Sony HCD-FLX7D, HCD-FLX5D Service Manual

SERVICE MANUAL

DVD DECK RECEIVER

E Model

HCD-FLX5D/FLX7D

Australian Model

HCD-FLX5D

SPECIFICATIONS

HCD-FLX5D/FLX7D

Ver 1.0 2004.04

9-877-739-01 Sony Corporation

2004D05-1 Home Audio Company

© 2004.04 Published by Sony Engineering Corporation

– Continued on next page –

HCD-FLX5D/FLX7D are the amplifier, DVD player,

tape deck and tuner section in DHC-FLX5D/FLX7D .

Model Name Using Similar Mechanism NEW

DVD

DVD Mechanism Type CDM53N-DVBU14

Section

Base Unit Name DVBU14

Optical Traverse Unit Name DBU-1

TAPE

Model Name Using Similar Mechanism NEW

Section

The following measured at AC 127, 220, 240 V,

50/60 Hz (Saudi Arabian model only)

The following measured at AC 120, 220, 240 V,

50/60 Hz (except for Saudi Arabian model)

MULTI mode

DIN power output at stereo mode (rated)

45 + 45 watts

(8 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

Front speaker: 60 + 60 watts

(8 ohms at 1 kHz, 10%

THD)

Center speaker: 60 watts

(16 ohms at 1 kHz, 10%

THD)

Rear speaker: 60 + 60 watts

(8 ohms at 1 kHz, 10%

THD)

Sub woofer: 100 watts

(8 ohms at 100 Hz, 10%

THD)

2.1CH mode

DIN power output at stereo mode (rated)

70 + 70 watts

(8 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

Front speaker: 120 + 120 watts

(8 ohms at 1 kHz, 10%

THD)

Sub woofer: 240 watts

(8 ohms at 100 Hz, 10%

THD)

Inputs

VIDEO/SAT IN L/R (phono jacks):

voltage 250 mV/450mV,

impedance 47 kilohms

OPTICAL DIGITAL IN (Square optical connector

jacks, rear panel) :

wavelength ——

MIC (phone jack) : sensitivity 1 mV,

impedance 10 kilohms

Outputs

VIDEO OUT L/R (phono jacks):

voltage 250 mV,

impedance 1 kilohms

VIDEO OUT: 1 Vp-p, 75 ohms

S VIDEO OUT: Y: 1 Vp-p, 75 ohms

C: 0.286Vp-p, 75 ohms

COMPONENT VIDEO OUT:

Y: 1 Vp -p, 75 ohm

P

B

: 0.7 Vp-p, 75 ohms

P

R

: 0.7 Vp-p, 75 ohms

PHONES (stereo mini jack):

accepts headphones of

8 ohms or more

FRONT L/R: Use only the supplied

speaker SS-FLX9

REAR L/R: Use only the supplied

speaker SS-RS9

CENTER: Use only the supplied

speaker SS-CT9

S.WOOFER: Use only the supplied

speaker SS-WG9

Amplifier section:

Photo: HCD-FLX7D

2

HCD-FLX5D/FLX7D

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

The following caution label is located inside the apparatus.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

Disc player section

Laser Semiconductor laser

(DVD and SA-CD:

λ=650 nm,

CD: λ=780 nm)

Emission duration:

continuous

Frequency response DVD (PCM 48 kHz):

2 Hz − 22 kH

= (±1 dB)

CD: 2 Hz − 20 kHz =

(±1 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format

NTSC, PAL

OPTICAL DIGITAL OUT (Square optical

connector jack, rear panel)

wavelength 660 nm

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 50 − 13,000 Hz (±3 dB),

using Sony TYPE I

cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 − 108.0 MHz

(50-kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Latin American model: 530 − 1,710 kHz

(with the tuning

interval set at 10 kHz)

531 − 1,710 kHz

(with the tuning

interval set at 9 kHz)

Saudi Arabian model: 531 − 1,602 kHz

(with the tuning

interval set at 9 kHz)

Other models: 530 − 1,710 kHz

(with the tuning

interval set at 10 kHz)

531 − 1,602 kHz

(with the tuning

interval set at 9 kHz)

Antenna AM loop antenna

Antenna terminals External antenna

terminal

Intermediate frequency 450 kHz

General

Power requirements

Saudi Arabian model: 120 − 127 V, 220 V or

230 − 240 V AC,

50/60 Hz

Adjustable with

voltage selector

Australian model: 230 − 240 V AC,

50/60 Hz

Thailand model: 220 V AC, 50/60 Hz

Korean model: 220 V AC, 60 Hz

Other models: 120 V, 22 0 V or

230 − 240 V AC,

50/60 Hz

Adjustable with

voltage selector

Power consumption 425 watts

Dimensions (w/h/d) Approx. 235 × 435 ×

420 mm

Mass Approx. 15.0 kg

Design and specifications are subject to change

without notice.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

3

HCD-FLX5D/FLX7D

*The “DVD VIDEO” logo is a trademark.

**DHC-FLX7D only

Discs that this system cannot

play

• CD-ROMs (PHOTO CDs included)

• All CD-Rs other than music and VCD

format CD-Rs

• Data part of CD-Extras

• DVD-ROMs

• DVD Audio discs

This system can play the

following discs

Format of discs Disc logo

DVD VIDEO*

Super Audio CD**

VIDEO CD

Music CD

Depending on the DVD, no region code

indication may be labeled even though

playing the DVD is prohibited by area

The region code is located below the

COMPONENT VIDEO OUT jacks on the

rear panel.

Note on playback operations of

DVDs and VIDEO CDs

Some playback operations of DVDs and

VIDEO CDs may be intentionally set by

software producers. Since this system plays

DVDs and VIDEO CDs according to the disc

contents the software producers designed,

some playback features may not be available.

Also, refer to the instructions supplied with

the DVDs or VIDEO CDs.

Note on PBC (Playback Control)

(VIDEO CDs)

This system conforms to Ver. 1.1 and Ver. 2.0

of VIDEO CD standards. You can enjoy two

kinds of playback depending on the disc type.

Copyrights

This product incorporates copyright protection

technology that is protected by U.S. patents

and other intellectual property rights. Use of

this copyright protection technology must be

authorized by Macrovision, and is intended for

home and other limited viewing uses only

unless otherwise authorized by Macrovision.

Reverse engineering or disassembly is

Disc type You can

VIDEO CDs

without PBC

functions

(Ver. 1.1 discs)

Enjoy video playback (moving

pictures) as well as music.

VIDEO CDs

with PBC

functions

(Ver. 2.0 discs)

Play interactive software using

menu screens displayed on the TV

screen (PBC Playback), in addition

to the video playback functions of

Ver. 1.1 di scs. Moreover, you can

play high-resolution still pictures,

if they are included on the disc.

Region code of DVDs you can

play on this system

You r system has a region code printed on the

back of the unit and will only play DVDs

labeled with identical region code.

DVDs labeled will also be played on this

system.

If you try to play any other DVD, the

message “Playback prohibited by area

limitations.” will appear on the TV screen.

ALL

Some CD-Rs/CD-RWs or DVD-Rs/DVD-RWs

cannot be played on this system depending upon the

format or the recording quality or physical condition

of the disc, or the characteristics of the recording

Furthermore, the disc will not play if it has not been

correctly finalized. For more information, see the

operating instructions for the recording device.

device.

restrictions.

prohibited.

Note

4

HCD-FLX5D/FLX7D

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 5

2. GENERAL

Location of Controls ....................................................... 9

Setting the Clock ............................................................. 10

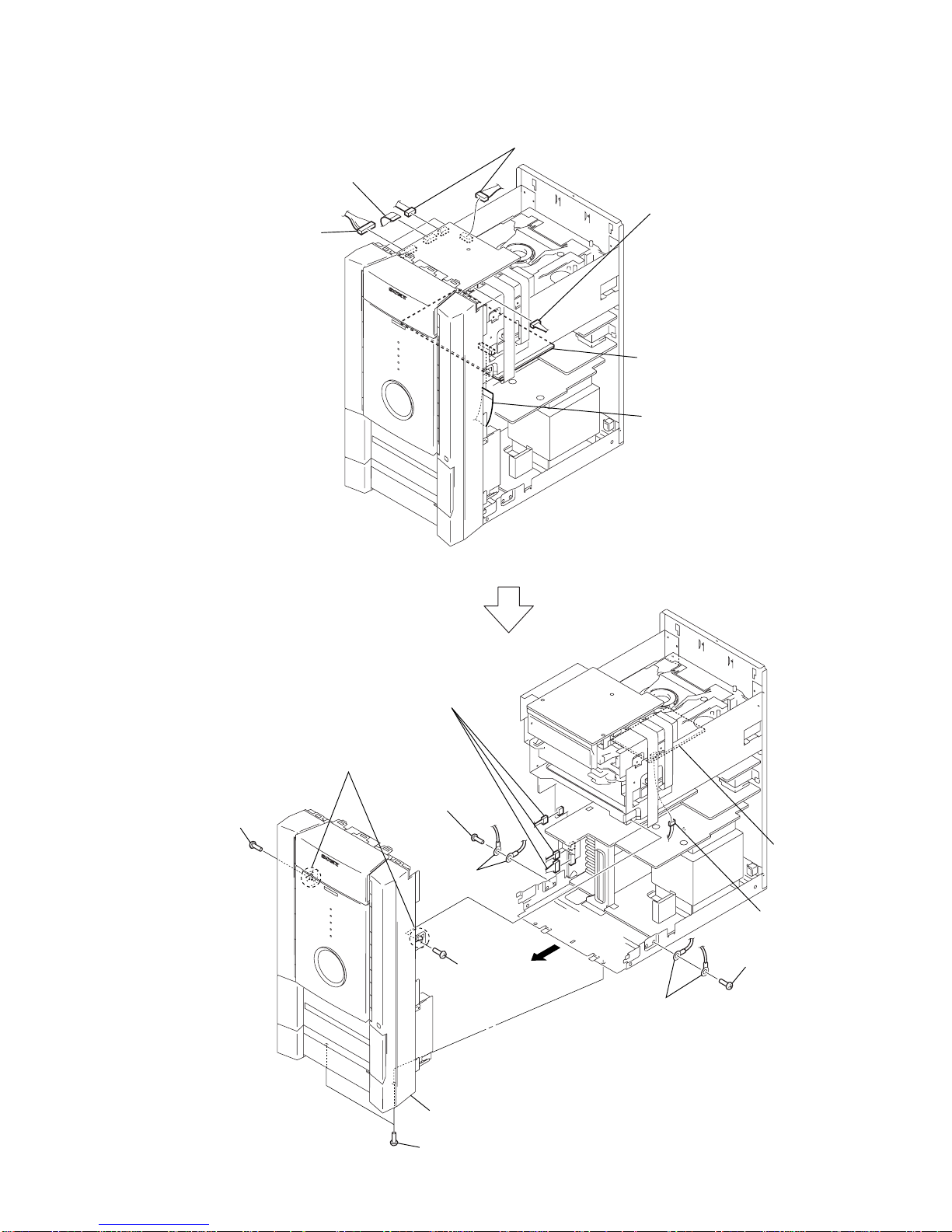

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 11

3-2. Cover (Top), Cover (Back) ............................................. 12

3-3. Case ................................................................................. 12

3-4. Front Panel Assy ............................................................. 13

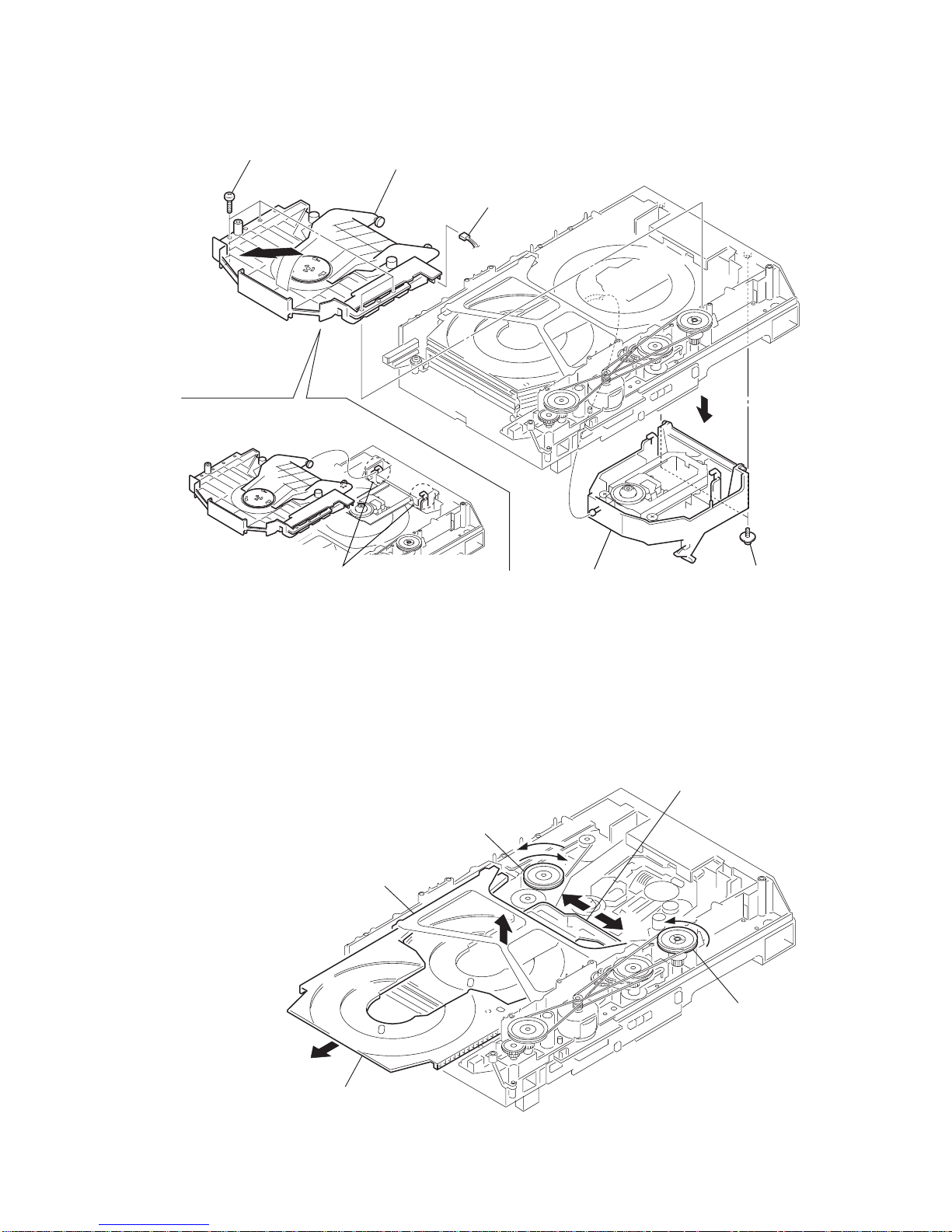

3-5. Mechanical (Cassette) Deck ........................................... 14

3-6. GC Board......................................................................... 14

