Sony DSC W30 - Cybershot 6MP Digital Camera, Cyber-Shot DSC-W30, Cyber-Shot DSC-W40 Service Manual

SERVICE MANUAL

LEVEL 2

Link

Link

Revision History

Revision History

How to use

Acrobat Reader

How to use

Acrobat Reader

Sony EMCS Co.

DSC-W30/W40_L2

Internal memory

ON BOARD

Internal memory

ON BOARD

SERVICE NOTE

MODEL INFORMATION TABLE

SPECIFICATIONS

FRAME SCHEMATIC DIAGRAM

BLOCK DIAGRAMS

DISASSEMBLY

PRINTED WIRING BOARDS

REPAIR PARTS LIST

SCHEMATIC DIAGRAMS

Ver. 1.5 2008.09

DIGITAL STILL CAMERA

2008I0500-1

© 2008.9

Published by Kohda TEC9-876-935-32

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Argentine Model

Brazilian Model

Japanese Model

Tourist Model

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

• Precaution on Replacing the SY-143 Board

DSC-W30/W40

Photo: DSC-W30/Silver

Revised-1

Replace the previously issued

SERVICE MANUAL 9-876-935-31

with this manual.

— 2 —

DSC-W30/W40_L2

SPECIFICATIONS

Camera

[System]

Image device 7.18 mm (1/2.5 type) color

CCD, Primary color filter

Total pixel number of camera

Approx. 6 183 000 pixels

Effective pixel number of camera

Approx. 6 003 000 pixels

Lens Carl Zeiss Vario-Tessar

3× zoom lens

f = 6.3 – 18.9 mm (38 –

114 mm when converted to a

35 mm still camera)

F2.8 – 5.2

Exposure control Automatic exposure, Scene

Selection (7 modes)

White balance Automatic, Daylight, Cloudy,

Fluorescent, Incandescent,

Flash

File format (DCF compliant)

Still images: Exif Ver. 2.21

JPEG compliant, DPOF

compatible

Movies: MPEG1 compliant

(Monaural)

Recording media Internal Memory (32 MB)

“Memory Stick Duo”

FlashRecommended distance (ISO

set to Auto): approx. 0.2 m to

4.2 m (7 7/8 inches to 13 feet

93/8 inches) (W)/approx.

0.3 m to 2.2 m (11 7/8 inches to

7 feet 2 5 /8 inches) (T)

[Input and Output connectors]

A/V OUT jack (Monaural)

Minijack

Video: 1 Vp-p, 75 Ω,

unbalanced, sync negative

Audio: 327 mV (at a 47 kΩ

load)

Output impedance 2.2 kΩ

USB jack mini-B

USB communication

Hi-Speed USB (USB 2.0

compliant)

[LCD screen]

LCD panel 5.1 cm (2.0 type) TFT drive

Total number of dots

84 960 (354×240) dots

[Power, general]

Power Rechargeable battery pack NP-

BG1, 3.6 V

AC-LS5K AC Adaptor (not

supplied), 4.2 V

Power consumption (during shooting with the

LCD screen on)

1.0W

Operating temperature

0 to 40°C (32 to 104°F)

Storage temperature

–20 to +60°C (–4 to +140°F)

Dimensions 89.8×59.0×22.9 mm

(3 5/8 inches × 2 3/8 inches ×

29/32 inches) (W/H/D,

excluding protrusions)

Mass DSC-W40

Approx. 186 g (6.6 oz)

(including NP-BG1 battery

pack and neck strap, etc.)

DSC-W30

Approx. 153 g (5.4 oz)

(including NP-BG1 battery

pack and wrist strap, etc.)

Microphone Electret condenser microphone

Speaker Dynamic speaker

Exif Print Compatible

PRINT Image Matching III

Compatible

PictBridge Compatible

BC-CSG battery charger

Power requ irements

AC 100 to 240 V, 50/60 Hz,

2 W

Output voltage DC 4.2 V, 0.25 A

Operating temperature

0 to 40°C (32 to 104°F)

Storage temperature

–20 to +60°C (–4 to +140°F)

Dimensions Approx. 62 × 24 × 91 mm

(2 1/2 × 31/32 ×3 5/8 inches)

(W/H/D)

Mass Approx. 75 g (2.7 oz)

Rechargeable battery pack NP-BG1

Used battery Lithium-ion battery

Maximum voltage

DC 4.2 V

Nominal voltage DC 3.6 V

Capacity 3.6 Wh (960 mAh)

Design and specifications are subject to change

without notice.

— 3 —

DSC-W30/W40_L2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, sho w obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. FLEXIBLE Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flo w) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

