Page 1

AP44

Quick Guide

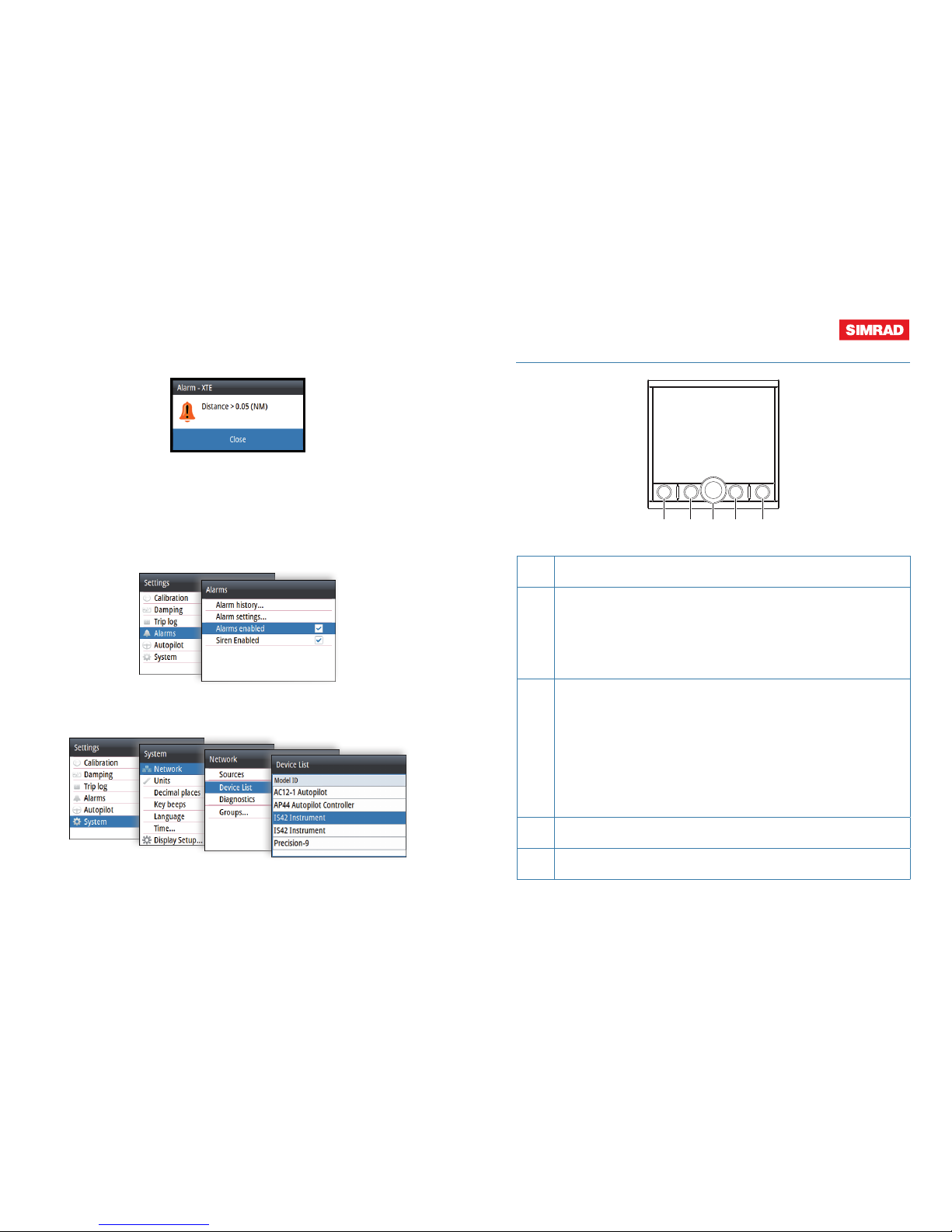

1 2 3 4 5

STBY MODE AUTO

MENU

X

1

STBY key

Press to turn the autopilot to Standby mode.

2

MENU/X key

With no menu active:

• Press to display the Settings menu

• Press and hold to display the Display setup dialog

Menu and dialog operation:

• Press to return to previous menu level or to exit a dialog.

3

Rotary knob

Menu and dialog operation:

• Turn to move up and down in menus and dialogs

• Turn to adjust a value

• Press to select a menu option and to enter the next menu level

In FU mode:

• Turn to set rudder angle

In AUTO, NoDrift and Wind mode:

• Turn to change set heading/set course/set wind angle

4

MODE key

Press to display the Mode list

5

AUTO key

Press to turn the autopilot to AUTO mode

EN

Alarms

Alarm indication

Acknowledging the alarms

Acknowledge alarms by pressing the rotary knob. A reminder reappears at given

intervals for as long as the alarm condition exists.

Enabling the alarm system and the alarm siren

Accessing the Device list

*988-11194-001*

Page 2

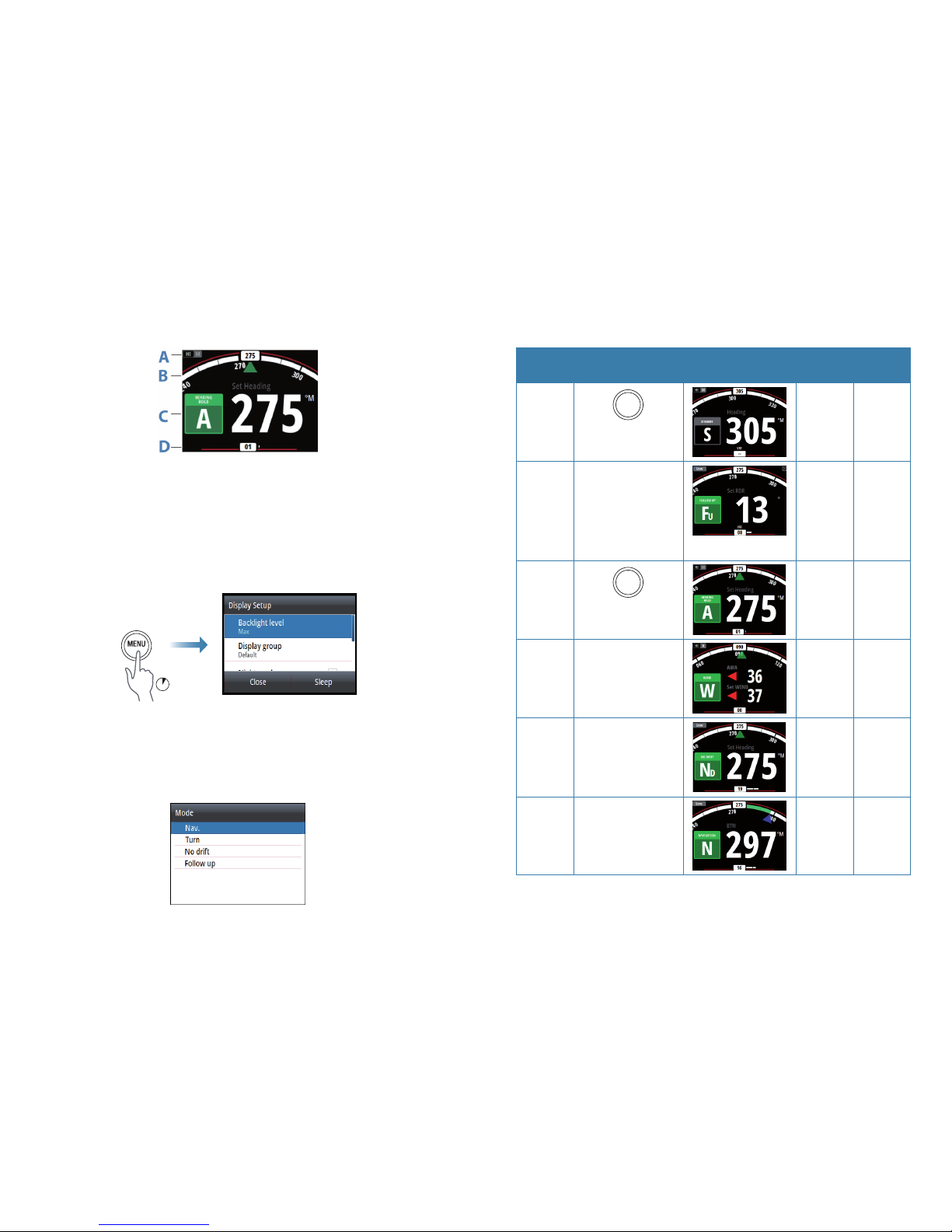

Autopilot modes

Mode Activate Mode display Rotary knob

Press Rotate

Standby

STBY

Switch to

FU mode

No action

Follow-up From any mode:

select the Follow-up

option in the Mode

list.

From Standby mode:

press the rotary knob.

No action Set the

rudder

angle

AUTO

AUTO

No action Adjust

the set

heading

Wind* From AUTO mode:

select the Wind

option in the Mode

list

No action Adjust set

wind

NoDrift From AUTO mode:

select the NoDrift

option in the Mode

list.

No action Adjust the

set course

NAV From any mode:

select the NAV option

in the Mode list.

No action No action

¼ Note: * Mode is only available when the boat type is set to SAIL.

The autopilot page

The content varies with active mode. All modes include:

• Response (AC12N/AC42N/SG05) / Profile (NAC-2/NAC-3) mode (A)

• Heading indicator, analog and digital (B)

• Autopilot mode indication (C)

• Rudder indicator, analog and digital (D)

