Sony DNE-0050 Service manual

D-NE004/NE005/

NE0050/NE006

SERVICE MANUAL

Ver. 1.3 2005.12

Photo: D-NE006

SPECIFICATIONS

US Model

Canadian Model

AEP Model

D-NE004/NE005/NE006

UK Model

E Model

D-NE005/NE0050/NE006

Australian Model

Tourist Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type

Optical Pick-up Name DAX-25E

CDM-3525A/3525AJ

D-NE005

D-NE004

D-NE005

D-NE006

System

Compact disc digital audio system

Laser diode properties

Emission duration: Continuous

Laser output: Less than 44.6 µW (This output is the value measured at a

distance of 200 mm from the objective lens surface on the optical pick-up

block with 7 mm aperture.)

Power requirements

• Two LR6 (size AA) batteries: 1.5 V DC × 2

• AC power adaptor (DC IN 4.5 V jack):

220 V, 50 Hz (NE005: EE,EU8/NE006: EU8, EE, E18)

120 V, 60 Hz (C&SA, MX)

Dimensions (w/h/d) (without projecting parts and controls)

Approx. 139.8 × 28.8 × 139.8 mm

Mass (excluding accessories)

Approx. 200 g

Operating temperature

5°C - 35°C

MPEG Layer-3 audio coding technology and patents licensed from

Fraunhofer IIS and Thomson.

Design and specifications are subject to change without notice.

Supplied accessories

AC power adaptor (1)

(NE005: EE, EU8/NE0050: C&SA, MX/NE006: EU8, EE, E18)

Headphones (1)

Remote control (1) (supplied with D-NE006 only)

Battery life* (approx. hours)

(When the CD player is used on a flat and stable place.)

Playing time varies depending on how the CD player is used.

When using two Sony alkaline batteries LR6 (SG)

(produced in Japan)

G-PROTECTION G-on G-off

Audio CD 16 11

MP3 CD (Recorded at 128 kbps) 23 23

* Measured value by the standard of JEITA (Japan Electronics and

Information Technology Industries Association).

• The indicator sections of roughly show the remaining battery

power. One section does not always indicate one-fourth of the battery

power.

9-879-861-04

2005L02-1

© 2005.12

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Division

Published by Sony Engineering Corporation

D-NE004/NE005/NE0050/NE006

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 3

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 4

3-2. Upper Lid Assy, Cabinet (Middle) Assy,

Cabinet (Lower) Assy...................................................... 4

3-3. Optical Pick-Up (CDM-3525A) ...................................... 5

3-4. JACK Board, MAIN Board ............................................. 5

3-5. LPF Board ....................................................................... 6

4. TEST MODE ............................................................... 7

5. ELECTRICAL ADJUSTMENT ............................. 7

6. DIAGRAMS ................................................................. 8

6-1. Block Diagram ................................................................ 9

6-2. Printed Wiring Board

– MAIN Board (Side A), LPF Board (Side A) – ............. 10

6-3. Printed Wiring Board

– MAIN Board (Side B), LPF Board (Side B),

JACK Board – ................................................................. 11

6-4. Schematic Diagram – MAIN Board (1/2),

JACK Board (1/2) – ........................................................ 12

6-5. Schematic Diagram – MAIN Board (2/2), LPF Board,

JACK Board (2/2) – ........................................................ 13

6-6. IC Pin Function Description ............................................ 15

7. EXPLODED VIEWS

7-1. Upper Lid, Cabinet (Middle) Section .............................. 17

7-2. Cabinet (Lower) Section ................................................. 18

8. ELECTRICAL PARTS LIST .................................. 19

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PA RT NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈSES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPÉMENTS

PUBLIÉS PAR SONY.

SECTION 1

SERVICING NOTES

D-NE004/NE005/NE0050/NE006

Ver. 1.2

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

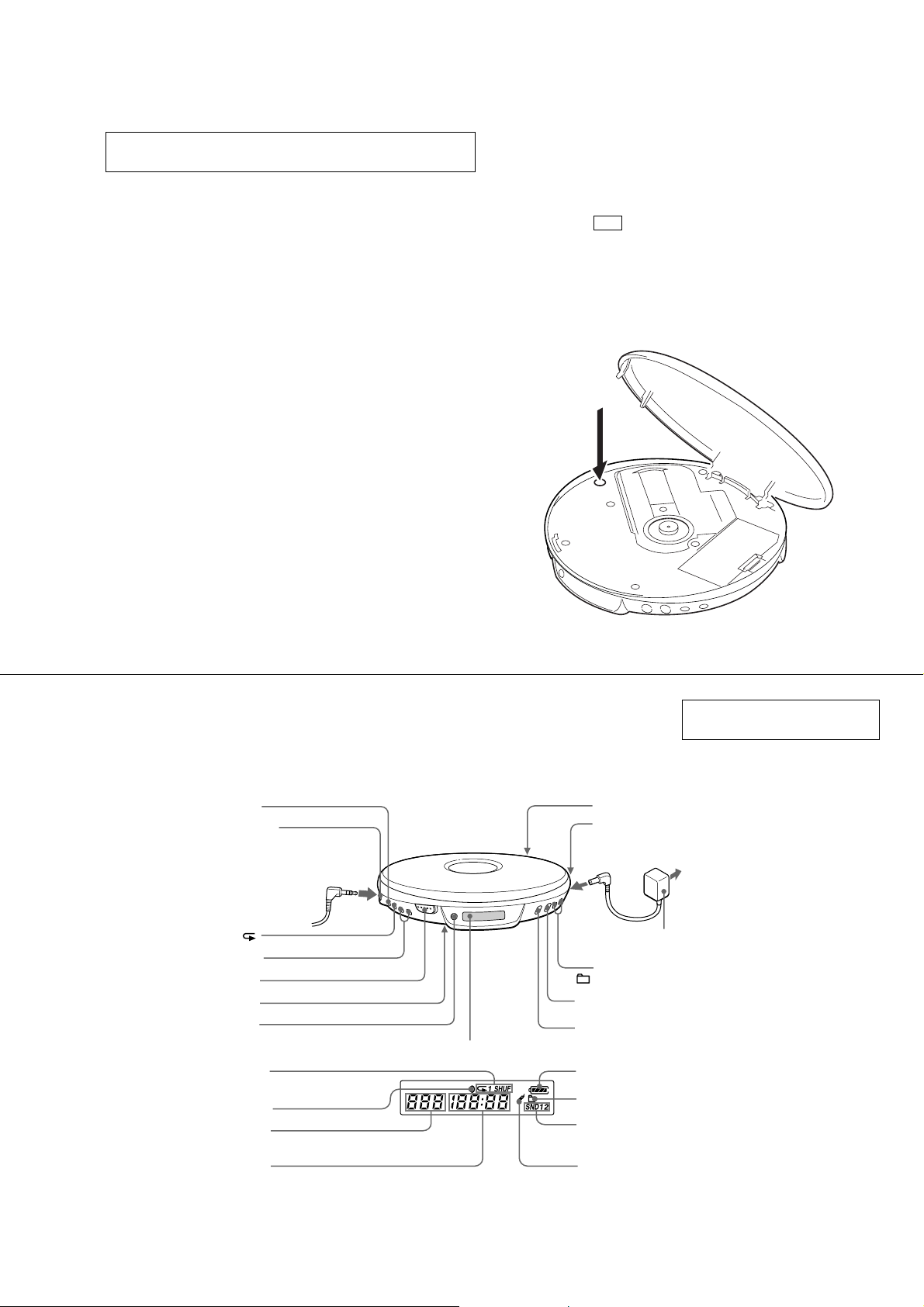

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S811. (push switch type)

The following checking method for the laser diode is operable.

