Page 1

BSM-3

Installation Manual

ENGLISH

simrad-yachting.com

Page 2

Page 3

Preface

Disclaimer

As Navico is continuously improving this product, we retain the

right to make changes to the product at any time which may not be

reflected in this version of the manual. Please contact your nearest

distributor if you require any further assistance.

It is the owner’s sole responsibility to install and use the instrument

and transducers in a manner that will not cause accidents, personal

injury or property damage. The user of this product is solely

responsible for observing safe boating practices.

NAVICO HOLDING AS AND ITS SUBSIDIARIES, BRANCHES AND

AFFILIATES DISCLAIM ALL LIABILITY FOR ANY USE OF THIS PRODUCT

IN A WAY THAT MAY CAUSE ACCIDENTS, DAMAGE OR THAT MAY

VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals,

user guides and other information relating to the product

(Documentation) may be translated to, or has been translated from,

another language (Translation). In the event of any conflict between

any Translation of the Documentation, the English language

version of the Documentation will be the official version of the

Documentation.

This manual represents the product as at the time of printing.

Navico Holding AS and its subsidiaries, branches and affiliates

reserve the right to make changes to specifications without notice.

Trademarks

NMEA 2000 is a registered trademark of the National Marine

Electronics Association.

Navionics is a registered trademark of Navionics SpA.

Simrad is a trademark of Kongsberg Maritime AS Company

registered in the US and other countries and is being used under

license.

B&G, Lowrance, StructureScan, Navico, SonicHub, SimNet, Skimmer,

InsightHD, Broadband Radar, Broadband Sonar, and SonarHub are

trademarks of Navico, registered in the US and other countries.

Copyright

Copyright © 2014 Navico Holding AS.

| BSM-3 Installation Manual

| 3

Page 4

Warranty

The warranty card is supplied as a separate document.

In case of any queries, refer to the brand web site of your display or

system: www.simrad-yachting.com

Declarations and conformance

This equipment is intended for use in international waters as well as

coastal sea areas administered by countries of the E.U. and E.E.A.

Compliance Statements

BSM-3:

• Comply with CE under EMC directive 2004/108/EC

• Comply with the requirements of level 2 devices of the

Radiocommunications (Electromagnetic Compatibility)

standard 2008.tra es

The relevant Declaration of Conformity is available in the following

website, under the model documentation section:

www.simrad-yachting.com

Warning

The user is cautioned that any changes or modifications not

expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is

no guarantee that the interference will not occur in a particular

installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from

that of the receiver

• Consult the dealer or an experienced technician for help.

4 |

| BSM-3 Installation Manual

Page 5

About this manual

!

This document describes how to install the BSM-3 and connect the

unit to transducers and display units.

Separate installation instruction for transducers are included with

the transducer package.

The BSM-3 is compatible with the following MFD displays and

systems:

• NSE

• NSO, NSO evo2

• NSS, NSS evo2

http://support.simrad-yachting.com

¼ Note: Make sure the MFD has up-to-date software, - refer to the

website: www.simrad-yachting.com

Important text that requires special attention from the reader is

emphasized as follows:

¼ Note: Used to draw the reader’s attention to a comment or some

important information.

Warning: Used when it is necessar y to warn personnel that they should

proceed carefully to prevent risk of injury and/or damage to equipment/pe r sonnel.

