Page 1

HCD-ED1

SERVICE MANUAL

Ver 1.1 2001. 06

With SUPPLEMENT-1

(9-922-706-81)

HCD-ED1 is the tuner, deck, CD and

amplifier section in CMT-ED1.

This stereo system is equipped with the Dolby* Btype noise reduction system.

*Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

CD

SECTION

T APE

DECK

SECTION

Model Name Using Similar Mechanism NEW

Base Unit Type BU17-BD19

Optical Pick-up Type KSS-213BA/S-N

Model Name Using Similar Mechanism NEW

T ape T r ansport Mechanism T ype CMAL2Z076A

US Model

Canadian Model

AEP Model

UK Model

E Model

SPECIFICA TIONS

— Continued on next page —

9-922-706-12

2001F0200-1

© 2001.6

COMPACT DISC DECK RECEIVER

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

– 1 –

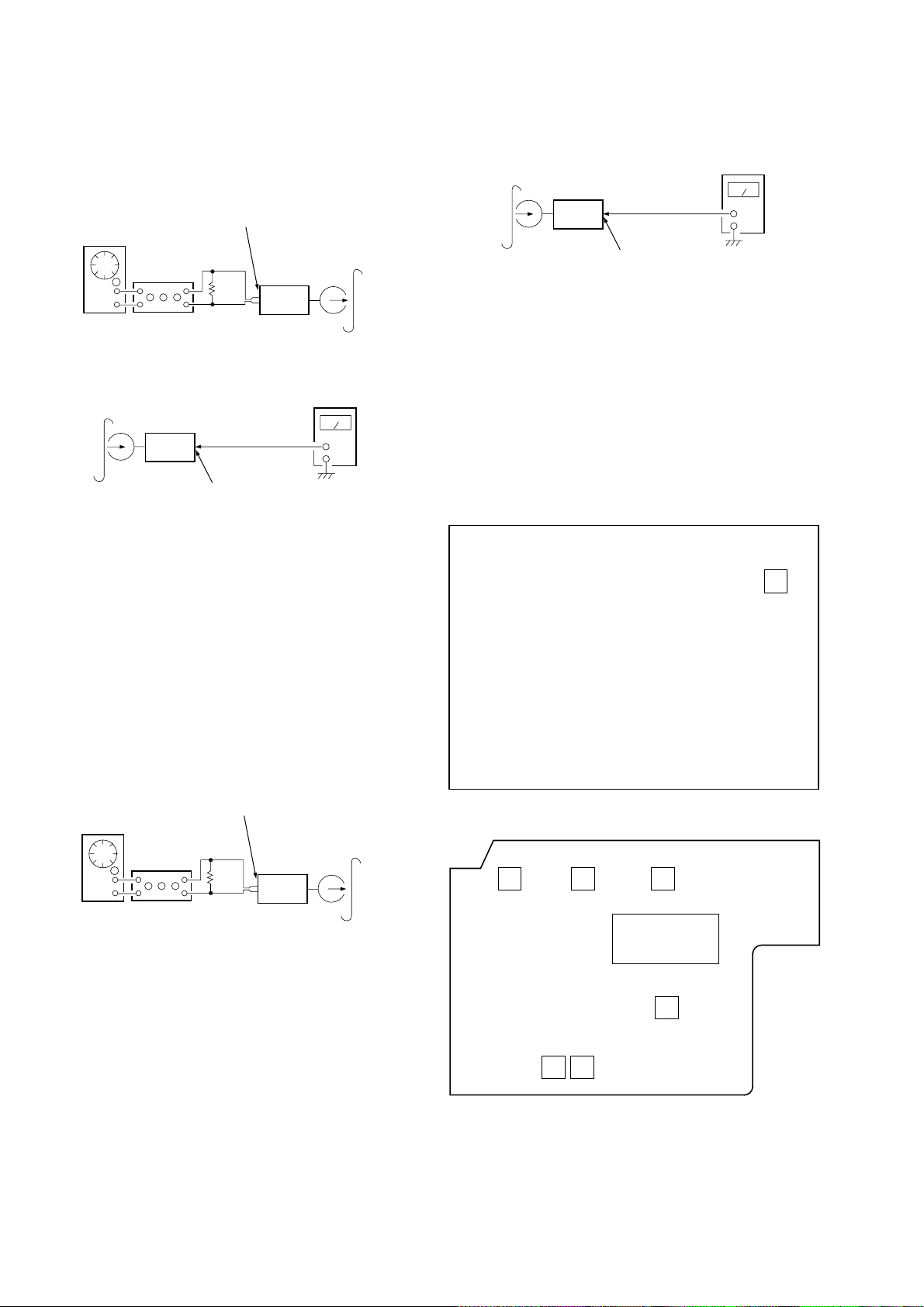

Page 2

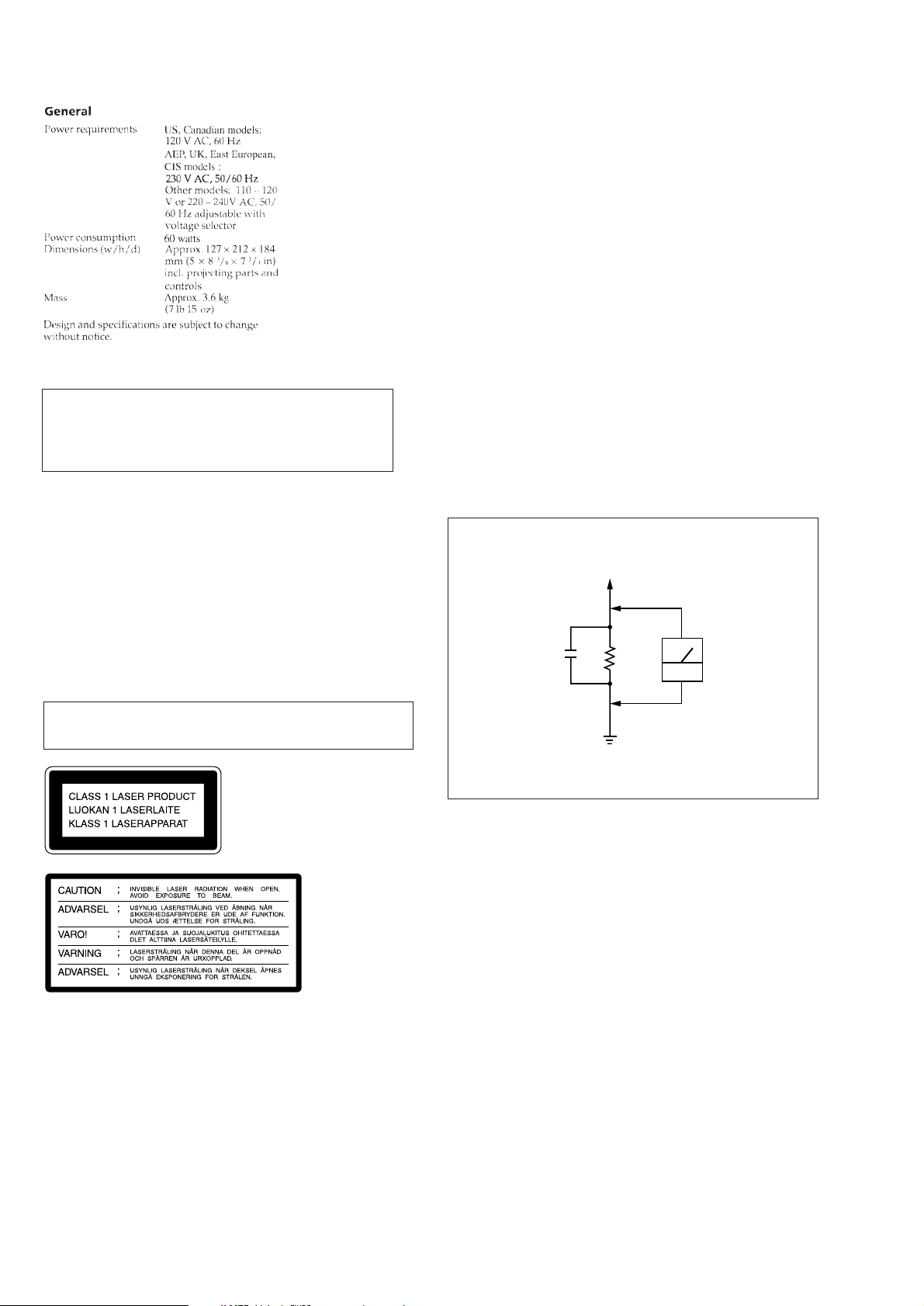

CAUTION

AC

voltmeter

(0.75V)

1.5k

Ω

0.15µF

Parts on Set

Earth Ground

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage fr om any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 3

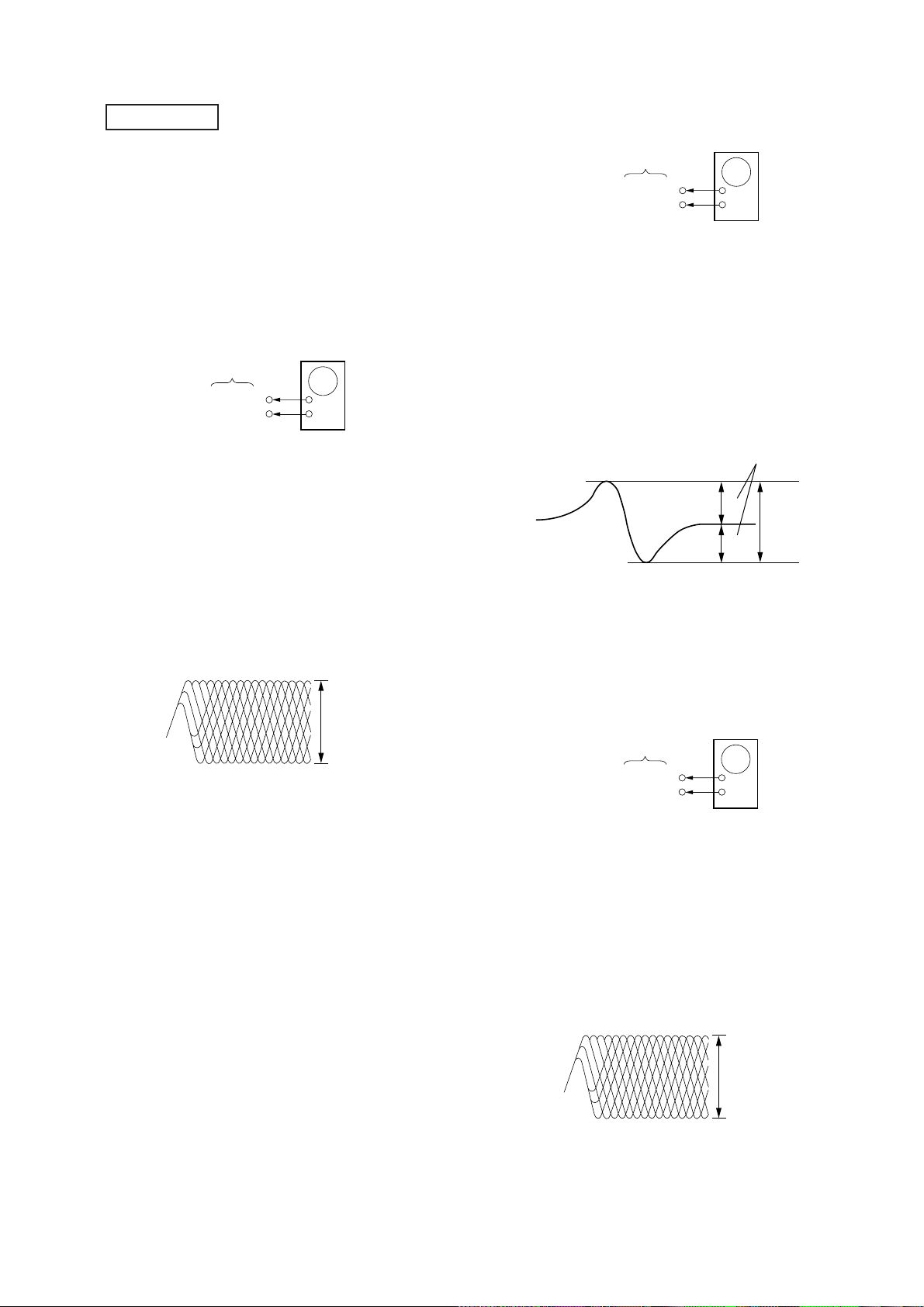

SERVICING NOTE

TABLE OF CONTENTS

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference g enerated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

1. GENERAL .......................................................................... 4

2. DISASSEMBLY

2-1. CD Door, CD Base and Base Unit........................................ 6

2-2. Rear Panel ........................................................................... 6

2-3. Bottom Cover and Front Panel Block ................................... 7

2-4. Door Cover Assy and Mechanical Deck (Cassette) .............. 7

3. MECHANICAL ADJUSTMENTS ............................... 8

4. ELECTRICAL ADJUSTMENTS ................................. 8

5. DIAGRAMS

5-1. Circuit Boards Location...................................................... 13

5-2. IC Pin Function ...................................................................14

5-3. Schematic Diagram — CD Section — ............................... 16

5-4. Printed Wiring Board — CD Section — ............................. 19

5-5. Schematic Diagram — Input/Output Section — ................ 21

5-6. Printed Wiring Board — Input/Output Section — .............. 23

5-7. Printed Wiring Board — Deck Section — .......................... 25

5-8. Schematic Diagram — Deck Section — ............................ 27

5-9. Schematic Diagram — Display Section — ........................ 30

5-10. Printed Wiring Board — Display Section — ................... 33

5-11. Schematic Diagram — Power Section — ........................ 36

5-12. Printed Wiring Board — Power Section — ..................... 39

5-13. IC Block Diagrams ........................................................... 41

MODEL IDENTIFICATION

— AC POWER SUPPLY CODE —

AEP, East European, CIS model

(Without voltage selector)

Singapore, Malaysia,

Hong Kong model

(With voltage selector)

UK model

6. EXPLODED VIEWS

6-1. CD Section ......................................................................... 45

6-2. Rear Panl Section................................................................ 46

6-3. Front Panel Section ............................................................. 47

