Page 1

simatic

© Siemens AG 2007

Catalog ST PCS 7 · November 2007

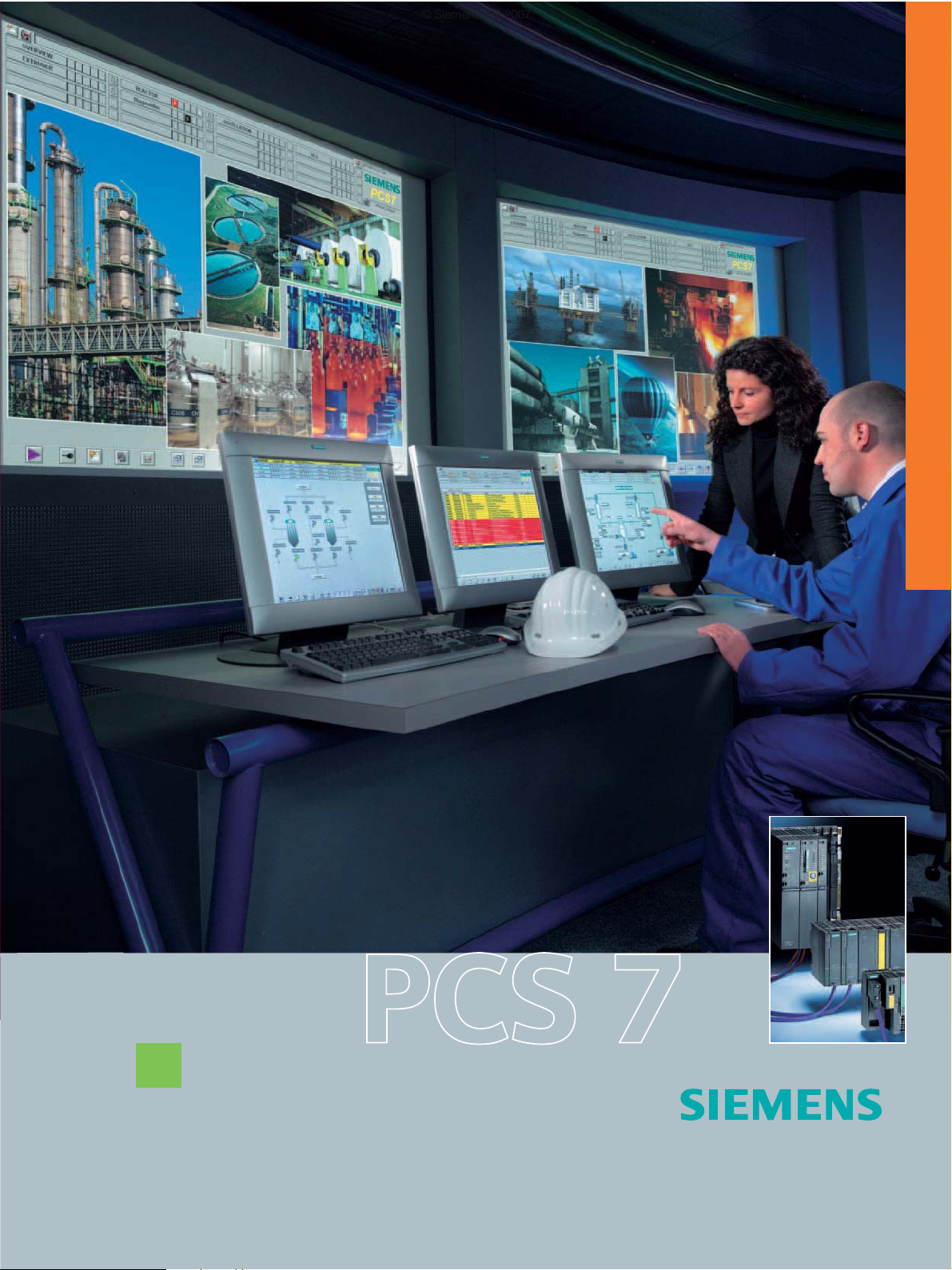

SIMATIC PCS 7

Process Control System

Page 2

Related catalogs

© Siemens AG 2007

SIMATIC

Add-ons for the SIMATIC PCS 7

Process Control System

Only PDF:

(E86060-K4678-A121-A6-7600)

SIMATIC

Migration solutions with the

SIMATIC PCS 7

Process Control System

Order no.:

E86060-K4678-A131-A3-7600

SIMATIC

Products for Totally Integrated

Automation and Micro Automation

Order no.:

E86060-K4670-A101-B1-7600

E86060-K4670-A151-A3-7600 (News)

SIMATIC HMI

Human Machine Interface

Systems

Order no.:

E86060-K4680-A101-B5-7600

Industrial Communication

Industrial Communication for

Automation and Drives

Order no.:

E86060-K6710-A101-B5-7600

E86060-K6710-A121-A2-7600 (News)

ST PCS 7.1

ST PCS 7.2

ST 70

ST 80

IK PI

Training for Automation and ITC

Industrial Solutions

Order no.:

E86060-K6850-E101-B8 (in German)

Catalog CA 01

the Offline Mall of

Automation and Drives

Order no.:

E86060-D4001-A100-C6 (CD-ROM)

E86060-D4001-A500-C6 (DVD)

A&D Mall

Internet:

www.siemens.com/automation/mall

I

T

C

TELEPERM M

AS 488/TM

Automation Systems

Only PDF:

(E86060-W3812-A100-A3-7600)

Field Instruments

for Process Automation

Order no.:

E86060-K6201-A101-A9-7600

PLT 112

FI 01

Page 3

SIMATIC PCS 7

© Siemens AG 2007

Introduction

1

Process Control System

Version 7.0

Catalog ST PCS 7 ·

October 2007

Supersedes:

Catalog ST PCS 7 · March 2007

The products contained in this catalog

can also be found in the e-Catalog CA 01

Order No.:

E86060-D4001-A110-C6-7600 (CD-ROM)

E86060-D4001-A510-C6-7600 (DVD)

Please contact

your local

Siemens branch

© Siemens AG 2007

System-neutral components

2

Starter systems

3

Engineering system

4

Operator system

5

Batch automation

6

SIMATIC Route Control

7

Asset Management

8

The products and systems described in this

catalog are manufactured/distributed under

application of a certified

quality management

system in accordance

with DIN EN ISO 9001

(Certified Registration

No. 1323-QM). The certificate is recognized by

all IQNet countries.

Communication

Automation systems

Process I/O

IT world

Migration to SIMATIC PCS 7

Ordering data for previous version

SIMATIC PCS 7 V6.1

Update/upgrade packages

9

10

11

12

13

14

15

s

Appendix

16

Page 4

Siemens Automation and Drives.

© Siemens AG 2007

Welcome

More than 70,000 people aiming for the same goal:

increasing your competitiveness. That's Siemens

Automation and Drives.

We offer you a comprehensive portfolio for sustained

success in your sector, whether you're talking automation engineering, drives or electrical installation systems. Totally Integrated Automation (TIA) and Totally

Integrated Power (TIP) form the core of our offering.

TIA and TIP are the basis of our integrated range of

products and systems for the manufacturing and process

industries as well as building automation. This portfolio

is rounded off by innovative services over the entire life

cycle of your plants.

Learn for yourself the potential our products and

systems offer. And discover how you can permanently

increase your productivity with us.

Your regional Siemens contact can provide more information. He or she will be glad to help.

1/2

Siemens ST PCS 7 · November 2007

Page 5

© Siemens AG 2007

Siemens ST PCS 7 · November 2007

1/3

Page 6

Sharpen your competitive edge.

© Siemens AG 2007

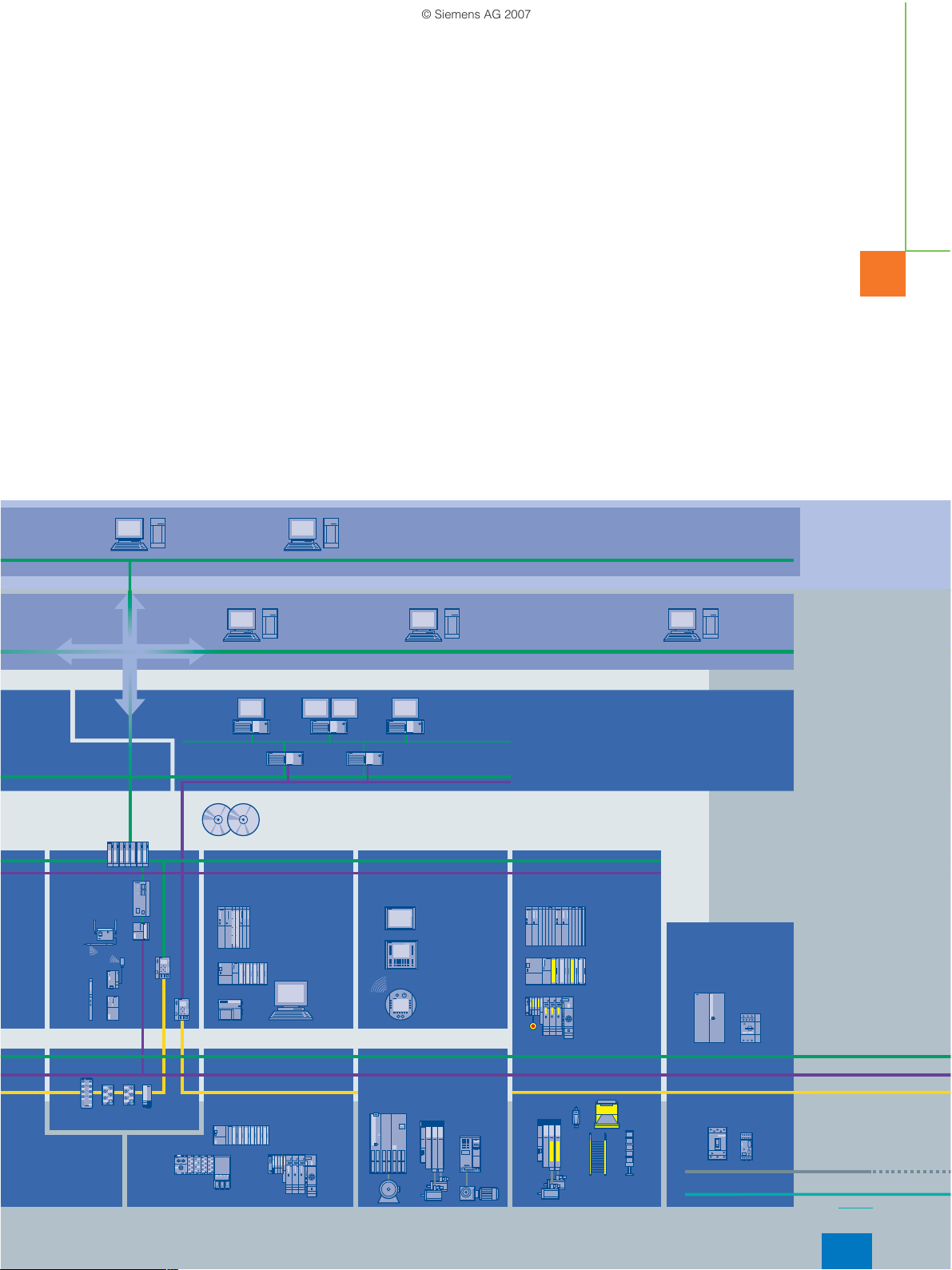

Totally Integrated Automation

With Totally Integrated Automation (TIA), Siemens is the only

manufacturer to offer an integrated range of products and systems for automation in all sectors - from incoming goods to outgoing goods, from the field level through the production control

level to connection with the corporate management level.

On the basis of TIA, we implement solutions that are perfectly

tailored to your specific requirements and are characterized by a

unique level of integration. This integration not only ensures significant reductions in interface costs but also guarantees the

highest level of transparency across all levels.

Management Level

Operations Level

Control Level

ERP Enterprise Resource Planning

Ethernet

MES Manufacturing Execution Systems

Ethernet

SIMATIC PCS 7

Process Control (DCS)

Industrial Software for

Design and Engineering

Installation and Commissioning

Operation

SINUMERIK

Computer Numeric Control

Maintenance

Modernization

and Upgrade

SIMOTION

Motion Control System

Field Level

Totally

Integrated

Automation

1/4

PROFINET

Industrial Ethernet

PROFIBUS

Siemens ST PCS 7 · November 2007

PROFIBUS PA

HART

HART

Process Instrumentation

AS-Interface

SIMATIC Sensors

Page 7

SIMATIC IT

© Siemens AG 2007

It goes without saying that you profit from Totally Integrated

Automation during the entire life cycle of your plants - from the

first planning steps, through operation, right up to modernization. Consistent integration in the further development of our

products and systems guarantees a high degree of investment

security here.

Totally Integrated Automation makes a crucial contribution

towards optimizing everything that happens in the plant and

thus creates the conditions for a significant increase in productivity.

