Page 1

INSTRUCTION MANUAL

Simrad AP35

Autopilot

Page 2

Note!

Simrad AS makes every effort to ensure that the information contained within this

document is correct. However, our equipment is continuously being improved and

updated, so we cannot assume liability for any errors which may occur.

Warning!

The equipment to which this manual applies must only be used for the purpose for

which it was designed. Improper use or maintenance may cause damage to the

equipment or injury to personnel. The user must be familiar with the contents of

the appropriate manuals before attempting to operate or work on the equipment.

Simrad AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Copyright

© 2003 Simrad AS

The information contained within this document remains the sole property of

Simrad AS.

No part of this document may be copied or reproduced in any form or by any

means, and the information contained within is not to be communicated to a third

party, without the prior written consent of Simrad AS.

Page 3

Instruction Manual

22083083H 1

Instruction Manual

This manual is intended as a reference guide for operating and

correctly installing the Simrad AP35 autopilot.

Great care has been paid to simplify operation and set-up of the

AP35, however, an autopilot is a complex electronic system. It is

affected by sea conditions, speed of the vessel, hull shape and

size.

Please take time to read this manual to get a thorough

understanding of the operation and system components and their

relationship to a complete AP35 autopilot system.

Other documentation material that is included in this manual is a

warranty card. This must be filled out by the authorized dealer

that performed the installation and mailed in to activate the

warranty.

Page 4

Simrad AP35 Autopilot

2 22083083H

Document revisions

Rev Date Written by Checked by Approved by

– 05.02.96 NG IK ThH

A 25.06.96 NG ThH

B 08.09.97 NG IK ThH

C 31.08.98 NG IK GHR

D 31.05.99 NG IK ThH

E 07.08.01 NG ThH

F 21.12.01 NG TR

G 04.06.02 NG IK TR

H 08.10.03

Document history

Rev. – Original Issue

A Changes on modification record and table of contents. Page 2-5:

Amendment to operational sequence of R3000X. Page 2-13: Changes in

text. Page 3-2: Amendment to specifications on Junction units. Page 4-1:

New page references in text. Page 4-3 and 6-1: Call attention upon

feedback alignment. Page 4-11: Included drawing of control unit

connection. Remaining pages of chapter 4 changed due to displacement of

text/s. Page 4-28 and 4-29: Changes in text. Page 4-30 and 4-31: New

layout on interface setup table.

B RFC35R Rate Compass, RI35 Rudder Angle Indicator and S35 NFU

Steering Lever included. Page 2-5: Corrected course change rate of

R3000X. Page 3-2: Supply voltage for junction units added. Max

Clutch/bypass load added. Page 3-12: NMEA messages list updated. Page

4-6: Drawings for junction units terminal boards included. Page 4-26:

Minor change in text. Table of contents, List of s and Distributor list

updated.

C New V1R2 s.w. in AP35 Control Unit. Initial rudder ref. setting. Page 2-

6: Added note. Page 4-1: Added point 5g. Page 4-25: Added “Initial

Rudder” to Dockside Items. Page 4-28: Added text. Page 4-29: Added

“Initial Rudder” explanation. Page 4-36: Corrected text in 1st. and 3rd.

paragraph.

D Added text on page 1-1 (4

th

paragraph), page 1-2 (table), page 2-10 (last

paragraph). New display picture one page 4-29. Corrected specifications

for Special Turn mode, page 3-1. Added “Modification on PCB”, page 5-

2.

E New layout. RF45X included. Dataline drawings replaced by IS15

drawings. CI300X connection drawing replaced. Display pictures updated

according to new software version, V1R3. NMEA compass added.

CD100A included.

F Following corrections: STBY button section 2.3. Conductor color on

figure 4-19. HDM message on page 83. Added FU35 under Comm.

Failure alarm page 95.

G Minor corrections in text on page 58, 83 and 85. Distributor list updated.

H Updated according to software version V1R4. RFC35R substituted by

RC25. FU35 substituted by FU50. Modifications on RF45X.

Page 5

Instruction Manual

22083083H 3

Contents

1 GENERAL INFORMATION ............................................................................................... 9

1.1 Introduction .............................................................................................................. 9

1.2 How to use this manual............................................................................................. 9

1.3 System components ................................................................................................ 10

1.4 AP35 Control Unit .................................................................................................. 10

1.5 Junction units .......................................................................................................... 11

1.6 Rudder Feedback units ........................................................................................... 11

RF300 Rudder Feedback Unit ................................................................................ 11

RF45X Rudder Feedback Unit ............................................................................... 11

1.7 Heading Sensors ..................................................................................................... 11

RFC35 Electronic Fluxgate Compass..................................................................... 11

RC25 Rate Compass............................................................................................... 12

CDI35 Course Detector Interface and CD100A (CD109) Course Detector........... 12

NMEA compass...................................................................................................... 12

Other compass models............................................................................................ 12

1.8 Optional equipment ................................................................................................ 12

R3000X Remote Control ........................................................................................ 12

S35 NFU Steering Lever ........................................................................................ 12

FU50 Follow-Up Steering Lever ............................................................................ 12

F1/2 NFU Remote .................................................................................................. 13

RI35 Mk2 Rudder Angle Indicator......................................................................... 13

2 OPERATION OF THE AUTOPILOT............................................................................... 15

2.1 Overview ................................................................................................................ 15

2.2 ON/OFF - Standby mode........................................................................................ 16

2.3 Follow-Up steering ................................................................................................. 17

2.4 Non-Follow-Up steering ......................................................................................... 17

2.5 NFU Steering lever ................................................................................................. 17

2.6 NFU Push button remote control ............................................................................ 17

2.7 R3000X Remote Control ........................................................................................ 18

2.8 S35 NFU Steering Lever ........................................................................................ 18

2.9 Automatic Steering ................................................................................................. 19

2.10 Automatic Speed selection ..................................................................................... 20

2.11 Manual speed selection........................................................................................... 20

2.12 Navigating with the AP35 ...................................................................................... 21

Selecting a different Navigator............................................................................... 22

2.13 WORK-mode.......................................................................................................... 23

2.14 TURN-mode ........................................................................................................... 24

2.15 Dodging .................................................................................................................. 25

Dodge in NAV........................................................................................................ 25

2.16 Multiple station system........................................................................................... 25

2.17 Lock function.......................................................................................................... 26

2.18 User Set-up Menu ................................................................................................... 27

3 TECHNICAL SPECIFICATIONS..................................................................................... 29

Page 6

Simrad AP35 Autopilot

4 22083083H

3.1

AP35 Autopilot System .......................................................................................... 29

3.2 AP35 Control Unit .................................................................................................. 30

3.3 Junction units .......................................................................................................... 30

3.4 RFC35 Fluxgate compass ....................................................................................... 32

3.5 RC25 Rate Compass ............................................................................................... 33

3.6 CDI35 Course Detector Interface ........................................................................... 33

3.7 RI35 Mk2 Rudder Angle Indicator ......................................................................... 34

3.8 RF300 Rudder Feedback Unit ................................................................................ 35

3.9 RF45X Rudder Feedback Unit ............................................................................... 36

3.10 R3000X Remote ..................................................................................................... 37

3.11 CI300X Compass Interface..................................................................................... 37

3.12 NI300X NMEA Interface ....................................................................................... 38

3.13 S35 NFU Steering Lever ........................................................................................ 38

3.14 F1/2 Remote Control .............................................................................................. 39

3.15 FU50 Steering Lever............................................................................................... 40

3.16 IP protection ........................................................................................................... 41

4 INSTALLATION ................................................................................................................. 43

4.1 General.................................................................................................................... 43

4.2 Installation checklist ............................................................................................... 43

4.3 Unpacking and handling ......................................................................................... 44

4.4 Determine system configuration ............................................................................. 44

4.5 AP35 System Layout .............................................................................................. 45

4.6 RF300 Rudder feedback ......................................................................................... 45

4.7 RF45X Rudder Feedback Unit ............................................................................... 47

Electrical connection .............................................................................................. 48

4.8 Junction unit ........................................................................................................... 49

Cable connections................................................................................................... 49

Grounding and RFI................................................................................................. 50

Junction unit terminals............................................................................................ 50

4.9 Drive unit ................................................................................................................ 51

Connecting a reversible pump ................................................................................ 53

Connecting a hydraulic linear drive........................................................................ 53

Connecting a solenoid valve................................................................................... 54

4.10 Control unit............................................................................................................. 54

Panel mounting ....................................................................................................... 54

Bracket mounting ................................................................................................... 54

ROBNET network cables ....................................................................................... 55

4.11 RFC35 Fluxgate Compass ...................................................................................... 57

4.12 RC25 Rate Compass ............................................................................................... 58

4.13 R3000X Remote Control ........................................................................................ 59

4.14 FU50 Steering Lever............................................................................................... 59

4.15 S35 NFU Steering Lever ........................................................................................ 60

4.16 F1/2 Remote Control .............................................................................................. 60

4.17 RI35 Mk2 Rudder Angle Indicator......................................................................... 61

RI35 Mk2 illumination ........................................................................................... 61

Page 7

Instruction Manual

22083083H 5

Zero adjust .............................................................................................................. 61

Reversed deflection ................................................................................................ 62

4.18 Interfacing............................................................................................................... 63

4.19 Single NMEA input/output..................................................................................... 63

4.20 Double NMEA input/output ................................................................................... 63

4.21 Additional NMEA output on Port 2........................................................................ 64

4.22 NMEA Compass in................................................................................................. 64

4.23 Radar Clock/Data.................................................................................................... 64

4.24 IS15 Instrument ...................................................................................................... 65

4.25 Analog Repeater ..................................................................................................... 66

4.26 Digital Repeater ...................................................................................................... 66

4.27 External Alarm ....................................................................................................... 67

4.28 NI300X NMEA Interface Unit ............................................................................... 67

4.29 CI300X Analogue Interface Unit............................................................................ 68

4.30 CD100A Course Detector....................................................................................... 69

4.31 CDI35 Interface ...................................................................................................... 70

4.32 Software Setup Procedure....................................................................................... 71

Description of Installation Settings ........................................................................ 71

Installation Settings Menu ...................................................................................... 72

Language selection ................................................................................................. 72

Dockside settings.................................................................................................... 73

Drive unit voltage selection .................................................................................... 74

Alignment for RF45X Rudder Feedback Unit........................................................ 75

Rudder Feedback Calibration ................................................................................. 75

Automatic Rudder Test........................................................................................... 77

Transition Speed ..................................................................................................... 77

Autotrim WORK .................................................................................................... 78

Initial Rudder.......................................................................................................... 78

Master reset............................................................................................................. 78

Interface Settings .................................................................................................... 79

4.33 Sea Trial.................................................................................................................. 83

Rudder zero adjust .................................................................................................. 83

Compass calibration................................................................................................ 84

Compass Offset....................................................................................................... 84

Automatic tuning .................................................................................................... 85

View parameters ..................................................................................................... 86

Manual parameter adjust......................................................................................... 87

4.34 Final sea trial .......................................................................................................... 88

4.35 Providing user training ........................................................................................... 89

5 MAINTENANCE ................................................................................................................. 90

5.1 Control unit............................................................................................................. 90

5.2 Junction Unit........................................................................................................... 90

5.3 Rudder Feedback .................................................................................................... 90

5.4 Compass.................................................................................................................. 90

5.5 Drive unit ................................................................................................................ 90

5.6 Exchange of software programme .......................................................................... 91

Modification on AP35 PCB.................................................................................... 92

Page 8

Simrad AP35 Autopilot

6 22083083H

6

TROUBLE SHOOTING ..................................................................................................... 93

6.1 Alarms .................................................................................................................... 93

6.2 NMEA Test............................................................................................................. 96

6.3 System Data Menu.................................................................................................. 97

7 SPARE PARTS LIST .......................................................................................................... 98

