Page 1

14

U64A

Operator’s

Guide

Page 2

14Ü64A

PREFACE

Thank you for your purchase of this sewing machineThis machine will provide you with excellent performance in sewing from light to heavy material (lawn to

denim). Please refer to this booklet for proper use and optimum service.

Safety Cautions:

^ Be sure that the electrical voltage of the socket outlet (wail receptacle) is the same as the rated

voltage of the motor.

® Disconnect the powerdine plug from the socket outlet when changing needles, presser foot or

throat plate, or when leaving the machine unattended- This eiiminaies the possibility of start

ing the machine by accidentally pressing the speed controller.

^ Do not pull the fabric while you are stitching as this may deflect the needle, causing it to break^ Before cleaning your machine, disconnect the powerdine plug from the socket outlet.

^ Do not attempt to adjust the motor belt. Contact your nearest Service Center should any

adjustment be required.

Handle the foot controller with care and avoid dropping it on the fioor. Be sure not to place

anything on top of it.

^ When sewing closely watch the area being sewn to avoid injuries from needles and knives.

^ Use only the handle to lift and move the machine.

V

^ A Trademark of THS ЗШОВЯ COMPANY

Copyright €> 1986 THE SINGER COMPANY

Ah' Rights Reserved Throughout The World

У

Page 3

CONTENTS

Page

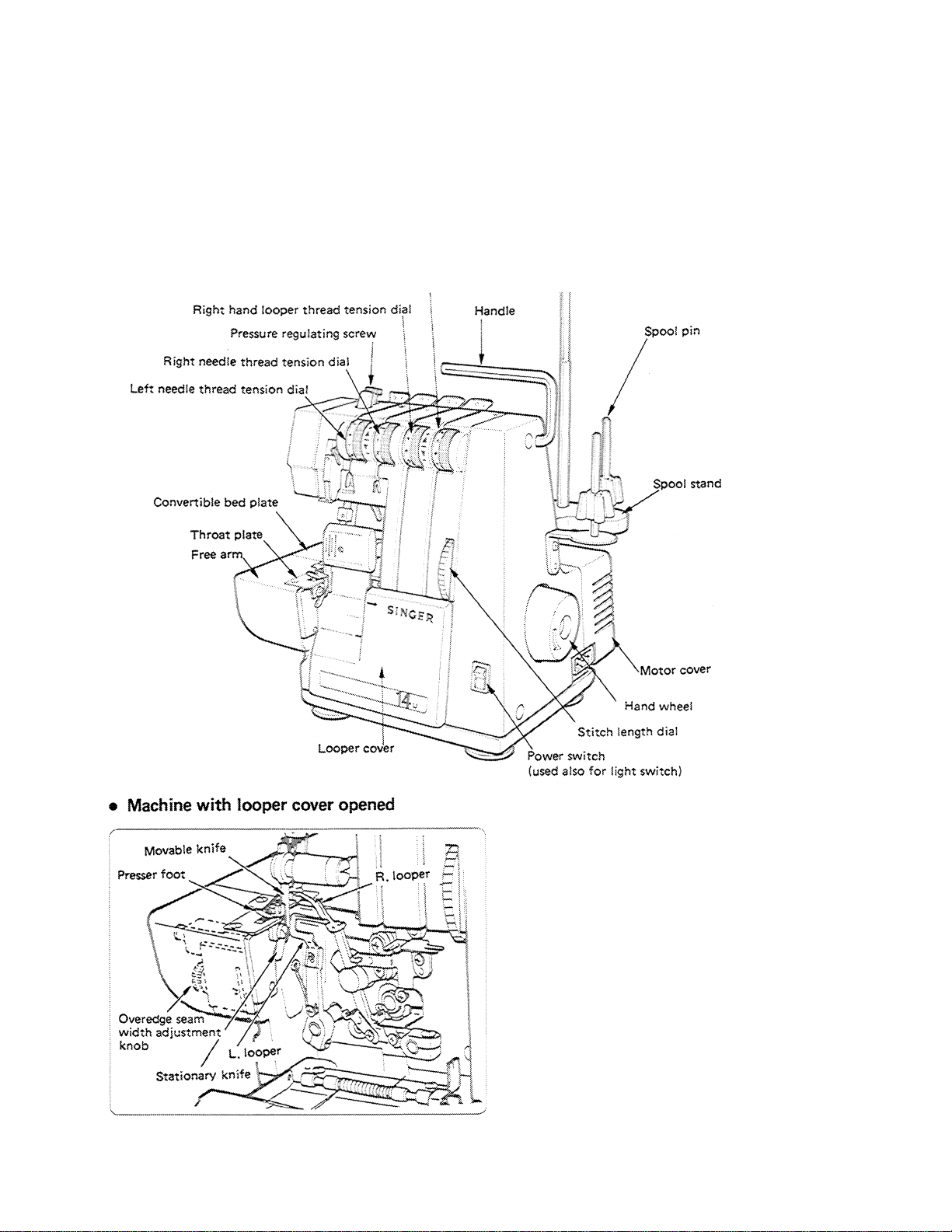

1. Principal parts......................................................................................................................................... 2

2. Preparatiorx prior to sewing....................................................................................................................3

3. Threading the machine .......................................................................................................................... 4

« Setting up the thread guide holder......................................................................................................4

• How to open looper cover....................................................................................................... 5

® How to remove cylinder cover................................................................................................ 5

« How to thread your machine correctly.....................................................................................6

^ How to change threads ............................................................................................................ 9

4. Chain off and test sew ............................................................................................................................9

5. How to adjust thread tension .............................................................................................................. 10

6. How to adjust stitch length................................................................................................................... 12

7. How to adjust overedge seam width .................................................................................................. 12

8. How to roll hem................................................................................................................................. 13

9. Free arm sewing (tubular work)......................................................................................................... 15

10. Seam guide lines................................................................................................................................. 15

1 L Edge guide ......................................................................................................................................... 16

12. Variation stitch ................................................................................................................................ 16

Ornamental stitching....................................................................................................................... 16

« Blindstitching .................................................................................................................................. 18

« Braiding by chaining-off

^ Pin tucking....................................................................................................................................... 19

^ Reinforced (tapes) overedge stitching

» Turning square comers ..................................................................................................................... 20

13. How to replace needles........................................................................................................................ 21

14. How to replace stationary knife........................................................................................................... 21

15. How to exchange light bulb ................................................................................................................. 21

16. How to adjust presser foot pressure

17. Lubrication

18. Reasons for poor stitches and how to make adjustment.................................................................... 23

.................................. ...............

