Page 1

DSC-F77/FX77

Ver 1.0 2002. 10

Revision History

Revision History

Link

Link

Before starting adjustments

Before starting adjustments

Adjusting items when replacing main parts and boards

Adjusting items when replacing main parts and boards

CAMERA SECTION ADJUSTMENTS

CAMERA SECTION ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

INITIALIZATION OF A, B, D, E, F, 7, 9 PAGE DATA

INITIALIZATION OF A, B, D, E, F, 7, 9 PAGE DATA

VIDEO SYSTEM ADJUSTMENTS

VIDEO SYSTEM ADJUSTMENTS

CAMERA SYSTEM ADJUSTMENTS

CAMERA SYSTEM ADJUSTMENTS

LCD SYSTEM ADJUSTMENTS

LCD SYSTEM ADJUSTMENTS

SECTION 6

ADJUSTMENTS

SERVICE MODE

SERVICE MODE

ADJUSTING REMOTE COMMANDER

ADJUSTING REMOTE COMMANDER

DATA PROCESS

DATA PROCESS

SERVICE MODE

SERVICE MODE

ADJ

Contents of LEVEL 2 and LEVEL 3 Service Manual

CONTENTS

1. SERVICE NOTE

2. DISASSEMBLY

3. BLOCK DIAGRAMS

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

5. REPAIR PARTS LIST

OVERALL

POWER

CD-415 BOARD, ST-78

BOARD, KK-29 BOARD,

FP-585 FLEXIBLE, FP-586

FLEXIBLE

EXPLODED VIEWS

ELECTRICAL PARTS LIST

LEVEL 2

a

a

LEVEL 3

✕

✕

✕

SY-81 BOARD,

BT-14 BOARD (FX77)

✕

a

BT-14 BOARD (FX77),

(

SY-81 BOARD

)

9-929-997-51

Sony EMCS Co.

2002J0500-1

©2002.10

Published by DI Customer Center

Page 2

DSC-F77/FX77

TABLE OF CONTENTS

Section Title Page Section Title Page

6. ADJUSTMENTS

Before Starting Adjustment ·······················································6-1

1-1. Adjusting Items when Replacing

Main Parts and Boards ····················································6-2

6-1. Camera Section Adjustments··········································· 6-3

1-1. Preparations Before Adjustments ····································6-3

1-1-1.List of Service Tools ························································6-3

1-1-2.Preparations ·····································································6-4

1-1-3.Discharging of the Flashlight Power Supply···················6-4

1-1-4.Precautions ······································································6-6

1. Setting the Switch····························································6-6

2. Order of Adjustments ······················································ 6-6

3. Subjects ···········································································6-6

4. Preparing the Flash Adjustment Box·······························6-7

1-2. Initialization of A, B, D, E, F, 7, 9 Page Data ·················6-8

1-2-1.Initialization of A, D Page Data ······································6-8

1. Initializing A, D Page Data ··············································6-8

2. Modification of A, D Page Data ······································6-8

3. A Page Table···································································· 6-8

4. D Page Table···································································· 6-8

1-2-2.Initialization of B, E, F, 7, 9 Page Data ··························· 6-9

1. Initializing B, E, F, 7, 9 Page Data ··································6-9

2. Modification of B, E, F, 7, 9 Page Data···························6-9

3. B Page Table ····································································6-9

4. E Page Table ····································································6-9

5. F Page Table ··································································6-10

6. 7 Page Table···································································6-12

7. 9 Page Table···································································6-12

1-2-3.Initialization of Bluetooth ·············································6-12

1. Initializing of Bluetooth Revision History ···················· 6-12

2. Checking of Bluetooth Function ···································6-12

1-3. Video System Adjustments············································6-13

1. Video Sync Level Adjustment ·······································6-13

2. Video Burst Level Check··············································· 6-13

1-4. Camera System Adjustments·········································6-14

Data Setting During Camera System Adjustments········6-14

Picture Frame Setting ···················································· 6-15

1. HALL Adjustment ·························································6-16

2. Flange Back Adjustment

(Using the minipattern box) ··········································6-17

3. Flange Back Adjustment

(Using the flange back adjustment chart)······················ 6-18

4. Flange Back Check························································6-18

5. F No. Compensation······················································ 6-19

6. Mechanical Shutter Adjustment ···································· 6-19

7. Light V alue Adjustment················································· 6-20

8. Mixed Color Cancel Adjustment···································6-20

9. Auto White Balance 3200K Standard Data Input ·········6-21

10. Auto White Balance 5800K Standard Data Input ·········6-22

11. Auto White Balance 5800K Check 1 ····························6-23

12. Auto White Balance 5800K Check 2 ····························6-24

13. Auto White Balance 5800K Check 3 ····························6-25

14. Auto White Balance 3200K Check 1 ····························6-26

15. Auto White Balance 3200K Check 2 ····························6-27

16. Auto White Balance 3200K Check 3 ····························6-28

17. Color Reproduction Adjustment····································6-29

18. CCD White Defect Compensation ································6-30

19. CCD Black Defect Compensation·································6-31

20. Strobe White Balance Adjustment·································6-32

21. AF Illumination Check ··················································6-33

1-5. LCD System Adjustments ·············································6-34

1. LCD Initial Data Input (1)············································· 6-35

2. LCD Initial Data Input (2)············································· 6-35

3. VCO Adjustment (SY-81 Board)···································6-36

4. PSIG Level Adjustment (SY-81 Board) ························ 6-36

5. Bright Adjustment (SY-81 Board)·································6-37

6. Contrast Adjustment (SY-81 Board)······························6-37

7. VG Center Adjustment (SY-81 Board)··························6-38

8. V-COM Adjustment (SY-81 Board) ······························6-38

9. White Balance Adjustment (SY-81 Board) ···················6-39

6-2. Service Mode·································································6-40

2-1. Adjusting Remote Commander ·····································6-40

1. Used the Adjusting Remote Commander ······················6-40

2. Precautions upon Using the Adjusting

Remote Commander······················································ 6-40

2-2. Data Process ··································································6-41

2-3. Service Mode·································································6-42

1. Setting the Test Mode ····················································6-42

2. Bit Value Discrimination ···············································6-42

3. Mode Dial Check (1) ·····················································6-43

4. Mode Dial Check (2) ·····················································6-43

5. Switch Check (1) ···························································6-43

6. Switch Check (2) ···························································6-43

7. Switch Check (3) ···························································6-43

8. Switch Check (4) ···························································6-44

9. LED Check ····································································6-44

10. Self Diagnosis Code ······················································ 6-44

* The color reproduction frame is shown on page 6-45

— 2 —

Page 3

COVER

COVER

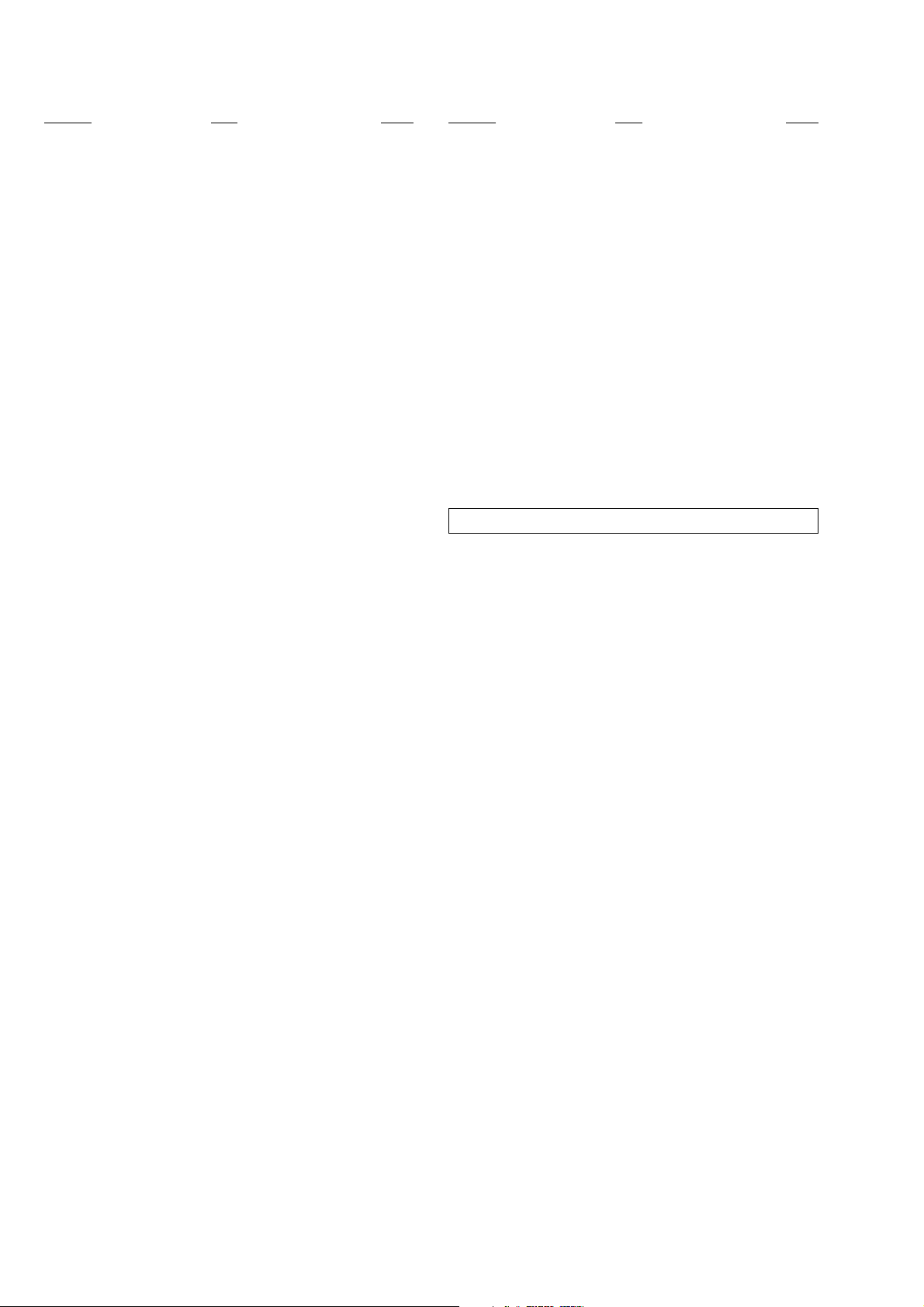

Before starting adjustment

EVR Data Re-writing Procedure When Replacing Board

The data that is stored in the repair board, is not necessarily correct.

Perform either procedure 1 or procedure 2 or procedure 3 when replacing board.

Procedure 1

Save the EVR data of the machine in which a board is going to be replaced. Download the saved data after a

board is replaced.

DSC-F77/FX77

SECTION 6

ADJUSTMENTS

(Machine before starting repair)

Save the EVR data

to a personal computer.

Procedure 2

Remove the EEPROM from the board of the machine tha t is going to be repaired. Install the removed EEPR OM

to the replaced board.

PC PC

Remove the EEPROM and install it.

(Former board)

(New board)

(Machine after a board is replaced)

Download the saved

data to a machine.

Procedure 3

When the data cannot be saved due to defective EEPROM, or when the EEPROM cannot be removed or installed, save the data from the same model of the same destination, and download it.

(Machine to be repaired)

Download the data.

Save the data.

(The same model of the same destination)

After the EVR data is saved and downloaded, check the

respective items of the EVR data.

(Refer to page 6-2 for the items to be checked.)

