Page 1

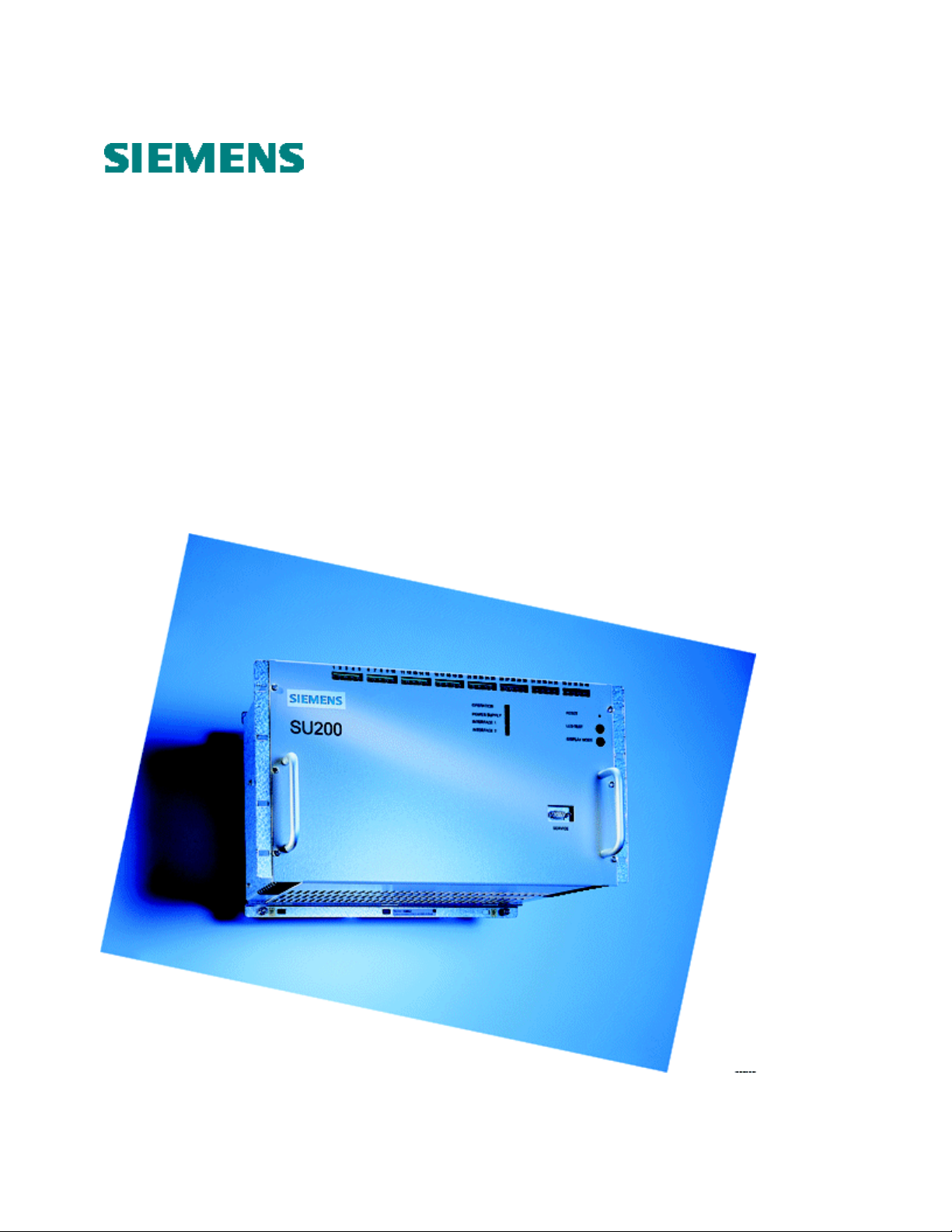

SU200

Distributed I/O Unit

for MC-based Substation Control Systems

User manual

Order no: LGW : AB03 - Y200A – A

Page 2

Page: 2 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Version history

Version Date Comment

1 1. Feb 1997 Initial version.

2 15. Sep 1997 Document reformatted.

New functionality in SU200DIA V2.13.

3 26. Jan 1998 Encoding of bits used for selecting active/passive master corrected.

4 16. Nov 1999 Rewritten for SU200 software release 3.0

5 08. Jan 2001 New option for 220VAC Relay Output Voltage.

6 30.Aug 2001 Rule file syntax enhanced.

7 22.Nov 2001 Latch programming example for rule file revised

8 14.May 2002 New system message indicating analogue input card faulty.

Firmware version 3.10

9 05.Jun 2002 New fail-to-safe configuration and analogue input scaling in SU200DIA described

Firmware version 3.40

10 14.Jun 2002 New version of SU200DIA (V 3.50.1)

11 17.Oct 2002 Message 103 is no longer a common message (sent on PROFIBUS)

Siemens AS reserves the right to make technical alterations. The information contained in this manual is not binding

Copyright Siemens AS 1997-2002. All Rights Reserved

Table of contents

1. Introduction ________________________________________________________________ 8

1.1. Application ____________________________________________________________________ 8

1.2. Features_______________________________________________________________________ 9

1.3. Interfaces_____________________________________________________________________ 10

2. Technical data______________________________________________________________ 11

2.1. General data __________________________________________________________________ 11

2.1.1. Digital inputs______________________________________________________________________ 11

2.1.2. Relay outputs______________________________________________________________________ 11

2.1.3. Analogue inputs____________________________________________________________________ 11

2.1.4. Power supply______________________________________________________________________ 12

2.1.5. Processors ________________________________________________________________________ 12

2.1.6. Time synchronising inputs ___________________________________________________________ 13

2.1.7. Fieldbus interfaces for optical transmission media _________________________________________ 13

2.1.8. Fieldbus interfaces for electrical transmission media _______________________________________ 13

2.1.9. Serial interface for parameterisation and diagnostics _______________________________________ 14

Page 3

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 3 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

2.1.10. Serial interface for firmware download__________________________________________________ 14

2.1.11. LED indications____________________________________________________________________ 14

2.1.12. Electromagnetic compatibility and interference immunity ___________________________________ 14

2.1.13. Climatic strain _____________________________________________________________________ 15

2.1.14. Mechanical stress __________________________________________________________________ 15

2.1.15. Dielectric strength __________________________________________________________________ 16

2.1.16. Equipment design __________________________________________________________________ 16

2.1.17. Conformity _______________________________________________________________________ 16

2.2. Memory capacity ______________________________________________________________ 16

2.3. Ordering data _________________________________________________________________ 17

2.4. Block diagram_________________________________________________________________ 18

3. Design 19

3.1. Construction __________________________________________________________________ 19

3.2. Modules ______________________________________________________________________ 20

3.2.1. Power supply module _______________________________________________________________ 20

3.2.2. CPU and communications module _____________________________________________________ 21

3.2.3. LED module ______________________________________________________________________ 22

3.2.4. Relay output module ________________________________________________________________ 23

3.2.4.1. Relay output monitoring _________________________________________________________ 24

3.2.4.2. Relay output circuitry ___________________________________________________________ 24

3.2.5. Digital input module ________________________________________________________________ 25

3.2.5.1. Electrical time synchronisation port ________________________________________________ 26

3.2.6. Analogue input module______________________________________________________________ 26

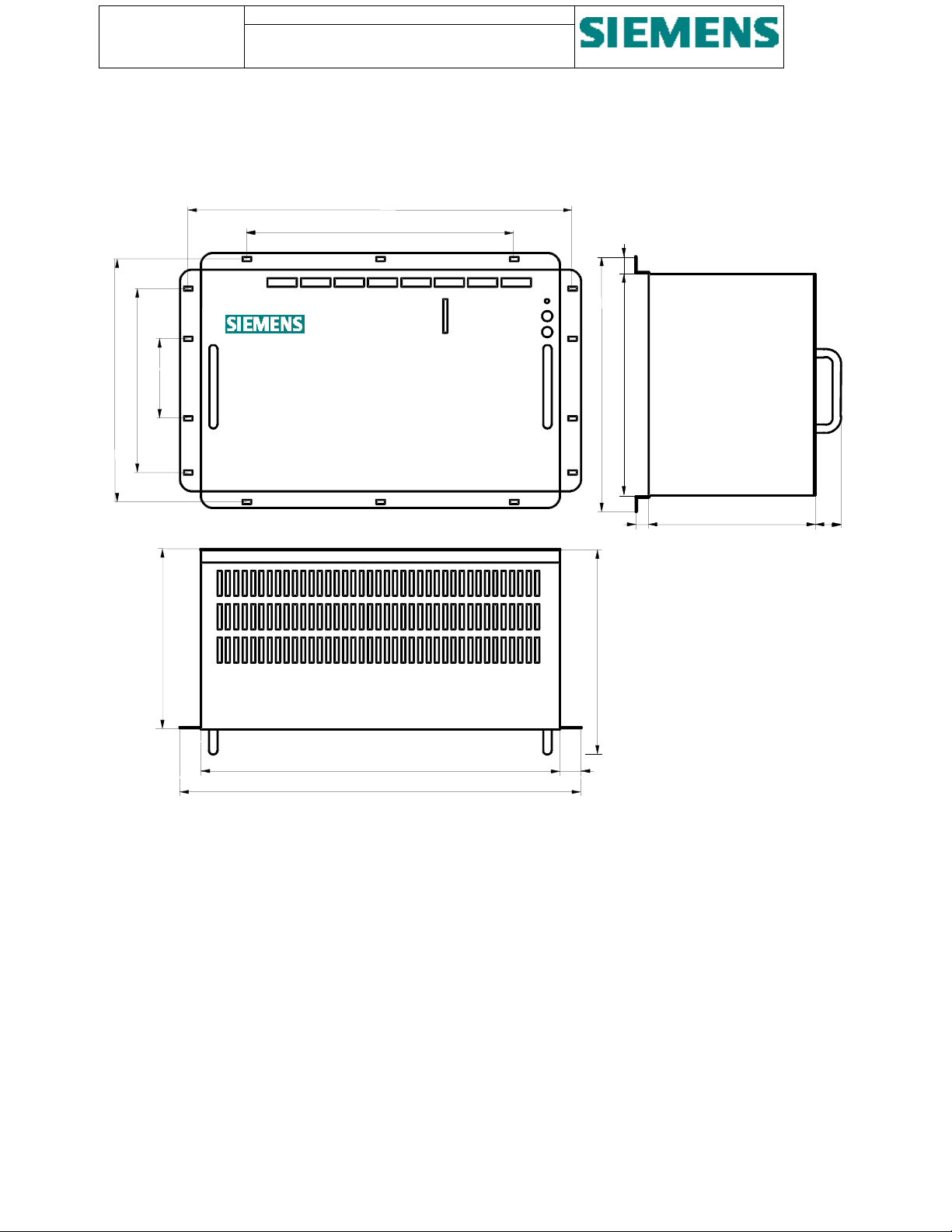

3.3. Dimensions ___________________________________________________________________ 28

3.4. Connections ___________________________________________________________________ 28

4. Method of operation _________________________________________________________ 31

4.1. Operation principle ____________________________________________________________ 31

4.2. Self-monitoring ________________________________________________________________ 31

4.3. Redundancy __________________________________________________________________ 32

4.4. Data transfer __________________________________________________________________ 33

4.4.1. Fieldbus__________________________________________________________________________ 33

4.4.2. Network configuration ______________________________________________________________ 33

4.4.3. Principle of operation _______________________________________________________________ 33

4.4.4. Transmission media_________________________________________________________________ 33

4.4.5. Electrical transmission media _________________________________________________________ 34

4.4.6. Optical transmission media ___________________________________________________________ 34

4.5. Telegram structure_____________________________________________________________ 34

4.5.1. From SU200 to Master ______________________________________________________________ 34

4.5.2. From master to SU200 ______________________________________________________________ 38

4.6. Communications control ________________________________________________________ 38

4.6.1. From SU200 to master ______________________________________________________________ 38

4.6.1.1. Control byte #1 ________________________________________________________________ 39

4.6.1.2. Control byte #2 ________________________________________________________________ 40

4.6.2. From master to SU200 ______________________________________________________________ 41

4.6.2.1. Control byte #1 ________________________________________________________________ 41

4.6.2.2. Control byte #2 ________________________________________________________________ 42

4.6.3. Communications monitoring__________________________________________________________ 42

4.7. Cyclic buffer __________________________________________________________________ 42

Page 4

Page: 4 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

4.8. Clock control__________________________________________________________________ 42

5. Controls and displays ________________________________________________________ 44

5.1. LED display __________________________________________________________________ 44

5.2. Buttons_______________________________________________________________________ 47

5.3. Serial interfaces _______________________________________________________________47

6. SU200DIA _________________________________________________________________ 48

6.1. Parameterisation ______________________________________________________________ 49

6.1.1. PROFIBUS address_________________________________________________________________ 50

6.1.2. Master mode ______________________________________________________________________ 50

6.1.3. Enable analogue inputs ______________________________________________________________ 50

6.1.4. Signal ID _________________________________________________________________________ 51

6.1.5. LED_____________________________________________________________________________ 51

6.1.6. Logic ____________________________________________________________________________ 52

6.1.7. Mode ____________________________________________________________________________ 52

6.1.8. Timing___________________________________________________________________________ 52

6.1.9. Default parameter values_____________________________________________________________ 53

6.1.10. Managing parameter files ____________________________________________________________ 53

6.2. Diagnostics ___________________________________________________________________ 54

6.2.1. Firmware version___________________________________________________________________ 54

6.2.2. Date and time _____________________________________________________________________ 54

6.2.3. Message list_______________________________________________________________________ 55

6.2.4. Digital inputs______________________________________________________________________ 56

6.2.5. Analogue inputs____________________________________________________________________ 56

6.2.6. Managing message files _____________________________________________________________ 56

6.3. Tools menu ___________________________________________________________________ 57

6.3.1. Local Control _____________________________________________________________________ 58

6.3.2. Simulate Digital Inputs ______________________________________________________________ 59

6.3.3. Fail-To-Safe configuration ___________________________________________________________ 60

6.3.4. Impulse counter values ______________________________________________________________ 60

6.3.5. Analogue input scaling ______________________________________________________________ 61

6.3.6. System parameters__________________________________________________________________ 62

6.3.7. Rules ____________________________________________________________________________ 63

6.3.7.1. Example of rules:_______________________________________________________________ 65

6.3.7.2. SET function __________________________________________________________________ 66

6.3.7.3. RESET function _______________________________________________________________ 66

6.3.7.4. BLOCK function_______________________________________________________________ 66

6.3.7.5. ABLOCK function _____________________________________________________________ 66

6.3.7.6. ENABLE function______________________________________________________________ 66

6.3.7.7. AENABLE function ____________________________________________________________ 66

6.3.7.8. Rule file macros _______________________________________________________________ 66

6.3.7.9. Actions when communication with active master is interrupted___________________________ 67

6.3.7.10. Override rule control in local mode_________________________________________________ 67

6.3.7.11. Rule download report ___________________________________________________________ 67

6.3.7.12. Priority_______________________________________________________________________ 67

6.3.7.13. Rule file syntax ________________________________________________________________ 68

6.3.7.14. Rule file example_______________________________________________________________ 70

6.3.8. Communication____________________________________________________________________ 71

6.3.9. Firmware tool _____________________________________________________________________ 72

6.3.10. Reading/writing memory or I/O-ports___________________________________________________ 72

6.3.11. Downloading new firmware __________________________________________________________ 74

7. Installation ________________________________________________________________ 75

7.1. Unpacking ____________________________________________________________________ 75

Page 5

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 5 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

