Page 1

Contents

SIMATIC

S5-135U/155U

System Manual

This manual has the

order number:

Notes on Using this Manual

and on the CE Symbol

Centralized and Distributed

Configuration of a Programmable Controller

Installation Guidelines

Central Controllers and

Expansion Units

Power Supply Units

CPUs, Memory Cards,

Memory Submodules,

Interface Submodules

Multiprocessor Operation/

Coordinators

Interface Modules

1

2

3

4

5

6

7

6ES5998-0SH21

12/98

C79000-G8576-C199

Release 06

Digital Input/Output Modules

Analog Input/Output Modules

Monitoring Module

Connector Assignments

Appendices

Appendix

Guidelines for Handling

Electrostatically-Sensitive

Devices (ESD)

Index

8

9

10

11

A

B

Page 2

Safety Guidelines

!

#$.()0'*)/$).)*/$ .2#$#4*0.#*0'*. -1 /* ).0- 4*0-*2)+ -.*)'.! /4.2 ''./*

+-*/ //# +-*0/)*)) / ,0$+( )/# . )*/$ .- #$"#'$"#/ $)/# ()0'42-)$)"

/-$)"' )- (-& .!*''*2.*-$)"/*/# ' 1 '*!)" -

Warning

$)$/ ./#/ /#. 1 - + -.*)'$)%0-4*-.0./)/$'+-*+ -/4(" )- .0'/$!+-*+ -+- 0/$*).)*//& )

Note

-2.4*0-// )/$*)/*+-/$0'-'4$(+*-/)/$)!*-(/$*)*)/# +-*0/#)'$)"/# +-*0/*-/*+-/$0'+-/*!/# *0( )//$*)

Qualified Personnel

Correct Usage

!

!

!

# 1$ .4./ ((4*)'4 . /0+)*+ -/ $)*)%0)/$*)2$/#/#$.()0'

)'4 .#*0' ''*2 /*$)./'')2*-&*)/#$. ,0$+( )/0'$!$ + -.*). !$) .+ -.*).2#*- 0/#*-$5 /**(($..$*)/*"-*0))/*/"$-0$/. ,0$+( )/).4.6

/ (.$)*-) 2$/# ./'$.# .! /4+-/$ .)./)-.

*/ /# !*''*2$)"

Warning

#$. 1$ )$/.*(+*) )/.(4*)'4 0. !*-/# ++'$/$*). .-$ $)/# /'*"*-/# / #)$'

.-$+/$*))*)'4$)*)) /$*)2$/# 1$ .*-*(+*) )/.!-*(*/# -()0!/0- -.2#$##1 )

++-*1 *-- *(( ) 4$ ( ).

#$.+-*0/)*)'4!0)/$*)*-- /'4).! '4$!$/$./-).+*-/ ./*- . /0+)$)./'' *-- /'4)

*+ -/ )($)/$) .- *(( )

Caution

!

)" -*! 3+'*.$*)$!// -4$.$)*-- /'4- +' +' *)'42$/#.( *- ,0$1' )//4+

- *(( ) 4/# ()0!/0- -$.+*. *!0. // -$ .*-$)"/*/# ()0!/0- -.$)./-0/$*).

Warning

6

Trademarks

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design, are

reserved.

$ ( ).

Bereich Automatisierungs- und Antriebstechnik

Geaschaeftsgebiet Industrie Automatisierungssysteme

Postfach 4848,D-90327 Nuernberg

R)R)R - - "$./ - /- (-&.*!

#$-+-/$ .0.$)"!*-/# $-*2)+0-+*. .)4*/# -)( .$)/#$.*0( )/2#$#- ! -/*/- (-&.($"#/

$)!-$)" 0+*)/# -$"#/.*!/# /- (-&*2) -.

Siemens Aktiengesellschaft

C7-633, C7-634 Control Systems

Disclaimer of LiabilityCopyright E Siemens AG 1993 All rights reserved

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be

precluded entirely, we cannot guarantee full agreement. However,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

E Siemens AG 1993

0% //*#)" 2$/#*0/+-$*-)*/$

6ES5998-0SH21

Page 3

Contents

1 Notes on Using this Manual and on the CE Symbol 1-1. . . . . . . . . . . . . . . . . . . . . . .

Notes on Using this Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes on the CE Symbol 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes for Machine Manufacturers 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notes 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Centralized and Distributed Configuration of a Programmable Controller 2-1. . .

2.1 Application 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Centralized and Distributed Configuration 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Installing a PLC with Centralized Configuration 2-4. . . . . . . . . . . . . . . . . . . . . .

2.2.2 Installing a PLC with Distributed Configuration 2-5. . . . . . . . . . . . . . . . . . . . . . .

2.3 Examples 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Installation Guidelines 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Principles of Installation of Systems for EMC 3-2. . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Overview of Possible Types of Interference 3-2. . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 The Most Important Basic Rules for Ensuring EMC 3-6. . . . . . . . . . . . . . . . . .

3.2 Installation of Programmable Controllers for EMC 3-8. . . . . . . . . . . . . . . . . . . .

3.2.1 Basic Rules for Assembling and Grounding the Inactive Metal

Parts 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Example of Cabinet Assembly for EMC 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Example of Rack and Wall Mounting for EMC 3-11. . . . . . . . . . . . . . . . . . . . . . .

3.3 Wiring of Programmable Controllers for EMC 3-12. . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Routing of Cables 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Equipotential Bonding 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Shielding of Cables and Lines 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Special Measures for Interference-Free Operation 3-17. . . . . . . . . . . . . . . . . . .

3.3.5 Checklist for the Electromagnetically Compatible Installation

of Control Systems 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Power Supplies for Programmable Controllers and I/Os 3-20. . . . . . . . . . . . . .

3.4.1 Power Supplies for Control Systems with SIMATIC S5 3-20. . . . . . . . . . . . . . .

3.4.2 Connecting the Programmable Controller and Load Power 3-21. . . . . . . . . . . .

3.4.3 Connecting Non-Floating or Floating Modules 3-26. . . . . . . . . . . . . . . . . . . . . . .

3.5 Interference-Free Installation of Centralized and Distributed

Interface Circuits 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Interference-Free Installation of Centralized Interface Circuits 3-28. . . . . . . . .

3.5.2 Interference-Free Installation of Distributed Interface Circuits 3-28. . . . . . . . . .

3.6 Interference-Free Connection of Monitors 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . .

System Manual

C79000-G8576-C199-06

iii

Page 4

Contents

3.6.1 Interference-Free Connection of a Monitor to the CP of the S5

Controller 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Shielding and Grounding 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Selection and Installation of Cabinets with SIMATIC S5 3-33. . . . . . . . . . . . . . .

3.7.1 Types of Cabinet 3-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 Clearances in Cabinets 3-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.3 Removal of Power Dissipation from Cabinets 3-37. . . . . . . . . . . . . . . . . . . . . . . .

3.7.4 Examples for Determining the Type of Cabinet 3-38. . . . . . . . . . . . . . . . . . . . . .

3.7.5 Determining the Power Dissipation of Modules 3-39. . . . . . . . . . . . . . . . . . . . . .

4 Central Controllers and Expansion Units Power Supply Units 4-1. . . . . . . . . . . . .

4.1 S5-135U/155U Central Controller 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Technical Description 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Installation 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Startup 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 Repair Guidelines 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.5 Technical Specifications 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Expansion Units 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Technical Description of the Expansion Units 4-16. . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Installing the Expansion Units 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Technical Specifications of the Expansion Units 4-18. . . . . . . . . . . . . . . . . . . . .

4.3 Power Supply Units 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Product Overview 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Setting and Connecting the Power Supply Unit 4-23. . . . . . . . . . . . . . . . . . . . . .

4.3.3 Fault Indications/Fault Diagnostics 4-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Maintenance and Repairs 4-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Description of Internal Sequences in the Power Supply Unit 4-49. . . . . . . . . . .

4.3.6 Technical Specifications of the Power Supply Units 4-51. . . . . . . . . . . . . . . . . .

4.4 6ES5 955-3NA12 Power Supply Unit 4-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Technical Description 4-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Setting the Power Supply Unit 4-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Installation 4-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Operation 4-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Maintenance 4-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.6 Technical Specifications 4-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Fan Submodules 4-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Technical Description 4-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Setting and Connecting the Fan Submodule 4-72. . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 Technical Specifications 4-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 CPUs, Memory Cards, Memory Submodules, Interface Submodules 5-1. . . . . . . .

5.1 CPU 948B -3UA13 or CPU 948B -3UA23 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Technical Description 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Installation and Startup 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Interfaces of the CPU 948 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Technical Specifications 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CPU 948 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Technical Description 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Installation and Startup 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

C79000-G8576-C199-06

System Manual

Page 5

Contents

5.2.3 Interfaces of the CPU 948 5-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Technical Specifications 5-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 CPU 928B -3UB21 5-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Technical Description 5-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Installation and Startup 5-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Technical Specifications 5-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 CPU 928B 5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Technical Description 5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Installation and Startup 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Technical Specifications 5-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 CPU 928 -3UA21 5-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Technical Description 5-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Installation and Startup 5-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Technical Specifications 5-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 CPU 928 5-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Technical Description 5-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Installation and Startup 5-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Technical Specifications 5-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 CPU 922 5-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Technical Description 5-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Installation and Startup 5-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.3 Technical Specifications 5-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 374 Flash EPROM Cards 5-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.1 Technical Description 5-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.2 Notes on Operation 5-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.3 Technical Specifications 5-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 376 Memory Submodules 5-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.1 Technical Description 5-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.2 Notes on Operation 5-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.3 Technical Specifications 5-83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 377 Memory Submodules 5-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.1 Technical Description 5-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.2 Notes on Operation 5-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.3 RAM Submodules with Battery Backup 5-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.4 Technical Specifications 5-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 1 Interface Submodules 5-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.1 Installing and Removing the Interface Submodules 5-93. . . . . . . . . . . . . . . . . . .

5.1 1.2 PG Submodule 5-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 1.3 V.24 Submodule 5-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 1.4 TTY Submodule 5-106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.5 RS422 A/485 Submodule 5-112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.6 SINEC L1 Submodule 5-118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.7 Technical Specifications of the Interface Submodules 5-122. . . . . . . . . . . . . . . .

System Manual

C79000-G8576-C199-06

v

Page 6

Contents

6 Multiprocessor Operation/Coordinators 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Introduction 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Starting the Multiprocessor Operation 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Coordinator Modes 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 923A Coordinator Module 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Technical Description 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Settings on the Coordinator 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 923C Coordinator Module 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Technical Description 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Settings on the Coordinator 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Technical Specifications of the Coordinators 6-28. . . . . . . . . . . . . . . . . . . . . . . .

7 Interface Modules 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 The 300 and 312 Interface Modules 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Indicators and Controls 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Modes/Jumper Assignments of the IM 300 7-5. . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 The 301 and 310 Interface Modules 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Indicators and Controls 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Modes/Jumper Assignments of the IM 301 7-11. . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 The 304 and 314 Interface Modules 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Indicators and Controls 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Modes/Jumper Assignments of the IM 304 7-15. . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Modes/Jumper Assignments of the IM 314 7-17. . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Technical Specifications 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 6ES5 721 Connecting Cable 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 6ES5 7602 Terminator 7-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Digital Input/Output Modules 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Technical Description 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Design 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Function of the Enable Inputs 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Special Features of the 432 Digital Input Module 8-8. . . . . . . . . . . . . . . . . . . . .

8.1.4 Special Features of the DI/DQ 482 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Installation and Startup 8-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Setting the Module Address 8-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Removing and Inserting Modules 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Marking of Modules 8-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Connecting the Signal Lines 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 Connection of Outputs in Parallel and Switching On

the Load via a Contact 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.6 Short-Circuit Protection and Fusing 8-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.7 Arc-Quenching for Inductive Loads 8-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Common Technical Specifications 8-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Specification Sheets for the Modules 8-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 6ES5 420-4UA13/4UA14 Digital Input Module 8-30. . . . . . . . . . . . . . . . . . . . . . .

