TO Basics

Vesa Kovalainen & Pyry-Pekka Lehto

siemens.com/tia-portalUnrestricted © Siemens AG 2020

Unrestricted © Siemens AG 2018

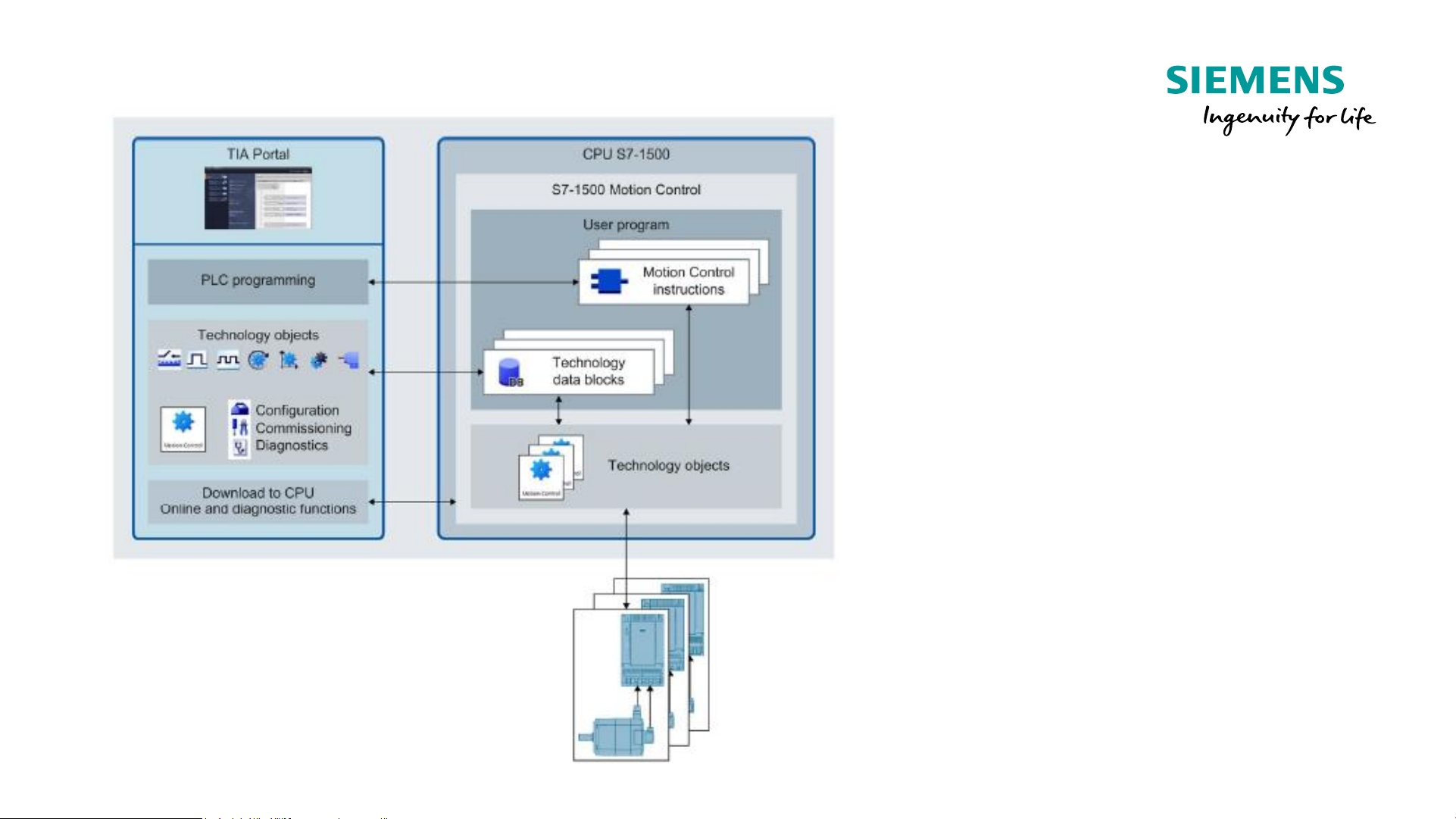

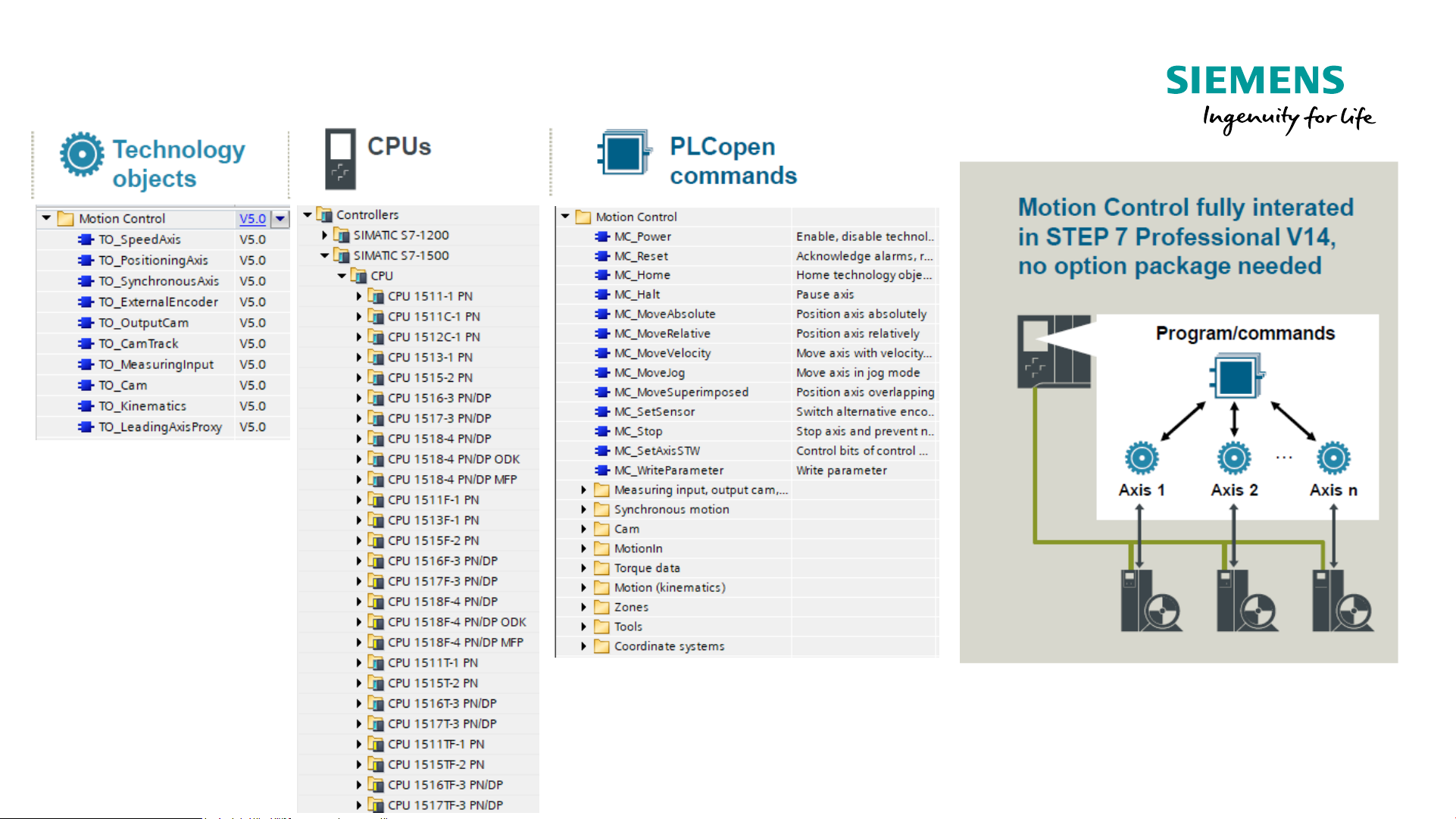

Technology objects for Motion Control

- Motion control function in 1200/1500-CPU

- Easy to configure w/o deep knowledge of

drives

- Can be configured as Real or Virtual

1)

axis

- Visual user interface

- Each TO has it’s own:

• Configuration

• Control panel

2)

• Diagnostics

3)

• Datablock

• Simulation

2)

