Page 1

Automation and Drives - SCE

Training Document

for Comprehensive Automation Solutions

Totally Integrated Automation (T I A)

MODULE F6

Operator Control

with

WinCC flexible 2005

and

TP177B

T I A Training Document Page 1 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 2

Automation and Drives - SCE

This document has been written by Siemens AG for training purposes for the project entitled "Siemens

Automation Cooperates with Education (SCE)".

Siemens AG accepts no responsibility for the correctness of the contents.

Transmission, use or reproduction of this document is only permitted within public training and educational

facilities. Exceptions require the prior written approval by Siemens AG (Michael Knust

michael.knust@siemens.com

).

Offenders will be liable for damages. All rights, including the right to translate the document, are reserved,

particularly if a patent is granted or utility model is registered.

We would like to thank the following: Michael Dziallas Engineering, the teachers at vocational schools, and all

others who helped to prepare this document.

T I A Training Document Page 2 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 3

Automation and Drives - SCE

1.

PREFACE.....................................................................................................................................................6

2. OPERATOR CONTROL WITH WINCC FLEXIBLE ....................................................................................8

2.1 SYSTEM DESCRIPTION .................................................................................................................................8

2.2 INSTALLATION/DEINSTALLATION ...................................................................................................................9

2.2.1 System Prerequisites.........................................................................................................................9

2.2.2 Installing WinCC flexible ..................................................................................................................10

2.2.3 Deinstalling WinCC flexible .............................................................................................................10

2.2.4 Totally Integrated Automation..........................................................................................................11

3. PROJECT DESCRIPTION .........................................................................................................................12

3.1 HARDWARE CONFIGURATION .....................................................................................................................12

3.2 PLANT DESCRIPTION .................................................................................................................................13

3.3 TASK DEFINITION.......................................................................................................................................14

3.4 CONFIGURATION........................................................................................................................................14

4 STEP7 PROJECT "COLOR MIXING PLANT“ .............................................................................................15

4.1 NEW PROJECT ..........................................................................................................................................15

4.2 HARDWARE CONFIGURATION .....................................................................................................................17

4.3 LIBRARY OF THE COLOR MIXING PLANT ......................................................................................................18

4.4 ASSIGNMENT LIST .....................................................................................................................................20

4.5 CONTROL PROGRAM .................................................................................................................................21

4.5.1 Function Block FB1..........................................................................................................................21

4.5.2 Variable Declaration ........................................................................................................................22

4.5.3 Inserting Panel Inputs FB5 as Multi Instance Block from the Program Library...............................23

4.5.4 Tank Block FB10 .............................................................................................................................26

4.5.5 Automatic Program Sequence FB15 ...............................................................................................29

4.5.6 Manual Operation FC20 ..................................................................................................................30

4.5.7 Mixer Motion FB25...........................................................................................................................31

4.5.8 Automatic and Manual Lamps .........................................................................................................31

4.5.9 Organization Block OB1 ..................................................................................................................32

4.6 LOADING TO THE CPU ...............................................................................................................................33

4.7 PROGRAM TEST ........................................................................................................................................33

5 SIMATIC HMI STATION ................................................................................................................................34

5.1 INSERTING AN HMI STATION ......................................................................................................................34

5.2 CONFIGURING THE HMI STATION ...............................................................................................................36

5.3 CHECKING THE CONNECTION WITH NETPRO ...............................................................................................37

5.4 OPENING THE HMI STATION.......................................................................................................................38

6 WINCC FLEXIBLE ENGINEERING SYSTEM ..............................................................................................39

6.1 PROGRAM INTERFACE................................................................................................................................39

6.1.1 Menus and Symbol Bars..................................................................................................................40

6.1.2 Work Space .....................................................................................................................................41

6.1.3 Project Window................................................................................................................................42

6.1.4 Property Window .............................................................................................................................43

T I A Training Document Page 3 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 4

Automation and Drives - SCE

6.1.5 Tool Window ....................................................................................................................................44

6.1.6 Output Window ................................................................................................................................45

6.1.7 Object Window.................................................................................................................................45

6.1.8 Resetting the Arrangement..............................................................................................................45

6.2 CONFIGURING DISPLAYS............................................................................................................................ 46

6.2.1 Display Template .............................................................................................................................47

6.2.2 Generating Displays ........................................................................................................................51

6.2.3 Inserting Graphic Displays...............................................................................................................52

6.2.4 Configuring Display Changes ..........................................................................................................55

6.3 SETTINGS AT THE TOUCH PANEL TP177B COLOR PN/DP ...........................................................................58

6.3.1 Setting the Date and the Time of Day .............................................................................................59

6.3.2 Setting the MPI Address ..................................................................................................................60

6.3.3 Setting the Profibus DP Address .....................................................................................................61

6.3.4 Assigning the Ethernet Address ......................................................................................................61

6.3.5 Setting the Transfer Properties........................................................................................................62

6.3.6 Transfer Mode .................................................................................................................................62

6.4 CHECKING FOR CONSISTENCY ...................................................................................................................63

6.5 TRANSFER SETTINGS AND DATA TRANSFER UNDER WINCC FLEXIBLE ..........................................................63

6.6 BUTTON END ...........................................................................................................................................65

6.7 CONFIGURING A CONNECTION....................................................................................................................67

7 DISPLAY AND OPERATOR OBJECTS .......................................................................................................68

7.1 LEVELS .....................................................................................................................................................68

7.2 BASIC OBJECTS ........................................................................................................................................69

7.3 EXPANDED OBJECTS .................................................................................................................................71

8 DISPLAY AND OPERATOR OBJECTS IN THE PROJECT "COLOR MIXING PLANT“............................72

8.1 CONFIGURING DISPLAY AND OPERATOR OBJECTS IN THE PICTURE“TANK1“..................................................72

8.1.1 Configuring the Bar Display.............................................................................................................72

8.1.2 Configuring the Linear Regulator.....................................................................................................76

8.1.3 Configuring a Button ........................................................................................................................79

8.1.4 Representing the Valve Function in Color.......................................................................................83

8.1.5 Testing the Picture “Tank1“ in Runtime ...........................................................................................86

8.2 CONFIGURING THE DISPLAY AND OPERATOR OBJECTS IN THE PICTURES “TANK2“ AND “TANK3“....................87

8.3 OBJECTS IN THE BASIC DISPLAY.................................................................................................................89

8.3.1 Tank Levels and Valve Representations.........................................................................................89

8.3.2 Configuring the Mixer Motor ............................................................................................................90

8.3.3 Configuring the Manual Mode for the Outflow Valve of the Container ........................................... 95

8.3.4 Switching Operating Modes.............................................................................................................97

8.3.5 Configuring the Fill Entries...............................................................................................................99

8.3.6 Configuring the “START“ Button....................................................................................................101

8.3.7 Configuring the Mixer Motion.........................................................................................................103

8.4 CONFIGURING OBJECTS IN THE PERMANENT WINDOW...............................................................................107

8.4.1 Configuring Text Fields..................................................................................................................107

8.4.2 Configuring the Output Fields........................................................................................................108

9 CONFIGURING MESSAGES ......................................................................................................................111

9.1 ANALOG MESSAGES ................................................................................................................................111

T I A Training Document Page 4 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 5

Automation and Drives - SCE

9.2 BIT MESSAGES........................................................................................................................................111

9.3 MESSAGE WINDOW .................................................................................................................................112

9.4 MESSAGE INDICATOR ..............................................................................................................................114

9.5 TESTING THE MESSAGE CONFIGURATION IN RUNTIME ...............................................................................115

10 CONFIGURING RECIPES .......................................................................................................................116

10.1 ADDING RECIPES .................................................................................................................................116

10.2 SPECIFYING DATA SETS.......................................................................................................................117

10.3 GENERATING THE PICTURES “RECIPE INPUT“ AND “RECIPE SELECTION“ .................................................117

10.3.1 Configuring the Picture “Recipe Input“ ..........................................................................................117

10.3.2 Configuring the picture "Recipe Selection“....................................................................................119

10.3.3 Configuring Buttons for Display Change .......................................................................................120

10.4 SELECTING RECIPES IN RUNTIME..........................................................................................................122

10.5 Entering New Recipes in Runtime.................................................................................................123

11 CONFIGURING USER MANAGEMENT..................................................................................................124

11.1 SETTING UP THE USER GROUP .............................................................................................................124

11.2 SETTING UP USERS .............................................................................................................................125

11.3 ASSIGNING AUTHORIZATIONS ...............................................................................................................126

11.3.1 Protecting the Start Button.............................................................................................................126

11.3.2 Protecting Data Selection ..............................................................................................................127

11.3.3 Protecting Recipe Input .................................................................................................................127

11.3.4 Protecting the Operating Mode Selection......................................................................................128

11.4 TESTING USER MANAGEMENT IN RUNTIME ............................................................................................129

The following symbols are provided as a guide through Module F6:

Information

Installation

Programming

Sample Exercise

Notes

T I A Training Document Page 5 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 6

Automation and Drives - SCE

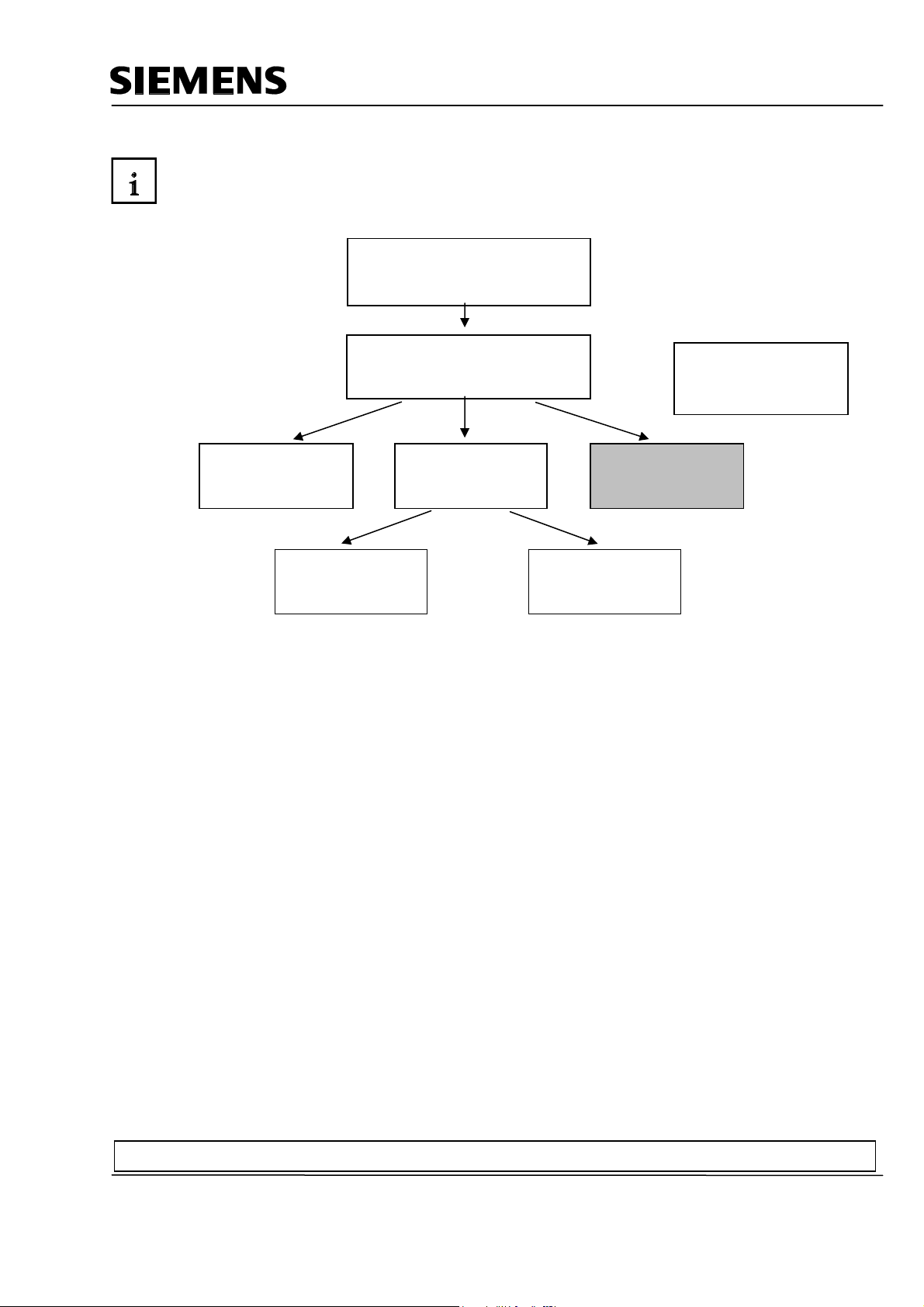

y

days

odules

1. PREFACE

In terms of its contents, Module F6 is part of the teaching unit entitled 'Process Visualization’.

2 to 3 da

Additional Functions of

Programming

Languages

Frequency Converter

on SIMATIC S7

2 to 3 days Modules

Learning Objective:

In Module F6, the reader is introduced to the essential functions of the software WinCC flexible

2005.

Typical task definitions are processed using a sample system.

• Installing the software

Fundamentals of

STEP7 Programming

s Modules A

STEP7 Programming

2 to 3

Industrial Fieldbus

Systems

2 to 3 days Modules

M

B

Plant Simulation with

SIMIT SCE

1 to 2 days Modules G

Process

Visualization

2 to 3 days Modules

IT Communication

wirh SIMATIC S7

• Steps for generating a Step7 project

• Inserting an HMI station

• Interface of WinCC flexible

• Configuring display and operator objects

• Configuring messages

• Generating recipe management

• Setting up user management

Prerequisites:

• Knowledge in handling Windows

• Fundamentals of PLC programming with STEP 7 (for example, Module A3 - 'Startup’

PLC Programming with STEP 7)

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 6 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 7

