Siemens SATURN IIE EPABX, SATURN IIE Installation Test Procedures

Siemens Practices

Installation Series

:

A30808-X5130-8120-1-8928

1

Issue 1, May 1986

’

1

!

Issued by Office Systems Group

5500 Broken Sound Boulevard

N.W., Boca Raton,

Florida 33431

--___________-

Siemcns Information Systems, Inc.

(305) 994-8100 l Telex: 515052

----- -

..-

-----

Printed in U.S.A.

SATURN

IIE

EPABX

A30808X5130-8120-1-8328

Installation Test Procedures Issue 1, May

1906

SECTION

PAGE

l.CO INTRDCUCTlON

............;.............

.1-l

Purpose ..................................

l-l

scope ....................................

1-l

Siemens SATURN

IIE

Practices ................. l-l

Siemens Customer Support Services. ...........

l-l

2.00

PREP/%KGXIY

ACTIVITY ...................

2-1

Cener21.

.................................

2-1

Test Equipment Required. ...................

2-l

Handling Precautions for

PC&

with

MOS Integrated

Circuiis.

....................

2-l

PC6

Removal and Replacement Guidelines.......

2-1

Initial Visual Inspection Procedures

..............

2-1

3.CO

GROUND TESTS ..........................

3-l

General.

..................................

3-l

System Ground Test. ........................

3-1

Shelf Ground Continuity Test. .................

3-1

4.00 POWER-UP TESTS ........................

4-l

Genera I..................................

4-1

Power-Up/Output Voltage Tests. ...............

4-l

5.00

OPERATING PROGRAM

LOAD!NG

............

5-1

General.

..................................

5-1

Loading

Operafing Dis!~.

.....................

5-l

Inputting CMU

Data

to

Floppy

Disk. ............

5-l

&CO

ON-FINE

DlAGrGxTlC

TESTS ...............

6-3

General.

..................................

6-l

Connection of Maintenance Phone

and Modem ..............................

6-l

MDF Cross-Connecting

Prccedures.

............

6-1

System Diagnostic Tests; ....................

6-12

7.CO

INSTALLATION TEST

PRCCEDURES CHEC#L!ST

7-l

General

...................................

7-l

l=lGURE

PAGE

2.00 Signal

Cab!e

Distribution for the SATURN

IIE

System (Basic Cabinet). ................

2.01 Signal Cable Distribution for the SATURN

IIE

System (Expansion Cabinet).

............

2.02 Power/Ground Distribution for the SATURN

IIE

System (Basic Cabinet). ................

2.03 Power/Ground Distribution for the SATURN

IIE

System (Expansion Cabinet) .............

3.00 System Ground Test Connections

..........

3.01 Shelf Ground Continuity Test Connections.

...

4.00 Location of Input Voltage Connectors on

Basic Backplane. .....................

4.01 Location of Input Voltage Connectors on

LTU Backplane .......................

5.00 Floppy Disk and Storage Envelope .........

5.01 Power System Unit (Front View).

...........

5.02 Floppy Disk Loading Procedures.

..........

5.03

CIOP

Printed Circuit Board ...............

6.00 Maintenance Phone and Maintenance-Related

Cress-Connections ....................

6.01

Modem

Cross-Connections ...............

.

2-4

2-5

2-6

2-7

3-2

3-3

. .

4-5

.

4-6

5-l

5-4

5-5

5-6

6-2

6-z

6.02 Single -Line Telephone Cross-Connections

Using SLMA

PCB

. . . 6-3

6.03 Single

-Line

Telephone Cross-Connections

Using

SLAi6

PCB

6.04 Siemens Digital

Teiephone

Cross-Connections

Using SLMD PCB. .

6.05 SATURN Attendant Console Cross-Connections

6.06 CO and

CID

Trunk Cross-Conneciions .

6.07 Two-Wire (Type I) E&M Trunk

Cross-Connec?ions

6.08 Four-Wire

(T;lce

I)

E&M

Trunk Cross-Connections

6-3

63

G-4

E-5

G-5

G-S

_.

6.09 Two-Wire

(Type II)

E&M Trunk Cross-Connections . 6-6

6.10 Four-Wire

(?ype

II)

E&M

Trunk Cross-Connections . 6-7

6.il

Recorded

Anncuncement

(DID and Tie Trunk

Vacant Number Intercept, and ACD

Announcement

Service)

Cross-Connections 6-7

6.12 Code

Ca!ling

(With or Without Answerback)

Cross-Connections . . 6-8

6.13 Dial Ciciation

(DTMF)

Cross-Conneciions. 6-8

6.14 Music-en-Hold Cross-Connections Using

TMBA4

PCB . . . . 6-9

6.15 Music-on-Ho!d Cross-Connecticns Using

SLMAISLA16

PCB . . . . . . 6-9

6.16 Paging With Answerback Cross-Connections 6-10

6.17 Paging Without Answerback Cross-Connections. . 6-10

6.18 Universal Night Answer (UNA) Cross-Connections

E-11

6.49 Attendant

Conscie

Keypad and

Fcaturo

Button

Depiassion

Ssquonce

G-:3

620

Siemens

DYIiD Te!ephono Buttcn Ccpressicn

Sequence . . . . . . . . . . . . . .

6-21

6.21 Siemens JR-DYAD

Te!ephone

Euitcn

Depression

Sequence

. . 6-23

1.00 Mnemonics Used in This Practice .............. l-l

2.CO

PCB and

Powar

Supply Removal

Guidelines

.....

2-2

2.01 Visual

Inspeciion

...........................

2-3

3.00 System Ground Test. ........................

3-l

3.01 Shelf Ground Continuity

Test

..................

3-1

4.00 Power-Up/Output

Voitnge

Test .................

4-l

5.00 Loading Procedures fcr Operating Disk. .........

5-2

5.01

CIOP

DIP

Swiich

Settings ....................

5-3

5.02 LED Display Values for Leading Errors

..........

5-4

6.00 Tone Generator Test

........................

6-13

6.01 Tone

Genera:or

Test

I\!umbers

................

G-i3

6.02 DTMF

Receiver

Test ........................

G-14

6.03 Station Line Test. ..........................

6-14

6.04 DTMF Pad Test

............................

6-15

6.05 Console Test

...............................

6-16

6.06 Attendant Console Displayable Characters. ......

6-19

6.07 Siemens Digital Telephone - DYAD Button Test 6-20

6.08 Siemens Digital Telephone - JR-DYAD

Button Test . . . . .

6.09 Siemens

Digiial

Telephone

-DYAD

Display Test

6.10 Siemens Digital Telephone Displayable

Characters . .

6.11 Outgoing Trunk Test .

6.12 Placing Circuit(s) In-Service

6.13 Taking Circuit(s) Out-of-Service

7.CO Insta!lation

Test Procedures Checklist

G-22

6-24

6-25

6-26

6-27

6-27

7-l

SATURN

IIE

EPABX

installation Test Procedures

A30808-X5130-0120-l-0928

Issue 1, May

1986

.

1.01

Purpose. The equipment comprising the SATURN

IiE

(SATURN Ii-Expanded) System is

compleYely

tested at the factory prior to shipment. The inspections and tests covered in

this practice verify that the EPABX equipment has been

properly installed; ensure that no damage

wasIncurred

during transit; and confirm that the sysiem is completely operational. Table 1.00 defines the mnemonics usedthroughout

ihis

practice.

CAUTION

lnstalbtion

test procedures on the

SATL’RN I/E EPABX

must be performed only by

Siemer;s cetiified

personnel.

1.02

Sccpe.

This practice is

divided

into the following sec-

tions which are presented in the sequential order of

per-for-

mance

after initial installation of a SATURN

IIE

System. When

additional equipment is installed to an existing and active

SATURN

IIE

System, it is the responsibility of craft person-

nel to determine the sequential order of the test procedures

contained in

tihese

sections.

ACD

Au;omaiic Cafl

Disiribution

ALiVl

Alarm

ASCII American Standard Code for Information

lntarchange

CIOP

Controller/Input-Ouiput

Prccessor

CMU Customer Memory Update

co Central Office

CONF Conference Module

COT

Central Office Trunk

DCI Data Communication Interface

DID Direct Inward Dialing

DIP

Dual

lnline

Package

DP

Dial Pulse

DTE Da?a

Terminal Equipment

DTMF

Dual Tone Multifrequency

EIA

Electronics Industries Association

EPABX

Electronic Private Automatic Branch Exchange

FDD Floppy Disk Drive

IRAM

Input Random Access Memory

LTU

Line/Trunk Unit

LTUPS

Line/Trunk Unit Power Supply

LED Light-Emitting Diode

MCA Memory Control and Attenuation

MDF

Main Distribution Frame

MEM3

25Gkb Memory

MEM4

1Mb

Memory

MOS

Metal Oxide Semiconductor

MRA Material Return Authorization.

MSM

Memory Support Module

MTCE

Maintenance

00s

Out-of-Service

ORAM

Output Random Access Memory

PABX

Private Automatic Branch Exchange

PCB Printed Circuit Board

PEN

Port Equipment Number

PIMD

Premium Instrument Module Digital

PSC

Parallel/Serial Converter

PSU

Power Supply Unit

a. Section

l.CO -

Introduction

b. Section 2.00 - Preparatory

Activiiy

c. Section 3.00 - Ground Tests

d. Section 4.00 - Power-Up Tests

e. Section 5.00 - Operating Program Loading

f. Section

6.80

-

On-Lina Diagnostic Tesis

g.

Section 7.00 -

lnstallaticn

Test

Procedures

Checklist

7.03

Siemens SATURN

IIE Prac:iccs.

The practices, issue

numbers and dates for the SATURN

IIE

EPABX are

lists3

in the

Practices Documentation Index A.30808~X5130-AlgO- * -E987 Al-

ways refer to the !aiest issue of the application

indcx

to ob-

tain the latest issue number of a practice.

