SOMFY Freevia 280,Freevia 300 Operating And Installation Manual

Freevia 280

Freevia 300

Operating and installation guide

Instrukcja montażu i obsługi

5057966C

FreeVia 280

+

FreeVia 300

8

14

17

15

16

6

11

9

9

8

12

20

10

3

7

21

22

18

1

2

5

4

13

19

1

EN

TABLE OF CONTENTS

WELCOME .........................................................................................2

Who are Somfy? 2

Assistance 2

SAFETY INSTRUCTIONS .................................................................2

PRODUCT DESCRIPTION ................................................................3

Composition of the kit 3

Maximum weight and dimensions of the gate 4

Motor dimensions 4

General view of the installation 5

Technical specications 5

PRELIMINARY OPERATIONS ..........................................................6

Pre-installation checks 6

Tools required 6

Electrical preequipment 7

Safety instructions 7

1. PREPARING THE BASE ...............................................................8

2. MOUNTING ....................................................................................9

3. ELECTRICAL CONNECTIONS ...................................................12

4. QUICK COMMISSIONING ...........................................................14

5. FITTING THE COVER .................................................................15

OPERATION ....................................................................................16

Operation in sequential mode 16

Operation in automatic mode 17

Obstacle detection operation 17

Area lighting operation 17

Operation of the 3 button control points or remote controls 18

Unlocking/locking the motor 18

ADVANCED PARAMETER SETTING .............................................19

Selecting the buttons of your 2 or 4 button remote control 19

Memorising a 2 or 4 button remote control 19

Memorising a 3 button remote control 19

Activating pedestrian opening 20

Activating AUTO CLOSE mode 20

ACCESSORIES ...............................................................................21

SOLAR POWER ..............................................................................29

TROUBLESHOOTING GUIDE .........................................................30

2

EN

WELCOME

Thank you for choosing a Somfy product. This equipment has been designed, manufactured

and distributed by Somfy in accordance with a quality policy complying with the ISO 9001

standard.

Who are Somfy?

Somfy develops, manufactures and sells automatic control devices for domestic opening

and closing systems. We offer alarm systems, automatic control devices for awnings, roller

shutters, garages and gates. We guarantee all Somfy products will meet your expectations in

terms of safety, comfort and time saving on a daily basis.

At Somfy, the pursuit of quality is a continuous process of improvement. Somfy's reputation

has been built upon the reliability of its products and the Somfy brand is synonymous with

innovation and technological expertise worldwide.

This product fully complies with the essential safety guidelines and specications set out by the

directive according to the EN 60335-2-103 standard.

Assistance

Getting to know our customers, listening to them, meeting their needs: this is Somfy’s approach.

For further information on how to choose, purchase or install Somfy systems, please ask for

advice at your DIY store or contact a Somfy advisor directly for help and assistance.

Somfy UK Hotline : 0113 391 30 30

Internet: www.somfy.com

SAFETY INSTRUCTIONS

Before installing your motor, carefully read all the instructions in this guide. All the instructions

given must be followed closely and this guide must be stored in a safe place throughout the

service life of your product.

Failure to follow these installation instructions may result in serious injury or damage to the

equipment. Somfy shall not be held liable in this event.

This device is not designed to be used by persons (including children) whose physical, sensory

or mental capacity is impaired, or persons with little experience or knowledge, unless they are

under supervision or have received instructions on using the device by a person responsible

for their safety.

Do not allow children to play with the xed control devices.

Remote controls must be placed out of sight and out of reach.

If you are using a switch without a locking device***, ensure that other people remain at a

distance.

Frequently check the product to detect any defects in balance in the gate or any signs of wear.

Do not use the motor if it requires repair or adjustment.

Disconnect the supply motor during cleaning operations or other maintenance operations.

Before installing the motor, ensure that the driven part is in good mechanical condition, that it

is correctly balanced and that it opens and closes correctly.

Ensure that any danger zones (crushing, cutting, trapping) between the driven part and the

surrounding xed parts created by the opening of the driven part are avoided.

3

EN

Watch your gate while it is moving.

Any switch without a locking device*** must be in direct view of the driven part, but away from any

mobile parts. It must be installed at a minimum height of 1.5 m and must not be accessible to the

public, unless it is key-operated. Ensure that people remain at a distance when it is in use.

Maintain a clear area of 500 mm from the end of the gate when it is completely open.

After installation, ensure that the mechanism is correctly adjusted and that the protection

system and any manual release mechanism operate correctly.

Somfy declares that this product complies with the essential requirements and other relevant

provisions of Directive 1999/5/EC. A Declaration of Conformity is available at www.somfy.

com/ce. Product can be used in the European Union and Switzerland.

*** example: interphone, key lock, code keypad...

PRODUCT DESCRIPTION

This motor is designed for sliding doors on individual residential properties.