................................................................................................................

....

......................................................................................... 19

.................................................................................................... 22

..................................................................

18

22

19. Relationship between cloth, thread and needle

20. Accessories.......................................................................................................................................... 25

2L Speciñcation of the 14Ü64A machine

.................................................................................................

....................................................... , .......................

24

25

Page 4

S * ii S « >1^ S i?>*^ C« *■ i"** •» '«• ’ft*»

Thread guide holder

Left hand iooper thread tension dial

Page 5

"^ ^ ^ -0«% ^ ^ «''i. ^ *'''«* iW, 'f ~"

2

a *. ^ 'x*^ d - Cci- y», '<«*/ „ ^ ■«» vs y. s, V* '<i*^

----

«wv«-^

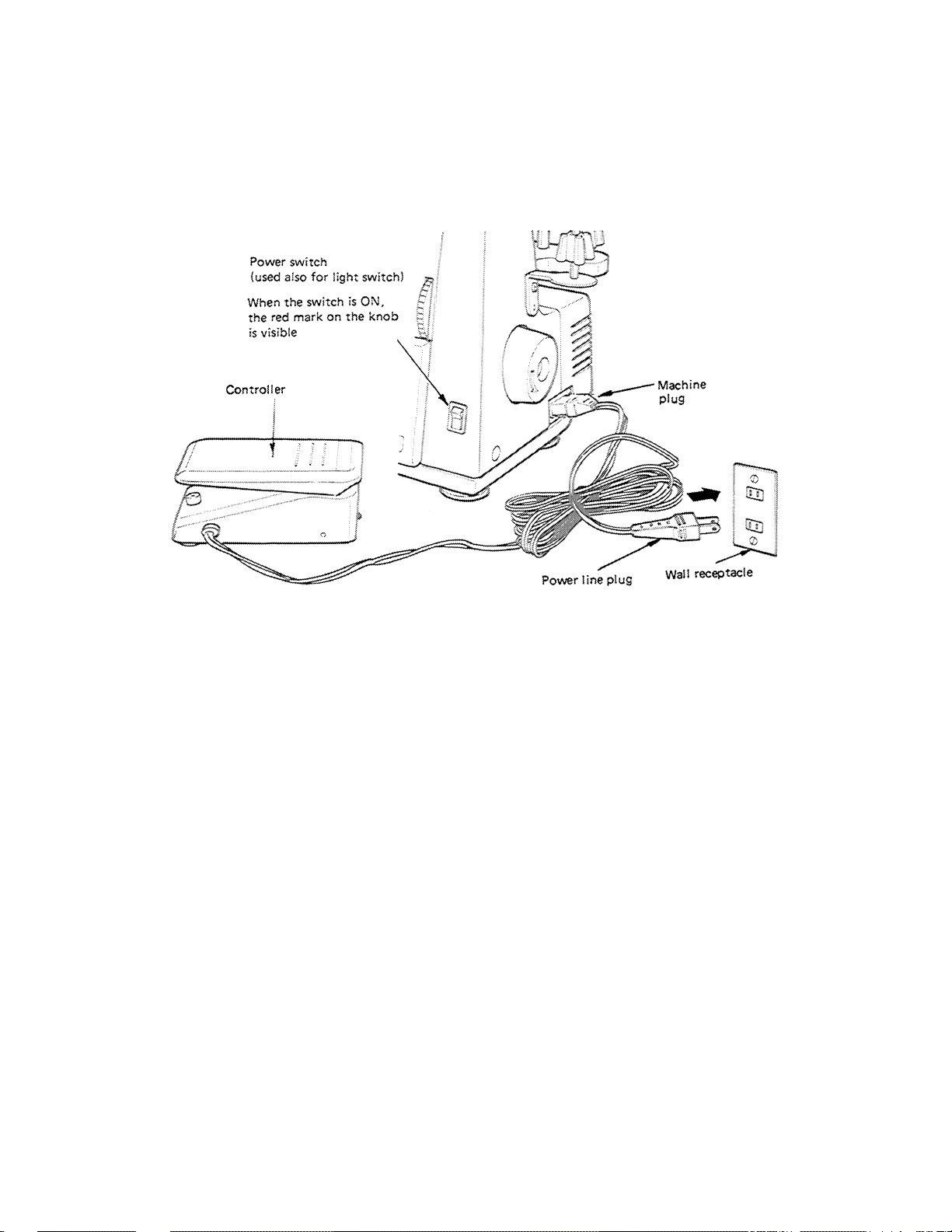

Connect the machine plug to the electncal receptacle of your machine and the power line plug to the wall

receptacle.

To run the machine and control the speed, press the speed controller. The harder you press, the faster the

machine will sew. To stop the machine from sewing, remove your foot from the speed controller.

Caution:

^ Be sure that the e^ectncai voltage of the socket outlet (wah receptadei Is the same as the rated voltage of

the motor.

^ Handle the foot controller with care and avoid dropping It on the floor. Be sure not to place anything

on top of It.

® Disconnect the powerdine plug from the socket outlet when changing needles, presser feet or throat

plates, or when leaving the machine urnttended. This allmilnates the possibility of startingthe machine

by accidentally pressing the speed controller.

Before cleaning your machine, disconnect the power-line plug from the socket outlet.