| BSM-3 Installation Manual

| 5

Page 6

Contents

7 Introduction

7 BSM-3 module layout

7 Parts included in package

9 Installation and wiring

9 Mounting location

10 Securing BSM-3 module

11 Wiring

12 Connecting the BSM-3 to your display

13 Transducer connection

13 BSM-3 connectors

14 Transducer with a 7-pin connector

14 Transducer with bare wires

15 Airmar transducers

18 Trouble shooting

19 Technical specication

21 Dimensional drawings

22 Spare parts and accessories

22 Spare parts

22 Accessories

22 Transducers

6 |

Contents | BSM-3 Installation Manual

Page 7

Introduction

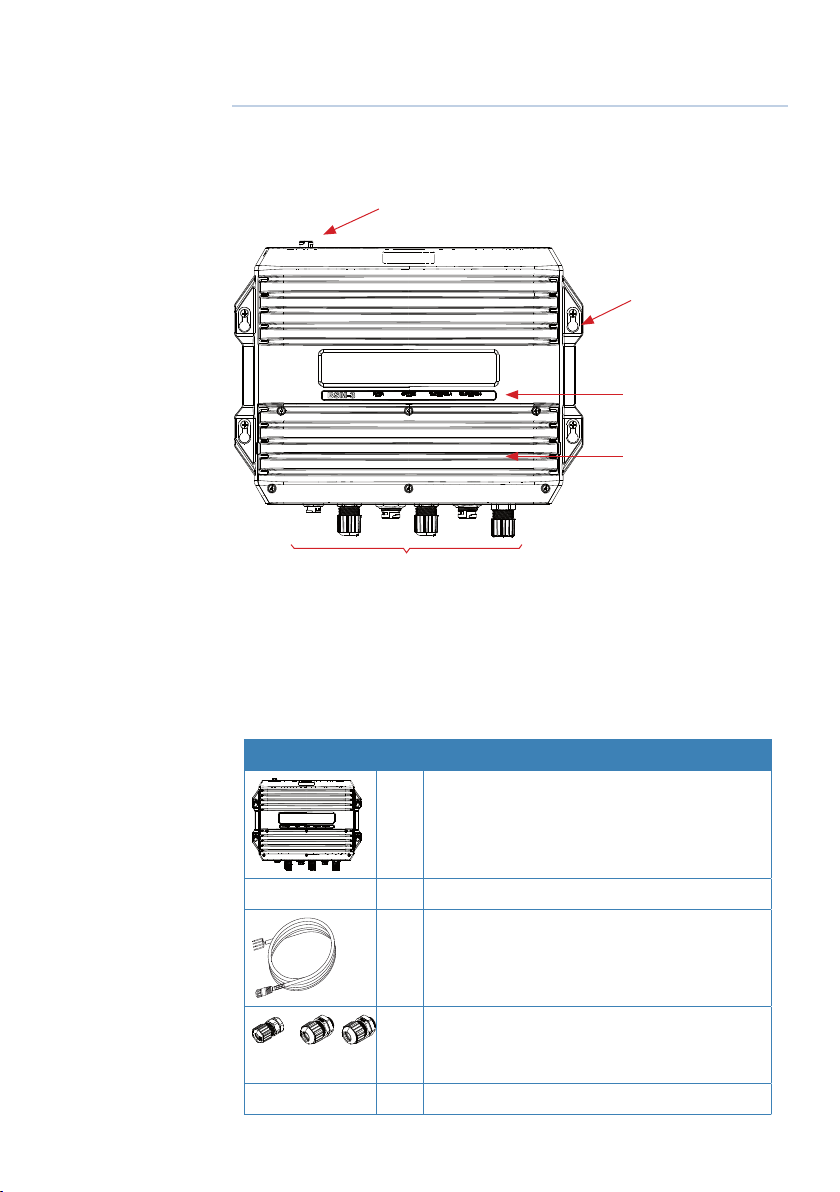

BSM-3 module layout

1

ethernet

connector

GroundinG

screW

le d s tat u s

indicators

removable

cover

connectors

Parts included in package

For spare parts and part numbers, see“Spare parts and accessories”

on page 22.

