HCD-FX900W

SERVICE MANUAL

Ver. 1.1 2006.09

HCD-FX900W is the amplifier, DVD/CD

and tuner section in DAV-FX900W.

This system incorporates with Dolby* Digital and Dolby Pro

Logic (II) adaptive matrix surround decoder and the DTS**

Digital Surround System.

* Manufactured under license from Dolby Laboratories.

“Dolby,” “Pro Logic,” and the double-D symbol are trademarks

of Dolby Laboratories.

** Manufactured under license from Digital Theater Systems, Inc.

“DTS” and “DTS Digital Surround” are trademarks of Digital

Theater Systems, Inc.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND

TOTAL HARMONIC

DISTORTION

(FTC Output Power): FL/FR/SL/SR: 84 W/ch

Amplifier section

Surround mode (reference )

*Depending on the sound field settings and the source,

there may be no sound output.

** When connecting the surround speakers to the system

by the speaker cords.

3 ohms at 160 - 20,000 Hz,

0.7 % THD

SW: 162 W 1.5 ohms at 25

- 160 Hz, 0.7 % THD

C: 84W 3 ohms at 500 20,000 Hz, 0.7% THD

RMS output power, 10 %

THD

Front: 143 W + 143 W

(with SS-TS55)

Center*: 143 W

(with SS-CT52)

Surround*: 143 W + 143

W** (3 ohms)

Subwoofer*: 285 W

(with SS-WS53)

Inputs (Analog)

TV/VCR 1, TV/VCR 2 (AUDIO IN)

Sensitivity: 450/250 mV

AUDIO IN Sensitivity: 250/125 mV

Inputs (Digital)

TV/VCR1 (COAXIAL IN)/TV/VCR2 (OPTICAL IN)

impedance: 75 ohms/–

Outputs (Analog)

Phones Accepts low-and high-

impedance headphones.

Super Audio CD/DVD system

Laser Semiconductor laser

(Super Audio CD/DVD:

λ = 650 nm)

(CD: λ = 790 nm)

Emission duration:

continuous

Signal format system NTSC

Tuner section

System PLL quartz-locked digital

synthesizer system

FM tuner section

Tuning range 87.5 – 108.0 MHz

(100 kHz step)

Antenna (aerial) FM wire antenna (aerial)

Antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

US Model

Canadian Model

Model Name Using Similar Mechanism HCD-FX10

Mechanism T ype CDM69EH-DVBU101

Optical Pick-up Name

AM tuner section

Tuning range 530 – 1,710 kHz (with the

Antenna (aerial) AM loop an tenna (aerial)

Intermediate frequency 450 kHz

Video section

Outputs VIDEO: 1 Vp-p 75 ohms

Inputs TV/VCR1: 1 Vp-p

KHM-310CAB/C2NP

interval set at 10 kHz)

531 – 1,710 kHz (with the

interval set at 9 kHz)

S VIDEO:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

HDMI OUT: Type A (19

pin)

75 ohms

TV/VCR2: 1 Vp-p

75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

— Continued on next page —

9-887-193-02

2006I16-1

© 2006.09

SUPER AUDIO CD/DVD RECEIVER

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

HCD-FX900W

r

General

Power requirements 120 V AC, 60 Hz

Power consumption On: 170 W

Dimensions (approx.) 445 × 71× 400 mm

Mass (approx.) 6.0 kg (13 lb 4 oz)

Design and specifications are subject to change

without notice.

Standby: 0.3 W (at the

Power Saving mode)

5

/8 × 2 7/8 × 15 3/4

(17

inches) (w/h/d) incl.

projecting parts

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

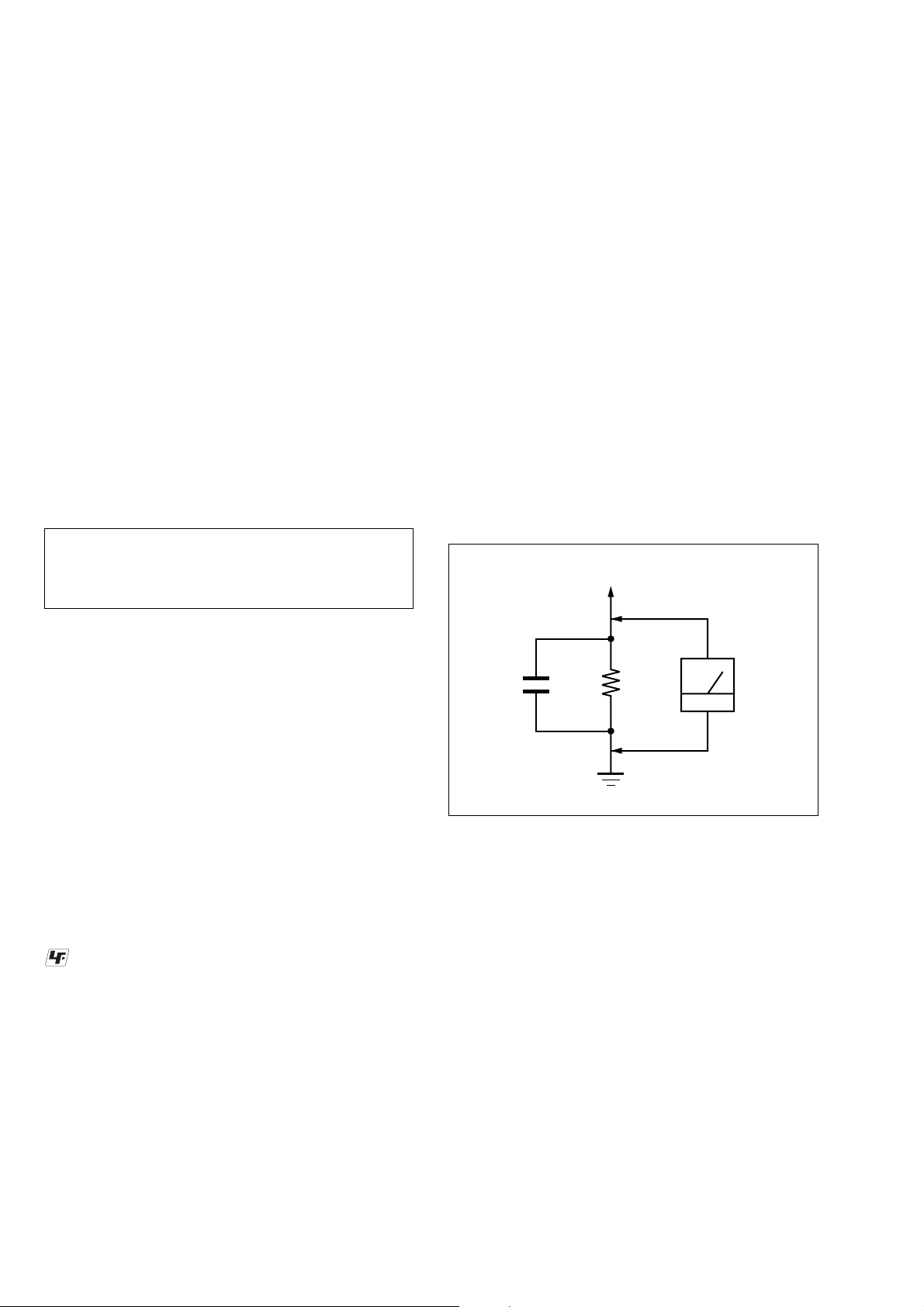

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter. The “limit” indication

is 0.75 V, so analog meters must hav e an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

TABLE OF CONTENTS

HCD-FX900W

1. SERVICING NOTE ................................................... 4

2. GENERAL ................................................................... 12

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 15

3-2. Top Panel, Side Panel ...................................................... 16

3-3. JACK Board, Front Panel Section ................................... 17

3-4. KEY Board, FL Board..................................................... 18

3-5. Button (Disc/Play/Power) ................................................ 19

3-6. I/O Board, D.C. Fan ........................................................ 19

3-7. DIAT TX XM Board ....................................................... 20

3-8. DMB12 Board ................................................................. 20

3-9. MAIN Board.................................................................... 21

3-10. SP Board.......................................................................... 22

3-11. POWER Board ................................................................ 22

3-12. DVD Mechanism Deck (CDM69EH-DVBU101) ........... 23

3-13. Base Unit (DVBU101) .................................................... 23

3-14. Optical Pick-up (KHM-310CAB) ................................... 24

3-15. SW Board, Bracket (Top) Assy ....................................... 24

3-16. RELAY Board ................................................................. 25

3-17. Motor (Stocker) Assy (Stocker)(M761) .......................... 25

3-18. Motor (Roller) Assy (Roller)(M781) ............................... 26

3-19. Motor (Mode) Assy (Mode)(M771) ................................ 26

3-20. Rubber Roller (Slider) Assy ............................................ 27

3-21. Timing Belt (Front/Rear)................................................. 27

3-22. Cam (Gear) ...................................................................... 28

3-23. SENSOR Board............................................................... 28

4. ASSEMBLY

4-1. How To Install The Cam (Eject Lock) ............................ 29

4-2. How To Install The Cam (Gear) ...................................... 29

4-3. How To Install The Gear (Mode C)................................. 30

4-4. How To Install The Gear (Mode Cam)............................ 30

4-5. How To Install The Rotary Encorder (S702),

Gear (Stocker Communication)....................................... 31

4-6. How To Install The Stocker Assy .................................... 31

5. TEST MODE ............................................................... 32

6. ELECTRICAL ADJUSTMENT ............................. 36

7. DIAGRAMS

7-1. Block Diagram – RF Section –....................................... 38

7-2. Block Diagram – VIDEO Section – ............................... 39

7-3. Block Diagram – AMP Section – ................................... 40

7-4. Block Diagram – AUDIO Section – ............................... 41

7-5. Block Diagram – POWER Section –.............................. 42

7-6. Block Diagram – DIAT Section – .................................. 43

7-7. Printed Wiring Boards – CHANGER Section –.............. 44

7-8. Schematic Diagram – CHANGER Section – ............. 45

7-9. Printed Wiring Board – DMB12 Section (Side A) – ...... 46

7-10. Printed Wiring Board – DMB12 Section (Side B) – ...... 47

7-11. Schematic Diagram – DMB12 Section (1/7) – .............. 48

7-12. Schematic Diagram – DMB12 Section (2/7) – .............. 49

7-13. Schematic Diagram – DMB12 Section (3/7) – .............. 50

7-14. Schematic Diagram – DMB12 Section (4/7) – .............. 51

7-15. Schematic Diagram – DMB12 Section (5/7) – .............. 52

7-16. Schematic Diagram – DMB12 Section (6/7) – .............. 53

7-17. Schematic Diagram – DMB12 Section (7/7) – .............. 54

7-18. Printed Wiring Board – MAIN Section (Side A) – ........ 55

7-19. Printed Wiring Board – MAIN Section (Side B) – ........ 56

7-20. Schematic Diagram – MAIN Section (1/8) –................. 57

7-21. Schematic Diagram – MAIN Section (2/8) –................. 58

7-22. Schematic Diagram – MAIN Section (3/8) –................. 59

7-23. Schematic Diagram – MAIN Section (4/8) –................. 60

7-24. Schematic Diagram – MAIN Section (5/8) –................. 61

7-25. Schematic Diagram – MAIN Section (6/8) –................. 62

7-26. Schematic Diagram – MAIN Section (7/8) –................. 63

7-27. Schematic Diagram – MAIN Section (8/8) –................. 64

7-28. Printed Wiring Boards – FL/KEY Section – ................... 65

7-29. Schematic Diagram – FL/KEY Section – ...................... 66

7-30. Printed Wiring Boards – JACK/SP Section –.................. 67

7-31. Schematic Diagram – JACK/SP Section – ..................... 68

7-32. Printed Wiring Board – I/O Section (Side A) –............... 69

7-33. Printed Wiring Board – I/O Section (Side B) – ............... 70

7-34. Schematic Diagram – I/O Section – ............................... 71

7-35. Printed Wiring Board – POWER Section –.................... 72

7-36. Schematic Diagram – POWER Section – ...................... 73

7-37. Printed Wiring Board – DIAT TX XM Section – ........... 74

7-38. Schematic Diagram – DIAT TX XM Section (1/2) –..... 75

7-39. Schematic Diagram – DIAT TX XM Section (2/2) –..... 76

8. EXPLODED VIEWS

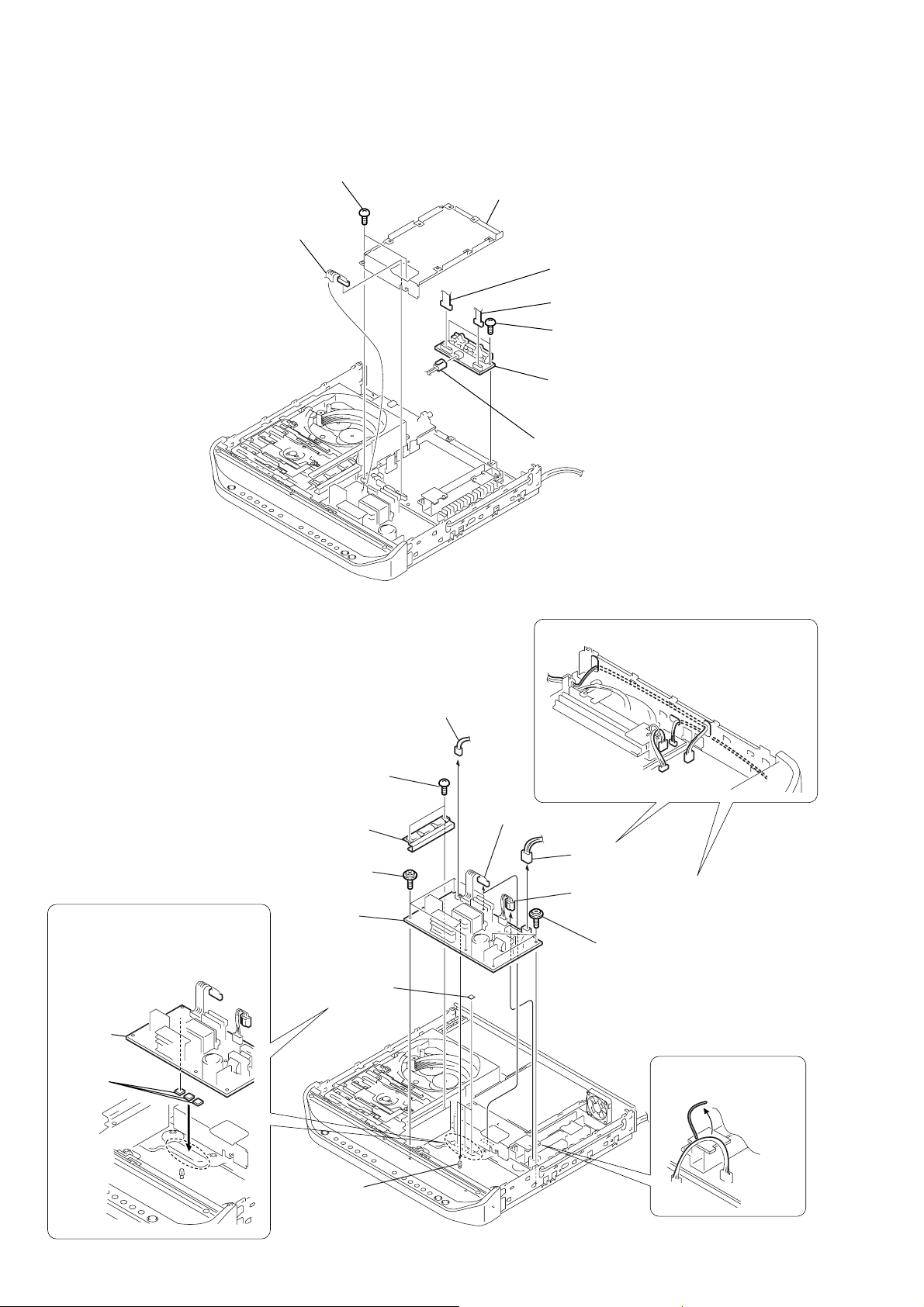

8-1. Overall Assy .................................................................... 92

8-2. Front Panel Assy .............................................................. 93

8-3. Chassis Section-1 ............................................................ 94

8-4. Chassis Section-2 ............................................................ 95