8.4.2 6ES5 430-4UA13/4UA14 Digital Input Module 8-32. . . . . . . . . . . . . . . . . . . . . . .

vi

C79000-G8576-C199-06

System Manual

Page 7

Contents

8.4.3 6ES5 431-4UA12 Digital Input Module 8-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.4 6ES5 432-4UA12 Digital Input Module 8-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.5 6ES5 434-4UA12 Digital Input Module 8-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.6 6ES5 435-4UA12 Digital Input Module 8-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.7 6ES5 436-4UA12 Digital Input Module 8-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.8 6ES5 436-4UB12 Digital Input Module 8-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.9 6ES5 441-4UA13/4UA14 Digital Output Module 8-48. . . . . . . . . . . . . . . . . . . . .

8.4.10 6ES5 451-4UA13/4UA14 Digital Output Module 8-50. . . . . . . . . . . . . . . . . . . . .

8.4.11 6ES5 453-4UA12 Digital Output Module 8-52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.12 6ES5 454-4UA13/4UA14 Digital Output Module 8-54. . . . . . . . . . . . . . . . . . . . .

8.4.13 6ES5 455-4UA12 Digital Output Module 8-56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.14 6ES5 456-4UA12 Digital Output Module 8-58. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.15 6ES5 456-4UB12 Digital Output Module 8-60. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.16 6ES5 457-4UA12 Digital Output Module 8-62. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.17 6ES5 458-4UA12 Digital Output Module 8-64. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.18 6ES5 458-4UC11 Digital Output Module 8-67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.19 6ES5 482-4UA11 Digital Input/Output Module 8-69. . . . . . . . . . . . . . . . . . . . . . .

9 Analog Input/Output Modules 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Technical Description 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Common Technical Specifications 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 The 460 Analog Input Module 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 Design 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Function of the Enable Input 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.3 Special Features of the 460 Analog Input Module 9-8. . . . . . . . . . . . . . . . . . . .

9.3.4 Setting the Module Address 9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.5 Removing and Inserting Modules 9-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.6 Marking of Modules and Front Connectors 9-15. . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.7 Connecting the Signal Lines 9-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.8 Connection of Sensors 9-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.9 Connecting a Compensating Box for Thermal E.M.F. Measurement 9-19. . . .

9.3.10 Connecting Resistance Thermometers in the Standard Pt 100 Range 9-20. .

9.3.11 Connecting Resistance Thermometers in the Extended Pt 100 Range 9-21. .

9.3.12 Broken Wire Signal 9-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.13 Connecting Transducers 9-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.14 Measured-Value Representation 9-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.15 Technical Specifications 9-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 The 463 Analog Input Module 9-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 Design 9-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Function of the Enable Input 9-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Special Features of the 463 Analog Input Module 9-39. . . . . . . . . . . . . . . . . . . .

9.4.4 Setting the Module Address 9-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.5 Removing and Inserting Modules 9-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.6 Marking of Modules and Front Connectors 9-44. . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7 Connecting the Signal Lines 9-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.8 Measured-Value Representation 9-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.9 Technical Specifications 9-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 The 465 Analog Input Module 9-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.1 Design 9-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Function of the Enable Input 9-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Manual

C79000-G8576-C199-06

vii

Page 8

Contents

9.5.3 Special Features of the 465 Analog Input Module 9-54. . . . . . . . . . . . . . . . . . . .

9.5.4 Setting the Module Address 9-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.5 Removing and Inserting Modules 9-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.6 Marking of Modules and Front Connectors 9-61. . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.7 Connecting the Signal Lines 9-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.8 Connecting a Compensating Box for Thermal E.M.F. Measurement 9-63. . . .

9.5.9 Connecting Resistance Thermometers to the 465 Analog Input Module 9-64.

9.5.10 Broken Wire Signal for Resistance Thermometers 9-66. . . . . . . . . . . . . . . . . . .

9.5.11 Connecting Transducers 9-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.12 Measured-Value Representation 9-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.13 Technical Specifications 9-72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 The 466 Analog Input Module 9-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 Design 9-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 Special Features of the 466 Analog Input Module 9-77. . . . . . . . . . . . . . . . . . . .

9.6.3 Startup 9-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.4 Removing and Inserting Modules 9-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.5 Marking of Modules and Front Connectors 9-86. . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.6 Connecting the Signal Lines 9-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.7 Connecting Sensors to the 466 Analog Input Module 9-88. . . . . . . . . . . . . . . . .

9.6.8 Measured-Value Representation 9-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.9 Technical Specifications 9-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 The 470 Analog Output Module 9-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.1 Design 9-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.2 Function of the Enable Input 9-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.3 Special Features of the 470 Analog Output Module 9-102. . . . . . . . . . . . . . . . . .

9.7.4 Setting the Module Address 9-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.5 Removing and Inserting Modules 9-105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.6 Marking of Modules and Front Connectors 9-107. . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.7 Connecting the Signal Lines 9-108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.8 Connecting Loads to the 470 Analog Output Module 9-109. . . . . . . . . . . . . . . . .

9.7.9 Measured-Value Representation 9-111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.10 Technical Specifications 9-112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Monitoring Module 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Application 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.1 Design 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.2 Mode of Operation 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.3 Block Diagram 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.4 Fault Detection 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.5 Resetting 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Installation 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Possible Configurations 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Removing and Inserting 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Connecting the RESET Input 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.4 Switch Positions of the Relay Contact 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.5 Installation Guidelines 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Operation 10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1 Addressing 10-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.2 Setting the Address Switches S1, S2, S3, S4 10-12. . . . . . . . . . . . . . . . . . . . . . .

10.3.3 Setting the Switch S5 10-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

C79000-G8576-C199-06

System Manual

Page 9

Contents

10.4 Technical Specifications 10-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Address Table 10-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Connector Assignments 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Appendix A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Guidelines for Handling Electrostatically Sensitive Devices (ESD) B-1. . . . . . . . .

B.1 What is ESD? B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Electrostatic Charging of Persons B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 General Protective Measures Against Electrostatic Discharge Damage B-4.

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Manual

C79000-G8576-C199-06

ix

Page 10

Contents

x

C79000-G8576-C199-06

System Manual

Page 11

Notes on Using this Manual and on the CE Symbol

Notes on Using this Manual

The S5-135U/155U PLC is a member of the family of SIMATIC S5

programmable (logic) controllers. The controller can be used in single and in

multiprocessor operation with up to four CPUs. In multiprocessor operation,

each CPU processes its individual user program independently of the other

CPUs (multicomputing).

CPUs Available

The following are available as CPUs:

CPU 948 for fast word and binary signal processing especially

CPU 928B for fast word and binary signal processing and for

CPU 928 for fast binary signal processing and for word

CPU 922

(R processor)

1

fast double-word and floating point processing and for

large programs with a high storage requirement;

programming in STEP 5.

When you use a CPU 948 you have an S5-155U PLC.

communication; programming in STEP 5.

processing; programming in STEP 5.

for word processing (computing controlling

monitoring signaling); programming in STEP 5.

Slots

System Manual

C79000-G8576-C199-06

You can combine the CPUs arbitrarily at the CPU slots in the central

controller:

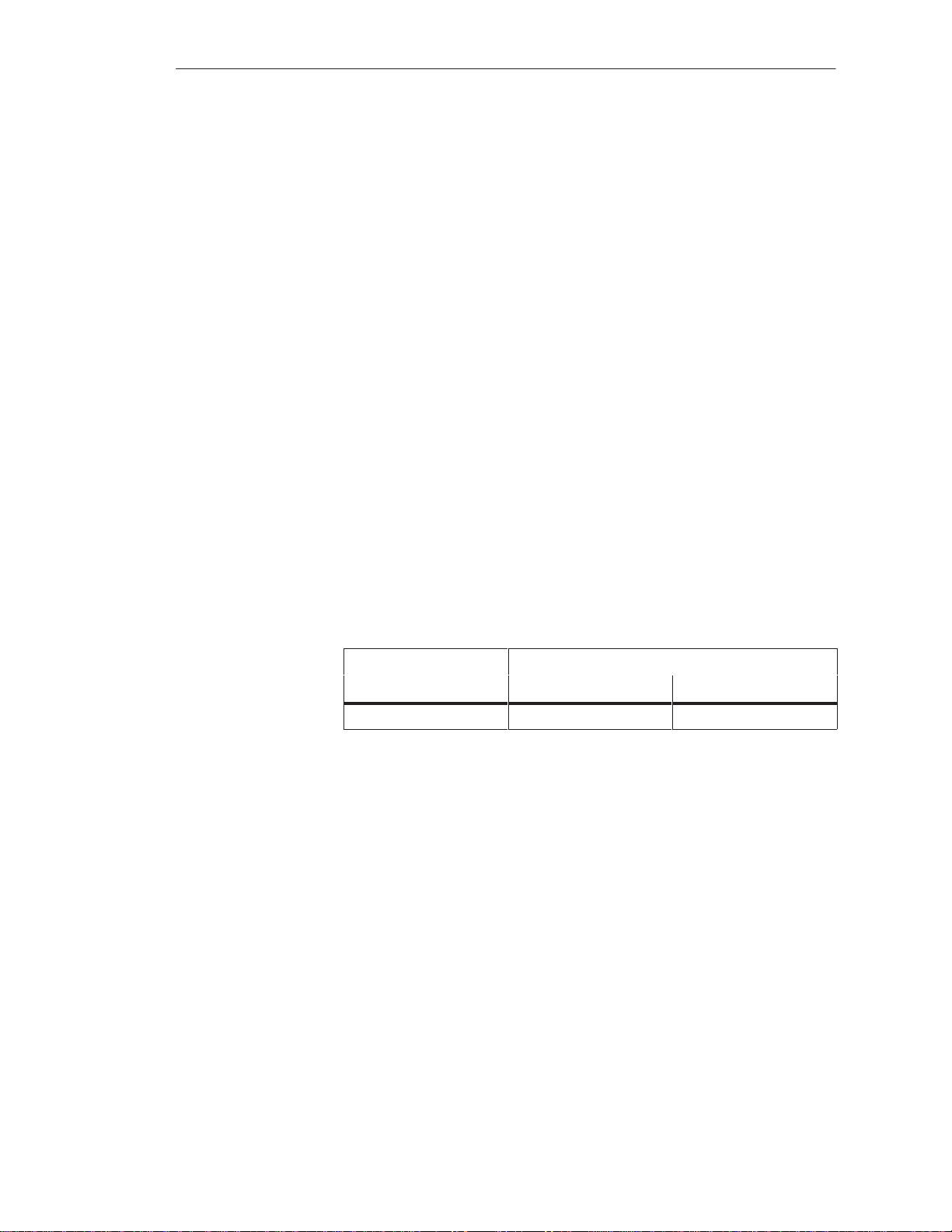

CPU Slot Requirement

CPU 948/CPU 928B/CPU 928 2 slots

CPU 922/CPU 928-3UA21/

CPU 928B-3UB21

CPU 948B-3UA13/ -3UA23

1 slot

1-1

Page 12

Notes on Using this Manual and on the CE Symbol

How the Manual is

Organized

Given as a guide in the following are pointers on how this manual is

organized; they will assist you when using your S5-135U/155U

programmable controller.

At the start of this manual you will find the “Safety-Related Guidelines”

and the “ESD Guidelines.” You must observe these to the letter and

follow them during the entire time you are working with the

S5-135U/155U PLC. If your PLC requires repair, you must observe the

Repair Guidelines in Section 4.1.4.

Chapter 3 contains the Installation Guidelines with information on

interference-free installation of the S5-135U/155U PLC.

Which of the remaining chapters of this manual you may require when

working with your PLC will depend on the extent of your automation task

and on the configuration of your PLC.

For a basic configuration in single-processor operation without expansion

units, you will need the following chapters:

Chapter 4 describes the central controller (CC) in Section 4.1. Described

are the technical features, installation, startup and maintenance of the CC.

Section 4.3 describes the power supply units. You will find a separate

description of the 6ES5 955-3NA12 power supply unit in Section 4.5.

Both sections describe the installation and startup as well as the necessary

maintenance on the power supply units. The 24 V/4 A load power supply

is described in Section 4.4.

