Page 1

DSR-PD100/PD100P

SERVICE MANUAL

Ver 1.5 2003. 05

RMT-811

US Model

Canadian Model

DSR-PD100

AEP Model

DSR-PD100P

C MECHANISM

NTSC model: DSR-PD100

PAL model: DSR-PD100P

Photo: DSR-PD100

SPECIFICATIONS

MICROFILM

— Continued on next page —

DIGITAL CAMCORDER

Page 2

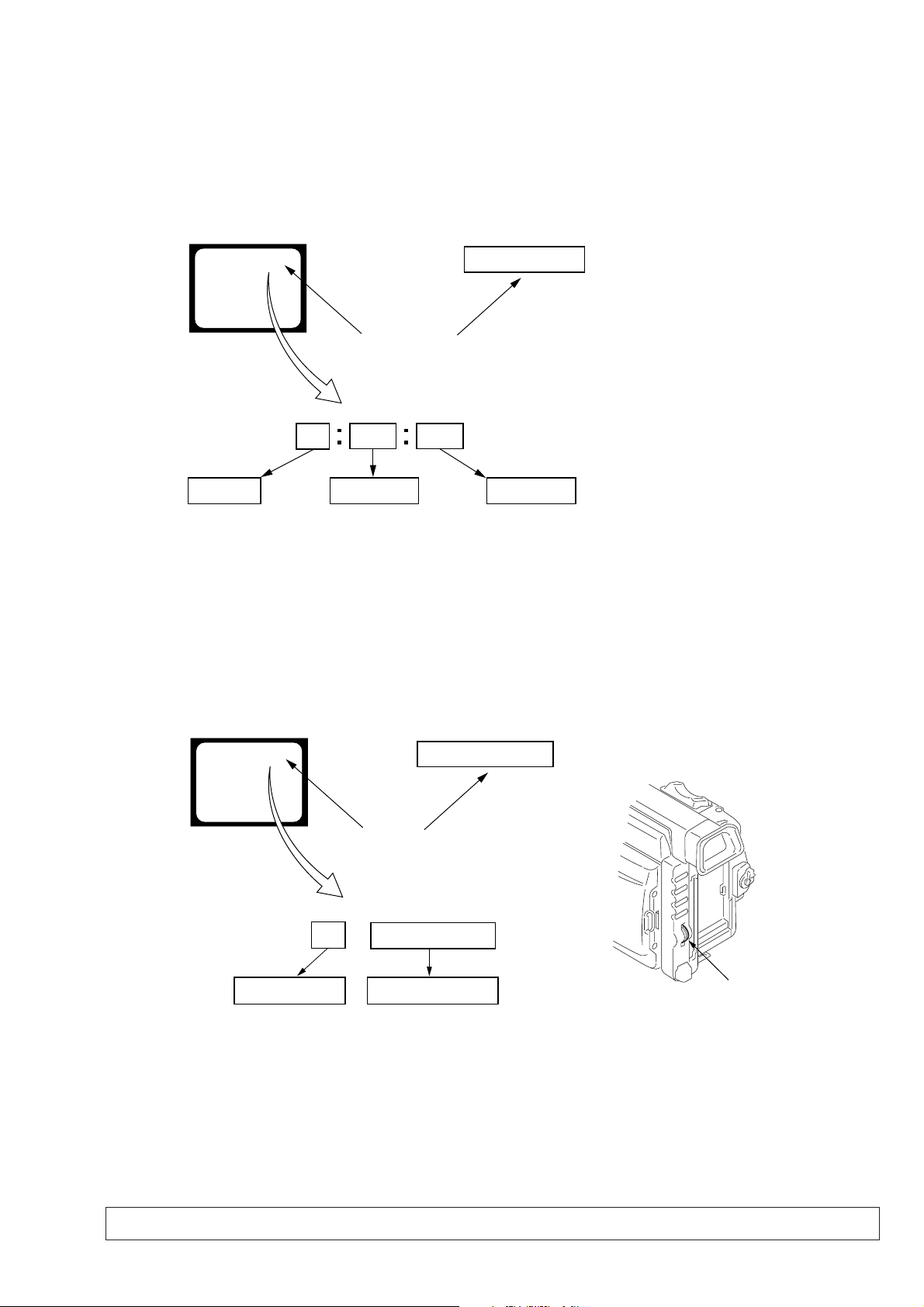

SELF-DIAGNOSIS FUNCTION

Control dial

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewf inder, LCD screen

or LCD window what to do. This function consists of two display;

self-diagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen LCD window

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

3 1

Block

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder, LCD screen or LCD window consists of an alphabet

and 4-digit numbers, which blinks at 3.2 Hz. This 5-character display

indicates the “repaired by:”, “block” in which the problem occurred,

and “detailed code” of the problem.

C : 3 1 : 11

Detailed Code

Refer to page 8.

Self-diagnosis Code Table.

3. SERVICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VTR or PLAYER”, and continue pressing the “STOP” key for 5 seconds

continuously. The service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder or LCD screen

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

C : 3 1 : 1 1

Self-diagnosis Codes

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

LCD window

3 C : 3 1 : 11

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will be backed up by the coin-type lithium battery of CK-80 board BT7200. When this coin-type lithium battery

is removed, the “self-diagnosis display” data will be lost by initialization.