7.2. Mounting _____________________________________________________________________ 75

7.3. Connection ___________________________________________________________________ 76

7.3.1. Earth connection ___________________________________________________________________ 76

7.3.2. Connection of control wires __________________________________________________________ 76

7.3.3. Connection of optical data lines (fieldbus) _______________________________________________ 77

7.3.4. Connection of electrical data lines (fieldbus) _____________________________________________ 78

7.3.5. Cable entry fitting __________________________________________________________________ 81

7.3.6. Connecting points __________________________________________________________________ 82

8. Commissioning _____________________________________________________________ 83

8.1. General ______________________________________________________________________ 83

8.2. Checking the auxiliary power supply ______________________________________________ 83

8.3. Checking the fieldbus link _______________________________________________________ 83

8.4. Checking the clock control and time synchronisation ________________________________ 84

8.4.1. Checking the clock control ___________________________________________________________ 84

8.4.2. Checking the time synchronisation _____________________________________________________ 84

8.5. Checking the digital input _______________________________________________________ 84

8.6. Checking the command output ___________________________________________________85

8.7. Checking the analogue inputs ____________________________________________________ 85

8.8. Checking the self-monitoring function_____________________________________________ 85

9. Maintenance and fault tracing_________________________________________________ 87

Appendix A SU200DIA Parameter-files _____________________________________________ 88

Appendix B DIP switches ________________________________________________________ 90

Appendix C PROFIBUS Test Tool _________________________________________________ 92

C.1. Setting up the PROFIBUS network _______________________________________________ 94

C.1.1. Setting up PROFIBUS master card CP5613 ______________________________________________ 94

C.1.2. Setting up PROFIBUS master card CP5412 ______________________________________________ 95

C.2. Configuring and using the COM PROFIBUS application from Siemens AG _____________ 96

C.2.1. SU200 GSD file ___________________________________________________________________ 97

C.2.2. Creating a PROFIBUS network set-up for SU200 _________________________________________ 97

Appendix DReplacing FLASH memory devices _____________________________________ 100

Appendix E General Terminal Diagram____________________________________________ 101

Appendix F Connection diagram for power supply / communications____________________ 102

Appendix GConnection diagram for I/O ___________________________________________ 103

Figures

Figure 1 - Principle arrangement of a station control and monitoring system with incorporated SU200 9

Figure 2 - Overview 10

Figure 3 - Memory map 16

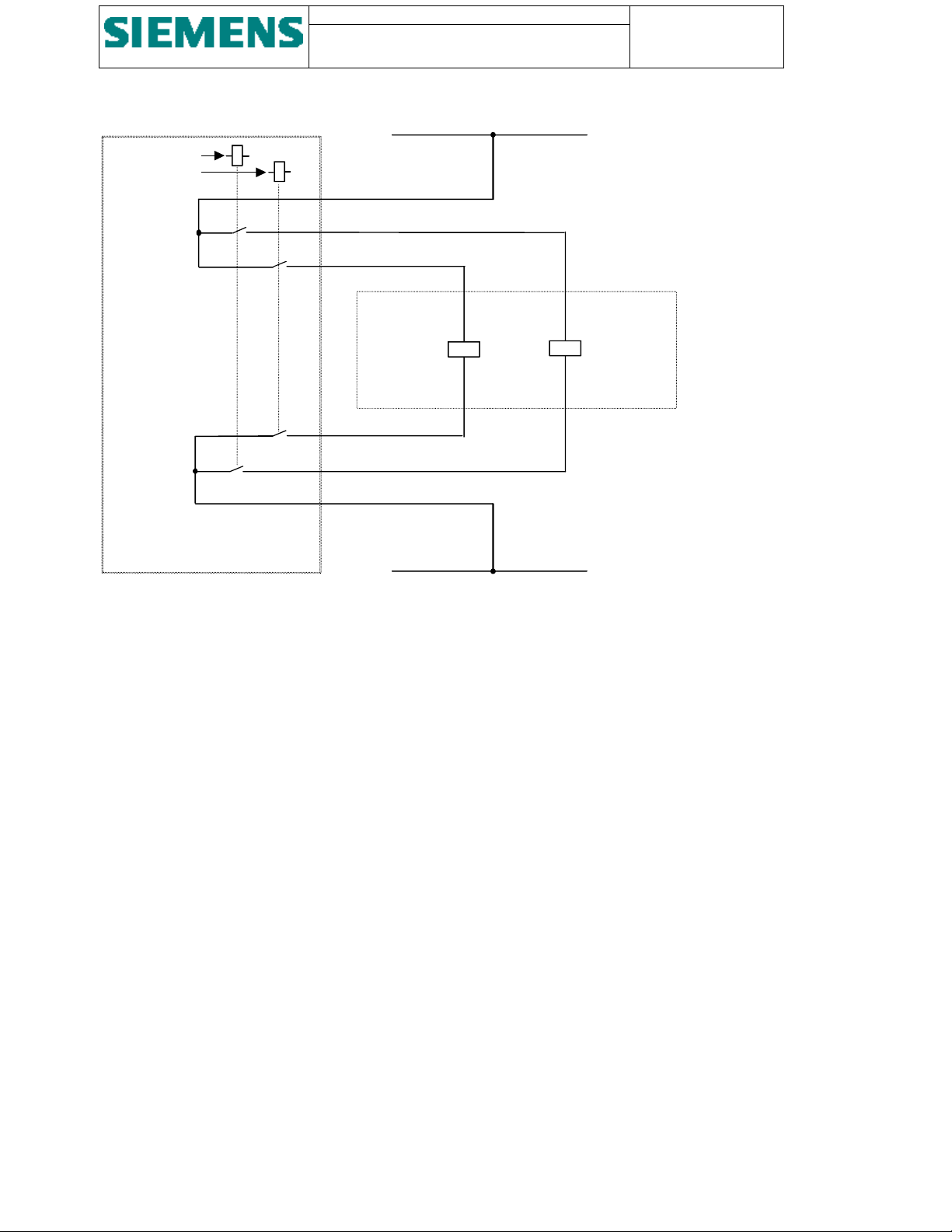

Figure 4 - Block diagram 18

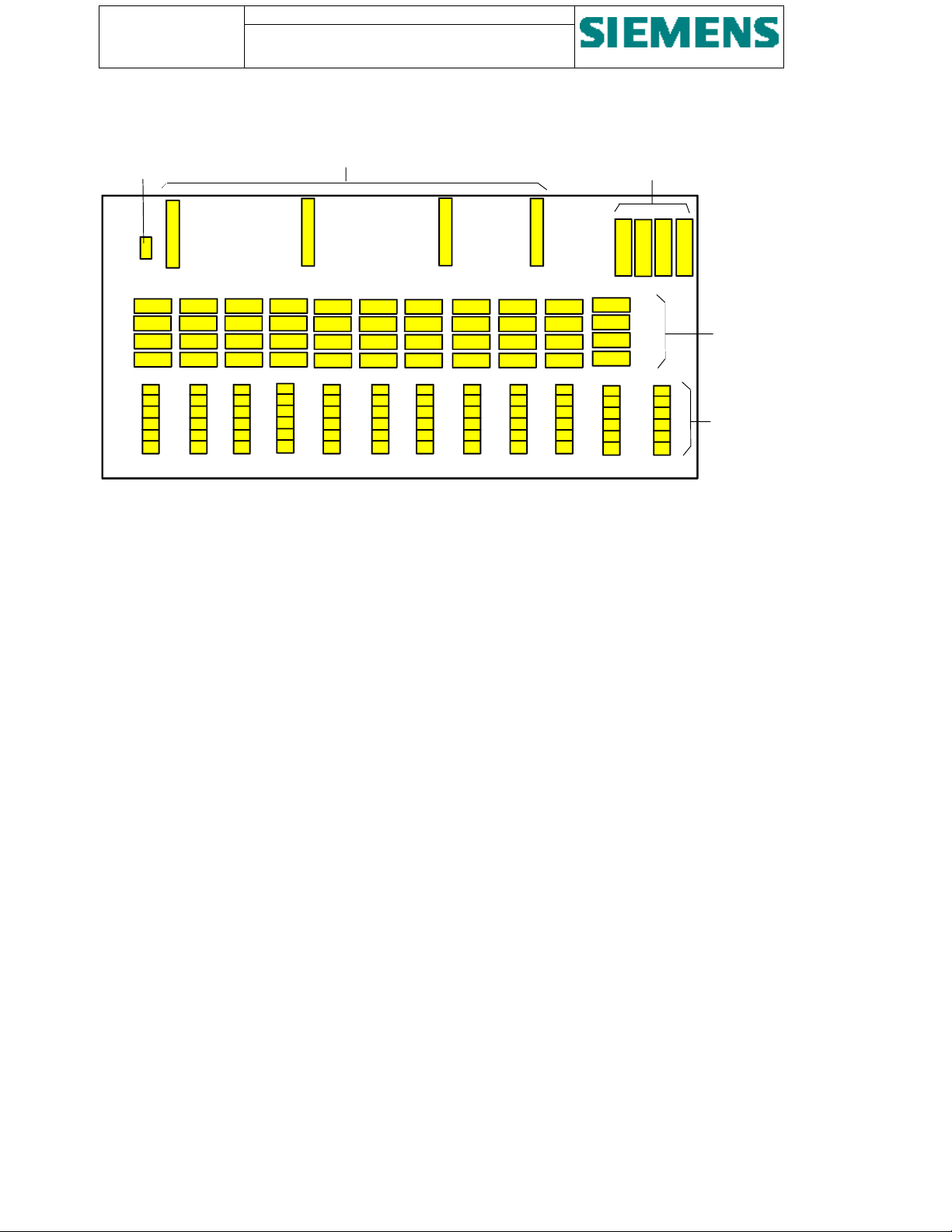

Figure 5 - Modular arrangement of SU200 20

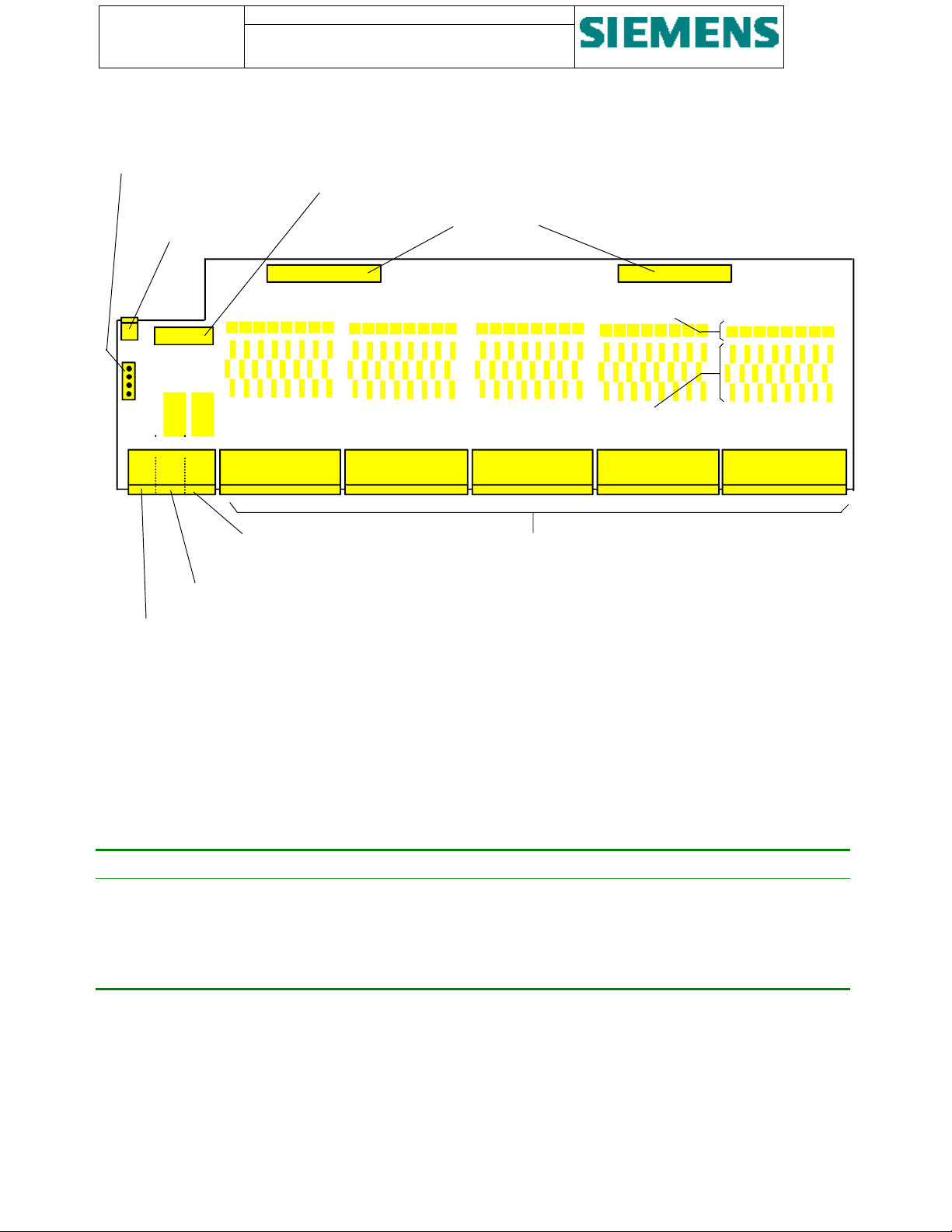

Figure 6 - Layout of power supplies modules 21

Figure 7 - Layout of CPU and communications module 22

Page 6

Page: 6 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Figure 8 - Layout of LED module 23

