BAR DATA HANDBOOK

AISI/SAE

Chemical Compositions

and Metallurgical Data

8000 North County Road 225 East | Pittsboro, Indiana 46167

(877) 683-2277 | f: (317) 892-7005

SECOND EDITION

1

TABLE OF CONTENTS

INTRODUCTION

SDI OVERVIEW 3

COMPANY HISTORY 4

PRODUCTS AND SERVICES 5

PROCESS DESCRIPTION AND CAPABILITIES 7

STEEL CHEMISTRIES

MAJOR STEEL GROUPS 11

AISI-SAE GRADE SERIES OVERVIEW 12

STANDARD CARBON STEELS 15

RESULFURIZED CARBON STEELS 16

REPHOSPHURIZED AND RESULFURIZED CARBON STEELS 16

HIGH MANGANESE CARBON STEELS 17

CARBON AND CARBON-BORON H-STEELS 17

CHEMICAL RANGES AND LIMITS OF CARBON STEELS 18

PERMISSIBLE VARIATIONS OF CARBON STEEL 19

STANDARD ALLOY STEELS 20

STANDARD ALLOY H-STEELS 24

STANDARD ALLOY RH-STEELS 29

SAE POTENTIAL STANDARD STEELS 31

FORMER SAE EX AND PS STEELS 33

FORMER STANDARD SAE STEELS 37

BEARING QUALITY STEELS 50

ASTM A105 55

ASTM A182 56

ASTM A193 58

ASTM A213 59

ASTM A350 61

ASTM A572 62

ASTM A588 63

ASTM A920 64

CHEMICAL RANGES AND LIMITS OF ALLOY STEELS 65

PERMISSIBLE VARIATIONS OF ALLOY STEELS 66

SELECT AEROSPACE SPECIFICATIONS 67

SELECT DIN SPECIFICATIONS 70

HARDENABILITY

STANDARD HARDENABILITY REQUIREMENTS 83

RESTRICTED HARDENABILITY REQUIREMENTS 107

SELECT DIN HARDENABILITY REQUIREMENTS 114

2

TABLE OF CONTENTS

MECHANICAL PROPERTIES

ASTM A105 131

ASTM A350 131

ASTM A434 132

ASTM A182 133

ASTM A193 135

ASTM A572 136

ASTM A588 136

ASTM A615 137

ESTIMATED MECHANICAL PROPERTIES OF STEEL BARS 139

MECHANICAL PROPERTY VARIATIONS WITH CARBON CONENT 150

BAR PROPERTIES

COLD DRAWN OR TURNED AND POLISHED TOLERANCES 151

RECOMMENDED COLD SHEARING LIMITATIONS 152

CARBURIZING RATES 156

RECOMMENDED MAXIMUM HOT WORKING TEMPERATURES 157

CRITICAL TRANSFORMATION TEMPERATURES 158

PERMISSIBLE VARATIONS IN HOT ROLLED BAR CROSS SECTIONS 160

NOMINAL CORNER RADII OF RCS BARS 160

PERMISSIBLE VARIATIONS IN HOT ROLLED LENGTH 161

PERMISSIBLE VARIATIONS IN HOT ROLLED BAR STRAIGHTNESS 161

EQUIVALENT CROSS SECTION BY BAR SIZE AND SHAPE 163

HOT ROLLED BAR WEIGHTS 164

HOT ROLLED BAR REDUCTION RATIOS AT SDI 167

STEEL PROPERTIES

GRAIN SIZE 171

EFFECTS OF ALLOYING ELEMENTS ON STEEL PROPERTIES 172

PRACTICAL INFORMATION

GLOSSARY OF METALLURGICAL TERMS 175

ROLES OF ALLOYING ELEMENTS IN STEEL 176

HEAT TREATING TERMS 180

MECHANICAL PROPERTY TERMS 183

MICROSTRUCTURAL TERMS 185

STEEL DEFECT TERMS 187

HARDNESS CONVERSION TABLE 189

COMMON COVERSION FACTORS 191

3

STEEL DYNAMICS ENGINEERED BAR PRODUCTS

COMPANY OVERVIEW

Steel Dynamics Incorporated (SDI) Engineered Bar Products Division is a

world class supplier of Special Bar Quality steel. The Engineered Bar

Products Division is located in Pittsboro, Indiana, which is just west of

Indianapolis. The Engineered Bar Products facility offers a wide range

of carbon, alloy, and custom designed steel grades to meet exacting

customer demands.

The major markets that are served by the Engineered Bar Products

Division include off highway construction equipment, agricultural

applications, heavy truck, automotive, forging operations, and the gas

and oil well industry.

The Engineered Bar Products Division employs approximately 390

employees and has an annual capacity of 625,000 tons.

MISSION STATEMENT

Steel Dynamics is committed to product and process improvement.

Our mission statement is:

To meet or exceed customer expectations with regard to quality,

service, and price

To be a world-class supplier by continually improving our

processes, equipment, and systems

To be a safe working environment for all employees

To continue to enhance the skills of our employees through

ongoing training and education

ISO 9001 CERTIFICATION

Steel Dynamics Engineered Bar Products Division attained ISO

9001:2000 certification in September 2004.

In January 2010, Steel Dynamics achieved ISO 9001:2008 certification.

4

COMPANY HISTORY

SDI purchased the mill in Pittsboro, Indiana, out of bankruptcy from

Qualitech LLC in February 2003. Qualitech declared bankruptcy in 1999

and ceased operations in 2001.

A significant capital investment was undertaken to bring the existing

facility up to SDI standards, which included the following:

Completely rebuilding the ladle metallurgy facility and the

addition of new ladle cars

New carbon and lime system and baghouse upgrades at the

Electric Arc Furnace

The continuous caster was modified to allow for the capacity to

cast 7”x7” billets

An 8 stand Morgardshammar finishing mill was added to the

existing Pomini mill

Upgrades were made to the shipping department, which handles

incoming scrap, as well as finished inventory and outgoing

products

An additional 40 acres was purchased for rail infrastructure and

scrap storage

The Engineered Bar Products Division made its first shipments of SBQ

products in December 2003, and the facility became profitable in April

2004.

An additional upgrade was made in mid 2006 to add a 150,000 square

foot bar finishing facility with the capability to offer value added

services such as heat treatment, straightening, turning and polishing,

bar inspection, and precision cutting. The free-standing facility has the

capacity to finish 160,000 tons of bars annually.

5

PRODUCTS AND SERVICES

SDI produces special bar quality (SBQ) and merchant bar quality (MBQ)

steel in rounds ranging in diameter from 1 to 9 inches and round

cornered squares (RCS) ranging in diameter from 2-1/2 to 8 inches. The

facility also has the ability to produce rebar in sizes 5 through 11. The

production and availability of rebar is based on market conditions.

SDI produces a wide range of carbon and low alloy steels, such as:

Plain carbon steels (AISI series 10xx)

Resulfurized carbon steels (AISI series 11xx)

Rephosphorized and Resulfurized carbon steels (AISI series 12xx)

High Manganese carbon steels (AISI series 13xx and 15xx)

Cr Alloy Steels (AISI series 51xx and 52xx)

Cr-Mo Alloy Steels (AISI series 41xx)

Ni-Cr-Mo Alloy Steels (AISI Series 43xx, 47xx, 86xx, and 88xx)

Vanadium micro-alloy steels (10V45, 11V41)

Boron Treated Steels

Structural Grades ASTM A36 and A572 Grade 50

Low Alloy Tube and Flange Grades (T2/F2, T11/F11, T22/F22)

The grades listed above are a summary of those produced at the

Engineered Bar Products facility. Please inquire for grades not listed

above or for custom designed grades.

Hot-Rolled cut lengths are available between 16 and 40 feet. Steel

Dynamics can maintain all ASTM tolerances for diameter, length, and

straightness on all hot rolled products.

The Engineered Bar Products Rolling Mill metallurgical lab has the

capability to provide the full spectrum of metallurgical testing including

tensile, hardness, charpy impact, grain size, jominy, microcleanliness,

macrocleanliness, and aircraft quality testing.

6

The Engineered Bar Products Bar Finishing facility is equipped to

perform heat treating operations such as Quench and Temper,

Normalizing, and Annealing (LP, Spheroidize, Cold Shear, Stress

Relieve). In addition to heat treating, the Bar Finishing facility can

provide additional services such as:

Straightening

Turning and Polishing

Cutting to Length

Shot Blasting

Non Destructive Testing

The Bar Finishing Metallurgical Lab at Steel Dynamics has the capability

to provide metallurgical testing such as tensile, hardness, and charpy

impact following heat treatment. The lab is also equipped with a

scanning electron microscope that is used for research and product

evaluation purposes.

7

PROCESS DESCRIPTION AND CAPABILITIES

MELTING AND CASTING

SDI is equipped with one Electric Arc Furnace (EAF). The EAF is charged

with approximately 115 tons of primarily scrap metal in order to yield

an aim tapped heat size of 100 tons. Heats are killed following tap with

a Silicon-Manganese addition.

Following tap, heats are treated at a Ladle Metallurgy Facility (LMF). At

the LMF, slag additions and modifiers are used to work the slag and

trap inclusions. Alloy additions are made at the LMF, as well as reheating the steel for further processing or shipment to the caster.