Automation and Drives - SCE

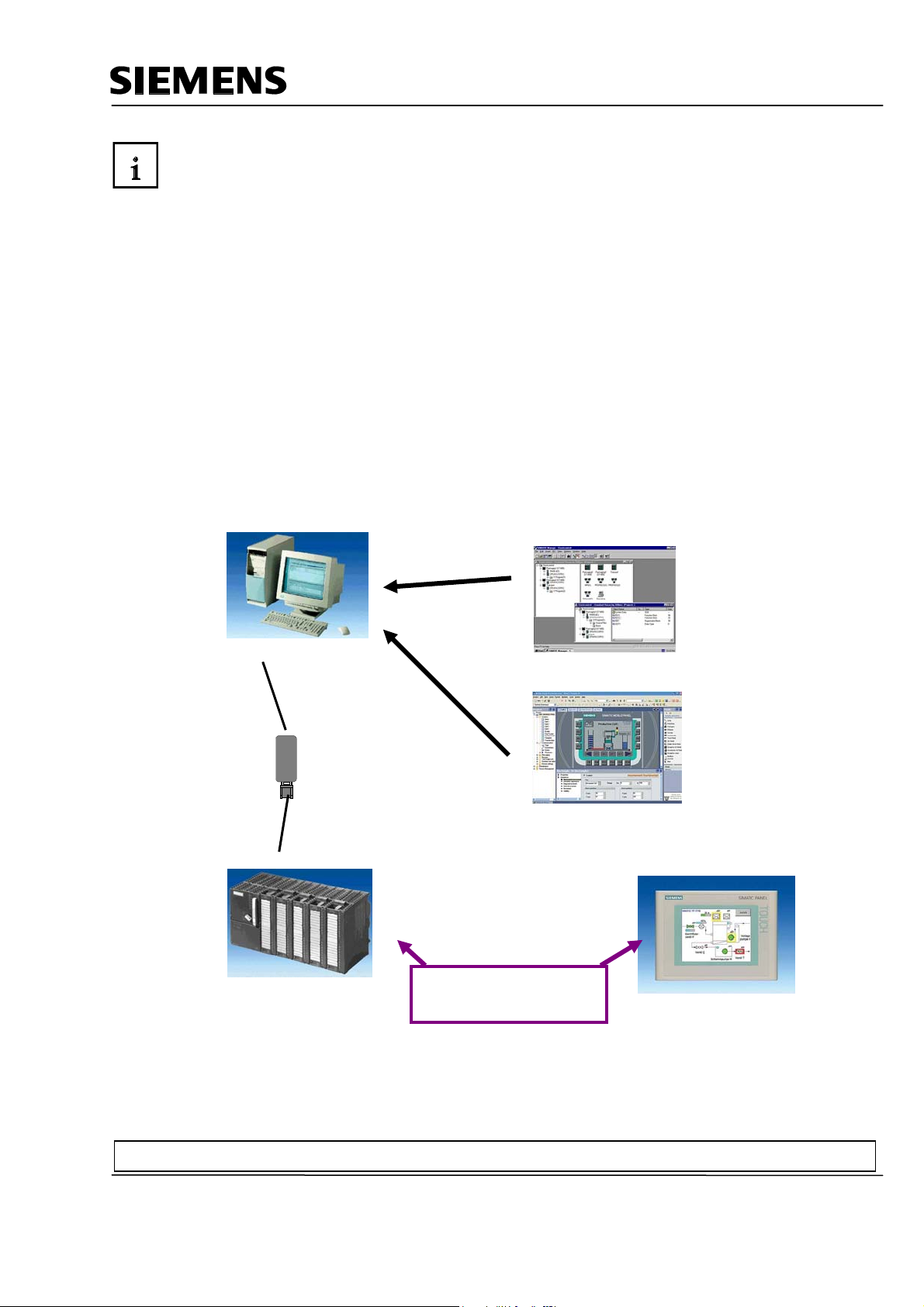

Hardware and software required

1 PC, operating system Windows 2000 SP4 or Windows XP Professional SP1 and SP2 with MS

Internet Explorer V6.0 SP1

Pentium IV with 1.6 GHz, 512MB RAM, approx. 1.5GB free hard disk storage

2 Software STEP7 V 5.4

3 Configuring software WinCC flexible 2005 Advanced

4 MPI interface for the PC (for example, PC Adapter USB)

5 Sample configuration for PLC SIMATIC S7-300:

- Power supply: PS 307 2A

- CPU: CPU 314

- Digital inputs: DI 16x DC 24V

- Digital outputs: DO 16x DC 24V/0.5A

6 Touch Panel TP177B

7 MPI or Profibus DP data cable for connecting the TP177B to the controller

1 PC

2 STEP7 V5.3

4 PC Adapter

3 Configuring Software WinCC

flexible 2005 Advanced

5 SIMATIC S7-300

7 MPI or Profibus DP

Data Cable

6 Touch Panel TP177B

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 7 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 8

Automation and Drives - SCE

2. OPERATOR CONTROL WITH WINCC FLEXIBLE

2.1 System Description

Since processes are becoming more and more multi-layered and the demands on the functionality of

machines and plants are increasing, the operator needs a high-performance tool for controlling and

monitoring production plants. An HMI system (Human Machine Interface) represents the interface

between a human being (the operator) and the process (machine/plant). The controller actually

controls the process. That is, there are two interfaces: one between the operator and WinCC flexible

(at the operator panel), and another interface between WinCC flexible and the controller.

The WinCC flexible Engineering System is the software that is used to handle all required

configuring tasks. The WinCC flexible Edition determines which operator panels of the SIMATIC

HMI spectrum can be configured.

WinCC flexible Runtime is the software for process visualization. In runtime, the project is executed

in the process mode.

WinCC flexible performs the following tasks:

• Displaying the process

The process is mapped to the operator panel. If a status changes in the process, for example, the

display at the operator panel is updated.

• Operating the process

The operator can operate the process by means of the graphic operator interface. For example, the

operator can specify a setpoint for the controller, or start a motor.

• Reading out messages

If critical process states occur in the process, a message is triggered automatically; for example, if

the specified limit is exceeded.

• Archiving process values and messages

The HMI system can archive messages and process values. In this way, you can document the

process characteristics, and you can also access older production data later.

• Documenting process values and messages

The HMI system can read out messages and process values as protocol. Thus, you can have

production data read out after the end of a shift, for example.

• Managing process parameters and machine parameters

The HMI system can store parameters for processes and machines in recipes. With one operational

step, you can transfer these parameters from the operator panel to the controller, in order to change

production to another product variant.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 8 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 9

Automation and Drives - SCE

2.2 Installation/Deinstallation

2.2.1 System Prerequisites

WinCC flexible supports all common PC platforms that are IBM/AT compatible. Although values for a

minimum configuration are specified, you should use as a guide the recommended values for an

optimum configuration, for WinCC flexible to operate efficiently.

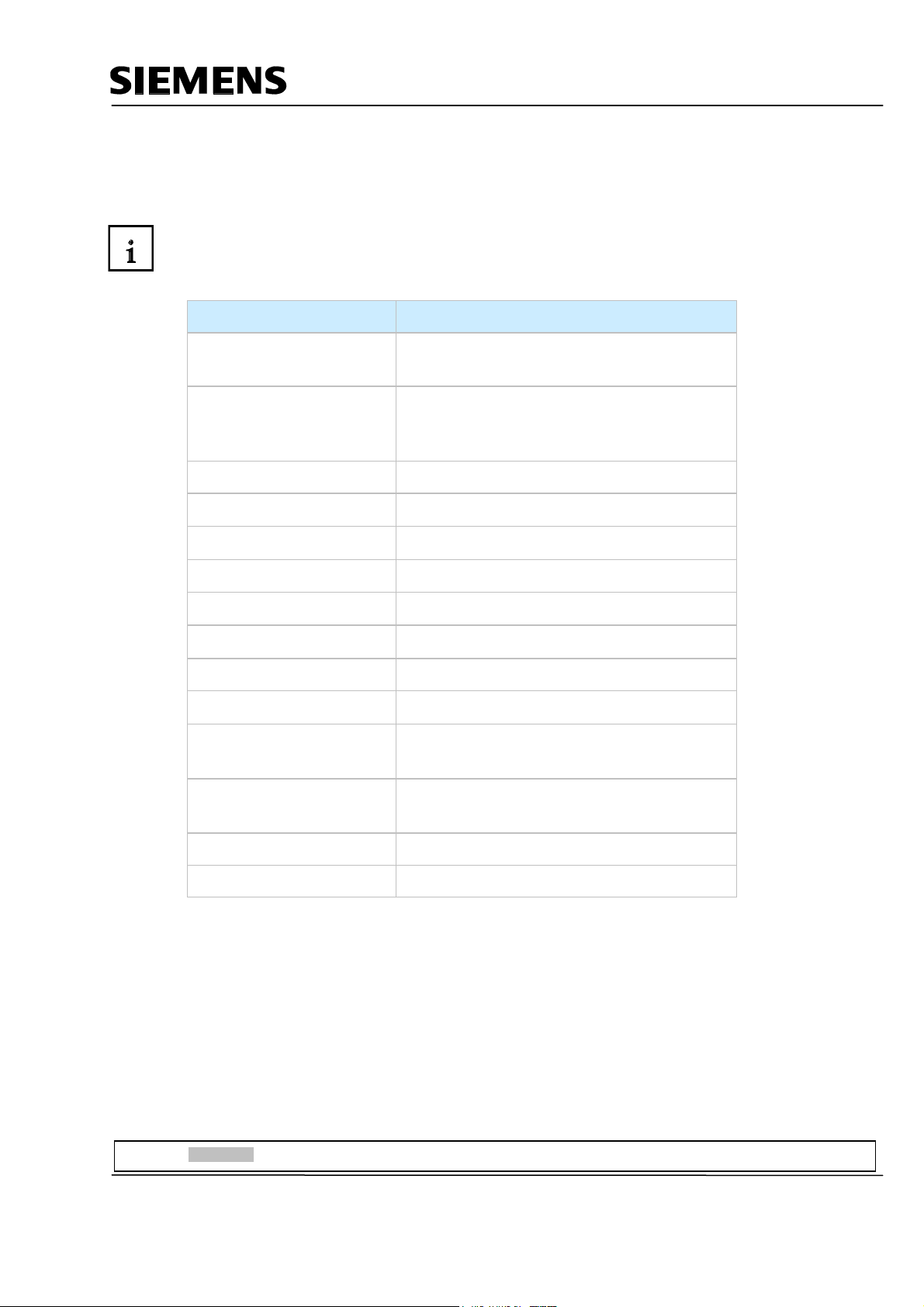

System Prerequisites for WinCC flexible ES

Operating System

Windows 2000 SP4, Windows XP Professional

SP1 and SP2

For multi-lingual configurations: Windows 2000

SP4 MUI, Windows XP Professional SP1 and

SP2 MUI

Processor

• Minimum

Pentium 4

• Recommended ≥ Pentium 4, 2.0 GHz

Resolution

• Minimum

1024 x 768

• Recommended ≥ 1280 x 1024

RAM

• Minimum

512 Mbyte

• Recommended ≥ 1 Gbyte, ≥ 512 Mbyte for WinCC flexible

micro

Hard disk drive (free

memory)

1)

≥ 1 Gbyte

Diskette drive 2)

CD-ROM

3.5“/1.44 Mbyte

for software installation

1) In addition to WinCC flexible, Windows also makes demands on the free hard disk drive capacity.

For example, free memory should be provided for the swap out file. The following formula has proven successful: Size of swap out file = 3

times the size of the RAM.

Additional information is provided in the Windows documentation

2) To transfer the License Key

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 9 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 10

Automation and Drives - SCE

2.2.2 Installing WinCC flexible

After all system requirements that have been mentioned are met, install WinCC flexible from the CDROM. Select the scope for installing components and product languages.

• Standard installation: recommended

• Minimum installation: to save memory

• User defined installation: to specify yourself which components and product languages are

installed

In addition, the required licenses have to be transferred. You can install the licenses along with the

components and product languages, or you can install them subsequently. If you have obtained

WinCC flexible options, install each option separately. An option is installed by loading the

associated license key.

Detailed information regarding the installation are provided in the Installation Instructions on the CDROM 'WinCC flexible Software CD1’ in the folder "Documents\<Language>\Installation Guides“.

2.2.3 Deinstalling WinCC flexible

Close all applications that are open, particularly the WinCC flexible Engineering System and WinCC

flexible Runtime. Deactivate WinCC flexible Smart Start.

Additional notes on WinCC flexible Smart Start are provided in the chapter "WinCC flexible Smart

Start".

Open the system control by means of "Start ► Settings ► System Control".

In the system control, double click on the entry "Software". The dialog "Software" is opened.

In the dialog "Software", select the entry "SIMATIC WinCC flexible 2005". The button

"Change/remove" is displayed.

Click on the button "Change/Remove". The WinCC flexible InstallShield Wizard is opened.

Activate the option "Remove program" and click on the button "Continue".

Confirm the deinstallation with "OK". WinCC flexible is removed from the configuring computer.

In the dialog that follows, close the deinstallation with the button "Complete".

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 10 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 11

Automation and Drives - SCE

2.2.4 Totally Integrated Automation

In addition to an HMI system such as WinCC flexible, a complete automation solution includes other

components, such as controller, process bus and periphery. WinCC flexible offers a particularly

extensive integration with components from the SIMATIC product family:

• Integrated configuring and programming

• Integrated data management

• Integrated communication

Integration in SIMATIC STEP 7

Process variables are the connecting link for communication between controller and the HMI system.

Without the advantages of Totally Integrated Automation, you have to define each variable twice:

once for the controller, and once for the HMI system.

Integrating SIMATIC STEP7 into the configuration interface lowers error frequency and configuring

effort. While you are configuring, you are directly accessing the STEP7 symbol table and the

communication settings:

- The STEP7 symbol table includes the data point definitions (for example, addresses or data

types) that were specified when you generated the control program.

- The communication settings contain the bus addresses and the control protocols

- Communication is set with NetPro, for example.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 11 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 12

Automation and Drives - SCE

3. PROJECT DESCRIPTION

3.1 Hardware Configuration

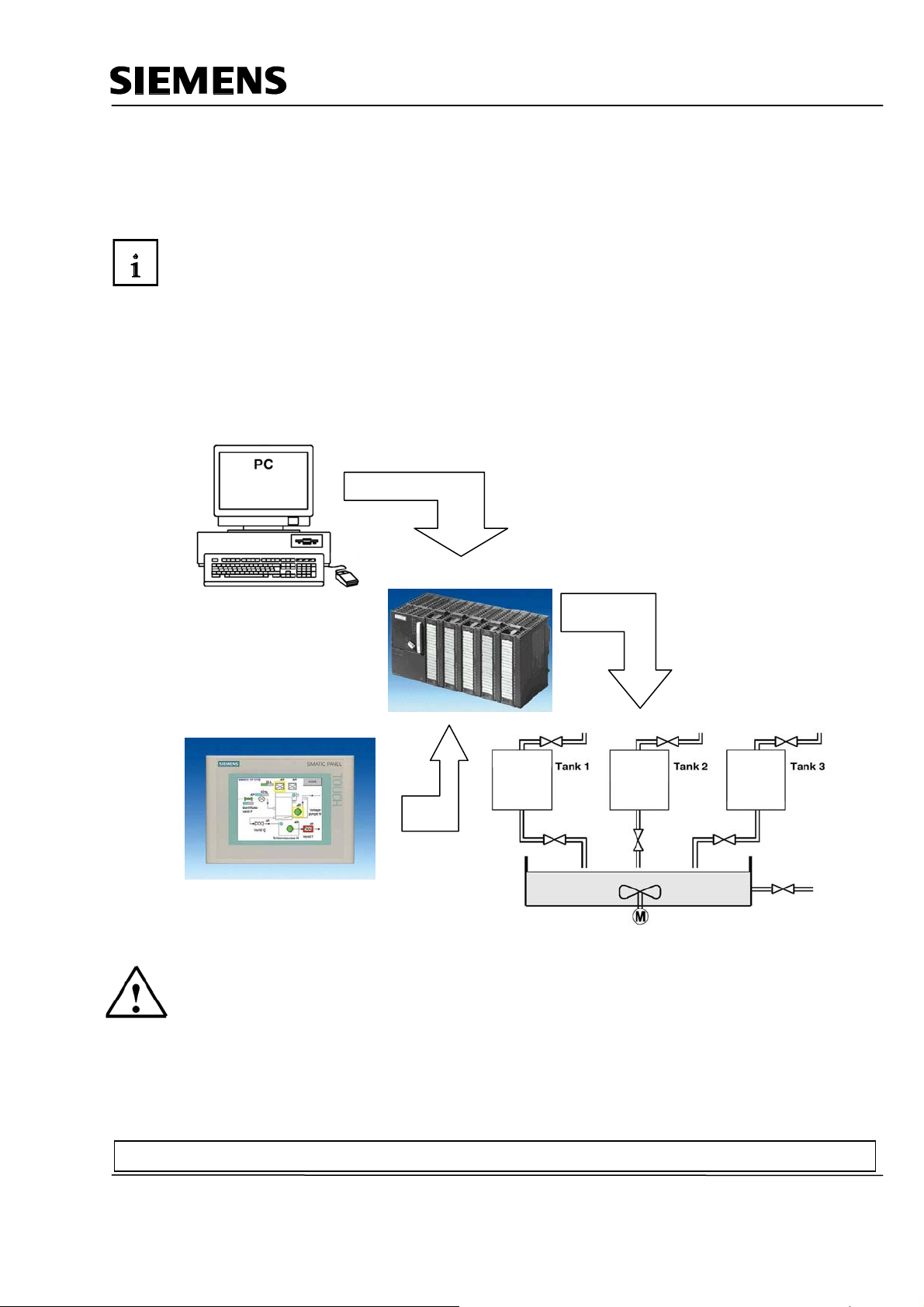

In our sample program for a color mixing plant, we are using a programming device with the WinCC

flexible 2005 Advanced Engineering System and WinCC flexible 2005 Runtime.

