Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

Conditions Générales d’utilisation

3 Jahre Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

www.silverlinetools.com

3 años de garantía

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 Jaar Garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassing

Page 2

R

E

L

I

V

N

L

I

S

POWER

R

E

E

A

G

N

43cc Petrol Brush Cutter

267969

2-Stroke

43cc Petrol Brush Cutter

Débroussailleuse à essence 43cm

43-cm³-Benzin-Motorsense

Desbrozadora de gasolina 43 cm³

Decespugliatore a petrolio 43 cm³

43 cm³ benzine bosmaaier

www.silverlinetools.com

3

Page 3

4

6

3

2

1

5

7

12

11

13

10

8

9

2

Page 4

2-Stroke

43cc Petrol Brush Cutter

English .................. 4

Français ................ 8

Deutsch ................. 12

®

Español ................. 16

Italiano .................. 20

Nederlands ............ 24

www.silverlinetools.com

3

Page 5

GB

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent

important information about the product or instructions on its use.

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Wear hand protection

Read instruction manual

This product emits poisonous fumes

Conforms to relevant legislation and safety

standards

Environmental Protection

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your local authority or retailer for recycling advice

Specification

Engine Displacement: ..............42.7cc

Engine type: .............................2 stroke

Max engine power: ..................1.25kW at 6500rpm

Fuel: .......................................Unleaded petrol /

2 stroke oil mix

(40:1)

Fuel tank capacity: ..................1 litre

Spark plug type: ......................LD L7T, 0.7mm gap

No load speed: ........................9000rpm

Idling speed: ............................2800rpm

Cutting width: .........................255mm blade

440mm spool

Weighted vibration: ..................3.687m/s²

Uncertainty: ............................1.5m/s

Sound pressure: ......................87.7dB(A)

Sound power: .........................112dB(A)

Uncertainty: ............................3dB

Weight (kg): ............................9kg

The sound intensity level for the operator may exceed 85dB(A) and

sound protection measures are necessary.

As part of our ongoing product development, specifications of

Silverline products may alter without notice.

2

General Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for future reference.

Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents

b) Do not operate tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust

c) Keep children and bystanders away while operating a powered

tool. Distractions can cause you to lose control

Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating a powered tool. Do not use a powered tool

while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating a powered tool

may result in serious personal injury

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate conditions will reduce

personal injuries

c) Prevent unintentional starting. Ensure the switch is in the off-

position when not operating the tool and make use of other safety

features which prevent unintentional starting

d) Remove any adjusting key or wrench before turning the powered

tool on. A wrench or a key left attached to a rotating part of the tool

may result in personal injury

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the tool in unexpected situations

f) Dress properly. Do not wear loose clothing or jewelry. Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving parts

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards

WARNING: User exposure to tool vibration can result in loss of sense of

touch, numbness, tingling and reduced ability to grip. Long term exposure

can lead to a chronic condition. If necessary limit the length of time exposed

to vibration. Use the figures provided in the specification relating to vibration

if provided to calculate the duration and frequency of operating the tool.

The 2002/44/EC directive relating to vibration in the workplace may provide

useful information even for domestic use of tools. In the first instance of

feeling uncomfortable due to vibration STOP using the tool immediately.

WARNING: Always wear ear protection where the sound level exceeds

80dB and limit the time of exposure if necessary. If sound levels are

uncomfortable even with ear protection stop using the tool immediately and

check the ear protection is correctly fitted and provides the right level of

sound attenuation for the level of sound produced by your tool.

Tool use and care

a) Maintain tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect

the tool’s operation. If damaged, have the tool repaired before

use. Many accidents are caused by poorly maintained tools

b) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

to control

c) Use the tool’s accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions

and the work to be performed. Use of the tool for operations

different from those intended could result in a hazardous situation

Service

a) Have your tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the

tool is maintained

4

4

Page 6

43cc Petrol Brush Cutter267969

Internal Combustion Safety

Dangerous environment

• Do not use petrol tools in damp or wet conditions, or expose them to rain.

Provide adequate surrounding work space and keep area well lit.

• Do not use petrol tools where there is a risk of explosion or fire from

combustible material, flammable liquids, flammable gases, or dust of an

explosive nature

Switch off

• Ensure that the engine has stopped before attaching any accessories

to the tool.

• If the tool stops unexpectedly ensure that the power is switched off and

the engine is not running before attempting to check the tool

Running-in the engine

• New tools should be used at moderate speed

• Do not maintain high engine speed until the engine is completely run-in

• The engine will not be capable of developing maximum power until the

end of the running-in period

• When first using the tool, periodically stop and check that all nuts and

screws are securely fastened and tighten them as necessary

• Do not use fuels containing methanol or ethanol, as these may cause

internal damage to the fuel tank and fuel lines

Warning

• Never leave the tool running unattended

• Never leave the machine unattended when parts are still hot

Servicing

• We recommended that your tool is serviced shortly after its first use

• In normal use, have the tool serviced regularly

• Do not modify any of the components of this tool. To do so would

invalidate your guarantee, and could result in injury to yourself or others

around you

• Always have your tool serviced at an authorized service centre

Storage

• Clean the tool completely after use

• Be careful not to damage the fuel tank, or fuel lines, when it is placed

on the ground

• Ensure that the tool will not be subject to impact damage; any damage

could cause the tool to become unsafe

• Store the tool away from direct sunlight

• Ensure that fuel and oil is stored in a safe place, away from heat, direct

sunlight or any source of ignition

• Whenever the machine is likely to be out of use for an extended period of

time, proceed as follows:

• Empty the fuel tank completely

• Protect all metal engine parts from corrosion by coating them with oil

• Remove the spark plug, put a few drops of oil into the cylinder and then

pull the recoil starter 2 to 3 times in order to distribute the oil evenly

• Replace the spark plug

• Never store the machine where children may gain access to it

THIS PRODUCT PRODUCES POISONOUS EXHAUST FUMES AS SOON AS

THE ENGINE IS RUNNING. THESE GASES MAY BE COLOURLESS AND

ODOURLESS. TO REDUCE THE RISK OF SERIOUS OR FATAL INJURY,

NEVER RUN THE MACHINE INDOORS, OR IN POORLY VENTILATED

AREAS. ENSURE PROPER VENTILATION WHEN WORKING IN TRENCHES

OR OTHER CONFINED SPACES.

Brush Cutter

& Line Trimmer Safety

WARNING: Petrol fumes are combustible, DO NOT SMOKE when handling/

using this tool

• Always check the work area for hidden objects, fencing, cables etc.

Ensure that material to be cut does not contain any objects. Be sure that

it is safe to cut before starting the job

• Always wear appropriate safety equipment. Use of this tool requires

gloves, eye or face protection, dust mask, ear defenders, hard hat, and

sturdy clothing

• Assess your own physical condition. Using a brush cutter, even a smaller

model, is physically demanding. Do not start a job unless you are

confident that you are fit and strong enough to complete it. Never use

a brush cutter when tired, unwell, or under the influence of any kind of

drugs or alcohol

• Check that other people are a safe distance away from the work area

before starting to cut. Never allow children or pets near to the work area

• Do not use this product in wet conditions. Ensure that material to be cut

is dry before starting work

• Do not use this tool if any guards are missing or damaged

• This tool should only be used in an upright position, with the spool or

blade close to the ground

• Walk slowly when carrying this tool. Freshly cut grass or brush is slippery,

and may conceal trip hazards

• Only use correct nylon trimmer line or specialist blades. Attempting to

use any other kind of cutting accessory is highly dangerous

• Never pass arms or legs near to the blade when cutting. Always stand in

a stable position, well back from the cutting area

• If the brush cutter jams, switch off immediately. Allow the engine to

completely stop before attempting to clear jammed material

• Be prepared for the possibility of kickback. In some circumstances, if

used incorrectly, the brush cutter may be thrown back towards the user.

