Page 1

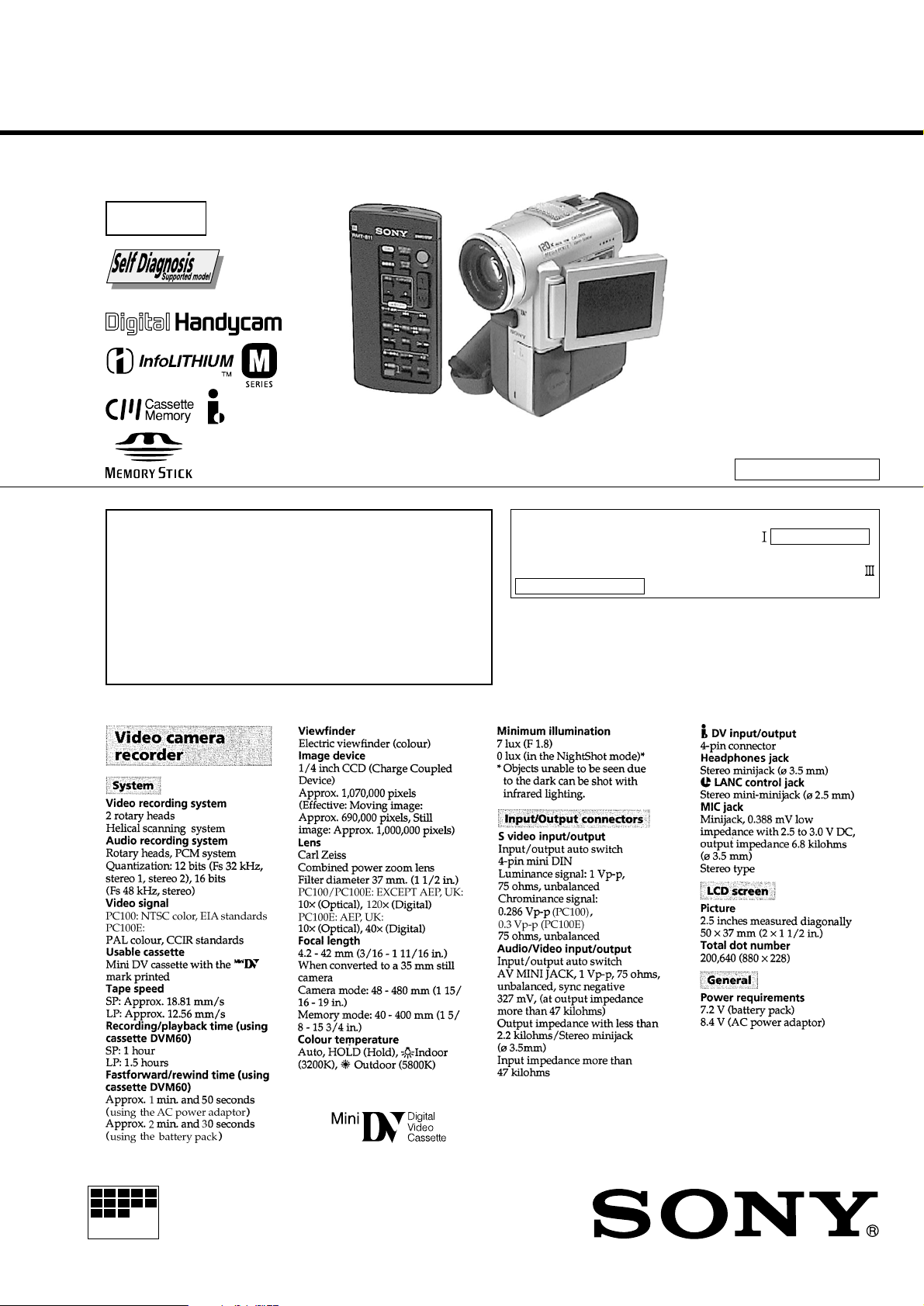

DCR-PC100/PC100E

RMT-811

Ver 1.2 2001. 12

SERVICE MANUAL

SERVICE MANUAL

Level 2

Photo : DCR-PC100

On the VC-227 board

This service manual provides the information that is premised

the circuit board replacement service and not intended repair

inside the VC-227 board.

Therefore, schematic diagram, printed wiring board and

electriacal parts list of the VC-227 board are not shown.

The following pages are not shown.

Schematic diagram .......................... Pages 4-13 to 4-42

Printed wiring board......................... Pages 4-43 to 4-46

Electrical parts list............................ Pages 6-18 to 6-25

US Model

Canadian Model

Korea Model

DCR-PC100

AEP Model

UK Model

Australian Model

Chinese Model

DCR-PC100E

E Model

Hong Kong Model

Tourist Model

DCR-PC100/PC100E

D300 MECHANISM

For MECHANISM ADJUSTMENTS, refer to the “DV

MECHANICAL ADJUSTMENT MANUAL

(original: 9-973-815-11, supplement: 9-973-815-81)

and “DV MECHANICAL ADJUSTMENT MANUAL

D200 MECHANISM ” (original: 9-973-981-11).

DCR-PC100 : NTSC model

DCR-PC100E : PAL model

D MECHANISM”

SPECIFICATIONS

— Continued on next page —

DIGITAL VIDEO CAMERA RECORDER

MICROFILM

Page 2

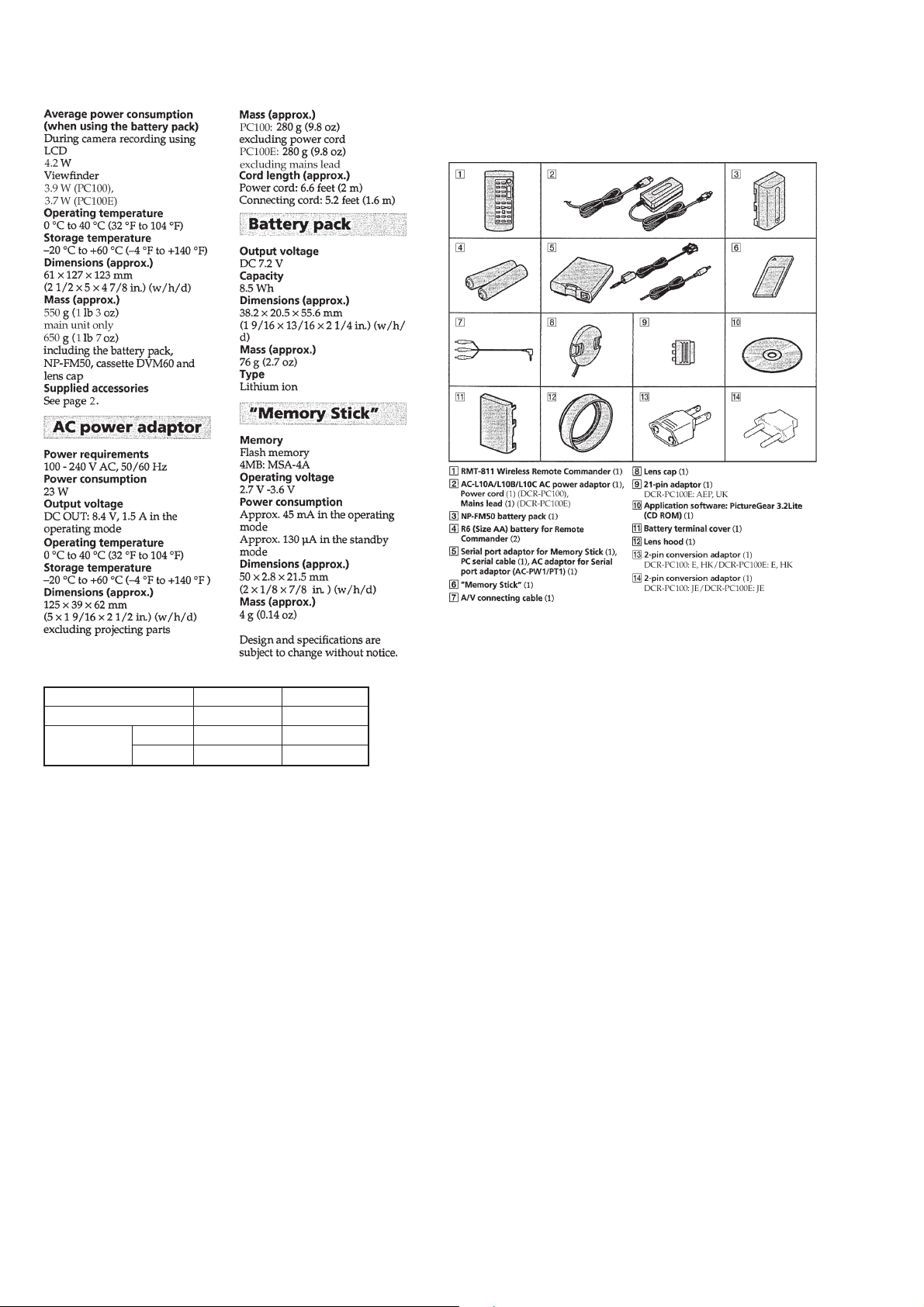

• SUPPLIED ACCESSORIES

Check that the following accessories are supplied with your

camcorder.

• DIFFERENCE TABLE

Model

Color System

Lens

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Optical

Digital

SAFETY-RELATED COMPONENT WARNING!!

DCR-PC100

NTSC

10 ×

120 ×

DCR-PC100E

PAL

10 ×

120 ×, 40 × *

*: AEP, UK model

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

• Abbreviation

AUS: Australian model

JE: Tourist model

CND: Canadian model

CN: Chinese model

HK: Hong Kong model

KR: Korea model

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

Page 3

TABLE OF CONTENTS

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS ····························· 6

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ································································6

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION······································· 7

2. SELF-DIAGNOSIS DISPLAY ·········································· 7

3. SERVICE MODE DISPLAY ············································· 7

3-1. Display Method ··································································7

3-2. Switching of Backup No. ··················································· 7

3-3. End of Display···································································· 7

4. SELF-DIAGNOSIS CODE TABLE··································· 8

1. GENERAL

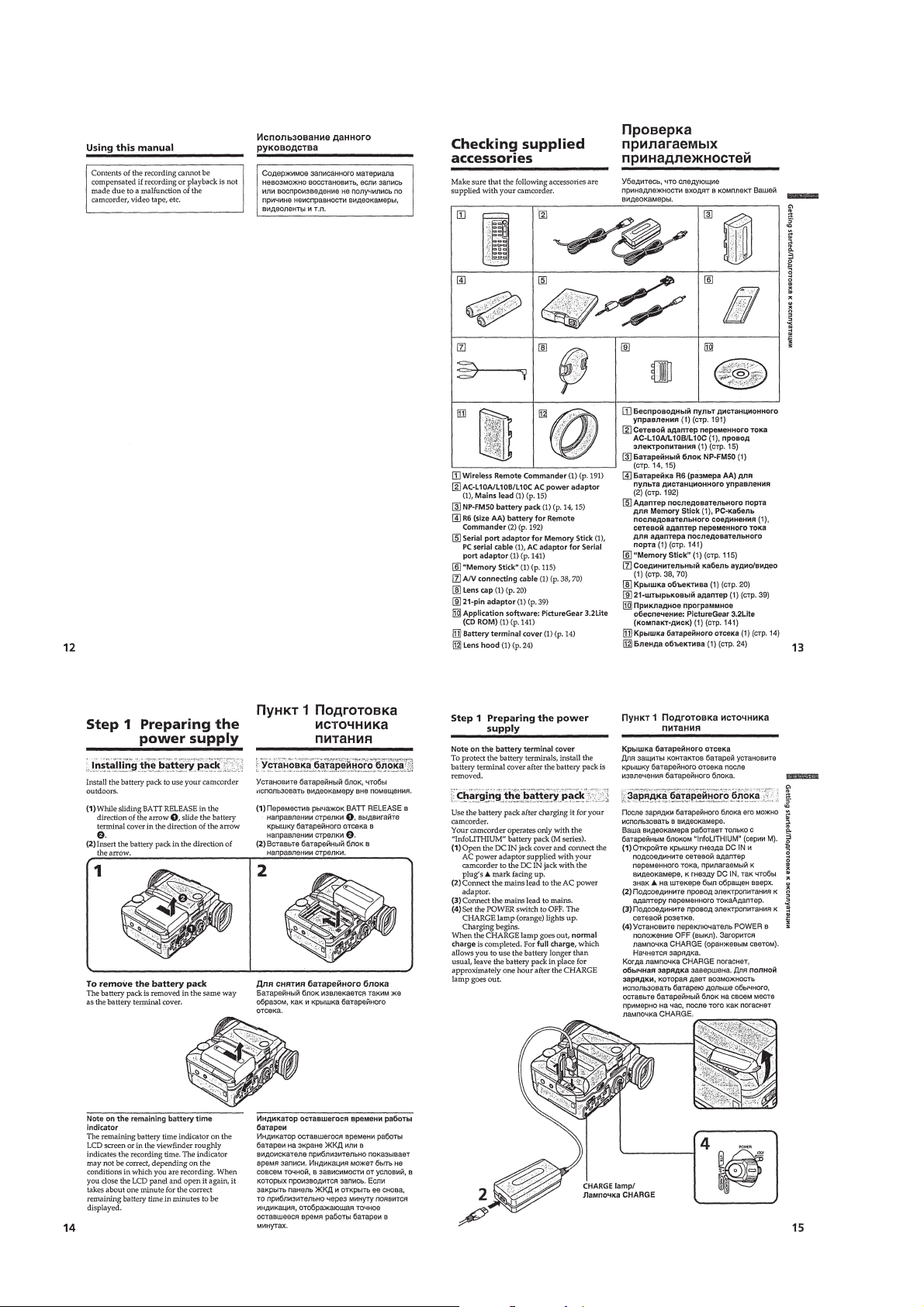

Quick Start Guide ······································································1-1

Getting started ···········································································1-1

Using this manual ··································································1-1

Checking supplied accessories ··············································1-2

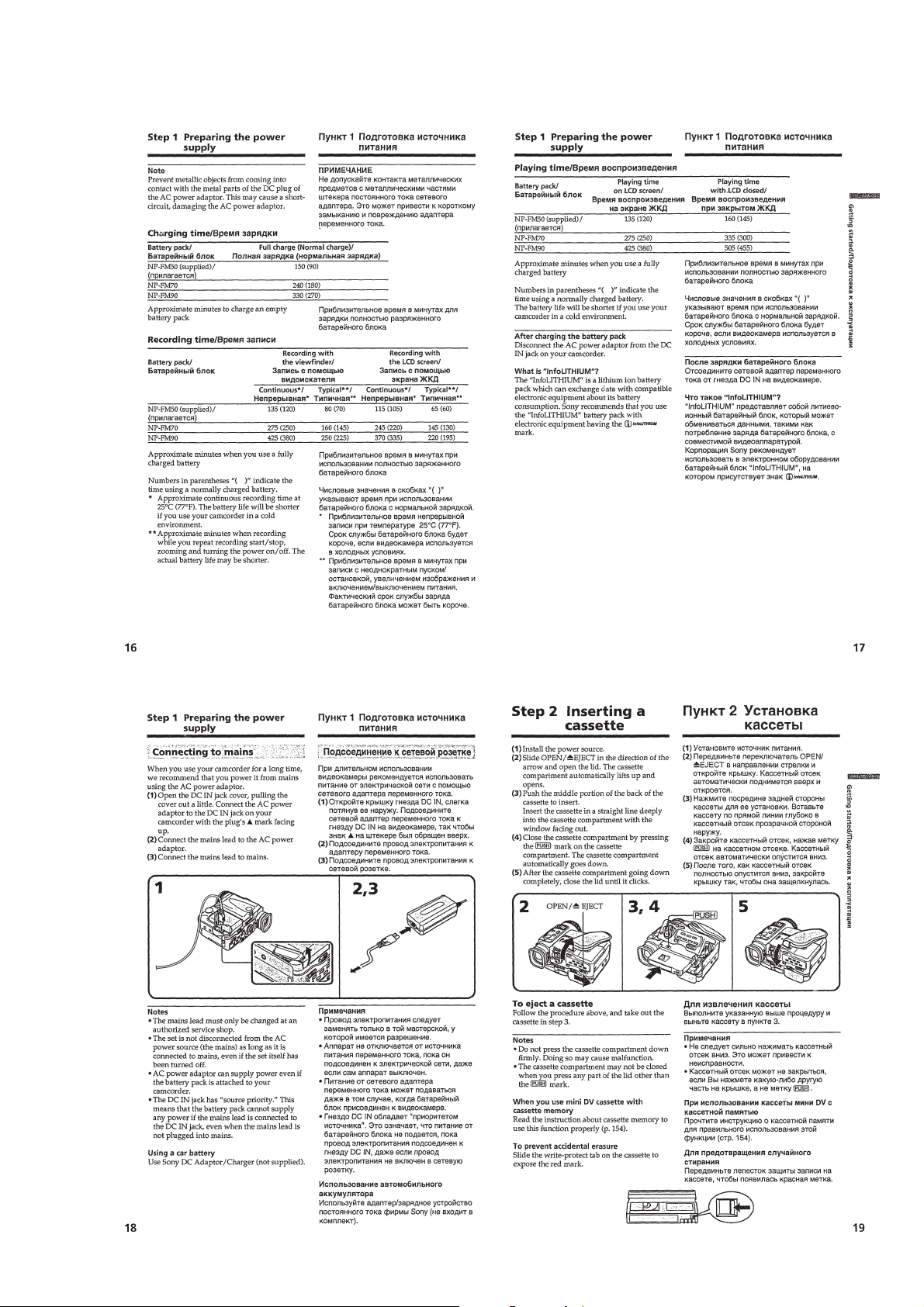

Step 1 Preparing the power supply ········································1-2

Installing the battery pack····················································1-2

Charging the battery pack ····················································1-2

Connecting to mains ····························································1-3

Step 2 Inserting a cassette······················································1-3