Chapter 5 contains the instructions for the individual CPUs. Described

here are the technical features, installation and startup of the individual

CPUs. The various methods of operating the CPUs are also described, as

are the CPU statuses where they can be directly indicated by the LEDs on

the module. If you use memory submodules or memory cards (CPU 948),

you can look up the necessary information in Sections 5.7 to 5.9.

Chapter 8 and Chapter 9 describe the digital and analog I/O modules.

Described here are the installation, wiring and operation of these

modules. Individual I/O modules exhibit specific features which are

discussed in separate chapters.

To configure your PLC with expansion units (EUs) you will need the

following chapters:

Chapter 2 shows how you can configure a PLC with expansion units in a

centralized or distributed arrangement.

Described in Chapter 4, Section 4.2, are the EU 183U, EU 184U, EU

185U and EU 187U. Those EUs which operate with their own power

supply unit are described in Section 4.3.

Chapter 7 describes the interface modules (IMs) which serve for data

communication between central controllers and expansion units.

1-2

C79000-G8576-C199-06

System Manual

Page 13

Notes on Using this Manual and on the CE Symbol

To operate two or more CPUs in multiprocessor mode in your PLC, you will

need Chapter 6.

Chapter 6 describes multiprocessor operation. This chapter contains all

the measures you must take for startup of the PLC in multiprocessor

operation. Described in Sections 6.5 and 6.6 are the 923C and 923A

coordinators.

In Chapter 11 are the connector assignments of the individual modules and

subracks.

The Appendix contains the ordering data for the products described in this

manual, references to further reading and the index of keywords in this

manual.

System Manual

C79000-G8576-C199-06

1-3

Page 14

Notes on Using this Manual and on the CE Symbol

Notes on the CE Symbol

EC Directive on

EMC 89/336/EEC

Fields of

Application

The following applies to the SIMATIC products described in this manual:

Products which carry the CE symbol fulfil the requirements for the EC

Directive 89/336/EEC on “electromagnetic compatibility.”

The EC declarations of conformity and the documentation relating to this are

available to the authorities concerned, according to the above EC Directive,

Article 10 (2), from:

Siemens Aktiengesellschaft

Automation Group

A&D AS E48

Postfach 1963

D-92209 Amberg

Products which do not carry the CE symbol meet the requirements and

standards given in this manual under the respective “Technical

Specifications” sections.

For SIMATIC S5, the following fields of application apply according to this

CE symbol:

Field of Application

Requirement for

Observing the

Installation

Guidelines

Installing the

Devices

Working on

Cabinets

Emitted Interference Noise Immunity

Industry EN 50081-2: 1993 EN 50082-2: 1995

The installation guidelines and safety-related guidelines given in this manual

must be observed during startup and when operating SIMATIC S5 devices.

Moreover, the following rules must be observed when using certain modules.

Programmable controllers of the type SIMATIC S5-135U/S5-155U must be

installed in metal cabinets according to these installation guidelines.

To protect the modules from static discharge, the user must discharge his

body’s electrostatic charge before opening a cabinet.

1-4

C79000-G8576-C199-06

System Manual

Page 15

Notes on Using this Manual and on the CE Symbol

Notes on

Additional measures are required when using the following modules.

Individual Modules

A shielded signal cable is required for the following modules:

Order Number Module

6ES5 432-4UA12 Digital input module 432

6ES5 453-4UA12 Digital output module 453-4

6ES5 457-4UA12 Digital output module 457-4

6ES5 482-4UA12 Digital I/O module 482-4 for IP 257

A filter (SIFI C B841213-C-B30 or equivalent) is required in the 230 V AC load voltage supply

for the following modules:

Order Number Module

6ES5 436-4UA12 Digital input module 436-4

6ES5 436-4UB12 Digital input module 436-4

6ES5 456-4UA12 Digital output module 456-4

6ES5 456-4UB12 Digital output module 456-4

A filter (SIFI C, B841213-C-B30 or equivalent) is required in the 24 V DC load voltage supply

for the following modules:

Order Number Module

6ES5 261-4UA11 Proportioning module IP 261

6ES5 432-4UA12 Digital input module 432

6ES5 453-4UA12 Digital output module 453-4

6ES5 457-4UA12 Digital output module 457-4

6ES5 465-4UA12 Analog input module 465-4

6ES5 470-4UB12 Analog output module 470-4

System Manual

C79000-G8576-C199-06

1-5

Page 16

Notes on Using this Manual and on the CE Symbol

Notes for Machine Manufacturers

Introduction

The SIMATIC programmable controller is not a machine in the sense of the

EC Directive on machines. Therefore, there is no declaration of conformity

for SIMATIC as regards the EC Directive 89/392/EEC on machines.

EC Directive

89/392/EEC on

Machines

The EC Directive 89/392/EEC on machines controls machine requirements.

Here, a machine is understood to be the entire sum of devices or parts

involved (see also EN 292-1, paragraph 3.1).

SIMATIC is part of the electrical equipment for a machine and must

therefore be included in the procedure for checking conformity by the

machine manufacturer.

Electrical

Equipment for

Machines to EN

60204

The EN 60204-1 standard (machine safety, general requirements for the

electrical equipment for machines) applies to the electrical equipment for

machines.

The following table should help you with the declaration of conformity and

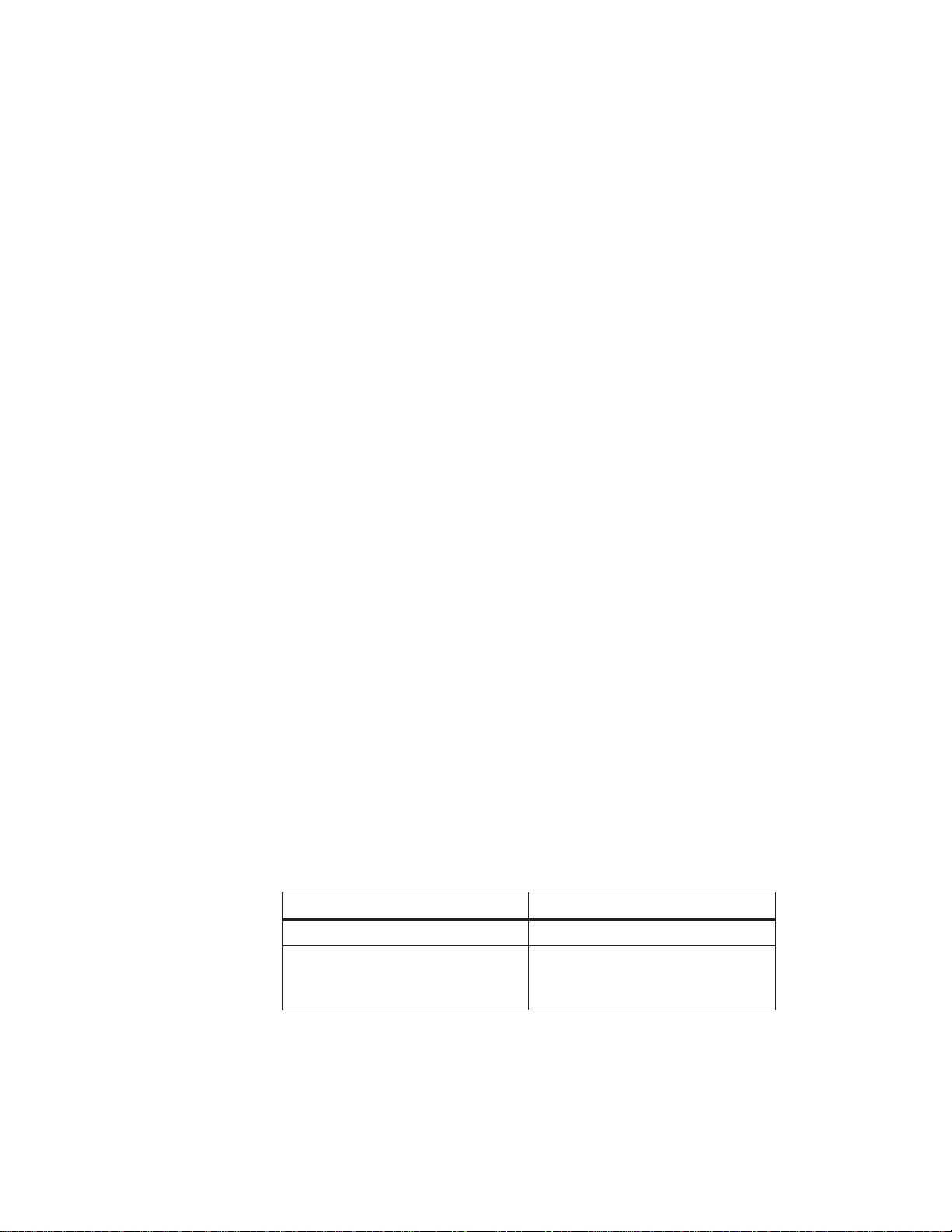

shows which criteria apply to EN 60204-1 (as at June 1993) for SIMATIC.

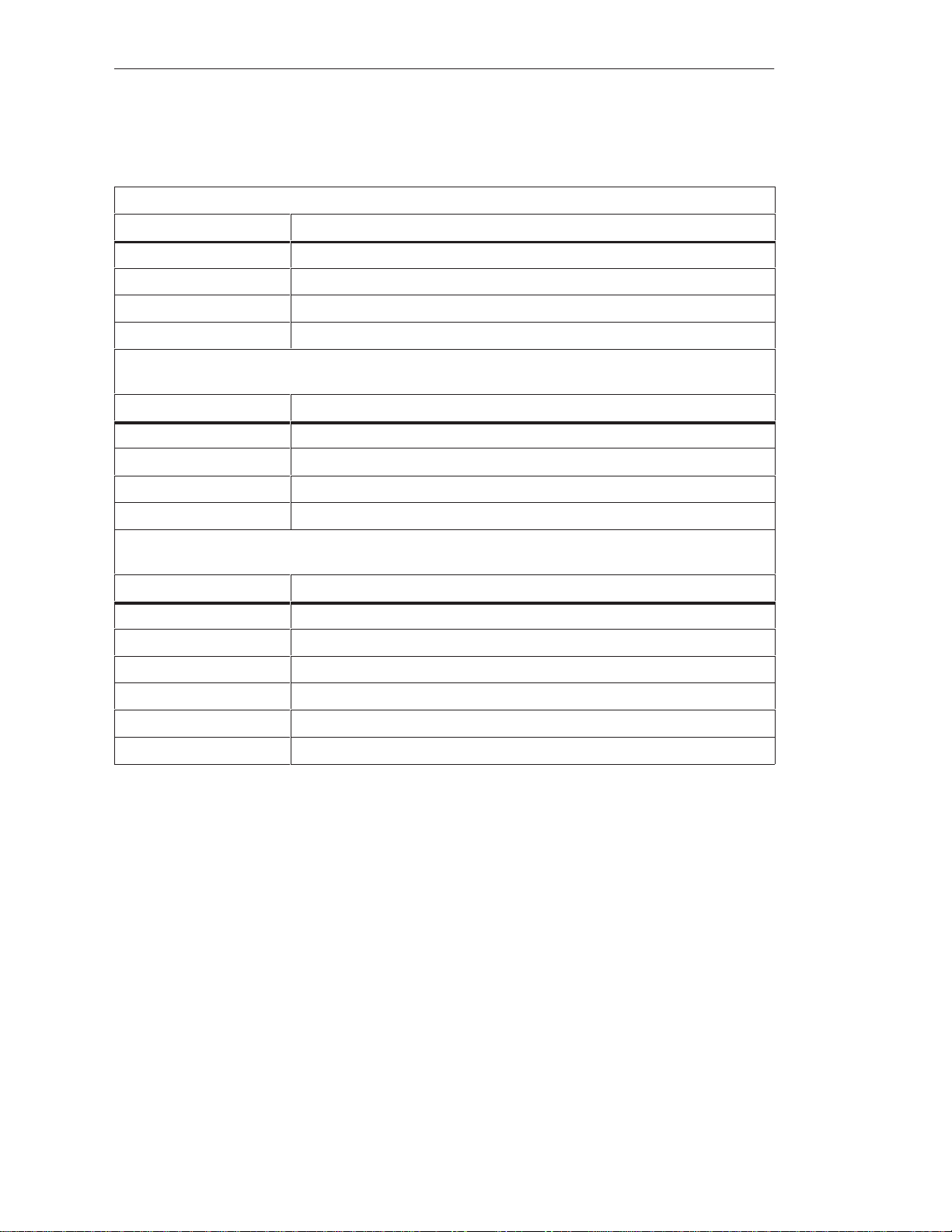

EN 60204-1 Subject/Criterion Remarks

Para. 4 General requirements Requirements are fulfilled if the machines are

assembled/installed according to the

installation guidelines.