Item No. Description

1 BSM-3 sounder module

1 Ethernet cable, 1.8 m (6 ft)

Power cable (bare wires), 2 m (6.5 ft)

1

Cable glands for bare wire transducer

installation

Introduction | BSM-3 Installation Manual

| 7

Page 8

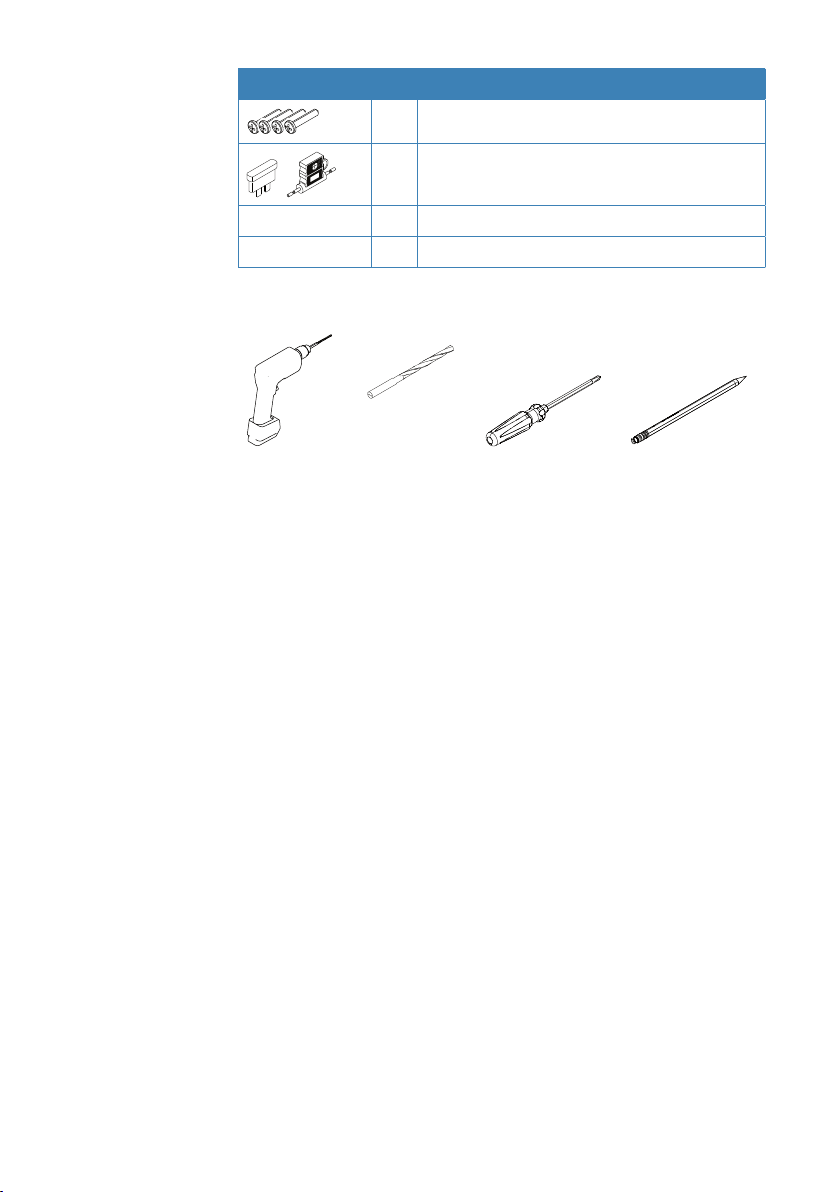

Item No. Description

4 Screws

Spare Fuse kit including;

1

3A Fuses and fuse holders

1 Warranty card

1 This manual

Required tools and supplies

2 mm

(5/64”)

Drill

Drill Bit Screw driver Pencil

8 |

Introduction | BSM-3 Installation Manual

Page 9

2

Installation and wiring

Mounting location

Before installing the BSM-3, consider location and cable runs

necessary to connect the module to display unit, transducer and

power source.

The mounting location must allow for required working area when

connecting the cables. Also ensure that the location allows viewing

the unit’s LED indicators.

The units should be mounted with special regard to the units’

environmental protection, temperature range and cable length.

The mounting surface needs to be structurally strong, with as little

vibration as possible. If possible, mount the unit close to the edges

of a panel to minimize vibration.

