Page 1

INSTRUCTION MANUAL

Robertson AP45

Autopilot

20220042/6/02

Page 2

This page is intentionally left blank.

Page 3

NOTE!

Simrad Egersund AS makes every effort to ensure that the information

contained within this document is correct. However, our equipment is

continuously being improved and updated, so we cannot assume liability for

any errors which may occur.

The information contained within this document remains the sole property of

Simrad Egersund AS. No part of this document may be copied or reproduced

in any form or by any means, and the information contained within is not to be

passed on to a third party, without the prior written consent of

Simrad Egersund AS.

Warning

The equipment to which this manual applies must only be used for the

purpose for which it was designed. Improper use or maintenance may

cause damage to the equipment or injury to personnel. The user must

be familiar with the contents of the appropriate manuals before

attempting to operate or work on the equipment.

Simrad Egersund AS disclaims any responsibility for damage or

injury caused by improper installation, use or maintenance of the

equipment.

Simrad Egersund AS Telephone: +47 51 46 20 00

Nyåskaien Telefax: +47 51 46 20 01

P.O. Box 55

N-4379 Egersund, Norway

Page 4

Robertson AP45

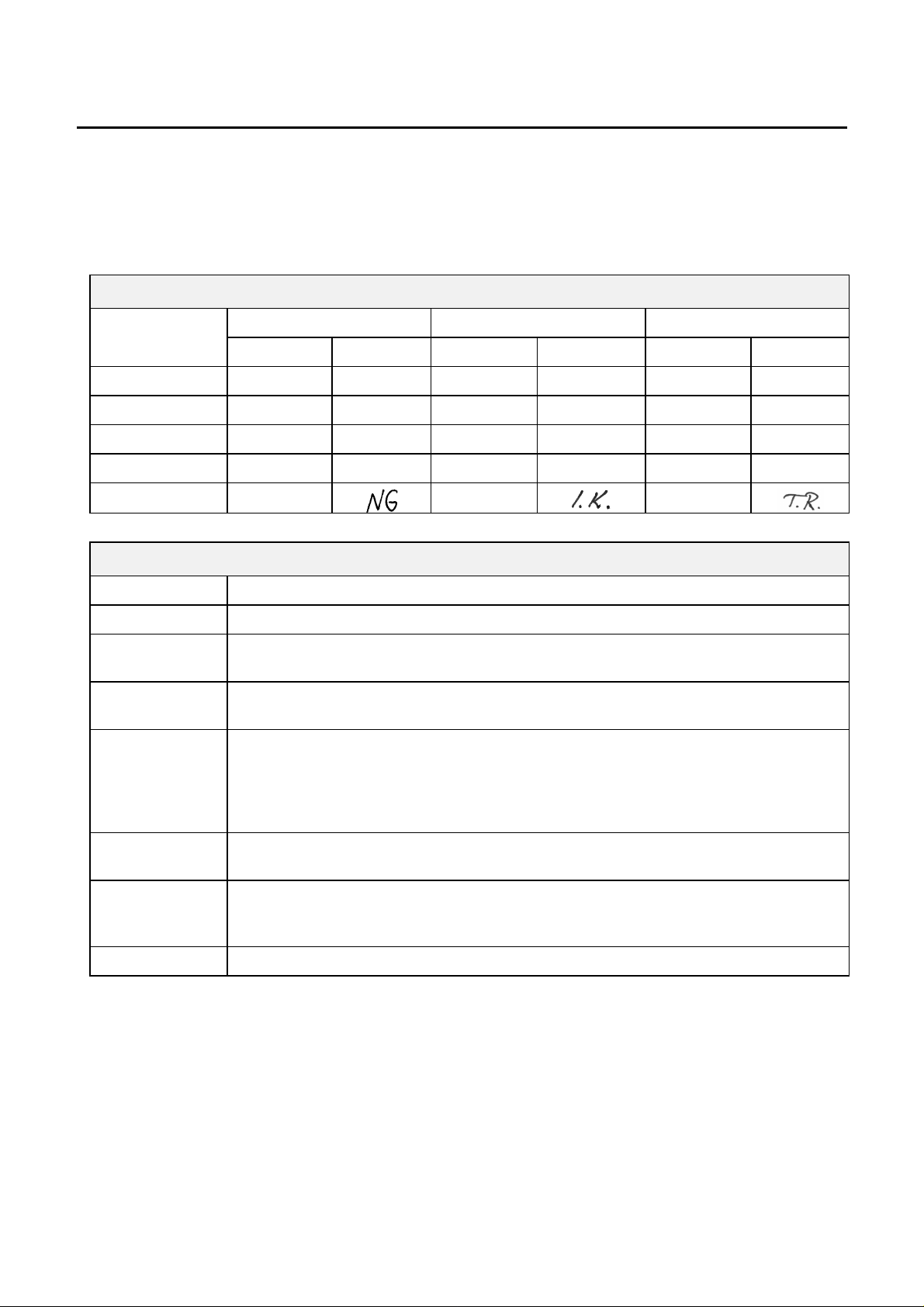

Modification record

Rev. Written by Checked by Approved by

MODIFICATION RECORD

Robertson AP45 Autopilot

Document revisions

Date Sign. Date Sign. Date Sign.

January 1996 08.01.96

September 1997 08.09.97

October 1998 01.10.98

September 1999 15.09.99

N.G.

N.G.

N.G.

N.G.

08.01.96

08.09.97

01.10.98

15.09.99

I.K.

I.K.

I.K.

I.K.

08.01.96

08.09.97

01.10.98

15.09.99

Th.H.

Th.H.

Th.H.

Th.H.

June 2002 29.05.02 29.05.02 29.05.02

Document history

Rev. Action/Changes/References

September 1990 Covers the software versions V1R0, V1R1, V1R2 and V1R3. New rudder feedback

RF45 included.

January 1996 Updated to software version V1R4. Major extensions of section 3 and 5. RI40

substitutes RI45. G45 included.

September 1997 Modifications due to improved protection against electro magnetic interference,

page 5-1, 5-2, 5-17 and 8-1. J45A grounding page 5-21. Modification on fig. 5-29.

“Soft start” function included on page 3-6. Corrected number of bushings on page 526 and page 5-28. Missing length group 60-100 ft included on page 6-4. Corrected

text in fig. 6-2. Page 5-33: Switch position 8 and 9 changed to NMEA 0183.

October 1998 Minor corrections on following pages: 2-5, 2-6, 2-11, 2-12, 5-3, 5-8, 5-20, 5-21, 5-31,

5-33, 6-1, 7-1, 7-2, 7-4 and 8-3.

September 1999 RI40 substituted by RI9, RI101 by RI35. RF45 substituted by RF45X. S3

substituted by S35. Removed the NMEA0180, inverse polarity. RFC250 substituted

by RFC35NS. New distributor list.

June 2002 Note on page 5-31 included. New distributor list.

To assist us in making improvements to this manual, we would welcome comments and constructive

criticisms. Please send all such comments, in writing to:

Simrad Egersund AS

Documentation Department

P.O. Box 55,

N-4379 Egersund

Norway

Simrad Robertson AS

Egersund - Norway

Page 5

Robertson AP45

A

Modification record

IMPORTANT!

n autopilot is a very useful navigational aid, but DOES NOT under any

circumstance replace a human navigator.

Do not use automatic steering when:

• In heavy traffic areas or in narrow waters

• In poor visibility or extreme sea conditions

• When in areas where use of autopilot is prohibited by law

When using an autopilot:

• Do not leave the helm unattended

• Do not place any magnetic mat erial or equipment near magnetic or

fluxgate compass used in the autopilot system

Verify at regular intervals course and position of vessel

• Always switch to Standby mode in due time to avoid hazardous situations

Simrad Robertson AS

Egersund - Norway

Page 6

Robertson AP45

Modification record

Simrad Robertson AS

Egersund - Norway

Page 7

Robertson AP45 Autopilot

Table of contents

1. GENERAL INFORMATION..................................................1-1

2. OPERATION OF THE AUTOPILOT...................................2-1

Page I

TABLE OF CONTENTS

Introduction...................................................................................................................1-1

System description.........................................................................................................1-1

AP45 Control Unit.........................................................................................................1-1

Heading Sensors............................................................................................................1-1

Rudder Feedback Units.................................................................................................1-2

Junction units.................................................................................................................1-3

Optional equipment.......................................................................................................1-3

Remote Controls............................................................................................................ 1-3

Rudder Angle Indicators................................................................................................1-4

General..........................................................................................................................2-1

Front Panel ....................................................................................................................2-1

Mode selection ..............................................................................................................2-1

Parameter setting...........................................................................................................2-3

Course selection.............................................................................................................2-4

Navigating with the AP45..............................................................................................2-5

Mixed mode, XTE & CTS.............................................................................................2-5

XTE mode.....................................................................................................................2-6

Steering by bearing to waypoint (CTS).........................................................................2-8

Remote Controls General............................................................................................2-10

F200-40 Remote Control.............................................................................................2-10

S9 Steering Lever........................................................................................................2-11

FU91 Follow up Steering Lever ..................................................................................2-14

Fault warnings.............................................................................................................2-16

3. DESIGN AND THEORY OF OPERATION.........................3-1

Automatic Steering ........................................................................................................3-1

AP45 Control Unit.........................................................................................................3-2

CD109 Course Detector ................................................................................................3-2

Rudder Feedback Units.................................................................................................3-3

RF45X Rudder Feedback Unit......................................................................................3-3

RF14XU Rudder Feedback Unit (optional)...................................................................3-3

Junction Units................................................................................................................3-4

J45S Junction Unit.........................................................................................................3-4

J45A Electronic Junction Unit.......................................................................................3-6

4. TECHNICAL SPECIFICATIONS........................................4-1

AP45 Control Unit.........................................................................................................4-1

CD109 Course Detector ................................................................................................4-2

RFC35NS Fluxgate compass.........................................................................................4-3

G40A Gyro Interface.....................................................................................................4-4

G45 Gyro Interface........................................................................................................4-4

FI100-40 Fluxgate Interface..........................................................................................4-5

RF45X Rudder Feedback Unit......................................................................................4-5

RF14XU Rudder Feedback Unit...................................................................................4-6

J45S Junction Unit.........................................................................................................4-7

J45A Junction Unit........................................................................................................4-7

S9 Steering Lever..........................................................................................................4-8

FU91 Steering Lever.....................................................................................................4-8

S35 Steering Lever........................................................................................................4-9

F1/2 Remote Control...................................................................................................4-10

F200-40 Remote Control.............................................................................................4-10

RI35 Rudder Angle Indicator ......................................................................................4-11

Simrad Robertson AS

Egersund - Norway

Page 8

Page II Robertson AP45 Autopilot

Table of contents

RI9 Rudder Angle Indicator ........................................................................................4-12

5. INSTALLATION.....................................................................5-1

Unpacking and handling................................................................................................5-1

General..........................................................................................................................5-1

AP45 Control Unit.........................................................................................................5-1

Connector assemble.......................................................................................................5-2

Heading sensors.............................................................................................................5-4

General..........................................................................................................................5-4

Magnetic compass.........................................................................................................5-4

RFC35NS Fluxgate Compass........................................................................................5-6

Mounting.......................................................................................................................5-6

Connection.....................................................................................................................5-7

Calibration.....................................................................................................................5-7

Alignment......................................................................................................................5-8

FI100-40 Fluxgate Interface..........................................................................................5-8

G40A Gyro Interface Unit.............................................................................................5-9

G45 Gyro Interface Unit..............................................................................................5-11

RGC Signal Interface Unit...........................................................................................5-12

RF45X Rudder Feedback Unit....................................................................................5-13

RF14XU Rudder Feedback Unit.................................................................................5-14

J45S Junction Unit.......................................................................................................5-19

J45A Junction Unit......................................................................................................5-21

Optional equipment.....................................................................................................5-26

F200-40 Remote Control.............................................................................................5-26

S9 Steering Lever........................................................................................................5-26

FU91 Steering Lever...................................................................................................5-28

F1/2 Remote Control...................................................................................................5-30

S35 Steering Lever......................................................................................................5-30

RI9 Rudder Angle Indicator ........................................................................................5-31

RI35 Rudder Angle Indicator ......................................................................................5-33

Panel mounting............................................................................................................5-34

Bracket mounting........................................................................................................5-34

Illumination.................................................................................................................5-35

Zero adjust...................................................................................................................5-35

Reversed deflection.....................................................................................................5-35

Connection to Navigation Receiver.............................................................................5-36

Watch alarm ................................................................................................................5-37

6. START-UP PROCEDURE/ COMMISSIONING.................6-1

Power ON......................................................................................................................6-1

Rudder Feedback Adjustment........................................................................................6-1

Direction of Rudder Movement.....................................................................................6-1

Rudder speed.................................................................................................................6-2

Course Detector Alignment...........................................................................................6-2

Selection of parameter settings......................................................................................6-2

Select language..............................................................................................................6-3

Type of Heading Sensor................................................................................................ 6-4

Off Course limit.............................................................................................................6-4

Vessel's length............................................................................................................... 6 -4

Counter rudder...............................................................................................................6-5

Rudder limit...................................................................................................................6-5

Rudder deadband...........................................................................................................6-5

NMEA-format...............................................................................................................6-5

Disengage of autotrim-function in WORK-mode..........................................................6-5

Disengage of Off Course alarm in Work mode .............................................................6-6

Sea Trial ........................................................................................................................6-6

Simrad Robertson AS

Egersund - Norway

Page 9

Robertson AP45 Autopilot

Table of contents

7. TROUBLE SHOOTING .........................................................7-1

8. SPARE PARTS AND DRAWINGS.......................................8-1

9. SALES AND SERVICE WORLDWIDE (990901)...................9-1

Page III

Fault warnings...............................................................................................................7-1

Debug/Adjust mode.......................................................................................................7-5

AP45 Control Unit.........................................................................................................8-1

CD109 Course Detector ................................................................................................8-4

G40A Gyro Interface.....................................................................................................8-5

G45 Gyro Interface........................................................................................................8-7

FI100-40 Fluxgate Interface..........................................................................................8-9

RF45X Rudder Feedback..............................................................................................8-9

