Sony CDPCX-50, CDPCX-571 Service manual

CDP-CX50/CX571

SERVICE MANUAL

Photo : CDP-CX50

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-46

Base Unit Type KSM-213BFN/M-NP

Optical Pick-up Type KSS-213B/S-N

SPECIFICATIONS

US Model

Canadian Model

AEP Model

E Model

Australian Model

CDP-CX50/CX571

UK Model

CDP-CX571

MICROFILM

COMPACT DISC PLAYER

— 1 —

TABLE OF CONTENTS

1. SERVICING NOTE

.......................................................... 3

2. GENERAL .......................................................................... 4

3. DISASSEMBLY

3-1. Front Panel ........................................................................... 9

3-2. Illumination ASSY................................................................9

3-3. Base Unit and Magnet Holder............................................. 10

3-4. CD Mechanism Section ...................................................... 11

4. TEST MODE .....................................................................12

5. MESHANICAL ADJUSTMENTS .............................. 15

6. ELECTRICAL ADJUSTMENTS ............................... 18

7. DIAGRAMS

7-1. Circuit Boards Location ......................................................20

7-2. Printed Wiring Board — BD Section —............................. 21

7-3. Schematic Diagram — BD Section — ............................... 23

7-4. Printed Wiring Board — Main Section —.......................... 26

7-5. Schematic Diagram — Main Section — ............................ 29

7-6. Printed Wiring Board — Panel Section — ......................... 32

7-7. Schematic Diagram — Panel Section — ............................ 35

7-8. IC Pin Functions ................................................................. 38

7-9. IC Block Diagrams ............................................................. 44