(Machine to be repaired)PC

6-1

Page 4

DSC-F77/FX77

RadarW

RadarW

COVER

COVER

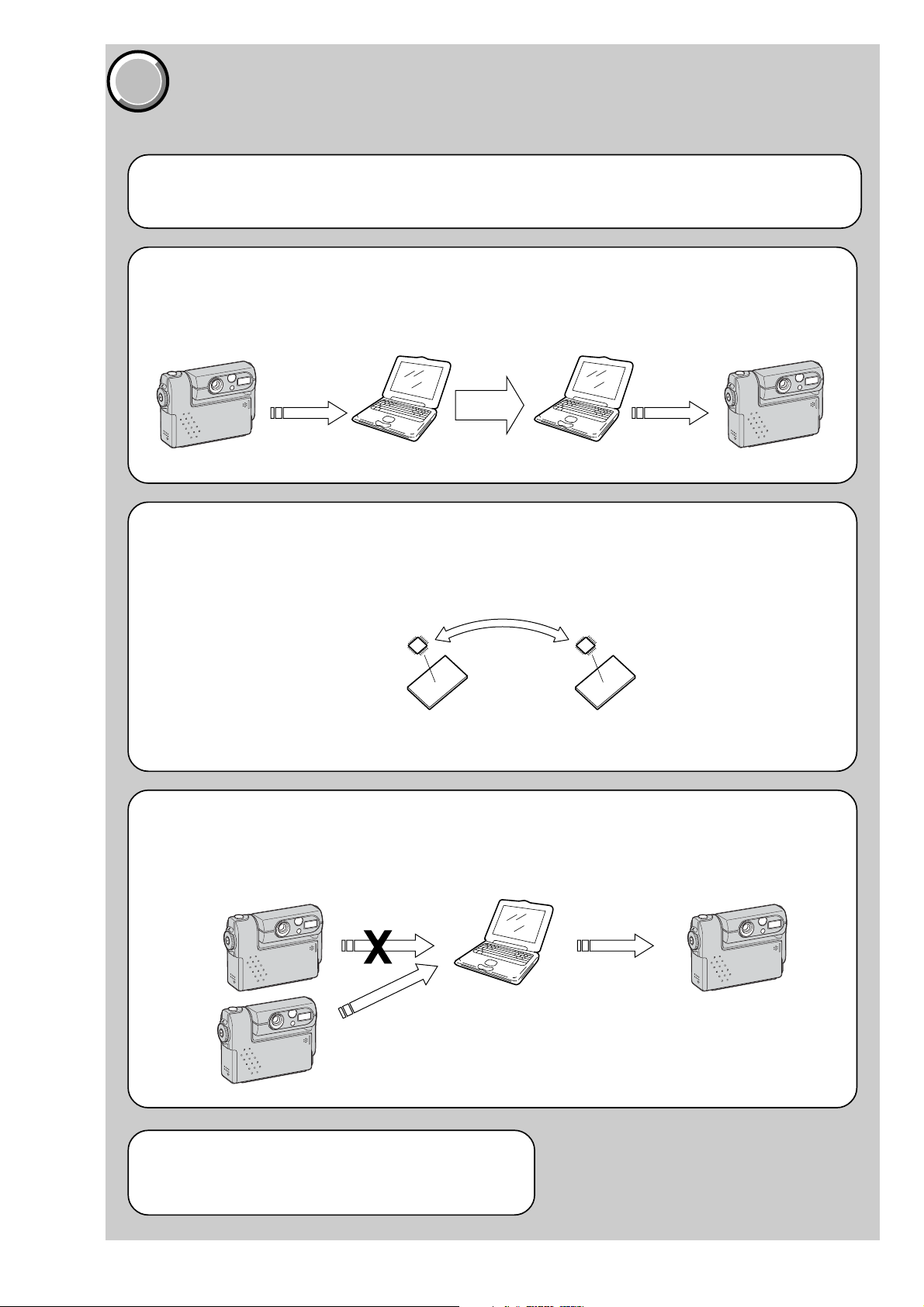

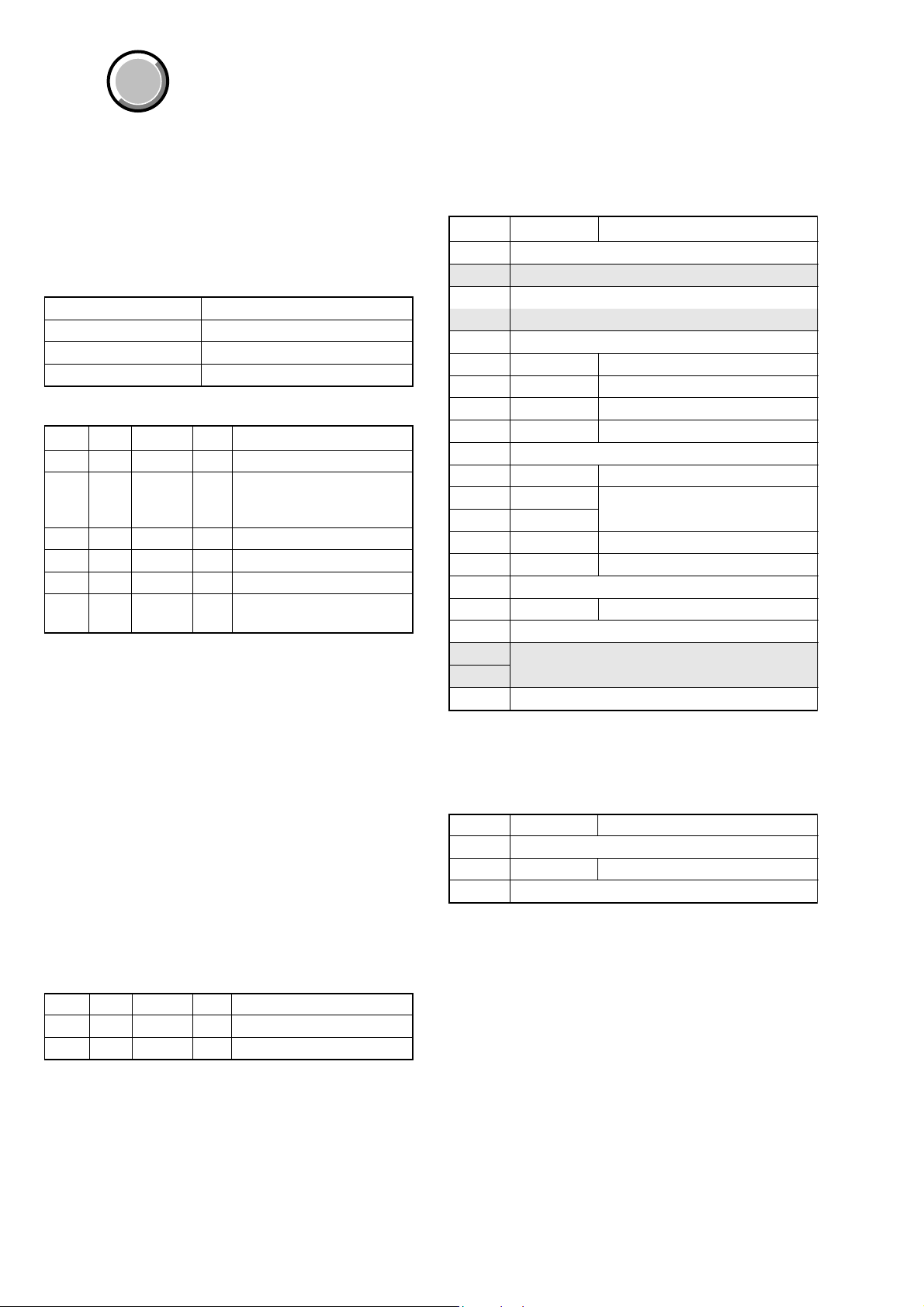

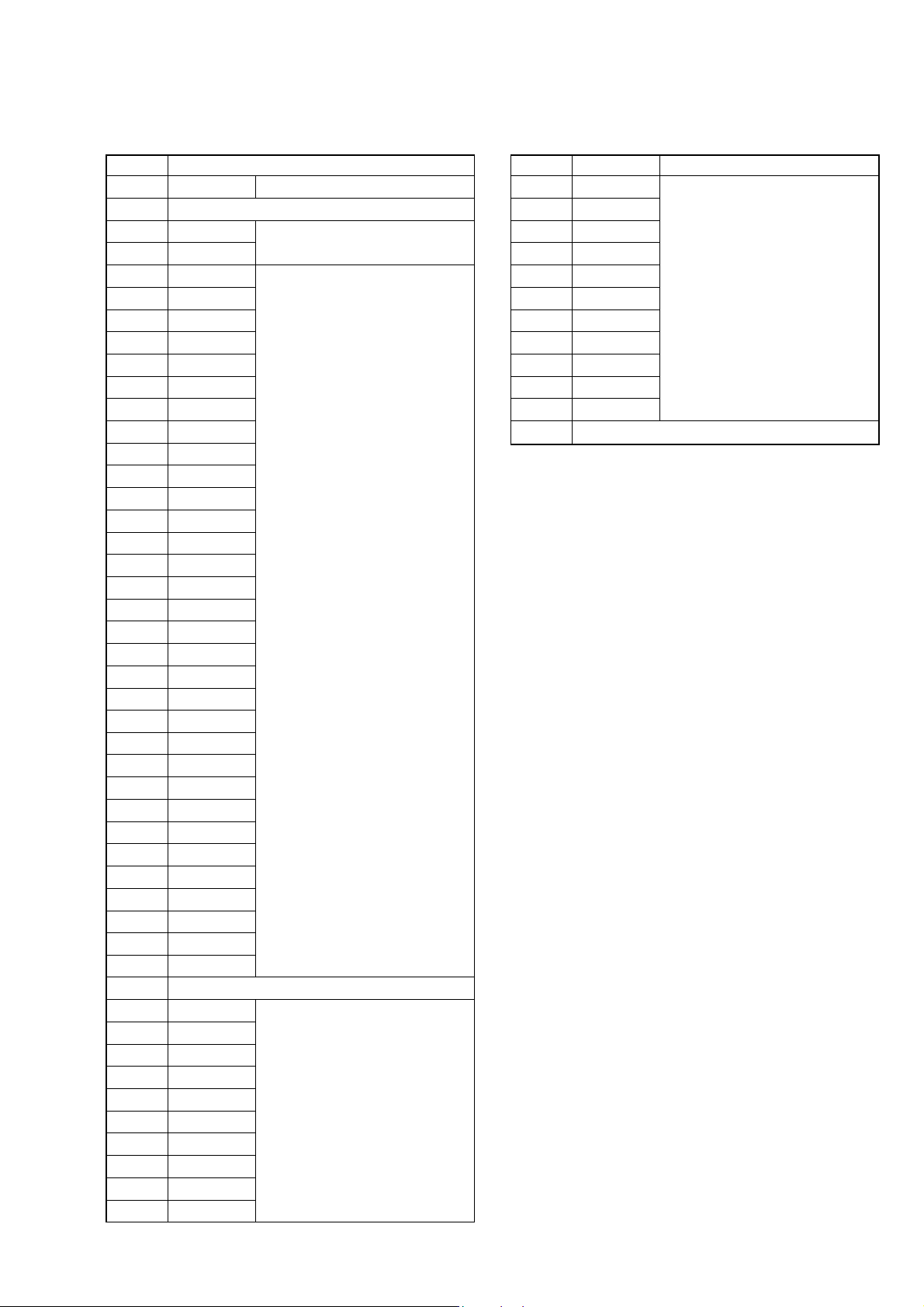

1-1. Adjusting items when replacing main parts and boards

When replacing main parts and boards, adjust the items indicated by z in the following table.

Replaced parts

Block Mounted parts Board

replacement replacement replacement

Note: DSC-FX77 only

Adjustment section Adjustment

Initialization of A, B, D,

E, F, 7, 9 page data

Video Video sync level adj.

Camera Hall adj.

LCD LCD initial data input

Initialization of

A, D page data

Initialization of

B, E, F, 7, 9 page data

Initialization of

Bluetooth (Note)

Flange back adj.

F No. compensation

Mechanical shutter adj.

Light value adj.

Mixed color cancel adj.

Auto white balance

standard data input

Color reproduction adj.

CCD (white and black)

defect compensation

Strobe white balance adj.

AF illumination check

VCO adj.

PSIG level adj.

Bright adj.

Contrast adj.

VG center adj.

V-COM adj.

White balance adj.

(LCD panel)

(Back light)

(CCD imager)

(Timing generator, S/H, AGC, A/D)

(EVR)

(Camera DSP, 128M SDRAM)

(VIDEO AMP)

(LCD drive)

(AF illuminator)

LCD901

D901

IC001

IC151

IC602

IC651

IC301

IC701

D102

(COMPLETE) (Note)

Lens block assy

Flash unit

LCD block

LCD block

CD-415 board

SY-81 board

SY-81 board

SY-81 board

SY-81 board

SY-81 board

ST-78 board

BT-14 board

zz

zz

zz z

zz z z

zzzzz

zz zzz

zz zzz

zzz zzz

zzz zzz

zz z zz

zz z zz

zz z zz

zzzz

zzz zzzz

zzzzzz

zz

zzz

zzz

zzz

zzz

zzz

zzzz

zz z z z

EEPROM

(COMPLETE)

(COMPLETE)

