Sony HCD-101 Service manual

HCD-101

SERVICE MANUAL

• HCD-101 is the CD PLAYER,

TUNER and AMPLIFIER

sections in CMT-101.

SPECIFICATIONS

AEP Model

UK Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM50

Optical Pick-Up Type KSS-313A

Tuner section

T uning range

2 band model

European model: FM : 87.5-108MHz

(50kHz step)

AM : 522–1,611kHz

Other models: FM : 87.5–108MHz

(50kHz step)

AM : 531–1,602kHz

(at 9kHz interval)

530–1,710kHz

(at 10kHz interval)

3 band model FM : 87.5–108MHz

(50kHz step)

MW : 522–1,611kHz

(at 9kHz interval)

LW : 144–288kHz

(at 3kHz interval)

Intermediate frequency FM : 10.7MHz

AM : 450kHz

Aerial terminals FM : 75Ω unbalanced

AM : External aerial

terminal

Timer Quartz lock system

Timer setting One-minute step

Sleep timer 10–minute step, max.

90minutes

CD player section

System Compact disc digital

audio system

Laser Semiconductor laser

(λ=780nm)

Laser output power Less than 44.6µW*

* This output is the value measured at a distance of 200mm from

the objective lens surface on the optical pick-up block with 7mm

aperture.

Frequency response 5Hz–20kHz

Signal to noise ratio More than 90dB

Harmonic distortion Less than 0.05%

Amplifier section

European model:

DIN power output 15+15 W (4Ω at 1kHz, DIN

Continuous RMS power output

21+21 W (4Ω at 1kHz, 10%

THD)

Music power output 26+26 W

Other model

Rated RMS power output16+16 W (4Ω at 1kHz, 1% THD,

AC240V/AC120V)

Reference RMS power output

22+22 W (4Ω at 1kHz, 10% THD,

AC240V/AC120V)

Inputs VIDEO/PC IN jack : Stereo

phone jack, sensitivity 500mV,

impedance 47kΩ

— Continued on next page —

COMPACT COMPONENT SYSTEM

MICROFILM

TABLE OF CONTENTS

Outputs VIDEO/PC OUT jack : Stereo phone

jack, 250mV, 1kΩ

DIGIT AL OUT (CD OPTICAL OUT):

Square optical connector jack, –18dBm,

wave jength 660nm

PHONES (headphones) jack :

Stereo mini jack, accepts head phones of

8Ω or more.

General

Power requirements

European model 220–230V AC, 50/60Hz

Other models 110–120V or 220–240V

AC, 50/60Hz adjustable

with voltage selector

Power consumption 66W (when connected to TC-TX101,

MDS-MX101)

Dimensions Approx. 142×125×260mm (w/h/d) incl.

projecting parts and controls

Mass Approx. 4.1kg

SERVICE NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

1. GENERAL

······································································ 3

2. DISASSEMBLY

2-1. Case ····················································································4

2-2. Front Panel Section ···························································· 4

2-3. PRE Board ·········································································· 5

2-4. Function board, Relay board, SP TM board, Trans board,

Power board········································································ 5