3-7. DVD Mechanism Block .................................................. 15

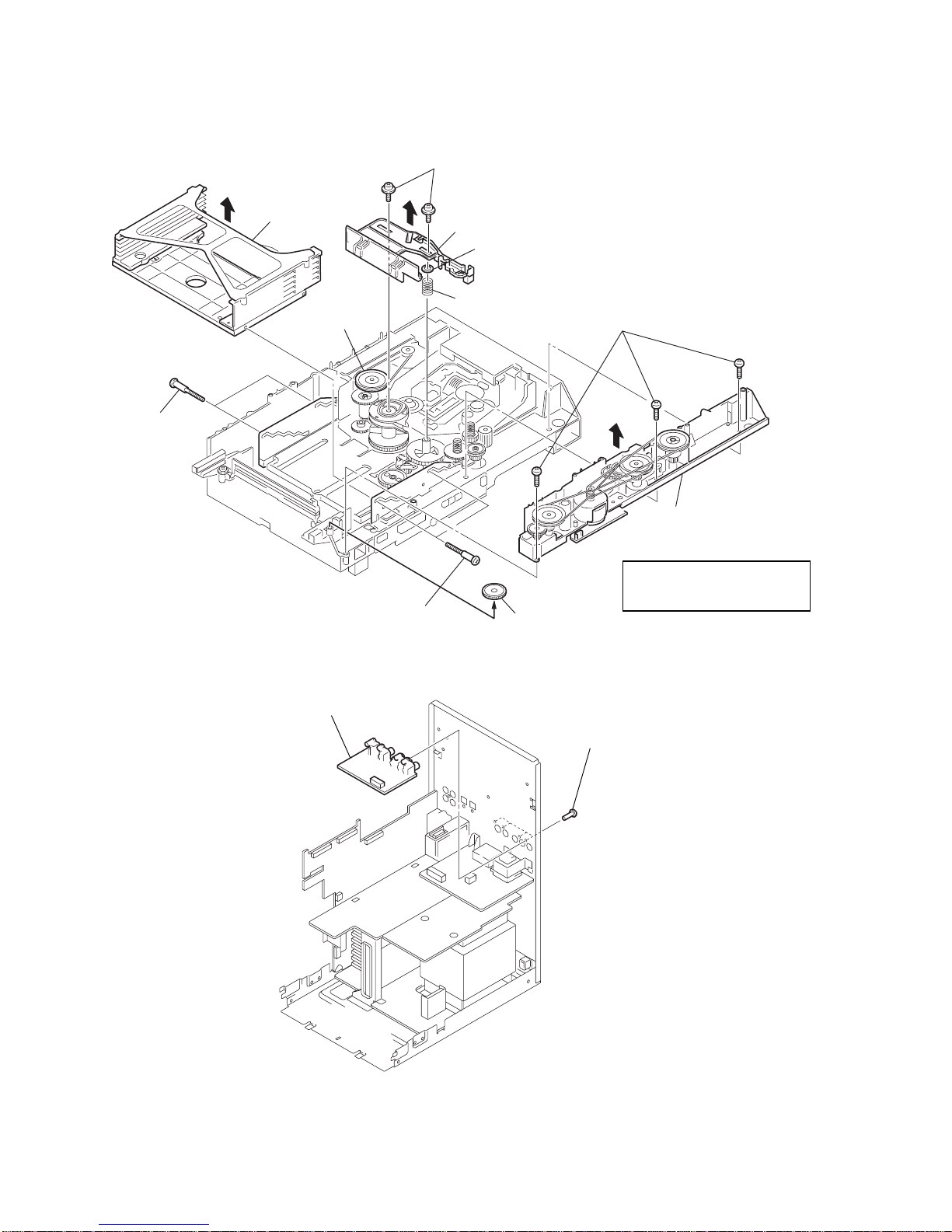

3-8. DSP Board....................................................................... 15

3-9. DVD Mechanism Deck (CDM53N-DVBU14) .............. 16

3-10. Fitting Base (Guide) Assy, Bracket (Chassis),

Magnet Assy .................................................................... 16

3-11. Base Unit (DVBU14) ...................................................... 17

3-12. Tray (Sub)........................................................................ 17

3-13. Chassis (Mold B) Section, Stocker Section,

Slider (Selection) ............................................................ 18

3-14. VIDEO Board .................................................................. 18

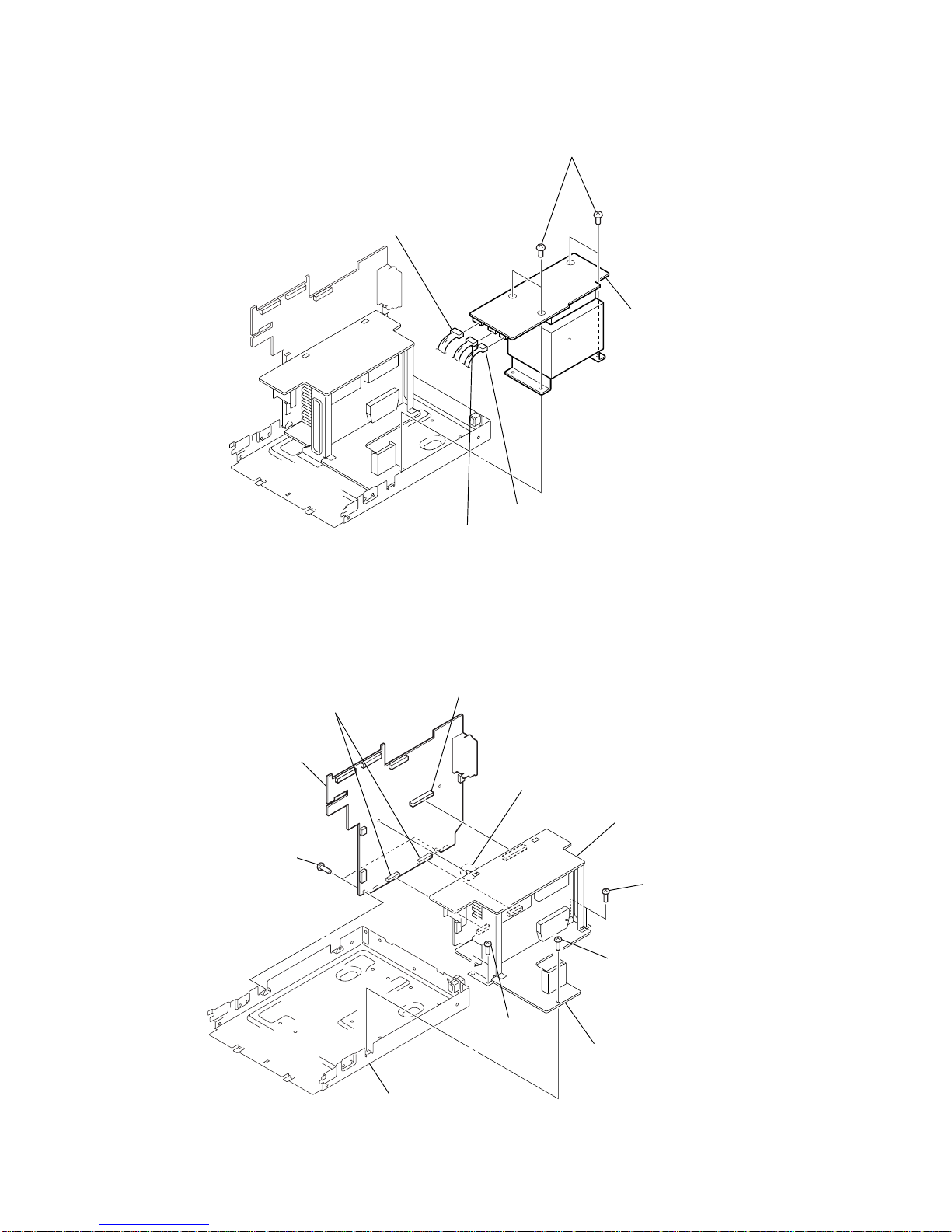

3-15. SUB TRANS Board ........................................................ 19

3-16. Back Panel Section.......................................................... 19

3-17. TRANS Board ................................................................. 20

3-18. SP RELAY Board............................................................ 20

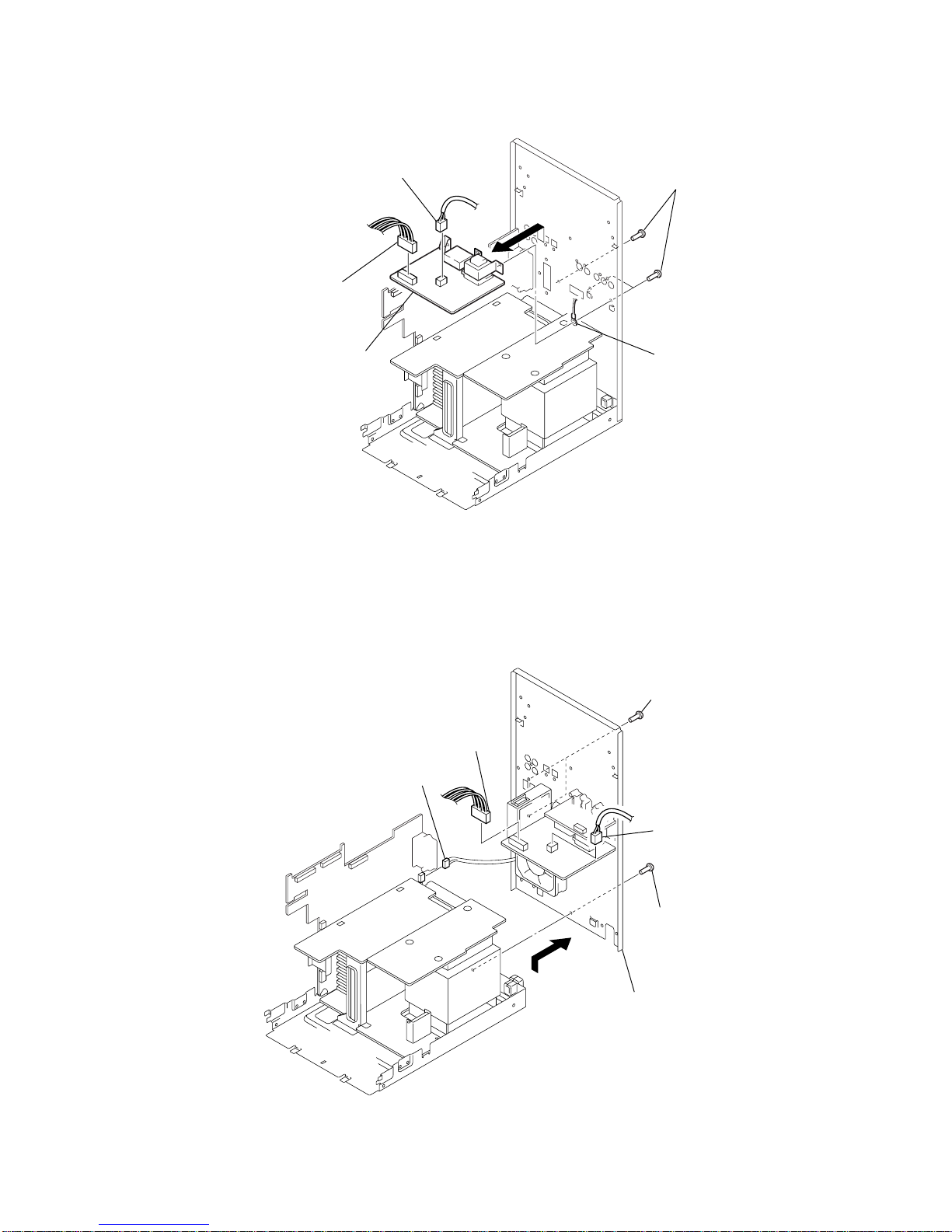

4. ASSEMBLY

4-1. Assembly Flow................................................................ 21

4-2. Gears Installation ............................................................ 21

4-3. Slider (Selection) Installation......................................... 22

4-4. Stocker Section Installation............................................ 22

4-5. Chassis (Mold B) Section Installation............................ 23

5. TEST MODE.............................................................. 24

6. ELECTRICAL ADJUSTMENTS......................... 33

7. DIAGRAMS

7-1. Block Diagram − RF SERVO Section −........................ 34

7-2. Block Diagram − TUNER/TAPE DECK Section − ...... 35

7-3. Block Diagram − AUDIO DSP Section (1/2) −

(FLX7D only).................................................................. 36

7-4. Block Diagram − AUDIO DSP Section (2/2) − ............ 37

7-5. Block Diagram − POWER AMP Section −................... 38

7-6. Block Diagram − VIDEO Section − .............................. 39

7-7. Block Diagram

− DISPLAY/POWER SUPPLY Section − ...................... 40

7-8. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 41

7-9. Printed Wiring Board – RF Board −.............................. 42

7-10. Schematic Diagram – RF Board −................................. 43

7-11. Printed Wiring Board

− MB Board (Component Side) − .................................. 44

7-12. Printed Wiring Board

− MB Board (Conductor Side) − .................................... 45

7-13. Schematic Diagram − MB Board (1/7) − ...................... 46

7-14. Schematic Diagram − MB Board (2/7) − ...................... 47

7-15. Schematic Diagram − MB Board (3/7) − ...................... 48

7-16. Schematic Diagram − MB Board (4/7) − ...................... 49

7-17. Schematic Diagram − MB Board (5/7) − ...................... 50

7-18. Schematic Diagram − MB Board (6/7) − ...................... 51

7-19. Schematic Diagram − MB Board (7/7) − ...................... 52

7-20. Schematic Diagram − DSP Board (1/3) − ..................... 53

7-21. Schematic Diagram − DSP Board (2/3) − ..................... 54

7-22. Schematic Diagram − DSP Board (3/3) − ..................... 55

7-23. Printed Wiring Board

− DSP Board (Component Side) − ................................ 56

7-24. Printed Wiring Board

− DSP Board (Conductor Side) − .................................. 57

7-25. Printed Wiring Board − MC Board − ............................. 58

7-26. Schematic Diagram − MC Board − ................................ 59

7-27. Printed Wiring Board

− FRONT REAR AMP Board − ..................................... 60

7-28. Schematic Diagram

− FRONT REAR AMP Board − ..................................... 61

7-29. Printed Wiring Board

− CENTER SW AMP Board − ...................................... 62

7-30. Schematic Diagram

− CENTER SW AMP Board − ....................................... 63

7-31. Printed Wiring Boards − SPEAKER Section −............. 64

7-32. Schematic Diagram − REGULATOR Board − ............. 65

7-33. Schematic Diagram − SP RELAY Board (1/2) −.......... 66

7-34. Schematic Diagram − SP RELAY Board (2/2) −.......... 67

7-35. Printed Wiring Board − GC Board − ............................. 68

7-36. Schematic Diagram − GC Board − ................................ 69

7-37. Printed Wiring Boards − CHANGER Section − ........... 70

7-38. Schematic Diagram − CHANGER Section −................ 71

7-39. Printed Wiring Boards − CD DOOR Section −............. 72

7-40. Schematic Diagram − CD DOOR Section − ................. 73

7-41. Printed Wiring Boards − PANEL Section − .................. 74

7-42. Schematic Diagram − PANEL Section − ...................... 75

7-43. Printed Wiring Board − MIC Board − ........................... 76

7-44. Schematic Diagram − MIC Board − .............................. 77

7-45. Printed Wiring Board − VIDEO Board − ...................... 78

7-46. Schematic Diagram − VIDEO Board − ......................... 79

7-47. Printed Wiring Board − TRANS Board − ..................... 80

7-48. Schematic Diagram − TRANS Board − ........................ 81

7-49. Printed Wiring Board − SUB TRANS Board − ............ 82

7-50. Schematic Diagram − SUB TRANS Board − ............... 83

8 EXPLODED VIEWS

8-1. Cover Section .................................................................118

8-2. Mechanical (Cassette) Deck Section .............................119

8-3. CD MOTOR/CD DOOR SW1/MIC/PANEL (U)/

TC DOOR/TC DOOR SW Boards Section...................120

8-4. Moving Panel Section .................................................... 121

8-5. Front Panel Section ........................................................ 122

8-6. DSP/GC/MC/MB/REGULATOR Boards Section ........123

8-7. Power Tansformer Section .............................................124

8-8. CENTER SW AMP/FRONT REAR AMP

Boards Section ............................................................... 125

8-9. SP RELAY Board Section .............................................126

8-10. DVD Mechanism Deck Section-1

(CDM53N-DVBU14)..................................................... 127

8-11. DVD Mechanism Deck Section-2

(CDM53N-DVBU14)..................................................... 128

8-12. DVD Mechanism Deck Section-3

(CDM53N-DVBU14)..................................................... 129

8-13. DVD Mechanism Deck Section-4

(CDM53N-DVBU14)..................................................... 130

8-14. Base Unit Section (DVBU14)........................................ 131

9. ELECTRICAL PARTS LIST .............................. 132

5

HCD-FLX5D/FLX7D

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure :

Press two buttons of

Z (DVD) and [ ] simultaneously for five

seconds. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by

turning power on/off with the [I/ ] button.