— 7 —

Page 3

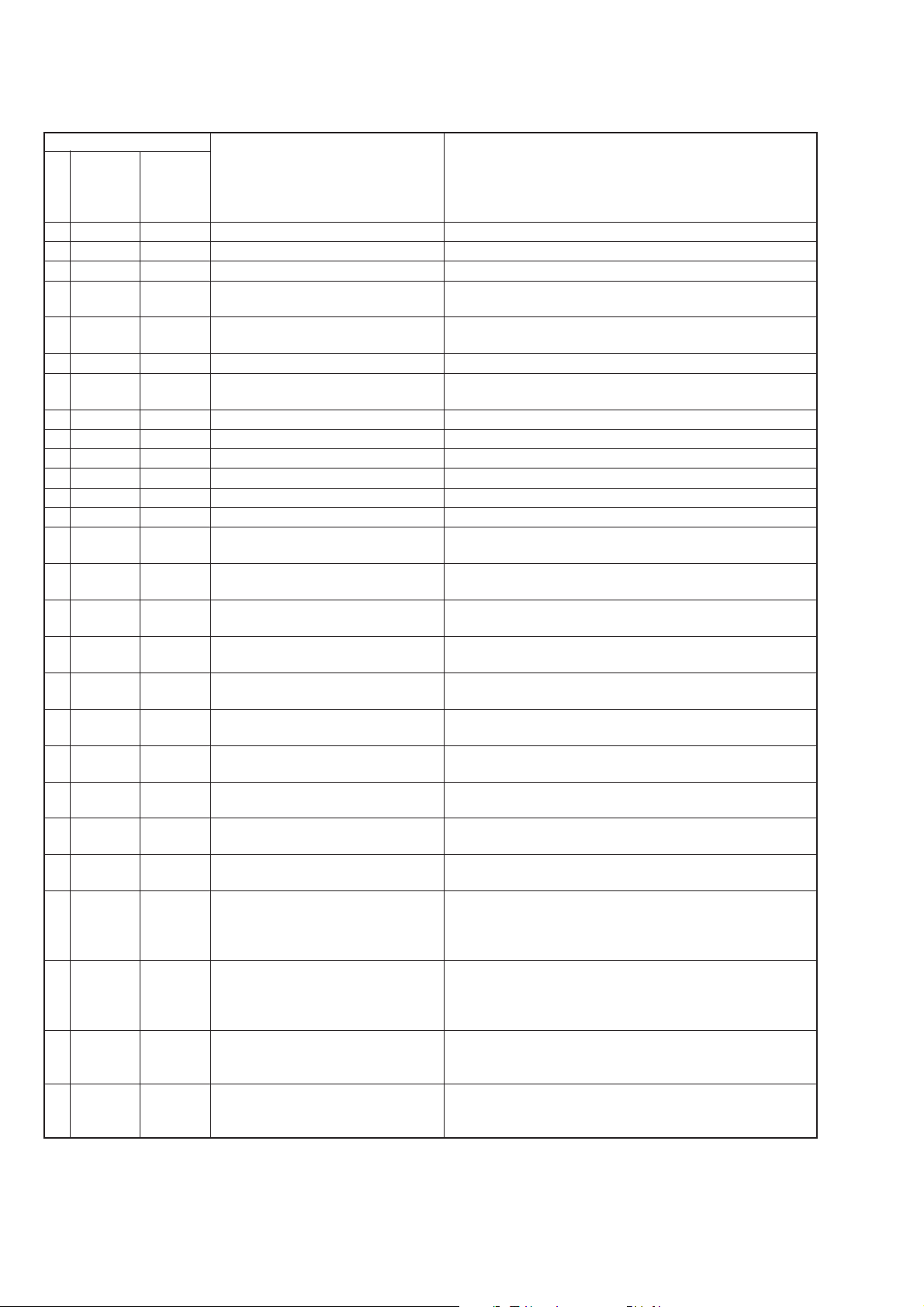

4. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

Block

Function

21

22

23

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

Symptom/State

Condensation.

Video head is dirty.

Non-standard battery is used.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Correction

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Use the info LITHIUM battery.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus reset sensor (Pin !º of CN500 of VC-

208 board) when focusing is performed when the control dial is

rotated in the focus manual mode, and the focus motor drive circuit

(IC500 of VC-208 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (Pin !™ of CN500 of VC208 board) when zooming is performed when the zoom lens is

operated and the zoom motor drive circuit (IC500 of VC-208 board)

when zooming is not performed.

Inspect pitch angular velocity sensor (SE451 of SE-75 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE450 of SE-75 board)

peripheral circuits.

