Page 1

1

Derwent 90cm Ceiling Hood

Installation & User Instructions

Please read these instructions carefully before installing and

operating this appliance

Page 2

2

Contents

1. Introduction

3

2. Health and Safety

3-4

3. Installation

4-9

3.1 Assembly Instructions

4-7

3.2 Ducting Options

5

3.3 Motor Options

5-6

3.4 Electrical Wiring

6-8

3.4.1 Electrical Wiring Diagram

7

3.4.2 Controls

8

4. Use & Maintenance

8

4.1 Cleaning the Metal Filters

8

4.2 Cleaning the Hood

8

5. Technical Data

8

6. Dimensions

9-11

6.1 Derwent 90cm Ceiling Hood

9-10

6.2 1240 T1 Motor

10

6.3 1250 T2 Motor

11

Page 3

3

1. Introduction

Dear Customer,

We wish to thank you for choosing this Silverline

cooker hood. In order to get the best performance

from your appliance we recommend that you read

this booklet carefully before operating the appliance

for the first time.

Revisions to the publication

In order to improve the product, to keep this

publication up to date the manufacturer reserves the

right to make modification without any advance

notice. Any reproduction, even in part, of this manual

without the consent of the manufacturer is

prohibited.

Care of the manual and how to consult it

Take good care of this manual and keep it in a

place which can be easily and quickly reached.

If this manual should be lost or destroyed, or if it

is in poor condition, ask for a copy from your

retailer, providing product identification data.

Information which is essential or that requires

special attention is shown in bold text.

ATTENTION

This warning sign indicates that the

message to which it refers should be

carefully read and understood, because

failure to comply with what these notices

say can cause serious damage to the

extractor and put the user’s safety at risk.

INFORMATION

This symbol is used to highlight

information which is important for proper

extractor operation. Failure to comply with

these provisions will compromise use of

the boiler and its operation will not be

satisfactory.

MANUAL

Indicates that you should carefully read

this manual or the related instructions.

2. Health and Safety

Installation of the cooker hood, making

electrical connections, checking its operation

and maintenance are all tasks which should be

carried out by qualified and authorised

personnel.

Install the cooker hood in accordance with the

regulations in force in your local area, region and

country.

For the correct use of the appliance and to

prevent accidents, the instructions given in this

booklet must always be followed.

Before beginning any operation, the user, or

whoever is preparing to operate on the

appliance, must have read and understood the

entire contents of this instruction booklet.

All responsibility for improper use is taken

entirely by the user and as such relieves Silverline

of any civil or criminal responsibility.

In view of the fact that it is an electrical appliance,

do not touch the appliance with wet hands.

Before carrying out any cleaning or maintenance

operation, make sure in advance that the

appliance is isolated from the mains electricity

supply.

Incorrect installation or faulty maintenance (not

conforming to the requirements set out in this

booklet) can cause harm to people, animals or

property. In such cases Silverline is absolved from

any civil or criminal responsibility.

This product complies with EU Directive

EU2002/96/EC.

The crossed bin symbol on the appliance indicates

that the product, at the end of its life, must be

disposed of separately from domestic waste, either by

taking it to a separate waste disposal site for electric

and electronic appliances or by returning it to your

dealer when you buy another similar appliance. The

user is responsible for taking the appliance to a special

waste disposal site at the end of its life. If the disused

appliance is collected correctly as separate waste, it

can be recycled, treated and disposed of ecologically.

WARNINGS:

- This appliance can be used by children aged from

8 years and above and persons with reduced

physical, sensory or mental capabilities, or lack of

experience and knowledge if they have been

given supervision or instruction concerning use of

the appliance in a safe way and understand the

hazards involved.

- Children shall not play with the appliance.

Cleaning and user maintenance shall not be made

by children without supervision.

Page 4

4

- Before cleaning or performing any periodic or

urgent maintenance to the hood, isolate the

mains supply and turn the main switch off.

- Do not connect the hood to any piping used for

combustion appliances, such as burners, boilers

or fire places.

- Check that the main power supply corresponds

to the voltage required by the hood, which is

given on the silver label stuck inside the hood.

Ensure that the electric system is correctly

earthed and that the earth discharge works

correctly.

- When cooking do not use any materials that

could form high or unusual flames. Oil that has

been used twice and fats are very dangerous

and could easily catch fire. Do not prepare

flambé dishes under the hood.

