Sony DSR-PD175P, DSR-PD177P, DSR-PD198P Service Manual

DSR-PD175P/PD177P/PD198P

RMT-831

SERVICE MANUAL

Ver. 1.1 2009.09

Revision History

Revision History

Revised-1

Replace the previously issued

SERVICE MANUAL 9-852-721-11

with this Manual.

N MECHANISM (MDX-N221)

Link

Link

SPECIFICATIONS

Photo: DSR-PD175P

BLOCK DIAGRAMS

AEP Model

E Model

Chinese Model

REPAIR PARTS LIST

MODEL INFORMATION TABLE

SERVICE NOTE

DISASSEMBLY

The components identified by mark 0 or

dotted line with mark 0 are critical for safety .

Replace only with part number specified.

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS

ADJUSTMENTS

DSR-PD175P/PD177P/PD198P

Sony EMCS Co.

DIGITAL CAMCORDER

2009I0800-1

© 2009.09

Published by Tokai TEC9-852-721-12

These specifications are extracted from instruction manual of

DSR-PD175P/PD177P.

SPECIFICATIONS

System

Video recording system (DVCAM (DV))

2 rotary heads, Helical scanning system

Still image recording system

Exif V er . 2.2*

Audio recording system (DVCAM (DV))

Rotary heads, PCM system

Quantization: 12 bits

Fs32kHz (channel 1/2 stereo),

Quantization: 16 bits

Fs48kHz (channel 1/2 stereo)

Video signal

PAL color, CCIR standards

Usable cassette

Mini DV cassette with the mark

printed or Mini DVCAM cassette with

the mark printed

Tape speed (DVCAM)

Approx. 28.221 mm/s

Tape speed (DV SP)

Approx. 18.831 mm/s

Recording/playback time (DVCAM)

41 min (using a PDVM-40ME cassette)

Recording/playback time (DV SP)

63 min (using a PDVM-40ME cassette)

Fast forward/rewind time

Approx. 2 min 40 s (using a PDVM 40ME cassette and rechargeable battery

pack)

Approx. 1 min 45 s (using a PDVM 40ME cassette and AC Adaptor)

Viewfinder

Electric viewfinder (color, black and white)

Picture

1.1 cm (0.45 type, aspect ratio 16:9)

Total dot number

1 226 880 (approx. 852 × 3[RGB] ×

480)

Image device

6.0 mm (1/3 type) 3CMOS sensor

Recording Pixels (DV16:9 still

recording):

Max. 1.20 Mega (1 440 × 810)

pixels**

Gross: Approx. 1 120 000 pixels

Effective (movie, 16:9):

Approx. 1 037 000 pixels

Effective (movie, 4:3):

Approx. 778 000 pixels

Effective (still, 16:9):

Approx. 1 037 000 pixels

Effective (still, 4:3):

Approx. 778 000 pixels

Lens

G Lens

20 × (Optical), Approx. 30 × (Digital,

when [D.EXTENDER] is set to [ON])

Focal length

f=4.1 - 82.0 mm (3/16 - 3 1/4 in.)

When converted to a 35 mm still

camera

29.5 -590 mm (1 3/16 - 23 1/4 in.)

(16:9),

36.1 -722 mm (1 7/16 - 28 1/2 in.)

(4:3)

F1.6 - 3.4

Filter diameter: 72 mm (2 7/8 in.)

Color temperature

[AUTO]

(one push) A/B

[INDOOR] (3 200K)

[OUTDOOR] (5 800K±7 offset levels)

[MANU WB TEMP] (2 300K 15 000K in 100K steps)

Minimum illumination

1.5 lx (lux) (Fixed Shutter Speed 1/25,

auto gain, auto iris) (F 1.6)

* “Exif” is a file format for still images,

established by the JEITA (Japan

Electronics and Information Technology

Industries Association). Files in this

format can have additional information

such as your camcorder’s setting

information at the time of recording.

** The unique pixel array of Sony's

ClearVid CMOS sensor and image

processing system (Enhanced Imaging

Processor) allows for still image

resolution equivalent to the sizes

described.

Output connectors

A/V Remote Connector

10-pin connector

When A/V connecting cable is

connected

Video signal: 1 Vp-p, 75 Ω (ohms)

Luminance signal: 1 Vp-p, 75 Ω (ohms)

Chrominance signal: 0.3 Vp-p (burst

signal), 75 Ω (ohms)

Audio signal: -10 dBu (at load

impedance 47 kΩ (kilohms)), Output

impedance with less than 2.2 kΩ

(kilohms) (0 dBu=0.775 Vrms)

i (headphones) jack

Stereo-minijack (Ø 3.5 mm)

Input/Output connectors

LANC jack

Stereo mini-minijack (Ø 2.5 mm)

INPUT1/INPUT2 jack

XLR 3-pin, female,

-48 dBu: 3kΩ (kilohms)

+4 dBu: 10kΩ (kilohms)

(0 dBu=0.775 Vrms)

DV jack

i.LINK interface (IEEE 1394, 4-pin

connector S100)

LCD screen

Picture

8.0 cm (3.2 type, aspect ratio 16:9)

Total dot number

921 600 (1 920 × 480)

DSR-PD175P/PD177P/PD198P

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor)

Average power consumption

During camera recording using the

internal microphone, and the

viewfinder with normal brightness:

DVCAM (DV) recording 6.0 W

During camera recording using the

internal microphone, and the LCD with

normal brightness:

DVCAM (DV) recording 6.2 W

Operating temperature

0 ºC to 40 ºC (32 ºF to 104 ºF)

Storage temperature

-20 ºC to +60 ºC (-4 ºF to +140 ºF)

Dimensions (approx.)

169 × 188 × 401 mm

(6 3/4 × 7 1/2 × 15 7/8 in.)

(w/h/d)

including the projecting parts

Mass (approx.)

2.2 kg (4 lb 14 oz) including the lens

hood with lens cover

AC Adaptor AC-L100/AC-L100C

Power requirements

AC 100 V - 240 V, 50 Hz/60 Hz

Current consumption

0.35 A - 0.18 A

Power consumption

18 W

Output voltage

DC 8.4 V***

Operating temperature

0 ºC to 40 ºC (32 ºF to 104 ºF)

Storage temperature

-20 ºC to +60 ºC (-4 ºF to +140 ºF)

Dimensions (approx.)

48 × 29 × 81 mm

(1 15/16 × 1 3/16 × 3 1/4 in.)

(w/h/d)

excluding the projecting part

Mass (approx.)

170 g (6.0 oz) excluding the power cord

(mains lead)

*** See the label on the AC Adaptor for other

specifications.

Design and specifications are subject to change

without notice.

— 2 —

Model information table

Model

DSR-PD175P

DSR-PD177P

DSR-PD198P

Destination

• Abbreviation

CH : Chinese model

AEP

E

CH

DSR-PD175P/PD177P/PD198P

— 3 —

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

Dispose of used batteries according to the instructions.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

DSR-PD175P/PD177P/PD198P

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less pr one to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 4 —

1. SERVICE NOTE

1-1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power suppl y (8.4V), the po wer is shut off so

that the unit cannot operate.

These following method is available to prevent this.

Method:

Use the AC adaptor (AC-L100/L100C).

1-2. TO T AKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Remove the Power supply.

2 Remove two screws and the CS lid (93501) assy.

3 Supply +4.5V from the DC power supply to the loading motor and unload.

CS lid (93501) assy

Loading motor

DC power supply

(+ 4.5 Vdc)

1-3. SETTING THE “FORCED POWER ON” MODE

It is possible to turn on power by adjustment remote commander (RM-95 or NEW LANC JIG).