RF14XU Rudder Feedback Unit...................................................................................8-9

J45S Junction Unit.......................................................................................................8-10

J45A Junction Unit......................................................................................................8-12

F200-40 Remote Control.............................................................................................8-14

S9 Steering Lever........................................................................................................8-16

S35 Steering Lever......................................................................................................8-16

FU91 Steering Lever...................................................................................................8-16

RI9 Rudder Angle Indicator ........................................................................................8-17

RI35 Rudder Angle Indicator ......................................................................................8-17

LIST OF DRAWINGS

FIG. 1-1 AP45 SYSTEM LAYOUT - BASIC SYSTEM WITH OPTIONS ................................1-1

F

IG. 2-1 AP45 CONTROL UNIT - FRONT PANEL...........................................................2-1

F

IG. 3-1 AUTOPILOT PRINCIPLE DIAGRAM...................................................................3-1

F

IG. 3-2 PROCESSOR CONTROLLED AUTOPILO T ...........................................................3-1

F

IG. 3-3 COURSE DETECTOR PRINCIPLE......................................................................3-2

F

IG. 3-4 RF45X PRINCIPLE .........................................................................................3-3

F

IG. 3-5 BASIC SYSTEM................................................................................................3-4

F

IG. 3-6 SOLENOIDS WITH POSITIVE COMMON ............................................................3-5

F

IG. 3-7 SOLENOIDS WITH NEGATIVE COMMON...........................................................3-5

F

IG. 3-8 J45A PRINCIPLE ............................................................................................3-6

F

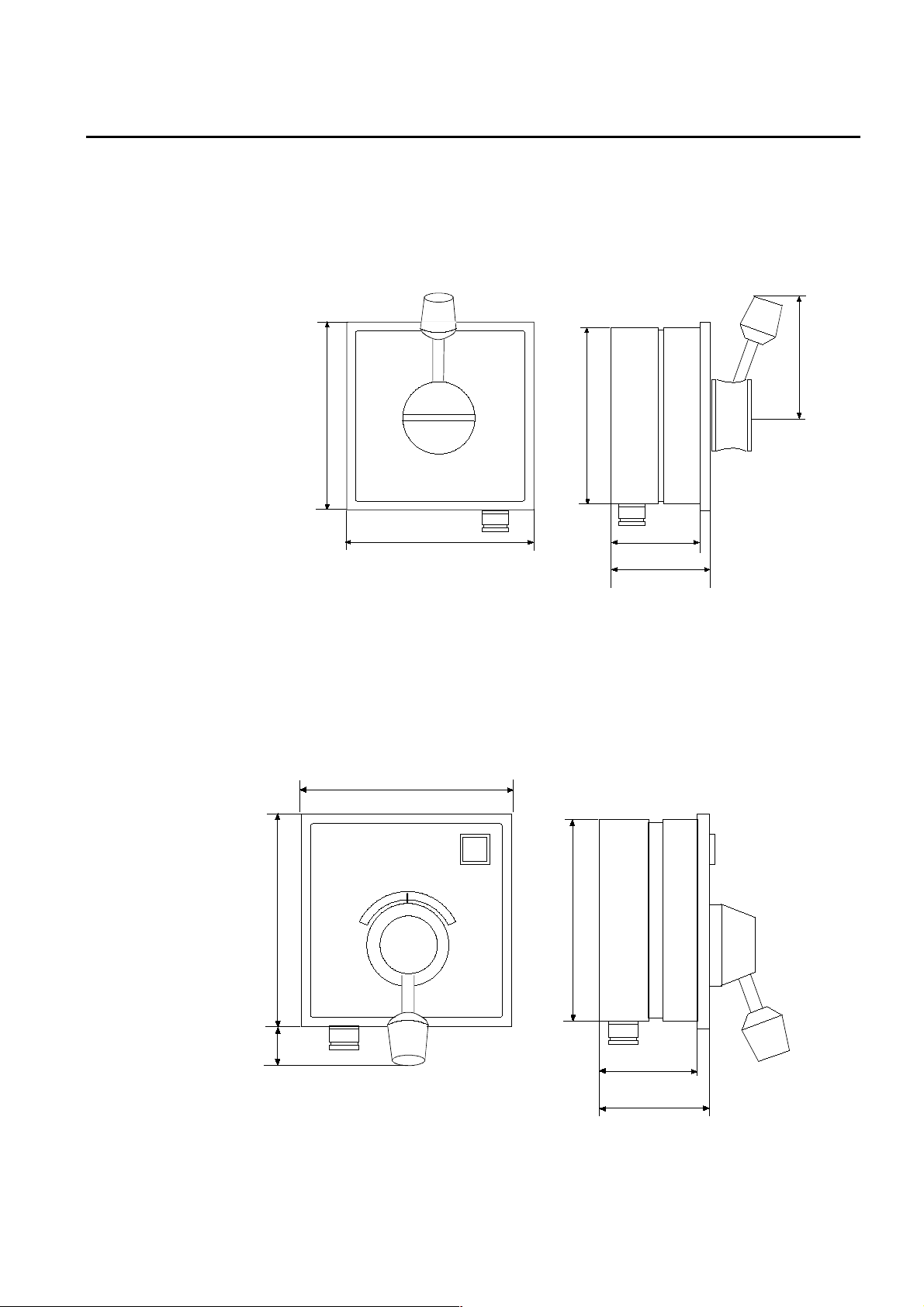

IG. 4-1 AP45 CONTROL UNIT - DIMENSIONS.............................................................4-1

F

IG. 4-2 CD109 COURSE DETECTOR............................................................................4-2

F

IG. 4-3 RFC35NS - DIMENSIONS ..............................................................................4-3

F

IG. 4-4 G40A GYRO INTERFACE - DIMENSIONS.........................................................4-4

F

IG. 4-5 FI100-40 FLUXGATE INTERFACE - DIMENSIONS ...........................................4-5

F

IG. 4-6 RF45X RUDDER FEEDBACK - DIMENSIONS...................................................4-5

F

IG. 4-7 RF14XU RUDDER FEEDBACK UNIT - DIMENSIONS........................................4-6

F

IG. 4-8 J45S/J45A/G45 - DIMENSIONS .....................................................................4-7

F

IG. 4-9 S9 STEERING LEVER - DIMENSIONS ..............................................................4-8

F

IG. 4-10 FU91 STEERING LEVER - DIMENSIONS.......................................................4-8

F

IG. 4-11 S35 STEERING LEVER - DIMENSIONS ..........................................................4-9

F

IG. 4-12 F1/2 REMOTE CONTROL - DIMENSIONS.....................................................4-10

F

IG. 4-13 F200-40 REMOTE CONTROL DIMENSIONS.................................................4-10

F

IG. 4-14 RI35 RUDDER ANGLE INDICATOR - DIMENSIONS......................................4-11

F

IG. 4-15 RI9 RUDDER ANGLE INDICATOR - DIMENSIONS........................................4-12

F

IG. 5-1 AP45 CONTROL UNIT - PANEL MOUNT .........................................................5-1

F

IG. 5-2 AP45 CONTROL UNIT - BRACKET MOUNTING ...............................................5-1

F

IG. 5-3 CONTROL UNIT - CONNECTOR MOUNTING......................................................5-2

F

IG. 5-4 AP45 EXTERNAL CABLING DIAGRAM .............................................................5-3

F

IG. 5-5 CD109 COURSE DETECTOR - MOUNTING ......................................................5-5

F

IG. 5-6 AP45/RFC35NS - CONNECTION...................................................................5-7

F

IG. 5-7 RFC35NS - INTERNAL CONNECTION ...........................................................5-7

Simrad Robertson AS

Egersund - Norway

Page 10

Page IV Robertson AP45 Autopilot

Table of contents

FIG. 5-8 AP45/FI100-40 FLUXGATE INTERFACE - WIRING.........................................5-8

F

IG. 5-9 G40A GYRO INTERFACE CONNECTIONS........................................................5-9

F

IG. 5-10 G40A PC-BOARD - SWITCH LOCATION.......................................................5-10

F

IG. 5-11 CONNECTION TO G45 EXCITATED SYNCHRO TRANSMITTER.......................5-11

F

IG. 5-12 CONNECTION TO GYRO EXCITATED SYNCH RO T RANSMITTERS ...................5-11

F

IG. 5-13 G45 INPUT/OUTPUT...................................................................................5-12

F

IG. 5-14 AP45/RGC SIGNAL INTERFACE UNIT - WIRING........................................5-12

F

IG. 5-16 RF45X RUDDER FEEDBACK UNIT - MOUNTING........................................5-13

F

IG. 5-17 RF14XU - MOUNTING...............................................................................5-14

F

IG. 5-18 RF45 TEMPLATE SCALE 1:1 ......................................................................5-15

F

IG. 5-19 SCREEN TERMINATION...............................................................................5-17

F

IG. 5-20 RF14XU INTERNAL WIRING......................................................................5-18

F

IG. 5-21 RF14XU/J45S - WIRING ...........................................................................5-19

F

IG. 5-22 J45A JUNCTION UNIT GROUNDING...........................................................5-21

F

IG. 5-23 AP45 WIRING DIAGRAM - BASIC SYSTEM (015936H).................................5-22

F

IG. 5-24 AP45 WIRING DIAGRAM - SOLENOIDS WITH POSITIVE COMMON (015936H)5-23

F

IG. 5-25 AP45 WIRING DIAGRAM - SOLENOIDS WITH NEGATIVE COMMON (015936H)5-24

F

IG. 5-26 AP45/J45 WIRING DIAGRAM......................................................................5-25

F

IG. 5-27 F200-40/AP45 - WIRING DIAGRAM............................................................5-26

F

IG. 5-28 S9 MOUNTING ...........................................................................................5-26

F

IG. 5-29 S9/AP45 - WIRING DIAGRAM .....................................................................5-27

F

IG. 5-30 S9 STEERING LEVER - INTERNAL WIRING..................................................5-27

F

IG. 5-31 FU91 MOUNTING ......................................................................................5-28

F

IG. 5-32 FU91 WITHOUT MODE SWITCHING ............................................................5-28

F

IG. 5-33 FU91 WITH MODE SWITCHING...................................................................5-29

F

IG. 5-34 FU91 MULTIPLE INSTALLATION................................................................5-29

F

IG. 5-35 S35, F1/2 - AP45 - WIRING DIAGRAM........................................................5-30

F

IG. 5-36 AP45 WIRING DIAGRAM - J3 W/MULTIPLE INPUT......................................5-30

F

IG. 5-37 RI9 WIRING DIAGRAM................................................................................5-31

F

IG. 5-38 RI9 INPUT SIGNAL SELECTION ..................................................................5-32

F

IG. 5-39 RI35-J45A WIRING DIAGRAM...................................................................5-33

F

IG. 5-40 RI35-J45S WIRING DIAGRAM ...................................................................5-33

F

IG. 5-41 PANEL MOUNTING......................................................................................5-34

F

IG. 5-42 RI35 BRACKET MOUNTING .......................................................................5-34

F

IG. 5-43 N40 NAV. INTERFACE MOUNTING (FOR MAIN PCBS WITH REVISION UP TO

AND INCLUDING REVISION

F

IG. 5-44 AP45/NAVIGATION RECEIVER - WIRING ....................................................5-37

F

IG. 5-45 WA9 CIRCUIT/WIRING DIAGRAM ...............................................................5-37

F

IG. 6-1 AP45 INSTALLATION LOOP............................................................................6-3

F

IG. 6-2 COUNTER RUDDER SETTINGS.........................................................................6-7

F

IG. 8-1 AP45 EXPLODED VIEW ..................................................................................8-2

F

IG. 8-2 AP45 SIGNAL REFERENCE.............................................................................8-3

F

IG. 8-3 CD109 - SPARE PARTS...................................................................................8-4

F

IG. 8-4 G40A COMPONENT REFEREN CE ....................................................................8-5

F

IG. 8-5 G40A CIRCUIT DIAGRAM ...............................................................................8-6

F

IG. 8-6 G45 COMPONENT REFEREN CE.......................................................................8-7

F

IG. 8-7 G45 CIRCUIT DIAGRAM..................................................................................8-8

F

IG. 8-8 RF14XU - SPARE PARTS................................................................................8-9

F

IG. 8-9 J45S COMPONENT REFERENCE...................................................................8-10

F

IG. 8-10 J45S CIRCUIT DIAGRAM.............................................................................8-11

F

IG. 8-11 J45A COMPONENT REFERENCE.................................................................8-12

F

IG. 8-12 J45A CIRCUIT DIAGRAM ............................................................................8-13

F

IG. 8-13 F200-40 COMPONENT REFEREN CE............................................................8-14

F

IG. 8-14 F200-40 CIRCUIT DIAGRAM .......................................................................8-15

F

IG. 8-15 RI40 EXPLODED VIEW ...............................................................................8-17

G).............................................................................5-36

Simrad Robertson AS

Egersund - Norway

Page 11

Robertson AP45 Autopilot

General Information

Page 1-1

1. GENERAL INFORMATION

Introduction

System descriptio n

Today Simrad manuf acture a comple te range of au topilots for all types o f vessels,

from leisure bo ats up to advanced steer ing systems for merch ant marine vessels.

Our factory for these products – branded Robertson – is located in Egersund, on

the south/west coast of Norway. The comp any’s inv olve men t in autop ilots beg an in

1953 with equipment for the North Sea fishing fleet.

In 1982 the world's first microprocessor based autopilot, the Robertson AP100, was

introduced and shortly after the AP9 and AP40 systems followed.

The AP45 autopilot described in this document is based on the experience with the

AP40 and the AP9 models. A series of improvements based upon this experience

has been implemented in the new model and special attention has been paid to

simplified operation.