— 8 —

Page 4

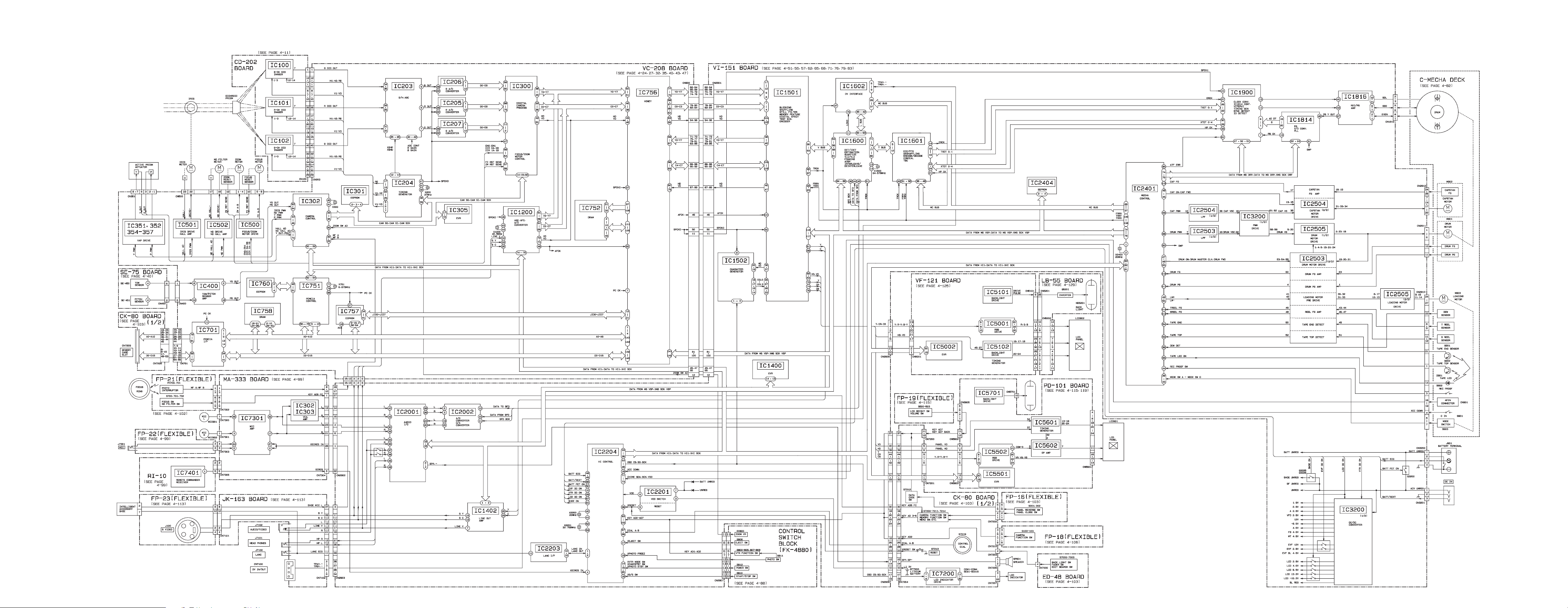

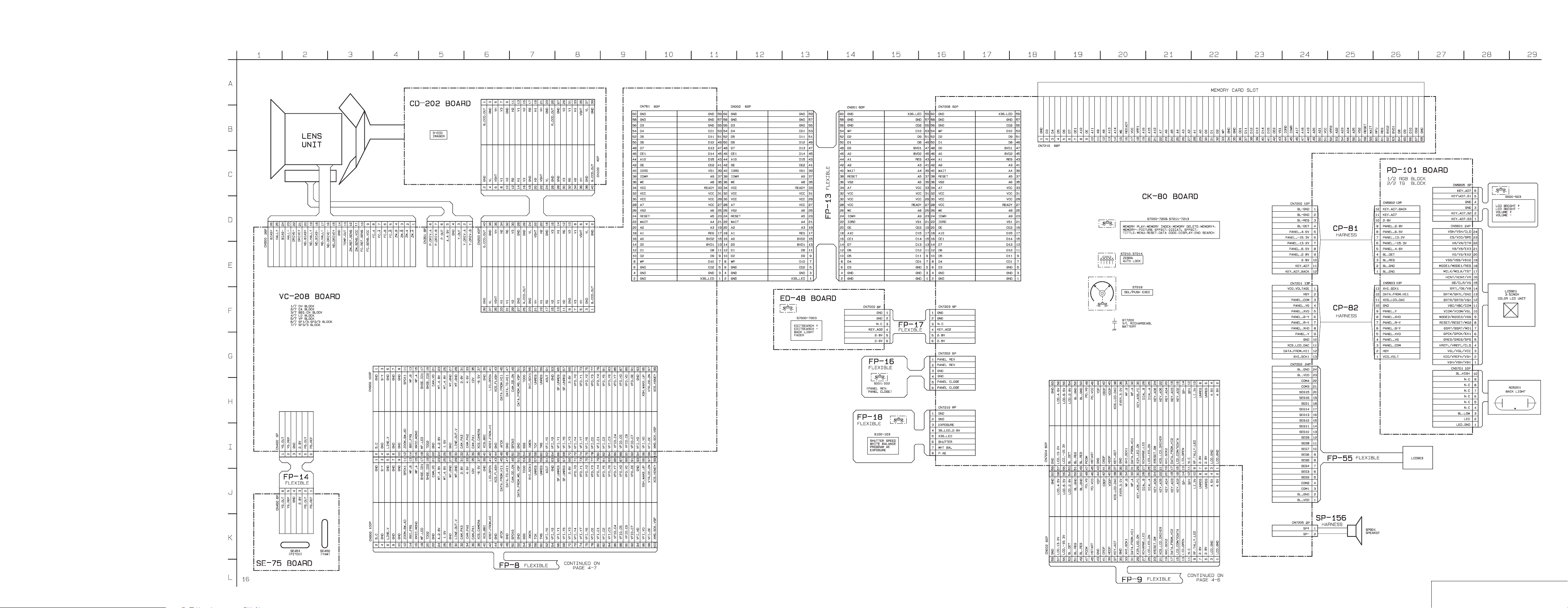

3-1. OVERALL BLOCK DIAGRAM

SECTION 3

DSR-PD100/PD100P

BLOCK DIAGRAMS

3-1 3-2 3-3 3-4

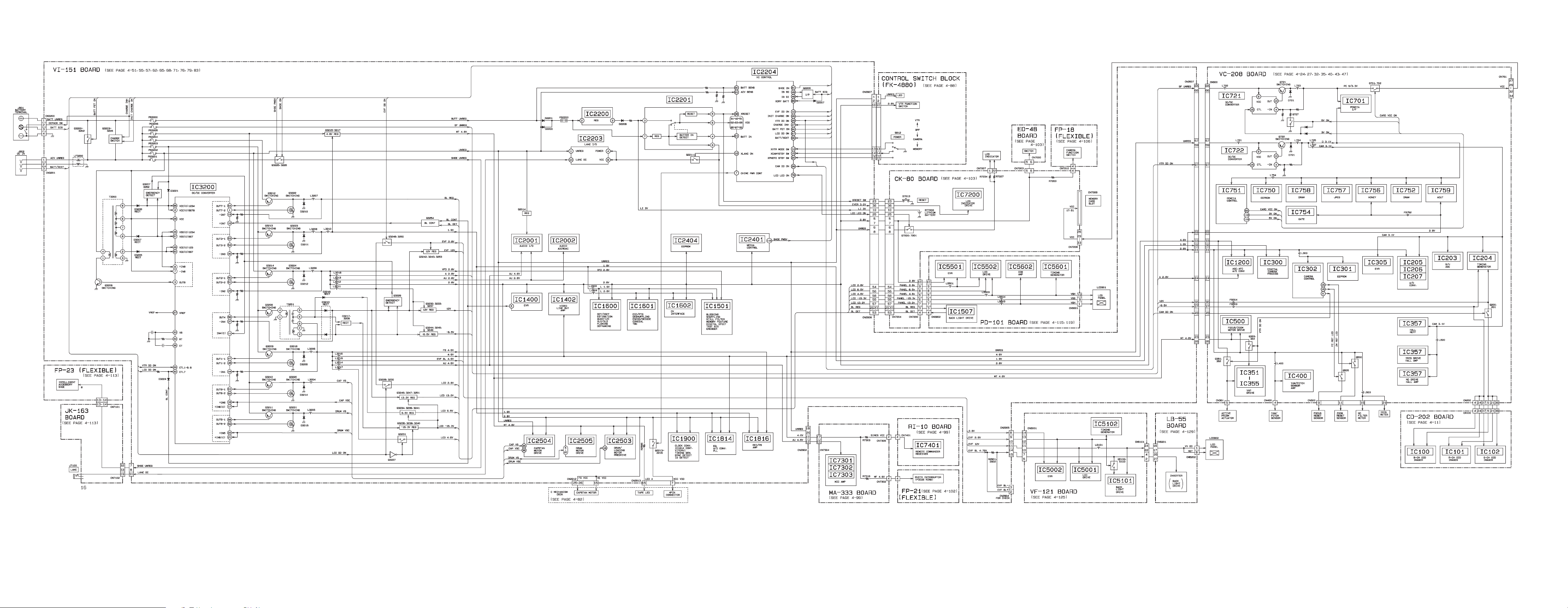

Page 5

DSR-PD100/PD100P

3-2. POWER BLOCK DIAGRAM

3-5 3-6 3-7 3-8E

Page 6

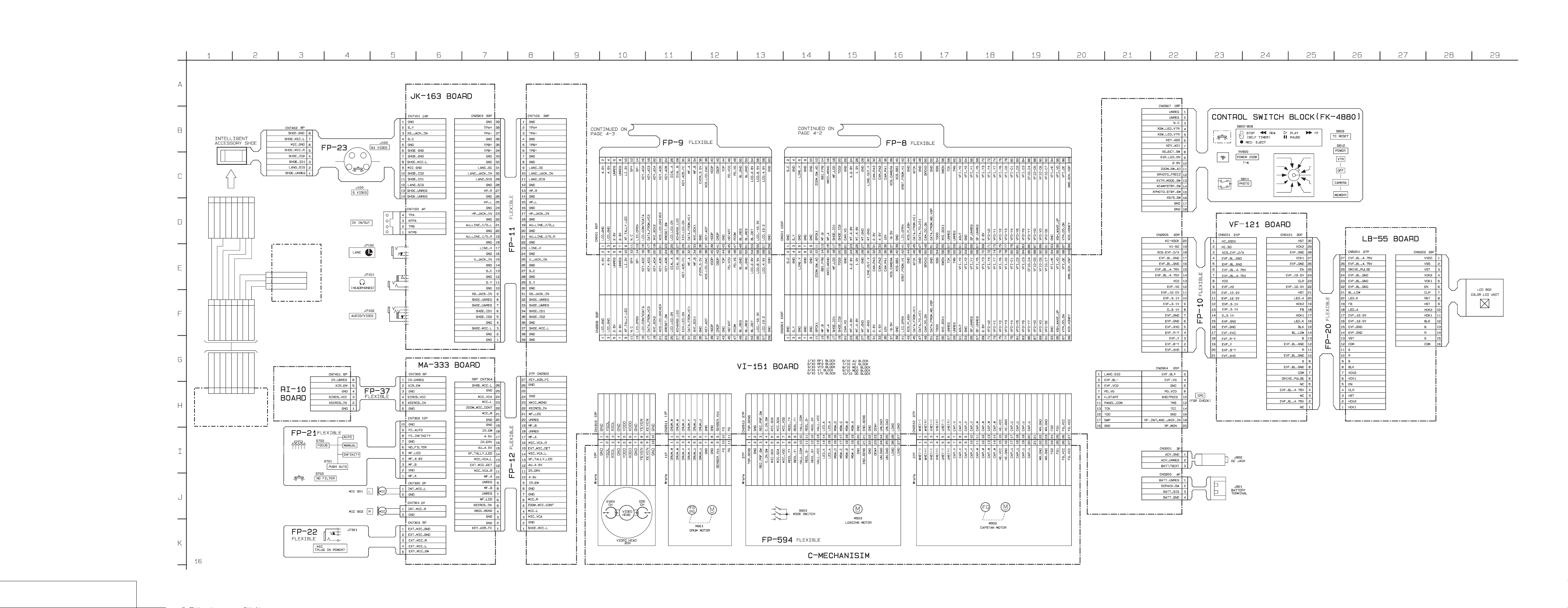

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM-1

SECTION 4

DSR-PD100/PD100P

4-1 4-2 4-3 4-4

FRAME SCHEMATIC DIAGRAM-1

Page 7

DSR-PD100/PD100P

FRAME SCHEMATIC DIAGRAM-2

8765432

XL-51 HARNESS

SHOE UNREG

LANC SIG

SHOE ID1

SHOE ID 2

8765432

SHOE UNREG

SHOE ID1

MIC GND

SHOE MIC L

SHOE UNREG

SHOE ID1

MIC GND

SHOE MIC L

8765432

CN101

8P

SHOE MIC R

MIC GND

SHOE MIC L

SHOE GND

DD GND

+46V

SHOE GND

DD GND

+46V

PLUG

1

CONNECTOR

SHOE GND

1

2

3

1

DD UNREG

DD UNREG

1

DD-120

BOARD

DD UNREG

+46V

DD GND

CN201

3P

FRAME SCHEMATIC DIAGRAM-2

XL-2 BOARD

4-5 4-6 4-7 4-8

Page 8

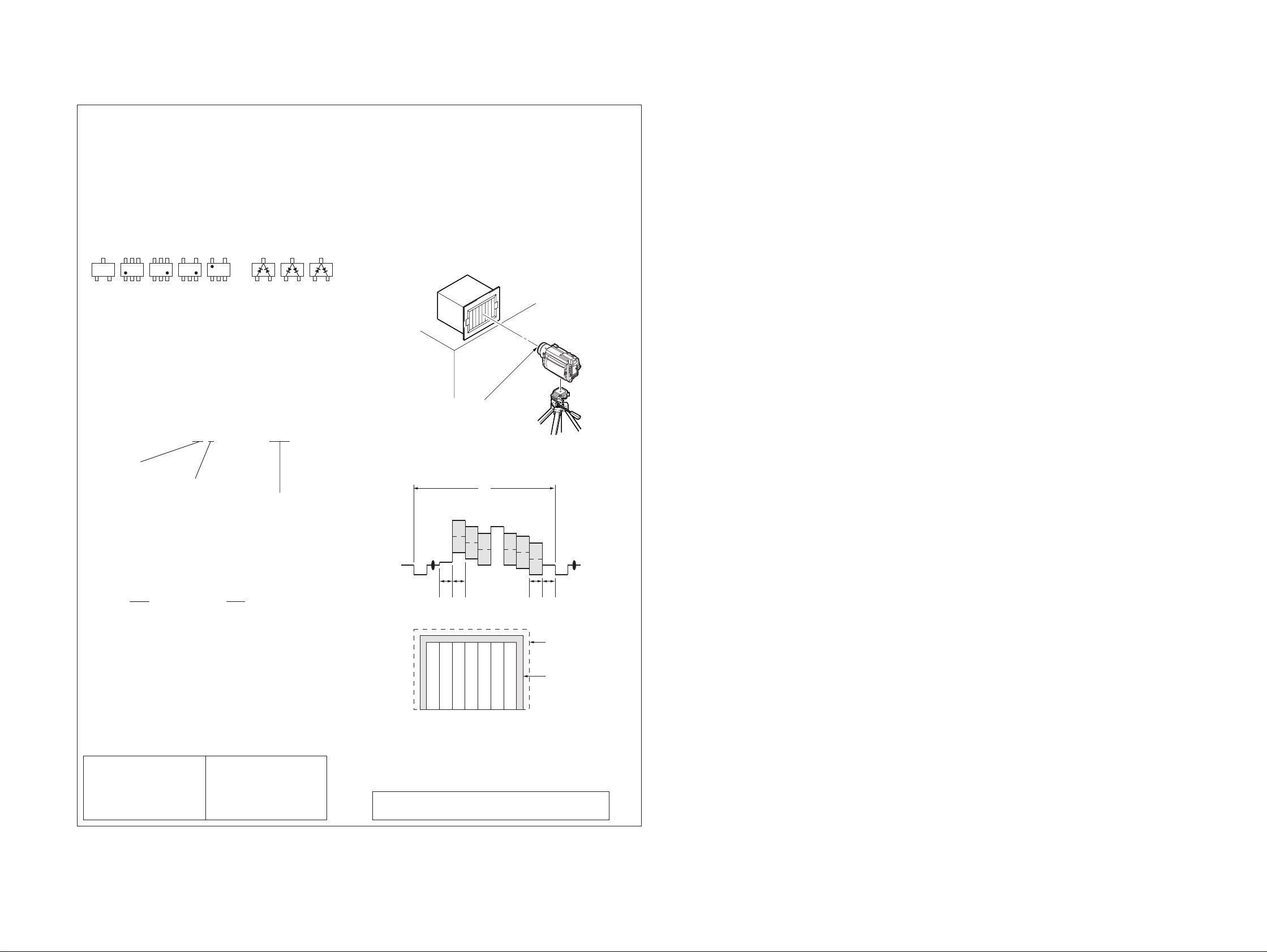

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR WIRING BOARDS AND SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DSR-PD100/PD100P

DSR-PD100/PD100P

(For printed wiring boards)

• b: Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are few cases that the part printed on diagram

isn’t mounted in this model.

• Chip parts.

Transistor Diode

C

5

BE

64

2

13

5

46

2

31

45

2

31

12

4

53

3

21321321

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µµF.

50V or less are not indicated except for electrolytics and

tantalums.

• Chip resistors are 1/10W unless otherwise noted.

kΩ=1000Ω, MΩ=1000kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX indicate

that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2 : non flammable resistor

• 1 : fusible resistor

• C : panel designation

• A : B+ Line *

• B : B– Line *

• J : IN/OUT direction of (+,–) B LINE. *

• C : adjustment for repair. *

• Circled numbers refer to waveforms. *

*Indicated by the color red.

Note :

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the measurement points and ground when camera shoots color bar chart of

pattern box. They are reference values and reference waveforms. *

(VOM of DC 10 MW input impedance is used.).

• Voltage values change depending upon input impedance of VOM

used.)

1. Connection

Pattern box

95 cm

Front side of the lens

2. Adjust the distance so that the output waveform of Fig. a and

the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Cyan

White

Green

Yellow

Magenta

Fig.b (Picture on monitor TV)

3. • The LINE REC w avefo rm shows the wavef orm when the color

for signal (video signal) is input from a color bar pattern.

• The LINE OUT waveform shows the wavefor m when the

signals are connected to the S-VIDEO and VIDEO/AUDIO

jacks but not to other jacks.

When indicating parts by reference number, pleas include

the board name.

