Sony HCD-DZ556KB, HCD-DZ750K Service Manual

HCD-DZ555K/DZ556KB/

Amplifier section

Stereo mode (rated) 108 W + 108 W (at 3 ohms,

1 kHz, 1 % THD)

Surround mode (reference)

RMS output power

FL/FR/C/SL/SR*: 142 watts

(per channel at 3 ohms,

1 kHz, 10 % THD)

Subwoofer*: 140 watts (at

3 ohms, 80 Hz, 10 % THD)

*Depending on the sound field settings and the source,

there may be no sound output.

Inputs (Analog)

TV/VIDEO (AUDIO IN) Sensitivity: 450/250 mV

AUDIO IN/MIC 1 Sensitivity:

AUDIO IN 250/125 mV/

MIC 1 1 mV

MIC 2 Sensitivity: 1 mV

DVD system

Laser Semiconductor laser

(DVD: λ = 650 nm)

(CD: λ = 790 nm)

Emission duration:

continuous

Signal format system

Mexican and Latin American models:

NTSC

Other models: NTSC/PAL

Tuner section

System PLL quartz-locked digita l

synthesizer

FM tuner section

Tuning range 87.5-108.0 MHz (50 kHz

step)

Antenna (aerial) FM wire antenna (ae r ial)

Antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

Mexican, and Latin American models:

530 – 1,710 kHz (with the

interval set at 10 kHz)

531 – 1,710 kHz (with the

interval set at 9 kHz)

Middle Eastern models: 531 – 1,602 kHz (with the

interval set at 9 kHz)

Australian and New Zealand models:

531 – 1,710 kHz (with the

interval set at 9 kHz)

530 – 1,710 kHz (with the

interval set at 10 kHz)

Other models: 531 – 1,602 kHz (with the

interval set at 9 kHz)

530 – 1,610 kHz (with the

interval set at 10 kHz)

Antenna (aerial) AM loop antenna (aerial)

Intermediate frequency 450 kHz

Video section

Outputs VIDEO: 1 Vp-p 75 ohms

S VIDEO:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

HDMI OUT: Type A (19

pin)

DZ750K model:

DZ555K/DZ556KB models:

RMS output power

FL/FR/C/SL/SR*: 143 watts

(per chan nel at 3 ohms, 1

kHz, 10 % THD)

Subwoofer*: 285 watts (at

1.5 ohms, 80 Hz, 10 %

THD)

DZ750K

SERVICE MANUAL

Ver. 1.1 2007.05

Photo : HCD-DZ750K

HCD-DZ555K/DZ556KB/DZ750K are the amplifier, DVD/CD

and tuner section in DAV-DZ555K/DZ556KB/DZ750K.

This system incorporates with Dolby* Digital and Dolby Pro Logic (II)

adaptive matrix surround decoder and the DTS** Digital Surround System.

* Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic”, and the double-D symbol are trademarks of

Dolby Laboratories.

** Manufactured under license from DTS, Inc.

“DTS” and “DTS Digital Surround” are registered trademarks of DTS,

Inc.

SPECIFICATIONS

E Model

HCD-DZ555K/DZ556KB/DZ750K

Australian Model

HCD-DZ555K/DZ750K

Model Name Using Similar Mechanism HCD-DZ150K

Mechanism T ype CDM85-DVBU102

Optical Pick-up Name

KHM-313CAA/C2RP

9-887-602-02

2007E16-1

© 2007.05

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

— Continued on next page —

DVD RECEIVER

HCD-DZ555K/DZ556KB/DZ750K

Ver. 1.1

General

Power requirements

Mexican models: 120 V AC, 60 Hz

Latin American models: 11 0 - 240 V AC, 50/ 60 Hz

Saudi Arabian models: 127 - 240 V AC, 50/60 Hz

Other models: 220 - 240 V AC, 50/60 Hz

Power output (DIGITAL MEDIA PORT)

DC OUT: 5 V, 700 mA

(except for Mexican and

LaLatin American models)

Power consumption

DZ556KB model:

tin American and Saudi Arabian mod els:

On: 165 W

Standby: 0.3 W (at the

Power Saving mode)

Other models: On: 150 W

Standby: 0.3 W (at the

Power Saving mode)

DZ750K model:

On: 160 W

Standby: 0.3 W (at the

Power Saving mode)

Dimensions (approx.) 430 ×63 × 380 mm (w/h/d)

incl. projecting parts

Mass (approx.) DZ555K/DZ556KB: 4.1 kg

DZ750K: 4.2 kg

Design and specifications are subject to change

without notice.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

This marking is located on

the rear exterior.

(Except for Korean model)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

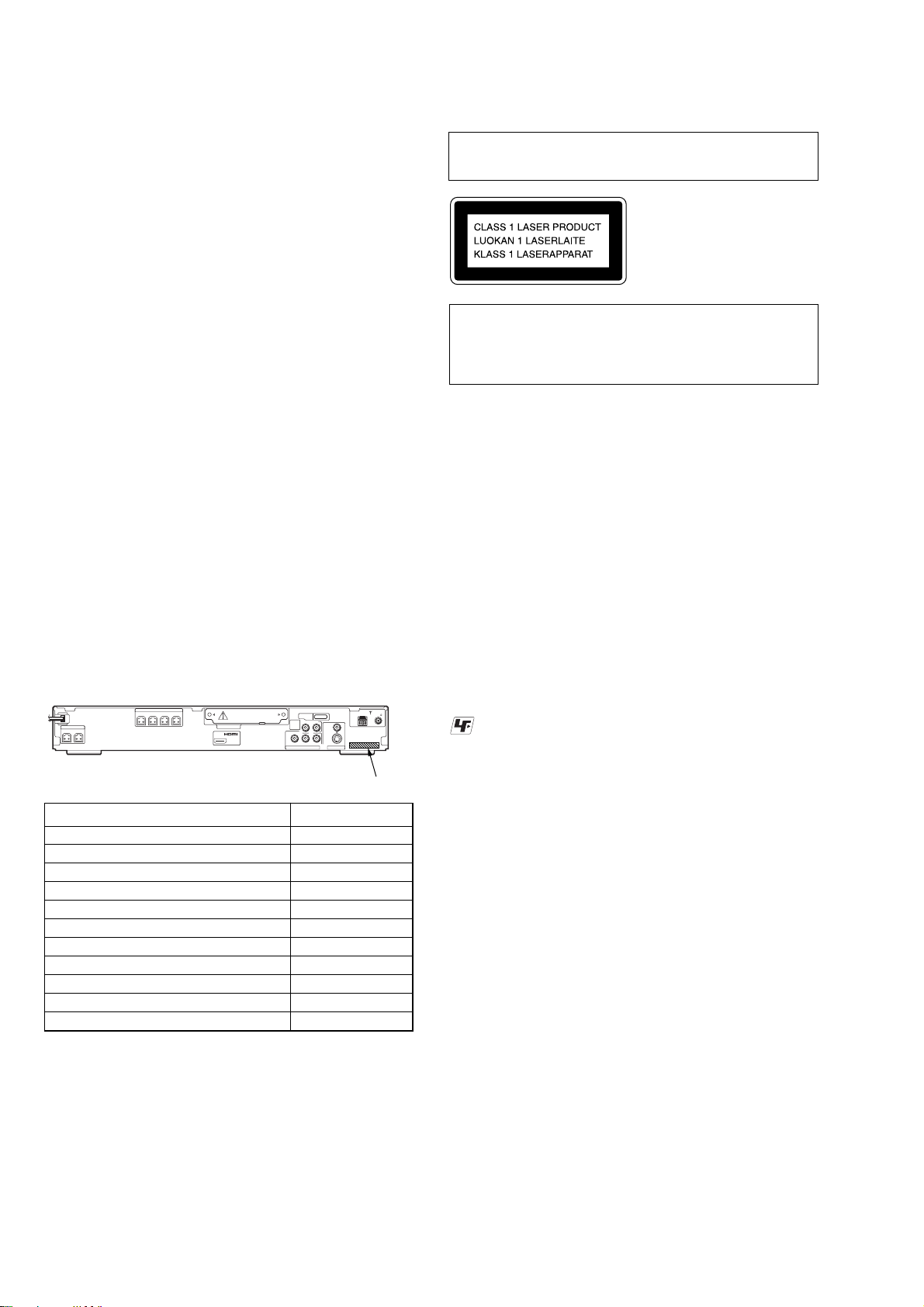

MODEL IDENTIFICATION

– Rear Panel –

SPEAKER

FRONT R

SPEAKER

CENTER WOOFER

FRONT L SUR R SUR L

DIR-TC1

OUT

(DVD ONLY)

(DVD ONLY)

TV /

VIDEO

YPB/CBPR/C

DMPORT

RLAUDIO IN

Model Part No.

DZ555K: SP model 2-896-163-0[]

DZ555K: AUS model 2-896-163-3[]

DZ555K: KR model 2-896-163-4[]

DZ556KB: E3 model 3-094-633-3[]

DZ556KB: MX model 3-094-633-4[]

DZ556KB: E32 model 3-094-633-6[]

DZ556KB: E12 model 3-094-633-7[]

DZ556KB: EA model 3-095-152-5[]

DZ750K: E3 model 2-896-163-6[]

DZ750K: SP model 2-896-163-7[]

DZ750K: AUS model 2-896-163-9[]

•Abbreviation

AUS:Australian model

E3 : 220 – 240V AC area in E model

E12 : 220 – 240V AC area in E model

E32 : 110 – 240V AC area in E model

EA : Saudi Arabia model

KR : Korean model

MX : Mexican model

SP : Singapore model

AM

VIDEO

S VIDEO

(DVD ONLY)

R

MONITOR OUTCOMPONENT VIDEO OUT

Parts No.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

COAXIAL

FM75

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

Special Component Notice

The components identified by mark 9 contain confidential

information.

Strictly follow the instructions whenever the components are repaired

and/or replaced.

2

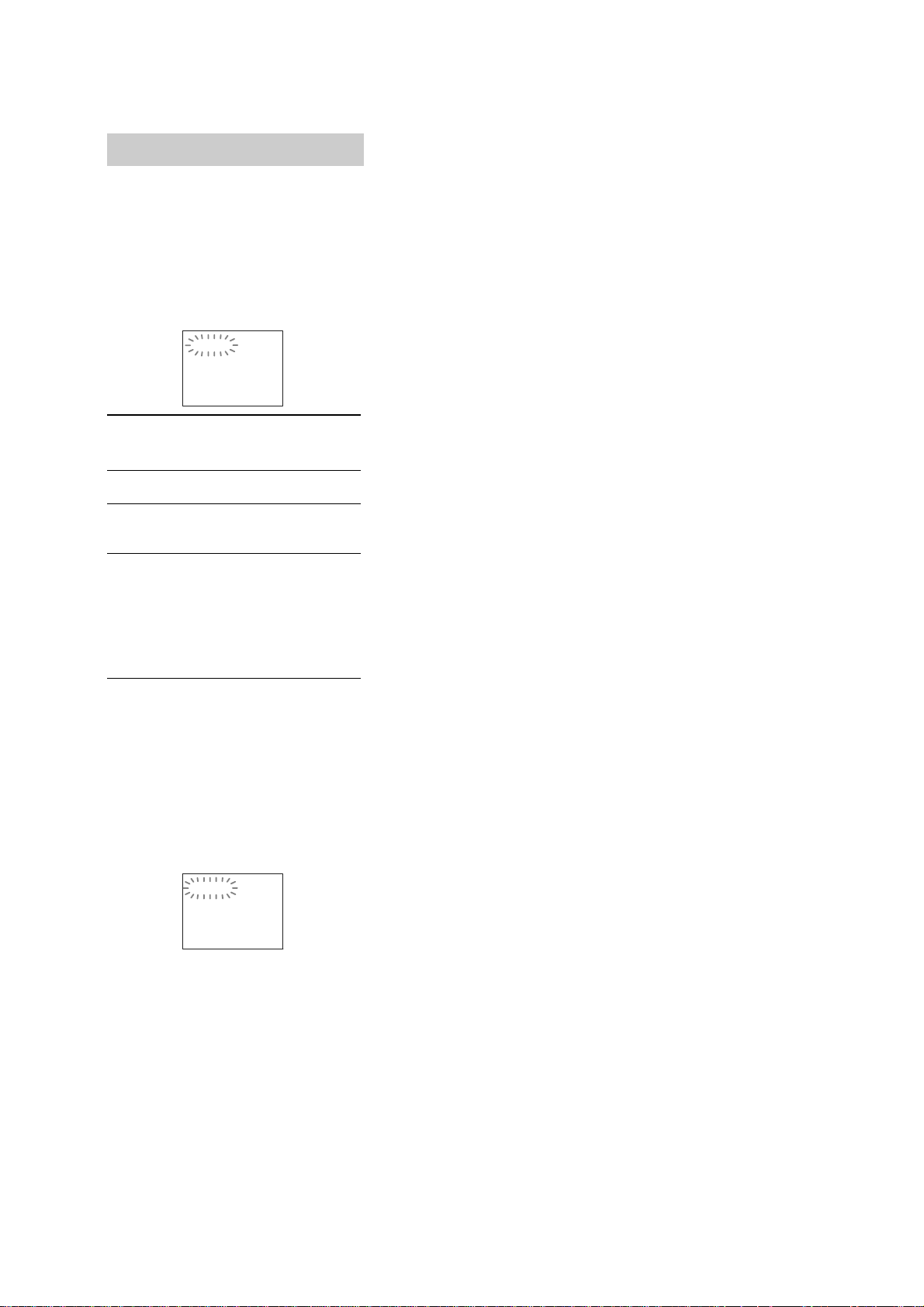

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the self-diagnosis function is activated to

prevent the system from malfunctioning, a 5character service number (e.g., C 13 50) with a

combination of a letter and 4 digits appears on

the screen and the front panel display. In this

case, check the following table.

C:13:50

HCD-DZ555K/DZ556KB/DZ750K

First 3

characters of

the service

number

C 13 The disc is dirty.

C 31 The disc is not inserted correctly.

E XX

(xx is a number)

Cause and/or corrective action

,Clean the disc with a soft cloth

,Restart the system, then re-insert

the disc correctly.

To prevent a malfunction, the

system has performed the selfdiagnosis function.

,Contact your nearest Sony

dealer or local authorized Sony

service facility and give the 5character service number.

Example: E 61 10

When displaying the version

number on the TV screen

When you turn on the system, the version

number [VER.X.XX] (X is a number) may

appear on the TV scree n. A lthough this is not a

malfunction and for Sony service use on ly,

normal system operation will not be possible.

Turn off the system, a nd the n turn o n the system

again to operate.

VER.X.XX

3

HCD-DZ555K/DZ556KB/DZ750K

Ver. 1.1

TABLE OF CONTENTS

1. SERVICING NOTE ................................................... 5

2. GENERAL ................................................................... 9

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 12

3-2. Case (DS), Front Panel Assy ........................................... 13

3-3. FL Board.......................................................................... 14

3-4. JACK Board, P-SW Board (DZ555K/DZ556KB) .......... 15

3-5. JACK Board, P-SW Board (DZ750K) ............................ 15

3-6. Front Panel, Ornament (DZ750K)................................... 16

3-7. Tuner (FM/AM) ............................................................... 16

3-8. DMPORT Board (Except MX, E32) ............................... 17

3-9. DIAT-CON Board ............................................................ 17

3-10. IO-S-OUT Board ............................................................. 18

3-11. POWER Board ................................................................ 18

3-12. SPEAKER Board, D.C. Fan ............................................ 19

3-13. MAIN Board (DZ555K/DZ556KB) ................................ 20

3-14. MAIN Board (DZ750K) .................................................. 21

3-15. DVD Mechanism Deck (CDM85-DVBU102) ................ 22

3-16. Tray.................................................................................. 22

3-17. Belt, MS-203 BOARD .................................................... 23

3-18. Optical Pick-up (KHM-313CAA) ................................... 24

4. TEST MODE ............................................................... 25

5. ELECTRICAL ADJUSTMENT ............................. 30

6. DIAGRAMS

6-1. Block Diagram – RF/VIDEO Section – ......................... 32

6-2. Block Diagram – AUDIO/AMP Section – ...................... 33

6-3. Block Diagram – POWER Section – ............................... 34

6-4. Printed Wiring Board – MAIN Board (Side A) –........... 35

6-5. Printed Wiring Board – MAIN Board (Side B) – ........... 36

6-6. Schematic Diagram – MAIN Board (1/10) – ................. 37

6-7. Schematic Diagram – MAIN Board (2/10) – ................. 38

6-8. Schematic Diagram – MAIN Board (3/10) – ................. 39

6-9. Schematic Diagram – MAIN Board (4/10) – ................. 40

6-10. Schematic Diagram – MAIN Board (5/10) – ................. 41

6-11. Schematic Diagram – MAIN Board (6/10) – ................. 42

6-12. Schematic Diagram – MAIN Board (7/10) – ................. 43

6-13. Schematic Diagram – MAIN Board (8/10) – ................. 44

6-14. Schematic Diagram – MAIN Board (9/10) – ................. 45

6-15. Schematic Diagram – MAIN Board (10/10) – ............... 46

6-16. Printed Wiring Board – IO-S-OUT Board – .................. 47

6-17. Schematic Diagram – IO-S-OUT Board – ..................... 48

6-18. Printed Wiring Board – DIAT-CON Board – ................. 49

6-19. Schematic Diagram – DIAT-CON Board – .................... 49

6-20. Printed Wiring Boards – FL, JACK Board – .................. 50

6-21. Schematic Diagram – FL Board – .................................. 51

6-22. Schematic Diagram – JACK Board – ............................. 52

6-23. Printed Wiring Boards – SPEAKER, P-SW Board – ..... 53

6-24. Schematic Diagram – SPEAKER, P-SW Board – ......... 53

6-25. Printed Wiring Board – MS-203 Board –....................... 54

6-26. Schematic Diagram – MS-203 Board – ......................... 54

6-27. Printed Wiring Board – DMPORT Board (EA) – .......... 55

6-28. Schematic Diagram – DMPORT Board (EA) – ............. 55

6-29. Printed Wiring Board – POWER Board – ...................... 56

6-30. Schematic Diagram – POWER Board – ......................... 57

7. EXPLODED VIEWS

7-1. Overall Section ................................................................ 72

7-2. Front Panel Section ......................................................... 73

7-3. Chassis Section................................................................ 74

7-4. DVD Mechanism Deck Section (CDM85-DVBU102) ... 75

8. ELECTRICAL PARTS LIST .................................. 76

•Abbreviation

E32 : 110 – 240V AC area in E model

EA : Saudi Arabia model

MX : Mexican model

4

SECTION 1

SERVICING NOTE

HCD-DZ555K/DZ556KB/DZ750K

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

DISC TRA Y LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the x button and the A button simultaneously for f iv e

seconds again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by turning

power on/off with the ?/1 button.