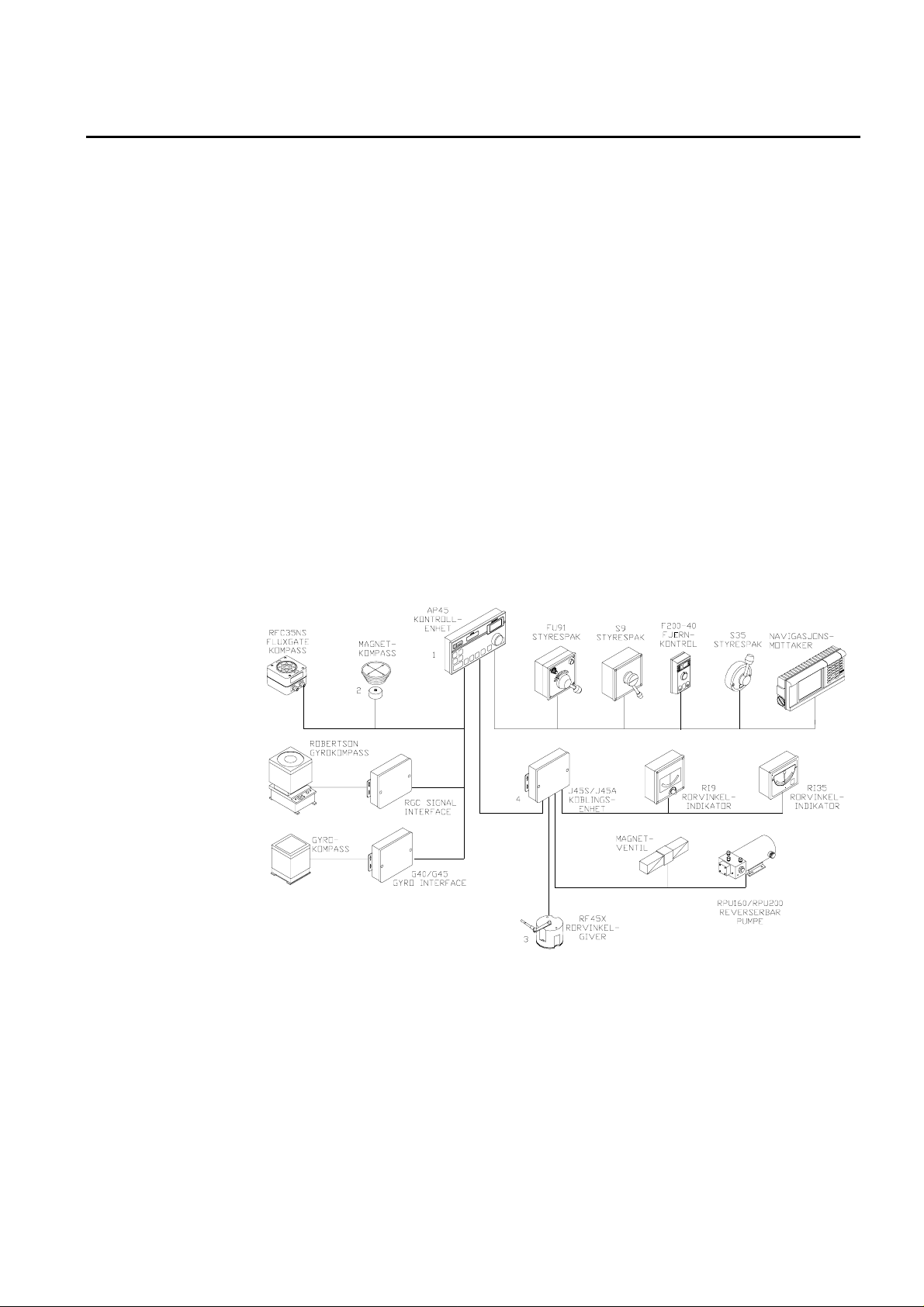

The standard AP45 system consists of the following units (refer to Fig. 1-1):

1. AP45 Control Unit with accessories

2. Heading sensor

3. Rudder Feedback Unit with transmission link

4. Junction Unit

AP45 Control Unit

Heading Sensors

Fig. 1-1

AP45 System layout - Basic system with options

All settings and operation of the autopilot take place on the control unit. In

addition to push bu ttons it has two LCD-displays and a cou rse selector knob on

the front panel. The control unit is made of seawater resistant aluminium and has

a polyester coating to protect it against the environment. The main electronics are

located in the control unit, and connection to other system components are by high

quality connectors to facilitate reliability and easy maintenance.

The AP45 autopilot can be used with one of three different types of heading

sensors:

Simrad Robertson AS

Egersund - Norway

Page 12

Page 1-2 Robertson AP45 Autopilot

General Information

1. Magnetic compass with CD109 Course Detector

2. RFC35NS Fluxgate compass*

3. Gyrocompass (using optional G40A or G45 Interface Unit)

*) For other types of Fluxgate Compass the FI100-40 Fluxgate Interface must be

used.

CD109 Course Detector

CD109 is a magnetic sensor in moulde d plastic which is mounted on the vesse l's

magnetic compass to transfer the heading to the control unit.

RFC35NS Fluxgate Compass

This is an electronic sense unit with NMEA- and sine/cosine output. The compass

has a 0,3 m ”pigtail” cable. RFC35NS substitutes the RFC250 Fluxgate compass.

RFC250 cable (P/N 20183554) is necessary at new installations.

G40A/G45 Gyro Interface Unit

The gyro interface unit is connected between the AP45 and a gyro compass. It

utilises the repeater sign al outpu t from the gy ro co mpass to g enerate a sine/co sine

heading signal for the autopilot.

G40A to be used with stepper or geared synchro signal. G45 to be used with

synchro 1:1 signal.

Rudder Feedback Units

FI100-40 Fluxgate Interface

FI100-40 is an interface unit to be co nnected betw een the AP45 and an e lectronic

fluxgate compass with sine/cosine output, e.g. VDO, Marinex, Sowester, Brooks &

Gatehouse.

RF45X Rudder Feedback Unit

This unit transmits two electrical signals proportional to the rudder angle. One

signal operates as a feedback for the autopilot, the other as drive signal for rudder

angle indicators. The unit is mounted close to the rudder stock and is mechanically

connected to the rudder by the T45 Transmission link.

RF14XU Rudder Feedback Unit

This unit can replace the RF45 Rudder Feedback Unit in installations where a

more rugged construction of the feedback unit is preferred. Besides electronic

circuitry to generate feedback signals for the autopilot and rudder angle indicators

it has been provided with 2 sets of limit switches. RF14XU can not drive the RI101

Rudder Angle Indicator, but all other types of Robertson indicators.

Simrad Robertson AS

Egersund - Norway

Page 13

Robertson AP45 Autopilot

General Information

Page 1-3

Junction units

Optional equipment

Remote Controls

Except for a bigger cabinet, the J45S and the J45A junction un its describe d in this

manual are identical to the previous versions, J200S-40 and J101A-40

respectively.

J45S Junction unit

The J45S Junction Unit will operate continuously running hydraulic power units

with directional valves as Robertson RPU3 or similar. The unit contains a printed

circuit board with terminal block, fuse, galvanic isolated solid state output to

switch the solenoids and start relay for the Power Unit. All mounted in an

aluminium cabinet with polyester coating.

J45A Electronic Junction Unit

The unit provides variable speed control of reversible hydraulic power units (e.g.

Robertson RPU80, RPU100 RPU160 or RPU200) and mechanical power units

(MRD100 or HLD2000). The unit consists of a prin ted circuit board with termin al

block, fuse and drive electronics, mounted in the same type of aluminium cabinet

as the J45S.

A series of options are available for the basic AP45 system.

S9 Non-follow-up (NFU) steering lever

S9 is a splash proof steering lever for bulkhead or console mounting. The unit is

constructed of a machined alum inium housing. The intern al mechanism of the S9

permits locking of the lever in the mid-position to avoid inadvertent operation.

When connected to the AP45, the S9 can also be used to switch the mode of the

autopilot when the lever is pulled out or pushed in.

FU91 Follow-Up (FU) steering lever

FU91 is a splash proof steering lever for bulkhead or console mounting. The unit

has a 45-0-45 degrees dial and a Push to take command bu tton. By positio ning th e

lever, a desired rudder angle can be set without using a rudder angle indicator.

Dimensions and design are the same as the S9, and it has a mid-position detent.

S35 Non Follow Up (NFU) Steering Lever

S35 is designed for indoor and outdoor bulkhead mounting. The lever is spring

loaded to midposition. It also has a “Mode” button that is not used when connected

to AP45.

F1/2 Remote Control (NFU)

F1/2 is a handheld control for push button steering, fitted w ith a rubber grip. It is

made of cast seawater resistant aluminium and fitted with a 10 meter (30 ft.)

cable.

F200-40 Remote Control

F200-40 is a multifunction hand he ld remote control with a 4-digit LCD display

and a course sele ctor knob to set course or rudder angle . It has push bu ttons for

power steering, course adjustment and mode selection between power steering,

dodging and auto steering. The unit consists of a PC board moun ted in a splash

proof aluminium cabinet fitted with a 7m (23 ft) cable connecting to the control

unit.

Simrad Robertson AS

Egersund - Norway

Page 14

Page 1-4 Robertson AP45 Autopilot

General Information

Rudder Angle Indicators

RI9 Rudder Angle Indicator

RI9 is an analogue indicator showing the rudder position at angles up to 45

degrees on each side of midship position. The scaling is 2 degrees pr. division.

The scale illumination is adjustable by a knob on the front.

The housing is constructed of painted aluminium inte nded for e ither bulkhead o r

console mounting. The splash proof construction is suitable for exposed mounting

locations.

RI35 Rudder Angle Indicator

RI35 is an analogue indicator showing the rudder position at angles up to 45

degrees on each side of midship position. The scaling is five degrees pr. division.

A front panel key is used for rudder zero adjustment and illumination adjustment.

The splash proof construction allows panel, bulkhead or bracket mounting in

exposed locations, such as b rid ge wings as wel l a s wheel hous e and engi ne room.

RI35 is delivered with a 20 meter (65 feet) cable.

Simrad Robertson AS

Egersund - Norway

Page 15

Robertson AP45 Autopilot

Operation

General

Page 2-1

2. OPERATION OF THE AUTOPILOT

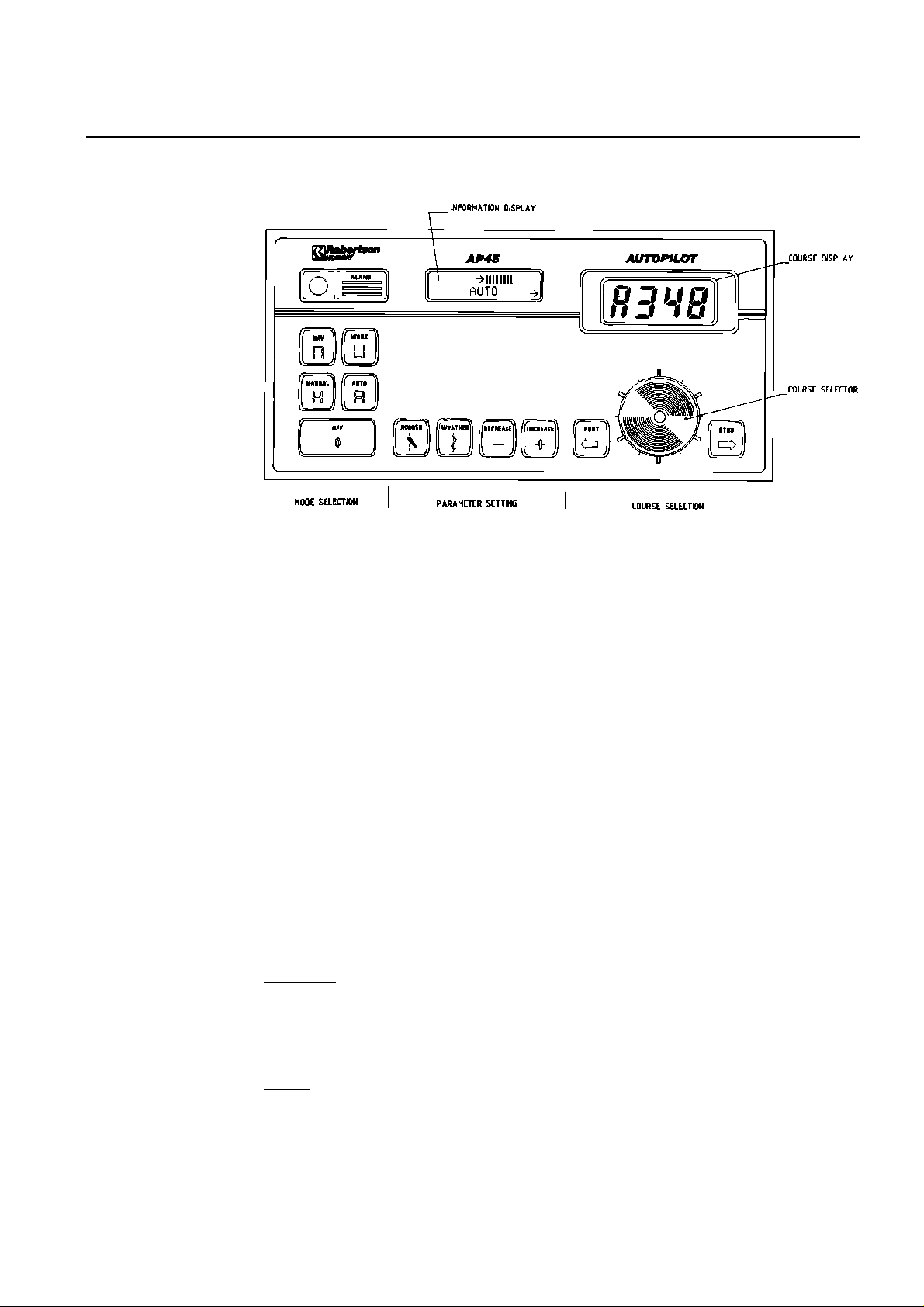

Fig. 2-1

AP45 Control Unit - front panel

Front Panel

Mode selection

AP45 autopilot is operated by means of keypad push buttons on the front panel. To

facilitate operation, the buttons are marked with text and symbo ls. The buttons

are backlighted, activated mode buttons being brighter than the others.

Course selection is made by the rotary Cou rse Selecto r Knob . Course adjustme nts

in steps of one degree can be achieved by the port or starboard push b u ttons.

The front panel has two LCD d isplays, referred to as the information disp lay (left

side) and the course display (right side). An alarm buzzer and an alarm reset

button is also on the front panel.

