SONY DSC W35 Service Manual

SERVICE MANUAL

Ver. 1.0 2010.11

Internal memory

Internal memory

ON BOARD

ON BOARD

DSC-W510

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Korea Model

Argentine Model

Brazilian Model

983454511.pdf

Revision History

Ver. Date History Contents

1.0 2010.11 Official Release — —

S.M. Rev.

issued

Photo: Silver

SERVICE NOTE (Check the following note before the service.)

1-1. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

1-2. DEDICATED A/V CABLE (OPTIONAL ACCESSORY)

1-3. REGARDING FUSE

1-4. ORNAMENTAL RING A OR BARRIER ASSY REPLACING METHOD

1-5. OPTICAL STEPPING MOTOR (F1380) REPLACING METHOD

1-6. DC MOTOR WORM A ASSY REPLACING METHOD

1-7. CAM TUBE BLOCK ASSY AND STRAIGHT TUBE LUBRICATED ASSY AND

1 GROUP FRAME REPLACING METHOD

1-8. FINAL INSPECTION

The components identified

by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number

specified.

DSC-W510

9-834-545-11

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

DIGITAL STILL CAMERA

Sony Corporation

2010K29-1

© 2010.11

Published by Sony Techno Create Corporation

SPECIFICATIONS

Camera

[System]

Image device:

7.79 mm (1/2.3 type) color CCD,

Primary color filter

Total pixel number of camera:

Approx. 12.4 Megapixels

Effective pixel number of camera:

Approx. 12.1 Megapixels

Lens: 4 × zoom lens

f = 4.7 mm - 18.8 mm (26 mm 105 mm (35 mm film equivalent))

F2.8 (W) - F5.9 (T)

Exposure control: Automatic exposure,

Scene Selection (9 modes)

White balance: Automatic, Daylight,

Cloudy, Fluorescent 1/2/3,

Incandescent, Flash

Recording interval for Burst mod

Approx. 1.0 second

File format:

Still images: JPEG (DCF Ver. 2.0,

Exif Ver. 2.3, MPF Baseline)

compliant, DPOF compatible

Movies: AVI (Motion JPEG)

Recording media: Internal Memory

(approx. 6 MB), “Memory Stick

Duo” media, SD card

Flash: Flash range (ISO sensitivity

(Recommended exposure Index)

set to Auto):

Approx. 0.2 m to 4.8 m (7

inches to 15 ft 9 inches) (W)/

approx. 0.2 m to 2.3 m (7 7/8

inches to 7 ft 6 5/8 inches) (T)

e:

7/8

[Input and Output connectors]

(USB)/A/V OUT terminal:

Video output

Audio output (Monaural)

USB communication

USB communication: Hi-Speed USB

(USB 2.0)

[LCD screen]

LCD panel:

6.7 cm (2.7 type) TFT drive

Total number of dots: 230 400 (960

× 240) dots

[Power, general]

Power: Rechargeable battery pack

NP-BN1, 3.6 V

Power consumption (during shooting):

1.1 W

Operating temperature: 0

°F to 104 °F)

(32

Storage temperature: –20

(–4

°F to +140 °F)

Dimensions: 96.0 mm × 54.0 mm ×

19.9 mm (3 7/8 inches ×

2 1/4 inches × 1 3/16 inches)

excluding protrusions)

(W/H/D,

Mass: Approx. 119 g (4.2 oz)

(including NP-BN1 battery pack

and “Memory Stick Duo” media)

Microphone: Monaural

Speaker: Monaural

Exif Print: Compatible

PRINT Image Matching III:

Compatible

°C to 40 °C

°C to +60 °C

BC-CSN/BC-CSNB battery

charger

Power requirements: AC 100 V to

240 V, 50 Hz/60 Hz, 2 W

Output voltage: DC 4.2 V, 0.25 A

Operating temperature: 0

(32

°F to 104 °F)

Storage temperature: –20

°F to +140 °F)

(–4

Dimensions: Approx. 55 mm × 24 mm

× 83 mm (2 1/4 inches ×

3 1/32 inches × 3 3/8 inches)

(W/H/D)

Mass: Approx. 55 g (1.9 oz.)

