Page 1

Instruction Manual

Revision A.2

May 2007

Cal=Trak SL-800 Primary Gas Flow Calibrator

Instruction Manual

Revision A3 June 2008

Page 2

Worldwide Locations to Serve You

CORPORATE HEADQUARTERS

5 Harris Court, Building L Monterey, CA, 93940 USA

Phone (831) 373-0200 (800) 866-0200 Fax (831) 373-4402

www.sierrainstruments.com

EUROPE HEADQUARTERS

Bijlmansweid 2, 1934RE Egmond a/d Hoef, The Netherlands

Phone +31 72 5071400 Fax +31 72 5071401

ASIA HEADQUARTERS

Room A618, Tomson Centre

188 Zhang Yang Rd, Pu Dong New District, Shanghai, PR China 200122

Phone + 8621 5879 8521 Fax +8621 5879 8586

2

Page 3

Table of Contents

Sierra Instruments Contact Information 2

Table of Contents 3

1.0 General Description 5

2.0 Theory of Operation 5

3.0 Cal=Trak Layout 7

4.0 Unpacking Checklist 7

5.0 Warnings 8

6.0 Installation 9

6.1 Attaching and Removing Flow Cells 9

6.2 Connecting the Cal=Trak to a Flow Source 9

6.3 The Cal=Trak Measurement Cycle 9

6.4 Application Precautions 11

6.5 Comparison vs. Calibration, the “4-to-1 rule” 11

7.0 Installation Diagrams and Application Guide 12

7.1 Comparison of Cal=Trak with Piston or Bell Provers 12

7.2 Vacuum Comparison of Cal=Trak with Piston or Bell Provers 13

7.3 Comparison of Cal=Trak with Laminar Flow Element Transfer Standards 14

7.4 Comparison of Cal=Trak with Sonic Nozzle Transfer Standards 14

7.5 Vacuum Comparison of Cal=Trak with Sonic Nozzle Transfer Standards 15

7.6 Calibration of Mass Flow Controllers (MFCs) 15

7.7 Calibration of Mass Flow Meters (MFMs) 16

7.8 Calibration of Rotameters (Variable Area Flow Meters) 16

8.0 Operating Instructions 17

8.1 The Cal=Trak Keypad 18

8.2 How to Use the Cal=Trak Keypad 18

8.3 Factory Default Settings 19

8.4 Taking Readings 19

8.5 Setting User Preferences 20

8.6 Setup Menu 1, Calibration ID #, Gas Constant, Calibration Type 20

8.7 Setup Menu 2, Reading Type, # in Average, Minutes/Reading 21

8.8 Setup Menu 3, Temp. Correction Factor, Temp. & Pressure Formats 21

8.9 Setup Menu 4, Date, Time & Battery Voltage 21

8.10 Setup Menu 5, Date & Time Formats 22

8.11 Setup Menu 6, Leakage & LCF (Leakage Correction Factor) 22

9.0 Battery System 22

9.1 Battery Maintenance and Storage 22

10.0 Maintenance 22

11.0 Quality Assurance 23

11.1 Leak Test Procedure 23

11.2 Calibration 24

11.3 Returning Your Unit for Calibration or Service 25

14.4 Shipment 25

11.5 Replacement Parts & Accessories 25

11.6 Additional Information 26

3

Page 4

12.0 Limited Warranty 27

Appendices

A Cal=Trak Trouble Shooting Guide 28

B Cal=Trak Specifications 31

C Cal=Soft Communication Program 32

4

Page 5

1.0 General Description

The Sierra Cal=Trak SL-800 is the most accurate commercially available gas flow calibrator. Using near-frictionless piston technology, it

combines the accuracy of a primary standard with unequaled speed and convenience.

The Cal=Trak consists of two primary sections. The base houses the main computer, time base and barometric pressure sensors while the

flow cell performs the actual physical measurements using a precision-machined graphite composite piston and borosilicate glass tube. The

flow cell also contains the integrated temperature sensor. The base has 9-pin connector and two guide pins on its upper surface into which

the interchangeable flow cells are installed.

Mass (Standardized) or volumetric flow readings are obtained with the push of a button. The Cal=Trak can be set to take flow readings

manually, one reading at a time, or automatically, in the auto-read mode. The Cal=Trak can be programmed for up to 100 readings in an

averaging sequence. It can be used to measure gas flow rates from most positive pressure sources or under vacuum. Please contact Sierra

Instruments for special precautions before using your Cal=Trak under vacuum.

The Cal=Trak includes a convenient LCD user interface in the base unit. In addition, an RS-232 port for computer interface capability is

provided. An Application program for downloading data from Cal=Trak into Microsoft Excel is on the included CD-ROM. See Appendix

C: Cal=Trak Software Instructions for Data Downloading at the end of this Manual.

2.0 Theory of Operation

The Sierra Cal=Trak SL-800 is a true primary gas standard. The time required for the graphite composite piston to traverse a known

distance through the flow cylinder is precisely measured and an internal computer calculates the flow. The volumetric accuracy of the

instrument is built into its dimensional characteristics. Standardization of the gas flow readings to obtain mass flow is achieved with

precisely calibrated temperature and pressure sensors.

Piston provers like the Cal=Trak are characterized by the most basic of quantities: length and time. As flow is necessarily a derived unit, a

dimensionally characterized system would be as close as possible to direct traceability from national dimensional standards.

An idealized piston prover would consist of a mass-less, friction-less, leakproof, shape-invariant and impermeable piston inserted within the

flow stream and enclosed by a perfect cylinder. The time that the piston takes to move a known distance (which implies a known volume)

then yields the volumetric flow Q as:

π

Q = V / T =

Where:

• V is measured volume

• T = measurement time

• r = radius of cylinder

• h = length (height) of measurement path

Such a device would be as accurate as its physical dimensions and its clock, with almost insignificant drift mechanisms. Although such

idealized devices do not exist, we believe the Cal=Trak offers close to ideal performance (Figure 1).

The Cal=Trak clearance-sealed prover uses a piston and cylinder fitted so closely that the viscosity of the gas under test results in a leakage

small enough to be insignificant. For reasonable leakage rates, such a gap must be approximately 10 microns. As a practical matter, the

piston and cylinder are made of graphite and borosilicate glass because of their low, matched temperature coefficients of expansion and low

friction.