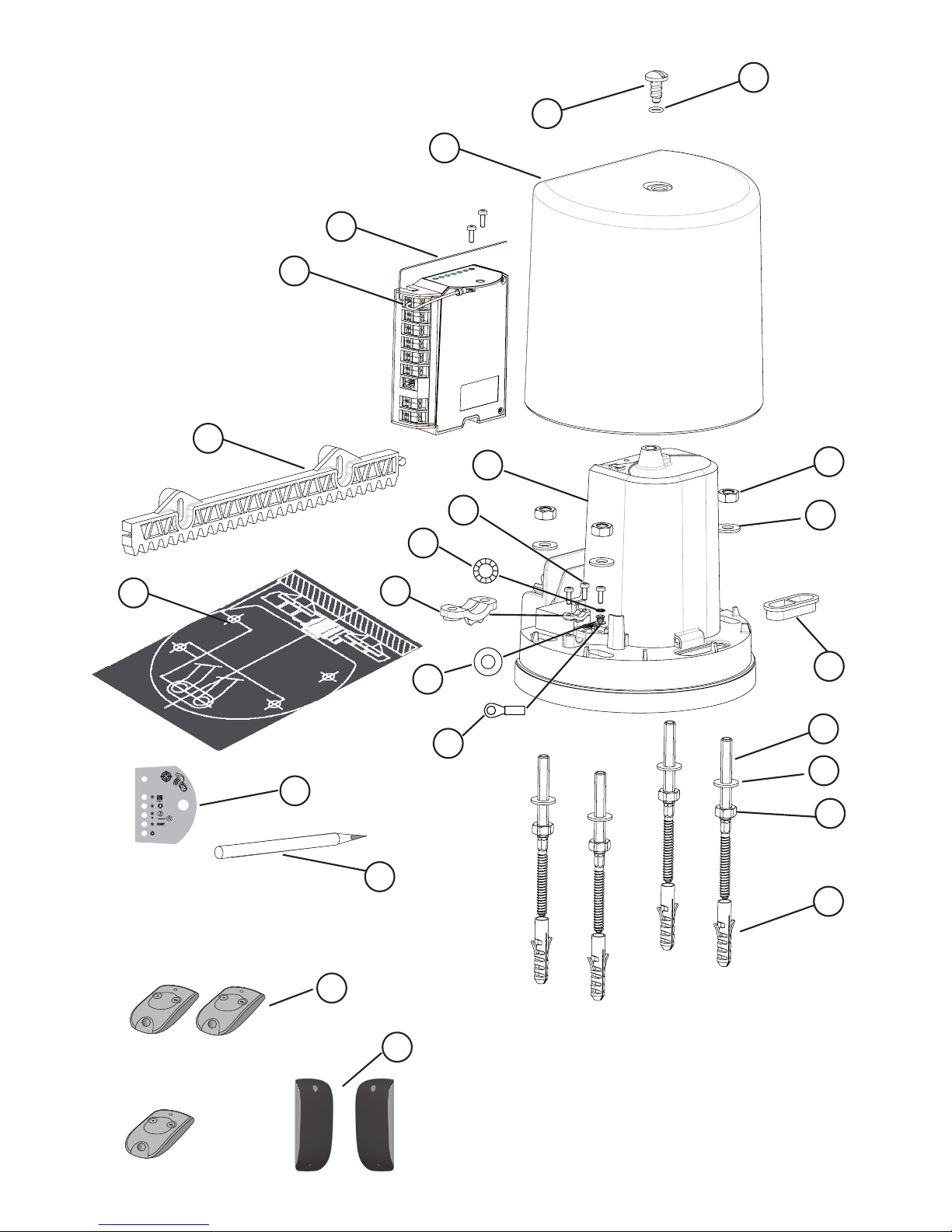

Composition of the kit

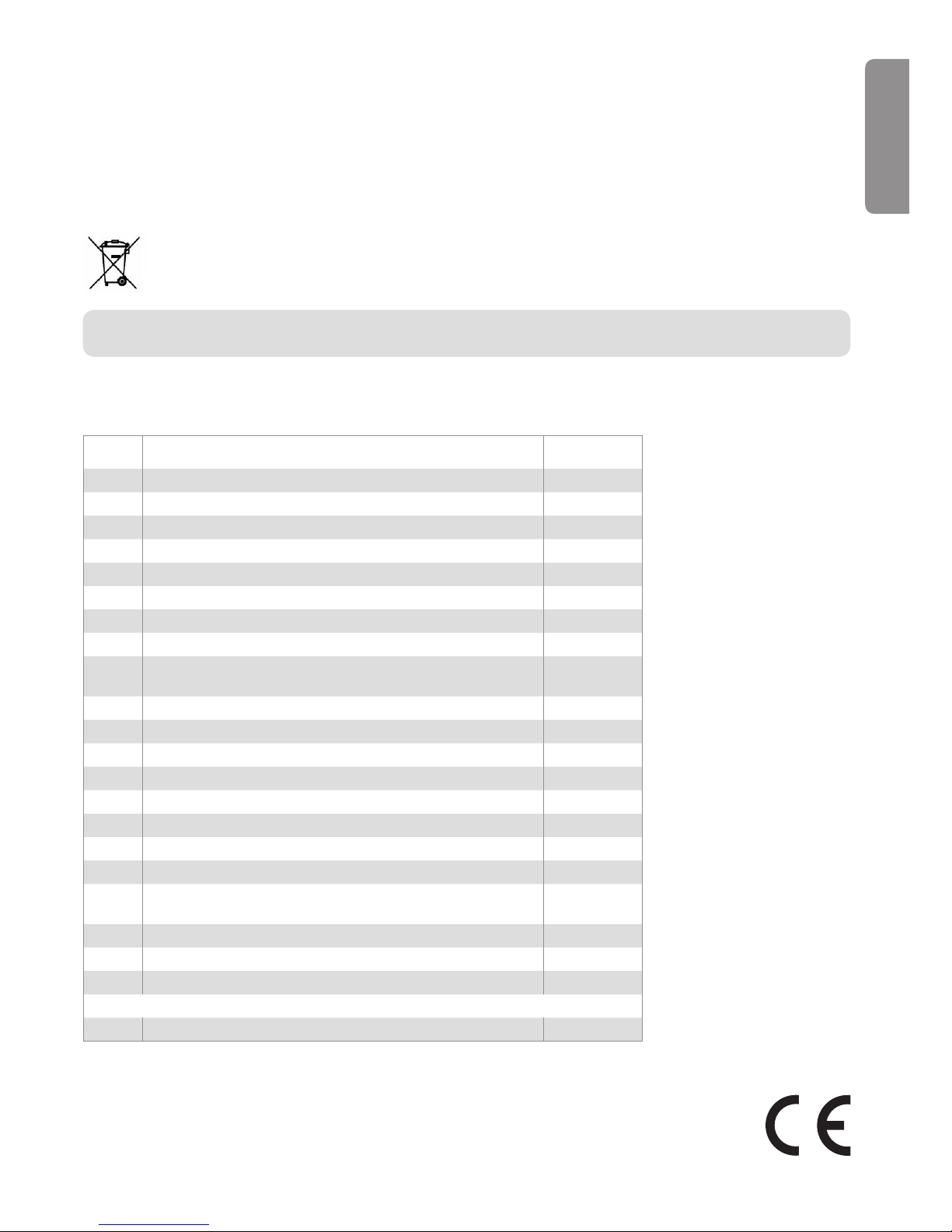

No. Description Quantity

1 Cover 1

2 Aerial 1

3 Electronic unit 1

4 Motor 1

5 Cover screw 1

6 O-ring (9 x 2) 1

7 Rack (33 cm) 12

8 Galvanised screw (M10) 8

9

Galvanised medium plain washer (10.5 x 22 x

2)

8

10 Cable grommet 1

11 Dual thread lag screws (M10 x 15) 4

12 Plug (12 x 60 S12) 4

13 Galvanised TCB self-tapping screw (M4 x 12) 3

14 Serrated washer (AZ4) 1

15 Cable clip 1

16 Medium plain washer (M4 x 10) 1

17 Insulated round terminal (D4) 1

18

Installation template to be cut out (printed on

card)

1

19 Electronic unit label 1

20 Pencil 1

21 Keytis NS 2 RTS remote control 1/2

Only in the FreeVia 300 kit

22 Set of photoelectric cells 1

Do not throw away your scrapped equipment or used batteries with household waste.

It is your responsibility to dispose of your electronic equipment in the relevant recycling

points.

4

EN

Maximum weight and dimensions of the gate

Max. weight (W) 300 kg

Max. height. (H) 2 m

Max. width. (W) 5 m

Size of motor (in mm)

