Page 1

OPERATING INSTRUCTIONS

3.300.916/B

FOR MODELS:

TIG250

IMPORTANT OPERATING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Page 2

2

IMPORTANT: BEFORE STARTING THE EQUIPMENT,

READ THE CONTENTS OF THIS MANUAL, WHICH MUST

BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR

THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHINE.

THIS EQUIPMENT MUST BE USED SOLELY FOR WELDING OPERATIONS.

1 SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARMFUL TO

YOURSELF AND OTHERS. The user must therefore be educated against the hazards, summarized below, deriving from

welding operations. For more detailed information, order the

manual code 3.300.758

ELECTRIC SHOCK - May be fatal.

· Install and earth the welding machine according to

the applicable regulations.

· Do not touch live electrical parts or electrodes with

bare skin, gloves or wet clothing.

· Isolate yourselves from both the earth and the workpiece.

· Make sure your working position is safe.

FUMES AND GASES - May be hazardous to your health.

· Keep your head away from fumes.

· Work in the presence of adequate ventilation, and

use ventilators around the arc to prevent gases from

forming in the work area.

ARC RAYS - May injure the eyes and burn the skin.

· Protect your eyes with welding masks fitted with filtered lenses, and protect your body with appropriate safety garments.

· Protect others by installing adequate shields or curtains.

RISK OF FIRE AND BURNS

· Sparks (sprays) may cause fires and burn the skin;

you should therefore make sure there are no flammable materials in the area, and wear appropriate

protective garments.

NOISE

This machine does not directly produce noise excee-

ding 80dB. The plasma cutting/welding procedure

may produce noise levels beyond said limit; users

must therefore implement all precautions required by law.

PACEMAKERS

· The magnetic fields created by high currents may affect the

operation of pacemakers. Wearers of vital electronic equipment (pacemakers) should consult their physician before

beginning any arc welding, cutting, gouging or spot welding

operations.

EXPLOSIONS

· Do not weld in the vicinity of containers under pressure, or in the presence of explosive dust, gases or

fumes. · All cylinders and pressure regulators used in

welding operations should be handled with care.

ELECTROMAGNETIC COMPATIBILITY

This machine is manufactured in compliance with the

instructions contained in the harmonized standard EN50199,

and must be used solely for professional purposes in an

industrial environment. There may be potential difficulties in ensuring electromagnetic compatibility in nonindustrial environments.

IN CASE OF MALFUNCTIONS, REQUEST ASSISTANCE

FROM QUALIFIED PERSONNEL.