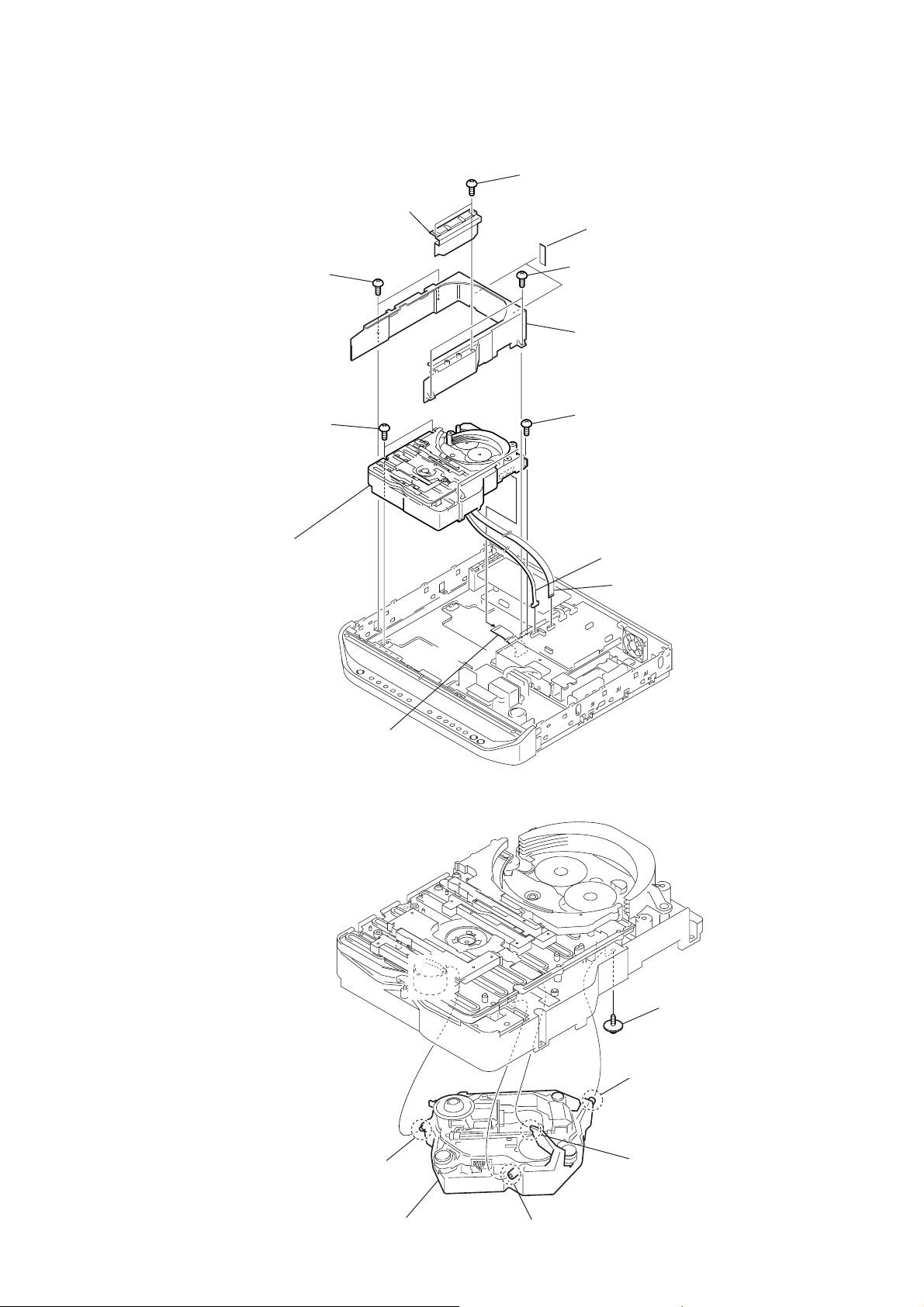

8-5. DVD Mechanism Deck Section-1

(CDM69EH-DVBU101) ................................................. 96

8-6. DVD Mechanism Deck Section-2

(CDM69EH-DVBU101) ................................................. 97

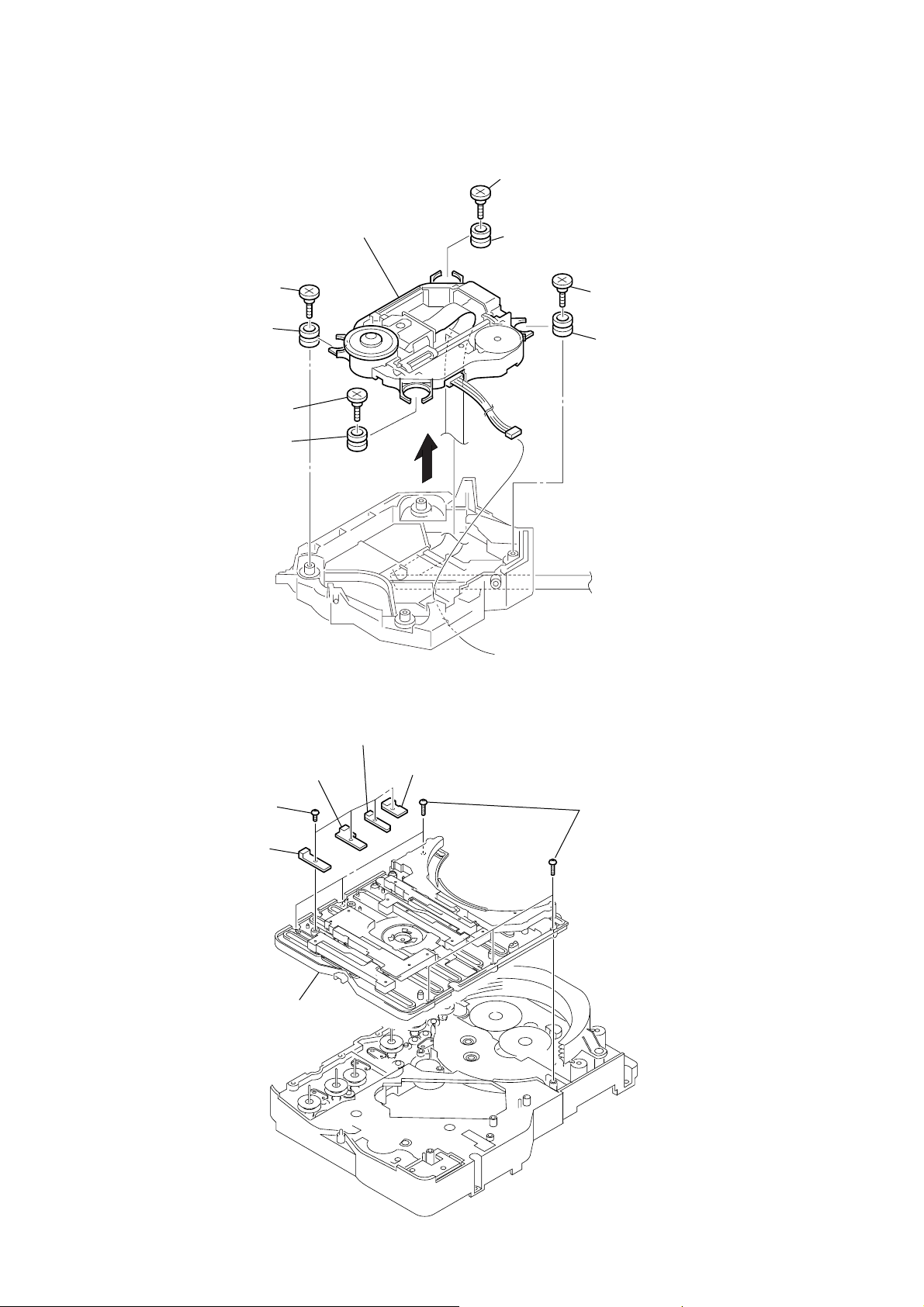

8-7. DVD Mechanism Deck Section-3

(CDM69EH-DVBU101) ................................................. 98

8-8. DVD Mechanism Deck Section-4

(CDM69EH-DVBU101) ................................................. 99

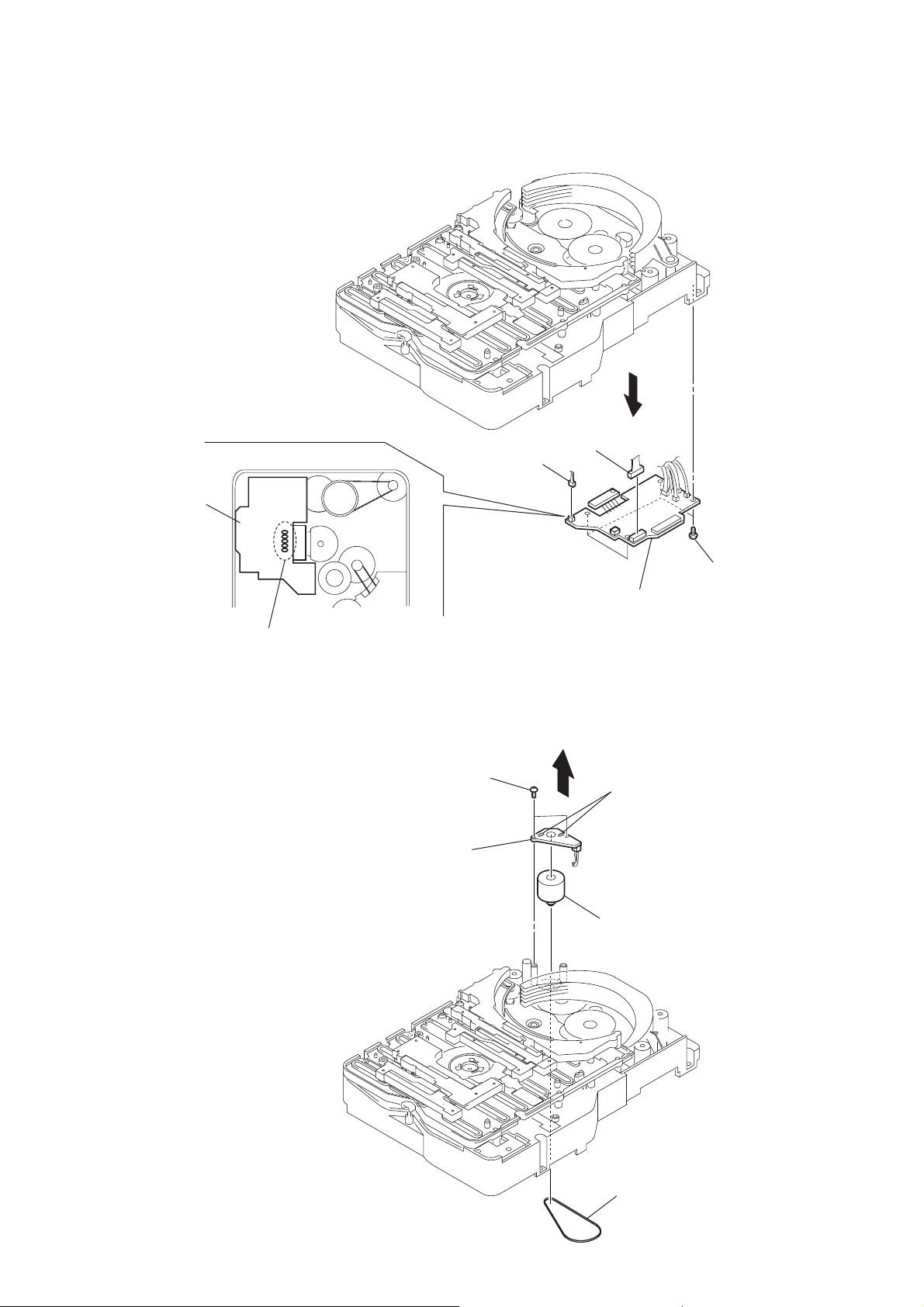

8-9. DVD Mechanism Deck Section-5

(CDM69EH-DVBU101) ................................................ 100

8-10. DVD Mechanism Deck Section-6

(CDM69EH-DVBU101) ................................................ 101

8-11. Optical Pick-up Section (KHM-310CAB/C2RP)...........102

9. ELECTRICAL PARTS LIST ................................. 103

3

HCD-FX900W

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

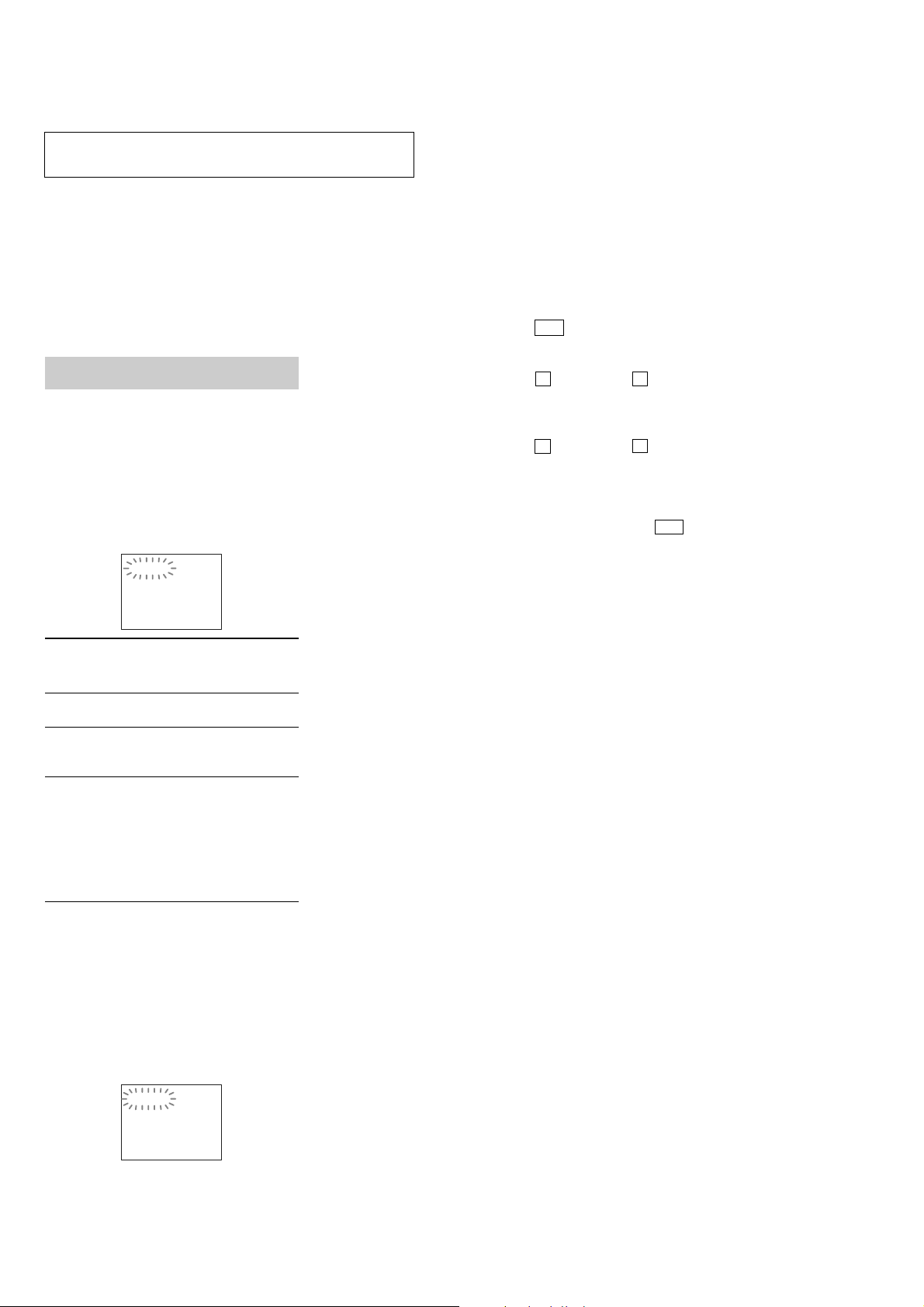

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the self-diagnosis function is activated to

prevent the system from malfunctioning, a 5character service number (e.g., C 13 50) with a

combination of a letter and 4 digits appears on

the screen and the front panel display. In this

case, check the following table.

C:13:50

First 3

characters of

the service

number

C 13 The disc is dirty.

C 31 The disc is not inserted correctly.

E XX

(xx is a number)

Cause and/or corrective action

,Clean the disc with a soft cloth

,Restart the system, then re-insert

the disc correctly.

To prevent a malfunction, the

system has performed the selfdiagnosis function.

,Contact your nearest Sony

dealer or local authorized Sony

service facility and give the 5character service number.

Example: E 61 10

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

DISC SLOT LOCK

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the x stick and the A button simultaneously for five

seconds.

5. The message “LOCKED” is displayed and the slot is locked.

Releasing Procedure :

1. Press the x stick and the A button simultaneously for five

seconds again.

2. The message “UNLOCKED” is displayed and the slot is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

Note on DMB12 board replacement

New part of EEP ROM (IC103, IC706) on the DMB12 board cannot

be used. Therefore, if the mounted DMB12 board (A-1154-509-A)

is replaced, exchange new EEP ROM (IC103, IC706) with that used

before the replacement.

When displaying the version

number on the screen

When you turn on the system, the version

number [VER.X.XX] (X is a number) may

appear on the screen. Although this is not a

malfunction and for Sony service use only,

normal system operation will not be possible.

Turn off the system, and then turn on the system

again to operate.