SIMATIC WinCC

SCADA System

SIMATIC NET

Industrial

Communication

SIMATIC Controllers

Modular/ Embedded/ PC-based

SIMATIC Distributed I/O

SIMATIC HMI

Human Machine Interface

SINAMICS Drive Systems

Safety Integrated

SIRIUS Industrial Controls

SENTRON Switching Devices

SIMOCODE pro

Motor Management System

Siemens ST PCS 7 · November 2007

AS-Interface

Totally

Integrated

Power

KNX/ EIB

GAMMA

abus

t

ins

1/5

Page 8

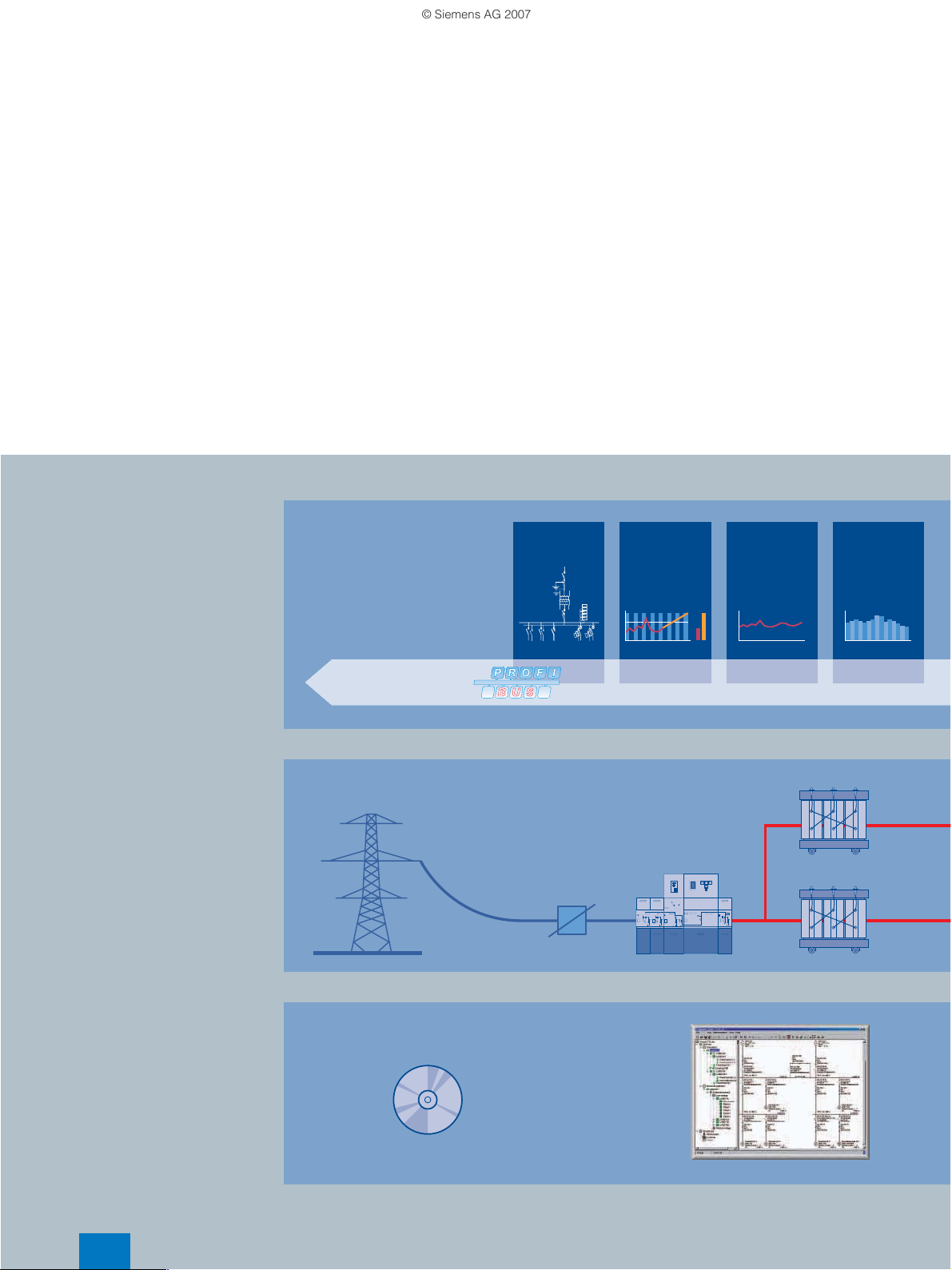

Integrated energy distribution from a single source.

© Siemens AG 2007

Totally Integrated Power

Totally Integrated Power (TIP) brings together all the components

of electrical energy distribution into an integrated whole. Thus TIP

provides the answer to growing market demands in the planning,

construction and use of utility buildings and industrial buildings.

On the basis of TIP, we offer integrated solutions for energy distribution, from medium voltage to the power outlet. Totally Integrated Power is based here on integration in planning and configuring as well as on perfectly matched products and systems.

Communication

Communication

Process/production

Process/production

automation

automation

Products and systems

Products and systems

HMI Graphs Prognoses

HMI Graphs Prognoses

U

I

U

cos o

I

P

cos o

P

W

W

PROCESS FIELD BUS

Load

Load

manage-

management

ment

£ 110 kV

1/6

Planning

Planning

and configuration

and configuration

Siemens ST PCS 7 · November 2007

Page 9

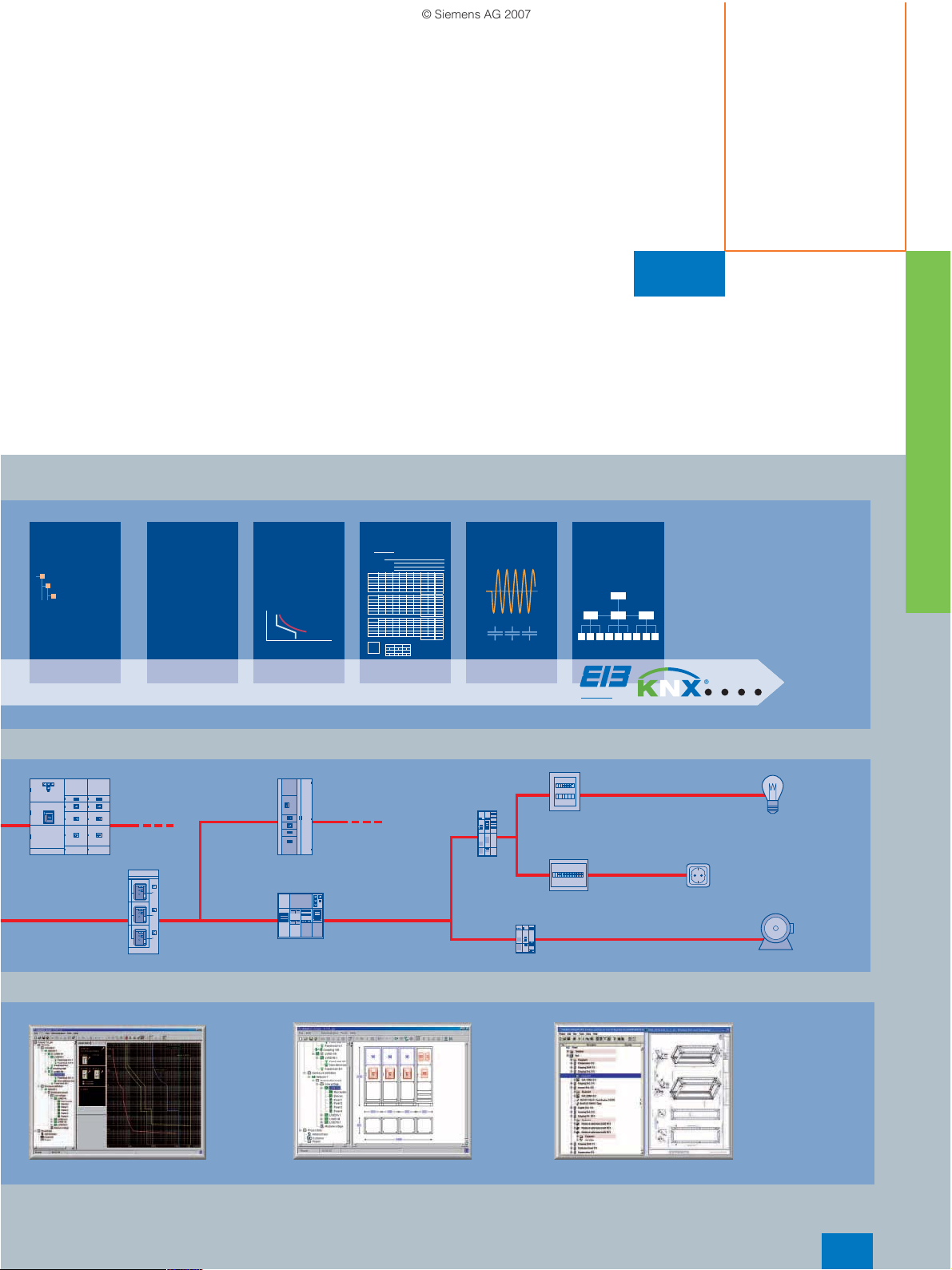

Totally Integrated Power offers communication

© Siemens AG 2007

and software modules for connecting the energy

distribution systems to industrial automation and

building automation. This enables the implementation of significant savings potential.

Main-

Maintenance

tenance

Substation

Substation

Distribution

Distribution

Maintenance

Maintenance

task

task

Hall 1 Air conditioning system

Hall 1 Air conditioning system

checkup

checkup

Distribution 3 Replacing circuit

Distribution 3 Replacing circuit

breaker contacts

breaker contacts

Infeed II Replacing meters

Infeed II Replacing meters

Message/

Message/

error

error

manage-

management

ment

Selective

Selective

protection

protection

Protocols Power

Protocols Power

DATE:

EMPLOYEE

COST CENTER

PAY PERIOD BEGINNING

PAY PERIOD ENDING

DATE

TUE

WED

FRI

THUR

MON

SUN

SUN

SUN

TUE

MON

TUE

MON

REGULAR HOLIDAY OTHER

OVER THE HOURS

TIME & ONE-HALF

SICK VACATION

SAT

TOTAL HOURS

WED

FRI

THUR

SAT

TOTAL HOURS

WED

FRI

THUR

SAT

TOTAL HOURS

IN

OUT

IN

OUT

OVERTIME

DATE

IN

OUT

IN

OUT

OVERTIME

DATE

IN

OUT

IN

OUT

OVERTIME

CODES

V=VACATION

H=HOLIDAY

S=SICK

quality

quality

TOTAL

SUN

TOTAL

SUN

TOTAL

SUN

Cost center

Cost center

instabus EIB

Building

Building

automation

automation

Siemens ST PCS 7 · November 2007

1/7

Page 10

Protecting the environment

© Siemens AG 2007

and resources.

Environmental sustainability

Environmental protection will continue to grow in importance

as a result of progressive urbanization and global population

growth. These global mega-trends make the careful and sustainable handling of natural resources a central challenge.

We are convinced that every individual - and especially

every company - has an ecological responsibility. At Siemens

Automation and Drives, we stand by this conviction. Our high

environmental protection goals are part of our strict environmental management. We investigate the possible effects of our

products and systems on the environment right back at the development stage. We concern ourselves, for example, with the

question of how to reduce power consumption in plant

operation - and we offer appropriate solutions, such as our

energy-saving motors that cut power consumption in industrial

manufacturing by up to 40% thanks to their high efficiency

levels.

Our products and systems comply with the EC Directive

RoHS (Restriction of Hazardous Substances). All the relevant

Siemens AG sites are, of course, certified in accordance with

DIN EN ISO 14001.

Our commitment goes well beyond compliance with the relevant directives and legislation: we are an active driving force

behind environmental protection, through further development of environmental management systems, for example,

and we are involved in professional associations such as the

German Electrical and Electronic Manufacturers Association

(ZVEI).