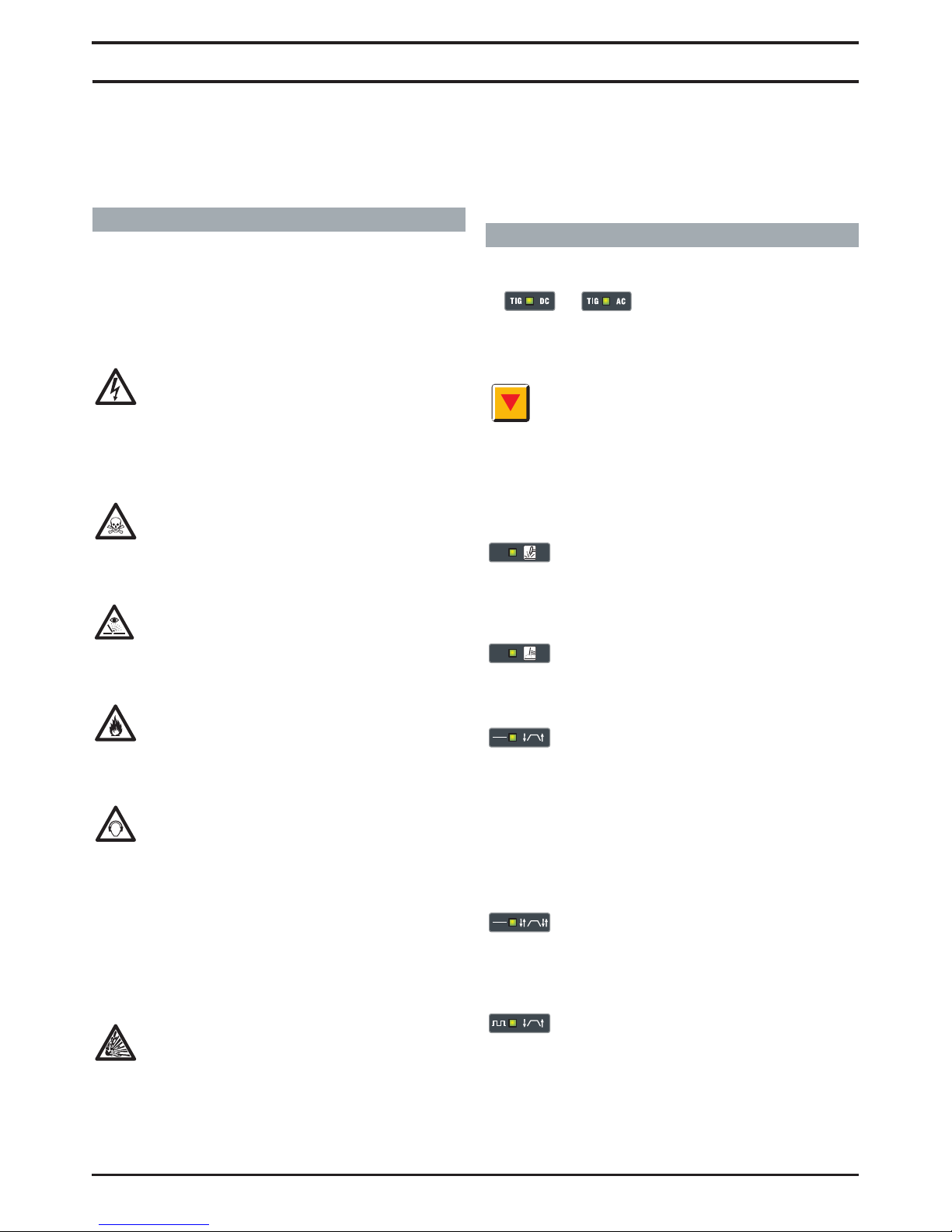

2 DESCRIPTION OF THE EQUIPMENT

Led Mode

C D

These LEDs shows the welding mode selected by the

AC/DC switch AF

Mode key E.

When selected, one of the following LEDs lights:

F, G, H, L, M or N.

In TIG mode there will always be two LEDs lit: one indicating

HF or striking start mode, and the other indicating continuous or pulse mode with 2- or 4-stage command. The

selection changes each time the button is pressed.

The LEDs light alongside the various symbols to display your

choice:

F - LED. TIG welding with arc started without

high frequency.

To light the arc, press the torch trigger or foot switch and

touch the tungsten electrode to the workpiece, then lift it.

This move must be quick and decisive (0.3 sec.).

L - LED. TIG welding with arc started with high

frequency.

To light the arc, press the torch trigger or foot switch: a high

voltage/frequency pilot spark will light the arc.

G - LED. Continuous 2-stage TIG welding

(manual).

When the torch trigger or foot switch is pressed, the current

begins to increase over the previously set "slope up" time,

until it reaches the value set by means of the knob AA.

When the switch is released, the current begins to drop over

the previously set "SLOPE DOWN" time, until it returns to

zero.

IN THIS POSITION, YOU MAY CONNECT THE PEDAL

CONTROL ACCESSORY TIG250FP.

H - LED. Continuous 4-stage TIG welding

(automatic).

This program differs from the previous one in that the arc is

both started and shut off by pressing and releasing the torch

trigger or foot switch.

M - LED. Pulsed 2-stage TIG welding

(manual).

