SERVICE MANUAL

CDP-D500

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type

Base Unit Name BU-5R

Optical Pick-up Name KSS-213B/K-N

CDM19G-5R

SPECIFICATIONS

– Continued on next page –

COMPACT DISC PLAYER

MICROFILM

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

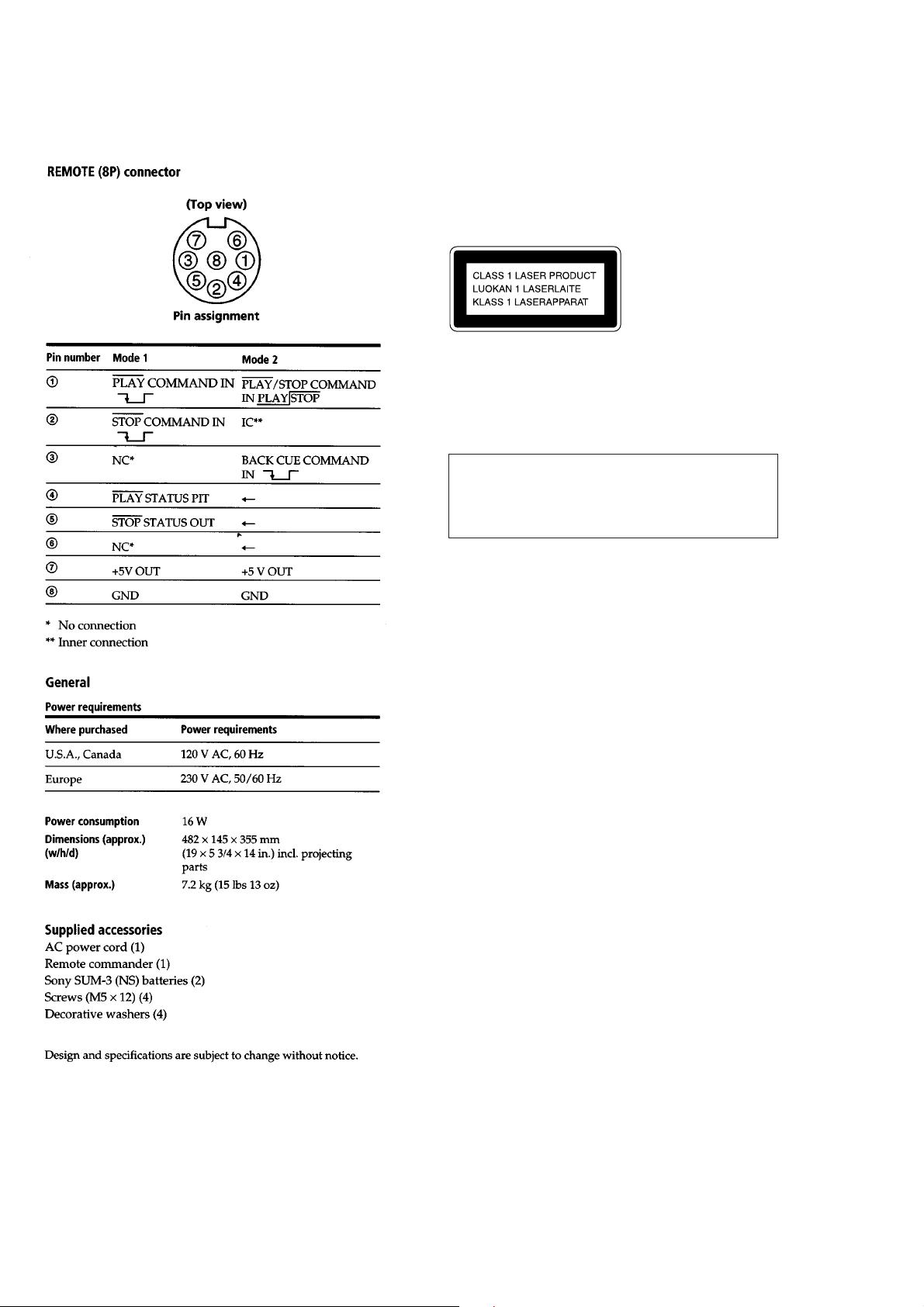

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on the

rear exterior.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMA TIQ UES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

– 2 –

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

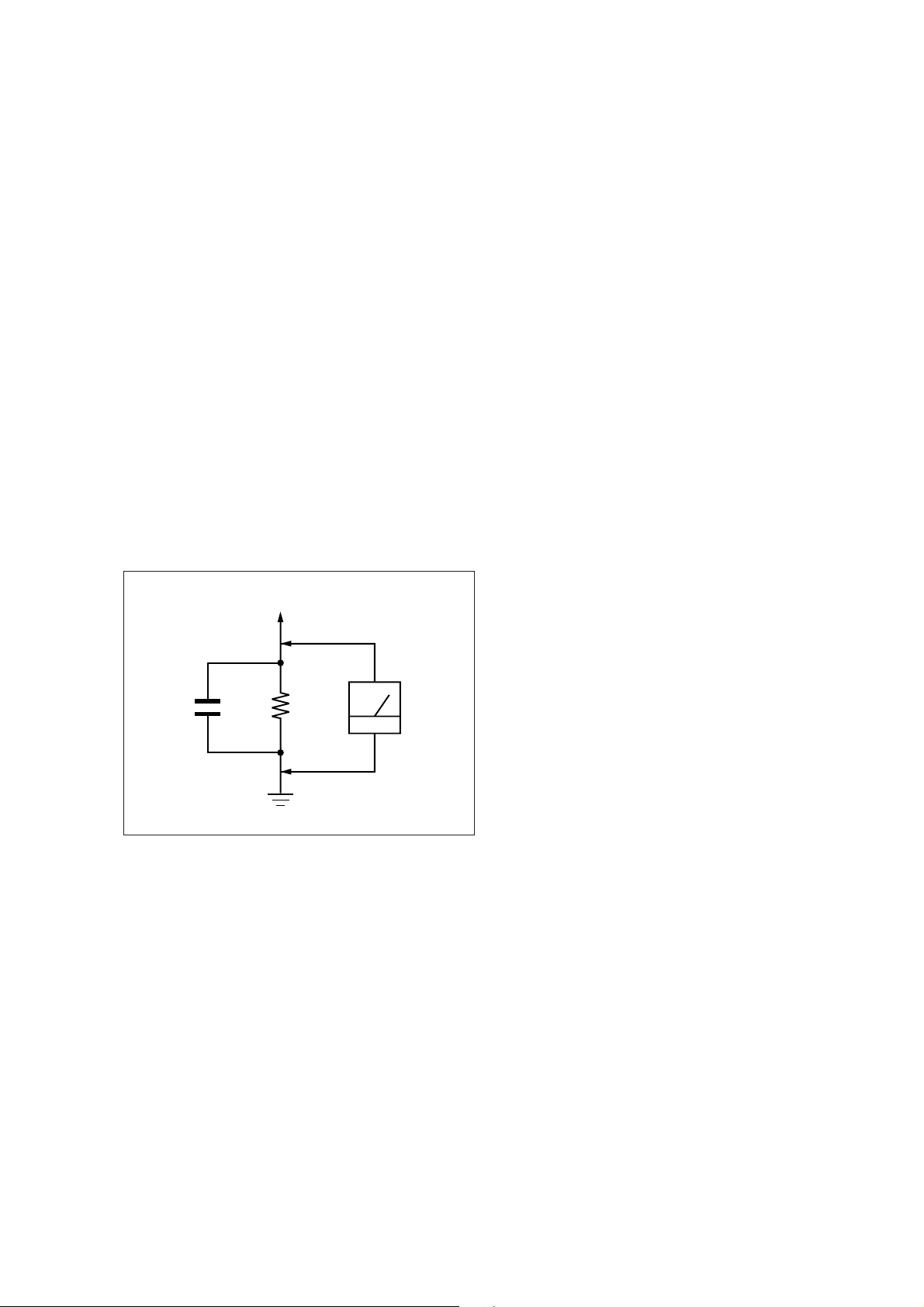

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V AC range are suitable. (See Fig. A)

TABLE OF CONTENTS

1. SERVICING NOTES

................................................... 4

2. GENERAL ..................................................................... 5

3. DISASSEMBLY............................................................ 13

4. TEST MODE ................................................................. 15

5. ELECTRICAL ADJUSTMENTS ............................ 16

6. DIAGRAMS

6-1. Block Diagram................................................................... 19

6-2. Printed Wiring Boards – CD Section –.............................. 23

6-3. Schematic Diagram – CD Section – .................................. 25

6-4. Printed Wiring Boards – Main Section – ........................... 28

6-5. Schematic Diagram – Main Section – ............................... 31

6-6. Schematic Diagram – Panel Section –............................... 36

6-7. Printed Wiring Boards – Panel Section – .......................... 41

6-8. IC Pin Function Description .............................................. 46

7. EXPLODED VIEWS ................................................... 49

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

8. ELECTRICAL PARTS LIST .................................... 54

– 3 –

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Make POWER switch on with no disc inserted and disc table

closed.