The color mixing plant is controlled by means of a SIMATIC S7-300. By using a touch panel

(TP177B), the operator can operate the process using the graphic operator interface. For example,

the operator can specify a setpoint for the controller, or start a motor.

The programming device, the SIMATIC S7-300 controller and the operator panel TP177B are

connected to each other by means of the MPI.

The color mixing plant is connected to the controller with digital inputs and outputs.

PC for Configuring

TP177B as operator panel

Note

With WinCC flexible 2005 Runtime, the touch panel TP177B can also be represented on the

programmer. However, when starting WinCC flexible Runtime, the MPI address of the panel

(MPI=1) is set automatically on the programmer. When using a real panel, the MPI address has to

first be reset on the programmer to MPI=0.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 12 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 13

Automation and Drives - SCE

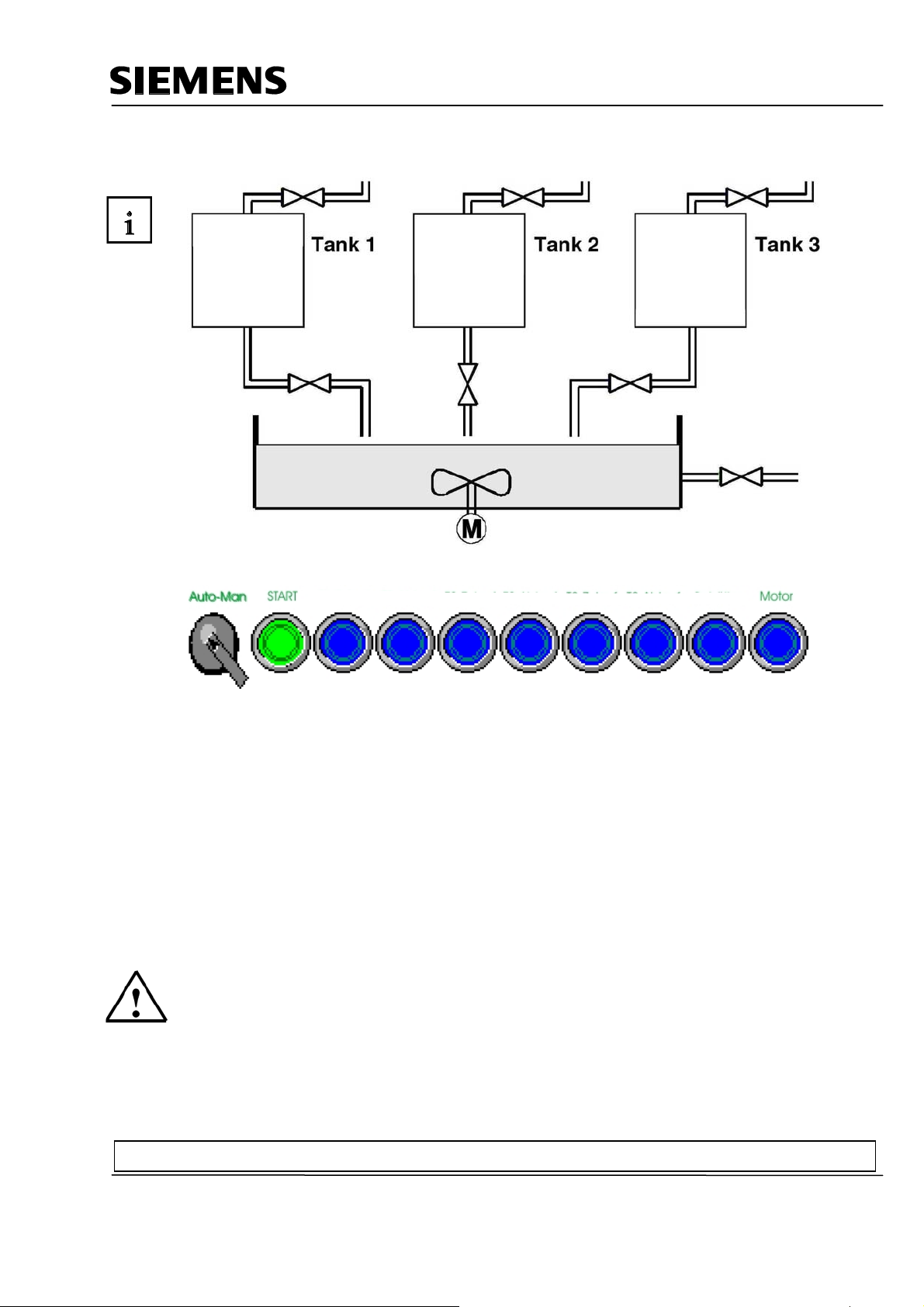

3.2 Plant Description

T1 Inflow

T1 Outflow

T2 Inflow T2 Outflow

T3 Inflow

Container

A color mixing plant is controlled with a SIMATIC S7-300 in the automatic or in the manual mode. In

the "Automatic“ mode, the three tanks are filled with a two step control. At the minimum level, the

inflow valve opens automatically, and after the maximum level is reached, it is closed again. After the

start button is operated, the specified program is executed: first, the outflow valves are opened and

the container is filled from tanks with the specified amounts. After the outflow valves are closed, the

mixer motor is started. After the mixing time has expired and after a short idle phase, the outflow

valve of the container is opened and the finished color mixture is drained. When the container is

empty, the lamp of the start button lights up, and a new color mixture can be started.

In the "Manual“ mode, the automatic outflow is canceled, and all valves as well as the mixer motor

can be operated manually. The lamps in the buttons for manual operation are lit.

Note

The specified amounts and the time base are determined by the program. If you want another color

mixture, the specified amounts and the time base have to be changed, and a new program has to be

loaded to the controller.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 13 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 14

Automation and Drives - SCE

3.3 Task Definition

At the color mixing plant, the program was changed with the programmer each time the mixing ratio

changed. Since such changes are not only time consuming, but also dangerous if wrong entries are

made, it was decided to expand the color mixing plant with a TouchPanel TP177B.

By using the panel, the following requirements are to be met:

- The color mixing plant can also be operated with the panel.

- The levels of the tanks and the container are to be displayed as a bar and also as a numerical

value.

- The motion of the mixing motor is to be shown graphically.

- The specified amounts are to be entered on the panel.

- The minimum and maximum levels of the three tanks are to be entered in separate tank

graphics.

- The operating modes can be switched using the panel; the respective operating mode is

displayed on the panel.

- The completed mixtures are to be stored on the panel as recipes; the operator only has to select

them.

- The levels are monitored. If danger arises, messages are to be read out.

- The color mixing plant can only be operated after a password was entered.

- Panel TP177B is to communicate with the SIMATIC S7-300 controller by means of the MPI.

3.4 Configuration

On the programmer, process visualization is generated for the color mixing plant, using the

configuring software WinCC flexible 2005 Advanced. The process values are represented by

graphics and graphic objects. Default values can be transferred to the controller with operating

elements. The operator panel and the machine or the process communicate by means of variables

via the controller. The value of a variable is written to a memory area (address) in the controller.

There, it is read by the operator panel.

Process visualization is stored and after generation, it is transferred by the programming device to

the operator panel TP177B.

After the panel is powered up, the process can be monitored and the plant can be operated.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 14 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 15

Automation and Drives - SCE

4 STEP7 PROJECT "COLOR MIXING PLANT“

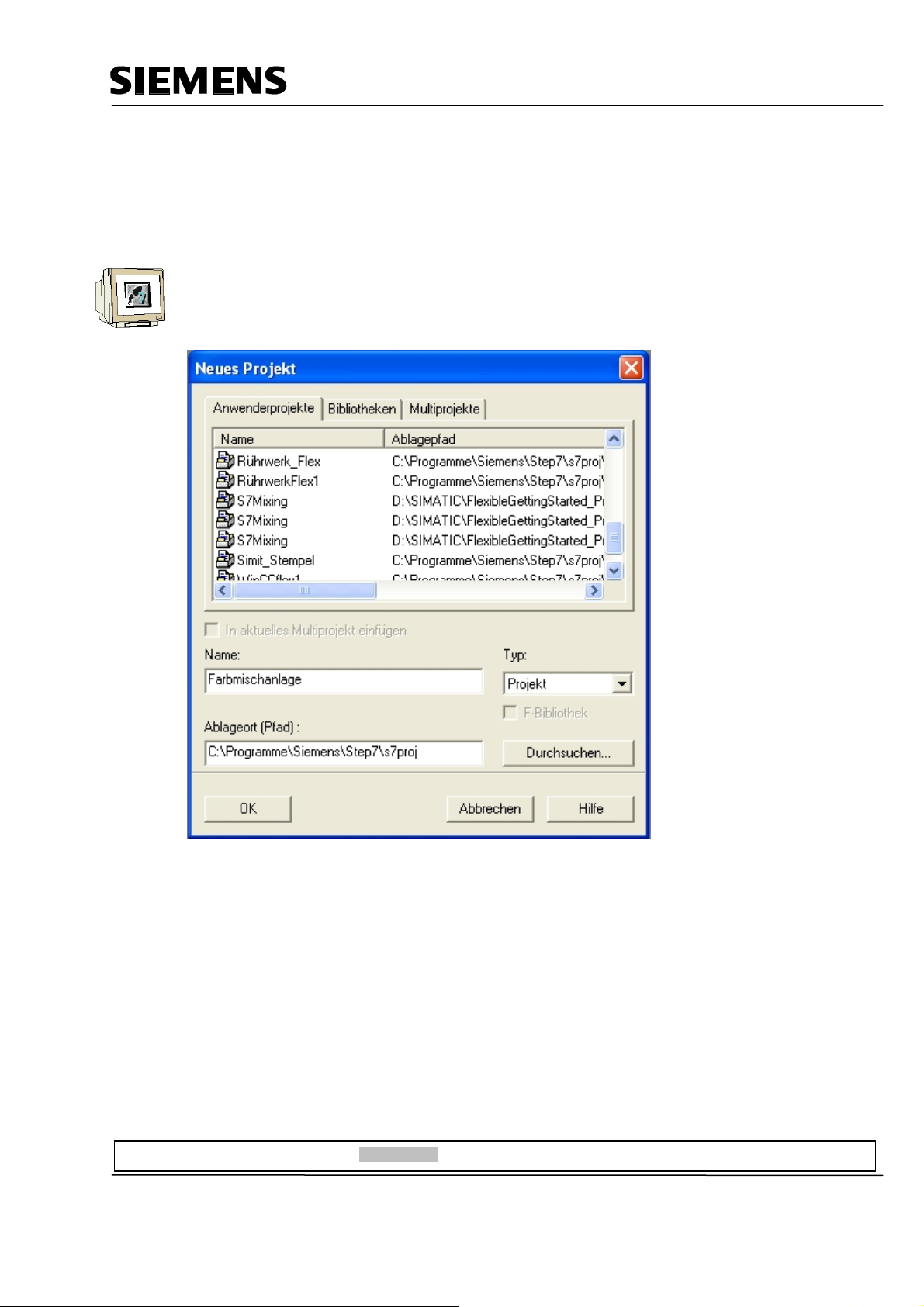

4.1 New Project

Start the SIMATIC Manager.

Create a new project with the Name “Color Mixing Plant“.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 15 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 16

Automation and Drives - SCE

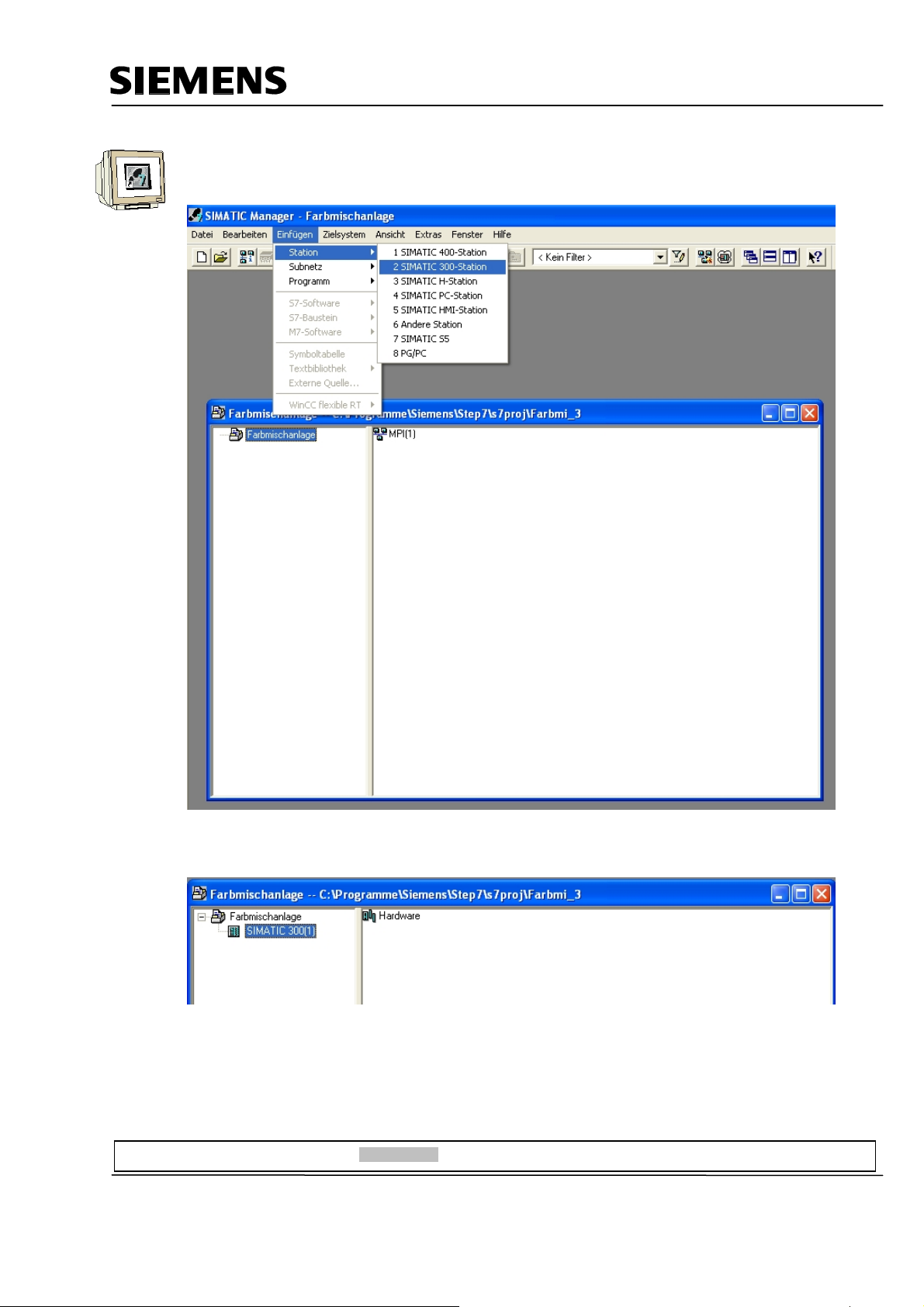

Insert the SIMATIC 300 Station.