Operate the VTR function using the adjustment remote commander.

1-3-1. Setting the “Forced Camera Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 01 and press the “PAUSE (Write) ” button of the adjustment remote commander.

1-3-2. Setting the “Forced VTR Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 02 and press the “PAUSE (Write) ” button of the adjustment remote commander.

1-3-3. Exiting the “Forced Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: 10, set data: 00 and press the “PAUSE (Write) ” button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

DSR-PD175P/PD177P/PD198P

1-1

1-4. USING SERVICE JIG

Connect the CPC-13 jig (J-6082-443-A) to the CN1004 on the VC-597 board.

Pin No. Signal Name Pin No. Signal Name

1 (20) REG_GND 11 (10) EEP_SO_C

2 (19) RF_MON 12 (9) EEP_SO_S

3 (18) REG_GND 13 (8) EEP_SCK_C

4 (17) SWP 14 (7) EEP_SCK_S

5 (16) FRRV 15 (6) D_2.8V

6 (15) REG_GND 16 (5) MD2_C

7 (14) GND 17 (4) MD2

8 (13) GND 18 (3) XCS_MC_FLASH_C

9 (12) EEP_SI_C 19 (2) XCS_MC_FLASH

10 (11) EEP_SI_S 20 (1) XSYS_RST

Note: The pin number in ( ) is test ter minal number of

CN1004 on the VC-597 board.

VC-597 BOARD (SIDE B)

CPC-13

(J-6082-443-A)

1

10

20

1

1

20

CN1004

20

11

1-5. SELF-DIAGNOSIS FUNCTION

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Refer to “1-5-3. Self-diagnosis Code Table”.

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen shows a 4-digit display consisting of an

alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Detailed Code

DSR-PD175P/PD177P/PD198P

1-2

1-5-3. Self-diagnosis Code Table

Self-diagnosis Code

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

04

06

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

00

10

11

20

21

22

23

24

30

40

42

72

97

98

99

10

11

20

21

22

23

24

30

40

42

60

Symptom/State

Non-standard battery is used.

The battery is too hot.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

S reel

side tape slacking when unloading

T reel fault.

S reel fault.

T reel and S reel FG short fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

Retry fault when catching one’s finger

in cassette compartment.

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

LOAD direction loading motor timeout.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

T reel and S reel FG short fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum

operations.

Difficult to adjust focus

(Cannot initialize focus.)

Correction

Use the InfoLITHIUM battery.

Replace the battery or remove it and put it in cool place.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

If it does not recover, inspect the focus MR sensor of lens drive

block (Pin q;, qs of CN5002 on the VC-597 board).

If not faulty, inspect the focus motor drive circuit

(IC6001 on the VC-597 board).

DSR-PD175P/PD177P/PD198P

1-3

Self-diagnosis Code

Repaired by:

C

C

C

C

E

E

E

E

E

E

E

E

E

E

E

E

Block

Function

32

32

32

32

20

61

61

61

62

62

62

62

62

62

62

62

Detailed

Code

72

97

98

99

00

10

11

30

00

01

02

03

10

11

12

20

Symptom/State

Retry fault when catching one’s finger

in cassette compartment.

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

Vector fault (Judgement with the set

state that is impossible actually for fault

of sensors.)

EEPROM data are rewritten.

Zoom operations fault

(Cannot initialize zoom lens.)

Focus lens initializing failure and zoom

lens initializing failure occur simultaneously.

Reset position detect error when

stepper iris is initialized.

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Abnormality of IC for steadyshot.

IC for steadyshot and micro controller

communication abnormality among.

Shift lens initializing failure

Shift lens overheating (Pitch)

Shift lens overheating (Yaw)

Abnormality of lens thermister

Correction

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Make EEPROM data correct value.

Inspect the zoom MR sensor of lens drive block (Pin es, ef of

CN5002 on the VC-597 board) when zooming is performed when

the zoom switch is operated and the zoom motor drive circuit

(IC6001 on the VC-597 board) when zooming is not performed.

Check both C: 32: 60 and E: 61: 10 of the self-diagnosis code.

Turn on the power and set to T (telephoto) end by rotating the

ZOOM manual ring. While observing the iris blades in the lens,

turn on the power again and check the iris blades in the lens

work properly. Inspect the iris drive motor of lens drive block

(Pin qh to ql of CN5002 on the VC-597 board), when the iris

does not operate. Inspect the iris reset sensor of lens drive block

(Pin qd to qg of CN5002 on the VC-597 board), when the iris

operate.

Inspect pitch angular velocity sensor (SE8501 on the GY-014

board) peripheral circuits.

Inspect yaw angular velocity sensor (SE8502 on the GY-014

board) peripheral circuits.

Inspect the steadyshot circuit (IC7001 on the VC-597 board). If

it does not recover, replace the VC-597 board. (Note) If an error

occurs again, replace the lens block.

Inspect the steadyshot circuit (IC7001 on the VC-597 board).

Inspect the EEPROM (IC4202 on the VC-597 board). If it does

not recover, replace the VC-597 board. (Note) If an error occurs

again, replace the lens block.

Inspect the IC7001 and peripheral circuits on the VC-597 board.

If it does not recover, replace the VC-597 board. (Note) If an

error occurs again, replace the lens block.

Inspect the IC7001 and peripheral circuits on the VC-597 board.

If it does not recover, replace the VC-597 board. (Note) If an

error occurs again, replace the lens block.

Inspect the IC7001 and peripheral circuits on the VC-597 board.

If it does not recover, replace the VC-597 board. (Note) If an

error occurs again, replace the lens block.

Note: When replacing the VC-597 board, remove the EEPR OM (IC4202) from the VC-597 board that is going to be repaired. Install the removed EEPROM

(IC4202) to the replaced VC-597 board.

DSR-PD175P/PD177P/PD198P

1-4E

2. DISASSEMBLY

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

NOTE FOR REPAIR

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

NOTE FOR DISCONNECTING THE HARNESS (COAXIAL CABLE)

When disconnecting the harness (COAXIAL CABLE), do not

pull the harness part but pull off the connector body with tweezers

etc.

Harness

(coaxial cable)

Tweezers etc.

DSR-PD175P/PD177P/PD198P

2-1

2-1. IDENTIFYING PARTS

Handle Section

• AS-060 Board

• FP-966 Flexible Board

• FP-967 Flexible Board

• FP-981 Flexible Board

• FP-982 Flexible Board

• GP-025 Board

• HT-002 Board

• KY-105 Board

• MA-454 Board

• PD-372 Board

• PI-029 Board

• VF-178 Board

• XL-010 Board

BT Panel Section

• HP-153 Board

• JK-376 Board

Cabinet (R) Section

• CK-204 Board

• FP-969 Flexible Board

• MD-141 Board

• Mechanism Deck

MD-141

VC-597

- DISASSEMBLY FLOW -

2-2-1. OVERALL SECTION-1

• Cabinet (L) Section

• VC-597 Board

• Main Frame

2-2-2. OVERALL SECTION-2

• Cabinet (R) Section

• Handle Section-1

• Lens Section

2-2-3. CABINET (R) SECTION

• MD Section

• CK-204 Board

• AL Lid (93000)

2-2-4. MD SECTION

• Mechanism Deck

Cabinet (L) Section

• MS-405 Board

2-2-5. HANDLE SECTION-1

• EVF Section

• Microphone Holder Assy

2-2-6. HANDLE SECTION-2

• Control Panel Block

• PI-029 Board

• LCD Section

2-2-7. HANDLE SECTION-3

• GP-025 Board

• XL-010 Board

• Handle Section-4

VC-597 Board

Lens Section

• GY-014 Board

• Prism Device

(CM-097/104 Board)

2-2-10. CABINET (L) SECTION

• Cabinet (L) Block

• Cabinet (G) Block

2-2-9. LCD SECTION

• Hinge Block

• LCD

DSR-PD175P/PD177P/PD198P

2-2-8. HANDLE SECTION-4

• AS-060 Board

• Microphone Section

2-2

HELP

EXPLODED VIEW

B

C

G

D

E

F

H

H

HELP

2-2. DISASSEMBLY

2-2-1. OVERALL SECTION-1

Follow the disassembly in the numerical order given.

