Page 1

Manual

Simrad AP14

Autopilot

Page 2

Page 3Page 2

The technical data, information and illustrations contained in this publication were to the best of our knowledge correct at the time of going to print. We reserve the right

to change specifications, equipment, installation and maintenance instructions without notice as part of our policy of continuous development and improvement.

No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form, electronic or otherwise without prior permission from Simrad

Navico Ltd.

No liability can be accepted for any inaccuracies or omissions in the publication, although every care has been taken to make it as complete and accurate as possible.

© 1999 Simrad Navico Ltd

For service and advice please contact the main Simrad dealer in your country of residence.

E03716 Issue 1.1

30/11/1999 MDL

1. General

1.1 Introduction

1.2 AP14H & AP14R Configurations

2. Operation

2.1 General

2.2 Autopilot Mode

2.3 Adjusting Course

2.4 Nav Mode

2.5 Set Key

2.6 Dodge

2.7 Backlighting

2.8 Alarms

2.8.1 Off Course Alarm

2.9 Default Boat Speed

2.10 Adjusting Dodge Angle

3. Parameter Adjustment

3.1 Rudder Movement (Gain)

3.2 Seastate

3.3 Autotrim

4. Installation - AP14H Hydraulic Drive

4.1 Pump Installation SRP12

4.2 Bleeding The Steering System

4.2.1 Two or Three Line Systems

4.2.2 Pressurised Systems

4.3 Linear Feedback Unit SLF12

4.4 Fitting Control Unit SHC14

4.5 Fitting Compass Unit SHS12

4.6 Fitting Course Computer SCP12

4.7 Electrical Installation

4.8 Interfacing via NMEA

CONTENTS

5. Installation - AP14R Rotary Drive

5.1 Drive Installation

5.2 Removing Existing Steering Helm

5.3 Fitting Drive Unit SRD12

5.4 Changing the Steering Cable

5.5 Fitting Control Unit SHC14

5.6 Fitting Compass Unit SHS12

5.7 Electrical Installation

5.8 Interfacing via NMEA

6. Commissioning

6.1 Commissioning Checks

6.1.1 Installation Check

6.2 Compass Orientation

6.3 Compass Adjustment

6.4 Setting Rudder Limits

6.5 Seatrial / Compass Calibration

7. Appendix

7.1 Advice On Operation

7.2 Warning

7.3 NMEA Sentences Received

7.4 Fault Finding

7.5 Optional Accessories

7.6 Specification & Dimensions

7.7 Service & Warranty

Page 3

Page 5

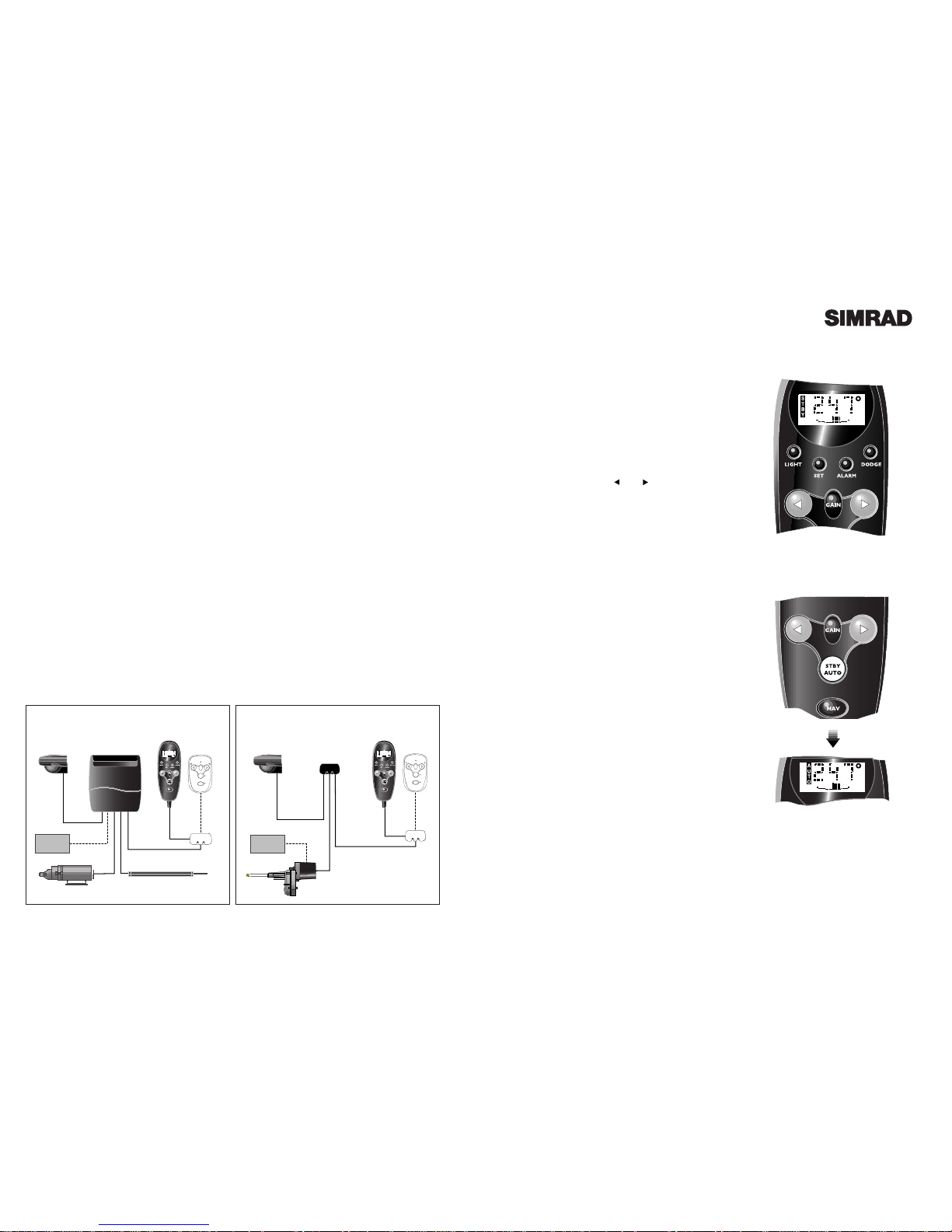

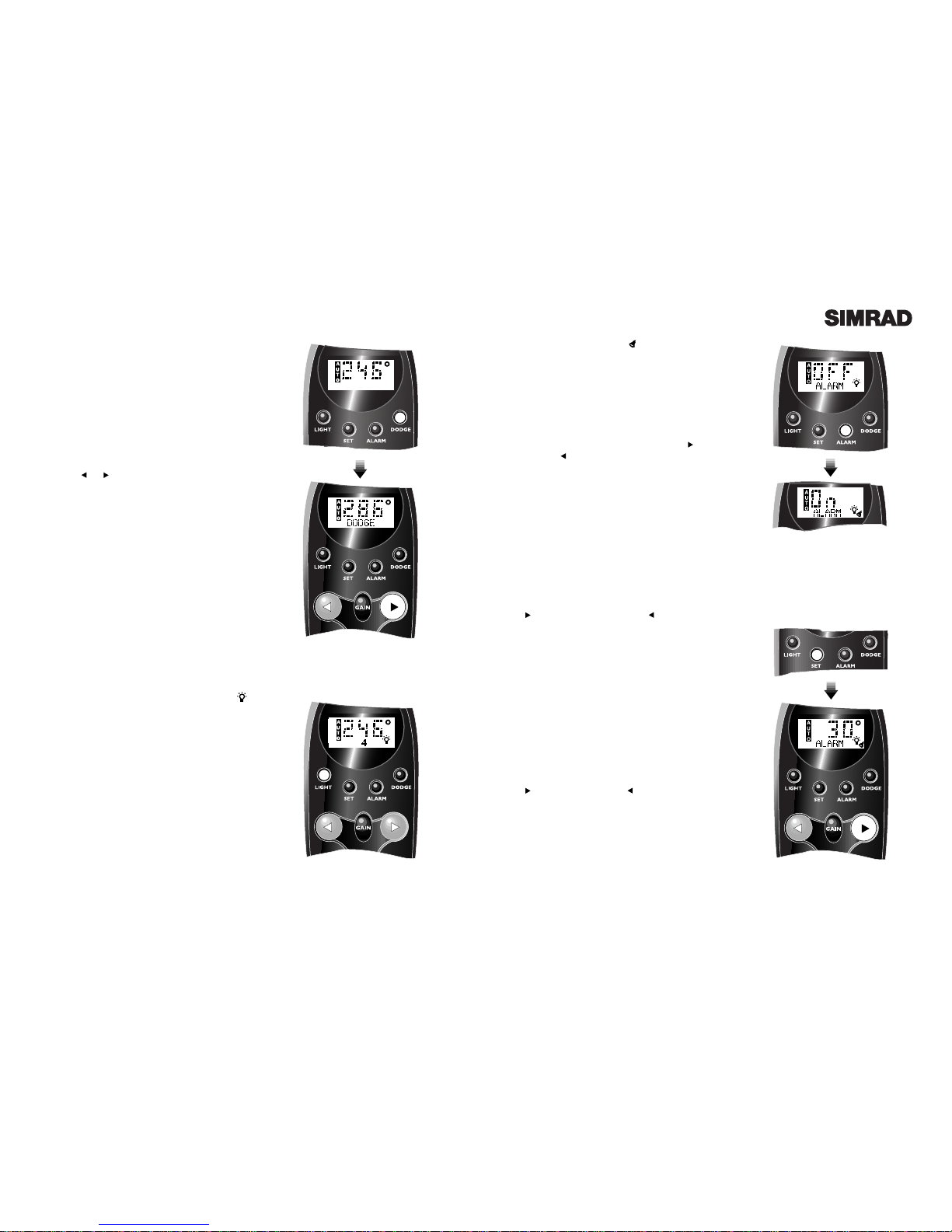

Fig 2.1 - Standby Mode (AP12H / AP14H)

Fig 2.2 - Engaging autopilot Mode

2 Operation

2.1 General

The keypad of the AP14 is easy to operate. Using the five

main keys it is simple to change modes, set the course to

steer and adjust navigational functions.

When powered up the AP14 enters Standby Mode indicated by the STBY legend in the display (Fig 2.1)

While in Standby Mode, the helmsman is in control. The

boat can be hand steered using the helm as normal, or

“power steered” using the and (Port and Starboard)

keys on the controller.

• All functions are confirmed audibly by a “beep” and

visually on the display. The display also shows the current magnetic bearing of the vessel.

• If fitted to an AP14H version, the display will also show

the rudder angle (Fig 2.1).

2.2 Autopilot Mode

To engage Autopilot Mode, press the Stby/Auto key and

the pilot will lock onto the current course (Fig 2.2). The

AUTO legend will show on the display while the pilot is

in Autopilot Mode.

• To lock the pilot onto the desired course, either steer the

correct course and then engage the pilot, or engage the

pilot and then adjust the heading until the correct course

is being steered (see section 2.3).

AP14R Rotary Pilot - it is recommended that if a sudden

course change is necessary while in Auto Mode (e.g. to

avoid an obstacle) the clutch is disengaged and the

autopilot is returned to Standby Mode by pressing

Stby/Auto.

In an emergency the clutch can be overridden by

firmly turning the steering helm, although the autopilot will

try to bring the boat back to the set course.

AP14H Hydraulic Pilot - The autopilot must be disengaged by pressing Stby/Auto if a sudden course change

is necessary otherwise the autopilot will counteract any

movement made manually to the helm.

Page 4

1 General

1.1 Introduction

Combining sophisticated electronics with advanced software and powerful drives, the Simrad AP14

autopilot provides accurate and dependable steering in varying sea conditions with minimal current

consumption.