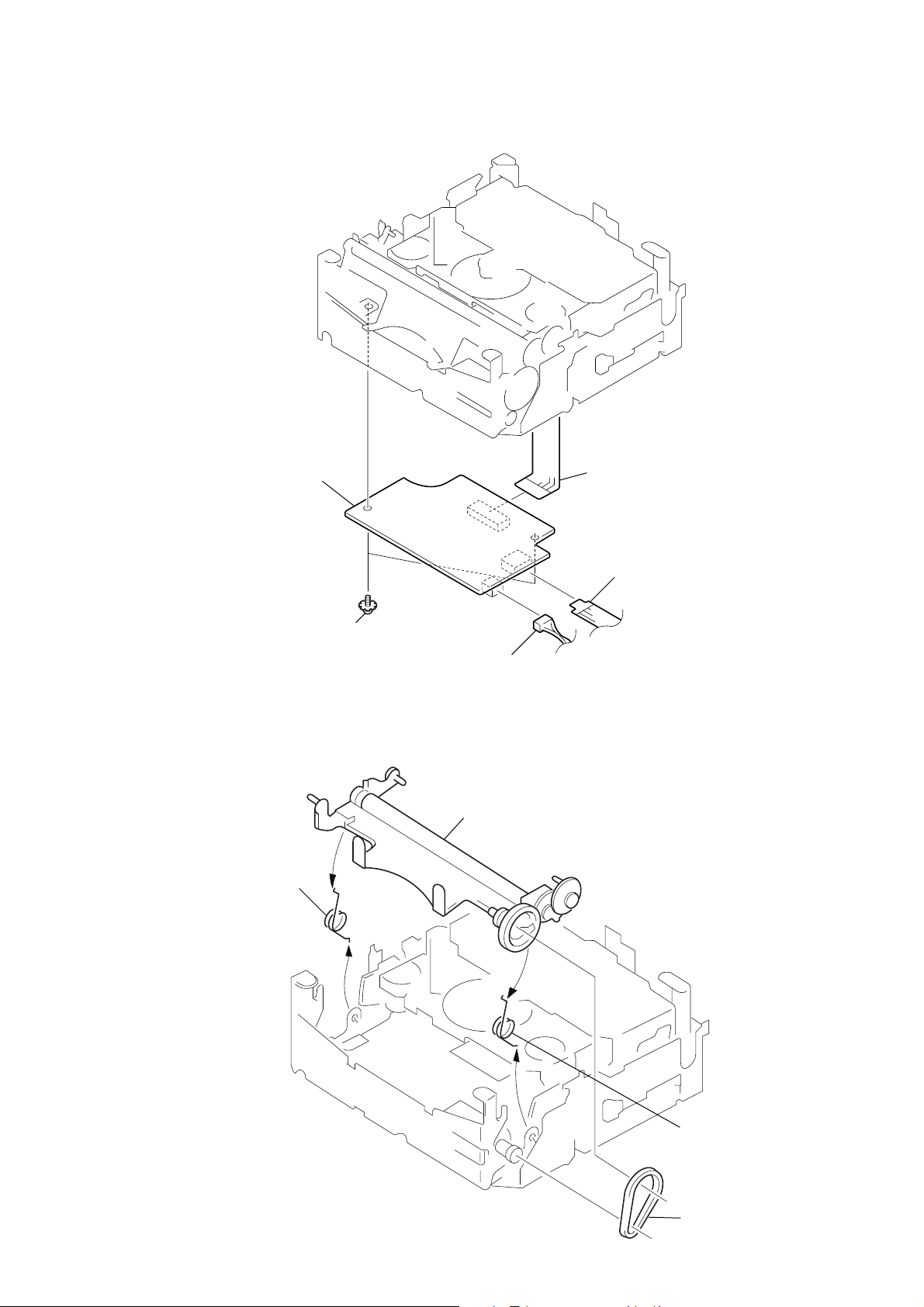

2-5. Mechanism Deck ································································ 6

2-6. Chassis (T2) Assy······························································· 6

2-7. BD Board············································································ 7

2-8. Roller Arm Block Assy······················································· 7

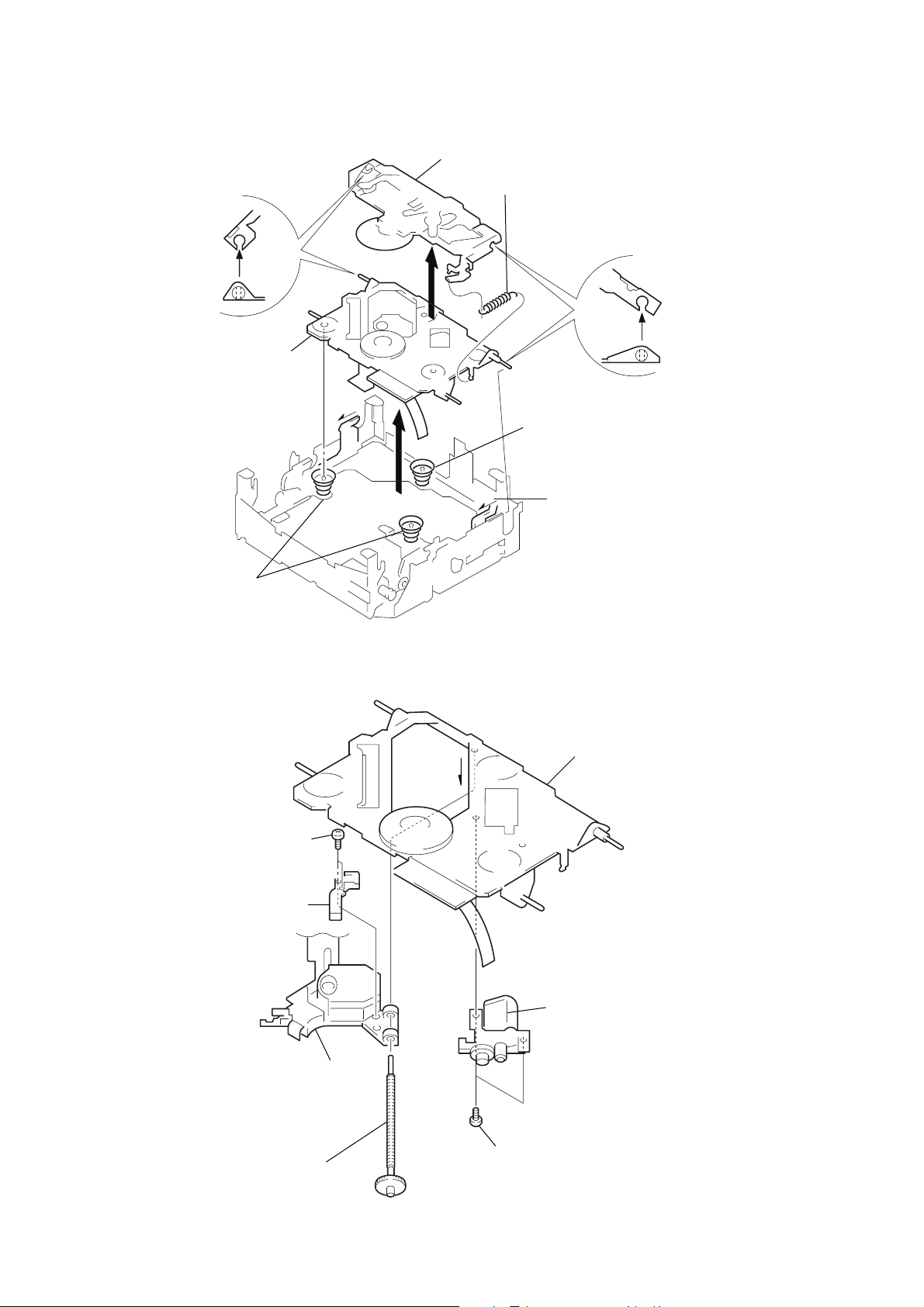

2-9. Chassis (OPT), Chucking Arm Assy ·································· 8

2-10. Motor (SL) Assy (M102), Optical Pick-Up························ 8

3. TEST MODE ·································································· 9

4. ELECTRICAL ADJUSTMENT ······························ 11

5. DIAGRAMS

5-1. Circuit Boards Location ··················································· 14

5-2. Block Diagram ································································· 15