r2 h / T

5

Page 6

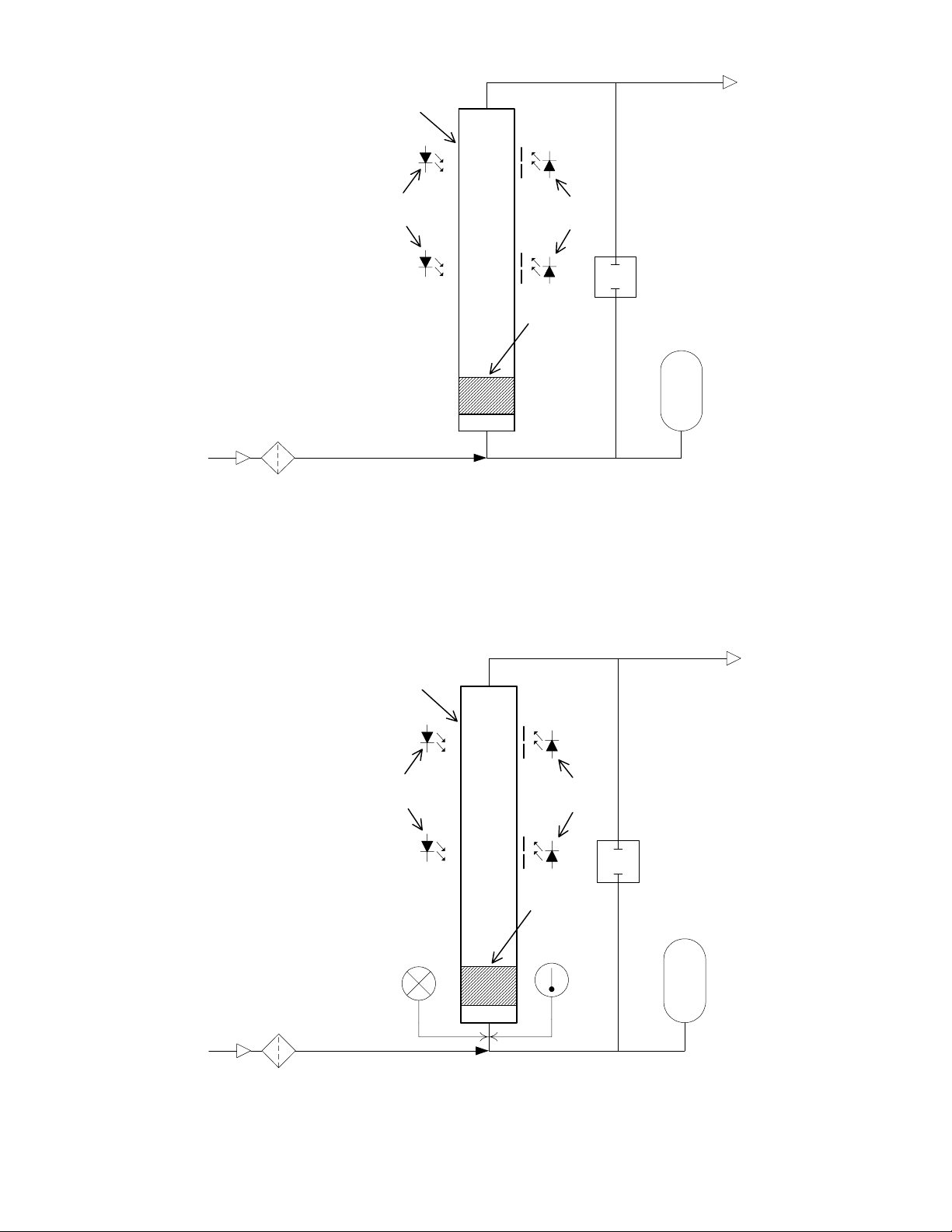

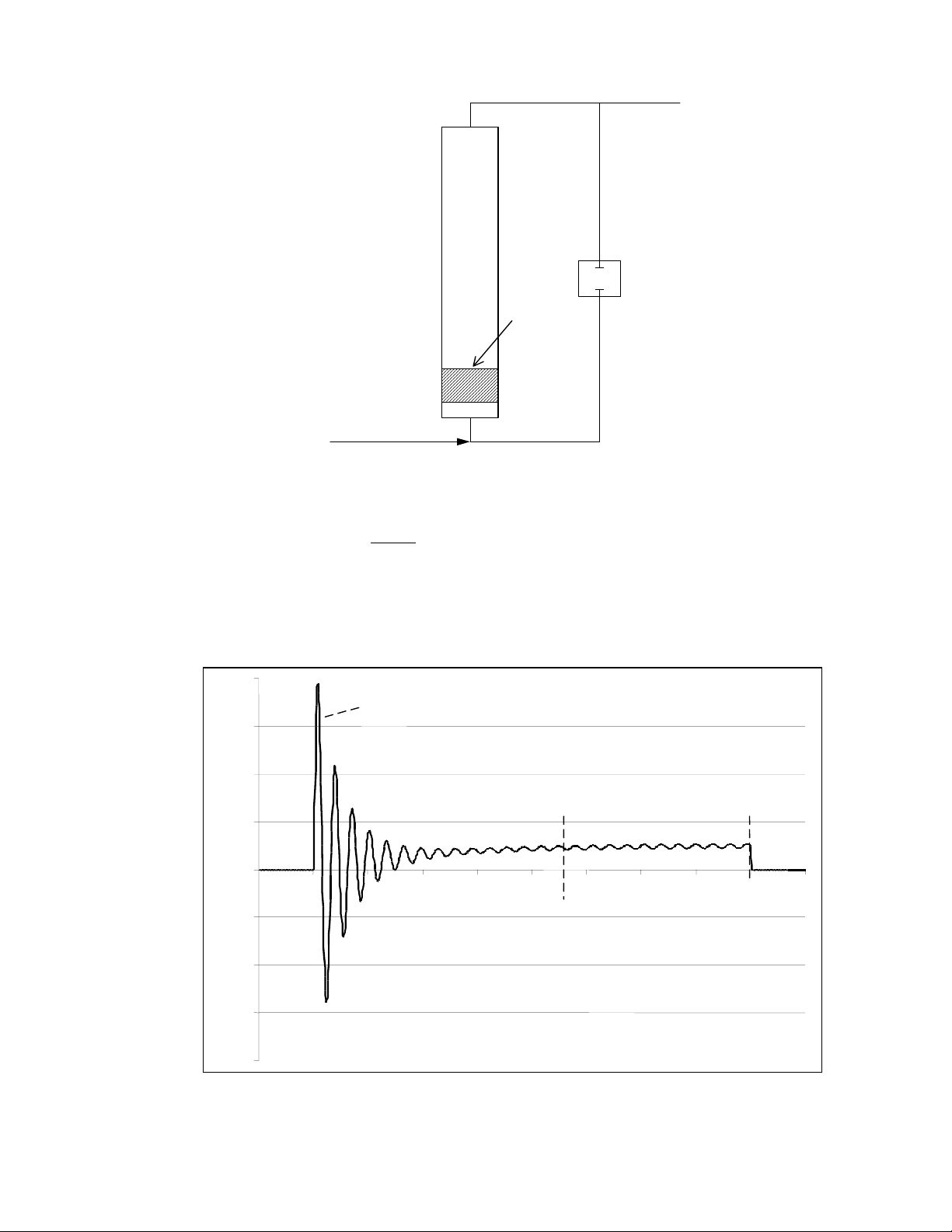

Cylinder

Vent

Light

Emitter

Inlet

Inlet Filter

Photodiode

/ Collimator

Bypass Valve

Piston

Inventory Volume

Figure 1 Idealized Automatic Piston Prover

In order to make an intrinsically volumetric device useful for measurement of gases, it is generally necessary to adjust the readings to a

standardized temperature and pressure, yielding mass flow. For this reason, we include temperature and pressure transducers to allow

computation of standard (mass) flow by the internal computer (Figure 2).

Vent

Cylinder

Inlet

Inlet Filter

Light

Emitter

Piston

Absolute

Transducer

Temperature

Transducer

Figure 2 Practical Piston Prover

Photodiode

/ Collimator

Bypass Valve

Inventory Volume

6

Page 7

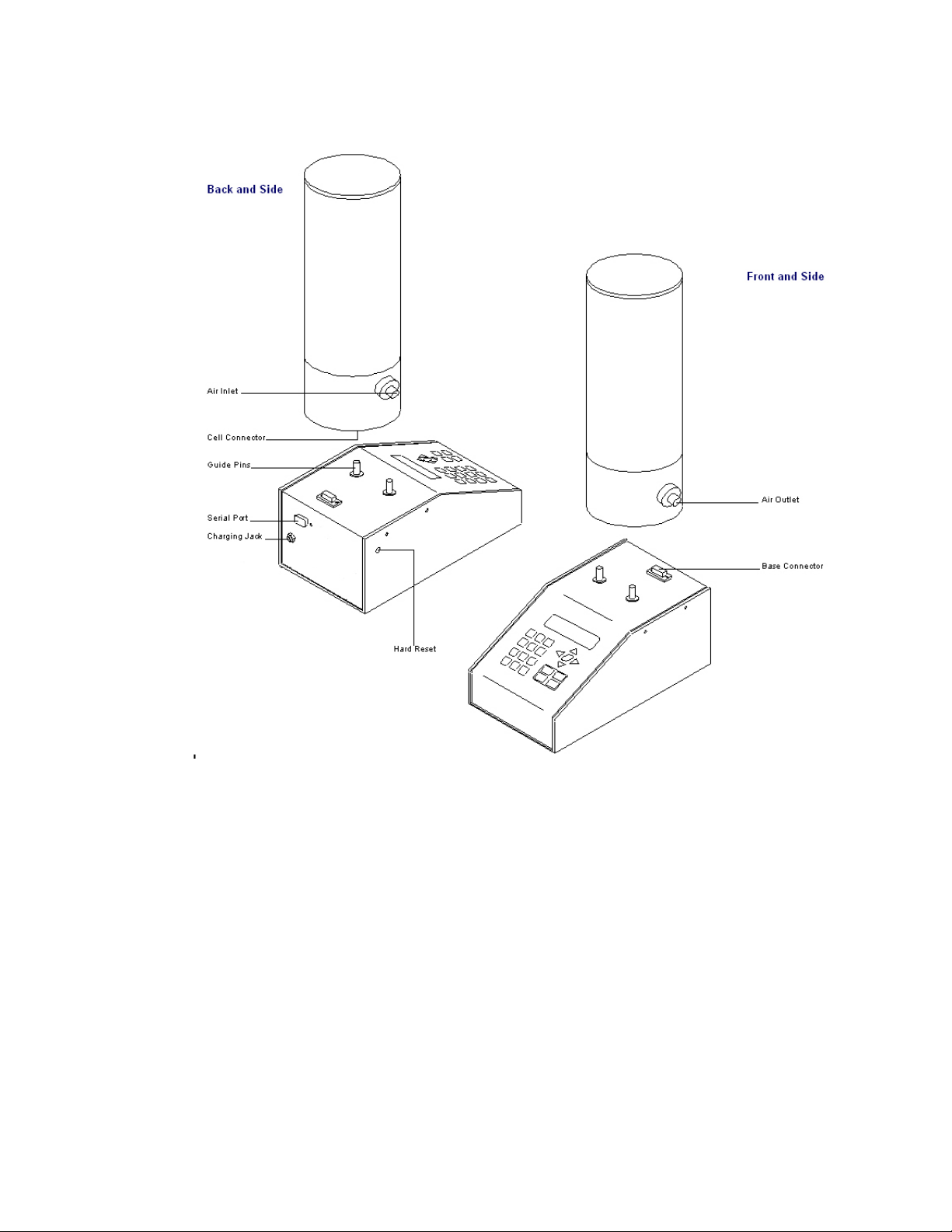

3.0 Cal=Trak Layout

4.0 Unpacking Checklist

Your Sierra Cal=Trak has been packaged with care and includes all components necessary for complete operation. Please take a moment to

check that you have received the following items. If you believe you have not received a full shipment or if you have any questions, please

contact Sierra immediately.

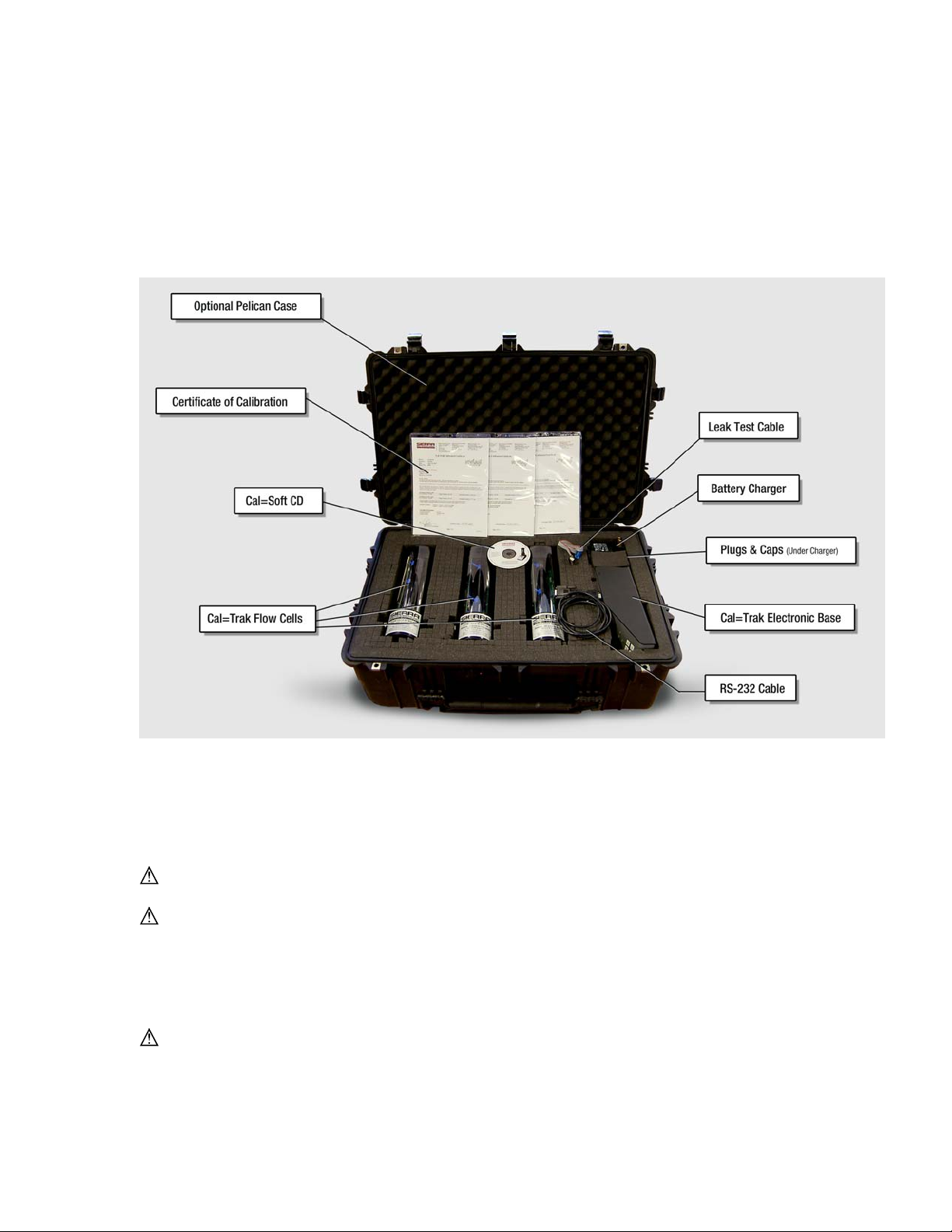

Your Cal=Trak SL-800 Base Includes

• Cal=Trak SL-800 Electronic Base

• Battery Charger

• Leak Test Cable

• RS-232 Cable

• Instruction Manual

• Certificate of Calibration (behind top cover foam insert)

• Warranty Card (behind top cover foam insert)

• Cal=Soft CD-ROM (Application software for downloading data to your computer and making calibration certificates)

7

Page 8

Each of Your Cal=Trak SL-800 Flow Cells Includes

• Cal=Trak SL-800 Flow Cell

• Leak Test Plug

• Certificate of Calibration (behind top cover foam insert)

• Warranty Card (behind top cover foam insert)

If you purchased your calibrator with the Cal=Trak case, it should look like this when you receive it:

5.0 Warnings

The Sierra Cal=Trak is not rated intrinsically safe and is not for use with explosive gasses or for use in explosive environments.