6-4. Mechanism Deck Section (Cassette) .................................. 48

6-5. Base Unit Section (BU17-BD19)........................................ 49

7. ELECTRICAL PARTS LIST ........................................ 50

US, Canadian model

– 3 –

Page 4

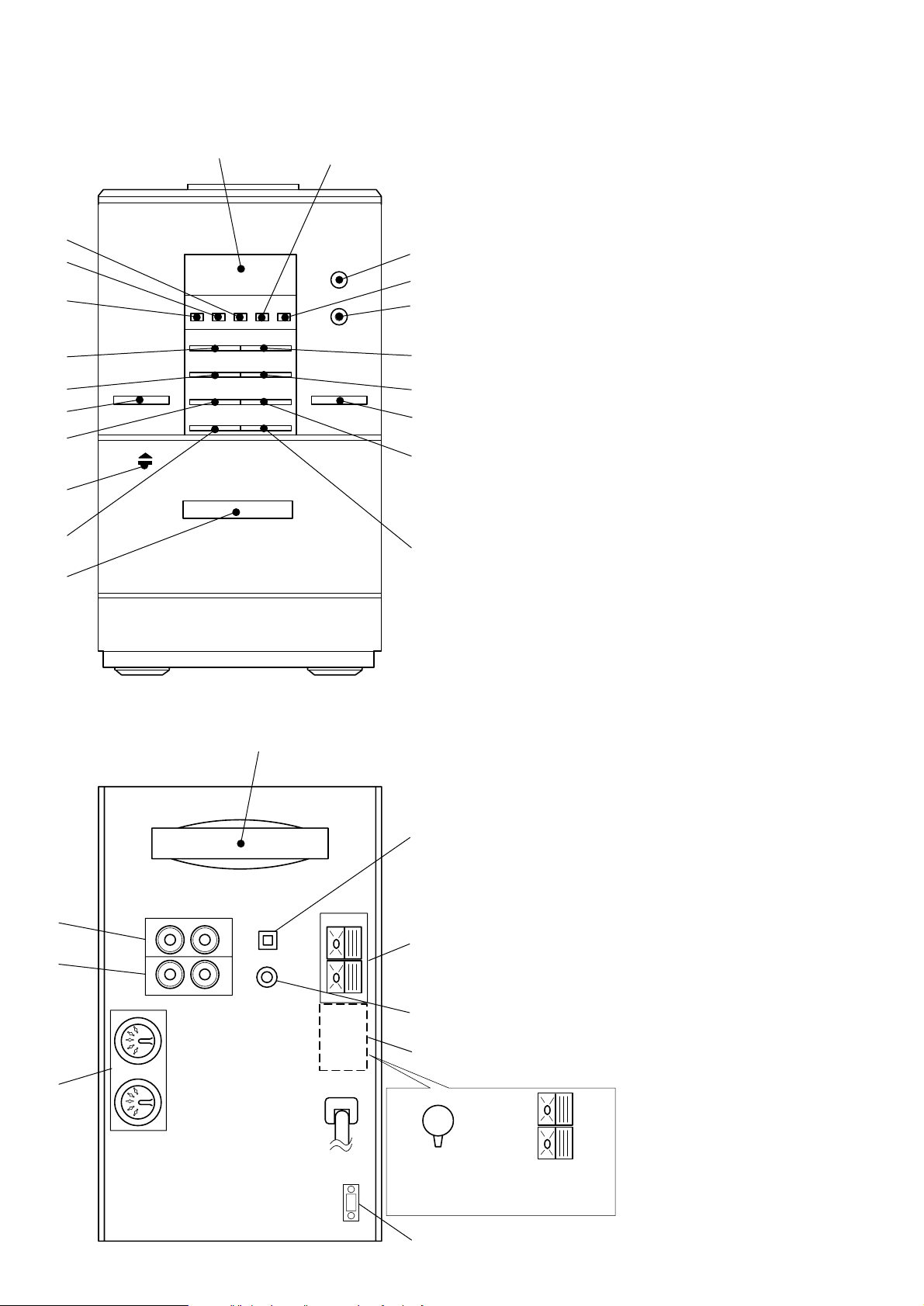

Location of Parts and Controls

FRONT PANEL

1

2

3

4

5

6

7

8

9

20

SECTION 1

GENERAL

19

18

17

16

15

14

13

1 Displa y windo w

2 DBFB lamp

3 CD SYNC lamp

4 REC lamp

5 ª button

6 BAND FM ∏ button

7 POWER b utton

8 TUNING ≠ º – button

9 § button (Push open)

1 0 V OLUME – b utton

1 1 DECK Lid

1 2 VOLUME + button

1 3 TUNING ‚± + button

14 FUNCTON b utton

1 5 BAND AM π button

16 · button

17 SOUND MODE b utton

1 8 WIDE lamp

19 Remote sensor

2 0 NEAR F. lamp

10

11

REAR PANEL

2

3

12

1

1 AM ANTENNA

2 MD IN jacks

9

8

3 MD OUT jacks

4 SPEAKER jacks

5 V OLT AGE SELECT OR s witc h

(Malaysia, Singapore , Hong K ong models onl y)

6 FM ANTENNA terminal

7 PHONES jack

8 AM ANTENNA terminals

9 OPTICAL terminal

7

6

4

AEP,UK,

East European

,CIS model

US,Canadian,

Singapore,Malaysia,

Hong Kong model

5

– 4 –

Page 5

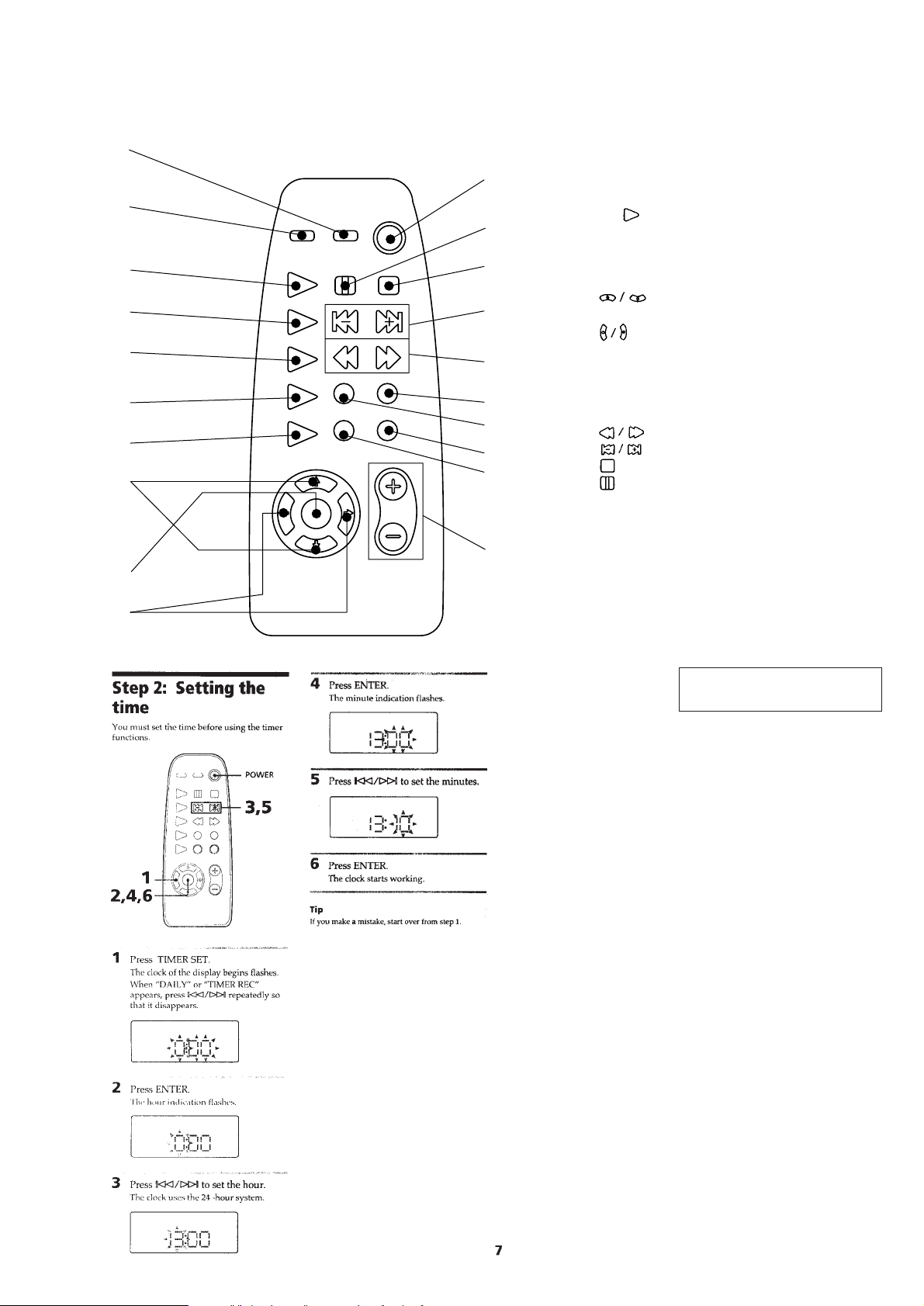

REMOTE

1

10

20

2

19

3

4

5

6

18

17

16

15

14

7

8

13

12

1 DISPLAY button

2 DBFB b utton

3 CD b utton

4 TUNER/BAND button

5 TAPE œ button

6 DIR MODE button

7 CD REPEA T button

8 b uttons

9 ON/OFF b utton

1 0 b uttons

1 1 VOL (+/–) b utton

12 STEREO/MONO b utton

1 3 TUNING/PLAY MODE button

14 DOLBY NR b utton

15 r REC b utton

1 6 (re wind/fast f orwar d) b uttons

1 7 AMS* b uttons

18 (stop) b utton

19 (pause) b utton

20 POWER s witc h

*AMS=Auto Music Sensor

11

9

This section is extracted from

instruction manual.

