Page 1

SieMo S50037 Data Book PRELIMINARILY

Data Book

Siemens Bluetooth™ Module

SieMo-S50037

S50037-Q5-*

Copyright Siemens AG 2002 All Rights Reserved.

Page 1/30

Page 2

SieMo S50037 Data Book PRELIMINARILY

SieMo S50037

-Module

KEY Features

Bluetooth V1.1 prequalified

Input sensitivity –85 dBm

Point-to-multipoint functionality

Firmware below HCI embedded, or stand alone operation

Class 2 Bluetooth device, 2 dBm

HCI optionally via high-speed UART, BCSP and USB

Interface data rate UART to 1.5 MBPS, USB high speed 1.1 (12 MBPS)

Frequency range 2.402 – 2.480 GHz

Temperature range 0-40° centigrade (qualified)

Mechanical outline 32.8 x 16.8 x 3 mm³ (34 x 18 x 3 mm³ for sample quantities)

Power supply 3.25V-6V, Max. 120 mA

GFSK modulation, frequency hopping, 79 channels spaced by 1 MHz

Internal Crystal oscillator

50 Ohm Antenna connector

SMD mountable

Description:

The SieMo S50037 is a Class2 Bluetooth Module which can be integrated into various electronic

devices to give them Bluetooth functionality.

The connections to the environment consist of a single positive power supply, a 50 Ohm Antenna

connector, UART, SPI, BCSP USB and PCM Interface, 6 PIO lines, control signals for an external

Power Amplifier and one Pin which allows to switch between two different firmware versions.

SieMo is shipped as an HCI Module, which means that the lower Bluetooth stack up to HCI is

included in the Firmware and it can be changed into a stand-alone Module with the complete BTstack and some simple applications running on the module via a firmware upgrade.

The module supports synchronous voice transmission as well as asynchronous data transfer.

File Name: SieMo_S50037 Data Book.doc Page 2/30

Page 3

SieMo S50037 Data Book PRELIMINARILY

Author Part of this Document Department

Canbolant D. Regulatory Statements, Bluetooth™ Trademark PSE PRO RCD 3

Jatschka T. Technical Clauses PSE PRO RCD 3

File Name: SieMo_S50037 Data Book.doc Page 3/30

Page 4

SieMo S50037 Data Book PRELIMINARILY

General Information

History

Issue Date Reason for Changes

01 2002-02-12 Initial issue

02 2002-02-25 Redesign of document structure, inserting of the Clause Regulatory

Statements

03 2002-03-13 Enhanced Details in Interface Description

04 2002-03-21 Manufacturing aspects added, minor corrections.

05 2002-03-22 Mechanical Information added, minor corrections

06 2002-04-24 minor corrections

Table 1: History

References

[1] http://www.bluetooth.com

[2] http://www.csr.com

4/30

Page 5

SieMo S50037 Data Book PRELIMINARILY

CONTENT

General Information .................................................................................................... 4

History................................................................................................................................ 4

References......................................................................................................................... 4

Electrical Characteristics............................................................................................. 8

Absolute Maximum Ratings................................................................................................ 8

Recommended Operating Conditions................................................................................. 8

Timing Characteristics........................................................................................................ 8

I/O Terminal Characteristics............................................................................................... 8

Power Consumption........................................................................................................... 9

Radio Characteristics......................................................................................................... 9

Output Spectrum.............................................................................................................. 10

Modulation Spectrum.................................................................................................... 10

Output spectrum in the whole 2,4 GHz ISM band (Max Hold) ....................................... 11

Flatness of output power Vs time.................................................................................. 11

Spurious emissions on the antenna port....................................................................... 11

VCO Settling................................................................................................................. 12

S-Parameter of the Antenna port.................................................................................. 12

Pin Description.......................................................................................................... 13

Pinout Diagram ................................................................................................................ 13

Pin description table......................................................................................................... 13

Interface Description................................................................................................. 16

PCM Interface .................................................................................................................. 16

Overview ...................................................................................................................... 16

Description ................................................................................................................... 16

Generic PCM Interface ................................................................................................. 16

PCM Timing.................................................................................................................. 17

Timing graphs............................................................................................................... 18

UART Interface ................................................................................................................ 19

Overview ...................................................................................................................... 19

UART Settings.............................................................................................................. 19

Timing graphs............................................................................................................... 20

USB Interface...................................................................................................................21

Overview ...................................................................................................................... 21

Disconnect and Resume Signalling .............................................................................. 21

Power Modes................................................................................................................ 21

USB Timing .................................................................................................................. 22

Serial Peripheral Interface................................................................................................ 22

Overview ...................................................................................................................... 22

Instruction Cycle ........................................................................................................... 22

Single-Cycle Operation................................................................................................. 22

Multi-Slave Operation ................................................................................................... 23

Writing to SieMo ........................................................................................................... 23

SPI Timing.................................................................................................................... 23

Reading from SieMo..................................................................................................... 24

Auto-Increment Operation............................................................................................. 24

5/30

Page 6

SieMo S50037 Data Book PRELIMINARILY

Manufacturing aspects, Handling.............................................................................. 25

Regulatory Statements ............................................................................................. 26

General ............................................................................................................................ 26

European Union (EU) and EFTA Member States ............................................................. 26

United States of America (USA)....................................................................................... 27

Bluetooth-Trademark ............................................................................................... 29