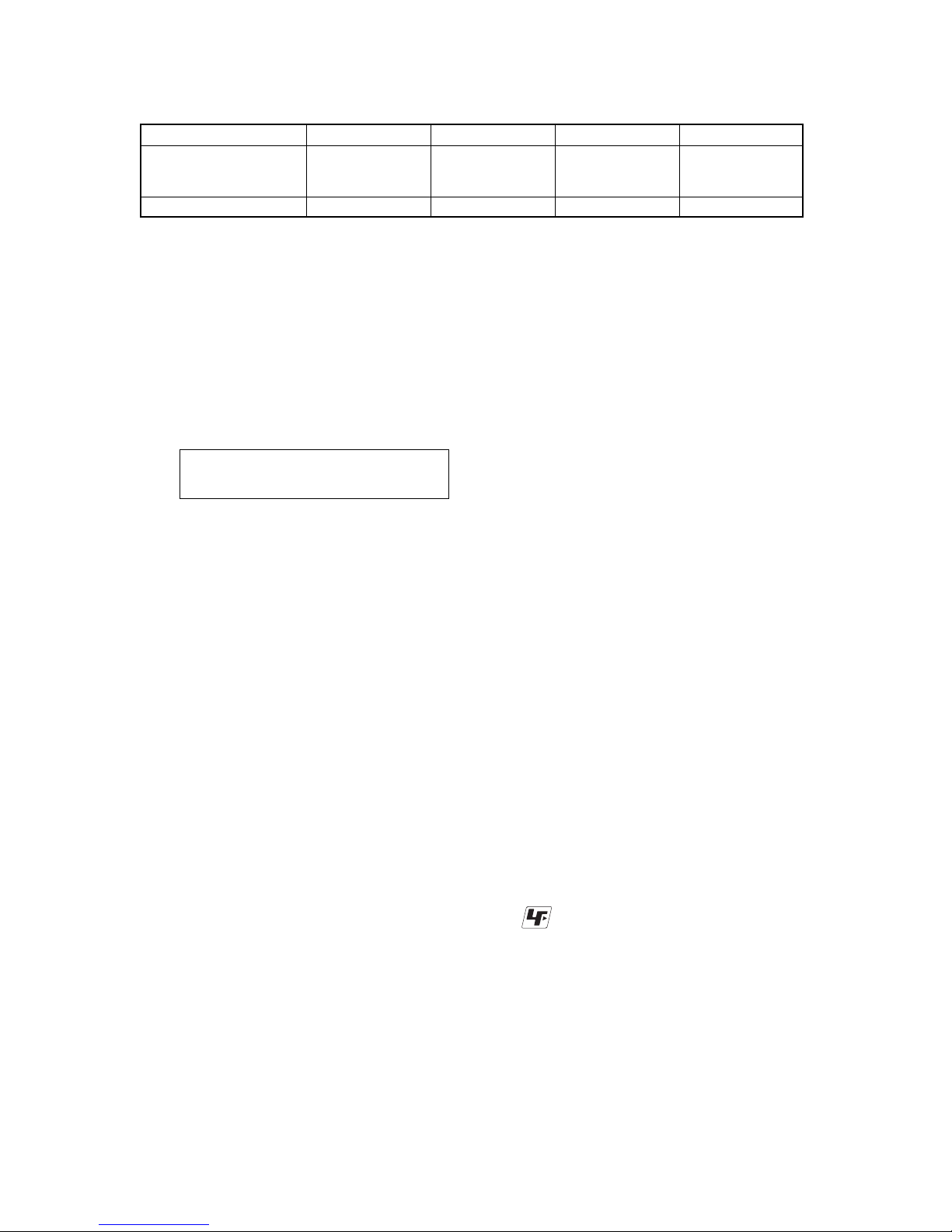

Model DSC-W30/Silver DSC-W30/White DSC-W30/Blue DSC-W40/Black

Destination

US, CND, AEP, UK,

US, CND, AEP, E, US, CND, AEP, E, CND, AEP, UK, E,

E, AUS, HK, CH,

AUS, HK, KR, J, JE AUS, HK, KR, J, JE AUS, KR

KR, AR, BR, J, JE

CONTROL SW BLOCK SW110T SW110T SW110T SW120TB

Model information table

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND: Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

NE : North European model

— 4 —

DSC-W30/W40_L2

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. Description on Self-diagnosis Display ····························1-1

1-2. Process After Fixing Flash Error·····································1-1

1-3. Method for Copying or Erasing the Data in Internal

Memory ··········································································· 1-2

1-4. Precaution on Replacing the SY-143 Board ····················1-3

2. DISASSEMBLY

2-1. Disassembly·····································································2-2

2-2. Exchange Method of Barrier Assy ··································2-6

2-3. Exchange Method of Zoom Motor Unit··························2-9

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/2)···········································3-1

3-2. Overall Block Diagram (2/2)···········································3-2

3-3. Power Block Diagram ····················································· 3-3

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ··············································4-1

4-2. Schematic Diagrams························································4-3

4-3. Printed Wiring Boards ···················································4-17

4-4. Mounted Parts Location ················································4-26

5. REPAIR PARTS LIST

5-1. Exploded Vie ws······························································· 5-2

5-2. Electrical Parts List ·························································5-6

Section Title Page

1-1

DSC-W30/W40_L2

1. SERVICE NOTE

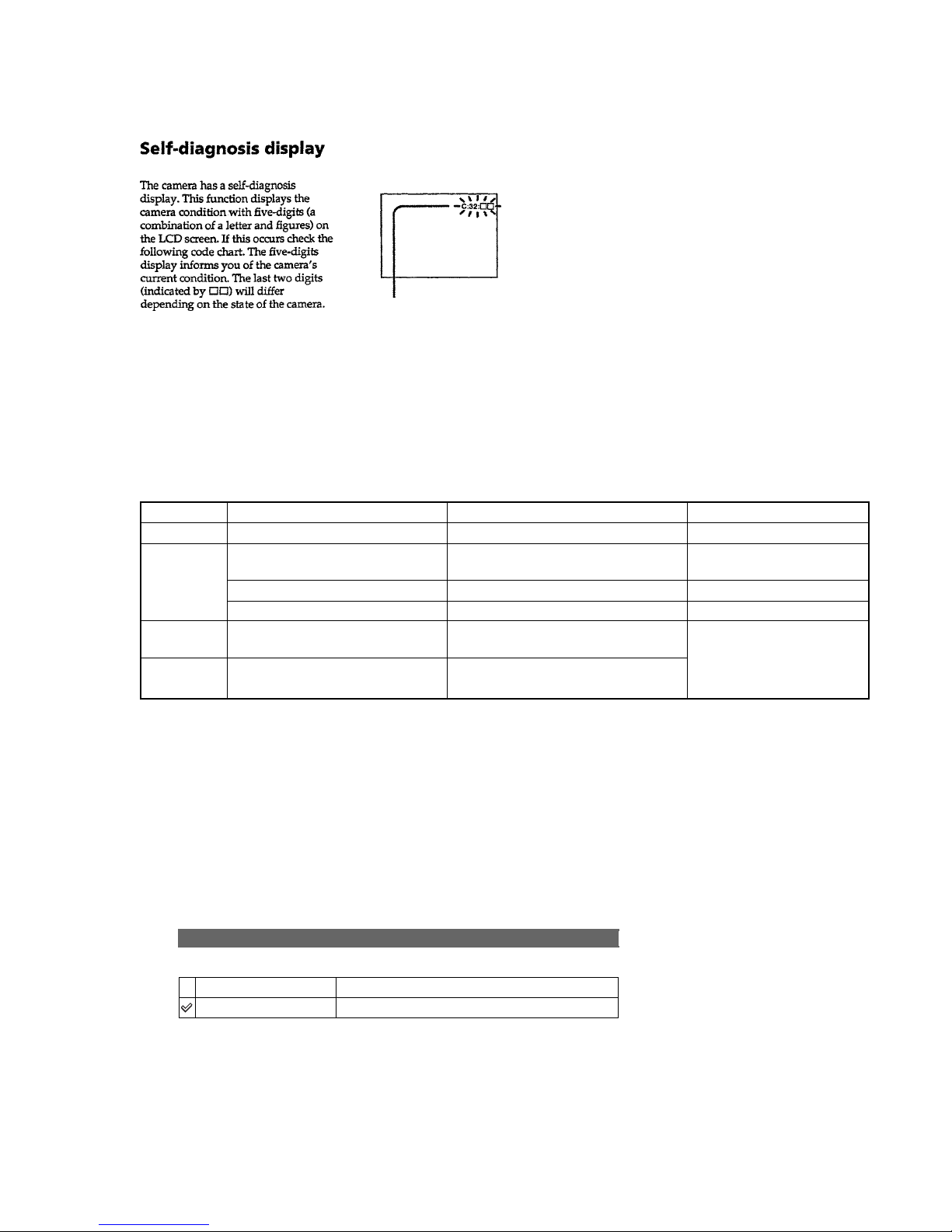

Self-diagnosis display

• C: ss: ss

You can reverse the camera

malfunction yourself. (However,

contact your Sony dealer or local

authorized Sony service facility

when you cannot recover from the

camera malfunction.)

• E: ss: ss

Contact your Sony dealer or local

authorized Sony service facility.

Display Code

C:32:ss

C:13:ss

Countermeasure

Turn the power off and on again.

Format the “Memory Stick” or internal

memory.

Cause

Trouble with hardware.

“Memory Stick” or internal memory is

unformatted.

Caution Display During Error

SYSTEM ERROR

FORMAT ERROR

MEMORY STICK ERROR

E:61:ss

E:91:ss

1-1. DESCRIPTION ON SELF-DIAGNOSIS DISPLAY

Insert a new “Memory Stick”. “Memory Stick” is broken.