– 5 –

Page 6

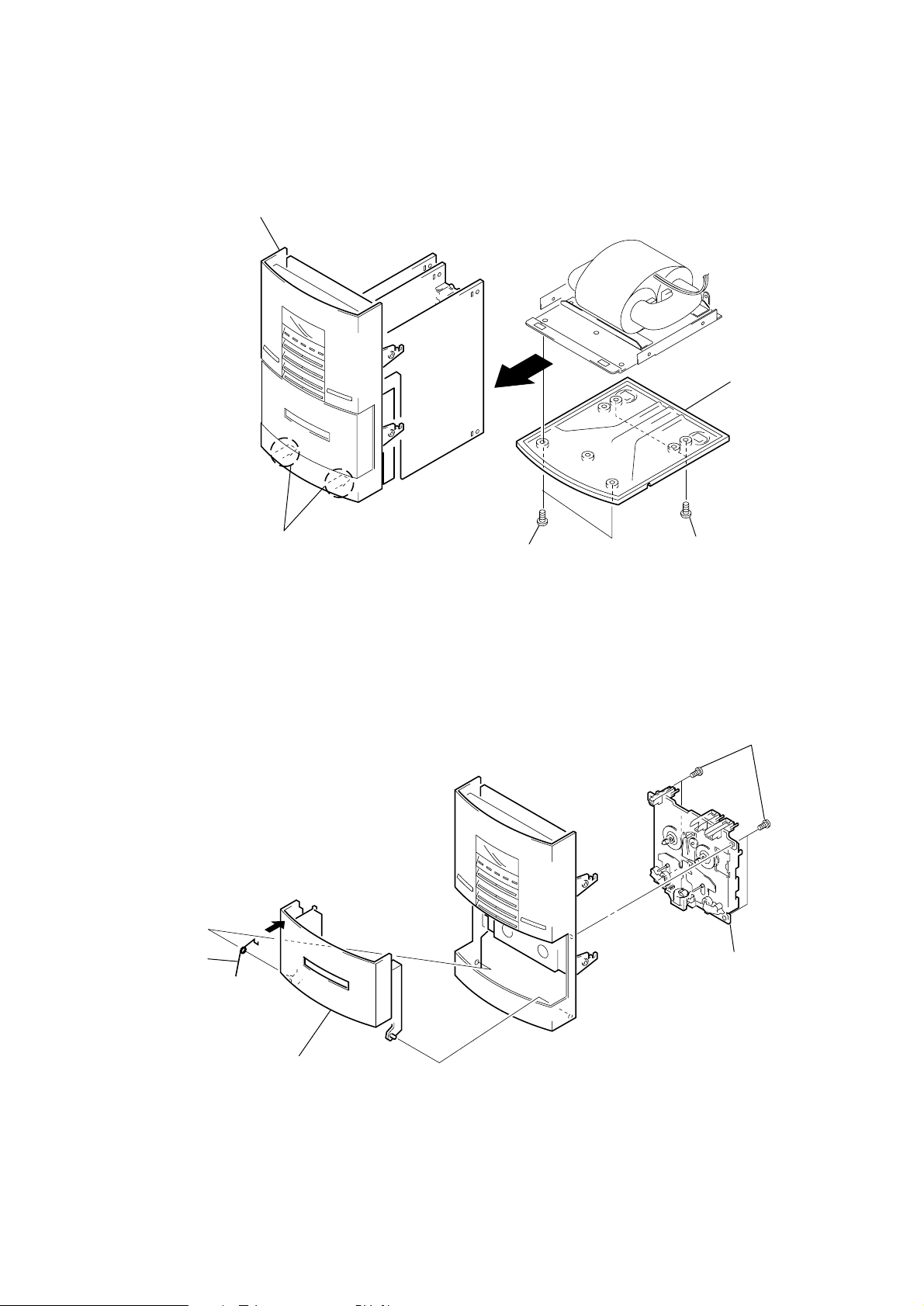

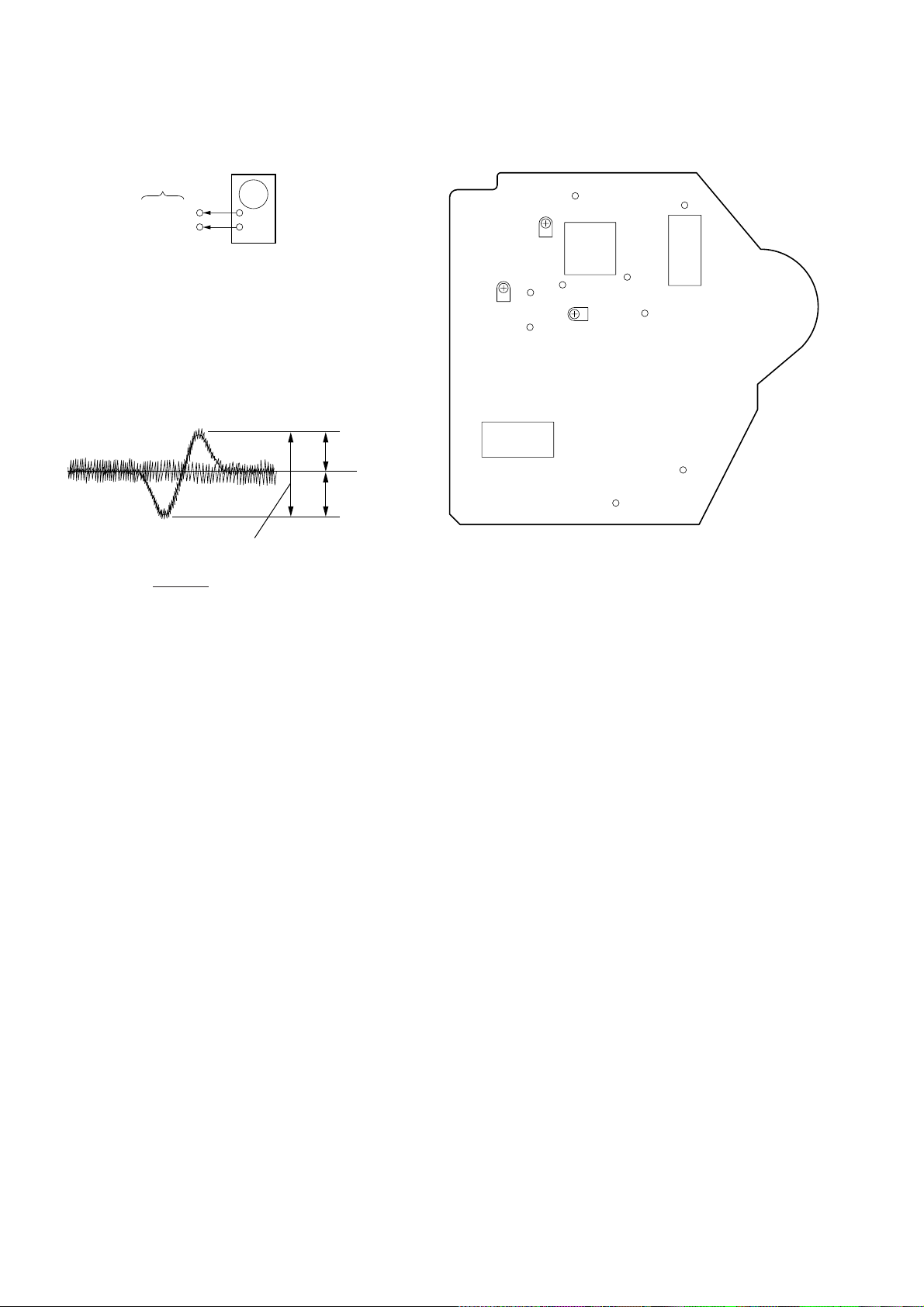

DISASSEMBLY

Note: Follo w the disassemb ly pr ocedure in the n umerical or der given.

2-1. CD DOOR, CD BASE AND BASE UNIT

5

Two hook screws

7

Three screws (K3x8)

!¡

CD base

6

Three screws (K3x8)

SECTION 2

2

Bar rubber

1

4

Hinge spring

9

Three screws (K3x8)

8

Two hook screws

Open the CD door.

3

Hinge pin

2-2. REAR PANEL

5

!∞

Side bracket

Two springs

(compression)

!£

!¢

Two washers

!º

Three screws (K3x8)

!ª

Base unit

!•

Two springs (compression)

!¶

Two washers

!§

Two screws (TPG P2x8)

!™

Wire (Flat type)

Two screws (TPG P2x8)

7

Rear panel

1

Two screws

(BVTP 3x10)

2

Screw

(BVTP 3x8)

3

Two screws

(BVTP 3x8)

– 6 –

6

Side bracket

4

Three screws

(BVTP 3x8)

Page 7

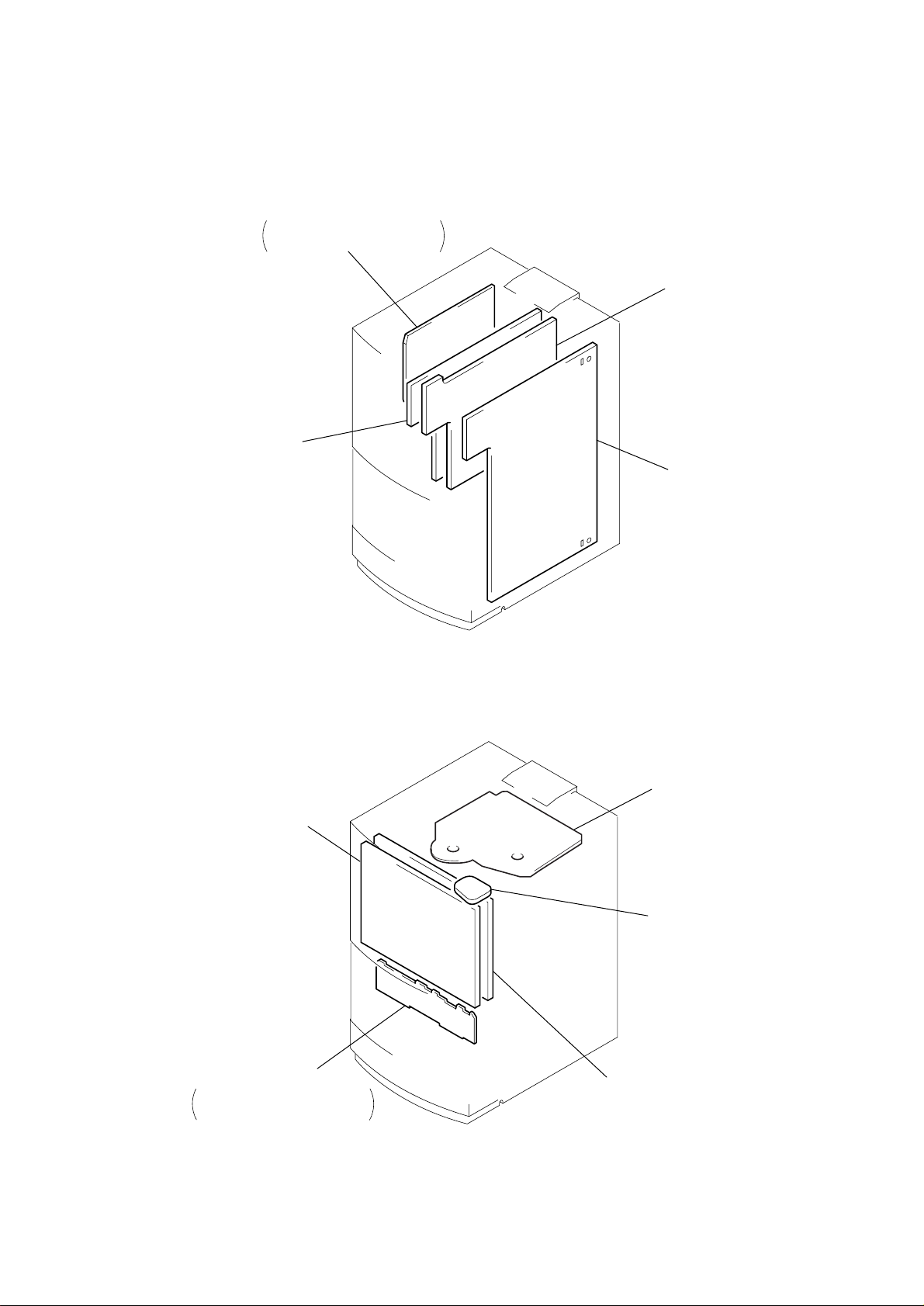

2-3. BOTTOM COVER AND FRONT PANEL BLOCK

r

k

5

Front panel block

4

Two claws

1

Two screws

(BVTP 3x8)

3

2

Two screws

(BVTP 3x8)

Bottom cove

2-4. DOOR COVER ASSY AND MECHANICAL DECK (CASSETTE)

A

3

Door spring

1

Open the Door cover ASSY. (Push the A portion.)

2

Door cover assy

4

Four screws

(BVTP 3x10)

5

Mechanical dec

(cassette)

– 7 –

Page 8

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured alcohol-moistened

swab :

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

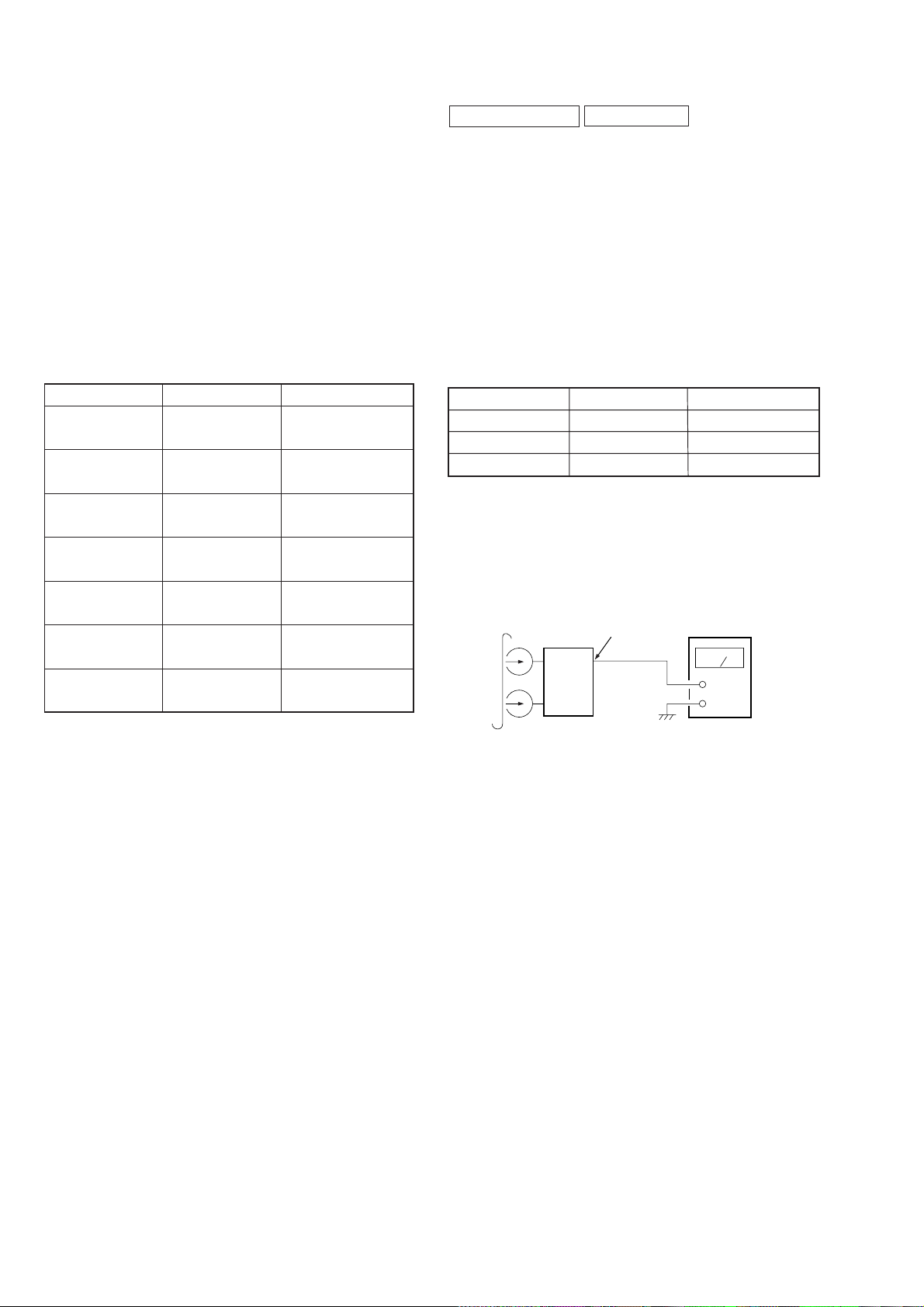

Torque Measurement

Torque Torque meter

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

Meter reading

28 to 71g • cm

(0.39 – 0.99 oz • inch)

1 to 7g • cm

(0.01 – 0.10 oz • inch)

28 to 71g • cm

(0.39 – 0.99 oz • inch)

1 to 7g • cm

(0.01 – 0.10 oz • inch)

56 to 122g • cm

(0.78 – 1.69 oz • inch)

100g or more

(3.53 oz or more)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head damagnetizer.

(Do not bring the head demagnetizer close to the erase head.)

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-ch.

7. Switches and controls should be set as follows unless otherwise

specified.

Tape

P-4-A100

WS-48B

P-4-L300

Record/Playback Head Azimuth Adjustment

Procedure :

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

Signal

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

MD OUT (JK301)

Used for

Azimuth Adjustment

Tape Speed Adjustment

Level Adjustment

level meter

REV tension

CQ-403R

100g or more

(3.53 oz or more)

set

+

–

– 8 –

Page 9

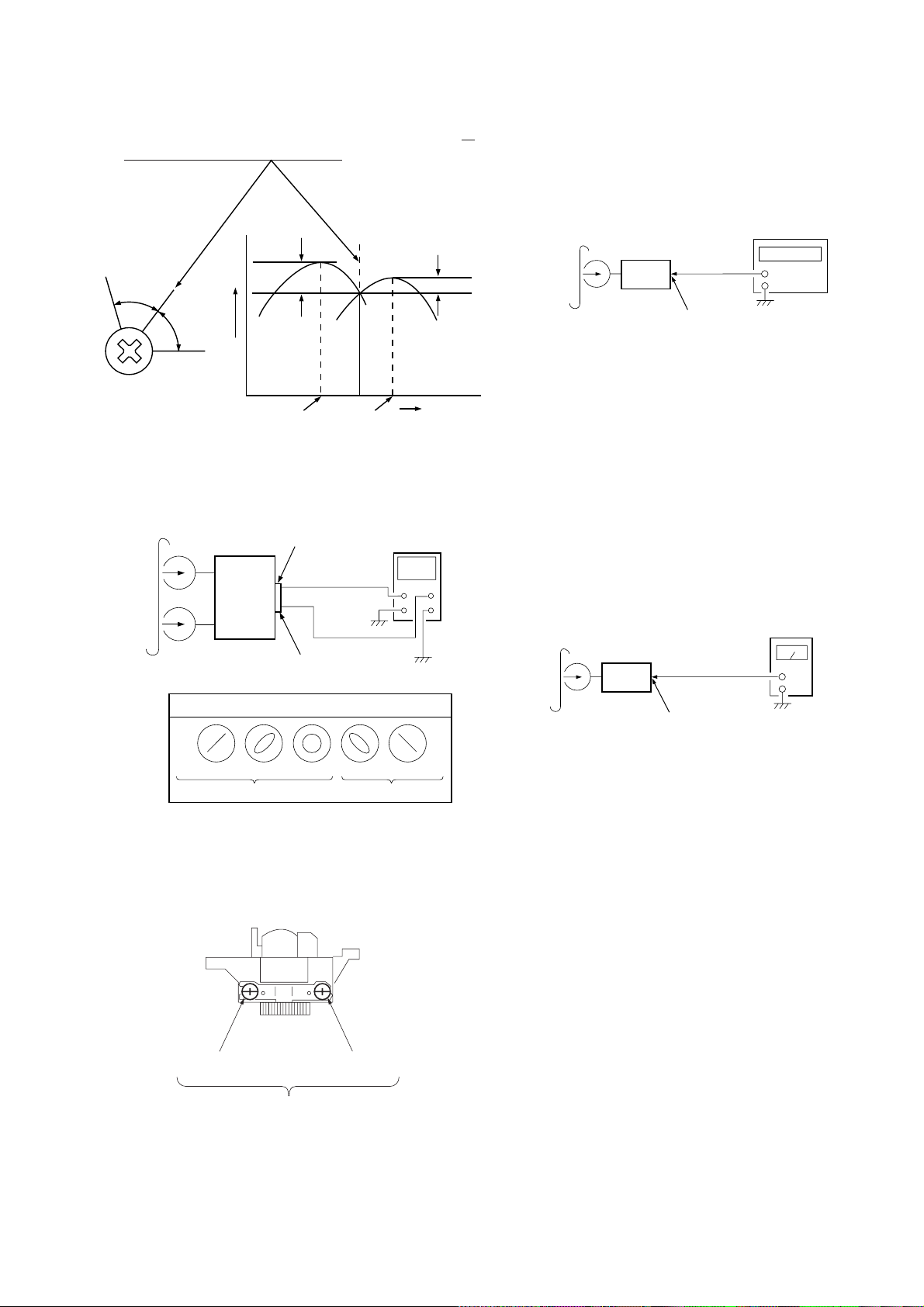

2. Turn the adjustment scre w and check output peaks. If the peaks

r

r

do not match for L-CH and R-CH, turn the adjustment screw so

that outputs match within 1 dB of peak.

