SOMFY Elixo 500 230 V Installation Manual

somfy.com

Elixo 500 230 V

EN

Installation manual

ES

Manual de instalación

PT

Manual de instalação

EL

Εγχειρίδιο εγκατάστασης

5054409A

Elixo 500 230 V

CONTENTS

GENERAL INFORMATION 2

SAFETY 2

General information 2

Safety instructions 2

PRODUCT DESCRIPTION 3

Composition of the kit 3

Description of the motorisation 3

General motor size 3

Area of application 4

General view of a standard installation 4

INSTALLATION 4

Assembling the release lever 4

Disengaging the motorisation 4

Installing the motorisation 5

Wiring 6

QUICK COMMISSIONING 7

Memorising the remote controls 7

Setting the motor torque 7

MOTORISATION OPERATION 8

CONNECTING ADDITIONAL DEVICES 8

230 V integrated fl ashing amber light 8

Photoelectric cells 8

Electric eye 8

Wired keypad 8

Wired keyswitch 9

EN

PARAMETER SETTING 9

CLEARING THE REMOTE CONTROLS 10

DIAGNOSTICS 10

TECHNICAL DATA 10

Copyright © 2008 Somfy SAS. All rights reserved. 1

Elixo 500 230 V

GENERAL INFORMATION

This product, installed in accordance with this guide, complies with EN 12453 and EN 13241-1 standards.

Hereby, Somfy, declares that this product is in compliance with the essential requirements and other relevant provisions

EN

of Directive 1999/5/EC. A declaration of conformity is available on the website at www.somfy.com/ce (Elixo 500 230V),

usable in EU, CH and NO.

SAFETY

General information

Always read this installation guide and the attached safety instructions before installing this Somfy product.

This Somfy product must be installed by a professional motorisation and home automation installer, for whom these

instructions are intended.

The use of any safety components not approved by Somfy remains the sole responsibility of the installer.

These instructions describe how to install, commission and operate this product.

Moreover, the installer must comply with current standards and legislation in the country in which the product is being

installed, and inform his customers of the conditions for use and maintenance for the product.

Any usage outside of applications defi ned by Somfy constitutes non-compliance, and is therefore not covered by

the guarantee. In this event, as for all usage not consistent with the instructions given herein, Somfy accepts no

responsibility for harm or damage.

Safety instructions

Before installation, ensure that the gate frame conforms to current standards, particularly:

The gate sliding rail must be straight and horizontal and the wheels must be able to support the weight of the gate.•

The gate should move easily over its entire travel distance and there should be no sign of excessive side sway.•

The upper guide should allow the gate exact clearance to ensure regular, silent movement.•

End stops must be installed on the ground at both the opening and closing stop positions.•

The position in which the motorisation mechanism will be fi tted must allow for safe and easy manual release. •

If after evaluation the gate system does not meet the conditions set out above, they must be repaired or, if necessary,

replaced.

The selected safety accessories for the installation must comply with the current standards and regulations in force in the

country in which the product is being installed.

Ensure that there are no danger zones (risk of crushing, cutting, trapping) between the gate and the surrounding fi xed

elements caused by the opening movement of the gate.

On a barred gate, if the bars are more than 40 mm apart, install an appropriate safety device to prevent cutting.

Maintain a clear area of 500 mm behind the gate when it is completely open.

Take care while the gate is moving.

Place the fi xed control devices and remote controls out of the reach of children.

Any switch without a locking device must be installed in direct view of the gate and away from any mobile parts. The

minimum height at which it must be installed is 1.5 m. It must not be accessible to the public.

During installation of the motorisation:

Remove any jewellery (bracelets, chains, etc.).•

For drilling and welding operations, wear special glasses and suffi cient protection.•

Use the appropriate tools.•

Do not connect to the mains or to a backup battery before installation is complete.•

Be careful when handling the motorisation system to prevent any risk of injury.•

In order to operate, the motorisation must be supplied with 230 V 50 Hz. The electric supply should:

solely be used for the motorisation,•

have a minimum cross section of•

be fi tted with an approved all-pole switch with contact openings of at least 3.5 mm, fi tted with a protection device •

(fuse or circuit breaker with a 16 A rating) and a differential device (30 mA),

be installed in accordance with the current electrical safety standards.•

It is recommended that the installation be fi tted with a lightning conductor (in compliance with standard NF C 61740,

maximum residual voltage 2 kV).

1.5 mm²,

2 Copyright © 2008 Somfy SAS. All rights reserved.

Elixo 500 230 V

Regularly check the condition of the gate. Gates in poor condition must be repaired, reinforced or even replaced. Check

that the various motorisation component’s screws and fi ttings are correctly tightened.

Before carrying out work on the installation, switch off the power supply.

PRODUCT DESCRIPTION

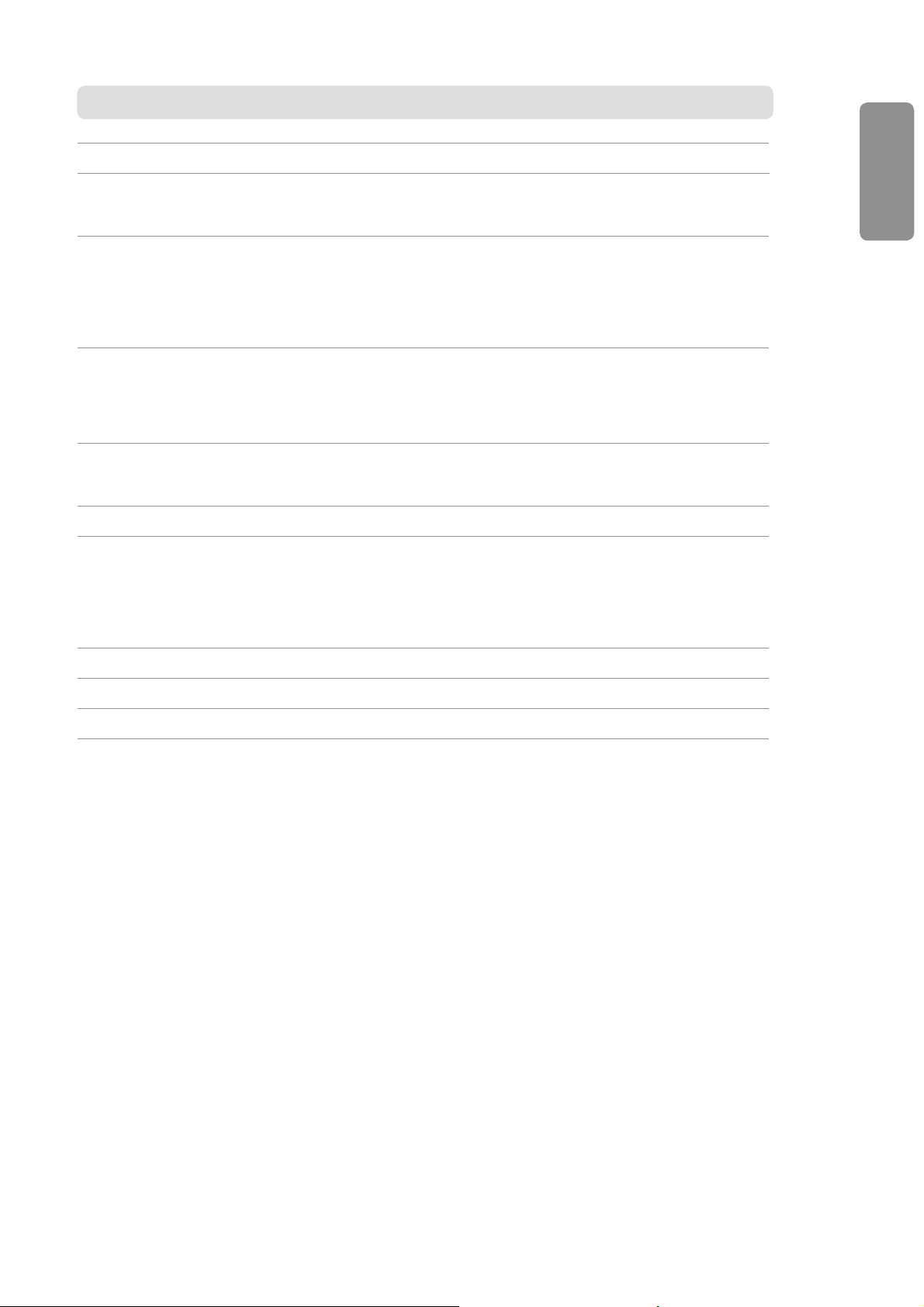

Contents of the standard kit

1 Elixo 230 V Motor x 1

2 Keytis 2 RTS remote control x 2

3 RTS 3 m offset aerial x 1

Ground mounting kit:

4a Lag screws x 4

4b Nut x 8

4c Washer x 4

4d Plug x 4

4e Base plate x 1

5 Manual release handle assembly x 1

6 Handle locking key x 2

7 End limit brackets x 2

8 Torque setting handle x 1

9 Spanner x 1

Description of the motorisation

1 Control unit and capacitor

2 Motor

3 Reduction unit with worm screws - helicoid drive wheel

4 Mechanical clutch on the motor shaft

5 End limit unit

6 Pinion with release mechanism

EN

1

5

6

5

6

2

4

a

4

b

4

c

4

d

4

e

8

7

3

9

1

2

3

4

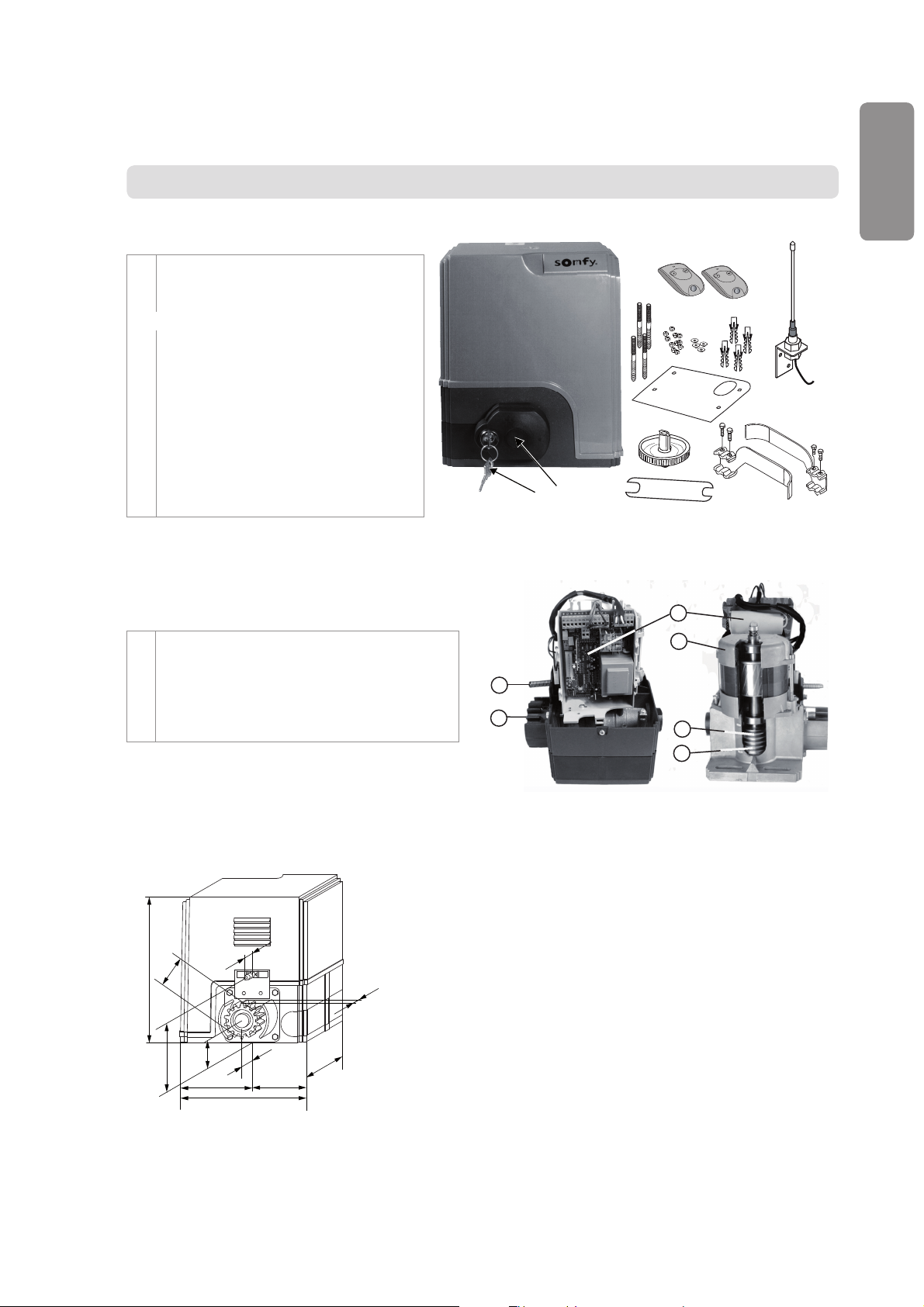

General motor size

260

Øp56

122

Copyright © 2008 Somfy SAS. All rights reserved. 3

37

22

50

131

227

43

159

96

Elixo 500 230 V

E

E

D

C

F

G

A

B

C

E

E

D

F

G

i

i

H

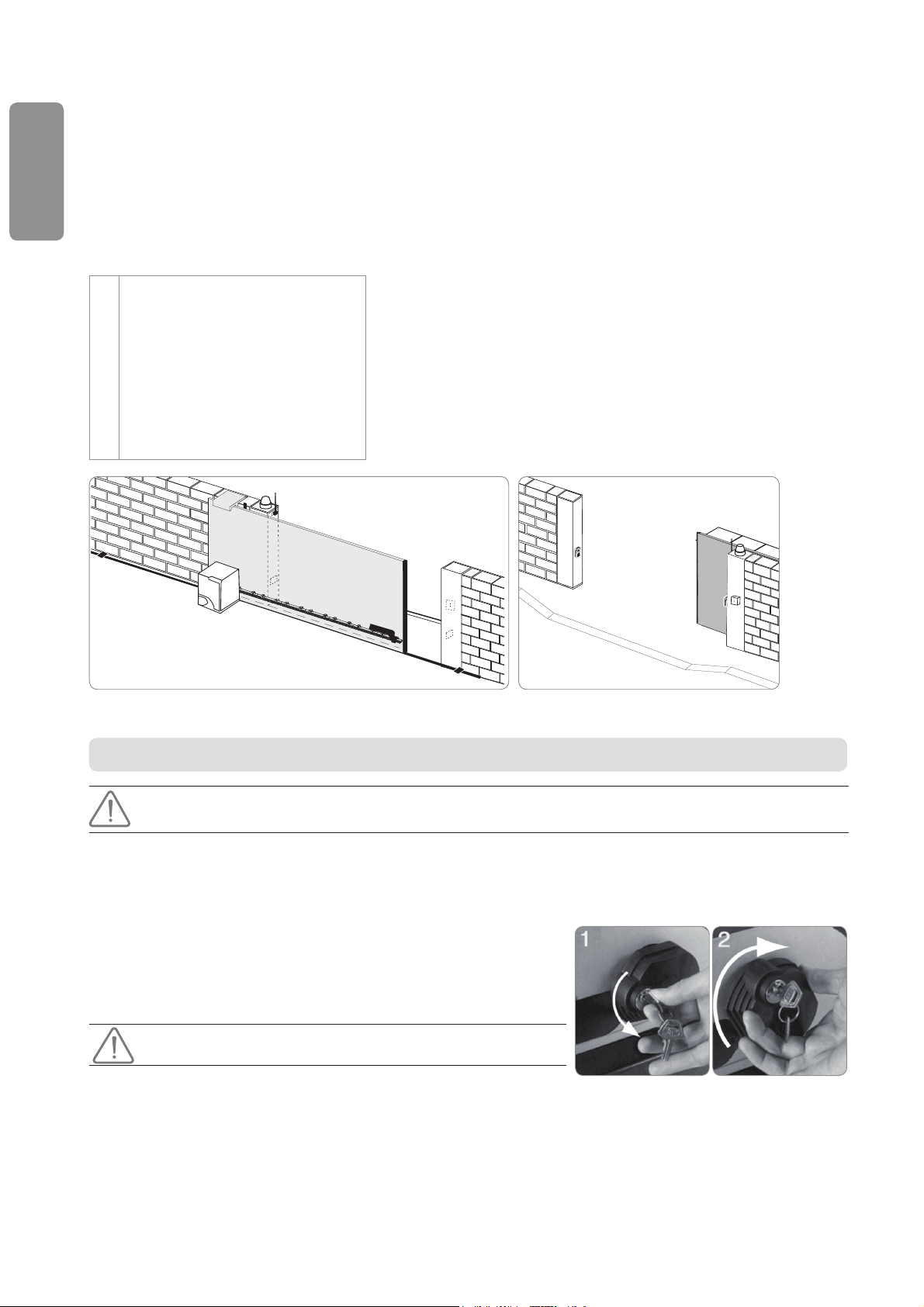

Area of application

Sliding gates up to 500 kg and carrying out 100 operations per day.

In order to comply with standard EN 12453, an active edge sensor fi tted with autotest electronics (Bircher Reglomat