Do not run the transducer cabling near the BSM-3 power cables,

any VHF antenna coax cables or any DC or AC power cables. Avoid

placing Ethernet cables close to VHF antennas.

The BSM-3 conforms to the appropriate Electromagnetic

Compatibility (EMC) standards, but proper installation is required

to get best use and performance from this product. Ensure you

have as much separation as possible between different electrical

equipment, (see diagram below).

X

Electromagnetic interference

Gasoline fumes

Vibration

Heat

RADAR

1.5 m (5 ft) Min

Radio or AIS Transmitter

Installation and wiring | BSM-3 Installation Manual

2.0 m (6.5 ft) Min

Sunlight

Salt spray

X

Physical damage

Compass

1.8 m (6 ft) Min

| 9

Page 10

Securing BSM-3 module

Mount the BSM-3 on a vertical surface with the power and

transducer cable connections exiting downwards.

Fasten the BSM-3 by using the 4 stainless steel self tapping screws

included with the unit.

10 |

Installation and wiring | BSM-3 Installation Manual

Page 11

Wiring

!

!

The BSM-3 has convenient connectors to attach power and

transducers. It is also supplied with cable glands to allow for

transducers that don’t have a 7 pin connector.

The BSM-3 contains high voltages and specialized parts; the

operator should never remove the module’s cover without

removing the power connection.

Removing the transducer cable from the BSM-3 while the

module is powered on can cause sparks. Remove the transducer

cables only after the module has been disconnected from its

power source.

Grounding the unit

For additional safety install grounding cable in ground screw hole as

indicated on illustration. Recommended 16 awg wire.

Power

The unit has no power key and will turn on when power is applied.

When used in an NSE/NSS/NSO evo2 system, it is recommended to

connect the BSM-3 to the Power control bus, and set display system

to power control master.

BSM-2

BSM-2

Black

Yellow

Blue

(n/c)

12 - 24 V DC

Red

NSE

Power

Control bus

Black

Red

Yellow

Blue

(n/c)

+

Yellow

Blue

(n/c)

_

12 - 24 V DC

Black

Red

Switch

_

+

If the BSM-3 is connected directly to the vessel’s battery, the module

will continue to draw power even when it is not in operation. It is

recommended that the yellow power cable wire be fitted with an

optional on/off switch, allowing the BSM-3 to be powered off when

not in use.

Installation and wiring | BSM-3 Installation Manual

| 11

Page 12

Connecting the BSM-3 to your display

SINGLE

MULTIPLE

The BSM-3 connects to your display system over an Ethernet

network, either directly or via a Network Expansion Port.

When connected to an NSO, the RJ45 to 5 pin cross-over Ethernet

cable included with the NSO system must be used.

¼ Note: Above not relevant to NSO evo2

For details refer to the display system’s Installation manual.

DISPLAY

SYSTEM

DISPLAY

SYSTEM

A

BSM-3 NEP-2

B

_

+

12 - 24 V DC

transducers

Ref Description

A Ethernet cable

B BSM-3 Power cable

C Transducer cables

C

12 |

Installation and wiring | BSM-3 Installation Manual

Page 13

Transducer connection

BSM-3 connectors

3

A B C D E F

POWER

Ref Description

A Power 12 or 24 V DC (9-32 V DC) 4 pin connector

B Speed Input

C Transducer port 1 : 7 pin blue connector:

Connect medium or high frequency transducers.

D Cable gland for independent temperature input:

Tied to Transducer 1

E Transducer port 2 : 7 pin blue connector:

Connect low frequency transducers

F Cable gland for independent temperature input:

Tied to Transducer 2

SPEED

TRANSDUCER 1

TEMPERATURE 1 TEMPERATURE 2

TRANSDUCER 2

Transducer connection | BSM-3 Installation Manual

| 13

Page 14

Transducer with a 7-pin connector

C

E

Most Airmar transducers as of 2014 are available with 7-pin blue

connectors including dual channel transducers. These connect

to the corresponding connectors on the BSM-3. Dual channel

transducers will have two connectors and will be labeled.