L-CH

peak

output

level

within

1dB

within 1dB

Tape Speed Adjustment

Procedure :

Mode : Playback

test tape

WS-48B

(3kHz, 0dB)

set

frequency counte

+

–

MD OUT (JK301)

R-CH

screw

position

peak

L-CH

peak

R-CH

peak

screw

position

3. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

in phase

MD OUT (JK301)

L

set

R

MD OUT (JK301)

Waveform of oscilloscope

45

°

90

°

good

135

oscilloscope

°

180

wrong

°

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

1. Insert the WS-48B into the deck, and playback.

2. Adjust the VR770/RELAY board so that the frequency counter

reading becomes 3000 ± 90 Hz.

Adjustment Location : RELAY board

Sample Value of Wow and flutter

W.RMS (JIS) less than 0.3%

(test tape: WS-48B)

Playback Level Adjustment

Procedure :

Mode : Playback

test tape

P-4-L300

(315Hz, 0dB)

set

MD OUT (JK301)

level mete

Deck is VR703 (L-CH) and VR704 (R-CH)

so that adjustment within the following adjustment level.

Adjustment level :

Playback level: 301.5 to 338.3 mV (–8.2 to –7.2 dB) level difference between the channels: within ±0.5 dB

Adjustment Location : TAPE PREAMP board

Adjustment Location :

FWD side

Adjustment screw

REV side

– 9 –

Page 10

Record Bias Adjustment

r

r

2. Mode: Playback

Procedure :

1. Mode : Record

MD IN (JK301)

1) 315Hz

2) 10kHz

AF OSC

600

attenuator

}

50 mV (–23.8 dB)

Ω

blank tape

CS-123

set

2. Mode : Playback

recorded

position

set

MD OUT (JK301)

level mete

Confirm playback the signal recorded in step 1 become adjustment

level as follows.

If these levels do not adjustment level, adjustment the VR701 (LCH) and VR702 (R-CH) on the TAPE PREAMP board to repeat

steps 1 and 2.

recorded

position

set

MD OUT (JK301)

level mete

Confirm playback the signal recorded in step 1 become adjustment

level as follows.

If these levels do not adjustment level, adjustment the VR705 (LCH) and VR706 (R-CH) on the TAPE PREAMP board to repeat

steps 1 and 2.

Adjustment level :

Playback level : 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location : TAPE PREAMP board

Adjustment Location

[RELAY BOARD] (Component Side)

VR770

Adjustment level : Playback output of 10kHz level diffrence

against 315Hz reference should be ±0.5 dB.

Adjustment Location : TAPE PREAMP board

Record Level Adjustment

Procedure :

1. Mode: Record

MD IN (JK301)

315Hz 50 mV (–23.8 dB)

AF OSC

attenuator

600

Ω

set

blank tape

CS-123

[TAPE PREAMP BOARD] (Component Side)

VR704

VR703 VR706

VR702

VR701

42

1

IC703

VR705

22

21

– 10 –

Page 11

CD SECTION

symmetry

A

B

within 2.4

±

0.7 Vp-p

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with lens cleaning liquid

when the signal level is low than specified value with the following checks.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure:

1. Connect oscilloscope to test point TP (RF).

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Adjust RV101 so that the waveform is clear.

(Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.)

5. After adjustment, check the RF signal level.

• RF signal

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

+

–

S Curve Check

oscilloscope

BD board

TP (FEO)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and Ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 2.4 ± 0.7

Vp-p.

S-curve waveform

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

• Tak e sweep time as long as possible and light up the brightness to obtain best waveform.

level : 1.3 ± 0.3 Vp-p

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

+

–

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200 mV

TIME/DIV : 500 nS

level : 1.3 ± 0.3 Vp-p

– 11 –

Page 12

E-F Balance (1 Track Jump) Check

V

(Without remote commander)

oscilloscope

BD board

TP (TE)

TP (VC)

+

–

Procedure :

1. Connect oscilloscpe to test point TP (TE) on BD board.

2. Turn Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button. (Becomes the 1 track jump mode)

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0Vdc, and check this level.

1 track jump waveform

Adjustment Location:

[BD BOARD] — Component Side —

RF

RV101

IC101

RV103

TEO

VC

FEO

RV102

TEI

FEI

FOK

IC102

A

0

B

LEVEL : 300 ± 100 mVp-p

Specified level: • x 100 = less than ± 7%

A – B

2 (A + B)

• A + B = 300 ± 100 mVp-p

6. Remove the lead wire connected in step 1.

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therfore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

IC104

PCK

GND

– 12 –

Page 13

5-1. CIRCUIT BOARDS LOCATION

d

FM/AM TUNER

THIS BLOCK IS SUPPLIED

AS THE ASSEMBLED BLOCK

TAPE PREAMP board

SECTION 5

DIAGRAMS

FUN/SURROUND boar

VOL/POWER board

DISPLAY board

CONTROL BLK ASSY

THIS BLOCK IS SUPPLIED

AS THE ASSEMBLED BLOCK

BD board

CD DOOR SW board

RELAY board

– 13 –

Page 14

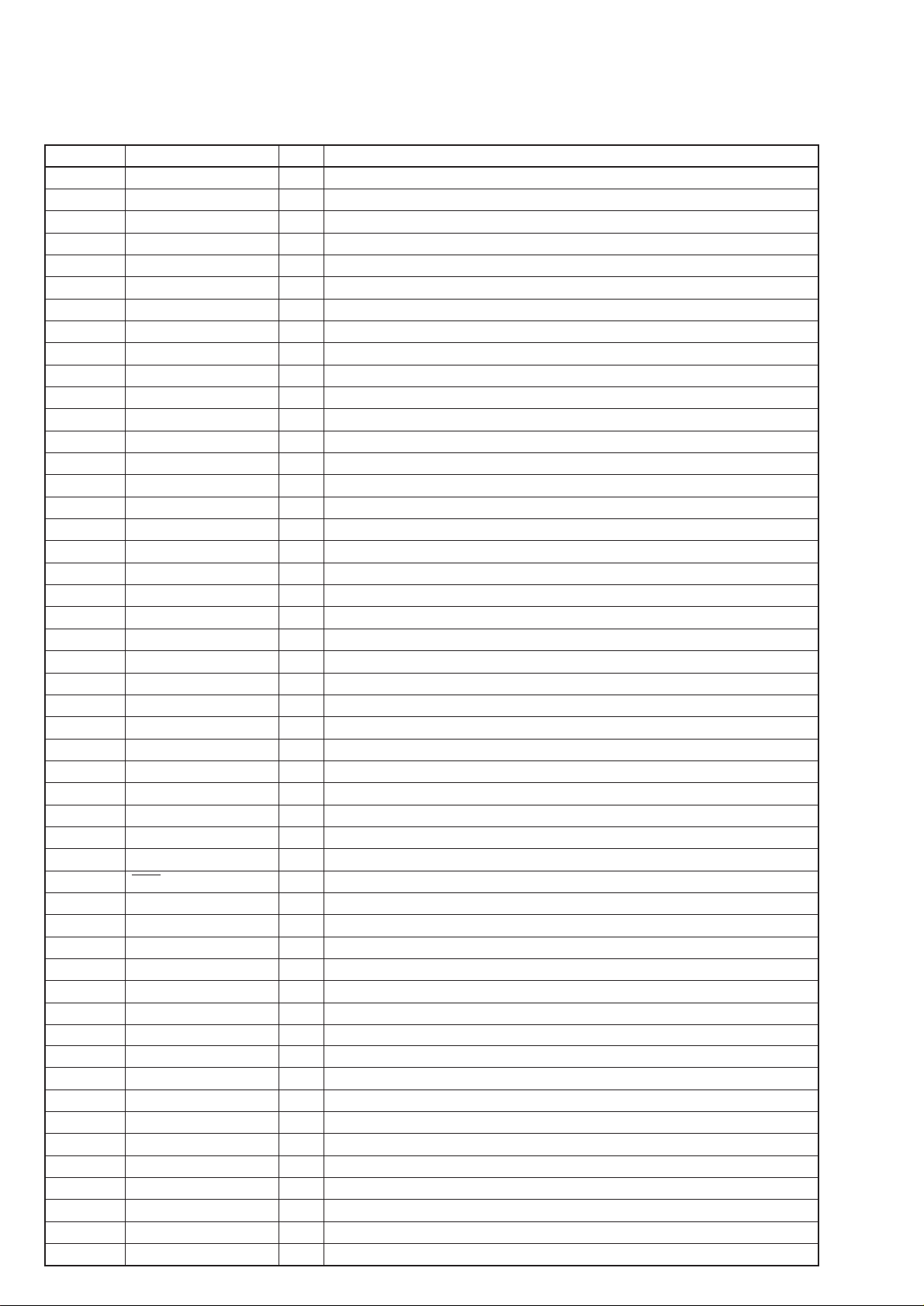

5-2. IC PIN FUNCTION

• IC201 MASTER CONTROL (TC9613)

Pin No. Pin Name I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

GND

XOUT

XIN

RESET

TUNED

STEREO

TEST

POWDEC

REMOTE

PLL CE

PLL CLK

PLL DATAI

PLL DATAO

SERVO CK

SUB Q

DATA

MUTE D

CDPOWER

CLOSESW

FSW

SENSE

MLAT

XLAT

XRST

SCOR

PLAYSW

MTRSNS

TAPEIN

MOTOR

SOL

AMS

PLYMUTE

REC/PB

DOLBYNR

RECMUTE

BIAS

REC LED

CD SYNC

WIDE

KEYIO 1

KEYIO 2

BANDAREA

N.C

LOUDSEL

N.C

FRECSW

RRECSW

AREF

AGND

GND

—

Ground

O

8 MHz Oscillator output

I

8 MHz Oscillator input

I

CPU reset input

I

Station detector input

I

Stereo signal input

I

Test pin (Connected to ground)

I

Power down detect input

I

Remote signal input

O

Chip enable output

O

Clock output

I

Data input

O

Data output

O

Servo clock output

I

Servo subq data & status input

O

Servo command data output

O

Digital mute control output

O

CD power supply output

I

Top loading close switch input

O

Servo focus down output

I

Servo status SENSE input

O

D/A MLAT output

O

Servo command latch output

O

Servo chip reset output

I

Servo SUBQ sync input

I

Tape play switch input

I

Tape motor reel sense input

I

Tape in switch input

O

Tape control output

O

Tape control output

I

Tape music search input

O

Tape play back mute signal output

O

Tape control output

O

Tape control output

O

Tape recording mute signal output

O

Tape control output

O

Record LED output

O

CD SYNC LED output

O

Wide LED output

I

AD key input (16 keys)

I

AD key input (16 keys)

—

Band area option (Not used)

—

Not used

I

Loudness initial select input

—

Not used

I

Tape forward record switch input

I

Tape reverse record switch input

I

A/D convert refrence input (+5V)

I

A/D convert Input ground input

—

Ground

– 14 –

Page 15

Pin No. Pin Name I/O Function

51

52

53

54

55

56

57

58

59

60

61

62

63

64-91

92

93

94

95

96

97

98

99

100

VDD

NARROW

NORMAL

LOUD

DBFB

VOL CLK

VOL DATA

VOL STB

FUNC A

FUNC B

MDMUTE

POWER

MUTE A

SEG27-SEG0

COM3

COM2

COM1

COM0

VLC

N.C

N.C

N.C

VDD

—

+5V power supply

O

Narrow LED output

O

Normal LED output

O

Loudness on/off control output

—

Not used (Connected to ground)

O

Volume control clock output

O

Volume control data output

O

Volume control strobe output

O

TAPE/TUNER control signal output (00: TAPE/01: TUNER)

O

CD/MD control signal output (10: CD/11: MD)

O

MD/REC ON mute output

O

System power output

O

Audio mute control output

O

LCD segment output

O

LCD common 3 output

O

LCD common 2 output

O

LCD common 1 output

O

LCD common 0 output

O

LCD drive power supply output

—

Not used (Connected to ground)

—

Not used (Connected to ground)

—

Not used (Connected to ground)

—

+5V power supply

– 15 –

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

5-13. IC BLOCK DIAGRAMS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32313029282726252423222120