The Sierra Cal=Trak is designed for use at ambient pressures. This is easiest to obtain by leaving the outlet open to atmospheric

pressure. For vented applications, up to 5 inches of water column (12 mbar or 0.18 PSI) at the outlet fitting maybe used without impact on

measurement accuracy. More than this pressure will add additional uncertainty to the flow readings. Do not use the Cal=Trak with a

differential pressure above 0.35 bar (5 PSI). In other words, the pressure differential across the flow cell must be less than 0.35 bar or the

flow cell may be damaged. Please visit www.sierrainstruments.com for the most current product specifications.

The Sierra Cal=Trak is for use with clean laboratory air or other inert, non-corrosive gases only.

8

Page 9

6.0 Cal=Trak Installation

6.1 Attaching & Removing Flow Cells

The Sierra Cal=Trak accepts interchangeable cells for different flow ranges. If user tries to enter “Run Menu” prior to installing a flow cell,

the unit indicates “No Cell” and returns to the “Main Menu” after a 5 second delay.

Attaching Flow Cells

1. Position the selected flow cell into the electronics base opening with its silver Sierra Instruments label facing you.

2. Locate the guide pins; when the guide pins are engaged, press down firmly.

3. When the power is turned on, the base electronics will sense which cell is installed and display the appropriate units for that cell.

Removing Flow Cells

Grasp the flow cell firmly by the base of the cylinder and lift upward out of the base.

6.2 Connecting the Cal=Trak to a Flow Source

As the accuracy of the Cal=Trak is dependent upon the mechanical set-up (plumbing) of the device under test, it is useful to review the

basic operation of the calibrator prior to plumbing. Always remember the following important guidelines:

1. The accuracy of the Cal=Trak is dependent upon its source being stable. An unstable flow source may produce inconsistent

readings.

2. Sierra Instruments’ Cal=Trak is designed to be used at ambient pressures. This is easily accomplished by leaving the outlet of the

flow cell open to atmosphere for positive pressure installations or the inlet open to atmosphere for vacuum installations. If a vent

hose is required on the outlet fitting, a maximum pressure of 5 inches water column (0.18 psi or 12 mbar) above ambient is

acceptable. Exhaust pressure of more than this amount will add additional uncertainty to the flow measurements of Cal=Trak.

One way to reduce exhaust pressure is to increase the diameter of the vent line. Do not subject the Cal=Trak to a differential

pressure above 0.35 bar (5 PSI). In other words, the pressure drop across the Cal=Trak calibrator must not exceed 0.35 bar (5

PSI) or damage may occur. In vacuum scenarios, make certain that the pressure drawn across the Cal=Trak does not exceed 0.35

bar (5 PSI).

3. Flow direction is indicated by the arrow on the top of the flow cell. To use a pressure flow source, connect to the inlet fitting, or

to use a vacuum flow source, connect to the outlet fitting.

6.3 The Cal=Trak Measurement Cycle

Operation of a Cal=Trak is extraordinarily simple, and little training is required. However, any measurement interacts with the device being

calibrated to some degree. Often, these interactions are negligible. However, sometimes device interactions can seriously affect

measurement accuracy. Here we will explain what happens during a Cal=Trak measurement to aid in installing and using the instrument

appropriately.

In its inactive state, the Cal=Trak will, like any device, exhibit a constant insertion pressure drop. At all but the highest flows, the pressure

drop is very small. In the inactive state, gas flows from the inlet to the outlet through the bypass valve (Figure 3

cycle begins, the bypass valve closes, and the gas is directed into the cylinder, effectively inserting the piston in series with the gas flow,

allowing measurement. Timing commences after the piston has accelerated to the flow stream’s speed. At the end of the timed cycle, the

valve opens and the piston falls to its inactive position at the bottom of the cylinder.

). When a measurement

9

Page 10

Piston

Outlet

Bypass Valve

Inle t

Figure 3 Basic Piston Prover

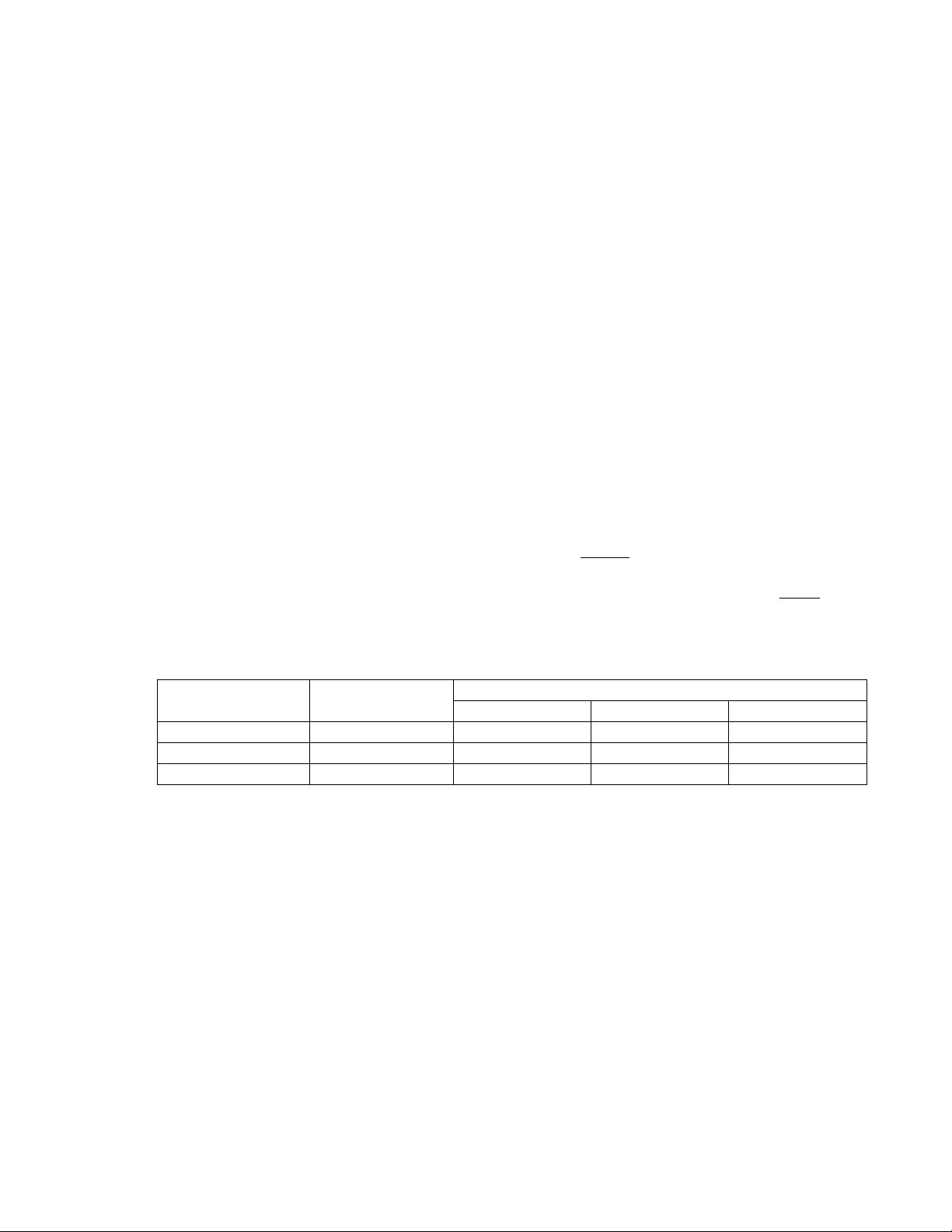

In real-world applications, there are significant dynamics to consider. At the beginning of a cycle, pressure rises rapidly until the piston

accelerates to the speed of the flow stream. Figure 4

is an illustration of a typical Cal=Trak’s internal pressure during a measurement cycle.

A near-maximum flow rate is illustrated to accentuate the pressure variations. The initial pressure pulse, lasting some tens of milliseconds,

reaches a peak of about 0.5 kPa, or 0.5% of its working, near-atmospheric pressure. The pressure settles out to about 0.1 kPa (0.1% of

working pressure) during the timed period. This pressure represents the added pressure due to the weight of the piston. Very small

oscillations continue due to the piston’s under damped nature.

0.8

Initial Pressure Pulse

0.6

0.4

0.2

0

0 100 200 300 400 500 600 700 800 900 1000

-0.2

Intracell Pressure (kPa)

-0.4

M illiseconds

Timing

Begins

Timing

Ends

-0.6

-0.8

Figure 4 Cal=Trak Internal Pressure

10

Page 11

6.4 Application Precautions

Although the Cal=Trak’s dynamic pressure effects are very small, in some circumstances they may affect the measurement or interact with

the device under test. For the above reasons, certain precautions should be observed when using a Cal=Trak.

Initial Pressure Pulse

The initial pressure pulse is small, about 1% of an atmosphere or less. However, even so small an increase may affect some very sensitive

transducers for several seconds. Two examples of this are the resonant transducers used in LFE systems such as the DH Instruments

Molbloc or capillary-based systems. For this reason, the LFE instrument may not be accurate for a number of seconds after the start and the

end of a Cal=Trak measurement cycle. When calibrating such systems, a stable flow source should be used and the LFE read before and

after the Cal=Trak cycle.

Intra-Cycle Pressure Change

After the initial brief pressure pulse, the change in insertion pressure is typically 0.1% of an atmosphere (~0.1 kPa or 1 cm water column).

This is usually insignificant. For example, flow from a 100 kPa gauge pressure (15 psi) source will change by 0.1%. However, very low

pressure sources will show larger flow change during a Cal=Trak cycle and may require compensating calculations to achieve Cal=Trak’s

best applied accuracy.

Inventory (Dead) Volume

Inventory volume consists of all the space contained between the flow source’s point of restriction and the timed portion of the cylinder.

This includes tubing, empty space within the Cal=Trak base, the lower portion of the measuring cylinder and any other space contained

within the test setup.

It is important to keep inventory volume to a minimum. Excess inventory volume amplifies

the Cal=Trak cell. In extreme cases, the excess volume also prevents gas pressure from accelerating the piston properly, causing significant

errors in readings. Ideally, the volume contained between the cell and the flow source should be on the order shown in Table 1

shows the volume as an equivalent length of tubing.

the effects of minute pressure variations within

, which also

Table 1 Recommended Maximum External Volume and Tubing Lengths

Recommended Max.

Cell Size

Small (SL-500-10) 9 1.2 (47.2”) 0.3 (11.8”) N/A

Medium (SL-500-24) 46 6.5 (256”) 1.6 (63.0”) 0.7 (27.6”)

Large (SL-500-44) 118 16.7 (658”) 4.2 (165”) 1.9 (74.8”)

Volume (cc)

Recommended Maximum Length—meters (inches)

3mm ID (1/8“) 6mm ID (1/4“) 9mm ID (3/8“)

6.5 Comparison vs. Calibration

Calibration consists of comparing an instrument with one of significantly greater accuracy (ideally, at least four times the accuracy of the

device under test--the “4 to 1 rule” widely accepted by industry). We use the term “comparison” in most of the following applications

because, depending upon their respective accuracies, either device can be calibrating (or simply compared with) the other.