6/30

Page 7

SieMo S50037 Data Book PRELIMINARILY

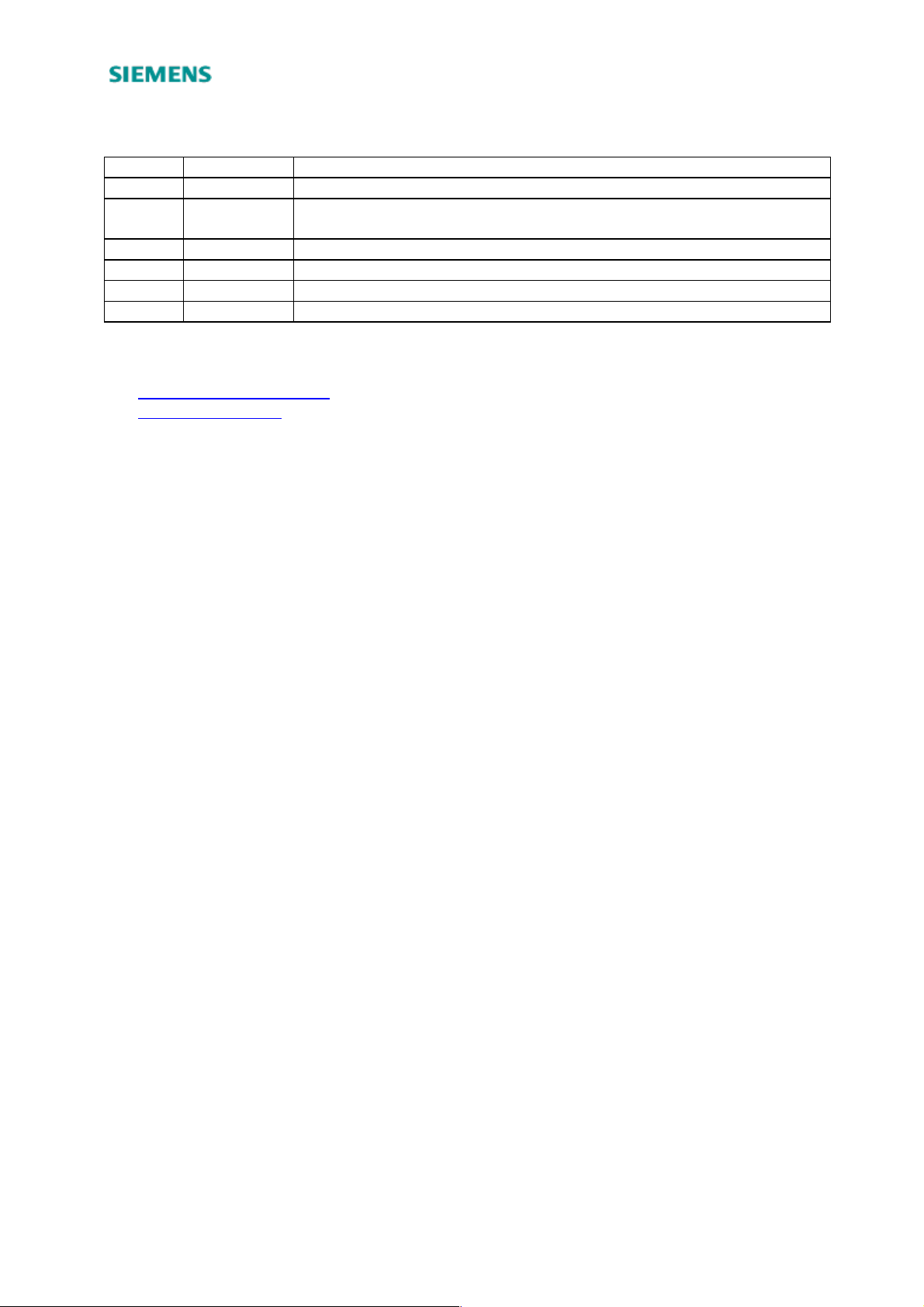

ANT

SWITCH

TXEN/RX

LNA

EN

Balun

V

REG

XTAL

FLASH

RAM

DSP

2.4 GHz Radio

Power

Supply

µP

BC01b

V

I/O

CC V

MODE

SPI

USB

UART

PCM

PIO 2-6

Reset

IO

figure 1 Block Diagram

figure 2 Default HCI- FW Stack optional FW stack for standalone operation

7/30

Page 8

SieMo S50037 Data Book PRELIMINARILY

Electrical Characteristics

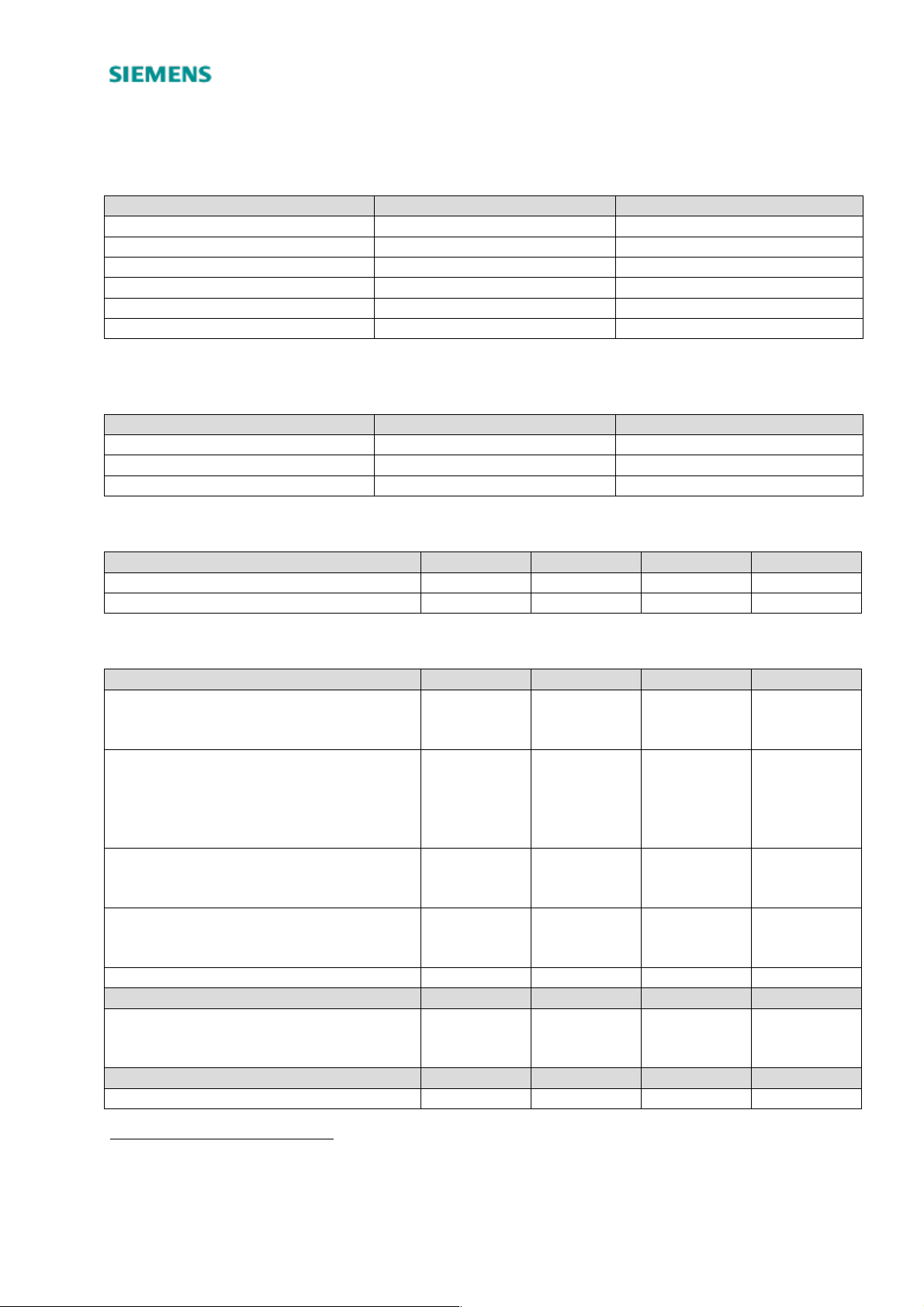

Absolute Maximum Ratings

Rating Min. Max.

Storage Temperature -30°C +85°C

Supply Voltage Vcc (no damage) -7V +7V

Supply Voltage Vcc-IO 0V +3.6V

5V Tolerant Terminals -0.4V +5.5V

Other Terminals -0.4V +3.55V

Input Rf Power, in band 5dBm

Recommended Operating Conditions

Operating Condition Min. Max.

Ambient Temperature Range

1

0°C +40°C

Supply Voltage, Vcc +3.2V +6V

Supply Voltage, Vcc -IO 3V 3.4V

Timing Characteristics

Parameter Min. Typ. Max. Unit

System start up time from Power on 1230 ms

RESET# signal duration 2 ms

I/O Terminal Characteristics

Vcc = 3.3V unless otherwise stated

Digital Terminals Min. Typ. Max. Unit