°C to 40 °C

°C to +60 °C

Rechargeable battery pack

NP-BN1

Used battery: Lithium-ion battery

Maximum voltage: DC 4.2 V

Nominal voltage: DC 3.6 V

Maximum charge voltage: DC 4.2 V

Maximum charge current: 0.9 A

Capacity:

typical: 2.3 Wh (630 mAh)

minimum: 2.2 Wh (600 mAh)

Design and specifications are subject to

change without

notice.

Danger of explosion occurs if battery is incorrectly replaced.

Caution

Replace only with the same or equivalent type.

Dispose of used batteries according to the instructions.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS LIST

ARE CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY

SONY.

SAFETY CHECK-OUT

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT

LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched”

or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 350°C during

repairing.

• Do not touch the soldering iron on the same conductor of the circuit

board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

UNLEADED SOLDER

This unit uses unleaded solder.

Boards requiring use of unleaded solder are printed with the lead free

mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with the

lead free mark due to their particular size.)

: LEAD FREE MARK

Be careful to the following points to solder or unsolder.

• Set the soldering iron tip temperature to 350°C approximately.

If cannot control temperature, solder/unsolder at high temperature

for a short time.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Be sure to control soldering iron tips used for unleaded solder and

those for leaded solder so they are managed separately. Mixing unleaded solder and leaded solder will cause detachment phenomenon.

DSC-W510

– 2 –

1. SERVICE NOTE

1-1. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

The data can be copied/erased by the operations on the Setup screen. (When erasing the data, execute formatting the internal memory.)

Note1: When replacing the Main Board Assy, erase the data in internal memory of main board before replacement.

Note2: When replacing the Main Board Assy, execute formatting and initialize the internal memory after replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to a memory card.

1. Insert a memory card with sufficient free capacity into the camera.

2. MENU

Notes

•

•

•

•

t

Use a fully charged battery pack. If you attempt to copy image files using a battery pack with

little remaining charge, the battery pack may run out, causing copying to fail or possibly

corrupting the data.

Images cannot be copied individually.

The original images in the internal memory are retained even after copying. To delete the

contents of the internal memory, remove the memory card

internal memory ([Format] in [Internal Memory Tool]).

A new folder is created on the memory card and all the data will be copied to it. You cannot

choose a specific folder and copy images to it.