For example, a 0.2% LFE can calibrate a 1% mass flow controller, while a 0.15% Cal=Trak can calibrate a 0.6% LFE. On the other hand, a

0.15% lab prover cannot calibrate a 0.15% Cal=Trak to its rated accuracy (or vice-versa). One can calibrate the other to only 0.3% with

great certainty, so we simply call it a comparison.

11

Page 12

7.0 Installation Diagrams and Application Guide

A

7.1 Comparison of Cal=Trak with Piston or Bell Provers

Piston or bell provers have a much longer measurement time than the Cal=Trak. For this reason, it is possible to compare them

simultaneously, but certain precautions must be observed. When the Cal=Trak begins its cycle, the piston’s weight causes the internal

pressure to rise by about 0.001 atmospheres (~0.1 kPa). If a simple pressure regulator feeds the test chain, we are simply using the

resistance of the entire flow chain to set our flow rate. The rate will then change significantly when the Cal=Trak is in its measurement

cycle. This will cause the actual flow measured during the Cal=Trak cycles to be less than the average flow seen by the piston or bell

prover.

To render this effect insignificant, the flow must not be affected significantly by the Cal=Trak’s cyclic pressure increase. This can be

achieved by use of a sonic nozzle as the stable flow source, or by feeding a fixed restrictor with a precisely regulated pressure of more than

200 kPa, as is used in factory calibration of the Cal=Trak. Note that at 200 kPa (30 PSI), the dynamic flow decrease of a simple restrictor

caused by the piston’s weight will be about 0.05%. In certain circumstances, the sonic nozzle or porous plug flow generator may be

replaced with a mass flow controller (MFC) specifically tailored to this task. An example is the Sierra Model C100L-10, -24 and -44, each

specifically built to provide a stable flow source for the Cal=Trak calibrator.

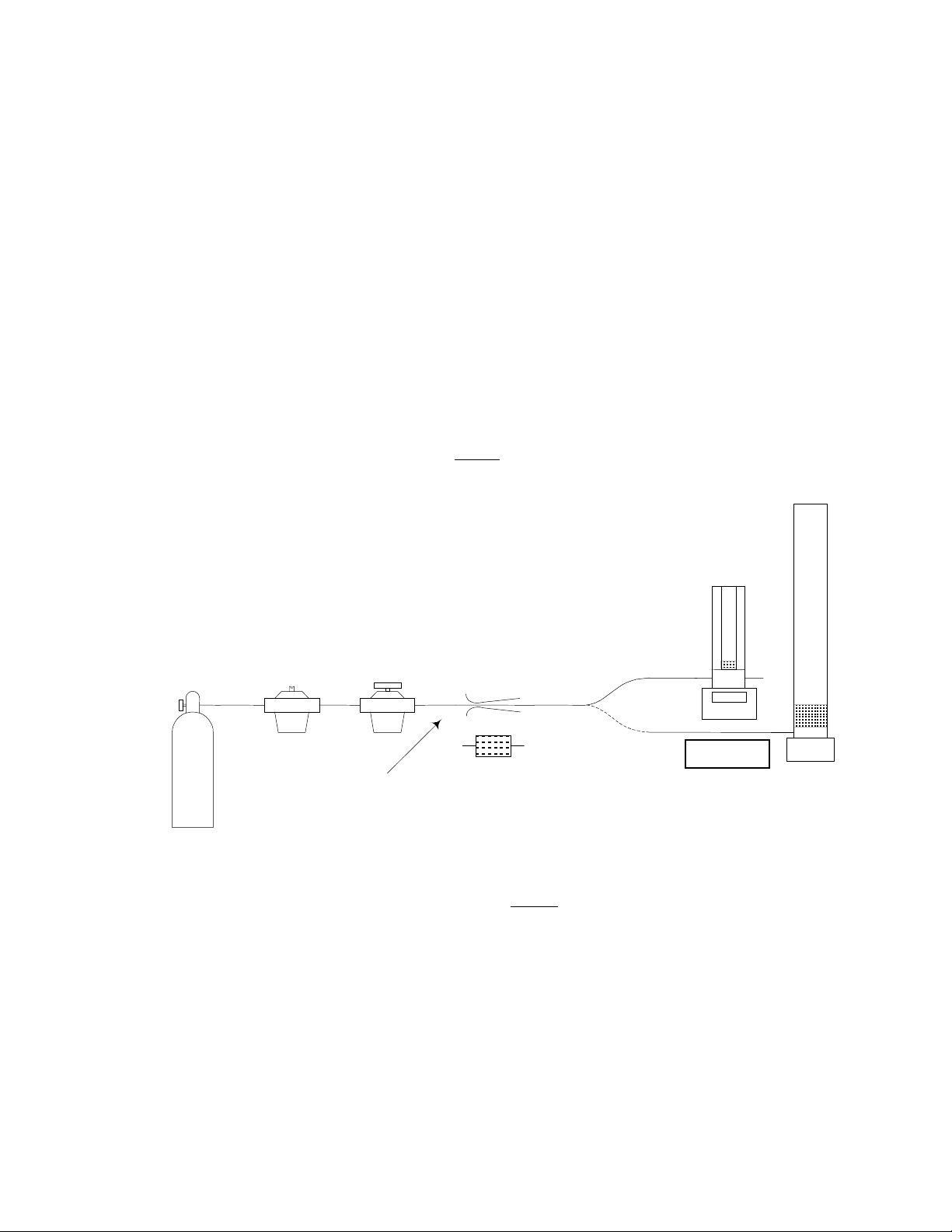

For this type of calibration, we can use the setup shown in Figure 5

a properly sized flow restrictor. A piston or bell prover cycle is instituted. The Cal=Trak and the prover can then be alternately measured

using the fixed flow source.

. The adjustable regulator is used to set the flow rate within the range of

Gas

Supply

An alternative approach can be used with piston provers, as shown in Figure 6.

a Cal=Trak. The Cal=Trak is then started in a cyclical mode, averaging its flow. Before the prover ends its cycle, the Cal=Trak is stopped

and the average flow read.

The Cal=Trak can be set for sufficient cycles in its average to allow interruption by the “stop” button, or smaller averages, such as 5 or 10

readings, can be taken during the prover cycle. It should be noted that the periodic pressure pulses might cause oscillations in bell provers,

reducing the bell prover’s accuracy somewhat.

Fixed

Regulator

djustable

Regulator

Stable Pressure

> 200 kPa

Figure 5 Setup for Piston or Bell Provers

Sonic

Nozzle

OR Porous Plug

DryCal

Cal=Trak

Piston or

Bell Prover

A cycle is initiated on the prover, which is much slower than

12

Page 13

A

Gas

Supply

Fixed

Regulator

djustable

Regulator

Stable Pressure

> 200 kPa

Figure 6 Alternative Setup for Piston Provers

Sonic

Nozzle

OR Porous Plug

Cal=Trak

DryCal

Piston or

Bell Prover

7.2 Vacuum Comparison of Cal=Trak with Piston or Bell Provers

The Cal=Trak operates similarly in both pressure and suction applications. Sometimes, however, users wish to compare the Cal=Trak under

suction (vacuum) conditions. With a piston or bell prover, the setup of Figure 7

atmospheric pressure.

The restrictor should be sized to provide a drop of at least 70 kPa (21 inches or 500 mm Hg). The purpose of the restrictor is to render the

piston insertion pressure change (0.1 kPa) relatively insignificant, as in the similar pressure calibration methodology.

In volumetric, comparisons, it is important to compensate for the difference in outlet temperature from input temperature. Although the

pressure is the same on each end, the restrictor and the pump affect the outlet temperature and flow must be normalized to the inlet

(ambient) temperature.

can be used. Note that the inlet to the Cal=Trak is at

Restr ictor

DryCal

Cal=Trak

Figure 7 Vacuum Setup for Piston or Bell Provers

Vacuum Pump

13

Page 14

7.3 Comparison of Cal=Trak with Laminar Flow Element Transfer Standards

A

A

When the Cal=Trak begins its cycle, the piston’s acceleration causes the internal pressure to spike briefly by about 0.01 atmosphere (~1

kPa). The pressure then remains elevated by about 0.001 atmosphere (~0.1 kPa) due to the piston’s weight. If a simple pressure regulator

feeds the test chain, we are simply using the resistance of the entire flow chain to set our flow rate. The rate may then change significantly

when the Cal=Trak is in its measurement cycle. This will cause the actual flow measured during the Cal=Trak cycles to be less than the

average flow seen by the laminar flow element (LFE). Moreover, the initial pressure pulse may cause the LFE instrument’s sensitive

pressure transducers to be destabilized for several seconds. For the latter reason, the LFE instrument should be read only immediately

before the Cal=Trak reading, and afterward only when the LFE instrument’s readings stabilize. At low flows, the Cal=Trak measurement

may take sufficient time to allow LFE stabilization. In that case, the instruments can be read simultaneously.

In addition, the flow must not be affected significantly by the Cal=Traks’s cyclic pressure increase. This can be achieved by use of a sonic

nozzle as the stable flow source, or by feeding a fixed restrictor with a precisely regulated pressure of more than 200 kPa. (At 200 kPa [30

PSI], the dynamic flow decrease caused by the piston’s weight will be about 0.05%.)

For this type of calibration, we can use the setup shown in Figure 8

a properly sized flow restrictor.

. The adjustable regulator is used to set the flow rate within the range of

Gas

Supply

Fixed

Regulator

Stable Pressure

> 200 kPa

djustable

Regulator

Sonic

Nozzle

OR Porous Plug

Figure 8 Setup for LFEs

LFE Meter

DryCal

Cal=Trak

7.4 Comparison of Cal=Trak with Sonic Nozzle Transfer Standards

A high quality sonic nozzle used above its critical pressure ratio will supply a constant flow despite changes in its outlet pressure. For this

reason, a calibrated sonic nozzle can be compared to a Cal=Trak by simply connecting its outlet to the Cal=Trak’s inlet as shown in

.

Figure 9

Fixed

Regulator

djustable

Regulator

Pressure

Transducer

Sonic Nozzle

DryCal

Cal=Trak

Stable Pressure

> Critical

Figure 9 Setup for Sonic Nozzle Transfer Standard

14

Page 15

7.5 Vacuum Comparison of Cal=Trak with Sonic Nozzle Transfer Standards

The Cal=Trak operates similarly in both pressure and suction applications. Sometimes, however, users wish to compare the Cal=Trak under

suction (vacuum) conditions. With a calibrated sonic nozzle, a simple setup such as that shown in Figure 10

Cal=Trak flow cell at atmospheric pressure. There is one precaution, however. The sonic nozzle’s pressure must be measured during the

Cal=Trak cycle to obtain the actual flow that the Cal=Trak is measuring. In turn, the pressure transducer must not be upset by the

Cal=Trak’s initial pressure pulse and must have rapid response relative to the Cal=Trak cycle time. This method is therefore most suitable

for flows in the lower part of a Cal=Trak’s range.