ref. ELE040/080A0J0/1/XXXX/2 + ref.ESA25-24ACDC) must be installed on the motorisation. After installing the active

edge sensor, it is essential that a stress test be carried out using measurement equipment which conforms to the requi-

EN

rements set out in clause 5.1.1 of standard EN 12445.

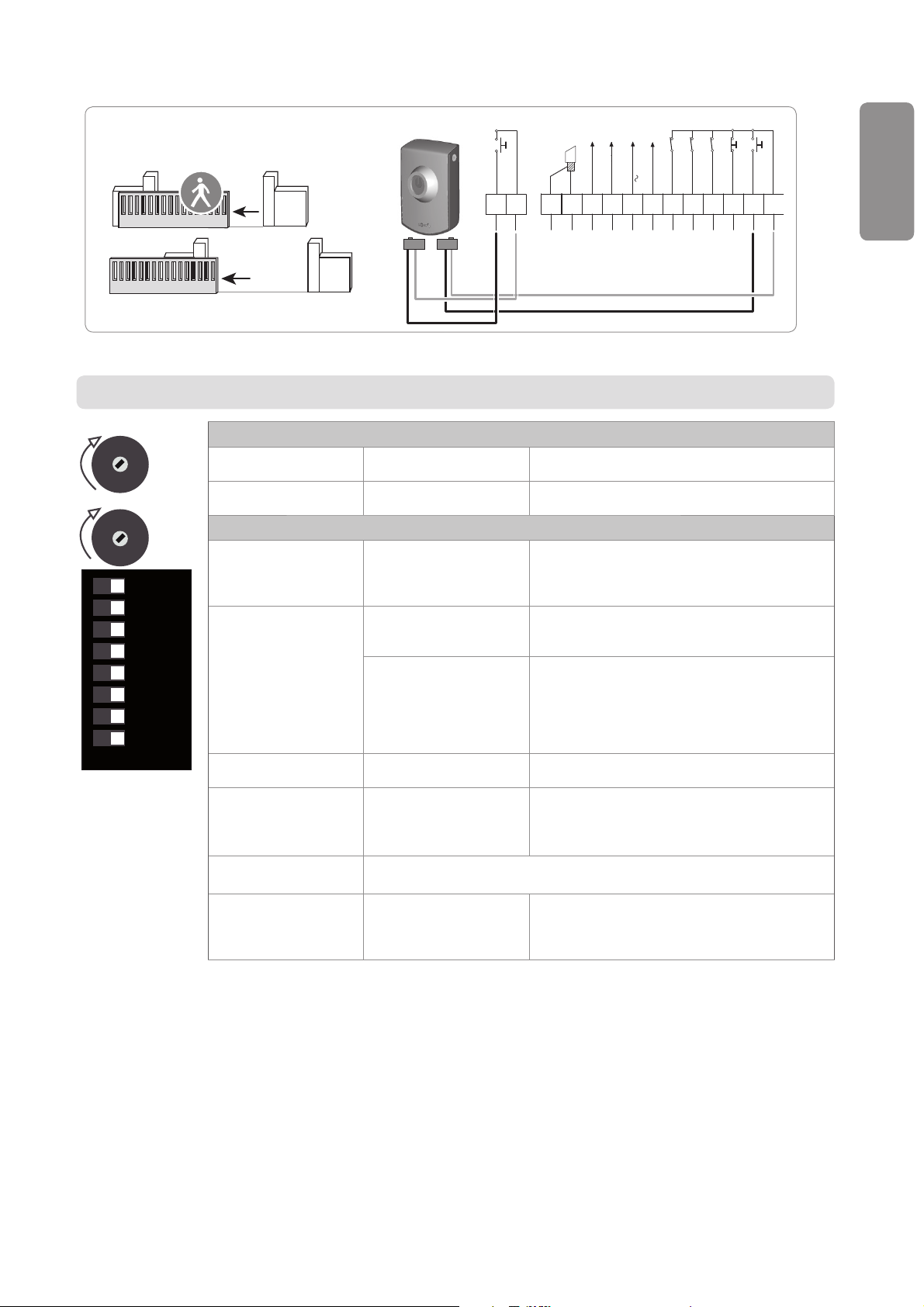

General view of a standard installation

A Motor

B Rack

C Aerial

D Orange light

E Set of photoelectric cells

F Key lock

G Active safety edge sensor

H End limit brackets

i End stops in the ground

INSTALLATION

The motorisation must be disengaged during installation.

Assembling the manual release handle

Insert the release handle into the specifi c housing on the motor.[1]

Tighten the release handle.[2]

Fit the screw cover.[3]

Disengaging the motorisation

Turn the key a quarter of a turn to the left. [1]

Turn the release handle to the right.[2]

Do not forcibly push the gate. Hold the gate over its entire travel

during manual manoeuvres.

