Page 1

S

S

S

E

CK

%DECK%ANC H E R S %

CK%ANC H E R

%DECK%ANC H E R S %

ECK%ANC H E R

DECK ANCHORS

%DECK%ANC H E R S %

ECK%ANC H E R

DECK%ANC H E R S %DECK%ANC H E R S % DECK%A N C H E R S %DECK%ANC H E R S % DECK%ANC HERS % D E C K %ANCHERS% DECK%A N C

Page 2

SECTIO

T

l

.

l

n

.

a

CH

TE

n

svent

y

t

c

l

et

T

x

e

s

23/4

dle

s

SPECIFICATION & DESIGN MANUAL(

METAL DECK ANCHOR AND WOOD DECK ANCHOR

PRODUC T(DESCRIPTION

Metal Deck Anchor concrete inserts are designed for installation in and through metal

composite deck (i.e. “pan-deck”) used to support newly poured concrete or roof slabs.

After pre- drilling the deck and installation, the protective sleeve of the insert protrudes below

the surface of the deck allowing overhead attachment of steel threaded rod in sizes ranging from

1/4" to 7/8" in diameter. The sleeve prevents sprayed

dampening products from clogging the internal threads of the insert. It also prevents burying,

masking or losing the insert location. The unique, six sided impact plate o

rotation within the concrete as a steel threaded rod is being installed.

Wood Deck Anchor concrete inserts are installed onto wooden forms used to support newly

poured concrete slabs, roof slabs or walls. When the forms are stripped, the color-coded

is visibly embedded in the concrete surface. The inserts allow the attachment of steel

threaded rod or threaded bolts

sided impact plate o

threaded bolt is being installed.

A coil thread design is available for upon request in 1/2" and 3/4" sizes for

forming applications.

ers resistance to rotation within the concrete as a steel threaded rod or

in sizes ranging from 1/4" to 3/4" in diameter. The unique six

Wood Deck Anchor

GENERAL(APPLICATIONS(AND(USES

t Hanging Pipe and Sprinkler Systems t Suspending Conduit and Cable Trays

t Lighting Systems and Overhead Utilities t HVAC Ductwork and Strut Channels

tt

Suspended Ceilings

Concrete Framework

ionnndh

d

evef the

ade

repr material and acoustical

material andacoustical

insertl

la

tall

n

ormssed tosupport

r

l

iam

a ste

que

nduitn

rk

ndruthannel

ugh

e

nsert

ers resistance to

ed

ttach

/

oofslabs.

trudeselow

angi

sistan

h

uniqi

a

ewly

tee

ng

for

SECTION CONTENTS Page No.

General Information ................. 01

Generlnformation

ateria

Material

Stee

Steel

Installatio

Installation

Performance Data...................... 05

rformance Dat

NTEN

............. 02

...........

................... 03

..................3

........ 04

......

Metal Deck Anchor

FEATURES(AND(BENEFITS

t Higher load values due to full thread engagement

t Color coded by size for all trades

t Low overall installed cost

Wood Deck Anchor

ANCHOR MATERIALS

AN

Carbon Steel and Engineered Plastic

IAL

ROD/ANCHOR SIZE RANGE (TYP.)

1/4" to 7/8" threaded rod for Metal

Deck Anchor Concrete Inserts

1/4" to 3/4" threaded rod for Wood

Deck Anchor Concrete Inserts

1/2" and 3/4" coil thread for Wood

Deck Anchor Concrete Inserts

SUITABLE BASE MATERIALS

Normal-Weight Concrete

Structural Lightweight Concrete

24110(South(Peculiar(Drive( PECULIAR,(MO(64078 800.821.3944( FAX:(800.758.5950( (WWW(SIOUXCHIEF.COM

01

Page 3

!"#$%&%$'(%)* + ,#!%-* .'*/'01

.'(#2%'0 !"#$%&%$'(%)*!

Metal Deck Anchor

Anchor Component Component Material

Insert Body AISI 1008 Carbon Steel

Flange AISI 1008 Carbon Steel

Spring Steel Music Wire

Zinc Plating ASTM B 633 (Yellow Dichromate)

Protective Sleeve Engineered Plastic

!(##01!"#$%&%$'(%)*!

Material Properties for Threaded Rod

Steel Description

Standard carbon rod

High strength carbon rod

Stainless Rod

(Type 304 / 316 SS)

(ASTM)

A 36

A 307, Grade C

A 193, Grade B7

F 593, Condition CW

Rod Diameter

3/8 thru 2 1/2

3/4 thru 1 1/2

Allowable Steel Strength for Threaded Rod

Nominal

Anchor

Diameter

d

in.