VER.X.XX

4

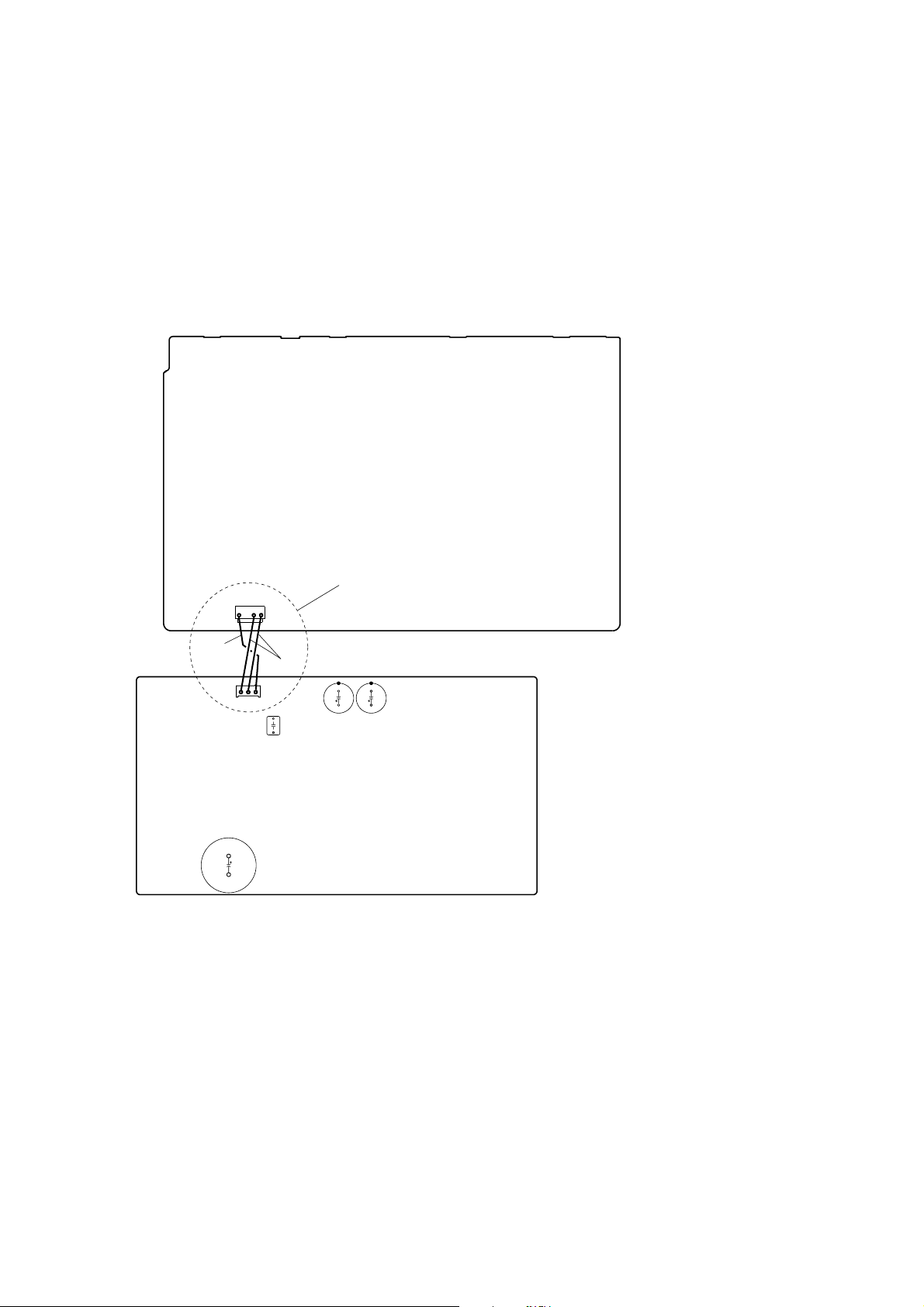

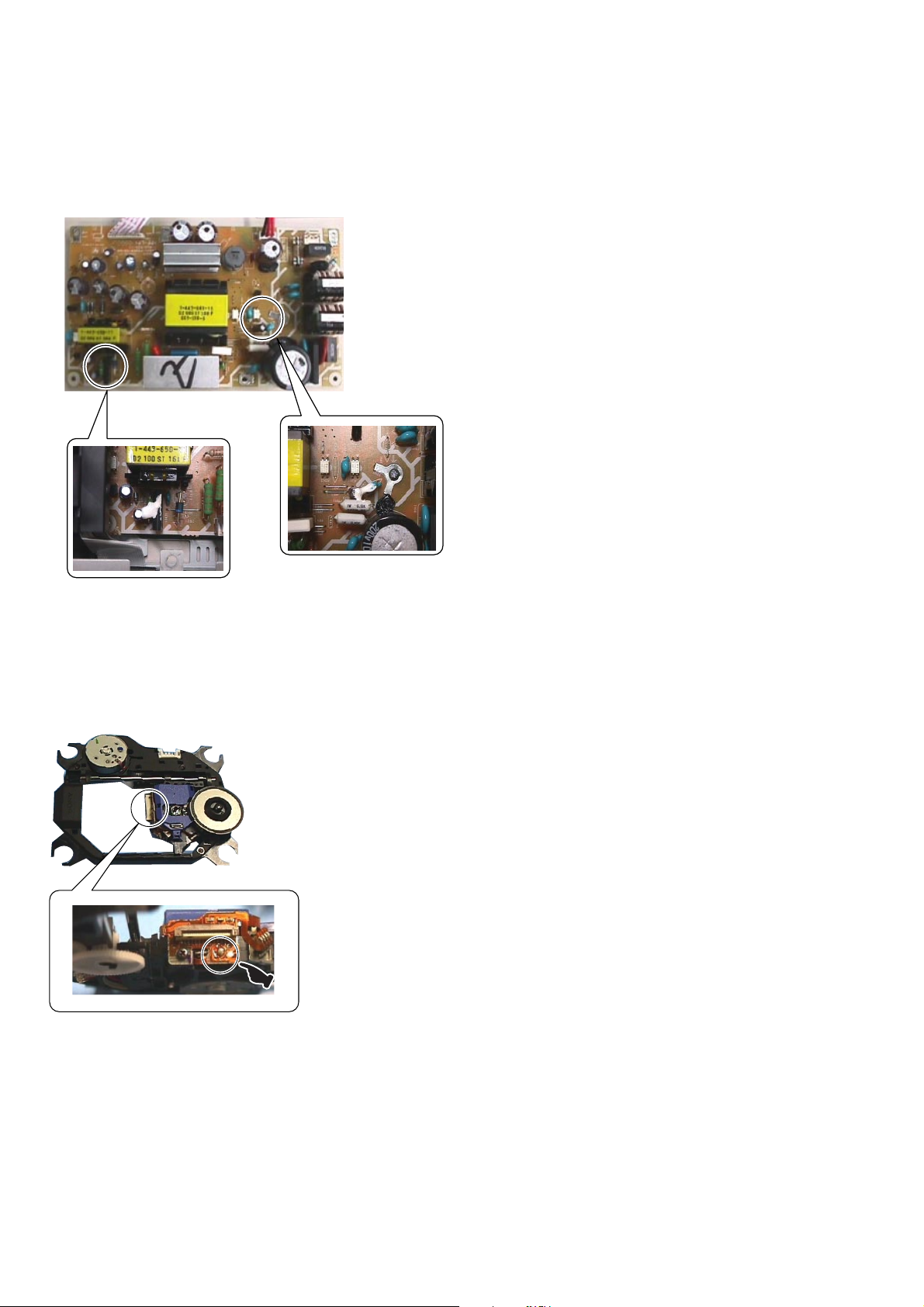

Discharge the charged electricity in capacitors to prevent electric shock as follows

When disassembling the machine, be sure to discharge the charged electricity in the following capacitors.

Use a resistor of 800 ohms, 2 Watts for discharging the following capacitors.

POWER board

C903 : 600V

C932, C933, C939, CN902 : 30V

MAIN board

CN3002 : 30 V

MAIN BOARD

HCD-FX900W

POWER BOARD

BLACK

CN902

C903

CN3002

C939

RED

*

Connect the specified resistor

between black and red leads

C933 C932

5

HCD-FX900W

Fix the capacitors with adhesive agent as follows

Fixing the capacitors with adhesive agent is required by the safety regulation.

Be sure to fix the capacitors with adhesive agent when part or circuit board is replaced.

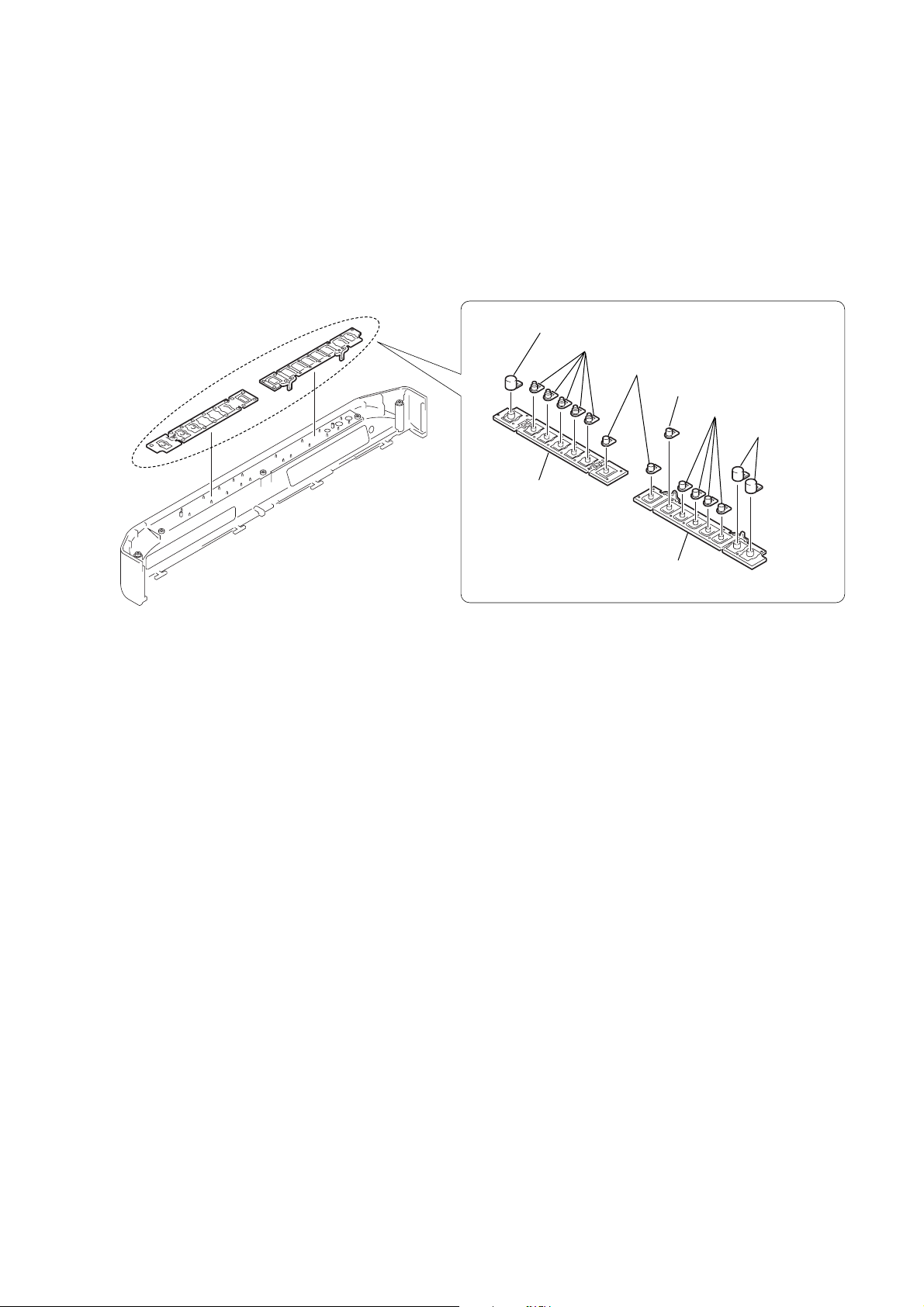

POWER BOARD

PRECAUTION WHEN INSTALLING A NEW OP UNIT /

PRECAUTION BEFORE UNSOLDERING THE STATIC ELECTRICITY

PREVENTION SOLDER BRIDGE

When installing a new OP unit, be sure to connect the flexible printed circuit board first of all before removing the static

electricity prevention solder bridge by unsoldering. Remove the static electricity prevention solder bridge by unsoldering

after the flexible printed circuit board has already been connected.

(Do not remove nor unsolder the solder bridge as long as the OP unit is kept standalone.)

6

HCD-FX900W

Precaution when replacing the BUTTON

Please apply the adhesive agent to the BUTTON BASE (PLAY) when replacing the BUTTON (PLAY) or BUTTON (POWER)

or BUTTON (STOP).

Please apply the adhesive agent to the BUTTON BASE (POWER) when replacing the BUTTON (DISC) or BUTTON (POWER)

or BUTTON (STOP).

BUTTON (POWER)

BUTTON (DISC)

BUTTON (STOP)

BUTTON (PLAY)

BUTTON (STOP)

BUTTON (POWER)

BUTTON (POWER)

BASE

BUTTON (PLAY)

BASE

7

HCD-FX900W

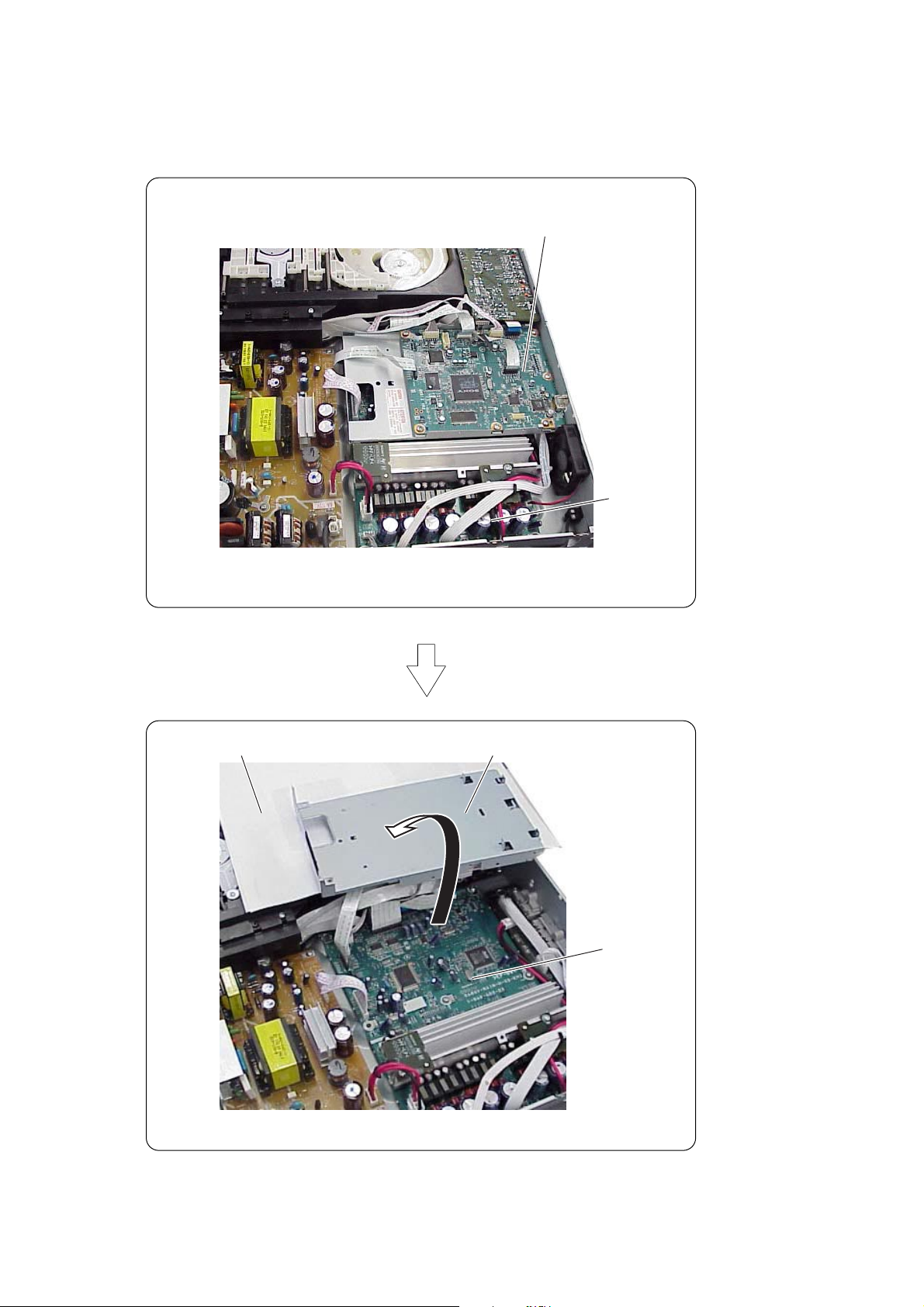

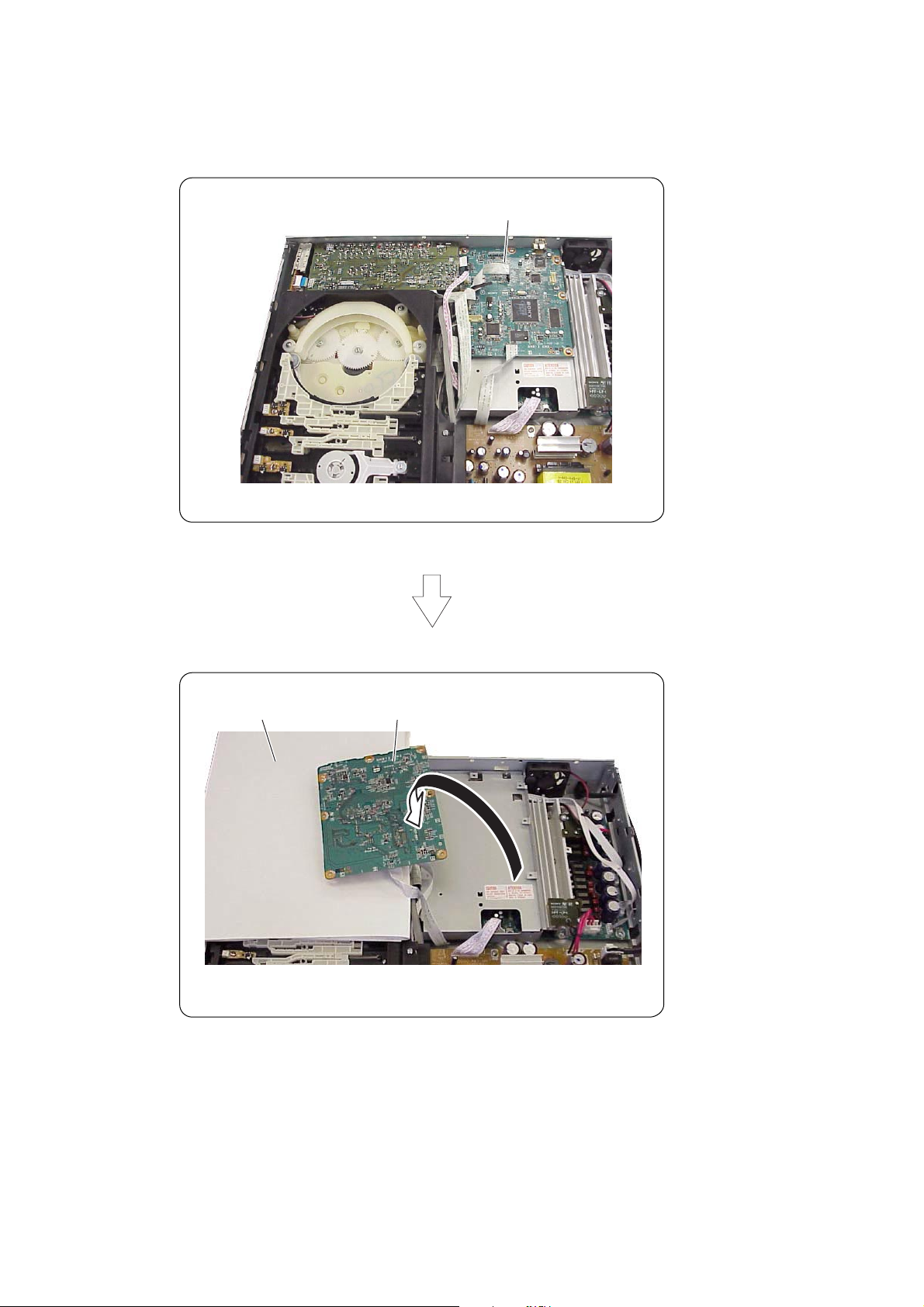

• MAIN board service position (side A)

