Singer 71K101 Instruction Manual

•

INSTRUCTIONS

SEWING.

FOR

MAKING

WITH

FOR

USING

AND

SINGER

71K101

STRAIGHT

SQUARE

ADJUSTING

MACHINE

BUTTONHOLES

BARRED

ENDS

USE

SINGER*

OILS

They

The

TYPE

When

stain on

TYPE

type

TYPE

and

insure

following

B —

an oil is

fabrics,

D —

OTHER

E —

For

stitching

required.

F -

For oil lubricated motors and plain bearings in

tables

NOTE;

1 gallon

LUBRICANTS

freedom

longer life to sewing equipment

are ihe

MANUFAaURING

MANUFACTURING

THREAD

lubricating

fabricsorleather

MOTOR

and

All of the

and

from

lubricating

correct

lubricants

MACHINE

desired

which

will

produceaminimum

even after a long period of storage,

MACHINE

SINGER*

LUBRICANT

the

needle

LUBRICANTS

threadofsewing

whereathread

OIL

transmitters.

above

5 gallon cans.

oils

ore

trouble

for

OIL,

OIL,

and give

this

machine:

HEAVY

HEAVY

machines

available in 1 quart,

GRADE

of

use:

GRADE

lubricant

power

for

is

GEAR

BALL BEARING LUBRICANT

1

LUBRICANT

This

specially

lubrication on manufacturing sewing machines.

This

pure

of

ball

electric

etc.

Furnished In 1 lb.

prepared greaseIsrecommended

0'reaseisspecially

bearings

transmitters,

for gear

designed

and

ball

thrust

ball bearing hangers of power tables,

and4lb.

for the

bearingsofmotors

tins.

lubrication

and

Form

(861)

K6441

INSTRUCTIONS

FOR

USING

AND

ADJUSTING

SINGER

SEWING MACHINE

HIGH

THE

*A

Trademark

SPEED

SINGER

of THE SINGER

MANUFACTURING

7IkI0I

GEAR

MANUFACTURING

COMPANY

DRIVEN

FEED

COMPANY

PrintedinU.S.A.

Copyright

under

international

Copyright

Union

DESCRIPTION

Machine

in cotton, linen,

This

which

stitches

conditions.

71k101

is designed for making

rayon

and

silk fabrics,

machine has a positive,

controls

are

the

movement

uniformly spaced around

of

gear

the

knit

driven,

work

the

goods,etc.

By simply changing the stitch regulating gear,

of

stitchesinthe

of stitch regfulating

The

stop

of

gears

havingaratio

stop

camtoone-halfofthe

cam

has

two

othersothat

stop cam

rod

extra

to

stop

turns

drops

into

long spiral

without

Machine

barred

threads

to1inch

Check

Washer

ends,

and

long

Complete

40045

be furnished, on

can

be supplied additionallyatan

Unless

fitted

J

inch

Whip

by

substituting

the

machine;

otherwise

with

a f inch knife

buttonholes.

Stitch

249633

40028

Stitch

For

Machine

249682-30

249725-36

249727-40

249744-45

For

other

buttonhole

gears

canbevaried,asdesired.

on page 16.)

motion mechanism of

of 2 to 1 for

speed of

stop

notches located diametrically opposite each

when

the

stop

motion

only a

one of

part

of a revolution before

the

notchestostop

springinthe

shock.

71k101

the

makes

the

hole

being

buttonhole

can

alsobemadeonthis

249758,

are

Clamp

purl

cut

andaknifeofthe

order,

in place of

ordered,

Buttonholes

the

following

Shuttle

Shuttle

Bobbin

Body

Regulating

7IK10I

Teeth

"

"

"

gears

and

the

and

three

canbeproducedonabove

parts

Case complete

Gears for

specifications see

this

machine includes a

reducing

the

-sewing shaft.

mechanism is engaged,

the

stop cam

stitch

gear

buttonholes

from f to f inch long.

cut

after

stitching.

machinebyusing

Check

required

the

extra

71k101

Holder

length.

regular

charge.

machine

additional

in placeofsimilar

Whip

Stitch

page

straight

clamp

buttonholes

intermittent

so

that

feed

the

buttonhole under all

the

number

(See

list

pair

the

speed of

The

the

stop

the

the

interlocking

machine. A single,

helps the machine

with

square

Both

Buttonholes

271946,

These

parts

up

Clamp

Fibre

will

equipment,orthey

willbesent

knives for §, ^

out

and

machine

parts

on

16.