1 Cabinet (L) Section (1-1 to 1-8)

2 VC-597 Board (2-1 to 2-17)

3 Main Frame (3-1 to 3-2)

2

VC-597 Board

1

Cabinet (L)

Section

(See Page 2-12)

2-17E

1-8E

(#49)

1-7

(#49)

1-6

1-5

(#49)

2-15

(#50)

F

A

VC-597

G

B

H

C

2-16

(#50)

D

E

F

G

H

3-2E

(#49)

A

A

B

B

C

C

D

D

3-1

(#49)

3

Main Frame

HARDWARE LIST

Overall Section-2

(See Page 2-4)

E

E

1-4

(#49)

1-3 (Disconnect the

flexible board)

DSR-PD175P/PD177P/PD198P

1-2

1-1

(#49)

Disconnect the flexible boards

and harnesses.

2-12

2-13

2-14

2-1

HELP01

2-3

2-102-11

VC-543VC-597

2-2

2-3

HELP02

2-7 2-9

2-8

2-4 2-5

2-6

2-2-2. OVERALL SECTION-2

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Cabinet (R) Section (1-1 to 1-8)

2 Handle Section-1 (2-1 to 2-5)

3 Lens Section (3-1)

2-1

(Open)

2-4

(#119)

2-2

(#49)

2-3

2-5E

(#119)

1

Section

2

Handle Section-1

(See Page 2-7)

Cabinet (R)

(See Page 2-5)

1-2

(Open)

MD-141

1-7

(#49)

1-3

(#49)

HARDWARE LIST

1-6

1-5

(Claws)

1-4

(#49)

3-1E (#119)

BT Panel Section

Note: Prism Device cautions

Tighten screws in the following order.

1

2

3

1-1

(#154)

HELP03

1-8E

(#49)

Note:

On installation of the lens block,

adjust the position of the

ND filter switch.

3

Lens Section

HELP04

Be sure not to insert the harnesses

forcefully.

(Standard: Insertion; 15N, Pull out; 10N)

DSR-PD175P/PD177P/PD198P

2-4

EXPLODED VIEW

2-2-3. CABINET (R) SECTION

Follow the disassembly in the numerical order given.

1 MD Section (1-1 to 1-2)

2 CK-204 Board (2-1 to 2-9)

3 AL Lid (93000) (3-1 to 3-7)

1

MD Section

(See Page 2-6)

1-2E

(#53)

MD-141

HARDWARE LIST

3

AL Lid (93000)

3-7E

2-4

(#53)

2-1

2-7

(#50)

2-9E

3-1

(#121)

2-5

(#53)

3-2

(#53)

CK-204

A

2-8

A

1-1

2-2

3-4

(#53)

2-6

(#53)

3-5

3-6

3-3

2-3

DSR-PD175P/PD177P/PD198P

2

CK-204 Board

2-5

2-2-4. MD SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Mechanism Deck (1-1 to 1-12)

1

Mechanism Deck

HARDWARE LIST

1-12E

1-4

(#50)

MD-141

1-9

1-1

(#153)

1-10

(#15)

1-11

1-8

1-7

1-6

1-5

1-3

(#153)

1-2

(#153)

DSR-PD175P/PD177P/PD198P

HELP05

2-6

EXPLODED VIEW

Ver. 1.1 2009.09

2-2-5. HANDLE SECTION-1

Follow the disassembly in the numerical order given.

1 EVF Section (1-1 to 1-10)

2 Microphone Holder Assy (2-1 to 2-2)

HELP06 HELP07

1

EVF Section

1-9

(Open)

1-7

1-10E

(#49)

1-4

1-8

(#49)

1-6

Secure (UPPER) CABINET (93000) ASSY

Note:

tightening screws in the order A to D.

D

C

A

B

1-5

(#49)

HARDWARE LIST

1-2 (#49)

1-1 (Open)

2-2E

(#119)

2-1

(Open)

1-3

2

Microphone Holder Assy

Handle Section-2

(See Page 2-8)

DSR-PD175P/PD177P/PD198P

2-7

EXPLODED VIEW

Ver. 1.1 2009.09

2-2-6. HANDLE SECTION-2

Follow the disassembly in the numerical order given.

1 Control Panel Block (1-1 to 1-5)

2 PI-029 Board (2-1 to 2-11)

3 LCD Section (3-1 to 3-2)

1-4 (#49)

1

Control Panel

Block

Note:

KY-105

HARDWARE LIST

Be sure not to

touch these parts.

1-2

1-1 (#49)

2-6 (#50)

2

PI-029 Board

Handle Section-3

(See Page 2-9)

2-5

2-4

2-9

(#50)

2-10

PI-029

1-3

(#53)

1-5E

2-2

HELP08

2-1

2-3

3-1 (#49)

3-2E (#119)

2-11E

HELP08

2-8

2-7

LCD Section

3

(See Page 2-11)

DSR-PD175P/PD177P/PD198P

2-8

EXPLODED VIEW

Ver. 1.1 2009.09

2-2-7. HANDLE SECTION-3

Follow the disassembly in the numerical order given.

1 GP-025 Board (1-1 to 1-2)

2 XL-010 Board (2-1 to 2-11)

3 Handle Section-4 (3-1 to 3-6)

3-6E

3-5 (#49)

1-2E

GP-025

3-3 (#49)

3-4

1

GP-025 Board

1-1 (#50)

2-6

(#49)

HARDWARE LIST

3-1 (#49)

3-2

2-1

(#119)

3

Handle Section-4

(See Page 2-10)

2

XL-010 Board

2-8

2-7

(#119)

2-2

2-11E

2-10

2-5

2-9

(#50)

2-4

(#49)

2-3

DSR-PD175P/PD177P/PD198P

2-9

EXPLODED VIEW

Ver. 1.1 2009.09

2-2-8. HANDLE SECTION-4

Follow the disassembly in the numerical order given.

1 AS-060 Board (1-1 to 1-4)

2 Microphone Section (2-1 to 2-7)

2-7E

2-1

2-5 (#49)

HARDWARE LIST

2-2 (#49)

2-3

2-4

HELP10

1-2

1-3

(#50)

AS-060

1

AS-060 Board

1-4E (#53)

1-1

HELP09

2

Microphone Section

2-6 (#49)

DSR-PD175P/PD177P/PD198P

2-10

EXPLODED VIEW

2-2-9. LCD SECTION

Follow the disassembly in the numerical order given.