8 SALES AND SERVICE WORLDWIDE (300903) ......................................................... 101

List of Figures

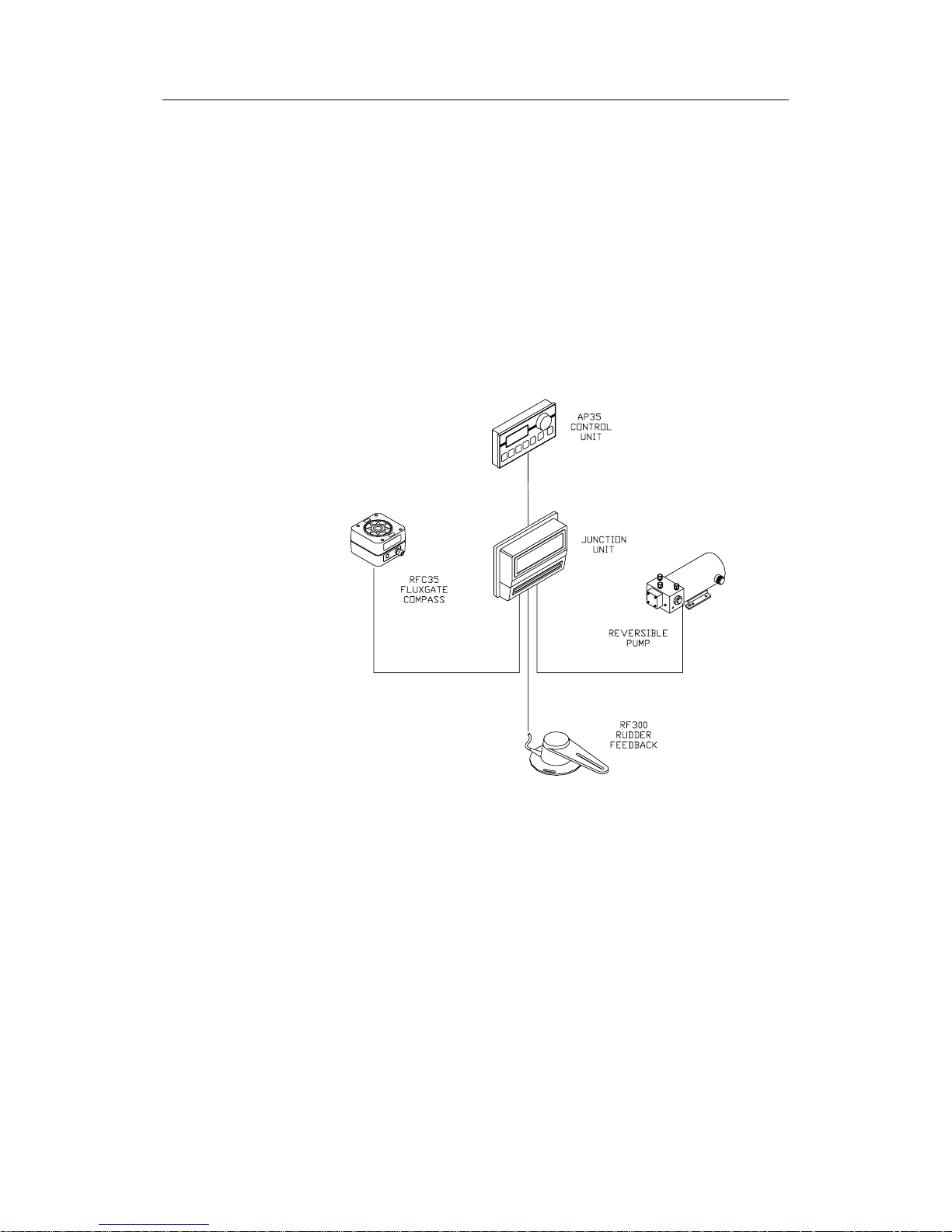

FIGURE 1-1 AP35 BASIC SYSTEM .................................................................................10

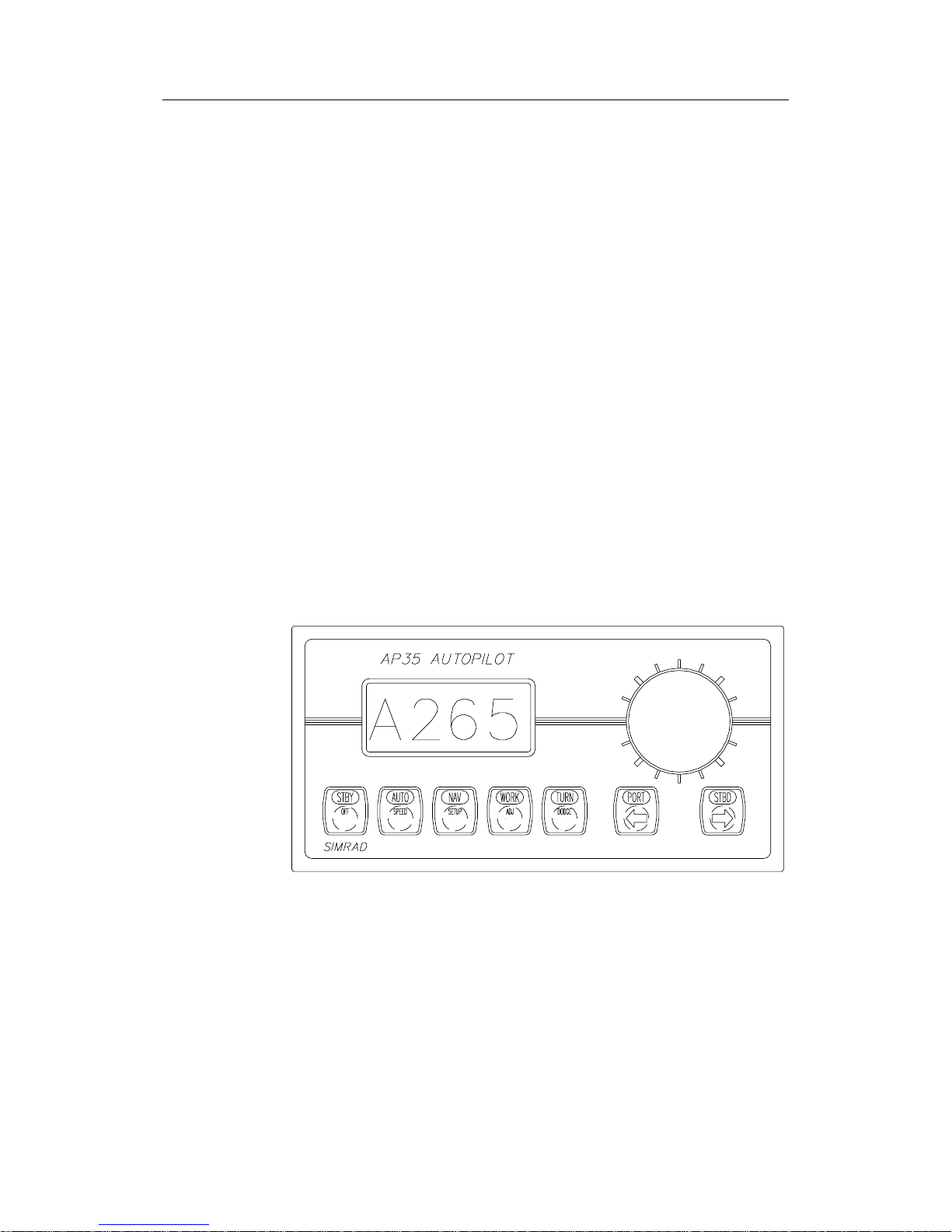

FIGURE 2-1 AP35 FRONT PANEL................................................................................... 15

FIGURE 3-1 AP35 CONTROL UNIT - DIMENSIONS DRW. NO. N3-208305...............30

FIGURE 3-2 J300X/J3000X JUNCTION UNIT - DIMENSIONS ..................................... 31

FIGURE 3-3 J300X-40 JUNCTION UNIT - DIMENSIONS .............................................31

FIGURE 3-4 RFC35 FLUXGATE COMPASS – DIMENSIONS ......................................32

FIGURE 3-5 RI35 MK2 DIMENSIONS............................................................................. 34

FIGURE 3-6 RF300 RUDDER FEEDBACK - DIMENSIONS.......................................... 35

FIGURE 3-7 TRANSMISSION LINK - DIMENSIONS.................................................... 35

FIGURE 3-8 RF45X RUDDER FEEDBACK UNIT .......................................................... 36

FIGURE 3-9 RF45 TRANSMISSION LINK...................................................................... 36

FIGURE 3-10 R3000X - DIMENSIONS ............................................................................37

FIGURE 3-11 CI300X AND NI300X - DIMENSIONS.....................................................38

FIGURE 3-12 S35 - DIMENSIONS.................................................................................... 39

FIGURE 3-13 F1/F2 - DIMENSIONS ................................................................................39

FIGURE 3-14 FU50 DIMENSIONS .................................................................................. 40

FIGURE 4-1 AP35 SYSTEM LAYOUT WITH OPTIONS................................................45

FIGURE 4-2 RF300 MOUNTING (019356)....................................................................... 46

FIGURE 4-3 RF300 CONNECTION .................................................................................. 46

FIGURE 4-4 RF45X RUDDER FEEDBACK UNIT - MOUNTING .................................47

FIGURE 4-5 RF45X CONNECTION .................................................................................48

FIGURE 4-6 J3XX MOUNTING........................................................................................ 49

FIGURE 4-7 J3XX – SCREEN TERMINATION............................................................... 50

FIGURE 4-8 CONNECTING A REVERSIBLE PUMP .....................................................53

FIGURE 4-9 CONNECTING A HYDRAULIC LINEAR DRIVE..................................... 53

FIGURE 4-10 CONNECTING A SOLENOID VALVE..................................................... 54

FIGURE 4-11 AP35 PANEL MOUNTING ........................................................................54

FIGURE 4-12 AP35 BRACKET MOUNTING...................................................................55

FIGURE 4-13 CONTROL UNIT CONNECTION.............................................................. 56

FIGURE 4-14 RFC35 MOUNTING.................................................................................... 57

FIGURE 4-15 RFC35 CONNECTION ...............................................................................58

FIGURE 4-16 RC25 CONNECTION TO AP35 CONTROL UNIT ................................... 58

FIGURE 4-17 R3000X CONNECTION .............................................................................59

FIGURE 4-18 S35 CONNECTION TO JUNCTION UNIT................................................60

FIGURE 4-19 F1/2 CONNECTION.................................................................................... 60

FIGURE 4-20 RI35 MK2-J3000X/J300X WIRING DIAGRAM........................................61

FIGURE 4-21 SINGLE NMEA CONNECTION............................................................... 63

FIGURE 4-22 DOUBLE NMEA CONNECTION............................................................. 63

FIGURE 4-23 NMEA COMPASS CONNECTION............................................................ 64

FIGURE 4-24 RADAR CLOCK/DATA CONNECTION ..................................................64

FIGURE 4-25 IS15 INSTRUMENTS / J3XX CONNECTION ..........................................65

FIGURE 4-26 IS15 EXPANDER / J3XX CONNECTION................................................. 65

FIGURE 4-27 AR77 AND AR68 ANALOG REPEATER CONNECTION...................... 66

FIGURE 4-28 DR75 DIGITAL REPEATER CONNECTION ..........................................66

FIGURE 4-29 EXTERNAL ALARM CONNECTION.......................................................67

FIGURE 4-30 NI300X CONNECTION.............................................................................. 68

FIGURE 4-31 CI300X CONNECTIONS............................................................................ 69

Page 9

Instruction Manual

22083083H 7

FIGURE 4-32 CD100A MOUNTING................................................................................. 70

FIGURE 4-33 CDI35 CONNECTION ................................................................................ 70

FIGURE 4-34 INSTALLATION SETTINGS MENU ........................................................73

FIGURE 5-1 J3000X/J300X/J300X-40 MAIN PC-BOARD ..............................................91

FIGURE 5-2 AP35 PCB, COMPONENT LAYOUT .......................................................... 91

Page 10

Simrad AP35 Autopilot

8 22083083H

This page is intentionally left blank.

Page 11

General Information

22083083H 9

1 GENERAL INFORMATION

1.1 Introduction

Congratulations on the purchase of your new Simrad AP35 autopilot system

and thank you for selecting what we feel is the most advanced autopilot

system available on the market today.

Today Simrad manufacture a complete range of autopilots for all types of

vessels, from leisure boats up to advanced steering systems for merchant

marine vessels. Our factory for these products Simrad Egersund AS, is

located in Egersund on the south/west coast of Norway. The company's

involvement in autopilots began in 1953 with equipment for the North Sea

fishing fleet under the brand name Robertson. Professional mariners around

the world acknowledge that the Robertson and Simrad brand names are

synonymous with the absolute best in autopilot technology.

The AP35 autopilot from Simrad represents yet another step forward in

autopilot technology with the intent to provide small fishing boats and work

boats up to 45 feet with a host of new features. The system can be expanded

and enhanced with a selection of options and accessories.

The brain in the AP35 autopilot system is the single "intelligent" junction

unit that communicates with all other system modules on the ROBNET

network. The ROBNET has been developed to establish a reliable digital

communication and power distribution network between the units in the

system. The ROBNET simplifies installation and enables the AP35 system

to be easily expanded at any time. Any unit that is connected to the autopilot

system via Robnet is called a Robnet Unit (See table on page 11).

1.2 How to use this manual

This manual is intended as a reference guide for operating, installing and

maintaining the Simrad AP35 autopilot. Great care has been paid to simplify

operation and set-up of the AP35, however, an autopilot is a complex

electronic system. It is affected by sea conditions, speed of the vessel, hull

shape and size.