Figure 9 - Layout of relay output module 24

Figure 10 - Output circuitry 25

Figure 11 - Layout of digital input module 26

Figure 12 - Layout of analogue input module 27

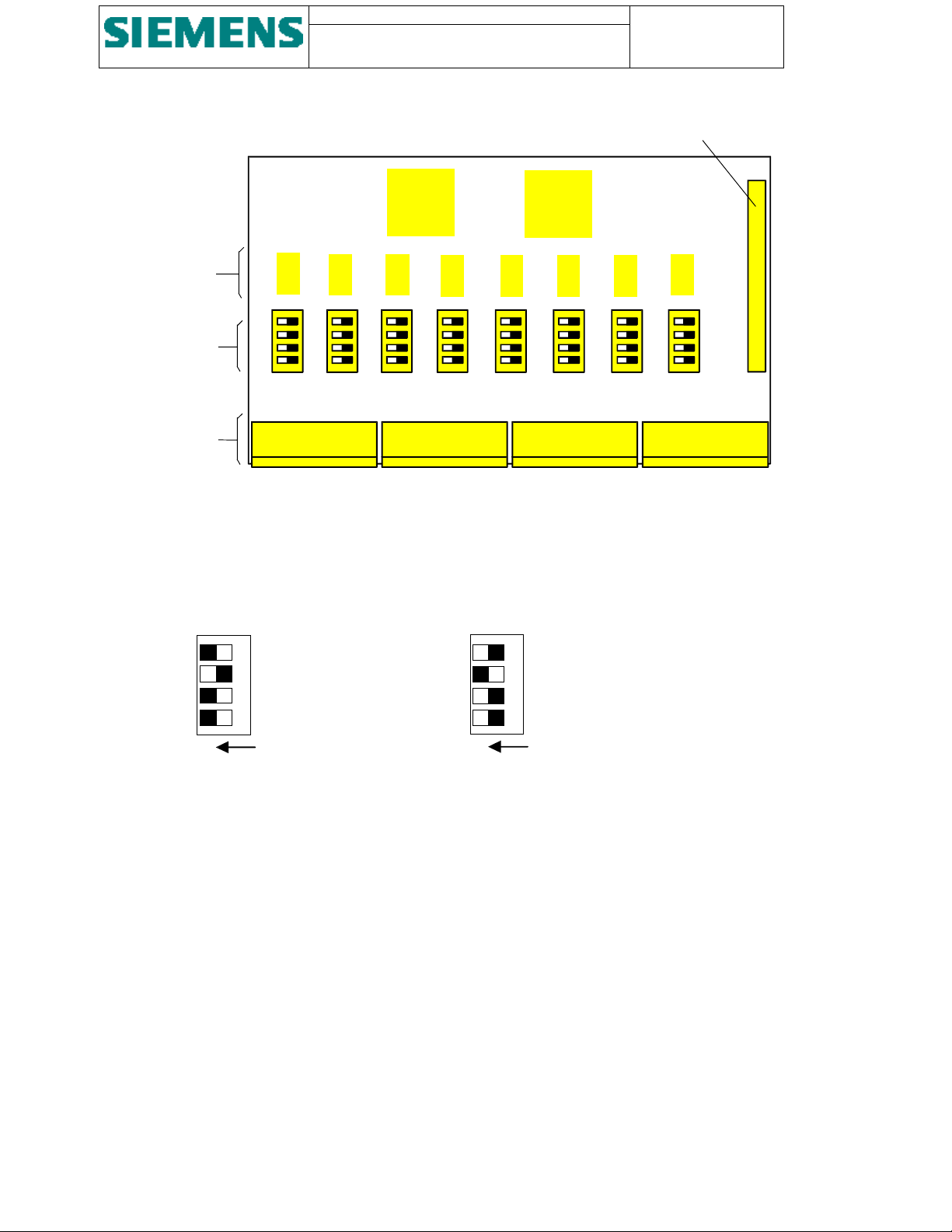

Figure 13 - DIP switches for type of analogue input signal 27

Figure 14 - Dimensions 28

Figure 15 - Plug-and-socket connection of external wiring 29

Figure 16 - Types of connecting plugs with internal circuitry 30

Figure 17 - Structure of telegrams from SU200 to master 36

Figure 18 - Continued: Structure of telegrams from SU200 to master 37

Figure 19 - Structure of telegrams from master to SU200 38

Figure 20 - Arrangement of control byte #1 in telegram from SU200 to master 39

Figure 21 - Arrangement of control byte #2 in telegram from SU200 to master 40

Figure 22 - Arrangement of control byte #1 in telegram from master to SU200 41

Figure 23 - Arrangement of control byte #2 in telegram from master to SU200 42

Figure 24 - Buttons and LED’s 44

Figure 25 - Status LED's 46

Figure 26 - Start-up window of SU200DIA 48

Figure 27 - Main window of SU200DIA 49

Figure 28 - Dead- and filter time of digital inputs 52

Figure 29 - Firmware version in SU200DIA 54

Figure 30 - Date and time in SU200DIA 54

Figure 31 - Message list in SU200DIA 55

Figure 32 - Digital inputs in SU200DIA 56

Figure 33 - Analogue inputs in SU200DIA 56

Figure 34 - The Tools menu in SU200DIA 57

Figure 35 - Local Control in SU200DIA 58

Figure 36 - Simulate digital inputs in SU200DIA 59

Figure 37 - The fail-to-safe configuration in SU200DIA 60

Figure 38 - Impulse counters in SU200DIA 61

Figure 39 - The analogue input scaling configuration in SU200DIA 61

Figure 40 - System parameters window in SU200DIA 62

Figure 41 - Rules menu in SU200DIA 63

Figure 42 - Rule file syntax – flow control 68

Figure 43 - Rule file syntax - continued 69

Figure 44 - Setting communication port in SU200DIA 71

Figure 45 - Firmware tool 72

Figure 46- Monitor commands in firmware tool 73

Figure 47 - Serial port used for firmware download 74

Figure 48 - Mounting beads 76

Figure 49 - Plug-and-socket connection of external wiring 77

Figure 50 - Optical bus terminals 78

Figure 51 - Connection of electrical data lines 79

Figure 52 - Terminal arrangement of bus connector 80

Figure 53 - Allocation of CPU DIP switch 1 and 2 80

Figure 54 - Delivery configuration of CPU DIP switches 81

Figure 55 - Cable entry of SU200 81

Figure 56 - Connecting points of SU200 82

Figure 57 - System message 101, SU200 time not yet synchronised 84

Figure 58 - System message 101, SU200 time has been synchronised 84

Figure 59 - DIP switch 1 90

Figure 60 - DIP switch 2 90

Figure 61 - PROFIBUS Test Tool 92

Figure 62 - Checking the CP5613 card installation 95

Figure 63 - Selecting database for CP5613 95

Figure 64 - Setting the CP5412 access point 96

Figure 65 - Selecting database for CP5412 96

Figure 66 - Restarting CP5412 96

Page 7

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 7 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Figure 67 - COM PROFIBUS station types 97

Figure 68 - COM PROFIBUS network set-up 98

Figure 69 - Setting PROFIBUS network speed 98

Figure 70 - Exporting COM PROFIBUS network set-up to a LDB file 99

Tables

Table 1 - System messages generated by the self-monitoring facility 32

Table 2 - Transmission of various types of telegrams 35

Table 3 - OPERATION LED 44

Table 4 - POWER SUPPLY LED 45

Table 5 - INTERFACE LED’s 45

Table 6 - Setting master mode in SU200DIA 50

Table 7 - Default parameter values 53

Table 8 - Parameter menu in SU200DIA 53

Table 9 - Message menu in SU200DIA 57

Table 10 - Rules menu in SU200DIA 64

Table 11 - State variables in rules 65

Table 12 - Rule function types 65

Table 13 - Actions on communication interrupt for rule functions 67

Table 14 - Testing system messages 86

Table 15 - Parameter file format - General section 88

Table 16 - Parameter file format - Digital input signals section 88

Table 17 - Parameter file format - Extended section for versions later than 3.40 89

Table 18 - PROFIBUS Test Tool controls 94

Page 8

Page: 8 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

1. Introduction

1.1. Application

The task of SU200 is to serve as a decentralised field control device in a microprocessor based station control and

monitoring system.

SU200 is developed for data collection, data pre-processing, data transfer and command output at the field control level

in medium-voltage and high-voltage substations, power stations and industrial plants.

SU200 is designed to be located in the immediate vicinity of the process with hard-wired parallel interfacing to the

various control devices Thus, a distributed intelligence ensures that process data is collected, logged and pre-processed

where it is generated.

Communications with the central control station is made via a PROFIBUS fieldbus, which offers interface for both

high-speed handling as well as for comprehensive interchange of process data.

The following functions are implemented:

• Acquisition and filtering of binary signals, e.g. from switchgear control and protection units

• Acquisition of analogue values

• Transmission of process data to the central control station

• Reception, conversion and output of relay commands from the central control station

• Time tagging and recording of messages

• Guaranteed data delivery of messages

• Self-monitoring / plausibility checking

• Monitoring of communications links

SU200 is designed to serve as part of a station control and monitoring system.

The functionality of SU200, together with an appropriate fieldbus link and the managing and co-ordinating functionality

of a central control station enables the execution of a large number of tasks.

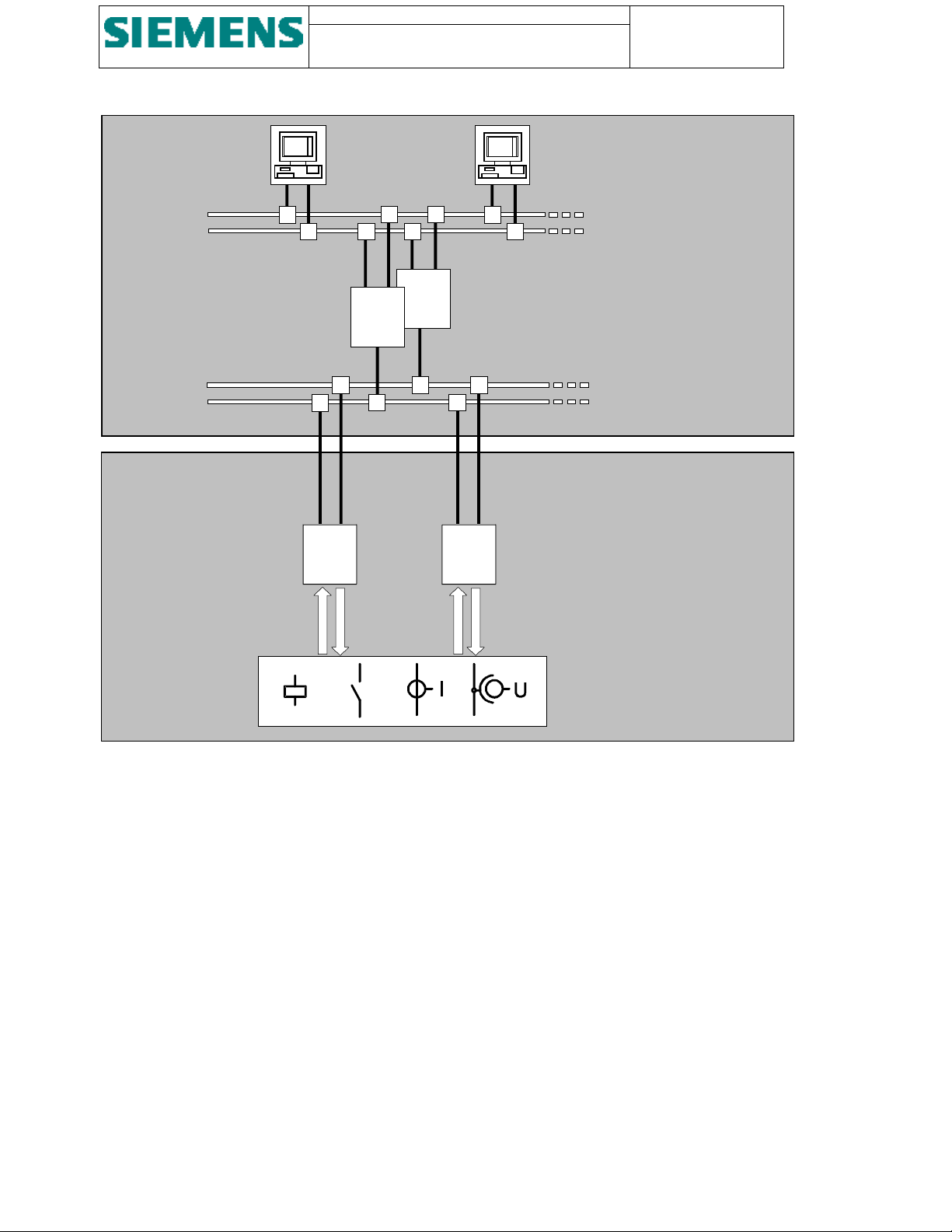

Figure 1 shows how SU200 is incorporated in a structured station control and monitoring system.