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S811 with a screwdriver having

a thin tip as shown in Fig.1.

3. Press the u button.

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power

control circuit or optical pick-up is faulty.

In this operation, the objective lens will move up and down 2

times along with inward motion for the focus search.

S811

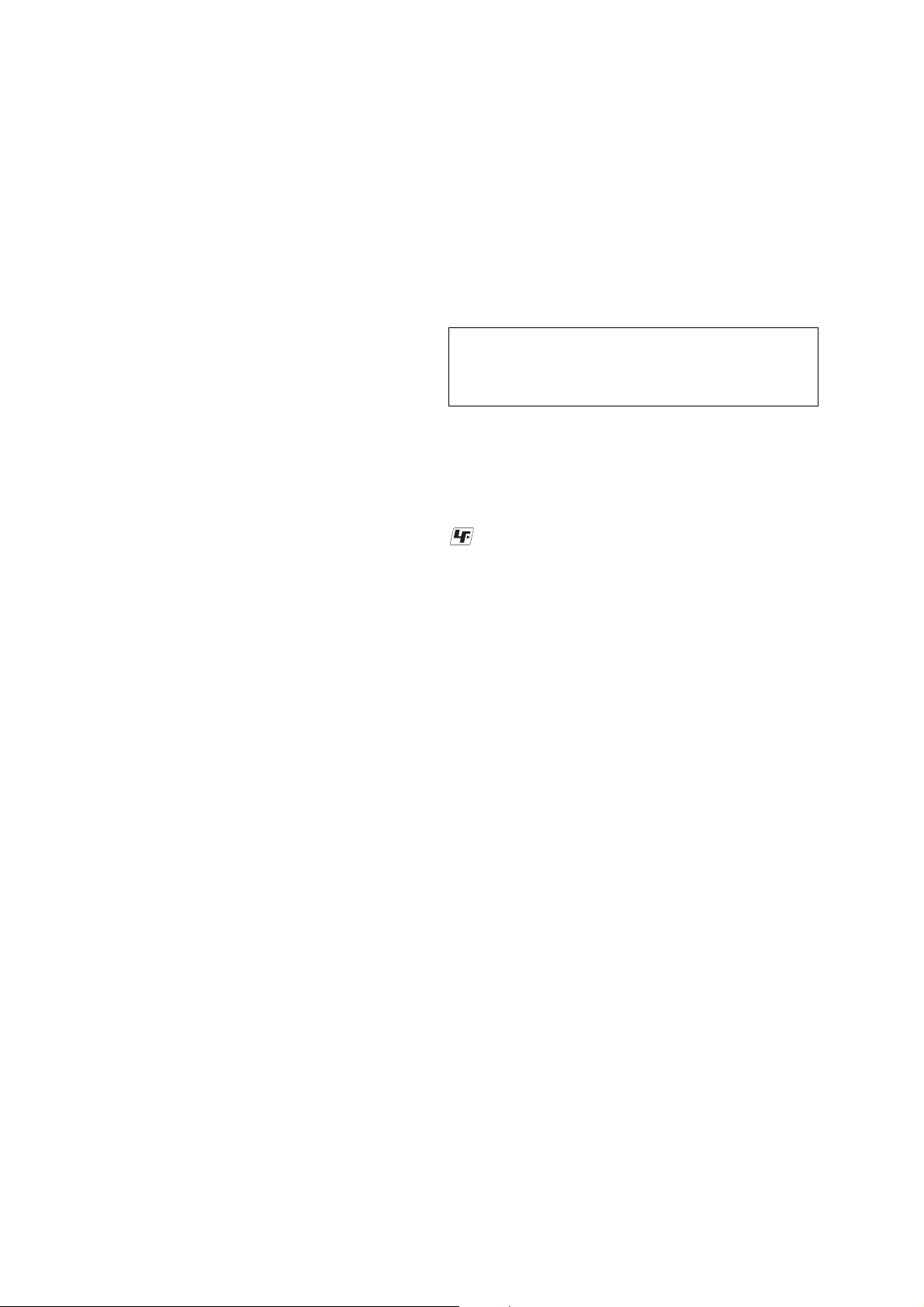

LOCATING THE CONTROLS

SOUND/AVLS

i (headhpones) jack

Headphones

P MODE/

VOL +*/–

OPEN

HOLD (rear)

GROUP

Play mode

SECTION 2

GENERAL

Display

Fig. 1 Method to push the S811

This section is extracted from

instruction manual.

LINE OUT (European and Tourist model only)

DC IN 4.5V

to an AC outlet

AC power adaptor

•

./>

(group)–/+

*(play/pause)

u

(stop)

x

Remaining battery power

MP3 indicator

Track number

Playing time

* The button has a tactile dot.