Correct use and regular maintenance will significantly reduce the chance

of kickback occurring

• Do not work alone. Ensure that there is someone nearby to help in an

emergency

• Always stop the tool before crossing gravel paths or roads

www.silverlinetools.com

www.silverlinetools.com

5

5

Page 7

GB

GB

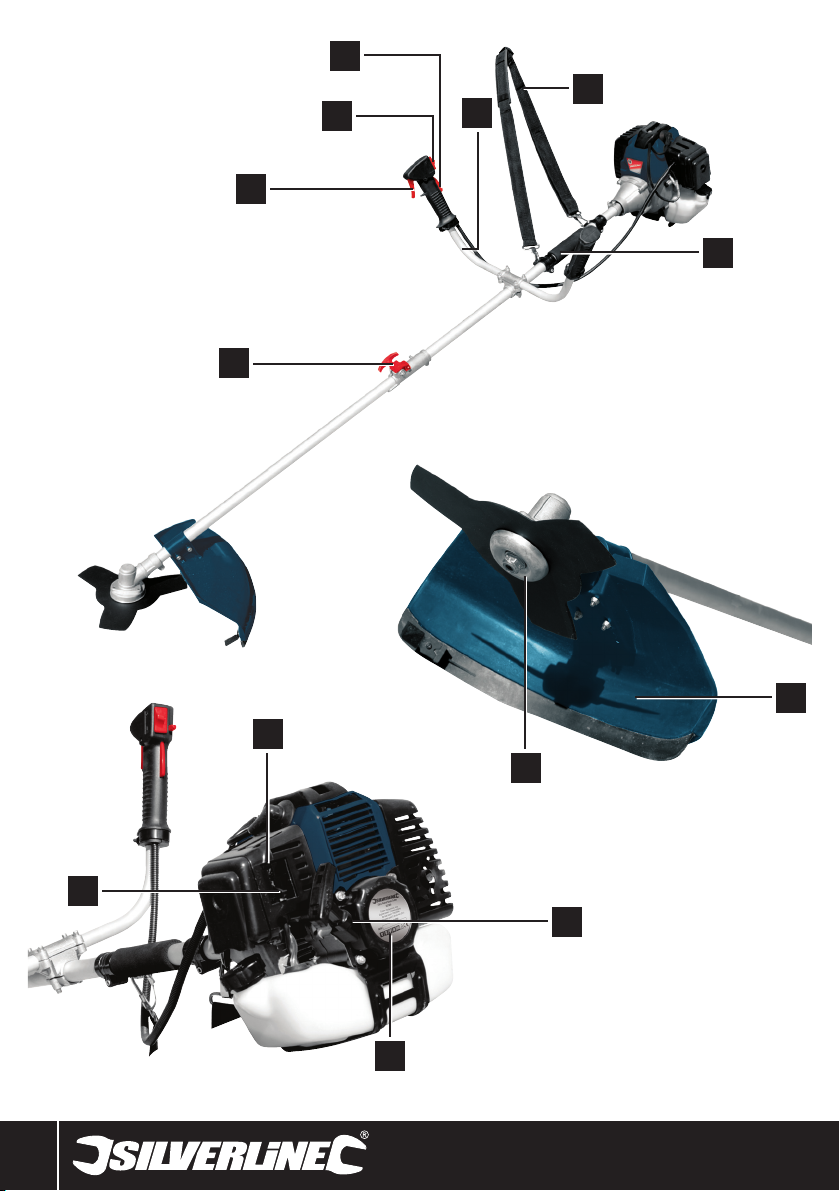

Product Familiarisation

1 Split Shaft Coupler

2 Trigger Throttle

3 Ignition Switch

4 Safety Switch

5 Bull Handle

6 Shoulder Strap

7 Main Handle

8 Recoil Starter

9 Fuel Cap

10 Choke Lever

11 Idle Adjustment Screws

12 Blade Guard

13 Spindle

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all

its features and functions

• Ensure that all parts of the tool are present and in good condition. If

any parts are missing or damaged, have such parts replaced before

attempting to use this tool

Assembling Your Brush Cutter

• Ensure that all parts of your brush cutter are present and in good

condition. If any part is missing, or damaged, have such parts replaced

before attempting to use this tool

Connect the shaft

1. Loosen the coupler fastening knob

2. Slide the shaft into the Coupler (1) and ensure that the

patterned shaft has fully engaged

3. Tighten the coupler fastening knob and check that the shaft is

correctly engaged and cannot fall out

Fitting the blade guard

• Attach the Blade Guard (12) to the shaft using the supplied bolts

Fitting the bull handle

• Attach the Bull Handle (5) to the brush cutter using the supplied bolts

Fitting the spool

NOTE: The spool is a left-handed screw-fit onto the spindle

1. Remove the blade bush and locking nut

2. Secure the spindle by putting a hex key through the locking hole

located on the spindle housing

3. Tighten the spool by hand - do not over-tighten

NOTE: The spool does not need to be tightened by a tool

Fitting the blade

1. Secure the spindle by putting a hex key through the lockinghole

located on the spindle housing

2. Loosen the locking nut by rotating it clockwise (left-handed nut)

3. Locate the blade onto the spindle bush ensuring that the blade rotation

matches the direction of the shaft rotation

4. Tighten the securing nut by rotating it anti-clockwise

Before Use

WARNING: Make sure a suitable fire extinguisher is available and nearby

when filling and operating this tool. Also there may be highly flammable

materials you may encounter in use like dry vegetation.

Fuelling

• Always refuel in a safe place, well away from the work area and any

source of heat or ignition. Avoid contact with the fuel. DO NOT SMOKE

• Only add fuel when the engine is stationary, and has cooled completely

• Fuel should always be pre mixed, do not mix fuel in the petrol tank. Only

mix as much fuel as you intend to use. Use 40 parts unleaded petrol to

every 1 part 2-stroke oil. Always use 2-stroke oil

Note: It is recommended to use a 25:1 fuel/oil mix for the first 5-10 fills as

you run in the engine.

• Remove the Fuel Cap (9). Fill the tank with fuel mixture to the level of the

filler hole, and then replace the fuel cap

• Make sure that any fuel spillage is completely cleaned up and disposed

of according to local laws and regulations

• Move the brush cutter well away from the fuelling area before starting

engine

• Keep extra fuel well away from the work area

Note: Petrol octane reduces over time which leads to poor starting and

possible damage to the engine. Do not store fuel for longer than 2 months.

Starting the engine

WARNING: This brush cutter will produce toxic fumes as soon as it is

running. DO NOT attempt to start the engine indoors, or in any kind of

enclosed space. Always wear appropriate safety protection - see Brush

Cutter & Line Trimmer Safety.

1. Place the brush cutter onto the ground, ensuring that the spool is not

in contact with any object

2. Squeeze the priming bulb until it is filled with fuel. (The priming bulb is

located just above the fuel tank on the underside of the choke housing)

3. Set the Choke Lever (10) to the 'OFF' position (if the engine is already

warm, set the choke lever to the 'ON' position)

4. Set the Ignition Switch (3) to the 'I' position

5. Press down on the Main Handle (7) to steady the brush cutter. Grip the

Recoil Starter (8), and pull gently to remove slack

6. Pull the recoil starter firmly to start the engine. Do not wrap the

starter cord around your hand, always guide the cord back into the

casing

7. The engine should start after a few pulls. Squeeze the Trigger Throttle

(2) to accelerate the engine

8. As the engine warms, move the Choke Lever (10) to the 'ON' position.

The engine will warm up quickly due to its size, therefore the choke

will not need to be left on for long

NOTE: If the engine sounds like it may stall, move the choke into the 'ON'

position and squeeze the trigger throttle to its half way position.

NOTE: If you are having difficulty starting the engine, hold the trigger throttle

down into the halfway position whilst pulling on the recoil starter.

Stopping the engine

1. Release the Trigger Throttle (2) and allow the engine to idle

2. Move the Ignition Switch (3) to the '0' position. The engine will stop

WARNING: Be aware that the spool or blade may continue to spin for a few

moments after the engine has stopped. Do not attempt to stop the blade;

allow it to slow down gradually

Engine adjustments

• When adjusted properly, the engine should idle smoothly and accelerate

without hesitation. The blade or spool should not move when the engine

is idling

• To make the engine idle at a higher speed, rotate the Idle Adjustment

Screw (11) clockwise

• To make the engine idle at a lower speed, rotate the idle adjustment

screw anti-clockwise

6

6

Page 8

43cc Petrol Brush Cutter267969

Using Your Brush Cutter

WARNING: Using a brush cutter correctly is a technical skill. A brush cutter

used incorrectly can be highly dangerous. The information presented below

is general guidance only. If you are not entirely confident in your ability to

use this tool safely DO NOT USE.

Cutting

• Always maintain a secure footing; if it is not possible to reach the cutting

area from a secure position, do not cut

• Carefully assess the safest way to cut (see Avoiding Kickback section).

Every cut made using a brush cutter is unique, every cut presents its own

safety considerations. Always consider how material may move or fall

when it has been cut. Make sure that material will not fall towards you,

and that the blade will not become trapped

• Use the correct cutting tool for the job. Use the spool for cutting grass

and light brush, or for cutting against a hard edge. Use the blade for

heavy brush cutting

• When using the spool, the cutting line will gradually wear away. To

release more line, run the engine at high speed and bump the spool onto

hard ground

• Always hold the brush cutter securely. Always keep the spool or blade

close to ground level

• With the engine running at full speed, move the spool or blade through

the material to be cut. When cutting grass, move the cutter in a sweeping

arc by pivoting from side to side as you move forwards

• Allow the spool or blade to work steadily through the material. It should

not be necessary to use force to make the cut. Slow cutting indicates a

blunt blade

• Do not allow the blade to contact the ground, or any object other than

that which you intend to cut

• Be aware of the cutting position. Try to cut in such a way that waste

material is not projected towards you

• Release the Trigger Throttle (2) as soon as the cut is complete. Running

the engine at full throttle without a load will cause rapid wear to the

engine

Avoiding kickback

• Kickback is usually caused when the blade teeth 'bite' into a solid object.