Please take time to read this manual to get a thorough understanding of the

operation and system components and their relationship to a complete AP35

autopilot system.

Other documentation materials that are provided with your system include a

warranty card. This must be filled out by the authorized dealer that

performed the installation and mailed in to activate the warranty.

Page 12

Simrad AP35 Autopilot

10 22083083H

1.3 System components

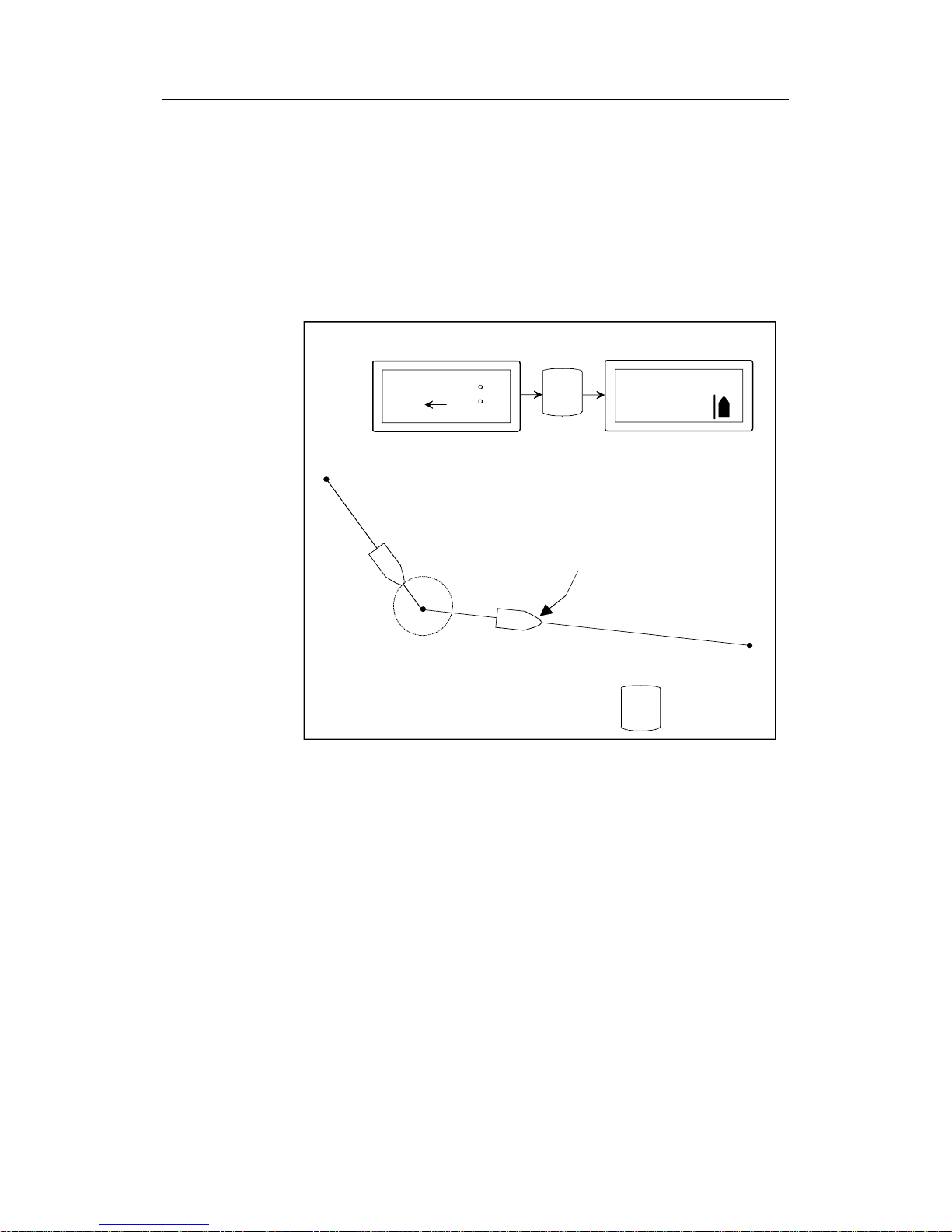

A basic AP35 system consists of the following units (refer to Figure 1-1):

• AP35 Control Unit with accessories

• Heading sensor

• Rudder Feedback Unit with transmission link

• Junction Unit

• Drive unit

The basic system can be expanded with remote control unit, hand held

remote and steering lever.

Figure 1-1 AP35 Basic system

1.4 AP35 Control Unit

A compact autopilot control for panel, bulkhead or bracket mounting. Large

LCD display for readout of autopilot data and rotary course selector. It has

two Robnet connectors for system inter- connection and expansion.

Page 13

General Information

22083083H 11

1.5 Junction units

The junction unit is the central in the AP35 autopilot system. It contains the

steering computer, interface circuits to all system components and drive

circuits for the drive unit motor and clutch. Three models, J300X, J300X-40

and J3000X are available.

Junction unit comparison chart:

J3000X J300X (J300X-40)

Supply voltage 10-28 V 10-40 V

Motor current (continuous/peak) 6/10 A 10/20A (20/40A)

Number of Robnet units* (+J3xx) 2 5

NMEA ports (input/output) 1 2

Solenoid output x x

Input for NFU control x x

External alarm x

Radar clock/data interface x

* AP35 Control Unit, RC25 Rate Compass, FU50 Follow-up lever, CI300X

Compass Interface, NI300X NMEA Interface.

1.6 Rudder Feedback units

RF300 Rudder Feedback Unit

Rudder feedback unit with transmission link and 10 m (30 feet) of cable.

Transforms the angular travel of the rudder to a digital signal read by the

autopilot steering computer.

RF45X Rudder Feedback Unit

This unit transmits two electrical signals proportional to the rudder angle.

One signal operates as a feedback for the autopilot, the other as drive signal

for rudder angle indicators. The unit is mounted close to the rudder stock and

is mechanically connected to the rudder by the RF45 Transmission link.

1.7 Heading Sensors

The AP35 autopilot can be used with the following combinations of heading

sensors:

RFC35 Electronic Fluxgate Compass

A compact heading sensor from Simrad with 15 m (45 feet) of cable. The

direction of the earth's magnetic field is sensed by a floating ring core in a

fluxgate coil and transformed to a digital signal read by the autopilot steering

computer.

Page 14

Simrad AP35 Autopilot

12 22083083H

RC25 Rate Compass

Fluxgate compass with integrated rate of turn sensor. Provides a dramatic

improvement to the dynamic performance of both the autopilot and a

stabilized radar display.

Same dimensions as RFC35.

CDI35 Course Detector Interface and

CD100A (CD109) Course Detector

Interface and sensor unit to connect AP35 to a magnetic compass. The AP35

provides excitation current for CD100A and converts the analogue sin/cos

signal to digital two wire format for the autopilot steering computer.

NMEA compass

Any NMEA 0183 compass with HDT, HDG or HDM messages can be

connected directly to the J300X/J300-40X junction units.

Other compass models

The optional CI300X can interface AP35 to fluxgate compasses with

heading signal on a sine/cosine format or gyro with 1:1 synchro.

1.8 Optional equipment

A series of options are available for the basic AP35 system.

R3000X Remote Control

A small handheld remote control with two push buttons for power steering

or course selection (port and starboard), and one push button with built-in

lighted indicator for mode selection.

S35 NFU Steering Lever

S35 is designed for indoor and outdoor bulkhead mount and made of shock

resistant polyxymethylene. The lever has spring loaded return to midposition. A push button with light indicator is used for mode selection when

connected to a Simrad J3XX junction unit.

FU50 Follow-Up Steering Lever

The FU50 Follow-up steering lever features a dial (scale) with 5° rudder

angle markings. The rudder will move and stop at the angle selected on the

dial. The FU50 has a mid-position indent, buttons for (limited) mode

selection, and mode indicators (STBY, FU, AUTO, NAV, WORK, and

THRUSTER*). It is designed for indoor and outdoor bulkhead- or panelmounting. Refer to the FU50 manual.

* With AP50 Autopilot only.

Page 15

General Information

22083083H 13

F1/2 NFU Remote

Handheld control for push button steering, fitted with a rubber grip. Made of

cast seawater resistant aluminium and fitted with a 10 meter (30 ft.) cable.

RI35 Mk2 Rudder Angle Indicator

The RI35 Mk2 is manufactured in non-corrosive aluminum with a nonreflective black finish.

The indicator is made in standard modular size (132x108 mm) to match the

Simrad AP35 autopilot.

The instrument gives a continuous reading of the rudder position up to 45

degrees to each side of midship position. A front panel key is used for rudder

zero adjustment and illumination adjustment.

The splash proof construction allows panel, bulkhead or bracket mounting in

exposed locations, such as bridge wings as well as wheel house and engine

room.

Note ! See Figure 4-1 for illustrations or section 3 for technical specifications.

Page 16

Simrad AP35 Autopilot

14 22083083H

This page is intentionally left blank.

Page 17

Operation

22083083H 15

2 OPERATION OF THE AUTOPILOT

Caution ! An autopilot is a very useful navigational aid, but DOES NOT under any

circumstance replace a human navigator.

Do not use automatic steering when:

• In heavy traffic areas or in narrow waters

• In poor visibility or extreme sea conditions

• In areas where use of autopilot is prohibited by law

When using an autopilot:

• Do not leave the helm unattended

• Do not place any magnetic material or equipment near magnetic or

fluxgate compass used in the autopilot system

• Verify at regular intervals course and position of vessel

• Always switch to Standby mode, and reduce speed in due time to avoid

hazardous situations

2.1 Overview

Figure 2-1 AP35 Front Panel

The control unit shown above can operate as a stand alone unit in an

autopilot system or combined in a multistation system. In a multistation

system the command can easily be transferred from one unit to another.

Units not in control will display "Inactive".

The AP35 system is capable of the following primary steering modes: STBY

(manual steering), AUTO, NAV, WORK and TURN, each mode having a

dedicated push button.

Each of the mode push buttons is clearly identified with the primary function

in large text, and a secondary function listed in smaller text. Each button

provides you with the ability to access a primary display, a secondary

display and/or multiple function displays.

Page 18

Simrad AP35 Autopilot

16 22083083H

A group of user adjustable settings are provided in the AP35 USER SETUP

MENU (page 27). The settings allows adjustment of display visibility,

selection of heading sensors, navigation and position sources and the ability

to select between automatic or manual adjustable sea state filter.

Alarms are presented in plain text to alert you of system and external data

failure conditions. Alarms include both audible and visual presentations. The

alarm listing is on page 93.

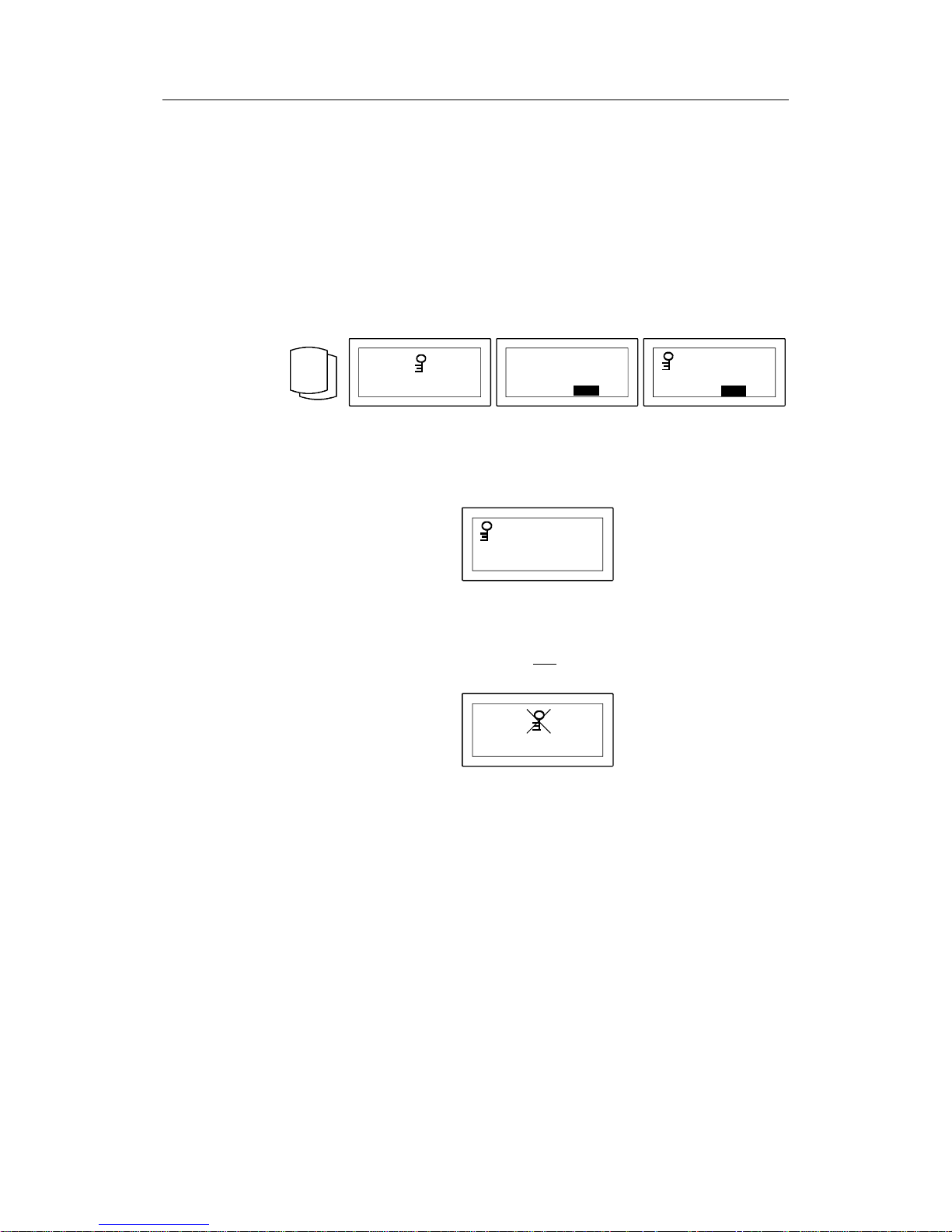

2.2 ON/OFF - Standby mode

A single press on the STBY button switches the system ON and the

following status displays are shown:

HW rev. 0

SW V1R4

* AP35 *

* Robertson *

P00 M00 S000

SW V1R8

* J300X *

* Robertson *

Software V(ersion) and R(elease)

Autopilot model

Hardware revision

Software V(ersion) and R(elease)

Junction unit model

Self check

Main board revision

Power board revision

SW and HW revisions shown are examples only

After approx. 5 seconds the system is operative and the unit that was turned

on will show the STBY mode Primary Display. Other units in a multistation

system will display "Inactive". Control can be available at any unit by

pressing the STBY button.

A long press (2-3 sec.) on the STBY button switches the system OFF.

Note ! In an emergency it is possible on a multistation system to turn OFF the

system at any control unit by pressing down the STBY button for 2-3

seconds.

STBY mode is also the mode that is used when steering the boat manually.

Second Press

S123

STBY

OFF

Secondary Display

First Press

STBY

OFF

Primary Display

5 sec.

S123

RFC

HI

12

Standby mode.

Current heading from RFC

compass.

HI speed selected.

Rudder angle: 12 degrees

to starboard.

Standby mode.

Current heading.

Page 19

Operation

22083083H 17

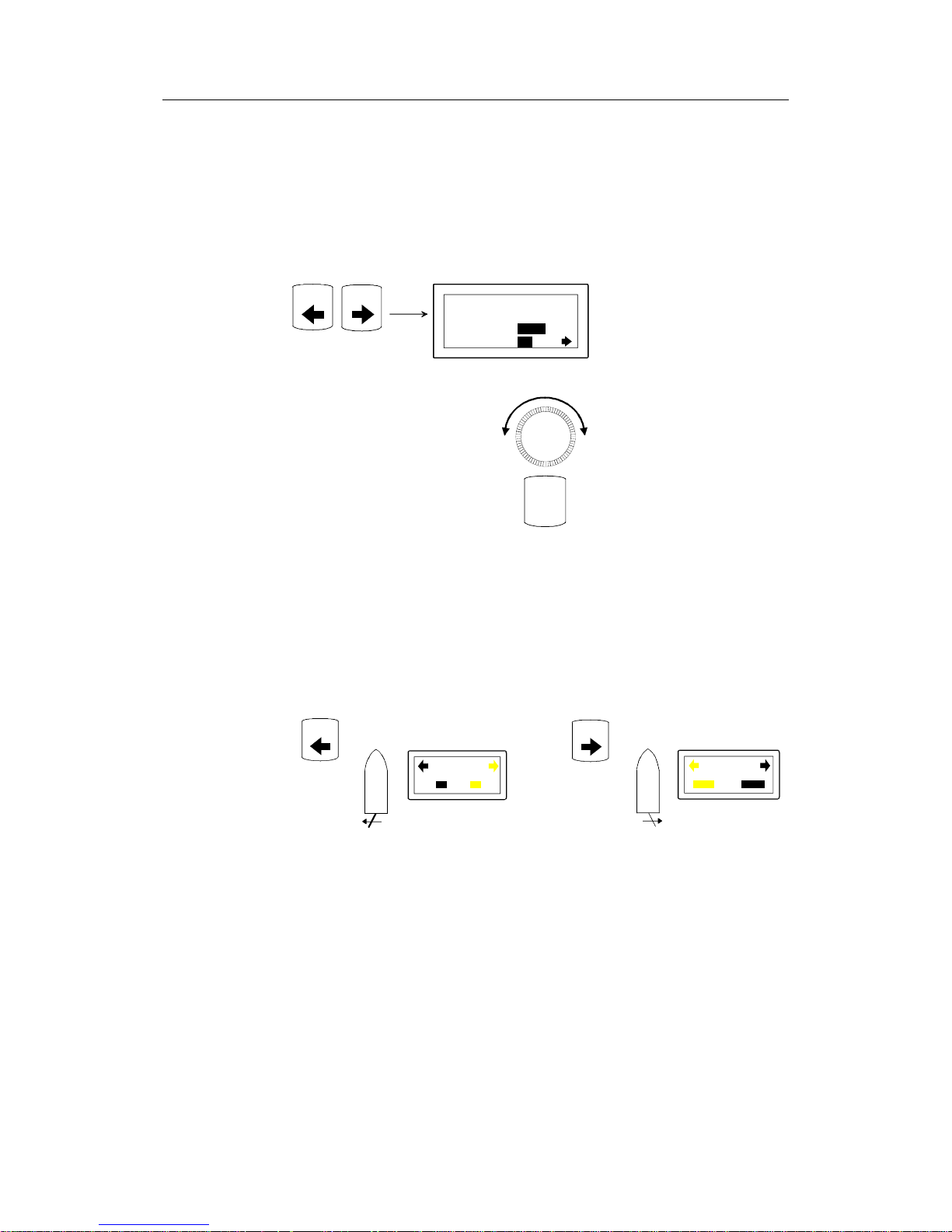

2.3 Follow-Up steering

When both the PORT and STBD push buttons are pressed simultaneously

the AP35 is set to Follow-Up steering mode and rudder commands can be set

by the course dial. One revolution of the dial equals 45° rudder command.

The rudder will move to the commanded angle and stop.

Press both buttons

simultaneously to

activate Follow-Up

FU

22

12

STBD

PORT

Follow-Up mode.

Commanded rudder angle:

22° to stbd.

Rudder angle:12

P

S

Use course knob to

command rudder angle.

STBY

OFF

Return to manual control in

STBY by pressing the

STBY button.

WARNING ! While in Follow-Up mode, you cannot take manual control of the

vessel.

2.4 Non-Follow-Up steering

In STBY mode, when the PORT or STBD push button is pressed separately,

the actual rudder angle is shown on the secondary display and the rudder will

move as long as the button is pressed.

03

NFU

A

ctivates

PORT

Rudder

command

05

NFU

Activates

STBD

Rudder

command

Actual rudder angle

Actual rudder angle

PORT

STBD

2.5 NFU Steering lever

In STBY mode the rudder will move as long as the lever is offset to Port or

Starboard

2.6 NFU Push button remote control

In STBY mode the rudder will move as long as the Port or Starboard button

is pressed.

Note ! When a NFU steering lever or remote control is operated, the control unit(s)

become "Inactive".

Page 20

Simrad AP35 Autopilot

18 22083083H

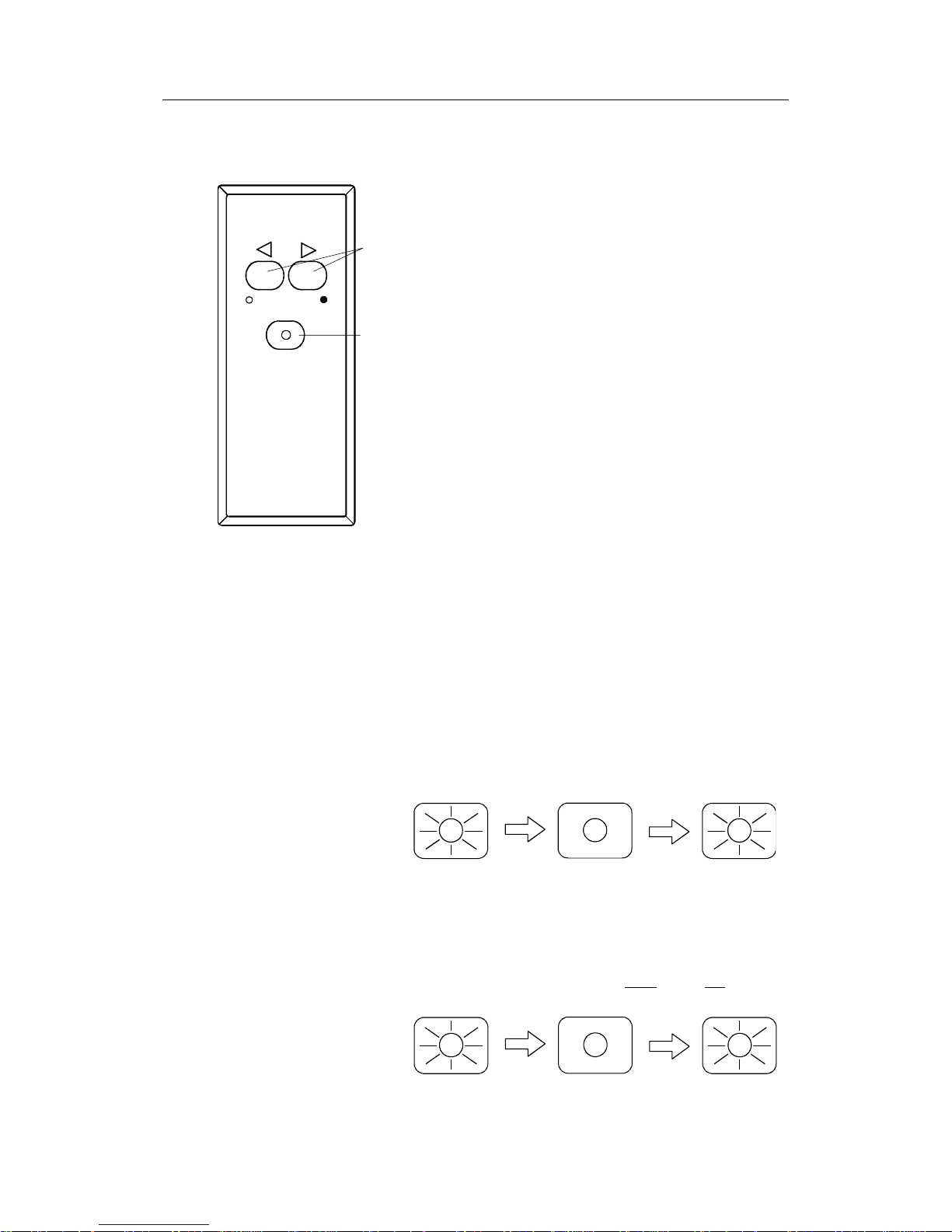

2.7 R3000X Remote Control

Note!

When in AUTO/WORK mode, pressing

the buttons will change the set course

1° per push. If you keep the button

pressed, it will automatically change

the course in increments of 3°/second.

Operation of mode button returns the

autopilot to initial mode except when in

Nav mode:

AUTO

→

STBY → AUTO

WORK

→

STBY → WORK

NAV

→

STBY →AUTO

Nav and Work modes can only be

entered from the control unit.

2.8 S35 NFU Steering Lever

STBY: The rudder will move as long as the lever is offset to Port

or Stbd (NFU steering). The mode button is lit each time

the lever is offset.

AUTO/WORK: The set course will be changed by 3°/sec. when the lever

is offset to port or Stbd.

The mode button remains lit as long as the autopilot is in

AUTO or WORK mode (and NAV mode).

Mode change sequence is as follows:

AUTO AUTOSTBY

STBYWORK WORK

Operation of mode button returns the autopilot to initial

mode.

NAV: It is not possible to change set course by the lever.

Pressing the mode button brings the autopilot to Stby

mode, but next press brings it to Auto

mode, not back to

Nav mode.