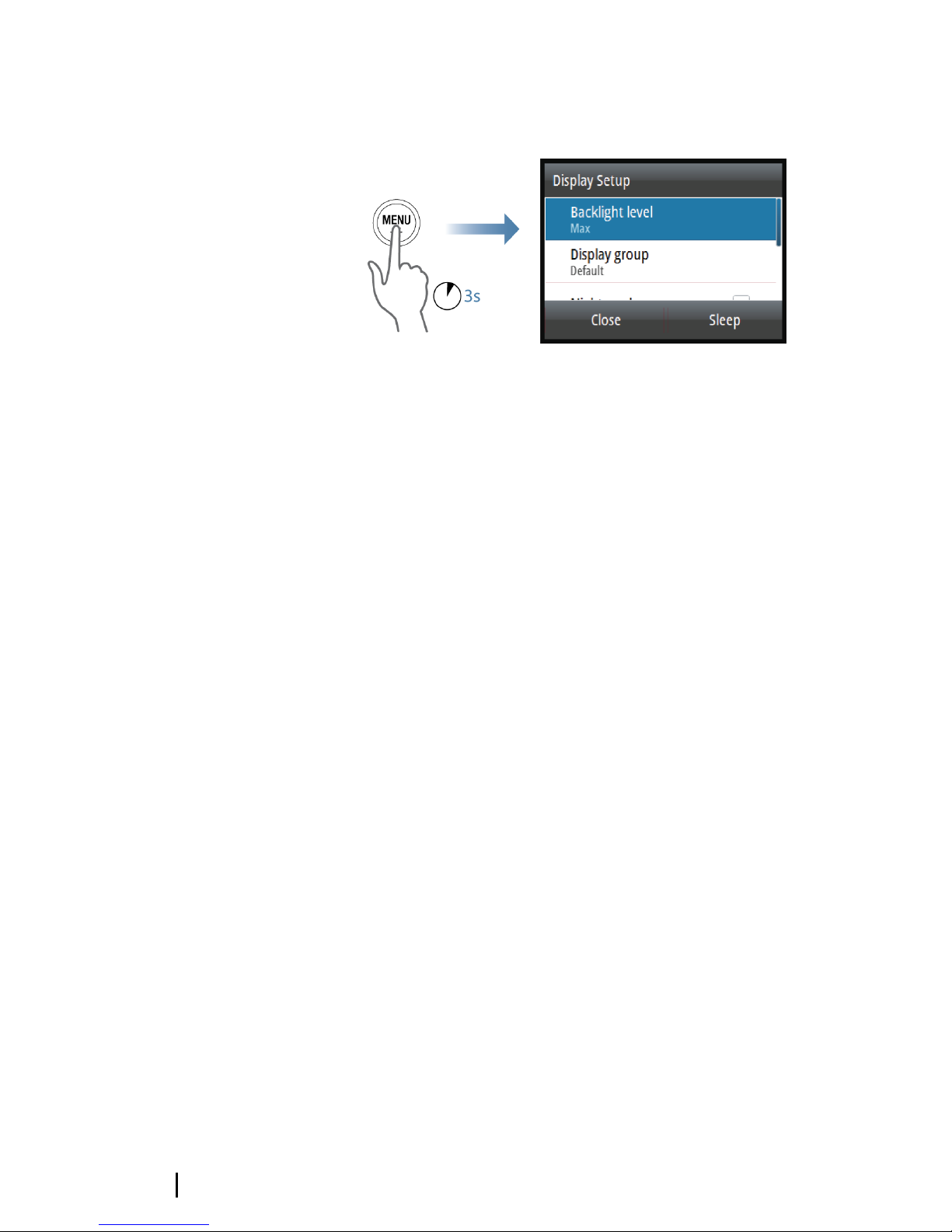

Display setup

x

3s

When the Backlight level field is active, subsequent presses on the MENU key adjusts

backlight level in decrements of 30% .

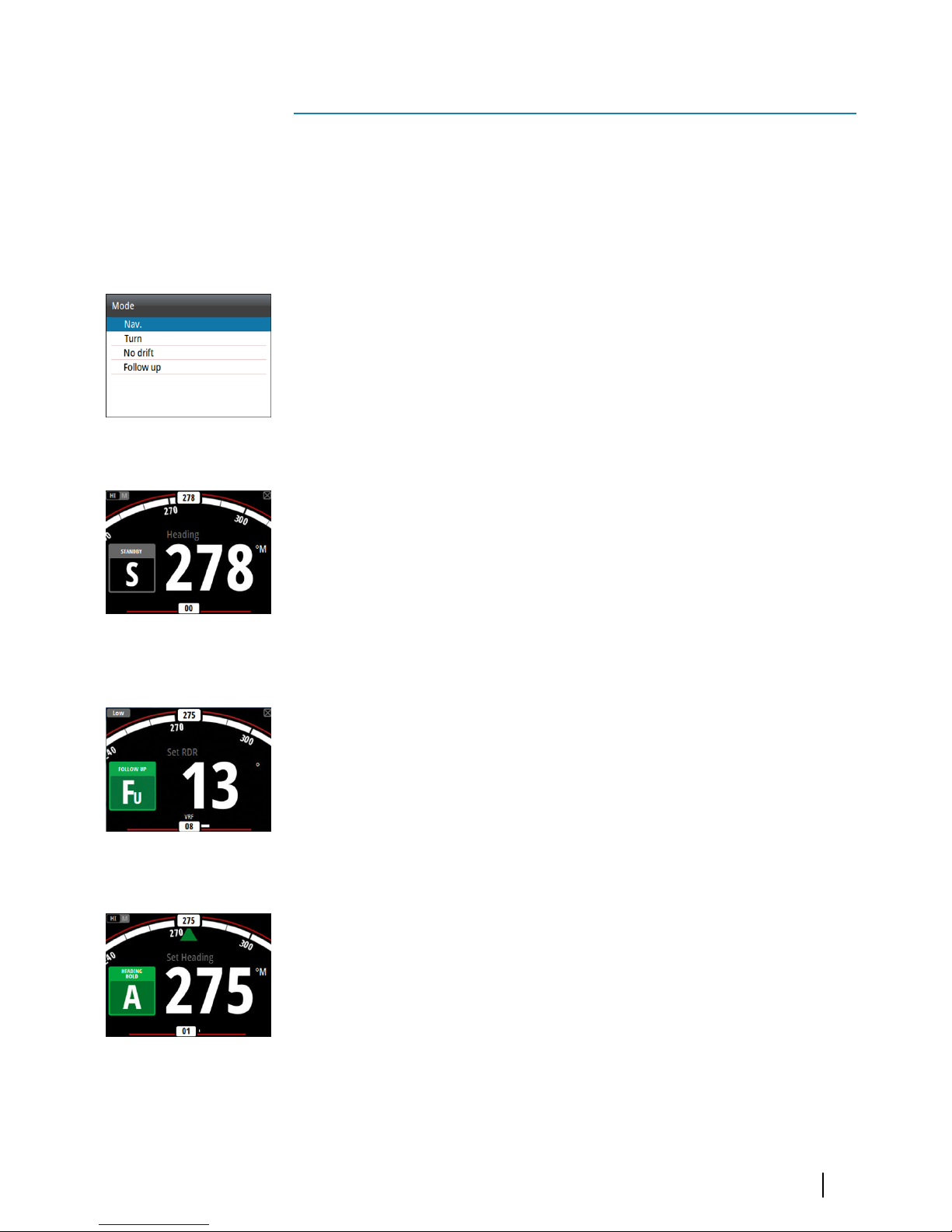

Selecting an autopilot mode using the MODE key

Press the MODE key and select the relevant option from the Mode list.

Page 3

ENGLISH

AP44

Operator Manual

www.simrad-yachting.com

Page 4

Page 5

Preface

Disclaimer

As Navico is continuously improving this product, we retain the

right to make changes to the product at any time which may not be

reflected in this version of the manual. Please contact your nearest

distributor if you require any further assistance.

It is the owner’s sole responsibility to install and use the equipment

in a manner that will not cause accidents, personal injury or

property damage. The user of this product is solely responsible for

observing safe boating practices.

NAVICO HOLDING AS AND ITS SUBSIDIARIES, BRANCHES AND

AFFILIATES DISCLAIM ALL LIABILITY FOR ANY USE OF THIS PRODUCT

IN A WAY THAT MAY CAUSE ACCIDENTS, DAMAGE OR THAT MAY

VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals, user

guides and other information relating to the product

(Documentation) may be translated to, or has been translated from,

another language (Translation). In the event of any conflict between

any Translation of the Documentation, the English language version

of the Documentation will be the official version of the

Documentation.

This manual represents the product as at the time of printing.

Navico Holding AS and its subsidiaries, branches and affiliates

reserve the right to make changes to specifications without notice.

Trademarks

Simrad® is used by license from Kongsberg.

NMEA® and NMEA 2000® are registered trademarks of the National

Marine Electronics Association.

Copyright

Copyright © 2016 Navico Holding AS.

Warranty

The warranty card is supplied as a separate document.

In case of any queries, refer to the brand website of your display or

system: www.simrad-yachting.com.

Preface | AP44 Operator Manual

3

Page 6

Compliance statements

This equipment complies with:

• CE under EMC directive 2014/30/EU

• The requirements of level 2 devices of the Radio communications

(Electromagnetic Compatibility) standard 2008

The relevant Declaration of conformity is available in the product's

section at the following website: www.simrad-yachting.com.

About this manual

This manual is a reference guide for operating the AP44. It assumes

that all equipment is installed and configured, and that the system

is ready to use.

The manual assumes that the user has basic knowledge of

navigation, nautical terminology and practices.

Important text that requires special attention from the reader is

emphasized as follows:

Ú

Note: Used to draw the reader’s attention to a comment or

some important information.

Warning: Used when it is necessary to warn

personnel that they should proceed carefully to

prevent risk of injury and/or damage to equipment/

personnel.

Manual version

This manual is written for software version 1.0. The manual is

continually updated to match new software releases. The latest

available manual version can be downloaded from www.simradyachting.com.

4

Preface | AP44 Operator Manual

Page 7

Contents

7 Introduction

7

Manuals

8 AP44 Front panel and keys

9 The autopilot page

10 Basic operation

10 Safe operation with the autopilot

10 Turning the unit on and off

11 Operating the menu system

12 Display setup

13 Autopilot modes

13 Selecting an autopilot mode

13 Standby mode

13 Follow-up (FU) mode

13 AUTO mode (Heading hold)

15 Wind mode

16 NoDrift mode

17 Heading capture

17 NAV mode

19 Turn pattern steering

23 Using the autopilot in an EVC system

24 Trip log

25 Alarms

25 Alarm indication

25 Acknowledging the alarms

26 Enabling the alarm system and the alarm siren

27 Alarm history

28 Software setup

28 Calibration

33 Damping

34 Autopilot settings

40 System settings

Contents | AP44 Operator Manual

5

Page 8

45 Maintenance

45

Preventive maintenance

45 Cleaning the display unit

45 Checking the connectors

45 Software update

48 Menu flow chart

50 Technical specifications

51 Dimensional drawing

52 Terms and abbreviations

54 Supported data

54 NMEA 2000 PGN (transmit)

54 NMEA 2000 PGN (receive)

6

Contents | AP44 Operator Manual

Page 9

Introduction

The AP44 is a networked autopilot display and control unit.

The unit is compatible with a range of Navico autopilot computers,

including AC12N, AC42N, NAC-2, NAC-3 and SG05 autopilot

computers.

The AP44 systems include several modules that need to be

mounted in different locations on the vessel and that need to

interface with at least three different systems on the boat:

• The boat’s steering system

• The boat’s electrical system (input power)

• Other equipment onboard

All parts of the autopilot system must be installed and configured

according to supplied documentation prior to using the autopilot.

The following steps are required:

• Mechanical installation and wiring of all units. Refer to separate

documentation for the units

• Software setup of the system. Refer to "Software setup" on page 28

• Commissioning and setup of the autopilot computer. Refer to

the installation and commissioning documentation for your

autopilot computer

Manuals

The following documentation is available for the AP44 system:

• AP44 Operator manual (988-11189-00n) - this manual

•

AP44/IS42/Triton2 Installation guide (988-11229-00n)

•

AP44/IS42/Triton2 Mounting template (988-11230-00n)

• NAC-2/NAC-3 Autopilot computer Commissioning manual

(988-11233-00n)

• AC12N/AC42N Installation manual (988-10276-00n)

Ú

Note: The last digit in the part numbers is the document's

revision code. The latest version of all documents can be

downloaded from the product website on www.simradyachting.com.