Group indicator

Sound mode

Bookmark

3

D-NE004/NE005/NE0050/NE006

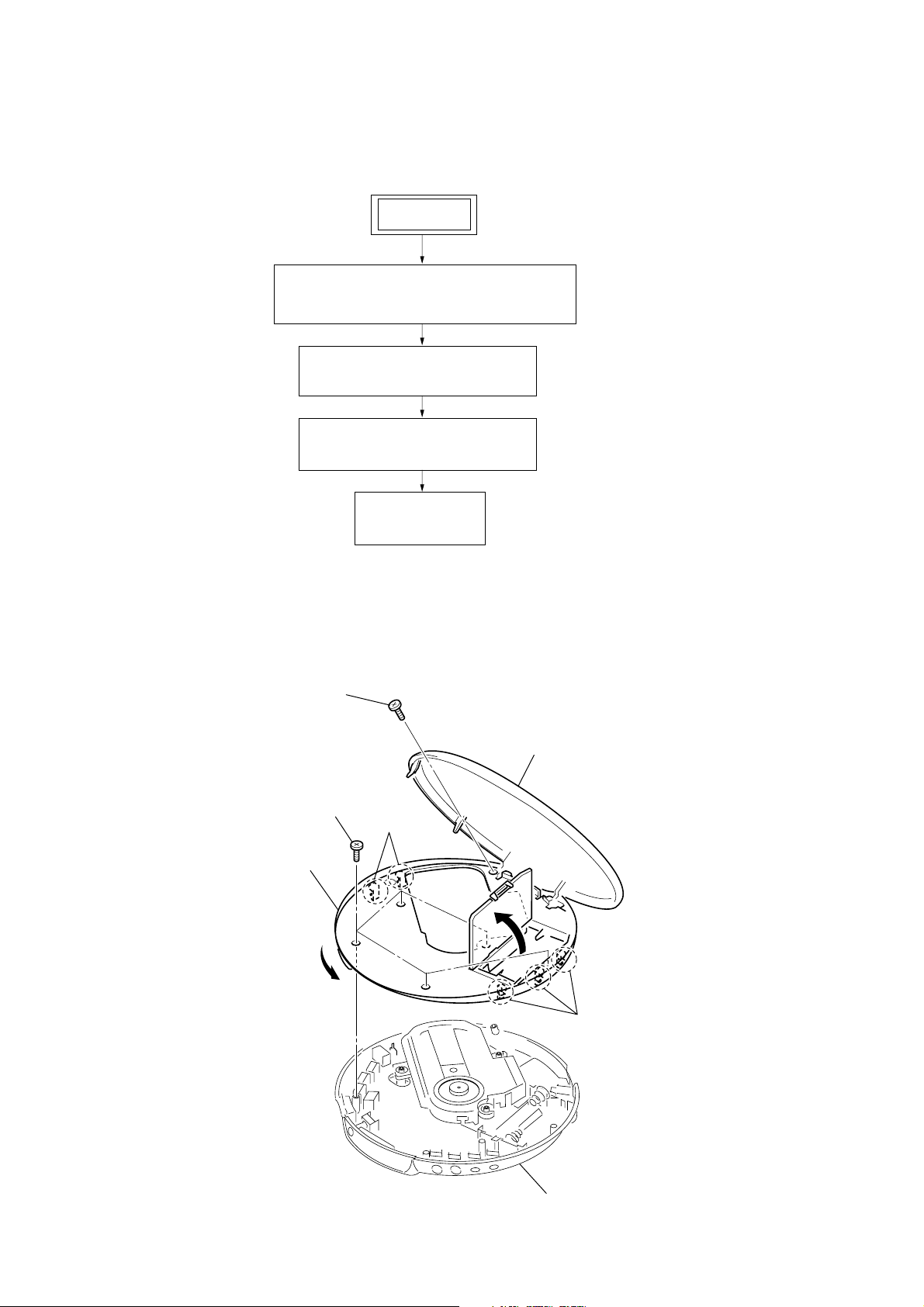

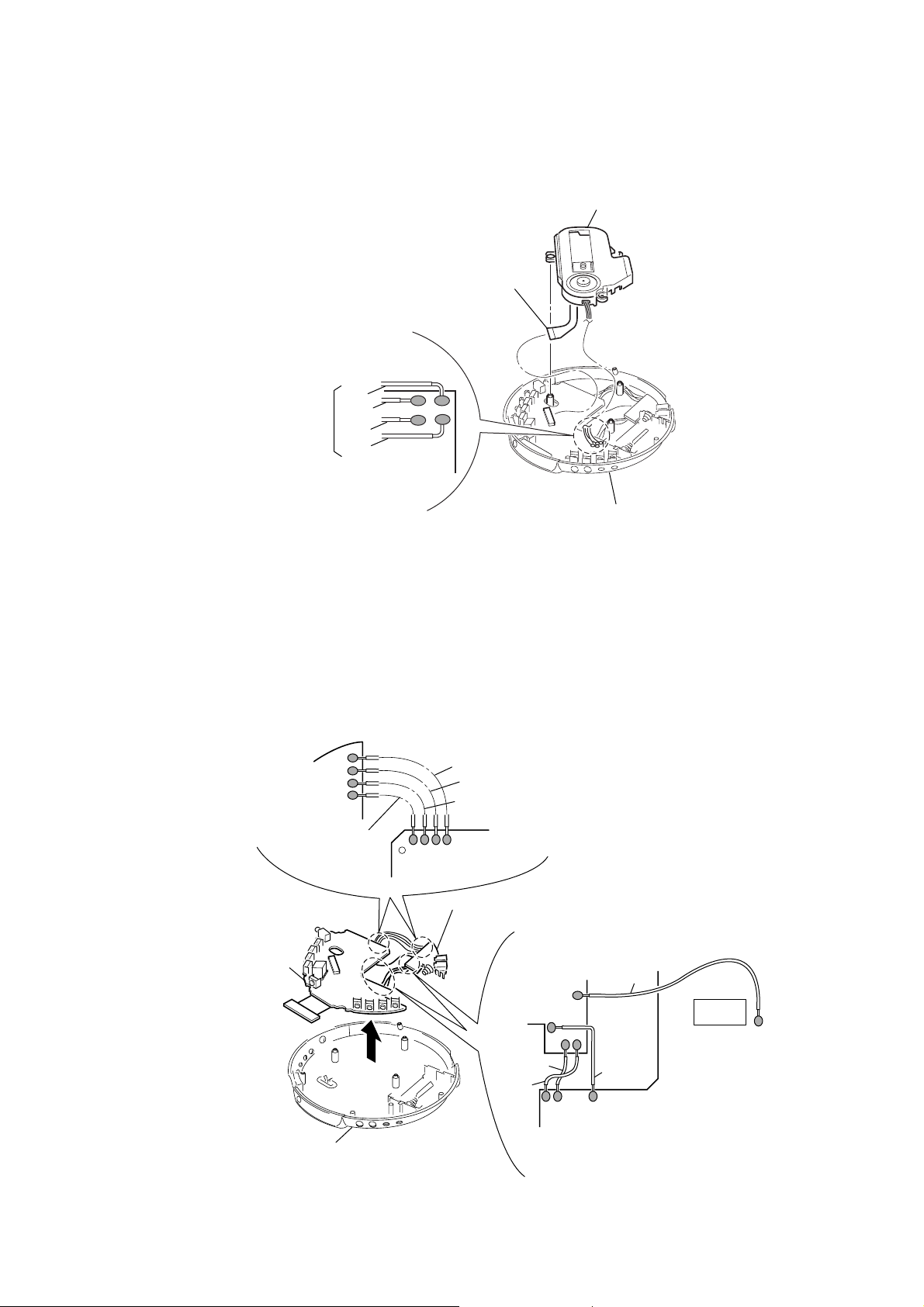

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

3-2. UPPER LID ASSY, CABINET (MIDDLE) ASSY, CABINET (LOWER) ASSY

(Page 4)

3-3. OPTICAL PICK-UP (CDM-3525A)

(Page 5)

3-4. JACK BOARD, MAIN BOARD

(Page 5)

SECTION 3

DISASSEMBLY

SET

3-5. LPF BOARD

(Page 6)

Note: Follow the disassembly procedure in the numerical order given.