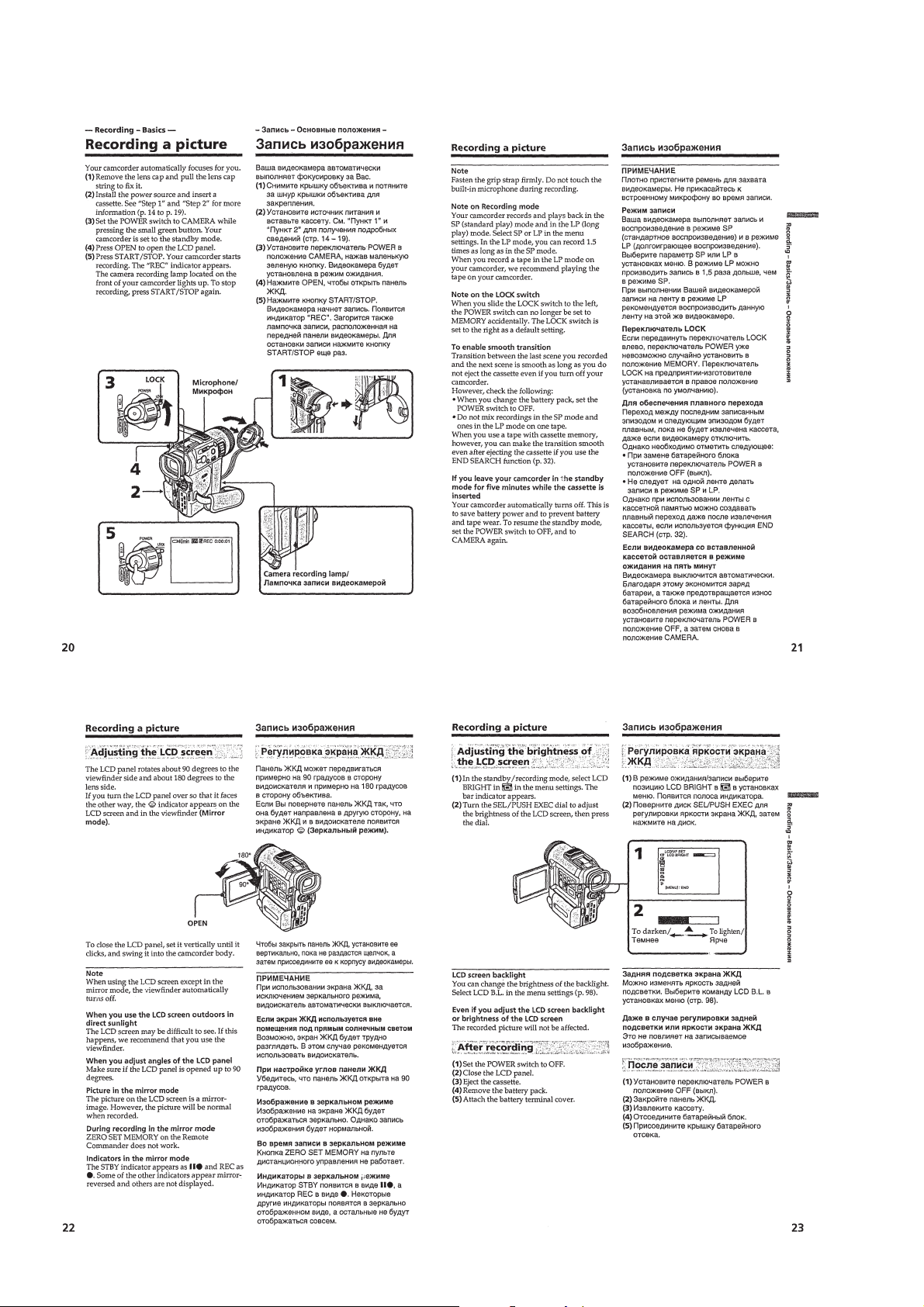

Recording –Basics ·····································································1-4

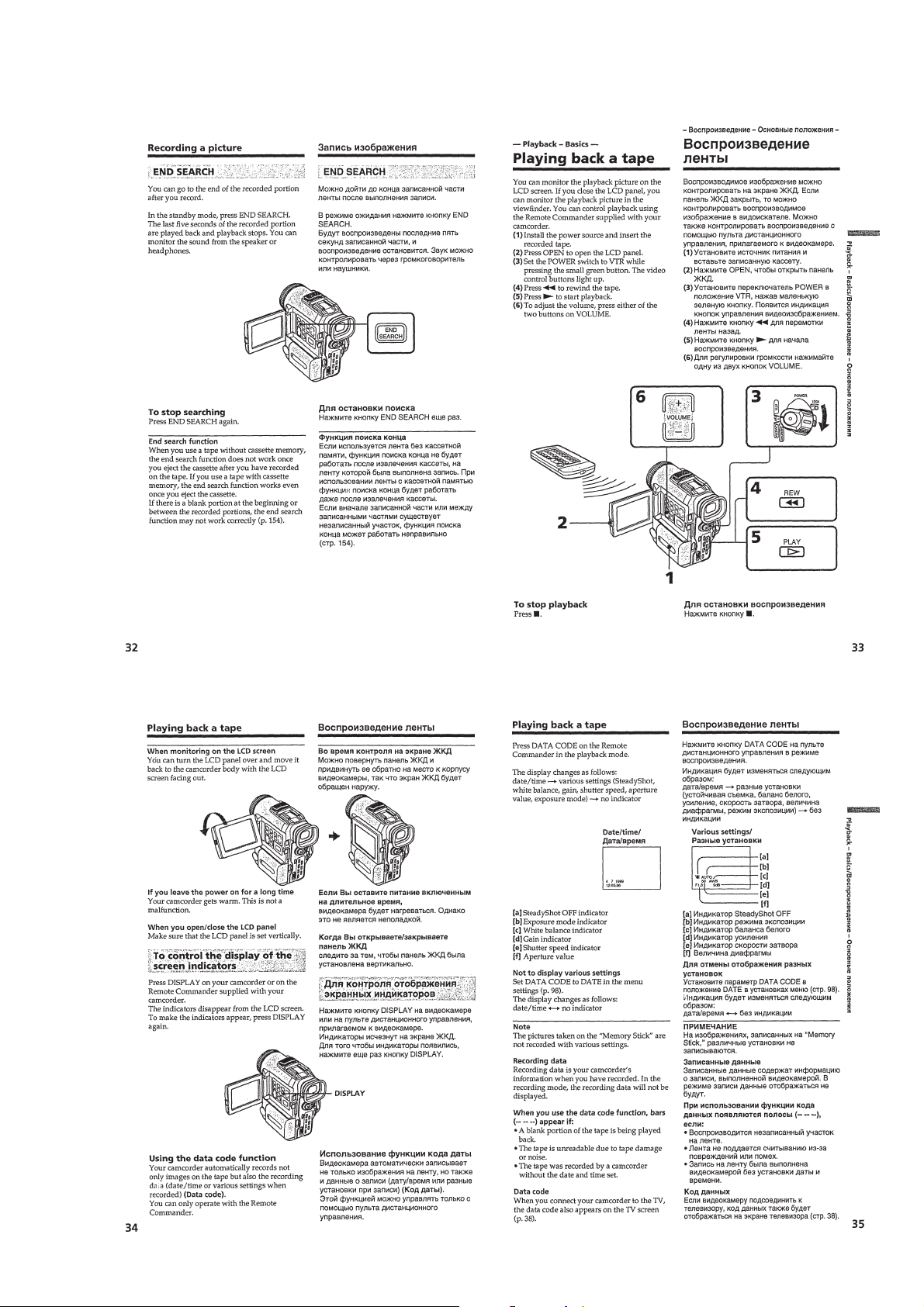

Recording a picture································································ 1-4

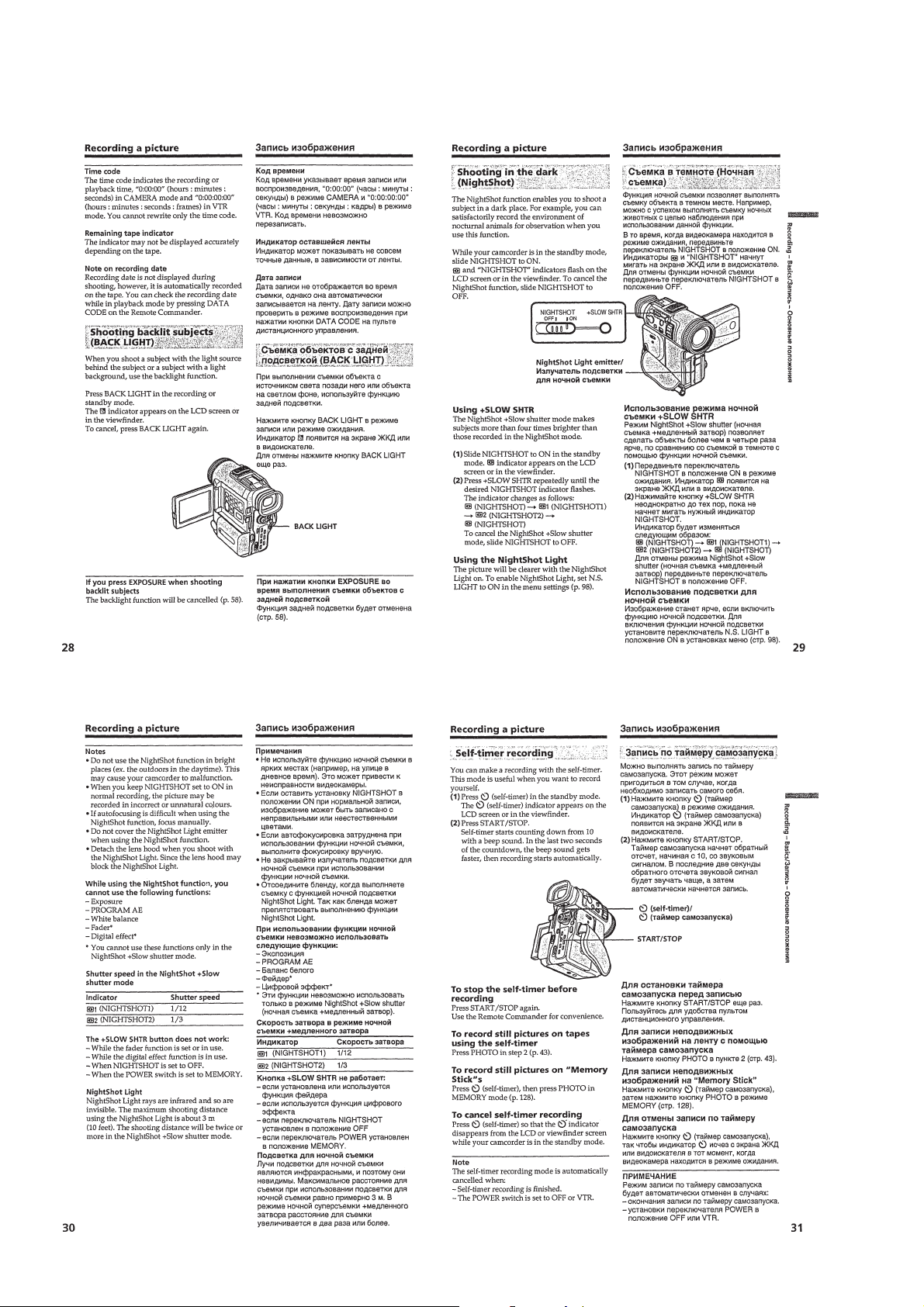

Shooting backlit subjects (BACK LIGHT)··························1-6

Shooting in the dark (NightShot)·········································1-6

Self-timer recording····························································· 1-6

END SEARCH ····································································1-7

Playback –Basics ·······································································1-7

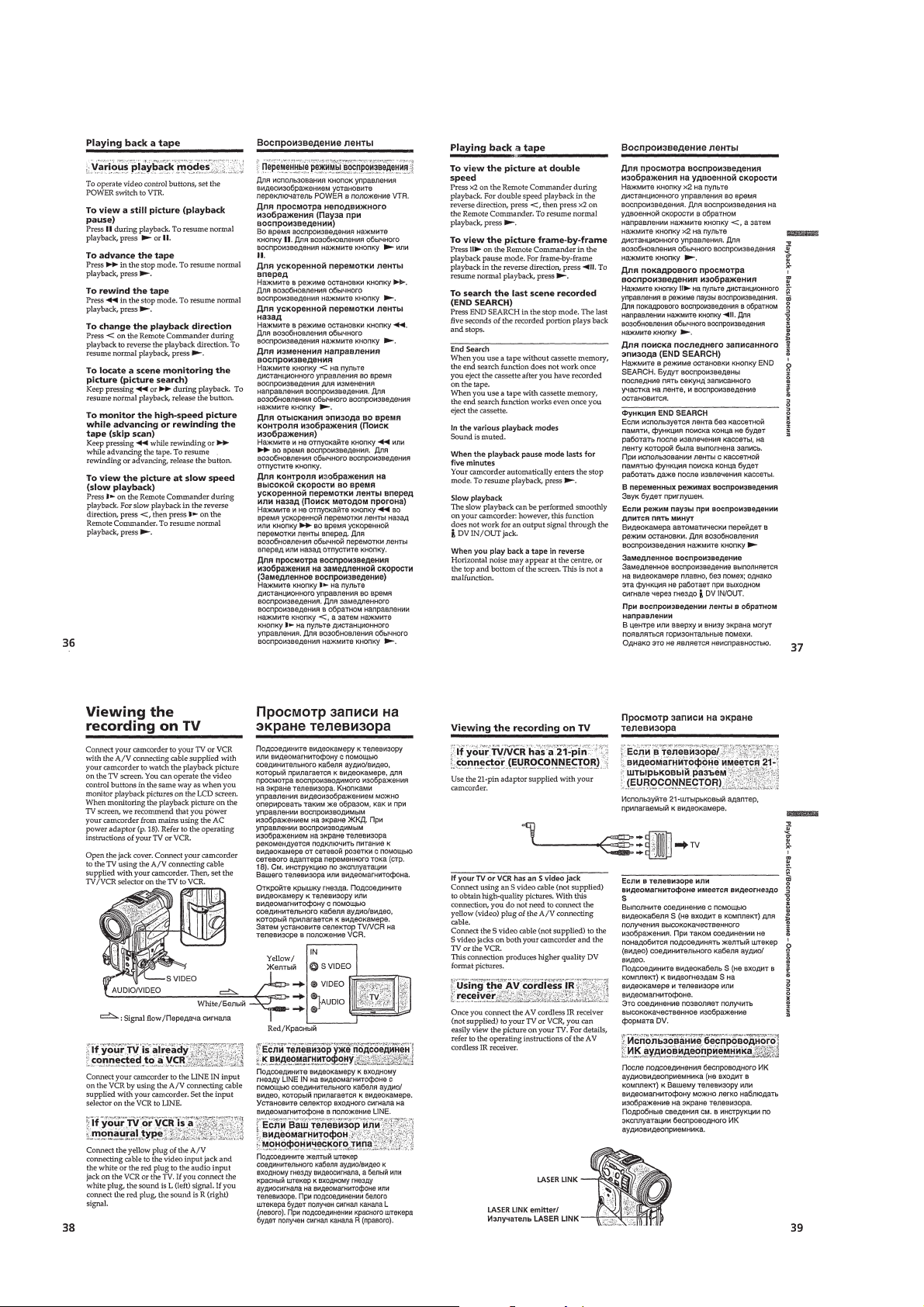

Playing back a tape ································································1-7

