Snap-On TIG 250 AC-DC Service Manual

CEBORA S.p.A. 1

TIG 250 AC-DC

POWER SOURCE art. 236.76

SERVICE MANUAL

3.302.221 15/01/07

CEBORA S.p.A. 2

CONTENTS

1 - GENERAL INFORMATION..........................................................................................................................3

1.1 - Introduction. ................................................................................................................................................. 3

1.2 - General service policy. .................................................................................................................................3

1.3 - Safety information........................................................................................................................................3

1.4 - Electromagnetic compatibility......................................................................................................................3

2 - SYSTEM DESCRIPTION..............................................................................................................................4

2.1 - Introduction. ................................................................................................................................................. 4

2.2 - Technical specifications................................................................................................................................4

2.3 - Description of TIG 250 AC/DC power source. ............................................................................................ 4

3 - MAINTENANCE............................................................................................................................................7

3.1 - Periodic inspection, cleaning........................................................................................................................ 7

3.2 - Operating sequences.....................................................................................................................................7

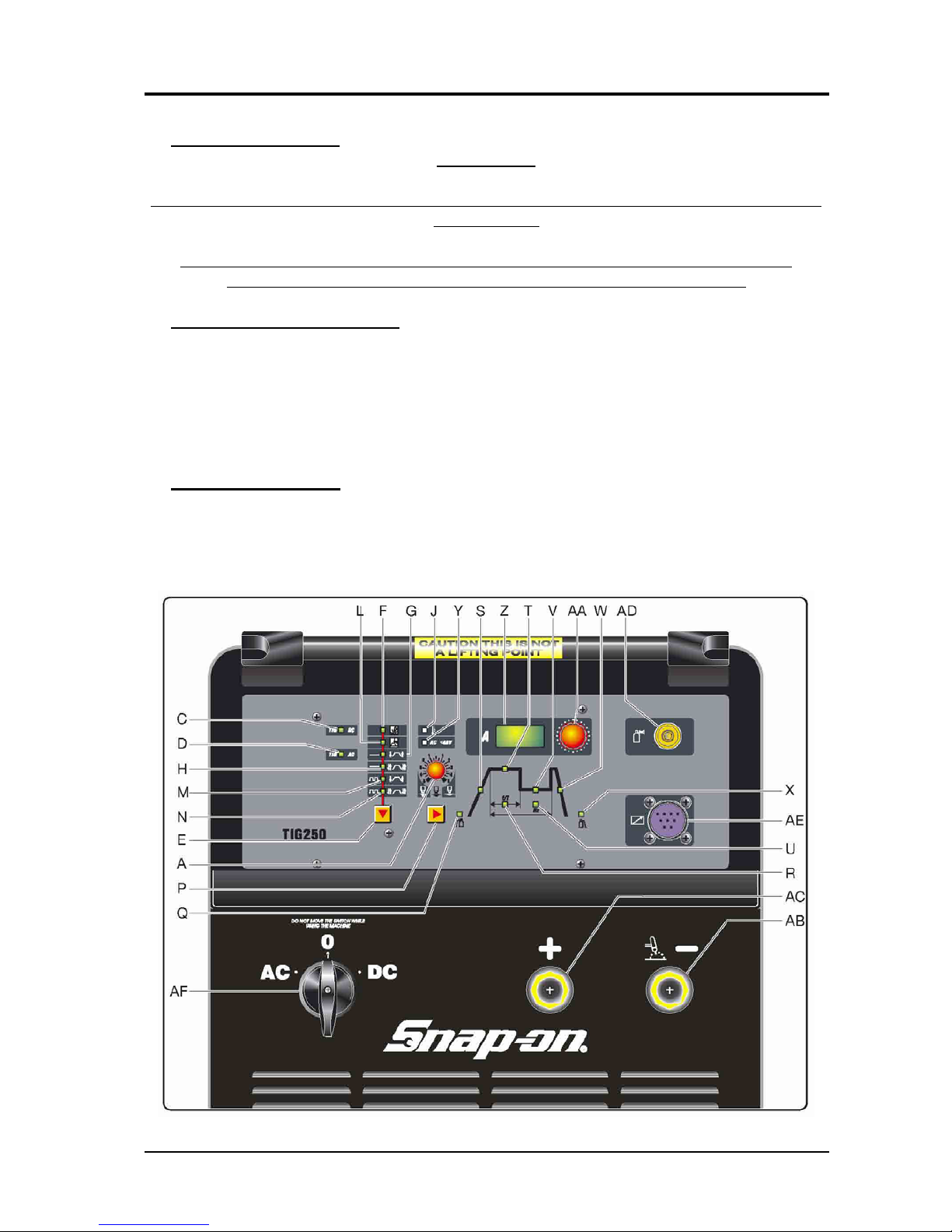

3.2.1 - Control panel commands and signals.........................................................................................................7

3.2.2 - Power Source TIG operation. .................................................................................................................... 8

3.3 - Troubleshooting..........................................................................................................................................10

3.3.1 - The power source does not start, control panel off..................................................................................10

3.3.2 - Power source powered, control panel on, fan (45) stopped.....................................................................12

3.3.3 - System powered, display and signals do not show the correct values..................................................... 13

3.3.4 - The start button produces no effect.......................................................................................................... 15

3.3.5 - In TIG mode, no gas flows from the torch...............................................................................................16

3.3.6 - In TIG mode, gas flows from the torch, the arc does not strike (no high fre quency). .............................17

3.3.7 - In open circuit operation, the output voltage is not regular. ....................................................................19

3.3.8 - In resistive load operation, the output voltage is n ot regul ar...................................................................22

3.3.9 - AC operation, arc unstable, welding irregular.........................................................................................24