NOTE OF REPLACING THE MB BOARD

When replacing the MB board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 24)

2. Press the [2] key of the remote commander, and set the “DRIVE

MANUAL OPERATION”. (See page 28)

3. Press the [6] key of the remote commander, and set the “2-6,

Memory Check”. (See page 30)

4. Press the [CLEAR] key of the remote commander, and initialize Memory.

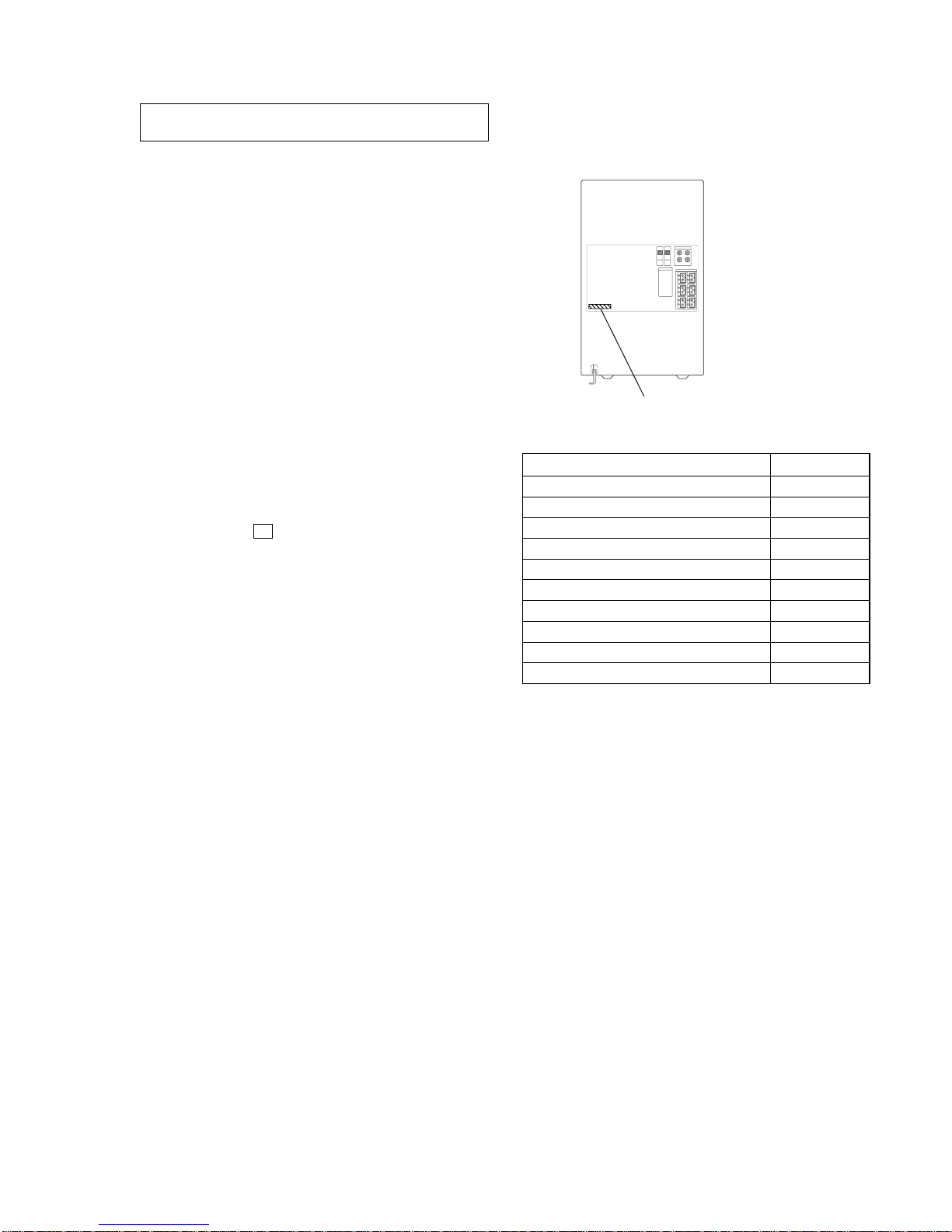

SECTION 1

SERVICING NOTES

• MODEL IDENTIFICATION

– Back Panel –

MODEL PART No.

FLX5D: EA 4-252-041-01

FLX5D: SP, MY 4-252-041-11

FLX5D: E3, E15 4-252-041-21

FLX5D: TH 4-252-041-31

FLX5D: E2 4-252-041-41

FLX5D: PH 4-252-041-51

FLX5D: KR 4-252-041-61

FLX5D: AUS 4-252-041-71

FLX7D: EA 4-253-684-01

FLX7D: E15 4-253-684-11

PART No.

x

1

• Abbreviation

AUS: Australian model

E2: 120 V AC area in E model

E3: 240 V AC area in E model

E15: 220V − 240 V AC area in E model

EA: Saudi Arabia model

KR: Korean model

MY: Malaysia model

PH: Philippines model

SP: Singapore model

TH: Thai model

6

HCD-FLX5D/FLX7D

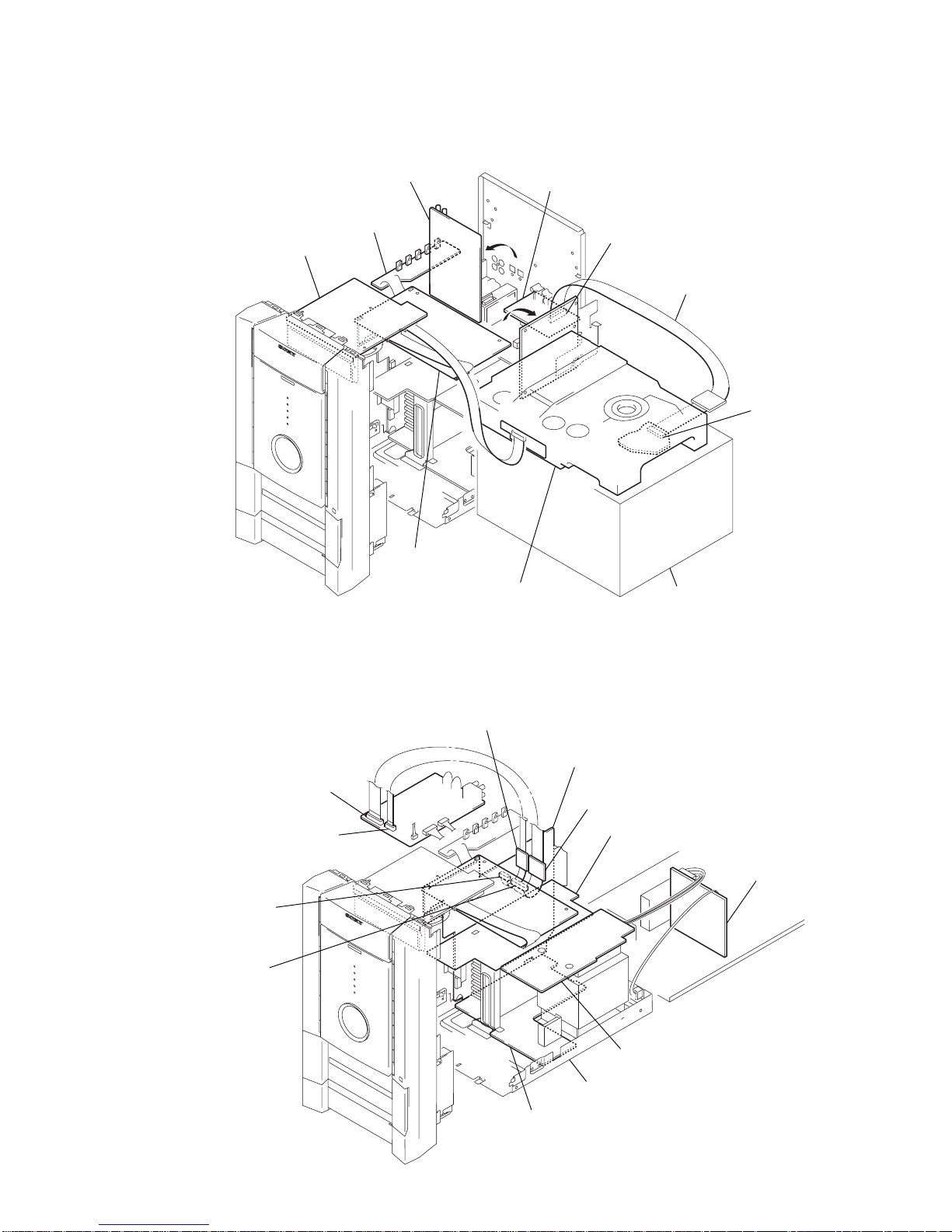

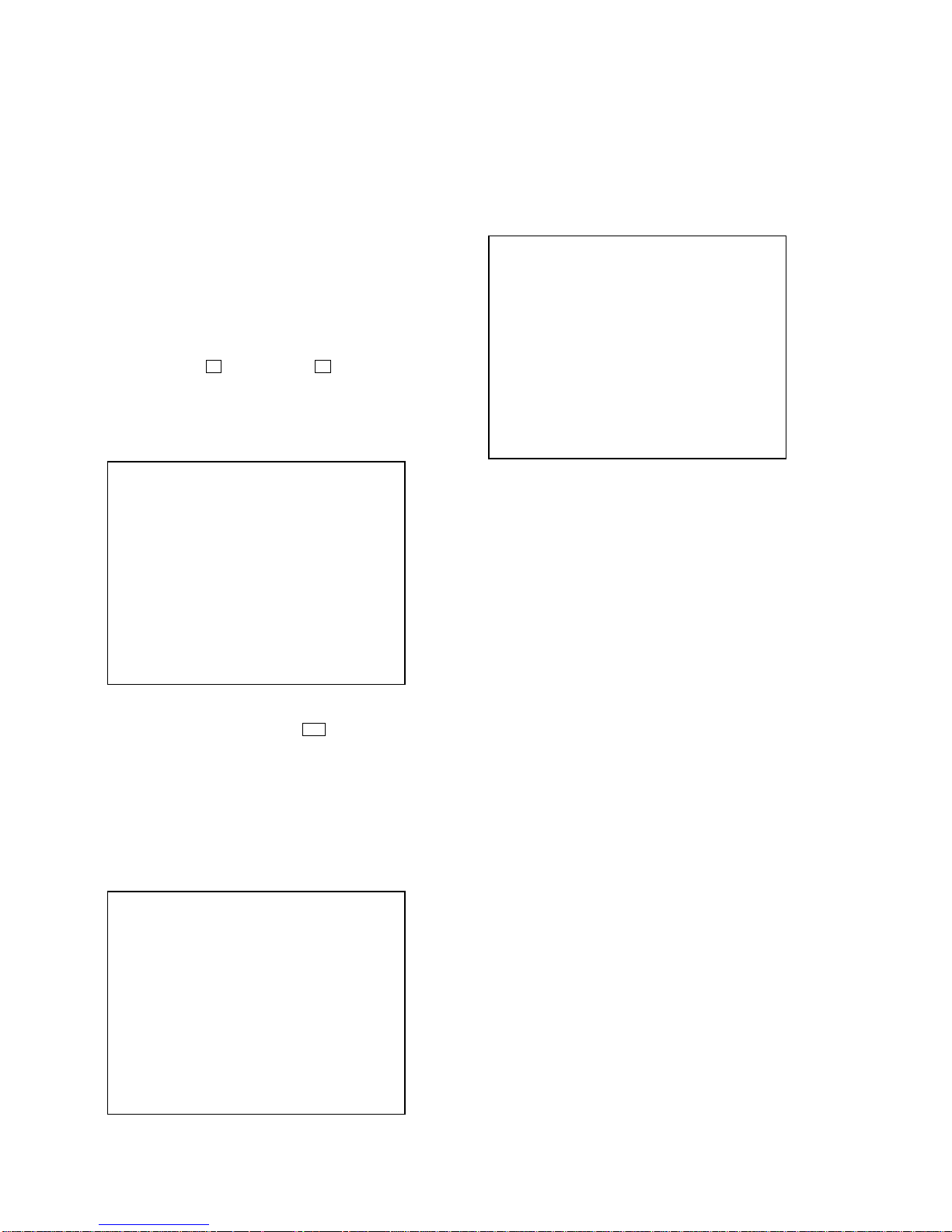

DVD MECHANISM DECK SERVICE POSITION

• In checking the DVD mechanism deck section (CDM53N-DVBU14), prepare e xtension jig (Part No. J-2501-103-A: 1.00 mm Pitch, 29

cores, Length 300 mm).

DVD mechanism deck

(CDM53N-DVBV14)

Any board to put.

MB board (CN501

)

RF board (CN002)

Connect extension jig (J-2501-103 A)

to the MB board (CN501) and

RF board (CN002).

7

HCD-FLX5D/FLX7D

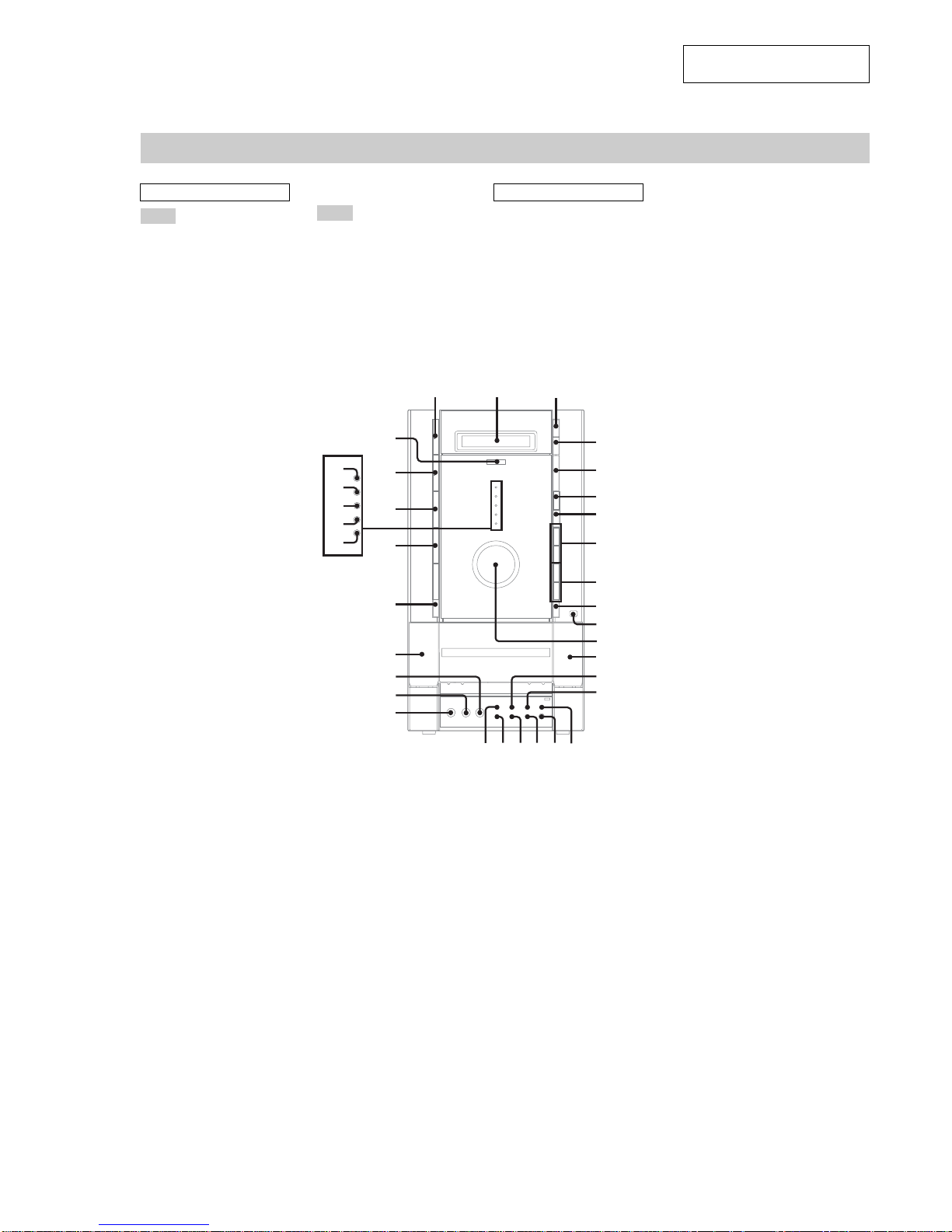

DSP/GC/MB/MC/REGULATOR AND VIDEO BOARDS SERVICE POSITION

• In checking the DSP/GC/MB/MC/REGULA T OR and VIDEO boards, prepare e xtension jig (Part No. J-2501-103-A: 1.00 mm Pitch, 29

cores, Length 300 mm).