The AP14, a state of the art autopilot system with many advanced features, is simple to operate and

occupies little space on the dash. The keypad accesses all functions and pilot status is indicated clearly in the backlit LCD display.

To ensure the best results from your autopilot it is essential that the unit is installed correctly please read this manual thoroughly before attempting installation and use.

Thank you for choosing Simrad

We hope you will also be interested in our full range of marine electr onic equipment, which ar e all manufactured to the same high standards as the AP14. Please contact your nearest Simrad Agent for a catalogue showing our full range of high tech marine electronic equipment.

Simrad operate a policy of continual development and reserve the right to alter and improve the

specification of their products without notice.

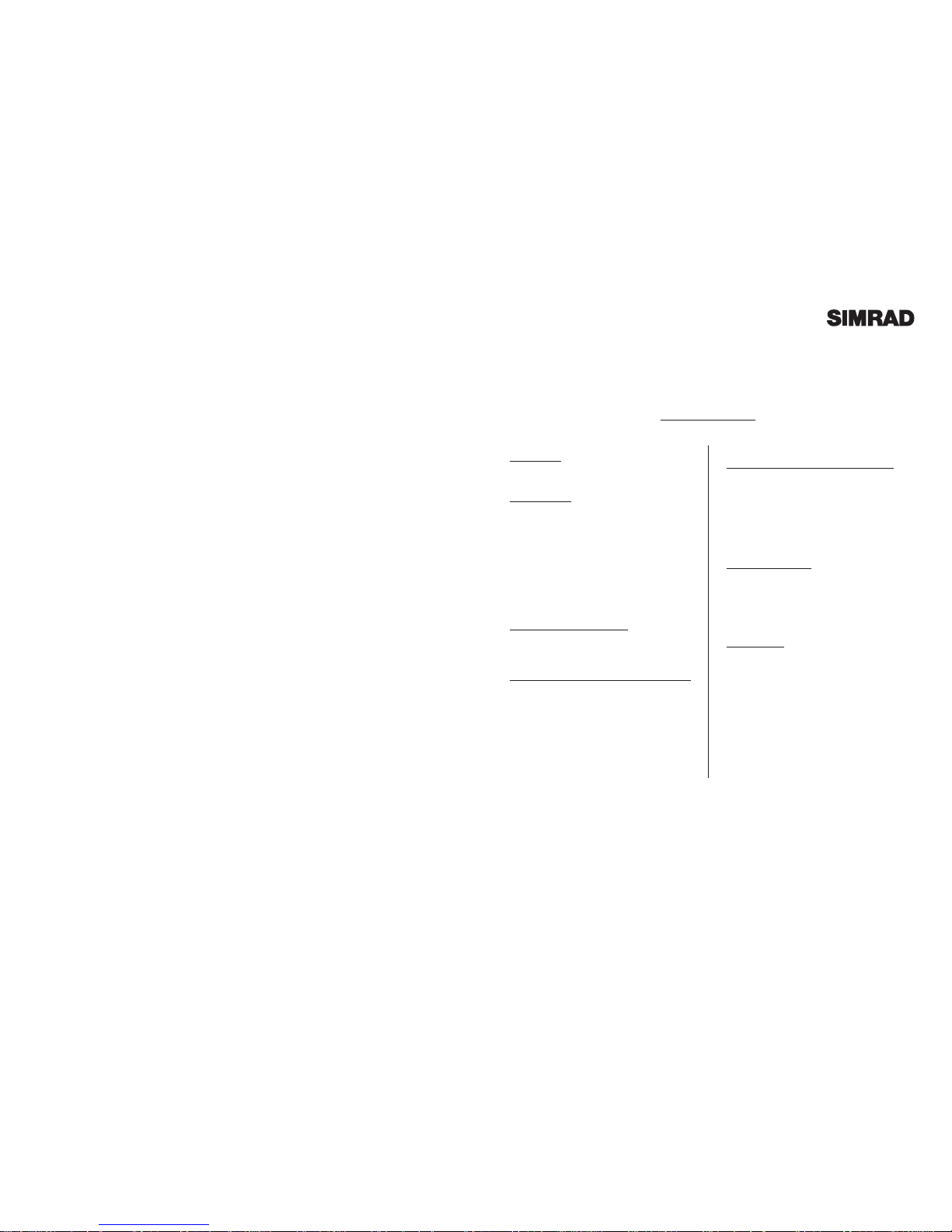

1.2 AP14 System Configurations

The AP14 autopilot system is designed for power vessels and is available in two configurations.

• The AP14H - designed for hydraulically steered boats with a ram displacement of 15 in

3

(250cc).

• The AP14R - designed for powerboats with a push-pull steering cable system which are 30 ft (9M) or

smaller in length.

Although the operation and functions of these two versions are identical, there are some differences

in the configuration and installation of the AP14H and AP14R. To make installation easier, there are

two separate installation sections in this manual. Section 4 relates to the installation of the AP14H

Hydraulic version, section 5 is for the AP14R Rotary version. Some of the setup and calibration routines apply only to the AP14H, but this is clearly indicated at the beginning of the relevant section.

SHS12

Compass

SCP12

Course Computer

GPS

(NMEA)

SRP12

Hydraulic Pump

SLF12

Linear Feedback Unit

GPS

(NMEA)

SHS12

Compass

SJB12

Junction Box

SRD12

Rotary Drive Unit

AP14H Hydraulic Drive Option

AP14R Rotary Drive Version

Optional

Fixed

Control

SFC12

Optional

Fixed

Control

SFC12

Control

SHC14

Control

SHC14

Page 4

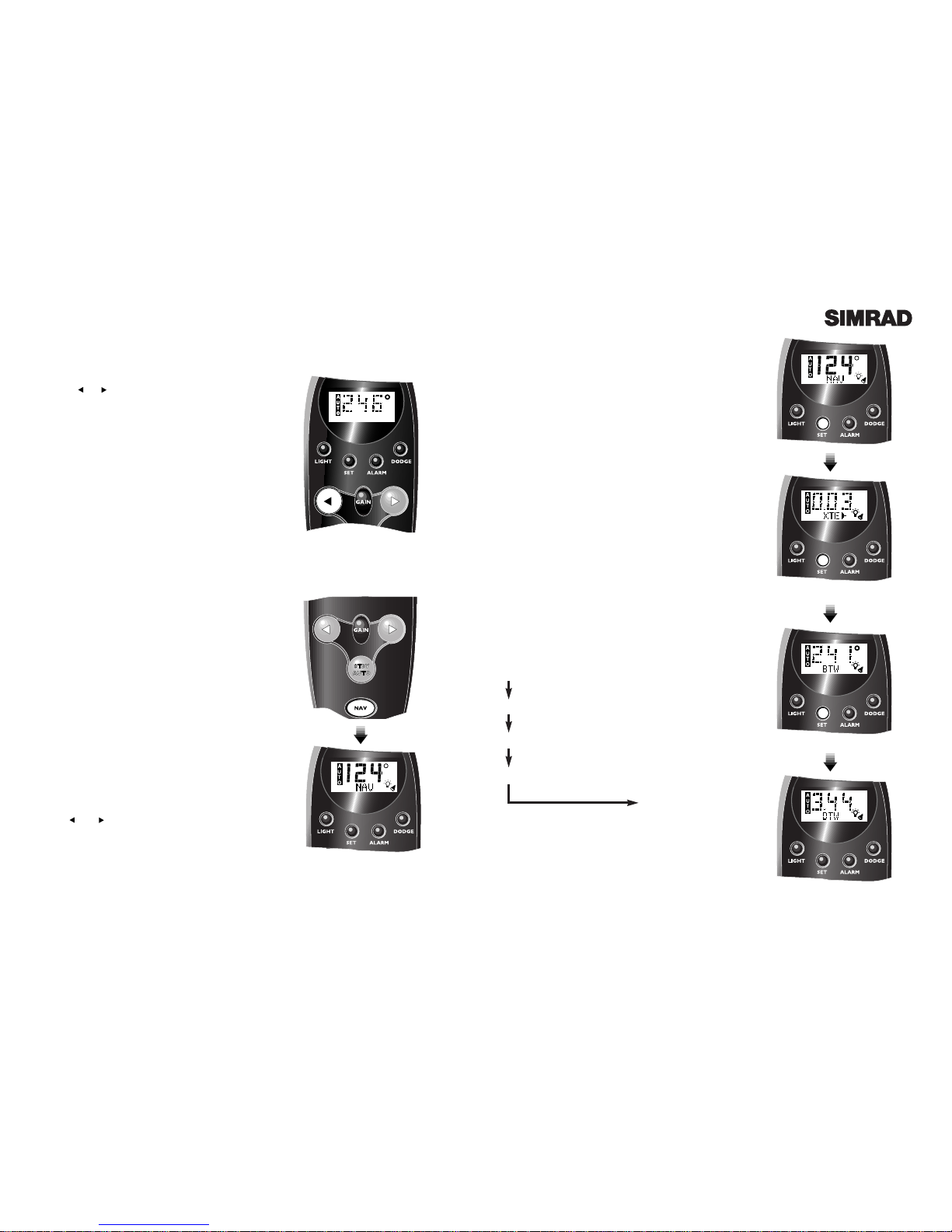

Page 7

• If Cross Track Error data is being received, but no

Bearing To Waypoint data, then the display will show

“– – –” instead of the Bearing To Waypoint.

2.5 Set Key

The Set key performs several functions, including adjusting the parameters of the AP14 such as seastate, dodge

angle etc. Refer to the relevant sections for more information on these.

In addition, depending on the NMEAdata being received

by the AP14, the following data can be displayed by

pressing the Set key the specified number of times -

Press SET Data Shown

1 Cross Track Error [XTE] (Fig 2.5)

2 Bearing To Waypoint [BTW] (Fig 2.6)

3 Distance To Waypoint [DTW] (Fig 2.7)

• The individual data will only be shown if it is being

received from the navigational receiver , so for example, if

BTW is not being received, the second press will show

DTW. Subsequent pr esses of the Set key will access functions in the following order -

SEASTATE SETTING (Section 3.2)

OFF COURSE ALARM ANGLE (Section 2.8)

DODGE ANGLE (Section 2.10)

DEFAULT BOAT SPEED (Section 2.9)

Page 6

2.3 Adjusting Course

While in Autopilot Mode, precise course adjustments can

be easily made -

• Press the or key once to make a 1º course adjustment, confirmed by one beep and on the display by the

new heading shown

• Press and hold the key for a 10º course change, confirmed by a double beep and on the display by the new

heading shown (Fig 2.3).

2.4 Nav Mode

The AP14 has an inbuilt interface which allows it to be

connected to NMEA0183 compatible equipment such as

GPS, LORAN, Chart Plotters etc.

Once connected, the AP14 can steer using data from this

source in addition to the compass, allowing a highly accurate course to waypoint

• To enter Nav Mode the pilot must be in Auto Mode and

receiving waypoint or route data from the navigational

receiver.

Press Nav to activate Nav Mode (Fig 2.4). The display will

show NAV and the pilot will steer to the first waypoint.

• If no NMEA information is being received, the AP14

will beep twice and will not enter Nav Mode.

• If Nav is pressed while in Standby mode, the pilot will

beep once if Nav Mode is available when in Auto Mode,

or twice if Nav Mode will not be available.

At the target waypoint, an intermittent alarm will sound.

As a safety feature (to avoid an unexpected course

change) the next waypoint will not be loaded until the

Nav key is pressed again. When the boat reaches the final

waypoint, the pilot will switch back to Auto Mode, holding the current course.