3.4 - Alarm signals.............................................................................................................................................. 25

3.4.1 - Led (Y) off. Power source output voltage greater than 48 Vac...............................................................25

3.4.2 - Led (F) on. Temperature of the transformer (46) or inductor (50) too high, or low pressure of the coolant

fluid.

........................................................................................................................................................25

4 - COMPONENTS LIST...................................................................................................................................26

4.1 - Power source art. 236.76 : see file ESP236.76.pdf enclosed at the end of the manual............................... 26

4.2 - Components table : see file ESP236.76.pdf enclosed at the end of the manual..........................................26

4.3 - Spare parts list. ........................................................................................................................................... 26

5 - ELECTRICAL DIAGRAMS ........................................................................................................................27

5.1 - Power source art. 236.76 : see file SCHE236.76.pdf enclosed at the end of the manual............................27

5.2 - Waveforms. ................................................................................................................................................27

5.2.1 - Output voltage with open-circuit power source (par. 3.3.7). ................................................................... 27

5.2.2 - Firing pulses for SCR1 with open-circuit power source (par. 3.3.7). ......................................................27

5.2.3 - Firing pulses for SCR2 with open-circuit power source (par. 3.3.7). ......................................................27

5.2.4 - Output current with power source loaded in table conditions (par. 3.3.8)...............................................28

5.2.5 - Output voltage with power source loaded in table conditions (par. 3.3.8)...............................................28

5.2.6 - Firing pulses for SCR3 with power source loaded in table conditions (par. 3.3.8).................................. 28

5.3 - Mains filter board (51) code 5.600.993/A. ................................................................................................. 29

5.4 - Fuse board (4) code 5.602.288....................................................................................................................29

5.5 - Control board (40) code 5.602.293/ A.........................................................................................................30

5.6 - Shut-off board (48) code 5.602.289............................................................................................................31

5.7 - Snubber board (6) code 5.602.294..............................................................................................................32

5.8 - HF board (42) code 5.602.290.................................................................................................................... 32

5.9 - HF-filter board (41) code 5.602.291...........................................................................................................33

5.10 - Connector board (49) code 5.602.292. .......................................................................................................33

5.11 - Diode group (19) code 3.200.090/A...........................................................................................................34

3.302.221 15/01/07

CEBORA S.p.A. 3

1 - GENERAL INFORMATION

1.1

- Introduction.