IC604

SY-81 board

ST-78 board

SY-81 board

RadarW

RadarW

RadarW

Supporting

Table 6-1-1

6-2

Page 5

COVER

COVER

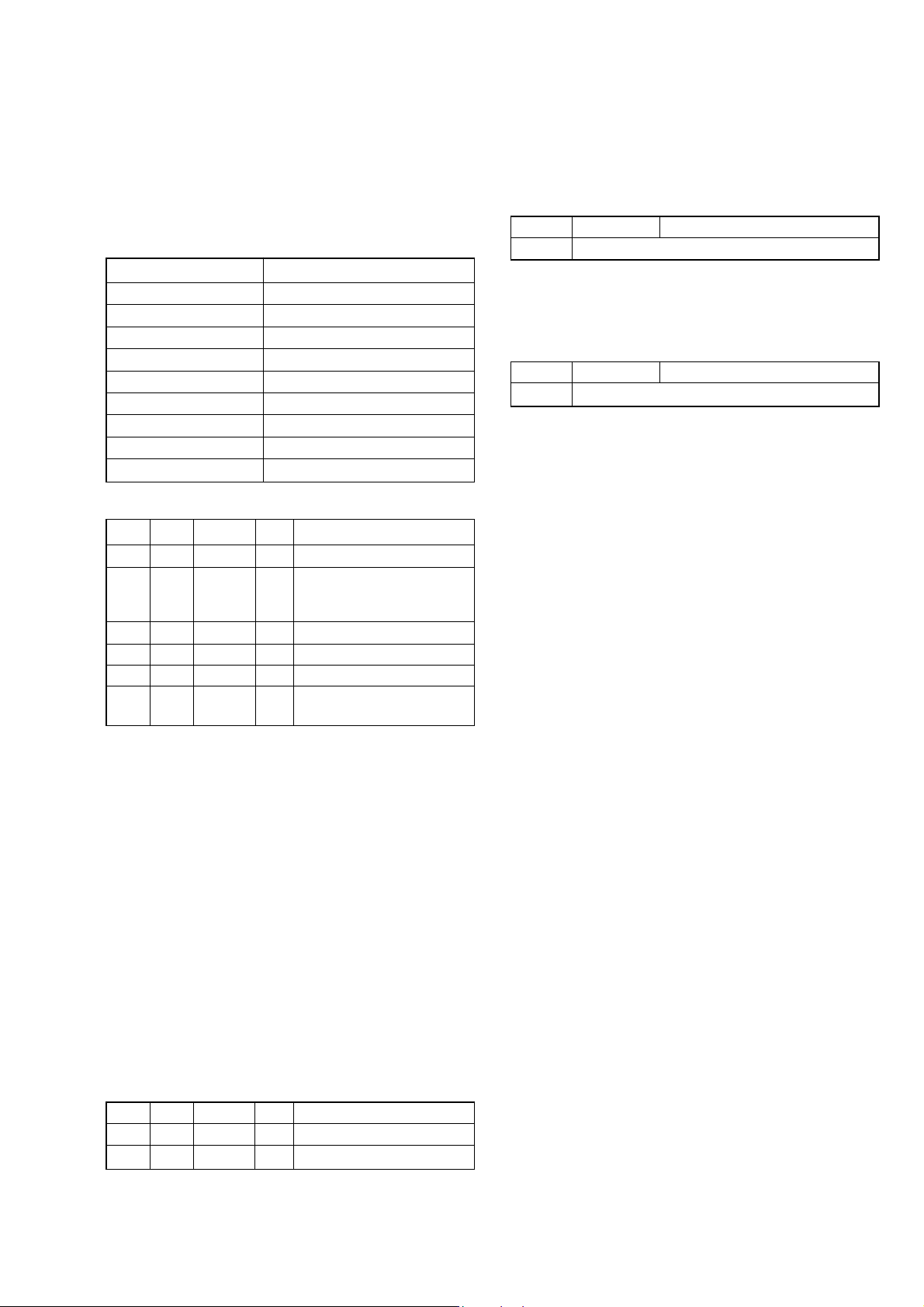

6-1. CAMERA SECTION ADJUSTMENTS

1-1. PREPARATIONS BEFORE ADJUSTMENTS

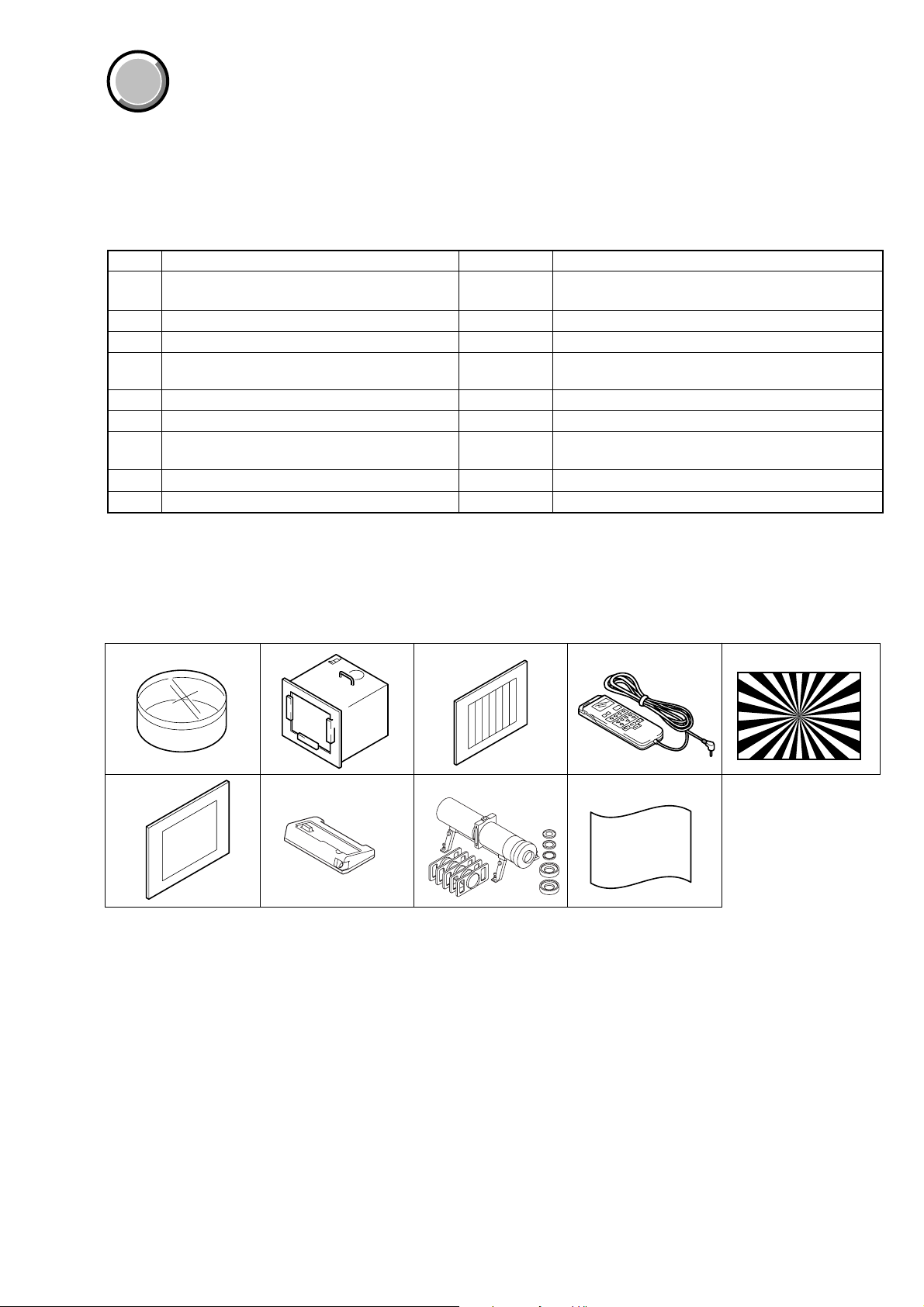

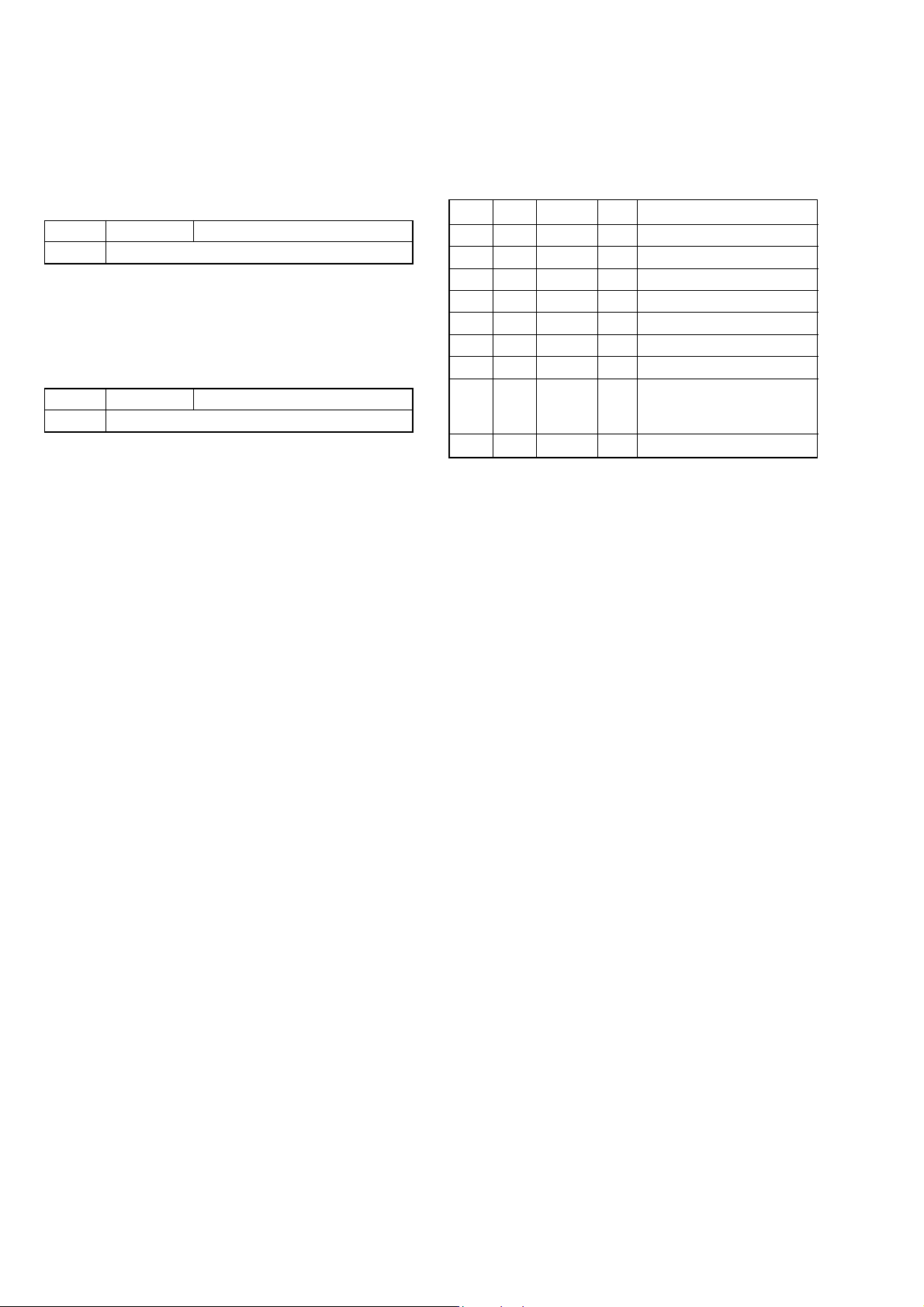

1-1-1. List of Service Tools

• Oscilloscope • Color monitor • Vectorscope

• Digital voltmeter • Frequency counter

DSC-F77/FX77

Ref. No.

J-1

Filter for color temperature correction (C14)

J-2

Pattern box PTB-450

J-3

Color bar chart for pattern box

Adjusting remote commander (RM-95 upgraded).

J-4

(Note 1)

J-5

Siemens star chart

J-6

Clear chart for pattern box

J-7

Cradle with LANC jack

J-8

Minipattern box

J-9 Back ground paper J-2501-130-A For adjusting the strobe

Note 1: If the micro processor IC in the adjusting remote

commander is not the new micro processor (UPD7503GC56-12), The pages cannot be switched. In this case,

replace with the new micro processor (8-759-148-35).

J-1

J-2

Name

Parts Code

J-6080-058-A

J-6082-200-A

J-6020-250-A

J-6082-053-B

J-6080-875-A

J-6080-621-A

J-6082-548-A

J-6082-353-B

J-3 J-4

Auto white balance adjustment/check

White balance adjustment/check

For checking the flange back

For connecting the adjusting remote commander

For connecting the color monitor

For adjusting the flange back

Usage

J-5

J-6 J-7

J-8 J-9

Fig. 6-1-1

6-3

Page 6

DSC-F77/FX77

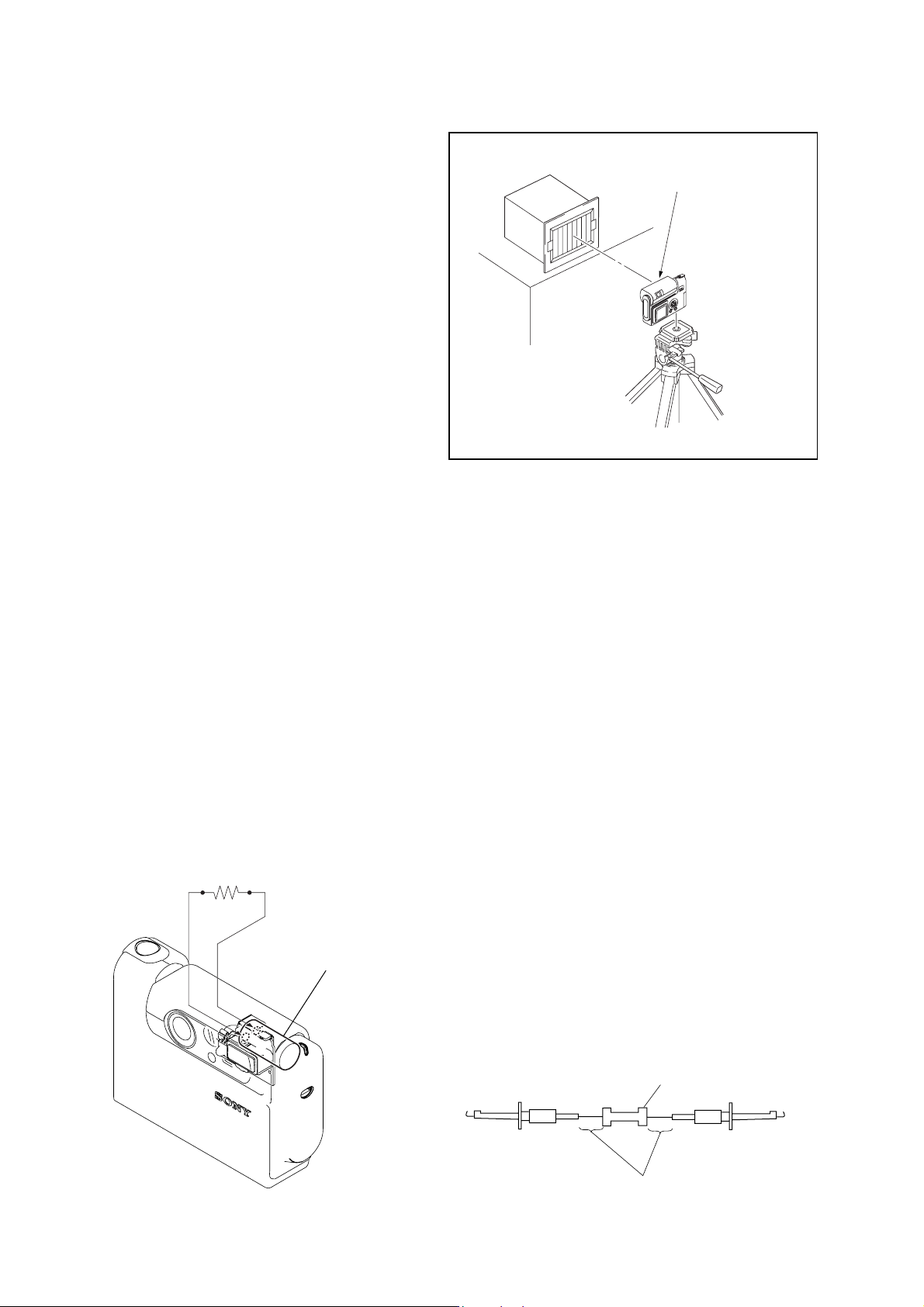

1-1-2. Preparations

Note 1: For details of how remove the cabinet and boards, refer

to “2. DISASSEMBLY”.