A few simple operations like pressing a button and/or turning the Course Selector

Knob is required in ordin ary use of the autopilot. All other instructions and data

required for the operation is stored in the autopilot at delivery from Robertson.

The front panel can be divided into three sections: Mode selection, Parameter

setting and Course selection.

Together with th e OFF-button and the 4 m ode buttons, this section also contains

an alarm buzzer and ALARM RESET-button.

MANUAL

The MANUAL button serves two purposes. It switches on the autopilot and selects

manual steering mode. In this mode the Course Display gives a digital readout of

compass heading, while the vessel can be steered manually by helm or steering

lever(s).

AUTO

The AUTO-mode is used under normal conditions when the boat is steered

automatically on a preset course.

When the AUTO-button is pressed, the autopilot selects the current vessel

heading as "course to steer".

Simrad Robertson AS

Egersund - Norway

Page 16

Page 2-2 Robertson AP45 Autopilot

Operation

Any difference betwe en co ur se to ste er and the v e ssel's actu al he ad ing w ill the n be

shown as a bargraph in the Information Display. One bar equals one degree.

Rudder commands are indicated by an arrow in the lower left or right corner of

the information display de pending upon which direction th e autopilot commands

the rudder to move.

WORK

The WORK-mode is an automatic mode to be used under operational conditions

different from those normally found when a vessel is under motor power on a

preset course. Examples are trawling, towing, sailing, slow speed etc.

In WORK-mode the PORT- and STBD-buttons can be used for immediate rudder

off-set (trim) if necessary. This manual off-set compensates for the built-in

autotrim which needs time to b uild up the appropriate off-set.

The Information Display shows the off-set value when the PORT- or STBD button

is pressed.

Boats under sail power and some trawlers may need a rudder off-set when steered

by hand. To avoid cancellation of the rudder off-set when changing to automatic

steering, the WORK-mode can be selected directly from MANUAL-mode. The

rudder off-set is then maintained as "on course" reference. This off-set is also

maintained when changing from WORK to NAV mode.

If the AUTO-mode is selected from MANUAL-mode, the rudder is first taken to

midposition before a sufficient off-set of the rudder is built-up automatically

(autotrim).

A different RUDDER value may be preferred in WORK-mode as compared to that

in AUTO-mode. The WORK-mode value will be stored in the AP45 memory for

later use.

Note!

Pair-trawling that requires manual trim only, will also require that the autotrim

be disabled. Refer to “Disengage of autotrim-function in WORK-mode”, page 6-5,

for specific details.

NAV

NAV-mode is used when a navigation receiver is connected to the autopilot for

automatic waypoint steering. To be able to use the NAV-mode with older AP45

(below s.n. 4000), the main PCB must be equipped with the N40 Navigation

Interface.

When the NAV-mode is selected, the AP45 automatically monitors the signals

from the navigation system. If the signals are absent or in a different format than

the data format selected in the AP45, an alarm w ill be given to ale rt the operato r.

See “Navigating with the AP45” page 2-5.

OFF

The autopilot is switched off by pressing the OFF-button for 2 seconds, during

which time the alarm will sound. Th e alarm cease s when th e AP45 is switch ed of f.

If the OFF-button is released before two seconds have elapsed, the auto pilot will

continue to operate as before and the alarm signal is automatically reset.

Rudder commands will stop as long as the OFF-button is pressed. All pre-set

parameters in the autopilot are stored while the unit is switched off.

Simrad Robertson AS

Egersund - Norway

Page 17

Robertson AP45 Autopilot

Operation

ALARM

The acoustic alarm is reset by pressing the red alarm push button.

Alarm messages shown on the information display are described under “Fault

warnings”, page 2-16.

Page 2-3

Parameter setting

General

The middle section of the AP45 control unit contains 4 push buttons and an

Information Di splay. The display sho ws selected mod e, deviation f rom set co urse,

parameter settings and other user information. When RUDDER or WEATHER

buttons are pressed, the display shows which button has been activated and to

what level the value has bee n set by th e n um be r of bars as w ell as in pl ain f igu re s.

The display returns to normal read-out, showing the selected mode one minute

after the last press on one of the buttons.

The text in the Information Display can be in one of five selectable languages:

English, French, German, Spanish and Norwegian (see “Select language”, page 6-

3.

Turn on

Turn on the AP45 by pressing the MANUAL button. The information display will

show for approx. three seconds:

SOFTWARE V_R_

MANUAL

Then it switches to:

NON FOLLOW UP

MANUAL

If the autopilot is connected to and set up for a g yrocompass with g eared synchro

or stepper signal, the display will show at turn on:

GYROADJUST

PRESS +/-

Use the + or - butto n until the autopilot display shows th e same heading as the

gyrocompass.

Then press the MANUAL button and the display will again show:

NON FOLLOW UP

MANUAL

When clear of obstacles and in open waters, steer your vessel on course and press

the AUTO button.

The display will now show:

→←

AUTOMATIC

and the autopilot will automatically keep your vessel on course.

INCREASE and DECREASE

Simrad Robertson AS

Egersund - Norway

Page 18

Page 2-4 Robertson AP45 Autopilot

A

Operation

These buttons are used to alter vario us settings. Each time one button is pr essed,

the value shown on the Informatio n Display, will increase (+) or decre ase (—) by

one unit. The value is also shown as a graphical bar. If a button is pressed for

more than two seconds, the value will auto matically increase or decrease u ntil the

button is released.

RUDDER

When the RUDDER button is pressed, the Information Display shows selected

RUDDER value. The RUDDER value sets the ratio between rudder angle and

heading error (p-factor).

Example: If RUDDER is set to 1.0 and there is a heading error of 2 degrees, the

rudder angle will be 2 degrees. (Heading error x RUDDER value = rudder angle).

The correct RUDDER setting is dependant upon the size and speed of the vessel.

The RUDDER value should increase with decreasing speed.

RUDDER should be set separately in WORK-mode, to optimise the autopilot

performance.

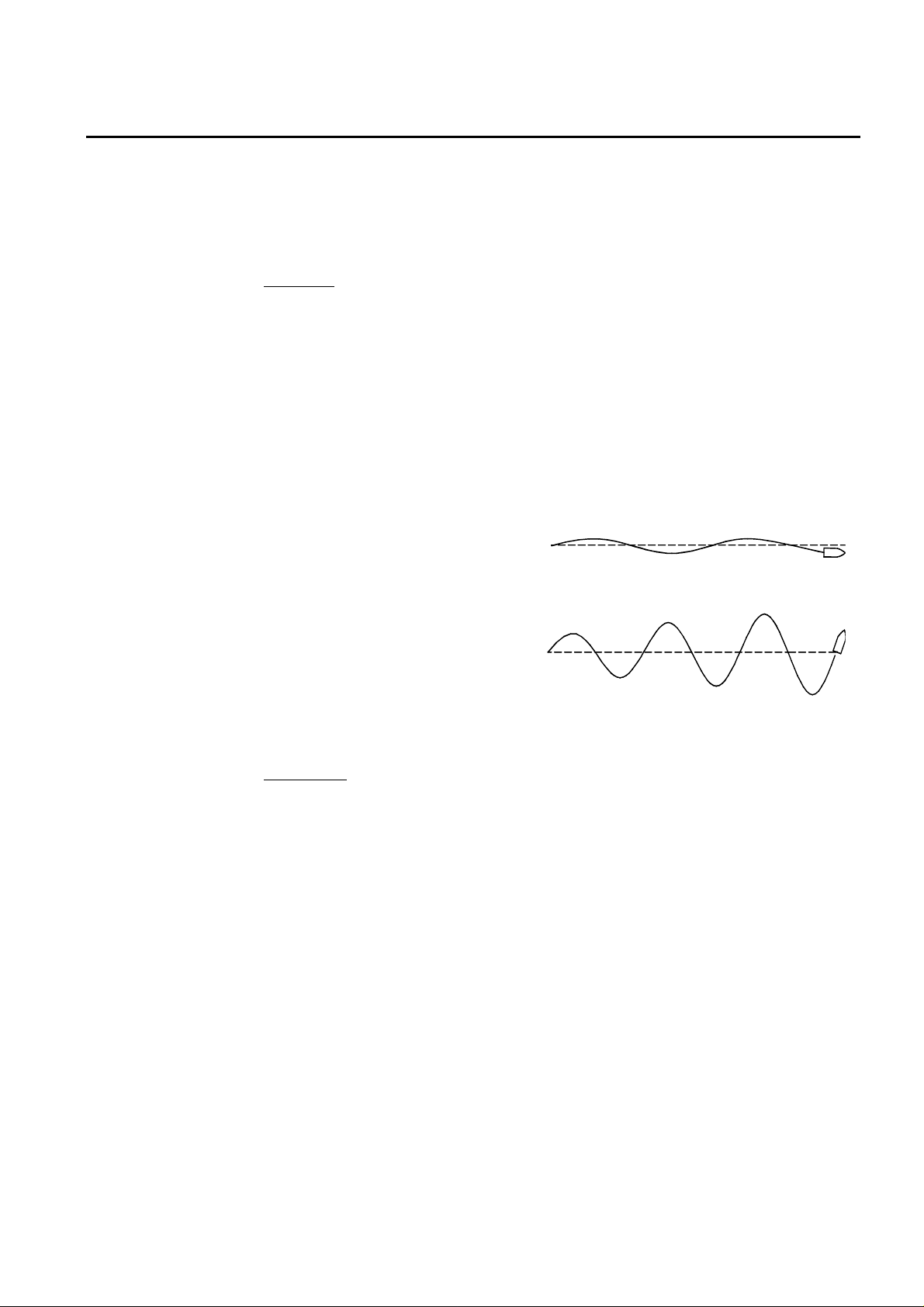

Examples of incorrect RUDDER settings:

A value which is too low gives

relatively large and slo w oscillations

(s-ing) around set course, and several

rudder commands are given in the

same direction before the vessel is

back on course.

Course selection

A value which is too high will give

quick and in worst case increasing

B

oscillations (s-ing) around set course.

The correct setting of RUDDER will be app ro ximate ly in th e mid dle o f th e se tting s

described in A and B above.

WEATHER

The WEATHER setting determines the amount of degrees the vessel may fall off

the set course before any response is given from the rudder. In calm weather it

should be set to OFF which means that theoretically the autopilot allows no

deviation from set course. The WEATHER value should be increased with

increasing sea state.

In conditions where active steering is requ ired, (e.g. following sea condition) , the

value should be reduced.

The course selection section on the au topilot consists of a course d isplay, a cou rse

selector knob and two course adjustment buttons, PORT and STBD.

The Course Display gives a readout of actual ships heading in MANUAL-mode

and set course in AUTO-, WORK- and NAV-mode. The selected mode is also

shown to the left on the display by the same letter as on the mode buttons.

The course selector knob is used for major course changes in AUTO- and WORKmode. To activate the knob it must be pressed down, released, and then turned.

Clockwise turns gives a starboard cou rse chan ge and vice v ersa. O ne re vo lu tion on

the course selector knob is equal to a 60 degree course change. If the knob is not

turned within 10 seconds, it has to be pressed again.

Simrad Robertson AS

Egersund - Norway

Page 19

Robertson AP45 Autopilot

Operation

The PORT and STBD push buttons are for minor course adjustments, pressed

once gives a one degree course change in the appropriate direction. In WORK-

mode however, the buttons are used for manual rudder trim, and course

changes can therefore only be made by the course selector knob.

Page 2-5

Navigating with the AP45

The AP45 has the capability to use steering information from an external

navigator (GPS, LORAN, Plo tter) to dir ect the boat to a sp ecific w aypo int lo cation,

or through a route of waypoints. In the NAV mode, the AP45 uses the heading

sensor as it's primary source of heading for course keeping. The steering

information received from the external navigator alters the set course to direct the

AP45 to the destination waypoint.

Note!

Navigational steering must only be used in open waters. The process of having an

external navigation receiver direct an autopilot can be a slow acting process. By

selecting the NAV mode, the AP45 is set for automatic steering on the current set

course and then waits for the user to accept the course change to the destination

waypoint.

To obtain satisfactory navigation steering, the following points must be fulfilled

prior to entering the NAV mode:

• The AP45 autosteering must be tested and found satisfactory.

• The navigation receiver must be operating and the navigation system (GPS,

LORAN, Decca) must be in full operating mode with adequate signal

characteristics for valid position and steering data.

• The magnetic compass or Fluxgate must have a minimum of deviation.

• At least one waypoint must be entered and selected as the current waypoint in

the navigation receiver.