Page 9

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 9 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

STATION

CONTROL

LEVEL

FIELD

CONTROL

LEVEL

I/O

CC

1

CC

I/O

Operator control / MMI

Local Area Network / LAN

(redundant)

Central control station

(redundant / hot standby)

Fieldbus

(redundant)

Serial interface

n

SU200

Parallel interface

Process

Figure 1 - Principle arrangement of a station control and monitoring system with incorporated SU200

1.2. Features

• Redundant power supply

• Redundant optical communications interface for multi-master configuration, hot standby

• Redundant electrical communications interface for multi-master configuration, hot standby

• Open communications interface according to PROFIBUS DP protocol standard

• Optical and electrical time synchronisation signal input

• Serial interface according to transmission standard V.24 / V.28 for easy parameterisation, diagnostics and local

control

• Serial interface according to transmission standard V.24 / V.28 for firmware upgrades and special services

• Real time task scheduling with 1 ms resolution

• Internal HW / SW clock with an accuracy of ≤ 10

• Message buffer for storage of up to 500 process messages and 50 system messages

• Digital input dead time / filter time: both configurable in the range from 1 ms. to 2500 seconds

• High availability through self-monitoring

• Error-secured output using internal plausibility checking

• Noise protected and isolated input and output circuitry

• High performance verified by way of extensive type tests and field tests (CE conformity)

-5

(36 ms/hour).

Page 10

Page: 10 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

• Local display of input / output status

• Indication and signalling of internal faults

• Clear arrangement of controls and indications

• Standardised plug-in connectors for external connection

• Simple installation with the use of a pre-tested and compact unit

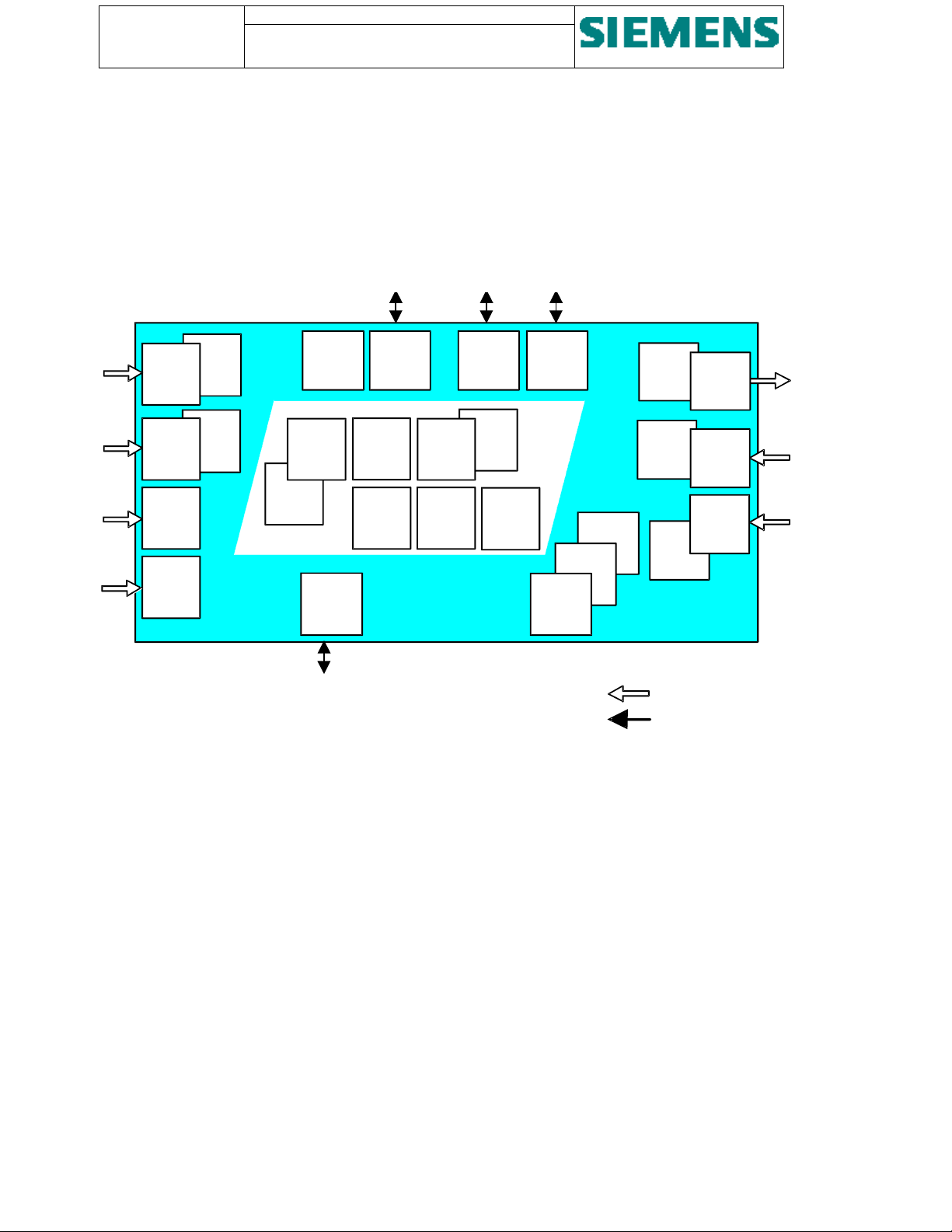

Figure 2 shows the general drawing of SU200

Power

Series

Supply

Power

# 1

Line

Filter

Power

Series

Supply

Power

# 2

Line

Filter

Electrical

Time

Synchron.

Input

Optical

Time

Synchron.

Input

Figure 2 - Overview

LED

Input /

Output

Status

Controls &

Service

Displays

Electrical

Profibus

Interface 1

RS 485

System

Software

Download

Interface

Electrical

Profibus

Interface 2

RS 485

Series

Self-

power

monitoring

line

filter

Internal

Clock

(Accuracy

36 ms/h)

Cyclic

Power

Message

Supply

Buffer

# 1

400 PM

Time

Tagging

1 ms

Optical

Profibus

Interface 1

Cyclic

Buffer

100 SM

EMC

Optical

Profibus

Interface 2

Diagnos

tics

Parameterization

Interface

Local

Control

Plausi

bility

Check

+/-20 mA

or

+/-10 V

Setting

Dead /

Filter

Time

0-250 ms

Parallel interfacing

Serial interfacing

24

Outputs

Channels

15/25 A

8

Analogue

Input

Channels

40

Digital

Input

Channels

1.3. Interfaces

Figure 2 shows all interfaces provided in SU200.

Parallel interfacing to the process (e.g. switchgear) is provided for:

• Power supply

• Switching or initiation of external control devices

• Check-back indication and alarm signalling of external control and switching devices

• Measuring of analogue values

• Time synchronisation of internal clock via electrical trigger signals

• Time synchronisation of internal clock via optical trigger signals

Serial interfaces are provided for:

• Communications with central control station

• Parameterisation, diagnostics and local control

• Downloading of system firmware

Page 11

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

2. Technical data

2.1. General data

2.1.1. Digital inputs

Number of inputs: 40 channels

Rated auxiliary voltage: Optional DC 24V, 110/125V, 220V

Page: 11 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Voltage range:

Signal level / voltage limits: L-signal: 0 up to 40 % of nominal value

Input dead time 1 to 2550 seconds configurable

Input filter time: 1 to 2550 seconds configurable

Power consumption per channel:

Galvanic isolation: Optocoupler

Connection: Plug-in connectors, terminal screw 4 mm

±20 % of nominal value

H-signal: 50 up to 120 % of nominal value

≈ 1.1 W (2.5 mA with 220V DC)

2.1.2. Relay outputs

Number of outputs: 24 channels / relays, each consisting of 2 NO contacts, with grouped

circuits (for common potential) of each 2 channels

Maximum switching voltage: Option 3: 225VDC / 175VAC, Standard

Option 4: 350 VDC / 275 VAC ( Ref. Ordering data )

Maximum switching current: 15 A for max. 4 seconds (channels 1 up to 22)

25 A for max. 4 seconds (channels 23 and 24)

2

Maximum continuous current: 8 A (channels 1 up to 22)

10 A (channels 23 and 24)

Switching capacity (power

rating):

Galvanic isolation: Relays

Connection: Plug-in connectors, terminal screw 4 mm

Voltage-dependent:

50 - 270 W (output channels 1 up to 22)

35 - 500 W (output channel 23 and 24)

2.1.3. Analogue inputs

Number of inputs: 8 channels

2

Page 12

Page: 12 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Rated value:

Measurement range:

Optional ±20mA or ±10V

Measuring range is converted into ±200%

Resolution: 12 bits + sign

Linearity of A/D converter:

Accuracy of A/D converter:

Measuring error:

± 1 bit

≤ 0.1 %

≤ 2% of nominal value

Dead time of input filter: 0.8 ms (20 mA input), 50 µF (10 V input)

Power consumption per channel: 20 mW (current input) / 2 mW (voltage input)

Burden per voltage / current path:

50 kΩ (voltage input) / 200 Ω (current input)

Galvanic isolation: Via series-connected external measuring transducer / transmitter

Connection: Plug-in connectors, terminal screw 2.5 mm

2.1.4. Power supply

2

Number of supplies: 2 (parallel operation)

Rated voltage: Optional DC 24V, 110/125V, 220V

Voltage range: 50 % up to 120 % of nominal value

Voltage ripple:

Power consumption: Approx. 16 W (quiescent)

Permissive supply interruption: 100 ms.

EMC: Series power line filter

Galvanic isolation: DC / DC-converter

Connection: Plug-in connectors, terminal screw 4 mm

2.1.5. Processors

Central Controller: 1 unit SAF 80C167 / 40 MHz

< 10%

Approx. 48 W (50% of input/output activated)

Approx. 80 W (100% of input/output activated)

115/250 V∼, 50/60 Hz, 3 A

2

(16 bit processor)

Communication: 2 units SAF 80C165 / 40 MHz

(16 bit processor used in 8 bit mode)

Watchdog: Automatic reset with failure indication

Page 13

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

2.1.6. Time synchronising inputs

Number of optical trigger input: 1

Page: 13 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Connection:

Optical fibre bayonet coupling / type ST

Number of electrical trigger input: 1

Signal voltage level: Optional DC 24 V, 48 V, 110/125 V, 220 V

Voltage range:

Connection: Plug-in connectors, terminal screw 4 mm

±20 % of nominal value

2

Accuracy of internal clock: 10-5 (36 ms/hour)

2.1.7. Fieldbus interfaces for optical transmission media

Transmission speed: 9.6 / 19.2 / 93.75 / 187.5 / 500 / 1500 kBaud (optional 3 / 6 / 9 / 12 MBaud)

Transmission protocol: Protocol PROFIBUS DP according to EN 50 170 part 3

32 bytes of user data for transmission

12 bytes of user data for receiving

Number of optical ports: Redundant interface:

4 bus terminals (2 receiver, 2 transmitter)

Connection:

Optical fibre bayonet coupling / type ST

Cable type: Fibre optic cables with plastic or glass fibres 62.5 / 125 µm

Optical wave length: 820 nm (glass)

Permissive line attenuation: Max. 8 dB/km

Transmission distance: Max. 2 km

2.1.8. Fieldbus interfaces for electrical transmission media

Transmission standard: RS-485

Transmission protocol: Protocol PROFIBUS DP according to EN 50 170

32 bytes of user data for transmission

12 bytes of user data for receiving

Transmission speed: 9.6 / 19.2 / 93.75 / 187.5 / 500 / 1500 kBaud (optional 3 / 6 / 9 / 12 MBaud)

Number of electrical ports: 2 (redundant)

Connection: 9-pole SUB-D-jack

Cable type: 2-core double shielded cable

Page 14

Page: 14 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

2.1.9. Serial interface for parameterisation and diagnostics

Transmission standard: V.24 / V.28, RS-232

Transmission speed: 9.6 kBaud

Connection: 9-pole SUB-D-jack

Physical Layer: Emulated UART

Link Layer: SIEMENS ST1 Protocol

Hamming Distance: 4

2.1.10. Serial interface for firmware download

Transmission standard: V.24 / V.28

Transmission speed: 9.6 kBaud

Connection: 9-pole SUB-D-jack

Physical Layer: UART

Link Layer: IEC 870 Series 101

Hamming Distance: 4

2.1.11. LED indications

Digital input activated: Green LED per channel (switch-selectable)

Command output activated: Green LED per channel (switch-selectable)

Service availability: Green LED, steady light for healthy operation, blinking light (1s) for

malfunction

Power supply: Green LED, steady light for both power supply units in operation, blinking light

for failure of power supply unit 1 (2s) or unit 2 (1s)

Fieldbus communication link 1: Green LED for healthy operation

Blinking light (1s) for transmission blocked

Fieldbus communication link 2: Green LED for healthy operation

Blinking light (1s) for transmission blocked

2.1.12. Electromagnetic compatibility and interference immunity

In accordance with harmonised standard EN 50082-2, 1995 / industrial applications

Conducted HF interference:

IEC 1000-4-6 = ENV 50141

Radiated HF interference, EM-field

amplitude-modulated (1kHz):

IEC 1000-4-3 = ENV 50140

Class III

10 V, 150 kHz to 80 MHz

Class III

10 V/m, 80 to 1000 MHz

Page 15

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 15 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Radiated HF interference, EM-field

pulse frequency. Modulated:

Class III

10 V/m, 900 MHz

(200Hz) ENV 50204

Fast transients (burst):

IEC 1000-4-4

Lightning Impulse (surge):

IEC 1000-4-5

Class IV, 4 kV (power supply) / 2 kV (signal lines), 5/50 ns., 1 min each

polarity

Class IV , 4 kV, 1.2/50 µs (enclosure)

Class III , 2 kV, 1.2/50 µs (DC input )

Positive / negative, 1 impulse per min.

Electrostatic discharge / ESD:

IEC 1000-4-2

Radiated power frequency

interference / magnet field:

IEC 1000-4-8

Class IV , 10 positive and negative discharges,

15 kV (peak) contact, 8 kV (peak) air

Class V

100 A/m continuously

1000 A/m short-time 1 s

Higher severity of test as required per standard

If higher severity is required, an external series filter element is connected

Supplementary

HF disturbance (1 MHz-impulse):

IEC 255-22-1

Class III / 2.5 kV (peak) comm. mode / 1 kV diff., 1 MHz, 400 shots/s, duration

2 s

In accordance with harmonised standard EN 50081-2, 1995 / industrial applications

Radio interference/field intensity:

Limit class A

EN55011 / CISPR 11

2.1.13. Climatic strain

Permissive ambient temperature

- during operation: -5 to +55°C (recommended values in

-40 to +70°C (values are only guaranteed at appropriate climate conditioning

inside weather-protected cubicles)

- during storage: -25 to +55°C

- during transportation: -25 to +70°C

Permissive humidity:

Annual average ≤75 % relative humidity.