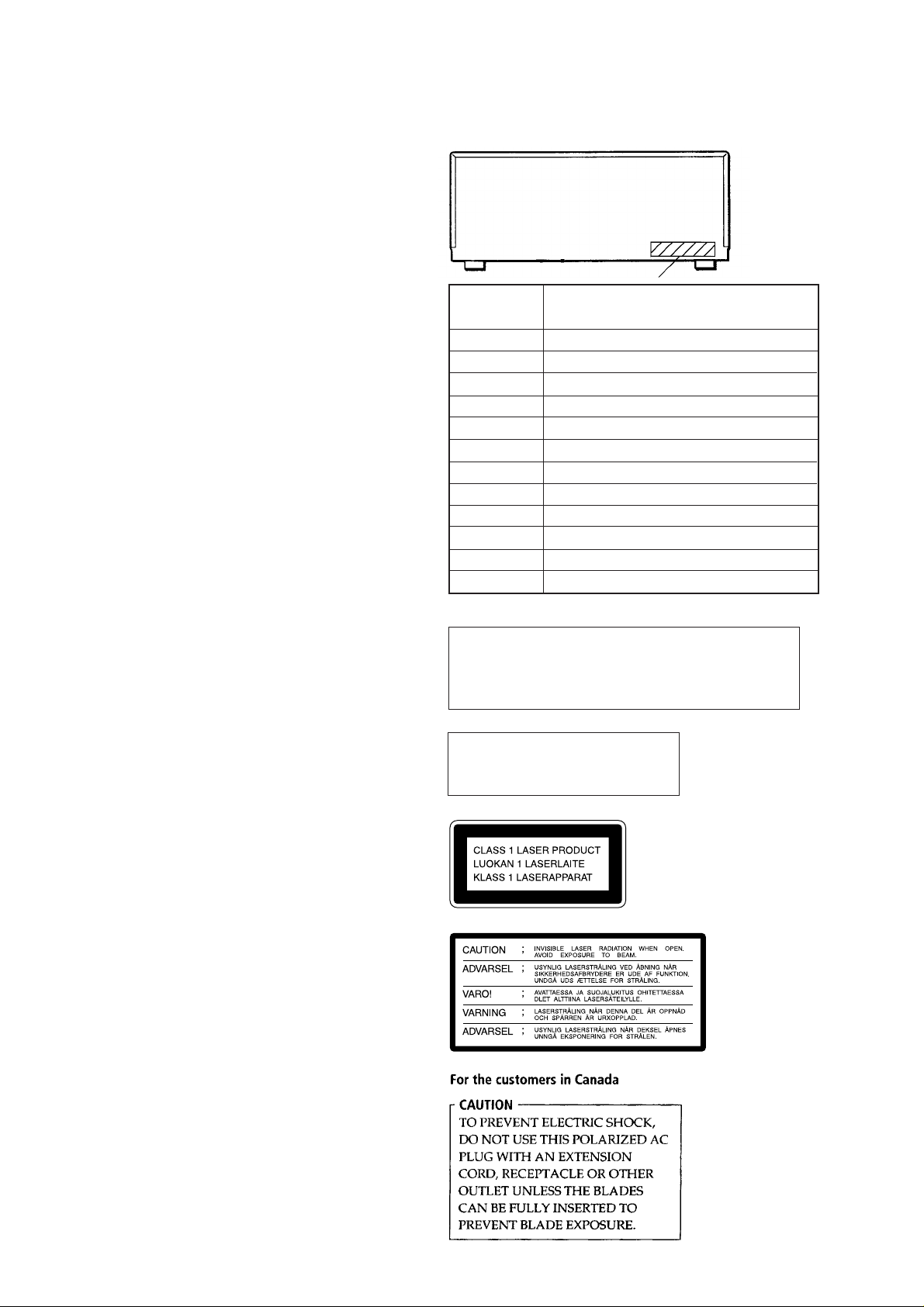

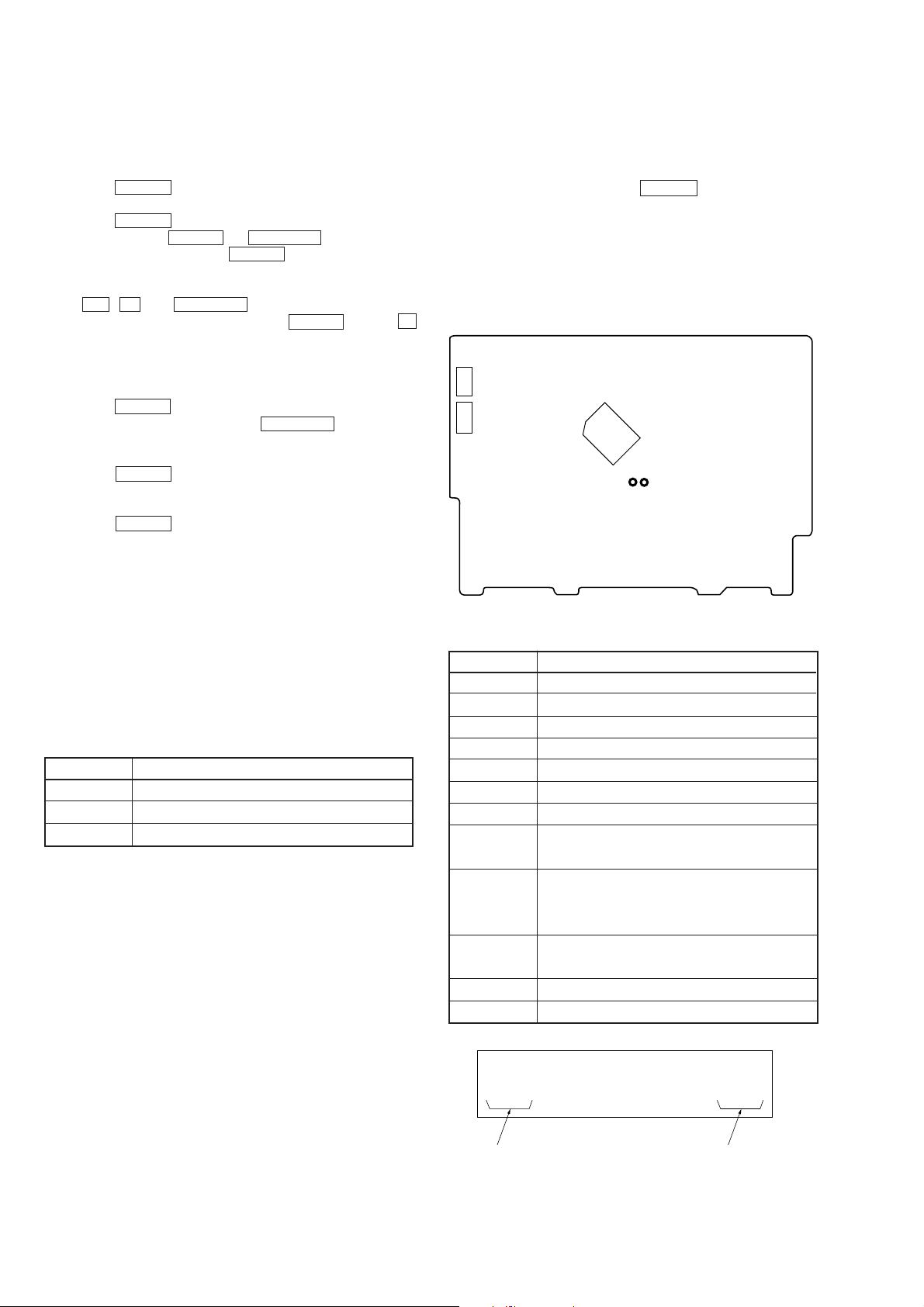

MODEL IDENTIFICATION

— BACK PANEL —

PARTS No.

4-987-981-01

4-987-981-11

4-987-981-21

4-987-981-31

4-987-981-41

4-987-981-51

4-989-203-01

4-989-203-11

4-989-203-21

4-989-203-31

4-989-203-41

4-989-203-51

CX50 : US model

CX50 : Canadian model

CX50 : AEP, G model

CX50 : Australian model

CX50 : E model

CX50 : Singapore model

CX571 : US model

CX571 : Canadian model

CX571 : E model

CX571 : Singapore, Australian model

CX571 : AEP, G model

CX571 : UK model

MODEL

8. EXPLODED VIEWS

8-1. Case Section........................................................................ 46

8-2. Front Panel Section ............................................................. 47

8-3. Chassis Section ................................................................... 48