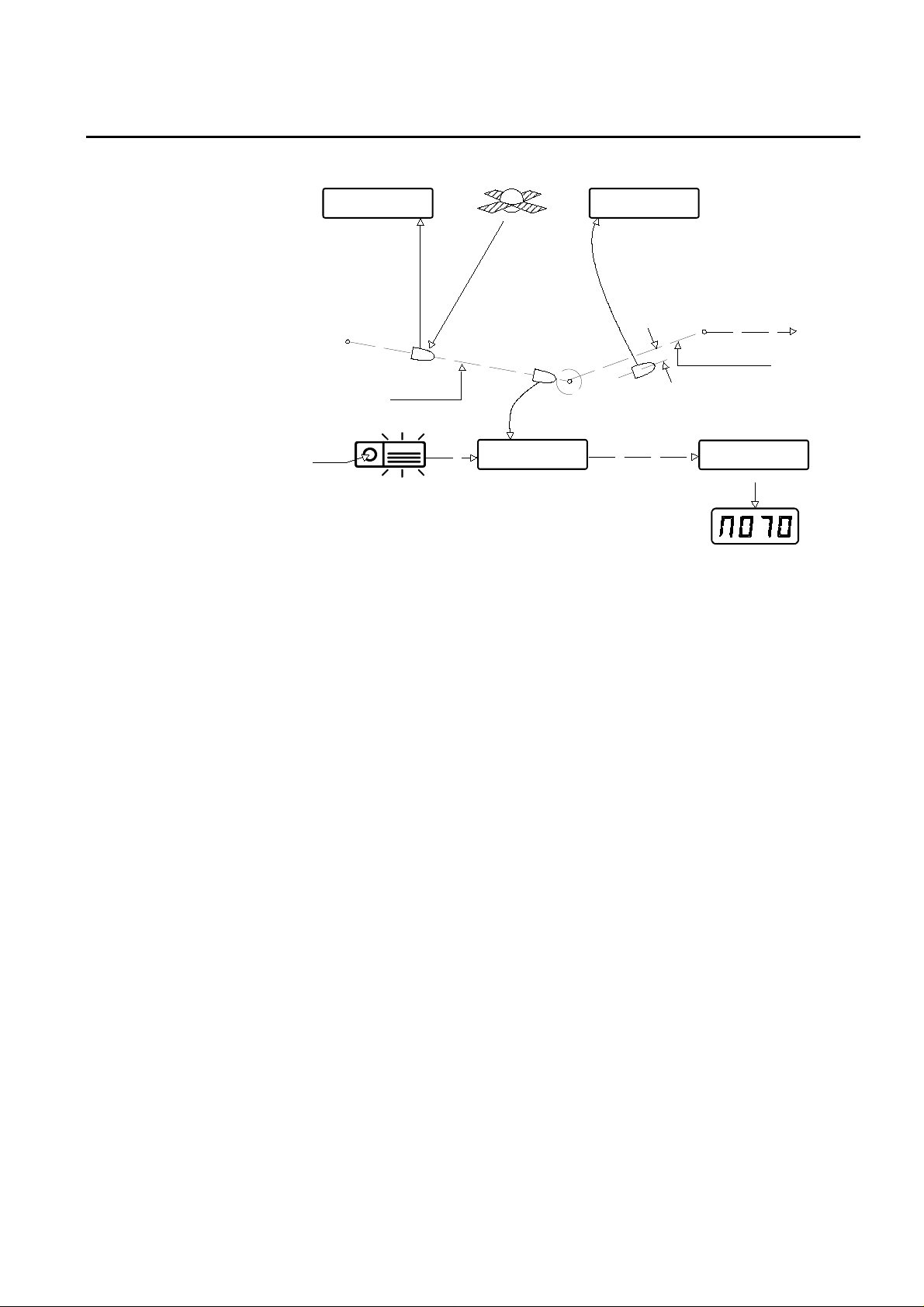

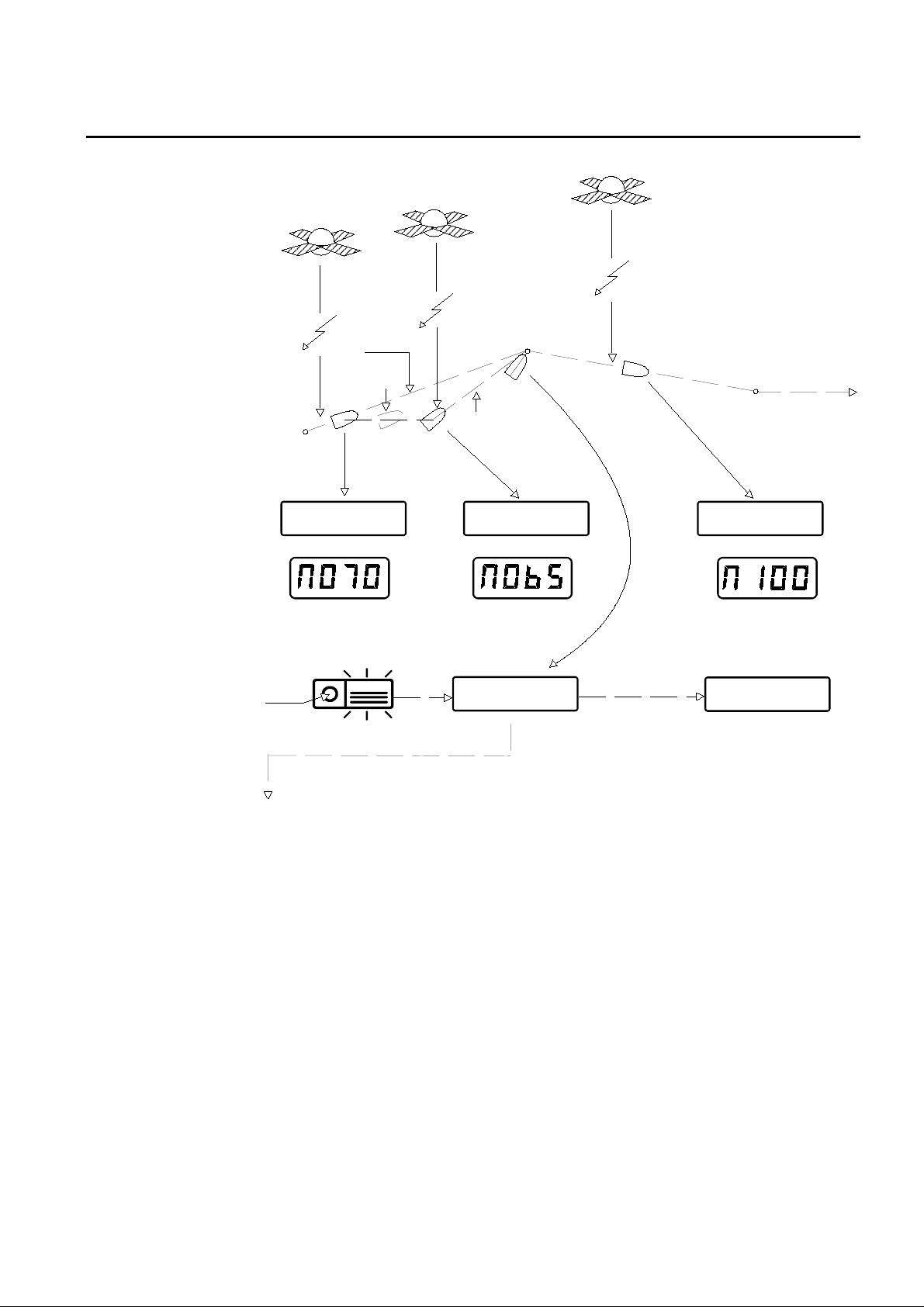

Mixed mode, XTE & CTS

The AP45 is from the factory set up to steer in mixed mode operation (CTS &

XTE). This combines the straight steering capability of cross track error (XTE)

steering in conjunction with the turning capability of bearing mode steering (CTS).

When operating the AP45 in NAV mode to automatically steer through a route of

waypoints, it will steer to th e first waypo int in the route af ter you accept the first

waypoint as the location to steer to. When you arrive at the waypoint, you will

need to verify that the upcoming course change is acceptable. Verification is

performed by pre ssing the Alarm rese t button af ter the ale rt sc re e n is disp lay ed . I f

no verification is received, the AP45 will continue on the current set course in

AUTO mode.

Simrad Robertson AS

Egersund - Norway

Page 20

Page 2-6 Robertson AP45 Autopilot

Operation

GPS satellite

00° ON TRAC K

NAVIGATION

INF O D IS PLA Y

WAYPOINT 1

RESET

Heading =100°

ALARM

WAYPOINT 2

ACCEPT CHANGE?

Y: RESET N: AUTO

INFO DISPLAY

04° XTE =R0.01NM

NAV IGA TION

INFO DISPL AY

XTE

RESET

WAYPOINT 3

New head ing = 70°

10MIN CH G 30°

NAVIGATION

INFO DIS P LAY

COURSE DISPLAY

Note!

Steering through a route of waypoints with the AP45 allows you the total flexibility

for automatic waypoint sequencing, but combines the safety feature of requiring

operator acknowledge for course changes in excess of 10 degrees.

If the AP45 is connected to a Nav. receiver that does not transmit a message with

bearing to next waypoint, it will pick a XTE message and steer on Cross Track

Error only. In that case you have to revert to AUTO mode at each waypoint and

manually change set course to equal bearing to next waypoint and then select NAV

mode again.

XTE mode

When the AP45 steers using cross track error only, it corrects the set course in

order to keep the vessel on a straight track between two waypoints. Bearing

change at waypoints must be made manually by temporarily go to Auto mode change set course - and revert to Nav. mode.

Use the following procedure for XTE steering:

1. Enter the desired bearing line(s) to the Nav. receiver using the present position

and the first waypoint or destination. Distance between waypoints should be of

minimum 2-3 n.m. Otherwise there may not be sufficient time for the system to

calculate the XTE, and fo r the autop ilot to alte r the cour se and bring th e ve ssel

onto the bearing line again.

2. Read the calculated bearing to waypoint from the Nav.receiver.

3. Select AUTO-mode on the AP45 , and set the course to the waypoint showed on

the navigation receiver.

Before going to step 4, ensure that the XTE is within +/- 0.1 n.m. to avoid

hazardous course change when selecting NAV-mode.

4. Select NAV-mode on the AP45. The autopilot now automatically changes the

set course to reduce the Cross Track Error (XTE) to zero. The information

display shows the number of degrees the autopilot has changed the set course,

and the XTE in 1/100's of a nautical mile. Note that the display readout will be

delayed, depending upon the NAV. FILTER setting.

Simrad Robertson AS

Egersund - Norway

Page 21

Robertson AP45 Autopilot

Operation

5. As the vessel gets within the arrival circle set on the navigational receiver, or

Page 2-7

Example:

05° XTE=R 0.02Nm

NAVIGATION

R indicates that the vessel is located to the right of the bearing line, and L

indicates to the left of the bearing line.

00° ON TRACK

NAVIGATION

05° is the number of degrees course correction relative to initial set course. As

the vessel approaches the bearing line, the correction value decreases and

when the vessel is on track, the information display shows:

Note!

The display may show X number of degrees course correction even if it says “ON

TRACK”.

as the vessel passes the perpendicular line to the waypoint, the receiver

transmits a "data not valid" signal to the autopilot. An alarm will then activ ate

and the course to steer will no longer be updated.

To proceed to the next waypoint, the procedure should be repeated from step 2

onwards.

Procedure:

• Reset the alarm on the autopilot and navigational receiver.

• Select “AUTOPILOT” mode on the autopilot

• Use Course Change knob/button s on the autopilot to set the new course given

by the Nav. receiver.

• Press “NAV”

NOTE!

Navigational steering is a slow acting process and the vessel normally follows the

bearing line with a deviation of ±0.02 - 0.03 n.m.(40-50 meters). Higher deviation

may temporarily occur due to rapid change of current, wind, speed or at start-up

from a position off the track line.

05° XTE = R0.02NM

L LEFT

NAVIGATION

INFO D IS P L A Y

05°

BEARING LINE

WAYPOINT 3

00° ON TRACK

NAVIGA T ION

INFO D IS P L AY

WAYPOINT 1

R RIGHT

XTE= R0.02NM

RESET

ALARM

POOR NAVDATA

CHANGE MODE

INFO D IS P LA Y

Simrad Robertson AS

Egersund - Norway

WAYPOINT 2

NAV.RECEIVER

ALARM

Page 22

Page 2-8 Robertson AP45 Autopilot

Operation

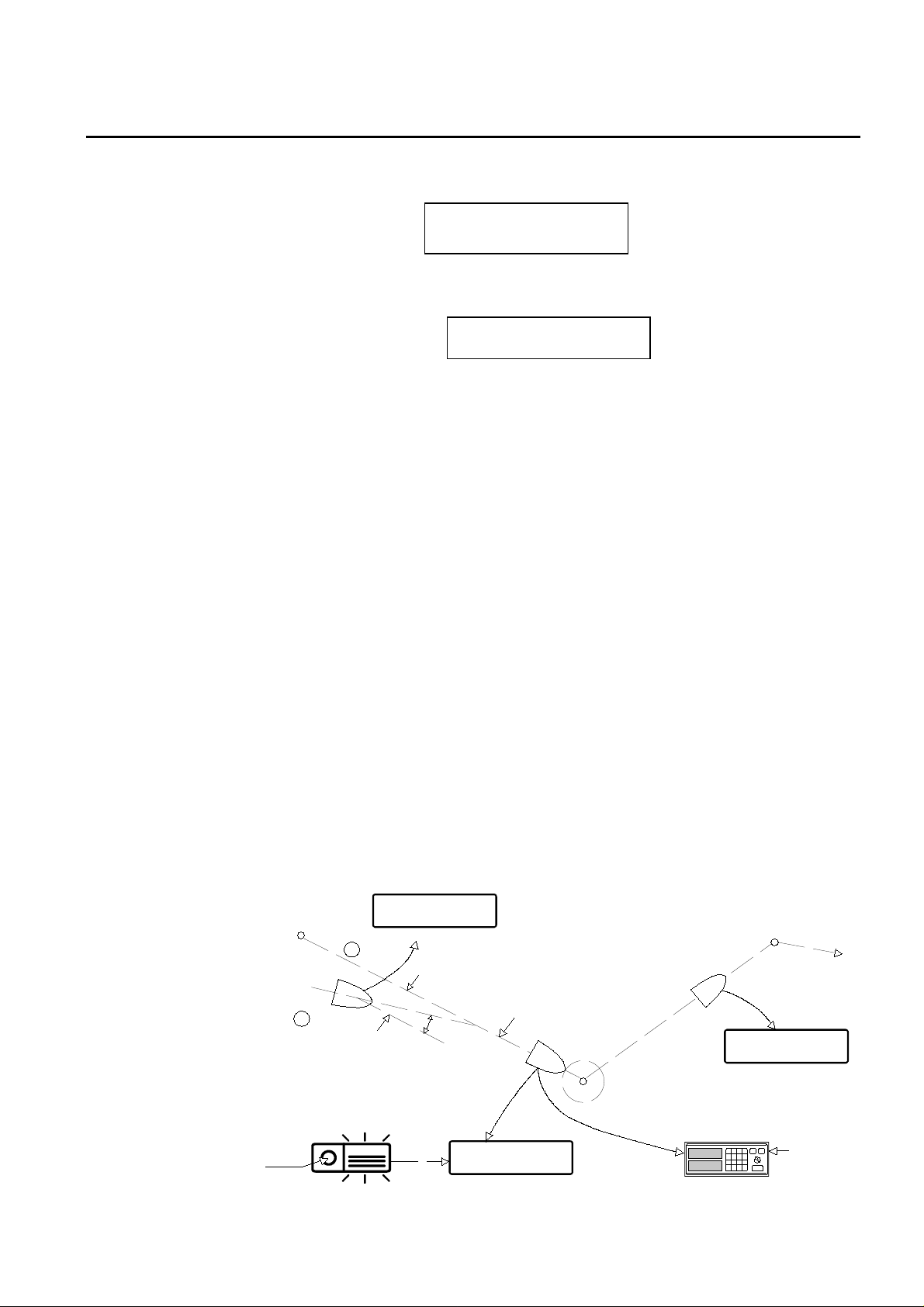

Steering by bearing to waypoint (CTS)

For some navigational receivers, bearing to a waypoint or course to steer is used

as the steering information.