Page 6

Thread the :::cGh:::8

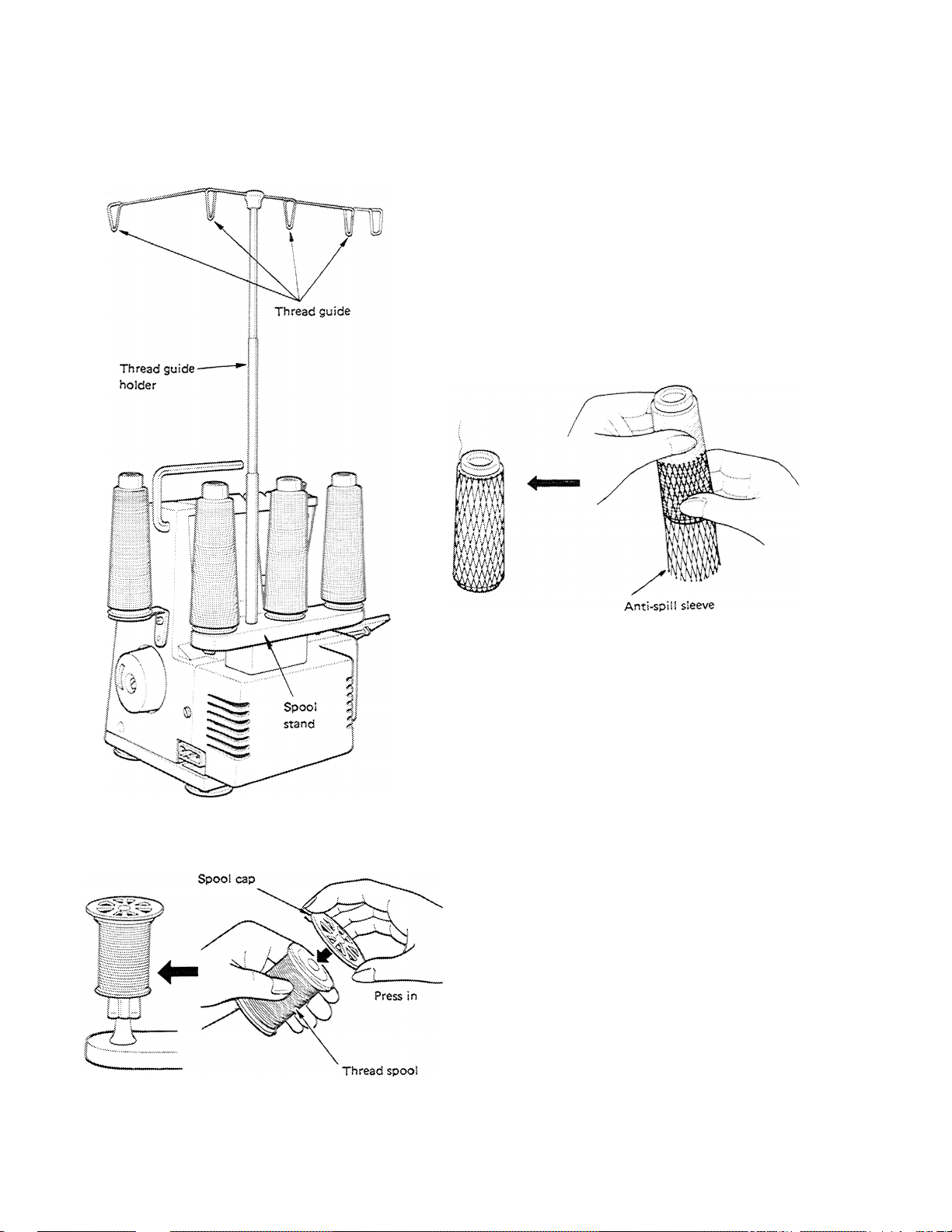

Setting up the thread guide holder

Extend the thread guide holder as far as possible and set

the thread guides so that they are located right above

the spool pins.

Place the thread on the spool stand as shown in the

figure at the left.

When using synthetic threads that easily spill off the cop

(cone), slip the anti-spill sleeve furnished with the

machine over the thread from the bottom of the cop

(cone) leaving the thread end hanging free at the top of

the anti-süiil sleeve as shown above.

When using a regular thread spool, fit the

spool cap supplied with the machine onto the

thread soooi as shown at left.