Input Voltage:

input logic level low

V

IL

V

input logic level high

IH

Input Current:

CMOS input (V

CMOS input + pull-up (V

CMOS input + pull-down (V

=3.3V or 0V)

I

=3.3V or 0V)

I

=3.3V or

I

0V)

Output Voltage:

output logic level low (IO = 4.0mA)

V

OL

output logic level high (IO = -4.0mA)-Vcc_IO-0.2

V

OH

Tri-state Leakage Current:

(VI = 0V)

I

OZL

I

(VI = 3.3V)

OZH

CI Input Capacitance 2.5 - 10 pF

Power-on Reset Min. Typ. Max. Unit

Vcc falling threshold

Vcc rising threshold

Hysteresis

USB Terminals

Input thresholds:

-0.4

0.7 Vcc_IO

-1

-20

20 / 2

1,2

-1

-1

2.35

2.50

130

-

-

-

-

-

-

-

-

-

2.45

2.60

150

0.3 Vcc_IO

Vcc_IO + 0.4

1

-125

125

0.2

-

1

1

2.55

2.70

170

V

V

µA

µA

µA

V

V

µA

µA

V

V

mV

1

The module is qualified for this temperature range. Functionality has been tested form –40 to +80°

with a small number of samples. Components are specified form –20°C to 70°C. Radio performance

decreases with rising temperature.

2

PIO terminals have weak pull-down resistors (1/10th current of standard pull-down resistors).