By double clicking on Hardware, start the hardware configuration.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 16 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 17

Automation and Drives - SCE

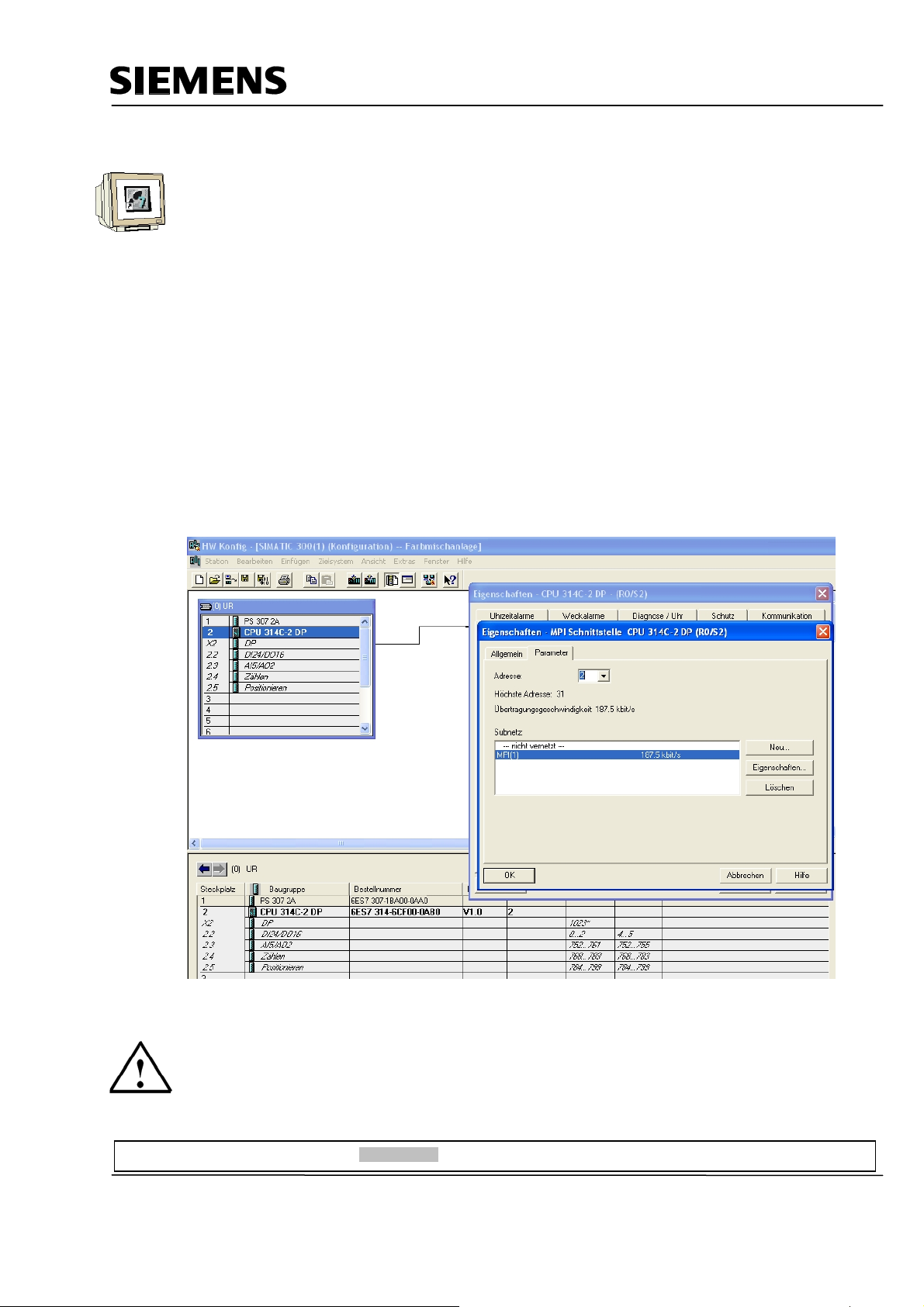

4.2 Hardware Configuration

Enter the hardware configuration of the controller you are using. Take note of the settings in the

sample configuration.

For our mixing plant, we are using the following hardware:

Slot 1: PS307 2A 6ES7 307-1BA00-0AA0

Slot 2: CPU 314C-2DP 6ES7 314-6CF00-0AB0

The CPU 314C-2DP is assigned the Profibus DP Addr.2 and is connected.

The CPU 314C-2DP is assigned the MPI Addr.2 and is connected.

The clock flag is set to MB100.

At the integrated inputs and outputs DI24/DO16, the inputs are set starting with Address 0, and the

outputs starting with Address 4.

Save and compile the hardware configuration.

Load the hardware to the PLC.

Close the hardware configuration.

Note

The SIMATIC S7 controller can also be simulated with the PLC simulator PLC SIM.

However, the simulator has to be started prior to loading the hardware to the CPU.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 17 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 18

Automation and Drives - SCE

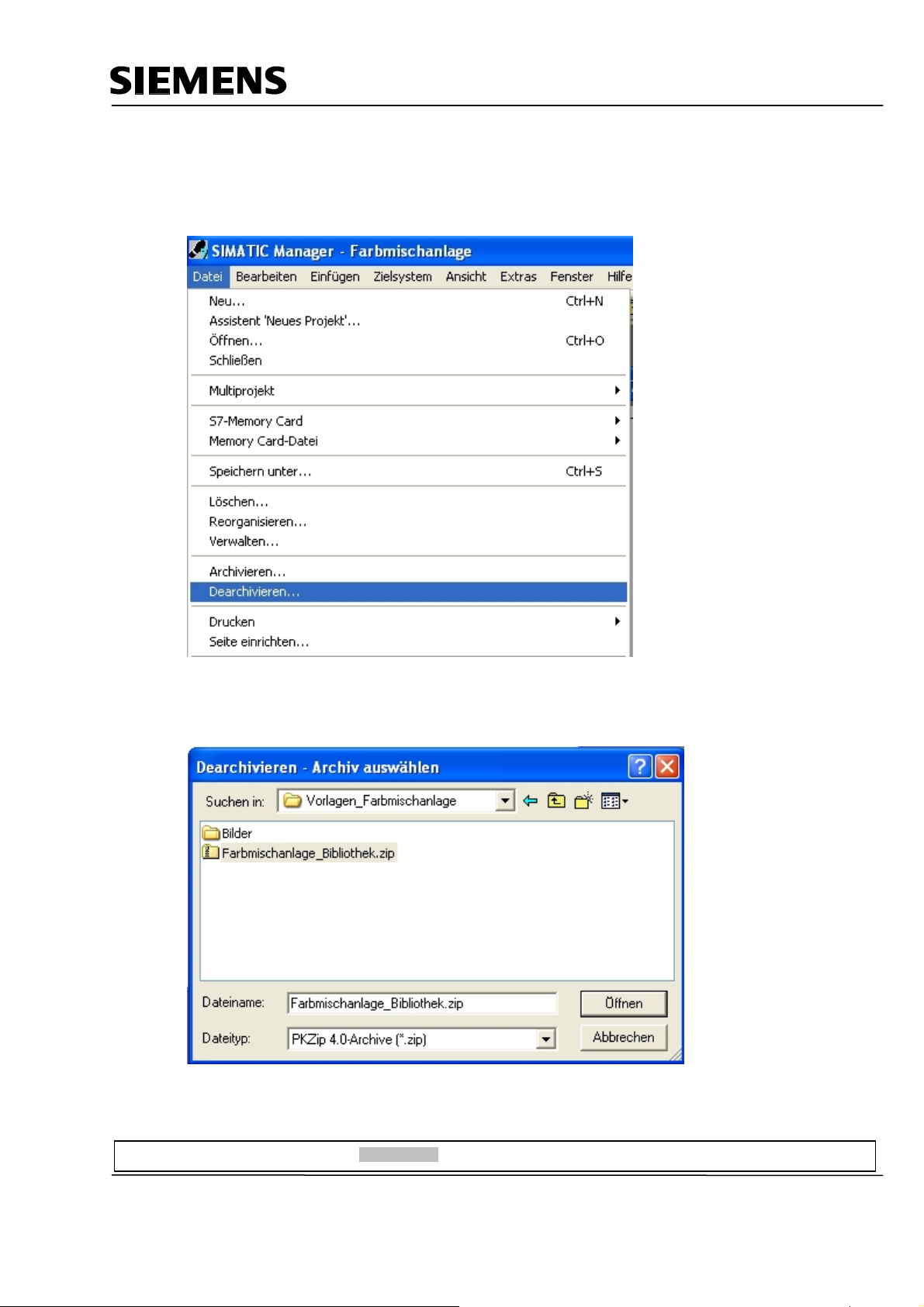

4.3 Library of the Color Mixing Plant

First, the library with the program blocks has to be imported to the SIMATIC Manager. To this end,

select the function Dearchive in the menu File.

From the template directory, select the file “Color mixing plant_Library“.

Click on the button “Open“.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 18 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 19

Automation and Drives - SCE

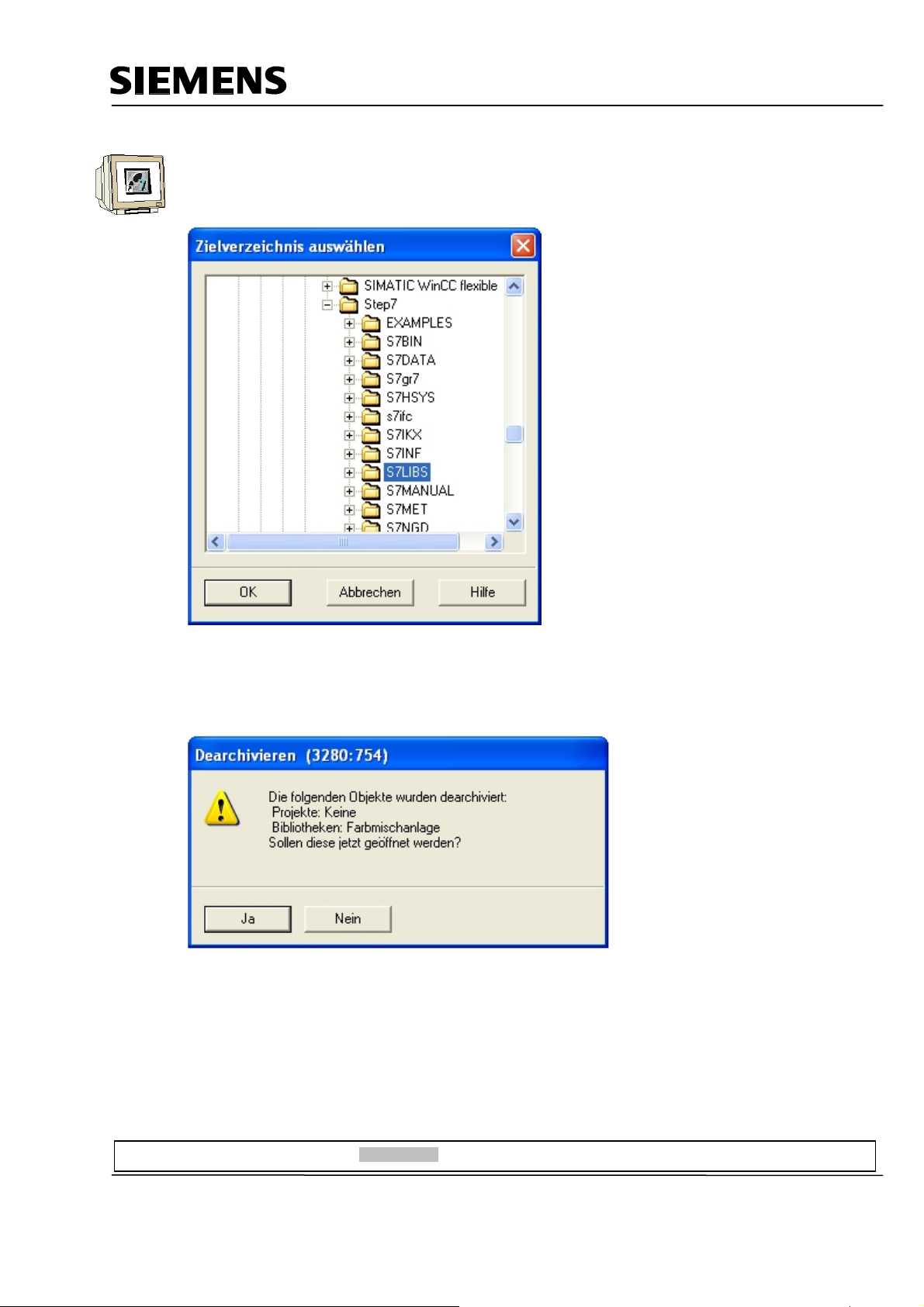

As destination directory, select the folder “S7LIBS“ in the Step7 directory.

Confirm with OK.

In the following window, click on the button “No“

<<the following objects were dearchived: Projects: None. Libraries: color mixing plant. Do you want to open

them now?>>

The project library “Color mixing plant“ was copied to the library directory. Here, all required program

blocks are stored.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 19 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 20

Automation and Drives - SCE

r

r

A

r

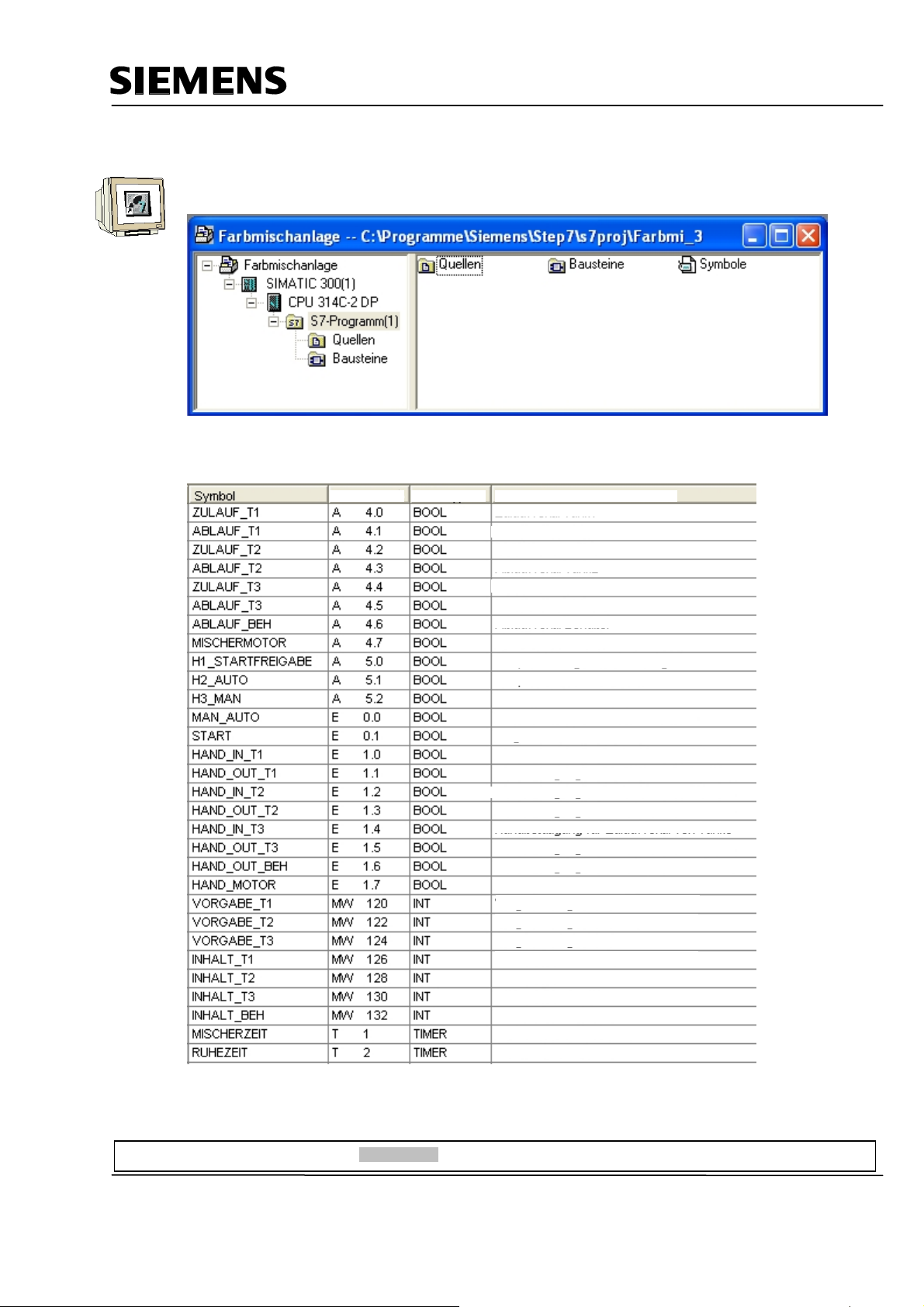

4.4 Assignment List

Open the project window in the symbol table.

