Siemens WF 723 C Programming Manual

Equipment for Special Machines

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

WF 723 C

Positioning Module

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Edition 04.97Programming Guide

Preface

1

WF 723 C

Positioning Module

Programming Guide

Basic Definitions

Program Execution /

Subroutines

Programming of

Traversing Blocks

M-Functions

with Special Function

2

3

4

5

Valid for firmware V1.2

Edition April 1997

Tool Offsets

Programming in S5 Format

Appendix

6

7

8

Note

Because of clear arrangement, this documentation does not inform about all details of all

types of the product. Therefore, it cannot take into account all possible cases of

installations, operation and maintenance.

If you require additional information or have special questions, please seek further

particulars from your local SIEMENS office.

The content of this documentation is not part of an earlier or existing agreement,

acceptance or legal matter. All obligations by SIEMENS are set in the corresponding

sales contract which also contains the complete and single valid settlement. The

contract guarantee will not be enlarged or limited by this documentation.

BERO, SIMATIC, SIMODRIVE, SINEC, SINUMERIK, STEP are registered trade marks of Siemens.

The remaining designations contained in this programming guide may be trade marks whose use

through third parties for their own purposes may infringe the rights of the owners of the mark.

Subject to technical changes.

The reproduction, transmission or use of this document or of its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

supplied by patent grant or registration of a utility model or

design, are reserved.

©

Siemens AG 1997 All Rights Reserved

Contents

1 Preface

2 Basic Definitions

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 1

2.2 Traversing program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 1

2.2.1 Channel structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 2

2.2.2 Feed axes in the traversing program . . . . . . . . . . . . . . . . . . . . 2 – 3

2.2.3 Synchronism in the traversing program . . . . . . . . . . . . . . . . . . 2 – 3

2.2.4 Coordination of the control signals in the traversing program . . . 2 – 3

2.2.5 Memory capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 3

2.2.6 Program number / subroutine number . . . . . . . . . . . . . . . . . . . 2 – 3

2.2.7 Program structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 4

2.3 Traversing block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 4

2.3.1 Block structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 4

2.3.2 Block number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 5

2.3.3 Axis assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 5

2.3.4 G-functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 6

2.3.5 Path information (position) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 8

2.3.6 Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 8

2.3.7 M-functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 9

2.3.8 Tool offset number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 10

2.3.9 Dwell time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 10

3 Program Execution / Subroutines

3.1 Program execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 1

3.2 Skippable blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 2

3.3 Subroutines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 3

3.3.1 Subroutine call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 3

3.3.2 Subroutine execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 3

3.3.3 Programming guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 4

3.4 Block search forwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 5

3.4.1 Automatic block search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 5

3.4.2 Manual block search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 6

3.4.2.1 Entry point in the main program . . . . . . . . . . . . . . . . . . . . . . . 3 – 6

3.4.2.2 Entry point in subroutine level 1 . . . . . . . . . . . . . . . . . . . . . . . 3 – 6

3.4.2.2 Entry point in subroutine level 2 . . . . . . . . . . . . . . . . . . . . . . . 3 – 7

3.4.3 Conditions of block search forwards . . . . . . . . . . . . . . . . . . . . 3 – 7

3.4.4 Program start after activation of block search forwards . . . . . . . 3 – 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 – 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 1