- Once the specialised technician has completed

the installation of the hood equipped with a

remote motor, all the leads, connectors, ground

connections and the remote motor must not be

accessible to the user. Only the installer is

granted access by removing screwed on panel.

- Respect local legislation and regulations issued

by the relative authorities regarding the exhaust

air when the suction is operating. Failure to

respect and perform all maintenance and

cleaning operations described in this handbook

could cause a fire hazard.

ATTENTION: Accessible parts may become hot when

the hood is used with cooking appliance.

3. Installation

The minimum safety distance between the bottom of

the hood and the top of the cooking hob must be

650mm, smaller distances must be previously

authorised by the manufacturer. The maximum is

1.6m.

When the suction function is operating i.e. exhausting

the filtered air on the outside, a suitable

compensation system must be used according to

current standards in force. The diameter of the fume

exhaust pipe must be the same or greater than the

diameter of the hood pipe union.

There must be sufficient ventilation in the room where

the hood is installed, to allow simultaneous use of

other appliances that use gas or other fuels.

3.1 Assembly Instructions

Attention: Before proceeding with the installation,

make sure that the screws and the anchors supplied,

are suitable for the type of wall/ceiling the hood will be

fixed to.

To assemble the hood use the accessories that are

supplied and follow the instructions given in the

enclosed hand book.