(Settings) t (Memory Card Tool) t [Copy] t [OK] t z

after copying, then format the

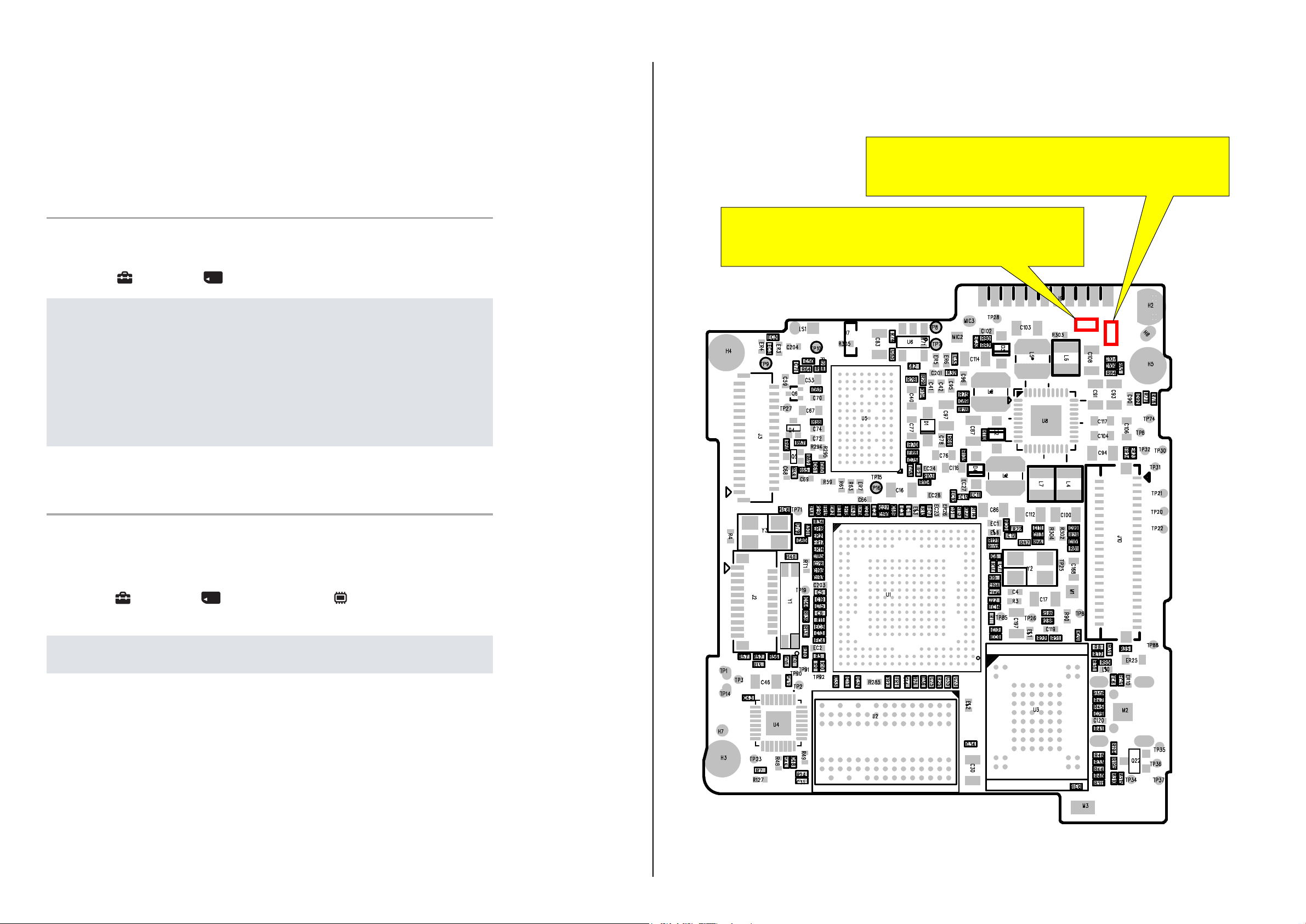

1-3. REGARDING FUSE

• MAIN BOARD

Ref. No: F1

Part No: 1-576-415-11

Description: FUSE, MICRO (1608 TYPE) (2A/32V)

Ref. No: F2

Part No: 1-576-415-11

Description: FUSE, MICRO (1608 TYPE) (2A/32V)

F1

F2

Method for Formatting the Internal Memory

Format

Formats the memory card or the internal memory. When you use a memory card with this

camera for the first time, it is recommended to format the card using the camera for stable

performance of the memory card before shooting. Note that formatting permanently erases all

data on the memory card, and is unrecoverable. Save precious data on a computer, etc.

1. MENU

t [Format] t [OK] t z

Note

•

t

Note that formatting permanently erases all data including even protected images.

(Settings) t (Memory Card Tool) or (Internal Memory Tool)

1-2. DEDICATED A/V CABLE (OPTIONAL ACCESSORY)

Dedicated A/V cable is not supplied with this model.

For details of the dedicated A/V cable, refer to the “Checking supplied accessories” page.