5-3. Schematic Diagram –BD Section– ··································· 18

5-4. Printed Wiring Board –BD Section–································ 21

5-5. Printed Wiring Board –Panel Section–····························· 23

5-6. Schematic Diagram –Panel Section – ······························ 25

5-7. Printed Wiring Board –PRE Section– ······························ 27

5-8. Schematic Diagram –PRE Section– ································· 29

5-9. Printed Wiring Board –Function Section– ······················· 31

5-10. Schematic Diagram –Function Section– ··························33

5-11. Printed Wiring Board –Power Section– ···························36

5-12. Schematic Diagram –Power Section– ······························39

5-13. IC Pin Function ································································ 42

5-14. IC Block Diagrams ··························································· 44

6. EXPLODED VIEWS

6-1. Front Panel Section ·························································· 47

6-2. Chassis Section································································· 48

6-3. Mechanism Deck Section-1 (CDM50)····························· 49

6-4. Mechanism Deck Section-2 (CDM50)····························· 50

7. ELECTRICAL PARTS LIST ···································51

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

— 2 —

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

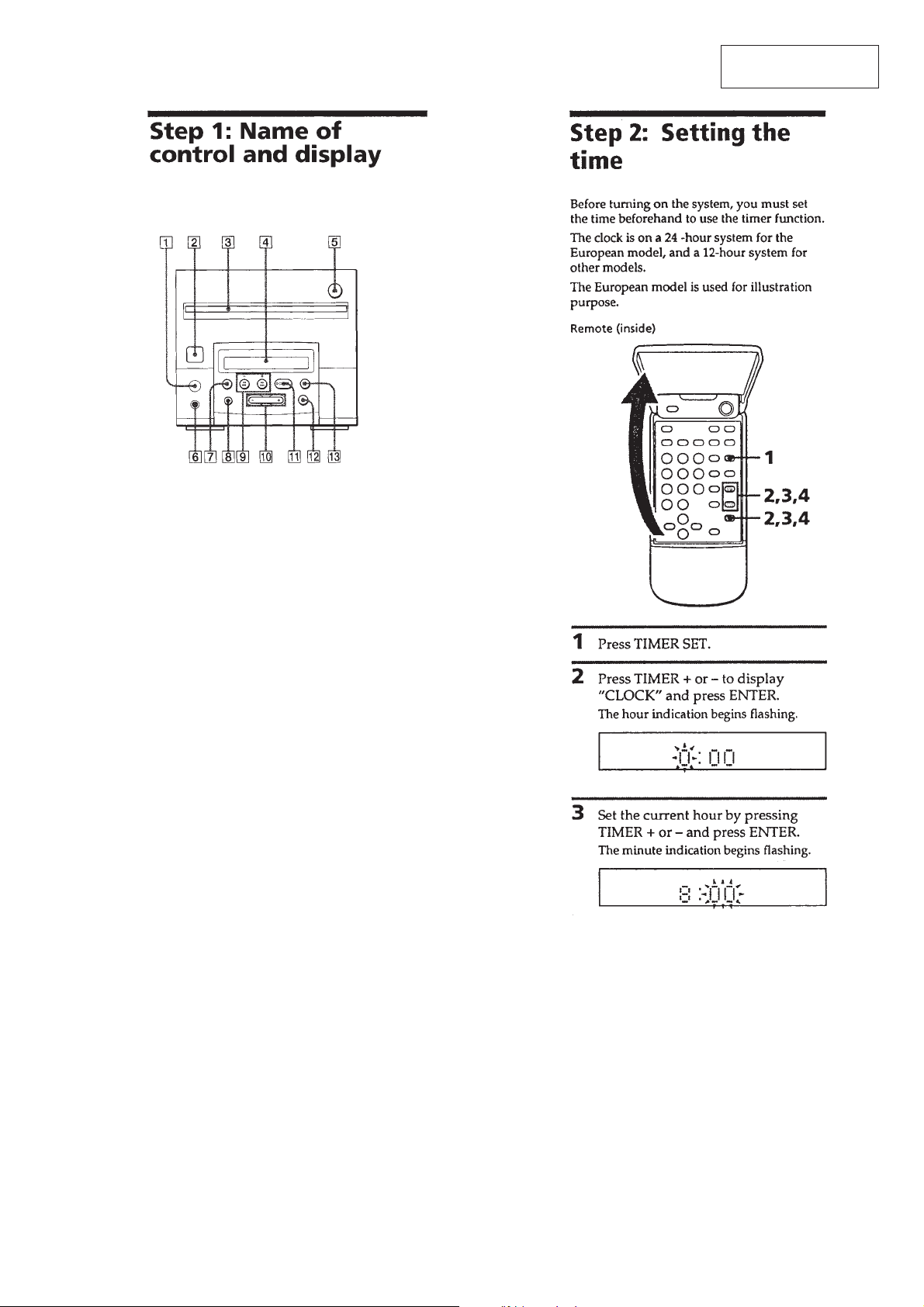

SECTION 1

GENERAL

1 Remote control signal sensor

2 Power switch

3 CD insertion slot

4 Display window

5 6 (CD EJECT) button

6 PHONES terminal

7 BAND button

8 DBFB button

9 =0/)+ (Cue-up musics, or fast rewind / fast

forward) button

0 VOL+/– button

!¡ ^ (CD playback or pause) button

!™ FUNCTION button

!£ p (CD stop) button

This section is extracted

from instruction manual.

