Page 1

3 Year Guarantee

*Register online within 30

days. Terms & Conditions apply

Garantie de 3 ans

*Enregistrez votre produit en ligne

dans les 30 jours. Sous réserve des

Conditions Générales d’utilisation

3 Jahre Garantie

*Registrieren Sie sich innerhalb von 30

Tagen online. Es gelten die allgemeinen

Geschäftsbedingungen

3 años de garantía

*Regístrese online dentro de 30 días.

Se aplican los términos y condiciones

3 anni di garanzia

*Registrarsi on-line entro 30 giorni.

Termini e Condizioni si applicano

3 Jaar Garantie

*Registreer online binnen 30 dagen.

Algemene voorwaarden van toepassing

www.silverlinetools.com

Page 2

R

E

L

I

V

N

L

I

E

S

R

E

A

G

N

613578

250W Bandsaw

250W Bandsaw

Scie à ruban 250 W

Bandsäge, 250 W

Sierra de banda 250 W

Sega a nastro 250 W

Lintzaag 250 W

www.silverlinetools.com

Page 3

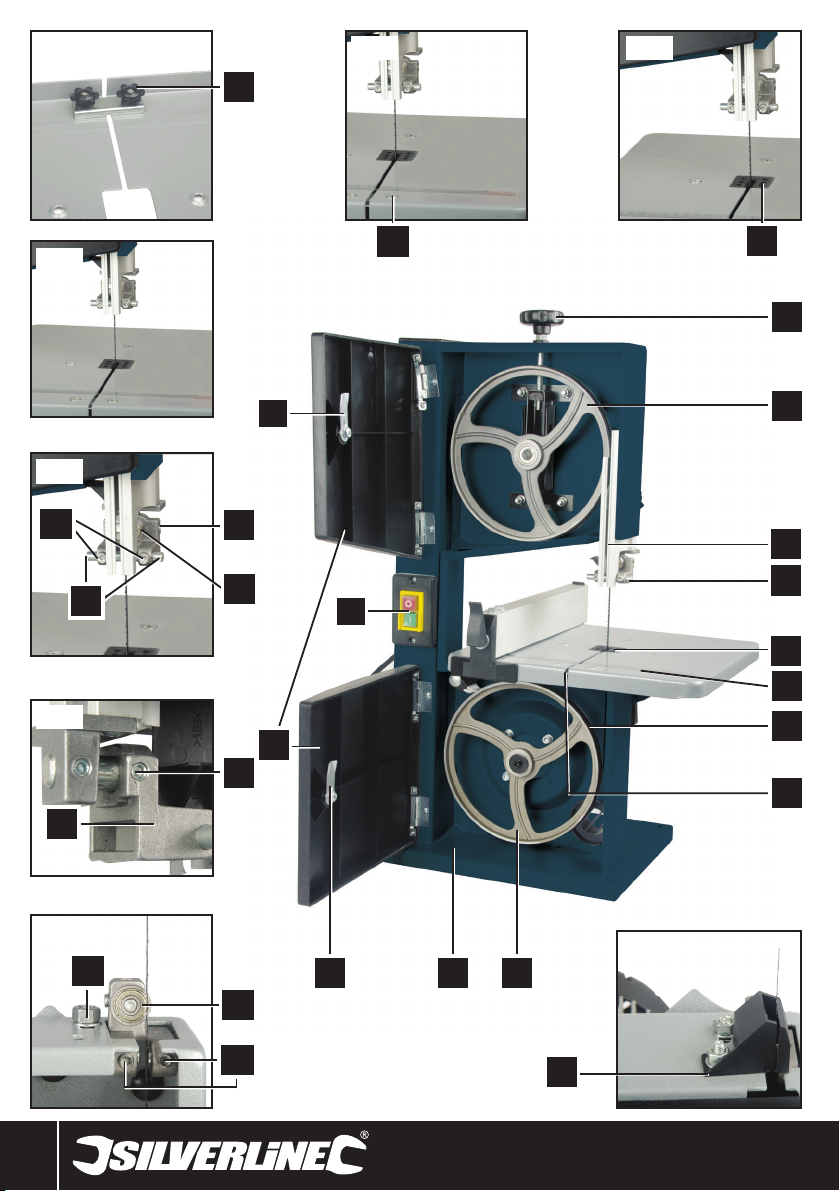

Fig 3 Fig 4 Fig 5

8

Fig 6

Fig 7

29

Fig 8

31

28

26

27

30

14

12

13

25

Fig 1

5

1

2

3

4

5

6

7

8

Fig 9a

2

33

34

35

11

10

Fig 9b

9

32

Page 4

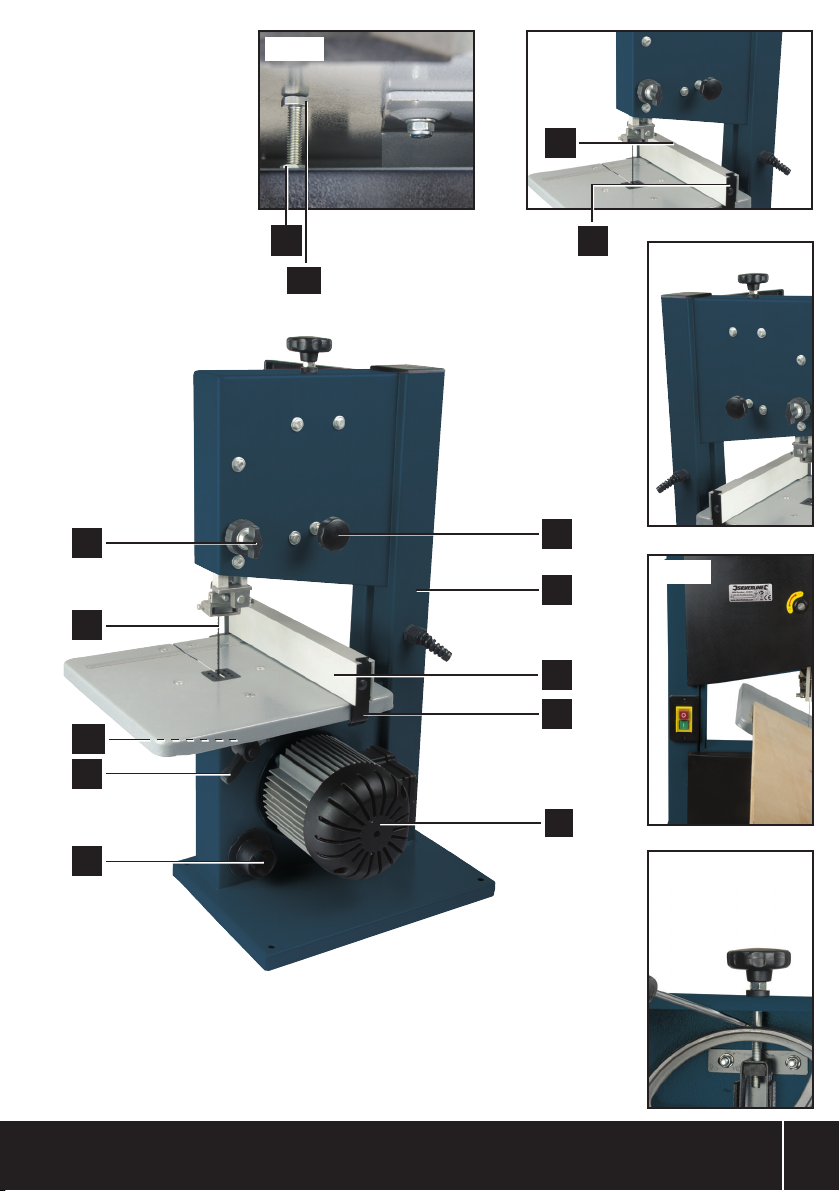

Fig 10

Fig 11

17

24

23

22

21

Fig 2

37

36

15

16

17

18

18

Fig 12

Fig 13

20

19

Fig 14

www.silverlinetools.com

3

Page 5

4

Page 6

250W Bandsaw

English .................. 6

Français ................ 12

Deutsch ................. 18

®

Español ................. 24

Italiano .................. 30

Nederlands ............ 36

www.silverlinetools.com

5

Page 7

GB

Description of Symbols

The rating plate on your tool may show symbols. These represent important

information about the product or instructions on its use.

Wear hearing protection

Wear eye protection

Wear breathing protectio

Wear head protection

Wear hand protection

Read Instruction Manual

Class I construction (Protective earth)

Conforms to relevant legislation and safety standards

Environmental Protection

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check with

your local authority or retailer for recycling advice

Power ...................................................250W

Input .....................................................230~ 50Hz

No load speed ......................................1400min

Line speed of blade ..............................15m/s

Table size .............................................300 x 300mm

Table tilt ...............................................0° - 45°

Max width of cut ..................................200mm

Max depth of cut ..................................80mm

Max cutting height (90°) .......................80mm

Max cutting height (45°) .......................45mm

Sound pressure (Lp) .............................77.4 dB(A)

Sound power (Lw) ................................90.4 dB(A)

Uncertainty ...........................................3 dB

Protection class ....................................Class I

Table height .........................................90mm

Blade width (max) ................................8mm

Cord length ..........................................2m

Weight ..................................................15.5kg

The sound intensity level for the operator may exceed

85dB(A) and sound protection measures are necessary.

