Page 1

Guaranteed Forever

*Register online within 30

days. Terms & Conditions apply

Garantie à vie

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

termes et conditions appliquées

Lebenslange Garantie

*Innerhalb von 30 Tagen online

registrieren. Es gelten die Allgemeinen

Geschäftsbedingungen

Garantía de por vida

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

Garanzia a vita

*Registrare il vostro prodotto on-line entro

30 giorni. Termini e condizioni si applicano

Levenslange garantie

*Registreer uw product binnen 30

dagen online. Algemene voorwaarden

zijn van toepassing

www.silverlinetools.com

Page 2

Chain Block

5 Tonne / 3m Lift Height

282517

Chain Block

Palan à main à chaîne

Kettenzug

Polipasto manual de cadena

Paranco di catena

Handtakel

www.silverlinetools.com

Page 3

1

2

3

6

5

4

2

Page 4

N

A

T

R

E

A

U

G

FOREVER

R

E

G

I

S

E

D

I

L

T

N

E

O

R

*

E

N

®

Chain Block

5 Tonne / 3m Lift Height

English .................. 4

Français ................ 8

Deutsch ................. 12

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

Conforms to relevant legislation and safety standards

Specification

Working Load Limit (WLL):............... ...........................5000kg

Standard lifting height: ................................................ 3000mm

Max. fixing point elevation: ......................................... 2.7m

Minimum distance between hooks: ............................ 600mm

Operating effort (chainpull) to lift full load: .................. 382N

Load chain dimensions ............................................... 10 x 30mm

Block diameter: ........................................................... 210mm

Block thickness:.......................................................... 165mm

Hook opening: ............................................................. 50mm

Net weight: ................................................................. 29.6kg

Operating temperature range: ..................................... -10 to +50°C

As part of our ongoing product development, specifications of Silverline products

may alter without notice.

General Safety

WARNING Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in a serious injury.

WARNING: This tool is not intended for use by persons (including children)

with reduced, physical or mental capabilities or lack of experience

or knowledge unless they have been given supervision or instruction

concerning use of the tool by a person responsible for their safety. Children

must be supervised to ensure that they DO NOT play with the tool.

Save all warnings and instructions for future reference.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) DO NOT operate tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

c) Keep children and bystanders away while operating or using this tool.

Distractions can cause you to lose control.

2) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating or using this tool. DO NOT operate or use the tool while you

are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating or using the tool may result in serious

personal injury. Work sensibly at all times with regular breaks if necessary.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal

injuries.

c) Remove any adjusting key or wrench before operating the tool. A

wrench or a key left attached to a rotating part of the tool may result in

personal injury.

d) DO NOT overreach. Keep proper footing and balance at all times. This

enables better control of the tool in unexpected situations.

e) Dress properly. DO NOT wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

3) Tool use and care

IMPORTANT: Tools used outdoors may require more regular cleaning and surface

treatment to prevent corrosion, as well as replacement grease or oil on moving

parts to maintain them in good working condition.

a) Maintain tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the tool’s

operation. If damaged, have the tool repaired before use. Many accidents

are caused by poorly maintained tools.

b) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

c) Use the tool’s accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work

to be performed. Use of the tool for operations different from those intended

could result in a hazardous situation.

4) Service

a) Have your tool serviced or repaired by a qualified repair person using

only identical replacement parts. This will ensure that the safety of the tool

is maintained.

4

Page 6

282517 Chain Block

Lifting Tool Safety

Inspect the equipment

• Before use, check the condition of the equipment, paying particular attention

to cables, locking mechanisms, and hydraulic fittings. Cables should be free

from kinks and should not show any evidence of fraying or cutting. Locking

mechanisms should work freely and should be clean of excessive dirt or grease.

Hydraulic fittings should be in good condition and free from leaks

• Any additional supports should be capable of taking the full weight of the object

to be lifted, along with some additional capacity as a precautionary measure

• All safety devices (including automatic) should be tested before use

• Check that the hooks are sound. If a hook has more than a 10° twist out of true,

or has an excessive throat opening, it should be replaced

• Check all hook safety latches are not damaged or bent and completely seal the

hook openings

• If any part of the lifting equipment is found to be damaged or worn, it must be

repaired with genuine replacement parts at an authorised service centre before

the equipment is used

• Lifting equipment should be inspected by a qualified person at least once each

year and the results of the inspection recorded in an inspection book for future

reference

• The brake on a lifting tool should never come into contact with oil or grease

• DO NOT modify any lifting equipment. Any attempt to tamper with this

equipment will invalidate its guarantee and could result in serious injury to

yourself or others around you

Locating the lifting tool

• Locate the lifting tool in a suitable, well-lit work area

• Keep work area clean and tidy and free from unrelated materials

• Never use a lifting tool in wet, explosive or corrosive environments

Attaching a load

• Any load must only be attached/supported by the proper lifting points

• Winches/jacks should not be used in conjunction with any other lifting device/s

• The load must be free to lift. If the load is caught, or restricted during lifting,

overloading of the lifting equipment will result

• Before attaching a load, ensure that it is stable, and will remain stable

throughout the lifting process

• Never wrap the chain around a load, or use the load chain as a sling

Danger area

• When an object is being lifted, the areas directly below and around the area

should be considered highly dangerous. DO NOT reach into, or enter this area

• Lifting equipment must be operated from a position where the operator is not at

risk from a falling load (i.e. outside of the danger area)

• Protective headgear (e.g. hardhat) and protective footwear, should be worn by

the operator, and any person near to the danger area

• Never use a lifting tool or any other overhead lifting equipment for lifting

persons

During a lift

• The operator should have constant eye contact with the load. If it is impractical

for the operator to have constant eye contact, then the danger area should be

sealed off, and additional persons with full view of the operating area must be

used to relay instructions to the operator

• Lifting equipment must only be operated by persons who are clearly familiar

with the operating instructions

• DO NOT change from lifting to lowering rapidly. Allow the load to come to a

complete stop before changing direction

• If the lifting equipment is unable to raise a load, stop immediately. The lift load

capacity has been exceeded

• When lowering a load, make allowance for the fact that a load will usually run

on for a few centimetres after the mechanism has been stopped

• Lifting equipment must never be used for any purpose other than vertical lifts

• DO NOT lift an object to a greater height than is absolutely necessary

• Never leave a suspended load unattended

• If you are in any way unsure about the safe method of using this equipment,

DO NOT use it

Product Familiarisation

1 Mounting Hook

2 Block

3 Hand Chain

4 Load Hook

5 Safety Bar

6 Load Chain

Intended Use

Portable, hand-operated manual chain hoist, for vertical lifting of loads. This device

is designed for temporary operation only, and should not be used for permanent

suspension of loads. Domestic use only.

Unpacking Your Tool

• Carefully unpack and inspect your tool. Familiarise yourself with all its features

and functions

• Ensure that all parts of the tool are present and in good condition. If any parts

are missing or damaged, have such parts replaced before attempting to use

this tool

Before Use

Installing the chain block

WARNING: Ensure the chain block is suspended from a structure capable of

supporting a load of at least 1½ x the safe working load of the block.