— 3 —

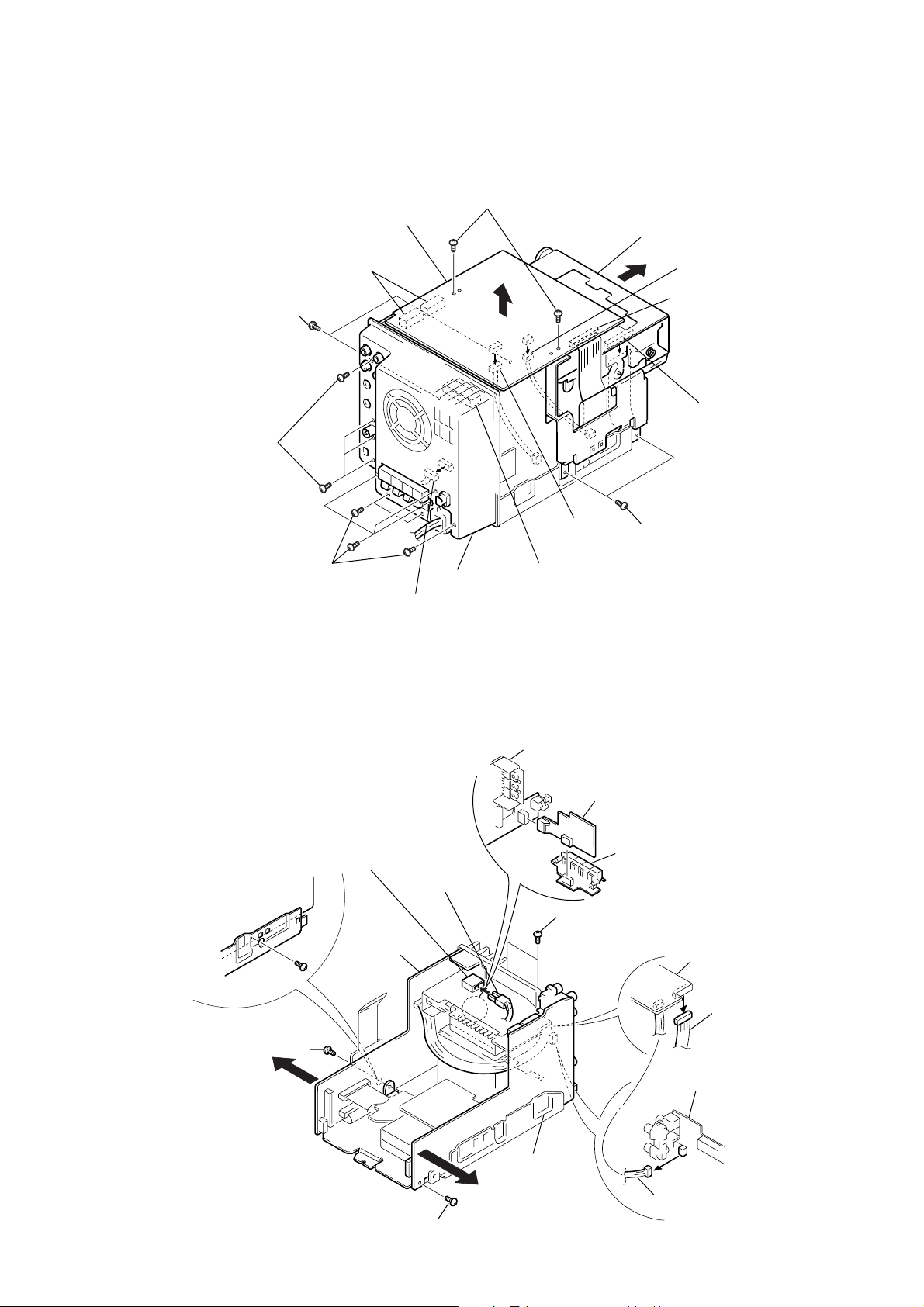

2-1. CASE

1

Two screws (Case 3 TP2)

SECTION 2

DISASSEMBLY

2

Remove the case upward in the

direction of the arrow.

2-2. FRONT PANEL SECTION

claw

1

Two screws (Case 3 TP2)

3

Wire (Flat Type)

(27 Core)

2

Pull the front panel out.

4

Connector

(CN916)

1

Two screws

(BV/Ring S Tight)

— 4 —

5

Front panel section

2-3. PRE board

1

Four screws

(BVTP 3

!¡

(CN420, CN422)

5

Two screws

(BVTT 3

×

8)

1

Six screws

(BVTP 3

!™

PRE board

Two Connectors

×

6)

×

8)

2

Connector

(CN814)

4

3

Back Panel

Two screws (BVTP 3×8)

!º

Connector

(CN423)

!£

Remove CN911

6-pin (Posistor board)

8

CDM50

5

Two screws

(BVTT 3

7

Connector (CN107)

9

Wire (Flat type) (21 Core)

(CN421)

6

Wire (Flat type)

(30 Core)

×

6)

2-4. FUNCTION board, RELAY board, SP TM board, TRANS board, POWER board

Power board

6

Relay board

7

SP TM board

Trans board

Function board

5

Screws

(BVTP 3

!º

Power cord (CN902)

×

8)

9

Power board

!¡

Trans board

8

Two screws (BVTT 3×6)

3

Connector (CN910)

1

Screws (BVTP 3×8)

— 5 —

4

Function board

2

Connector (CN404)