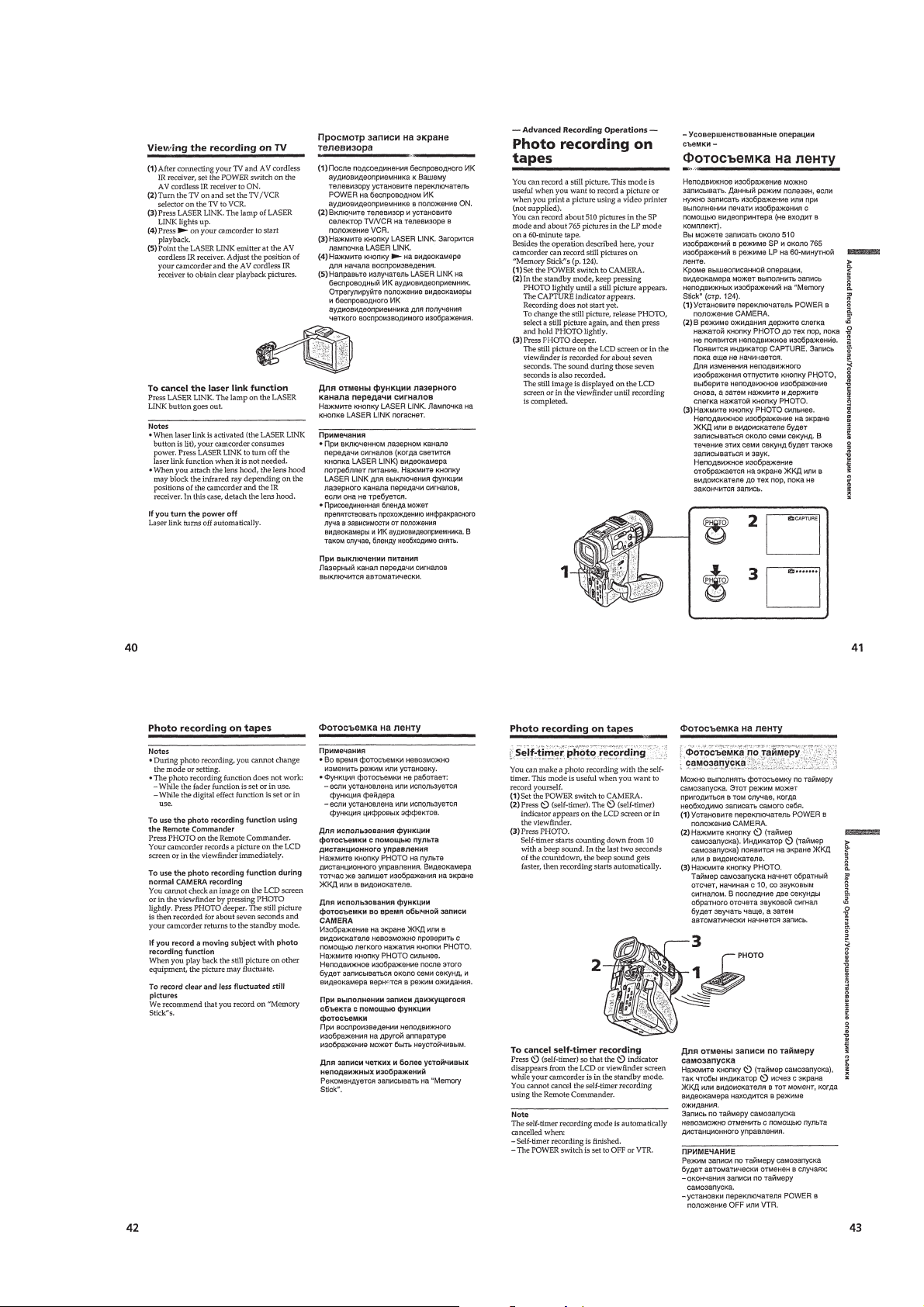

Viewing the recording on TV ················································1-8

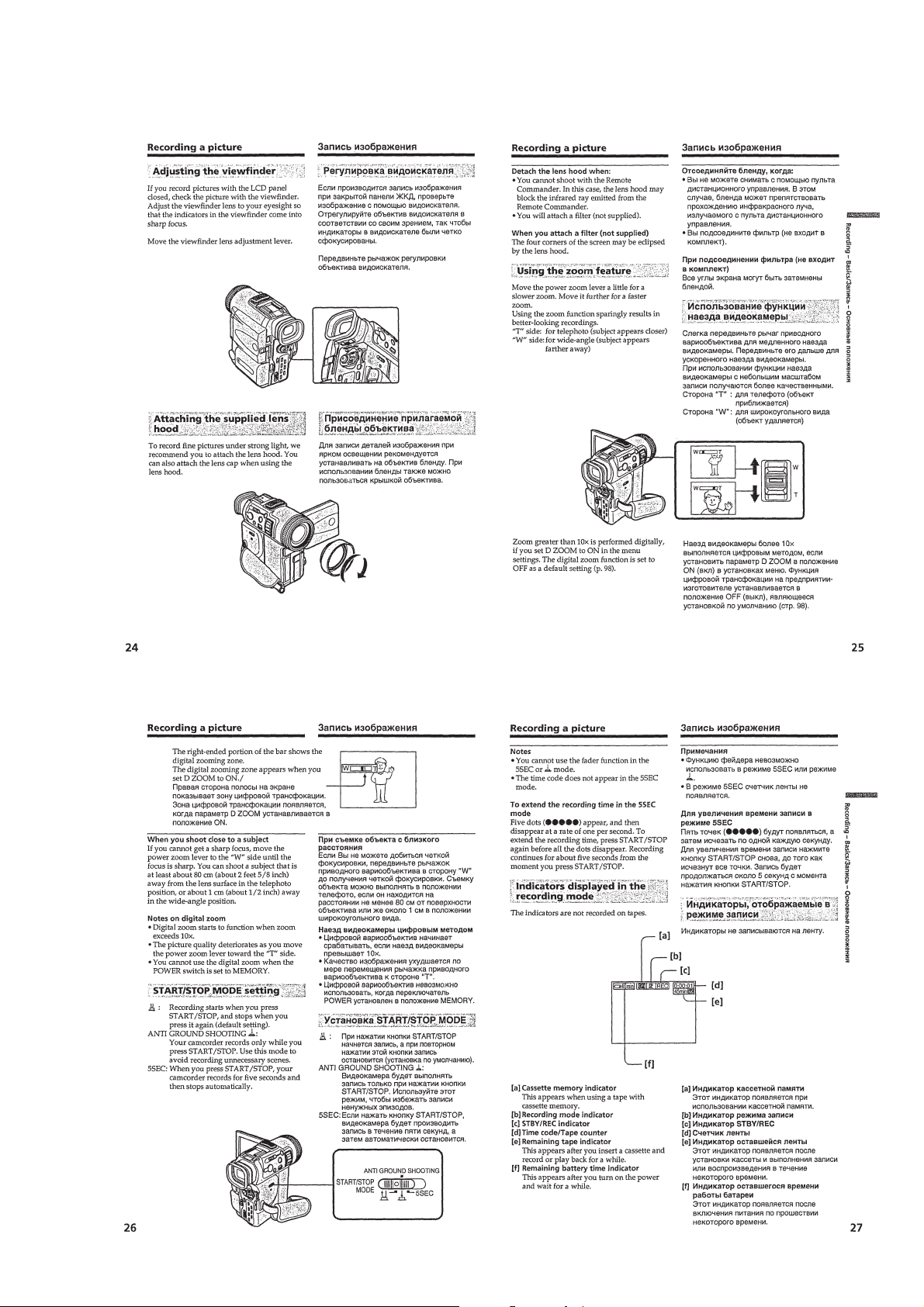

Advanced Recording Operations···············································1-9

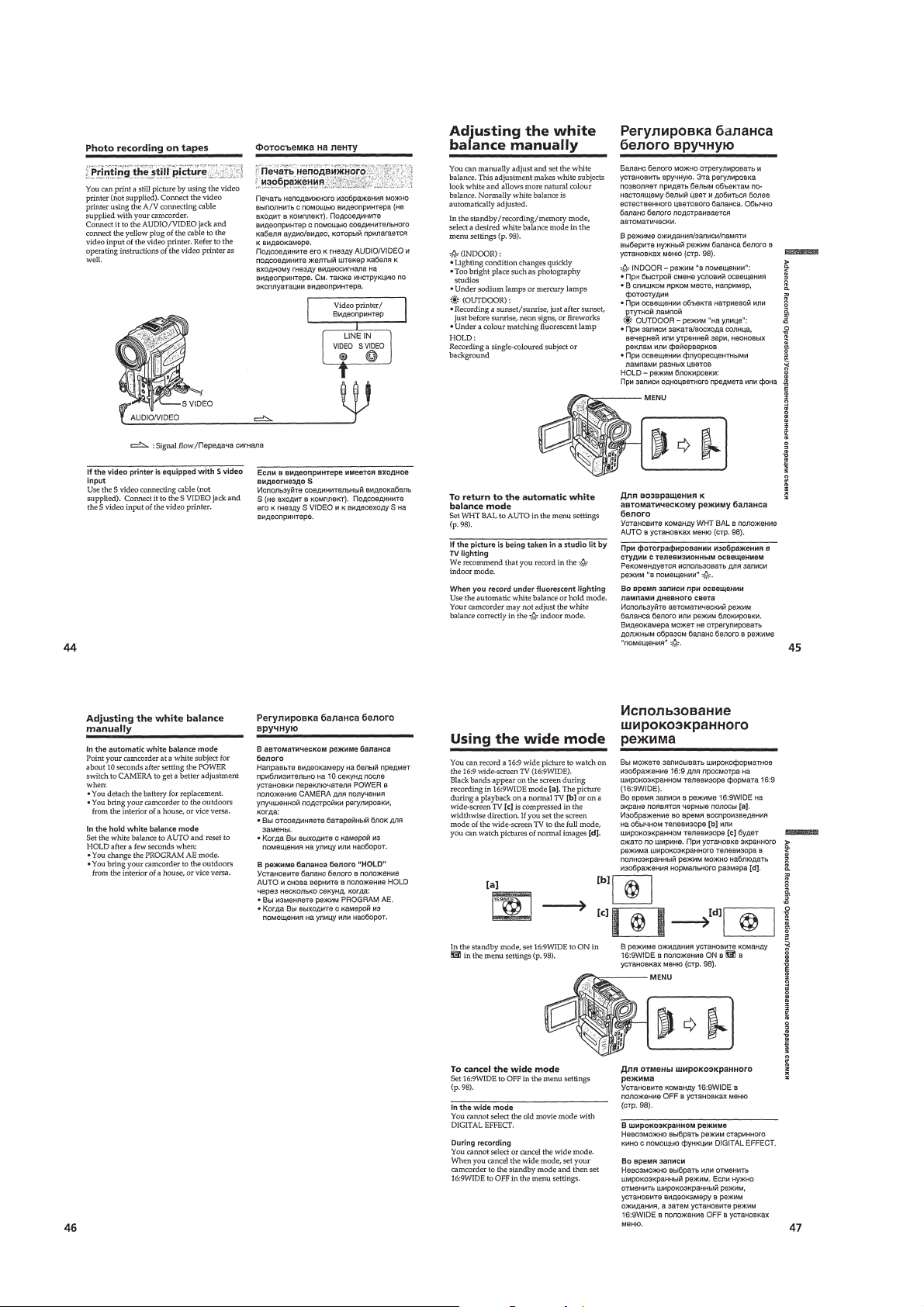

Photo recording on tapes ·······················································1-9

Adjusting the white balance manually·································1-10

Using the wide mode ···························································1-10

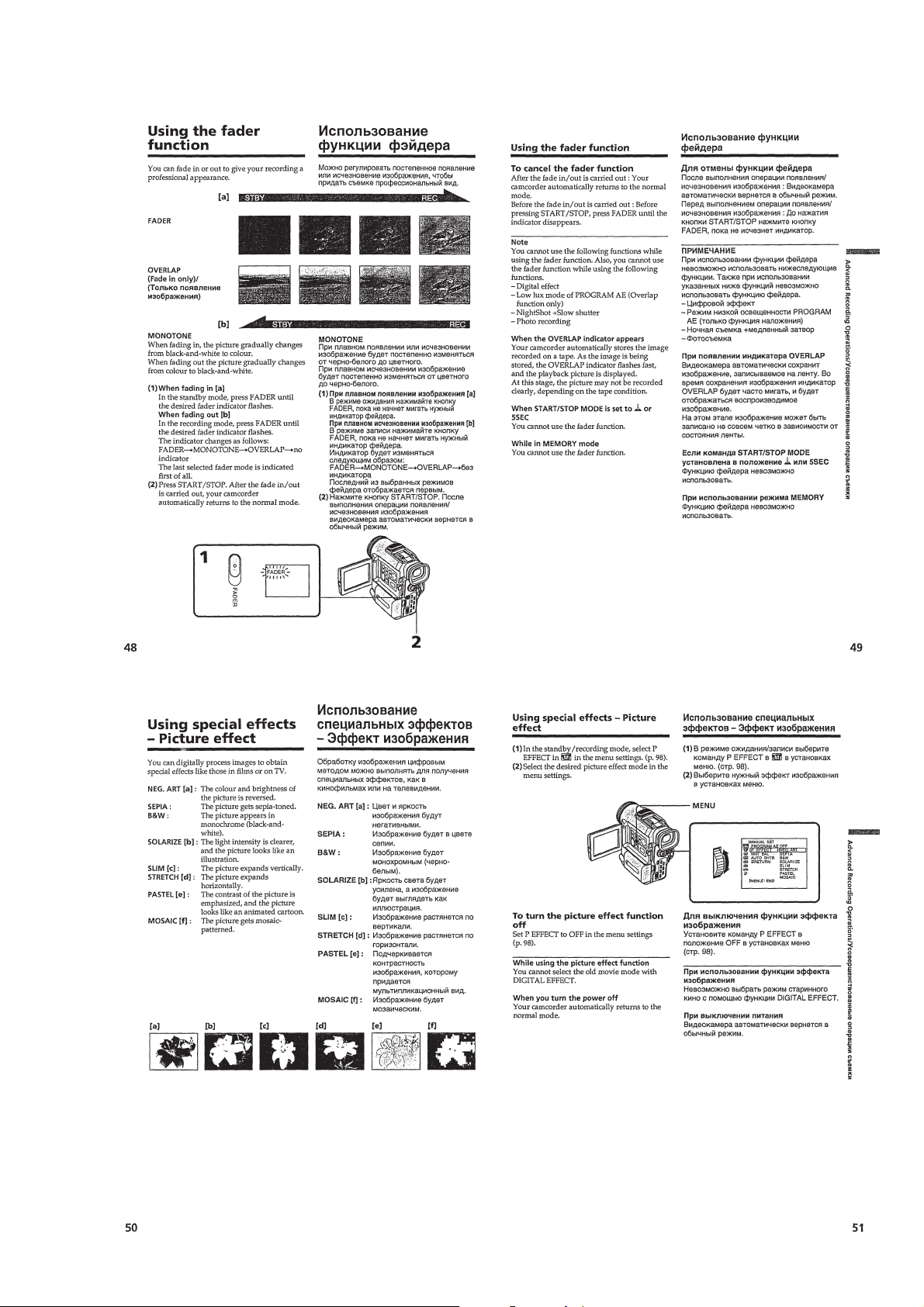

Using the fader function ······················································ 1-11

Using special effects –Picture effect····································1-11

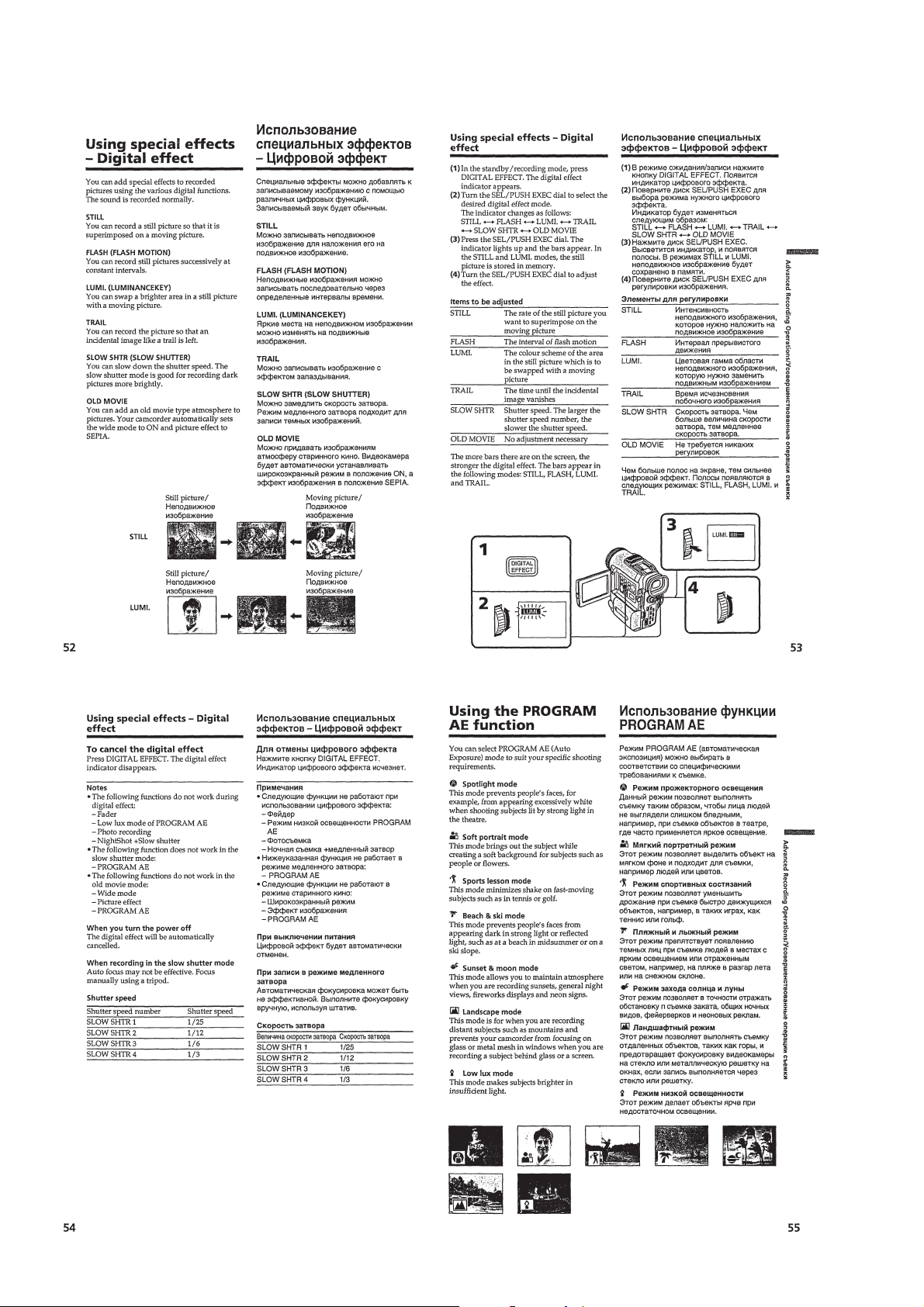

Using special effects –Digital effect····································1-12

Using the PROGRAM AE function ·····································1-12

Adjusting the exposure manually ········································ 1-13

Focusing manually······························································· 1-13

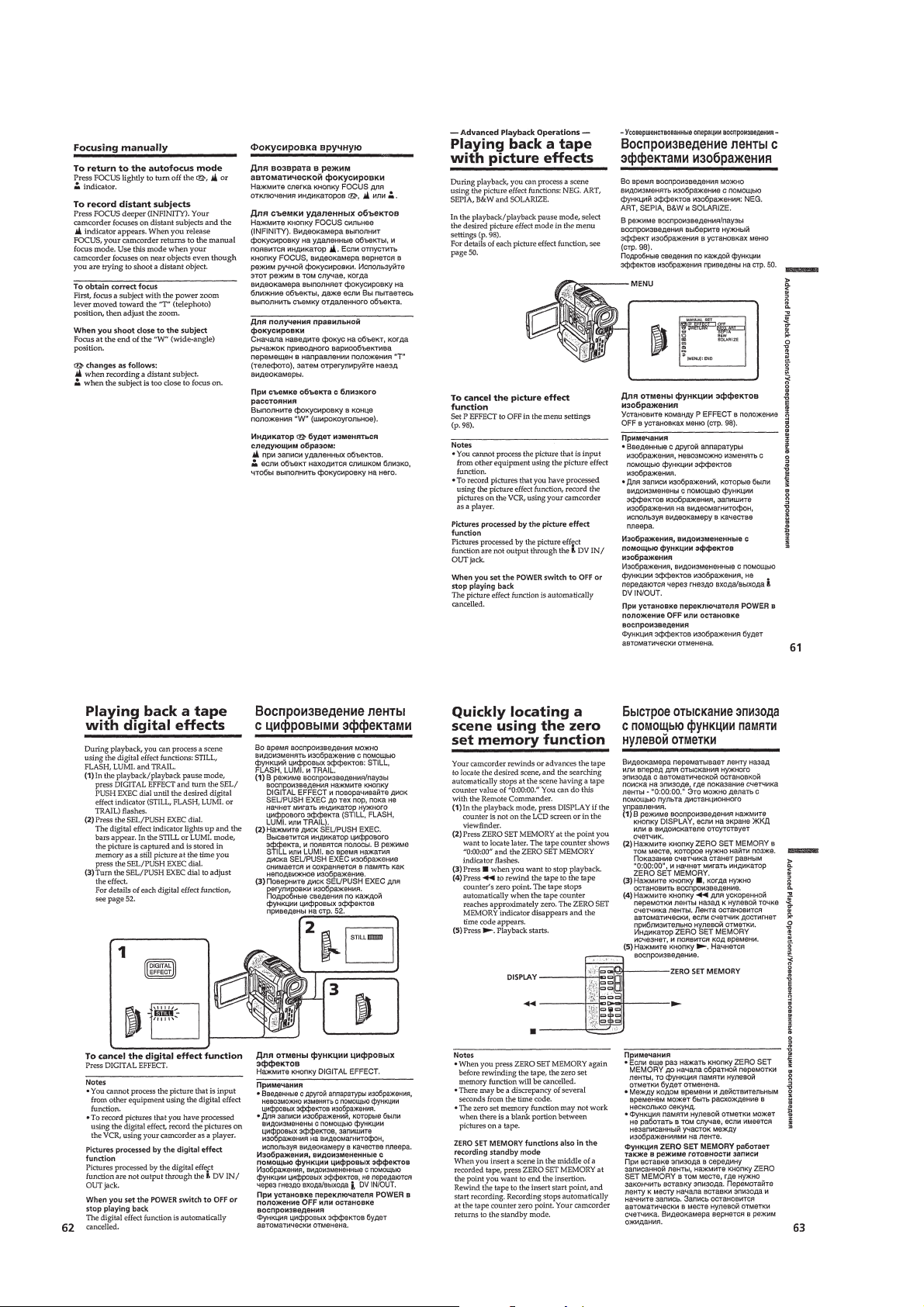

Advanced Playback Operations···············································1-14

Playing back a tape with picture effects ······························1-14

Playing back a tape with digital effects ·······························1-14

Quickly locating a scene using the zero set memory

function ················································································1-14