724

Siemens

Cus;oma: Sqpsrt

Services.

Sicrnons

maintains a nationwide network

cf

field

service

offices. Con-

tact the Siemens regional

oifice

for any engineering

es-

sistance

that may be

requked.

TaS!e

1.00 Mnemonics Used in This Practice

DEFiN1TfON

i-i

SATURN

IIE

EPABX

Installation Test Procedures

.

Table 1.00 Mnemonics Used in This Practice (Continued)

[\fiNEMDNIC *

DEFINITION

RAUP Remote Access Unit/Ports

RGEN Ring Generator

S-416

Subscriber Line Module Analog - 16 lines

SLMA

Subscriber Line Module Analog

SLMA-S

Subscriber Line Module Analog - Station

SLMD

Subscriber Line Module Digital

SMXTG

Signal Multiplexer/Tone Generator

SPC

Stored-Program-Controlled

SPG

Single Point Ground

TMBA-2

Two-Wire E&M Trunk

TMBA-4 Four-Wire E&M Trunk

TMBM

Central Office Trunk

TMIE

Direct Inward Dialing Trunk

TMS

Transmission Measuring Set

TSTAPP

Test - Apparatus

TSTDIAG

Test - Maintenance Diagnostic

TTY

Teletypewriter

UNA

Universal Night Answer

ZUNA Zoned Universal Night Answer

-48PS

-48Vdc

Power Supply

l-2

(2 pages)

SATURN

IIE

EPABX

A30808-X5130-B120-l-8928

Installation Test Procedures Issue 1, May 1986

2.01

General. This section describes the test equipment required to perform the installation test procedures, handling

precautions for Printed Circuit Boards

(PCBs)

with Metal Oxide Semiconductor (MOS) integrated circuits, guidelines for

removal and replacement of

PCBs

and powei supplies, and

initial visual inspection procedures.

2.02 Test Equipment Required. The following test equipment is required to perform the procedures contained in this

practice:

a. Digital Multimeter. A digital multimeter of

gocd

com-

mercial quality with an accuracy of + 1.0% or better.

The digital multimeter is used to perform the ground

tests and output voltage tests.

b.

Maintenance Test Phone. For both Dial Pulse (DP) and

Dual Tone Multifrequency

(DTMF)

systems, a lineman’s

test set or a single line

te!ephone.

A modular jack

(MTCE PHONE) is provided on the front

panal

of the

PSU for

conneciing

the maintenance test phone when

equipped with a modular plug. When the maintenance

test phone is not equipped with a modular plug, a station appearance can be used via the Main Distribution Frame

(MDF).

The

mainienance

test phone is used

to perform the on-line diagnostic tests.

c. Data Service Terminal. A Keyboard-Send-Receive

(KSR) daia terminal equipped with a standard ASCII

keyboard and an EIA RS-232C interface (Silent 700

Series - Model 743 KSR - Texas Instruments, or

equivalent). The data service terminal is used to input

installation dependent data (i.e., system data base) into

system memory when the standard data base format

is supplied with the SATURN

IIE

System.

d. -Transmission Measuring Set. A transmission measur-

ing set (TMS) used to measure the transmission quality of a trunk or station (Hewlett Packard HP-355iA or

equivalent). Refer to the manual On-Line

DiagnostiC

Tests, Outgoing Trunk Test and Station Line

Tosl.

2.03 handling Precautions for

PCBs wifh MCS Integmt-

ed

Circuiklt

is important that craft personnel handling

FCBs

with MOS integrated circuits free themselves from electrostatic

charge by touching a grounded cabinet frame before handling

such

PCEs,

or by wearing grounded wrist straps.

Failur:,

to

observe this practice may result in damage to

MO3 PCBs

due to electrostatic discharge.

WARNING

lirazardous

voltages

exist r&h.%

the

eqo&ment

cabins?.

Be extremely careful when

perr”orming fcsa-

incjtroubleshooting

procedures

with

the

oquipmcr;t

panel(s) removed.

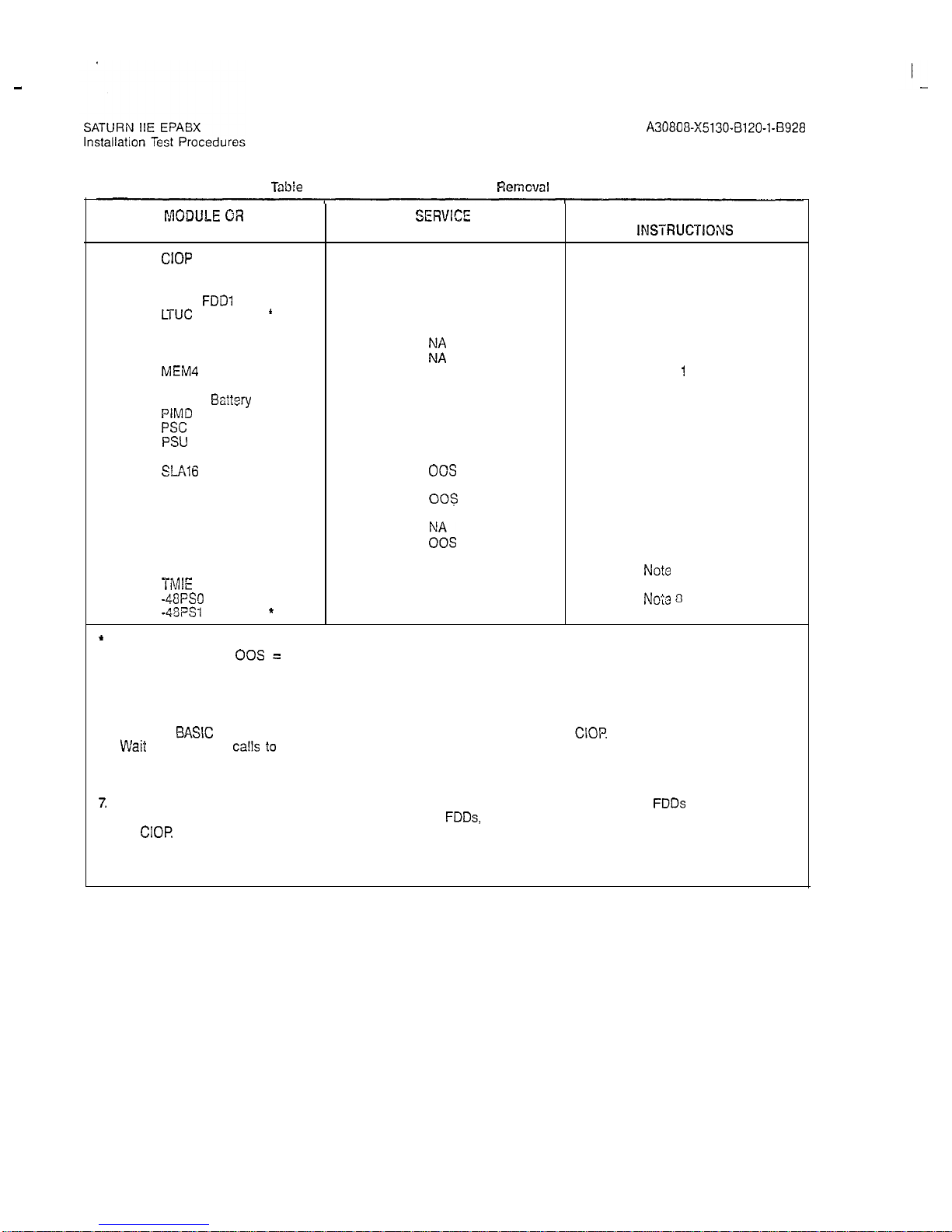

2.04

PCB Removal and

P,ep!acemenZ Guide%%

In many

instances during testing, the corrective action for a procedure

in which the proper verification was not obtained requires that

a PCB or a power supply be removed and replaced with a

spare.

Tablo

2.00 provides the guidelines that

shou!d

be

o!)-

served when removing and

rep!acing PCBs

and

powor SI:;X-

plies in an active

sysicm.

2.05

lnifial Visual kspactizn Procedurx.

The

visu’al

in-

spection procedures contained in

Tab!e

2.01 must be

psrfcrmcd

to ensure that the equipment comprising the SATURN

ItE

Sys-

tem has been properly installed and configured to meet the

installation requirements. Before proceeding

wiih

the visual in-

spections, the front, rear and side panels of the

cabinei should

be removed to

allcw

thorough inspection of the equipment.

2-1

-

Table

2.00 PC3 and Power Supply

Remcval

Guidelines

I’AODIJLE OR SERVEC”

SPECIAL

UNIT

STATE

INSTRUCTKWIS

CIOP

NA

CONF . NA

DTMF 00s

FDDO,

FDDl

NA

LTUC

f

NA

LTUPS

l

NA

MCA

MEM3

kz

MEM4

NA

MSM

l

NA

MSM

Baitery

l NA

PIMD

00s

PSC

NA

PSU

NA

RAUP

NA

SLAl6

00s

SLMA-0 00s

SLMA-S

003

SLMD 00s

SMXTG

ES

TMBA-2

TMBA-4

00s

TMBM

00s

TMIE

00s

-48PS.l

NA

-48PSt

f

NA

*

Optional depending upon customer/system requirements.

NA = Not Applicable;

00s =

Out-of-Service

Notes 1 and 2

Notes 1 and 2

Note 3

None

Note 4

Note 5

Notes 1 and 2

Notes 1 and 2

Notes 1 and 2

Note 1

Note 6

Note 3

Notes 1 and 2

Note 7

Notes 1 and 2

Note 3

Note 3

Note 3

Note 3

Notes 1 and 2

Note 3

Note 3

No?e

3

Note 3

Note 8

Noie 3

Notes:

1.