DMB12 board, HDMI bracket

MAIN board

(side A)

DMB12 board, HDMI bracketinsulating sheet

MAIN board

(side A)

8

• MAIN board service position (side B)

HCD-FX900W

front panel section

(from the FL board)

Extension cable :

J-2501-245-A

(1mm / 23pin / L300)

Extension cable :

J-2501-242-A

(1mm / 11pin / L300)

CN504

MAIN

BOARD

(side A)

DVD

Mechanism deck

Extension cable :

J-2501-248-A

(1mm / 27pin / L300)

CN501

CN621

CN701

CN672

CN651

CN109

DMB12

BOARD

CN4501

CN4301

Extension cable :

J-2501-242-A

(1mm / 11pin / L300)

CN201

I/O BOARD

CN102

CN1801

In such a case, the

extension cables

became necessary.

MAIN board (side B)

To check the side B of

the MAIN board, remove the

DMB12 board, I/O board,

and the MAIN board.

It became a resolution with

MAIN board.

Extension cable :

J-2501-242-A

(1mm / 11pin / L300)

DMB12 board, HDMI bracket

DIAT TX XM board

DIAT TX XM

BOARD

Extension cable :

J-2501-102-A

(1mm / 13pin / L300)

I/O board

insulating

sheet

9

HCD-FX900W

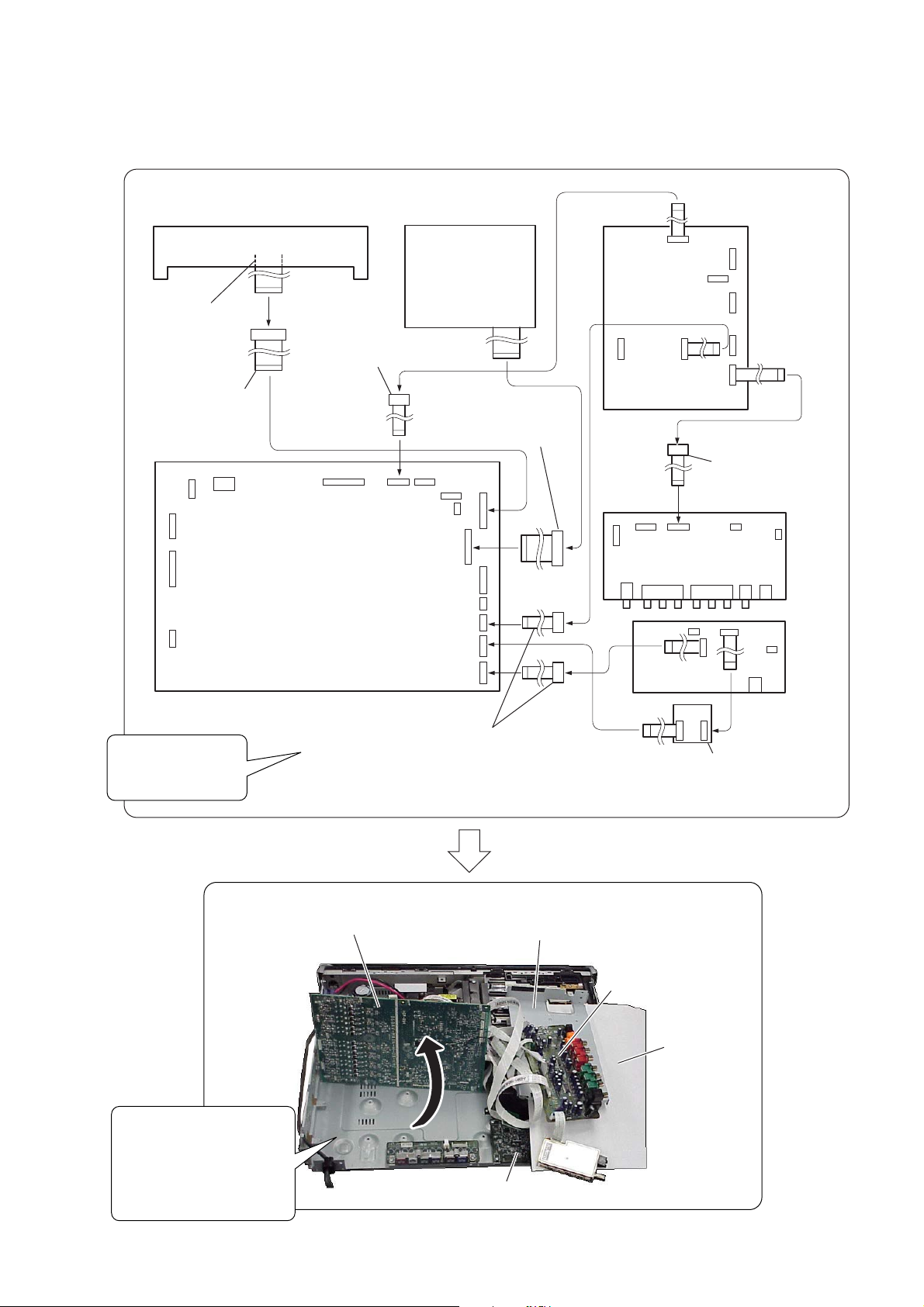

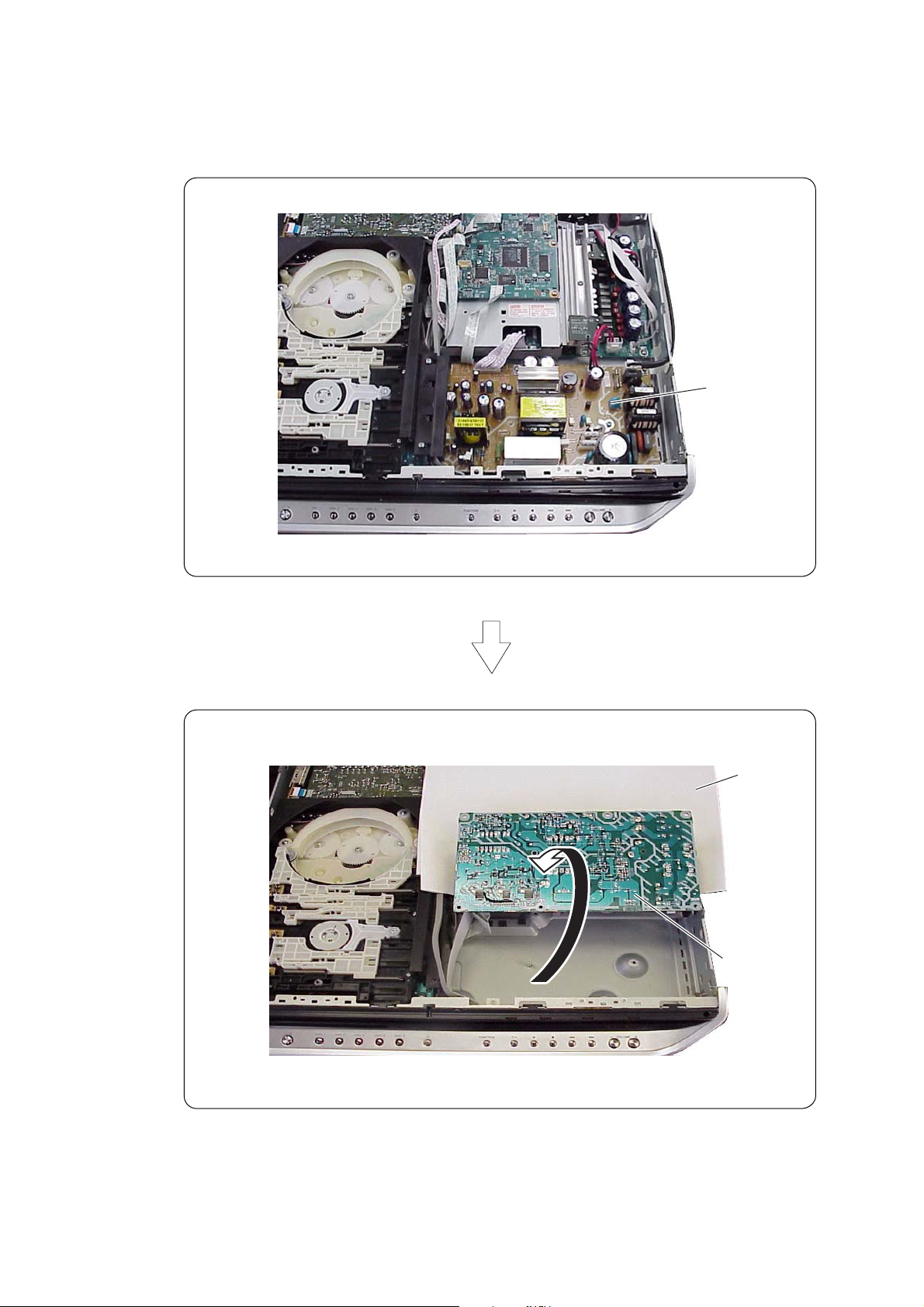

• DMB12 board service position

DMB12 board

DMB12 boardinsulating sheet

10

•POWER board service position

HCD-FX900W

POWER board

insulating

sheet

POWER board

11

HCD-FX900W

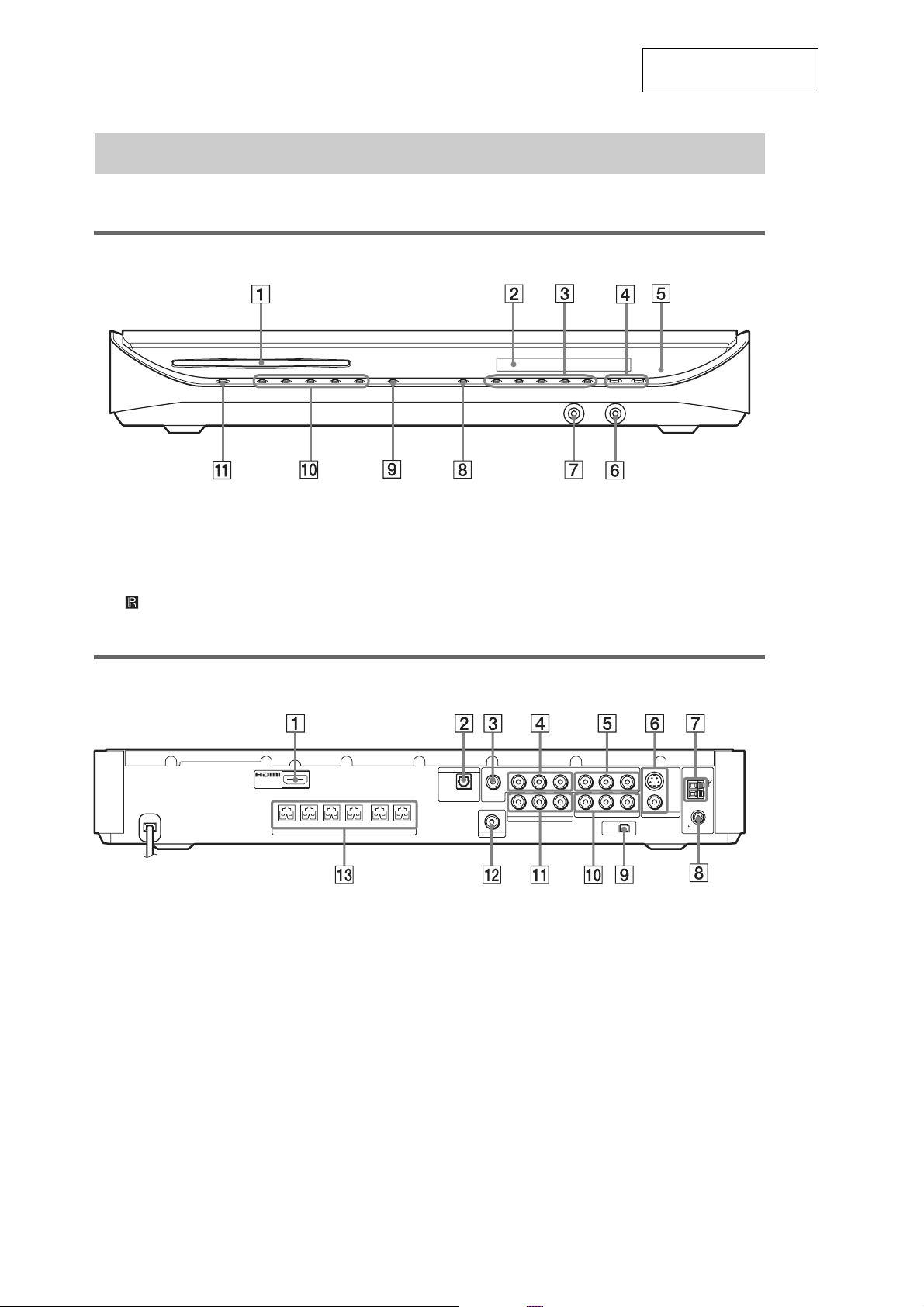

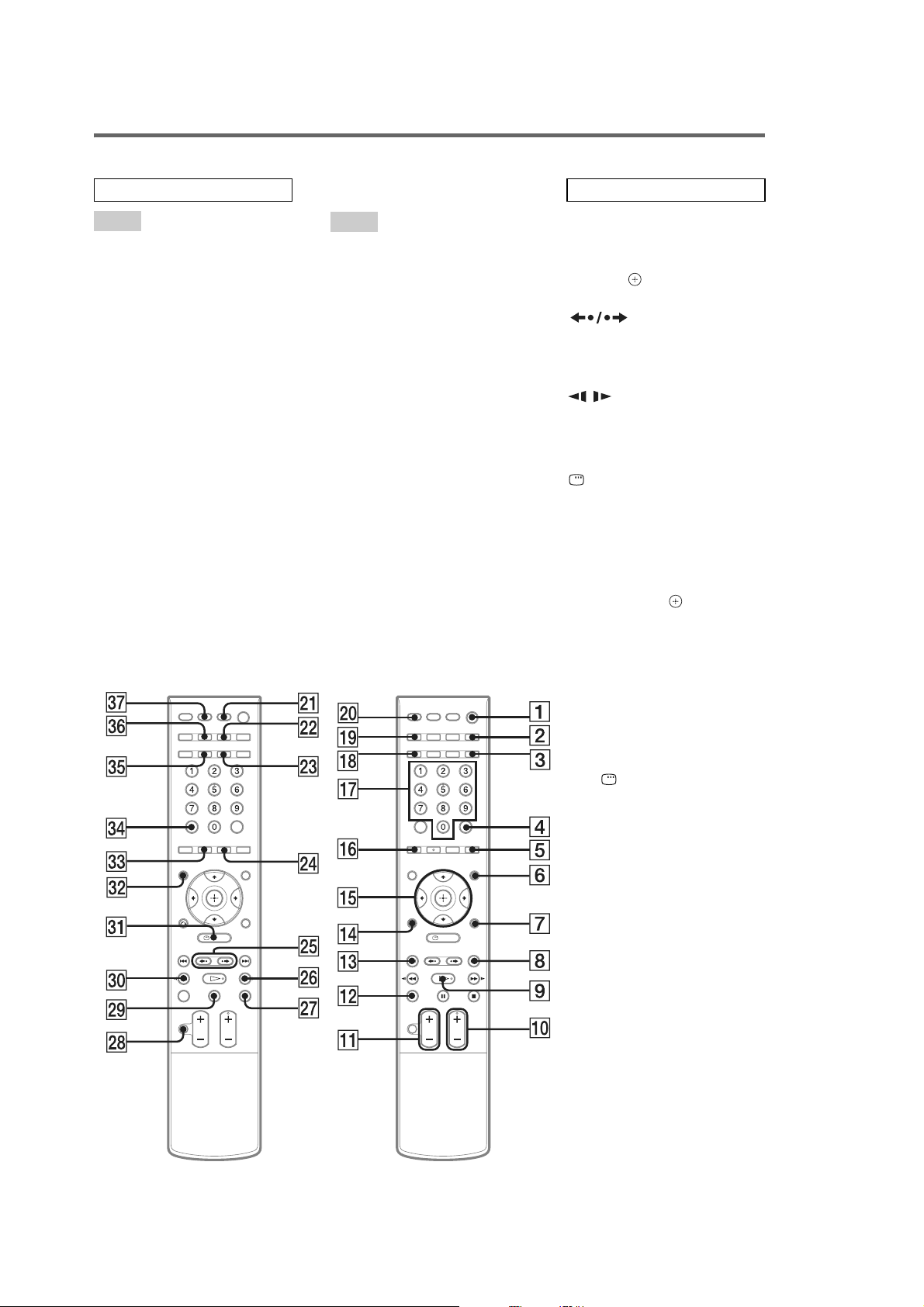

Index to Parts and Controls

For more information, refer to the pages indicated in parentheses.