2. Confirm that the following operation is performed while observing the objective lens.

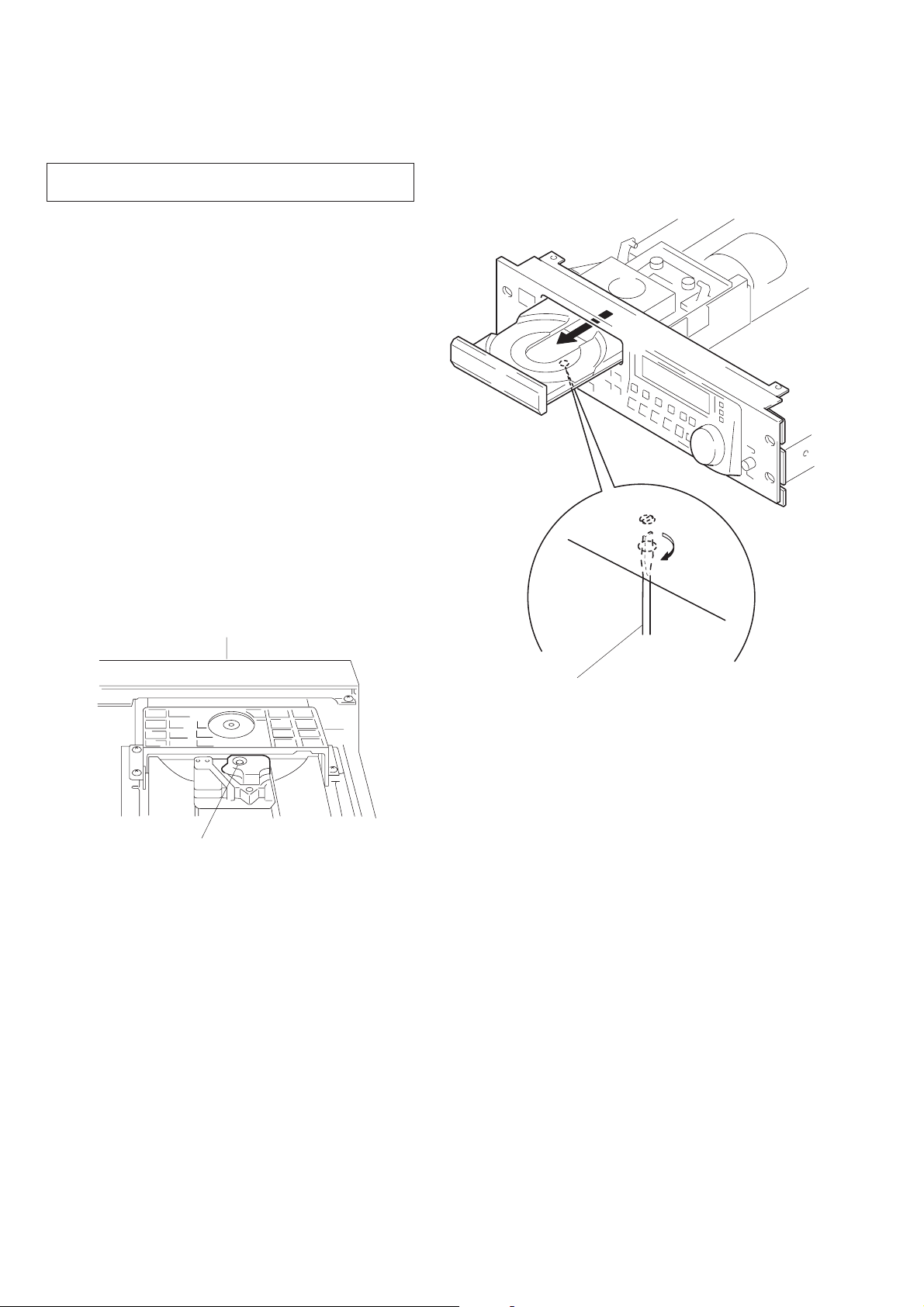

HOW T O OPEN THE DISC TRAY WHEN PO WER SWITCH

TURNS OFF

Front Panel side

1

Confirm that laser beam spread.

2

Up and down motion of the objective lens. (3 times)

Insert a tapering driver into the aperture of the unit bottom,

and turn to the direction of arrow.

* To close the disc tray, turn the driver in the reverse direction.