3-2. UPPER LID ASSY, CABINET (MIDDLE) ASSY, CABINET (LOWER) ASSY

4

screw

upper lid assy

3

five screws

5

two claws

cabinet (middle) assy

2

1

OPEN

6

three claws

cabinet (lower) assy

4

3-3. OPTICAL PICK-UP (CDM-3525A)

)

2

Unsolder four lead wires

1

CN501

D-NE004/NE005/NE0050/NE006

3

optical pick-up (CDM-3525A

To/From

Optical pick-up

(CDM-3525A)

MAIN Board (side A)

3-4. JACK BOARD, MAIN BOARD

3

Unsolder four lead wires (AEP, EE, EU8 only)

JACK Board

(side B)

BLK

ORG

GRY

RED

cabinet (lower) assy

• Abbreviation

EE : East European

EU8 : European model other than UK, EE

and Russian

BLK

GRY

RED

ORG

MAIN Board (side B)

5

MAIN board

1

cabinet (lower) assy

4

JACK board

2

Unsolder four lead wires

JACK Board

(side B)

RED

BLK

WHT

BLU

IC602

26 50

MAIN Board (side B)

125

TP412

SGND

5

D-NE004/NE005/NE0050/NE006

3-5. LPF BOARD

1

Unsolder six lead wires

2

cushion

3

LPF board

C103(+)

TP842

SEG5

TP841

CDM4

WHT

BRN

YEL

TP843

DVDD

ORG

RED

LPF Board

BLK

TP844

RCH

TP307

AUGND2

4

adhesive sheet

MAIN Board

MAIN Board (side B)

MAIN Board (side A)

6

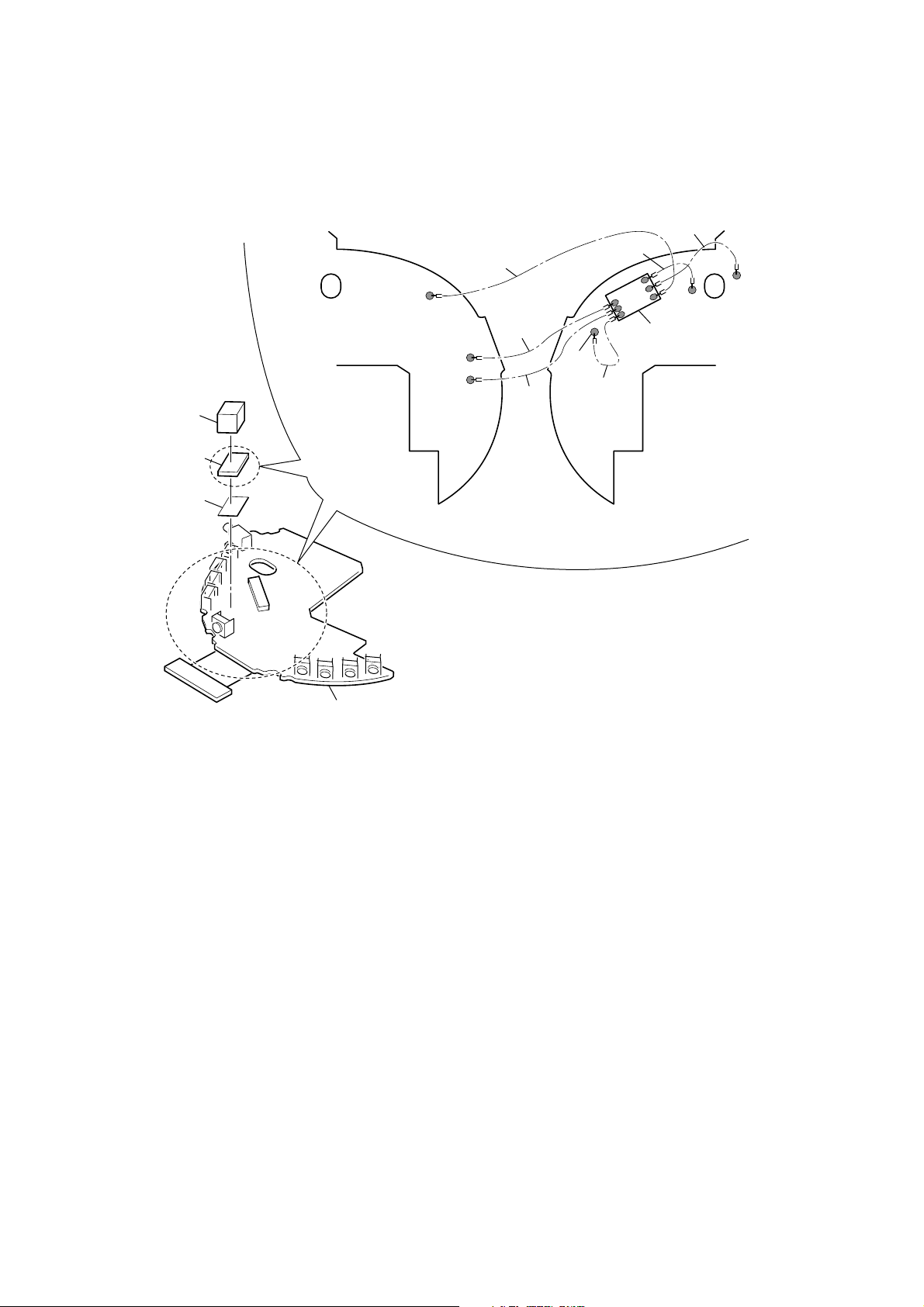

SECTION 4

)

TEST MODE

D-NE004/NE005/NE0050/NE006

SECTION 5

ELECTRICAL ADJUSTMENTS

Procedure:

1. Make a solder bridge to short SL803 (TEST) on the MAIN

board side B.

2. Press the u button.

3. Confirm LCD displays all lights.

4. Confirm the version of the microcomputer will be displayed

in 2 or 3 seconds.

5. To exit this mode, stop supplying power.

6. SL803 is opened by taking the solder bridge.

SL803

(TEST)

(SIDE B)MAIN BOARD

0

C420

1

06

C411

C412

C410

CB414

BATT+

IC401

C403

C404

L401

1

40

C408

R409

C409

21

R802

SL803

(TEST)

61

80

FB801

60

1

TP841

R820

C811

R823

IC801

R829

R835

VDR801

C632

R811

R824

R826

41

40

21

20

R812

C623

The CD section adjustments are done automatically in this set.

Adjusting Procedure:

1. Perform check in the order given.

2. Use YEDS-18 disc (Part No: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement :DC4.5 V in DC IN jack.

(J401)

VOLUME button : Minimum

HOLD switch :OFF

Focus Bias Check

Condition:

• Hold the set in horizontal state.

TP604

(RF)

C110

RB301

BLU

R101

D303

FB302

oscilloscope

(AC range)

+

–

SL801

(OPEN)

SL801

(OPEN)

FB301

R111

L101

C308

C106

R102

VDR101

C310

VDR201

R202

C206

S808

Connection:

ORG

RED

X601

R618

FB605

FB401

R416

R418

(SIDE B)MAIN BOARD

GRY

BLK

TP604

(RF)

C627

1

50

C640

BLU

25

R629

C612

R623

R621

2

FB601

R632

R619

IC602

R626

R622

C633

26

BLU

R617

S811

(OPEN)

Procedure:

1. Make a solder bridge to short SL801 (OPEN) on the MAIN

board side B.

2. Connect the oscilloscope to the test point TP604 (RF) on the

MAIN board side B.

3. Set a disc. (YEDS-18)

4. Press the u button.

5. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (

) in the

center of the waveform can be clearly distinguished.

RF Signal Reference Waveform (Eye Pattern)

VOLT/DIV : 500 mV (With the 10 : 1 probe in use

TIME/DIV : 500ns

RF level

±

0.2 Vp-p

1.3

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy

watch-ing.