VIDEO board

MB board

(CN501)

Connect extension jig (J-2501-103-A)

to the MB board (CN501) and

RF board (CN002).

RF board

(CN002)

Any box to put.

DVD mechanism deck

MC board

GC board

REGULATOR board

DSP board

Connect extension jig (J-2501-242-A) to the

DSP board (CN601) and MC board (CN103).

SP RELAY board

Connect extension jig (J-2501-086-A) to the

DSP board (CN602) and MC board (CN104).

FRONT REAR AMP board

SVB TRANS board

TRANS board

chassis

CENTER SW AMP board

Note: When you check the reverse-side side of

CENTER SW AMP board, please move

from a chassis.

MC board

(CN104)

MC board

(CN103)

DSP board

(CN601)

DSP board

(CN602)

CENTER SW AMP/FRONT REAR AMP/SP RELAY/SUB TRANS AND TRANS BOARDS SERVICE

POSITION

• In checking the CENTER SW AMP/FRONT REAR AMP/SP RELAY/SUB TRANS and TRANS boards, prepare two extension jigs

(Part No. J-2501-242-A: 1.00 mm Pitch, 11 cores, Length 300 mm and Part No. J-2501-086-A: 1.00 mm Pitch, 19 cores, Length

300 mm).

8

HCD-FLX5D/FLX7D

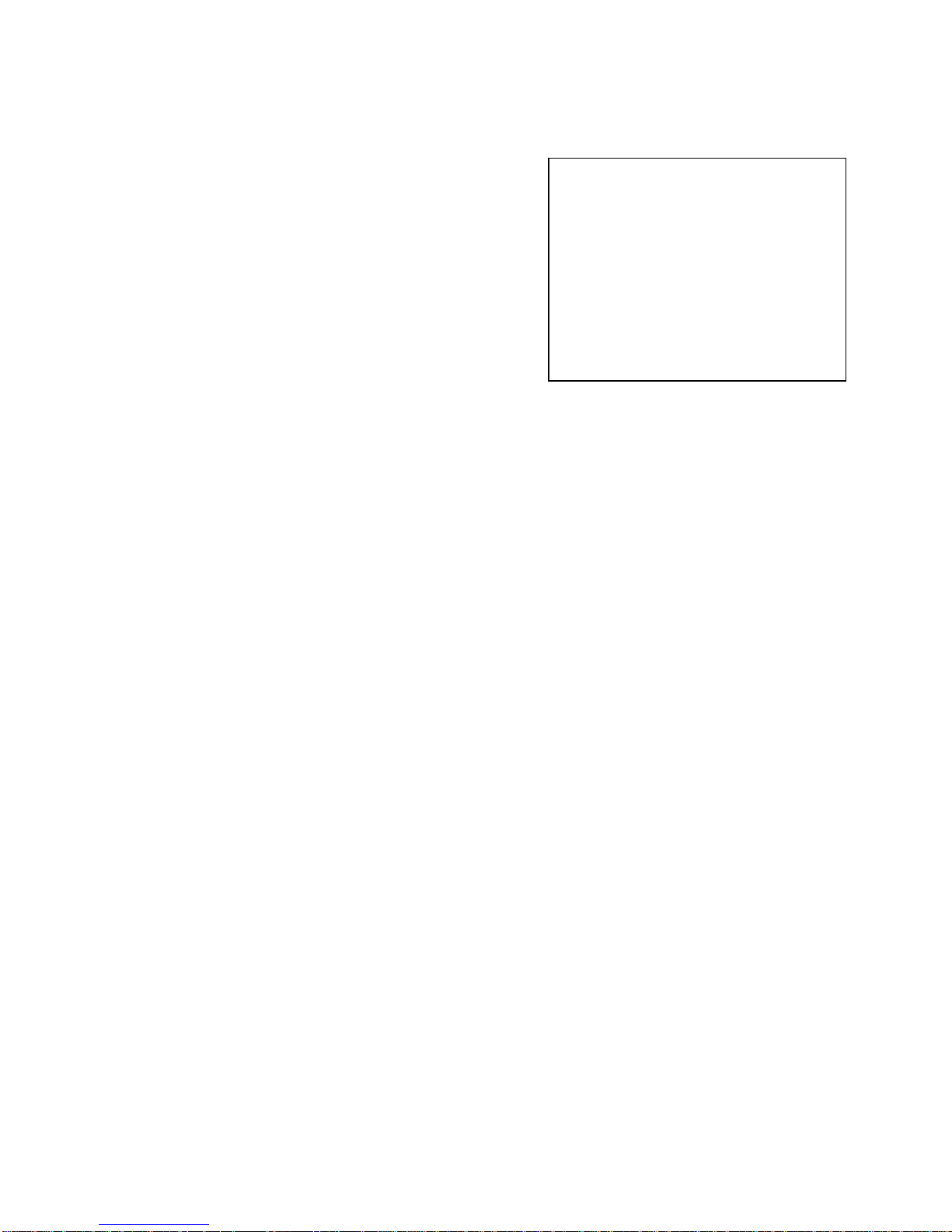

Connection:

Procedure:

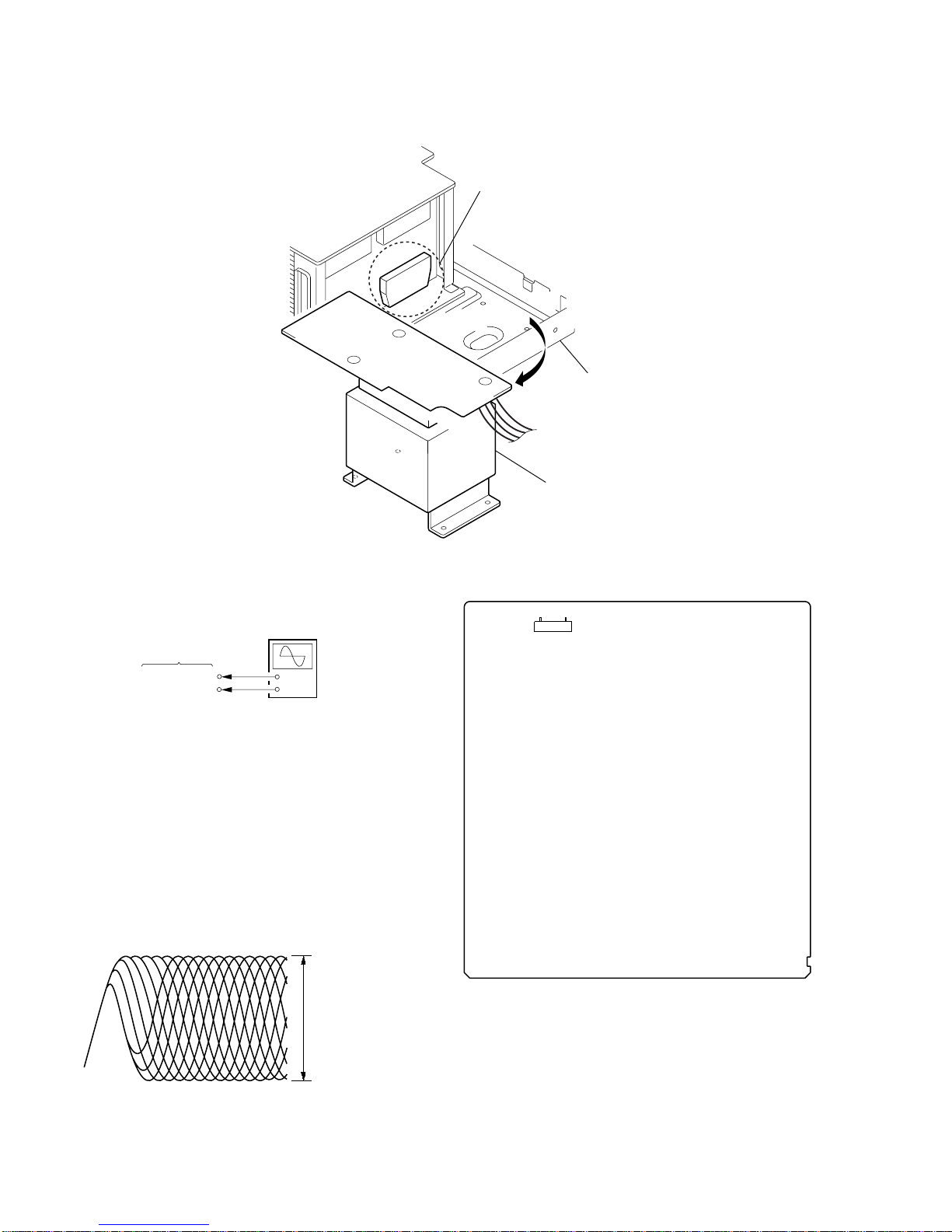

1. Connect an oscilloscope to test point 1 pin and 3 pin

of CN901 on the MB board.

2. Turn the power on.

3. Put the disc (LUV-P01) (Part No.:4-999-032-01) (CD)

in to playback.

4. Conf

5. Put the disc (TDV-520CSO) (Part No.:J-2501-236-A)

(DVD) in to playback.

6. Perform Comfirmation in the same manner as step 4.

irm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: A clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

+

–

oscilloscope

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

CD: 1.05

±

0.2 Vp-p

DVD: 1.09

±

0.2 Vp-p

DECISION TO PASS OR FAIL OF THE OPTICAL

PIC-UP BLOCK

CN901 1 pin

CN901 3 pin

MB board

IC501

chassis

power transformer

(T911)

IC501 SERVICE POSITION

•When you check IC501, please move a power trans former (T911) from a chassis.

Checking Location:

– MB BOARD (Component Side) –

71

CN901

9

HCD-FLX5D/FLX7D

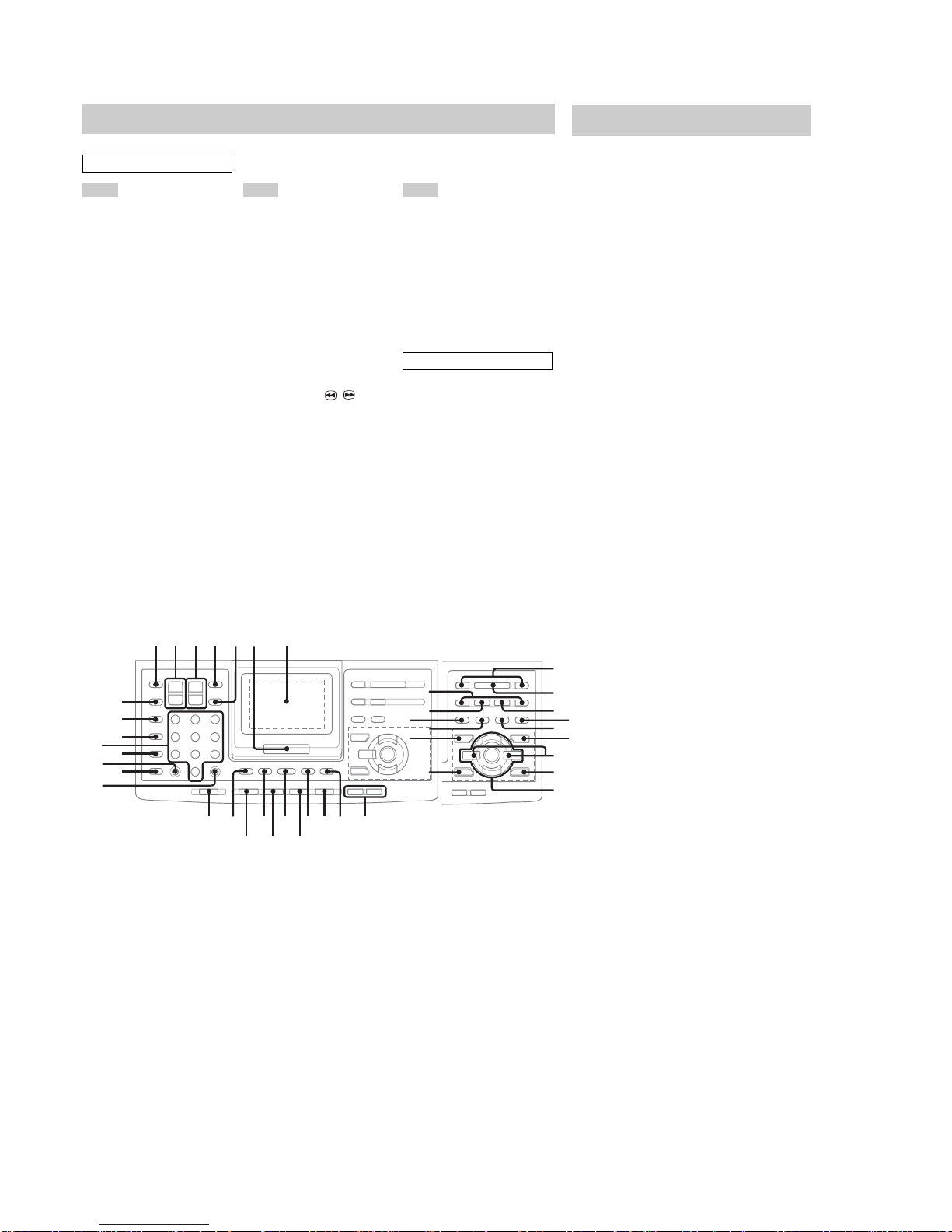

SECTION 2

GENERAL

This section is extracted from

instruction manual.