Heats that require degas treatment have the slag layer removed by

means of a mechanical rake. These heats are then treated at the

Vacuum Tank Degasser (VTD). Typical gas levels following VTD

treatment are 2 ppm H2, 80 ppm N2, and 20 ppm O2.

The continuous caster is a three strand, vertical curved radius machine.

Each strand is equipped with automatic mould level control and

electromagnetic stirring. Five withdrawal straightener units are used to

straighten the strands and also apply soft reduction. The dimensions of

the semi-finished bloom are 10.3 x 14.1 inches.

ROLLING

The rolling mill is equipped with a walking beam furnace with a capacity

of 125 tons per hour. Blooms are de-scaled after exiting the furnace,

and then proceed through a five stand roughing mill, a six stand

intermediate mill, and an eight stand finishing mill. Dimensional control

is maintained by optical laser gauges and manual micrometer checks.

Bars are sheared after reaching their final dimension onto a 125 feet

long walking beam cooling bed. Bars are then trimmed to the specified

cut length and bundled together for shipment.

8

HEAT TREATING

The Bar Finishing facility is equipped with five Sauder Energy Car

Bottom furnaces. There is one high temperature furnace capable of

reaching 2100°F, while the others are capable of reaching 1800°F. The

furnaces are limited to a maximum bar length of 33 feet. The quench

tank has a 30,000 gallon capacity and is capable of providing agitation

and temperature control. Water is the only quench media used at the

Bar Finishing facility. The minimum bar diameter that can be quenched

is 2.5 inches.

BAR INSPECTION

There are two inspection lines at the Bar Finishing facility, a small bar

inspection line (SBIL) and a large bar inspection line (LBIL). The SBIL can

accommodate round bars ranging in diameter from one to five inches

while the LBIL can accommodate round bars from 2.5 to 9 inches and

round cornered squares from 2.5 to 8 inches. Both lines can

accommodate bar lengths of 15 to 45 feet.

At the SBIL, bars are rotary straightened and chamfered prior to

inspection. Surface inspection is performed via a Forester Magnetic

Flux Leakage unit, capable of 100% surface coverage with seam

detection of 0.3 mm for smaller bars and 0.5 mm for larger bars.

Ultrasonic inspection is performed via a rotary immersion UT inspection

unit, capable of 100% volumetric coverage using normal incidence and

shear waves. Ultrasonic inspection is capable of detecting 1mm wide

defects. The SBIL is also equipped with a 100% Eddy Current grade

verification coil.

On the LBIL, bars are shot blasted and pass through an Eddy Current

grade verification coil. Surface inspection is performed via an Eddy

Current surface inspection unit, capable of 100% surface coverage with

seam detection of 0.5mm. Ultrasonic inspection is performed via a

Magnetic Analysis Corp 48 channel transducer with four fixed heads,

capable of 100% volumetric coverage. Ultrasonic inspection is capable

of detecting 1mm wide defects.

9

TURNING AND POLISHING

The turning line has a capacity of 1.031 inch to 4.25 inch incoming

diameter, and is capable of meeting ASTM A108 tolerances. The line

can accommodate bar lengths ranging from 14 to 25 feet. The line is

equipped with bar chamfering, facing, and etching capabilities. The

straightener/polisher is capable of attaining greater than 25Ra surface

finish. The turning line is equipped with an Eddy Current tester for

surface inspection.

STRAIGHTENING

The bar finishing facility has a Bronx Nine Roll straightener and a #5

Medart Two Roll straightener. The units are capable of meeting both

standard and special straightness tolerances as listed in ASTM A29.

MULT CUT-TO-LENGTH SAWING

Cut-to-length sawing is accomplished with two Nishijimax Precision

Carbide Rotary Saws, with a capacity of 1.00 to 5.9 inch rounds. The

saws can produce cut lengths from 0.5 to 118 inches, with a standard

length tolerance of +/- 0.010” or 0.25 mm.

A Hem High Speed Double Column band saw line is also available. It has

a capacity of 4 to 25 inch rounds as well as being able to cut bundles.

Cut lengths are available from 5 to 24 feet, with a tolerance of -0/+0.25

inches.

10

NOTES

11

MAJOR STEEL GROUPS

Carbon Steel

Carbon steel usually contains up to 1.65% manganese, and contains no

other added elements to provide any specific alloying effects, except for

deoxidation or grain size control. Carbon steels are often classified

according to carbon concentration, i.e. low, medium, and high carbon

steels. The term ‘plain carbon steel’ is often used to describe steels

which only contain residual concentrations of impurities other than

carbon and manganese.

The greatest quantity of steel produced falls into the low-carbon

classification, and is typically less than 0.25% carbon. Low-carbon steels

are typically unresponsive to heat treatments intended to form

martensite and strengthening is usually accomplished through cold

working. Low-carbon steels are relatively soft and weak but have

excellent ductility and toughness.

Medium-carbon steels have carbon concentrations typically between

0.25% and 0.60%, and may be heat treated by austenitizing, quenching,

and tempering to improve their mechanical properties. Mediumcarbon steels are stronger than low-carbon steels, but with a reduction

in ductility and toughness. High-carbon steels have carbon

concentrations typically between 0.60% and 1.4%, and are the hardest

and strongest of the carbon steels, but with the least amount of

ductility.

Microalloy Steel

Microalloy steels, or High Strength Low Alloy (HSLA) steels, are a group

of low-carbon steels which contain a small but deliberate addition of

one or more alloying elements such as: vanadium, columbium, and

titanium. These steels have increased strength, combined with good

ductility in the hot rolled condition. These properties are achieved by a

combination of fine grain size and precipitation of finely dispersed

particles throughout the steel’s microstructure. Some HSLA steels have

improved atmospheric corrosion.

Alloy Steel

Steel containing significant quantities of one or more alloying elements

(other than carbon and the commonly accepted amounts of

manganese, and silicon) added to make changes in mechanical or

physical properties. Common alloying elements include nickel,

chromium, and molybdenum, among others.

12

AISI-SAE GRADE DESIGNATIONS

The most widely used system for designating carbon and alloy steels

was developed by the American Iron and Steel Institute (AISI) and the

Society of Automotive Engineers (SAE). In this system, a particular

designation implies the same limits and ranges of chemical composition

for both an AISI steel and the corresponding SAE steel. Any differences

between AISI and SAE grade designations or limits of chemical

composition are unintentional. The fact that a particular steel grade is

listed by AISI or SAE implies only that it has been produced in

appreciable quantity. It does not imply that other grades are

unavailable, nor does it imply that any particular steel producer makes

all of the listed grades. All compositions are expressed as weight

percents. The SAE designations are published in the annual SAE

handbook under various SAE standards. These standards are comprised

entirely of listings of SAE designations and the limits and ranges of

chemical composition defined by these designations.

UNS DESIGNATIONS

The Unified Numbering System (UNS) has been developed by the AISI,

SAE, and several other technical societies, trade associations, and

United States government agencies. A UNS number, which is a

designation of a chemical composition and not a specification, is

assigned to each chemical composition of a metallic alloy. Existing

systems of designations, including the AISI-SAE system for steels, have

been incorporated into the UNS designations.

The UNS designation of a metallic alloy consists of a letter and five

numerals. The letters indicate the broad class of alloys, and the

numerals define specific alloys and modifications within each class. For

practical purposes, carbon and alloy steel bars begin with the letters G

or H, the latter describing H-band steels. The first four numerals usually

describe the AISI-SAE steel grade designation. The last numeral is

typically a zero, unless the steel is modified as follows: a 1 in the last

digit signifies boron; a 4 in the last digit signifies lead; a 6 in the last digit

indicates Electric Furnace practice with reduced levels of phosphorus

and sulfur. The Unified Numbering System is described in greater detail

in the latest editions of SAE J1086 and ASTM E 527. The grades in this

13

manual will be described with the standard AISI-SAE designation

instead of the UNS designation.

Certain elements are present in small quantities in most steels. They

are not intentionally added, but exist in the steel due to the raw

materials used during production. These elements are considered

residual or incidental as long as they do not exceed specified maximum

limits. The common residual elements of concern are Cu, Ni, Cr, and

Mo, with common accepted maximum limits of: 0.35% Cu, 0.25% Ni,

0.20% Cr, and 0.06% Mo according to SAE and ASTM standards. All

standard grades listed are subject to these residual maximum limits

unless otherwise noted. Any differences in the maximum residual limits

must be agreed upon by purchaser and supplier.