DSC-W510

1-1

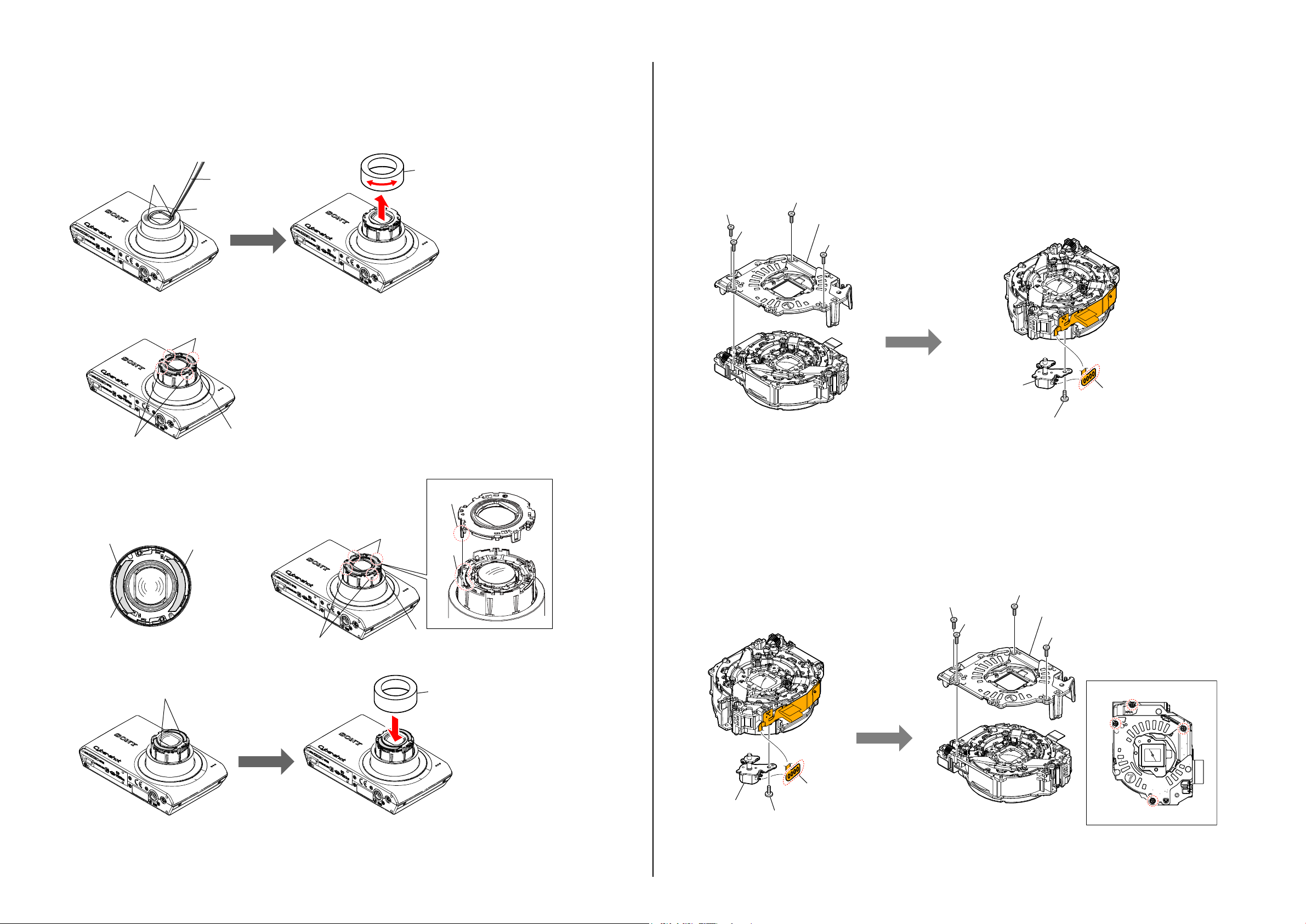

1-4. ORNAMENTAL RING A OR BARRIER ASSY REPLACING METHOD

REMOVAL

1 Turn on the power switch and extend the lens.

2 Detach the battery.

3 Pour a solvent such as alcohol from two places A to the tweezers or a needle shown below into a gap of Ornamental Ring A.

4

Remove while turning the Ornamental Ring A right and left.

A

5

Remove Barrier Assy by disengaging four claws.

Tweezers

Solvent

Claw

Ornamental Ring A

1-5. OPTICAL STEPPING MOTOR (F1380) REPLACING METHOD

REMOVAL

1

Remove four screws, and remove the Rear Mirror Plate.

2

Remove one screw.

3

Remove the four soldering, and remove the Optical Stepping Motor (F1380).

Screw

Screw

Screw

Rear Mirror Plate

Screw

Claw

INSTALLATION

Affix two Barrier Tapes to Barrier Assy.

1

Note:

The tape must not be wrinkled.

With four claws fitted in position, install the Barrier Assy.