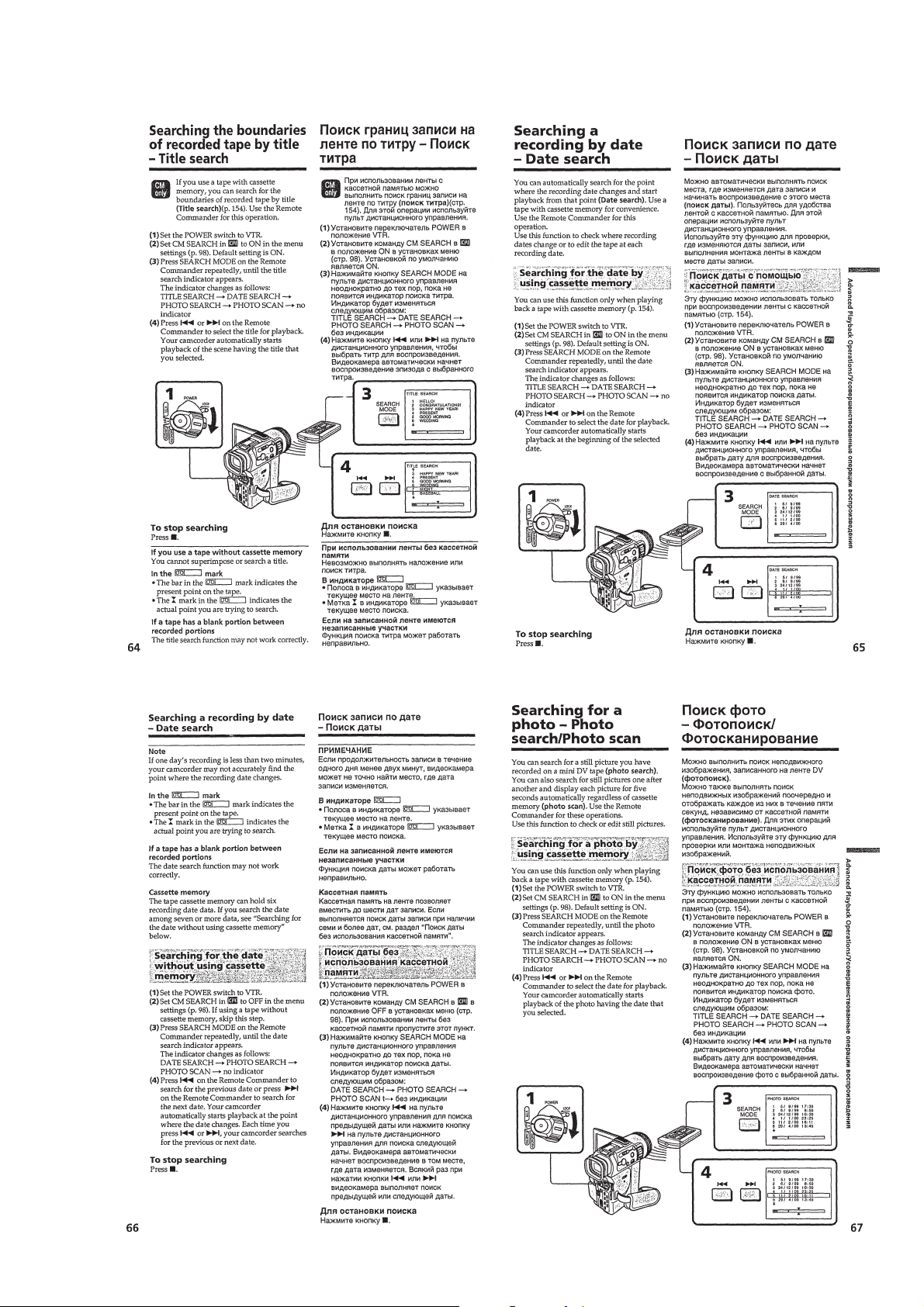

Searching the boundaries of recorded tape by title

–Title search·········································································1-15

Searching a recording by date –Date search························1-15

Searching for a photo-Photo search/Photo scan ··················1-15

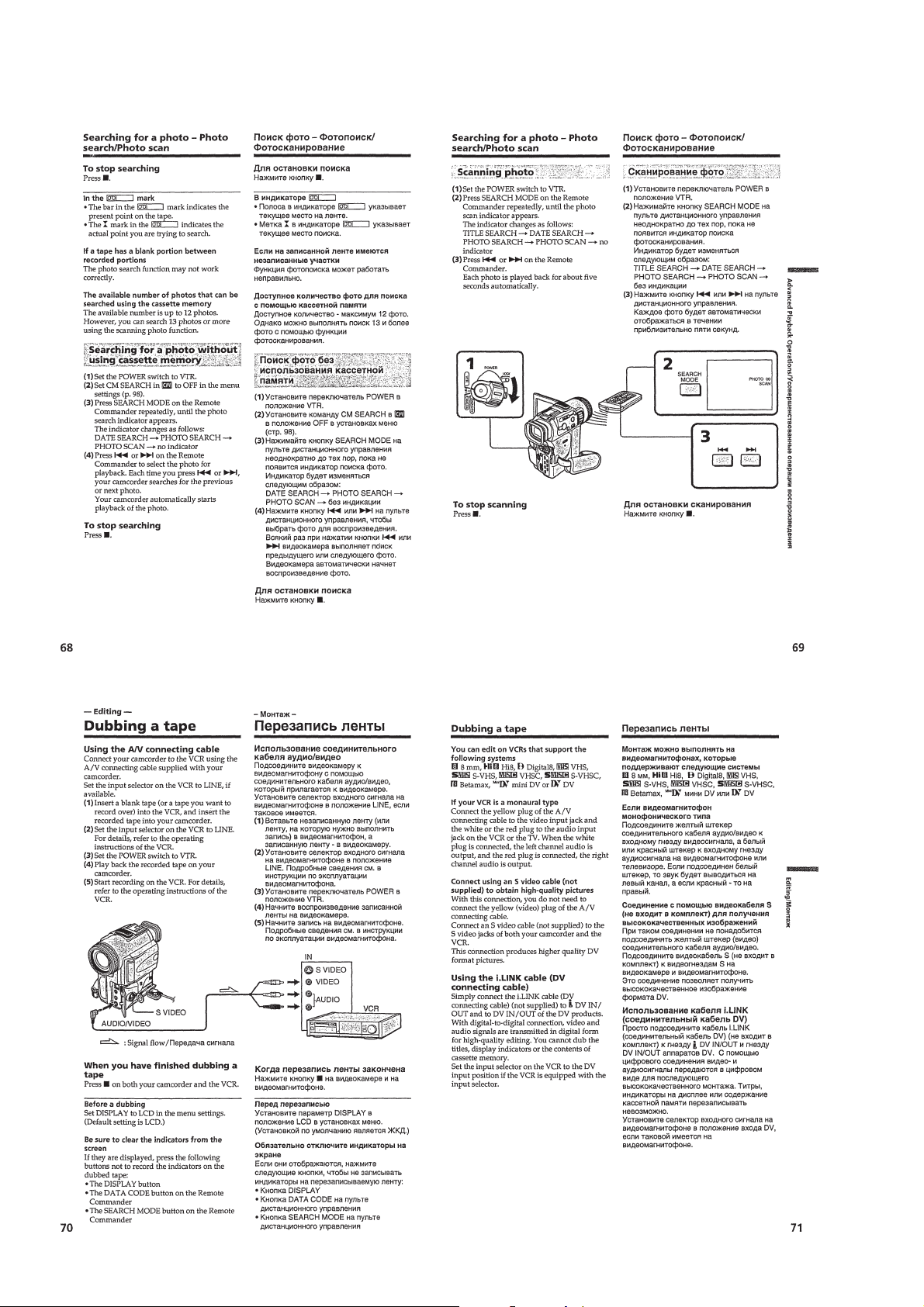

Editing ·····················································································1-16

Dubbing a tape ·····································································1-16

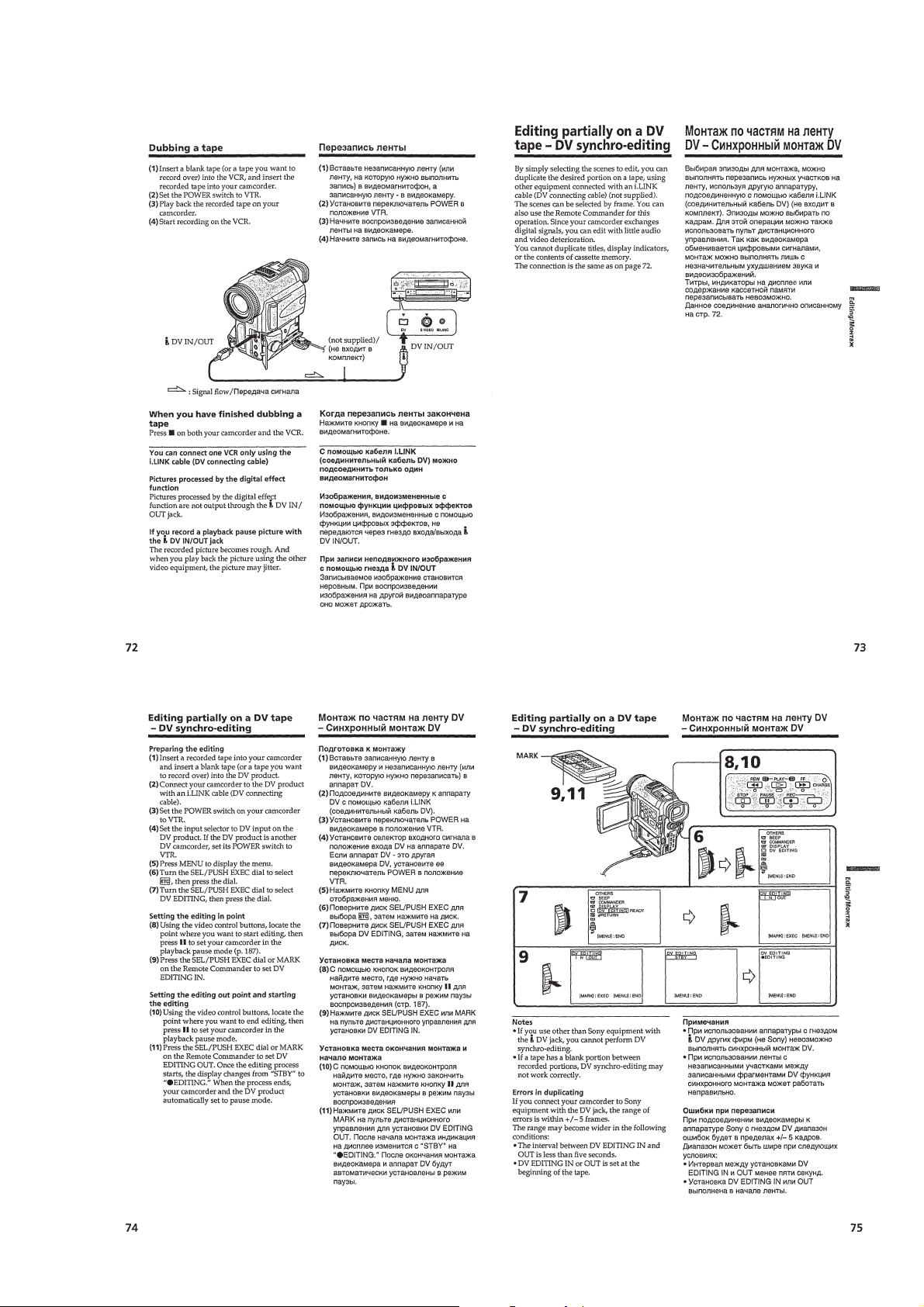

Editing partially on a DV tape –DV synchro-editing ··········1-17

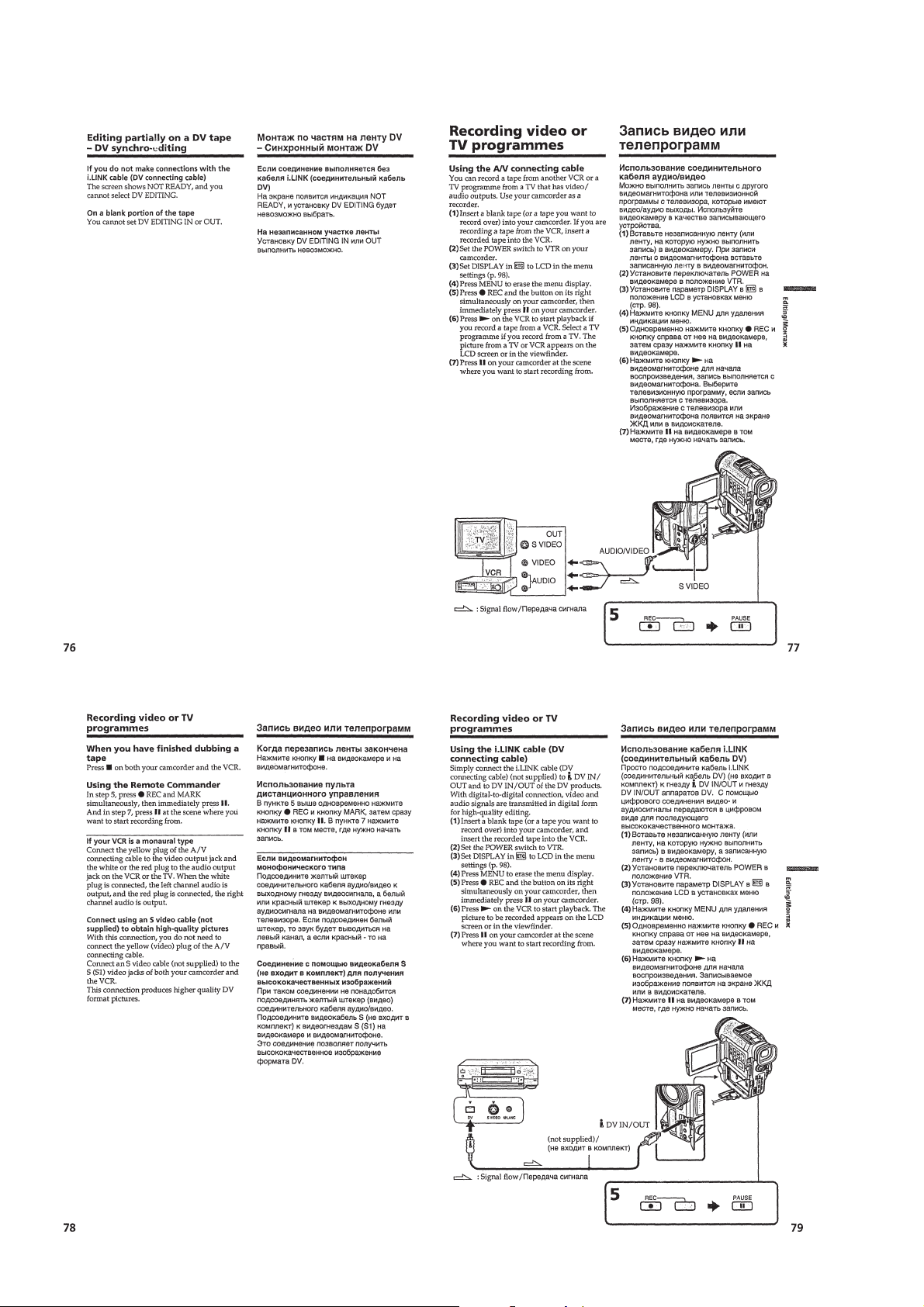

Recording video or TV programmes ···································1-18

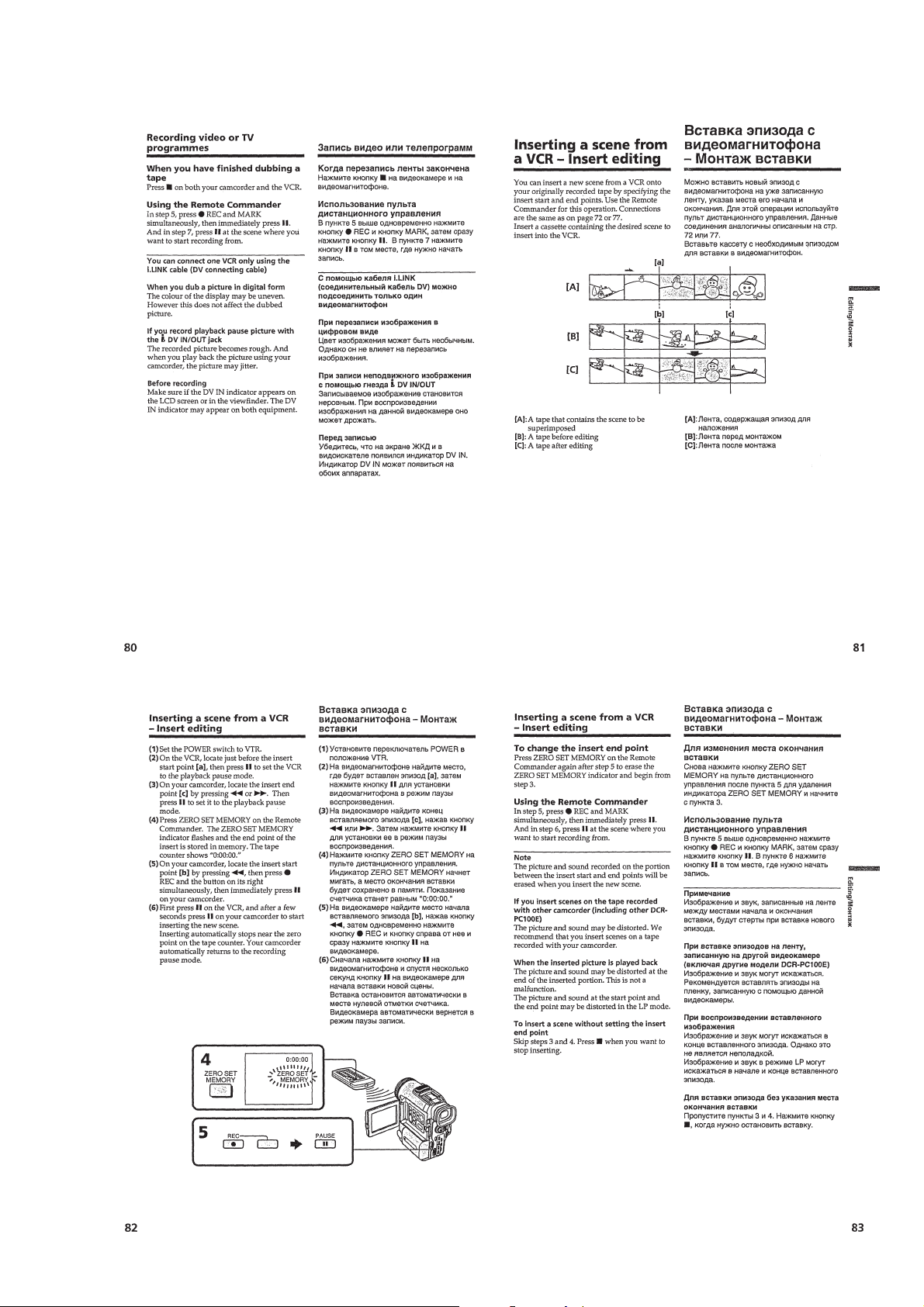

Inserting a scene from a VCR –Insert editing······················1-19

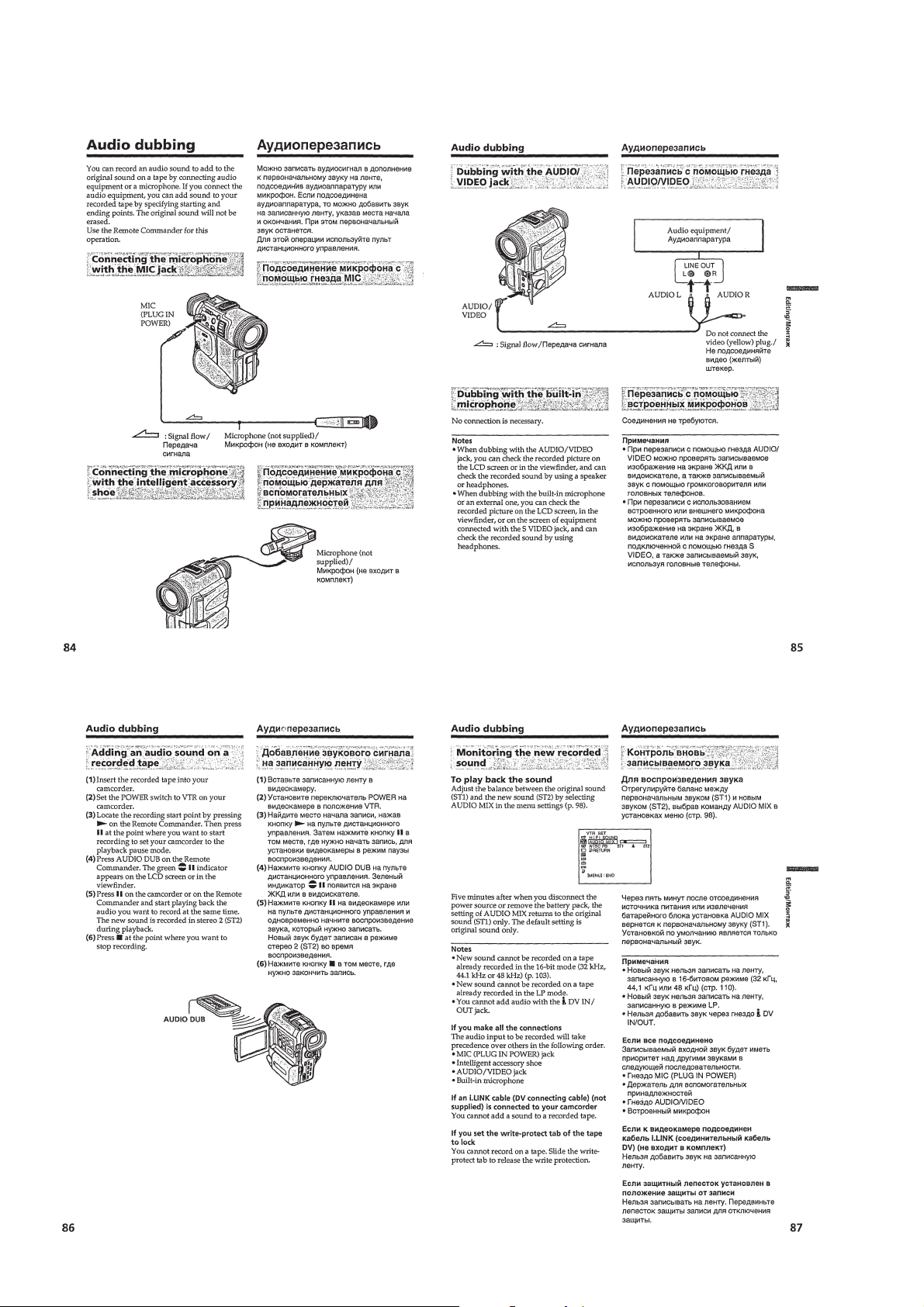

Audio dubbing ·····································································1-20