1/8

Siemens ST PCS 7 · November 2007

Page 11

© Siemens AG 2007

Siemens ST PCS 7 · November 2007

1/9

Page 12

Introduction

© Siemens AG 2007

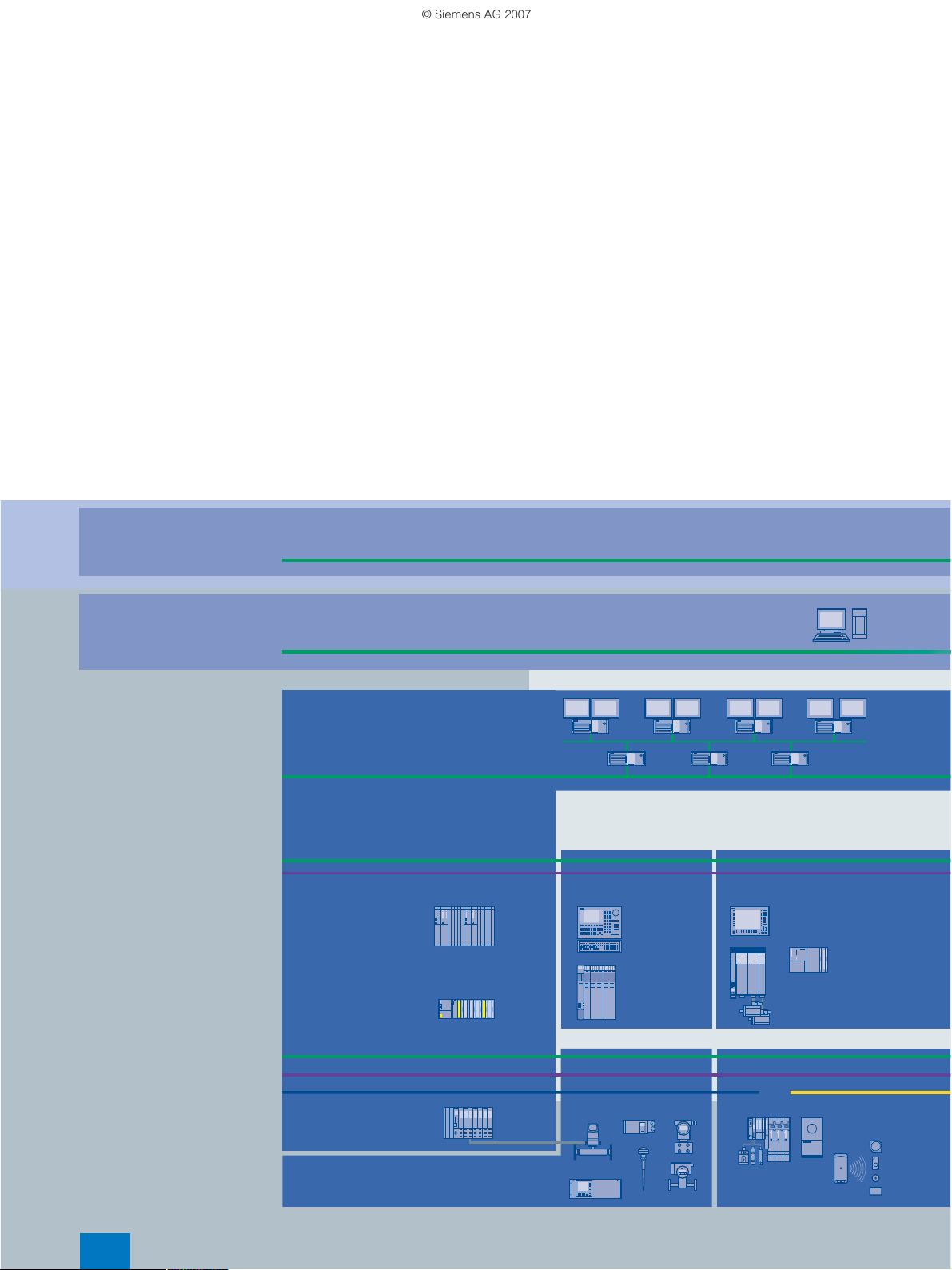

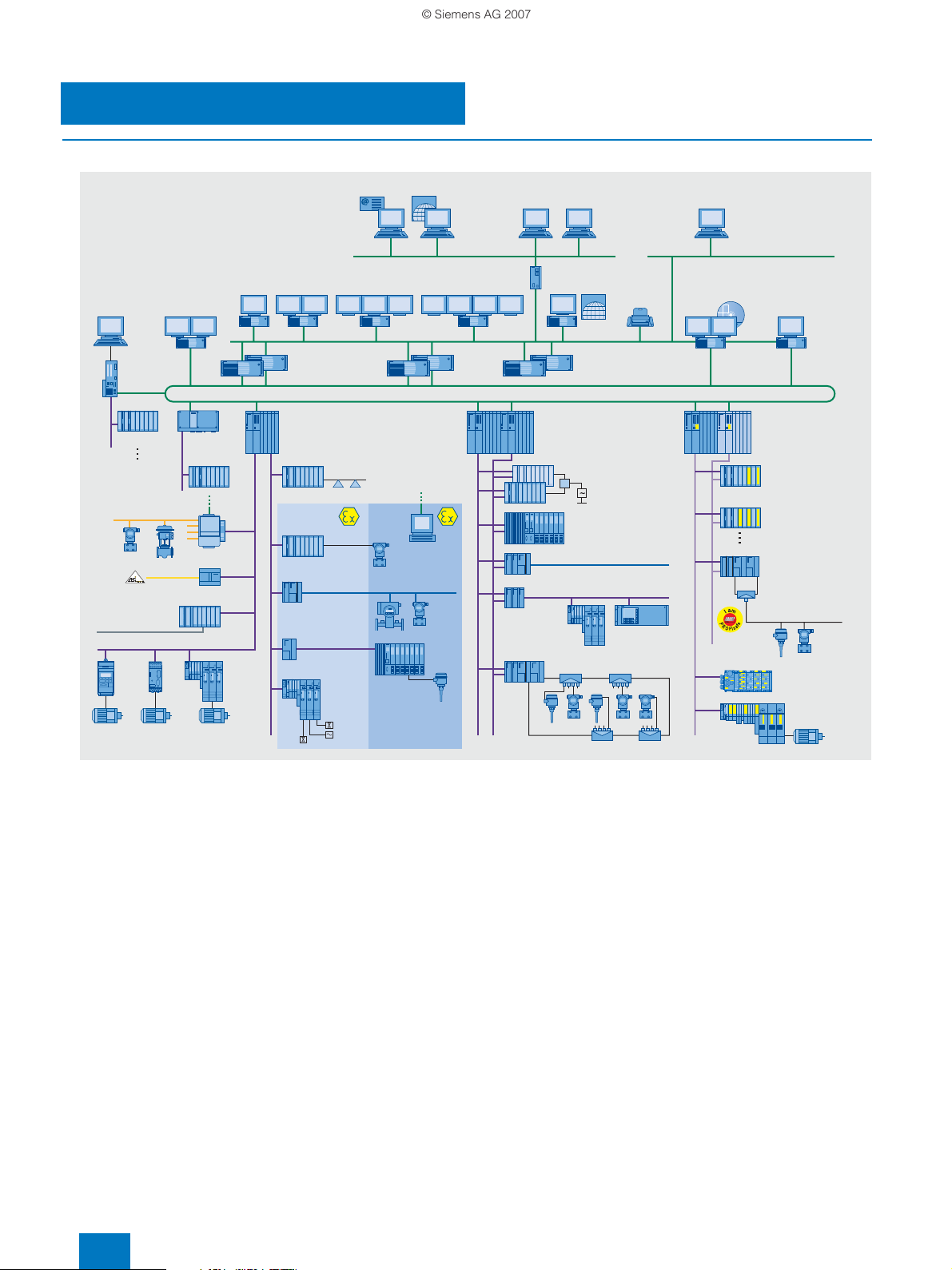

System architecture

SIMATIC PCS 7 V7.0

■

Overview

SIMATIC PCS 7

Takes you beyond the limits!

ET 200M

FF-H1

ET 200M

with CP 341

Integrated Drives

OS

Single Station

SIMATIC

PCS 7

AS RTX

DP/FF Link

DP/AS-Interface link

SIMATIC

PCS 7 BOX

Modbus, serial connection

OS / Route Control

Server

Standard

automation

systems

Ex I/O, HART

DP/PA link

PROFIBUS DP

PROFIBUS DP

INTERNET

OS / Batch / Route Control

Clients

OS-LAN, single/redundant

Industrial Ethernet, single/redundant

ET 200M

Weighing systems

Zone 1Zone 2

ET 200M

ET 200S

Ex operator

terminal

PROFIBUS PA

ET 200iSP

HART

Web Client

Office LAN (Ethernet)

Security

Modules

PROFIBUS DP

SAP

Web Server/

OpenPCS 7

Fault-tolerant

automation

systems

MTA

DP/PA link

Y link

DP/PA link

PROFIBUS PA

Network

printer

INTERNET

Ethernet

Batch/archive

server

ET 200M

single/redundant

ET 200iSP

PROFIBUS PA

, NO

CO

x

Active Field Distributors

Management information/

Manufacturing Execution System

SIMATIC IT

x

Engineering

Station

PROFIBUS DP

Asset Management/

Maintenance station

Safety-related

automation

systems

ET 200M

Standard and

F modules

ET 200M

F modules

DP/PA link

with redundant

DP/PA couplers

Active Field Splitter

PROFIBUS PA

ET 200pro

ET 200S

SIMATIC PCS 7 system configuration

Totally Integrated Automation with SIMATIC PCS 7

The SIMATIC PCS 7 process control system is a significant component of Totally Integrated Automation (TIA), the unique basis

offered by Siemens for uniform and customized automation in all

sectors of the production, process and hybrid industries. Using

TIA, Siemens is the only company able to offer uniform automation technology on one single platform for all applications of process automation, starting with input logistics, covering production or primary processes as well as downstream (secondary)

processes, up to output logistics. This is suitable for optimization

of all operating sequences of an entire company, i.e. from the

ERP (Enterprise Resource Planning) level and MES (Management Execution System) level to the control level, right down to

the field level.

Integrated in a holistic automation solution for a production site,

automation of the primary processes is the prime task of SIMATIC PCS 7. On the other hand, secondary processes (e.g. filling, packaging) or input/output logistics (e.g. raw material distribution, storage) are frequently implemented using the PLCbased or PC-based components of SIMATIC.

The advantages of Totally Integrated Automation, in particular

the uniform data management, communication and configuration, are already evident during planning and engineering, but

also during installation and commissioning, everyday operation

as well as maintenance, repairs and modernization.

Uniform data management means that all software components

access a common database. Within a project, inputs and modifications are therefore only necessary at one point. This reduces

the work required, and simultaneously avoids potential faults.

Once symbolic identifications have been introduced, they are

understood by every software component. Data consistency is

also guaranteed even if several persons are working simultaneously on a project. Parameters defined in the engineering system can be transferred beyond the network limits down to sensors, actuators or drives in the field.

Uniform communication from the corporate management level

down to the field level is based on internationally recognized

standards such as Industrial Ethernet or PROFIBUS, and also

supports the global flow of information via the Internet. Since the

hardware and software components involved also use these

communications mechanisms, connections are extremely easy

to configure, also cross-system or over different networks.

The use of an engineering system with a uniform and matched

range of tools minimizes the configuration overhead. The engineering tools for the application software, the hardware components and the communications functions can be called from a

central project manager (SIMATIC Manager). This is also the basic application for creation, management, saving and documentation of a project.

Compatibility of further developments is guaranteed within TIA.

This also guarantees that the company’s investments have a secure future, and allows the company to modernize and expand

the plants throughout the complete lifecycle.

1/10

Siemens ST PCS 7 · November 2007

Page 13

Introduction

© Siemens AG 2007

System architecture

SIMATIC PCS 7 V7.0

■

Benefits

With its pioneering design, modular and open architecture

based on state-of-the-art SIMATIC technology, consistent application of industrial standards, and the I&C functionality paired

with high-performance, the SIMATIC PCS 7 process control system allows cost-effective implementation and economical operation of I&C plants in all phases of their lifecycle and with consideration of all aspects: from planning, engineering,

commissioning, training, through operation, maintenance and

repair, up to expansion and refurbishment. In the process, SIMATIC PCS 7 combines high-performance and reliability with

simple and safe operation and maximum convenience.

You primarily profit from Totally Integrated Automation with the

SIMATIC PCS 7 process control system through:

7 Calculable development, implementation and lifecycle costs

7 Minimization of engineering overhead

7 Facilities for process optimization

7 Adaptability to changing requirements

7 Advantages resulting from the use of standard SIMATIC com-

ponents, such as:

- Low hardware and engineering costs

- Proven quality and stability

- Simple, fast definition and selection of system components

- Low costs for spare parts

- Short delivery times for spare parts and expansion components

- Global availability

- Savings in logistics, maintenance and training costs

■

Function

A consistent and homogeneous overall system

SIMATIC PCS 7 is a modern process control system that can be

used alone or in combination with other systems, e.g. SIMATIC,

SIMOTION or drive systems, as a consistent and homogenous

overall system. Its popularity is increasing along with the demand for seamlessly integrated universal automation engineering solutions, which is determined by sustained competition and

price pressure, the demand for increasingly flexible production

plants and the need for increased productivity.

Against the background of ever-increasing complexity, in particular due to the merging of automation engineering with information technology, horizontal and vertical integrated system platforms are being increasingly accepted in comparison to

automation solutions with so-called "best-in-class products".

Totally Integrated Automation with SIMATIC PCS 7 combines

consistent data management, communication and configuration

with outstanding system properties and high performance. This

guarantees that the typical demands placed on a process control system are comprehensively satisfied, and that you are perfectly equipped for future requirements:

7 Simple and reliable process control

7 User-friendly operation and visualization, also using the

Internet

7 Powerful, fast and consistent system-wide engineering

7 System-wide online modifications

7 System openness at all levels

7 Flexibility and scalability

7 Redundancy at all levels

7 Safety-related automation solutions

7 Extensive fieldbus integration

7 Flexible solutions for batch processes

7 Efficient control of material transport

7 Asset management for I&C equipment (diagnostics, preven-

tive maintenance and repairs)

7 Direct interface with the IT world

7 Advanced security concept for safeguarding the I&C system.

Flexibility and scalability

As a result of its modular architecture based on selected hardware and software components from the standard SIMATIC

range, SIMATIC PCS 7 can be applied effectively in small and

large plants alike. It allows easy expansion or system modification to enable customers to meet the changing production requirements of their facility. SIMATIC PCS 7 is scalable from a

small single system consisting of approx. 160 process tags (motors, valves, PID controllers), such as might be used for a laboratory system or a test center, up to a distributed multi-user system with client/server architecture and approx. 60,000 process

tags, such as might be used for automation of a very large production plant or for groups of connected facilities.

SIMATIC PCS 7 thus covers all sizes of plant - and if the plant

grows, SIMATIC PCS 7 grows with it!

Open for the future

SIMATIC PCS 7 is based on modular hardware and software

components, which are perfectly matched to one another due to

their conformance with TIA. These components can be expanded and innovated seamlessly and with little effort and are

open for the future via long-term stable interfaces. This makes

long-term protection of customer investments possible, despite

the fast pace of innovation and short product cycles.

SIMATIC PCS 7 consistently applies new, powerful technologies

together with internationally established industrial standards

such as IEC, XML, PROFIBUS, Ethernet Gigabit technology,

TCP/IP, OPC, ISA-88 or ISA-95, just to mention a few.

Openness with SIMATIC PCS 7 covers all levels, and equally applies to automation systems and process I/Os as to industrial

communications networks, operator systems or engineering

systems.

Not just system architecture and communication are characterized by openness. This is a feature also evident in the programming and data transfer interfaces for user programs as well as in

the import and export functions for graphics, text and data, e.g.

from the CAD/CAE world. SIMATIC PCS 7 can therefore also be

combined with components from other vendors, and integrated

in existing infrastructures.

