Siemens SAT 12, SMT 12 Installation Instructions Manual

s

SAT 12/SMT 12

SLT 12 UK

20 800 771.0-010

Installation instructions

Q

W

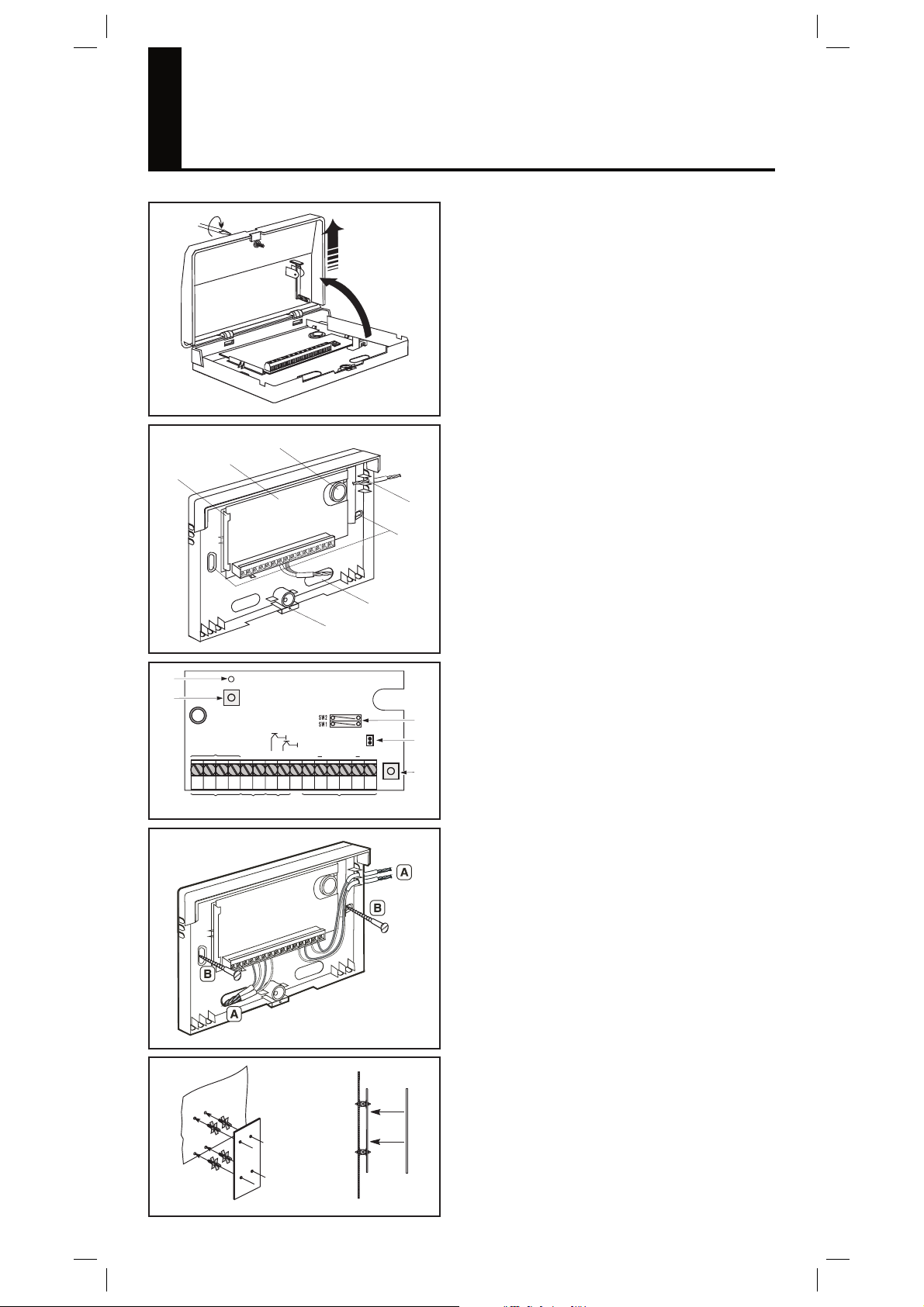

Fig. 1

U

T

Fig. 2

8AA11830 - E0 - 10/10/2003 - UK - SNR 811830.0-001

I

U

Fig. 3

Y

Q

W

E

R

Q

E-Bus

NC

B2

NC

B1-

B3

B4+

Y

Emply

Z4

Z3

O2

O1

3

1

2

T

Z2

7

8

6

4

5

R

W

Z1

E

9

1. Product description

This transponder is supplied either as an SAT 12 with

a housing or an SMT 12 without the housing.