1

Introduction | AP44 Operator Manual

7

Page 10

AP44 Front panel and keys

1 2 3 4 5

STBY

MODE AUTO

MENU

X

1 STBY key

Press to turn the autopilot to Standby mode.

2 MENU/X key

With no menu active:

• Press to display the Settings menu

• Press and hold to display the Display setup dialog

Menu and dialog operation:

• Press to return to previous menu level or to exit a dialog

3 Rotary knob

Menu and dialog operation:

• Turn to move up and down in menus and dialogs

• Turn to adjust a value

• Press to select a menu option and to enter the next menu

level

In FU mode:

• Turn to set rudder angle

In AUTO, NoDrift and Wind mode:

• Turn to change set heading/set course/set wind angle

4 MODE key

Press to display the Mode list

5 AUTO key

Press to turn the autopilot to AUTO mode

8

Introduction | AP44 Operator Manual

Page 11

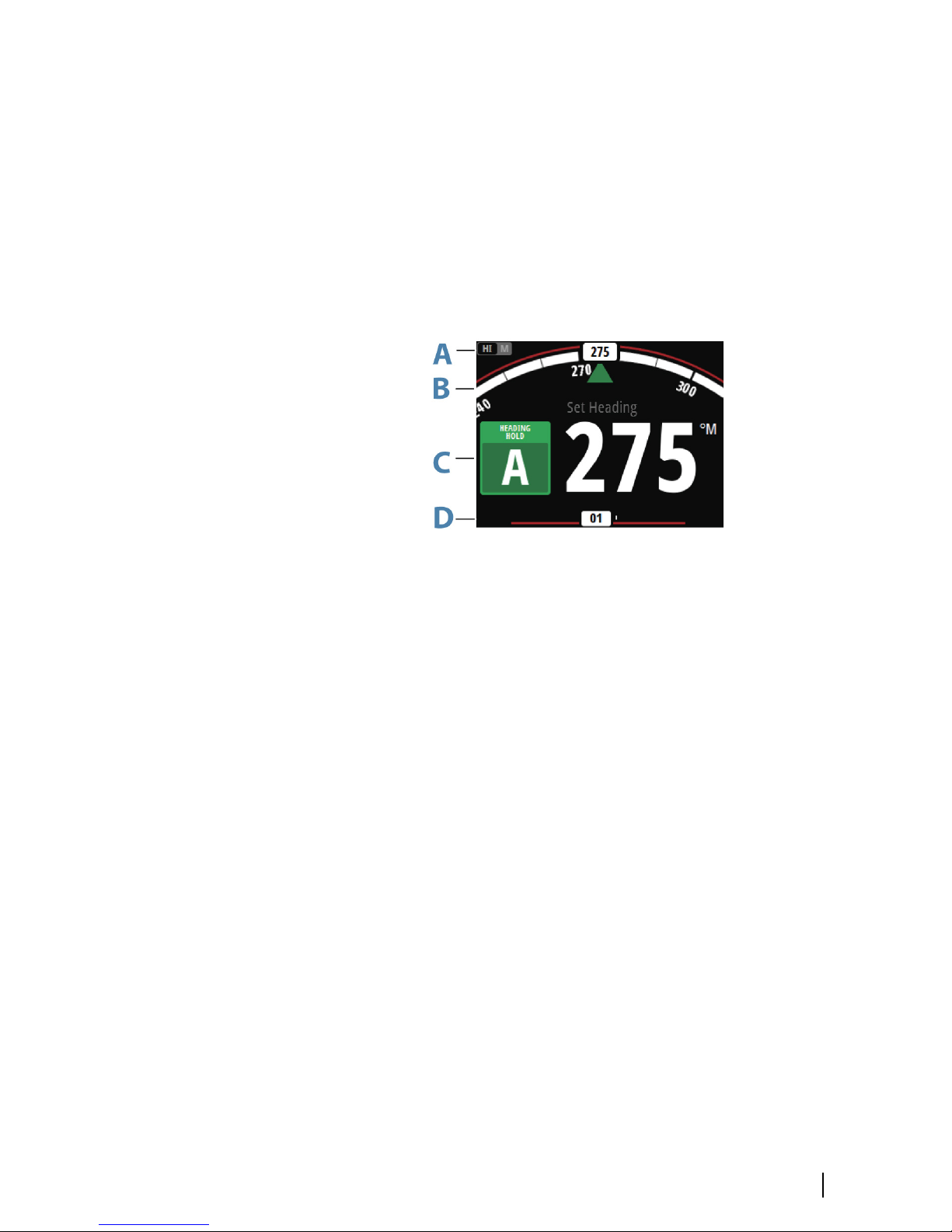

The autopilot page

The content of the autopilot page varies with active mode. All

modes include:

• Response (AC12N/AC42N/SG05) / Profile (NAC-2/NAC-3) mode

(A)

• Heading indicator, analog and digital (B)

• Autopilot mode indication (C)

• Rudder indicator, analog and digital (D)

For more information, refer to the separate mode descriptions and

to the "Terms and abbreviations" on page 52.

Introduction | AP44 Operator Manual

9

Page 12

Basic operation

Safe operation with the autopilot

Warning: An autopilot is a useful navigational aid,

but DOES NOT replace a human navigator.

Warning: Ensure the autopilot has been installed

correctly, commissioned and calibrated before use.

Do not use automatic steering when:

• In heavy traffic areas or in narrow waters

• In poor visibility or extreme sea conditions

• When in areas where use of an autopilot is prohibited by law

When using an autopilot:

• Do not leave the helm unattended

• Do not place any magnetic material or equipment near the

heading sensor used by the autopilot system

• Verify at regular intervals the course and position of the vessel

• Always switch to Standby mode and reduce speed in due time to

avoid hazardous situations

Turning the unit on and off

The unit has no power key, and it will be running as long as power is

connected to the NMEA 2000 network backbone.

First time startup

When the unit is started for the first time and after a factory reset,

the unit displays a setup wizard. Respond to the setup wizard

prompts to select some fundamental setup options. These settings

can later be changed and further configuration made as described

in "Software setup" on page 28.

2

10

Basic operation | AP44 Operator Manual

Page 13

Sleep mode

In Sleep mode, the backlight for screen and keys are turned off to

save power. The system continues to run in the background.

You select Sleep mode from the Display setup dialog, activated by

pressing and holding the MENU key. Switch from Sleep mode to

normal operation by a short press on the MENU key.

Operating the menu system

All settings and configuration in the unit are available from the

Settings menu, activated by pressing the MENU key.

• Turn the Rotary knob to move up and down in the menus and in

the dialogs

• Confirm a selection by pressing the Rotary knob

• Return to previous menu level by pressing the MENU key

Edit a numeric value

1. Turn the Rotary knob to select the entry field

2. Press Rotary knob to turn the field into edit mode

-

The left digit starts flashing

3. Turn the Rotary knob to set the value for the flashing digit

4. Press the Rotary knob to move focus to the next digit

5. Repeat step 3 and 4 until all digits are set

6. Press the Rotary knob to leave edit mode for the selected field

7. Turn the Rotary knob to select the Cancel or Save buttons, then

press the Rotary knob to confirm your selection and to close the

dialog

Selected field Field in edit mode

Ú

Note: You can at any time press the MENU key to leave a

dialog without saving the entries.

Basic operation | AP44 Operator Manual

11

Page 14

Display setup

The display setup can be adjusted at any time from the Display

setup dialog, activated by pressing and holding the MENU key.

The following options are available:

• Backlight level: Adjusts the backlight level from Min (10%) to Max

(100%) in 10% increments

-

When the Backlight level field is active, subsequent presses on

the MENU key adjusts backlight level in decrements of 30%

• Display group: Defines which network group the unit belongs to

• Night mode: Activates/deactivates the night mode color palette

• Night mode color: Sets the night mode color palette

• Invert day color: Changes the background color for the pages

from default black to white

• Sleep: Turns the backlight for screen and keys off to save power

Ú

Note: All changes made to the display setup will apply to all

units belonging to the same display group. For more

information about network groups, refer to "Network groups" on

page 43.

12

Basic operation | AP44 Operator Manual

Page 15

Autopilot modes

The autopilot has several steering modes. The number of modes

and features within the mode depend on the autopilot computer,

the boat type and available inputs, as explained in the description of

the following steering modes.

Selecting an autopilot mode

You select Standby mode and AUTO mode by pressing the

dedicated STBY and AUTO keys.

You select other modes and automatic features by selecting the

relevant option from the Mode list, activated by pressing the MODE

key.

Standby mode

Standby mode is used when you steer the boat at the helm.

• Switch to Standby mode by pressing the STBY key.

Ú

Note: If sensor data vital for autopilot operation (e.g. rudder

response) is lost when the autopilot is running in an automatic

mode, the system will automatically switch to Standby mode.

Follow-up (FU) mode

In FU mode you turn the rotary knob to set the rudder angle. The

rudder will move to the commanded angle and then stop.

• Switch to FU mode from any mode by selecting the Follow-up

option in the Mode list, or switch directly from Standy mode to

FU mode by pressing the rotary knob.

