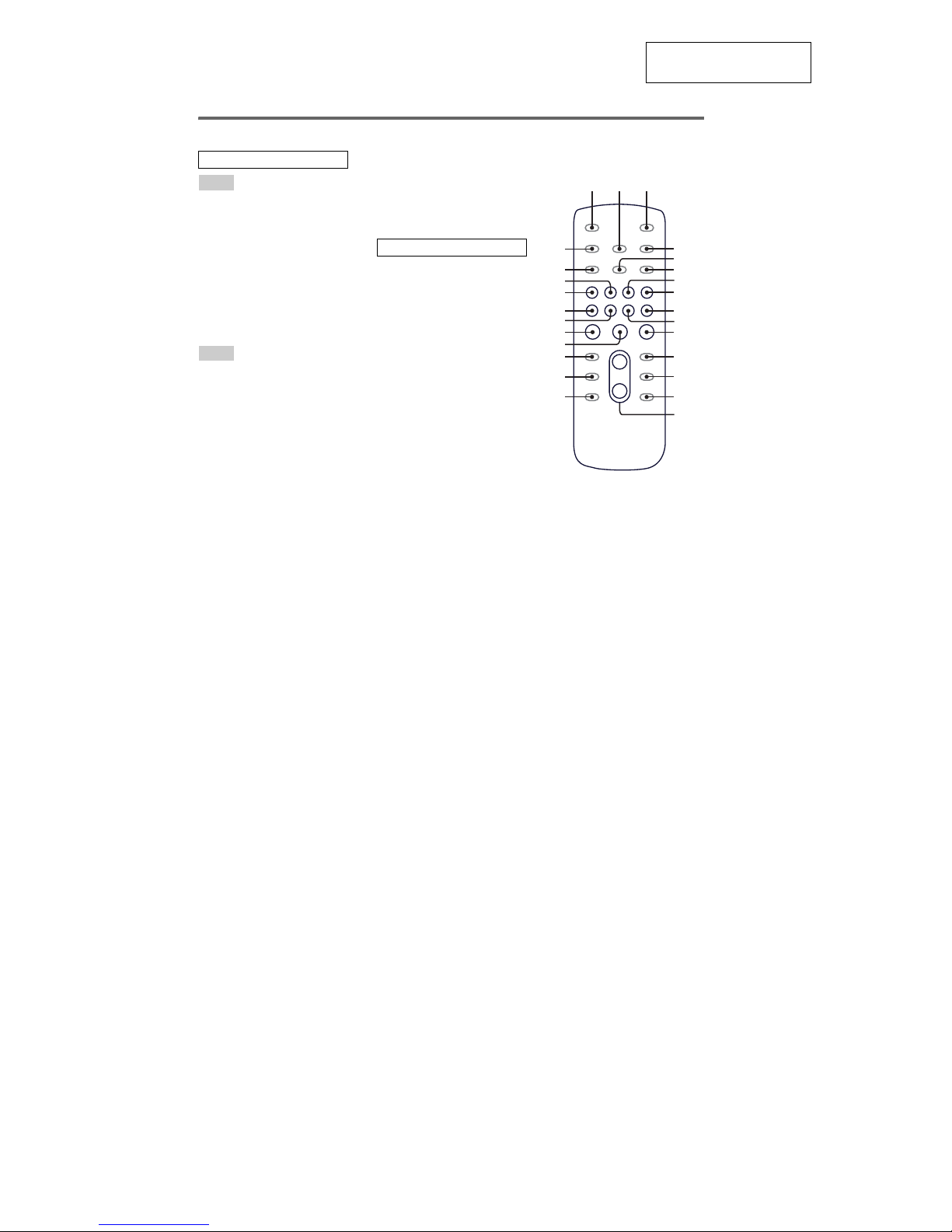

This section is extracted

from instruction manual.

Remote control

ALBUM + qf

ALBUM – qh

CD wf

CLEAR qk

CLOCK/TIMER SELECT 2

CLOCK/TIMER SET 4

DISC SKIP qd

DISPLAY wh

ENTER qs

EQ qj

FM MODE 6

FUNCTION 8

PLAY MODE 5

REPEAT 6

SLEEP 1

TAPE wd

TUNER/BAND 7

TUNER MEMORY wg

TUNING MODE 5

VOLUME +/– qg

The + button has a tactile dot.*

?/1 (power) 3

x (stop) qa

X (pause) ql

N (play) w;

–. (go backward) ws

>+ (go forward) wa

m (rewind) q;

M (fast forward) 9

*Use the tactile dot as a reference

when operating the system.

ALPHABETICAL ORDER

A – E

F – Z

SYMBOLS

7

5

q;

qg

qh

qj

qk

w;

ws

wd

wg

wh

qf

qd

qs

qa

9

8

6

4

3

12

ql

wa

wf

Use buttons on the remote for the operation.

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET.

“CLOCK” appears in the display. Then, the

hour indication flashes in the display.

3

Press –. or >+ repeatedly to set

the hour.

4

Press ENTER.

The minute indication flashes in the

display.

5

Press –. or >+ repeatedly to set

the minute.

6

Press ENTER.

The clock starts functioning.

To adj ust the c lock

1

Press CLOCK/TIMER SET.

“SET” appears in the display, then “PLAY

SET?” flashes in the display.

2

Press –. or >+ repeatedly to select

“CLOCK SET?”, then press ENTER.

The hour indication flashes in the display.

3

Do the same procedures as step 3 to 6

above.

Not es

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

You cannot set the clock in Power Saving Mode

.