It should be noted that cycling of the Cal=Trak would cause a slight change in the nozzle’s inlet pressure. Even though the pressure

transducer is read during the Cal=Trak cycle, the nozzle may not achieve internal thermal equilibrium during the cycle, slightly reducing

accuracy.

can be used with the inlet to the

DryCal

Cal=Trak

Pressure

Transducer

Sonic Nozzle

Stable Pressure

> Critical

Figure 10 Vacuum Setup for Sonic Nozzle Transfer Standard

Vacuum Pump

7.6 Calibration of Mass Flow Controllers (MFCs)

Modern mass flow controllers have fast response times on the order of milliseconds. They can simply be connected to an appropriate inert

gas source and their output stream applied to the Cal=Trak, as in Figure 11

to the MFCs actual indicated flow and not to its control signal.

If a slow flow controller is to be calibrated, it is best to calibrate it in its metering mode. Apply the appropriate signal to fully open the

controller’s internal valve (full scale or digital “open), and calibrate the device as shown for mass flow meters (MFMs), below.

Remember that the Cal-Trak is designed to be operated at ambient pressure. If the outlet pressure of the MFC is atmospheric, then Figure 9

is correct. If the outlet pressure of the MFC is above ambient, insert a back-pressure regulator and a pressure gauge between the MFC and

the Cal=Trak. Adjust the back pressure regulator until the pressure gauge reads the correct pressure for the MFC under test (usually the

same pressure the device will see in its normal operation). Calibrate under the actual operating pressures with the outlet of the Cal=Trak at

atmospheric pressure.

. Proper calibration consists of comparing the Cal=Trak reading

15

Page 16

A

A

k

Gas

Supply

djustable

Regulator

Figure 11 Setup for Calibrating MFCs

MFC

DryCal

Cal=Trak

7.7 Calibration of Mass Flow Meters (MFMs)

Mass flow meters can be calibrated with the setup of Figure 12, which is similar to that shown for LFE transfer standards. Again, the flow

must not be affected significantly by the Cal=Trak’s cyclic pressure increase. This can be achieved by use of a sonic nozzle as the stable

flow source, or by feeding a fixed restrictor with a precisely regulated pressure of more than 200 kPa. (At 200 kPa [30 PSI], the dynamic

flow decrease caused by the piston’s weight will be about 0.05%.) Alternately, a stable mass flow controller may be used to maintain

specific flows into the MFM under test. In this scenario, the MFC will function as a pressure stabilizer and precision flow regulator with

the Cal=Trak defining the accuracy of the device under test. Contact Sierra Instruments for special Smart-Trak flow controllers designed

for this application.

If the MFM under test must be calibrated at pressure (i.e. because it is always used under pressure) then a fine resolution valve (needle

valve) and a gauge should be installed between the MFM and the Cal=Trak. Adjust the valve until the pressure gauge reads the correct

pressure for the MFM under test.

Gas

Supply

Fixed

Regulator

Figure 12 Setup for Calibrating Mass Flow Meters

djustable

Regulator

Stable Pressure

> 200 kPa

OR MFC

Sonic

Nozzle

OR Porous Plug

Flow Meter

DryCal

Cal=Tra

7.8 Calibration of Rotameters (Variable Area Flow Meters)

Variable-area meters can become unstable when connected in series with a volume. Cavity resonance may even occur. They are best

calibrated using the setup of Figure 13

or a large “swamping” pressure restriction is used to render the differences in the two devices’ insertion pressures insignificant with respect

to the required accuracy.

. The flow stream is alternately applied to the Cal=Trak and to the device under test. A sonic nozzle

16

Page 17

k

Variable Area Meter

(Rotameter)

Fixed

Regulator

Figure 13 Setup for Calibrating Rotameters (Variable Area Flow Meters)

Adjustable

Regulator

Stable Pressure

> 200 kPa

Sonic

Nozzle

OR Porous Plug

A

B

DryCal

Cal=Tra

8.0 Operating Instructions

Charging the Cal=Trak Battery

The Sierra Cal=Trak is powered by an internal lead-acid battery. The battery will power the instrument for 6–8 hours of continuous use and

has a typical service life of approximately 2–4 years, depending on use. The Cal=Trak provides a convenient 65-minute automatic shut-off

to extend battery life.

Before using your calibrator, be sure that the battery system has been adequately charged to ensure that it will perform to its specifications

and maintain operation for the calibration period. If "B" is indicated in the upper right hand corner of the display during operation,

recharging is required.

To charge, connect the Sierra supplied charger into a standard wall outlet. Be sure to use only Sierra-approved batteries and AC

adapters/chargers for all Cal=Trak flow calibrators. Insert the Cal=Trak charger’s barrel plug end into the charging jack located on the left

rear side of the SL-800 base. The green Charge LED will illuminate. Full charge takes 8 –12 hours, and the Cal=Trak can charge while

being used. Upon full charge, the charger will taper to a trickle mode automatically. The unit may be charged indefinitely without damage

to the battery.

Turning the Cal=Trak On

Press On to start the Cal=Trak. An opening screen will appear indicating the instrument’s software revision level followed by the “Main

Menu”.

Turning the Cal=Trak Off

The Cal=Trak has a battery saving automatic shut off system. After 65 minutes of inactivity, the Cal=Trak will shut off. Alternatively, the

unit can be shut off manually by pressing the Reset button followed by the number 0 from the “Main Menu”.

LCD Backlight

The Cal=Trak’s LCD display includes a backlight function to illuminate the display. The default setting for the backlight is always on. If

you wish to conserve battery power you may wish to turn the backlight off or enable the backlight only when inputting information on the

keypad.

To turn the backlight off, from the “Main Menu” press the Light button one time. To enable the backlight only when inputting information

on the keypad press the Light button a second time. To return to the default setting of always on, press the Light button a third time.

17

Page 18

Low Battery Indicator

A low battery condition is indicated by a “B” appearing in the upper right hand corner of the LCD. The low battery indicator allows the user

to connect to an external power source prior to the unit powering down. Time between low battery indication and loss of power varies

depending on the current application.

8.1 Cal=Trak Keypad

8.2 How To Use the Cal=Trak Keypad

General Menu Navigation

Use the Up/Down arrows to navigate between different lines within a menu. Use the Enter button to select a field to be modified and to

lock in any changes. Use the keypad for data entry such as entering a User ID number; use the Up/Down arrows to toggle fields such as

temperature or pressure units. Use the Fwd and Back keys to advance to the following menu or return to the previous menu.

18

Page 19

Keypad Function

t

The keypad is used for both numeric and alpha character entry. When pressed, each alphanumeric button will display its corresponding

number. If pressed again within two seconds the unit will display the first corresponding letter for that key. Repeat this process for

additional letters on the same key. A space may be inserted by pressing the 0 key twice. To go back, use the back arrow. The Cal=Trak will

overwrite previous entries. Use the Enter key to lock in any selections.

Reset Button

Clears both the current reading and the group average and opens the valve, allowing the piston to return to its

resting state.

Stop Button

Stops current reading and opens the valve, allowing the piston to return to its resting state.

Auto Button

Initiates automatic readings (must be accessed from the “Run Menu”). If the Reading type has been set to “Cont” in “Setup Menu – 2”, the

unit will run until the preset average is reached and then start the cycle over. If the Reading type has been set to “Burst” in “Setup Menu –

2”, the unit will run until the preset average is reached and then stop.

Read Button

Initiates a single reading (must be accessed from the “Run Menu”).

8.3 Factory Default Settings

The Sierra Cal=Trak has a number of user definable features and settings. To return to factory default settings press Reset followed by Save

from the “Main Menu”

Parameters Factory Settings Optional Settings

No. of Readings in an Averaging Sequence 10 1–100

Atmospheric Pressure mm Hg mBar, kPa, PSI

Temperature °C °F

Standardized Temperature Setting 0 °C 0.0–50.0 °C

Date Format MM/DT/YR DT/MM/YR

Time Format AM/PM 24 Hr

8.4 Taking Readings

Main Menu

Run

Setup

Leak Tes

1 Press Enter, Read, or Auto to enter the “Run Menu”.

19

Page 20

t

• Press the Read button to initiate a single reading.

• Press the Auto button to initiate multiple readings.

• Press the Stop button to stop current flow reading and open valve.

• Press the Reset button to clear the display of current data.

8.5 Setting User Preferences

The Sierra Cal=Trak offers enhanced electronics options that allow the user to define parameters specific to their application. There are six

Setup Menus in all. For a comprehensive flowchart of the complete menu tree, please see Appendix B.

General Menu Navigation

Use the Up/Down arrows to navigate between different lines within a menu. Use the Enter button to select a field to be modified and to

lock in any changes. Use the keypad for data entry such as # of readings in an averaging sequence; use the Up/Down arrows to toggle fields

such as temperature or pressure units. Use the Fwd and Back keys to advance to the following menu or return to the previous menu.

Keypad Function

The keypad is used for both numeric and alpha character entry. When pressed, each alphanumeric button will display its corresponding

number. If pressed again within two seconds the unit will display the first corresponding letter for that key. Repeat this process for

additional letters on the same key. A space may be inserted by pressing the 0 key twice. To go back, use the back arrow. The Cal=Trak will

overwrite previous entries. Use the Enter key to lock in any selections.

8.6 Setup Menu 1, Calibration ID #, Gas Constant, Calibration Type

Run

Setup

Leak Tes

To enter “Setup Menu – 1” from the “Main Menu”, select Setup and press Enter.

Sensor Factor 1.000

Cal. Type Std.

Option 1, “Sensor Factor”

This option changes the gas constant or K-factor for instruments that are used with any gas other than air or nitrogen, but originally

calibrated by the device manufacturer using air or nitrogen and a factor. Gas conversion factors vary by device manufacturer. Please consult

the instrument manufacturer’s gas conversion multipliers for the device under test and enter the appropriate factor here. The input range for

this option is 0.200–2.000. The default setting is for 1.000, the setting for air or nitrogen.

Main Menu

Setup Menu – 1

20

Page 21

Option 3, “Cal. Type”

This option changes the sample type being displayed. Toggles between “std.” (standardized or mass flow readings as used by MFM or MFC

devices) and “vol.” (volumetric readings as used on PD/rotameters)

8.7 Setup Menu 2, Reading Type, # in Average & Minutes/Reading

Option 1, “Reading Type”

Toggles between “Cont” (continuous auto-read) and “Burst” (performs continuous auto-read, then stops after the quantity in averaging

sequence is reached [as programmed below in Setup Menu 2, Option 2, # in Average])

Option 2, “# in Average”

Changes the quantity in an averaging sequence (consecutive readings) from 1 to 100. When used in “Burst” mode, the Cal=Trak stops after

this number of readings.

Option 3, “Min./Reading”

Specifies the time interval (in minutes) between flow readings. A setting of “00” means continuous readings (no interval).

8.8 Setup Menu 3, Pressure Units, Temp. Units, and Temp. Correction Factor

Option 1, “Pres. Units”

This option allows you to toggle between pressure units of: mmHg, kPa, mBar, or PSI

Option 2, “Temp. Units”

This option allows you to set the temperature units for ° F or ° C.