STBYNAV AUTO

Note ! NAV and WORK mode can only be entered from a control unit.

STBY-AUTO

Simrad R3000X

STBY/AUTO mode button.

AUTO, WORK or NAV

mode is when lamp is lit

Push buttons for Port and

Stbd NFU commands

SIMRAD

Page 21

Operation

22083083H 19

2.9 Automatic Steering

The AUTO mode is used to make the AP35 steer the boat automatically on a

set heading. AUTO is always available from any mode or function within the

AP35 by a single push on the AUTO button. When the AUTO mode is

selected, the AP35 automatically selects the current boat heading as the set

course and the current rudder angle to compensate for wind/current.

Note ! If Init Rudder “Midship” is selected (see Dockside settings, page 73 the

rudder will move to midship (0

°

).

In AUTO, the AP35 is issuing rudder commands to keep the boat on the set

heading. Determination of the boat heading is provided by the magnetic

compass course detector or RFC35 Fluxgate Compass (or an optional

heading sensor) for course keeping in AUTO mode.

The AP35 will keep the boat on the set heading until a new mode is selected

or a new heading is set with either the course dial or the PORT or STBD

buttons. One revolution of the dial equals 45° course change.

Once the course is changed to a new set heading, the boat will automatically

turn to the new heading and continue to steer straight.

First Press

AUTO

SPEED

A315

313

LO

02

Primary Display

Automatic steering mode.

Set heading.

Boat heading.

LO speed selected.

Rudder angle: 02°

STBD

PORT

Port Starboard

Course adjust

1 degree/push

Course change

CW: Starboard

CCW: Port

Second Press

AUTO

SPEED

A315

Secondary Display

The secondary display is

also shown for 3 seconds

when the PORT or STBD

button, or the course dial is

activated from primary

display.

Page 22

Simrad AP35 Autopilot

20 22083083H

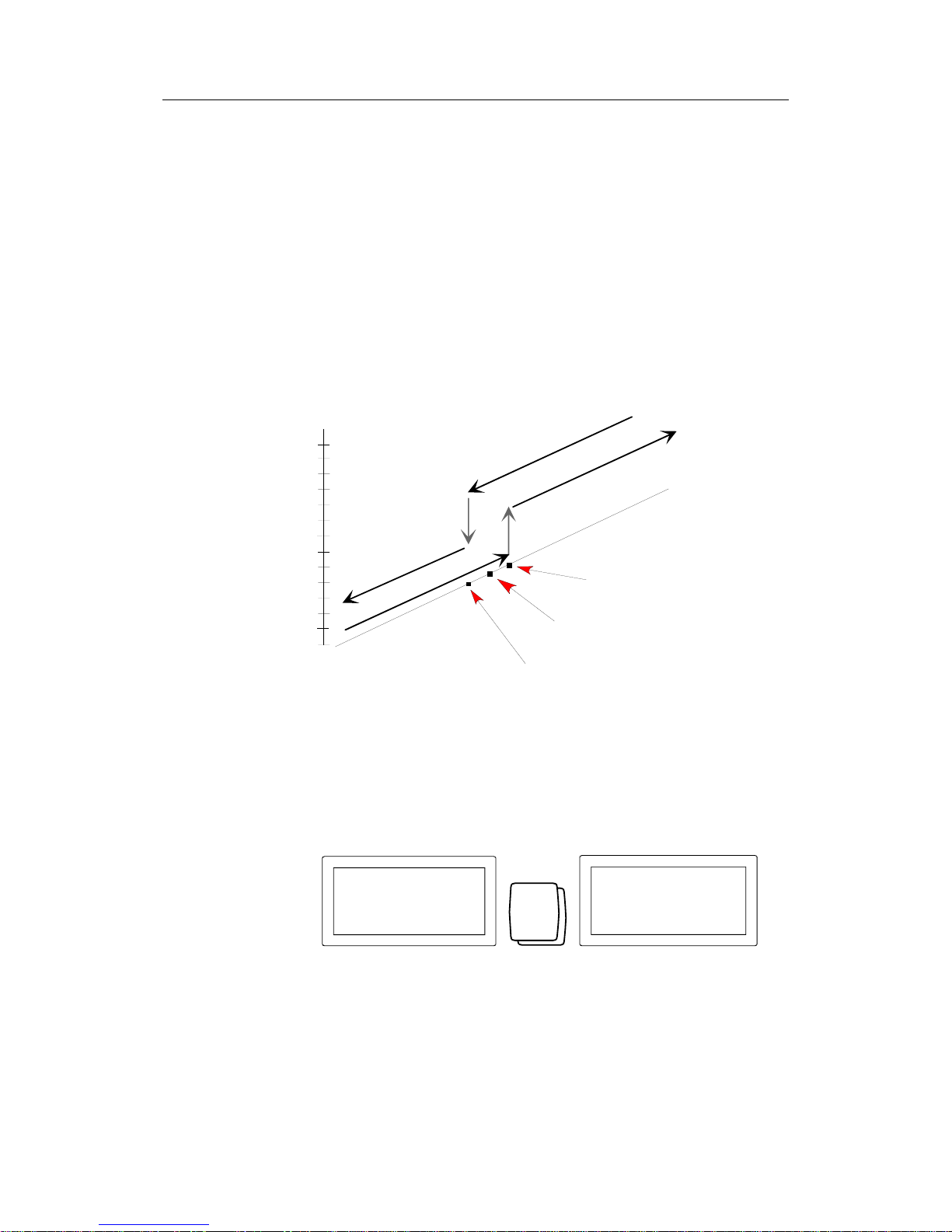

2.10 Automatic Speed selection

The AP35 provides two different sets of steering parameters for controlling

the response of the boat at different speeds (HI or LO) while in AUTO and

NAV modes.

The AP35 always selects the HI speed steering parameters when first

switched on. This is a safety feature. After initial turn on, selection of the

steering parameters is done automatically, based on the availability of input

data from either an external speed log or an external navigator, or manually.

The AP35 automatically selects the HI or LO parameter set. The speed at

which the AP35 changes from HI to LO (or opposite) is determined by the

"Transition Speed" set in the Installation Setup Menu.

26

24

22

20

18

16

14

12

10

8

6

4

2

0

H

I

s

p

e

e

d

p

a

r

a

m

e

t

e

r

s

L

O

s

p

e

e

d

p

a

r

a

m

e

t

e

r

s

Transition Speed set to 9 Knots

Example of

Transition speeds with

AUTOMATIC Speed parameter

selection

Transition to HI parameters

with increasing speed: 10 Knot

s

Transition to LO parameters

with decreasing speed: 8 Knots

2.11 Manual speed selection

Select AUTO mode. To toggle between HI and LO speed parameters, press

the "AUTO" button two times quickly (Double click).

If you change boat speed it is recommended that you select HI or LO

parameters correspondingly.

setting

HI

AUTO

SPEED

setting

LO

The manually selected steering parameter set (HI or LO) will remain in

effect until you re-enter AUTO mode or restarts.

Page 23

Operation

22083083H 21

2.12 Navigating with the AP35

The AP35 has the capability to use steering information from an external

navigator (GPS, Chart Plotter) to direct the boat to a specific waypoint

location, or through a route of waypoints. In the NAV mode, the AP35 uses

the heading sensor as it's source of heading for course keeping. The steering

and speed information received from the external navigator alters the set

course to direct the AP35 to the destination waypoint.

Note ! Navigational steering must only be used in open waters. The process of

having an external navigation receiver direct an autopilot can be a slow

acting process. By selecting the NAV mode, the AP35 is set for automatic

steering on the current set course and then waits for the user to accept the

course change to the destination waypoint.

To obtain satisfactory navigation steering, the following points must be

fulfilled prior to entering the NAV mode:

• The AP35 autosteering must be tested and found satisfactory.

• The navigation receiver must be operating and the navigation system

(GPS, Chart Plotter) must be in full operating mode with adequate signal

characteristics for valid position and steering data.

• At least one waypoint must be entered and selected as the current

waypoint in the navigation receiver.

• The navigation source in the AP35 USER SETUP menu must be set for

the navigator that contains the current waypoint.

The AP35 is designed to steer in “mixed mode” operation. This combines

the straight steering capability of cross track error (XTE) steering in

conjunction with the turning capability of bearing mode steering (course to

steer (CTS)).

N

.02 Nm

If required course change

is safe, press NAV to accept

Third press

Second press

OK:? Press NAV

Chg.

Brg.

WP: WP 001

135

016

Required course change

Bearing WP-WP (leg)

Waypoint Name

XTE Display

GPS1

N-HI

135 1.25 Nm

Nav. Mode, HI speed param.

Bearing and distance to WP

from present position

Nav source

Boat is .02 Nm to the left

of track.

First Press

NAV

SETUP

NAV

SETUP

NAV

SETUP

Page 24

Simrad AP35 Autopilot

22 22083083H

When operating the AP35 in NAV mode to automatically steer through a

route of waypoints, the AP35 will steer to the first waypoint in the route after

you accept the first waypoint as the location to steer to. When you arrive at

the waypoint, the AP35 will display an alert screen with the proposed new

course information displayed. If the required course change is more than 10°

you will need to verify that the upcoming course change is acceptable.

Verification is performed by pressing the NAV button after the alert screen

is displayed. If no verification is received, the AP35 will continue on the

current set course in AUTO mode.

Origin

Waypoint 2

OK:? Press NAV

Chg.

Brg.

WP: WP 002

094

075

New heading accepted

automatically after

NAV/SETUP button is pressed

At the arrival of each new waypoint in a route:

Waypoint arrival zone

(determined by the navigator)

Waypoint 1

Prompt displayed to advise

required course change

N

.01 Nm

Regain manual

steering at any

time by pressing:

XTE on WP2 track

NAV

SETUP

STBY

OFF

Selecting a different Navigator

If you have more than one Navigation source connected to the AP35, you

will be able to choose any for Navigation. Refer to the User Set-up menu for

details on selecting a different Navigator.

Note ! If the AP35 is connected to a Nav. receiver that does not transmit a message

with bearing to next waypoint, it will pick a XTE message and steer on Cross

Track Error only. In that case you have to revert to AUTO mode at each

waypoint and manually change set course to equal bearing to next waypoint

and then select NAV mode again.

Page 25

Operation

22083083H 23

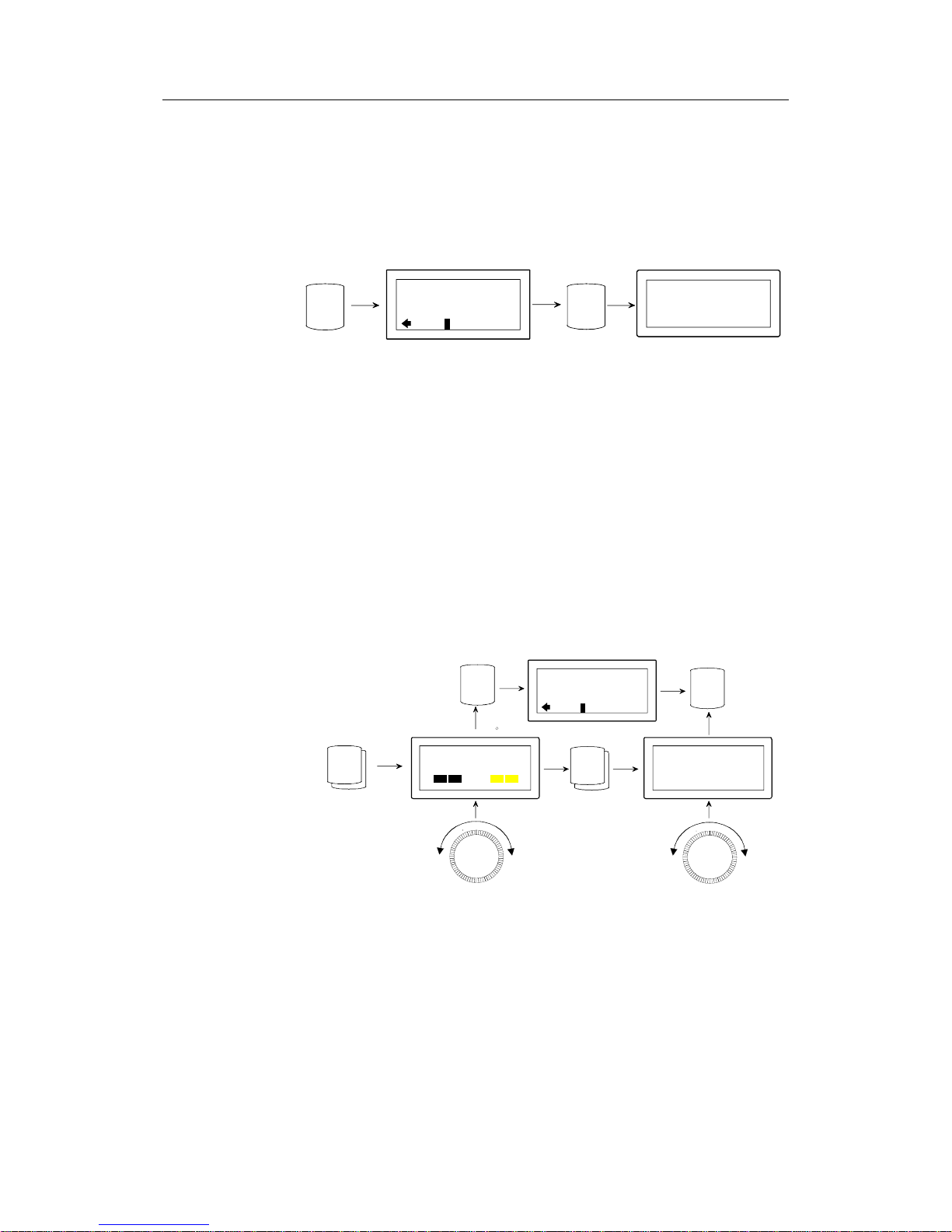

2.13 WORK-mode

The WORK-mode is an automatic steering mode to be used under

operational conditions different from those normally found when a vessel is

in transit on a preset course. Examples are trawling, towing, trolling on one

engine, slow speed etc.