8-4. Mechanism Deck Section 1 (CDM-46) .............................. 49

8-5. Mechanism Deck Section 2 (CDM-46) .............................. 50

8-6. Optical Pick-up Section (KSM-213 BFN/M-NP)............... 51

9. ELECTRICAL PARTS LIST ........................................ 52

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

The laser component in this product

is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This caution label

is located inside

the unit.

— 2 —

SECTION 1

SERVICING NOTE

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

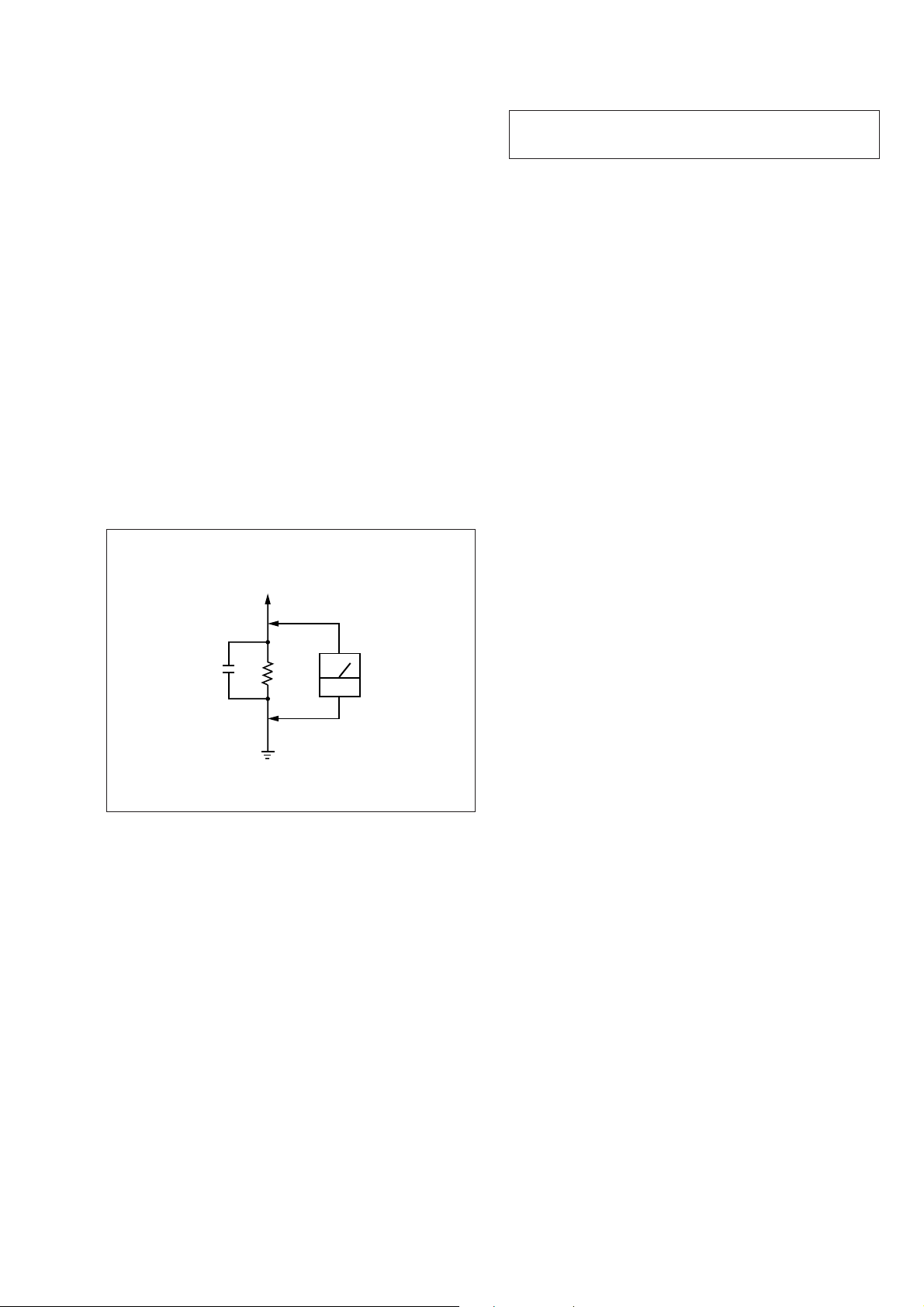

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output repeatedly.

0.15

Ω

µ

F

1.5k

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT . NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