Enter the symbol assignments in the symbol table.

ddress

CommentData Type

Inflow valve Tank 1

Outflow valve Tank 1

Inflow valve Tank 2

Outflow valve Tank 2

Inflow valve Tank 3

Outflow valve Tank 3

Outflow valve Containe

Motor for the mixe

Lamp for program start enable

Lamp for automatic mode

Lamp for manual mode

Manual-Automatic switch Auto = 1

Start program

Manual operation for inflow valve of Tank 1

Manual operation for outflow valve of Tank

Manual operation for inflow valve of Tank

Manual operation for outflow valve of Tank

Manual operation for inflow valve of Tank 3

Manual operation for outflow valve of Tank

Manual operation for outflow valve of container

Manual operation for mixer motor

Specified amount for Tank1

Specified amount for Tank2

Specified amount for Tank 3

Tank content Tank1

Tank content Tank2

Tank content Tank3

Tank content of containe

Mixer time in S5 format

Idle time in S5 format

Save and Close the symbol table.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 20 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 21

Automation and Drives - SCE

4.5 Control Program

4.5.1 Function Block FB1

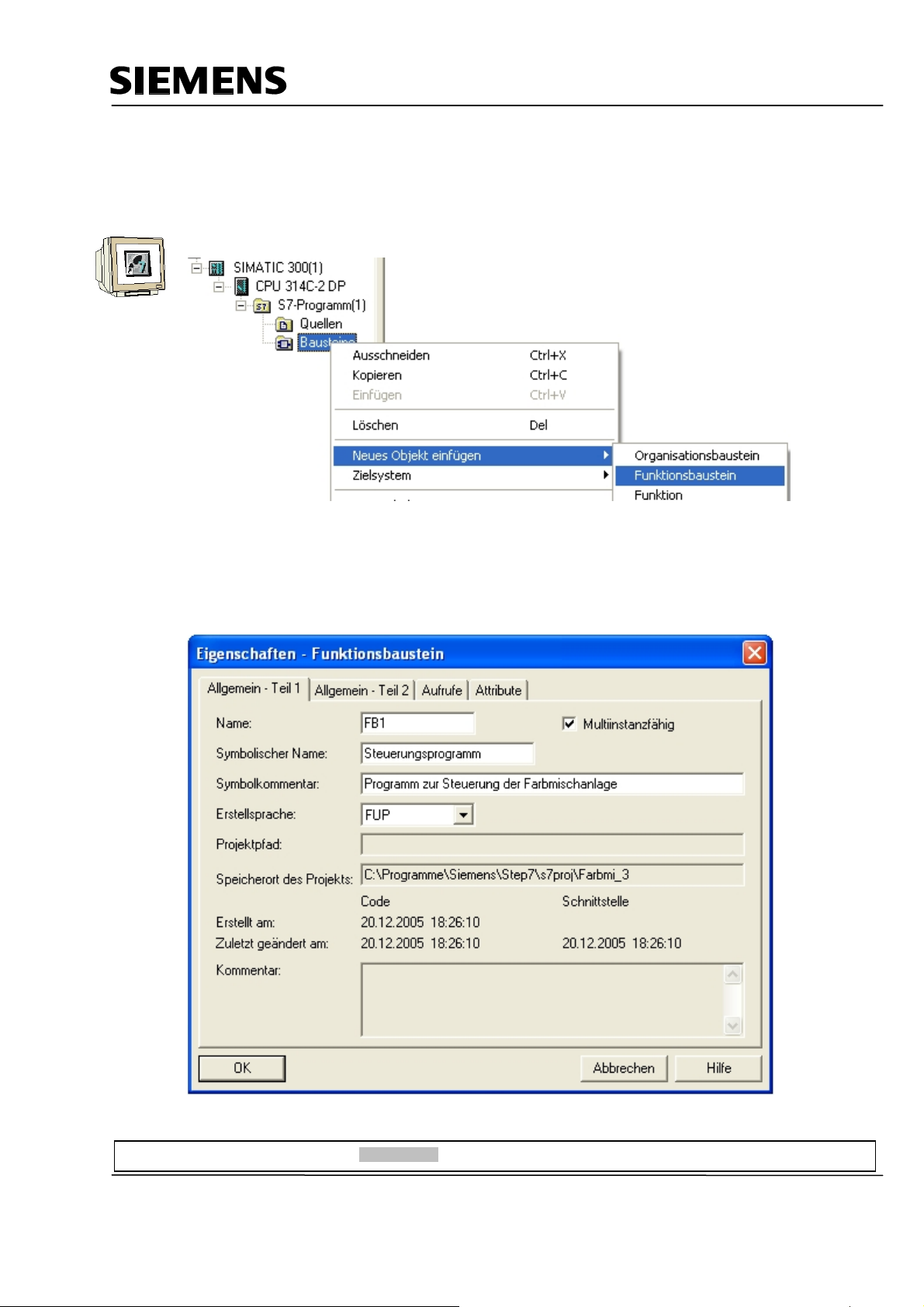

With the right mouse key, generate the FB1 in the folder Blocks.

Enter the symbolic name and the symbol comment.

Select the programming language “FBD“.

Place the check mark at Multi-instance capability.

Confirm with OK.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 21 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 22

Automation and Drives - SCE

4.5.2 Variable Declaration

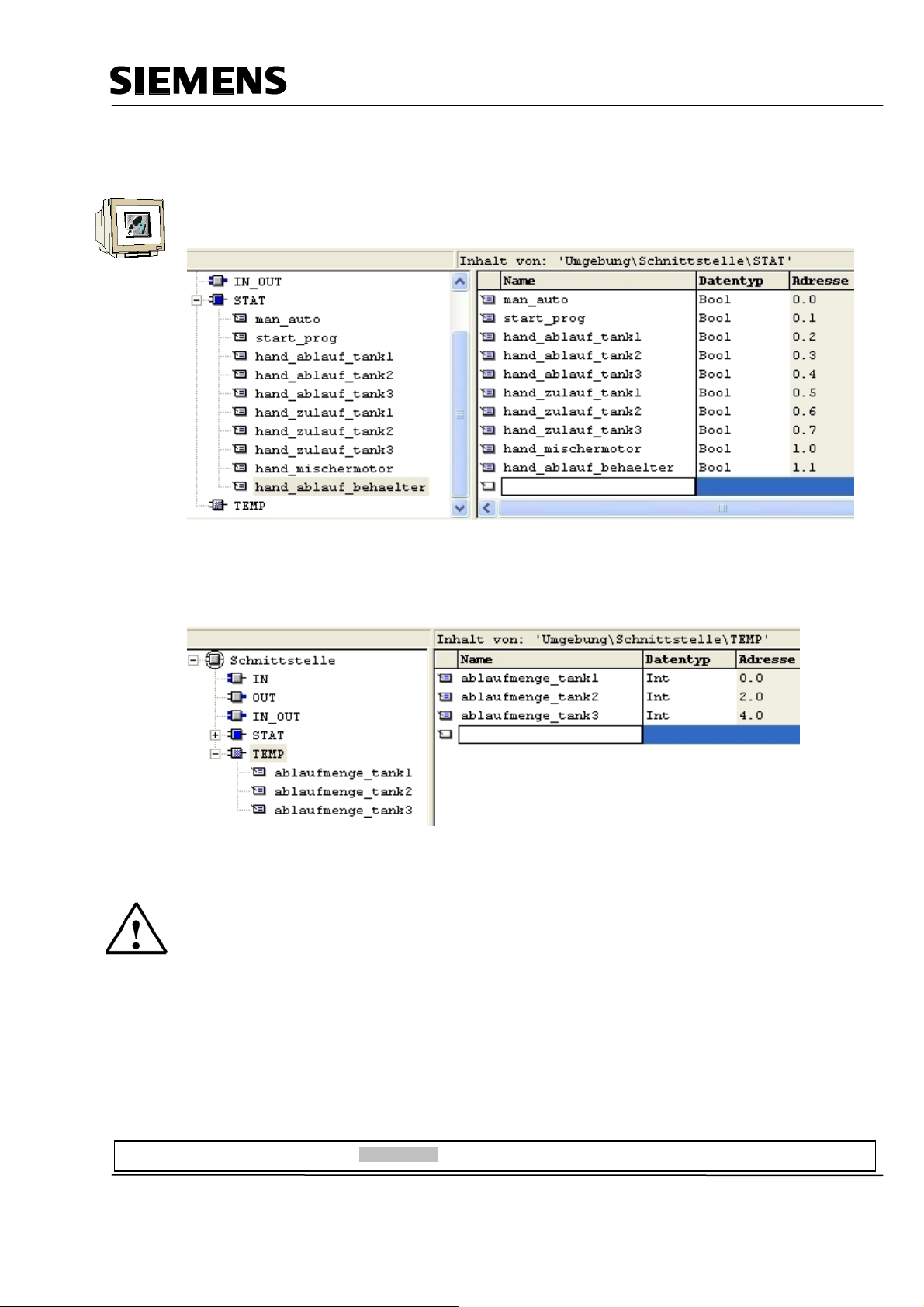

Open FB1 with a double click.

Enter the following STAT variables.

<<hand_ablauf = manual outflow; hand-zulauf = manual inflow; hand_ablauf_behaelter = manual outflow

container>>

Enter the following TEMP variables.

<<ablaufmenge = outflow amount>>

Note

The STAT variables are connected to the operator buttons on touch panel TP177B.

The TEMP variables are needed for passing on values in FB1.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 22 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 23

Automation and Drives - SCE

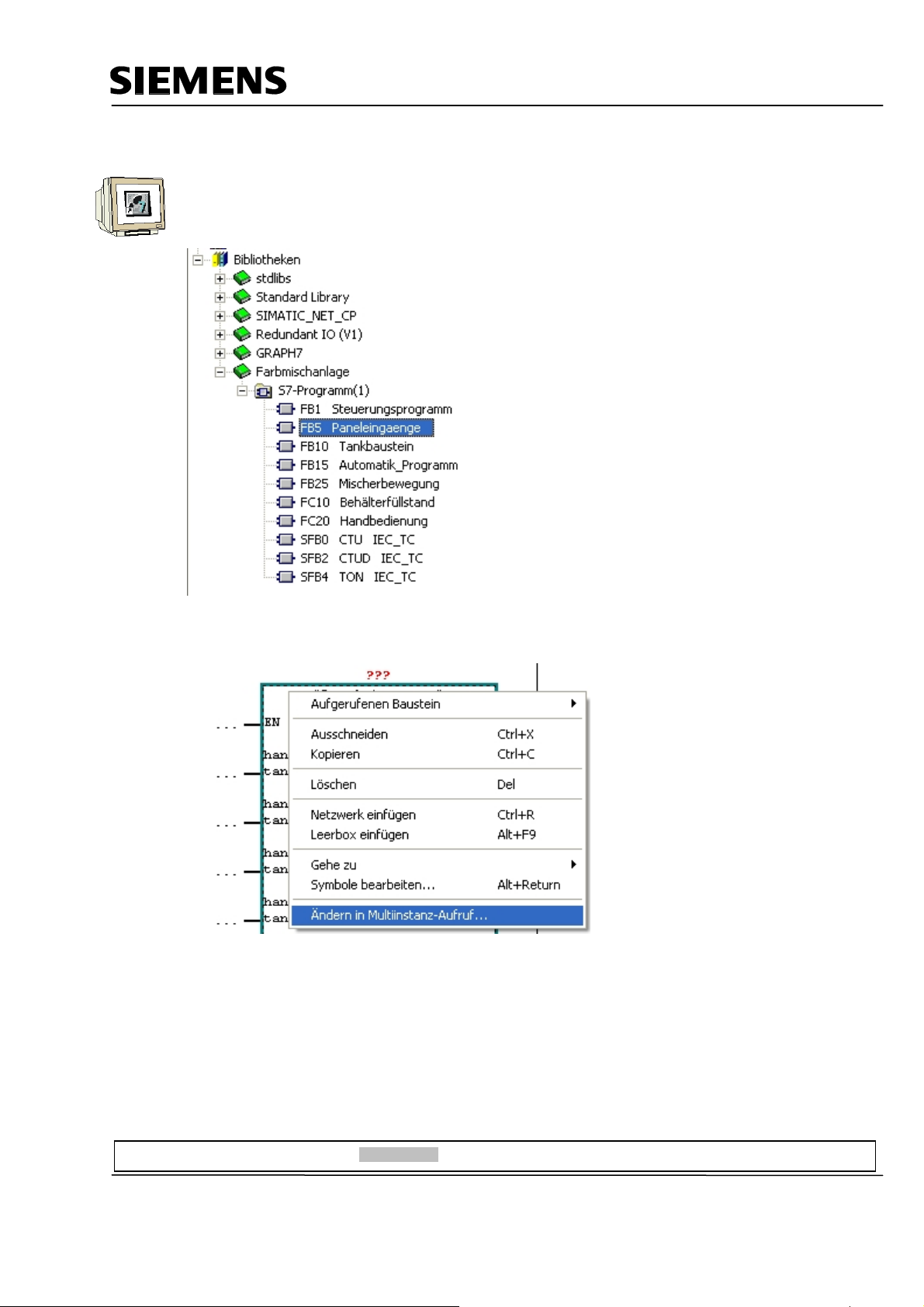

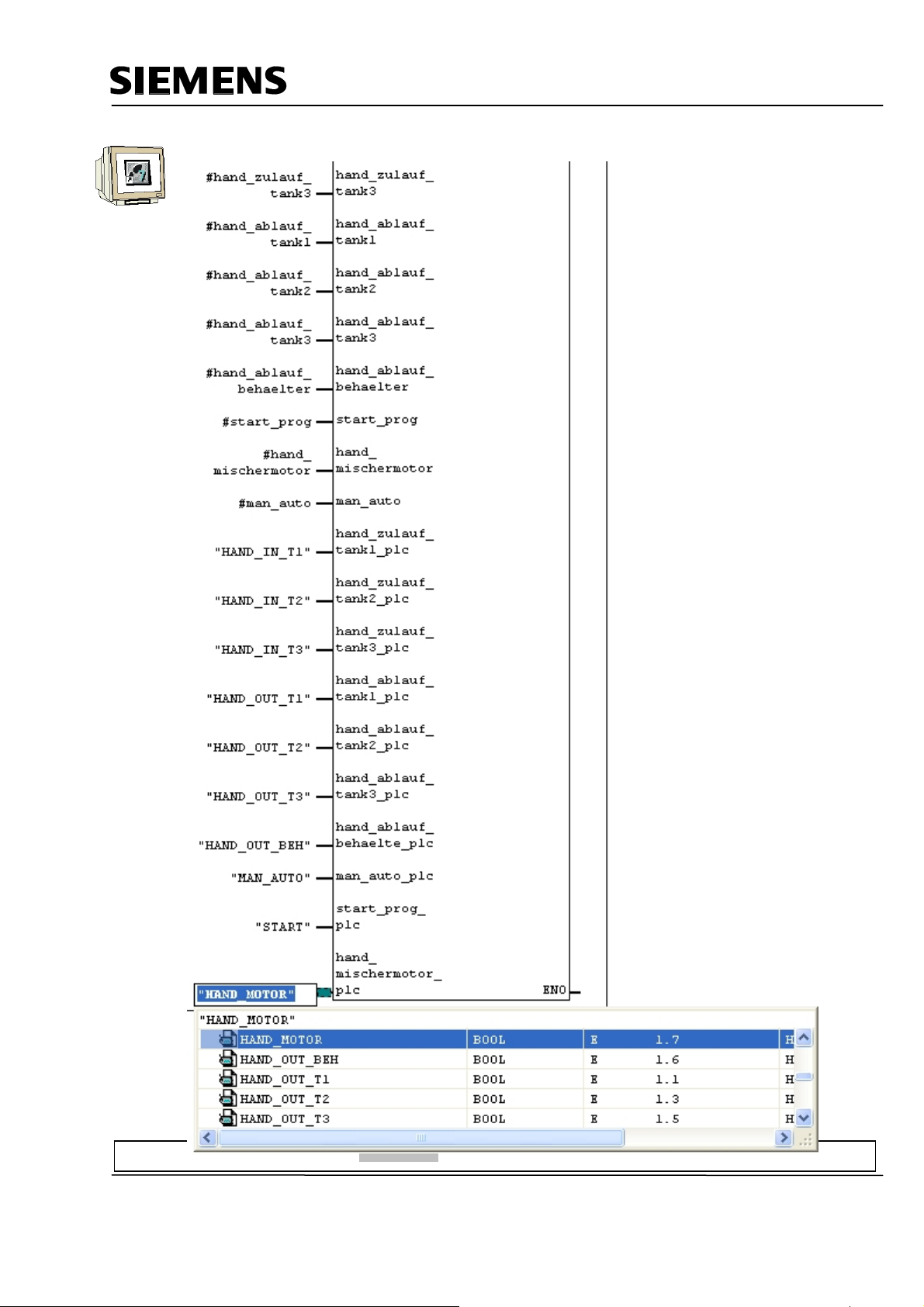

4.5.3 Inserting Panel Inputs FB5 as Multi Instance Block from the Program Library

Drag FB5 for the panel inputs from the library “Color mixing plant“ to Network 1.