Siemens ST PCS 7 · November 2007

1/11

Page 14

Introduction

© Siemens AG 2007

1/12

Siemens ST PCS 7 · November 2007

Page 15

System-neutral

© Siemens AG 2007

components

2/2 System documentation

2/4 Administration

2/6 Operating system

2/7 SIMATIC PCS 7 Industrial

2/7 Introduction

2/10 Basic hardware

2/16 Multi-VGA graphics cards

2/17 Operator panels/monitors

2/18 Special configurations

Workstation

Siemens ST PCS 7 · November 2007

Page 16

System-neutral components

© Siemens AG 2007

2

System documentation

■

Overview

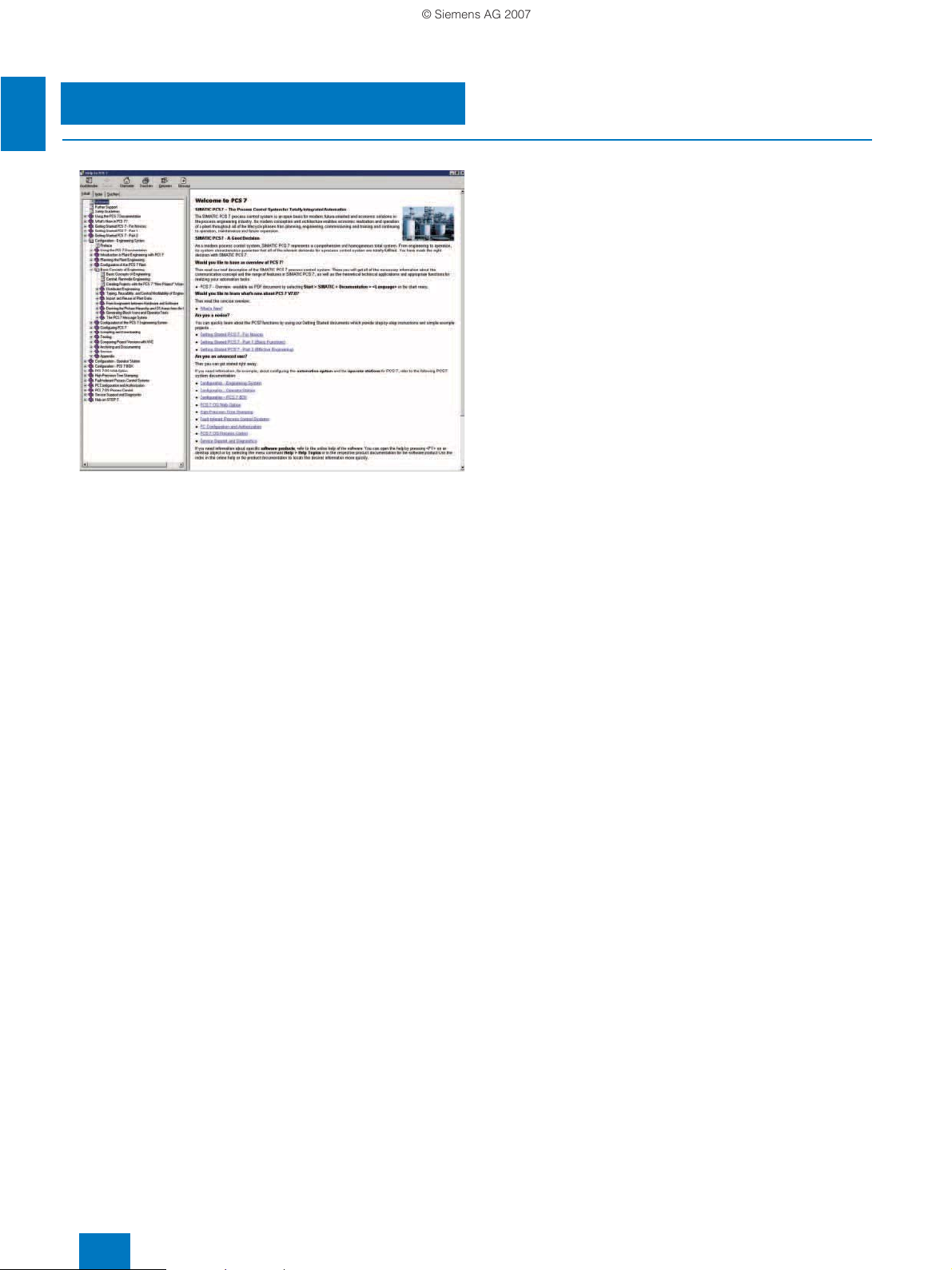

The system documentation of the SIMATIC PCS 7 process control system is an integral component of the SIMATIC PCS 7 system software. It is available in two versions:

• As online help (HTML help)

• As electronic documentation in Acrobat Reader format (PDF)

The 3-language documentation (German, English, French) pro-

vides both beginners and experienced users with valuable information on all aspects of the process control system. The range

extends from the system introduction, covers initial steps and

cross-system topics, up to a description of individual system

components. With the "Getting Started" documentation you can

gain initial practical experience using example projects.

SIMATIC PCS 7 Programming Instructions Driver Blocks

Programming Instructions for creating drive blocks and with the

title "SIMATIC PCS 7 Programming Instructions Driver Blocks"

can be ordered separately. These Programming Instructions

help the advanced SIMATIC PCS 7 user to create system-conform driver blocks, which can be placed like standard blocks on

system plans and automatically parameterized and interconnected in HW-Config.

S7 Manual Collection

As a supplement to the SIMATIC PCS 7 system documentation,

the S7 Manual Collection provides comprehensive information

on all system components offered in the context of SIMATIC S7.

This multi-language collection of electronic manuals on DVD

contains documentation on the following in addition to the

SIMATIC PCS 7 system documentation:

• SIMATIC S7-200/300/400,

• SIMATIC C7,

• LOGO! logic module,

• SIMATIC DP,

• SIMATIC PC,

• SIMATIC programming devices,

•STEP7,

• engineering software,

• runtime software,

• SIMATIC PCS 7,

• SIMATIC HMI and

• SIMATIC NET.

The electronic manuals of the S7 Manual Collection are usually

in 5 languages (German, English, French, Italian, Spanish),

those of the integral SIMATIC PCS 7 system documentation

mostly in 3 languages (German, English, French).

For the migration of existing plants, you may also require detailed information on the system components of TELEPERM M or

SIMATIC S5.

TELEPERM M Manual Collection

The TELEPERM M Manual Collection comprises TELEPERM M

manuals in 2 languages (German, English) on CD.

S5 Manual Collection

An S5 Manual Collection in 2 languages (German, English) on

CD, which contains all electronic manuals concerning

SIMATIC S5, rounds off the range of available information.

2/2

Siemens ST PCS 7 · November 2007

Page 17

System-neutral components

© Siemens AG 2007

■

Selection and Ordering Data Order No

SIMATIC PCS 7 Programming

Instructions Driver Blocks V7.0

for SIMATIC PCS 7 V6.1 and V7.0

Electronic documentation on CD,

in 2 languages (German, English)

Type of delivery: CD, certificate of

license, terms and conditions

SIMATIC S7 manuals

S7 Manual Collection

Electronic manuals on DVD, in

5 languages (German, English,

French, Italian, Spanish)

S7 Manual Collection maintenance service for 1 year

Type of delivery: Current DVD

"S7 Manual Collection" and the

three subsequent updates

TELEPERM M migration manuals

TELEPERM M Manual

Collection

Electronic manuals on CD, in

2 languages (German, English)

SIMATIC S5 manuals

S5 Manual Collection

Electronic manuals on CD, in

2 languages (German, English)

D) Subject to export regulations: AL: N, ECCN: 5D992B1

6ES7 653-1XD07-8YX8

6ES7 998-8XC01-8YE0 D)

6ES7 998-8XC01-8YE2 D)

6DL5 900-8AX03-8YX8 D)

6ES5 998-7WE02 D)

System documentation

■

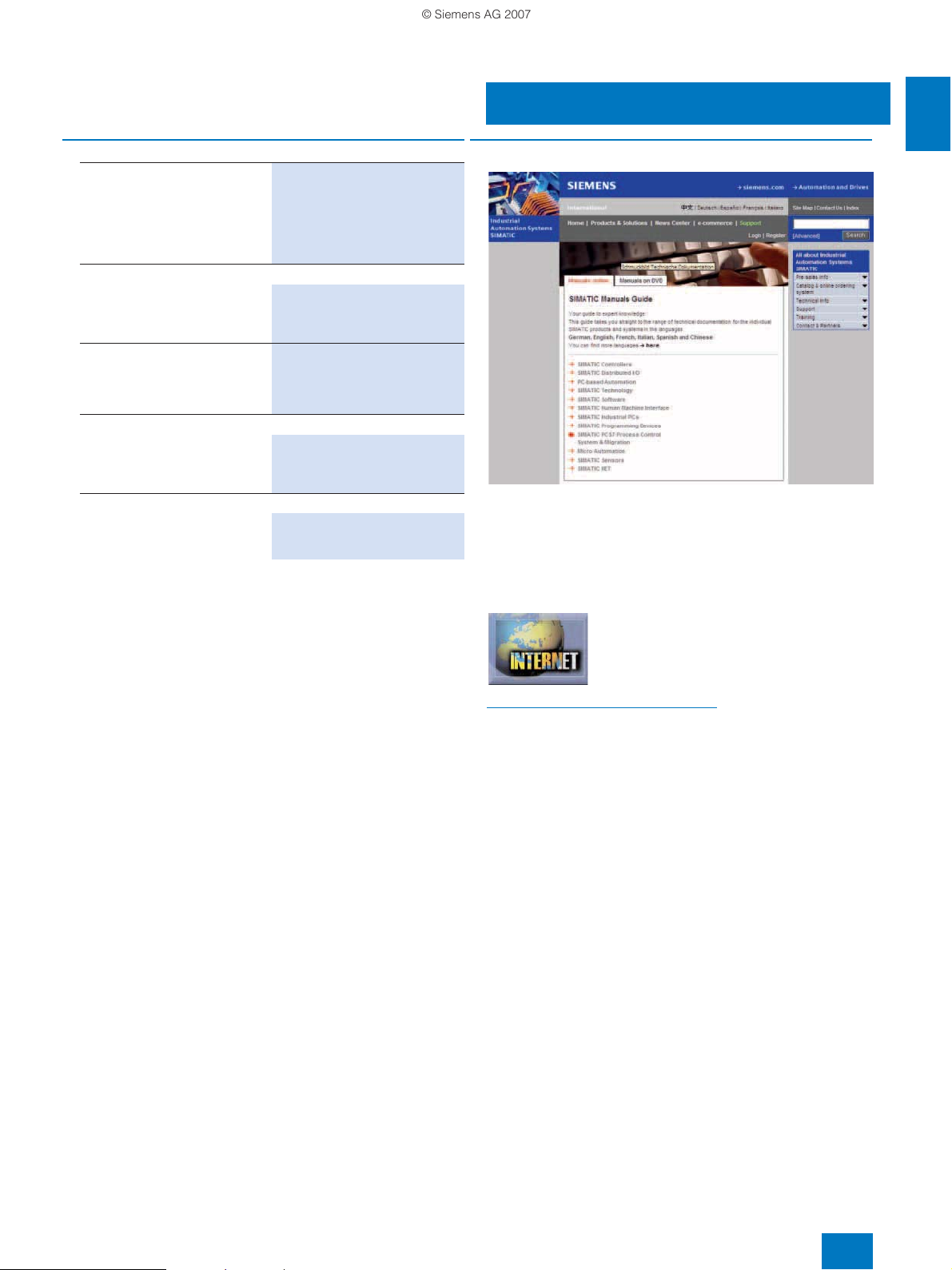

More information

The "SIMATIC Guide Manuals" on the Internet directs you

straight to the complete range of technical documentation available for SIMATIC products and systems in German, English,

French, Italian, Spanish and Chinese. If other languages are

available, you can also find them there. You can select individual

documents from this range for viewing or downloading.

Additional information is available in the Internet under:

2

http://www.siemens.com/simatic-docu

Siemens ST PCS 7 · November 2007

2/3

Page 18

System-neutral components

© Siemens AG 2007

2

Administration

■

Overview

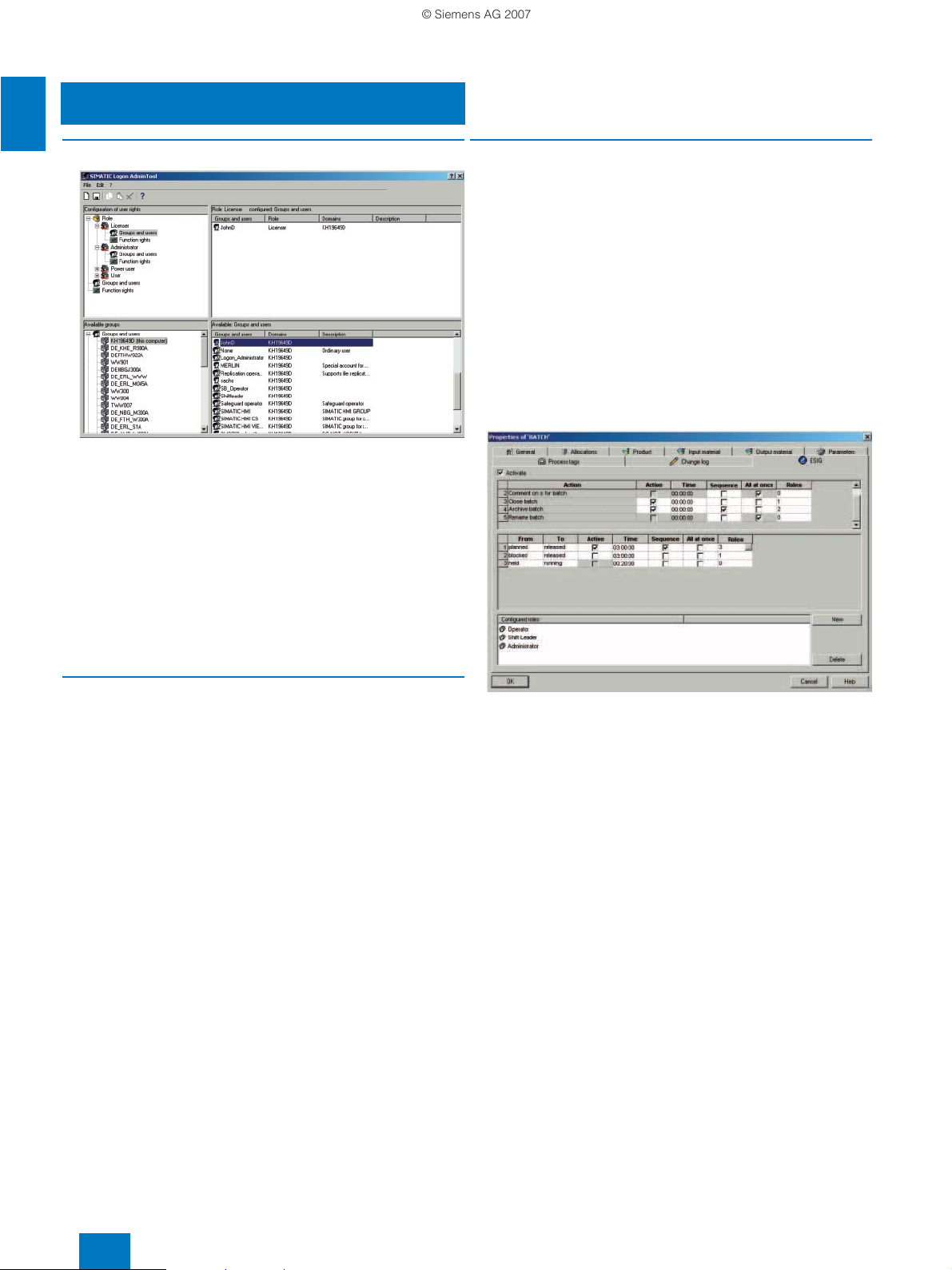

Central user management, access control and electronic

signature

SIMATIC Logon is a central user administration function with access control based on Windows 2000/XP and Windows Server

2003 for:

• System components of SIMATIC PCS 7

• Non-system components linked via an interface

It can be used to fulfill the validation requirements of 21 CFR Part

11. An electronic signature function can also be used in conjunction with SIMATIC Logon.

SIMATIC Logon Upgrade

All previous versions can be upgraded to the current version.