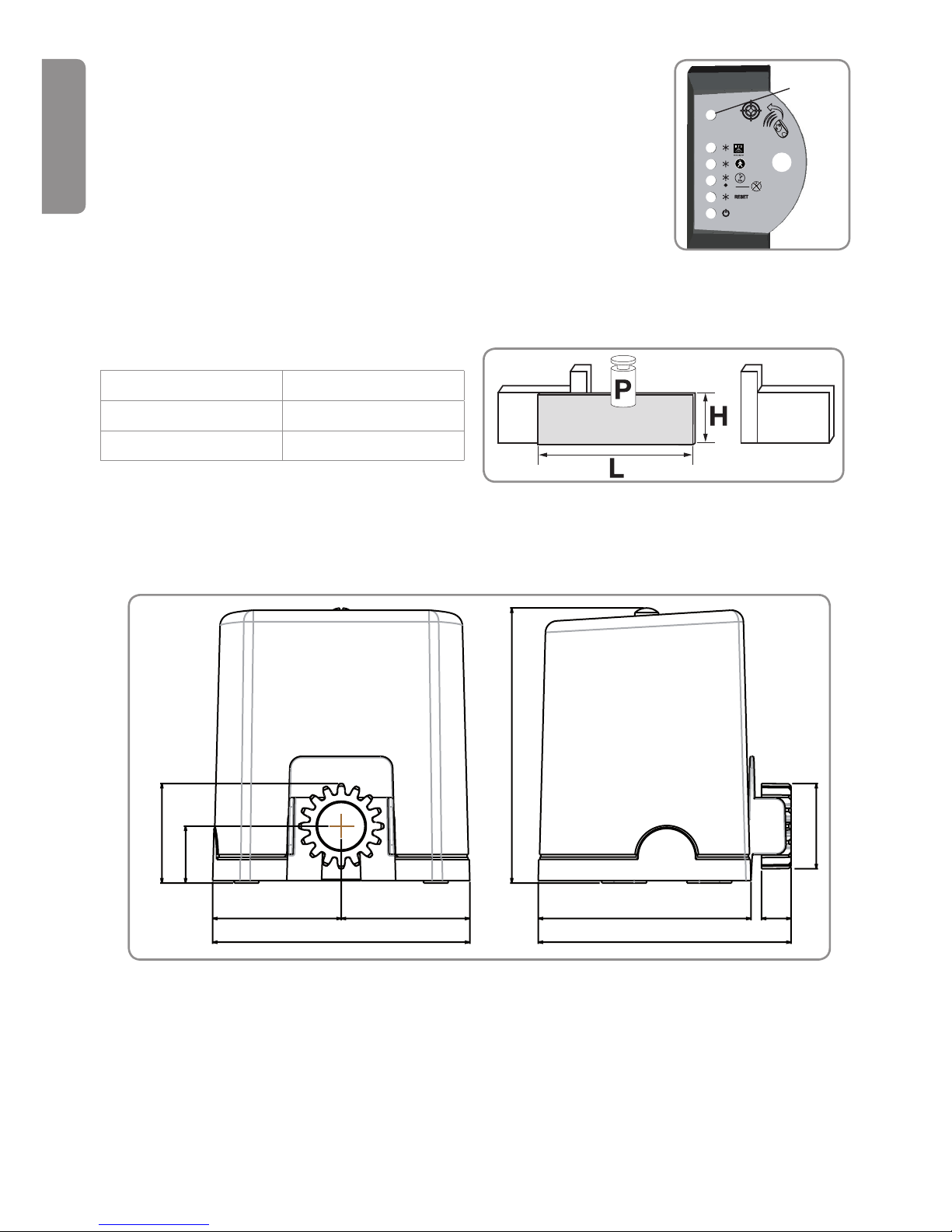

Ambient light detector

The motor's electronic unit is tted with an ambient light detector

which detects whether or not the cover is tted. This means that

settings mode is only available when the cover is removed. If the

cover is tted, the motor is in standby mode.