• Install the chain block, so the bottom of the hand chain sits between 500 and

100mm from the ground

• The user must be able to operate the hand chain safely, from a location to the

side of the suspended load

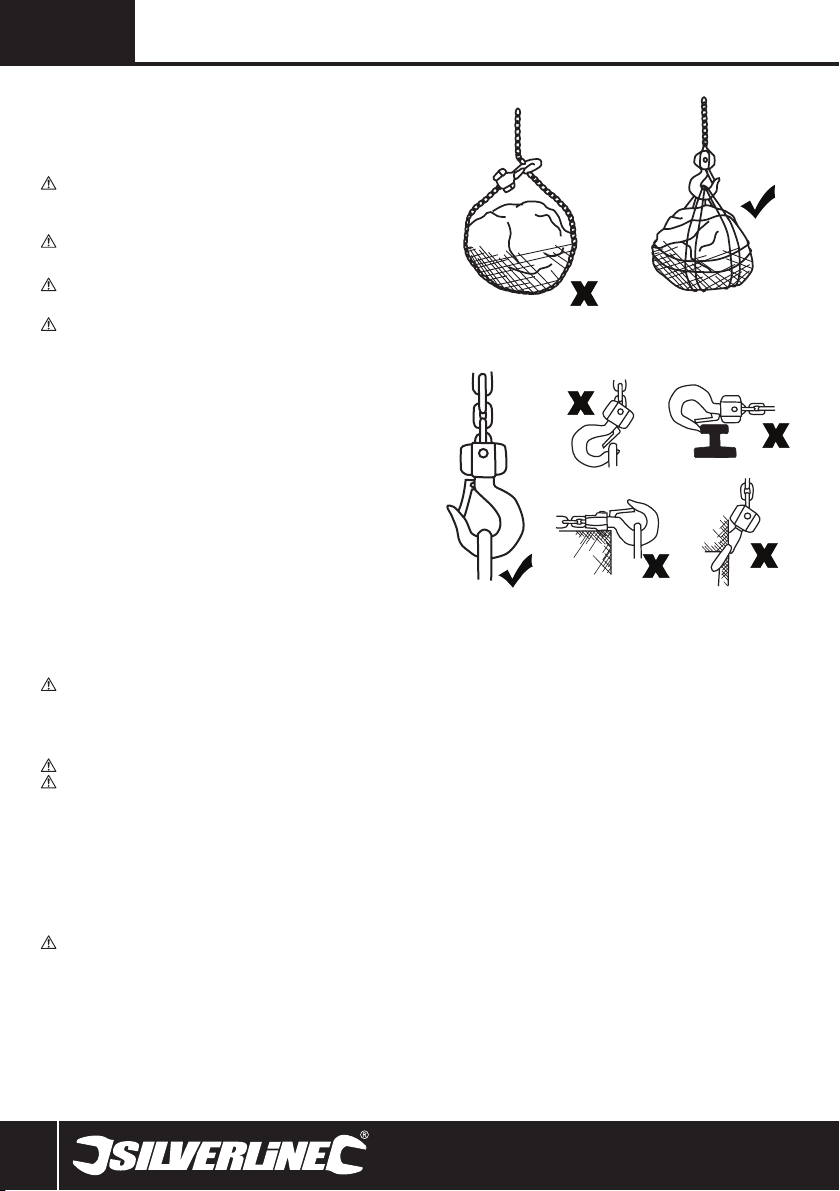

Attaching the load

WARNING: DO NOT use the chain as a sling. This may cause damage to the chain.

• Attach load to Load Hook (4), using slings, chains or other lifting devices,

suitable for the type, shape and weight of the load (see Fig.1)

• Centre the load on the Load Hook correctly (see Fig.1)

WARNING:

• NEVER load the Load Hook in front of the Safety Bar (see Fig. 3-A)

• NEVER load the Load Hook tip (See Fig. 3-B)

• NEVER load the Load Hook off the centre line (See. Fig. 3-C)

• NEVER load the Load Hook sideways (See Fig. 3-D)

WARNING: ALWAYS ensure that the Mounting Hook (1) is fully engaged, with its

Safety Bar (5) securely closed.

www.silverlinetools.com

5

Page 7

GB

Operation

Note: This lifting device must ONLY be used by competent operators. All users

must be trained in the use of lifting equipment. Inexperienced users must receive

instruction prior to using this device. A risk assessment must be carried out before

undertaking any lifting operations.

WARNING: ALWAYS wear personal protective equipment appropriate for the work

area and type of load, including but not limited to eye protection, gloves, hard hat,

protective shoes and hearing protection.

Lifting

WARNING: ALWAYS evacuate bystanders from the immediate lifting area. Clearly

communicate when lifting commences and finishes. NEVER allow anybody to

stand under a suspended load.

WARNING: Raise and lower in a smooth, controlled manner. DO NOT shock load

the chain block by allowing the attached load to fall freely, even for very short

distances. Ensure the chain moves freely and does not twist.

WARNING: The brake may become hot during prolonged use of the chain block.

Stop using the tool intermittently to ensure the brake does not overheat.

1. Smoothly pull the Hand Chain (3) until the Load Chain (6) is taut. Confirm that

it is vertical (i.e. not pulling at an angle).

2. Start to raise load. Check that it is level with no possibility of the load tilting

and/or slipping from its restraints

3. If necessary, lower the load and readjust slings to obtain a safe, level lift

4. Stop lifting at approxima tely 100mm to check that the brake will hold the

load

5. Continue to raise load to required height in a slow and controlled manner. DO

NOT raise the load so far that the Load Hook (4) comes into contact with the

Block (2)

6. To lower the load, pull down on the opposite side of the Hand Chain. Again,

lower smoothly and slowly and DO NOT lower so far as to completely extend

the full length of the Load Chain

Accessories

• Additional lifting equipment and accessories, including lifting slings, are

available from your Silverline stockist

Maintenance

Note: All lifting equipment must be regularly inspected and maintained by a

competent person, in accordance with local laws and regulations (e.g. Lifting

Equipment Regulations, etc.). Maintenance must be recorded in a dedicated

service record (see end of this manual).

WARNING: Carry out a visual inspection of all components, every time the chain

block is used, and listen for any unusual sounds during operation. Perform an indepth examination every time the device has not been used for some time. Should

any damage be detected, remove the device from service immediately, and return

it to an authorised Silverline service centre for repairs. If the device is beyond

repair, it must be rendered unusable and discarded.

WARNING: Inspect and test the brake mechanism before every use.

WARNING: This tool does not contain any user-serviceable parts. Never

disassemble the chain block. Always return the device to an authorised Silverline

service centre for maintenance and repairs.

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts to wear

quickly, and shorten the device’s service life. Clean the body of your machine

with a soft brush, or dry cloth. If available, use clean, dry, compressed air to

blow through the ventilation holes (where applicable)

Lubrication

• Lubricate all moving parts with a suitable lubricant spray, at regular intervals

• Keep the load chain and both hook shanks clean and lubricated

WARNING: Never allow oil or grease to come into contact with the brake

mechanism.

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

• Tools may contain traces of tool oil, other lubricants and pollutants. Therefore,

tools should not be disposed of with household waste

• Contact your local waste disposal authority for information on the correct way

to dispose of this tool

WRONG RIGHT

A

C

Figure 1

Figure 2

B

D

6

Page 8

Silverline Tools Guarantee

Silverline Tools Guarantee

This Silverline product comes with a 3 year guarantee

Register this product at www.silverlinetools.com within 30 days of purchase

in order to qualify for the 3 year guarantee. Guarantee period begins

according to the date of purchase on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the fault.

You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date, your

name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean and

safe state for repair, and should be packaged carefully to prevent damage or

injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

Chain Block282517

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created in

PDF format for you to print out and keep with your purchase.

The repair or replacement of your product under guarantee provides benefits

which are additional to and do not affect your statutory rights as a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse, neglect,

careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in these

guarantee conditions are not covered by the guarantee.

CE Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declares that the

Identification code: 282517

Description: Chain Block

Conforms to the following Directives:

• Machinery Directive 2006/42/EC

• EN13157+A1:2009

Notified body: TUV Rheinland, Nurnberg, Germany

The technical documentation is kept by: Silverline Tools

Date: 24/01/14

Signed by:

Director

Name and address of the manufacturer:

Powerbox Ltd., Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ, United Kingdom

www.silverlinetools.com

7

Page 9

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles. Ces

symboles constituent des informations importantes relatives au produit ou des

instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port du masque respiratoire

Port du casque

Port de gants

Lire le manuel d’instructions

Conforme à la réglementation et aux normes de sécurité pertinentes

Spécifications

Limite de charge de travail (LCT:............... ..................5000 kg

Hauteur de montée standard: ..................................... 3000 mm

Elévation maximale. du point de fixation: .................... 2.7 m

Distance minimale entre les crochets: ........................ 600 mm

Effort opérationnel pour

soulever la charge complète: ...................................... 382 N

Dimensions chaine de levage ..................................... 10 x 30 mm

Diamètre du bloc: ....................................................... 210 mm

Largeur du bloc: .......................................................... 165 mm

Ouverture crochet: ...................................................... 50 mm

Poids net: .................................................................... 29.6 kg

Plage de température de fonctionnement: .................. -10 to + 50°C

En raison de développements de produit continus, les spécifications Silverline

peuvent être modifiée sans préavis.

Consignes générales de sécurité

ATTENTION : Veuillez lire l’intégralité des consignes de sécurité et des

instructions. Le non-respect de ces consignes et instructions peut entraîner un

risque de choc électrique, d’incendie et/ou se traduire par des blessures graves.