■

Function

SIMATIC Logon Admin Tool

Using the SIMATIC Logon Admin Tool it is possible to assign the

roles defined in the SIMATIC PCS 7 applications (e.g. Automation License Manager and SIMATIC BATCH) to the Windows

users/user groups. Administrators with the necessary Windows

administrator privileges can also use the SIMATIC Logon Admin

Tool to edit Windows users and user groups.

SIMATIC Logon Service

The login dialog of the SIMATIC Logon Service is activated when

an application is started which is managed by SIMATIC Logon.

The user receives his specific privileges after making the login,

password and domain entries. The SIMATIC Logon Service dialog for logoff, user change or password edit can be called in the

applications.

SIMATIC Electronic Signature

■

Design

The optional chipcard reader can be used for access control in

addition to the keyboard. SIMATIC Logon additionally supports

logon devices which can be operated with a Microsoft device

driver for the respective operating system (e.g. logon devices on

a USB interface). It is also possible to connect logon devices via

a separately created device-specific drive.

The number of SIMATIC Logon licenses required depends on

the number of clients/single stations that access applications for

which SIMATIC Logon is used for access protection.

SIMATIC Logon was developed for the SIMATIC PCS 7 process

control system but can also be used together with other SIMATIC

products in the context of Totally Integrated Automation (TIA),

e.g. with SIMATIC WinCC. A requirement for working together is

that user groups have already been created in the partner applications, or can be defined.

SIMATIC Logon is already integrated in the system software

of the SIMATIC PCS 7 V7.0 process control system. Separate

licenses are not required in this context.

The SIMATIC Electronic Signature means that operations cannot

be performed until enabled by previously assigned Windows

users/user groups. Users/user groups are assigned to the operations in the respective application.

At the moment this function is implemented as a system function

only on SIMATIC BATCH. However, the Electronic Signature can

be used on any products in the specific applications.

The software products listed here under "Selection and ordering

data" are only relevant to use in the TIA environment.

2/4

Siemens ST PCS 7 · November 2007

Page 19

System-neutral components

© Siemens AG 2007

■

Selection and Ordering Data Order No.

only for TIA applications

SIMATIC Logon V1.4

Single license for 1 installation

7 languages (German, English,

French, Spanish, Italian, Chinese, Japanese), executes with

Windows 2000 Professional SP4,

Windows 2000 Server, Windows

XP Professional SP2 or Windows

Server 2003 SP1 and R2

Engineering software and electronic documentation on CD

Type of delivery: CD, license key

disk, emergency key disk, certificate of license, terms and conditions

SIMATIC Logon Upgrade to

V1.4

Single license for 1 installation

7 languages (German, English,

French, Spanish, Italian, Chinese, Japanese), executes with

Windows 2000 Professional SP4,

Windows 2000 Server, Windows

XP Professional SP2 or Windows

Server 2003 SP1 and R2

Engineering software and electronic documentation on CD

Type of delivery: CD, license key

disk, emergency key disk, certificate of license, terms and conditions

Options

Chipcard reader USB

Chipcard reader with USB interface,

driver software and operating

instructions

Chipcard

Chipcard for chipcard reader;

1 card required per user;

package with 10 chipcards

B) Subject to export regulations: AL: N, ECCN: EAR99H

6ES7 658-7BX41-2YA0

6ES7 658-7BX41-2YE0

6ES7 652-0XX02-1XC0 B)

6ES7 652-0XX05-1XD1

Administration

■

Options

Access security by means of chipcard reader

A chipcard reader can be used to check a person’s authorization

to access and operate a single station or a client. This method of

access security uses the chipcard as a "key" to the operator terminals. Operations are only allowed when the card is actually inserted in the reader.

The unmistakable identification of access rights is required in

particular for plants which have to meet validation requirements.

The chipcard reader is compliant with EN 55022 Class B and

EN 50082-1 standards.

The reader is available with an USB interface for the connection

of the operator station.

Note:

The reader with USB interface can only be used with SIMATIC Logon.

2

Siemens ST PCS 7 · November 2007

2/5

Page 20

System-neutral components

© Siemens AG 2007

2

Operating system

■

Overview

Operating system upgrade

When existing SIMATIC PCS 7 systems are updated to

Version 7.0, it may also be necessary to upgrade the operating

system.

If you replace your existing hardware by new SIMATIC PCS 7

Industrial Workstations from this catalog when carrying out an

upgrade, the Windows XP Professional or Windows Server 2003

operating systems including 5 CAL (Client Access Licenses) required for SIMATIC PCS 7 V7.0 are already included in the scope

of delivery. You can also purchase individual operating systems

or additional Client Access Licenses (CAL) from Fujitsu Siemens

Computers GmbH.

Contact address for quotations and orders

Fujitsu Siemens Computers GmbH

Mr. Dominikus Besserer

Phone: +49 821 804-2434

Fax: +49 821 804-2972

E-mail: dominikus.besserer@fujitsu-siemens.com

Note:

Please note when ordering that SIMATIC PCS 7 V7.0 is operated

together with Windows XP Professional Service Pack 2 and

Windows Server 2003 Service Pack 2.

Release 2 of Windows Server 2003 has not been approved

for SIMATIC PCS 7 V7.0.

2/6

Siemens ST PCS 7 · November 2007

Page 21

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

■

Overview

We offer a range of modern, powerful SIMATIC PCS 7 Industrial

Workstations for the systems positioned in the SIMATIC PCS 7

system architecture above the controller level, e.g. for engineering, operation and monitoring (also via Internet/intranet), batch

control, route control, asset management or IT applications etc.

These are optimized for use as single station, client or server,

and can be expanded specific to the system.

Introduction

■

Design

Microsoft Windows operating system

The multi-language Microsoft Windows XP Professional or

Server 2003 operating system as well as the SIMATIC PCS 7

system software for OS or ES/OS are preinstalled on the SIMATIC PCS 7 Industrial Workstation. The Microsoft Server 2003

operating system is supplied with 5 CALs (Client Access Licenses). You can purchase further CALs from Fujitsu Siemens

Computers GmbH (see page 2/6).

Monitors and multi-VGA operation

The core component of the SIMATIC PCS 7 Industrial Workstation is a SIMATIC industrial PC without keyboard or monitor. This

basic hardware can be combined with the industrial LCD monitors recommended in the Section "HMI devices/monitors" for

SIMATIC PCS 7 in the Catalog "PC-based Automation" to suit the

operating environment and the customer’s requirements.

Using a multi-VGA graphics card, the visualization of a project/

subproject when engineering or a plant/unit in process operation

can be divided among up to 4 process monitors per operator

station with application of different views (see page 2/16).

This is supported in the SIMATIC PCS 7 workstations designed

as clients by additional hardware versions:

• SIMATIC PCS 7 OS Client RACK PC 547B WXP with multiVGA graphics card "2 Screens" and

• SIMATIC PCS 7 OS Client RACK PC 547B WXP with multiVGA graphics card "4 Screens"

Clients and single stations with a standard graphic interface

module for controlling a process monitor can also be expanded

by a multi-VGA graphics card "2 Screens" or "4 Screens" (see

page 2/16).

2

Siemens ST PCS 7 · November 2007

2/7

Page 22

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

2

Introduction

■

Options

Notes on the use of other basic hardware and non-SIMATIC software

Siemens guarantees the compatibility of hardware and software

for system configurations based on components in this catalog.

The system test confirms that the system software of the

SIMATIC PCS 7 process control system can be run on the

SIMATIC PCS 7 Industrial Workstations offered in this catalog.

Despite comprehensive tests, it cannot be excluded that the

function of a SIMATIC PCS 7 system could be disturbed or interfered with as a result of additional non-SIMATIC software, i.e.

software which has not been explicitly approved for SIMATIC

PCS 7.

If you use hardware other than the basic hardware offered in this

catalog, or additional non-SIMATIC software, this is at your own

risk. If compatibility problems arise as a result of these hardware/

Requirements on the configuration of the SIMATIC PCS 7 basic hardware

Depending on the application of the SIMATIC PCS 7 basic hardware, the following hardware requirements must be observed.

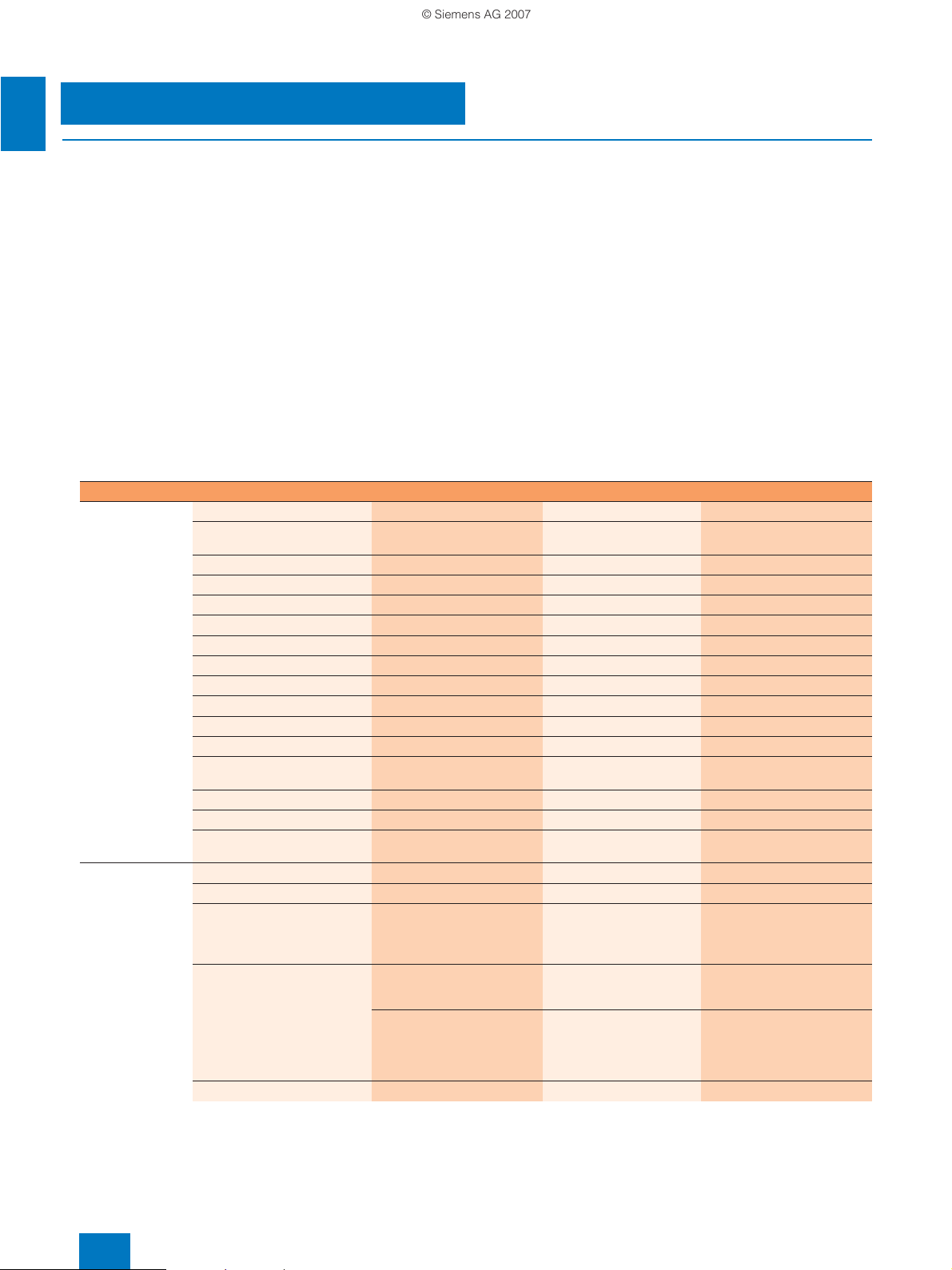

Minimum configuration of basic hardware depending on target system

Target systems

Technical

specifications of

basic hardware

Engineering station (ES) ●

Engineering station with server

operating system

OS single station ●

OS server ●

OS client ●

Central archive server ●

PCS 7 Web server ●

Maintenance station (MS) ●

BATCH single station ●

BATCH server ●

BATCH client ●

Common OS/BATCH client ●

Route Control (RC) single sta-

tion

Route Control server ●

Route Control client ●

Common OS/BATCH/Route

Control single station

Processor, clock Intel Pentium IV, 2 GHz Intel Pentium IV, 2 GHz Intel Pentium IV, 2 GHz

Main memory (RAM) 2 GB 1 GB 512 MB

Hard disk

• Storage capacity 120 GB 120 GB 80 GB

• Size of C partition 20 GB 20 GB 20 GB

Network adapter,

communications interfaces

Optical drive DVD-ROM DVD-ROM DVD-ROM

RJ45 connection (Fast Ethernet) for terminal bus (OS-LAN)

CP1613 A2 or RJ45 network

card (Fast Ethernet) with BCE

for plant bus (ES, as well as

BATCH/OS/RC on one PC)

software components, the support provided for elimination

thereof is not free of charge.

The licenses for plant bus communication via Industrial Ethernet,

i.e. for Basic Communication Ethernet (BCE) and CP 1613 communication are bound to the SIMATIC PCS 7 Industrial Workstations. Depending on the selected type of communication, the

SIMATIC PCS 7 Industrial Workstations for single stations and

servers are delivered either with a BCE license or CP 1613 license. If you are not using SIMATIC PCS 7 V7.0 on SIMATIC

PCS 7 Industrial Workstations, you additionally require a

SIMATIC PCS 7 BCE V7.0 license (Order No. 6ES7 650-1CD072YB5) for all single stations or servers which are connected to

the plant bus via a standard network card and not via a CP 1613.

