Page 1

User Manual

- R19 -

Page 2

2 User Manual

Introduction

UE Warranty

Non-UE Warranty

Conformity

Specifications

IDEX / FFF Technology

Safety

Safety Signage

Setting Up Your Printer

Unboxing

Contents

Set up

Getting started

Setup Assistant

Mirror and Duplication modes

Installing shims

First Printing

Starting Out With BCN3D Cura

Your first dual print

First Mirror/Duplication print

Firmware Upgrade

Functionalities

Operation and maintenance

Change hotend

Clean and lubricate axes

Hotend cleaning

Filament

Maintenance Plan

BCN3D Technologies Technical Assistance Services

Diagram Of The Sigma R19

Return Policy

Terms And Conditions Of Service

Open Source

Contents

3

3

5

8

9

10

10

12

13

13

14

15

21

21

24

26

28

29

29

33

34

36

38

38

44

48

50

53

54

55

57

58

59

Page 3

User Manual 3

List of Consumable components

This document lists the Consumable

components that, due to their natural

detoriotation, are excluded from the

Warranty: Hotends, Teflon Tube, Glass

printing surface, Filament Spools, Glue

Stick, Printed Parts, Calibration Gauges,

Shims, Lubrication Kit.

Technical Support

For any questions or problems with

BCN3D Products, please contact us at:

c/ Esteve Terrades, 1

Edifici RDIT del PMT, 2a Planta 216

08860 Castelldefels, Barcelona (España)

email: support@bcn3dtechnologies.com

Tel: +34 934137088

Fundació Privada Centre CIM

c/ Llorens i Artigas, 12

08028 Barcelona (España)

Tel. +34 934017171

CIF: G63749162

Fundació Privada Centre CIM (“Fundació CIM”) grants

this Warranty to the BCN3D brand Product users.

This Warranty is only valid in the country where the

Product has been purchased originally, as long as it

is member of the European Union, Iceland, Norway,

Switzerland, Liechtenstein or Turkey. Otherwise, review

the Warranty for non EU countries.

Fundació CIM guarantees that, within the Warranty

Period, Fundació CIM or an authorized service company

will correct, in a reasonable commercial time, the claims

related with the non-conforming Product according to

the following clauses.

Warranty Period

The Warranty Period starts when the Product is first

delivered to the end-user.

The Warranty period lasts twenty-four (24) months.

Both the parts that suffer wear and tear due to the

normal operation of the Product and the “Consumable”

elements are not covered by this Warranty.

The present Warranty is invalidated in case of incurring

in any of the cases exposed in the Exclusions chapter.

In case of resale, repair or substitution of the

Products the Warranty is not extended. The repaired

or substituted parts are covered until the end of the

Warranty Period or during six (6) months, depending on

which date is later.

EU Warranty

Introduction

Page 4

4 User Manual

How to get Warranty Service

In case of non-conformity with the Product:

1 Notify the seller before the end of the Warranty

Period

2 Supply all the information to Fundació CIM or to the

authorized service company about the nature of the

claim in the period of two (2) months since its detection

and never after the end of the Warranty Period.

3 Supply the original proof of purchase, which includes

the Product serial number

In case of doubt, contact the Fundacio CIM Technical

Assistant Service (“TAS”) (support@bcn3dtechnologies.

com) or the authorized service company

Claim handling

1 The remedy of the non-conforming Product is solely

determined by Fundació CIM or the authorized service

company within a reasonable commercial time.

2 The amendment may consist in the repair, part

replacements or total substitution of the Product,

depending on each situation and disposed by Fundació

CIM or the authorized service company (unless the

current legislation states it otherwise).

3 The client takes responsibility for the transport of the

machine to the facilities of BCN3D (going and return).

4 Fundacio CIM or the authorized service company,

depending on which handles the claim, bears the repair,

parts replacement or Product substitution costs.

5 All damaged, defective or replaced parts or Products

become the property of Fundació CIM or the authorized

service company.

Exclusions

This Warranty does not cover:

1 Physical damage caused by an inappropriate

transport (not using the official packaging) or handling

(including unlimitedly the damages caused by sharp or

cutting elements, bending or compressing parts or fall

of the Product).

2 The normal wear and tear occurred for the product

normal use, including unlimitedly the wear of moving

parts, control panels or elements interacting with the

product operation.

3 The damages inflicted by the non-compliance of the

Maintenance Plan specified in the Product User Manual.

4 Malfunctions or damage caused by modifications,

alterations or repairs by any individual or company

not authorized by Fundació CIM. The Consumable

replacements are excluded of this point.

5 Damage caused by power grid failures

6 Damage caused by abuse, misuse, accidents or

neglect using the Product.

7 Resulting damages of exposing the Product to floods,

fire, humidity, spillage of food or chemicals, corrosion,

oxidation, extreme weather conditions or any other

external agent.

8 Damages caused by the use of software non

recommended by Fundació CIM.

9 Damages caused by the use of printing materials non

recommended by Fundació CIM .

10 The components considered as Consumables,

EU Warranty

Page 5

User Manual 5

Fundació Privada Centre CIM (“Fundació CIM”) grants

this Warranty to the BCN3D Technologies brand

Product users.

This Warranty is only valid in the country where the

Product has been purchased originally, as long as it is

not member of the European Union, Iceland, Norway,

Switzerland, Liechtenstein or Turkey. Otherwise, check

the Warranty for EU countries.

Warranty Period

The Warranty Period starts when the Product is first

delivered to the end-user.

The Warranty period lasts twelve (12) months. Both

the parts that suffer wear and tear due to the normal

operation of the Product and the “Consumable”

elements are not covered by this Warranty.

The present Warranty is invalidated in case of incurring

in any of the cases exposed in the Exclusions chapter.

In case of resale, repair or substitution of the Products

the Warranty is not extended. The repaired or substituted parts are covered until the end of the Warranty

Period or during six (6) months, depending on which

date is later.

Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not

apply to you.

How to get Warranty Service

In case of non-conformity with the Product:

1 Notify the seller before the end of the Warranty

Period

Non-EU Warranty

EU Warranty

However, this Warranty does not limit either the consumer user rights specified in the legislation nor the the

rights against the seller, also defined in the legislation.

Fundació CIM waives all liability for any loss of businesses, loss of contracts, loss of benefits, loss of savings,

increase of costs or expenses due to the use of any

of its Products. Likewise, Fundació CIM refuses any

indirect, incidental, collateral damage by the use of its

Products.

numbered in the annexed document.

Limitations and Disclaimers

This Warranty is the end user’s sole and exclusive

remedy against Fundació CIM and the sole and exclusive responsibility of Fundació CIM to defects in their

Products. Therefore, this Warranty supersedes any

other warranties issued by Fundació CIM, either oral or

written in any form.

Page 6

6 User Manual

Claim handling

1 The remedy of the non-conforming Product is solely

determined by Fundació CIM or the authorized service

company within a reasonable commercial time.

2 The amendment may consist in the repair, part

replacements or total substitution of the Product,

depending on each situation and disposed by Fundació

CIM or the authorized service company (unless the

current legislation states it otherwise).

3 The client takes responsibility for the transport of the

machine to the facilities of BCN3D (going and return).

4 Fundacio CIM or the authorized service company,

depending on which handles the claim, bears the repair,

parts replacement or Product substitution costs.

5 All damaged, defective or replaced parts or Products

become the property of Fundació CIM or the authorized

service company.

2 Supply all the information to Fundació CIM or to the

authorized service company about the nature of the

claim in the period of two (2) months since its detection

and never after the end of the Warranty Period.

3 Supply the original proof of purchase, which includes

the Product serial number

In case of doubt, contact the Fundacio CIM Technical

Assistant Service (“TAS”) (sat@bcn3dtechnologies.com)

or the authorized service company.

Exclusions

This Warranty does not cover:

1 Physical damage caused by an inappropriate

transport (not using the official packaging) or handling

(including unlimitedly the damages caused by sharp or

cutting elements, bending or compressing parts or fall

of the Product).

2 The normal wear and tear occurred for the product

normal use, including unlimitedly the wear of moving

parts, control panels or elements interacting with the

product operation.

3 The damages inflicted by the non-compliance of the

Maintenance Plan specified in the Product User Manual.

4 Malfunctions or damage caused by modifications,

alterations or repairs by any individual or company

not authorized by Fundació CIM. The Consumable

replacements are excluded of this point.

5 Damage caused by power grid failures

6 Damage caused by abuse, misuse, accidents or

neglect using the Product.

7 Resulting damages of exposing the Product to floods,

fire, humidity, spillage of food or chemicals, corrosion,

oxidation, extreme weather conditions or any other

external agent.

8 Damages caused by the use of software non

recommended by Fundació CIM.

9 Damages caused by the use of printing materials non

recommended by Fundació CIM .

Non-EU Warranty

Page 7

User Manual 7

10 The components considered as Consumables,

numbered in the annexed document. Some states do

not allow the exclusion of incidental or consequential

damages, so the above limitation or exclusion may not

apply to you.

Limitations and Disclaimers

This Warranty is the end user’s sole and exclusive

remedy against Fundació CIM and the sole and

exclusive responsibility of Fundació CIM to defects in

their Products. Therefore, this Warranty supersedes any

other warranties issued by Fundació CIM, either oral or

written in any form.

However, this Warranty does not limit either the

consumer user rights specified in the legislation nor

the the rights against the seller, also defined in the

legislation.

Fundació CIM waives all liability for any loss of

businesses, loss of contracts, loss of benefits, loss of

savings, increase of costs or expenses due to the use of

any of its Products. Likewise, Fundació CIM refuses any

indirect, incidental, collateral damage by the use of its

Products.

Non-EU Warranty

Page 8

8 User Manual

2006/42/EEC Machinery Directive

2006/95/EEC Low Voltage Directive

2004/108/EEC Electromagnetic Compatibility Directive (EMC)

2011/65/EU Restrictions on the use of hazardous substances in electrical and elec-

tronic equipment (RoHS)

The Sigma R19 printer has been manufactured in compliance with the following harmonised standards, and consequently conforms to the essential requirements established by the Directives:

2006/42/EEC UNE-EN ISO 12100:2012; UNE-EN ISO13732-1 :2008; EN ISO 7010:2012

2006/95/EEC UNE-EN 60204-1;UNE-EN 60947-3:2009

2004/108/EEC UNE-EN 55022:2011; UNE-EN 55024:2011; UNE-EN 61000-4-3-2:2007

Changes / modifications not approved by the responsible party could void the user’s authority to operate the

equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

The CIM Private Foundation Centre declares that the Sigma R19 printer complies with the essential requirements

and any other applicable or mandatory provisions of the Directives.

It complies with the essential requirements of the European Directives:

Conformity

Fundació Privada Centre CIM

Llorens i Artigas, 12 08028 Barcelona.

Tel: +34 934017171

www.fundaciocim.org

REI-RAEE: 6107

Page 9

User Manual 9

Manufacturing technology

Architecture

General dimensions

Weight

Printing volume

Number of extruders

Nozzle diameter

Layer height

Positioning resolution

Operating temperature

Maximum extruder temperature

Maximum printing surface temperature

Filament diameter

Compatible material

Electronics

Connectivity

Firmware

Operating sound

Compatible files

Software preparation files

Power supply

Electrical energy consumption

Fused filament fabrication (FFF)

Independent dual extruder (IDEX)

465 mm x 440 mm x 680 mm (fully assembled)

15 kg (without filament spools)

210 x 297 x 210 mm

2

0.3 / 0.4 standard / 0.5 Special / 0.6 / 0.8 / 1mm

0.05-0.5 mm (depending on the nozzle diameter)

Axis X: 0.0125 mm

Axis Y: 0.0125 mm

Axis Z: 0.001 mm

15 ºC - 35 ºC

290 ºC

100 ºC

2.85 ± 0.05 mm

PLA / ABS / Nylon / PET-G / TPU / PVA / Composites / Others

BCN3D Electronics v1.0

SD card (autonomous operation), USB

BCN3D Sigma - Marlin

50 dBA

gcode

Recommended: BCN3D Cura

Compatible: Slic3r, Simplify3D,...

AC 84–240 V, AC 3.6-1.3A, 50–60 Hz

240W

Specifications

Page 10

To avoid potential residual risks the user should read and understand the following safety measures (you are

strongly advised to read this before using the machine).

To highlight the areas where extra care should be taken, safety alert stickers have been affixed to the relevant parts

of the machine to warn the user of potential hazards.

Any modifications made to the machine without the manufacturer´s approval will invalidate the product´s

Declaration of Conformity (CE) and warranty.

Consequently, the Fundació CIM and BCN3D Technologies ARE EXEMPT FROM ANY LIABILITY IF THE USER DOES

NOT FOLLOW THE INSTRUCTIONS FOR USE:

IDEX / FFF technology

Safety

The Sigma R19 is a 3D printer which uses

fused filament fabrication (FFF) technology,

which manufactures objects by depositing

molten material in a series of layers. Objects

are created using a digital model of the object,

which is sliced into thin layers. When printing

the extruder print head moves along the axis

to deposit the material for one layer at a time,

before moving slightly upwards to begin printing

a new layer. This process is repeated until the

object has been completed.

Since FFF technology requires deposite material on top of plastic previously

extruded, certain complex geometries with overhangs require additional support

structures to be successfully printed. However, printing supports with the same

material of the model can result in many post-processing problems.

The Independent Dual Extruder System (IDEX) is BCN3D’s unique approach to avoid this issue and also offers a

bunch of new key features. The two extruders are controlled independently, so that when one extruder is not being

used it can be kept away from the printing area to prevent the plastic from oozing onto the object and spoiling the

final result.

Having two independent extruders offer the user the ability to print, not only with soluble supports, but also multimaterial objects, print in two different colors or even combine different nozzle sizes to get more resistant parts or

cut down the printing process.