8/30

Page 9

SieMo S50037 Data Book PRELIMINARILY

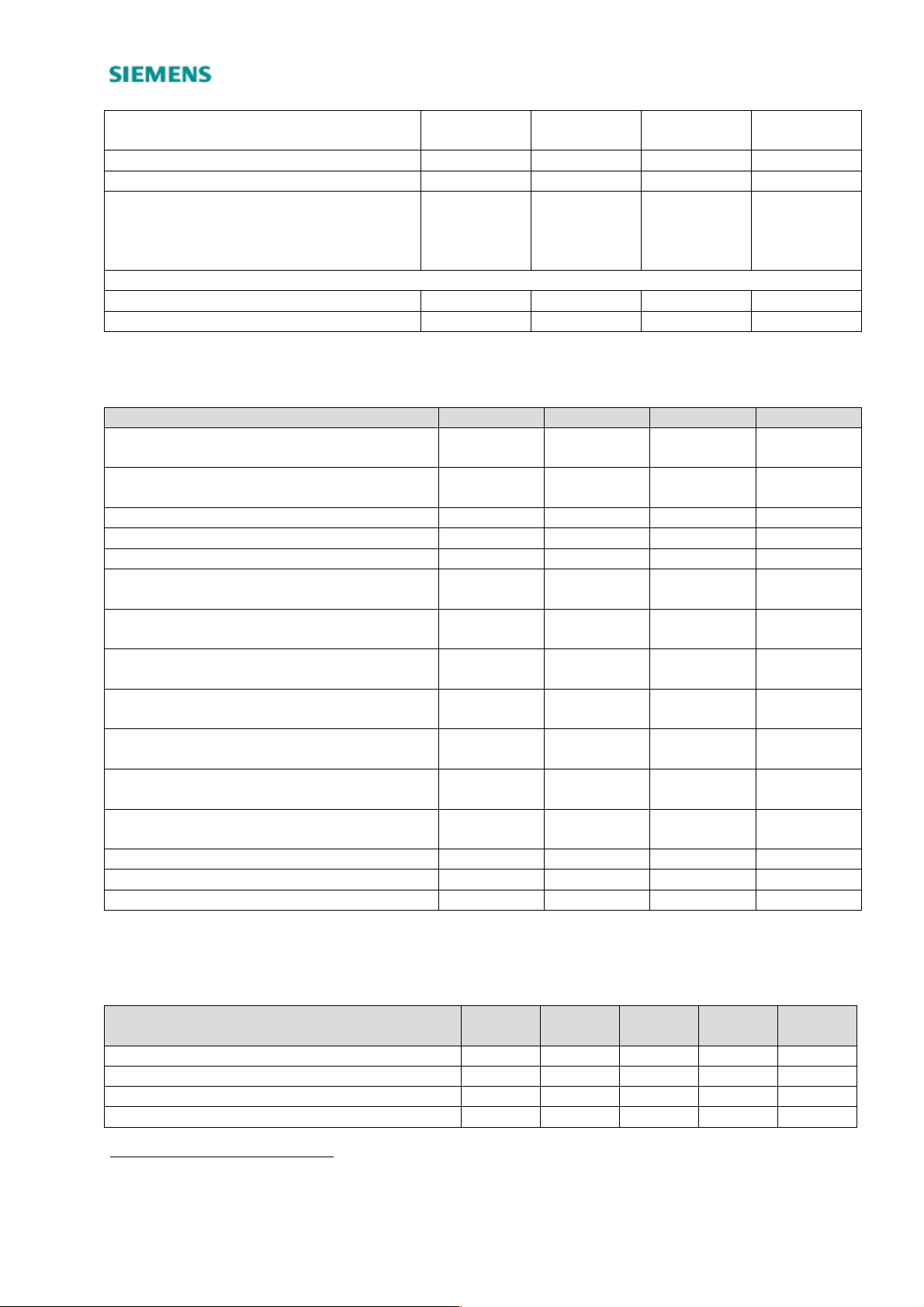

input logic level low

V

IL

V

input logic level high

IH

-

0.7 Vcc_IO

-

-

0.3 Vcc_IO

-

V

V

Input leakage current -1 - 1 µA

CI Input Capacitance 2.5 - 10 pF

Output levels (to correctly terminated

USB)

output logic level low

V

OL

V

output logic level high

OH

0

2.8

-

-

0.2

Vcc_IO

V

V

PIO Port

Output voltage Vcc-IO-0.4 - Vcc-IO V

Output (source/sink) current - - 8 mA

Power Consumption

Vcc = 3.3V, Ta = 20°C unless otherwise stated

Mode Min. Typ. Max. Unit

SCO connection HV3 (1s interval sniff

mode)

SCO connection HV1 (1s interval sniff

mode)

ACL data transfer 720kbps USB - 85 - mA

Peak current during RF burst - - 120 mA

Leakage current (all off) - 120 - µA

Idle (after reset or power up) UART, 115.2

KBPS

Idle (after reset or power up) UART, 9.6

KBPS

Idle (after reset or power up) UART,

1382.4 KBPS

ACL data transfer 115.2kbps UART

MASTER, transmit data

ACL data transfer 115.2kbps UART

SLAVE, transmit data

ACL data transfer 115.2kbps UART

MASTER, receive data

ACL data transfer 115.2kbps UART

SLAVE, receive data

Connected, no data-transfer, MASTER 12 mA

Connected, no data-transfer, SLAVE 61 mA

Inquiery 82 93 mA

-44-mA

-74-mA

3mA

1.5 mA

20 mA

30 43 mA

71 mA

28 38 mA

77 mA

Radio Characteristics

Vcc = 3.3V, f = 2.45GHz, Ta = 20°C unless otherwise stated

Receiver Min. Typ. Max. BT-

Spec

Sensitivity at 0.1% BER

Sensitivity at 0.1% BER

3

4

Ta = 40°C - -80 -77 -70 dBm

- -85 -82 -70 dBm

Sensitivity at 0.1% BER Ta = 0°C - -90 -85 -70 dBm

Maximum received signal

3

Measured according to the Bluetooth specification 1.1

4

Up to five spurious responses within Bluetooth limits are allowed

5

At carrier –3MHz

5

-13--20dBm

Unit

9/30

Page 10

SieMo S50037 Data Book PRELIMINARILY

C/I Co-channel

Adjacent channel selectivity C/I 1MHz

2nd adjacent channel selectivity C/I 2MHz

3rd adjacent channel selectivity C/I >3MHz

Image rejection C/I

Maximum level of intermodulation interferers

3, 6

6

3

3

3, 4

3, 5

-9-11dB

--2- 0dB

- -34 - -30 dB

- -45 - -40 dB

--14- -9dB

- -30 - -39 dBm

1dB compression point at 1.9 GHz -30 - dBm

Transmitter Min. Typ. Max. BT-

Unit

Spec

RF transmit power

3

-2 0 2 -6 to +4 dBm

RF transmit power 3 Ta = 40°C -4 -1 1 -6 to +4 dBm

RF transmit power 3 Ta = 0°C +1 +2 +3 -6 to +4 dBm

RF power control range

3

- 30 - 16 dB

RF power control range resolution - 4 - - dB

20 dB bandwidth for modulated carrier - 930 - <1000 kHz

2nd adjacent Channel transmit power

3rd adjacent Channel transmit power

3

3

--47-25<-20dBc

--52-45<-40dBc

Output Spectrum

Modulation Spectrum

figure 3 Modulation spectrum on single channel with PRBS9 Payload, DH1 packet cable loss (approx.

3dB) not corrected.

6

Measured at f1-f2 = 5MHz

10/30

Page 11

SieMo S50037 Data Book PRELIMINARILY

Output spectrum in the whole 2,4 GHz ISM band (Max Hold)

figure 4 Output spectrum with Frequency Hopping measured with MAXHOLD cable loss (approx. 3dB)

not corrected.

Flatness of output power Vs time

figure 5 output power during a DH5 packet, cable loss (approx. 3dB) not corrected.

Spurious emissions on the antenna port

figure 6 Spurious emission up to 8GHz, green line is with DUT offline. Cable loss not corrected.

