Siemens WF 725, WF 726 Planning Instructions

Equipment for Machine Tools

WF 725/WF 726

Positioning Modules

Planning Instructions

NC- Auxiliary axis and tool magazine

for SINUMERIK 3GA4

Edition August 1990

This publication was produced on the Siemens 5800 Office System.

Subject to change without prior notice.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

©

Siemens AG 1990 All Rights Reserved

Introduction

1

Description of the Functions

Technical Data

Use of the ”Programming

and Display Functions”

Checklist for Start-up/Search for Errors

Appendix

2

3

4

5

6

Index

Page

1 Introduction

2 Description of the Functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

2-1

2.1 Auxiliary axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.1 Description of the FB 203 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Notes for use of the FB 203

2.1.3 Parameterisation of the FB 203

2.2 Tool magazine drive

2.2.1 Description of the FB 204

2.2.2 Notes for use of the FB 204

2.2.3 Parameterisation of the FB 204

2.3 Input/Output of Machine Data and Operating Data

2.3.1 Description of the FB 205

2.3.2 Notes for use of the FB 205

2.3.3 Parameterisation of the FB 205

2.3.4 Allocation of the data block for tool magazine drive

3 Technical Data

3.1 Overview of blocks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Notes for the PLC software ”Programming and display functions”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

2-5

2-5

2-7

2-7

2-10

2-10

2-12

2-12

2-14

2-15

2-16

3-1

3-1

3-2

3.1.2 Notes for the PLC software ”Basic functions” . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Notes for the ”Basic program” and ”Package 1” of SINUMERIK 3

3.1.4 Overview of the used data blocks

3.2 Memory storage demand

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Example for memory storage calculation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

3-3

3-3

3-4

3-5

3.3 Start-up

3.3.1 Start-up function of the WF 725 or WF 726

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6

3-6

3.3.2 Start-up functions of the tool magazine drive . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4 Selection of Mode and Operating Submode

3.5 General notes for use

3.6 Flags, times, counters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6

3-7

3-8

4 Use of Programming and display func tions”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

4.1 Programming example

4.2 Structure of the block calls

5 Checklist for Start-up and search for errors

5.1 Supply of parameters

5.2 Data block (DB) for tool magazine axis

5.3 Machine data (MD) of the WF 725 or WF 726

5.4 Supply of Operating Submode (BA) and Mode

6 Appendix

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

4-4

5-1

5-1

5-1

5-1

5-1

6-1

6.1 Explanation of the function block (FB) descriptions . . . . . . . . . . . . . . . . . . . 6-1

6.2 Error messages of the WF 725 or WF 726 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Data codings in the data block (DB) - Axis

6.4 Overview of Machine Data

6.5 Overview of Interface

6.6 List of the used abbreviations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6

6-10

6-13

6-21

6.7 Needed Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6.8 Documentations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

08.90 Introduction

1 Introduction

This planning instruction describes the PLC software ”Programming and Display functions”

for WF 725 and/or WF 726 in SINUMERIK 3, GA4.

For many manufacturers of tool machines, it is desirable to be able to position auxiliary axes

in addiition to the four axes which can be traversed over the NC control of the medium

power class SINUMERIK 3, GA4.

With this, a tool magazine, a tool supplier or a loading portal could be realised with the tool

machine.

With the help of the positioning modules WF 725 and/or WF 726, up to 21 additional

auxiliary axes can be positioned without having to evade to an NC control of the higher class.

The PLC software described here fulfills the following functions:

– Setting of a single traversing block to the WF 725 or WF 726

Traversing path, traversing feed rate and path conditions are set over R-parameters

freely selectable in an NC part program. When the NC part program is executed, the

data is transmitted to the WF 725 or WF 726, and the auxiliary axes are immediately

traversed.

– Positioning of a tool magazine

Up to 120 magazine place positions can be selected over a parameter. The rotational

direction - ”right”, ”left” or ”shortest distance” can also be selected.

– Input/Output of Machine data and Operating Data

With display masks, the data mentioned above can be entered and changed. This

simplifies the start-up of the WF 725 or ”F 746.

– Display on the NC operator panel

The following data is shown for the selected axis

• Actual value

• Residual traversing path

• Feed rate

• Error

Or for positioning of tool magazine axes:

• Magazine location command

• Actual magazine location

• Error

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

1 - 1

Introduction 08.90

Notes for use:

The PLC software ”Programming and display functions” can be used in SINUMERIK 3, GA4B

or SINUMERIK 3, GA4C with single or double PLC.