Setting the clock

7

HCD-GNX780/GNX880

SECTION 3

DISASSEMBLY

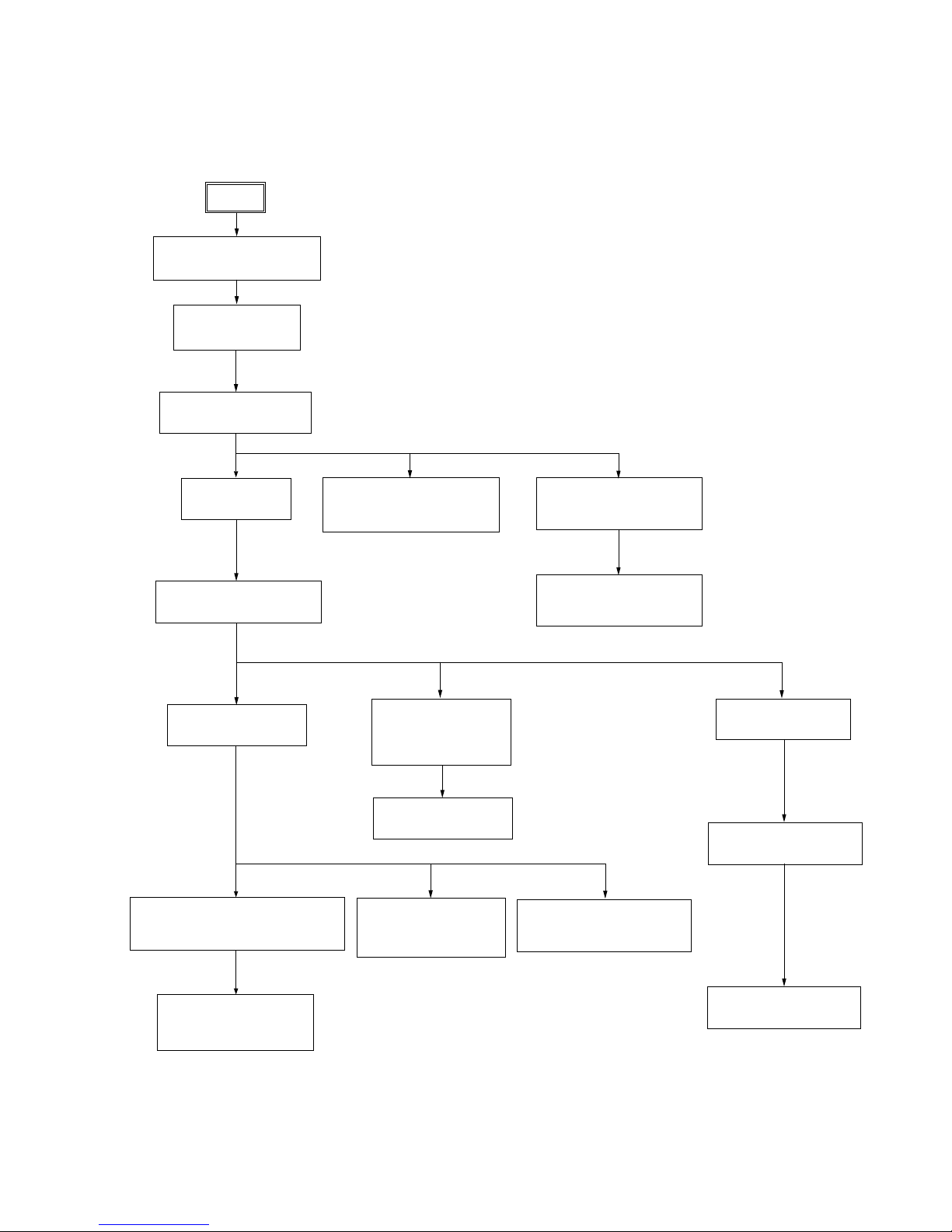

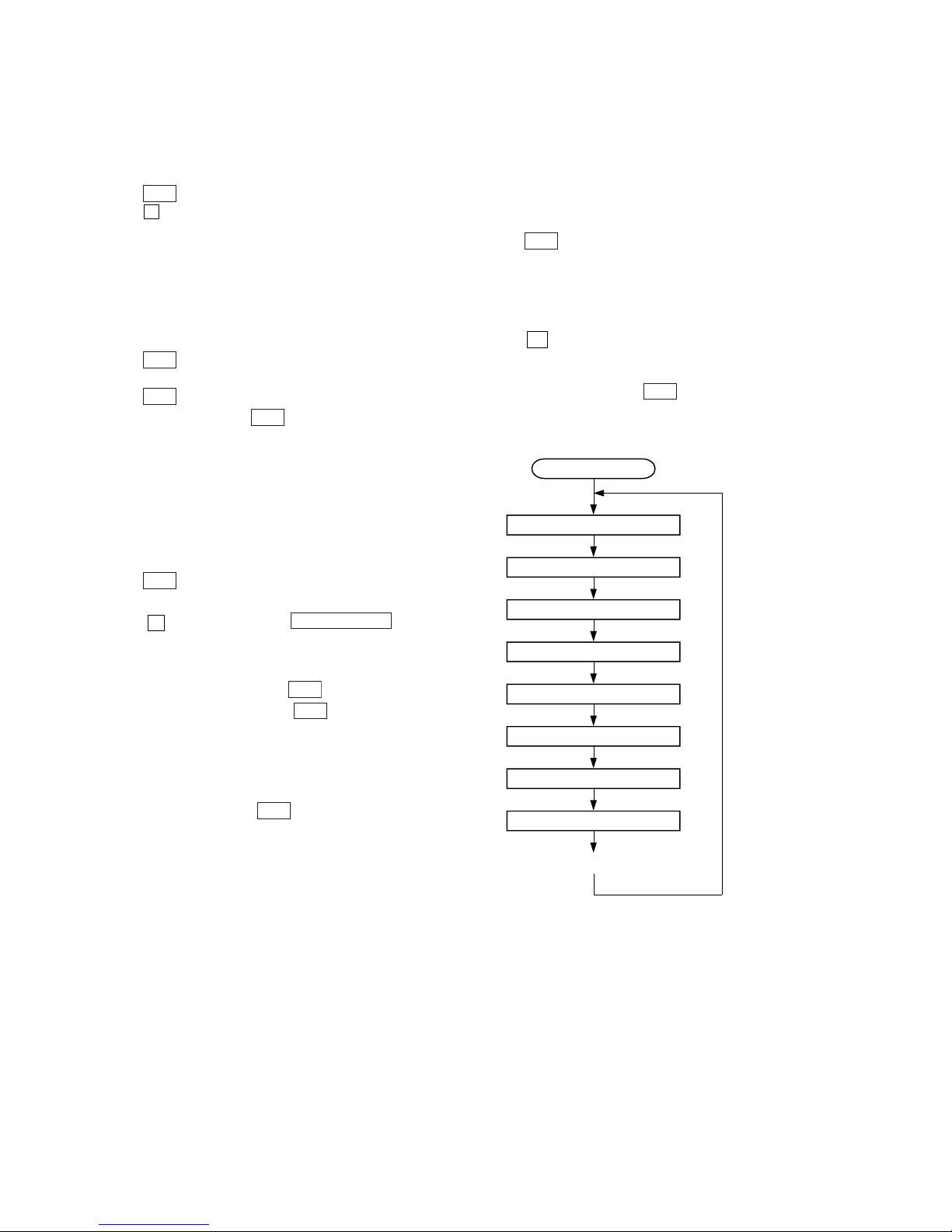

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

3-2.SIDE PANEL, TOP CASE

(Page 8)

3-3.LOADING PANEL

(Page 8)

3-4.FRONT PANEL ASSY

(Page 9)

3-5.TUNER PACK

(Page 9)

3-14.POWER TRANSFORMER

(T1200)

(Page 14)

3-12.POWER AMP PC BOARD ASSY,

MAIN BOARD

(Page 13)

3-9.CD MECHANISM DECK

(Page 11)

3-7.CD-SW BOARD,

PANEL BOARD

(Page 10)

3-6.TAPE MECHANISM DECK,

MIC BOARD

(Page 10)

3-15.CDG BOARD,

DRIVER BOARD,

SW BOARD

(Page 14)

3-11.PRIMARY BOARD

EFFECTOR BOARD

(Page 12)

3-18.MOTOR (TB) BOARD

(Page 16)

3-19.MOTOR (LD) BOARD

(Page 16)

3-17.SENSOR BOARD

(Page 15)

3-13.SURROUND BOARD,

PA BOARD

(Page 13)

3-8.FUNCTION BOARD,

JOG BOARD

(Page 11)

3-10.BACK PANEL

(Page 12)

3-16.BD84 BOARD

(Page 15)

SET

8

HCD-GNX780/GNX880

Note: Follow the disassembly procedure in the numerical order given.

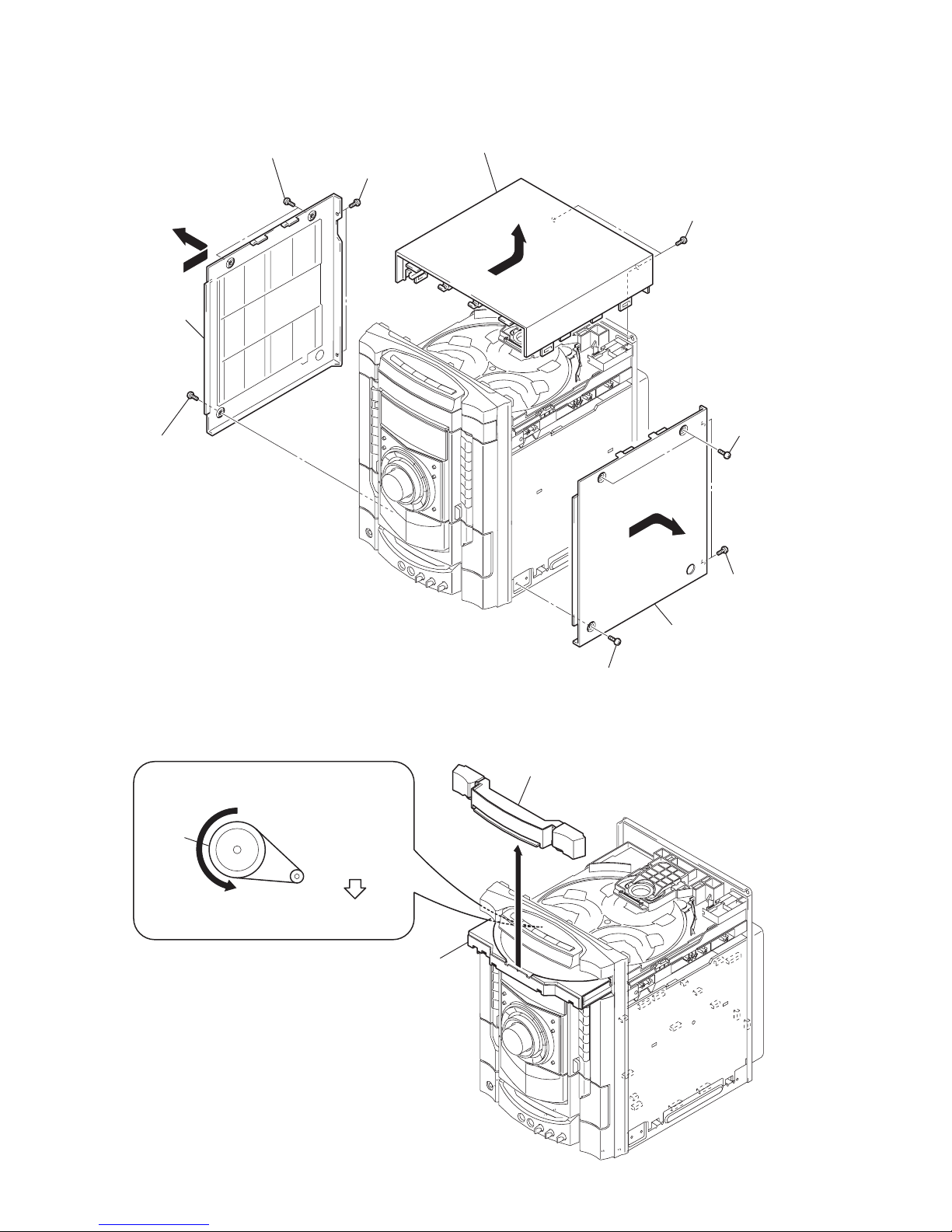

3-2. SIDE PANEL, TOP CASE

3-3. LOADING PANEL

1

screw (case 3 TP2)

(3

×

8)

2

two screws

(case 3 TP2)

(3

×

12)

3

two screws

(+BVTP 3

×

10)

4

5

PANEL (SIDE-R)

6

screw

(case 3 TP2)

(3×8)

7

two screws

(case 3 TP2)

(3

×

12)

8

two screws

(+BVTP 3

×

10)

9

0

PANEL (SIDE-L)

qa

two screws

(+BVTP 3

×

12)

qs

qd

CASE (TOP)

CD mechanism deck (CDM74KF-F1BD84)

1

Turn the pulley to the arrow direction.