Transducer with bare wires

Remove connectors

1. Remove cover.

14 |

2. Remove terminal blocks and disconnect the connector wires for

both transducer ports including wires going to temperature and

speed terminals.

3. Remove connector lock nut and remove connector.

4. Select cable inlets according to cable diameter and labelling on the

front plate.

5. Disassemble the appropriate cable gland, and thread the gland

parts on to the cable.

Transducer connection | BSM-3 Installation Manual

Page 15

6. Insert the gland housing in to the BSM-3 case and secure with nut.

7. Pass the gland securing nut over the bare wires and along the cable.

8. Pass the cable through the gland housing.

9. Terminate the wires to the terminal blocks according to the terminal

specification in the following pages

10. Connect the terminal blocks to the corresponding connector block

11. Tighten the cable gland outer sealing nuts by hand

12. Close the BSM-3 cover and secure the cables.

Port Gland size Cable diameter

Transducer 1&2 M20 10.0 mm - 14.0 mm (3.94” - 5.51”)

Power

Speed

Temperature 1

Temperature 2

M16 6.0 mm - 10.0 mm (2.36” - 3.94”)

Airmar transducers

The wiring diagram below shows how to connect an Airmar

transducer (B265).

¼ Note: On some models Low frequency XDCR+ wire (blue/white) can

be yellow.

On some transducer models temperature brown cable is connected

internally to XID GND, and there is no need to connect bare and

brown cable together.

Transducer connection | BSM-3 Installation Manual

| 15

Page 16

Consult XDCR documentation for correct wiring diagram before

connecting transducer!

Ref Color Function

A Orange XID

B Shield XID ground (if available)

C Brown Thermistor (XID ground)

D White Thermistor

E Shield High freq. depth shield

F Black High freq. negative

G Blue High freq. positive

H Orange XID *

I Brown Thermistor (XID ground) *

J Shield Low freq. depth shield

K Black and white (or black) Low freq. negative

L Blue/white or yellow Low freq. positive

* Dual transducer installation only

16 |

SPEED

SPD IN

GND

SPD PWR

1

TEMP HIGH

J5

TEMP HIGH

GND

XDCR ID HIGH

1

J4

XDCR Z2

XDCR Z3

XDCR HIGH

XDCR Z1

IMP SEL

XDCR -

SHIELD

XDCR +

TEMP LOW

J8

1

G

A B C D E F

H

Transducer connection | BSM-3 Installation Manual

TEMP LOW

GND

XDCR ID LOW

1

I

J6

XDCR LOW

J7

XDCR Z1

XDCR Z2

XDCR Z3

J

IMP SEL

XDCR -

SHIELD

XDCR +

1

K

L

Page 17

Setting up the transducers

The BSM-3 is compatible with Airmar’s Transducer ID protocol. If you

have an Airmar transducer that supports this feature, BSM-3 will

read your transducer’s specification at start-up and automatically

adjust the frequency and temperature settings. The transducer’s XID

wire (orange) should be connected to the XDCR_ID_HIGH/LOW

terminal in the TEMP HIGH/LOW connector as shown below.

TEMP HIGH

TEMP HIGH

GND

XDCR ID HIGH

1

J5

Ref Color Signal

A

B

Orange XID

Shield XID GND

A B

If your transducer doesn’t support Airmar’s Transducer ID protocol,

the transducer selection and configuring needs to be done from

the display as shown on the graphics below.

A detailed description is found in the relevant documentation for

the display.