11/30

Page 12

SieMo S50037 Data Book PRELIMINARILY

VCO Settling

figure 7 VCO settling during FH operation in two different time-scales

S-Parameter of the Antenna port

figure 8 S11 on the antenna port in transmit mode

figure 9 S11 on the antenna port in receive mode

12/30

Page 13

SieMo S50037 Data Book PRELIMINARILY

Pin Description

Pinout Diagram

figure 10 SieMo Pinout, bottom view

Pin description table

Row X,D,E and F are by default not provided with soldering bumps

Pin Name Type Pin Description

RF

ANT Rf in/out T2 Antenna output, 50Ω; unconditionally

stable; DC path to GND

TX-EN CMOS output,

pulled down

RX-EN CMOS output

pulled down

TX-PWR Analogue output F67Ramping control output for external PA,

Power

V

CC

VCC-

IO

Power C6 Power Supply 3.25-6V

Power C4 Power Supply for all IO-Pins, 3.0-3.4V, can

UART-Interface

TxD CMOS output, 5V

tolerant, pulled down

RxD CMOS input, 5V

tolerant, pulled down

RTS CMOS input A6 UART Ready To Send

CTS CMOS output B6 UART Clear To Send

F57Control output for external switch or PA

F47Control output for external switch or LNA

need not be used, ramping is done on the

module.

be connected to V

REG

B5 UART data output

A5 UART data input

N.C.

not connected not connected X1-X6,F2,F3 Do not connect. Will be

used in future versions.

not connected not connected C2,C3,C5, R4-6,T4-T6 Do not connect.

7

No Bump

13/30

Page 14

SieMo S50037 Data Book PRELIMINARILY

USB-Interface

D+ CMOS bi-directional B1 USB D+

D- CMOS bi-directional B2 USB DUSB_PULL_UP

/

PIO[2]

USB_WAKE_UP

=USB_RESUME

PIO[3]

USB_ON/ PIO[4] CMOS bi-directional,

USB_DETACH/

PIO[5]

CMOS bi-directional,

pulled down

CMOS bi-directional,

pulled down

/

pulled down

CMOS bi-directional,

pulled down

D18USB Pull-up, internally attached to D+, only

used with corresponding USB-settings.

B4 Output goes high to wake up PC when in

USB mode

, only used with corresponding USB-settings.

D23USB On (Input. Senses when VBUS is high

wakes SieMo)

settings.

C1 Chip detaches from USB when this line is

high

, only used with corresponding USB-settings.

PCM-Interface

PCM_IN CMOS input

pulled down

PCM_OUT CMOS output

pulled down

PCM_SYNC CMOS bi-directional,

pulled down

PCM_CLK CMOS bi-directional,

pulled down

A1 Synchronous 8kss-1data input

A2 Synchronous 8kss-1data output

A3 Synchronous data strobe

A4 Synchronous data clock

SPI-Interface

SPI-CSB CMOS input, 5V

tolerant, pulled up

SPI-CLK CMOS input, 5V

tolerant, pulled down

SPI-MOSI CMOS input, 5V

tolerant, pulled up

SPI-MISO CMOS output,

tristate

E13SPI Chip Select

E23SPI Clock

E33SPI Data Input

E43SPI Data Output

PIO-Interface

PIO[2]/USB_PULL

_UP

PIO[3]/USB_WAK

E_UP

PIO[4]/USB_ON CMOS bi-directional,

PIO[5]/USB_DETACHCMOS bi-directional,

PIO[6]/ CMOS bi-directional,

PIO[7]/ CMOS bi-directional,

CMOS bi-directional,

pulled down

CMOS bi-directional,

pulled down

pulled down

pulled down

pulled down

pulled down

D13Programmable IO line

B4 Programmable IO line

D23Programmable IO line

C1 Programmable IO line

D53Programmable IO line

D63Programmable IO line

Special Functions

RESET# CMOS input

pulled up

V

REG

SCAN_ENABLE

TEST-A

TEST-B

MODE

Output D4 3.15V regulated output. Can be connected to V

CMOS input F13For Test only, do not connect

CMOS input E53For Test only, do not connect

CMOS input E63For Test only, do not connect

CMOS input

pulled down

R3 Reset# input

D33Selects second Firmware, if programmed

GND

Main GND B3 'digital'GND

Antenna (RF)

GND

8

No Bump

R1,R2,

T1,T3

RF-Ground

, only used with corresponding USB-

CCIO

14/30

Page 15

SieMo S50037 Data Book PRELIMINARILY

figure 11 dimmensions

15/30

Page 16

SieMo S50037 Data Book PRELIMINARILY

Interface Description

PCM Interface

Overview

PCM Pulse Code Modulation is a

standard method used to digitise

human voice

Four-wire, full duplex serial interface

used to transfer a single voice channel

to an external audio codec

Maximum of one SCO connection is

possible using the PCM interface

Further SCO channels must use the

HCI protocol layer

Data format is 13 bit linear PCM

Description

Pulse Code Modulation (PCM) is the

standard method used to digitise human

voice patterns for transmission over digital

communication channels. Through its

PCM interface, SieMo provides hardware

support for continual transmission and

reception of PCM data, thus reducing

processor overhead for wireless headset

applications.

SieMo offers a bi-directional digital audio

interface that routes directly into the

baseband layer of the on-chip firmware (it

does not pass through the HCI protocollayer). Hardware on SieMo allows the data

to be sent to and received from a SCO

connection. Only one SCO connection can

be supported by the PCM interface at any

one time. Any additional SCO connections

must receive and transmit their data over

the HCI protocol layer. The data format is

13-bit linear PCM. SieMo can operate

either as a master (with an output clock of

256kHz) or as a slave (with the input clock

varying between 128kHz and 512kHz).

When in slave mode and using higher

clock rates SieMo can support Motorola's

Synchronous Serial Interface (SSI)

standard that allows multiple bi-directional

audio channels to be multiplexed onto a

single physical connection.