Up to 95 % relative humidity for 30 days a year.

Moisture condensation not permissible

2.1.14. Mechanical stress

Earthquake:

Vibration:

Shock: during operation: 10 g, 16 ms

during operation: 3 to 35 Hz, ±10 mm amplitude / 1,5 g acceleration

during operation: 10 to 500 Hz, ±0,15 mm amplitude / 2 g acceleration

during transportation 5 to 500 Hz, ±7,5 mm amplitude / 2 g acceleration

during transportation 15 g, 11 ms

accordance with Standard EN 60721)

Page 16

Page: 16 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

2.1.15. Dielectric strength

High voltage:

2.5 kV (rms), 50 Hz, 1 min

IEC 255-5

Insulation resistance:

2 kV DC, 1 min (>100 MΩ)

IEC 255-5

Impulse voltage:

IEC 255-4

5 kV (peak), 1.2/50 µs, 0.5 J

3 positive and 3 negative shots at 5 s intervals

2.1.16. Equipment design

Dimensions:

(width x height x depth)

Weight: approx. 13 kg

Degree of protection: IP 20

486 x 298 x 220 mm (see chapter Dimensions)

2.1.17. Conformity

This product is in agreement with the requirements of the specification of the applicable council directive in relation to

electromagnetic compatibility (publication 89/336/EWG).

This device has been developed and manufactured for service in industrial plants.

This declaration of conformity is based on tests according to harmonised standards EN 50081-2 and EN 50082-2

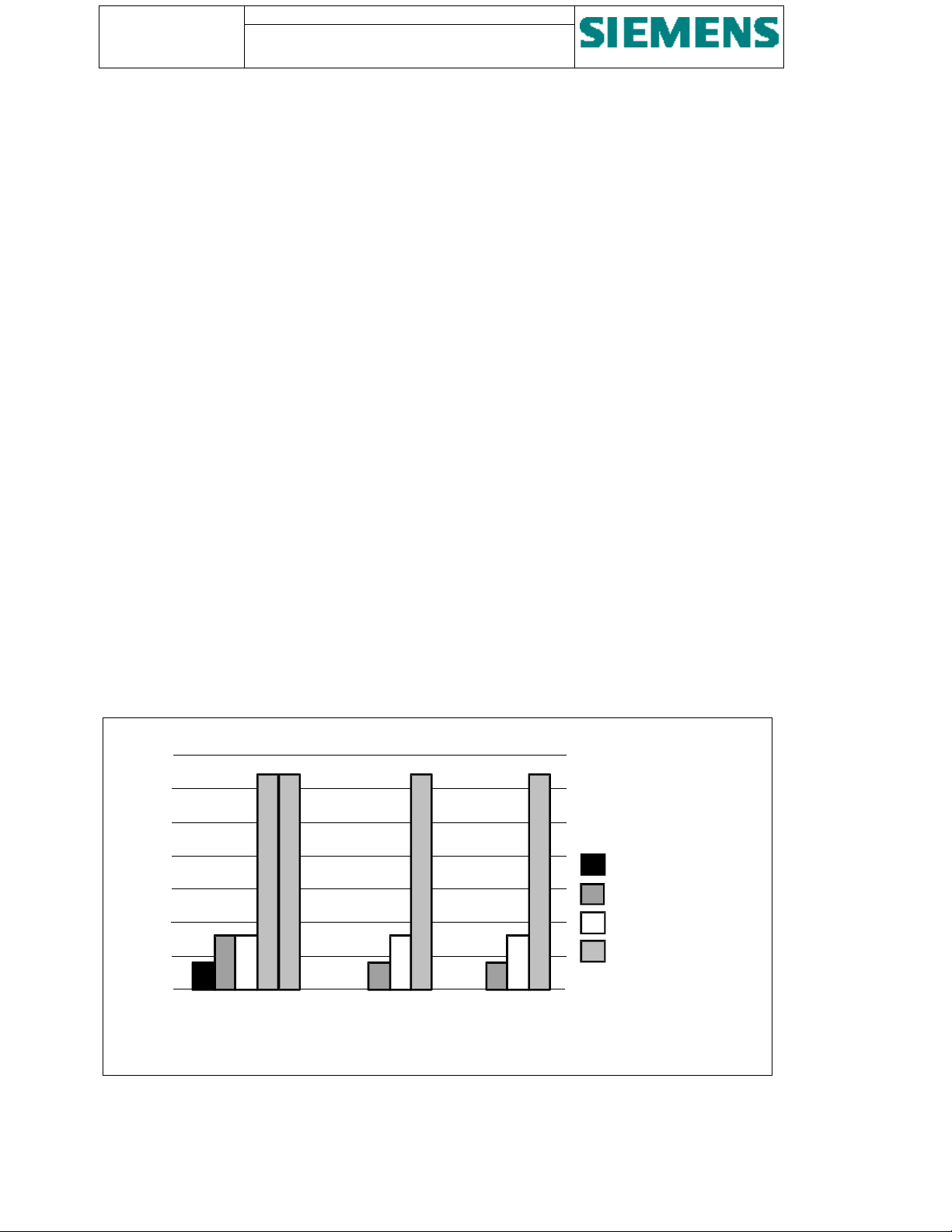

2.2. Memory capacity

kByte

140

120

100

80

60

40

20

0

Main CPU Subsystem 1

Figure 3 - Memory map

EEPROM

Dual-port RAM

RAM

Flash

Subsystem 2

Page 17

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 17 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

2.3. Ordering data

SU200 can be supplied in 6 versions, dependent on the power supply voltage and digital input

voltage.

2 options are possible depending on the maximum Relay Output Voltage.

The analogue input module is standard.

Designation Ordering number Remark

Distributed Input/Output unit SU200

Power supply: 220V DC Digital Input: 220 V DC

Power supply: 110 / 125V DC Digital Input: 110 / 125 V DC

Power supply: 24V DC Digital Input: 24 V DC

Power supply: 110 / 125V DC Digital Input: 24 V DC

Power supply: 220 V DC Digital Input: 110 / 125 V DC

Power supply: 220 V DC Digital Input: 24 V DC

Option: With analogue input module

Without analogue input module

Maximum Relay output Voltage 225VDC/175VAC

Maximum Relay output Voltage 350VDC/275VAC

LGW: AB03-A101 -A- /AA

⇑⇑⇑⇑⇑

A

B

C

G

H

J

Diagnostic/ Parameterisation Software LGW : AB03 - Y100A - A

Complete documentation LGW : AB03 - Y200A - A

Accessories:

Bus connector (PROFIBUS) 45° cable outgoing

Bus connector (PROFIBUS) 90° cable outgoing

Bus connector (PROFIBUS) axial outgoing

Ref. Simatic Accessories

Ref. Simatic Accessories

Ref. Simatic Accessories

⇑

⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

⇑⇑⇑⇑

1 Obsolete

2 Obsolete

3 Standard

4

Optical link module (PROFIBUS OLM)

Plug-in connector (PHOENIX) 9-pole for binary input

Plug-in connector (PHOENIX) 6-pole for command output

Plug-in connector (PHOENIX) 6-pole for analogue input

External protective m.c.b. for SU200 auxiliary supply

circuitry

Ref. Simatic Accessories

18 04 97 5

18 04 94 6

17 57 05 1

5 SX5 201-7

5 SX2 202-7 (5 SX2 102-7)

5 SX9 100

PC 4/9-ST-7,62

PC 4/6-ST-7,62

MSTB 2,5/

6-ST-5,08

110 V-220 VDC

24 VDC

1NO,1NC

aux. contact

Page 18

Page: 18 of 103

y

g

p

p

y

y

(

)

p

g

g

(

g

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

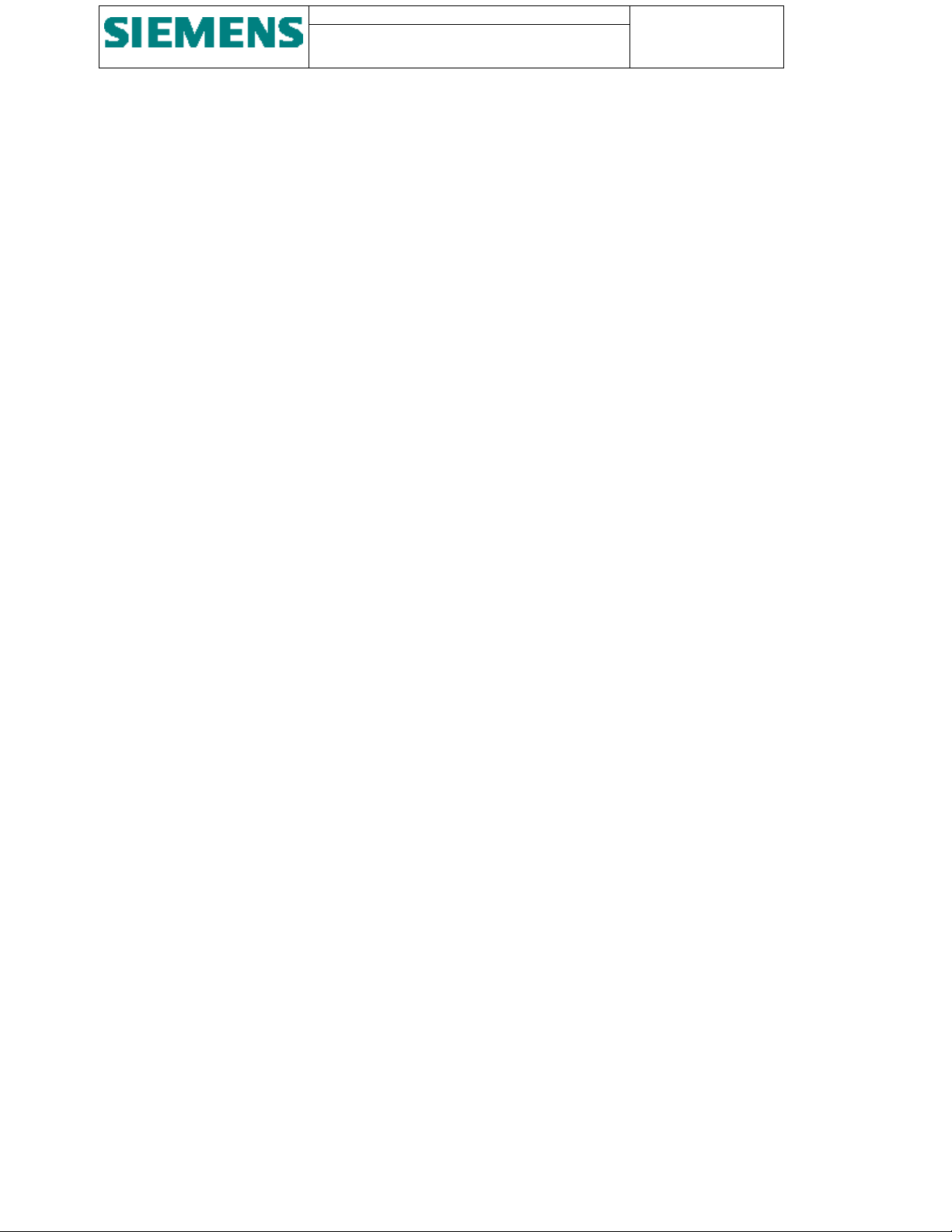

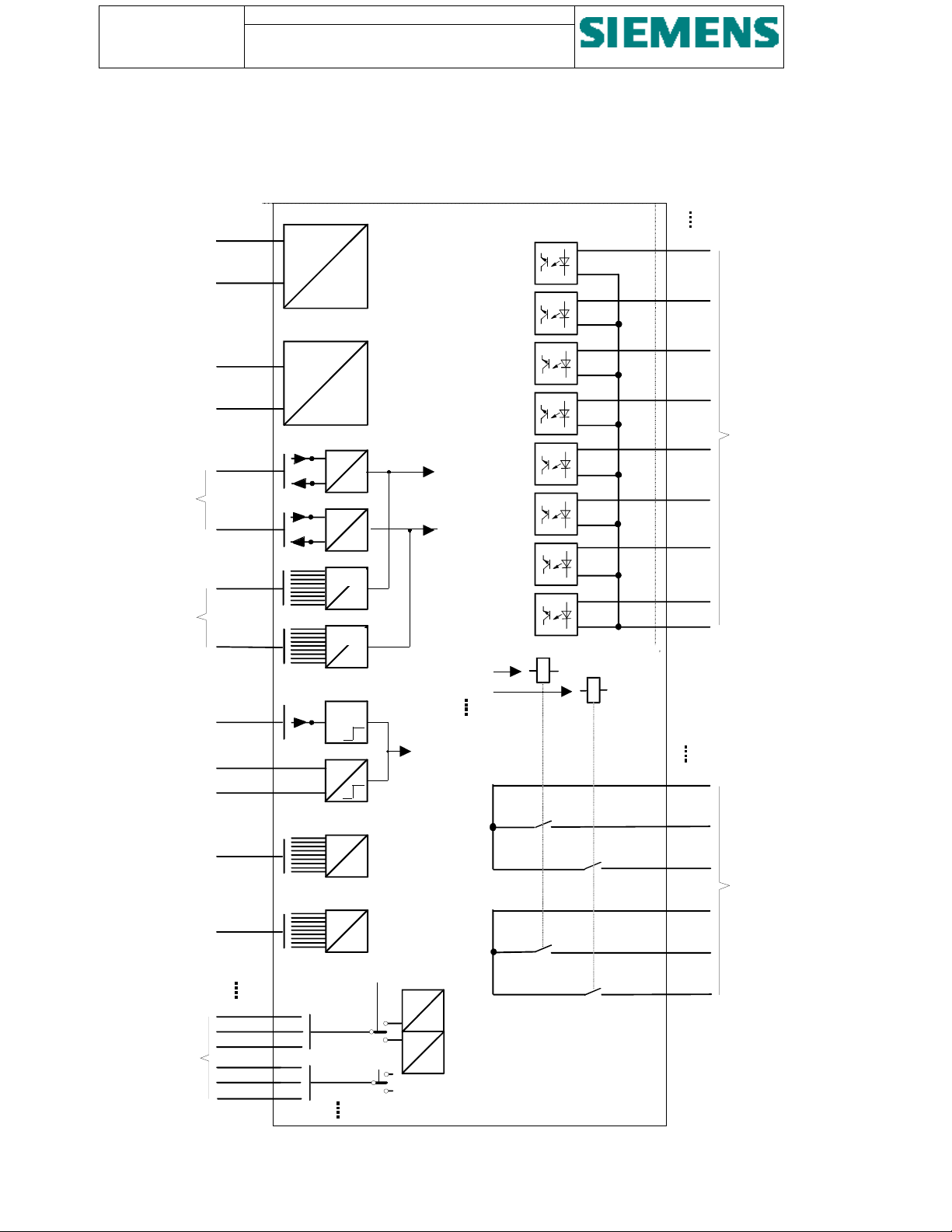

2.4. Block diagram

+

-X1:

Power suppl

circuit 1

=

-

-X11:

-X15:

1

=

2

Power supply

circuit 2

Optical

fieldbus

interface

(PROFIBUS)

Electrical

fieldbus

interface

PROFIBUS

O

tical time

synchronising

ort

Electrical time

s

nchronisin

input

Parameterisation

and diagnostics

ort

Firmware

download

interface

8 channels:

Analo

ue input

nals

si

from external

measuring

transducers or

transmitters)

-X2:

-X4:

-X6:

-X3:

-X5:

-X8:

-X7:-+

-X9:

-X10:

-X41:

-X44:

+

=

-

=

3

4

40 channels:

5

OPT.