– 4 –

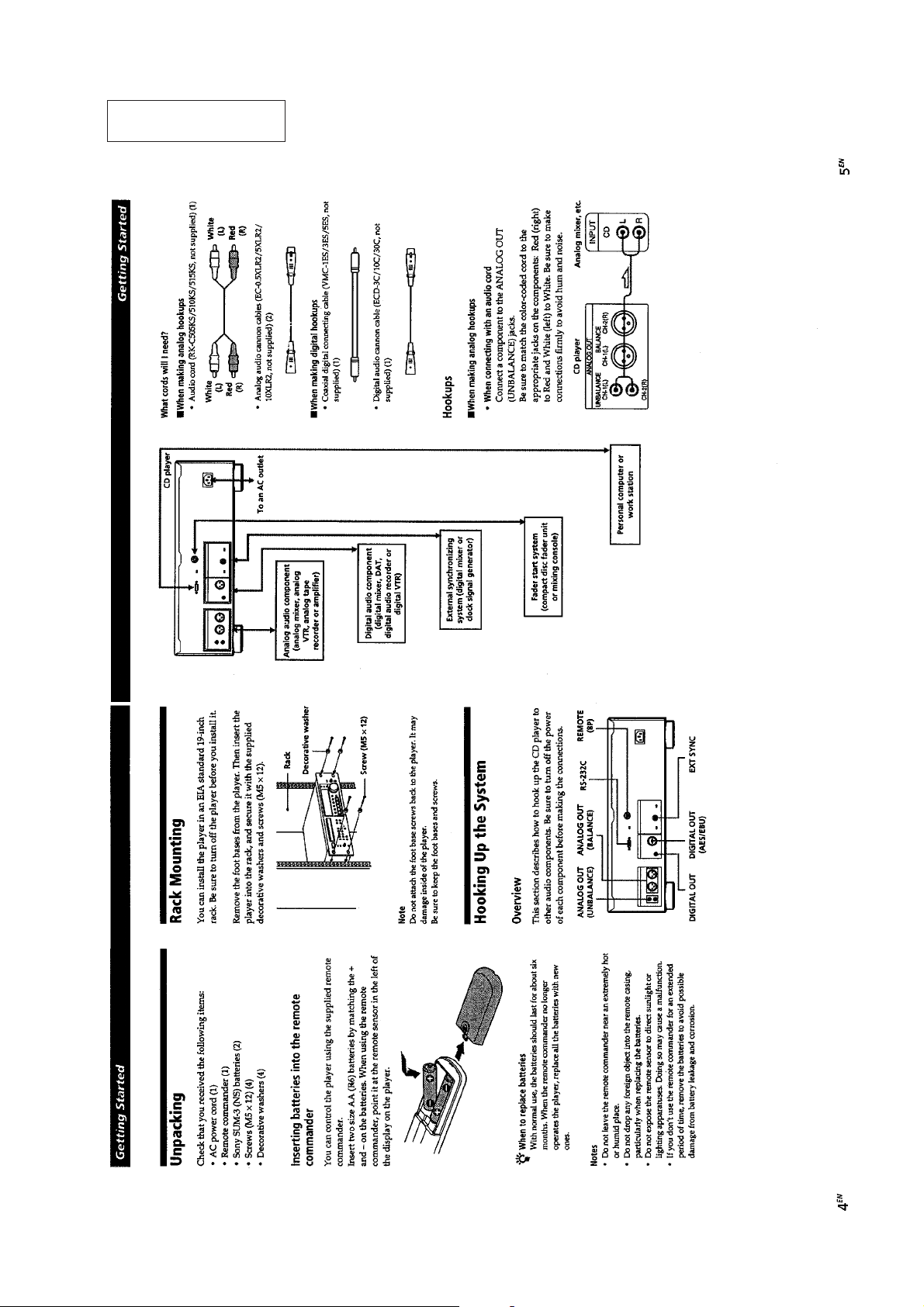

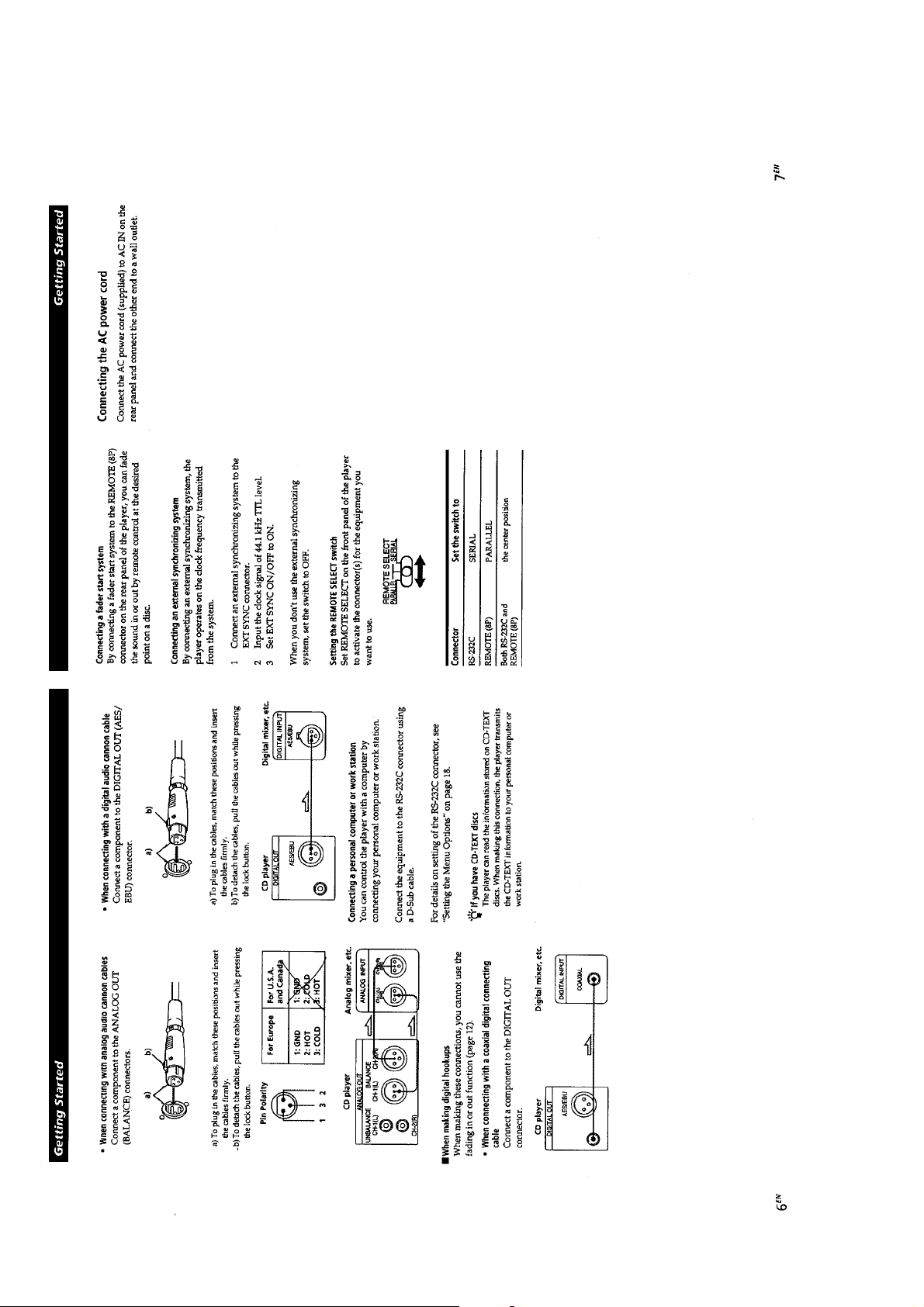

This section is extracted

from instruction manual.