— 3 —

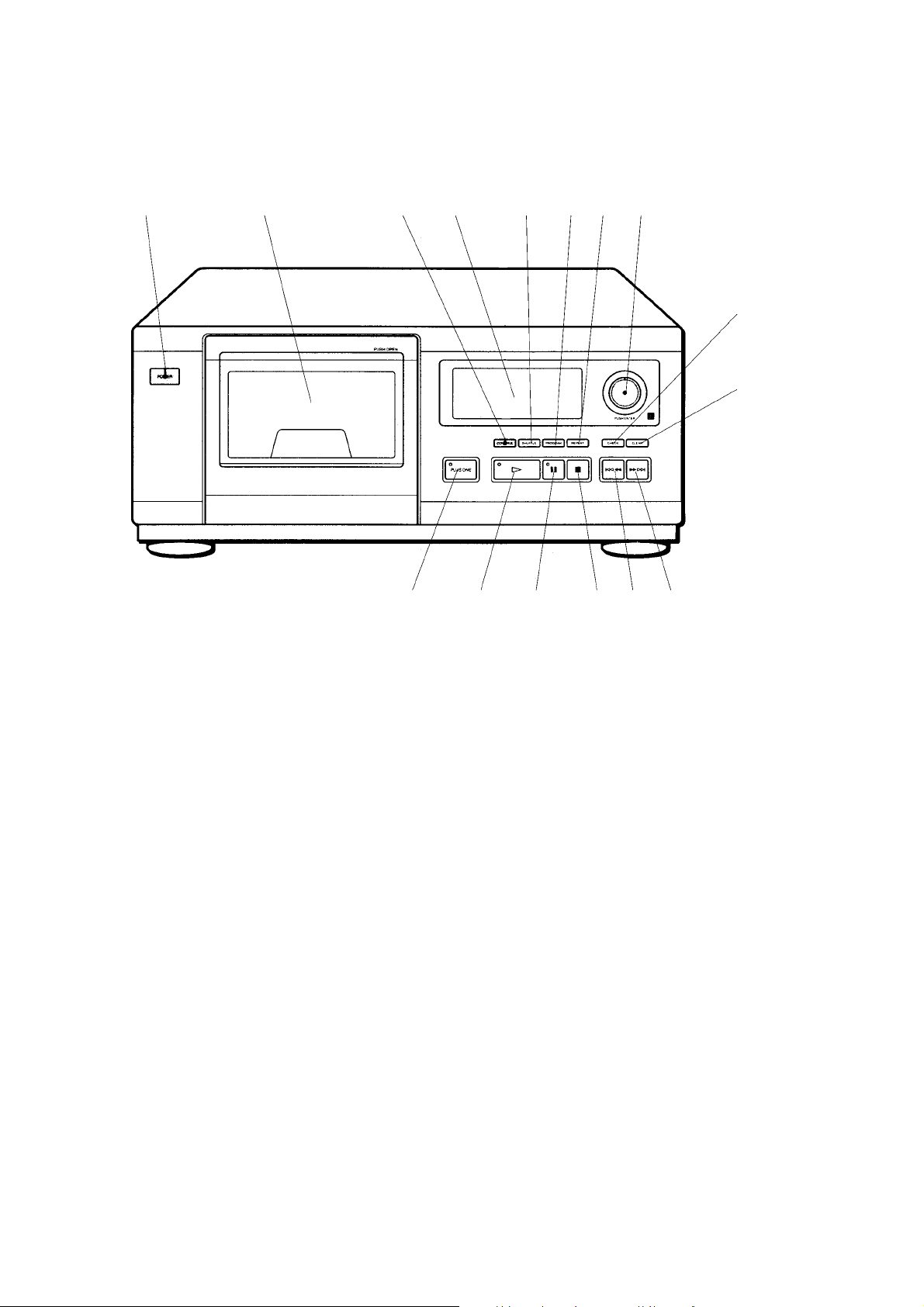

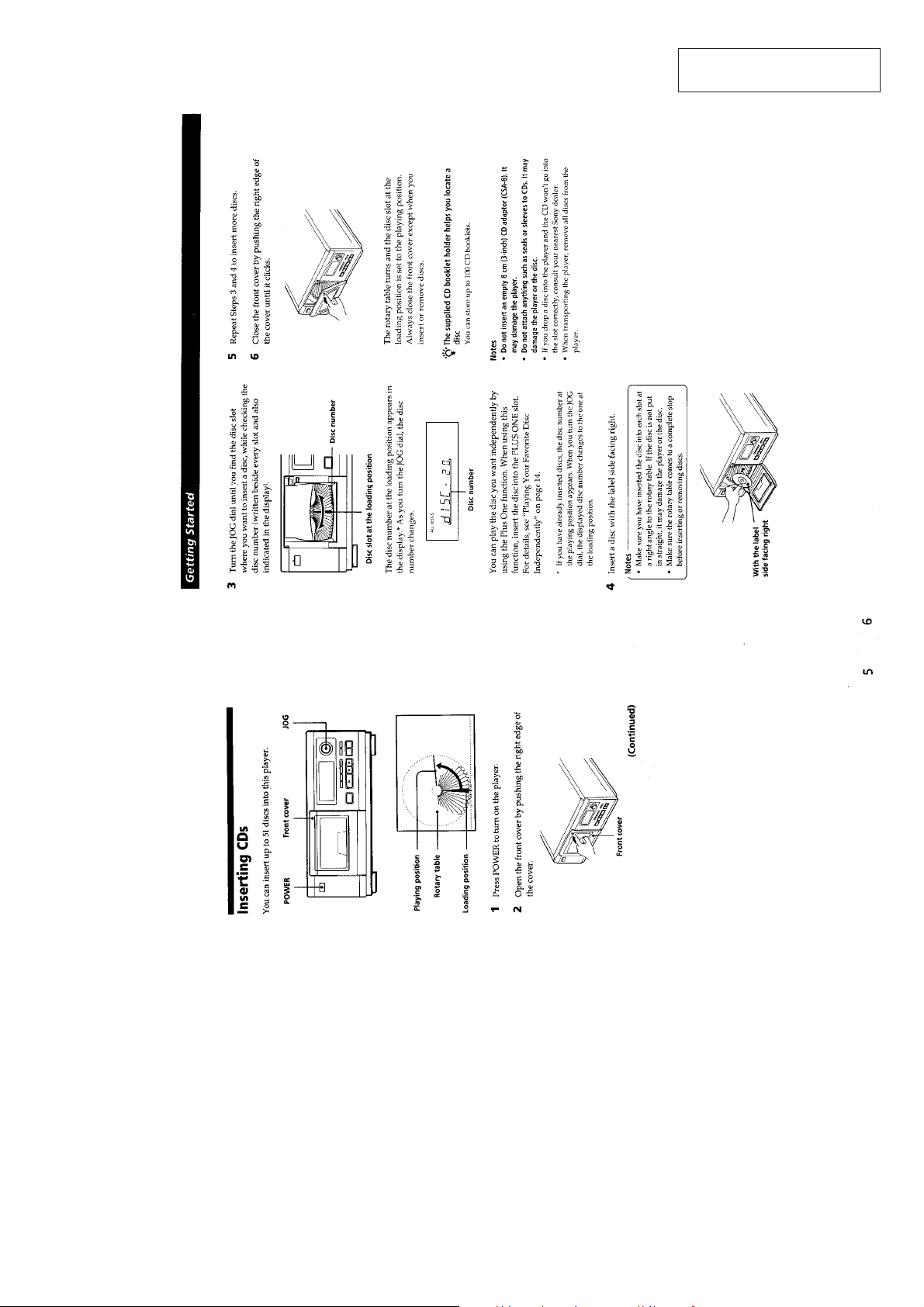

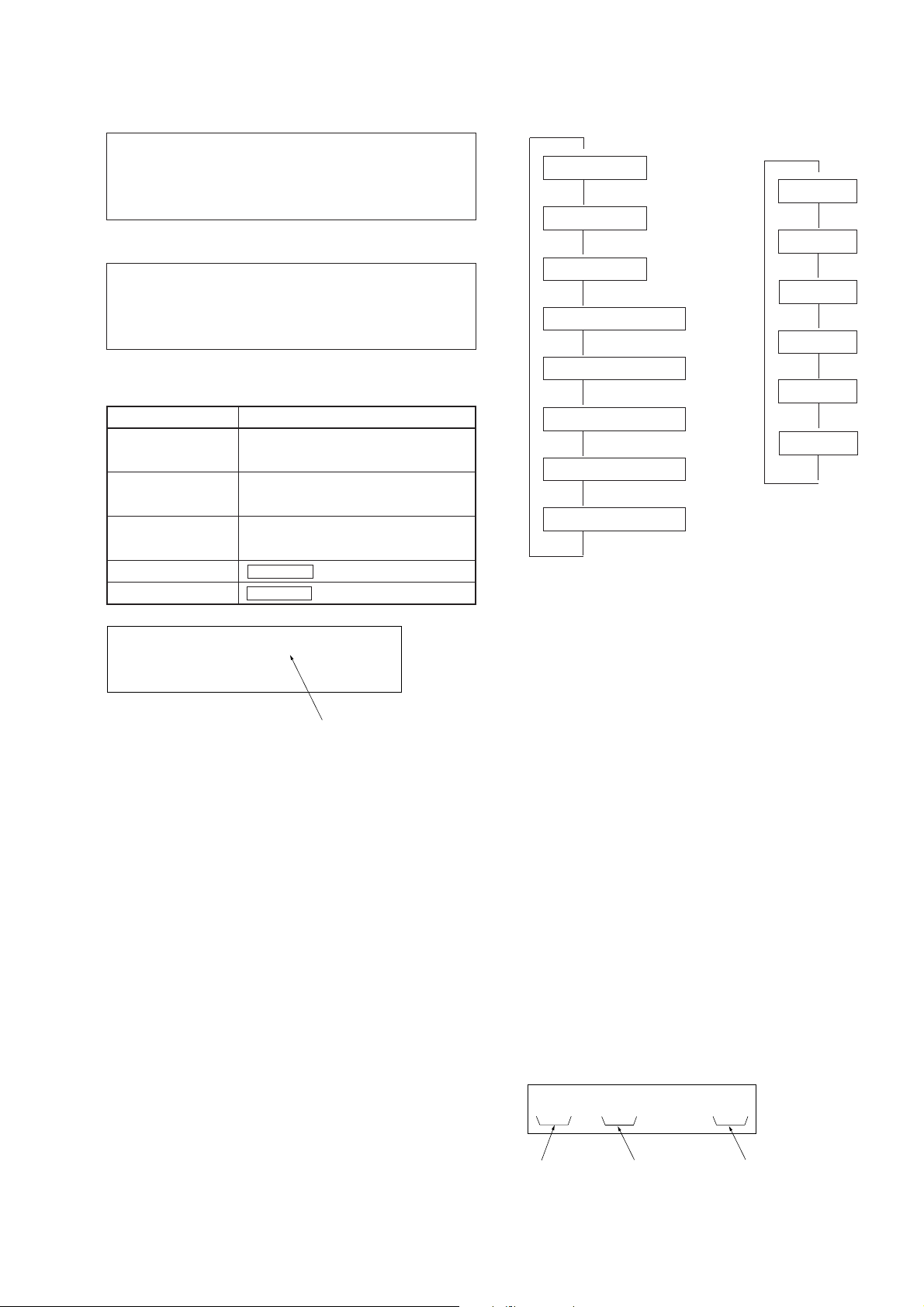

LOCATION OF PARTS AND CONTROLS

Front Panel

SECTION 2

GENERAL

1 POWER switch

2 Front cover

3 CONTINUE button

4 Display window

5 SHUFFLE button

6 PROGRAM button

7 REPEAT button

8 DISC/PUSH ENTER button

21

3

87654

9

0

!§ !∞ !¢ !£ !™ !¡

9 CHECK button

!º CLEAR button

!¡ ) ± button

!™ ≠ 0 button

!£ p button

!¢ P button

!∞ · button

!§ PLUS ONE button

— 4 —

This section is extracted from

instruction manual.