On cleaning discs, disc/lens cleaners

• Do not use cleaning discs or disc/lens cleaners

(including wet or spray types). These may cause the apparatus

to malfunction.

IMPORTANT NOTICE

Caution: This system is capable of holding a still video image or

on-screen display image on your television screen indefinitely.

If you leave the still video image or on-screen display image

displayed on your TV for an extended period of time you risk

permanent damage to your television screen.

Projection televisions are especially susceptible to this.

Attention when transported

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press the ?/1 button to turn the set on.

2. Press the [FUNCTION] button to set the function “DVD”.

3. Remove all discs, and then press two buttons H and ?/1

simultaneously.

4. After a message “MECHA LOCK” is displayed on the

fluorescent indicator tube, pull out the AC plug.

5. To exit from this mode, press the ?/1 button to turn the set

on.

x button and the A button simultaneously for five

Note about CDs/DVDs

The system can play CD-ROMs/CD-Rs/CDRWs recorded in the

following formats:

– audio CD format

– VIDEO CD format

– MP3 audio tracks, JPEG image files, and DivX video files of

format conforming to ISO 9660 Level 1/Lev el 2, or its extended

format, Joliet

The system can play DVD-ROMs/DVD+RWs/DVD-RWs/

DVD+Rs/DVD-Rs recorded in the following formats:

– MP3 audio tracks, JPEG image files, and DivX video files of

format conforming to UDF (Universal Disc Format)

Example of discs that the system cannot play

The system cannot play the following discs:

• CD-ROMs/CD-Rs/CD-RWs other than those recorded in the

formats listed on “Note about CDs/DVDs”

• CD-ROMs recorded in PHOTO CD format

• Data part of CD-Extras

•DVD Audios

• Super Audio CD

•DATA DVDs that do not contain MP3 audio tracks, JPEG

image files, or DivX video files

•DVD-RAMs

Also, the system cannot play the following discs:

•A DVD VIDEO with a different region code

•A disc that has a non-standard shape (e.g., card, heart)

•A disc with paper or stickers on it

•A disc that has the adhesive of cellophane tape or a sticker

still left on it

Notes about CD-R/CD-RW/DVD-R/DVD-RW/DVD+R/

DVD+RW

In some cases, CD-R/CD-RW/DVD-R/DVD-RW/DVD+R/

DVD+RW cannot be played on this system due to the recording

quality or physical condition of the disc, or the characteristics of

the recording device and authoring software.

The disc will not play if it has not been correctly finalized. For

more information, see the operating instructions for the recording

device.

Note that some playback functions may not work with some

DVD+R Ws/D VD+Rs, even if the y have been correctly finalized. In

this case, view the disc by normal playback. Also some DATA CDs/

DATA DVDs created in Packet Write format cannot be played.

Copyrights

This product incorporates copyright protection technology that is

protected by U.S. patents and other intellectual property rights. Use

of this copyright protection technology must be authorized by

Macrovision, and is intended for home and other limited viewing

uses only unless otherwise authorized by Macrovision. Reverse

engineering or disassembly is prohibited.

This system incorporates with Dolby* Digital and Dolby Pro Logic

(II) adaptive matrix surround decoder and the DTS** Digital

Surround System.

* Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic”, and the double-D symbol are

trademarks of Dolby Laboratories.

** Manufactured under license from DTS, Inc.

“DTS” and “DTS Digital Surround” are registered trademarks

of DTS, Inc.

5

HCD-DZ555K/DZ556KB/DZ750K

How to open the disc table when power switch turns off

Insert a tapering driver into the aperture of the unit bottom, and slide it in the direction of the arrow.

Peel off the seal and so the lever is moved

in the direction of the arrow with the thin rod.

seal

disc tray

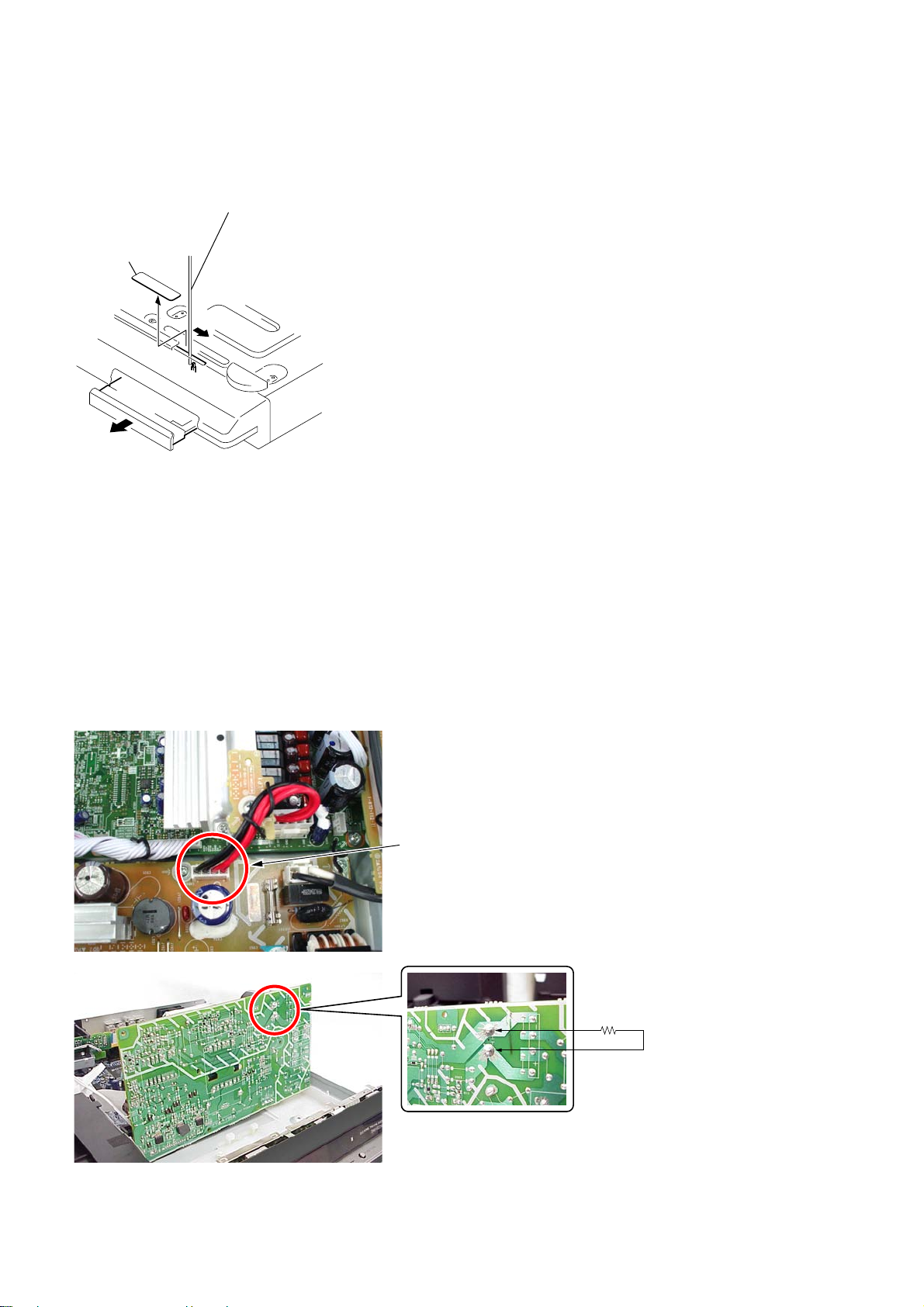

Discharge the charged electricity in capacitors to prevent electric shock as follows

When disassembling the machine, be sure to discharge the charged electricity in the following capacitors.

Use a resistor of 800 ohms, 2 Watts for discharging the following capacitors.

POWER board

C903: 440 V (Except Mexican model) / 240 V (Mexican model)

C932, C933, C934, CN904: 30 V

MAIN board

CN3002: 30 V

Point of capacitor discharge for C932, C933, C934:

Connect to the red and black wire of CN904

800

Ω

/2W

Point of capacitor discharge for C903:

Connect to the foot of CN903

6

HCD-DZ555K/DZ556KB/DZ750K

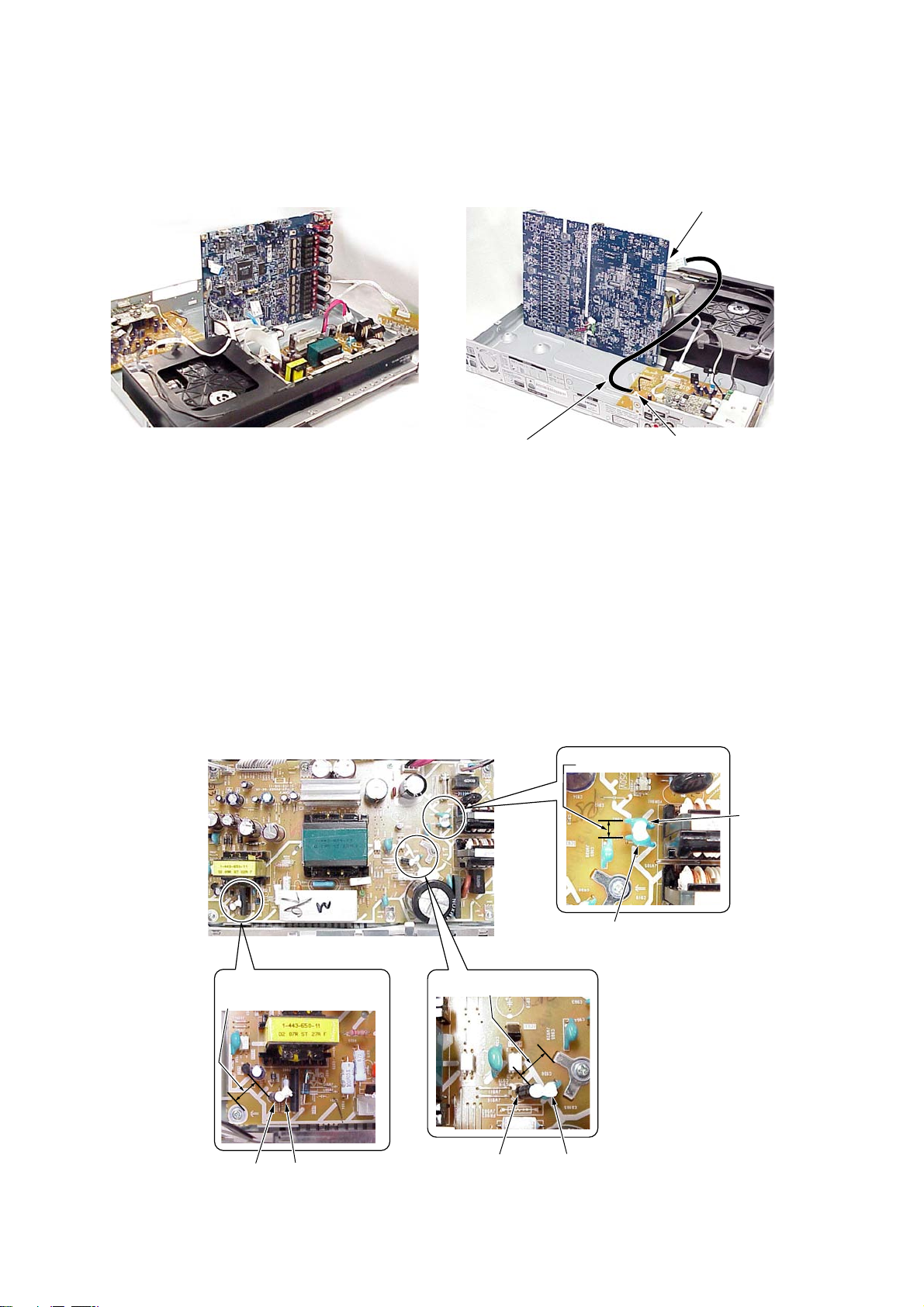

MAIN board service position

Please take the above-mentioned position in the repair of MAIN board.

In that case, it is necessary the following extension cable during CN304 on IO-S-OUT board and CN4302 on MAIN board.

CN4302

jig P/N: J-2501-242-A

(pitch 1.00 mm/11p/length 300 mm)

CN304jig

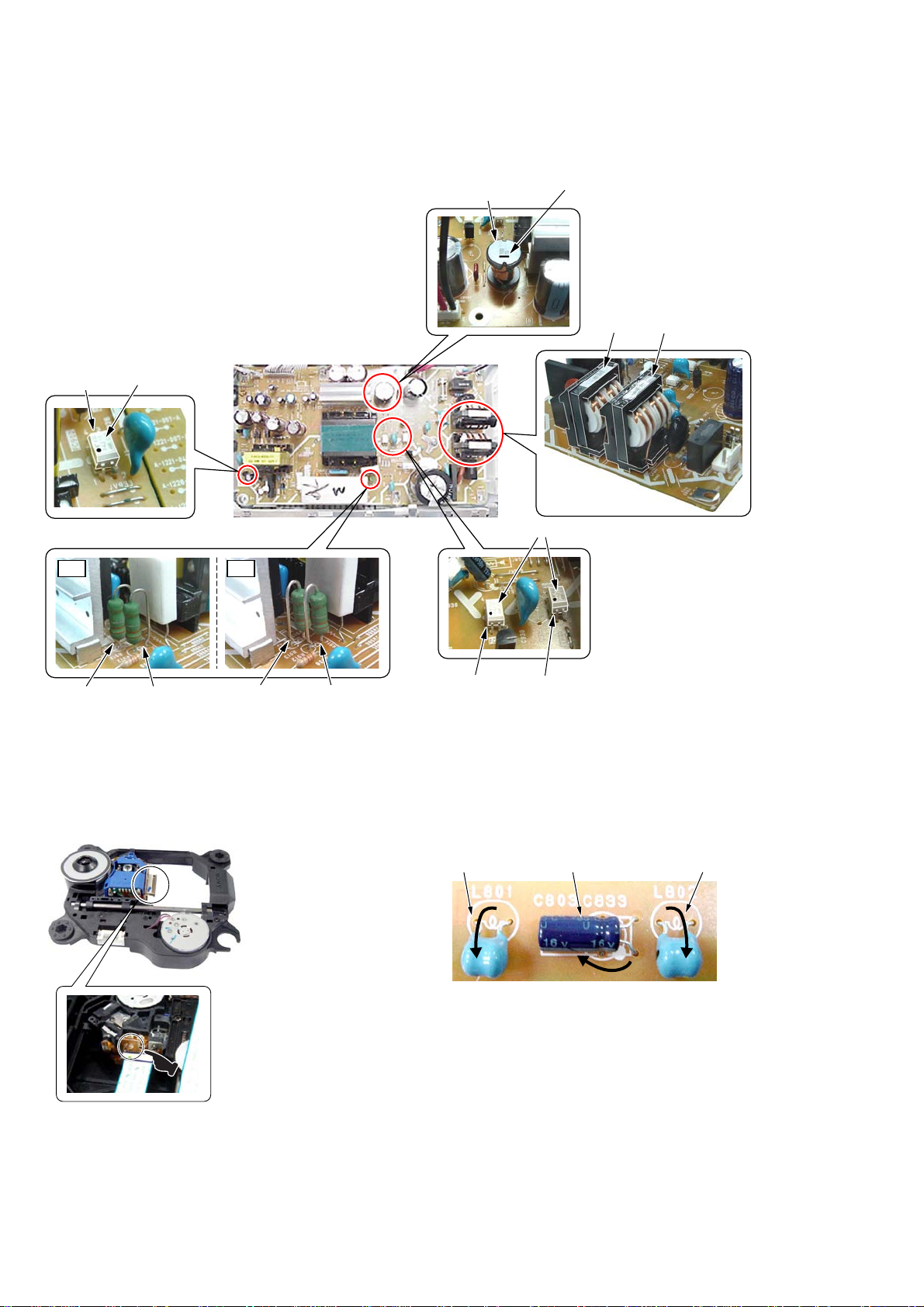

Parts that require fixing using adhesive agent

The following parts on the POWER board must be fixed by using the adhesive agent (such as Sony Bond Master) as it is specified by Safety

Regulations. When any part or printed circuit board is replaced during repair work, be sure to confirm that the following capacitors and resistors

are fixed by using the adhesive agent (such as Sony Bond Master) without fail.

POWER board: • C924 and R927 (refer to below fig.)

• C913 (Push down to C903 side and so fix.)

• C910 and C930 (refer to below fig.)

• EB905 side of C903

• EB905 side of C934

• C964 and C963 (refer to below fig.)

• Space between C933 and C932

• C908 and Q901 (Don’t touch IC901.)

POWER BOARD

OK:more than 3.5mm

NG:less than 3.5mm

C963

OK:more than 8mm

NG:less than 8mm

Don't incline C924 to outside.