Front panel

SECTION 2

GENERAL

This section is extracted

from instruction manual.

A Disc slot (33)

B Front panel display (100)

C Disc operation (33)

D VOLUME –/+ (33)

E (remote sensor) (9)

Rear panel

OUT

(DVD ONLY)

FRONT R FRONT L SUR R SUR LCENTER WOOFER

A HDMI OUT jack (27)

B TV/VCR 2 (OPTICAL DIGITAL IN) jack

(31)

C TV/VCR 1 (DIGITAL IN COAXIAL) jack

(31)

D TV/VCR 1 (AUDIO IN R/L, VIDEO IN)

jacks (31)

E TV/VCR 1 (COMPONENT VIDEO IN)

jacks (31)

SPEAKER

F PHONES jack (33)

G AUDIO IN/A.CAL MIC jack (21, 35)

H FUNCTION (33)

I A (eject) (33)

J DISC 1-5 (33)

K "/1 (on/standby) (33)

OPTICAL

DIGITAL

IN

TV/VCR2

COAXIAL

TV/VCR1

DIR-T1

RLAUDIO IN VIDEO INDIGITAL IN

RLAUDIO IN VIDEO IN

TV/VCR2

COMPONENT VIDEO IN

YPB/CBPR/C

YPB/CBPR/C

COMPONENT VIDEO OUT

XM

R

S VIDEO

(DVD ONLY)

AM

VIDEO

R

MONITOR OUT

FM

75

COAXIAL

F MONITOR OUT (S VIDEO/VIDEO) jacks

(27)

G AM terminal (16)

H COAXIAL FM 75Ω jack (16)

I XM jack (64)

J COMPONENT VIDEO OUT jacks (27)

K TV/VCR 2 (AUDIO IN R/L, VIDEO IN)

jacks (31)

L DIR-T1 jack (16)

M SPEAKER jacks (16)

12

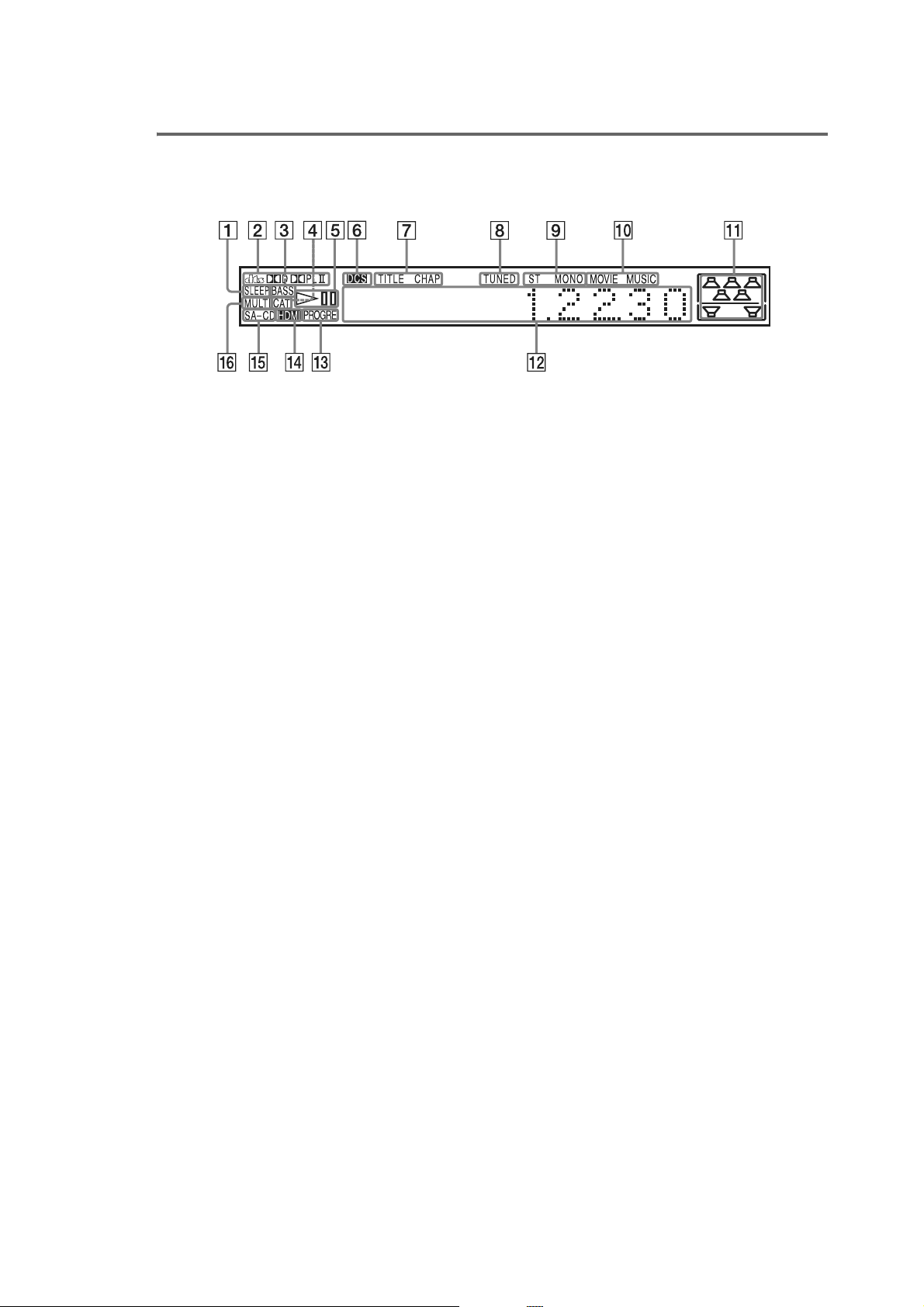

Front panel display

About the indications in the front panel display

HCD-FX900W

A Lights up when the sleep timer is set.

(70)

B Current surround format (Except for

JPEG and Super Audio CD)

C Lights up when the DYNAMIC BASS is

selected. (69)

D Lights up when the one category mode

is selected. (64)

E Playing status (DVD function only)

F Lights up when Digital Cinema Sound

(DCS) is activated. (37)

G Lights up when the time information of

a title or chapter appears in the front

panel display. (DVD only) (50)

H Lights up when a station is received.

(Radio only) (62)

I Monaural/Stereo effect (Radio only)

(62)

J Lights up when the music or movie

mode is selected. (36)

K Indicates the selected [SPEAKER

FORMATION]. (74)

L Displays system’s status such as

chapter, title, or track number, time

information, radio frequency, playing

status, sound field, etc.

M Lights up when the system outputs

progressive signals (DVD function

only). (29)

N Lights up when the HDMI OUT jack is

correctly connected to HDCP (highbandwidth digital content protection)

compliant device with HDMI or DVI

(digital visual interface) input. (27)

O Lights up when Super Audio CD/CD is

loaded.

P Lights up during MULTI channel

playback. (Super Audio CD only) (53)

13

HCD-FX900W

Remote control

ALPHABETICAL ORDER

A – O

AMP MENU3) 7 (24, 35, 70,

106)

ANGLE 5 (52)

2)

AUDIO

ed (48)

CATEGORY +/– wg (64)

CATEGORY MODE 5 (64)

CLEAR ef (41, 62, 68, 79)

D.TUNING wf (62)

DISC SKIP qs (33)

DISPLAY 2 (50, 63)

DYNAMIC BASS 3 (69)

1)

ENTER

4 (21, 24, 35, 41, 61,

71)

2)

FUNCTION +/–

0 (29, 33, 35,

43, 61, 74)

MENU 6 (47, 61)

MOVIE/MUSIC wd (36)

MUTING wk (33)

2)

Number buttons

qj (41, 62, 67,

71)

P – Z

PICTURE NAVI qh (42, 68)

PRESET +/– 8 qd (62)

PROGRESSIVE qk (29)

SA-CD/CD ws (53)

SLEEP eh (70)

SOUND FIELD eg (37)

SUBTITLE wf (52)

THEATRE SYNC wa (69)

TOP MENU es (47)

TUNING +/– wh e; (61)

TV w; (67)

2)

TV CH +/–

0 (67)

TV VOL +/– qa (67)

TV/VIDEO ql (67)

VOLUME +/–

qa (33, 62, 84)

BUTTON DESCRIPTIONS

[/1 (on/standby) 1 (21, 24, 33,

43, 62)

TV [/1 (on/standby) ej (67)

3)

C/X/x/c/

qg (21, 24, 35, 41,

61, 71)

REPLAY/

ADVANCE wg (33)

./> qd 8 (33)

m/M e; wh (40)

/ e; wh (40)

2)

H (play)

9 (33, 43, 72)

x (stop) wj (34, 43, 71)

X (pause) wl (34)

DISPLAY

3)

ea (22, 41, 71,

102)

3)

O RETURN

qf (42)

-/-- ef (67)

1)

The ENTER button is the same

function as the button.

2)

The H, number 5, AUDIO, and

FUNCTION + (TV CH +)

buttons have tactile dots. Use

the tactile dots as referen ces

when operating the system.

3)

After pressing the TV button w;,

you can control the menu on a

Sony TV. On the menu screen,

the DISPLAY button ea

doubles as the MENU button,

and the AMP MENU button 7

double as the TOOLS button.

Note that depending on the

component, you may n ot be able

to use some or all of the buttons.

14

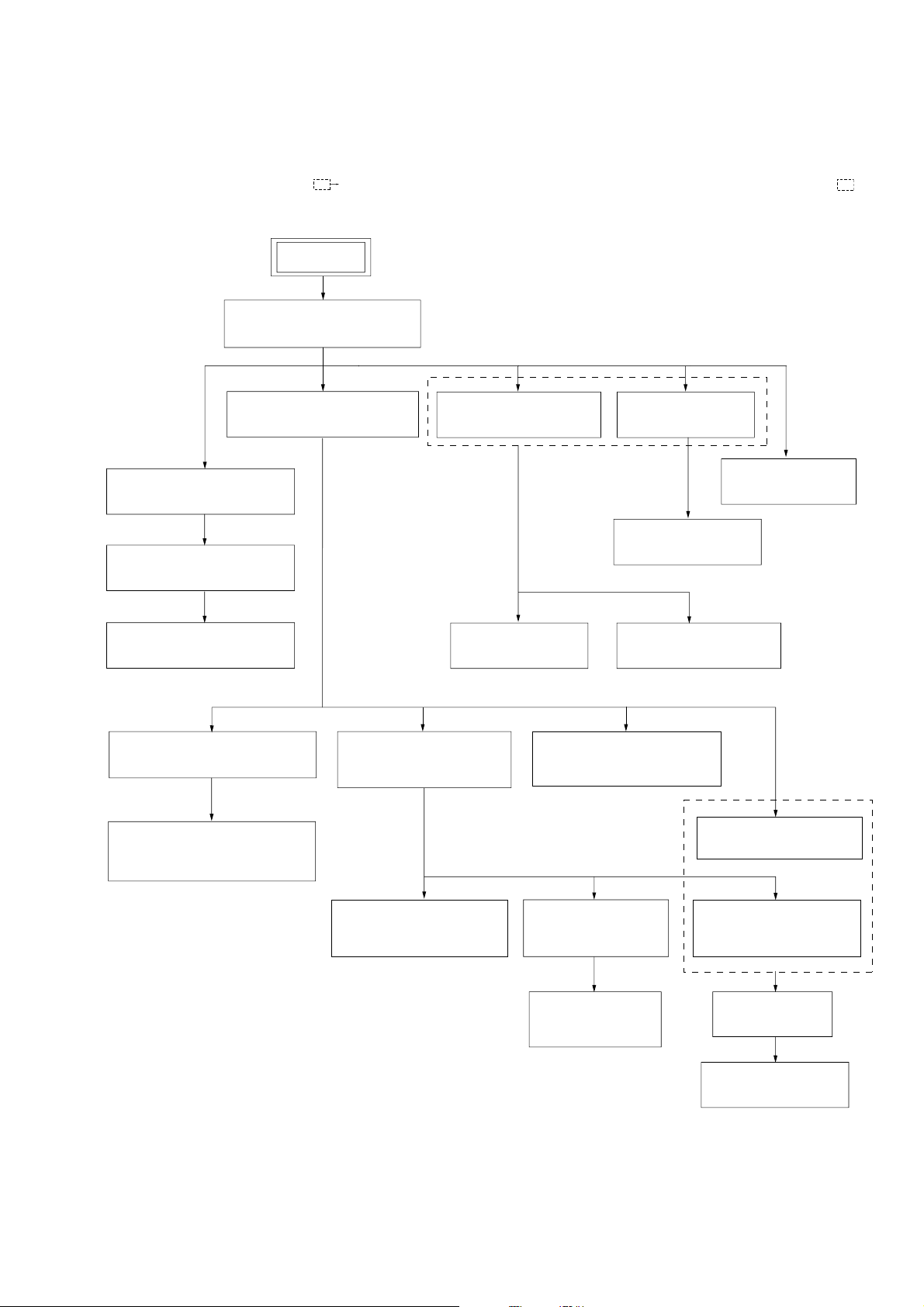

HCD-FX900W

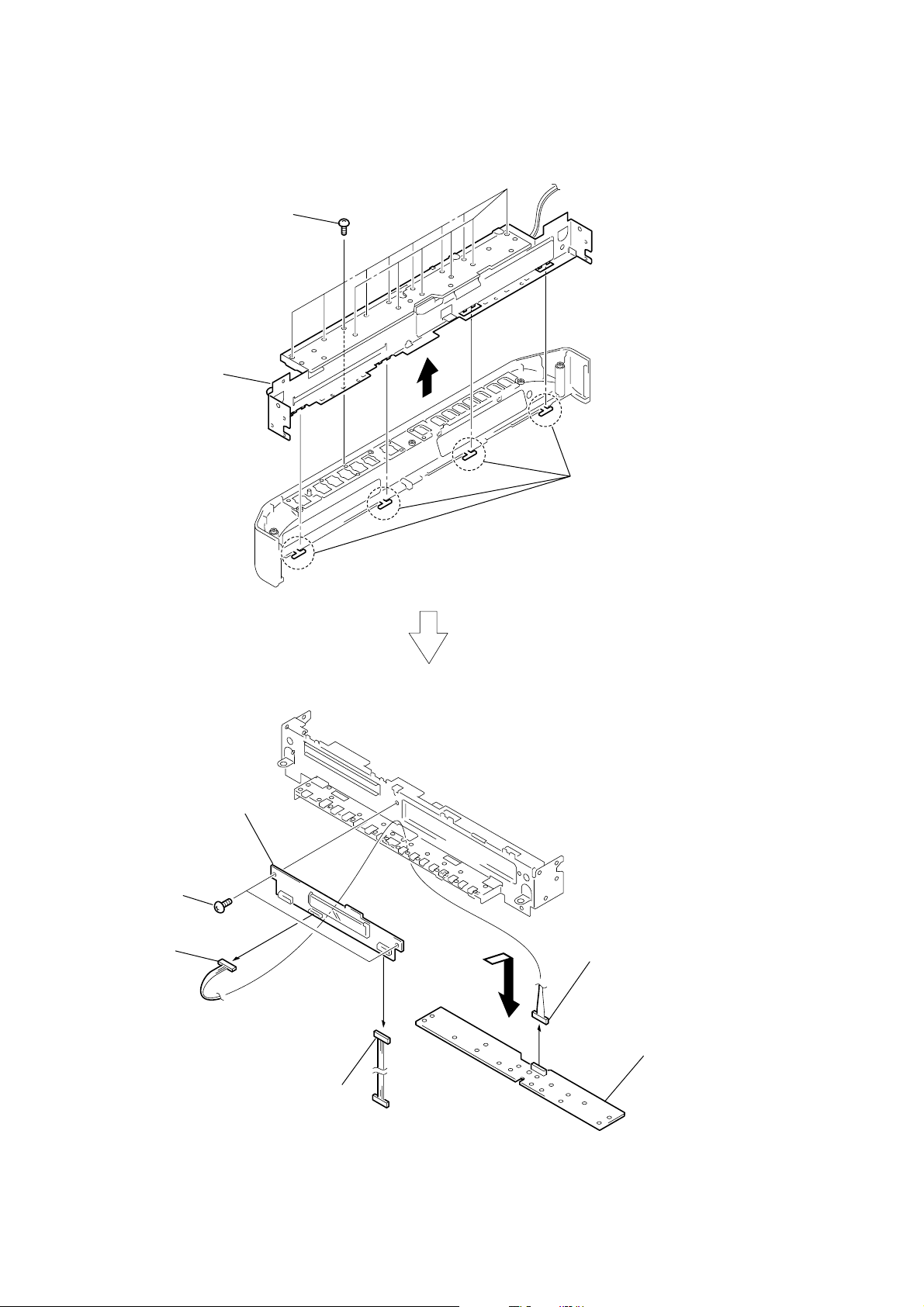

3-3.JACK BOARD,

FRONT PANEL SECTION

(Page 17)

3-11. POWER BOARD

(Page 22)

3-8. DMB12 BOARD

(Page 20)

3-10.SP BOARD

(Page 22)

3-9. MAIN BOARD

(Page 21)

3-6. I/O BOARD,

D.C. FAN

(Page 19)

3-7. DIAT TX XM BOARD

(Page 20)

3-4.KEY BOARD, FL BOARD

(Page 18)

3-5.BUTTON

(DISC/PLAY/POWER)

(Page 19)

3-12. DVD MECHANISM DECK

(CDM69EH-DVBU101)

(Page 23)

SET

3-2. TOP PANEL, SIDE PANEL

(Page 16)

3-13.BASE UNIT(DVBU101)

(Page 23)

3-20.RUBBER ROLLER

(SLIDER) ASSY

(Page 27)

3-21.TIMING BELT

(FRONT/REAR)

(Page 27)

3-22.CAM (GEAR)

(Page 28)

3-23.SENSOR BOARD

(Page 28)

3-15.SW BOARD,

BRACKET (TOP) ASSY

(Page 24)

3-14.OPTICAL PICK-UP

(KHM-310CAB)

(Page 24)

3-19.MOTOR (MODE)

ASSY (MODE) (M771)

(Page 26)

3-18.MOTOR (ROLLER)

ASSY (ROLLER) (M781)

(Page 26)

3-17.MOTOR (STOCKER)

ASSY (STOCKER) (M761)

(Page 25)

3-16.RELAY BOARD

(Page 25)

SECTION 3

DISASSEMBLY

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

•The dotted square with arrow ( ) prompts you to move to the next job when all of the works within the dotted square ( ) are

completed.