Rudder angle

Set course

Second Press

WORK

ADJ

First Press

WORK

ADJ

W315

W 315

313

LO

02

At such incidents some boats may need a rudder off-set when steered by

hand. By selecting WORK-mode directly from STBY-mode the rudder offset is maintained and becomes the TRIM value.

When in WORK mode a quick double press on the WORK button will

access the TRIM display and the rotary course dial can then be used to adjust

the trim value if needed. The (manual) trim compensates for the autotrim

which needs time to build up the appropriate rudder off-set. The TRIM

setting is not stored.

A different RUDDER (GAIN) setting may be preferred in WORK mode as

compared to that in AUTO (Lo)-mode. A second quick double press on the

WORK button following that for the TRIM display will give access to the

RUDDER display. The RUDDER value can then be set by the course dial.

The RUDDER value set in WORK mode will be stored in the AP35 memory

and is automatically recalled when returning to WORK mode.

Change value

CW: Increase

CCW: Decrease

10

TRIM

Quick double press

Quick double press

0.50

RUDDER

WORK

ADJ

WORK

ADJ

WORK

ADJ

WORK

ADJ

Trim direction

CW: Stbd

CCW: Port

Trim value 10 port

W

315

313

LO

02

The LO (speed) parameters of Counter Rudder (C-RUDD) and Autotrim are

automatically selected in WORK mode. The autotrim function and the Offcourse alarm are controlled by speed input and are automatically turned off

at speeds below 2 kts. If no speed input is provided the autotrim is

permanently on and the Off-course alarm operates as in AUTO mode.

If you prefer to have complete manual control of the rudder trim in WORK

mode, the autotrim can be permanently disabled at the installation setup.

From software version V1R2 onwards the off course alarm is permanently

disabled in Work mode. See your s.w. version on initial start-up.

Note ! Pair-trawling requires manual trim only, and the autotrim should be

permanently disabled at the installation setup.

Page 26

Simrad AP35 Autopilot

24 22083083H

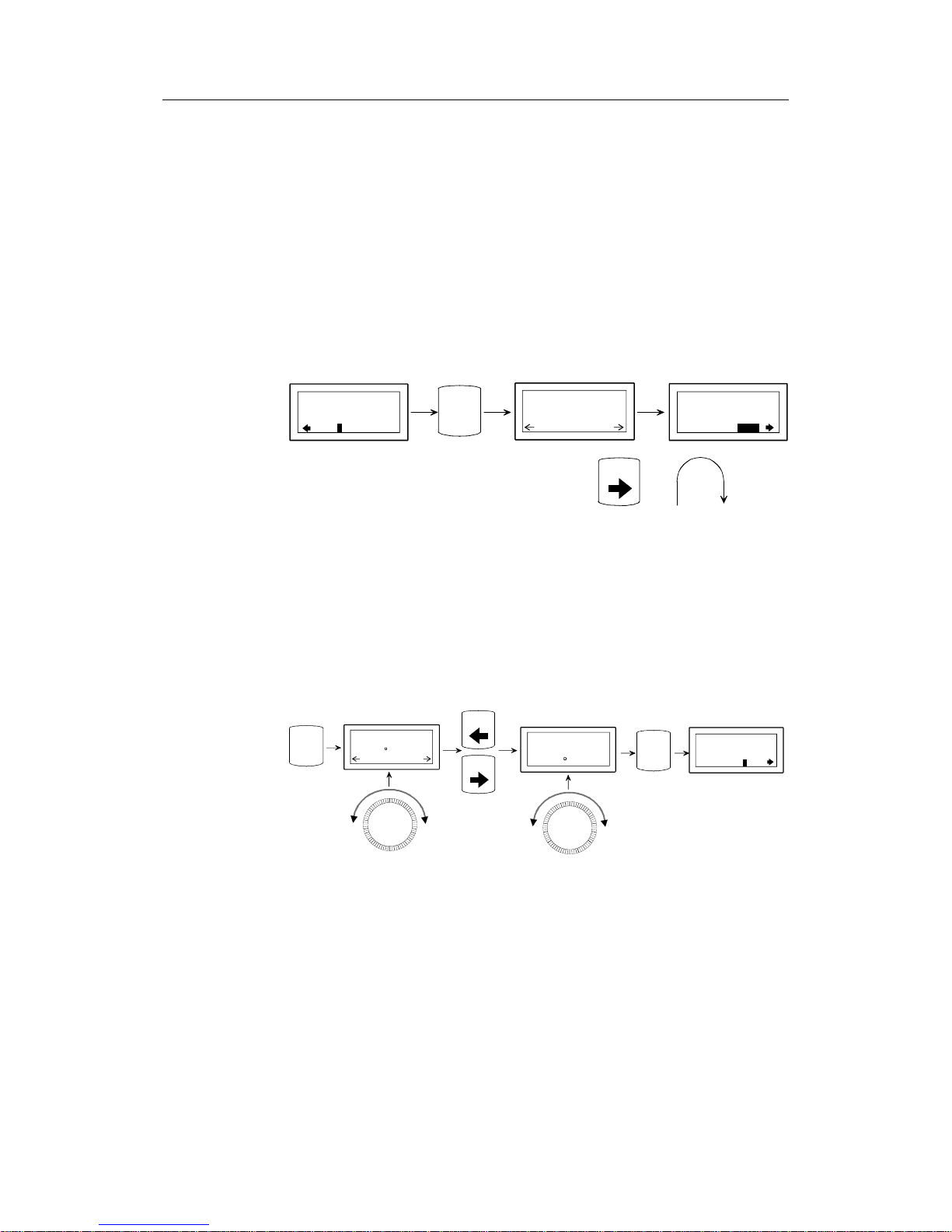

2.14 TURN-mode

The AP35 provides special turn features when in AUTO or WORK modes.

U-Turn changes the current set course to be 180 degrees in the opposite

direction. The user may decide if the U-Turn should be made to Port or

Starboard to bring the boat on the new course. U-Turn is activated by a

single push on the TURN button. After the single push, the AP35 will

continue on the set course until you press either the PORT or STBD button

to select the direction to make the U-Turn. If you do not press PORT or

STBD within 1 minute, the AP35 will return to the AUTO mode and stay on

course.

First Press

TURN

DODGE

Press to select STBD U-turn

U-turn prompt

New course

Boat

makes

STBD

U-turn

Present course

Press

U TURN

STBD

A315

313

LO

02

A

313

135

LO

18

C-Turn changes the current set course continuously. The user may decide if

the C-Turn should be made to Port or Starboard. C-Turn is activated by a

second push on the TURN button, and can only be activated when the AP35

is in AUTO or WORK modes. The AP35 will continue on the set course

until you press either the PORT or STBD button to select the direction to

make the C-Turn. If you do not press PORT or STBD within 1 minute, the

AP35 will return to the AUTO mode and stay on course.

The turn rate can be adjusted before the turn is initiated or during the turn.

Set turn rate

CW: Increase

CCW: Decrease

AUTO

SPEED

Second

press

TURN

DODGE

Press

C TURN

090 /min

PORT

STBD

A265

C-TURN

090 /min

Adjust turn rate while turn ing

CW: Increase

CCW: Decrease

New set course

Turn

Set course is

continuously changing

A278280

LO

02

Note ! Increasing turn rate gives smaller circle or vice versa.

To leave C-turn press any of the Mode buttons. When pressing the AUTO

button the new set course is the one shown on the display at the instant the

button is pressed.

Page 27

Operation

22083083H 25

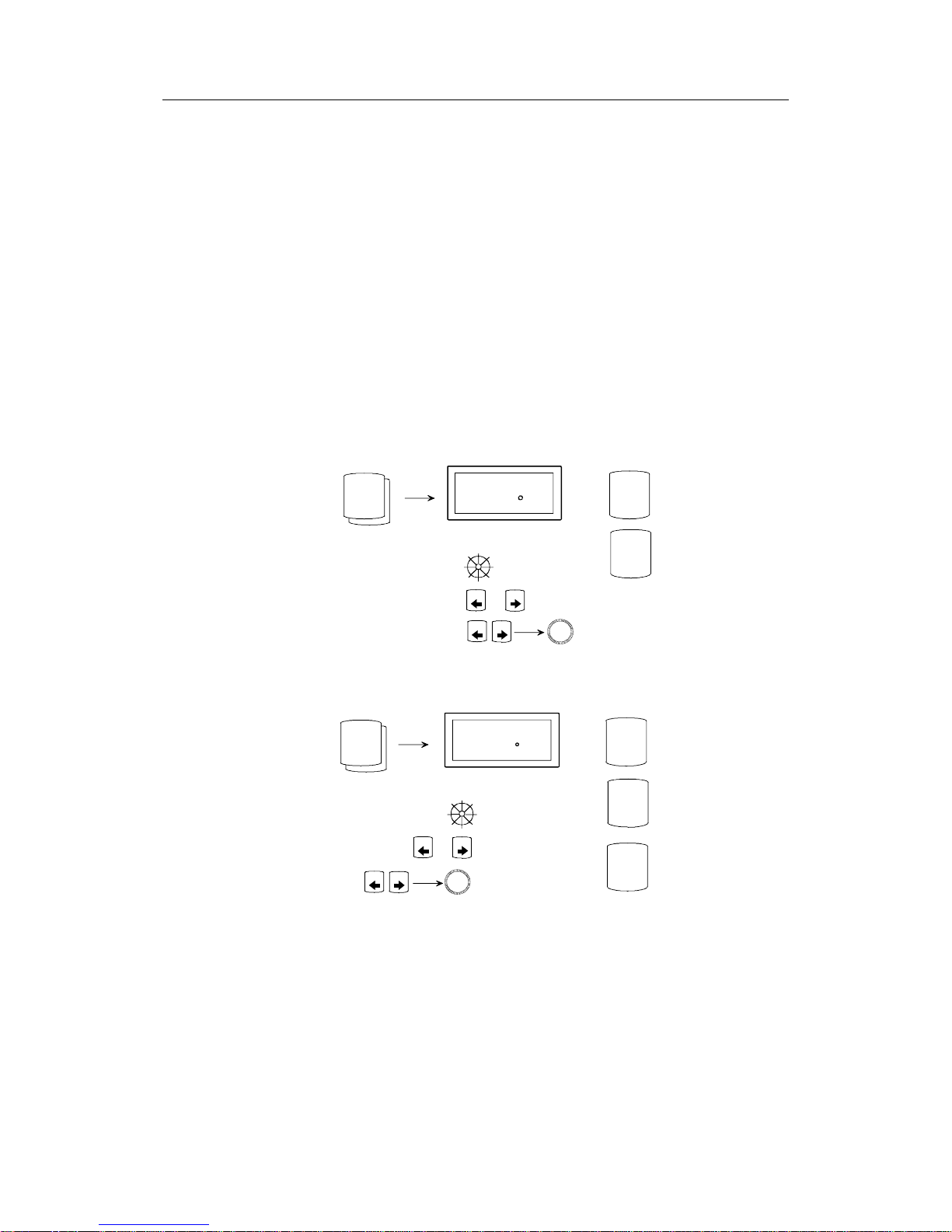

2.15 Dodging

The AP35 also provides the capability for dodging.