C924 R927

OK:more than 8mm

NG:less than 8mm

C910

C930

C964

7

HCD-DZ555K/DZ556KB/DZ750K

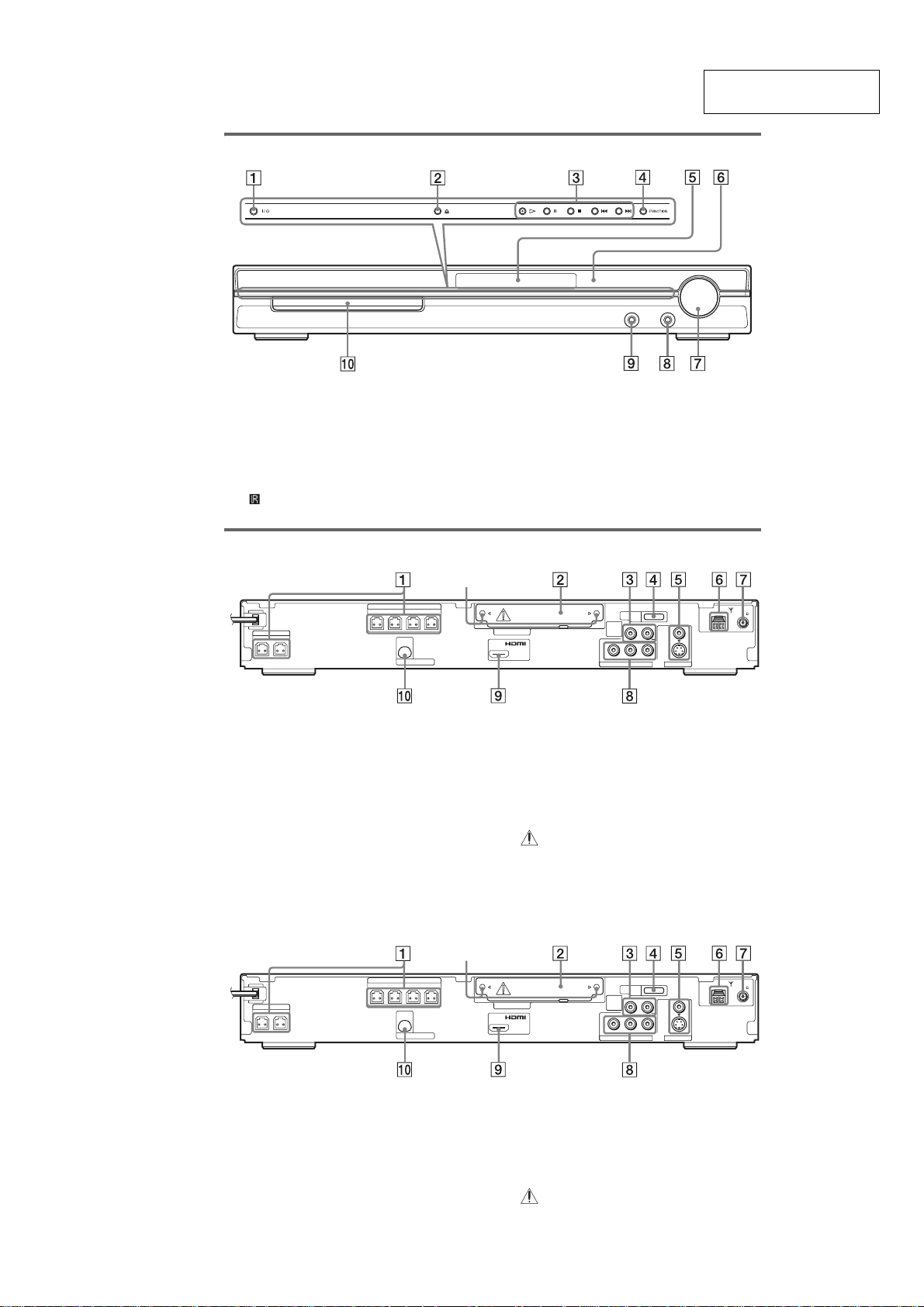

Attention of the direction at replacement

Please defend and install the direction of the below fig in the following parts on the POWER board.

mark this side

PC902

L931

POWER BOARD

mark this side

LF902 LF901

OK NG

R913 R912 R913 R912

Precaution when installing a new OP unit /

Precaution before unsoldering the static electricity

prevention solder bridge

mark this side

PC901

PC903

Note on replacement of C803, C802, L801,

and L802

Please fold in the directtion of the arrow and set up at

replacement of C803, C802, L801, and L802 on FL board.

L801 L802C803

+

–

When installing a new OP unit, be sure to connect the flexible

printed circuit board first of all before removing the static

electricity prevention solder bridge by unsoldering.

Remove the static electricity prevention solder bridge by

unsoldering after the flexible printed circuit board has already

been connected.

(Do not remove nor unsolder the solder bridge as long as the

OP unit is kept standalone.)

8

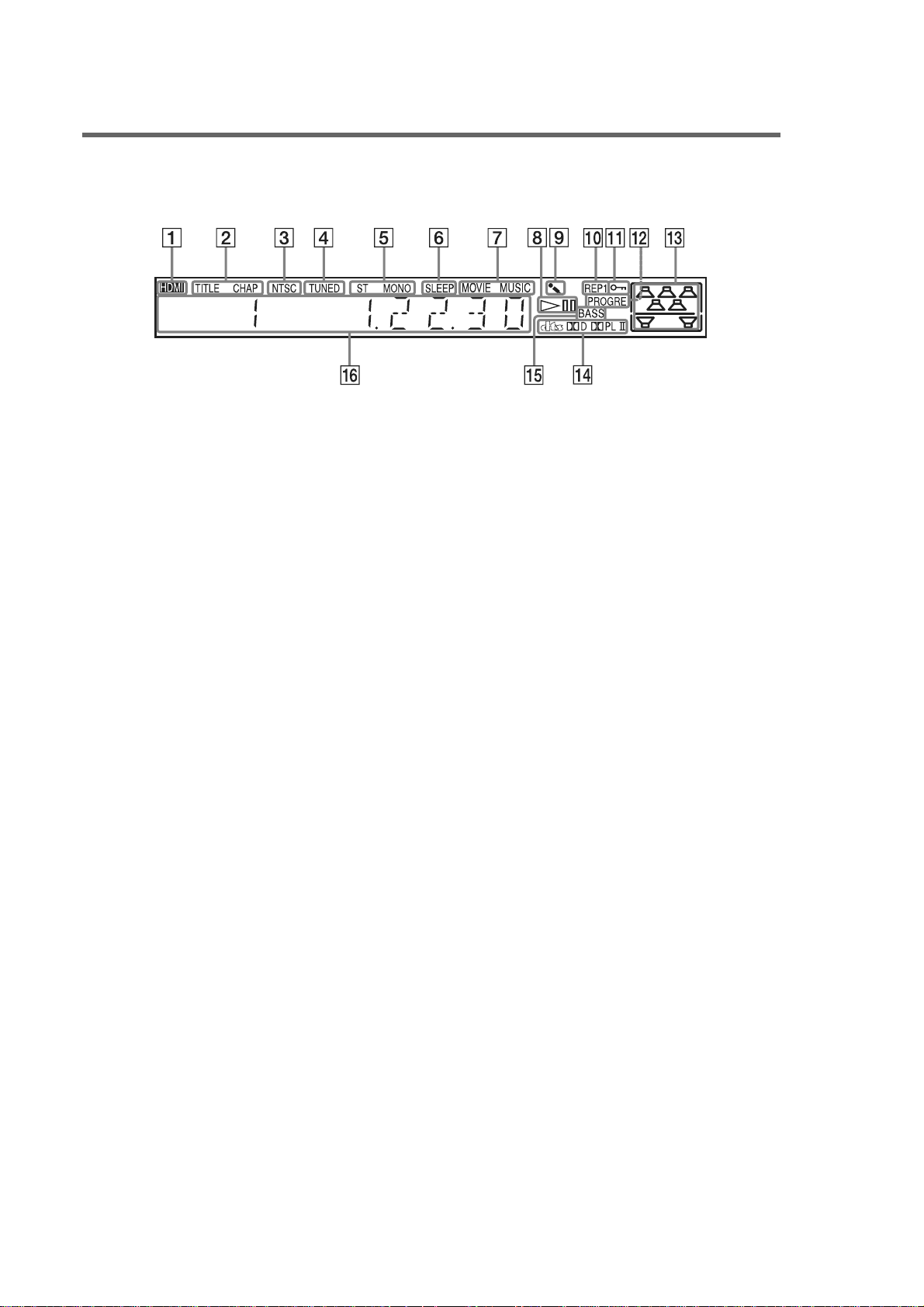

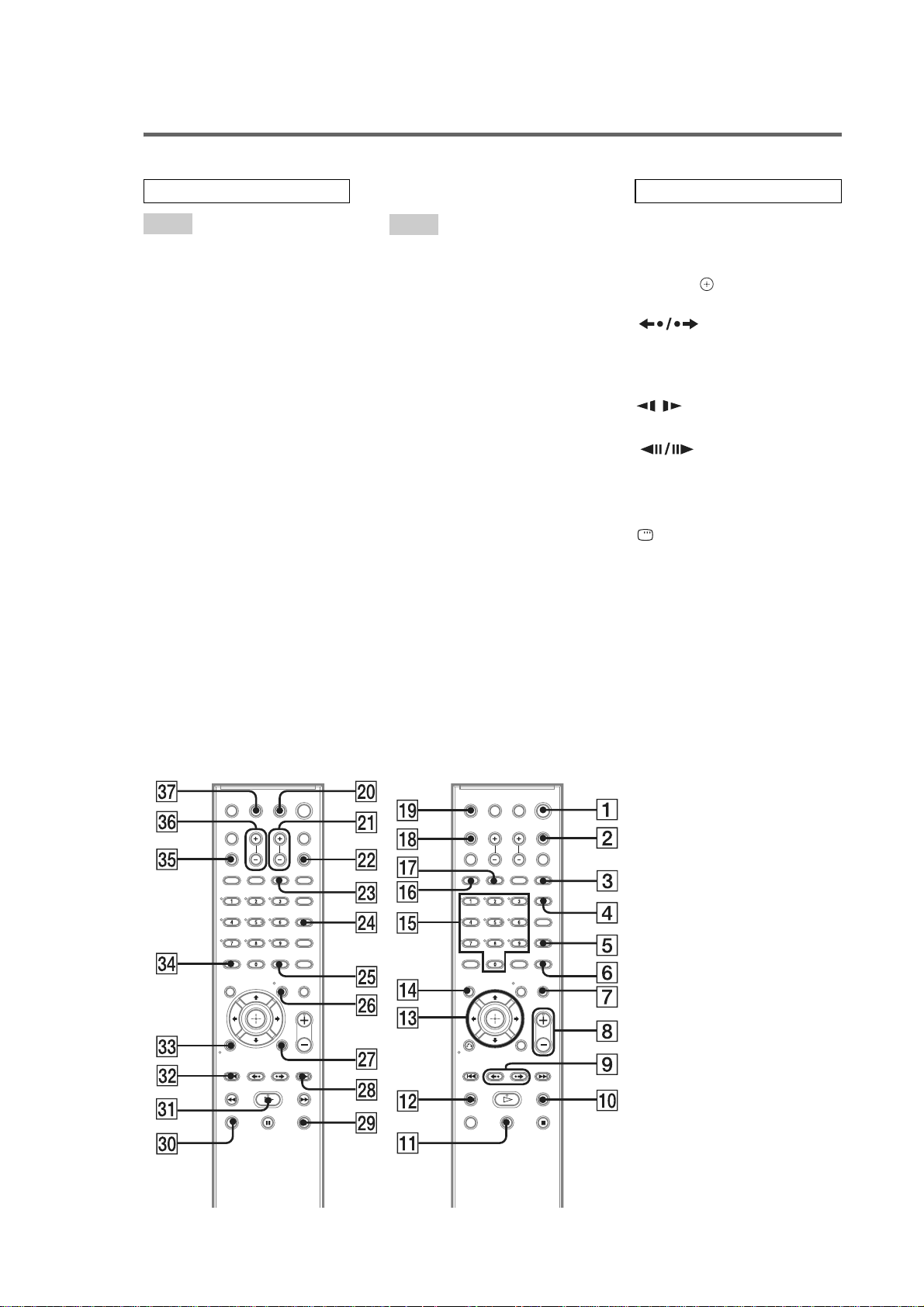

Front panel

SECTION 2

GENERAL

HCD-DZ555K/DZ556KB/DZ750K

This section is extracted

from instruction manual.

A "/1 (on/standby) (31)

B A (open/close) (31)

C Disc operation (31)

D FUNCTION (31)

E Front panel display (101)

F (remote sensor) (9)

Rear panel

DZ555K/DZ556KB

SPEAKER

FRONT R

FRONT L SUR R SUR L

SPEAKER

CENTER WOOFER

D-LIGHT SYNC OUT

A SPEAKER jacks (15)

B DIR-TC1 slot for the WAHT-SD1 (29)

C TV/VIDEO (AUDIO IN R/L) jacks (29)

D DMPORT (DIGITAL MEDIA PORT) jack

(except for Mexican and Latin

American models) (29, 69)

E MONITOR OUT (S VIDEO/VIDEO) jacks

(25)

F AM terminal (15)

G COAXIAL FM 75Ω jack (15)

Screws*

G VOLUME control (31)

H MIC 2 jack (64)

I AUDIO IN/MIC 1/A.CAL MIC jack (20, 29,

64)

J Disc tray (31)

COAXIAL

AM

FM75

DIR-TC1

OUT

(DVD ONLY)

TV /

VIDEO

(DVD ONLY)

YPB/CBPR/C

DMPORT

RLAUDIO IN

VIDEO

S VIDEO

(DVD ONLY)

R

MONITOR OUTCOMPONENT VIDEO OUT

H COMPONENT VIDEO OUT jacks (25)

I HDMI OUT jack (25)

J D-LIGHT SYNC OUT jack (29)

(Singaporean, Mexican, and Latin

American models only)

* CAUTION

Please do not remove the screws before

installing the WAHT-SD1.

DZ750K

Screws*

SPEAKER

FRONT R

FRONT L SUR R SUR L

SPEAKER

CENTER WOOFER

D-LIGHT SYNC OUT

A SPEAKER jacks (19)

B DIR-TC1 slot for the WAHT-SD1 (33)

C TV/VIDEO (AUDIO IN R/L) jacks (33)

D DMPORT (DIGITAL MEDIA PORT) jack

(33, 73)

E MONITOR OUT (S VIDEO/VIDEO) jacks

(29)

F AM terminal (19)

G COAXIAL FM 75Ω jack (19)

AM

DIR-TC1

OUT

(DVD ONLY)

TV /

VIDEO

(DVD ONLY)

YPB/CBPR/C

DMPORT

RLAUDIO IN

VIDEO

S VIDEO

(DVD ONLY)

R

MONITOR OUTCOMPONENT VIDEO OUT

H COMPONENT VIDEO OUT jacks (29)

I HDMI OUT jack (29)

J D-LIGHT SYNC OUT (Singaporean

model only) jack (33)

* CAUTION

Please do not remove the screws before

installing the WAHT-SD1.

COAXIAL

FM75

9

HCD-DZ555K/DZ556KB/DZ750K

Front panel display

About the indications in the front panel display

A Lights up when the HDMI OUT jack is

correctly connected to HDCP (highbandwidth digital content protection)

compliant device with HDMI or DVI

(digital visual interface) input. (25)

B Lights up when the time information of

a title or chapter appears in the front

panel display. (DVD only) (47)

C Lights up when the color system is set

to NTSC. (Asian, Australian, and Middle

Eastern models only)

D Lights up when a station is received.

(Radio only) (60)

E Stereo/Monaural effect (Radio only)

(61)

F Lights up when the sleep timer is set.

(68)

G Ligh t s u p when the movie or music

mode is selected. (34)

H Playing status (DVD function only)

I Lights up when the karaoke mode is

on. (64)

J Current repeat mode (43)

K Lights up when the child lock f unction

is set to on. (70)

L Lights up when the system outputs

progressive signals (DVD function

only). (27)

M Indicates the selected [SPEAKER

FORMATION]. (74)

N Current surround format (Except for

JPEG)

O Lights up when the DYNAMIC BASS is

selected. (68)

P Displays system’s status such as

chapter, title, or track number, time

information, radio frequency, playing

status, sound field, etc.

10

Remote control

HCD-DZ555K/DZ556KB/DZ750K

ALPHABETICAL ORDER

A – O

ANGLE 5 (49)

AUDIO 4 (44)

CLEAR ef (38, 63, 79)

D.TUNING wf (61)

DISPLAY ej (47, 62)

DVD MENU wh (44, 57, 63)

DVD TOP MENU qf (44)

DYNAMIC BASS wd (68)

ECHO qk (65)

ENTER wg (63)

FUNCTION ws (27, 31, 32, 39,

60, 74)

KARAOKE PON 2 (66)

KEYCON #/b wa (66)

MIC VOL +/– eh (65)

MOVIE/MUSIC qj (34)

MUTING 7 (31)

Number buttons* qg (38, 61, 63,

71)

P – Z

PICTURE NAVI 6 (39, 63)

PRESET +/– wk es (61)

SCORE eg (67)

SOUND FIELD qh (35)

SUBTITLE wf (50)

SYSTEM MENU wg (23, 33, 63,

69, 107)

THEATRE SYNC w; (64)

TUNING +/– 0 qs (60)

TV e; (63)

TV CH +/– wk es (63)

TV INPUT ej (63)

TV VOL +/–* 8 (63)

VIDEO FORMAT 3 (27)

VOLUME +/–* 8 (31, 61, 85)

BUTTON DESCRIPTIONS

[/1 (on/standby) 1 (20, 23, 31,

39, 61)

TV [/1 (on/standby) 1 (63)

C/X/x/c/ qd (20, 23, 33, 38,

60, 71)

REPLAY/

ADVANCE 9 (31)

./> es wk (31)

m/M qs 0 (37)

/SLOW qs 0 (37)

H (play)* ea (31, 39, 73)

STEP 9 (37)

x (stop) wl (31, 39, 71)

X (pause) qa (31)

Z (open/close) ql (31)

DISPLAY wj (21, 38, 71,

102)

O RETURN ed (39)

-/-- ef (63)

*The H, number 5, and

VOLUME + (TV VOL+)

buttons have tactile dots. Use

the tactile dots as references

when operating the syst em.