Note - If a course correction is made while in Nav Mode

using the and keys, the boat will gradually return to

the original track, so that the boat can avoid an obstacle

without exiting Nav Mode or having to reset the boat on

the correct course.

Pressing Nav when in Standby mode will bring up the

current Bearing To Waypoint (BTW) on the display.

Fig 2.3 - Course adjustment to Port

Fig 2.4 - Activating Nav Mode

Fig 2.6 - Bearing To Waypoint

Fig 2.7 - Distance To Waypoint

Fig 2.5 - Cross Track Error

Nm

Nm

Return

Page 5

Page 9

2.6 Dodge

The Dodge function allows the autopilot to dodge to port

or starboard by a specified angle (normally 40º), and then

return to the original course. This function is useful for

avoiding obstacles in the path of the boat.

A Dodge can only be initiated in Auto mode. Press the

Dodge key - the display will show DODGE.

• If no further key is pressed within 5 seconds, the display will return to normal.

Press either or within 5 seconds to choose the direction to dodge (Fig 2.8). The display will show the new

heading selected and DODGE will flash in the display.

Selecting a dodge in the opposite direction while the

manoeuvre is in progress will cancel it, and the boat will

return to its original course.

• The default dodge angle is 40º, but this can be adjusted

- see section 2.10.

2.7 Backlighting

To switch the display backlighting on and off, press

Light.

To set the backlighting level (1-5), press and hold Light.

The SHC14 will step through each lighting level, which

will be shown on the display (Fig 2.9). Release the Light

button when the desired lighting level has been selected.

• While the backlighting is on, the Lamp symbol will

be shown. The backlighting level set is retained by the

SHC14 even if it is disconnected from the power.

2.8 Alarms

When an alarm is triggered by the autopilot ALARM will

flash in the display. To acknowledge and cancel the

alarm, press Alarm.

• The alarm may continue to sound at the autopilot if the

alarm condition still exists.

2.8.1 Off-course Alarm

The Off-course Alarm will sound if the boat goes off course

further than a pre-set limit for more than 10 seconds.

To toggle the alarm on and of f, press and hold the Alarm

FIg 2.8 - Dodging to Starboard

Press

& hold

Fig 2.9 - Selecting backlighting level

Page 8

key (Fig 2.10). The alarm icon will be displayed while

the alarm is on.

• If the off course alarm sounds, press Alarm to

acknowledge and disable the alarm.

The off-course limit can be set from 10-60º. Press Set (see

section 2.5) until ALARM appears at the bottom of the display (Fig 2.11). The display will show the alarm limit set.

While ALARM is shown in the display, press to increase

the value and to decrease it.

• If no key is pressed within 5 seconds, the controller will

return to the main display and the value currently

entered will be set.

2.9 Default Boat Speed

The AP14 needs to know how fast the boat is going for

accurate performance when in Nav Mode. If this information is not available through the NMEA input, an

average value can be manually entered.

Press Set (see section 2.5) until SPEED appears on the

display. The main boat speed will be shown in knots.

Press to increase the setting and to decrease it.

• If no key is pressed within 5 seconds, the controller will

return to the main display and the speed currently

entered will be set.

• This option will not appear if the true boat speed is

being received through the NMEA input.

2.10 Adjusting Dodge Angle

The SHC14 is set with a default dodge angle of 40º, but

this can be adjusted to any value between 10 and 40º.

Press Set (see section 2.5) until DODGE appears in the

display and the display shows the current dodge angle.

Press to increase angle and to decrease it.

• If no key is pressed within 5 seconds, the controller will

return to the main display and the dodge angle currently

entered will be set.

Fig 2.10 - Turning off-course alarm on

Fig 2.11 - Setting off-course alarm

Pressed

3 times

Pressed

and held

Page 6

Fig 3.4 - Auto Seastate

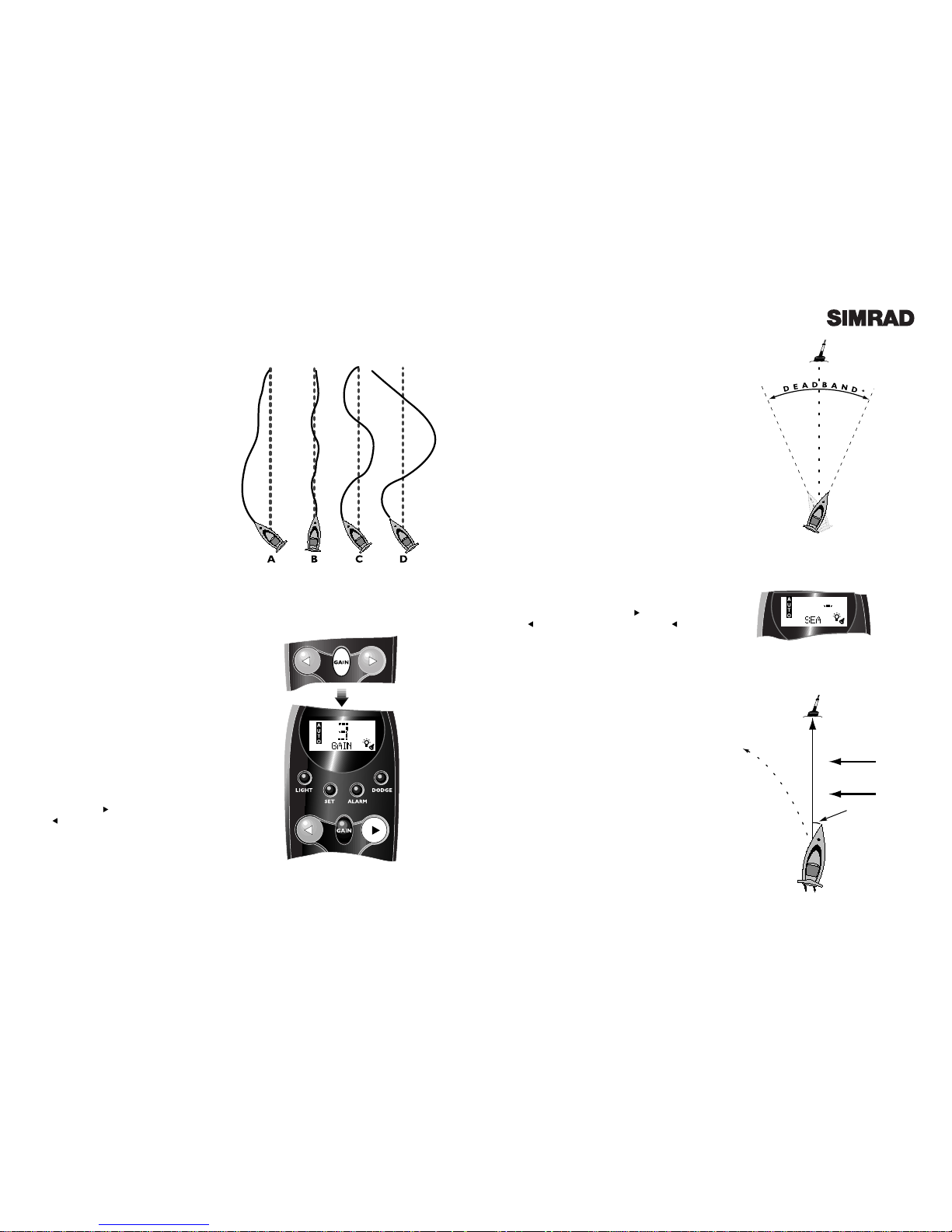

3.2 Seastate

In a rough sea, more heading errors will be

detected by the pilot as the heavy seas yaw the

boat back and forth. The pilot would normally

be overworked trying to correct every error,

causing unnecessary strain on the unit and

excessive drain on the batteries.

The AP14 monitors the course errors as it goes

and it allows a “dead band” within which the

boat can go off course without corrections being

made (Fig 3.3). This is automatically set and

updated by the pilot to give the best compromise between course holding and battery consumption, but can be set manually if wished.

The Seastate can be adjusted in all modes, without interrupting the operation of the pilot.

Press Set (see section 2.5) until the display

shows SEA on the bottom line, along with the

Seastate setting (1-10º or “–” for the fully automatic Seastate setting).

To increase the Seastate, press . To decrease,

press . To select auto Seastate, press until

“–” appears in the display (Fig 3.4).

• If no key is pressed within 5 seconds, the controller will return to the main display and the

Seastate currently entered will be set.

3.3 Autotrim

To compensate for changing conditions, a rudder bias (sometimes known as rudder trim) is

applied in order to steer a straight course. The

amount varies according to factors such as

wind strength, boat speed, and trim tab setting.

If this was not done then the boat would tend to

veer off course.

The AP14 monitors the average course error

and applies a bias to the rudder to compensate

until the optimum condition is reached (Fig

3.5). This bias is applied gradually to not upset

the normal performance of the pilot, so it may

take a minute or so to fully compensate after a

major course change.

Fig 3.3 - Seastate “deadband”

Average Course

Fig 3.5 - Autotrim principle

COURSE HELD

WIND

&

TIDE

Autotrim

applied

(Course Without Autotrim)

Page 10

Page 11

3 Parameter Adjustment

The AP14 uses highly advanced steering software, which constantly assesses how the boat is

being affected by the sea conditions. By adjusting its own performance, the pilot is able to

maintain the most accurate course for these conditions, just as a human pilot would. So in a

rough sea, the pilot is not overworked and battery drain is kept to a minimum.

3.1 Rudder Movement (Gain)

The AP14 will make corrections if it detects that

the boat is off course. How much rudder it

applies to correct this is set by the Gain (sometimes referred to as the rudder ratio).

• The Gain setting can be compared to driving

a motor vehicle - at high speeds, very little

helm movement is necessary to steer the vehicle (LOW Gain). When driving at slow

speeds, more helm movement is necessary

(HIGH Gain).

• Fig 3.1A shows when the Gain is too low: the

boat takes a long time to correct the heading.

• Fig 3.1B is ideal - errors are quickly corrected.

• Fig 3.1C the Gain is too high - the boat starts

to “S”, or oscillate around the correct heading.

• Excessive Gain (Fig 3.1D) makes the boat

oscillate increasingly off course.

The Gain can be adjusted in all modes, without

interrupting the operation of the pilot.

Press Gain once. The display will show GAIN

on the bottom line, along with the Gain setting

(1-9). The default setting is 5, which should give

good course keeping in most situations.

To increase, press (Fig 3.2). To decrease Gain,

press .

• If no key is pressed within 5 seconds, the controller will return to the main display and the

Gain currently entered will be set.