— 5 —

— 6 —

— 7 —

— 8 —

SECTION 3

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

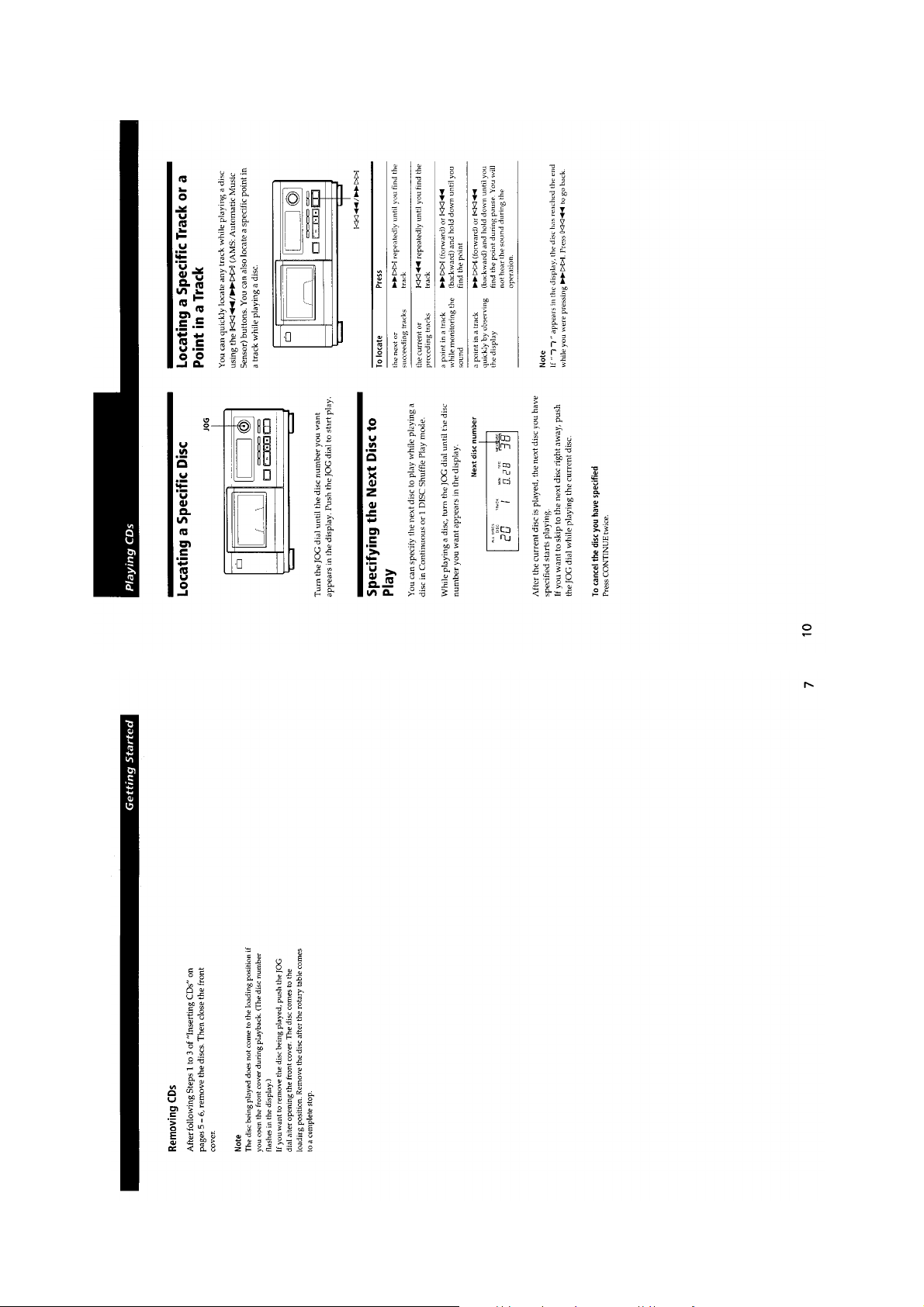

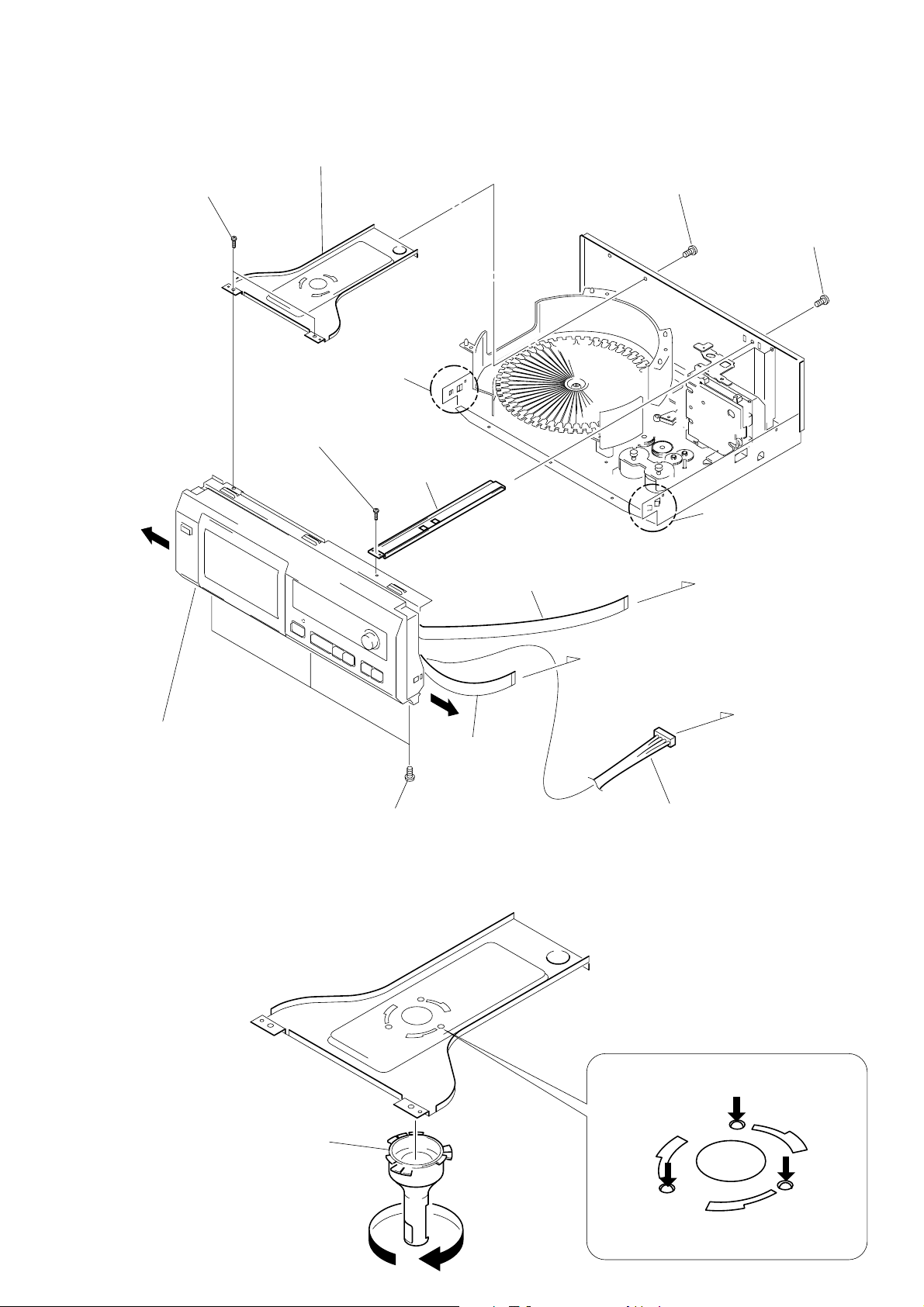

3-1. FRONT PANEL

2

Two screws (BVTT3x6)

A

3

Bracket

(ILLUMINATION)

!¡

claw

Expand the front panel

in the direction of arrow

to release catching claws.

5

Screw

(BVTT3x6)

A

6

Reinforcement

7

Flat type wire

(11 core)

1

Screw (BVTT3x6)

4

Screw (BVTT3x6)

!™

claw

Expand the front panel

in the direction of arrow

to release catching claws.

AUDIO board: CN801

B

!£

Front panel

3-2. ILLUMINATION ASSY

While pressing arrows A, B, and

C

, rotate the illumination assembly

in arrow direction

D

and remove it.

8

0

Three screws

(BVTT3x10)

B

Flat type wire

(9 core)

BD board: CN103

9

AUDIO board: CN803

Connector (7P)