Front side

Pulley

2

Pull out disc tray

3

4

loading panel

9

HCD-GNX780/GNX880

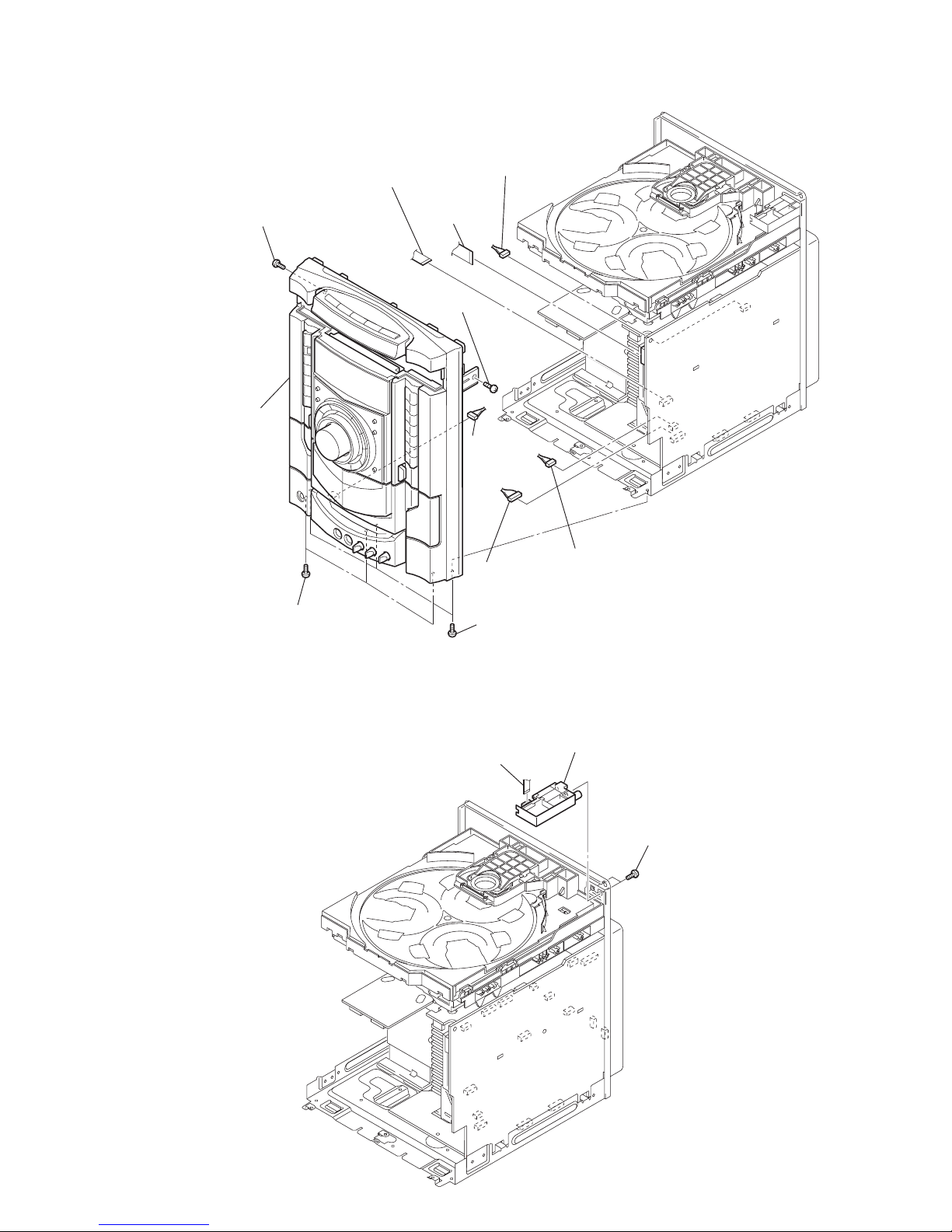

3-4. FRONT PANEL ASSY

3-5. TUNER PACK

1

three screws

(+BVTP 3

×

10)

2

three screws

(+BVTP 3

×

10)

3

screw

(+BVTP 3

×

10)

4

screw

(+BVTP 3

×

10)

5

front panel assy

6

connector

(CN100)

7

wire (flat type)

(CN508)

8

wire (flat type)

(CN509)

9

connector

(CN503)

q;

connector

(CN1102)

qa

connector

(CN507)

1

two screws

(+BVTP 3×6)

2

wire (flat type)

(CN1)

3

tuner pack

10

HCD-GNX780/GNX880

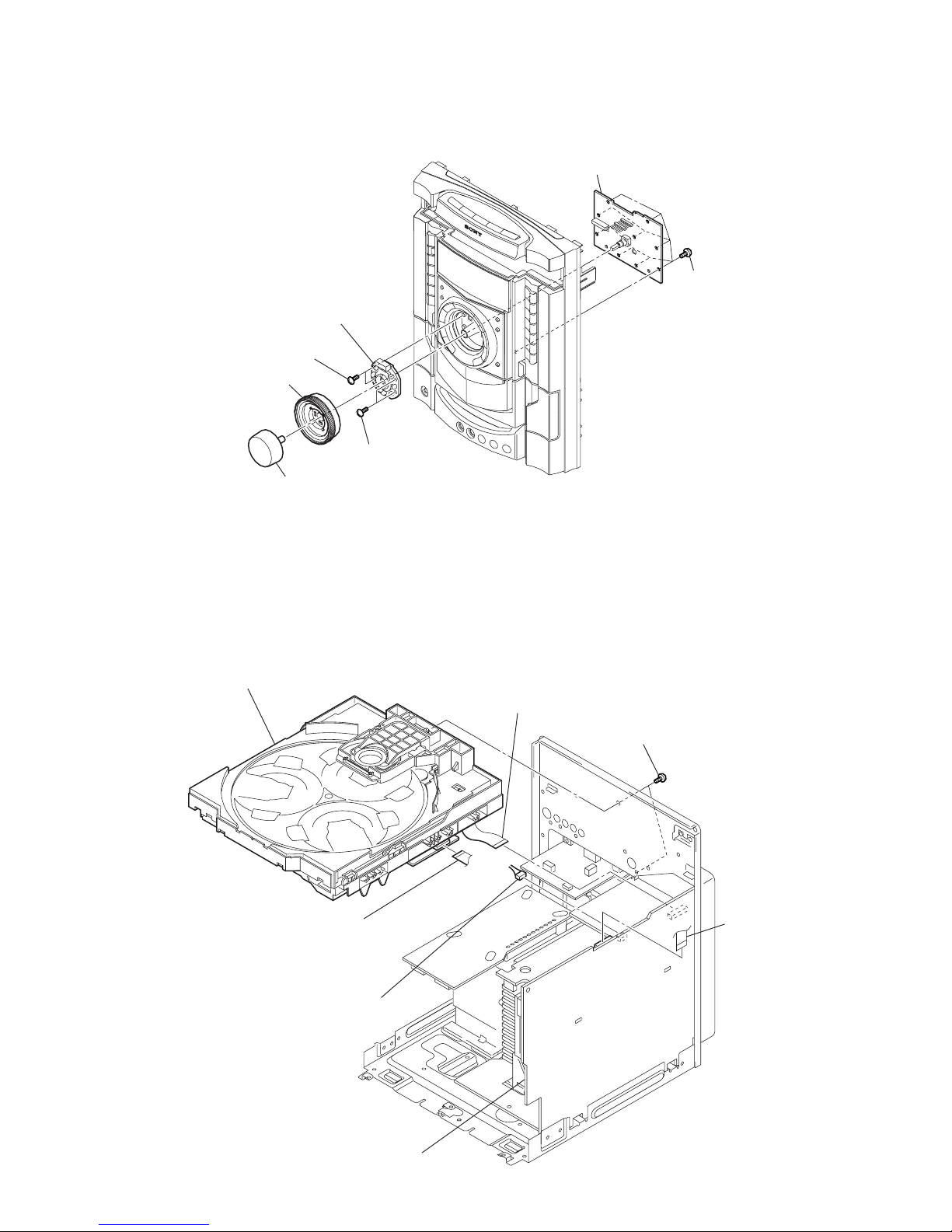

3-6. TAPE MECHANISM DECK, MIC BOARD

3-7. CD-SW BOARD, PANEL BOARD

1

three screws

(+BVTP2.6 (3CR))

2

two screws

(+BVTP2.6 (3CR)

)

3

tape mechanism deck

4

three screws

(+BVTP2.6 (3CR))

5

bracket (MIC)

7

MIC board

6

knob (MIC)

5

three screws

(+BVTP2.6 (3CR))

1

two screws

(+BVTP2.6 (3CR))

6

wire (flat type)

(CN900)

7

wire (flat type)

(CN902)

4

three screws

(+BVTP2.6 (3CR))

3

CD-SW board

8

PANEL boar

d

CD-SW board

CD-SW board

bracket portion

button (DISC)

button (DISC)

button (DISC)

(side view)

bracket portion

A

A

B

B

2

Pull up the bracket portion of button (DISC) in the arrow A direction and

pull out CD-SW board in the arrow

B

direction.