SECTION 2

GENERAL

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

– 10 –

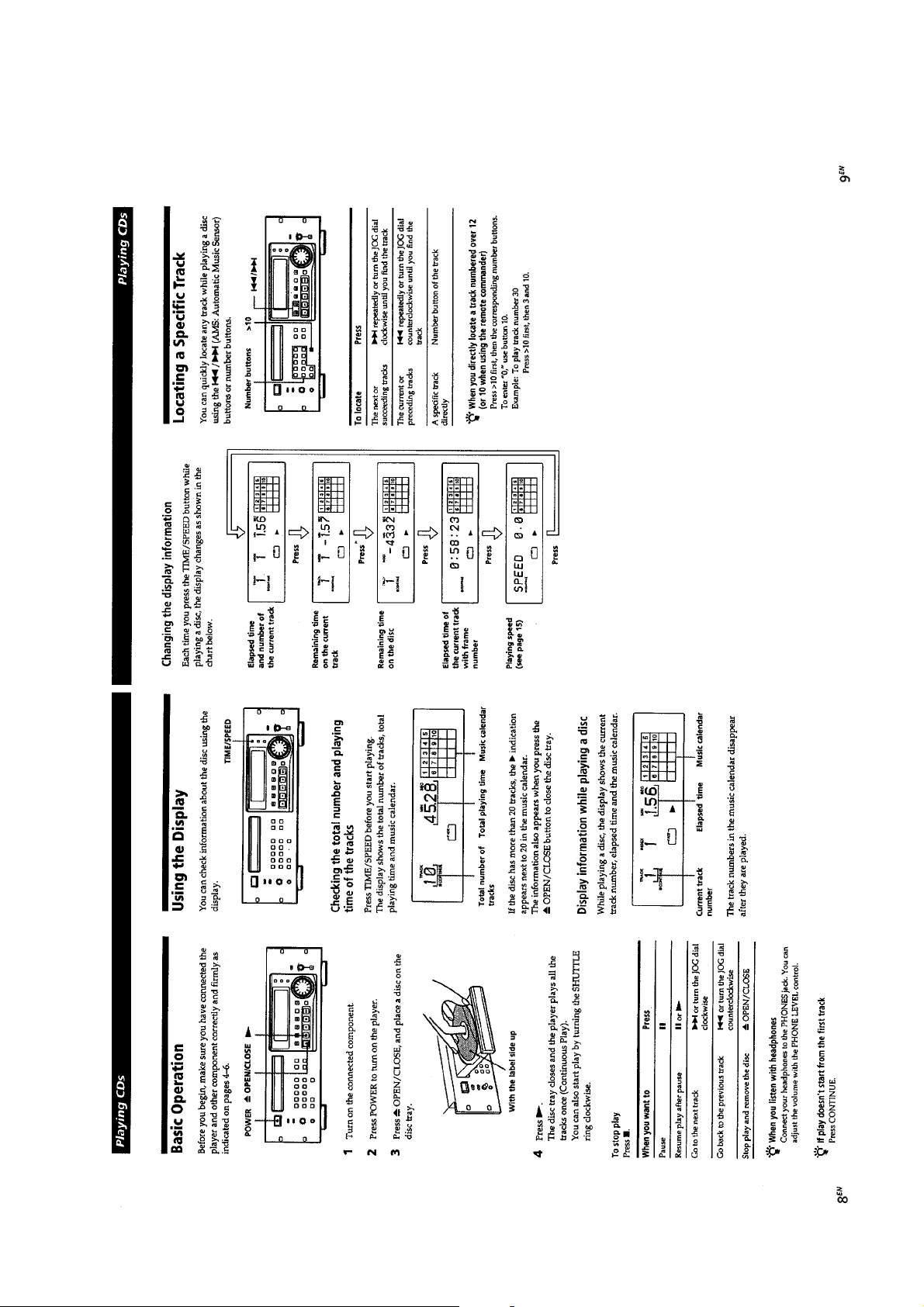

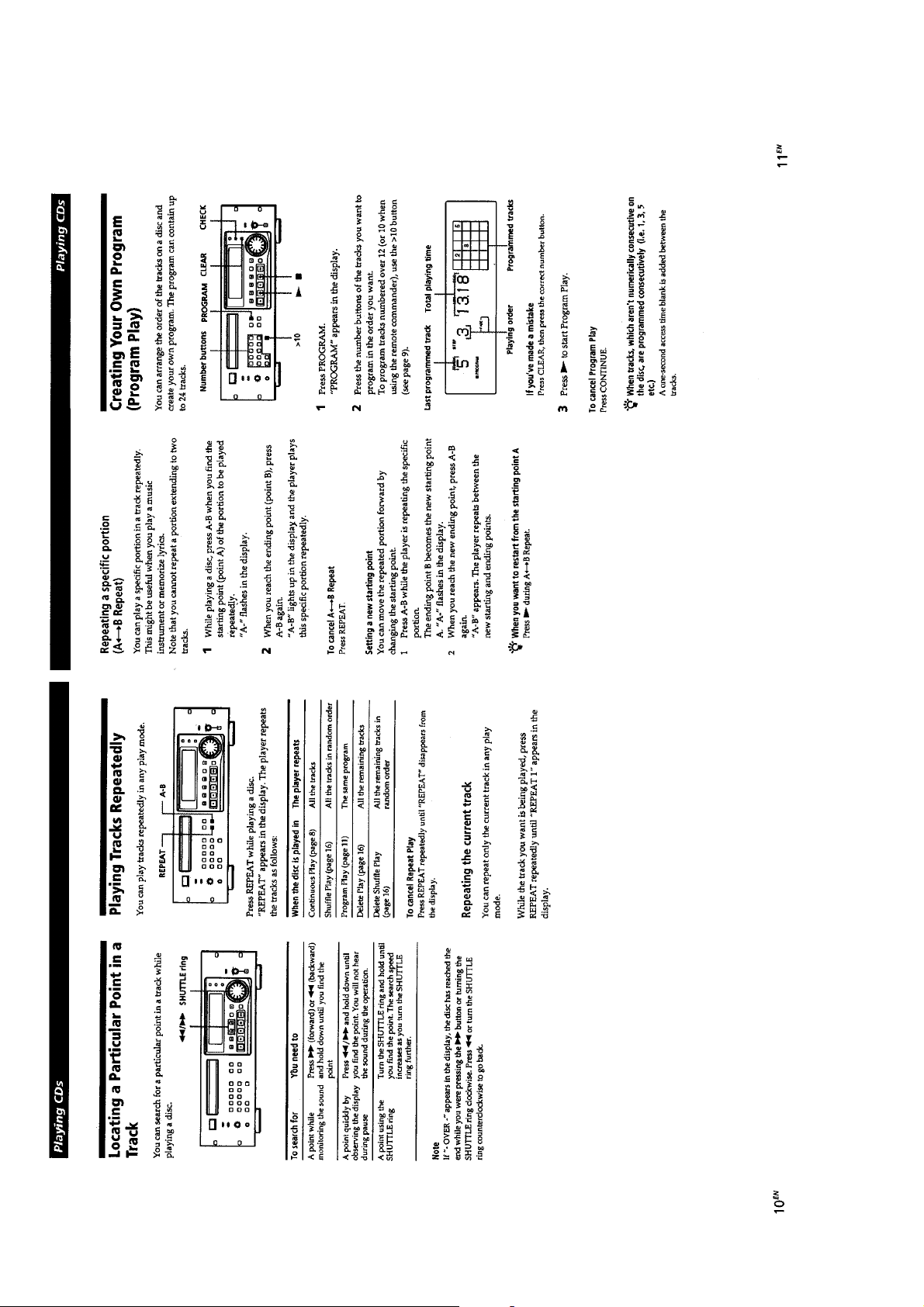

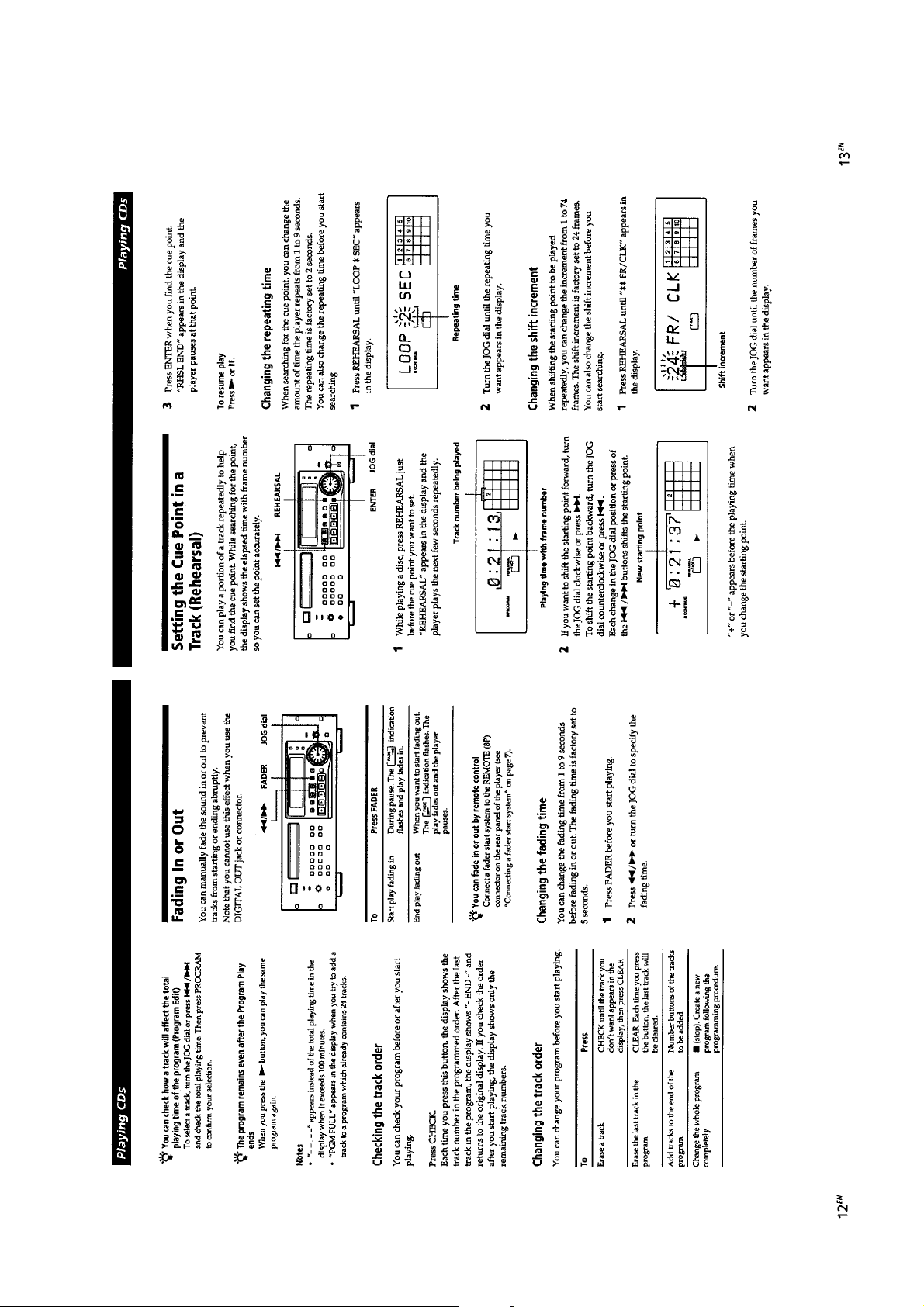

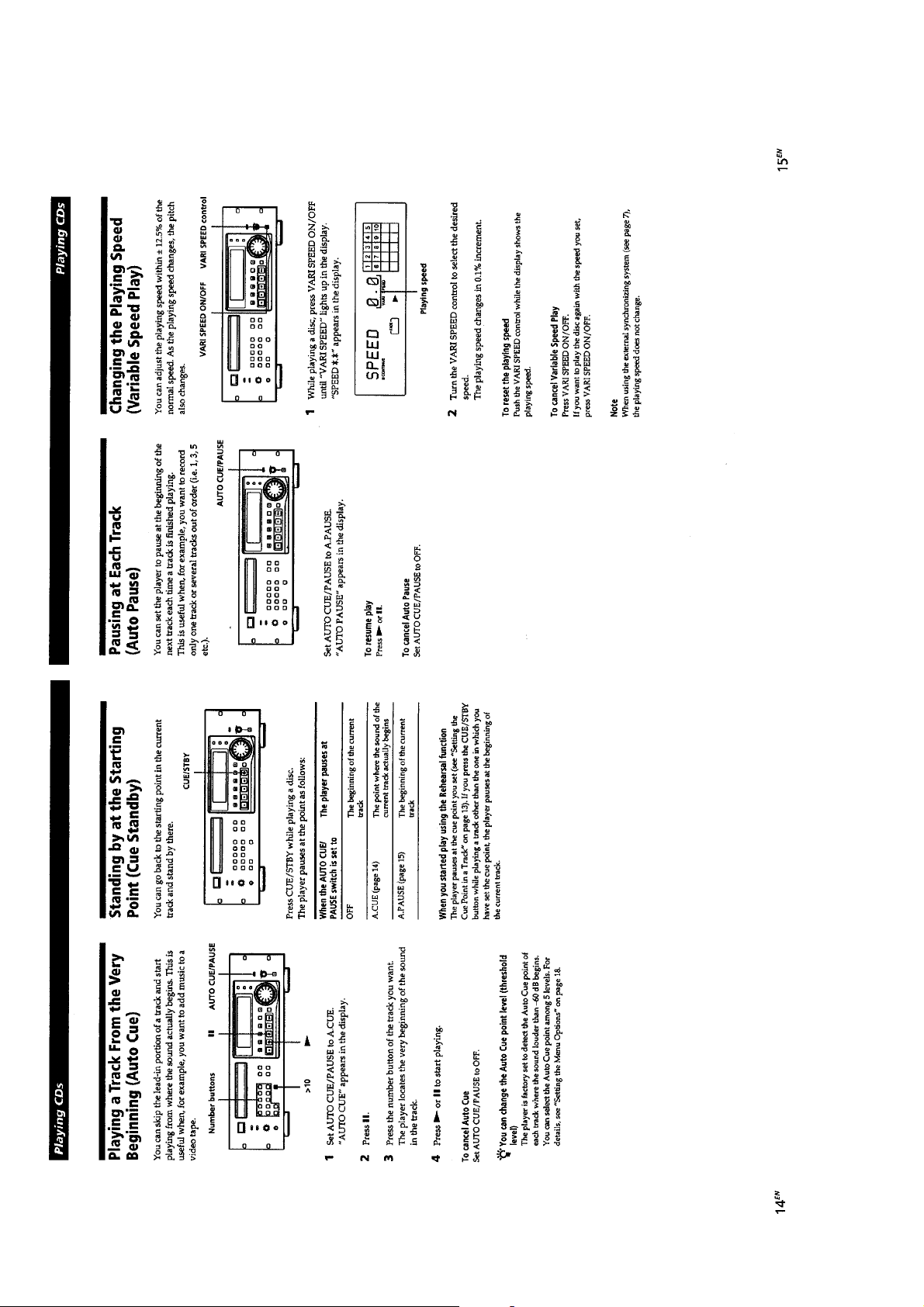

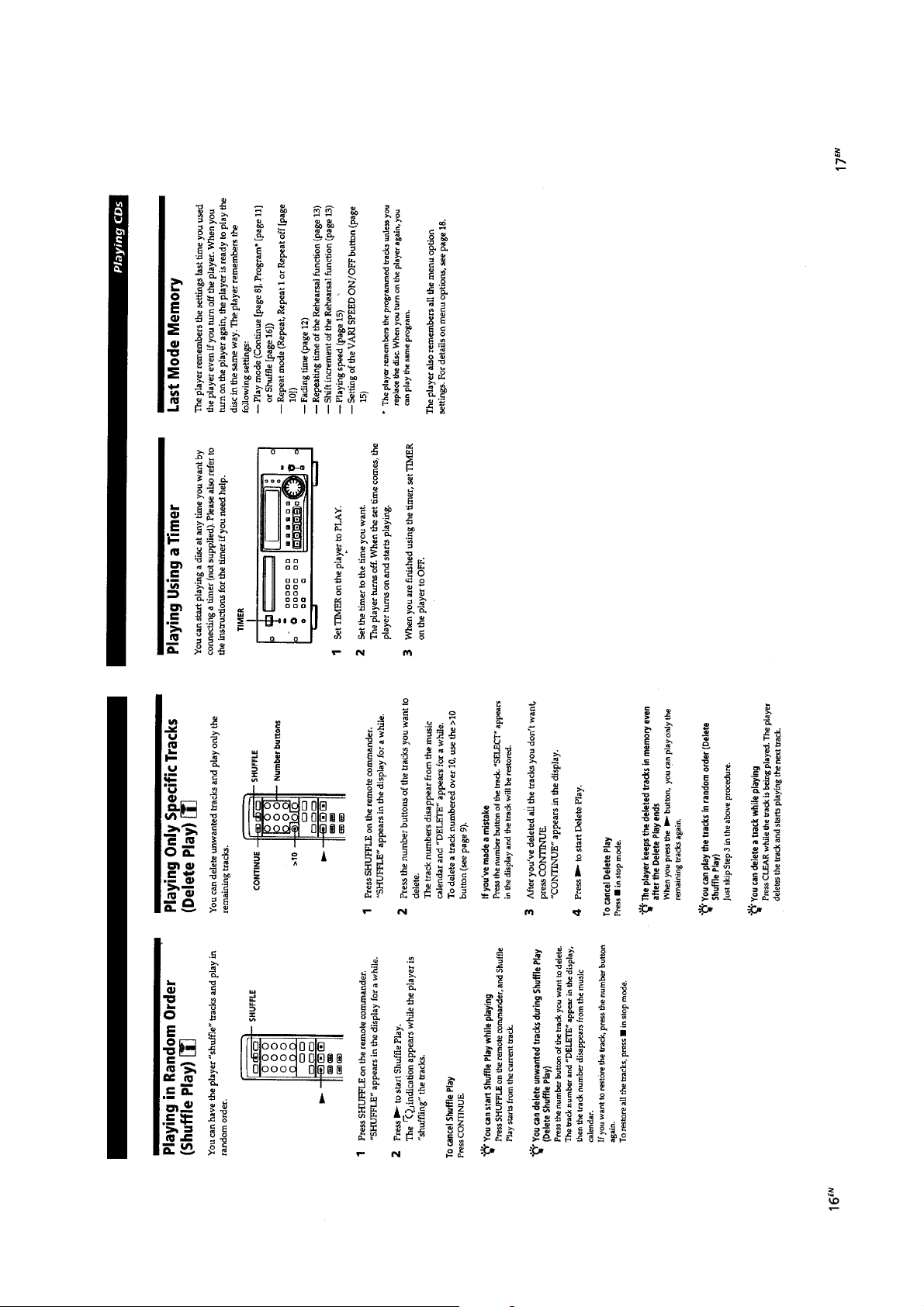

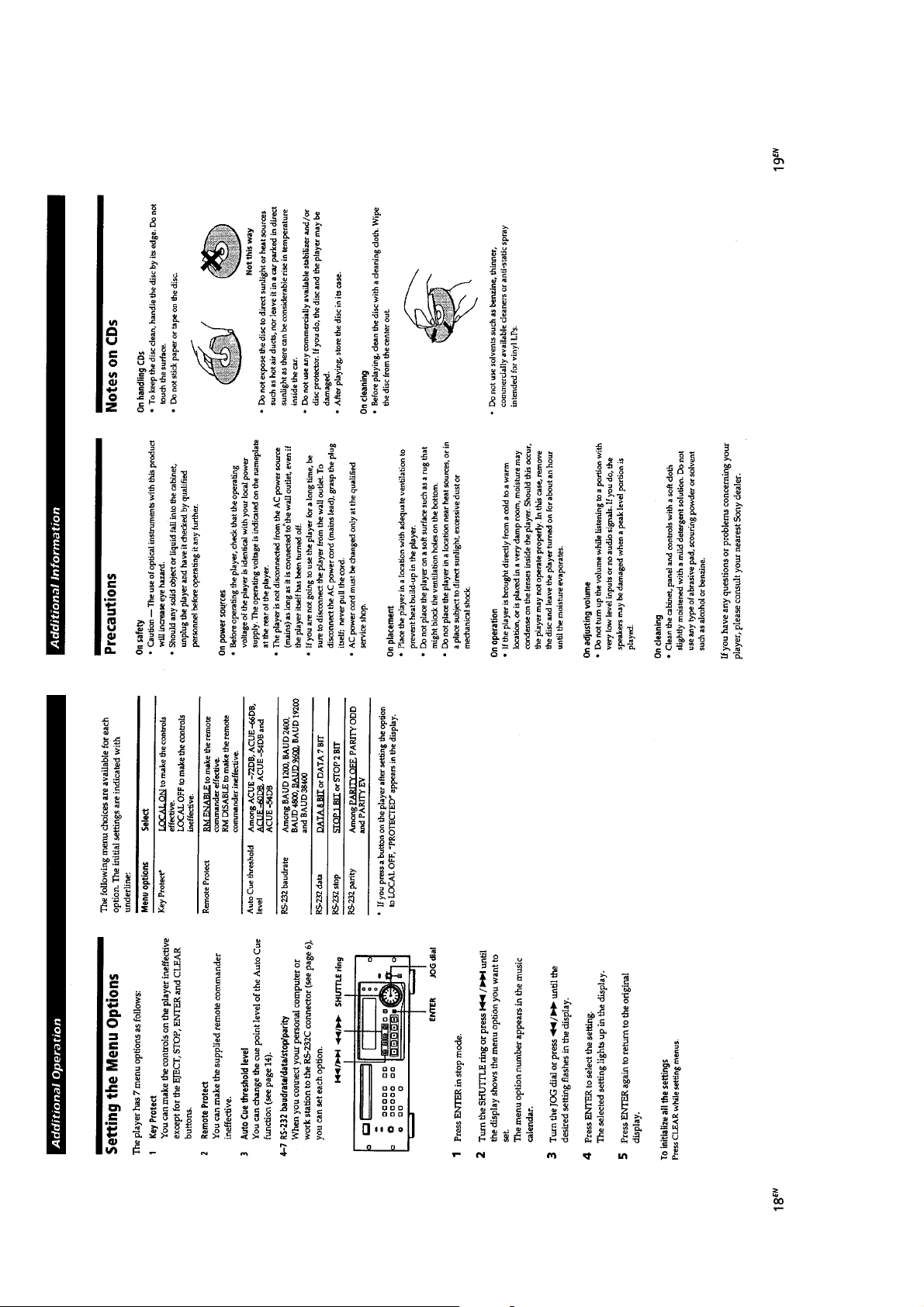

Playing CDs

– 11 –

– 12 –

SECTION 3

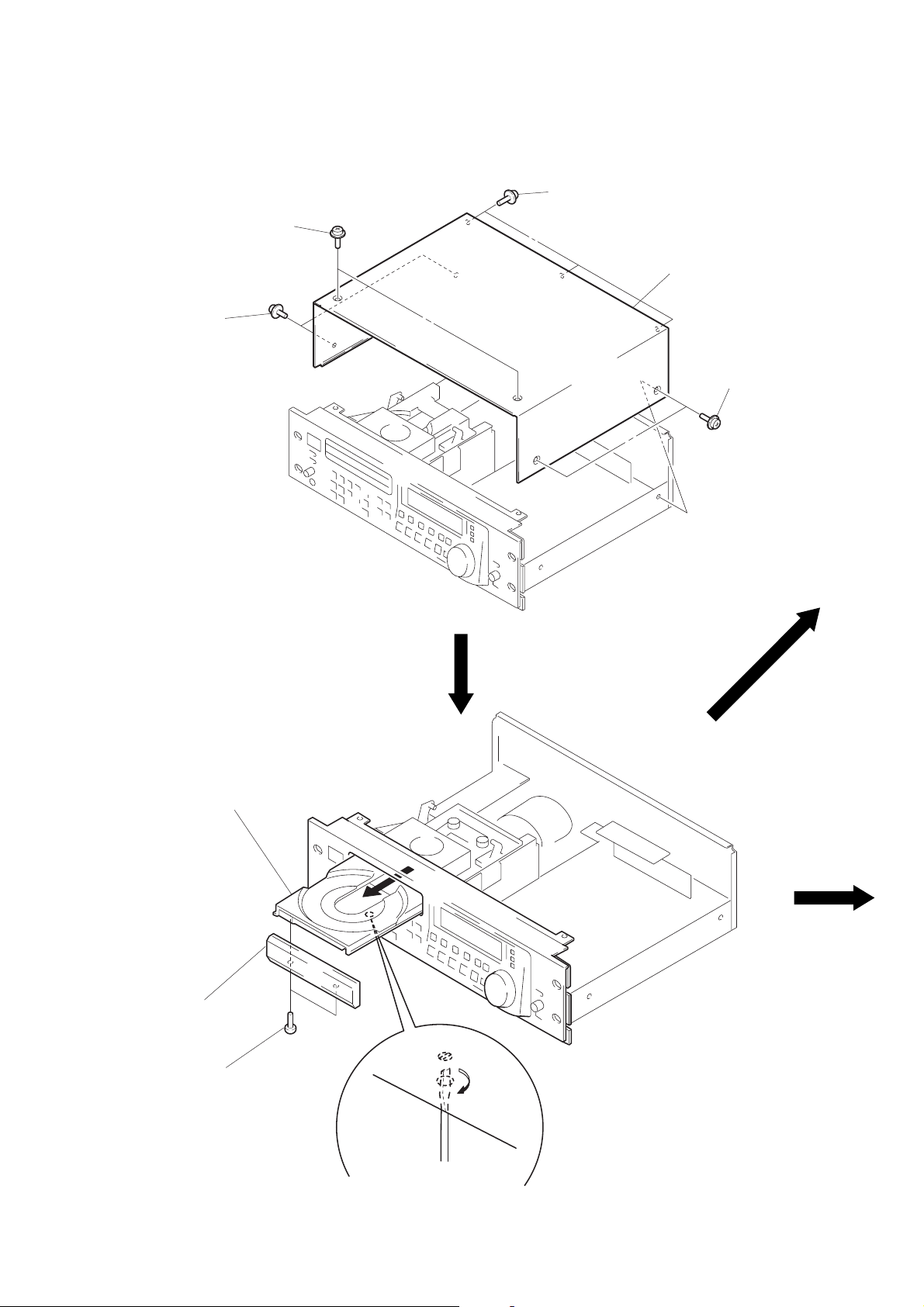

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

1

three screws

×

10)

(M3

1