ILLUMINATION ASSY

D

— 9 —

A

B

C

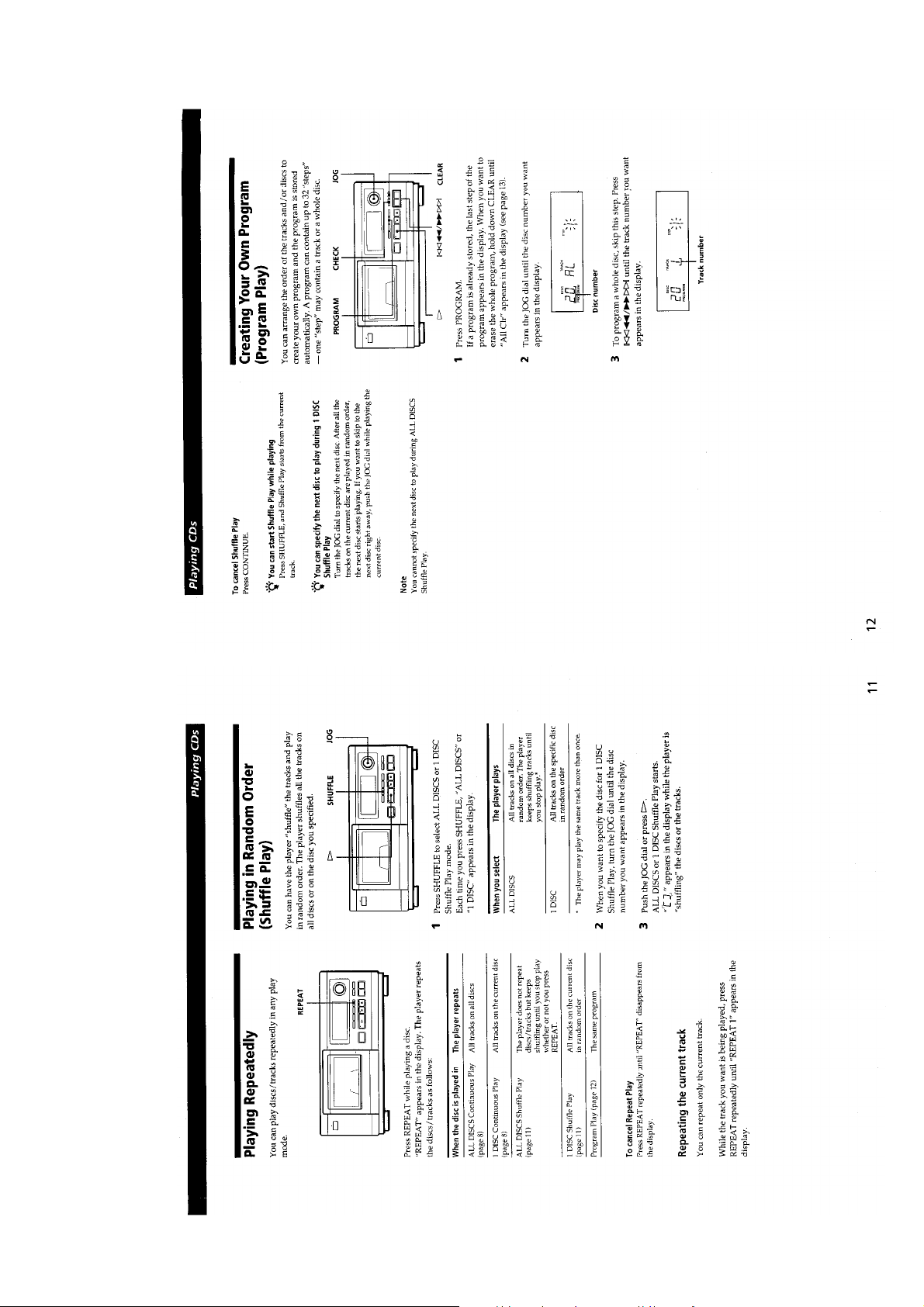

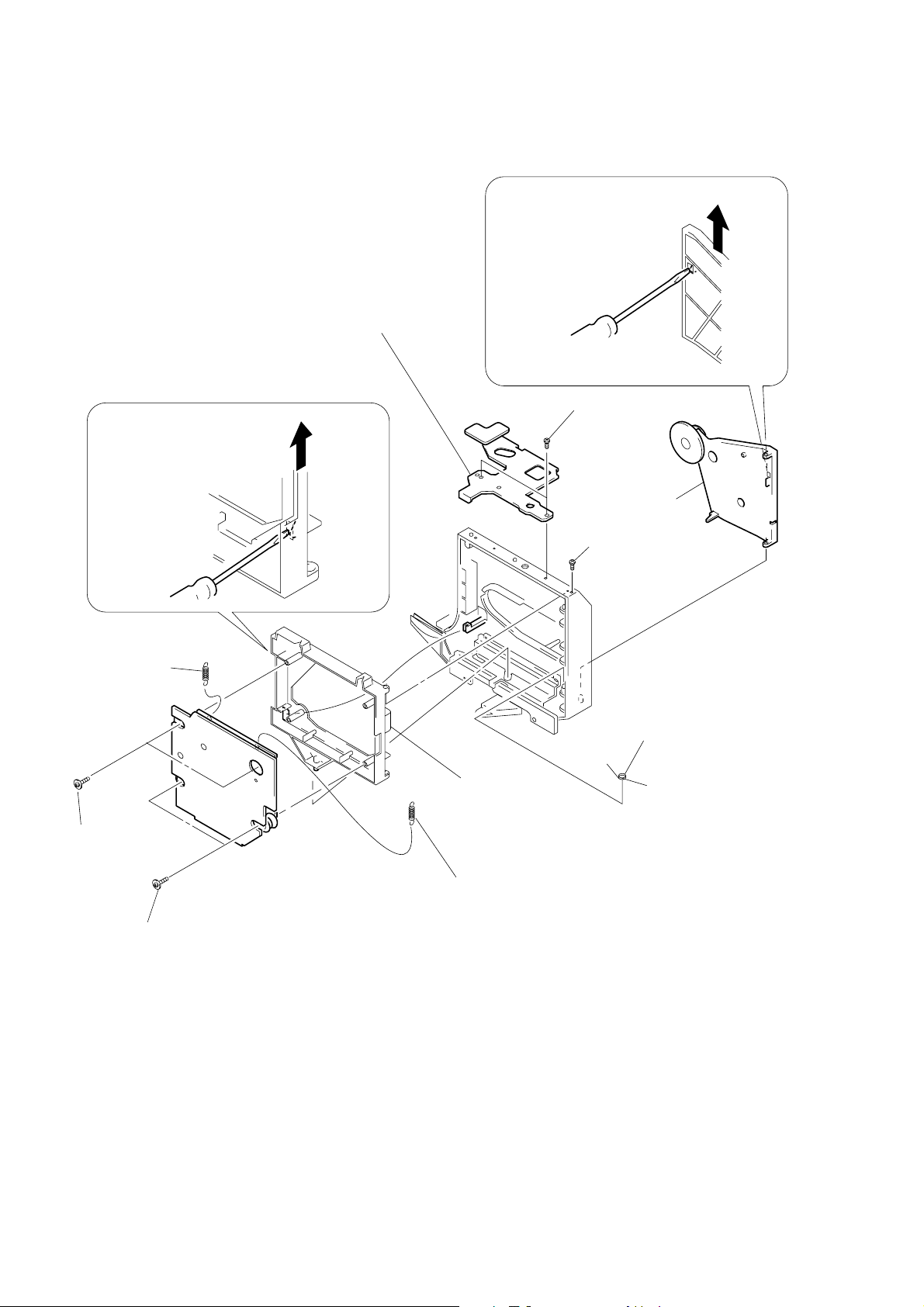

3-3. BASE UNIT AND MAGNET HOLDER

Remove in the arrow direction

while pressing the claw with a

screwdriver, etc.

2

Bracket

Remove in the arrow direction

while pressing the claw with a

screwdriver, etc.

1

Two screws

(BTP2.6x8)

4

Magnet holder

3

Screw

(BTP2.6x10)

7

Tension coil

spring (F-1)

5

Two screws

(PTPWH2.6x8)

6

Two screws

(PTPWH2.6x8)

9

BU holder

8

Tension coil spring (F-2)

0

Torsion spring (Holder)

— 10 —

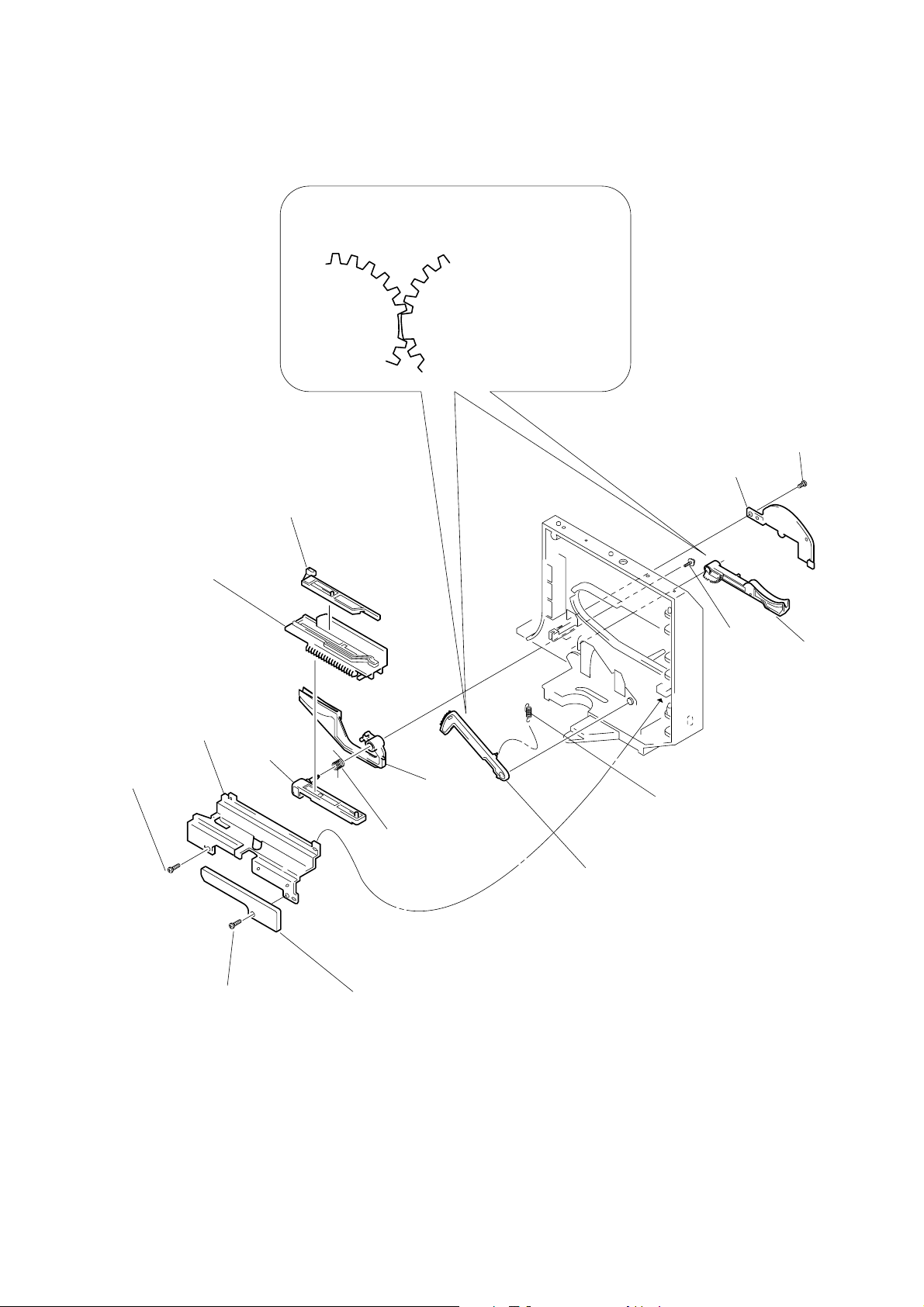

3-4. CD MECHANISM SECTION

6

Slider (Lock)

NOTE:

Adjust the position of the gear

as shown in the figure when

attaching.