1 Hinge Block (1-1 to 1-10)

2 LCD (2-1 to 2-9)

1-2 (Claws)

1

Hinge Block

HELP11

1-3

1-1 (#49)

1-10E

1-9

(#49)

HARDWARE LIST

2-9E

1-5

(#49)

1-8

2-3 (#50)

1-6

(Dowels)

1-4

2-6 (#50)

PD-372

2-5

1-7

(Claws)

2-8

2-2

2-7 (Claws)

2-4 (Claws)

2-1

2

LCD

DSR-PD175P/PD177P/PD198P

2-11

EXPLODED VIEW

2-2-10. CABINET (L) SECTION

Follow the disassembly in the numerical order given.

1 Cabinet (L) Block (1-1 to 1-3)

2 Cabinet (G) Block (2-1 to 2-7)

HARDWARE LIST

place: 1-1 (#49)One

places: 1-2 (#53)Twelve

1-1 (#49)

2

Cabinet (G) Block

B

A

2-4

2-1

A

2-3

(#53)

2-2

2-5

(#53)

1

Cabinet (L) Block

1-3E

(Claws)

1-2

(#53)

2-7E

(Remove the Grip Belt)

DSR-PD175P/PD177P/PD198P

2-6

B

2-12E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

HELP01

How to arrange Harness (DC-IN Connector).

VC-597

Crease the Harness (DC-IN Connector)

as shown in the figure.

HELP02

How to arrange Harness (Coaxial Cable).

VC-597

Harness

(Coaxial Cable)

(R)

DSR-PD175P/PD177P/PD198P

Harness

(Coaxial Cable)

(G)

Harness

(Coaxial Cable)

(B)

HELP

HELP03

How to arrange Harnesses (Coaxial Cable).

Harness (Coaxial Cable) (R)

Harness (Coaxial Cable) (B)

Harness (Coaxial Cable) (G)

HELP04

Sticking standard of the Lens Radiation Sheet (2828).

Sticking standard

Lens Radiation

Sheet (2828)

HELP05

How to fold the FP-983 Flexible Board.

Valley fold

FP-983 Flexible Board

Lens Heat Sink

MD-141 Board

MD-141

DSR-PD175P/PD177P/PD198P

FP-983 Flexible Board

HELP

HELP06

Confirm the Viewfinder Lens Adjustment Lever is on the left side when installing

the VF Lens Assy.

VF Lens Assy

Eye Cup (93000) Assy

Viewfinder Lens

Adjustment Lever

HELP07

Sticking standard of the Non Woven (T0.25)

FP-974 Flexible Board

Reinforcing Part

Non Wov en (T0.25)

Crease

1.0mm

DSR-PD175P/PD177P/PD198P

HELP

HELP08

PI-029PI-029

How to arrange Harnesses and Flexible Board.

The Harness (SW-116) wrap around

the Harness (PR-074).

Harness (SW-116)

Harness (PR-074)

Harness (PR-074),

Harness (SW-116)

Arrange the harnesses PR-074

and SW-116 under the flexible

cable holder.

Flexible Holder

Roll up the harness (speaker

(1.8 cm)) to the claw.

Craw

Arrange FP-966 flexible

board inside the pin.

Pin

FP-966 Flexible Board

Harness

(Loudspeaker (1.8cm))

DSR-PD175P/PD177P/PD198P

HELP

HELP09

How to bent the Speaker Grille.

Bent the Speaker Grille.

Bend to the hole of

Speaker Grille.

Speaker Grille

HELP10

Crease the harness (Microphone) two points as shown in the figure.

Microphone

Non Wov en (T0.25)

2 1mm

MA-454 Board

Microphone

Crease the Harnesses

(Microphone)

DSR-PD175P/PD177P/PD198P

HELP

HELP11

How to arrange Harnesses (SW-116).

Panel Hinge

Cabinet (B)

Claws

Harness (SW-116)

DSR-PD175P/PD177P/PD198P

HELP

Link

Link

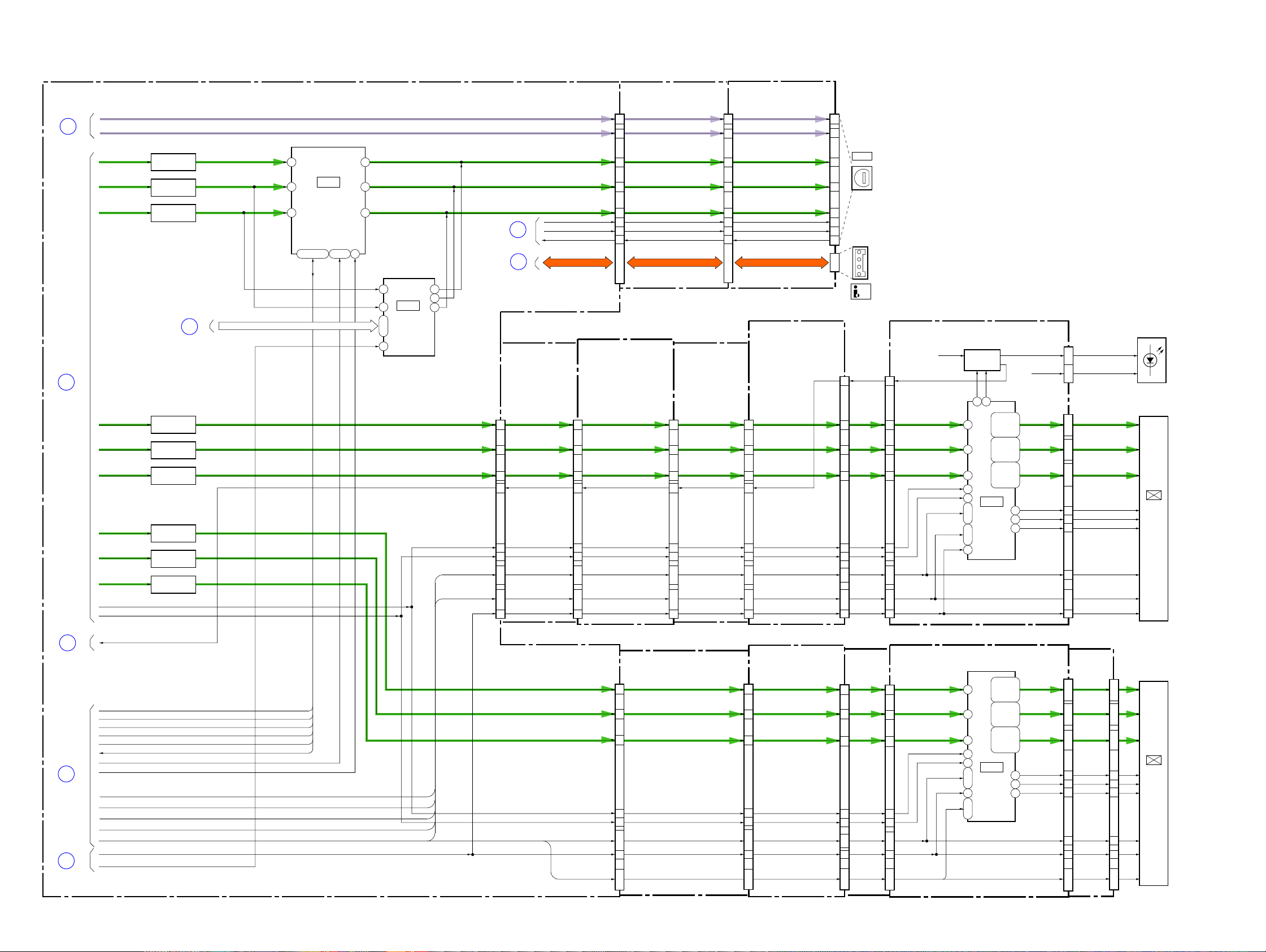

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/9)