- PLC-open commands

- Similar programming apart which drive is used

- No additional installations nor licenses are

needed

1) Not 1200

2) Not MeasuringInput, OutputCam, Camtrack, Cam

3) Not Cam

Unrestricted © Siemens AG 2018

Technology objects for Motion Control

1) Application

2) Technology object

3) CPU

4) Programming

Unrestricted © Siemens AG 2018

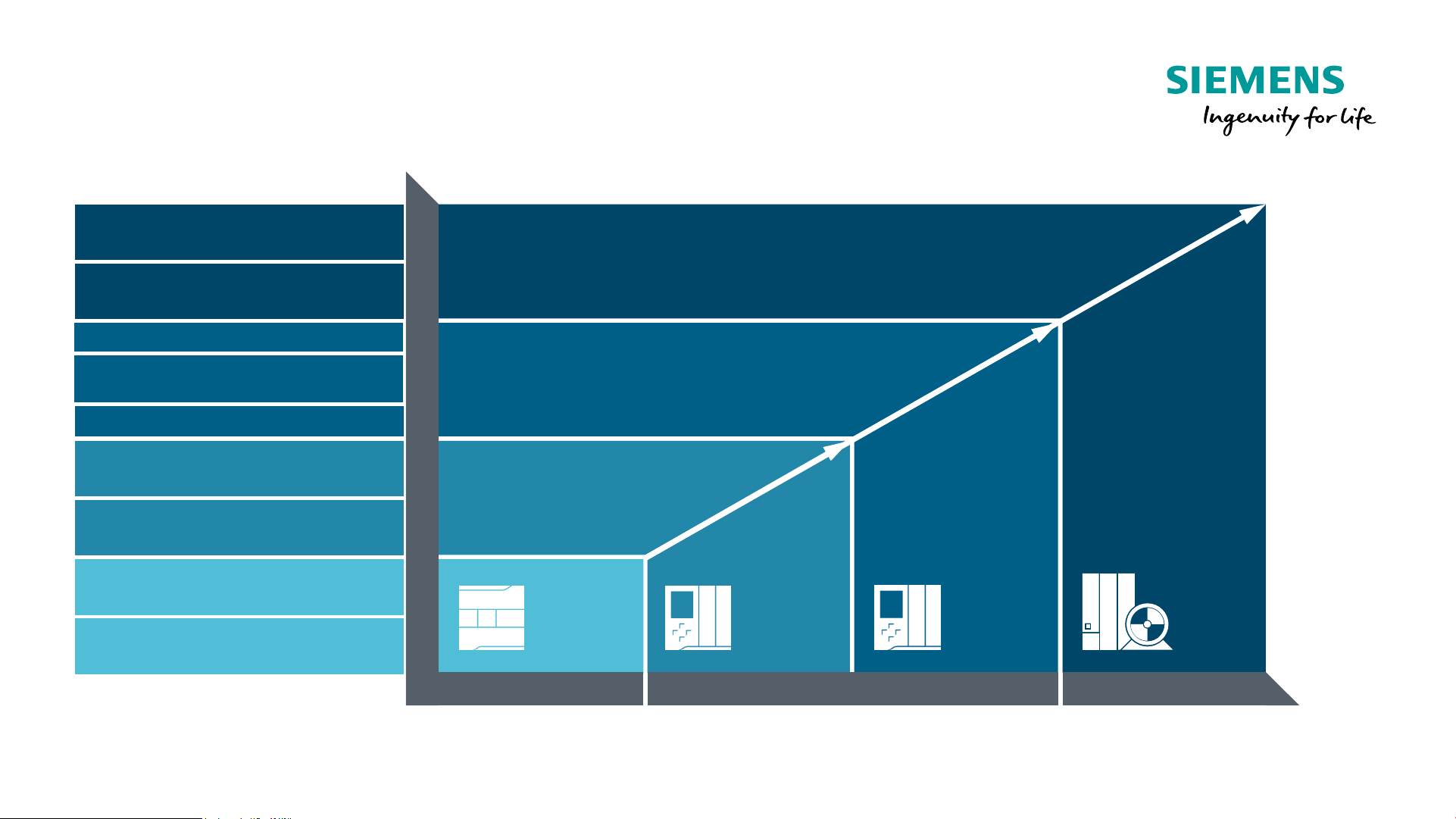

Technology objects for Motion Control

Correct controller to each application

2nd PROFINET IRT interface

High-performance Motion Control

4)

Gearing

1)