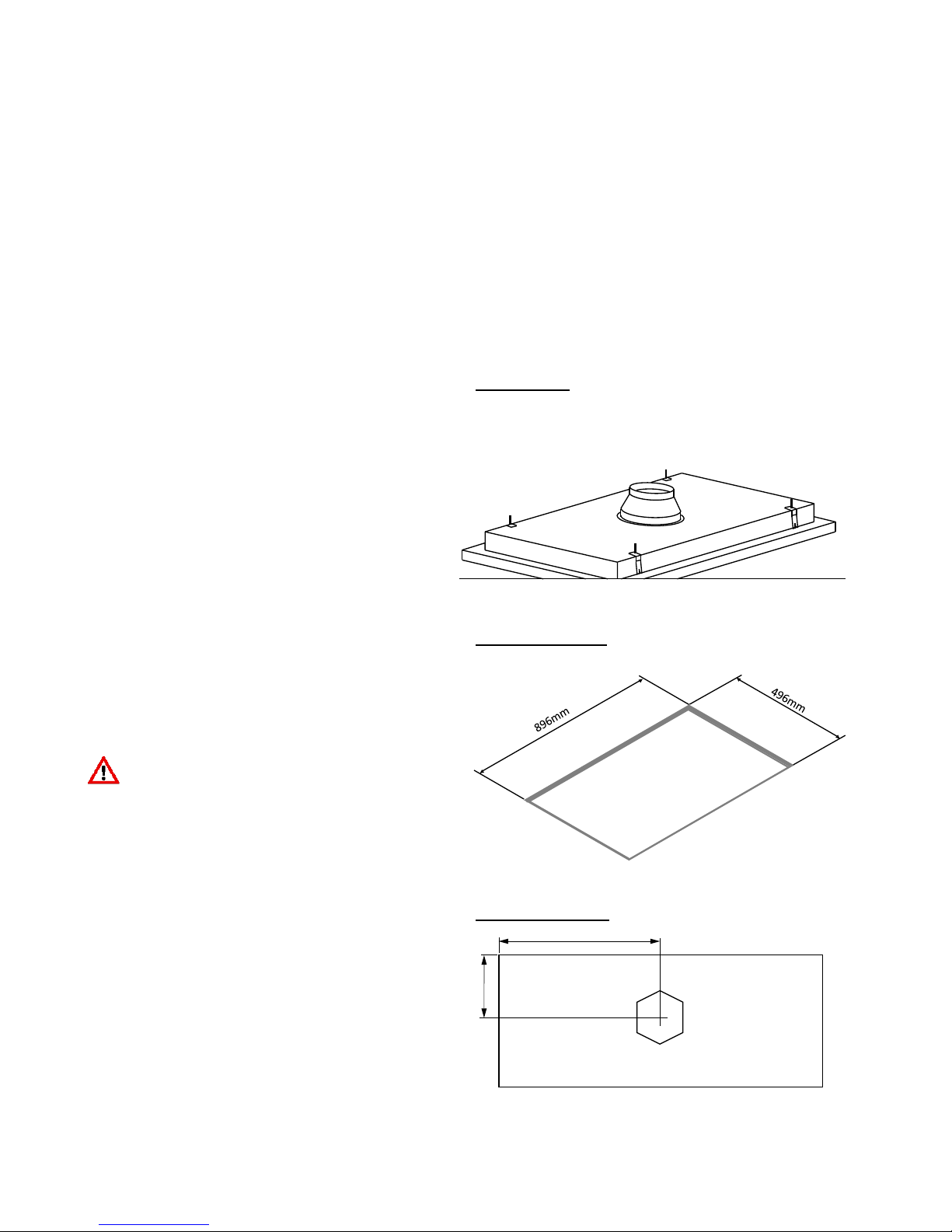

Hanger Hooks

The Derwent has 4 hanger hooks at each corner to

secure the hood to the ceiling (Fig 1).

Fig 1

Cut-out dimensions

Fig 2

Ducting Dimensions

Fig 3

445

250

Page 5

5

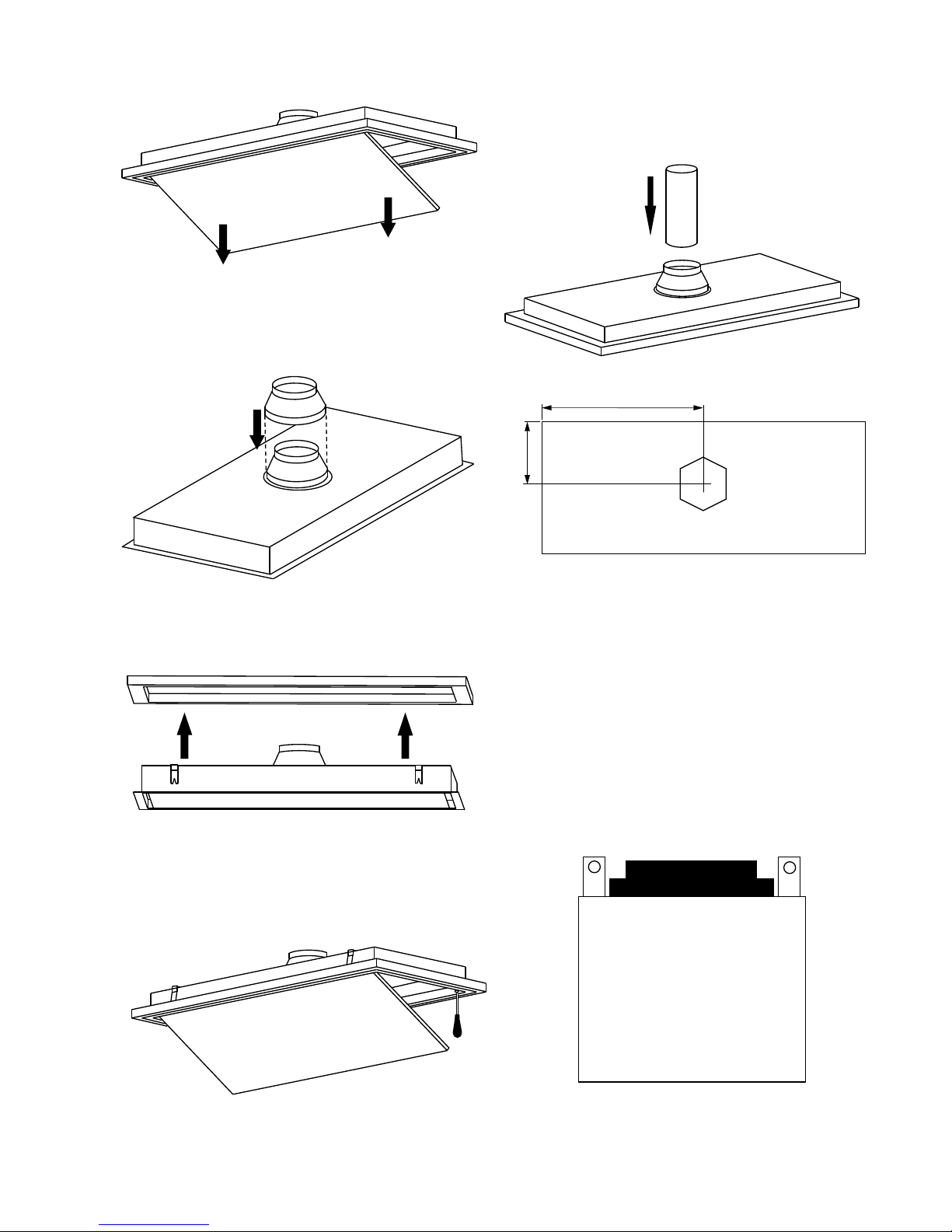

1. Pull down on the glass panel to reveal the grease

filters (Fig 4).