10 User Manual

Page 11

User Manual 11

Safety

Very important. As with any other appliance, do not touch the terminals of the mains, the

switch, or the power supply. There is a risk of electrocution. The other cables of the machine

operate at 24V and there is no risk whatsoever.

Connect the machine to an electrical outlet according to the current legislation.

Do not connect or disconnect any device and/or electrical connector when the machine is

connected to the power supply.

Keep all of your body and all objects away from the moving parts of the machine when they are

moving.

Do not touch the hot parts (heated bed and hot-ends) when the machine is switched on, and

wait 15 minutes after it has been switched off before touching them.

Handle the glass printing surface with care. Make sure it is not dropped or hit with anything as

this could seriously damage it.

The printing materials are not innocuous and emit toxic fumes. Always print in open or wellventilated spaces and use a protective mask.

Do not breathe closer than 25 cm from the tool head when printing.

Supervise the printer while it is printing to make sure it is working properly.

In the event of emergency, stop the machine immediately by pressing the switch, and

disconnect the power supply.

This device is not a toy. It should only be used by minors under 16 under the supervision of an

adult.

The spatula is a dangerous tool that can cause injuries. Use it only to remove plastic rests

when running the calibration assistant.

Page 12

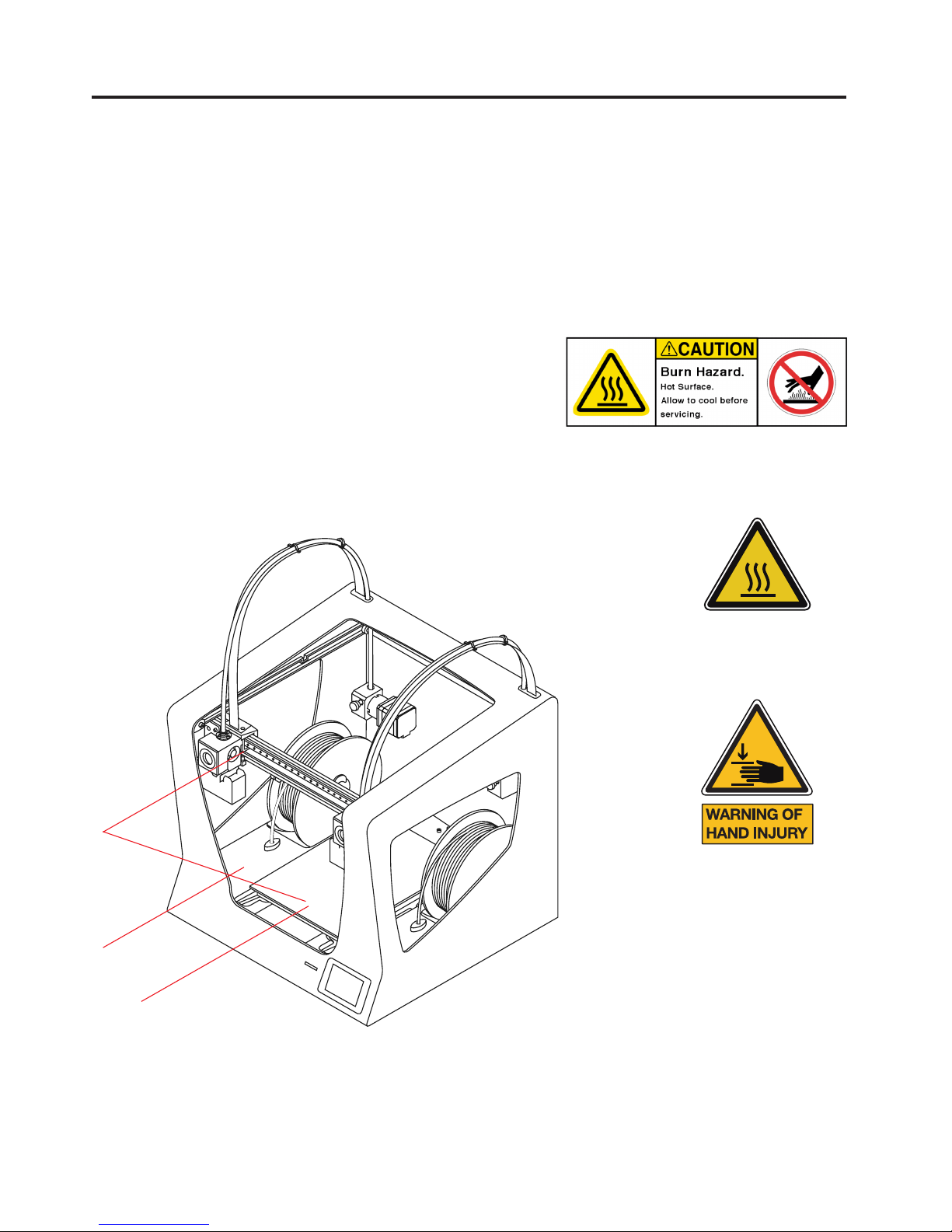

Safety signage

The following stickers have been affixed to the printer

to warn users about the hazardous areas of the

machine, and actions which are not recommended as

they will stop the machine from working properly.

1 Pictogram: Danger. Hot

surface.

2 Pictogram: Danger. Will

cause burns.

3 Pictogram: Risk of trapped hand/ finger.

12 User Manual

1

3

2

Page 13

User Manual 13

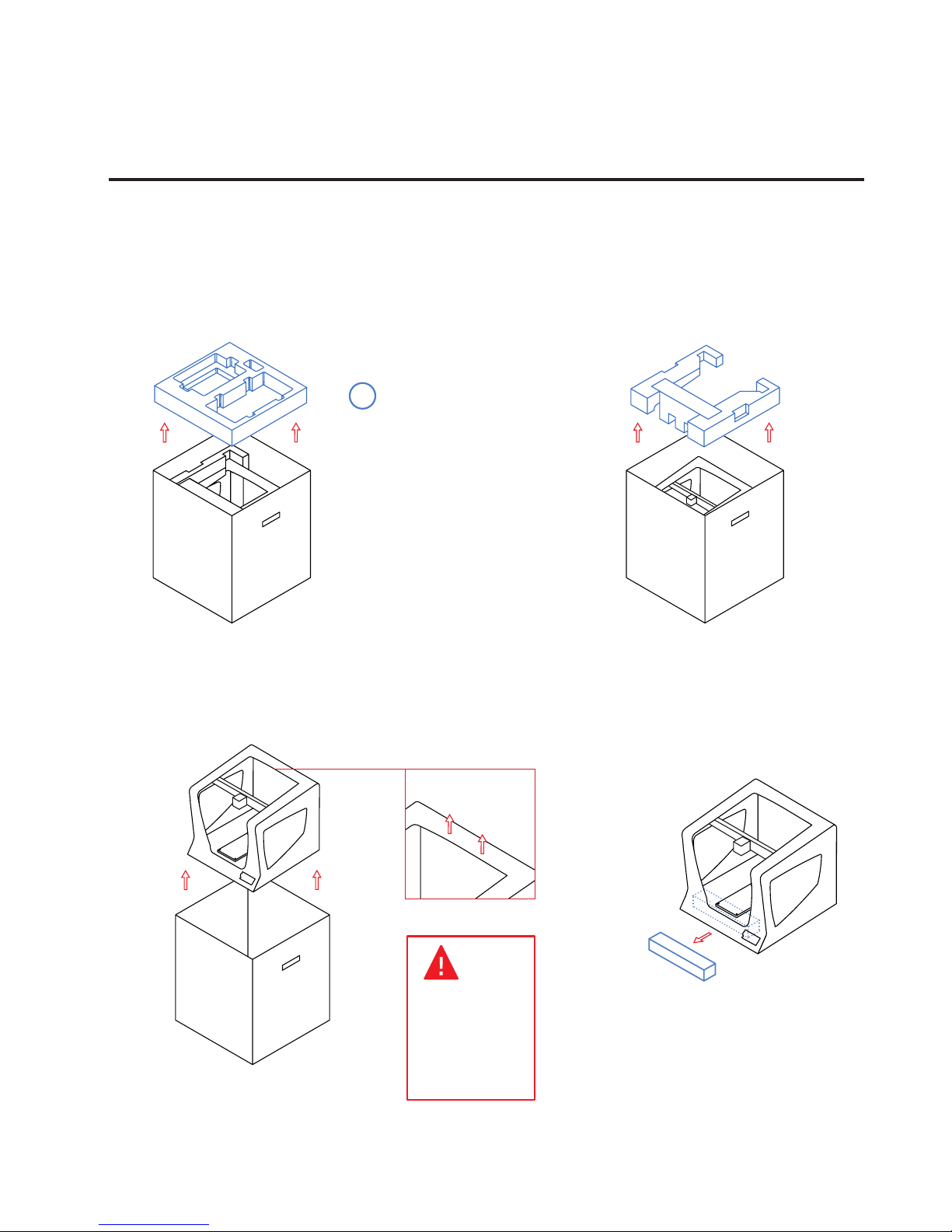

Unboxing

Setting up your printer

The Sigma R19 is delivered in a well-secured cardboard box which measures 550 x 660 x 570mm. We recommend

you to follow the steps below in order to unpack your 3D printer correctly:

1. 2.

3. 4.

Retain packaging for

warranty service.

i

Take out the printer with the plastic bag. Finally, remove the plastic bag

and the foam under the platform.

Proper zone

to take out the

printer with

your hands.

Page 14

14 User Manual

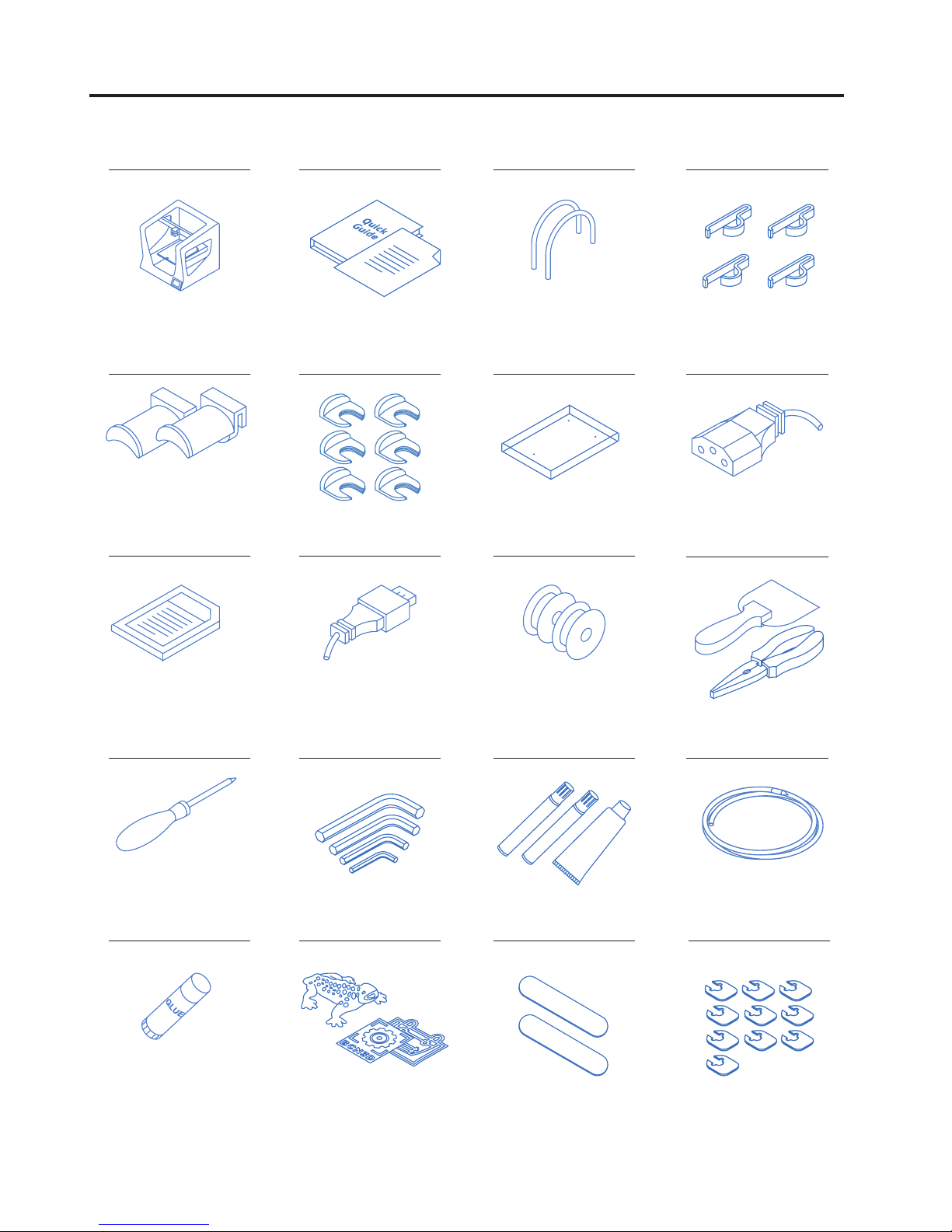

Contents

with 0.4mm hotends

2 Spool holders

SD card

Cross-head screwdriver

Glue Stick

Quick start guide and warranty

6 Clips

USB cable

4 Allen keys

Sample print/Stickers

2 Teflon tubes

Glass printing surface

2 PLA spools

Lubrication Kit

2 Calibration gauges

4 Flat cable clips

Power Cable

Spatula and Pliers

Nylon cleaning filament

10 Shims

Sigma R19:

Page 15

User Manual 15

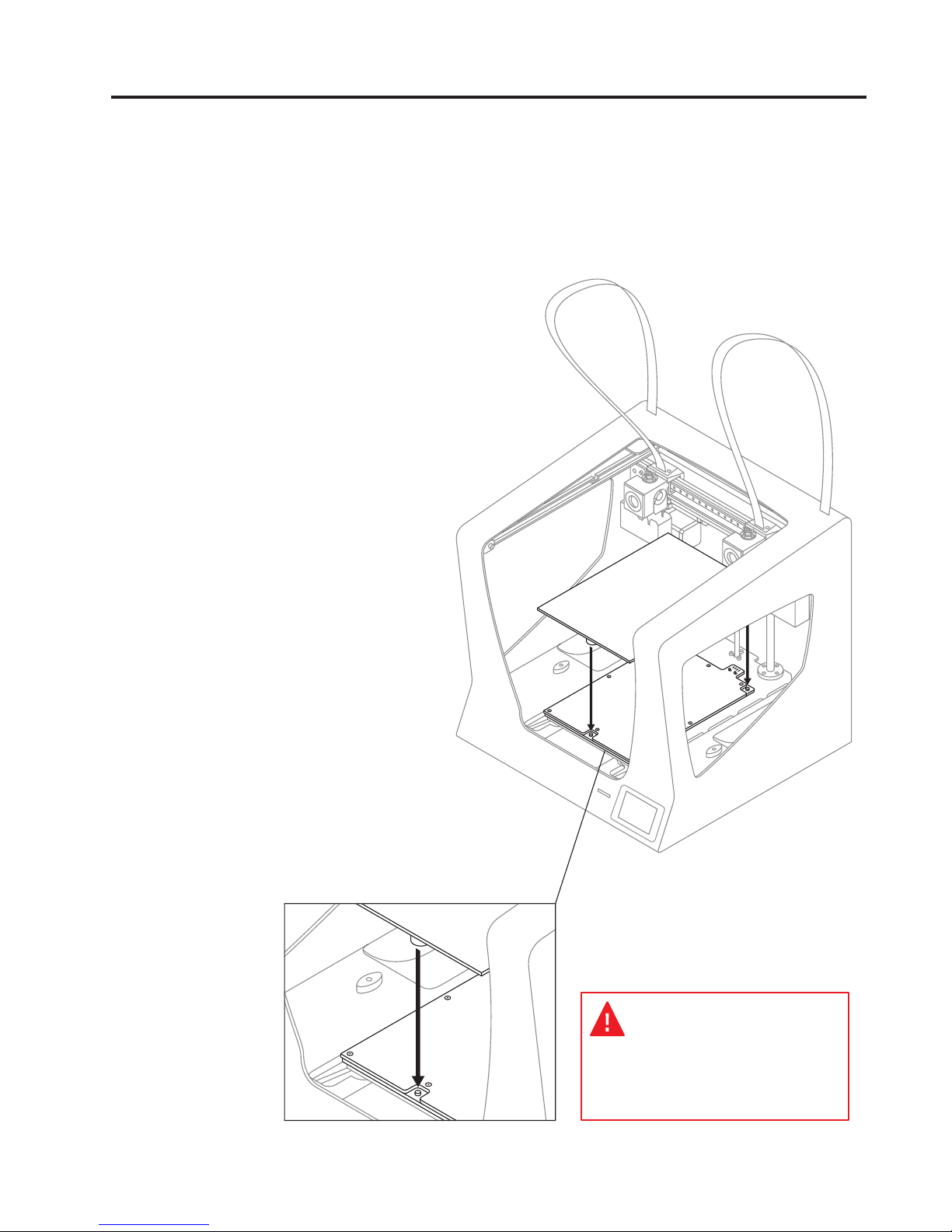

Set up

In order to ensure the safe packaging and transport of

your printer some of the components have been sent

unassembled. Before starting to print with the Sigma

R19 printer you need to assemble them in order to

complete the setting up process.

If you have any queries while assembling the machine,

please contact BCN3D Technologies technical service at

support@bcn3dtechnologies.com.

Follow the steps below to prepare the printer:

1.

Place the glass printing

surface on the platform. The

slots must match.

The glass printing surface must be

handled with care. In case of breakage,

may cause injuries.

Page 16

16 User Manual

Set up

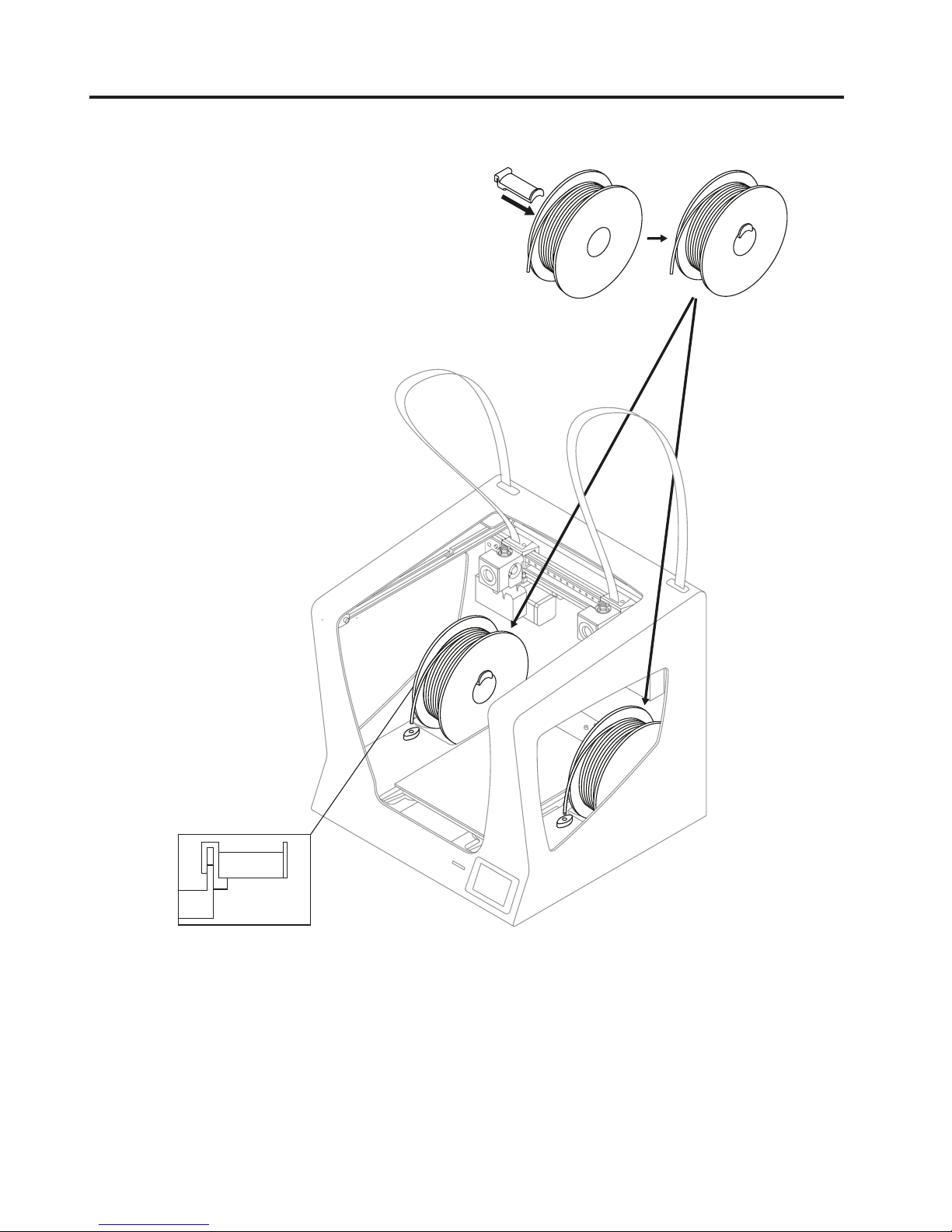

2.

Place the spools holders into the spools.

3.

Fit them into the indicated holes.

Page 17

User Manual 17

Set up

4.

Move Y axis manually

towards the front in order to

work more comfortably.

5.

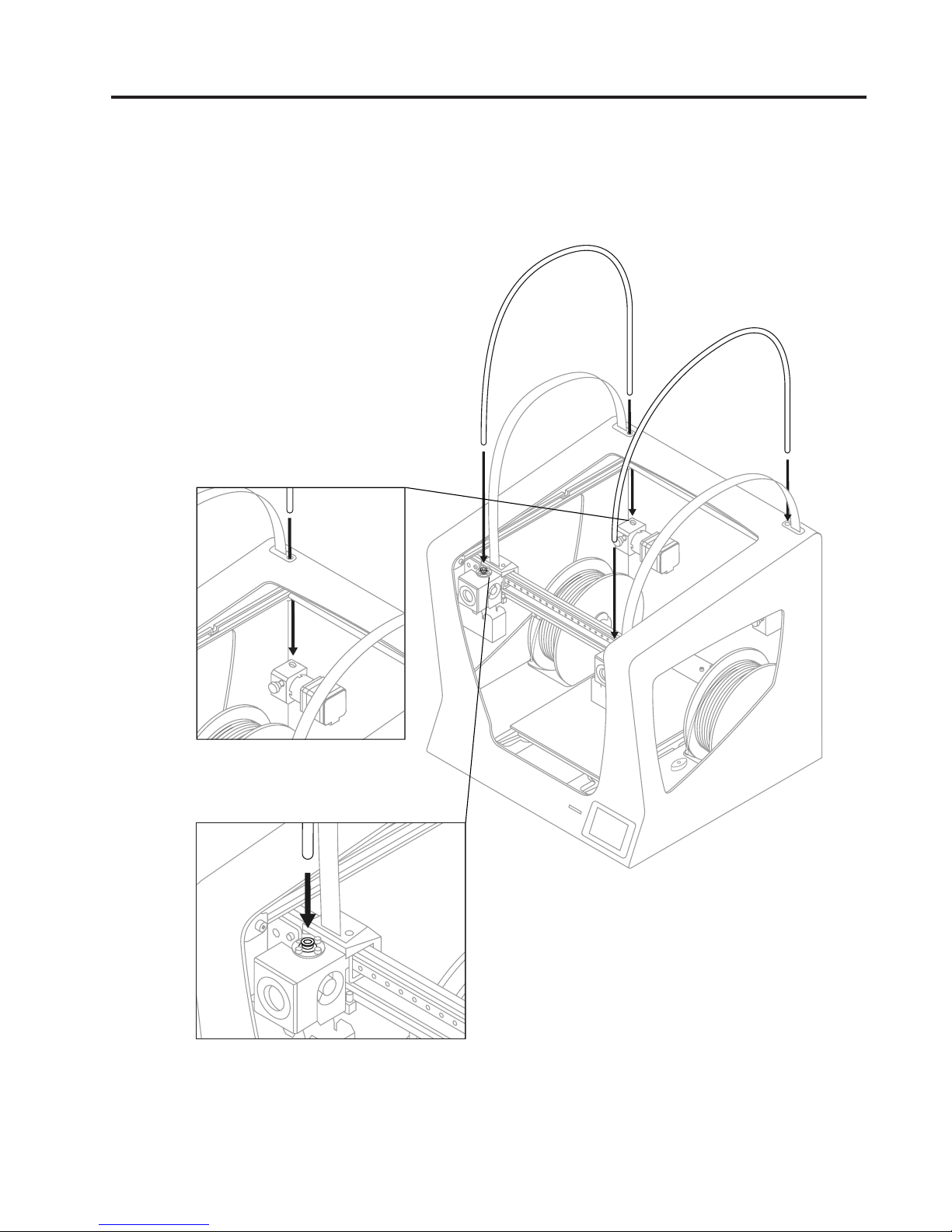

Insert the teflon tube until it

stops.

6.

Insert the opposite end

of the teflon tube into the

hotend’s hole until it stops.