14

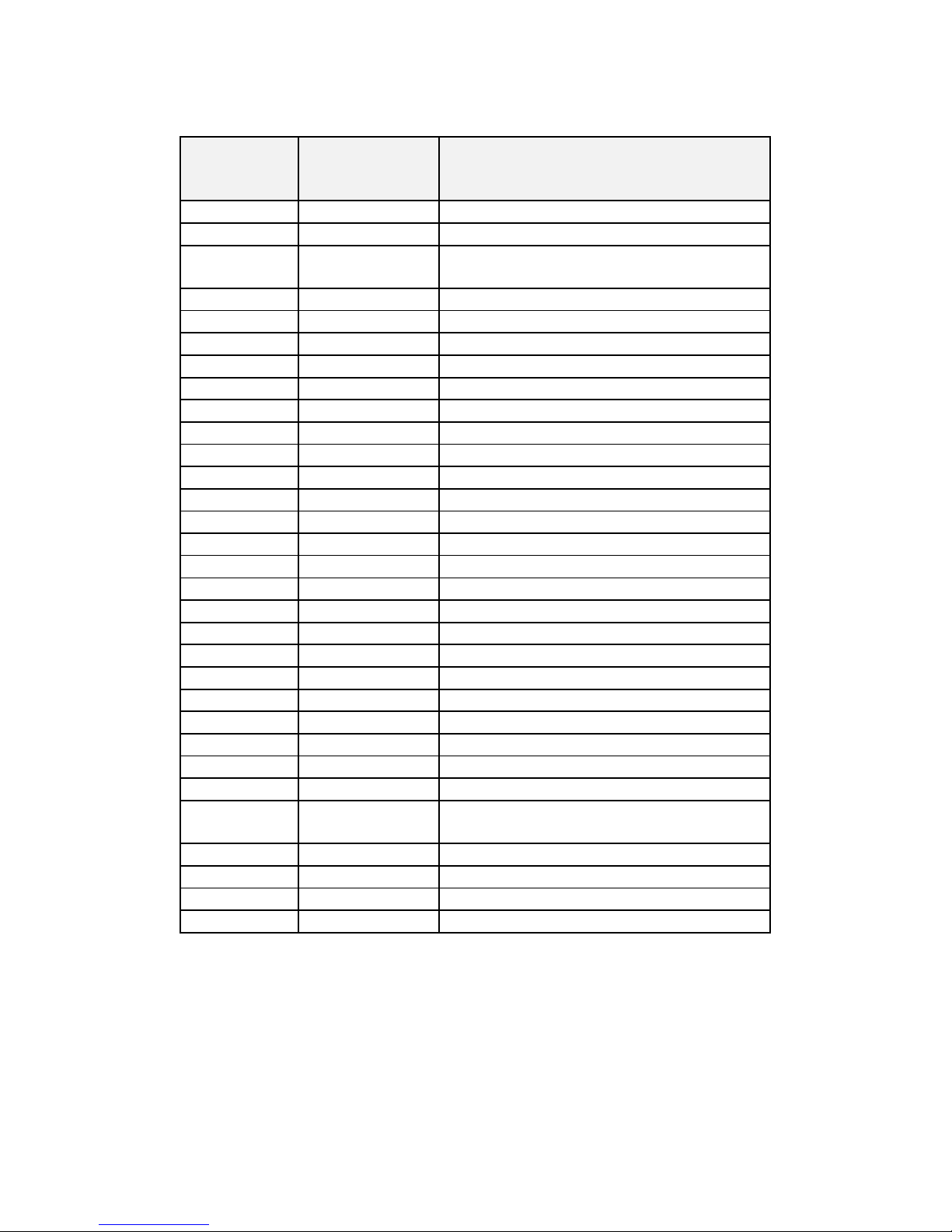

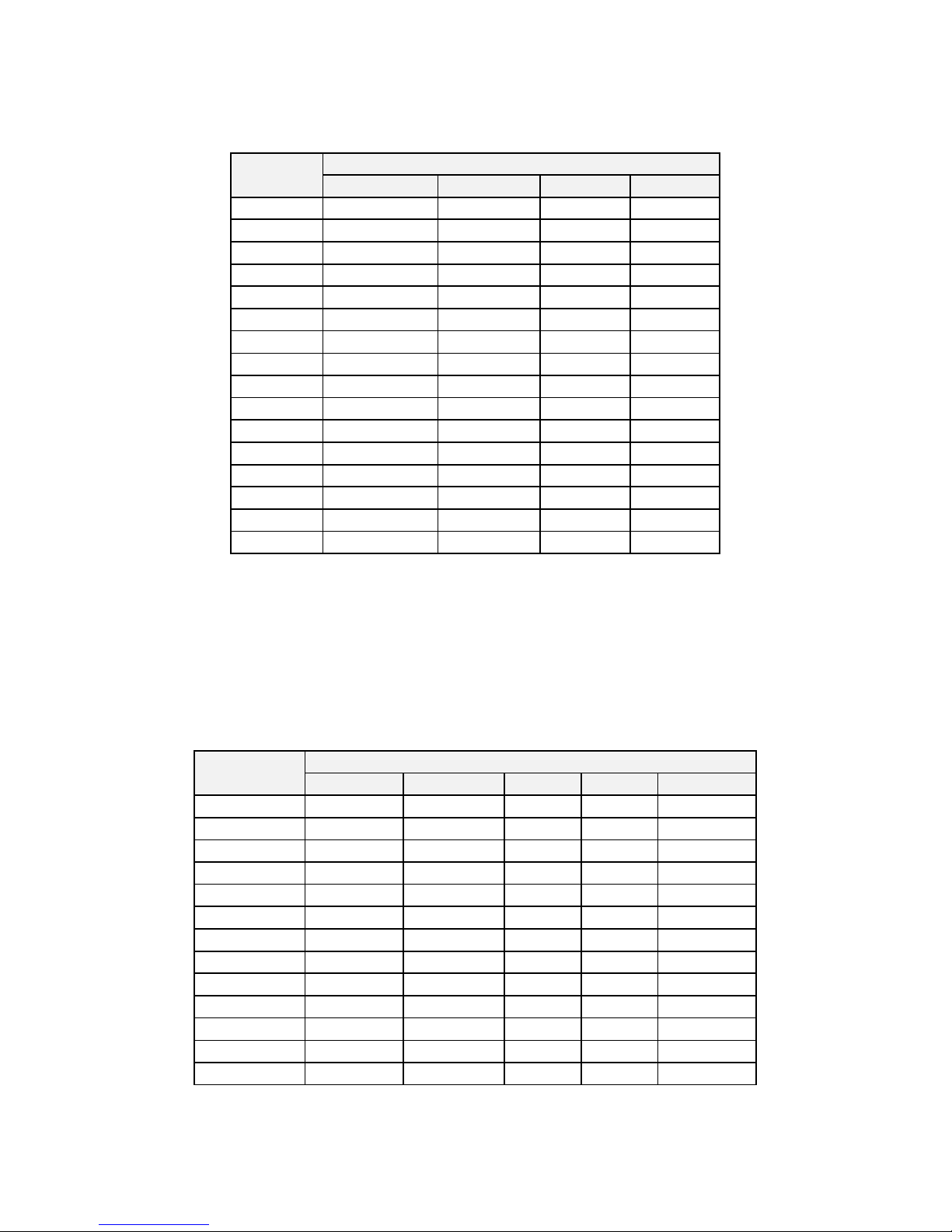

AISI-SAE GRADE SERIES OVERVIEW FOR CARBON & ALLOY STEELS

Grade

Series

Designation

Principal

Identifying

Elements

Nominal Weight Percentage of

Indentifying Elements

10xx

Mn

Mn (0.45, 0.65, 0.75, 0.85) – S (0.050 Max)

11xx

Mn-S

Mn (0.85, 1.15, 1.50) – S (Over 0.050)

12xx

Mn-P-S

Mn (0.85, 0.93, 1.00) – P (0.065, 0.095) –

S (0.20, 0.29, 0.31)

13xx

Mn

Mn (1.75)

15xx

Mn

Mn (0.90, 1.00, 1.15, 1.25,1.50)

23xx

Ni

Ni (3.50)

25xx

Ni

Ni (5.00)

31xx

Ni-Cr

Ni (1.25) – Cr (0.65, 0.80)

32xx

Ni-Cr

Ni (1.75) – Cr (1.07)

33xx

Ni-Cr

Ni (3.50) – Cr (1.50, 1.57)

34xx

Ni-Cr

Ni (3.00) – Cr (0.77)

40xx

Mo/Mo-S

Mo (0.20,0.25) or Mo (0.25) – S (0.040)

41xx

Cr-Mo

Cr (0.50, 0.80, 0.95) – Mo (0.12, 0.20, 0.30)

43xx

Ni-Cr-Mo

Ni (1.85) – Cr (0.50, 0.80) – Mo (0.25)

44xx

Mo

Mo (0.50)

46xx

Ni-Mo

Ni (0.85, 1.85) – Mo (0.20, 0.25)

47xx

Ni-Cr-Mo

Ni (1.05) – Cr (0.45) – Mo (0.20, 0.35)

48xx

Ni-Mo

Ni (3.50) – Mo (0.25)

50xx(x)

Cr

Cr (0.30, 0.50)

51xx(x)

Cr

Cr (0.80, 0.90, 1.00)

52xx(x)

Cr

Cr (1.45)

61xx

Cr-V

Cr (0.60, 0.95) – V (0.15)

81xx

Ni-Cr-Mo

Ni (0.30) – Cr (0.40) – Mo (0.12)

86xx

Ni-Cr-Mo

Ni (0.55) – Cr (0.50) – Mo (0.20)

87xx

Ni-Cr-Mo

Ni (0.55) – Cr (0.50) – Mo (0.25)

88xx

Ni-Cr-Mo

Ni (0.55) – Cr (0.50) – Mo (0.35)

92xx

Si/Si-Cr

Si (2.00) or Si (1.40) – Cr (0.70) or

Si (1.00) – Cr(0.55)