11

HCD-GNX780/GNX880

3-8. FUNCTION BOARD, JOG BOARD

3-9. CD MECHANISM DECK

3

FUNCTION board

2

nine screws

(+BVTP2.6 (3CR))

5

two screws

(+BVTP2.6 (3CR))

6

two screws

(+BVTP2.6 (3CR))

1

knob vol

4

knob jog assy

7

JOG board

MAIN board

2

CD mechanism deck

4

wire (flat type)

(CN701)

6

wire (flat type)

(CN504)

5

connector

(CN560)

3

wire (flat type)

(CN505)

1

two screws (+BVTP 3×8)

12

HCD-GNX780/GNX880

3-10. BACK PANEL

3-11. PRIMARY BOARD, EFFECTOR BOARD

1

connector

(CN1200)

2

connector

(CN1204)

3

wire (flat type)

(CN1501)

6

two screws (GNX880)

screw (GNX780)

(+BVTP 3×10)

4

five screws

(+BVTP 3×10)

5

two screws

(+BVTP 3×12)

7

two screws

(+BVTP 3×12)

9

connector

(CN580)

8

back panel

1

connector

(CN101)

2

connector

(CN201)

3

screw

(+BVTP 3

×

8)

5

two screws

(+BVTP 3

×

10)

4

PRIMARY board

6

EFFECTOR board

13

HCD-GNX780/GNX880

3-13. SURROUND BOARD, PA BOARD

3-12. POWER AMP PC BOARD ASSY, MAIN BOARD

1

connector

(CN1213)

2

connector

(CN1212)

8

connector

(CN105)

3

screw

(+BV3 (3-CR))

4

two screws

(+BV3 (3-CR))

5

screw

(+BV3 (3-CR))

6

screw

(+BVTP 3

×

10)

7

power AMP PC board assy

9

two screws

(+BVTP 3

×

10)

q;

screw

(+BVTP 3

×

10)

qa

MAIN board

(GNX880)

4

connector

(CN607)

1

two screws

(+BVTP 3

×

10)

2

two screws

(transistor)

3

SURROUND board

5

two screws

(+BVTP 3

×

10)

6

holder

7

three screws

(+BVTP 3

×

10)

8

two screws

(transistor)

9

two screws

(+BVTP 3

×

10)

qa

screw

(+BVTP 3

×

10)

0

heat sink

qs

bracket

(GNX880)

qd

PA board

(GNX880)

14

HCD-GNX780/GNX880

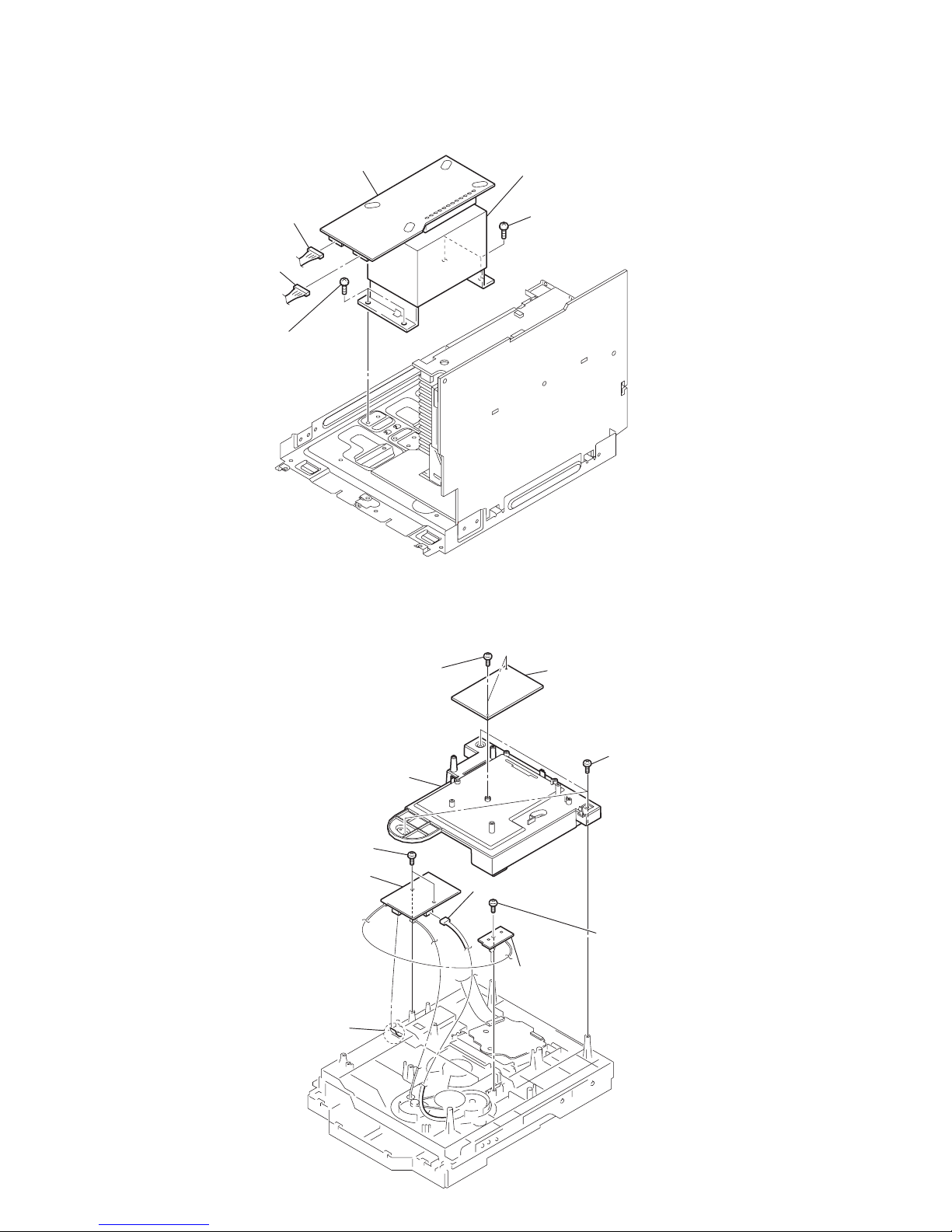

3-14. POWER TRANSFORMER (T1200)

3-15. CDG BOARD, DRIVER BOARD, SW BOARD

1

connector

(CN1213)

2

connector

(CN1212)

3

two screws

4

two screws

5

power transfomer (T1200

)

TRANS board

7

connector (CN703)

4

cover (CDM)

8

DRIVER

board

2

CDG

board

0

SW board

6

wire (flat type) (CN702)

5

two

screws

(+BTTP (M2.6))

3

three

screws

(+BVTP 3

×

10

)

1

two

screws

(+BVTP 3

×

10)

9

screw

(+BTTP (M2.6))

15

HCD-GNX780/GNX880

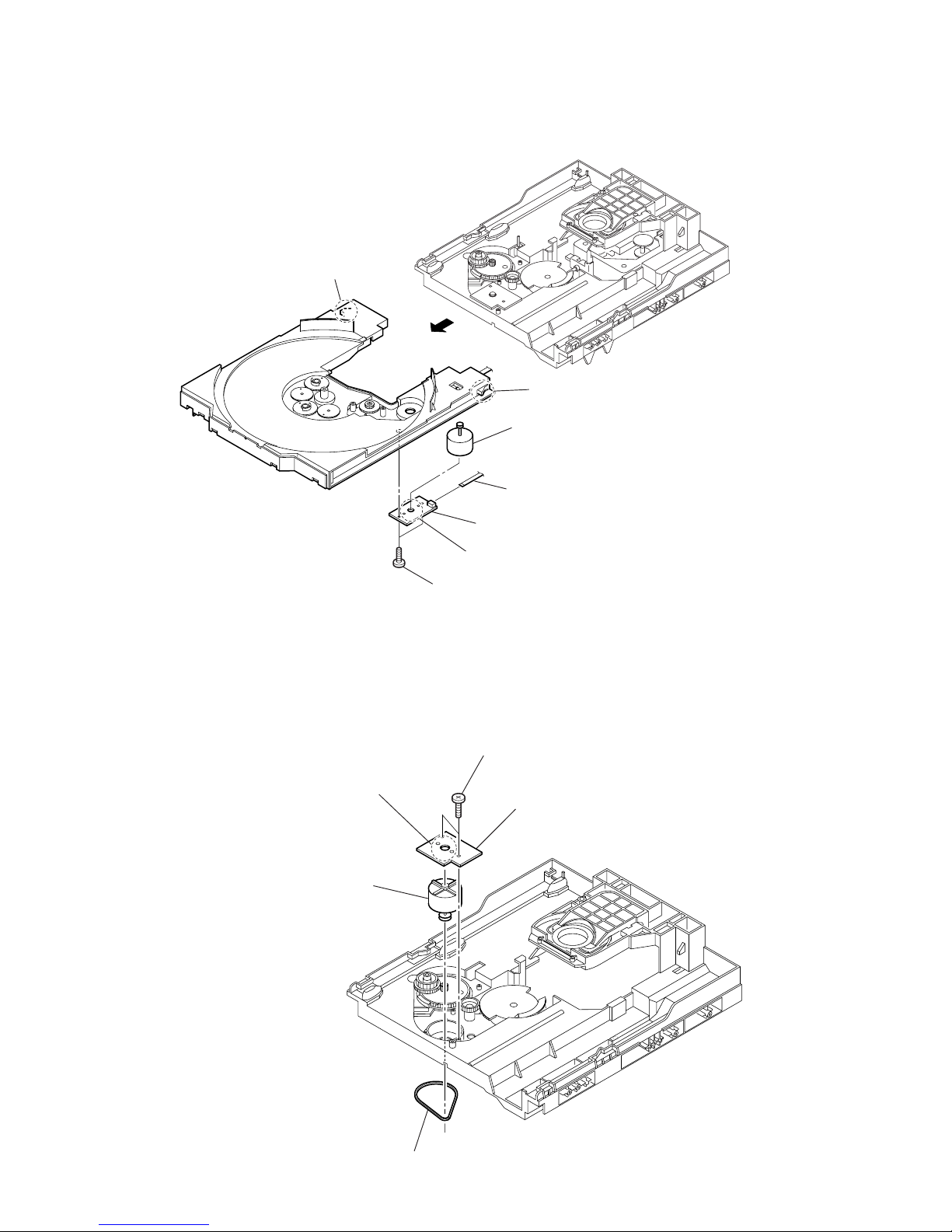

3-16. BD84 BOARD

3-17. SENSOR BOARD

5

two

coil springs

(insulator)