Note 2: When performing only the adjustments, the lens block

and boards need not be disassemble.

1) Connect the equipment for adjustments according to Fig. 6-1-

5.

2) Connect the adjusting remote commander to cradle with LANC

jack (J-6082-548-A).

Note 3: Setting the “Forced CAMERA mode power ON Mode”

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 21, set data: 04, and press

the PAUSE button of the adjusting remote commander.

The above procedure will enable the camera power

to be turned on. After completing adjustments, be

sure to exit the “Forced CAMERA mode power ON

Mode”.

Pattern box

Front of the lens

L

L = About 30 cm

Note 4: Exiting the “Forced CAMERA mode power ON Mode”

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 21, set data: 00, and press

the PAUSE button of the adjusting remote commander.

3) Select page: 0, address: 01, and set data: 00.

1-1-3. Discharging of the Flashlight Power Supply

The capacitor which is used as power supply of flashlight is charged

with 200 V to 300 V voltage. Discharge this voltage before starting adjustments in order to protect service engineers from electric

shock during adjustment.

Discharge procedure

1. Press the FLASH button (SY -81 board S855 (CONTR OL UP))

and set the NO FLASH mode.

2. Fabricate the discharging jig as shown in Fig. 6-1-4 locally by

yourself. Connect the discharging jig to the positive (+) and

negative (–) terminal of the flash voltag e charge capacitor . Allow ten seconds to discharge the voltage.

R:1 kΩ/1 W

(Part code:

1-215-869-11)

Fig. 6-1-2

Capacitor

1 kΩ/1 W

Wrap insulating tape.

Fig. 6-1-4Fig. 6-1-3

6-4

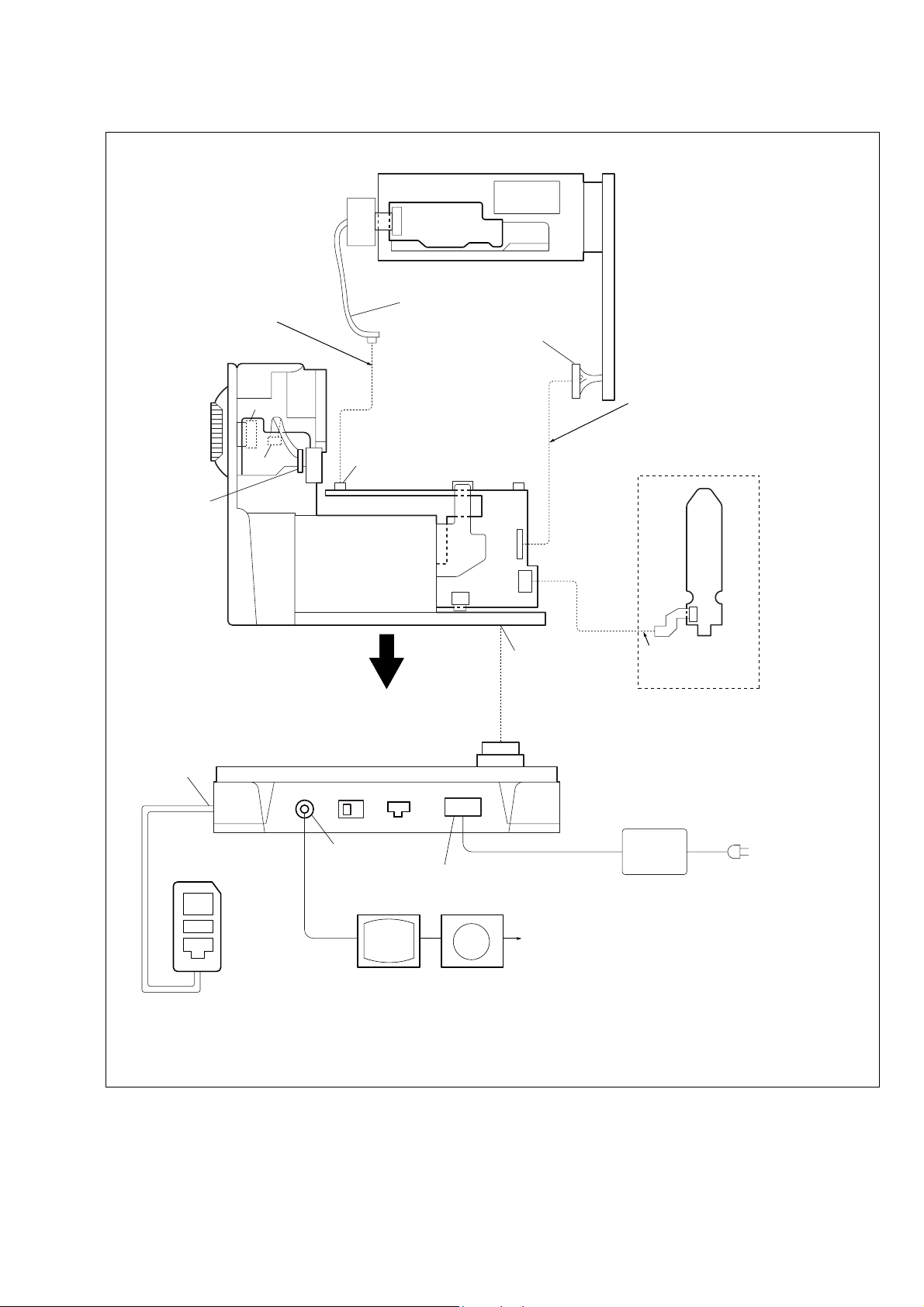

Page 7

CN001

CD-415 board

DSC-F77/FX77

Must be connected when

performing the camrera system

adjustment. (Note 1)

CN853

CN851

KK-29

flexible

board

CN151

SY-81 board

FP-585 flexible

CN601

CN401

FP-587

flexible

SS-173 harness

CN402

CN351

CN352

Connect to

SY-81 board CN503

(Multi connector)

Must be connected when

performing the strobe adjustment

and AF illumination check. (Note 2)

DSC-FX77 only

BT-14 board

CN1001

Must be connected

when performing the

Bluetooth check.

Connect to

LANC jack

Adjustment remote

commander

Audio/Video jack

Color monitor

DC IN jack

Vectorscope

Cradle with LANC jack

(J-6082-548-A)

Terminated at 75 Ω

AC power adaptor

Note 1: When CN151 on SY-81 board is removed, turn on the power after setting the mode dial “PLAY”.

Note 2: When CN351 on SY-81 board is removed, press the FLASH button (CONTROL UP) to change to “NO FLASH” mode.

Fig. 6-1-5

6-5

Page 8

DSC-F77/FX77

1-1-4. Precautions

1. Setting the Switch

Unless otherwise specified, set the switches as follows and perform adjustments.

1. Mode Dial .......................................... CAMERA

2. ZOOM button

(SY-81 board S852, S853) ................. WIDE end

3. DSPL/LCD ON/OFF button

(SY-81 board S856) ........................... OSD OFF

4. VIDEO OUT (SET UP setting)......... NTSC

2. Order of Adjustments

Basically carry out adjustments in the order given.

Color bar chart (Standard picture frame)

H

Yellow

Cyan

White

Magenta

Green

AB B

A=B

Red

Blue

A

Enlargement

B

A

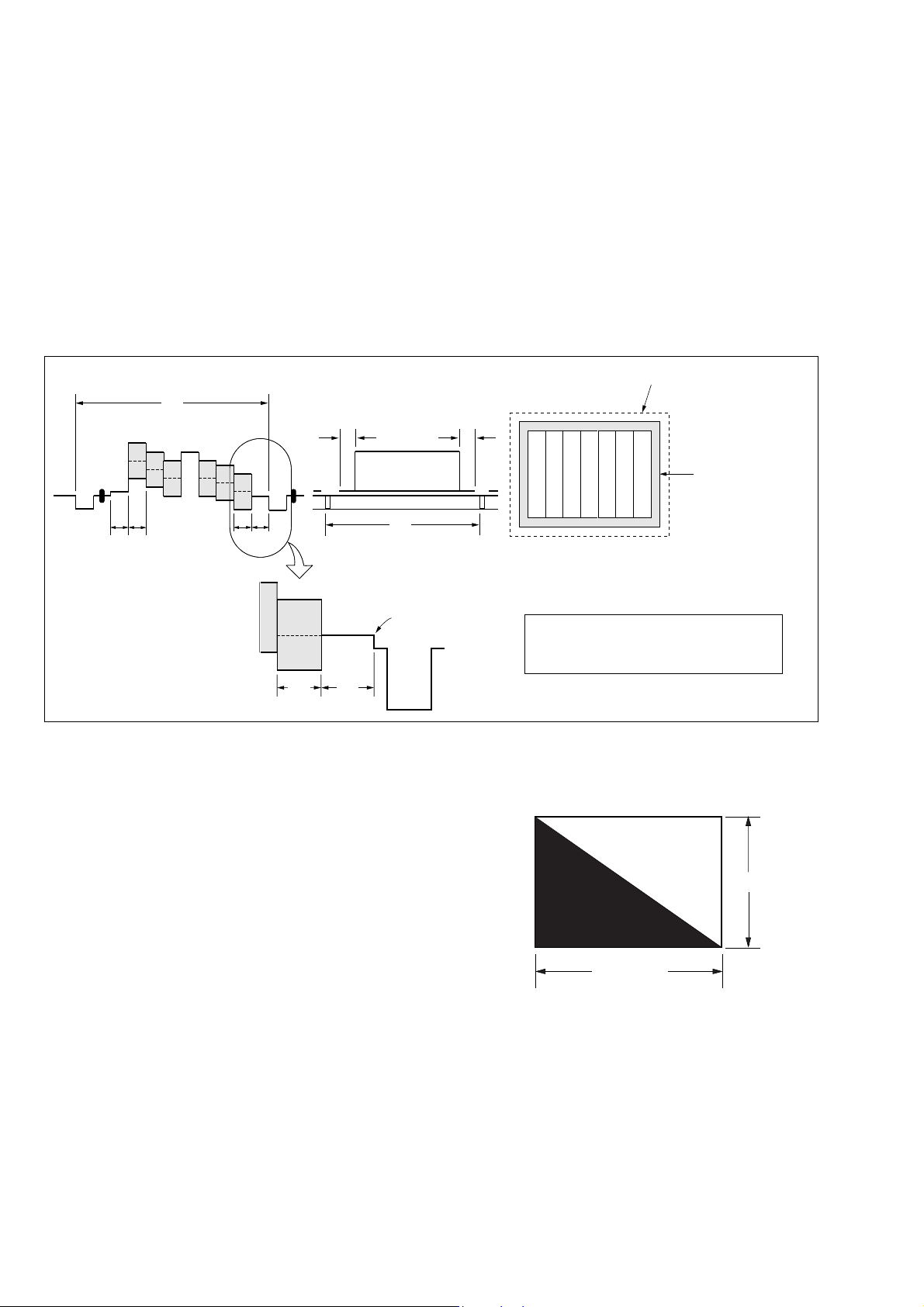

3. Subjects

1) Color bar chart (Standard picture frame).

When performing adjustments using the color bar chart, adjust the picture frame as shown in Fig. 6-1-6. (Standard picture frame)

2) Clear chart (Standard picture frame)

Remove the color bar chart from the pattern box and insert a

clear chart in its place. (Do not perform zoom operations during this time)

3) Chart for flange back adjustment

Join together a piece of white A0 size paper (1189mm × 841

mm) and a piece of black paper to make the chart shown in

Fig. 6-1-7.

C=D

V

Difference in level

DC

Fig. 6-1-6

Electronic beam scanning frame

Red

Cyan

White

Green

Yellow

Fig. b (monitor TV picture)

Adjust the camera zoom and direction to

obtain the output wavefor m shown in Fig a

and the monitor TV display shown in Fig. b.

Black

Magenta

1189 mm

Blue

CRT picture frame

White

841 mm

Note: Use a non-reflecting and non-glazing vellum paper. The

size must be A0 or larger and the joint between the white

and black paper must not have any undulations.