The purpose of this manual is to train personnel assigned to carry out maintenance on the TIG

250 AC/DC Power Source, art. 236.76.

1.2

- General service policy.

It is the responsibility of the customer and/or operator to use the equipment appropriately, in

accordance with the instructions in the Instructions Manual, as well as to maintain the equipment

and related accessories in good working condition, in compliance with the instructions provided

in the Service Manual.

Any internal inspection or repairs must be carried out by qualified personnel who are

responsible for any intervention on the equipment.

It is forbidden to attempt to repair damaged electronic boards or modules; replace them with

original Cebora spare parts.

1.3

- Safety information.

The safety notes provided in this manual are an integral part of those given in the Instruction

Manual. Therefore, before working on the machine, please read the paragraph on safety

instructions in the aforementioned manual.

Always disconnect the power cord from the mains, before accessing the interior of the

equipment.

Some internal parts, such as terminals and dissipaters, may be connected to mains or

otherwise hazardous potentials. It is therefore forbidden to work with the safety guards removed

from the machine unless strictly necessary. In this case, take special precautions such as wearing

insulating gloves and footwear, and working in a perfectly dry environment with dry clothing.

1.4

- Electromagnetic compatibility.

Please read and observe the instructions provided in the paragraph “Electromagnetic

compatibility” of the Instruction Manual.

3.302.221 15/01/07

CEBORA S.p.A. 4

2 - SYSTEM DESCRIPTION

2.1

- Introduction.

The TIG 250 AC/DC is un electronic power source suitable for AC/DC TIG welding with

high-frequency arc striking.

It may be used together with a range of accessories for various types of applications (see list

in the Sales catalogue).

The operator interface is developed via the control panel built into the power source.

2.2

- Technical specifications.

To check the technical specifications, see the plates affixed to the equipment, the Instruction

Manual, and the Sales Catalogue.

2.3

- Description of TIG 250 AC/DC power source.

The TIG 250 AC/DC is a controlled-current power source, made up of a single-phase

transformer and a converter that can be configured as a rectifier bridge for direct current

applications, or as a static switch for alternating current applications.

The configuration may be selected using the AC/DC selector switch (30)(AF) on the front

panel.

Referring to the electrical diagram in par. 5.1, drawing 4.1 and table 4.2, one may identify the

main blocks that make up the power source.

The main switch (15), on the rear panel, directly powers the transformer (46) and the terminal

board (52), to which are connected the various internal services of the power source.

The power source can operate with either mains at 208 Vac or at 230 Vac, depending on the

setting of switch (15). As an effect of the primary circuit of the transformer (46) which acts as an

autotransformer, the terminal board (52) and thus all internal services connected to it are always

powered at 230 Vac.

The mains filter board (51), connected to the terminal board (52), contains the filter to reduce

conducted interference reflected in the mains.

The transformer (46) has a second power winding, with voltage and current values suitable for

welding, and two secondary service circuits; all windings are made up of two half-windings

arranged on the two columns of the magnetic core.

One 30 Vac service winding powers the circuits for the signals that dialogue outside the

power source through the connector board (49).

The second service winding a 27 Vac powers the thermal protection circuits of the power

source (thermostats on inductor (50) and transformer (46)) and to measure the pressure of the

liquid in the cooling unit.

The secondary power circuit of the transformer (46) is connected to the current converter,

made up of the thyristor group (47) (SCR1 and SCR2), the diode module (19) (D1, D2, D3), the

inductor (50) and the AC/DC selector switch (30). The electrical diagram of the power source in

par. 5.1 shows the operating table of the AC/DC selector switch (30).