●

●

●

RJ45 connection (Fast Ethernet) for terminal bus

(OS-LAN)

CP1613 or RJ45 network

card (Fast Ethernet) with

BCE for plant bus (ES, MS,

OS single station/server and

RC single station/server)

RJ45 connection (Fast Ethernet) for terminal bus (OS-LAN)

--

2/8

Siemens ST PCS 7 · November 2007

Page 23

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

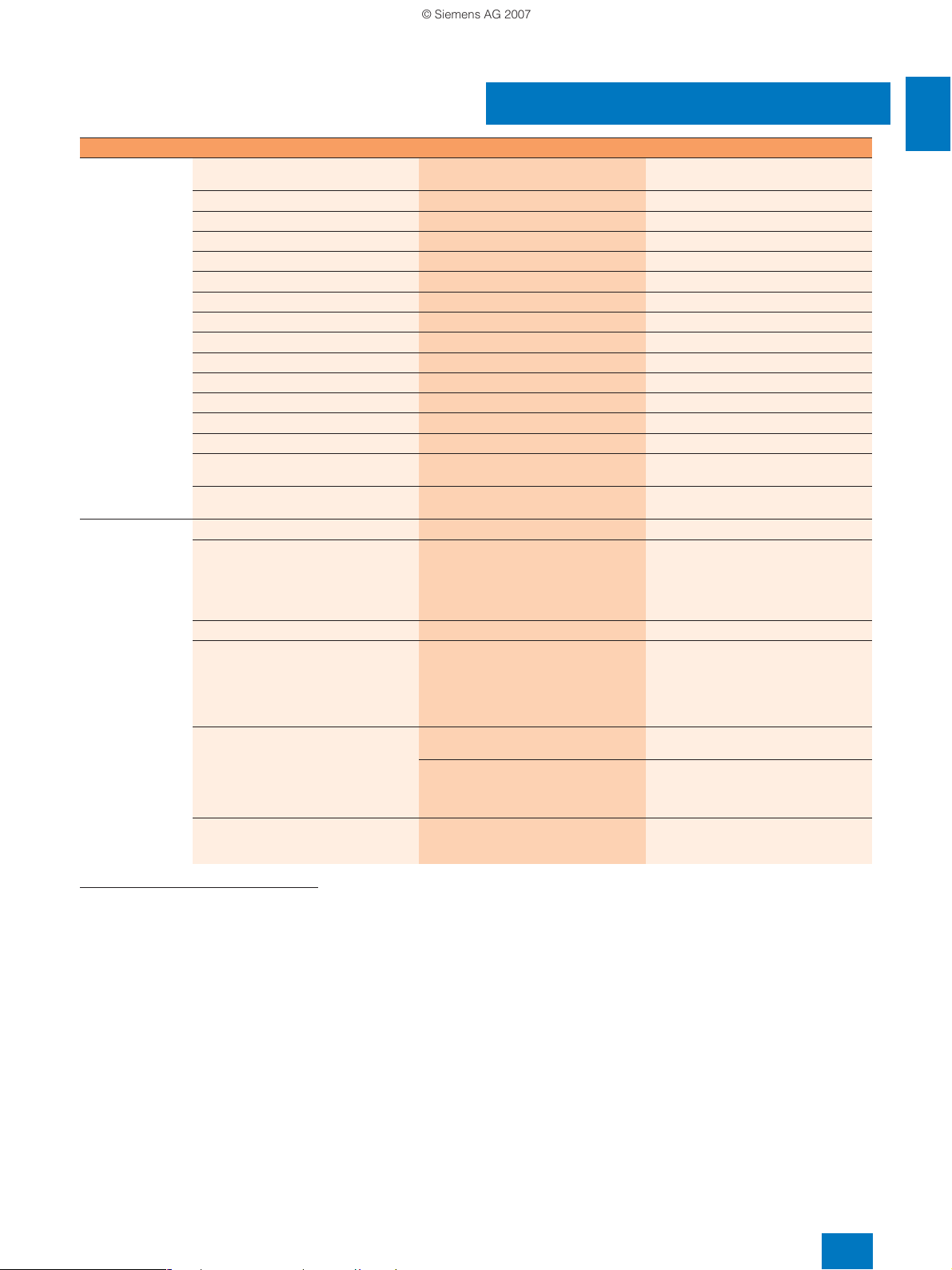

Recommended configuration of basic hardware depending on target system

Target systems

Technical

specifications of

basic hardware

Engineering station with server operating

system

OS single station ●

OS server ●

OS client ●

Central archive server ●

PCS 7 Web server ●

Maintenance station (MS) ●

BATCH single station ●

BATCH server ●

BATCH client ●

Common OS/BATCH client ●

Route Control (RC) single station ●

Route Control server ●

Route Control client ●

Common OS/BATCH/Route Control

single station

Engineering station with server operating

system

PC type SIMATIC Rack PC 547B

CPU

• Processor, clock Intel Core 2 Duo E6600 / 2 x 2.4 GHz Intel Core 2 Duo E6600 / 2 x 2.4 GHz

• Front Side Bus (FSB) 1066 MHz 1066 MHz

• Second Level Cache 4 MB 4 MB

Main memory (RAM) 2 GB 1 GB

Hard disks

• Number, storage capacity, type 2 x 250 GB SATA in RAID 1 network for

• Size of C partition 50 GB 50 GB

Network adapter,

communications interfaces

Optical drive DVD writer (DVD±RW) for engineering

server and ES/OS single stations;

1 x 250 GB SATA for client systems

RJ45 connection (Gigabit Ethernet) for

terminal bus (OS-LAN) on board

CP1613 A2 or RJ45 Ethernet network

card 10/100/1000 Mbit/s with BCE for

plant bus (ES, MS, OS single station/

server and RC single station/server)

station; DVD-ROM for all other target

systems

Introduction

●

●

●

1 x 250 GB SATA

RJ45 connection (Gigabit Ethernet) for

terminal bus (OS-LAN) on board

--

DVD-ROM

2

Additional recommendations/limitations

• It is generally of advantage for the system performance if the

technical specifications of the basic hardware, e.g. clock,

main memory or hard disk, are above the recommended values listed in the table. This particularly applies to multiproject

engineering.

• A requirement for integration of PC-based SIMATIC PCS 7 basic hardware into the PC diagnostics of the SIMATIC PCS 7

asset management is the SIMATIC PC DiagMonitor software.

This belongs to the scope of delivery of SIMATIC PCS 7 Industrial Workstations and SIMATIC PCS 7 BOX RTX/416 and cannot be executed on other systems.

• For long-term archiving with large quantity frameworks, we

recommend the PCS 7 Premium server from the Catalog

ST PCS 7.1 (Add-ons for the SIMATIC PCS 7 process control

system) as the central archive server. However, the PCS 7

Premium server cannot be integrated into the PC diagnostics

of the SIMATIC PCS 7 asset management.

• For increased data availability on the central archive server,

we recommend a RAID hard disk system (at least RAID 1).

Siemens ST PCS 7 · November 2007

2/9

Page 24

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

2

Basic hardware

■

Overview

The SIMATIC PCS 7 Industrial Workstations are based on a

SIMATIC Rack PC of type 547B which features powerful, innovative Intel PC architecture of 19" design. They are certified by the

CE marking for use in offices and industrial environments, and

comply with the specific requirements of process control technology.

■

Application

Specially optimized versions are available for operation as single stations, servers or clients. The operating system and the following ES/OS software of the SIMATIC PCS 7 process control

system are already preinstalled when delivered:

• Single station: PCS 7 Engineering Software for AS/OS (including OS Runtime software)

• Server: PCS 7 OS Software Server

• Client: PCS 7 OS Software Client

You only need the corresponding licenses in order to use the

preinstalled SIMATIC PCS 7 software.

Note:

Please note the standard installation if you use the SIMATIC

PCS 7 Industrial Workstations within the SIMATIC PCS 7 process control system for other tasks, e.g. as basic hardware for

SIMATIC BATCH, SIMATIC Route Control, StoragePlus, Central

Archive Server or PCS 7 Web Server. You can then extend or reject the existing SIMATIC PCS 7 installation, and restore it for the

operating system using the restore DVD.

The CP 1613 communication integrated in the IE version of the

SIMATIC PCS 7 Workstation for single stations and servers is a

combination of CP 1613 communications processor and

S7-1613 communications software. When using fault-tolerant

automation systems, the SIMATIC PCS 7 Workstation requires

the S7-REDCONNECT software instead of the S7-1613 communications software. The S7-REDCONNECT Upgrade is suitable

for upgrading the communications software (for ordering data,

see page 9/29).

2/10

Siemens ST PCS 7 · November 2007

Page 25

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

■

Design

2 slots for 5.25" drives

Operational display

Hard disk access

Fan/temperature status

AC power supply Extension slots:

Interfaces for keyboard,

mouse, 4 x US B 2.0,

COM1, LPT1, VGA,

Audio, Gigabit Ethernet

3.5" diskette

drive

2 x USB

Power switch

Optical drive

4 x PCI, 2 x PCIe x1,

1 x PCIe x16

The SIMATIC PCS 7 Industrial Workstations of type Rack PC

547B have a painted all-metal housing of 19" rack design which

is particularly protected against dust by a filter and pressurized

ventilation. This mechanically and electromechanically rugged

housing has a service-friendly design. The SIMATIC PCS 7 Industrial Workstations of type Rack PC 547B can be positioned

and installed horizontally or vertically. High-grade components

with high MTBF values and monitoring functions for the inner

housing temperature, fan and program execution permit reliable

24-hour continuous operation at ambient temperatures between

5 and 40 °C.

The SIMATIC PCS 7 Industrial Workstations of type Rack PC

547B have the following features:

• Motherboard with future-oriented Intel architecture for modern

Core 2 Duo processors, based on Intel 945G Express chipset

• Powerful AGP graphics with Dynamic Video Memory, sound

(Line In, Line Out, Mic.) and 10/100/1000 Mbit/s Ethernet RJ45

port integrated onboard

• PCI-Express technology (1 PCIe x16 and 2 PCIe x1 slots)

• 6 slots for drives:

- At the front: three 5.25" slots (1 occupied by DVD-ROM/

DVD-RW) and

- one 3.5" slot (occupied by diskette drive)

- Inside: two 3.5" slots (occupied by 1 hard disk on the client,

and 2 hard disks on the server and ES/OS single station)

• Increased system availability through RAID 1 with 2 SATA

hard disks and NCQ technology (Native Command Queuing)

on the server and ES/OS single station

• Second serial interface (for server) available (COM2)

Basic hardware

• Total of 6 USB 2.0 interfaces (4 at rear, 2 at front)

• High electromagnetic compatibility (CE-certified for industrial

and office environments)

• Dust protection by means of pressurized ventilation in conjunction with a front fan and a dust filter

• PC front complies with IP30 degree of protection when the

front door is closed

• Front door can be locked to prevent unauthorized access to

swap media, control elements and interfaces located at the

front

• Easy and fast installation and maintenance of PC components: access to the front drives through a hinged front door;

only 3 screws to open the device

• 3 LEDs on the front of the PC visualize the operating status:

- Power (switched on)

- HD (hard disk access)

- Status (fan and temperature monitoring)

• Suitable for easy mounting with telescopic rails

• Easy to remove fixing bracket with handles

• Card hold-down device to secure PC modules during transportation and to protect them from vibration and shock

• Power supply unit with temperature-controlled fan

• Power connector lock for the power supply cable

• SIMATIC PC DiagMonitor diagnostics software for monitoring

program execution (watchdog), temperature, fan speed, hard

disk status and system failure (heartbeat); including operating

hours counter

• Can be integrated into the system diagnostics of the SIMATIC

PCS 7 asset management by means of SIMATIC PC DiagMonitor

Restore DVD

The operating system and SIMATIC PCS 7 software are preinstalled on the basic devices. Two restore DVDs are supplied for

quickly restoring the delivered status if required.

• Restore DVD 1 only contains the operating system with default

settings for optimum PCS 7 operation

• Restore DVD 2 contains a full installation (operating system

plus ES/OS software including SQL server)

2

Siemens ST PCS 7 · November 2007

2/11

Page 26

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

2

Basic hardware

■

Technical specifications

SIMATIC PCS 7 Industrial Workstation (single station/server/client)

Design and equipment features

Design

Degree of protection to EN 60529

Motherboard

Chipset

CPU

• Processor base LGA 775

• Processor / clock

• Front Side Bus (FSB)

• Second Level Cache

Main memory (SDRAM)

•Type Dual channel DDR2-667 SDRAM

• Maximum configuration

• Standard configuration

Motherboard slots

Slots for drives

• On the front 1 x 3.5" (occupied by diskette

• On the inside

RAID controller

Hard disks

• Storage volumes / features 250 GB / 3.5" SATA, 8 MB cache,

• Single station/server

•Client

19" rack, 4 HU, for horizontal and

vertical installation, prepared for

easy mounting with telescopic

rails, 19" fixing bracket with handle, easy to remove

IP30 with front door closed; IP20

at rear

FSC D2156-S21

Intel 945G Express

Intel Core 2 Duo E6600 /

2x2.4GHz

1066 MHz

4 MB

(PC2-5300)

4 memory bases in total

(expandable to 4 GB)

Single station/server:

2GB (2x1GB)

Client: 1 GB (2 x 512 MB)

4 x PCI (max. 265 mm long)

2 x PCIe x1

1 x PCIe x16

drive)

3 x 5.25" (1 occupied by

DVD-ROM/DVD±RW)

2 x 3.5" for hard disk drives

(2 occupied with server/single

station; 1 occupied with client)

RAID controller Intel ICH7R with

Intel Storage Manager software

(onboard)

7200 rpm, NCQ

SATA-RAID 1 (mirror) with 2 hard

disks

1 SATA hard disk

■

Technical specifications (cont.)