Transducer connection | BSM-3 Installation Manual

Airmar B265 (10k)

| 17

Page 18

4

Trouble shooting

POWER NETWORK TRANSDUCER-2TRANSDUCER-1

Ind. Status Description

No power connection

Power

Network

Transducers

Off

On - Red System starting

On - Green System operational

Flashing -

Red/Green

Off

On - Green Ethernet connected and ok

Off Transducer not connected

Flashing every

0.5 second Green

Flashing every

second -

Green

On - Green System operational

Check power and power cable

Check yellow wire

Software error or unit

reprogrammed

Restart the unit

If still not ok, contact Customer

Support

No Ethernet connection

Check cable

Verify that remote unit is turned

ON

Initializing transmitter

Searching for bottom signal

18 |

Trouble shooting | BSM-3 Installation Manual

Page 19

5

Technical specication

Compliance and environmental

Compliance CE, C-TICK

Technical

standards

Waterproof IPX5

Humidity Up to 95% at 35°C non-condensing

Storage

temperature

Operating

temperature

General

Connectors 6 Glands and 1 Ethernet

Weight 4.8 kg (10.6 lbs)

Dimensions

(WxHxD) mm/

in

Mounting 4 keyholed mounting tabs

Power requirements

Power

consumption

Sonar specications

Power output 250 Watts RMS

Frequencies Broadband Frequencies Transceiver High:

Transmitter and

receiver type

IEC 60945,

IEC 60529

–30°C to +70°C

–15°C to +55°C

340x100x289 mm

(13.38x3.94x11.37 inches)

Range dependent – normally less than 10 W

2,000 Watts (peak to peak)

130-210 kHz; 85-145 kHz

Broadband Frequencies Transceiver Low:

40-60 kHz; 25-45 kHz

Narrowband Frequencies Transceiver High:

200 kHz; 83 kHz

Narrowband Frequencies Transceiver Low:

50 kHz; 38 kHz; 28 kHz

Dual Broadband tuned receivers

Dual tuned CHIRP transmitters

Technical specication | BSM-3 Installation Manual

| 19

Page 20

Pulse Length Range Dependent - to 70 ms max

Max. transmit

rate

Range dependent – to 20 Hz in shallow depths.

User selectable.

Range scales 5, 8, 10, 15, 20, 30, 40, 60, 80,100,120, 150, 200,

250, 300, 400, 500, 600, 700, 800, 900, 1000, 1500,

2000, 4000, 6000, 8000, 10,000, 12,000, 15,000

NOTE: all numbers above in ft. can be

changed to metrics in NSE/NSO/NSS unit.

Range control Auto/manual range with zoom, alternating dual

frequency display with CHIRP, simultaneous

with narrowband

Zoom size Auto/manual x2, x3, x4, x5, x6, x7, x8 (user

selectable)

DC Voltage requirements

Voltage 10.7–32 VDC (for 12 or 24 VDC systems)

Interfaces

Network Ethernet 10/100

20 |

Technical specication | BSM-3 Installation Manual

Page 21

Dimensional drawings

6

100 mm (3.94”)109 mm (4.29”)

340 mm (13.38”)

320 mm (12.60”)

250 mm (9.84”)

289 mm (11.38”)

Dimensional drawings | BSM-3 Installation Manual

| 21

Page 22

Spare parts and accessories

Spare parts

7

Part no. Description

000-00128-001 Power cable

Hardware mounting accessories including

000-10412-001

000-10414-001 Terminal block

003-9558-00 Cable gland kit

003-8590-00 Fuse Kit

4 screws;

8Gx1, PAN POZI, S/T, 16, LO-HEAD

Accessories

Part no. Description

000-0127-51 Ethernet cable yellow 5 Pin 2 m (6.5 ft)

000-0127-29 Ethernet cable yellow 5 Pin 4.5 m (15 ft)

000-0127-30 Ethernet cable yellow 5 Pin 7.7 m (25 ft)

000-0127-37 Ethernet cable yellow 5 Pin 15.2 m (50 ft)

000-10029-001 NEP-2 Network Expansion Port (Yellow connectors)

Transducers

For a full list of compatible transducers please refer to the transducer

selection guide on http://www.simrad-yachting.com/transducerguide/

22 |

Spare parts and accessories | BSM-3 Installation Manual

Page 23

Page 24

*988-10719-001*

Loading...

Loading...