OVERALL BLOCK DIAGRAM (2/9)

OVERALL BLOCK DIAGRAM (3/9)

OVERALL BLOCK DIAGRAM (4/9)

OVERALL BLOCK DIAGRAM (5/9)

OVERALL BLOCK DIAGRAM (6/9)

OVERALL BLOCK DIAGRAM (7/9)

OVERALL BLOCK DIAGRAM (8/9)

OVERALL BLOCK DIAGRAM (9/9)

POWER BLOCK DIAGRAM (1/4)

POWER BLOCK DIAGRAM (2/4)

POWER BLOCK DIAGRAM (3/4)

POWER BLOCK DIAGRAM (4/4)

DSR-PD175P/PD177P/PD198P

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/9)

PRISM

DEVICE

CM-097 BOARD (R)

DOA0 - DOA11,

DOB0 - DOB11

J2, K2, L2, L3,

E2, F2, G2, H2,

C4, C3, D3, E3,

B4, B3, C2, D2,

F3, G3, H3, J3,

K3, L4, M4, M3

SENSOR_HD,

J10, K10, H9 G10, H10

M7

J9

J2, K2, L2, L3,

E2, F2, G2, H2,

C4, C3, D3, E3,

F3, G3, H3, J3,

K3, L4, M4, M3

J10, K10, H9 G10, H10

M7

J9

J2, K2, L2, L3,

E2, F2, G2, H2,

C4, C3, D3, E3,

F3, G3, H3, J3,

K3, L4, M4, M3

J10, K10, H9 G10, H10

M7

J9

SENSOR_VD

CMOS_SO, CMOS_SCK,

CMOS_XCS

CHCK

XSYS_RST

DOA0 - DOA11,

DOB0 - DOB11

SENSOR_HD,

SENSOR_VD

CMOS_SO, CMOS_SCK,

CMOS_XCS

CHCK

XSYS_RST

DOA0 - DOA11,

DOB0 - DOB11

SENSOR_HD,

SENSOR_VD

CMOS_SO, CMOS_SCK,

CMOS_XCS

CHCK

XSYS_RST

LENS DRIVE

BLOCK (1/3)

IRIS

(SHUTTER)

DICHROIC

PRISM

IC3001

CMOS

IMAGER

CM-104 BOARD (G)

B4, B3, C2, D2,

IC5001

CMOS

IMAGER

CM-097 BOARD (B)

B4, B3, C2, D2,

IC3001

CMOS

IMAGER

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-597 BOARD (1/9)

CN3005

CN5005

CN3005

27 - 16, 15 - 434, 3331, 30, 28

32

29

27 - 16, 15 - 434, 3331, 30, 28

32

29

27 - 16, 15 - 434, 3331, 30, 28

32

29

CN1201

22 - 33, 34 - 4515, 1618, 19, 21

CMOS_SO, CMOS_SCK,

17

20

CN1202

22 - 33, 34 - 4515, 1618, 19, 21

CMOS_SO, CMOS_SCK,

XCS_CMOS_G

17

20

CN1203

22 - 33, 34 - 4515, 1618, 19, 21

CMOS_SO, CMOS_SCK,

XCS_CMOS_B

17

20

AD_R_A02 - AD_R_A13, AD_R_B02 - AD_R_B13

SENSOR_HD,

SENSOR_VD

XCS_CMOS_R

CHCK

XSYS_RST

AD_G_A02 - AD_G_A13, AD_G_B02 - AD_G_B13

SENSOR_HD,

SENSOR_VD

CHCK

XSYS_RST

AD_B_A02 - AD_B_A13, AD_B_B02 - AD_B_B13

SENSOR_HD,

SENSOR_VD

CMOS_SO, CMOS_SCK,

XCS_CMOS_R, XCS_CMOS_G,

CHCK

XSYS_RST

A_2.8V

X1401

83.16MHz

SENSOR_HD,

SENSOR_VD

XCS_CMOS_B

CHCK

CHCK

EXOSC

XSYS_RST

U2, V2, U3, R7, T4, V3, U4,

V1, W2, W1, Y2, W3, V4,

W4, Y4, AA4, V5, W5, Y5,

AA5, V6, W6, Y6, V7

D17, A18, B18,

D15, A16, B16,

L7, L4 - L1, M7, M4 - M1,

N7, N4, P3, P1, P2, N1, P4,

P7, R1 - R4, T1, T2

A15, B15,

IC1401

CAMERA

SIGNAL

PROCESSOR

(3/24)

C1, C2, D3 - D1, H7,

E4 - E2, F4 - F2, G3, G2,

H4 - H1, J7, J4, J3, J2,

K4, K3

R9, R8G9, V16

V10, R10,

V11 - V13

AA8

AA7

Y8

IC1601

512M

SDRAM

(4/24)

SD_DQ00 - SD_DQ31

SD_A00 - SD_A12, SD_BA0, SD_BA1

SD_CK

V21

SD_XCS

R21

B20, C21

C18, A19, B19,

B17, C17

C16, D16, A17,

AA11

C15

HDI_VD

D24A00_CAM - D31A07_CAM

DXXA08_CAM - DXXA13_CAM

A14

B10

A10

D9

C9

B9

A11

C10

D10

A6

D5

C5

C7

B7

D6

A3

D7

XSYS_RST

SD_DQ00 - SD_DQ31

SD_CK

J1

SD_XCS

J8

HDI_VD

IC_1401_BUS_CLK

XCS_IC_1401_BUS

XCS_IC_1401_RAM

CAM_VD

CAM_VD_HS

CAM_FLD

ALE_CAM

RDX_CAM

WR01_CAM

DSCK_VM

EN1

DIRA1

DIRB1

EN2

DIRA2

IC_6001/IC_6501_CK

DIRB2

IR_RST_SENS

1

OVERALL (8/9)

(PAGE 3-8)

HDI_HD, HDI_VD, HDI_OE

3

OVERALL (2/9)

(PAGE 3-2)

2

OVERALL (2/9)

(PAGE 3-2)

6

OVERALL (7/9)

(PAGE 3-7)

7

OVERALL (6/9)

(PAGE 3-6)

OVERALL (2/9)

(PAGE 3-2)

HDI_Y0 - HDI_Y7

HDI_C0 - HDI_C7

VCK

OVERALL (5/9)

(PAGE 3-5)

AUIN11

IC_1801_ADAO1

XPOWER_DOWN_DA1

CK256FSO

CK64FSO

CKFSO

CK13MFO1

CK64FSO

CKFSO

SD_DQ00_IC_1801 - SD_DQ15_IC_1801

SD_A00_IC_1801 - SD_A12_IC_1801

4

5

IC1602

256M

SDRAM

(4/24)

SSS

XWEN

D0_VM - D15_VM

A1_VM - A19_VM

DACK1_IC_1801

DREQ1_IC_1801

XWAIT_VM

XCS_IC_1801_VM

CKFSO

DSCK_VM

SD_CK_IC_1801

F2

SD_XCAS_IC_1801

F7

SD_XWE_IC_1801

F8

SD_XRAS_IC_1801

F9

AE23

V22

V24

T19

K3

L6

AA22, AD23

AE20, W19, Y19,

AD22, AC19, AE21,

AB18, AC18

W18, Y18, AD20,

Y17, AC17, AD19,

U1

AC22

AE22, AC20,

C4

D6

C6

AE3

IC1801

BASE BAND

AD10

SIGNAL

PROCESSOR,

DOWN

CONVERTER,

D/A

CONVERTER

(5/24)