(mm)

1/4 0.0491 940 940 2,160 1,210 485 485 1,030 625

(6.4) (1.2) (4.2) (4.2) (9.7) (5.4) (2.2) (2.2) (4.6) (2.8)

3/8 0.1104 2,115 2,115 4,375 3,630 1,090 1,090 2,255 1,870

(9.5) (2.8) (9.5) (9.5) (19.7) (16.3) (4.9) (4.9) (10.1) (8.4)

1/2 0.1963 3,755 3,755 7,775 6,470 1,940 1,940 4,055 3,330

(12.7) (5.0) (16.9) (16.9) (35.0) (29.1) (8.7) (8.7) (18.2) (15.0)

5/8 0.3068 5,870 5,870 12,150 10,130 3,025 3,025 6,260 5,210

(15.9) (7.8) (26.4) (26.4) (54.7) (45.6) (13.6) (13.6) (28.2) (23.4)

3/4 0.4418 8,455 8,455 17,495 12,400 4,355 4,355 9,010 6,390

(19.1) (11.2) (38.0) (38.0) (78.7) (55.8) (19.6) (19.6) (40.5) (28.8)

7/8 0.6010 11,510 11,510 23,810 16,860 5,930 5,930 12,265 8,680

(22.2) (15.3) (51.8) (51.8) (107.1) (75.9) (26.7) (26.7) (55.2) (39.1)

Area of

Rod

in.

(mm)

ASTM

A36

lbs.

(kN)

Allowable Tension

ASTM

A307

Grade C

lbs.

(kN)

Grade B7

ASTM

A193

lbs.

(kN)

Wood Deck Anchor

Anchor Component Component Material

Insert Body AISI 1008 Carbon Steel

Flange Engineered Plastic

Zinc Plating ASTM B 633 (Yellow Dichromate)

(inch)

All

3/8 thru 4

3/8 thru 5/8

ASTM

F593

304/316 SS

lbs.

(kN)

Minimum Yield

Strength, f

36.0

36.0

105.0

65.0

45.0

ASTM

A36

lbs.

(kN)

(ksi)

y

Allowable Shear

ASTM

A307

Grade C

lbs.

(kN)

Minimum Ultimate

Strength, f

58.0

58.0

120.0

100.0

85.0

ASTM

A193

Grade B7

lbs.

(kN)

304/316 SS

(ksi)

u

ASTM

F593

lbs.

(kN)

02

%*!('00'(%)* !"#$%&%$'(%)*!

Metal Deck Anchor

Dimension

Metal Hole Saw Diameter (in.) 13/16 13/16 13/16 1 3/16 1 3/16 1 3/16

Drilling Speed (rpm)

Height of Spring (in.)

Insert Thread Length (in.)

Length of Sleeve (in.)

Thread Size, UNC

Overall Length (in.)

Steel Flange Thickness (in.)

1/4” 3/8”

700-900 700-900 700-900 500-700 500-700 500-700

2 2 2 2 2 2

3/8 5/8 11/16 15/16 1 1/8 1 5/16

3 3/8 3 3/8 3 3/8 3 3/8 3 3/8 3 3/8

1/4-20 3/8-16 1/2-13 5/8-11 3/4-10 7/8-9

5 5/16 5 5/16 5 5/16 5 5/16 5 5/16 5 5/16

5/64 5/64 5/64 5/64 5/64 5/64

Rod/Anchor Size

1/2” 5/8” 3/4” 7/8”

Wood Deck Anchor

Dimension

Insert Thread Length (in.)

Plastic Flange Dia. (in.)

Plastic Flange Thickness (in.)

Thread Size, UNC

Overall Length (in.)

(in.)

345561!789:1";<8=>?@1,@>A;1 "#$/0%'2B1.)1C46DE E66FE35FGH441 &'IJ1E66FDKEFKHK61 1LLL1!%)/I$M%#&F$).

1/4” 3/8”

3/8 5/8 11/16 15/16 1 1/8

1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

7/64 7/64 7/64 7/64 7/64

1/4-20

1 7/8 1 7/8 1 7/8 1 7/8 1 7/8

3/4 3/4 3/4 3/4 3/4

3/8-16

Rod/Anchor Size

1/2”

1/2-13

5/8” 3/4”

5/8-11 3/4-10

Page 4

INSTALLATION GUIDELINES

Prior to pouring concrete, use the

recommended diameter metal hole saw

to drill a hole through the metal deck

at the location the insert is needed.