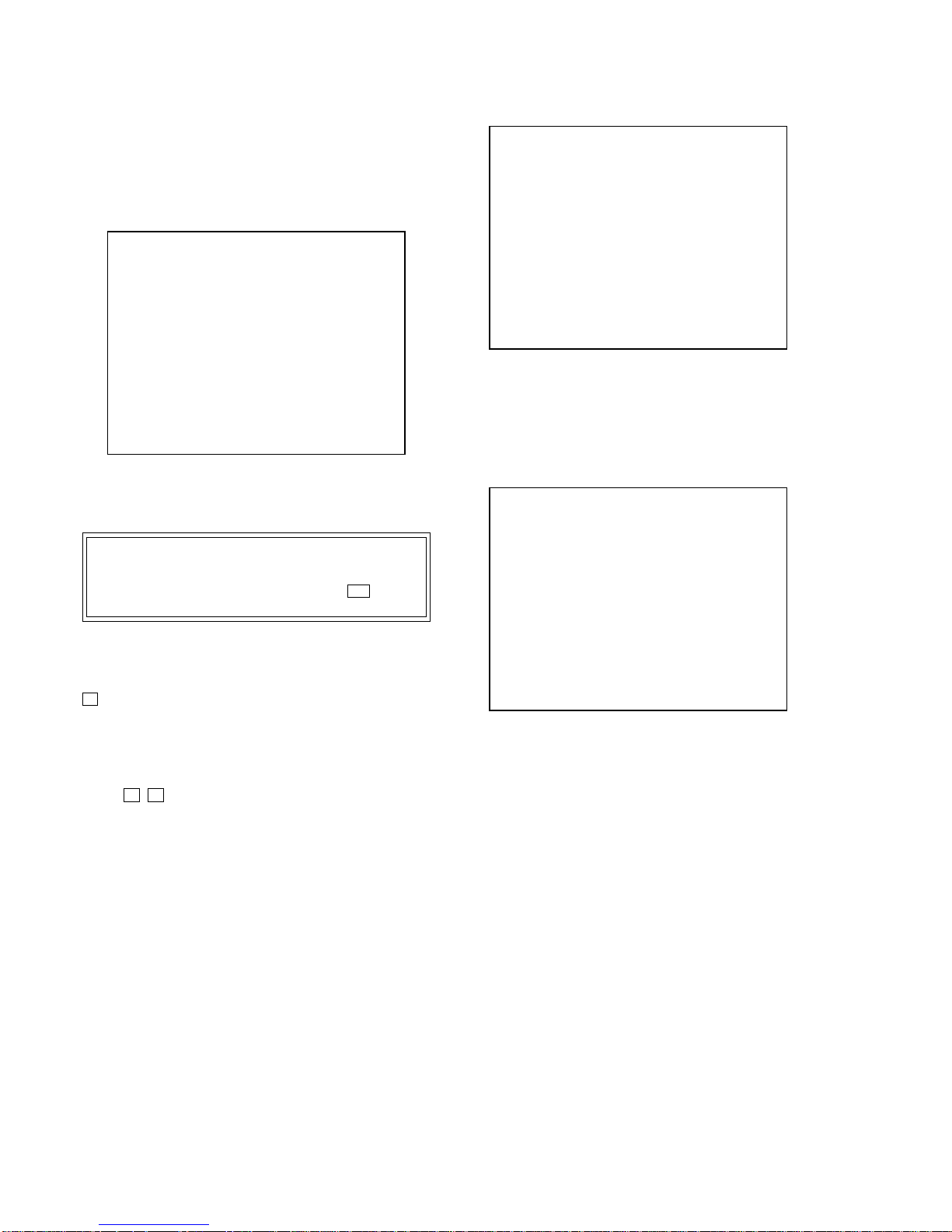

LOCATION OF CONTROLS

CD SYNC HI-DUB qg

Deck A wg

Deck B qd

DIGITAL wa

DISC SELECT 3

DISC 1 indicator es

DISC 2 indicator ea

DISC 3 indicator e;

DISC 4 indicator wl

DISC 5 indicator wk

Display window 2

DISPLAY qh

DVD ef

MIC jack ws

MIC LEVEL wd

MULTI CHANNEL DECODING

indicator eg

REC PAUSE/START qk

Remote sensor qa

TAPE A/B wj

TUNER/BAND ed

VIDEO/SAT w;

VOLUME qs

?/1 (power) 1

Z (disc tray) 4

A Z (deck A) wh

Z B (deck B) 0

hH (play) 5

X (pause) 6

x (stop) 7

./> (go back/go forward)

8

−/m, M/+ (rewind, fast

forward) 9

Main unit

ALPHABETICAL ORDER

A – L

M – Z

BUTTON DESCRIPTIONS

Z

?/1

Z

Z

x

X

>

.

+

M

m

–

hH

1 2 3

ed

wj

wh

wg

wd

ws

ef

eg

es

ea

wl

wk

e;

waw;wfqlqkqjqh

qf

qs

qa

qd

q;

7

6

5

4

9

8

qg

ECHO LEVEL wf

EFFECT ql

GROOVE qf

Headphones jack qj

10

HCD-FLX5D/FLX7D

2.1CH/MULTI* e;

ALBUM +/− ed

AMP MENU 9

Remote Control

ALPHABETICAL ORDER

A – E

ANGLE ek

AUDIO el

CLEAR ql

CLOCK/TIMER SELECT* wf

B

v

V

1 2 3 456 7

890qa

qs

qd

qf

qg

qh

qjqk

ql

wh

wg

wf

ws

w;

wa

wd

Bb

v

V

wk

wj

wl

e;

ea

es

ef

ed

eg

eh

ej

ek

el

r;

ra

CLOCK/TIMER SET wf

D.SKIP 5

digipad 7

DISPLAY 4

DSP EDIT* ej

DVD qh

DVD DISPLAY* qa

DVD MENU qa

DVD SETUP* 9

DVD TOP MENU qg

EFFECT* es

ENTER 6

FUNCTION 0

GAME MODE eh

GROOVE* ef

KARAOKE PON* eh

MOVIE MODE es

MUSIC MODE ej

Numeric buttons wd

P FILE* el

PLAY MODE/DIRECTION w;

TAPE A/B qs

TOOL MODE ef

TUNER MEMORY* w;

TUNER/BAND qf

TUNING +/− ra

TV/VIDEO wh

TV ?/1 1

TV CH +/− 3

TV VOL +/− 2

VOLUME +/− 8

?/1 (power) qk

hH (play) wk

X (pause) r;

x (stop) wl

. (go back) wj

> (go forward) wj

m (rewind) ra

M (fast forward) ra

V/v/B/b/ENTER eg

>10 wa

*To use these functions, press the

button while pressing SHIFT.

F – S T – V

BUTTON DESCRIPTIONS

PRESET +/− wj

PREV/NEXT wj

REPEAT/FM MODE ws

RETURN O e;

SCAN/SLOW t / T ra

SELECT wk

SHIFT qd

SLEEP wg

SONY TV DIRECT qj

SUBTITLE ea

1 Tu rn on the system.

2 Press CLOCK/TIMER SET on the

remote.

3 Press . or > repeatedly to set the

hour.

4 Press ENTER on the remote.

5 Press . or > repeatedly to set the

minutes.

6 Press ENTER on the remote.

To adjust the clock

1 Press CLOCK/TIMER SET on the remote.

2 Press . or > repeatedly to select

“CLOCK SET?”, then press ENTER on the

remote.

3 Do the same procedures as step 3 to 6

above.

Note

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

Setting the clock

11

HCD-FLX5D/FLX7D

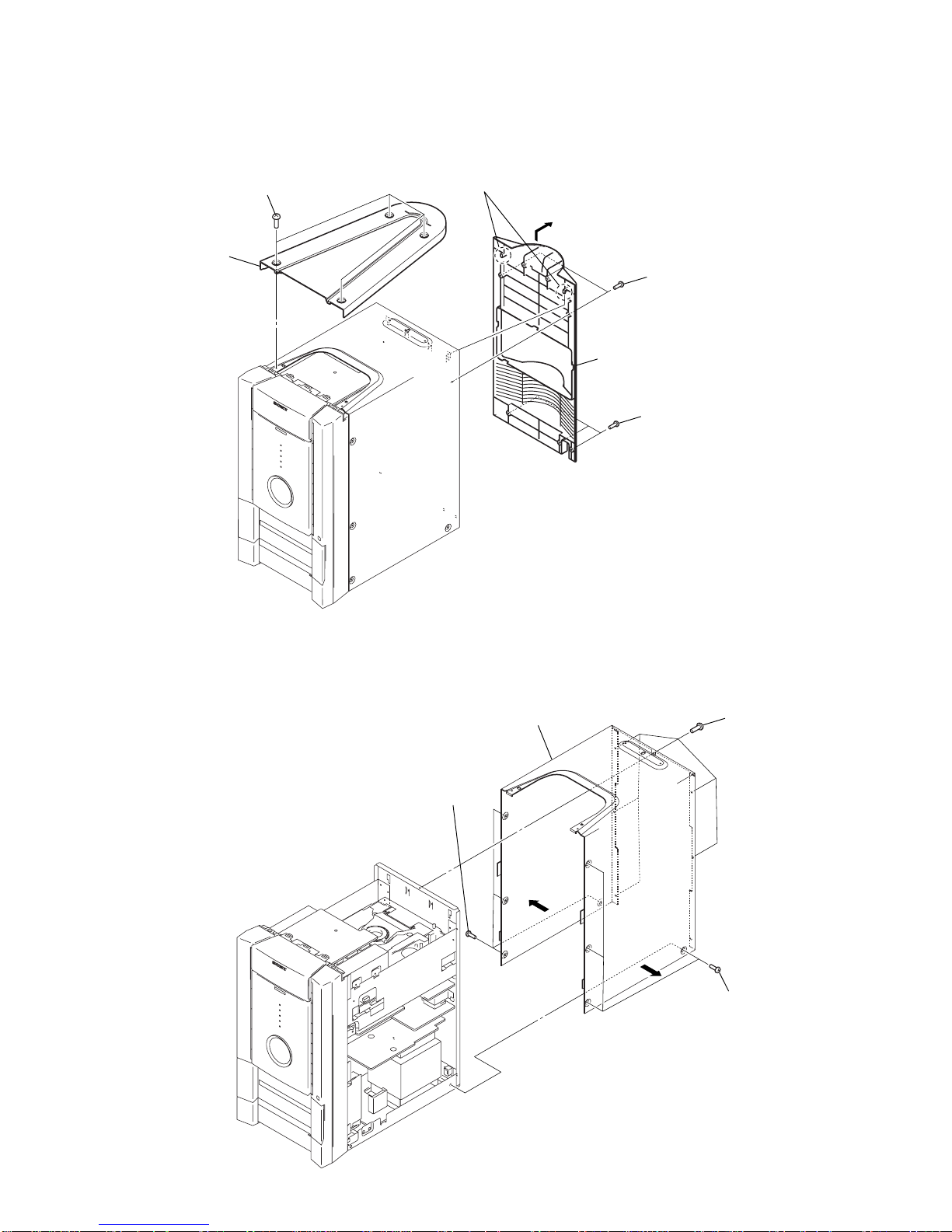

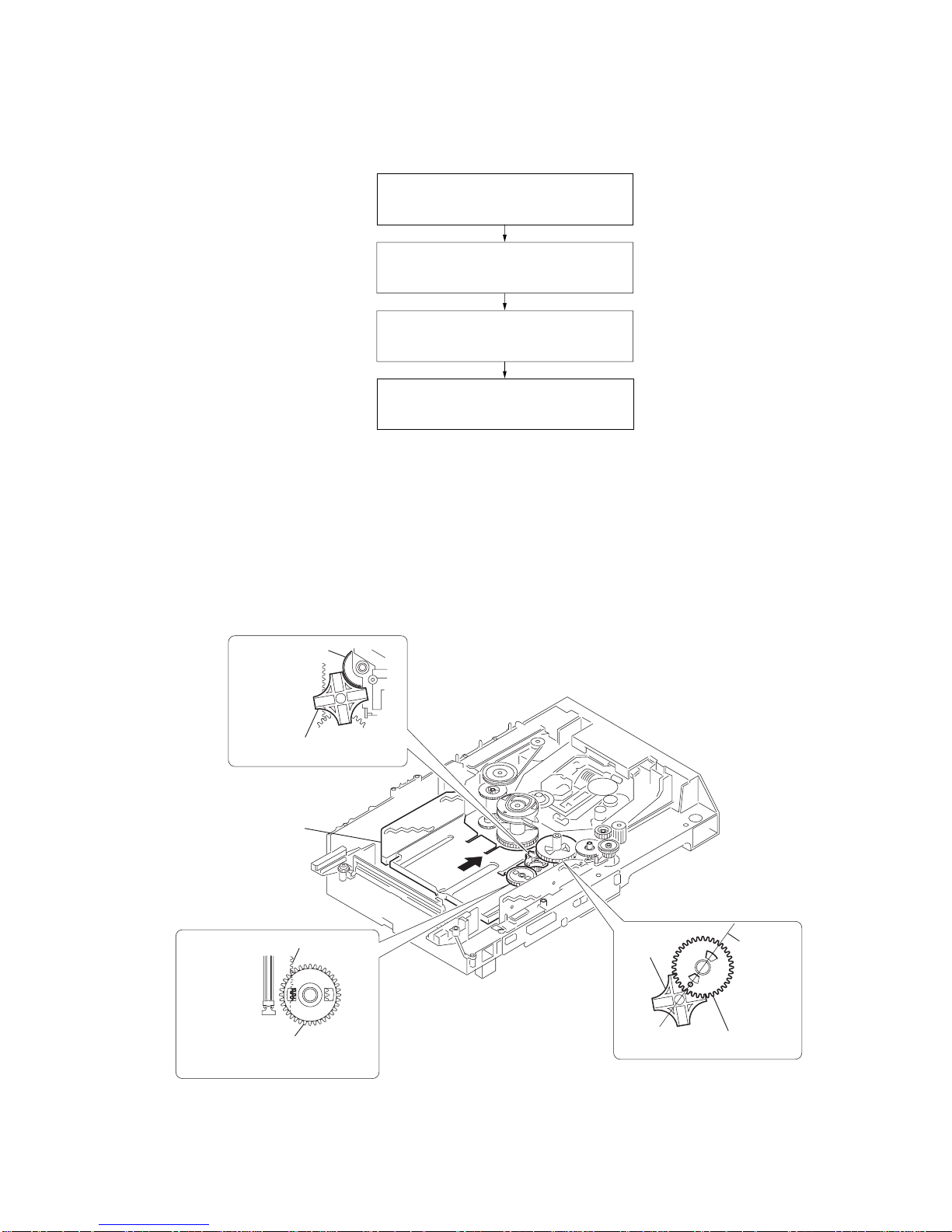

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SECTION 3

DISASSEMBLY

3-3. CASE

(Page 12)

3-2. COVER (TOP),

COVER (BACK)

(Page 12)

3-6. GC BOARD

(Page 14)

3-10. FITTING BASE (GUIDE)ASSY,

BRACKET (CHASSIS),

MAGNET ASSY

(Page 16)

3-13. CHASSIS (MOLD B) SECTION,

STOCKER SECTION,

SLIDER (SELECTION)

(Page 18)

3-7. DVD MECHANISM BLOCK

(Page 15)

3-12. TRAY (SUB)

(Page 17)

3-9. DVD MECHANISM DECK

(CDM53N-DVBU14)

(Page 16)

3-8. DSP BOARD

(Page 15)

3-17. TRANS BOARD

(Page 20)

3-18. SP RELAY BOARD

(Page 20)

3-14. VIDEO BOARD

(Page 18)

3-15. SUB TRANS BOARD

(Page 19)

3-16. BACK PANEL SECTION

(Page 19)

3-11. BASE UNIT

(DVBU14)

(Page 17)

3-4. FRONT PANEL ASSY

(Page 13)

3-5. MECHANICAL

(CASSETTE) DECK

(Page 14)

SET

12

HCD-FLX5D/FLX7D

Note: Follow the disassembly procedure in the numerical order given.