Fig. 6-1-7

6-6

Page 9

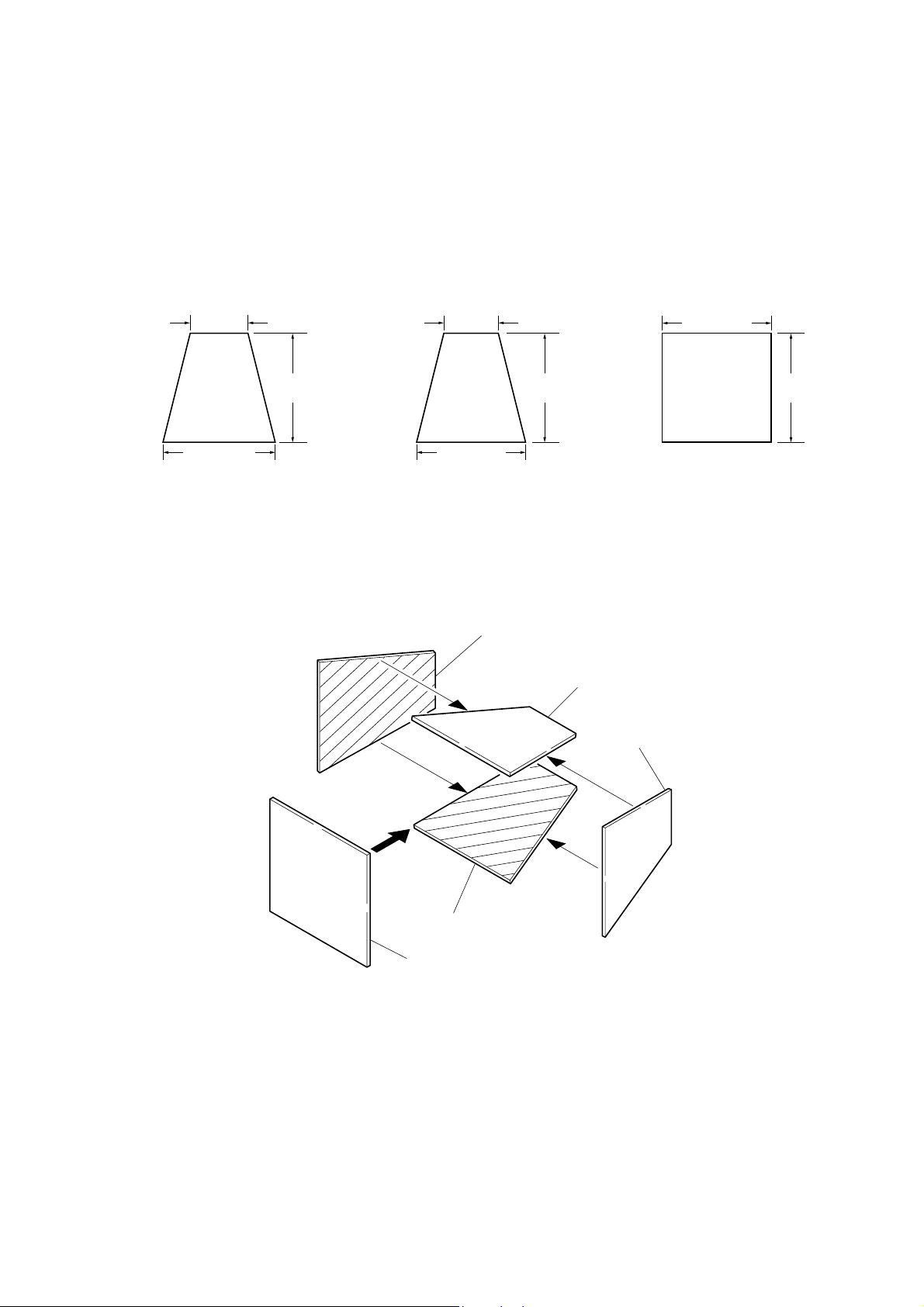

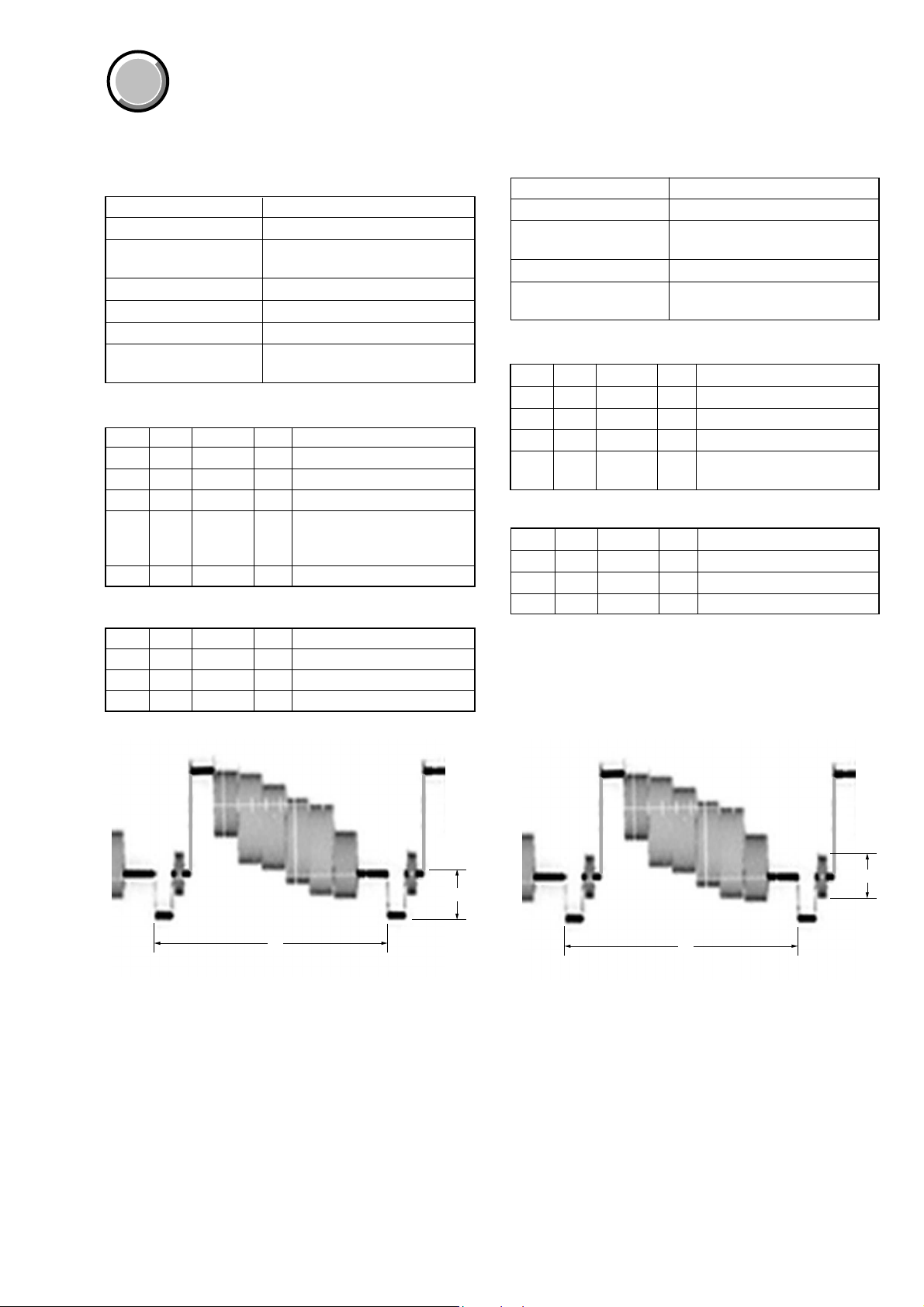

4. Preparing the Flash Adjustment Box

A dark room is required to provide an accurate flash adjustment.

If it is not available, prepare the flash adjustment box as given

below;

1) Provide woody board A, B and C of 15 mm thickness.

Dimensions without brackets are for a box of 1 m in depth.

Dimensions in brackets are for a box of 50 cm in depth.

DSC-F77/FX77

woody board A (2)

530 mm

(400 mm)

1026 mm

(513 mm)

1030 mm

(730 mm)

woody board B (2)

500 mm

(370 mm)

1000 mm

(700 mm)

Fig. 6-1-8

2) Apply black mat paint to one side of woody board A and B.

3) Attach background paper (J-2501-130-A) to woody board C.

4) Assemble so that the black sides and the background paper

side of woody board A, B and C are internal. (Fig 6-1-9)

1026 mm

(513 mm)

woody board A

woody board C (1)

1000 mm

(700 mm)

1000 mm

(700 mm)

woody board B

woody board B

woody board C

Fig. 6-1-9

woody board A

6-7

Page 10

DSC-F77/FX77

COVER

COVER

1-2. INITIALIZATION OF A, B, D, E, F, 7, 9 PAGE

DAT A

1-2-1. Initialization of A, D Page Data

1. Initializing A, D Page Data

Note: If the A, D page data has been initialized, the following

adjustments need to be performed again.

1) Modification of A, D page data

2) Video system adjustments

3) LCD system adjustments

Adjsuting page A

Adjsuting Address 00 to FF

Adjusting page D

Adjusting Address 10 to 7F

Initializing Method:

Order Page Address Data Procedure

10 0101

Set the following data

24 03

34 002D

44 01 2D Press PAUSE button.

54 02 Check the data changes to “01”.

6

2. Modification of A, D Page Data

If the A, D page data has been initialized, change the data of the

“Fixed data-2” address shown in the following table by manual

input.

Modifying Method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) New data for changing are not shown in the tables because

they are different in destination. When changing the data, copy

the data built in the same model.

Note: If copy the data built in the different model, the

camera may not operate.

3) When changing the data, press the PAUSE button of the

adjusting remote commander each time when setting new data

to write the data in the non-volatile memory.

4) Check that the data of adjustment addresses is the initial v alue.

If not, change the data to the initial value.

10: DSC-F77

0F: DSC-FX77

Perform “Modification of

A, D page Data”.

3. A Page table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing the A, D Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of A, D Page Data”)

Address Initial value Remark

00 to 4E Fixed data-1 (Initialized data)

4F Fixed data-2

50 to 5A Fixed data-1 (Initialized data)

5B Fixed data-2

5C to 81 Fixed data-1 (Initialized data)

82 80 VCO adj. (NTSC mode)

83 96 VCO adj. (PAL mode)

84 9E V-COM adj.

85 BD Bright adj.

86 Fixed data-1 (Initialized data)

87 38 PSIG level adj.

88 94

89 72

8A 46 Contrast adj.

8B 36 VG center adj.

8C to 9F Fixed data-1 (Initialized data)

A0 80 Video sync level adj.

A1 to A7 Fixed data-1 (Initialized data)

A8

A9

AA to FF Fixed data-1 (Initialized data)

4. D Page table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing the A, D Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of A, D Page Data”)

Address Initial value Remark

10 to 20 Fixed data-1 (Initialized data)

21 00 Test mode

22 to 7F Fixed data-1 (Initialized data)

White balance adj.

Fixed data-2

Processing after Completing Modification of A, D Page Data:

Order Page Address Data Procedure

12 0029

22 01 29 Press PAUSE button.

6-8

Page 11

DSC-F77/FX77

1-2-2. Initialization of B, E, F, 7, 9 Page Data

1. Initializing B, E, F, 7, 9 Page Data

Note: If the B, E, F, 7, 9 Page data has been initialized,

“Modification of B, E, F, 7, 9 Page Data” and following

adjustments need to be performed again.

1) Modification of B, E, F, 7, 9 page data

2) Camera system adjustments

Adjusting page B

Adjusting Address 00 to FF

Adjusting page E

Adjusting Address 00 to FF

Adjusting page F

Adjusting Address 00 to FF

Adjusting page 7

Adjusting Address 00 to FF

Adjusting page 9

Adjusting Address 00 to FF

Initializing Method:

Order Page Address Data Procedure

10 0101

Set the following data

26 03

36 002D

46 01 2D Press PAUSE button.

56 02 Check the data changes to “01”.

6

10: DSC-F77

0F: DSC-FX77

Perform “Modification of B,

E, F, 7, 9 page Data”.

3. B Page Table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing B, E, F, 7, 9 Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of B, E, F, 7, 9 Page Data”)

Address Initial value Remark

00 to FF Fixed data-1 (Initialized data)

4. E Page Table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing B, E, F, 7, 9 Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of B, E, F, 7, 9 Page Data”)

Address Initial value Remark

00 to FF Fixed data-1 (Initialized data)

2. Modification of B, E, F, 7, 9 Page Data

If the B, E, F, 7, 9 Page data has been initialized, change the data

of the “Fixed data-2” address shown in the following tables by

manual input.

Modifying Method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) New data for changing are not shown in the tables because

they are different in destination. When chang ing the data, copy

the data built in the same model.

Note: If copy the data built in the different model, the

camera may not operate.

3) When changing the data, press the PAUSE button of the

adjusting remote commander each time when setting new data

to write the data in the non-volatile memory.

4) Check that the data of adjustment addresses is the initial v alue.

If not, change the data to the initial value.

Processing after Completing Modification of B, E, F, 7, 9

Page data

Order Page Address Data Procedure

12 0029

22 01 29 Press PAUSE button.

6-9

Page 12

DSC-F77/FX77

5. F Page Table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing the B, E, F, 7, 9 Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of B, E, F, 7, 9 Page Data”)

Address Initial value Remark

00 to 0F Fixed data-1 (Initialized data)

10 FF

11 FF

12 FF

13 FF

14 00

15 90

16, 17 Fixed data-1 (Initialized data)

18 36

19 54

1A 87

1B 71

1C 11

1D 49

1E 00

1F 00

20 00

21 00

22 00

23 00

24 20

25 20

26 BA

27 46

28 0A

29 00

2A to 3D Fixed data-1 (Initialized data)

3E FF Flange back adj.