ATTENTION : Cet appareil n’est pas conçu pour être utilisé par des personnes

(enfants compris) ayant des capacités physiques ou mentales réduites, ou

n’ayant pas la connaissance ou l’expérience requise, à moins d’être sous la

supervision d’une personne responsable de leur sécurité ou d’avoir reçu les

instructions nécessaires. Les enfants ne doivent pas s’approcher et jouer avec

cet appareil.

Veuillez conserver ces instructions et consignes de sécurité pour référence

ultérieure.

1) Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils dans des environnements explosifs, tels qu’à

proximité de liquides, de gaz ou de poussières inflammables.

c) Eloigner les enfants et les passants pendant l’utilisation d’un appareil

électrique. Ceux-ci peuvent provoquer une perte d’attention et faire perdre

la maîtrise de l’appareil.

2) Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation de

l’appareil. Ne pas utiliser un appareil électrique lorsque l’on se trouve

dans un état de fatigue, ou sous l’influence de drogues, d’alcool ou

de médicaments. Un moment d’inattention pendant l’utilisation d’un outil

électrique peut se traduire par des blessures graves.

b) Porter un équipement de protection approprié. Toujours porter une

protection oculaire. Le port de masque à poussières, chaussures de

sécurité antidérapantes, casque de sécurité et protections antibruit adaptés

aux différentes conditions de travail réduit le risque de blessures corporelles.

c) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil en marche. Une clé ou un instrument de réglage laissé fixé à un

élément en rotation de l’appareil peut entraîner des blessures.

d) Ne pas essayer d’atteindre une zone hors de portée. Se tenir toujours

en position stable permettant de conserver l’équilibre. Cela permet de

mieux contrôler l’appareil électrique dans des situations inattendues.

e) Porter des vêtements appropriés. Ne pas porter de vêtements amples ou

des bijoux pendants. Eloigner cheveux, vêtements et gants des pièces

en mouvement. Les vêtements amples, les bijoux pendants et cheveux

longs peuvent être happés par les pièces en rotation

3) Utilisation et entretien des appareils

Important : Des appareils utilisé à l’extérieur peuvent demander un entretien

plus régulier, particulièrement un traitement anticorrosion des surfaces, ainsi que

le graissage ou la lubrification des éléments mobiles pour garder le produit en

bonne condition

a) Entretien des appareils. Vérifier que les éléments rotatifs soient bien

alignés et non grippés. S’assurer de l’absence de pièces cassées

ou endommagées susceptibles de nuire au bon fonctionnement

de l'appareil. Si l’appareil est endommagé, le faire réparer avant toute

utilisation. De nombreux accidents sont dus à un mauvais entretien d’un

outil.

b) Veiller à ce que les outils de coupe soient tenus affûtés et propres. Des

outils de coupe bien entretenus, aux tranchants bien affûtés, sont moins

susceptibles de se gripper et sont plus faciles à contrôler.

c) Utiliser l’appareil, les accessoires et outils à monter conformément à

ces instructions, en tenant compte des conditions de travail et de la

tâche à réaliser. Toute utilisation d’un appareil autre que celle pour laquelle

il a été conçu peut entraîner des situations à risque.

4) Révision

a) Ne faire réparer ou entretenir votre appareil électrique que par un

réparateur qualifié utilisant uniquement des pièces de rechange

identiques.

8

Page 10

Palan à main à chaîne282517

Consignes de sécurité relatives

aux équipements de levage

Inspection de l'équipement

• Avant utilisation, toujours vérifier l'état de l'équipement, notamment des

câbles, des mécanismes de blocage et des raccords hydrauliques. Les câbles

ne doivent présenter ni coques, ni signes d'effilochage ou de coupure. Les

mécanismes de blocage doivent fonctionner sans accroc, et doivent être

exempts de poussières et d’accumulation de graisse. Les raccords hydrauliques

doivent être en bon état et parfaitement étanches.

• Tous les supports supplémentaires doivent pouvoir supporter le poids maximum

de l'objet à soulever, avec une marge supplémentaire par mesure de précaution.

• Tous les systèmes de sécurité (y compris automatiques) doivent être testés

avant utilisation.

• Vérifier que les crochets soient fonctionnels. Un crochet présentant une

distorsion de 10° ou bien une ouverture trop importante doit être remplacée.

• Vérifier que le linguet de sécurité des crochets n’est pas endommagé ni tordu et

ferme parfaitement l’ouverture du crochet.

• Toute partie de l'équipement de levage s'avérant endommagée ou usée doit

être réparée, les pièces endommagées devant être remplacées par des pièces

d'origine dans un centre d'entretien agréé, avant toute utilisation.

• L'équipement de levage doit être inspecté par un technicien qualifié au moins

une fois par an, et les résultats de l'inspection doivent être consignés dans un

carnet pour référence ultérieure.

• Le frein de l’équipement de levage ne doit jamais venir en contact avec des

produits lubrifiants (graisse, huile…).

• Ne pas modifier l'équipement de levage. Toute modification apportée à

l’équipement représente un risque de blessures pour l’utilisateur ainsi que pour

les personnes environnantes, et invalidera la garantie.

Mise en place de l’équipement de levage

• Installer l’équipement de levage dans une zone de travail bien éclairée.

• Tenir la zone de travail propre et rangée, sans encombrement de matériaux et

d’objets superflus.

• Ne jamais utiliser d’équipement de levage dans un environnement humide,

explosif ou corrosif.

Fixation d'une charge

• Une charge ne doit être fixée / soutenue que par les points de levage adéquats.

• Ne pas utiliser de treuil ou de cric en sus d’un autre équipement de levage.

• La charge doit toujours pouvoir être soulevée sans entrave. Si la charge se

coince ou est entravée pendant le levage, il se produit une surcharge pour

l'équipement de levage.

• Fixer la charge de manière à ce qu'elle soit stable, et à ce qu'elle reste stable

pendant l'opération de levage.

• Ne jamais enrouler la chaîne autour d’une charge et ne jamais utiliser la chaîne

de charge en guise d’élingue.

Zone dangereuse

• La zone située juste en dessous de l’objet soulevé, ainsi que le périmètre

directement environnant, doivent être considérés comme zones dangereuses.

Ne pas pénétrer à l'intérieur de cette zone tant que l’objet ne repose pas sur

une surface de support.

• L'équipement de levage doit être manœuvré à partir d'un emplacement dans

lequel l'opérateur n'est pas menacé par la chute de la charge (c’est-à-dire à

l'extérieur de la zone dangereuse).

• L'opérateur et toute personne proche de la zone dangereuse doivent porter

un dispositif de protection de la tête (par exemple un casque dur) et des

chaussures de protection.

• L'équipement de levage ne doit en aucun cas servir à soulever des personnes.

Pendant une opération de levage

• L'opérateur doit être en mesure de garder un contact visuel constant avec

la charge. Si, pour des raisons pratiques, ceci n’est pas possible, la zone

dangereuse doit être bouclée et toute autre personne ayant une vue directe

et complète sur la zone de manœuvre doit contribuer à transmettre les

instructions à l'opérateur.

• L'équipement de levage doit être uniquement utilisé par des personnes ayant

une parfaite connaissance des consignes d’utilisation.

• Ne pas passer rapidement d'une manœuvre de levage à une manœuvre

d'abaissement. Laisser la charge s'arrêter complètement avant de changer le

sens du mouvement.

• Si l'équipement n’est pas en mesure de soulever une charge, arrêter

immédiatement car la capacité maximum de levage a été dépassée.

• Lors de l’abaissement d’une charge, tenir compte du fait qu'elle continuera à

descendre pendant quelques centimètres après l'arrêt du mécanisme.

• L'équipement de levage ne doit jamais être utilisé pour une application autre

qu'un levage à la verticale.

• Ne pas soulever d’objet à une hauteur supérieure à la hauteur strictement

nécessaire

• Ne jamais maintenir la charge suspendue en hauteur sans surveillance.

• En cas de doute quant au mode d’utilisation le plus sûr de cet équipement,

s’abstenir de l’utiliser.

Se familiariser avec le produit

1 Crochet de montage

2 Bloc

3 Chaine manuelle

4 Crochet de levage

5 Barre de sureté

6 Chaine de levage

Utilisation prévue

Palan à chaine portable à commande manuelle pour les tâches de levage

verticales. Cette appareil est conçu pour une utilisation temporaire et ne devrait

pas être utilisé pour la suspension permanente de charges. Pour un usage

domestique seulement.