System outage (halts call processing). Set BASIC PS circuit breaker on PSU to off.

2.

Open FDD and remove floppy disk before removing PCB. After new PCB is inserted, reinsert floppy disk, close

FDD, set

BASK

PS circuit breaker on PSU to on, and press reset switch on

CIOP

3. VVait

for in-process

ca!ls

i0

complete.

4.

Removal places one-half of ports in shelf out-of-service.

5.

Before removal, set related LTUPS circuit breaker on PSU to off. Removal places all ports in shelf out-of-service.

6.

Battery may be replaced with power applied to system.

7.

System outage (halts call processing). Before removal, set all circuit breakers to off, open

FDDs

and remove flop-

py disks. After replacement, reinsert floppy disks, close

FDDs,

set circuit breakers to on, and press reset switch

on

CIOR

8.

Set related circuit breaker on PSU to off. May halt call processing depending upon system configuration and

traffic. If there are two -48Vdc power supplies (where system includes an Expansion Cabinei), the remaining supply may have sufficient capacity to support system operation.

A30808-X5130-8120-l-8928

Issue 1, May 1986

2-2

I

.-

A30808-X5130-B120-l-8928

Issue 1, May 1986

SATURN

IIE

EPABX

Installation Test Procedures

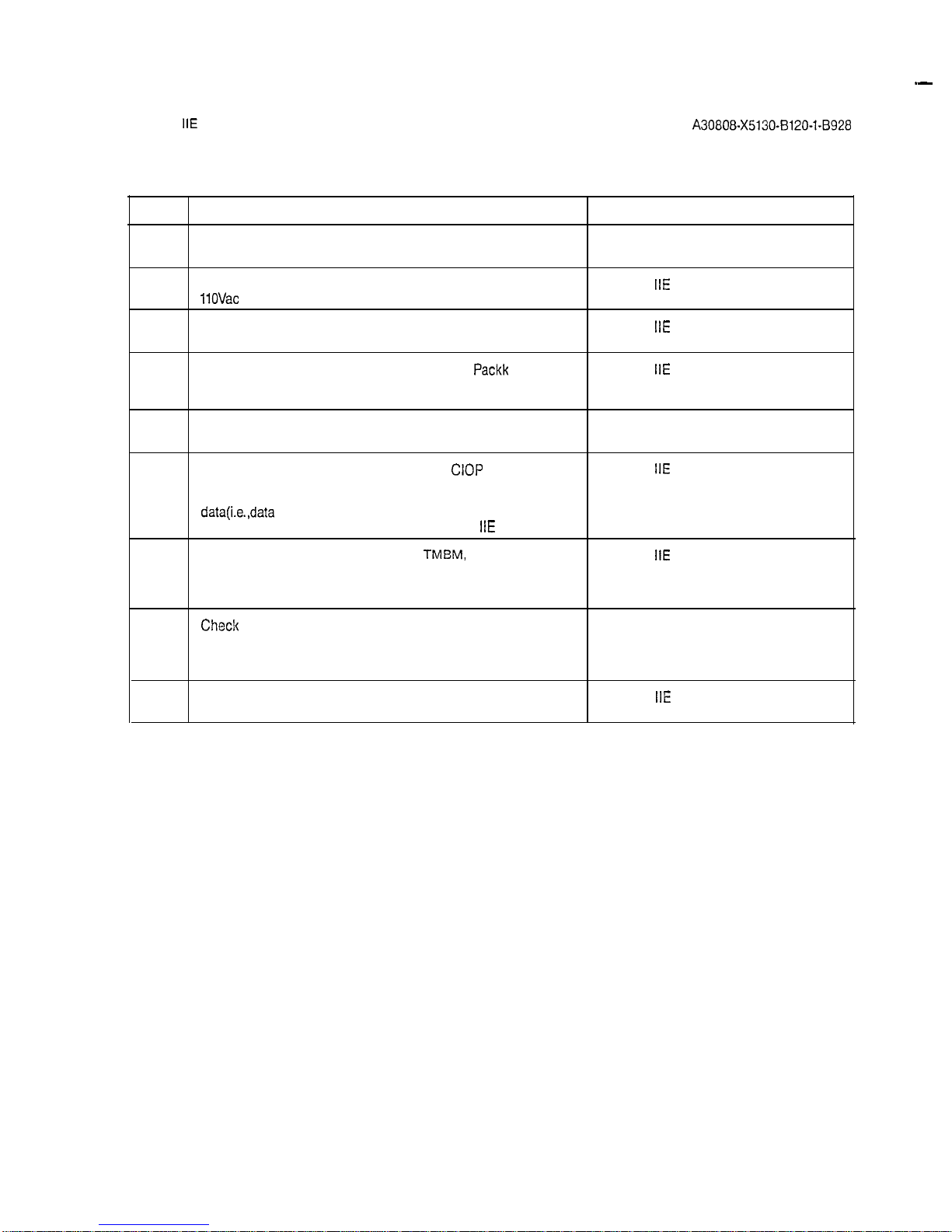

Table 2.01 Visual Inspection

STEP

VISUAL INSPECTION REFERENCE

1

Check that the cabinet ac power cord is not connected to an

electrical outlet.

2

Check that the -48Vdc power supply is strapped for SATURN

IIE

EPABX Installation

11OVac

or 22OVac. Procedures Practice (Section 4.00)

3

Check that all circuit breakers on the Power System Unit SATURN

IIE

EPABX Installation

(PSU) are in the OFF position and fuses inserted. Procedures Practice (Section 4.00)

4

If the MSM is installed, check that the Battery

Packk

is not SATURN

IIE

EPABX Installation

connected but inserted into corresponding position. Also Procedures Practice (Section 4.00)

check that the PSU is strapped for MSM operation.

5

Check that each PCB in the system is withdrawn from its

backplane connector.

6

Check that the DIP switch settings for the

CIOP

board are set SATURN

IIE

EPABX Installation

to meet the operating characteristics of the particular data Procedures Practice (Section 4.00)

service terminal to be used to input the installation-dependent

data(i.e.,data

base) into system memory when the standard

data base format is supplied with the SATURN

IIE

System.

7

Check that each trunk-type PCB (i.e.,

TMEM,

TMIE, TMBA-2 SATURN

IIE

EPABX Installation

and/or TMBA-4) is properly strapped according to the Procedures Practice (Section 4.00)

operating characteristics of the trunk facility of the Central

Office (CO) or distant PABX.

8

Chec!c

that the intercabinet signal and power/ground cabling Figures 2.00 through 2.03

arrangements are complete and all connectors are firmly seated according to the referenced illustrations (Figures 2.00

through 2.03).

9

Check that Berg Clips are on pins 27 and 28 of unused SATURN

IIE

EPABX Installation

signal cable connectors on basic shelf. Procedures Practice (Section 4.00)

2-3

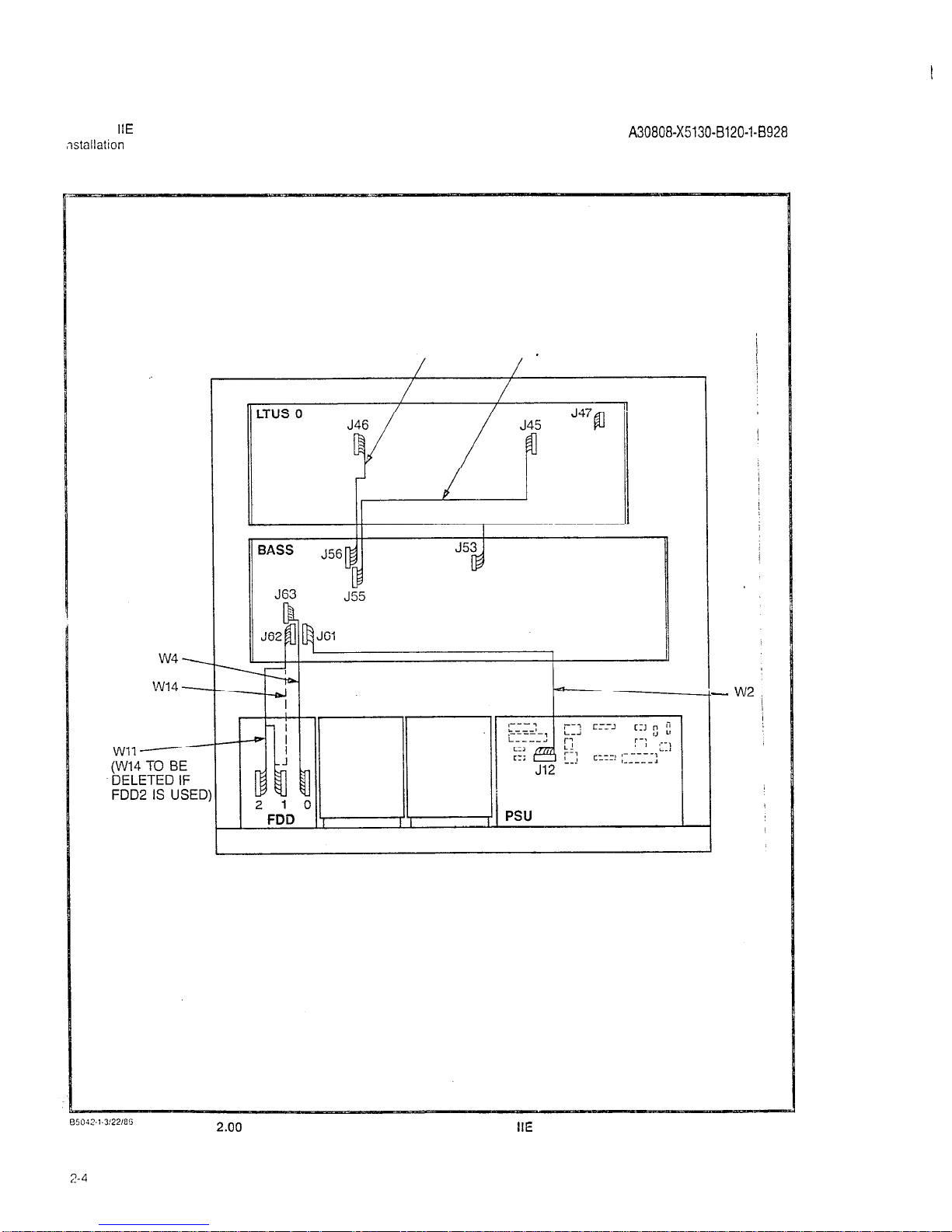

w3 w13

-

I

I

SATURN

IIE

EPABX

,xtallation

Test Procedures

A30808-X5130-B120-l-5928

Issue 1, May 1986

Figure

2.00

Signal Cable Distribution for the SATURN

IIE

System (Basic Cabinet)