Typically, inserts are installed in the

for easier access during installation.

However, it is also acceptable to install

metal deck.

From the topside of the metal deck,

place the Metal Anchor Insert's

color-coded, plastic protective sleeve

through the pre-drilled hole. The

spring-loaded impact plate and cause

it to stand upright. Either step on the

anchor with your foot or using a hand

held hammer, strike the head of the

anchor with enough force to cause the

tapered portion of the protective plastic

sleeve to push through the metal deck,

clamping the deck surface between the

are installed, concrete pouring may

commence. The clamping pressure

generated by the spring keeps the

sleeve perpendicular to the deck

surface during the pour.

Either before or after the concrete

has been placed, tap the appropriate

diameter steel thr eaded rod or

threaded bolt through the opening

at the end of the plastic sleeve and

screw into the internally threaded

insert. Minimum thread engagement

should be one anchor diameter.

Concrete should be allowed

to properly cure and achieve

its design compressive strength

before loading the threaded rod

with the intended assembly.

For safety purposes, it is best to wait

until the insert is ready to be put in

service before screwing the steel

threaded rod into place.

Chuck Carbide Hole Saw

Drill Deck Holes

Push Anchor into Place

Set by Stepping on Anchor

SPECIFICATION & DESIGN MANUAL

Wood Deck AnchorMetal Deck Anchor

Prior to pouring concrete over the

wood form, place the Deck Anchor

on the surface of the wood form at

the desired location. Strike the impact

plate of the insert with a hand held

hammer, until the plastic color-coded

When all inserts are installed, concrete

pouring may commence.

After the wood forms are removed,

Carefully remove any unbroken

nails by swiping with a hammer.

Eye protection should be worn when

appropriate diameter steel rod or

threaded bolt can be inserted into the

into the internally threaded insert.

Minimum thread engagement

should be one anchor diameter.

Concrete should be allowed to

properly cure and achieve its design

compressive strength before loading

the rod or threaded bolt with the

intended assembly.

For safety purposes, it is best to wait

until the insert is ready to be put in

service before screwing the steel

threaded rod into place.

Set Wood Deck Anchor

into Place

Hammer in Insert

Pour Co ncret e

Pour Con cret e.