If a satellite navigator is used, it should have compass and log input to ensure

proper dead reckoning between each fix.

1. Set the navigation receiver to calculate bearing to a waypoint from present

position.

2. Select AUTO-mode on the AP45, and set the course selector knob to the bearing

showed on the navigation receiver.

3. Select NAV-mode. The output signals from the navigation receiver will correct

the course to steer to make the vessel steer towards the waypoint.

The Information display shows time since last update and the amount of course

change in degrees, while the course display shows the new course to steer.

08 MIN CHG:05°

NAVIGATION

1. If the corrections from the navigation receiver initiates a course change greater

than 10 degrees, the autopilot alarm is activated and the course change has to

be acknowledged using the ALARM RESET button.

A typical sailing situation is illustrated in figure below.

Simrad Robertson AS

Egersund - Norway

Page 23

Robertson AP45 Autopilot

Operation

WAYPOINT 1

Update

HDG=70°

Drift

Tr a n s it s a te llite s

Update

Page 2-9

Update

WAYPOINT 2

Heading: 100°

WAYPOINT 3

NEW HDG 65°

RESET

08MIN C H G 00°

NAVIGATION

INFO D I SP LA Y

COURSE DISPLAY

ALARM

00MIN CHG 05°

NAVIGATION

INFO DISPLAY INFO DISPLAY

COURSE DISPLAY COURSE DISPLAY

ACCEPT CHANGE?

Y: RESET N: AUTO

INFO D IS P LA Y

RESET

15MIN C H G 00°

NAVIGATION

15MIN C H G 00°

NAVIGATION

Waypoint 2 has been reached. Continue as follows:

• If the heading to next waypoint, showed on the heading display, is accepted,

press RESET.

If not, press AUTOPILOT mode and continue without Nav. Steering

By pressing RESET, the ne w heading is automatically entered and the autopilot

will turn the vessel towards the new heading.

When reaching waypoint 3, repeat the same procedure.

Simrad Robertson AS

Egersund - Norway

Page 24

Page 2-10 Robertson AP45 Autopilot

Operation

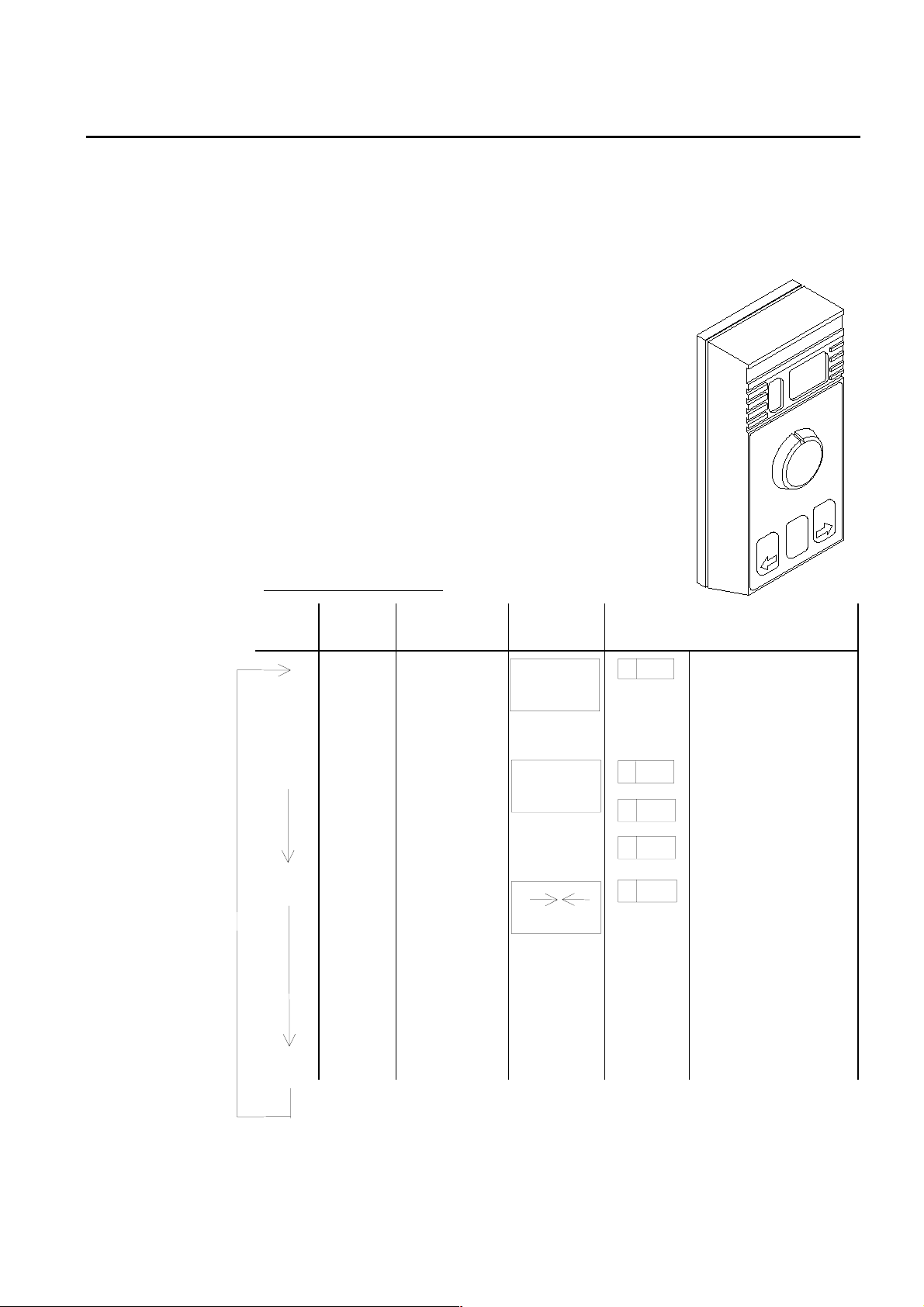

Remote Controls General

F200-40 Remote Control

The different types of Remote Controls that can be connected to AP45, have

different way of operation, depending on the system configuration.

The F200-40 hand held remo te control makes it possible

to remotely control the AP45 autopilot.

The following control functions are obtainable:

• Display that shows vessel heading or set course like

the course display on the control uni t.

• Course selection by a rotating knob

• Course adjustments by push buttons

• Mode selection

• Manual steering by course selector knob (Follow-Up)

• Manual steering by push buttons (Non-Follow-Up)

Option (selected during installation or sea trial):

• Dodging by means of course selector knob and

automatic return to previous set course.