Option 3, “Temp Corr”

This option is used to set the standardization (mass flow) reference temperature. Use the keypad to enter the numerical value of the

reference temperature. For mass flow units of slpm, a reference temperature of 21.1°C is commonly used. For mass flow units of nlpm, a

reference temperature of 0.0°C is common. Check the specific reference conditions for each DUT.

8.9 Setup Menu 4, Date, Time & Battery Voltage

This menu has an alternate navigation method.

21

Page 22

Within this menu, use the Fwd and Back arrows to change between different options and to move about within each option, use Up and

Down arrows to alter settings. Date and time formats are specified using Setup Menu 5, Date and Time Formats. This guide is written using

the factory default settings.

Option 1, Date

This option allows you to set the date.

Option 2, Time

This option allows you to set the time.

Battery Voltage cannot be adjusted, but is displayed for reference.

8.10 Setup Menu 5, Date & Time Formats

Option 1, “Date”

Toggles between “MT/DT/YR” or ”DT/MT/YR” date format.

Option 2, “Time”

Toggles between “AM/PM” or ”24 Hr” time format.

Option 3, “Auto Off”

Toggles between “Enable” or “Disable” 65-minute auto-shut off.

8.11 Setup Menu 6, PTV and PTVM (formerly Leakage & Leakage Correction Factor)

There is a very small gap between the piston and the interior of the glass flow cylinder, allowing a known volume of gas to leak past during

calibrations. This is the underlying operating principal of the Sierra Cal=Trak, and what allows the elimination of fluid seals used in earlier

piston prover designs like the Sierra Cal=Bench. At low flows, the fixed leakage past the piston becomes a greater percentage of the overall

measurement uncertainty. The leakage of each individual flow cylinder is quantified at our factory using nitrogen, and entered into the

Cal=Trak as the Piston Tare Value (PTV), to be factored into subsequent readings. This is part of the factory calibration.

The Leakage rate is based upon the viscosity of nitrogen. For proper calibration with gases other than nitrogen (or air), the PTV multiplier

(PTVM)—factory-set to 1.000—allows the user to adjust the Cal=Trak to account for different gas viscosities. The PTVM is based upon

the difference between the viscosity of nitrogen and the viscosity of the gas under test, expressed as a ratio (PTVM = the viscosity of

nitrogen/viscosity of the gas being used). To optimize low flow calibrations of alternate gases, the user should determine this ratio and

adjust the PTVM as necessary. Note: since the Leakage rate is fixed for a particular flow cylinder, the use of a PTVM greater than 1.000

22

Page 23

will alter the factory-specified low-end flow of that flow cylinder. To calculate the low-end flow of a flow cylinder while using a PTVM

other than 1.000, multiply the PTVM by the factory-specified low-end flow of the cylinder in question. The resulting number is the new

low-end flow of that cylinder at the manufacturer’s rated accuracy specification.

For example, to calculate the effect on the low-end flow specification of a Cal=Trak Model SL-800-10 (low flow cylinder) while calibrating

with actual hydrogen gas:

The viscosity of N

these should be expressed as 165.31/83.21, or 1.988. Enter 1.988 as the new LCF for calibration of hydrogen. Since the original minimum

flow specification of the Cal=Trak Model SL-800-10 is 5 sccm, the new adjusted minimum would be 1.988 * 5 = 9.94 sccm.

at 0° C is 165.31 microPoise. The viscosity of hydrogen at 0° C is 83.21 microPoise. To determine the new PTVM,

2

PTV 0.460 ccm

PTVM 1.000

Option 1, "PTV"

This is the Leakage rate of a particular cell. It is factored into all flow readings to obtain a leakage-independent flow reading. The PTV is

part of the factory calibration and non-adjustable.

Option 2, "PTVM"

This is the PTV Multiplier, and is multiplied by the Leakage value to enhance accuracy at lower flows when using gases other than nitrogen

or air. The LCF factory setting is 1.000, although it may be changed to any value between 0.200 and 3.00 using the keypad. For further

information, please contact Sierra.

Setup Menu – 6

9.0 Battery System

The Sierra Cal=Trak is powered by an internal lead-acid battery. The battery will power the instrument for 6–8 hours of continuous use and

has a typical service life of approximately 2–4 years, depending on use. The Cal=Trak provides a convenient 65-minute automatic shut-off

to extend battery life.

The Cal=Trak can be charged by the Sierra single station charger when plugged into a standard power source outlet.

9.1 Battery Maintenance & Storage

Battery Maintenance

Lead-acid batteries will not exhibit the “memory effect’’ common to nickel-cadmium batteries due to continuous charging and no further

conditioning is required to maintain full performance.

Long-Term Storage

Long-term storage without charging can damage the battery pack, therefore if the Cal=Trak is not used regularly, it should be fully charged

at least once every three months. When possible, periodically leave your Cal=Trak on charge overnight.

10.0 Maintenance

Although the Sierra Cal=Trak is a rugged instrument, certain care and maintenance requirements must still be met. When not in use always

store your Cal=Trak in a clean, dry environment. Sierra Instruments provides a range of cases ideal for storage and transportation of your

23

Page 24

Cal=Trak calibrator. See Chapter 12-5 Accessories or contact Sierra Instruments for details. Wipe only with a damp cloth and do not spray

t

with liquid solvents or use abrasive cleaners.

Any service to the Sierra Cal=Trak must be performed by Sierra maintenance personnel.

Current service or calibration information and pricing can be received by contacting Sierra Instruments, Inc. at any of the locations listed on

the front cover. Alternatively, you can contact us via our web site www.sierrainstruments.com

.

11.0 Quality Assurance

11.1 Leak Test Procedure

A quality assurance self-test feature is provided to verify proper integrity of the flow cell. It is recommended that the self-check leakage test

be conducted periodically as part of an ongoing quality assurance program. Passing the leak test does not ensure proper function of the

Cal=Trak. It does ensure that total leakage is within the product’s allowable limits. To ensure proper function of the Cal=Trak annual

factory calibration is recommended. The leak test may take as long as 6 hours or more to complete per fitting.

Since the leak test may take several hours, it is recommended to plug the charger into the base during the leak test to prevent the unit from

turning off.

To Initiate the Leak Test

Place the Cal=Trak on a flat, vibration-free surface.

1

2 While in the “Main Menu” install the leak test cable (included with the Cal=Trak base unit) between the 9-pin Cal=Trak

Base Connector and the 9-pin Cell Connector.

Run

Setup

Leak Tes

Main Menu

3 From the “Main Menu” remove the cell and select “Leak Test”

4 After a leak test is initiated, the display will read:

5 Place the leak test plug over either the inlet or the outlet port fitting on the Cal=Trak flow cell.

6 Invert the Cal=Trak flow cell

7 Push any key to comm ence t he leak test. At this point the Cal=Trak will time the descent of the piston. The leak test may

take up to 6 hours to complete. The display will read:

8A If the test is completed successfully, the display will read:

24

Page 25

8B If the unit fails the leak test, the display will appear similar to the following picture. Please make a note of the number that

is displayed and contact Sierra customer service.

-

9 Repeat the procedure with the leak test port cap over the opposite port fitting.

10. To stop the leak test at any time press the RESET button.

Leak Test Illustration: Leak Test in Progress

Inverted Cell

Leak Test Plug

Leak Test Cable

Swagelock Fitting

Base

11.2 Calibration

As a quality assurance measure, Sierra recommends annual calibration of all measurement instruments. However, how often you have your

Cal=Trak calibrated is an internal quality control decision. The determining factors are whether the unit passes the internal leak test, quality

system requirements if applicable, and the conditions in which the unit is used. Units used in a laboratory setting may require calibration

less frequently than a unit that is used in a manufacturing environment. The annual calibration program is an elective and is therefore not

included as a warranty item. Expedited “RUSH” turnaround service is also available at an additional cost. Please contact the factory for

more information on available calibration services and pricing.

25

Page 26

Calibration Includes

Cleaning (if required)

•

Valve adjustment (if required)

•

Battery capacity test

•

Internal computer program upgrade as necessary

•

Mechanical upgrades as necessary

•

Run-in test

•

Dynamic performance test

•

NIST-traceable calibration certificate

•

11.3 Returning Your Unit for Calibration or Service

Prior to returning your Cal=Trak for service or calibration, please contact Sierra Instruments, Inc. for an RMA number. You can

request an RMA number from any Sierra office or via our web site, www.sierrainstruments.com

without an RMA number or your service may be delayed.

. Do not return your calibrator

11.4 Shipment

When shipping the Sierra Cal=Trak please ensure that the packaging is adequate to protect the instrument. When possible the Cal=Trak

should be shipped in the optional storage case. Sierra Instruments, Inc. is not responsible for damage that occurs during shipment.

When transporting by air, the internal solenoid valve must be in the Open position to avoid possible cell damage. To open the valve, from

the “Run Menu”, press the Stop button. The valve position may be verified by sealing both the inlet and the outlet fitting. The piston should

move freely up and down the cylinder.

11.5 Replacement Parts & Accessories

Part Description

SL-800-B Base Unit

SL-800-10 Low Flow Cell, range 5 sccm to 500 sccm

SL-800-24 Medium Flow Cell, range 50 sccm to 5 slpm

SL-800-44 High Flow Cell, range 500 sccm to 50 slpm

PEL-1600 Pelican case with foam insert, fits 1 base, 1 cell & accessories

PEL-1650 Pelican case with foam insert & wheels, fits 1 bases, 2–3 cells & accessories

800 BAT Battery, 6V lead-acid

UNIVERSAL 120/240V battery charger; please specify plug configuration

FOAM-1600 Replacement foam insert for Pel-1600

FOAM-1650 Replacement foam insert for Pel-1650

LT-CABLE Leak test cable

CA-23 RS-232 cable for PC connection

26

Page 27

11.6 Additional Information

Technical Specifications for your Cal=Trak calibrator can be found in Appendix C of this manual. Should you desire more information on

Sierra Instruments and our products, you are welcome to visit our website at: www.sierrainistruments.com

.

Additional information on the Cal=Trak calibration systems are available by clicking on the Cal=Trak photos at the lower left, which will

take you to dedicated pages on our flow calibrators. You can also obtain a copy of the Cal=Trak Uncertainly Analysis from any of our 3

offices or more than 100 distributors world-wide.

27

Page 28

12.0 Limited Warranty

The Sierra Cal=Trak SL-800 is warranted to the original end user to be free from defects in materials and workmanship under normal use

and service for a period of 1 year from the date of purchase as shown on the purchaser’s receipt. The Cal=Trak’s battery is warranted for 6

months from the original purchase date. If the unit was purchased from an authorized reseller a copy of an invoice or packing slip showing

the date of purchase may be required to obtain warranty service.

The obligation of Sierra Instruments Inc. under this warranty shall be limited to repair or replacement (at our option), during the warranty

period, of any part which proves defective in material or workmanship under normal use and service provided the product is returned to

Sierra Instruments Inc. with transportation charges prepaid.