When the torch trigger or foot switch is pressed, the current

begins to increase over the previously set "slope up" time,

until it reaches the value set by means of the knob AA.

When the trigger is released, the current begins to drop over

the previously set "SLOPE DOWN" time, until it returns to

zero.

INSTRUCTION MANUAL FOR ARC WELDING MACHINE

Page 3

3

IN THIS POSITION, YOU CANNOT CONNECT THE

PEDAL CONTROL ACCESSORY TIG250FP.

N - LED. Pulsed 4-stage TIG welding (auto-

matic).

This program differs from the previous one in that the arc is

both started and shut off by pressing and releasing the torch

trigger or foot switch.

J - LED - THERMAL PROTECTION

Lights when the operator exceeds the duty cycle or percentage intermittence admissible for the machine, and simultaneously blocks the current output.

NOTE: In this condition the fan continues cooling the

power source.

Y - LED

This LED never be lit to ensure safe welding conditions in AC

mode.

A - BALANCE CONTROL

This knob makes it possible to vary the halfperiods of the square wave when working in

TIG AC, welding aluminium.

The point where the two half-waves meet is

zero.

This position will give you less current absorption, reduced

electrode consumption and an ideal ratio between the width

and depth of the bead. If you wish to increase penetration,

turn the knob counter-clockwise; for a cleaner weld with less

penetration, turn the knob clockwise.

THIS FUNCTION IS ENABLED ONLY WHEN TIG WELDING

IS SELECTED IN AC.

AA - KNOB

Adjusts the welding current T.

Also, in combination with the push-button P,

you may:

- adjust the pre gas Q

- adjust the second level of current V

- adjust the "slope up" S

- adjust the "slope down" W

- adjust the pulse frequency U

- adjust the post gas X

- adjust the t/T ratio R

Z - Display

Displays the welding current and the settings selected

by means of the push-button P and adjusted via the knob AA.

LF GJYSZTVAAWAD

X

AE

U

R

AC

AB

C

D

H

M

N

E

A

P

Q

AF

Page 4

D.C

.

A.C. (frequency 6o Hz)

Pos. Max Penetration Pos. Balanced zero Pos. Max Cleaning

Electrode Type

Tungsten Tungsten Tungsten Tungsten Tungsten Tungsten Tungsten

Thorium 2% Pure Zr 0,8% Pure Zr 0,8% Pure Zr 0,8%

ø in Red Green White Green White Green White

1.0 - 0,040” 5A - 80A 20A - 60A 20A - 80A 20A - 30A 20A - 50A 20A - 30A 20A - 40A

1.6 - 1/16” 70A - 150A 50A - 100A 70A - 150A 30A - 60A 50A - 80A 20A - 40A 30A - 60A

2.4 - 3/32” 150A - 250A 100A - 160A 140A - 235A 60A - 120A 80A - 140A 40A - 100A 60A - 120A

3.2 - 1/8” 200A - 350A 150A - 210A 225A - 325A 80A - 160A 100A - 180A 60A - 140A 80A - 160A

4 - 5/32” 300A - 400A 200A - 275A 300A - 400A 100A - 240A 150A - 280A 80A - 200A 150A - 250A

4

P - SELECTOR

When this button is pressed, the LEDs light in suc-

cession:

Warning: only those LEDs that refer to the chosen welding

mode will light; i.e., in continuous TIG welding the LED U,

representing the pulse frequency, will not light.

Each LED indicates the parameter that may be adjusted by

means of the knob AA while the LED itself is lit. Five seconds

after the last variation, the LED involved will shut off; the

main welding current will be displayed, and the corresponding LED T lights.

Q - Led

Pre gas. this LED lights on when the pregas function is active (0,05-3 sec.).

S - LED

Slope up. This is the time in which the current, starting from the minimum, reaches

the set current value. (0-10 sec.)

T - LED

Main welding current.

V - LED

Second level of welding or base current.