2. Supply package

The SAT 12 package contains the following :

- One SAT 12 Housing (only SAT 12).

- One SMT 12 transponder (board).

- 8 terminating resistors (4.7 kOhm).

- One set (4 off) of mounting studs (only SMT 12).

- One SLT 12 language kit complete with :

- Installation instructions.

- One Wiring diagram.

- One cable with socket connector for external

tamper contact (only SMT 12).

3. Mounting instructions

The SAT 12 and SMT 12 are designed for mounting

in dry indoor rooms. They must not be exposed to

either dripping or splashing water. The SMT 12 is

designed for installation either in an power supply

unit or a suitable flush-type box.

3.1 Open housing (fi g. 1)

1 - Slacken the retaining screw Q.

2 - Remove the cover W.

3.2 Product overview (fi g. 2)

Housing (SAT 12 only) with the following:

- Mounting holes W.

- Holes or knockouts Q,E for cables.

- Eye R for sealing.

- Locking tab T to hold the circuit board.

- SMT 12 circuit board Y.

- Knockout U for the back tamper contact screw.

3.2.1 SMT 12 circuit board (fi g. 3)

- Wire jumpers Q for programming glass break

alarm inputs.

- Plug connector W for external tamper contact,

connected in parallel to the tamper contact E.

- Tamper contact of SAT 12 housing E.

- Four inputs R.

- Two «open collector» outputs T.

- E-Bus connection Y.

- Address key U.

- LED I flash if the E-Bus communication is correct

3.3 Fit SAT 12 housing (fi g. 4)

1 - If necessary, break out the knockouts for

cables (A).

2 - Insert cables.

3 - Secure the base using 2 screws (B).

3.4 Fit SMT 12 circuit board

1 - Engage the mounting studs in the holes (fig. 5A).

2 - Fit circuit board (fig. 5B).