The resulting reactionary force may make the brush cutter violently 'kick'

• Always use a sharp blade. Blunt blades are more likely to jam

• Always cut at full speed. At part speed the brush cutter may not be

able to drive the blade through the material, resulting in jamming and

kickback

• Check the cutting area for foreign bodies. Contacting wire, concrete,

brick, or other materials can cause sudden loss of control

• Do not attempt to make cuts through material thicker than recommended

for your blade

• For added control when cutting thicker material, use the left hand edge of

the blade. This will cause the brush cutter to pull away from you, rather

than push towards you

2. Remove the spool and spring

3. Clean all components and inspect for damage. Replace any damaged

items

4. Check eyelets are in their correct position

WARNING: Never operate the trimmer without the Eyelets (1).

5. Thread the new line through the anchor in the spool until the line

lengths are equal. Do not exceed maximum capacity of spool

6. Holding the Spool (5) with the line clamp slots uppermost, wind

the line clockwise in the spool using a finger to keep the two lines

separate

7. Lock the two ends of the line in the line clamp slots

8. Place the Spring (4) over the Arbor Bolt (3)

9. With the line clamp slots facing downwards into the housing, thread

the ends of the line through the Eyelets (1) in the housing. Do not allow

the line to become caught under the spool

10. Place the Bump Button (6) in the centre of the spool

11. Replace the Cover (7) by aligning the tabs and then twisting so that the

tabs engage with the slots in the cover

12. Pull the line free from the line clamp slots

13. Check that a maximum 100 – 125mm of line extends equally from

each eyelet. Trim line as necessary

1

2

3

4

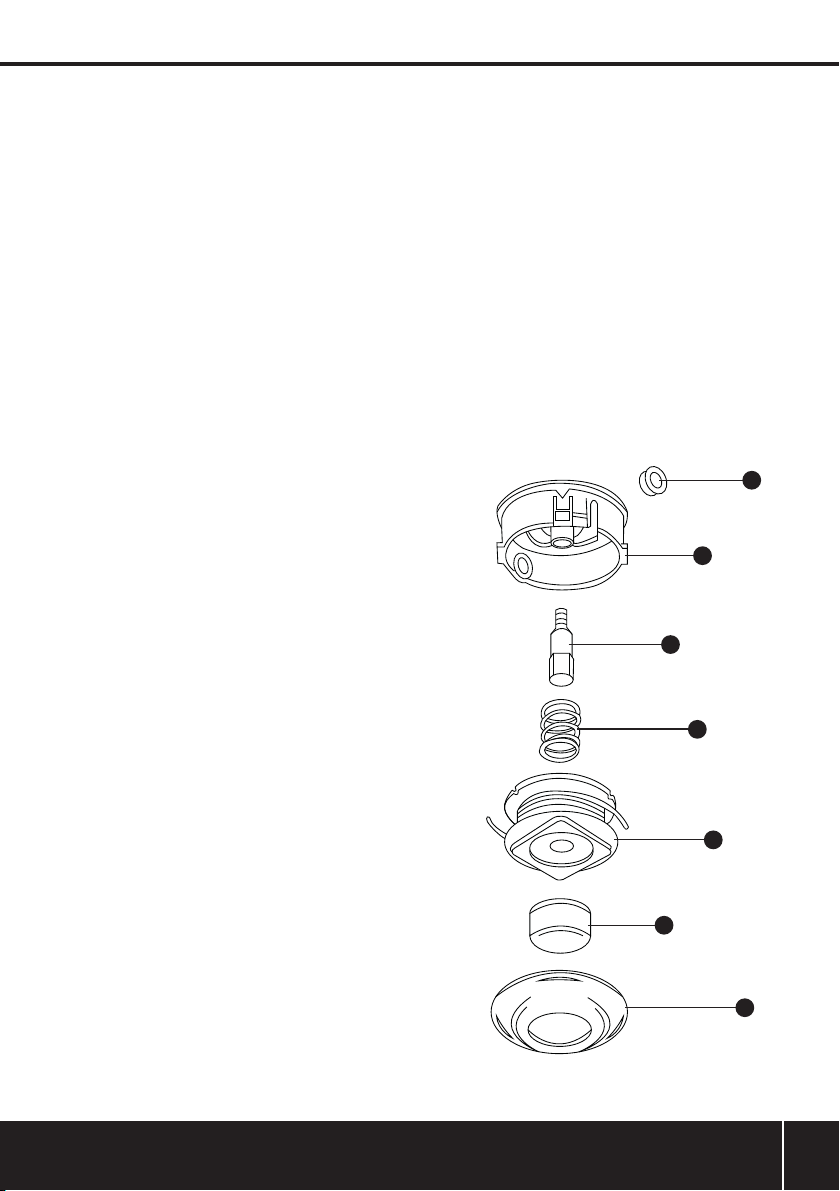

Trimmer Line Installation

Instructions

1) Eyelet (x2)

2) Housing

3) Arbor Bolt

4) Spring

Maximum capacity of spool

•2.0mm dia line: 12.2m

•2.4mm dia line: 8.5m

•2.7mm dia line: 7.9m

NOTE: Operating with trimmer line of uneven length will increase vibration.

Always ensure the line is wound evenly and trimmed to equal lengths from

the Eyelets (1).

1. Depress the tabs in the housing and twist the cover to release.

Remove the cover and bump button

5) Spool

6) Bump Button

7) Cover

5

6

7

www.silverlinetools.com

www.silverlinetools.com

7

7

Page 9

GB

Maintenance

WARNING: Always stop the engine, and allow to cool fully, before

performing any cleaning / maintenance.

Spark plug

• The spark plug should be checked regularly

• Remove the spark plug using the spanner supplied

• The electrode gap should be set to 0.7mm

• If the plug appears to be fouled, or burnt, the engine is not running

properly. Check for correct fuel mixture, and proper engine adjustment.

If necessary very lightly clean the spark plug with a suitable soft wire

brush or other tool

• If the electrode is heavily pitted, or eroded, replace the spark plug with a

new one of the same type

• Always tighten spark plug properly before use

Cleaning

• Keep your machine clean at all times. Dirt and dust will cause internal

parts to wear quickly, and shorten the machine’s service life

• Clean the body of your machine with a cloth and detergent

• The fuel tank contains a filter that should be regularly cleaned with

fresh petrol

• The air filter should be removed and cleaned regularly. To access the

filter, undo the retaining screw on the side of the brush cutter body,

and remove the cover. The air filter element should be cleaned using

household detergent, dried, and re-oiled with regular machine oil.

Reassemble before using the brush cutter

Storage

• Allow the brush cutter to cool fully before preparing for storage

• Drain out all fuel and oil

• If the brush cutter is to be stored for an extended period, wipe over all

metal surfaces with an oiled cloth. Remove the spark plug, and pour a

small amount of oil into the cylinder. Replace spark plug, and pull the

starting handle to distribute oil

• Store the brush cutter in a clean, dry, place away from heat and direct

sunlight. Ensure that the brush cutter is stored where children cannot

gain access

Recycling and disposal of petrol

engine powered tools, fuel and oil

• Tools powered by petrol based internal combustion engines must not be

disposed of with household waste. Such tools should be taken to your

local recycling centre and disposed of according to current environmental

protection requirements

• Petrol, oil and petrol-oil-mixtures are hazardous waste and have to be

treated as such. Oil and fuel must not be disposed of with household

waste. Improper disposal may be regarded a criminal offence in your

country. Contact your local authority or dealer for correct disposal

procedures for oil and old fuels

8

Page 10

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at silverlinetools.com within 30 days of purchase

in order to qualify for the 3 year guarantee. Guarantee period begins

according to the date of purchase on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockist where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

43cc Petrol Brush Cutter267969

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorized by: Silverline Tools

Declares that the

Description: 43cc Petrol Brush Cutter

Product Code: 267969

Conforms to the following Directives:

• Non road mobile machiner y directive 2004/26/EC

• Machiner y directive 2006/42/EC

• EMC directive 2004/108/EC

• Noise emission in the environment by outdoor equipment 2000/14/EC

• EN ISO11806:-1:2011

• EN ISO14982:2009

The technical documentation is kept by: Silverline Tools

Notified body: Jiangsu TUV Product Services LTD

Place of declaration: Shanghai, China

Date: 15/10/12

Signed by:

Director

Name and address of Manufacturer or Authorised

representative:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil,

Somerset, BA22 8HZ United Kingdom

www.silverlinetools.com

9

Page 11

F

Description des symboles

La plaque signalétique figurant sur votre outil peut présenter des

symboles. Ces symboles constituent des informations importantes

relatives au produit ou des instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masques respiratoires

Port du casque

Port de gants

Lire le manuel d’instructions

Ce produit émet des vapeurs toxiques

Conforme à la réglementation et aux normes de sécurité

Protection De L’environnement

pertinentes

Les produits électriques usagés ne doivent pas être

jetés avec les ordures ménagères. Veuillez les recycler

dans les centres prévus à cet effet. Pour de plus amples

informations, veuillez contacter votre municipalité ou point

de vente.