three screws

×

10)

(M3

1

three screws

(M3

×

10)

2

case

1

two screws

(M3

×

10)

LOADING PANEL

2

Pull the disc table

4

loading panel

3

two screws

×

(BVTP3

10)

– 13 –

1

Insert a tarpering driver into the

aperture of the unit bottom,

and turn to the direction of arrow.

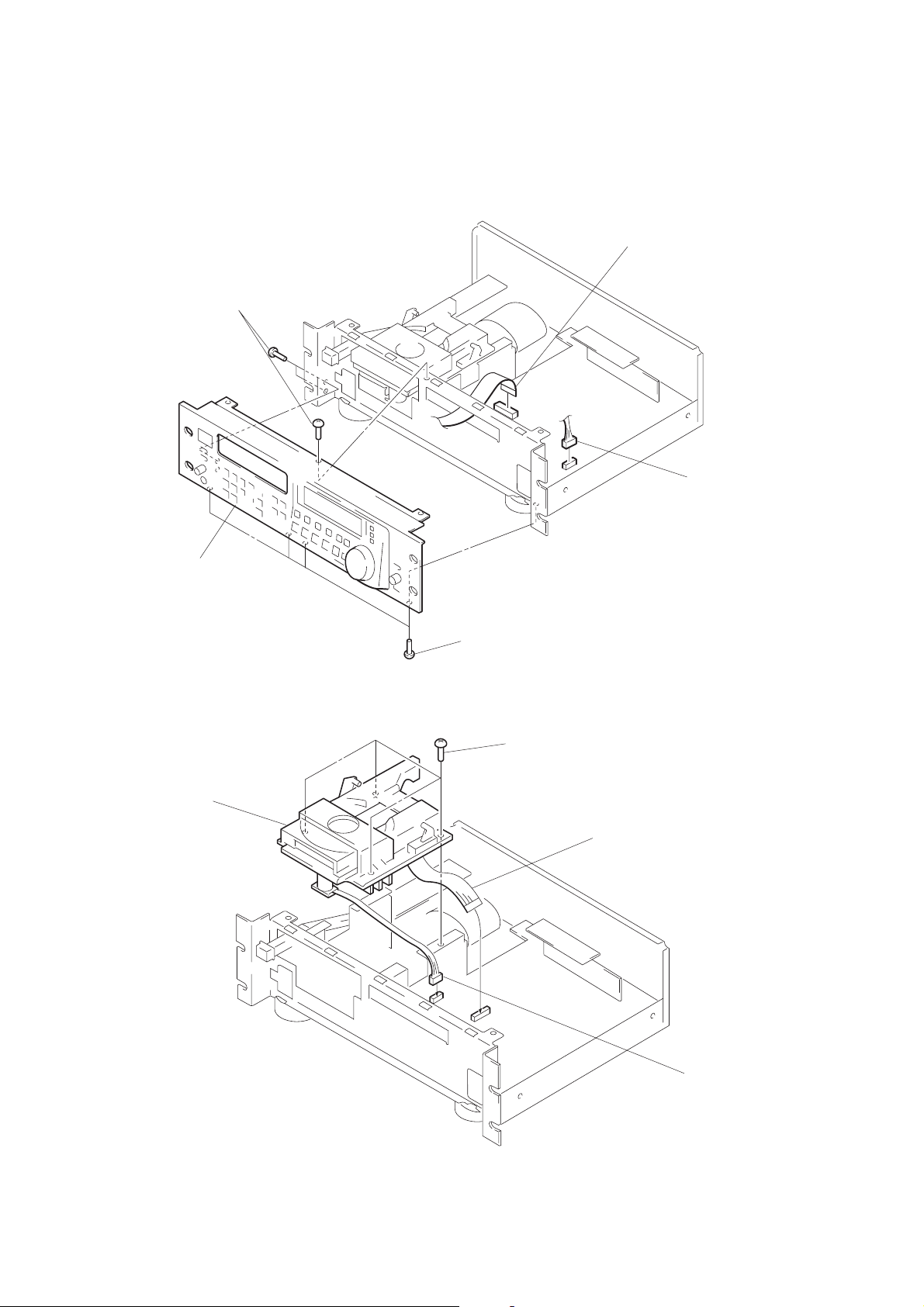

FRONT PANEL SECTION

3

4

front panel

three screws

(BVTT3

×

8)

1

flat wire (27 core)

(CN501)

2

connector

(CN331)

MECHANISM DECK

4

mechanism deck

3

four screws

(BVTT3

×

8)

3

four screws

(BVTT3

×

8)

1

flat wire (19 core)

(CN401)

2

connector

(CN531)

– 14 –

Key Check

(tact switch)

1) Connect the test point TP (ADJ) on MAIN board to the

ground with a lead wire on MAIN board.

2) Turn on the power with turning OFF the TIMER SW.

↓

“KEY TEST” shall be shown.

3) When the TA CT SW is pushed, the order of pushing is shown

on digit 0 and 1.

4) It will count up until 34 which is the maximum ke y number .

“END” will be shown after 34.