!¢

Cover

(Lever)

!£

Screw

(BTP2.6x8)

3

Screw

(BTP2.6x8)

7

Slider (Cam)

4

Cam cover

1

Screw

(BTP2.6x8)

0

Slider

(Loading)

2

SW board

8

Disc holder

(A)

9

Torsion spring

(Loading)

!¡

!™

Loading lever ASSY

5

Screw

(BTP2.6x8)

Tension coil spring (Lever)

!∞

Disc holder

(B)

— 11 —

SECTION 4

TEST MODE

DISPLAY CHECK MODE

NOTE:

This will not work properly if the DISC is set to any slit.

1. Press the POWER button, turn ON the power, and set a CD in

any slit.

2. Press the POWER button, and turn OFF the power.

3. While pressing the CHECK and PLUS ONE buttons together

with the power OFF , press the PO WER b utton and turn ON the

power .

4. All the segments of the fluorescent indicator tube light up, and

the · , P , and PLUS ONE LEDs light up.

5. To exit the display check mode, press the PO WER button or p

button.

ADJ MODE

1. Press the POWER button to turn the power ON.

2. Open the front cover, and press the PLUS ONE button.

3. Set the disc (YEDS-18 : 3-702-101-01) in the PLUS ONE slit.

4. Close the front cover, and chuck the disc.

5. Press the POWER button, and turn OFF the power.

6. Connect TP (TP301:ADJ) of the DISPLAY board and the ground

with a lead wire.

7. Press the POWER button and turn ON the power.

The ADJ mode is set with the above.

FLUORESCENT INDICATOR TUBE, LED ALL LIT,

AND KEY CHECK MODE

Connect TP (TP302:AF ADJ) of the DISPLA Y board and the ground

with the power OFF and press the POWER button.

The fluorescent indicator tube and LEDs all light up.

When a button is pressed, the left side of the indicator tube will

show how many buttons have been pressed so far.

(However, buttons already pressed once will not be counted.)

The right side will show the numbers corresponding to the pressed

buttons.

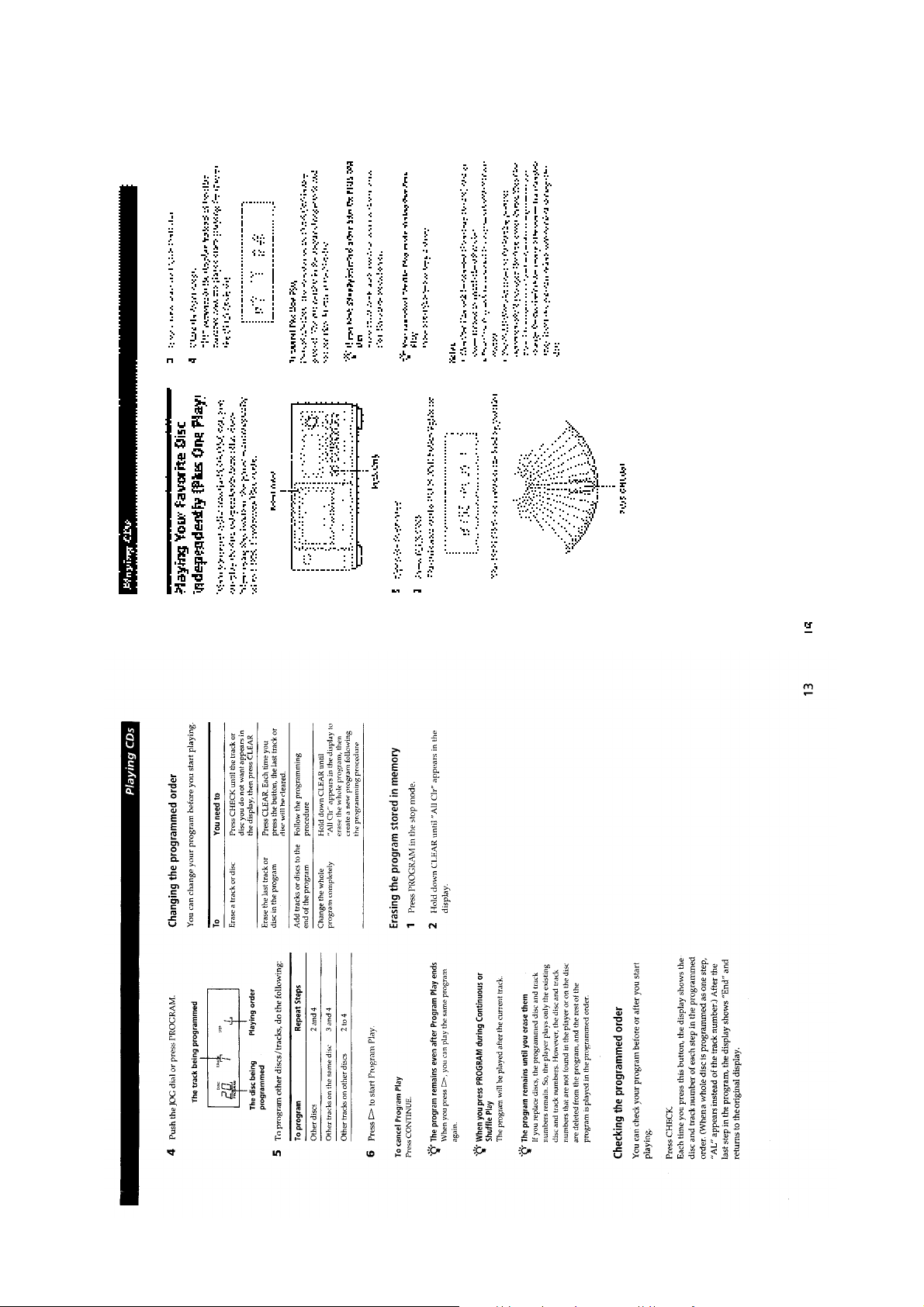

[ DISPLAY BOARD ] — CONDUCTOR SIDE —

CNP801

CNP804

IC801

TP301

(ADJ)

TP302

(AFADJ)

Differences with normal mode

• No high speed search is performed during access

• Ignored even if GFS becomes L

• Ignored even if Q data cannot be read

• Spindle servo gain is set to 12 cm mode (Even with 8 cm disc)

The following special functions will work when certain functions

are pressed in this mode.

Special functions in ADJ mode

(The ( ) buttons function only with the general purpose remote.)

Button Function

(3)

(8)