9

two

coil springs

(insulator)

6

two

insulators

0

two

insulators

qs

s

crew (+BVTP 2.6 (3CR))

7

t

wo screws

(+BTTP (M2.6))

3

screw

(+BTTP (M2.6))

2

h

older (213) ASSY

8

t

wo stoppers (BU)

qd

Remove the four solderings of motor.

qf

CN101 (flat type)

qg

BD84

board

qh

optical pick-up

(KSM-215DCP/C2NP)

1

floating

screw

(+PTPWH M2.6)

4

floating

screw

(+PTPWH M2.6)

qa

2

t

ray

3

b

elt (table)

5

p

ulley (table)

8

s

crew

(+BTTP (M2.6))

0

SENSOR board

7

g

ear (geneva)

9

connector

(

CN731)

1

floating

screw

(+PTPWH M2.6)

6

floating

screw

(+PTPWH M2.6)

4

floating

screw

(+PTPWH M2.6)

16

HCD-GNX780/GNX880

3-18. MOTOR (TB) BOARD

6

Remove the two solderings of motor.

8

MOTOR (TB) board

7

t

able motor assy (M741)

5

two

screws

(+BTTP (M2.6))

4

3

wire (flat type) 5 core (CN742)

1

stopper

2

stopper

3-19. MOTOR (LD) BOARD

4

Remove the two solderings of motor.

3

MOTOR (LD) board

1

b

elt (loading)

5

l

oading motor assy (M751)

2

two

screws

(+BTTP (M2.6))

17

HCD-GNX780/GNX880

[MC TEST MODE]

• This mode is used to check operations of the respective sections

of Amplifier, Tuner, and Tape.

Procedure:

* To enter MC Test Mode

1. Press x button, [ENTER] button and [DISC 3] button

simultaneously.

2. The CD ring indicators TAPE A and B indicators flash on the

fluorescent indicator tube. The function is changed to TV.

* Check of Amplifier

1. Press [EQ BAND] button repeatedly until a message “GEQ

MAX” appears on the fluorescent indicator tube. GEQ

increases to its maximum.

2. Press [EQ BAND] button repeatedly until a message “GEQ

MIN” appears on the fluorescent indicator tube. GEQ decreases

to its minimum.

3. Press [EQ BAND] button repeatedly until a message “GEQ

FLAT” appears on the fluorescent indicator tube. GEQ is set

to flat.

4. When the [VOLUME] knob is turned clockwise even slightly,

the sound volume increases to its maximum and a message

“VOLUME MAX” appears on the fluorescent indicator tube.

5. When the [VOLUME] knob is turned counter-clockwise even

slightly, the sound volume decreases to its minimum and a

message “VOLUME MIN” appears on the fluorescent

indicator tube.

* Tape function

1. When a tape is inserted in Deck B and recording is started, the

function is changed to TV automatically. When [CD SYNC]

button is pressed during recording in function, ALC (Automatic

Logic Control) is turned on.

2. During recording, press

m

will stop the recording and

the function is changed to TAPE B and rewind the tape in

Deck B until the recording start position and playback of the

tape in Deck B is started. If the [REC PAUSE/ START] button

is pressed for a pause and pressed again to resume recording

during recording time, when the tape is rewind, the tape will

be rewind until the position where the pause is applied.

* To release MC Test mode.

1. To release this mode, press

?/1

button.

2. The cold reset is enforced at the same time.

[COLD RESET]

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customer.

Procedure:

1. Press x button, [ENTER] button, and

?/1

button

simultaneously.

2. The fluorescent indicator tube becomes blank for a while, and

the set is reset.

[GC TEST MODE]

• This mode is used to check the fluorescent indicator tube,

LEDs, keys, VOLUME jog, OPERATION DIAL jog, AMS

jog, destination, software version and VACS level.

Procedure:

1. Press x button, [ENTER] button and [DISC 2] button-

simultaneously.

2. All LEDs and segments in fluorescent indicator tube are lighted

up. All LEDs are lighted up in red color.

3. When you want to enter the software version display mode,

press [DISC 1] button. The model is displayed.

Press [DISC 1] button again to show destination.

4. Each time [DISC 1] button is pressed, the display changes from

MC version, GC version, SYS version, CD version, CDDM

version, CDMA version, CDMB version, BDA version, BDB

version, ST version, TC version, TA version, TM version in

this order, and returns to the MC version display.

5. When [DISC 3] button is pressed while the version numbers

are being displayed except model and destination, the date of

the software creation appear. When [DISC 3] button is pressed

again, the display returns to the software version display. When

[DISC 1] button is pressed while the date of the software

creation is being displayed, the date of the software creation

is displayed in the same order of software version display.

6. Press [DISC 2] button, the key check mode is activated.

7. In the key check mode, the fluorescent indicator tube displays

“K 0 V0J0”.

Each time a button is pressed, “K” value increases. However,

once a button has been pressed, it is no longer taken into

account.

“V” value increases in the manner of 0,1, 2, 3 ... if [VOLUME]

knob is turned clockwise, or it decreases in the manner of 0,

9, 8, 7 ... if [VOLUME] knob is turned counter-clockwise.

“J” value increases in the manner of 0,1, 2, 3 ... if [OPERATION

DIAL] knob is turned clockwise, or it decreases in the manner

of 0, 9, 8, 7 ... if [OPERATION DIAL] knob is turned counterclockwise.

8. When [DISC 3] button is pressed after all LEDs and segments

in fluorescent indicator tube light up, the fluorescent indicator

tube displays “VACS A+B FAPC”. A is VACS level which is

trigger by signal level, B is VACS level which is trigger by

temperature and C is VACS level which is trigger by APVACS

(Abuse Protection VACS).

F is shown if the fan is turned in high speed and vice-versa.

The signal level, which will trigger VACS A is shown in the

center area of fluorescent indicator tube.

9. When [EX-CHANGE/DISC SKIP] button is pressed after all

LEDs and segments in fluorescent indicator tube light up,

alternate segments in fluorescent indicator tube would light

up. If you press [EX-CHANGE/DISC SKIP] button again, another

half of alternate segments in fluorescent indicator tube would

light up. Pressing [EX-CHANGE/DISC SKIP] button again

would cause all segments lights up.

10. To release this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

SECTION 4

TEST MODE

18

HCD-GNX780/GNX880

[VACS ON/OFF]

• This mode is used to switch ON and OFF the VACS (Variable

Attenuation Control System).

Procedure:

1. Press

?/1

button to turn the set ON.

2. Press x button and [ILLUMINATION]

button simultaneously.

The message “VACS OFF” or “VACS ON” appears on the

fluorescent indicator tube.

[TUNER STEP CHANGE]

• The step interval of AM channels can be toggled between 9

kHz and 10 kHz.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Press [TUNER/BAND] button to select the “AM”.

3. Press

?/1

button to turn the set OFF.

4. Press [ENTER] button and

?/1

button simultaneously. The

system will turn ON automatically. The message “AM 9k

STEP” or AM 10k STEP” appears on the fluorescent indicator

tube and thus the channel step is changed.

[CD SERVICE MODE]

• This mode let you move the CD sled motor freely. Use this

mode when you want to clean the optical pick-up.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select CD function.

3. Press x , [ENTER] button, and

Z

OPEN/CLOSE

button

simultaneously.

4. The CD service mode is activated. The message “SERVICE

MODE” appears on the fluorescent indicator tube.

5. With the CD in stop status, press

M

to move the optical

pick-up to outside track, or press

m

to move to inside

track. The message “SLED OUT” or “SLED IN” appears on

the fluorescent indicator tube.

6. To turn on or off the laser, press [DIRECTION] button. The

message “LD ON” or “LD OFF” appears on the fluorescent

indicator tube.

7. To release this mode, press

?/1

button.

[CD AGING MODE]

This mode can be used for operation check of CD section.

• If an error occurs, the aging operation would stops and the

status is displayed.

• If there are no error occurs, the aging operation would

continues repeatedly.

Procedure:

1. Press

?/1

button to turn the set ON

2. Select CD function.

3. Load three discs on the disc tray.

4. Press [PLAY MODE] button on the remote repeatedly to select

the “ALL DISCS” mode, and press the [REPEAT] button on

the remote repeatedly to select “REPEAT OFF” mode.

5. Press x button, [ENTER] button, and [EX-CHANGE/DISC

SKIP] button simultaneously.

6. Aging operation is started.

7. To release this mode, press

?/1

button or disconnect the

power cord to turn the power OFF.