Fig 3.1 - Effects of Gain setting

Fig 3.2 - Adjusting Gain setting

Page 7

Page 13

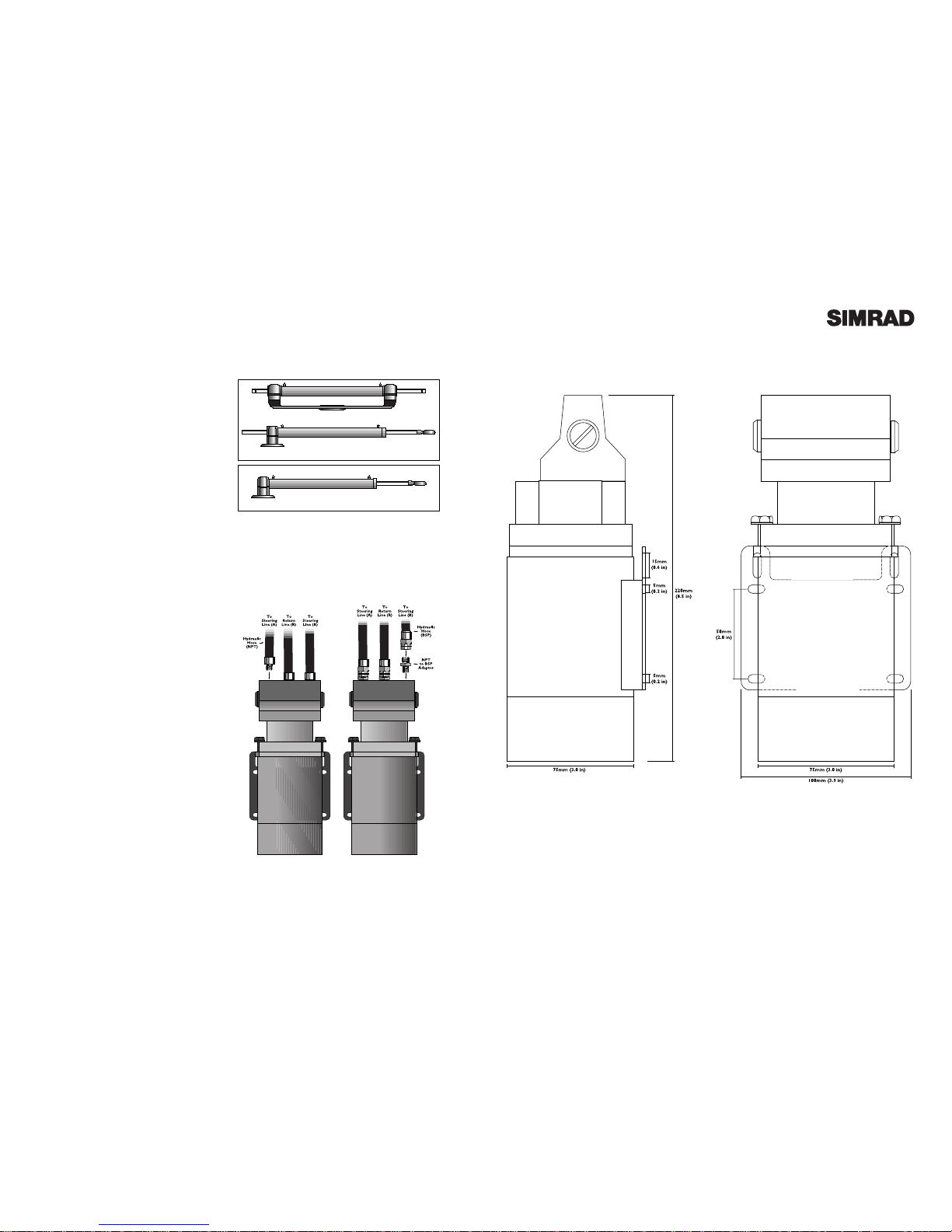

Balanced

Unbalanced

Fig 4.1 - Hydraulic ram types

4 Installation - AP14H

Section 4 covers the installation of the AP14H

Hydraulic version. Please refer to section 5

for AP14R Rotary version installation instructions.

4.1 Pump Installation

The AP14H links a reversing pump into the existing hydraulic steering system on the boat using Tfittings. The pump reproduces the effect caused

by turning the helm, so the pilot can steer the boat

without attaching any device directly to the helm.

Confirm that the volume of the cylinder of the

hydraulic ram is within the capacity of the

SRP12 pump. For the pilot to operate efficiently,

the cubic capacity of the boat’s ram must be less

than 250cc (15 in

3

). With hydraulic systems the

ram size is related to the steering load.

• If the volume of the ram cylinder is not known

then an approximate calculation can be made for

a balanced cylinder (these have the rod emerging from both ends of the cylinder - unbalanced

rams have the rod emerging from one end only

- Fig 4.1).

Volume = 3.142 x S(R2- r2)

S = Stroke length

R = Cylinder bore radius

r = Push rod radius

If S, R and r are in inches, the volume will be in

cubic inches (in

3

). If they are in centimetres, then

the volume will be in cubic centimetres (cc).

An ideal location for the pump is in a

gas/inflammable vapour free area, where it will

not be immersed in water.

The pump accepts hoses with

1

⁄4in NPT fittings.

NPT to BSP adaptors are supplied with European

versions to convert BSP hoses to NPT type if necessary (Fig 4.2).

• Try to keep hydraulic fluid loss during connection to the pump as low as possible - this will

help to reduce the time and effort required later

to bleed the system of trapped air.

• Absolute cleanliness is essential - even the

smallest particle of dirt could clog the check

valves in the pump.

BSP System

NPT System

Fig 4.2 - SRP12 pump hose connections

Page 12

Fig 4.3 - Hydraulic pump & mounting dimensions

Components supplied -

M5 x 25mm st stl hex set screw x 4

M5 st stl plain washer x 8

M5 st stl full nut x 4

1

/

4

in(NPT) -

1

/

4

in BSP adaptor x 3 (European version only)

Page 8

Fig 4.4 - Connecting pump to common hydraulic

steering configurations

Page 15

Three Line System

Pressurised System

Second steering position

(if applicable)

Second steering position

(if applicable)

Two Line System

Return port (use lower

port if two are fitted)

Page 14

• The helm unit must be fitted with check valves - most are fitted as standard. If not, it will be necessary to install a separate check valve between the helm unit and the SRP12 pump.

Fig 4.4 shows the correct connection for the most common steering configurations on boats with

hydraulic steering. If the boat has a different steering system to the ones shown then consult the

steering manufacturer or a qualified marine engineer before attempting to install the SRP12.

• The hydraulic pump can be mounted in any orientation except upside down - that is, mounted with the valve ports pointing straight down. The pump will not prime in this position.

Choose a location so that it can connect easily with the existing hydraulic system - check that there

is easy access to the pump hydraulic connections and valves before mounting. Bolt the unit securely to a sturdy part of the boat to avoid vibration that could damage the interconnecting hoses.

Remove the protective plugs from the valve ports and connect the pump to the steering system using

flexible hoses to reduce the vibration being transmitted from the pump to the hydraulic lines. Make

sure that the correct fittings are used and fit the NPT to BSP adaptors if necessary. If it is necessary to

seal a tapered fitting use a recommended hydraulic oil sealant - never use PTFE tape.

• If the boat has a pressurised steering system, always release the air through the valve on the reservoir before cutting the hydraulic lines.

• It is not important which way round the pump outlet connections A& B are connected to the steering lines, as the pilot automatically sets the correct polarity when the unit is configured.

4.2 Bleeding The Steering System

The hydraulic system should be bled according to the manufacturer’s instructions. Make sure the correct oil is used to fill the system. If there are no manufacturer’s instructions available then follow these

basic instructions -

• Bleeding the steering system is a job for at least two people - one at the helm and one at the ram.

• Allow at least 2 litres (4 pints) of hydraulic fluid when bleeding a single helm system, plus an extra

litre (2 pints) for each additional steering position.

• Use a cup to catch oil lost during bleeding - the oil can be reused if filtered through a fine mesh

first. Any contamination could clog or impair the functioning of the steering system.

• These instructions assume that turning the helm clockwise will extend the ram and turning it

counter-clockwise will retract it. The cylinder may be installed the other way around so that the

helm is turned counter-clockwise to extend the ram. Check the orientation before bleeding.

4.2.1 Two or Three Line Systems

1. Fill the helm or reservoir to the indicated fill line..

2. Loosen the hose fitting to port Aon the SRP12 pump.

3. Turn the helm slowly from lock to lock until a steady stream of oil comes from the hose fitting.

Retighten the hose fitting.

4. Repeat steps 2 & 3 with port B.

5. Repeat steps 2 & 3 with the return (R) port.

6. Prime the SRP12 pump by connecting it directly to 12v and driving the rudder to the endstop (Red

to 12v+, Black to Ground). Reverse the connections (Black to 12v+, Red to Ground) to run the pump

to the other endstop. Make sure that the oil level in the helm/reservoir is kept topped up while doing

this. NOTE - Running the pump dry for more than a few seconds can damage it. The hoses run-

ning to the pump must be primed by following steps 2 to 5.

Page 9

Page 17

4.2.2 Pressurised Systems

Bleeding a pressurised system is a more complicated procedure than a standard two or three

line system. Simrad recommends that you

enquire with the steering system manufacturer

for specific bleeding instructions. However, the

following instructions apply to most Hynautic

or similar pressurised systems.

1. Loosen the relief valve screws. Unscrew by

hand counter-clockwise as far as they will go.

2. The reservoir should be fitted with an air

valve of the type used on car tyres. Connect

a foot pump or compressed air line to the

valve and begin to pressurise the system

slowly (Fig 4.7).

3. As the system is pressurised, the oil level in

the reservoir should drop as it is forced into the

system. Stop pressurising the system if the oil

level drops below the fill line - release the air

pressure in the system through the air valve by

pushing the centre pin, remove the reservoir

filler cap and top up the reservoir. Replace the

filler cap.

4. Continue pressurising the system and topping up the reservoir until the manufacturer’s

recommended pressure is reached.

5. Do not allow the reservoir to empty.

Always depressurise the system as described

in step 3 before removing the reservoir filler

cap.

6. Loosen the hose fitting to port A on the

SRP12 pump.

7. Bleed until a steady stream of oil comes from

the hose fitting. Retighten the hose fitting.

8. Repeat steps 6 & 7 with port B.

9. Repeat steps 6 & 7 with the Return (R) port.

10. If there is more than one steering position,

start with the highest helm. Turn the helm

slowly (less than

1

⁄2 revolution per second) 6

times in one direction only.

11. Repeat the above step with each successively lower helm position (Fig 4.8). This includes

the SRP12 pump.

12. Prime the SRP12 pump by connecting it

directly to 12v and driving the rudder to the

endstop (Red to 12v+, Black to Ground).

Reverse the connections (Black to 12v+, Red to

Ground) to run the pump to the other endstop.

Make sure that the oil level in the helm/reser-

Fig 4.7 - Pressurising steering system

Fig 4.8 - Purging sequence

FLYBRIDGE

1. Helm

CABIN

2. Second Helm

ENGINE BAY

3. SRP12

Page 16

7. Turn the helm clockwise until the ram is fully

extended.

8. Open the bleed valve on the ram cylinder

nearest to the extended ram. If there are no

bleed valves fitted to the cylinder, loosen the

nut connecting the hydraulic hose to the cylinder to allow the air to escape. Do not com-

pletely undo the bleed valve or nut.

9. Holding the ram to stop it retracting into the

cylinder, turn the helm anti-clockwise until a

steady stream of oil comes out of the bleeder

with no air bubbles (Fig 4.5). Drain at least

1

⁄2

litre (1 pint) of oil to ensure all air is purged

from the system. Retighten the bleed valve.

10. Keep the reservoir/helm unit filled up as oil

is pushed down into the system. Never allow

the oil level to drop below the rotor which

can be seen through the top filler hole in the

helm pump.

11. When all the air has been bled from the

lines, keep hold of the ram and slowly turn the

helm while tightening the bleed valve/nut.

12. Release ram and continue to turn the helm

counter-clockwise until the ram is fully retracted.

13. Open the bleed valve/hose nut on the

opposite end of the cylinder.

14. Holding the ram to stop it extending from

the cylinder, turn the helm clockwise until a

steady stream of oil comes out of the bleeder

with no air bubbles (Fig 4.6). Drain at least

1

⁄2

litre (1 pint) of oil to ensure all air is purged

from the system. Retighten the bleed valve.

15. Keep the reservoir/helm unit filled up as oil

is pushed down into the system, taking care

that the oil level never drops below the rotor

which can be seen through the top filler hole in

the helm pump.