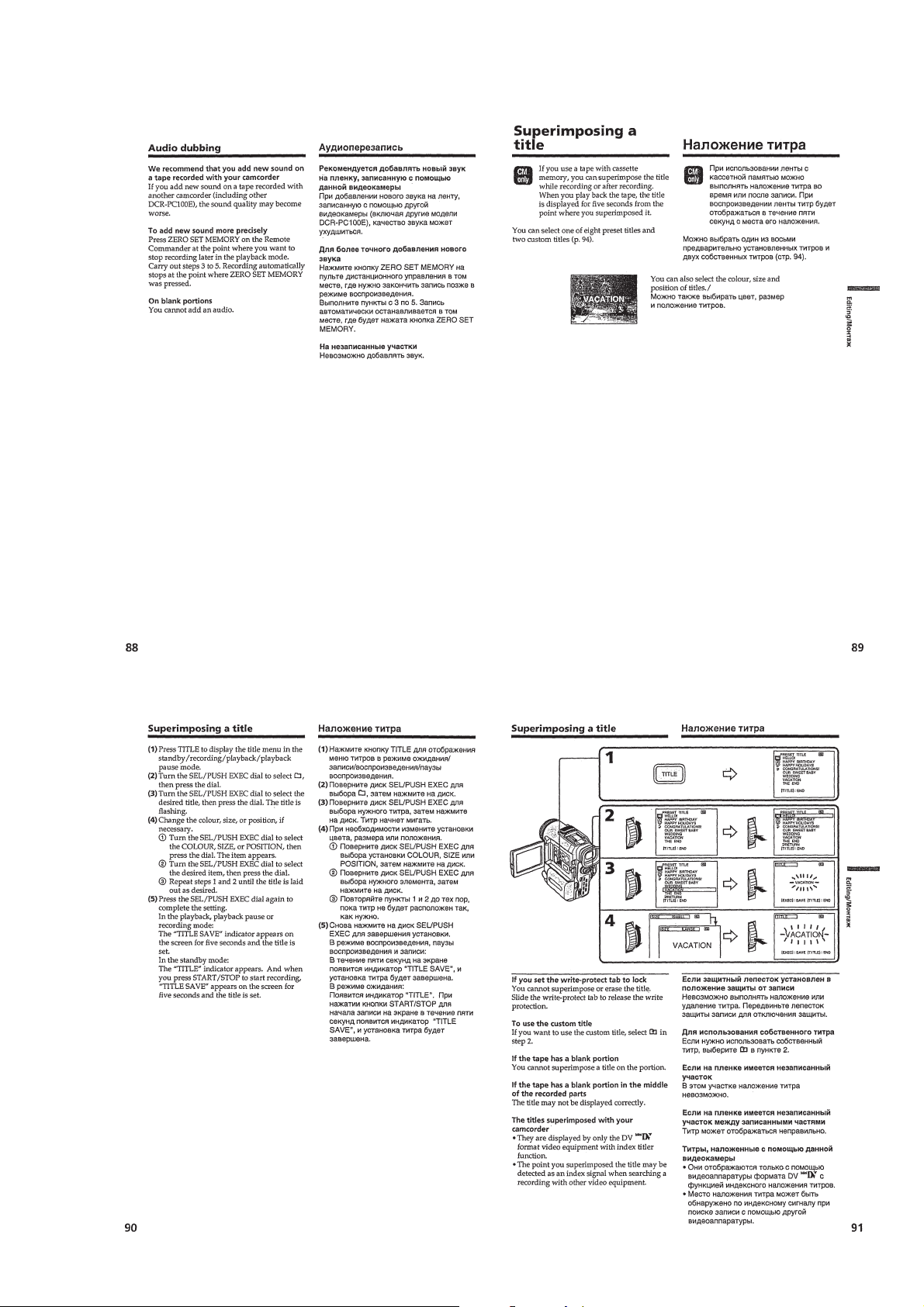

Superimposing a title ··························································· 1-21

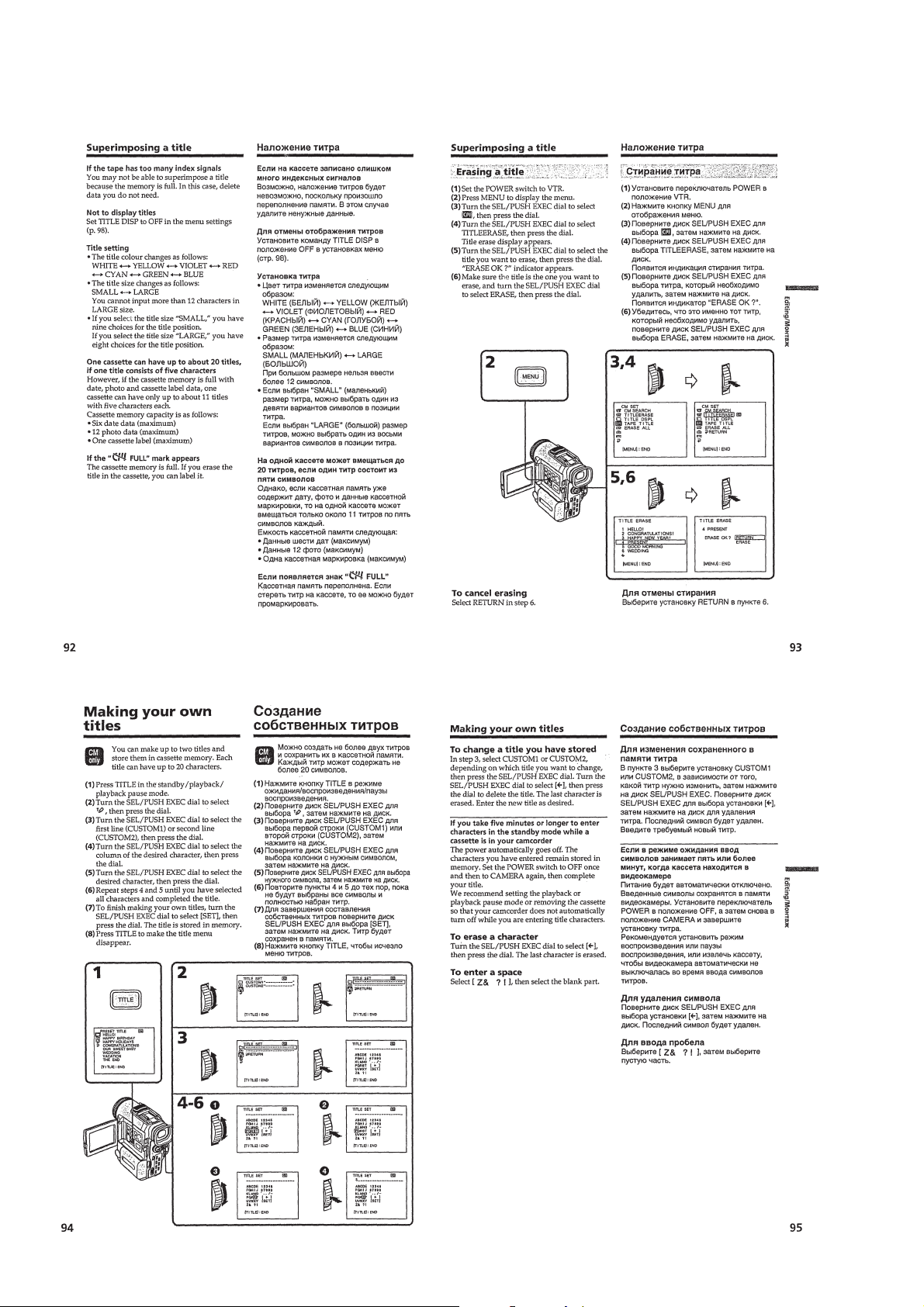

Making your own titles ························································1-22

Labeling a cassette ·······························································1-23

Customizing Y our Camcorder ·················································1-23

Changing the menu settings················································· 1-23

Resetting the date and time·················································· 1-25

“Memory Stick” Operations ····················································1-26

Using a “Memory Stick” –introduction ·······························1-26

Recording still images on “Memory Stick”s

–Memory photo recording ···················································1-28

Superimposing a still picture in a “Memory Stick”

on a moving picture –MEMORY MIX································1-29

Recording an image from a mini DV tape as a still image ··1-30

Copying still images from a mini DV tape –Photo save ······1-31

Viewing a still picture –Memory photo playback················1-31

Copying the image recorded on “Memory Stick”s to

mini DV tapes ······································································1-32

Playing back images continuously –SLIDE SHOW·············· 1-33

Preventing accidental erasure –Image protection ················1-33

Deleting images ···································································1-34

Writing a print mark –PRINT MARK·································1-35

Additional Information ····························································1-35

Usable cassettes ···································································1-35

Troubleshooting ···································································1-36

Self-diagnosis display ··························································1-38

Warning indicators and messages ········································1-38

Using your camcorder abroad··············································1-38

Maintenance information and precautions···························1-39

Quick Reference ······································································1-40

Identifying the parts and controls ········································1-40

Quick Function Guide ·························································1-43

2. DISASSEMBLY

2-1. LCD UNIT, PD-125 BOARD ·········································2-2

2-2. MD BLOCK-1·································································2-3

2-3. MR-44 BOARD, MD BLOCK-2 ····································2-4

2-4. LENS ASSEMBLY, EVF BLOCK ASSEMBLY,

CONTROL SWITCH BLOCK (ME-4950) ····················2-5

2-5. VC-227 (VC-227P) BOARD, SPEAKER, MEMORY

STICK CONNECTOR, MICROPHONE UNIT,

MA-367 BOARD ····························································2-5

2-6. HINGE ASSEMBL Y·······················································2-6

2-7. DC-IN CONNECTOR, BATTERY TERMINAL BOARD,

FJ-25 BOARD ·································································2-6

2-8. CCD/CD BLOCK ASSEMBLY, MF RING BLOCK

ASSEMBLY ···································································· 2-8

2-9. VF-138 BOARD, VF HOLDER ASSEMBLY,

EYE CUP ASSEMBLY···················································2-8

2-10. CONTROL SWITCH BLOCK (FK-4950) ····················· 2-9

2-11. CIRCUIT BOARDS LOCATION ································· 2-10

2-12. FLEXIBLE BOARDS LOCATION ······························2-11

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM-1·································3-1

OVERALL BLOCK DIAGRAM-2·································3-3

OVERALL BLOCK DIAGRAM-3·································3-5

3-2. POWER BLOCK DIAGRAM-1 ·····································3-7

POWER BLOCK DIAGRAM-2 ·····································3-9

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM-1 ···························· 4-1

FRAME SCHEMATIC DIAGRAM-2 ····························4-3

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ············································4-5

• CD-234 (CCD IMAGER)

PRINTED WIRING BOARD ·························4-7

• CD-234 (CCD IMAGER)

SCHEMATIC DIAGRAM ····························4-11

Shematic diagram and printed wiring board of the

VC-227 board are not shown.

Pages from 4-13 to 4-46 are not shown.

— 3 —

Page 4

• MR-44 (CONNECTOR, DRUM/CAPSTAN MOTOR

DRIVE, TIMING GENERATOR, REC/PB HEAD AMP,

LASER LINK)

PRINTED WIRING BOARD ·······················4-47

• FP-91 (MODE), FP-92 (TOP/END SENSOR,

TAPE LED), FP-242 (S/T REEL SENSOR)

PRINTED WIRING BOARDS ·····················4-49

• MR-44 (CONNECTOR)(1/5)

SCHEMATIC DIAGRAM ····························4-51

• MR-44 (DRUM/CAPSTAN MOTOR DRIVE)(2/5)

SCHEMATIC DIAGRAM ····························4-53

• MR-44 (ID DETECT, TIMING GENERATOR)(3/5)

SCHEMATIC DIAGRAM ····························4-55

• MR-44 (REC/PB HEAD AMP)(4/5)

SCHEMATIC DIAGRAM ····························4-57

• MR-44 (LASER LINK)(5/5)

SCHEMATIC DIAGRAM ····························4-59

• FJ-25 (VIDEO IN/OUT, DC IN)

SCHEMATIC DIAGRAM ····························4-61

• FJ-25 (VIDEO IN/OUT, DC IN)

PRINTED WIRING BOARD ·······················4-63

• CONTROL SWITCH BLOCK (FK-4950)

SCHEMATIC DIAGRAM ····························4-67

• CONTROL SWITCH BLOCK (ME-4950)

SCHEMATIC DIAGRAM ····························4-69

• MA-367 (MIC AMP)

PRINTED WIRING BOARD ·······················4-71

• MA-367 (MIC AMP)

SCHEMATIC DIAGRAM ····························4-73

• PD-125 (RGB DRIVER, TG)

PRINTED WIRING BOARD ·······················4-75

• PD-125 (RGB DRIVER)(1/2)

SCHEMATIC DIAGRAM ····························4-77

• PD-125 (TG)(2/2)

SCHEMATIC DIAGRAM ····························4-79

• VF-138 (LCD DRIVER)(1/2)

SCHEMATIC DIAGRAM ····························4-81

• VF-138 (BACK LIGHT DRIVER)(2/2)

SCHEMATIC DIAGRAM ····························4-83

• VF-138 (LCD DRIVER, BACK LIGHT DRIVER)

PRINTED WIRING BOARD ·······················4-85

4-3. WAVEFORMS ······························································4-87

4-4. MOUNTED LOCATION ··············································4-92

5 ADJUSTMENTS

1. Before starting adjustment···············································5-1

1-1. Adjusting items when replacing main parts and boards.·5-2

5-1. CAMERA SECTION ADJUSTMENT ···························5-4

1-1. PREPARATIONS BEFORE ADJUSTMENT

(CAMERA SECTION) ···················································5-4

1-1-1.List of Service Tools ························································5-4

1-1-2.Preparations ·····································································5-5

1-1-3.Precaution ········································································5-7

1. Setting the Switch····························································5-7

2. Order of Adjustments ······················································5-7

3. Subjects ···········································································5-7

1-2. INITIALIZATION OF B, C, D, E, F, 7 PAGE DATA·····5-8

1-2-1.INITIALIZATION OF C PAGE DATA···························5-8

1. Initializing the C Page Data·············································5-8

2. Modification of C Page Data··········································· 5-8

3. C Page Table ····································································5-8

1-2-2.INITIALIZATION OF D PAGE DATA ························5-10

1. Initializing the D Page Data ··········································5-10

2. Modification of D Page Data·········································5-10

3. D Page Table··································································5-11

1-2-3.INITIALIZATION OF B PAGE DATA·························5-12

1. Initializing the B Page Data···········································5-12

2. Modification of B Page Data·········································5-12

3. B Page Table ··································································5-13

1-2-4.INITIALIZATION OF E, F, 7 PAGE DATA ·················5-13

1. Initializing the E, F, 7 Page Data ···································5-13

2. Modification of E, F, 7 Page Data ·································5-13

3. Modification of F Page Data ·········································5-14

4. F Page Table ··································································5-14

5. E Page Table ··································································5-17

6. 7 Page Table···································································5-19

1-3. CAMERA SYSTEM ADJUSTMENTS ························5-21

1. 54MHz/66MHz Origin Oscillation Adjustment

(CD-234 board) ·····························································5-21

2. Zoom Key Center Adjustment ·······································5-21

3. HALL Adjustment ·························································5-22

4. MR Adjustment ·····························································5-22

5. Flange Back Adjustment (Using Minipattern Box)·······5-23

6. Flange Back Adjustment

(Using Flange Back Adjustment Chart and Subject

More Than 500m Away)···············································5-24

6-1. Flange Back Adjustment (1)··········································5-24

6-2. Flange Back Adjustment (2)··········································5-24

7. Flange Back Check························································5-25

8. Picture Frame Setting ····················································5-25

9. Color Reproduction Adjustment····································5-26

10. MAX GAIN Adjustment ···············································5-27

11. Auto White Balance & LV Standard Data Input ···········5-27

12. Auto White Balance Adjustment ···································5-28

13. White Balance Check ····················································5-28

14. Mechanical Shutter Data Input······································5-29

15. Angular Velocity Sensor Sensitivity Adjustment ··········5-29

1-4. COLOR ELECTRONIC VIEWFINDER

SYSTEM ADJUSTMENT ············································5-30

1. VCO Adjustment (VF-138 board)·································5-30

2. Bright Adjustment (VF-138 board) ·······························5-31

3. Contrast Adjustment (VF-138 board)····························5-31

4. White Balance Adjustment (VF-138 board)··················5-32

1-5. LCD SYSTEM ADJUSTMENT ···································5-33

1. VCO Adjustment (PD-125 board)·································5-33

2. Black Limit Adjustment (PD-125 board) ······················5-34

3. Bright Adjustment (PD-125 board) ·······························5-34

4. Gamma-1 Adjustment (PD-125 board) ·························5-35

5. Contrast Adjustment (PD-125 board)····························5-35

6. Center Level Adjustment (PD-125 board) ·····················5-36

7. White Balance Adjustment (PD-125 board)··················5-36

5-2. MECHANISM SECTION ADJUSTMENT··················5-37

2-1. HOW TO ENTER RECORD MODE WITHOUT

CASSETTE ···································································5-37

2-2. HOW TO ENTER PLAYBACK MODE

WITHOUT CASSETTE················································5-37

2-3. TAPE PATH ADJUSTMENT········································5-37

1. Preparation for Adjustment ···········································5-37

2. Processing after Completing Operations:······················5-37

5-3. VIDEO SECTION ADJUSTMENT······························5-38

3-1. PREPARATIONS BEFORE ADJUSTMENTS ············5-38

3-1-1.Equipment to Required··················································5-38