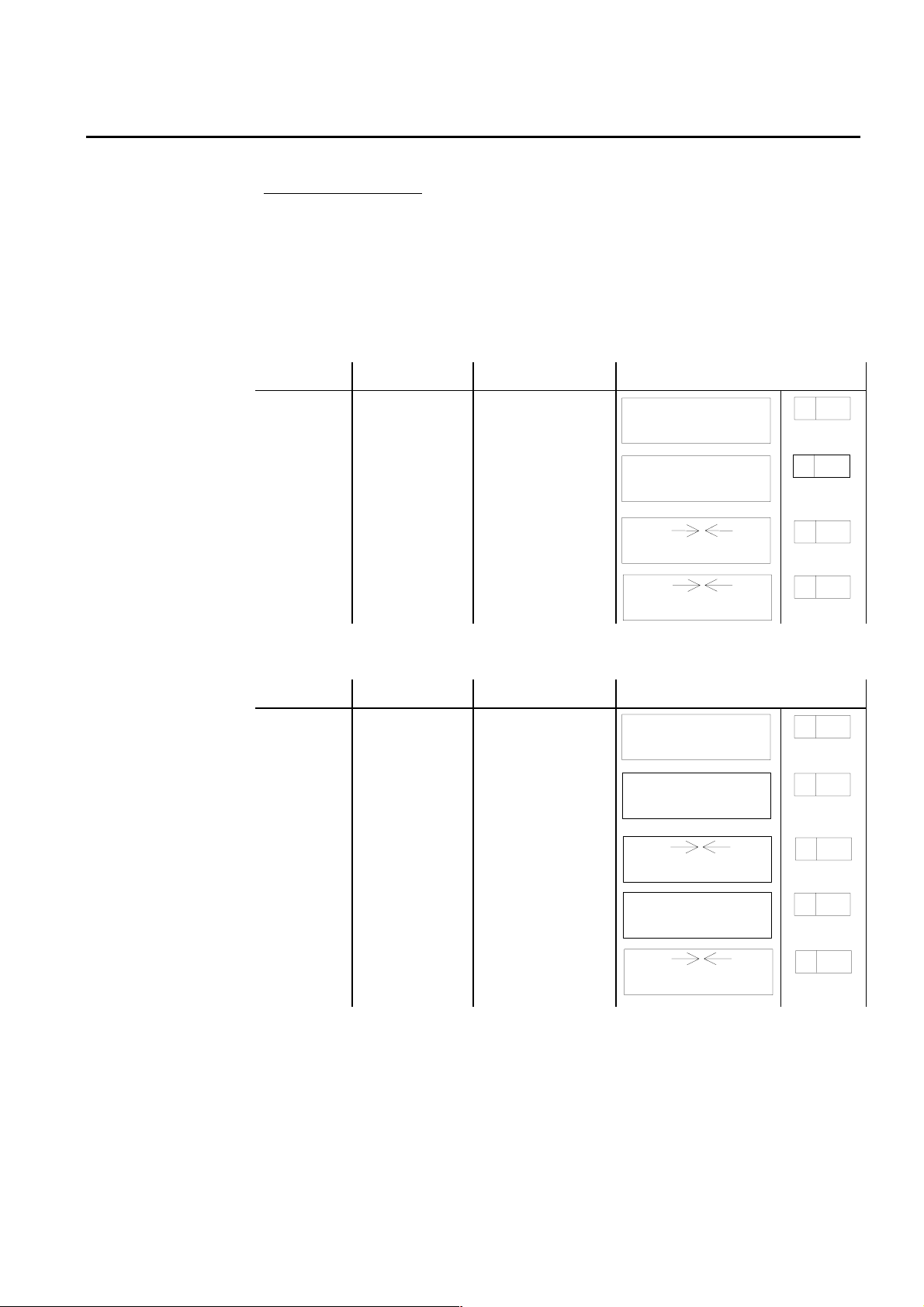

F200-40 without dodging

Press AP45

Mode

MANUAL

Function AP45

Display

NFU

steering by

F200

NON

FOLLOW UP

MANUAL

F200 Display

H 080 Vessel’s heading

PORT/STBD

push buttons

MODE MANUAL

Follow-Up

steering by

F200 course

selector

F200

FOLLOW UP

MANUAL

F ¯ 00

F

é 04

F

ù 32

Amidships, no

rudder command

4° port rudder

command

32° starboard rudder

command

MODE AUTO

Autosteering

Course set

A 146 Set course

AUTO

by the

AP45/F200

course

selector or

PORT/ STBD

button on

both

MODE

Simrad Robertson AS

Egersund - Norway

Page 25

Robertson AP45 Autopilot

Operation

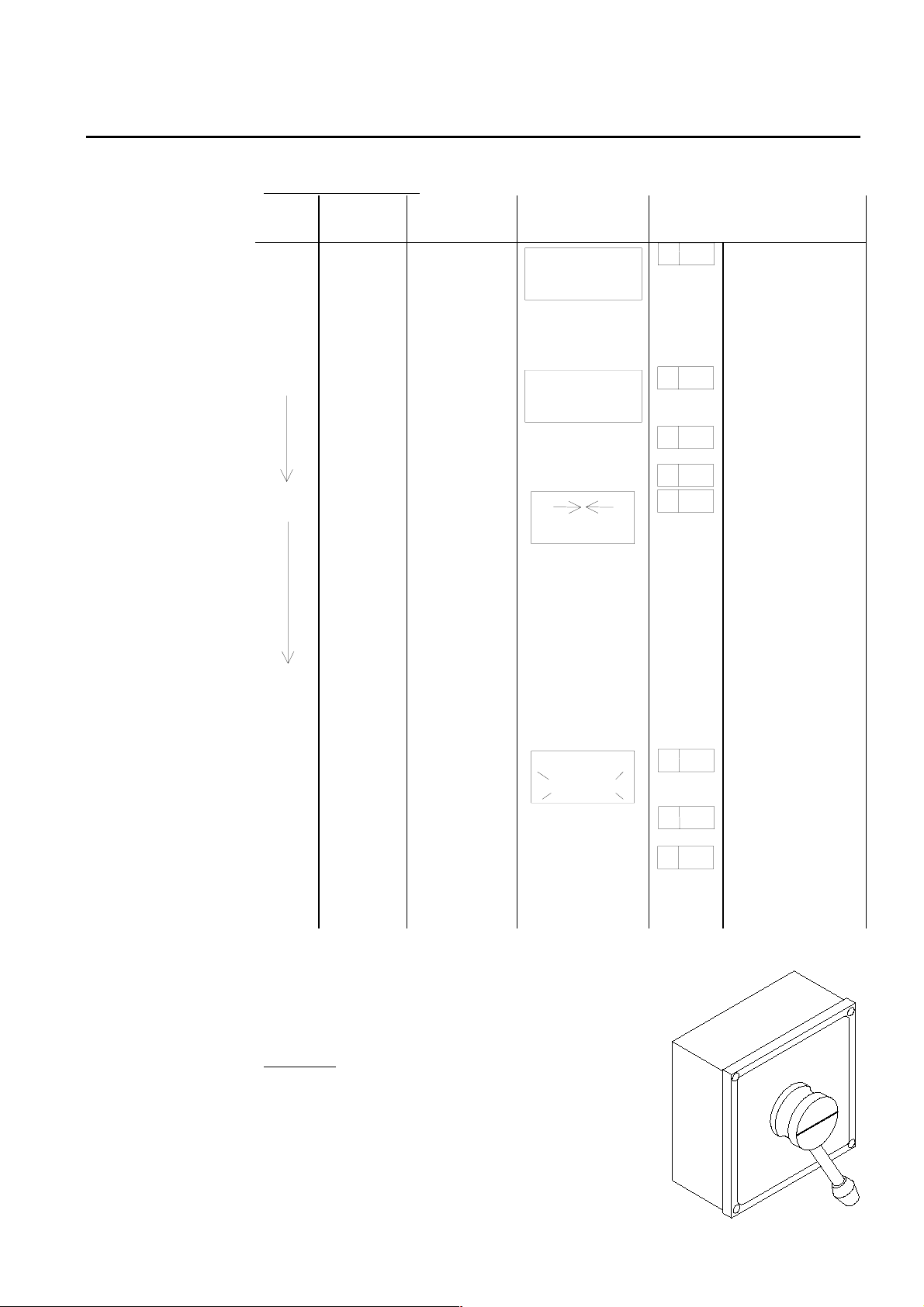

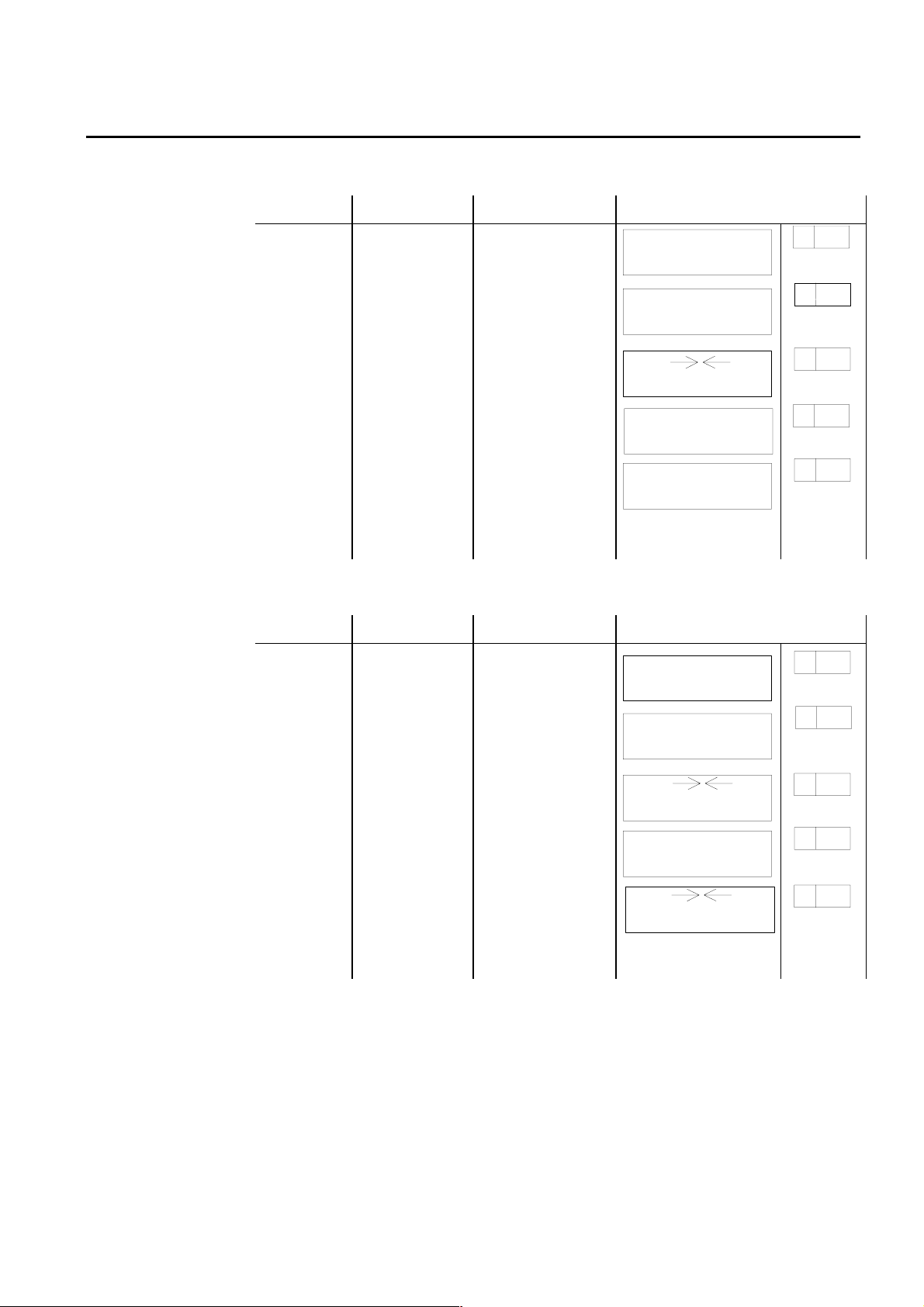

F200-40 with dodging

Page 2-11

Press AP45

Mode

MANUAL

MODE MANUAL

MODE AUTO

MODE

long

press

MODE

short

press

MODE

Returns

to

MANUAL

AUTO

Function AP45 Display F200 Display

NFU

steering by

NON FOLLOW UP

MANUAL

H 080 Vessel’s heading

F200

PORT/STBD

push

buttons

Follow-Up

steering by

F200 course

selector

F200 FOLLOW UP

MANUAL

F ¯00

é 04

F

Amidships, no

rudder command

4° port rudder

command

32° starboard

F

Autosteering

Course set

ù 32

A 146 Set course

AUTO

rudder command

by the

AP45/F200

course

selector or

PORT/

STBD

button on

both

DODGING

made by the

F200 course

selector

* * * * * * *

DODGING

F ¯00

é 04

F

Amidships, no

rudder command

4° port rudder

command

32° starboard

F

ù 32

rudder command

Returns to

previous set

course

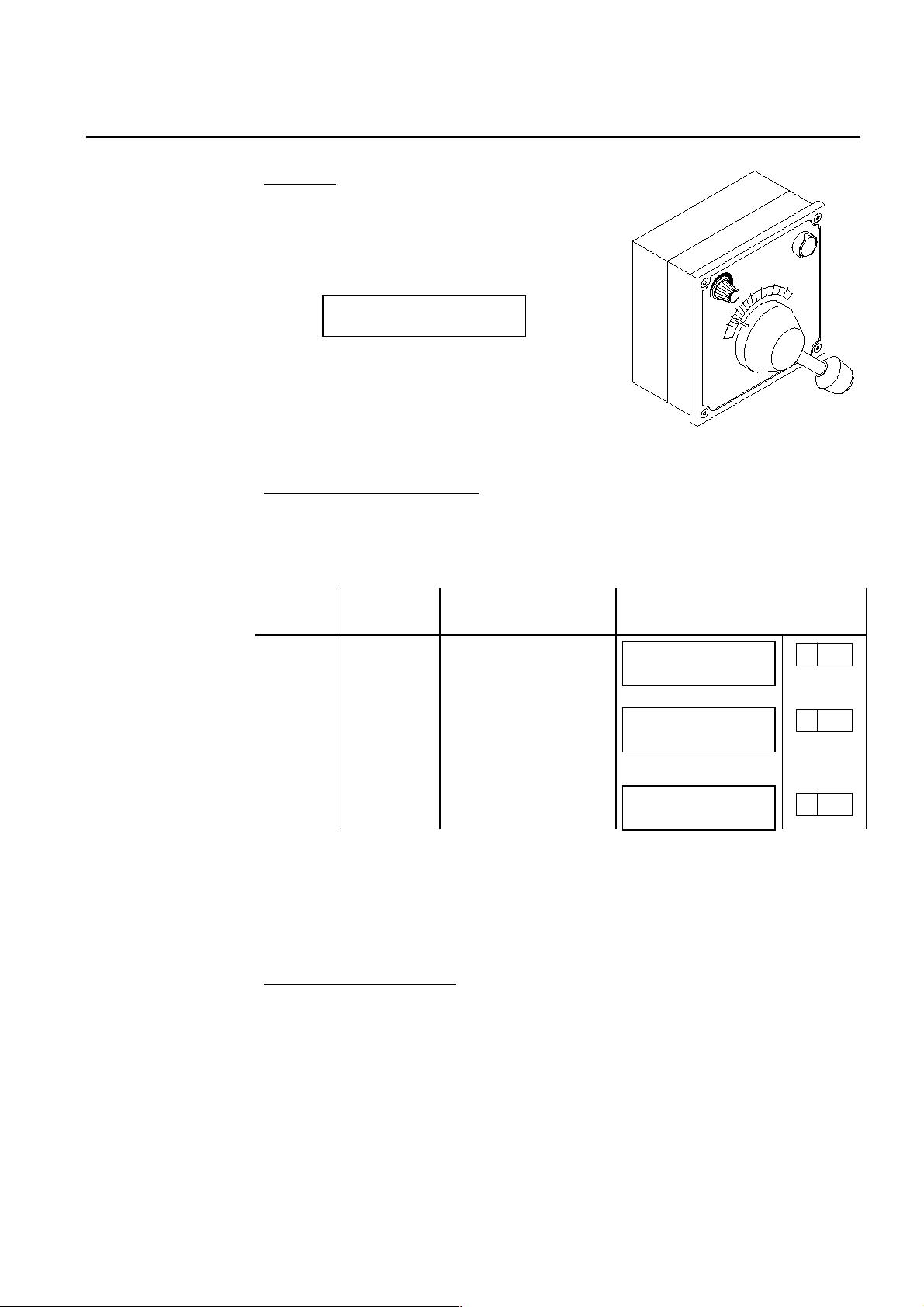

S9 Steering Lever

The S9 steering lever is intended for use together with

e.g. AP45 Autopilot. Several units ca n be connected in

parallel, but only if configured as alternative 1 (see

next page)

Operation

Activation is achieved by pulling out the lever. The

lever is spring loaded to mid position , and can be use d

for starboard or port rudder commands. After

finishing the manoeuvres the lever will be locked

when pushed back to non-operational position.

Simrad Robertson AS

Egersund - Norway

Page 26

Page 2-12 Robertson AP45 Autopilot

Operation

Alternative operation.

The S9 can be configured in four alternatives. At delivery from Robertson the S9 is

connected for alternative 1. If alternative 2, 3 or 4 is to be used, S9 has to be

modified according to the chapter “S9 Steering Lever”, page 5-26.

Note!

If a F200-40 also is connected, only alternative 1 can be used.

Alternative 1 (No resistor)

S9 Lever AP45 Mode Function AP45 Displays

IN MANUAL S9 locked NON FOLLOW UP

MANUAL

OUT MANUAL NFU steering by

moving lever to

NON FOLLOW UP

MANUAL

left or right

IN AUTO,

WORK

OUT AUTO,

WORK

S9 locked

AUTOMATIC

Course change

by moving lever AUTOMATIC

Alternative 2 (R = 1K)

S9 Lever AP45 Mode Function AP45 Displays

IN MANUAL S9 locked NON FOLLOW UP

MANUAL

OUT MANUAL NFU steering by

moving lever to

NON FOLLOW UP

MANUAL

left or right

IN AUTO,

WORK

S9 locked

AUTOMATIC

H 080

H 080

A 146

A 146

H 080

H 080

A 146

OUT AUTO,

WORK

IN AUTO,

WORK

Dodging made by

lever

S9 locked.

Return to

previous course

Simrad Robertson AS

Egersund - Norway

DODGING H 080

A 146

AUTOMATIC

Page 27

Robertson AP45 Autopilot

Operation

Alternative 3 (R = 3K)

S9 Lever AP45 Mode Function AP45 Displays

Page 2-13

IN MANUAL S9 locked NON FOLLOW UP

MANUAL

OUT MANUAL NFU steering by

moving lever to

NON FOLLOW UP

MANUAL

left or right

IN AUTO,

WORK

OUT MANUAL NFU-steering by

IN MANUAL

Remains in

manual mode

until new mode

has been selected

on control unit.

S9 locked

moving lever

S9 locked.

Return to

previous course

AUTOMATIC

NON FOLLOW UP

MANUAL

NON FOLLOW UP

MANUAL

Alternative 4 (R = 5,1K)

S9 Lever AP45 Mode Function AP45 Displays

IN MANUAL S9 locked NON FOLLOW UP

MANUAL

H 080

H 080

A 146

H 080

H 080

H 080

OUT MANUAL NFU steering by

moving lever to

left or right

IN AUTO,

S9 locked

WORK

OUT MANUAL NFU-steering by

moving lever

IN AUTO,

WORK

S9 locked.

Continues on

new set course,

same as vessel’s

heading

NON FOLLOW UP

MANUAL

AUTOMATIC

NON FOLLOW UP

MANUAL

AUTOMATIC

H 080

A 146

H 080

A 080

Simrad Robertson AS

Egersund - Norway

Page 28

Page 2-14 Robertson AP45 Autopilot

Operation

FU91 Follow up Steering Lever

Operation

The FU91 is activated by operating the push to

take command (PTTC) button. When in

“COMMAND”, the button light is switched on

and the autopilot INFO display will show:

FOLLOW UP

HELMSMAN

Rudder commands are made by setting the lever

to the required rudder angle, wherafter th e

rudder will move to the commanded angle and

stop.