Page 18

18 User Manual

Set up

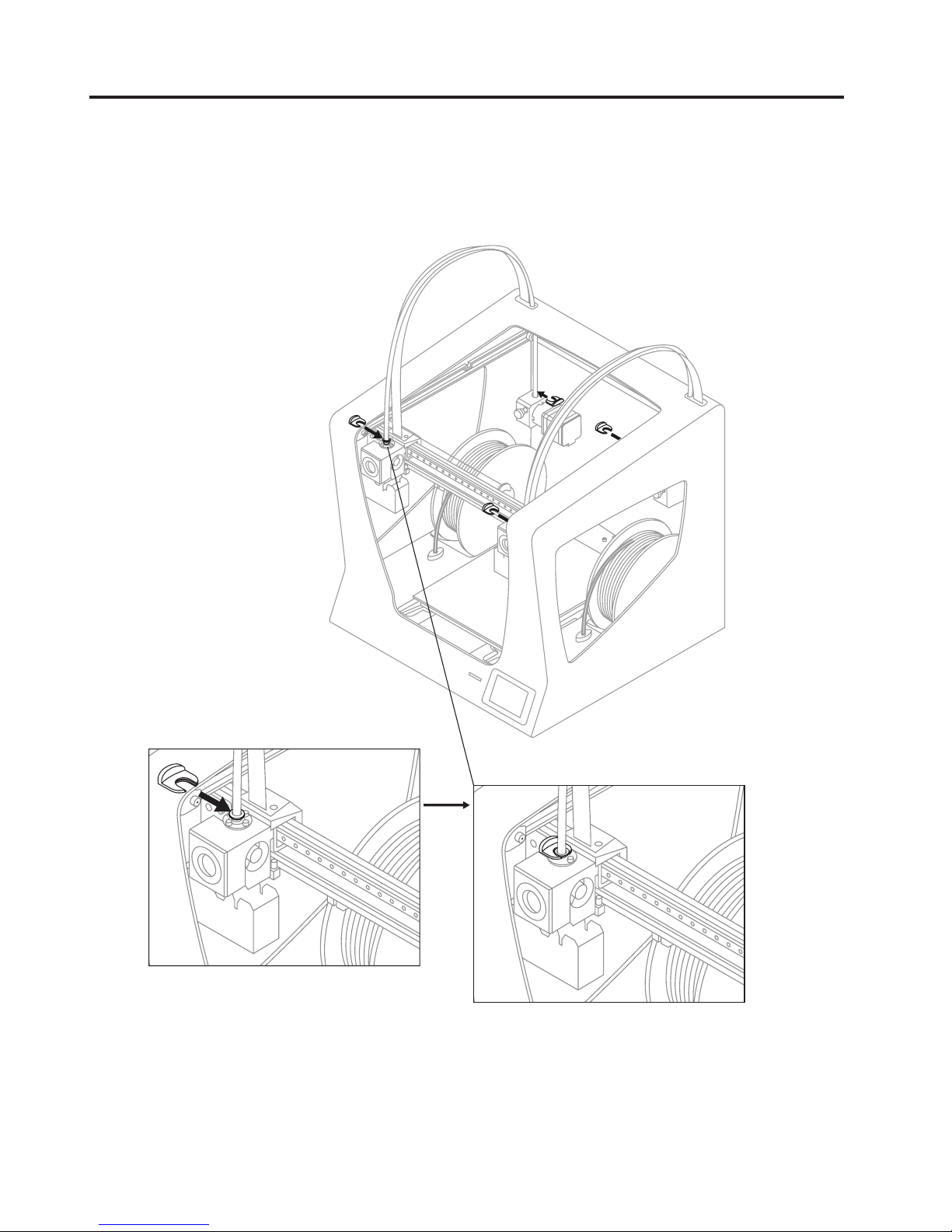

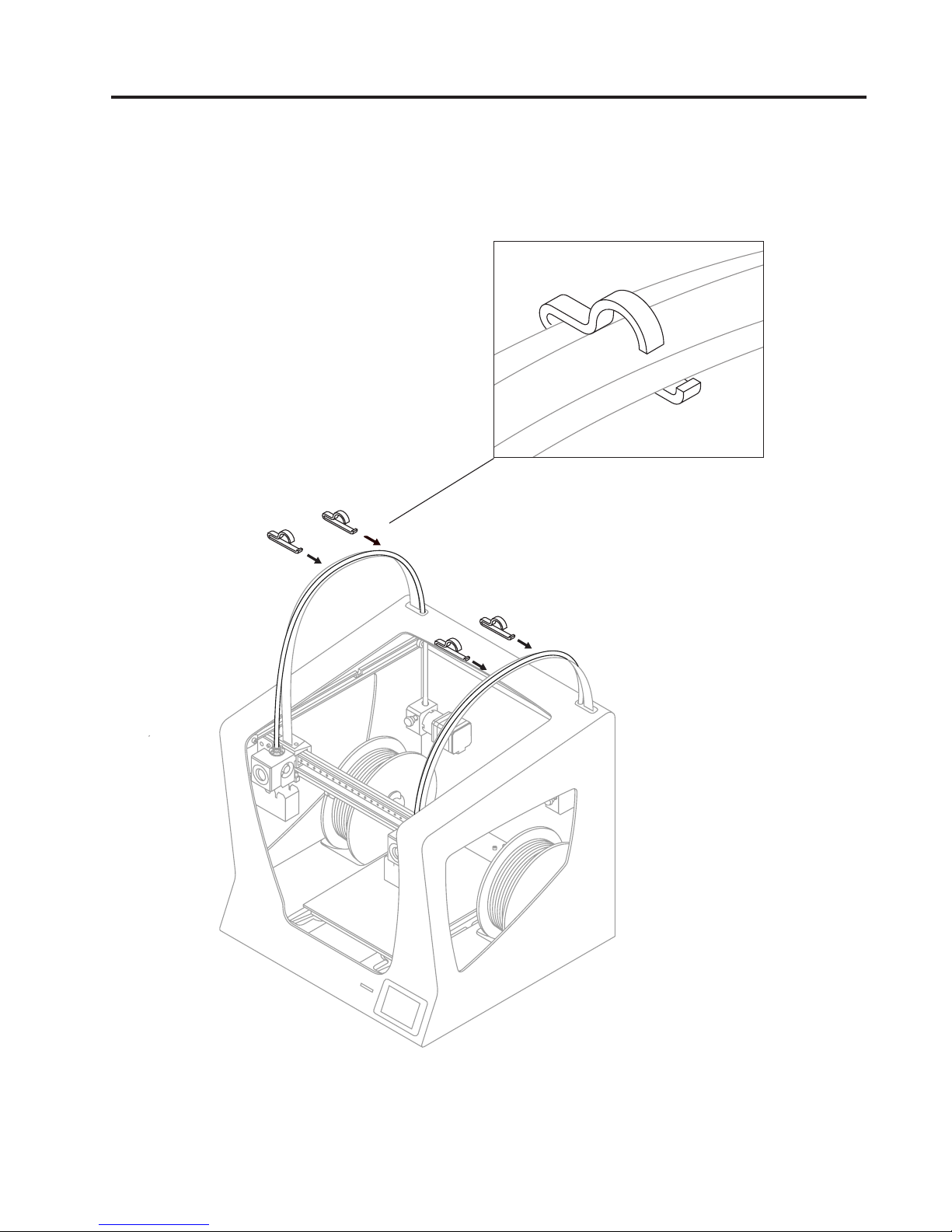

7.

Attach the teflon tubes with

the clips.

Page 19

User Manual 19

8.

Put together the teflon tube with the

hotend cable using the flat cable clips.

Set up

Page 20

20 User Manual

Set up

9.

Connect the power supply

cable. The plug is located at

the rear of the machine.

10.

Insert the SD card into the reader.

Page 21

User Manual 21

Getting started

1. Welcome

4. Select material

Choose PLA.

7. Printer calibration

Press Next.

8. Glass printing surface calibration.

6. Repeat the process for the second

extruder.

Setup Assistant

Warning: Extruders

will be heated up. This

process could take 1

or 2 minutes.

9. Turn calibration screw

as indicated in the touchscreen.

2. Setup Assistant 3. Load filament

Press Next.

5. Follow screen’s instructions

in order to load the filament.

Press Accept.

Cut the filament at 45º to

ease the insertion.

Page 22

22 User Manual

Setup Assistant

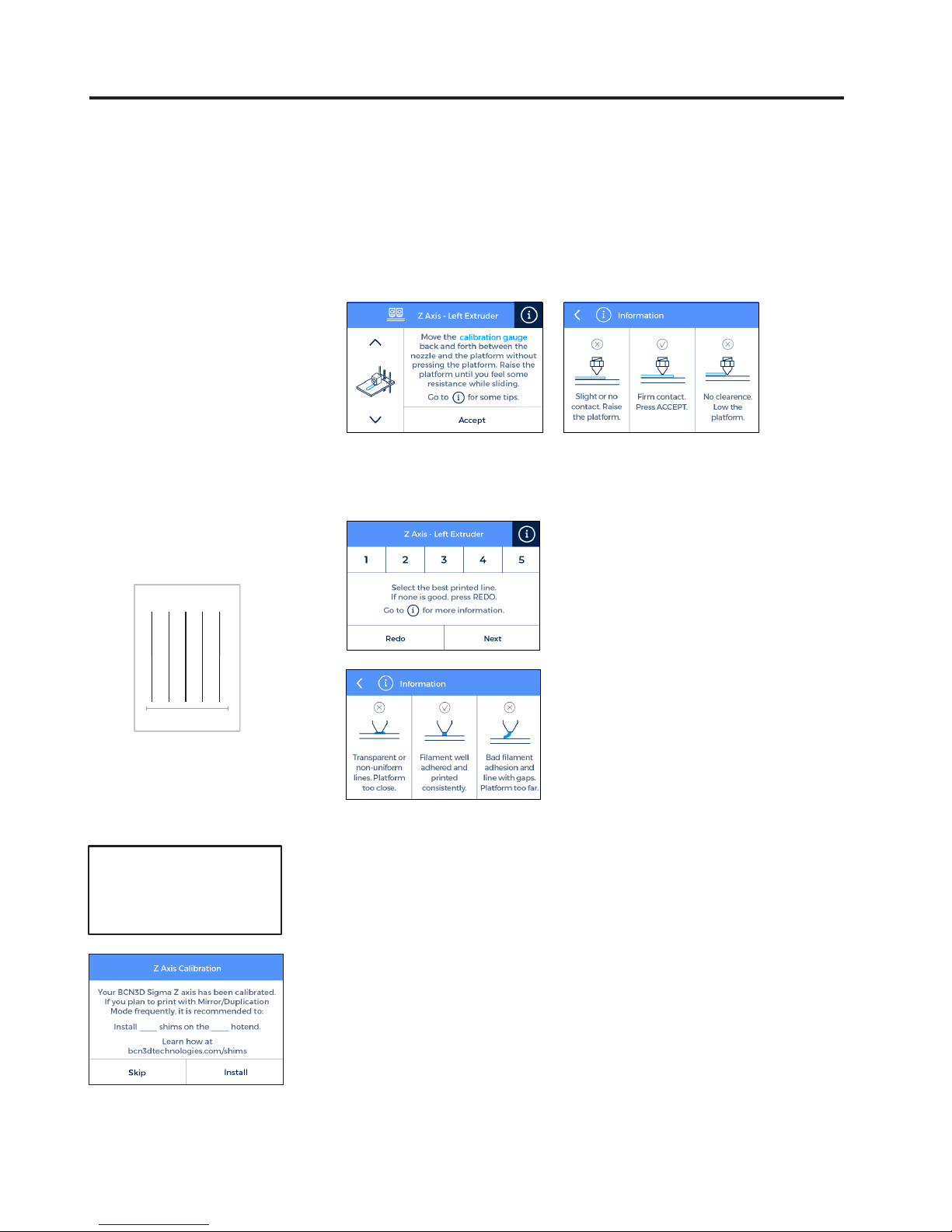

10. Z Axis calibration

To carry out the following

process, when indicated on

the screen, apply a thin and

uniform layer of glue stick on

the entire printing surface

glass to ensure a better

calibration.

11. Place the Calibration Gauge between the nozzle and the

printing surface glass. Hold the gauge by the end and move

it back and forth, without pressing the platform. Raise the

platform until you feel some resistance while sliding the

gauge. The gauge should not flex.

· If the nozzle is too close

to the glass, the line will be

transparent or non-uniform.

· The line must be adhered to

the printing glass and with

no gaps.

· If the nozzle is too far to

the glass, the line won’t

be properly adhered to the

printing glass and will be

gaps in it.

13. Select the best line. 12. The printer will print a

test to validate the previous

process.

1 5

NOTE: Depending on the

Z axis calibration, it may

appear this recommendation

screen.

If so, please check next

section: “Installing shims”

(page 26) for a detailed

explanation of the reason,

benefits and procedure to

perform this operation.

14. Repeat processes 11-13

for the second extruder.

Page 23

User Manual 23

Setup Assistant

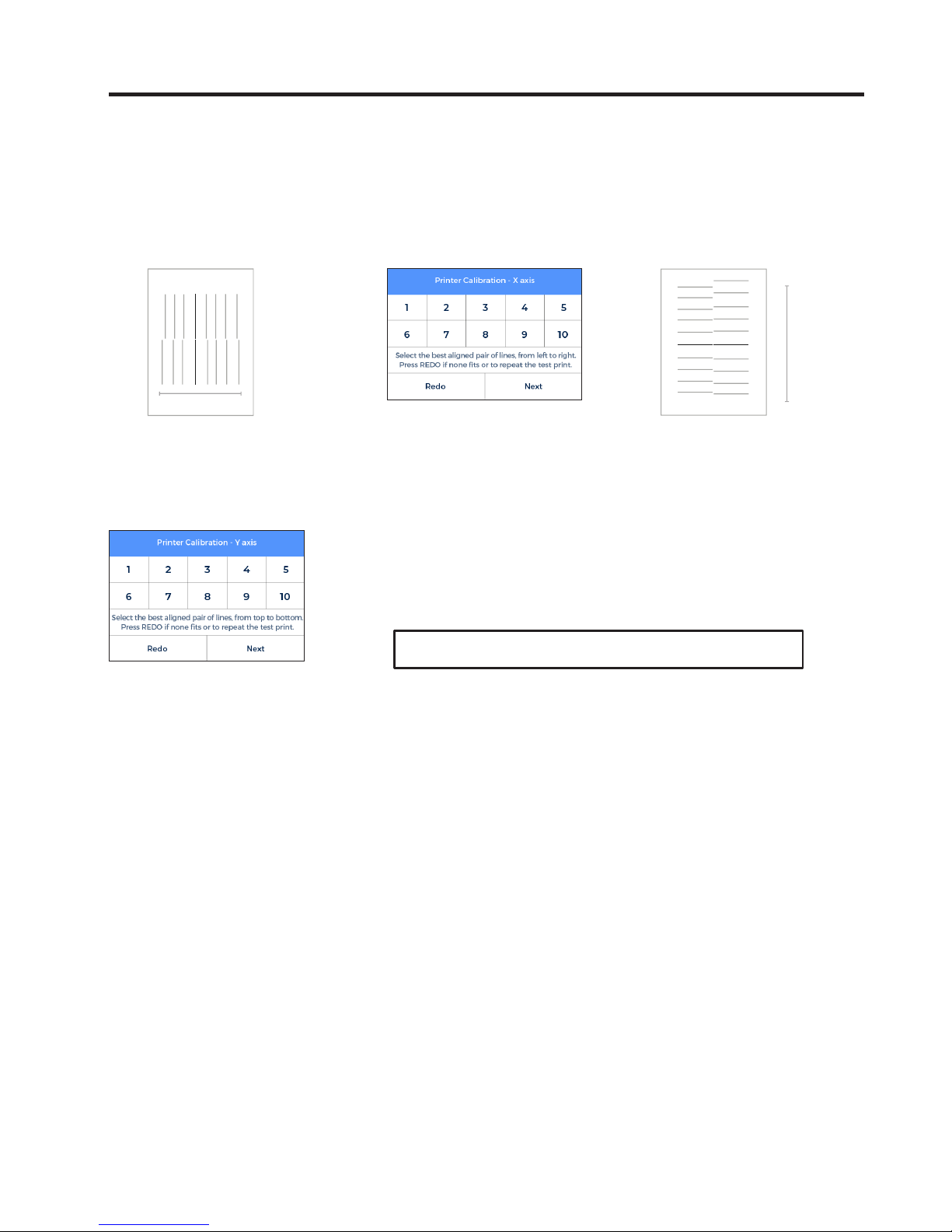

16. Choose best aligned

couple of lines.