3-1-2.Precautions on Adjusting···············································5-39

3-1-3.Adjusting Connectors ····················································5-40

3-1-4.Connecting the Equipment ············································5-40

3-1-5.Checking the Input Signals············································5-40

3-1-6.Alignment Ta pes····························································5-41

3-1-7.Input/Output Level and Impedance ·······························5-41

3-2. SYSTEM CONTROL SYSTEM ADJUSTMENT········5-42

1. Initialization of B, C, D, E, F, 7 Page Data ···················5-42

2. Serial No. Input ·····························································5-42

2-1. Company ID Input·························································5-42

2-2. Serial No. Input ·····························································5-42

3. Battery End Check (VC-227 board) ······························5-44

— 4 —

Page 5

3-3. SERVO AND RF SYSTEM ADJUSTMENT ··············· 5-45

1. Cap FG Duty Adjustment (VC-227 board) ···················5-45

2. T reel FG Duty Adjustment (VC-227 board) ·············· -5-45

3. PLL f0 & LPF f0 Adjustment (VC-227 board)···············5-45

4. Switching Position Adjustment (VC-227 board)··········· 5-46

5. AGC Center Level and APC & AEQ Adjustment ·········5-46

5-1. Preparations before adjustments····································5-46

5-2. AGC Center Level Adjustment (VC-227 board) ···········5-46

5-3. APC & AEQ Adjustment (VC-227 board) ····················5-47

5-4. Processing after Completing Adjustments ····················5-47

6. PLL f0 & LPF f0 Final Adjustment (VC-227 board)······5-47

3-4. VIDEO SYSTEM ADJUSTMENTS·····························5-48

3-4-1.Base Band Block Adjustments ······································ 5-48

1. Chroma BPF f0 Adjustment (VC-227 Board)················5-48

2. S VIDEO OUT Y Level Adjustment (VC-227 Board) ·· 5-48

3. S VIDEO OUT Chroma Level Adjustment

(VC-227 Board)·····························································5-49

4. AV OUT Y, Chroma Level Check (VC-227 Board) ······5-49

5. PLL Adjustment (VC-227 Board) ·································5-50

3-4-2.BIST Check ···································································5-51

1. Playback System Check ················································ 5-51

1-1. Preparation for Playback ··············································· 5-51

1-2. IC1900(TRX) BIST(PB) Check····································5-51

1-3. IC1601(TFD) BIST(PB) Check ····································5-51

1-4. IC1600(SFD) BIST(PB) Check····································· 5-51

1-5. IC1501(VFD) BIST(PB) Check····································5-52

2. Recording System Check ·············································· 5-53

2-1. Preparations for recording·············································5-53

2-2. IC1501(VFD) BIST(REC) Check·································5-53

2-3. IC1600(SFD) BIST(REC) Check··································5-53

2-4. IC1601(TFD) BIST(REC) Check ·································5-54

2-5. IC1900(TRX) BIST(REC) Check·································5-54

3-5. IR TRANSMITTER ADJUSTMENTS ·························5-55

1. IR Video Carrier Frequency Adjustment

(MR-44 board)·······························································5-55

2. IR Video Deviation Adjustment (MR-44 board) ··········· 5-55

3. IR Audio Deviation Adjustment (MR-44 board)···········5-56

3-6. AUDIO SYSTEM ADJUSTMENTS ····························5-57

1. Playback Level Check ··················································· 5-58

2. Overall Level Characteristics Check ·····························5-58

3. Overall Distortion Check···············································5-58

4. Overall Noise Level Check············································5-58

5. Overall Separation Check·············································· 5-58

5-4. SERVICE MODE··························································5-59

4-1. ADJUSTMENT REMOTE COMMANDER ················5-59

1. Using the adjustment remote commander ····················· 5-59

2. Precautions upon using the adjustment

remote commander ························································ 5-59

4-2. DATA PROCESS··························································· 5-60

4-3. SERVICE MODE··························································5-61

1. Setting the Test Mode ···················································· 5-61

2. Emergence Memory Address ········································5-61

2-1. EMG Code (Emergency Code) ·····································5-61

2-2. MSW Code····································································5-62

3. Bit value discrimination ················································ 5-63

4. Switch check (1) ····························································5-63

5. Switch check (2) ····························································5-64

6. Record of Use check······················································5-64

6-1-6.CASSETTE COMPARTMENT AND DRUM ASSY

SECTION ········································································ 6-6

6-1-7.LS CHASSIS SECTION ·················································6-7

6-1-8.MECHANISM CHASSIS BLOCK SECTION-1 ··········· 6-8

6-1-9.MECHANISM CHASSIS BLOCK SECTION-2 ··········· 6-9

6-2. ELECTRICAL PARTS LIST ········································ 6-10

Parts list of the VC-227 board is not shown.

Pages from 6-18 to 6-25 are not shown.

* Parts reference sheet and color reproduction frame are

shown on page 226 and 227.

6. REPAIR PARTS LIST

6-1. EXPLODED VIEWS ······················································6-1

6-1-1.CABINET (R) SECTION-1 ············································6-1

6-1-2.CABINET (R) SECTION-2 ············································6-2

6-1-3.CABINET (R) SECTION-3 ············································6-3

6-1-4.CABINET (L) BLOCK ASSEMBLY ·····························6-4

6-1-5.LENS ASSEMBLY, EVF BLOCK ASSEMBLY ············ 6-5

— 5 —

Page 6

SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery

terminal using the regulated power supply (8.4 V), the power is

shut off so that the unit cannot operate.

This following two methods are av ailable to prev ent this. Take note

of which to use during repairs.

Method 1.

Connect the servicing remote commander RM-95 (J-6082-053-B)

to the LANC jack, and set the commander switch to the “ADJ”

side.

Method 2.

Use the DC IN terminal. (Use the A C po wer adaptor (A C-L10, A CVQ800 etc. ))

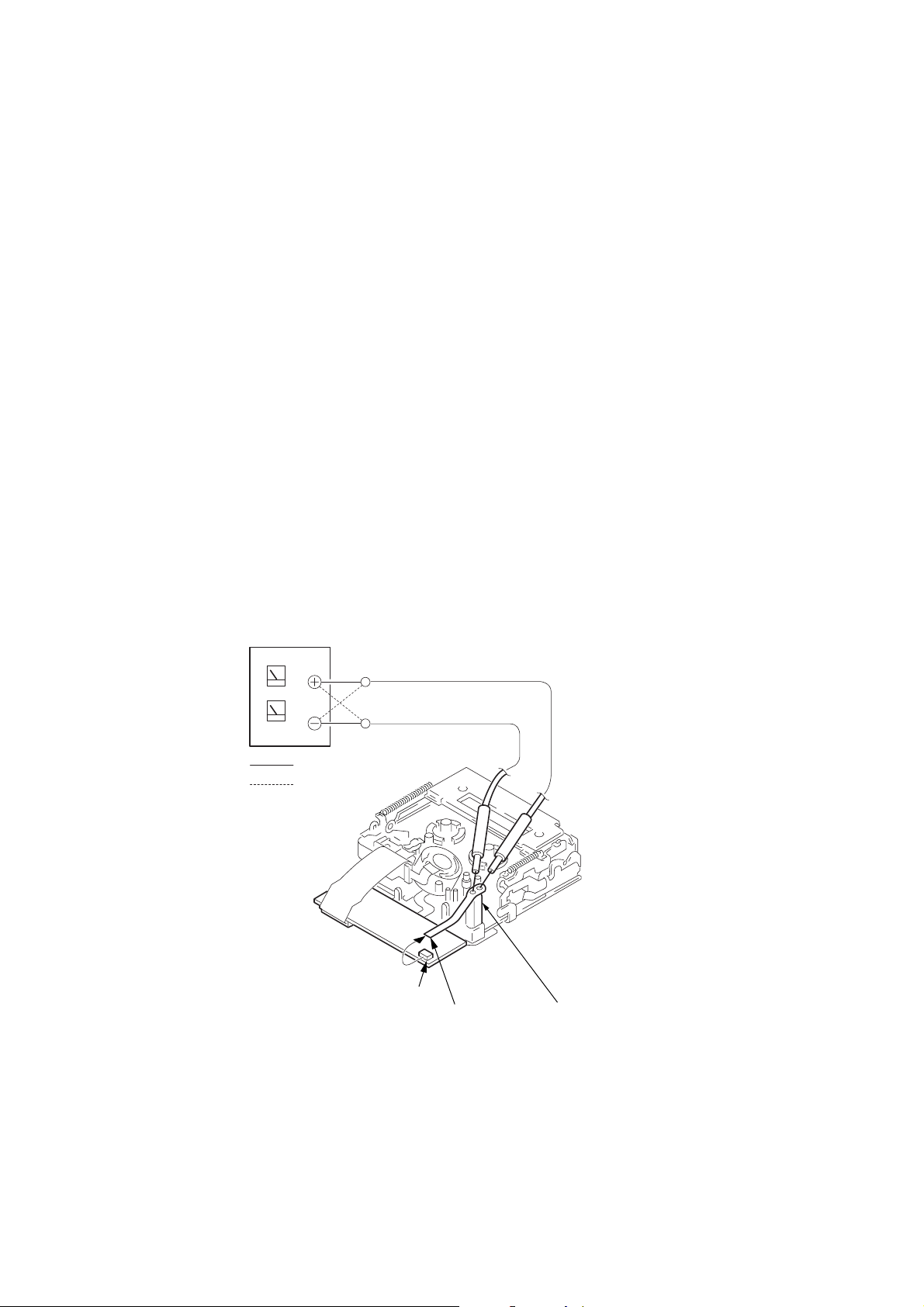

2. TO TAKE OUT A CASSETTE WHEN

NOT EJECT (FORCE EJECT)

1 Refer to 2-2 to remove the shoe cover.

2 Refer to 2-3. to remove the cabinet (L) assembly.

3 Refer to 2-3. to remove the mechanism deck.

4 Disconnect from CN2303 (4P, 0.8mm) of MR-44 board.

5 Add +4.5 V from the DC PO WER SUPPLY and unload with a

pressing the cassette compartment.

DC power supply

(+4.5Vdc)

: Unloading

: Loading

MR-44

BOARD

CN2303

Disconnect from CN2303 (4P)

of MR-44 board.

Loading motor

— 6 —

Page 7

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewf inder, LCD screen

or LCD window what to do. This function consists of two display;

self-diagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

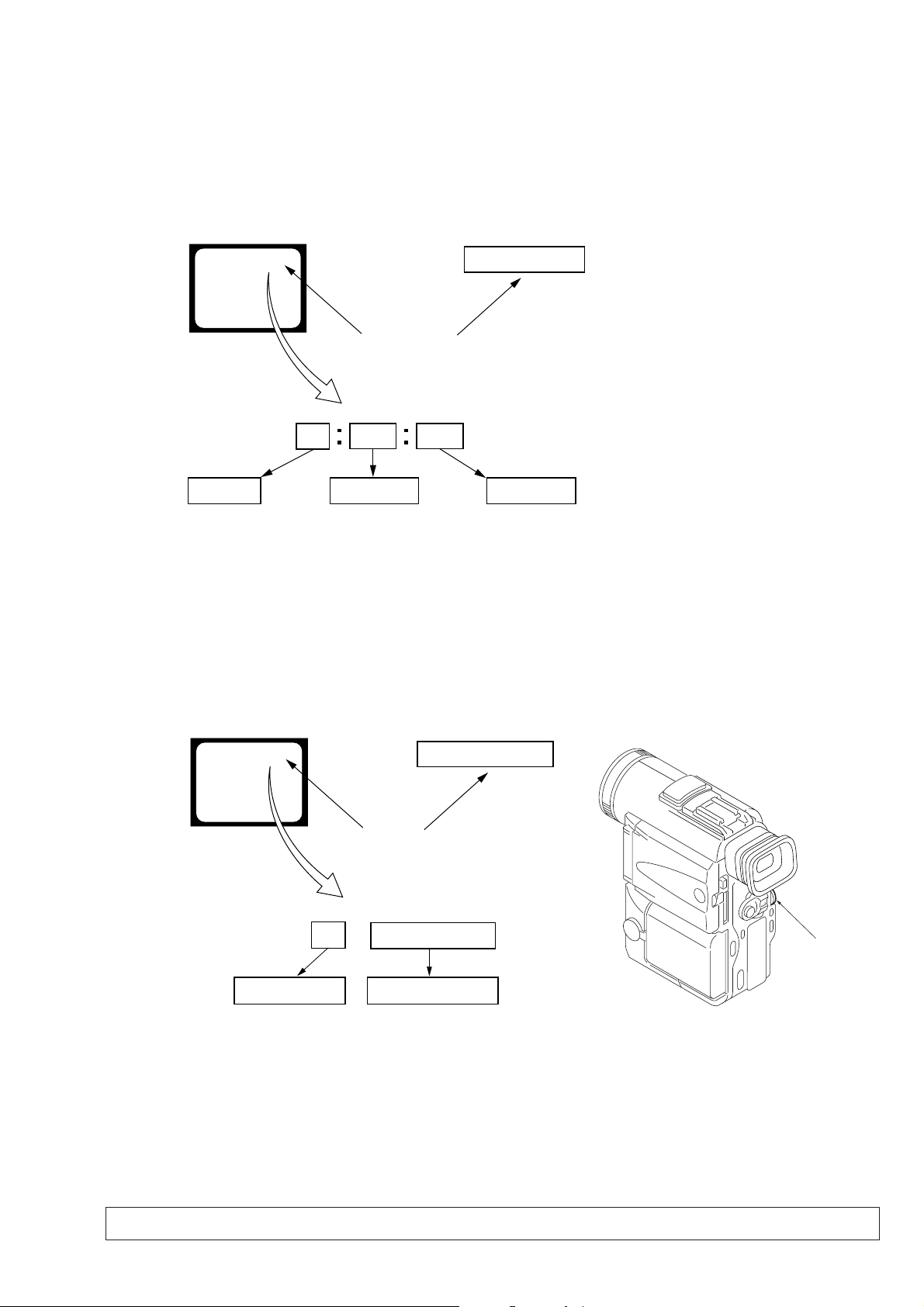

Viewfinder or LCD screen LCD window

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Tu r n o n power again.

3 1

Block

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder, LCD screen or LCD window consists of an alphabet

and 4-digit numbers, which blinks at 3.2 Hz. This 5-character display

indicates the “repaired by:”, “block” in which the problem occurred,

and “detailed code” of the problem.

C : 3 1 : 11

Detailed Code

Refer to page 8.

Self-diagnosis Code Table.

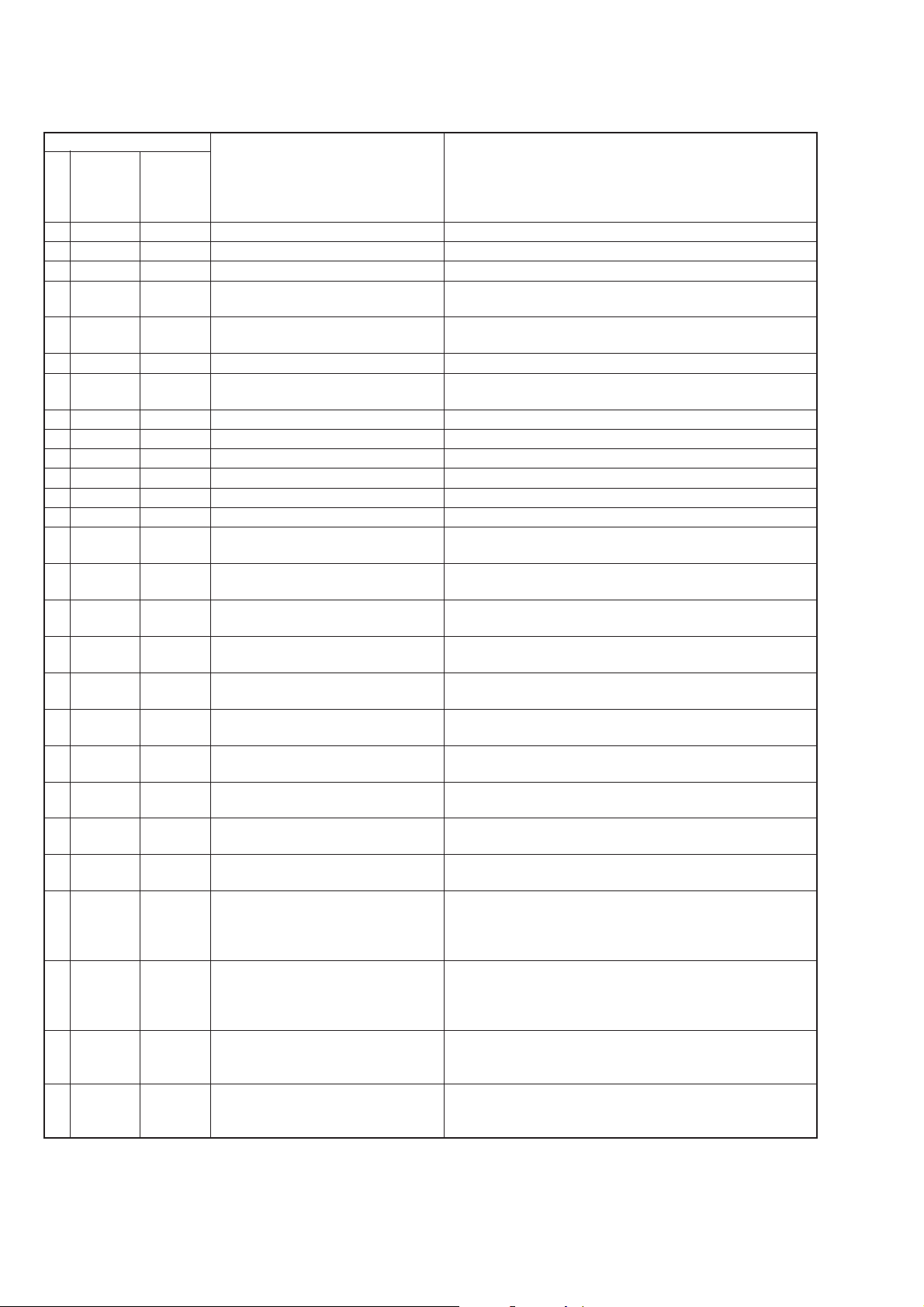

3. SERVICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to “VTR”, and continue pressing the “STOP” key for 5 seconds continuously. The

service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder or LCD screen

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

C : 3 1 : 1 1

Self-diagnosis Codes

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

LCD window

3 C : 3 1 : 11

Control dial

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will be backed up by the coin-type lithium battery (BT1050) of the control switch block (FK-4950). When the

control switch block is removed, the “self-diagnosis display” data will be lost by initialization.