The

When

should

The

the

edge of

the

leg

maximum

the

machines

turn

To

speed recommended is 2000

areinoperation,

overtothe

Set

Up

Machines

machineisusually

the

table

nearest

sections.

Speed

the

tight

leftasindicatedbythe

on

Power

set

the

rront

SINGER* Universal

Tables

so

that

its

operator,

Pd<j<!ofTable

about

face

stitches

per

machine

arrowinFig.

plateistoward

midway

minute.

pulley

5.

between

Fig.

2.

Underside

and

Chain

be

bored

another

(D2,

Fig.

bracket

lifting

lever

on

the

underside

in line with

the

undersideofthe

hand

treadle, l-^asten

the

hand

treadle

6).

and

to

left

of

and

table

hole

the

lever

the

One

( B,

starting

There

showing

hole

Fig.5)and

are four treadle chain pulleys (C, H, J and K, Fig. 2).

Belt

should

lever

each consisting of a

these

pulleys

below

chain

pulley

the

adjusting

(II)

acljnsting^ slide

{K, Fig-. 2)

clamp

slide

to

the

and

1)iillc\- {(1. Fig. 2) to

starting

slide on

2) to

slide on

lever (D2, I-'ig. 6)

the

right

the

underside of

the

rigiit

Bass one chain from the left treadle

pulley

(II)

and

under

the pulley

of

Power

Guides

for

the

for

for

chain

the

Low

a single pulley.

underside

(B,

Fig. 5)

hand

treadle.

the

table

the

first pulley

in line with

the

directly

and

over

in line with

straight

(K),

then

Table,

Shaft

Drive

to

connect

chaintoconnect

of

the

and

in

Fasten

directly

(K).

table

direct))'

the

chain

Fasten

table

line

the

over

Fasten

with

one of

directly

with

second

the

below

adjusting

fourth pulle)' (J. Fig.

the

cliain

adjusting

the

pulley ((1).

up and over the

up

through

the

the

with

the

chain

the

the

hole

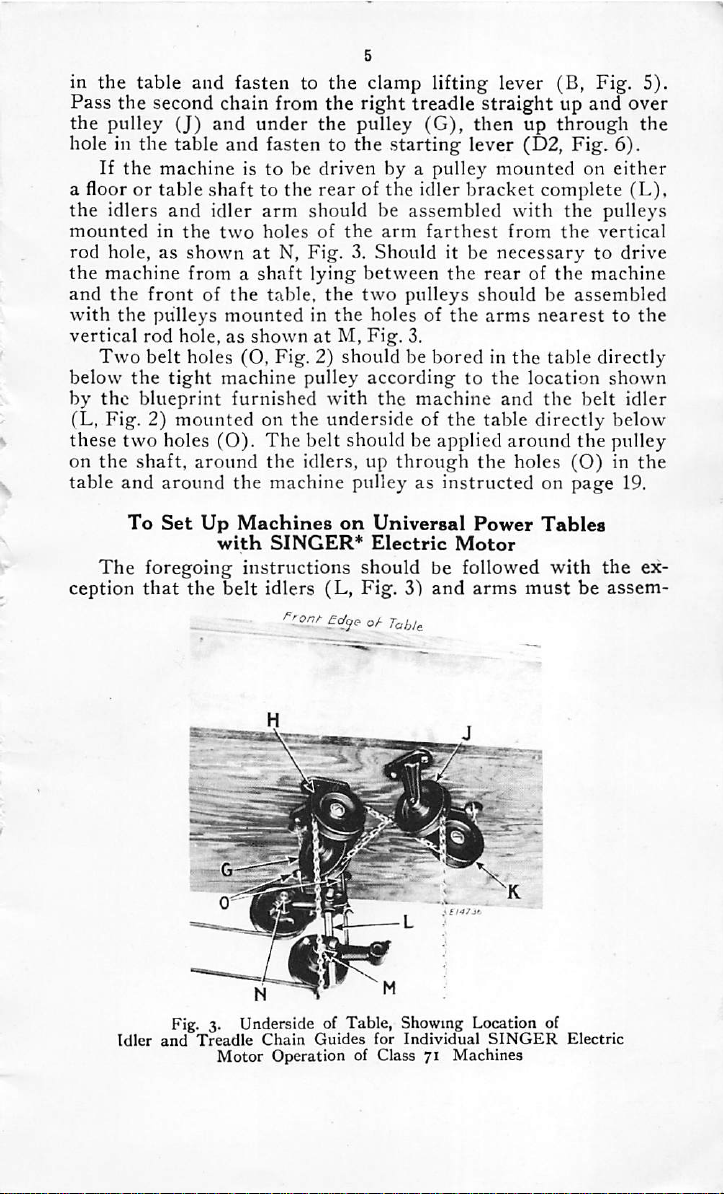

in the table and fasten to the clamp lifting lever (B, Fig. 5).