Déballage

• Déballer précautionneusement votre outil et l’inspecter. Se familiariser avec ses

caractéristiques et ses fonctions

• S’assurer que toutes les pièces sont présentes et en bon état. Si des pièces

manquent ou sont endommagées, remplacer ces pièces avant d’essayer

d’utiliser cet outil.

Avant l’utilisation

Installer le palan à chaine

ATTENTION ! : S’assurer que le palan de chaine soit suspendu d’une structure

capable de soutenir une charge d’au moins 1½ x la charge maximum pratique

du palan.

• Installer le palan à chaine, de manière que le bas de la chaine manuelle repose

entre 500 et 100 mm du sol

• L’utilisateur doit être en mesure d’opérer la chaine manuelle en toute sécurité,

situé sur le côté du poids suspendu

Suspendre la charge

ATTENTION ! : NE PAS utiliser la chaine comme élingue. Ceci peut endommager

la chaine.

• Attacher la charge au Crochet de levage (4) en utilisant des chaines, des

élingues ou d’autres dispositifs de levage, adaptés au type, à la forme et au

poids de la charge (voir Fig. 1)

• Centrer la charge sur le crochet de levage correctement (voir Fig. 1)

ATTENTION ! :

• Ne JAMAIS charger le Crochet de levage à l’avant de la Chaine de sureté (voir

Fig. 3-A)

• Ne JAMAIS charger l’extrémité du Crochet de levage (voir Fig. 3-B)

• Ne JAMAIS charger le Crochet de levage en dehors de la ligne centrale (voir

Fig. 3-C)

• Ne JAMAIS charger le Crochet de levage sur le côté (voir Fig. 3-D)

ATTENTION : TOUJOURS s’assurer que le Crochet de montage(1) soit parfaitement

enclenché, et que la barre de sureté soit fermée de manière sure.

www.silverlinetools.com

9

Page 11

F

Utilisation

Note : Ce dispositif de levage doit être utilisé UNIQUEMENT par des utilisateurs

compétents. Tous les utilisateurs doivent être formés pour l’utilisation de dispositifs

de levage. Les utilisateurs inexpérimentés doivent être formés avant d’utiliser ce

dispositif. Une évaluation des risques doit être effectuée avant toute opération

de levage.

ATTENTION : TOUJOURS porter un Equipement de protection individuelle approprié

pour le lieu de travail et le type de charge incluant sans s’y limiter une protection

oculaire, des gants, un casque protecteur, des chaussures de protection et une

protection auditive.

Pendant une opération de levage

ATTENTION ! : TOUJOURS évacuer les personnes présentes dans la zone de

levage. Communiquer clairement quand le levage commence et finit. Ne JAMAIS

permettre à qui que ce soit d’être en dessous de la charge suspendue.

ATTENTION ! : Lever et abaisser en douceur et de manière maitrisée. Ne pas

abaisser la charge avec un effet de choc en laissant la charge suspendue tomber

en chute libre, même pour de très petites distances. S’assurer que la chaine

circule librement et ne se tord pas.

ATTENTION ! : Le frein peut devenir chaud lors d’un usage prolongé du palan de

chaine. Arrêter d’utiliser l’outil de manière intermittente afin de s’assurer que le

frein ne surchauffe pas.

1. Tirer la Chaine manuelle (3) en douceur jusqu’à ce que la Chaine de levage

(6) soit tendue. S’assurer qu’elle est verticale (c’est-à-dire qu’elle ne tire pas

sur un angle).

2. Commencer à lever la charge. Vérifier qu’elle est verticale et qu’il n’y a

aucune possibilité que la charge ne se penche et/ou ne s’échappe de ses

attaches.

3. Si nécessaire, abaisser la charge et réajuster les attaches afin d’obtenir un

levage vertical en toute sécurité.

4. Arrêter le levage à environ 100 mm pour vérifier que le frein va supporter la

charge.

5. Continuer à lever la charge jusqu’à la hauteur requise d’une manière lente et

maitrisée. NE PAS lever la charge si haute que le Crochet de levage (4) entre

en contact avec le Bloc (2).

6. Pour abaisser la charge, tirer sur le côté opposé de la Chaine manuelle.

De nouveau abaisser lentement et en douceur et NE PAS abaisser jusqu’à

extension complète de la Chaine de levage.

Accessoires

• Des équipements de levage additionnels et des accessoires, comprenant des

élingues de levage, sont disponibles chez votre stockiste Silverline.

Lubrification

• Lubrifiez régulièrement les parties mobiles avec un vaporisateur de lubrifiant

adéquat.

• Garder la chaine de levage et les tiges des deux crochets propres et lubrifiés

ATTENTION ! : Ne JAMAIS laisser de l’huile ou de la graisse entrer en contact avec

le mécanisme de freinage

Rangement

• Ranger cet outil dans un endroit sûr, sec et hors portée des enfants.

Recyclage

Lorsque l’appareil n’est plus en état de fonctionner et qu’il n’est pas réparable,

recyclez l’appareil conformément aux régulations nationales.

• L’outil peut contenir des traces d’huile, de lubrifiants et d’autres polluants donc

l’outil ne doit pas être jeté avec les ordures ménagères

• Contactez les autorités locales compétentes en matière de gestion des déchets

pour vous informer de la procédure à suivre pour recycler les outils électriques.

MAUVAIS CORRECT

Entretien

Note: Tout équipement de levage doit être régulièrement inspecté et entretenu

par une personne compétente, en accord avec les lois et règlements du pays (par

exemple La Règlementation régissant les équipements de levage). L’entretien

doit être noté dans un carnet d’entretien consacré (voir la fin de ce manuel

d’utilisation).

ATTENTION ! : Effectuer une inspection visuelle des éléments, à chaque fois que le

palan de chaine est utilisé, et écouter pour tout bruit inhabituel lors de l’utilisation.

Effectuer une inspection approfondie chaque fois que le dispositif n’a pas été

utilisé depuis longtemps. Si vous repérez d’éventuels dommages, retirer l’appareil

du service immédiatement et le ramener à votre centre de réparation agréé par

Silverline. Si l’appareil ne peut être réparé, le rendre inutilisable et le jeter.

ATTENTION ! : Inspecter et tester le mécanisme de freinage avant chaque

utilisation.

ATTENTION ! : Cet outil ne contient aucune pièce susceptible d’être réparée

par l’utilisateur. Ne jamais désassembler le palan à chaine. Toujours amener le

dispositif à un centre de réparation agréé par Silverline pour l’entretien et les

réparations.

Nettoyage

• Gardez l’appareil propre. La poussière et la saleté provoquent l’usure rapide des

éléments internes de l’appareil, ce qui réduit sa durabilité. Utilisez une brosse

souple ou un chiffon sec pour le nettoyage. Si possible, nettoyez les orifices de

ventilation à l’air comprimé propre et sec.

10

Figure 1

A

C

B

D

Figure 2

Page 12

Garantie Silverline

Ce produit Silverline bénéficie d’une garantie de

3 ans

Enregistrez ce produit sur le site silverlinetools.com dans les 30 jours

suivant l’achat afin de bénéficier de la garantie de 3 ans. La période de

garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Conditions de garantie des outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom, votre

adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de garantie

seront vérifiées par Silverline Tools pour établir si la défaillance du produit est

liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie seront

rectifiées par la réparation de l’outil, sans frais (hormis les frais de port) ou

par son remplacement par un outil en parfait état de fonctionnement.

Les pièces ou les outils remplacés deviendront la propriété de Silverline Tools.

Palan à main à chaîne282517

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement et

saisissez :

• Vos informations personnelles

• Les informations concernant le produit et l’achat

Vous recevrez le certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires en

tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par Silverline

Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances de

l’outil indiquées dans ces conditions de garantie ne sont pas couvertes par

cette garantie.

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Code d’identification : 282517

Description : Palan à main à chaîne

Est conforme aux directives suivantes :

• Directive sur les machines 2006/42/CE

• EN13157+A1:2009

Organisme notifié : TUV Rheinland, Nurnberg, Allemagne

La documentation technique est conservée par : Silverline Tools

Date : 24/01/14

Signature :

Directeur général

Nom et adresse du fabricant ou de son représentant agréé :

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ Royaume-Uni

www.silverlinetools.com

11

Page 13

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole abgebildet.