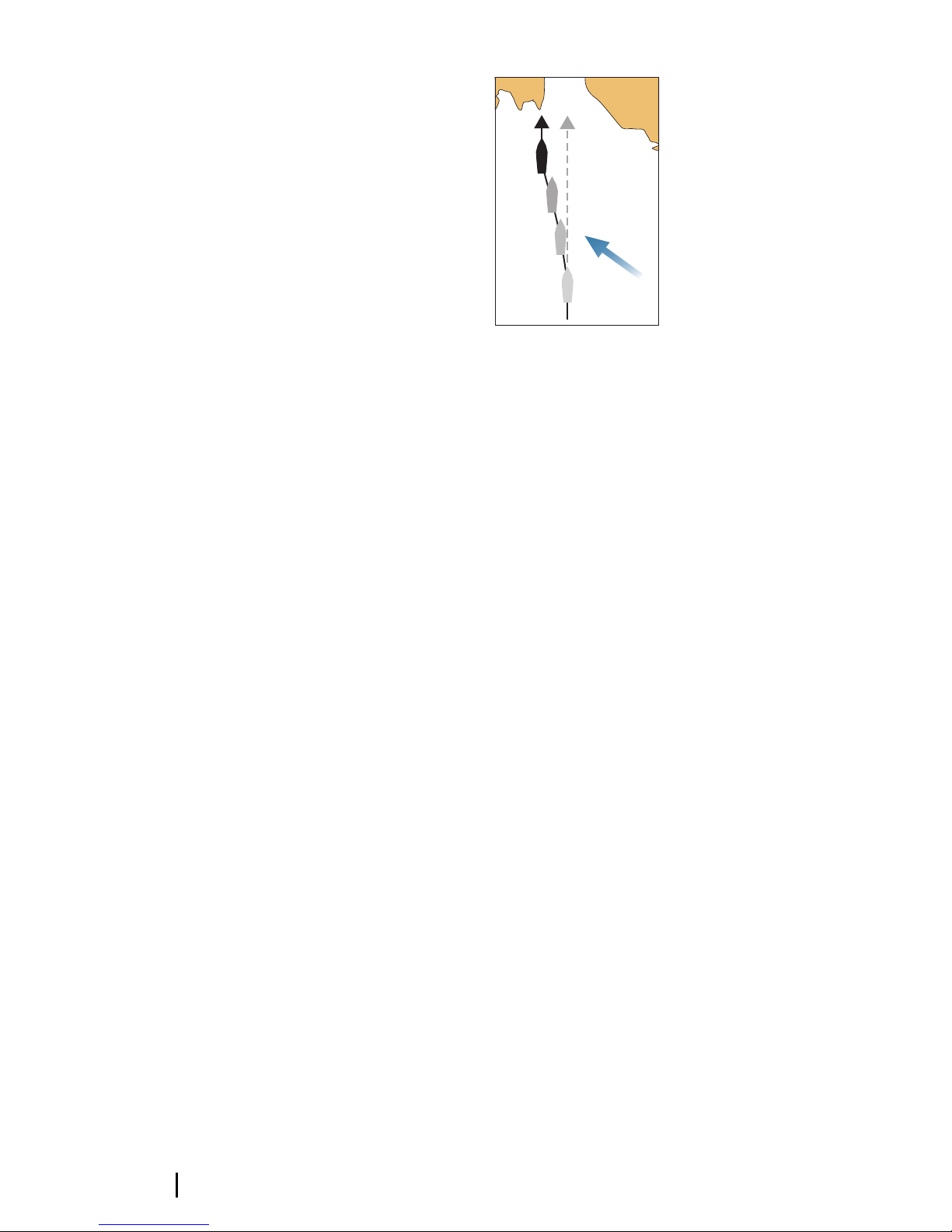

AUTO mode (Heading hold)

In AUTO mode the autopilot issues rudder commands required to

steer the vessel automatically on a set heading. In this mode the

autopilot does not compensate for any drifting caused by current

and/or wind (A).

3

Autopilot modes | AP44 Operator Manual

13

Page 16

A

• Switch to AUTO mode by pressing the AUTO key. When the

mode is activated, the autopilot selects the current boat heading

as the set heading.

Changing set heading in AUTO mode

You adjust the set heading by turning the rotary knob.

An immediate heading change takes place. The new heading is

maintained until a new heading is set.

Tacking and Gybing in AUTO mode

Ú

Note: Only available when the boat type is set to SAIL.

Tacking and Gybing in AUTO mode uses the heading as reference.

The tacking/gybing operation changes the set heading to port or

starboard with a fixed angle.

The tacking parameters are set in the Setup/Sailing parameters: The

Tack angle defines the tacking angle, while the Tack time defines

the rate of turn during the tack/gybe. Refer to "Autopilot settings" on

page 34.

• Initiate the Tack or Gybe function by selecting the Tack/Gybe

option in the Mode list.

-

The turn is started when the direction is selected in the dialog.

14

Autopilot modes | AP44 Operator Manual

Page 17

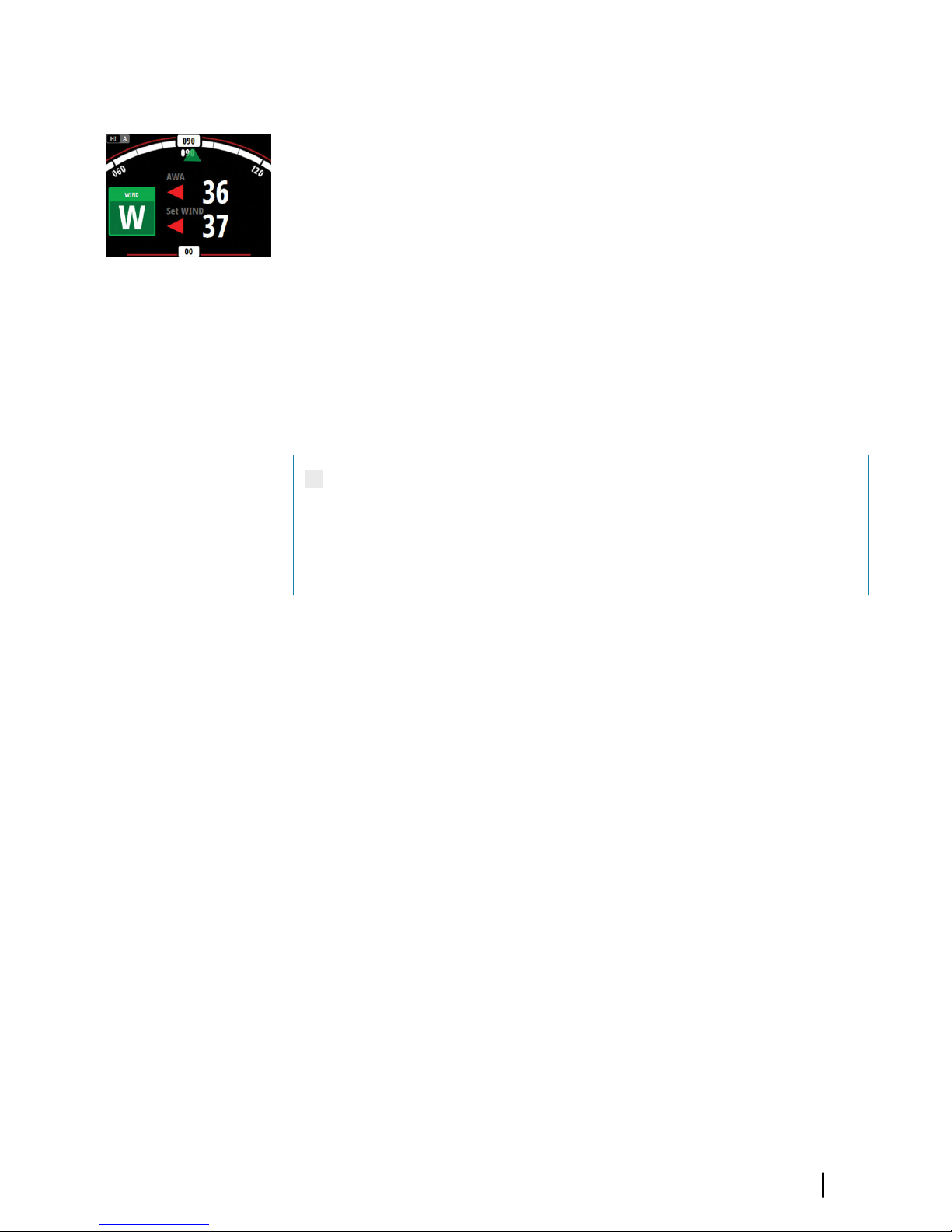

Wind mode

Ú

Note: Wind mode is only available when the boat type is set to

SAIL. It is not possible to activate wind mode if wind

information is missing.

When wind mode is engaged, the autopilot captures the current

wind angle as steering reference, and adjusts the heading of the

boat to maintain this wind angle.

Prior to entering wind mode the autopilot system must be

operating in AUTO mode and with valid input from the wind

transducer.

• Switch to Wind mode by selecting the Wind option in the Mode

list

Warning: In wind mode the autopilot steers to the

apparent or true wind angle and not to a compass

heading. Any wind shift could result in the vessel

steering on an undesired course.

Tacking and Gybing in Wind mode

Tacking and Gybing in Wind mode can be performed when sailing

with apparent or true wind as the reference. In either case the true

wind angle must be less than 90 degrees (tacking) and more than

120° (gybing).

The tacking/gybing operation will mirror the set wind angle on the

opposite tack.

The rate of turn during the tack/gybe is set by the Tack time in the

Setup/Sailing menu. Refer to "Autopilot settings" on page 34.

• Initiate the Tack or Gybe function by selecting the Tack/Gybe

option in the Mode list.

• Confirm the tack/gybe in the dialog.

Autopilot modes | AP44 Operator Manual

15

Page 18

Ú

Note: The autopilot will temporarily add a 5 degree bear-away

on the new tack to allow the boat to pick up speed. After a

short period the wind angle will return to the set angle.

Ú

Note: If the Tack/Gybe is not confirmed the dialog will close

after 10 seconds, and the requested tack/gybe will not be

initiated.

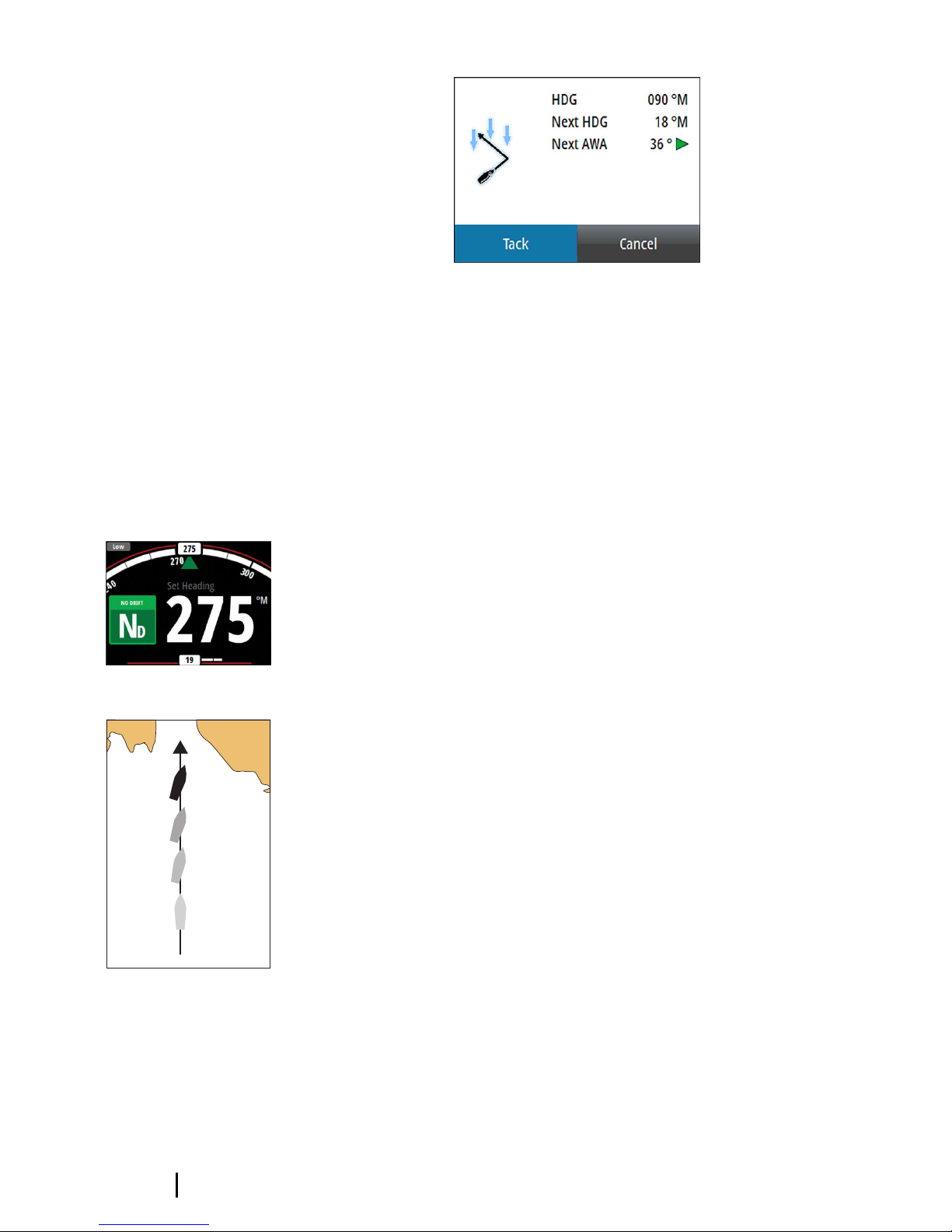

NoDrift mode

Ú

Note: It is not possible to select NoDrift mode if GPS position

and heading information is missing.