16. When all the air has been bled from the

lines, keep hold of the ram and slowly turn the

helm while tightening the bleed valve/nut.

17. Maintain the helm or reservoir at the indicated fill line.

18. Check every joint and tube for leaks.

19. Fasten all tubing down to prevent fracture

due to vibration.

20. The manufacturer’s instructions should give

details of the correct number of turns lock to

lock when the system is properly bled. An

excessive number of turns indicates that there is

still air in the system.

Fig 4.5 - Bleeding starboard hydraulic line

Fig 4.6 - Bleeding port hydraulic line

Page 10

Page 19Page 18

voir is kept topped up while doing this. NOTE

- Running the pump dry for more than a few

seconds can damage it. The hoses running to

the pump must be primed by following steps

6 to 9.

13. After completing the cycle with each helm

position to the lowest position (including the

SRP12 pump) loosen the bleed valves (or the

hose fittings if there are no bleed valves) on the

ram cylinder one at a time, allowing air to bleed

out until a steady stream of oil comes out of the

bleeder with no air bubbles. Drain at least

1

⁄2 litre

(1 pint) of oil to ensure all air is purged from the

system. Retighten the bleed valve.

14. Check the reservoir level. If it is less than

half full, depressurise the system, remove the

filler cap and top up the oil level. Pressurise the

system until the manufacturer’s recommended

pressure is reached.

15. Repeat steps 10 to 14, turning each helm in

the opposite direction.

16. Retighten the two relief valve screws.

17. Turn one of the helms hard over.

18. Open the bleed valve/fitting on the ram

cylinder at the end that the ram is extended

from. Bleed until there is a steady stream of oil

with no air bubbles (Fig 4.9). Retighten the

bleed valve.

19. Turn the helm hard over in the opposite

direction. Repeat step 18, opening the opposite

bleed valve this time (Fig 4.10).

20. Check the reservoir fluid level - leave reservoir

1

⁄2 to 2⁄3 full.

21. Pressurise the system until the manufacturer’s recommended pressure is reached.

22. The manufacturer’s instructions should

give details of the correct number of turns lock

to lock when the system is properly bled. An

excessive number of turns indicates that there is

still air in the system.

Fig 4.9 - Bleeding first hydraulic line

Fig 4.10 - Bleeding second hydraulic line

Fig 4.13 - Ram mounting using fixing kit

4.3 Linear Feedback Unit SLF12

The Linear Feedback Unit SLF12 measures the

rudder position and can be installed on most

types of boat, including I/O or Outboard drives. It is important that the SLF12 is properly

installed with the maximum possible stroke

(minimum 150mm [6.0 in]), or it will not give an

accurate reading.

The SLF12 is mounted onto the hydraulic ram

cylinder using two mounting saddles (Fig 4.11).

Make sure that the maximum stroke of the

hydraulic ram is less than the 300 mm (12.0 in)

maximum stroke of the SLF12. The saddles

support the SLF12 body, and can then be positioned on the back of the ram cylinder. Check

that the SLF12 and ram are exactly parallel.

Use the cable ties supplied to secure the SLF12

and saddles onto the ram.

The SLF12 rod is attached to the ram using the

fixing kit supplied (Fig 4.12). Fit the U-bolt and

bracket to the ram, checking that it will not

interfere with the movement of the ram at any

point of steering. Rotate the assembly until the

SLF12 rod can be fixed to the slot in the bracket

using the two nuts supplied (Fig 4.13) Refer to

section 6.3 before tightening the nuts.

When satisfied with the positioning, tighten the

U-Bolt nuts fully, and then turn the helm hard

over from lock to lock, checking that the SLF12

rod does not bend at any time - this means that

the SLF12 is not exactly parallel to the ram, and

should be adjusted accordingly.

If the SLF12 cannot be fixed to the ram as

described, an accessory kit is available separately (part LFK500) which can be ordered through

your local Simrad agent. This contains a separate mounting foot and balljoint assembly for

the end of the feedback rod, allowing the SLF12

to be independently fixed to the rudder arm.

• Do not fix the SLF12 directly to the rudder

arm if it is attached to the ram using the

mounting saddles, as the feedback rod will

bend when the rudder is at full lock.

• If connecting to a Teleflex HC5345 steering

cylinder the optional LFKSeastar kit should

be ordered.

FIg 4.11 - Mounting saddles (x 2)

Fig 4.12 - Fixing kit

Rudder Arm

Ram Cylinder

Cable Tie

SLF12

Fixing

Kit

Page 11

Page 21

4.4 Fitting Control Unit SHC14

The SHC14 controller is supplied with a cradle

that can be screwed to a convenient bulkhead

using the supplied self-tapping screws. Drill

2.5mm (0.1 in) pilot holes for the screws.

• If fitting to glassfibre (GRP) countersink the

holes before screwing in to avoid splitting the

gelcoat.

The SHC14 is fitted with a coiled cable ending

in a four-pin plug. This connects to the autopilot via a weatherproof socket assembly and

junction box.

• Fit the bulkhead socket to a vertical surface to

prevent standing water gathering around or in

the socket. Always fit the weather cap when the

remote is not plugged in.

To fit the socket to the dash, a 25mm (1 in) hole

will need to be drilled for the socket, which is

fixed using the four self-tapping screws provided with the socket assembly. Drill 2mm (0.1 in)

pilot holes for the screws.

• Again, to avoid splitting the gelcoat if fitting to

GRP, countersink the holes before screwing in.

4.5 Fitting Compass Unit SHS12

The compass should be positioned as close to

the centreline of the boat as possible (Fig 4.15),

in one of four possible orientations (see section

6.2). If the boat is GRP or wooden, the compass

can be mounted below deck, but must be at

least 1m (3 ft) away from any metallic objects

such as stereo speakers, heating units etc.

• If the boat has a metal hull (this includes ferrocement), the compass must be mounted

above decks on a mast or pole between one and

two metres (3 to 7 feet) above deck.

When mounting, make sure that the compass is

the right way up and is level. The compass unit

can be screwed to a vertical bulkhead using the

two No.6 x

3

/

4in self tapping screws provided. If

screwing into GRP, drill pilot holes and countersink them properly, which will stop the gelcoat splitting when the screws are tightened.

Fig 4.15 - Mounting compass unit

BOTTOM

VIEW

SIDE

VIEW

BOW

BOW

Page 20

Fig 4.14 - Connecting control unit

Length of

Cable Run

Under 5M

(16.6Ft)

5-10M

(33.3Ft)

Cross Section

Area

2.5mm

2

4mm

2

Conductor

Type

50/0.25

56/0.3

AWG

13

12

Fig 4.17 - Cable selection table

Fig 4.16 - Mounting Course Computer

4.6 Fitting Course Computer SCP12

Locate the course computer in a moisture, heat

and vibration free area, somewhere between the

boat’s power source and the pump to minimise

power cable lengths.

• The SCP12 should be mounted vertically with

the cooling fin uppermost, and be easily accessible once installed.

The unit is held in place using three No.6 x 1 in

self tapping screws. To access the mounting

holes, remove the terminal cover by loosening

the three screws holding it in place. Drill and

countersink three pilot holes in the indicated

positions if screwing to GRP (Fig 4.16).

4.7 Electrical Installation

• The SCP12 should be connected to the boat’s

battery via the main switch panel with a properly rated breaker or fuse and switch. It will be

much easier to configure the rudder limits if the

switch is close to the SHC14 control.

• All AP14H components wire directly to the

SCP12 course computer. The terminal bay is

clearly labelled, and each terminal block has a

specific cable channel.

• It is important that the correct diameter

cable is used to supply the 12v power to the

SCP12, depending on the length of run necessary (Fig 4.17). For this reason, the SCP12

should be fitted as close to the power supply

and pump as possible.

The SLF12, SHC14 and SHS12 are all connected

to the course computer using three conductor

cables (red, white and black). Each cable is connected to the marked terminal in the connection

bay (Fig 4.18 - over). For good connections, wire

ends should be tinned if the cables are shortened.

Poor connections will impair performance.

• The cables should be kept away from cables

which carry radio or pulsed signals (1m / 3 Ft

minimum distance is recommended).

Each cable should then be led through the

appropriate cable channel, which will hold the

cables firmly in position when the terminal

cover is replaced.

TOP VIEW

SIDE VIEW

Page 12

Fig 4.20 - Connecting using NMEA interface :

no Common (–) wire

NMEA OUT

DATA (+)

4.8 Interfacing via NMEA

The AP14 includes a built in NMEA0183 interface so GPS, Loran and Chart Plotters can be

connected directly to it. This allows the Nav

Mode (Steer to GPS) function to be used.

To interface with the AP14, the NMEA OUT

connections of the equipment should be wired

to the respective NMEAIN Data and Common

(COM) terminals of the AP14 course computer (Fig 4.19).

• Some manufacturers may refer to the connections as NMEA OUT + and – instead of

NMEA Data and Common.

• Certain equipment may have connections

marked NMEA IN. Do not use these.

• If the equipment does not have a NMEA

Common (or –) connection, the NMEA

Common terminal of the SCP12 course computer should be connected to ground by linking it to the BATT – terminal (Fig 4.20).

• If the vessel has more than one battery bank,

when connecting the AP14 to the power supply

always check that the pilot and the receiver are

not connected to a different battery bank. This

is to avoid a possible voltage drop between the

interfaced equipment which would render the

equipment inoperative.

• The receiver must be running an active route

or waypoint for the Nav Mode function to

operate.

• While any NMEA0183 compatible receivers

should interface with the AP14, Simrad cannot

guarantee operation with other manufacturer’s

equipment, as the Nav Mode function is

dependant on specific NMEA0183 sentences of

the correct format being available (see section

7.3). Read the relevant section in the receiver’s

manual before attempting to interface the AP14

with this equipment. If necessary, contact the

manufacturer’s technical support department

or speak to a qualified technical dealer.

Fig 4.19 - Connecting using NMEA interface

NMEA OUT

DATA (+)

NMEA OUT

COMMON (–)