Pass the second chain from the

the

pulley

(J)

and

under

hole in the table and fasten to the

If

the

machineistobedriven

a floorortable

the

idlers

mounted

rod

hole, as

the

machine from a

and

the

frontofthe

with

the

vertical

below

by

Two

the

rod

belt

the

blueprint

(L, Fig. 2)

these

two

on

the

shaft,

table

and

To

The

foregoing

ception

that

shafttothe

and

idler

in

the

two

shownatN,

shaft

pulleys

mountedinthe

hole, as

holes (O,

tight

machine

furnished

shownatM,

mountedonthe

holes

(O).

around

around

Set

the

Up

with

Machines

instructions

the

belt

arm

holes

table,

Fig.2)shouldbeboredinthe

The

the

machine pulley as

SINGER*

idlers

right

treadle

the

pulley

rear

of the idler

(G),

starting

by a

pulley

then

lever (D2,

bracket

should be assembled

of

the

arm

farthest

Fig.3.Should

lying

between

the

two

holes of

Fig.

pulley

accordingtothe

with

the

underside of

belt

should he applied

idlers, up

it be

the

pulleys should be assembled

the

3.

machine

the

through

instructedonpage

on

Universal

Electric

Power

Motor

should be followed

(L,

Fig.

3")

and

arms

straight

up

mounted

complete

with

from

necessary

rearofthe

arms

nearesttothe

table

location

and

the

table

directly

around

the

holes

Tables

with

must

up and over

through

Fig.

on

the

6).

either

(L),

the

pulleys

the

vertical

to

drive

machine

directly

shown

belt

idler

below

the

pulley

(O)inthe

19.

the

ex

be

assem-

hiedasillustrated

the

Fig.

on

pulley of

3) in

page

19.