Interchangeable drives

• Diskette drive 3.5" diskette drive 1.44 MB

• DVD drive in ES/OS single station

• DVD drive in server/client

Graphics card

• Graphics memory

• Resolutions. frequencies, colors

Mouse

Interface modules / interfaces

• OS-LAN interface module 10/100/1000 Mbit/s Ethernet

• Plant bus interface module (single

station/server), alternatives

- RACK PC 547B BCE Ethernet network card RJ45 (PCI)

- RACK PC 547B IE

•USB

•Serial

• Parallel

•Audio

•VGA

• Keyboard

•Mouse

DVD writer (DVD±RW) 5.25" ATAPI

Read

:

• DVD-ROM: single layer 16x,

dual layer 12x

• DVD-R/+R: single layer 16x,

dual layer 7x

• DVD-RW/+RW 13x

• CD-ROM/CD-R 48x, CD-RW 40x

:

Write

• DVD+R 18x, DVD+RW 8x,

DVD-R 18x, DVD-RW 6x

• DVD+R9 (DL) 8x, DVD-R DL 8x

• CD-R 48x, CD-RW 32x

DVD-ROM 5.25" ATAPI

:

Read

• DVD-ROM: single layer 16x,

dual layer 8x

• DVD+R/RW, DVD-R/RW 8x,

DVD-RAM 2x

• CD-ROM, CD-R 32x,

CD-RW 20x

Intel GMA950 graphics controller

(on board), 2D and 3D engine

integrated in chipset, up to

2048 x 1536 pixels with 75 Hz

image refresh rate

Dynamic video memory technology (up to 224 MB)

• Up to 800 x 600 at 120 Hz, 32 bit

colors

• Up to 1280 x 1024 at 100 Hz,

32 bit colors

• Up to 2048 x 1536 at 75 Hz,

16 bit colors

Optical mouse

(RJ45) on board,

Broadcom BCM5751 controller

10/100/1000 Mbit/s

CP 1613 A2 communications

processor

6 x USB 2.0, 4 x at rear and 2 x at

front, high current in each case

Server: 1 x COM1 and 1 x COM2

(each V.24), 9-contact Sub-D

connector

Single station/client: 1 x COM1

(V.24), 9-contact Sub-D connector

1 x LPT1 (25-pin, EPP and ECP)

1 x Line In; 1 x Micro In; 1 x Line

Out (2 x 0.5 W/8 Ω); Realtek

ALC262 Audio Codec

1 x Sub-D socket, 15-contact

1 x PS/2

1 x PS/2

2/12

Siemens ST PCS 7 · November 2007

Page 27

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

■

Technical specifications (cont.)

Operating systems and diagnostics software

ES/OS single station/client

Server

System-tested SIMATIC industrial

software

Monitoring/diagnostics functions

Watchdog

Temperature

Fans

Displays

Safety

Protection class

Safety directives

Noise level

Operation < 45 dB (A) to DIN 45635

Electromagnetic compatibility (EMC)

Emitted interference (AC)

Immunity to conducted interference

on the supply lines

Immunity to interference on signal

lines

Immunity to static discharge

Immunity to high-frequency

irradiation

Magnetic field

Microsoft Windows XP

Professional MUI, 6 languages,

selectable: German, English,

French, Italian, Spanish, Chinese

Microsoft Windows Server 2003

(standard edition) MUI,

6 languages, selectable:

German, English, French, Italian,

Spanish, Chinese

SIMATIC PC DiagMonitor

• Monitoring of program execution

• Monitoring time adjustable in the

software

Violation of permissible operating

temperature

Speed monitoring for:

•Front fan

• Processor fan

• Power supply fan

Front LEDs

• Power (device switched on)

• HD (access to hard disk)

• Status (fan/temperature

monitoring)

Protection class I compliant with

IEC 61140

EN 60950-1;

UL60950;

CSA C22.2 No. 60950-00

EN 55022 Class B; FCC Class A

EN 61000-3-2 Class D,

EN 61000-3-3

± 2 kV (to IEC 61000-4-4, burst)

± 1 kV (to IEC 61000-4-5,

symmetrical surge)

± 2 kV (to IEC 61000-4-5,

unsymmetrical surge)

± 2 kV (to IEC 61000-4-4, burst,

length > 3 m)

± 2 kV (to IEC 61000-4-5, symmetrical surge, length > 30 m)

± 4 kV, contact discharge

(to IEC 61000-4-2)

± 8 kV, atmospheric discharge

(to IEC 61000-4-2)

1 V/m, 2 to 2.7 GHz

10 V/m, 80 MHz to 1 GHz and

1.4 to 2 GHz, 80% AM

(to IEC 61000-4-3)

10 V, 10 kHz to 80 MHz

(to IEC 61000-4-6)

100 A/m, 50 Hz/60 Hz

(to IEC 61000-4-8)

■

Technical specifications (cont.)

Climatic conditions

Temperature

• Operation

• Storage/transport

Relative humidity

• Operation

• Storage/transport

Mechanical environmental conditions

Vibrations

• Operation

• Storage/transport

Shock

• Operation

• Storage/transport

Approvals

CE living accommodation (emitted

interference)

CE industrial areas (noise immunity)

cULus

Basic hardware

Tested according to

IEC 60068-2-2, IEC 60068-2-1,

IEC 60068-2-14

+5 ... +40 °C (no DVD writer

operation),

+5 ... +35 °C (without limitation)

CPU up to 65 W power loss

Gradient: max. 10 °C/h,

no condensation

-20 ... +60 °C

Gradient: max. 20 °C/h,

no condensation

Tested according to

IEC 60068-2-78, IEC 60068-2-30

5 ... 80% at 25 °C

(no condensation)

Gradient: max. 10 °C/h,

no condensation

5 ... 95% at 25 °C

(no condensation)

Gradient: max. 20 °C/h,

no condensation

Tested according to

IEC 60068-2-6, 10 cycles

20 ... 58 Hz, amplitude 0.015 mm;

58 ... 200 Hz: 2 m/s²

Note: No mechanical interferences are tolerable when writing

with CD/DVD writers.

5 ... 8.51 Hz, amplitude 3.5 mm;

8.51 ... 500 Hz: 9.8 m/s²

Tested according to

IEC 60068-2-27

Half sine: 9.8 m/s², 20 ms,

100 shocks per axis

Note: No mechanical interfer-

ences are tolerable when writing

with CD/DVD writers.

Half sine: 250 m/s², 6 ms,

1000 shocks per axis

EN 61000-6-3:2001

EN 61000-6-2:2005

60950-1

2

Siemens ST PCS 7 · November 2007

2/13

Page 28

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

2

Basic hardware

■

Technical specifications (cont.)

Power supply

Nominal supply voltage

Frequency

Short-term voltage dip

Power consumption (with 210 W

secondary)

AC input current

Max. current output

Dimensions and weights

Overall dimensions in mm

(W x H x D)

Weight

■

Selection and Ordering Data Order No.

SIMATIC PCS 7 Industrial Workstation, single station version

SIMATIC PC in 19" rack, without

monitor, keyboard and printer;

Core 2 Duo E6600 2.4 GHz processor, 2 GB RAM (2 x 1 GB),

sound, SATA-RAID 1 with 2 hard

disks of 250 GB, graphics controller on board with dynamic

video memory, DVD writer

DVD±RW IDE, 3.5" diskette drive,

optical mouse, Ethernet

10/100/1000 Mbit/s (RJ45) on

board for connection to OS-LAN;

SIMATIC PC DiagMonitor diagnostics software and 2 restore

DVDs;

SIMATIC PCS 7 ES/OS software

preinstalled

Windows XP Professional MUI

operating system

(German, English, French, Italian,

Spanish, Chinese)

• SIMATIC PCS 7 ES/OS 547B

BCE WXP

Connection to plant bus with

Ethernet network card RJ45

(PCI) 10/100/1000 Mbit/s and

Basic Communication Ethernet

(BCE) for up to 8 automation

systems (not fault-tolerant

systems)

• SIMATIC PCS 7 ES/OS 547B

IE WXP

Connection to plant bus with

CP 1613 A2 communications

processor

100 to 240 V AC, wide-range

(90 to 264 V AC)

50 ... 60 Hz (minimum 47 to

maximum 63 Hz, sinusoidal)

16 ms at 0.85 of nominal supply

voltage (max. 10 events per hour;

recovery time min. 1 s)

310 W (approx 68% efficiency)

Continuous current up to 7 A (up

to 30 A for 5 ms during startup)

•+3.3V: 24 A

•+5V: 26 A

(total power for +3.3 V and +5 V

max. 190 W)

• +12 V: 15 A

• -12 V: 0.2 A

aux

: 2 A

•+5V

433.5 x 176.5 x 445.5

16 ... 23 kg

6ES7 650-0NF07-0YX0 D)

6ES7 650-0NF07-0YX1 D)

■

Selection and Ordering Data Order No.

SIMATIC PCS 7 Industrial Workstation, server version

SIMATIC PC in 19" rack, without

monitor, keyboard and printer;

Core 2 Duo E6600 2.4 GHz processor, 2 GB RAM (2 x 1 GB),

sound, SATA-RAID 1 with 2 hard

disks of 250 GB, graphics controller on board with dynamic

video memory, DVD-ROM IDE,

3.5" diskette drive, optical mouse,

Ethernet 10/100/1000 Mbit/s

(RJ45) on board for connection to

OS-LAN;

SIMATIC PC DiagMonitor diagnostics software and 2 restore

DVDs;

SIMATIC PCS 7 OS software for

server preinstalled

Windows Server 2003 MUI

operating system

(German, English, French, Italian,

Spanish, Chinese)

• SIMATIC PCS 7 OS Server

547B BCE SRV03

Connection to plant bus with

Ethernet network card RJ45

(PCI) 10/100/1000 Mbit/s and

Basic Communication Ethernet

(BCE) for up to 8 automation

systems (not fault-tolerant

systems)

• SIMATIC PCS 7 OS Server

547B IE SRV03

Connection to plant bus with

CP 1613 A2 communications

processor

SIMATIC PCS 7 Industrial Workstation, client version

SIMATIC PC in 19" rack, without

monitor, keyboard and printer;

Core 2 Duo E6600 2.4 GHz processor, 1 GB RAM (2 x 512 MB),

SATA hard disk of 250 GB, graphics controller on board with

dynamic video memory, DVDROM IDE, 3.5" diskette drive, optical mouse, Ethernet

10/100/1000 Mbit/s (RJ45) on

board for connection to OS-LAN;

SIMATIC PC DiagMonitor diagnostics software and 2 restore

DVDs;

SIMATIC PCS 7 OS software for

client preinstalled

Windows XP Professional MUI

operating system

(German, English, French, Italian,

Spanish, Chinese)

• SIMATIC PCS 7 OS Client 547B

WXP

- without multi-VGA graphics

card

- with Multi-VGA graphics card

"2 Screens"

- with Multi-VGA graphics card

"4 Screens"

D) Subject to export regulations: AL: N, ECCN: 5D992B1

6ES7 650-0NH07-0YX0 D)

6ES7 650-0NH07-0YX1 D)

6ES7 650-0NG07-0YX0 D)

6ES7 650-0NG07-0YA0 D)

6ES7 650-0NG07-0YB0 D)

2/14

Siemens ST PCS 7 · November 2007

Page 29

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

■

Selection and Ordering Data Order No.

Additional and expansion components

Memory modules for expanding

the main memory

• 512 MB memory expansion for

SIMATIC Rack PC 547B

(1 x 512 MB), DDR2-667

SDRAM

• 1 GB memory expansion for

SIMATIC Rack PC 547B

(2 x 512 MB),

DDR2-667 SDRAM,

kit for dual-channel technology

• 2 GB memory expansion for

SIMATIC Rack PC 547B

(2 x 1 GB), DDR2-667 SDRAM,

kit for dual-channel technology

SIMATIC PC keyboard

(USB connection)

• International key assignment 6ES7 648-0CB00-0YA0

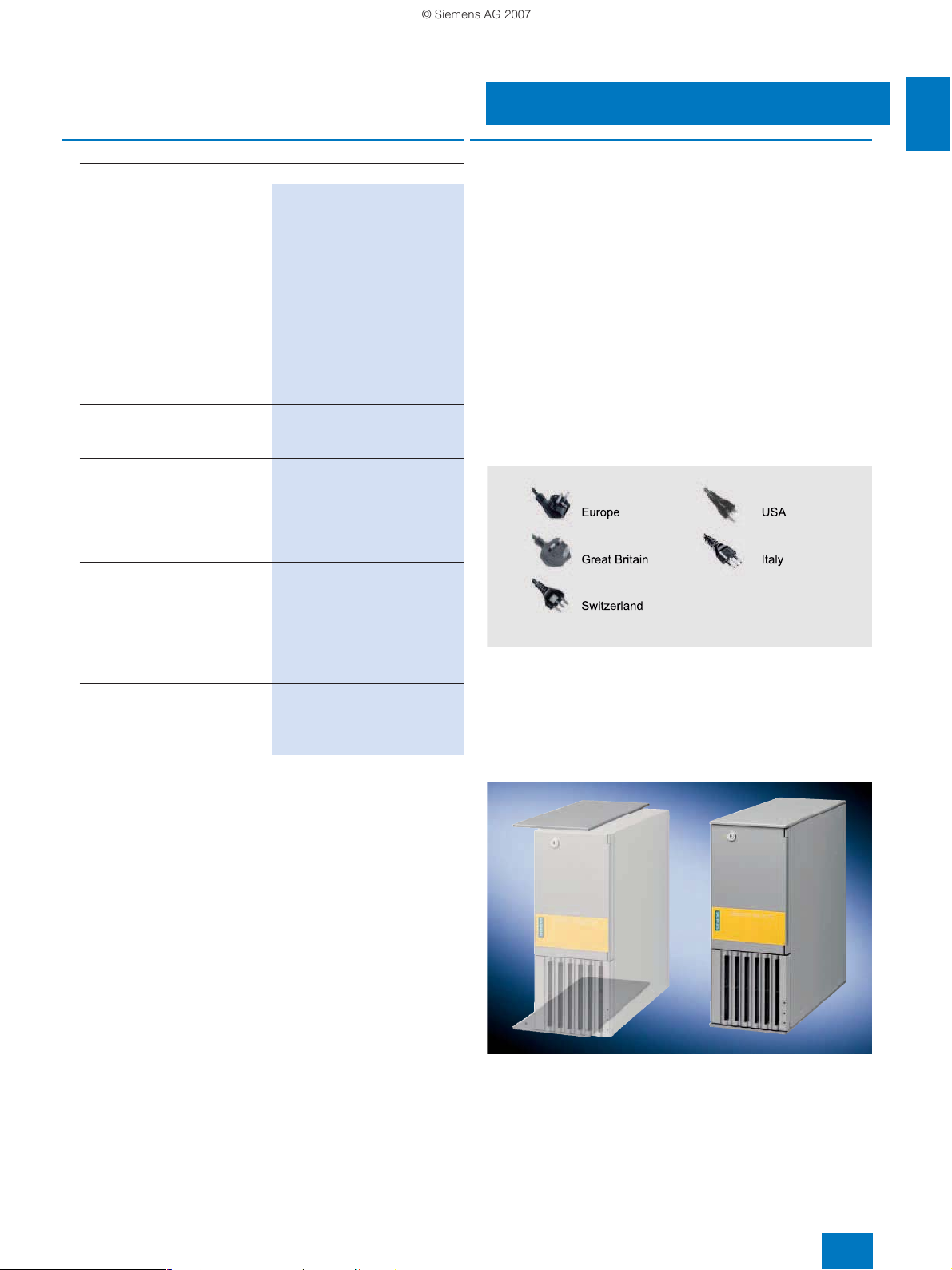

Tower kit for SIMATIC PCS 7

Industrial Workstations

based on Rack PC 547B and

IL 43

• Tower kit for conversion of a

Rack PC into an industrial

To we r P C

3-m power cable for Rack PC

• For Great Britain 6ES7 900-0BA00-0XA0

• For Switzerland 6ES7 900-0CA00-0XA0

•For USA 6ES7 900-0DA00-0XA0

•For Italy 6ES7 900-0EA00-0XA0

•For China 6ES7 900-0FA00-0XA0

SIMATIC NET S7-REDCONNECT

Upgrade

For communication with faulttolerant AS systems, see page

9/29

B) Subject to export regulations: AL: N, ECCN: EAR99H

1)

The PCS 7 systems are delivered as standard with a "European power

cable". The country-specific versions listed above are required for some

countries.