This applies for the following controls:

SINUMERIK 3T, 3TE

SINUMERIK 3TT, 3TTE

SINUMERIK 3M, 3ME

SINUMERIK 3G, 3GE

SINUMERIK 3FA

Up to seven WF 725 or WF 726 positioning modules can be used in a control.

Prerequisite for the use of the PLC software descibed here is the use of the PLC software

”Basic functions” (see chapter 6.7).

1 - 2 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

08.90 Description of the functions

2 Description of the functions

2.1 Auxiliary Axis

2.1.1 Description of the FB 203

With the FB-Auxiliary axis it is possible to enter a single traversing block in R-parameters into

the NC and to transmit the block to the set axis with the help of M-functions. With a further

M-function, the axis can be started. Parameterisation of the ”basic functions” must,

however, be executed according to the start-up and planning instruction of the

WF725/WF726.

The function block supplies the following functions:

• Transmission of path, feed rate and first G-function from the NC part program to the WF

module with the help of R-parameters.

• Display of check back signals on the monitor screen of the NC. The following values are

shown for each axis (BCD):

– Actual value

– Residual path

– Feed rate

– 1st G-Function

– Error messages of the WF725/WF726

– MODE of the module

– Operating Submode of the axis

– Wrong MODUS

– Wrong axis number in clear text

The residual traversing path will only be updated with start.

The axis number is selected over a parameter of the FB205.

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

2 - 1

Description of the functions 08.90

Check back signals of the auxiliary axis on the screen of SINUMERIK 3

Example:

# # # # # # # # # # # # # #

R U E C K - M E L D U N G E N A C H S E 1 2

M O D U S 1 B A 3 F E H L E R 2 0 1

I S T - W E R T - 1 0 0 0 0 0 0

R E S T V E R F A H R W E G 0

G - F U N K T I O N 9 0

G E S C H W I N D I G K E I T 5 0 0 0

F A L S C H E R M O D U S

Significance:

Check back signals Axis 12

Mode 1 Operating Submode 3 Error 201

Actual Value - 1000000

Residual path - 0

G-Function - 90

Feed rate 5000

Wrong mode

2 - 2 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

08.90 Description of the functions

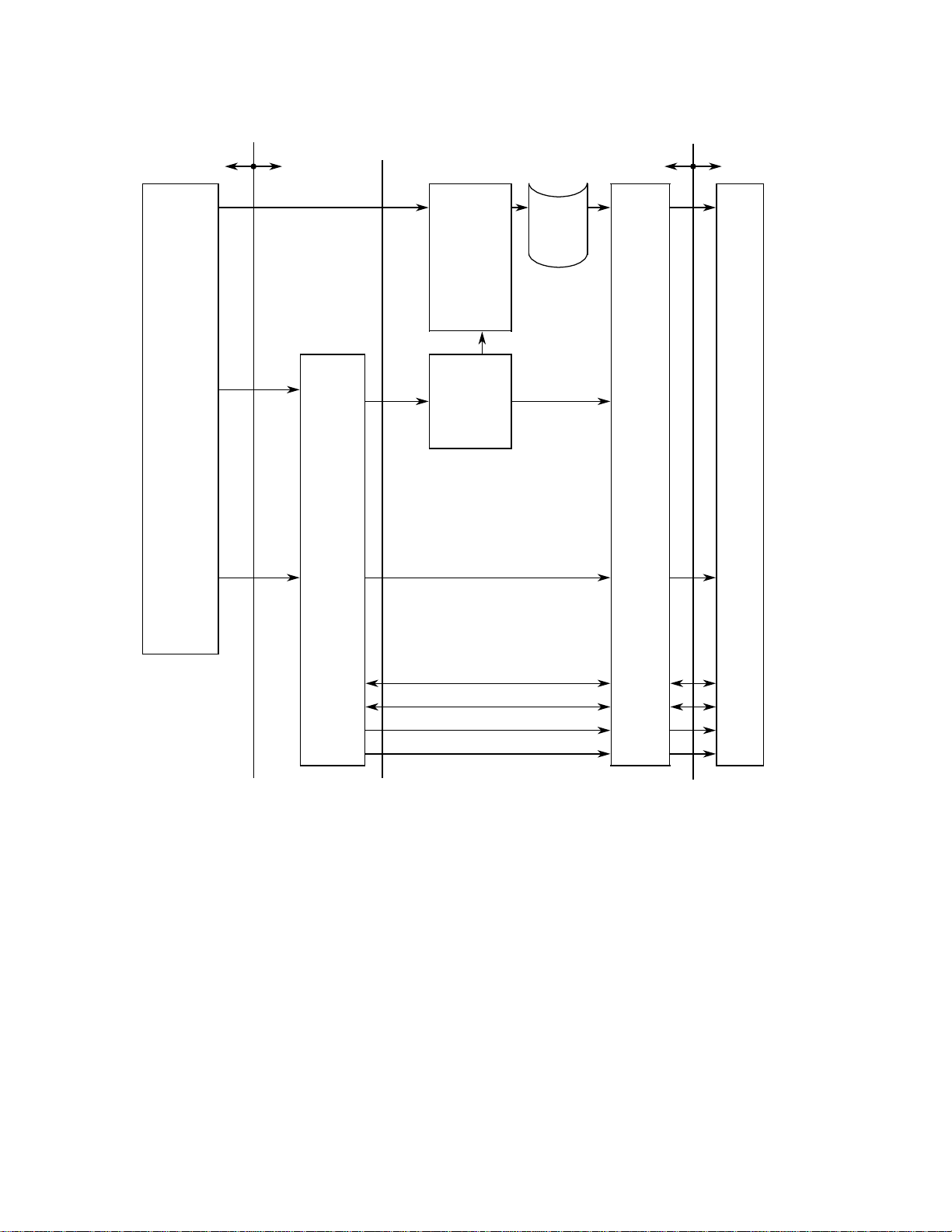

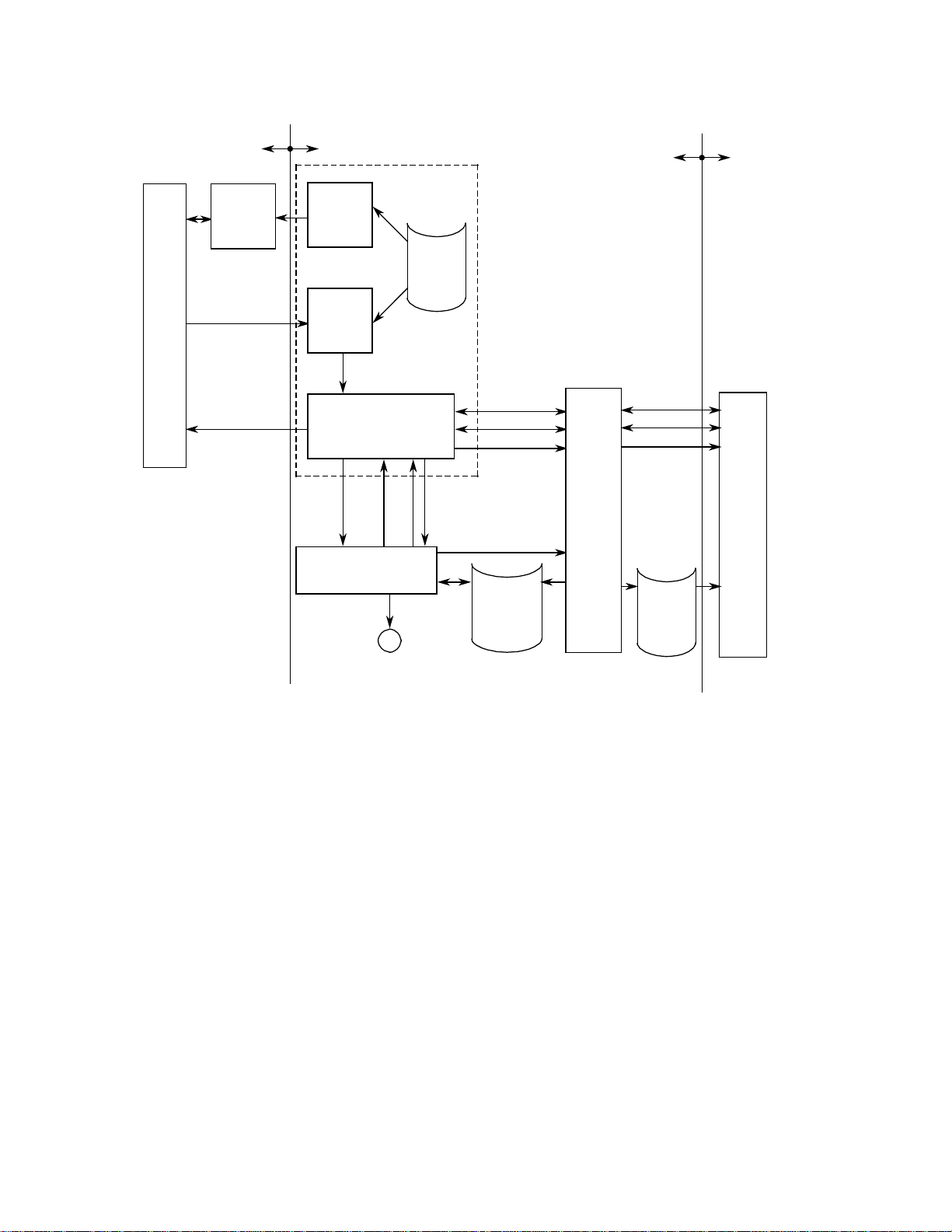

NC Part

program

PLC

R-Parameter

M-Function

M-Function

FB

program

User

W-UE

FB61

NC-Data output

blockwise (from

basic program of

SINUMERIK 3)

FB203

Auxiliary

axis

DB

Axis 1

START

FB

”Basic

functions”

for WF725/

WF726

PLC

WF725/WF726NC

Firmware

Figure 1 Structure of the software

MODE

SUBMODE

START

STOP

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

2 - 3

Description of the functions 08.90

Example for NC program PP:

%100

N1 G00 X200 Z300 LF

:

:

N10 R50=100 R51=500 R52=90 M46 LF

(X) (F) (G)

:

:

N20 R50=80000100 R51=200 R52=91 M46 LF

(X) (F) (G)

:

:

N30 . . . .

It is not possible to program a negative R-parameter value for setting a negative traversing

path to the WF 725/WF 726. The value must be chosen so that the bit with the highest value

is set (Internal presentation, please compare with interface in the PLC area).

Representation

positive values: 0000 0000 to 7999 9999

negative values: 8000 0001 to 9999 9999

2 - 4 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

08.90 Description of the functions

2.1.2 Notes for use of the FB 203

• FBs to be loaded:

”Basic functions” (for use of WF725): FB207, 210, 211, 216

”Basic functions” (for use of WF726): FB207, 210, 211, 215, 216, 217

• The block must be called once for each axis.

• To transmit an R-parameter from the NC to the WF 725/ WF 726, the user must decode

the M-function set in the NC-program and set the corresponding bit in the parameter

W-UE. The values of the R-parameter ranges from 0 to 999 999.

• The parameter DU-8 is set at the end of a data transmission for one cycle. The user can

now start the corresponding axis.

• The user must realise the read-in disable and the read-in enable of the NC. The signal

DU-L (Data transmission operating) can be used for this.

• The display buffer for the feed rate is in the DB79 of DW117, 118.