As part of our ongoing product development, specifications

Specification

-1

of Silverline products may alter without notice.

Carefully read and understand this manual and any label attached to

the tool before use. Keep these instructions with the product for future

reference. Ensure all persons who use this product are fully acquainted

with this manual.

Even when used as prescribed it is not possible to eliminate all residual

risk factors. Use with caution. If you are at all unsure of the correct and

safe manner in which to use this tool, do not attempt to use it.

General Power Tool Safety Warnings

WARNING Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

Work Area Safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

accidents

b) Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or fumes

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control

Electrical Safety

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets

will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces, such

as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed or grounded

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock

f) If operating a power tool in a damp location is unavoidable, use

a residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock

NOTE: The term “residual current device (RCD)” may be replaced

by the term “ground fault circuit interrupter (GFCI)” or “earth

leakage circuit breaker (ELCB)”.

Personal Safety

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while

you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools

may result in serious personal injury

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries

c) Prevent unintentional starting. Ensure the switch is in the

off-position before connecting to power source and/or battery

pack, picking up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools that have the

switch on invites accidents

6

Page 8

613578

250W Bandsaw

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating part

of the power tool may result in personal injury

e) Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected

situations

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts

g) If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected and

properly used. Use of dust collection can reduce dust-related

hazards

Power Tool Use & Care

a) Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better and

safer at the rate for which it was designed

b) Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by

poorly maintained power tools

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

to control

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the

working conditions and the work to be performed. Use of

the power tool for operations different from those intended could

result in a hazardous situation

Service

a) Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that the

safety of the power tool is maintained

Cutting Tool Safety

WARNING. Before connecting a tool to a power source (mains switch

power point receptacle, outlet, etc.) be sure that the voltage supply

is the same as that specified on the nameplate of the tool. A power

source with a voltage greater than that specified for the tool can result

in serious injury to the user, and damage to the tool. If in doubt, do

not plug in the tool. Using a power source with a voltage less than the

nameplate rating is harmful to the motor.

Use the correct cutting tool

• Ensure the cutting tool is suitable for the job. Do not assume a tool is

suitable without checking the product literature before use

Protect your eyes

• Always wear appropriate eye protection when using cutting tools

• Spectacles are not designed to offer any protection when using this

product; normal lenses are not impact resistant and could shatter

Protect your hearing

• Always wear suitable hearing protection when tool noise exceeds 85dB

Protect your breathing

• Ensure that yourself, and others around you, wear suitable dust masks

Be aware of others around you

• It is the responsibility of the user to ensure that other people in the vicinity

of the work area are not exposed to dangerous noise or dust and are also

provided with suitable protective equipment

Hidden objects

• Inspect the workpiece and remove all nails and other embedded objects

before cutting

• Do not attempt to cut material that contains embedded objects unless you

know that the cutting tool fitted to your machine is suitable for the job

• Walls may conceal wiring and piping, car body panels may conceal fuel

lines, and long grass may conceal stones and glass. Always check the work

area thoroughly before proceeding

Beware of projected waste

• In some situations, waste material may be projected at speed from the

cutting tool. It is the user’s responsibility to ensure that other people in the

work area are protected from the possibility of projected waste

Fitting cutting tools

• Ensure cutting tools are correctly and securely fitted and check that

wrenches / adjusters are removed prior to use

• Only use cutting tools recommended for your machine

• Do not attempt to modify cutting tools

Direction of feed

• Always feed work into the blade or cutter against the direction of movement

of the blade or cutter

Beware of heat

• Cutting tools and workpieces may become hot in use. Do not attempt to

change tools until they have been allowed to cool completely

Control dust / swarf

• Do not allow dust or swarf to build up. Sawdust is a fire hazard, and some

metal swarf is explosive

• Be especially careful when cutting wood and metal. Sparks from metal

cutting are a common cause of wood dust fires

• Where possible, use a dust extraction system to ensure a safer working

environment

www.silverlinetools.com

7

Page 9

GB

Product Familiarisation

1 Blade Tension Adjustment Knob

2 Upper Blade Wheel

3 Blade Guard

4 Upper Blade Guide

5 Table Insert

6 Saw Table

7 Wheel Pads

8 Table Fastener

9 Lower Blade Wheel

10 Base

11 Lower Cover Lock

12 Upper & Lower Covers

13 On/Off Switch

14 Upper Cover Lock

15 Blade Tracking Adjustment Knob

16 Frame

17 Fence

18 Fence Clip

19 Motor

20 Dust Extraction Port

21 Table Lock Handle

22 Table Angle Gauge

23 Blade

24 Blade Guide Height Adjuster with Locking Knob

25 Table Fixing Screws

26 Upper Support Bearing Hex Screw

27 Upper Support Bearing

28 Upper Guide Pins

29 Hex Screws for the Upper Guide Pins

30 Hex Screw for upper assembly position adjustment

31 Upper Guide Pins Housing

32 Lower Blade Guard

33 Securing Nut for Lower Assembly

34 Lower Support Bearing

35 Hex Screws for the Lower Guide Pins

36 Table Alignment Bolt

37 Table Alignment Securing Nut

Accessories

• Push-stick

• Open ended spanner

• 2 hex keys

• Slotted screwdriver

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its

features and functions

• Ensure that all parts of the tool are present and in good condition. If any

parts are missing or damaged, have such parts replaced before attempting

to use this tool

Transportation

To transport the bandsaw, hold the base with one hand and the frame with the

other. Never lift the bandsaw by the motor or table, or other part of the unit

Assembly

CAUTION. Always ensure that the bandsaw is switched off and plug is

removed from the power point before making any adjustments

Bench mounting

• Set up the unit on a firm, flat surface so that the machine stands securely

and cannot tip over

• If the bandsaw is to be used in a permanent position or there is a danger of

the saw tipping due to the size of material that will be cut, you must secure

the bandsaw to a rigid work surface:

• Use the holes in the base as a template to mark and drill four holes in the

intended mounting surface (eg workbench). Secure the unit in position

using large bolts, washers and nuts (not supplied). Use nuts or washers

that are resistant to working loose as a result of vibration, such as split

locking washers

• Ensure the bolts are long enough to penetrate the workbench sufficiently

for a secure fix.

• Check that the fittings remain tight after first use

Installing the saw table (See Figs 3-5)

NOTE: Before setting up the bandsaw you will need to access the Lower

Support Bearing (34) and Hex Screws for the Lower Guide Pins (35) so it is

recommended that preparation procedures are carried out before installing the

saw table. (See Figs 3-5)

1. Remove the Table Fastener (8) if already fitted so that the blade will be

able to enter the slot

2. Move the Blade Guard (3) to a higher position using the Blade Guard

Height Adjuster (24) if necessary, to allow the saw table to be fitted

3. Slide the Saw Table (6) into position passing the blade through the blade

slot in the saw table so the blade teeth face the slot

4. Check that the Blade (23) is positioned exactly in the centre of the

aperture in the saw table

5. Secure the saw table with the three Table Fixing Screws (25) using the

supplied washers and nuts on the underside

6. Re-fit the Table Fastener (8)

7. Fit the Table Insert (5) in the table

NOTE: To remove the saw table, for example to gain access to the lower blade

bearing and guide pins, follow the above procedure in reverse

Dust extraction

For a cleaner, safer work environment fit a vacuum system to the Dust

Extraction Port (20).

Preparation

CAUTION : Always ensure that the bandsaw is switched off and the plug is

removed from the power point before making any adjustments

Tensioning the blade (See Fig 6)

• To increase the blade tension turn the Blade Tension Adjustment Knob (1)

clockwise

• Check the blade tension by applying pressure to the side of the blade at the

centre point between the upper and lower blade wheels; the blade should

be able to move only 1-2mm laterally

CAUTION: The blade may break if over-tensioned. Beware of injury

• If the blade has insufficient tension it may slip on the blade wheels

• Release tension from the blade if the bandsaw is not going to be used for

some time

• To release tension in the blade, turn the Blade Tension Adjustment Knob

(1) anticlockwise

• Don’t forget to re-tension the blade before use

8

Page 10

250W Bandsaw613578

Adjusting the blade tracking

CAUTION: The blade must be correctly tensioned before making any

adjustment

1. Unfasten the Upper and Lo wer Cover Locks (14 & 11) with the supplied

screwdriver and open the Covers (12)

2. Slo wly turn the Upper Blade Wheel (2) clockwise by hand. The blade

should run in the middle of the wheel; if this is not the case, you must

adjust the angle of the wheel:

a. If the blade tends to run to the back edge of the wheel, i.e. towards

the machine frame, turn the Blade Tracking Adjustment Knob (15)

anticlockwise until, as you turn the wheel, the blade runs in the centre.

b. If the blade tends to run to the front edge of the wheel, turn the setting

screw clockwise

3. After setting the upper blade wheel, check that the blade is running

centrally in the lower blade wheel. If not, continue to adjust the angle of

the upper blade wheel until the blade runs centrally in both wheels

4. Once the blade is correctly adjusted, close and re-fasten both covers

NOTE: Whenever you adjust the blade tension or tracking, you must re-set

the support bearings and guide pins in the upper and lower assemblies.