Turn the power off and on again. Trouble with internal memory.

INTERNAL MEMORY ERROR

Checking of lens drive circuit.

When failed in the focus and zoom

initialization.

—

Checking of flash unit or replacement

of flash unit. (Note)

Abnormality when flash is being

charged.

Note: After repair, be sure to perfom “1-2. PROCESS AFTER FIXING FLASH ERROR”.

1-2. PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E : 91 : ** ) occurs, to prevent any abnormal situation caused by high voltage, setting of the

flash is changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Flash error code can be initialized by the operations on the Setup screen.

Method for Initializing the Flash Error Code

Initializes the settin g to th e default setting.

1 Select [OK] with v on the control button, then press z.

The message “Initialize all settings Ready?” appears.

2 Select [OK] with v, then press z.

The settings are reset to the defau lt setting.

•Make sure that the power is not disconnected during resetting.

Initialize

OK

See the following procedure.

Cancel

Cancels the resettin g.

1-2

DSC-W30/W40_L2

1-3. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

The data can be copied/erased by the operations on the Setup screen. (When erasing the data, execute formatting the internal memory.)

Note 1: When replacing the SY-143 board, erase the data in internal memory of the board before replacement.

Note 2: When replacing the SY-143 board or the IC202 on the SY-143 board, execute formatting and initialize the internal memory after

replacement.

Method for Copying the Data in Internal Memory

Method for Formatting the Internal Memory

Copies all images in the internal memory to a “Memory Stick Duo”.

1 Insert a “Memory Stick Duo” having 32 MB or larger capacity.

2 Select [OK] with v on the control button, then press z.

The message “All data in internal memory will be copied Ready?” appears.

3 Select [OK] with v, then press z.

Copying starts.

•Use a fully charged battery pack or the AC Adaptor (not supplied). If you attempt to copy image files

using a battery pack with little remaining charge, the battery pack may run out, causing copying to fail or

possibly corrupting the data.

•You cannot copy individual images.

•The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Sti ck Duo” after copying, then execute the [Format] command in

(Internal Memory Tool).

•You cannot select a folder copied on a “Memory Stick Duo”.

•Even if you copy data, a (Print order) mark is not copied.

Copy

OK

See the following procedure .

Cancel

Cancels the copying.

Copying

102_COPY

This item does not appear when a “Memory Stick Duo” is inserted in the camera.

The default settings are marked with .

Formats the internal memory.

•Note that forma tting irr evocably erases all data in the inter nal me mory, including even protected images.

1 Select [OK] with v on the control button, then press z.

The message “All data in internal memory will be erased Ready?” appears.

2 Select [OK] with v, then press z.

The format is complete.

Format

OK

See the following procedure .

Cancel

Cancels the formatting.

1-3

DSC-W30/W40_L2

1-4. PRECAUTION ON REPLACING THE SY-143 BOARD

VIDEO OUT Default Data and Exif Model Data Check

When you replace to the repairing board, the written data of repairing board also might be changed to original setting.

When the data has changed because of board replacing etc., check the data setting (VIDEO OUT Default Data, Exif Model Data) is right. If

not, rewrite to the right value.

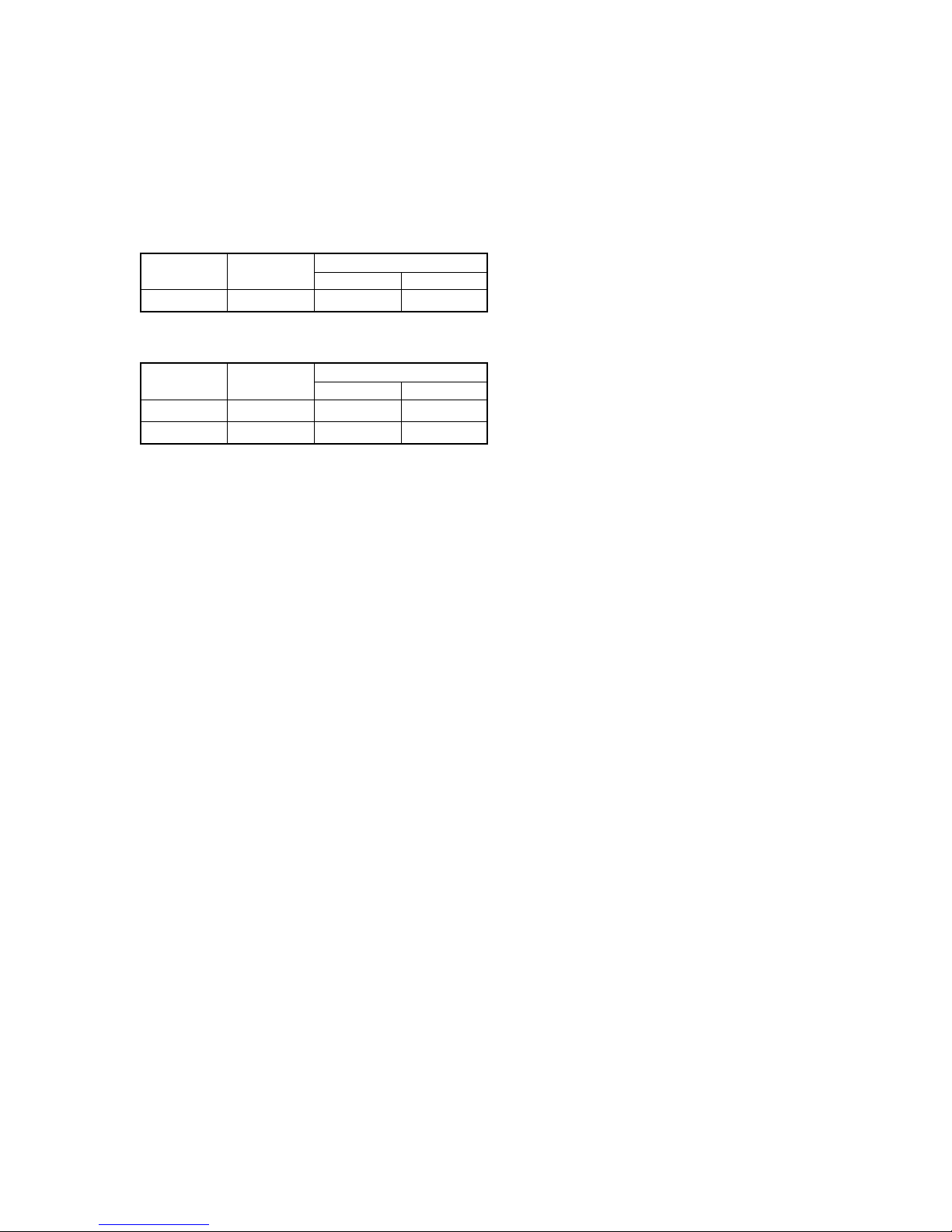

VIDEO OUT Default Data

Exif Model Data

Writing Method:

1) Select page: 00, address: 01, and set data: 01.

2) Select page: 4F, address: 8D, and set the VIDEO OUT Default Data.

3) Select page: 8F, address: E5 and E6, and set the Exif Model Data.