Fig 4

2. Remove the grease filters and place the

200/150mm ducting adapter to the back of the

hood (Fig 5).

Fig 5

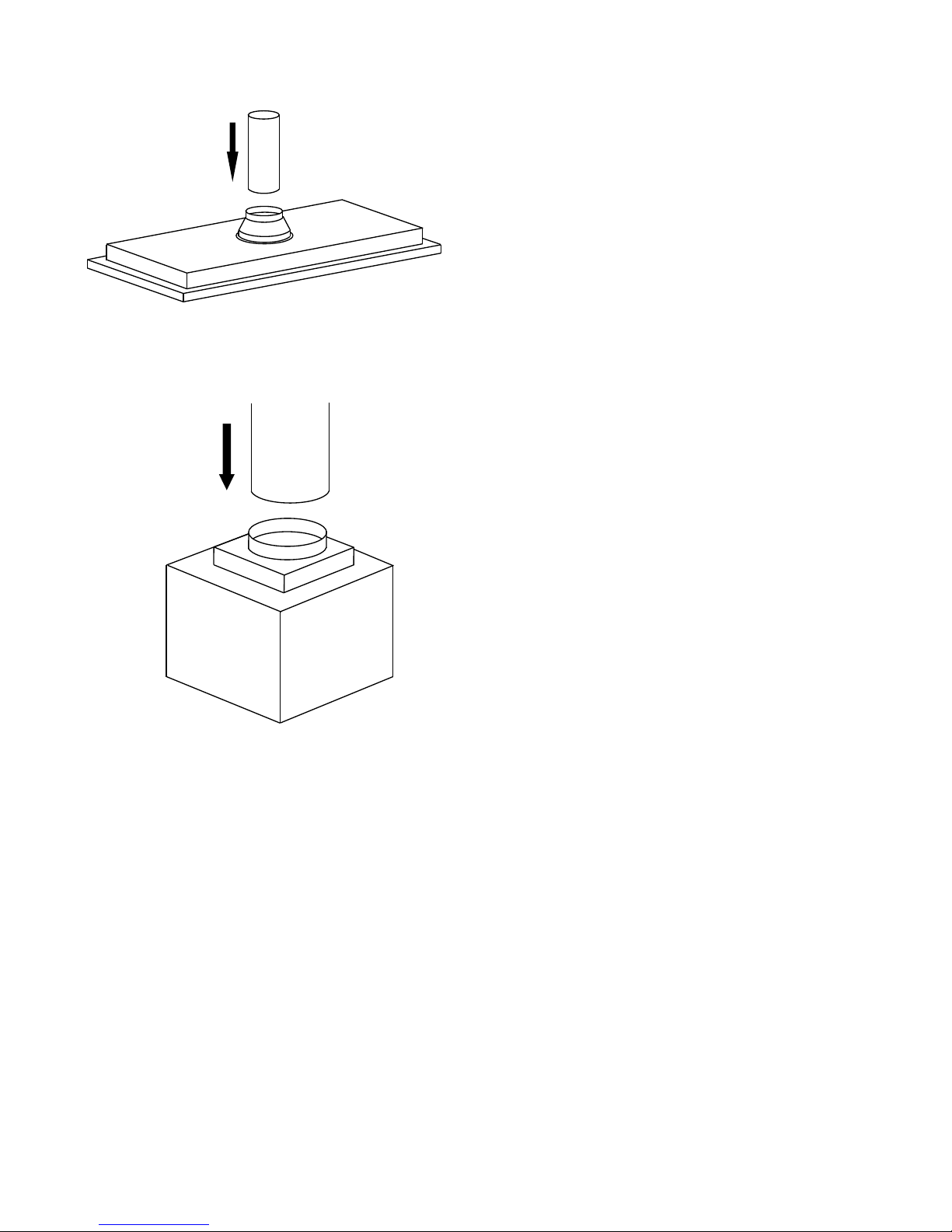

3. Put the Derwent up into the ceiling (Fig 6).

Fig 6

4. Make sure the hanger hooks are in position and

tighten the screws to clamp the hood to the

ceiling (Fig 7).