. . . . . . . . . . . . . . 3 – 1

4 Programming of Traversing Blocks

4.1 Coordinate system and reference points . . . . . . . . . . . . . . . . . 4 – 1

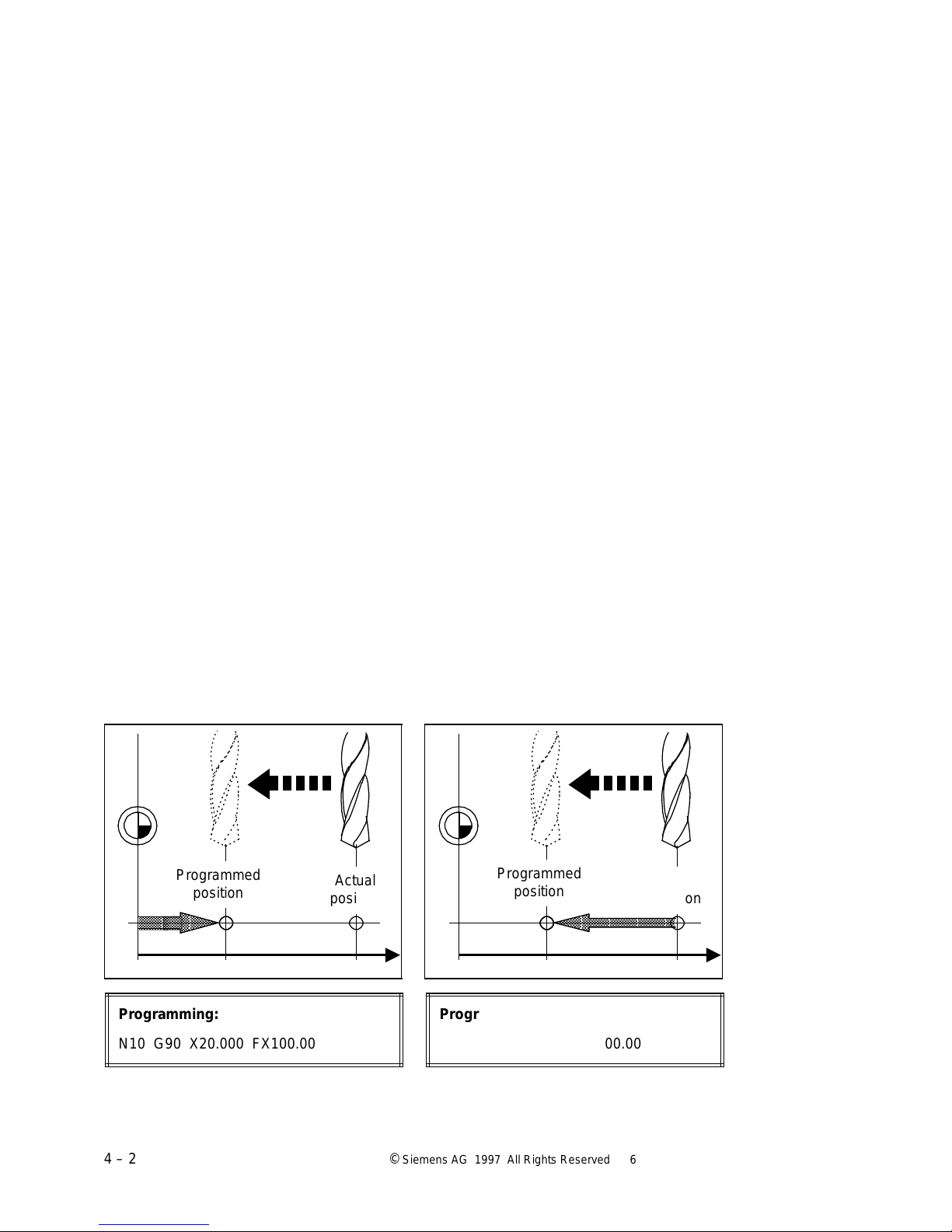

4.2 Dimensions G90, G91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 2

4.2.1 Linear axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 2

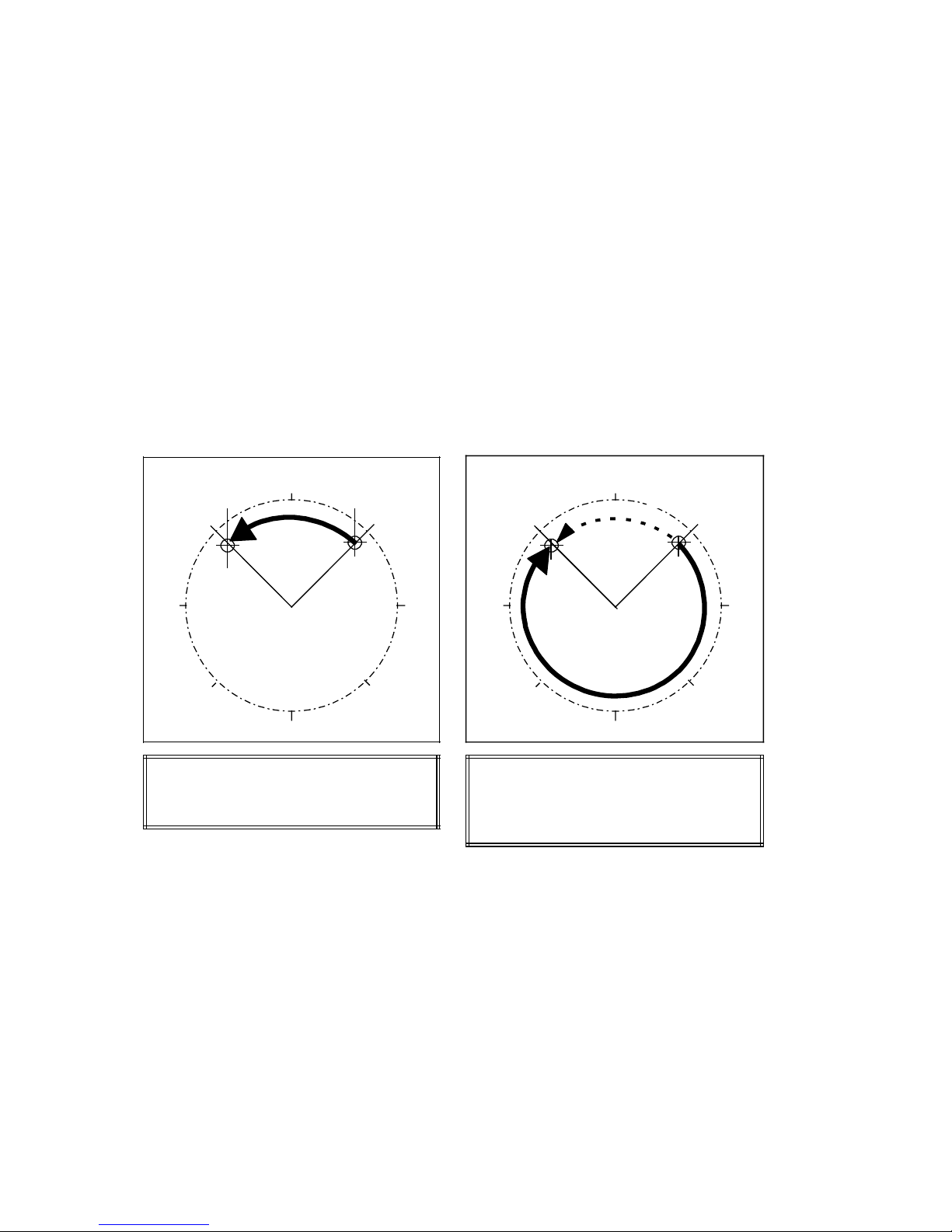

4.2.2 Rotary axis, shortest distance G68 . . . . . . . . . . . . . . . . . . . . . 4 – 3

4.3 Dwell time G04 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 4

4.4 Zero point offset G53, G54 to G59 . . . . . . . . . . . . . . . . . . . . . 4 – 5

4.5 Chaining with rapid traverse G76 . . . . . . . . . . . . . . . . . . . . . . 4 – 7

4.6 Chaining with axis velocity G77 . . . . . . . . . . . . . . . . . . . . . . . 4 – 8

4.7 Interpolation with rapid traverse G00 . . . . . . . . . . . . . . . . . . . 4 – 10

4.8 Interpolation with path velocity G01 . . . . . . . . . . . . . . . . . . . 4 – 11

. . . . . . . . . . . . . 4 – 1

4.9 Synchronism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 13

4.9.1 Permanent synchronism . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 13

4.9.2 Selectable synchronism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 13

4.9.3 Tracking synchronism (G79 . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 14

4.9.4 Synchronism in combination with interpolation and chaining . . 4 – 15

4.10 Collision monitoring (G96, G97) . . . . . . . . . . . . . . . . . . . . . . 4 – 16

4.10.1 Specifying a deceleration value . . . . . . . . . . . . . . . . . . . . . . 4 – 16

4.10.2 Specifying a rapid input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 16

4.10.3 Collision monitoring - Example . . . . . . . . . . . . . . . . . . . . . . . 4 – 17

4.11 Block transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 19

4.11.1 Maximum loop-over G64 . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 19

4.11.2 Exact stop G60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 22

4.11.3 Loop-over window 1 or 2 (G66, G67) . . . . . . . . . . . . . . . . . . 4 – 25

4.11.4 Path-dependent chaining (G63) . . . . . . . . . . . . . . . . . . . . . . 4 – 27

4.11.5 Block transitions with different coupling types . . . . . . . . . . . . 4 – 30

4.11.6 M-functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 31

4.11.6.1 Output of M-functions during positioning . . . . . . . . . . . . . . . . 4 – 31

4.11.6.2 Output of M-functions before positioning . . . . . . . . . . . . . . . . 4 – 32

4.11.6.3 Output of M-functions after positioning . . . . . . . . . . . . . . . . . 4 – 33

4.11.7 External block change G50, G51) . . . . . . . . . . . . . . . . . . . . . 4 – 34

4.11.8 Flying actual-value setting G87, G88, G89 . . . . . . . . . . . . . . 4 – 36

4.11.9 Program-dependent external read-in enable (G99) . . . . . . . . . 4 – 38

4.11.10 Acceleration override G30 to G39 . . . . . . . . . . . . . . . . . . . . . 4 – 39

5 M-Functions with Special Function

5.1 Stop at block end M00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 1

5.2 Continuous loop M18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 1

5.3 Subroutine end M17/M29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 2

5.4 Program end M02/M30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 2

6 Tool Offsets

6.1 Tool offset G43, G44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 1

6.2 Tool offset memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 2

6.3 Variants of tool offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 3

6.3.1 Tool length offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 3

6.3.2 Tool length wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 4

6.4 Direction of tool length offset . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 5

7 Programming in S5 Format

8 Appendix

8.1 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 – 1

8.2 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 – 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 1

. . . . . . . . . . . . . . . . . . . . 7 – 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 – 1

. . . . . . . . . . . . . 5 – 1

04.97 Preface

1 Preface

What information is to be

found in this manual?

For whom is this manual

intended?

What prior knowledge is

needed?

Finding your way about

the manual.

This manual gives you detailed information about the

programming of the positioning module. The programming of

functions is described in the context. Examples and practical

tips provide improvement for your own cases of application.

See the end of this manual for application area, contents and

target group of this WF 723 C manual.

This programming guide is intended for machine design

engineers who plan to use the WF 723 C and have to observe

the relevant guidelines.

The target group must be qualified according to the definitions

on page 1-2.

Beside this programming guide, all general safety regulations,

regulations of the VDE and the national safety rules must be

observed.

This programming guide is divided up into the sections:

➤ Basic description

➤ Programming

Each chapter of this programming guide is a self-contained unit.

In the appendix, you will find an alphabetic index.

Improvements required? Please do not hesitate to inform us if you have any suggestions

or improvements, using the form at the end of this manual. We

will try to consider your suggestions in the next edition.

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

1 – 1

Preface 04.97

Definitions/

Explanation of Terms

Qualified personnel

Attention

Caution

Persons being in charge of installation, mounting and operating

the product must be qualified by e.g.:

➤ Training, instruction or permission to switch, earth and mark

and electrical circuits ans devices according to standard

safety regulations.

➤ Training and instruction of care and use of appropriate safety

equipment according to standard safety regulations.

➤ Training in first aid.

ATTENTION

Slight injury or damage to property may

occur if the prescribed precautionary

measures are not observed.

CAUTION

Danger

Death, grievous bodily harm or considerable

damage to property may occur if the

prescribed precautionary measured are not

observed.

DANGER

Death, grievous bodily harm or considerable

damage to property will occur if the

prescribed precautionary measures are not

observed.

1 – 2 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Preface

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

Notes

Cross references

Necessary calculations

Changes as against the

former edition

This symbol draws your attention to important

and useful information.

This symbol refers to certain information in a

manual.

The data marked with this symbol must be

calculated and not determined empirically.

The edition of June 1996 was revised on the following pages:

2-7

4-27 to 4-30

7-5, 7-12

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

1 – 3

Preface 04.97

1 – 4 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Basic Definitions

2 Basic Definitions

2.1 Overview

The WF 723 C positions up to three position-controlled axes, both independent of each other

and coordinated and combined. functions like linear interpolation, synchronism and chaining, in

addition to simple point-to-point positioning processes, are an important part of today's

automation tasks. Further possibilities, such as flying actual-value setting, external block

change, the use of tool offsets, zero point offsets and the output of M-functions, are also

offered by the WF 723 C module.

These functions are applied in:

• Handling devices

• Portals

• Press feeding devices

• Wood working machines

• Storage and retrieval units

• Special machines

• Packaging machines

Furthermore, the roll feed function is integrated in the WF 723 C. The roll feed serves for fast

and exact positioning of highly dynamic conveyors

This functions is applied in:

• Sheet metal working machines

• Packaging and filling machines

To make all these possibilities available for the user, the programming of traversing programs

is the means to formulate information and translate it into a language understandable to the

WF module.

2.2 Traversing program

The program structure is defined according to DIN 66025. A traversing program consists of a

sequence of up to 200 traversing blocks and is assigned to a programm number.

The traversing program is situated in the RAM memory of the WF module and is buffered by

the SIMATIC S5.

In case of a RAM memory failure the RAM memory contents of the

WF module is lost.

The programming examples are displayed according to DIN 66025. Inputs

via COM 723 are entered in this format. The programs are stored in the

SIMATIC S5 and the WF in S5 format. See a comparison of DIN format and

S5 format in the chapter ”programming in S5 format”.