Output cams

Measuring input

Positioning

Speed control

Basic Midrange High-End

Basic

Controller

Standard CPU

Advanced

Controller

Standard CPU

T

Advanced

Controller

T-CPU

SIMOTION

Motion

Controller

Cross-PLC synchronous operation

3)

Camming & Gearing

2)

Kinematic functions

with conveyor tracking

5)

1)

Synchronization without specification of the synchronous position

2)

Synchronization with specification of the synchronous position

3)

In one project

4)

Cross-project synchronization; cams with dynamic size;

2 servo for axis groups

5)

planned for FW-Update V2.8.x (V16)

Unrestricted © Siemens AG 2018

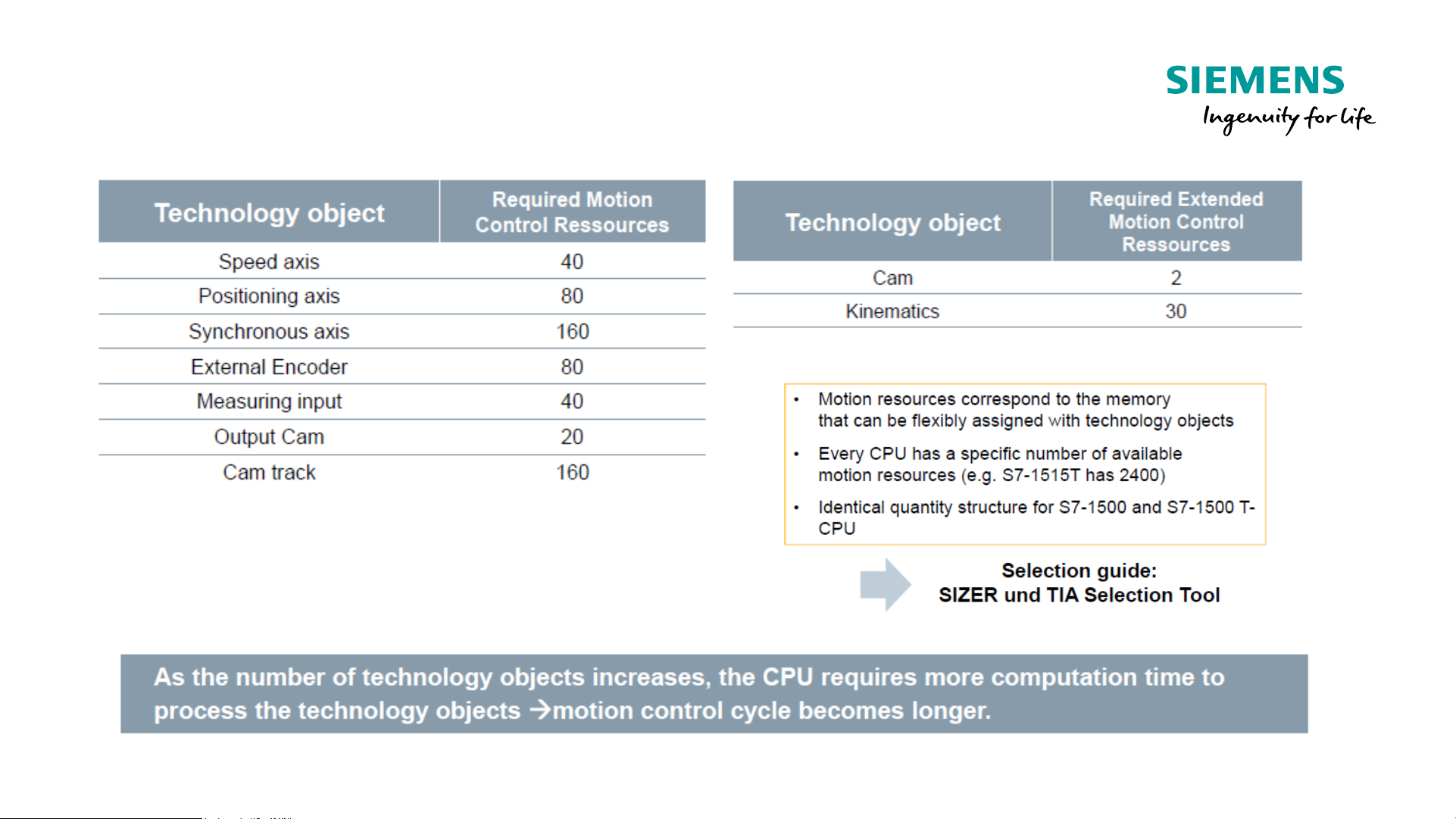

Technology objects for Motion Control

Motion Control resources

Unrestricted © Siemens AG 2018

Technology objects for Motion Control

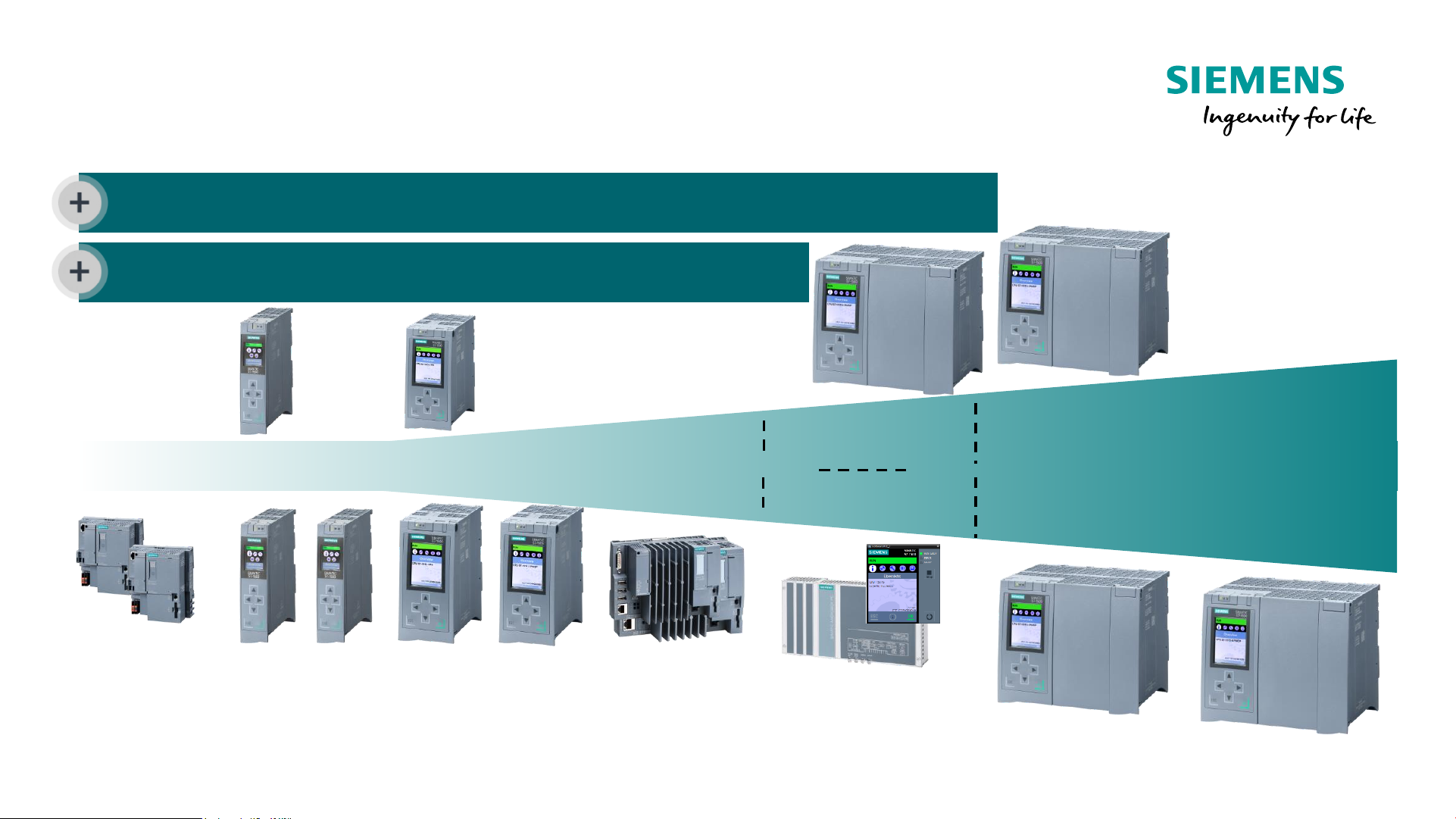

Amount of axes and performance

Scalable according to amount of axes and

performance

Identical basic motion control functions in each CPU

*)