Page 7

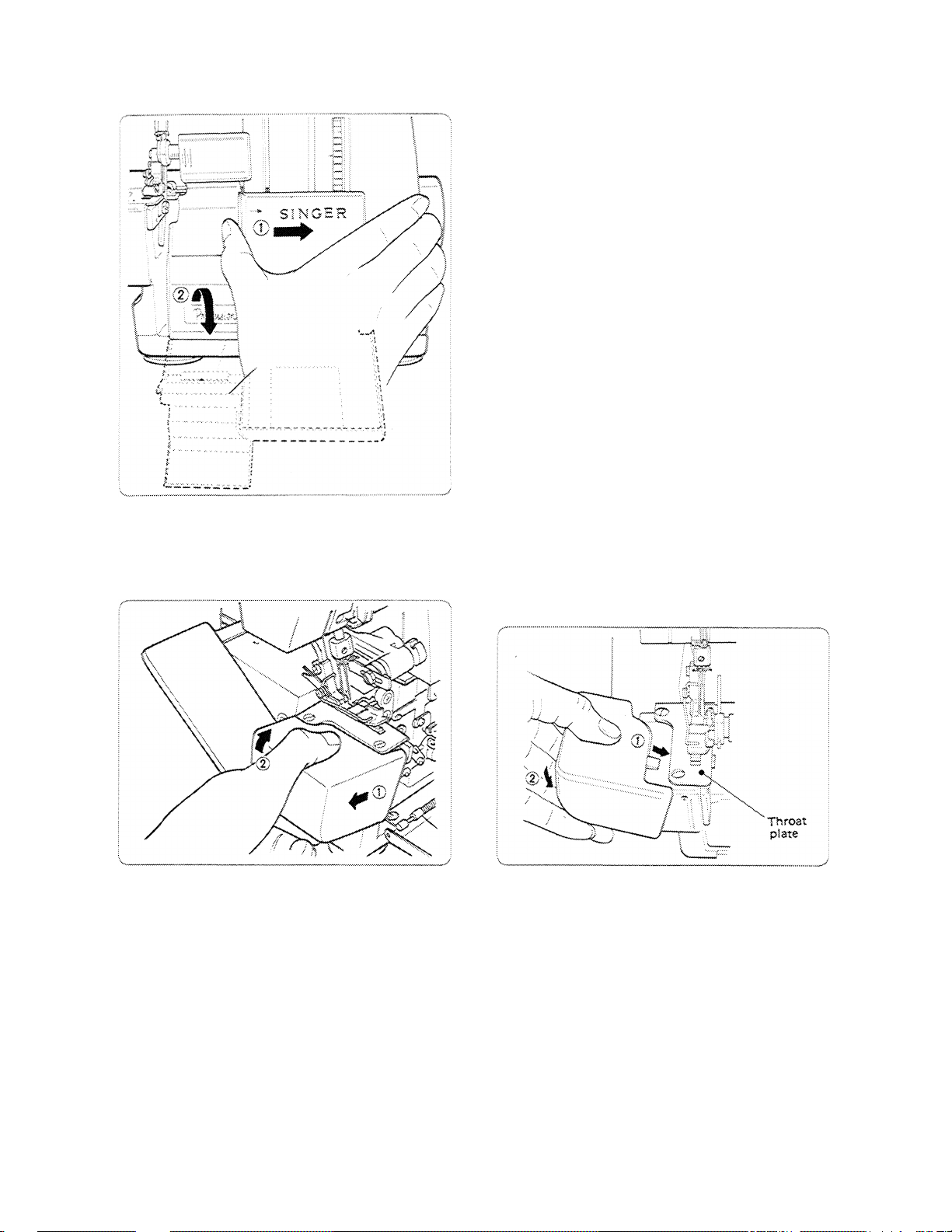

# How to open looper cover

Be sure rooper cover is ciossd when sewing.

• How to remove cylinder cover

0 Push the cover to the ri^ht

far as it will go and

(D Full cover down toward you.

To replace cover

as

0 While pulling the cylinder cover to the left,

0 Lift cover upward and off the machine.

Do not hold the cylinder cover when moving the maohme.

0 Place tab on top of cover under the

throat plate.

0 Press cover downward to the right.

Page 8

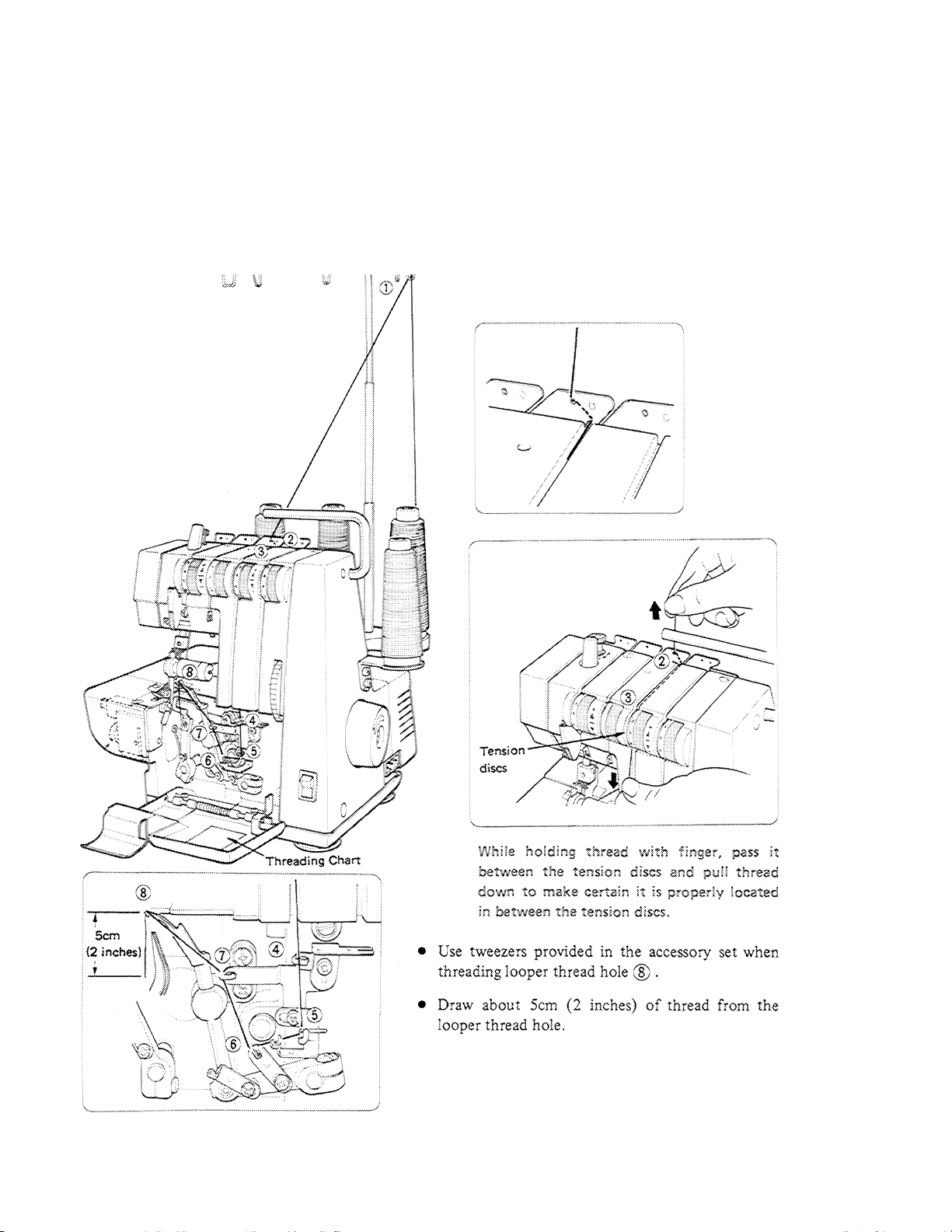

• How to thread your machine correctly

Correct sewing cannot be obtained when machine is threaded incorrectly.

Threading is diagrammed on the inner side of the looper cover and identified with colors on the various

thread guides.

(1) Open looper cover. Thread the right looper in the order (T) to (|)- as indicated in the figure below,

(threading points marked in orange)

Page 9

(2) Thread left looper in sequence from @ to 0 (marked in yellow color). Cylinder cover must also be

removed when threading this part. (Refer to page 5 for cylinder cover removal).

Wh^e holding thread with finger,

pass It between the tension discs

and puh thread down to make

certain It is properly located In

between the tension discs.

Turn hand wheel toward you

until left looper is at left as far

as it will go and thread looper

thread hole (§) from left to

right. (Use tweezers provided in

your accessory set).

Turn hand wheel toward you until

the looper is at right as far as

it will go passing the thread under

the throat plate, then using the

tweezers, thread the looper thread

hole 0 from front to back. Draw

about 5cmi (2 inches) of thread

from thread hole.