Sie vermitteln wichtige Informationen über das Produkt oder dienen als

Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Schutzhandschutzschuhe tragen

Bedienungsanleitung sorgfältig lesen

Erfüllt die entsprechenden rechtlichen Vorschriften und

Sicherheitsnormen

Technische Daten

Max. Tragfähigkeit (WLL):............... .............................5000 kg

Standardhubhöhe: ...................................................... 3000 mm

Max. Höhe für Anschlagpunkt: ....................................2,7 m

Mindestabstand zwischen Haken: ............................... 600 mm

Kettenzugkraft zur Hebung der vollen Last:................. 382 N

Lastkettenabmessungen............................................. 10 x 30 mm

Kettenzugdurchmesser: .............................................. 210 mm

Kettenzugbreite:..........................................................165 mm

Hakenöffnung: ............................................................ 50 mm

Eigengewicht: ............................................................. 29,6 kg

Betriebstemperaturbereich: ........................................ -10 bis +50 °C

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte können sich die

technischen Daten von Silverline-Produkten ohne vorherige Ankündigung ändern.

Allgemeine Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und Anweisungen

können schwere Verletzungen verursachen.

WARNUNG: Dieses Werkzeug darf nicht von Personen (wie z.B. Kindern) mit

eingeschränkten körperlichen oder geistigen Fähigkeiten oder von Personen

ohne Erfahrung im Umgang mit einem solchen Werkzeug betrieben werden,

außer wenn sie von einer für ihre persönliche Sicherheit verantwortlichen

Person in der Benutzung unterwiesen worden sind und dabei beaufsichtigt

werden. Kinder müssen beaufsichtigt werden, um sicherzustellen, dass sie das

Werkzeug nicht als Spielzeug verwenden.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die Zukunft auf.

1) Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet. Unordnung

oder unbeleuchtete Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Werkzeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube

befinden.

c) Halten Sie Kinder und andere Personen während der Benutzung des

Werkzeugs fern. Bei Ablenkung können Sie die Kontrolle über das Werkzeug

verlieren.

2) Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen Sie

mit Vernunft an die Arbeit mit einem Werkzeug. Benutzen Sie kein

Werkzeug, wenn Sie müde sind oder unter dem Einfluss von Drogen,

Alkohol oder Medikamenten stehen. Ein Moment der Unachtsamkeit beim

Gebrauch des Werkzeuges kann zu ernsthaften Verletzungen führen. Arbeiten

Sie stets konzentriert und legen Sie bei Bedarf regelmäßig Pausen ein.

b) Tragen Sie persönliche Schutzausrüstung und immer eine Schutzbrille.

Das Tragen persönlicher Schutzausrüstung, wie Staubmaske, rutschfeste

Sicherheitsschuhe, Schutzhelm oder Gehörschutz, je nach Art und Einsatz

des Werkzeuges, verringert das Risiko von Verletzungen.

c) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie die

Arbeit mit dem Werkzeug aufnehmen. Ein Werkzeug oder Schlüssel, der

sich in einem drehenden Werkzeugteil befindet, kann zu Verletzungen führen.

d) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für

einen sicheren Stand und halten Sie jederzeit das Gleichgewicht. Auf

diese Weise lässt sich das Werkzeug in unerwarteten Situationen besser

kontrollieren.

e) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder

Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern von sich

bewegenden Teilen. Lockere Kleidung, Schmuck oder lange Haare können

von sich bewegenden Teilen erfasst werden.

3) Werkzeugbenutzung und -pflege

WICHTIGER HINWEIS: Im Freien benutzte Werkzeuge bedürfen gegebenenfalls

häufigerer Reinigung und gründlicherer Oberflächenpflege, um Korrosion zu

verhindern. Bewegliche Teile müssen zudem öfter geschmiert werden, damit der

einwandfreie Betriebszustand gewährleistet ist.

a) Pflegen Sie Werkzeuge mit Sorgfalt. Kontrollieren Sie, ob bewegliche

Teile einwandfrei funktionieren und nicht klemmen, ob Teile gebrochen

oder so beschädigt sind, dass die Funktion des Werkzeuges

beeinträchtigt ist. Lassen Sie beschädigte Teile vor dem Einsatz des

Werkzeugs reparieren. Viele Unfälle haben ihre Ursache in schlecht

gewarteten Werkzeugen.

b) Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig gepflegte

Schneidwerkzeuge mit scharfen Schneidkanten verklemmen sich weniger

und sind leichter zu führen.

c) Verwenden Sie Werkzeugzubehör, Einsatzwerkzeuge usw.

entsprechend diesen Anweisungen. Berücksichtigen Sie dabei die

Arbeitsbedingungen und die auszuführende Tätigkeit. Der Gebrauch

von Werkzeugen für andere als die vorgesehenen Anwendungen kann zu

gefährlichen Situationen führen.

4) Service

a) Lassen Sie Ihr Werkzeug nur von qualifiziertem Fachpersonal und nur

mit Original-Ersatzteilen warten und reparieren. Damit wird sichergestellt,

dass die Sicherheit des Werkzeuges erhalten bleibt.

12

Page 14

Kettenzug282517

Sicherheitshinweise für

Hebezeuge

Werkzeug überprüfen

• Überprüfen Sie vor dem Gebrauch stets den Zustand des Werkzeugs.

Achten Sie dabei insbesondere auf Drahtseile, Schließmechanismen und

Hydraulikverschraubungen. Drahtseile dürfen keine Knicke oder Anzeichen

von Einschnitten oder Ausreißen aufweisen. Schließmechanismen müssen

frei arbeiten sowie frei von übermäßigem Schmutz und Schmierfett sein.

Hydraulikverschraubungen müssen sich in einwandfreiem Zustand befinden

und leckfrei sein.

• Alle zusätzlichen Stützvorrichtungen müssen in der Lage sein, das gesamte

Gewicht der zu hebenden Last zu tragen sowie über eine gewisse zusätzliche

Kapazität als Sicherheitsreserve verfügen.

• Alle Schutzeinrichtungen (einschließlich automatische) müssen vor dem

Gebrauch geprüft werden.

• Überprüfen Sie, dass die Haken intakt sind. Falls ein Haken um mehr als 10°

verbogen ist oder eine übermäßige Halsöffnung aufweist, muss er ersetzt

werden.

• Überprüfen Sie, dass keine der Sicherheitsverriegelungen an den Haken

beschädigt oder verbogen ist. Die Sicherheitsverriegelungen müssen die

Hakenöffnungen vollständig verschließen.

• Falls ein Teil des Hebezeugs beschädigt oder verschlissen ist, muss es vor dem

Gebrauch von einer autorisierten Fachwerkstatt gegen ein Originalersatzteil

ausgetauscht werden.

• Hebezeuge müssen mindestens einmal jährlich von qualifiziertem Fachpersonal

überprüft werden. Die Untersuchungsergebnisse sollten zur späteren Einsicht in

einem Inspektionsbuch aufgezeichnet werden.

• Die Bremse des Hebezeugs darf niemals mit Öl oder Fett in Berührung kommen.

• Hebezeuge dürfen nicht modifiziert werden. Jeder Versuch, dieses Gerät

zu manipulieren, führt zum Erlöschen der Garantie und kann ernsthafte

Verletzungen der eigenen Person oder in der Nähe befindlicher Personen

verursachen.

Hebezeug positionieren

• Positionieren Sie das Hebezeug in einem geeigneten, gut beleuchteten

Arbeitsbereich.

• Halten Sie den Arbeitsbereich sauber und ordentlich sowie frei von nicht

benötigten Gegenständen.

• Verwenden Sie ein Hebezeug niemals in nasser, explosiver oder korrosiver

Umgebung.

Anschlagen einer Last

• Lasten dürfen nur an den entsprechenden Hebepunkten angeschlagen/

abgestützt werden.

• Winden/Hebeböcke dürfen nicht in Verbindung mit anderen Hebezeugen

eingesetzt werden.

• Es muss stets freier Hub der Last gewährleistet sein. Wenn die Last sich

verfängt oder während des Hebevorgangs behindert wird, führt dies zur

Überlastung des Hebezeugs.

• Hängen Sie eine Last immer nur so an, dass sie vor und während des gesamten

Hebevorgangs stabil gelagert ist.