6ES7 648-2AF30-0HA0 B)

6ES7 648-2AF40-0HB0 B)

6ES7 648-2AF50-0HB0 B)

6ES7 648-1AA00-0XC0

1)

Basic hardware

■

Accessories

Keyboards

The SIMATIC PCS 7 Industrial Workstations are delivered without

a keyboard. The SIMATIC PC keyboard with USB connection, for

example, is suitable for process operation with SIMATIC PCS 7.

The SIMATIC PC keyboard is a standard MF2 keyboard with

105 keys, without additional special functions. It combines the

convenience of an office keyboard with the EMC of an industrial

device. Standards/approvals: UL 1950, CSA C22.2 No. 950,

FCC Part 15, subpart B, class B, VDE-GS (EN 60950/ZHI/618),

CE, C-TICK-Mark (Australia).

Power supply cable for Rack PC

The SIMATIC PCS 7 systems are delivered as standard with a

"European power cable". This can be used in Germany, France,

Spain, Netherlands, Belgium, Sweden, Austria and Finland.

The country-specific versions listed in the Ordering data are required for other countries. The following picture shows the appearance of the power supply plugs:

Country-specific power supply cables for Rack PC

Tower Kit

A Tower Kit for converting a SIMATIC PCS 7 Industrial Workstation of Rack PC design into an industrial Tower PC can be ordered as an option. The Tower Kit is suitable for SIMATIC PCS 7

Industrial Workstations based on the Rack PC types 547B and

IL 43.

2

Siemens ST PCS 7 · November 2007

2/15

Page 30

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

2

Multi-VGA graphics cards

■

Overview

The SIMATIC PCS 7 industrial workstations are supplied as standard with a graphics interface module for controlling one process monitor. The multi-VGA graphics cards "2 Screens" and

"4 Screens" are available for multi-channel mode with 2 or up to

4 process monitors.

Using a multi-VGA graphics card, the visualization of a

project/subproject when engineering or a plant/unit in process

operation can be divided among up to 4 process monitors per

operator station with application of different views. These

project/plant sections can all be operated using just one keyboard and one mouse. Compared to single-channel mode, it is

thus possible to enormously improve the efficiency, convenience

and ergonomics of engineering and process control.

■

Technical specifications

Multi-VGA graphics cards

Memory

• Graphics card "2 Screens"

• Graphics card "4 Screens"

Clock

Max. analog resolution per channel

Max. digital resolution per channel

Electromagnetic compatibility

(EMC)

• Emitted interference EN 55022 Class B

• Noise immunity

Slot requirement

■

Selection and Ordering Data Order No.

Multi-VGA Graphics Card

"2 Screens"

for operating 2 process monitors

on 1 station

Type of delivery:

Dual graphics card, driver CD,

manual, 1 dual DVI cable for

2 digital outputs, 2 adapters for

VGA outputs

Multi-VGA Graphics Card

"4 Screens"

for operating 4 process monitors

on 1 station

Type of delivery:

Quad graphics card, driver CD,

manual, 2 dual DVI cables for

4 digital outputs, 4 adapters for

VGA outputs

B) Subject to export regulations: AL: N, ECCN: EAR99H

32 MB DDRAM per output

2 x 32 MB

4 x 32 MB

360 MHz integrated RAMDAC

2048 x 1536 at 24 bpp and 85 Hz

1280 x 1024

EN 50082

1 PCI slot

6ES7 652-0XX03-1XE0 B)

6ES7 652-0XX03-1XE1 B)

2/16

Siemens ST PCS 7 · November 2007

Page 31

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

■

Overview

Operating devices

In addition to the mouse and SIMATIC PC keyboard described

as operating devices in the Section "Basic hardware", you can

find further devices such as fingerprint mouse, trackball or

Ex-PC operator panel in the Catalog ST PCS 7.1 (Add-ons for

the SIMATIC PCS 7 process control system).

Process monitors

We recommend the SCD 19101-D industrial monitor (LCD color

monitor) for the SIMATIC PCS 7 process control system.

In addition, industrial LCD monitors with IP65 degree of protection (front) are available for installation in desks, control cabinets

or 19" racks. These are available from:

• the Catalog ST PC "PC-based Automation" or

• the A&D Mall/CA 01 under "Automation Systems – PC-based

Automation - Expansion Components - Industrial LCD Monitors"

■

Benefits

Outstanding characteristics of the SCD 19101-D LCD monitor

include:

7 Rugged, fail-safe and long-life industrial design:

- High resistance to shock and vibration

- Extremely high electromagnetic compatibility

- Anti-glare and hardened mineral glass pane for high

mechanical protection

- IP20 degree of protection

- Complies with CE standard "Industry"

7 Modern design with exceptional ergonomics:

- Sharp and high-contrast picture with uniform brightness

- No flickering

- Large reading angle up to 170° horizontal and vertical

- Automatic picture adjustment (Auto Adjust)

7 No X-rays

7 Low energy consumption and heat development

7 Small space requirement and low weight

7 Configuration using on-screen display (OSD)

7 Long service life

Operator panels/monitors

■

Technical specifications

Monitor SCD 19101-D

Screen

Line frequency

Image refresh rate

Power supply

Dimensions (WxHxD) in mm

Degree of protection

Weight

Detailed technical data can be found in

• Catalog ST PC "PC-based Automation" or

• the Mall/CA 01 at "Automation systems - Monitors, printers and

input devices for industry"

■

Selection and Ordering Data Order No.

SCD 19101-D industrial LCD

monitor

(same design as SCD 1898-I)

Desktop unit, 230 V AC,

48 cm (19") screen diagonal,

horizontal frequency 50...97 kHz,

IP20 degree of protection

Additional and expansion components

Connection cable

• Video + Touch, 1.8 m long 6AV8 107-0BA00-0AA0

• Video + Touch, 5 m long 6AV8 107-0DA00-0AA0

• Video + Touch, 10 m long 6AV8 107-0FA00-0AA0

• Video, connecting cable 20 m

long

B) Subject to export regulations: AL: N, ECCN: EAR99H

19" (48 cm) TFT color monitor,

1280 x 1024 pixels,

16 million colors

50 ... 97 kHz

30 ... 100 Hz

110/230 V AC

465 x 444 x 91 (depth of

stand 240)

IP20

Approx. 10 kg

6GF6 220-1DA01 B)

6AV8 107-0HB00-0AA0

2

Siemens ST PCS 7 · November 2007

2/17

Page 32

System-neutral components

© Siemens AG 2007

SIMATIC PCS 7 Industrial Workstation

2

Special configurations

■

Overview

The SIMATIC PCS 7 Industrial Workstations offered in the catalog section "Basic hardware" already cover the majority of applications. In the case of special system requirements, particularly

if several supplementary/expansion components such as multiVGA graphics card, signal module or memory expansion have

to be integrated at the same time, we also offer the possibility for

ordering completely assembled special configurations of these

SIMATIC PCS 7 Industrial Workstations.

A special SIMATIC PCS 7 Industrial Workstation can be compiled interactively on the Internet using a configurator, and its

Order No. generated in the process. This can subsequently be

transferred to the shopping cart for ordering.

Configurator in the A&D Mall

The configurator "Special SIMATIC PCS 7 Industrial Workstations" is integrated in the catalog & online ordering system "A&D

Mall" (www.siemens.com/automation/mall). It can be accessed

there in two manners:

Selection using quick link "Configuration list"

A selection window in which all available configurators are cate-

gorized according to technical criteria is opened when you click

the quick link "Configuration list" on the right side of the A&D Mall

(see figure). You can find the configurator "Special SIMATIC

PCS 7 Industrial Workstations" here in the category "Process

automation".

Selection using the "Siemens A&D product tree"

If you click the link "Products" at the second position in the hori-

zontal primary navigation (see blue area at the top in the figure),

the "Siemens A&D product tree" is displayed on the left. Navigate there from "Process automation" via "Process control systems", "SIMATIC PCS 7 V7.0" and "SIMATIC PCS 7 Industrial

Workstations" on to "Special configurations". Select the

"Configurators" tab here, and then the configurator "Special

SIMATIC PCS 7 Industrial Workstations".

2/18

Siemens ST PCS 7 · November 2007

Page 33

Starter systems

© Siemens AG 2007

3/2 SIMATIC PCS 7 BOX

3/2 Introduction

3/4 SIMATIC PCS 7 BOX RTX

3/8 SIMATIC PCS 7 BOX 416

3/13 Runtime Basic Packages

Siemens ST PCS 7 · November 2007

Page 34

3

© Siemens AG 2007

Starter systems

SIMATIC PCS 7 BOX

Introduction

■

Overview

SIMATIC PCS 7 BOX 416

with WinAC Slot 416

hardware controller

SIMATIC PCS 7 BOX RTX with

WinAC RTX software controller

SIMATIC PCS 7 AS RTX with

WinAC RTX software controller

Runtime system with

AS functionality

Scalable automation performance in the bottom performance range of

SIMATIC PCS 7

(for SIMATIC PCS 7 AS RTX, see page 10/4)

SIMATIC PCS 7 BOX systems are compact and rugged industrial PCs as low-price starter solutions for process automation

with SIMATIC PCS 7. They are available in two versions:

• SIMATIC PCS 7 all-in-one system

with functionality for automation (AS), HMI (OS) and engineering (ES)

• SIMATIC PCS 7 Runtime system

with AS and OS functionality

Expanded by distributed process I/Os on the PROFIBUS, each

version represents a complete process control system for small

applications.

■

Application

The SIMATIC PCS 7 BOX starter systems can be used for various

applications:

• Small production applications

• Enclosed subprocesses (package units)

• Automation of a laboratory or test center

As a fully adequate member of the SIMATIC PCS 7 range, they

work with the PCS 7 standard system software, are scalable, and

can be expanded without destroying the compatibility. However,

the engineering and runtime licenses for AS and OS are limited

to 2000 POs (process objects).

Use as asset management station

SIMATIC PCS 7 BOX can be incorporated into the PC diagnostics of the SIMATIC PCS 7 asset management using the SIMATIC

PC DiagMonitor software. Equipped as an all-in-one system with

software licenses for SIMATIC PDM and SIMATIC PCS 7 asset

management, they are additionally suitable for use as a maintenance station. For further information, see Chapter "Asset management".

Runtime systems with AS and

OS functionality

or all-in-one systems

with AS, OS and ES functionality

■

Design

Two SIMATIC PCS 7 BOX systems with different performances

are currently available:

• SIMATIC PCS 7 BOX RTX with WinAC RTX software controller

• SIMATIC PCS 7 BOX 416 with WinAC Slot 416 hardware controller

Together with the compact SIMATIC PCS 7 AS RTX Microbox automation system (see page 10/4), these allow finer scaling of the

automation performance in the bottom performance range of

SIMATIC PCS 7. It is then possible to react more variably to individual customer requirements with small applications. With regard to the achievable quantity framework, the SIMATIC PCS 7

BOX systems are approximately comparable with the following

standard automation systems:

• SIMATIC PCS 7 BOX 416 with an AS 416

• SIMATIC PCS 7 BOX RTX with an AS 414

In a direct comparison of the two systems, the SIMATIC PCS 7

BOX RTX impresses primarily due to the following advantages:

• Low price

• Very fast program execution

Particular advantages of the SIMATIC PCS 7 BOX 416 are:

• High availability

• Support of changes to the configuration during runtime (CiR)

through the stand-alone WinAC Slot CPU

ES

SIMATIC PCS 7 BOX

Stand-alone operation using example of a SIMATIC PCS 7 BOX 416

PDM OS

24 V DC

CPU 416-2

DP MPI/DP

CP 5611

onboard

PROFIBUS DP PROFIBUS MPI/DP

DP/PA

link

PROFIBUS PA

3/2

Siemens ST PCS 7 · November 2007

Page 35

ES

© Siemens AG 2007

Ethernet

onboard

Plant bus

PDM OS

CP 5611

Ethernet

onboard

onboard

PROFIBUS

OS-LAN (Terminal bus)

CPU 416-2

DP MPI/DP

24 V DC

DP/PA

link

OS

server

SIMATIC PCS 7 BOX

PROFIBUS MPI/DP

PROFIBUS PA

OS clients

Starter systems

SIMATIC PCS 7 BOX

Introduction

SIMATIC PCS 7 BOX systems can be operated in stand-alone

mode and also in the system network with other SIMATIC PCS 7