See also the explanations on the previous

pages.

Para. 11.2 Digital I/O interfaces Requirements are fulfilled.

Para. 12.3 Programmable equipment Requirements are fulfilled if the machines are

installed in lockable cabinets to protect them

from memory modifications by unauthorized

persons.

Para. 20.4 Voltage tests Requirements are fulfilled.

1-6

C79000-G8576-C199-06

System Manual

Page 17

Safety Notes

Notes on Using this Manual and on the CE Symbol

Risks Involved in the Use of So-Called SIMATIC-Compatible Modules of

Non-Siemens Manufacture

“The manufacturer of a product (SIMATIC in this case) is under the general

obligation to give warning of possible risks attached to his product. This

obligation has been extended in recent court rulings to include parts supplied

by other vendors. Accordingly, the manufacturer is obliged to observe and

recognize such hazards as may arise when a product is combined with

products of other manufacture.

For this reason, we feel obliged to warn our customers who use SIMATIC

products not to install so-called SIMATIC-compatible modules of other

manufacture in the form of replacement or add-on modules in SIMATIC

systems.

Our products undergo a strict quality assurance procedure. We have no

knowledge as to whether outside manufacturers of so-called

SIMATIC-compatible modules have any quality assurance at all or one that is

nearly equivalent to ours. These so-called SIMATIC-compatible modules are

not marketed in agreement with Siemens; we have never recommended the

use of so-called SIMATIC-compatible modules of other manufacture. The

advertising of these other manufacturers for so-called SIMATIC-compatible

modules wrongly creates the impression that the subject advertised in

periodicals, catalogs, or at exhibitions had been agreed with us. Where

so-called SIMATIC-compatible modules of non-Siemens manufacture are

combined with our SIMATIC automation systems, we have a case of our

product being used contrary to recommendations. Because of the variety of

applications of our SIMATIC automation systems and the large number of

these products marketed worldwide, we cannot give a concrete description

specifically analyzing the hazards created by these so-called

SIMATIC-compatible modules. It is beyond the manufacturer ’s capabilities

to have all these so-called SIMATIC-compatible modules checked for their

effect on our SIMATIC products. If the use of so-called SIMATIC-compatible

modules leads to defects in a SIMATIC automation system, no warranty for

such systems will be given by Siemens.

System Manual

C79000-G8576-C199-06

In the event of product liability damages due to the use of so-called

SIMATIC-compatible modules, Siemens are not liable since we took timely

action in warning users of the potential hazards involved in so-called

SIMATIC-compatible modules.”

1-7

Page 18

Notes on Using this Manual and on the CE Symbol

1-8

C79000-G8576-C199-06

System Manual

Page 19

Centralized and Distributed Configuration of a Programmable Controller

This chapter contains an overview of the methods of configuring an

S5-135U/155U PLC. You will find a description of the types of

communication between a central controller and the expansion units, and an

overview of the interface modules required for the different types of

communication.

2

Chapter

Overview

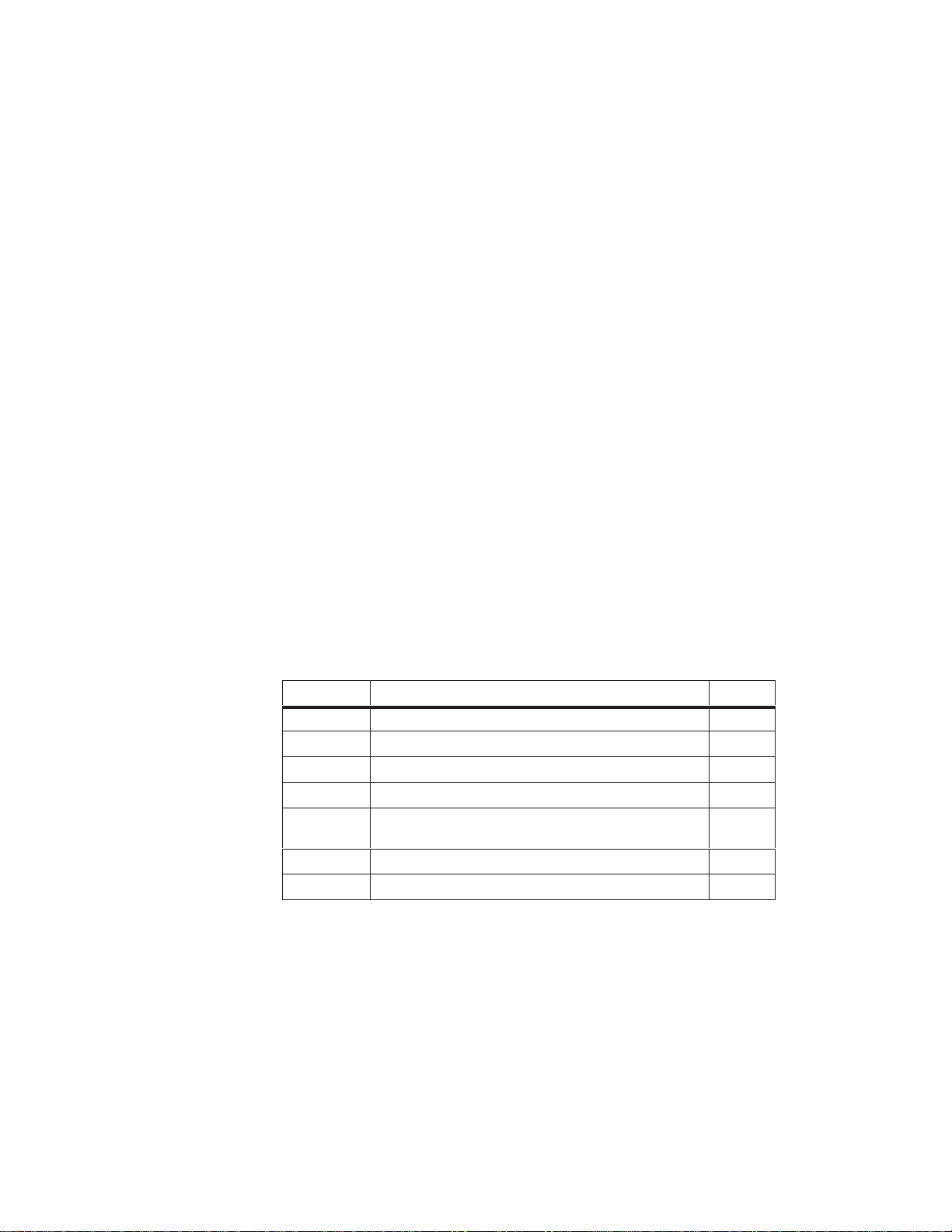

Section Contents Page

2.1 Application 2-2

2.2 Centralized and Distributed Configuration 2-3

2.3 Examples 2-6

System Manual

C79000-G8576-C199-06

2-1

Page 20

Centralized and Distributed Configuration of a Programmable Controller

2.1 Application

The S5-135U/155U programmable controllers comprise a central controller

(CC) and, if required, one or more expansion units (EUs). You need EUs

when there are insufficient slots in the CC for the modules to be used.

Various interface modules (IMs) are available for communication between

the CC and the EUs and between the EUs. It is therefore possible to install an

EU or EUs in the immediate vicinity of the CC (centralized configuration) or

at some distance (distributed configuration). A combination of both types of

configuration is also possible by connecting additional EUs in a centralized

configuration with a distributed EU (see Figure 2-5).

This is clarified on the following pages.

2-2

C79000-G8576-C199-06

System Manual

Page 21

Centralized and Distributed Configuration of a Programmable Controller

2.2 Centralized and Distributed Configuration

You can install a PLC in centralized or distributed configuration according to

your application.

IF ... THEN ...