Red

Blue

Red

Blue

Electron beam

scanned frame

CRT picture frame

4-9

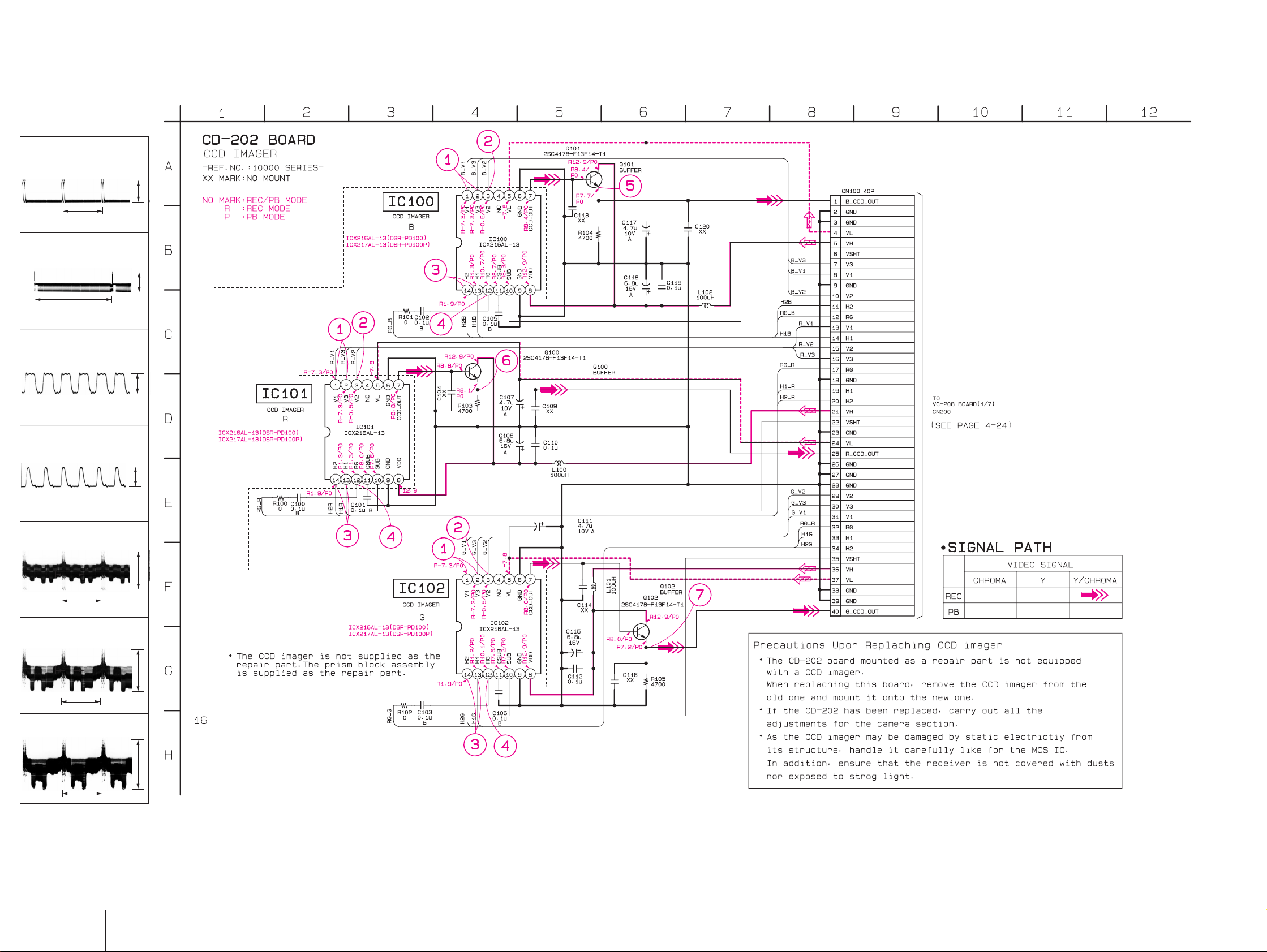

Page 9

DSR-PD100/PD100P

CD-202

CAMERA REC

IC100 1, 2

1

IC101 1, 2

IC102 1, 2

IC100 3, IC101 3

2

IC102 3

IC100 !£, !¢

3

IC101 !£, !¢

IC102 !£, !¢

13.5 MHz

IC100 !™, IC101 !™

4

IC102 !™

BOARD

H

V

8.4Vp-p

22Vp-p

3.0Vp-p

5

Q101 E

6

Q100 E

7

Q102 E

13.5 MHz

H

H

H

H

H

3.0Vp-p

0.6Vp-p

0.6Vp-p

0.5Vp-p

CCD IMAGER

CD-202

4-11 4-12

Page 10

DSR-PD100/PD100P

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-17 for printed wiring board.

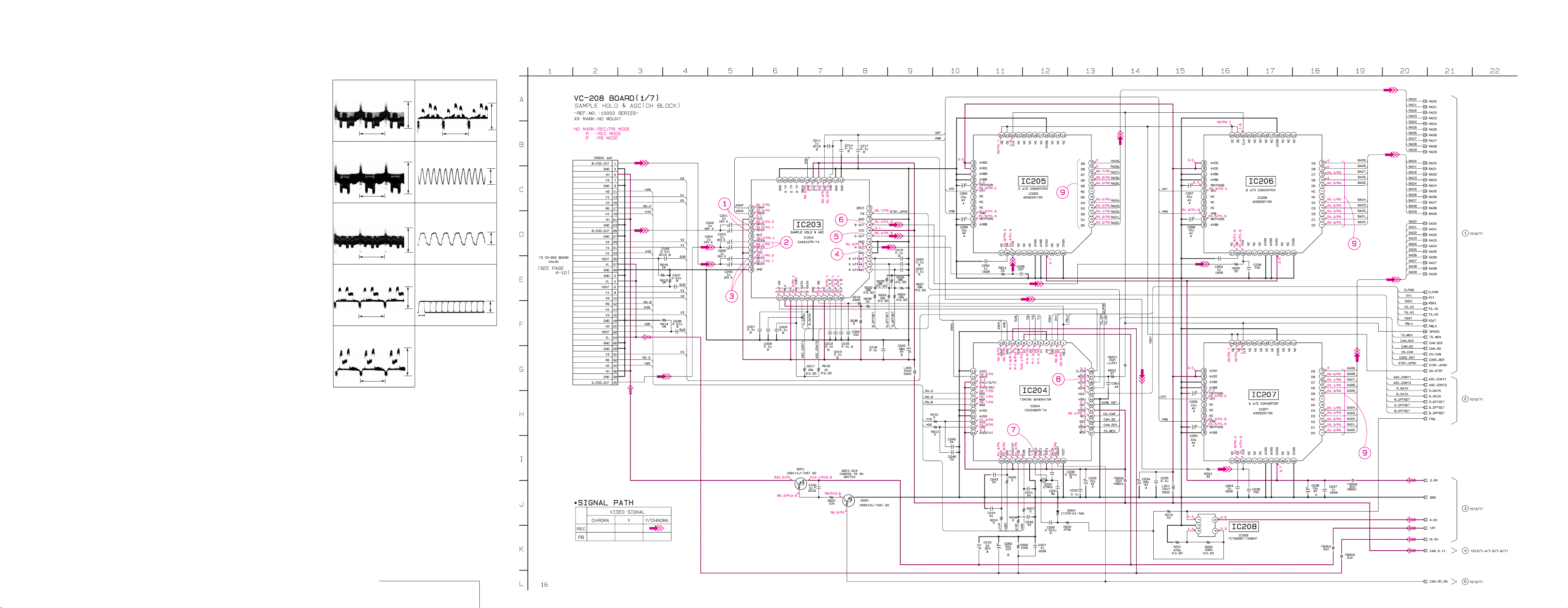

VC-208

1

CAMERA REC

2

CAMERA REC

3

CAMERA REC

4

CAMERA REC

BOARD (1/7)

IC203 @•, @ª

H

IC203 #¡, #™

H

IC203 #¢, #∞

H

IC203 5

6

0.6Vp-p

0.5Vp-p

0.6Vp-p

IC203 9

CAMERA REC

7

IC204 #¡

CAMERA REC

8

IC204 $¶

CAMERA REC/PB

9

IC205 1 – 5 , 8 – !™

IC206 1 – 5 , 8 – !™

IC207 1 – 5 , 8 – !™

CAMERA REC

H

27.0 MHz

13.5 MHz

0.34Vp-p

3.4Vp-p

3.0Vp-p

H

5

IC203 7

CAMERA REC

H

0.28Vp-p

0.34Vp-p

74 nsec

2.8Vp-p

SAMPLE HOLD & AGC

VC-208 (1/7)