the

motor,

table

in

Fig.3.The

around

and

around

the

belt

idlers, up

the

machine

shouldbeapplied

through

the

pulleyasinstructed

around

holes (O,

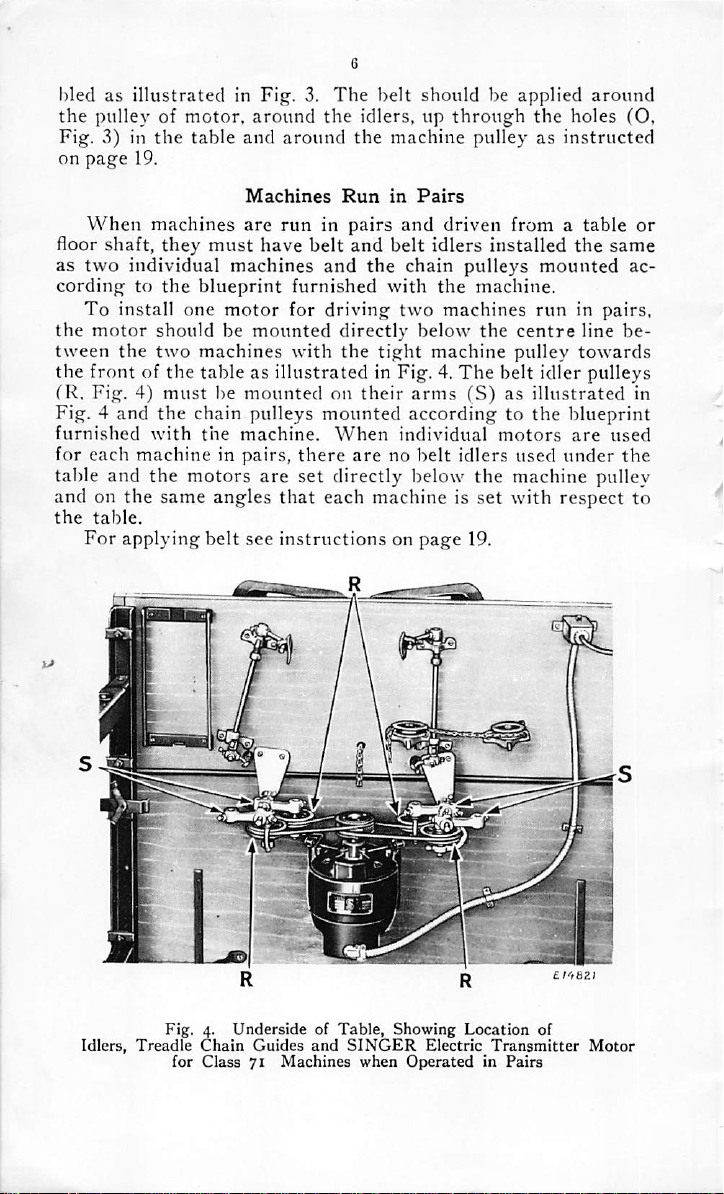

When

floor

as

two

cordingtothe

To

the

tween

the

frontofthe

fR.

Fig. 4

furnished

for

each

machines

shaft,

they

must

individual machines

blueprint

install

motor

the

one

motor

shouldbemounted

two

machines

tableasillustrated

Fig.4)must

and

with

be

the

chain pulleys

the

machineinpairs,

table and the motors

andonthe

the

table.

For

same angles

applying

belt

Machines

are

have

mounted

machine.

are

that

see

instructionsonpage

Run

in

Pairs

runinpairs

belt

and

furnished

for

driving

directly

with

the

on

mounted

When

there

and

and

belt

the

chain pulleys

with

two

below

tight

in Fig. 4.

their

arms

according to

individual

arenobelt

driven from a

idlers

installed

the

machine.

machines

the

machine

pulley

The

belt idler pulleys

(S)asillustrated

motors

idlers

used

set directly below the machine pulley

each machine is set

with

19.

table

the

mounted

runinpairs,

centre

the

line

towards

blueprint

are

under

respect

or

same

ac

be

in

used

the

to

Idlers,

Fig.4.UndersideofTable,

Treadle

for

Chain

Class

Guides

71

Machines

and

Showing

SINGER

when

OperatedinPairs

Location

Electric

of

Transmitter

Motor

To

Oil

the

Machine

Use

'TYPE

Machine Company.

coverofthis

When

B"or'TYPE

For

description of

book.

the

machine is received from

D"

OIL,

sold by

these

the

Singer

oils, see inside

factory, it should be

Sewing

front

thoroughly cleaned and oiled. Oil should be applied at each of

Fig.

5.

Oiling

Also

Pointsatthe

Adjustments

Rightofthe

on

the

Machine

Machine

the places designated by the unmarked arrows in Figs. 5. 6. 7. 21

and

26-

When

oiled

regularlvtoensure

wearofthe

It is

the

important

feed gears

for

machine.

the

machine

parts

which

to use

and

Fig.6.Oiling

Also

is in

continuous

easy

running

areinmovable

either

of the above heavy grades of oil

and

prevent

contact.