11

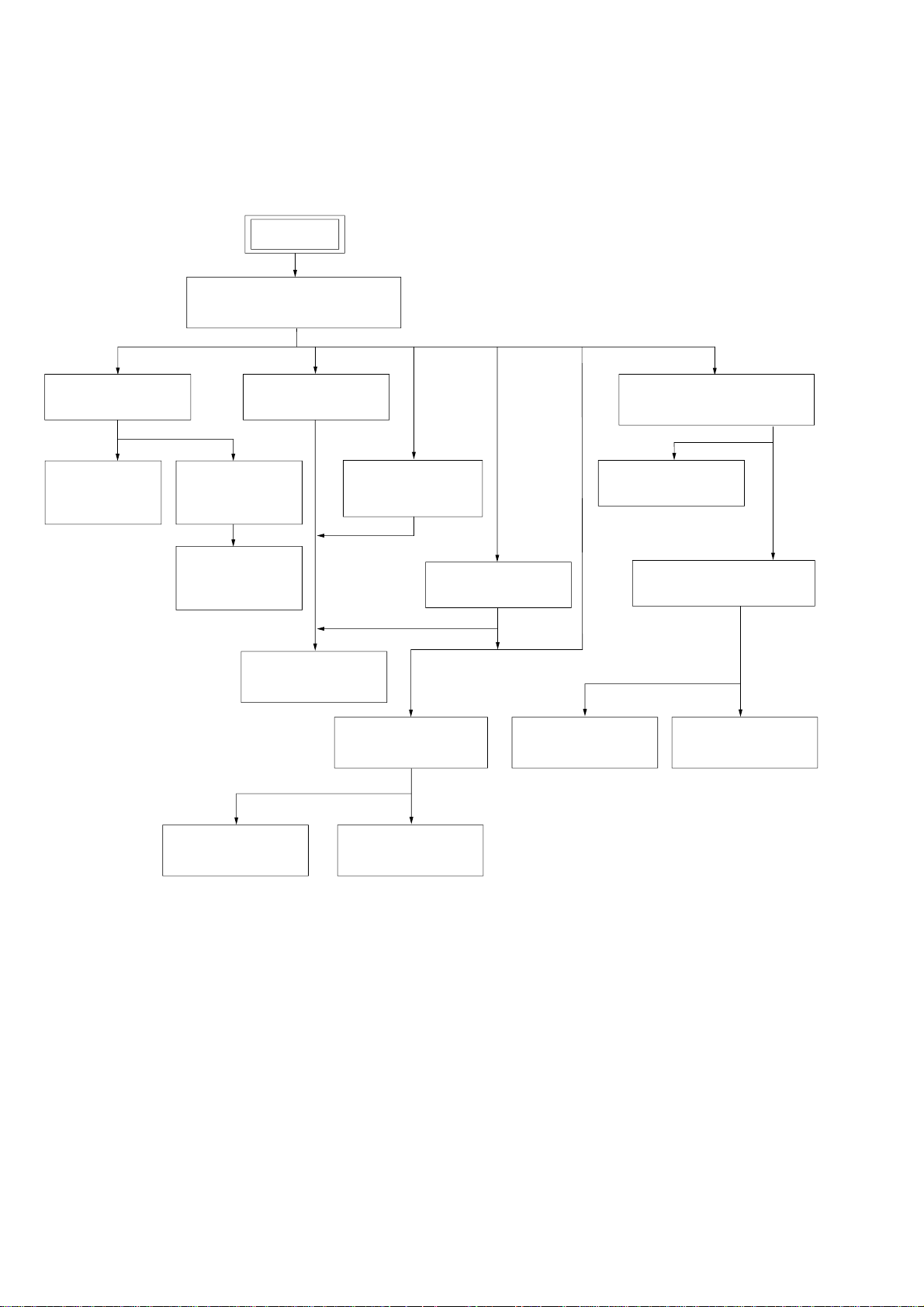

HCD-DZ555K/DZ556KB/DZ750K

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

SET

3-2. CASE (DS),

FRONT PANEL ASSY

(Page 13)

SECTION 3

DISASSEMBLY

• Abbreviation

E32 : 110 – 240V AC area in E model

MX : Mexican model

3-3. FL BOARD

(Page 14)

3-4. JACK BOARD,

P-SW BOARD

(DZ555K/DZ556KB)

(Page 15)

3-7. TUNER (FM/AM)

3-5. JACK BOARD,

P-SW BOARD

(DZ750K)

(Page 15)

3-6. FRONT PANEL,

ORNAMENT

(DZ750K)

(Page 16)

3-10. IO-S-OUT BOARD

(Page 16)

(Page 18)

3-8. DMPORT BOARD

(EXCEPT MX, E32)

(Page 17)

3-9. DIAT-CON BOARD

3-12. SPEAKER BOARD,

D.C. FAN

(Page 19)

(Page 17)

3-18. OPTICAL PICK-UP

(KHM-313CAA)

(Page 24)

3-15. DVD MECHANISM DECK

(CDM85-DVBU102)

(Page 22)

3-11. POWER BOARD

(Page 18)

3-16. TRAY

(Page 22)

3-17. BELT,

MS-203 BOARD

(Page 23)

12

3-13. MAIN BOARD

(DZ555K/DZ556KB)

(Page 20)

3-14. MAIN BOARD

(DZ750K)

(Page 21)

Note: Follow the disassembly procedure in the numerical order given.

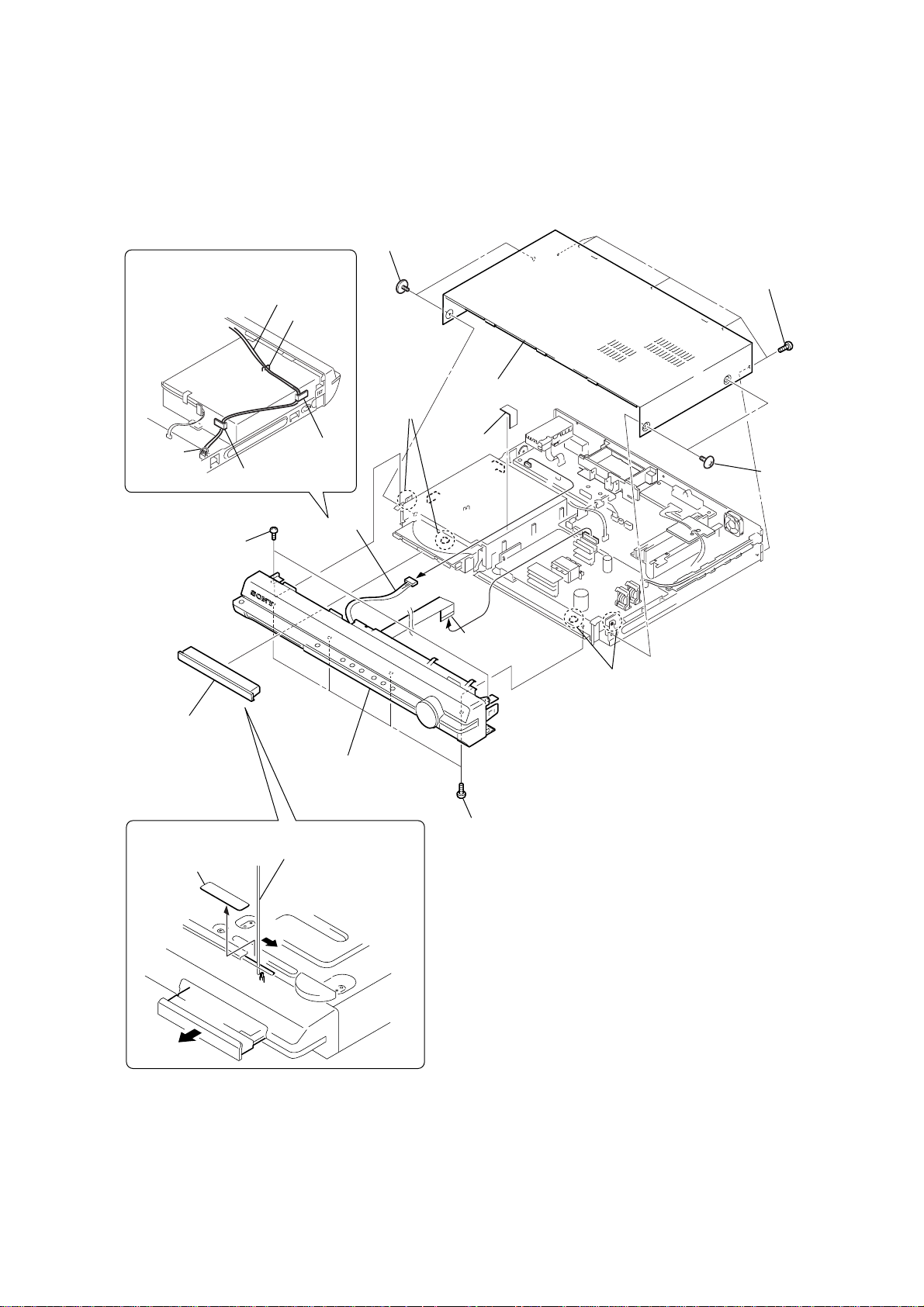

3-2. CASE (DS), FRONT PANEL ASSY

5

two screws

(CASE3 TP2)

Route the harness as shown below.

harness

notch

qg

two

claws

q;

lead pin

rib

rib

unweaved

cloth

8

case (DS)

HCD-DZ555K/DZ556KB/DZ750K

7

five screws

(+BVTP 3

6

two screws

(CASE3 TP2)

×

8)

9

two

screws

(+BVTP

4

loading panel

1

seal

qs

connector 5P

)

(CN302)

qh

front panel assy

2.6 × 10

2

The lever is moved in the direction

of the arrow with the thin rod.

qa

w

ire (flat type)

21core (CN502)

qd

four screws

(+BV 3

×

6)

qf

two claws

3

13

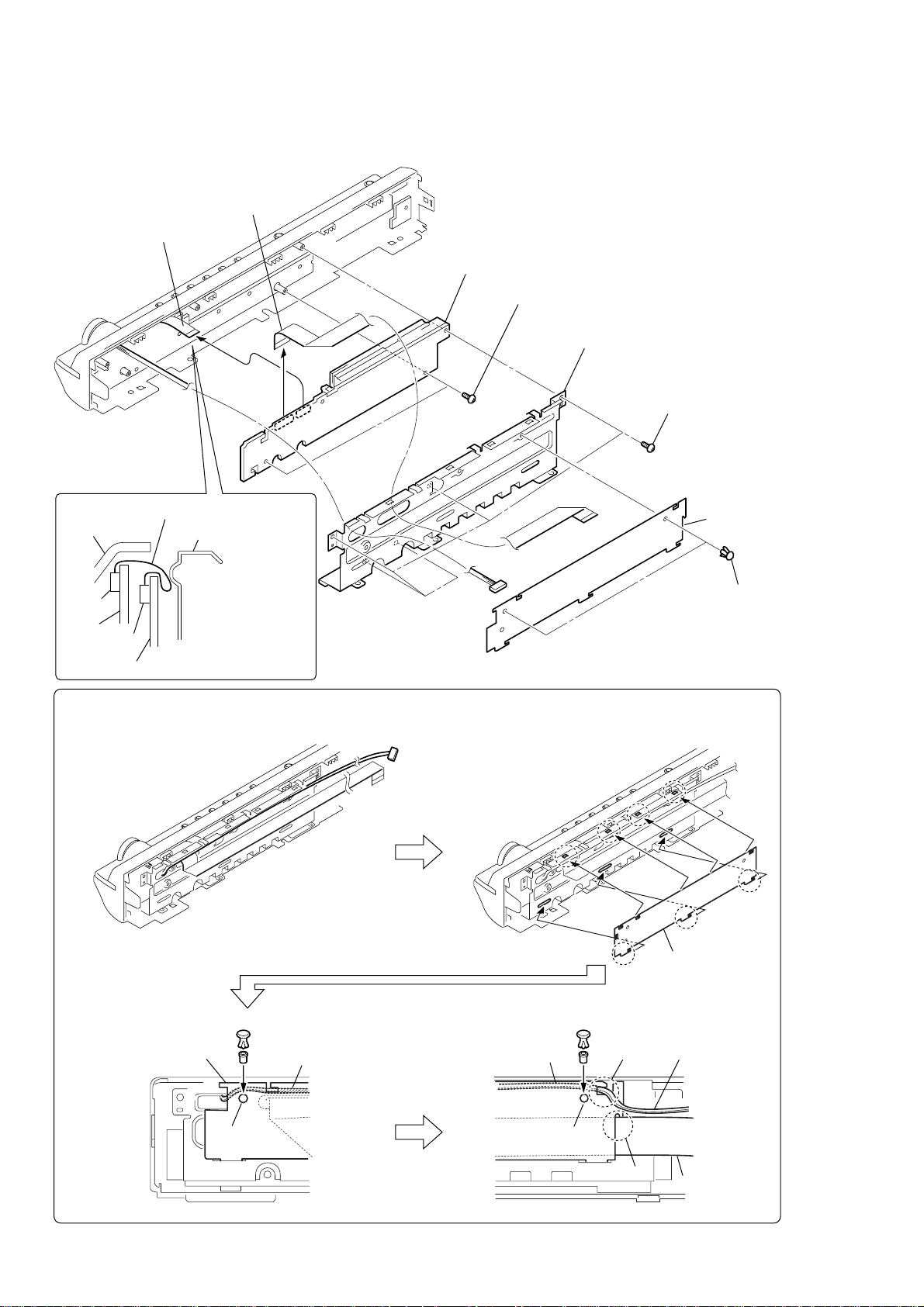

HCD-DZ555K/DZ556KB/DZ750K

3-3. FL BOARD

7

wire (flat type)

6

wire (flat type)

13core (CN805)

21core (CN801)

8

FL board

5

two

screws

(+BVTP 2.6

×

10)

4

shield plate (FR)

3

five

screws

(+BVTP 2.6

×

10)

wire (flat type) 13core

front panel

CN806

JACK

CN805

board

FL board

shield plate (FR)

Route the wire

(flat type) 13core

as shown in the figure.

PRECAUTION DURING THE RETAINER (DS) INSTALLATION

(1) Assemble seven claws securely.

retainer (DS)

2

retainer (DS)

1

two

rivets

14

(2) Route the harness as shown below. (3) Route the harness as shown below.

retainer (DS)

rivet rivet

harness

hole

retainer (DS)

hole

groove

groove

harness

wire (flat type)

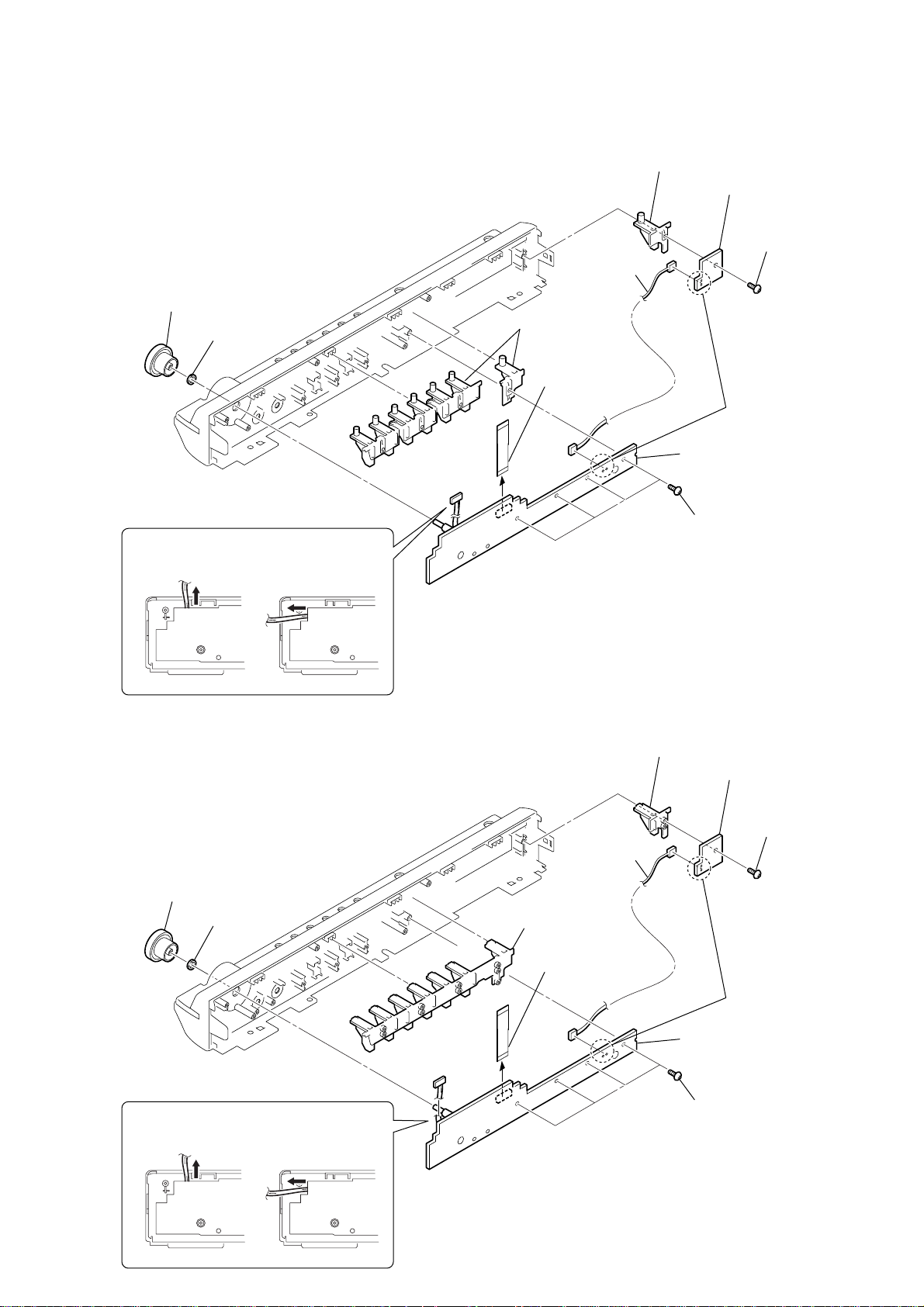

3-4. JACK BOARD, P-SW BOARD (DZ555K/DZ556KB)

1

knob (vol)

2

nut

4

button (AIO)

5

wire (flat type)

13core (CNP806)

HCD-DZ555K/DZ556KB/DZ750K

7

button (AIO)

q;

P-

SW board

6

screw

9

harness

qa

JACK board

(+BVTP

8

Remove the

solderings.

2.6 × 10

)

Route the harness as shown below.