Page 23

+–

+–

To 12v + DC

To 0 v

NMEA0183 In

To Control Unit SHC14

To Compass Unit SHS12

To Feedback Unit SLF12

To Pump

Fig 4.18 - Course Computer SCP12 connections

Page 22

Page 13

Page 25

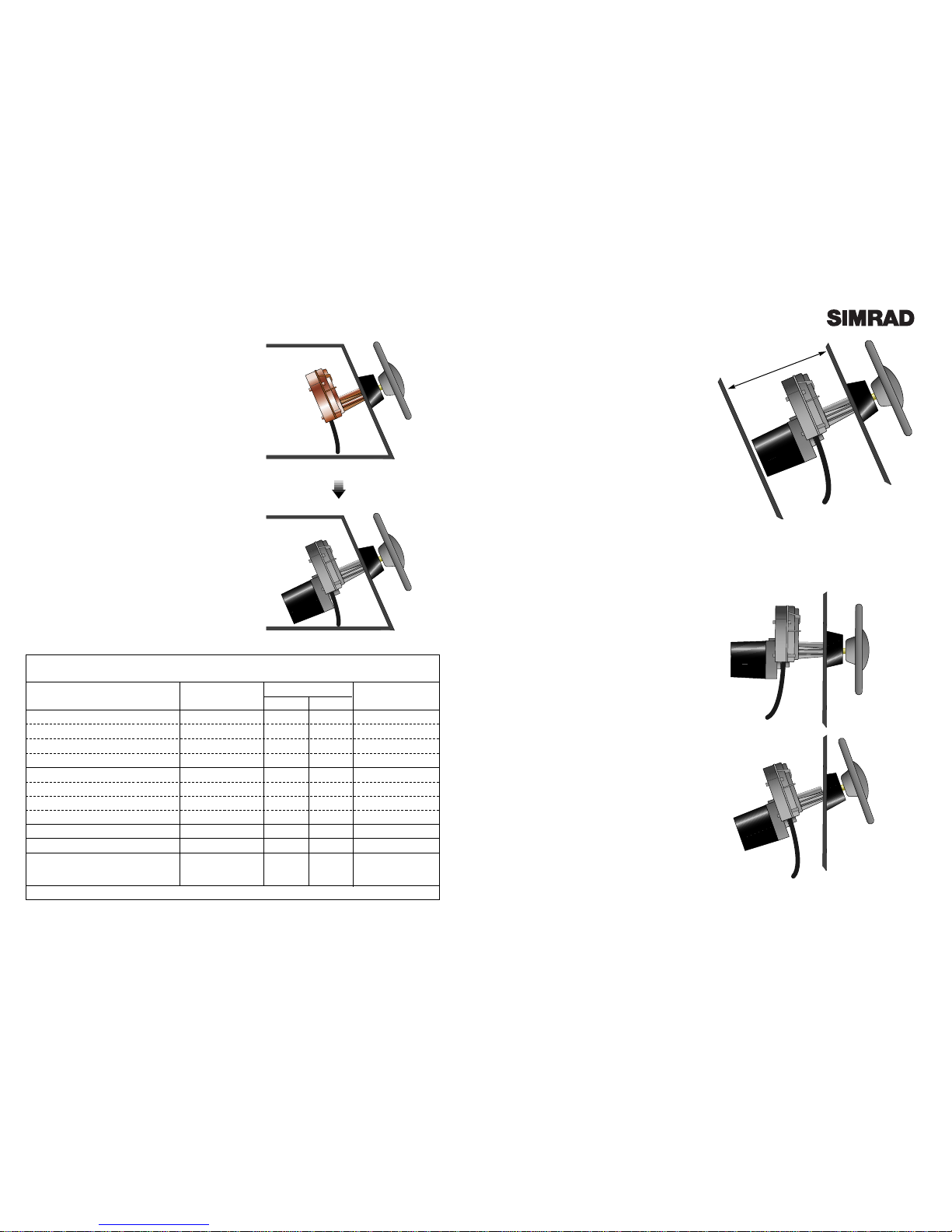

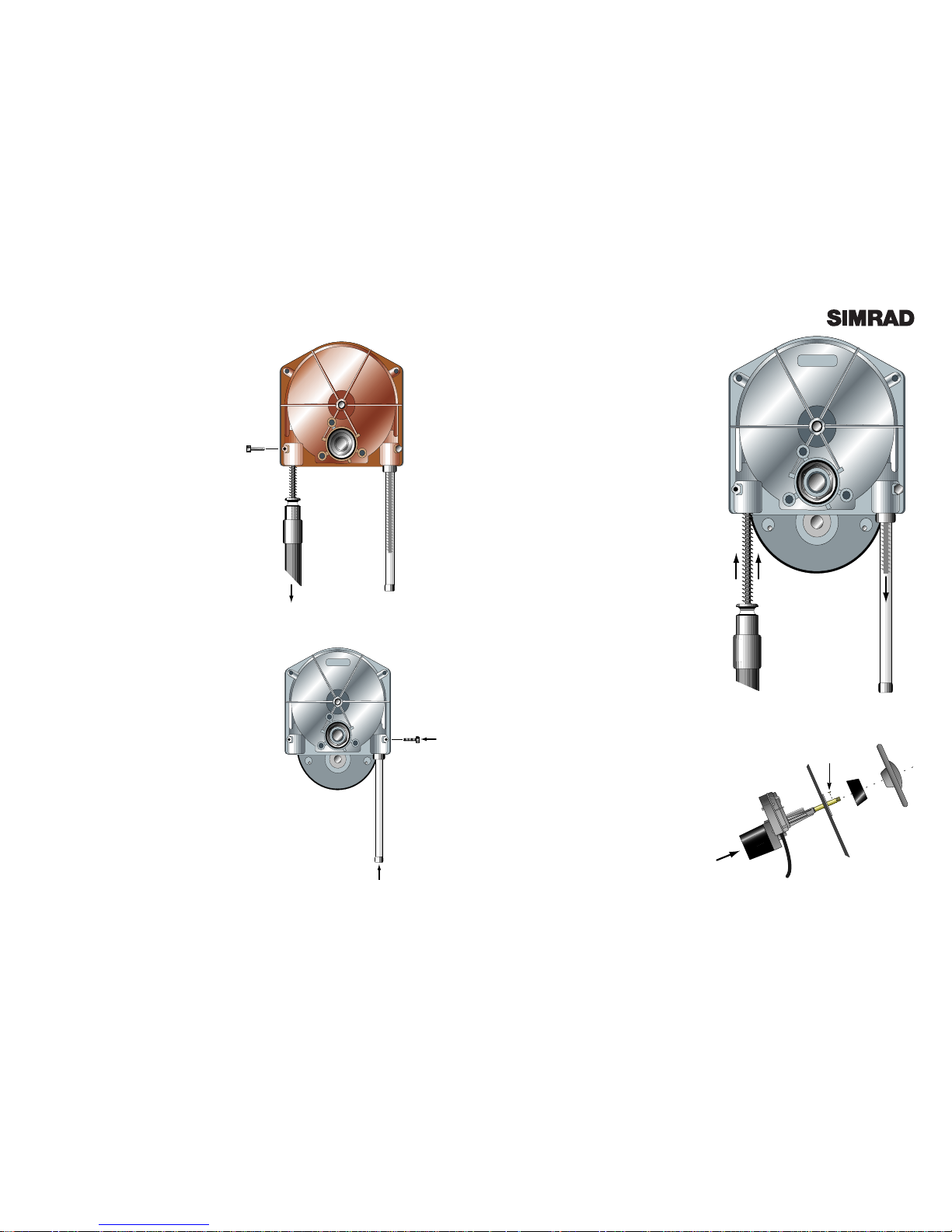

5 Installation - AP14R

Section 5 covers the installation of the AP14R

Rotary drive version only. Please refer to section 4 for AP14H Hydraulic version installation instructions.

5.1 Drive Installation

The SRD12 drive is a combined steering helm

and gearbox which completely replaces the

existing steering helm unit (Fig 5.1).

The drive unit is based on the popular Morse

CMD290 helm unit and is directly compatible

with this.

• The drive can also be fitted onto boats using

other systems including Teleflex, Uflex, Acco,

Mercury, Volvo Penta, Detmar, rack and pinion

etc. Depending on the system, it may be necessary to fit an adaptor or change the cable and

dashboard bezel kit. Refer to the table below

for more details. All codes quoted are Morse

part numbers and are available from Morse

suppliers.

Fig 5.1 - SRD12 totally replaces helm unit

AP14R Compatibility Guide

Helm System

Cable Bezel Kit Needed Cable Needed

Adaptor Needed

20º 90º

Morse CMD290 NO NO NO NO

Morse CMD250 NO 308561 308559 NO

Morse CMD200 rack & pinion NO 306527 306504 304411-xx*

Morse CMD2 NO 306527 306504 304411-xx*

Teleflex Safe-T / Big-T 300959 308561 308559 NO

Teleflex rack & pinion NO 308527 308504 304411-xx*

Teleflex Non-feedback NO 308561 308559 NO

Teleflex Quick Connect Safe-T NO 308561 308559 NO

Volvo NO 308561 308559 NO

Detmar Square or Round Rack NO 308561 308559 304411-xx*

ACCO / Mercury NO 308561 308559 304411-xx*

Wheel must also be changed for one

with a 18.75mm (

3

⁄4 in) shaft

*xx = length in inches (1 inch = 25mm)x

Page 24

To be able to fit the AP14R to the boat, the following basic requirements must be met -

1. The boat must have at least one single cable

steering helm. Dual cable systems, which are

for high performance boats or boats over 11m

(35 Ft) cannot be adapted for the AP14R.

However, the AP14R can be fitted to boats with

two steering positions, providing that one has a

single cable helm.

2. There must be a minimum of 250mm (10.0 in)

clearance behind the dashboard for the drive

unit to fit (Fig 5.2).

• If the boat has a Morse CMD290 helm system

fitted, it can be directly replaced with the

SRD12 drive unit.

• Other rotary helm units may need a cable

adaptor, dashboard bezel kit, or the whole

steering cable may need to be replaced (see

compatibility guide, page 21).

• On boats with rack and pinion steering it will

be necessary to change the steering cable.

• ACCO or Mercury steering systems will also

need to change the steering wheel for one with

a 18.75mm (

3

⁄4 in) shaft aperture.

5.2 Removing Existing Steering Helm

To remove the existing steering helm, take the

steering wheel off then unbolt and remove the

helm unit. If it is a rack and pinion system then

the rack will need to be unbolted from the pinion before it can be removed.

Check that there is enough clearance behind the

dashboard for the drive unit before installing obstructions such as electrical wiring and throttle cables may need to be re-routed.

If a bezel kit is needed, note the angle that the

helm is mounted to the dashboard. Bezel kits

are available either in the standard 90º configuration, or 20º if the helm is fitted at an angle to

the dashboard (Fig 5.3). Note that tilting wheel

systems use the existing (original) bezel kit.

Fig 5.3 - Bezel kits available

90º

20º

Fig 5.2 - Minimum clearance required

250mm (10.0 in)

Page 14

Page 27

• Use the bezel plate as a template to mark the

mounting holes that will need to be drilled.

• Take care when drilling not to damage or

sever any wiring or cables behind the dashboard - if necessary tape these out of the way

temporarily until the holes have been drilled.

• If it is necessary to enlarge the existing steering shaft hole in the dashboard for the drive

unit, use a piece of wood clamped over the hole

as a guide for the hole saw. This will ensure

that the hole is cut accurately and the bit does

not jump while drilling, which could scratch or

damage the dashboard. Exercise caution while

doing this.

Fit the bezel plate to the dashboard, but do not

fit the plastic cover at this point.

Remove the steering cable from the helm unit

by unfastening the retaining bolt at the cable

entry and exit ports. Pull the cable outer away

from the helm unit (Fig 5.4), then the cable

inside can be wound out by turning the steering

shaft (it may help if the wheel is refitted).

• Make a careful note of how the helm unit is

fitted to the dash and which side of the helm

that the cable is inserted - if this is refitted incorrectly the steering will work in reverse.

If the steering cable is not compatible with the

SRD12 drive unit it will need to be changed for

a Morse cable, which can be ordered from any

Morse stockist. The part number of the cable is

304411-xx, where xx refers to the length of the

cable required in inches (1 inch = 25mm).

See section 5.4 for advice on changing the cable.

5.3 Fitting SRD12 Drive Unit

Before winding the cable into the SRD12 drive

unit, apply a thin coat of Teflon grease to the

exposed section of the cable. Insert the plastic

take-up tube into the exit port and refit the

retaining bolt to hold it in place (Fig 5.5).

If required, fit the cable adaptor to the steering

cable to enable it to fit to the drive unit.

Insert the steering cable into the entry port of

Fig 5.4 - Remove retaining bolts to allow cable outer

to be disconnected

Fig 5.5 - Fit take-up tube to the exit port and replace

retaining bolt

Page 26

the drive unit and wind it in by turning the

steering shaft. The cable should wind into the

drive unit and emerge through the exit port into

the take-up tube (Fig 5.6). Push the cable outer

retainer into the entry port and refit the retaining bolt to hold it in place.