Sierra Instruments Inc. shall have no liability to repair or replace any Sierra Instruments Inc. product:

Which has been damaged following sale, including but not limited to damage resulting from improper electrical voltages or

•

currents, defacement, misuse, abuse, neglect, accident, fire, flood, act of God or use in violation of the instructions furnished by

Sierra Instruments Inc.,

Where the serial number has been altered or removed or

•

Which has been repaired, altered or maintained by any person or party other than Sierra Instruments, Inc. or a Sierra-authorized

•

service center

This warranty is in lieu of all other warranties, and all other obligations or liabilities arising as a result of any defect or deficiency of the

product, whether in contract or in tort or otherwise. All other warranties, expressed or implied, including any implied warranties of

Merchantability and fitness for a particular purpose, are specifically excluded. In no event shall we be liable for any special, incidental or

consequential damages for breach of this or any other warranty, express or implied.

28

Page 29

Appendix A: Cal=Trak Troubleshooting Guide

A-1.0 Unit does not turn on

Battery may be deeply discharged or dead.

Plug charger into unit

1

2 Confirm that the Charge LED is lit

3 Wait 10 minutes and try turning unit on again.

4 If the unit still does not work, please contact Sierra.

A-2.0 Unit suddenly turns off

Battery may not be fully charged.

1 Plug charger into unit.

2 Plug cell into unit.

3 Turn on the Cal=Trak.

4 Enter “Setup Menu – 4” to check battery voltage.

5 Battery voltage should be 6.00 volts or higher.

A-3.0 “B” appears in the upper right corner in the run screen

Battery is getting low and should be recharged.

A-4.0 The Charge LED does not light when charger plugged in

1 Is the wall outlet working properly?

2 Are you using the correct charger? Please be sure to be using a Sierra 12V charger

3 Is the charger working properly? If possible, measure the voltage with a voltmeter. The voltage should be greater than 12 volts.

A-5.0 “No Cell” appears on display

“No Cell” is displayed when the cell is not connected to the base.

1 If the cell and the base are connected, check the cell connection to the base by removing and reconnecting the cell to the base.

2 If display still reads “No Cell” after it has been established that the base and the cell have a firm connection, please contact Sierra.

A-6.0 Settings have been lost or seem to have changed

If the battery is removed or allowed to discharge your settings may be lost. Reprogram instrument to desired settings. See Section 8.0,

Setting User Preferences.

A-7.0 “Piston Error” appears on display

This error message could be caused by any of the following:

29

Page 30

1A The piston is not reaching the bottom in the time allotted by the program.

Push any key to return to the Read Screen.

•

If you want the Cal=Trak to start taking readings again, press Read or Auto.

•

1B The piston does not return to the bottom of the cell at all.

The flow rate may be too high for the cell being used, make sure that the flow is in the specified range.

•

Water vapor may have condensed inside the cell if the cell has been moved from one location to another. Allow the cell to come

•

to ambient temperature and the piston should fall naturally as the condensation evaporates.

The flow cell may have been used with a gas other than air or nitrogen. Some gases are naturally “sticky”. If you have used the

•

cell with another gas, run nitrogen gas to the inlet port at a pressure below 5 psig while keeping the outlet port open to atmosphere. The

nitrogen gas will slowly purge out the “sticky” gas previously used and the piston will return to the bottom of the cell.

A-8.0 The piston does not move when the “Read” or “Auto” is pushed

1 Is the cell connected to the base?

2 Is a flow source connected?

3 Is the flow source connected correctly (Pressure vs. Vacuum)?

4 Is the flow source inadvertently set too low?

5 Are any of the ports sealed?

6 Are any of the tubes pinched?

7 Are any of the connections loose or leaking? This can happen especially easily with Swagelok fittings.

8 Can you hear the valve working? If not, contact Sierra.

A-9.0 When taking readings, the flow seems off.

1 Are any of the connections loose or leaking? (Swagelok fittings are especially prone to this.)

2 Are any of the tubes pinched?

3 Is the gas constant set to the correct number? See Section 8.1, Setup Menu 1, Calibration ID #, Gas Constant, Calibration

Type.

4 If you are using the cell within bottom 10% of its flow rating with a gas other than air, check to make sure the LCF

(Leakage Correction Factor) is set correctly. See Section 8.6, Setup Menu 6, Leakage & LCF.

5 Make sure your standardized temperature matches the current DUT. If a standardization temperature of 21C is used with

a DUT having a standardization temperature of 0C, an error of approximately 7.5% can result.

A-10.0 Readings taken with the Cal=Trak do not correlate to those taken with another flow

meter

Please check previous question. If that does not solve your problem, please check the following:

1 Are you comparing volumetric flow with standardized flow? See Section 8.1, Setup Menu 1, Calibration ID #, Gas Constant,

Calibration Type.

2 If both units are set to “Standardized”, are both units set to the same standardized conditions? See Section 8.3, Setup Menu 3, Temp.

Correction Factor, Temp. & Pressure Formats. If a standardization temperature of 21C is compared against a standardization

temperature of 0C, an error of approximately 7.5% can result.

3 Are there any large containers in the flow stream, such as extra tubing, large damper(s), Magnehelic gauges, etc.? These items can

cause inaccurate readings.

4 Is the flow source strong enough that it will not be affected by small variants of back pressure?

A-11.0 During Leak Test, “Leakage > 9.999 ccm” appears on display

1 Check for poor connections on either the pressure or suction port.

2 Make sure all fittings are tight.

30

Page 31

A-12.0 The Cal=Trak does not appear to be sending data through the serial (RS-232) port

1 Review Appendix C: Cal=Soft Software Instructions beginning on page 33 of this Manual.

2 Is the serial cable plugged into the correct COM port and the Cal=Trak?

3 Is cable correct? The cable should be a 1 to 1 connection, not a null modem cable.

A-13.0 Resetting the Cal=Trak

There is a Hard Reset button recessed on the back left-hand side of the Cal=Trak. Use the Hard Reset button in order to override current

operation and return to the “Main Menu”. All settings will be retained; however, current flow data will be lost.

A-14.0 Contact Sierra for Assistance

If the above tips do not get your calibrator functioning correctly, you are welcome to contact your local Sierra distributor.

Or, you may contact any of our three locations for additional Sierra Instruments Technical Support:

CORPORATE HEADQUARTERS

5 Harris Court, Building L

Monterey, CA 93940

USA

hone (831) 373-0200 (800) 866-0200 Fax (831) 373-4402

P

EUROPE HEADQUARTERS

Bijlmansweid 2

1934RE Egmond a/d Hoef

The Netherlands

Phone +31 72 5071400 Fax +31 72 5071401

ASIA HEADQUARTERS

Room 618, Tomson Centre Bldg. A

188 Zhang Yang Road

Pu Dong New District

Shanghai, PR China, 200122

Phone +8621 5879 8521/22 Fax +8621 5879 8586

Please have the following information available before calling Sierra for support:

•

Your Cal=Trak model and serial number

Instruments being calibrated and/or used with the Cal=Trak

•

Your Windows version and service pack level (i.e. Windows 2000 sp3, Windows XP Sp1)

•

The COM port you are operating with (i.e. COM1, COM2, COM3, COM4)

•

31

Page 32

Appendix B: Cal=Trak Specifications

Configuration: Interchangeable modular flow cells, all calibrated elements except crystal time base are in cell

Base Unit

Size 6" W x 10.5" D x 4" H 15.2 cm W x 26.7 cm D x 10.2 cm H

Weight 4.2 lbs 1.9 kg

Flow Cells

Size 13" H x 4” diameter 33 cm H x 10.2 cm diameter

Weight 5.8 lbs 2.6 kg

Flow Ranges:

Model Optimum Flow Range

Cal=Trak SL-800-10 5.0 sccm–500 sccm

Cal=Trak SL-800-24 50 sccm–5 slm

Cal=Trak SL-800-44 500 sccm–50 slm

Maximum flow rate is 50 slm at sea level, at higher altitudes piston may not return at flow rates higher than 40 slm.

Absolute Accuracy, Single Readings

All accuracies are based on % of readings. Averaging multiple readings will increase repeatability and accuracy.

Flow Cell Standardized (15°–30°C)

Cal=Trak SL-800-10 ±0.15%

Cal=Trak SL-800-24 ±0.15%

Cal=Trak SL-800-44 ±0.15%

Suitable Gases Non-corrosive, humidity less than 70%, non-condensing

Time per Reading Approximately 1 to 60 seconds, flow & cell dependent

Operating Modes Single cycle, continuous cycling or 1 to 255 minute intervals

Measuring Cell Graphite composite piston in borosilicate glass cylinder

Temperature Range 15–30 C

Temperature & Pressure Sensors Located below piston in flow cell; barometric pressure sensor located in base unit

Valve magnetic acting design (to prevent heating of gas stream), self-relieving

Battery System Internal continuously chargeable sealed 6V lead-acid battery

AC Charger | Adapter 100–240 VAC 47–63 Hz

Self-Test Piston Tare Value (Leak Rate)

Outputs Illuminated LCD display, RS-232 serial port (CSV format)

Warranty 1 year

Note: Annual calibration offered by Sierra is elective and is not included as a warranty item.

Software Revision 2.03

All specifications are subject to change. Please contact Sierra or visit our web site at www.sierrainstruments.com for the most current

product information.

32

Page 33

Appendix C: Cal=Soft v 2.0 Communication Program

1.0 Introduction

This is the second version of the Sierra Cal=Soft concept. It was created to support the new Cal=Trak firmware version 2.03 which began

shipping in the first few months of 2008. This program enables the transfer of flow data from your Cal=Trak into an Excel spreadsheet for

data series analysis. The data is collected in the program in a convenient format which can generate a Calibration Certificate, if desired.

Currently you can automatically certify a Sierra 100 series, use any Sierra 100 Series MFC automatically as a flow generator to calibrate

other flow meters and perform manual entry for calibration of any analog MFM or MFC instruments. The program cannot communicate

directly with analog units or but this should be available by late 2008.

Cal=Soft is written in Visual Basic embedded in an Excel Spreadsheet as a “macro.”

Requirements

Your Cal=Trak base must be loaded with firmware version 2.03 or above

•

A PC with Windows XP. A local serial port is convenient, but a USB port may be used with appropriate adapters.

•

Microsoft Excel 2000 (or higher)

•

WinZip or an equivalent program for extracting from zipped files

•

Administrator rights in Windows 2000, XP

•

2.0 Installation

The CD-Rom provided from Sierra Instruments contains the Cal=Soft Calibration Program, a short instruction manual and some

troubleshooting hints. Load the CD-Rom into your computer. Select the Excel program “Cal=Soft” and copy it to your computer in a

convenient location. Open the program and Enable Macros, if prompted.

3.0 Operating Instructions for Cal=Soft Software

Cal=Soft is separated into 4 separate worksheets for convenience.

Worksheet descriptions:

Short Manual

Operating Screen

screen view on the Operating Screen go to top bar and select: View -> Zoom and adjust the zoom to a suitable value

Startup

sheet and opens a Visual basic screen. If the red screen window is shown, do not select any worksheet with your mouse! Only leave this

window by pressing EXIT.

Calibration sheet

be printed and saved later on. You can make changes to this sheet (f.i. replace the Logo with your own), but DO NOT insert rows or

columns!!

Instrument Information

here. These instruments can be selected in the Operating screen and the relevant information will be entered in the calibration sheet.

: A copy of this operation manual included inside the Cal=Soft program.