15

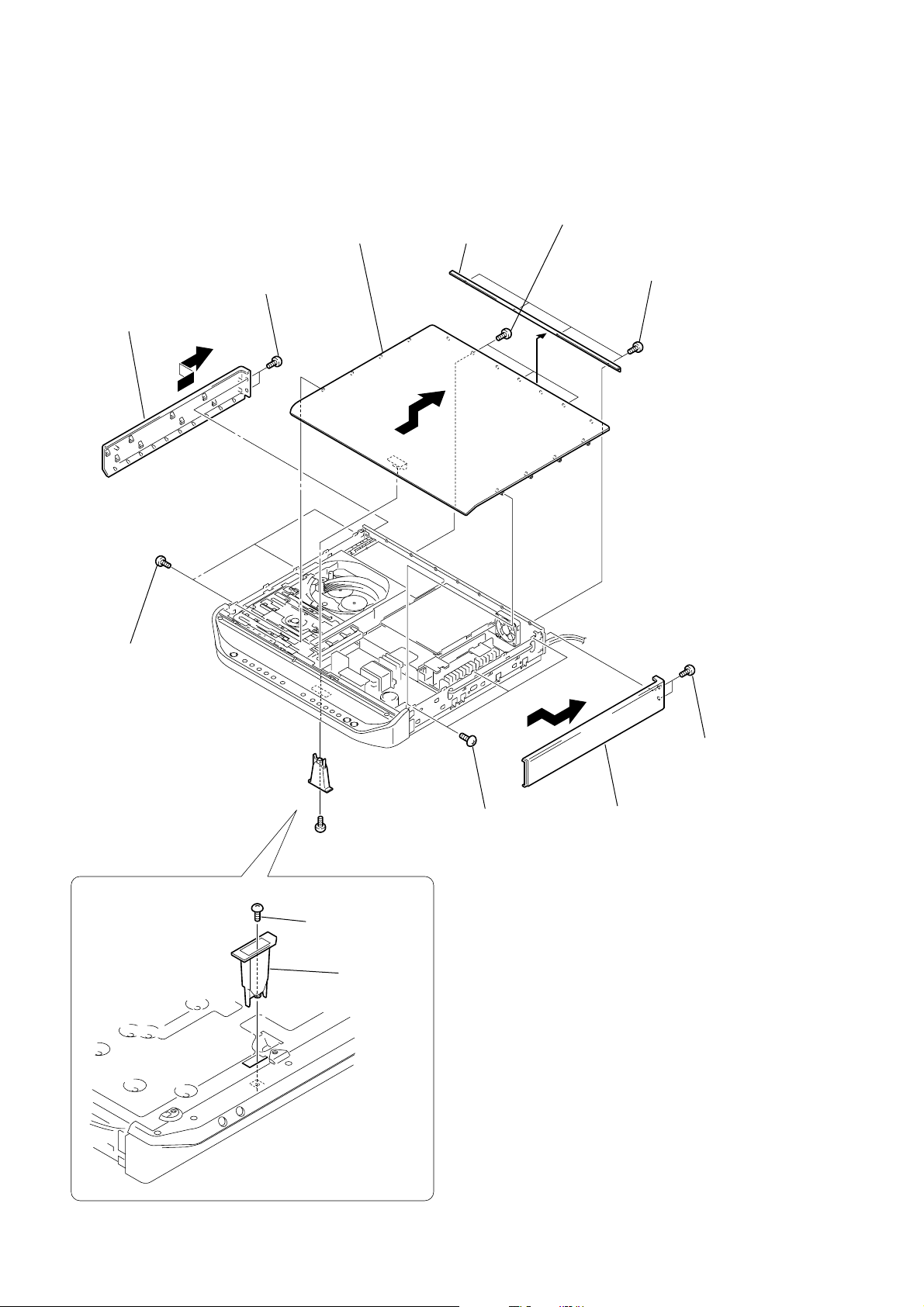

HCD-FX900W

Note: Follow the disassembly procedure in the numerical order given.

3-2. TOP PANEL, SIDE PANEL

qs

top (T3.5) panel

1

2

side panel (L)

two tapping

(+BV 3 × 8)

screws

6

top panel (rear)

7

three tapping

(+BV 3 × 8)

5

(+BV 3 × 8)

screws

four tapping

screws

q;

three tapping

(+BV 3 × 8)

screws

8

tapping

9

cover (FJ)

screw

(+BVTP 3 × 12)

qa

three tapping

(+BV 3 × 8)

screws

3

(+BV 3 × 8)

4

side panel (R)

two tapping

screws

16

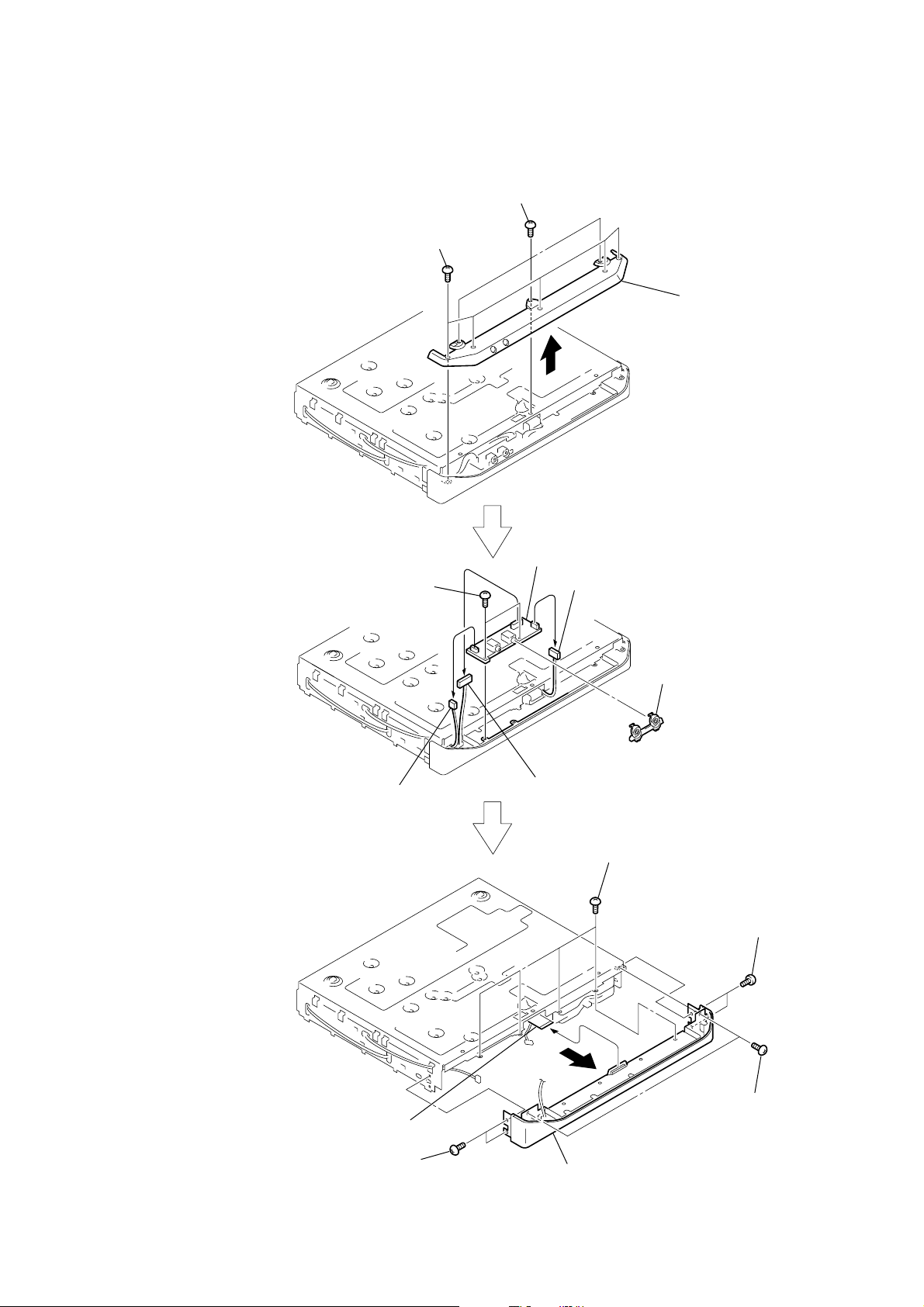

3-3. JACK BOARD, FRONT PANEL SECTION

1

three tapping screws

(+BV 3

×

6)

3

lower panel

qs

two tapping screws

(+BV 3 × 6)

qd

two tapping screws

(+BV 3 × 6)

qg

front panel section

qf

two tapping screws

(+BV 3 × 6)

qa

four tapping screws

(+BV 3

×

6)

7

two screws

(+B 2.6 × 4)

9

JACK board

2

five tapping screws

(+BVTP 3 × 10)

6

connector

(CN402)

5

connector

(CN401)

4

connector

(CN403)

8

jack panel

q;

wire (flat type)

23core(CN801)

HCD-FX900W

17

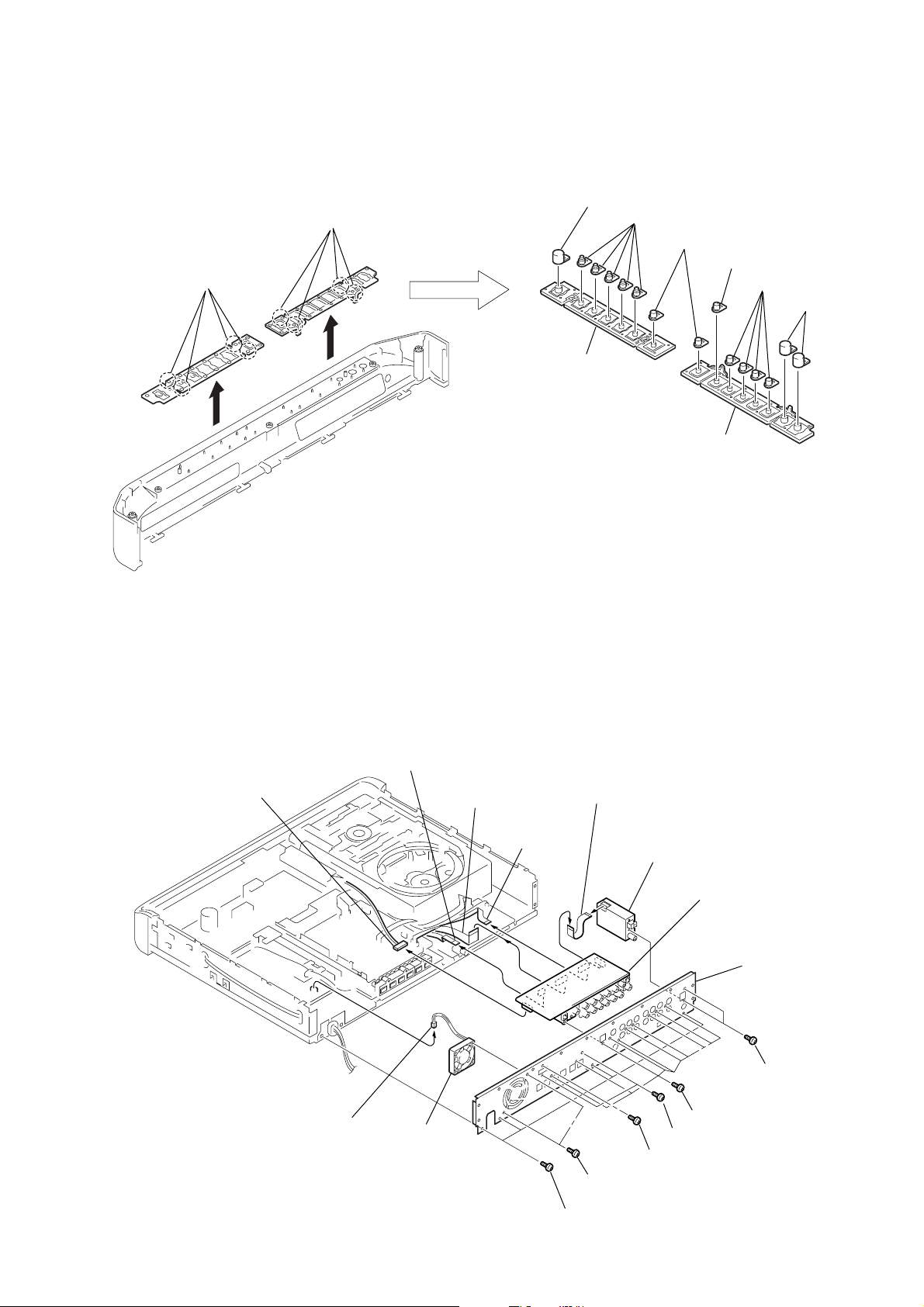

HCD-FX900W

d

3-4. KEY BOARD, FL BOARD

1

fourteen

(+BTP 2 × 6)

3

FL board,

KEY board,

front chassis

screws

2

four

claws

8

two

screws

(+BV 3 × 6)

7

connector

(CN803)

9

FL board

6

connector

(CN802)

4

connector

(CN804)

5

KEY boar

18

3-5. BUTTON (DISC/PLAY/POWER)

2

Remove the button base (play)

at the melted points.

1

Remove the button base (power)

at the melted points.