• Wickeln Sie die Kette niemals um eine Last und benutzen Sie die Lastkette

keinesfalls als Schlinge.

Gefahrenbereich

• Beim Anheben jedweder Last ist der Bereich direkt unterhalb sowie ein

angemessener Bereich um die Last herum immer als überaus gefährlich

anzusehen. Betreten Sie diesen Bereich nicht, und reichen Sie auch nicht in den

Bereich hinein, bis die Last ausreichend abgestützt ist.

• Hebezeuge müssen von einer Position aus bedient werden, in welcher der

Bediener keiner Gefahr durch möglicherweise fallende Lasten ausgesetzt ist

(d.h. außerhalb des Gefahrenbereichs).

• Der Bediener sowie in der Nähe des Gefahrenbereichs befindliche Personen

müssen Kopfschutz (z.B. Schutzhelm) und Sicherheitsschuhe tragen.

• Verwenden Sie Hebezeuge niemals zur Beförderung von Personen.

Während des Hebevorgangs

• Der Bediener muss während des gesamten Hebevorgangs ein Auge auf die Last

haben. Falls sich dies als für den Bediener nicht praktikabel erweisen sollte,

dann muss der Gefahrenbereich abgeriegelt werden. In diesem Fall müssen

andere Personen mit voller Sicht auf den Arbeitsbereich eingesetzt werden, um

Anweisungen an den Bediener zu übermitteln.

• Hebezeug darf nur von Personen bedient werden, die mit der

Bedienungsanweisung vollständig vertraut sind.

• Nehmen Sie keine abrupten Wechsel zwischen Anheben und Absenken vor.

Lassen Sie die Last zum völligen Stillstand kommen, bevor Sie die Richtung

ändern.

• Brechen Sie den Vorgang unverzüglich ab, wenn das Hebezeug eine Last nicht

anzuheben vermag. Die Hublastkapazität ist dann überschritten worden.

• Bedenken Sie beim Absenken einer Last, dass eine Last gewöhnlich noch einige

Zentimeter weiterläuft, nachdem der Mechanismus angehalten wurde.

• Hebezeug darf nur für senkrechtes Heben und keine anderen Tätigkeiten

benutzt werden.

• Heben Sie Gegenstände nicht höher als absolut notwendig.

• Lassen Sie eine angehobene Last niemals unbeaufsichtigt in der Luft.

• Sollten Sie in irgendeiner Weise unsicher bezüglich der sicheren Benutzung

dieses Geräts sein, verwenden Sie es nicht.

Produktübersicht

1 Oberhaken

2 Kettenzug

3 Handkette

4 Lasthaken

5 Hakensicherung

6 Lastkette

Bestimmungsgemäße

Verwendung

Tragbarer, handbetätigter Kettenzug zum senkrechten Anheben von Lasten.

Dieses Werkzeug ist ausschließlich für kurzzeitige Einsätze konzipiert und darf

nicht zur dauerhaften Aufhängung von Lasten verwendet werden. Nicht für den

gewerblichen Gebrauch.

Auspacken des Werkzeugs

• Packen Sie Ihr Werkzeug vorsichtig aus und überprüfen Sie es. Machen Sie sich

vollständig mit all seinen Eigenschaften und Funktionen vertraut.

• Vergewissern Sie sich, dass sämtliche Teile des Werkzeugs vorhanden und in

einwandfreiem Zustand sind. Sollten Teile fehlen oder beschädigt sein, lassen

Sie diese ersetzen, bevor Sie das Werkzeug verwenden.

Vor Inbetriebnahme

Befestigen des Kettenzugs

WARNUNG! Sorgen Sie dafür, dass der Kettenzug an einer Konstruktion

angebracht wird, die mindestens das Eineinhalbfache der Kettenzugtraglast

tragen kann.

• Bringen Sie den Kettenzug so an, dass sich das untere Ende der Handkette 10

bis 50 cm über dem Boden befindet.

• Der Benutzer muss sich seitlich zur Last stellen und in der Lage sein, die

Handkette aus dieser Position sicher zu bedienen.

Anschlagen der Last

WARNUNG! Benutzen Sie die Kette nicht als Schlinge, da dies die Kette

beschädigen könnte.

• Hängen Sie die anzuhebende Last mittels Hebebändern, Ketten oder anderer

für die Art, Form und das Gewicht der Last geeigneter Anschlagmittel in den

Lasthaken (4) ein (siehe Abb. 1).

• Zentrieren Sie die Last richtig am Lasthaken (siehe Abb. 1).

www.silverlinetools.com

13

Page 15

D

WARNUNG!

• Hängen Sie die Last niemals vor die Hakensicherung (5) (Abb. 3-A).

• Hängen Sie die Last niemals an die Hakenspitze (Abb. 3-B).

• Hängen Sie die Last niemals außerhalb des Hakenschwerpunktes ein (Abb. 3-C).

• Hängen Sie die Last niemals seitlich in den Haken ein (Abb. 3-D).

WARNUNG! Vergewissern Sie sich stets, dass der Oberhaken (1) ordnungsgemäß

befestigt und die Hakensicherung geschlossen ist.

Bedienung

Hinweis: Dieses Hebemittel darf nur von entsprechend geschulten Personen

betrieben werden. Unerfahrene Benutzer müssen zunächst sorgfältig in der

Verwendung des Werkzeugs untergewiesen werden. Vor der Durchführung von

Hebevorgängen muss stets eine Gefährdungsbeurteilung durchgeführt werden.

WARNUNG! Tragen Sie stets für den Arbeitsbereich und die jeweilige Lastart

angemessene persönliche Schutzausrüstung, darunter u.a. Augenschutz,

Schutzhandschuhe, Schutzhelm, Sicherheitsschuhe und Gehörschutz.

Anheben der Last

WARNUNG! Halten Sie Umstehende stets aus dem unmittelbaren Arbeitsbereich

fern. Kündigen Sie Beginn und Ende des Hebevorgangs klar und deutlich an.

Achten Sie darauf, dass sich niemand jemals unter einer angehobenen Last

befindet.

WARNUNG! Heben und senken Sie die Last auf kontrollierte und ruckfreie Weise.

Vermeiden Sie unbedingt, selbst über kurze Strecken, dass die angehängte Last

frei fällt, weil der Kettenzug dadurch Stoßbelastungen ausgesetzt würde. Die Kette

muss frei laufen und darf sich nicht verdrehen.

WARNUNG! Die Bremse kann während länger andauernder Nutzung des

Kettenzugs heiß werden. Unterbrechen Sie in diesem Fall den Betrieb des

Werkzeugs in regelmäßigen Abständen, damit die Bremse nicht überhitzt.

1. Ziehen Sie die Handkette (3) ohne ruckartige Bewegungen an, bis die

Lastkette (6) gespannt ist. Vergewissern Sie sich, dass der Kettenzug

senkrecht ausgerichtet ist (d.h. er darf nicht in schräger Richtung ziehen).

2. Beginnen Sie, die Last zu heben. Vergewissern Sie sich, dass sie waagerecht

liegt und keine Gefahr besteht, dass die Last kippen und/oder von ihren

Halterungen abrutschen könnte.

3. Falls erforderlich, senken Sie die Last ab und passen Sie die Hebebänder neu

an, um die Last sicher und waagerecht zu heben.

4. Halten Sie die Last bei etwa 10 cm an, um zu prüfen, ob die Bremse die Last

halten kann.

5. Heben Sie die Last dann weiter langsam und in kontrollierter Weise bis auf

die gewünschte Höhe an. Ziehen Sie sie nur so hoch, dass der Lasthaken (4)

nicht mit dem Kettenzug (2) in Berührung kommt.

6. Ziehen Sie zum Senken der Last die gegenüberliegende Seite der Kette nach

unten. Lassen Sie die Last wiederum ruckfrei und langsam herab und achten

Sie darauf, dass die Lastkette nicht auf ihre ganze Länge ausgezogen wird.

Zubehör

• Weitere Anschlagmittel und entsprechendes Zubehör einschließlich

Hebebändern können über Ihren Silverline-Fachhändler bezogen werden.

Instandhaltung

Hinweis: Sämtliche Anschlagmittel müssen regelmäßig durch eine sachkundige

Person in Übereinstimmung mit den geltenden gesetzlichen Bestimmungen

und Verordnungen (wie Vorschriften zu Lastaufnahmeeinrichtungen)

kontrolliert und gewartet werden. Wartungsarbeiten müssen in einem

entsprechenden Wartungsnachweis verzeichnet werden (siehe Beispiel in dieser

Gebrauchsanleitung).