2

Barrier Assy

Barrier Tape

3

Peel off release papers of Barrier Tapes.

4

Install Ornamental Ring A and press it lightly.

Barrier Tape

Barrier Tape

Barrier Assy

Claw

Claw

Barrier

Lever

Hole

Barrier Assy

Ornamental Ring A

INSTALLATION

1 Solder the four locations.

2

Install the Optical Stepping Motor (F1380) with one screw.

*

Tightening torque = 0.049±0.01N•m (0.5±0.1kgf•cm)

3

Install the Rear Mirror Plate with the four screws in the order of numbers.

*

Tightening torque = 0.049±0.01N•m (0.5±0.1kgf•cm)

Screw

Optical Stepping

Motor (F1380)

Screw

Solder

Screw

Screw

Rear Mirror Plate

Screw

4

DSC-W510

1-2

Optical Stepping

Motor (F1380)

Screw

Solder

1

2

3

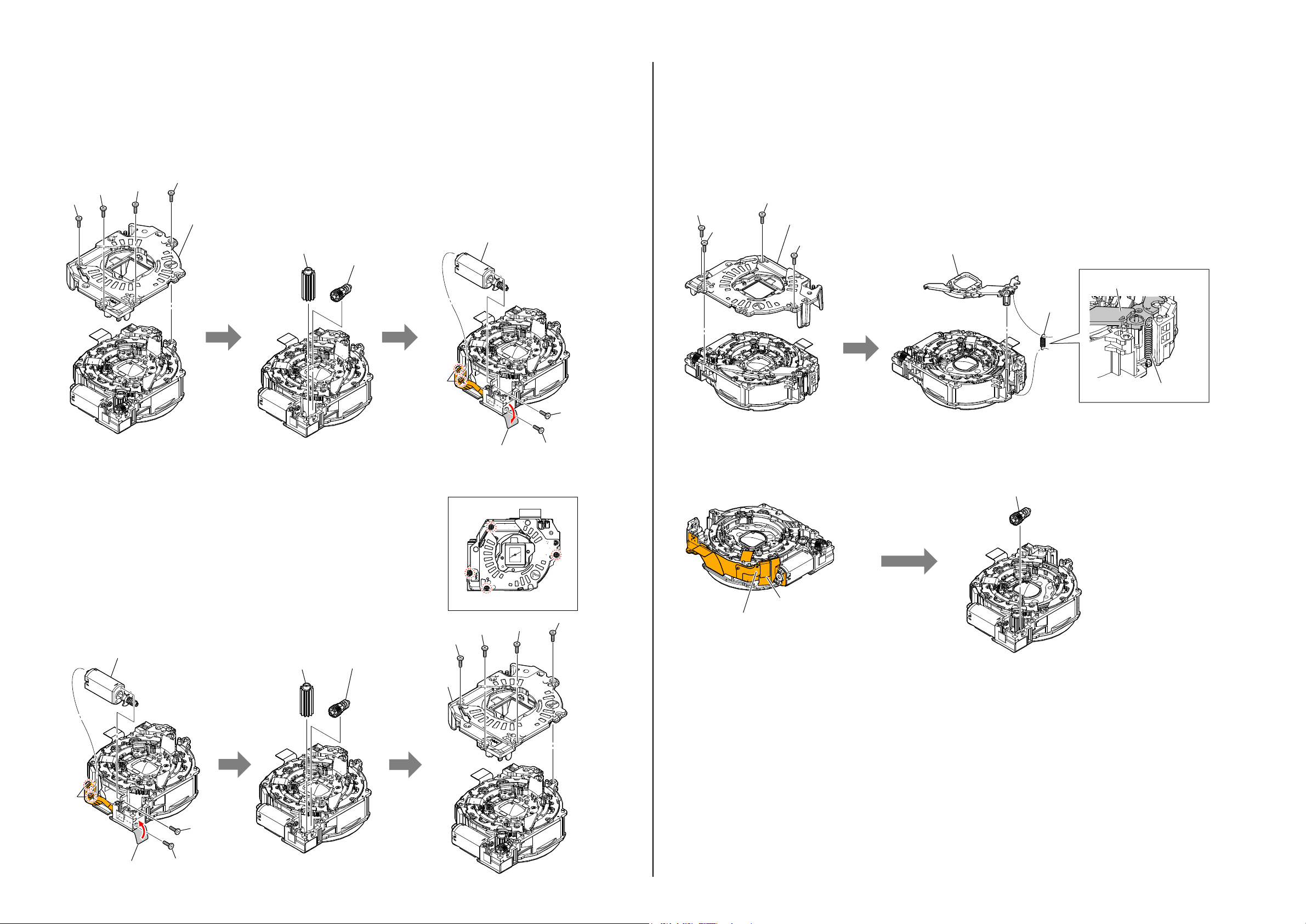

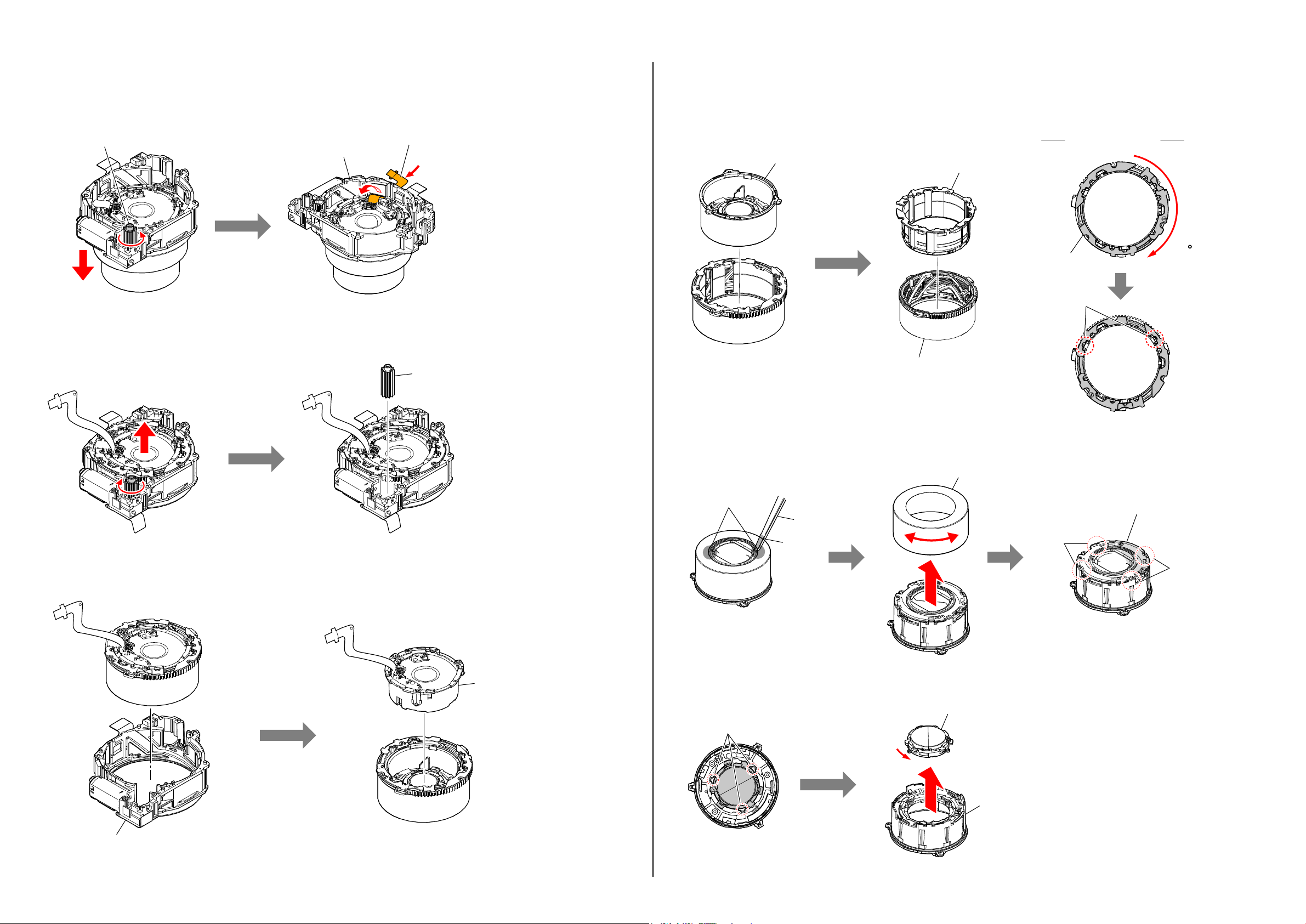

1-6. DC MOTOR WORM A ASSY REPLACING METHOD

REMOVAL

1

Remove four screws, and remove the Rear Mirror Plate.

2

Remove the Naruto Gear Lubricated Assy and Warm B Lubricated Assy.

3 Peel off the FG Seal.

4

Remove two screws.

5

Remove the two soldering, and remove the DC Motor Worm A Assy.

Screw

Rear Mirror Plate

Naruto Gear

Lubricated Assy

Warm B

Lubricated Assy

Screw

Screw

Screw

DC Motor Worm A Assy