OPT.

RS-485

9-pole

RS-485

OPT.

EL.

9-pole

V.24 /

V.28

9-pole

V.24 /

V.28

settable

(+)

1

(M)

2

(-)

(+)

(M)

(-)

channel 1

channel 2

3

4

5

6

Circuit 1

Circuit 2

Clock control

20mA

10V

Channel 1

Channel 2

6

7

8

9

1

3

5

2

4

6

-X21:

-X32:

Di

ital input

signals

24 channels:

Double

rela

output

Figure 4 - Block diagram

Page 19

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 19 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

3. Design

3.1. Construction

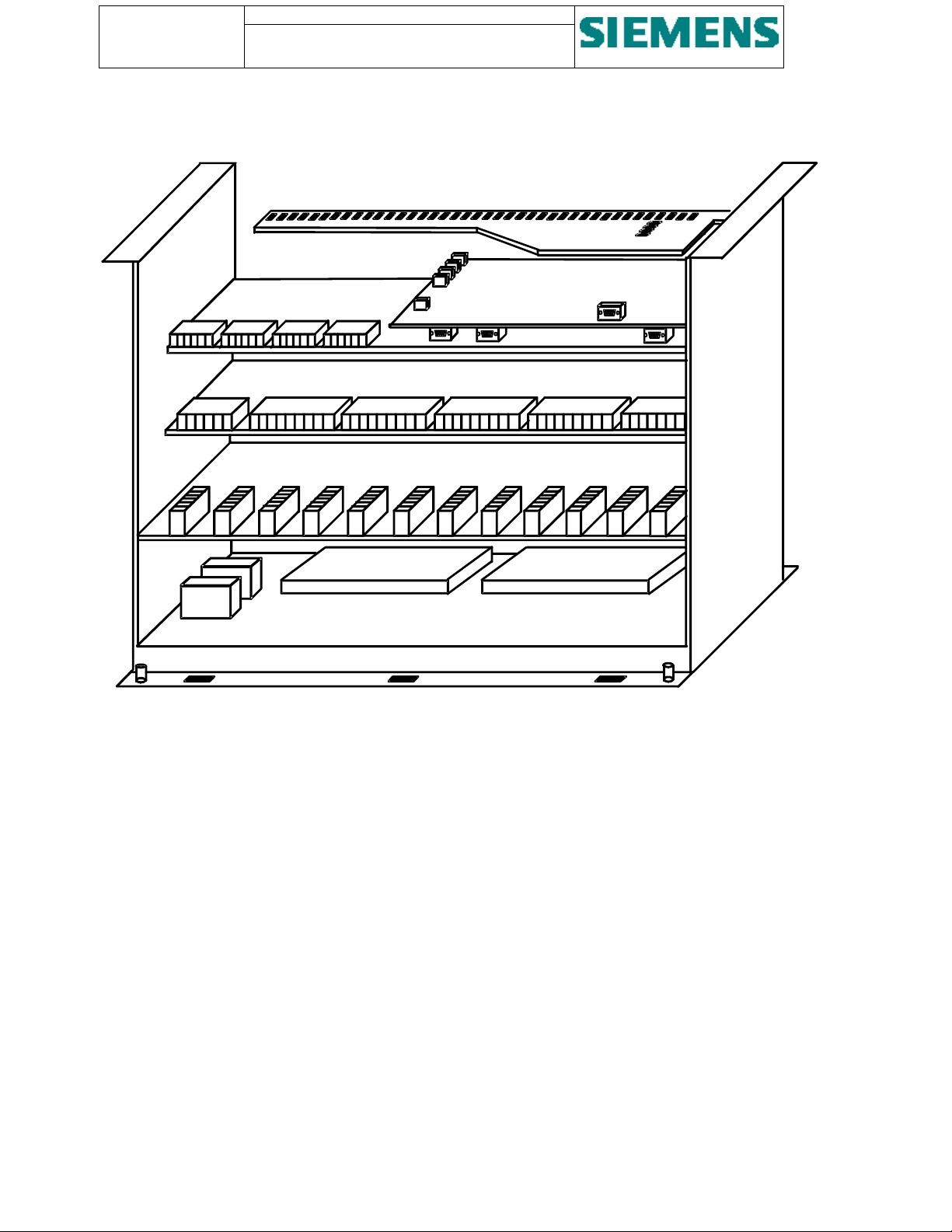

SU200 is made as an enclosed compact device in an IP20 metal housing and is designed for surface mounting on

standard subrack frames or for cubicle mounting.

SU200 contains the following components:

• Power supply modules

• Processors and communications module

• LED module

• Relay output module

• Digital input module

• Analogue input module

Page 20

Page: 20 of 103

g

A

y

p

r

y

pply

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

LED module

Central processin

nalogue input

module

Binar

and communications module

input module

Out

Power suppl

module 1

Filte

Figure 5 - Modular arrangement of SU200

3.2. Modules

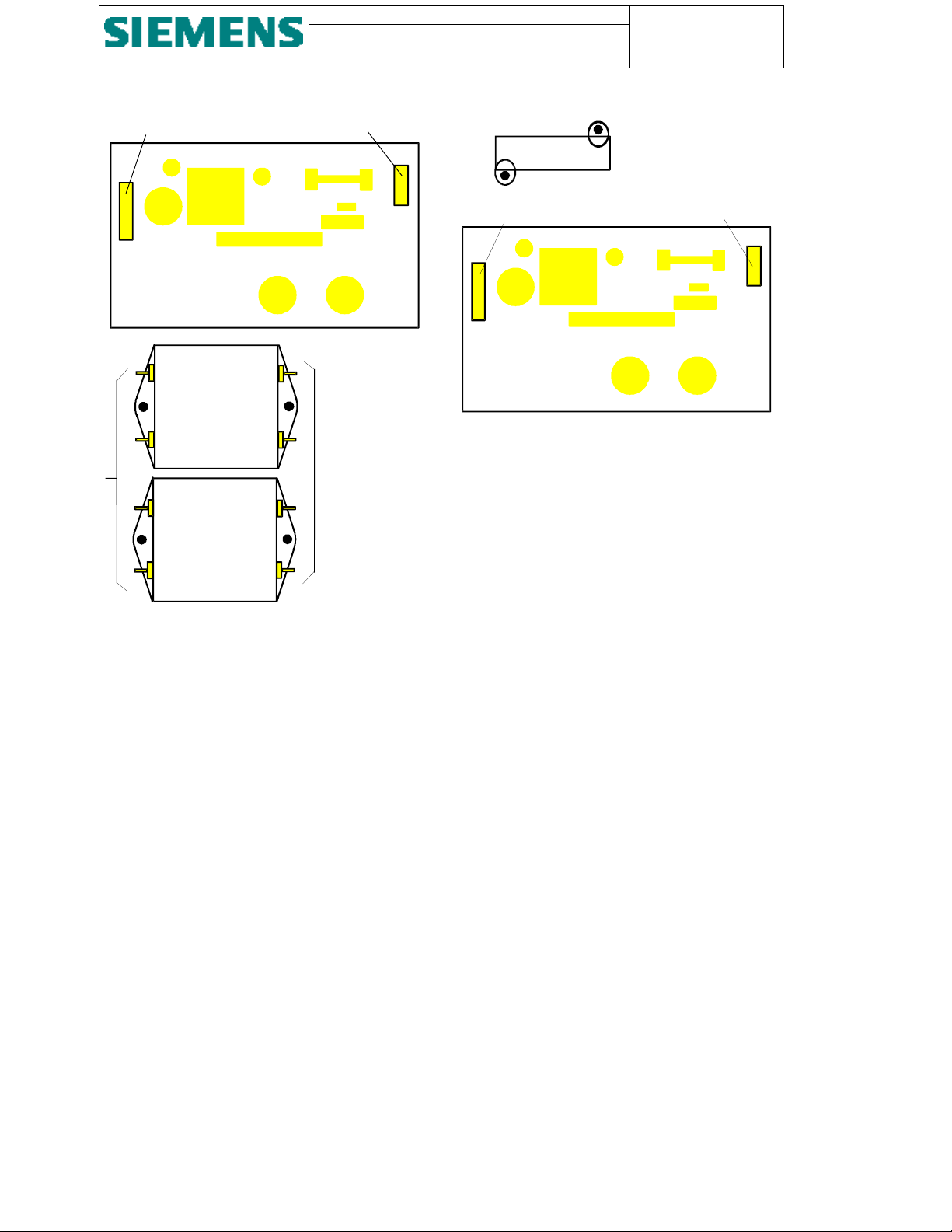

3.2.1. Power supply module

ut module

Power su

module 2

The power supply of SU200 is arranged with two independent modules forming a redundant system. The internal

auxiliary voltages for the individual modules of SU200 are provided in a switch mode solution and distributed by way

of ribbon cable connections.

For the connection of the external power supply, 4 mm

2

plug-in connectors are provided on the input module.

The external power supply is fed through series power line filters in order to increase the interference immunity / EMC.

The device can be supplied in three versions, whereas the rated power supply can be 24 V, 110/125 V or 220 V DC.

Page 21

SU200 User manual

r

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 21 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Output connector

X2

Power supply #1

Series power

line filter #1

Series power

line filter #2

Input connector

X1

Resisto

Output connector

X2

Power supply #2

(Bottom plate of SU200)

Input connector

X1

Input

connectors

Output

connectors

Figure 6 - Layout of power supplies modules

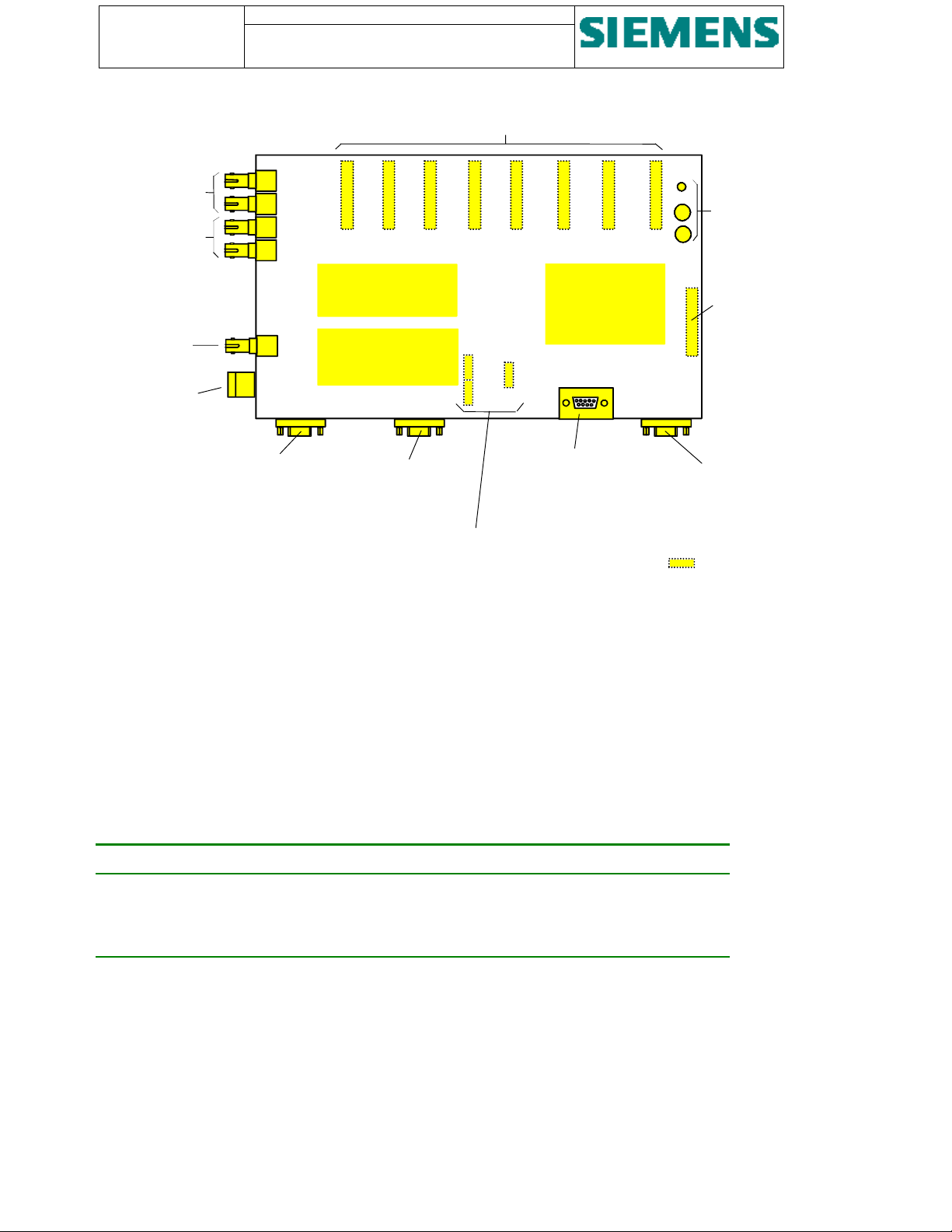

3.2.2. CPU and communications module

The central processor unit (CPU) is responsible for pre-processing of acquired process data and organising of the data

exchange with the central control station.