Page 10

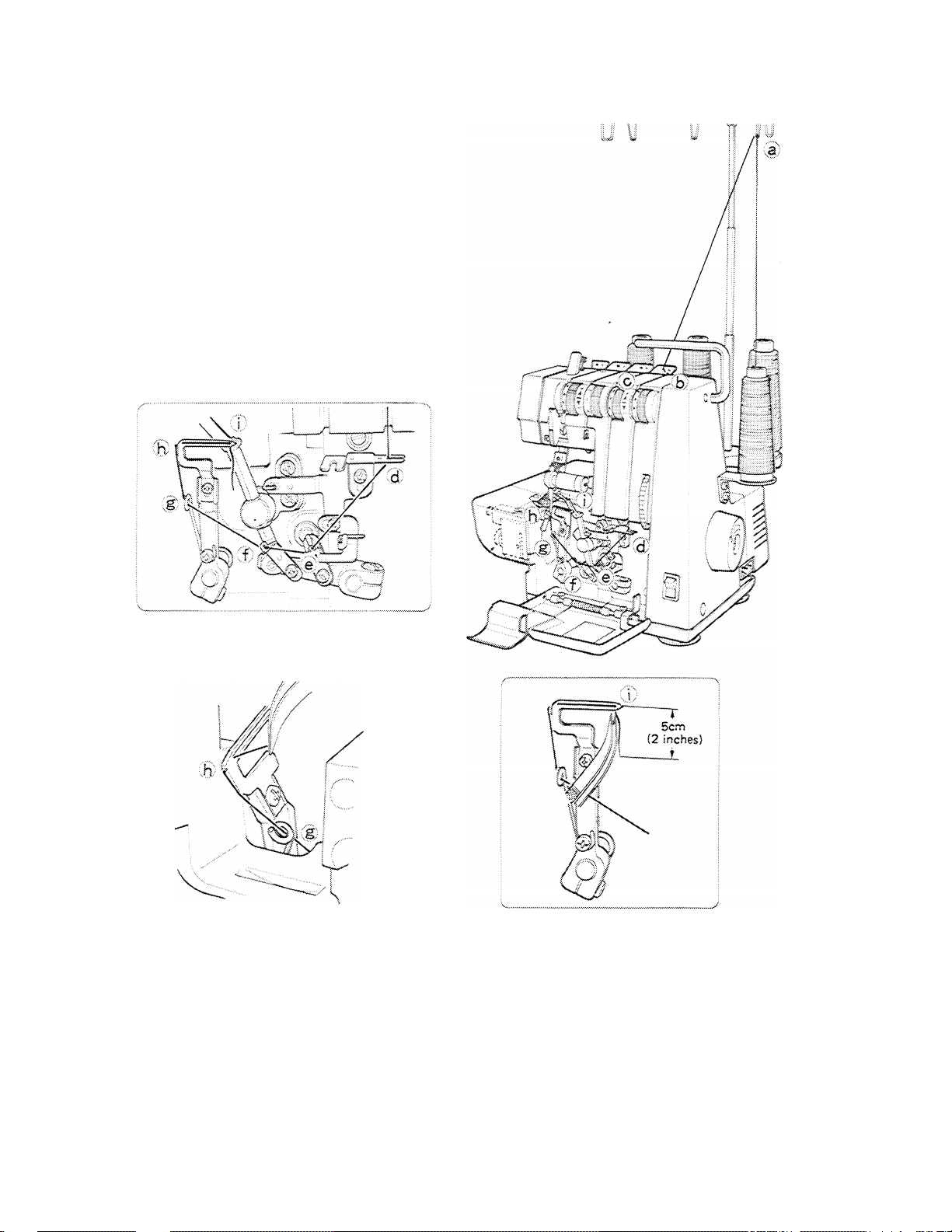

(3) Thread the left needle thread in the order ® to ® (blue mark).

Threading of needle eye ® becomes easier when the movable knife is set at the non-operating posi

tion (See figure on page 12 for movable knife non-operating position).

holdmc thraac with

finger^ pass it between the

tension discs and pull thread

down to make certain it is

property located m between

the tension discs.

• Lower needle bar when

threading © and © .

• Use tweezers to thread

needle eye ® .

• Draw about 5cm (2 inches)

of thread from needle eye.

(4) Thread the right needle thread in the order (g) to (D (green mark).

Threading of needle eye © becomes easier when the movable knife is set at the non-operating position

(See figure on page 12 for movable knife non-operating position).

Page 11

m How to change threads

When you wish to change the left needle

thread, right needle thread, left looper

thread or right looper thread with a different

thread, the following steps will make the

changing convenient.

(1) Cut the thread near the spool and tie

the end to the thread you wish to

change to as shown in figure at right.

Raise presser foot.

(2)

Note tension reference numbers.

(3)

Turn the tension dials down toward the

(4)

(-) mark until the dial stops and draw

the' thread out so that the tie knot of

the threads extend about 5cm (2

inches) from the presser foot. When

drawing needle thread through the

needle eye, stop the tie knot before the

needle eye. cut the thread and pass it

through the needle eye.

Return tension dials to reference num

(5)

bers.

i^nor

4. Chair, off and test sew

i

-------

;

«

3^

Thread cutter.

/

S:XCER

^4. ;

c? •

:■ :

j ■.

- - -

When the machine is completely threaded,

turn the hand wheel toward you 2 or 3 turns

while holding the 4 threads applying a slight

tension as shown in figure at left.

r

After chaining off, make a test stitch on a

sample of your fabric so that you can adjust

the thread tensions correctly.

After completing the

seam, chdin off approx.

5cm (2 inches) as shown

in figure at left and cut

thread with the thread

cutter on the presser

foot.

Page 12

S & ■ * &

CSWifel^^W » WCa.V*^ ^W»wv>Ov*W*i

Adjust thread tension to suit the type of material and si2e of the thread used. The thread tension dials on

this machine are a one-tum system and as the number on the thread tension dials increases, the thread

tension becomes tighter.

Ki^ht looper thread

1) 2-needle. 4-thread overedge stitching.

• Correct thread tension

Be sure the threads are correctly threaded otherwise

proper thread tension cannot be obtained (See page 6).