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

2 – 1

Basic Definitions 04.97

2.2.1 Channel structure

In principle, the WF 723 C possesses 3 channels, in accordance with its 3 axes. Therefore, it

is possible to have all axes execute their own traversing programs simultaneously. for this

purpose, however, the traversing program must only contain information for the related axis.

As all axes are treated as equivalent, all axes are master axes.

If in one traversing program the information of mor than one axis is formulated, this information

belongs to a channel. Coordination in the form of program preselection and start is always

carried out by the master axis. The other axes appearing in the traversing program are slave

axes.

Example:

a) Each axis with its own program

Program 10 ➯ axis A* ➯ master axis: channel 1

Program 20 ➯ axis B* ➯ master axis: channel 2

Program 30 ➯ axis C* ➯ master axis: channel 3

b) 2 axes in one program, 1 axis with its own program

Program 10 ➯ axis A* ➯ master axis

➯ axis C* ➯ slave axis

or

➯ axis A* ➯ slave axis

➯ axis C* ➯ master axis

Program 20 ➯ axis B* ➯ master axis: channel 2

c) 3 axes in one program

Program 10 ➯ axis A* ➯ master axis

➯ axis B* ➯ slave axis

➯ axis C* ➯ slave axis

or

➯ axis A* ➯ slave axis

➯ axis B* ➯ master axis

➯ axis C* ➯ slave axis

or

➯ axis A* ➯ slave axis

➯ axis B* ➯ slave axis

➯ axis C* ➯ master axis

channel 1

channel 1

channel 1

channel 1

channel 1

2 – 2 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Basic Definitions

2.2.2 Feed axes in the traversing program

If the axis is used as a feed axis, the traversing block must contain exclusively the information

of this one feed axis. Furthermore, the traversing program must be started in this axis.

If two or three feed axes are operated, these must be supplied in separate channels, i.e. with

their own traversing programs, with the exception of permanent synchronism (see channel

structure, example a).

2.2.3 Synchronism in the traversing program

Axes as well as feed axes can be operated in permanent synchronism. The coupling of the

axes is not effected by the traversing program, but through machine data. The machine data

determine which axis is the master axis and which is the slave axis for the synchronism. Only

the master axis has to be programmed in the traversing program. The slave axes "follow"

automatically.

2.2.4 Coordination of the control signals in the traversing program

As the master axis is the coordinating axis, program preselection and start are effected in this

axis. In addition, the operating mode "automatic" or "single block" must be preset in the

master axis. To operate the slave axes contained in the traversing program as slave axes, they

must be switched to the "slave" operating mode, otherwise the WF 723 C will not start

program execution.

For further details on the operation of the control signals, see the

description of functions, chapter "control and acknowledgment signals"

and the operating mode "automatic, single block and slave".

2.2.5 Memory capacity

Up to 200 programs or subroutines can be stored at the same time in the program memory.

The sum of traversing blocks must not exceed 1000 for S5 format. One traversing block in DIN

format may consist of several traversing blocks in S5 format.

2.2.6 Program number / Subroutine number

The figures 1 to 200 are possible program or subroutine numbers.

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

2 – 3

Basic Definitions 04.97

2.2.7 Program structure

A traversing program consists of a number of traversing blocks, which are processed in

ascending order of the block numbers. Start and end of the program need not be marked. The

first traversing block is automatically the start of the program and the last traversing block, the

end of the program. For better readability of the programs, special M-functions which

according to DIN 66025 effect program end (M02, M30) or subroutine end (M17, M29), can be

used.

In principle, subroutines do not differ from main programs, as they become subroutines only

when called from a traversing program, i.e. subroutines can also be run as main programs.

2.3 Traversing blocks

A traversing block contains all data to execute a processing step, e.g. positioning, dwelling or

output of switching functions.

2.3.1 Block structure

A traversing block consists of:

• Character for block start

• Block number

• Number of words containing data for the execution of a processing step

N Block No. Word Word Word

Programming:

N10 G.. X.. Y.. Z.. F.. M.. D..

N20 L.. P..

/ N30 ...

/ . . . . . . . . . . . Skip identifier for skip block

N . . . . . . . . . . Block number

G . . . . . . . . . . G-functions

X, Y, Z . . . . . . Path information of axes (preferably linear axes)

A, B, C . . . . . . Path information of axes (preferably rotary axes)

XY, XZ, AYX, etc. Path information of syncronous axes (selectable aynchronism), the first

axis being the master axis of the synchronism).

Any combinations of axes A, B, C, X , Y, Z are possible, with 2 or 3 digits.

X . . . . . . . . . . Indication of the dwell time

F . . . . . . . . . . Path velocity for interpolation

FX, FY, FZ, etc. Axis velocity for chanining

M . . . . . . . . . . M-function (machine function)

D . . . . . . . . . . Tool offset number

L . . . . . . . . . . Subroutine number

P . . . . . . . . . . Number of loops

2 – 4 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Basic Definitions

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

A word is an element of a traversing block and consists of an address character and a

sequence of digits. The address character is an alphanumerical sequence of digits. The

sequence of digits may have a sign and a decimal point. The sign must be located between

the address character and the sequence of digits, a positive sign is not entered. No blank is

admitted between the address and the value.

Examples:

Address

X

1.000

Word

Value

Y

-2.000

Word

M1=

Word

10

2.3.2 Block number

Programming:

N10 G90 G43 X100.000 F4000.00 M1=10 M2=11 M3=12 D1

Block numbers from 1 to 200 are admitted. The blocks may be assigned to any number but

make sure that the program is executed in ascending order of the block numbers. It is

recommended to define the block numbers in steps of five (5, 10, 15 ...) to be able to insert

further blocks subsequently.

2.3.3 Axis assignment

The physical hardware axes A*, B* and C* are situated on the WF 723 C module. A logic name

(X, Y, Z for linear axes and A, B, C for rotary axes) can be assigned to each hardware axis by

means of machine data 38.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

MD-

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

I SSI W

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

No.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

38

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

aaaaaaaaaaa

Axis assignment

Designation

Lower limit Upper limit

1 : X-axis

2 : Y-axis

3 : Z-axis

4 : A-axis

5 : B-axis

6 : C-axis

When creating traversing programs the axis definitions (path information) refer to these logic

axis entries.

Programming:

N10 G90 G01 X100.000 Y100.000 F10000.00

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

a

a

a

Unit

a

a

––

2 – 5

Basic Definitions 04.97

Example 1: Machine tool with 3 linear axes

Hardware axis A*: Axis X ➯ MD 38 = 1

Hardware axis B*: Axis Y ➯ MD 38 = 2

Hardware axis C*: Axis Z ➯ MD 38 = 3

Example 2: Machine tool with 2 linear axes and 1 rotary axis

Hardware axis A*: Axis X ➯ MD 38 = 1

Hardware axis B*: Axis A ➯ MD 38 = 4

Hardware axis C*: Axis Y ➯ MD 38 = 2

You may assign linear and rotary axes as required. Wrong axis assignments

are programming errors and may lead to incorrect movements of the axes.

It is not allowed to assign one logic axis twice to one module.