WARNUNG! Führen Sie bei jedem Einsatz des Kettenzugs eine Sichtprüfung durch

und achten Sie darauf, ob Sie während des Betriebs ungewöhnliche Geräusche

wahrnehmen. Eine eingehende Prüfung muss vorgenommen werden, wenn

das Werkzeug über einen längeren Zeitraum nicht zum Einsatz kam. Werden

Schäden festgestellt, muss das Werkzeug sofort aus dem Verkehr gezogen und

einer zugelassenen Silverline-Werkstatt zur Reparatur übergeben werden. Ist

das Werkzeug irreparabel beschädigt, ist es nicht mehr zu verwenden und muss

entsorgt werden.

WARNUNG! Überprüfen Sie den Bremsmechanismus vor jedem Gebrauch.

WARNUNG! Dieses Werkzeug enthält keine vom Benutzer wartbaren Teile. Den

Kettenzug niemals demontieren. Wartungsarbeiten und Reparaturen dürfen nur von

zugelassenen Silverline-Werkstätten durchgeführt werden.

Silverline Tools Garantie

Reinigung

• Halten Sie Ihr Gerät stets sauber. Durch Staub und Schmutz verschleißen die

inneren Teile schnell und die Lebensdauer des Gerätes wird verkürzt. Säubern

Sie das Gerätegehäuse mit einer weichen Bürste oder einem trockenen Tuch.

Die Lüftungsöffnungen (wenn vorhanden) mit sauberer, trockener Druckluft

reinigen, sofern verfügbar.

Schmierung

• Schmieren Sie alle beweglichen Teile in regelmäßigen Abständen mit einem

geeigneten Sprühschmiermittel.

• Halten Sie den Kettenzug sauber und schmieren Sie die Lastkette und beide

Lasthakenschenkel regelmäßig.

WARNUNG! Öl und Fett dürfen niemals mit dem Bremsmechanismus in Berührung

kommen!

Lagerung

• Gerät an einem sicheren, trockenen Ort außerhalb der Reichweite von Kindern

lagern.

Entsorgung

• Werkzeuge können Öl und Spuren anderer Schmiermittel sowie Schadstoffe

enthalten. Werkzeuge dürfen daher niemals über den Hausmüll entsorgt

werden.

• Lassen Sie sich von der zuständigen Behörde bezüglich der ordnungsgemäßen

Entsorgung dieses Werkzeugs beraten.

FALSCH

Abbildung1

A

C

RICHTIG

B

D

Abbildung 2

14

Page 16

Silverline-Tools-Garantie

Dieser Silverline-Artikel wird mit einer

3-Jahres-Garantie angeboten

Registrieren Sie diesen Artikel unter silverlinetools.com innerhalb von 30

Tagen nach dem Kauf, um die 3-Jahres-Garantie zu aktivieren.

Der Garantiezeitraum beginnt mit dem Kaufdatum auf Ihrem Kaufbeleg.

Garantiebedingungen

Der Garantiezeitraum beginnt mit dem Kaufdatum im Einzelhandel, das auf

dem Kaufbeleg angegeben ist.

BITTE BEWAHREN SIE DEN KAUFBELEG AUF!

Falls dieser Artikel innerhalb von 30 Tagen nach dem Kauf einen Defekt

aufweisen sollte, bringen Sie es bitte mit Ihrem Kaufbeleg zu dem

Fachhändler, bei dem es gekauft wurde, und informieren Sie ihn über die

Mängel. Das Gerät wird daraufhin ersetzt oder der Kaufpreis zurückerstattet.

Falls dieser Artikel nach Ablauf von 30 Tagen nach dem Kauf einen Mangel

aufweist, senden Sie es bitte an:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Großbritannien

Der Garantieanspruch muss während der Garantiezeit gestellt werden.

Sie müssen den Originalkaufbeleg mit Angabe des Kaufdatums einreichen

und Ihren Namen und Ihre Adresse sowie den Ort des Kaufs angeben, bevor

etwaige Arbeiten durchgeführt werden können.

Sie müssen genaue Angaben über den zu behebenden Defekt machen.

Alle innerhalb der Garantiefrist gemachten Forderungen werden von Silverline

Tools daraufhin überprüft werden, ob es sich bei den Mängeln um einen

Material- oder Fertigungsfehler handelt.

Versandkosten werden nicht zurückerstattet. Alle Artikel sollten sich in

sauberem und sicherem Zustand befinden und sorgfältig verpackt zur

Reparatur eingeschickt werden, um Schäden oder Verletzungen während des

Transports zu vermeiden. Die Annahme unangemessener oder unsicherer

Lieferungen kann von uns verweigert werden.

Alle Arbeiten werden von Silverline Tools oder seinen autorisierten

Reparaturwerkstätten durchgeführt.

Die Reparatur oder der Ersatz des Artikels führt nicht zur Verlängerung des

Garantiezeitraums.

Mängel, bei denen unsere Prüfung ergibt, dass sie unter die Garantie fallen,

werden durch kostenlose Reparatur des Werkzeugs (ohne Versandkosten)

oder Ersatz durch ein Werkzeug in einwandfreiem Zustand behoben.

Kettenzug282517

Registrierung Ihres Kaufs

Gehen Sie auf silverlinetools.com, klicken Sie auf „Registrierung“’ und geben

Sie Folgendes ein:

• Ihre persönlichen Angaben

• Produktdetails und Kaufinformationen

Sobald dieser Artikel registriert worden ist, wird Ihre Garantiebescheinigung

im PDF-Format erzeugt. Bitte drucken Sie sie aus und bewahren Sie sie

zusammen mit Ihrem Produkt auf.

Einbehaltene Werkzeuge oder Teile, die ersetzt wurden, gehen in den Besitz

von Silverline Tools über.

Die Reparatur bzw. der Ersatz Ihres Artikels unter dieser Garantie erfolgt

zusätzlich zu Ihren gesetzlichen Rechten als Verbraucher und hat keine

nachteiligen Folgen auf diese.

Durch die Garantie abgedeckt ist:

Die Reparatur des Artikels, nachdem zur Zufriedenheit von Silverline Tools

nachgewiesen wurde, dass der Defekt durch fehlerhaftes Material oder

mangelhafte Arbeitsausführung bedingt ist und in den Garantiezeitraum fällt.

Wenn ein Ersatzteil nicht mehr erhältlich ist oder nicht mehr hergestellt wird,

kann Silverline Tools es gegen einen funktionellen Ersatz austauschen.

Verwendung des Artikels innerhalb der EU.

Durch die Garantie nicht abgedeckt ist:

Silverline Tools garantiert keine Reparaturen, die durch Folgendes

erforderlich geworden sind:

Normale Verschleißerscheinungen, die trotz Verwendung entsprechend

der Bedienungsanleitung entstehen, z.B. an Messern, Bürsten, Riemen,

Glühbirnen, Batterien usw.

Ersatz von mitgeliefertem Zubehör wie etwa Bohrspitzen, Klingen,

Schleifblättern, Schneidscheiben und anderen zugehörigen Teilen.

Unfallschäden und Fehler, die durch unsachgemäße Verwendung oder

Wartung, Missbrauch, Nachlässigkeit oder fahrlässige Bedienung oder

Handhabung des Artikels entstanden sind.

Verwendung des Artikels für andere als normale Haushaltszwecke.

Jegliche Veränderungen oder Modifikationen des Artikels.

Die Verwendung von Teilen oder Zubehör, die keine Originalkomponenten

von Silverline Tools sind.

Fehlerhafte Montage (außer, wenn von Silverline Tools vorgenommen).

Reparaturen oder Änderungen, die von anderen als Silverline Tools oder

seinen autorisierten Reparaturwerkstätten durchgeführt wurden.

Ansprüche, die über die Rechte zur Behebung von Mängeln an dem in

diesen Garantiebedingungen genannten Werkzeug hinausgehen.