4) Click [Save] on the SEUS screen.

5) Select page: 80, address: 34, and check that the data is “00”.

6) Select page: 80, address: 30, and check that the data is “00”.

7) Select page: 00, address: 01, and set data: 00.

Address

33 34E58F

Page

Data

DSC-W30 DSC-W40

30 30E68F

Address

00 018D4F

Page

Data

NTSC PAL

1-4E

DSC-W30/W40_L2

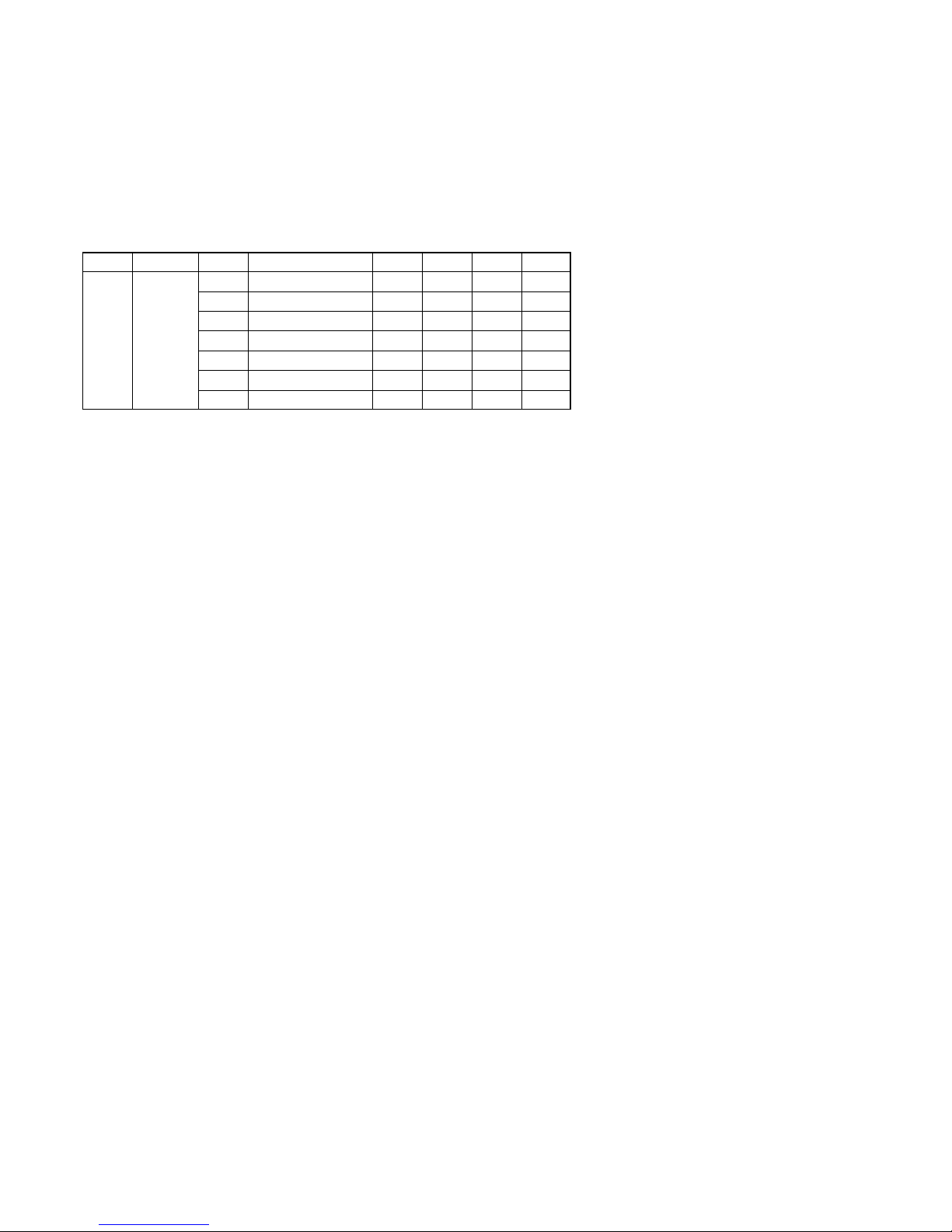

Initial Language Data Check

If the SY-143 board was replaced, initial language setting may be changed. Accordingly, change the following data so as to set same initial

language as that of the set distributing in each region.

Initial language: Language displayed at the next starting if the setting of Setup menu was reset.

It is different from the language setting selectable with the menu.

Initial Language Data

Page Address Data Language GP1 GP2 GP3 GP4

4F 8C

00 English zzz

01 Japanese z

04 Spanish zz

06 Portugal z

08 Simplified Chinese z

0B Russian z

0D Korean z

Note: GP1 is fixed to Japanese.

GP2 is fixed to English.

GP3 is either English, Spanish, or Russian.

GP4 is either English, Spanish, Portugal, Simplified Chinese, or Korean.

Writing Method:

1) Select page: 00, address: 01 and set data: 01.

2) Select page: 4F, address: 8C, and set the Initial Language Data.

3) Select page: 40, address: 38, and set data: 00.

4) Click

[Save] on the SEUS screen.

5) Select page: 80, address: 34, and check that the data is “00”.

6) Select page: 80, address: 30, and check that the data is “00”.

7) Select page: 00, address: 01, and set data: 00.

8) Turn off the camera.

9) Turn on the camera. Execute “Initialize” of Setup screen.

10) Check the language displayed when the camera starts.

2-1

2. DISASSEMBLY

DSC-W30/W40_L2

NOTE FOR REPAIR

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, dont’ pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, dont’ press down at wire of connector.

It is possible that a wire is snapped.

• Do not apply excessive load to the gilded flexible board.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

DISCHARGING OF THE ST-133 BOARD’S CHARGING CAPACITOR (C901)

The charging capacitor (C901) of the ST-133 board is charged

up to the maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by

the charged voltage which is kept without discharg ing when the

main power of the unit is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To pr eparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code: 1-215-869-11)