4 Copyright © 2008 Somfy SAS. All rights reserved.

Installing the motorisation

25 mm

14 mm

h

25

>23

h100 130

85

77

h

25

50

>23

h100 130

2 mm

60 mm

20 mm

55 mm

100 mm<h<110 mm

110 mm<h<130 mm

NO OK

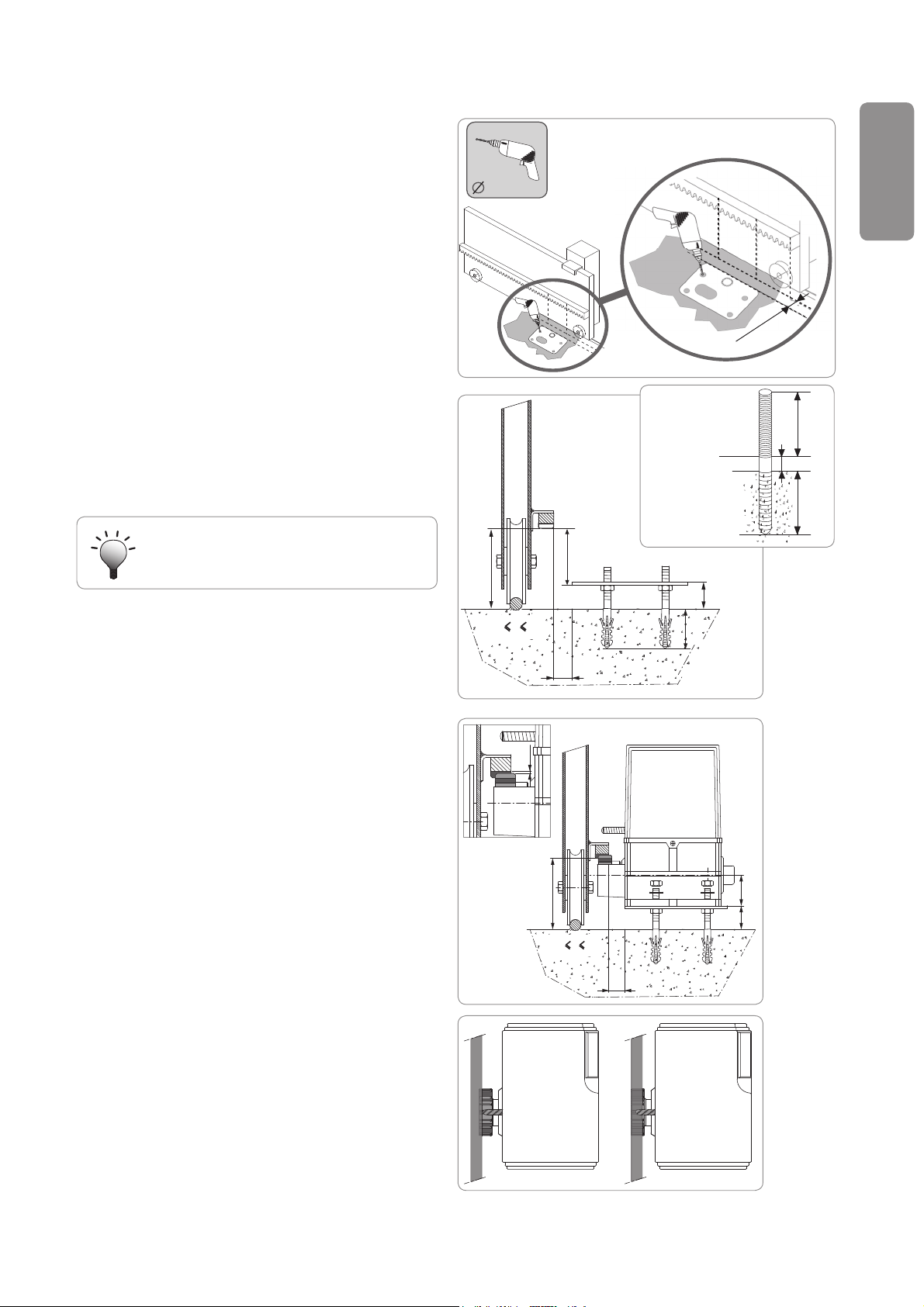

Fitting the mounting system

The motor mounting kit provided is to be used on a concrete

base. For all other types of mounting, use the appropriate

fi ttings.

Position the base plate:[1]

parallel to the gate,•

with the symbol on the pinion pointing towards the gate,•

by moving it by 25 mm in relation to the front line of the •

rack (if the rack is fi tted with a cover, measure from the

line on the rack, not on the cover),

so that it does not obstruct movement and to ensure the •

gate is able to open and close completely.

Mark the location for the ground mountings.[2]

Drill to a depth of 85mm.[3]

Insert the plugs.[4]

Tighten the lag screws on:[5]

the threaded section for a rack height of between 110 and •

130 mm,

the threaded section + the unthreaded section for a rack •

height of between 100 and 110 mm.

Elixo 500 230 V

EN

To facilitate tightening of the lag screws, use 2

nuts to form a “double nut”.

Screw a nut onto each lag screw.[6]

Place the base plate onto the lag screws with the symbol [7]

on the pinion pointing towards the gate. It must be a

minimum of 23 mm from the ground.

Mounting the motor

Position the motor on the lag screws, insert it and push it [1]

towards the gate.

Ensure the pinion is correctly positioned under the rack[2]

Set the height of the motor and/or the rack to ensure a [3]

clearance of approximately 2 mm between the rack and the

pinion. This setting is important to prevent premature wear

of the pinion and rack; the pinion must not be supporting

the weight of the gate.

Check:[4]

that the setting nuts all come into contact with the base of •

the motor,

the motor is level,•

the gate runs correctly,•

the clearance between the rack and pinion does not vary •

signifi cantly over the gate’s travel.

Fit a washer and nut onto each lag screw in order to fi t the [5]

motor.

Copyright © 2008 Somfy SAS. All rights reserved. 5

Elixo 500 230 V

5 mm

15 mm

a

b

181516

17

a

b

5

M

1

GND

2

3

4

N

L

DXSX

Fitting the end limit brackets

Manually move the gate to the open position.[1]

Position a bracket onto the rack so that it activates the motor end limit contact. [2]

Screw the bracket onto the rack.[3]

Manually move the gate to the closed position then repeat steps 2 and 3 to fi t [4]

EN

the second bracket to the rack.

