Page 1

FTS INSTALLATION

INSTRUCTIONS

Ref.900156D

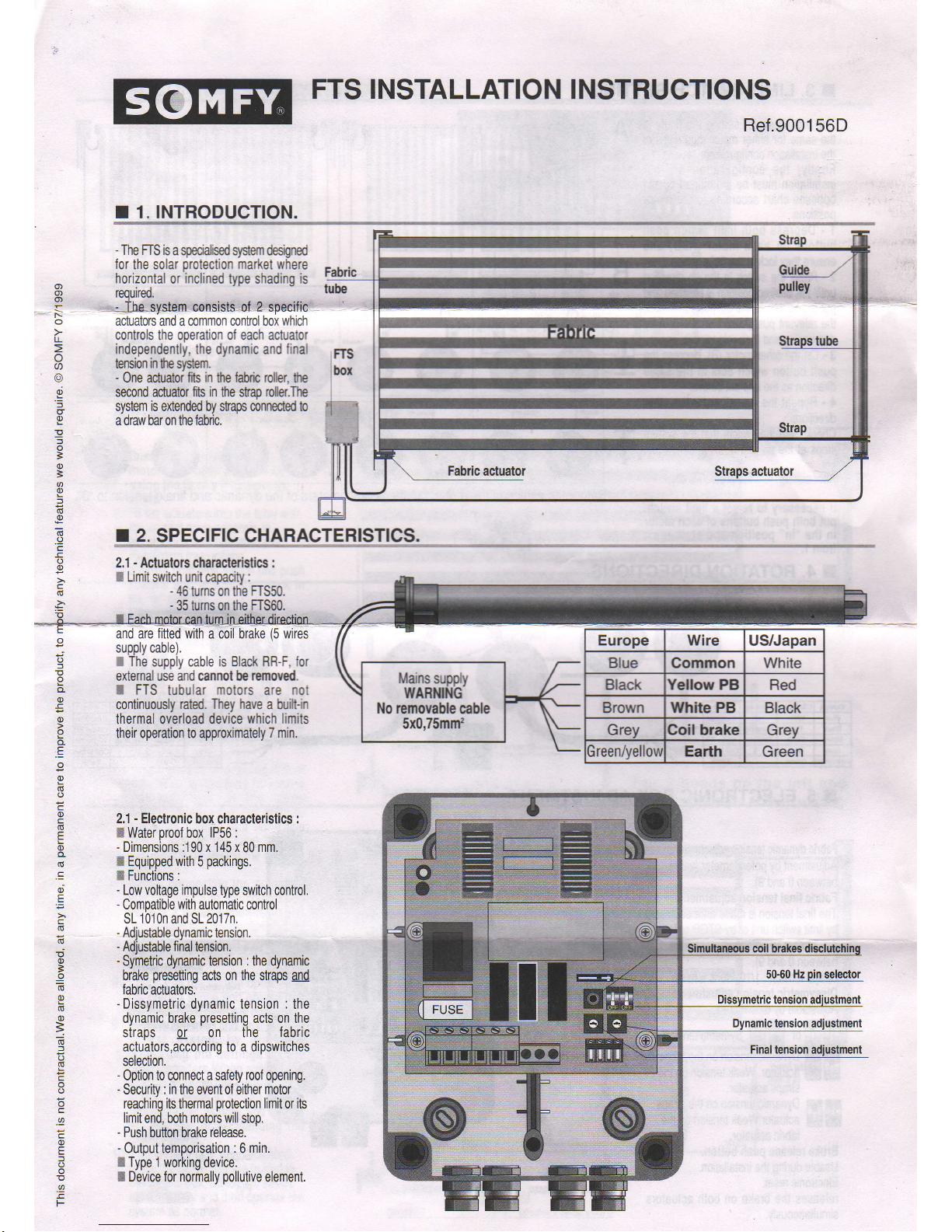

r 1. INTRODUCTION.

..-

È

TL

U)

o

€)

J

o

=

3

o

=

a

0)

f

d

c)

d

.E

!

q)

c

G

-

The FIS is

a

Eærallsed

system dæigned

for

the solar

protection

market

where

horizontal

or

inclined

type shading

is

reourreo.