17. Y Axis calibration

The printer will print

horizontal lines.

15. X Axis calibration

The printer will print vertical

lines.

18. Choose best aligned

couple of lines.

1

10

1 10

Congratulations! Your printer has been calibrated and it’s ready to print.

Page 24

24 User Manual

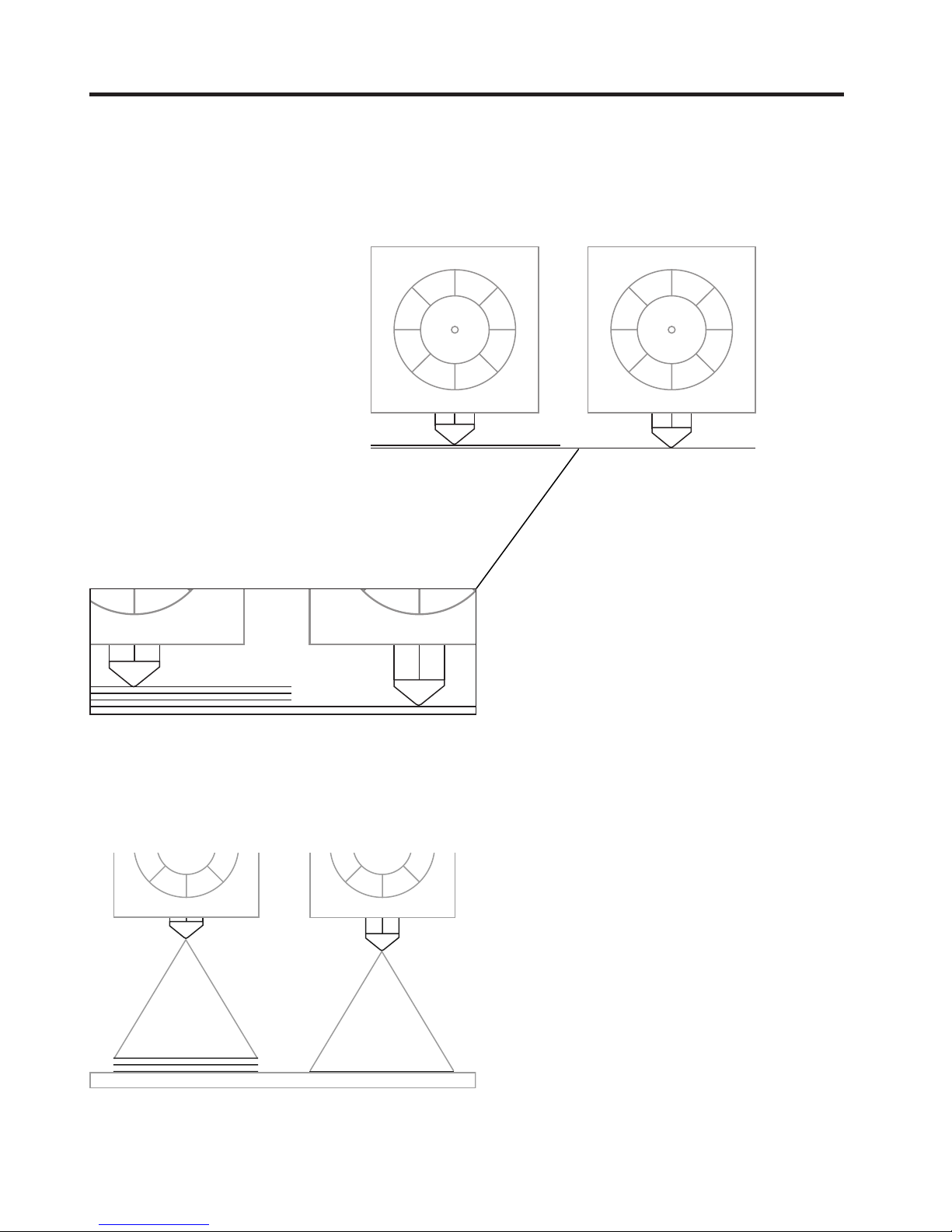

Mirror and Duplication modes

The Sigma features two new printing modes:

Mirror and Duplication. In these modes both

toolheads work simoultaniously.

To do it successfully it is key important to make

sure both nozzle tips are exactly at the same

height. However, due to manufacturing and

assembly tolerances the offset between tips

can be up to 0.5mm.

The Sigma automatically corrects the offsets

when printing in Duplication/Mirror modes.

However, this correction distorts the first layer

of the model by repeating it as many times as

needed.

Page 25

User Manual 25

Mirror and Duplication modes

To avoid such distortion there are different options:

1. Enable raft in BCN3D Cura.

The offset will be corrected in the first layers of the raft,

so the model won’t be affected by any Z offset.

2. Install shims to mechanically correct the Z offset.

Printing a raft takes time and spends material. For

those users planning to use frequently the Mirror or

Duplication modes, it is highly recommended to install

the shims when it is suggested during the Printer Cali-

bration process.

Page 26

26 User Manual

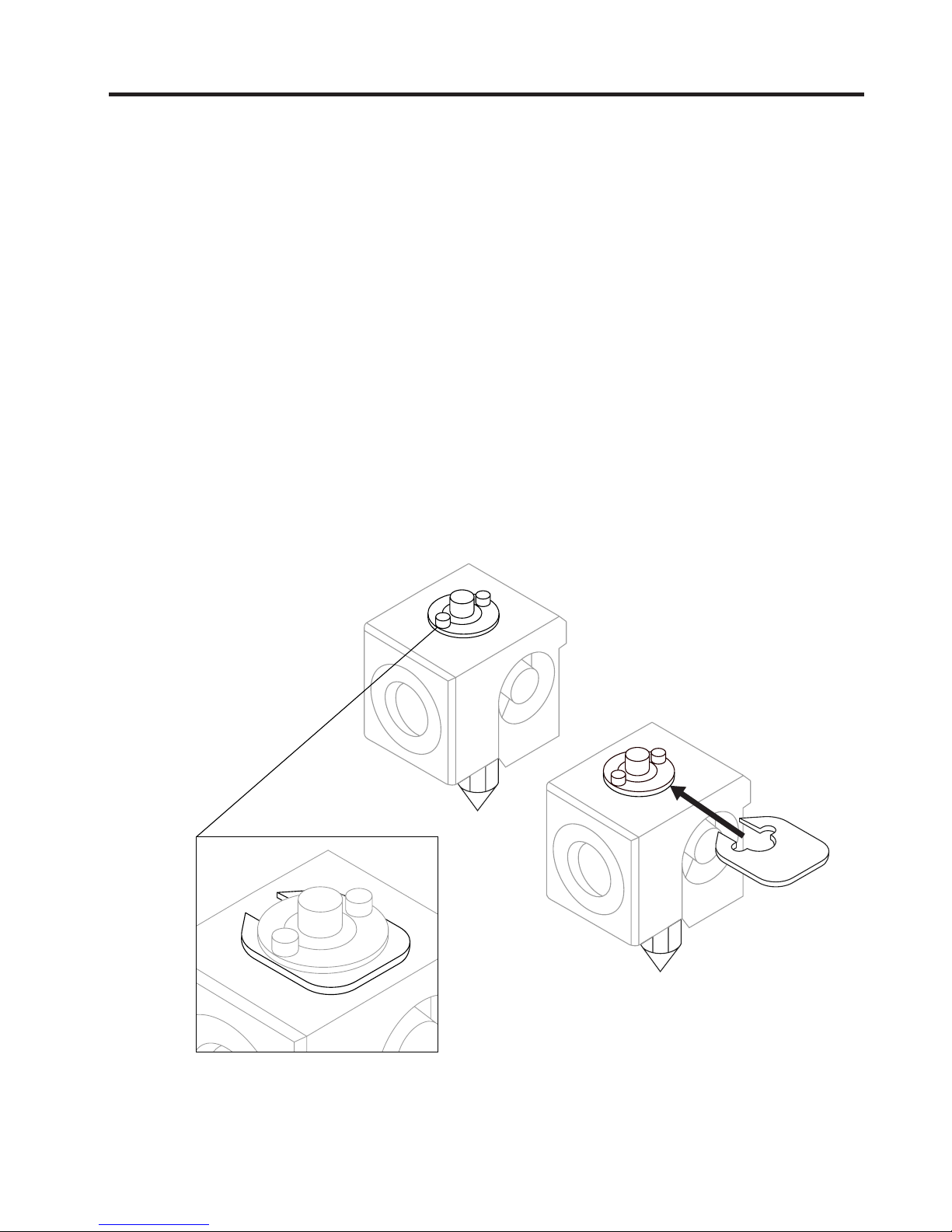

Installing shims

During the Printer Calibration process or before printing

a job with Duplication or Mirror mode, the Sigma may

suggest you to install shims to correct the Z offset

between nozzle tips.

Once you confirm you want to install the shims,

remember de number of shims to install on which hotend and just follow the screen instructions:

1.

Wait until the printer cools

down to avoid any dangerous

manipulation.

2.

Turn off the machine.

3.

Unscrew the 2 bolts at the

specified hotend .

4.

Install as many shims as

were indicated in the screen.

Page 27

User Manual 27

Installing shims

5.

Screw the bolts again.

6.

Turn on the machine and

follow the instructions on

the screen.

Page 28

28 User Manual

First print

After the calibration process has been completed, you can access the printing menu. The first object you will print

with the Sigma R19 is the Draudi figure, as it will allow you to check that everything is working properly and you

are now ready to start printing your own objects. Make sure that the glass is clean, and apply a small amount of the

included glue stick. Learn how to usethe slicing software BCN3D Cura and how to print your own objects in the next

chapter.

Print --> Sample Parts --> Dual --> Dual Draudi --> SR19_DualDraudi

Page 29

User Manual 29

Starting out with BCN3D Cura

Your first dual print

BCN3D Cura is a free and easy-to-use 3D printing software that prepares your digital model for 3D printing. Such

a complex process has been carefully optimized and tested for BCN3D products. As a result, the user enjoys a

flawless 3D printing experience while increases the reliability of the process.

BCN3D Cura takes profit easily of all the benefits of IDEX system: simply merge multi-material or multi-colour

models or generate customized support structures. It includes validated printing profiles to increase the printing

success rate.

Visit https://www.bcn3dtechnologies.com/en/3d-printer/bcn3d-cura/ and download the suitable version of BCN3D

Cura for your Operative System. Once downloaded, follow the installation wizard.

1. Open BCN3D Cura previously downloaded and installed.

2. Select Sigma R19 R19 in

the menu Add printer.

Page 30

30 User Manual

Your first dual print

3. Click Open File. 4. Select files to print.

5. Click the model and

assign the extruder to

print with.

Page 31

User Manual 31

Your first dual print

6. Select the models by Shift+Left Click. Selected mo-

dels will be highlighted with a blue outline.

Right click on any of the selected models, and select

Merge Models.

7. Select profile.

8. Click Prepare to generate the printing file.

10. Safely remove the SD card from the com-

puter and insert it in the printer. After that,

turn it on.

9. Insert the SD card in your computer and

save the file.

Page 32

32 User Manual

Your first dual print

11. Select Print in the main menu of Sigma’s

touchscreen.

12. Select the file to print.

Congratulations! You have started printing your first 3D part with the Sigma R19.