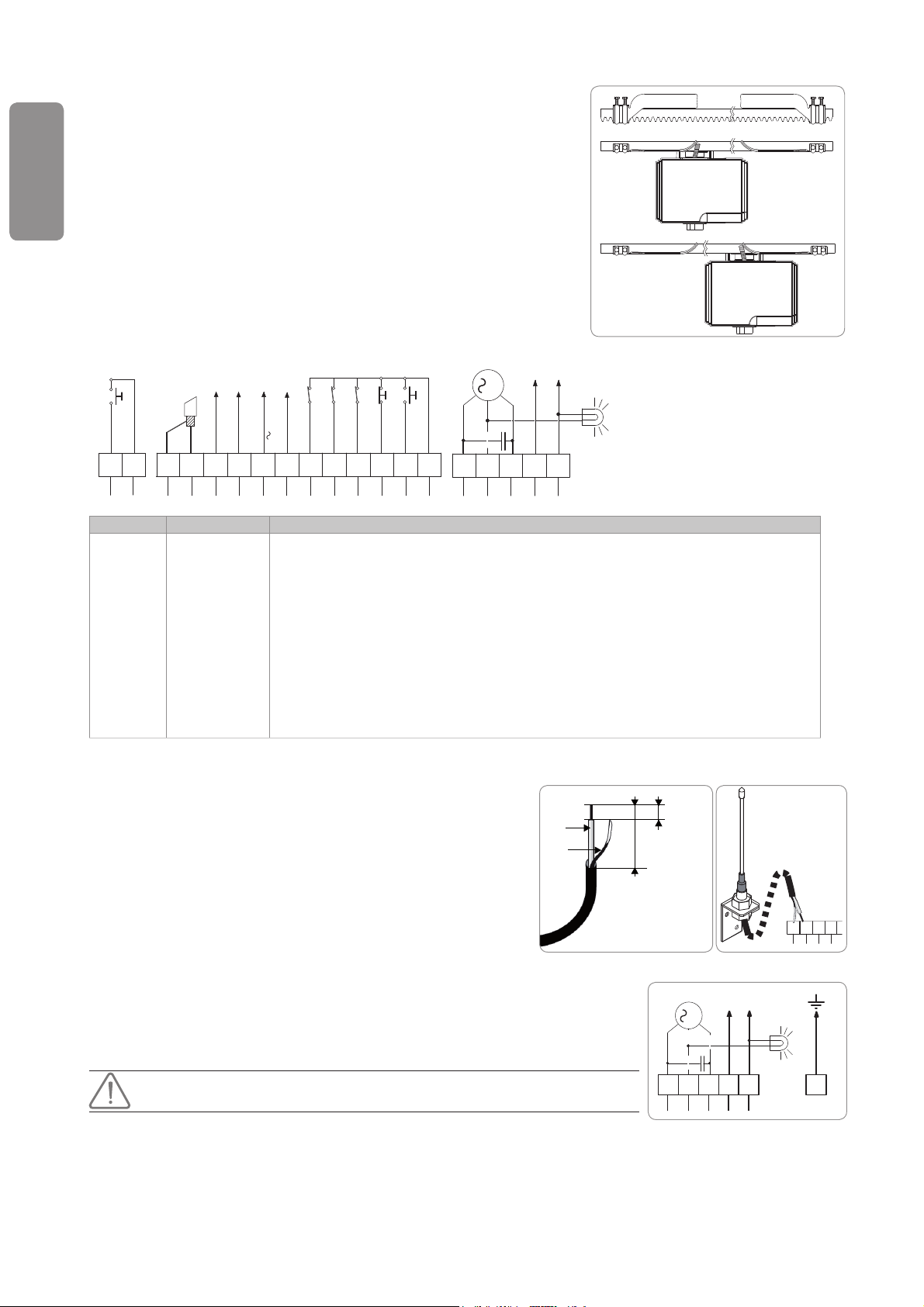

Wiring

General wiring diagram

PED

24V

NC

SWC

NCSTNO

PHOT

N

L

M

BL

COM

NC

NC

SWO

0V

20

Terminals Description Function

1 N Neutral single-phase 230 V~, 50-60 Hz power supply

2 L Live single-phase 230 V~, 50-60 Hz power supply

3-4-5 Motor connection (4 = shared, 3 and 5 = motor and capacitor)

1-4 230 V output, fl ashing orange light

7 COM Shared by control inputs (8-9-10-11-12)

8 START Control point input, sequential operation

9 STOP Control point input (closing only)

10 PHOT Photoelectric cell input

11 SWO Opening end limit contact

12 SWC Closing end limit contact

13-14 0V-24V~ Alternating 24 V output for power supply to the additional devices

15-16 Unused outputs

17 ANT Aerial core

18 ANT Aerial braid

19 COM Shared

20 PED Pedestrian opening control point input

19

18

17

16

141513

12

11

10

5

3

7

8

9

4

1

2

Aerial wiring

For optimum reception, the aerial must not be cut and must be as far away

as possible from the power supply terminal blocks and wires. The aerial

must always be installed at a height and must be visible from a distance.

Do not fi t the aerial to a metal post or behind a wire fence.

Cut the coaxial cable if it is too long. Shortening the cable will improve the

signal (a coaxial cable

insulating screw joint will distort the signal).

The mounting plate is an active component of the aerial. It must not be

removed or modifi ed.

which is too long, extended or connected with an

Connection to the power supply

To connect the motor to the power supply, use a standard multicore cable with a minimum

cross section of 3x1.5mm².

Inputs 9 and 10 must be bridged to terminal 7 if they are not used to connect a

safety device.

6 Copyright © 2008 Somfy SAS. All rights reserved.

Checking the motorisation wiring

A

B

2 s

[1]

[2]

.......2 min........

2 s

[1]

[2]

.......2 min........

A

B

Elixo 500 230 V

Wire Terminal Terminal

Motorisation to the left (A) Motorisation to the right (B)

Motor connection Black 3 5

Brown 5 3

End limit connection Red 11 12

Brown 12 11

Black 7 7

Switch on the power to the installation before commissioning.