Caractéristiques techniques

Cylindrée : .......................................... 42,7 cm³

Moteur : ........................................... 2 temps

Puissance moteur maxi : .................... 1,25 kW/6500 tr/min

Carburant :.......................................... Mélanged’essence

sans plomb /huile

2 temps (40:1)

Capacité du réservoir : ........................ 1Litre

Bougie d’allumage : ............................ LD L7T, écartement entre

électrodes 0,7 mm

Vitesse à vide : .................................... 9000rpm

Vitesse au ralenti : .............................. 28000 tr/min

Largeur de coupe :.............................. Lame de 255 mm

bobine de 440 mm

Vibrations pondérées : ........................ 3,687 m/s²

Incertitude : .........................................1,5 m/s2

Pression sonore : ................................ 87,7 dB(A)

Puissance sonore :.............................. 112 dB(A)

Incertitude :................................ ........ 3 dB

Poids :...................................... ...........9 kg

L’intensité sonore peut dépasser 85 dB(A) et il est recommandé que

l’opérateur prenne des mesures de protection sonore.

Du fait de l’évolution constante de notre développement produits, les

caractéristiques techniques des produits Silverline peuvent changer

sans notification préalable.

Consignes générales de sécurité

AVERTISSEMENT Veuillez lire l’intégralité des consignes de sécurité

et des instructions. Le non-respect de ces consignes et instructions peut

entraîner un risque de choc électrique, d’incendie et/ou se traduire par des

blessures graves.

Veuillez conserver ces instructions et consignes de sécurité pour

référence ultérieure.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils dans des environnements explosifs, tels

qu’à proximité de liquides, de gaz ou de poussières inflammables.

c) Eloigner les enfants et les passants pendant l’utilisation d’un

appareil électrique. Ceux-ci peuvent provoquer une perte d’attention

et faire perdre la maîtrise de l’appareil.

Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation

de l’appareil. Ne pas utiliser un appareil électrique lorsque l’on

se trouve dans un état de fatigue, ou sous l’influence de drogues,

d’alcool ou de médicaments. Un moment d’inattention pendant

l’utilisation d’un outil électrique peut se traduire par des blessures

graves.

b) Porter un équipement de protection approprié. Toujours porter

une protection oculaire. Le port de masque à poussières, chaussures

de sécurité antidérapantes, casque de sécurité et protections antibruit

adaptés aux différentes conditions de travail réduit le risque de

blessures corporelles.

c) Eviter tout démarrage accidentel ou intempestif. S’assurer que

l’interrupteur marche-arrêt soit en position d’arrêt lorsque l’appareil

n’est utilisé.

d) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil en marche. Une clé ou un instrument de réglage laissé fixé

à un élément en rotation de l’appareil électrique peut entraîner des

blessures physiques.

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir

toujours en position stable permettant de conserver l’équilibre.

Cela permet de mieux contrôler l’appareil électrique dans des

situations inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements

amples ou des bijoux pendants. Eloigner cheveux, vêtements et

gants des pièces en mouvement. Les vêtements amples, les bijoux

pendants et cheveux longs peuvent être happés par les pièces en

rotation.

g) Si l’appareil est pourvu de dispositifs destinés au raccord

d’équipements d’extraction et de récupération de la poussière/

sciure, s’assurer qu’ils soient bien fixés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les risques dus à la

poussière.

ATTENTION : L’exposition de l’utilisateur aux vibrations d’un outil peut

engendrer la perte de sens du toucher, des engourdissements, picotements

et réduire la préhension de l’appareil. Des expositions prolongées peuvent

engendrer l’apparition chronique de ces symptômes. Si nécessaire,

réduisez le temps d’utilisation de l’outil. Utilisez les cas de figure avec

les caractéristiques relatives aux vibrations, si données, pour calculer la

durée et la fréquence de l’utilisation de l’appareil. Les normes directives

2002/44/CE relatives aux vibrations sur le lieu de travail peuvent fournir

des informations pratiques même pour un usage domestique. Si dans

un premier temps vous commencez à sentir inconfortable à cause des

vibrations, ARRÊTER immédiatement l’utilisation de l’appareil.

ATTENTION : Toujours porter des protections auditives lorsque le niveau

sonore excède 80 dB et limiter le temps d’exposition. Si les niveaux sonores

ne sont pas assez atténués avec un casque anti-bruit arrêter l’utilisation de

l’appareil, et vérifiez bien que la protection sonore soit bien appropriée par

rapport au niveau sonore.

Utilisation et entretien des appareils

a) Entretien des appareils. Vérifier que les éléments rotatifs

soient bien alignés et non grippés. S’assurer de l’absence de

pièces cassées ou endommagées susceptibles de nuire au bon

fonctionnement de l'appareil. Si l’appareil est endommagé, le

faire réparer avant toute utilisation. De nombreux accidents sont

dus à un mauvais entretien d’un outil.

10F10

Page 12

Débroussailleuse à essence 43 cm³267969

b) Veiller à ce que les outils de coupe soient tenus affûtés et

propres. Des outils de coupe bien entretenus, aux tranchants bien

affûtés, sont moins susceptibles de se gripper et sont plus faciles à

contrôler.

c) Utiliser l’appareil, les accessoires et outils à monter

conformément à ces instructions, en tenant compte des

conditions de travail et de la tâche à réaliser. Toute utilisation d’un

appareil autre que celle pour laquelle il a été conçu peut entraîner des

situations à risque.

Révision

a) Ne faire réparer votre appareil électrique que par un réparateur

qualifié utilisant uniquement des pièces de rechange identiques.

Consignes de sécurité relatives

aux appareils à combustion

interne

Environnements dangereux

• N’utilisez pas un outil à moteur à essence dans un environnement

humide et ne l’exposez pas à la pluie. Prévoyez un espace de travail

adéquat et assurez un éclairage correct de la zone.

• N’utilisez pas l’outil à moteur à essence s’il existe un risque d’explosion

ou d’incendie dû à des matières combustibles, des liquides ou des gaz

inflammables, ou à de la poussière de nature explosive.

Eteignez l’outil avant d’installer un accessoire

• Assurez-vous que le moteur de l’outil soit arrêté avant la pose d’un

accessoire.

• Si l’outil cesse de fonctionner de manière inattendue, assurez-vous que

le moteur soit bien arrêté avant de procéder à son inspection.

Rodage du moteur

• Lorsque l’outil est neuf, prenez soin de faire tourner le moteur à régimes

modérés.

• Ne conser vez pas un régime élevé tant que le moteur n’est pas rodé.

• Le moteur ne développe sa pleine puissance qu’à la fin de la période

de rodage.

• Avant d’utiliser l’outil pour la première fois et après vous être assuré que

le moteur est arrêté, vérifiez le serrage des vis et des écrous.

• N’utilisez aucun carburant contenant du méthanol ou de l’éthanol car ils

peuvent endommager le réservoir et les conduites de carburant.

Avertissement

• Attendez que l’outil se soit complètement arrêté avant de vous en

éloigner.

• Ne vous éloignez pas de l’outil tant que certaines de ses pièces sont

encore chauds.

Révisions

• Nous vous conseillons de faire réviser l’outil peu après la première

utilisation.

• Par la suite, faites réviser l’outil de manière régulière.

• Ne modifiez pas les composants de l’outil. Ceci invaliderait non

seulement votre garantie mais pourrait également vous faire courir le

risque de vous blesser ou de blesser d’autres personnes autour de vous.

• Ne faites réviser l’outil que par un centre agréé.

Rangement

• Lorsque vous n’avez plus besoin de l’outil, nettoyez-le soigneusement.

• Lorsque vous posez l’outil sur le sol, veillez à ne pas endommager le

réservoir et les conduites de carburant.

• Veillez à ne pas faire tomber l’outil, ce qui pourrait l’endommager et

rendre son utilisation dangereuse.

• Rangez l’outil à l’abri de la lumière directe du soleil.

• Assurez-vous que le carburant et l’huile soient conser vés dans un endroit

sûr, éloigné de toute source de chaleur, à l’abri de la lumière directe du

soleil et de toute source d’étincelle.

• Avant de ranger l’outil pour une période prolongée, procédez comme

suit :

• Videz complètement le réser voir de carburant.

• Protégez de la corrosion toutes les pièces métalliques du moteur en y

appliquant une couche d’huile.

• Retirez la bougie, introduisez quelques gouttes d’huile dans le cylindre

puis tirez 2 ou 3 fois sur le lanceur à rappel pour répartir l’huile

uniformément.

• Remettez la bougie en place.

• Rangez toujours la machine hors de portée des enfants.

CET OUTIL PRODUIT DES GAZ D’ÉCHAPPEMENT TOXIQUES DÈS QUE LE

MOTEUR TOURNE. CES GAZ PEUVENT ÊTRE INCOLORES ET INODORES.

POUR RÉDUIRE LE RISQUE D’ACCIDENT GRAVE, VOIRE MORTEL, NE

L’UTILISEZ PAS À L’INTÉRIEUR NI DANS UN ENDROIT MAL AÉRÉ.

VEILLEZ À CE QUE LA VENTILATION SOIT SUFFISANTE LORSQUE VOUS

TRAVAILLEZ DANS UNE TRANCHÉE, OU TOUT AUTRE LIEU EXIGU.