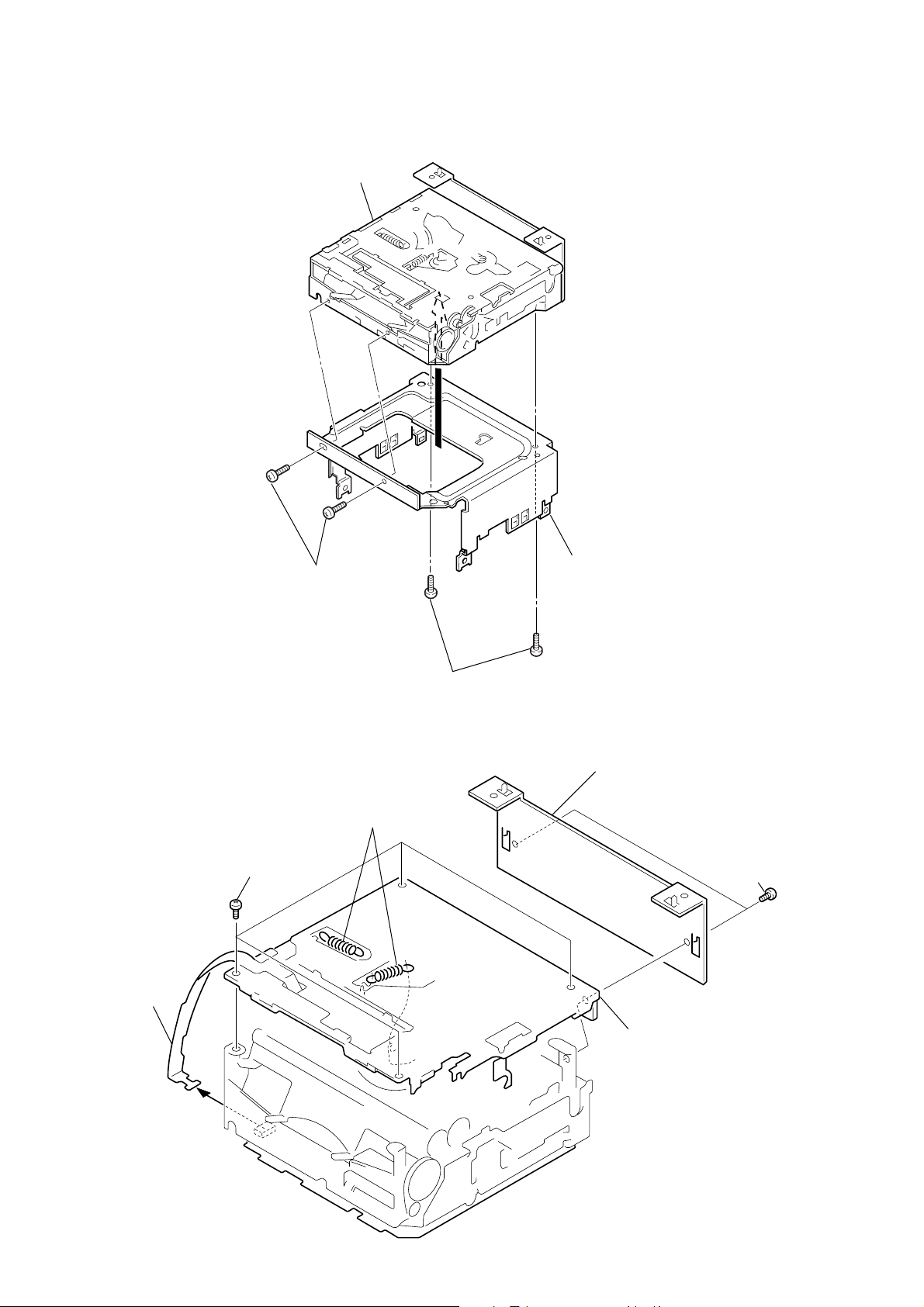

2-5. MECHANISM DECK (CDM50)

3

Mechanism Deck (CDM50)

1

Two screw (BVTT 2.6×6)

2

Bracket (CDM)

2-6. CHASSIS (T2) ASSY

3

Four screws

(BVTT 3

4

Sensor Flexible

board

1

Two screw (BVTT 2.6×6)

2

Bracket

5

Tension coil spring

1

×

6)

6

Chassis (T2) assy

Two screws

(BVTT 2.6

×

6)

— 6 —

2-7. BD board

)

5

BD board

4

Flexible board

(CN101)

3

Flexible board

(CN106)

1

Two screws

(BVTT

2-8. ROLLER ARM BLOCK ASSY

1

Spring (press)

×

2)

2

Connectir (CN104)

3

Roller arm block assy

— 7 —

1

Spring (press)

2

BELT (L

2-9. CHASSIS (OPT) ASSY, CHUCKING ARM ASSY

)

6

Move the Chucking arm assy

to the position shown in the

illustration and move it up.

2

Chassis (OPT)

assy

7

Chucking arm assy

5

Spring (CH)

6

Move the Chucking arm assy

to the position shown in the

illustration and move it up.

4

Spring (FL2)

A

Two Spring (FL)

3

2-10. MOTOR (SL) ASSY (M102), OPTICAL PICK-UP (KSS-313A)

A

4

Screws

(+P 1.7

5

Gear (SL Feed)

×

4)

1

Move the lever in the

direction of arrow (A).

7

Chassis (OPT) assy

6

Optical Pick-Up

(KSS-313A)

3

Move the shift (SL)

assy in the direction

of arrow

A

remove

it from chassis (OPT)

and optical Pick-up.

1

Two screws (+BVTT 3×6)

— 8 —

2

Motor (SL)assy (M102

SECTION 3

TEST MODE

There are two methods to enter the TEST mode.

• How to Enter the Test Mode - 1

Remove the AC power cord from wall outlet, and press [EJECT

6]. While pressing [EJECT 6], connect the AC power cord to

wall outlet.

• How to Enter the Test Mode - 2

(This method toggles between “Entering the TEST Mode” and

“Exiting the TEST Mode”.)

Turn on the main power. While pressing [TUNING +], press

[DBFB], release hand from [DBFB] then press [FUNCTION].

(Keep pressing [TUNING] all the way.)

Pressing these buttons again in the same order exits the TEST

mode.

* The small ATT segment lights in the center top of display during

the TEST mode.

* T o exit the TEST mode, disconnect the AC po wer cord from wall

outlet, or use “How to Enter the TEST Mode - 2”.

1. Audio volume control setting (Can be adjusted only during TEST

mode.)