93xx

Ni-Cr-Mo

Ni (3.25) – Cr (1.25) – Mo (0.12)

94xx

Ni-Cr-Mo

Ni (0.45) – Cr (0.40) – Mo (0.12)

97xx

Ni-Cr-Mo

Ni (0.55) – Cr (0.20) – Mo (0.20)

98xx

Ni-Cr-Mo

Ni (1.00) – Cr (0.80) – Mo (0.25)

Note: xx(x) in the last two (or three) digits indicates that the carbon content, in hundredths of a

percent, is to be inserted. (Carbon and Alloy Steels, ASM International, 1996, pg 14)

15

STANDARD CARBON STEELS

ASTM A 576 – 90b (Reapproved 2006)

Steel Grade

Chemical Composition Limits, Percent

A,B,C

C

Mn

P max

S max 1008

0.10 max

0.30/0.50

0.040

0.050

1010

0.08/0.13

0.30/0.60

0.040

0.050

1012

0.10/0.15

0.30/0.60

0.040

0.050

1015

0.13/0.18

0.30/0.60

0.040

0.050

1016

0.13/0.18

0.60/0.90

0.040

0.050

1017

0.15/0.20

0.30/0.60

0.040

0.050

1018

0.15/0.20

0.60/0.90

0.040

0.050

1019

0.15/0.20

0.70/1.00

0.040

0.050

1020

0.18/0.23

0.30/0.60

0.040

0.050

1021

0.18/0.23

0.60/0.90

0.040

0.050

1022

0.18/0.23

0.70/1.00

0.040

0.050

1023

0.20/0.25

0.30/0.60

0.040

0.050

1025

0.22/0.28

0.30/0.60

0.040

0.050

1026

0.22/0.28

0.60/0.90

0.040

0.050

1029

0.25/0.31

0.60/0.90

0.040

0.050

1030

0.28/0.34

0.60/0.90

0.040

0.050

1035

0.32/0.38

0.60/0.90

0.040

0.050

1037

0.32/0.38

0.70/1.00

0.040

0.050

1038

0.35/0.42

0.60/0.90

0.040

0.050

1039

0.37/0.44

0.70/1.00

0.040

0.050

1040

0.37/0.44

0.60/0.90

0.040

0.050

1042

0.40/0.47

0.60/0.90

0.040

0.050

1043

0.40/0.47

0.70/1.00

0.040

0.050

1044

0.43/0.50

0.30/0.60

0.040

0.050

1045

0.43/0.50

0.60/0.90

0.040

0.050

1046

0.43/0.50

0.70/1.00

0.040

0.050

1049

0.46/0.53

0.60/0.90

0.040

0.050

1050

0.48/0.55

0.60/0.90

0.040

0.050

1053

0.48/0.55

0.70/1.00

0.040

0.050

1055

0.50/0.60

0.60/0.90

0.040

0.050

1060

0.55/0.65

0.60/0.90

0.040

0.050

1070

0.65/0.75

0.60/0.90

0.040

0.050

1078

0.72/0.85

0.30/0.60

0.040

0.050

1080

0.75/0.88

0.60/0.90

0.040

0.050

1084

0.80/0.93

0.60/0.90

0.040

0.050

1090

0.85/0.98

0.60/0.90

0.040

0.050

1095

0.90/1.03

0.30/0.50

0.040

0.050

A

When Si is required, the following ranges are commonly specified: 0.10% max,

0.10/0.20%, 0.15/0.35%, or 0.20/0.40%. The range of 0.15/0.35% is most common.

B

Copper can be specified when required as 0.20% minimum.

C

The elements Bi, Ca, Se, or Te may be added as agreed between purchaser and supplier.

16

RESULFURIZED CARBON STEELS

ASTM A 576 – 90b (Reapproved 2006)

Steel

Grade

Chemical Composition Limits, Percent

A,B

C

Mn

P Max

S

1109

0.08/0.13

0.60/0.90

0.040

0.08/0.13

1110

0.08/0.13

0.30/0.60

0.040

0.08/0.13

1116

0.14/0.20

1.10/1.40

0.040

0.16/0.23

1117

0.14/0.20

1.00/1.30

0.040

0.08/0.13

1118

0.14/0.20

1.30/1.60

0.040

0.08/0.13

1119

0.14/0.20

1.00/1.30

0.040

0.24/0.33

1132

0.27/0.34

1.35/1.65

0.040

0.08/0.13

1137

0.32/0.39

1.35/1.65

0.040

0.08/0.13

1139

0.35/0.43

1.35/1.65

0.040

0.13/0.20

1140

0.37/0.44

0.70/1.00

0.040

0.08/0.13

1141

0.37/0.45

1.35/1.65

0.040

0.08/0.13

1144

0.40/0.48

1.35/1.65

0.040

0.24/0.33

1145

0.42/0.49

0.70/1.00

0.04

0.04/0.07

1146

0.42/0.49

0.70/1.00

0.040

0.08/0.13

1151

0.48/0.55

0.70/1.00

0.040

0.08/0.13

A

When Si is required, the following ranges are commonly specified: 0.10% max, 0.10/0.20%,

0.15/0.35%, or 0.20/0.40%. The range of 0.15/0.35% is most common.

B

The elements Bi, Ca, Se, or Te may be added as agreed between purchaser and supplier.

REPHOSPHORIZED AND RESULFURIZED CARBON STEELS

ASTM A 576 – 90b (Reapproved 2006)

Steel

Grade

Chemical Composition Limits, Percent

A,B,C

C

Mn P S

Pb

1211

0.13 max

0.60/0.90

0.07/0.12

0.10/0.15

...

1212

0.13 max

0.70/1.00

0.07/0.12

0.16/0.23

1213

0.13 max

0.70/1.00

0.07/0.12

0.24/0.33

...

1215

0.09 max

0.75/1.05

0.04/0.09

0.26/0.35

...

12L14

0.15 max

0.85/1.15

0.04/0.09

0.26/0.35

0.15/0.35

A

When Pb is required as an added element to a standard steel, a range of 0.15/0.35% is specified.

Such a steel is identified by inserting the letter “L” between the second and third numerals of the

grade designation.

B

The elements Bi, Calcium, Se, or Te may be added as agreed between purchaser and supplier.

C

It is not common practice to produce these steels to specified limits for Si because of the adverse

effect on machinability.

Note: SDI does not produce leaded steels. 12L14 is provided for information only.

17

HIGH MANGANESE CARBON STEELS

ASTM A 576 – 90b (Reapproved 2006)

Steel

Grade

Chemical Composition Limits, Percent

A,B,C,D

C

Mn

P max

S max

1513

0.10/0.16

1.10/1.40

0.040

0.050

1518

0.15/0.21

1.10/1.40

0.040

0.050

1522

0.18/0.24

1.10/1.40

0.040

0.050

1524

0.19/0.25

1.35/1.65

0.040

0.050

1525

0.23/0.29

0.80/1.10

0.040

0.050

1526

0.22/0.29

1.10/1.40

0.040

0.050

1527

0.22/0.29

1.20/1.50

0.040

0.050

1536

0.30/0.37

1.20/1.50

0.040

0.050

1541

0.36/0.44

1.35/1.65

0.040

0.050

1547

0.43/0.51

1.35/1.65

0.040

0.050

1548

0.44/0.52

1.10/1.40

0.040

0.050

1551

0.45/0.56

0.85/1.15

0.040

0.050

1552

0.47/0.55

1.20/1.50

0.040

0.050

1561

0.55/0.65

0.75/1.05

0.040

0.050

1566

0.60/0.71

0.85/1.15

0.040

0.050

1572

0.65/0.76

1.00/1.30

0.040

0.050

A When Si is required, the following ranges are commonly specified: 0.10% max,

0.10/0.20%, 0.15/0.35%, or 0.20/0.40%. The range of 0.15/0.35% is most common.

B

Copper can be specified when required as 0.20% minimum.

C

When B is specified, the typical range is 0.0005 to 0.003%.

D

The elements Bi, Ca, Se, or Te may be added as agreed between purchaser and supplier.

CARBON AND CARBON BORON STEELS SUBJECT TO END

QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 304 – 05)

Steel

Grade

Chemical Composition Limits, Percent

C

Mn

P max

S max

Si

1038 H

0.34/0.43

0.50/1.00

0.040

0.050

0.15/0.30

1045 H

0.42/0.51

0.50/1.00

0.040

0.050

0.15/0.30

1522 H

0.17/0.25

1.00/1.50

0.040

0.050

0.15/0.30

1524 H

0.18/0.26

1.25/1.75

0.040

0.050

0.15/0.30

1526 H

0.21/0.30

1.00/1.50

0.040

0.050

0.15/0.30

1541 H

0.35/0.45

1.25/1.75

0.040

0.050

0.15/0.30

15B21 HA

0.17/0.24

0.70/1.20

0.040

0.050

0.15/0.30

15B30 H

A

0.26/0.34

0.70/1.20

0.040

0.050

0.15/0.30

15B35 H

A

0.31/0.39

0.70/1.20

0.040

0.050

0.15/0.30

15B37 H

A

0.30/0.39

1.00/1.50

0.040

0.050

0.15/0.30

15B41 H

A

0.35/0.45

1.25/1.75

0.040

0.050

0.15/0.30

15B48 H

A

0.43/0.53

1.00/1.50

0.040

0.050

0.15/0.30

15B62 H

A

0.54/0.67

1.00/1.50

0.040

0.050

0.40/0.60

A

Boron treated, with typical range 0.0005 to 0.0030%.