you wish to position the modules as closely as

possible to the CC and can accept longer cable runs to

the process,

you wish to position the I/O modules as closely as

possible to the process and can accept longer cable

runs to the CC,

choose the

centralized

configuration

choose the

distributed

configuration

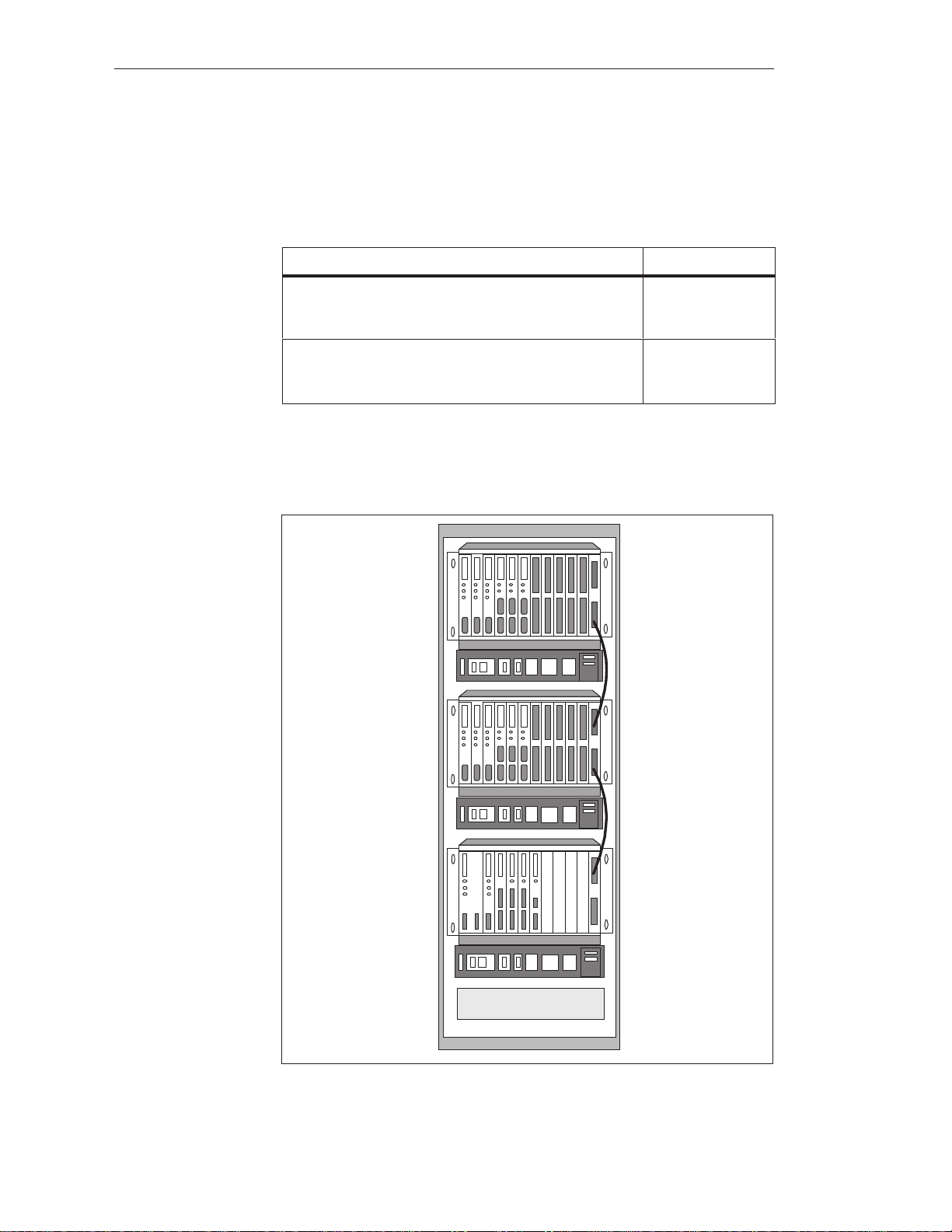

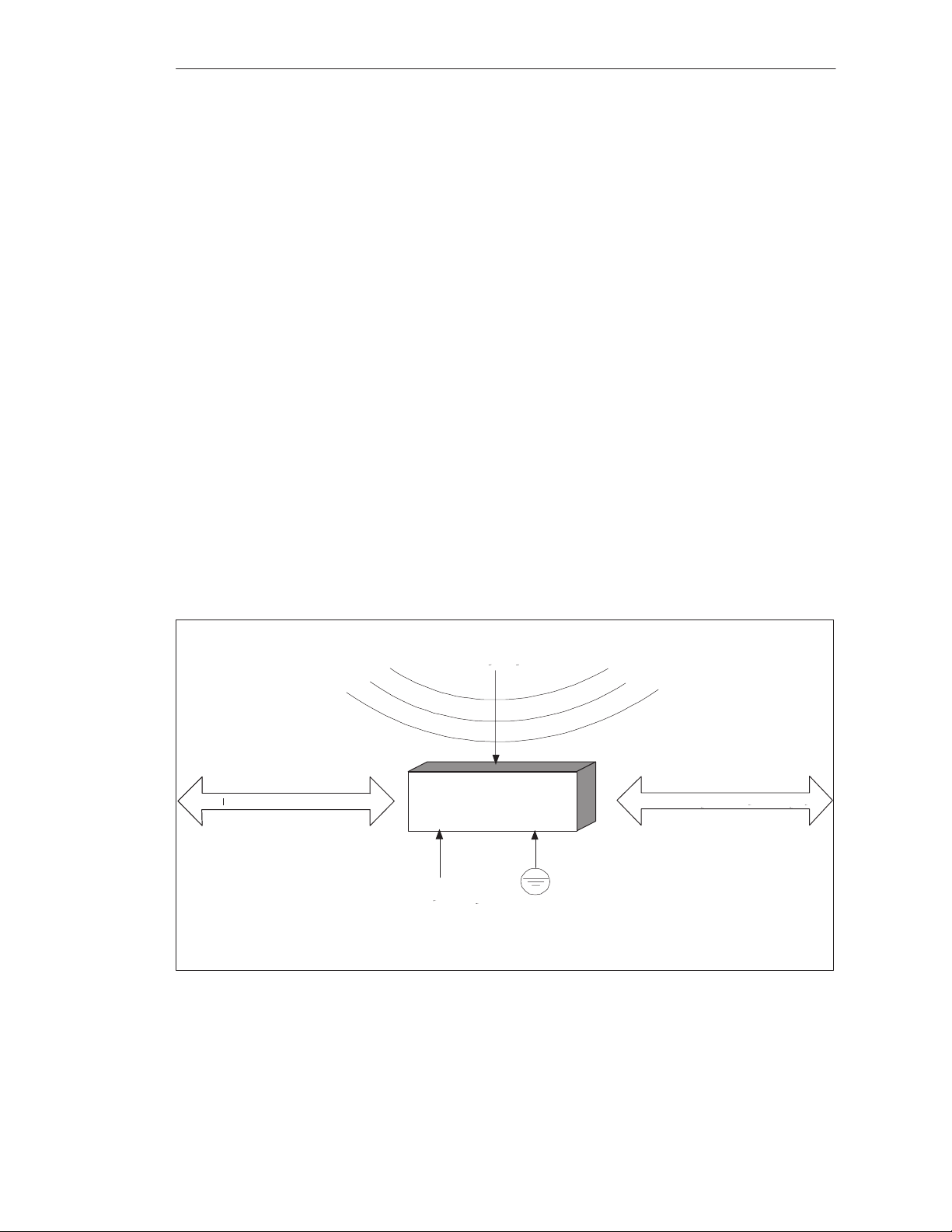

With the centralized configuration, you can install the CC and EUs in the

same cabinet or in adjacent cabinets. Data transmission is parallel. Shown in

the following figure is a centralized configuration.

EU

System Manual

C79000-G8576-C199-06

EU

CC

Load Power Supply

Figure 2-1 Centralized Configuration

2-3

Page 22

Centralized and Distributed Configuration of a Programmable Controller

With the distributed configuration, a distinction is made between parallel and

serial communication. The main features of these types of communication

are as follows:

S Parallel fast data transmission line length of up to 600 m

S Serial slower data transmission line length of up to 3000 m

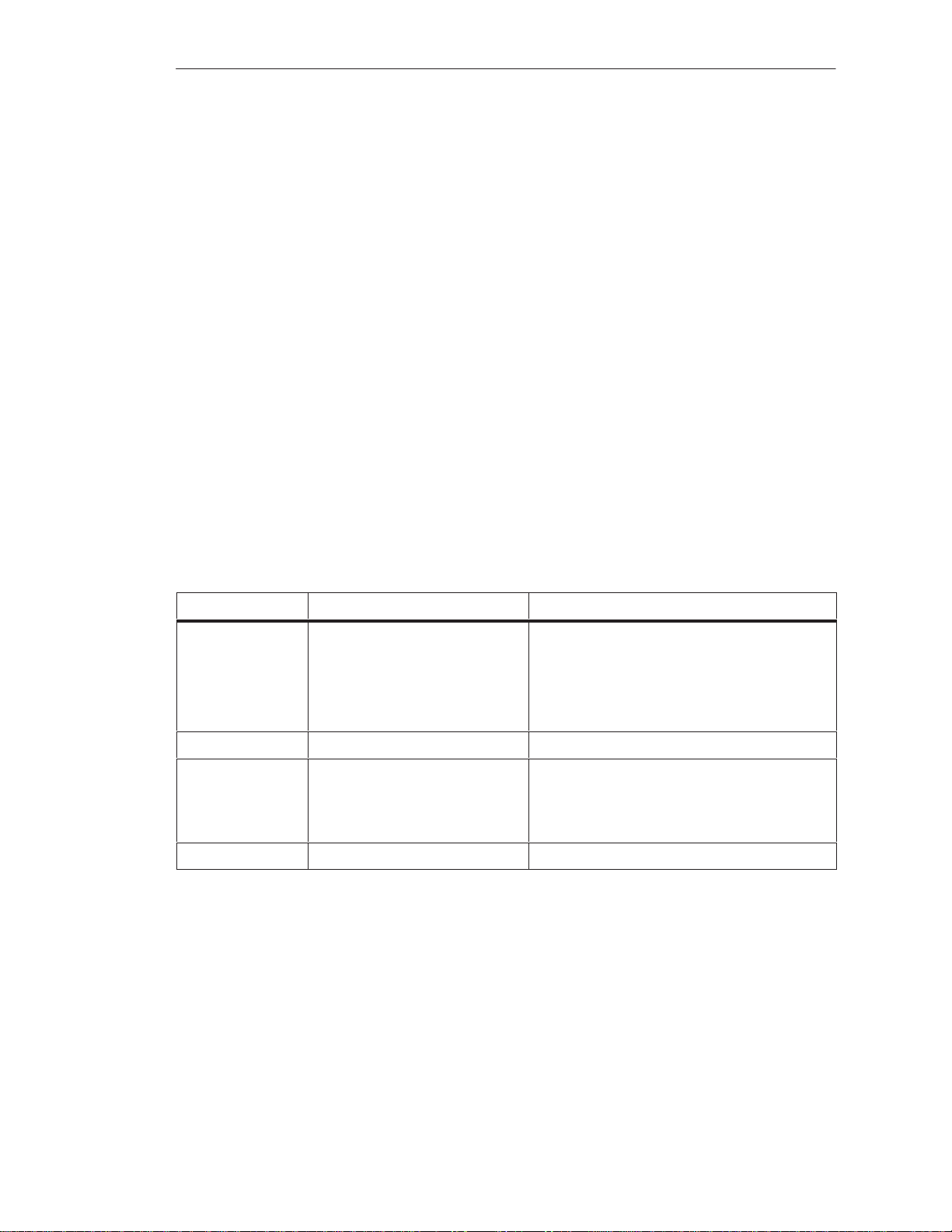

2.2.1 Installing a PLC with Centralized Configuration

The following table shows which interface modules and connecting cables

can be used for connecting the various expansion units to the CC in a

centralized configuration.

Interface Module

Expansion Unit Interface Module

in the CC

IM 300-3

6ES5 300-3AB11

EU 183U

EU 185U

IM 312-3

6ES5 312-3AB11

(I/O mod. only)

IM 301-3 1)

6ES5 301-3AB13

EU 183U

EU 185U

IM 312-3

6ES5 312-3AB31

(I/O mod. only)

IM 300-5

6ES5 300-5CA11

IM 301-5

1)

6ES5 301-5CA12

IM 300-5

6ES5 300-5LB11

1)

This IM has a second interface for distributed communication.

2)

The last IM 312-3 always requires a 6ES5 760-0AB11 terminator .

EU 184U

EU 187U

EU 184U

EU 187U

IM 312-5

6ES5 312-5CA11

IM 312-5

6ES5 312-5CA21

ER 701-1 IM 306

6ES5 306-7LA11

in the EU

2)

2)

Connecting Cable

Max. Distance

fixed to the IM 312 module

0.5 m; 0.95 m

fixed to the IM 312 module

0.5 m; 0.95 m

fixed to the IM 312 module

0.5 m; 1.5 m

fixed to the IM 312 module

0.5 m; 1.5 m

6ES5 705-0xxxx

0.5 m to 2,5 m

2-4

To install a PLC in a centralized configuration, you must observe the

following conditions:

S A centralized configuration is generally only suitable for connecting I/O

modules (DI, DO, AI, AO) and some intelligent I/O modules (IPs) in the

EU (see the Configuring Aids in the catalog and Chapter 4).

S The line length between the IM in the CC and the last IM in the EU must

not exceed 2 m.