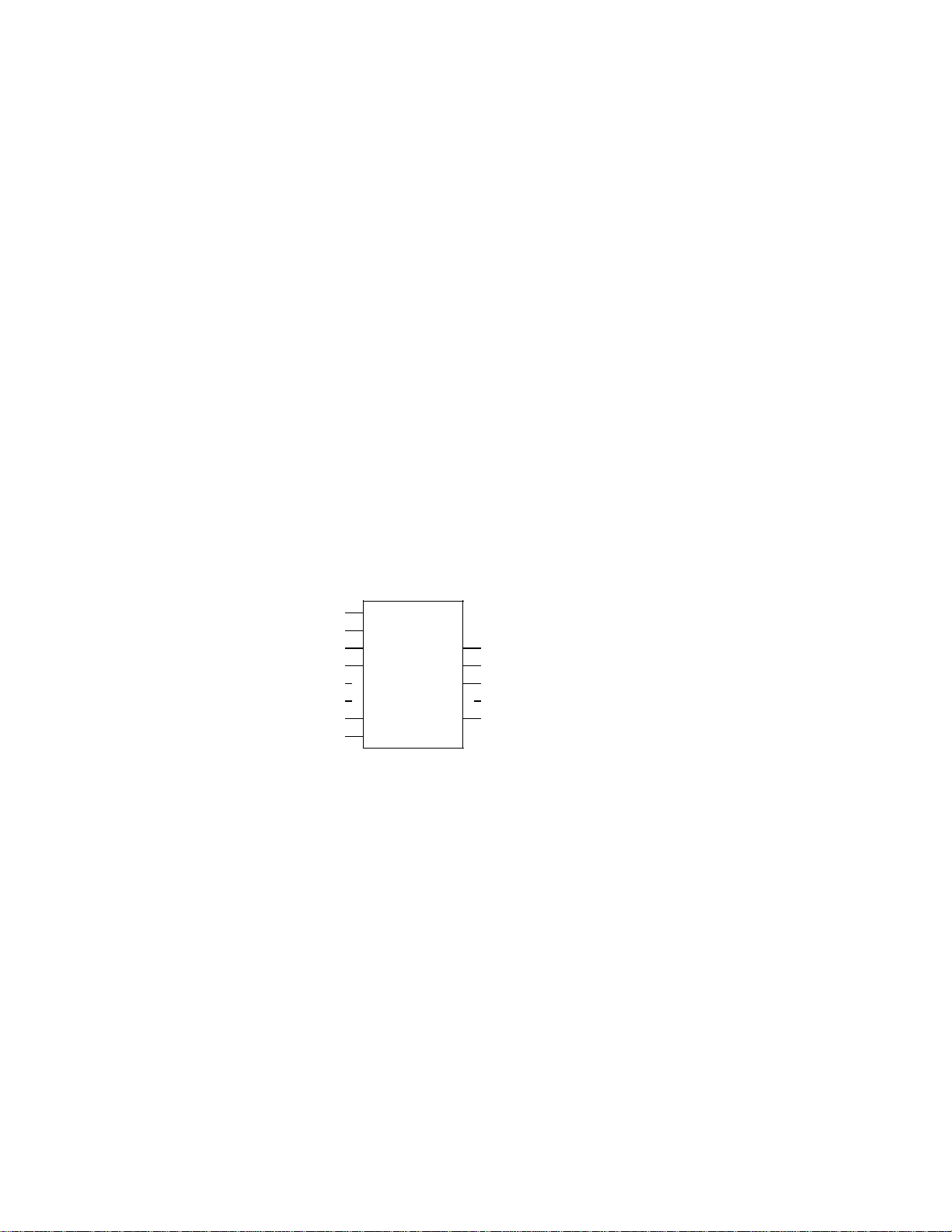

2.1.3 Parameterisation of the FB 203:

HILFS-A

B

D,KH

D,KH

D,KH

D,KF

§E,BY

§E,BY

Signal description:

DBZU Assignment-DB (Parameterisation like FB211 from the ”Basic functions”)

RPW R-Parameter number for the path

RPG R-Parameter number for the first feed rate

RPGFR-Parameter-Nr. for the 1. G-Funktion

ACHS ACHS-NR.1... 21

Number of the axis to which the contents of the parameters must be transmitted.

NC NC-NR. 1... 4

Number of the NC from which the R-Parameter is to be read out.

DBZU

RPW

RPG

RPGF

ACHS

NC

W-UE

FEHL

DU-L

DU-B

§

A,BY

A,BI

I A,BI

W-UE Transmit values (Start of transmission)

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

2 - 5

Description of the functions 08.90

Bit no. Significance

0

Transmit path to the WF

1

Transmit feed rate to the WF

2

Transmit 1st G-function to WF

3

reserved

7

reserved

The different bits are set with an M-function each. It is possible to transmit either 1

value, 2 values or 3 values at the same time to an NC. The values are transmitted

from the W-UE at the positive edge only when DU-L and DU-B are zero.

FEHL Parameterisation errors:

Bit no. Significance

wrong NC number

0

wrong axis number

1

wrong MODUS

2

reserved

3

reserved

7

DU-L Data transmission active is 1,

as long as the data is transmitted to the WF

DU-B Data transmission ended

is set at the end of transmission for a PLC cycle

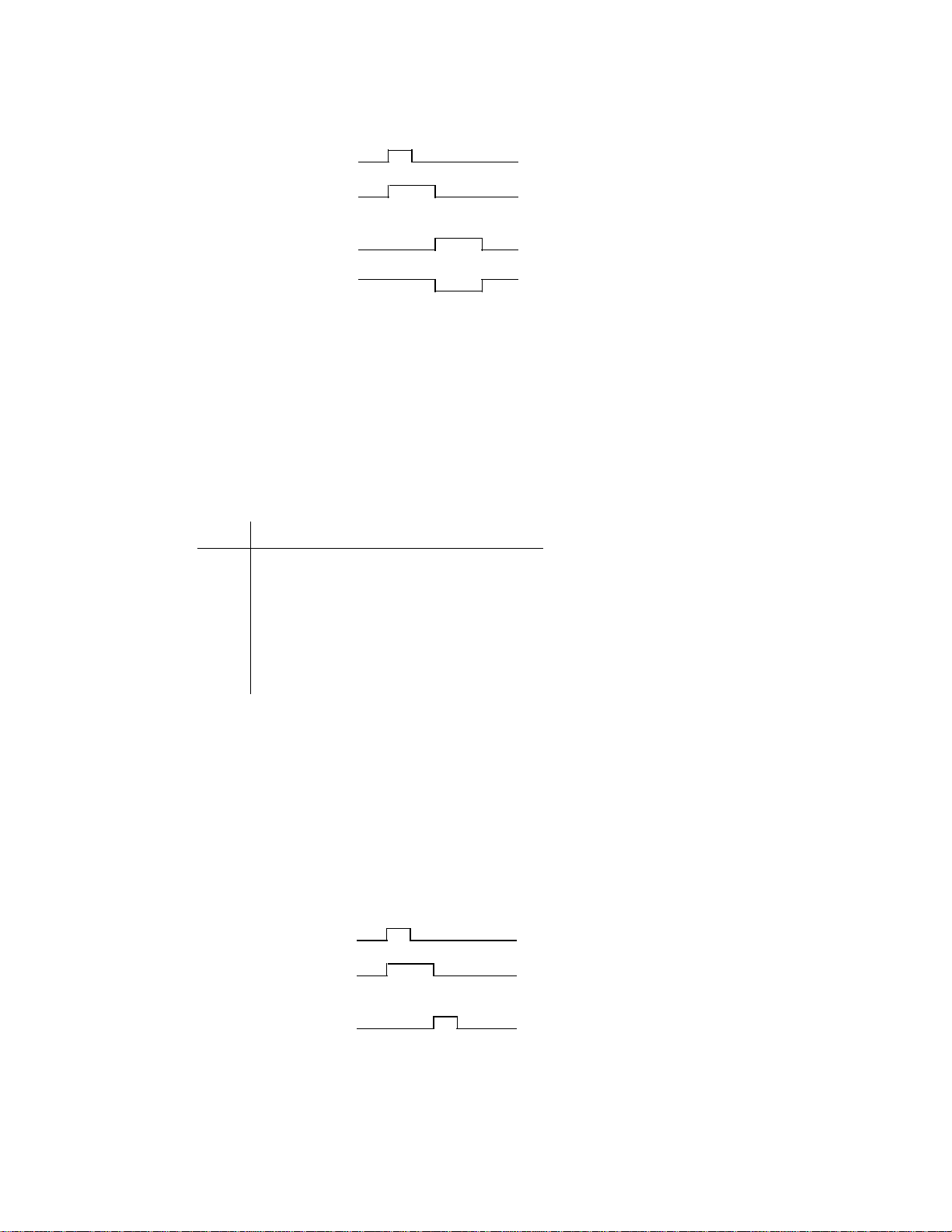

Demand

(set by the user)

Data transmission active

Transnmission ended

Note:

The signal DU-L can be used by the user for read-in disable.

1 Cycle

2 - 6 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

08.90 Description of the functions

2.2 Tool magazine drive

2.2.1 Description of the FB 204

The tool magazine drive positions up to 3 tool magazines or turrets. The maximum number

of magazine locations is 120 per axis. The command values for the single magazine locations

are deposited in a DB in form of a table.

The function block supplies the following functions:

• Transmission of feed rate from the DB tool magazine drive to the WF725/WF726 (Axis

1...3)

• Calculation of command position from revolver/magazine location number and

transmission to the WF725/WF726 (Axis 1...3)

• Output of the message ”Magazine position reached” after end of positioning.

• During conventional operation, the axis is traversed about 1 position each with the

signals jog+/jog-. When jog+/jog- are continually signalled, then the next position is

traversed to.

• Display of check back signals on the NC screen. For each axis, the following values are

shown (BCD):

– present magazine location number

– magazine location number to be traversed to

– Error messages of the WF725/WF726

– MODE of the module

– Operating submode of the axis

– Wrong MODUS

– Wrong axis number in clear text

If traversing is executed with jog+/jog-, the command magazoine location will not be

updated, instead, the value is displayed which is set as a parameter.

The axis number is selected with a parameter of the FB 205.

Der FB204 ermittelt aus der Magazinplatznummer anhand der Tabelle (DB WZ-M-A) den

Positionswert für die WF725/WF726 und startet anschließend die angewählte Achse.

Aus dem Istwert der von der Achse zurückgemeldet wird, wird durch Vergleich mit der

Tabelle (DB-WZ-M-A) der momentan angefahrene Magazinplatz ermittelt und über den

Parameter POSI im Dual-Code dem Anwender mitgeteilt. Ist der gewünschte Magazinplatz

erreicht, wird ein Ausgangsparameter gesetzt. Das Signal Datenübertragung läuft wird

ebenfalls als Parameter ausgegeben.