Based on the position of the AC/DC selector switch (30), the converter acts as a Halfcontrolled rectifier to generate and regulate direct current, or as static switch to generate and

regulate alternating current (in the latter instance the frequency of the alternating output current

corresponds to the supply voltage frequency of the power source).

The SCR1 and SCR2 (47) receive the driver signals from the control board (40), through the

shut-off board (48), and the output current is regulated by the control board (40) by changing the

firing angle of SCR1 and SCR2 (47).

3.302.221 15/01/07

CEBORA S.p.A. 5

NOTE

In the shut-off board (48) there are two low-powered thyristors, inserted into two similar

circuits, one of which is always connected and available, while the other is parallel connected to

the first through a relay, when the welding current exceeds approximately 50 Aac. Both are

controlled by the same driver signal and thus work simultaneously.

Because of this characteristic, in this manual these two thyristors shall be considered as a

single one, known as SCR3, “the shut-off thyristor”.

SCR3 and the circuits of the shut-off board (48) serve to force SCR2 (47) to shut off during

AC operation. This function, simultaneous with the engagement of SCR1 (47), makes it possible

to generate the high voltage pulse necessary to perforate the oxidation that forms when welding

certain materials (aluminium and similar) and thus makes it possible to maintain the arc when the

polarity of the welding current changes. This function repeats during each period of the welding

current.

Since the value reached by the high voltage depends on the type of oxidation that the material

presents, a special circuit of the control board (40) makes sure that this voltage does not reach

levels hazardous for operation of the converter. If necessary, it prematurely engages SCR2 (47).

In this case welding is poor quality in AC (see par. 3.3.9).

At the converter output, on the connection before the “-”output terminal (AB) of the power

source, is connected to the HF transformer (28) which, appropriately driven by the HF board

(42), generates high voltage and high frequency to strike the arc in TIG welding.

Operation of the HF board (42) is dependent upon the presence of 27 Vac alternating voltage

on the connector J9, terminals 5 and 6, of control board (40) (HF board (42) power stage power

supply) and the HF start command on the connector J9, terminals 7 and 8, of control board (40)

(HF relay start command).

The connection before the “+”(AC) output terminal of the power source hosts the Hall-effect

current transducer (5), which sends to the control board (40) the output current feedback signal,

used to regulate the welding current.

Near the output terminals of the power source is the HF-filter board (41), which is of primary

importance to TIG operation with HF, since it prevents the HF pulse from climbing through the

internal circuits of the power source, damaging other parts. Thus,

during various maintenance

operations, make sure that this board is always firmly connected to the original terminals before

activating HF start-up.

The mains voltage, again at 230 Vac, to power the service transformer (4) combined with the

fuse board (4), is drawn from the terminal board (52). This transformer provides both the supply

voltages needed by the various sections of the control board (40) and the synchronization signal

of the pulse generators on control board (40). This is why it is important to match the polarity of

the connections for both the primary circuit of the service transformer (4) and the secondary

synchronization circuit leading to connector J4.

The control board (40) is the heart of the power source. It supervises management of the other

boards with more specialized functions, regulates the welding current by generating the pulses to

send to the thyristors (47). It contains the microprocessor that manages all of the functions of the

power source, including those that interface with the user, obtained via the control panel built

into the board itself.

The signal of the power source output voltage, is drawn from the output terminals of the

converter. Appropriately filtered by the snubber board (6), this signal continues toward the

control board (42), where it is used to check for any presence of “hazardous voltage” at the

power source output (see par. 3.4.1).

3.302.221 15/01/07

CEBORA S.p.A. 6

The snubber board (6) also includes the load resistors for SCR1 and SCR2 (47), which make

it possible for SCR1 and SCR2 (47) to function correctly even with an open circuit power

source, and the capacitor C1, which helps strike the arc in DC mode.