In NoDrift mode the vessel is steered along a calculated track line,

from present position and in a direction set by the user. If the vessel

is drifting away from the track line due to current and/or wind (A),

the vessel will follow the line with a crab angle.

Prior to entering NoDrift mode the autopilot system must be

operating in AUTO mode and with valid input from GPS and

heading sensor.

• Switch to NoDrift mode by selecting the NoDrift option in the

Mode list

-

The autopilot will draw an invisible track line based on current

heading from the vessel’s position

The autopilot will now use the position information to calculate the

cross track distance, and automatically steer along the calculated

track.

Changing set course in NoDrift mode

You adjust the set course by turning the rotary knob.

An immediate course change takes place. The new course is

maintained until a new course is set.

16

Autopilot modes | AP44 Operator Manual

Page 19

Dodging

Ú

Note: Only available for AC12N/AC42N autopilot computers.

If you need to avoid an obstacle when using NoDrift mode, you can

set the autopilot to Standby mode and power steer or use the helm

until the obstacle is passed.

If you return to NoDrift mode within 60 seconds you can select to

continue on previous set bearing line.

If you do not respond, the dialog disappears and the autopilot goes

to NoDrift mode with current heading as set bearing line.

Heading capture

When the vessel is turning in AUTO or NoDrift mode, an instant repress on the AUTO key activates the heading capture function. This

will automatically cancel the turn, and the vessel will continue on

the heading read from the compass the very moment you pressed

the AUTO key.

NAV mode

Ú

Note: NAV mode requires a compatible chartplotter connected

to the network.

It is not possible to select NAV mode if heading information is

missing, or if steering information is not received from the

external chartplotter.

Warning: NAV mode should only be used in open

waters. Navigation mode must not be used while

sailing, as course changes may result in unexpected

tacks or gybes!

In NAV mode the autopilot uses steering information from an

external chartplotter to direct the vessel to one specific waypoint

location, or through a series of waypoints.

In NAV mode, the autopilot's heading sensor is used as heading

source for course keeping. Speed information is taken from SOG or

from selected speed sensor. The steering information received from

the external chartplotter alters the set course to direct the vessel to

the destination waypoint.

Autopilot modes | AP44 Operator Manual

17

Page 20

To obtain satisfactory navigation steering, the autopilot system

must have valid input from the chartplotter. Autosteering must be

tested and determined satisfactory prior to entering NAV mode.

Ú

Note: If the chartplotter does not transmit a message with

bearing to next waypoint, the autopilot will steer using Cross

Track Error (XTE) only. In that case you must revert to AUTO

mode at each waypoint and manually change set course to

equal bearing to next waypoint and then select NAV mode

again.

Prior to entering NAV mode the chartplotter must be navigating a

route or towards a waypoint.

• Initiate NAV mode by selecting the NAV option in the Mode list

• Confirm to switch to NAV mode in the dialog.

Turning in NAV mode

When your vessel reaches a waypoint, the autopilot will give an

audible warning and display a dialog with the new course

information.

There is a user defined limit for the allowed automatic course

change to next waypoint in a route. If the course change is more

than this set limit, you are prompted to verify that the upcoming

course change is acceptable.

• If the required course change to the next waypoint is less than

the course change limit, the autopilot will automatically change

the course. The dialog will disappear after 8 seconds unless

cleared by the Pages key.

• If the required course change to next waypoint is more than the

set limit, you are prompted to verify that the upcoming course

change is acceptable. If the turn is not accepted, the vessel will

continue with the current set heading.

18

Autopilot modes | AP44 Operator Manual

Page 21

Course change less than set limit Course change larger than set limit

The course change limit setting depends on the autopilot

computer:

• NAC-2/NAC-3: Course chg confirm angle, refer to "Steering (NAC-2/

NAC-3)" on page 35

• AC12N/42N and SG05: Navigation change limit, refer to

"Automatic steering (AC12N/AC42N)" on page 39

Turn pattern steering

The system includes a number of automatic turn steering features

when the autopilot is in AUTO mode.

Ú

Note: Turn pattern steering is not available if the boat type is

set to Sail. Instead the tack/gybe feature is implemented.

Turn variables

All turn patters, except the U-turn, have settings that you adjust

before you start a turn or at any time when the boat is in a turn.

The turn settings are available from the Autopilot settings dialog.

The variables are described for each turn pattern option in the

following pages.

Starting and stopping a turn

Ú

Note: For starting a DCT turn, see "Depth contour tracking (DCT)" on

page 21.

You start the turn by selecting the turn option in the Mode list,

followed by selecting the port or starboard options in the turn

dialog to select the turn direction.

Autopilot modes | AP44 Operator Manual

19

Page 22

You can at any time stop the turn by pressing the STBY key to

return to Standby mode and manual steering.

C-turn (Continuous turn)

Steers the vessel in a circle.

• Turn variable:

-

Rate of turn. Increasing the value makes the vessel turn a

smaller circle.

U-turn

Changes the current set heading to be 180° in the opposite

direction.

The turn rate is identical to Turn rate (NAC-2/NAC-3) and Rate limit

(AC12N/AC42N) setting (refer to "Autopilot settings" on page 34). The

turn rate cannot be changed during the turn.

Spiral turn

Makes the vessel turn in a spiral with a decreasing or increasing

radius.

• Turn variables:

- Initial radius

- Change/turn. If this value is set to zero, the boat will turn in a

circle. Negative values indicate decreasing radius while positive

values indicate increasing radius.

Zigzag turn

Steers the vessel in a zigzag pattern.

You set the initial heading change before the turn is started.

During the turn you can alter the main heading by turning the

rotaty knob (only for AC12N/AC42N autopilot computers).

20

Autopilot modes | AP44 Operator Manual

Page 23

• Turn variables:

-

Course change (A)

- Leg distance (B)

B

A

Square turn

Makes the vessel automatically turn 90° after having travelled a

defined leg distance.

During the turn you can alter the main heading by turning the

rotaty knob (only for AC12N/AC42N autopilot computers).

• Turn variable:

-

Leg distance

Lazy-S turn

Makes the vessel yaw around the main heading.

You set the selected heading change before the turn is started.

During the turn you can alter the main heading by turning the

rotaty knob (only for AC12N/AC42N autopilot computers).

• Turn variables:

- Course change (C)

- Turn radius (D)

D

C

Depth contour tracking (DCT)

Makes the autopilot follow a depth contour.

Ú

Note: DCT turn pattern is only available if the system has a valid

depth input.

Warning: Do not use the DCT turn pattern unless the

seabed is suitable. Do not use it in rocky waters where

the depth is varying significantly over a small area.

Autopilot modes | AP44 Operator Manual

21

Page 24

To initiate a DCT turn:

• Ensure that you have depth reading on the panel or on a

separate depth instrument

• Steer the boat to the depth you want to track, and in the

direction of the depth contour

• Activate AUTO mode, then select depth contour tracking while

monitoring the depth reading

• Select the port or starboard option in the turn dialog to initiate

the depth contour steering to follow the bottom sloping to

starboard or to port

Port option

(depth decreases to port)

Starboard option

(depth decreases to starboard)

• Turn variables:

-

Depth gain. This parameter determines the ratio between

commanded rudder and the deviation from the selected depth

contour. The higher depth gain value the more rudder is

applied. If the value is too small it will take a long time to

compensate for drifting off the set depth contour, and the

autopilot will fail to keep the boat on the selected depth. If the

22

Autopilot modes | AP44 Operator Manual

Page 25

value is set too high the overshoot will increase and the

steering will be unstable.

-

CCA. The CCA is an angle that is added to or subtracted from

the set course. With this parameter you can make the boat yaw

around the reference depth with lazy-s movements. The larger

the CCA the bigger yawing will be allowed. If the CCA is set to

zero there is no S-ing.

- Ref. depth. This is the reference depth for the DCT function.

When DCT is initiated the autopilot reads the current depth

and set this as the reference depth. The reference depth can be

changed when the function is running.

Ú

Note: If depth data is lost during DCT the autopilot will

automatically switch to AUTO mode.

It is recommended to turn ON the AP Depth Data Missing alarm

when using DCT. When this alarm is activated an alarm will be

raised if the depth data is lost during DCT.

Using the autopilot in an EVC system

When the AP44 is connected to an EVC system via the SG05, you

can take manual control of the steering regardless of the autopilot

mode.

The mode indicator is replaced by a dash to indicate EVC override.

The system returns to AP44 control in Standby mode if no rudder

command is given from the EVC system within a predefined period.

Autopilot modes | AP44 Operator Manual

23

Page 26

Trip log

The Trip log is available from the Settings menu.

The Trip log is a temporary page. It remains on the screen until you

press the STBY or AUTO key.

There are three log options available:

• Trip 1: records distance traveled through the water (Log input)

• Trip 2: records distance traveled via GPS input

• Log: shows total distance run from system installation or from a

system restore

Ú

Note: Trip 1 requires correctly calibrated boat speed for

accurate trip records.

Trip 2 requires a compatible GPS connected to the network.

You start, stop and reset the active Trip log from the menu,

activated by pressing the rotary knob.

4

24

Trip log| AP44 Operator Manual

Page 27

Alarms

The system continuously checks for dangerous situations and

system faults while the system is running. The alarm system can be

activated if any alarm settings are exceeded.

Ú

Note: If sensor data vital for autopilot operation (e.g. rudder

response) is lost when the autopilot is running in an automatic

mode, the system will automatically switch to Standby mode.

Alarm indication

An alarm situation is indicated with an alarm pop-up. If you have

enabled the siren, the alarm message is followed by an audible

alarm.

A single alarm is displayed with the name of the alarm as the title,

and with details for the alarm.

If more than one alarm is activated simultaneously, the alarm popup can display 2 alarms. The alarms are listed in the order they occur

with the alarm activated first at the top. The remaining alarms are

available in the Alarms dialog.

Type of messages

The messages are classified according to how the reported situation

affects your vessel. The following color codes are used:

Color Importance

Red Critical

Orange Important

Yellow Standard

Blue Warning

Green Light warning

Acknowledging the alarms

The most recent alarm is acknowledged by pressing the rotary

knob.