This block is needed for connecting the input signals from the panel to the inputs of the controller.

Right click on the inserted block and select “Change in multi-instance call“.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 23 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 24

Automation and Drives - SCE

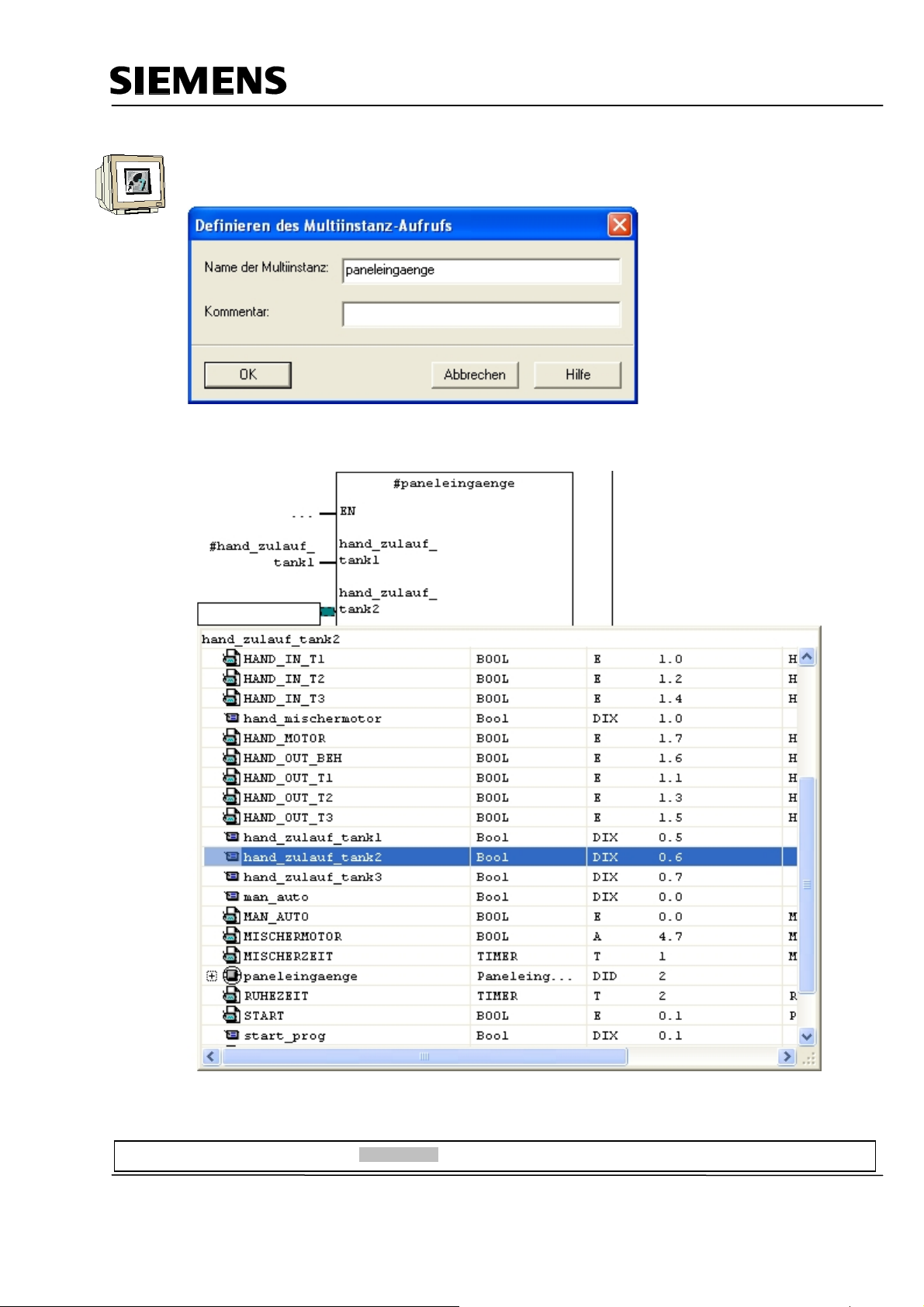

Enter the name “panel inputs“.

Confirm with OK.

Wire the upper 10 inputs of the block to the STAT variables.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 24 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 25

Automation and Drives - SCE

Wire the lower 10 inputs of the block with the symbolic names.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 25 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 26

Automation and Drives - SCE

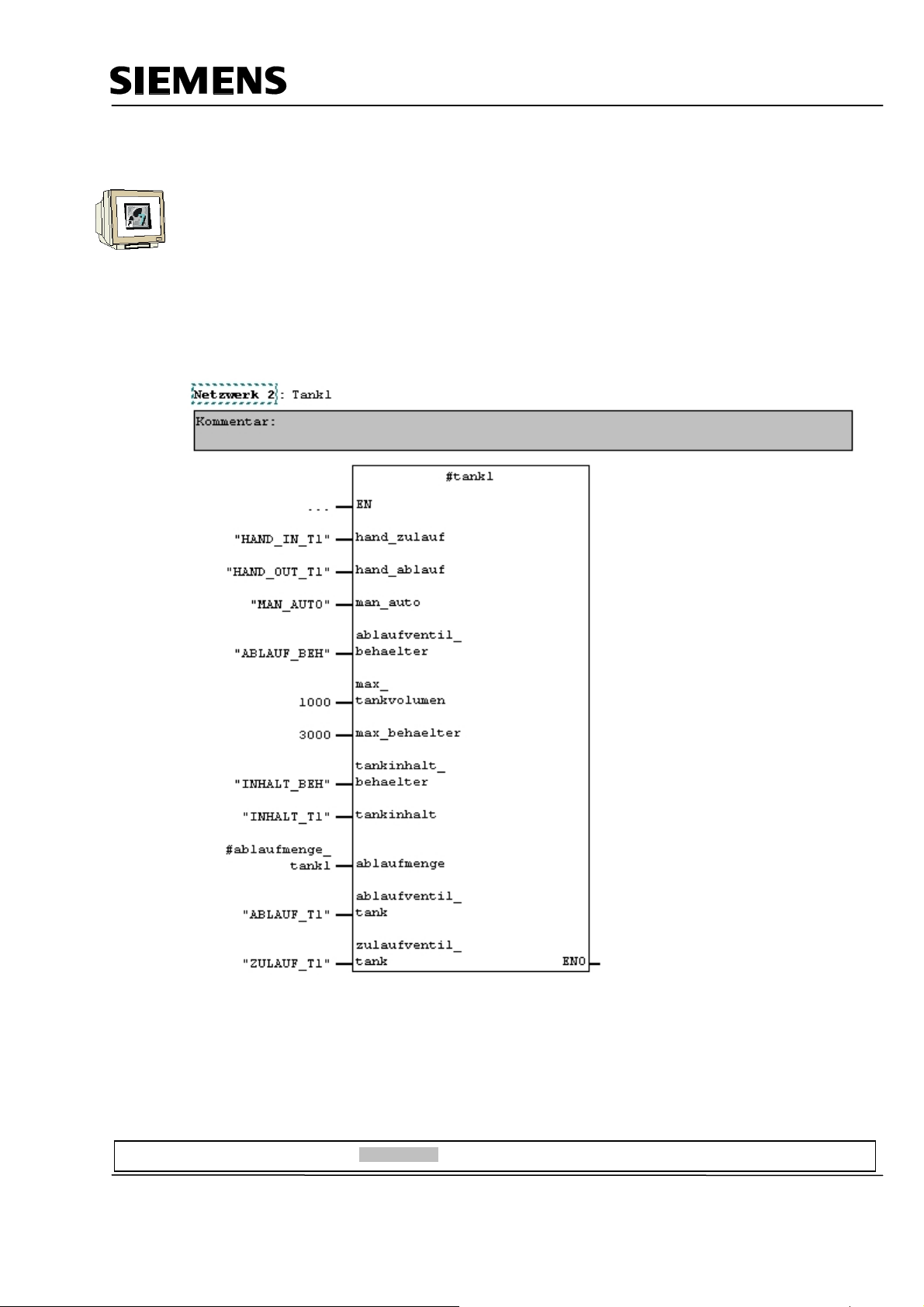

4.5.4 Tank Block FB10

Create a new network.

Drag the tank block FB10 from the library to Network 2.

Right click on the inserted block.

Select “Change to multi-instance call“

Enter the name “tank1“.

Confirm with OK.

This block contains the two step control and the calculations for simulating the level. When level

sensors are used, only the two step control would be necessary. Wire the block’s inputs.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 26 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 27

Automation and Drives - SCE

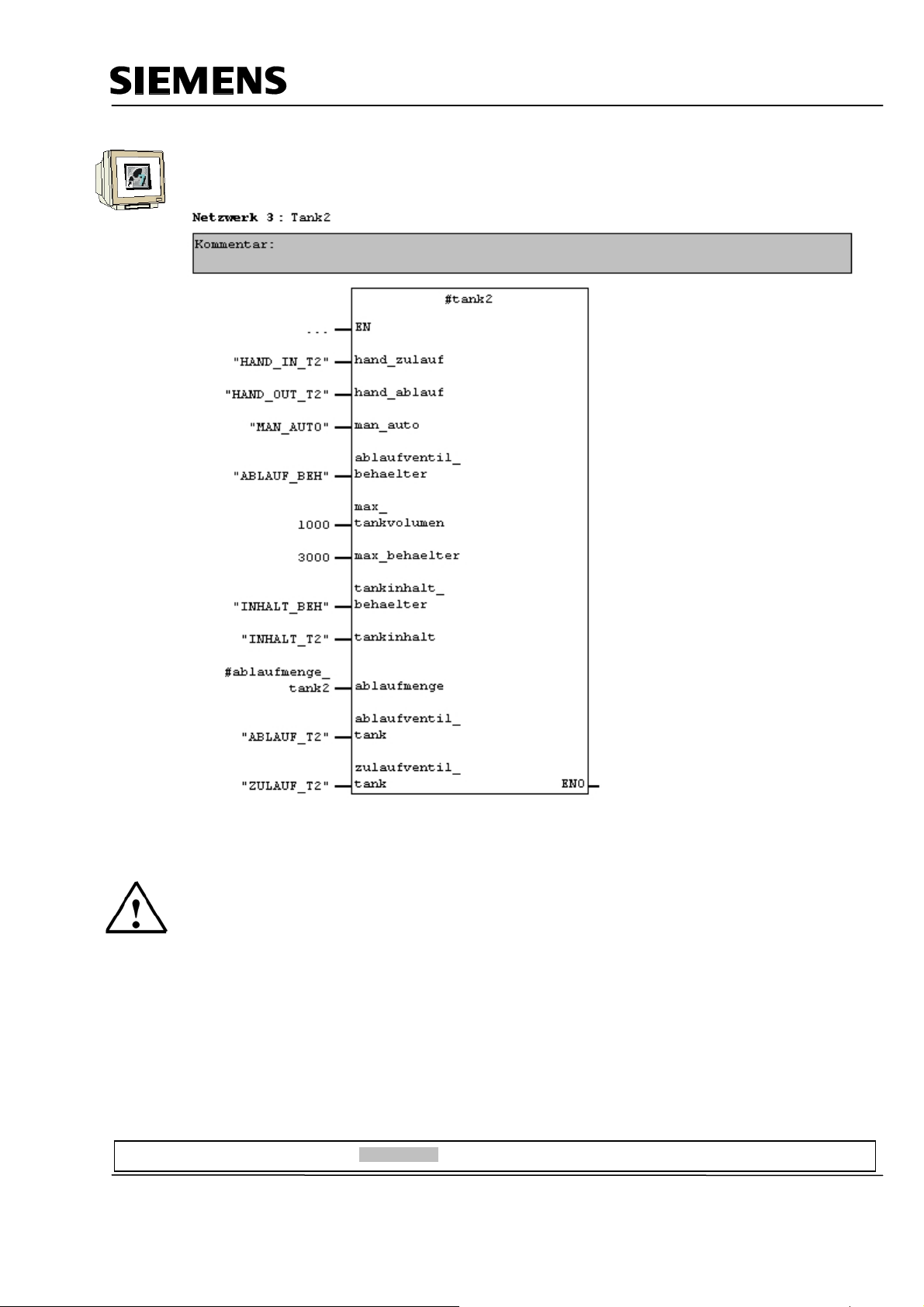

Repeat the steps for Tank2 in Network 3.

Note

Writing the symbolic names in “CAPITALS“ and the variables in “lower case letters“ makes better

assignments possible.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 27 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 28

Automation and Drives - SCE

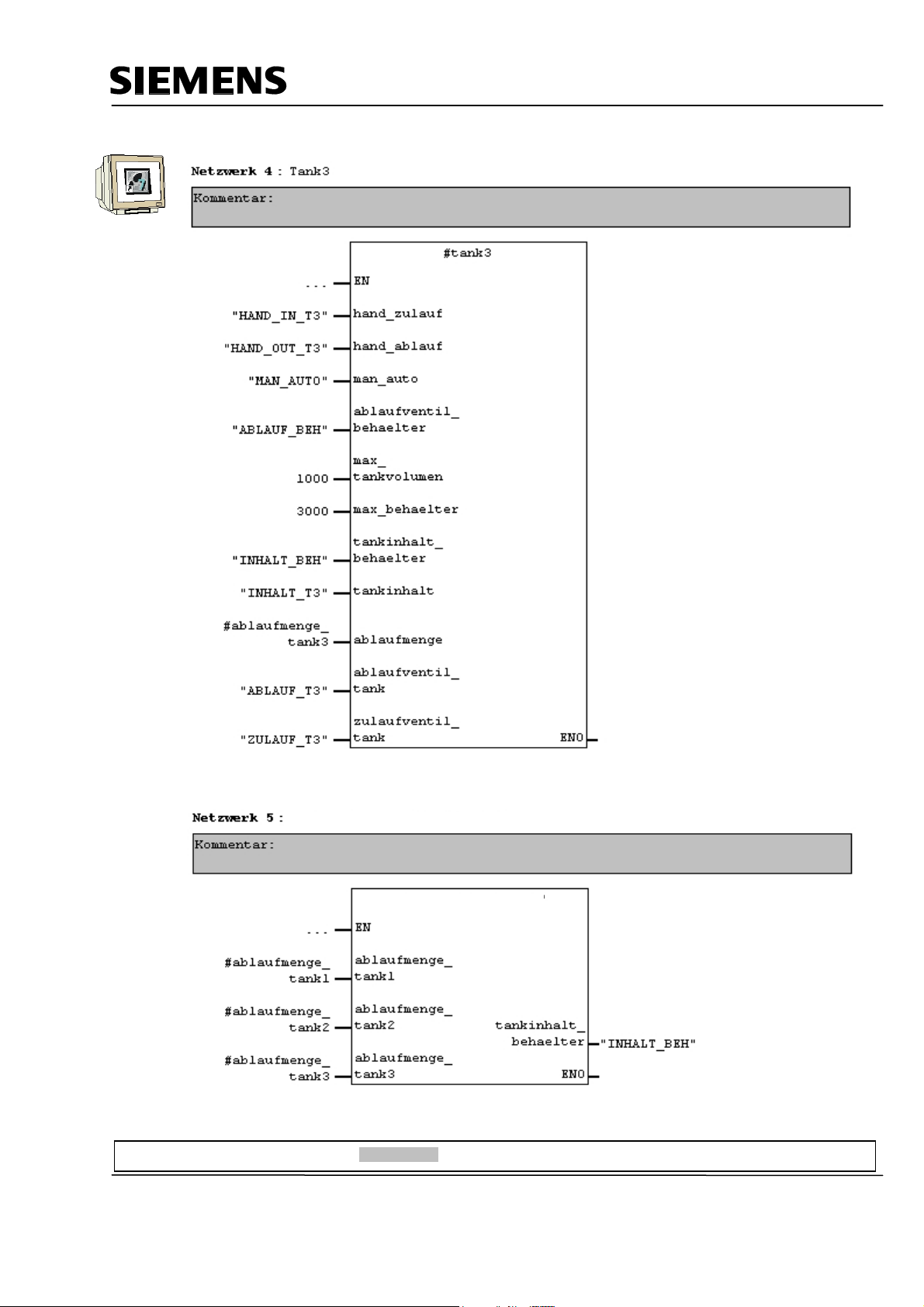

Repeat the steps for Tank3 in Network 4.