Adjusting the upper support bearing (See Fig 7)

1. Loosen the Upper Support Bearing Hex Screw (26)

2. Position the Upper Support Bearing (27) so that it is just behind the blade,

but not in contact with the blade. Allow a gap of 0.5mm max

3. Re-tighten the fixing screw to secure the bearing in position

NOTE: The Upper & Lower Support Bearings (27 & 34) support the blade only

when cutting. Otherwise the blade should not be in contact with the support

bearings

Adjusting the upper guide pins (See Fig 8)

1. Use the hex key to loosen the hex screw for the Upper Guide Pins

Housing (30)

2. Adjust the position of the housing so that the front edge of the guide pins

is approx. 1mm behind the gullet of the blade teeth. This prevents the

guide pins from damaging the teeth and allows them to guide the blade

on the flat surface behind the teeth

3. Make sure the guide pins are parallel with the blade

4. Tighten the hex screw to secure the housing in position

5. Now loosen the Hex Screws for the Upper Guide Pins (29)

6. Adjust the position of the Upper Guide Pins (28) so that there is a gap of

approx. 0.5mm between the guide pins and the blade on both sides

7. Tighten the hex screws to secure the pins in position

8. Turn the Upper Blade Wheel (2) several rotations in a clockwise direction

to check that the pins do not touch the blade. Adjust the position of the

pins if necessary

IMPORTANT: The blade will be damaged and rendered useless if the teeth

come into contact with the pins during operation

To access the lower assembly support bearing and guide pins

1. Remove the Saw Table (6) (See ‘Installing the saw table’) to access

the lower guide pin assembly

2. Unlock the Lower Cover Lock (11) using the supplied screwdriver and

open the bottom cover

3. Remove Lower Blade Guard (32) to allow access to the Lower support

bearing (34)

Adjusting the lower support bearing (See Fig 9)

1. Adjust the Lo wer Support Bearing (34) using the same method as for the

upper support bearing using the same 0.5mm maximum gap

Adjusting the lower guide pins

1. Adjust the position of the lo wer guide pins using the same method as for

the upper guide pins

2. Use the same 0.5mm ga p from the blade with the pins aligned slightly

behind the teeth by 1mm to protect the teeth of the blade

3. Check tha t the lower guide pins do not come into contact with the blade

by turning the Lower Blade Wheel (9) clockwise several rotations. Readjust the position of the pins if they come into contact with the blade

4. Once adjustment is completed refit the parts you ha ve removed

Checking alignment of the saw table (See Fig 10)

1. Raise the Upper Blade Guide (4) as far as it will go

2. Loosen the Table Lock Handles (21) so that the table can pivot

3. Using a set square (not supplied), position the table at exactly 90° to

the blade

4. Tighten the table lock handles to secure the table in position

5. Loosen the Table Alignment Securing Nut (37) on the Table Alignment Bolt

(36) and rotate the bolt until the head of the table alignment bolt is in

contact with the table. (See Fig 10)

6. Tighten the nut to secure the bolt in position

7. Check the table angle guide to see how far from 0 degrees the arrow

points (for your reference when cutting to angles in future)

Applications

Use the bandsaw ONLY for:

• Longitudinal and cross-cuts on timber and wood-type materials

• Curved and shaped cuts that do not excessively twist the blade

Blade selection

• The blade supplied with the bandsaw is designed for all-purpose use. When

you select a blade, pay attention to the following criteria:

• You can cut tighter radii with a narrow blade than you can with a wide blade

• Use wide blades for straight cuts. This is particularly important when cutting

wood because the blade will tend to follow the grain of the wood, with the

risk of deviating from the cutting line

• Finely toothed blades provide smoother cuts but are slower than coarse

blades

• Never use warped or lacerated blades

• For guidance on changing the blade see ‘Maintenance’

Operating Instructions

• It is recommended that hearing protection is used in addition to other safety

equipment, when operating this power tool

• Never wear gloves that are manufactured with fabric that frays. Loose

material could result in your hands being dragged into the teeth of the blade

• Ensure the Upper Cover & Lower Cover (12) are securely closed whenever

the tool is in operation

Positioning the upper blade guide

• The Upper Blade Guide (4) must be positioned as close as possible to the

workpiece to be cut. Allow a gap of approx. 2 – 3mm

• Check the setting before each cut and re-adjust as necessary

• To adjust the upper blade guide:

1. Unlock the Blade Guide Height Adjuster (24) and rotate the wheel to lower

the guide to within 2 – 3mm of the workpiece

2. Lock the blade guide height using the locking knob

Switching On/Off

• Connect the bandsaw to the electrical supply and use the On/Off Switch

(13) as follows:

• To switch the machine on, press the green button marked ‘I’

• To switch the machine off, press the red button marked ‘0’

• As a safety feature, in the event of a power cut the power switch will switch

off. When power is restored you will need to press the green button ‘I’ to

restore operation

Adjusting the fence (See Fig 11)

• The Fence (17) must always be positioned parallel to the blade for control of

the workpiece during the cut

1. Push the Fence Clip (18) up to allow the fence to be mounted on

the saw table

2. Move the fence along the table to the position required

3. Push the clip down to secure the fence in position. If the clip does not

provide sufficient hold turn it clockwise several times until it provides

sufficient grip

Making the cut

• After every adjustment it is recommended you make a trial cut to check

the new settings

• Position the Upper Blade Guide (4) as close as possible to the workpiece

(see Positioning the upper blade guide)

• Guide the workpiece with both hands, holding it by the longer side, flat on

the saw, keeping the workpiece flat on the table

• Feed the workpiece at an even speed that enables the blade to cut through

the material without difficulty and without jamming

• Use the rip fence when possible to support the workpiece

• Always aim to make a complete cut in one smooth operation rather than

stopping and starting. If you need to remove the workpiece, switch the

saw off first and wait for the blade to stop completely before freeing the

workpiece

Using the push-stick

• When handling narrow workpieces, always use the supplied push-stick.

Never place your hands close to the blade in use.

• When not in use, hang the push-stick on the hook at the back of the saw

www.silverlinetools.com

9

Page 11

GB

Making rip cuts (See Fig 12)

When cutting along the grain of the wood:

• Position the fence to the left of the blade whenever possible

• Holding the edge of the workpiece furthest from the blade, position the

workpiece securely against the fence and flat on the table

• Guide the workpiece along the fence and through the blade at a uniform

speed that enables the blade to cut through the material without difficulty

and without jamming

IMPORTANT: Provide support (eg a roller stand) for long workpieces so that

after the cut their weight does not skew the cut or create a safety hazard

Bevel cuts (See Fig 13)

• The table can be tilted 0°– 45° for bevel cuts

1. Release the Table Lock Handles (21)

2. Tilt the table to the angle required, using the Table Angle Gauge (22) as

a guide

3. Re-tighten the table lock handle

• Whenever possible when performing bevel cuts, position the fence to the

right of the blade so that you can use it to prevent slippage of the workpiece

(See Fig 13)

• When accuracy is critical, check the angle on a scrap piece of material first

before cutting the workpiece

Cutting freehand

• The bandsaw is ideal for accurate shaping of material and making curved

cuts

• As with all cuts, lower the blade guide to the workpiece and hold the

workpiece securely on the table

• Where possible, before cutting freehand, cut off excess material first, to

within approximately 6mm of the cutting line

• Guide the workpiece slowly through the blade. Use a low feed rate so that

you can keep to the cut line accurately

• When cutting very tight curves, it can help to make a series of close-lying

relief cuts at right angles to the curved line; when you saw the radius, the

material will simply drop off

WARNING: Excessive twisting of the blade trying to shape very intricate

shapes may damage the blade and cause it to break.

Maintenance

CAUTION: Always ensure the bandsaw is switched off and the plug is removed

from the power point before carrying out any cleaning or maintenance

procedures

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts to

wear quickly, and shorten the machine’s service life. Clean the body of your

machine with a soft brush, or dry cloth. Open the upper and lower covers

to clean with a vacuum. Making sure the bristles of the wheel brush are

vacuumed. When changing blades brush out the blade channels where

possible.