3F to 51 Fixed data-1 (Initialized data)

52 00

53 00

54 to 57 Fixed data-1 (Initialized data)

58 53

59 3A

5A 20

5B 5B

5C 7D

5D 5D

5E 00

5F 00

60 00

61 00

62 00

63 00

64 00

AF illumination check

Flange back adj.

Flange back adj.

Hall adj.

F No. compensation

Address Initial value Remark

65 30

66 FE

67 6D

68 68 Hall adj.

69 to 6D Fixed data-1 (Initialized data)

6E 00

6F 00

70 29

71 83

72 1F

73 DF

74 29

75 0C

76 22

77 6D

78 to 87 Fixed data-1 (Initialized data)

88 19

89 66

8A 30

8B 6E

8C 19

8D A7

8E 32

8F FB

90 to 9F Fixed data-1 (Initialized data)

A0 29

A1 90

A2 60

A3 80

A4 03

A5 E9

A6 63

A7 83

A8 D5

A9 FE

AA 73

AB 45

AC 63

AD 83

AE 03

AF E9

B0 00 AWB 3200K standard data input

B1 00 AWB 5800K standard data input

B2 00 AWB 3200K standard data input

B3 00 AWB 5800K standard data input

Light value adj.

Mixed color cancel adj.

AWB 3200K standard data input

AWB 5800K standard data input

AWB 5800K standard data input

Color reproduction adj.

6-10

Page 13

F Page Table

Address Initial value Remark

B4 00 AWB 3200K standard data input

B5 Fixed data-1 (Initialized data)

B6 28

B7 6E

B8 10

B9 6B

BA 0F

BB F6

BC 0F

BD F7

BE 0F

BF F2

C0 0F

C1 F7

C2 00

C3 00

C4 00

C5 00

C6 00

C7 30

C8 1B

C9 12

CA 0D

CB 08

CC 80

CD 88

CE 98

CF 90

D0 88

D1 00

D2 00

D3 00

D4 00

D5 00

D6 00

D7 14

D8 to DA Fixed data-1 (Initialized data)

DB 00

DC 00

DD 00

DE 00

DF 00

E0 00

E1 00

E2 00

E3 00

E4 00

Strobe white balance adj.

Mechanical shutter adj.

Strobe white balance adj.

DSC-F77/FX77

Address Initial value Remark

E5 00

E6 00

E7 00

E8 00

E9 00

EA 00

EB 00

EC 00

ED 00

EE 00

EF 00

F0 to FF Fixed data-1 (Initialized data)

Strobe white balance adj.

6-11

Page 14

DSC-F77/FX77

6. 7 Page Table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing B, E, F, 7, 9 Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of B, E, F, 7, 9 Page Data”)

Address Initial value Remark

00 to FF Fixed data-1 (Initialized data)

7. 9 Page Table

Note 1: Fixed data-1: Initialized data.

(Refer to “1. Initializing B, E, F, 7, 9 Page Data”)

Note 2: Fixed data-2: Modified data.

(Refer to “2. Modification of B, E, F, 7, 9 Page Data”)

Address Initial value Remark

00 to FF Fixed data-1 (Initialized data)

1-2-3. Initialization of Bluetooth (DSC-FX77)

1. Initializing of Bluetooth Revision History

Initializing Method:

Order Page Address Data Procedure

10 0101

25 002D

35 01 2D Press PAUSE button.

45 02 Check the data changes to “01”.

55 0001

65 01 2F Press PAUSE button.

75 02 Check the data changes to “01”.

Check the data (Note)

85 03

90 0100

Note: When the result of this check is “Defective”, try initializ-

ing again. If it keeps failing, SY-81 board may be defective.

2. Checking of Bluetooth Function

Refer to the Bluetooth Function Operating Instructions from page

7 to page 8 (Japanese model: page 10 to page 12) to check that

sending/receiving images can be executed normally.

00: Normal

01: Defective

6-12

Page 15

COVER

COVER

DSC-F77/FX77

1-3. VIDEO SYSTEM ADJUSTMENTS

1. Video Sync Level Adjustment

Adjust the sync level of the composite video signal output.

Mode PLAY

Signal Arbitrary

Measurement Point Video terminal of A/V OUT jack

(75 Ω terminated)

Measuring Instrument Oscilloscope

Adjustment Page A

Adjustment Address A0

Specified Value A = 286 ± 5 mVp-p (NTSC mode)

A = 300 ± 5 mVp-p (PAL mode)

Adjusting method:

Order Page Address Data Procedure

10 0101

2A 02 03 Press PAUSE button

34 F104

Change the data and set the

4A A0

5A A0 Press PAUSE button

Processing after Completing Adjustments:

Order Page Address Data Procedure

1A 02 00 Press PAUSE button

24 F100

30 0100

sync level (A) to the specified

value.

2. Video Burst Level Check

Check the burst level of the composite video signal output.

Mode PLAY

Signal Arbitrary

Measurement Point Video terminal of A/V OUT jack

(75 Ω terminated)

Measuring Instrument Oscilloscope

Specified Value A = 286 ± 30 mVp-p (NTSC mode)

A = 300 ± 30 mVp-p (PAL mode)

Adjusting method:

Order Page Address Data Procedure

10 0101

2A 02 03 Press PAUSE button

34 F104

4

Processing after Completing Adjustments:

Order Page Address Data Procedure

1A 02 00 Press PAUSE button

24 F100

30 0100

Check that the burst level (A)

is satisfied the specified value.

H

Fig. 6-1-10

A

A

H

Fig. 6-1-11

6-13

Page 16

DSC-F77/FX77

COVER

COVER

1-4. CAMERA SYSTEM ADJUSTMENTS

Before perform the camera system adjustments, check that the

specified values of “VIDEO SYSTEM ADJUSTMENTS” are satisfied.

Note: For “CAMERA SYSTEM ADJUSTMENTS”, perform in

order of item numbers.

Data setting during camera system adjustments

Perform the following data setting before the camera system adjustments.

It is not necessary to perform the following data setting ev erytime

when you perform some items of camera system adjustments continuously unless the power is turned off. Only when the power is

turned off during this adjustments, perform the data setting again,

then continue the adjustments.

Set up setting:

1) VIDEO OUT of SET UP setting............... NTSC (NTSC mode)

(This adjustment must be performed in NTSC mode, so don't

set the SET UP setting to “PAL”)

Data setting method:

Order Page Address Data Procedure

10 0101

Set the bit value of bit 5 is

2A 01

32 10

4A 02

5D 21 04 Press PAUSE button.

66 C1

76 6C01

8Wait for 1 second.

97 0A 04 Press PAUSE button.

10 E 96 00 Press PAUSE button.

Note 1:For the bit values, refer to “6-2. SERVICE MODE”,

“2-3. 2. Bit value discrimination”.

Note 2: In case of wrong data.

• Select page: 2, address: 00 and set data: 29.

• Select page: 2, address: 01 and set data: 29.

• Select page: 2, address: 0C, set the bit value of bit 1 is

“1”.

• Select page: 2, address: 04 and set data: 04.

Set the adjusting remote commander to normal LANC,

and the power will be turned, off and on automatically .

Note 3: Repeat the “Data setting method”, if the power was turned

off and on during the “CAMERA SYSTEM ADJUSTMENTS”.

“1”, and press PAUSE

button. (Note 1)

Check the bit values of bit3,

bit4 and bit5 are “1”.

(Note 1, 2)

Set the bit value of bit 1 is

“1”, and press PAUSE

button. (Note 1)

Check the data changes to

“02”.

After completing the camera system adjustments,

release the data setting:

Order Page Address Data Procedure

17 0A 00 Press PAUSE button.

2E 96 40 Press PAUSE button.

36 6C00

4D 21 00 Press PAUSE button.

Set the bit value of bit 1 is

5A 02

6A 01

70 0100

“0”, and press PAUSE

button. (Note 1)

Set the bit value of bit 5 is

“0”, and press PAUSE

button. (Note 1)

6-14

Page 17

DSC-F77/FX77

Color bar chart picture frame

Monitor TV picture frame

E=F

V

EF

Picture Frame Setting

Mode CAMERA

Subject Color bar chart

(Standard picture frame with the

zoom at WIDE end)

Measurement Point Video terminal of A/V OUT jack

(75 Ω terminated)

Measuring Instrument Oscilloscope and monitor TV

Specified Value A=B, C=D, E=F

Note 1: Displayed data of the page 1 of adjusting remote com-

mander.

1:XX:XX

YL data

YH data

Switch setting

1) MACRO (Control button) ..........................ON

Setting method:

Order Page Address Data Procedure

1

Shoot the color bar chart

with the zoom WIDE end.

Enter the output of VIDEO

2

OUT to the monitor TV, and

move the position as shown

in Fig. 6-1-14.

Horizontal width of one color

(B, C) and that of black (A,

3

D) on the color bar chart

should be same. (See Fig. 61-12)

With vertical width of black

(E, F) set in same, the color

4

bar chart should come to the

center of monitor TV. (See

Fig. 6-1-13)

5

Check that the color bar on

the monitor TV is focused.

60 0322

71

Note down the YH and YL

data. (Note 1)

How to reset the zoom and focus when they deviated:

Order Page Address Data Procedure

16 2C01

26 92 YL (Note 2)

36 93 YH (Note 2)

46 01 79 Press PAUSE button.

56 07

Check the data changes to

“01”.

66 01 00 Press PAUSE button.

Note 2: The data noted down at step 7 of “Setting method”.

Check on the oscilloscope

1. Horizontal period

A=B

B

A

C=D

C

D

Fig. 6-1-12

2. Vertical period

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

Fig. 6-1-13

Check on the monitor TV

Fig. 6-1-14

6-15

Page 18

DSC-F77/FX77

RadarW

RadarW

RadarW

RadarW

1. HALL Adjustment

Mode CAMERA

Subject Not required

Adjustment Page F

Adjustment Address 58 to 5D, 68

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Adjusting method:

Order Page Address Data Procedure

1

26 016D

36 02

Note 2: The adjustment data will be automatically input to page:

F, address: 58 to 5D, and 68.

RadarW

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Press PAUSE button.

(Note 2)

Check the data changes to

“01”.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

Release the data setting

2

performed at step 1.

(Refer to page 6-14)

6-16

Page 19

DSC-F77/FX77

2. Flange Back Adjustment

(Using the minipattern box)

RadarWRadarWRadarW

The inner focus lens flange back adjustment is carried out automatically. In whichever case, the focus will be deviated during

auto focusing/manual focusing.

Mode CAMERA

Subject Siemens star chart with ND filter

for minipattern box (Note 1)

Measurement Point Displayed data of page: F,

address: 3E

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address 18 to 29, 3E, 52, 53

Specified Value

Date of page: F , Address: 3E is “00”

Note 1: Dark Siemens star chart.

Note 2: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Preparations before adjustments:

1) The minipattern box is installed as shown in the following figure.

Note 3: The attachment lenses are not used.

2) Install the minipattern box so that the distance between it and

the front of lens of camera is less than 3 cm.

3) Make the height of minipattern box and the camera equal.

4) Check the output voltage of the regulated power supply is the

specified voltage ± 0.01 Vdc.

5) Check that the center of Siemens star chart meets the center of

shot image screen.

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

camera system adjustment”.

(Refer to page 6-14)

26 01 13 Press PAUSE button.

36 0127

46 02

Press PAUSE button.

(Note 4)

Check the data changes to

“01”.

5F 3E Check the data is “00”.

Note 4: The adjustment data will be automatically input to page:

F, address: 18 to 29, 3E, 52 and 53.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

Release the data setting

2

performed at step 1.

(Refer to page 6-14)

3

Perform “Flange Back

Check”.

Specified voltage:The specified voltage varies according to the

minipattern box, so adjustment the power supply output voltage to the specified voltag e written on the sheet which is supplied with the minipattern box.

Below 3 cm

Minipattern box

Camera

Camera

table

Output voltage : Specified voltage ± 0.01 Vdc

Red (+)

Black (–)

Yellow (SENS +)

White (SENS –)

Black (GND)

Regulated power supply

Output current : more than 3.5 A

Need not connected

Fig. 6-1-15

6-17

Page 20

DSC-F77/FX77

RadarW

RadarW

RadarW

RadarW

3. Flange Back Adjustment

(Using the flange back adjustment chart)

The inner focus lens flange back adjustment is carried out automatically. In whichever case, the focus will be deviated during

auto focusing/manual focusing.

Mode CAMERA

Subject Flange back adjustment chart

Measurement Point Displayed data of page: F,

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address 18 to 29, 3E, 52, 53

Specified Value

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Preparations before adjustments:

1) Place the Flange back adjustment chart 2.0 m from the front

of the lens.

2) Check that the center of Flange back adjustment chart meets

the center of shot image screen.

Adjusting method:

Order Page Address Data Procedure

1

26 01 13 Press PAUSE button.

36 0115

46 02

5F 3E Check the data is “00”.

Note 2: The adjustment data will be automatically input to page:

F, address: 18 to 29, 3E, 52 and 53.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

2

3

RadarW

(2.0 m from the front of lens)

(Luminance: 300 to 400 lux)

address: 3E

Date of page: F, Address: 3E is “00”

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Press PAUSE button.

(Note 2)

Check the data changes to

“01”.

Release the data setting

performed at step 1.

(Refer to page 6-14)

Perform “Flange Back check”.

4. Flange Back Check

Mode CAMERA

Subject Siemens star

Measurement Point Check operation on monitor TV

Measuring Instrument

Specified value Lens is Focused

Checking method:

Order Page Address Data Procedure

1

2

3

46 9000

56 9100

66 9200

76 93B0

86 01 79 Press PAUSE button.