4-24 4-25 4-26

Page 11

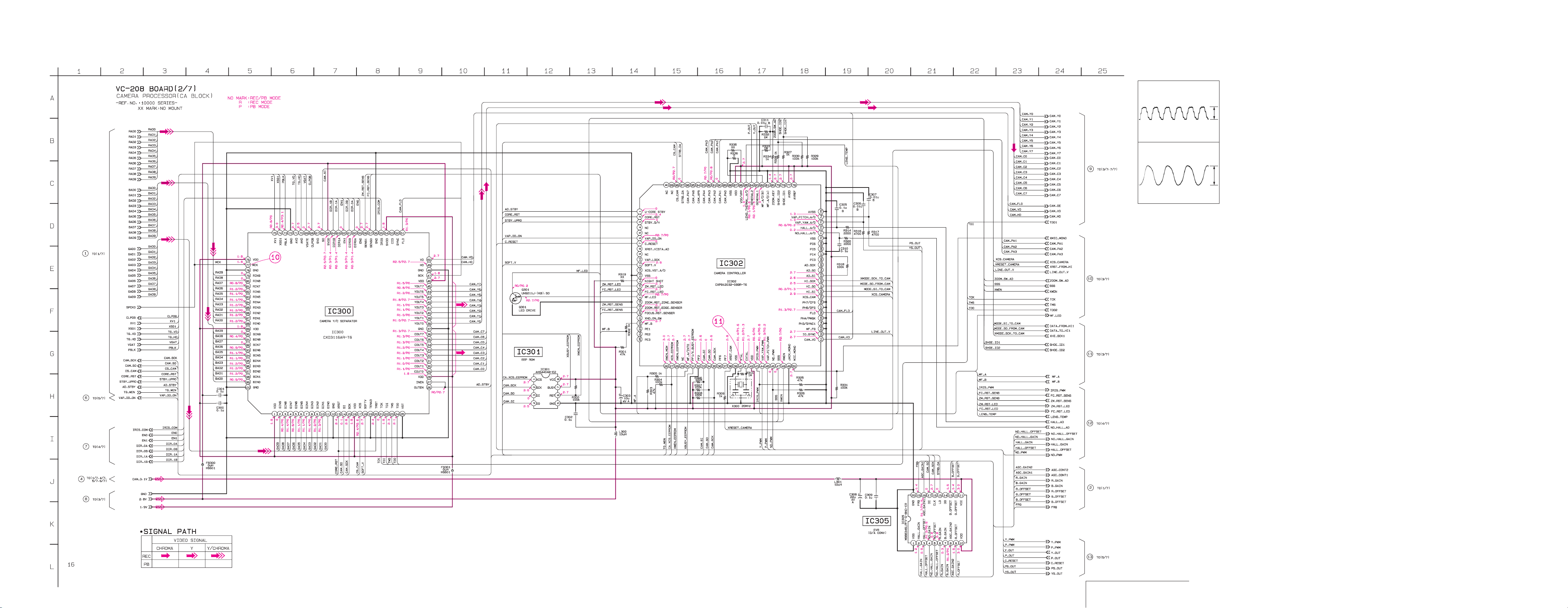

For schematic diagram

• Refer to page 4-17 for printed wiring board.

DSR-PD100/PD100P

DSR-PD100/PD100P

VC-208

!º

CAMERA REC/PB

!¡

CAMERA REC/PB

BOARD (2/7)

IC300 &¶

13.5MHz

IC302 $º

20.0MHz

3.0Vp-p

2.8Vp-p

4-27 4-28 4-29

CAMERA PROCESSOR

VC-208 (2/7)

Page 12

DSR-PD100/PD100P

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-17 for printed wiring board.

VC-208

BOARD (3/7)

!™ IC1200 @∞

LINE REC (NTSC)

H

!™ IC1200 @∞

CAMERA REC/PB

H

!£ IC1200 #£

LINE REC (NTSC)

H

!£ IC1200 #£

CAMERA REC/PB

0.44Vp-p

1.0Vp-p

0.5Vp-p

H

1.5Vp-p

!¢ IC1200 #¢

LINE REC (NTSC)

H

0.44Vp-p

!¢ IC1200 #¢

CAMERA REC/PB

2.0Vp-p

3.0Vp-p

IC1200 $¢

!∞

LINE REC

40.5MHz

H

!§ IC1200 ^¡ – ^•

CAMERA REC/PB,

LINE REC

4-31

74 nsec

2.8Vp-p

BASE BAND INPUT

VC-208 (3/7)

4-32 4-33 4-34

Page 13

For schematic diagram

• Refer to page 4-17 for printed wiring board.

DSR-PD100/PD100P

DSR-PD100/PD100P

4-35 4-36

4-37

MOTOR DRIVE

VC-208 (4/7)

Page 14

DSR-PD100/PD100P

)

SE-75 (YAW/PITCH SENSOR) PRINTED WIRING BOARD

— Ref. No. SE-75 Board; 10,000 Series —

SE-75 BOARD

C450 B-2

C451 A-2

CN450 A-2

L450 B-1

SE450 B-2

SE451 C-1

For schematic diagram

• Refer to page 4-17 for printed wiring board of VC-208.

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

There are few cases that the part printed on this

diagram isn’t mounted in this model.

LB-55

(EVF BACK-LIGHT)

VF-121

(COLOR EVF)

ED-48

(USER CONTROL)

SE-75

(YAW/PITCH SENSOR)

JK-163

(AUDIO/VIDEO IN/OUT)

RI-10

(SIRCS RECEIVER)

MA-333

(STEREO MIC AMP)

CK-80

USER CONTORL,

LCD DRIVE

PD-101

(RGB DRIVER, TIMING GENERATOR, BACK-LIGHT

1-670-999-

12

VAP DRIVER

VC-208 (5/7)

YAW/PITCH SENSOR

/

SE-75

4-39 4-40 4-41 4-42

Page 15

For schematic diagram

• Refer to page 4-17 for printed wiring board.

DSR-PD100/PD100P

VC-208 BOARD (6/7)

CAMERA REC/PB

!¶ IC722 !º

2.3µsec

0.8Vp-p

4-43 4-44 4-45 4-46

CARD CONTROL, PWM CONTROL

VC-208 (6/7)

Page 16

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-17 for printed wiring board.

HONEY, PCMCIA CONTROL

VC-208 (7/7)

4-47 4-48 4-49 4-50

VC-208

!•

CAMERA REC/PB

BOARD (7/7)

IC751 &¶

6.85MHz

3.8Vp-p

Page 17

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DSR-PD100/PD100P

VI-151 BOARD (1/10)

1 IC1816 1, 2, 6, 7

CAMERA REC

6.8msec

3.5Vp-p

2 IC1816 !¡, !™

CAMERA REC

6.8msec

2.0Vp-p

3 IC1816 @¶ PB

0.35Vp-p

6.8msec

4 IC1816 $º

CAMERA REC/PB

41.7MHz

5 IC1816 $™

CAMERA REC

25nsec

6 IC1814 !£ PB

41.85MHz

7 IC1814 !∞ – @º PB

25nsec

2.3Vp-p

2.2Vp-p

2.0Vp-p

2.2Vp-p

4-51 4-52 4-53

8 IC1814 #¡

CAMERA REC/PB

6.8msec

2.6Vp-p

REC/PB AMP

VI-151 (1/10)

Page 18

DSR-PD100/PD100P

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-91 for printed wiring board.

VI-151

CAMERA REC

9

BOARD (2/10)

IC1900 $¡

13.5MHz

3.2Vp-p

TIMING GENERATOR

VI-151 (2/10)

4-55 4-56

Page 19

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DSR-PD100/PD100P

DSR-PD100/PD100P

VI-151

!º

CAMERA REC

!º

(NTSC)

!¡

CAMERA REC

!¡

(NTSC)

BOARD (3/10)

Q1500 E

H

Q1500 E LINE REC

Q1501 E

H

Q1501 E LINE REC

0.22Vp-p

0.3Vp-p

H

0.2Vp-p

H

!™

Q1502 E

CAMERA REC

H

!™

Q1502 E LINE REC

(NTSC)

H

0.3Vp-p

0.34Vp-p

0.38Vp-p

4-57 4-58 4-59

VIDEO INTERFACE

VI-151 (3/10)

Page 20

DSR-PD100/PD100P

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-91 for printed wiring board.