IPC4x7D, IPC6x7D ja IPC8x7D

1)

Positioning axes

1511 1513 1515 1516

1517

1510SP

1512SP

1515SP PC

ET 200SP

Open Controller

1507S*

S7-1500

Software Controller

1511T/TF 1515T/TF

1517T/TF

1516T/TF

Max. 5-10 Axes

1)

7-30 Axes

1)

30-60 Axes

1)

64-128 Axes

1)

40-80 Axes

1)

1518

Unrestricted © Siemens AG 2018

New

System Portfolio – SIMATIC S7-1500 Motion Control

Amount of axes and features

Motion Control

functionality

Performance

(TIA Portal V16)

SIMATIC S7

-1500 Controller

Distributed

Controller

Drive

Controller

CPU 1511

CPU

1513

CPU 1515

CPU

1516

CPU 1516T

CPU 1517

CPU 1518

CPU 1515SP PC2

1504D TF

1507D TF

Number

Positioning

axes

Typical

3)

5 7 55 70 128 30 10 55

Maximum

10 30 80 128 128 30 30 160

Cross-PLC

synchronous operation

Technology

Kinematics functions

Camming

Gearing1(with

synchronous position)

Gearing2(without

synchronous position)

Standard

Output cam /

Measuring input

Positioning

Open-

loop speed control

abs

.

rel.

1)

Synchronization with specification of the synchronous position

2)

Synchronization without specification of the synchronous position

3)

In 4 ms at 35% CPU load

Unrestricted © Siemens AG 2018

Technology objects for Motion Control

When to use Technology objects

-”If motion control is something else than speed control -> TO”

-Readymade FBs w/o TO for speed controlled axis:

SINA_SPEED, SINA_SPEED_20, SINA_SPEED_352 (G120_PZD352)

https://support.industry.siemens.com/cs/document/109747655/sinamics-s-g-v%3A-simple-cyclic-funktions-blocks-forcontrolling-a-sinamics-in-tia-portal-?dti=0&lc=en-US

https://support.industry.siemens.com/cs/document/109738702/libraries-in-the-tia-portal?dti=0&lc=en-WW

.

TIA15.1

TIA13..15

Reference variables: Drive param. p2000→

Unrestricted © Siemens AG 2018

LdrvSafe: SIMATIC-safety library for SINAMICS G/S

Readymade FBs for PROFIsafe-control

SIMATIC - Failsafe library LDrvSafe to control the Safety Integrated functions of the SINAMICS drive family

https://support.industry.siemens.com/cs/ww/en/view/109485794

Unrestricted © Siemens AG 2018

Technology objects for Motion Control

Organization blocks

- When TO is created, simultaneously OB91 and OB92 are created where

motion control tasks are executed

• Highest priority (1500: 26, 1200: 25)

• Shall not to be interrupted

- OB91 Cycle time

- Shorter cycle loads CPU

• Cyclic: RT, cyclic but not synchronous: G120

• Synchronous to the bus: IRT, synchronous execution tied to CPU’s

send clock. HW support required: V90/S210/S120

• With IRT and DSC: longer Cycle time do not affect positioning

accuracy because position control at Servo CU.

RT = Real time

IRT= Isochronous real time

DSC = Dynamic servo control

Unrestricted © Siemens AG 2018

Teknologiaobjektit liikkeenohjaukseen

Control loop

-Drive speed controller must be tuned before tuning TO

position controller

-DSC “positiong controller at servo CU; TO gives only

setpoint”

-PreControl ja Gain improves motion dynamics and

reduce following error

• Too large gains cause position overshoot

especially with frequency converters

-Substitute time delays setpoint to position controller in

relation to PreControl. Can be used to compensate

position overshoot with large gains. In typical cases no

need to adjust from 0.