SATURN

IIE

EPABX

Installation Test Procedures

A30808-X5130-B120-l-8928

issue 1, May 1986

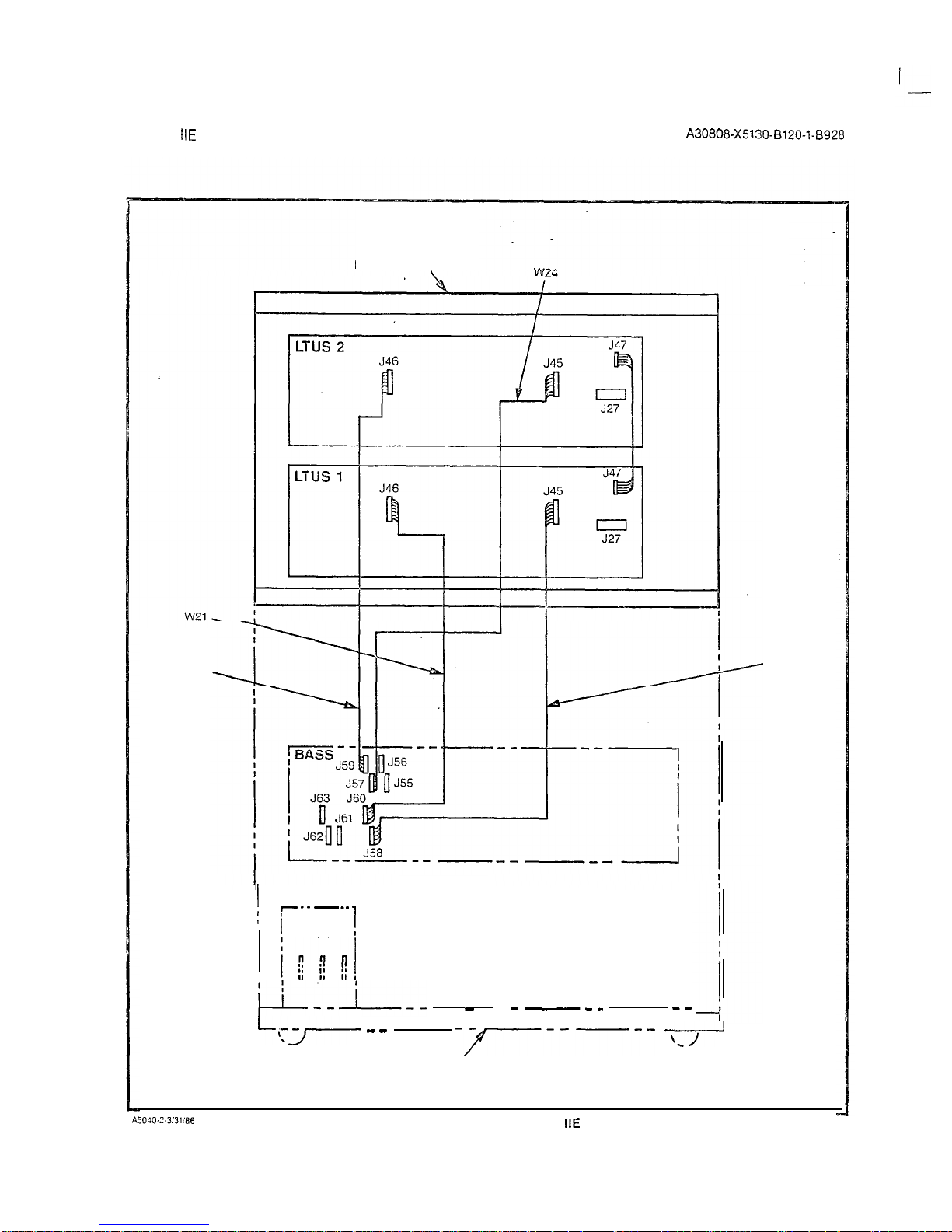

W23

EXPANSION CABINET

\

I

--- ---

: ]

1

FDD

:

,

i;wi!

i-L--i--

-

_-__

--

LiTJ-. - -

-r-----

*

W22

BASIC CA&NET

A5040-2.313186

Figure 2.01 Signal Cable Distribution for the SATURN

IIE

System (Expansion Cabinet)

2-5

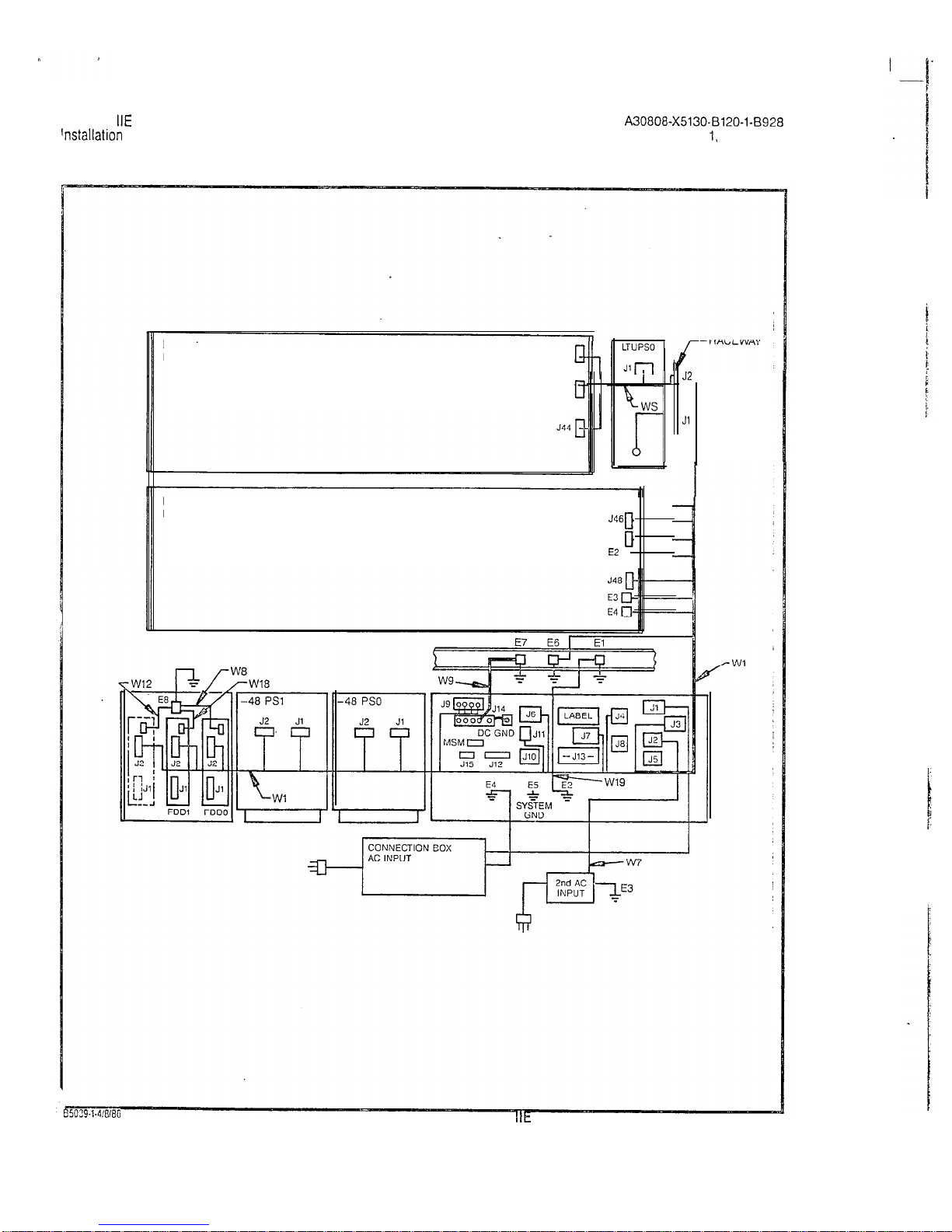

SATURN

IIE

EPABX

tnstallation

Test Procedures

A30808-X5130-8120-1-8928

Issue 1, May 1986

LTUSO

LINE TRUNK UNIT SHELF

J42

J43

r JP

L

Jl

BASS

BASIC SHELF

El a----

J46

J47

E2

05039.1..wmG

Figure 2.02 Power/Ground Distribution for the SATURN

IIE

System (Basic Cabinet)