52535455565758596061626364

19

FOK

MON

MDP

MDS

LOCK

TEST

FILO

FILI

PCO

VSS

AVSS

CLTV

AVDD

RF

BIAS

ASYI

ASYO

ASYE

WDCK

DATA

XRST

SENS

MUTE

SQCK

SQSO

EXCK

SBSO

SCOR

V

SS

WFCK

EMPH

DOUT

C4M

FSTT

XTSL

XTAO

XTAI

MNTO

SERVO AUTO

SEQUENCER

CPU

INTERFACE

DIGITAL

CLV

SUB CODE

PROCESSOR

EFM

DEMODULATOR

DIGITAL

PLL

ASYMMETRY

CORRECTOR

D/A

INTERFACE

ERROR

CORRECTOR

16K

RAM

DIGITAL

OUT

CLOCK

GENERATOR

LRCK

BCLK

GTOP

XUGF

XPCK

V

DD

GFS

RFCK

CZPO

XROF

MNT3

MNT1

XLON

SPOD

SPOC

SPOB

SPOA

CLKO

V

DD

XLTO

DATO

CNIN

SEIN

CLOK

XLAT

3

5

14

4

5

3

6

CD SECTION

IC102 BA6397FP

IC101 CXA1782BQ

BUFFER

PHD2

PHD1

36

35 34

37FE BIAS

38F

39E

40EI

41VEE

42TEO

43LPFI

44TEI

45ATSC

46TZC

47TDFCT

48VC

F IV AMP

BAL1

BAL2

TOG1

TOG2

• WINDOW COMP

PHD

–

+

–

+

APC

–

+

RF IV AMP1

+

RF IV AMP2

–

+

–

+

E IV AMP

BAL3

TOG3

ATSC

–

+

–

TE AMP

33

+

–

FE AMP

+

1

FEO

LD

–

2

FEI

–

+

32

DFCT

3

FDFCT

RF M

–

+

FOK

+

LEVELS

–

TTL

IIL

–

+

FZC COMP

TZC COMP

DFCT

FS4

RF O

31

–

+

–

+

• IIL DATA RESISTOR • INPUT SHIFT RESISTOR

RF I

30

–

+

+

–

MIRR

TOG1-3 FS1-4 TG1-2 TM1-7 PS1-4

BAL1-3

–

–

+

+

–

• ADDRESS DECODER

+

• OUTPUT DECODER

CB

29CP28

DFCT

CC126CC225FOK

27

OUT1A

–

+

24 SENS

IIL

+

–

TTL

TTL

23 C. OUT

22 XRST

21 DATA

20 XLT

IIL

19 CLK

18 VCC

OUT1B

IN1A

IN1B

TR-B

REG 0

XRST

GND

IN2A

IN2B

OUT2A

OUT2B

GND

OP-OUT

–

+

HPF COMP LPF COMP

–

+

+

–

TM1

4

FGD

• FCS PHASE

COMPENSATION

5

FLB

FS2

+

–

6

FE O

TG1

FS1

7

FE M

• TRACKING

• PHASE

COMPENSATION

9

8

TGU

SRCH

TM7

TG2

TM6

TM5

TM4

TM3

• ISET

TM2

• F SET

TG2

11

FSET

10

17 ISET

–

16 SL 0

+

15 SL M

14 SL P

+

1312TA O

–

TA M

DRIVE

1

2

BUFFER

DRIVE

3

4

5

6

7

8

9

BUFFER

10

11

12

13

14

DRIVE

BUFFER

DRIVE

LEVEL

SHIFT

LEVEL

SHIFT

IC103 CXD2507AQ

THERMAL

SHUT DOWN

REGULATOR

DRIVER MUTE

LEVEL

SHIFT

LEVEL

SHIFT

BUFFER

DRIVE

BUFFER

DRIVE

BUFFER

DRIVE

BUFFER

DRIVE

28

GND

27

OUT4A

26

OUT4B

25

IN4A

24

IN4B

23

VC

VCC VCC

22

CC

V

21

VCC

20

IN3B

19

IN3A

18

OUT3B

17

OUT3A

16

OP+

15

OP–

– 41 –

– 42 –

Page 27

IC104 PCM1710U-B

LRCIN

DIN

BCKIN

CLKO

XTI

XTO

DGND

V

VCC2R

GND2R

EXT1R

EXT2R

VOUTR

GND1

1

2

3

4

5

6

7

8

DD

9

10

11

12

13

14

INPUT

INTERFACE DIGITAL

TIMING

CONTROL

5-LEVEL DAC

RIGHT

LOW-PASS FILTER

RIGHT

3-STAGE AMP

RIGHT

FILTER

NOISE

SHAPER

MODE

CONTROL

5-LEVEL DAC

LEFT

LOW-PASS FILTER

LEFT

3-STAGE AMP

LEFT

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ML/DSD

MC/DM2

MD/DM1

MUTE

MODE

CKSL

DGND

DD

V

VCC2L

GND2L

EXT1L

EXT2L

VOUTL

VCC1

DECK SECTION

IC701 BA3126N

1

2 3

GND

REC SW1

POWER SECTION

IC461 TC9260P

1VSS

2

OUT

3

IN

L-CH

VOLUME

LD1

LD2

4

5

PB SW1

4

CONT

INPUT/OUTPUT SECTION

IC301 MC14052BCP

VDD

2

1

141516 13 12 11 10 9

5

GND

L-CH

LATCH

6

7

VCC

PB SW2

R-CH

LATCH

9

8

GND

REC SW2

12 3 456 78

0

2

16

VDD

15

OUT

14

IN

LD1

LD2

R-CH

VOLUME

13

12

COMMON30

COMMON

SEL.A

SEL.B

DECODER

3

1

INHIBIT

EE

V

VSS

AGND

11

6

CS

7

8

CK

DATA DECODER,

STB GENERATOR

INPUT REGISTER

AGND

10

STB

9

DATA

– 43 –

Page 28

IC351 TA2041F

13

GND

VREF

14

OUT1

15

BIAS

12

CC

V

EXT IN

PS4

PS3

HF1

LF IN1

VCC

VCC

16

SWITCH

abc

VCC

17

LF5

18

19

VCC

20

LF4

21

LF3

VCC

22

23

IN1

24

VCC

VCC

SWITCH

V

CC

VCC

11

SW

c

a

b

VCC

VCC

VCC

VCC

SWB

10

SWA

9

OUT2

MIX

8

LEVEL

SW C

7

6

LF2

PS2

5

PS1

4

3

LF1

LF IN2

2

1

IN2

– 44 –

Page 29

SECTION 6

t

EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may have

some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

• The mechanical parts with no reference number in

the exploded views are not supplied.

6-1. CD SECTION

18

#3

10

#2

9

• Hardware (# mark) list and accessories and packing materials are given in the last of this parts list.

• Abbreviation

CND : Canadian model

EE : East European model

HK : Hong Kong model

SP : Singapore model

MY : Malaysia model

2

4

5

7

8

17

#1

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

1

3

6

4

#2

16

#4

#2

#3

14

#2

10

11

12

18

#3

13

#5

#5

15

#5

Base uni

11

12

#3

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 4-997-375-01 GLASS DOOR W/PRINGING

2 4-997-373-01 HINGE PLATE

3 4-997-355-01 DOOR HINGE

4 4-997-365-01 HINGE PIN

5 4-997-370-01 BAR RUBBER

6 4-997-356-01 HINGE SPRING

7 4-997-349-01 CD BASE

8 4-997-367-01 PUSH BUTTON

9 4-997-369-01 CUSHION

10 4-997-345-01 HOOK SCREW

11 4-948-503-01 SPRING (BU), COMPRESSION

12 4-997-372-01 WASHER

13 1-783-091-11 WIRE (FLAT TYPE)

* 14 4-997-350-01 BACK COVER (US,CND,MY,SP,HK)

* 14 4-997-350-11 BACK COVER (AEP,UK,EE,CIS)

15 4-997-353-01 PICK UP COVER

* 16 A-4407-244-A CD DOOR SW BOARD, COMPLETE

17 4-977-376-01 STOP SPRING

18 4-977-371-01 STOPPER

– 45 –

Page 30

6-2. REAR PANEL SECTION

d

65

66

64

54

(UK)

54

(EXCEPT

US,CND,UK)

not supplied

51

#8

62

#7

56

#8

T501

57

52

62

58

#7

53

#7

62

#6

S501 (MY,

SP,HK)

62

#7

#7

#6

#13

#7

#6

#7

55

51

63

(HK)

54

(US,CND)

not supplie

59

FRONT PANEL

#7

61

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 51 4-997-363-01 SIDE BRACKET

52 1-693-400-21 FM/AM TUNER (AEP,UK,EE,CIS)

52 1-693-400-31 FM/AM TUNER (US,CND)

52 1-693-400-41 FM/AM TUNER (MY,SP,HK)

* 53 4-997-368-11 REAR PANEL (AEP)

* 53 4-997-368-21 REAR PANEL (UK)

* 53 4-997-368-31 REAR PANEL (EE,CIS)

* 53 4-997-368-41 REAR PANEL (US,CND)

* 53 4-997-368-51 REAR PANEL (MY,SP)

* 53 4-997-368-61 REAR PANEL (HK)

! 54 1-551-478-00 CORD, POWER (POLAR.SPT-2)(US,CND)

! 54 1-555-750-00 CORD, POWER (AEP,EE,CIS,MY,SP,HK)

! 54 1-751-535-11 CORD, POWER (UK)

55 4-997-358-01 AC CORD BUSHING

* 56 A-4407-243-A TAPE PREAMP BOARD, COMPLETE

60

The components identified by

61

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

* 58 A-4407-239-A VOL/POWER BOARD, COMPLETE

* 58 A-4407-240-A VOL/POWER BOARD, COMPLETE (US,CND)

* 58 A-4407-241-A VOL/POWER BOARD, COMPLETE (MY,SP,HK)

* 59 4-997-364-01 BOTTOM BOARD

60 4-997-352-01 BOTTOM COVER

61 4-997-366-01 RUBBER FOOT

* 62 4-997-378-01 PC BOARD BRACKET

! 63 1-770-019-11 ADAPTOR, CONVERSION PLUG 3P (HK)

64 X-4949-451-1 AM ANT SUB ASSY

65 1-501-659-11 ANTENNA (FM) (US,CND,MY,SP,HK)

66 1-501-985-11 LEAD, ANTENNA (AEP,UK,EE,CIS)

! S501 1-771-308-11 SELECTOR, POWER (MY,SP,HK)

! T501 1-431-697-21 TRANSFORMER, POWER (AEP,UK,EE,CIS)

! T501 1-431-697-31 TRANSFORMER, POWER (US,CND)

Les composants identifiés par

une marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

(AEP,UK,EE,CIS)

* 57 A-4407-242-A FUN/SURROUND BOARD, COMPLETE

! T501 1-431-697-41 TRANSFORMER, POWER (MY,SP,HK)

– 46 –

Page 31

6-3. FRONT PANEL SECTION

Z201

102

114

113

103

112

105

104

#7

106

#7

109

#6

107

111

#9

#6

110

#5

115

108

101

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 4-997-351-01 DOOR COVER

102 4-997-354-01 DOOR SPRING

103 X-4949-450-1 CASS DOOR SUB ASSY

104 1-773-009-11 WIRE (FLAT TYPE) (15 CORE) (AEP,UK,EE,CIS)

104 1-751-688-11 WIRE (FLAT TYPE) (13 CORE)

(US,CND,MY,SP,HK)

* 105 A-4407-247-A DISPLAY BOARD, COMPLETE (AEP,UK,EE,CIS)

* 105 A-4407-248-A DISPLAY BOARD, COMPLETE (US,CND)

* 105 A-4407-249-A DISPLAY BOARD, COMPLETE (MY,SP,HK)

* 106 A-4407-245-A RELAY BOARD, COMPLETE

107 4-997-361-01 GEAR DAMPER

108 X-4949-449-1 FRONT PANEL SUB ASSY

109 4-997-362-01 DOOR LATCH

110 1-759-548-11 DECK, MECHANICAL

111 4-997-357-01 GEAR HOLDER

112 4-997-381-01 LCD HOLDER

113 4-997-382-01 LIGHT BAR

114 4-997-383-01 DISPLAY FILTER

115 4-997-374-01 SOLDER LUG

Z201 1-803-020-11 DISPLAY PANEL, LIQUID CRYSTAL

– 47 –

Page 32

Ver 1.1 2001.06

6-4. MECHANISM DECK SECTION (CASSETTE)

152

not supplied

not supplied

not supplied

not

not supplied

not supplied

not supplied

supplied

not supplied

M901

not supplied

not supplied

155

153

157

not supplied

not supplied

#11

#11

not

supplied

(including )

154

not supplied

A

A

not

supplied

#12

156

151

159

not

supplied

not supplied

not supplied

158

Ref. No. Part No. Description Remark

151 1-759-548-11 DECK, MECHANICAL

152 X-4949-565-1 CONTROL BLK ASSY

153 X-4949-566-1 CLUTCH BLK ASSY

154 X-4949-563-1 PLA TE HD BLK ASSY

155 4-997-983-01 BEL T MAIN

156 X-4949-568-1 ROLLER PINCH BLK R ASSY

157 X-4949-569-1 ROLLER PINCH BLK L ASSY

158 4-997-984-01 F/R BEL T

159 X-4949-567-1 CLUTCH BLK2 ASSY

M901 X-4949-564-1 MTR MAIN BLK ASSY (CAPST AN/REEL)

– 48 –

Page 33

6-5. BASE UNIT SECTION (BU17-BD19)

Ver 1.1 2001.06

201

202

#10

203

205

204

M101

M102

207

208

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

204

206

Les composants identifiés par

une marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

! 201 8-848-387-01 OPTICAL PICK-UP KSS-213BA/S-N

202 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

203 4-917-567-01 GEAR (M)

204 4-951-940-01 INSULATOR (BU)

205 4-917-565-01 SHAFT, SLED

206 4-917-564-01 GEAR (P), FLATNESS

* 207 A-4673-402-B BD BOARD, COMPLETE

208 4-951-620-01 SCREW (2.6X8), +BVTP

M101X-4950-066-1 MOTOR ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

– 49 –

Page 34

BD

Note:

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

When indicating parts by reference

number, please include the boar d

name.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* A-4673-402-B BD BOARD, COMPLETE

******************

< CAPACITOR >

ELECTRICAL PARTS LIST

• Due to standardization, replacements in the parts list

may be different from the parts specified in the

diagrams or the components used on the set.

• -XX, -X mean standardized parts, so they may have

some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

• RESISTORS

All resistors are in ohms

METAL: Metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F : nonflammable

C146 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C147 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C148 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C149 1-164-346-11 CERAMIC CHIP 1uF 16V

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA..., uPA...: µPA..., uPB...: µ PB ...,

uPC...: µPC..., uPD...: µ PD...