96 07

10

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 0100

26 9300

3

RadarWRadarWRadarW

(50 cm from the front of the lens)

(Luminance: 200 to 400 lux)

Place the Siemens star 50 cm

from the front of the lens.

To open the IRIS , decrease

the luminous intensity to the

Siemens star up to a point

before noise appear on the

image.

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Check the data changes to

“01”.

Check that the lens is

focused.

Release the data setting

performed at step 3.

(Refer to page 6-14)

6-18

Page 21

RadarW

RadarW

RadarW

RadarW

RadarW

RadarW

5. F No. Compensation

Compensate the unevenness of the iris meter sensitivity.

Mode CAMERA

Subject Clear chart

Adjustment Page F

Adjustment Address 5E to 64

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Adjusting method:

Order Page Address Data Procedure

1

2

36 01BB

46 02

Note 2: The adjustment data will be automatically input to page:

F, address: 5E to 64.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

2

RadarW

(Standard picture frame with the

zoom at WIDE end)

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”.

(Refer to page 6-15)

Press PAUSE button.

(Note 2)

Check the data changes to

“01”.

Release the data setting

performed at step 1.

(Refer to page 6-14)

DSC-F77/FX77

RadarW

RadarW

6. Mechanical Shutter Adjustment

Adjust the period which the mechanical shutter is closed, and compensate the exposure.

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Measurement Point Displayed data of page: 6,

address: AB

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address B8 to D7

Specified Value

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Adjusting method:

Order Page Address Data Procedure

1

2

36 01AD

46 02

56 AB Check the data is “00”.

Note 2: The adjustment data will be automatically input to page:

F, address: B8 to D7.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

2

Date of page: 6, Address: AB is “00”

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”.

(Refer to page 6-15)

Press PAUSE button.

(Note 2)

Check the data changes to

“01”.

Release the data setting

performed at step 1.

(Refer to page 6-14)

RadarW

6-19

Page 22

DSC-F77/FX77

RadarW

RadarW

RadarW

RadarW

RadarW

RadarW

7. Light V alue Adjustment

Adjust the standard LV value.

Mode CAMERA

Subject Clear chart

Measurement Point Displayed data of page: 1 (Note

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address 65 to 67

Specified Value AE level 1: 0FE0 to 1020

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 2: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:

XX:XX

Adjusting method:

Order Page Address Data Procedure

1

2

36 010D

46 02

50 0306

61

7F 65

Note 3: The adjustment data will be automatically input to page:

F, address: 65 to 67.

RadarW

(Standard picture frame with the

zoom at WIDE end)

2) and page: F, address: 65

AE level 2: 10 to 50

Displayed data

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”.

(Refer to page 6-15)

Press PAUSE button.

(Note 3)

Check the data changes to

“01”.

Check that the displayed data

(Note 2) satisfies the AE

level 1 specified value.

Check that the displayed data

satisfies the AE level 2

specified value.

RadarW

RadarW

8. Mixed Color Cancel Adjustment

To perform mixed color cancel adjustment based on data of each

color in color bar.

Mode CAMERA

Subject Color bar chart

(Standard picture frame with the

zoom at WIDE end)

Adjustment Page F

Adjustment Address 6E and 6F

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

2

36 02 Check the data is “00”.

46 01 D7 Press PAUSE button.

56 01D5

66 02

Note: The adjustment data will be automatically input to page:

F, address: 6E and 6F.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

2

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”.

(Refer to page 6-15)

Press PAUSE button.

(Note)

Check the data changes to

“01”.

Release the data setting

performed at step 1.

(Refer to page 6-14)

RadarW

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

20 0300

Release the data setting

3

performed at step 1.

(Refer to page 6-14)

6-20

Page 23

DSC-F77/FX77

RadarW

RadarW

9. Auto White Balance 3200K Standard Data Input

RadarW

RadarW

RadarW

Adjust the white balance standard data at 3200K.

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Adjustment Page F

Adjustment Address 70 to 77, B0, B2, B4

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

2

36 B6 Note down the data.

46 B603

57 44 Check the data is “20”.

66 02 Check the data is “00”.

76 3701

86 01 11 Press PAUSE button.

96 38

10 6 01 C1 Press PAUSE button. (Note)

11 6 02

12 6 01 00 Press PAUSE button.

13 6 02 Check the data is “00”.

14 6 37 02

15 6 01 0B Press PAUSE button.

16 6 02

17 6 01 00 Press PAUSE button.

18 6 02 Check the data is “00”.

19 6 37 04

20 6 01 0B Press PAUSE button.

21 6 02

22 6 01 00 Press PAUSE button.

23 6 02 Check the data is “00”.

24 6 37 06

25 6 01 0B Press PAUSE button.

26 6 02

Note: The adjustment data will be automatically input to page:

F, address: 70 to 77, B0, B2 and B4.

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 3700

26 01 00 Press PAUSE button.

36 B6 Set data noted down at step 3.

Release the data setting

4

performed at step 1.

(Refer to page 6-14)

6-21

Page 24

DSC-F77/FX77

10. Auto White Balance 5800K Standard Data Input

RadarWRadarWRadarW

Adjust the white balance standard data at 5800K.

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Filter Filter C14 for color temperature

correction

Adjustment Page F

Adjustment Address 88 to 8F, A0 to A3, B1, B3

Adjusting method:

Order Page Address Data Procedure

1 Place the C14 filter on the

lens.

Perform “Data setting during

2

3

4F A0 29 Press PAUSE button.

5F A1 90 Press PAUSE button.

6F A2 60 Press PAUSE button.

7F A3 80 Press PAUSE button.

86 B6 Note down the data.

96 B603

10 6 02 Check the data is “00”.

11 7 44 10 Press PAUSE button.

12 6 37 07

13 6 01 11 Press PAUSE button.

14 6 38

15 6 01 C3 Press PAUSE button. (Note)

16 6 02

17 7 44 20 Press PAUSE button.

18 6 01 00 Press PAUSE button.

19 6 02 Check the data is “00”.

20 6 37 08

21 6 01 A5 Press PAUSE button.

22 6 02

23 6 01 00 Press PAUSE button.

24 6 02 Check the data is “00”.

25 6 37 0A

26 6 01 A5 Press PAUSE button.

27 6 02

28 6 01 00 Press PAUSE button.

29 6 02 Check the data is “00”.

30 6 37 0C

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Order Page Address Data Procedure

31 6 01 A5 Press PAUSE button.

32 6 02

Note: The adjustment data will be automatically input to page:

F, address: 88 to 8F, A0 to A3, B1 and B3.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 3700

26 01 00 Press PAUSE button.

36 B6 Set data noted down at step 8.

4

5

Check the data changes to

“01”.

Release the data setting

performed at step 2.

(Refer to page 6-14)

Remove the C14 filter on the

lens.

6-22

Page 25

RadarW

RadarW

RadarW

RadarW

11. Auto White Balance 5800K Check 1

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Filter Filter C14 for color temperature

correction

Measurement Point Displayed data of Page: 1 (Note)

Measuring Instrument Adjusting remote commander

Specified Value R ratio: 2790 to 2B90

B ratio: 5E80 to 6280

R-Y level data: 007A to 0086

B-Y level data: 007A to 0086

Note: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:XX:XX

Displayed data

Checking method:

Order Page Address Data Procedure

1

2

3

46 B6 Note down the data.

56 B603

66 02 Check the data is “00”.

77 44 10 Press PAUSE button.

86 3713

96 01 11 Press PAUSE button.

10 6 38

11 6 01 C3 Press PAUSE button.

12 6 02

13 0 03 04

14 1

15 0 03 05

16 1

17 0 03 2C

18 1

19 0 03 2D

20 1

21 7 44 20 Press PAUSE button.

22 6 01 00 Press PAUSE button.

Place the C14 filter on the

lens.

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

RadarW

DSC-F77/FX77

Order Page Address Data Procedure

23 6 02 Check the data is “00”.

24 6 37 14

25 6 01 3F Press PAUSE button.

26 6 02

27 0 03 04

28 1

29 0 03 05

30 1

31 0 03 2E

32 1

33 0 03 2F

34 1

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

26 3700

36 01 00 Press PAUSE button.

46 B6 Set data noted down at step 4.

5

6

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

Release the data setting

performed at step 2.

(Refer to page 6-14)

Remove the C14 filter on the

lens.

6-23

Page 26

DSC-F77/FX77

12. Auto White Balance 5800K Check 2

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Filter Filter C14 for color temperature

correction

Measurement Point Displayed data of Page: 1 (Note)

Measuring Instrument Adjusting remote commander

Specified Value R ratio: 2790 to 2B90

B ratio: 5E80 to 6280

R-Y level data: 007A to 0086

B-Y level data: 007A to 0086

Note: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:XX:XX

Displayed data

Checking method:

Order Page Address Data Procedure

1

2

3

46 B6 Note down the data.

56 B603

66 02 Check the data is “00”.

76 3716

86 01 3F Press PAUSE button.

96 02

10 0 03 04

11 1

12 0 03 05

13 1

14 0 03 2E

15 1

16 0 03 2F

17 1

Place the C14 filter on the

lens.

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

RadarWRadarWRadarW

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

26 3700

36 01 00 Press PAUSE button.

46 B6 Set data noted down at step 4.

Release the data setting

5

6

performed at step 2.

(Refer to page 6-14)

Remove the C14 filter on the

lens.

6-24

Page 27

RadarW

RadarW

RadarW

RadarW

13. Auto White Balance 5800K Check 3

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Filter Filter C14 for color temperature

correction

Measurement Point Displayed data of Page: 1 (Note)

Measuring Instrument Adjusting remote commander

Specified Value R ratio: 2790 to 2B90

B ratio: 5E80 to 6280

R-Y level data: 007A to 0086

B-Y level data: 007A to 0086

Note: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:XX:XX

Displayed data

Checking method:

Order Page Address Data Procedure

1

2

3

46 B6 Note down the data.

56 B603

66 02 Check the data is “00”.

76 3718

86 01 3F Press PAUSE button.

96 02

10 0 03 04

11 1

12 0 03 05

13 1

14 0 03 2E

15 1

16 0 03 2F

17 1

Place the C14 filter on the

lens.

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

RadarW

DSC-F77/FX77

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

26 3700

36 01 00 Press PAUSE button.

46 B6 Set data noted down at step 4.

Release the data setting

5

6

performed at step 2.

(Refer to page 6-14)

Remove the C14 filter on the

lens.

6-25

Page 28

DSC-F77/FX77

14. Auto White Balance 3200K Check 1

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Measurement Point Displayed data of Page: 1 (Note)

Measuring Instrument Adjusting remote commander

Specified Value R ratio: 3E00 to 4200

B ratio: 3E00 to 4200

R-Y level data: 007E to 0082

B-Y level data: 007E to 0082

Note: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:XX:XX

Displayed data

Checking method:

Order Page Address Data Procedure

Perform “Data setting during

1

2

36 B6 Note down the data.

46 B603

56 02 Check the data is “00”.

67 44 Check the data is “20”.

76 370D

86 01 11 Press PAUSE button.

96 38

10 6 01 C1 Press PAUSE button.

11 6 02

12 0 03 04

13 1

14 0 03 05

15 1

16 0 03 2C

17 1

18 0 03 2D

19 1

20 6 01 00 Press PAUSE button.

21 6 02 Check the data is “00”.

22 6 37 0E

23 6 01 0F Press PAUSE button.

24 6 02

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

Check the data changes to

“01”.

RadarWRadarWRadarW

Order Page Address Data Procedure

25 0 03 04

Check that the displayed data

26 1

27 0 03 05

28 1

29 0 03 2E

30 1

31 0 03 2F

32 1

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

26 3700

36 01 00 Press PAUSE button.

46 B6 Set data noted down at step 3.

5

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

Release the data setting

performed at step 1.

(Refer to page 6-14)

6-26

Page 29

RadarW

RadarW

RadarW

RadarW

15. Auto White Balance 3200K Check 2

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Measurement Point Displayed data of Page: 1 (Note)

Measuring Instrument Adjusting remote commander

Specified Value R ratio: 3E00 to 4200

B ratio: 3E00 to 4200

R-Y level data: 007E to 0082

B-Y level data: 007E to 0082

Note: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:XX:XX

Displayed data

Checking method:

Order Page Address Data Procedure

Perform “Data setting during

1

2

36 B6 Note down the data.

46 B603

56 02 Check the data is “00”.

66 3710

76 01 0F Press PAUSE button.

86 02

90 0304

10 1

11 0 03 05

12 1

13 0 03 2E

14 1

15 0 03 2F

16 1

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

RadarW

DSC-F77/FX77

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

26 3700

36 01 00 Press PAUSE button.

46 B6 Set data noted down at step 3.

Release the data setting

5

performed at step 1.

(Refer to page 6-14)

6-27

Page 30

DSC-F77/FX77

16. Auto White Balance 3200K Check 3

Mode CAMERA

Subject Clear chart

(Standard picture frame with the

zoom at WIDE end)

Measurement Point Displayed data of Page: 1 (Note)

Measuring Instrument Adjusting remote commander

Specified Value R ratio: 3E00 to 4200

B ratio: 3E00 to 4200

R-Y level data: 007E to 0082

B-Y level data: 007E to 0082

Note: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:XX:XX

Displayed data

Checking method:

Order Page Address Data Procedure

Perform “Data setting during

1

2

36 B6 Note down the data.

46 B603

56 02 Check the data is “00”.

66 3712

76 01 0F Press PAUSE button.

86 02

90 0304

10 1

11 0 03 05

12 1

13 0 03 2E

14 1

15 0 03 2F

16 1

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check that the displayed data

(Note) satisfied the R ratio

specified value.