Then Ins tall Rod

24110 South Peculiar Drive PECULIAR, MO 64078 800.821.3944 FAX: 800.758.5950 WWW SIOUXCHIEF.COM

Install Rod

03

Page 5

SPECIFICATION & DESIGN MANUAL

PERFORMANCE DATA

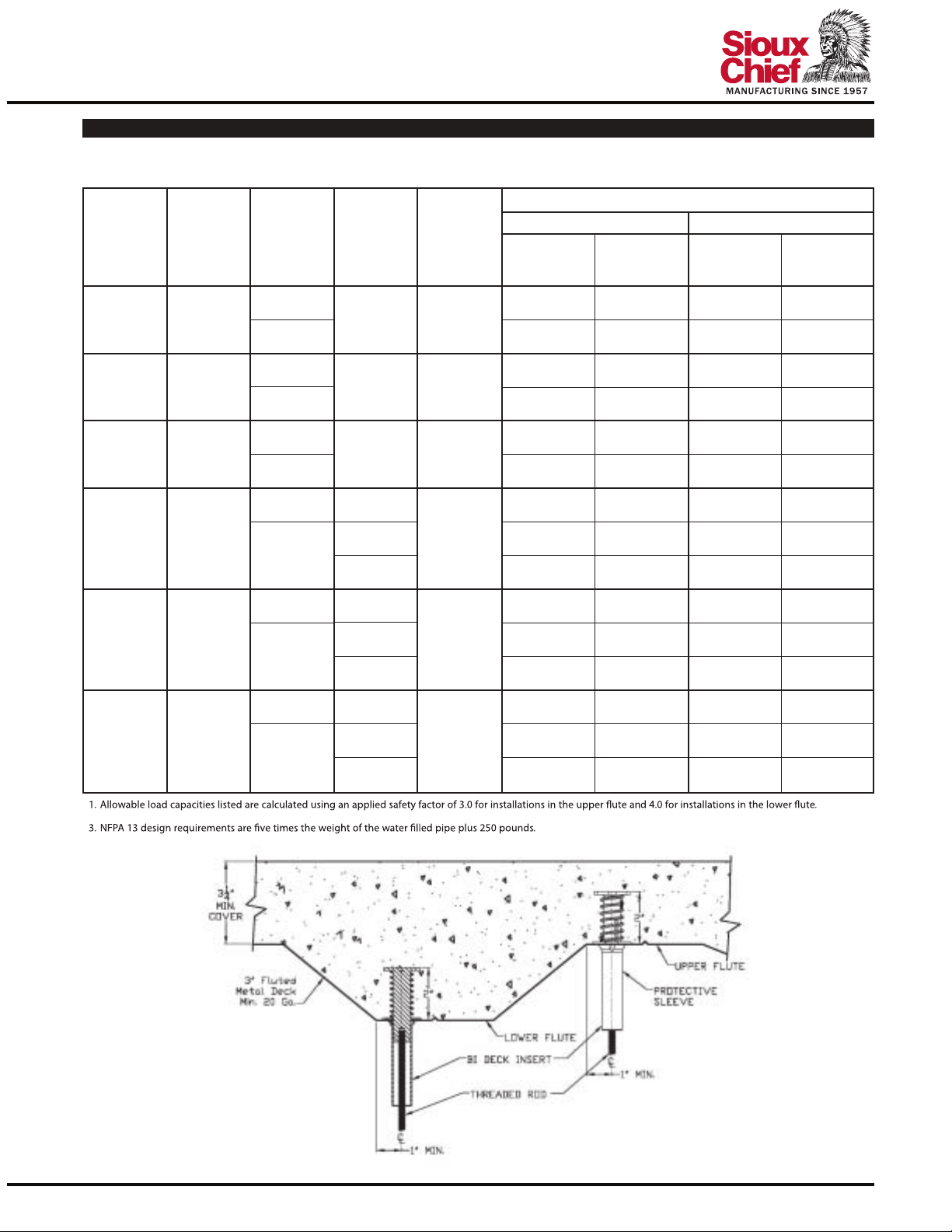

Ultimate and Allowable Load Capacities for Metal Deck Anchor Inserts Installed in Structural Lightweight

Concrete over Metal Deck

Rod/Insert

Diameter

d

in.

(mm)

1/4

(6.4)

3/8

(9.5)

1/2

(12.7)

5/8

(15.9)

3/4

(19.1)

7/8

(22.2)

Embedment

Depth

h

v

in.

(mm)

2

(50.8)

2

(50.8)

2

(50.8)

2

(50.8)

2

(50.8)

2

(50.8)

1,2,3,4

Flute

Location

in

Deck

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Minimum

Insert

Spacing

in.

(mm)

9

(228.6)

9

(228.6)

9

(228.6)

9

(228.6)

9

(228.6)

12

(304.8)

9

(228.6)

9

(228.6)

12

(304.8)

9

(228.6)

9

(228.6)

12

(304.8)

Minimum

End

Distance

in.

(mm)

12

(304.8)

12

(304.8)

12

(304.8)

12

(304.8)

12

(304.8)

12

(304.8)

f´

≥

3,000 psi (20.7 MPa)

c

Ultimate Load Allowable Load

Tension Shear Tension Shear

lbs. lbs. lbs. lbs.

(kN) (kN) (kN) (kN)

4,450 2,500 1,115 835

(20.0) (11.3) (5.0) (3.8)

3,320 2,500 830 625

(14.9) (11.3) (3.7) (2.8)

5,750 3,350 1,915 1,115

(25.9) (15.1) (8.6) (5.0)

3,320 3,350 830 840

(14.9) (15.1) (3.7) (3.8)

7,110 3,350 2,370 1,115

(32.0) (15.1) (10.7) (5.0)

3,320 3,350 830 840

(14.9) (15.1) (3.7) (3.8)

8,810 3,350 2,935 1,115

(39.6) (15.1) (13.2) (5.0)

3,960

3,960 3,350 990 840

(17.8) (15.1) (4.5) (3.8)

8,810 3,350 2,935 1,115

(39.6) (15.1) (13.2) (5.0)

3,960

3,960 3,350 990 840

(17.8) (15.1) (4.5) (3.8)

8,810 3,350 2,935 1,115

(39.6) (15.1) (13.2) (5.0)

3,960

3,960 3,350 990 840

(17.8) (15.1) (4.5) (3.8)

–

–

–

990

)5.4()8.7 1(

990

)5.4()8.7 1(

990

)5.4()8.7 1(

–

–

–

04

2. The allowable working load must be the lesser of the insert capacity or the steel strength of the threaded rod.

4. Allowable loads for anchors to resist short-term loads such as earthquake or wind may be increased by 33-1/3 percent for the duration of the load where permitted by code.