2-2

DSC-W30/W40_L2

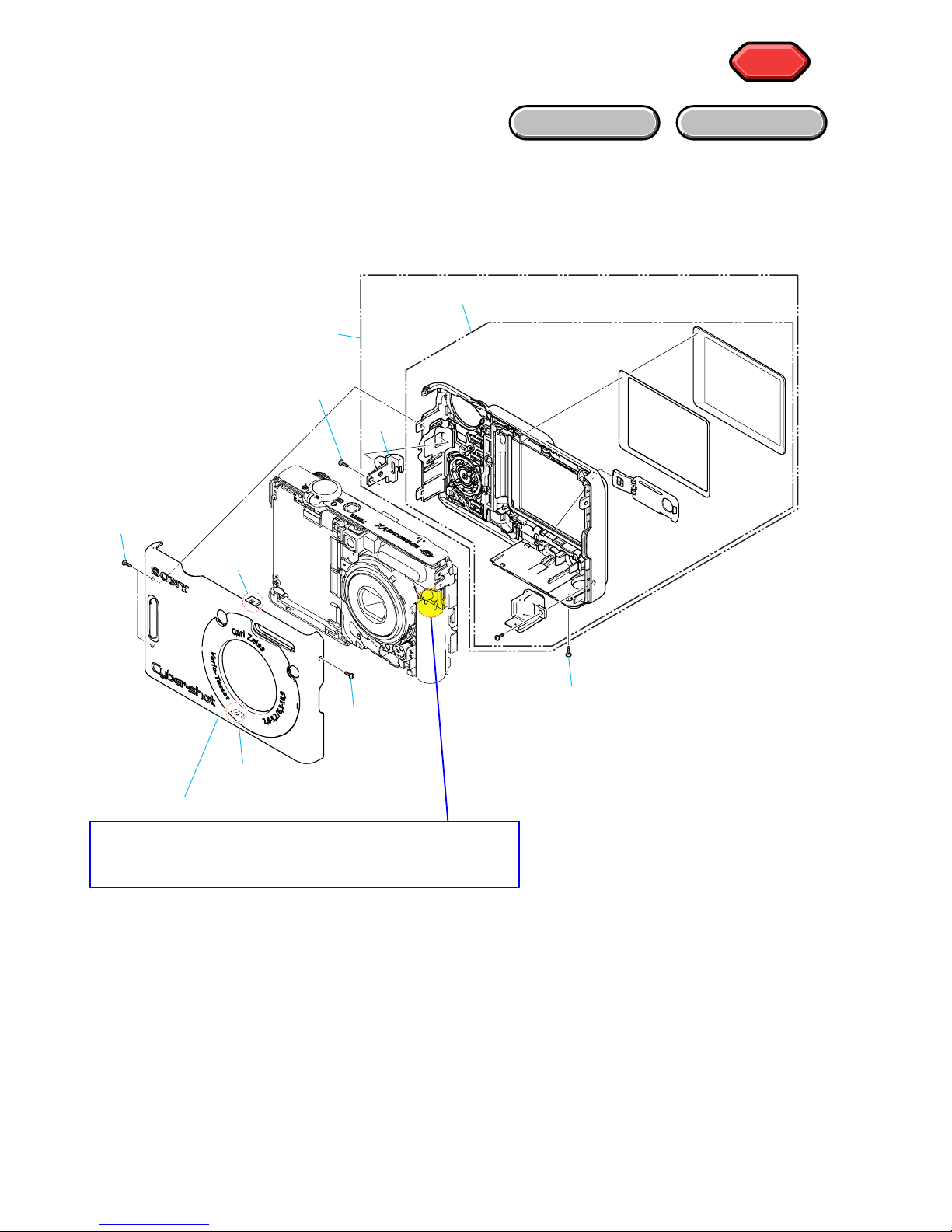

2-1. DISASSEMBLY

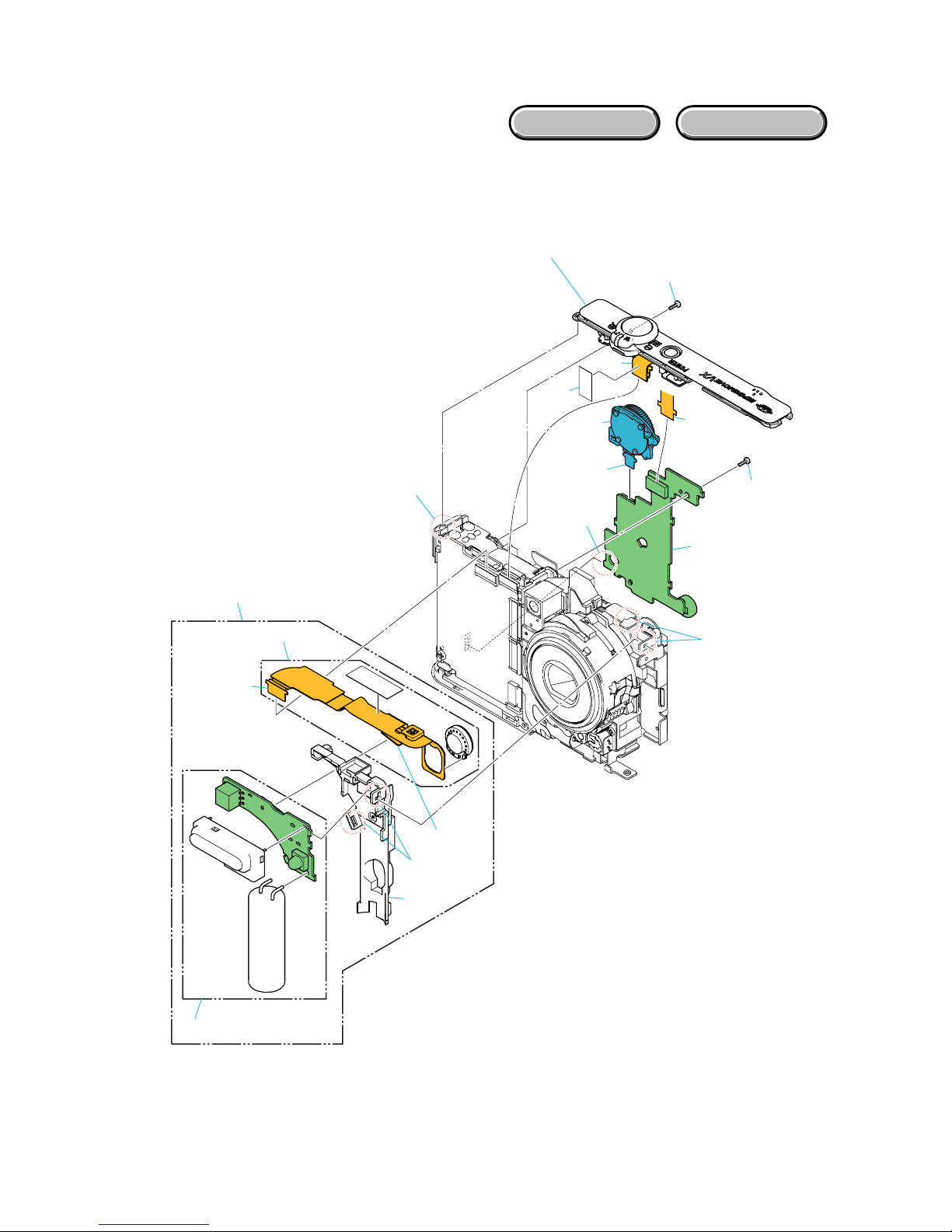

2-1-1. CABINET BLOCK

HELP

HELP

2 Cabinet (Rear) Block Assy

1 Cabinet (Front) Block Assy

1-1 (#20/#21)

1-3 (#20/#21)

1-2 (#20/#21)

2-1 (#20)

2-3

2-2

Refer to page 2-1

" Discharging of the ST-133 board’s charging capacitor (C901) ",

when discharging the capacitor.