..-

Tie-system,csnsislgof

I

specifig'

actuators

and a

common æntrol box which

controls

the ooeration of each actuator

independenlly, the dynamic

and

final

tension

in

tn sy$em.

-

One actuator fiS in he fahic roller,

tp

sæond actuator

fib in

tp stæ

rdb.Ttp

system

is

extended by stap ænnæled to

a draw bar on the fabric.

r 2.

SPECIFIC CHARACTERISTICS.

I

+i

o

l

q)

€

c)

.E

o

q)

(s

o

c

o

c

(É

E

Q)

o-

(É

.c

o,

E

c

(d

(d

!

o

È

=

(g

o

(t

c)

=

r

l

G

E

o

o

o

c

.9.

c

0)

E

f

.0

E

F

2.1

-

Aciuators

characterislics :

I

Limit

switch unit æpacity

:

-

46

tums on the

FIS50.

-

35 tums on the

ffS60.

with

a coil

brake

(5

wires

supply cable).

I The

supply cable

is

Black RR-F.

for

external use and ænnol be

removed.

I

FTS

tubular

motors

are

nol

continuously

rated. Tïey have

a fuill-in

thermal overload device

which limits

their operation to approximately

7 min.

2.1 - Eleclronic box characleristics :

ffi Water

oroof box

lP56 :

-

Dimensions :1

90

x 145 x

80

mm.

ffi Equipped

with

5

packings.

ffi Functions :

-

Low voltage impulse

type switch control.

-

Comoatible

with

automatic control

SL 1 01 0n and SL 201 7n.

-

Adiustable dynamic tension.

-

Adjustable

final

tension.

-

Symetric dynamic tension : the dynamic

brake

presetÏing

acts on the straps

and

fabric actuators.

-

Dissymetric

dynamic tension : the

dynamic brake

presetting

acts on the

straps or on the

fabric

actuators,according to a dipswitches

selection.

-

0ption to connect

a salety roof

opening.

-

Securitv

: in

the event oT either

motor

reachirig its

thermal

prolection

limil

or

its

limit

end, both

motors will

stop.

-

Push

button brake

release.

-

Output temporisation : 6

min.

e

Type 1 working device.

X Device for normally

pollutive

element.