6. Stop revolving of the disc motor by pressing the x button.

7. SL801 is opened by taking the solder bridge.

7

D-NE004/NE005/NE0050/NE006

Ver. 1.2

SECTION 6

DIAGRAMS

• Note for Printed Wiring Boards and Schematic Diagrams

Note on Printed Wiring Boards.

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• a : Through hole.

• f : internal component

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Abbreviation

8E : General Asian model

AUS : Australian model

CND : Canadian model

E18 : Singaporean, Indian, Malaysian, Vietnamese and South

African model

EU8 : European model other than UK, EE and Russian

EE : East European model

EA : Saudi Arabia model

JE : Tourist model

• Indication of transistor.

C

Q

B

E

D

Q

G

S

These are omitted.

These are omitted.

•Waverforms

Note on Schematic Diagrams.

• All capacitors are in µF unless otherwise noted. (p: pF) 50 WV or

less are not indicated except for electrolytics and tantalums.

• All resistors are in Ω and 1/

• f : internal tolerance.

• C : panel designation.

Note:

The components identified

by mark 0 or dotted line

with mark 0 are critical for

safety.

Replace only with part

number specified.

• A : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 3.3 V and fed with regulated dc power supply

from battery terminal.

•Voltages and waveforms are dc with respect to ground under nosignal conditions.

no mark : CD PLAY

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY

• Abbreviation

8E : General Asian model

AUS : Australian model

CND : Canadian model

E18 : Singaporean, Indian, Malaysian, Vietnamese and South

African model

EE : East European model

EU8 : European model other than UK, EE and Russian

EA : Saudi Arabia model

JE : Tourist model

4

W or less unless otherwise specified.

Note:

Les composants identifiés

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

IC601 ya XO

1

0.5 V/DIV, 50 ns/DIV

IC801 yd XOUT4M

2

238 ns

1 V/DIV, 0.1 µs/DIV

8

59 ns

1.3 Vp-p

3.4 Vp-p

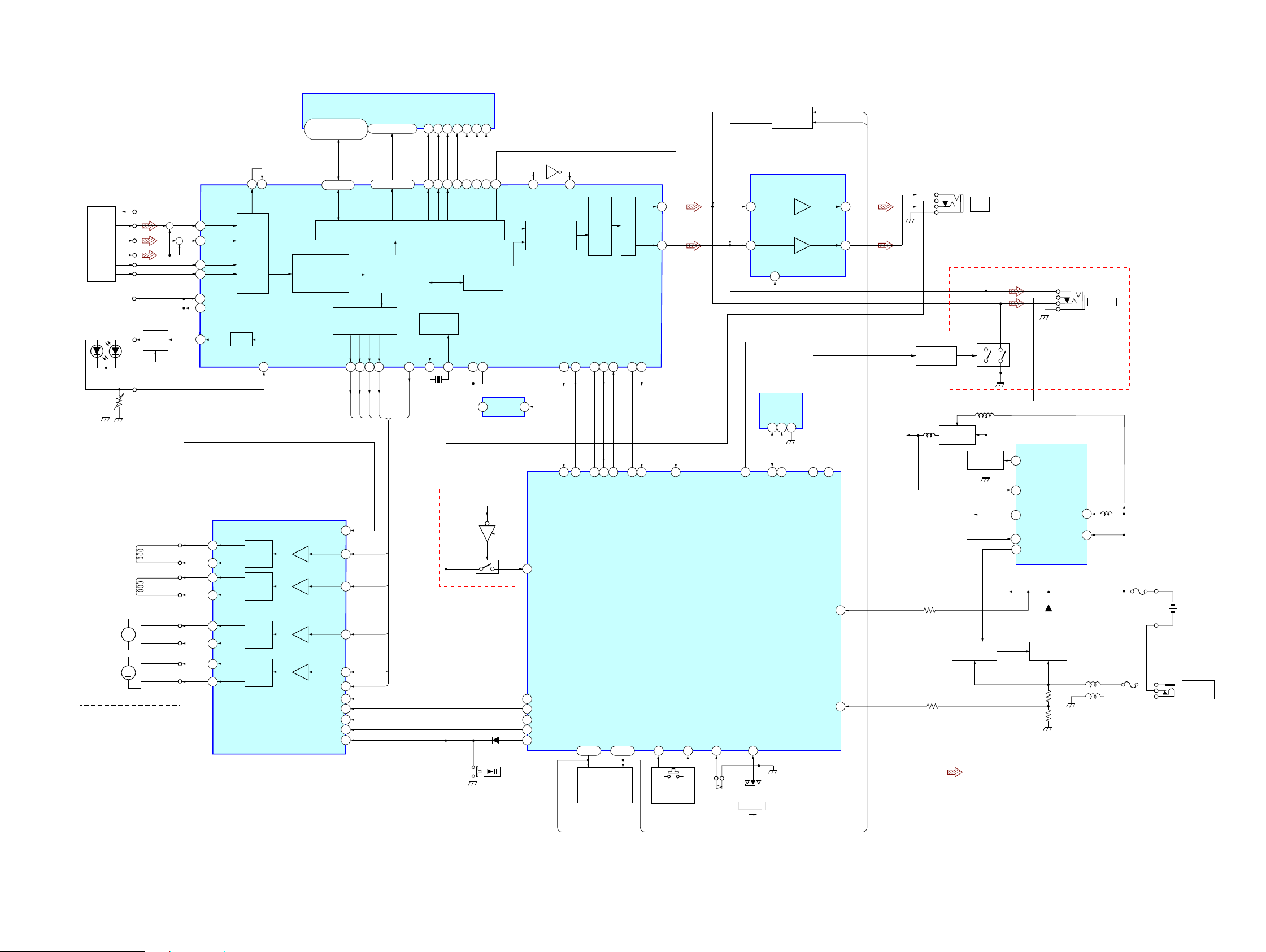

6-1. BLOCK DIAGRAM

D-NE004/NE005/NE0050/NE006

Ver. 1.2

IC602 SDRAM(16M)

OPTICAL

DEVICE

(CDM-3525A/3525AJ)

VCC

OP IC

VC

LD

PD

FOCUS

COIL

TRACKING

COIL

(SLED)

M

(SPINDLE)

M

SEG5

COM4

OUT1

1

OUT2

767

XLINE_DET

XLINEOUT_MUTE

66

BATT+

65

DC IN

DDC

MUTE DRIVE

Q301

L403

SWITCHING

• Signal Path

• Abbreviation

J301

i

AEP, EE, EU8, JE

J302

LINE OUT

Q302

L402

IC401 (2/2)

Q404

SWITCHING

Q403

VG

+VBAT

DC IN DETECT

Q402

: CD PLAY

EE : East European

EU8 : European model other than UK, EE and Russian

DC/DC CONVERTER

SW

37

VSYS

38

VG

36

DCIN

30

31

REGB

+B SWITCH

Q401

D403

PVCC

LG

35

L401

21

F402

F401

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION LR6)

2PCS. 3V

J401

DC IN 4.5V

!