C79000-G8576-C199-06

System Manual

Page 23

pp

Centralized and Distributed Configuration of a Programmable Controller

2.2.2 Installing a PLC with Distributed Configuration

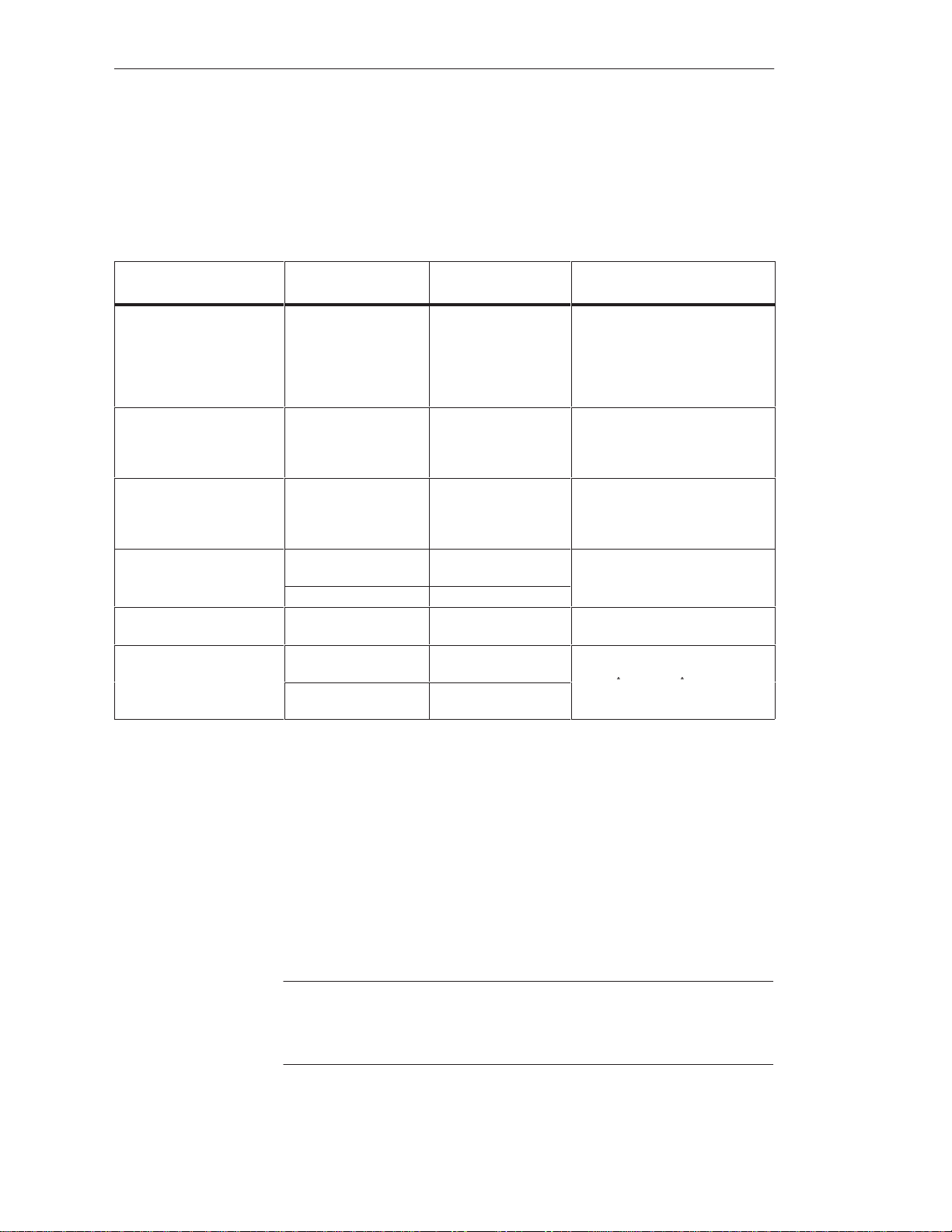

To install a PLC in a distributed configuration, you have a choice of

parallel/symmetrical and serial communication. The following table shows

which interfaces and connecting cables can be used to connect the various

expansion units (EUs/ERs) to the CC in a distributed configuration.

Interface Module

in the CC

IM 301-3

6ES5 301-3AB13

(not for S5-155H)

IM 301-5

6ES5 301-5CA12

IM 304

6ES5 304-3UB11

IM 308

6ES5 308-3UA12

IM 308-B

6ES5 308-3UB11

IM 307

6ES5 307-3UA11

Expansion Unit Interface Module in

the EU

EU 183U

ER 701-2

ER 701-3

EU 183U

EU 185U

ER 701-2

ER 701-3

EU 183U

EU 185U

ER 701-2

ER 701-3

EU 183U

EU 185U

ET 100U

(Catalog ST 52.1)

ICM 560 –

ET 200 IM 318-B

ER 701-2

ER 701-3

EU 183U

EU 185U

1)

IM 310

6ES5 310-3AB11

1)

IM 310

6ES5 310-3AB11

1)

IM 314

6ES5 314-3UA11

IM 318-3

6ES5 318-3UA11

IM 318-8

6ES5 318-8MA12

6ES5 318-8MB11

IM 317

6ES5 317-3UA11

IM 317

6ES5 317-3UA11

Connecting Cable

Max. Permiss. Line Length

6ES5 721-0xxxx

1 m to 200 m

6ES5 721-0xxxx

1 m to 600 m

6ES5 707-5AA00

V45551-F21-B5

up to 3000 m

Cable connection

6ES5 722-2xxxx

Fiber optic cable up to 1500 m

1)

The last IM 310 or IM 314 always requires a 6ES5 760-1AA11 terminator.

System Manual

C79000-G8576-C199-06

The ER 701-2 and ER 701-3 always additionally require an IM 306 for

communication via an IM 304, IM 307 or IM 308.

To install a PLC in a distributed configuration, you must observe the

following conditions:

S With the IM 301/IM 310 pair of interface modules, you can only use I/O

modules (DI, DO, AI, AO) and IPs without page addressing in the EUs.

S With the IM 304/314 pair of interface modules, you can use all IPs, CPs

and I/O modules in the EU 185U.

Note

The IM 307/317, IM 308/318 and IM 308-B/318-B each have their own

manual (see catalog).

2-5

Page 24

Centralized and Distributed Configuration of a Programmable Controller

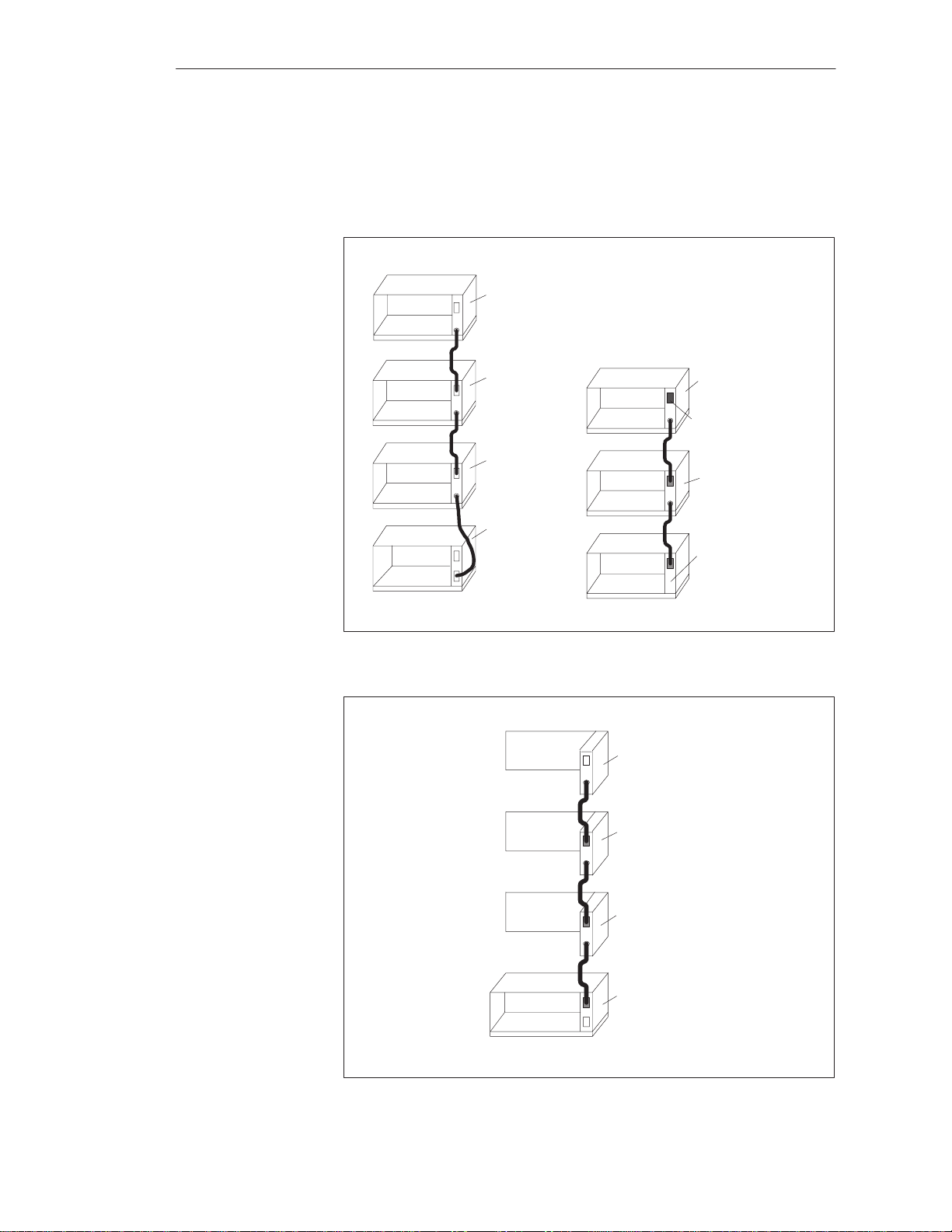

2.3 Examples

Given in the following are some examples of centralized and distributed

configuration of various SIMATIC S5 components.

3 EUs max.

EU 184U

EU 184U

EU 184U

CC S5-135U/155U

IM 312-5

IM 312-5

IM 312-5

IM 300-5

4 EUs max.

EU183U

EU183U

CC S5-135U/155U

IM 312-3

6ES5 760-0AB11

IM 312-3

IM 300-3

Figure 2-2 Centralized Configuration of an S5-135U/155U with the IM 300

and IM 312

3 ERs max.

2-6

ER 701-1

ER 701-1

ER 701-1

IM 306

IM 306

IM 306

IM 300-5LB

CC S5-135U/155U

Figure 2-3 Centralized Configuration of an S5-135U/155U with ER 701s

C79000-G8576-C199-06

System Manual

Page 25

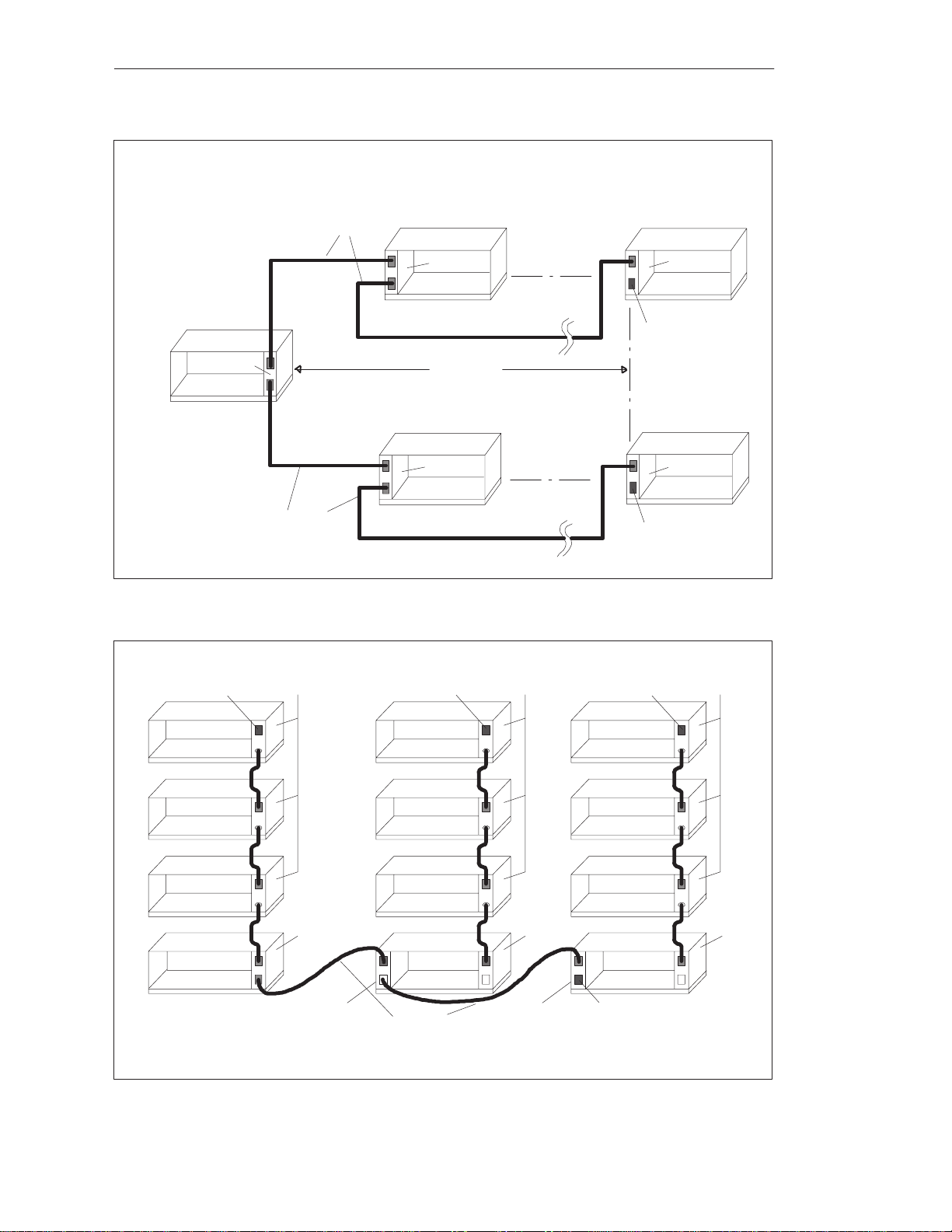

IM 304

CC S5-135U/155U

Centralized and Distributed Configuration of a Programmable Controller

6ES5 721-0xxx0

EU185U

IM 314

600m max.