(NG)(OK)

JACK board JACK board

3-5. JACK BOARD, P-SW BOARD (DZ750K)

1

knob (vol)

2

nut

4

button (base)

5

wire (flat type)

13core (CNP806)

9

7

harness

3

four

(+BVTP

button (base)

q;

qa

JACK board

screws

2.6 × 10

P-

SW board

6

screw

(+BVTP

8

Remove the

solderings.

)

2.6 × 10

)

Route the harness as shown below.

(NG)(OK)

JACK board JACK board

3

four

(+BVTP

screws

2.6 × 10

)

15

HCD-DZ555K/DZ556KB/DZ750K

3-6. FRONT PANEL, ORNAMENT (DZ750K)

6

ornament

4

six

claws

5

button (cap)

3-7. TUNER (FM/AM)

3

tuner (FM/AM)

2

wire (flat type) 9core

3

front panel

1

screw

(+BVTP

1

2.6 × 10

two

screws

(+BVTT

)

2.6 × 6

2

six

claws

)

16

3-8. DMPORT BOARD (EXCEPT MX, E32)

2

claw

3

wire (flat type)

9core (CN201)

4

connector

3p (CN203)

HCD-DZ555K/DZ556KB/DZ750K

• Abbreviation

E32 : 110 – 240V AC area in E model

MX : Mexican model

5

DMPORT board

1

screw

(+BVTP

3 × 8

)

3-9. DIAT-CON BOARD

2

connector

2p (CN903)

4

screw

(+BVTP

3 × 8

5

)

claw

6

8

two screws

(+BVTP

q;

7

DIAT-CON board

qa

two screws

(+BVTP

qs

claw

3 × 10

)

9

lid (diat-p)

two screws

(+BVTP

3 × 10

1

wire (flat type)

11core (CN1809)

3 × 8

)

case (diat )

3

Remove the harness.

)

17

HCD-DZ555K/DZ556KB/DZ750K

)

3-10. IO-S-OUT BOARD

8

screw

(+BV

3 × 6

9

IO-S-OUT board

6

connector

5p (CN302)

5

wire (flat type)

5core (CN307)

1

two screws

(+BV

3 × 6

)

2

)

bracket

(DIAT DS)

7

three

screws

(+BVTP

3 × 8

)

4

wire (flat type) 21core (CN605) (EXCEPT MX, E32

wire (flat type) 17core (CN607) (MX, E32)

3

wire (flat type)

11core (CN304)

3-11. POWER BOARD

Attach the heat radiation sheets

on the chassis, and then install

the POWER board.

radiation sheets

7

eight screws

(+PWH 3

qa

POWER board

q;

cover (PWB)

9

Remove the two claws

in the direction of the

arrow

B

.

4

connector

2p (CN907)

3

connector

12p (CN906)

• Abbreviation

E32 : 110 – 240V AC area in E model

MX : Mexican model

1

connector

4p (CN3002)

×

8)

B

A

Clamp the harnesses with a

lead pin or a similar tool so

that they do not touch this

screw and the heatsink (AMP).

heatsink (AMP)

screw

harness

5

connector 2p (CN903)

8

Remove the POWER board

and the cover (PWB) in the

direction of the arrow

lead pin

A

.

Attention at assembling

POWER board.

Because of prevention of

damage caused by creep of

radiation sheets, outfit a power

board with the set after fiting

the cover (PWB) on the POWER

board.

18

6

screw

(+BV 3

2

×

6)

connector

2p (CN901)

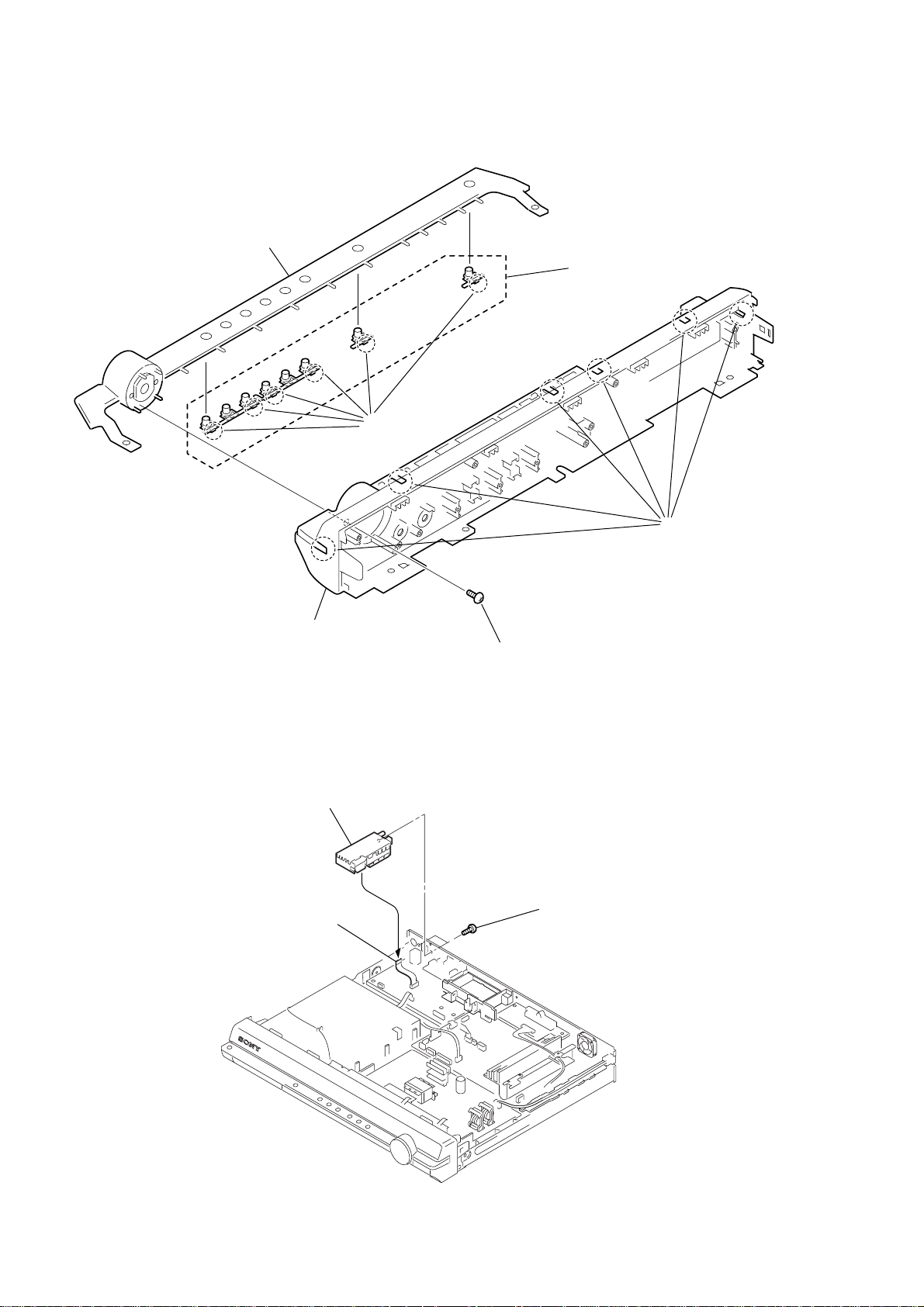

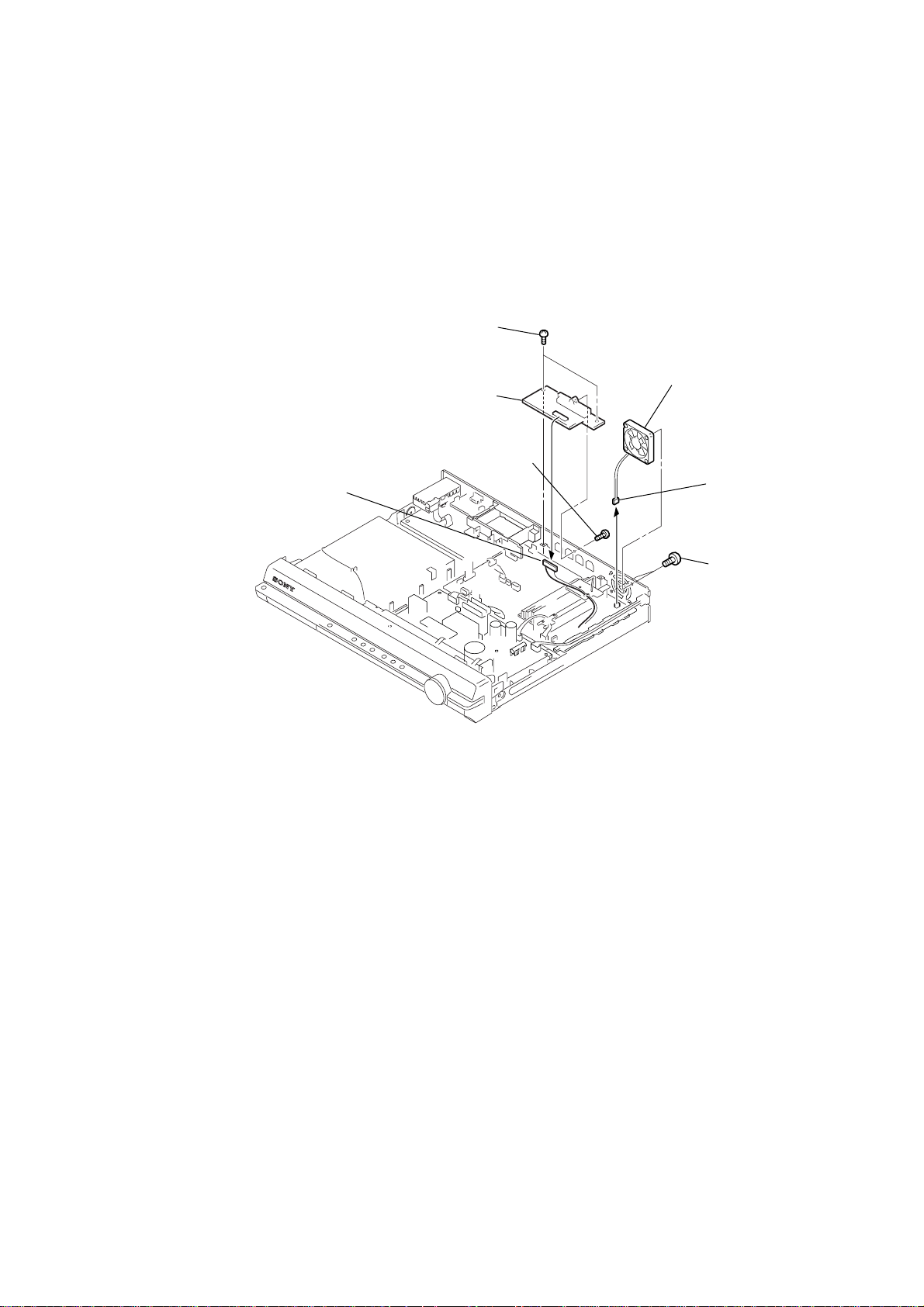

3-12. SPEAKER BOARD, D.C. FAN

)

1

connector

8p (CN303)

3

two

(+BV

4

SPEAKER board

2

screws

3 × 6

screw

(+BVTP

HCD-DZ555K/DZ556KB/DZ750K

)

7

D.C. fan

3 × 8

)

5

connector

2p (CN3000)

6

two screws

(+BVTT

4 × 8

19

HCD-DZ555K/DZ556KB/DZ750K

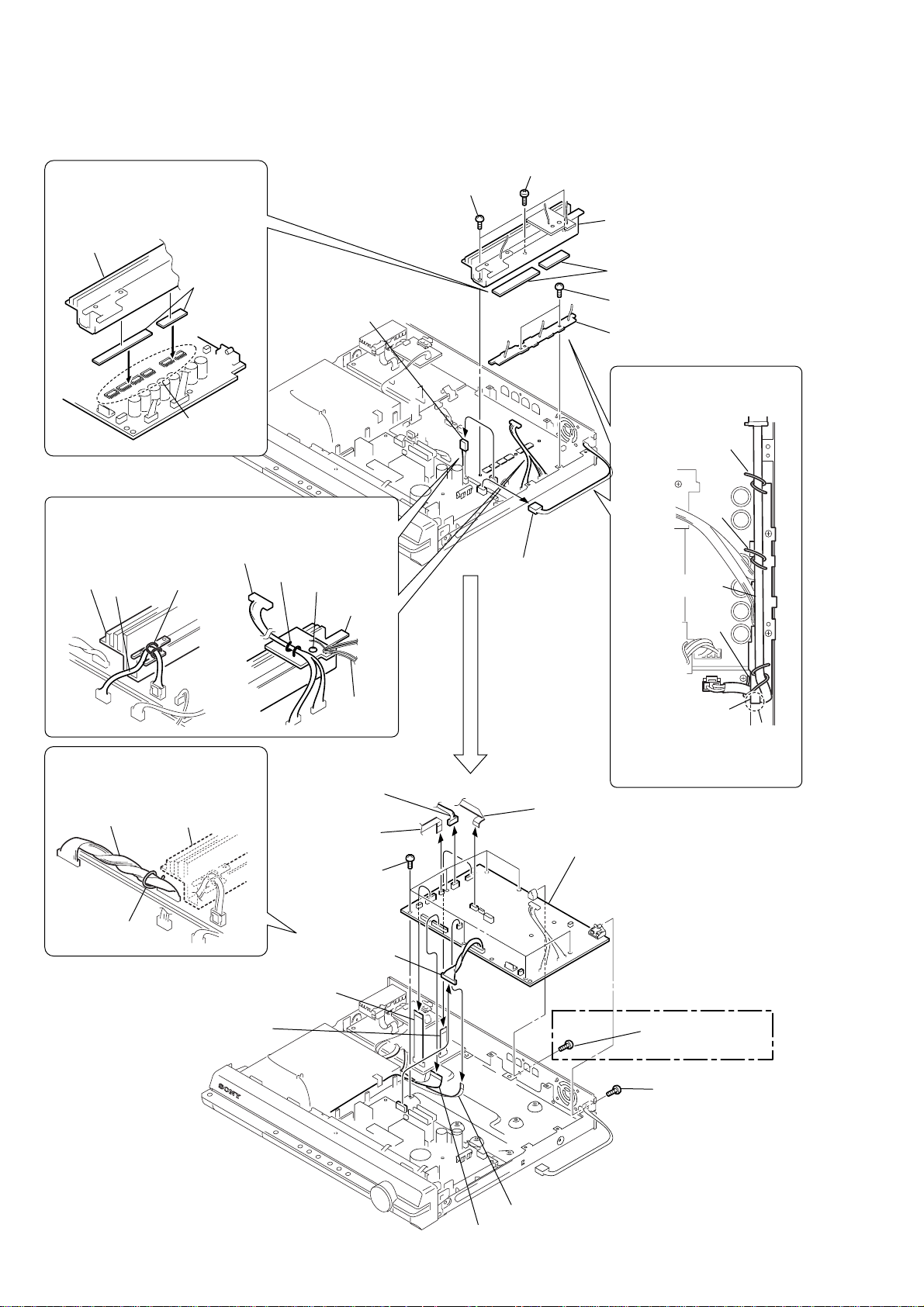

3-13. MAIN BOARD (DZ555K/DZ556KB)

Attaching the two radiation sheets

on the IC MAIN board first, and then

attach the heatsink (AMP).

heatsink (AMP)

radiation

sheets

1

connector

4p (CN3002)

IC on the

MAIN board

5

two screws (+BV 3 × 10)

6

screw (+BVTP 3 × 12)

7

8

3

4

Route the power code according

to a white line on the

INSURATOR board.

heatsink (AMP),

HEATSINK B board,

HEATSINK A board

two radiation sheet

two

screws (+BV 3 × 6)

INSURATOR

board

lead pin

Clamp the harnesses with a lead pin or a similar tool so that

they do not touch this screw and the heatsink (AMP).

heatsink

(AMP)

harness

Clamp the harness with a lead pin

or a similar tool so that they do not

touch the heatsink (AMP).

harness

lead pin

lead pin

heatsink (AMP)

harness

lead pin

q;

qa

wire (flat type)

5core (CN1202)

ql

screw

heatsink

(AMP)

harness

(D.C. fan)

connector

6p (CN1201)

seven

screws

(+BV 3

×

6)

qs

connector

12p (CN906)

2

connector

2p (CN901)

Must not remove the power code

from the part of A of the

INSURATOR board.