• CAPACITORS

uF : µF

• COILS

uH : µH

• Abbreviation

CND : Canadian model

EE : East European model

HK : Hong Kong model

SP : Singapore model

MY : Malaysia model

SECTION 7

C101 1-126-607-11 ELECT CHIP 47uF 20% 4V

C102 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C103 1-164-346-11 CERAMIC CHIP 1uF 16V

C105 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C106 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C107 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C108 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C109 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C110 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C111 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C112 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C113 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C114 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C115 1-126-607-11 ELECT CHIP 47uF 20% 4V

C116 1-163-016-00 CERAMIC CHIP 0.0039uF 10% 50V

C117 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C118 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C119 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C120 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C121 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C122 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C123 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C124 1-126-607-11 ELECT CHIP 47uF 20% 4V

C125 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C126 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C127 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C128 1-163-135-00 CERAMIC CHIP 560PF 5% 50V

C129 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C130 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C131 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C132 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C133 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C134 1-164-346-11 CERAMIC CHIP 1uF 16V

C135 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C136 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C137 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C139 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C140 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C141 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C142 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C145 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C153 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C154 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

< CONNECTOR >

CNU101 1-770-014-11 CONNECTOR, FFC/FPC 16P

CNU102 1-770-013-11 CONNECTOR, FFC/FPC 19P

< IC >

IC101 8-752-074-34 IC CXA1782CQ

IC102 8-759-291-06 IC BA6397FP

IC103 8-752-372-94 IC CXD2507AQ

IC104 8-759-185-29 IC PCM1710U-B

< MOTOR >

M101 X-4917-523-4 MOTOR ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q102 8-729-424-08 TRANSISTOR UN2111

Q103 8-729-421-22 TRANSISTOR UN2211

< RESISTOR >

R102 1-216-001-00 METAL CHIP 10 5% 1/10W

R103 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R104 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R105 1-216-093-00 METAL CHIP 68K 5% 1/10W

R106 1-216-093-00 METAL CHIP 68K 5% 1/10W

R107 1-216-093-00 METAL CHIP 68K 5% 1/10W

R108 1-216-093-00 METAL CHIP 68K 5% 1/10W

R109 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R112 1-216-083-00 METAL CHIP 27K 5% 1/10W

R113 1-216-083-00 METAL CHIP 27K 5% 1/10W

R114 1-216-101-00 METAL CHIP 150K 5% 1/10W

R115 1-216-101-00 METAL CHIP 150K 5% 1/10W

R116 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R117 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R118 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R119 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R120 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R121 1-216-114-00 METAL GLAZE 510K 5% 1/10W

– 50 –

Page 35

DISPLAYCD DOOR SWBD

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R122 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R123 1-216-099-00 METAL CHIP 120K 5% 1/10W

* A-4407-244-A CD DOOR SW BOARD, COMPLETE

***************************

R124 1-216-091-00 METAL CHIP 56K 5% 1/10W

R125 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R126 1-216-063-91 METAL GLAZE 3.9K 5% 1/10W

R127 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R128 1-216-105-91 METAL GLAZE 220K 5% 1/10W

R129 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R130 1-216-079-00 METAL CHIP 18K 5% 1/10W

R131 1-216-079-00 METAL CHIP 18K 5% 1/10W

R132 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R133 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R134 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R135 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R136 1-216-073-00 METAL CHIP 10K 5% 1/10W

R137 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R138 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R139 1-216-033-00 METAL CHIP 220 5% 1/10W

R140 1-216-081-00 METAL CHIP 22K 5% 1/10W

R141 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R142 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R143 1-216-121-91 METAL GLAZE 1M 5% 1/10W

R144 1-216-073-00 METAL CHIP 10K 5% 1/10W

R145 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R146 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R147 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R148 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R149 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R150 1-216-037-00 METAL CHIP 330 5% 1/10W

R151 1-216-037-00 METAL CHIP 330 5% 1/10W

R152 1-216-037-00 METAL CHIP 330 5% 1/10W

R153 1-216-082-00 METAL GLAZE 24K 5% 1/10W

R154 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R156 1-216-085-00 METAL CHIP 33K 5% 1/10W

R157 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R158 1-216-001-00 METAL CHIP 10 5% 1/10W

< SWITCH >

S211 1-771-298-11 SWITCH, PUSH (CD DOOR)

**************************************************************

* A-4407-247-A DISPLAY BOARD, COMPLETE (AEP,UK,EE,CIS)

*************************************

* A-4407-248-A DISPLAY BOARD, COMPLETE (US,CND)

*********************************

* A-4407-249-A DISPLAY BOARD, COMPLETE (MY,SP,HK)

***********************************

4-997-381-01 LCD HOLDER

4-997-382-01 LIGHT BAR

4-997-383-01 DISPLAY FILTER

< CAPACITOR >

C200 1-126-514-11 ELECT 22uF 20% 16V

C201 1-102-962-00 CERAMIC 30PF 5% 50V

C202 1-102-953-00 CERAMIC 18PF 5% 50V

C203 1-136-165-00 FILM 0.1uF 5% 50V

C204 1-136-165-00 FILM 0.1uF 5% 50V

C205 1-126-916-11 ELECT 1000uF 20% 6.3V

C206 1-136-165-00 FILM 0.1uF 5% 50V

C207 1-136-165-00 FILM 0.1uF 5% 50V

C208 1-136-165-00 FILM 0.1uF 5% 50V

C209 1-136-165-00 FILM 0.1uF 5% 50V

C212 1-136-165-00 FILM 0.1uF 5% 50V

C213 1-126-177-11 ELECT 100uF 20% 10V

C220 1-136-165-00 FILM 0.1uF 5% 50V

C230 1-102-934-00 CERAMIC 1.0PF +-0.25PF 50V

C232 1-126-177-11 ELECT 100uF 20% 10V

< CONNECTOR >

< VARIABLE RESISTOR >

RV101 1-241-396-11 RES, ADJ, METAL GLAZE 22K

RV102 1-241-396-11 RES, ADJ, METAL GLAZE 22K

RV103 1-241-396-11 RES, ADJ, METAL GLAZE 22K

< SWITCH >

S101 1-572-085-11 SWITCH, LEAF (LIMIT)

< VIBRATOR >

X101 1-579-280-11 VIBRATOR, CRYSTAL (16.9344MHz)

**************************************************************

* CN1 1-568-858-11 SOCKET, CONNECTOR 15P (AEP,UK,EE,CIS)

* CN1 1-784-568-11 CONNECTOR, FFC 13P (US,CND,SP,MY,HK)

< DIODE >

D201 8-719-920-76 DIODE 1S2076

D202 8-719-920-76 DIODE 1S2076

D203 8-719-920-76 DIODE 1S2076

D210 8-719-920-76 DIODE 1S2076

D211 8-719-920-76 DIODE 1S2076

D212 8-719-920-76 DIODE 1S2076

< IC >

IC201 8-759-497-90 IC TC9613

IC202 8-749-014-39 IC PIC-21041TH2

IC203 8-759-165-80 IC PST600C-T

< COIL >

L201 1-410-521-11 INDUCTOR 100uH

– 51 –

Page 36

DISPLAY FUN/SURROUND

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< DIODE >

LD201 8-719-989-30 DIODE EL204HD (WIDE)

LD202 8-719-989-30 DIODE EL204HD (NEAR F)

LD203 8-719-989-30 DIODE EL204HD (DBFB)

LD204 8-719-989-30 DIODE EL204HD (CD SYNC)

LD205 8-719-989-30 DIODE EL204HD (REC)

< CONNECTOR >

M201 1-784-348-11 CONNECTOR 12P

M202 1-784-347-11 CONNECTOR 10P

M203 1-784-349-11 CONNECTOR 25P

< LAMP >

R260 1-247-828-11 CARBON 750 5% 1/4W

R261 1-249-416-11 CARBON 820 5% 1/4W F

R262 1-249-418-11 CARBON 1.2K 5% 1/4W F

(US,CND)

R263 1-249-419-11 CARBON 1.5K 5% 1/4W F

R264 1-247-838-00 CARBON 2K 5% 1/4W

R270 1-249-393-11 CARBON 10 5% 1/4W F

R278 1-249-413-11 CARBON 470 5% 1/4W F

R279 1-249-413-11 CARBON 470 5% 1/4W F

R280 1-249-413-11 CARBON 470 5% 1/4W F

R281 1-249-413-11 CARBON 470 5% 1/4W F

R282 1-249-413-11 CARBON 470 5% 1/4W F

R290 1-249-429-11 CARBON 10K 5% 1/4W

PL201 1-517-743-11 LAMP

< TRANSISTOR >

Q201 8-729-119-78 TRANSISTOR 2SC2785-HFE

Q204 8-729-900-63 TRANSISTOR DTA124ES

Q205 8-729-900-63 TRANSISTOR DTA124ES

Q206 8-729-900-63 TRANSISTOR DTA124ES

Q207 8-729-900-63 TRANSISTOR DTA124ES

Q208 8-729-900-63 TRANSISTOR DTA124ES

< RESISTOR >

R200 1-249-429-11 CARBON 10K 5% 1/4W

R201 1-249-435-11 CARBON 33K 5% 1/4W

R202 1-249-424-11 CARBON 3.9K 5% 1/4W F

R203 1-249-429-11 CARBON 10K 5% 1/4W

R204 1-249-437-11 CARBON 47K 5% 1/4W

R205 1-249-429-11 CARBON 10K 5% 1/4W

R208 1-249-437-11 CARBON 47K 5% 1/4W

R209 1-249-429-11 CARBON 10K 5% 1/4W

R210 1-249-429-11 CARBON 10K 5% 1/4W

R222 1-249-429-11 CARBON 10K 5% 1/4W

R223 1-249-429-11 CARBON 10K 5% 1/4W

R225 1-249-429-11 CARBON 10K 5% 1/4W

R226 1-249-429-11 CARBON 10K 5% 1/4W

R227 1-249-429-11 CARBON 10K 5% 1/4W

R229 1-249-429-11 CARBON 10K 5% 1/4W

< SWITCH >

S200 1-571-760-11 SWITCH, KEY BOARD (POWER)

S201 1-571-760-11 SWITCH, KEY BOARD (VOLUME +)

S202 1-571-760-11 SWITCH, KEY BOARD (VOLUME –)

S203 1-571-760-11 SWITCH, KEY BOARD (TUNING +/) +)

S204 1-571-760-11 SWITCH, KEY BOARD (TUNING = 0/–)

S205 1-571-760-11 SWITCH, KEY BOARD (BAND P/FM)

S206 1-571-760-11 SWITCH, KEY BOARD (BAND AM/p)

S207 1-571-760-11 SWITCH, KEY BOARD (PLAY ª TC)

S208 1-571-760-11 SWITCH, KEY BOARD (PLAY CD/TC ·)

S209 1-571-760-11 SWITCH, KEY BOARD (FUNCTION)

S210 1-571-760-11 SWITCH, KEY BOARD (SOUND MODE)

< VIBRATOR >

X201 1-767-791-11 VIBRATOR, CRYSTAL (8MHz)

< LIQUID CRYSTAL DISPLAY >

Z201 1-803-020-11 DISPLAY PANEL, LIQUID CRYSTAL

**************************************************************

* A-4407-242-A FUN/SURROUND BOARD, COMPLETE

*****************************

* 4-997-378-01 PC BOARD BRACKET

7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

R230 1-249-429-11 CARBON 10K 5% 1/4W

R239 1-249-425-11 CARBON 4.7K 5% 1/4W F

R240 1-249-425-11 CARBON 4.7K 5% 1/4W F

R246 1-249-429-11 CARBON 10K 5% 1/4W

R247 1-249-429-11 CARBON 10K 5% 1/4W

R248 1-249-429-11 CARBON 10K 5% 1/4W

R250 1-247-807-31 CARBON 100 5% 1/4W

R253 1-249-425-11 CARBON 4.7K 5% 1/4W F

(US,CND,AEP,UK,EE,CIS)

R254 1-249-420-11 CARBON 1.8K 5% 1/4W F

(US,CND)

R254 1-249-418-11 CARBON 1.2K 5% 1/4W F

(AEP,UK,EE,CIS)

R255 1-249-413-11 CARBON 470 5% 1/4W F

R256 1-249-412-11 CARBON 390 5% 1/4W F

R257 1-249-412-11 CARBON 390 5% 1/4W F

R258 1-249-414-11 CARBON 560 5% 1/4W F

R259 1-249-415-11 CARBON 680 5% 1/4W F

– 52 –

< CAPACITOR >

C307 1-102-074-00 CERAMIC 0.001uF 10% 50V

C308 1-102-074-00 CERAMIC 0.001uF 10% 50V

C309 1-124-907-11 ELECT 10uF 20% 50V

C310 1-126-963-11 ELECT 4.7uF 20% 50V

C311 1-161-772-11 CERAMIC 0.1uF 10% 25V

C312 1-161-772-11 CERAMIC 0.1uF 10% 25V

C313 1-126-963-11 ELECT 4.7uF 20% 50V

C314 1-126-963-11 ELECT 4.7uF 20% 50V

C315 1-124-907-11 ELECT 10uF 20% 50V

C316 1-124-907-11 ELECT 10uF 20% 50V

C317 1-124-443-00 ELECT 100uF 20% 10V

C318 1-124-443-00 ELECT 100uF 20% 10V

C319 1-102-114-00 CERAMIC 470PF 10% 50V

C320 1-102-114-00 CERAMIC 470PF 10% 50V

C351 1-137-378-11 FILM 0.22uF 5% 50V

C352 1-137-378-11 FILM 0.22uF 5% 50V

Page 37

FUN/SURROUND

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C353 1-137-378-11 FILM 0.22uF 5% 50V

C354 1-137-378-11 FILM 0.22uF 5% 50V

C355 1-137-371-11 FILM 0.015uF 5% 50V

C356 1-137-365-11 FILM 0.0015uF 5% 50V

R317 1-249-425-11 CARBON 4.7K 5% 1/4W F

R318 1-249-425-11 CARBON 4.7K 5% 1/4W F

R319 1-249-441-11 CARBON 100K 5% 1/4W

R320 1-249-441-11 CARBON 100K 5% 1/4W

RELAY

C357 1-130-489-00 MYLAR 0.033uF 5% 50V

C358 1-137-367-11 FILM 0.0033uF 5% 50V

C359 1-130-481-00 MYLAR 0.0068uF 5% 50V

C360 1-137-367-11 FILM 0.0033uF 5% 50V

C361 1-130-481-00 MYLAR 0.0068uF 5% 50V

C362 1-137-365-11 FILM 0.0015uF 5% 50V

C363 1-137-365-11 FILM 0.0015uF 5% 50V

C365 1-124-907-11 ELECT 10uF 20% 50V

C366 1-124-907-11 ELECT 10uF 20% 50V

C367 1-104-664-11 ELECT 47uF 20% 16V

C368 1-124-443-00 ELECT 100uF 20% 10V

C369 1-124-907-11 ELECT 10uF 20% 50V

C370 1-124-907-11 ELECT 10uF 20% 50V

C398 1-161-772-11 CERAMIC 0.1uF 10% 25V

< DIODE >

D351 8-719-920-76 DIODE 1S2076

D352 8-719-920-76 DIODE 1S2076

D353 8-719-920-76 DIODE 1S2076

< IC >

IC301 8-759-000-48 IC MC14052BCP

IC302 8-759-505-55 IC NJM4558L

IC351 8-759-497-89 IC TA-2041F

< JACK >

JK301 1-784-362-11 JACK, PIN 4P (MD IN/OUT)

