Page 1

SERVICE MANUAL

Ver. 1.1 2009.07

Revision History

Revision History

Internal memory

Internal memory

ON BOARD

ON BOARD

Revised-1

Replacement of the previously issued

SERVICE MANUAL 9-852-674-11

with this manual.

Photo: Silver

DSC-S930

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Korea Model

Brazilian Model

Tourist Model

Link

Link

SPECIFICATIONS

SERVICE NOTE

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

DISASSEMBLY REPAIR PARTS LIST

BLOCK DIAGRAM

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

DSC-S930

Sony EMCS Co.

DIGITAL STILL CAMERA

2009G0500-1

© 2009.7

Published by Kohda TEC9-852-674-12

Page 2

SPECIFICATIONS

Camera

[System]

Image device:

7.7 mm (1/2.3 type) color CCD, Primary color

filter

Total pixel number of camera:

Approx. 10.3 Megapixels

Effective pixel number of camera:

Approx. 10.1 Megapixels

Lens: 3 zoom lens f = 6.4 – 19.2 mm (36 –

108 mm (35 mm film equivalent)) F2.9 (W) –

5.4 (T)

Exposure control: Automatic exposure, Scene

Selection (7 modes)

White balance: Automatic, Daylight, Cloudy,

Fluorescent 1, 2, 3, Incandescent, Flash

File format:

Still images: JPEG (DCF Ver. 2.0,

Exif Ver. 2.21 ) compliant, DPOF compatible

Movies: AVI (Motion JPEG)

Recording media: Internal Memory (approx.

12 MB), “Memory Stick Duo” media

Flash: Flash range (ISO sensitivity

(Recommended Exposure Index) set to Auto):

approx. 0.5 to 3.0 m (1 feet 7 3/4 inches to

9feet 10 1/8 inches) (W)/approx. 0.5 to 1.5 m

(1 feet 7 3/4 inches to 4 feet 11 1/8 inches) (T)

Recording interval of Burst:

Approx. 1.0 seconds

[Input and Output connectors]

USB communication:

Hi-Speed USB (USB 2.0 compliant)

[LCD screen]

LCD panel: 6.0 cm (2.4 type) TFT drive

Total number of dots: 112 320 (480×234) dots

[Power, general]

Power: LR6 (size AA) Alkaline batteries (2), 3 V

HR15/51:HR6 (size AA) Nickel-Metal

Hydride batteries (2) (sold separately), 2.4 V

ZR6 (size AA) Oxy Nickel Primary Battery

(2) (sold separately), 3 V

Power consumption (during shooting):

1.2 W

Operating temperature: 0 to 40°C (32 to 104°F)

Storage temperature: –20 to +60°C (–4 to +140°F)

Dimensions: 89.5×61.0×26.1 mm

(3 5/8 × 2 1/2 × 1 1/16 inches) (W/H/D,

excluding protrusions)

Mass: Approx. 167 g (5.9 oz) (including two

batteries and strap, etc.)

Microphone: Monaural

Buzzer

Exif Print: Compatible

PRINT Image Matching III: Compatible

PictBridge: Compatible

Design and specifications are subject to change

without notice.

DSC-S930

— 2 —

Page 3

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

Dispose of used batteries according to the instructions.

CAUTION

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DO TTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

•Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DSC-S930

— 3 —

Page 4

Ver. 1.1 2009.07

The changed portions from

Ver. 1.0 are shown in blue.

1. SERVICE NOTE

1-1. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

The data can be copied/erased by the operations on the Setup screen. (When erasing the data, execute formatting the internal memory.)

Note 1: When replacing main board, erase the data in internal memory of the board before replacement.

Note 2: When replacing main board, execute formatting and initialize the internal memory after replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to “Memory Stick Duo” med ia.

1 Insert “Memory Stick Duo” media having sufficient free capacity.

2 Select [Copy] with v/V on the control button, then press z.

The message “All data on internal memory will be copied” appears.

3 Select [OK] with v, then press z.

Copying starts.

To c a ncel copying

Select [Cancel] in step 3, then press z.