stop motion mechanism in

Pointsinthe

Adjustments

Baseofthe

on

the

Machine

use,itshould

unnecessary

the

rearofthe

Machine

be

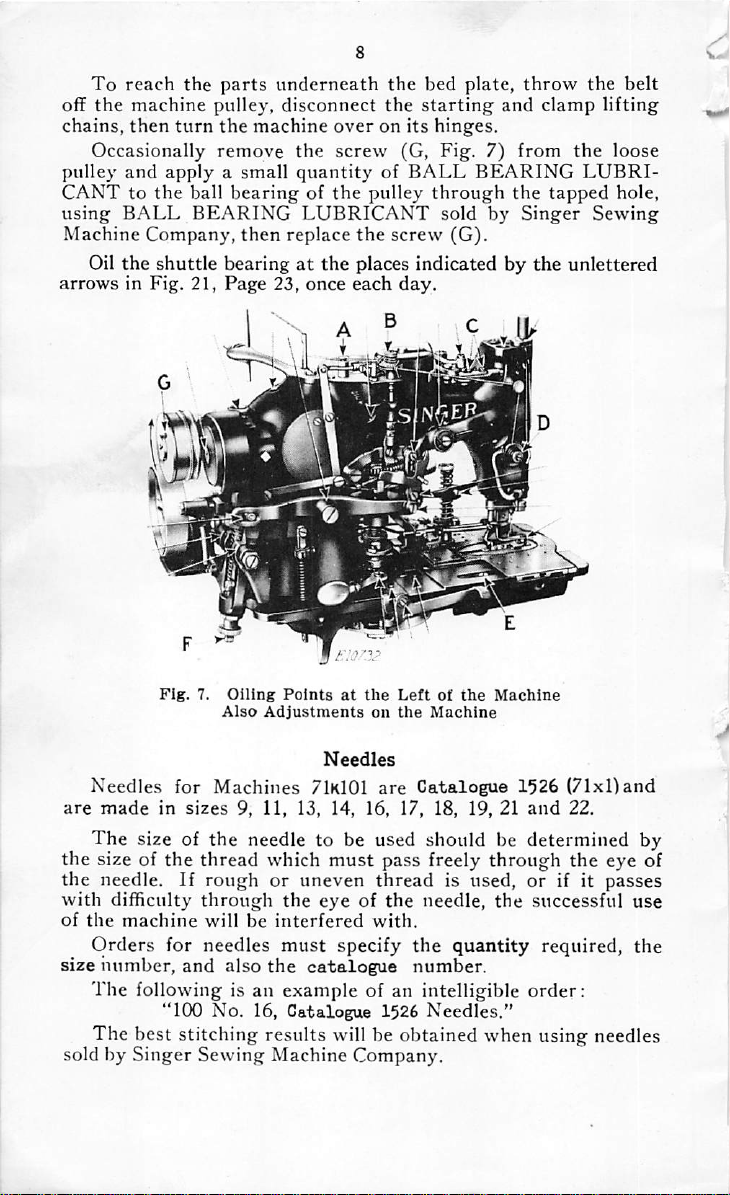

To

reach

the

off

the

machine

chains,

then

turn

Occasionally remove

pulley

CANTtothe

using

Machine

arrows

and

BALL

Oil

the

in Fig. 21,

applyasmall

ball

BEARING

Company,

shuttle

parts

underneath

pulley,

the

disconnect

machine

the

quantity

bearingofthe

LUBRICANT

then

replace

bearingatthe

Page

23,

once

the

bed plate,

the

starting

overonits

screw

pulley

hinges.

(G, Fig. 7) from

of

BALL

through

sold by

the

screw

(G).

places indicated by

each

day.

throw

and

clamp

BEARING

the

tapped

Singer

the

the

belt

lifting

the

loose

LUBRI

hole,

Sewing

unlettered

Fig.

7.

Oiling

Points

at

the

are

Needles

made

The

size of

in

for

sizes

Also

Adjustments

Needles

Machines

9, 11, 13, 14, 16, 17, 18, 19, 21

the

needle to be used should be

71k101

Leftofthe

on

the

are

Machine

Catalogue

Machine

1526

and

determined

(71xl)and

22.

by

the size of the thread which must pass freely through the eye of

the

with

of

size

the

Orders

The

needle. If

difficulty

machine

number,

following is an

rough

through

will

be

for needles

and

also

'TOO

No.

or

the

interfered

must

the

example

16,

Catalogue

uneven

eye of

specify

catalogue

thread

with.

the

is used,

needle,

the

the

quantity

number.

of an intelligible

1526

Needles."

or

if it passes

successful use

required,

order:

the

The best stitching results will be obtained when using needles

sold by Singer Sewing Machine Company.

For

needle.

For

needle.