DQ00-07

2,3,5,6,8,9,11,12,39,

40,42,43,45,46,48,49

80 79

RFI

DDC

A

B

C

E

F

LD

DRIVER

Q601

DDC

SLED+

SLED-

SPINDLE+

SPINDLE-

+

F+

F-

T+

T-

BD

3

AC

2

+

E

6

F

7

ASY

10

VBIAS

4

LD

9

18

17

19

20

23

22

25

24

EQO

RF

SIGNAL

GEN.

APC

PD

8

IC401 (1/2)

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE MOTOR DRIVE

FO+

DRIVER

FO-

TRK-

DRIVER

TRK+

SLED+

DRIVER

SLED-

SPID+

DRIVER

SPIN-

AMP

AMP

AMP

AMP

SERVO

SIGNAL

GEN.

FOCUS

MUTE34

MUTE1

39,42-48

VREF

TRK

SLED

CLV

CLK

RESET

DQ00-07

DIGITAL SERVO

SIGNAL PROCESSOR

FDOUT

13 14 15 16

FOCUS

11

10

9

8

7

3

4

5

6

2

OFF

1

WP

TDOUT

TRK

FOCUS

19-24,27-32

PROCESSOR

SDOUT

CLVOUT

CLV

SLED

TRK

SLED

CLV

CLK

A0-11

32-21

A00-A11

MP3 &

ADPCM CORE

DIGITAL

SIGNAL

56

17 16 15

34 35 36 37 38

RASX

CLK88

16.9344MHz

CLK

RAS

CASX

CLOCK

OSC

XO

X601

CAS

WEX

XI

60 33 4961

WE

LDQM

14 36

LDQM

NE006

UDQM

CLK

35 34

17 18 19

RCLK

UDQM

16K SRAM

VDD_CORE1

5 1

+VBAT

Q802

Q801

CKE

A13

RCKE

VDD_CORE2

IC603

REG

VOUT

VIN

VG

D803

S801

Q602

7563

FLAG0

AD_MONI0

1 BIT

55

62

CLK

XIN4M

DAC

SUBSYQ

SUBSYQ

SEG1

I

2-21 77-80

CRYSTAL

DISPLAY

X8 OVER

SAMPLING

DIGITAL FILTER

IC601

RF AMP, SERVO,

DIGITAL SIGNAL PROCESSOR,

SDRAM CONTROLLER,

D/A CONVERTER

DDC

WREM

70

MMUTE2

76

75

MMUTE1

57

XRESET

74

XP.OFF

43

K_PLAY

SEG5

MCK

DIN/DOUT

MCK

DIN OUT

SEG20

LCD801

LIQUID

R/W

RW

COM1

LINE

AMP

I

LDACO

RDACO

RESTB

535750515254

XXRESET

COM4

COM4

BUSY

BUSY

KEY MATRIX

S802 – S809

65

KEY1

51

FIFO

IC801

SYSTEM

CONTROL

KEY2

OPEN/CLOSE

4167 68 40

S811

(OPEN)