84

72

232

48

109

218 214

109

180

25

Light

sensor

5

EN

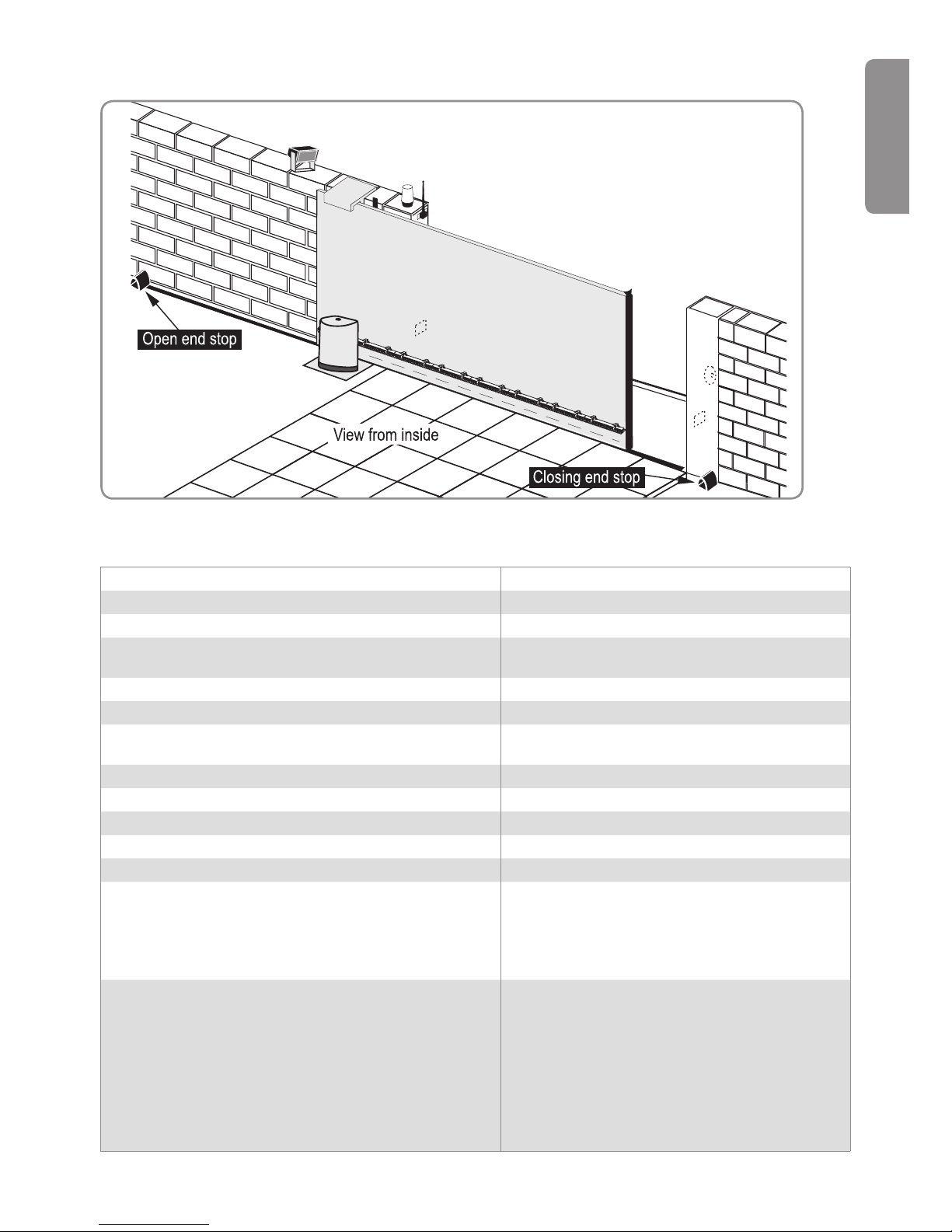

General view of the installation

Technical data

Supply voltage ~ 230 V/Solar

Motor type 24 Vdc

Motor output 150 W

Max. power consumed

(with area lighting)

600 W

Standby consumption 4.5 W

Average frequency of movements per day 20 cycles/day

Opening speed*

3 m in 16 seconds, excluding slow zone

(20 cm)

Automatic obstacle detection Compliant with standard EN 12 453

Operating temperature - 20°C to + 60°C

Thermal protection Yes

Protection rating IP 44

Integrated radio receiver Yes

Remote controls:

Radio frequency

Range in eld of use

Storage quantity

433.42 MHz

~50 m

16

Possible connections:

Output for orange light

Area lighting output, contact supplied

Accessories supply output

Backup battery input

Photoelectric cell input

Dry contact control input

Flashing, 24 V, 10 W

500 W max. (~ 230 V)

24 V - 15 W max, 230V only

Yes

Yes (BUS)

Yes, 230V only

* The opening time varies according to the gate specications.

6

EN

Pre-installation checks

Checking your gate ►

Your gate must be in good condition: ensure that its structure is suitable for automatic

control and that it conforms to the relevant standards.

Your gate must remain horizontal throughout its travel, and must open and close

manually with ease. Ensure that the gate travels straight at ground level, and that there

are no sticking points that may prevent it from sliding correctly.