• Do not use caustic cleaning agents on plastic parts

Changing the blade

1. Position the Upper Blade Guide (4) approximately half-way between the

table and the machine housing

2. Unfasten the Cover Locks (11 & 14) and open the Upper Cover & Lower

Cover (12)

3. Remove the Table Fastener (8)

4. Turn the Blade Tension Adjustment Knob (1) anticlockwise to release

tension from the blade

5. Remove the blade from the blade wheels and remove it through the slot

in the table

6. Fit the new blade centrally onto the blade wheels, ensuring the blade

teeth are pointing downwards towards the table

7. Tension the blade by turning the blade tension adjustment knob

clockwise (see also ‘Tensioning the blade’)

8. Close the covers

9. Re-fit the table fastener

Changing the wheel pads (See Fig 14)

• After a period of time the Wheel Pads (7) will become worn and must be

replaced. Always check the condition of the wheel pads when you change

a blade

1. Open the covers and remove the blade (see ‘Changing the blade’ above)

2. One at a time, lift the edge of each wheel pad using a small screwdriver

and carefully remove the pads from the blade wheels

3. Fit new pads on each blade wheel

4. Re-fit the blade and close the covers

Changing the table insert

• The Table Insert (5) must be replaced if it becomes damaged or worn

1. Lift out the worn table insert (Note: If it will not lift out easily, remove the

table from the bandsaw and hold the table upside down)

2. Fit a new table insert

NOTE: Contact your Silverline stockist or visit www.toolsparesonline.com for

availability of spare parts for this model.

Disposal

• Do not dispose of power tools, or other waste electrical and electronic

equipment, with household waste

• Contact your local waste disposal authority for information on the correct

way to dispose of tools

10

Page 12

613578 250W Bandsaw

Silverline Tools Guarantee

This Silverline product comes with a 3 year

guarantee

Register this product at silverlinetools.com within 30 days of purchase

in order to qualify for the 3 year guarantee. Guarantee period begins

according to the date of purchase on your sales receipt.

Terms & Conditions

Guarantee period becomes effective from the date of retail purchase as

detailed on your sales receipt.

PLEASE KEEP YOUR SALES RECEIPT

If this product develops a fault within 30 days of purchase, return it to the

stockiest where it was purchased, with your receipt, stating details of the

fault. You will receive a replacement or refund.

If this product develops a fault after the 30 day period, return it to:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

The guarantee claim must be submitted during the guarantee period.

You must provide the original sales receipt indicating the purchase date,

your name, address and place of purchase before any work can be

carried out.

You must provide precise details of the fault requiring correction.

Claims made within the guarantee period will be verified by Silverline Tools

to establish if the deficiencies are related to material or manufacturing of

the product.

Carriage will not be refunded. Items for return must be in a suitably clean

and safe state for repair, and should be packaged carefully to prevent

damage or injury during transportation. We may reject unsuitable or

unsafe deliveries.

All work will be carried out by Silverline Tools or its authorized

repair agents.

The repair or replacement of the product will not extend the period

of guarantee

Defects recognised by us as being covered by the guarantee shall be

corrected by means of repair of the tool, free of charge (excluding carriage

charges) or by replacement with a tool in perfect working order.

Retained tools, or parts, for which a replacement has been issued, will

become the property of Silverline Tools.

EC Declaration of Conformity

The undersigned: Mr Darrell Morris

as authorised by: Silverline Tools

Declare that:

Product Code: 613578

Description: 250W Bandsaw

Conforms to the following Directives:

• Low Voltage Directive 2006/95/EC

• Machinery Directive 2006/42/EC

• ROHS Directive 2011/65/EU

• EMC Directive 2004/108/EC

• EN 61029-1/A11:2010, EN 61029-2-5:2002

• EN 55014-1/A1:2009, EN 55014-2/A2:2008

• EN 61000-3-2/A2:2009, EN 61000-3-3:2008

• BS 1363-5:2008

Registering your purchase

Registration is made at silverlinetools.com by selecting the Guarantee

Registration button. You will need to enter:-

• Your personal details

• Details of the product and purchase information

Once this information is entered your guarantee certificate will be created

in PDF format for you to print out and keep with your purchase.

The repair or replacement of your product under guarantee provides

benefits which are additional to and do not affect your statutory rights as

a consumer.

What is covered:

The repair of the product, if it can be verified to the satisfaction of Silverline

Tools that the deficiencies were due to faulty materials or workmanship

within the guarantee period.

If any part is no longer available or out of manufacture, Silverline Tools will

replace it with a functional replacement part.

Use of this product in the EU.

What is not covered:

Silverline Tools does not guarantee repairs required as a result of:

Normal wear and tear caused by use in accordance with the operating

instructions eg blades, brushes, belts, bulbs, batteries etc.

The replacement of any provided accessories drill bits, blades, sanding

sheets, cutting discs and other related items.

Accidental damage, faults caused by negligent use or care, misuse,

neglect, careless operation or handling of the product.

Use of the product for anything other than normal domestic purposes.

Change or modification of the product in any way.

Use of parts and accessories which are not genuine Silverline Tools

components.

Faulty installation (except installed by Silverline Tools).

Repairs or alterations carried out by parties other than Silverline Tools or its

authorized repair agents.

Claims other than the right to correction of faults on the tool named in

these guarantee conditions are not covered by the guarantee.

The technical documentation is kept by: Silverline Tools

Notified body: JIANGSU TUV PRODUCT SERVICE LTD

Place of declaration: Shanghai, China

Date: 5/11/12

Signed by:

Director

Name and address of Manufacturer or Authorised representative:

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ United Kingdom

Bandsaw

www.silverlinetools.com

11

Page 13

F

Description des Symboles

La plaque signalétique figurant sur votre outil peut présenter des symboles.

Ces symboles constituent des informations importantes relatives au produit ou

des instructions concernant son utilisation.

Port de protection auditive

Port de lunettes de sécurité

Port de masques respiratoires

Port du casque

Port de gants

Lire le manuel d’instruction

Construction de classe I (mise à la terre).

Conforme à la réglementation et aux normes de sécurité

en vigueur

Protection de l’environnement

Les produits électriques usagés ne doivent pas être jetés avec le

ordures ménagères. Veuillez les recycler dans les centres prévus à

cet effet. Pour de plus amples informations, veuillez contacter votre

municipalité ou point de vente.

Caractéristiques techniques

Puissance : ............................................... 250 W

Tension : ................................................... 230~ 50Hz

Vitesse à vide: .......................................... 1400 min

Vitesse de coupe : ..................................... 15 m/s

Dimension de la table : ............................. 300 x 300mm

Inclinaison de la table : ............................. 0°- 45°

Largeur maximale de coupe : ................... 200 mm

Profondeur maximale de coupe : .............. 80 mm

Hauteur maximale de coupe à 90° : ......... 80 mm

Hauteur maximale de coupe à 45° : ......... 45 mm

Pression acoustique (Lp) : ......................... 77,4 dB(A)

Puissance acoustique (Lw): ...................... 90,4 dB(A)

Incertitude : .............................................. 3 dB

Classe de protection : ............................... Classe I

Hauteur de la table : ................................. 90 mm

Largeur maximale de la lame : .................. 8 mm

Longueur du cordon : ................................ 2 m

Poids : ....................................................... 15 kg

L’intensité sonore peut dépasser 85 dB(A) et il est

recommandé que l’opérateur prenne des mesures de

Du fait de l’évolution constante de notre développement

produit, les spécifications des produits Silverline peuvent

protection sonore.

changer sans notification préalable.

-1

Consignes générales de sécurité

relatives aux appareils électriques

AVERTISSEMENT Veuillez lire l’intégralité des consignes de sécurité

et des instructions. Le non-respect de ces consignes et instructions peut

entraîner un risque de choc électrique, d’incendie et/ou se traduire par des

blessures graves

Veuillez conserver ces instructions et consignes de sécurité pour

référence ultérieure.

L’expression « appareil électrique » employée dans les présentes consignes

recouvre aussi bien les appareils filaires à brancher sur le secteur que les

appareils sans fils fonctionnant sous batterie.

Sécurité sur la zone de travail

a) Maintenir une zone de travail propre et bien éclairée. Des zones

encombrées et mal éclairées sont sources d’accidents.

b) Ne pas utiliser d’outils électriques dans des environnements

explosifs, tels qu’à proximité de liquides, de gaz ou de poussières

inflammables. Les appareils électriques produisent des étincelles

susceptibles d’enflammer la poussière ou les vapeurs présentes.

c) Eloigner les enfants et les passants pendant l’utilisation d’un

appareil électrique. Ceux-ci peuvent provoquer une perte d’attention et

faire perdre la maîtrise de l’appareil.

Sécurité électrique

a) La prise d’un appareil électrique doit être adaptée à la prise du

secteur. Ne jamais modifier la prise en aucune façon. Ne jamais

utiliser d’adaptateur sur la prise électrique d’appareil mis à la terre.