4 EUs max.

EU 185U

IM 314

6ES5 760-1AA11

EU185U

IM314

6ES5 721-0xxx0

Figure 2-4 Distributed Configuration of an S5-135U/155U with the IM 304 and IM 314

6ES5 760-0AB11

EU 183U

EU 183U

EU 183U

IM 312-3 IM 312-3

6ES5 760-0AB11

EU 183U

EU 183U

EU 183U

4 EUs max.

6ES5760-0AB11

EU 183U

EU 183U

EU 183U

EU 185U

IM 314

6ES5 760-1AA11

IM312-3

IM 300-3

IM 310-3

EU 183U

6ES5 760-0AA11

CC S5-135U/155U

IM 301-3

IM 310-3

EU 183U

6ES5 721-0xxx0

Figure 2-5 Distributed Configuration of an S5-135U/155U with Expansion Units in Centralized Configuration

System Manual

C79000-G8576-C199-06

IM 300-3

2-7

Page 26

Centralized and Distributed Configuration of a Programmable Controller

2-8

C79000-G8576-C199-06

System Manual

Page 27

Installation Guidelines

The Installation Guidelines provide you with information for the

interference-free installation of the SIMATIC S5-135U/155U programmable

controllers.

This chapter describes the following:

Paths which serve for interference pickup in programmable controllers,

and five rules for ensuring electromagnetic compatibility (EMC)

Interference-free installation of the programmable controllers

Cable routing, the connecting of cable shields and equipotential bonding

between equipment

The power supplies for control and load circuits, and the different

grounding concepts

Shielding and grounding for the connection of centralized and distributed

expansions and monitors to programmable controllers

The selection and design of cabinets

3

Chapter

Overview

Section Description Page

3.1 Principles of Installation of Systems for EMC 3-2

3.2 Installation of Programmable Controllers for EMC 3-8

3.3 Wiring of Programmable Controllers for EMC 3-12

3.4 Power Supplies for Programmable Controllers and I/Os 3-20

3.5 Interference-Free Installation of Centralized and

Distributed Interface Circuits

3.6 Interference-Free Connection of Monitors 3-30

3.7 Selection and Installation of Cabinets with SIMA TIC S5 3-33

3-28

System Manual

C79000-G8576-C199-06

3-1

Page 28

Installation Guidelines

3.1 Principles of Installation of Systems for EMC

What Does EMC

Mean?

Electromagnetic compatibility (EMC) is understood to mean the capability of

electrical equipment to operate correctly in a defined electromagnetic

environment, without being affected by the environment and without

affecting the environment to an unacceptable degree.

All SIMATIC S5 products have been developed for applications in harsh

industrial environments and meet high requirements for EMC. Before

installing the control system, however, you should still carry out EMC

planning and involve possible interference sources in the assessment.

Described in the following chapter are

the various paths over which interference can be picked up in the PLC,

typical interference sources and their coupling mechanisms,

basic rules for ensuring EMC.

3.1.1 Overview of Possible Types of Interference

Electromagnetic interference can be picked up over different paths by the

programmable controller:

Fields

SINEC Bus System

Programmable

Controller

Power Supply

Protective Conductor

Figure 3-1 Electromagnetic Interference with Programmable Controllers

3-2

I/O Signal Lines

C79000-G8576-C199-06

System Manual

Page 29

Installation Guidelines

Depending on the propagation medium (conducted or non-conducted

interference) and distance from the source, interference can be picked up by

the programmable controller via different coupling mechanisms.

A distinction is made between the following:

Direct coupling

Capacitive coupling

Inductive coupling

Radiated interference

System Manual

C79000-G8576-C199-06

3-3

Page 30

s

g

Installation Guidelines

Coupling

Mechanisms and

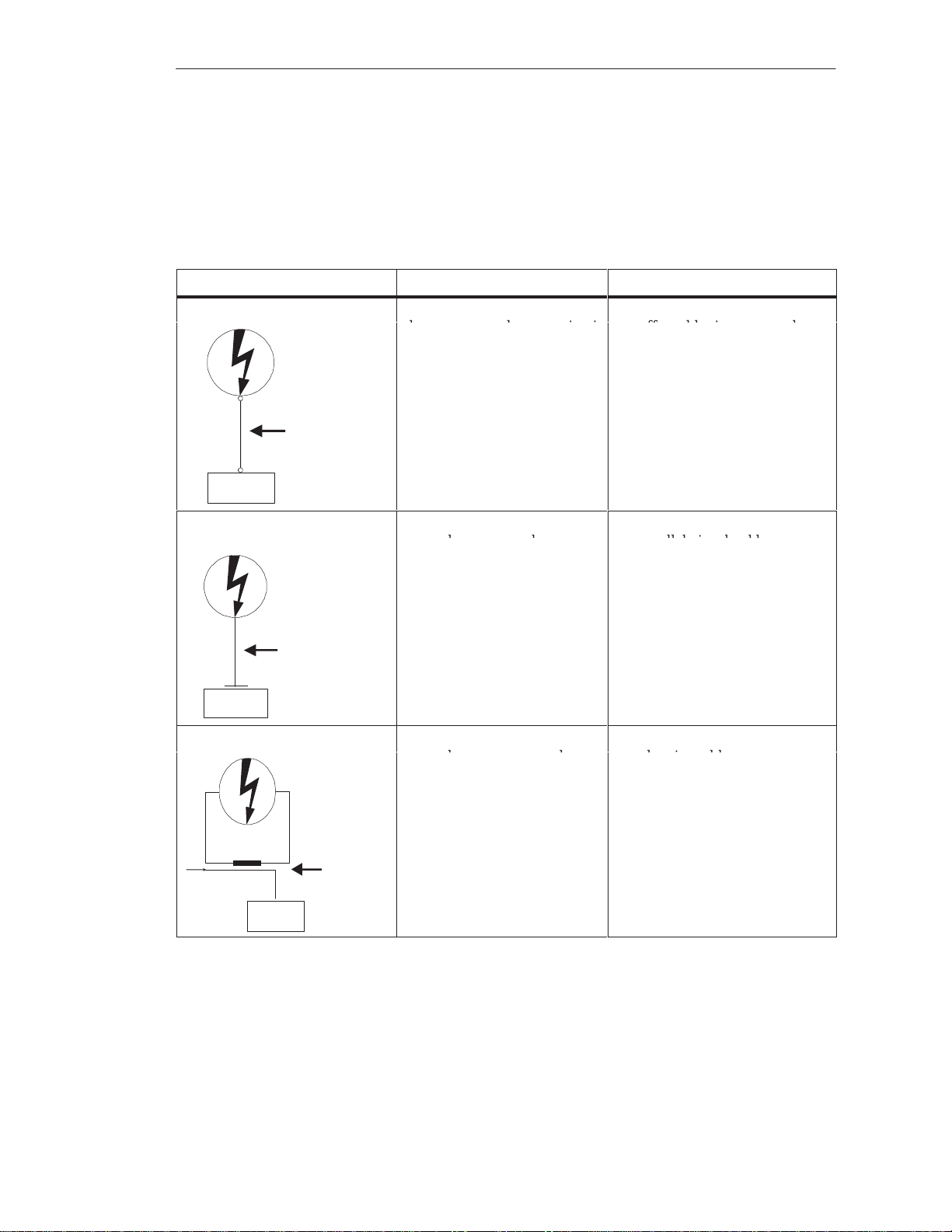

Shown in the following table are the four different coupling mechanisms,

their causes, and possible interference sources.

Typical

Interference

Sources at a

Glance

Coupling Mechanism Cause Typical Interference Sources

Direct Coupling Direct or metallic coupling

always occurs when two circuit

Interference

have a common conductor

Switched devices (supply

affected by inverters and

external power supply units)

Motors being started

Different potentials of

component cases with a

common power supplys

Static discharges

SIMATIC S5

Direct Coupling

Path

Capacitive Coupling Capacitive or electrical coupling Interference pickup via

Interference

Capacitive Coupling

Path

occurs between conductors

which are at different potentials.

The degree of coupling is

proportional to the voltage

variation as a function of time.

parallel signal cables

Static discharge of the

operator

Contactors

SIMATIC S5

Inductive Coupling Inductive or magnetic coupling

occurs between two conductor

Signal

3-4

Interference

Inductive

Coupling Path

SIMATIC S5

loops through which current is

flowing. Interference voltages

are induced by the magnetic

fluxes associated with the

currents. The degree of couplin

is proportional to the current

variation as a function of time.

Transformers, motors,

electric welders

Parallel AC supply cables

Cables whose currents are

switched⁄

Signal cables with a high

frequency

Unconnected coils

C79000-G8576-C199-06

System Manual

Page 31

Coupling Mechanism Typical Interference SourcesCause

n

Installation Guidelines

Radiated Interference There is a radiation path when a

conductor is subjected to an

electromagnetic wave.

Interference

Radiation Path

SIMATIC S5

Impinging of the wave results i

induced currents and voltages.

Local transmitters

(e.g. two-way radios)

Spark gaps (spark plugs,

collectors in electric motors,

welders)

System Manual

C79000-G8576-C199-06

3-5

Page 32

Installation Guidelines

3.1.2 The Most Important Basic Rules for Ensuring EMC

It is often sufficient to comply with a few elementary rules for ensuring

EMC. When installing the control system, therefore, observe the following

five basic rules.

When installing the programmable controllers, provide large-area good

quality grounding of the inactive metal parts (see Section 3.2).

Make a large-area low-impedance interconnection of all inactive metal

parts.

For screw connections on painted and anodized metal parts, either use

special contact washers or remove the insulating protective layers.

If possible, do not use aluminum parts. Aluminum oxidizes easily and is

therefore less suitable for grounding.

Make a central connection between the chassis ground and the

ground/protective ground conductor system.

Ensure proper routing of lines when wiring (see Sections 3.3.1 and 3.3.2).

Arrange the cabling in line groups. (AC power cable, power supply lines,

signal lines, data lines)

Always install AC power cables and signal or data lines in separate ducts

or bunches.

Route the signal and data lines as closely as possible to grounded surfaces

such as cabinet elements, metal bars and cabinet panels.

Ensure that cable shields are properly secured (see Section 3.3.3).

Data lines must be shielded. The shield should be connected at both ends.

Analog lines must be shielded. For the transfer of signals with low

amplitudes, it may be advisable to connect the shield at only one end.

Provide the line shields with a large-area connection to a shield/protective

conductor bar immediately after the cabinet inlet, and secure the shields

with cable clamps. Route the grounded shield as far as the module

without interruption, but do not connect the shield there again.

Ensure that the shield/protective ground bar has a low-impedance

connection to the cabinet.

Use metal or metallized connector cases for shielded data lines.

3-6

C79000-G8576-C199-06

System Manual

Page 33

Installation Guidelines

Employ special EMC measures for particular applications (see

Section 3.3.4).

Fit quenching elements to all inductances which are not controlled by

SIMATIC S5 modules.

Use incandescent bulbs for illuminating cabinets, and avoid fluorescent

lamps.

Create a standard reference potential; ground all electrical apparatus if

possible (see Sections 3.4 and 3.5).

Use specific grounding measures. Grounding of the control system is a

protective and functional measure.

System parts and cabinets with central controllers and expansion units

should be connected to the ground/protective conductor system in star

configuration. This serves to avoid the creation of ground loops.

In the case of potential differences between system parts and cabinets,

install equipotential bonding conductors of sufficient rating.