18

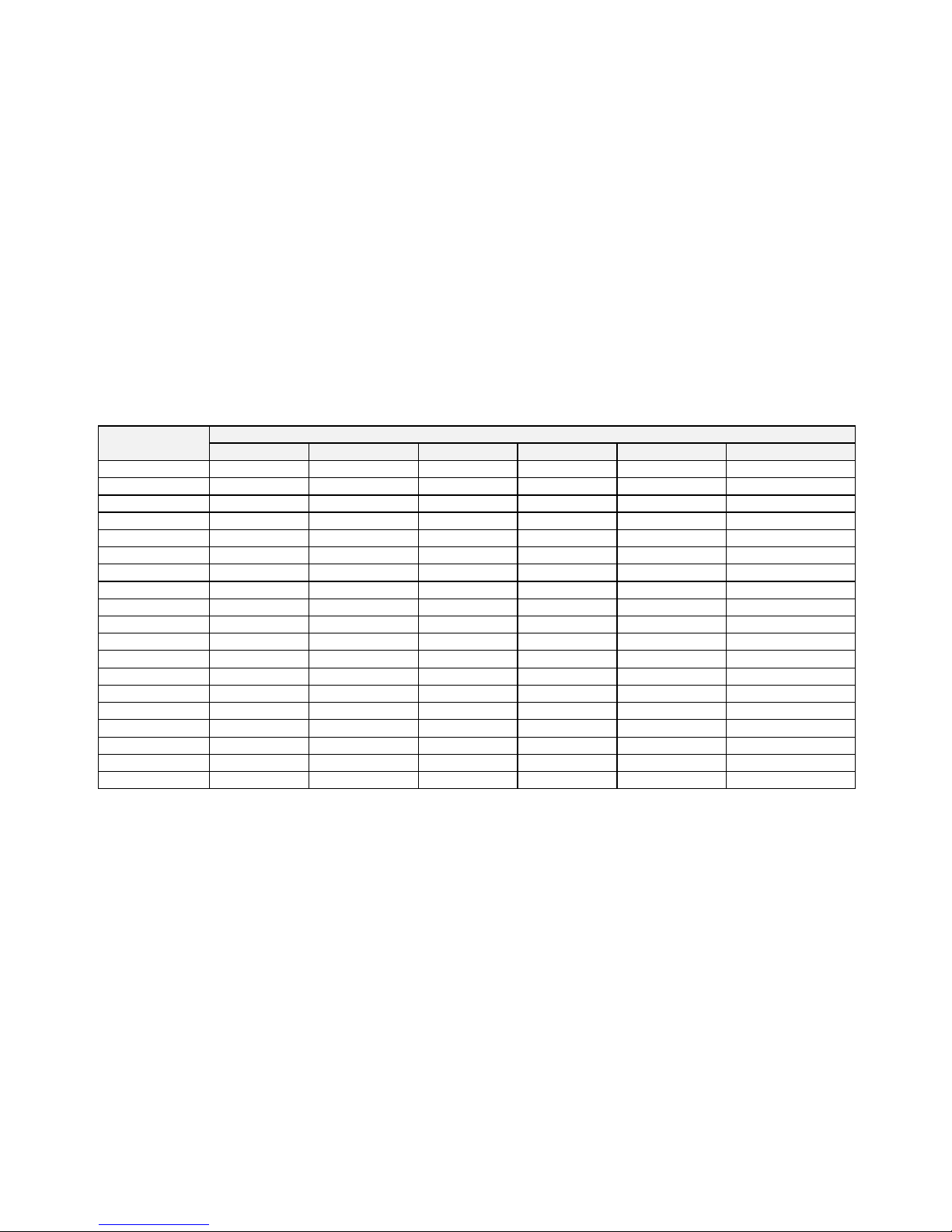

CHEMCAL RANGES & LIMITS OF HOT ROLLED CARBON STEELS

ASTM A 576 – 90b (Reapproved 2006)

Element

A

When Maximum of

Specified Element is:

Chemical

Range

Conventional

Lowest Maximum

Carbon –

(When Mn

does NOT

exceed 1.10%)

...

...

0.06

Thru 0.12

...

...

Over 0.12 thru 0.25

0.05

...

Over 0.25 thru 0.40

0.06

...

Over 0.40 thru 0.55

0.07

...

Over 0.55 thru 0.80

0.10

...

Over 0.80

0.13

...

Carbon –

(When Mn

DOES exceed

1.10%)

Over 0.12 thru 0.25

0.06

...

Over 0.25 thru 0.40

0.07

...

Over 0.40 thru 0.55

0.08

...

Over 0.55 thru 0.80

0.11

...

Over 0.80

0.14

...

Manganese

...

...

0.35

Thru 0.40

0.15

...

Over 0.40 thru 0.50

0.20

...

Over 0.50 thru 1.65

0.30

...

Phosphorus

...

...

0.03

Thru 0.04

...

...

Over 0.04 thru 0.08

0.03

...

Over 0.08 thru 0.13

0.05

...

Sulfur

Thru 0.05

...

0.05

Over 0.05 thru 0.09

0.03

...

Over 0.09 thru 0.15

0.05

...

Over 0.15 thru 0.23

0.07

...

Over 0.23 thru 0.50

0.09

...

Silicon

B

Thru 0.10

...

0.10

Over 0.10 thru 0.15

0.08

...

Over 0.15 thru 0.20

0.10

...

Over 0.20 thru 0.30

0.15

...

Over 0.30 thru 0.60

0.20

...

Copper

When Cu is required as an added element, 0.20% minimum is

generally specified

LeadC

Lead is reported only as a range of 0.15 to 0.35% since it is

usually added to the mould or ladle stream as the steel is

poured

Boron

Boron treated steels are typically produced to a range of

0.0005 to 0.003%

A

The specification for the elements Bi, Ca, Se, and Te will be agreed upon between purchaser and

supplier.

B

It is not common practice to produce a Rephosphorized and Resulfurized carbon steel to specified

limits for Si because of its adverse effect on machinability.

C

A heat analysis for Pb is not determinable, since Pb is added to the ladle stream.

19

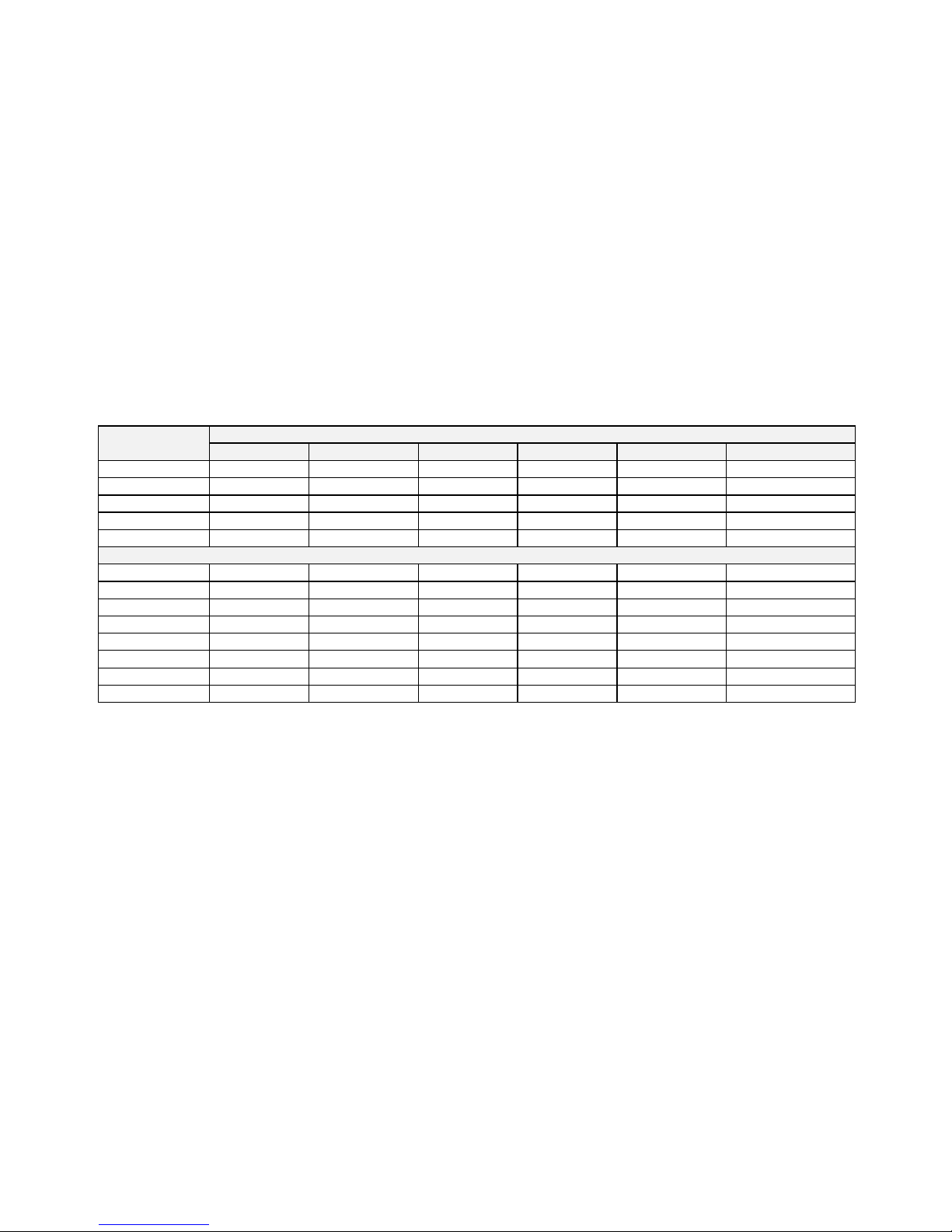

PERMISSIBLE VARIATIONS FOR PRODUCT ANALYSIS OF CARBON STEEL

ASTM A 29/A 29M – 05

Element

Limit, or Maximum of

Specified Range (%)