Set each of the thread tension dials to the settings shown below

and test sew.

Extension

Fabric^v^

Li$ht

wieght

Left

needle

thread

3

Ri^hl

needle

thread

2

Right j Left

looper looper

thread thread

6

Left needle

thread tension

dial (blue) \

2

\ \“T

MSf / ^

Left 7**

Right

needle

needle

threQd^

thread

Topside

—....■.........

Ri9ht needte

thread tension

dial (green)

—'

Right looper

thread tension

dial (orange)

Left looper

thread

Underside

Left loo pet

thread tension

dial (yellow)

Medium

weight

Heavy

^ weight

5

6

3

5

6

7

/

2

2

With following figure as reference, adjust the thread tension dials to obtain correct tension.

When right looper thread lies on the underside

Turn right looper dial (orange) toward the i^)

mark. Or, turn left looper dial (yellow) toward

the {—) mark.

When left needle thread tension is too loose.

Right looper

thread

vihen left looper thre^ appears oh the top.

Turn left looper dial (yellow) toward the (+)

mark.

Or, turn right looper dial (orange) toward the

(~) mark.

When right needle thread tension is too loose.

Right needle teft needle

thread thread

Topside

Turn left needle thread tension dial (blue)

toward the (+) mark.

10

^ Underside

Lett looper

thread

right needle thread tension dial (green)

i urn

toward the (+) mark.

...y'

Page 13

2) Standard 1-needle, 3-thread overedge stitching

This machine can do I -needle. 3-thread overedge stitching by using only the right needle.

Always remove the left needle

♦ Correct thread tension

Be sure the threads are correctly threaded otherwise

proper thread tension cannot be ohtzined (See page 6).

Set each of the thread tension dials to the settings shown

below and test sew.

Thread tension

Fabric

Light weight

Medium weight

Heavy weight

Right needle Right looper

thread

thread

2 6

3

5

6

7

Left looper

thread

2

2

2

Right looper thread

Needle thread

Left iooper

thread

Topside

L

Needle thread Right looper Left iooper

tension dial , thread tension thread tension

(green) \ dial (orange) dial (yellow)

Underside

With following figure as reference, adjust the thread tension dials to obtain correct tension.

When right looper thread hes

on the underside of fabric.

Needle thread

Right looper-'T?-^^^ ^ ,

thread Left looper

Topside Underside

Turn right looper dial (orange)

toward the (+) mark.

Or, turn left iooper dial

(yellow) toward the {—) nnark.

thread

When left looper thread

appears on the top.

Left looper

thread

\

Right looper / \

thread y

Needle^

thread

Topside ^ Underside

Turn left looper dial (yellow)

toward the (-^) mark.

Or, turn right looper dial

(orange) toward the (—) mark-

When needle thread tension is

too loose.

Right iooper

Left looper

thread thread

Topside t t ^

Turn needle thread tension

dial (green) toward the (+)

mark.

Underside

__

y

11

Page 14

6. Hcv7 to Eojost Stitch length

The stitch length dial on this machine is pre-set to 3mm for

normal sewing condition. Since the adjustment can be made

easily, adjust the stitch length to 4mm when sewing heavy weight

fabrics such as quilting and to 2mm when sewing light weight

fabrics such as lining fabric, crepe, etc. and you will obtain ex

cellent seams without puckerings.

7. Hcvr to ae|ost overedge seam width

Overedge seam width of this machine is set to 3,5mm for normal sewing conditions, however it can be

increased up to 5mm for overedging heavy weight fabrics as instructed below,

(1) Before making the adjustment, be sure that the power line plug is disconnected from the wall re

ceptacle,

(2) Open the looper cover, (See page 5)

(3) Turn the hand wheel toward you, lower the movable knife as far as it will go and set it in the non

operating position as shown in figure below.

(4) Remove the cylinder cover. (See page 5).

(5) Turn the overedge seam width adjustment knob and

with the graduations on the throat plate as a rule, adjust

to desired seam width.

(6) Replace the cylinder cover. (See page 5)

(7) Return the movable knife to its original position and

close the cover.

Note: Do not set the overedge seam width below 3.5mm

as this may cause the stationary knife to mterfere

with the throat plate.

12

Page 15

This machine can do the 2 types of standard and ri^nt looper thread wrapped rolled hem stitching with a

seam width of 13mm.

Always remove the left needle

1. Fabric, needle, thread and stitch length

Fabric: Light to medium weight (See page 24)

♦ Rolled hemming is done by rolling the fabric and overedging (seam width L5mm), and is not

suited for heavy or stiff fabrics*

Needle: Singer Cat. No. 204$, #I L f ^

Thread: A variety of thread combinations can be used for rolled hemming.

Stitch length adjustment (See page 12)

For rolled hemming* set the stitch length dial to '"2” or ‘T” and a fine seam

can be obtained.

2. How to exchange throat plate

A throat plate for roiled hem stitching has been furnished in the accessories for

this mzchme. By exchanging the ordinary overedge throat plate on the machine

with a rolled hemming throat plate by the following procedure, the machine can

be used for rolled hem stitching.

1. First of all, always disconnect the power line plug from

the receptacle.

2. Turn the hand wheel towards you until the needle is at

its highest point.

3. Lift the presser foot.

4. Remove the cylinder cover, (see page 5),

5. Unscrew the throat plate screw (1) and remove the throat

plate.

6. Install the rolled hem.ming throat plate and replace the

screw (1).

7. Replace the cylinder cover (See page 5).

:

L

Ш

Ч

___

Roiled hemming

throat plate

Note: ^ When, replacing the throat plate, be carefiil that the thread is not

caught between the throat plate and machine.

^ Set seam width to the ''M"" mark on the roiled hemming throat plate.

^ To set seam width, align left edge of stationary knife holder with the

mark on the rolled humming throat plate.

Be sure the stationary knife is not in contact with the edge of throat

plate.

13

Page 16

3. How to adjust thread tension

1. Standard rolled hem stitching

As adjustments are the same as 1-needle, 3-thread overedge stitching, refer to page 1 L

2. Right looper thread wrapped rolled hem stitching (roiled hem variation)

♦ Correct thread tension

ficult to roll a fine seam can be obtained by this

stitching.