•Use a fully charged battery pack. If you attempt to copy image files using a battery pack with little

remaining charge, the battery pack may run out, causing copying to fail or possibly corrupting the data.

•You cannot select images to copy.

•The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Stick Duo” media after copying, then format the internal memory

([Format] in [Internal Mem o ry Tool]).

•A new folder is created on the “Memory Stick Duo” media and all the data will be copied to it. You cannot

choose a specific folder and copy images to it.

•The (Print order) marks on the images are not copied.

Method for Formatting the Internal Memory

This item does not appear when “Memory Stick Duo” media is inserted in the camera.

Format

Fo

rmats the internal memory.

•Note that formatting permanently erases all data in the internal memory, including even protected images.

1 Select [Format] with v/V on the control button, then press z.

The message “All data on internal memory will be erased” appears.

2 Select [OK] with v, then press z.

Formatting starts.

To cancel formatting

Select [Cancel] in step 2, then press z.

DSC-S930

1-1E

Page 5

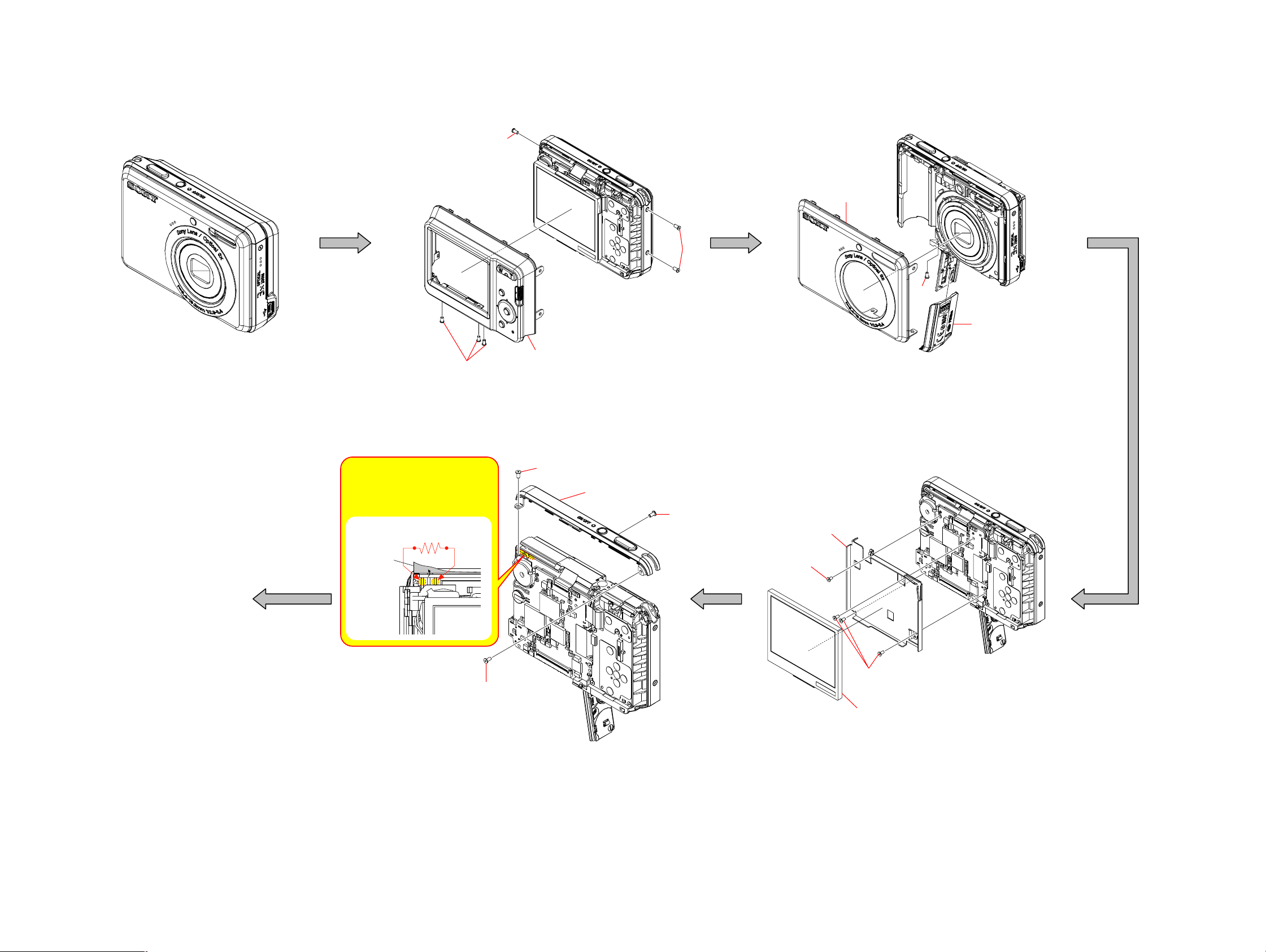

The following flow chart shows the disassembly procedure.

2-1. DISASSEMBLY

2. DISASSEMBLY

1

2

1

1

3

3

2

(To page 2-2)

1

SCREW_TP_1.7_3.5_A0.5_D2.5

2

SCREW TP 1.7 ∗3

3

CABINET (REAR) ASSY

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between two points

with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code: 1-215-869-11)

Turn over

the mylar

1

1

2

1

1