Press [CD STOP p] and [VOL–] at the same time

→ VOL MINIMUM appears

Press [CD STOP p] and [VOL+] at the same time

→ VOL MAXIMUM appears

* The audio volume data is kept stored even after the main power

is turned off.

2. Audio balance setting (Can be adjusted only during TEST

mode.)

Press [CD STOP p] and [DBFB] at the same time

→ LEFT 10 appears

Press [CD STOP p] and [FUNCTION] at the same time

→ RIGHT 10 appears

Press [CD STOP p] and [CD EJECT 6] at the same time

→ CENTER appears

* The audio balance data is kept stored even after the main power

is turned off.

5. Watch operation check (Can be operated only while the main

power is off.)

Press [FUNCTION] and [BAND] at the same time. → Watch

starts counting.

Various CD tests

Pressing the two keys at the same time enables the various

adjustment and test as follows in the TEST mode, and “ATT”

segment is flashing.

1) Pressing [TUNING–] and [CD EJECT 6] at the same time :

The present normal tracking balance value (“31” to “36”) is

displayed when the above key operation is performed and

(TRBAL.) is displayed.

The tracking gain is fixed to “3F” (TOG1 to TOG2: all off)

2) Pressing [TUNING–] and [DBFB] at the same time :

(SHUFFLE) is displayed.

• ADJUSTMENT mode

When the above key operation is performed, the machine

enters the ADJUSTMENT mode. The “SHUFFLE” flashes

on display tube.

During the ADJUSTMENT mode:

The CLV gain is not switched to 8 cm. (The CLV gain is

fixed to 12 cm always.)

The machine is ready to enter the AF-ADJUSTMENT mode

as described below.

3) Pressing [TUNING–] and [FUNCTION] at the same time :

(SHUFFLE) and (PROGRAM) are displayed.

• AF-ADJUSTMENT mode

After the machine enters the ADJUSTMENT mode by the

key operation as described in step 2), the machine can enter

the AF-ADJUSTMENT mode by pressing the above key

operation. [TUNING – /FUNCTION]

The “SHUFFLE” and “PROGRAM” flash on display.

3. Key test and FL display tube test (Can be adjusted only during

TEST mode.)

• Press [VOL-] and [BAND] at the same time→All FL tubes

light. Pressing the following key in this status enables key

checks as follows.

• Display depending upon the pressed key

[FUNCTION] → KEY NO. 1

[VOL –] → KEY NO. 2

[VOL +] → KEY NO. 3

[BAND] → KEY NO. 4

[TUNING+] → KEY NO. 5

[EJECT 6] → KEY NO. 6

[TUNING –] → KEY NO. 7

[STOP p] → KEY NO. 8

[PLAY ^] → KEY NO. 9

[DBFB] → KEY NO. 10

• [POWER] → Returns to the TEST mode

* Note: After all keys are (KEY No.1 to KEY No.10) tested,

CHECK OK!! appears.

The following items have no relation with the TEST mode.

4. Initial setting (All clear of all memories)

Disconnect the AC power cord. While pressing [POWER],

connect the AC power cord to wall outlet.

During the AF-ADJUSTMENT mode, the tracking and sled

servos are turned off in addition to the ADJUSTMENT mode.

The machine stops the GFS error check which is normally

performed by software.

• Sled motor check

When disc is removed by pressing EJECT during the AFADJUSTMENT mode, the sled can be moved to inner

circumference or outer circumference by pressing [TUNING–

] or [TUNING+]. At this time, because the microprocessor

is not sensing the sled position, be careful when moving the

sled not to damage gears and other mechanism.

4) Pressing [TUNING–] and [VOL–] at the same time :

• No CDM mode

[1] is displayed.

When the above key operation is performed, the control on

the slot mechanism which takes in and ejects a CD disc is

stopped.

At this time “1” on the display flashes.

During the no CDM mode,

The TOC data is deleted by the [CD EJECT 6] key.

(When the TEST mode is cleared and a CD disc is inserted,

machine reads the TOC again.)

— 9 —

5) Pressing [TUNING–] and [VOL+] at the same time :

• Aging mode

The machine enters the aging mode by inserting a CD disc

and performing the above button

operation. The display starts counting the aging operation

with COUNT display, and “REPEAT” flashes.

Aging operation

1. Machine takes a disc into the machine.

2. Reads the TOC.

3. Accesses to the last track.

4. Plays back the last 2 seconds.

5. Ejects the disc.

The one complete operation from step 1 to step 5 is one count.

The cycle is repeated. However, steps 2 to 4 are skipped in all

modes other than the CD function.

Steps 1 and 5 are skipped in the no CDM mode.

The aging operation ends when an error occurs.

Aging error display

“Load Error” : Loading operation is not completed in four

seconds.

“Eject Error” : Eject operation is not completed in four

seconds.

“Q TOC Err” : The Q data could not be read during eight

seconds. (During TOC read)

“Q SRCH Err” : The Q data could not be read during eight

seconds. (During track search)

“Q PLAY Err” : The Q data could not be read during eight

seconds. (During PLAY)

“FOK UP Err” : Focus could not be locked in. (During

setup)

“FOK TOC Err” : Focus is un-locked many times. (During

TOC read)

“FOK SRCH Err” : Focus is un-locked many times. (During

track search)

“FOK PLAY Err” : Focus is un-locked several times. (During

play)

“GFS UP Err” : GFS error. (During setup)

“GFS TOC Err” : GFS error. (During TOC read)

“GFS PLAY Err” : GFS error. (During play)

** Other troubles

“TW*SW*”

TW : Numbers of times that the machine could not read

TOC.

SW : Numbers of times that the machine could not

complete the track search within 16 seconds.

To exit the aging mode and to return the TEST mode, press

[TUNING – ] and [VOL +] at the same time.