9

two buttons

(power)

q;

button (play) base

3

button (power)

8

four buttons (stop)

5

two buttons (stop)

4

five buttons (disc)

7

button (play)

6

button (power) base

HCD-FX900W

3-6. I/O BOARD, D.C. FAN

q;

connector

(CN302)

8

connector

(CN3000)

qa

wire (flat type)

7core (CN304)

qs

wire (flat type)

19core (CN301)

9

D.C. fan

qf

9core (CN303)

qd

wire (flat type)

11core (CN201)

wire (flat type)

qh

3

2

two screws (+BV 3 × 8)

tuner

qg

I/O board

7

back panel

5

ten screws (+BV 3 × 8)

4

two screws (+BTP 3 × 8)

screw (+B 3 × 6)

6

(+BVTT 3

two screws

×

6)

1

four screws (+BV 3 × 6)

19

HCD-FX900W

)

3-7. DIAT TX XM BOARD

4

connector

(CN903)

6

DIAT TX XM board

5

four screws (+BV 3 × 6)

3

connector

(CN101)

3-8. DMB12 BOARD

7

three screws (+BV 3 × 6)

1

wire (flat type)

11core(CN109)

0

DMB12 board

4

connector

(CN601)

2

connector

(CN201)

2

wire (flat type)

13core(CN102)

1

wire (flat type)

11core(CN1801)

3

wire (flat type)

24core(CN101)

5

wire (flat type)

11core(CN4301)

8

four screws (+BV 3 × 6

6

wire (flat type)

11core(CN4501)

20

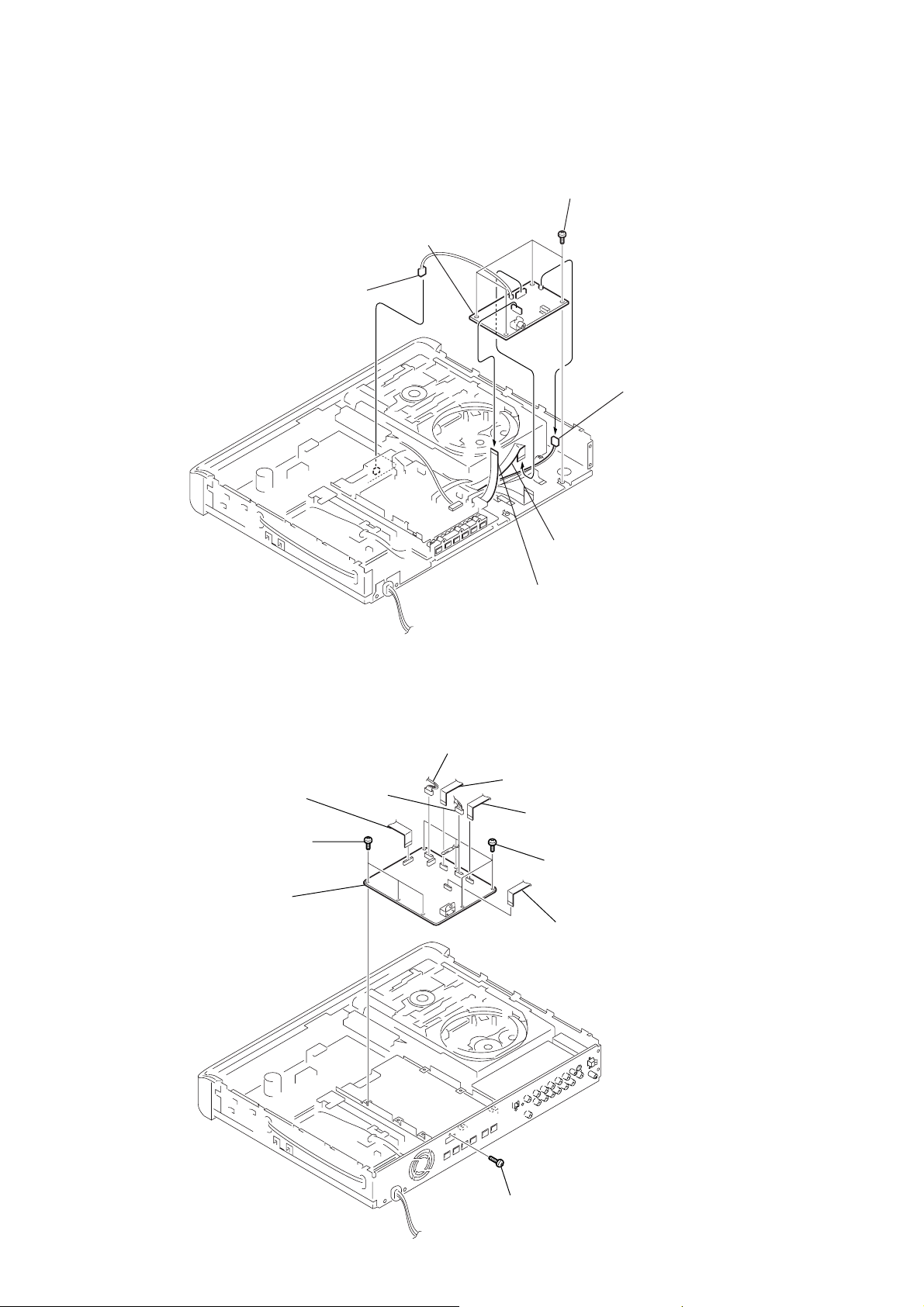

9

screw (+B 3 × 8)

3-9. MAIN BOARD

2

qs

wire (flat type)

13core (CN672)

0

wire (flat type)

11core (CN701)

9

wire (flat type)

7core (CN702)

8

wire (flat type)

19core (CN601)

7

wire (flat type)

27core (CN621)

6

wire (flat type)

23core (CN501)

two screws (+BV 3 × 8)

1

connector

(CN506)

3

HDMI bracket

qa

wire (flat type)

11core (CN651)

qf

connector

(CN3002)

qg

(CN3001)

HCD-FX900W

Route the harnesses as shown below.

connector

qd

Remove the harnesses

from the lead pins.

5

connector

(CN505)

4

wire (flat type)

11core (CN504)

ql

two screws (+BV 3 × 8)

wj

MAIN board

qk

screw (+BVTP 3 × 12)

qh

two screws

(+BV 3

qj

two heatsink

boards

w;

heatsink

(AMP)

wa

two radiation sheets

ws

six screws

(+BV 3

wd

×

8)

×

8)

When re-assembling, attaching the

two heat radiation sheets on the

IC MAIN board first, and then attach

the heat sink (AMP).

heatsink (AMP)

heat

radiation

sheets

wh

connector

(CN1302)

wf

connector

(CN1303)

wg

connector

(CN1301)

IC on the

MAIN board

21

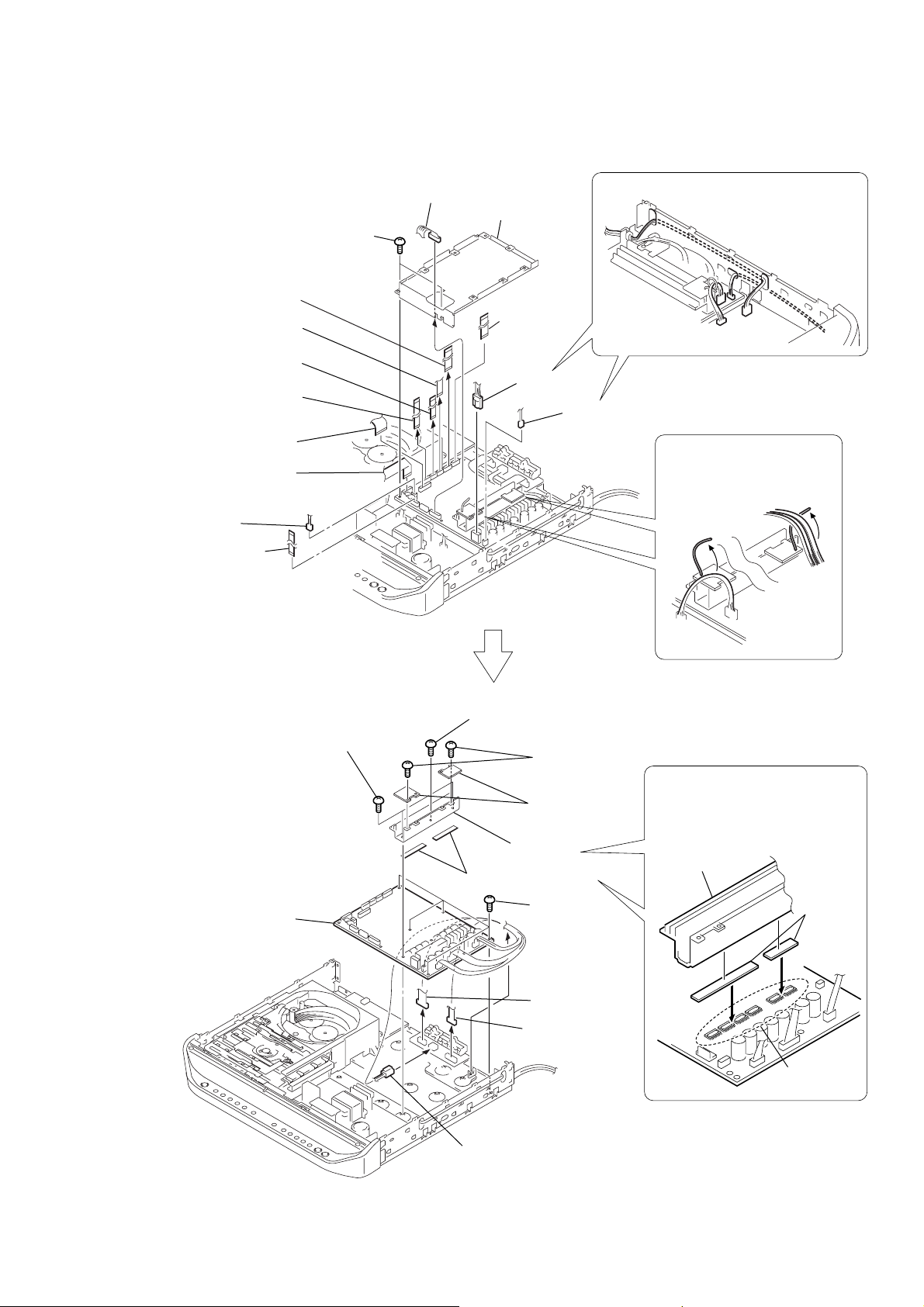

HCD-FX900W

3-10. SP BOARD

2

two screws (+BV 3 × 8)

1

connector

(CN506)

3

HDMI bracket

4

connector

(CN1303)

6

connector

(CN1301)

7

two screws (+BV 3 × 6)

8

SP board

5

connector

(CN1302)

3-11. POWER BOARD

When re-assembling, attaching the

three heat radiation sheets on the

chassis first, and then attach

POWER board.

POWER

board

three heat radiation

sheets

6

two screws

(+BV 3

7

wire cover

8

four screws

(+PWH 3

qa

POWER

board

qs

three radiation

sheets

1

connector (CN903)

×

6)

×

8)

3

connector (CN506)

Route the harnesses as shown below.

5

connector (CN901)

4

connector (CN3002)

9

three screws

(+PWH 3

×

8)

2

Remove the harnesses

from the lead pins.

22

q;

pc board

holder

)

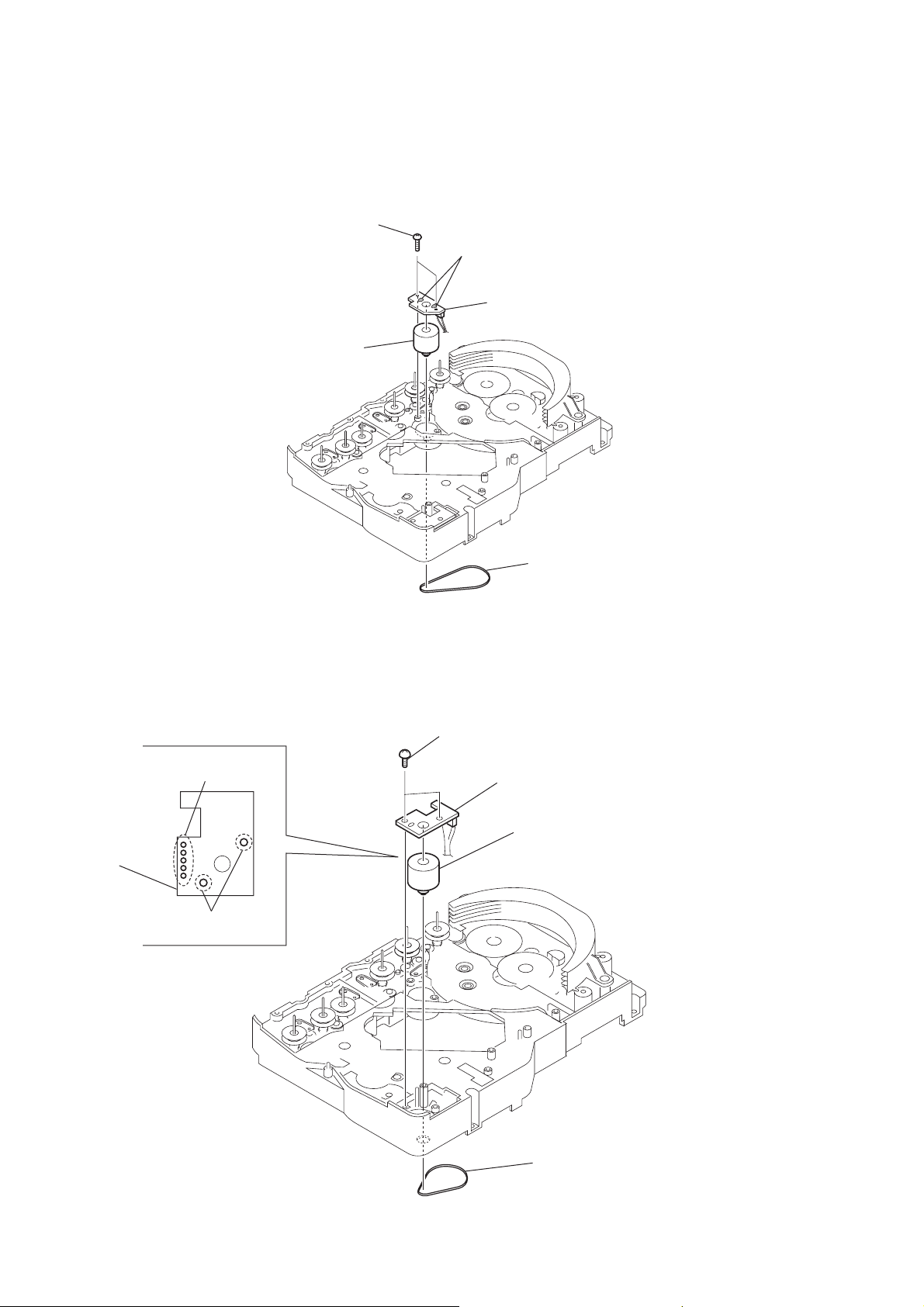

3-12. DVD MECHANISM DECK (CDM69EH-DVBU101)

2

wire cover

3

two screws

(+BV 3 × 6)

7

two screws

(+BV 3 × 6)

1

two screws

(+BV 3 × 6)

4

(+BV 3 × 6)

6

8

(+BV 3 × 6)

5

two filament types

(12 × 45)

two screws

cdm cover

two screws

HCD-FX900W

qs

DVD mechanism deck

(CDM69EH-DVBU101)

3-13. BASE UNIT (DVBU101)

qa

wire (flat type)

27core(CN701)

9

connector (CN601

q;

wire (flat type)

24core(CN101)

3

boss

6

base unit (DVBU101)

1

floating screw (+PTPWH M2.6)

2

boss

5

boss

4

boss

23

HCD-FX900W

3-14. OPTICAL PICK-UP (KHM-310CAB)

0

optical pick-up

(KHM-310CAB)

2

insulator screw

7

insulator

1

insulator screw

6

insulator

5

3

insulator screw

8

insulator

4

insulator screw

9

insulator

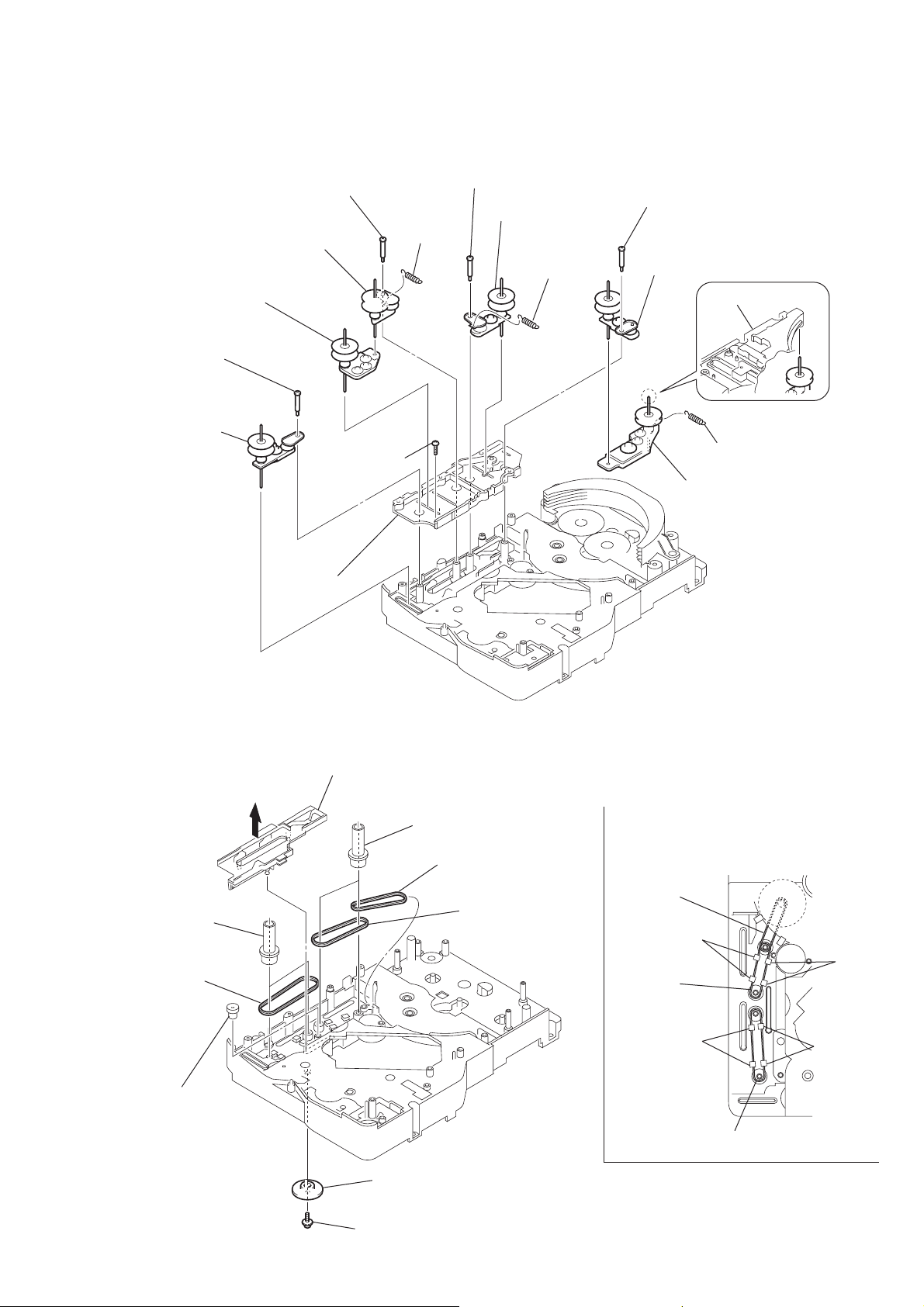

3-15. SW BOARD, BRACKET (TOP) ASSY

4

3

SW (2) board

1

four

screws

×

(+BTP2.6

2

SW (1) board

7

6)

bracket (top) assy

SW (3) board

5

SW (4) board

6

six screws

(+BVTP2.6)

24

3-16. RELAY BOARD

HCD-FX900W

– bottom view –

RELAY board

1

Remove five solders.