Consignes de sécurité relatives

aux débroussailleuses et

coupe-bordures

AVERTISSEMENT : les vapeurs d’essence sont inflammables,

NE FUMEZ PAS lors de la manipulation et de l’utilisation d’un

appareil à essence.

• Inspectez toujours la zone de coupe et prenez note des objets cachés, du

grillage, des câbles, etc. ainsi que des dangers potentiels.

• Portez toujours un équipement de protection approprié. Il est

indispensable de porter gants, lunettes ou protection du visage, masque

anti-poussières, casque antibruit, casque dur et vêtements résistants.

• Evaluez votre propre condition physique. L’utilisation d’une

débroussailleuse, même s’il s’agit d’un modèle plus petit, est très

physique. Ne commencez pas un travail si vous n’êtes pas certain d’être

suffisamment résistant pour le terminer. Evitez de travailler si vous êtes

fatigué, souffrant ou sous l’influence de drogue ou d’alcool.

• Avant de commencer la coupe, vérifiez l’absence de toute personne

alentours. Eloignez toujours les enfants et les animaux.

• Ne pas utiliser l’appareil en zone mouillée ou par temps humide.

• N’utilisez pas l’appareil si ses protections sont endommagées ou

manquantes.

• L’appareil doit uniquement être utilisé dans une position verticale, le fil ou

la lame étant près du sol.

• Avancez lentement lorsque vous portez cet outil. L’herbe ou les

broussailles fraîchement coupées sont glissantes et peuvent provoquer

un trébuchage.

• Utilisez uniquement un fil nylon pour coupe-bordure adapté et des lames

spécifiques sous peine de risque grave.

• Ne jamais approcher les bras ou les jambes près de la lame lors de la

coupe. Restez toujours à distance raisonnable de la tête de coupe et dans

une position stable.

• Si la débroussailleuse se bloque, éteignez-la immédiatement. Attendez

que le moteur s’arrête complètement avant d’essayer d’enlever le

blocage.

• Gardez à l’esprit que la machine peut subir un recul et vienne rebondir

contre l’utilisateur. Une utilisation correcte et un entretien convenable

réduiront considérablement ce risque.

• Ne travaillez jamais seul. Assurez-vous toujours que quelqu’un se trouve

à proximité pour vous aider en cas d’urgence.

• Arrêtez toujours l’appareil avant de traverser une route ou un chemin

gravillonné.

www.silverlinetools.com

www.silverlinetools.com

11

11

Page 13

F

Se familiariser avec le produit

1 Raccord central manche

2 Accélérateur

3 Bouton de marche-arrêt

4 Interrupteur de sécurité

5 Guidon

6 Bandoulière

7 Poignée principale

8 Poignée du lanceur

9 Bouchon du réservoir

10 Starter

11 Vis de réglage du ralenti

12 Protection

13 Axe

Déballage et montage

• Assurez-vous que votre débroussailleuse a été livrée complète et que

tous ses éléments soient en bon état.

• Si des pièces sont endommagées ou manquantes, faites-les remplacer

avant toute utilisation.

Raccord du manche

1. Desserrer le bouton de fixation du raccord (1).

2. Introduisez le manche dans le raccord.

3. Serrez le bouton de fixation et vérifiez que le manche soit solidement

introduit.

Installation de la protection de la lame

• Installez la protection de la lame (12) à l’extrémité du manche au moyen

des boulons fournis.

Installation du guidon

• Installez le guidon (5) sur le manche au moyen des boulons fournis.

Installation de la bobine de fil

NOTA : La bobine se fixe sur l’axe par vissage à gauche.

1. Enlevez la bague et le contre-écrou de la lame.

2. Maintenez l’axe en plaçant une clé mâle dans le trou de blocage situé

sur le carter de l’axe.

3. Vissez la bobine à la main sans trop serrer.

Installation de la lame

1. Maintenez l’axe en plaçant une clé mâle dans le trou de

blocage situé sur le carter de l’axe.

2. Desserrez le contre-écrou (sens des aiguilles d’une montre.

3. Placez la lame sur la bague de l’axe en vous assurant que le

sens de rotation de la lame corresponde à celui de l’arbre.

4. Vissez le contre-écrou (sens inverse des aiguilles d’une

montre).

Avant utilisation

ATTENTION : Assurez-vous d’avoir un extincteur à disposition lorsque vous

effectuez le remplissage ou utiliser cet outil. Vous pouvez vous trouver à

proximité de matière extrêmement inflammables, tel que de la végétation

sèche.

Remplissage du réservoir

• Remplissez le réser voir dans un lieu sûr éloigné du lieu de travail et de

toute source de chaleur ou flamme. Evitez tout contact avec le carburant.

NE PAS FUMER.

• Assurez-vous que le moteur soit arrêté et ait complètement refroidi.

• Le carburant doit avoir été préalablement mélangé à l’extérieur du

réservoir. Mélangez uniquement la quantité de carburant nécessaire.

Utilisez 40 volumes d’essence sans plomb pour 1 volume d’huile 2 temps

à base de pétrole.

Remarque : Il est recommandé d’utiliser un mélange essence /huile 25 :1

lors des 5-10 premiers remplissages pour faire tourner le moteur.

• Enlevez le bouchon du réser voir (9) et versez le mélange 2 temps

jusqu’au niveau de l’orifice de remplissage et revissez le bouchon.

• Assurez-vous de bien nettoyer tout déversement accidentel du mélange.

• Ne démarrez pas l’appareil à l’endroit où le remplissage a été effectué.

• Ne laissez pas le restant de carburant près de la zone où vous travaillez.

Démarrage du moteur

AVERTISSEMENT : cet appareil produira une fumée toxique dès sa mise en

marche. Ne démarrez jamais cet appareil à l’intérieur ou dans un espace

clos. Portez toujours des vêtements de protection adaptés.

1. Placez l’appareil sur le sol, en vous assurant que la lame/le fil soit

écarté de tout obstacle éventuel.

2. Appuyez sur la pompe d’amorçage, qui se trouve juste au

dessus du réservoir, sous le carter du starter. Appuyez sur

cette pompe jusqu’à ce qu’elle soit remplie de carburant.

3. Mettez le bouton du starter (10) sur la position 'OFF' (si le

moteur est déjà chaud, mettez le bouton du starter sur la

position 'ON').

4. Faites passer le bouton de marche-arrêt (3) sur le repère 'I'.

5. Appuyez sur la poignée principale (7) vers le bas pour

stabiliser l’appareil. Tirez lentement sur la poignée du lanceur (8) pour

la tendre.

6. Tirez vivement sur la poignée du lanceur pour démarrer le

moteur. N’enroulez pas le fil autour de la main et ne le

relâchez pas soudainement.

7. Le moteur devrait démarrer après quelques tentatives.

Appuyez sur la gâchette d’accélération (2) pour faire accélérer le

moteur.

8. Une fois que le moteur chauffe, faites passer le starter (10) sur la

position 'ON'. Le moteur sera vite chaud étant donné sa taille, il ne

sera donc pas nécessaire de laisser le starter bien longtemps.

NOTA : s’il semble que le moteur va caler, placez le starter sur la position

'ON' et appuyez sur la gâchette d’accélération en la maintenant à micourse.

NOTA : Si vous avez des difficultés à démarrer le moteur, maintenez

l’accélérateur à mi-course pendant que vous tirez sur la poignée du lanceur.

Arrêt du moteur

1. Relâchez la gâchette d’accélération (2) et laissez le moteur tourner à

vide.

2. Faites passer le bouton de marche-arrêt (3) sur la position 'O' et le

moteur s’arrêtera.

AVERTISSEMENT: sachez que la bobine ou la lame pourra continuer de

tourner quelques instants après l’arrêt du moteur. N’essayez pas de l’arrêter

par vous-même.

Réglages du moteur

• Lorsqu’il est correctement réglé, le moteur doit tourner de manière

régulière et accélérer sans à-coups. La lame et le fil ne devraient pas

tourner lorsque le moteur tourne à vide.

• Pour faire tourner le moteur à vitesse plus élevée, tournez la vis de

réglage de vitesse (11) dans le sens des aiguilles d’une montre.

• Pour ralentir la rotation, tournez la vis de réglage dans le sens.

12F12

Page 14

Débroussailleuse à essence 43 cm³267969

Utilisation de la débroussailleuse

AVERTISSEMENT : l’utilisation d’une débroussailleuse peut s’avérer

extrêmement dangereuse et demande une certaine technique. Les

informations ci-dessous ne sont données qu’à titre indicatif. Si vous n’êtes

pas entièrement certain de votre aptitude à utiliser cet appareil en toute

sécurité, NE L’UTILISEZ PAS.

Coupe

• Prenez toujours une posture stable, si vous risquez de perdre l’équilibre

lors de la coupe, abstenez-vous.

• Pensez soigneusement à la façon la plus sûre de procéder (cf. 'Eviter

le recul' ci-dessous). Chaque coupe présente ses propres observations

de sécurité. Anticipez toujours ses effets, tenez-vous à l’écart de tout

végétal susceptible de tomber vers vous et évitez que la lame ne vienne

à se bloquer..