To correctly adjust the th.TQd.d tension, set the dials as follows from the standard thread tension dial sett

ings.

a. Turn the right looper thread tension dial (orange) one half graduation towards the (—) mark.

b. Turn the left looper thread tension dial (yellow) 2 3 graduations towards the (*^) mark.

Sli^t adjustment will give better thread tensions.

When right looper

thread is too loose

When left looper

thread is too loose

щмш

Needle thread / .«Ov /" \

Right looper

thread

Topside

Turn right looper thread tension

dial (orange) towards the (+)

mark.

Left looper

thread \

Underside

Needle thread

Right looper

thread

Topside/Clg:

Turn left looper thread tension

dial (yeilow) towards the (+)

mark.

Or, turn right looper thread ten

sion dial (orange) towards the

(—) mark.

4. How to sew

Underside

Left looper

thread

When needle thread is

too loose

¡4^"* Left looper

thread '

Topside

Turn needle thread dial (green)

towards the (+) mark.

Needle thread

Underside

Sewing

• See page 9, ‘"4. Chain off and test sew’k

• For rolled hemming, if a slight tension is applied to the material in the sewing direction, a finer seam

finish can be obtained.

• At the start of sewing, slightly pull the end of the chain off so it will not be entangled in the stitch.

14

Page 17

• The minimum overedge stitch width that can be obtain*

ed for relied hemming is approximately 1.5mm since the

cutting width cannot be set below 3.5mm.

♦ When using threads that spill easily; slip the anti-spill

net furnished with the m.achine over the thread from

the bottom of the cone and place it on the spool stand

so as the bottom of the net folds inside the cone.

9. Free arm sewmz vrerki

s .inss

Use seam guide lines on looper cover to measure seam allow

ances.

Thick line on extreme right is 5/8 inch from center of right

needle. Other lines are 1/8 inch apart.

Page 18

w «

For ornamental and blind (overedge) stitching, use of the edge

guide attachment is very convenient.

Attach edge guide as shown in figure.

12. Vcristicn stitch

• Ornamental 3 thread stitching

Ornamental stitching can be used for various applications.

Preparation

• Use ordinary overedge throat plate.

. Remove left needle.

• The right iooper thread forms the decorative stitch, therefore fine and unobtrusive threads should be

used for the needle and left Iooper.

Example: Right Iooper thread ..................

Left Iooper thread ........................extra fine

Needle thread ...............................extra fine

Stitch length

I. Set thread tensions to normal sewing condition for 1 needle, 3 thread overedge stitch and make a test

sample. (See page 11).

. When making above adjustment, the right Iooper thread tension should be adjusted as light as

possible.

♦ Make a test sample with two ply fabric.

(+) mark so that the right Iooper thread will come

as close as possible to the needle thread as shown in

the sketch.

3. Turn needle thread tension dial (green) toward (-)

mzik so that right Iooper thread, left Iooper thread

and needle thread will all come to the edge of fabric

as shown in the sketch.

.................................

Wooly nylon

2—3

16

Underside

Page 19

4. Open iooper cover.

5. Turn hand wheel toward you to bring movable knife to its lowest position and place it in the non

operating position as shown in sketch below.

knife

holder

Push the movable knife holder to the

right as far as it mil go and turn the knob

As shown above, the movable knife

will be in a non-operating position.

in the directiorx shown.

6. Attach edge guide to machine.

7. Fold fabric m half with the wrong side facing.

8. Place fabric under the foot with the fold resting against the wall of edge guide. Adjust edge guide so

that it is positioned in the center of the seam width as shown in the sketch.

9- When stitching is completed, unfold fabric and press the stitching from the underside of the fabric.

17

Page 20

3-Thread blindstitching

Blindstitching provides a durable hem finish that is almost invisible* It is best suited for sewing cuffs on

knitwear and skirt hems.

Preparation

Remove left needle

Material

Throat plate

Thread tensions

Knit fabric

Ordinary overedge throat plate

Set tensions to normal sewing condition for 1 needle, 3 thread overedge stitching

(see page 11),

Stitch length dial

Set stitch length dial to 4-5.

With the underside up, place the threefold fabric under the foot with the soft fold resting against the wall

of edge guide as shown in the sketch. Lower the foot, and make a test sample to see that the needle will

pierce the edge of the fold. Adjust position of edge guide if necessary.

♦ Braiding by chainingoff

Chained-off braids can be used for making 3 ply or 4 ply braids.

To make chained-off braids, place movable knife in the non-operating position. Insert filler cord such as

woollen yam or tape through hole in foot and chain-off*

18

Page 21

• 3*Thread pin tucking

Pin tucking is a useful decoration when sewing blouses and children’s clothes. Pin tucking is accomplished

before cutting out garment,

• Use ordinary overedge throat plate or rolled hemming throat plate,

• Remove left needle.

• Before sewing on your garment, always make a test stitch on a sample of your fabric so that you can

adjust the thread tensions correctly for standard 1 needle, 3 thread overedge stitching,

• Place movable knife in non-operating position,

• Fold fabric in half with the wrong side facing.

• Place fabric under the foot with the fold resting against the wall of edge guide,

• Adjust edge guide so that the stitches will Just overcast the edge of the fold as shown in the sketch,

• Lower the foot and sew. When stitching is completed, press pin tuck to lay flat on one side.

♦ Remforced (tapes) overedge stitching

Inserting a tape while overedge stitching, will give a much more durable seam.

a. Remove front cover screw (1) and

install tape guide attachment,

b. Pass tape as shown in figure through

tape guide 0 , tape guide (|), hole

(3) in presser foot and draw to rear

from under presser foot.

Page 22

• Turning square corners

Outside comer

Cutting

line

2 cm

L Cut out approxiniately

2cm from the comer in

line with the overedge

seam edge.

inside comer

2cm

N

2. Sew to point A, one stitch

beyond edge of fabric and

stop machine.

3. Raise needle and presser

foot,

4. Fun fabric to the rear of

machine just enough to

release the thread caught

on the finger of the throat

plate.

WcJ'

5, Turn fabric and lower

presser foot so that its

finger is positioned on the

edge of fabric.

6. Pull slack threads up, then

start to sew.

1. Cut fabric at seam edge.

2. Place movable knife in

nomoperating position.

20

3. Fold fabric as shown in

sketch.