9

wire (flat type) 24core (CN1101)

w;

MAIN board

lead pin

power cord

lead pin

INSURATOR

board

A

qd

wire (flat type) 21core (CN605) (EXCEPT MX, E32)

wire (flat type) 17core (CN607) (MX, E32)

qf

wire (flat type) 11core (CN4302)

• Abbreviation

E12 : 220 – 240V AC area in E model

E32 : 110 – 240V AC area in E model

MX : Mexican model

SP : Singapore model

20

qh

wire (flat type) 5core (CN702)

qg

wire (flat type) 21core (CN502)

(DZ555K: SP)

(DZ556KB: E12, E32, MX)

qk

screw

(+BVTP 3

qj

×

screw

(+BVTP 3

8)

×

8)

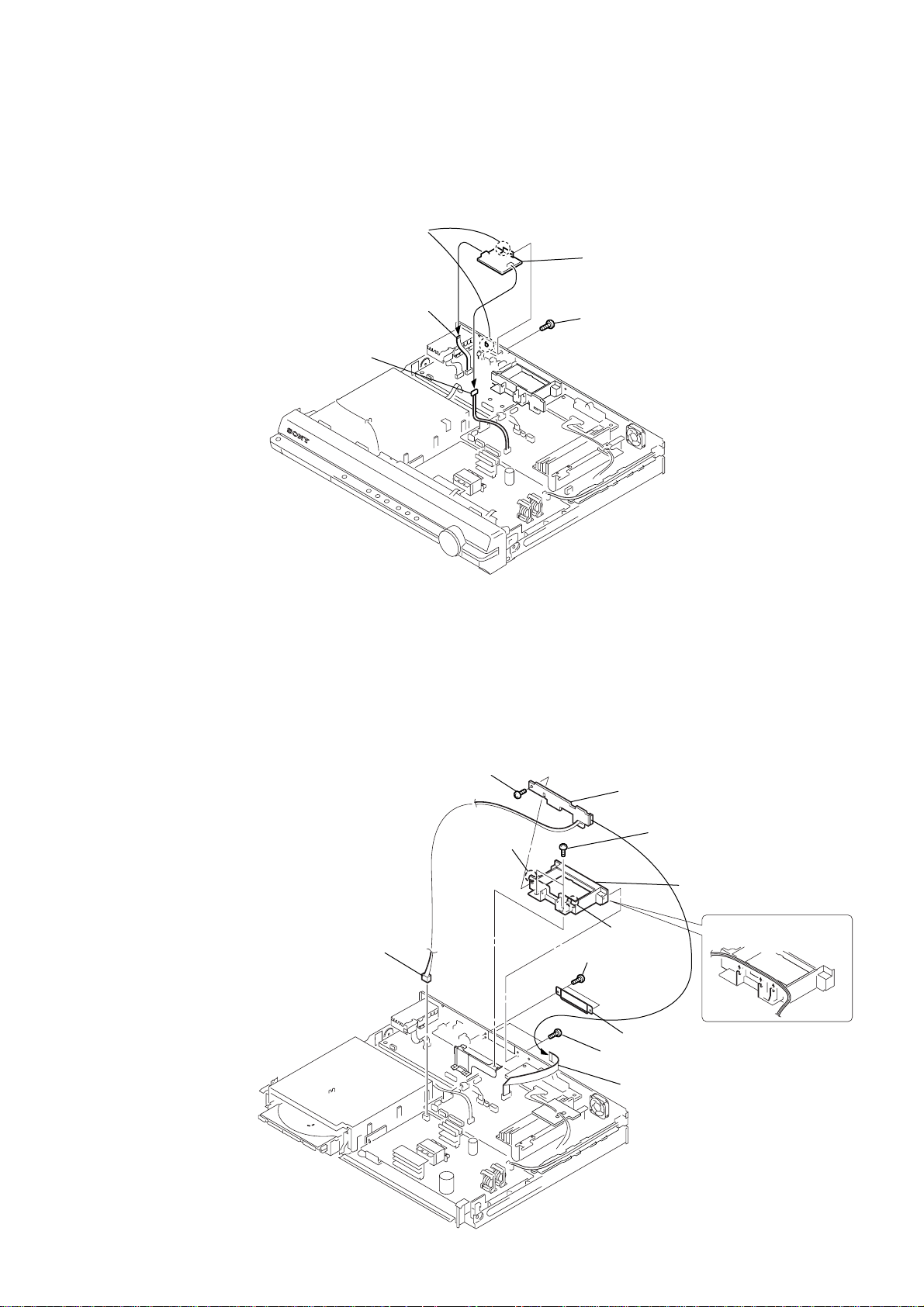

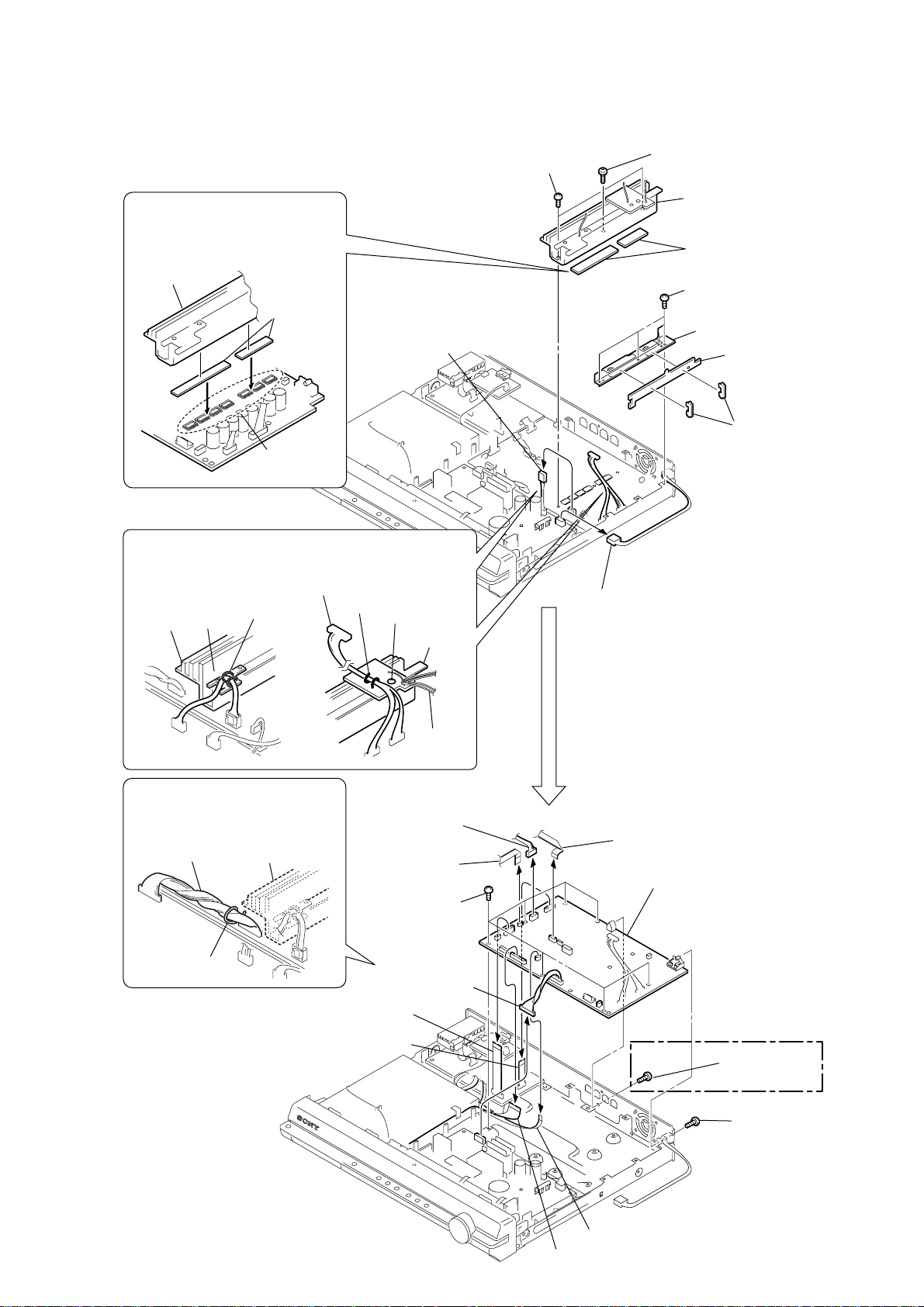

3-14. MAIN BOARD (DZ750K)

3

connector

2p (CN901)

2

two SUPPORT

boards

1

connector

4p (CN3002)

Attaching the two radiation sheets

on the IC MAIN board first, and then

attach the heatsink (AMP).

heatsink (AMP)

radiation

sheets

IC on the

MAIN board

7

two screws (+BV 3 × 10)

9

heatsink (AMP),

HEATSINK B board,

HEATSINK A board

q;

two radiation sheet

8

screw (+BVTP 3 × 12)

4

INSURATOR

board

5

three

screws (+BV 3 × 6)

wa

seven

screws

(+BV 3

×

6)

heatsink

(AMP)

harness

harness

lead pin

lead pin

heatsink

(AMP)

harness

(D.C. fan)

harness

lead pin

screw

Clamp the harnesses with a lead pin or a similar tool so that

they do not touch this screw and the heatsink (AMP).

Clamp the harness with a lead pin

or a similar tool so that they do not

touch the heatsink (AMP).

heatsink (AMP)

qs

connector

6p (CN1201)

qf

connector

12p (CN906)

qa

wire (flat type) 24core (CN1101)

qd

wire (flat type)

5core (CN1202)

qh

wire (flat type) 11core (CN4302)

qk

wire (flat type) 5core (CN702)

ql

screw

(+BVTP 3

×

8)

w;

screw

(+BVTP 3

×

8)

ws

MAIN board

qj

wire (flat type) 21core (CN502)

(DZ750K: SP)

qg

wire (flat type) 21core (CN605)

6

bracket

(DIAT DS)

HCD-DZ555K/DZ556KB/DZ750K

• Abbreviation

SP : Singapore model

21

HCD-DZ555K/DZ556KB/DZ750K

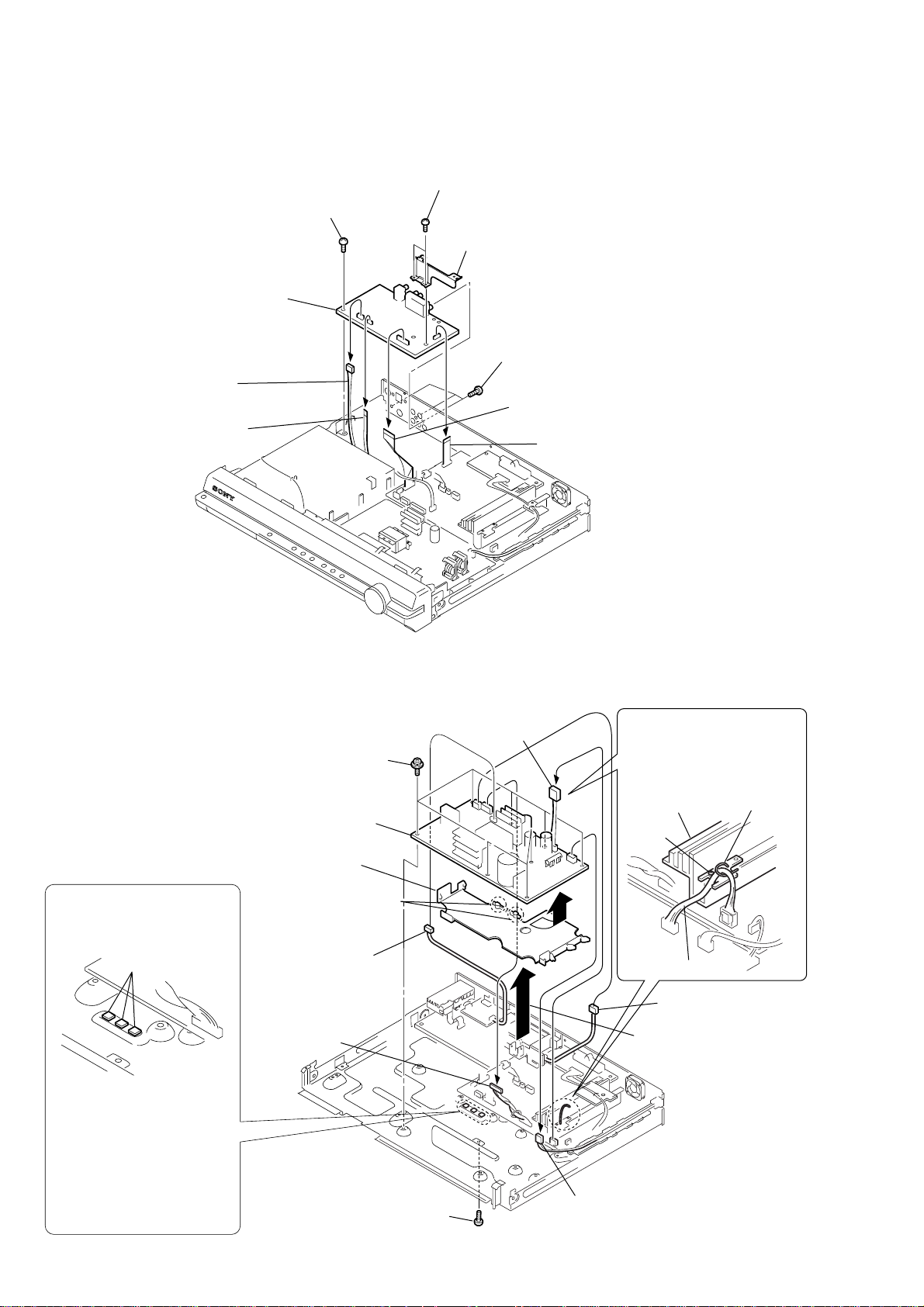

3-15. DVD MECHANISM DECK (CDM85-DVBU102)

9

three

screws (+BV 3 × 6)

q;

cover (MD)

qa

three

screws (+BV 3 × 6)

qd

DVD mechanism deck

(CDM85-DVBU102)

4

unweaved

cloth

2

unweaved

cloth

1

wire (flat type)

5core (CN307)

3

Remove the wire.

8

Remove the wire and harnesses.

qs

wire (flat type) 5core

3-16. TRAY

1

Move the chuck cam

in the direction of the arrow.

7

connector 6p (CN1201)

bottom side

5

wire (flat type) 24core

(CN1101)

6

wire (flat type) 5core

(CN1202)

3

two claws

22

2

4

5

tray

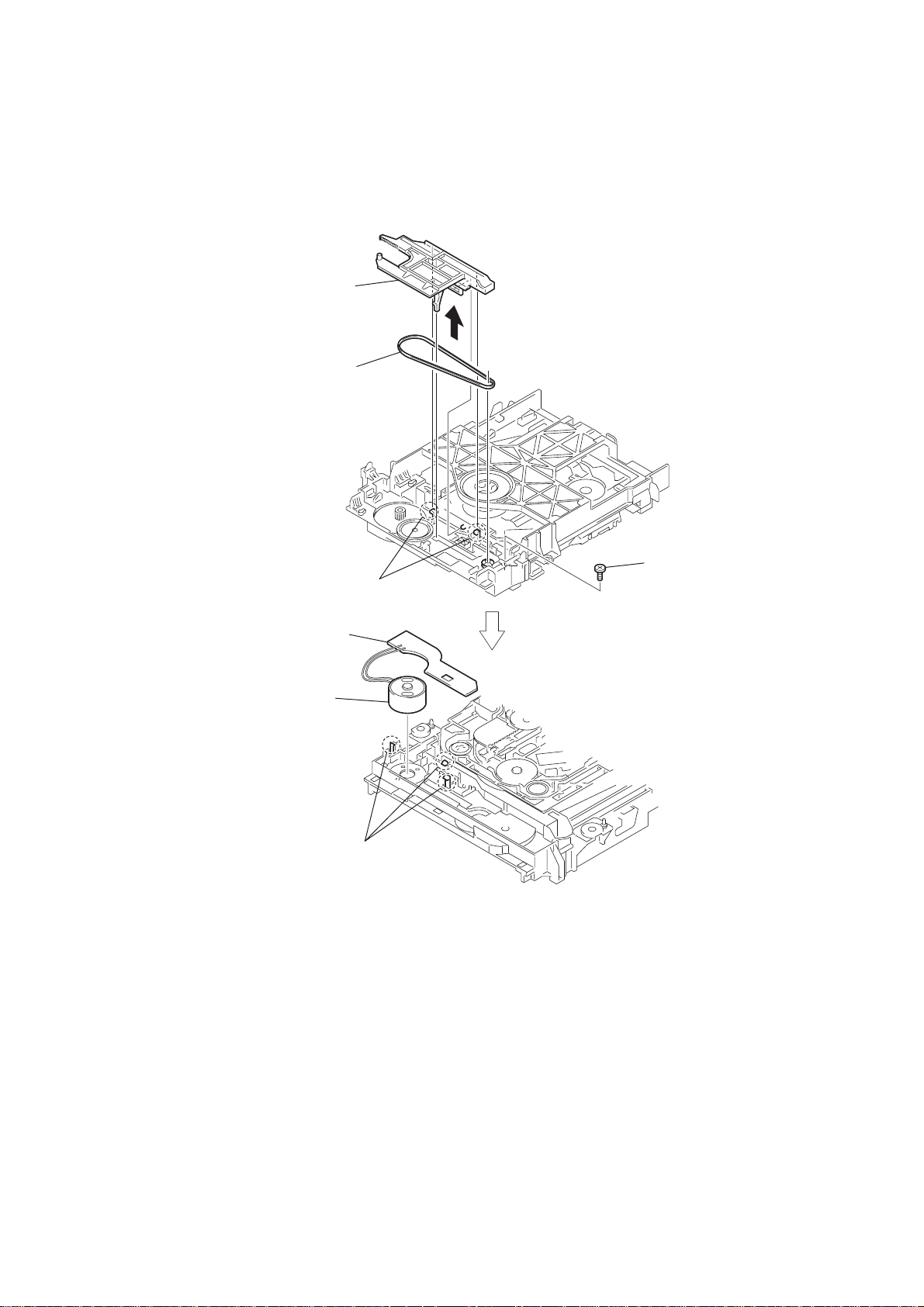

3-17. BELT, MS-203 BOARD

2

chuck cam

3

HCD-DZ555K/DZ556KB/DZ750K

belt

7

MS-203 board

6

DC motor

1

two claws

5

three claws

4

screw

(M 1.7

×

2.5)