2-6

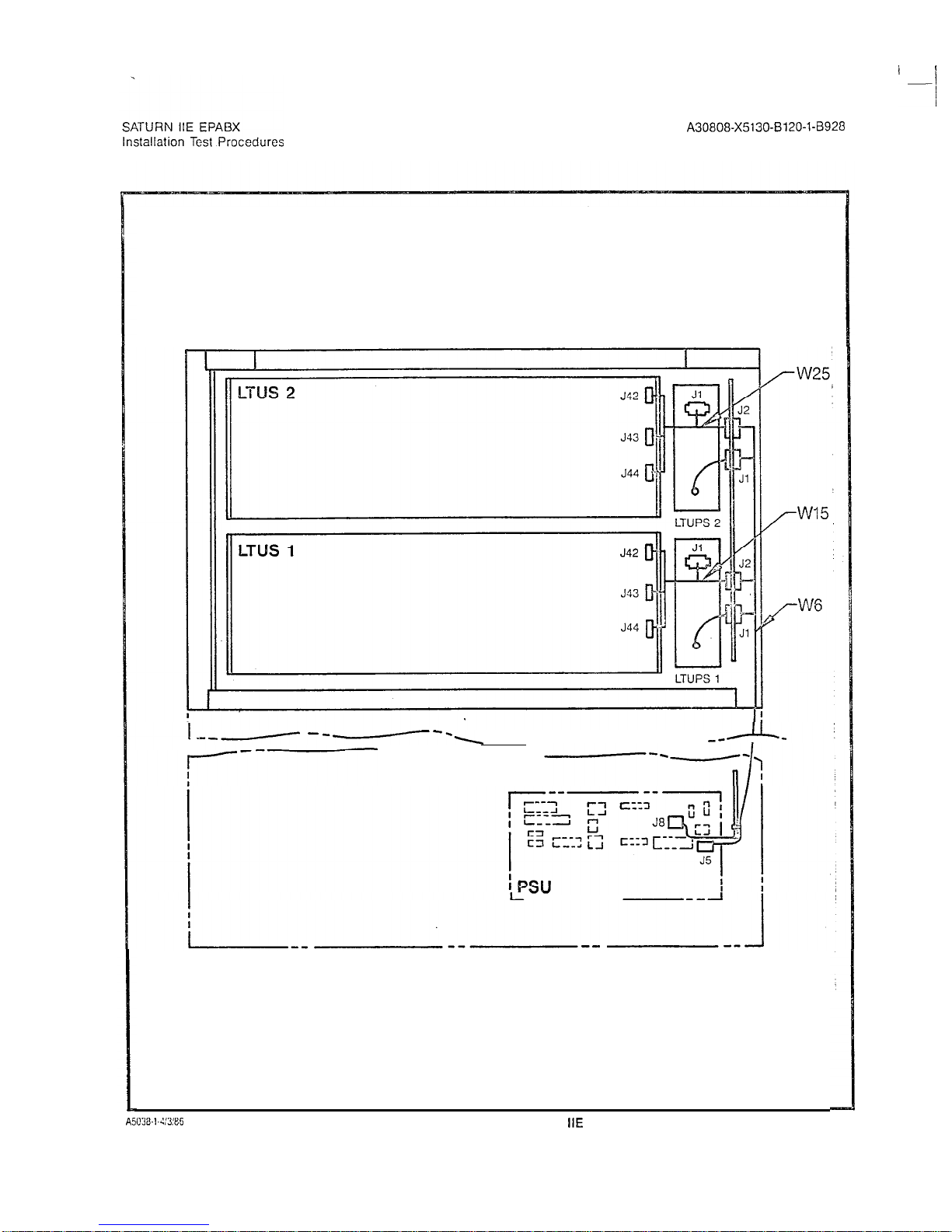

A30808-X5130-B120-l-8920

Issue 1, May 1986

EXPANSION CABINET REF.

L

--M--e--\

----

-,-,

------

-----

BASIC‘CABINET REF.

A5U38-1-4:3:86

Figure 2.03 Power/Ground Distribution for the SATURN

IIE

System (Expansion Cabinet)

2-7 (2-8 blank)

SATURN

IIE

EPABX

A30808-X5130-B120-l-8928

Installation Test Procedures

issue 1. May 1986

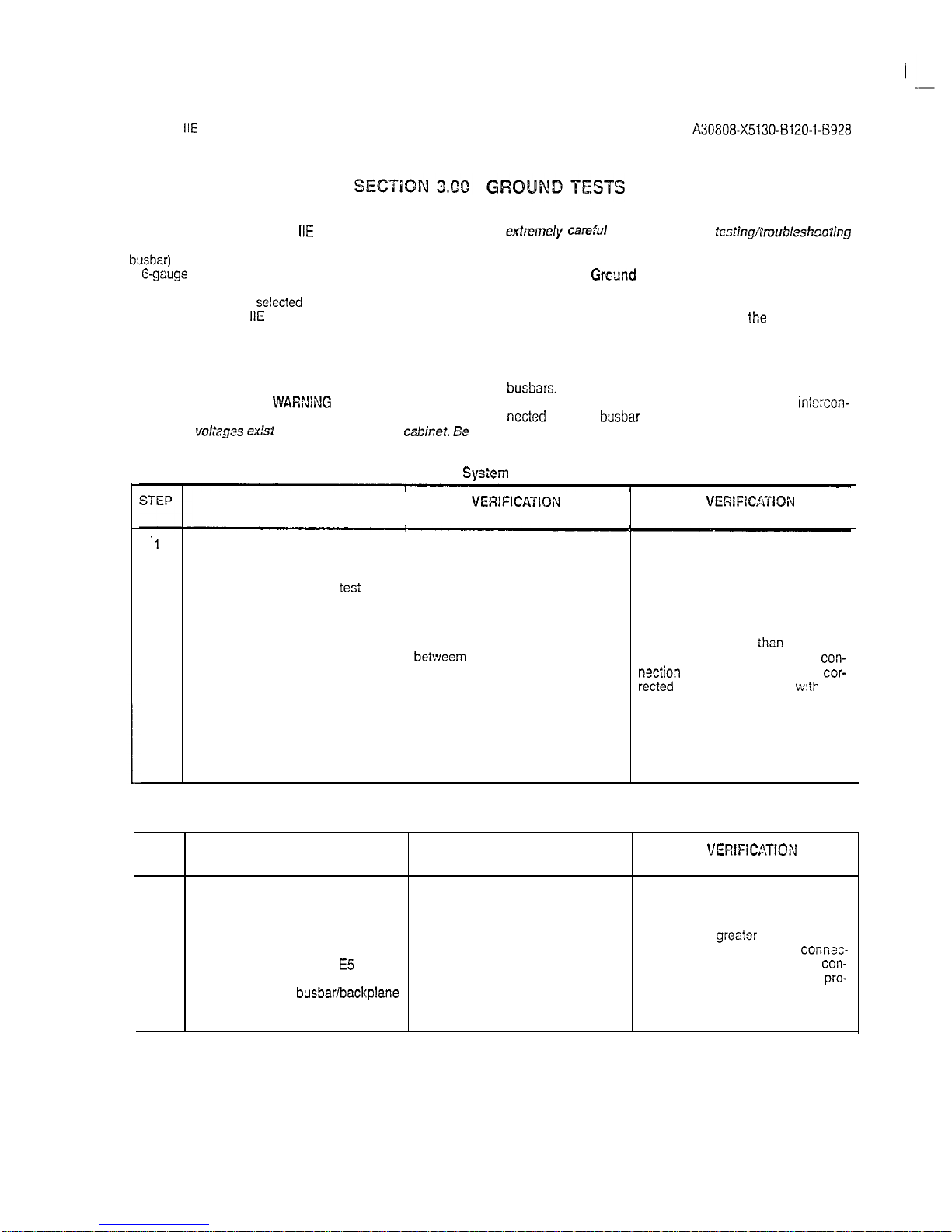

3.01

General. The SATURN HE System must be connected

to an earth ground (i.e., metallic cold water pipe or master ground

busbar)

in addition to the safety ground in the ac power cord.

A

G-gauge

(twisted copper wire) conductor should be connected between the grounding lug E5 located on the bottom of the

cabinet frame and the

snlccted

earth ground (refer to Section

3.00 in the SATURN HE EPABX Installation Procedures practice for details). The following tests must be performed to en-

sure that proper earth ground connections have been

accomplished, and that ground connections within the cabinet

assembly have not been damaged or loosened during shipment.

WARNiNG

Hazardous

voltsgos txkt

within the equipment

csbinef. Ee

extremely ca-ej’Ll

when performing

t~s%i~g/l’roubiesh~oting

procedures with the equipment panel(s) removed.

3.02

System

Grcund

Test. Before proceeding with the test’

procedures indicated in Table 3.00, check that the earth

ground connections are secure and ground conductors are

firmly positioned on grounding lug E5 at

ihe

bottom of the

cabinet frame.

3.03

Shelf Ground Continuity Test. Each LTU shelf assem-

bly within the cabinet assembly is grounded via two vertical

busbars.

Beiore proceeding with the test procedures indicat-

ed in Table 3.01, check that each shelf backplane is

iniercon-

netted

with the

busbar

flanges and adequately secured into

position.

Table 3.00

System

Ground Test

PROCEDURE

VERlFlCATlON

IF

VERlFlCATION

IS NOT OBTAINED

.l

If connected, remove ac power cord

from commercial power outlet.

2

Short digital multimeter

tesi

leads

together and noie resistance of test

leads.

3

Set digital multimeter to lowest

Resistance measured should be If a reading greater

ihan

2 ohms is

resistance range and connect its

betweem

0 and 2 ohms greater than obtained, the faulty ground

con-

leads between the U-ground pin of the measured test lead resistance.

nection

must be isolated and

cor-

the ac power cord and the U-ground

rected

befora continuing

wi?h

the

socket in the commercial power

installation test procedures

outlet (refer to Figure 3.00 for details).

4

Repeat procedure with second ac Same as step 3 above. Same as step 3 above.

power cord if optional expansion

cabinet is incorporated into system.

Table 3.01 Shelf Ground Continuity Test

STEP

PROCEDURE

VERIFICATION IF

VERIFICATiON

IS NOT OBTAINED

1

If connected, remove ac power cord

from commercial power outlet.