3-17. MOTOR (ST OCKER) ASSY (ST OCKER)(M761)

3

two screws

(+BVTP2.6)

5

stocker motor board

5

connector

(CN703)

4

connector

(CN710)

4

3

6

RELAY board

2

Remove two solders.

2

four screws

(+BVTP2.6)

6

motor (stocker) assy

(stocker) (M761)

1

belt (stocker)

25

HCD-FX900W

3-18. MOTOR (ROLLER) ASSY (ROLLER)(M781)

3

two screws

(+BVTP2.6)

5

motor (roller) assy

(roller)(M781)

2

Remove two solders.

4

ROLLER MOTOR

board

3-19. MOTOR (MODE) ASSY (MODE)(M771)

1

Remove five solders

of rotary encoder.

MODE MOTOR

board

2

Remove two solders

of motor (M771).

3

two screws

(+BVTP2.6)

1

belt (roller V)

4

MODE MOTOR board

6

motor (mode) assy

(mode) (M771)

26

5

belt (mode V)

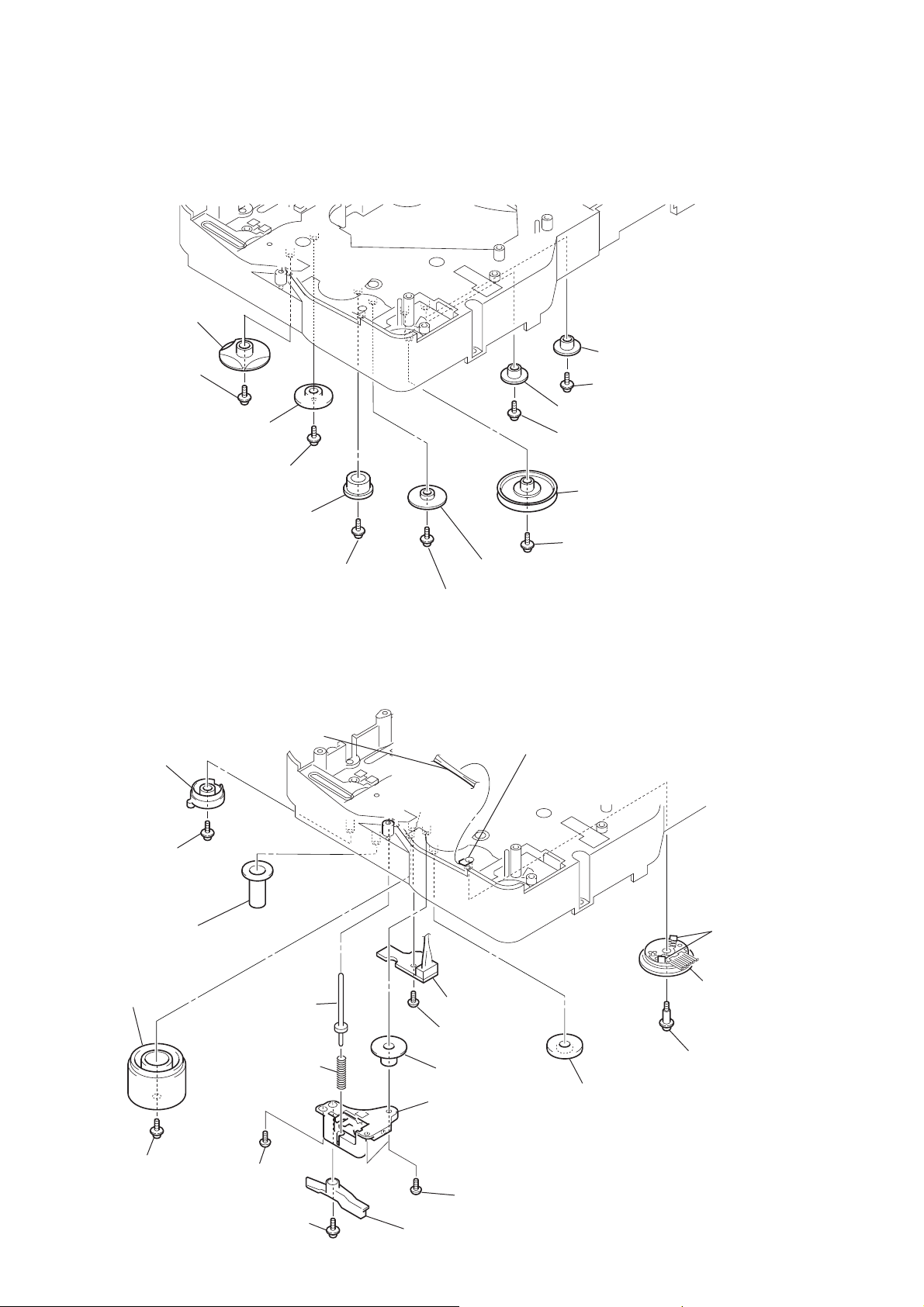

3-20. RUBBER ROLLER (SLIDER) ASSY

8

step screw

0

rubber roller

(slider 4) assy

qa

rubber roller

(slider 2) assy

qs

step screw

qd

rubber roller

(slider 1) assy

qf

screw

(+BVTP2.6

×

9

tension

spring

(slider 2)

8)

5

step screw

7

rubber roller

(slider 1) assy

6

tension spring

(slider 4)

1

step screw

2

rubber roller

(slider S) assy

4

HCD-FX900W

bracket (top) assy

3

tension spring

(base slider 5)

rubber roller

(slider 5) assy

qg

sub chassis

3-21. TIMING BELT (FRONT/REAR)

3

5

two gears

(center)

6

timing belt

(front)

slider (mode cam) assy

7

two gears (center)

8

timing belt (rear)

9

timing belt (rear)

When install three timing belts,

its pass under each claws.

timing belt

(rear)

claw

timing belt

(rear)

claw

4

gear

(timing)

2

gear (mode cam)

: Note

1

screw

(+PTPWH2.6

×

Note: Refer to assembly (Section 4)

8)

claw

timing belt (front)

claw

27

HCD-FX900W

3-22. CAM (GEAR)

qf

cam (gear)

: Note

qd

screw

qs

gear(mode cam)

qa

screw

(+PTPWH2.6

0

gear (mode C)

:Note

6

gear (mode 5)

5

screw (+PTPWH2.6 × 8)

4

gear (mode 5)

3

screw (+PTPWH2.6 × 8)

×

8)

2

pulley

(mode deceleration)

1

screw(+PTPWH2.6 × 8)

Note: Refer to assembly

(Section 4).

3-23. SENSOR BOARD

q;

cam (eject lock)

: Note

9

screw

(+PTPWH2.6

qd

gear (eject lock)

qs

cam (BU U/D)

ql

harness

×

8)

8

shaft

(shutter)

7

compression spring

(shutter)

9

screw

(+PTPWH2.6

×

8)

7

screw (+PTPWH2.6 × 8)

wa

SENSOR board

w;

screw

(+BVTP2.6

6

gear (mode A)

5

base (shutter) block

8

gear (mode D)

qk

×

8)

claw

qf

gear

(mode B)

qh

two claws

qj

rotary encoder

(S771)

qg

screw

(+PWH 2

×

6)

28

qa

screw

(+PTPWH2.6

3

×

8)

1

screw

(+BVTP2.6

screw

(+PTPWH2.6

×

8)

4

two screws

×

8)

2

lever shutter (A)

(+BVTP2.6

×

8)

Note: Refer to assembly (Section 4).

SECTION 4

ASSEMBLY

•This set can be assembled in the order shown below.

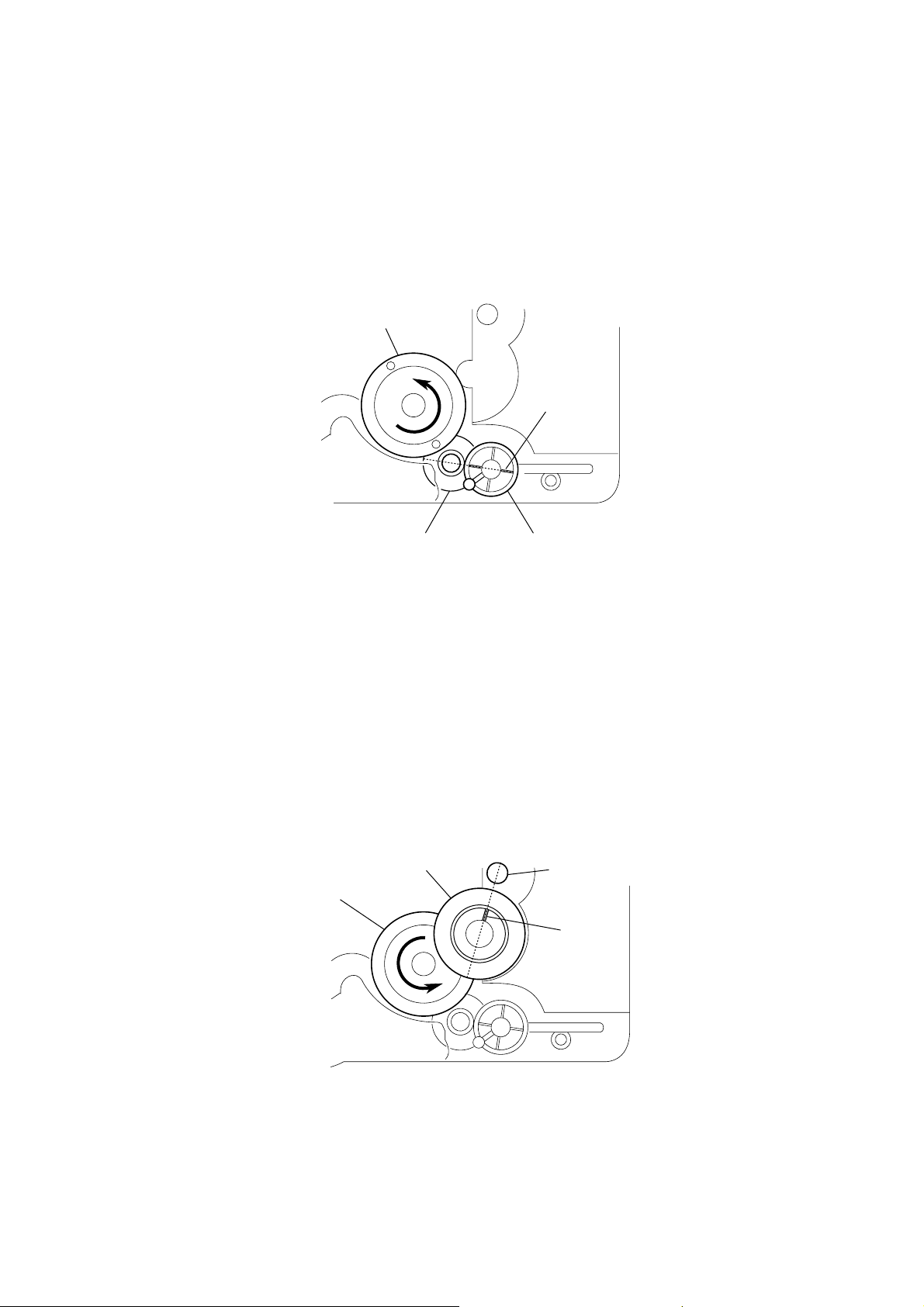

4-1. HOW TO INSTALL THE CAM (EJECT LOCK)

1

Rotate the cam (BU U/D) fully in the direction of arrow.

2

Engage the gear (eject lock) and the gear of the cam (eject lock)

aligning the mark with the center of the gear (eject lock).

cam (BU U/D)

HCD-FX900W

mark

gear (eject lock)

4-2. HOW TO INSTALL THE CAM (GEAR)

1

Check that the cam (BU U/D) can not be rotated in the direction of arrow.

2

Align the mark on the cam (gear) with the boss as shown in the figure

and install the cam (gear).

cam (gear)

cam (BU U/D)

cam (eject lock)

– bottom view • front –

boss

mark

– bottom view • front –

29

HCD-FX900W

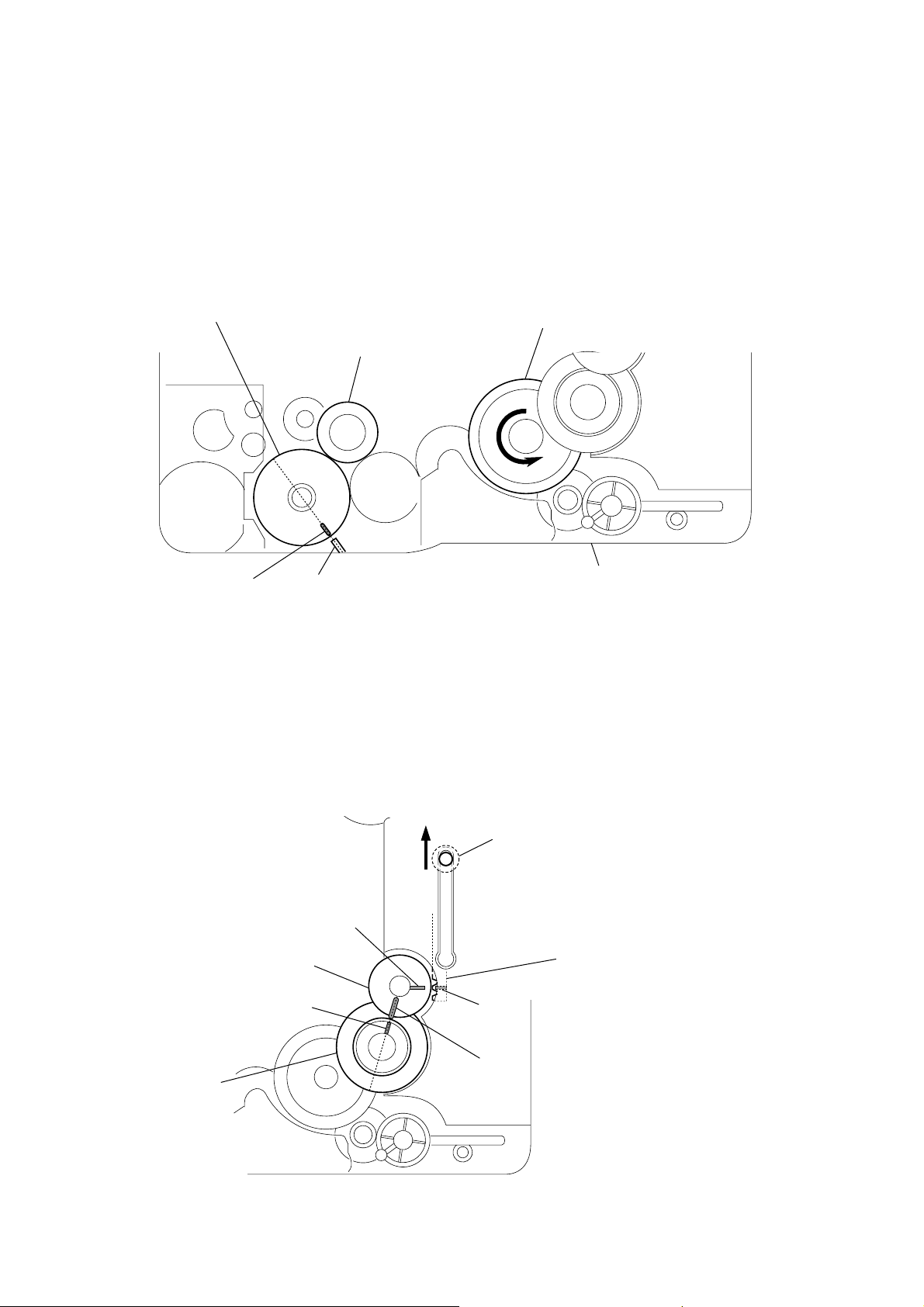

4-3. HOW TO INSTALL THE GEAR (MODE C)

1

Align the mark on the rotary encoder (S771) with the projection of the assy.

2

Check that the cam (BU U/D) can not be rotated in the direction of arrow.

3

Install the gear (

rotary encoder

(S771)

mode

C)

gear (

mode

cam (BU U/D)

C)

mark projection

4-4. HOW TO INSTALL THE GEAR (MODE CAM)

1

Slide the shaft in the direction of arrow.

2

Align mark A on the gear (mode cam) with mark B on the slider (mode cam) assy,

then install the gear (mode cam).

3

Check that mark C on the gear (mode cam) is in alignment with mark D on the cam (gear).

mark

A

gear (mode cam)

mark

D

– bottom view • front –

shaft

mark

B

chassis

slider (mode cam) assy

30

cam (gear)

– bottom view • front –

mark

C

Loading...

Loading...