Can not exceed main welding current value.

U - LED

Pulse frequency (0.5-20 Hz). This is the

number of times per second that the wel-

ding current achieves main welding current value.

Led R.

t/T ratio (see fig. 2).

The t time may vary from 40 to 60 % of the

T total time. It controls how long the main welding current

level is mantained before it drops to the base current value 40 to 60% of total time T.

W - LED

Slope down. This is the time in which the

current reaches the minimum value and the

arc shuts off. (0-10 sec.)

X - LED

Post gas. Adjusts the time gas flows after

welding ends. (0-30 sec.)

AF - AC/DC SELECTOR SWITCH

AE - 14-PIN CONNECTOR

The following remote controls are connected to

this connector:

a) foot control

b) torch with start button

AD - GAS FITTING

This is where the gas hose of the TIG welding

torch is to be connected.

AB - Negative output terminal (-)

AC -Positive output terminal (+)

3 TIG WELDING

By selecting, by means of the AC/DC switch, TIG AC welding mode you may weld aluminium, aluminium

alloys,brass and magnesium, while selecting TIG DC

allows you to weld stainless steel, iron and copper.

This welding machine is suitable for welding stainless steel,

iron, or copper using the TIG procedure.

Connect the earth cable connector to the positive pole (+) of

the welding machine, and the clamp to the workpiece as

close as possible to the welding point, making sure there is

good electrical contact.

Connect the power connector of the TIG torch to the negative pole (-) of the welding machine.

fig. 2

Table A

Page 5

5

Connect the torch connector to the welding machine connector AE.

Connect the torch gas hose fitting to the fitting AD on the

machine, and the gas hose from the cylinder pressure regulator to the gas fitting AN on the rear panel.

DESCRIPTION OF EQUIPMENT (REAR PANEL).

AG - 208/230 Selector Switch - used for selecting the input

supply voltage and for turning the machine on. “ON” is

towards the selected voltage. “OFF” is at the 12 o’clock

position.

AH - Voltage Change Disc - to lock the selector switch in the

desired voltage position.

AI - Fuse - 2Amp - 250Volt - slow blow.

AL - Socket - for connecting the safety cable of the cooling

unit (TIG 250 H2O Only) TIG 250 GAS requires the installation of the TIG 250JP Jumper Plug.

AM - Power Imput Cord.

AN - Gas Inlet Fitting - This is where the gas hose from the

cylinder regulator attaches.

AO - Socket - for Cooling Unit (230 Volts - max 400W). Do

NOT connect other power tools.

3.1 PRIMARY CIRCUIT CONNECTIONS

• After final inspection, the welding machine is connected to the voltage indicated on the rear panel-230V

Factory pre-set.

• If you wish to change the supply voltage:

- Set the knob AG to the 12 o’clock position (machine OFF).

- Remove the knob AG of the selector switch by unscrewing

the holding screw.

- Position the voltage change disc AH so that the knob can only

turn towards the desired voltage, indicated on the rear panel.

- Insert the knob and lock it in place with the screw.

• Connect the power cord AM: the yellow-green wire of the

cord must be connected to an efficient grounding socket.

the remaining wires must be connected to the power supply

line through an isolator switch, located near the area if possible, to allow rapid shut-off in case of emergency.

The capacity of the overload cut-out switch or fuses installed in a serial connection with the switch must be the same

as the current l

1

absorbed by the machine.

The absorbed current l1can be determined by reading the

technical specifications indicated on the machine, in regards

to the supply voltage U1available.

Any extension cords must be sized appropriately for the

absorbed current I1.

How to turn the machine on.

Use switch AG - turn switch towards the selected input voltage (230V factory pre-set).

Do not touch live parts and output terminals while the machine is powered.

The first time the machine is turned on, select the mode

using the push-button E, and the welding parameters by

means of the key P and the knob AA as described in paragraph 2.