4. Sew to point B, as close as

possible to the diagonal

fold. Leave

fabric.

needle in

5. Raise presser foot, leaving

the needle in the fabric,

6, Refold fabric so that the

overedge is in line with the

already sewn seam.

Page 23

13. r-cv;t3 rsp^£C3 r.ssd^ss

Use Singer needles Cat. No. 2045 avaiiable in sizes #I 1 and #14.

To remove the needles:

® Be sure the power line plug is disconnected from the wall receptacle.

» Turn the hand wheel toward you until the needle is at its highest

position. Loosen the needle set screw with a screwdriver and remove

needles.

To replace the needle:

0 Insert the needles into the needle bar hole as far as they will go with

flat surface to the rear and securely tighten the needle set screw.

14. Hcv; to rsplccs st£t:oo£ry koifs

The stationary knife should be changed when it becomes dull.

The stationary knife can be replaced according to the following steps, however if them are any difficulties

experienced, call your Singer representative to make the adjustment.

(1) Be sure that the power line plug is disconnected from

the wall receptacle.

(2) Open the looper cover and set the movable knife in the

non-operating position (see page 12).

(3) Loosen the stationary knife set screw and remove the

stationary knife.

(4) Place a new stationary knife in the groove of the

stationary knife holder, align the cutting edge level

with the top surface of the throat plate and tighten set

screw.

(5) Return the miOvable knife to its original position.

15. How to exchange light bulb

First of all, be sure to disconnect power-line plug.

Remove light cover as shown in figure, turn bulb to left and

remove. To replace, push bulb into socket and turn to right.

Light bulb is a bayonet type and be sure to purchase a

12 volt, 6 watt bulb when replacing.

Page 24

16, to £¿7^31 crasser foot pressi

The presser foot pressure of this machine i$

preadjusted at the factory to suit the sewing of

medium weight fabrics.

it may become necessary to adjust the pressure

in the case of delicate or heavy weight fabric.

For light weight fabric — Decrease the pressure

(as shown at left).

Heavy weight fabric

(as shown at left).

Increase the pressure

n. Lybricatlon

Occasional lubrication is required. The oiling points shown on the figure below should be lubricated

periodically.

22

Page 25

18, Reasons for poor stitches ar.o hc*A* tc ntaks Ezyss’lrr.ent

Whenever sewing difficulty is encountered, make the adjustments as noted below.

Condition Reason

When the fabric is not

feeding.

When the needle breaks.

When the thread breaks.

When stitches skip.

♦ Insufficient presser foot pressure.

• Needle not inserted properly.

• Fabric being pulled too hard.

• Loose needle set screw.

• Incorrect threading.

♦ Bent needle or needle point

damaged.

♦ Thread tension too tight.

♦ Thread tangled.

• Needle inserted incorrectly.

♦ Needle bent or needle point

damaged-

• Needle set loosely.

• Incorrect threading.

♦ Wrong needle used.

Method of Adjustments

(reference pages)

• Increase presser foot pressure

(psge 22).

♦ Insert needle correctly or replace

with correct needle (page 21).

♦ Do not pull the fabric by hand.

Use hand only to guide the fabric.;

♦ Tighten screw firmly.

• Thread machine correctly (page

6).

• Replace needle (page 21).

• Adjust tension (page 10).

♦ Thread correctly (page 6).

• Insert needle correctly (page 21).

♦ Replace needle (page 21).

• Set needle firmly in position

(page 21).

• Thread machine correctly

(page 6).

• Use Singer Cat. 2045, #1L #14.

When stitches are

irregular.

When fabric puckers

When the machine does

not operate.

♦ Insufficient presser foot

pressure.

♦ Thread tension not balanced.

♦ Thread tension too tight.

♦ Threading incorrect or tangled.

♦ Power line plug not connected.

♦ Increase presser foot pressure

(page 22).

• Adjust tensions (page 10).

• Adjust tension (page 10).

• Rethread machine (page 6),

♦ Connectwith power source.

23

Page 26

» MW '*• ''’**1^ -H » W* » ♦ »

ifi s^oth, thrSi

Type of Fabric Type of Thread

Light Weight

Lawn, Organdy,

Voil, Crepe, etc.

Medium Weight

Muslin, Soccer,

Satin, Gabardine

Broadcloth, etc.

Heavy Weight

Oxford, Denim

Tweed, Corduroy

Serge

Cotton #100

Silk #100

Spun #80 - #90

Tetron #80 - #100

Cotton ~I6Q — #80

Snk#50

Spun #60 - #80

Tetron #60 - #80

Cotton #4-0 — #60

Silk #40 - #60

Spun #60 - #80

Meedle

Singer Cat, No. 2045

#11

#11, #14

#14

Knit

Tricot

Jersey

Wool (woven, knit)

Tetron #50 ~ #80

Spun #80 — #90

Tetron #60 — #80

Spun #60 - #80

Tetron #60#80

Cotton #60 — #80

Spun #60 — #80

Tetron #50 ~~ #60

Wooley nylon

Wooley tetron

#11

#11, #14

#11, #14

24

Page 27

(accessory box)

Needle Set

Screwdriver (medium size)

2.

Screwdriver (small size)

3.

Tweezers 1

4.

Thread unwinder spool cap

5.

Stationary knife

6.

7.

Brush

Oiler

8.

Machine cover

9.

Anthspili net

iO.

11. Rolled hemming throat plate

21. Specificatio!

1

.4^

1

1

4

I

1

I

1

4

1

1 Item

j Sewing speed

j Stitch length (feed amount)

1

1 Overedge stitch width

Needle bar stroke

Presser foot rise

Needle

Number of threads

Machine dimensions

Weight

Specification

1,500 spm maximum

I 5 mm (Standard: Rolled hemming F 2, ordinary

overedge 3)

Rolled hemming 1,5mm, ordinary overedge 3.5 5mm

(standard 3.5mm)

27 mm

5 mm

Rolled hemming Singer Cat. No. 2045 #11

Ordinary overedge Singer Cat, No. 2045#11, #14

4

width 257mm X depth 231mm X height 313mm

9 kg

Page 28

Form U3616 (Rev. 386)

Pan No. 379017*002 (Rev, 2)

Printed in Japan

Loading...

Loading...