The connector (13) on the rear panel of the power source is connected to the pressure switch

on the cooling unit; it is connected in series to the thermostats on transformer (46) and inductor

(50), on the same alarm line that reaches the control board (40). When the cooling unit is not

connected, it is necessary to make a bridge on connector (13) between terminals 1 and 3, to

prevent the power source from remaining blocked.

The fan (45), to cool the power elements of the power source, is powered directly by terminal

board (52) and therefore always at 230 Vac.

On the front panel is the connector board (49), which acts as an interface for the power source

input and output signals. It dialogues directly with the control board (40) and contains the filters

to eliminate disturbances on the power source input and output signals.

These signals include:

− Power source start, from torch trigger.

− External adjustment of the welding current via external potentiometer.

The signals processed by the electronic boards and present at their connectors are listed in the

tables in chapter five of this manual.

3.302.221 15/01/07

CEBORA S.p.A. 7

3 - MAINTENANCE

WARNINGS

ANY INTERNAL INSPECTION OR REPAIRS MUST BE CARRIED OUT BY QUALIFIED

PERSONNEL.

UNPLUG THE POWER SOURCE FROM THE MAINS BEFORE REMOVING THE

PROTECTIVE COVERS AND ACCESSING THE INTERNAL PARTS.

3.1

- Periodic inspection, cleaning.

Periodically remove any dirt or dust to ensure smooth air flow, and thus keep the internal

elements of the power source cool.

Check the conditions of the output terminals, the output and power cables of the power

source; replace if damaged.

Check the conditions of the internal power connections on the electronic boards; if you find

“loose” connections, tighten them or replace the connectors.

3.2

- Operating sequences.

The following sequences reflect proper machine operation. They may be used as guidelines

for troubleshooting. After each repair, they must be carried out without encountering any error or

impediment.

3.2.1 - Control panel commands and signals.

3.302.221 15/01/07

CEBORA S.p.A. 8

NOTE

Operations preceded by this symbol refer to operator actions.

♦ Operations preceded by this symbol refer to machine responses that must occur following an

operator action.

3.2.2 - Power Source TIG operation.

Connect the gas supply to the fitting on the rear panel.

Connect the TIG torch to the negative pole (AB) of the power source.

Connect the cable of the positive pole (AC) of the power source to the workpiece.

Connect the power source to the mains.

Close the switch (15) on the rear panel in the position corresponding to the mains voltage.

♦ System powered.

♦ On control panel all leds and display light on (lamp test).

♦ After one second, display (Z) shows the version of the program inserted into

control board (40) (es.: P01).

Correct?

♦ Subsequently, display (Z) indicates the programmed current; the Mode signaling

are lit as set before the last time the unit was shut off.

NO (see 3.3.1, 3.3.2, 3.3.3).

YES

Press the button (E) several times; the “Mode” selection is repeated in sequence.

Press the button (P) several times; the “Cicle” selection is repeated in sequence.

♦ Each time the button (E) is pressed, the leds G, H, M and N light in sequence,

together with one of leds (F) or (L), that lit alternatively one each other.

Correct?

♦ Each time the start button (P) is pressed, the leds Q, S, T, R, V, U, W and X light

in sequence, according with the “Mode” selected.

NO (see 3.3.3).

YES

WARNINGS

DURING THE FOLLOWING TESTS DO NOT AIM THE TORCH AT PEOPLE OR PARTS

OF THE BODY, BUT ONLY TOWARDS AN OPEN SPACE OR THE WORKPIECE.

DO NOT TRY TO MEASURE THE OUTPUT VOLTAGE DURING THESE STEPS. THE

PRESENCE OF HIGH FREQUENCY MAY DAMAGE THE INSTRUMENT OR THE

POWER SOURCE ITSELF.

With switch AC/DC (30) select the TIG-DC or TIG-AC process.

Use the button (E) to select the TIG-CONTINUOUS with HF, 2-STAGE “Mode”, leds (L)

and (G) lit.