24110 South Peculiar Drive PECULIAR, MO 64078 800.821.3944 FAX: 800.758.5950 WWW SIOUXCHIEF.COM

Page 6

PERFORMANCE DATA

SPECIFICATION & DESIGN MANUAL

Ultimate and Allowable Load Capacities for Wood Deck Anchor Inserts Installed

in Normal-Weight Concrete

1,2,3,4,5

Minimum Concrete Compressive Strength (f´c)

Rod/

Insert

Embed.

Depth

Diameter

d

in.

(mm)

(mm)

1/4

(6.4)

(50.8)

3/8

(9.5)

(50.8)

1/2

(12.7)

(50.8)

5/8

(15.9)

(50.8)

3/4

(19.1)

1. Allowable load capacities listed are calculated using an applied safety factor of 3.0.

2. The allowable working load must be the lesser of the insert capacity or the steel strength of the threaded rod.

3. Linear interpolation may be used to determine ultimate loads for intermediate compressive strengths.

5. Allowable loads for anchors to resist short-term loads such as earthquake or wind may be increased by 33-1/3 percent for the duration of the load where permitted by code.

(50.8)

in.

h

2

2

2

2

2

Minimum

Insert

Spacing

v

(mm)

(228.6) (152.4) (20.9) (7.0) (38.0) (12.7)

(228.6) (152.4) (20.9) (7.0) (33.1) (11.0)

Minimum

End

Distance

in.

in.

(mm)

964,650

964,650

lbs. lbs. lbs. lbs. lbs. lbs. lbs. lbs.

(kN) (kN) (kN) (kN) (kN) (kN) (kN) (kN)

3,000 psi (20.7 MPa) 4,500 psi (31.1 MPa)

Ultimate Load

Allowable Load

–

–

1,550

1,550

–

–

Ultimate Load Allowable Load

8,440

7,350

–

–

2,815

2,450

–

–

Ultimate and Allowable Load Capacities for Wood Deck Anchor Inserts Installed in Structural

Lightweight Concrete

Rod/Insert

Diameter

d

in.

(mm)

1/4

(6.4)

3/8

(9.5)

1/2

12.7

(

)

5/8

15.9

(

)

3/4

(19.1)

1. Allowable load capacities listed are calculated using an applied safety factor of 3.0.

2. The allowable working load must be the lesser of the insert capacity or the steel

strength of the threaded rod.

plus 250 pounds.

4. Allowable loads for anchors to resist short-term loads such as earthquake or wind

may be increased by 33-1/3 percent for the duration of the load where permitted

by code.

Embedment

1,2,3,4

Minimum

Depth

Insert

Spacing

h

v

in.

(mm)

2

(

50.8) (228.6) (152.4) (19.2) (7.6) (6.4) (2.5)

2

(

50.8) (228.6) (152.4) (19.2) (23.8) (6.4) (7.9)

2

(

50.8) (228.6) (152.4) (19.2) (32.3) (6.4) (10.8)

2

(50.8)

2

(50.8)

in.

(mm)

9 6 4,270 1,680 1,425 560

9 6 4,270 5,280 1,425 1,760

9 6 4,270 7,180 1,425 2,395

9 6 4,600

(228.6)

12 9 4,600 7,590 1,535 2,530

(304.8) (228.6) (20.7) (34.2) (6.9) (11.4)

9 6 4,600

(228.6)

12 9 4,600 7,590 1,535 2,530

(304.8) (228.6) (20.7) (34.2) (6.9) (11.4)

Minimum

End

Distance

in.

(mm)

(152.4)

(152.4)

f´

≥

3,000 psi (20.7 MPa)

c

Ultimate Load Allowable Load

Tension Shear Tension Shear

lbs. lbs. lbs. lbs.

(kN) (kN) (kN) (kN)

(20.7)

(20.7) (6.9)

–

–

1,535

(6.9)

1,535

–

–

24110 South Peculiar Drive PECULIAR, MO 64078 800.821.3944 FAX: 800.758.5950 WWW SIOUXCHIEF.COM

05

Loading...

Loading...