Check that the displayed data

(Note) satisfied the B ratio

specified value.

Check that the R-Y level data

(Note) satisfied the specified

value.

Check that the B-Y level data

(Note) satisfied the specified

value.

RadarWRadarWRadarW

Processing after Completing Adjustment:

Order Page Address Data Procedure

10 0300

26 3700

36 01 00 Press PAUSE button.

46 B6 Set data noted down at step 3.

Release the data setting

5

performed at step 1.

(Refer to page 6-14)

6-28

Page 31

RadarW

RadarW

RadarW

R-Y

B-Y

R

B

G

M

G

Y

E

C

Y

Burst position

W

RadarW

17. Color Reproduction Adjustment

Adjust the color separation matrix coefficient so that proper color

reproduction is produced.

Mode CAMERA

Subject Color bar chart

(Standard picture frame with the

zoom at WIDE end)

Measurement Point Video terminal of A/V OUT jack

(75 Ω terminated)

Measuring Instrument Vectorscope

Adjustment Page F

Adjustment Address A4 to AF

Specified Value All color luminance points

should settle within each color

reproduction frame.

Menu setting:

1) VIDEO OUT of SET UP menu

................................ NTSC (NTSC mode)

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

2

36 02 Check the data is “00”.

4E 96 Check the data is “00”.

56 01 AB Press PAUSE button.

66 1280

7Wait for 1 second.

86 1200

9Wait for 2 seconds.

10 6 37 1F

11 6 01 A9 Press PAUSE button. (Note)

12 6 02

13

Note: The adjustment data will be automatically input to page:

F, address: A4 to AF.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 3700

26 01 00 Press PAUSE button.

3

camera system adjustment”.

(Refer to page 6-14)

Perform “Picture Frame

Setting”. (Refer to page 6-15)

Check the data changes to

“01”.

Check the each color luminance point is in each color

reproduction frame.

Release the data setting

performed at step 1.

(Refer to page 6-14)

RadarW

DSC-F77/FX77

Fig. 6-1-16

6-29

Page 32

DSC-F77/FX77

RadarW

RadarW

RadarW

RadarW

18. CCD White Defect Compensation

Mode CAMERA

Subject Not required

Measurement Point Displayed data of page: 6,

address: 55

Measuring Instrument Adjusting remote commander

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 2: The“CCD White Defect Compensation” should be made

when the set warms up at certain duration after the power

was turned on, as it is affected with the temperature.

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

2E 64 Note down the data.

3E 64 1E Press PAUSE button.

4E 69 Note down the data.

5E 69 0C Press PAUSE button.

66 01 8B Press PAUSE button.

76 02

86 55

96 01 00 Press PAUSE button.

10 E 64 0F Press PAUSE button.

11 E 69 60 Press PAUSE button.

12 6 01 87 Press PAUSE button.

13 6 02

14 6 55

camera system adjustment”.

(Refer to page 6-14)

Check the data changes to

“01”.

Check the data.

00 to 7F: Normal

80 to FF: Defective

Check the data changes to

“01”.

Check the data.

00: Normal

01 to FF: Defective

RadarW

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

Set data noted down at step

2, and press PAUSE button.

Set data noted down at step

4, and press PAUSE button.

Release the data setting

performed at step 1.

(Refer to page 6-14)

2E 64

3E 69

4

6-30

Page 33

RadarW

RadarW

RadarW

RadarW

19. CCD Black Defect Compensation

Mode CAMERA

Subject Clear chart

(25 cm from the front of lens)

(Note 3)

Measurement Point Displayed data of page: 6,

address: 55

Measuring Instrument Adjusting remote commander

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 2: Check that there are no dust, no dirt and reflection of the

clear chart.

Note 3: Any subject other than the clear chart should be in the

screen.

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

2E 65 Note down the data.

3E 65 4C Press PAUSE button.

46 2C01

56 9200

66 9300

76 01 79 Press PAUSE button.

86 3008

96 07

10 Wait for 4 seconds.

11 6 01 8D Press PAUSE button.

15 6 02

13 6 55

14 6 01 00 Press PAUSE button.

15 E 65 5A Press PAUSE button.

16 6 01 89 Press PAUSE button.

17 6 02

18 6 55

camera system adjustment”.

(Refer to page 6-14)

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data.

00: Proceed to “Processing

after Completing Adjustment”

01 to 14 : Normal

15 to FF : Defective

Check the data changes to

“01”.

Check the data.

00: Normal

01 to FF: Defective

RadarW

DSC-F77/FX77

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

26 2C00

36 3000

4E 65

5

Set data noted down at step

2, and press PAUSE button.

Release the data setting

performed at step 1.

(Refer to page 6-14)

6-31

Page 34

DSC-F77/FX77

RadarW

RadarW

RadarW

RadarW

20. Strobe White Balance Adjustment

Adjust the white balance when the strobe light flashed.

Mode CAMERA

Subject Flash adjustment box (Note 3)

(50 cm from the front of lens)

Measurement Point Displayed data of page: 1 (Note

4) and page: F, address: E8, EA,

EC, EE

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address B6, B7, DB to EF

Specified Value Y level data: 03 to 09

R-Y level data:

FA to FF or 00 to 06 (Note 4)

B-Y level data:

FA to FF or 00 to 06 (Note 4)

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 2: Perform this adjustment in the Flash adjustment box.

Note 3: Refer to “4. Preparing the Flash adjustment box”.

(See page 6-7)

Note 4: The right four digits of the page: 1 displayed data of the

adjusting remote commander.

1:

XX:XX

B-Y level data

R-Y level data

Note 5: “Strobe White Balance Adjustment” is available only

once after the power is turned on. Turn the power off,

then on again if the adjustment is retried.

Switch setting:

1) FLASH (Control button) .............. ON

Adjusting method:

Order Page Address Data Procedure

Perform “Data setting during

1

26 2C01

36 92FF

46 93FF

56 6C01

66 01 79 Press PAUSE button.

76 07

86 01 67 Press PAUSE button.

9 Check the flashing.

10 6 02

11 F E8

12 6 01 00 Press PAUSE button.

13 6 01 67 Press PAUSE button.

14 Check the flashing.

15 6 02

camera system adjustment”.

(Refer to page 6-14)

Check the data changes to

“01”.

Check the data changes to

“01”.

Check that the displayed data

satisfies the Y level data

specified value.

Check the data changes to

“01”.

RadarW

Order Page Address Data Procedure

16 6 01 00 Press PAUSE button.

17 6 01 67 Press PAUSE button.

18 Check the flashing.

19 6 02

20 6 01 00 Press PAUSE button.

21 6 01 67 Press PAUSE button.

22 Check the flashing.

23 6 02

24 6 01 00 Press PAUSE button.

25 6 01 B9 Press PAUSE button. (Note 6)

26 Check the flashing.

27 6 02

28 6 01 00 Press PAUSE button.

29 6 01 E7 Press PAUSE button.

30 Check the flashing.

31 6 02

32 Wait for 1 second.

EA Check that the displayed data

33 F EC satisfies the Y level data

EE specified value.

34 0 03 02

35 1

Note 6: The adjustment data will be automatically input to page:

F, address: B6, B7 and DB to EF.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

26 9200

36 9300

46 2C00

56 6C00

60 0300

7

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Check the data changes to

“01”.

Check that the R-Y, B-Y level

data (Note 4) satisfies the

specified value.

Release the data setting

performed at step 1.

(Refer to page 6-14)

6-32

Page 35

DSC-F77/FX77

21. AF Illumination Check

Check the deviation of optical axis of AF illuminator.

Mode CAMERA

Subject Flash adjustment box (Note 3)

Measurement Point Displayed data of page: F,

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address 10 to 15

Specified Value

Note 1: Perform checking by making the shooting surface of the

Flash adjustment box perpendicular to the optical axis of

the camera.

Note 2: Perform this checking in the Flash adjustment box.

Restrict external light to enter the Flash adjustment box

as less as possible.

Note 3: Refer to “4. Preparing the Flash adjustment box”.

(See page 6-7)

Adjusting method:

Order Page Address Data Procedure

1

29 A9 Note down the data.

39 A9

46 01 EF Press PAUSE button. (Note 4)

56 02

6F 10 Check the data is “00”.

Note 4: The adjustment data will be automatically input to page:

F, address: 10 to 15.

RadarWRadarWRadarW

(50 cm or 1 m from the front of

lens)

address: 10

Data of page: F , Address: 10 is “00”

Perform “Data setting during

camera system adjustment”.

(Refer to page 6-14)

Set the following data, and

press PAUSE button.

06: 50 cm

04: 1 m

Check the data changes to

“01”.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

29 A9

3

Set data noted down at step

2, and press PUASE button.

Release the data setting

performed at step 1.

(Refer to page 6-14)

6-33

Page 36

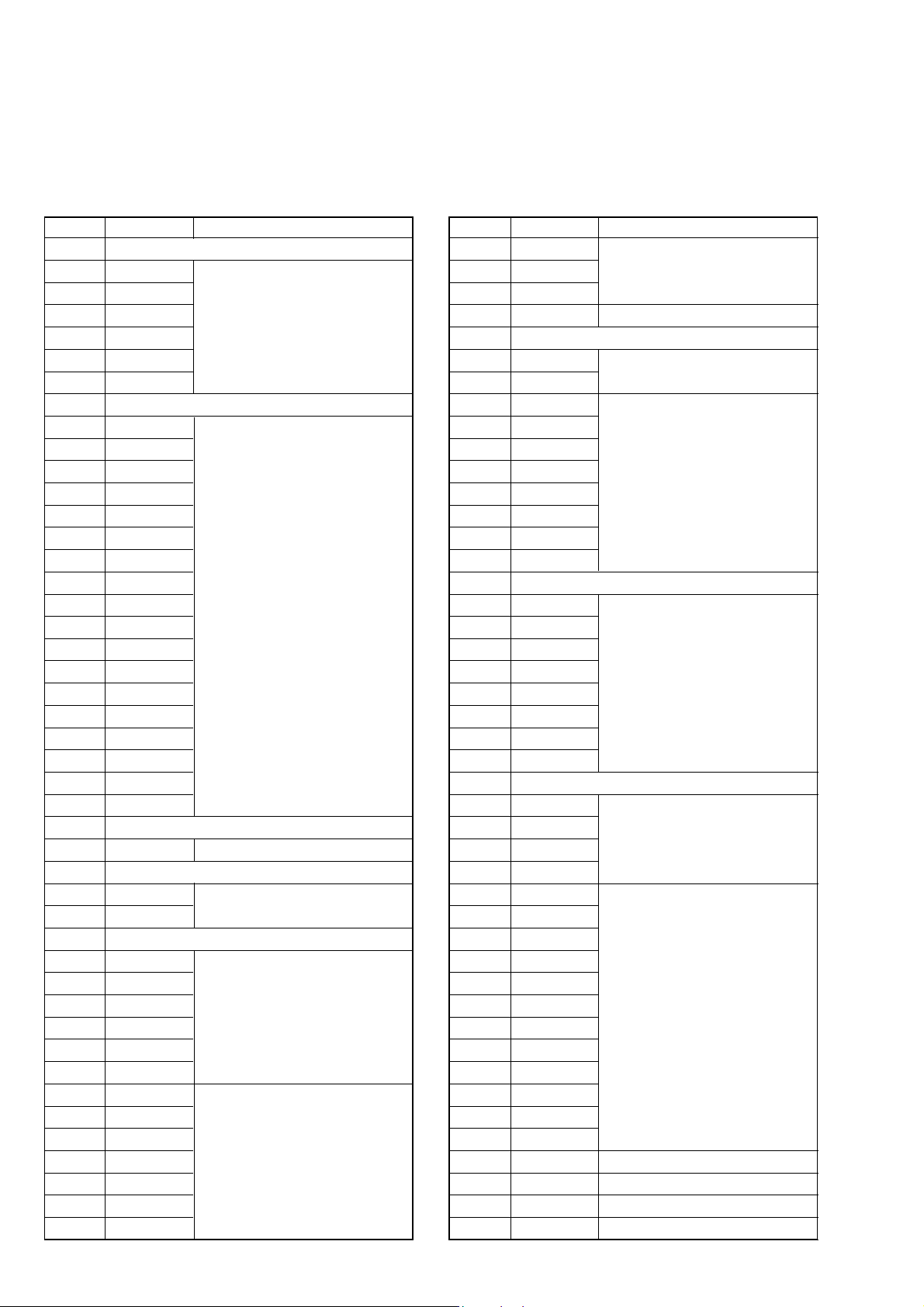

DSC-F77/FX77

COVER

COVER

1-5. LCD SYSTEM ADJUSTMENTS

Note 1: Taken an extreme care not to destroy the liquid crystal

display module by static electricity when replacing it.

Note 2: Set the LCD BRIGHTENSS (SET UP setting) to the

NORMAL.

[Measuring points]

Measuring points for LCD system adjustment exsists on SY-81

board.

Adjust it after setting it as service position referring to “ 2. DISASSEMBLY”.

Measuring points are indicated in the figure shown below.

JL704

JL702

JL701

Fig. 6-1-17

6-34

Page 37

DSC-F77/FX77

1. LCD Initial Data Input (1)

Mode PLAY

Signal Arbitrary

Adjustment Page A

Adjustment Address

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, and enter the data given in the follo wing table.

Note: Press the PAUSE button each time the data are set, as the

data are written to non-volatile memory (EEPROM).

Address Data Remark

67 15

68 22

69 21

6A 38

6D 4C Fixed value

6E 4C

6F 4C

80 C4

81 18