SCREW_TP_1.4_3.5_A0.3_D2.5_N

2

CABINET (FRONT) ASSY

3

BT, LID

3

1

2

4

DSC-S930

1

SCREW_TP_1.4_3_A_0.2_D=2.5

2

CABINET (UPPER) ASSY

2-1

1

SCREW TP 1.4 ∗2.5

2

SCREW_TP_1.4_3_A_0.2_D=2.5

3

LCD BRACKET

4

LCD

Page 6

(From page 2-1)

2

1

SCREW_TP_1.4_3_A_0.2_D=2.5

2

ST BLOCK ASSY

1

2

1

1

SCREW_TP_1.4_3_A_0.2_D=2.5

2

SW BLOCK

2

1

1

SCREW_TP_1.4_3_A_0.2_D=2.5

2

MAIN BOARD

1

2

HELP01

4

3

1

MYLAR SHEET

2

CCD PLATE SHEET

3

SCREW_TP_1.4_3_A_0.2_D=2.5

4

CCD ASSY

5

LOW PASS FILTER SET

5

HELP02

HELP01

HELP02

1

3

2

1

SCREW_TP_1.4_3.5_A0.3_D2.5_N

2

LENS BLOCK ASSY

3

MAIN FRAME SUB ASSY

DSC-S930

2-2E

Page 7

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

HELP01

Be careful about the Lens Assy

Don't press the Barrier part.

Don't press the Sensor holder.

HELP02

Be careful of the weld.

Keep clean these Pins.

Don't press the AF motor.

DSC-S930

HELP

Page 8

3-1. OVERALL BLOCK DIAGRAM

3. BLOCK DIAGRAM

CCD sensor

Memory

+3.3V

+1.8VD

+13V

-7.5V

+3.1V_CDS

DGND

+3.1VD

+1.8VD

DGND

CDS

+3.3V

+1.8VD

+13V

-7.5V

+3.1V_CDS

DGND

CDS

MEMORY

+3.1VD

+1.8VD

DGND

MEMORY

POWER

CCD[0..11]

MFD_CLE

MFD_ALE

MFD_WP

MFD_WE

MFD_RE

MFD_CE

MFD_RDY

MFD[0..7]

MEM_UDM

MEM_LDM

MEM_CKE

MEM_CK

MEM_CKN

MEM_A[0..12]

MEM_CS

MEM_CAS

MEM_RAS

MEM_WE

MEM_UDQS

MEM_D[0..15]

MEM_BA0

MEM_BA1

MEM_LDQS

PXCLK

CCD_HD

CCD_VD

TG_ON

TG_EN

CDS_EN

AFE_RST

AFE_SCK

AFE_SDA

TG_SGL

PXCLK

CCD[0..11]

CCD_HD

CCD_VD

TG_ON

TG_EN

CDS_EN

AFE_RST

AFE_SCK

AFE_SDA

TG_SGL

MFD_CLE

MFD_ALE

MFD_WP

MFD_WE

MFD_RE

MFD_CE

MFD_RDY

MFD[0..7]