1-5 (Claw)

1-4 (Claw)

EXPLODED VIEW

HARDWARE LIST

2-3

DSC-W30/W40_L2

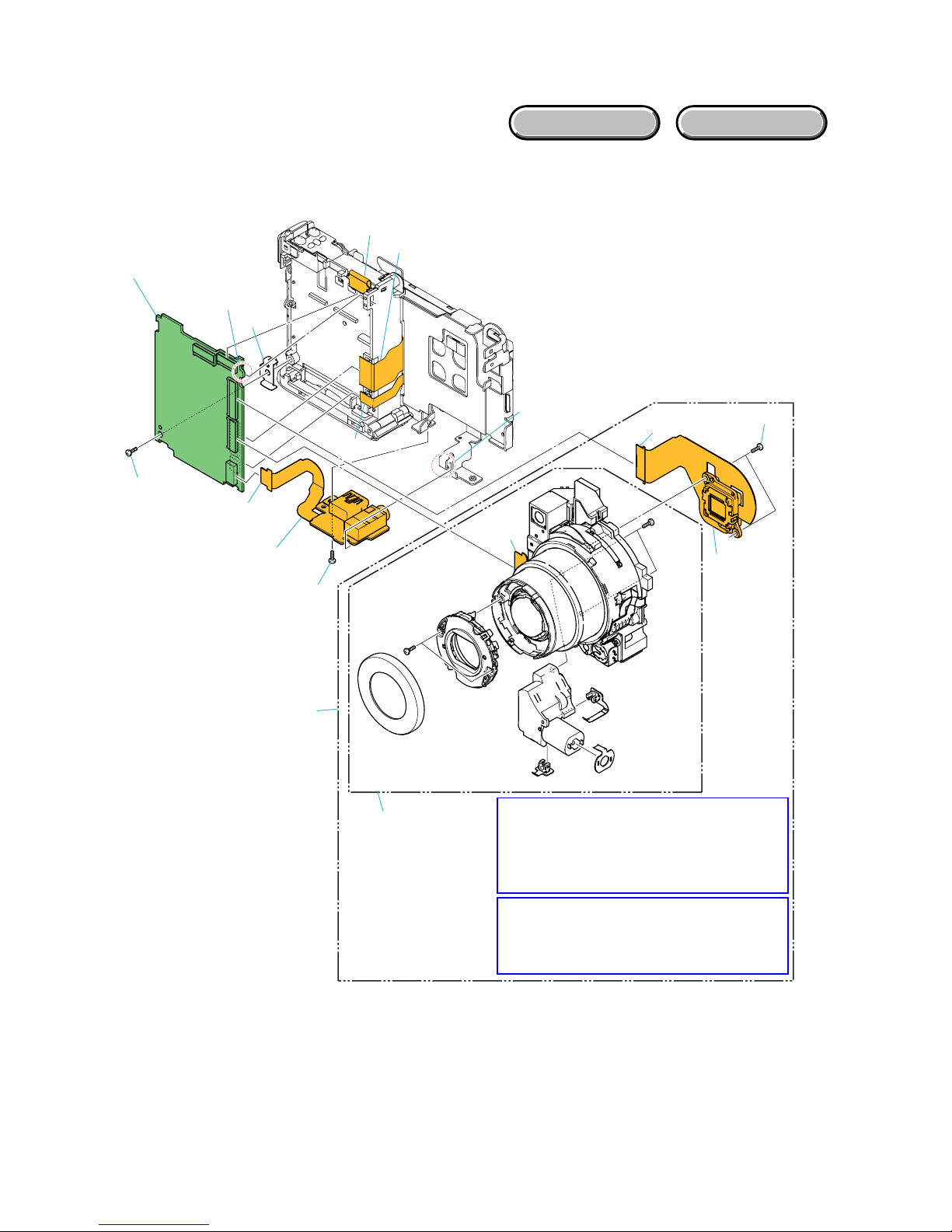

2-1-2. CABINET (UPPER) BLOCK

SW-462

2 Cabinet (Upper) Block Assy

1 SW-462 Board

1-3 (#5)

1-4

(Claw)

1-2

1-1

1-5

2-3 (#5)

2-2

2-1

2-4 (Boss)

3 ST-133 Board

3-2 (Claw)

3-1

3-4

3-7

3-5

3-3

3-6 (Claw)

ST-133

ST-134

EXPLODED VIEW

HARDWARE LIST

2-4

DSC-W30/W40_L2

2-1-3. LENS BLOCK

1-4 (#19)

1-1

1-2

1-5

1-3

1 Lens Unit

CD-604

Note 1:When you exchange barrier block

assembly and ornamental ring (A),

be sure to follow the procedure

carried on "2-2. Exchange Method

of Barrier Assembly" (2-6 page).

Note 2:When you exchange zoom motor

unit, be sure to follow the procedure

carried on "2-3. Exchange Method

of Zoom Motor Unit" (2-9 page).

2-2 (#20)

2-1

2 JK-302 Flexible Board

JK-302

SY-143

3-3 (Claw)

3 SY-143 Board

2-3 (Claw)

3-2 (#5)

3-1

3-4

3-5

3-6

EXPLODED VIEW

HARDWARE LIST

2-5

DSC-W30/W40_L2

2-1-4. BT HOLDER BLOCK

1 DC-104 Flexible Board

1-1 (Claw)

1-6

1-3

2-1 (Claw)

2-2

(Claw)

1-2

(Claw)

1-4

(Claw)

1-5

(Claw)

2 LCD Unit

HELP

HELP

DC-104

EXPLODED VIEW

HARDWARE LIST

2-6

DSC-W30/W40_L2

2-2. EXCHANGE METHOD OF BARRIER ASSY

Service parts

Part Number Part Name Quantity

1 2-673-650-01 Ring (A), Ornamental 1

2 2-673-652-01 Barrier Assy 1

3 2-673-651-01 Tapping screw (B1.2×4) 2

Tools used

Torque driver

Soldering iron

Weight about 60g

Adhesive tape (ornamental ring fixed) (2-677-885-01)

2-2-1. PEEL OFF OLD ORNAMENTAL RING A

The Ornamental Ring A has adhered to the Barrier Assy strongly and accordingly, use a soldering iron to weaken the adhesive force.

Heat four circled portions with the soldering iron.

Heating temperature is about 300ºC.

Beware of a burn since the entire Ornamental Ring becomes hot.

* As the adhesive force of Ornamental Ring A is considerably large, the forced peeling will damage the group-1 frame.

Insert the tip of tweezers, etc. into a notch of the group-1 frame and prize the ring.

* Take extreme care so as not to damage the coated surface of the group-1 frame.

In case of difficult peeling, heat the ring again with the soldering iron.

If this re-heating failed, it may be advisable that the ring be peeled while heating the portions 1 → 2 in the under figure one by one

sequentially.

* Discard the removed Ornamental Ring A.

1

2

3

Tip

1

2

2-7

DSC-W30/W40_L2

2-2-2. REMOVE OLD BARRIER ASSY

1 Remove two screws.

* Discard the removed screws.

2 Remove the Barrier Assy.

* Discard the removed Barrier Assy.

* After removing the Barrier Assy, if the “G1 Dust-Proof Ring” was removed, it must be returned to the home position.

In returning the ring, adjust the location of a projection to the lens direction.

This is an important part to prevent the dust and light from coming in.

* After removing the Barrier Assy, take extreme care not to drop dust or foreign substances in the lens barrel.