• Utilisez le fil pour couper l’herbe et les broussailles tendres ou pour

couper contre un bord dur. Servez-vous de la lame pour couper les

broussailles épaisses.

• Le fil de coupe s’usera progressivement. Pour le faire avancer, faites

tourner le moteur rapidement et tapez la bobine sur un sol dur.

• Tenez toujours l’appareil fermement.

• En faisant tourner le moteur à pleine vitesse, déplacez la lame ou la

bobine dans la végétation à couper. Pour couper de l’herbe, avancez en

effectuant un mouvement d’arc de cercle avec la débroussailleuse.

• Laissez le fil ou la lame couper de façon régulière. Ne forcez pas sur

l’appareil. Une coupe laborieuse indique que la lame est émoussée.

• Ne laissez pas la lame heurter le sol ou tout autre objet.

• Essayez de couper de façon à ce que les déchets ne soient pas projetés

vers vous.

• Relâchez la gâchette d’accélération (2) dès que la coupe est terminée. Le

moteur s’usera plus rapidement s’il tourne à vide à pleine vitesse.

Eviter le recul

• Un recul se produit lorsque les dents de la lame « mordent » dans un

objet solide. La force de réaction risque de violemment propulser la

débroussailleuse contre vous.

• Utilisez toujours une lame affûtée. Les lames émoussées risquent

davantage de se coincer.

• Coupez toujours à pleine vitesse. Une vitesse intermédiaire peut ne pas

faire pénétrer la lame dans la matière à couper, provoquant blocages

et recul.

• Vérifiez qu’il n’y a aucun corps étranger ou objet enfoncé sur la zone

de coupe.

• N’essayez pas de couper des matières plus épaisses que celles

préconisées pour la lame.

• Pour une meilleure maitrise lors de la coupe de matières épaisses,

utilisez le tranchant gauche de la lame. Cela permet à la débrousailleuse

de s’écarter de vous plutôt que d’être poussée vers vous.

Instructions d’installation du fil

de coupe

1) Œillet (x2)

2) Boîtier

3) Boulon d’axe

4) Ressort

5) Bobine

6) Butoir

7) Couvercle

2. Retirez la bobine et le ressort.

3. Nettoyez tous les composants et contrôlez qu’ils ne soient pas abîmés.

Remplacez tout élément endommagé.

4. Vérifiez que les oeillets soient bien placés.

AVERTISSEMENT: N’utilisez jamais l’appareil sans les oeillets (1).

5. Passez le fil neuf dans l’oeilleton du centre de la bobine, en faisant

ressortir autant de fil d’un côté que de l’autre de l’oeilleton, puis

regroupez les deux longueurs d’un même côté. Ne dépassez pas la

capacité maximale de la bobine indiquée ci-dessus.

6. En tenant la bobine (5) de manière à ce que les évidements coince-fils

soient orientés vers le haut, enroulez le fil dans le sens des aiguilles

d’une montre en plaçant votre index entre les deux fils pour bien les

séparer.

7. Faites passer chaque extrémité dans- son évidement coince-fil

respectif.

8. Placez le ressort (4) sur le boulon d’axe (3) monté dans le boîtier.

9. Les évidements coince-fil étant orientés vers le bas, enfilez l’extrémité

de chaque fil dans son oeillet (1) respectif. Attention à ne pas coincer

de fil sous la bobine.

10. Placez le butoir (6) au centre de la bobine.

11. Remettez le couvercle (7) en place et encliquetez les rainures du

couvercle dans les ergots du boîtier.

12. Tirez brièvement sur chaque fil pour le décoincer de son

évidement.

13. Vérifiez que 10 à 12,5 cm de fil ressorte bien de chaque oeillet.

Coupez à la longueur voulue si nécessaire.

1

2

3

4

5

Capacité maximale de la bobine

•Fil de 2,0 mm de diam. : 12,2 m

•Fil de 2.4mm de diam. : 8,5 m

•Fil de 2,7 mm de diam. : 7,9 m

NOTA : l’utilisation de fils de coupe de longueurs différentes d’un côté et de

l’autre favorisera les vibrations. Assurez-vous que le fil soit uniformément

enroulé et sorte des oeillets (1) à des longueurs égales.

1. Enfoncez les ergots du boîtier et faites tourner le couvercle pour le

retirer. Retirez également le butoir.

6

7

www.silverlinetools.com

www.silverlinetools.com

13

13

Page 15

F

Entretien

AVERTISSEMENT : Arrêtez toujours le moteur et laissez-le refroidir

complètement avant toute opération d’entretien.

• Il est recommandé de faire examiner l’appareil par un service d’entretien

peu après la première utilisation.

• Ultérieurement, faites entretenir l’outil de manière régulière.

• Ne modifiez aucun composant de l’outil car vous vous priveriez du

bénéfice de la garantie en courant de surcroît le risque de vous blesser

ou de blesser d’autres personnes alentours.

• Ne faites entretenir l’outil que par un centre agréé.

Bougie

• Vérifiez régulièrement la bougie.

• Enlevez la bougie à l’aide de la clé fournie.

• L’écartement entre les électrodes devrait être réglé à 0,7 mm.

• Si la bougie est encrassée ou noire, le moteur ne fonctionne pas

correctement. Vérifiez que le mélange 2 temps et les réglages du moteur

sont corrects. Si besoin, nettoyez légèrement les bougies avec une

brosse métallique douce ou autre.

• Si l’électrode est très rongée ou corrodée, remplacez-la par une bougie

du même type.

• Serrez toujours correctement la bougie avant d’utiliser l’appareil.

Nettoyage

• Gardez votre appareil propre en permanence. La saleté et la poussière

useront rapidement les pièces internes, réduisant ainsi la durée de vie

de l’appareil.

• Nettoyez le carter de l’appareil avec un chiffon et un produit détergent.

• Le réser voir dispose d’un filtre qui doit être régulièrement nettoyé avec

de l’essence pure.

• Enlevez et nettoyez régulièrement le filtre à air. Pour accéder au filtre,

dévissez la vis de fixation située sur la partie latérale du carter de la

débroussailleuse et enlevez le carter. Nettoyez l’élément du filtre à air

avec un produit détergent ménager, séchez et graissez-le avec de l’huile

moteur normale. Réinstallez les pièces avant utilisation.

Rangement

• Laissez l’appareil refroidir complètement avant de le ranger.

• Vidangez toute l’essence et toute l’huile.

• Si la débroussailleuse ne doit être remisée pendant une longue période,

passez un chiffon huilé sur toutes ses surfaces métalliques. Enlevez la

bougie et versez un peu d’huile dans le cylindre. Remettez la bougie en

place et tirez sur la poignée du lanceur 2 ou 3 fois pour faire circuler

l’huile.

• Conser vez la débroussailleuse dans un endroit propre et sec, à l’abri de

la chaleur et de la lumière directe du soleil, hors de portée des enfants.

Recyclage des outils à essence,

carburant et huile.

• Les outils alimentés par combustion interne par essence ne doivent

pas être rejetés avec les ordures ménagères. De tels outils doivent être

amenés dans un centre de recyclage pour y être recyclés selon les lois

en vigueur de la protection environnementale.

• Essence, huile, et mélanges d’essence et d’huile sont des résidus

à risque et doivent être traités comme produits dangereux. Les

carburants et l’huile ne doivent donc pas être mélangés avec les ordures

ménagères. Ne pas rejeter ces substances correctement ces substances

peut être considéré comme un acte criminel. Contactez votre revendeur

ou la collectivité chargée de la collecte des déchets pour de plus amples

informations concernant le recyclage de ce type de déchet.

14

Page 16

Garantie Silverline Tools

Ce produit Silverline bénéficie d’une garantie

de 3 ans

Enregistrez ce produit sur le site silverlinetools.com dans les 30 jours

suivant l’achat afin de bénéficier de la garantie de 3 ans. La période de

garantie commence à partir de la date d’achat figurant sur votre facture

d’achat.

Conditions de Garantie des Outils Silverline

La période de garantie prend effet à compter de la date de l’achat en

magasin, comme indiqué sur votre facture d’achat.

VEUILLEZ CONSERVER VOTRE FACTURE D’ACHAT.

Si ce produit est défectueux pendant les 30 jours qui suivent l’achat,

retournez-le au magasin où vous l’avez acheté, avec votre facture, en

expliquant en détail le problème. Le produit sera remplacé ou vous serez

remboursé(e).

Si ce produit est défectueux après cette période de 30 jours,

retournez-le à :

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, Royaume Uni

Toute demande de service sous garantie doit être soumise pendant la

période de garantie.

Avant toute intervention sous garantie, vous devez présenter la facture

d’achat originale sur laquelle doivent figurer la date d’achat, votre nom,

votre adresse et le lieu d’achat.

Vous devez expliquer en détail la défaillance nécessitant réparation.

Les demandes de service sous garantie faites pendant la période de

garantie seront vérifiées par Silverline Tools pour établir si la défaillance du

produit est liée à un vice de matériau ou de fabrication.