2

Set digital multimeter to lowest Resistance measured should be If a reading

greator

than 1 ohm is

resistance range and connect its between 0 and 1 ohm greater than obtained, the faulty ground

connec-

leads between ground lug E5 located the measured multimeter test lead

tion must be corrected before

con-

at the bottom of the cabinet frame,

resistance. tinuing the installation test

pro-

and one of the

busbar/backplane

cedures.

attaching screws for each existing

LTU shelf (refer to Figure 3.01)

3-l

SATURN

IIE

EPABX

A30808-X5130-B120-l-8928

Installation Test Procedures Issue 1, May 1986

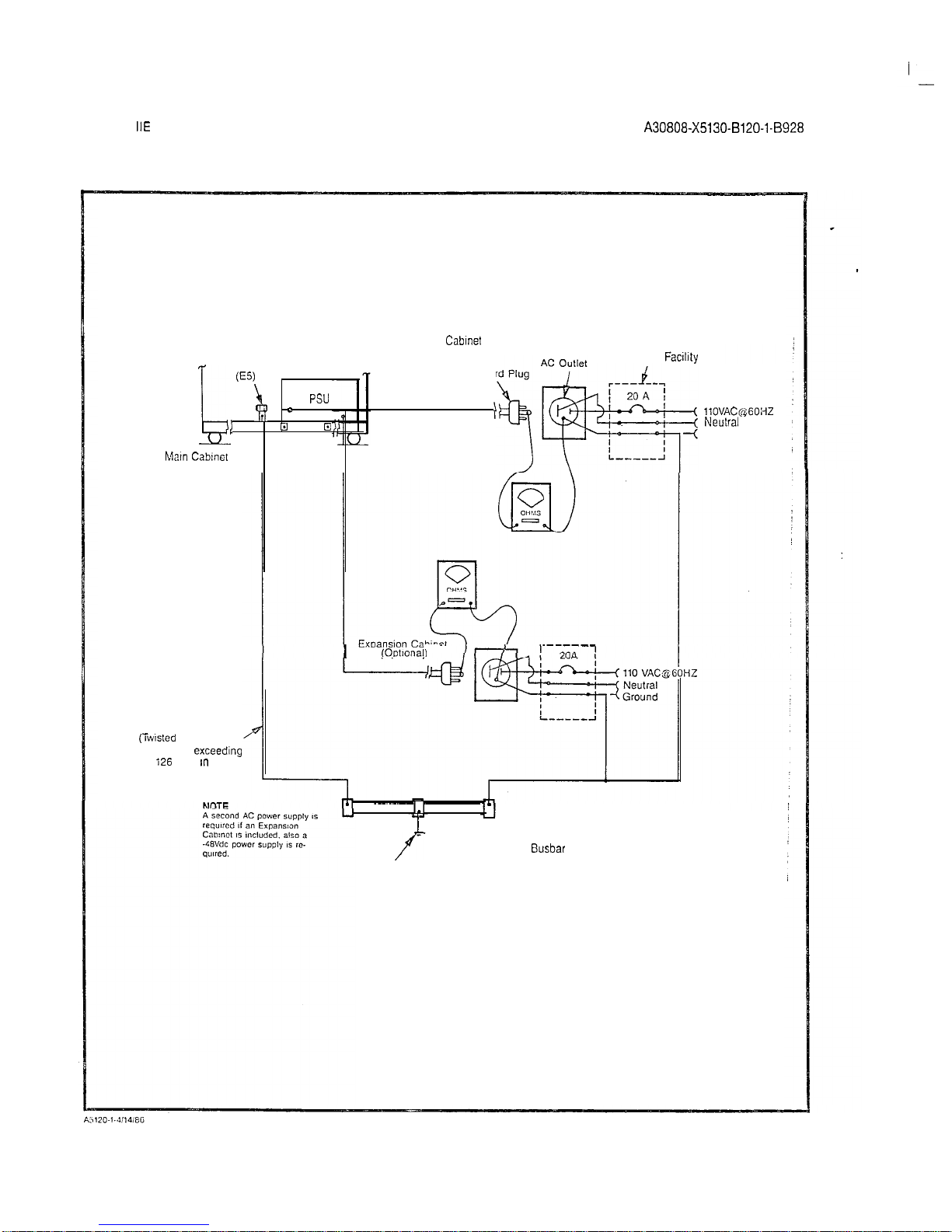

BASIC Cabinet

GND

LUG

Fuse Box Facility

(ES)

,

5,

B D

Power co

PSU

f

llOVAC~$GOi-fZ

El

El

Neulral

Ground

hlatn Cabmel

(Rear View)

Recommended: B-gauge

(iwtsted

Copper Wire)

conductor not

exceedmg

i26

feet m length.

I

(Ootlonall

I.1

f

Master Ground

Busbar

Earth Ground Note: Single Point Ground (SPG) configuration IS shown

Figure 3.00 System Ground Test Connections

3-2

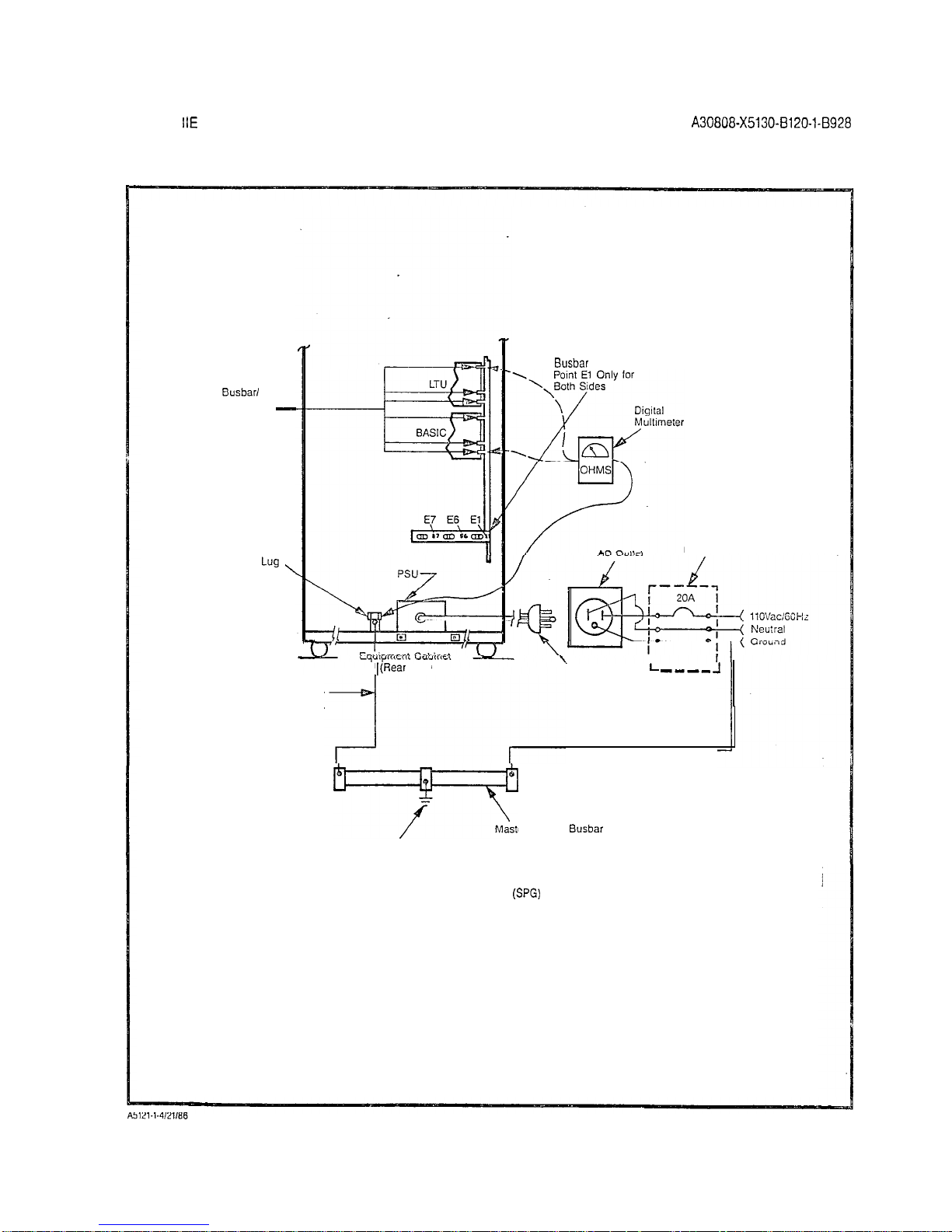

SATURN

IIE

EPABX

Installation Test Procedures

A30808-X5130-8120-1-8928

Issue 1, May 1986

Busbar/

Backplane

-

Attaching

Screws

GND

Lug

No. E5

’

7

-

Recommended: 6 Guage

(twisted copper wire) conductor

not exceeding 126 feet in length.