1-7. CAM TUBE BLOCK ASSY AND STRAIGHT TUBE LUBRICATED ASSY AND

1 GROUP FRAME REPLACING METHOD

REMOVAL

Remove four screws, and remove the Rear Mirror Plate.

1

Remove the 3 Group Spring.

2

3

Remove the 3 Group Frame.

Screw

Screw

Screw

Rear Mirror Plate

Screw

3 Group Frame

3 Group Frame

3 Group

Spring

INSTALLATION

1 Solder the two locations.

2

Install the DC Motor Worm A Assy with two screws.

∗

Tightening torque = 0.049±0.01N•m (0.5±0.1kgf•cm)

2 Put the FG Seal.

2 Install the Naruto Gear Lubricated Assy and Warm B Lubricated Assy.

3

Install the Rear Mirror Plate with the four screws in the order of numbers.

∗

Tightening torque = 0.049±0.01N•m (0.5±0.1kgf•cm)

DC Motor Worm A Assy

Naruto Gear

Lubricated Assy

Warm B

Lubricated Assy

Solder

Screw

Rear Mirror Plate

4

FG Seal

1

Screw

2

Screw

Screw

Screw

Screw

3

4 Disconnect the Iris Flexible Board from connector of 2 Frame Assy.

Remove the Naruto Gear Lubricated Assy.

5

Flexible Board

Iris Flexible Board

of 2 Frame Assy

3 Group Spring

Warm B

Lubricated Assy

Solder

DSC-W510

FG Seal

Screw

Screw

1-3

6 Rotate the Naruto Gear Lubricated Assy and the lens is drawn out.