Aging mode sequence:

Start (from disc 1)

Disc chucking

TOC reading

Play first track for 2 seconds

Play last track for 2 seconds

EX-CHANGE open/close

Open the disc tray

Disc skip

Close the disk tray

Change the next disc

19

HCD-GNX780/GNX880

Display

M*$$%%&&##00

3) Display of no disc errors

D*: The number of mechanical error (“00” is latest one)

(Rotate

>

.

knob in the direction of either to display next

error)

$$: Error type

01: Focus error

02: GFS error

03: Setup error

%%: Not used

&&:

00: No disc judgment without chucking retry.

01: No disc judgment after chucking retry.

##: The state when judged as no disc

01: Stop

02: Setup

03: TOC reading

04: Access

05: Playback

06: Pause

07: Manual search (Play)

08: Manual search (Pause)

[CD REPEAT 5 LIMIT OFF MODE]

• The number of repeat for CD playback is 5 times when the

repeat mode is “REPEAT ALL”. This mode enables CD to

repeat playback for limitless times.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select CD function.

3. Press x button, [CD] button and [DISC 1] button

simultaneously to enter the CD repeat 5 limit off mode and

the fluorescent indicator tube displays “LIMIT OFF”.

4. To release this mode, operate the cold reset. (Refer to the “MC

COLD RESET”)

[CD SHIP MODE (WITH MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable

to vibration and clears all data including preset data stored in

the RAM to initial conditions. Use this mode when returning

the set to the customer after repair.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select CD function.

3. Press x

button,

[SOUND FLASH]

button and

?/1

button

simultaneously.

The set will power off automatically.

4. After the “STANDBY” blinking display finish, a message

“MECHA LOCK” is displayed on the fluorescent indicator

tube and the CD ship mode is set.

Display

D*$$%%&&##00

• Display when an error occurred (CD Error Code Mode)

Procedure:

1. Press x button, [ENTER] button and [DISC 1] button

simultaneously to enter the error code display mode.

2. The fluorescent indicator tube displays the number of total

error.

3. Each time

M

m

knob is rotated, display change as

below.

Display of total error

>

+

direction

–

.

direction

Display of Mechanical errors

>

+

direction

–

.

direction

Display of no disc errors

4. To clear the error record, operate the cold reset. (Refer to the

“MC COLD RESET”)

5. To release this mode, press the

?/1

button or disconnect

the power plug to turn the power OFF.

1) Display of total error

Em**: The number of mechanical errors.

Ed **: The number of no disc errors after chucking the disc.

2) Display of mechanical errors

M*: The number of mechanical error (“00” is latest one)

(Rotate

>

.

knob in the direction of either to display next

error)

$$: Not used

%%: Loading related error (Second figure is not used)

D: Stop by the problem other than mechanical problem while

closing.

E: Stop by the problem other than mechanical problem while

opening.

C: Stop by the problem other than mechanical problem while

chucking up.

F: Stop by the problem other than mechanical problem while

chucking down.

&&: Emerging error

01: Stop while chucking up.

02: Stop while chucking up.

03: Time-out of EX-CHANGE open.

05: Time-out of EX-CHANGE close.

##: Not used

Display

Em**Ed**

20

HCD-GNX780/GNX880

[CD TRAY LOCK MODE]

• This mode let you lock the disc trays. When this mode is

activated, the disc tray will not open when

Z

OPEN/CLOSE

button or [EX-CHANGE/DISC SKIP] button is pressed. The

message “LOCKED” will be displayed in the will be displayed

on the fluorescent indicator tube.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select CD function.

3. Press x button and

Z

OPEN/CLOSE

button

simultaneously and hold down until “LOCKED” or

“UNLOCKED” displayed on the fluorescent indicator tube

(around 5 seconds).

[VIDEO/MD SWITCHING]

• This mode let you switch from VIDEO to MD and vice-versa.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select VIDEO function.

3. Press [VIDEO/MD] button and

?/1

button simultaneously.

The function will change to MD. Press the same buttons again

to change from MD to VIDEO.

[TCM OFFLINE MODE]

• This mode prevents set from power off automatically when

TCM is not connected.

Therefore, measurements can be done even when TCM is not

connected during production.

• Procedure:

1. When the system in turned off, press [EQ BAND] button,

[TAPE A/B] button and

?/1

button simultaneously. The

set will power on automatically.

2. The message “TCM OFFLINE” will be displayed on the

fluorescent indicator tube.

[CD SHIP MODE (WITHOUT MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable

to vibration. Use this mode when returning the set to the

customer after repair.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select CD function.

3. Press [CD] button and

?/1

button simultaneously. The set

will power off automatically.

4. After the “STANDBY” blinking display finish, a message

“MECHA LOCK” is displayed on the fluorescent indicator

tube and the CD ship mode is set.

[CD POWER MANAGE]

• This mode let you switch on or off power supply to the BU

during TUNER function.

• When CD POWER is set to OFF, the power supply to the BU

is cut off during TUNER function. It will increase the time

taken to access CD when function change from TUNER to

CD but it will improve tuner reception.

• When CD POWER is set to ON, the power supply to the BU

is not cut off during TUNER function. It will reduce the time

taken to access CD when function change from TUNER to

CD but it will decrease tuner reception performance.

Procedure:

1. Press

?/1

button to turn the set ON.

2. Select CD function.

3. Press

?/1

button to turn the set OFF.

4. Press x button and

?/1

button simultaneously. The set

will power on automatically.

5. The message “CD POWER ON” or “CD POWER OFF” will

be displayed on the fluorescent indicator tube.

21

HCD-GNX780/GNX880

SECTION 5

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Tor que Measurement

2.9 mN • m to 6.9 mN • m

FWD CQ-102C 30 to 70 g • cm

(0.42 – 0.97 oz • inch)

FWD

0.15 mN • m to 0.59 mN • m

back tension

CQ-102C 1.6 to 6 g • cm

(0.022 – 0.08 oz • inch)

4.8 mN • m to 16.7 mN • m

FF/REW CQ-201B 49 to 170 g • cm

(0.69 – 2.36 oz • inch)

Mode Torque meter Meter reading

0 dB=0.775 V

DECK SECTION

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

•Test Tape

RECORD/PLAYBACK HEAD AZIMUTH ADJUSTMENT

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

set

MAIN board

CN510

Pin

1

(L-CH)

Pin

3

(R-CH)

MAIN board

CN510

Pin

2

(GND)

+

–

level meter

test tape

P-4-A100

(10 kHz, –10 dB)

22

HCD-GNX780/GNX880

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

3. Mode: Playback

4. After the adjustments, apply suitable locking compound to

the pats adjusted.

Adjustment Location: Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

Screw

position

L-CH

peak

within

1dB

Output

level

L-CH

peak

R-CH

peak

within

1dB

Screw

position

R-CH

peak

MAIN

board

CN510

set

test tape

P-4-A100

(10 kHz, –10 dB)

pin

3

oscilloscop

e

L-CH

R-CH

V

H

waveform of oscilloscope

in phase 45°90°135°180

°

good

wrong

pin

2

pin

1

L

R

CDG SECTION

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

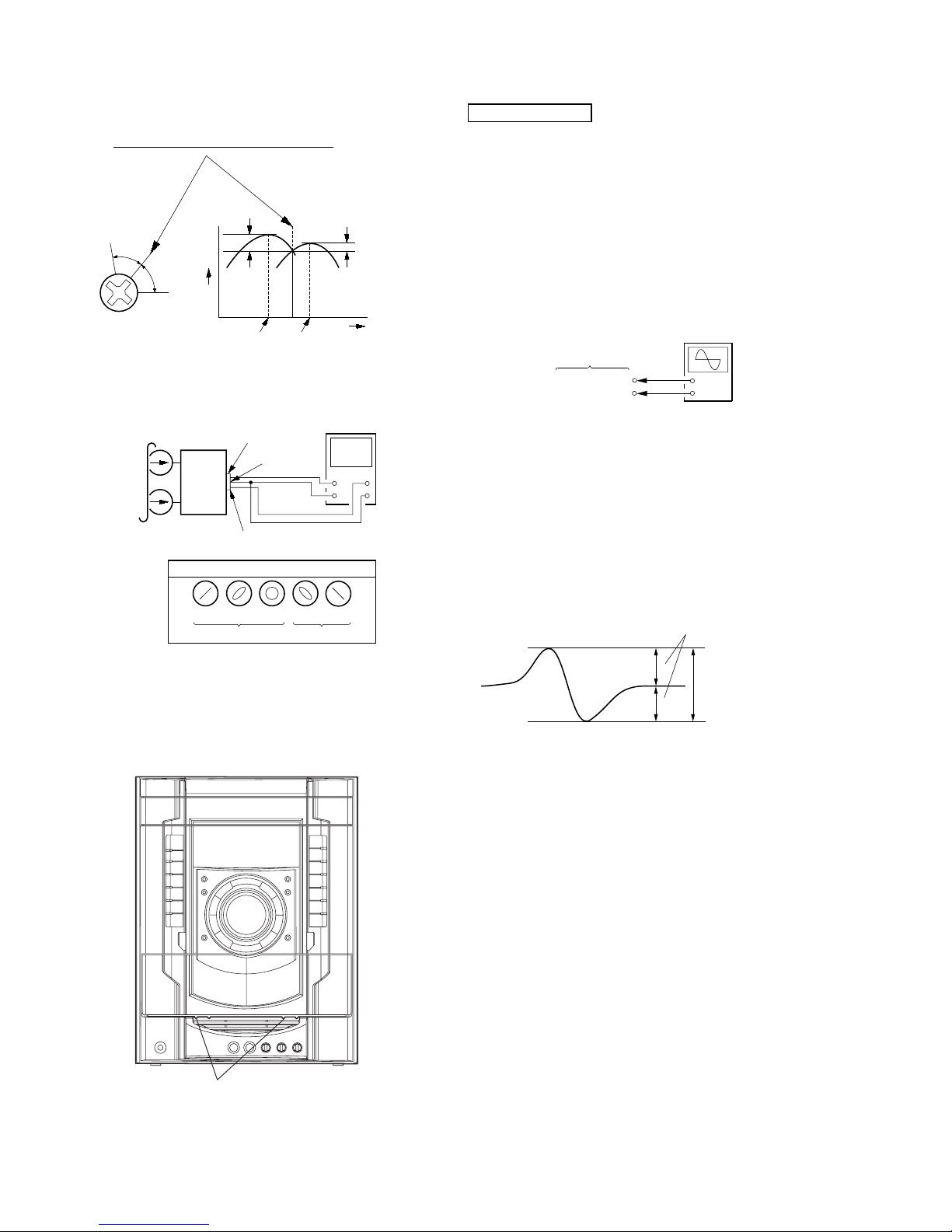

S-curve Check

Connection:

Procedure:

1. Connect an oscilloscope to test point JPO102 (FE1) and TP

117(VC) on the CD board.

2. Turn the power on.

3. Put the disc (YEDS-18) in and turned power switch on again

and actuate the focus search. (actuate the focus search when

disc table is moving in and out)

4. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within

2.4 ± 1 Vp-p.

S-curve waveform

Note:

•Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

•Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Checking Location: CD board (SIDE B)

(See page 24.)

+

–

CD board

JPO102 (FE1)

TP117 (VC)

oscilloscope

A

B

symmetry

within 2.4

±

1 Vp-p

azimuth

screw

23

HCD-GNX780/GNX880

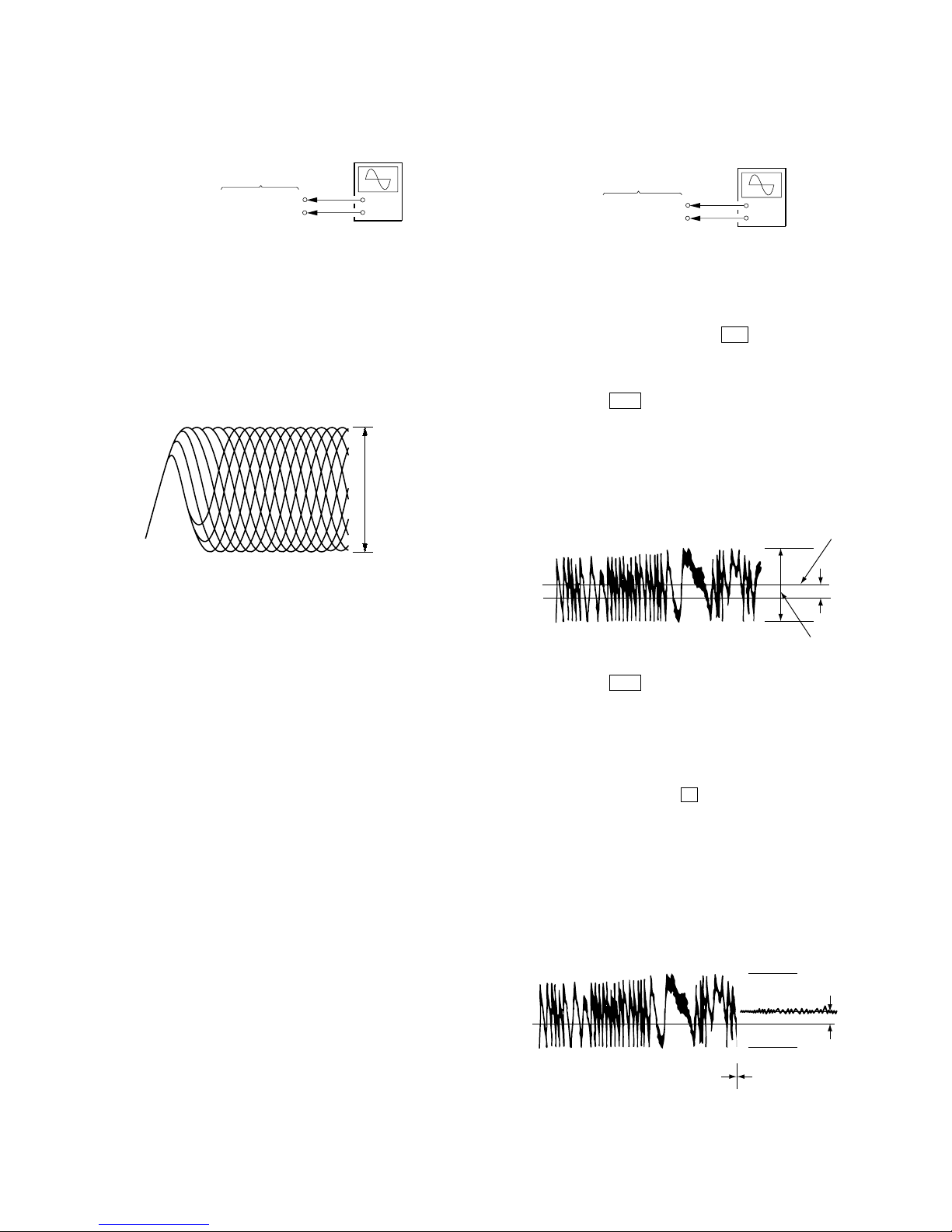

RFAC Level Check

Connection:

Procedure:

1. Connect an oscilloscope to test point TP124 (RFAC) and TP

117(VC) on the CD board.

2. Turn the power on.

3. Put the disc (YEDS-18) in to playback the number five track.

4. Confirm that oscilloscope waveform is clear and check RFAC

signal level is correct or not.

Note: A clear RFAC signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RFAC signal waveform

Checking Location: CD board (SIDE B)

(See page 24.)

E-F Balance Check

Connection:

Procedure:

1. Connect an oscilloscpe to test point TPO103 (TE1) and TP117

(VC) on the CD board.

2. Turn the power on.

3. Select the function “CD”.

4. Press three buttons of [ENTER], M , and

[SURRUUND MODE] simultaneously to set the CD service

mode.

5. Put the disc (YEDS-18) in to playback the number five track.

6. Press the . button. The message “TRAVERSE” is

displayed. (The tracking servo and the sledding servo are

turned OFF)

7. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

Tr averse Waveform

8. Press the . button. The message “TRAVERSE” is

displayed. (The tracking servo and sledding servo are turned

ON)

Confirm the C (DC voltage) is almost equal to the A (DC

voltage) is step 5.

9. To exit from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Press three buttons of x , [CLEAR], and [DISPLAY]

simultaneously. (cold reset)

Notes:

• Always move the optical pick-up to most inside track

when exiting from this mode. Otherwise, a disc will not

be unloaded.

• Do not run the sled motor excessively, otherwise the gear

can be chipped.

Tr averse Waveform

Checking Location: CD board (SIDE B) (See page 24.)

+

–

CD board

TP124 (RFAC)

TP117 (VC)

oscilloscope

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 0.9 ± 0.4 Vp-p

+

–

CD board

JPO103 (TE1)

TP117 (VC)

oscilloscope

0V

B

level: 1.0 ± 0.5 Vp-p

Center of

the waveform

A (DC

voltage)

0V

Tr acking servo

Sled servo

ON

C (DC

voltage)

Tr acking servo

Sled servo

OFF

24

HCD-GNX780/GNX880

Checking Location:

– BD84 BOARD (SIDE B) –

TP117 (VC)

TP124 (RFAC)

JPO103 (TE1)

JPO102 (FE1)

IC101

25

HCD-GNX780/GNX880

SECTION 7

DIAGRAMS

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 V or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/

4

W or less unless otherwise

specified.

•%: indicates tolerance.

• f : internal component.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

BD84 board

no mark: CD PLAY

Other boards

no mark: TUNER (FM/AM)

( ) : CD PLAY

< > : TAPE PLAY

[ ] : TAPE REC

* : Impossible to measure

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : TUNER (FM/AM)

E : TAPE PLAY (DECK A)

d : TAPE PLAY (DECK B)

G : RECORD

J : CD PLAY

N : MIC INPUT

c : CDG

g : VIDEO

Note: The components identified by mark 0 or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

(The other layers' patterns are not indicated.)

• Indication of transistor.

Caution:

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

C

B

These are omitted.

E

Q

B

These are omitted.

CE

Q

B

These are omitted.