Fig. 4

Fig. 5

A

B

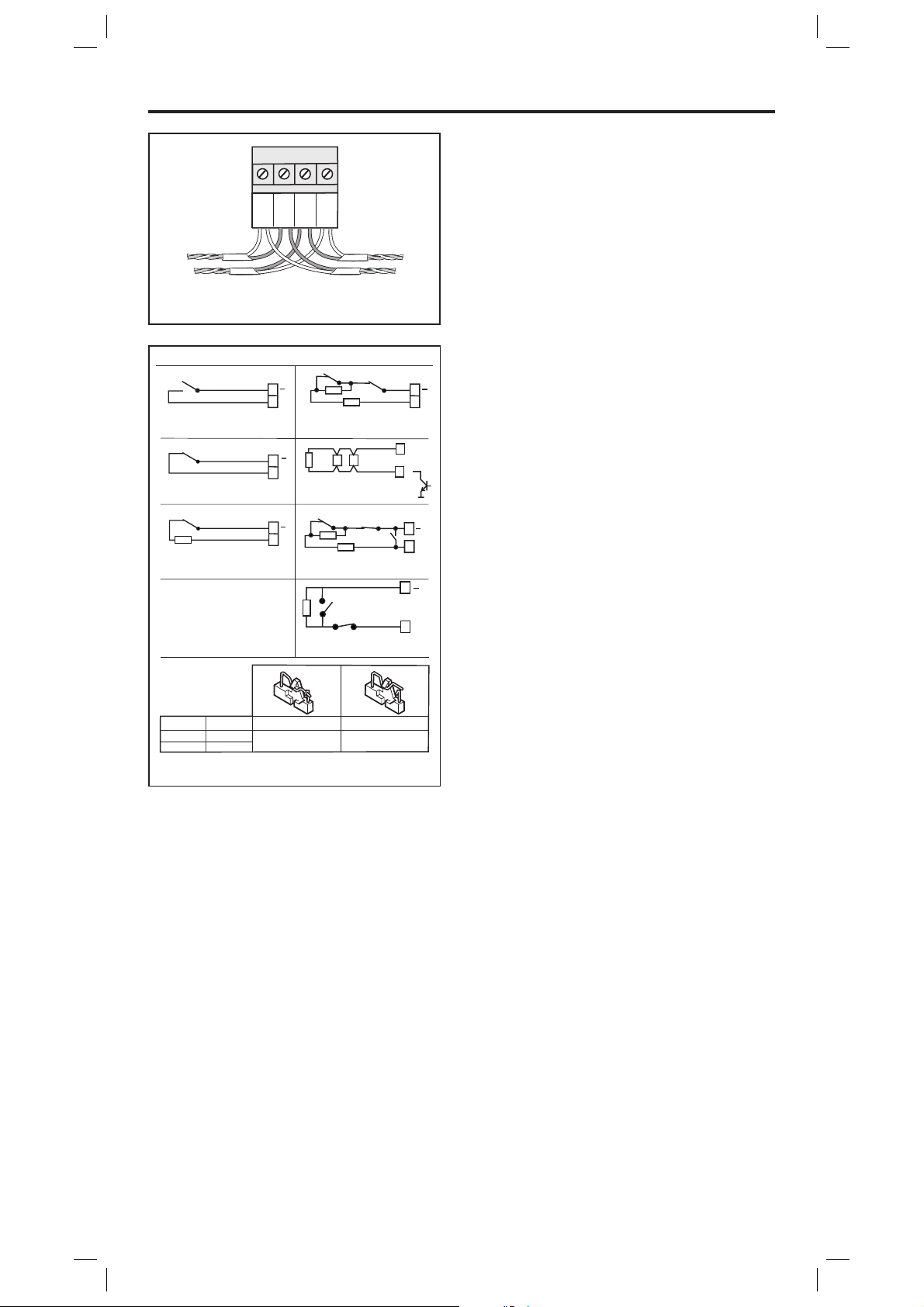

E-Bus from the

central control unit

Fig. 6

1. Normally open contact

2. Normally closed contact

4k7

3. Normally closed contact

monitored

Z1

SW 1

Z2

SW 2

Fig. 7

B3

B2

B1-

B4+

E-Bus to other

Input modes

Z

Z

Z

ClosedInput OpenSwitch

To connect a maximum

of 20 glass break sensors

4k7

4. Alarm & tamper monitored

4k7

5. Glass break sensors

Alar

4k7

6. Emergency exit

Alarm

4k7

7.

Fire input

accessories

Alar

m

Tamper

4k7

Tamper

m

Reset

4k7

Troub

le

All other modes

4. Wiring

The terminals are shown in fig. 3 and on the wiring

diagram glued to the inside of the cover.

4.1 E-Bus (fi g. 6)

Cable type 24 AWG 7 x Ø 0,2 mm is recommended.

The to tal length of the E-Bus cable must not exceed

500 m. The E-Bus must be connected to the cen tral

control unit (B1-, B2, B3, B4+). It may be routed in

parallel to other accessories. If shielded cable is used,

all the shields must be connected at one point, e.g. at

an NC terminal.

4.2 Tamper contact

If the SMT 12 circuit board is not fitted in the SAT

12 housing, the plug connector (fig. 3 W) must be

connected to an external tamper contact or be shortcircuited. Use the socket connector provided to connect

Z

to an external tamper con tact.

4.3 Inputs (fi g. 7)

All inputs can be operated in modes 1 to 4 and 6 to

Z

O

7 (fig. 7). Inputs Z1 to Z2 can also be operated with

glass break alarms. To do this, the relevant switches

SW1 to SW2 must be closed and one terminal of each

glass break sensor connected to one of outputs O1 to

O2, which must be programmed for «Latching sensor

reset». When wiring fire detectors, any trou ble out put

present can be looped directly into the line. For fire

Z

detectors where the power has to be disconnected

to reset the alarm, the negative can be connected

via an output which is programmed as a «Latching

sensor reset» output.

The emergency exit has to be wired like mode 6. A

short circuit of the input will reset the corresponding

Z

output.

5. Close and seal the housing

1 - Engage the cover in the retainer at the top (fig. 1).

2 - Close the cover and tighten the retaining screw

(fig. 1).

3 - Use eye (fig. 2 R) for sealing.

6. Technical data

Supply from the E-Bus

Power consumption min. 6 mA

Power consumption max. 19 mA

2 outputs «open collector» 12 V, 150 mA

4 inputs Programmable

Terminating resistors 4.7 kOhm

Operating temperature -10° C to +55° C

Housing ABS

Dimensions in mm, SAT 12 H 86 x W 135 x D

27 Safety class, SAT 12 IP 30

Environmental class, SAT 12 II

Weight, SAT 12 130 g

Dimensions in mm, SMT 12 H 52 x W 91 x D 20

Weight, SMT 12 50 g

The right to make technical changes to the described equipment without

prior notice is reserved.

Loading...

Loading...