Create a new network and drag tank block FC10 from the library to Network 5.

Calculating the container level

Container Level

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 28 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 29

Automation and Drives - SCE

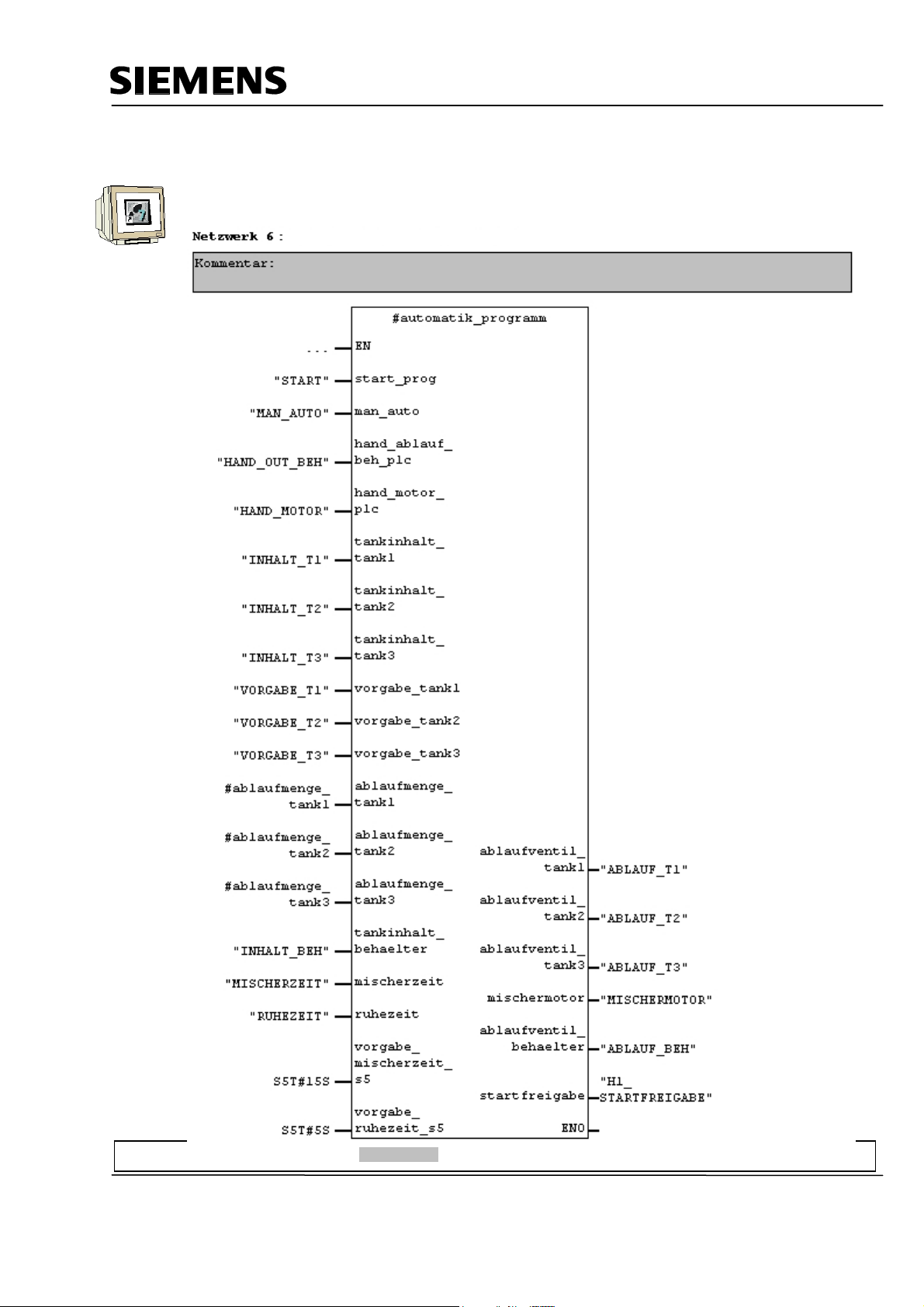

4.5.5 Automatic Program Sequence FB15

The automatic program sequence is described in the plant description.

Automatic Program Sequence

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 29 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 30

Automation and Drives - SCE

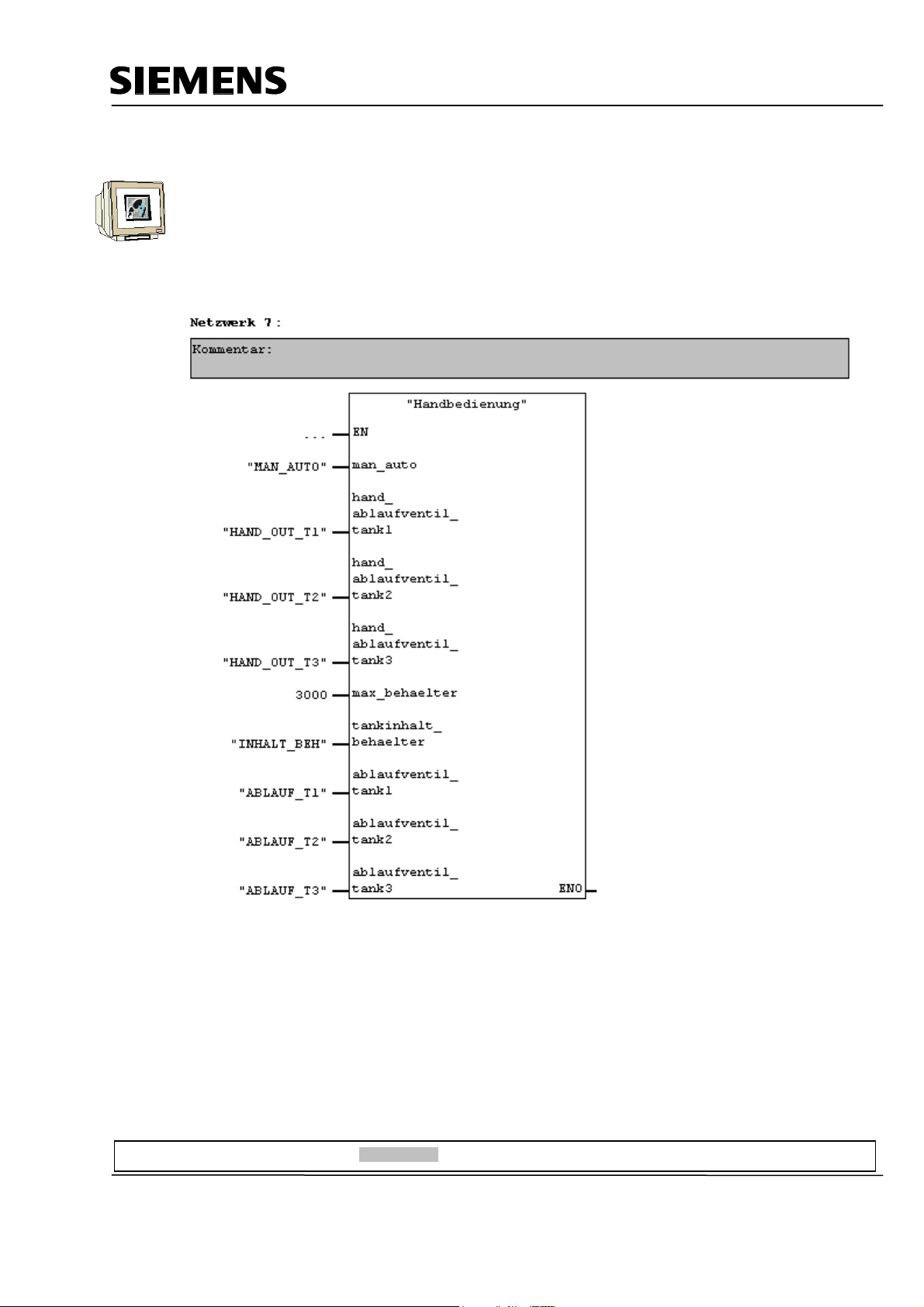

4.5.6 Manual Operation FC20

Create a new network and drag the FC20 from the library to Network 7.

This block contains the manual operation of the tanks’ outflow valves in the manual mode.

This FC20 has to be called after the FB15, since the automatic valve operations of the FB15 have to

be overwritten by the manual mode in FC20.

Wire the inputs of the block.

Manual mode of the outflow valves of the tanks

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 30 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 31

Automation and Drives - SCE

4.5.7 Mixer Motion FB25

This block is necessary to simulate the mixer motion. When the mixer motor is in operation, a count

in 150ms cycles, of the value 0 to 12 is incremented.

Simulate mixer motion

4.5.8 Automatic and Manual Lamps

In the last FB1 network, assignments for the automatic and manual lamps are generated.

Assign authomatic and manual lamp

FB1 is now completed.

Save and Close FB1.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 31 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 32

Automation and Drives - SCE

4.5.9 Organization Block OB1

Open OB1 by double clicking on it.

Drag FB1 from the folder “FB Blocks“ to Network 1 for the control program

Enter DB1 as instance data block.

In the message window, click on the button “Yes“.

OB1 is now complete.

Save and Close OB1.

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 32 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 33

Automation and Drives - SCE

4.6 Loading to the CPU

The control program for the color mixing plant is not completed.

In the project window, highlight the folder Blocks and then click on the button “Load“

4.7 Program Test

After loading the control program to the CPU, switch the controller to the RUN mode.

Test your program. For example, at the tank blocks, you can monitor the levels.

With “Monitor/control variables“, you can enter levels (MW120 to MW124).

Preface Installation Project Description Step7 Projekt HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 33 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 34

Automation and Drives - SCE

5 SIMATIC HMI STATION

5.1 Inserting an HMI Station

In your project window, highlight the project name “Color mixing plant“ (Farbmischanlage) and insert

a SIMATIC HMI station.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 34 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 35

Automation and Drives - SCE

The properties of WinCC flexible RT are opened.

As device type, select TP 177B color PN/DP.

Confirm with OK.

SIMATIC WinCC flexible ES is started and a SIMATIC HMI station is inserted.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 35 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 36

Automation and Drives - SCE

5.2 Configuring the HMI Station

At the inserted SIMATIC HMI station, click on Configuration.

Connect the SIMATIC HMI station with the MPI network.

Click on Save and Compile.

Close the configuration.

Note

In the WinCC flexible project, a connection via the MPI is generated automatically.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 36 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 37

Automation and Drives - SCE

5.3 Checking the Connection with NetPro

Start NetPro by clicking on the button in the SIMATIC Manager.

Here, you can check the communication connections very easily.

Also, you can make changes or corrections subsequently with NetPro.

With a double click, the module’s properties are opened.

IMPORTANT NOTE

NetPro, the hardware configuration, and WinCC flexible access a joint data base and must not be

opened at the same time.

If one of these programs is opened, only reading functions are often possible in the next program.

The advantage is that a change of the MPI address, for example, is accepted in all programs.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 37 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 38

Automation and Drives - SCE

5.4 Opening the HMI Station

Right click on “WinCC flexible RT“ and select Open Object.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Project Messages Recipes User Management

T I A Training Document Page 38 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 39

Automation and Drives - SCE

6 WINCC FLEXIBLE ENGINEERING SYSTEM

6.1 Program Interface

The work environment of WinCC flexible consists of several elements. Some of these elements are

coupled to certain editors and are visible only if the corresponding editor is active.

WinCC flexible consists of the following elements:

Menu Bar Symbol Bar Tool Window

Output Window

Project Window

Object Window

Work Area

Library

Property Window

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 39 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 40

Automation and Drives - SCE

6.1.1 Menus and Symbol Bars

The menus and the symbol bars contain all the functions you need to configure your operator panel.

If a corresponding editor is active, menu commands or symbol bars are visible specific to the editor.

If you point to a command with the mouse pointer, you will get a corresponding QuickInfo for each

function.

When a new project is set up, the symbol bars are positioned at the upper screen boundary as a

matter of standard. The position of the symbol bars is coupled to the user that is signed on in

Windows. If you have moved symbol bars with the mouse, the positions that the symbol bars had at

the last close are restored after starting WinCC flexible.

The following menus are available in WinCC flexible:

The availability of the menus and their instruction set depends on the editor that is used.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 40 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 41

Automation and Drives - SCE

6.1.2 Work Space

In the work space, the objects of the project are edited. All elements of WinCC flexible are arranged

around the work space. Except for the work space, you can arrange and configure all elements

according to your own requirements; for example, shifting or hiding.

In the work space, project data is edited either in table form (for example, variables) or graphically

(for example, a process image). Each opened editor is represented in the work space on its own tab

sheet. For graphic editors, each element is represented by a separate tab sheet. If you have several

editors opened at the same time, only one tab sheet is active. To switch to another editor, click on

the corresponding register sheet. You can have a maximum of 20 editors opened at the same time.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 41 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 42

Automation and Drives - SCE

6.1.3 Project Window

The project window is the central control point for project processing. All constituent parts and all

available editors of a project are displayed as a tree structure in the project window and can be

opened from there. To each editor, a symbol is assigned. With it, you can identify the associated

objects. Only those elements are displayed in the project window that the selected operator panel

supports. In the project window, you can access the device settings of the operator panel, language

support, and version management.

The project window represents the structure of the project hierarchically

• Project

• Operator panels

• Folders

• Objects

In the project window, objects are set up and opened for processing. You can set up folders to

structure the objects of your project. The project window is operated similar to the Windows

Explorer. For all objects, you can call a context menu where the most important commands are

combined.

Elements of graphic editors are shown in the project window and in the object window. Elements of

tabular editors are displayed only in the object window.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 42 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 43

Automation and Drives - SCE

6.1.4 Property Window

In the property window, the properties of objects are edited; for example, the color of picture objects.

The property window is available only in certain editors.

In the property window, the properties of the selected object, arranged by categories, are displayed.

As soon as you exit an input field, the values that were changed are effective.

If you enter an invalid value, it is displayed with a background color.

Using QuickInfo, information is provided about the valid value range, for example.

IMPORTANT NOTE

The inputs in the property window are not accepted by operating the input key, but by exiting the

field, or by clicking on another field. Please note where you are clicking after making inputs via the

keyboard. Otherwise, you will possibly be changing to the properties of the selected object, or a

check mark is placed in a check box in the property window, since the area of focus is very large.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 43 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 44

Automation and Drives - SCE

6.1.5 Tool Window

The tool window provides you with a selection of objects that you can insert in your pictures; for

example, graphic objects and control elements. In addition, the tool window includes libraries with

completed library objects, and collections of picture blocks.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 44 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 45

Automation and Drives - SCE

6.1.6 Output Window

In the output window, system messages are displayed standard in the sequence in which they occur.