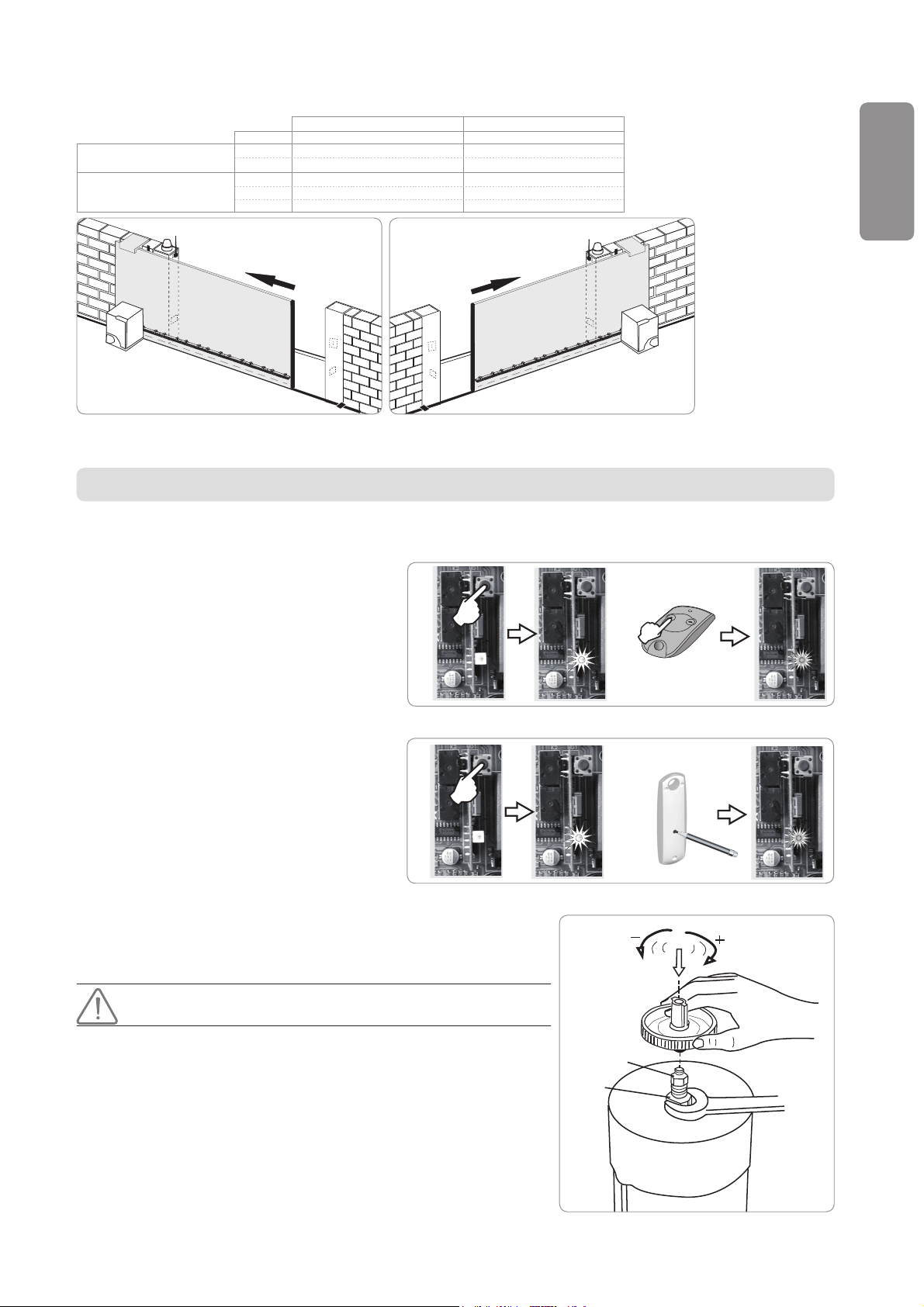

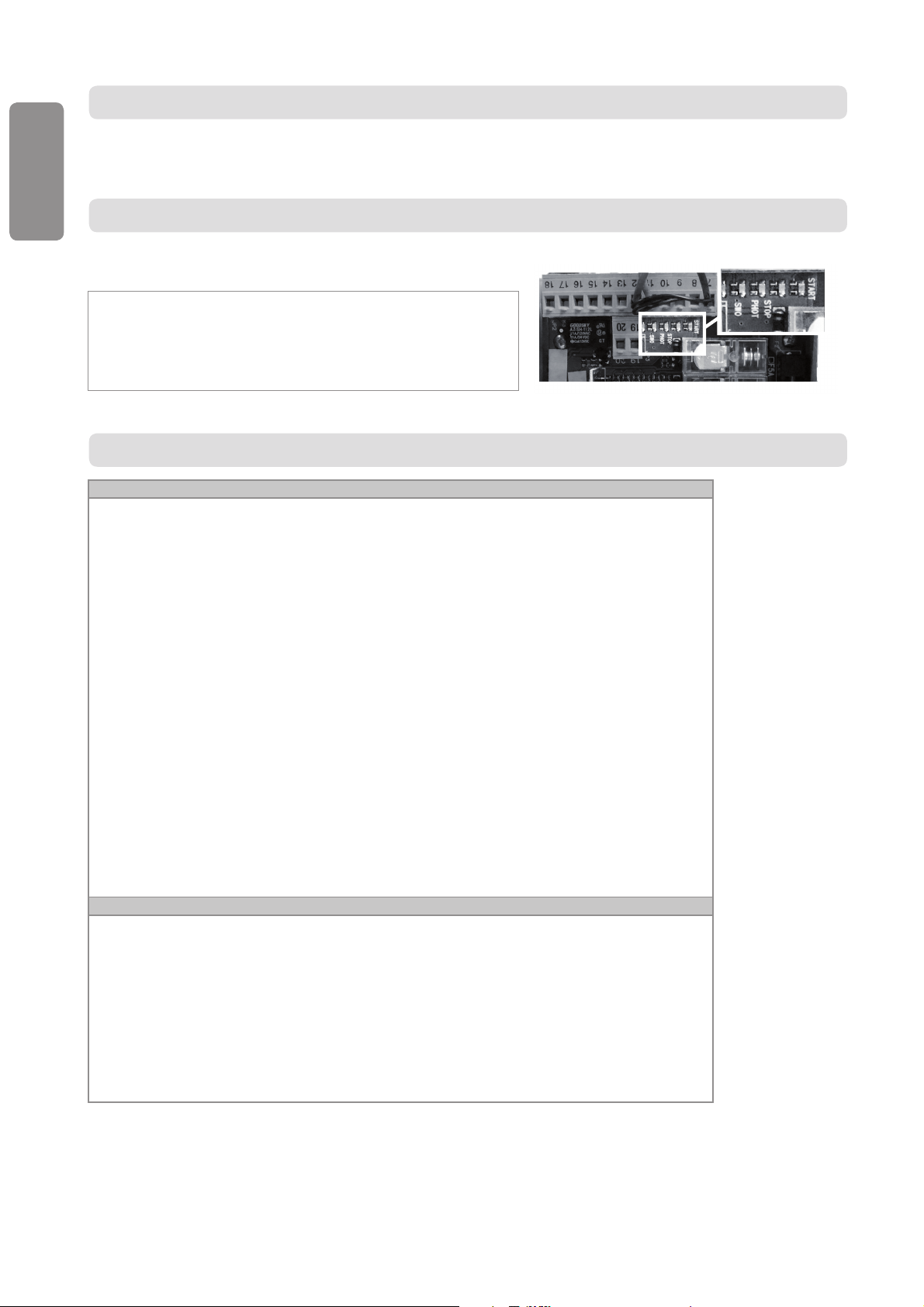

QUICK COMMISSIONING

Memorising the remote controls

To memorise a remote control:

Press the PROG button on the control unit for [1]

2 seconds. The red indicator light will come on.

Press a channel on the remote control to which [2]

the motorisation will be linked within 2 minutes.

The red indicator light fl ashes, the remote control

has been memorised.

If this procedure is carried out using a channel which

has already been memorised, this channel will be

cleared.

To add other remote controls: repeat the above

procedure.

To add a Telis type remote control:

Press the PROG button on the control unit for [1]

2 seconds. The red indicator light will come on.

Press the PROG button on the back of the Telis. [2]

This must be done within 2 minutes. The red

indicator light fl ashes, the remote control has

been memorised.

To exit programming mode without programming a

remote control: briefl y press the PROG button on the

control unit.

EN

Setting the motor torque

The motor torque must be set in accordance with current safety

standards before operating the motorisation.

[1] Turn off the power supply.

[2] Using the spanner provided, lock the motor shaft “A”.

[3] Using the torque setting handle, tighten the automatic tightening nut “B” to

increase the torque or loosen it to reduce the torque.

AT THIS STAGE IN THE INSTALLATION, THE MOTORISATION IS OPERATIONAL.

Copyright © 2008 Somfy SAS. All rights reserved. 7

Elixo 500 230 V

5

M

1

234

N

L

24V

ac/dc

0V C NC NO

12345

12

24V

ac/dc

0V

CR

CE

24V

IIß RC

0V

BL

NC

PHOT

COM

NCSTNO

18

7

NC

SWCNCSWO

8

9

11

12

141513

10

16

17

24V

IIß RC

0V

BL

NC

PHOT

NCSTNO

7

NC

SWC

COM

NC

SWO

8

9

11

12

141513

10

16

T1

C1 R1 V

R3

T2 C2 R2

T3 C3

H

P2

M

P1+HE – V

}

}

7 s

24V

0V

19

20

STOPNCPHOT

NC

START

COM

NO

7

NC

SWO

SWC

NC

PED

8

9

11

12

14

13

10

MOTORISATION OPERATION

See pages 2 to 3 in the user’s manual.