MEM_UDM

MEM_LDM

MEM_CKE

MEM_CK

MEM_CKN

MEM_A[0..12]

MEM_CS

MEM_CAS

MEM_RAS

MEM_WE

MEM_UDQS

MEM_D[0..15]

MEM_BA0

MEM_BA1

MEM_LDQS

DSP

PXCLK

CCD[0..11]

CCD_HD

CCD_VD

TG_ON

TG_EN

CDS_EN

AFE_RST

AFE_SCK

AFE_SDA

TG_SGL

MFD_CLE

MFD_ALE

MFD_WP

MFD_WE

MFD_RE

MFD_CE

MFD_RDY

MFD[0..7]

MEM_UDM

MEM_LDM

MEM_CKE

MEM_CK

MEM_CKN

MEM_A[0..12]

MEM_CS

MEM_CAS

MEM_RAS

MEM_WE

MEM_UDQS

MEM_D[0..15]

MEM_BA0

MEM_BA1

MEM_LDQS

USB_DET

USB_D+

USB_D-

AUX_OUT

MIC_IN

MD1

MS_INS

MSDATA[0..3]

MS_BS

MS_PWON

MS_CLK

STA_LED

MODE_SW

KEY_SW

KEY_TELE

KEY_WIDE

ZOOM_PR

FOCUS_PI

ZOOM_PI

LENS_RST

LENS_EN

LENS_SCLK

LENS_SDATA

FOCUS[0..3]

SHUTTER0

SHUTTER1

USB_D+

USB_D-

AUX_OUT

MIC_IN

MD1

MS_INS

MSDATA[0..3]

MS_BS

MS_PWON

MS_CLK

STA_LED

MODE_SW

KEY_SW

KEY_TELE

KEY_WIDE

ZOOM_PR

FOCUS_PI

ZOOM_PI

LENS_RST

LENS_EN

LENS_SCLK

LENS_SDATA

FOCUS[0..3]

SHUTTER0

SHUTTER1

JACK_AUDIO

USB_DET

USB_D+

USB_DAUX_OUT

+3.1V_CDS

MIC_IN

MD1

JACK_AUDIO

MS_CARD

MS_INS

MSDATA[0..3]

MS_BS

MS_PWON

MS_CLK

STA_LED

MODE_SW

KEY_SW

KEY_TELE

KEY_WIDE

MS_CARD

LENS

ZOOM_PR

FOCUS_PI

ZOOM_PI

LENS_RST

LENS_EN

LENS_SCLK

LENS_SDATA

FOCUS[0..3]

SHUTTER0

SHUTTER1

LENS

+14V

+3.1VD

DGND

+3.1VD

DGND

+4.3VD

DGND

+14V

+3.1VD

+3.1V_CDS

DGND

+3.1VD

DGND

+3.1VD

+4.3VD

DGND

USB JACK

memory stick

MODE_SW

LENS Module

DSC-S930

Batt

VP

FLASH_VP

+4.3VD

+3.3V

+1.8VD

+1.2VD

+3.1VD

+3.3VS

+14V

+13V

-7.5V

DGND

POWER

VP

FLASH_VP

+4.3VD

+3.3V

+1.8VD

+1.2VD.

+3.1VD

+3.3VS

+14V

+13V

-7.5V

DGND

BAT_CHK

BAT_AD

PWR_CTRL

CCD_ON

BAT_CHK

BAT_AD

PWR_CTRL

CCD_ON

VP

FLASH_VP

+3.1V_CDS

+3.3VS

+3.1VD

+1.8VD

+1.2VD

DGND

DSP

BAT_CHK

BAT_AD

PWR_CTRL

CCD_ON

VP

FLASH_VP

+3.1V_CDS

+3.3VS

+3.1VD

+1.8VD

+1.2VD

DGND

3-1E

LCD_ON

LCD_EN

SCLK

SDATA

LCD_MCLK

LCD[0..7]

LCD_HD

LCD_VD

LCD_ON

LCD_EN

SCLK

SDATA

LCD_MCLK

LCD[0..7]

LCD_HD

LCD_VD

LCD

LCD_ON

LCD_EN

SCLK

SDATA

LCD_MCLK

LCD[0..7]

LCD_HD

LCD_VD

LCD

+3.1VD

+4.3VD

DGND

+3.1VD

+4.3VD

LCD

DGND

Page 9

4. REPAIR PARTS LIST

NOTE:

• -XX, -X mean standardized parts, so they may have some differences from

the original one.