The type and diameter of the electrode to be used must be

selected according to table A:

The flow of inert gas must be set to 30 CFH.

If you are using gas-lens type accessories, the gas throughput may be reduced to approximately 15 CFH. The diameter

of the ceramic nozzle must be 4 to 6 times the diameter of

the electrode.

Use D.I.N. 10 protective glasses for up to 75A, and D.I.N. 11

from 75A up.

3.1.1 Connections for cooling unit.

AI - Fuse 2A-250V slow blow.

AL - Socket for connecting the safety cable of the cooling

unit.

AO - Socket for cooling unit (230 Volts-max. 440 W).

Do not connect other power tools.

3.2 CHOOSING THE ELECTRODE DIAMETER FOR A

CORRECT ARC IGNITION EITHER IN DC OR IN AC (HOT

START).

To allow the setting up of the welding machine, a submenu is available to adjust some parameters.

To enter the submenu, press at the same time for 3

seconds the keys E and P.

By means of the encoder AA, when selecting the wanted

electrode 0.040” - 1/16” - 3/32” - 1/8” - 5/32”, the automatic Hot Start function is activated. To confirm the electrode diameter, press and release the key E.

208 V 230 V

AG

AH

AI

AL

AM

AN

AO

Page 6

6

Page 7

7

Part #

Ref. Model Description

# TIG250

1 5801298 LEFT SIDE PANEL

2 5803803 SUPPORT

3 5803775 COVER

4 5610097 AUXILIARY TRANFORMER

5 5710307 TRANSDUCER

6 5602294 SNUBBER CIRCUIT

7 5802855 CENTER DEVIDER

8 5803876 GAS CYLINDER SUPPORT

9 CKS251028 BELT

10 3175603 FUSE HOLDER

11 3175563 FUSE

12 3175370 SOCKET

13 3170235 CONNECTOR

14 3060431 SUPPORT

15 3190132 SWITCH

16 CKS250874 STRAIN RELIEF

17 CKS251110 INPUT CABLE

18 5802477 BACK PANEL

19 3200090 RECTIFIER

20 5801297 RIGHT SIDE PANEL

21 CKS251094 CAP

22 CKS251098 FIXED WHEEL

23 3080052 AXLE

24 5803804 SUPPORT

25 5803805 SUPPORT

26 5801773 BOTTOM

27 5800527 SUPPORT

28 5610055 HF TRANSFORMER

29 3130079 WHEEL

30 3190517 SWITCH

31 5802183 FRONT PANEL

32 3175354 CONNECTOR

33 5802184 FRONT PANEL

34 3070015 PROTECTION

35 3070336 FRAME

36 5803956 HANDLE

37 3060247 SUPPORT

38 CKS250920 KNOB

39 CKS251089 KNOB

40 5602293 MICRO CIRCUIT

41 5602291 FILTER CIRCUIT

42 5602290 HF CIRCUIT

43 CKSB7105370 SOLENOID VALVE

44 3065118 FAN

45 3165051 MOTOR

46 5610096 TRANSFORMER

47 5605539 SCR. GROUP

48 5602289 CIRCUIT

49 5602292 CONNECTOR CIRCUIT

50 3205314 INDUCTOR

51 5600993 FILTER CIRCUIT

52 3170068 TERMINAL BOARD

ALL CONSUMABLES AND REPAIR PARTS

SHOULD BE ORDERED THROUGH YOUR

SNAP-ON DEALER.

Page 8

8

A BLACK

BRED

C GREY

D WHITE

E GREEN

F PURPLE

WIRING DIAGRAM COLOR CODE

G YELLOW

H BLUE

K BROWN

J ORANGE

I PINK

L PINK-BLACK

M GREY-PURPLE

N WHITE-PURPLE

O WHITE-BLACK

P GREY-BLUE

Q WHITE-RED

R GREY-RED

S WHITE-BLUE

T BLACK-BLUE

U YELLOW-GREEN

V BLUE

Loading...

Loading...