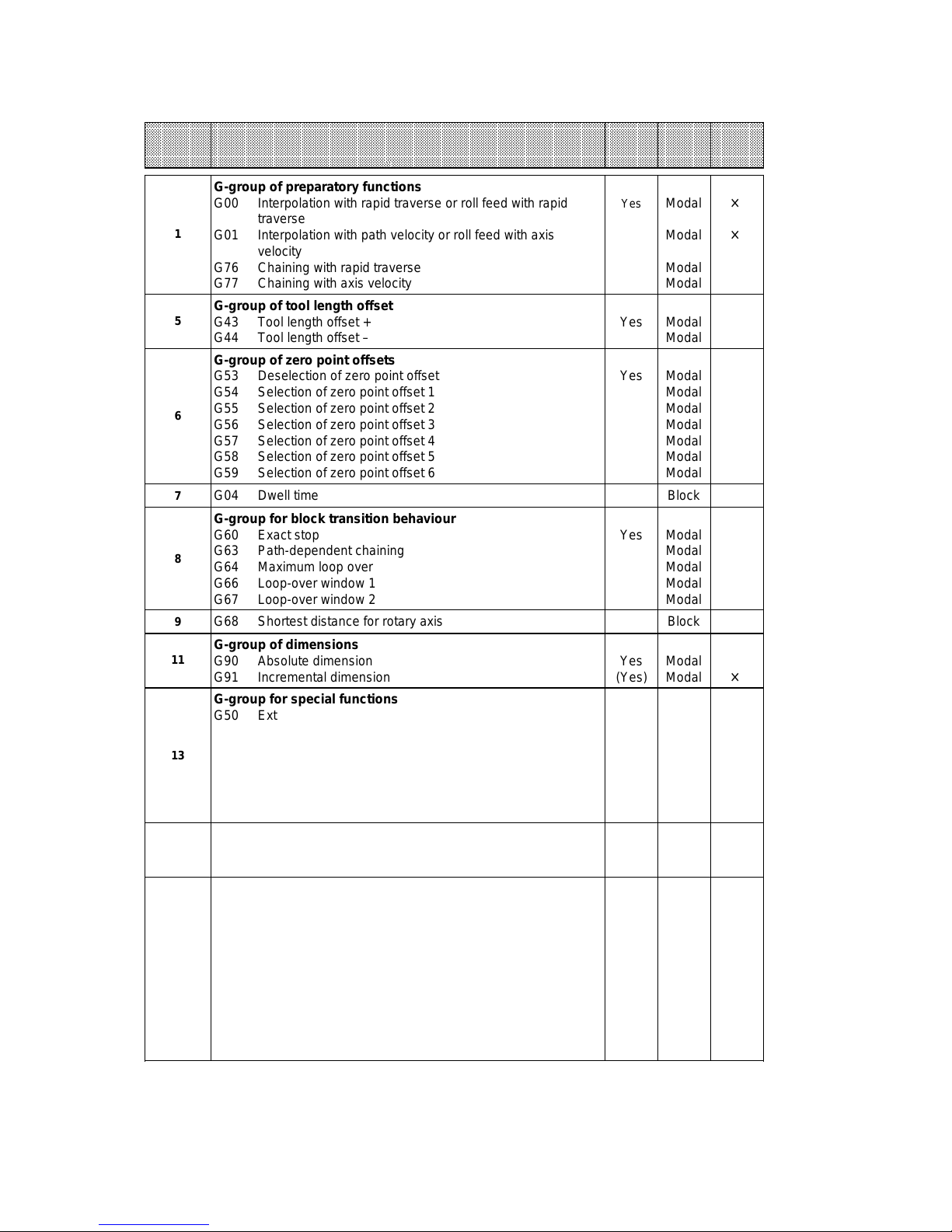

2.3.4 G-functions

On the one hand, the type of movement is defined via the G-functions, on the other hand, they

serve to call offsets, displacements, and special functions.

The G-functions are divided into G-groups according to their definitions. In each G-group there

is a switch-on status or basic position, i.e. the G-function is active without selection.

Example: G00 - interpolation with rapid traverse for the first G-group.

The effectiveness of G-functions is characterised by ”modal” or ”block (local)”. G-functions

effective block by block are only effective in the programmed block. Modally effective Gfunctions are active until they are replaced by other G-functions of the same G-group.

Example: G77 - chaining with axis velocity deselects G76 - chaining with rapid traverse.

Programming:

N10 G90 G43 X100.000 F4000.00 M1=10 M2=11 M3=13 D1

Several G-functions may be defined in one traversing block. Each program is a self-contained

unit, separated from other traversing programs. Therefore, all G-groups are in basic position at

the beginning of the program and brought in the required position if necessary.

For roll feed, only a limited number of G-functions are admissible

(see table G-functions).

2 – 6 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Basic Definitions

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

DIN group

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

G-function

Basic

position

active

Effectiveness

Roll

feed

G-group of preparatory functions

G00 Interpolation with rapid traverse or roll feed with rapid

Modal

×

Yes

traverse

1

G01 Interpolation with path velocity or roll feed with axis

Modal

×

velocity

G76 Chaining with rapid traverse

G77 Chaining with axis velocity

Modal

Modal

G-group of tool length offset

5

G43 Tool length offset +

G44 Tool length offset –

Yes Modal

Modal

G-group of zero point offsets

G53 Deselection of zero point offset

G54 Selection of zero point offset 1

G55 Selection of zero point offset 2

6

G56 Selection of zero point offset 3

G57 Selection of zero point offset 4

G58 Selection of zero point offset 5

G59 Selection of zero point offset 6

7

G04 Dwell time Block

Yes Modal

Modal

Modal

Modal

Modal

Modal

Modal

G-group for block transition behaviour

G60 Exact stop

G63 Path-dependent chaining

8

G64 Maximum loop over

G66 Loop-over window 1

G67 Loop-over window 2

9

G68 Shortest distance for rotary axis Block

Yes Modal

Modal

Modal

Modal

Modal

G-group of dimensions

11

G90 Absolute dimension

G91 Incremental dimension

Yes

(Yes)

Modal

Modal

×

G-group for special functions

G50 External block change with absoute dimension

G51 External block change with incremental dimension

G79 Synchronization

13

G87 Flying actual-value setting - deselction

G88 Flying actual-value setting / continuous rotation –

G89 Flying actual-value setting / continuous rotation +

G99 Program-dependent external read-in enable

Block

Block

Block

Block

Block

Block

Block

×

G-group for collision monitoring

14

G96 Selection collision monitoring

G97 Deselection collision monitoring Yes

Modal

Modal

G-group for acceleration/braking

G30 100% override acceleration/braking

G31 10% override acceleration/braking

G32 20% override acceleration/braking

G33 30% override acceleration/braking

16

G34 40% override acceleration/braking

G35 50% override acceleration/braking

G36 60% override acceleration/braking

G37 70% override acceleration/braking

G38 80% override acceleration/braking

G39 90% override acceleration/braking

Yes Modal

Modal

Modal

Modal

Modal

Modal

Modal

Modal

Modal

Modal

×

×

×

×

×

×

×

×

×

×

a

a

a

a

a

a

a

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

2 – 7

Basic Definitions 04.97

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

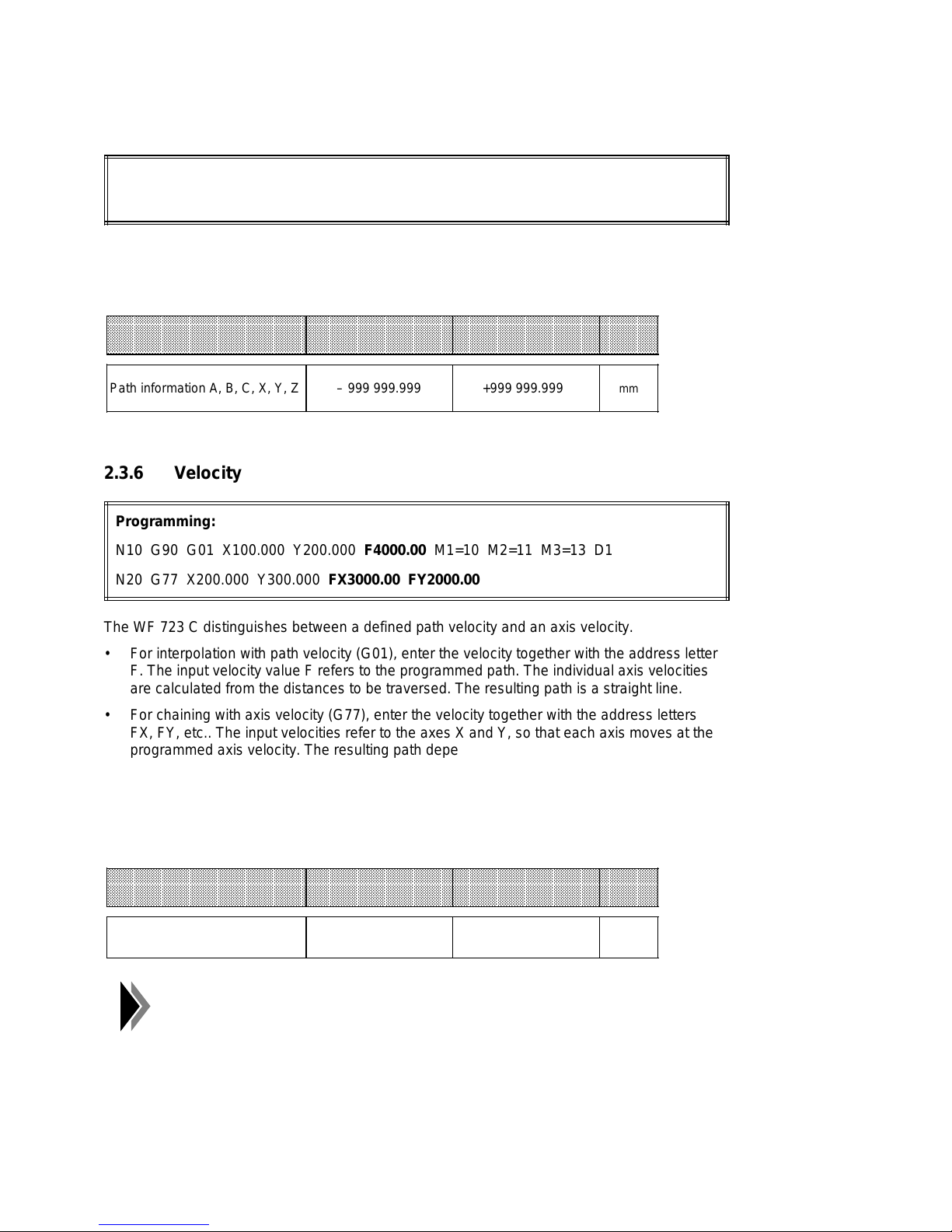

2.3.5 Path information (position)

Programming:

N10 G90 G43 G01 Z100.000 F4000.00 M1=10 M2=11 M3=13 D1

The path information is defined by the address character for the axis designation (X, Y, Z ...)

and the position value. A negative or positive sign may be entered with the path information.