Les frais de port ne seront pas remboursés. Les articles retournés doivent

être convenablement propres et sûrs pour être réparés et devraient être

emballés soigneusement pour éviter tout dommage ou toute blessure

pendant le transport. Nous pouvons refuser les livraisons qui ne sont pas

convenables ou sûres.

Toute intervention sera effectuée par Silverline Tools ou ses agents de

réparation agréés.

La réparation ou le remplacement du produit ne dépassera pas la période

de garantie.

Les anomalies que nous reconnaissons être couvertes par la garantie

seront rectifiées par la réparation de l’outil, sans frais (hormis les

frais de port) ou par son remplacement par un outil en parfait état de

fonctionnement.

Débroussailleuse à essence 43 cm³267969

Enregistrement de votre achat

Visitez silverlinetools.com, sélectionnez le bouton d’enregistrement et

saisissez :

• Vosinformationspersonnelles

• Lesinformationsconcernantleproduitetl’achat

Vous recevrez le Certificat de garantie en format PDF. Veuillez l’imprimer et

le conserver avec votre achat.

Les pièces ou les outils remplacés deviendront la propriété de Silverline

Tools.

La réparation ou le remplacement de votre produit sous garantie vous

apporte des avantages ; ces avantages s’ajoutent à vos droits statutaires

en tant que consommateur sans les affecter aucunement.

La présente garantie couvre:

La réparation du produit, s’il peut être vérifié, à la satisfaction de Silverline

Tools, que les défaillances du produit ont été provoquées par un vice de

matériau ou de fabrication au cours de la période de garantie.

Si une pièce n’est plus disponible ou n’est plus fabriquée, Silverline Tools la

remplacera par une pièce de rechange opérationnelle.

Utilisation de ce produit dans l’UE.

La présente garantie ne couvre pas:

Silverline Tools ne garantit pas les réparations nécessaires du produit

engendrées par :

L’usure normale provoquée par l’utilisation conforme aux instructions

d’utilisation, par exemple les lames, les charbons, les courroies, les

ampoules, les batteries, etc.

Le remplacement de tout accessoire fourni tel que les forêts, les lames, les

feuilles abrasives, les outils de coupes et les autres articles associés.

Les dommages et les défaillances accidentels causés par une utilisation ou

un entretien négligent, une mauvaise utilisation, un manque d’entretien ou

une utilisation ou une manipulation imprudente du produit.

L’utilisation du produit à des fins autres que son utilisation domestique

normale.

Le moindre changement ou la moindre modification du produit.

L’utilisation de pièces et d’accessoires qui ne sont pas des composants

véritables de Silverline Tools.

Une installation défectueuse (sauf si l’installation a été réalisée par

Silverline Tools).

Les réparations ou les modifications réalisées par des tiers autres que

Silverline Tools ou ses agents de réparation agréés.

Les demandes de service autres que le droit de rectifier les défaillances

de l’outil indiquées dans ces conditions de garantie ne sont pas couvertes

par cette garantie.

Déclaration de conformité CE

Le soussigné: Mr Darrell Morris

Autorisé par: Silverline Tools Ltd

Déclare que le produit:

Description: Débroussailleuse à essence 43 cm³

Code du produit: 267969

Est conforme aux directives suivantes

• Émissions des engins mobiles non routiers 2004/26/CE

• Directive sur les machines 2006/42/CE

• Compatibilité électromagnétique 2004/108/CE

• Émissions sonores dans l’environnement des matériels destinés à être

utilisés à l’extérieur des bâtiments 2000/14/CE

• EN ISO11806:-1:2011

• EN ISO14982:2009

La documentation technique est enregistrée par: Silverline Tools

Organismes notifiés: Jiangsu TÜV Product Services LTD

Lieu de la déclaration: Shanghai, Chine

Date : 15/10/12

Signé par :

Directeur

Nom et adresse du fabricant ou de son représentant agréé :

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ Royaume-Uni

www.silverlinetools.com

15

Page 17

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole

abgebildet. Sie vermitteln wichtige Informationen über das Produkt oder

dienen als Gebrauchsanweisung

Gehörschutz tragen.

Augenschutz tragen.

Atemschutz tragen.

Kopfschutz tragen.

Handschutz tragen.

Bedienungsanleitung sorgfältig lesen.

Produziert giftige Dämpfe!

Erfüllt die entsprechenden rechtlichen Vorschriften

und Sicherheitsnormen.

Umweltschutz

Werkzeuge mit Verbrennungsmotoren dürfen nicht mit

dem Hausmüll entsorgt werden. Bringen Sie diese zu

Ihrem lokalen Recycling- oder Wertstoffhof, und lassen

Sie das Gerät dort in Übereinstimmung mit geltenden

Umweltschutzanforderungen und -Gesetzen entsorgen.

Technische Daten

Hubraum: ...............................42,7 cm³

Motor-Bauart: ........................Zweitakt

Max. Motorleistung: ...............1,25 kW bei 6.500 min-1

Kraftstoff: ...............................Bleifreies Benzin /

Zweitaktmischung

(Mischungsverhältnis 40:1)

Kraftstoffbehälterinhalt: .........1 Liter

Zündkerze: .............................Typ LD L7T,

Elektrodenabstand: 0,7 mm

Max. Drehzahl: .......................9.000 min-1

Leerlaufdrehzahl: ...................2.800 min

Schnittbreite: .........................Messer: 255 mm,

Faden: 440 mm

Bewertete Vibration: ..............3,687 m/s²

Unsicherheit: ..........................1,5 m/s²

Schalldruckpegel: ..................87,7 dB(A)

Schallleistungspegel: ............112 dB(A)

Unsicherheit .......................... 3 dB(A)

Gewicht : ............................... 9 kg

Der Schallintensitätspegel kann für den Bediener 85 dB(A) übersteigen

und Lärmschutzmaßnahmen sind notwendig.

Aufgrund der fortlaufenden Weiterentwicklung unserer Produkte

können sich die technischen Daten von Silverline-Produkten ohne

vorherige Ankündigung ändern.

-1

Allgemeine Sicherheitshinweise

WARNUNG! Lesen Sie alle Sicherheitshinweise und Anweisungen.

Versäumnisse bei der Einhaltung der Sicherheitshinweise und Anweisungen

können elektrischen Schlag, Brand und/oder schwere Verletzungen

verursachen.

Bewahren Sie alle Sicherheitshinweise und Anweisungen für die

Zukunft auf.

Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und gut beleuchtet.

Unordnung oder unbeleuchtete Arbeitsbereiche können zu Unfällen

führen.

b) Arbeiten Sie mit dem Werkzeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube

befinden.

c) Halten Sie Kinder und andere Personen während der Benutzung

des Werkzeugs fern. Bei Ablenkung können Sie die Kontrolle über

das Gerät verlieren.

Sicherheit von Personen

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen

Sie mit Vernunft an die Arbeit mit einem Werkzeug. Benutzen

Sie kein Werkzeug, wenn Sie müde sind oder unter dem Einfluss

von Drogen, Alkohol oder Medikamenten stehen. Ein Moment der

Unachtsamkeit beim Gebrauch des Werkzeuges kann zu ernsthaften

Verletzungen führen.

b) Tragen Sie persönliche Schutzausrüstung und immer eine

Schutzbrille. Das Tragen persönlicher Schutzausrüstung, wie

Staubmaske, rutschfeste Sicherheitsschuhe, Schutzhelm oder

Gehörschutz, je nach Art und Einsatz des Werkzeuges, verringert das

Risiko von Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte Inbetriebnahme. Vergewissern

Sie sich, dass das Werkzeug ausgeschaltet ist, wenn es nicht

verwendet wird, und dass andere evtl. vorhandene Einschaltsperren

aktiviert sind.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor

Sie das Werkzeug einschalten. Ein Werkzeug oder Schlüssel, der

sich in einem drehenden Geräteteil befindet, kann zu Verletzungen

führen.

e) Vermeiden Sie eine unnatürliche Körperhaltung. Sorgen Sie für

einen sicheren Stand und halten Sie jederzeit das Gleichgewicht.

Auf diese Weise lässt sich das Elektrowerkzeug in unerwarteten

Situationen besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung

oder Schmuck. Halten Sie Haare, Kleidung und Handschuhe fern

von sich bewegenden Teilen. Lockere Kleidung, Schmuck oder lange

Haare können von sich bewegenden Teilen erfasst werden.

g) Wenn Staubabsaug- und -auffangeinrichtungen montiert werden

können, vergewissern Sie sich, dass diese angeschlossen sind

und richtig verwendet werden. Verwendung einer Staubabsaugung

kann Gefährdungen durch Staub verringern.