CHECK

Tracking servo , sled servo OFF

Tracking servo, sled servo ON

S shape observation mode

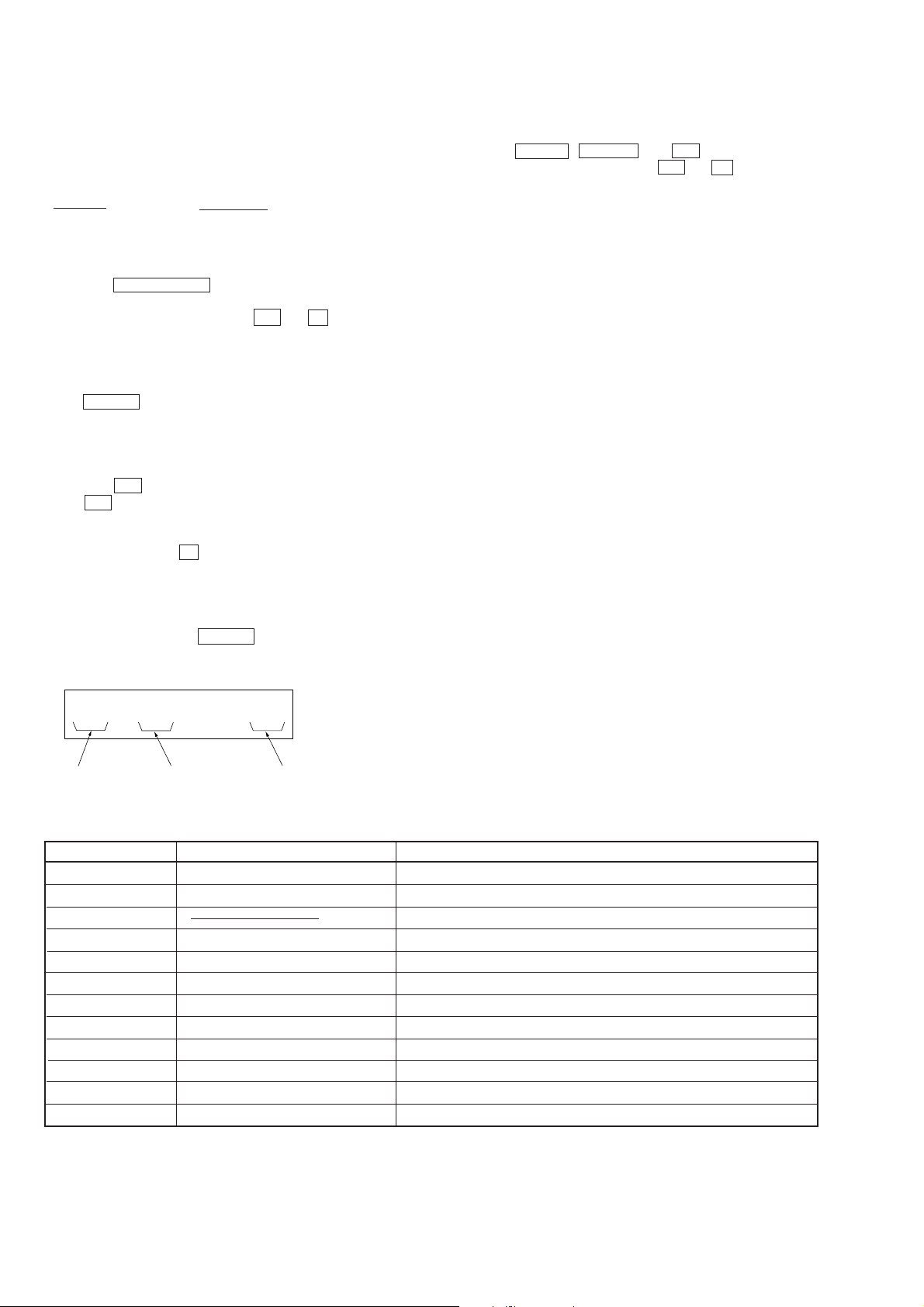

Buttons and Corresponding Button Numbers

Button Button Number or Display

CONTINUE

SHUFFLE

PROGRAM

REPEAT

CHECK

CLEAR

PLUS ONE

·

P

p

≠ 0

) ±

1

2

3

4

5

6

7

8 (The fluorescent indicator tube and LED near by

(D801) are lit while pressed.)

9 (The fluorescent indicator tube (segment check) is

partially lit and LED near by (D802) is lit while

pressed.)

10 (The fluorescent indicator tube is partially lit while

pressed (grid check).)

11

12

— 12 —

05

Count up

12

Button number

1. Grid check

PROGRAM

REPEAT

REMOTE

2. Segment check

2

--

-nn

1

Key Inputs Other than Buttons and How to Display

Key input Display

Rotate the JOG knob to

the right

Rotate the JOG knob to

the left

Press the JOG knob

(ENTER)

Door cover “Close”

Door cover “Open”

Fluorescent indicator tube block indicator

lights up in the order of 1 n 2 n ...8 n 1.

Fluorescent indicator tube block indicator

lights up in the order of 8 n 7 n ... 1 n 8.

Fluorescent indicator tube block indicator

goes OFF.

PLUS ONE LED lights up

PLUS ONE LED goes OFF

12345678

Sequence of Aging Mode

Order of Disc Change

(1 cycle takes 3 minutes)

$

1. Disc change

$

2. Load in

$

3. TOC read

$

4. Access of last track

$

5. 3 second playback

$

6. Access of first track

$

7. 3 second playback

$

1. No. 51

$

2. No. 20

$

3. No. 40

$

4. No. 30

$

5. No. 10

$

6. N0. 40*

$

$

8. Load out

$

* DISC No. 40 chucks twice during one cycle.

To differentiate, the “8” on the block indicator of the fluorescent indicator tube will light up during the second chucking.

Special Functions in Aging Mode

block indicator

AGING MODE

• Mode which repeatedly changes and plays back discs automatically in the unit.

• It will repeat aging as long as no errors occur.

• If an error occurs during aging, it will stop all servos, motors, etc.

instantaneously, display the error number, and stop oper ations.

However , the stopping conditions dif fer according to whether the

unit is equipped with the “self-protection function during errors”

described later.

The function serves to maintain the state of the unit when errors

occur.

There are some useful function in the aging mode.

• Disc setting mode*1

• Switching of use/disuse of protection function in errors *2

• Aging cycle count function *3

*1 Disc setting mode:

5 discs are set before setting the aging mode. This mode makes

the setting of these discs more easy.

*2 Switching of use/disuse of protection function in errors:

Function which voluntarily corrects errors which occur during

normal operations by retries.

If this function is not provided, all operations will be stopped

without retiring. It is suitable for checking errors with low reproducibility.

If this function is provided, and errors can be corrected by retries, aging will be continued without stopping.

(The normal aging should be performed with “be”.)

*3 Aging cycle count function:

Functions which displays the number of agings carried out on

the Fluorescent indicator tube in numbers. One aging cycle consists of six discs.

DISC

51

TRACK

MIN SEC

1

0.01

0.1

Disc number Track number

— 13 —

Agings carried

(Hexadecimal)

Aging procedure:

Some operating method will be changed depending on if the following jig for the aging mode exists or not.

• Jig

Parts. No Description

J-2501-123-A Remote commander (For aging mode)

With remote commander for aging mode:

1. Turn ON the power of the unit. Open the front cover.

2. Press the AGING START button of the remote commander for

aging mode.

3. When the disc set mode is set, the · and P LEDs blink.

4. Rotate the JOG dial. The slits (No. 10, 20, 30, 40, 51) for setting

the discs will come forward. Insert the discs into these slits. Do

not set the discs in other slits.

5. Set the use/disuse of the self protection function in errors. Press

the REPEAT button. When REPEAT is displayed on the fluorescent indicator tube, the self protection function during the

error will become “Use”.

If the REPEAT display is OFF, it means that the function is not

used. (Normally set to “Use” when performing aging.)

7. Press the · button.

8. The · LED blinks, the aging mode is set, and aging is started.

9. The aging cycle lasts 3 minutes. When problems occur during

aging, the error number will be displayed on the fluorescent indicator tube, and the P LED will light up.

(Refer to the following table for the details of the errors.)

10. Aging will be repeated as long as no errors occur.

11. After each aging cycle, the number displayed on the Fluores-

cent indicator tube will increase.

12. To end aging, press the POWER button

Without remote commander for aging mode:

1. Turn ON the power of the unit. Open the front cover.

2. Press the CLEAR , ≠0 , and · buttons in order.

3. When the disc set mode is set, the · and P LEDs blink.

The following procedure is the same as in the case “With remote

commander for aging mode”.

Error Display

DISC

51

Disc number

Error code

Code number

Err 01

Err 02

Err 03

Err 04

Err 05

Err 06

Err *1

Err *2

Err *3

Err *4

Err *5

Err *6

0C

number of agings

DISC sensor check 1

DISC sensor check 2

Table operation check 2

Loading operation check 1

Loading operation check 2

BU related check 1

BU related check 2

BU related check 3

BU related check 4

BU related check 5

BU related check 6

Err

26

Error code

Name

Contents

No disc in the specified slit

Disc in other slits

No function

No table sensor input

Load in timeover

Load out timeover

Access timeover

High speed search NG

Q data read error

BU operation (From focus search to until signal can be read) timeover

GFS monitor error

Focus cannot be imposed by focus search

The * numbers mean the following according to the state of the unit during aging

2 : From chucking to end of TOC read

3 : From end of TOC read to end of last track playback

4 : From end of last track playback to end of first track playback

— 14 —

Loading...

Loading...