Display selection during aging

The display can be switched by pressing the [TUNING–] and

[FUNCTION] at the same time :

Example of display

Count display

Elapsed time display

Other errors

Normal display

" COUNT 723 " (Machine has repeated for 723 times.)

" 12 : 05 : 35 " (12 hours 5 minutes 35 seconds have elapsed.)

" TW 2 SW 1 "

— 10 —

V

A

B

symmetry

within 2.4

±

0.7 Vp-p

+

–

BD board

TP (RF)

TP (VC)

oscilloscope

V

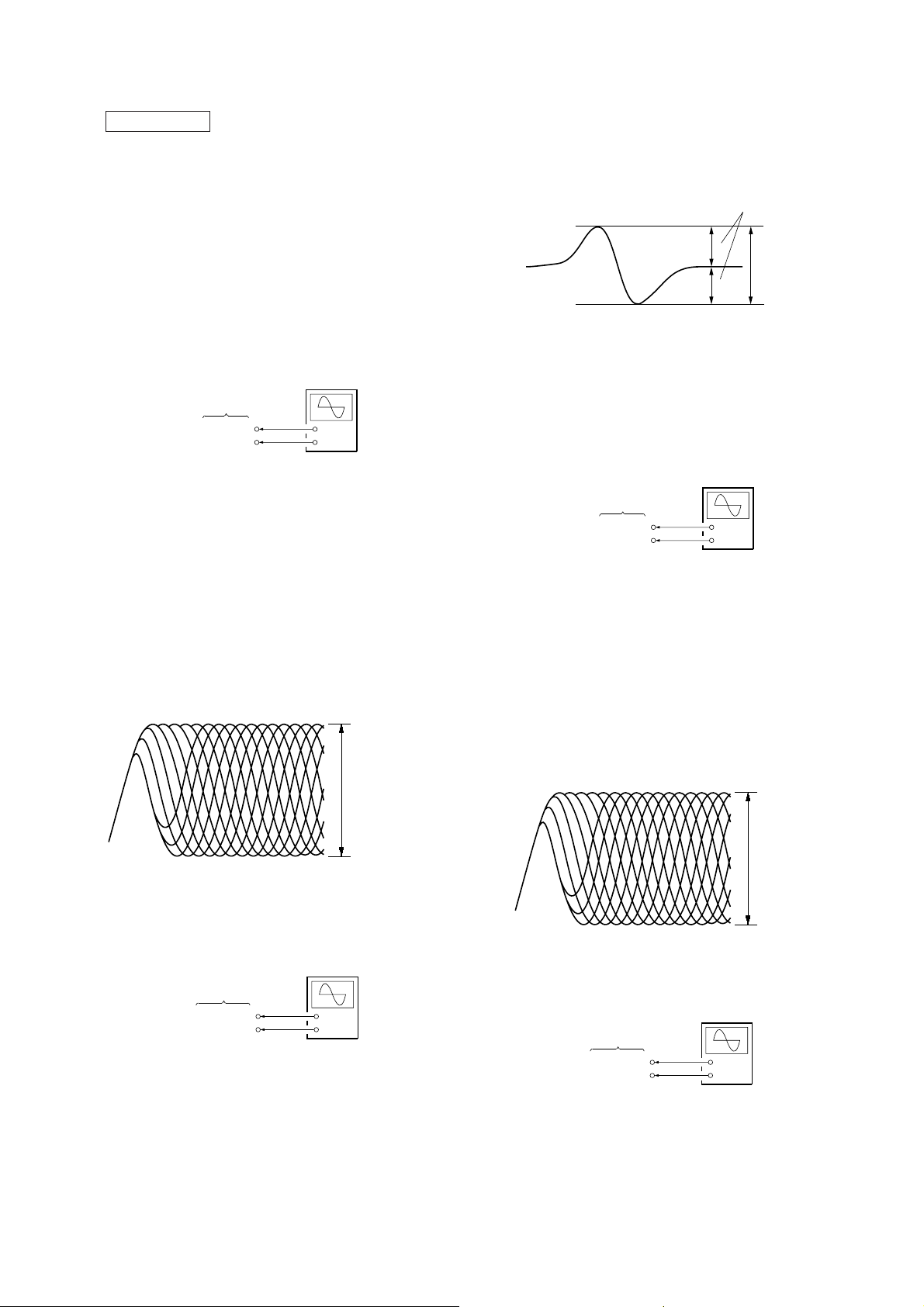

SECTION 4

ELECTRICAL ADJUSTMENTS

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indica ted.

3. Use the oscilloscope with more than 10MΩ impedance.

4. Clean an object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

5. When optical pickup is replaced during repair, perform the focus

bias adjustment.

Focus Bias Adjustment

oscilloscope

(DC range)

BD board

TP (RF)

TP (VC)

+

–

This adjustment is to be done when the optical block is replaced.

Adjustment procedure:

1. Connect oscilloscope to test point TP (VC) and TP (RF) on BD

board.

2. Turned power switch ON. (Stop state)

3. Insert disc (YEDS-18) and press the ^ button.

4. Adjust R V101 so that the oscilloscope wav eform is as shown in

the figure below (eye pattern).

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV: 200 m

TIME/DIV: 500 ns

5. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And conf irm that peak to peak le vel is within

2.4 ± 0.7 Vp-p.

S-curve waveform

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure that the ratio of

A:B or B:A is more than 10:7.

• Select a longer sweep time and increase the brightness to

obtain best waveform.

RF Level Check

Procedure:

1. Connect oscilloscope to test point TP (VC) and TP (RF) on BD

board.

2. Turned Power switch on.

3. Insert the disc (YEDS-18) and press the ^ button.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct.

Note: Clear RF signal waveform means that the shape “≈” can be

clearly distinguished at the center of the waveform.