The FB204 calculates the position value for the WF 725/WF 726 from the magazine location

number of the table (DB WZ-M-A). The FB then starts the selected axis. The presently

traversed magazine location is calculated from the actual value signalled back from the axis

by comparing with the table (DB-WZ-M-A). This value is then transmitted to the user in the

binary code with the parameter POSI. If the desired magazine location is reached, then an

output parameter is set. The signal Data transmission active is also read out as a parameter.

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

2 - 7

Description of the functions 08.90

Checkbacks of the tool magazine drive on the screen of SIMUMERIK 3

Example:

# # # # # # # # # # # # # #

R U E C K - M E L D U N G E N W Z - M - A 3

M O D U S 1 B A 3 F E H L E R 2 0 1

M A G A Z I N - P L A T Z S O L L 1 2

M A G A Z I N - P L A T Z I S T 6 4

F A L S C H E R M O D U S

Significance:

Check back signals WZ - M - A 3

Mode 1 Operating Submode 3 Error 201

Magazine location command 12

Magazine location actual 64

Wrong mode

2 - 8 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

08.90 Description of the functions

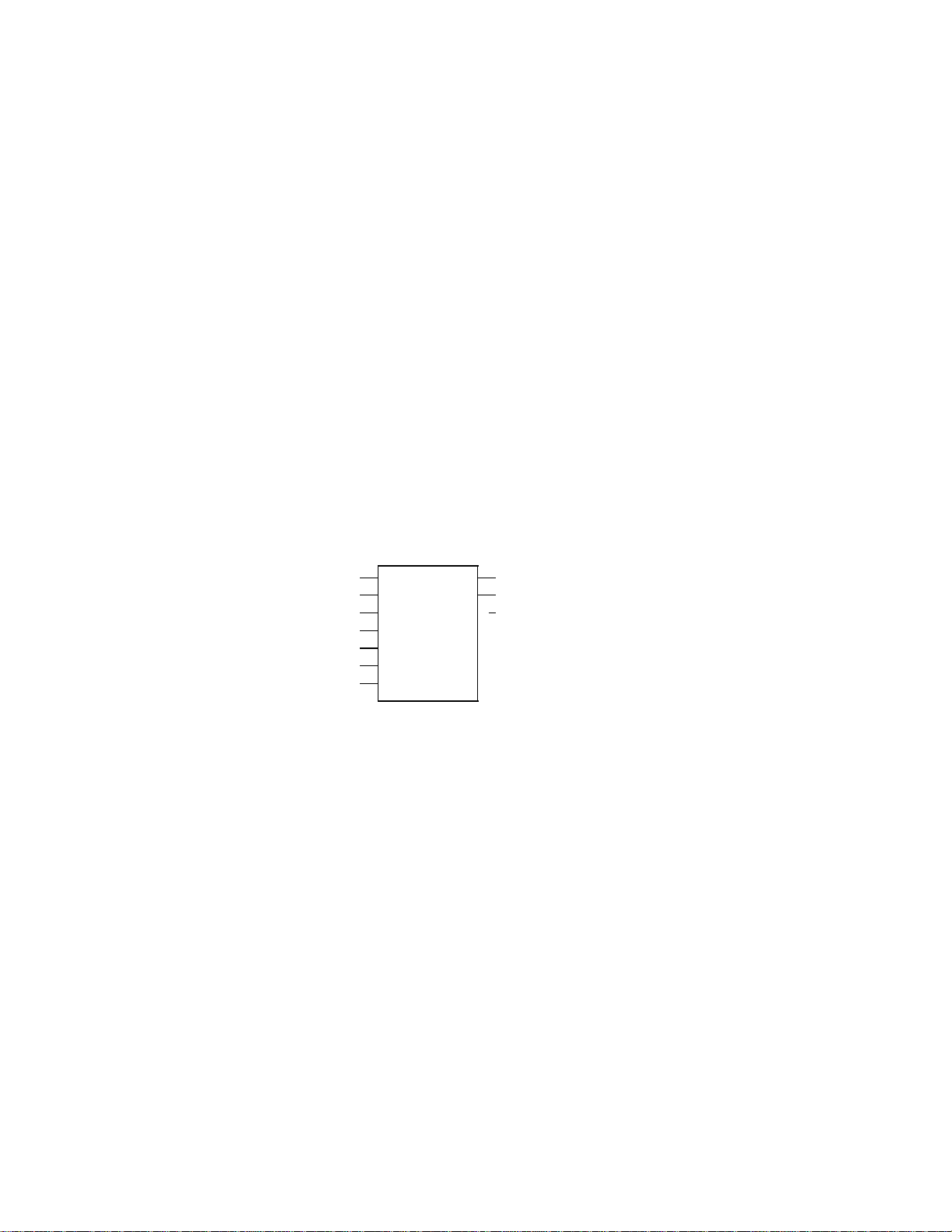

NC

PP

NC

Part

program

TO-Area

Tool

offset

values

T-Word

PLC

FB

Load data

to NC

FB

Selection

of tool

User

DB

Revolver

allocation

WF725/WF726PLC

FB

Read-in enable

FB 204

Figure 1.2 Structure of the software

Soll-Magazin-Platz

User

Act-Pos.Com-Pos.