I(Rear

View)

Busbar

Grounded at

Fuse Box Facility

\

I

L

---_

-I

Power

Cord Plug

7

Master Ground

Busbar

Earth Ground

Note: Single Point Ground (SPG) configuration is shown

Figure 3.01 Shelf Ground Continuity Test Connections

3-3 (3-4 blank)

I

-_

SATURN

IIE

EPABX

installation Test Procedures

A30808-X5130-BlZO-l-8928

Issue 1, May 1986

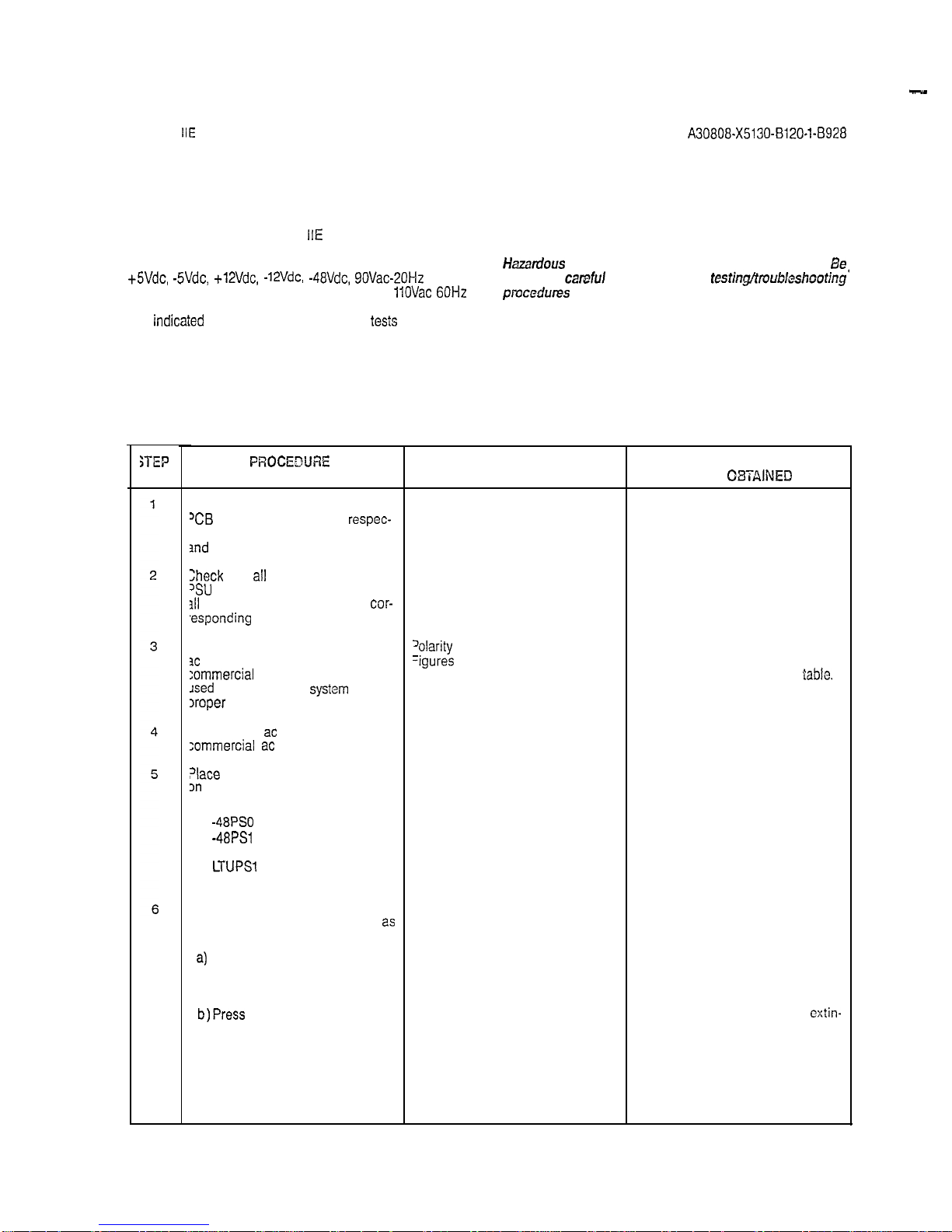

SECTION 4.00 POWER-UP TESTS

4.01

General. The SATURN

IIE

System makes use of distributed power in the equipment cabinet. Several power supplies are used in the system. These power supplies provide

+5Vdc, -SVdc, +12Vdc, -12Vdc, -48Vdc, 90Vac-20Hz

ringing

voltage and message waiting voltage, from a

11OVac 60Hz

input power source. After satisfactorily performing the ground

tests

indicaied

in Section 3.00, the following

tests

must be per-

formed to ensure that proper power cable connections have

been accomplished and that the power supplies inside the

cabinet assembly have not been damaged during shipment.

WARNING

Hazardous

voltages exist within the equipment cabinet.

Be

extremely

careful

when performing

testin@roubkshootjng’

pmcedures

with the equipment panel(s) removed.

4.02

Power-Up/Output Voltage Tests. Before proceeding with

the test procedures indicated in Table 4.00, check that all power cable assemblies are properly secured into their corresponding locations. Note that the test procedures in Table 4.00 include

procedures for testing the optional MSM, when equipped in the

system.

Table 4.60 Power-Up/Output Voltage Test

YiEP

PROCEDtJRE

f not previously done, extract each

‘CB

in the system from its

respec-

ive backplane connector in basic

md

LTU shelves.

Check

that

all

circuit breakers on the

‘SU

are in the off positions and that

311

fuses are inserted in their

cor-

,esponding

locations.

Jsing the digital multimeter (or an

3c

polarity indicator), verify that the

:ommercial

ac power receptacle

Jsed

for powering the

systsm

has the

Iroper

polarity.

Connect the

ac

power cord(s) to the

zommercial

ac

power receptacle(s).

?lace

the following circuit breakers

on

the PSU to the on (up) position:

a) Basic PS

b)

-48PSO

c)

-48PSl

(if equipped)

d) LTUPSO (if equipped)

e)

LTUPSl

(if equipped)

9 LTUPS2 (if equipped)

If the optional MSM module is

equipped in the system, proceed

2s

follows:

2)

If not previously done, connect

and insert battery pack into

the MSM assembly.

b)Press

the BATTERY TEST

switch on the PSU and

release after verification has

been obtained.

VERIFICATION

‘olarity

indication must coincide with

=igures

3.00 and 3.01.

The associated green LED should

light steadily.

IF VERIFICATION

IS NOT

08TAlNED

if polarity indication does not coincide, correct before proceeding with

the remainder of test in this

lable.

If the green LED remains

cxtin-

guished, the battery pack is below

acceptable voltage limits. Let MSM

charge battery pack and retry test after 30 minutes have elapsed. If green

LED remains extinguished, the battery pack is defective and requires

replacement.

‘l-1

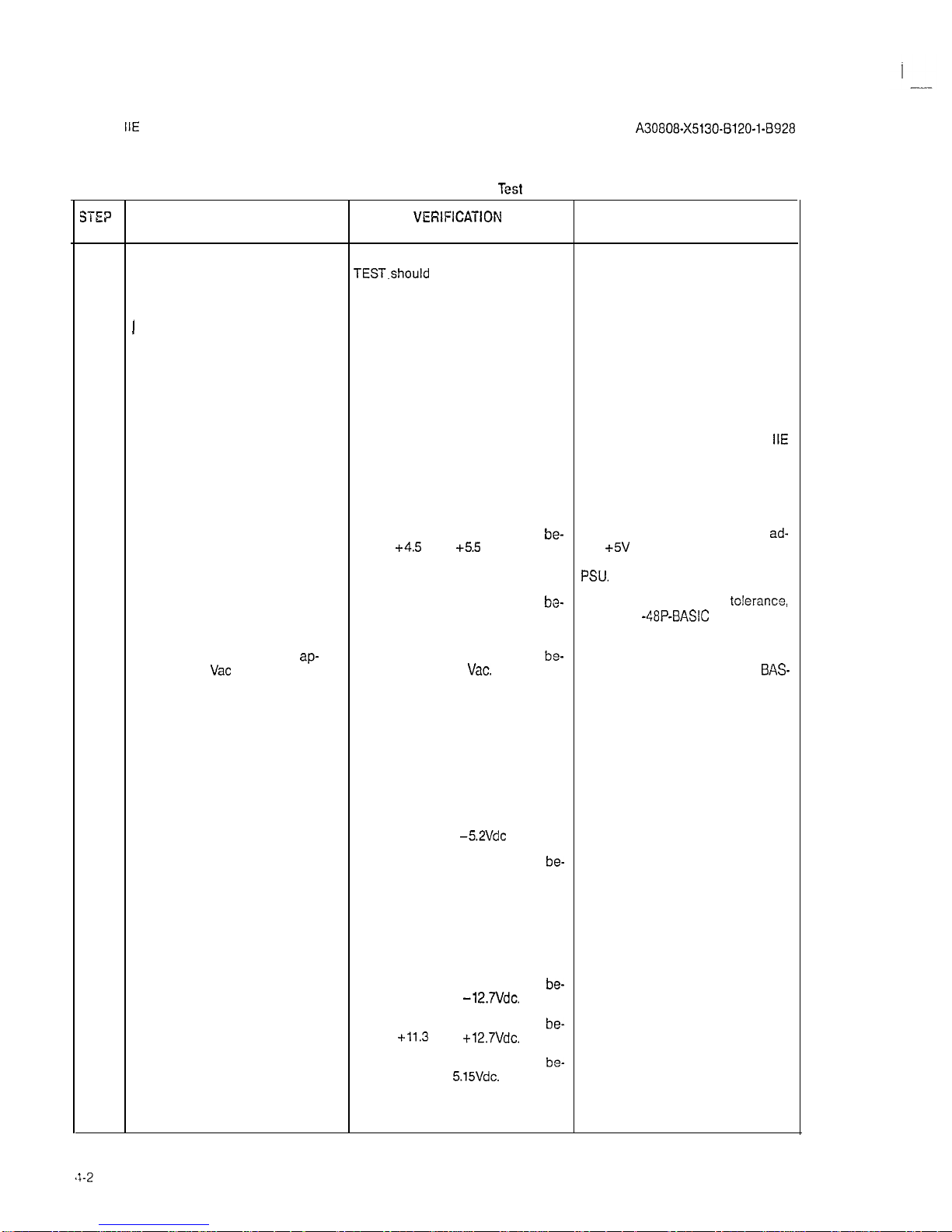

SATURN

IlE

EPABX

Installation Test Procedures

A30808-X5130-8120-1-8928

issue 1, May 1986

Table 4.00 Power-Up/Output Voltage

Test

(Continued)

SE?