— 7 —

Page 8

4. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus MR sensor (Pin wf,wg of CN171 of

CD-234 board) when focusing is performed when the control dial

is rotated in the focus manual mode, and the focus motor drive circuit

(IC401 of VC-227 board) when the focusing is not performed.

Inspect the lens block zoom MR sensor (Pin 2,3 of CN171 of

CD-234 board) when zooming is performed when the zoom lens is

operated and the zoom motor drive circuit (IC401 of VC-227 board)

when zooming is not performed.

Inspect pitch angular velocity sensor (SE451 of MA-367 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE450 of MA-367 board)

peripheral circuits.

— 8 —

Page 9

SECTION 1

GENERAL

DCR-PC100/PC100E

This section is extracted from instruction

manual. (DCR-PC100E model)

1-1

Page 10

1-2

Page 11

1-3

Page 12

1-4

Page 13

1-5

Page 14

1-6

Page 15

1-7

Page 16

1-8

Page 17

1-9

Page 18

1-10

Page 19

1-11

Page 20

1-12

Page 21

1-13

Page 22

1-14

Page 23

1-15

Page 24

1-16

Page 25

1-17

Page 26

1-18

Page 27

1-19

Page 28

1-20

Page 29

1-21

Page 30

1-22

Page 31

1-23

Page 32

1-24

Page 33

1-25

Page 34

1-26

Page 35

1-27

Page 36

1-28

Page 37

1-29

Page 38

1-30

Page 39

1-31

Page 40

1-32

Page 41

1-33

Page 42

1-34

Page 43

1-35

Page 44

1-36

Page 45

1-37

Page 46

1-38

Page 47

1-39

Page 48

1-40

Page 49

1-41

Page 50

1-42

Page 51

1-43E

Page 52

SECTION 2

DISASSEMBLY

The following flow chart shows the disassembly procedure.

DCR-PC100/PC100E

2-1. LCD unit, PD-125 board

2-2. MD block-1

2-3. MR-44 board, MD block-2

2-4. Lens assembly, EVF block assembly,

Control switch block (ME-4950)

DCR-PC100/PC100E

2-5. VC-227 (VC-227P) board, Speaker,

Memory stick connector,

Microphone unit, MA-367 board

2-6. Hinge assembly

(Perform the disassembling after steps

LCD service position

MD block service position-1

Note : Use the parts only which can be

removed easily from outside of

the MD block.

2-10. Control switch block (FK-4950)

MR-44 board,

MD block service position-2

2-8. CCD/CD block assembly,

MF ring block assembly

2-9. VF-138 board, VF holder assembly,

Eye cup assembly

1-6

of 2-1 is complete. )

2-7. DC-IN connector, Battery terminal board, FJ-25 board

Service position

(Mainly for voltage measurement and check)

2-1

Page 53

NOTE: F ollo w the disassembly procedure in the numerical order given.

2-1. LCD UNIT, PD-125 BOARD

2

LCD cabinet (R)

assembly

1

Two screws (M1.7 × 2.5),

lock ace, p2

4

Screw (M1.7 × 2.5),

lock ace, p2

REMOVING THE PD-125 BOARD

3

Back light

Cold cathode

fluorescent tube

7

Inverter

transformer unit

1

LCD unit

(24P)

4

PCB clip

2

Remove the

three solderings

6

Remove the

six solderings

8

PD-125 board

PD-125

Board

5

PCB clip

PD-125

Board

9

Screw (M1.7 × 2.5),

lock ace, p2

6

PT-125 harness

(4P)

5

PT-126 harness

(13P)

qs

PD-125 board/

Inverter transformer unit

7

Two screws (M1.7 × 2.5),

lock ace, p2

qa

Back light

Cold cathode

fluorescent tube

q;

LCD unit

3

Screw (M1.7 × 2.5),

lock ace, p2

A

[LCD SERVICE POSITION]

Base (Use box or the like.)

LCD unit

A

Adjustment remote

commander (RM-95)

PT-126 harness (13P)

PT-125 harness (4P)

PD-125

8

LCD cabinet (L) assembly

Board

LANC

jack

Back light

Cold cathode

fluorescent tube

PD-125 board

Inverter transformer unit

2-2

AC adaptor

(8.4Vdc)

(AC-VQ800)

(AC-L10)

AC IN

Page 54

2-2. MD BLOCK-1

5

Screw (M1.7 × 4),

lock ace, p2

3

Two screws (M1.7 × 4),

lock ace, p2

4

Shoe cover

9

Cabinet (L) block assembly

8

Screw (M1.7 × 4),

lock ace, p2

7

Push the eject knob in

the direction of the arrow,

and open the cassette lid.

q;

Cabinet (R) block assembly

6

Two screws (M1.7 × 4),

lock ace, p2

[MD BLOCK SERVICE POSITION-1]

Note: Use the parts only which can be removed easily from outside of the MD block.

CPC-8 jig

AC adaptor

AC IN

Adjustment remote

commander (RM-95)

(8.4Vdc)

(AC-VQ800)

(AC-L10)

DC IN

MD block

2

CPC lid

1

Screw (+K M1.7)

CPC-8 jig

(J-6082-388-A)

Cabinet (R) block assembly

Cabinet (L) block assembly

2-3

Page 55

2-3. MR-44 BOARD, MD BLOCK-2

)

1

Three screws (M1.7 × 2.5),

lock ace, p2

6

MD block

MD frame,

Cover assembly

MR-44 Board

VC-227

Board

3

IR window

When re-assembling, attach it to the

cabinet (R) block assembly before

installing the MD block.

2

MR-44 board (100P)

5

MR-44 board

[MR-44 BOARD, MD BLOCK SERVICE POSITION-2]

M

R-44 Board

VC-227

AC IN

Adjustment remote

commander (RM-95)

MR-44 board

AC adaptor

(8.4Vdc)

(AC-VQ800)

(AC-L10)

4

Two screws (M1.7 × 2.5),

lock ace, p2

MD block

MD frame,

Cover assembly

Insert an insulation sheet between the

MD block and the VC-227 (VC-227P) board.

MR-44 board (100P)

CPC-8 jig

(J-6082-388-A

Cabinet (R) block assembly

Cabinet (L) block assembly

2-4

CPC-8 jig

DC IN

Page 56

2-4. LENS ASSEMBLY, EVF BLOCK ASSEMBLY, CONTROL SWITCH BLOCK (ME-4950)

VC-227

Board

[REMOVING THE CONTROL

SWITCH BLOCK (ME-4950)]

1

Control switch block

(ME-4950) (5P)

3

Control switch block

(ME-4950)

2

Peel off the adhering portion.

3

Lens assembly

2

CCD/CD block assembly

(CD-234 board) (60P)

1

T wo screws

(M1.7

×

2.5),

lock ace, p2

4

Screw (M1.7 × 2.5),

lock ace, p2

5

VF-138 board

(20P)

6

EVF block assembly

A

C

D

E

B

A

C

B

D

E

VC-227

Board

3

qf

[REMOVING THE MEMORY STICK CONNECTOR]

[REMOVING THE MICROPHONE UNIT]

[REMOVING THE MA-367 BOARD]

3

Remove the

eleven solderings

5

Memory stick

connector

4

FP-128

flexible board

2

FP-130

flexible board

(9P)

8

FP-128

flexible board

(33P)

qa

FP-129

flexible board

(5P)

1

T wo tapping

screws (M1.7

×

4)

1

T apping

screw (M1.7

×

5)

2

Microphone

holder assembly

3

Microphone

fixed plate

4

Microphone sheet

5

Microphone sheet (2)

6

Microphone unit

1

Microphone unit (4P)

2

MS holder assembly

3

Three screws

(M1.7

×

2.5),

lock ace, p2

qd

Four screws

(M1.7

×

2.5),

lock ace, p2

qs

VC-227 board (PC100)

VC-227P board (PC100E)

5

Three screws (M1.7 × 2.5),

lock ace, p2

6

Control switch block

(ME-4950) (5P)

2

T wo screws

(M1.7

×

2.5),

lock ace, p2

4

Speaker (2P)

4

MA-367

board

1

MA-367 board

(20P)

7

FJ-25 board (50P)

q;

PT-126 harness

(13P)

9

PT-125 harness

(4P)

2-5. VC-227 (VC-227P) BOARD, SPEAKER, MEMORY STICK CONNECTOR,

MICROPHONE UNIT, MA-367 BOARD

2-5

Page 57

2-6. HINGE ASSEMBLY

f

Perform the disassembling after steps 1 – 6 of 2-1 is complete.

[REMOVING THE HINGE ASSEMBLY]

4

Blind plate assembly

1

3

Remove

the two claws

7

Hinge assembly

5

Peel off the adhering portion.

6

FP-129 flexible board

PT-125

harness

(4P)

2

PT-126

harness

(13P)

8

7

T wo screws

(M1.7

lock ace, p2

6

Two spring bolts

×

(M1.7

2.5)

×

4),

1

Release the claw (a) in the

direction of the arrow

then release the two claws (b).

claw (b)

B

claw (a)

claw (b)

2

Hinge cover (front)

C

3

Change the direction

of the hinge assembly

to the direction shown

by the arrow (C).

5

Hinge cover (rear)

B

first

4

Screw

×

(M1.7

lock ace, p2

2.5),

2-7. DC-IN CONNECTOR, BATTERY TERMINAL BOARD, FJ-25 BOARD

7

5

Remove

the two claws

6

T erminal

fixed plate

4

Screw

(M1.7 × 2.5),

lock ace, p2

Battery terminal board

2

DC fixed plate

1

Screw

(M1.7 × 2.5),

lock ace, p2

3

DC-IN connector

8

T wo screws

(M1.7 × 2.5),

lock ace, p2

9

Screw

(M1.7 × 2.5),

lock ace, p2

qa

(M1.7 × 2.5),

lock ace, p2

qs

FJ-25 board

q;

S terminal cover

in the direction o

the arrow A

A

T wo screws

Open the

2-6

Page 58

[SERVICE POSITION (Mainly for voltage measurement and check)]

MD block

MD frame,

Cover assembly

AC adaptor

AC IN

(8.4Vdc)

(AC-VQ800)

(AC-L10)

Adjustment remote

commander (RM-95)

FJ-25 board

Memory stick connector/

MS holder assembly

Cabinet (L) assembly/

Cabinet (G) assembly/

Control switch block

(FK-4950)

Base (Use box or the like.)

Base (Use box or the like.)

MR-44 board

DC-IN connector

FJ-25 board (50P)

FJ-25

FJ-25

FP-128

flexible board

(33P)

-125

D

P

oard

B

Battery

terminal board

LCD unit

PD-125 board

MR-44 Board

MR-44 board

(100P)

VC-227 board (PC100)

VC-227P board (PC100E)

VC-227

Board

Blind plate assembly

Hinge assembly

Insert an insulation sheet

between the MD block and

the VC-227 (VC-227P) board.

CPC-8 jig

(J-6082-388-A)

MA-367 board

(20P)

VF-138 board

(20P)

Base

(Use box or

the like.)

EVF block assembly

CCD/CD block assembly

(CD-234 board) (60P)

Lens assembly

PT-126 harness (13P)

PT-125 harness (4P)

FP-129 flexible board (5P)

2-7

Page 59

2-8. CCD/CD BLOCK ASSEMBLY, MF RING BLOCK ASSEMBLY

3

Flexible board

2

CD heat sink/

1

T apping screw

(M1.7

×

CD insulating sheet/

CD heat transfer sheet

4)

[REMOVING THE

MF RING BLOCK ASSEMBLY]

1

Tapping screw (M1.7 × 4)

3

Remove the claw

2

Remove the two claws

4

MF ring block

assembly

Be careful not to damage the

flexible board to be removed

3

at step

.

(from lens device) (33P)

qa

Lens device

(LSV-660A)

4

T apping screw

(M1.7

×

q;

Lens frame

4)

7

8

Optical filter block

9

T wo tapping

screws (M1.7

6

CCD/CD block assembly

Never remove the CCD imager

(IC101) from the CD-234 board

because position alignment

between the CCD imager and

the CD-234 board is difficult.

5

T wo tapping

screws (B1.7

Seal rubber (W)

×

4)

×

6)

2-9. VF-138 BOARD, VF HOLDER ASSEMBLY, EYE CUP ASSEMBLY

[REMOVING THE EYE CUP ASSEMBLY]

5

Eye cup assembly

qf

VF holder assembly

qd

LCD cushion (1)

6

qs

LCD (LCX027AK-J)

q;

VF holder lid

8

Cushion (3)

5

Light guide plate

block (6P)

2

Remove the

three claws

LCD (LCX027AK-J)

(16P)

qa

Cushion (2)

9

Remove the

four claws

4

Remove the

two claws

7

VF-138 board

1

T wo tapping

screws (B1.7)

2

4

3

VF window

VF spacer

1

VF blind sheet

3

Remove the

four claws

2-8

Page 60

2-10.CONTROL SWITCH BLOCK (FK-4950)

A

B

A

4

Six screws

(M1.7 × 2.5),

lock ace, p2

2

Three screws

(M1.7

×

2.5),

lock ace, p2

7

Cabinet (L) assembly

9

Cabinet (G) assembly

4

T wo screws

(M1.7

×

2.5),

lock ace, p2

8

Two tapping screws

(M1.7 × 4)

qs

Control switch block

(FK-4950)

q;

Remove the

two solderings

1

Remove the

two claws

qa

V/L rechargeable

battery

1

Screw (M1.7 × 2.5),

lock ace, p2

3

Screw

(M1.7 × 2.5),

lock ace, p2

5

Screw

(M1.7

×

2.5),

lock ace, p2

3

FK flexible clamp

6

Remove the control switch

block that is attached to the

cabinet (L) assembly, from

the cabinet (L) assembly.

Be careful that the flexible

must not be caught.

Be careful not to damage the control

switch block's (FK-4950) flexible.

5

Slide the cabinet (G) assembly in

the direction of the arrow

B

and

release the three claws.

6

Remove an end of

the grip belt from

the bracket cap.

2

FP-128

flexible board (30P)

2-9

Page 61

2-11.CIRCUIT BOARDS LOCATION

T

CD-234

(CCD IMAGER)

MR-44

CONNECTOR,

DRUM/CAPSTAN MOTOR

DRIVE, TIMING GENERA TOR,

REC/PB HEAD AMP,

LASER LINK

MA-367

(MIC AMP)

VF-138

(LCD DRIVER, BACK LIGHT DRIVER)

PD-125

(RGB DRIVER, TG)

INVERTER

TRANSFORMER UNI

VC-227

A/D, CAMERA CONTROL, JPEG

DIGITAL STILL CONTROL,

MEMORY STICK I/F, AGC, AFC,

LINE OUT AMP, VFD, SFD, LIP/TFD,

ZOOM MOTOR CONTROL,

MODE CONTROL, HI CONTROL,

AUDIO, DC/DC CONVERTER

FJ-25

(VIDEO IN/OUT, DC IN)

2-10

Page 62

2-12.FLEXIBLE BOARDS LOCATION

FP-242

(S/T REEL SENSOR)

FP-129

(PANEL OPEN)

(From LENS BLOCK)

FP-130

From INTELLIGENT

ACCESSORY SHOE

CONTROL SWITCH BLOCK

(ME-4950)

FP-128

From CONTROL SWITCH

BLOCK (FK-4950)

CONTROL SWITCH BLOCK

(FK-4950)

FP-586

(From LOADING MOTOR)

(From DRUM MOTOR)

(From VIDEO HEAD)

FP-91

(MODE)

FP-92

TOP/END SENSOR,

TAPE LED

2-11E

Page 63

SECTION 3

BLOCK DIAGRAMS

DCR-PC100/PC100E

3-1. OVERALL BLOCK DIAGRAM-1

IRIS

METER

ND FILTER

METER

FOCUS

MOTOR

ZOOM

MOTOR

MIC 901

MIC

L

MIC

R

J7301

MIC

INTTELIGENT

ACCESSORY

SHOE

LENS ASSY

IRIS

(SHUTTER)

M

H

H

M

MR

M

M

MR

NIGHT SHOT

FOCUS

RING

MA-367 BOARD

CN7300

3

1

R

L

2

73

7

46

3

5

44

SHOE MIC L

LANC SIG

CN7306

IC7301

CN171

(4-73)

MIC AMP

20

19

15

16

29

31

28

33

24

25

22

21

12

11

2

3

27

9

6

SE450

YAW SENSOR

SE451

PITCH SENSOR

CD-234 BOARD

(4-11) (4-11)

IC101

CCD

IMAGER

1-4,10-12,14

V1-V4

RG,H1,H2

40-42,44,45,

9,12,13

(4-11)

IC102

TIMING

GENERATOR

IRIS DRIVE

+,-

39

39

37

37

IRIS HALL

+,-

35

35

38

38

ND HALL

+,-

47

47

48

48

ND DRIVE

+,-

57

57

56

56

44

F MR A,B

44

43

43

58

58

FOCUS +,-

55

55

60

60

ZOON +,-

59

59

33

33

Z MR A,B

34

34

46

46

53

53

F0,F1

54

54

CN101

CN201

9

9

12

12

L

32

2

2

R

17

1

1

2

•

47

18

18

CN7305

CN2924

8

12

8

16,17,22

CCD

OUT

IC501

6

21

8

19

3

25

5

23

IC104

11

33

34

35

25

29

30

1

•

2

•

47

IC412

IC413

IRIS DRIVE

IRIS HALL AMP

ND FILTER

DRIVE

SHUTTER

DRIVE

FOCUS MOTOR

DRIVE

ZOOM MOTOR

DRIVE

IC401

(4-33)

YAW/PITCH

SENSOR

AMP

(SEE PAGE 3-6)

CDS,

AGC

1,13,14

X101

66MHz

X301

20MHz

TO

OVERALL

BLOCK DIAGRAM

(3/3)

CLPDM,

XSHP,XSHD

18

2

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

CCD OUT(+)

CCD OUT(-)

5

•

4

HD,VD,FLD

MCK

CN101

(4-31)

IRIS PWM

I HALL AD

IC411

14

16

PWMO

EN0

10

33

11

12

13

YAW AD

PITCH AD

IC404

34

PWM1

EN1

31

32

(4-31)

1

46

12

15

14 43

(4-34)

30

IC302

18

CAMERA CONTROL

40

41

73

74

DATA FROM HI,DATA TO HI,XHI SCK

ZOOM SW AD

OSD CS,SO,SCK

Y,CR,CB,HD,VD

IR V,IR L,IR R

LANC SIG

VC-227 BOARD(1/3)

24

24

36

26

26

32

13

13

16

16

15

15

7

7

10

10

CAM SO,SI,SCK

11

11

12

12

CN201

(4-32)

ND HALL

AMP

ND FILTER

PRE DRIVE

(4-31)

FOCUS/

ZOOM

MOTOR

CONTROL

IRIS PWM

ND PWM

46

ND HALL AD

83

I HALL AD

84

33

34

CAM SO,SI,SCK

35

64

AD SO,AD SCK

65

ZOOM SW AD

80

60

|

62

IC201

16

ND HALL AD

ND PWM

IRIS COM

SHUTTER ON

23

28

27

26

(4-13)

A/D

CONVERTER

47 48

•

AD SO,SI,SCK

IC251

(CARILLON)

2

|

11

AD0-AD9

(4-13)

IC203

16Mbit

SDRAM

SPCKO(IC251)

(4-34)

IC303

14

13 EVR

(4-33)

IC301

4

3

EEPROM

2

(4-19)

18

|

31

1

|

13

•

38

|

48

IC763

64Mbit

SDRAM

78

|

65

60

61

CAMERA

SIGNAL

62

PROCESS

57

109

A0-A11

|

122

89

DQ0-DQ15

|

107

42

43

45

15

14

20

|

35

2

|

13

•

42

|

53

A0-A13

D0-D15

165

|

181

193

|

212

(4-15)

13

PLL

RC

PROCESS

9

10

247

|

238

251

|

248

253

|

256

33

|

25

24

|

DRAM

20

16

17

18

223

222

|

213

233

|

224

237

236

234

37

36

143

138

|

130

161

|

155

154

|

145

SPCKO

(IC251)

Y0-Y7

C0-C8

HD,VD,OE

JID0-JID7

A0-A10

SPCK1

SPCK0

AFCK

SYSCLK(IC761)

46

48

51

|

58

61

|

68

72

73

71

Y0-Y7

C0-C3

HD,VD OE

Y0-Y7

C0-C3

HD,VD,OE

AFCK(IC1200)

SPCKO(IC251)

(4-26)

IC1502

(4-22)

IC1200

(BBI)

AGC,AFC,

A/D CONV.