Fig 7

3.2 Ducting Options

The Derwent is ducted using either rigid ducting from

the back of the hood (Fig 7 & Fig 8).

Fig 7

Fig 8

3.3 Motor Options

The Derwent ceiling hood can be fitted with either the

1240 T1 750m3/h motor or the 1250 T2 1400m3/h

motor. This can be installed anywhere along the

ducting but no more than 6m away.

1. The motor is fixed to the wall using the L brackets

supplied. Screw the motor to the L brackets and

attach through A & B points to the wall (Fig 9).

Fig 9

445

250

A

B

Page 6

6

2. Mount the rigid ducting onto the plastic

connector of the hood (Fig 10).

Fig 10

3. Install the ducting work up to the air inlet of the

motor (Fig 11).

Fig 11

4. Install ducting between the air outlet on the

motor and the external vent.

3.4 Electrical Wiring

The electrical wiring must be performed by a

specialised electrician fully respecting current

standards and legislation in force. Check that the

power supply corresponds to the voltage requested

by the hood, which is given on the silver label stuck

inside the hood. Ensure that the wiring system

conforms to current standards and the earth

discharge works efficiently. Pay special attention to

the hood power cable, ensure that it does not pass

through any holes without a cable clamp. For direct

connection to the electrical mains it is necessary to

provide a device that ensures disconnection from the

electrical mains, with an opening distance of the

contacts that allows the complete disconnection

under the conditions of overvoltage category III, in

accordance with the rules of installation. The plug or

Omni polar switch must be accessible when the unit is

installed.

If the power cord is damaged, it must be replaced by

a special cord or assembly available from the

manufacturer or its service agent. The cable must be

of type H05VV-F 3 x 0.75mm2 minimum cross-section.

The manufacturer declines all responsibility if the

current accident prevention standards in force are not

respected, which are needed for the wiring system to

operate correctly.

Page 7

7

3.4.1 Electrical Wiring Diagram

Motor

Brown

Red

White

Yellow

Grey

Black

Lights

To control

buttons on hood

Blue

Brown

Mains

Supply

Page 8

8

3.4.2 Controls

The Derwent ceiling hood is controlled by remote

control. This allows the user to control the hoods

on/off functions, lights and the 4 motor speeds.

Fig 12

Turns the hood on/off at motor speed 2.

Increases motor speed.

Decreases motor speed.

Turns lights on/off.

4. Use & Maintenance

Before beginning any sort of cleaning or

maintenance work, turn the power off to the hood

by turning the main switch to 0 (OFF).

4.1 Cleaning the Metal Filters

The metal filters fitted in the hood should be washed

every 2-3 months, depending on how much the hood

is used, using hot water and a liquid detergent that is

not too aggressive.

The metal filters can be removed by the special

handle, unhooking the front part of the filter and

pulling it downwards (Fig 13).

Fig 13

4.2 Cleaning the Hood

The surfaces of the hood should be cleaned

frequently, to avoid the risk of having to remove built

up and encrusted deposits and stains.

For painted or copper plated hoods just a soft cloth

with warm water and a neutral detergent. Do not

pour the detergent directly onto the hood or use

powdery or abrasive products.

For stainless steel hood, use special products and

cloths for satin finish stainless steel (not abrasive,

corrosive detergents or detergents containing

chloride), ensuring to clean in the same direction as

the satin finish.

Do not use aggressive products, chemical solvents or

derivatives of oil distillates that could leave oily traces

which could cause oxidation and polymerisation.

The manufacturer accepts no responsibility for

damage to the surface of the hood due to failure to

respect these instructions.