23

HCD-DZ555K/DZ556KB/DZ750K

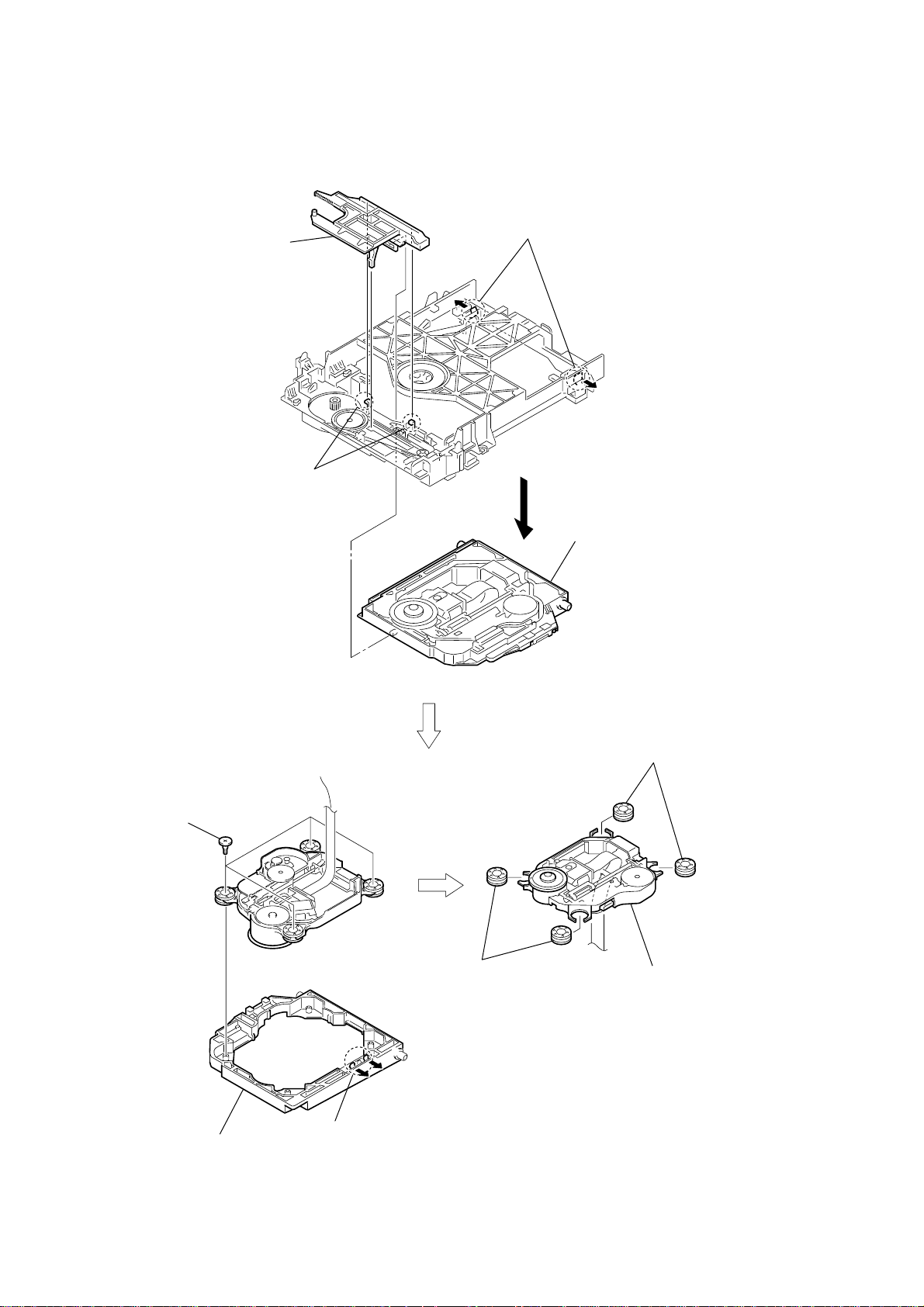

3-18. OPTICAL PICK-UP (KHM-313CAA)

2

chuck cam

1

two claws

3

two claws

6

four insulator screws

9

two insulators

4

base unit

0

(KHM-313CAA)

8

two insulators

optical pick-up

24

7

bu holder

5

two claws

SECTION 4

TEST MODE

HCD-DZ555K/DZ556KB/DZ750K

Note: Incorrect operations may be performed if the test mode is not

entered properly.

In this case, press the ?/1 button to turn the power off, and retry

to enter the test mode.

1. Cold Reset

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press three buttons x , A and ?/1 simultaneously.

3. When this button is operated, display as “COLD RESET” for

a while and all of the settings are reset.

2. Panel Test Mode

•This mode is used to check the software version, FL and KEY .

2-1. Display Test Mode

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press three buttons X , . and A simultaneously.

3. When the display test mode is activated, all segments are turned

on.

4. To e xit from this mode, press three b uttons X , . and A

simultaneously.

2-2. V ersion T est Mode

Procedure:

1. When the display test mode is activated, press the . button

and the message “DS4K/4KB” (DZ555K, DZ556KB),

“DS8K” (DZ750K) are displayed, the version test mode is

activated.

2. Whenever the . button is pressed, the display changes in

the following order.

“DS8K” (Model name) t “ASIA2*1” (Destination) t MC

*1: ASIA2 changes depending on destination.

3. Press the > button and the date of the software production

is displayed.

4. Press the > button again and the version is displayed.

5. To e xit from this mode, press three b uttons X , . and A

simultaneously.

2-3. Key Test Mode

Procedure:

1. When the display test mode is activated, press the H button,

to select the key test mode.

2. To enter the KEY test mode, the fluorescent indicator displays

“K0 V0”. Each time an another button is pressed, “KEY” v alue

increases. However, once a button is pressed, it is no longer

taken into account. When all keys are pressed correctly, “K8

V0” is displayed.

3. When the V OLUME control is turned in the direction of (+),

“V0” is changed to “V1”, then ... “V9”.

When the V OLUME control is turned in the direction of (–),

“V0” is changed to “V9”, then ... “V1”.

4. To e xit from this mode, press three b uttons X , . and A

simultaneously.

3. Disc Tray Lock

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the power on.

2. Press the FUNCTION button to set DVD function.

3. Insert a disc.

4. Press the x button and the A button simultaneously for five

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the x button and the A button simultaneously for five

seconds again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by turning

power on/off with the ?/1 button.

4. DVD Ship Mode

Use this mode when returning the set to the customer after repair.

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press the FUNCTION button to set the function “DVD”.

3. Remove all discs, and then press two buttons H and ?/1

simultaneously.

4. After a message “MECHA LOCK” is displayed on the

fluorescent indicator tube, pull out the AC plug.

5. To exit from this mode, press the ?/1 button to turn the set

on.

5. AM Step Change

•A step of AM channels can be changed over between 9 kHz

and 10 kHz.

Procedure:

1. Press the ?/1 button to turn the power on.

2. Select the function “TUNER”, and press FUNCTION button

to select the BAND “AM”.

3. Press the ?/1 button to turn the power off.

4. Press two buttons > and ?/1 simultaneously, and the

display of fluorescent indicator tube changes to “ AM 9k STEP”

or “ AM 10k STEP”, and thus the channel step is changed over .

6. Product Out

This mode moves the optical pick-up to the position durable to

vibration and clears all data including preset data stored in the RAM

to initial conditions. Use this mode when returning the set to the

customer after repair.

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press the FUNCTION button to set the function “DVD”.

3.

Remove all discs, and then

?/1 simultaneously.

4. After the “ST ANDBY” blinking display finishes, the message

“MECHA LOCK” is displayed on the fluorescent indicator

tube disconnect the A C po wer plug, then the ship mode is set.

7. Demo Play Out

It is a mode to release the demonstration reproduct by the dedicated

demonstration disc.

Setting Procedure:

1. Press the ?/1 button to turn the power on.

2. Press the FUNCTION button to set the function “DVD”.

3. During playback the DEMO Disc, press the x and H

buttons for five seconds simultaneously.

4. The message “DEMO OFF” is displayed, a mode to reproduct

the demonstration is released.

press three buttons > , A and

25

HCD-DZ555K/DZ556KB/DZ750K

8. Volume Test

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press three buttons . , H and > simultaneously.

3. The message “VOLUME MIN” is displayed.

4. When the V OLUME control is turned in the direction of (+),

the message “VOLUME MAX” is displayed.

5. When the V OLUME control is turned in the direction of (–),

the message “VOLUME MIN” is displayed.

6. To exit from this mode, press the ?/1 button to turn the set

off, the message “COLD RESET” is displayed.

Note: The se gments of the frame of SPEAKER FORMATION are blinking

while test mode.

9. Protection Factor (SD Detection/DC Detection)

Identification Test Mode

When an error is detected, the FL tube alternately displays

“PROTECTOR h PUSH POWER”.

Press the ?/1 button.

r

* Buttons other than the ?/1 button are invalid.

“STANDBY” blinks three times on the FL tube.

r

The protection release state (POWER OFF) is established.

(No FL tube display)

r Press the ?/1 button.

The power to the system turns on, and the normal operation is

established. (Restore)

During the protection state:

1. If the AC plug is connected or disconnected during the

protection state, the protection state is released, and the normal

operation is established. (The protection state is not

maintained.)

2. The protection factor is displayed by pressing the

FUNCTION , A and > buttons at the same time during

the protection state

(during the “PRO TECTOR h PUSH POWER” display).

k When SD is detected: Repeats

“SD DETECT h PUSH POWER”.

k When DC is detected: Repeats

“DC DETECT h PUSH POWER”.

10. Automatic Acoustic Field Calibration Microphone

Test Mode

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press the FUNCTION button to set the function “ DVD”.

3. Insert ECM-AC2 supplied as an accessory into the AUDIO

IN/MIC 1/A.CAL MIC jack.

4. While pressing the X and A buttons simultaneously, turn

the VOLUME control in the direction of (+) .

5. Confirm that the following are shown on the display panel.

1 The JACK inserted/non-inserted detection display and the

STEREO/MONO detection display.

Content of display Discriminant state

NON Not detected

ST STEREO

MN MONO

2 Presence of DIGITAL voice input to the microcomputer.

(OK: input, NG: no input)

3 The value of the MIC input to the microcomputer. (shown

“0 – 255” (Changes in real time))

* * * * * * * *

123

11. Color System Change-over (EXCEPT E32, MX)

It is a mode to switch the color system (PAL/NTSC).

Procedure:

1. Press the ?/1 button to turn the power on

2. Press the FUNCTION button to set the function “DVD”.

3. Press the ?/1 button to turn the power off.

4. While pressing the X button, press the ?/1 button

simultaneously.

5. Each time you perform this operation the color system toggles

between P AL and NTSC. “NTSC” lights up in the front display

when “NTSC” is selected.

PL: SD detection

When the “L” output from the SD (shutdown) port on the SMASTER POWER Driv er is detected, the power system other

than that of the FL tube is turned off, and the protection state

is established.

DC detection

When the “L” output from the power/speaker error detection

circuit (DC detection port) is detected for two seconds

continually, the po wer system other than that of the FL tube is

turned off, and the protection state is established.

26

HCD-DZ555K/DZ556KB/DZ750K

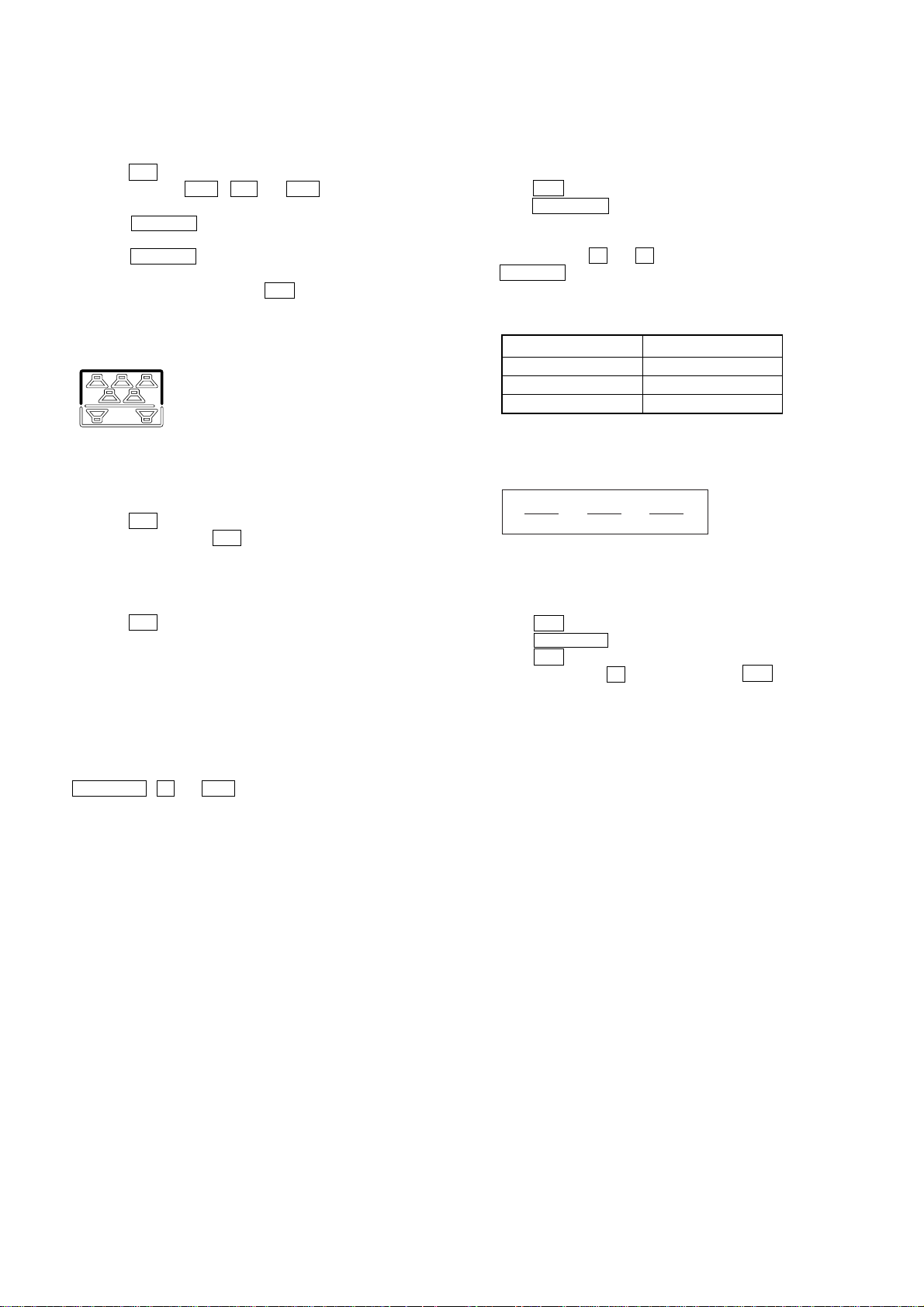

12. Digital Media Port Test

1. Connect the DMPORT CHECK JIG (P/N: J-2501-309-A) with

the terminal DMPORT.

2. Press the ?/1 button to turn the power on.

3. Confirm that both LEDs of the DMPORT confirmation JIG

lights. (Confirmation the power supply line.)

4. Set the FUNCTION button with “DMPORT” on this model.

5. Press the X , . buttons and turn the VOLUME control

in the direction of (+) simultaneously, the DMPOR T test mode

is activated.

6. It is confirmed that “DMPORT OK” is displayed on this set

display. (Confirmation of communication line)

7. To a pinjack of the DMPORT confirmation JIG input

information relevant to audio signal (sine-wa ve 1.0Vrms) and

composite video signal (white 100% 1.0Vp-p, color bar, etc.)

8. Confirm the output of speakers and monitor TV. (Confirmation

of analog signal)

9. To e xit from this mode, press the X , . buttons and turn

the VOLUME control in the direction of (+).