5

Alarms| AP44 Operator Manual

25

Page 28

This removes the alarm notification, and silences the alarm from all

units that belong to the same alarm group. A reminder reappears at

given intervals for as long as the alarm condition exists.

Ú

Note: An alarm received from non Navico units on the network

must be acknowledged on the unit generating the alarm.

Enabling the alarm system and the alarm

siren

You enable the alarm system and the alarm siren from the Alarms

menu.

Individual alarm settings

You enable/disable the single alarm and set the alarm limits from

the Alarms settings dialog.

• Press the rotary knob to display the menu from where you can

enable/disable the alarm and set the alarm limit

26

Alarms| AP44 Operator Manual

Page 29

Alarm history

The Alarm history dialog stores alarm messages until they are

manually cleared.

You show alarm details for a selected alarm and clear all alarms in

the alarm history by pressing the rotary knob when the Alarm

history dialog is active.

Menu options Alarm details

Alarms| AP44 Operator Manual

27

Page 30

Software setup

Prior to use, the AP44 requires a number of settings be configured

in order for the system to perform as expected. Access to the

required options are found in the Settings menu, accessed by

pressing the MENU key.

Ú

Note: The following settings are described in other sections of

this manual:

"Trip log" on page 24

"Alarms" on page 25

Calibration

Ú

Note: Once the unit is setup and before you proceed with

calibration ensure all network sources are selected and

configured. Refer to "System settings" on page 40.

Boat speed

Speed calibration is necessary to compensate for hull shape and

paddlewheel location on your boat. For accurate speed and log

readings, it is essential that the paddlewheel is calibrated.

SOG reference

This is an auto calibration option that uses speed over ground (SOG)

from your GPS, and compares the average of SOG against the

average boat speed from the speed sensor for the duration of the

calibration run.

Ú

Note: This calibration should be made in calm sea with no

effect from wind or tidal current.

6

28

Software setup| AP44 Operator Manual

Page 31

• Bring the boat up to cruising speed (above 5 knots), then

• Select the SOG reference option

When the calibration is completed the Boat speed calibration scale

will show the adjusted percentage value of the boat speed.

Distance reference

Allows you to calibrate the log via a distance reference. You will

need to complete consecutive runs, under power at a constant

speed made along a given course and distance.

Ú

Note: The distance should be greater than 0.5 NM, ideally 1 NM.

To eliminate the effect of tidal conditions it is advisable to

perform at least two runs, preferably three, along the measured

course.

Referring to the diagram, A and B are the markers for each run. X is

the actual distance for each run.

• Enter the desired distance in nautical miles that you would like to

calculate the distance reference over

• When the boat gets to the predetermined starting position of the

distance reference calculation, start the calibration timer

• As the boat passes marks A and B on each run, instruct the

system to start and stop and finally OK to end calibration.

x

BA

Use SOG as boat speed

If boat speed is not available from a paddle wheel sensor, it is

possible to use speed over ground from a GPS. SOG will be

displayed as boat speed and used in the true wind calculations and

the speed log.

Software setup| AP44 Operator Manual

29

Page 32

Wind

MHU (Masthead unit) alignment

This provides an off set calibration in degrees to compensate for any

mechanical misalignment between the masthead unit and the

center line of the vessel.

To check the masthead unit alignment error we recommend you

use the following method which involves a sailing trial:

• Sail on a starboard tack on a close hauled course and record the

wind angle, then repeat the process on a port tack

• Divide the difference between the two recorded numbers and

enter this as the wind angle off set

If the starboard apparent wind angle is greater than the port angle,

then divide the difference by 2 and enter this as a negative offset.

If the port angle is greater than the starboard then divide the

difference by 2 and enter this as a positive offset.

Enter the offset it into the MHU Align calibration field.

Depth

Depth offset

All transducers measure water depth from the transducer to the

bottom. As a result, water depth readings do not account for the

distance from the transducer to the lowest point of the boat (for

example; bottom of the keel, rudder, or propeller) in the water or

from the transducer to the water surface.

• For depth below keel (A): Set the distance from transducer to the

bottom of the keel as a negative value. For example, -2.0.

• For depth below transducer (B): no offset required.

• For depth below surface (waterline) (C): Set the distance from

transducer to the surface as a positive value. For example,+0.5.

30

Software setup| AP44 Operator Manual

Page 33

A B C

+0.5

+0.0

-2.0

Aft depth offset

This option allows the system to display two depth readings.

The Aft depth is calibrated in the same manner as the Depth offset.

Ú

Note: Aft Depth is only available when a valid signal is received

from a second and compatible NMEA 2000 or NMEA 0183

device.

Heading

Ú

Note: All magnetic compasses must be calibrated to ensure

correct heading reference.

The calibration must be made on the active compass.

The calibration should be done in calm sea conditions and with

minimal wind and current to obtain good results.

Offset

The Offset option is used for compensating for any difference

between the boat’s center line (A) and the compass lubber line (B).

1. Find the bearing from the boat position to a visible object. Use a

chart or a chart plotter

2. Steer the boat so that the center line of the boat is aligned with

the bearing line pointing towards the object.

3. Change the offset parameter so that the bearing to the object

and the compass readout becomes equal.

Ú

Note: Make sure that both the compass heading and the

bearing to the object have the same unit (°M or °T).

B

A

x

Software setup| AP44 Operator Manual

31

Page 34

User triggered calibration

Ú

Note: Before the calibration is started, make sure that there is

enough open water around the vessel to make a full turn.

The Calibrate option is used for manually starting the heading

calibration procedure.

During this calibration, the compass measures the magnitude and

direction of the local magnetic field.

The illustration shows magnitude of local field in percentage of

earth's magnetic field (A), direction of local field (B) with respect to

the boat's centerline (C).

Follow the on-screen instruction, and use about 60-90 seconds to

make a full circle. Keep turning until the system reports a pass.

• If the local magnetic field is stronger than the earth’s magnetic

field (the local field is reading more than 100%), the compass

calibration will fail.

• If the local field is reading more than 30%, you should look for

any interfering magnetic objects and remove them, or you

should move the compass to a different location. The (local) field

angle guides you to the local interfering magnetic object.

Ú

Note: In certain areas and at high latitudes the local magnetic

interference becomes more significant, and heading errors

exceeding ±3° may have to be accepted.

Automatic calibration

An auto calibration option is available for compasses that offers a

fully automatic calibration procedure.

See more instructions in the documentation delivered with your

compass.

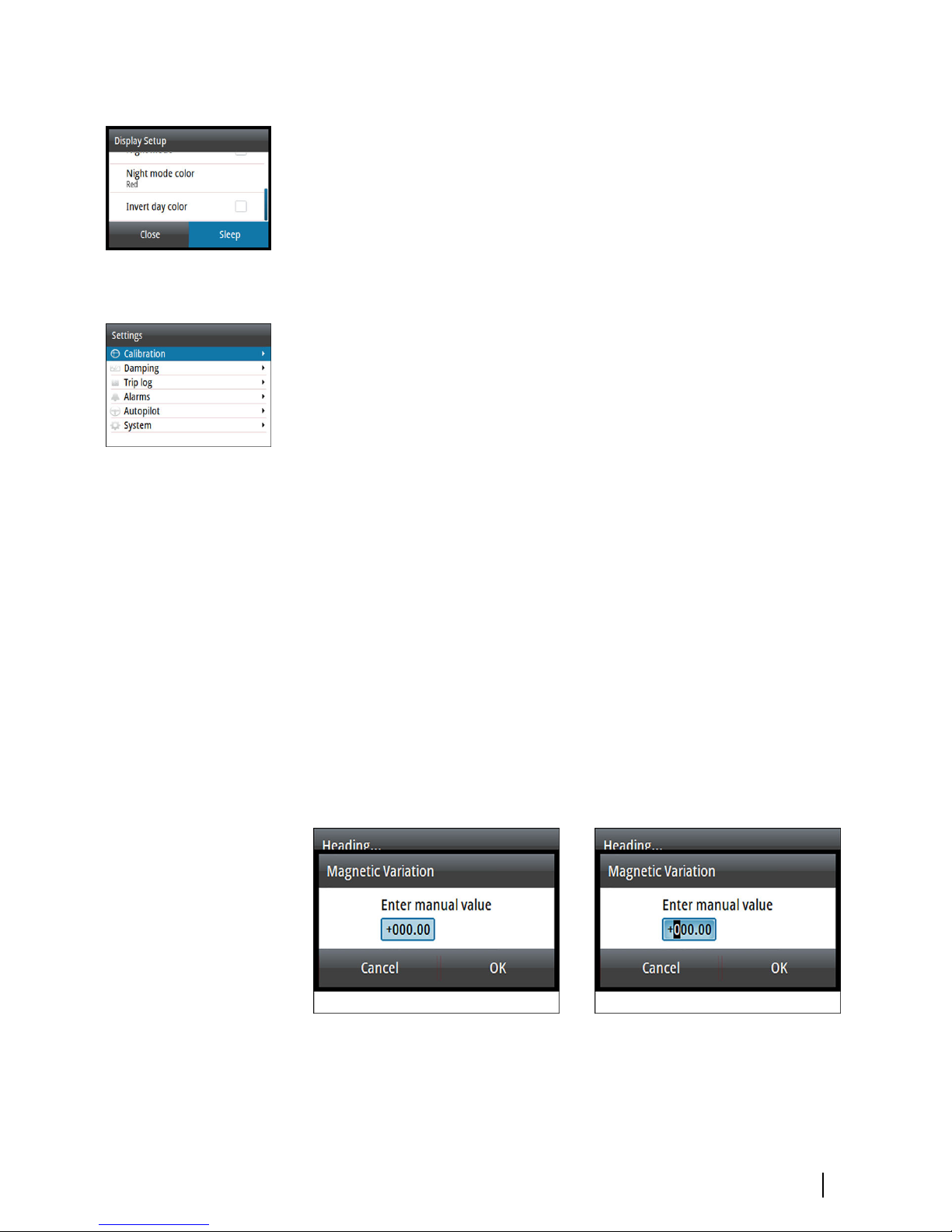

Magnetic variation

Defines how magnetic variation is handled by the system.

• Auto: Receives variation data from a network source

• Manual: Used for manually entering a value for the magnetic

variation

20%

0

30˚

030˚

B

C

A

32

Software setup| AP44 Operator Manual

Page 35

Use COG as heading

If heading data is not available from a compass sensor, it is possible

to use COG from a GPS. COG will be used in the true wind

calculations.

Ú

Note: The autopilot cannot be operated using COG as the

heading source. COG cannot be calculated when stationary.

Pitch/Roll

If a suitable sensor is fitted, the system will monitor the inclination of

the vessel. The offset value should be entered to adjust the readings

so that while the vessel is stationary at the dock, the Pitch and Roll

value reads 0.

Environment

If a suitable sensor is fitted, the system will monitor the current

sea/air temperature and barometric pressure.