• Items marked “*” are not stocked since they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

•The mechanical parts with no reference number in the exploded views are not

supplied.

• Due to standardization, replacements in the parts list may be different from

the parts specified in the components used on the set.

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

NE : North European model

TW : Taiwan model

TH : Thai model

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

• Color Indication of Appearance Parts

Example:

(SILVER) : Cabinet’s Color

(Silver) : Parts Color

DSC-S930

4-1

Page 10

4-1. EXPLODED VIEWS

4-1-1. OVERALL SECTION

2

11

10

10

2

2

1

(Note)

3

2

2

6

5

(Note)

2

2

9

2

4

2

2

2

8

2

7

7

10

13

Main Frame Section

(See page 4-3)

12

Note: The adjustment is not required after replacing these

parts.

Ref. No. Part No. Description Ref. No. Part No. Description

1 A-1709-330-A ST BLOCK ASSY (Note)

2 3-288-943-01 SCREW_TP_1.4_3_A_0.2_D=2.5

3 X-2348-652-1 CABINET (UPPER) ASSY

4 3-113-001-01 SCREW TP 1.4*2.5

5 4-140-963-01 LCD (Note)

6 X-2348-646-1 CABINET (REAR) ASSY (S) (SILVER)

6 X-2348-647-1 CABINET (REAR) ASSY (B) (BLACK)

6 X-2348-648-1 CABINET (REAR) ASSY (P) (PINK)

7 3-113-005-01 SCREW TP 1.7*3

8 4-140-962-01 LCD BRACKET

9 A-1709-329-A SW BLOCK

10 4-145-605-01 SCREW_TP_1.7_3.5_A0.5_D2.5

11 X-2348-649-1 CABINET (FRONT) ASSY (S) (SILVER)

11 X-2348-650-1 CABINET (FRONT) ASSY (B) (BLACK)

11 X-2348-651-1 CABINET (FRONT) ASSY (P) (PINK)

12 4-140-969-01 BT, LID (S) (SILVER)

12 4-140-970-01 BT, LID (B) (BLACK)

12 4-140-971-01 BT, LID (P) (PINK)

13 4-137-871-01 SCREW_TP_1.4_3.5_A0.3_D2.5_N

DSC-S930

4-2

Page 11

Ver. 1.1 2009.07

The changed portions from

Ver. 1.0 are shown in blue.

4-1-2. MAIN FRAME SECTION

ns: not supplied

52

Lens Section

(See page 4-4)

51

JC1

53

F2

F1

54

51

51

ns

ns

ns

ns

• Refer to page 4-1 for mark 0.

Ref. No. Part No. Description Ref. No. Part No. Description

51 4-137-871-01 SCREW_TP_1.4_3.5_A0.3_D2.5_N

52 X-2348-653-1 MAIN FRAME SUB ASSY

53 3-288-943-01 SCREW_TP_1.4_3_A_0.2_D=2.5

54 A-1735-180-A MAIN MOUNTED PC BOARD

0 F1 1-576-363-11 FUSE (1A/30V)

0 F2 1-576-913-11 FUSE, MICRO (1608 TYPE) (1.6A/36V)

JC1 4-134-399-01 CONNECTOR, USB

DSC-S930

4-3

Page 12

Ver. 1.1 2009.07

The changed portions from

Ver. 1.0 are shown in blue.

4-1-3. LENS SECTION

ns: not supplied

104

ns

101

102

103

105

ns

ns

102

Ref. No. Part No. Description Ref. No. Part No. Description

101 4-140-965-01 CCD PLATE SHEET

102 3-288-943-01 SCREW_TP_1.4_3_A_0.2_D=2.5

103 4-140-964-01 FILTER SET, LOWPASS

104 A-1709-331-A LENS BLOCK ASSY

105 A-1735-183-A CCD BLOCK ASSY

DSC-S930

4-4

Page 13

4-2. ACCESSORIES

Checking supplied accessories.