lilains

supply

wARlill{G

No

æmovabb cable

5x0,75mrf

Europe Wire

US/Japan

Blue Common White

Black

Yellow

PB Red

Brown White PB Black

Grey Doil brake Grey

ireenffellou

Earth

Green

Simultaæous coil brakes

50-60

Hz

tension

tension

Final tension

Page 2

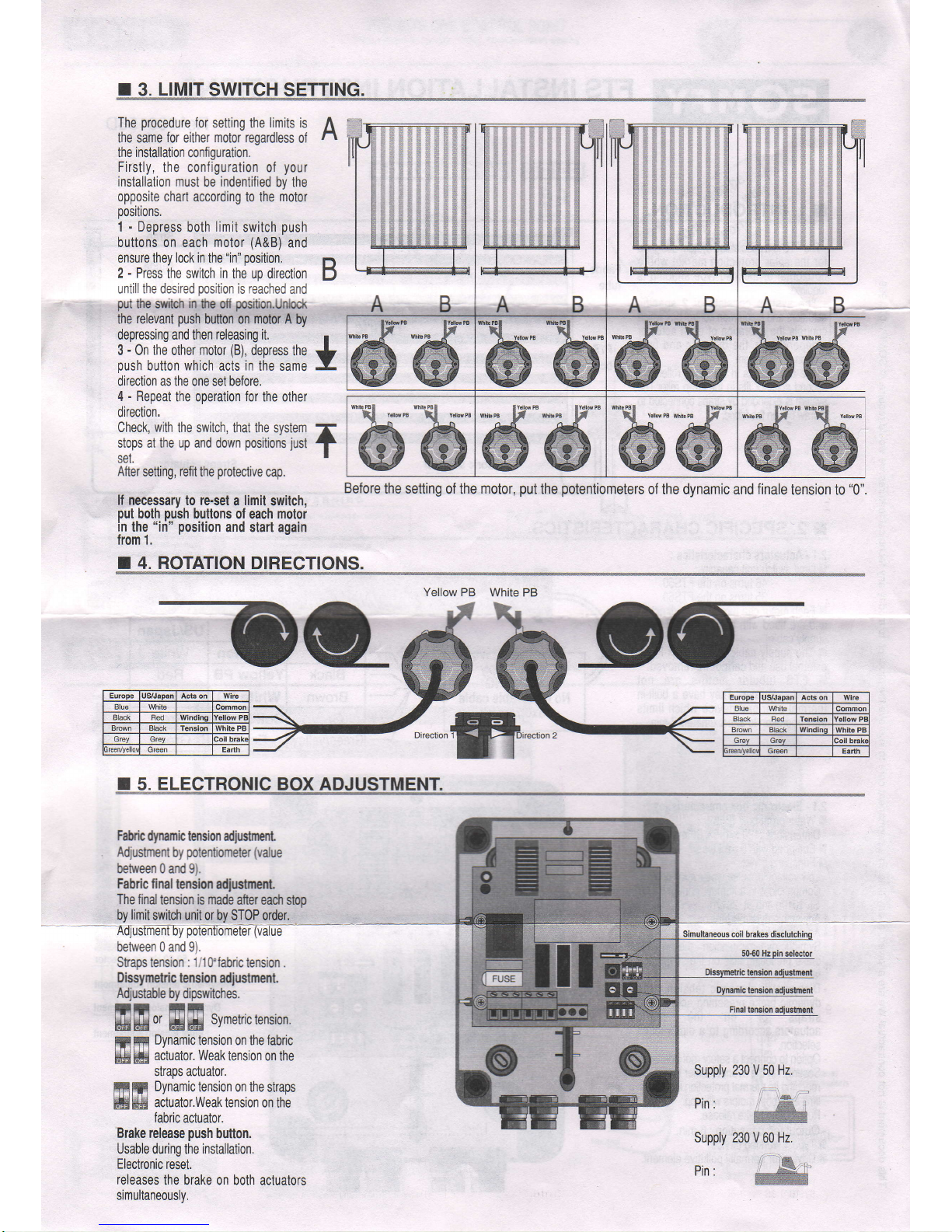

The

procedure

for

setting

the

limits is

the same

for

either

motor regardless

of

lhe installation

conf

iguration.

Firstly,

the configuration of

your

installation

must be indentified

by lhe

opposite chart according

to the

motor

positions.

1 - Depress

both

limit

switch

push

buttons on each

motor

(A&B)

and

ensure they lock in

lhe

"in" position.

2 - Press

the switch in

the up direction

untill the desired

position

is reached

and

put

the slvrtch

in

the off

posibon.Unlodr

the

relevant

push

button on motor A

by

depressing and then

releasing it.

3 - 0n the other

motor

(B),

depress

the

push

button which

acts

in

the same

direction as lhe one set before

4 - Repeat

the operation

for

the

other

direction,

Check,

with

the

switch,

that the system

stops at lhe up and down

positions

just

set.

After

setting,

refit

the

protective

cap.

lf necessary

to

re-set

a

limit

switch,

put

both

push

buttons

of each

motor

in

the

"iri" position

and start again

from 1.

r 4. ROTATION DIRECTIONS.

A;J

B

*

I

ffi

A B

A B

W

A

B A B

W"

@-w'

w"w@W

WNhèPBI WhfuPBI

\l

:** \

"'*m

@@

tYdlowP8 lYèrlowPB

**:

It

www

ly'

@@

snePBl

lYello{PB

{

"u**

*n'nru

IrÉ

,,q ,H\

rEt

TiST

***

llfl'"

*\

*u**

@@

Before

the setting

of the

motor,

put

the

potentiometers

of the dynamic and finale

tension to

"0".

Yellow PB

White PB

-3Q-

ofl

r

5.

ELECTRONIC

BOX ADJUSTMENT.

Fahh

dynamic tension adjustnent

Adjustmenl

by

polentiometer

(value

between 0 and 9I.

Fabric final

tension

adjusfnent

The final

tension

is made

after

each stop

by

limit

switch unit

or by STOP order.

Adjuslmfifty

poiêntkimeGr

(ùâlue

--

between

0 and 9).

Straps tension :

1;1

0'fabric tension

.