SERVO

FREQUENCY CONVERTER

Unrestricted © Siemens AG 2018

Technology objects for Motion Control

Manuals

https://support.industry.siemens.com/cs/document/109749263/simatic-s7-1500-s7-1500t-motion-control-v4-0-in-tia-portal-v15?lc=en-US

Motion control manual for TIA Portal – 1500T

https://support.industry.siemens.com/cs/document/109749262/simatic-s7-1500-s7%E2%80%911500-motion-control-v4-0-in-tia-portal-v15?lc=en-US

Motion control manual for TIA Portal - 1500

Motion control manual for TIA Portal - Kinematics

https://support.industry.siemens.com/cs/document/109749264/simatic-s7-1500-s7-1500t-kinematics-functions-v4-0-in-tia-portal-v15?lc=en-US

Motion control manual for TIA Portal - 1200

https://support.industry.siemens.com/cs/document/109754206/simatic-step-7-s7-1200-motion-control-v6-0-in-tia-portal-v15?lc=en-US

Application examples for motion control

https://www.automation.siemens.com/mc-app/sinamics-application-examples/Home/Index?language=en

Unrestricted © Siemens AG 2018

Technology objects for Motion Control

Tips

1) Frequency converters OFF1-ramps has to set 0s! All addional ramps at frequency converter cause additional delay

to position controller and worsen the quality of positioning.

2) The datatype of Technology object is not automatically recognized (i.g TO_PositioningAxis). They have to manually

typed completly.

3) Enable: level 0-1-0, Execute: rising edge

4) Motion tasks can be intrerrupted with another task

5) For same axis (TO) can have multiple similar or different motion tasks

6) Commands’ ”Done” stays True as long as ”Execute” stays True. If only pulse (1 cycle) given to ”Execute”; Done

stays True only one program cycle.

7) Motion task commands are ”normally” called in OB1. If faster reaction due to very rapid sequencies is needed,

commands can be called in other OBs as well, i.g in Pre/PostServo-OB:ssa. Command is effective when OB-servo

is executed next time .

8) MC_MoveVelocity and MC_MoveJog are positioning controlled as default. Set ”PositionControlled”-input False if

this not preferable.

Live Demo

Unrestricted © Siemens AG 2018

Unrestricted © Siemens AG 20XX

17.04.2019Page 16

Interested to hear about the upcoming

webinars?

You will find all the upcoming webinars from here:

www.siemens.fi/webinaarit

If you want to be the first one to hear about our webinars –

register to our distribution list!

Also feel free to register straight away to any of the

interesting webinars.

www.siemens.fi/webinaarit

Upcoming industry

webinars

Next webinar:

Advanced Technology Objects for efficient motion control

Friday 3.4.2020 at 14:00-14:45

Unrestricted © Siemens AG 20XX

17.04.2019Page 17

Contact Customer Care Center

Prepare to provide the following information:

✓ Question or fault description

✓ All Siemens product, system and/or software version related

information regarding the support request

✓ Please attach files and pictures to support request sent with

email

✓ How do you wish to be contacted? (we call you or send email)

010 511 3100customercare.fi

@siemens.com

Our experts at your service during weekdays 8:00 – 16:00

System failure?

Technical detail?

Feedback?

www.siemens.fi/asiakaspalvelu

Unrestricted © Siemens AG 20XX

17.04.2019Page 18

Productivity and inspiration with the help

of expert training

Have a look at our upcoming training offerings, enroll

for courses and login to your MyTraining account

050 4783 555koulutus.fi@

siemens.com

Web-based e-learning or tailored training program?

Let’s plan it together!

Vikatilanne?

Tekninen kysymys?

Palaute?

www.siemens.fi/koulutus

SITRAIN

Automation Training

Unrestricted © Siemens AG 2018

siemens.com

Subject to changes and errors. The information given in this document only contains general descriptions and/or performance features which may

not always specifically reflect those described, or which may undergo modification in the course of further development of the products. The requested

performance features are binding only when they are expressly agreed upon in the concluded contract.

All product designations, product names, etc. may contain trademarks or other rights of Siemens AG, its affiliated companies or third parties.

Their unauthorized use may infringe the rights of the respective owner.

Vesa Kovalainen

Application Engineer

vesa.kovalainen@siemens.com

Pyry-Pekka Lehto

Sales Specialist Motion Control

pyry-pekka.lehto@siemens.com

Thank you for your attention!

Subject to changes and errors. The information given in this document only contains general descriptionsand/or performance features which may

not always specifically reflect those described, or which may undergo modification in the course of further development of the products. The requested

performance features are binding only when they are expressly agreed upon in the concluded contract.

All product designations, product names, etc. may contain trademarks or other rights of Siemens AG, its affiliated companies or thirdparties.

Their unauthorized use may infringe the rights of the respective owner.

siemens.com/tia-portal

Loading...

Loading...