< CONNECTOR >

M301 1-573-834-11 CONNECTOR, BOARD TO BOARD 20P

< TRANSISTOR >

Q301 8-729-231-55 TRANSISTOR 2SC2878-AB

Q302 8-729-231-55 TRANSISTOR 2SC2878-AB

Q303 8-729-201-53 TRANSISTOR 2SA1015-GR

< RESISTOR >

R301 1-249-417-11 CARBON 1K 5% 1/4W F

R302 1-249-417-11 CARBON 1K 5% 1/4W F

R303 1-249-417-11 CARBON 1K 5% 1/4W F

R304 1-249-417-11 CARBON 1K 5% 1/4W F

R305 1-249-417-11 CARBON 1K 5% 1/4W F

R306 1-249-417-11 CARBON 1K 5% 1/4W F

R307 1-249-425-11 CARBON 4.7K 5% 1/4W F

R308 1-249-425-11 CARBON 4.7K 5% 1/4W F

R309 1-249-421-11 CARBON 2.2K 5% 1/4W F

R310 1-249-421-11 CARBON 2.2K 5% 1/4W F

R311 1-249-441-11 CARBON 100K 5% 1/4W

R312 1-249-441-11 CARBON 100K 5% 1/4W

R313 1-249-441-11 CARBON 100K 5% 1/4W

R314 1-249-441-11 CARBON 100K 5% 1/4W

R315 1-249-441-11 CARBON 100K 5% 1/4W

R316 1-249-441-11 CARBON 100K 5% 1/4W

– 53 –

R321 1-247-903-00 CARBON 1M 5% 1/4W

R322 1-247-903-00 CARBON 1M 5% 1/4W

R323 1-249-417-11 CARBON 1K 5% 1/4W F

R324 1-249-417-11 CARBON 1K 5% 1/4W F

R329 1-247-815-91 CARBON 220 5% 1/4W

R330 1-247-815-91 CARBON 220 5% 1/4W

R335 1-249-425-11 CARBON 4.7K 5% 1/4W F

R336 1-249-425-11 CARBON 4.7K 5% 1/4W F

R337 1-249-417-11 CARBON 1K 5% 1/4W F

R338 1-249-417-11 CARBON 1K 5% 1/4W F

R339 1-249-441-11 CARBON 100K 5% 1/4W

R340 1-249-441-11 CARBON 100K 5% 1/4W

R341 1-249-437-11 CARBON 47K 5% 1/4W

R342 1-249-437-11 CARBON 47K 5% 1/4W

R343 1-249-425-11 CARBON 4.7K 5% 1/4W F

R344 1-249-425-11 CARBON 4.7K 5% 1/4W F

R345 1-249-437-11 CARBON 47K 5% 1/4W

R346 1-249-437-11 CARBON 47K 5% 1/4W

R347 1-249-425-11 CARBON 4.7K 5% 1/4W F

R348 1-249-421-11 CARBON 2.2K 5% 1/4W F

R351 1-249-430-11 CARBON 12K 5% 1/4W

R352 1-249-430-11 CARBON 12K 5% 1/4W

R353 1-249-431-11 CARBON 15K 5% 1/4W

R354 1-249-431-11 CARBON 15K 5% 1/4W

R355 1-249-429-11 CARBON 10K 5% 1/4W

R356 1-249-432-11 CARBON 18K 5% 1/4W

R357 1-249-425-11 CARBON 4.7K 5% 1/4W F

R358 1-249-425-11 CARBON 4.7K 5% 1/4W F

R359 1-249-437-11 CARBON 47K 5% 1/4W

R360 1-249-437-11 CARBON 47K 5% 1/4W

R361 1-249-417-11 CARBON 1K 5% 1/4W F

R362 1-249-417-11 CARBON 1K 5% 1/4W F

R363 1-249-429-11 CARBON 10K 5% 1/4W

R364 1-249-429-11 CARBON 10K 5% 1/4W

R367 1-249-417-11 CARBON 1K 5% 1/4W F

R368 1-249-417-11 CARBON 1K 5% 1/4W F

R369 1-249-421-11 CARBON 2.2K 5% 1/4W F

R370 1-249-421-11 CARBON 2.2K 5% 1/4W F

! R551 1-202-725-00 SOLID 3.3M 10% 1/2W

(US,CND)

**************************************************************

* A-4407-245-A RELAY BOARD, COMPLETE

**********************

< CAPACITOR >

C210 1-161-051-00 CERAMIC 0.01uF 10% 50V

C211 1-126-941-11 ELECT 470uF 20% 16V

C214 1-124-472-11 ELECT 470uF 20% 10V

C215 1-102-106-00 CERAMIC 100PF 10% 50V

C216 1-102-106-00 CERAMIC 100PF 10% 50V

C217 1-161-051-00 CERAMIC 0.01uF 10% 50V

C218 1-124-472-11 ELECT 470uF 20% 10V

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

Page 38

RELAY

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C229 1-102-074-00 CERAMIC 0.001uF 10% 50V

C235 1-126-233-11 ELECT 22uF 20% 50V

C236 1-126-233-11 ELECT 22uF 20% 50V

C241 1-102-125-00 CERAMIC 4700PF 10% 50V

C242 1-102-125-00 CERAMIC 4700PF 10% 50V

C245 1-161-772-11 CERAMIC 0.1uF 10% 25V

C246 1-126-942-61 ELECT 1000uF 20% 16V

C789 1-161-051-00 CERAMIC 0.01uF 10% 50V

C797 1-161-051-00 CERAMIC 0.01uF 10% 50V

C799 1-161-051-00 CERAMIC 0.01uF 10% 50V

CNU102 1-770-067-11 CONNECTOR, FFC/FPC 19P

D200 8-719-911-55 DIODE U05G

D206 8-719-911-55 DIODE U05G

D207 8-719-911-55 DIODE U05G

D208 8-719-920-76 DIODE 1S2076

D209 8-719-920-76 DIODE 1S2076

D770 8-719-911-55 DIODE U05G

D771 8-719-911-55 DIODE U05G

TAPE PREAMP

< CONNECTOR >

< DIODE >

R235 1-249-429-11 CARBON 10K 5% 1/4W

R236 1-249-429-11 CARBON 10K 5% 1/4W

! R237 1-212-966-00 FUSIBLE 22 5% 1/2W F

R245 1-249-429-11 CARBON 10K 5% 1/4W

R265 1-249-429-11 CARBON 10K 5% 1/4W

R266 1-249-429-11 CARBON 10K 5% 1/4W

R267 1-249-429-11 CARBON 10K 5% 1/4W

R268 1-249-429-11 CARBON 10K 5% 1/4W

R271 1-249-429-11 CARBON 10K 5% 1/4W

R288 1-249-429-11 CARBON 10K 5% 1/4W

R289 1-249-429-11 CARBON 10K 5% 1/4W

R291 1-249-429-11 CARBON 10K 5% 1/4W

R295 1-249-415-11 CARBON 680 5% 1/4W F

R296 1-249-415-11 CARBON 680 5% 1/4W F

R298 1-249-435-11 CARBON 33K 5% 1/4W

R299 1-249-435-11 CARBON 33K 5% 1/4W

R771 1-249-425-11 CARBON 4.7K 5% 1/4W F

R772 1-249-434-11 CARBON 27K 5% 1/4W

R773 1-247-856-00 CARBON 11K 5% 1/4W

R774 1-249-430-11 CARBON 12K 5% 1/4W

R775 1-249-430-11 CARBON 12K 5% 1/4W

R776 1-249-418-11 CARBON 1.2K 5% 1/4W F

R777 1-249-418-11 CARBON 1.2K 5% 1/4W F

< COIL >

L203 1-408-096-00 INDUCTOR 470uH

< CONNECTOR >

* M704 1-564-715-11 PIN, CONNECTOR (SMALL TYPE)13P

< TRANSISTOR >

Q202 8-729-029-86 TRANSISTOR DTC124ESA

Q203 8-729-200-36 TRANSISTOR 2SA966-Y

Q213 8-729-029-86 TRANSISTOR DTC124ESA

Q214 8-729-029-86 TRANSISTOR DTC124ESA

Q215 8-729-029-86 TRANSISTOR DTC124ESA

Q770 8-729-200-36 TRANSISTOR 2SA966-Y

Q771 8-729-200-36 TRANSISTOR 2SA966-Y

Q772 8-729-029-86 TRANSISTOR DTC124ESA

Q773 8-729-029-86 TRANSISTOR DTC124ESA

< RESISTOR >

R206 1-249-430-11 CARBON 12K 5% 1/4W

R207 1-249-418-11 CARBON 1.2K 5% 1/4W F

R213 1-247-807-31 CARBON 100 5% 1/4W

R214 1-247-807-31 CARBON 100 5% 1/4W

R215 1-247-807-31 CARBON 100 5% 1/4W

R217 1-247-807-31 CARBON 100 5% 1/4W

R218 1-247-807-31 CARBON 100 5% 1/4W

R219 1-247-807-31 CARBON 100 5% 1/4W

R220 1-247-807-31 CARBON 100 5% 1/4W

R221 1-247-807-31 CARBON 100 5% 1/4W

R224 1-247-843-11 CARBON 3.3K 5% 1/4W

R231 1-249-429-11 CARBON 10K 5% 1/4W

R232 1-249-439-11 CARBON 68K 5% 1/4W

R233 1-249-429-11 CARBON 10K 5% 1/4W

R234 1-249-429-11 CARBON 10K 5% 1/4W

< VARIABLE RESISTOR >

VR770 1-230-497-11 RES, ADJ, CARBON 22K

< CONNECTOR >

* W103 1-564-704-11 PIN, CONNECTOR (SMALL TYPE) 2P

W201 1-784-351-11 CONNECTOR 12P

W202 1-784-350-11 CONNECTOR 10P

W203 1-784-352-11 CONNECTOR 25P

W301 1-573-852-11 CONNECTOR, BOARD TO BOARD 20P

W703 1-766-718-11 CONNECTOR, BOARD TO BOARD 17P

W901 1-766-718-11 CONNECTOR, BOARD TO BOARD 17P

**************************************************************

* A-4407-243-A TAPE PREAMP BOARD, COMPLETE

****************************

* 4-997-378-01 PC BOARD BRACKET

7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

< CAPACITOR >

C483 1-161-051-00 CERAMIC 0.01uF 10% 50V

C484 1-161-051-00 CERAMIC 0.01uF 10% 50V

C700 1-161-051-00 CERAMIC 0.01uF 10% 50V

C703 1-102-113-00 CERAMIC 390PF 10% 50V

C704 1-102-113-00 CERAMIC 390PF 10% 50V

C705 1-104-666-11 ELECT 220uF 20% 10V

C706 1-104-666-11 ELECT 220uF 20% 10V

C707 1-102-106-00 CERAMIC 100PF 10% 50V

C708 1-102-106-00 CERAMIC 100PF 10% 50V

C709 1-137-372-11 FILM 0.022uF 5% 50V

C710 1-137-372-11 FILM 0.022uF 5% 50V

C711 1-124-907-11 ELECT 10uF 20% 50V

C712 1-124-907-11 ELECT 10uF 20% 50V

– 54 –

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

Page 39

TAPE PREAMP

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C713 1-124-443-00 ELECT 100uF 20% 10V

C714 1-104-665-11 ELECT 100uF 20% 16V

C715 1-124-443-00 ELECT 100uF 20% 10V

C716 1-137-399-11 FILM 0.1uF 5% 50V

C717 1-124-907-11 ELECT 10uF 20% 50V

C719 1-161-051-00 CERAMIC 0.01uF 10% 50V

C720 1-161-051-00 CERAMIC 0.01uF 10% 50V

C721 1-102-981-00 CERAMIC 300PF 5% 50V

C722 1-102-981-00 CERAMIC 300PF 5% 50V

C723 1-102-112-00 CERAMIC 330PF 10% 50V

C724 1-102-112-00 CERAMIC 330PF 10% 50V

C725 1-102-112-00 CERAMIC 330PF 10% 50V

* M701 1-564-709-11 PIN, CONNECTOR (SMALL TYPE) 7P

* M703 1-766-720-21 CONNECTOR, BOARD TO BOARD 17P

Q702 8-729-194-57 TRANSISTOR 2SC945-P

Q704 8-729-194-57 TRANSISTOR 2SC945-P

Q705 8-729-194-57 TRANSISTOR 2SC945-P

Q706 8-729-141-83 TRANSISTOR 2SB1094-LK

Q707 8-729-194-57 TRANSISTOR 2SC945-P

< CONNECTOR >

< TRANSISTOR >

< RESISTOR >

C726 1-102-112-00 CERAMIC 330PF 10% 50V

C727 1-104-993-91 FILM 0.01uF 5% 200V

C728 1-124-907-11 ELECT 10uF 20% 50V

C729 1-137-371-11 FILM 0.015uF 5% 50V

C730 1-137-367-11 FILM 0.0033uF 5% 50V

C731 1-137-367-11 FILM 0.0033uF 5% 50V

C732 1-137-367-11 FILM 0.0033uF 5% 50V

C741 1-124-907-11 ELECT 10uF 20% 50V

C742 1-124-907-11 ELECT 10uF 20% 50V

C743 1-137-368-11 FILM 0.0047uF 5% 50V

C744 1-137-368-11 FILM 0.0047uF 5% 50V

C745 1-102-125-00 CERAMIC 4700PF 10% 50V

C746 1-102-125-00 CERAMIC 4700PF 10% 50V

C747 1-137-399-11 FILM 0.1uF 5% 50V

C748 1-137-399-11 FILM 0.1uF 5% 50V

C749 1-124-907-11 ELECT 10uF 20% 50V

C750 1-124-907-11 ELECT 10uF 20% 50V

C751 1-124-903-11 ELECT 1uF 20% 50V

C752 1-124-903-11 ELECT 1uF 20% 50V

C753 1-124-907-11 ELECT 10uF 20% 50V

C754 1-124-907-11 ELECT 10uF 20% 50V

C756 1-161-051-00 CERAMIC 0.01uF 10% 50V

C758 1-126-962-11 ELECT 3.3uF 20% 50V

C761 1-124-443-00 ELECT 100uF 20% 10V

C762 1-124-443-00 ELECT 100uF 20% 10V

R485 1-249-395-11 CARBON 15 5% 1/4W F

R486 1-249-395-11 CARBON 15 5% 1/4W F

R701 1-247-807-31 CARBON 100 5% 1/4W

R702 1-247-807-31 CARBON 100 5% 1/4W

R703 1-247-889-00 CARBON 270K 5% 1/4W

R704 1-247-889-00 CARBON 270K 5% 1/4W

R705 1-249-404-00 CARBON 82 5% 1/4W F

R706 1-249-404-00 CARBON 82 5% 1/4W F

R707 1-247-863-91 CARBON 22K 5% 1/4W

R708 1-247-863-91 CARBON 22K 5% 1/4W

R709 1-247-882-11 CARBON 130K 5% 1/4W

R710 1-247-882-11 CARBON 130K 5% 1/4W

R711 1-247-850-11 CARBON 6.2K 5% 1/4W

R712 1-247-850-11 CARBON 6.2K 5% 1/4W

R713 1-247-815-91 CARBON 220 5% 1/4W

R714 1-247-815-91 CARBON 220 5% 1/4W

R715 1-249-437-11 CARBON 47K 5% 1/4W

R716 1-247-815-91 CARBON 220 5% 1/4W

R717 1-249-430-11 CARBON 12K 5% 1/4W

R718 1-249-430-11 CARBON 12K 5% 1/4W

R719 1-249-389-11 CARBON 4.7 5% 1/4W F

R720 1-249-389-11 CARBON 4.7 5% 1/4W F

R721 1-247-863-91 CARBON 22K 5% 1/4W

R722 1-247-863-91 CARBON 22K 5% 1/4W

R723 1-249-381-11 CARBON 1 5% 1/4W F

C798 1-161-772-11 CERAMIC 0.1uF 10% 25V

C799 1-102-074-00 CERAMIC 0.001uF 10% 50V

C801 1-124-907-11 ELECT 10uF 20% 50V

C802 1-161-772-11 CERAMIC 0.1uF 10% 25V

< IC >

IC701 8-759-508-69 IC BA3126N

IC702 8-759-261-93 IC NJM4580LD

IC703 8-759-363-21 IC HA12203NT

JK800 8-749-923-04 IC TOTX178 (OPTICAL)