Dissymetric

lension adjustment.

Adjustable

by dipswitches.

rr iiltt

H#bi#

0r

HH#

symermc

tensron.

Dynamic

tension on the fabric

actualor. Weak

tension on the

straps actuator.

Dynamic

tension on the

straps

actuator.Weak tension on

the

fabric

actuator.

Brake

release

push

button.

Usable during the installation.

Electronic

resel.

releases

the

brake on both actuators

simultaneouslv.

SFil

H,çH#

F!'l!il!

ËHM

Simultaneous coil

Supply

Pin :

230 V

50

Hz.

Supply 230 V

60

Hz.

Pin :

Page 3

r

6. CONTROL BOX

CONNECTIONS.

-

The

commons wire

(blue)

from

both

actuators

are connected 1o

terminal 3.

-

The

earth wire

(yellow/green)

from

both actualors

must

be

connected lo

the

supply earth using a

connector

block.

-

An impulse

type

switch can

be

connected

to terminals

10,1

1

and

12.

-

lT no

safety device is fitted,

then

bridge

terminals

10

and 13

(done

in

Tactory).

iôt

BuÏ'Thd

attuator supply

and the security control cables

together in

the same slive.

r 7. INSTALLATION

PROCEDURE.

lc

i lO

i iE

I tÉ

I to

I t:

-*El-Ë

gRç

o_2,<

1 - Ensure

the correct size of

motors has

been selected

by

using the Somfy FfS

sdector

chart.

2 - Fit

the actuators

into

the tube with

the conecl drive adapters in

accordance with

our standard

installation instruclions.

3

-

depress both

limit

switch unil

push

buttons and ensure

they

lock in

the

"in'position.

4 - Mount

the motorised

barrels onto

uref

respeuuve

stop

ring re1.910002

must

be

Dynamic tension

with

the

motor

end

bracket.Ensure

thal both banels are

parallel.

5 - Attach

the

fabric

to the

lube.Connect the

test

lead

ref.137080

to the motor

as shown

and wind

the

labric

around the

tube. Set the

"in"

limit

by

releasing

the

relevant

push

button.

6

-

Fit

the

pulleys

and straps.Adjust

the straps as

required

to

ensure

that thev are

all the same

lenglh.Cdnnect

the test lead

to

molor

as shown

and

wind

the

straps around the

tube.Set the

"out"

limit

by

releasing

the relevant

button.

7-Before

connecting the actuators

and the

switch to the control box

set the

2

potentiometers

to "0"

and ensure that all the dioswitches

are

in

the'up"position.Connect

the

actualors and switch to the control

box as shown.

8 - Check that the system operates in

the conect sense and ensure that

the

limits have

been set conectly.

9 - Set the dynamic and final

lension

in

lhe system by

gradually

increasing

the settings on the

potentiometers.When

setting the

final

tension

in

the system, care

should be taken to

ensure lhat the

fabric

and all

fixtures

and fittinos

are capable of withsanding

tËe

operating

load.

1O-lf

the straps have to be adjusted,

press

the brake

release

button in

ihe control box, adjust the straps

as

necessary

and then operale the

system as normal.

For 2 heads

on the left

and

fabric

and straps above winding

Page 4

FTS WITTIONE

CONTROL

POINT

2 motor heads on the right. Fabric and straps above winding

WARNING

I Do not forget to connecl the eanh wirês,

IThe

wires section is depending on the

number and the Ëted

power

ol

the

aduarore

Oblique : US

wiring

For 2

heads

on the

right

and

fabric

and straps above

winding

FTS WITH

ONE CONTROL

POINT

2 motor heads on the right. Fabric and

straps

above winding

ËÈp.9Èæ,9

ffi

e

ilililil1

TTTÏTI-| I I

#ËËÊ#.sËEs

5 core cable

lndividual

control switch

\

o

o

=

o

\^

Y

E

E

o-

o

=

o

WARNING

lYou

hâve to identilicate the ^andv

direction ol each aduato6.

a Do not forget to connd the eadh wires,

lThe wires section is depending on the

number and the rated

power

of lhe

aclualo6.

I

Cables atter

installation must not ooerate

trâction on the têminals

Oblique : US wiring

Loading...

Loading...