System Manual

C79000-G8576-C199-06

3-7

Page 34

Installation Guidelines

3.2 Installation of Programmable Controllers for EMC

Measures for suppressing interference voltages are often applied only when

the control system is already operational and proper reception of a useful

signal is impaired. The reason for such interference is usually inadequate

reference potentials caused by mistakes in equipment assembly. Described in

the following sections are:

Basic rules for grounding the inactive metal parts

Examples of cabinet assembly for EMC

Example of rack and wall mounting for EMC

3.2.1 Basic Rules for Assembling and Grounding the Inactive Metal Parts

Ensure wide-area chassis grounding of the inactive metal parts when

mounting the equipment. Properly implemented grounding creates a uniform

reference potential for the control system, and reduces the effects of

picked-up interference.

Chassis grounding is understood to mean the electrical connection of all

inactive parts. The entirety of all interconnected inactive parts is the chassis

ground.

Inactive parts are conductive parts which are electrically isolated from active

parts by basic insulation, and can only develop a voltage in the event of a

fault.

The chassis ground must not develop a dangerous touch voltage, even in

the event of a fault. The ground must therefore be connected to the protective

ground conductor. To prevent ground loops, locally separated ground

elements such as cabinets, structural and machine parts, must always be

connected to the protective ground system in star configuration.

Ensure the following when chassis grounding:

Connect the inactive metal parts with the same degree of care as the

active parts.

Ensure low-impedance metal-to-metal connections, e.g. with large-area

good quality contact.

When you are incorporating painted or anodized metal parts in the

grounding, these insulating protective layers must be penetrated. Use

special contact washers or remove the insulating layer.

Protect the connection points from corrosion, e.g. with grease.

Movable grounded parts such as cabinet doors must be connected via

flexible grounding strips. The grounding strips should be short and have a

large surface because the surface is decisive in providing a path to ground

for high-frequency interference.

3-8

C79000-G8576-C199-06

System Manual

Page 35

3.2.2 Example of Cabinet Assembly for EMC

The example of cabinet assembly in the figure shows the various measures,

the grounding of inactive metal parts and the connection of shielded cables.

This example applies only to grounded operation. Follow the points

numbered in the figure during assembly.

Installation Guidelines

1

2

3

Figure 3-2 Example of Cabinet Assembly for EMC

System Manual

C79000-G8576-C199-06

4

5

6

7

8

3-9

Page 36

Installation Guidelines

À Grounding strips

If there are no large-area metal-to-metal connections, you must

connect inactive metal parts such as cabinet doors and supports

with grounding strips. These should be short and have a large surface.

Á Cabinet members

The cabinet members should have a large-area connection to the

cabinet housing (metal-to-metal connection).

Mounting bracket for subrack

There must be a large-area metal-to-metal connection between

cabinet member and mounting bracket.

à Signal lines

With shielded signal lines, the shield must be secured to the

protective conductor bar or an additionally fitted shield bar using

large-area cable clamps.

Ä Cable clamp

The cable clamp must enclose and make contact with the shield braid

over a large area.

Å Shield bar

This bar must have a large-area connection to the cabinet members

(metal-to-metal connection). It serves for grounding the cable shields.

Æ Protective conductor bar

The protective conductor bar must have a large-area connection to

the cabinet members (metal-to-metal connection). The protective

conductor bar must be connected to the protective conductor system

via an external conductor (at least 10 mm2 ). This is essential for

providing a reliable path to ground for fault currents and interference

currents.

Ç Conductor to the protective conductor system (ground point)

The conductor must have a large-area connection to the protective

conductor system (ground point).

3-10

C79000-G8576-C199-06

System Manual

Page 37

3.2.3 Example of Rack and Wall Mounting for EMC

To operate your control system in a low-interference environment whilst

observing the permissible ambient conditions (see “Technical

Specifications”), you can mount the programmable controllers on racks or

directly on walls.

Picked-up interference should be given a path to large metal surfaces. You

should therefore secure standard sectional rails, shield and protective

conductor bars to metal structural elements. For wall mounting in particular,

installation on reference potential surfaces made of sheet steel has proved

advantageous.

When installing shielded cables, provide a shield bar for connecting the cable

shields. The shield bar can also be the protective conductor bar.

Ensure the following for rack and wall mounting:

S Suitable contacting aids should be used on painted and anodized metal

parts. Use special contact washers or remove the insulating protective

layers.

S Provide large-area, low-impedance metal-to-metal connections when

securing the shield/protective conductor bar.

S AC conductors must be covered.

Installation Guidelines

Connection to

P . Ground: 10 mm@

Figure 3-3 W all Mounting of an S5-135/155U PLC

System Manual

C79000-G8576-C199-06

Reference Potential

Surface

Shielded Signal

Line

Cable Clamp for

Shield Contact

Shield/Protective

Conductor Bar

3-11

Page 38

Installation Guidelines

3.3 Wiring of Programmable Controllers for EMC

The following section describes:

Routing of cables within and outside cabinets

Equipotential bonding between devices

Single and double-ended connection of cable shields

Checklist for electromagnetically compatible installation

3.3.1 Routing of Cables

This section covers the routing of bus, signal and supply lines. The purpose

cable routing is to suppress crosstalk between cables laid in parallel.

Routing of Cables

Within and

Outside Cabinets

Group A

Group B

Group C

Group D

For electromagnetically compatible routing of cables and lines, it is

expedient to subdivide the lines into the following line groups and lay the

groups separately.

Shielded bus and data lines (for programmer, OP, SINEC L1, SINEC L2,

printer, etc.)

Shielded analog lines

Unshielded lines for DC voltage v 60 V

Unshielded lines for AC voltage v 25 V

Coaxial cables for monitors

Unshielded lines for DC voltage > 60V and v 400V

Unshielded lines for AC voltage > 25V and v 400V

Unshielded lines for DC and AC voltage > 400V

Lines for SINEC H1

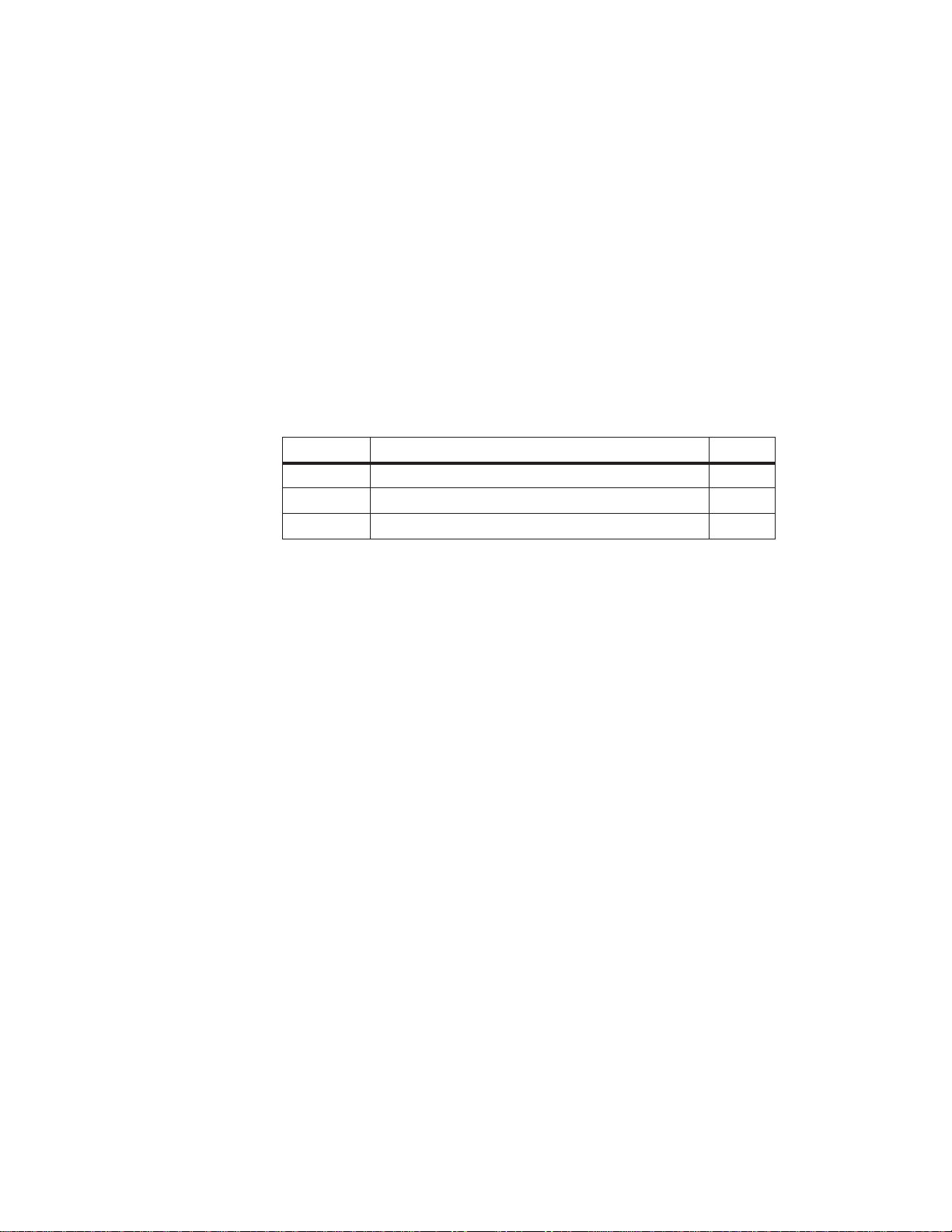

From the combination of individual groups in the following table, you can

read off the conditions for laying the line groups.

3-12

Group A

Group B

Group C

Group D

Group A Group B Group C Group D

C79000-G8576-C199-06

System Manual

Page 39

Legend for the table

Lines can be laid in common bundles or cable ducts.

Lines must be laid in separate bundles or cable ducts (without

minimum clearance).

Lines within cabinets must be laid in separate bundles or cable

ducts; outside the cabinets but within buildings, they must be laid

over separate cable routes with a clearance of at least 10 cm.

Lines must be laid in separate bundles or cable ducts with a

clearance of at least 50 cm.

Installation Guidelines

Routing of Cables

Outside Buildings

Lightning

Protection

!

Outside buildings, lay the lines on metal cable trays if possible. Provide the

joints between cable trays with an electrical connection and ground the cable

trays.

When laying lines outside buildings, you must observe the valid lightning

protection and grounding measures. The following applies in general:

Caution

Where cables and lines for SIMATIC S5 controllers are to be laid

outside buildings, you must apply measures for internal and external

lightning protection.

Outside the buildings, lay your lines either

in metal conduit grounded at both ends,

or

in concreted cable ducts with continuously connected reinforcement.

Protect the signal lines from overvoltages by means of

varistors

or

inert gas-filled surge diverters.

Equipotential

Bonding

System Manual

C79000-G8576-C199-06

Fit these protective devices at the cable entry into the building.

Note

Lightning protection measures always require an individual assessment of

the entire installation. For clarification, please consult your Siemens regional

office or a company specializing in lightning protection.

Ensure adequate equipotential bonding between the connected equipment

(see Section 3.3.2).

3-13

Page 40

Installation Guidelines

3.3.2 Equipotential Bonding

Between separate sections of an installation, potential differences can

develop if

S programmable controllers and I/O devices are connected via a

non-floating link, or

S cable shields are connected at both ends and are grounded at different

parts of the system.

Different AC supplies, for example, can cause potential differences. These

differences must be reduced by installing equipotential bonding conductors to

ensure functioning of the electronic components.

The following points must be observed for equipotential bonding:

S The lower the impedance of the equipotential bonding conductor, the

greater is the effectiveness of equipotential bonding.

S Where shielded signal lines are laid between the relevant sections of the

system and connected at both ends to the ground/protective conductor, the

impedance of the additional equipotential bonding conductor must not

exceed 10 % of the shield impedance.

S The cross-section of the equipotential bonding conductor must be rated

for the maximum circulating current. The following cross-sections of

copper have proved to be satisfactory in practice:

–16 mm@ of copper for equipotential bonding conductors

of up to 200 m in length

–25 mm@ of copper for equipotential bonding conductors

of more than 200 m in length.

S Use copper or zinc-plated steel for equipotential bonding conductors.

They must be given a large-area connection to the ground/protective

conductor and protect it from corrosion.

S The equipotential bonding conductor should be laid so that the smallest

possible areas are enclosed between the equipotential bonding conductor

and signal lines.

3-14

Signal Line