The offset value to be entered should adjust the reading from the

sensor to match a calibrated source.

Rudder

Starts the automatic calibration of the rudder feedback. This

procedure sets the correct relationship between the physical rudder

movement and the rudder angle readout.

Follow the instructions on the display to perform the rudder

feedback calibration procedure.

Advanced

This option is used for manually applying an offset to the displayed

data for third party sensors which cannot be calibrated through the

AP44.

Damping

If data appears erratic or too sensitive, damping may be applied to

make the information appear more stable. With damping set to off,

the data is presented in raw form with no damping applied.

Software setup| AP44 Operator Manual

33

Page 36

Autopilot settings

The autopilot settings can be split between settings done by the

user, and settings done during installation and commissioning of

the autopilot system.

• User settings can be changed for various operational conditions

or user preferences

• Installation settings are defined during commissioning of the

autopilot system. No changes should later be done to these

settings

Both user settings and installation settings depends on which

autopilot computer that is connected to the system.

NAC-2/NAC-3 Autopilot computer settings AC12N/AC42N Autopilot computer settings

The following sections describe the settings that can be changed by

the user. The settings are described per autopilot computer.

Installation settings are available in the documentation following

the autopilot computers.

Ú

Note: For Turn pattern settings, refer to "Turn pattern steering" on

page 19.

NAC-2/NAC-3 Autopilot computer

34

Software setup| AP44 Operator Manual

Page 37

Steering (NAC-2/NAC-3)

These options allow for manually changing parameters that were

set during the commissioning of the autopilot computer. For more

details, refer to the separate documentation for the autopilot

computer.

• Turn rate: Preferred turn rate used while turning in degrees per

minute

• Rudder gain: This parameter determines the ratio between

commanded rudder and the heading error. The higher rudder

value the more rudder is applied. If the value is too small it will

take a long time to compensate for a heading error, and the

autopilot will fail to keep a steady course. If the value is set too

high the overshoot will increase and the steering will be

unstable.

• Counter rudder: Relation between change in heading error and

applied rudder. Higher counter rudder will reduce applied rudder

faster when approaching the set heading

• Autotrim: Controls how aggressively the autopilot will apply

rudder to compensate for a constant heading offset, e.g. when

external forces such as wind or current affects the heading.

Lower autotrim will give faster elimination of a constant heading

offset

Ú

Note: In VRF mode this parameter controls the time constant of

the rudder estimate. A lower value makes the rudder estimate

faster, i.e. that it will more quickly catch up with the boat's

movements.

• Init rudder: Defines how the system moves the rudder when

switching from power steering to an automatic mode.

- Center: Moves the rudder to zero position

- Actual: Maintains the rudder offset

• Rudder limit: Determines the maximum rudder movement in

degrees from midship position that the autopilot can command

the rudder in the automatic modes. The Rudder limit setting is

only active during autosteering on straight courses, NOT during

course changes. Rudder limit does not affect Non-Follow-up

steering

Software setup| AP44 Operator Manual

35

Page 38

• Off heading limit: Sets the limit for the off heading alarm. An

alarm occurs when the actual heading deviates from the set

heading more than the selected limit

• Track response: Defines how fast the autopilot shall respond after

having registered a cross track distance

• Track approach angle: Defines the angle used when the vessel is

approaching a leg. This setting is used both when you start

navigating and when you use track offset

• Course change confirm angle: Defines the limits for course

change to next waypoint in a route. If the course change is more

than this set limit, you are prompted to verify that the upcoming

course change is acceptable.

Sailing (NAC-2/NAC-3)

Ú

Note: Sailing parameters are only available when the boat type

is set to Sail.

• Wind mode: Select what wind function the autopilot will use

when in wind mode

-

Auto:

If TWA is <70º: Wind mode will use AWA

If TWA is ≥70º: Wind mode will use TWA

- Apparent

- True

• Tack time: Controls the rate of turn (tack time) when performing

a tack in wind mode.

• Tack angle: Controls the angle that the boat will tack to between

50º - 150º in AUTO mode

• Manual speed: If neither boat speed or SOG data is available and

or deemed reliable a manual value for speed source can be

entered and used by the autopilot to aid steering calculations

36

Software setup| AP44 Operator Manual

Page 39

AC12N/AC42N Autopilot computer

Response (AC12N/AC42N)

The AC12N/42N includes three different sets of steering modes;

High (HI), Low (LO) and Wind. The mode can be automatically or

manually selected.

The speed at which the autopilot automatically changes from LO to

HI parameters (or opposite) is determined by the Transition speed

setting, defined during the commissioning of the autopilot. Refer to

the detailed description in the autopilot computer's

documentation.

You can manually fine tune each of the three response modes.

Level 4 is default with parameter values as set by the autotune

function. If no autotune is made (not recommended) the level 4

values are the factory default values.

• A low response level reduces the rudder activity and provides a

more “loose” steering

• A high response level increases the rudder activity and provides a

more “tight” steering. A too high response level causes the boat

to start lazy-s movements.

The Wind response is used on sailboats

• Increase the Wind value if the difference between the set wind

angle and the actual wind angle is too big

• Decrease the Wind value if the actual wind angle is S-ing around

the set wind angle, or if the rudder activity is too high

The performance mode is indicated in the top left corner of the

autopilot page.

• HI-A: High response mode set automatically

Software setup| AP44 Operator Manual

37

Page 40

• LO-A: Low response mode set automatically

• HI-M: High response mode set manually

• LO-M: Low response mode set manually

Ú

Note: If no speed input is available the autopilot defaults to LO

steering parameters when engaging an automatic mode. This is

a safety feature to prevent oversteering

Sea state filter (AC12N/AC42N)

This filter is used to reduce rudder activity and autopilot sensitivity

in rough weather.

• OFF: Sea state filter is disabled. This is the default setting.

• AUTO: Reduces rudder activity and autopilot sensitivity in rough

weather by an adaptive process. The AUTO setting is

recommended if you want to use the sea state filter.

• MANUAL: Linked to the steering response control settings

described previously. It may be used to manually find the

optimum combination of course keeping and low rudder activity

in rough but steady sea conditions.

Sailing (AC12N/AC42N)

Ú

Note: Sailing parameters are only available when the boat type

is set to Sail.

• Tack time: Controls the rate of turn (tack time) when performing

a tack in wind mode.

• Tack angle: Controls the angle that the boat will tack to between

50º - 150º in AUTO mode

• Wind mode: Select what wind function the autopilot will use

when in wind mode

-

Auto:

If AWA is ≤60º: Wind mode will use AWA

If AWA is >60º: Wind mode will use TWA

- Apparent

- True

• VMG optimizing: Optimize the VMG to wind. The function will be

active for 5–10 minutes after a new wind angle has been set and

only when beating.

38

Software setup| AP44 Operator Manual

Page 41

• Layline steering: When enabled the Cross Track Error (XTE) from

the navigator will keep the boat on the track line. If the XTE from

the navigator exceeds 0.15 Nm, the autopilot will calculate the

layline and track towards the waypoint.

Automatic steering (AC12N/AC42N)

This option allows for manually changing parameters that were set

during the commissioning of the autopilot computer. For more

details of the settings, refer to the separate documentation for the

autopilot computer.

• Transition speed: This is the speed at which the autopilot will

automatically change the steering parameter set from HI to LO

parameters, or vice versa. On power boats it is recommended to

set the Transition speed to a speed that represents the speed

where the hull begins to plane or the speed where you change

from slow to cruising speed

On sailboats the Transition speed should be set to 3-4 knots to

give the best response in a tack

• High/Low

-

Rudder gain: This parameter determines the ratio between

commanded rudder and the heading error. The higher rudder

value the more rudder is applied. If the value is too small it will

take a long time to compensate for a heading error, and the

autopilot will fail to keep a steady course. If the value is set too

high the overshoot will increase and the steering will be

unstable.

- Counter rudder: Relation between change in heading error and

applied rudder. Higher counter rudder will reduce applied

rudder faster when approaching the set heading

- Auto trim: Controls how aggressively the autopilot will apply

rudder to compensate for a constant heading offset, e.g. when

external forces such as wind or current affects the heading.

Lower autotrim will give faster elimination of a constant

heading offset

- Rate limit: The rate the vessel is turning in degrees per minute

• Minimum rudder: Some boats may have a tendency of not

responding to small rudder commands around the course

keeping position because of a small rudder, a rudder deadband,

Software setup| AP44 Operator Manual

39

Page 42

whirls/disturbance of the water-stream passing the rudder or it is

a single nozzle water jet boat. By manually adjusting the

minimum rudder function, the course keeping performance

might be improved on some boats. This will however increase

the rudder activity.

• Min wind angle starboard / Min wind angle port: This is the

minimum apparent wind angle that will keep the sails well

shaped and give an acceptable thrust. This parameter will vary

from boat to boat. The setting applies for the tack-prevent

function. It also applies when the autopilot is operating in

WindNAV mode. You can select different minimum wind angles

for port and starboard. The difference between port and

starboard will be taken into account when calculating the

Distance To Turn (DTT).

• Navigation change limit: Defines the limits for course change to

next waypoint in a route. If the course change is more than this

set limit, you are prompted to verify that the upcoming course

change is acceptable

System settings

Network

Sources

Data sources provide live data to the system.

The data may originate from modules internal to the unit (for

example internal GPS or sonar), or external modules connected to

the NMEA 2000 or via NMEA 0183 if available on the unit.

When a device is connected to more than one source providing the

same data, the user can choose the preferred source. Before

commencing with source selection make sure all external devices

and the NMEA 2000 backbone are connected and are turned on.

• Auto select: Looks for all sources connected to the device. If more

than one source is available for each data type, selection is made

from an internal priority list. This option is suitable for the

majority of installations.

40

Software setup| AP44 Operator Manual

Page 43

• Manual source selection: Manual selection is generally only

required where there is more than one source for the same data,

and the automatically selected source is not the one desired.

Device list

The Device list shows the devices that provide data. This may

include a module inside the unit, or any external NMEA 2000 device.

Selecting a device in this list will bring up additional details and

actions:

All devices allow allocation of an instance number in the configure

option. Set unique instance numbers on any identical devices on

the network to allow for the unit to distinguish between them. The

data option shows all data being output by the device. Some

devices will show additional options specific to the device.

Ú

Note: Setting the instance number on a 3rd party product is

typically not possible.

Diagnostics

The NMEA 2000 tab on the diagnostics page can provide

information useful for identifying an issue with the network.

Software setup| AP44 Operator Manual

41

Page 44

Ú

Note: The following information may not always indicate an

issue that can be simply resolved with minor adjustment to

network layout or connected devices and their activity on the

network. However, Rx and Tx errors are most likely indicating

issues with the physical network, which may be resolved by

correcting termination, reducing backbone or drop lengths, or

reducing the number of network nodes (devices).

Bus state

Simply indicates whether the bus is powered, but not necessarily

connected to any data sources. However, if bus shows as ‘off’, but

power is present along with an increasing error count, it is possible

that termination or cable topology is incorrect.