EN

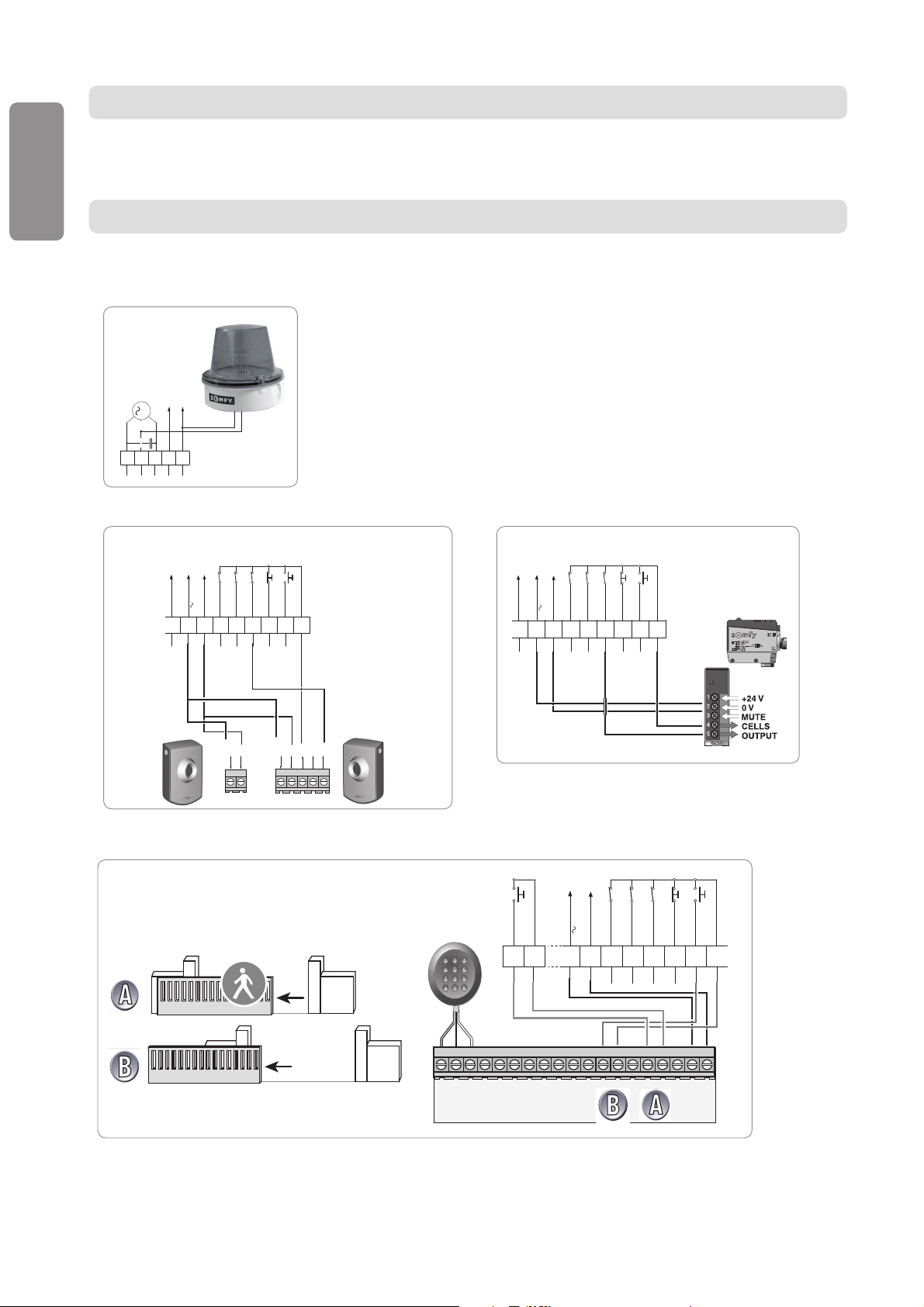

CONNECTING ADDITIONAL DEVICES

230 V integrated fl ashing amber light

(ref. 9 011 084)

Photoelectric cells Refl ex photoelectric cells

On the cell, set the DIP switch1 and the DIP switch2 to ON.

Wired keypad

8 Copyright © 2008 Somfy SAS. All rights reserved.

Wired keyswitch

7 s

A

A

B

B

24V

IIß RC

0V

19

20

STOPNCPHOT

NC

START

COM

NO

18

7

NC

SWO

SWC

NC

PED

8

9

11

12

141513

10

16

17

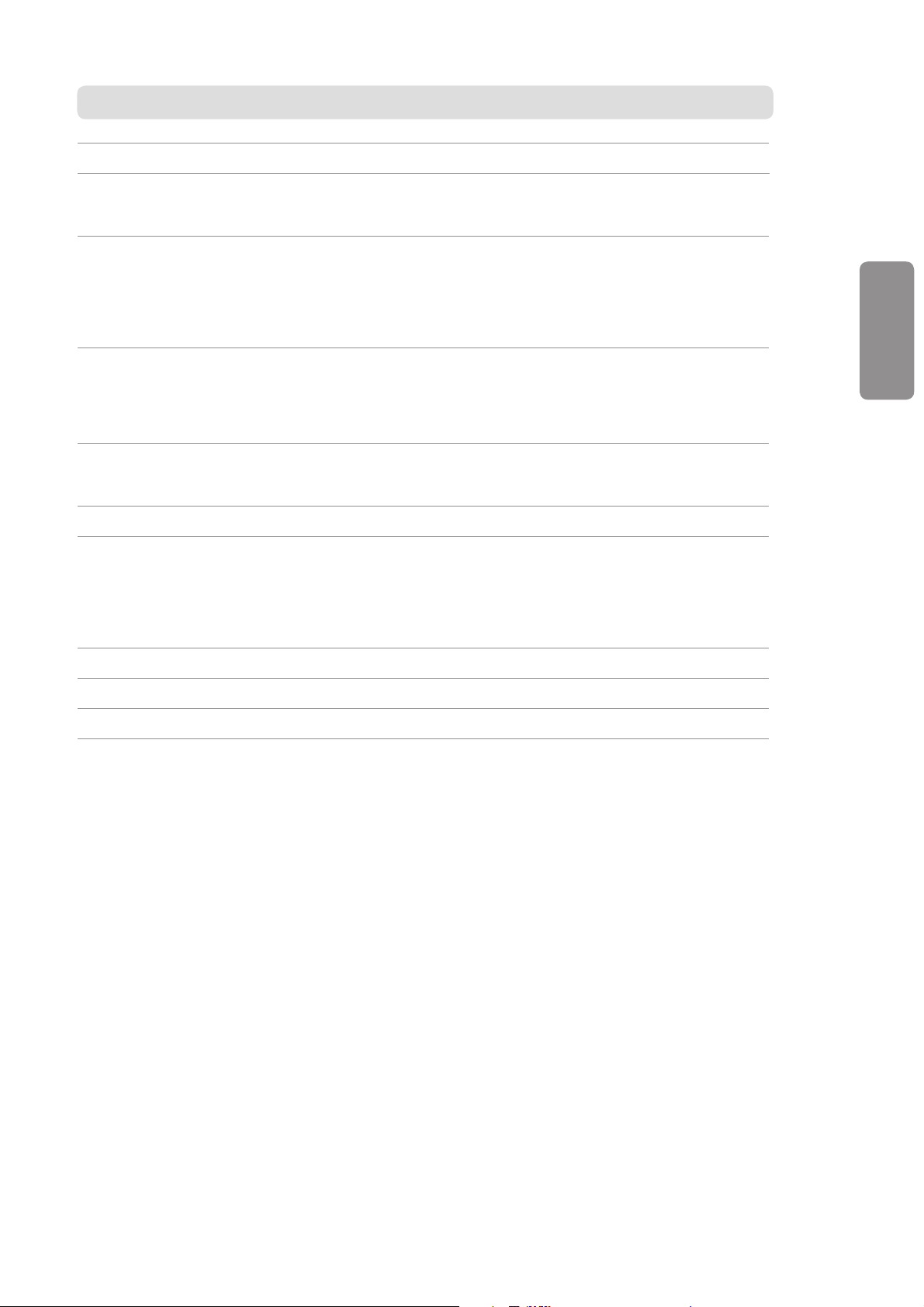

PARAMETER SETTING

Elixo 500 230 V

EN

ON

+

TCA

+

TW

-

DIP 8

DIP 7

DIP 6

DIP 5

DIP 4

DIP 3

DIP 2

DIP 1

OFF

Potentiometers: to modify the automatic closing time and the motor run time.

TCA:

Automatic closure time

TW:

Motor run time

Between 0 and 90

seconds

Between 0 and 120

seconds

Setting the time delay for automatic closing

(if DIP1 is ON).

The motor run time should be slightly longer than

the actual closing time of the gate.

DIP switch: to select the operating mode for the motor and its additional devices.

DIP 1:

Automatic closure

ON: Activates automatic

closure

The gate closes automatically after the

programmed time delay (TCA).

OFF: Deactivates

automatic closure

DIP 2:

Operation of the

photoelectric cells

ON: In closing mode only. In closing mode, the gate stops then reverses its

movement.

In opening mode, cells are inactive.

OFF: In opening and

closing mode.

In closing mode, the gate stops and reverses

its movement once the cells are no longer

obstructed.

In opening mode, the gate stops then

continues its movement once the cells are no

longer obstructed.

DIP 3:

Blocking impulses

DIP 4:

3 Step/4 Step

DIP 5

DIP 6

DIP 7

Pedestrian opening

ON: In opening mode only

Impulses during opening have no effect.

OFF: None

ON: Activates the 3 step

logic.

OFF: Activates the 4

step logic.

3 STEP = operation in semi-automatic mode

(see “User's manual” pg. 2).

4 STEP = operation in sequential mode

(see “User's manual” pg. 2).

DIP 5 and 6 are not used and have no effect on the operation of the motor

and its additional devices.

ON: Activates the

pedestrian opening.

OFF: Deactivates the

pedestrian opening.