Briefly press the torch start button.

♦ With switch AC/DC (30) in DC position led (C) remains lit and led (D) off. With

switch AC/DC (30) in AC position led (D) remains lit and led (C) off.

3.302.221 15/01/07

CEBORA S.p.A. 9

♦ Gas begins flowing from the torch, for as long as the button is held down.

Correct?

♦ Gas continues to flow from the torch for the duration of the post-gas time set, led

(X) lit, even after the start button is released.

NO (see 3.3.3, 3.3.4, 3.3.5).

YES

Press the start button and hold it down for approximately 5 seconds.

♦ Gas output begins; the high frequency is then generated to start the arc, as well as

the power source output DC voltage (AC voltage is generated only if output

current in present).

Correct?

♦ After approximately three seconds, the output voltage and high frequency are no

longer generated (TIG operation stops if there is no current at the power source

output after start) and the post-gas stage begins.

NO (see 3.3.6, 3.3.7).

YES

Use the knob (AA) to set the current based on the welding you intend to perform.

Move the torch near the workpiece and press the torch trigger.

♦ Begin welding. Turn the knob (AA) or the torch potentiometer to obtain the

current level suitable for the type of welding to be done.

Correct?

♦ During welding display (Z) indicates the welding current.

NO (see 3.3.3, 3.3.8).

YES

Release the torch start button.

♦ The arc shuts off immediately (if long ramp times are not set).

Correct?

♦ Gas continues to flow for the entire post-gas time.

NO (see 3.3.5).

YES

REGULAR OPERATION.

3.302.221 15/01/07

CEBORA S.p.A. 10

3.3

- Troubleshooting.

WARNINGS

ANY INTERNAL INSPECTION OR REPAIRS MUST BE CARRIED OUT BY QUALIFIED

PERSONNEL.

UNPLUG THE POWER SOURCE FROM THE MAINS BEFORE REMOVING THE

PROTECTIVE COVERS AND ACCESSING THE INTERNAL PARTS.

NOTE

The problems the machine may suffer (symptoms) are indicated in boldface.

Operations preceded by this symbol refer to situations that the operator must check into

(

causes).

♦ Operations preceded by this symbol refer to actions that the operator must carry out to solve

problems (solutions).

3.3.1 - The power source does not start, control panel off.

MAINS SUITABILITY TEST.

Correct?

No voltage for mains protection.

NO

YES

♦ Eliminate any short-circuits or insulation losses on the connections between

power cable, switch (15), terminal board (52), transformer (46) primary winding,

services transformer (4), fan (45) and socket (12) on rear panel.

♦ Make sure wiring between mains cable, switch (15) and transformer (46) primary

winding, with particular care to the connections that perform mains voltage

adjustment and between transformer (46) secondary winding and terminals “A” of

scr group (47) and “C8” of switch AC/DC (30). If you find damage connections

restore them, or devices in short-circuit replace them.

♦ Mains not suitable to power the power source (ex.: insufficient installed power).

MAINS CONNECTION TEST.

Correct?

Switch (15), terminals U and W = 230 Vac with both mains at 208 Vac or 230 Vac.

YES

NO

♦ Check power cable and plug and replace if necessary.

♦ Make sure wiring between mains cable, switch (15) and transformer (46) primary

winding, with particular care to the connections that perform mains voltage

adjustment and between transformer (46) secondary winding and terminals “A” of

scr group (47) and “C8” of switch AC/DC (30). If you find damage connections

restore them, or devices in short-circuit replace them.

♦ Check operation of the switch (15), making sure the contacts close in the sequence

shown in the table in the electrical diagram of par. 5.1.

♦ Check mains voltage conditions.

3.302.221 15/01/07

CEBORA S.p.A. 11

CONTROL BOARD (40) POWER SUPPLY TEST.