(slide switch)

Words as below shall be shown.

OFF ON

TIMER SW NULL (not shown) REPEAT

REMOTE CONTINUE/ Parallel ON → PROGRAM

SELECT SW PROGRAM Serial ON → CONTINUE

AUTO CUE/

PAUSE SW

NULL (not shown)

A.CUE ON → AUTO CUE

A.PAUSE ON → AUTO P AUSE

(JOG)

When dial the VARI SPEED JOG/AMS dial, the value on digit

6 and 7 will be clocwise/rev clockwise.

SECTION 4

TEST MODE

CXD2545 Servo Check

1) Connect the test point TP (ADJ) on MAIN board to the

2) Turn on the power, tuning ON the TIMER SW.

3) Establish as below articles with the combination of TENKEY

TIMER SW OFF 3 Tracking servo off

TIMER SW ON 1

ground with a lead wire on MAIN board.

and TIMER SW.

TENKEY MODE

8 Tracking servo on

S-cuve observe

(shuttle)

Is it turns to forward direction, calendar will show 1·2·3 and 4

and if turns to backward direction. Calendar will show 16·17·18

and 19.

EDP Bridge Check

1) Connect the test point TP (ADJ) on MAIN board to the

ground with a lead wire on MAIN board.

2) Turn on the power, with turning ON the TIMER SW.

3) Elements next to digit/segment will turn on and off mutually.

4) When both sides elements turn on at the same time the grid

is a bridge.

5) When the calendar does not work correctly, segment is a

bridge.

S-RAM Verify Check

1) Connect the test point TP (ADJ) on MAIN board to the

ground with a lead wire on MAIN board.

2) Turn on the power, with turning ON the TIMER SW and

CUE SW.

3) Address (0x8000~0x9fef) will be written by µ-com on the

digit 5 and 6, and they will be read by µ-com on the digit 8

and 9, then the value shall be shown on the digit 0 to 3.

When the written value do not agree with the read value,

“VERIFY ERROR” will be shown.

After that, it will show the position of address line and the

data line which are cause of S-RAM bridge and a float.

– 15 –

SECTION 5

ELECTRICAL ADJUSTMENTS

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

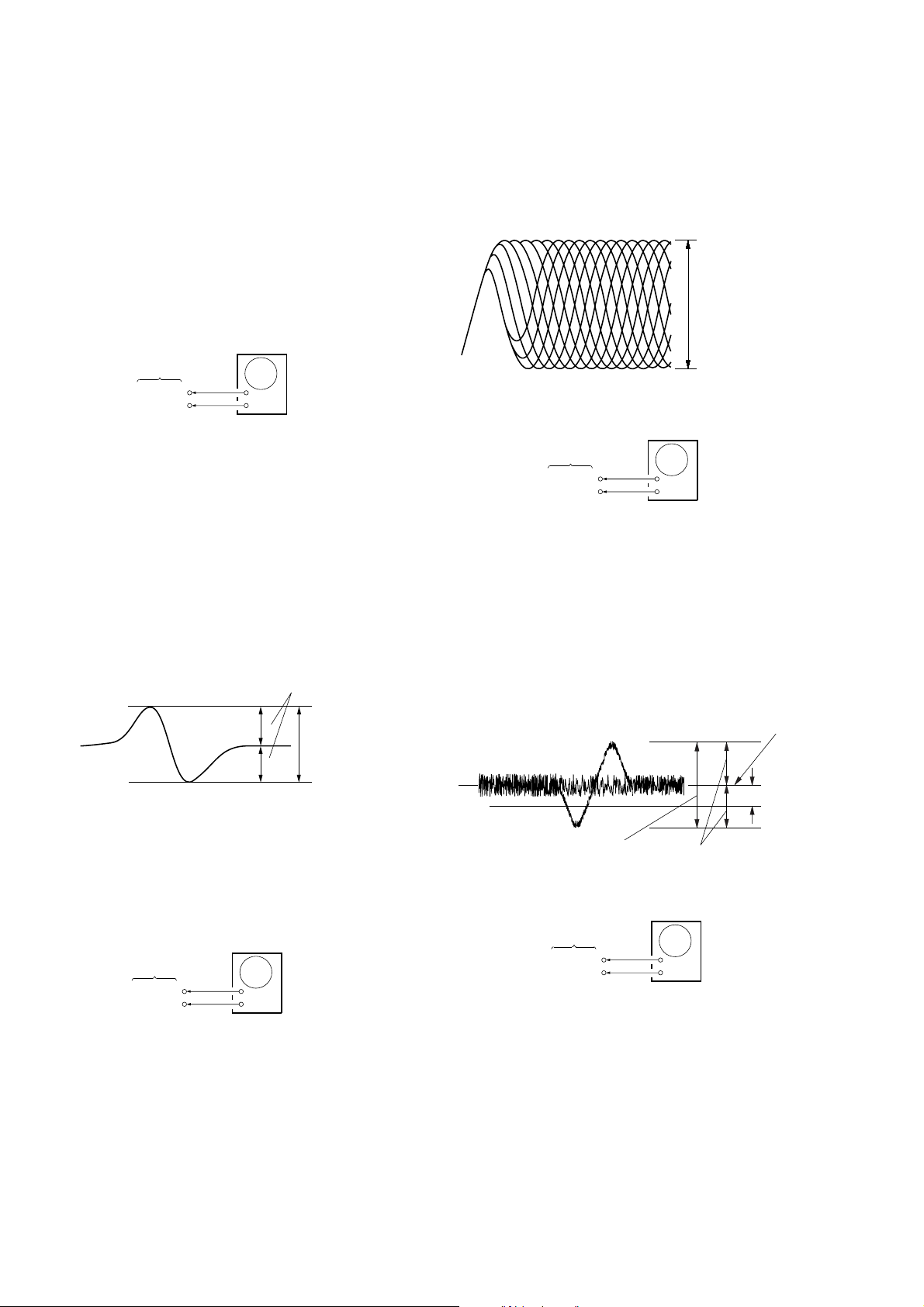

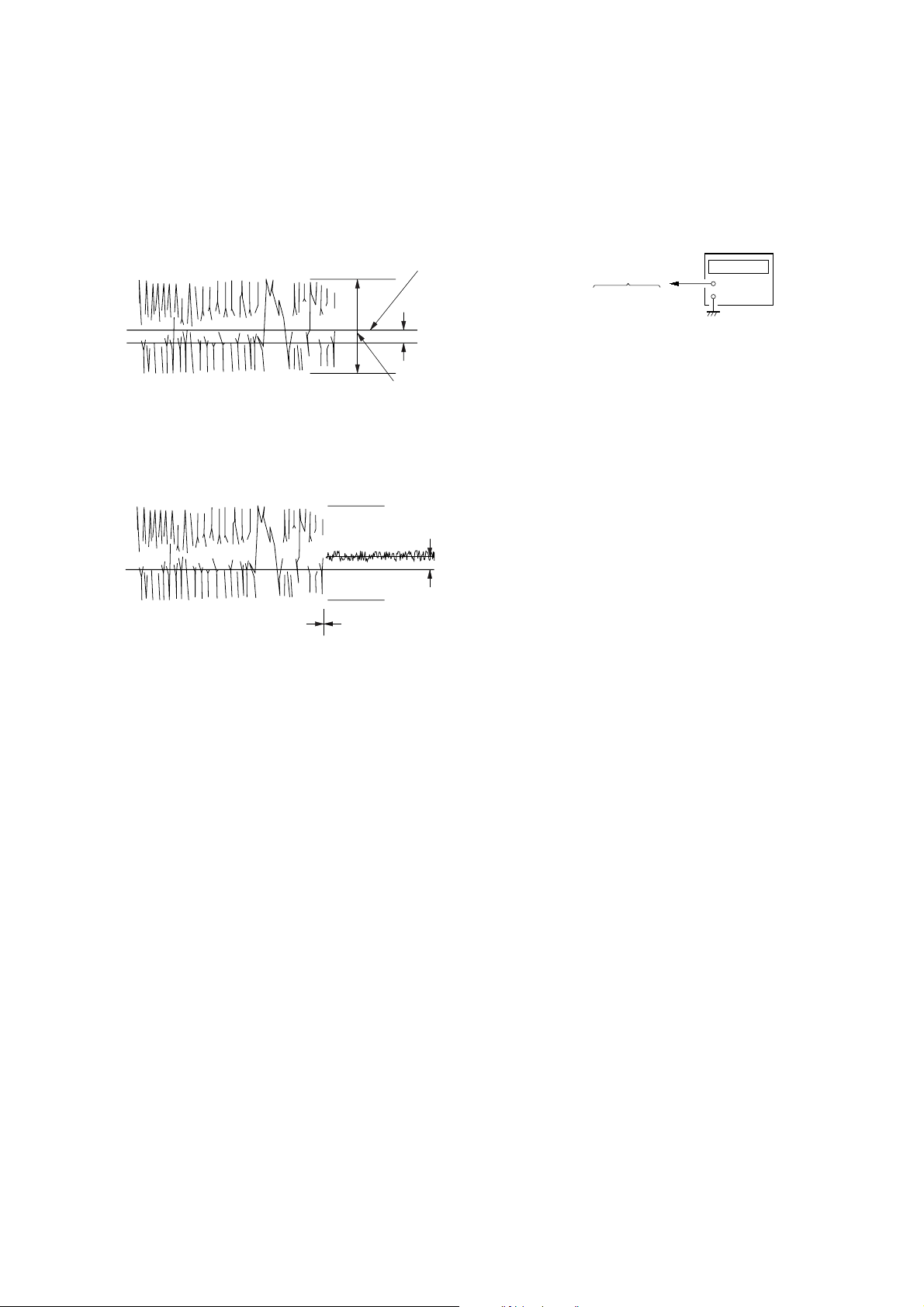

S-Curve Check

oscilloscope

BSL board

TP (FE)

TP (VC)

+

–

Procedure:

1. Connect the test point TP (ADJ) on MAIN board to the ground

with a lead wire on MAIN board.