Page 33

User Manual 33

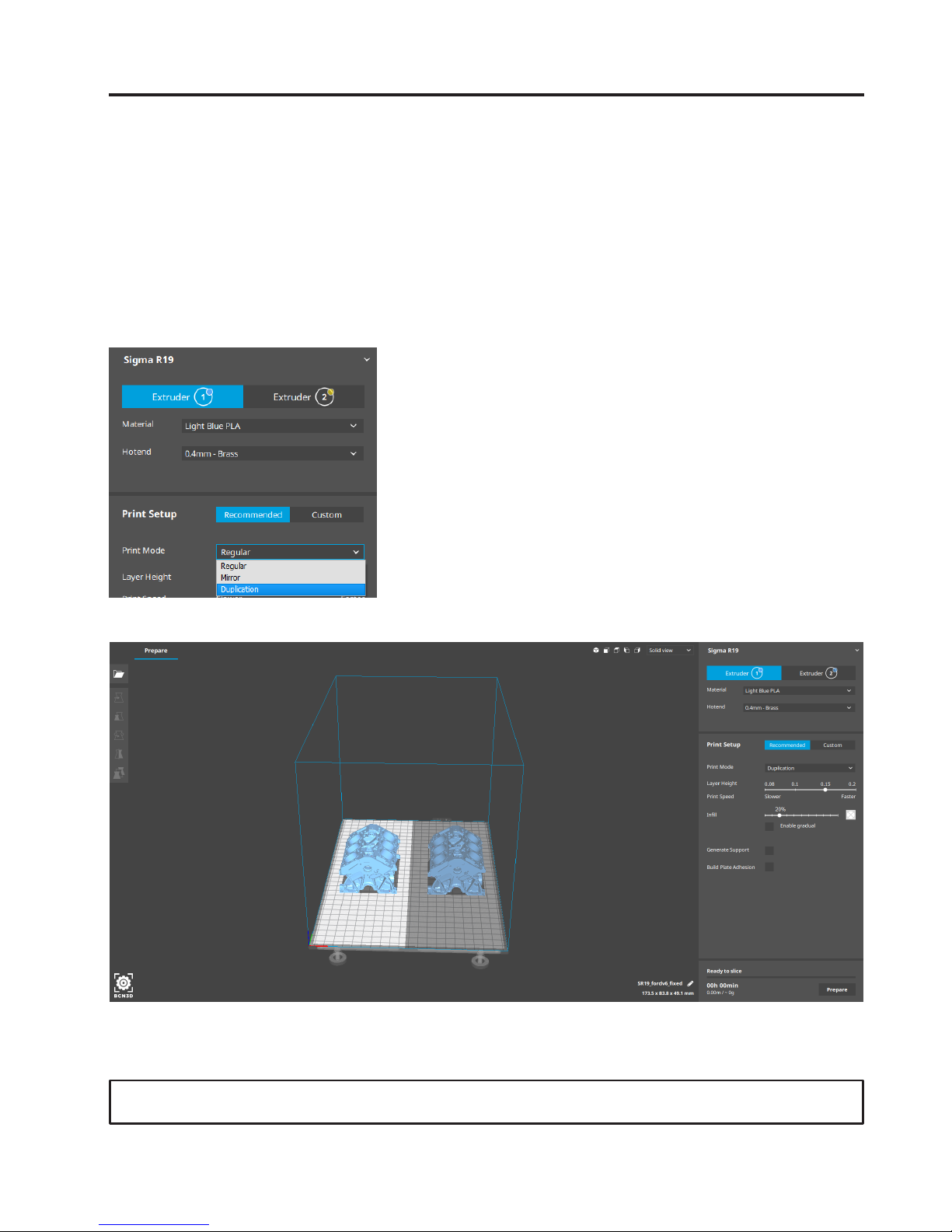

First Mirror /Duplication print

1. Load files to print and move, scale or rotate the

models as needed.

3. Select the desired printing mode in the

drop-down list.

4. Note how the available printing volume is reduced

and the loaded models automatically move to the left.

These models can still be modified. A preview of the

duplicated or mirrored parts is available at the right.

5. Click Prepare, save the file and print it.

2. Select the printing profile for the Left Extruder. Make

sure the hotend and material loaded at Right Extruder

are the same than in the Left Extruder.

Contact us if you have any questions about this process: support@bcn3dtechnologies.com

Page 34

34 User Manual

Firmware upgrade

At BCN3D Technologies we want you to have a great printing experience, and to achieve this we are continually

working to create new firmware upgrades for our printers. Follow this process through BCN3D Cura for checking if

the latest firmware version is installed on your printer. If not, it will get the latest firmware and it will be installed.

1. Use the USB cable to connect the Sigma to the computer.

3. Select Upgrade Firmware. 4. Click Automatically upgrade Firmware to download

and install the latest version available.

2. Open BCN3D Cura. Go to Settings --> Printer --> Manage Printers

Page 35

User Manual 3535 User Manual

Firmware upgrade

6. Once the process is completed, close the window.5. Wait until the firmware is installed. The process

may take a few minutes to complete.

¡Congratulations! You have upgraded the firmware of your Sigma R19.

Page 36

Functionalities

This section contains a description of Sigma R19

functionalities. The main menu is divided into three

large groups: print, utilities and temperatures. The first

covers all the standard printing functions. The second

includes functions such as calibration, maintenance,

settings. Finally, the third allows to preheat the printer.

Print

Located on the left-hand side of the main menu, select

a print job to start the printing process. You can control

some of the parameters of the settings while the object

is being printed from here.

Select object: When you access the printing function a

screen appears with a list of files and folders. Use the

onscreen arrows to navigate and then click on the

selected file to confirm your selection.

Print: This screen displays the progress of the printing

process and show the basic information about time left,

file progress and temperatures.

Press the Pause button to move the extruders

away from the object and stop the printing process.

When the printjob is paused it is possible to load/unload

or purge filament, adjust the light intensity as well as

cancel or resume the print.

The Stop button let’s you whether cancel the printing

process and take you back to the main menu or save

the printjob.

Settings: This option bring you a new menu:

–Temperatures: Adjust the hotend and heated bed

temperatures by using the arrows.

–Advanced settings: Adjust the speed, fan and

flow-rate values by using the arrows.

–Light intensity: Use the toggle to adjust the LED

luminosity.

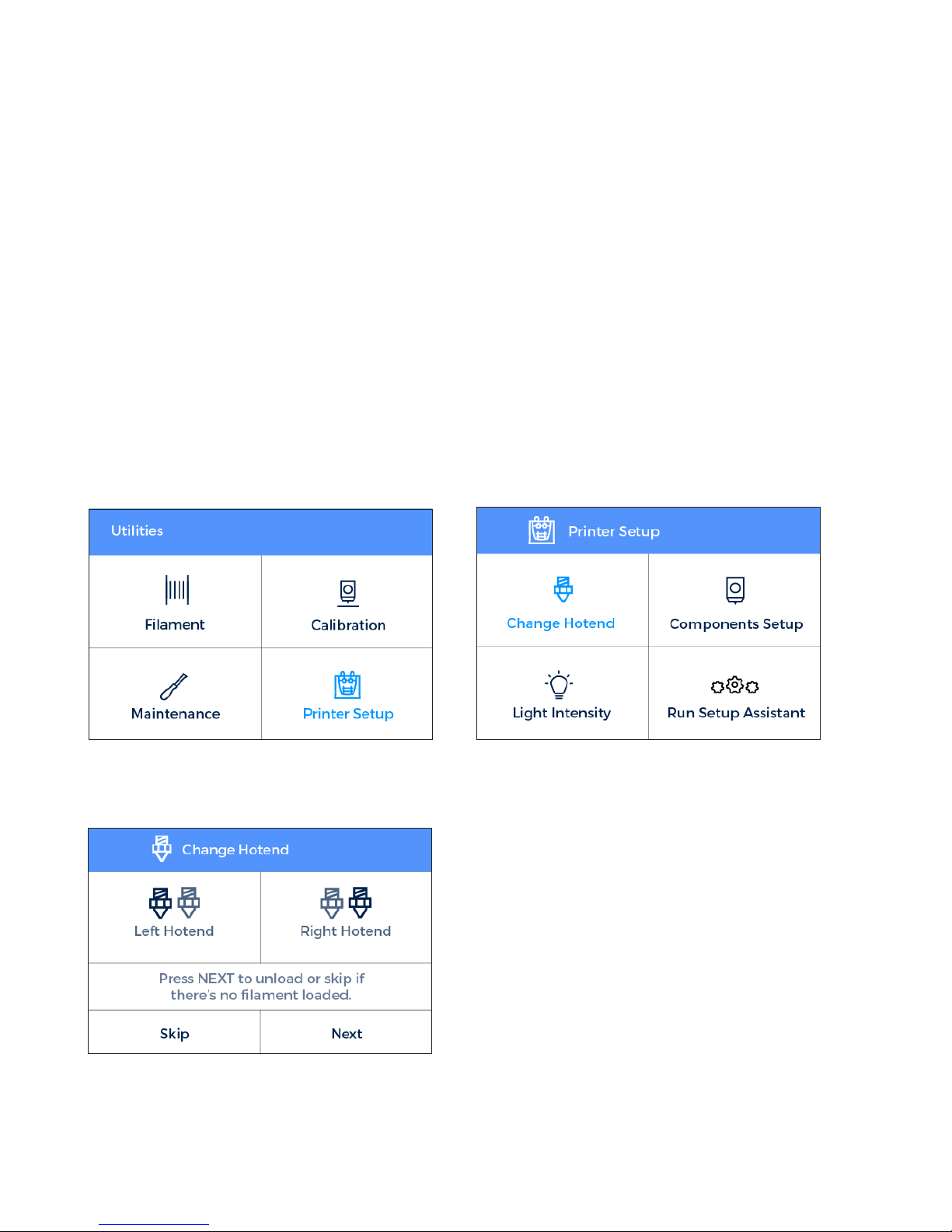

Utilities

Situated at the center of the main menu, allows you to

operate and maintain your printer.

Filament: this menu allows you to manage the filaments of the printer. The menu functions are:

–Load: This is for loading filament into one of

the extruders. You should first select the side where

you want to load the filament. Next, you should insert

the filament into the extruder following the onscreen

instructions (the extruder should first reach the right

temperature, which may take a few minutes). Once you

have inserted the filament the extruder can be adjusted

slightly to allow you to load the rest of the filament.

When purging we recommend you pull out a generous

amount of filament to ensure the extruder is purged

correctly.

BCN3D Filaments presets are offered, but it’s possible

to load different materials. Just select Custom and set

the 2 temperatures demanded. Follow the manufacturer indications to set the Printing Temperature and the

Heated Bed Temperature.

–Unload: This operation is the opposite of the

operation described above, although it is performed

in a similar way. After you have selected which side

you want to remove the filament from, wait until the

hot-end has reached the right temperature and then

remove the filament.

–Purge: This menu allows you to control the

temperature of the two hot-ends, and extract or

dislodge clogged filament. In order to be able to move

the filament, the temperature difference between the

objective temperature (under the thermometer) and the

actual temperature (under the extruder icon) should be

less than 10º C.

36 User Manual

Page 37

Calibrate: This menu allows you to calibrate the Sigma

R19 printing surface glass and extruders. This process

should be performed when components are replaced,

and during standard printer maintenance (described in

this manual).

–Printing Surface Calibration: This option allows

you to level the printing surface. The process is performed by an onscreen self-test run by the printer,

followed by instructions to correct the position. The

screen displays how many turns (in eighths of a turn)

each of the levelling screws should be turned, and in

which direction.

–Printer Calibration: This option allows you to

perform a full calibration, where the heated bed and the

relative positions of the extruders are calibrated. You

will be guided by onscreen instructions, and the aim is

to select the best of the different test prints performed

by the printer.

–Manual Fine Calibration: This option lets you to

manually modify the calibration values found in the

Printer Calibration process. On the left menu, select

the axis to adjust and press the arrows to correct the

calibration value.

Maintenance

–Move Printing Surface: This option lets you to

move the platform up and down.

–Hotend Cleaning Assistant: Perform this operation to clean the hotend. Just follow the instructions

of the screen. This operation is recommended when

you notice any sign of underextrusion, when switching

materials and after printing with soluble or special

materials.

–Autotune hotends: Select this operation every time

you change the hotend. The internal routine will check

the thermal behaviour of the hotends installed and will

allow the printer to have a better temperature control.

Printer Setup

- Change hotend: Start a guided process step by

step to change and calibrate a hotend.

- Printing Components Setup: Manually set up the

nozzle sizes installed in the printer and the use of the

Filament Runout Sensor.

- Light intensity: Use a toggle to adjust the Light

Intensity.

- Run Setup Assistant: A step by step process to

calibrate the printer, as it was straight out of the box.

Temperatures

Placed on the right-hand side of the main menu, lets

you to preheat or cooldown the hotends and the heated

bed. The preheat temperatures will be set depending on

the filaments loaded.

Functionalities

User Manual 37

Page 38

Operation and maintenance

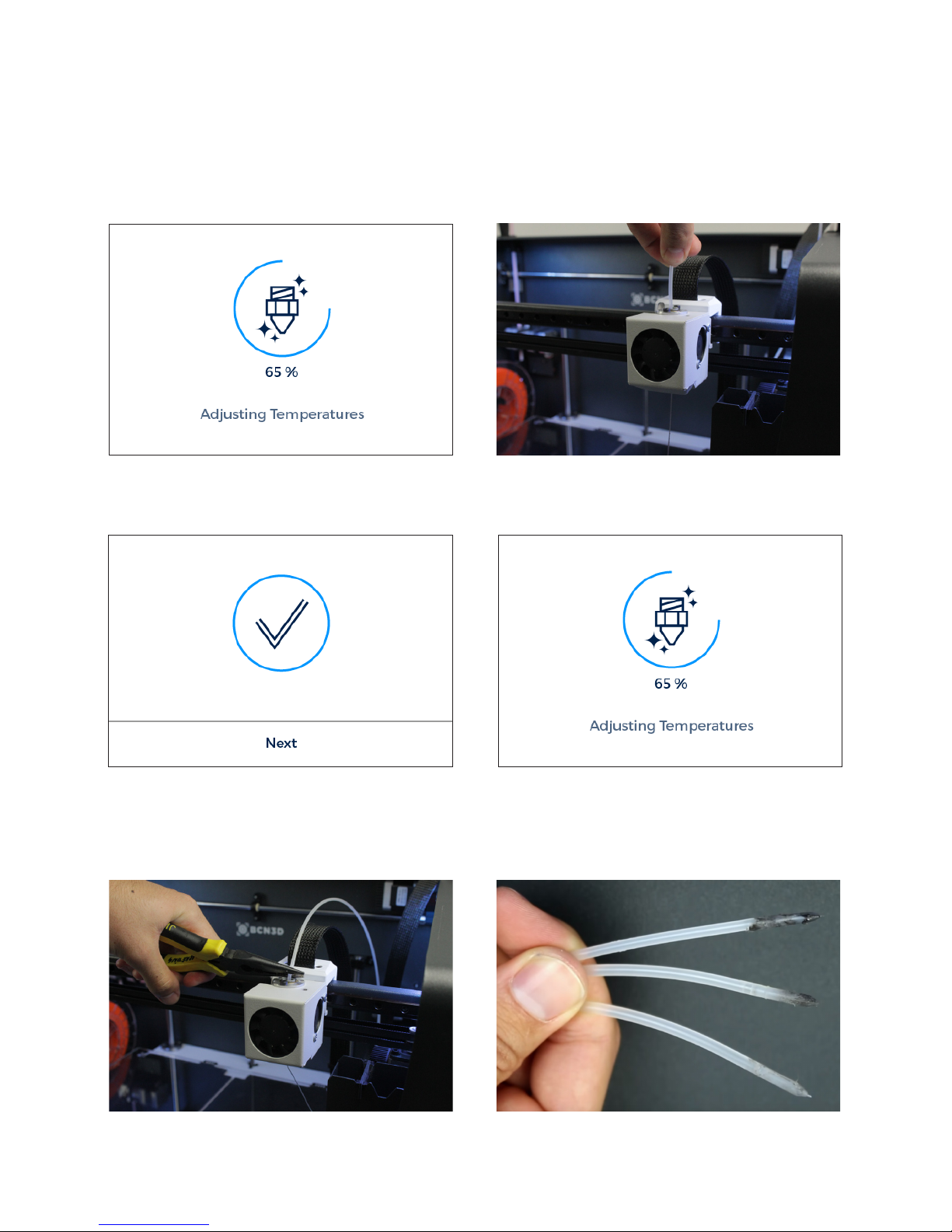

Change hotend

By default, the Sigma is equipped with 0,4 mm hotends, but is possible to change them to tackle different

print jobs.