OFF ON

3

5

56

XHP_MUTE

S812

HOLD

Q101 – 104

HEADPHONE AMP

IN1

IN2

XMUTE

2

IC802

EEPROM

SDA

EE_SDA/REM_SDA

HOLD

L.P.F

IC301

SCL7WP

65

24 382223505349474839

EE_SCL

D-NE004/NE005/NE0050/NE006

99

D-NE004/NE005/NE0050/NE006

Ver. 1.3

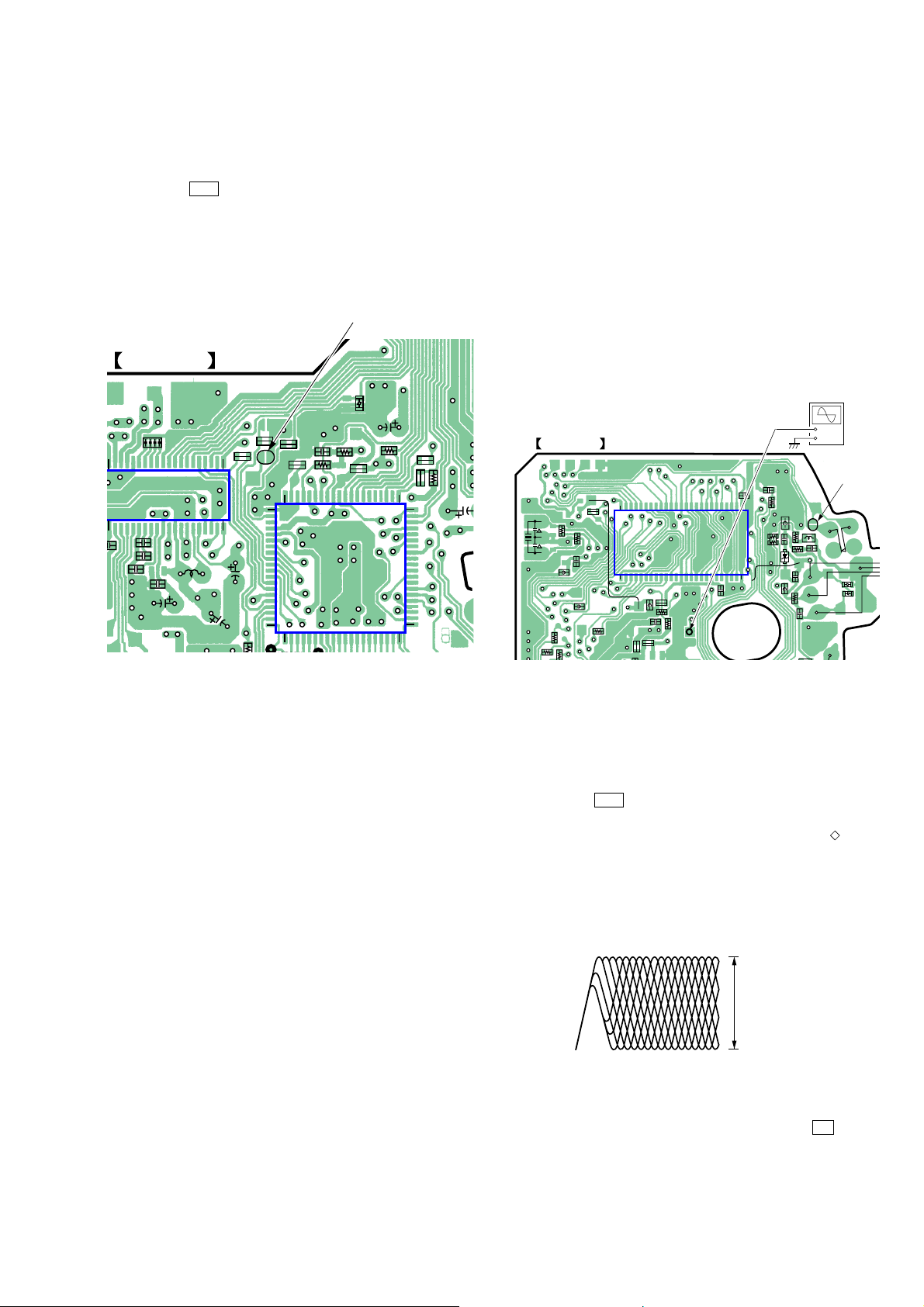

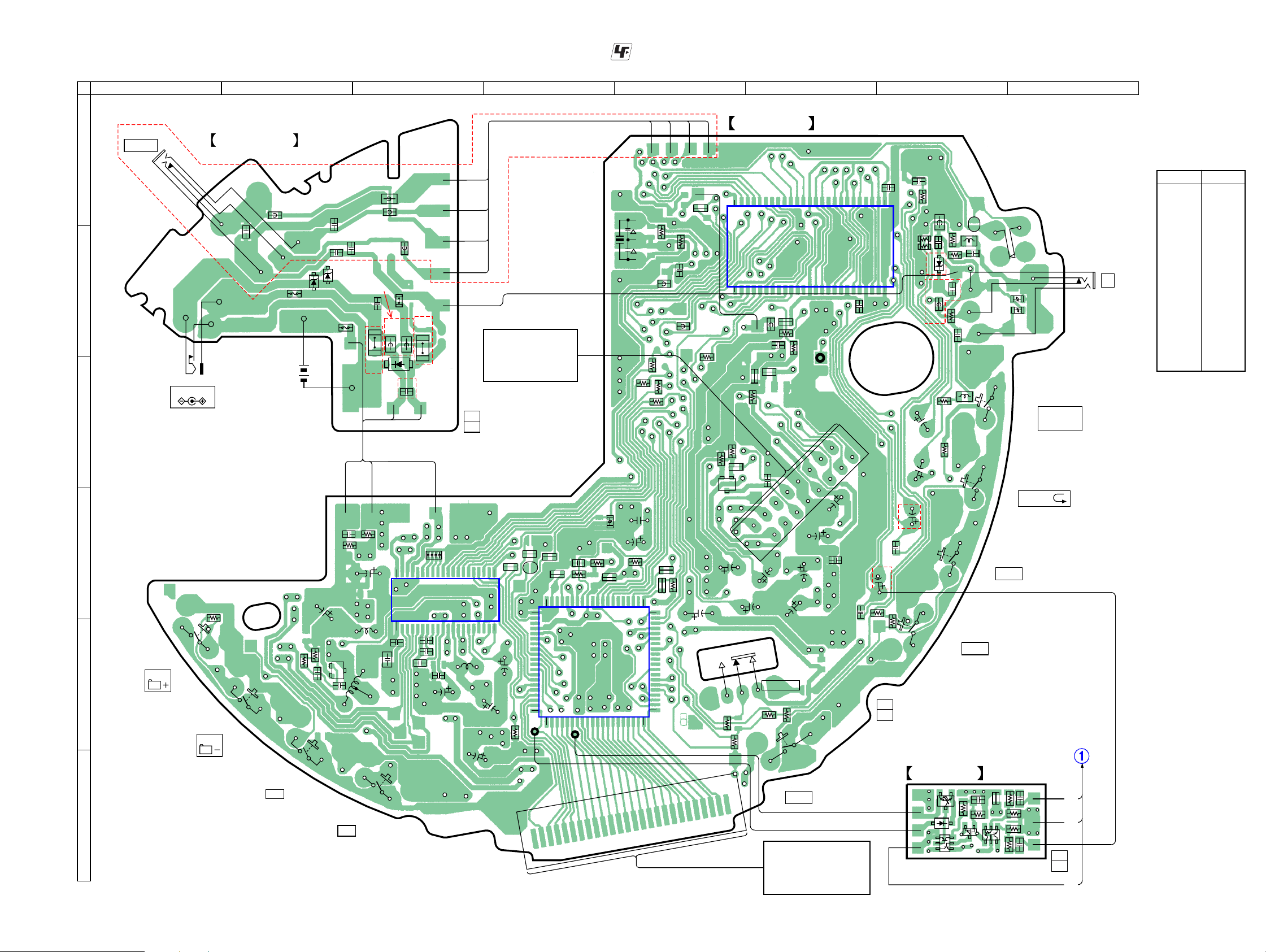

6-2. PRINTED WIRING BOARD – MAIN BOARD (SIDE A), LPF BOARD (SIDE A) –

:Uses unleaded solder.

1

2

3 4 5 6 7

8

(SIDE A)BOARDMAIN

C208

A

MAIN

BOARD

(SIDE B)

(Page 11)

B

< 1 >

C

< 2 >

C210

C301

RB305

R201

BLK

(AUGND2)

8

TP307

D

E

< 3 >

(SIDE A)LPF BOARD

RB302

IC301

E

R304

45

1

Q301

RED

C108

C303

Q302

R204

R104

R103

(AEP,EE,EU8,JE)

R203

TP844

(RCH)

R305R310R311

(AEP,EE,EU8,JE)

C102

C202

C625

E

Q602

RB304

RB620

C201

C641

C630

R308

C624

RB303

C101

R620

FB604

R624

C619

61

C620

R307

C629

C631

80

C618

R601

R615

R309

FB602

60

IC601

1

R613

R608

R607

(NE004:EE/NE005:US,CND,AEP,EE,E,

8E,AUS,EA/NE0050/NE006:EE,E18,JE)

C615

C609

ORG

C604

R614

R630

TP843

(DVDD)

C637

41

40

21

20

C611

R606

R303

C606

C626

C605

IC603

1

C634

34

(NE004:AEP/NE005:EU8/

(AEP,EE,

EU8,JE)

R640

5

NE006:AEP)

1

R808

R804

8

IC802

45

R847

R848

C805

R844

R817

C809

R818

R843

Q801

C812

R410

D810

RB806

D803

(NE006)

(NE006)

R827

Q802

C813

C814

C806

C808

VDR802

R801

C801

R407

E

(NE006)

C802

C807

R404

C413

C428

C405

R422

R406

R810

D403

R405

OPTICAL DEVICE

(CDM-3525A/3525AJ)

(1/2)

(SLED)

+– +–

M

BRN

ORG

L407

L406

Q401

Q402

R403

D401

R424

R862

SLED–

SLED+

(SPINDLE)

BLK

SPINDLE–

SPINDLE+

M

RED

Q403

E

• Semiconductor

Location

Ref. No.