Rx Overflows

The unit received too many messages for its buffer before the

application could read them.

Rx Overruns

The unit contained too many messages for its buffer before the

driver could read them.

Rx/Tx Errors

These two numbers increase when there are error messages, and

decrease when messages are received successfully. These (unlike

the other values) are not a cumulative count. Under normal

operation these should be at 0. Values around 96 upwards indicate

a heavily error prone network. If these numbers go too high for a

given device, it will automatically drop off the bus.

Rx/Tx Messages

Shows actual traffic in and out of device.

Bus Load

A high value here indicates network is near full capacity. Some

devices automatically adjust rate of transmission, if network traffic is

heavy.

Fast Packet Errors

Cumulative counter of any fast packet error. This could be a missed

frame, or a frame out of sequence etc. NMEA 2000 PGNs are made

42

Software setup| AP44 Operator Manual

Page 45

of up to 32 frames. The entire message will be discarded when a

frame is missed.

Ú

Note: Rx and Tx Errors often indicate an issue with the physical

network, which may be resolved by correcting termination,

reducing backbone or drop lengths, or reducing the number of

network nodes (devices).

Network groups

The Network Group function is used to control parameter settings,

either globally or in groups of units. The function is used on larger

vessels where several units are connected to the network. By

assigning several units to the same group, a parameter update on

one unit will have the same effect on the rest of the group

members.

Units

Provides setup of units of measure used on various data types.

Decimal places

Defines number of decimals used for speed and sea temperature.

Key beeps

Controls the loudness of the beep sound when a key is pressed.

Default setting: Loud

Language

Controls the language used on this unit for panels, menus, and

dialogs. Changing the language causes the unit to restart.

Time

Controls the local time zone offset, and the format of the time and

date.

Display setup

Displays the Display setup dialog.

The following options are available:

Software setup| AP44 Operator Manual

43

Page 46

• Backlight level: Adjusts the backlight level from Min (10%) to Max

(100%) in 10% increments

-

When the Backlight level field is active, subsequent presses on

the backlight key adjusts backlight level in decrements of 30%

• Display group: Defines which network group the unit belongs to

• Night mode: Activates/deactivates the night mode color palette

• Night mode color: Sets the night mode color palette

• Invert day color: Changes the background color for the pages

from default black to white

• Sleep: Turns the backlight for screen and keys off to save power

Files

File management system. Used to browse the contents of the unit's

internal memory and the content of a device plugged into the unit's

USB port.

Simulate

Runs the display with simulated data. Use the simulator to become

familiar with your unit before using it on the water.

When activated, the simulator mode is indicated on the display.

Restore defaults

Allows you to select which settings are to be restored to their

original factory settings.

Global reset

Resets the source selection on all displays connected to the

network.

About

Displays copyright information, software version, and technical

information for this unit.

44

Software setup| AP44 Operator Manual

Page 47

Maintenance

Preventive maintenance

The unit does not contain any field serviceable components.

Therefore, the operator is required to perform only a very limited

amount of preventative maintenance.

It is recommended that you always fit the supplied protective sun

cover when the unit is not in use.

Cleaning the display unit

A proper cleaning cloth should be used to clean the screen, where

possible. Use plenty of water to dissolve and take away salt remains.

Crystalized salt may scratch the coating if using a damp cloth. Apply

minimal pressure to the screen.

Where marks on the screen cannot be removed by the cloth alone,

use a 50/50 mixture of warm water and isopropyl alcohol to clean

the screen. Avoid any contact with solvents (acetone, mineral

turpentine, etc.), or ammonia based cleaning products, as they may

damage the anti-glare layer or plastic bezel.

To prevent UV damage to the plastic bezel, it is recommended that

the sun cover be fitted when the unit is not in use for an extended

period.

Checking the connectors

The connectors should be checked by visual inspection only.

Push the connector plugs into the connector. If the connector plugs

are equipped with a lock, ensure that it is in the correct position.

Software update

The AP44 includes a USB port of the back of the units. You use this

port for software updates.

You can update the software for the AP44 unit itself and for NMEA

2000 sensors connected to the network from the AP44.

You can check the units software version from the About dialog.

7

Maintenance| AP44 Operator Manual

45

Page 48

The software version for connected NMEA 2000 sensors is available

in the Device list.

The latest software is available for download from our website:

www.simrad-yachting.com.

Software update for the unit

1. Download the latest software from our website: www.simrad-

yachting.com, and save it to a USB device

2. Insert the USB device to the AP44 unit, and restart the AP44 unit

-

The upgrade will now start automatically the upgrade

procedure for all units

3. Remove the USB device when the update is completed.

Warning: Do not remove the USB device until the

update is completed. Removing the USB device before

the update is completed may damage the unit.

46

Maintenance| AP44 Operator Manual

Page 49

Software update for remote devices

1. Download the latest software from our website: www.simrad-

yachting.com, and save it to a USB device

2. Insert the USB device to the AP44 unit

3. Start the File explorer, and select the update file on the USB

device

4. Start the update from the file details dialog

5. Remove the USB device when the update is completed.

Maintenance| AP44 Operator Manual

47

Page 50

Menu flow chart

The system includes a Settings menu, accessed by pressing the

MENU key. The Settings menu gives access to settings for the

sensors, the vessel, the autopilot computer and for the system.

Level 1 Level 2

Calibration Boat speed...

Wind...

Depth...

Heading...

Roll/Pitch...

Environment...

Rudder...

Advanced...

Damping Heading

Aparent wind

True wind

Boat speed

SOG

COG

Attitude Roll

Attitude Pitch

Tide

Trip log Trip 1...

Trip 2...

Log...

Alarms Alarm history...

Alarm settings...

Alarms enabled

Siren Enabled

8

48

Menu flow chart| AP44 Operator Manual

Page 51

Level 1 Level 2

Autopilot, NAC-2 and NAC-3

* Refer to the NAC-2/NAC-3

Commissioning manual

(988-11233-00n)

Steering

Sailing

Turn patterns

Installation *

Autopilot, AC12N, AC42N

and SG05

** Refer to the AC12N/AC42N

Installation manual

(988-10276-00n)

Response

Sea state filter

Sailing

Automatic steering

Turn patterns

Installation **

System Network

Units

Decimal places

Key beeps

Language

Time

Display Setup...

Files

Simulate

Restore defaults...

Global reset...

About

Menu flow chart| AP44 Operator Manual

49

Page 52

Technical specifications

Dimensions Refer to "Dimensional drawing" on

page 51

Weight 0.32 kg (0.7 lbs)

Power consumption(@ 13.5

V)

Backlight OFF 1.35 W (100 mA)

Backlight MAX 2.16 W (160 mA)

Network load 4 LEN

Color Black

Display

Size 4.1" (diagonal). 4:3 Aspect ratio

Type Transmissive TFT-LCD. White

LED backlight

Resolution 320 x 240 pixels

Illumination White for day mode. Red, green,

blue or white for night mode

Environmental protection

Waterproof rating IPx7

Humidity 100% RH

Temperature

Operating -25° to +65ºC (-13°F to +149 ºF)

Storage -40° to +85ºC (-40°F to +185 ºF)

9

50

Technical specifications| AP44 Operator Manual

Page 53

Dimensional drawing

118 mm (4.64")

115 mm (4.52")

8 mm

(0.31")

36.5 mm

(1.43")

28.5 mm

(1.12")

97.5 mm (3.83")

48.5 mm (1.91")

STBY

MODE AUTO

MENU

X

10

Dimensional drawing| AP44 Operator Manual

51

Page 54

Terms and abbreviations

This list shows terms and abbreviations used in the pages and in

dialogs in the AP44 system.

AIR TEMP Air temperature

AIS Automatic Identification System

AVG SPD Average speed

AWA Apparent wind angle

AWS Apparent wind speed

BSPD Boat speed

BTW Bearing to waypoint

BWW Bearing Waypoint To Waypoint

COG Course Over Ground

CTS Course To Steer

DGPS Differential Gps

DTW Distance to next waypoint

DSC Digital Selective Calling

EPFS Electronic Position Fixing System

EPIRB Emergency Position Indicating Radio Beacon

ETA Estimated Time Of Arrival

ETW Estimated time of arrival to next waypoint

GLONASS Global Orbiting Navigation Satellite System

GMDSS Global Maritime Distress And Safety System

GNSS Global Navigation Satellite System

GPS Global Positioning System

HDG Heading

Km Kilometer

KN Knots

LL DIST Layline distance

LL TIME Layline time

m Meters

11

52

Terms and abbreviations| AP44 Operator Manual

Page 55

MAX SPD Maximum speed

MIN Minimum

MOB Man Over Board

NM Nautical Mile

OPP HDG Heading on opposite tack

POS Position

RM Relative Motion

RNG Range

ROT Rate Of Turn

RTE Route

SAR Search And Rescue

SOG Speed Over Ground

SPD Speed

STBD Starboard

STW Speed Through Water

TCPA Time To Closest Point Of Approach

TGT Target

TIME LOC Local time

TM True Motion

TRK Track

TRK CRS Track course to next waypoint

TWA True wind angle

TWD True wind direction

TWS True wind speed

WOL Wheel Over Line

WOP Wheel Over Point

WPT Waypoint name

WPT BRG Bearing to waypoint

WPT DIST Distance to waypoint

XTE Cross track error

Terms and abbreviations| AP44 Operator Manual

53

Page 56

Supported data

NMEA 2000 PGN (transmit)

59904 ISO Request

60928 ISO Address Claim

126208 ISO Command Group Function

126996 Product Info

127258 Magnetic Variation

NMEA 2000 PGN (receive)

59392 ISO Acknowledgement

59904 ISO Request

60928 ISO Address Claim

126208 ISO Command Group Function

126992 System Time

126996 Product Info

127237 Heading/Track Control

127245 Rudder

127250 Vessel Heading

127251 Rate of Turn

127257 Attitude

127258 Magnetic Variation

128259 Speed, Water referenced

128267 Water Depth

128275 Distance Log

129025 Position, Rapid Update

129026 COG & SOG, Rapid Update

129029 GNSS Position Data

129033 Time & Date

12

54

Supported data| AP44 Operator Manual

Page 57

129283 Cross Track Error

129284 Navigation Data

129539 GNSS DOPs

129283 Cross Track Error

129284 Navigation Data

130074 Route and WP Service - WP List - WP Name & Position

130306 Wind Data

130576 Small Craft Status

130577 Direction Data

Supported data| AP44 Operator Manual

55

Page 58

56

Supported data| AP44 Operator Manual

Page 59

Index

A

Alarms

Type of messages

25

Autopilot

Dodging 17

Modes 13

D

Damping 33

Device list 41

Diagnostics 41

K

Key beeps 43

L

Language 43

M

Manual

About 4

Version 4

P

Preventive maintenance 45

S

Settings

Unit of measure 43

System Settings

Key beeps 43

Language 43

Time 43

T

Time 43

U

Units of measure, setting

43

W

Warranty 3

Page 60

*988-11189-002*

Loading...

Loading...