74-76

8

CHARACTER

GENERATOR

13

JID0-JID7

OSD CS

OSD SO

OSD SCK

SYSCLK

43

44

33

25

34

HD

20

VD

•

19

18

•

|

17

COL3

•

16

•

14

X1200

40.5MHz

Y

C

V

DATA FROM HI,XHI SCK

34

IC756

41

18

17

12

9

(4-25)

8

7

IC1501

4

(VFD)

105

BLOCKING

104

SHUFFLING

100

STILL FILTER

MEMORY FEATURE

38

DIGITAL EFFECT

TEST SIG.

ENCODER

45

109

106

46

47

51

101

50

36

•

37

26COL0

•

27

•

28

•

33

DATA FROM MS VSP,XMS SCK VSP

X750

6,875MHz

27

(4-18)

JPEG

2,9-16

58-64

(4-29)

IC1602

(LIP)

DV INTERFACE

47

HD,VD

53

56

V BUS

•

58

61

TRCK

FRRV

TRRV

Y

CR

CB

Y

18

20

102

104

90

83

96

•

97

22

•

23

115

117

52

•

53

72

74

76

61

68

49-51

72

(4-17)

74

IC761

83

DIGITAL

STILL

CONTROL

84

79

LCKO

11

IC1600

(SFD)

DCT/IDCT

ESTIMATION

QUANTIZE

VLC/VLD

FRAMING

ADSP

INTERLEAVE/

DEINTERLEAVE

86

39

SFD BCK

2

IC764

4

45

90

44

DATA TO SFD

DATA FROM SFD

DATA TO SFD

SFD BCK

(4-18)

EEPROM

DI,CI

(4-18)

L BUS

(4-28)

45

DATA FROM SFD

42

93

25

29

51

TRCK

TPA+,-

6

TPB+,-

9

29

MC BUS

37

71

74

T BUS

•

77

80

13

14

X1600

24.576MHz

IC1402

(AOI)

LINE OUT

AMP

15

12

11

•

1 2

IC2002

1

2

5

12

(4-23)

(4-40)

(ADC&DAC)

D/A CONV.

A/D CONV.

SPCK1(IC251)

IC760

SHUTTER

SOUND

6

(4-29)

IC1601

(TFD)

ECC/PTG

DESHUFFLING

ENCODE/DECODE

CONCEAL

TBC

38

31

32

48

•

26

FRRV

TRRT

TRCK

DATA FROM MS VSP,DATA TO MS VSP,XMS SCK VSP

Y

16

CC

12

V

7

9

15

16

L

19

24

R

20

20

L

6

28

R

3

26

(4-20)

4

14

15

19

23

•

24

21

MC BUS

(4-39)

IC2001

(ABC)

AUDIO

I/O

TXDT 0-4

XTDT 0,1

TXDT 0-4

XTDT 0,1

MC BUS

FRRV,TRRT,TRRV

44

45

L

37

R

38

34

36

L

46

R

48

2

4

8

30

32

SPCK1

HP CKHP CK

L

R

A OUT

L

R

CN1601

DV IN/OUT

CRCKCRCK

TO

OVERALL

BLOCK DIAGRAM

(2/3)

(SEE PAGE

3-3)

FJ-25 BOARD

(1/2)

CN900

CN2904

IR V

IR L

IR R

CN2905

Y

50

50

C

46

46

V

47

47

40

40

36

36

37

37

41

41

1

SP +,-

2

(4-61)

YC

J990

G

L

V

R

R

L

SP-158

SPEAKER

S VIDEO

G

J950

AUDIO/VIDEO

J951

IC766

16Mbit DRAM

4-14 70-52

A0-A10

D0-D15

(4-20)

IC765

XTAL OSC

20-31

FAST PAGE

1-13

38-48

X751

20MHz

2

4

SYSCLK(IC761)

28

36

(4-20)

|

38

IC758

10

|

1

•

48

|

40

SCK

13

MEMORY

STICK

I/F

15

|

17

CN2918

29

|

33

FP-128

(FLEXIBLE)

(1/2)

CN002

MEMORY

STICK

(4-69)

16

3-1 3-2

Page 64

DCR-PC100/PC100E

OVERALL BLOCK DIAGRAM-2

VC-227 BOARD(2/3)

TO

OVERALL

BLOCK DIAGRAM

(1/3)

(SEE PAGE

3-2)

TO

OVERALL

BLOCK DIAGRAM

(3/3)

(SEE PAGE

3-6)

16

SPCK1

CRCK

TXDT 0-4

XTDT 0,1

HP CK

MC BUS

FRRV TRRT,TRRV

DATA FROM MS VSP,DATA TO MS VSP,XHS SCK VSP

(4-36)

IC2404

EEPROM

DATA FROM HI1,DATA TO HI1,XHI SCK

LCD PWM

CHIME SDA,CHIME SCK,CHIME VDD

XCC DOWN

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

CN2903

FOR ADJUSTMENTS

17 20

SWP

ATF ERR

95

60

78

|

(4-35)

IC2401

MECHA

CONTROL

26

|

37

FRRV

106

TRRT

2-4

TRRV

X2400

20MHz

|

108

74

|DATA FROM MS VSP,XMS SCK VSP

76

1

2

83

•

82

•

81

104

80

CAP FG

115

45

CAP ON,CAP FWD

•

46

CAP PWM

69

DRUM PWM

68

47

•

DRUM ON,DRUM MASTER CLK,DRUM FWD

48

•

63

DRUM FG

116

DRUM PG

117

49

LM+

•

LM-

50

TREEL FG

114

SREEL FG

113

TAPE END

54

TAPE TOP

53

DEW DET

96

TAPE LED ON

55

REC PROOF SW

44

39

MODE SW A - MODE SW D

|

42

CN2902

CN2902 CN2902

49

49

51

51

CN2301

|

10

7

11

38

32

|

36

37

40

12

64

55

27

60

63

61

IC2504

IC2503

SPCK1

TXDT 0-4

XTDT 0,1

SWP

11

38

32

36

37

40

12

64

55

27

60

63

61

CN2301

MR-44 BOARD

CRCK

HP CK

(4-54)

LPF

(4-53)

LPF

41

27

26

22

30

32

61

(1/2)

(1/2)

(4-55)

IC1900

(TRX)

CLOCK CONV.

IC1814 CONT.

VITERVI

TIMING GEN

SYNC DETECT

ID DETECT

47

50

DATA FROM MS DRP,DATA TO MS DRP,XMS SCK DRP

CN2301

36

939293

16

13

11

AD DT

6

6

1

PB CK

7

51

•29•

CAP VSC

18

IC3200

DRUM VSC

92

22

(4-41)

15

20

13

PWM

DRIVE

(4-57)

IC1814

(TRF)

EQ

A/D CONV.

PLL

22 24

34

(2/2)

PB Y OUT

42

•

31

SWP

50

50

73

73

•

•

70

70

Q3210

SWITCHING

61

Q3211

SWITCHING

58

95

95

97

97

94

94

96

96

71

71

26

26

68

68

52

52

53

53

75

75

72

72

45

45

48

48

80

80

76

76

17

17

79

79

78

78

85

85

|

|

88

88

43

43

44

44

46

46

16

16

CN2902 CN2301

40

42

27

CAP VS

DRUM VS

53,54,55

(4-58)

IC1816

(TRW)

REC/PB

AMP

17

13,15

35

5,20

(4-53)

60

4

41

42

45

48

50

52

IC2504

(4-54)

IC2505

(4-54)

IC2503

DRUM MOTOR DRIVE

LOADING MOTOR

TAPE END DETECT

TAPE TOP DETECT

6

•

7

2

•

1

CAPSTAN

FG AMP

CAPSTAN

MOTOR

DRIVE

DRUM

MOTOR

DRIVE

DRUM FG AMP

DRUM PG AMP

PRE DRIVE

REEL FG AMP

CN1810

ODD

EVEN

(2/2)

(1/2)

1,4,6,19,21,24

5

•

6

3

•

2

MR-44 BOARD(1/2)

18,19

31,33,34

2,23,18

19,20,21

(2/2)

63

1

30,32

31,33

12,13

43,44

46,47

49

51

(4-54)

8,17

IC2505

LOADING MOTOR

DRIVE

D-300MECHA DECK

CN2302

28

•

30

32

|

39

•

48

|

51

5

|

10

2

1

CN2303

9,16

4

11,14

(2/2)

CN2302

XCC DOWN

CN2304

3

1

20

21

22

23

24

27

18

25

12

|

15

11

4

|

1

DRUM

M902

CAPSTAN

M

M901

M

DRUM FG

DRUM PG

M

DEW

SENSOR

T REEL

SENSOR

S REEL

SENSOR

Q902

TAPE END SENSOR

Q901

TAPE TOP SENSOR

D901

TAPE LED

REC PROOF

4PIN

CONNECTOR

C IN

MODE

SWITCH

S902

FG

CAPSTAN

MOTOR

DRUM

MOTOR

M903

LOADING

MOTOR

S901

S903

(4-52)

CN901

3-3 3-4

Page 65

DCR-PC100/PC100E

OVERALL BLOCK DIAGRAM-3

CONTROL SWITCH BLOCK(ME-4950)

S1101-1112

MEMORY FUNCTION SW,

MENU SW,TITLE SW,

VOLUME SW,

DIGITAL EFECT SW,

END SEARCH SW,

DISPLAY SW

CONTROL SWITCH

BLOCK

(FK-4950)

S1001-1006,1009-1014,

S1050,1051,1054-1058

VTR FUNCTION SW

CAMERA FUNCTION SW

S1054

PHOTO FREEZE SW

S1059

EJECT SW

S1008

START/STOP SW

S1007

POWER SW

S1052

RESET

CONTROL

S1053

RV1001 ZOOM VR

BT1050

LITHIUM BATTERY

J952

LANC

J901

BATTERY

TERMINAL

S

DC IN 2

(4-67)

DIAL

CN1051

FJ-25 BOARD(2/2)

CN911

1

2

3

CN910

1

3

16

FP-128

(FLEXIBLE)

(2/2)

1

1

23

23

3

3

18

18

16

16

20

20

15

15

7

7

9

9

11

11

25

25

19

19

21

21

26

26

17

17

CN001

Q911

F915

F914

F913

F912

F911

PHOTO FREEZE

EJECT

S S SW

VTR,CAM,PHOTO

HI RESET

ZOOM

LI

F910

Q914-916

REG

Q918

(4-70)

CN1001

(4-69)

(4-61)

CN900

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

VC-227 BOARD(3/3)

CN2917

4

4

2

2

CN2918

12

23

13

18

7

9

19

15

16

17

24

22

21

11

20

23,24

21,22

10-12

29,30

LANC SIG

25

BATT SIG

26

BATT/EXT

34

BATT UNREG

28

A UNREG

B UNREG

4-6

C UNREG

1-3

D UNREG

7-9

42

39

CN2904

10-12

29,30

23,24

21,22

25

26

34

28

4-6

1-3

7-9

42

39

(4-41)

IC3200

DC/DC

CONVERTER

BATT FET ON

3

7

VTR DD ON

SHOE ON

(2/2)

(4-37)

IC2201

VDD SWITCH

RESET

UNREG

MT 4.8V

A 3.1V

D 3.1V

1.9V

LCD 2.8V

EVF 2.8V

A 2.8V

AU 2.8V

2.8V

-7.5V

15V

LCD 15.5V

LCD EVF 12V

3.3V

RP 4.6V

LCD 4.6V

4.6V

AU 4.6V

SHOE UNREG

(4-38)

IC2204

CN2902

LANC SIG

EVF VG

EVF VCO

VD

HD

Y

CR

CB

HD

CN2911

8

7

1

2

30

21

20

CN2301

8

IR V

7

IR L

1

IR R

2

SIRCS PWM

30

21

20

DATA FROM MS VSP,XMS SCK VSP

DATA FROM HI,DATA TO HI,XHI SCK

DATA FROM HI,DATA TO HI,XHI SCK

CN2916

2

4

1

4

CN2903

FOR

5

ADJUSTMENTS

10

VF-138 BOARD

CN5001CN2923

13

13

15

15

9

9

8

8

7

7

6

6

5

5

2

2

33

CN8002CN2915

22

CN8001

1

1

2

2

9

9

10

10

5

5

6

6

7

VG

VCO

KEY AD4

KEY AD5

KEY AD0

|

KEY AD3

XPHOTO FREEZE

XEJECT SW

XS/S SW

XVTR MODE SW

XCAM+STBY SW

XPHOTO STBY SW

DIAL A

DIAL B

VDD

XRESET

LANC IN

LANC OUT

IB SI

IB SO

BATT/EXT

HI CONTROL

XSIRCS IN

SIRCS CARRIER

SIRCS EN V

CHIME AD0

CHIME AD3

XCC DOWN

XCS OSD

OSD SO

XOSD SCK

KEY AD6

KEY AD7

VTR DD ON

SHOE ON

BATT FET ON

HI SCK

HI SO

4

Q2200,2203

36

MOD

59

40

X2200

20MHz

41

52

X2201

32KHz

53

71

|

|

73

18

44

|

46

33

HI SI

|

35

99

100

29

81

50

Y,CR,CB

HD,VD

LCD PWM

97

98

93

|

96

19

17

16

14

15

20

67

68

31

42

6

5

(4-37)

IC2203

11

LANC I/O

Q2206

51

62

63

65

87

38

10

1

12

2

48

I/F

49

66

1

41

46

48

18

14

13

(4-51)

IC2301

REMOTE COMMANDER

RECEIVER

(4-60)

IC7501

IR TRANSMITTER

(4-59)

IC7500

EVR

XCC DOWN

LCD PWM

200M SWAD

OSD CS,SO,SCK

LANC SIG

Y,CR,CB,HD,VD

IR V,IR L,IR R

S001

PANEL REVERSE SW

S002

PANEL OPEN SW

IC5001

20

19

(4-79)

19

IC8200

20

21

PD-125 BOARD

EVR

(4-82)

EVR

MR-44 BOARD

(2/2)

Q7500-7505

LED

22

DRIVE

TO

OVERALL BLOCK

DIAGRAM(2/3)

(SEE PAGE 3-3)

TO

OVERALL BLOCK

DIAGRAM(1/3)

(SEE PAGE 3-1)

FP-129

(FLEXIBLE)

9

45,27

20

21

8

•

9

•

10

13

14

8

•

9

•

107

D7501,7502

(IR LED)

(4-38)

INV CURRENT

(4-80)

IC5000

(4-82)

IC5002

TIMING

GENERATOR

VCO

34,35

IC8201

TIMING

GENERATOR

(4-78)

IC8001

RGB

DRIVE

DRIVE

44,42

VCO

LED

DRIVE

ND901

BACK LIGHT

Q8010

VG

CN5501

DET 23

BACK

2

LIGHT

|

5

CN5502

3

2

4

1

5

10

11

14

6

7

8

12

13

CN8200

COM

VG

COM

PSIG

VCO CENT

22

|

19

13

|

8

6

4

5

3

1

2

4

5

LCD902

LCD

PANEL

CN8201

FOR

ADJUSTMENTS

LCD901

LCD

PANEL

Q5500-5505

20

•

VR,VG,VB

22

RGB

(4-79)

•

20

16

12,16,17,18

20-24

INVERTER

BLOCK

1-3,39-45

37

20

•

22

•

24

COM

PSIG

VR,VG,VB

3-5 3-6

Page 66

DCR-PC100/PC100E

3-2. POWER BLOCK DIAGRAM-1

FJ-25 BOARD

(4-61)

Q917,

SHOE ON

Q912,

913

CHARGE

SWITCH

CONTROL

SWITCH

BLOCK

(ME-4950)

(4-70)

SWITCH

918

INIT CHARGE ON

J901

BATTERY

TERMINAL

S

J902

DC IN

1

2

3

1

2

3

CN911

BATT UNREG

BATT SIG

ACV UNREG

BATT/XEXT

CN910

LF910

Q910,

911

J952

LANC

BATT FET ON

F910

F911

F915

F914

F912

F913

CN900 CN2904

35

35

42

42

39

39

26

26

34

34

27

27

11

CN1001

( ) : Page No. shown in ( ) indicates the page to refer on the schematic diagram.

VC-227 BOARD(1/2)

4

1

Q3206

SWITCHING

2.8V

CN2917

Q914-916

4.8V

REG

T3200

INIT CHARGE ON

SHOE ON

BATT FET ON

BATT SIG

BATT/EXT

LANC DC

CN900 CN2904

29,30

•

21

22

29,30 29,30

10-12 10-12

4-6

7-9

1-3

Q3207

3252

5

D3206

RECT

6

8

D3207

RECT

2

D3205

RECT

3

VTR DD ON

(4-19) (4-18) (4-18)(4-18) (4-17) (4-20)

IC763

64M

SDRAM

2.8V

D3.1V

29,30

21•22

4-6

7-9

1-3

EMERGENCY

DETECT

VREF

SHOE UNREG

MT 4.8V

A 3.1V

3232

BATT UNREG

2828

UNREG

A UNREG

B UNREG

D UNREG

C UNREG

D3221

55

28

46

57

49

60

8

7

3

27

33

34

35

29

30

IC756

JPEG

VCC(0)1234

VCC(0)5678

VCC

VSS(0)1234

VSS(0)567

VDD(0)123

VDD(0)567

+IN8

-IN8

OUT8

VREF

VB

RT

CT

CTL1-6,8

CTL7

IC3200

DC/DC CONVERTER

(4-41)

OUT7-1

OUT7-2

OUT3-1

OUT3-2

OUT2-1

OUT2-2

IN4(C)

OUT1-1

OUT1-2

OUT6-1

OUT6-2

+IN6(C)

OUT5-1

OUT5-2

+IN5(C)

-IN7

-IN3

-IN2

OUT4

-IN4

-IN1

+IN6

+IN5

IC766 IC764

16M DRAM

FAST PAGE

64

12

13

53

54

40

50

51

43

56

37

11

47

48

44

61

62

18

17

58

59

22

21

EEPROM

Q3208

SWITCHING

SWITCHING

SWITCHING

SWITCHING

SWITCHING

SWITCHING

SWITCHING

FB755

Q3212

Q3213

Q3214

T3201 D3217

4

1

Q3209

Q3210

Q3211

IC761

DIGITAL