PROCEDURE

VEfiIFICATION

IF VERIFICATION

IS NOT OBTAINED

c) On the PSU, place the circuit

The red LED designated BATTERY If the red LED remains extinguished,

breaker designated BASIC PS

TEST.should

be steadily lit. replace the MSM.

in the off (down) position.

The red BATTERY TEST LED should

1

d) On the PSU, place the circuit If the red LED remains steadily lit,

breaker designated BASIC PS be extinguished. either the cabinet ac power cord is

to the on (up) position.

not connected to the commercial ac

power receptacle or a local ac power failure has occurred.

7

Set digital multimeter to appropriate

NOTE

dc voltage scale for the following If further troubleshooting information

tests.

is required during these testing

procedures, refer to SATURN

IIE

EPABX Maintenance and

Troubleshooting Practice.

8A

To measure the unloaded basic shelf

input voltages, proceed as follows:

a) On basic backplane shown in

Voltage measured should read

be-

If reading is not within tolerance,

ad-

Figure 4.00, take reading be- tween

+4.5

and

+5.5

Vdc. just

+5V

ADJUST potentiometer on

tween terminal El, E2, E3 or PSU. If still out-of-tolerance replace

E4 and ground.

PSU.

b) On basic backplane connector

Voltage measured should read

bo-

If reading is not within

to!erance,

J46, shown in Figure 4.00, take

tween -43 and -53Vdc.

check the

-48P-BASIC

fuse in PSU.

readings beiween pins 2 and 3. If fuse is good, replace -48PSO.

c) Set digital multimeter to

ap-

Voltage measured should be

be-

If the voltage is not present, check

propriate

Vat

scale and take

tween 75 and 100

Vat.

and replace RGEN fuse or RAC

BAS-

reading between pins 1 and 2 IC fuse on PSU. If fuses are good,

of J46.

replace RGEN PCB. If voltage still not

present, replace PSU.

d) Set digital multimeter to appropri-

ate Vdc scale and take readings

between the following pins on

basic backplane connector J47

(shown in Figure 4.00):

1) Pins 1 and 3.

2) Pins 2 and 3.

Voltage measured should be be-

If reading is not within tolerance,

tween -4.9 and

-5.2Vdc

replace the PSU.

Voltage measured should be

be-

If reading is not within tolerance,

tween -43 and -53Vdc check the -488 BASIC fuse on PSU.

If the fuse is good, replace -48PS0.

e) On basic backplane connector

J48, shown in Figure 4.00, take

readings between the following

pins:

1) Pins 1 and 4.

2) Pin 2 or 3 and pin 4.

3) Pins 4 and 5.

Voltage measured should read

be-

If reading is not within tolerance,

tween -11.3 and

-12.7Vdc.

replace the PSU.

Voltage measured should be

be-

If reading is not within tolerance,

tween

+11.3

and

+12.7Vdc.

replace the PSU.

Voltage measured should be

be-

If reading is not within tolerance,

tween 4.85 and

5.15Vdc.

check that J16 on the rear panel of

the PSU is strapped to the MSM terminal. If the strap is in place, replace

the MSM.

I

-

SATURN

IIE

EPABX

Installation Test Procedures

A3G808-X5130-B120-1-B928

Issue 1, May 1986

lbb!c

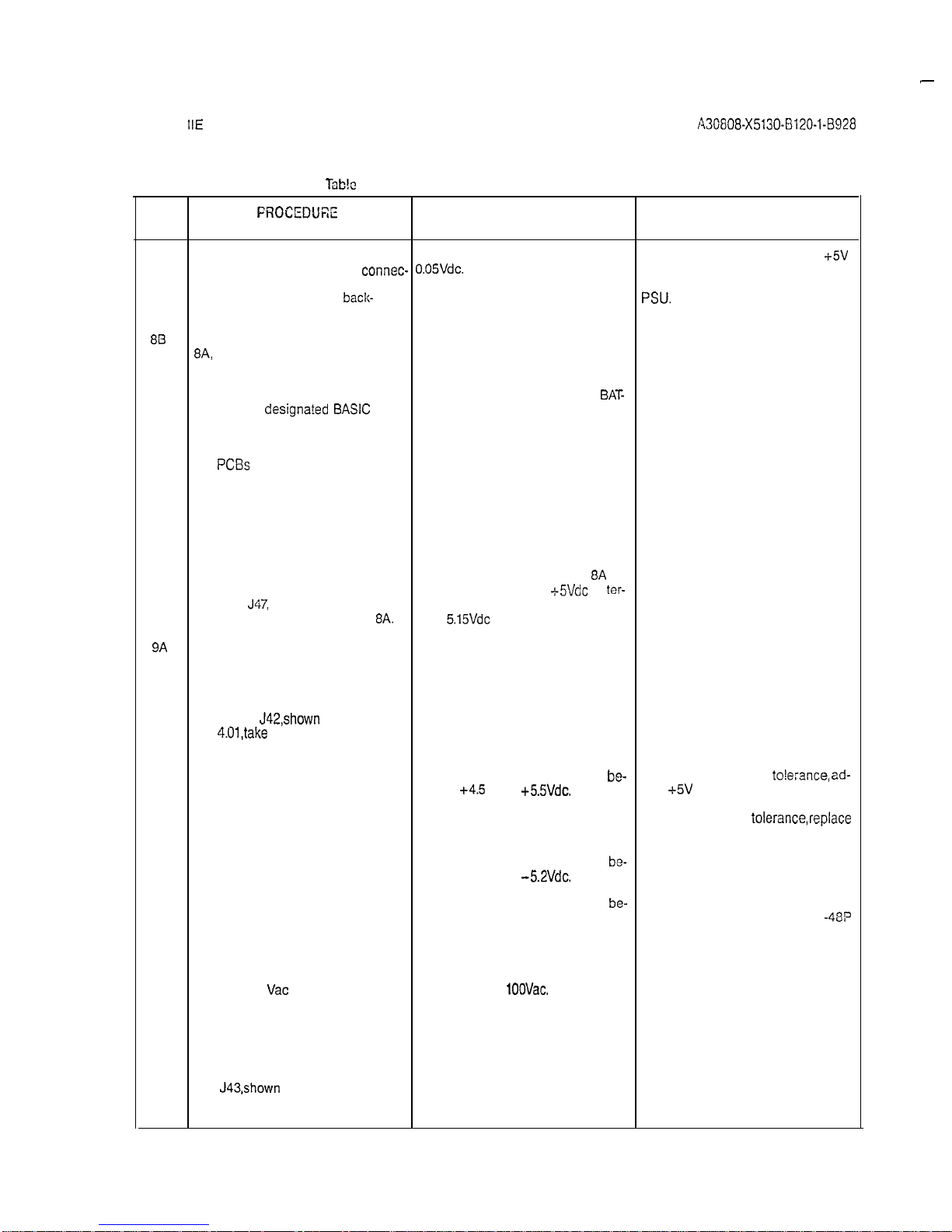

4.00 Power-Up/Output Voltage Test (Continued)

STEP

FROCEDUEE

VERIFICATION IF VERIFICATION

IS NOT OBTAINED

.

f) Connect positive lead of digital Voltage measured should read + If reading is not 0.05 Vdc, adjust

+5V

multimeter to pin 5 of

connec- 0.05Vdc.

ADJUST potentiometer on PSU. If

tor J48 and negative lead to

adjustment is not effective, replace

terminal El on basic

back-

PSU.

plane. (Refer to Figure 4.00.)

813

After satisfactorily completing step

8A,

proceed as follows to measure

the loaded basic shelf input voltages.

a) On the PSU, place the circuit The MSM red LED designated

BAT-

breaker

designa?ed BASIC

PS TERY TEST should be steadily lit.

in the off (down) position.

b) Plug all previously extracted

PCBs

on the basic shelf into

their respective backplane

connectors.

c) On the PSU, place the circuit

The MSM red LED designated BATbreaker designated BASIC PS TERY TEST should be extinguished.

in the on (up) position.

d) Repeat measuring procedures Same verification as in steps 8A a)

on basic backplane connectors

through e), except that

-t-S!/&

at

ter-

J46,

J47,

J48 and terminals

minal El should read between 4.85

El-E4 as indicated in step

8A.

and

5.15Vdc

under load.

9A

To measure the unloaded LTU shelf

input voltages (if applicable), proceed

as follows:

a) On the LTU backplane con-

nector

J42,shown

in Figure

4.01,take

a reading between

the following pins:

1) Pins 1 and 3.

Voltage measured should be

be-

If reading is not within

to!e:ance, ad-

tween

+4.5

and

+5.5Vdc.

just

+5V

ADJUST potentiometer on

LTUPS. If the adjustment does not

bring voltage into

tolerance,replace

LTUPS.

2) Pins 3 and 5.

3) Pins 3 and 4.

Voltages measured should be

be-

If reading is not within tolerance,

tween -4.9 and

-5.2Vdc.

replace appropriate LTUPS.

Voltage measured should be

be-

If reading does not coincide with

tween -43 and -53Vdc.

verification reading, check the

-48P

LTU fuse on PSU. If fuse is good,

replace -48PS0.

4) Set digital multimeter to

read

Vat

and connect be-

tween pins 2 and 3.

Voltage measured should be be- If voltage is not present,

tween 75 and

1OOVac.

check/replace RGEN fuse or RAC

LTUO fuse on PSU. If fuses are good,

replace PSU.

b) Set digital multimeter to ap-

propriate Vdc scale.

C) On LTU backplane connector

J43,shown

in Figure 4.01, take

a reading between the following pins:

4-3

Loading...

Loading...