3-2. COVER (TOP), COVER (BACK)

3-3. CASE

2

cover (top)

3

two screws

(BVTP3 × 8)

3

three screws

(BVTP3 × 8)

5

cover (back)

4

two claws

1

four screws

(case 3 TP2)

1

six screws

(BVTP3

×

8

)

2

four screws

(case 3 TP2)

3

3

4

case

2

four screws

(case 3 TP2)

13

HCD-FLX5D/FLX7D

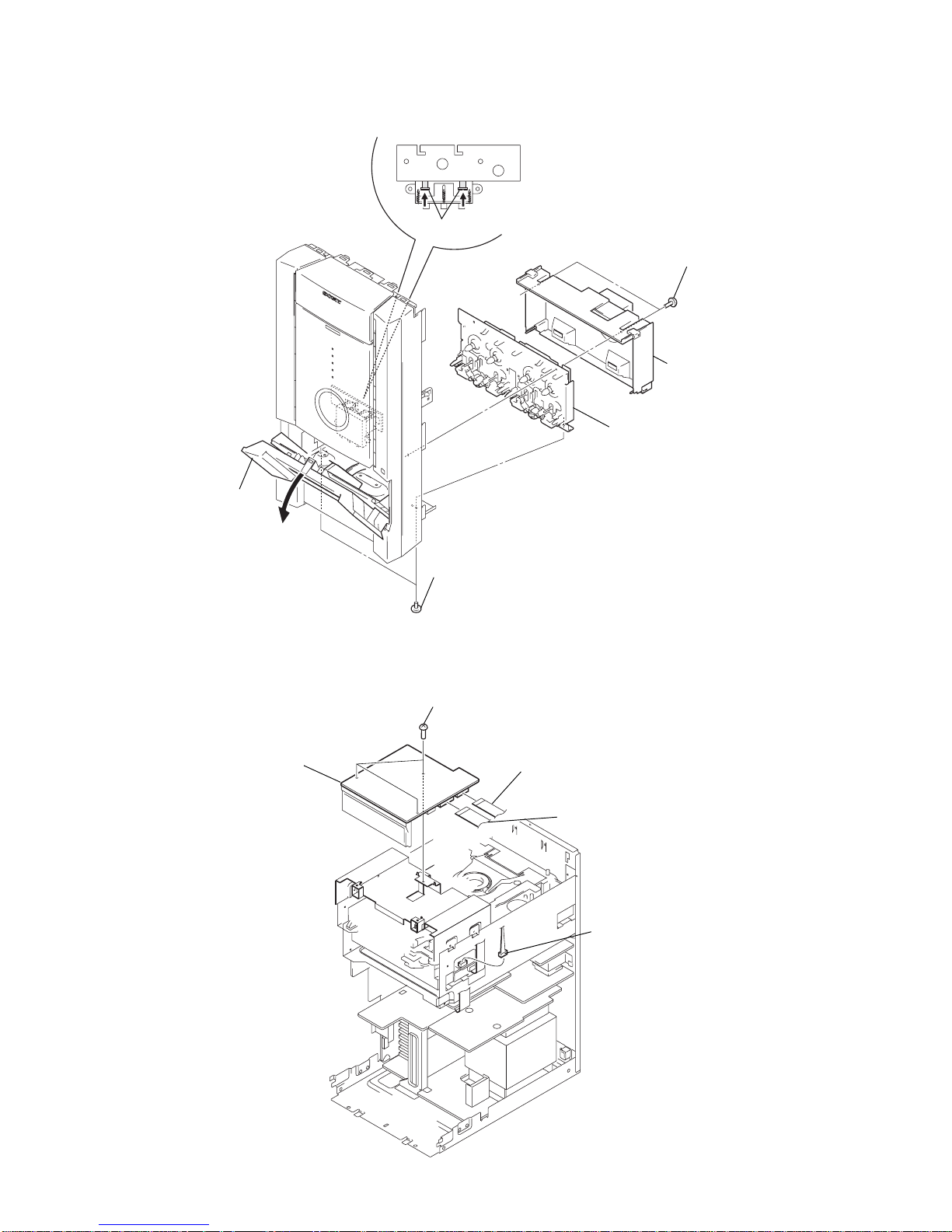

3-4. FRONT PANEL ASSY

3

connector

(CN201)

2

wire (flat type) (17 core)

(CN206)

3

two connectors

(CN203, CN208)

3

connector

(CN207)

MC board

1

wire (flat type) (17 core)

(CN109)

6

three connectors

(CN601, CN602,

CN808)

4

two claws

1

screw

(BVTP3

×

8)

1

screw

(BVTP3

×

8)

3

screw

(BVTP3

×

8)

2

two ground

terminals

2

two ground

terminals

5

6

connecto

r

(NO803)

DSP board

7

front panel assy

3

two screws

(BVTP3

×

8)

3

screw

(BVTP3

×

8)

14

HCD-FLX5D/FLX7D

3-5. MECHANICAL (CASSETTE) DECK

4

Push two plunger solenoids

1

two screws

(BVTP2.6

×

8

)

1

two screws

(BVTP2.6

×

3)

1

Open the lid (TC)

6

mechanical (cassette) deck

2

cover (TC)

3-6. GC BOARD

4

three screws

(BVTP3

×

8)

2

wire (flat type) (19 core

)

(CN202)

1

wire (flat type) (17 core)

(CN204)

3

connector

(CN701)

5

GC board

15

HCD-FLX5D/FLX7D

3-7. DVD MECHANISM BLOCK

4

two connectors

(CN805, CN806)

6

claw

2

two connectors

(CN702, CN703)

5

two claws

SP RELAY

board

MC board

7

DVD mechanism block

2

connector

(CN905)

2

connector

(CN903)

1

wire (flat type) (11 core)

(CN105)

1

wire (flat type)

(17 core) (CN204)

2

connector

(CN807)

3

six screws

(BVTP3 × 8

)

1

wire (flat type) (9 core)

(CN401) (FLX7D)

3-8. DSP BOARD

Note: Please turn a DSP/MB/MC boards side down and do not do decomposition work.

4

two screws

(BVTP3

×

8)

5

DSP board

2

wire (flat type) (19 core)

(CN602)

1

wire (flat type) (9 core)

(CN603) (FLX7D)

3

wire (flat type) (11 core

)

(CN601)

16

HCD-FLX5D/FLX7D

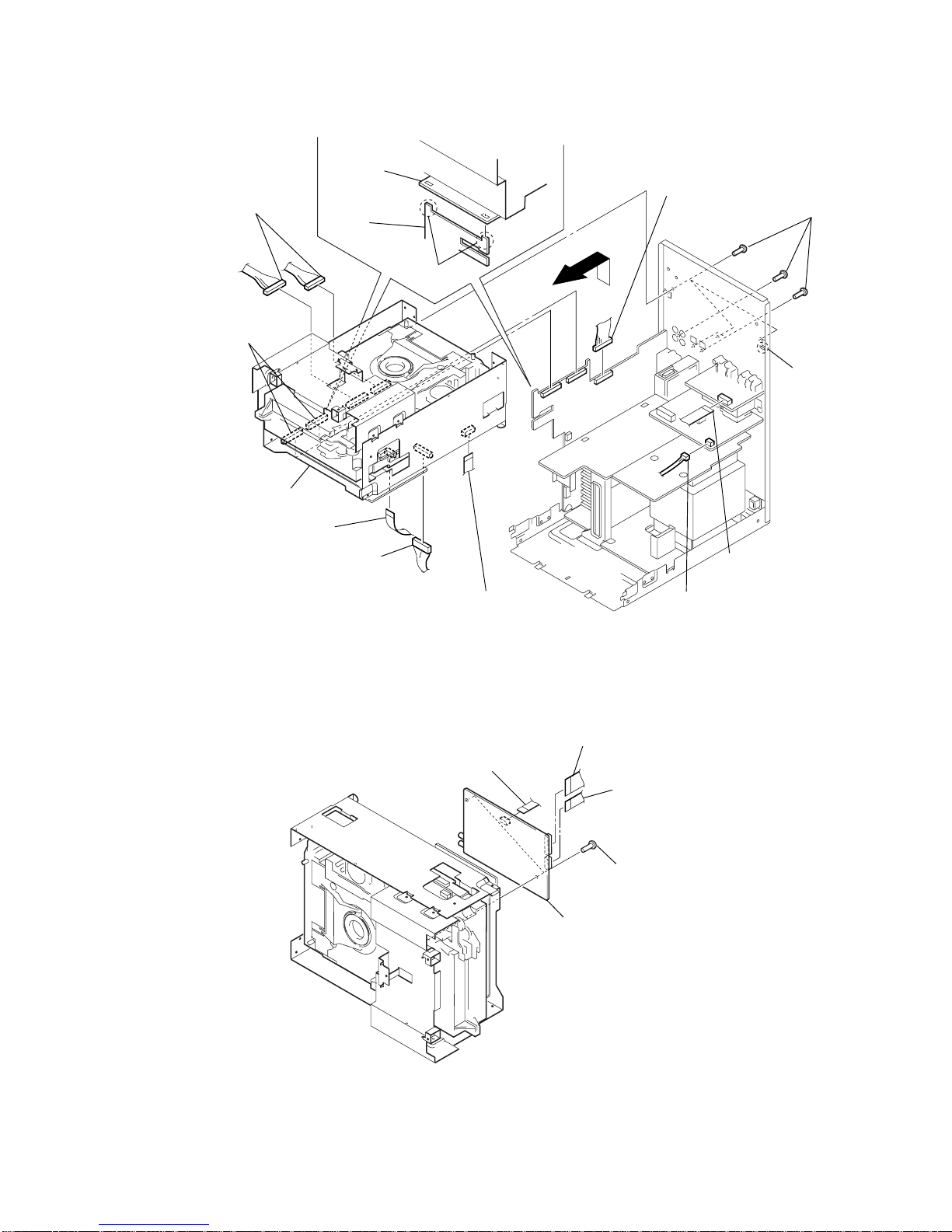

3-9. DVD MECHANISM DECK (CDM53N-DVBU14)

1

two screws

(BVTP3

×

8)

1

two screws

(BVTP3

×

8)

2

bracket (FL)

3

wire (flat type) (29core)

(CN501)

5

DVD mechanism deck

(CDM53N-DVBU14)

4

four screws

(BVTP3

×

8)

Note: Please turn a DSP/MB/MC boards side

down and do not do decomposition work.

3-10. FITTING BASE (GUIDE) ASSY, BRACKET (CHASSIS), MAGNET ASSY

1

two connectors

(CN709, CN715)

7

connecto

r

(CN710)

9

magnet assy

2

four screws

(BTTP M2.6)

8

four screws

(BTTP M2.6)

4

two screws

(BTTP M2.6)

6

bracket

(chassis)

5

two screws

(BTTP M2.6)

3

fitting base

(guide) assy

17

HCD-FLX5D/FLX7D

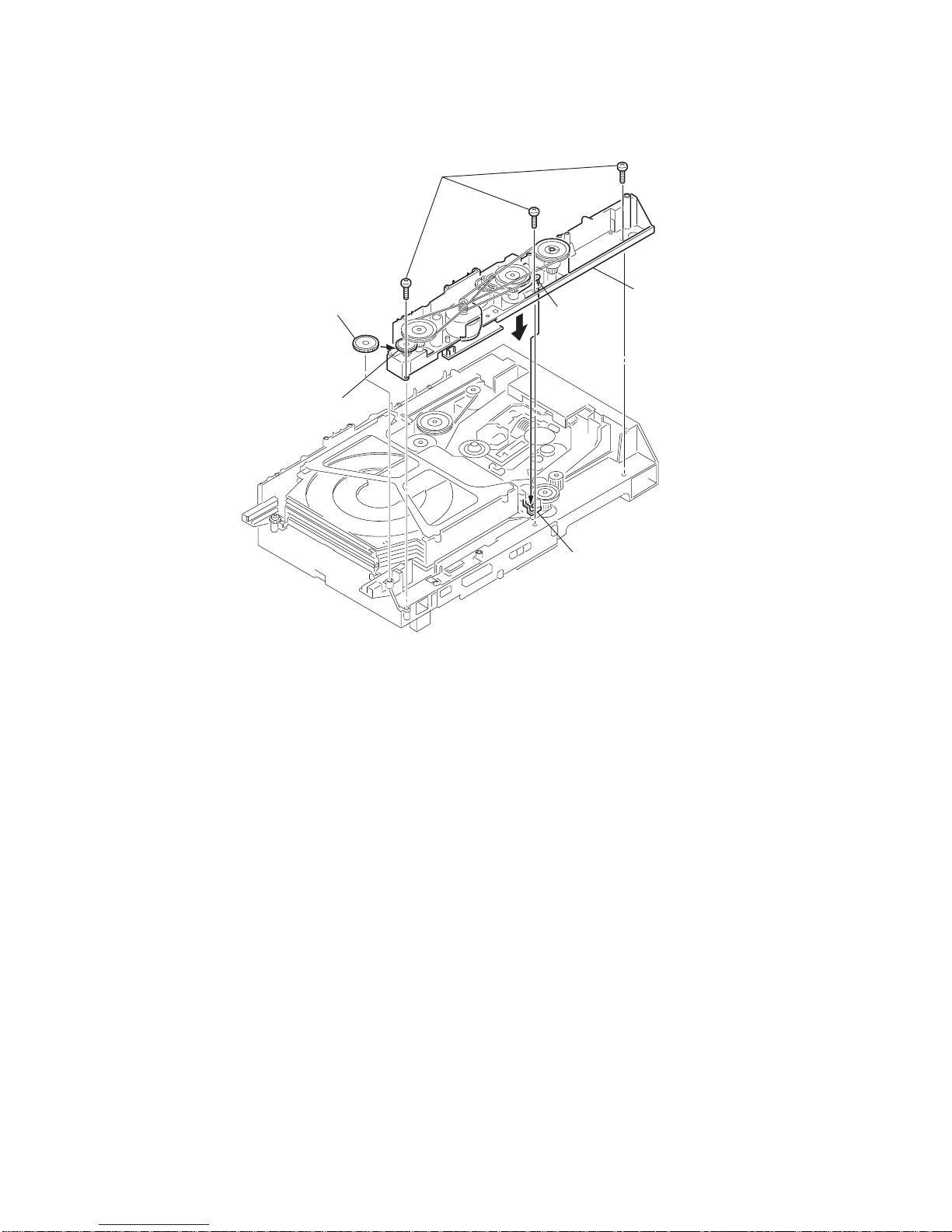

3-11. BASE UNIT (DVBU14)

6

base unit

(DVBU14)

5

two screws

(PTPWH M2.6

)

1

connector

(CN710)

4

magnet assy

3

two hooks

2

four screws

(BTTP M2.6)

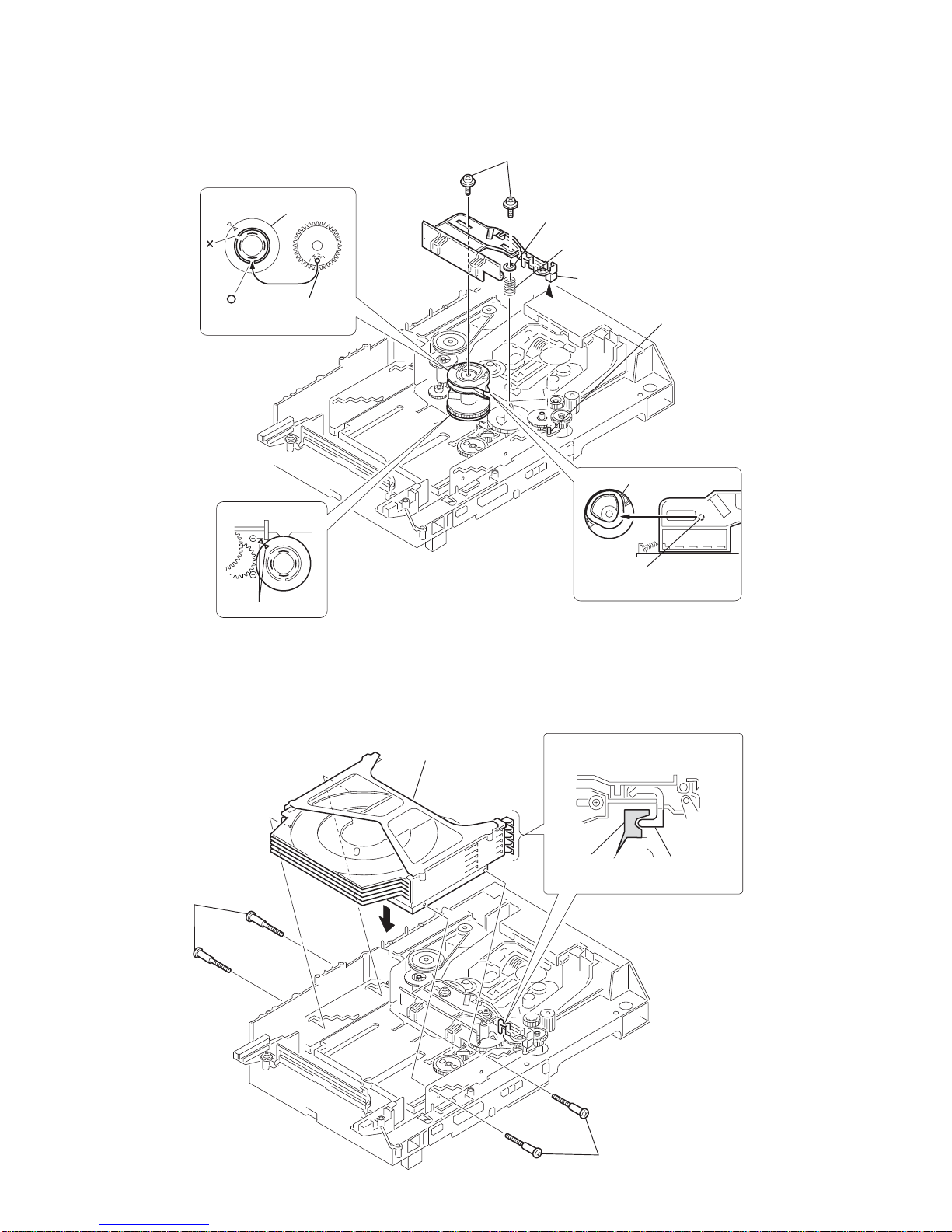

3-12. TRAY (SUB)

A

B

pully (LD)

stocker section

tray (sub)

slider (selection)

pully (mode)

1

Rotating the pulley (LD), shift the slider (selection) in the arrow A direction.