When entering positive values, no sign need be entered.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Designation

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Lower limit Upper limit

Unit

Path information A, B, C, X, Y, Z – 999 999.999 +999 999.999

mm

2.3.6 Velocity

Programming:

N10 G90 G01 X100.000 Y200.000 F4000.00 M1=10 M2=11 M3=13 D1

N20 G77 X200.000 Y300.000 FX3000.00 FY2000.00

The WF 723 C distinguishes between a defined path velocity and an axis velocity.

• For interpolation with path velocity (G01), enter the velocity together with the address letter

F. The input velocity value F refers to the programmed path. The individual axis velocities

are calculated from the distances to be traversed. The resulting path is a straight line.

• For chaining with axis velocity (G77), enter the velocity together with the address letters

FX, FY, etc.. The input velocities refer to the axes X and Y, so that each axis moves at the

programmed axis velocity. The resulting path depends on the distances to be traversed

and on the axis velocities.

Both during interpolation and during chaining, the WF 723 C monitors that no axis traverses at

a velocity higher than its own traversing velocity - maximally (MD 31). All velocity values are

modally effective.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Designation

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Lower limit Upper limit

Velocity F, FX, FY, ... 0.01 500 000.00

In case of roll feed, the velocities must be defined under F.

2 – 8 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

Unit

mm/min

WF 723 C (Programming Guide)

04.97 Basic Definitions

2.3.7 M-functions

Via M-functions the user has the possibility to define the control of his machine functions when

programming traversing programs.

Programming:

N10 G90 G43 G01 X100.000 F4000.00 M1=10 M2=11 M3=13 D1

M-functions are defined by the address character M1=, M2=, M3= and a figure between 0

and 254. Up to three M-functions can be programmed per traversing block. The user-assigned

M-functions may be programmed as desired. The M-functions with special functions must be

programmed in the M1 group (Exeption: M97 and M98).

• Assignment of M-functions

M1 M2 M3 Special functions

0 Stop at block end

1 1 1 User function

2 Program end

3-16 3-16 3-16 User functions

17 Subroutine end

18 Continuous loop

19-28 19-28 19-28 User functions

29 Subroutine end

30 Program end

31-96 31-96 31-96 User functions

97 97 97 Output programmable

98 98 98 Output programmable

99 99 99 User function

100-254 100-254 100-254 User functions

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

2 – 9

Basic Definitions 04.97

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

2.3.8 Tool offset number

The tool offset enables the user to adapt various offsets without changing the traversing

program.

Programming:

N10 G90 G43 G01 X100.000 F4000.00 M1=10 M2=11 M3=13 D1

The tool offset number is defined by the address character D and a figure between 0 and 20.

The corresponding offset is selected by assigning D1 to D20. In connection with G43 (positive

tool length offset) and G44 (negative tool length offset), the direction of the tool offset is

defined.

The entry of D0 deselects the tool length offset.

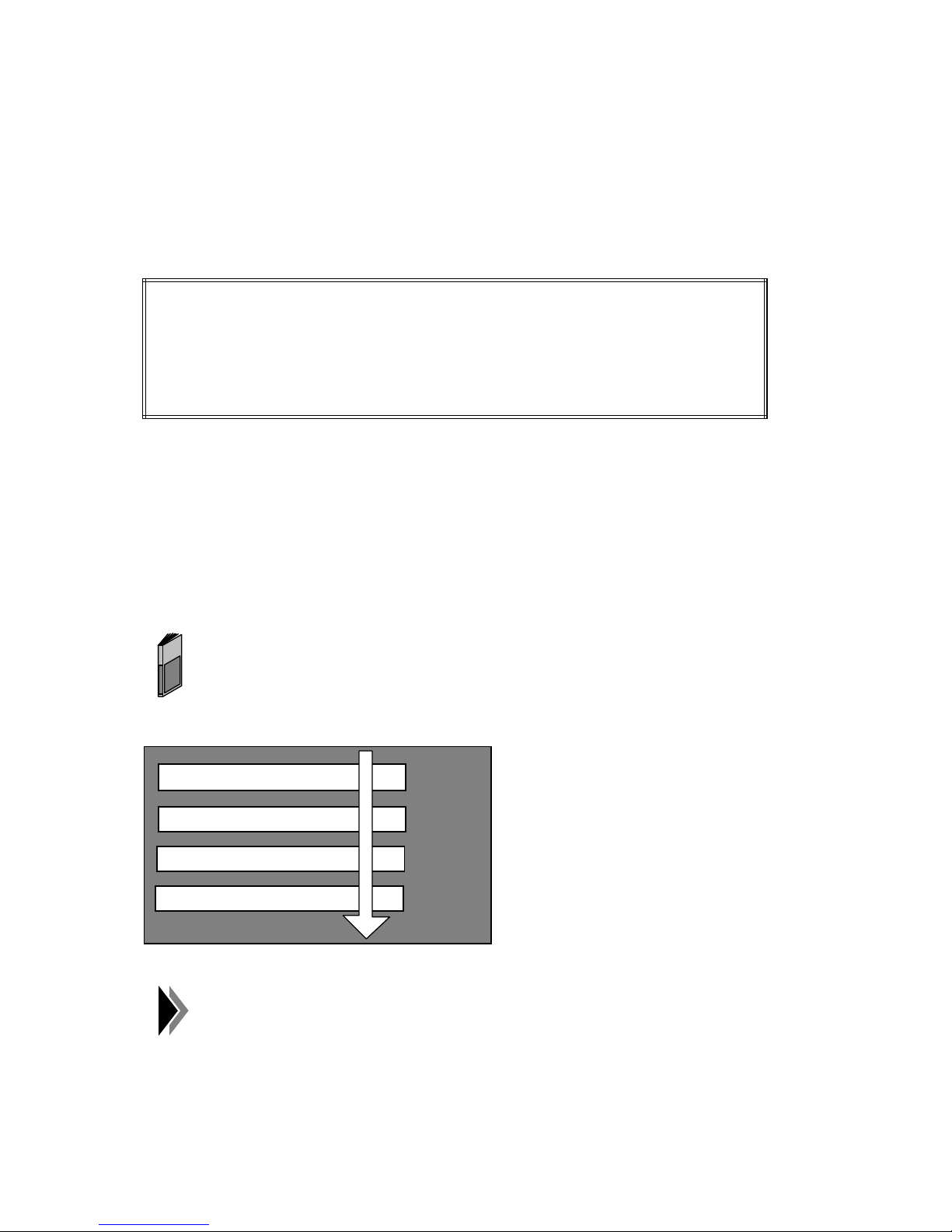

2.3.9 Dwell time

The dwell time is defined by the address character X and the dwell time value.

Programming:

N10 G04 X1.000 M1=10 M2=11 M3=13

A traversing block with dwell time may only contain the G function 04, time and M-functions.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Designation

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Dwell time 0.004 99.999

Lower limit Upper limit

Unit

s

If a block with dwell time is defined as the last block in the traversing

program, an automatic returned to the beginning of the program takes

place after executing the dwell time block (continuous loop).

2 – 10 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Program Execution / Subroutines

3 Program Execution /

Subroutines

3.1 Program execution

Programming:

N10 G90 G01 X100.000 Y200.000 F4000.00 M1=10 M2=11 M3=13

N20 G90 X300.000 F3000.00

N30 G90 Y400.000 F2000.00

N40 M1=30

A traversing program is defined by a number of traversing blocks, the block numbers in

ascending order determining the direction of processing.

The WF 723 C is provided with a traversing block decoder which edits the traversing blocks in

such a way that necessary calculations and verifications during execution of the traversing

block can be avoided. This ensures short block-change and executing times.

Apart from basic conditions that have to be met for starting a stored program, the program

number, the read-in enable and the start signal must be available. The read-in enable activates

the traversing block decoder, the start signal enables the traversing block execution.

For a detailed description, see the chapter "control and acknowledgment

signals" in the description of functions.