Tool magazine drive

M

Drive

PE

MODE

SUBMODE

STOP

Turn right/left

shortest distance

DB WZ-M-A

Command

value for

magazine

location

START

FB

”Basic

functions”

for

WF725/

WF726

Firmware

DB

Axis 1

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

2 - 9

Description of the functions 08.90

2.2.2 Notes for use of the FB 204

• FBs to be loaded:

”Basic functions” (for use of WF725): FB207, 210, 211, 216

”Basic functions” (for use of WF726): FB207, 210, 211, 215, 216, 217

Package 0: FB43

• DBs to be loaded: for each eaxis number

WZ-M-A 1: DB89

WZ-M-A 2: DB109

WZ-M-A 3: DB129

• The block must be called once for every tool magazine.

• If a magazine location is to be traversedm then the user must supply the signals RICH and

POSS. When STAR is set on the 1-signal, the corresponding path is transmitted to the

WF725/ WF 726, and the magazine is started at the end of the data exchange.

• The tool organisation must be realised by the user.

2.2.3 Parameterisation of the FB 204:

WZ-M-A

B

D,KF

§E,BY

§E,BY

E,BI /

E,BI /

E,BI

E,BI

Signal description:

DBZU Assignment DB to be supplied as FB211 in Standard I

ACHS Axis number 1-3

Number of the axis which is to be traversed

RICH Preselection of direction

0 = automatically shortest distance

1 = always right

2 = always left

DBZU

ACHS

RICH

POSS

STAR

G-UE

TIP+

TIP -

FEHL

POSI

MPE

GU-B

DU-L

A,BY

A,BY

A,BI

I A,BI

A,BI

POSS Command magazine location number (Hex-format)

STAR Start of axis

2 - 10 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

08.90 Description of the functions

1 Cycle

STAR

Data is transmitted

Magazine is

positioned

Magazine position

reached

As long as the data is transmitted or the magazine is positioned, a START by the user will not

be accepted.

G-UE Transmit feed rate

TIP+ Traverse to the right in the jog mode when the signal is 1.

TIP - Traverse to the right in the jog mode when the signal is 1.

FEHL Parameterisation error:

Bit no. Significance

0

free

1

wrong axis number

2

wrong mode

3

free

4

TIP+ and TIP- simultaneously

5

Error axis 1: magazine location number too high

6

Error axis 2: magazine location number too high

7

Error axis 3: magazine location number too high

POSI Actual magazine location number (Hexadecimal)

MPE Magazine location number reached

Nach Neustart oder Wiederanlauf wird das Signal Magazin-Position erreicht

zurückgesetzt. After start-up or restart, the signal Magazine Position Reached is set

back.

GU-B End of feed rate transmission

1 Cycle

Transmit feed rate

Data is transmitted

Transmission of feed

rate has ended

1 Cycle

DUL Data is transmitted

is ”1” Signal as long as data is exchanged to the WF

©

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

2 - 11

Description of the functions 08.90

2.3 Input/Output of Machine Data and Operating Data

2.3.1 Description of the FB 205

The function block supplies the following functions:

• Input/output of MD (Axis 1...21).

• Input/output of reference point feed rates (Axis 1...21).

• Input/output of feed rate 1 and 2 for the operating submode Jog.

• The displays are selected with a menu.

• The menu is selected over the PLC-key of the SINUMERIK 3 operator panel.

• The user sets the desired axis number over the parameter ACHS. If the mask operating

data is selected, then the displayed values are updated automatically as soon as the axis

number is changed. The values are not changed when a number is not valid, an error

message is read out as a parameter.

Menu output on the screen of SINUMERIK 3

# # # # # # # # # # # # # #

0 S T A T U S - 0 R U E C K - M E L D U N G

- 1 W F M A - D A T E N

- 2 W F B E T R - D A T E N

2 - 12 ©

WF 725/WF726 (PJ – NC Auxiliary axis and tool magazine for SINUMERIK 3GA4)

Siemens AG 1990 All Rights Reserved 6ZB5 440-0JB02

Loading...

Loading...