Note: This item is supplied with the unit as an accessory, but

is not prepared as a service part.

LR6 (Size AA) Alkaline Batteries

(Note)

Dedicated USB Cable

1-829-579-41

Wrist Strap

2-050-981-01

CD-ROM

“Cyber-shot application software”

“Cyber-shot Handbook”

“Cyber-shot Step-up Guide”

4-127-176-01

Instruction Manual

4-126-520-11

4-126-520-21

4-126-520-31

4-126-520-41

4-126-520-51

4-126-520-61

4-126-520-71

4-126-520-81

4-126-520-91

4-126-521-11

4-126-521-21

4-126-521-31

4-126-521-41

4-126-521-51

4-126-521-61

4-126-521-71

Cyber-shot Handbook (PDF)

The CD-ROM supplied contains all of language version of

the Cyber-shot Handbook (PDF) for printing.

・The printed matter is not supplied. If required, please

order it with the part number below.

∗

4-126-517-11 (

∗

4-126-517-21 (

∗

4-126-517-31 (

∗

4-126-517-41 (

∗

4-126-517-51 (

∗

4-126-517-61 (

∗

4-126-517-71 (

∗

4-126-517-81 (TRADITIONAL CHINESE)

∗

4-126-517-91 (SIMPLIFIED CHINESE)

∗

4-126-518-11 (

∗

4-126-518-21 (ARABIC)

∗

4-126-518-31 (PERSIAN)

∗

4-126-518-41 (KOREAN)

(

ENGLISH) (CND, AEP, UK, E, AUS, JE)

(

FRENCH, ITALIAN) (CND, AEP)

(

SPANISH, PORTUGUESE) (AEP, E, JE)

(

GERMAN, DUTCH) (AEP)

(TRADITIONAL CHINESE, SIMPLIFIED CHINESE)

(

RUSSIAN, UKRAINIAN) (AEP)

(ARABIC, PERSIAN)

(KOREAN)

(

POLISH, CZECH) (AEP)

(

HUNGARIAN, SLOVAK) (AEP)

(

SWEDISH, FINNISH) (AEP)

(NORWEGIAN,

(THAI, MALAYSIAN)

(

TURKISH, GREEK) (AEP)

(

ENGLISH, SPANISH) (US)

(SIMPLIFIED CHINESE)

ENGLISH

FRENCH

ITALIAN

SPANISH

PORTUGUESE

GERMAN

DUTCH

RUSSIAN

(KR, JE)

)

)

)

)

)

)

)

(E)

DANISH) (AEP)

(E)

(CH)

∗

∗

∗

)

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

4-126-518-51 (

4-126-518-61 (

4-126-518-71 (

4-126-518-81 (

4-126-518-91 (

4-126-519-11 (

4-126-519-21 (NORWEGIAN)

4-126-519-31 (

4-126-519-41 (THAI)

4-126-519-51 (MALAYSIAN)

4-126-519-61 (

4-126-519-71 (

4-126-519-81 (

(E, JE)

POLISH

)

CZECH

)

HUNGARIAN

SLOVAK

SWEDISH

FINNISH

DANISH

TURKISH

GREEK

UKRAINIAN

)

)

)

)

)

)

)

)

DSC-S930

4-5E

Page 14

[Regarding Fuse]

• MAIN BOARD

Ref. No.: F1

Part No.: 1-576-363-11

Description:FUSE, MICRO (1005 TYPE) (1A/30V)

Ref. No.: F2

Part No.: 1-576-913-11

Description:FUSE, MICRO (1608 TYPE) (1.6A/36V)

DSC-S930

Page 15

Reverse

985267412.pdf

Revision History

Ver.

1.0

1.1

Date

2009.02

2009.07

History

Official Release

Revised-1

(A1 09-069)

Contents

—

•Addition of Repair Parts

S.M. revised:Page 1-1, Page 4-3, Page 4-4

S.M. Rev.

issued

—

Yes

DSC-S930

Loading...

Loading...