Generic PCM Interface

For a generic PCM interface there is one

master and one slave device. The master

generates the clock and synchronisation

signals. The sync signal identifies the start

of the sample data and has an 8kHz

period. There are two types of frame sync:

long and short. In long frame sync mode

PCM_SYNC going high indicates the first

(and most significant) bit of the sample. It

must remain high for at least two clock

cycles, but this can be longer. In short

frame sync MSB start is signalled by sync

going low (normally it only goes high for

one clock cycle).

The clock runs at a higher rate than sync:

at least 8 x bits_per_sample MHz,

although higher rates are common. The

sample resolution is 13 bits/sample,

uncompressed. Several Motorola

CODECs allow their output gain to be

controlled via the addition of three extra

data bits after the audio data. SieMo

supports this feature, effectively raising the

bits per sample to 16. Data from both the

master and slave is clocked out on the

rising clock edge and sampled on the

falling edge. Master mode is the default

setting. In master mode SieMo generates

a 256kHz clock signal (PCM_CLK) and the

8kHz, long format synchronisation signal

(PCM_SYNC). Short frame sync is not

supported. See PCM Timing Diagrams for

more information.

Slave mode is selected by setting a

Persistent Store value. In slave mode

SieMo clocks output data on the rising

edge of the received clock signal and

samples incoming data on the falling edge.

The incoming clock frequency should be

between 128kHz and 512kHz. (Note that

128kHz is 8 x 16 kHz, therefore the

absolute minimum possible frequency for

the 8ksamples/sec and 16bits/sample (13

audio data plus three gain data). The

frame sync must be long format. Short

format is not supported (see SSI Mode

and Timing Diagrams in this section for

more information).

16/30

Page 17

SieMo S50037 Data Book PRELIMINARILY

PCM Timing

Symbol Parameter Min Typ Max Unit

f

CLK

(1)

t

sy:hd

t

sy:su

t

sdat:dt

t

dat:dt

t

fdat:dt

t

sy:low

t

dr:su

tdr:hd

PCM clock frequency 256 kHz

Clock duty cycle 50 %

Hold time from CLK low to SYNC high 1.95 us

Set-up time for SYNC high to CLK low 1.95 us

Delay time from CLK to valid MSB data 50 ns

Delay time from CLK high to PCM_OUT

50 ns

valid data

Delay time from SYNC or CLK, whichever

300

9

ns

is later, to PCM_OUT data line high

impedance

Hold time from 2nd CLK to SYNC low 300

Set-up time for PCM_IN valid to CLK low 300

Hold time for CLK low to PCM_IN invalid 300

1

1

1

ns

ns

ns

figure 12 PCM Master Timing

9

Assumes normal system clock operation. Figures may vary during low power modes

when system clock speeds are reduced.

17/30

Page 18

SieMo S50037 Data Book PRELIMINARILY

Timing graphs

figure 15 PCM clock (upper) Vs PCM sync in 2 different time-scales

figure 15 PCM OUT Vs PCM CLOCK in two different time-scales

figure 15 PCM OUT Vs PCM SYNC in two different time-scales

18/30

Page 19

SieMo S50037 Data Book PRELIMINARILY

UART Interface

Overview

Universal Asynchronous Receiver Transmitter

Standard 16550 compatible UART interface

Min 9600Baud, Max 1.5MBaud

UART_TX and UART_RX used to transmit data

UART_CTS and UART_RTS used to implement RS232 hardware flow control

The UART (Universal Asynchronous Receiver Transmitter) provides a simple mechanism to

communicate with other devices. The UART uses 4 (or 2 if HW – Handshake is not in use))

lines for serial data transmission.

figure 16 UART Directions

UART Settings

Property Possible Values Default Setting

Baud Rate Max 1.536 MBaud

Min 9600 baud

Flow Control RTS/CTS or None

Parity On or Off Off

Number of Stop

1 or 2 1

Bits

Note: To communicate with a standard PC a level-converter is required. SieMo uses 0V and

3V levels. Standard PC usually provide baudrates up to 115.2 kBit/s, if SieMo shall

communicate with a PC at higher data rates an accelerated serial port adapter and a

appropriate level converter is required. It is strongly recommended to use a level converter

with ESD protection. See Application below.

115.2 kBaud

10

RTS/CTS

10

The CTS input must be de-assigned by the host for the duration of at least 4 bits (e.g. 35 ms with a

baudrate of 115.2 kBaud). Any shorter period of de-assigning the handshake input can cause incorrect

function.

19/30

Page 20

SieMo S50037 Data Book PRELIMINARILY

Application: SieMo connected as DCE

figure 17 Connection to PC via level converter

Timing graphs

figure 18 UART TxD signal

figure 19 data output stopped by handshake input, delay time 84us

20/30

Page 21

SieMo S50037 Data Book PRELIMINARILY

USB Interface

Overview

12Mbits/s bit rate

BC01 operates as a peripheral USB

device

Two modes, bus powered and self

powered

Careful product design is required for

product to remain USB1.1 compliant

4 USB lines are required

Minimum voltage on VCC_IO terminal

is 3.0V for USB operation

The SieMo contains its own full-speed

(12Mbits/s) USB interface. To get a

product USB 1.1 certified, please visit

www.usb.org for further information. The

voltage on Vcc-IO must be between 3.0

and 3.4 V for USB operation. It is possible

to connect the Vcc-IO to the Vreg output of

the module, which provides a regulated

voltage of 3.15V.

Although SieMo is capable of meeting the

USB 1.1 specification, Siemens cannot

guarantee that an application circuit

designed around the IC is USB compliant.

The choice of application circuit,

component choice and PCB layout all

affect USB signal quality and electrical

characteristics. The information in this

document is intended as a guide and

should be read in association with the

USB 1.1 specification, with particular

attention being given to Chapter 7.

Independent USB qualification must be

sought before an application is deemed

USB compliant and can bear the USB

logo. Such qualification can be obtained

from a USB plugfest or from an

independent USB test house.

Disconnect and Resume Signalling

SieMo provides some signalling lines for

USB operation. These functions are

disabled by default but can be activated

via firmware settings.