EU-Konformitätserklärung

Name des Unterzeichners: Mr. Darrell Morris

Bevollmächtigt durch: Silverline Tools

Erklärt hiermit, dass das Produkt:

Ident.-Nr.: 282517

Produktbeschreibung: Kettenzug

Den folgenden Richtlinien entspricht:

• Maschinenrichtlinie 2006/42/EG

• EN 13157+A1:2009

Benannte Stelle: TÜV Rheinland, Nürnberg, Deutschland

Techn. Unterlagen bei: Silverline Tools

Datum: 24.01.2014

Unterzeichnet von:

Geschäftsführender Direktor

Name und Anschrift des Herstellers oder seines niedergelassenen

Bevollmächtigten:

Powerbox International Ltd, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ, Großbritannien

www.silverlinetools.com

15

Page 17

ESP

Descripción de los símbolos

Los símbolos siguientes pueden aparecer en la placa de características de su

herramienta. Éstos representan información importante sobre el producto o

instrucciones relativas a su uso

Lleve protección auditiva

Lleve protección ocular

Lleve protección respiratoria

Lleve un casco de seguridad

Lleve guantes de seguridad

Lea el manual de instrucciones

Conforme a las normas de seguridad y la legislación

correspondiente.

Características técnicas

Límite de carga de trabajo (WLL):............... ................ 5.000 kg

Altura estándar de elevación: ...................................... 3.000 mm

Elevación máxima del anclaje: .................................... 2,7 m

Distancia mínima entre ganchos: ................................ 600 mm

Esfuerzo máximo requerido para elevar la carga: ....... 382 N

Dimensiones de la cadena de carga ........................... 10 x 30 mm

Diámetro del cárter: .................................................... 210 mm

Grosor del cárter: ........................................................ 165 mm

Anchura de la boca del gancho: .................................. 50 mm

Peso neto: ................................................................... 29,6 kg

Temperatura de funcionamiento: ................................-10 a + 50° C

Como parte de nuestra política de desarrollo de productos, los datos técnicos de

los productos Silverline pueden cambiar sin previo aviso.

Instrucciones generales de

seguridad

ADVERTENCIA: Lea siempre el manual de instrucciones y las advertencias de

seguridad. No seguir estas advertencias e instrucciones puede causar descargas

eléctricas, incendios y/o lesiones graves.

ADVERTENCIA: No permita que los niños, personas discapacitadas

o personas no cualificadas utilicen esta herramienta. Mantenga esta

herramienta fuera del alcance de los niños.

Conserve estas instrucciones de seguridad para futuras referencias.

1) Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas de

trabajo desordenadas y oscuras son peligrosas y pueden provocar un

accidente.

b) No utilice herramientas eléctricas en atmósferas explosivas que

contengan líquidos, gases o polvos inflamables. Las herramientas

eléctricas producen chispas que pueden incendiar el polvo o los vapores.

c) Mantenga alejados a los niños y personas que se encuentren a su

alrededor mientras esté trabajando con una herramienta eléctrica. Las

distracciones pueden hacerle perder el control de la herramienta.

2) Manténgase alerta

a) fíjese en lo que está haciendo y use el sentido común cuando esté

utilizando una herramienta eléctrica. No use una herramienta eléctrica

si se encuentra cansado o bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracción mientras esté utilizando una

herramienta eléctrica puede provocar lesiones corporales graves.

b) Utilice siempre equipo de protección personal. Use siempre protección

ocular. El uso de dispositivos de seguridad personal (máscara antipolvo,

calzado de seguridad antideslizante, casco resistente y protecciones

auditivas adecuadas) reducirá el riesgo de lesiones corporales.

c) Retire todas las llaves de ajuste antes de encender la herramienta

eléctrica. Una llave enganchada en una parte móvil de la herramienta

eléctrica puede causar lesiones graves.

d) No adopte posturas forzadas. Manténgase en posición firme y en

equilibrio en todo momento. De este modo, podrá controlar mejor la

herramienta eléctrica en situaciones inesperadas.

e) Vístase adecuadamente. No lleve ropa holgada ni joyas. Mantenga el

pelo, la ropa y guantes alejados de las piezas móviles. La ropa holgada,

las joyas o el pelo largo pueden quedar atrapados en las piezas móviles.

3) Uso y mantenimiento

IMPORTANTE: Las herramientas utilizadas en exteriores deben limpiarse

regularmente y tratarse con productos anticorrosión. Para mantener la herramienta

en buen estado, lubrique las piezas móviles con grasa o aceite adecuado.

a) Revise regularmente sus herramientas eléctricas. Compruebe que

no haya piezas en movimiento mal alineadas o trabadas, piezas

rotas o cualquier otro problema que pueda afectar el funcionamiento

de la herramienta eléctrica. Si hay alguna pieza dañada, repare la

herramienta antes de volver a utilizarla.

La mayoría de accidentes son causados por herramientas eléctricas que

carecen de un mantenimiento adecuado.

b) Las herramientas de corte deben estar siempre afiladas y limpias.

Las herramientas de corte correctamente afiladas son menos propensas a

trabarse y son más fáciles de controlar.

c) Utilice la herramienta eléctrica y los accesorios siguiendo el manual

de instrucciones y teniendo en cuenta las condiciones y el trabajo

que necesite realizar. El uso de la herramienta eléctrica con un propósito

distinto al cual ha sido diseñada, podría ser peligroso.

4) Mantenimiento

a) Repare siempre su herramienta eléctrica en un servicio técnico

autorizado. Utilice únicamente piezas de recambio idénticas y

homologadas. Esto garantizará un funcionamiento óptimo y seguro de su

herramienta eléctrica.

16

Page 18

Polipasto manual de cadena282517

Instrucciones de seguridad para

herramientas de elevación

Inspeccione el equipo

• Antes de usarlo, compruebe siempre el estado del equipo, prestando especial

atención a los cables, mecanismos de bloqueo y racores hidráulicos. Los

cables deben estar libres de cocas y no deben estar desgastados o cortados.

Los mecanismos de bloqueo deben funcionar sin obstrucciones y no tener

suciedad o grasa excesiva. Los racores hidráulicos deben estar en buen estado

y sin fugas.

• Todos los apoyos adicionales deben poder soportar el peso completo del objeto

a elevar, más un margen de peso adicional como medida de seguridad.

• Todos los dispositivos de seguridad (incluyendo los automáticos) deben

probarse antes de su uso.

• Compruebe que los ganchos sean funcionales. Una distorsión de 10° del

gancho o una boca de gancho excesivamente ensanchada indican que el

gancho ha de cambiarse.

• Compruebe que los pestillos de seguridad están en buen estado y que cierran

completamente la boca del gancho.

• Si cualquier parte del equipo de elevación resulta dañada o desgastada, deberá

repararse con recambios originales en un centro de servicio autorizado antes

de poder usarla.

• El equipo de elevación debe ser inspeccionado por una persona cualificada por

lo menos una vez al año, tomando nota del resultado en el libro de inspección

como futura referencia.

• El freno del equipo de elevación nunca debe entrar en contacto con la grasa o

los lubricantes.

• No modifique ninguna parte del equipo. Cualquier intento de modificar el equipo

invalidará la garantía y podría ser causa de lesiones serias para usted o para las

personas que le rodeen.

Ubicación del equipo de elevación

• Sitúe el equipo de elevación en un lugar adecuado y bien iluminado.

• Mantenga la zona de trabajo limpia y ordenada, y libre de objetos innecesarios.

• Nunca utilice el equipo de elevación en entornos húmedos, explosivos o

corrosivos.

Sujeción de la carga

• La carga debe sujetarse / soportarse sólo en los puntos de elevación previstos.

• Los cabrestantes / elevadores no deben usarse en combinación con ningún otro

dispositivo de elevación.

• La carga no debe nunca sujetarse de forma que impida su elevación. Si la carga

se engancha o si se restringe su elevación, se producirá sobrecarga del equipo

de elevación.

• Sujete siempre la carga de forma que esté estable durante todo el proceso

de elevación.

• Nunca envuelva la cadena alrededor de la carga, y nunca utilice la cadena

como una eslinga.

Área de peligro

• Siempre que se alce un objeto, la zona directamente debajo y alrededor del

objeto se considerará altamente peligrosa. No entre en esta zona.

• El equipo de elevación debe utilizarse desde un lugar donde el operario no

corra ningún riesgo de que se le caiga la carga encima (es decir, fuera de la

zona de peligro).

• El operario y cualquier persona que se encuentre en la zona de peligro deben

utilizar protecciones para la cabeza (casco) y para los pies.

• En equipo de elevación no debe utilizarse para elevar personas bajo ninguna

circunstancia.

Durante la elevación