7 Pass the Flexible Board through the hole of the Fixed Stationary Tube.

qs

Remove the 1 Group Assy.

qd Rotate (about 120 degree) Straight Tube Lubricated Assy and align the two points of ditches of the Straight Tube Lubricated Assy with

ditches of the Cam Tube Block Assy, then remove the Straight Tube Lubricated Assy from the Cam Tube Block Assy.

Naruto Gear Lubricated Assy

8 Rotate the Naruto Gear Lubricated Assy and the lens is retractile..

9 Remove the Naruto Gear Lubricated Assy.

Fixed Stationary Tube

Flexible Board

Naruto Gear

Lubricated Assy

1 Group Assy

Cam Tube Block Assy

qf

Pour a solvent such as alcohol from two places.

qg

Remove while turning the Ornamental Ring A right and left.

qh

Remove Barrier Assy by disengaging four claws.

Eyepiece Side View

Straight Tube

Lubricated Assy

120

Straight Tube

Lubricated Assy

Ditch

Ornamental Ring A

q; Remove the Fixed Stationary Tube Block.

qa Remove the 2 Group Assy.

2 Group Assy

A

Tweezers

Solvent

qj

Remove the bond at the three points.

qk

Rotate 1 Group Lens Assy and remove it from the 1 Group Frame.

Bond

Barrier Assy

Claw

Claw

1 Group Lens Assy

1 Group Frame

Fixed Stationary Tube Block

DSC-W510

1-4

Loading...

Loading...