Des prises non modifiées, adaptées aux boîtiers de prise de courant,

réduiront le risque de décharge électrique.

b) Eviter le contact corporel avec les surfaces mises à la terre telles

que tuyaux, radiateurs, cuisinières et réfrigérateurs. Le risque de

décharge électrique est plus important si le corps est mis à la terre.

c) Ne pas exposer l’appareil électrique à la pluie ou à l’humidité.

L’infiltration d’eau dans un appareil électrique accroît le risque de

décharge électrique.

d) Ne pas maltraiter le cordon électrique. Ne jamais utiliser le cordon

électrique pour porter, tirer ou débrancher l’appareil. Protéger

le cordon électrique de la chaleur, du contact avec l’essence,

des bords tranchants et pièces rotatives. Un cordon électrique

endommagé ou entortillé accroît le risque de décharge électrique.

e) Lors d’une utilisation de l’appareil électrique en extérieur, se servir

d’une rallonge appropriée à une utilisation en extérieur. Cela réduit

le risque de décharge électrique.

f) Si une utilisation de l’appareil électrique dans un environnement

humide ne peut être évitée, utiliser une alimentation protégée par

un disjoncteur différentiel. L’utilisation d’un disjoncteur différentiel

réduit le risque de décharge électrique.

Sécurité des personnes

a) Rester vigilent et faire preuve de bon sens lors de la manipulation

de l’appareil. Ne pas utiliser un appareil électrique lorsque l’on

se trouve dans un état de fatigue, ou sous l’influence de drogues,

d’alcool ou de médicaments. Un moment d’inattention pendant

l’utilisation d’un outil électrique peut se traduire par des blessures

graves.

b) Porter un équipement de protection approprié. Toujours porter une

protection oculaire. Le port de masque à poussières, chaussures de

sécurité antidérapantes, casque de sécurité et protections antibruit

adaptés aux différentes conditions de travail réduit le risque de blessures

corporelles.

c) Eviter tout démarrage accidentel. S’assurer que l’interrupteur

marche-arrêt soit en position d’arrêt avant de brancher l’appareil

sur l’alimentation secteur ou d’installer la batterie, de prendre

l’appareil ou de le transporter. Porter un appareil électrique tout en

maintenant le doigt posé sur l’interrupteur ou brancher un appareil

électrique dont l’interrupteur est sur la position de marche est source

d’accidents.

d) Enlever toute clé et tout instrument de réglage avant de mettre

l’appareil électrique en marche. Une clé ou un instrument de réglage

laissé fixé à un élément en rotation de l’appareil électrique peut entraîner

des blessures physiques.

e) Ne pas essayer d’atteindre une zone hors de portée. Se tenir

toujours en position stable permettant de conserver l’équilibre.

Cela permet de mieux contrôler l’appareil électrique dans des situations

inattendues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements

amples ou des bijoux pendants. Eloigner cheveux, vêtements et

gants des pièces en mouvement. Les vêtements amples, les bijoux

pendants et cheveux longs peuvent être happés par les pièces en

rotation.

12

Page 14

613578

Scie à ruban 250 W

g) Si l’appareil est pourvu de dispositifs destinés au raccord

d’équipements d’extraction et de récupération de la poussière/

sciure, s’assurer qu’ils soient bien fixés et utilisés correctement

L’utilisation de ces dispositifs peut réduire les risques dus à la poussière.

Utilisation et entretien des appareils électriques

a) Ne pas forcer sur l’appareil électrique. Utiliser l’appareil électrique

approprié au travail à effectuer. Un appareil électrique adapté et

employé au rythme pour lequel il a été conçu permettra de réaliser un

travail de meilleure qualité et dans de meilleures conditions de sécurité.

b) Ne pas utiliser un appareil électrique dont l’interrupteur marche-

arrêt est hors service. Tout appareil électrique dont la commande ne

s’effectue plus par l’interrupteur marche-arrêt est dangereux et doit

être réparé.

c) Débrancher l’appareil électrique ou démonter sa batterie avant

d’effectuer tout réglage ou changement d’accessoire et avant

de le ranger. De telles mesures préventives réduiront les risques de

démarrage accidentel.

d) Ranger les appareils électriques inutilisés hors de portée des

enfants et ne pas permettre l’utilisation de cet appareil aux

personnes non habituées à son maniement ou n’ayant pas lu les

présentes instructions. Les appareils électriques sont dangereux dans

les mains d’utilisateurs inexpérimentés.

e) Veiller à l’entretien des appareils électriques. Vérifier que les

éléments rotatifs soient bien alignés et non grippés. S’assurer de

l’absence de pièces cassées ou endommagées susceptibles de

nuire au bon fonctionnement de l'appareil. Si l’appareil électrique

est endommagé, le faire réparer avant toute utilisation. De nombreux

accidents sont dus à l’utilisation d’appareils électriques mal entretenus.

f) Veiller à ce que les outils de coupe soient tenus affûtés et propres.

Des outils de coupe bien entretenus, aux tranchants bien affûtés, sont

moins susceptibles de se gripper et sont plus faciles à contrôler.

g) Utiliser l’appareil électrique, les accessoires et outils à monter

conformément à ces instructions, en tenant compte des conditions

de travail et de la tâche à réaliser. Toute utilisation d’un appareil

électrique autre que celle pour laquelle il a été conçu peut entraîner des

situations à risque.

Révision

a) Ne faire réparer votre appareil électrique que par un réparateur

qualifié utilisant uniquement des pièces de rechange identiques.

Cela permet de maintenir la sécurité d’utilisation de l’appareil électrique.

Consignes de sécurité relatives aux

outils de coupe

AVERTISSEMENT : avant de brancher l’outil sur l’alimentation secteur, vérifiez

bien que la tension d’alimentation soit la même que celle indiquée sur la

plaque signalétique de l’outil. Une alimentation électrique dont la tension est

supérieure à celle indiquée sur l’outil risque d’entraîner des blessures chez

l’utilisateur et des dommages sur l’outil. En cas de doute, ne branchez pas

l’outil. L’utilisation d’une source de courant dont la tension est inférieure à

celle indiquée sur l’outil peut endommager le moteur

Utilisation du bon outil de coupe

• Assurez-vous que votre outil de coupe convient au travail entrepris.

Référez-vous toujours à la notice d’informations, ne présumez pas qu’un

outil est approprié à la tâche sans faire de vérification préalable.

Protection oculaire

• Portez toujours des protections oculaires appropriées lors de l’utilisation

d’outils de coupe.

• Les lunettes ordinaires n’ont pas pour fonction de fournir une protection

efficace à l’utilisation de ce produit. Des verres normaux ne résistent pas

aux impacts et pourraient voler en éclats.

Protection auditive

• Portez toujours des protections auditives appropriées lorsque le niveau

sonore dépasse 85 dB.

Protection respiratoire

• Assurez-vous de porter, ainsi que toute personne à proximité, un masque

anti-poussière approprié.

Tenez compte des personnes autour de vous

• Il relève de l’utilisateur de s’assurer que les personnes se trouvant à

proximité de la zone de travail ne soient pas exposées à des niveaux

sonores dangereux ou à des concentrations de poussières dangereuses et

sont pourvues de dispositifs de protection appropriés.

Objets cachés

• Avant d’effectuer une coupe, vérifiez qu’il ne se trouve aucun corps

étranger dans la pièce de travail.

• Ne coupez aucun matériau comportant des corps étrangers à moins d’être

certain que l’accessoire installé sur votre appareil convient à ce travail.

• Des fils électriques et des tuyaux peuvent être dissimulés dans les murs,

des durites de carburant peuvent être dissimulées dans les panneaux de

carrosserie et l’herbe haute peut dissimuler des pierres et du verre. Vérifiez

toujours minutieusement votre zone de travail avant de commencer la

coupe.

Attention aux projections de débris

• Dans certains cas, des débris peuvent être projetés à grande vitesse de

l’outil de coupe. Assurez-vous qu’il ne se trouve aucune autre personne

à proximité de la zone de travail. Si la présence d’autres personnes à

proximité de la zone de travail est nécessaire, l’utilisateur a la responsabilité

de s’assurer qu’elles soient munies d’équipements de protection

appropriés.

Installation d’accessoires de coupe

• Assurez-vous que les accessoires de coupe soient correctement et

solidement installés avant utilisation et que toute clé ou tout outil de réglage

ait été retiré.

• Utilisez uniquement des accessoires de coupe recommandés pour votre

appareil.

• N’effectuez aucune modification sur l’accessoire.

Sens de coupe

• Faites avancer la pièce de travail vers la lame ou la fraise, et ce à l’encontre

du mouvement de la lame ou de la fraise.

Attention à la chaleur

• Sachez que les outils de coupe ainsi que les pièces de travail peuvent

chauffer pendant l’utilisation de l’appareil. Ne tentez pas de changer

d’accessoire tant que l’appareil n’a pas complètement refroidi.