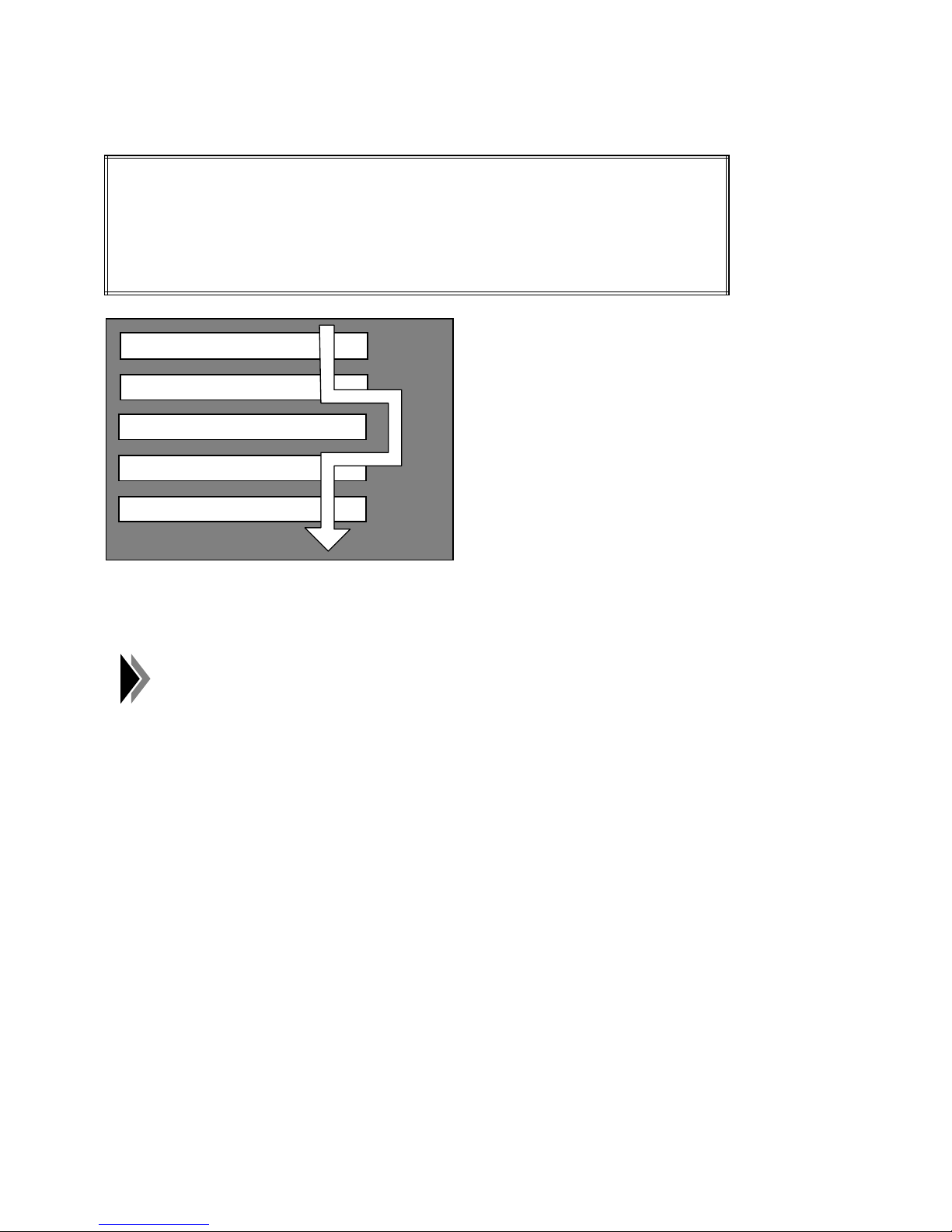

N10

N20

N30

N40

For roll feed, there is no pre-decoding of traversing block, as they have to

be started one by one externally.

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

3 – 1

Program Execution / Subroutines 04.97

3.2 Skippable blocks

Programming:

N20 G90 X1.000 F4000.00 M1=10 M2=11 M3=13

/ N30 G90 X2.000 F4000.00

N40 G90 X3.000 F4000.00

N50 M1=30

N10

N20

/ N30

N40

N50

Program blocks that shall not be executed with every program run can be marked as skippable

blocks by the character ”/”. The control signal Skip Block [SA] determines whether skippable

blocks are skipped.

The last traversing block of a program or subroutine must not be skipped.

3 – 2 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Program Execution / Subroutines

N50 ....

N30 L21 P ..

N20 L20 P ..

N1 ....

N50 ....

N30 L30 P ..

N10 ....

N40 ....

N10 ....

N30 ....

N20 L30 P ..

N10 ....

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

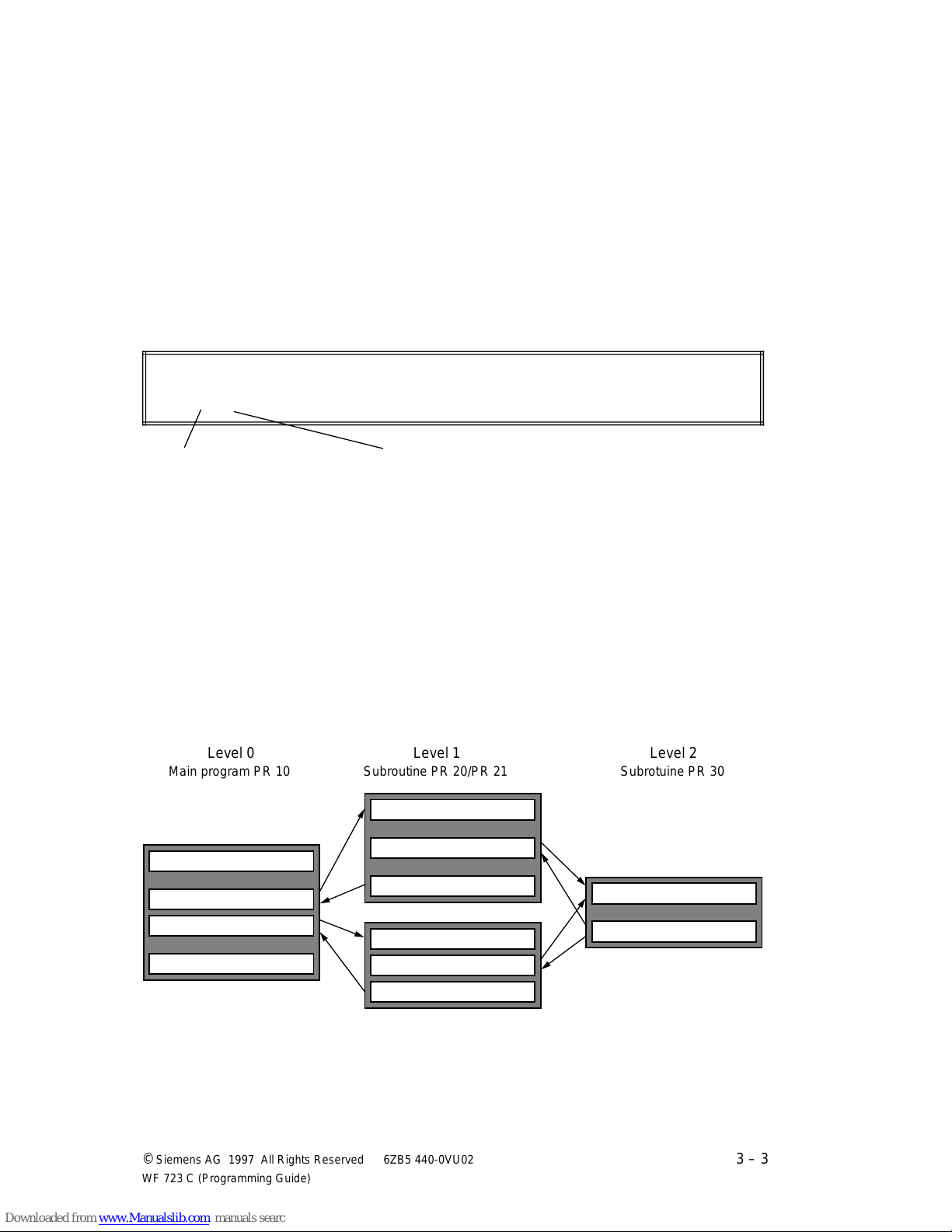

Level 0

Main program PR 10

aaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

Level 1

Subroutine PR 20/PR 21

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

Level 2

Subrotuine PR 30

3.3 Subroutines

The WF 723 C offers the subroutine technology for self-contained processes called or

executed several times.

3.3.1 Subroutine call

The subroutine call is defined by the address character L followed by a figure from 1 to 200.

The number of loops is defined by the address character P and a loop value from 0 to 65535.

Programming:

N10 L24 P23

Subroutine call with

Number of loops=23

program number 24

A traversing block with subroutine call must not contain other words apart from the number of

loops.

If 0 is entered as the number of loops, the subroutine will not be called.

3.3.2 Subroutine execution

The WF 723 C allows a two-level nesting depth, the number of subroutine calls being only

restricted by the memory space of the WF module.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

3 – 3

Program Execution / Subroutines 04.97

The WF 723 C does not distinguish between main program or subroutine, i.e. a subroutine can

be directly started like a main program or by a subroutine call.

A called subroutine is executed block by block, starting with the first block number, until a

return to the next higher level is effected. Such a return is triggered by a traversing block with

subroutine end (M17 or M29) or by the execution of the last traversing block of a subroutine.

Modally effective G-functions are effective starting at the block number in which they are

programmed. They stay also effective when jumping to subroutines or back to the main

program.

If a subroutine is terminated with M18, M18 will only be output as an

M-function

➯

no return function.

3.3.3 Programming guidelines

Please adhere to the following guidelines for subroutine execution:

• The 2-level nesting depth must not be exceeded, otherwise the program execution is

aborted and an error message is output.

• Calling a superior program (main program or subroutine) in the subroutine results in an

exceeded nesting depth and is illegal. It is also illegal that a program calls itself.

• When changing program levels, flying block change is not possible. Before the program

level is changed, the axes are brought to an exact stop.