WARNUNG: Bei der Benutzung mancher Werkzeuge wird der Benutzer

Vibrationen ausgesetzt, welche zum Verlust des Berührungssinnes, zu

Taubheitsgefühl, Kribbeln und zu einer Verminderung der Handgreifkraft

führen können. Langfristige Belastung kann zu chronischen Beschwerden

führen. Begrenzen Sie falls nötig die Exposition zu Vibrationen. Beurteilen

Sie die Vibrationsbelastung unter Zuhilfenahme der Technischen Daten des

jeweiligen Werkzeuges, und bestimmen Sie die zulässige Belastungsdauer

und –häufigkeit. Die EU-Direktive 2002/44/EG enthält Informationen

über zulässige Vibrationsbelastung am Arbeitsplatz und kann auch auf

Heimarbeiten angewandt werden. Beenden Sie die Benutzung eines

Werkzeuges sofort, wenn Sie in irgendeiner Art und Weise Unbehagen

aufgrund der Vibrationsbelastung fühlen.

WARNUNG: Tragen Sie in Bereichen wo der Lärmpegel 80 dB überschreitet

unbedingt angemessenen Gehörschutz, und begrenzen Sie die

Belastungsdauer wo nötig. Sollte trotz Gehörschutz Unbehagen irgendeiner

Art auftreten, beenden Sie die Arbeit unverzüglich und überprüfen Sie den

Gehörschutz auf korrekten Sitz und Funktion, und stellen Sie sicher, dass

dieser einen angemessenen Schutz für den Lärmpegel bietet, der von den

verwendeten Werkzeugen ausgeht.

16D16

Page 18

43-cm³-Benzin-Motorsense267969

Werkzeugbenutzung und -pflege

a) Pflegen Sie Werkzeuge mit Sorgfalt. Kontrollieren Sie, ob

bewegliche Teile einwandfrei funktionieren und nicht klemmen,

ob Teile gebrochen oder so beschädigt sind, dass die Funktion

des Werkzeuges beeinträchtigt ist. Lassen Sie beschädigte Teile

vor dem Einsatz des Gerätes reparieren. Viele Unfälle haben ihre

Ursache in schlecht gewarteten Werkzeugen.

b) Halten Sie Schneidwerkzeuge scharf und sauber. Sorgfältig

gepflegte Schneidwerkzeuge mit scharfen Schneidkanten

verklemmen sich weniger und sind leichter zu führen.

c) Verwenden Sie Werkzeugzubehör, Einsatzwerkzeuge usw.

entsprechend diesen Anweisungen. Berücksichtigen Sie dabei

die Arbeitsbedingungen und die auszuführende Tätigkeit.

Der Gebrauch von Werkzeugen für andere als die vorgesehenen

Anwendungen kann zu gefährlichen Situationen führen.

Service

a) Lassen Sie Ihr Werkzeug nur von qualifiziertem Fachpersonal und

nur mit Original-Ersatzteilen reparieren. Damit wird sichergestellt,

dass die Sicherheit des Werkzeuges erhalten bleibt.

Sicherheitshinweise für Geräte

mit Verbrennungsmotoren

Gefährliche Umgebung

• Verwenden Sie Benzinmotorgeräte nie in feuchter oder nasser

Umgebung und setzen Sie sie nie dem Regen aus. Sorgen Sie für einen

geeigneten und gut ausgeleuchteten Arbeitsbereich.

• Benutzen Sie Benzinmotorgeräte nicht an Orten, wo ein Explosionsoder Brandgefahr aufgrund brennbarer Materialien, entflammbarer

Flüssigkeiten, entflammbarer Gase oder entzündbaren Staubs besteht.

Schützen Sie Ihr Gehör

• Tragen Sie immer einen geeigneten Gehörschutz, wenn der

Lautstärkepegel des Werkzeugs 80 dB überschreitet. Es liegt in der

Verantwortung des Benutzers sicherzustellen, dass auch andere

Personen die sich in der Nähe des Arbeitsbereichs aufhalten, ebenfalls

ausreichend geschützt sind.

Schützen Sie Ihre Augen

• Verwenden Sie stets einen geeigneten Augenschutz.

Schützen Sie sich vor Vibrationen

• Tragbare Werkzeuge können Vibrationen erzeugen. Diese Vibra tionen

können gesundheitsschädigend sein. Wärmende Handschuhe können

zu einer guten Durchblutung der Finger beitragen. Tragbare Werkzeuge

sollten nie über längere Zeiträume ohne Pausen verwendet werden.

Vor dem Anschließen von Zubehör ausschalten

• Vergewissern Sie sich, dass der Motor ausgeschaltet ist, bevor Sie

Zubehör am Werkzeug anbringen.

• Wenn das Werkzeug unerwartet anhält, vergewissern Sie sich, dass der

Motor nicht läuft, bevor Sie das Werkzeug untersuchen.

Betrieb des Motors

• Lassen Sie den Motor bei neuen Werkzeugen nur mit mäßiger Drehzahl

laufen.

• Benutzen Sie erst dann höhere Motordrehzahlen, wenn der Motor

vollständig eingelaufen ist.

• Der Motor kann seine maximale Leistung erst nach Beendigung der

Einlaufzeit erreichen.

• Prüfen Sie vor dem ersten Gebrauch des Werkzeugs, dass alle

Muttern und Schrauben sicher befestigt sind, und ziehen Sie diese

gegebenenfalls nach.

• Verwenden Sie keine methanol- oder ethanolhaltigen Kraftstoffe, da

diese interne Schäden an Kraftstoffbehälter und -leitungen verursachen

können.

Warnhinweis

• Lassen Sie das Gerät niemals unbeaufsichtigt wenn der Motor noch läuft.

• Lassen Sie das Gerät niemals unbeaufsichtigt wenn Teile der Maschine

noch heiß sind.

Wartung

• Es wird empfohlen, dass Sie Ihr Werkzeug kurz nach dem ersten

Gebrauch warten lassen.

• Bei normalem Gebrauch muss das Werkzeug regelmäßig gewartet

werden.

• Versuchen Sie nicht, Komponenten des Werkzeugs zu modifizieren.

Der Versuch, das Werkzeug zu verändern, führt zum Verlust des

Garantieanspruchs und kann außerdem zu ernsthaften Verletzungen der

eigenen oder in der Nähe befindlicher Personen führen.

• Lassen Sie Ihr Werkzeug immer bei einer autorisierten

Reparaturwerkstatt warten.

Lagerung

• Reinigen Sie das Gerät nach dem Gebrauch gründlich.

• Achten Sie darauf, dass der Kraftstofftank oder die Kraftstoffleitungen

nicht beschädigt werden, wenn das Werkzeug auf den Boden gestellt

wird.

• Sorgen Sie dafür, dass das Gerät nicht durch Schläge oder Stöße

beschädigt wird, da das Gerät sonst möglicherweise nicht länger den

Sicherheitsansprüchen genügt.

• Gerät vor direkter Sonneneinstrahlung geschützt lagern.

• Sorgen Sie dafür, dass Kraftstoff und Öl an einem sicheren Ort und

geschützt vor Hitze, direkter Sonneneinstrahlung, allen Zündquellen

sowie außer Reichweite von Kindern aufbewahrt werden.

• Wenn das Gerät längere Zeit nicht benutzt werden wird, gehen Sie wie

folgt vor:

• Entleeren Sie den Kraftstofftank vollständig.

• Wischen Sie alle Metalloberflächen und Metallkomponenten des Motors

zum Schutz vor Korrosion mit einem geölten Lappen ab.

• Entfernen Sie die Zündkerze und geben Sie einige Tropfen Öl in den

Zylinder. Ziehen Sie den Starthebel zwei bis drei Mal, um das Öl

gleichmäßig zu verteilen.

• Setzen Sie die Zündkerze wieder ein.

• Sorgen Sie dafür, dass Kinder sich keinen Zugang zur Maschine

verschaffen können.

DIESES PRODUKT ERZEUGT GIFTIGE ABGASE, SOBALD DER MOTOR

LÄUFT. DIESE GASE KÖNNEN FARB- UND GERUCHLOS SEIN. LASSEN

SIE DIE MASCHINE NIEMALS IN GESCHLOSSENEN RÄUMEN ODER

IN SCHLECHT BELÜFTETEN BEREICHEN LAUFEN, UM DAS RISIKO

SCHWERER ODER LEBENSGEFÄHRLICHER

VERLETZUNGEN ZU REDUZIEREN. SORGEN SIE FÜR AUSREICHENDE

BELÜFTUNG, WENN IN GRÄBEN ODER IN ANDEREN BEENGTEN RÄUMEN

GEARBEITET WIRD.

Sicherheitshinweise für

Motorsensen und Rasentrimmer

• Untersuchen Sie den zu bearbeitenden Bereich vor Arbeitsbeginn stets

auf versteckte Gegenstände, Zäune, Kabel u.Ä. Sorgen Sie dafür, dass

das zu schneidende Material keinerlei Fremdkörper enthält, denn das

Berühren von Draht, Beton, Stein oder anderen Materialien kann zu

einem plötzlichen Verlust der Kontrolle über das Werkzeug führen.

Beginnen Sie den Schneidevorgang erst, wenn Sie sich sicher sind, dass

keinerlei Gefahr besteht.

• Tragen Sie angemessene Schutzausrüstung. Bei der Verwendung dieses

Geräts müssen Schutzhandschuhe, Augen- oder Gesichtsschutz, eine