Pressing the remote control briefl y partially opens

the gate and pressing and holding the remote

control fully opens the gate.

Fixed opening time: 7 seconds.

Copyright © 2008 Somfy SAS. All rights reserved. 9

Elixo 500 230 V

CLEARING ALL REMOTE CONTROLS

Press the PROG button on the motorisation control unit for more than 7 seconds. The indicator light fl ashes to indicate that all

remote controls have been cleared.

EN

DIAGNOSTICS

The auto-diagnostic LEDS, located on the control unit terminal, control the

operation of the motor and its additional devices.

DL2 START - lights up on the START command

DL3 STOP - goes out on the STOP command

DL4 PHOT - goes out if the photoelectric cells are not aligned or if they are

obstructed

DL5 SWO - goes out on the opening end limit command

DL6 SWC - goes out on the closing end limit command

TECHNICAL SPECIFICATIONS

MOTOR

Power supply 230 V 50Hz

Motor power supply 230 V AC

Motor revolutions 1400 rpm

Power consumption 290 W

Maximum consumed current 1.5 A (230 V) - 3 A (110 V)

Capacitor 10 μF (230 V) - 40 μF (110 V)

Thermal protection 110°C

Insulation category F

Reduction ratio 1/30

Revolutions at output 48 rpm

Pinion 4 mm module (14 teeth)

Gate speed 8.5 m/min

Maximum weight of the gate 500 kg

Maximum torque 20 Nm

Lubrication Permanent grease

Manual manoeuvres Mechanical release with handle

Number of cycles/day 100

Obstacle detection Friction clutch

Control unit Integrated

Operating temperature -20 °C to +60 °C

Index protection rating IP24

Weight 15 kg

Dimensions see “General motor size” pg. 3

ELECTRONICS

Accessories power supply 24 V (0.2 A maximum absorbed)

Automatic closure time between 0 and 90 seconds

Operating time between 0 and 120 seconds

Pedestrian opening time 7 seconds (fi xed)

Reversal pause 1 second approximately

Flashing orange light connection 230 V maximum 15 W

Fuses 250 V T 0.62 A and T 1 A

Built in radio receiver RTS

Number of storable remote controls 36

RTS remote control frequency 433.42 Mhz

Aerial resistance 50 Ohm (RG58)

10 Copyright © 2008 Somfy SAS. All rights reserved.

Elixo 500 230 V

ÍNDICE

CUESTIONES GENERALES 2

SEGURIDAD 2

Cuestiones generales 2

Normas de seguridad 2

DESCRIPCIÓN DEL PRODUCTO 3

Composición del kit 3

Descripción de la motorización 3

Dimensiones generales del motor 3

Ámbito de aplicación 4

Vista general de una instalación tipo 4

INSTALACIÓN 4

Ensamblaje del mango de desembrague 4

Desembrague de la motorización 4

Instalación de la motorización 5

Cableado 6

PUESTA EN SERVICIO RÁPIDA 7

Memorización de los telemandos 7

Ajuste del par del motor 7

ES

FUNCIONAMIENTO DE LA MOTORIZACIÓN 8

CONEXIÓN DE LOS PERIFÉRICOS 8

Luz naranja intermitente 230 V 8

Células fotoeléctricas 8

Célula réfl ex 8

Teclado de código por cable 8

Contacto de llave 9

PROGRAMACIÓN 9

BORRADO DE TELEMANDOS 10

DIAGNÓSTICO 10

CARACTERÍSTICAS TÉCNICAS 10

Copyright © 2008 Somfy SAS. All rights reserved. 1

Elixo 500 230 V

CUESTIONES GENERALES

Este producto, instalado conforme a las presentes instrucciones, permite una puesta en servicio conforme a las normas EN

12453 y EN 13241-1.

Por la presente, Somfy declara que este producto cumple con los requisitos básicos y demás disposiciones pertinentes recogidas en la

directiva 1999/5/CE. Puede consultar la declaración de conformidad válida para la UE, CH y NO en www.somfy.com/ce (Elixo 500 230 V).

SEGURIDAD

Cuestiones generales

ES

Lea siempre estas instrucciones de instalación y las normas de seguridad adjuntas antes de comenzar la instalación de este

producto Somfy.

La instalación de este producto Somfy deberá correr a cargo de un profesional de la motorización y la automatización de la

vivienda, a quien va dirigida esta guía.

El uso de cualquier accesorio de seguridad no validado por Somfy se realizará bajo la única responsabilidad del instalador.

Esta guía describe la instalación, puesta en marcha y funcionamiento del producto.

Por otro lado, el instalador deberá adecuarse a las normas y a la legislación vigente en el país de instalación y deberá informar

a sus clientes de las condiciones de uso y de mantenimiento del producto.

Todo uso diferente del ámbito de aplicación defi nido por Somfy se considera inapropiado. Esto conllevará, al igual que cualquier

otra inobservancia de las instrucciones que fi guran en este manual, la exclusión de responsabilidad y garantía por parte de Somfy.

Normas de seguridad

Antes de proceder a la instalación, asegúrese de que la estructura del portal es conforme a las prescripciones de las normas

vigentes, y en particular:

El raíl de deslizamiento del portal deberá ser lineal, horizontal y las ruedas deberán ser aptas para soportar el peso del portal.•

El portal deberá poder desplazarse con facilidad de forma manual a lo largo de su recorrido, y no deberá constatarse •

ningún bandazo lateral excesivo.

El guiado superior deberá permitir el juego exacto con el portal para asegurar un movimiento regular y silencioso.•

Los topes de parada en el suelo deberán instalarse tanto en la apertura como en el cierre.•

La posición establecida para la fi jación de la motorización deberá permitir efectuar el desembrague manual de la •

motorización de un modo fácil y seguro.

Si estos elementos comprobados no respondieran a las condiciones expuestas anteriormente, se deberán reparar o, cuando

fuera necesario, se deberán sustituir

La elección de los accesorios de seguridad de la instalación deberá ser conforme a las normas aplicables y reglamentaciones

vigentes en el país de instalación.

Asegúrese de que no existen zonas peligrosas (aplastamiento, cizallamiento, atasco) entre el portal y las partes fi jas

circundantes debidas al movimiento de apertura del portal.

Sobre un portal con barrotes, cuando los barrotes tengan un espacio superior a 40 mm entre ellos, instale el dispositivo de

seguridad adecuado para evitar el cizallamiento.

Conserve una zona despejada de 500 mm en la parte posterior del portal cuando esté completamente abierto.

Mantenga el portal a la vista durante el movimiento.

Mantenga los dispositivos de control fi jos y los dispositivos a distancia fuera del alcance de los niños.

Todo interruptor sin bloqueo deberá instalarse a la vista directa del portal, aunque alejado de las partes móviles. Deberá

instalarse a una altura mínima de 1,5 m y no deberá ser accesible al público.

Durante la instalación de la motorización:

Retírese todas las joyas (pulseras, cadenas y otras).•

Para las operaciones de taladrado y soldadura, utilice gafas especiales y las protecciones adecuadas.•

Utilice herramientas adecuadas.•

No se conecte a la red eléctrica o a una batería auxiliar antes de haber fi nalizado la instalación.•

Manipule con precaución el sistema de motorización para evitar cualquier riesgo de lesiones.•

Para su funcionamiento, la motorización deberá recibir una alimentación de 230 V 50 Hz. La línea eléctrica deberá:

estar reservada exclusivamente a la motorización,•

contar con una sección mínima de •

estar equipada con un interruptor omnipolar homologado con apertura de los contactos de al menos 3,5 mm, dotado con •

una protección (fusible o disyuntor de calibre 16 A) y un dispositivo diferencial (30 mA),

instalarse según las normas de seguridad eléctrica vigentes.•

1,5 mm²,

2 Copyright © 2008 Somfy SAS. All rights reserved.

Loading...

Loading...