Variance Over the

Maximum Limit or Under

the Minimum Limit (%)

CarbonA

Thru 0.25

0.02

Over 0.25 thru 0.55

0.03

Over 0.55

0.04

Manganese

Thru 0.90

0.03

Over 0.90 thru 1.65

0.06

Phosphorus

A,B

Basic steels

0.008 over

Acid Bessemer steel

0.01

Sulfur

A,B

0.008

Silicon

Thru 0.35

0.02

Over 0.35 thru 0.60

0.05

Copper

Under minimum only for Cu

bearing steels

0.02

LeadC

0.15 thru 0.35

0.03

A Rimmed and capped steels are not subject to rejection on product analysis unless misapplication

is clearly indicated.

B Resulfurized or Rephosphorized steels are not subject to rejection on product analysis for these

elements unless misapplication is clearly indicated.

C Product analysis tolerance for lead applies both over and under to a specified range of 0.15/0.35 %.

20

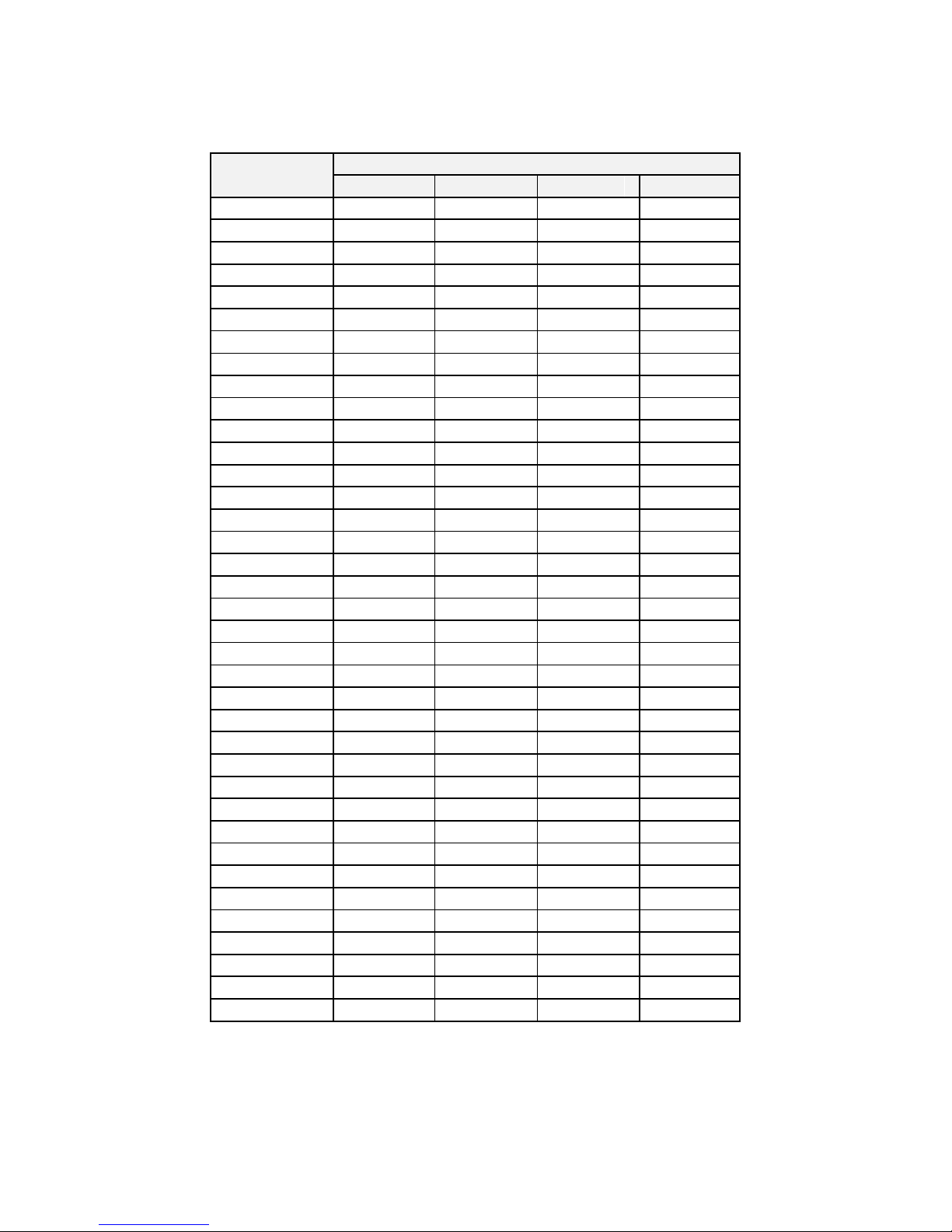

STANDARD ALLOY STEELS

(ASTM A 322 – 07)

Steel Grade

C

Chemical Composition Ranges and Limits, Percent

A,B

C

Mn

Ni

Cr

Mo

Other

1330

0.28/0.33

1.60/1.90

--

--

-- 1335

0.33/0.38

1.60/1.90

--

--

-- 1340

0.38/0.43

1.60/1.90

--

--

-- 1345

0.43/0.48

1.60/1.90

--

--

-- 4023

0.20/0.25

0.70/0.90

--

--

0.20/0.30

4024

0.20/0.25

0.70/0.90

--

--

0.20/0.30

S 0.035/0.050

4027

0.25/0.30

0.70/0.90

--

--

0.20/0.30

4028

0.25/0.30

0.70/0.90

--

--

0.20/0.30

S 0.035/0.050

4037

0.35/0.40

0.70/0.90

--

--

0.20/0.30

4047

0.45/0.50

0.70/0.90

--

--

0.20/0.30

4118

0.18/0.23

0.70/0.90

--

0.40/0.60

0.08/0.15

4120

0.18/0.23

0.90/1.20

--

0.40/0.60

0.13/0.20

4121

0.18/0.23

0.75/1.00

--

0.45/0.65

0.20/0.30

4130

0.28/0.33

0.40/0.60

--

0.80/1.10

0.15/0.25

4137

0.35/0.40

0.70/0.90

--

0.80/1.10

0.15/0.25

4140

0.38/0.43

0.75/1.00

--

0.80/1.10

0.15/0.25

4142

0.40/0.45

0.75/1.00

--

0.80/1.10

0.15/0.25

4145

0.43/0.48

0.75/1.00

--

0.80/1.10

0.15/0.25

4147

0.45/0.50

0.75/1.00

--

0.80/1.10

0.15/0.25

21

STANDARD ALLOY STEELS

(ASTM A 322 – 07)

Steel Grade

C

Chemical Composition Ranges and Limits, Percent

A,B

C

Mn

Ni

Cr

Mo

Other

4150

0.48/0.53

0.75/1.00

--

0.80/1.10

0.15/0.25

4161

0.56/0.64

0.75/1.00

--

0.70/0.90

0.25/0.35

4320

0.17/0.22

0.45/0.65

1.65/2.00

0.40/0.60

0.20/0.30

4340

0.38/0.43

0.60/0.80

1.65/2.00

0.70/0.90

0.20/0.30

E4340D

0.38/0.43

0.65/0.85

1.65/2.00

0.70/0.90

0.20/0.30

4615

0.13/0.18

0.45/0.65

1.65/2.00

--

0.20/0.30

4620

0.17/0.22

0.45/0.65

1.65/2.00

--

0.20/0.30

4621

0.18/0.23

0.70/0.90

1.65/2.00

--

0.20/0.30

4626

0.24/0.29

0.45/0.65

0.70/1.00

--

0.15/0.25

4715

0.13/0.18

0.70/0.90

0.70/1.00

0.45/0.65

0.45/0.60

4720

0.17/0.22

0.50/0.70

0.90/1.20

0.35/0.55

0.15/0.25

4815

0.13/0.18

0.40/0.60

3.25/3.75

...

0.20/0.30

4817

0.13/0.20

0.40/0.60

3.25/3.75

...

0.20/0.30

4820

0.18/0.23

0.50/0.70

3.25/3.75

...

0.20/0.30

5117

0.15/0.20

0.70/0.90

...

0.70/0.90

...

5120

0.17/0.22

0.70/0.90

...

0.70/0.90

...

5130

0.28/0.33

0.70/0.90

...