D401 E-6

D403 D-6

D803 D-5

D810 D-5

IC301 A-2

IC601 B-3

IC603 C-4

IC802 E-4

Q301 B-2

Q302 B-2

Q401 D-6

Q402 E-6

Q403 E-7

Q602 B-3

Q801 D-5

Q802 E-7

VDR802 E-5

Location

F

D-NE004/NE005/NE0050/NE006

1-868-890-

11

(11)

1-867-954-

1010

R850

12

(12)

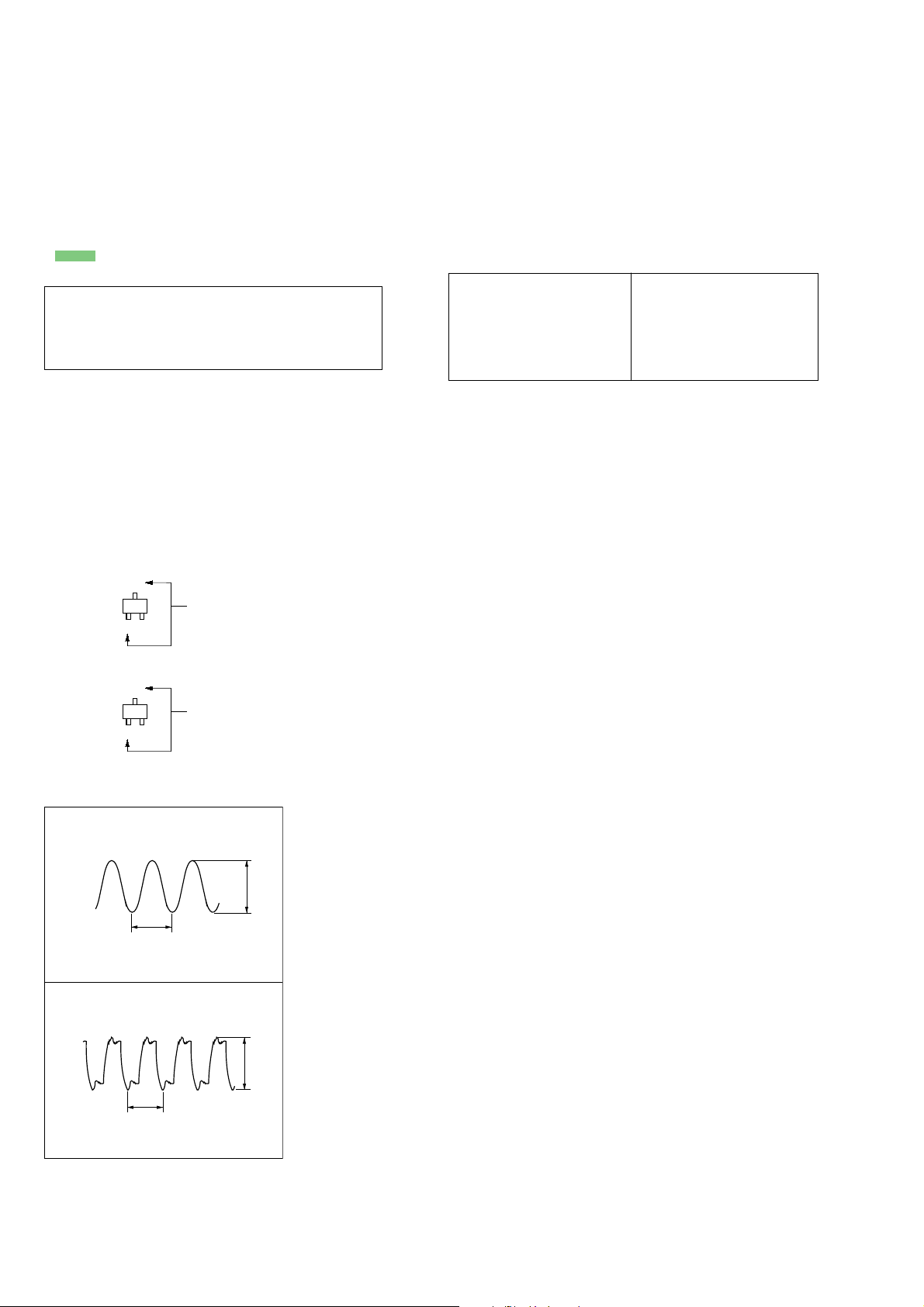

6-3. PRINTED WIRING BOARD – MAIN BOARD (SIDE B), LPF BOARD (SIDE B), JACK BOARD –

D-NE004/NE005/NE0050/NE006

Ver. 1.3

:Uses unleaded solder.

S809

S808

SOUND/

AVLS

BLK

RED

WHT

11

(11)

8

MAIN

BOARD

(SIDE A)

(Page 10)

< 1 >

< 2 >

< 3 >

J301

i

• Semiconductor

Location

Ref. No.

D101 F-7

D303 B-7

D402 C-3

D404 B-2

D406 B-2

IC401 D-3

IC602 B-6

IC801 E-4

Q101 F-7

Q102 F-7

Q103 F-7

Q104 F-7

Q404 E-2

Q601 C-5

VDR801 D-5

Location

1

(AEP,EE,EU8,JE)

J302

LINE OUT

2

JACK BOARD

3 4 5 6 7

(SIDE B)MAIN BOARD

ORG

RED

GRY

BLK

A

BLK

15

16

C607

C105

1-867-954-

C627

C640

(AEP,EE,EU8,JE)

R853

C633

FB401

R812

R629

R622

C623

BLU

R617

25

IC602

26

BLU

R632

FB601

R619

C612

R621

R623

R602

R604

R603

R605

E

Q601

C601

R828

1

C603

1

2

C610

C628

HOLD

ON

R846

R845

S812

T

.

OFF

S806

GROUP

C305

S806

R854

R626

TP604

C304

(RF)

C602

CN501

C402

LCD801

LIQUID CRYSTAL

DISPLAY

C427

L408

RED

DC IN+

C407

S807

FB303

FB202

FB304

(AEP,EE,EU8,JE)

L404

(AEP,EE,EU8,JE)

D402

C421

DC IN+

RED

20

C420

21

C406

C412

C411

R420

L405

BLK

C410

L409

DC IN–

1-867-955-

CB414

FB102

C109

B

DRY BATTERY

J401

DC IN 4.5V

SIZE "AA"

(IEC DESIGNATION LR6)

2PCS. 3V

F402

CN401

C209

C309

D406

(AEP,EE,EU8,JE)

F401

C306

D404

(EXCEPT AEP,EE,EU8,JE)

BATT+

WHT

CN402

C

BLK

DC IN–

C401

R401

C417

C416

C419

R415

E

R402

C420

L403

Q404

L402

S807

x

D

R849

S802

S802

>

E

S803

.

S803

S801

u

R414

S801

F

WHT

BATT+

IC401

C403

C404

GRY

RED

ORG

BLU

OPTICAL DEVICE

(CDM-3525A/3525AJ)

11

(11)

R409

1

40

L401

C810

C409

C408

R821

(2/2)

R802

SL803

(TEST)

61

80

FB801

R820

60

1

TP841

(CDM4)

YEL

22

C811

R823

R829

IC801

TP842

(SEG5)

BRN

R835

X601

CN801

R417

VDR801

C632

R811

FB605

41

20

R416

R419

C642

R618

R418

R824

R826

40

21

C110

1

(NE006)

BLU

50

C204

(AEP,EE,EU8,JE)

C203

C205

C103

WHT

S805

R852

12

(12)

TP103

BRN

TP102

YEL

TP101

ORG

R101

SL801

FB301

(OPEN)

R111

C308

RB301

R102

D303

C310

FB302

R211

S804

R202

C206

S808

L201

R851

S809

S805

VOL–

(NE006)

C104

LPF BOARD

Q101

R101

Q103

Q102

C102

R102

D101

L101

C106

VDR101

VDR201

S804

VOL+

(SIDE B)

R108

R105

R106

R107

Q104

R104

S811

(OPEN)

P MODE/

TP105

C105

TP106

TP104

C104

1-868-890-

D-NE004/NE005/NE0050/NE006

1111

Loading...

Loading...