VI-151 BOARD (4/10)

CAMERA REC/PB

!£ IC1600 !¢ (R1627)

24.58MHz

2.6Vp-p

DCT/IDCT

VI-151 (4/10)

4-62 4-63 4-64

Page 21

Ver 1.5 2003. 05

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DSR-PD100/PD100P

DSR-PD100/PD100P

LINE OUT (I/O BLOCK)

VI-151

!§

CAMERA REC/PB

!¶

CAMERA REC/PB

!•

CAMERA REC/PB

!ª

CAMERA REC/PB

BOARD (5/10)

IC1402 @∞

H

IC1402 @ª

H

IC1402 7

H

IC1402 !™

0.4Vp-p

0.26Vp-p

2.0Vp-p

H

@º

IC1402 !§

CAMERA REC/PB

H

1.2Vp-p

1.7Vp-p

4-65 4-66

LINE OUT

VI-151 (5/10)

4-67

Page 22

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-91 for printed wiring board.

AUDIO PROCESSOR

VI-151 (6/10)

4-68 4-69 4-70

Page 23

For schematic diagram

• Refer to page 4-91 for printed wiring board.

DSR-PD100/PD100P

VI-151

CAMERA REC/PB

@¡

@™

(X2201, R2262)

BOARD (7/10)

IC2204 $º (R2300)

20.0MHz

IC2204 %£

32.767kHz

3.0Vp-p

3.0Vp-p

4-71 4-72 4-73 4-74

HI CONTROL

VI-151 (7/10)

Page 24

DSR-PD100/PD100P

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-91 for printed wiring board.

VI-151

CAMERA REC/PB

@£

BOARD (8/10)

IC2401 1 (X2400)

20.0MHz

2.5Vp-p

4-76

MECHANISM CONTROL

VI-151 (8/10)

4-77 4-78

Page 25

For schematic diagram

• Refer to page 4-91 for printed wiring board.

• Refer to page 4-87 for FP-594 flexible board.

DSR-PD100/PD100P

VI-151

CAMERA REC/PB

BOARD (9/10)

DSR-PD100/PD100P

@¢ IC2503 4

6.7msec

@∞ IC2503 @™, @£, @¢

1.1msec

@§ IC2503 @∞, @§, @¶

1.1msec

@¶ IC2503 $∞

#º IC2503 ^º

2.6Vp-p

#¡ IC2503 ^£

0.1Vp-p

1.1msec

#™ IC2504 !¶

2.3Vp-p

0.92msec : DV

0.63msec : DVCAM

#£ IC2504 #¡, #£, #¢

1.1msec

900kHz

2.8Vp-p

0.23Vp-p

2.8Vp-p

0.56sec : DV

0.3sec : DVCAM

@• IC2503 $•

0.76sec : DV

0.3 sec : DVCAM

@ª IC2503 %¢

3µsec

2.7Vp-p

2.7Vp-p

2.8Vp-p

80msec : DV

55msec : DVCAM

#¢ IC2505 2, !•, @£

0.6Vp-p

2.2Vp-p

1.1msec

4-79 4-80 4-81 4-82

VI-151 (9/10)

DRUM/CAPSTAN MOTOR DRIVE

Page 26

DSR-PD100/PD100P

For schematic diagram

• Refer to page 4-91 for printed wiring board.

VI-151

CAMERA REC/PB

#∞

#§

#¶

BOARD (10/10)

IC3200 %§

2.5µsec

IC3200 %•

2.5µsec

IC3200 ^¡

2.5µsec

4.7Vp-p

4.7Vp-p

4.7Vp-p

DC/DC CONVERTER

VI-151 (10/10)

4-83 4-84 4-85 4-86

Page 27

FP-594 (LOADING MOTOR, S/T REEL SENSOR) PRINTED WIRING BOARD

— Ref. No.: FP-594 Board; 9,000 Series —

FP-594

BOARD

DSR-PD100/PD100P

M

LOADING

Q901

TAPE END

M902

MOTOR

DEW

SENSOR

S903

MODE SW

Q902

TAP E TOP

H901

S REEL

SENSOR

For printed wiring boards

• Refer to page 4-82 for FP-594 board schematic diagram.

S901

C IN

H902

T REEL

SENSOR

D901

TAPE

LED

S902

REC.P

CN901

MIC SW

• CONTROL SWITCH BLOCK (FK-4880) is replaced as a block.

So that there PRINTED WIRING BOARD are omitted.

4-87 4-88 4-89

FP-594

LOADING MOTOR, S/T REEL SENSOR

USER CONTROL

FK-4880

Page 28

DSR-PD100/PD100P

DSR-PD100/PD100P

4-99 4-100 4-101

STEREO MIC AMP

MA-333

SIRCS RECEIVER

/

RI-10

Page 29

DSR-PD100/PD100P

)

FP-16 (PANEL SWITCH) FLEXIBLE BOARD

FP-16 FLEXIBLE BOARD

S002

(PANEL CLOSE)

S001

(PANEL REV)

FP-16 1-670-983-

16

FP-18 (USER CONTROL) FLEXIBLE BOARD

FP-18 FLEXIBLE BOARD

8

1

11

mk

0

FP-18

FK-4880

(USER CONTROL)

FP-17

FP-23

(S-Y/C IN/OUT)

FP-16

FP-11

FP-13

FP-8

FP-19

(USER CONTROL)

USER CONTROL

CK-80, ED-48, FP-16, FP-18

For LED

1-670-985-

FP-18

(USER CONTROL

4-103 4-104 4-105 4-106

Page 30

DSR-PD100/PD100P

)

)

FP-23 (S VIDEO) FLEXIBLE BOARD

FP-23 FLEXIBLE BOARD

INTELLIGENT

ACCESSORY

SHOE

18

C

Y

S VIDEO

J100

1- 670

-990 -

FP- 23

JK-163 (AUDIO/VIDEO IN/OUT) PRINTED WIRING BOARD

— Ref. No. JK-163 Board; 10,000 Series —

JK-163 BOARD

C7100 C-4

C7101 D-4

C7102 C-5

C7103 D-4

C7104 C-1

CN7100 B-2

CN7101 C-1

8

1

1

14

11

CN7102 B-5

D7100 B-4

D7102 B-1

D7103 C-5

D7104 D-5

D7105 C-5

D7106 C-5

FB710 B-4

FB711 C-4

FB712 B-1

FB713 D-1

FB714 C-1

FB715 C-5

FB716 C-1

FB717 C-1

FB718 C-1

J7100 C-2

J7101 C-2

J7102 D-2

L7100 C-4

L7101 C-5

L7102 C-5

L7103 D-4

L7104 C-1

R7102 C-4

VDR711 C-4

VDR714 C-5

VDR715 B-5

VDR717 D-4

VDR718 C-5

FK-4880

(USER CONTROL)

FP-17

FP-23

(S-Y/C IN/OUT)

FP-16

FP-11

FP-13

FP-8

FP-19

(USER CONTROL)

For LED

FP-18

(USER CONTROL

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

• Chip parts

Diode

3

21

There are few cases that the part printed on this

diagram isn’t mounted in this model.

LB-55

(EVF BACK-LIGHT)

VF-121

(COLOR EVF)

ED-48

(USER CONTROL)

SE-75

(YAW/PITCH SENSOR)

JK-163

(AUDIO/VIDEO IN/OUT)

RI-10

(SIRCS RECEIVER)

MA-333

(STEREO MIC AMP)

CK-80

USER CONTORL,

LCD DRIVE

PD-101

(RGB DRIVER, TIMING GENERATOR, BACK-LIGHT

12

S-Y/C IN/OUT

FP-23

AUDIO/VIDEO IN/OUT

/

JK-163

4-111 4-112 4-113 4-114

Page 31

For schematic diagram

• Refer to page 4-121 for PD-101 printed wiring board.

• Refer to page 4-121 for FP-19 flexible board.