< JACK >

JK900 1-784-361-11 JACK (SMALL TYPE)(2)

< COIL >

L701 1-410-774-11 INDUCTOR 8.2mH

L702 1-410-774-11 INDUCTOR 8.2mH

L703 1-431-707-11 TRANSFORMER, BIAS OSCILLATION

L704 1-410-521-11 INDUCTOR 100uH

R724 1-247-863-91 CARBON 22K 5% 1/4W

R725 1-249-429-11 CARBON 10K 5% 1/4W

R741 1-249-435-11 CARBON 33K 5% 1/4W

R742 1-247-863-91 CARBON 22K 5% 1/4W

R743 1-249-417-11 CARBON 1K 5% 1/4W F

R744 1-249-417-11 CARBON 1K 5% 1/4W F

R745 1-249-426-11 CARBON 5.6K 5% 1/4W

R746 1-249-426-11 CARBON 5.6K 5% 1/4W

R749 1-249-441-11 CARBON 100K 5% 1/4W

R750 1-247-891-00 CARBON 330K 5% 1/4W

R751 1-249-429-11 CARBON 10K 5% 1/4W

R752 1-249-434-11 CARBON 27K 5% 1/4W

R753 1-249-429-11 CARBON 10K 5% 1/4W

R754 1-249-426-11 CARBON 5.6K 5% 1/4W

R757 1-249-429-11 CARBON 10K 5% 1/4W

R758 1-247-840-00 CARBON 2.4K 5% 1/4W

R759 1-249-432-11 CARBON 18K 5% 1/4W

R760 1-247-840-00 CARBON 2.4K 5% 1/4W

R761 1-247-866-11 CARBON 30K 5% 1/4W

R762 1-247-866-11 CARBON 30K 5% 1/4W

– 55 –

Page 40

Ver 1.1 2001.06

TAPE PREAMP VOL/POWER

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R763 1-249-437-11 CARBON 47K 5% 1/4W

R765 1-249-437-11 CARBON 47K 5% 1/4W

R766 1-249-437-11 CARBON 47K 5% 1/4W

< VARIABLE RESISTOR >

C510 1-126-943-11 ELECT 2200uF 20% 25V

C511 1-126-951-11 ELECT 470uF 20% 35V

C512 1-126-924-11 ELECT 330uF 20% 10V

C513 1-126-924-11 ELECT 330uF 20% 10V

C514 1-126-933-11 ELECT 100uF 20% 16V

VR701 1-230-499-11 RES, ADJ, CARBON 100K

VR702 1-230-499-11 RES, ADJ, CARBON 100K

VR703 1-230-497-11 RES, ADJ, CARBON 22K

VR704 1-230-497-11 RES, ADJ, CARBON 22K

VR705 1-230-495-11 RES, ADJ, CARBON 2K

VR706 1-230-495-11 RES, ADJ, CARBON 2K

**************************************************************

* A-4407-239-A VOL/POWER BOARD, COMPLETE

**************************

(AEP,UK,EE,CIS)

* A-4407-240-A VOL/POWER BOARD, COMPLETE (US,CND)

***********************************

* A-4407-241-A VOL/POWER BOARD, COMPLETE (MY,SP,HK)

*************************************

1-533-293-11 FUSE HOLDER

* 4-997-378-01 PC BOARD BRACKET

7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

< CAPACITOR >

C403 1-136-173-00 FILM 0.47uF 5% 50V

C404 1-136-173-00 FILM 0.47uF 5% 50V

C461 1-126-960-11 ELECT 1uF 20% 50V

C462 1-126-960-11 ELECT 1uF 20% 50V

C463 1-137-364-11 FILM 0.001uF 5% 50V

C464 1-137-364-11 FILM 0.001uF 5% 50V

C465 1-137-378-11 FILM 0.22uF 5% 50V

C466 1-137-378-11 FILM 0.22uF 5% 50V

C469 1-126-933-11 ELECT 100uF 20% 16V

C470 1-126-925-11 ELECT 470uF 20% 10V

C515 1-126-933-11 ELECT 100uF 20% 16V

C516 1-162-851-11 CERAMIC 0.1uF 10% 16V

C517 1-162-851-11 CERAMIC 0.1uF 10% 16V

C518 1-162-851-11 CERAMIC 0.1uF 10% 16V

C519 1-126-923-11 ELECT 220uF 20% 10V

C520 1-126-923-11 ELECT 220uF 20% 10V

C521 1-162-851-11 CERAMIC 0.1uF 10% 16V

C522 1-126-924-11 ELECT 330uF 20% 10V

C523 1-126-924-11 ELECT 330uF 20% 10V

C525 1-126-924-11 ELECT 330uF 20% 10V

C526 1-126-924-11 ELECT 330uF 20% 10V

C527 1-162-851-11 CERAMIC 0.1uF 10% 16V

C528 1-126-924-11 ELECT 330uF 20% 10V

C529 1-126-933-11 ELECT 100uF 20% 16V

C530 1-162-851-11 CERAMIC 0.1uF 10% 16V

C531 1-162-851-11 CERAMIC 0.1uF 10% 16V

C532 1-126-933-11 ELECT 100uF 20% 16V

C999 1-161-772-11 CERAMIC 0.1uF 10% 25V

< DIODE >

D401 8-719-920-76 DIODE 1S2076

D402 8-719-920-76 DIODE 1S2076

D487 8-719-200-02 DIODE 10E2

D502 8-719-067-67 DIODE W02G

D503 8-719-001-64 DIODE UZL-12L2

D504 8-719-910-25 DIODE HZ12B2L

D506 8-719-001-85 DIODE UZL-12H3

D507 8-719-001-76 DIODE UZL-12M3

D508 8-719-001-42 DIODE UZL-11M1

D5098-719-935-81DIODE UZL-7L2

D510 8-719-200-02 DIODE 10E2

D511 8-719-920-76 DIODE 1S2076

C471 1-162-851-11 CERAMIC 0.1uF 10% 16V

C475 1-126-964-11 ELECT 10uF 20% 50V

C476 1-126-964-11 ELECT 10uF 20% 50V

C477 1-137-399-11 FILM 0.1uF 5% 50V

C478 1-137-399-11 FILM 0.1uF 5% 50V

C479 1-126-948-11 ELECT 100uF 20% 35V

C480 1-126-948-11 ELECT 100uF 20% 35V

C481 1-102-106-00 CERAMIC 100PF 10% 50V

C482 1-102-106-00 CERAMIC 100PF 10% 50V

C483A 1-124-443-00 ELECT 100uF 20% 10V

C485 1-102-106-00 CERAMIC 100PF 10% 50V

C486 1-102-106-00 CERAMIC 100PF 10% 50V

C488 1-126-924-11 ELECT 330uF 20% 10V

C489 1-161-063-00 CERAMIC 0.1uF 10% 50V

C490 1-126-963-11 ELECT 4.7uF 20% 50V

C491 1-126-963-11 ELECT 4.7uF 20% 50V

C502 1-102-129-00 CERAMIC 0.01uF 10% 50V

C503 1-102-129-00 CERAMIC 0.01uF 10% 50V

C508 1-126-964-11 ELECT 10uF 20% 50V

C509 1-126-947-11 ELECT 47uF 20% 35V

< FUSE >

! F501 1-532-350-11 FUSE, TIME-LAG (T4AL 250V)

(AEP,UK,EE,CIS,MY,SP,HK)

! F501 1-532-746-11 FUSE, GLASS TUBE (4A 125V)(US,CND)

! F502 1-532-259-11 FUSE, TIME-LAG (T1.6AL 250V)

(AEP,UK,EE,CIS,MY,SP,HK)

! F502 1-532-742-11 FUSE, GLASS TUBE (1.6A 125V)(US,CND)

! F503 1-532-259-11 FUSE, TIME-LAG (T1.6AL 250V)

(AEP,UK,EE,CIS,MY,SP,HK)

! F503 1-532-742-11 FUSE, GLASS TUBE (1.6A 125V)(US,CND)

! F504 1-532-350-11 FUSE, TIME-LAG (T4AL 250V)

(AEP,UK,EE,CIS,MY,SP,HK)

! F504 1-532-746-11 FUSE, GLASS TUBE (4A 125V)(US,CND)

< IC >

IC461 8-759-497-88 IC TC9260P

IC472 8-759-261-93 IC NJM4580LD

IC501 8-759-701-57 IC NJM78M06FA

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

– 56 –

Page 41

VOL/POWER

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< JACK >

JK901 1-784-353-11 JACK (DIN)(SPEAKER L)

JK902 1-784-353-11 JACK (DIN)(SPEAKER R)

< CONNECTOR >

M501 1-564-234-11 PLUG, CONNECTOR (PIN CONTACT)8P

* M901 1-766-720-21 CONNECTOR, BOARD TO BOARD 17P

M902 1-564-707-11 PIN, CONNECTOR (SMALL TYPE) 5P

< TRANSISTOR >

Q486 8-729-201-53 TRANSISTOR 2SA1015-GR

Q487 8-729-231-55 TRANSISTOR 2SC2878-AB

Q488 8-729-231-55 TRANSISTOR 2SC2878-AB

Q501 8-729-281-53 TRANSISTOR 2SC1815-GR

Q502 8-729-201-53 TRANSISTOR 2SA1015-GR

Q503 8-729-201-53 TRANSISTOR 2SA1015-GR

Q504 8-729-209-15 TRANSISTOR 2SD2012

Q505 4-997-377-01 ISOLATION FILM

Q505 8-729-017-51 TRANSISTOR 2SB632K-E

Q506 8-729-281-53 TRANSISTOR 2SC1815-GR

Q507 4-997-377-01 ISOLATION FILM

Q507 8-729-188-23 TRANSISTOR 2SD882-P

Q508 4-997-377-01 ISOLATION FILM

Q508 8-729-188-23 TRANSISTOR 2SD882-P

Q509 4-997-377-01 ISOLATION FILM

Q509 8-729-188-23 TRANSISTOR 2SD882-P

Q510 8-729-017-51 TRANSISTOR 2SB632K-E

Q511 8-729-201-53 TRANSISTOR 2SA1015-GR

Q512 8-729-265-52 TRANSISTOR 2SC2655

R492 1-247-843-11 CARBON 3.3K 5% 1/4W

R493 1-249-437-11 CARBON 47K 5% 1/4W

R494 1-249-437-11 CARBON 47K 5% 1/4W

R495 1-249-425-11 CARBON 4.7K 5% 1/4W F

R496 1-249-425-11 CARBON 4.7K 5% 1/4W F

R497 1-249-441-11 CARBON 100K 5% 1/4W

R498 1-249-441-11 CARBON 100K 5% 1/4W

R499 1-247-895-91 CARBON 470K 5% 1/4W

! R501 1-213-044-51 FUSIBLE 2.2 5% 1W F

! R502 1-212-946-11 FUSIBLE 3.3 5% 1/2W F

R503 1-249-429-11 CARBON 10K 5% 1/4W

R504 1-249-421-11 CARBON 2.2K 5% 1/4W F

R505 1-247-863-91 CARBON 22K 5% 1/4W

R506 1-249-429-11 CARBON 10K 5% 1/4W

R507 1-249-437-11 CARBON 47K 5% 1/4W

R508 1-249-437-11 CARBON 47K 5% 1/4W

R509 1-247-807-31 CARBON 100 5% 1/4W

! R510 1-215-869-11 METAL OXIDE 1K 5% 1W F

R511 1-247-863-91 CARBON 22K 5% 1/4W

R512 1-249-431-11 CARBON 15K 5% 1/4W

! R514 1-212-853-00 FUSIBLE 6.8 5% 1/4W F

! R515 1-213-048-00 FUSIBLE 3.3 5% 1W F

R516 1-249-413-11 CARBON 470 5% 1/4W F

! R517 1-213-064-51 FUSIBLE 15 5% 1W F

R518 1-249-413-11 CARBON 470 5% 1/4W F

! R519 1-212-946-11 FUSIBLE 3.3 5% 1/2W F

R520 1-249-413-11 CARBON 470 5% 1/4W F

R521 1-249-413-11 CARBON 470 5% 1/4W F

R524 1-249-381-11 CARBON 1 5% 1/4W F

R525 1-247-887-00 CARBON 220K 5% 1/4W

< RESISTOR >

R457 1-247-863-91 CARBON 22K 5% 1/4W

R458 1-247-863-91 CARBON 22K 5% 1/4W

R461 1-249-429-11 CARBON 10K 5% 1/4W

R462 1-249-429-11 CARBON 10K 5% 1/4W

R463 1-247-895-91 CARBON 470K 5% 1/4W

R464 1-247-895-91 CARBON 470K 5% 1/4W

R465 1-249-425-11 CARBON 4.7K 5% 1/4W F

R466 1-247-815-91 CARBON 220 5% 1/4W

R467 1-249-429-11 CARBON 10K 5% 1/4W

R468 1-249-429-11 CARBON 10K 5% 1/4W

R469 1-249-429-11 CARBON 10K 5% 1/4W

R470 1-249-425-11 CARBON 4.7K 5% 1/4W F

R471 1-249-417-11 CARBON 1K 5% 1/4W F

R472 1-249-417-11 CARBON 1K 5% 1/4W F