The USB_DETACH and USB_WAKE_UP

terminals provide extra signalling

alongside the normal USB data lines. They

are not part of the USB specification and

full USB functionality can be attained

without their use. The Disconnect

message may be useful on its own, but it

is hard to see an application for

USB_RESUME in isolation.

USB_DETACH (Disconnect Signalling)

USB_DETACH is an input, when asserted

high, causes SieMo to put

USB_PULL_UP, USB_D- and USB_D+ in

a high-impedance state. This detaches the

device from the bus and is logically

equivalent to unplugging the module.

When USB_DETACH is taken low, SieMo

will connect back to USB and await

enumeration by the USB host.

USB_RESUME

USB_WAKE_UP is an active high output

used only when USB_DETACH is active to

wake-up the host and allow USB

communication to recommence. It

replaces the function of the USB Resume

message, which cannot be sent while

SieMo is effectively disconnected from the

bus.

Power Modes

SieMo is by default set to be powered from

the Bus. It can be set to a self powered

Device by changing firmware settings. In

this case the USB_ON must be connected

to the Vbus line via a 47k/22k

21/30

Page 22

SieMo S50037 Data Book PRELIMINARILY

figure 20 USB Power Modes- Applications

USB Timing

figure 21 USB Disconnect and Resume Signal Timing

Serial Peripheral Interface

Overview

Consistent with the Motorola SPI standard

SieMo always acts in slave mode

SPI_CLK is always generated by the host

SieMo uses 16-bit addresses and 16-bit data during serial peripheral interface transactions.

Such transactions will operate regardless of whether the internal processor is running or is

stopped. This section details the considerations required when interfacing to SieMo via the

four dedicated Serial peripheral interface terminals.

Instruction Cycle

Before SieMo can be addressed, SPI_CSB must be taken low (SPI_CSB = 0). Data on

SPI_MOSI is then clocked into the SieMo on the rising edge of the clock-line SPI_CLK.

When reading, SieMo will reply to the master on MISO, the data being valid on the falling

edge of the SPI_CLK. The master provides the clocking.

Single-Cycle Operation

After a serial peripheral interface transaction finishes, the master toggles SPI_CLK with

SPI_CSB high to initiate a new transaction. SPI_CSB must be high for at least two SPI_CLK

cycles.

22/30

Page 23

SieMo S50037 Data Book PRELIMINARILY

Multi-Slave Operation

SieMo should not be connected in a multi-slave arrangement by simple parallel connection of

slave MISO lines. When SieMo is deselected (SPI_CSB = 1), the SPI_MISO line does not

float. Instead, SieMo outputs 0 if the processor is running or 1 if it is stopped.

Writing to SieMo

To write to the SieMo, the 8-bit write command (00000010) is sent first (C[7:0] followed by a

16-bit address (A[15:0]). 16 bits of data (D:[15:0]) are sent.

Terminal Type Description Device

Terminal

SPI_CSB CMOS input Serial Peripheral Interface Chip

Select

SPI_CLK CMOS input Serial Peripheral Interface SPI

Clock

SPI_MOSI CMOS input Serial Peripheral Interface SPI

Data Input

SPI_MISO CMOS output Serial Peripheral Interface SPI

Data Output

GND B3 19

E1 2

E2 9

E3 8

E4 10

PC Parallel

Connector

SPI Timing

figure 22 SPI write operation a

figure 23 SPI write operation b

23/30

Page 24

SieMo S50037 Data Book PRELIMINARILY

Reading from SieMo

Reading is similar to writing, in that an 8-bit read command (00000011) is sent first, followed

by the address of the location to be read. The SieMo then outputs the 16-bit contents of the

location on MISO during bits D[15:0] and a check-word during T[15:0].The check-word is

composed of {command, address [15:8]}. The check-word may be used to 'sanity-check' a

read operation to a memory location. This overcomes the problem encountered with typical

serial peripheral interface slaves, whereby it is impossible to determine whether the data

returned by a read operation is valid data, or the result of the slave device not responding.

figure 24 SPI read timing a

figure 25 SPI read timing b

Auto-Increment Operation

Sending a command word and the address of a register every time it is to be read or written

can be a significant overhead, especially when large amounts of data are to be transferred.

SieMo offers increased data transfer efficiency via its auto-increment operation. During

operation, SieMo increments the address automatically. Only the data is transmitted or

received over the serial peripheral interface bus. SieMo keeps the previous command word.

figure 26 Example Auto-Increment Operation

24/30

Page 25

SieMo S50037 Data Book PRELIMINARILY

Manufacturing aspects, Handling

The SieMo device is moisture sensitive according to JEDEC / JST Level 4, e.g. should be

stored within Dry Pack until used, and exposed to ambient air of max. 30°C / 60% rel.

Humidity for a maximum of 72h.

As the device is electrostatic sensitive, standard ESD precautions need to be considered

during handling outside shipping container.

Standard Reflow according to JEDEC / JST with a maximum peak temperature of 220 -0 / +5

°C on device top is recommended.

Reference:

http://www.jedec.org

Default packaging consists of up to 5 Trays in one DryPack. Each Tray contains 20pcs of

SieMo. Other Packaging by request.

25/30

Page 26

SieMo S50037 Data Book PRELIMINARILY

Regulatory Statements

General

• This Bluetooth radio module has to be installed and used in accordance with the

technical description/installation instructions provided by the manufacturer.

• This Bluetooth radio module is intended to be placed on the market in all States, where

the Bluetooth

• For detail information concerning type approval of this module (e.g. where this module is

already pre-approved) please contact the authorised local distributor or the manufacturer.

European Union (EU) and EFTA Member States

This Bluetooth module is an assessed radio module in conformity with the R&TTE directive

1999/5/EC and has been provided with the CE mark accordingly.

TM

technology and the used frequency band is released.