0.80/1.10

... 5132

0.30/0.35

0.60/0.80

...

0.75/1.00

... 5135

0.33/0.38

0.60/0.80

...

0.80/1.05

...

22

STANDARD ALLOY STEELS

(ASTM A 322 – 07)

Steel Grade

C

Chemical Composition Ranges and Limits, Percent

A,B

C

Mn

Ni

Cr

Mo

Other

5140

0.38/0.43

0.70/0.90

...

0.70/0.90

... 5150

0.48/0.53

0.70/0.90

...

0.70/0.90

... 5155

0.51/0.59

0.70/0.90

0.70/0.90

... 5160

0.56/0.64

0.75/1.00

...

0.70/0.90

... E51100D

0.98/1.10

0.25/0.45

...

0.90/1.15

... E52100

D

0.98/1.10

0.25/0.45

...

1.30/1.60

... 6118

0.16/0.21

0.50/0.70

...

0.50/0.70

...

V 0.10/0.15

6150

0.48/0.53

0.70/0.90

...

0.80/1.10

...

V 0.15 min

8615

0.13/0.18

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8617

0.15/0.20

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8620

0.18/0.23

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8622

0.20/0.25

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8625

0.23/0.28

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8627

0.25/0.30

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8630

0.28/0.33

0.70/0.90

0.40/0.70

0.40/0.60

0.15/0.25

8637

0.35/0.40

0.75/1.00

0.40/0.70

0.40/0.60

0.15/0.25

8640

0.38/0.43

0.75/1.00

0.40/0.70

0.40/0.60

0.15/0.25

8642

0.40/0.45

0.75/1.00

0.40/0.70

0.40/0.60

0.15/0.25

8645

0.43/0.48

0.75/1.00

0.40/0.70

0.40/0.60

0.15/0.25

23

STANDARD ALLOY STEELS

(ASTM A 322 – 07)

Steel Grade

C

Chemical Composition Ranges and Limits, Percent

A,B

C

Mn

Ni

Cr

Mo

Other

8655

0.51/0.59

0.75/1.00

0.40/0.70

0.40/0.60

0.15/0.25

8720

0.18/0.23

0.70/0.90

0.40/0.70

0.40/0.60

0.20/0.30

8822

0.20/0.25

0.75/1.00

0.40/0.70

0.40/0.60

0.30/0.40

9259

0.56/0.64

0.75/1.00

...

0.45/0.65

...

Si 0.70/1.10

9260

0.56/0.64

0.75/1.00

...

...

...

Si 1.80/2.20

Standard Boron Steels

E

50B44

0.43/0.48

0.75/1.00

...

0.20/0.60

... 50B46

0.44/0.49

0.75/1.00

...

0.20/0.35

... 50B50

0.48/0.53

0.75/1.00

...

0.40/0.60

... 50B60

0.56/0.64

0.75/1.00

...

0.40/0.60

... 51B60

0.56/0.64

0.75/1.00

...

0.70/0.90

... 81B45

0.43/0.48

0.75/1.00

0.20/0.40

0.35/0.55

0.08/0.15

94B17

0.15/0.20

0.75/1.00

0.30/0.60

0.30/0.50

0.08/0.15

94B30

0.28/0.33

0.75/1.00

0.30/0.60

0.30/0.50

0.08/0.15

A

Unless noted, all grades have a Si range of 0.15 to 0.35%. Silicon may be specified to 0.10% maximum, which generally relates to severely cold-formed parts.

B

The maximum limits for P and S are 0.035% and 0.040% respectively, unless otherwise agreed upon between purchaser and supplier.

C

Grade designations correspond to the respective AISI and SAE designations. Grade compositions correspond to the respective AISI compositions.

D

The max S and P for Electric Furnace Quality Steels (grades preceded by an ‘E’) is 0.025 max.

E

These steels can be expected to contain 0.0005 to 0.003% B. If the usual Ti additive is not permitted, these steels can be expected to contain up to 0.005% B.

24

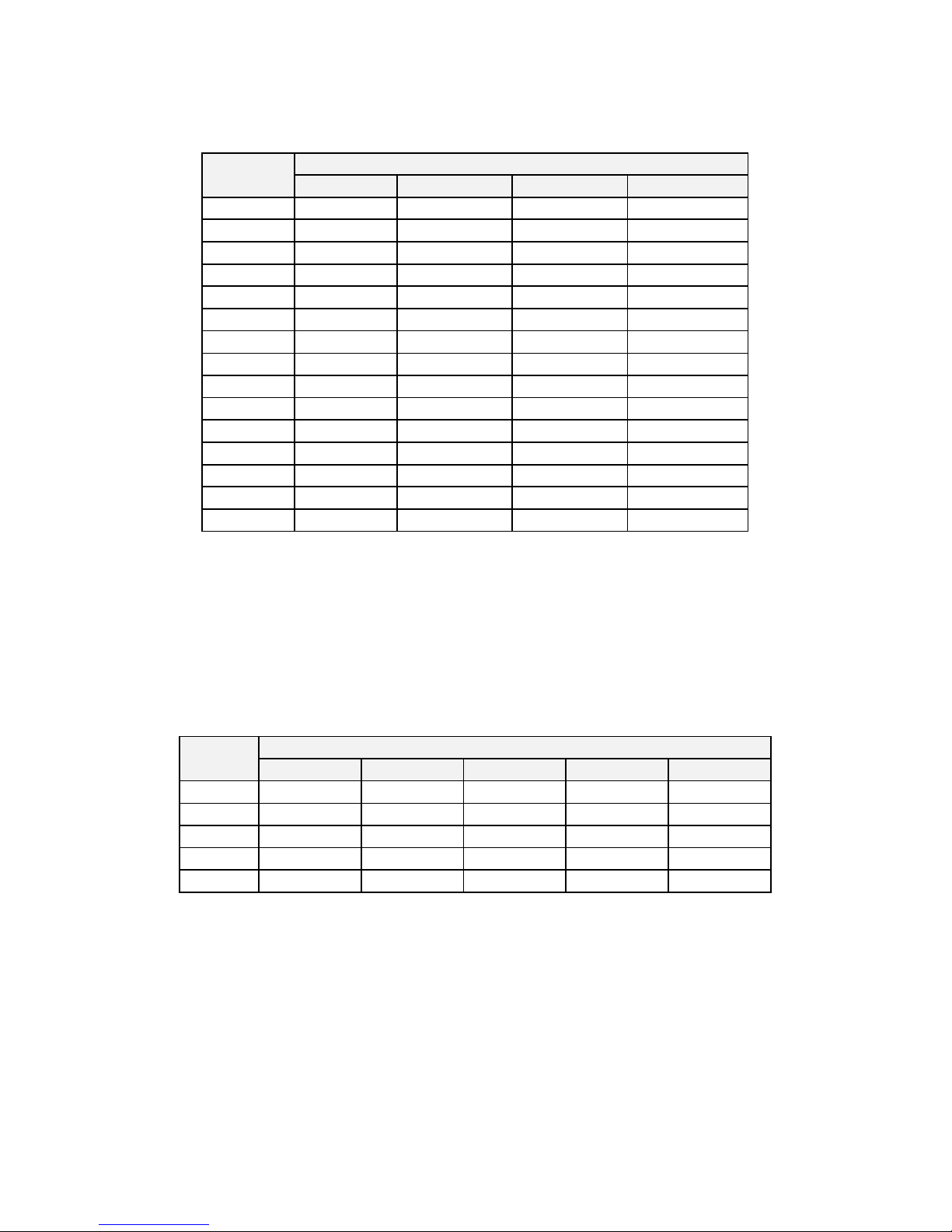

ALLOY STEEL GRADES SUBJECT TO END QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 304 – 05)

Steel Grade

Chemical Composition Ranges and Limits, PercentA

C

Mn

Si

Ni

Cr

Mo

1330 H

0.27/0.33

1.45/2.05

0.15/0.35

...

...

...

1335 H

0.32/0.38

1.45/2.05

0.15/0.35

...

...

...

1340 H

0.37/0.44

1.45/2.05

0.15/0.35

...

...

...

1345 H

0.42/0.49

1.45/2.05

0.15/0.35

...

...

...

4027 H

0.24/0.30

0.60/1.00

0.15/0.35

...

...

0.20/0.30

4028 H

B

0.24/0.30

0.60/1.00

0.15/0.35

...

...

0.20/0.30

4032 H

0.29/0.35

0.60/1.00

0.15/0.35

...

...

0.20/0.30

4037 H

0.34/0.41

0.60/1.00

0.15/0.35

...

...

0.20/0.30

4042 H

0.39/0.46

0.60/1.00

0.15/0.35

...

...

0.20/0.30

4047 H

0.44/0.51

0.60/1.00

0.15/0.35

...

...

0.20/0.30

4118 H

0.17/0.23

0.60/1.00

0.15/0.35

...

0.30/0.70

0.08/0.15

4130 H

0.27/0.33

0.30/0.70

0.15/0.35

...

0.75/1.20

0.15/0.25

4135 H

0.32/0.38

0.60/1.00

0.15/0.35

...

0.75/1.20

0.15/0.25

4137 H

0.34/0.41

0.60/1.00

0.15/0.35

...