The microprocessor carries out a full restart on power-up and reset.

For communications with the central control station, a redundant interface for both electrical and optical data

transmission media is provided.

For the connection of a redundant fibre optic fieldbus link, four bus terminals with bayonet coupling (ST standard ports)

are provided, consisting of two receiver and two transmitter ports designed to operate with 62.5/125 µm fibre optic

cables.

The receiver incorporates an integrated photo IC containing a photo-detector and dc amplifier driving an open-collector

output transistor.

The transmitter contains an 820 nm emitter capable of efficiently launching optical power into four different optical

fibre sizes.

The receivers are easily identified by their dark grey colour; transmitters are made in light grey colour.

In addition, 2 SUB-D jacks are provided on the CPU for the connection of a redundant electrical fieldbus link.

For the open communications, the protocol PROFIBUS-DP as defined by EN 50 170, part 3 is selected.

The fieldbus interface is arranged with subsystems containing a standard PROFIBUS-DP controller and a processor,

which communicates with the main CPU via dualport RAM.

Page 22

Page: 22 of 103

y

y

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Ribbon cable connectors

Optical fieldbus

Interface #1

Optical fieldbus

Interface #2

-X4:

-X6:

X8

X7

X6

Communications

Subs

stem 1

Optical time

synchr. input

Interconnector

for the electrical

-X17:

-X8:

-X3:

Communications

Subs

stem 1

-X5:

time synchr. signal

Electrical fieldbus

Interface #1

Electrical fieldbus

Interface #2

Connectors for

auxiliary power supply

Figure 7 - Layout of CPU and communications module

X9

X5

X4

X19

X3 X2 X1

Serial interface

and diagnostics

Main CPU

-X9:

Push-buttons

Ribbon cable

connector

X16

-X10:

Serial interface

for firmware

download

... underside of board

The module is equipped with the following interfaces:

• Optical interface for fieldbus #1

• Optical interface for fieldbus #2

• Electrical interface for fieldbus #1

• Electrical interface for fieldbus #2

• Optical time synchronisation signal input

• Serial interface for parameterisation and diagnostics

• Serial interface for download of firmware

Pushbuttons are provided for:

PUSH button Action

RESET Initiates a hardware reset

LED-TEST Initiates a firmware test and indicates proper function of the LED’s

DISPLAY MODE Initiates a change-over between LED display of digital input and relay output

3.2.3. LED module

The LED module is attached to the CPU module via spacer sleeves and contains

• 40 LED’s to provide status indication of either the input or the output channels. The DISPLAY MODE pushbutton

can be used to toggle between indication of the input status or the output status.

• 1 LED named OPERATION to provide status indication of the operating condition and service availability of the

CPU. Steady light indicate healthy operation, blinking light indicates malfunction

Page 23

SU200 User manual

p

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 23 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

• 1 LED named POWER SUPPLY to provide status indication of both power supply units. Steady light indicate

healthy operation, blinking light indicates malfunction

• 2 LED named INTERFACE 1 and INTERFACE 2 provides status indication of the operating condition of both

communications interfaces. Steady light indicate healthy operation, dark LED indicates communications out of

service

The interconnection to the CPU module is made via two ribbon cables.

40 LED's for input/output status indication

1 ...

... underside of board

O

erational LED's

OPERATION

POWER SUPPLY

INTERFACE 1

INTERFACE 2

... 40

Connectors to CPU board

Figure 8 - Layout of LED module

3.2.4. Relay output module

The relay output module is arranged with 24 noise protected and isolated double-command outputs.

The interconnection to the CPU module is made with four ribbon cables. For the external connection, 4 mm

connectors are provided.

The maximum switching current of 22 output channels is 15 A (4 s), 2 output channels are designed for a maximum

switching current of 25 A (4 s).

2

plug-in

Page 24

Page: 24 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Connector for

auxiliary power

supply (24 V)

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Ribbon cable connectors

Output relays of

channels #23 and #24

X13

X14

X15 X16

X17

Output relays of

channels #1 up to

#22

Base sockets for

plug connectors

-X21: -X22: -X23:

-X24:

-X25: -X26:

-X27: -X28:

-X29: -X30: -X31: -X32:

Figure 9 - Layout of relay output module

3.2.4.1. Relay output monitoring

All relay output channels are monitored for correct command output.

By way of feedback circuits, the output of an individual channel is only released after a plausibility check has been

executed and the output circuitry is considered as healthy.

In case of malfunction, the respective output group (two channels) is blocked and a corresponding system message is

sent to the central control station.

3.2.4.2. Relay output circuitry

Each relay output channel is provided with two NO (normal open) contacts.

The output channels are organised by groups of two channels. Two output channels are connected to common paths and

enable, on one hand, double-pole switching and, on the other hand, switching in both directions (e.g. closing and

opening of an external control/switching device).

Figure 10 shows the general output arrangement and a typical connection of a high voltage switching device.

Page 25

SU200 User manual

g

p

g

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

L+

Page: 25 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Channel #1

Channel #2

Figure 10 - Output circuitry

-X:

1

3

5

6

4

2

HV switching

device

L-

Closin

Coil

O

Coil

enin

3.2.5. Digital input module

The input module contains 40 noise protected and optical isolated digital input channels and can be supplied in three

versions for external signal voltage 24 V, 110/125 V and 220 VDC.

The interconnection to the CPU module is made with two ribbon cables. For the external connection, 4 mm

connectors are provided.

The input circuitry is provided in a grouped form. A group of eight digital input channels are connected to one common

path.

In addition, the electrical time synchronisation input and the two power supply inputs are provided on the input module.

2

plug-in

Page 26

Page: 26 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Link connector for

adaptation of electrical

time synchr. signal

Interconnector for

the electrical

time synchr. signal

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Interconnector for

auxiliary

power supply

Ribbon cable connectors

X7

X8

Optocouplers

X11

X10

X9

Resistance network

-X7: -X1: -X2: -X11: -X12: -X13: -X14: -X15:

Base socket for

external power supply input 2

Base sockets for

binary signal input

Base socket for

external power supply input 1

Base socket for

electrical time synchr.

signal input

Figure 11 - Layout of digital input module

3.2.5.1. Electrical time synchronisation port

The time synchronisation input can be adapted to four different voltage values by way of changing a link / jumper on

connector -X10.

Signal voltage Pin configuration on connector -X10

220 VDC No straps

110 VDC Strap 1-2

48 VDC Strap 1-3

24 VDC Strap 1-4

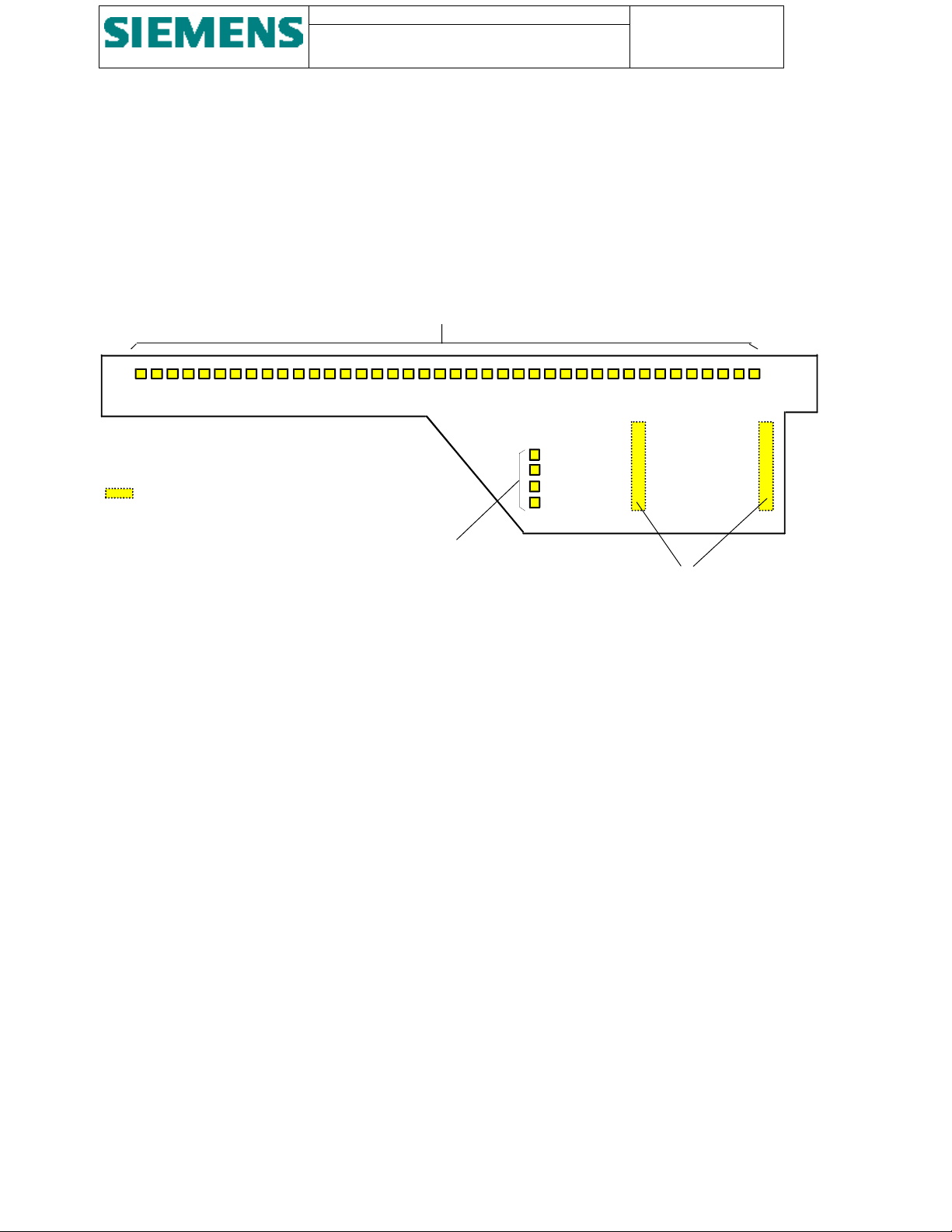

3.2.6. Analogue input module

SU200 can be optionally equipped with an analogue input module providing 8 analogue input channels.

The analogue input can be set for ±10V or ±20mA input rating and is therefore designed to acquire measured values of

external measuring transmitters or transducers with ±10V or ±20mA output rating.

The interconnection to the CPU module is made with one ribbon cable. For the external connection, 2.5 mm

connectors are provided.

2

plug-in

Page 27

Resistance

r

3

network

Dipswitches for

setting of the

input rating

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 27 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Ribbon cable connecto

S200 S201 S202 S203 S204 S205 S206 S207 X5

-X41:

-X42:

-X43: -X44:

Base sockets for

plug connectors

Figure 12 - Layout of analogue input module

Each channel of the analogue measuring input can be configured individually as ±10V input or ±20mA input.

The setting is done via a DIP switch provided for each channel.

Figure 13 shows the appropriate combinations.

+/- 20mA

ON

2

1

+/- 10V

3

1

ON

Figure 13 - DIP switches for type of analogue input signal

Page 28

Page: 28 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

3.3. Dimensions

465

322

19

81 190 76

220

SU200

Front view

432

486

Top view

27

250

298

260

14

202

Side view

34

Figure 14 - Dimensions

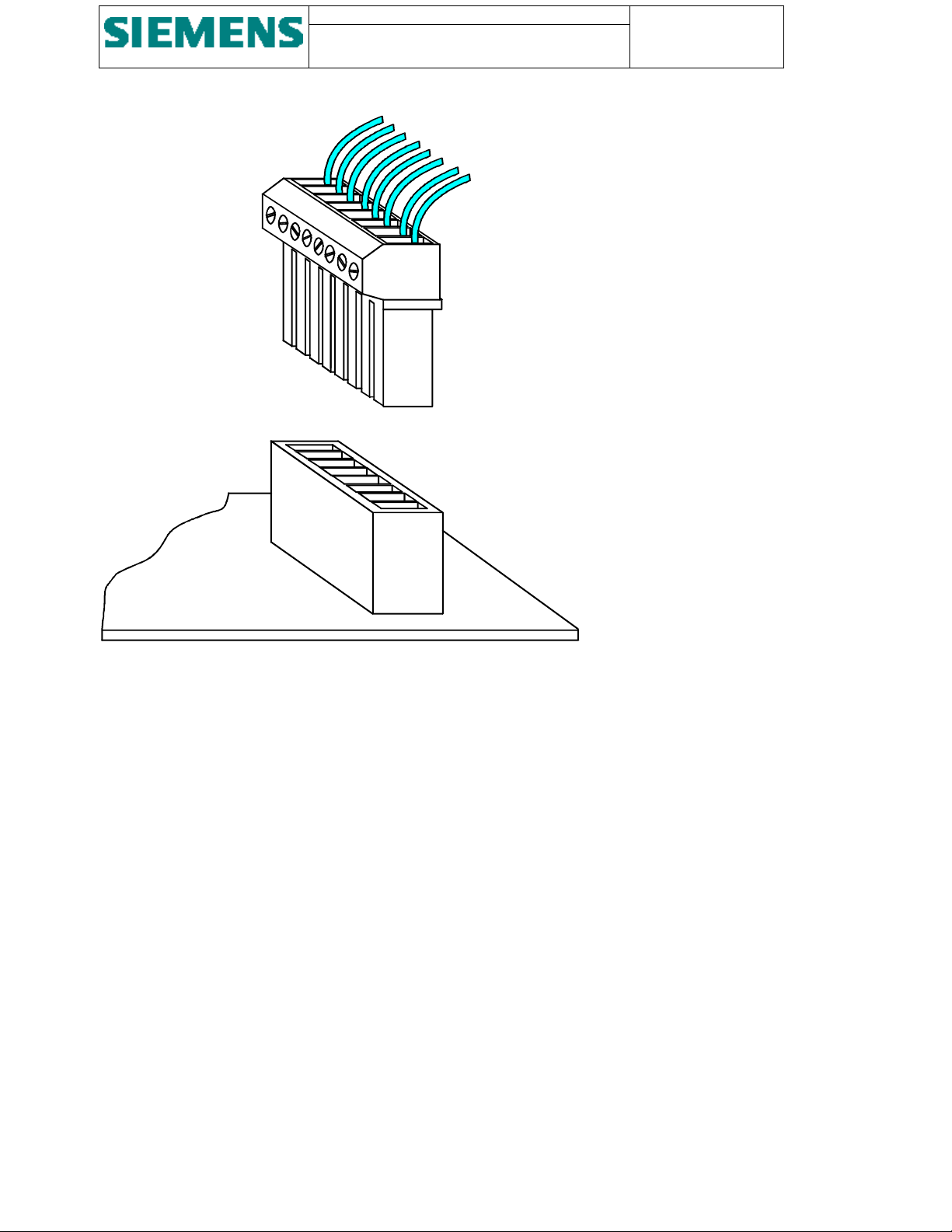

3.4. Connections

The connection of the external wires is done by way of standard plug-in connectors, consisting of plug connectors and

base sockets, which are fixed on the respective board.