2-2-3. INSTALL NEW BARRIER ASSY

1 Install new Barrier Assy.

2 Tighten two screws.

* Tightening torque = 0.5 kgf

1

1

2

2

2

1

2-8

DSC-W30/W40_L2

2-2-4. ADHERE THE ORNAMENTAL RING A

Apply an adhesive tape to two recesses on the top surface of the Barrier Assy.

Meeting a “notch” of the Ornamental Ring A with a “projection” of the g roup-1 frame, push the Ornamental Ring A into the group-1 frame.

* The projection of the spring for preventing static electricity must be tilted.

Put the 60g weight on the Ornamental Ring A so that the Ornamental Ring A does not float up until the adhesive hardens.

Note: Be careful not to give a shock.

* After the weight was put, no gap must be present in full circumference between Ornamental Ring A and group-1 frame.

A gap, if present, causes the crackle sound NG.

* The weight must push in the Ornamental Ring A only.

If the weight is put on the mold part of the Barrier Assy, the Ornamental Ring A will float up.

Completion after 30 minutes.

Adhesive

tape

Adhesive

tape

Do not put the weight on a black mold part.

Not gap in full circumference.

2-9E

DSC-W30/W40_L2

2-3. EXCHANGE METHOD OF ZOOM MOTOR UNIT

Service parts

Part Number Part Name Quantity

1 2-673-648-01 Zoom Motor Unit 1

2 2-673-649-01 BT2 P1.4×3 B3C 2

Tools used

Torque driver

2-3-1. REMOVE OLD ZOOM MOTOR UNIT

1 Remove two screws.

* Discard the removed screws.

2 Remove the Zoom Motor Unit.

3 Remove the Lens Flexible Board.

* Discard the removed Zoom Motor Unit.

2-3-2. INSTALL NEW ZOOM MOTOR UNIT

1 Install the Lens Flexible Board in new Zoom Motor Unit.

2 Install new Zoom Motor Unit in the Lens Block.

3 Tighten two screws.

* Tightening torque = 0.7 kgf

1

2

3

3

1

1

1

2

1

1

3

3

3

2

HELP

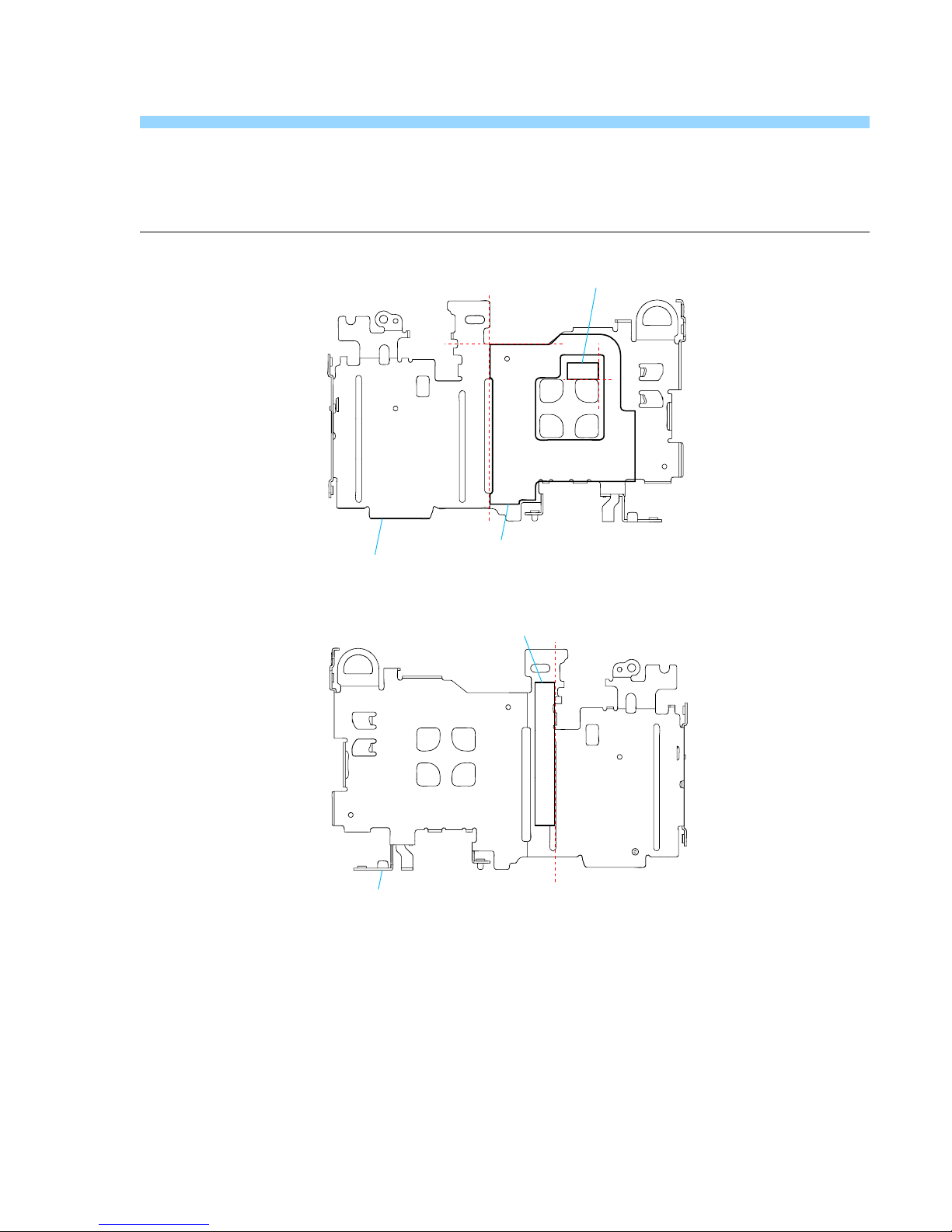

DSC-W30/W40_L2

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

Lens cushion (110)

LCD frame (110)

LCD reinforcement sheet (110)

LCD frame (110)

CD radiation cushion

DSC-W30/W40_L2

Link

Link

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (2/2)

OVERALL BLOCK DIAGRAM (1/2) POWER BLOCK DIAGRAM

DSC-W30/W40_L2

3-1

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

SY-143 BOARD (1/2)

XCS_FE

VSUB_CONT_PRE,

VSUB_CONT_POST

F2

U22

E1

CLKTGO

CAMERA DSP, CPU,

LENS CONTROL,

MODE CONTROL

(2/7)

J5

CA_FD

H5

CA_HD

CA_AD00 – CA_AD13

LENS

CCD

IMAGER

IC002

IC001

CD-604 FLEXIBLE BOARD

17 31

H10

K4

LENS BLOCK

CN301

ZOOM

MOTOR

M

FOCUS

MOTOR

M

FOCUS

RESET

SENSOR

ZOOM

SENSOR

1, 2

23 - 29, 31 - 35

K6, K5, J6, J5

16

LENS TEMP

SENSOR

BUFFER

11

19

7

22

30

D5

D6

8

1 - 3, 5, 6

14 - 16

8 - 10, 12

21, 22,

31, 32

2 - 4, 6

CCD_OUT

V1A,V1B,V2,V3A,V3B,V4

V5A,V5B,V6,V7A,V7B,V8

H1A, H2A, H1B, H2B

VHLD

VST

39

38

RG

27

Q302

CCD SIGNAL

PROCESS,

TIMING

GENERATOR

(1/7)