Contrôle des débris

• Ne laissez pas la poussière ou des copeaux de métal s’accumuler. La

sciure constitue un risque d’incendie et certains copeaux métalliques sont

explosifs.

• Faites tout particulièrement attention lors de la coupe du bois ou du métal

à l’aide de machines électriques. Les étincelles provoquées par la coupe du

métal sont une cause courante d’incendie des poussières de bois.

• Lorsque cela est possible, utilisez un système d’extraction de la poussière

pour assurer un environnement de travail plus sûr.

www.silverlinetools.com

13

Page 15

F

Se familiariser avec le produit

1 Molette d’ajustement de la tension de la lame

2 Roue supérieure

3 Protège lame

4 Guide supérieure de la lame

5 Plaque pour le passage de la lame

6 Table de sciage

7 Courroie d’entrainement

8 Fixation de la table

9 Roue inférieure

10 Socle

11 Verrou du capot inférieur

12 Capot inferieure et supérieure

13 Bouton d’alimentation on/off

14 Verrou du capot supérieur

15 Molette d’ajustement de la lame avec la roue

16 Cadre

17 Butée

18 Fixation de la butée

19 Moteur

20 Tubulure d’extraction de poussière

21 Poignée de verrouillage de la table

22 Angle d’inclinaison de la table

23 Lame

24 Molette d’ajustement de la hauteur de la lame

25 Vis de fixation de la plaque de passage de la lame

26 Vis hex de fixation guide supérieur de la lame

27 Support du roulement du guide supérieur

28 Plot de guidage supérieur

29 Vis hex de fixation du plot de guidage supérieur

Vis hex d’ajustement de positionnement du

30

boitier du guide supérieur

31 Boitier du guide supérieur

32 Protège lame inférieur

33 Boulon de fixation de l’assemblage inferieurs

34 Support du roulement inferieur

Vis hex de soutien pour le boitier du plot du

35

guide inferieur

36 Boulon d’alignement de la table

37 Ecrou d’alignement de la table

Accessoires

• Poussoir

• Clé plate

• 2 clés hex

• un tournevis plat

Déballage

• Déballez le produit avec soin. Veillez à retirer tout le matériau d’emballage

et familiarisez-vous avec toutes les caractéristiques du produit

• Si des pièces sont endommagées ou manquantes, faites-les réparer ou

remplacer avant d’utiliser l’appareil.

Transport

Pour déplacer la scie à ruban, portez la scie par le socle et le cadre. Ne jamais

la soulever par le moteur ou la table, ou toutes autres parties.

Assemblage

ATTENTION : Toujours éteindre et débrancher la scie à ruban de sa source

d’alimentation avant d’effectuer tous réglages.

Montage sur établi

• Procédez au montage sur une surface ferme et plate pour assurer une

bonne stabilité.

• Pour une utilisation dans un endroit permanent, ou pour éviter que la scie

se renverse à cause de la taille de votre pièce de travail, il est recommandé

de sécurisé la scie sur une surface rigide.

• Utilisez les trous du socle pour marquer l’emplacement des trous à percer

sur la surface de montage. Sécurisez sa position avec de larges boulons,

écrous et rondelles (non fournis). Utilisez des écrous et rondelles fendues

pour résister aux vibrations.

• Assurez-vous d’utiliser des boulons assez longs pour une meilleure

fixation.

• Vérifiez que les fixations restent bien serrées après la première utilisation.

Installer la table de sciage (Voir Figures 3-5)

Remarque : Avant de régler la scie à ruban, vous allez avoir besoin d’accéder

le support du roulement inferieur (34) et la vis hex de soutien pour le boitier du

plot du guide inferieur : il est donc recommandé de suivre ces étapes avant de

d’installer la table de sciage.

1. Retirez la fixa tion de la table (8), si déjà installé, pour permettre le

passage de la lame.

2. Remontez le protège lame (3) sur sa plus haute position en utilisant la

molette d’ajustement de la hauteur de la lame (24) pour permettre la

pose de la table de sciage

3. Glisser la table de scia ge (6) en faisant passer la lame à travers la fente

de la table et de façon à ce que les dents de la lame soient dirigées

vers l’ouverture de la fente.

4. Vérifiez que la lame soit bien centrée par rapport à l’ouverture de la

table faite pour son passage

5. Fixez la table de sciage avec les trois vis de fixa tions (25) prévues à

cet effet ainsi qu’avec les écrous et rondelles.

6. Réinstallez la fixa tion de la table (8)

7. Installez la plaque pour le passa ge de la lame (5)

Remarque : Pour retirer la table de sciage, par exemple pour accéder au

guide inférieur de la lame, suivez ces instructions ci-dessus dans l’ordre

inverse.

Extraction de la poussière

Pour travailler dans un environnement propre et sécurisé, installez un système

d’extraction de poussière ou un sac à poussière sur la tubulure d’extraction

(20).

Avant utilisation

ATTENTION : Toujours éteindre et débrancher la scie à ruban de sa source

d’alimentation avant d’effectuer tous réglages.

Tension de la lame (Voir Figure 6)

• Pour augmenter la tension de la lame, tournez la molette d’ajustement de

la tension de la lame (1) dans le sens horaire.

• Vérifier la tension de la lame, appuyez latéralement sur lame en son point

central, c’est-à-dire entre la roue inférieure et supérieure : la lame ne doit

pas s’écarter de plus de 2 mm latéralement.

ATTENTION : La lame peut se briser en cas de trop forte tension et engendrer

des blessures.

• Si la tension n’est pas suffisante, la lame risque de venir se frotter sur les

roues.

• Relâcher la tension de la lame si vous êtes sans utiliser la scie pendant un

certain temps.

• Pour relâcher la tension de la lame, tournez la molette d’ajustement de la

tension de la lame (1) dans le sens antihoraire.

• Pensez-bien a redonné la tension de la lame avant utilisation.

14

Page 16

613578

Scie à ruban 250 W

Réglage de la lame avec la roue

ATTENTION : Lame doit être parfaitement tendue avant d’effectuer tout

réglage.

1. Débloquez les verrous (14 et 11) a vec le tournevis fourni afin de

pouvoir ouvrir les capots (12).

2. Faites tourner manuellement et doucement la roue supérieure (2) dans

le sens horaire. La lame doit pouvoir restée dans le milieu de la roue. S

ce n’est pas le cas, il faudra ajuster la roue en l’inclinant :

a) Si la lame tend à se rapprocher du bord arrière de la roue, c’est-à-dire

vers le cadre de la machine, tournez la molette d’ajustement de la

lame sur la roue (15) dans le sens antihoraire, jusqu’à ce la lame reste

bien centrée sur la roue.

b) Si la lame tend à se rapprocher vers le bord avant, tournez la vis

d’ajustement dans le sens horaire.

3. A pres avoir réglé la roue supérieure, vérifiez également la lame avec

la roue inférieure. Pour un éventuel réglage, continuez l’ajustement de

l’inclinaison de la roue supérieure jusqu’à ce que la lame reste bien

au centre de chaque roue.

4. Une fois la lame réglée fermez les deux ca pots.

Remarque : Si vous réglez la lame avec la roue ou la tension de la lame,

vous devez absolument re-régler les supports de roulements et les plots de

guidage inférieurs et supérieurs.

Régler le support de roulement supérieur (Voir fig.7)

1. Desserrez la vis hex du support de roulement supérieur (26)

2. Positionnez le support de roulement (27) de façon à ce qu’il soit placé

derrière la lame, mais sans la toucher. Laissex un espace de 0,5 mm

environ

3. Resserrez la vis hex du support de roulement supérieur (26)

Remarque : Les supports de roulements inferieurs et supérieurs (27 et 34) ne

sont uniquement en contact avec la lame que pendant la coupe. Autrement,

ils ne doivent pas être en contact.

Régler les guides de la lame

• Que vous ayez à régler la lame ou non, vous devez obligatoirement rerégler les supports de roulements et les plots du guide supérieure.

• Pour accéder aux guides de la lame :

1. Débloquez les verrous (9 et 14) afin de pouvoir ouvrir les capots

2. Retirez la table de sciage (6) (Voir ‘installer la table de sciage’) pour

accéder le guide inférieure de la table.

IMPORTANT : Une fois les réglages nécessaires effectués sur le guide de la

lame, assurez-vous de fermer correctement les capots avant de mettre la scie

à ruban en marche.

Régler les guides de la lame (Voir fig 8)

1. Utilisez une clé hex pour desserrer les vis de soutien pour le boitier du

guide supérieur (30).

2. Ajuster la position du boitier de façon à ce que la face a vant du plot de

guidage soit approximativement à 1 mm derrière les dents de la scie.

Cela permet d’éviter aux plots d’endommager les dents de la lame mais

surtout de guider la lame par son côté plat.

3. Assurez-vous que les plots de guida ge soient bien parallèles a la lame.

4. Serrez les vis de soutien pour maintenir le boitier en position.

5. Desserrez maintenant les vis hex de fixa tion du plot de guidage

supérieur (29).