0.75/1.20

0.15/0.25

4140 H

0.37/0.44

0.65/1.10

0.15/0.35

...

0.75/1.20

0.15/0.25

4142 H

0.39/0.46

0.65/1.10

0.15/0.35

...

0.75/1.20

0.15/0.25

4145 H

0.42/0.49

0.65/1.10

0.15/0.35

...

0.75/1.20

0.15/0.25

25

ALLOY STEEL GRADES SUBJECT TO END QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 304 – 05)

Steel Grade

Chemical Composition Ranges and Limits, PercentA

C

Mn

Si

Ni

Cr

Mo

4147 H

0.44/0.51

0.65/1.10

0.15/0.35

...

0.75/1.20

0.15/0.25

4150 H

0.47/0.54

0.65/1.10

0.15/0.35

...

0.75/1.20

0.15/0.25

4161 H

0.55/0.65

0.65/1.10

0.15/0.35

...

0.65/0.95

0.25/0.35

4320 H

0.17/0.23

0.40/0.70

0.15/0.35

1.55/2.00

0.35/0.65

0.20/0.30

4340 H

0.37/0.44

0.55/0.90

0.15/0.35

1.55/2.00

0.65/0.95

0.20/0.30

E4340 H

0.37/0.44

0.60/0.95

0.15/0.35

1.55/2.00

0.65/0.95

0.20/0.30

4419 H

0.17/0.23

0.35/0.75

0.15/0.35

...

...

0.45/0.60

4620 H

0.17/0.23

0.35/0.75

0.15/0.35

1.55/2.00

...

0.20/0.30

4621 H

0.17/0.23

0.60/1.00

0.15/0.35

1.55/2.00

...

0.20/0.30

4626 H

0.23/0.29

0.40/0.70

0.15/0.35

0.65/1.05

...

0.15/0.25

4718 H

0.15/0.21

0.60/0.95

0.15/0.35

0.85/1.25

0.30/0.60

0.30/0.40

4720 H

0.17/0.23

0.45/0.75

0.15/0.35

0.85/1.25

0.30/0.60

0.15/0.25

4815 H

0.12/0.18

0.30/0.70

0.15/0.35

3.20/3.80

...

0.20/0.30

4817 H

0.14/0.20

0.30/0.70

0.15/0.35

3.20/3.80

...

0.20/0.30

4820 H

0.17/0.23

0.40/0.80

0.15/0.35

3.20/3.80

...

0.20/0.30

50B40 H

C

0.37/0.44

0.65/1.10

0.15/0.35

...

0.30/0.70

...

50B44 H

C

0.42/0.49

0.65/1.10

0.15/0.35

...

0.30/0.70

...

26

ALLOY STEEL GRADES SUBJECT TO END QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 304 – 05)

Steel Grade

Chemical Composition Ranges and Limits, PercentA

C

Mn

Si

Ni

Cr

Mo

5046 H

0.43/0.50

0.65/1.10

0.15/0.35

...

0.13/0.43

...

50B46 HC

0.43/0.50

0.65/1.10

0.15/0.35

...

0.13/0.43

...

50B50 H

C

0.47/0.54

0.65/1.10

0.15/0.35

...

0.30/0.70

...

50B60 H

C

0.55/0.65

0.65/1.10

0.15/0.35

...

0.30/0.70

...

5120 H

0.17/0.23

0.60/1.00

0.15/0.35

...

0.60/1.00

...

5130 H

0.27/0.33

0.60/1.00

0.15/0.35

...

0.75/1.20

...

5132 H

0.29/0.35

0.50/0.90

0.15/0.35

...

0.65/1.10

...

5135 H

0.32/0.38

0.50/0.90

0.15/0.35

...

0.70/1.15

...

5140 H

0.37/0.44

0.60/1.00

0.15/0.35

...

0.60/1.00

...

5145 H

0.42/0.49

0.60/1.00

0.15/0.35

...

0.60/1.00

...

5147 H

0.45/0.52

0.60/1.05

0.15/0.35

...

0.80/1.25

...

5150 H

0.47/0.54

0.60/1.00

0.15/0.35

...

0.60/1.00

...

5155 H

0.50/0.60

0.60/1.00

0.15/0.35

...

0.60/1.00

...

5160 H

0.55/0.65

0.65/1.10

0.15/0.35

...

0.60/1.00

...

51B60 H

C

0.55/0.65

0.65/1.10

0.15/0.35

...

0.60/1.00

...

6118 H

D

0.15/0.21

0.40/0.80

0.15/0.35

...

0.40/0.80

...

6150 H

E

0.47/0.54

0.60/1.00

0.15/0.35

...

0.75/1.20

...

27

ALLOY STEEL GRADES SUBJECT TO END QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 304 – 05)

Steel Grade

Chemical Composition Ranges and Limits, PercentA

C

Mn

Si

Ni

Cr

Mo

81B45 H

C

0.42/0.49

0.70/1.05

0.15/0.35

0.15/0.45

0.30/0.60

0.08/0.15

8617 H

0.14/0.20

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8620 H

0.17/0.23

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8622 H

0.19/0.25

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8625 H

0.22/0.28

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8627 H

0.24/0.30

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8630 H

0.27/0.33

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

86B30 H

C

0.27/0.33

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8637 H

0.34/0.41

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8640 H

0.37/0.44

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8642 H

0.39/0.46

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8645 H

0.42/0.49

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

86B45 H

C

0.42/0.49

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8650 H

0.47/0.54

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8655 H

0.50/0.60

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8660 H

0.55/0.65

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.15/0.25

8720 H

0.17/0.23

0.60/0.95

0.15/0.35

0.35/0.75

0.35/0.65

0.20/0.30

28

ALLOY STEEL GRADES SUBJECT TO END QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 304 – 05)

Steel Grade

Chemical Composition Ranges and Limits, PercentA

C

Mn

Si

Ni

Cr

Mo

8740 H

0.37/0.44

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.20/0.30

8822 H

0.19/0.25

0.70/1.05

0.15/0.35

0.35/0.75

0.35/0.65

0.30/0.40

9260 H

0.55/0.65

0.65/1.10

1.70/2.20

...

...

...

9310 H

0.07/0.13

0.40/0.70

0.15/0.35

2.95/3.55

1.00/1.45

0.08/0.15

94B15 H

C

0.12/0.18

0.70/1.05

0.15/0.35

0.25/0.65

0.25/0.55

0.08/0.15

94B17 H

C

0.14/0.20

0.70/1.05

0.15/0.35

0.25/0.65

0.25/0.55

0.08/0.15

94B30 H

C

0.27/0.33

0.70/1.05

0.15/0.35

0.25/0.65

0.25/0.55

0.08/0.15

A P and S in open-hearth steel is 0.035% and 0.040% respectively, while the P and S in electric furnace steel is 0.025% max (Grade preceded by an ‘E’).

B S range is 0.035 to 0.050%.

C These steels can be expected to have a 0.0005% minimum B content.

D V range is 0.10 to 0.15%.

E Minimum V content is 0.15%.

29

STEEL GRADES SUBJECT TO RESTRICTED END QUENCH HARDENABILITY REQUIREMENTS

(ASTM A 914/A 914M – 92; Reapproved 2005)

Steel Grade

Chemical Composition Ranges and Limits, PercentA

C

Mn

Si

Ni

Cr

Mo

15B21 RH

B

0.17/0.22

0.80/1.10

0.15/0.35

...

...

...

15B35 RH

B

0.33/0.38

0.80/1.10

0.15/0.35

...

...

...

3310 RH

0.08/0.13

0.40/0.60

0.15/0.35

3.25/3.75

1.40/1.75

...

4027 RH

0.25/0.30

0.70/0.90

0.15/0.35

...

...

0.20/0.30

4118 RH

0.18/0.23

0.70/0.90

0.15/0.35

...

0.40/0.60

0.08/0.15

4120 RH

0.18/0.23

0.90/1.20

0.15/0.35

...

0.40/0.60

0.13/0.20

4130 RH

0.28/0.33

0.40/0.60

0.15/0.35

...

0.80/1.10

0.15/0.25

4140 RH

0.38/0.43

0.75/1.00

0.15/0.35

...

0.80/1.10

0.15/0.25

4145 RH

0.43/0.48

0.75/1.00

0.15/0.35

...

0.80/1.10

0.15/0.25

4161 RH

0.56/0.64

0.75/1.00

0.15/0.35

...

0.70/0.90

0.25/0.35

4320 RH

0.17/0.22

0.45/0.65

0.15/0.35

1.65/2.00

0.40/0.60

0.20/0.30

4620 RH

0.17/0.22

0.45/0.65

0.15/0.35

1.65/2.00

...

0.20/0.30

4820 RH

0.18/0.23

0.50/0.70

0.15/0.35

3.25/3.75

...

0.20/0.30

50B40 RH

B

0.38/0.43

0.75/1.00

0.15/0.35

...

0.40/0.60

...

5130 RH

0.28/0.33

0.70/0.90

0.15/0.35

...

0.80/1.10

...

5140 RH

0.38/0.43

0.70/0.90

0.15/0.35

...

0.70/0.90

...

5160 RH

0.56/0.64

0.75/1.00

0.15/0.35

...

0.70/0.90

...

Loading...

Loading...