• If subroutine calls are programmed in skippable blocks, the subroutine will not be executed

if the control signal ”Skip block” [SA] is set.

• All definitions in the main program (G- functions, tool offset, zero point offsets, etc.) are

transferred to the subroutines.

3 – 4 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Program Execution / Subroutines

3.4 Block search forwards

With the "Block search forwards" function, you can start program execution at any point. This

is necessary, for example, if after an abortion of the program execution, you do not want to

start it from the beginning again.

The program will be aborted if during execution

• there is a WF "traversing" error message

(no error that has to be acknowledged with RESET)

• the operating mode is changed

Stopping the program execution by removing the control signal [ST] is not

a program abortion, i.e. by setting [ST], program execution is continued.

The "block search forwards" function distinguishes between "manual block search" and

"automatic block search". Block search forwards is activated by the commands "read in

manual block search" and "read in automatic block search".

The commands are described in the description of functions in chapter

"Command identification" (AK05).

3.4.1 Automatic block search

Upon a program abortion, the WF 723 C automatically saves the data of the interruption point.

After activation of automatic block search, program execution continues at the last point of

interruption, i.e. with the traversing block at which the program was interrupted.

An automatic block search can only be carried out after a program interruption has occurred.

After a RESET of the axis/axes [RST], no automatic block search is

possible.

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

3 – 5

Program Execution / Subroutines 04.97

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaa

a

a

aaa

aaa

aaa

aaa

aaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaa

a

a

a

a

a

aaa

a

a

a

a

a

a

a

aaa

a

aaa

a

aaa

a

aaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

3.4.2 Manual block search

For manual block search, the exact data of the entry point in the traversing program must be

defined to the WF 723 C.

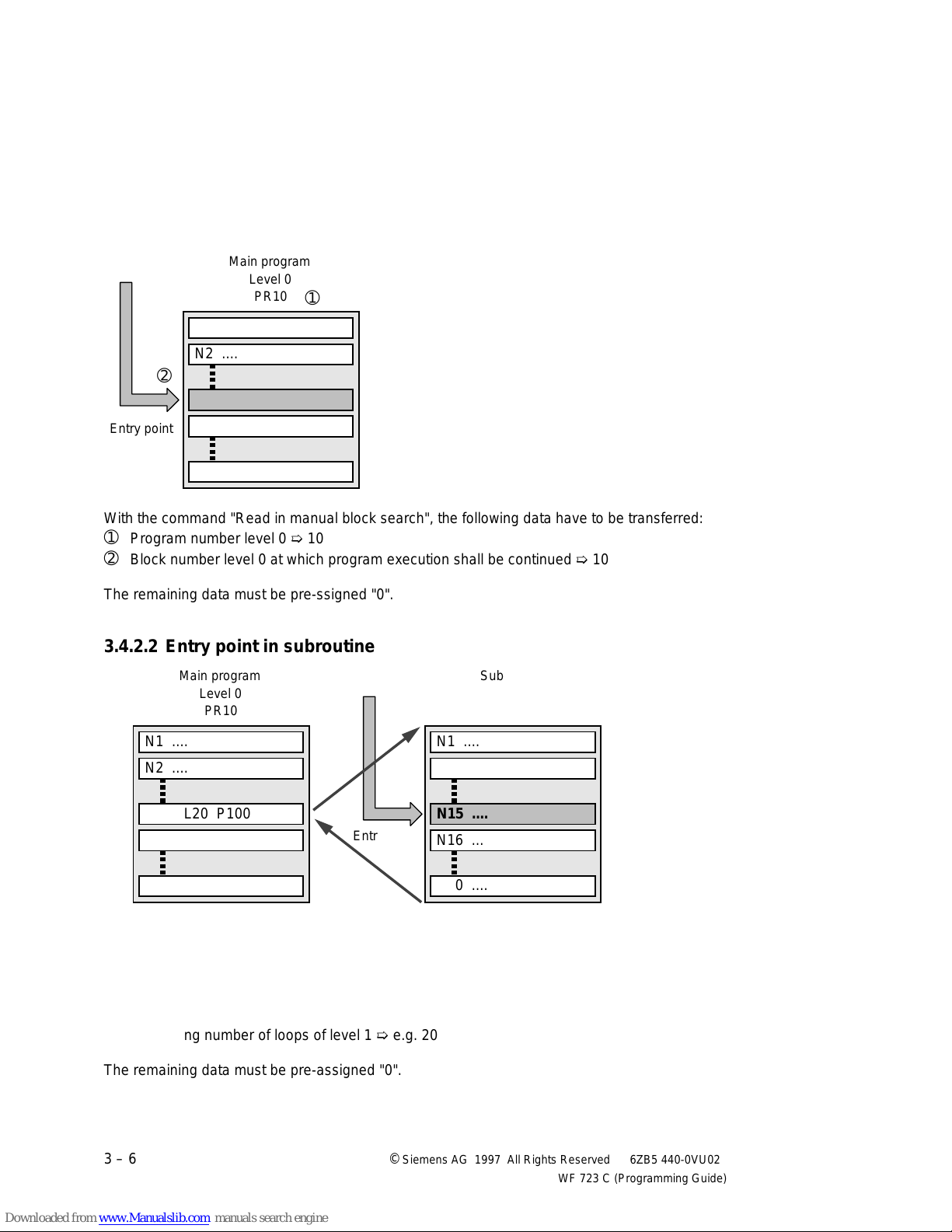

3.4.2.1 Entry point in the main program

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Main program

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Level 0

PR10

➀

a

a

a

a

a

a

N1 ....

N2 ....

➁

N10 ....

aaaaaaaaaaa

Entry point

aaaaaaaaaaa

N11 ....

N20 ....

With the command "Read in manual block search", the following data have to be transferred:

➀

Program number level 0 ➯ 10

➁

Block number level 0 at which program execution shall be continued ➯ 10

The remaining data must be pre-ssigned "0".

3.4.2.2 Entry point in subroutine level 1

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Main program

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Level 0

PR10

N1 ....

N2 ....

N10 L20 P100

➁

N11 ....

➀

➄

Entry point

aaaaaaaaa

aaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Subroutine

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Level 1

PR20

N1 ....

N2 ....

a

a

a

a

➃

a

a

N15 ....

a

a

N16 ....

➂

N20 ....

With the command "Read in manual block search", the following data have to be transferred:

①

Program number level 0 ➯ 10

➁

Block number level 0 at which the subroutine is called ➯ 10

➂

Program number level 1 ➯ 20

➃

Block number level 1 at which program execution shall be continued ➯ 15

➄

Remaining number of loops of level 1 ➯ e.g. 20

The remaining data must be pre-assigned "0".

3 – 6 ©

N20 ....

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Program Execution / Subroutines

aaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

aaa

a

a

a

a

a

aaa

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

aaa

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

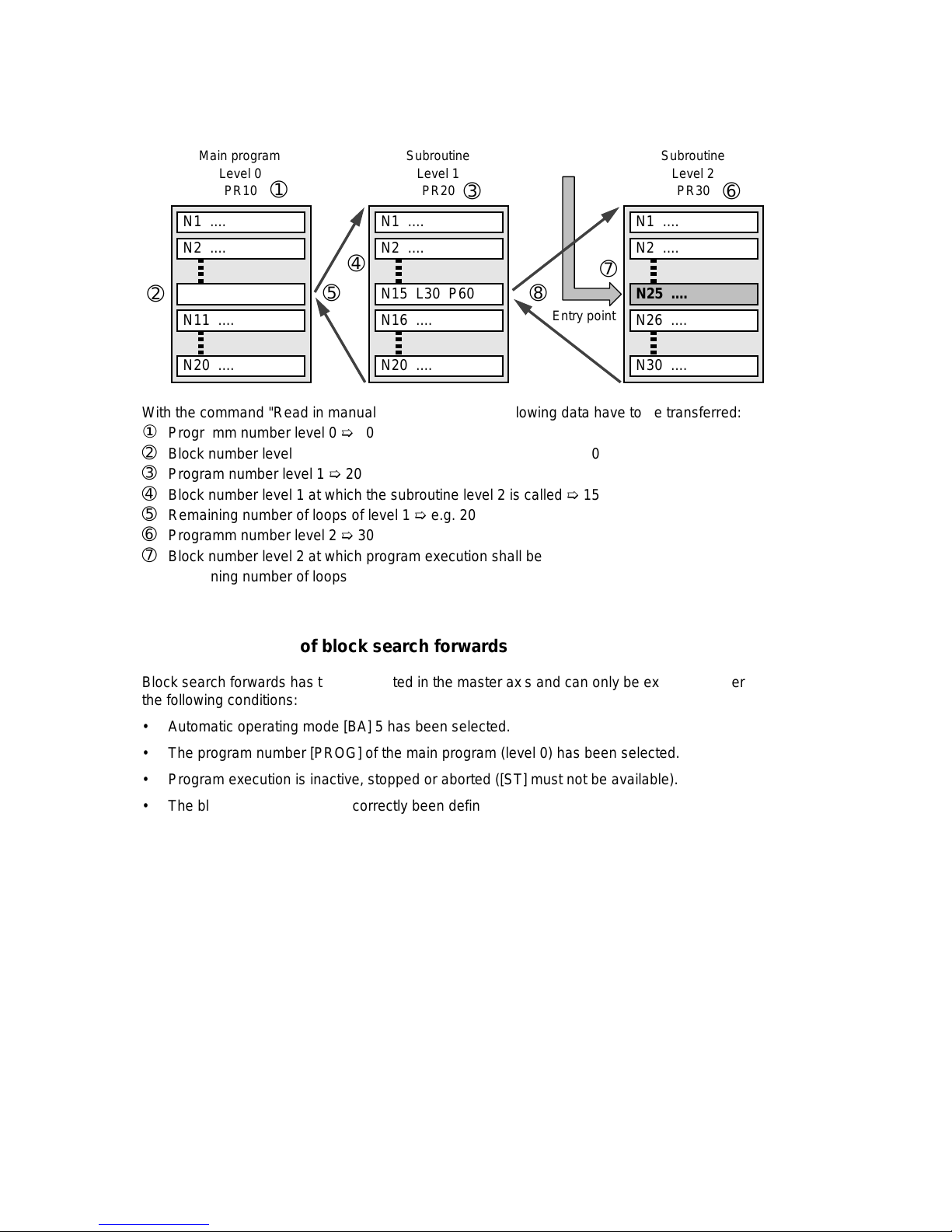

3.4.2.3 Entry point in subroutine level 2

aaaaaaaaaaaaaaaaaaaaa

Main program

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

Level 0

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

PR10

aaaaaaaaaaaaaaaaaaaaa

N1 ....

➀

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaa

Subroutine

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

Level 1

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

PR20

aaaaaaaaaaaaaaaaaaaaa

➂

a

a

a

a

a

a

N1 ....

aaaaaaaaaaaaaaaaaaaaa

Subroutine

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

Level 2

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

PR30

aaaaaaaaaaaaaaaaaaaaa

➅

a

a

a

a

a

a

N1 ....

a

a

a

a

a

a

a

a

N2 ....

a

a

a

a

N10 L10 P100

➁

a

a

N11 ....

N20 ....

➄

a

a

a

a

a

a

a

➃

a

a

a

a

a

N2 ....

N15 L30 P60

N16 ....

N20 ....

a

a

a

a

➇

a

a

Entry point

➆

aaaaaaaaaaa

aaaaaaaaaaa

a

a

a

a

a

a

N2 ....

N25 ....

N26 ....

N30 ....

With the command "Read in manual block search", the following data have to be transferred:

①

Programm number level 0 ➯ 10

➁

Block number level 0 at which the subroutine level 1 is called ➯ 10

➂

Program number level 1 ➯ 20

➃

Block number level 1 at which the subroutine level 2 is called ➯ 15

➄

Remaining number of loops of level 1 ➯ e.g. 20

➅

Programm number level 2 ➯ 30

➆

Block number level 2 at which program execution shall be continued ➯ 25

➇

Remaining number of loops of level 2 ➯ e.g. 5

3.4.3 Conditions of block search forwards

Block search forwards has to be activated in the master axis and can only be executed under

the following conditions:

• Automatic operating mode [BA] 5 has been selected.

• The program number [PROG] of the main program (level 0) has been selected.

• Program execution is inactive, stopped or aborted ([ST] must not be available).

• The block search data have correctly been defined.

Any faulty operation generates a corresponding Data exchange/traversing WF error message.

After successful activation through the command "read in automatic/manual block search", the

current block search data can be checked with the command "read out block search", as long

as program execution has not yet been started. Afterwards, the output block search data will

be "0".

©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

3 – 7

Program Execution / Subroutines 04.97

3.4.4 Program start after activation of block search forwards

Program decoding is effected from the beginning of the program. Axis movements and the

output of M-functions are only effected from the defined entry point. Tool offsets, zero point

offsets, self-holding G-functions and velocities are maintained up to the entry point.

Important hints:

• If a jump is made to a block with incremental dimension (G91), the entire traversing path

will be traversed, even if before the program abortion part of the path was already

traversed.

• M-functions of the block jumped to will be output, even if they were already output before

the program abortion.

• If a program execution is interrupted and the M-functions are still pending, they will be

deleted through the block search forwards.

3 – 8 ©

Siemens AG 1997 All Rights Reserved 6ZB5 440-0VU02

WF 723 C (Programming Guide)

04.97 Programming of Traversing Blocks

a

a

a

a

a

a

a

a

a

a

a

a

aaa

aaa

aaa

aaa

aaa

aaa

aaa

a

a

a

a

a

a

aaa

aaa

aaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

4 Programming of Traversing Blocks

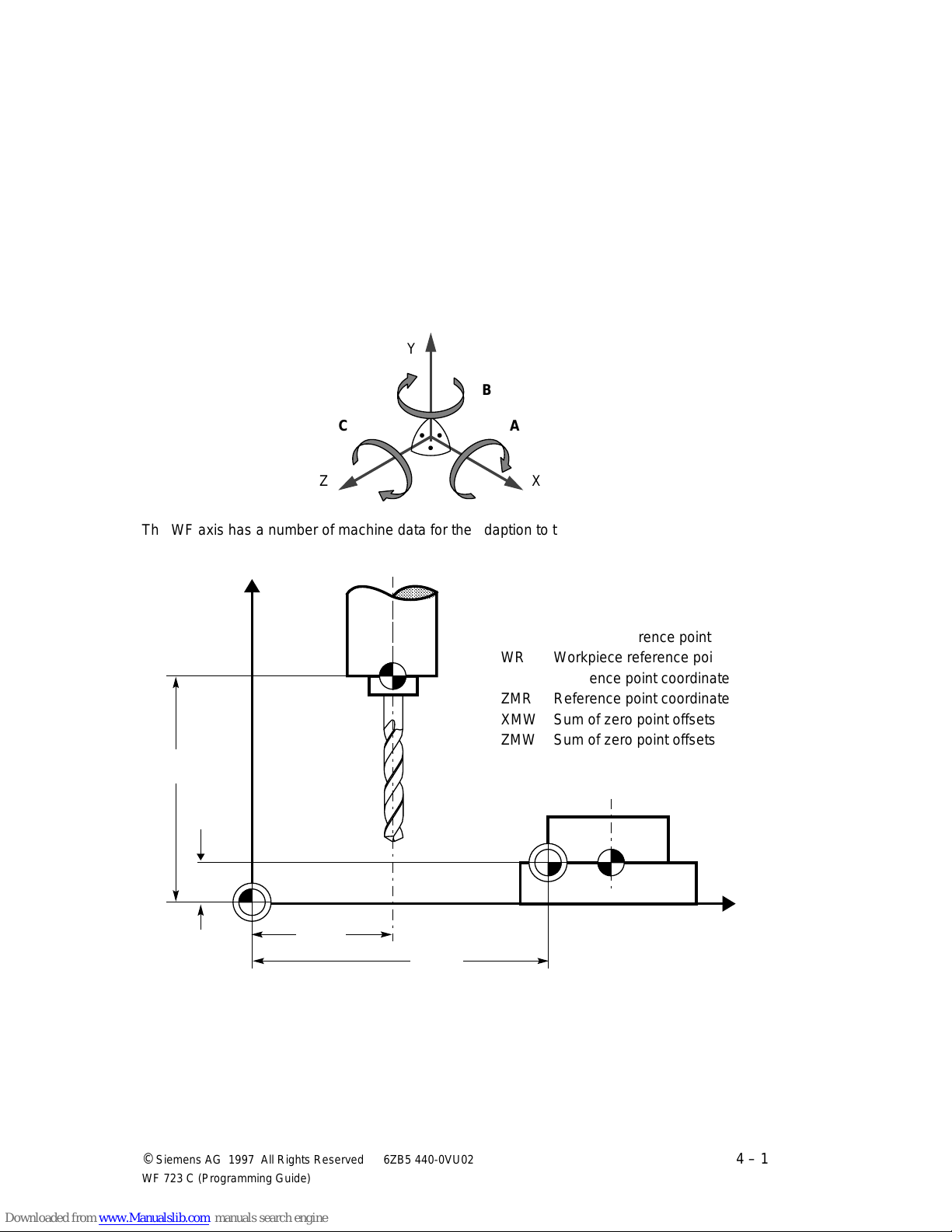

4.1 Coordinate system and reference point

The traversing directions of a machine tool refer to a coordinate system assigned to the

traversing axes of the machine tool. A right-handed and right-angled coordinate system with

the axes X, Y, and Z is used. The coordinate system is assigned to the main axes of the

machine tool.

Y

B

C

Z

A

X

The WF axis has a number of machine data for the adaption to the coordinate system that

have to be entered during installation.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

M Machine zero point

+Z

R

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

W Workpiece zero point

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

R Machine reference point

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

WR Workpiece reference point

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

XMR Reference point coordinate

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

ZMR Reference point coordinate

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

XMW Sum of zero point offsets