RF signal waveform

level:

1.3

±

0.3Vp-p

When observing the eye pattern, set the oscilloscope for AC

range and raise vertical sensitivity.

S-Curve Check

oscilloscope

BD board

TP (FEO)

TP (VC)

+

–

Procedure:

1. Connect as oscilloscope to test point TP (VC) and TP (FEO) on

BD board.

2. Connect a lead wire between test point TP (FOK) and Ground.

3. Turned Power switch on.

4. Insert disc (YEDS-18) and turned Power switch on again to

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

E-F Balance (Traverse) Check

Procedure:

1. Set up the TEST mode step 3) AF-ADJUSTMENT. (see page

2. Connect as oscilloscope to test point TP (TEO) on BD board.

3. Turned Power switch on.

4. Insert the disc (YEDS-18) in and press the ^ button.

5. Confirm that the oscilloscope waveform is symmetrical on the

— 11 —

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level:

±

0.3Vp-p

1.3

oscilloscope

(DC range)

BD board

TP (TEO)

TP (VC)

+

–

9.)

top and bottom in relation to 0V dc, and check the amplitude.

Traverse waveform

y

symmetr

A

0 V

B

amplitude: 300 ± 100 mVp-p

specified value:

A-B

×

•

2 (A+B)

•

A+B = 300 ± 100 mVp-p

100 = less than ± 7%

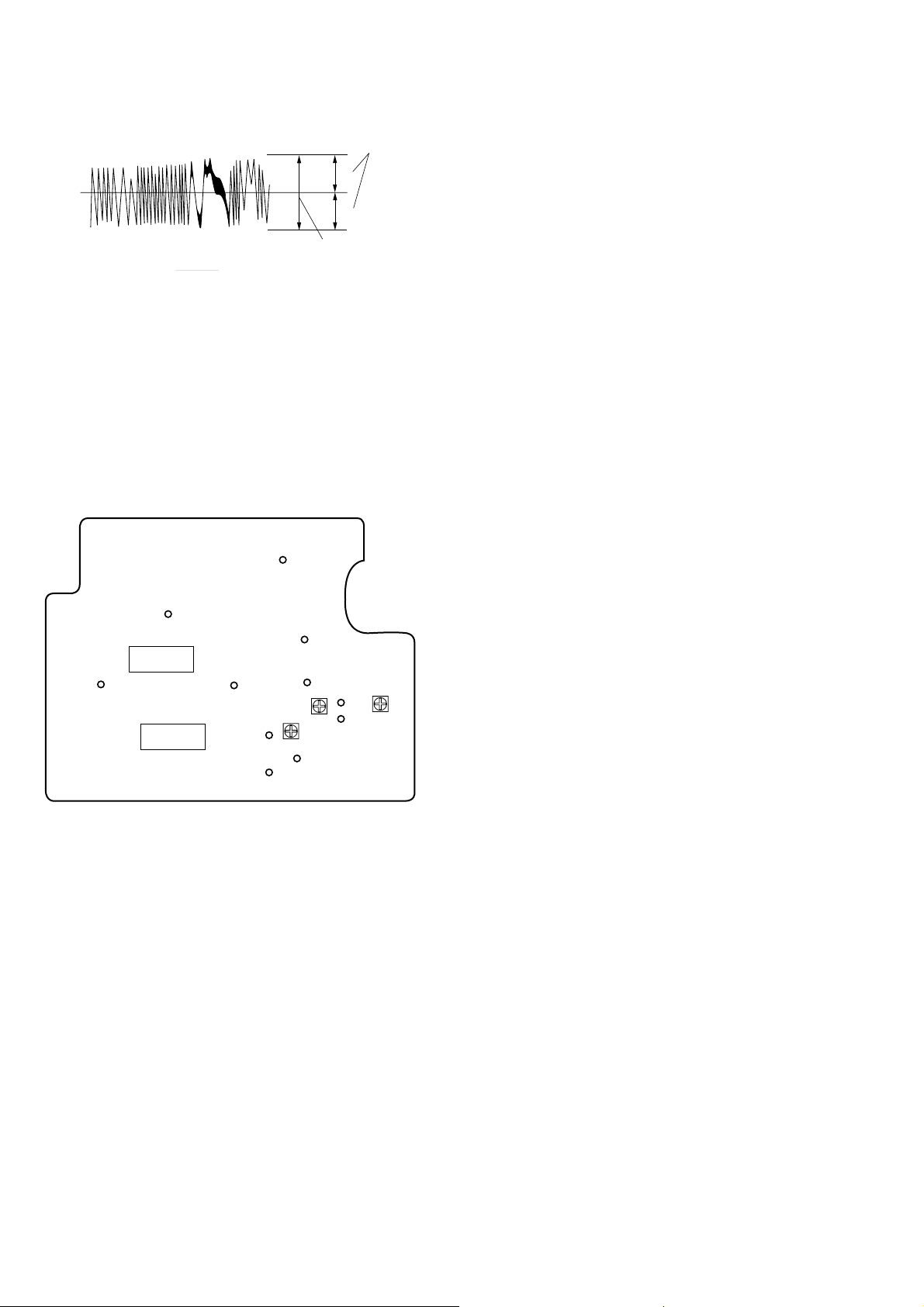

Focus/Tracking Gain Adjustment

This gain has a margin, so even if it is slightly off. There is no

problem.

Therefore, do not perform, RV102 and RV103 adjustment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

Adjustment Location:

[BD BOARD] — Component side —

(RF)

(PCK)

(VC)

IC102

IC104

(FOK)

(FEO)

(TAO)

(A.GND)

(D.GND)

RV103

RV102

(FEI)

(TEO)

RV101

(TEI)

— 12 —

— 13 —

Loading...

Loading...