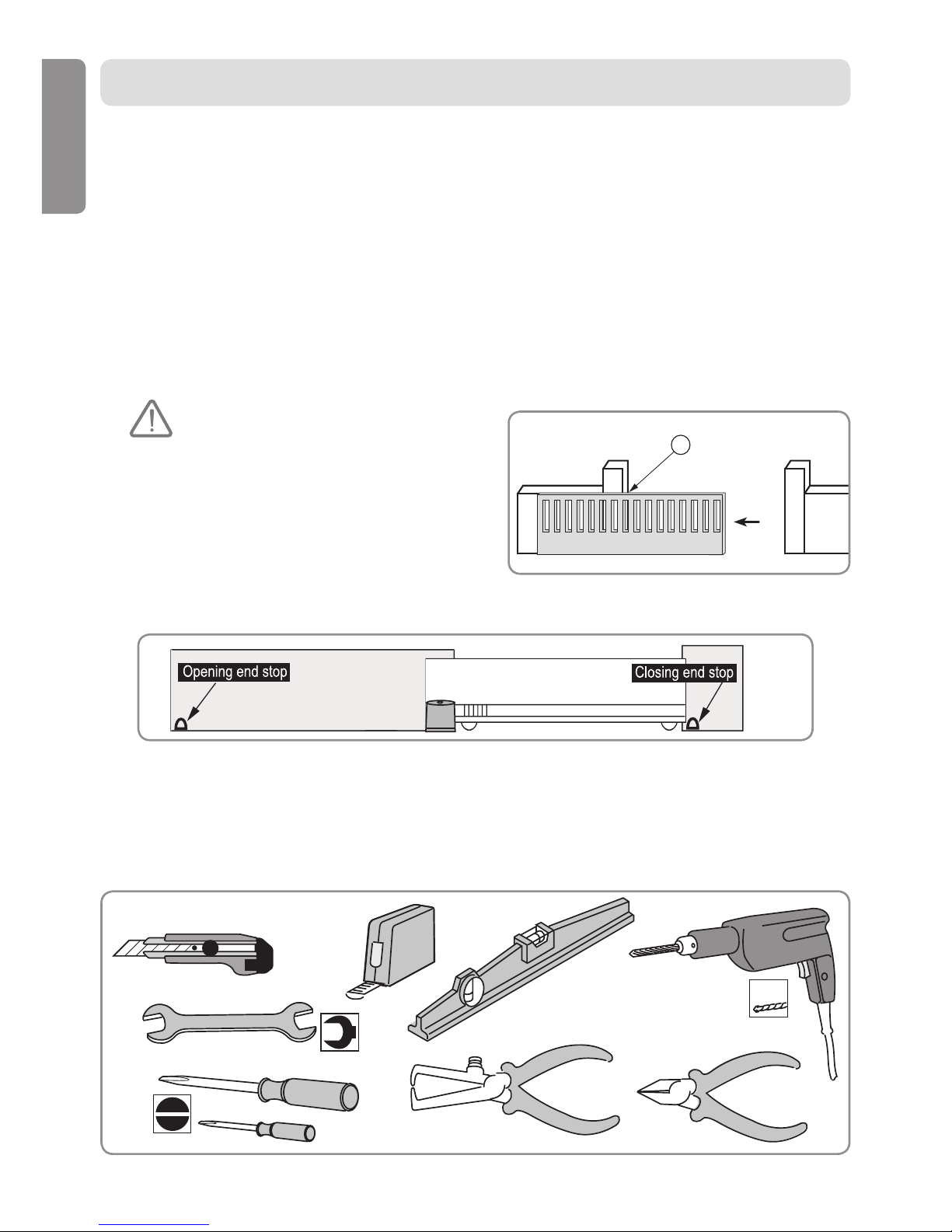

Types of gates which can be motorised ►

Your motor can be adapted to all types of sliding door (PVC, wood, metal etc.).

For a barred gate with bars spaced

more than 50 mm apart, it is essential

to install a mesh (40 x 40 mm type)

along the entire length of the gate.

This will prevent any risk of trapping

(see mark ‘C’ opposite).

Fitting end stops to the gate ►

The gate must be stopped by end stops

xed securely to the ground to delimit the travel of the gate on opening and closing.

Tools required

C

PRELIMINARY OPERATIONS

17

12

7

EN

Electrical preequipment

Ensure that you have an Orange ICT Ø 25 mm protective sheath for underground

cabling. If a cable conduit cannot be made, use a cable grommet which will

withstand the passage of vehicles (ref. 2400484).

Power supply (230 V only) ►

Fit a 230 V electrical input as close as possible to the motor.

The motor's electronic unit must be supplied with 230 V - 50 Hz with a exible 1.5 mm²

cable.

The electric line should be:

Exclusively reserved for the motor.•

Fitted with protection: •

– a 10 A fuse or breaker,

– a differential type device (30 mA).

Installed according to current electrical safety standards in the countries in which •

it is used.

An all-pole supply cut-off device must be provided:

either by using a supply cable tted with a plug,•

or by using a switch ensuring a minimum separation distance between the contacts •

of 3 mm on each pole (according to the EN 60335-1 standard).

It is recommended that you t a lightning conductor (max. residual voltage 2 kV).

The cells (as an option in the Freevia 280 pack) ►

The cells are essential for operation in automatic mode and for opening in public

areas.

Cell wiring • (see page 23)

Ensure that there is a sheathed connection between the two pillars for the cell wiring.

Drill holes in the two ends of the gate frame to feed through the sheaths. The cells

must be connected to the motor electronics using a 2 x 0.75 mm² cable. The feed

wires should arrive under the cells.

Cell location (see page 22).•

Orange light (optional) ►

It is recommended that you install an orange light for operation in automatic mode and

for opening in public areas.

Orange light wiring (see page 26) •

Allow the cable to be fed through for the installation of the orange light. The orange

light must be connected to the motor electronics using a 2 x 0.75 mm² cable.

Orange light location (see page 25)•

Safety instructions

The safety instructions must be followed throughout the installation:

Remove any jewellery (bracelets, chains, etc.) during installation.•

For drilling or welding operations, wear special goggles and sufcient protection.•

Use appropriate tools, specied on page 6.•

Be careful when handling the motorisation system to prevent any risk of injury.•

Do not connect the unit to the power supply or to the backup battery (optional) before the •

installation process is complete.