DSR-PD100/PD100P

PD-101

CAMERA REC/PB

1

BOARD (1/2)

IC5502 8

2

3

4

5

H

IC5502 9

H

IC5502 !º

IC5502 @º

IC5502 @™

0.3Vp-p

0.2Vp-p

H

2H

0.22Vp-p

4.2Vp-p

4.2Vp-p

4-115 4-116 4-117

6

7

2H

IC5502 @¢

4.2Vp-p

2H

IC5502 $¡

1.4Vp-p

2H

RGB DRIVER

PD-101 (1/2)

Page 32

DSR-PD100/PD100P

DSR-PD100/PD100P

PD-101

CAMERA REC/PB

8

9

!º

!¡

BOARD (2/2)

IC5601 @§

16.7MHz

IC5601 #¢

V

IC5601 #¶

H

IC5602 7

3.5Vp-p

3.5Vp-p

2.8Vp-p

2H

5.6Vp-p

4-118

TIMING GENERATOR, BACK-LIGHT

PD-101 (2/2)

4-119 4-120

Page 33

DSR-PD100/PD100P

VF-121

CAMERA REC/PB

1

BOARD

IC5001 8

H

0.28Vp-p

2

IC5001 9

3

IC5001 !º

H

0.18Vp-p

H

0.2Vp-p

4

IC5001 @º

5

IC5001 @™

7.6Vp-p

2H

2H

7.6Vp-p

6

IC5001 @¢

7

IC5101 !∞

2H

7.6Vp-p

H

11.0Vp-p

8

IC5102 @¶

9

IC1502 #∞

H

2.7Vp-p

H

3.0Vp-p

!º

IC5102 $¡

16.4MHz

3.0Vp-p

!¡

IC1502 $∞

2.8Vp-p

V

COLOR EVF

4-125 4-126 4-127

VF-121

Page 34

DSR-PD100/PD100P

)

LB-55 (EVF BACK-LIGHT) PRINTED WIRING BOARD

— Ref. No. LB-55 Board; 10,000 Series —

LB-55 BOARD

C5201 B-1

C5202 B-2

C5203 B-2

C5204 B-1

C5206 B-1

C5207 B-1

C5208 B-1

CN5201 B-4

CN5202 B-4

D5201 C-1

L5201 B-2

L5202 C-2

ND5201 E-4

Q5201 B-1

R5201 B-1

R5202 C-1

T5201 E-1

SE-75

(YAW/PITCH SENSOR)

VF-121

(COLOR EVF)

ED-48

(USER CONTROL)

LB-55

(EVF BACK-LIGHT)

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

• Chip parts

Diode

3

JK-163

(AUDIO/VIDEO IN/OUT)

RI-10

(SIRCS RECEIVER)

MA-333

(STEREO MIC AMP)

PD-101

(RGB DRIVER, TIMING GENERATOR, BACK-LIGHT

EVF BACK-LIGHT

LB-55

CK-80

USER CONTORL,

LCD DRIVE

21

There are few cases that the part printed on this

diagram isn’t mounted in this model.

4-128 4-129 4-130

Page 35

XL-2 (MIC AMP) PRINTED WIRING BOARD

CD-202

(CCD IMAGER)

VI-151

REC/PB AMP, TIMING GENERATOR, VIDEO INTERFACE,

DCT/IDCT, LINE OUT, AUDIO PROCESSOR,

HI CONTROL, MECHANISM CONTROL,

DRUM/CAPSTAN MOTOR DRIVE, DC/DC CONVERTER

VC-208

SAMPLE HOLD & AGC,

CAMERA PROCESSOR,

BASE BAND INPUT,

MOTOR DRIVE, VAP DRIVER,

CARD CONTROL,

PWM CONTROL,

HONEY/PCMCIA CONTORL

XL-2

(MIC AMP)

DD-120

DC/DC

CONVERTER

— Ref. No. XL-2 Board; 9,000 Series —

XL-2 BOARD

C100 E-2

C102 E-4

C103 D-2

C104 E-2

C105 E-2

C106 E-3

C107 A-5

C108 A-5

C109 E-2

C110 B-5

C111 B-5

C112 E-4

C113 D-4

C114 A-4

C115 B-4

C116 A-4

C117 E-4

C118 D-4

C119 A-4

C120 B-4

C121 B-4

C122 D-3

C123 D-3

C124 D-3

C125 D-3

C126 D-3

C127 D-3

C128 E-3

C129 E-3

C130 D-3

C131 B-5

C132 E-2

C133 E-4

CN101 A-4

CN102 A-2

D101 E-4

D102 E-4

D103 E-4

D104 E-4

D105 D-4

D106 D-4

D107 A-5

D108 A-5

D109 A-3

D110 A-3

IC101 E-2

IC102 A-5

IC103 B-4

L101 E-3

L102 D-3

L103 E-3

L104 E-2

PS101 E-3

Q101 E-4

Q102 E-1

R101 A-3

R102 A-5

R103 E-4

R104 E-1

R105 A-5

R106 A-5

R107 E-4

R108 D-4

R109 B-5

R110 B-5

R111 B-4

R112 B-4

R113 B-4

R114 B-4

R115 A-4

R116 D-4

R117 E-4

R118 B-4

R119 B-3

R120 A-3

R121 B-5

R122 E-4

R123 E-3

S101 D-2

S102 D-4

DSR-PD100/PD100P

800mA

For printed wiring boards

• This board is four-layer print board. However, the patterns of layers two and three have not been included

in the diagram.

• Chip parts

Transistor

BE

There are few cases that the part printed on this

diagram isn’t mounted in this model.

C

(SEE PAGE

4-135)

4-131 4-132 4-133

MIC AMP

XL-2

Page 36

DSR-PD100/PD100P

DD-120 BOARD

C201 D-3

C202 E-3

C203 B-2

C204 A-1

C205 A-1

C206 B-2

C207 B-3

C208 A-2

C209 A-2

C210 D-2

C211 A-2

C212 A-3

C213 E-3

C214 B-3

C215 D-2

C216 B-2

CN201 E-3

D201 B-2

IC201 A-2

L201 E-3

L202 D-3

L203 A-2

Q201 B-2

Q202 D-2

Q203 B-2

Q204 B-3

Q205 B-2

Q206 D-3

Q207 D-3

Q208 D-3

R201 B-2

R202 B-1

R203 B-1

R204 B-2

R205 B-2

R206 D-2

R207 B-3

R208 B-2

R209 A-2

R210 A-2

R211 B-3

R212 D-2

R213 A-2

R214 B-2

R215 B-2

R216 B-3

R217 B-3

R218 D-3

R219 D-3

DD-120 (DC/DC CONVERTER) PRINTED WIRING BOARD

— Ref. No. DD-120 Board; 9,000 Series —

For printed wiring boards

• This board is four-layer print board. However, the patterns of layers two and three have not been included

in the diagram.

• Chip parts

Transistor Diode

C

BE321

There are few cases that the part printed on this

diagram isn’t mounted in this model.

DD-120

DC/DC

CONVERTER

XL-2

(MIC AMP)

CD-202

(CCD IMAGER)

VC-208

SAMPLE HOLD & AGC,

CAMERA PROCESSOR,

BASE BAND INPUT,

MOTOR DRIVE, VAP DRIVER,

CARD CONTROL,

PWM CONTROL,

HONEY/PCMCIA CONTORL

(SEE PAGE

4-132)

VI-151

REC/PB AMP, TIMING GENERATOR, VIDEO INTERFACE,

DCT/IDCT, LINE OUT, AUDIO PROCESSOR,

HI CONTROL, MECHANISM CONTROL,

DRUM/CAPSTAN MOTOR DRIVE, DC/DC CONVERTER

DC/DC CONVERTER

4-134 4-135 4-136E

DD-120

Loading...

Loading...