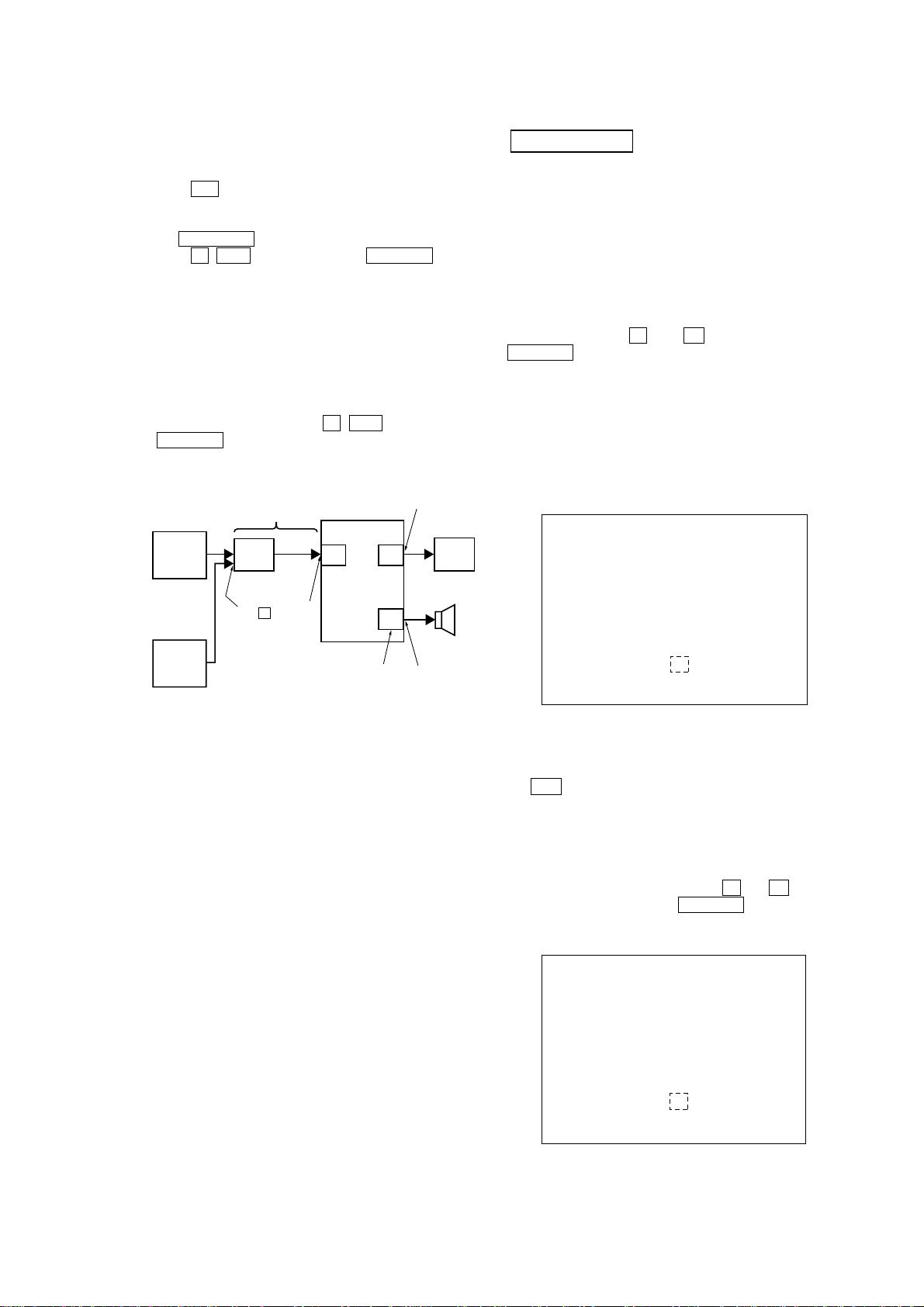

DMPORT

CHECK JIG

VIDEO

AUDIO

color pattern

generator

AF oscillator

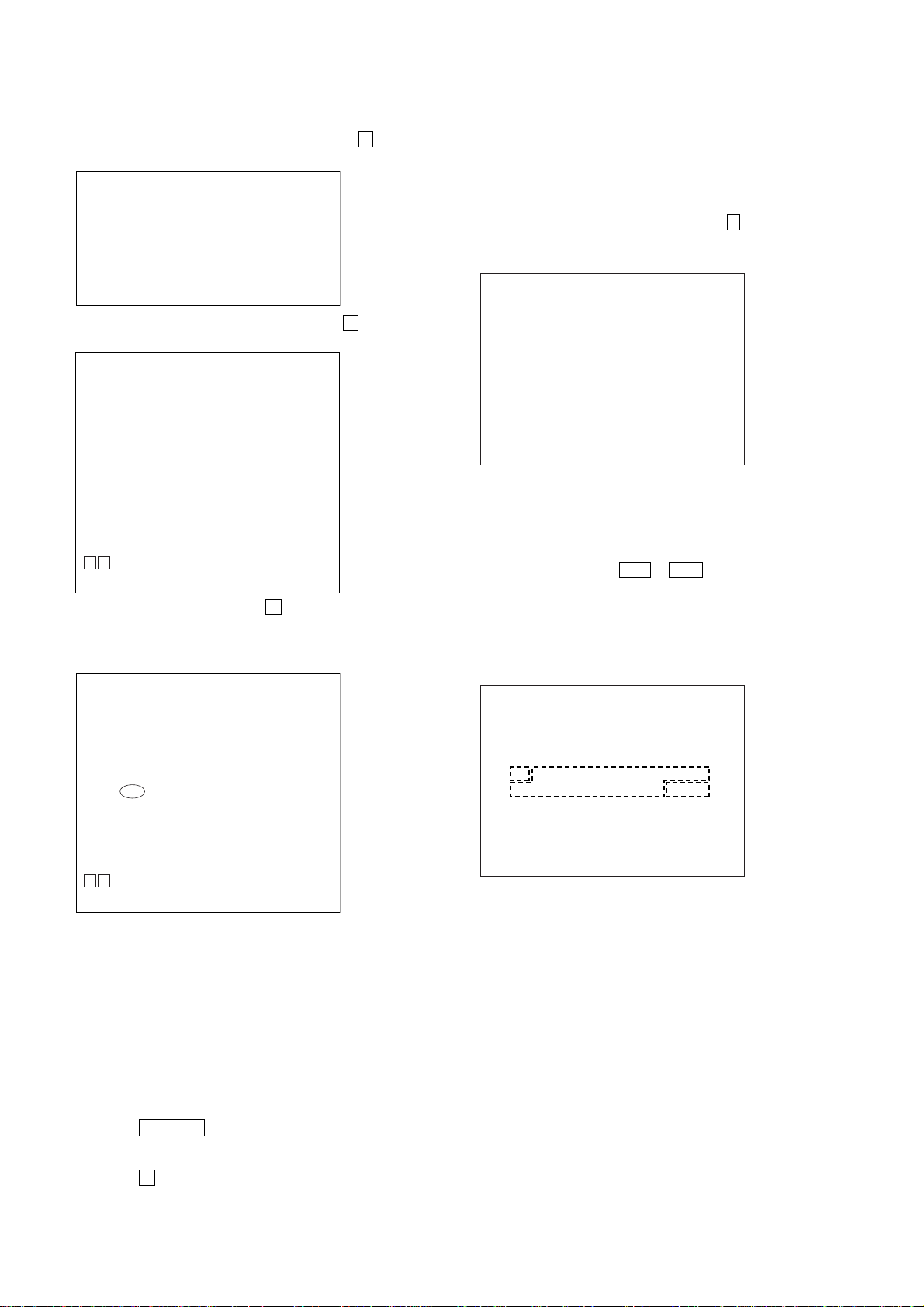

(P/N :

J-2501-309-A)

CN204

V

J001

SET

DMPORT

board

IO-S-OUT

SPEAKER

board

J301

board

FL speaker,

FR speaker

TB301

TV

DVD SECTION

13-1. General Description

The IOP measurement allows you to make diagnosis and adjustment

simply by using the remote commander and monitor TV. The

instructions, diagnosis results, etc. are given on the on-screen display

(OSD).

Be sure to execute the IOP measurement when a BU (Base Unit) is

replaced.

13-2. How To Enter Test Mode

While pressing the x and A buttons simultaneously, turn

VOLUME control in the direction of (+) with the DVD player in

power on.

The Test Mode starts, displayed “SERVICE IN” on this model

display then the menu shown below will be displayed on the TV

screen.

* The display of the “Model Name” of the “Remocon Diagnosis

Menu” change with the model and the destination. Refer to below

on the model name.

DZ555K, DZ556KB : DS4K

DZ750K : DS8K

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

1

Model Name

IF-con : V

Syscon : Ver.

*1: Changes depending on destination

: DS8K_ XX

er. XX.XX (XXXX)

The menu above is the Remocon Diagnosis Menu screen which

consists of five main functions. At the bottom of the menu screen, the

model name and IF-con version. To exit from the Test Mode, press

the ?/1 button on the remote commander.

*

X.XXX

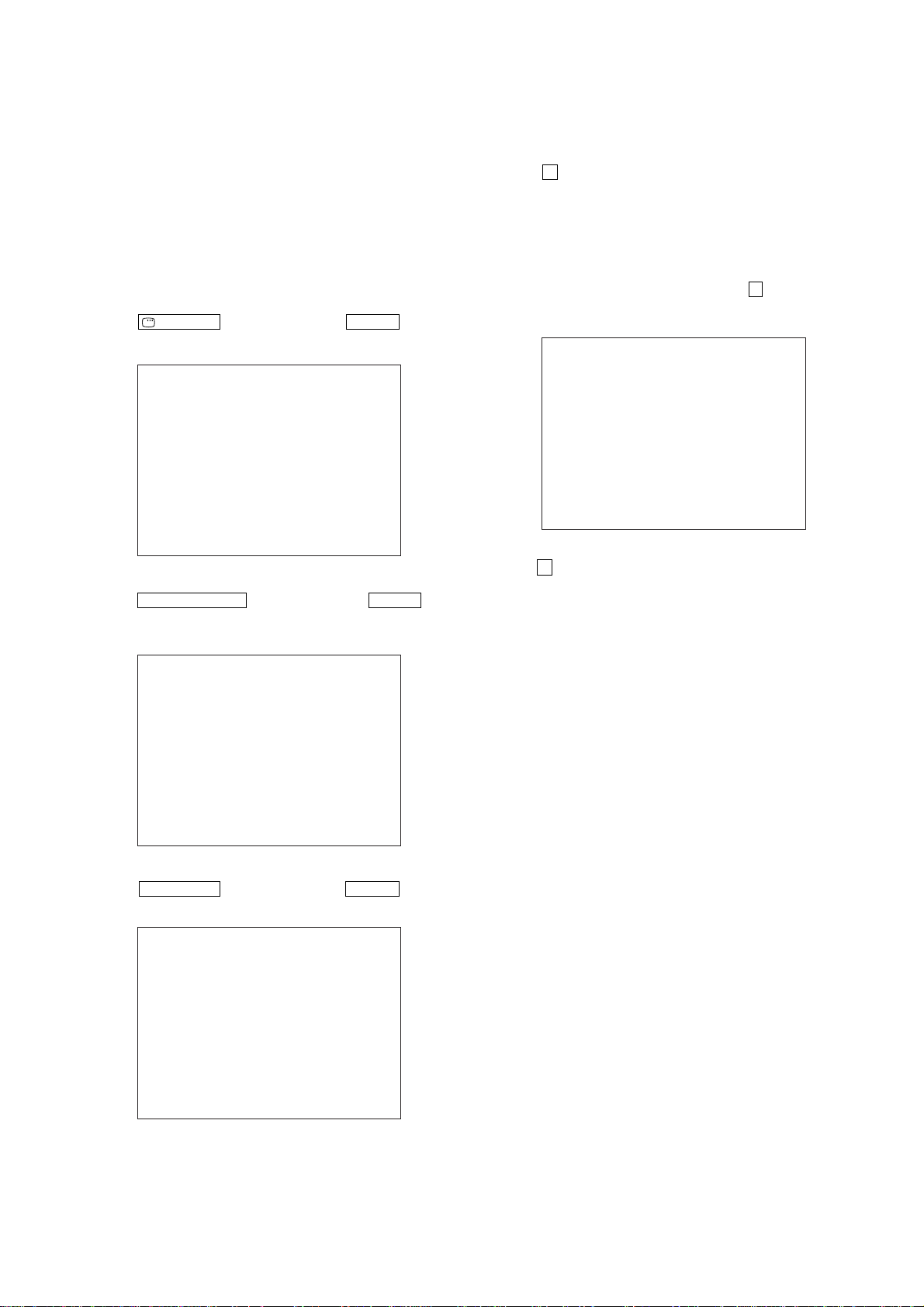

13-3. Executing IOP Measurement

In order to execute IOP measurement, the following standard

procedures must be followed.

(1) In power on, while pressing the x and A buttons

simultaneously, turn the VOLUME control in the direction

of (+).

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version information

1

Model Name

IF-con : Ver. XX.XX (XXXX)

Syscon : Ver. X.XXX

*1: Changes depending on destination

: DS8K_ XX

*

27

HCD-DZ555K/DZ556KB/DZ750K

(2) Select “2. Dri ve Manual Operation” by pressing the 2 button

on the remote commander. The screen will appear as shown.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time adjust

0. Return to Top Menu

(3) Select “3. Manual Adjustment” by pressing the 3 button on

the remote commander. The screen will appear as shown.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Oo Change Value

[RETURN] Return to previous menu

(4)Select “6.IOP” by pressing the 6 button on the remote

commander.

(5) Wait until a hexadecimal number appear.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop. 58:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Oo Change Value

[RETURN] Return to previous menu

(6) Convert each data from hexadecimal to decimal using

conversion table.

(7) Please find the label on the rear of the BU (Base Unit).

The default IOP value is written in the label.

(8) Subtract between these two values.

(9) If the remainder is smaller than 93 (decimal), then it is OK.

Ho wever if the v alue is higher than 93, then the BU is defecti ve

and need to be change.

(10) Press the RETURN button on the remote commander to

return back to previous menu.

(11) Press the 0 button on the remote commander to return to

Top Menu.

13-4. Emergency History

To check the emergency history, please follow the following

procedure.

(1) From the Top Menu of Remocon Diagnosis Menu, select “3.

Emergency History Check” by pressing the 3 button on the

remote commander. The following screen appears on the onscreen display.

Emg. History Check

Laser Hours CD 999h 59min

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 92 46 00

(2) You can check the total time when the laser is turned on during

playback of DVD and CD from the above menu. The maximum

time, which can be displayed are 999h 59min.

(3) You can check the error code of latest 10 emergency history

from the above menu. To view the previous or next page of

emergency history , press . or > button on the remote

commander. The error code consists of the following three

blocks. The first block indicates the error code. The second

block indicates the parameter and the third block indicates the

time of error code as shown below.

• Error Code

Emg. History Check

Laser Hours CD 999h 59min

*1*

01. 01 05 04 04

02. 02 02 01 01 00 A9 4B 00

[O] Return to Top Menu

2

00 00 00 00 00 00 23 45

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

DVD 999h 59min

00 92 46 00

*

3

*1 : Error Code

*2 : Parameter of error code

*3 : Time of error code

The meaning of error code is as below:

01: Communication error (No reply from syscon)

02: Syscon hung up

03: Power OFF request when syscon hung up

19: Thermal shutdown

24: MoveSledHome error

25: Mechanical move error (5 Changer)

26: Mechanical move stack error

30: DC motor adjustment error

31: DPD offset adjustment error

32: TE balance adjustment error

33: TE sensor adjustment error

34: TE loop gain adjustment error

35: FE loop gain adjustment error

36: Bad jitter after adjustment

40: Focus NG

42: Focus layer jump NG

28

HCD-DZ555K/DZ556KB/DZ750K

52: Open kick spindle error

51: Spindle stop error

60: Focus on error

61: Seek fail error

62: Read Q data/ID error

70: Lead in data read fail

71: TOC read time out (CD)

80: Can’t buffering

81: Unknown media type

13-4-1. Clear the Laser Hour

Press DISPLA Y button and then press CLEAR button on the

remote commander. The data for both CD and DVD data are reset.

Emg. History Check

Laser Hours CD 0h 0min

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 0h 0min

00 92 46 00

13-4-2. Clear the Emergency History

Press DVD T OP MENU button and then press CLEAR button on

the remote commander. The error code for all emergency history

would be reset.

13-4-4. Return to the Top Menu of Remocon Diagnosis

Menu

Press 0 button on the remote commander.

• Check Version Information

To check the version information, please follow the following

procedure.

(1) From the Top Menu of Remocon Diagnosis Menu, select “4.

Version Information” by pressing the 4 button on the remote

commander. The following screen appears on the on-screen

display.

Version information

Firm (Main) : Ver. x.xxx

Firm (Sub) : xx.xx

RISC : xxxxxx

8032 : xxxxxx

Audio DSP : xx.xx.xx.xx

Servo DSP : xx.xx.xx.xx

[O] Return to Top Menu

To return to the Top Menu of Remocon Dia gnosis Menu, press

0 button on the remote commander.

Emg. History Check

Laser Hours CD 999h 59min

01. 00 00 00 00

00 00 00 00 00 00 00 00

02. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 00 00 00

13-4-3. Clear the Initialize Setup Data

Press DVD MENU button and then press CLEAR button on the

remote commander.

Emg. History Check

Laser Hours CD 999h 59min

Initialize setup data...

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

29

HCD-DZ555K/DZ556KB/DZ750K

SECTION 5

ELECTRICAL ADJUSTMENT

DVD SECTION

When the optical pick-up assy is replaced, perform the “Executing

IOP Measurement”.

Executing IOP Measurement (See page 27)

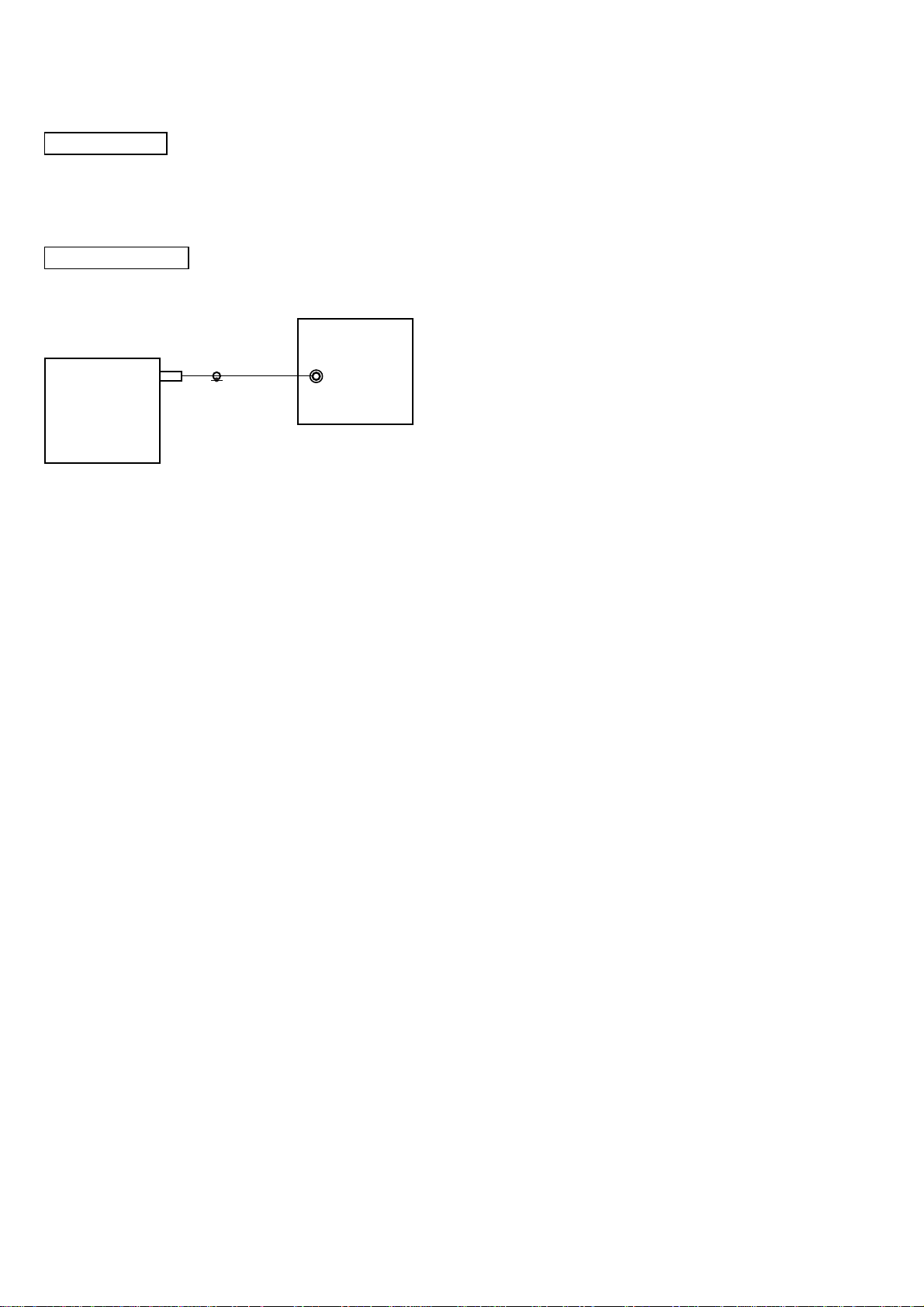

TUNER SECTION

[FM Tune Level Check]

generator

SET

Procedure:

1. Turn the power on.

2. Input the following signal from Signal Generator to FM

antenna input directly.

* Carrier Freq: A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confirm “TUNED” is lit on the display for A, B and C signals.

The mark of “TUNED” means “The selected station signal is

received in good condition.”

OUT (75

Ω

)

30

Loading...

Loading...