Never use high pressure cleaning equipment.•

8

EN

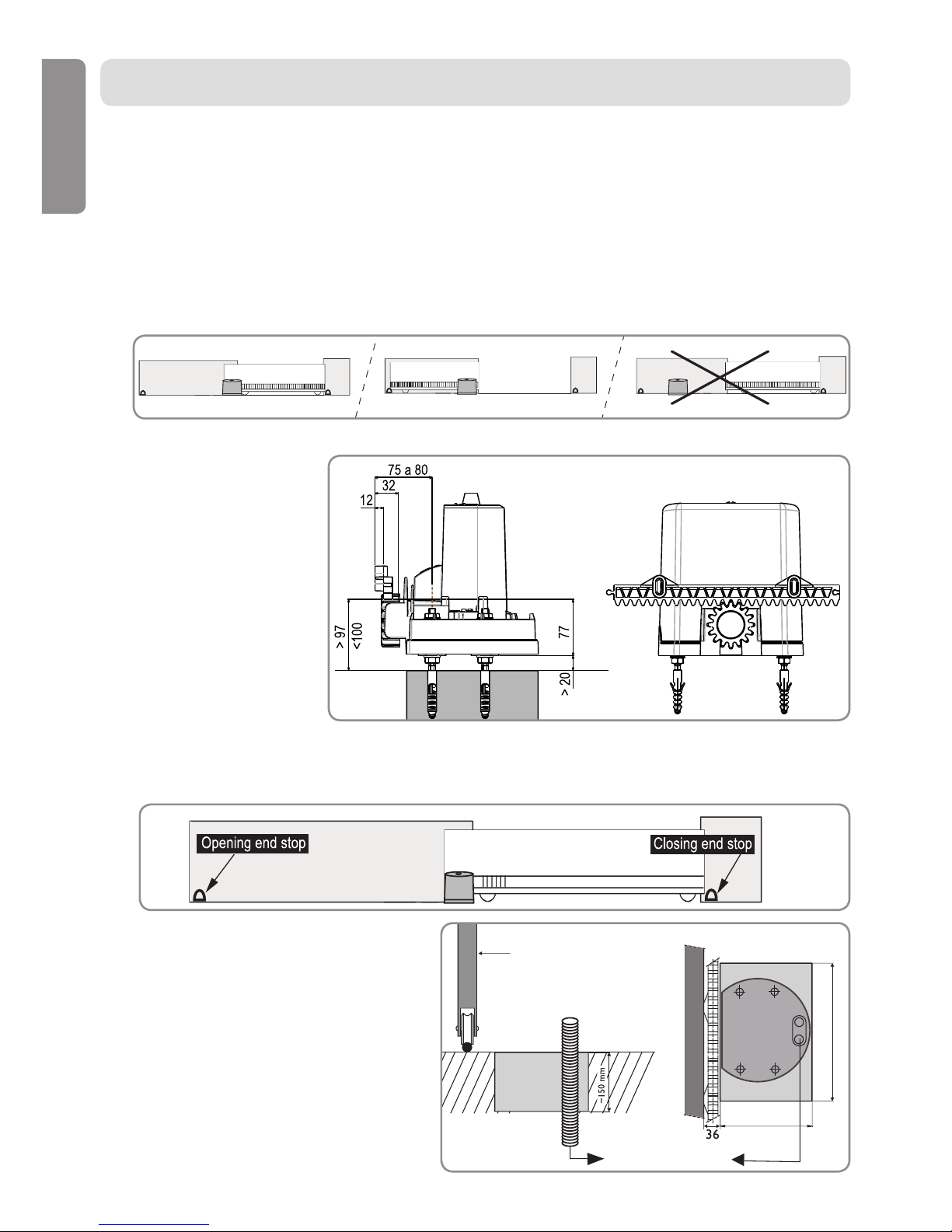

Fitting the end stops ►

The gate must be stopped by end stops which are securely xed to the ground and which

delimit the end of travel.

Base ►

The lag screws for mounting the

motor must be securely anchored to

the ground. The type and dimension

of the base depends on the nature

of the ground. Allow for the supply

cable to be fed through according to

the electrical standards in force in

the country of use.

1. PREPARING THE BASE

Steps

Positioning the motor•

Fitting the end stops•

Base•

Positioning the motor ►

Horizontal position

Ensure that the motor is always positioned in the eld of the gate when opening and closing.

Vertical position

Ensure that the motor

is raised off the ground

slightly (over 20 mm).