Control board (40), connector :

− J2, terminals 1 and 2 = 16 Vac, pulse generator synchronization signal for SCR1, SCR2 and

SCR3 on control board (40).

− J3, terminals 2 - 4 - 1 = 16 - 0 - 16 Vac, power supply to internal circuits of control board

(40).

− J3, terminals 5 - 4 - 6 = 8 - 0 - 8 Vac, power supply to microprocessor circuits on control

board (40).

− J5, terminals 1 - 2 = 26 Vac, start command circuit power supply.

− J6, terminals 4 - 5 - 6 = 7 - 0 - 7 Vac, pulse power source supply for SCR2 and SCR3.

− J6, terminals 1 - 2 = 7 Vac, pulse power source supply for SCR1.

Correct?

− J8, terminals 1 - 2 = 30 Vac, protection circuit power supply.

YES

NO

♦ Check the wiring between J2 control board (40) and J4 fuse board (4).

♦ Check the wiring between J3 control board (40) and J1 fuse board (4).

♦ Check the wiring between J5 control board (40) and 26 Vac signal winding of the

transformer (46).

♦ Check the wiring between J6 control board (40) and J2 fuse board (4).

♦ Check the wiring between J8 control board (40) and 30 Vac signal winding of the

transformer (46).

♦ With power source off, temporarily disconnect connectors J2, J3, J5, J6 and J8, on

control board (40) and check the resistance on the following points of control

board (40):

− Conn. J2, terminals 1 - 2 = approximately 900 ohm;

− Conn. J3, terminals 4 - 1 = 4 - 2 = >Mohm;

− Conn. J3, terminals 4 - 5 = 4 - 6 = >Mohm;

− Conn. J5, terminals 1 - 2 = >Mohm;

− Conn. J6, terminals 5 - 4 = 5 - 6 = >Mohm;

− Conn. J6, terminals 1 - 2 = >Mohm;

− Conn. J8, terminals 1 - 2 = >Mohm.

If incorrect replace control board (40).

♦ With power source off, temporarily disconnect connectors J2, J3, J5, J6 and J8, on

control board (40). Power up again and check once more for the presence of

voltage on the connectors of control board (40):

− Conn. J2, terminals 1 - 2 = 16 Vac (fuse F4 on fuse board (4);

− Conn. J3, terminals 4 - 1 = 4 - 2 = 16 Vac (fuse F1 on fuse board (4);

− Conn. J3, terminals 4 - 5 = 4 - 6 = 8 Vac (fuse F1 on fuse board (4);

− Conn. J5, terminals 1 - 2 = 22 Vac;

− Conn. J6, terminals 5 - 4 = 5 - 6 = 7 Vac (fuse F3 on fuse board (4);

− Conn. J6, terminals 1 - 2 = 7 Vac (fuse F2 on fuse board (4);

− Conn. J8, terminals 1 - 2 = 30 Vac.

If incorrect, make sure the fuses F1, F2, F3 on fuse board (4) are intact, or replace

fuse board (4) or service transformer (4) or power transformer (46).

♦ Replace control board (40).

3.302.221 15/01/07

CEBORA S.p.A. 12

3.3.2 - Power source powered, control panel on, fan (45) stopped.

FAN (45) TEST.

Correct?

Fan (45) terminals on terminal board (52) = 230 Vac, with switch (15) closed and mains

voltage both at 208 or 230 Vac.

NO

YES

♦ Make sure that there are no mechanical impediments blocking the fan (45).

♦ With the power source off, temporarily disconnect, the fan (45) terminals from

terminal board (52) and check resistance between terminals of fan (45). Correct

value = 50 ohm approximately. If incorrect replace the fan (45).

♦ Replace the fan (45).

♦ Check the wiring between switch (15), terminal board (52), the wired bridges on terminal

board (52) and fan (45) terminals.

♦ Check connections between transformer (46) primary winding and switch (15).

3.302.221 15/01/07

Loading...

Loading...