Position the drive unit behind the dashboard,

and bolt it to the bezel plate. Fit the plastic

cover over the bezel plate (this should simply

snap into place). Secure the bezel retaining ring

to the drive shaft, insert the locating key (or

“woodruff key”) into the recess on the steering

shaft and refit the steering wheel (Fig 5.7).

• Depending on the layout of the dashboard and

steering system, it may be easier to fit the drive

unit to the dashboard first, then insert the cable.

Rotate the wheel fully from lock to lock to check

that the steering works smoothly across its full

range and that it is steering in the right direction. If the rudder moves in the opposite direction to the wheel, the cable has been inserted

into the drive unit the wrong way and needs to

be inserted in the other port - swap the cable

and take-up tube over.

5.4 Changing the Steering Cable

The accessibility of the steering cable run will

depend on the size of the boat - on smaller

powerboats the cable is usually easily accessible, but larger boats may run the cable through

ducts that are more difficult to access.

• Changing the cable will be easier if a mouse

(or “tag line”) is attached to the end of the existing cable before it is removed. This can be used

to pull the new cable through.

• Use a strong line for the mouse that is not likely to snap easily, but is thin enough to pass

down the duct behind the cable.

• Tie the mouse securely to the cable and use

tape to reinforce the joint. Pull the cable

through from the rudder end while feeding the

mouse line from the steering end. When the old

cable has been completely removed, attach the

mouse to the new cable and use it to pull it back

through from the rudder end.

Fig 5.6 - Wind steering cable into helm

Fig 5.7 - Fitting drive to dashboard and attaching

wheel

Locating

(“Woodruff”) key

Page 15

Page 29

Attach the new cable to the steering arm of the

boat by pulling out the cotter pin and clevis pin

to release the old steering shaft and replacing it

with the new steering shaft. Line up the shaft

with the steering arm by turning the steering

wheel and re-insert the cotter and clevis pins.

5.5 Fitting Control Unit SHC14

The SHC14 controller is supplied with a cradle

that can be screwed to a convenient bulkhead

using the supplied self-tapping screws. Drill

2.5mm (0.1 in) pilot holes for the screws.

• If fitting to glassfibre (GRP) countersink the

holes before screwing in to avoid splitting the

gelcoat.

The SHC14 is fitted with a coiled cable ending

in a four-pin plug. This connects to the autopilot via a weatherproof socket assembly and

junction box.

• Fit the bulkhead socket to a vertical surface to

prevent standing water gathering around or in

the socket. Always fit the weather cap when the

remote is not plugged in.

To fit the socket to the dash, a 25mm (1 in) hole

will need to be drilled for the socket, which is

fixed using the four self-tapping screws provided with the socket assembly. Drill 2mm (0.1 in)

pilot holes for the screws.

• Again, to avoid splitting the gelcoat if fitting to

GRP, countersink the holes before screwing in.

Page 28

Fig 5.8 - Connecting control unit

5.6 Fitting Compass Unit SHS12

The compass should be positioned as close to

the centreline of the boat as possible (Fig 5.9), in

one of four possible orientations (see section

6.2). If the boat is GRP or wooden, the compass

can be mounted below deck, but must be at

least 1m (3 ft) away from any metallic objects

such as stereo speakers, heating units etc.

• If the boat has a metal hull (this includes ferrocement), the compass must be mounted

above decks on a mast or pole between one and

two metres (3 to 7 feet) above deck.

When mounting, make sure that the compass is

the right way up and is level. The compass unit

can be screwed to a vertical bulkhead using the

two No.6 x

3

/

4in self tapping screws provided. If

screwing into GRP, drill pilot holes and countersink them properly, which will stop the gelcoat splitting when the screws are tightened.

5.7 Electrical Installation

• The AP14R should be connected to the boat’s

battery via the main switch panel with a properly rated breaker or fuse and switch.

• The AP14R operates from a 12v DC supply.

Power is supplied to the system via the two

core cable from the SRD12 drive unit. Brown

is 12v+, Blue is 0v.

• If the power cable needs to be extended, the

correct diameter cable should be used,

depending on the length of run (Fig 5.10). For

this reason, it is recommended that any additional cable runs be as short as possible.

The SHC14 control unit, SHS12 compass and

SRD12 drive unit are wired together using the

SJB12 junction box supplied. All three cables

have the same core colours - Red, Black and

White, and the terminals in the junction box

are clearly marked (Fig 5.11 - over).

• For good connections, all wire ends should be

tinned if the cables are shortened. Poor connections will impair the performance of the pilot.

• The cables should be kept away from cables

which carry radio or pulsed signals (1m / 3 Ft

minimum distance is recommended).

Length of

Cable Run

Under 5M

(16.6Ft)

5-10M

(33.3Ft)

Cross Section

Area

2.5mm

2

4mm

2

Conductor

Type

50/0.25

56/0.3

AWG

13

12

Fig 5.10 - Cable selection table

Fig 5.9 - Mounting compass unit

BOTTOM

VIEW

SIDE

VIEW

BOW

BOW

Page 16

RED

NMEA OUT

DATA (+)

Fig 5.13 - Connecting using NMEA interface :

no Common (–) wire

5.8 Interfacing via NMEA

The AP14 includes an inbuilt NMEA0183 interface so GPS, Loran and Chart Plotters can be

connected directly to it. This allows the Nav

Mode (Steer to GPS) function to be used.

To interface with the AP14, the NMEA OUT

connections of the equipment should be wired

to the respective NMEA IN Data and Common

(COM) cores of the NMEAwire from the SRD12

drive unit (Fig 5.12).

NMEA Data - RED

NMEA Common - BLUE

• Some manufacturers may refer to the connections as NMEA OUT + and – instead of NMEA

Data and Common.

• Certain equipment may have connections

marked NMEA IN. Do not use these.

• If the equipment does not have a NMEA

Common (or –) connection, the NMEA

Common terminal of the SCP12 course computer should be connected to ground by linking it to the BATT – terminal (Fig 5.13).

• If the vessel has more than one battery bank,

when connecting the AP14 to the power supply

always check that the pilot and the receiver are

not connected to a different battery bank. This

is to avoid a possible voltage drop between the

interfaced equipment which would render the

equipment inoperative.

• The receiver must be running an active route or

waypoint for the Nav Mode function to operate.

• While any NMEA0183 compatible receivers

should interface with the AP14, Simrad cannot

guarantee operation with other manufacturer’s

equipment, as the Nav Mode function is

dependant on specific NMEA0183 sentences of

the correct format being available (see section

7.3). Read the relevant section in the receiver’s

manual before attempting to interface the AP14

with this equipment. If necessary, contact the

manufacturer’s technical support department

or speak to a qualified technical dealer.

Fig 5.12 - Connecting using NMEA interface

BLUE

NMEA OUT

COMMON (–)

0v

RED

NMEA OUT

DATA (+)

BLUE

NMEA OUT

COMMON (–)

Page 31Page 30

SHC14 Control Unit

SHS12 Compass

12v DC

NMEA0183 In

Brown / Blue

Red / Black / White

Red / Blue

Fig 5.11 - AP14R electrical installation

SRD12 Drive Unit

SJB12 Junction Box

Page 17

Page 33

6 Commissioning

6.1 Commissioning Checks

After installation has been completed, the following checks should be made before use -

1. Installation check - ensuring that the installation of all the components in the system is mechanically and electrically correct.

2. Seatrial - Auto compass calibration. The pilot should be set up for optimum course keeping

ability. If a navigational receiver is interfaced with the pilot, Nav Mode should also be tested.

6.1.1 Installation Check

CABLING

1. Are all the connections secure?

2. Does all wiring meet recommended lengths and sizes for the current/voltage?

3. Does the input power line have the correctly rated fuse or circuit breaker?

4. Where possible, are the cables run away from existing cables which carry radio frequency

or pulsed signals? (1m / 3 Ft distance is recommended).

5. Are cables neatly tied or clamped to prevent friction damage? (Ties every 0.5m / 1.5 Ft

intervals recommended minimum).

6. Are all wire ends tinned?

COURSE COMPUTER SCP12 (AP14H ONLY)

1. Is the Course Computer in a dry location away from excessive heat and vibration?

2. Is the Course Computer mounted on a vertical surface, with the cooling fin uppermost?

3. Is the Course Computer securely attached to a permanent structure?

4. Are all the cables properly fed through the cable clamp channels?

LINEAR FEEDBACK UNIT SLF12 (AP14H ONLY)

1. Has the unit been securely attached to the hydraulic ram of the boat using the supplied

mounting saddles?

2. Is the full stroke of the SLF12 between 150mm and 300mm (6.0in to 12.0in)?

3. Is the SLF12 correctly aligned with the rudder arm?

4. Has it been fitted so that the rod does not bend or distort at any point of steering?

5. When driven hard over from lock to lock, is the SLF12 free from any obstructions?

COMPASS SHS12

1. Has the compass been mounted the correct way up and is it level?

2. Has the compass been mounted in a position away from ferrous materials, loudspeakers,

heavy current carrying cables or other magnetic/electronic equipment to avoid deviation?

3. Has the compass been mounted as near as possible to the centrepoint of the boat to minimise heel angle?

HYDRAULIC PUMP (AP14H ONLY)

1. Have the correct fittings been used?

2. Has return line (R) been fitted from the pilot pump ?

3. Are check valves fitted if needed ?

4. Has the system been correctly bled of air ?

5. Is the tubing to the pump high pressure flexible material to reduce vibration?

Page 32

Fig 6.2 - Adjusting compass bearing

6.2 Compass Orientation

The SHS12 compass can be mounted pointing

four different ways - 0º, 90º, 180º or 270º to the

bow (Fig 6.1).

• The factory preset is 0º (pointing forward). If

the compass is mounted pointing any other

way, this must be programmed in before using

the pilot.

Press and hold Set until the controller beeps

twice.

Press Set again - the display will show the current offset.

Press to adjust the offset in 90º steps to port.

Press to adjust the offset in 90º steps to starboard - 90º, 180º, 270º.

• If no key is pressed within 5 seconds, the controller will return to the main display and the

orientation currently entered will be set.

6.3 Compass Adjustment

The bearing shown on the AP14 display can be

adjusted by ±15º so that it matches the boat’s

magnetic compass, or a known heading.

• This procedure should be performed after the

compass has been orientated (see section 6.2

above).

Press and hold the Set key. The controller will

beep twice and the display will show ADJUST

along with the current bearing detected by the

SHS12 fluxgate compass.

Use the and keys to adjust the displayed

bearing until it matches the boat’s magnetic

compass, or known heading (Fig 6.2).

• If no key is pressed within 5 seconds, the controller will return to the main display and the

bearing entered will be set.

• Note that the bearing can be adjusted by a

maximum of ±15º from the original. If the error

is greater than 15º, check that the SHS12 compass is not receiving interference from nearby

metallic, magnetic or electrical objects.

Fig 6.1 - Compass orientation

0º (No flashes)

180º (2 flashes)

90º (3 flashes)

270º (1 flash)

BOW

BULKHEAD

Pressed & held

Page 18

Page 35Page 34

Fig 6.5 - Rate of turn too slow

6.5 Seatrial / Compass Calibration

Before using the AP14, the compass must be calibrated

to compensate for any magnetic deviation caused by ferrous or magnetic objects surrounding it on the boat, such

as cockpit speakers etc.

1. With the boat motoring along slowly (2-3 knots) in

calm conditions press the key a number of times (or

manually steer) to induce a slow clockwise rotation of the

boat (approx 3º/sec).

2. Press and hold Gain, followed by the and keys

simultaneously to enter Auto Compass Calibration Mode

(Fig 6.4) The display shows the heading, and the bottom

line will show CAL.