Rack

min. 250 mm

min. 200 mm

Gate

Base

Base

Gate

cable feed

9

EN

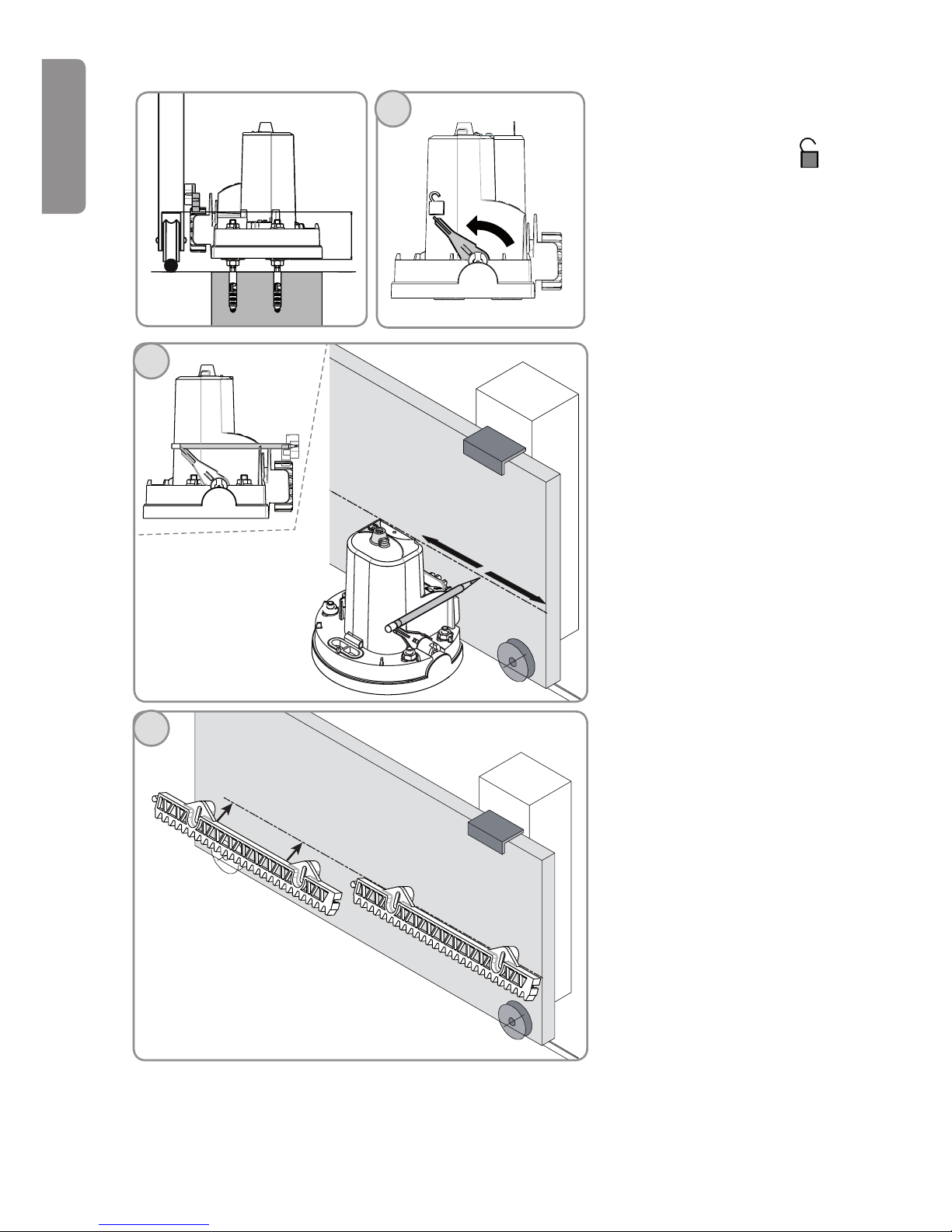

Mounting the motor ►

[1]. Tighten the 4 nuts (8) and add 4 washers (9).

[2]. Remove the cover (1) from the motor (4).

[3]. Position the motor on the

lag screws: ensure that

the bracket (base of the

motor) is no more than

25 mm above the ground.

The recommended space is

between 20 and 25 mm.

Use a spirit level to

check that the motor is level.

[4]. Once the motor is positioned at the right height

in relation to the ground, x it in place using the

washers (9) and tighten the 4 nuts (8).

[5]. Position the pre-drilled grommet (10) in the

opening through which the supply cable

should be fed.

Steps

Fitting the lag screws•

Mounting the motor•

Fitting the rack•

Mechanical adjustment•

Fitting the lag screws ►

[1]. Position the installation template (18) on the

ground and drill 4 holes using a drill bit (Ø

12 mm) suitable for the type of ground.

[2]. Insert the plugs (12). Screw in the lag

screws (11).

2. MOUNTING

Grease the lag screws lightly before

screwing them into the plugs.

10

EN

Fitting the rack ►

77

1

2

3

[1]. Check that the motor is

unlocked and that the

handle is in position

.

[2]. Use the pencil provided

(20) to mark the

position of the rack.

With one hand, hold

the pencil in the

notches provided on the

motor.

With the other hand, slide

the gate to trace the height

of the rack mounting.

[3]. Fix an initial rack component

(7) by positioning the top

of the rack on the line

drawn by the pencil.

Fix the other rack

components in the same

way. Use HSHC head

screws (ø 6) to suit the gate

material (metal, wood).

Up to 5 m of rack can be installed (set of 3 x 33 cm rack components, ref: 2400962).

Loading...

Loading...