: The start screen where you enter your details and from which you operate the program. Tip: If you cannot see the full

: A system sheet in which the visual basic operating mode operates. During the actual calibration the program will switch to this

: In this sheet we find the layout of the certificate. The data taken during the runs will be placed in this sheet and this can

: This is a small database in which you can enter your instruments description. Sierra models are already entered

33

Page 34

Introduction

This software in combination with a Sierra Cal=Trak can certify flow meters and flow controllers for gases and will generate a calibration

certificate. Depending on the capability of your DUT (Device Under Test) this can be done semi or fully automatic. If you connect a Sierra

100 series mass flow controller (MFC) by RS232 and a Cal=Trak by RS232, this software obtains most of its required settings and variables

from the 100 series and the certification requires minimal human intervention. If you calibrate a unit with a display, the readout will have to

be entered manually into the program during the certification. If you have a DUT with an analog output, you have to measure this output

with a DVM and enter the readout manually into this program during the certification.

The software communicates with the Cal=Trak through RS232 and will configure your calibrator automatically.

It is recommended that you power on your Cal=Trak, DUT, Sierra 100 Series MFC (if used) and then run the Cal=Soft program.

Setup Cal=Trak

To make the Cal=Trak communicate correctly with this software the following settings have to be made to the Cal=Trak before you start

using this program. After you switch the Cal=Trak on insure the following settings are indicated as below.

1) Setup Menu 1, See Section 8.7 on pg. 35

Choose STD or VOL based upon your DUT. For Mass flow meters or controllers, you must use STD.

Set the Sensor Factor = 1.000 for calibration with Air or Nitrogen gas.

2) Setup Menu 2, See Section 8.8 on pg. 36 of this Manual.

Set BURST "On".

It is not necessary to set the “# in AVERAGE,” because this value will be determined in the Software automatically.

You must set the “MIN/READING to 00”

3) Setup Menu 3, See Section 8.9

Select the proper units for Temperature and Pressure. Make them match your DUT.

Set the Reference temperature on 21.1 C (Standard conditions) or to 0.0 C (Normal conditions).

NOTE: some DUT instruments will have other Reference Conditions. Set up the Cal=Trak to match your DUT, then make sure in the next

section you set the Cal=Soft to the same units.

4) Cal=Trak to Computer cable

Connect the Cal=Trak to your Computer with a RS232 9-Pin to 9-Pin cable like the one supplied with your calibrator. The cable should not

be longer than 10 meters, but 1 meter cables can improve the reliability of the connection.

Trouble shooting digital comms:

When the program is not communicating with the Cal=Trak you will find in most cases one of the settings in the Cal=Trak is incorrect.

Please review steps 1-3 above, then check all the cables and perform a hard reset the Cal=Trak (See hole in the back of the Cal-Trak base).

Follow steps 1-3 again.

Please see if the basic communication is already happening:

When you press START on the operating screen, have a look at the display of the Cal=Trak. The program will move the Cal=Trak from the

Main Menu to the Run Mode. You will see this change just as if you had pressed the buttons yourself. Please verify that this is happening!

If this is not happening check the RS232 cables (Are they properly plugged in?) Check if you selected the correct com port for the Cal=Trak

in the Operating screen. Are you sure you did not select the Com port of the Sierra 100 series or DUT? Does your selected com port exist?

(see My Computer (Right mouse button) -> Properties -> Hardware -> Device Manager -> Ports (Com & LPT) to view the com ports on

your computer, and check that there are no errors reported.

34

Page 35

If you use a USB to RS 232 converter, this could be the problem. Sierra has tested the ASUS and CONRAD (Nr. 982417) and BELKIN

converters which all worked OK, but we cannot confirm that all converters will function properly.

If this does not solve the issues please write down the error. What do you see on the screen? Report what you have tried this far and report

to your Sierra agent or e-mail this to: service@sierrainstruments.com

Setup DUT

Insure that the Cal=Trak flow cell is suited for the range of the DUT. In general, flow instruments are commonly tested at 0-25-50-75-100%

of their rated maximum flow, so the Cal-Trak flow cell selected should be suited for 25% to 100% of the range of the DUT. Currently the

program is not suited to change Cal=Trak flow cells during a certification run. You would have to make 2 runs and merge the data

manually.

Connect a suitable gas supply to the DUT and insure the inlet pressure is correct. Set up the DUT to its operating condition. Please

remember the Cal=Trak only operates under atmospheric pressure conditions. If your DUT requires some back-pressure, place a back

pressure regulator between the DUT and the Cal=Trak.

Insure your system is free of leaks.

Setup Cal=Soft

Go to the tab marked "Operating screen". In this screen you find 4 steps that need to be taken to certify your DUT. The Operating screen

looks like this:

35

Page 36

Step 1--Enter information about you and the Cal=Trak

Company: Enter the name of your Company

Reference: Enter your reference number that will be shown on the calibration certificate

Project/file number: Enter your internal project number that will be shown on the calibration certificate

Date of calibration: Will be automatically filled in here. To enter date manually (Used for certificate data only) type in date.

Suggested recal date: Will be automatically filled in with today's date + 1 year

Software release: Current software version 2.03, cannot not be edited

System ERROR: Uncertainty of the Cal=Trak, factory set at 0.4%. Change to 0.2% for use with Cal=Trak SL-800.

Certificate type: Select the type of certificate you are going to generate (Determines title of the Certificate, no other effect)

Measured gas pressure: this information is obtained from the Cal=Trak

Measured Gas temperature: this information is obtained from the Cal=Trak

Calibration gas: Use the pull-down menu to select the gas you will use for the calibration. At this moment this is only suitable for Air and

Nitrogen. Consult factory for other gasses

Performed by: Enter your name here. It will be printed on the certificate

Comport Cal=Trak: Select the RS232 Com port to which the Cal=Trak will be connected (Selectable from Com port 1 to 10)

Shots/set: Enter the number of "shots" that the Cal=Trak will have to take at each flow point. (The more "Shots" the more accurate the result

will be but this will also take more time. Common settings for this are 4 to10 shots)

Max. Cal=Trak wait: This is the maximum time in seconds that the program will wait before it aborts it’s data collection. If the flow is very

low you might have to increase this time. It also determines how long the program will wait when you check the zero flow point.

Recommended setting is 30 or 60 seconds. If you select a value below 30 seconds, it is possible the program will stop it’s data collection

before the Cal=Trak completes its cycle. This would result in an error at one or more flow points.

Step 2--In this step you enter information about the DUT

Model: Select the unit you want to certify. The pull down list will show you a number of options that are defined under that Tab

"Instrument information". You can freely edit and add to this data base and than select your specific instrument. Data like accuracy and P+T

effects will be used in the calibration sheet. Only Sierra Models are programmed into the software upon delivery, but others may be added.

Power supply: Select the power supply for the unit (Only used for Certificate sheet data)

Input signal: Here you select the source of the setpoint signal to your DUT. For Flow meter enter NA. For RS232 for a Sierra 100 Series

MFC enter digital. For all others, choose from the pull-down menu the proper setpoint signal for your DUT.

Output signal: Here you select what kind of output your DUT is using. (for RS232 for a Sierra 100 Series, enter digital)

Comport DUT: Select the RS232 Com port on which the Sierra 100 Series will be connected (Selectable from Com port 1 to 10). This will

be used if your DUT is a Sierra 100 Series or if the Sierra 100 Series MFC will be automatically controlling flow into your DUT. If you

will control flow to your DUT manually, select “NONE.”

DUT settle time (s): When using a Sierra 100 Series MFC in automatic mode or when calibrating a Sierra 100 Series MFC, select the

number of seconds that you want your controller to stabilize after the Cal=Soft program gives it a setpoint. (60 seconds recommended).

DMMin serial number: If a DMM is used to measure the DUT setpoint analog signal you can enter the serial # of that DMM here.

DMMout serial number: If a DMM is used to measure the DUT output analog signal you can enter the serial # of that DMM here.

DUT serial number: Serial number of the DUT (If a Sierra 100 Series is connected through RS232, it obtains this automatically)

Maximum Flow: Enter the max range value of the DUT (Add no units, numbers only!) (If a Sierra 100 Series is connected through RS232,

the software obtains this value automatically)

Units: Enter the units of your DUT as you wish them to appear on the Calibration Certificate. The new firmware of Cal=Trak always reads

in “sccm” units, but the program will convert to your chosen units when it completes the certificate. If a Sierra 100 Series is to be used as

part of your calibration system, set the units of the 100 Series to “sccm” to match the Cal=Trak

Gas: enter the gas the DUT will be used with during normal operation. Note that many instruments are calibrated on nitrogen or air even if

they are to be used with a wide variety of gases. If a Sierra 100 Series is connected through RS232, it obtains this information

automatically.

K-Factor: Enter the K-factor that relates that calibration gas to the gas for which the DUT will be used. For air or nitrogen, enter 1.00.

36

Page 37

Reference temperature: Will be selected automatically based in the units selected (Normal= 0C, Standard=21.1C)

Reference pressure: Will be selected automatically based in the units selected

DUT inlet pressure: enter the inlet gas pressure to the DUT. (Used for certificate data only)

DUT outlet pressure: enter the outlet gas pressure of the DUT. (Used for certificate data only)

Calibration position: Enter the position in which your DUT is mounted during the calibration (Used for certificate data only)

Accuracy: Will be pulled down from the program’s instrument database "Instrument information" if you are calibrating a Sierra Model. If

you are calibrating an instrument of another manufacturer, enter the rated accuracy of the DUT here.

Repeatability: same as Accuracy above.

Temperature coefficient: Will be pulled down from the database "Instrument information" if you are calibrating a Sierra Model. For other

makes, enter the DUT coefficient here.

Pressure coefficient: Same as Temperature coefficient above.

Max Allowed deviation: Will be pulled down from the program’s database "Instrument information" based on the Sierra Model selected

(This value is the pass/fail criteria as shown on the calibration certificate. It is in general either the accuracy of the meter + uncertainty of

2

the calibrator or the RSS of the accuracy of both devices {Sq Root of [meter accy

+ calibrator accy2]}.

Step 3—Perform a calibration

Press the START button

This will begin the calibration routine. A red screen will appear in which several options are given to start the certification.

Do nothing until the window: "Please wait" disappears. The screen looks like this:

Never select with your mouse the background sheet or another sheet until after you press "Exit" or the program could stop running.

37

Page 38

Begin your calibration by defining the flow points that you will measure. These are pre-defined in the program under the heading “%FS” as

0,25,50,75,100. If you want to take data at these 5 points, continue to the next section. If you wish to select alternate flow points, click on

the grey box “%FS” and change to another percent as desired. In the example above, the second flow point has been changed from 25 to 20

using this method. You can only measure up to 5 points per calibration. Should you desire more than 5 points, you will need to run the

program more than one time.

Automatic Flow Calibration Using Sierra 100 Series MFC

If you have selected on the Operating Screen (Step 2) a “Setpoint to MFC” that is DIGITAL, the program will establish communication

with a Sierra 100 Series MFC via the selected COM port. All the squares at the bottom of the red screen will become active when “Please

wait” disappears. You may choose:

Auto Full Run

are given by the program and the values from the 100 series and the Cal=Trak are read automatically into the computer software. If the

DUT is not a Sierra 100 Series, but you are controlling the gas flow via a 100 series MFC, the program will automatically generate the