Changing the hotend is an easy operation that can be performed in a few minutes. You will need:

- Scissors or cutting pliers

- 2,5mm hex key

- Pliers

- Zip ties

1. Operating the printer via the LCD screen, go to Utilities --> Printer setup --> Change hotend.

2. Select the hotend to change and unload the filament (in case there’s some loaded).

3. Wait while the hotend cools down.

38 User Manual

Page 39

Operation and maintenance

4. Turn off the Sigma when the LCD indicates it.

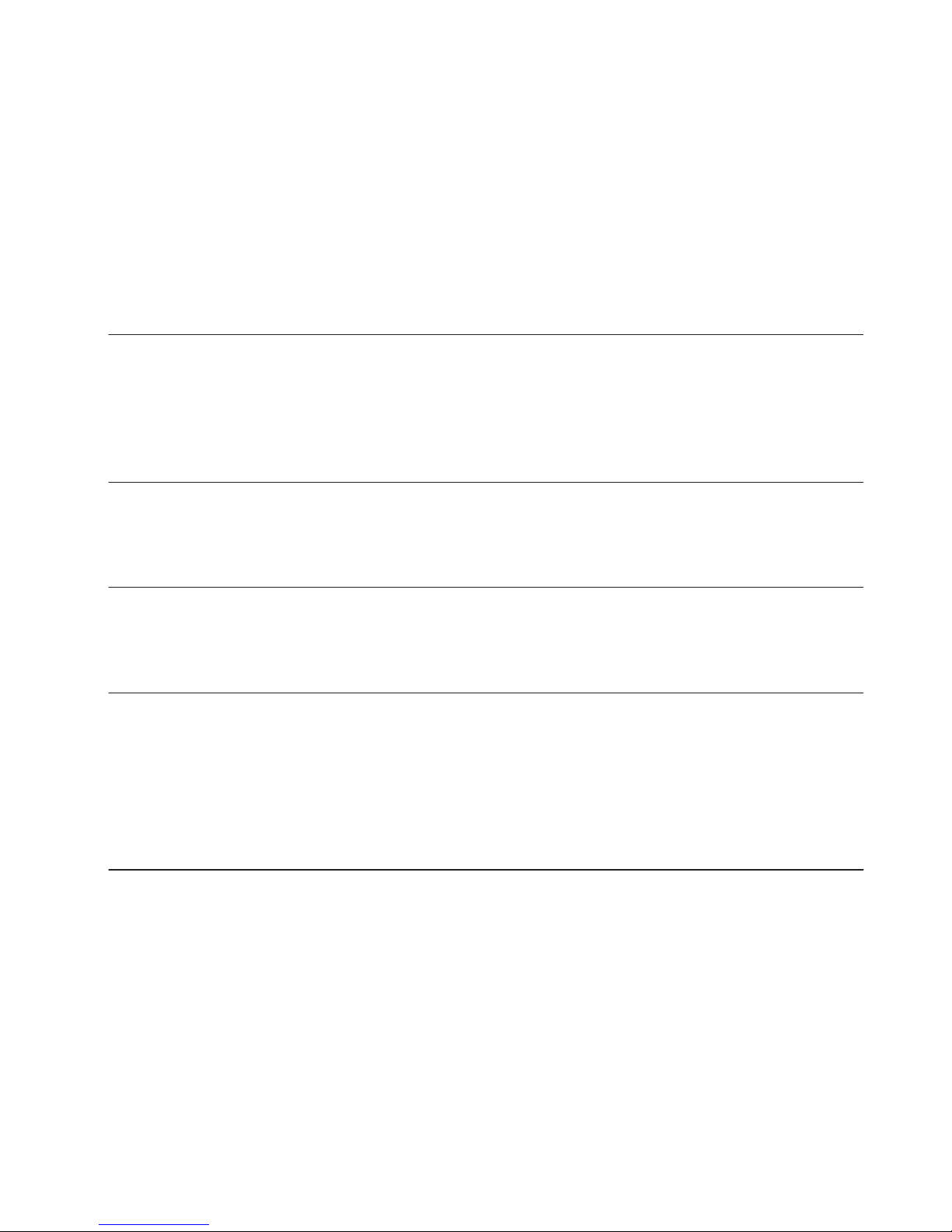

5. Remove the black clip. Then hold down the coupling collet and pull out the teflon tube.

User Manual 39

Page 40

Operation and maintenance

6. Unscrew the cover and remove it.

7. Unscrew the hotend.

8. Cut the zip tie and remove it.

40 User Manual

Page 41

Operation and maintenance

9. At the back of the toolhead carriage, press the connector to remove the cable of the hotend.

10. Remove the old hotend and place the new one, connecting it at the back of the toolhead carriage.

User Manual 41

Page 42

Operation and maintenance

11. Place and adjust the zip tie, cutting off the excess.

12. Screw the hotend, place the cover and screw it.

42 User Manual

Page 43

Operation and maintenance

14. Turn on the Sigma and follow the screen

instructions. Select the hotend size you have installed.

15. Load filament and perform an autotune operation.

16. Finally, calibrate the offset between hotends.

13. Insert the teflon tube until it stops, making sure it is well placed. Put back the black clip.

User Manual 43

Page 44

Operation and maintenance

Clean and lubricate axes

Periodically, according to the Maintenance Alerts via LCD screen, it is recommended to clean and grease the axes of

the Sigma with the lubrication kit to ensure smooth and precise performance of its mechanical components.

Follow these steps:

1. From the LCD screen, go to Utilities --> Maintenance --> Move printing surface. Lower the platform to the lowest

position to work more comfortably. Then turn off the machine

2. With absorbent paper or a cloth, remove any trace of dirt or dust at the two Z shaft bars. Next, clean the shaft

bars with the solvent pencil, making sure that it does not drip. Clean again the shaft bars with paper or a cloth.

44 User Manual

Page 45

Operation and maintenance

4. Clean grease and dust from the Z-axis motor spindle

with paper or a cloth. Turn the spindle manually to

access its rear.

3. Apply the lubricating oil pencil along the Z shaft bars,

making sure that it does not drip.

5. Apply the grease along the spindle of the Z-axis motor.

6. Turn on the Sigma and from the LCD screen, go

to Utilities --> Maintenance--> Move printing surface.

Raise and lower the platform twice to evenly distribute the oil and grease. Finally, remove the remnant

grease.

User Manual 45

Page 46

Operation and maintenance

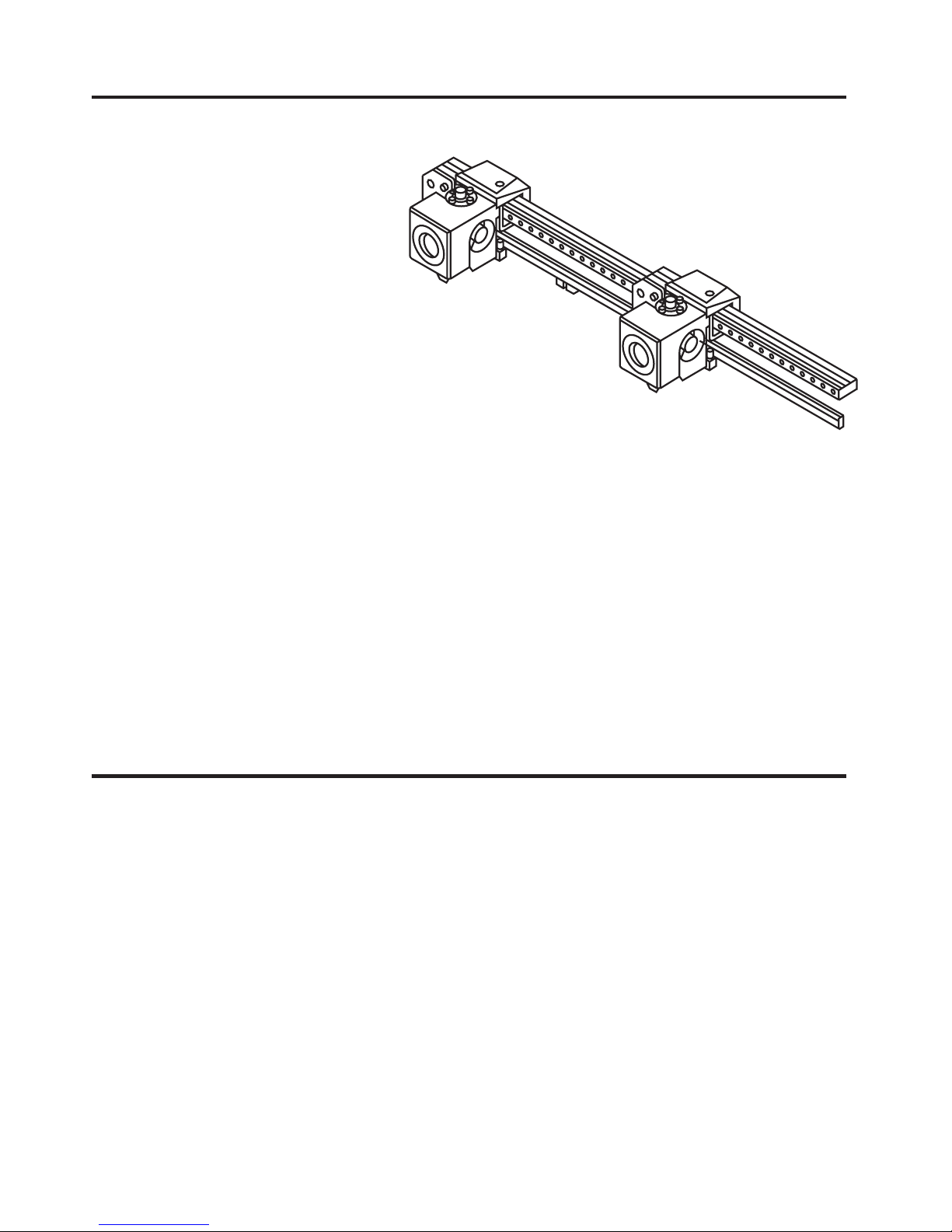

7. Once the process for the Z axis is finished, let’s clean and lubricate X and Y linear guides. First of all, turn off

the Sigma. During this process it’s recommended to manually move the axes in order to reach all the guide.

8. From the center towards the ends of the linear guides of the X and Y axes, remove dirt with an absorbent

paper or a cloth.

9. Clean the guides with the solvent pencil, making sure that it does not drip with special emphasis on the supe-

rior and inferior faces.

46 User Manual

Page 47

Operation and maintenance

11. Apply the lubricating oil pencil along the linear guides of the X and Y axes, with special emphasis on their

superior and inferior faces. Make sure there is no excess oil dripping.

10. Clean again the X and Y guides with an absorbent paper or a cloth.

User Manual 47

Page 48

Operation and maintenance

Hotend Cleaning

It is recommended to clean the hotend periodically and, especially, every time you switch materials. Ideally, use a

piece of nylon filament to perform this operation.

1. Operating the printer via the LCD screen, go to

Uilities --> Maintenance --> Hotend cleaning assistant.

2. Select the hotend to clean and, in case there’s

material loaded, press NEXT. Otherwise, select SKIP.

3. Remove the top teflon tube. First of all remove the black clip and then remove the top teflon tube by holding

down the cupling collet and pulling out the tube.

48 User Manual

Page 49

Operation and maintenance

4. Wait until the hotend heats up. 5. Push the nylon filament through the hotend until it

comes out clean of residues.

6. Press NEXT and keep pushing until new notice. 7. Wait while the hotend cools down.

8. Finally, when indicated in the screen, pull out the

piece of filament.

9. Repeat the process until the removed filament tip

comes out clean. Once it is clean, remember to put back

the teflon tube and the black clip.

User Manual 49

Page 50

Filament

The Sigma R19 printer gives the best printing results

when printing with BCN3D Filaments, although it

accepts many other materials from other

manufacturers.

BCN3D Filaments are industrial-grade materials

designed to deliver outstanding results for BCN3D

printers. BCN3D Filaments, formulated to ensure the

highest print quality, are common polymers in several

industries and cover the majority of the technical

applications. Those filaments are: PLA, ABS, Nylon,

PET-G, PVA, TPU and Composites. Visit our

dedicated website for detailed information about each

one. Furthermore, you will find the Technical and Safety

Datasheets of all of them.

https://www.bcn3dtechnologies.com/en/3d-printer/

filaments/

A brief description of those materials is given below:

PLA

PLA (Polylactic Acid) is a biodegradable, sustainable and

food safe polymer made from organic sources.