3. Allow the boat to turn through a minimum of 1

1

⁄4 turns

(450º) in approximately 2

1

⁄2 minutes, during which time

the fluxgate compass will automatically calibrate itself.

4. If the rate of turn is too high, the display will flash arrows pointing to Port indicating decrease the

angle of turn - press . If the rate or turn or boat speed is too slow the display will flash arrows

pointing to Starboard indicating increase the angle of turn (Fig 6.5) - press .

• It is recommended that the calibration is restarted if the Port arrows are shown more than twice.

A sequence of 4 beeps means that the calibration has been successful, and the AP14 will return to

Standby Mode.

• If after about four minutes the compass has not calibrated, an alarm will sound. Repeat the above

procedure, following the directions carefully. If the compass will still not calibrate then it is usually because the deviation being detected is too great, which may be due to the compass being too

close to a metallic or magnetic object (minimum safe distance - 1m [3 Ft]). Move the compass to a

position as close to the ideal centreline location as possible, but away from speakers, metallic superstructure etc. Repeat the above procedure.

• This should only need to be done once when the autopilot is first commissioned, unless the compass is changed, repaired, relocated or if any metallic objects have been installed or removed near

to the compass since it was calibrated. In the interests of accurate performance, always bear in

mind the location of the compass when installing any metallic objects on the boat. If in any doubt,

recalibrate the compass as shown above.

After calibrating the compass perform the following procedure -

1. Hold the course steady for 5-10 seconds.

2. Press Auto to engage the autopilot and lock onto the heading - in calm conditions a constant

heading should be held.

3. Alter course to Port and Starboard - the course change should be smooth without any sign of

overshooting.

4. Look back at the wake of the boat to get an indication of the steering performance over a distance of at least 3km (2 Miles). If there is any evidence of snaking or “S-ing”, try decreasing the

Gain setting (see section 3.1).

5. If a GPS is connected , the Nav Mode function should be tested over a longer distance.

Fig 6.4 - Auto Compass Calibration

POWER

ON

Fig 6.3 - Setting rudder limits

6.4 Setting Rudder Limits (AP14H only)

This two-stage procedure is used to -

• Define the maximum limits of the SLF12 pushrod stroke.

• Define the endstop and midstroke position of the rudder.

This data is permanently stored, so it will only be neces-

sary to repeat this procedure if the SCP12 is replaced or

the SLF12 is replaced/repositioned.

1. Turn the power to the pilot off at the breaker (or

switch). Press and hold the and keys while switching the power on.

2. The display will show CAL and PORT (Fig 6.3). If this

display is not shown, repeat step 1, holding the and

buttons down firmly.

3. Disconnect the SLF12 rod from the ram and pull it fully

from the feedback body (the rod is not physically

attached to the SLF12 and can be removed easily).

4. Slide the rod all the way into the feedback body as far

as it will go, then reattach the rod to the rudder . This sets

the maximum limits of the SLF12

5. Turn the helm hard over to Port, then back it off

1

⁄8th of

a turn. Push the key once, and the controller will beep,

showing STBD on the display.

6. Turn the wheel hard over to Starboard, then back it off

1

⁄8th of a turn. Push once - the controller will beep and

show CENTRE on the display.

7. Turn the helm to the midships position and press

Gain. The pump will drive the rudder briefly to test

the limits entered. If the rudder limits are accepted, the

controller will beep four times and the display will show

OKAY, otherwise it will sound a continuous alarm and

show FAIL, meaning that the calibration has failed repeat the above steps carefully.

• If the calibration still fails, this may indicate that the

hard over rudder position is beyond the sensing range of

the SLF12 or the system has not been bled properly and

the pump is airlocked. Try repositioning the SLF12 so

that the stroke is within the defined parameters (see section 4.3), bleed the system if necessary and repeat the

above procedure.

Note that the pilot will not enter Auto mode until the

rudder limits have been set.

Page 19

7.4 Fault Finding

Symptom

Pilot will not enter Auto mode.

Autopilot drops back into

Standby Mode.

Cannot select Nav Mode

Autopilot will not allow rudder

travel limits to be set*.

Autopilot does not maintain an

accurate course in Auto Mode.

Compass will not auto calibrate

Boat’s course is unstable when

in Auto mode.

Probable Cause

Rudder limits not entered*.

Rudder limits configuration

failed*.

Faulty connection to SLF12*

Faulty connection to SHS12.

Fault with SCP12* / SRD12†.

Low supply voltage to Drive

Unit or Course Computer*.

Navigational data not available.

Incorrect NMEAformat or sentences are being transmitted.

Destination not programmed

in navigator.

Power cable gauge too small.

SLF12 incorrectly wired or

installed.

Pump not primed or airlocked

Buttons not pressed properly

SHS12 compass has not been

calibrated.

SHS12 compass is encountering magnetic interference.

• If the boat’s magnetic

compass is being used as a reference, it is more likely that

this is inaccurate unless it has

being recently swung.

Turn rate too fast/slow

Conditions too rough

Deviation detected is too large

Gain setting is incorrect for

boat’s speed or type.

Remedy

Enter rudder limits* (see 6.3)

Check all connections.

Replace fuse.

Check battery charge.

Check all electrical connections and supply cables.

Check NMEA connections.

Refer to section 7.3 for correct

NMEA0183 sentence formats.

Check recommended cable

sizes (Fig 4.17)

Check SRP12 & SLF12 wiring

and installation.

Prime pump & bleed system.

Refer to section 6.4 to calibrate

the compass to compensate for

magnetic deviation.

Check area around SHS12 for

magnetic objects (loudspeakers, heavy current carrying

cables etc). Minimum compass safe distance is 1m (3 Ft).

Check course against other

reference (handbearing compass etc) and swing boat’s

compass if necessary.

Flashing LEDs above

Port/Starboard keys indicate

if turn rate is too fast or slow.

Calibration should be attempted in calm conditions

Check area around compass

for metallic objects/speakers

etc (min safe distance - 1m/3ft)

Adjust Gain to suit boat’s

speed: Low Speed=High Gain

High Speed=Low Gain

* - AP14H only † – AP14R only

Page 36 Page 37

7 Appendix

7.1 Advice On Operation

• When making course changes, be aware of the effect of a large course change on the boat, especially when travelling at high speed - the AP14 will respond very quickly to any instructions, so it

is advisable to reduce speed before changing course. This should particularly be remembered

when approaching a waypoint in Nav Mode - pressing Nav to head for the next waypoint could

result in a sudden and severe course change. This is one of the reasons that a constant vigil and

awareness of the situation must be maintained (see warning below).

• The Gain setting is critical on a high speed vessel like a power boat, because it affects the reaction speed of the autopilot. As you become more familiar with the operation of the AP14 and how

your own boat handles, it should be possible to tailor the Gain settings to suit the speed of the boat

and the conditions it is cruising under.

7.2 Warning

The AP14 is a highly advanced autopilot, and a valuable aid to enjoyable cruising. However, it

would be a mistake to become complacent. Like all electronic navigational equipment, it is an aid

to navigation and should not be used as a substitute for conventional navigational practice.

Remember - Maritime Law* requires that you keep a good look out at all times.

7.3 NMEA Sentences Received

The NMEA0183 information required for full functionality while in Nav Mode is as follows -

Cross track error

Bearing to destination waypoint

Arrival at waypoint indication

This information is extracted from the following NMEA0183 sentences -

XTE Cross Track Error

BWC Bearing & Distance To Destination Waypoint (Great Circle)

BWR Bearing & Distance To Destination Waypoint (Rhumb Line)

APA Cross Track Error, Bearing To Destination Waypoint and Arrival At Waypoint

APB Cross Track Error, Bearing To Destination Waypoint and Arrival At Waypoint

RMA Boat Speed

RMB Cross Track Error, Bearing, Distance and Arrival At Arrival Waypoint

RMC Boat Speed

NOTE - The Cross Track Error (XTE) information has a maximum value of 1.27 Nautical Miles. If

the XTE exceeds this while using Nav Mode, the AP14 will sound an alarm, exit Nav Mode and

return to Compass Auto Mode.

*IMO International Regulations for Preventing Collisions at Sea, Part B Rule 5 (1972)

Page 20

Page 39

In the event of the AP14H failing, the LED located under the terminal bay cover of the SCP12 Course

Computer can be used to identify the potential source of the problem -

Flashes Diagnosis Fault Location

2 Invalid rudder feedback reading from SLF12 SLF12

4 Current limit exceeded SRP12, SCP12

5 Control unit not connected SHC14

6 No compass data received SHS12

7 No compass/controls detected SHC14, SHS12, SCP12

8 Rudder limits not set / calibration failed SLF12, SCP12

In the event of the AP14R failing, the LED located on the circuit board under the black cover of the

SRD12 Drive Unit can be used to identify the potential source of the problem -

Flashes Diagnosis Fault Location

5 Control unit not connected SHC14

6 No compass data received SHS12

7 No compass/controls detected SHC14, SHS12, SRD12

8 Compass calibration failed SRD12

Page 38

7.5 Optional Accessories

The following optional accessories for the

AP14H and AP14R are available from your

Simrad dealer. Please quote the correct part

number when ordering.

SCJ12

Additional Control

Unit +

Junction Box

SCJ14

Hand Controller +

Junction Box

LFK500

SLF12 Feedback Mounting Accessory Kit -

balljoint & universal joint mounting foot.

(for AP14H hydraulic drive option only)

LFKSeastar

Kit for mounting SLF12 (AP14H only) to

Teleflex HC5345 cylinders

Page 21

Page 41

38 mm

(1.5 in)

66 mm

(2.6 in)

94 mm

(3.7 in)

46 mm

(1.8 in)

150 mm

(5.9 in)

162 mm

(6.4 in)

100 mm

(3.9 in)

79 mm

(3.1 in)

217 mm

(8.5 in)

25 mm

(1.0 in)

532 mm (21.28 in) Midstroke

250 mm (10.0 in)

150 mm (5.9 in)

180 mm (7.0 in)

7.6 Specification & Dimensions

AP14H SPECIFICATIONS

Supply Voltage 12v DC (10.8v-16v)

Average Power Consumption 3 Amps typically

Drive Output 15 Amps Max

Peak Flow Rate 1,000 cc/min (64 in

3

/min)

Peak Pressure 28 kg/cm

2

(1,000 psi, 67 bar)

Ram Capacity Min 90cc (5.4 in

3

)

Ram Capacity Max 250cc (15.25 in

3

)

AP14R SPECIFICATIONS

Supply Voltage 12v DC (10.8v-16v)

Average Power Consumption 0.7 Amps typically

Linear Thrust 175kg (385 lbs)

Max Torque 19.5Nm (170 lb/in)

Speed 15 rpm

Page 40

25 mm

(1.0 in)

65 mm

(2.56 in)

155 mm (6.33 in)

7.7 Service & Warranty

This unit is guaranteed for 2 years from date of retail sale. If it is necessary to have the unit

repaired, return it carriage prepaid to the agent in the country of purchase with a copy of the

receipted invoice showing the date of purchase. Where possible, return all the components unless

you are certain that you have located the source of the fault. If the original packing is not available, ensure that it is well cushioned in packing; the rigours of freight handling can be very different from the loads encountered in the marine environment for which the unit is designed.

For Warranty details, please refer to the Warranty Card supplied with this unit.

Page 22

Page 23

Manufacturer:

Simrad Navico

Star Lane, Margate

Kent CT9 4NP

United Kingdom

Telephone: +44 (0) 1843 290290

Telefax: +44 (0) 1843 290471

E-Mail: sales@simrad-navico.co.uk

WORLDWIDE MANUFACTURER OF MARI NE ELECTRONICS

Loading...

Loading...