The categories identify each WinCC flexible submodule that generated a system message. System

messages of the category "Generator" are generated, for example, during the consistency check.

To arrange the system messages, click on the header of the corresponding column. The output

window displays all system messages of the last action. If there is a new action, all previous system

messages are overwritten.

To provide continued access to existing system messages, they are stored in a separate log file.

Errors -for example, during generation- are displayed in color and can be selected by using the

context menu. You can jump to an error location or to a variable, copy system messages, or clear

them.

6.1.7 Object Window

In the object window, the contents of the folders in the project window are displayed.

The object window can be displayed permanently by docking it onto or shifting it into the project

window.

6.1.8 Resetting the Arrangement

In the menu “View“, click on “Reset arrangement“.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 45 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 46

Automation and Drives - SCE

6.2 Configuring Displays

A display can consist of static and dynamic parts. The controller does not update static parts, such

as texts and graphics.

Dynamic parts are connected to the controller, and visualize current values from the controller’s

memory. Visualization can be in the form of alpha-numerical displays, curves, and bars. Dynamic

parts also consist of inputs made at the OP that are written to the controller’s memory. They are

interfaced with the controller by means of Variables.

For our color mixing plant, five displays are to be generated initially.

Display Template

This display is set up automatically, and contains central functions.

In the upper area of the display, a permanent window is generated. Here, the levels of the tanks, of

the container and the project name are shown.

In the lower area of the display, the message window and the message indicator are shown. These

objects are also embedded in all displays, and are opened in the display’s foreground if there is a

message, for example.

Basic Display

This display also is set up automatically, and it is also defined as start picture. Here, the entire plant

is shown

Changing the operating mode, starting the mixing process, operating the mixer motor manually, and

opening the outflow valve can be performed by means of buttons. The motion of the mixer and the

states of the valves are shown graphically. By means of input fields, the amounts of the individual

additives are specified. In addition, it is to be possible to jump to the other displays. Using the button

END, the runtime at the panel is terminated, and a new transfer can be made.

Tank1

In the third picture, the valves of Tank1 can be operated manually. The maximum and minimum

amount of filling has to be preset at linear regulators. By means of buttons (Open valve), the inflow

and outflow valve can be opened or closed. The valves are shown graphically, and change color

when they are open.

The level is indicated in red. If the maximum level is reached, the inflow valve is closed in the

automatic mode. When the tank is completely full, the inflow valve can not be opened.

With additional buttons, you can switch to the other tanks, or to the basic display.

Tank2, Tank3

The displays for Tank2 and Tank3 are structured exactly like the display for Tank1.

The valves and the level of Tank2 are colored green.

The valves and the level of Tank3 are colored blue.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 46 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 47

Automation and Drives - SCE

6.2.1 Display Template

Specifying the permanent area, and changing the background color.

With a double click on Template, open the display Template in the project window.

Drag the bar in the upper area of the panel display window a little downward.

Change the background color in the property window for the permanent area to yellow.

Change the background color in the property window for the work area to white.

Note

If you open the Settings in the menu Options and display the Grid (Raster anzeigen), you can set

the permanent window to a size of 32 pixels.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 47 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 48

Automation and Drives - SCE

Inserting a text field

Drag and drop a text field from the tool window to the permanent window.

For the properties in the text field, enter “Color mixing plant“.

Caution! Do not press the input key.

Under Properties, click on Representation and remove the checkmark adjust automatically.

Change the size and the position of the text field.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 48 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 49

Automation and Drives - SCE

Under Properties, click on Text and

change the font size and the text orientation.

Inserting the date and time of day field

Drag a date/time of day field from the tool window and drop it in the permanent window.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 49 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 50

Automation and Drives - SCE

Under Properties, change the style of the fill type to “Transparent“

Under Properties, click on Representation and remove the check mark Adjust automatically.

Change the size and the position.

Under Properties, click on Text.

Change the font size and the orientation of the text.

For the time being, the display Template is completed.

Note

Now and then, you should save your project by clicking on the diskette symbol.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 50 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 51

Automation and Drives - SCE

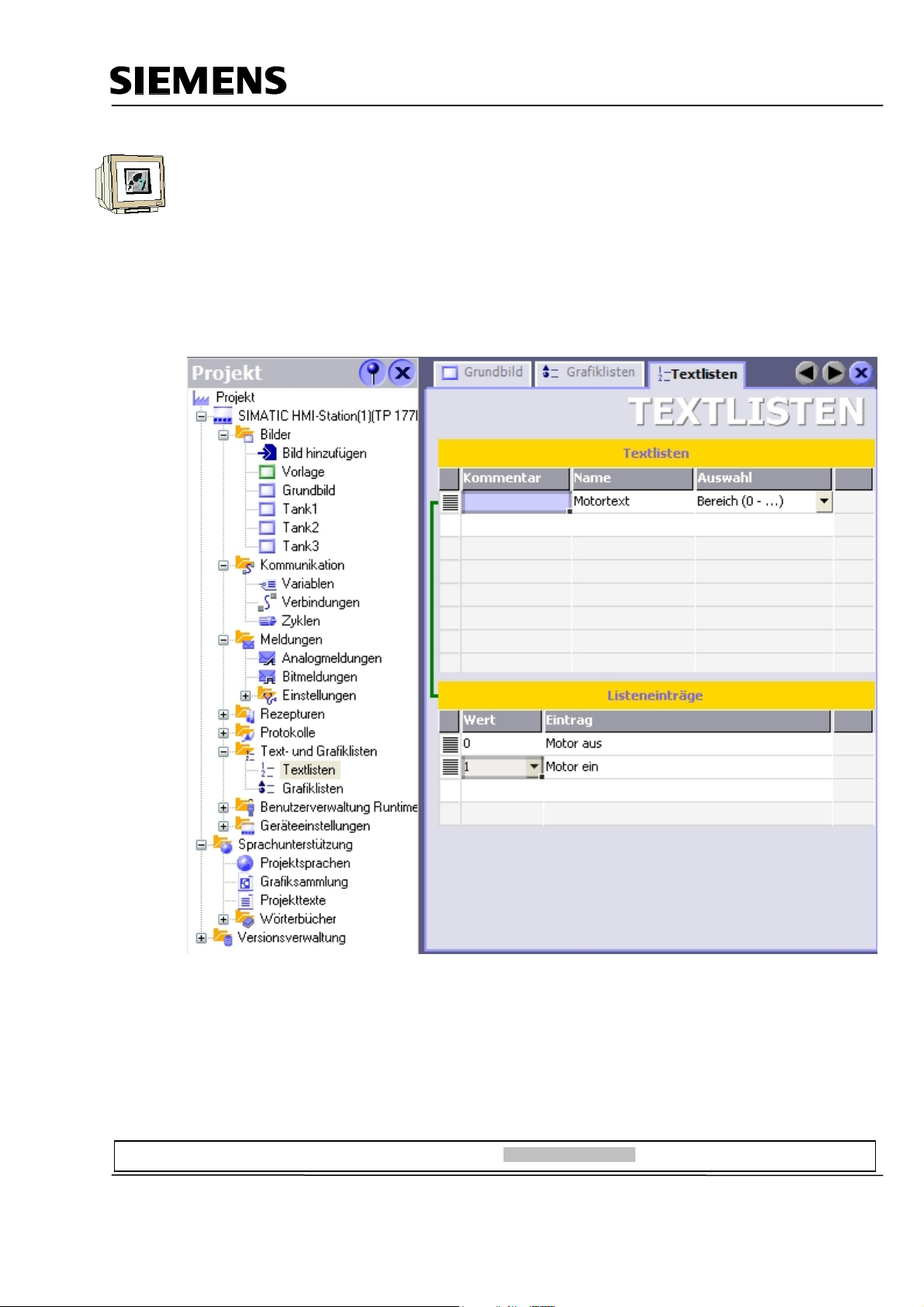

6.2.2 Generating Displays

In the project window, right click on Display1 and select Rename.

Enter “Basic display“ as the name for the picture.

Double click on Add picture and assign the name “Tank1“.

Generate the pictures for Tank2 and Tank3 also.

For all pictures, change the background color of the work area to white. To do this, click on the tabs

of the figures.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 51 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 52

Automation and Drives - SCE

6.2.3 Inserting Graphic Displays

Drag a graphic display to the work area of the basic figure.

In the property window of the graphic display, graphics can now be selected from the list. Using the

buttons, you can create new graphics from files or from OLE objects. You can also delete graphics

from the list.

The selected graphic appears in the preview window, and has to be inserted or removed with the

button Select or Deselect.

Double clicking on the graphic opens the graphics program.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 52 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 53

Automation and Drives - SCE

Click on Generate new graphic from OLE object.

Select Generate from file and click on Browse.

Highlight the figure “Plant.bmp“ and click on Open.

In the window that follows, confirm your selection with OK.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 53 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 54

Automation and Drives - SCE

Under Representation, change the size and position of the graphic.

Repeat these steps for inserting the graphics in figures Tank1 to Tank3.

Under Representation, change the size and the position of the three inserted graphics.

Note

If a graphic is inserted by means of an OLE object, the file name is retained.

Don’t forget to save!

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 54 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 55

Automation and Drives - SCE

6.2.4 Configuring Display Changes

By means of buttons, it is to be possible in each figure to change to the other three figures. In the

case of WinCC flexible, only the names of the figures have to be dragged from the project window to

the figure. The buttons are generated automatically.

Change the size and the position of the button.

Under text, select the font “Tahoma; 8pt“.

Repeat these steps for the buttons for Tank2 and Tank3.

In the tank figures, generate the buttons for the display change.

Change the width of the button “Basic display“ to 60.

You can also copy and insert prepared buttons.

Don’t forget to save!

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 55 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 56

Automation and Drives - SCE

Basic Display

Figure Tank1

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 56 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 57

Automation and Drives - SCE

Figure Tank2

Figure Tank3

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 57 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 58

Automation and Drives - SCE

6.3 Settings at the Touch Panel TP177B color PN/DP

Before we can perform the first test, the settings on the touch panel have to be executed first.

The following settings have to be made:

- Setting the date and time of day

- Assigning the MPI or Profibus DP address

- Assigning the Ethernet address

- Setting the transfer properties

Touch Panel TP177B processes with the operating system Windows CE and can, like all touch

panels, be operated directly on the screen. For better operation, you should use a touch pen, or

connect a mouse at the panel’s USB interface.

After starting the panel, the desktop appears and the window of the loader. At the lower edge of the

screen, the start bar is located. With it, you can -just as with other Windows systems- start the

programs or make settings.

Buttons in the Loader:

Transfer: Data transfer becomes active, and data can be entered by WinCC flexible

Start: Runtime is started, and process visualization appears on the panel

Control Panel: The Windows CE desktop is called

Taskbar: The start bar is opened

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 58 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 59

Automation and Drives - SCE

6.3.1 Setting the Date and the Time of Day

To set the date and the time of day, operate the button Control Panel.

This opens the desktop of Windows CE.

Select Date/Time to make the settings.

Set the time zone, the date and the time. Confirm with OK.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 59 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 60

Automation and Drives - SCE

6.3.2 Setting the MPI Address

To set the MPI address on the panel, click on “S7 Transfer Settings“

Select MPI and click on Properties.

Place a checkmark at “Panel is the only master on the bus“.

Assign the MPI Address 1 and confirm with OK.

Note

Many panels allow data transfers only if either the panel or the programmer is set as the only master

on the bus.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 60 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 61

Automation and Drives - SCE

6.3.3 Setting the Profibus DP Address

To set the Profibus DP address, click on “S7 Transfer Settings“ on the desktop.

Select Profibus and click on the button Properties.

Place the checkmark at “Panel is the only master on the bus“.

Assign the Profibus DP Address 1 and confirm with OK.

6.3.4 Assigning the Ethernet Address

On the desktop, operate the symbol

and select the Onboard LAN Ethernet Driver.

Click on the button Properties.

Here, you can make the settings for the Ethernet.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 61 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 62

Automation and Drives - SCE

6.3.5 Setting the Transfer Properties

On the desktop, click on the symbol

Select MPI/Profibus and click on the button Advanced.

In the window that follows, select MPI and confirm with OK.

Note

The settings at Transfer Settings have nothing to do with the connection settings in the

WinCC flexible project.

For example, data can be transferred between Panel TP177B and WinCC flexible by means of the

Ethernet interface, and the panel and the SIMATIC S7 controller can communicate by means of the

MPI.

6.3.6 Transfer Mode

Close the desktop and switch the panel to the Transfer Mode.

Connecting to host … appears in the transfer window.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 62 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 63

Automation and Drives - SCE

6.4 Checking for Consistency

Before you transfer the WinCC flexible project to the panel, the consistency should be checked. The

project is checked and generated.

Click on Consistency check of the project.

The result is displayed in the output window.

6.5 Transfer Settings and Data Transfer under WinCC flexible

In WinCC flexible, the settings have to be made for the transfer. Click on the button Settings for the

Transfer.

For Mode, select MPI/DP; enter 1 as station address.

Click on Transfer.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 63 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 64

Automation and Drives - SCE

Confirm overwriting the keyword list.

<<Do you want to overwrite the existing keyword list on the operator panel?>>

If the transfer settings are correct on the panel and in WinCC flexible, the transfer starts now.

After restarting the panel, the start picture appears in runtime.

Test all buttons for the display change.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 64 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 65

Automation and Drives - SCE

6.6 Button END

The project can only be transferred again if the panel TP177B is in the transfer mode. When the

panel powers up, the loader appears for a few seconds with the button “Transfer“. Before each

transfer, the panel would have to be taken off load so that a switchover to the transfer mode is

possible. Data is lost in that case; for example, the date and the time of day have to be reset.

For that reason, in our basic display we are creating a button for ending the runtime mode. Drag a

button into your basic display.

Change the text, the font size, the size 40 x 20, the position and the color (red) of the button.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 65 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 66

Automation and Drives - SCE

Under Events, select the function StopRuntime by Clicking on the function.

A configured function is referred to in bold print.

Under mode, other settings can be made.

For our panel TP177B, only Runtime is to be terminated.

Save your project and start the consistency check.

Note

If during the consistency check, lines that are marked blue that contain internal warnings occur, you

have to regenerate the entire project first.

In the menu “Project“, click on Generator and select Regenerate everything.

Perform a restart at the panel (take it briefly off load).

Switch the panel to the transfer mode.

Transfer your project to the panel.

Click on the END button

Reset the date and the time, and start Runtime.

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 66 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 67

Automation and Drives - SCE

6.7 Configuring a Connection

So far, we worked in our project without accessing the SIMATIC S7 controller.

On our panel, levels are to be displayed and fill setpoints are to be entered.

For operator and display objects that access the process values of a controller, first the connection

to the controller has to be configured.

Here, you specify how and by means of what interface the panel communicates with the controller.

Double click on the window Connections.

All parameters are already set through the settings in the hardware configuration.

Note

To set up a new connection, double click in the free field in the first column. Change the connection

parameters of the newly created connection

Preface Installation Project Description Step7 Project HMI Station WinCC flexible Projekt Messages Recipes User Management

T I A Training Document Page 67 of 129 Module

F6

Issued: 02/2008 Operator Control with WinCC flexible 2005

Page 68

Automation and Drives - SCE

7 DISPLAY AND OPERATOR OBJECTS

Display and operator objects are graphic elements with which process displays are designed.

In Runtime, all display and operator objects behave dynamically.

In addition, you can make the properties of objects dynamic.

One example of this is the graphic of a tank whose liquid level is displayed as varying, depending on

the corresponding process value.

Another example for the dynamic behavior of an object is a button that triggers a certain function. In

principle, you can make all graphic objects dynamic.

You can configure the following:

- The object changes its appearance: color and blinking.

- The object moves in the picture.

- The object is inserted/removed.

For operator elements, you can configure the following:

- The object is enabled or disabled for operation.

- By operating the object -for example, by clicking on it- an event is triggered to which the

processing of a function list is configured.

7.1 Levels