P22

M19

AC9

C24

R1

U2

M25

P25

D23

G22

E25

H23

K22

F24

J20

K25

J25

L22

B16

C17

P6, R2

P2, N1,

DV REC

T2, R4

P1, P4,

L2, M7

L4, K7,

DV PB

N2, M1

M2, M3,

N3

P3

K2

L3

A3

F10

C10

A9

B9

F9

L24

N22

M20

L20

D9

F8

G9

N7

K1

L1

AE16

AD17

AC14

AC15

D17

AB16

AE15

N20

W17, W16,

Y16

CK_IC_2201_O

IC_1801_LNOPR

IC_1801_LNOPB

IC_1801_LNOY

IC_1801_EVRE

IC_1801_EVGR

IC_1801_EVBL

IC_1801_PLRE

IC_1801_PLGR

IC_1801_PLBL

EP_XHD

EP_XVD

RYO0_DEHD, RYO1_DEVD,

RYO2_DEFLD_, RYO3_SGOUT

RCO0_EDHD, RCO1_EDVD,

RCO2_EDFLD_, RCO3_FRMREF

RYI0_DE0 - RYI3_DE3

RCI0_DE4 - RCI3_DE7

HYO_SLGATE

HCO_FYI1

HYI_PLL27IN

HCI_FYI0

TFS_FCO

THYRQ_FVDI

THCRQ_FHDI

VLAT_SYNC_FCI

FLAT_SYNC_FYO0

VLAT_IN_FYO1

FS_EDGE_REF

FRAT_REFO

ADATAOUT0

ADATAOUT1

IC_1801_SRCH

IC_1801_PCRERR

IC_1801_FLD27MF

MFLG_QRST

CK27MFO1

D24A00_IC_4401 - D31A07_IC_4401

DXXA08_IC_4401, DXXA09_IC_4401

WR01_IC_4401

RDX_IC_4401

SD_OSD_VD

XCS_IC_1801_IC_4401

XRST_VTR

IC_1801_OEREF

FRRV, TRRV, DRP

VREF

MCLK

9

OVERALL (4/9)

(PAGE 3-4)

10

OVERALL (3/9)

(PAGE 3-3)

11

OVERALL (4/9)

(PAGE 3-4)

12

OVERALL (5/9)

(PAGE 3-5)

DSR-PD175P/PD177P/PD198P

A

A

: VIDEO SIGNAL

: AUDIO SIGNAL

8

OVERALL (4/9)

(PAGE 3-4)

08

CK_IC_2201_I

IC_2201_VF_SYNC

AUIN21

AUIN22

ADATAIN0

ADATAIN1

CK27MFO1

B21

B24

P23

M24

L19

K24

M22

KASYAON

13

OVERALL (5/9)

(PAGE 3-5)

3-1

3-2. OVERALL BLOCK DIAGRAM (2/9)

VC-597 BOARD (2/9)

SWITCH

IC6002

AMP (21/24)

5

3

12

10

D_2.8V

D_2.8V

7

1

14

8

IR_RST_SENS

IRIS_A, IRIS_XA,

IRIS_B, IRIS_XB

L5004

XRST_IC_6001/IC_6501

Y_DRIVE_A, Y_DRIVE_B

P_DRIVE_A, P_DRIVE_B

LENS DRIVE BLOCK (2/3)

MANUAL

MR

ZOOM

RING

MANUAL

MR

FOCUS

RING

MI_F1_VCC

MI_F0_VCC

IRIS F1

SENSOR

MANUAL

IRIS

IRIS F0

RING

SENSOR

IRIS RESET

SENSOR

IRIS

MOTER

M

ZOOM

MOTOR

LENS TEMP

SENSOR

ND_VCC_A ND_VCC_D

ND

SENSOR

A - D

FOCUS

MOTOR

MR

ACTIVE LENS

ACTUATOR

YAW

ACTIVE LENS

ACTUATOR

PITCH

IR_RST

_VCC

MR

M

M

MZ_MR_XA, MZ_MR_A

MZ_MR_XB, MZ_MR_B

MF_MR_XA, MF_MR_XB,

MF_MR_B, MF_MR_A

MI_F1_VCC

18

MI_F0_VCC

TEMP_OUT

15

17

14

13

15

47

6

5

MI_F1_SENS

MI_F0_SENS

IR_RST_SENS

IR_RST_VCC

IRIS_A, IRIS_B,

IRIS_XA, IRIS_XB

Z_GMR_A, Z_GMR_B

ZOOM_A, ZOOM_XA,

ZOOM_B, ZOOM_XB

ND_VCC_A - ND_VCC_D

ND_SENS_A - ND_SENS_D

F_DRIVE+, F_DRIVE-

F_GMR_A, F_GMR_B

SHIFT_Y_DRIVE+,

SHIFT_Y_DRIVE-

SHIFT_Y_OUT

SHIFT_P_DRIVE+,

SHIFT_P_DRIVE-

SHIFT_P_OUT

CN5001

MZ_MR_XA AD_MZ_MR_A

MZ_MR_A

MZ_MR_XB

MZ_MR_B

2 - 5 8, 119, 10

Q5001

SWITCH

CN5002

(1/2)

Q5002

SWITCH

32, 34

27 - 20 16 - 19

Q5004, Q5005

36, 39, 42, 45

35, 38, 40, 4312, 10

50, 51

CN5003

10, 9

1, 2

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

MI_F1_SENS

MI_F0_SENS

MI_LED

IR_RST_LED

MZ_MR_A_DAC

AD_MZ_MR_B

MZ_MR_B_DAC

MI_F1_SENS

MI_LED

MI_F0_SENS

IR_RST_LED

Z_MR_A, Z_MR_B

ZOOM_A, ZOOM_XA,

ZOOM_B, ZOOM_XB

LENS_TEMP_AD

D_2.8V

ND_SW1 - ND_SW4 ND_SW1 - ND_SW4

FOCUS+, FOCUS-

F_MR_A, F_MR_B

YAW_AD_IC7001

PITCH_AD_IC7001

ZOOM_A, ZOOM_XA,

ZOOM_B, ZOOM_XB

Z_MR_A,

Z_MR_B

FOCUS+, FOCUS-

F_MR_A,

F_MR_B

AD_MZ_MR_A

MZ_MR_A_DAC

AD_MZ_MR_B

MZ_MR_B_DAC

MF_MR_XA,

MF_MR_XB,

MF_MR_B,

MF_MR_A

IRIS_A, IRIS_XA,

IRIS_B, IRIS_XB

P_DRIVE_A,

P_DRIVE_B

PITCH_AD_

IC7001

Y_DRIVE_A,

Y_DRIVE_B

YAW_AD_

IC7001

B4

C5

B12 D10

B11

K6, L4, F1, G3

E12, E10

F3, E3

B1, C4

B10

C2

B9

A2

FOCUS RING

B1, C4, C5, B11

K6, L4, L6, L7

B1, D1

H2

B10, D10

J9

IC6001

ZOOM/

FOCUS

MOTOR

DRIVE

(21/24)

IC6501

MANUAL

INPUT

(22/24)

IC7001

PITCH/YAW

DRIVE

(23/24)