Page 29

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

External wiring

Plug connector

Page: 29 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Base socket

Board

Figure 15 - Plug-and-socket connection of external wiring

The signal input is arranged with 9-pole plugs, for command output 6-pole plugs are provided. Thus, exchange of plug

connectors by mistake is prevented.

All plugs for digital input and output are designed with 4 mm

connectors with 2.5 mm

2

screw terminals are provided.

2

screw terminals. For the analogue input, 6-pole plug

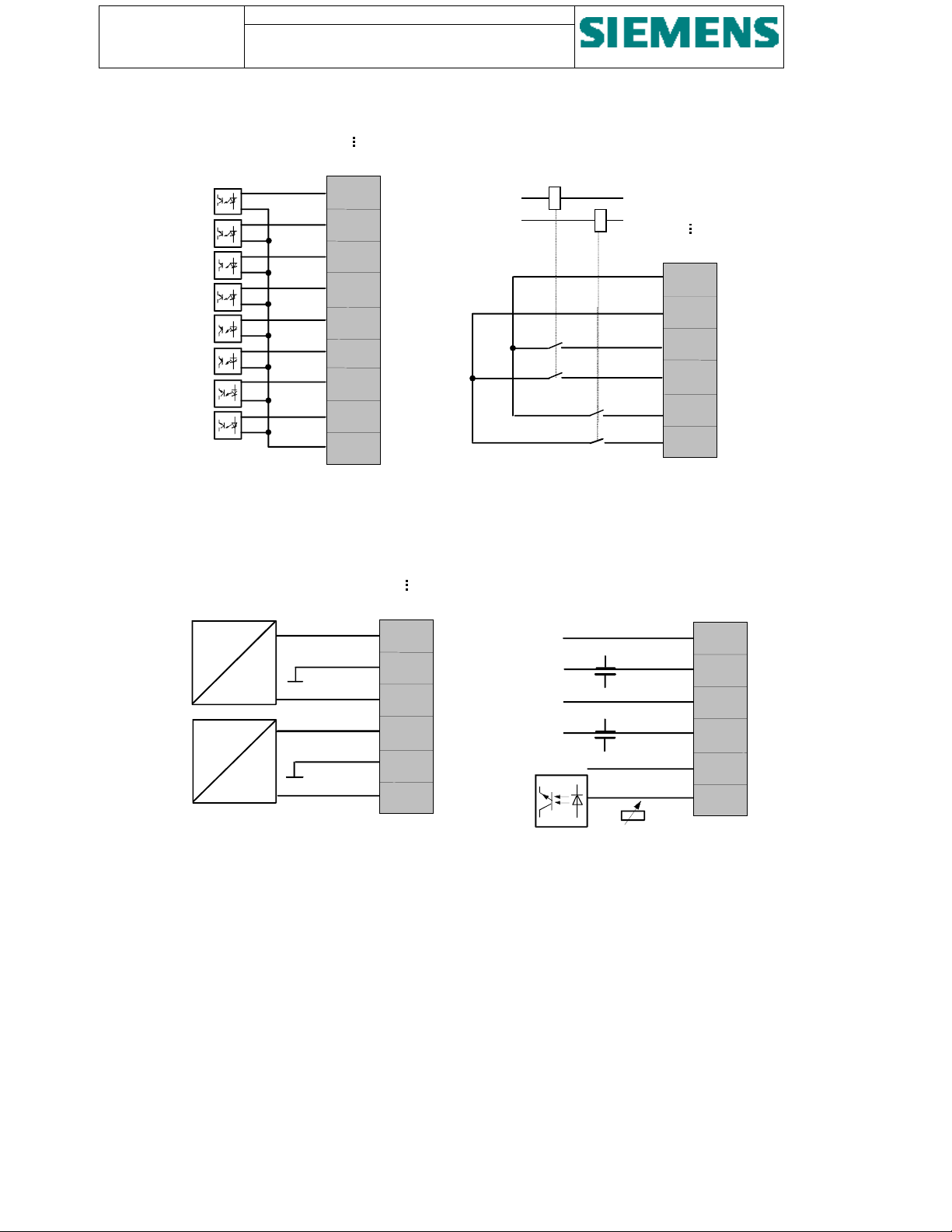

Figure 16 shows the various plug connector versions with the associated internal circuitry.

Page 30

Page: 30 of 103

put

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

Channel 8

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

-X11:

-X15:

1

Channel 1

Channel 2

2

3

4

5

6

7

8

9

-X21:

-X32:

1

2

3

4

5

6

Channel 1

Channel 2

9-pole plug-in connector for

digital input connection

10V /

20mA

10V /

20mA

6-pole plug-in connector for

analogue input connection

-X41:

-X44:

1

2

3

4

5

6

6-pole plug-in connector for

relay output connection

-

+

-

+

-

+

6-pole plug-in connector for

redundant power supply and

electrical time synchronization

in

-X2:

-X1:

-X7:

Figure 16 - Types of connecting plugs with internal circuitry

Page 31

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 31 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

4. Method of operation

4.1. Operation principle

SU200 is equipped with powerful 16 bit microprocessors. This provides fully digital pre-processing of process data.

Process data are acquired at the field level via the digital and analogue inputs of SU200. The values are formatted into

telegrams and transmitted via a fieldbus link to the central control station.

Each recognised status change of the digital inputs is converted into a process message, marked with date and time with

1 ms. resolution, and written into a message buffer. These time-tagged process messages are together with analogue

values passed on to the central control station.

Control commands from the central control station are converted and provided in parallel form at the output circuitry of

SU200.

Each of the relay output channels is arranged with a feedback control circuit in order to monitor correct command

output.

4.2. Self-monitoring

All hardware and firmware functions of SU200 are continuously monitored by way of plausibility checks. If

irregularities are detected in hardware or firmware, a system message marked with date and time is written into the

message buffer.

The time-tagged system messages are immediately transmitted to the central control station as a common system

message.

Figure 20 shows the individual single system messages and the combination into the respective common system

message, which is then transmitted to the central control station. All single system messages can however be read from

the message buffer using SU200DIA application

Page 32

Page: 32 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Local

message

Description Logic to

common

Common

message

Description

message

S-101 Unit start-up = S-141 Unit start-up

S-102 Time synchronising trigger signal missing

S-104 Power supply #1 failure

≥

S-142 Device disturbed

S-105 Power supply #2 failure

S-114 Power supply #1 healthy

&

S-143 Device disturbance cleared

S-115 Power supply #2 healthy

S-116 Time synchronising trigger signal received

S-106 CPU-RAM failure

S-107 EEPROM failure

S-108 Watchdog failure

≥

S-144 Device faulty

S-109 Communications interface #1 internal failure

S-110 Communications interface #2 internal failure

S-113 Analogue input card faulty.

S-117 Special function: Programmable interlocking rule

program checksum failure

S-118 FLASH memory write failure

S-1…S-12 Output group 1…12 faulty

S-146 Local control mode actuated = S-146 Local control mode

actuated

S-147 Remote control mode actuated = S-147 Remote control mode

actuated

S-103 Message buffer overflow - 500 unsent messages

stored.

No transmission to higher

control level

S-111 Communications interface #1 out of service - No transmission to higher

control level

S-112 Communications interface #2 out of service - No transmission to higher

control level

Table 1 - System messages generated by the self-monitoring facility

If single master mode is programmed, system message S-111 respectively S-112 is not generated if the second

communications channel is out of service.

4.3. Redundancy

SU200 is designed for fieldbus communications in single master or dual master configuration, whereas single master

configuration may be utilised via any of the two interfaces.

The redundant communications interface enables SU200 to be integrated in a station control system in hot standby

mode.

Page 33

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

A hot standby configuration at the higher station control level is achieved with an active and a passive central control

station (master), representing a two-channel configuration with a dynamic 1-out-of-2 redundancy. Both central control

stations run in a parallel mode, each with a full update of the process image at any time.

If a hardware or firmware error is detected in the active central control station, immediate and bumpless transfer to the

hot standby (passive central control station) is executed by means of an automatic switchover system and the hot

standby becomes active control unit.

The switchover between master and hot standby is executed without any loss of information and the process is kept

going.

SU200 is designed to accept and process orders received from the active central control station only. If SU200

recognises a switchover of the two central control stations via a specific bit pattern in the received telegrams, the actual

output commands are frozen for 3 seconds.

After 3 seconds, new output orders from the central control station are accepted by SU200 only if one single active

central control station is recognised, in all other cases the command output is reset (command ending).

Page: 33 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

4.4. Data transfer

4.4.1. Fieldbus

SU200 is designed for data interchange between station and field control level via a fieldbus.

For the open communications between the central control station (master) at the higher station control level and SU200

at the field control level, the PROFIBUS fieldbus is used.

PROFIBUS defines the technical and functional characteristics of a fieldbus and provides for extremely fast handling as

well as comprehensive interchange of process data.

PROFIBUS offers an extensive range of network components for electrical and optical transmission and combines

simple installation and service, good diagnostic facilities and an error-free transmission in an optimal manner.

4.4.2. Network configuration

With the use of star couplers, repeaters and/or optical link modules (OLM‘s) and optical link plugs (OLP‘s), the

PROFIBUS network can be configured individually in a in-line, ring or star topology and allows the linking of two-wire

(copper) and fibre optic transmission media.

4.4.3. Principle of operation

Data exchange on the PROFIBUS fieldbus runs in a programmed cycle using the principle of a master-slave system as

specified in European Norm EN 50 170.

Masters only may initiate requests for data, slaves may only respond to this requests.

4.4.4. Transmission media

SU200 is equipped with two ports for connection of an electrical transmission media and another two ports for

connection of an optical transmission media (redundant interface). Only one of the two communications interfaces

(electrical or optical) of SU200 can be in service at any time.

Page 34

Page: 34 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

SU200 User manual

This document is confidential and is the property of Siemens AS. It may not be

copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

4.4.5. Electrical transmission media

• The electrical PROFIBUS fieldbus is arranged with 2-core (twisted pair) double-shielded cable.

• Transmission standard RS 485 is utilised.

• The RS 485 interface operates on voltage differences and is therefore less sensitive to interference than a voltage or

current interface.

• The maximum number of nodes of an electrical fieldbus is 32 per segment.

• By means of repeaters a two-wire network can be extended to 127 nodes.

• SU200 is suitable for transmission speed of up to 1.5 MBaud. In particular cases, transmission speed of up to

12 MBaud is possible.

4.4.6. Optical transmission media

The fibre optic network is set up with duplex fibre optic cables (glass or plastic) and is insensitive to electromagnetic

interference.

FO cables serve to transmit signals by means of electromagnetic waves in the region of optical frequencies. SU200

transmitter and receiver are suitable for transmission speed of up to 5 MBaud.

For communications between bus nodes, there is no discernible difference between the two-wire and fibre optic

technology.

4.5. Telegram structure

4.5.1. From SU200 to Master

For the data transmission from SU200 to the central control station (master), the telegram is structured with 32 bytes of

user data.

SU200 will automatically switch between transmission of various types of telegrams:

AI

enabled

(and not

faulty)

No No Process- and system-messages are transmitted once they are generated. After

No Yes If there are no process- or system-messages to transmit, SU200 will transmit kWh

kWh counter Transmission of messages

acknowledgement from the master, SU200 will repeat transmitting the telegram

until a new process- or system-message is generated.

counter values continuously.

When a new process- or system-message is generated, SU200 will continuously

transmit the system/process-message until it’s acknowledged, thus while waiting

for acknowledgement, kWh counter values are not transmitted.

Yes No If there are no process- or system-messages to transmit, SU200 will transmit

analogue values continuously.

When a new process- or system-message is generated, SU200 will transmit this

message for 2 out of 3 times until it’s acknowledged, thus while waiting for

acknowledgement; analogue values are transmitted in every third telegram.

Page 35

SU200 User manual

)

)

)

)

p

)

g

)

)

p

)

g

)

)

g

)

)

)

)

)

)

g

)

)

)

g

)

)

)

g

)

)

)

)

)

)

g

)

)

)

g

)

)

)

(

)

(

)

This document is confidential and is the property of Siemens AS. It may not

be copied, reproduced, or disclosed in any form without the express written

consent of Siemens AS. Offenders are liable to the payment of damages. All

rights are reserved in the event of the grant of patent or the registration

Page: 35 of 103

Version: 11

Date: 17.Oct 2002

Order no: AB03-Y200-A

Yes Yes If there are no process- or system-messages to transmit, SU200 will continuously

alternate between transmission of kWh counter values and analogue input values.

When a new process- or system-message is generated, SU200 will transmit this

message for 2 out of 3 times and analogue values in every third telegram until the

message is acknowledged.

N/A N/A Message transmission blocked (In local control mode)

As described in the above situations but as if SU200 has no process- or systemmessages to transmit

Table 2 - Transmission of various types of telegrams

Four different types of telegram structures are used for communications:

• Message telegram (consisting of process messages or system messages)

• Analogue value telegram

• General scan telegram

• kWh counter telegram