9

Thread

Purl

Stitch buttonholes, use right twist thread in the

Whip

Stitch

buttonholes,

use

left

twist

thread

in

the

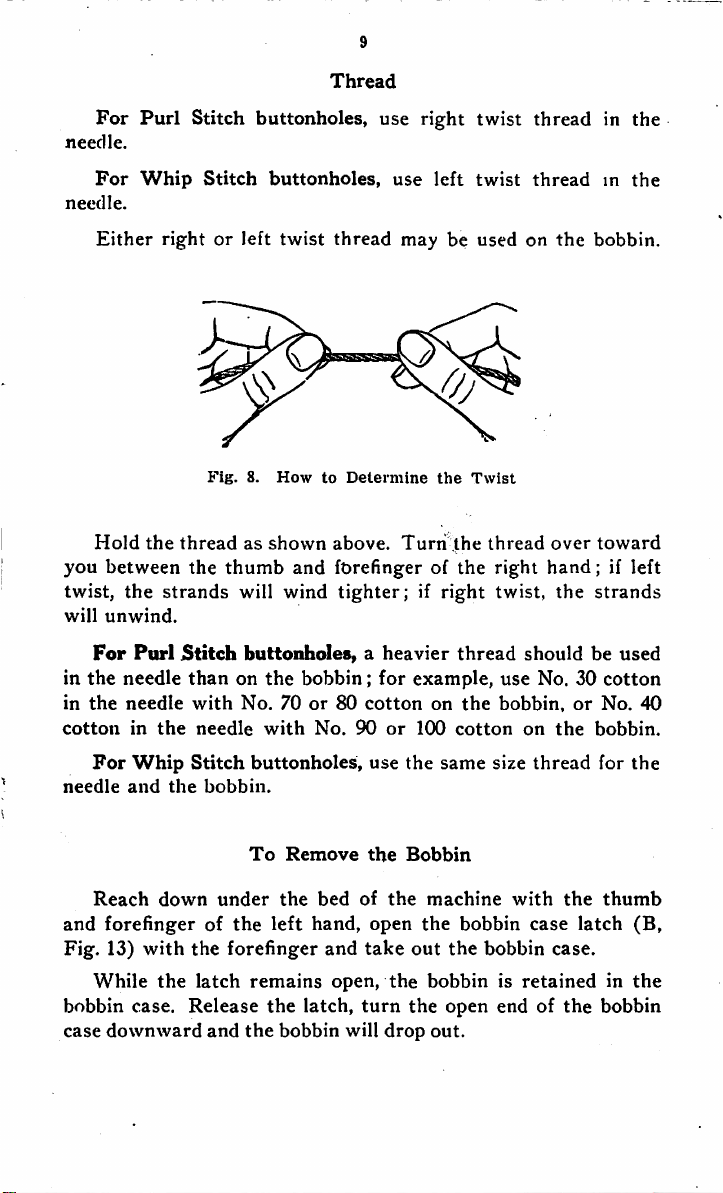

Hold

you

twist,

will

For

in

the

in

the

cotton

For

needle

Either

between

the

unwind.

Purl

needle

needle

in

Whip

and

rightorleft

Fig.

the

threadasshown

the

thumb

strands

Stitch

thanonthe

with

the

needle

Stitch

the

bobbin.

twist

8.

How

and

will wind

thread

to

above.

forefinger of

tighter;ifright

maybeusedonthe

Determine

Turn

buttonholes,aheavier

bobbin;

No.70or80cotton

with

No.

buttonholes,

90

for

or

use

example,

100

the

the

on

same

Twist

.the

the

thread

the

cotton

thread

right

over

hand;

twist, the

shouldbeused

use

No. 30

bobbin,

on

the

size

thread

bobbin.

toward

strands

or

bobbin.

for

if left

cotton

No.

40

the

Reach

and

Fig.

While

bobbin

case

down

forefingerofthe

13)

with

the

case.

downward

under

the

forefinger

latch

Release

and

To

Remove

the

left

remains

the

the

bobbin

bed

hand,

and

open,

latch,

of

turn

will

the

open

take

drop

Bobbin

the

machine

the

out

the

the

bobbinisretainedinthe

the

open

bobbin

bobbin

endofthe

with

case

case.

out.

the

latch

thumb

(B,

bobbin

To

Wind

10

the

Bobbin

Place

the

bobbin on

the

bobbin winder spindle

and

push it

up closeagainst the shoulder, having the small pin in the spindle

enter

the

slotinthe

bobbin.

£0375

Fig.

9.

Pass

(1,

Fig.9)on

Winding

the thread from the unwinder, through the thread guide

the

bobbin

winder

the

Bobbin

tension

bracket

attachedtothe

top of the machine, under between the tension discs (2, Fig. 9),

through

the

thread

guide

(3, Fig.

9),

wind

the

end of

the

thread

around the bobbin (4, Fig. 9) a few times, then push the bobbin

winder pulley against the moving belt.

When

sufficient thread

has been wound upon the bobbin, the bobbin winder will stop

autom^^'Ully.

Bobbins

can

be

wound

while

the

machine

stitching;

, -v

is

Loading...

Loading...