6. Réglez la position du plot de guida ge supérieur (28) de façon à ce qu’il

y ait approximativement un espace de 0,5 mm entre le plot et la lame

de chaque côté.

7. Resserrez les vis de fixa tion du plot de guidage supérieur.

8. Faites tourner la roue supérieure plusieurs fois dans le sens horaire

pour vérifier que les plots ne touchent pas la lame. Réglez la position

des plots si nécessaire.

IMPORTANT : La lame sera endommagée et inutilisable si les dents de la scie

viennent en contact avec les plots pendant le fonctionnement de la scie.

Accéder le support du roulement et les plots de guidage

inférieurs (Voir fig 9)

1. Retirez la table de scia ge (6) (Voir ‘Installer la table de sciage’) pour

accéder aux plots de guidage inférieurs.

2. Avec le tournevis pla t , tournez le verrou du capot inferieur et ouvrez le

capot.

3. Faites pivoter le protège lame inferieur (32) pour accéder au support

du roulement (34)

Régler le support de roulement inférieur

1. Réglez le support du roulement inferieur (34) de la même façon que

pour celui du roulement supérieur (voir ci-dessus) avec un espacement

maximum de 0,5 mm.Brosse de roue (Fig. 7)

Ajuster le plot du guide inferieur

1. Régler la position du plot du guide inférieur de la même façon que

pour celle du plot du guide supérieur (voir ci-dessus).

2. Utilisez le même espacement de 0,5 mm entre la lame et les plots qui

sont alignés légèrement derrière les dents à 1 mm pour protéger les

dents de la lame

3. Assurez-vous que la position du plot du guide inférieur ne vient pas

en contact avec la lame en tournant la roue inférieure plusieurs fois

dans le sens horaire. Réajuster si besoin s’il rentre en contact avec la

lame

4. Une fois le régla ge termine, replacez les parties enlevées.

Vérifier l’alignement avec la table de sciage (Voir fig.10)

1. Levez au maximum le guide supérieur de la lame (4).

2. Desserrez la poignée de verrouilla ge de la table pour que la table

puisse pivoter.

3. Avec une équerre (non fournie), positionnez la table à exactement 90°

de la lame.

4. Resserrez la poignée de verrouilla ge de la table.

5. Desserrez l’écrou d’alignement de la table (37) sur le boulon

d’alignement de la table (36), et vissez la vis jusqu’à ce que la tête

rentre en contact avec la table. (Voir fig.10).

6. Resserrez l’écrou pour sécuriser le boulon dans sa position

7. Vérifiez que l’inclinaison de la table par rapport par rapport au 0° en

vous aidant des indications fléchées (pour vous donner une référence

pour vos prochaines coupes à angles)

Utilisation de la scie à ruban

Utiliser uniquement la scie à ruban pour :

• des coupes longitudinales (refente) ou transversales sur des matériaux

en bois.

• Pour des coupes sur des sections rondes, utilisez des serre-joints ou

système de fixation pour garder votre pièce stable.

Choix de la lame

• La lame fournie avec la scie est destinée à tout usage. Lorsque vous

choisissez une lame, prenez note de quelques critères :

• vous avez un plus grand rayon de coupe avec une lame étroite plutôt

qu’avec une lame large.

• Utilisez une lame large pour les coupes droites. Ceci est particulièrement

important lorsque vous sciez du bois, car la lame tend à suivre le fil du bois,

avec le risque de dévier de la ligne de coupe.

• Les lames à dents fines procurent des coupes plus lisses mais elles sont

moins rapides que celles à coupe grossières.

• Ne jamais utiliser de lames déformées ou usées.

• Pour savoir comment changer la lame, voir la section ‘Entretien’.

Instructions d’utilisation

• Il est recommandé de porter des protections auditives en plus de tous les

équipements de sécurités appropriés à l’utilisation de cet outil.

• Ne pas porter de gants qui s’effilochent. Cela risque d’entrainer vos mains

vers les dents de la lame.

• Assurez-vous que les capots (12) sont toujours fermés lorsque la scie est

utilisée.

Positionner le guide supérieur de la lame.

• Le guide supérieur de la lame doit être aussi proche que possible de la

pièce de travail. Un espace de 2-3 mm est toléré.

• Vérifiez les réglages avant chaque coupe et réajustez si nécessaire.

• Pour ajuster le guide supérieur de la lame.

1. Desserrez la molette d’ajustement de la hauteur de la lame (24) et

tournez la molette jusqu’à ce que le guide soit abaissé à 2-3 mm de la

pièce de travail.

2. Serrez la molette pour sécuriser la position du guide.

Mise en Marche/Arrêt

• Branchez la scie à ruban sur son alimentation électrique et utilisez le

bouton d’alimentation comme suivant :

• Pour mettre la scie en marche, appuyez sur le bouton vert marqué ‘I’.

• Pour l’éteindre, appuyez sur le bouton rouge marqué ‘0’.

• Comme mesure de sécurité,en cas de coupure de courant, l’interrupteur

s’éteindra. Au retour du courant, vous devrez appuyer sur le bouton vert ‘I’

pour réinitialiser la machine.

www.silverlinetools.com

15

Page 17

F

Réglage de la butée (Voir fig. 11)

• La butée doit toujours être positionnée parallèlement à la lame pour un

meilleur contrôle pendant la coupe.

1. Poussez le clip de fixation de la butée vers le haut pour pouvoir installer

la butée.

2. Déplacer la butée le long de la table en fonction de la coupe à réaliser.

3. Abaissez le clip pour sécuriser la position de la butée. Si le clip ne

procure pas assez de prise de maintien, vissez-le plusieurs fois dans

le sens horaire jusqu’à ce que le serrage soit suffisant.

Effectuer une coupe

• Après chaque réglage, il est recommandé d’effectuer une coupe test afin

de vérifier les réglages.

• Positionnez le guide supérieur de la lame aussi proche que possible de la

pièce de travail (voir ci-dessus pour plus d’information).

• Guidez la pièce de travail avec les deux mains, en la tenant par le côté plat

le plus long et en la gardant bien plate sur la table.

• Nourrir le bois sur la lame à vitesse constante pour que la lame puisse

couper sans difficulté et sans gripper.

• Utilisez toujours la butée sauf si la pièce de travail ne le permet pas.

• Essayez toujours d’effectuer une couple d’un seul trait plutôt que de

s’arrêter et reprendre. Si vous avez à repositionner la pièce de travail,

éteignez d’abord la scie et attendez que la lame soit complètement à l’arrêt

avant de libérer la pièce.

Utiliser le poussoir

• Lorsque vous travaillez sur des pièces étroites, utilisez toujours un poussoir

(fourni). Ne jamais placer vos mains proches de la lame en cours de

fonctionnement.

• Lorsque vous ne l’utilisez pas, suspendez-le sur le crochet situé à l’arrière

de la scie.

Faire une refente (Voir fig.12)

Lorsque vous effectuez une coupe dans le sens du grain :

• Positionnez si possible, la butée sur la gauche de la scie.

• Positionnez le bord de la pièce le plus loin possible de la lame, posez bien à

plat la pièce le long de la butée.

• Guidez la pièce de travail le long de la butée tout en nourrissant le bois sur

la lame de façon constante.

IMPORTANT : Pour les longues pièces, n’hésitez pas d’utiliser une servante

ou tout autre support pour leur poids ne fausse pas la coupe ou provoque

un accident.

Coupe biseautée. (Voir fig 13)

• La table de sciage peut s’incliner de 0° à 45° pour les coupes biseautées.

1. Relâchez la poignée de verrouilla ge de la table (21)

2. Inclinez la table à l’angle voulu, un utilisant l’échelle de biseau (22)

comme guide.

3. Resserrez la poignée de verrouilla ge de la table

• Lors de coupe biseautée, positionnez si possible la butée sur la droite de la

scie pour éviter que la pièce de travail ne glisse. (Voir fig.13).

• Pour des coupes ultra-précises, vérifiez l’angle en effectuant une coupe test

sur une chute ou autre.

Coupe à main levée

• Cette scie à ruban est idéale pour donner des formes aux matériaux et

obtenir de belles courbes.

• Comme pour toutes les autres coupes, abaissez le guide de la lame sur la

pièce de travail et positionnez la pièce sur la table de sciage de manière

sûre.

• Avant d’effectuer une coupe à main levée, coupez, si possible, le surplus

de matériau se trouvant approximativemtent au-delà de 6 mm du trace

de coupe.

• Guidez la pièce de travail doucement sur la lame. Utilisez une vitesse faible

pour garder le contrôle et la précision de la coupe.

• Pour des courbes serrées, il peut être utile d’effectuer une série de coupe

à angle droit le long du tracé de la courbe, ce qui permettra au surplus de

matériau de tomber facilement à la fin de la coupe.