2

Rotating the pulley (mode) in the arrow direction, adjust the tray (sub) to be removed.

3

Rotating the pulley (LD), shift the slider (selection) in the arrow B direction.

4

Rotating the pulley (mode) in the arrow direction, remove the tray (sub) to be removed.

18

HCD-FLX5D/FLX7D

3-14. VIDEO BOARD

3-13. CHASSIS (MOLD B) SECTION, STOCKER SECTION, SLIDER (SELECTION)

6

stocker

section

1

three screws

(BVTP M2.6)

2

chassis (mold B) section

3

gear (eject)

4

two step screws

5

two step

screws

7

two screws

(PTPWH M2.6)

8

slider (selection)

9

washer

0

compression

spring

pully (LD)

Note: Rotating the pully (LD),

shift the slider (selection)

to the left.

1

four screws

(BVTP3 × 8

)

2

VIDEO board

19

HCD-FLX5D/FLX7D

3-15. SUB TRANS BOARD

2

three screw

s

(BVTP3 × 8)

1

connector

(CN902)

1

connector

(CN901)

5

SUB TRANS board

4

ground termina

l

3

3-16. BACK PANEL SECTION

2

two screws

(BVTP3 × 8)

1

connector

(CN902)

4

connector

(CN809)

5

back panel section

2

screw (BVTP3 × 8

)

1

connector

(CN901)

3

20

HCD-FLX5D/FLX7D

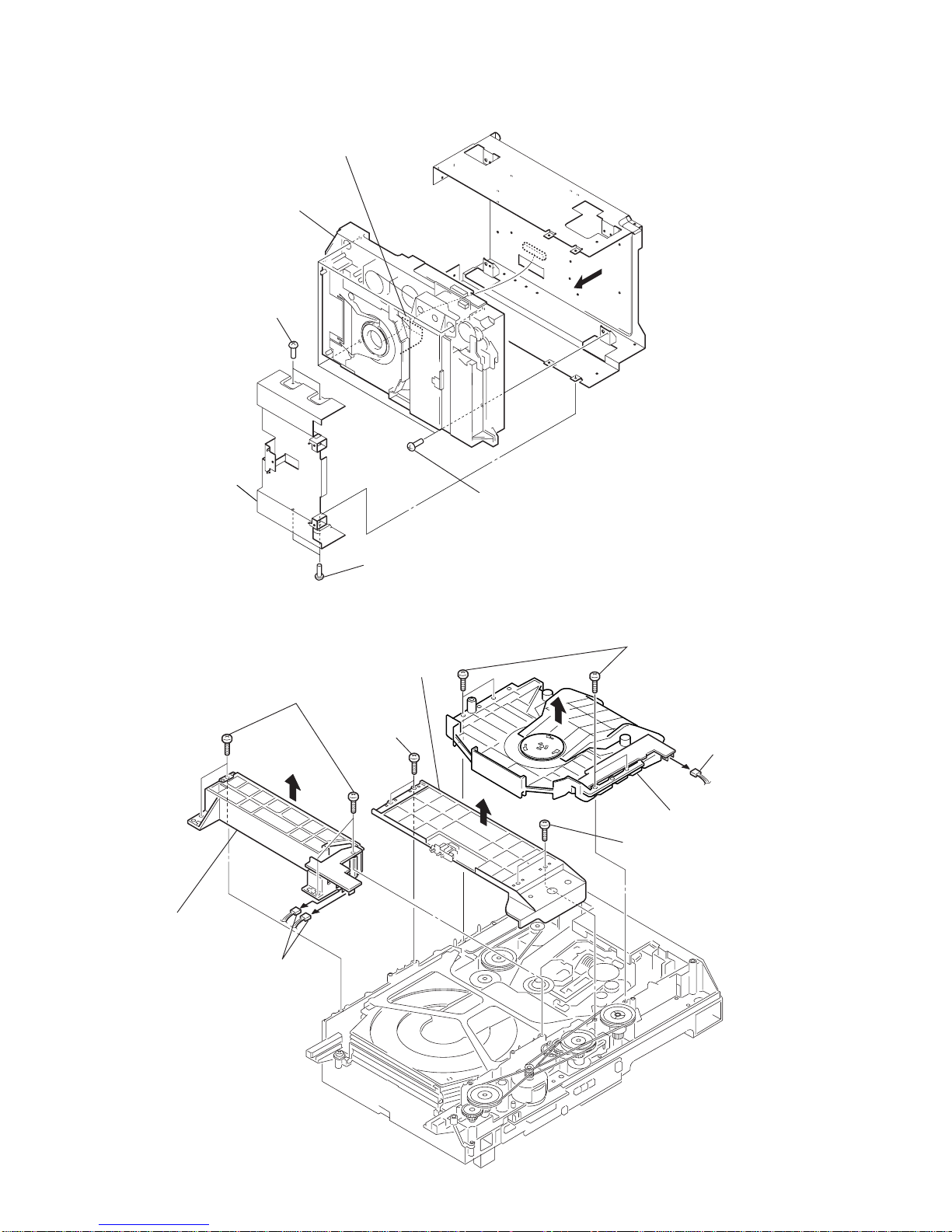

3-18. SP RELAY BOARD

3-17. TRANS BOARD

3

TRANS board

2

four screws

1

connector (CN915)

1

connector (CN914)

1

connector (CN916)

1

screw (BVTP3 × 8)

1

two screws

(BVTP3 × 8)

1

two screws

(BVTP3 × 8)

3

two connectors

(CN803, CN804)

5

connector

(CN801)

6

SP RELAY board

4

PC board holder

FRONT REAR AMP boar

d

CENTER SW AMP board

2

chassis

1

two screws

(BVTP3 × 8)

HCD-FLX5D/FLX7D

21

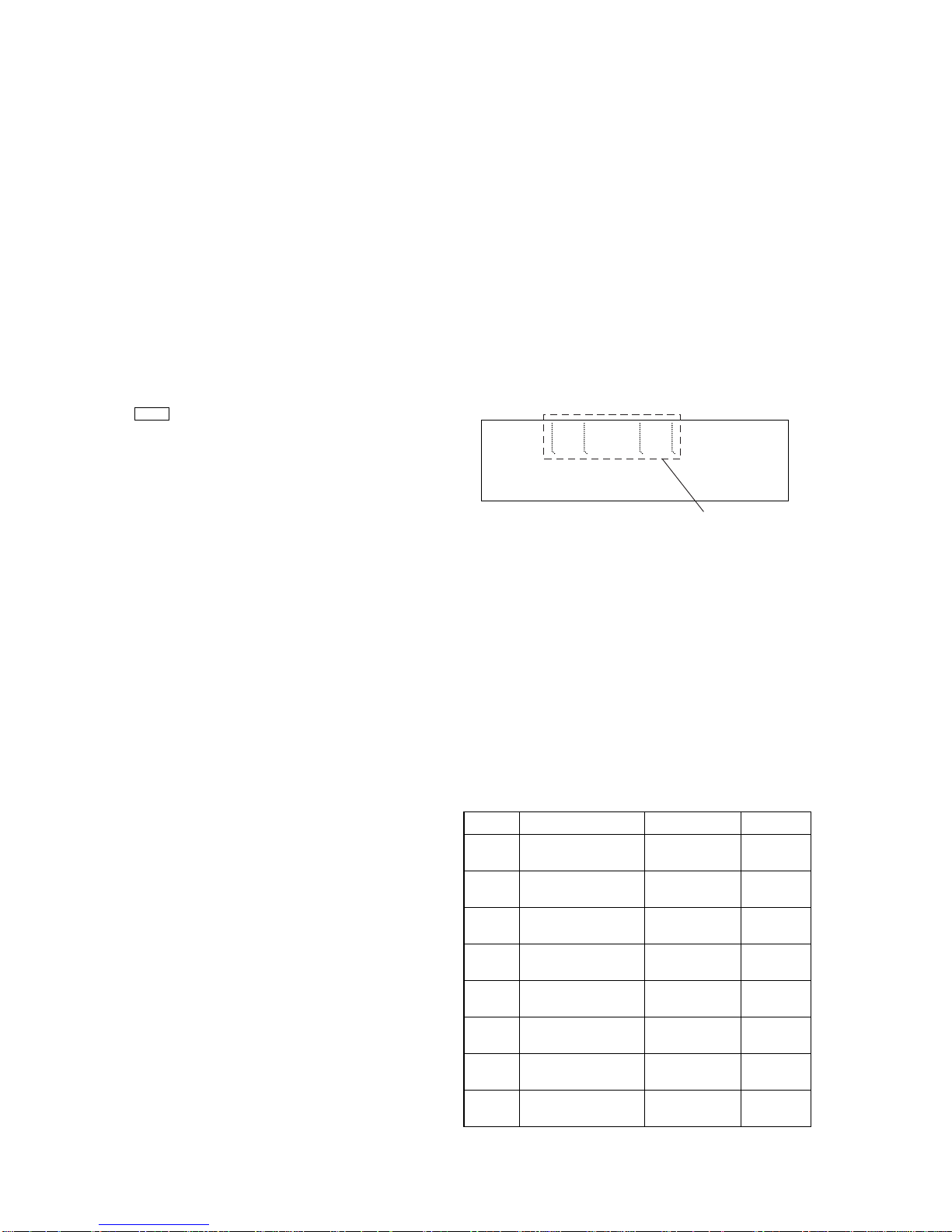

• This set can be assembled in the order shown below.

4-1. ASSEMBLY FLOW

SECTION 4

ASSEMBLY

4-4. STOCKER SECTION INSTALLATION

(Page 22)

4-3. SLIDER (SELECTION) INSTALLATION

(Page 22)

4-2. GEARS INSTALLATION

(Page 21)

4-5. CHASSIS (MOLD B) SECTION

INSTALLATION (Page 23)

1

Slide the slider (u/d)

fully in the arrow

direction.

3

gear (gear B)

2

gear (U/D slider)

4

gear (gear A)

portion A

Adjust the gear (gear B) with the

portion A as shown.

slider (U/D) gear

Adjust the gear so that it meshes with

the bottom tooth of slider (U/D) gear,

as shown.

gear

(gear B)

linearly

Adjust so as to be aligned with

gear B linearly, as shown.

4-2. GEARS INSTALLATION

Note: Follow the assembly procedure in the numerical order given.

HCD-FLX5D/FLX7D

22

2

portion A of tray (sub)

1

stocker section

3

two step screws

3

two step screws

Hook the portion A of tray (sub)

to the slider (selection).

portion A

of tray (sub)

sticking of

slider (selection)

2

gear (chuking)

6

two screws

(PTPWH M2.6)

5

washer

3

convex portion of

slider (selection)

4

compression spring

7

Insert the slider (selection)

into the portion A.

1

rotary encoder

rotary encoder

Align with the slot of

rotary encoder.

align marking

portion A

gear (chuking)

Insert a convex portion into

a groove of gear (chuking).

4-3. SLIDER (SELECTION) INSTALLATION

4-4. STOCKER SECTION INSTALLATION

HCD-FLX5D/FLX7D

23

3

three screws

(BVTP M2.6)

2

Insert the gear (eject)

under the gear (LD

deceleration).

1

Insert the portion A of

chassis (mold B) section

into the portion B of

slider (selection).

gear (LD deceleration)

portion A

portion B of

slider (selection)

4-5. CHASSIS (MOLD B) SECTION INSTALLATION

24

HCD-FLX5D/FLX7D

SECTION 5

TEST MODE

[COLD RESET]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons [ ], [DISPLAY], and [GROOVE] sim ulta-

neously.

2. The fluorescent indicator tube becomes blank instantaneously ,

and the set is reset.

[TUNER STEP CHANGE]

(Except FLX5D: Saudi Arabia/FLX7D: Saudi Arabia models)

• A step of AM channels can be changed ov er between 9 kHz and

10 kHz.

Procedure:

1. Press the [I/ ] button to turn the power on.

2. Select the function “TUNER”, and press [TUNER/BAND] but-

ton to select the BAND “AM”.

3. Press the [I/ ] button to turn the set OFF.

4. Press M + and [I/ ] buttons simultaneously , and the display

of fluorescent indicator tube changes to “ AM 9 K Step” or “AM

10 K Step”, and thus the channel step is changed over.

[FUNCTION CHANGE MODE]

• Select either VIDEO or MD of the external function input.

Procedure:

1. Press the [I/ ] button to turn the power on.

2. Hold do wn [VIDEO $SAT%] button then press [I/ ] button, and

release [I/ ] button first in order not in switch off the set immediately.

The another function of the previous function is selected, the

input level is also changed and displayed “SAT” or “VIDEO”.

[GC TEST MODE]

• This mode is used to check the software version, FL tube, LED,

keyboard and VACS.

Procedure:

1. Press three buttons [ ], [DISPLAY], and [EFFECT] simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

3. When you want to enter the software version display mode,

press [GROOVE] . The model number and destination are dis-

played.

4. Each time [GROOVE] is pressed, the display changes stating

from MC version, GC version, DP version, DVD version,

CDDM, CDMA, CDMB, BDA, BDB, ST version, TA version,

TM version, TC version, in this order.

5. When [CD SYNC HI-DUB] is pressed while the version num-

bers are being displayed except model number and destination, year, month and day of the software creation appear. When [CD SYNC HI-DUB] is pressed again, the display

returns to the software version display. When [GROOVE]

is pressed while year, month and day of the software creation

are being displayed, the year, month and day of creation of the

software versions are displayed in the same order of version

display.

6. Press [EFFECT] button, and the key check mode is activ ated.

7. In the ke y check mode, the fluorescent indicator tube displays

“KXX V0 C T”. Each time a button is pressed, “K” value

decreases.

However, once a button is pressed, it is no longer taken into

account.

“V” value increases like 1, 2, 3...if rotating [VOLUME] knob

in the clockwise, or it decreases like 0, 9, 8...if rotating in the

counterclockwise.

Each time the “CD DOOR LOCK DETECT” or “CD DOOR

OPEN/CLOSE DETECT” switch is turned on, “C” value in-

x

1

1

1

1

1

1

creases.

Each time the “CASSETTE LID OPEN/CLOSE DETECT”

switch is pressed, “T” value increases.

8. Also when [GROOVE] is pressed after lighting of all LEDs

and fluorecsent indicator tube, value of VACS appears.

9. To exit from this mode, press three buttons in the same manner as step 1, or disconnect the power cord.

[MC TEST MODE]

• This mode is used to check operations of the respective sections

of Amplifier, Tuner , and Tape.

1. Entering the MC Test Mode

Procedure:

1. Press the [I/ ] button to turn the power on.

2. Press the three b uttons of [ ], [DISPLAY] and [CD SYNC HI-

DUB] simultaneously.

3. The segments blinks on the fluorescent indicator tube as bellow.

2. Releasing the MC Test Mode

Procedure:

1. To release this mode, press the [I/ ] button.

2. The cold reset is enforced at the same time.

3. Check of Amplifier

Initial settings:

Input , DIGITAL

EQ , FLAT

Mode , MUSIC

VACS , OFF

Output channel setting:

Each time the [EFFECT] button is pressed, output channels switch

as following order.

x

x

1

DIGITAL

EFFECT

Blink

1

Order Channels Bass Manage VACS*

1

1

L t L

Through ON

R t R

2

L t L

Through OFF

R t R

3

L t SL

Through ON

R t SR

4

L t SL

Through OFF

R t SR

5

L t L, C, SL

on ON

R t R, SR, SW

6

L t L, C, SL

on OFF

R t R, SR, SW

7

L t C

Through ON

R t SW

8

L t C

Through OFF

R t SW

*1) “EFFECT” indication

25

HCD-FLX5D/FLX7D

[DVD SHIP MODE (NO MEMORY CLEAR) ]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the [I/ ] button to turn the power on.

2. Press the [DVD] and [I/ ] buttons simultaneously.

3. After the “STANDBY” display blinks, a message “LOCK” is

displayed on the fluorescent indicator tube, and the CD ship

mode is set.

[VACS ON/OFF MODE]

• This mode is used to switch on or off the VACS (Variable At-

tenuation Control System).