A4

CAM_VD

L12

IC_6001/IC_6501_CK

K12

XRST_IC_6001/IC_6501

H11

CAM_SO, CAM_SI,

CAM_SCK, XCS_SIO_CAM

H12, J12

J11, K11,

J9

K9

L9

M9

M8

L8

L9

M9

CAM_SO, CAM_SI,

CAM_SCK, XCS_SIO_IC_6001/IC_6501

H12, J12

J11, K11,

CAM_VD

L12

IC_6001/IC_6501_CK

K12

XRST_IC_6001/IC_6501

H11

CAM_SO, CAM_SI,

CAM_SCK, XCS_SIO_CAM

B5, A5

A4, B4,

CAM_VD

C9

DSCK_VM

A3

XRST_IC_7001_CPU XRST_IC_7001_CPU

A6

XRST_IC_7001

A7

PITCH_AD

G5

YAW_AD

J5

DATA

D6

CLK

D5

DIRB1

EN1

IC_6001/IC_6501_CK

DIRA1

IR_RST_SENS

DIRB2

EN2

DIRA2

2

OVERALL (1/9)

(PAGE 3-1)

R7004

4

OVERALL (1/9)

(PAGE 3-1)

3

OVERALL (1/9)

(PAGE 3-1)

LENS_TEMP_AD

SSS

XWEN

X4201

20 MHz

HDI_VD

D24A00_CAM - D31A07_CAM

DXXA08_CAM - DXXA13_CAM

IC_1401_BUS_CLK

XCS_IC_1401_BUS

XCS_IC_1401_RAM

CAM_FLD

CAM_VD_HS

ALE_CAM

WR01_CAM

RDX_CAM

CAM_VD

DSCK_VM

CAM_SO

CAM_SCK

XCS_SIO_CAM

XCS_SIO_IC_6001/IC_6501

XRST_IC_6001/IC_6501

CAM_SI

B4

A4

F20

F22

R22

IC4201

AB5

CAMERA

AC5

CONTROL

(17/24)

D1

C1

B6

K1

J1

H2

D13

D7

K4

L1

L4

A7

F23

AB11

Y11

AB10

C22

B22

B14

B12, A13, D11, D12

GENERAL_AD

K22

SYSTEM_AD

K20

XCS_EEP_C

F1

XCS_MC_FLASH_C

B17

MD2_C

E4

EEP_SI_C, EEP_SO_C, EEP_SCK_C

AB14, AC14,

AB13

ZOOM_SW_AD

M22

1

2, 5, 6

14

OVERALL (8/9)

(PAGE 3-8)

CS_SIRCS_1

A11

CS_SIRCS_2

B11

XSIRCS_IN

A10

2ND_ZOOM_AD 2ND_ZOOM_AD

N22

BODY_AD

N20

XSYS_RST

NTSC/XPAL_DET NTSC/XPAL_DET

SYS_V SYS_V

XFTR_NR XFTR_NR

Y7, AB7, AB6

XCS_CAMERA

F4

B13

AC6

F2

A17

B8

D4201

D4204

D4203

R4202 R4205

IC4202

128K

EEPROM

(17/24)

EEP_SI_C, EEP_SO_C, EEP_SCK_C

KEY_AD4

XB_TALLY_LED

D4202

XSYS_RST

SYS_V

2SS_KEY_AD2

HI_SI, HI_SO, XHI_SCKHI_SI, HI_SO, XHI_SCK

XCS_CAMERA

CN1004

XCS_MC_FLASH_C

MD2_C

CN1012

(1/4)

ZOOM_SW_AD

CN1015

(1/4)

SIRCS_SIG_FRONT

CN1008

(1/2)

XB_TALLY_LED

SIRCS_SIG_REAR

BODY_AD

15

OVERALL (8/9)

(PAGE 3-8)

16

OVERALL (6/9)

(PAGE 3-6)

17

OVERALL (5/9)

(PAGE 3-5)

CN5002

PITCH_AD

YAW_AD

DATA

CLK

(1/2)

(2/2)

3

5

8, 10, 12

10

FP-981

FLEXIBLE

BOARD (1/4)

CN004

(1/4)

48

39

35

1

3

2

2

4

7

6

CPC

(FOR CHECK)

FP-971

FLEXIBLE

BOARD

(1/4)

PHOTO

(LENS_AD)

SIRCS_SIG

(REC LAMP (BACK))

FP-967

FLEXIBLE

BOARD (1/2)

ZOOM_

SW_AD

CN003

(1/4)

D201

4

REMOTE

SENSOR

BODY_AD

49

IC201

(BACK)

MS-405 BOARD (1/4)

10

AS-060 BOARD

(1/4)

CN8801

(1/4)

SIRCS_SIG_FRONT

CN8602

(1/4)

PHOTO (LENS_AD)

CN8802

(1/4)

GP-025 BOARD (1/2)

CN7801

(1/2)

2SS_KEY_AD22SS_KEY_AD2

33

2nd_ZOOM_AD

31

R7802 R7806

R7801

32

GY-014 BOARD

CN8501

PITCH_AD

2

YAW_AD

4

DATA

7

CLK

6

CN8606

(1/2)

2

499

FP-982

FLEXIBLE

BOARD (1/4)

PI-029 BOARD

(1/4)

CN003

CN7004

(1/4)

(1/4)

32

CN004

(1/4)

CN7802

FIX

VAR

OFF

(HANDLE ZOOM)

S7801

LENS DRIVE BLOCK (3/3)

10

IC8501

13

PITCH/

YAW

SENSOR

25

AMP

24

CONTROL SWITCH BLOCK

(PZ93000) (1/2)

ZOOM_SW_ADZOOM_SW_AD

PHOTO

(LENS_AD)

CN7013

(1/2)

SIRCS_SIG

CONTROL SWITCH BLOCK

(GZ92000)

KEY_AD1

1

2nd_ZOOM_AD

3

PITCH SENSOR

1

21

YAW SENSOR

ASSIGN 7

PHOTO

FP-966 FLEXIBLE

BOARD

(1/2)

SIRCS_SIG

333

SE8501

SE8502

S501

RV501

WTy

(ZOOM)

4

START/STOP

(HANDLE ZOOM)

IC401

REMOTE

SENSOR

(FRONT)

S001

REC

z

RV001

WTy

08

DSR-PD175P/PD177P/PD198P

3-2

3-3. OVERALL BLOCK DIAGRAM (3/9)

VC-597 BOARD (3/9)

AUDIO_L_I/O

18

OVERALL (7/9)

(PAGE 3-7)

10

OVERALL (1/9)

(PAGE 3-1)

AUDIO_R_I/O

IC_1801_LNOPR

IC_1801_LNOPB

IC_1801_LNOY

OVERALL (7/9)

IC_1801_PLRE

IC_1801_PLGR

IC_1801_PLBL

IC_1801_EVRE

IC_1801_EVGR

IC_1801_EVBL

EP_XHD

EP_XVD

(PAGE 3-7)

Q2002

BUFFER

Q2003

BUFFER

Q2001

BUFFER

Q2005

BUFFER

Q2006

BUFFER

Q2004

BUFFER

Q2009

BUFFER

Q2007

BUFFER

Q2008

BUFFER

22

LINE_OUT_PR

LINE_OUT_C/PB

LINE_OUT_Y

VSP_SO_BU, XVSP_SCK_BU

6

4

2

XCS_IC_2002

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

JK-376 BOARDFP-973 FLEXIBLE BOARD

1

3

5

7

9

11

13

12

CN004

PANEL_R

PANEL_G

PANEL_B

BL_CONT

EP_XHD

EP_XVD

VD_SO,

VD_SI

XCS_LCD_AD,

XCS_LCD,

VD_SCK

XRST_VTR

CN9507

VIDEO/D3_Pr

TPA, NTPA, TPB, NTPBTPA-, TPA+, TPB+, TPB-TPA-, TPA+, TPB+, TPB-

15, 17, 19, 21

PI-029 BOARD (2/4)