CE

Q

Note on Printed Wiring Boards:

Note:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

26

HCD-GNX780/GNX880

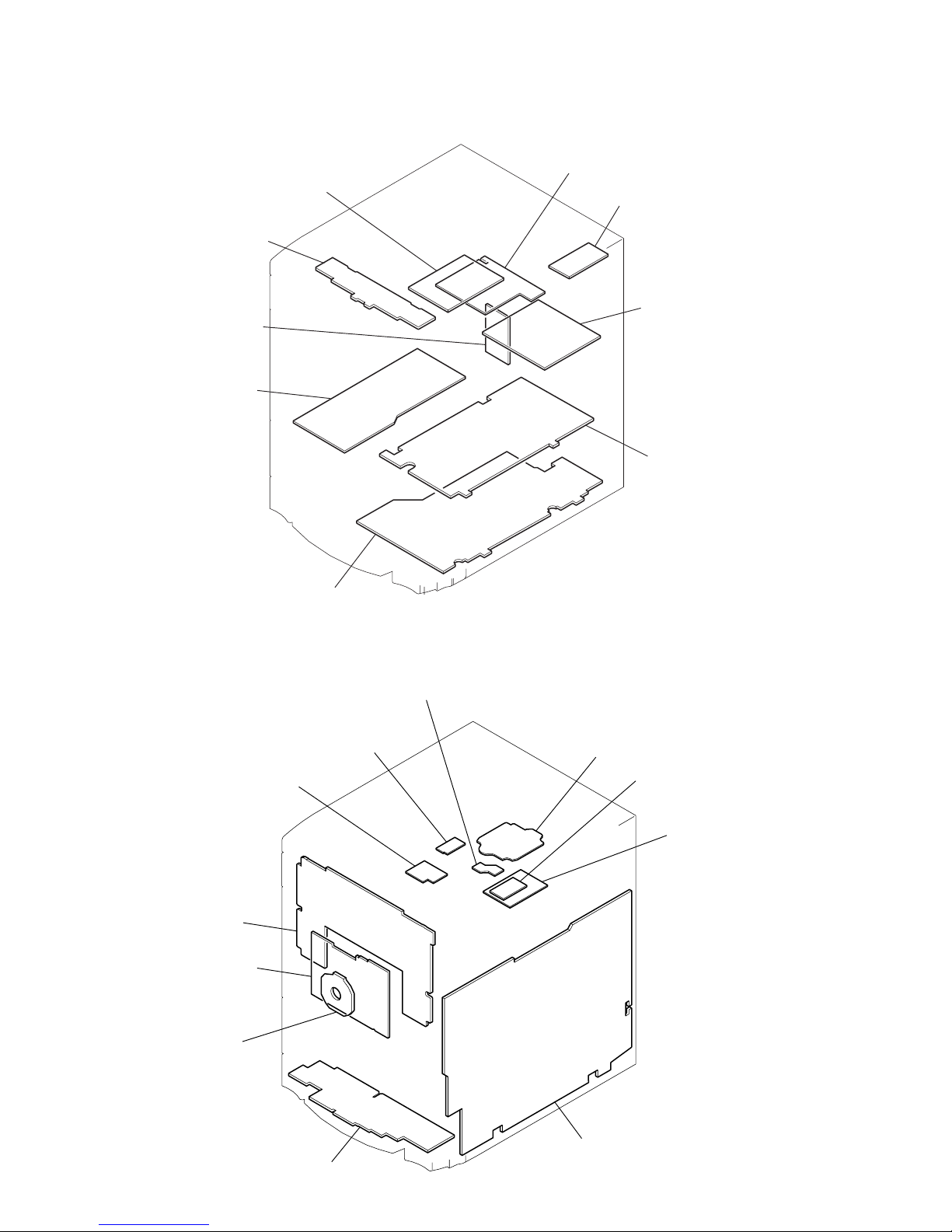

• CIRCUIT BOARDS LOCATION

MAIN board

MIC board

JOG board

PANEL board

FUNCTION board

MOTOR (LD) board

SW board

SENSOR board

BD84 board

DRIVER boar

d

MOTOR (TB) board

CD-SW board

CDG board

TRANS board

PA board

SURROUND board

EFFECTOR board

SWITCHING POWER

TUNER PACK

PRIMARY board

HCD-GNX780/GNX880

2727

HCD-GNX780/GNX880

7-1. BLOCK DIAGRAM – CDG SECTION –

A

MAIN

SECTION

(Page 29)

B

DISPLAY/POWER

SECTION

(Page 31)

OPTICAL PICK-UP

BLOCK

(KSM-215DCP/C2NP)

LD

DRIVER

Q10

CD DIGITAL

OUT

OPTICAL

CD MUTE

Q250,251

+3.3V

LD

GND

FOCUS

COIL

F+

F

T+

T

TRACKING

COIL

IC251

X171

16.9MHz

SL/SP MOTOR

DRIVER

12

6

11

13

14

VR

PD

15

16

17

18

4

26

23

2

20

MUTE

CH2OUT-F

CH1FIN

OUT

VREF

CH1RIN

CH2FIN

SFDR

OPIN+

CH2OUT-R

CH1OUT-R

CH1OUT-F

CH4OUT-R

CH4OUT-F

CH3OUT-F

CH3OUT-R

M

M

M101

(SPINDLE)

M102

(SLED)

S101

(LIMIT)

VCC

VC

A

B

C

D

E

F

DETECTOR

A

B

E

19

F

20

LD

36

PD

37

TFDR

11

FFDR

13

CH3FIN

9

OPTICAL

OUT

SSTP

7

MPD

6

95

XTACN

100

XRST

102

DATA

104

XLAT

105

CLOCK

86

AOUT2

81

AOUT1

71

DOUT

61

PCMD1

62

LRCKI

63

LRCK

65

PCMD

MP3

IC301

DECODER

SYSTEM

IC401 (1/5)

CONTROL

IC210

21

40

SDO0

11

LRCKIA

16

SFSY/LRCK1B

19

SDI0

14

77

XTAO

78

XTAI

55

VDD

VDD

VDDM

26

25

VC

27

C

28

D

29

107

SENS

XTCN

XRST

DATA

XLT

CLOCK

SENS

113

GFS

114

C2PO

TRDR

NC

NC

12

22

SRDR

CH3RIN

10

CH2RIN

FRDR

14

XRST

100

66

BCK

60

BCK1

BCKIA

15

SBSY/BCK1B

18

5

+3.3V

IC303

7

5 1

3

26

27

25

7

5

24

23

22

46

45

44

43

39

42

41

6

19

21

40

38

18

3

2

1

28

35

37

STANBY

36

PO11/BUCK/AD1

8

MIACK

7

MICK

6

MIDIO

4

MICS

5

MILP

2

RESET

41

SRMSTB

115

SCOR

SCOR

REG

CD MUTE DRIVE

Q540, 541

IC101

RF AMP, DSP, DAC

IC1002

DRAM

IC1001

VIDEO D/A

IC1003

+5V REG.

IC1006

VIDEO BUFFER

25,27,29,30

VA0-7

15-22

VD0-3

144

2623

RAS

CAS

A0-7

DQ1-4

X1002

14.31818MHz

60

XO159XI1

X1001

17.734475MHz

58

XO257XI2

+B SWITCH

Q1007,1008

NO402

CN402

IIC-CLK

IIC-DATA

IIC-CLK

IIC-DATA

3

4

CNVSS

J1001

TXD1

RTS1

ON BOARD

PROGRAM

CLK1

RXD1

CN VSS

RESET

RESET

VIDEO

OUT

VMUTE

133

WE

2822

CE

3

2

6

9

7

8

RAS

CAS

WE

CE

398

DATA

SBSO

5

110

SFSY

WFCK

299

CLCK

EXCK

6

MUTE

56

PDOWN

1,2,24,25

9-12,14-17

98

5

4

Q1004

SBSY

Q1005,1009

6

34

1

2

11 101312

IC1005

Q1010

VCC

55

SENTSC

54

RESET

Q1002,1006

52

DEN

37

GDET

MUTE DATA

HALT_CLK

PAL/_NTSC

CDG-RST

EVER+3.3V

CDG-DET

CDG/-POWER

CDG/_BGC

CDG/-DET

44

VDOUT

Q1001

33 31 32 9

MUTE DATA

HALT_CLK

VMUTE

CDG-RST

CDG-DET

CDG-POWER

CNVSS

VMUTE

CDG RST

CDG DET

CD POWER

CNVSS

VMUTE

CDG-POWER

1

4

2

3

PWR

VIN

SAVE

6

VCC

VOUT

1

3

VIN

VOUT

: CD

: CDG

• SIGNAL PATH

• R-CH is omitted due to same as L-CH.

: VIDEO

R-CH

CD-L

MP3 STB

MP3 REQ

XTCN

MP3 REQ

MP3 STB

MP3 CLK

MP3 CLK

MP3 ACK

MP3 ACK

MP3 DATA OUT

MP3 DATA

MP3 LP

MP3 LP

MP3 CS

MP3 RST

MP3 CS

MP3 RST

MP3 DATA IN

SCOR

SENS

CD-CLK

XLAT

CD-DATA

XRST

XTCN

SCOR

SENS

CLOCK

XLT

DATA

XRST

CD MUTE

LMR

LMF

TM-R

TM-F

TBL_SENS

E-1

E-2

E-3

OPEN SW

12

RESET

30

IIC-DATA

29

IIC-CLK

IC701

TABLE LOADING

MOTOR DRIVER

4

2

9

7

RIN

FIN

OUT1

OUT2

IC712

TABLE MOTOR DRIVER

4

2

9

7

RIN

FIN

OUT1

OUT2

M751

(TABLE LOADING)

M741

(TABLE)

S751

(OPEN)

ROTARY

ENCODER

INVERTER

M

M

IC731

TBL ADDRESS

SENS

S711

E-3

E-2

E-1

M+9V

Q731

Loading...

Loading...