2. Connect oscilloscope to test point TP (FE) on BSL board.

3. Turned Power switch on to set ADJ mode by TIMER SW OFF.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. TIMER SW ON.

6. Press the “1” button (s-cuve observe mode).

7. Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 3 ± 1 Vp-p.

S-curve wavef orm

symmetry

A

B

within 3

±

1 Vp-p

Note: A clear RF signal waveform means that the shape “≈” can

be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 1.2 Vp-p

+0.25

–0.20

E-F Balance (1 Track Jump) Check

oscilloscope

BSL board

TP (TE)

TP (VC)

+

–

Procedure:

1. Connect oscilloscope to test point TP (TE) on BSL board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button. (Becomes the 1 track jump mode)

5. Check the level B of the oscilloscope’s waveform and the A

(DC voltage) of the center of the Travers waveform.

Confirm the following :

A/B × 100 = less than ± 6 (%)

1 track jump waveform

Center of the waveform

B

Note: • Try to measure se veral times to make sure that the ratio of

A:B or B:A is more than 10:7.

• T ake sweep time as long as possible and light up the bright-

ness to obtain best waveform.

RF Level Check

oscilloscope

BSL board

TP (RF)

TP (VC)

+

–

Procedure:

1. Connect oscilloscope to test point TP (RF) on BSL board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

0V

level : 1.5 Vp-p symmetry

+1.5

–0.5

E-F Balance Check

oscilloscope

BSL board

TP (TE)

TP (VC)

+

–

Procedure:

1. Connect the test point TP (ADJ) on MAIN board on the ground

with a lead wire on MAIN board.

2. Connect oscilloscope to test point TP (TE) on BSL board.

3. Turn the Power switch on to set the ADJ mode. (TIMER SW

OFF)

4. Put disc (YEDS-18) in to play the number five track.

5. Press the “3” button. (The tracking servo and the sledding servo

are turned OFF.)

– 16 –

A (DC voltage)

6. Check the level B of the oscilloscope’s waveform and the A

)

)

r

(DC voltage) of the center of the Traverse waveform.

Confirm the following:

A/B × 100 = less than ± 6 (%)

Traverse waveform

Center of the waveform

B

RF PLL Free-run Frequency Check

Procedure:

1. Connect frequency counter to test point (XPLCK) with a lead

wire.

frequency counte

MAIN board

TP (XPLCK)

+

–

0V

level : 1.5 Vp-p

A (DC voltage

+1.5

–0.5

7. Press the “8” button. (The tracking servo and sledding servo are

turned ON.) Confirm the C (DC voltage) is almost equal to the

A (DC voltage) is step 6.

Traverse waveform

C (DC

0V

Tracking servo

Sledding servo

OFF

Tracking servo

Sledding servo

ON

voltage

8. Disconnect the lead wire of TP (ADJ) connected in step 1.

2. Turned Power switch on.

3. Put the disc (YEDS-18) in to play the number five track.

Confirm that reading on frequency counter is 4.3218 MHz.

Balance Level Adjustment

(Generally it does not need to adjust because it has alredy adjusted

before shipping.)

1. Turn on the disc (YEDS-18) and play the number 2 track (1 kHz

0 dBs)

2. Connect level meter to BALANCE OUT (J304)

3. Adjustment level

BALANCE OUT: +24 dBs

RV101 (L-CH)

RV201 (R-CH)

– 17 –

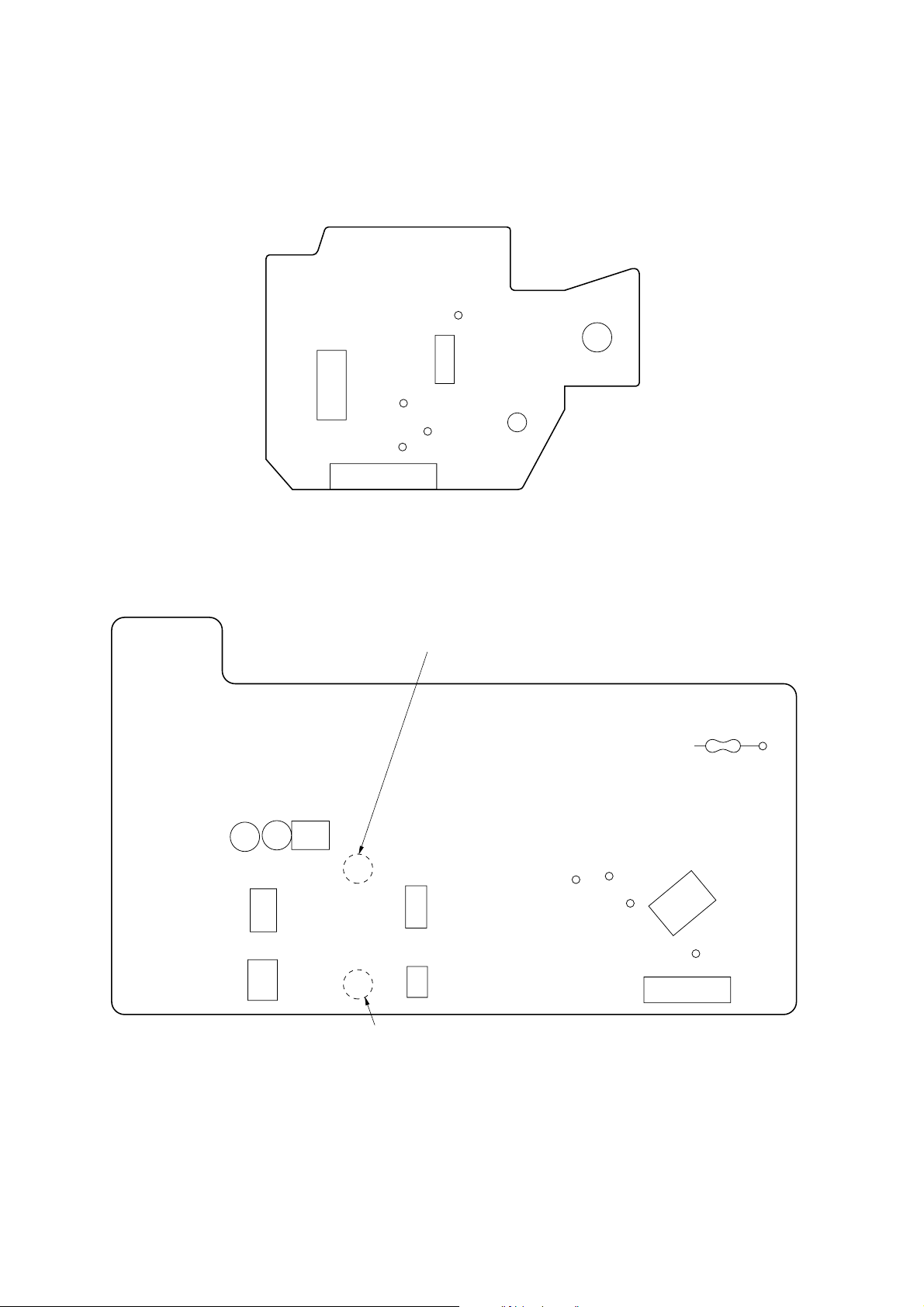

[BSL BOARD] — Side B —

[MAIN BOARD] — Component side —

IC21

CN01

TP

(VC)

TP

(RF)

TP (TE)

IC31

M102

TP

(FE)

C302

C301

IC302

IC301

IC601

RV101

BALANCE LEVEL (L-CH)

RV201

BALANCE LEVEL (R-CH)

IC304

IC303

TP

(FE1)

TP (TE1 )

TP

(VC)

R500

TP (ADJ)

IC401

TP

(XPLCK)

IC305

– 18 –

Loading...

Loading...