CN7004

(2/4)

(2/4)

2

3

4

15

8

7

23, 20

24, 25, 22

19

AUDIO_L

AUDIO_R

S_C/D3_Pb

S_Y/D3_Y

LANC_SIG

LANC_DC

JACK_AD

PANEL_R

PANEL_G

PANEL_B

BL_CONT

EP_XHD

EP_XVD

VD_SO,

VD_SI

XCS_LCD_AD,

XCS_LCD,

VD_SCK

XRST_VTR

IC2001

COMPONENT

OUT AMP

(6/24)

37 - 391, 48 - 44

AUDIO_L_I/O

AUDIO_R_I/O

31

33

35

OVERALL (8/9)

(PAGE 3-8)

18

17

IC2002

15

VIDEO

OUT AMP

(6/24)

20, 21

19

9

12

7

XCS_LCD_AD,

OVERALL (5/9)

PLRE

PLGR

PLBL

EP_XHD

EP_XVD

VD_SO,

VD_SI

XCS_LCD,

XVD_SCK

XRST_VTR

(PAGE 3-5)

CN1015

(2/4)

CN004

(2/4)

79

78

77

66

73

74

58, 61

57, 56, 59

62

23

24

FP-981

FLEXIBLE

BOARD

(2/4)

VIDEO/D3_PR

S_C/D3_PB

S_Y/D3_Y

LANC_SIG

LANC_DC

MULTI_JACK_IN

PANEL_R

PANEL_G

PANEL_B

BL_CONTBL_CONT

EP_XHD

EP_XVD

VD_SO,

VD_SI

XCS_LCD_AD,

XCS_LCD,

VD_SCK

XRST_VTR

CN003

CN1014

AS-060 BOARD (2/4)

CN8801

(2/4)

(2/4)

80

79

78

67

74

75

59, 62

58, 57, 60

63

20

18

16

14

12

10

8

9

6, 5, 3, 2

PLRE

PLGR

PLBL

EP_XHD

EP_XVD

VD_SO,

VD_SI

XCS_LCD_AD,

XCS_LCD,

VD_SCK

XRST_VTR

AUDIO_L_I/O

AUDIO_R_I/O

VIDEO/D3_Pr

S_C/D3_Pb

S_Y/D3_Y

LANC_SIG

LANC_DC

JACK_AD

CN8802

(2/4)

CN003

(2/4)

1

2

3

14

7

6

22, 19

23, 24, 21

18

FP-982

FLEXIBLE

BOARD

(2/4)

1

6

CN9508

AV/R

9

5

10

2

4

7

CN9509

1 - 4

DV

CN7002

914

21

20

19

17

16

4, 5

1 - 3

6

PD- 372 BOARD

CN6001

BL_CONT

2

3

4

6

7

VD_SO,

VD_SI

XCS_LCD_AD,

19, 1820 - 22

XCS_LCD,

XVD_SCK

XRST_VTR

17

BL_V

R_IN

G_IN

B_IN

XCS_LCD_AD,

XVD_SCK

XHD

XVD

VD_SO,

VD_SI

XRST_VTR

Q6001 - Q6003

BACKLIGHT

DRIVE

K1A9

D2

E1

F2

J1

K2

IC6001

LCD

DRIVE,

L2, L1L3, M2

A/D

CONVERTER

M3

A

: VIDEO SIGNAL

: AUDIO SIGNAL

A

A : VIDEO/AUDIO SIGNAL

CN6002

BL_H

5, 61, 2

BL_L

BL_-V

CN6004

R0 - R7

D12, C11

F12, E11,

G12, F11,

E12, D11,

G0 - G7

H12, G11

K12, J11,

L12, K11,

J12, H11,

B0 - B7

L8, M8,

L9, M9,

L11, M11

L10, M10,

XHDO

M4

XVDO

L4

DCLK

M5

VD_SO

XCS_LCD,

XVD_SCK

XRST_VTR

12

11

13

5

8

7, 6 30 - 3722 - 2914 - 21

D901

(BACKLIGHT)

LCD901

3.2 INCH

WIDE

COLOR

LCD

UNIT

BL_CONT

XLINE_CNT1A

XLINE_CNT1B

XLINE_CNT2

XLINE_CNT3A

XLINE_CNT3B

XD4CN

DDRA_SEL1 - DDRA_SEL3

XPSV_D4

XCS_LCD_AD

XCS_LCD

XCS_EVF

XCS_EVF_AD

VD_SO, VD_SI,

XRST_VTR XRST_VTR XRST_VTR

XCS_IC_2002

XVD_SCK

OVERALL (8/9)

OVERALL (6/9)

OVERALL (5/9)

08

19

(PAGE 3-8)

20

(PAGE 3-6)

21

(PAGE 3-5)

DSR-PD175P/PD177P/PD198P

CN1008

EVRE

EVGR

EVBL

EP_XHD

EP_XVD EP_XVD

VD_SO, VD_SI

XCS_EVF_AD,

XCS_EVF,

XVD_SCK

FP-967 FLEXIBLE BOARD

(2/2)

(2/2)

20

24

28

32

31

6, 5

4

9 - 7

3-3

EVF_R

EVF_G

EVF_B

EP_XHD

VD_SO,

VD_SI

XCS_EVF_AD,

XCS_EVF,

VD_SCK

GP-025 BOARD (2/2)

CN7801

(2/2)

14

10

6

2

3

28, 29

30 4 24

25 - 27

EVF_R

EVF_G

EVF_B

EP_XHD

EP_XVD

VD_SO,

VD_SI

XRST_VTR

XCS_EVF_AD,

XCS_EVF,

VD_SCK

CN7803

FP-974

FLEXIBLE

BOARD

17

18

19

EP_XHD

22

EP_XVD

21

6, 5

XRST_VTR

XCS_EVF_AD,

XCS_EVF,

VD_SCK

9 - 7

EVF_R

EVF_G

EVF_B

VD_SO,

VD_SI

VF-178 BOARD

CN6201

11

10

9

6

7

22, 2319 - 21

EVF_R

EVF_G

EVF_B

EP_XHD

EP_XVD

VD_SO,

VD_SI

XRST_VTR

XCS_EVF_AD,

XVD_SCK

D2

E1

F2

J1

K2

M3

L2, L1

L3, M2

IC6201

EVF

DRIVE,

A/D

CONVERTER

F12, E11,

G12, F11,

E12, D11,

K12, J11,

L12, K11,

J12, H11,

L8, M8,

L9, M9,

L10, M10,

M4

L4

M5

R0 - R7

D12, C11

G0 - G7

H12, G11

B0 - B7

L11, M11

XHDO

XVDO

DCLK

VD_SO

XRST_VTR

XVD_SCK,

XCS_EVF

CN6202

FP-776

FLEXIBLE

BOARD

22 - 2914 - 216 - 13

35

36

33

41

42

SCK, SCS

38, 39

R0 - R7

G0 - G7

B0 - B7

HSYNC

VSYNC

DCLK

SI

RESET

11

10

13

5

4

24 - 1732 - 2540 - 33

8, 7

LCD902

COLOR

EVF

UNIT

Loading...

Loading...