It is conform to the following specifications/Standards

∗∗∗∗)

:

Applied specifications/Standards Essential Requirement

(Corresponding article of R&TTE)

EN 300 328 (ETS 300 328): Part 1, V1.1.1 and

Part 2, V1.2.2 (2000-07)

EN 301 489-17 (ETS 300 826): V1.1.1 (2000-09)

EN 300 328 (ETS 300 328): Part 1, V1.1.1 and

Part 2, V1.2.2 (2000-07)

Electromagnetic Compatibility

(Art. 3.1b)

Radio Frequency Spectrum Efficiency

(Art. 3.2)

Note that the radio frequency band used by this equipment is not harmonised throughout

the European Community. According to the R&TTE directive 1999/5/EC is this equipment

a ‘Class 2’ equipment and marked accordingly with the assigned Class Identifier.

CE Conformity Marking:

∗∗∗∗ )

Safety requirement according to the article 3.1a of R&TTE Directive are not applicable on this

Bluetooth radio module, since it is intended to be integrated in final products/applications.

26/30

Page 27

SieMo S50037 Data Book PRELIMINARILY

Because this Bluetooth™ radio module is very small and intended to be integrated/installed

in final products (OEM products/applications) it is not practicable to place the label including

the CE conformity marking on it. Therefore the required labelling information is placed in this

technical description/installation manual of this radio module. However the CE conformity

marking refereed to in R&TTE Directive, Article 12 is displayed on the packaging of the radio

module in an appropriate form.

OEM products/applications, where this Bluetooth™ radio module is integrated/installed in,

has to be labelled in accordance with R&TTE Directive, Article 12.

An auxiliary label is included in the packaging of this radio module, which can be used for

that purpose and has to be permanently affixed to the OEM product/application or to it's data

plate and to it's packaging and to accompanying documents. The label has to be affixed

visibly (label data must be visible from the outside of the equipment enclosure) legibly and

indelibly.

Note that in case of using the provided auxiliary label, additionally following statement has

to be included in the users manual of the final product (OEM product/application):

Note that the radio frequency band used by this equipment is not harmonised throughout the

European Community. According to the R&TTE directive 1999/5/EC is this equipment

a ‘Class 2’ equipment and marked accordingly with the assigned Class Identifier.

United States of America (USA)

This Bluetooth radio module complies with part 15 of the Federal Communications

Commission (FCC) Rules and labelled in accordance with the FCC Rules.

FCC ID: P6L-SieMo-S50037

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Note that any changes or modifications to this equipment not expressly approved by the

manufacturer could void the user’s authority to operate this equipment.

Because this Bluetooth™ radio module is very small and intended to be integrated/installed

in OEM products/applications it is not practicable to place the label including the FCC

statement on it. Therefore the required labelling information is placed in this chapter of the

technical description/installation manual of this radio module. However the FCC identifier is

displayed on the packaging of the radio module in an appropriate form.

OEM products/applications, where this Bluetooth™ radio module is integrated/installed in,

has to be labelled in accordance with FCC Rules (section 15.19 and 47 CFR Ch. I: §2.925,

§2.926).

An auxiliary label is included in the packaging of this radio module, which can be used for

that purpose and has to be permanently affixed to the OEM product/application in a readily

visible (label data must be visible from the outside of the equipment enclosure) manner (e.g.

on an exterior surface of the equipment).

27/30

Page 28

SieMo S50037 Data Book PRELIMINARILY

Note that in case of using the provided auxiliary label, additionally following statement has

to be included in the users manual of the final product (OEM product/application):

This device complies with part 15 of the Federal Communications Commission (FCC) Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Note that any changes or modifications to this equipment not expressly approved by the

manufacturer could void the user’s authority to operate this equipment.

Manufacturer information concerning antenna:

The only antenna(s) approved for use with this Bluetooth™ radio module are those

documented in this construction file, and must be installed in the manner specified therein. In

all other cases, where the second manufacturer/installer desires to use an antenna with this

module that has not been previously approved for use with it, then one of the following

procedures has to be followed in order to ensure the compliance of the new antenna:

1. The Manufacturer of this Bluetooth radio module files a Class II permissive change to

approve the new antenna with the module.

2. The second manufacturer/installer obtains a separate FCC equipment authorisation for

the module and the new antenna.

28/30

Page 29

SieMo S50037 Data Book PRELIMINARILY

Bluetooth-Trademark

is a trademark owned by Bluetooth SIG, Inc., U.S.A, and licensed to

Siemens AG.

This product is a qualified Bluetooth

specifications version 1.1.

TM

product and compliant to the Bluetooth

TM

29/30

Page 30

SieMo S50037 Data Book PRELIMINARILY

Appendix A

List of figures

figure 1 Block Diagram ..........................................................................................................7

figure 3 Modulation spectrum on single channel with PRBS9 Payload, DH1 packet cable loss

(approx. 3dB) not corrected. ......................................................................................... 10

figure 4 Output spectrum with Frequency Hopping measured with MAXHOLD cable loss

(approx. 3dB) not corrected. ......................................................................................... 11

figure 5 output power during a DH5 packet, cable loss (approx. 3dB) not corrected. ........... 11

figure 6 Spurious emission up to 8GHz, green line is with DUT offline. Cable loss not

corrected. ..................................................................................................................... 11

figure 10 SieMo Pinout, bottom view.................................................................................... 13

figure 11 dimmensions......................................................................................................... 15

figure 12 PCM Master Timing .............................................................................................. 17

figure 16 UART Directions ................................................................................................... 19

figure 17 Connection to PC via level converter .................................................................... 20

figure 18 UART TxD signal .................................................................................................. 20

figure 19 data output stopped by handshake input, delay time 84us.................................... 20

figure 20 USB Power Modes- Applications .......................................................................... 22

figure 21 USB Disconnect and Resume Signal Timing ........................................................ 22

figure 22 SPI write operation a............................................................................................ 23

figure 23 SPI write operation b............................................................................................. 23

figure 24 SPI read timing a .................................................................................................. 24

figure 25 SPI read timing b .................................................................................................. 24

figure 26 Example Auto-Increment Operation ...................................................................... 24

30/30

Loading...

Loading...