FU91 may be connected to AP45 in two different

ways. See Fig. 5-32 and Fig. 5-33

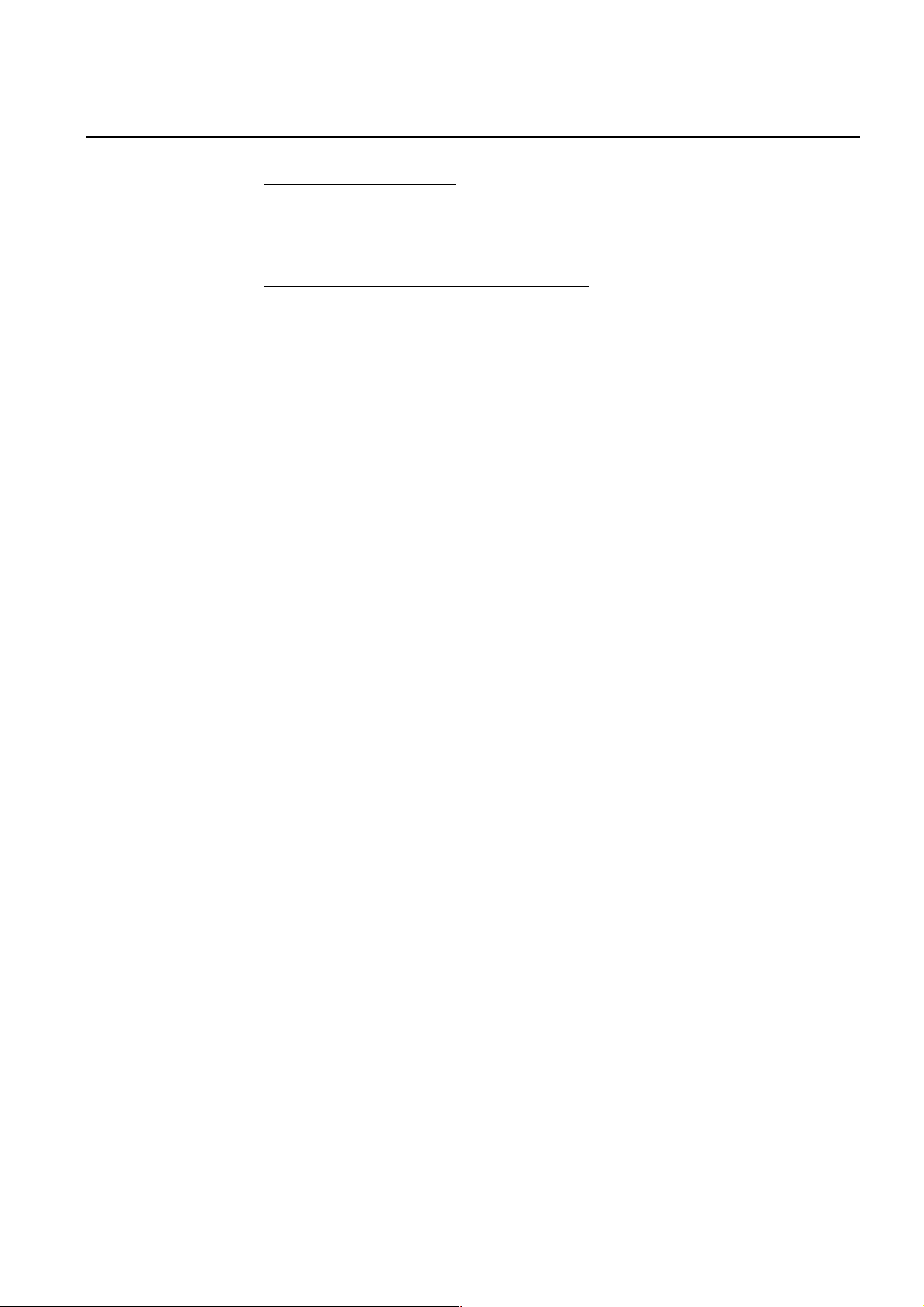

FU91 without mode switching

The lever can only be activated when the autopilot is in Helmsman mode. Pressing

the PTTC button repeatedly will toggle between NFU and FU mode on AP45. See

table below.

FU91

Switch

AP45

Mode

Function AP45 Displays

OFF MANUAL NFU steering by NFU

lever or push button

control

ON MANUAL Foll ow Up steering by

moving FU91 lever to

desired rudder angle

as read on FU91

ON-OFF AUTO Automatic steering

Note!

If the Helmsman button is pressed when the FU91 is active, or if a NFU lever is

operated, the autopilot will go to NFU mode even though the PTTC button light is

on. However, as soon as the FU91 is operated again (lever is moved), the autopilot

will resume FU mode.

For safety reason, the FU91 should always be switched to OFF when not in use.

FU91 with mode switching

The lever can be activated also with autopilot in Auto mo de. Pressing the PTTC

button brings the AP45 into Helmsman mode. Wh at mode/sequence you get when

pressing the PTTC button again is depending on w hich value of the re sistor R is

installed (Ref. page 5-29)

R = 1K: Auto - Dodge - Auto (previous course)

R = 3K: Auto Manual - Manual

R = 5,1K: Auto - Manual - Auto (new course)

NON FOLLOW UP

MANUAL

FOLLOW UP

MANUAL

* * * * *

AUTO

H 085

H 085

A 080

The mode change sequence is in principle similar to S9 oper ation alt. 2, 3 and 4

explained at page 2-12 and 2-13.

Simrad Robertson AS

Egersund - Norway

Page 29

Robertson AP45 Autopilot

Operation

Multiple FU91 installation

The operation of each lever is identical to above description of a single lever.

Activating one FU91 will deactivate the one that was previously active.

FU91 and S9 connected to the same autopilot

It is recommended not to have both S9 and FU91 in operational condition at the

same time. This may create confusion and inadvertent operation . The main rules

are:

• Always put the S9 lever to locked position after use .

• Always switch the FU91 to OFF after use.

Page 2-15

Simrad Robertson AS

Egersund - Norway

Page 30

Page 2-16 Robertson AP45 Autopilot

Operation

Fault warnings

The following fault warnings may be shown on the Information Display:

OFF COURSE

RESET ALARM

Course deviation is greater than selected off course alarm limit. Press the Alarm

button to cancel the alarm. The alarm is automatically reset when the vessel is

back within the limit.

RUDDER FEEDBACK

FAIL!

Indicates that the autopilot is not r eading r udder f eedback sig nal. By pre ssing the

alarm reset button, the audible alarm will be re set and th e auto pilot will sw itch to

a simulated signal, instead of the real. This is indicated by a flashing * * SIM * *

on the information display. Repair actions should be taken when back in port.

NO RESPONSE

FROM RUDDER

If a rudder command is not executed, or the rudder moves in wrong direction, this

message will be shown on the display. The reason can be a malfunction of the

steering gear, or simply that the steering gear is not switched on.

NAVDATA NOT REC.

CHANGE MODE

Check that the nav. receiver is turned on and set up properly (see nav. receiver

manual).

POOR NAVDATA

CHANGE MODE

Poor reception conditions or improper set-up of nav. receiver.

WRONG DATAFORMAT

NAVRECEIVER

Wrong NMEA-format selected on autopilot or transmitted by nav. receiver.

MAGN.COMP.FAIL

SELECT SENS.TYPE

All three messages indicate problems with reading the signals from the navigation

receiver. If you are unable to cure the problem, the NAV-mode should not be used

before a Robertson dealer has been consulted.

These alarms will be given w hen the autopilot is u nable to detect a proper sig nal

from the selected heading sensor. The reason can be a faulty sensor or wrong

selection of sensor (See “Type of Heading Sensor”, page 6-4).

FLUXGATE FAIL

SELECT SENS.TYPE

GYROCOMPASS FAIL

SELECT SENS.TYPE

DATA FAILURE

CHECK SETTINGS

If the autopilot should lose or read erratic data stored in the memory, this alarm

will be given, and the autopilot is simultaneously set to MANUAL-mode.

Simrad Robertson AS

Egersund - Norway

Page 31

Robertson AP45 Autopilot

Operation

A selection of standard settings is then automatically entered into the memory.

The standard settings will make the autopilot steer, but not to its best

performance on all vessels. They should therefore be checked (See “Selection of

parameter settings”, page 6-2).

If you prefer not to check the settings yourselves, enter the AUTO mode and

consult your Simrad Robertson dealer when back in port.

Only if Watch alarm function is enabled. Ref. “Watch alarm”, page 5-37.

The watch alarm warning signal is rep e ated ev e ry fo ur minute s as lon g as AP45 is

in Auto, Work or Nav mode and is reset by pressing Alarm reset button.

If you want to permanently disable the watch alarm function:

Press the hidden button above the + bu tton entering D ebug mode and then press

the WEATHER button repeatedly until the information display shows

SOFTWARE/RUNTIME. Press the DECREASE (-) button repeatedly (six times)

until the display shows DATA FAILURE - CHECK SETTINGS. Press the ALARM

RESET button and the Watch Alarm function is disabled.

Page 2-17

WATCH ALARM

PRESS RES BUTTON

Note!

This procedure is considered as a “Master reset” of the AP45 and you must therefore

check all settings described under “Selection of parameter settings”, page 6-2 or

consult your Simrad Robertson dealer when back in port.

For further explanation to Fault warnings, see page 7-1

Simrad Robertson AS

Egersund - Norway

Page 32

Page 2-18 Robertson AP45 Autopilot

Operation

.

Simrad Robertson AS

Egersund - Norway

Page 33

Robertson AP45 Autopilot

Design and theory of operation

3. DESIGN AND THEORY OF OPERATION

Page 3-1

Automatic Steering

An autopilot is an apparatus that controls the rudder of a vessel in order to

maintain a selected heading.

There are different design pr inciples for such an apparatus, but th ey all basically

operate as shown in Fi g. 3-1.

This diagram shows th at the vessel's heading is supplied from the compass to a

detector circuit. The de tector will sense when the vessel is off co urse and to what

side. The detected signal is amplified and directed to either energise the port or

starboard solenoids, i.e. make the rudder move one way or the other.

COMPASS

STBD. TRIGGER

DET AMP

PORT TRIGGER

SOLENOID

RUDDER

SOLENOID

FB

GYRO

COMPASS

MAG NE T IC

COMPASS

HEADING

CPU

KEYPAD

RUDDER POSITION

Fig. 3-1

Autopilot principle diag r am

PROG RAM

I/O

INTE RFACE

COURSE

SELE CTO R

DISPLAY

FEEDBACK

UNIT

DRIVER

RUDDER

FEEDBACK

RUDDER

SOLENO ID

VALVES

Fig. 3-2

Processor controlled autopilot

Simrad Robertson AS

Egersund - Norway

Page 34

Page 3-2 Robertson AP45 Autopilot

Design and theory of operation

In order to stop the rudder movement, a feedback signal is produced from the

feedback unit. The feedback signal w ill be compared with the comp ass signal and

when there is a balance between the two, the soleno id will be de-energise d. The

rudder has now been mov ed to a po sition that makes the ve ssel turn. This turn is

picked up by the compass and causes a new unbalance between the feedback

signal and the erro r signal which energise s the oppo site solenoid . Now the rudder

will start to move back towards the previous positio n, and the f eedback sign al will

again cancel out the unbalance and de-energise the solenoid to stop the rudder.

By utilising digital technology to perfo rm the function of an auto pilot, the typical

block diagram will be slightly changed. Even so, the basic operation should be

recognised on Fig. 3-2.

As we know, a microprocessor can only do what it has been programmed to. This is

called software. The program can be either fixed or partly adjustable to adapt the

microprocessor to the individual type of vessels. In Robertson terminology this is

called "setting parameters", and it will determine the performance of the autopilot.

AP45 Control Unit

CD109 Course Detector

The AP45 Control Unit contains two electro nic boards, the Control Board and the

Illumination Board. An optional navigation interface board (N40) may be supplied.

The Control Board contains the micro-computing circuitry, and a plug-in PC-board

for the Course Display. The alarm circuit is also mounted on this board.

The Illumination board consists of the display backlighting- and the Information

display electronics .

All interconnecting plugs for heading sensors, junction unit and remote controls

are mounted on the Control Board.

The two boards are intercon nected with a ribbon cable which are soldered to the

illumination board and plugged into the control board.

All parameter settings and operation of the autopilot are made using the push

buttons on the front panel.

CD109 is a magnetic compass sensor in moulded plastic. It is moun ted to a v esse l's

magnetic compass to transfer the heading information to the control unit. The

primary windings are excited by a pulsating sig nal. Dependant of the mag netism

induced by the position of the compass card magnets (Heading), pulses of variable

amplitude will be generated in the secondary sine and cosine windings. These

pulses are filtered through the R/C network and amplified before entering the A/D

converter.

N

S

Simrad Robertson AS

Egersund - Norway

HEAD 2 (COS)

HEAD 1 (SIN)

Exitation

R1

R2

C2

2.5V (Ref.)

Fig. 3-3

Course Detector principle

A/D

CONV.

Digital HeadingC1

Page 35

Robertson AP45 Autopilot

Design and theory of operation

Page 3-3

Rudder Feedback Units

RF45X Rudder Feedback Unit

The rudder feedback unit transmits rudder angle information to the control unit

and rudder angle indicators. It is mounted close to the rudder stock and

mechanically connected to the rudder tiller arm by a transmission link.

The RF45X contains a circular PCB carrying all the electronics and a long life

potentiometer con nected to the PCB by three wir es. The unit is rep airable in that

the electronics and the potentiometer can be replaced.

The electronics have two outpu t circuits. One circuit outputs f requency of 3400Hz

as midposition reference. It varies at a rate of 20Hz/degree, increasing when the

rudder moves to port and vice versa.

The other circuit outputs a current (0.1-1.1mA), to the rudder angel indicator(s)

(RI35 and RI9).

The RF45X is supplied with a fixed 4-wire, screened cable of 2 m (6 ft.). Th is cable

is meant to be spliced in the enclosed splash-proof junction box.

The shaft of the fe edback unit is free to travel 360 degre es, but only ±70 d egrees

from midposition are used for signal control.

The transmission link mechanically co nnects th e fee dback unit to the rudd er tille r

arm. It is made of stainless steel and has standard length of 450 mm.

RF14XU Rudder Feedback Unit (optional)

Fig. 3-4

RF45X principle

The RF14XU Rudder Feedback Unit consists of a glass-reinforced fire inhibiting

polyester housing with a mounting plate of seawater resistant aluminium.

Potentiometer, limit switches and an electro nic driv e mo dule are also containe d in

the unit. The electronic drive module comprises a voltage section and a frequency

section.

The voltage section outputs a voltage to the rudder angle indicator(s) which is

proportional to the rudder angle. The voltage varies ±9V with half of the supply