Dodging is useful in situations where you need to quickly take control of the

helm to steer around an obstruction, and then wish to return on the previous

set heading after performing the evasive manoeuvre. A quick double press

on the TURN/DODGE button activates dodging.

When in DODGE mode the course displayed is the current boat's heading,

however, the previous set course is remembered by the AP35. When

DODGE is displayed, the AP35 is no longer in control of the steering, and

you must either manually steer the boat or take control using either Non

Follow Up steering or Follow Up steering. On manual steering the clutch (or

bypass valve) in the drive unit will be disengaged when dodging. The AP35

will remain in the DODGE mode until you exit DODGE by a second press

on the TURN/DODGE button or select another mode.

Current heading

Selects AUTO mode

at the previous

set course

Selects AUTO mode

with current heading

as set course

Next Press

Quick double press

DODGE

265

Wheel

or

or both

Non Follow Up

Follow Up

Perform dodge using:

TURN

DODGE

AUTO

SPEED

STBD

PORT

PORT

STBD

TURN

DODGE

Dodge in NAV

Current heading

Selects NAV mode

at the current track

Selects AUTO mode

with current heading

as set course

Next Press

Quick double press

DODGE

265

Wheel

or

or both

Non Follow Up

Follow Up

Perform dodge using:

TURN

DODGE

AUTO

SPEED

STBD

PORT

PORT

STBD

TURN

DODGE

NAV

SETUP

Selects NAV mode

at present position

2.16 Multiple station system

In normal operation of multiple control units, control is accessible from

every control unit connected to the AP35 system. One control unit is "active"

and provides the user with access to all functions and enables the user to

change modes and set the course for automatic course keeping. All

remaining control units are "inactive" and have no effect on mode changes or

course selection. A single push of either the STBY (or AUTO or NAV)

buttons on an "inactive" control unit will allow transfer of command and

make it "active".

Page 28

Simrad AP35 Autopilot

26 22083083H

2.17 Lock function

The "LOCK" function is a safety feature included in the AP35 system to

disable all control units except for a single, user selected control unit

location.

When the "lock" function is in use, no transfer of command may take place;

only the "active" control unit stays in command.

To enable the "lock" function, make a quick double press on the STBY

button.

123

RFC

HI

12

STBY

OFF

STBY

OFF

S123

RFC

HI

12

The display on the "active" control unit will first show a single key icon

followed by the primary display on which the key icon will alternate with the

mode index.

The "locked" control units in the system will show:

Inactive

123

The “Lock function is disengaged by the following actions:

• The “active” control unit unlocks by a double press on the STBY button.

• The system is switched OFF by any

control unit (press STBY for 2-3

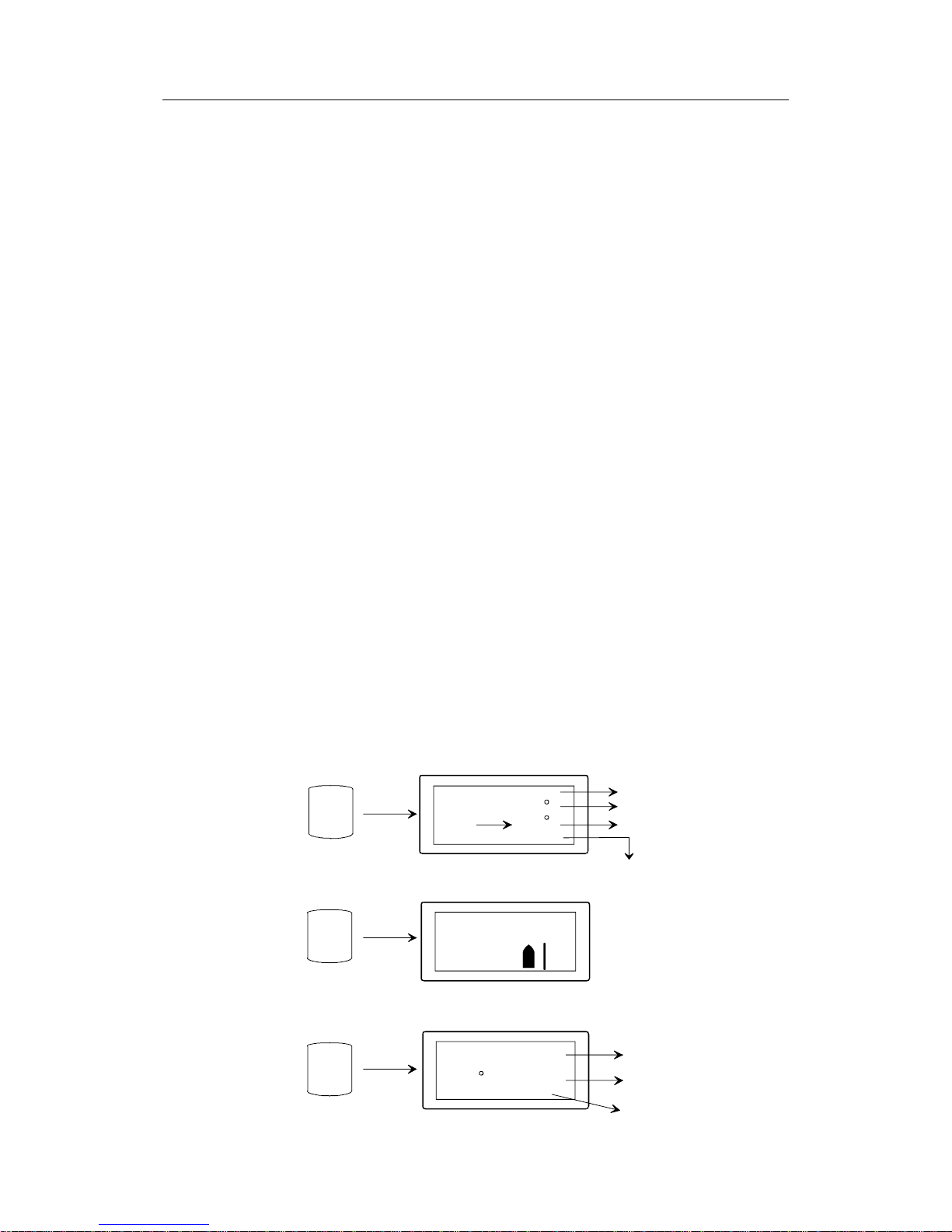

seconds).

After having "unlocked" the other control stations, the "active" control unit

will show the above symbol before the display returns to normal. All other

control units will return to the "inactive" state.

Page 29

Operation

22083083H 27

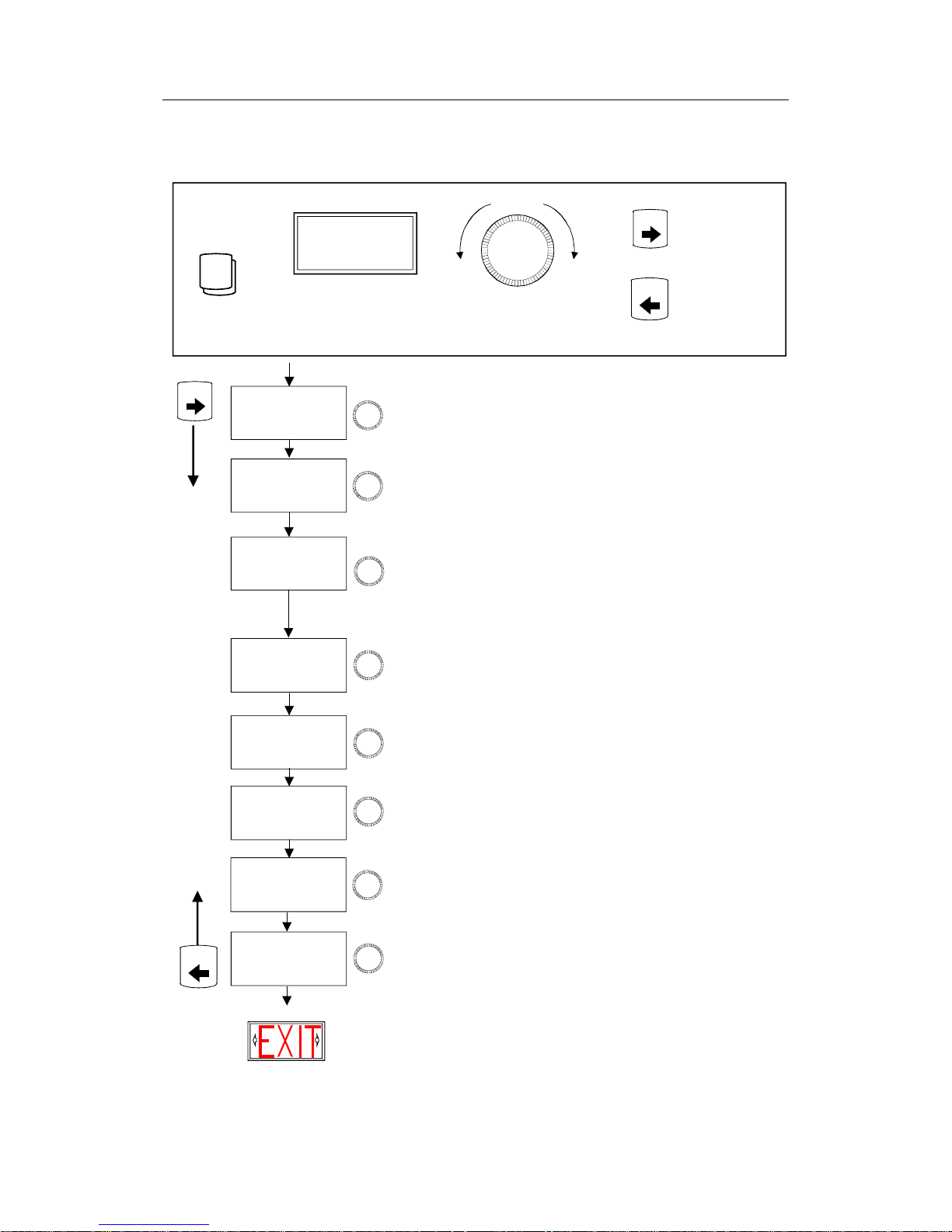

2.18 User Set-up Menu

NAV

SETUP

- SETUP -

Backlight

03

- SETUP -

Contrast

05

- SETUP -

Seastate

Filt.: OFF

- SETUP -

NAV. source:

GPS 1

- SETUP -

POS. Source:

GPS 1

Sequences

FWD in MENU

Sequences

BACK in

MENU

Adjust backlight of display and pushbuttons (10 steps,

10 = brightest). Setting is stored when system is

turned off, and resets to stored level at turn on.

Adjustment is local to the control head you adjust.

Adjust contrast of displays (10 steps). Setting is stored when

system is turned off, and resets to stored level at turn on.

Adjustment is local. All steps not available at high temperature

due to automatic temperature compensation.

Select the compass to be used for AUTO steering.

Refer to the interface setup table in section 4.

RFC COMP = Robertson Fluxgate compass

MAGNET COMP = Magnetic compass

OTHER FLUXG = Non-Robertson fluxgate compass (sin/cos)

GYRO COMP = Robertson gyrocompass (using 1:1 synchro)

NMEA COMP = NMEA compass

Scrolls through menu

selections or sets

value on menu items

Set the Sea State filter.

OFF: Provides precise steering but increases rudder activity.

AUTO: Reduces rudder activity and reduces sensitivity of

autopilot in rough weather automatically.

MANUAL: Sets yawband manually (1-10).

Select the source for NAV mode steering.

Refer to interface setup table in section 4.

Select the source of speed over ground (SOG) and position data

processed by the AP35. This option will appear whenever there is

more than one navigation receiver connected to the system.

Except when NMEA TEST or SYSTEM DATA is displayed, the menu

will disappear after 60 seconds if no key is pressed. It will disappear

immediately if any mode key (STBY, AUTO, NAV, WORK, TURN)

is pressed.

- SETUP -

Select Comp.:

RFC COMP.

Test functions for analysing system data (See "NMEA test" and

"System Data menu" under the "Trouble shooting" section).

NMEA TEST?

SYSTEM DATA?

Quick double

press

Enter User

Setup Menu

Displays User

Set-up Menu

- SETUP -

Backlight

03

TOP

BACK FWD

STBD

PORT

STBD

PORT

Note ! It is necessary to select the correct compass and Nav. source to make the

autopilot operate.

Page 30

Simrad AP35 Autopilot

28 22083083H

This page is intentionally left blank.