Procedure:

1. Press two b uttons of > and [A ] for more than 1 second

simultaneously.

2. When VACS is switch on, it displays “VACS OFF”.

When VACS is switch off, it displays “VACS O”.

[CD REPEAT 5 LIMIT OFF MODE]

Number of repeat for CD playback is 5 times when the repeat

mode is “REPEA T”. This mode enables CD to repeat playback for

limitless times.

Procedure:

1. Press the [I/ ] button to turn the power on, and press the [DVD]

button to select the function “DVD”.

2. Press two buttons of > and [CD SYNC HI-DUB] for more

than 1 second simultaneously to enter the CD repeat 5 limit off

mode.

3. To release this mode, operate the cold reset. (Refer to the “MC

COLD RESET”)

[DISC TRA Y LOCK]

Procedure:

1. Press the [I/ ] button to turn the power on.

2. Press the [DVD] button to select the function “DVD”.

3. Press two b uttons of Z (DVD) and x simultaneously for five

seconds.

4. The message “LOCKED” is displayed and the tray is locked.

(Even if exiting from this mode, the tray is still locked)

5. To exit from this mode, press two buttons of Z (DVD)

and x simultaneously for five seconds again.

6. The message “UNLOCKED” is displayed and the tray is unlocked.

Volume check:

1. When the

[VOLUME] knob is turned clockwise even slightly,

the sound volume increases to its maximum and a message

“VOLUME MAX” appears for two seconds, then the display

returns to the original display.

2. When the [VOLUME] knob is turned counterclockwise even

slightly, the sound volume decreases to its minimum and a

message “VOLUME MIN” appears for two seconds, then the

display returns to the original display.

Tuner Function

1. In the test mode, the default-preset channel is called e ven when

the TUNER is selected and an attempt is made to call the preset channel that has been stored in memory. (It means that the

memory is cleared)

2. The minimum, center and maximum frequency of each band

is set then.

4. Tape Recording Test

Procedure:

1. Enter the MC Test Mode.

2. Load tapes in both tape decks A and B.

3. Press the REC button to start recording.

4. Pressing the

–

m or M

+

buttons during recording returns

the tape to the recording start position and stops it at this position.

5. Pressing the “High Speed Dubbing” key while playing back

the tape of deck B switches the playback speed between “Normal Speed” and “High Speed”.

Note:

When the playback direction of the tape is set to other than “ONY WAY”,

the restriction on the number of times playback which can be repeated

will be cleared.

5. AMS Test Mode

Procedure:

1. Enter the MC Test Mode and press the [TAPE A/B] button to

set the TAPE function.

2. Insert a test tape AMS-110A or AMS-120 to deck A.

3. Press the > button to enter the AMS test mode.

4. After a tape is rewound first, the FF AMS is checked, and the

mechanism is shut off after detecting the AMS signal the AMS

signal twice.

5. Then the REW AMS is check ed and the mechanism is shut off

after detecting the AMS signal twice.

6. When the check is complete, a message of either OK or NG

appears.

6. ALC MODE

Procedure:

1. Enter the MC Test Mode and press the [REC PAUSE/START]

button 2 times to recording start.

2. While pressing the . button, ALC is on.

(normaly, ALC is off in recording state.)

[DVD SHIP MODE (MEMORY CLEAR) ]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the [I/ ] button to turn the power on.

2. Press three buttons x , [CD SYNC HI-DUB] and [DVD]

simultaneously.

3. After the “STANDBY” display blinks, a message “LOCK” is

displayed on the fluorescent indicator tube, and the CD ship

mode is set.

1

Z

1

1

1

1

26

HCD-FLX5D/FLX7D

[DVD TEST MODE GENERAL DESCRIPTION]

The T est Mode allo ws you to make dia gnosis and adjustment easily using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[TEST DISC LIST]

Use the following test disc on test mode.

TDV-520CSO (DVD-SL): PART No. J-2501-236-A

LUV-P01 (CD): PART No. 4-999-032-01

TDV-540C (DVD-DL): PART No. J-2501-235-A

Note: Do not use existing test disc for DVD.

[STARTING DVD TEST MODE]

1. Press the [I/ ] button to turn the power on.

2. Select the function “DVD”.

3. Press the [I/ ] button to turn the power off.

4. While pressing the x button, press the Z (DVD) button and

turn the [VOLUME] knob in the clock wise.

5. It displays “SERVICE IN” on the fluorescent indicator tube,

and displays the Test Mode Menu on the monitor screen as

follows. (At the bottom of the menu screen, the model name

and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :DHC-FLxx xx

Revision :x.xx

6. To execute each function, select the desired menu and press its

number on the remote commander (RM-SFL7).

7. To release from test mode, press the I/1 button and turn the

power off.

[OPERATING DVD TEST MODE]

0. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. GPIO

5. SD Bus

6. Video

7. Audio

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed for the key entry.

•

Example display

### Syscon Diagnosis ###

Diag All Check

No.2 Version

2-3. ROM Check Sum

Check Sum = 2320

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the [NEXT ] button to go to the

next item, or press the [PREV ] button to repeat the same

operation again.

To quit the diagnosis and return to Check Menu screen, press the

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the [RETURN] key on the remote commander to quit the

diagnosis, or press the [PREV ] button to repeat the same

check where an error occurred, or press the [NEXT ] button to

continue the check from the item next to faulty item.

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below.

Check Items List:

0-2. Version

0-2-1. All

0-2-2. Revision

0-2-3. ROM Check Sum

0-2-4. Model Type

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

0-7. Audio Check

>

.

>

.

1

1

27

HCD-FLX5D/FLX7D

0-2. Version

0-2-2. Revision

The revision number of ROM (IC204) that the program for

the DVD system processor (IC206) is stored.

(4 digits hexadecimal number)

0-2-3. ROM Check Sum

The revision number of ROM (IC204) that the program for

the DVD system processor (IC206) is stored.

0-2-4. Model Type

Model name is displayed. (DHC-FL5D or DHC-FL7D)

0-2-5. Region

Model destination code is displayed. (2 digits number)

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-2. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC206)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and MPEG

DECODER (IC206).

0-6. Video Check

Output the color bars for video level adjustment.

0-7. Audio Check

Output the test signal (1kHz sine wave) for 2 CH test.

1. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

Exit: RETURN

Normally, [10/0] is selected to adjust D VD (single layer), CD and

DVD (dual layer) in this order. But, individual items can be adjusted for the case where adjustment is suspended due to an error.

In this mode, the adjustment can be made easily through the operation following the message displayed on the screen.

The disc used for adjustment must be the one specified for adjustment.

1-0. ALL

Press the [10/0] key on the remote commander, and the servo set

data in EEPROM will be initialized. Then, 1. D VD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. You can finish the adjustment by pressing the [RETURN] button on the remote commander .

Note: During adjustment of each disc, the measurement for disc type judg-

ment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

1-1. DVD-SL (single layer)

Press the [1] key on the remote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

1-2. CD

Press the [2] key on the remote commander and insert a CD disc

following the message. Then the adjustment will be made through

the steps, then adjusted values will be written to the EEPROM.

1-3. DVD-DL (dual layer)

Press the [3] key on the remote commander and insert a D VD dual

layer disc following the message. Then the adjustment will be made

through the steps, then adjusted values will be written to the

EEPROM.

28

HCD-FLX5D/FLX7D

2-1. Disc Type

Disc Type

Disc Type Select

1. Disc Type Auto Check

2. Set Disc Type DVD

3. Set Disc Type CD

4. Set Disc Type Hybrid

Exit: RETURN

2-1-1. Disc Type Auto Check

1) Press the [1] key on the remote commander to display the Disc

Type Auto Check screen.

2) Insert a disc and press the [ENTER] key on the remote

commander.

3) It judges the type of inserted disc automatically and displays

the disc type and so on as below.

Disc Type Auto Check

Disc Type xx

Layer xx

Mirr Time xx

Mirr Count xx

FZC Count xx

PI Reference xx

PI Peak xx

ENTER.Execute

Exit: RETURN

Disc Type : CD, DVD or Hybrid (SACD)

Layer : SINGLE, DUAL or HYBRID

Mirr Time : Mirror time of between disc surface and record sur-

face when disc type judgment. (hexadecimal number)

Mirr Count : The number of times which mirror counts between

disc surface and record surface when disc type judging.

FZC Count : The number of times which focus zero cross points

of each layer when lens down.

PI Reference: The average of PI reference voltage. (hexadecimal

number)

PI Peak : PI peak level voltage. It performs only when disc

type judgment is successful. (hexadecimal number)

2-1-2. Disc Type DVD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: DVD single layer disc (12 cm)

[2]: DVD dual layer disc (0 layer, 12 cm)

[3]: DVD dual layer disc (1 layer, 12 cm)

[4]: DVD-RW disc (12 cm)

[5]: DVD single layer disc (8 cm)

[6]: DVD dual layer disc (0 layer, 8 cm)

[7]: DVD dual layer disc (1 layer, 8 cm)

[8]: DVD-RW disc (8 cm)

2. DRIVE MANUAL OPERATION

Note: This mode is used for design, and not used in service fundamen-

tally.

On the Test Mode Menu screen, press the [2] key on the remote

commander, and the Operation Menu will be displayed. For the

manual operation, each servo on/off control and adjustment can

be executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Non EEPROM Write Adjust

5. EEPROM Write Adjust

6. Memory Check

7. Disc Check Memory

8. Error Rate Display

9. SACD Water Mark

Exit: RETURN

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed when a disc is loaded.

Note:

1. Set correctly the disc type to be used on the Disc Type screen.

2. In case of an alarm, exit the manual operation menu immediately to stop the servo operation, and press the I/1 button to

turn the power off.

Basic operation:

(controllable from front panel or remote commander)

[POWER] :Power OFF (release the Test Mode)

Z : Stop and eject/Loading

[RETURN] : Return to Operation Menu or Test

Mode Menu

[PREV ], [NEXT ] :Transition between sub modes of

menu

[1] to [9], [10/0] : Selection of menu items

Cursor o/

O

: Increase/Decrease in manually ad-

justed value

>.

29

HCD-FLX5D/FLX7D

2-3. Track/Layer Jump

Track/Layer Jump

1. 1Tj FWD R.Lj L0>L1

2. 1Tj REV L.Lj L1>L0

3.500Tj Fine FWD U.Fj L0>L1

4.500Tj Fine REV D.Fj L1>L0

5.10kTj Dirc FWD

6.10kTj Dirc REV

7.20kTj Dirc FWD

8.20kTj Dirc REV

0. All Servo Off

Exit: RETURN

On this screen, track jump, etc. can be performed. Only for the

DVD dual layer disc, the focus jump and layer jump are displayed

in the right field

[1] 1Tj FWD : 1 track jump forward.

[2] 1Tj REV : 1 track jump reverse.

[3] 500Tj FWD : 500 track jump (fine search)forward.

[4] 500Tj REV : 500 track jump (fine search) reverse.

[5] 10kTj FWD : 10k track jump (direct search) forward.

[6] 10kTj REV : 10k track jump (direct search) reverse.

[7] 20kTj FWD : 20k track jump (direct search) forward.

[8] 20kTj REV : 20k track jump (direct search) reverse.

p

LjL0 t L1 : Layer jamp L0 t L1

P

LjL1 t L0 : Layer jamp L1 t L0

O

FjL0 t L1 : Focus jamp L0 t L1

o

FjL1 t L0 : Focus jamp L1 t L0

[10/0] :All servo off.

2-4. Non EEPROM Write Adjust

Non EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. Trk. Offset Fine

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number [1] to [10/0] from the remote commander. This

value is not stored in the EEPROM.

[1] Focus Offset: Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset : Adjusts tracking offset of the RF amp

(IC001) side.

[4] TRK. Offset : Adjusts tracking offset of the DSP (IC401)

side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of equalizer.

[10/0] : All servo off.

2-1-3. Disc Type CD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: CD disc (normal speed, 12 cm)

[2]: CD disc (double speed, 12 cm)

[3]: CD disc (normal speed, 8 cm)

[4]: CD disc (double speed, 8 cm)

[5]: CD-RW disc (normal speed, 12 cm)

[6]: CD-RW disc (double speed, 12 cm)

[7]: CD-RW disc (normal speed, 8 cm)

[8]: CD-RW disc (double speed, 8 cm)

2-1-4. Disc Type Hybrid

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: SACD Hybrid disc (SACD layer, 12 cm)

[2]: SACD Hybrid disc (CD layer, normal speed, 12 cm)

[3]: SACD Hybrid disc (CD layer, double speed, 12 cm)

[4]: SACD Hybrid disc (SACD layer, 8 cm)

[5]: SACD Hybrid disc (CD layer, normal speed, 8 cm)

[6]: SACD Hybrid disc (CD layer, double speed, 8 cm)

2-2. Servo Control

Note: Be sure to perform the disc type setup before performing this item.

Servo Control

1.LD off R.Sled FWD

2.Focus off L.Sled REV

3.SPDL off U.Sled Reset

4.CLVA off D.Sled Limit

5.Trk. off

6.Sled off

7.Fcs.Srch off

8.Fcs.OppL off

0.All Servo Off

Exit: RETURN

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CL VA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system

is faulty or RF is not present. In such a case, do not operate CL VA.

[1] LD : Turn on/off the laser.

[2] Focus :Search the focus and turn on the focus.

[3] SPDL :Turn on/off the spindle.

[4] CLVA :Turn on/off normal servo of spindle servo.

[5] Trk. : Turn on/off the tracking servo.

[6] Sled : Turn on/off the sled servo.

[7] FCS. Srch : Turn on/off the focus search.

[8] FCS. OppL : Tur n on/off the focus search to another

(oposite) layer of designated layer in Disc

Type setting. (dual layer disc only)

[10/0] : All servo off.

p

Sled FWD (right cursor) : Move the sled forward.

P

Sled REV (left cursor) : Move the sled reverse.

O

Sled FWD (up cursor) : Reset the sled.

o

Sled REV (down cursor): Limit in the sled.

30

HCD-FLX5D/FLX7D

2-5. EEPROM Write Adjust

EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. ——————

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number [1] to [10/0] from the remote commander, and

selected item is adjusted automatically. Thus value is stored in the

EEPROM.

[1] Focus Offset: Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset : Adjusts tracking offset of the RF amp

(IC001) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of equalizer.

[10/0] : All servo off.

2-6. Memory Check

Display images are shown as follows, and all two screens are able

to switch by theOkey (UP) or okey (DW).

EEPROM Data 1/2 CD SL L0 L1

Focus Gain xx xx xx xx

Trk. Gain xx xx xx xx

Focus Offset xx xx xx xx

Trk. Offset xx xx xx xx

EQ. Boost xx xx xx xx

PI Level xx xx -- -Fcs. Balance -- xx -- -Jitter xx xx xx xx

Mirror Time xx xx xx -FE Level -- xx -- -Traverse Lv1. -- xx -- -Next:DW Default:CLR Exit:RET

EEPROM Data 2/2 CDRW DVDRW

Focus Gain xx xx

Trk. Gain xx xx

Focus Offset xx xx

Trk. Offset xx xx

EQ. Boost xx xx

Next:UP Default:CLR Exit:RET

On this screen, current servo adjusted data stored in the EEPROM

are displayed. The adjusted data are initialized by pressing the

[CLEAR] key, but be careful that they are not recoverable after

initialization.

Before clearing the adjusted data, make a note of the set data.

2-7. Disc Check Memory

Disc Check Memory

1. SL Disc check

2. CD Disc check

3. DL Disc check

Exit: RETURN

On this screen, measure the mirror time of chucked disc, and write

to the EEPROM.

2-8. Error Rate Display

Error Rate Display

UC CR Address

PI1 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

PI2 Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

PO Err Now xx xxxx xxxxxxxx

Max xx xxxx xxxxxxxx

Avg xx xxxx xxxxxxxx

Exit: RETURN

On this screen, measure and display the error rate.

UC : Incorrect value

CR : Correct value

2-9. SACD Water Mark Check

SACD Water Mark Check

PSP AMP

PSN

Start: ENTER Exit: RETURN

On this screen, measure the PSP AMP value and PSN value of

SACD water mark.

Loading...

Loading...