ATTENTION : Des torsions excessives sur la lame pour effectuer des coupes

serrées peut endommager la lame , voire même la casser.

Entretien

ATTENTION : Toujours éteindre et débrancher la scie à ruban de sa source

d’alimentation avant d’effectuer toute manipulation d’entretien et de

nettoyage.

Nettoyage :

• Gardez l’appareil propre. Éliminez toujours la poussière et les particules

et ne laissez jamais les orifices de ventilation se boucher. Ne laissez pas

les déchets s’accumuler sur une partie quelconque de l’outil. Utilisez une

brosse souple ou un chiffon sec pour le nettoyage. Si possible, nettoyez les

orifices de ventilation à l’air comprimé propre et sec.

• N’utilisez pas d’agents caustiques sur les parties plastiques.

Changer la lame

1. Positionnez approximativement le guide supérieur de la lame (4) entre

la table et le boitier de la machine.

2. Relâchez les verrous des ca pots (11 et 14) afin d’ouvrir les capots (12).

3. Retirez la fixa tion de la table (8).

4. Tournez la molette d’ajustement de la tension de la lame (1) dans le sens

antihoraire pour relâcher la tension de la lame.

5. Retirez la lame des roues, et faites-la passer par la fente de la table.

6. Installez la nouvelle lame en s’assurant que les dents de la lame sont

dirigées vers le bas et vers la table.

7. Tendre la lame avec la molette d’ajustement de la tension de la lame (1)

dans le sens horaire (voir aussi ‘Tension de la lame’).

8. Refermez correctement les ca pots.

9. Repositionnez la fixa tion de la table.

Changer les courroies des roues

• Après un certain temps, les courroies s’usent et doivent être remplacée.

Vérifiez toujours l’état des courroies lorsque vous changez de lame.

1. Ouvrez les ca pots et retirez la lame (voir ‘changer la lame’ ci-dessus).

2. Soulevez chacun son tour, les bords de chaque courroies en utilisant un

petit tournevis et retirez-les avec précaution.

3. Installez les nouvelles courroies sur chaque roue.

4. Replacez la lame et fermez les ca pots.

Changer la plaque de passage pour la lame.

• La plaque pour le passage de la lame doit être remplacée si elle est

endommagée ou usée.

1. Soulevez la plaque usée. (Remarque : Si la plaque ne se soulève pas

facilement, démonter la table de sciage et retournez-la).

2. Posez la nouvelle plaque.

Remarque : Contactez votre revendeur Silverline ou visitez le site www.

toolsparesonline.com pour connaitre la disponibilité des pièces détachées de

ce modèle.

Recyclage

• Ne jetez pas vos appareils ni autres équipements électriques et

électroniques usagés avec les ordures ménagères.

• Contactez la collectivité chargée de la collecte des déchets pour de plus

amples informations concernant le recyclage de ce type de déchet.

16

Page 18

613578

Garantie Silverline Tools

Un produit Silverline bénéficie d’une garantie de 3 ans

Pour profiter de cette garantie, vous devez enregistrer le produit

sur Silverlinetools.com dans les 30 jours suivant l’achat. La période

de garantie débute le jour de l’achat mentionné sur la preuve d’achat.

Conditions de Garantie des Outils Silverline

La garantie et la période de garantie débutent le jour de l’achat

mentionné sur la preuve d’achat.

VEUILLEZ CONSERVER SOIGNEUSEMENT LA PREUVE D’ACHAT.

Si le produit présente une anomalie dans les 30 jours suivant l’achat,

retournez-le au revendeur, accompagné de la preuve d’achat et

en précisant en quoi consiste l’anomalie. Il vous sera remplacé ou

remboursé.

Si le produit développe un défault aprés la période de 30 jours,

renvoyez-l’à:

Silverline Tools Service Centre

PO Box 2988

Yeovil

BA21 1WU, UK

Une demande d’intervention au titre de la garantie doit être formulée

pendant la période de garantie.

Avant qu’une intervention puisse avoir lieu, vous devez fournir la

preuve originale d’achat sur laquelle doit figurer la date d’achat, vos

nom et adresse ainsi que le nom du revendeur.

Vous devez décrire de manière claire et détaillée l’anomalie

constatée.

Votre demande sera examinée par Silverline Tools qui déterminera

si l’anomalie provient d’un défaut de matière ou de fabrication et

s’assurera qu’elle s’est produite pendant la période de garantie.

Nous ne remboursons pas le transport. Tous les produits retournés doivent

se trouver dans un état de propreté et de sécurité convenant à une

réparation ; ils doivent être emballés soigneusement afin d’empêcher tout

dommage ou blessure pendant le transport. Nous nous réservons le droit

de refuser les produits retournés dans des conditions qui ne satisferaient

pas ces règles.

Tous les travaux de réparation sont réalisés par Silverline Tools.

La réparation ou le remplacement du produit ne prolongent pas la

période de garantie.

Les anomalies que nous reconnaissons comme couvertes par la

garantie seront corrigées par la réparation gratuite du produit (à

l’exclusion des frais de transport), ou par son remplacement.

Déclaration de conformité CE

Le soussigné : Mr Darrell Morris

Autorisé par : Silverline Tools

Déclare que le produit :

Nom/modèle : 613578

Nº de série/Type : Scie à ruban 250W

Est conforme aux directives suivantes :

• Directive sur les basses tensions 2006/95/CE

• Directive sur les machines 2006/42/CE

• Directive ROHS 2011/65/EU

• Compatibilité électromagnétique 2004/108/CE

• EN 61029-1/A11:2010, EN 61029-2-5:2002

• EN 55014-1/A1:2009, EN 55014-2/A2:2008

• EN 61000-3-2/A2:2009, EN 61000-3-3:2008

• BS 1363-5:2008

Scie à ruban 250 W

Enregistrement de l’achat

L’enregistrement s’obtient sur le site silverlinetools.com en cliquant

sur le bouton Guarantee Registration. Vous devez taper :

Les informations vous concernant

La désignation du produit et les éléments d’achat

Cela fait, le certificat de garantie est créé au format PDF ; vous

pouvez alors l’imprimer et le conserver avec votre achat.

Les produits ou les pièces ayant fait l’objet d’un remplacement

deviennent la propriété de Silverline Tools.

La réparation ou le remplacement d’un produit sous garantie offre

des avantages qui s’ajoutent à vos droits de consommateur prévus

par la loi sans leur porter préjudice.

Ce qui est couvert :

La réparation du produit s’il s’avère que l’anomalie constatée tient à

un défaut de matière ou de main d’œuvre survenu pendant la période

de garantie.

Si une pièce n’est plus disponible ni fabriquée, Silverline Tools la

remplace par une pièce similaire remplissant la même fonction.

L’utilisation du produit en Europe.

Ce qui n’est pas couvert :

La garantie Silverline Tools ne prend pas en charge les réparations

consécutives à:

L’usure et la détérioration normales causées par l’utilisation conforme

aux consignes d’emploi ; exemples de pièces d’usure : les lames, les

balais, les courroies, les ampoules, les batteries, etc.

Le remplacement des accessoires fournis tels que les forets, les

lames, les feuilles de papier abrasif, les disques de coupe et autres

articles similaires.

Les dommages accidentels, les défauts dus à une négligence, un

manque d’attention, un emploi abusif, un mauvais entretien, une

utilisation ou un traitement abusifs du produit.

L’utilisation du produit à des fins autres que l’usage domestique normal.

La modification du produit, de quelque manière que ce soit.

L’utilisation de pièces et d’accessoires qui ne sont pas des

composants d’origine Silverline Tools.

L’installation incorrecte du produit (sauf en cas d’installation par

Silverline Tools).

Les réparations ou les modifications effectuées par une entreprise

autre que Silverline Tools ou ses agents de réparation agréés.

Les demandes d’intervention sous garantie pour autre chose que la

correction de l’anomalie constatée sur le produit, ne sont pas prises

en considération.

La documentation technique est conservée par : Silverline Tools

Organisme notifié : JIANGSU TUV PRODUCT SERVICE LTD

Lieu de la déclaration : SHANGHAI, CHINE

Date : 5/11/12

Signature :

Directeur

Nom et adresse du fabricant ou de son représentant agréé :

Silverline Tools, Boundary Way, Lufton Trading Estate, Yeovil, Somerset,

BA22 8HZ Royaume-Uni

www.silverlinetools.com

17

Page 19

D

Beschreibung der Symbole

Auf dem Leistungsschild des Werkzeugs sind möglicherweise Symbole

abgebildet. Sie vermitteln wichtige Informationen über das Produkt oder

dienen als Gebrauchsanweisung.

Gehörschutz tragen

Augenschutz tragen

Atemschutz tragen

Kopfschutz tragen

Schutzhandschuhe tragen

Bedienungsanleitung sorgfältig lesen

Schutzklasse I (Schutzleiter)

Erfüllt die entsprechenden rechtlichen Vorschriften und