Page 31

Technical Specifications

22083083H 29

3 TECHNICAL SPECIFICATIONS

3.1 AP35 Autopilot System

Boat size and type: .........................Up to 45 feet, Power

Steering system types: ....................Hydraulic, Mechanical, Solenoids

Inter-unit connection: .....................ROBNET network or two-wire

supply/data

System ON/OFF:............................From control units

Supply voltage:...............................See junction units

Power consumption:.......................Dependent on system configuration

Environmental Protection:

Control Unit:...........................IP56

RFC35, RC25, CDI35,............IP56

RF300 .....................................IP56

J300X......................................IP44

NI300X, CI300X ....................IP44

EMC protection:.............................EN60945 : 1993, A1 : 1993

Automatic Steering control:

Rudder Drive: .........................Proportional rate or solenoid on/off

Parameter selection:................Automatic with manual override

Sea state control:.....................Adaptive sea state filter

Language selection:........................English, Norwegian, French, Spanish,

Italian, Dutch, Swedish, German.

Electronic Interface:

Navigation interface: ..............Standard (NMEA 0183)

NMEA input/output ports: Max. 6 (see junction units and NI300X

specifications)

Optional output: Simrad/Anritsu and Furuno radar display

(clock/data)

Heading sensors:

Standard:.................................RFC35 Electronic Fluxgate compass

Options: ..................................Magnetic compasses

RC25 Rate Compass

Simrad RGC gyrocompasses

NMEA Compasses

Course Selection:............................Rotary course dial and push button

Alarms: ...........................................Audible and visual, optional external

Alarm modes: .................................Off course, system failures, overload

Steering modes: ..............................Standby, Non-follow up, Follow-up,

Auto, Nav, Work

Special Turn mode: ........................Dodging, U-Turn, C-Turn (30-360°/min.)

Page 32

Simrad AP35 Autopilot

30 22083083H

3.2 AP35 Control Unit

Dimensions:....................................See Figure 3-1

Weight: ...........................................0,9 kg (2.0 lbs)

Display:

Type:.......................................Backlit LCD matrix display

Resolution:..............................80 x 32 pixels

Color:..............................................Black

Illumination: ...................................Adjustable in 10 steps

Environmental Protection:..............IP56

Safe distance to compass:...............0.5 m (1,6 ft)

Temperature:

Operating: ...............................0 to +55 °C (+32 to +130 °F)

Storage:...................................–30 to +80 °C (–22 to +176 °F)

Figure 3-1 AP35 Control Unit - dimensions

Drw. no. N3-208305

3.3 Junction units

Dimensions:....................................See Figure 3-2 and Figure 3-3

Weight:

J300X/J3000X ........................1,3 kg (2,9 lbs.)

J300X-40 ................................2,8 kg (6,2 lbs)

Supply voltage:

J3000X....................................10-28V DC

J300X/J300X-40.....................10-40V DC

Reverse voltage protection .............Yes (not J300X-40)

Power consumption: .......................5 Watt (electronics)

Clutch/bypass load: ........................Max 1,5 Amps

Motor / solenoid drive: ...................10 A continuous, 20 A for 5 seconds

Heading Sensor input: ....................Composite pulse width modulated

Rudder feedback input: ..................Frequency signal, 3400 Hz., 20 Hz/deg.

Rudder feedback units:...................RF300 or RF45X

Page 33

Technical Specifications

22083083H 31

NMEA input/output ports:..............J3000X: 1 (one)

J300X, J300X-40: 2 (two)

External Alarm: ..............................Open collector

Temperature range:

Operation: ............................... 0 to +55 °C (+32 to +130 °F)

Storage:...................................–30 to +80 °C (–22 to +176 °F)

Mounting: .......................................Bulkhead mount

Material: .........................................Anodized aluminium and black ABS

cover

Figure 3-2 J300X/J3000X Junction Unit - Dimensions

Figure 3-3 J300X-40 Junction Unit - Dimensions

Page 34

Simrad AP35 Autopilot

32 22083083H

3.4 RFC35 Fluxgate compass

Dimensions:....................................See Figure 3-4

Weight: ...........................................0,9 kg (2,0 lbs)

Supply and output:..........................Polarity independent 2-wire supply with

superimposed pulse width modulation

Automatic Performance:

Calibration: .............................Automatically activated by control head

Gain compensation: ................Automatically adjusted continuously

Repeatability:..................................± 0.5 degrees

Roll/Pitch:.......................................± 35 degrees

Accuracy:........................................<1° (rms)

Cable supplied:...............................15 m shielded cable

Temperature range:

Operation: ...............................0 to +55 °C (+32 to + 130 °F)

Storage:...................................–30 to +80 °C (–22 to +176 °F)

Environmental Protection:..............IP56

Mounting: .......................................Deck or bulkhead

Material: .........................................Black ABS

Figure 3-4 RFC35 Fluxgate Compass – Dimensions

Page 35

Technical Specifications

22083083H 33

3.5 RC25 Rate Compass

Dimensions:....................................See Figure 3-4

Weight: ...........................................0,9 kg (2,0 lbs)

Power consumption:.......................0,9 watts

Supply and interface:......................Robnet

Environmental Protection:..............IP56

Material: .........................................White ABS

Temperature range:

Operation:.............................0 to +55 °C (+32 to + 130 °F)

Storage: ................................–30 to +80 °C (–22 to +176 °F)

Mounting: .......................................Deck or bulkhead

Cable supplied:...............................15 m (49’) Robnet cable with connector

Automatic Performance:

Calibration:...........................Automatically activated by control head

Rate sensor stabilized heading output:

Accuracy: .............................<1.25° rms (after calibration)

Repeatability: .......................<0.2° rms

Roll/Pitch: ............................± 35 degrees

3.6 CDI35 Course Detector Interface

Dimensions:....................................See Figure 3-4

Weight: ...........................................0,9 kg (2,0 lbs) including cable

Power consumption:.......................0,9 watts

Supply and output:..........................Polarity independent 2-wire supply with

superimposed pulse width modulation

Environmental Protection:..............IP56

Safe distance to compass:...............0.1 m (0.3 ft.)

Material: .........................................Black ABS

Temperature range:

Operation: ...............................0 to +55 °C (+32 to + 130 °F)

Storage:...................................–30 to +80 °C (–22 to +176 °F)

Mounting: .......................................Deck or bulkhead

Cable supplied:...............................15 m (49’) single twisted pair, shielded

Automatic Performance:

Calibration: .............................Automatically activated by control head

Repeatability:..........................± 0.5 degrees

Accuracy: ± 1,0° after calibration (not including

errors from course detector)

Page 36

Simrad AP35 Autopilot

34 22083083H

3.7 RI35 Mk2 Rudder Angle Indicator

Dimensions:...............................See Figure 3-5

Weight: ......................................1.0 kg

Supply voltage:..........................12/24V DC –25%/+30%, polarity

independent

Power consumption:..................Max 3 W

Input signal:...............................Frequency 3400 Hz (midship reference),

±20Hz/degree, polarity independent

Current: 0.1 - 1.1mA (midship 0,6mA),

polarity independent

NMEA 0183 RSA (min. 10 Hz)

$--RSA,x.x,A,x.x,A*hh<cr><lf>

Output signal: ............................NMEA 0183 RSA 20Hz:

$--RSA,xx.x,A,,*hh<cr><lf>

Accuracy:...................................±1° (Indicator alone)

Temperature range:....................Storage: –30°C to +80°C

Operating: –10°C to +55°C

Environmental protection:.........IP56

Safe distance to

magnetic compass: ....................0.3 m (1 ft)

Cable: ........................................20 m, single twisted pair (not connected).

Figure 3-5 RI35 Mk2 Dimensions

Page 37

Technical Specifications

22083083H 35

3.8 RF300 Rudder Feedback Unit

Dimensions:....................................See Figure 3-6 and Figure 3-7.

Weight: ...........................................0,5 kg (1,1 lbs)

Rudder angle: .................................± 90 degrees

Output signal: .................................Polarity independent frequency signal

Frequency resolution: .............Centre: 3400 Hz, 20 Hz/degree of change

Linearity: ± 3 degrees up to 45 degrees of rudder

Cable supplied:...............................10 m twisted pair shielded cable

Mounting: ......................................Horizontal, vertical, upside down

Material: ........................................Polyacetal (POM)

Environmental Protection:..............IP56

Temperature range:

Operation: ...............................–10 to +55 °C (+14 to +130 °F)

Storage:...................................–30 to +80 °C (–22 to + 176 °F)

Transmission link: ..........................Stainless 350mm (13.8") with 2 ball

joints. Ball joint stud for rudder arm

requires 4.2mm dia hole and 5mm tap.

Figure 3-6 RF300 Rudder Feedback - Dimensions

Figure 3-7 Transmission link - Dimensions

Page 38

Simrad AP35 Autopilot

36 22083083H

3.9 RF45X Rudder Feedback Unit

Dimensions:....................................See Figure 3-8

Protection: ......................................IP56

Ambient temperature:.....................–10 - +55°C

Operating voltage: ..........................12V DC (autopilot supplied)

Frequency output, Feedback: .........3400Hz (midship reference)

Port: +20Hz/degree, stbd: -20Hz/degree

Current output, Indicator ................0.1mA - 1.1mA

Capacity:.........................................5 indicators in series

Rudder angle: .................................±45°

Cable length:...................................2 m (6 ft)

Figure 3-8 RF45X Rudder Feedback Unit

Figure 3-9 RF45 Transmission Link

Page 39

Technical Specifications

22083083H 37

3.10 R3000X Remote

Dimensions:......................................... See Figure 3-10

Weight:................................................. 0,4 kg (0,9 lbs)

Material: ..........................Epoxy-coated aluminum

Protection ..............................................................IP56

Safe distance to compass: .....................0.15 m (0.5 ft.)

Temperature range:

Operating: ..................–25 to +55°C (–13 to +130°F)

Storage:......................–30 to +80°C (–22 to +176°F)

Cable:...........................................7 m (23 ft.), shielded

Mounting bracket:........................................... Supplied

Figure 3-10 R3000X - Dimensions

3.11 CI300X Compass Interface

Dimensions:....................................See Figure 3-11

Weight: ...........................................0,9 kg (2,0 lbs)

Power consumption:.......................2 W

Gyro compass input:.......................Synchro 1:1 (RGC10/RGC11/RGC50

gyrocompasses)

Heading or windvane input: ...........Sin/cos max 12V DC

NFU steering lever input: ...............Port/stbd potential free contact

Robnet network interface: ..............2 network connectors

Cable inlets:....................................Rubber glands for cable diam. 10-14 mm

Mounting: .......................................Bulkhead mount

Material: .........................................Epoxy coated aluminium

Environmental Protection:..............IP44

Temperature range:

Operation: ............................... 0 to +55 °C (+32 to +130 °F)

Storage:...................................–30 to +80 °C (–22 to +176 °F)

pfjo^a=oPMMMu

STBY AUTO

Page 40

Simrad AP35 Autopilot

38 22083083H

Figure 3-11 CI300X and NI300X - Dimensions

3.12 NI300X NMEA Interface

Dimensions:....................................See Figure 3-11

Weight: ...........................................0,9 kg (2,0 lbs)

Power consumption:.......................3 W

NMEA183 input/output:.................4 ports, max output load 20 mA

Heading output: ..............................Simrad/Anritsu and Furuno radar display

(clock/data, 0-5V, 50 msec.)

NMEA instrument supply: .............12V DC, max 0.25A

Robnet network interface: ..............2 network connectors

Cable inlets:....................................Rubber glands for cable diam 10-14 mm

Mounting: .......................................Bulkhead mount

Material: .........................................Epoxy coated aluminium

Environmental Protection:..............IP44

Temperature range:

Operation: ............................... 0 to +55 °C (+32 to +130 °F)

Storage:...................................–30 to +80 °C (–22 to +176 °F)

3.13 S35 NFU Steering Lever

Dimensions: ........................ See Figure 3-12

Weight: ............................... 1.4 kg (inclusive cable)

Max. inductive load:............ 4A/24V DC, 60mA/110V AC, 25mA/220V AC

Temperature range:.............. Storage: –30 to 80° C

Operation: –10 to 55° C.

Environmental protection:... IP56

Safe distance to compass:.... 0.5 m (1,6 ft.)

Power consumption (light): . 6 mA

Cable: .................................. 10 m cable with six wires connected through

bottom gland

Note ! Cable gland may be moved to the back side.

Page 41

Technical Specifications

22083083H 39

Figure 3-12 S35 - Dimensions

3.14 F1/2 Remote Control

Dimensions:............... See Figure 3-13

Protection: ................. IP56

Cable length:.............. 10 meters (30 ft.)

Max. inductive load:.. 4A/24V DC,

60mA/110V AC,

25mA/220V AC.

Figure 3-13 F1/F2 - Dimensions

65 (2.6")

210 (8.3")

76 (3.0")

Page 42

Simrad AP35 Autopilot

40 22083083H

3.15 FU50 Steering Lever