IC301

26 C4

E7

VSUB

VSUB_CONT

Q301

A4

C2

XIC_101_RST_OUT

C1

XCAM_DR_PS

P21

D4

A3

A2

B3, C3

T4, R23

J25

LENS_TEMP

IRIS

(METER)

IRIS

MOTOR

M

SHUTTER

MOTOR

M

IC401

20, 21

12 - 158 - 1116 - 19

24, 26

2, 3, 5, 6, 27. 29

FOCUS

MOTOR

DRIVER

IRIS_M_IN, IRIS_M_EN

FC_DIR_A,

FC_DIR_B,

FC_BRK_A

ZM_DIR_A,

ZM_BRK_A,

ZM_BRK_B

MSHUT_DIR,

MSHUT_EN

FC_SENS, XFC_RST_LED

ZM_DC_FG_1A, ZM_DC_FG_1B,

XZM_FG_LED, ZM_SENS_1ST,XZM_RST_LED

ZOOM

MOTOR

DRIVER

SHUTTER

MOTOR

DRIVER

IRIS MOTOR

DRIVER

F_MOTOR_A, A(–), B, B(–)

Z_DC_MOTOR (+), (–) ZOOM_DC_+, DC_–

SHUTTER_(+), (–)

F_PI_SENS_OUT,

XFC_RST_LED

Z_BOX2_PI_SENS_COL, Z_BOX1_PI_SENS_COL,

Z_PI_SENS_OUT

XZM_RST_LED, Z_BOX1, BOX2,

SHUTTER_+, –

IRIS_ M_+, M_–

IRIS_ (+), (–)

CN401

FOCUS_A, A, B, B

D2, B1

D6, E6, B7, C6

B4, B5F4, F3

G1, E4

LENS DRIVE

(3/7)

30

ST-133 BOARD

ST-134 FLEXIBLE BOARD

R4

05

V23

R22

STRB_CHG

XAF_LED

MIC_SIG

XSTRB_FULL

ST_UNREG

Q001

FLASH

DRIVE

SP901

SPEAKER

MIC901

FLASH

UNIT

FLASH

CONTROL,

CHARGE

CONTROL

6

9

10

7

IC001

XE_H

TRIGGER

TRIGGER_GND

XE_L

+

C901

CHARGING

CAPACITOR

D002

3

5 4

1

2

15

T001

STRB_CHG_CONT

4

STRB_ON

CN704

CN001

12

17

22, 23

21

9

14

11

16

14

19

10 15

D003

SELF-TIMER/

AF ILLUMINATOR

SP+, SP-

XAF_LED

MIC_SIG

SP+, SP-

IC_101_AUOUT

XIC_101_RST_OUT

XIC_101_RST_OUT

XIC_101_RST_OUT

XIC_101_RST_OUT

XIC_101_RST_OUT

XIC_101_RST_OUT

2

OVERALL (2/2)

(PAGE 3-2)

USB_DP, USB_DM

AF4

W25

AE6

AF9

AB22

BACKLIGHT

2.0 INCH

COLOR

LCD

MONITOR

CN901

CN902

LCD901

PANEL UNIT

IC101

(1/2)

IC_101_AUIN

K26

L26

Y26

H26

U23

XCS_AUDIO

BL_L

BL_L

BL_H

BL_H

OVERALL (2/2)

(PAGE 3-2)

1

OVERALL (2/2)

(PAGE 3-2)

3

LCD_HD, LCD_VD,LCD_CK

MCK, HSYNC, VSYNC

LCD_D2 - LCD_D7

DATA0 - DATA5

IC202

IC201

128M SDRAM,

32M SUPER AND

(4/7)

BURST

FLASH

(4/7)

M7

B4

B4

E7

B5

DSP_QCLKE

DSP_QCLKE

DSP_QCLK

DSP_QCLK

IC_101_27M_CLKO

XCPU_CS0

N7

A18

A17

DSP_AQ0 – DSP_AQ11, DSP_DQ0 – DSP_DQ31,

DSP_DQM0 – DSP_DQM3, DSP_QBA0, DSP_QBA1

CPU_D00 – CPU_D15

CPU_D00- CPU_ D15

CPU_D00- CPU _D15

CPU_A01- CPU_A21

C5 - C8, D5 - D8, E4, E5,

E8, E9, F3 - F9, G2 - G5,

G9, G10, H2, H3, H4, H8,

H9, H10, J3 - J9, K3, K4,

K8, K9, L4, L5, L9, L10,

M4, M5, M9, M10

D21, D22, D20, B22, A22, A23,

B23, E20, E21, B24, A24, A25,

B25, C25, C26, B26, E10, A10,

D10, E11, B10, A11, B11, E12,

D11, D12, F12, B12, A12, E13,

D13, D14, F13, B15, F14, E14,

D17, D18, D16, B18, A19, B19,

E16, D19, E19, E17, B20, A20,

B21, A21

AB13, AA13, AE13, AF13,

AF12, AE12, AA12, AC12,

AC11, AB12, AE11, AF11,

AE10, AB11, AC10, AB10

E2 - E6, D5,

F2 - F7, G1,

G3, G5, G7

A1, A2, A6, A7, A8, B1,

B2, B3, B6, B7, B8, C1,

C2, C6, C7, C8, D1, D2,

D4, D8, E8

C9, C10, D9, D10, D11,

D12,E10, E11, J10, J11,

J12, K10,K11, K12, L11,

L12

AF21, AF20, AE20, AB18, AB19, AC19,AB16,

AE19, AF19, AF18, AE18, AA15, AC18, AC17,

AB15, AE17, AF17, AE16, AB14, AC16, AC15

XCS_ PANEL

XCS

XRST

IC_101_1_SO, XIC_101_1_SCK

IC_101_1_SO, XIC_101_1_SCK

IC_101_1_SO, XIC_101_1_SCK

IC_101_1_SO, XIC_101_1_SCK

IC_101_1_SO, XIC_101_1_SCK

SI,XSCK

V_LINE_OUT

VIDEO_AMP_ON

IC_101_VOUT

VIDEO AMP

(6/7)

53

4

IC602

MS_BS, MS_D0 – MS_D3, MS_CLK

G7, H6, G6, G5,

H5, H4, G4, F4,

E4, D7, H7, D4

D1, E1 - E3,

F1 - F3, G1 - G3,

H1 - H3, J1

K5, G4, H4, L5, H1,

H2, J1, J2, M5, J4,

K4,M6,K1, K2

D3, E3

D5, A6, B6, C5

R5, R25U4, E5

AC1, AD1

R6, U2

B8, D9, E9

AB6, AC4,

AE4, AE5,

AC5,AF6

B4, D5,D6,

E6 - E8

N5, L2, L4

P5, N2, N6

B2, C4, A2

P4, N4

B3, D4, V4,

V5, W4

1, 2

31

30

28,29

1, 2

5, 6

25 - 27 19 - 24

CPU_A20, CPU_A21

M3, E3

X102

33.75MHz

C1

Loading...

Loading...