5. Technical Data

Derwent 90cm with 1240 T1 Motor

Control

Remote Control

Colour/finish

Black Glass

Lighting

19w LED

Airflow (m3/h)

700

Noise (db)

54-59

Power (W)

229

Voltage (V)

230

Outlet Width (mm)

150

Weight (kg)

20

Derwent 90cm with 1250 T2 Motor

Control

Remote Control

Colour/finish

Black Glass

Lighting

19w LED

Airflow (m3/h)

1400

Noise (db)

54-69

Power (W)

439

Voltage (V)

230

Outlet Width (mm)

150

Weight (kg)

20

SILVERLINE

Page 9

9

6. Dimensions

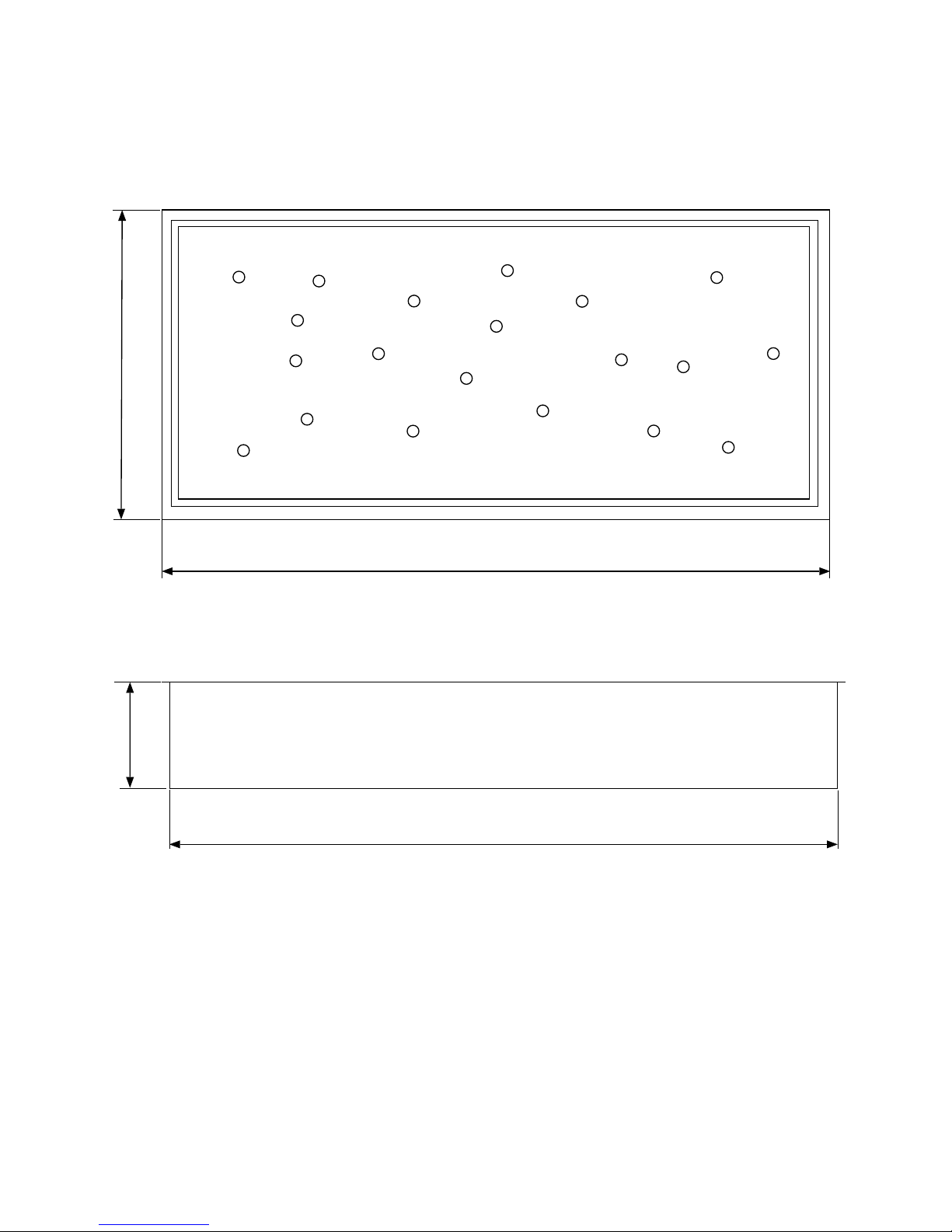

6.1 Derwent 90cm Ceiling Hood

890

115

900

500

Page 10

10

6.2 1240 T1 Motor

890

486

280

Page 11

11

6.3 1250 T2 Motor

335.5

Page 12

12

Loading...

Loading...