It is the most common used filament in FFF 3D printers

for its ease of use and wide range of applications,

specially those not mechanically or thermally

demanding. Definitely a good starting point to learn

about the 3D Printing manufacturing process.

PLA is compatible with PVA supports.

Once printed, PLA parts can withstand operating

temperatures up to 50ºC.

To ensure good bed adhesion use 3DLac, Dimafix or

Glue Stick.

ABS

ABS (Acrylonitrile Butadiene Styrene) is one of the

most common technical materials in several industries

around the globe. Its great mechanical and thermal

behavior make ABS the ideal polymer for countless

applications.

Traditionally a challenging material to print with FFF

printers, it has been re-formulated to ensure good

interlayer adhesion and to reduce warping. Printing with

ABS is more complex, and requires a certain amount of

care: it is not recommended for non-experienced users.

Once printed, ABS parts withstand operating

temperatures up to 85°C.

To ensure good bed adhesion use Dimafix.

Do not use layer cooling fans and avoid drafty or cool

rooms for best results.

For a better print quality use the BCN3D enclosure for

the Sigma.

Printing overhangs is easier if the layer fan is used.

It has average mechanical properties, although it

becomes slightly brittle when printing irregularlyshaped objects. At operating temperatures of 50º C

or more, the mechanical properties and rigidity of the

objects may decrease.

50 User Manual

Page 51

PVA

PVA (Polyvinyl alcohol) is a water-soluble polymer,

ideal to work as support material for multi-material 3D

Printing.

Optimized for the FFF manufacturing process, our PVA

works seamlessly with PLA, TPU, PET-G and Nylon,

becoming a reliable universal support material to print

complex geometries, large overhangs or intricate

cavities.

PVA supports allow to achieve better surface quality, to

orientate the part to get better mechanical properties

and even to print multi-component models and

mechanisms.

To ensure good bed adhesion use 3DLac, Dimafix or

Glue Stick.

PET-G

PET-G (Polyethylene terephthalate glycol-modified) is a

globally used co-polyester, from plastic water bottles to

cloth fibers and it is 100% recyclable.

As a technical material, PET-G provides good

mechanical properties and improved chemical and

thermal behaviors than PLA but with similar ease of

use.

It has an outstanding chemical resistance, a great

dimensional stability and toughness and a good glossy

surface quality. PET-G also offers a good abrasion

resistance, a high humidity resistance and it withstand

operating temperatures up to 70°C. It is compatible

with PVA supports.

To ensure good bed adhesion use 3DLac, Dimafix or

Glue Stick.

For a better print quality use the BCN3D enclosure for

the Sigma.

Nylon

Nylon (polyamide) is an extensively used material for its

unique mechanical and chemical properties.

Thanks to characteristics like durability, flexibility and

resistance to corrosion, Nylon is ideal for multiple

applications in the 3D printing field, like end-use parts

or custom jigs and fixtures. It is compatible with PVA

supports.

Once printed, nylon parts can withstand operating

temperatures up to 50ºC.

To ensure good bed adhesion use Dimafix or Glue Stick.

For a better print quality use the BCN3D enclosure for

the Sigma.

TPU

TPU (Thermoplastic Polyurethane) is a versatile rubberlike flexible material.

With Shore-A hardness of 95, TPU is a resistant

material for several industrial applications, both

mechanical or chemical. Moreover, it’s been especially

designed to improve the 3D printing experience.

Once printed, TPU parts withstand operating

temperatures up to 60ºC

To ensure good bed adhesion use 3DLac, Dimafix or

Glue Stick.

Composites

Composites are materials with a polymeric base infused

with other particles or fibers in different proportion.

From wood to metal particles to achieve an aesthetic

and attractive finish to carbon fibers to combine

lightness and mechanical performance, composite

materials for FFF printers unleash creativity.

Filament

User Manual 51

Page 52

General considerations

To ensure good adhesion between the printing surface

and the 3D printed part, you will need to use an

adhesive product that will be applied to the printing

surface before start printing. For general materials,

we recommend using the glue stick included with the

printer or a generic lacquer. However, for technical

materials such as ABS or PET-G, we recommend

Dimafix adhesive, available at our website.

We recommend using an enclosure when printing with

technical materials such as ABS, Nylon or PET-G. It

provides a constant interior temperature to prevent

warping and protects your working environment from

potentially harmful particles thanks to the HEPA filter.

More information at our website.

Nylon and PVA plastic are hygroscopic, that means

it readily absorbs water from the air. Make sure they

are dry before printing. Place them in an oven or in a

dehydrator at 50 ºC for 6 to 8 hours. After drying, store

it in an airtight container with desiccant.

Filament

52 User Manual

Page 53

Maintenance Plan

We recommend you carry out the maintenance procedures described in the table below in order to keep your printer running optimally. The procedures are grouped depending on frequency they should be performed is shown on

the right.

Daily

ACTION TO PERFORMFREQUENCY

Weekly

Monthly

Quarterly

Keep the printer free of dust and in a dry, cool place

Storage the spools in a dry, cool place

Remove the filament inside the Purge Tank

Remove the filament leftovers spread inside the printer

Clean the glass printing surface with warm water and soap

Clean the nozzles

Level the printing surface glass (also after a transportation)

Clean fans dust

Printer calibration (also after a transportation or replacing a hotend)

Check firmware updates

Check bolted and threaded joints

Clean and lubricate axes

Check tension of extruder springs

Check X/Y belt tension

Check connections of moving cables

User Manual 53

Page 54

54 User Manual

BCN3D Technologies

Technical Assistance Services

If you do not find a solution to your problem in this

manual, please contact the BCN3D Technologies team

through any of the following channels:

Technical Assistance

You can contact the technical assistance services by

email, and we will answer you as quickly as possible.

Please remember to include your phone number so we

can contact you.

support@bcn3dtechnologies.com

Email

If you have a question that is not related to technical

assistance, please send us an email to the address

below. A BCN3D Technologies expert will contact you as

quickly as possible.

info@bcn3dtechnologies.com

You can find all of this information in the Contact

Section of our website:

www.bcn3dtechnologies.com/en/sigma-contact

Be sure to include the serial number of your computer

whenever you send us a query to help us provide the

best possible services.

Page 55

User Manual 55

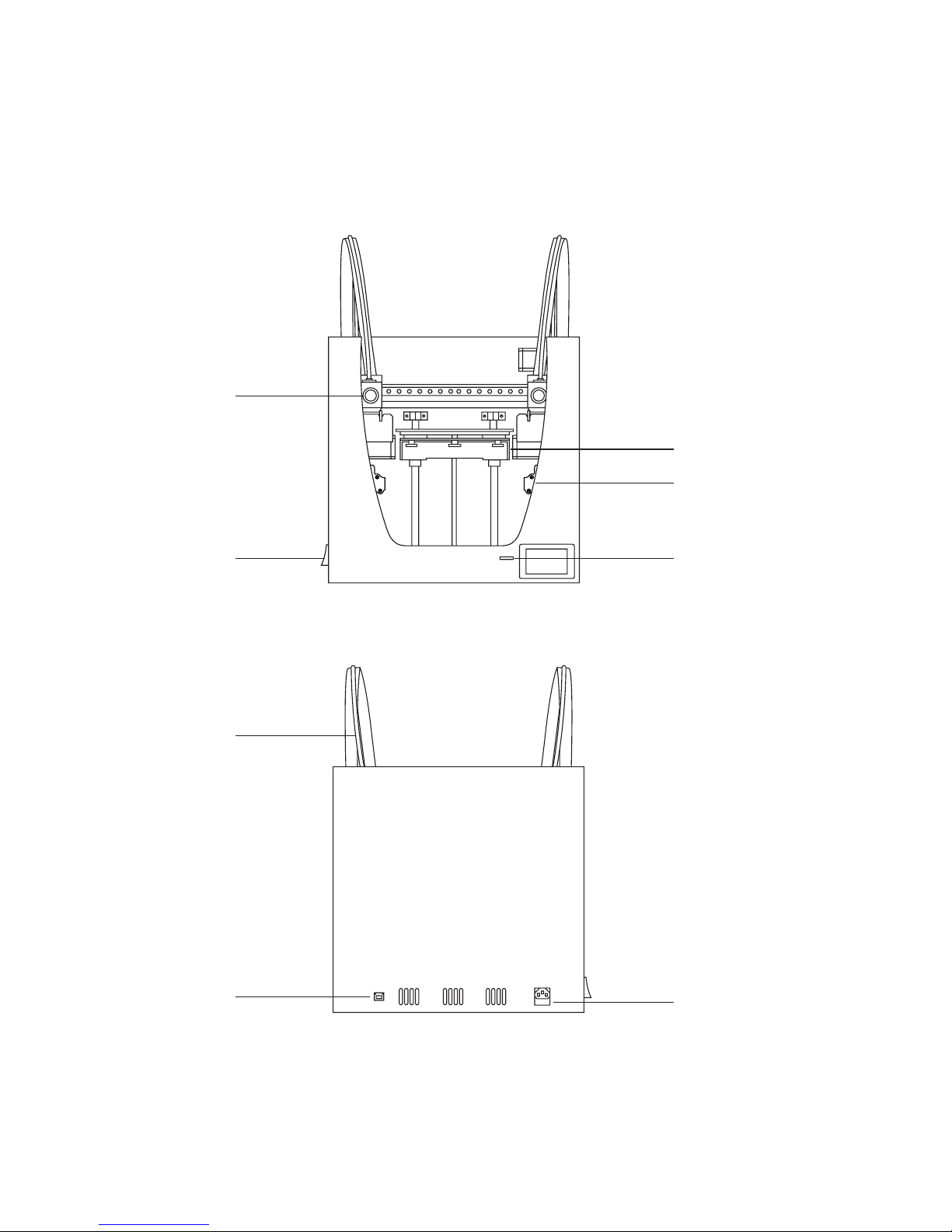

Diagram of Sigma R19

1 Teflon tube

2 Extruder

3 Hot-end cable

4 Spool mount

5 0.4mm Hotend

6 Purge chamber

7 Glass printing surface

8 SD Card reader

23

5

6

7

8

9

10

11

1

4

9 Touchscreen

10 Filament input hole

11 Plastic Spool

12 Switch

13 Platform

14 Power supply socket

15 USB port

16 Filament Runout Sensor

Page 56

56 User Manual

Diagram of Sigma R19

5

12

13

8

14

15

1

16

Page 57

Return Policy

Returns will only accepted for products that have not been used within a period of 14 business days, starting from

when the printer was delivered. Once this period has expired, all sales with be considered to be final. “Not used” is

understood to mean products that have never been assembled, switched on, programmed or altered in any other

way.

User Manual 57

Page 58

58 User Manual

Terms and conditions of service

The information in this manual is subject to change at any time without notice, and is provided solely for informational purposes. BCN3D Technologies reserves the right to change or modify the manual at any time at its sole

discretion, and you agree to be bound by any such changes and/or modifications. If you would like to get the most

up-to-date information, please contact BCN3D Technologies technical team at www.bcn3dtechnologies.com/

sigma-contact

The design of this manual and all the text, graphics, information, content and other materials are protected by

copyright and other laws. Some of the trademarks, trade names, service marks and logotypes (the “Trademarks”)

used are registered and unregistered trademarks, trade names and services marks that are the property of BCN3D

Technologies and its partners. Nothing contained in this manual grants or should be construed as granting, by

implication, estoppel, or otherwise, any license or right to use any Trademark without the written permission of

BCN3D Technologies. Any unauthorised use of the information, materials or trademarks may breach the laws regulating copyright, registered trademarks, privacy and publicity and/or other laws and regulations.

Page 59

Open source

Open source is a development model that promotes universal access by granting software licenses free of charge,

and also universal distribution, including subsequent improvements.

We believe that adopting an open source philosophy offers many advantages:

• More control: We can see everything that is happening with the source code, designs etc., and modify them to

suit our needs.

• It helps us learn: We can see and read the software designs that other people have made, which helps us to

become better programmers and engineers.

• Safety: Since the designs are open designs, a lot more people can modify and/or correct any errors that the

original programmer may have made.

• Making improvements quickly: The open source community provides a lot of information about how to improve the product. This helps us to fix errors and update programmes much more quickly.

Using open source licenses for the products we develop is a way of expressing our willingness to share, to collaborate with other people in a transparent way (so that others can see what we are doing and join in), to embrace

failure as a means of improving, and to expect, even encourage, everyone else to do the same.

BCN3D Technologies and its products would not be where they are today without the RepRap project and its open

source community. The RepRap project started out as an initiative whose objective was to develop a 3D printer

which could print most of its own components and be a low-cost printer. As an open source project, all of the designs produced by the project have been released under a free software General Public License (GPL).

This project does not only include hardware, but has been conceived as a complete ecosystem of tools for printing,

from the CAD/CAM software to the code read by the machine to print physical objects.

Sigma R19 printers use many open source tools and technologies, such as Marlin software and the Cura pre-processed software. The first controls all the printer´s components, while the second converts the 3D file into G-code,

a language the machine is able to understand.

Marlin firmware is published under a GPL license. This means that we must keep Marlin open, and must provide

our source code to end users. For this reason we have our repository on the Github platform, where we post all the

changes we make.

Cura software is published under an AGPLv3 license. This is the same as the GPLv3 general license but a paragraph

has been added to Section 13 which makes it obligatory to provide source code to those who use software through

a network. We therefore have repositories for each operating system so that users can access the source code.

Open Source is not only used for code, but also covers hardware. In our case all the mechanical and electronic parts

are published under a GPLv3 license.

BCN3D Technologies is firmly committed to open source initiatives, and we believe that with the help of the community we will be able to make better products.

User Manual 59

Page 60

60 User Manual MS-R19-2018-1

Loading...

Loading...