Page 1

6

6.1

Features

Antenna

Product photo

Limit distance Sg 1)

Dimensions

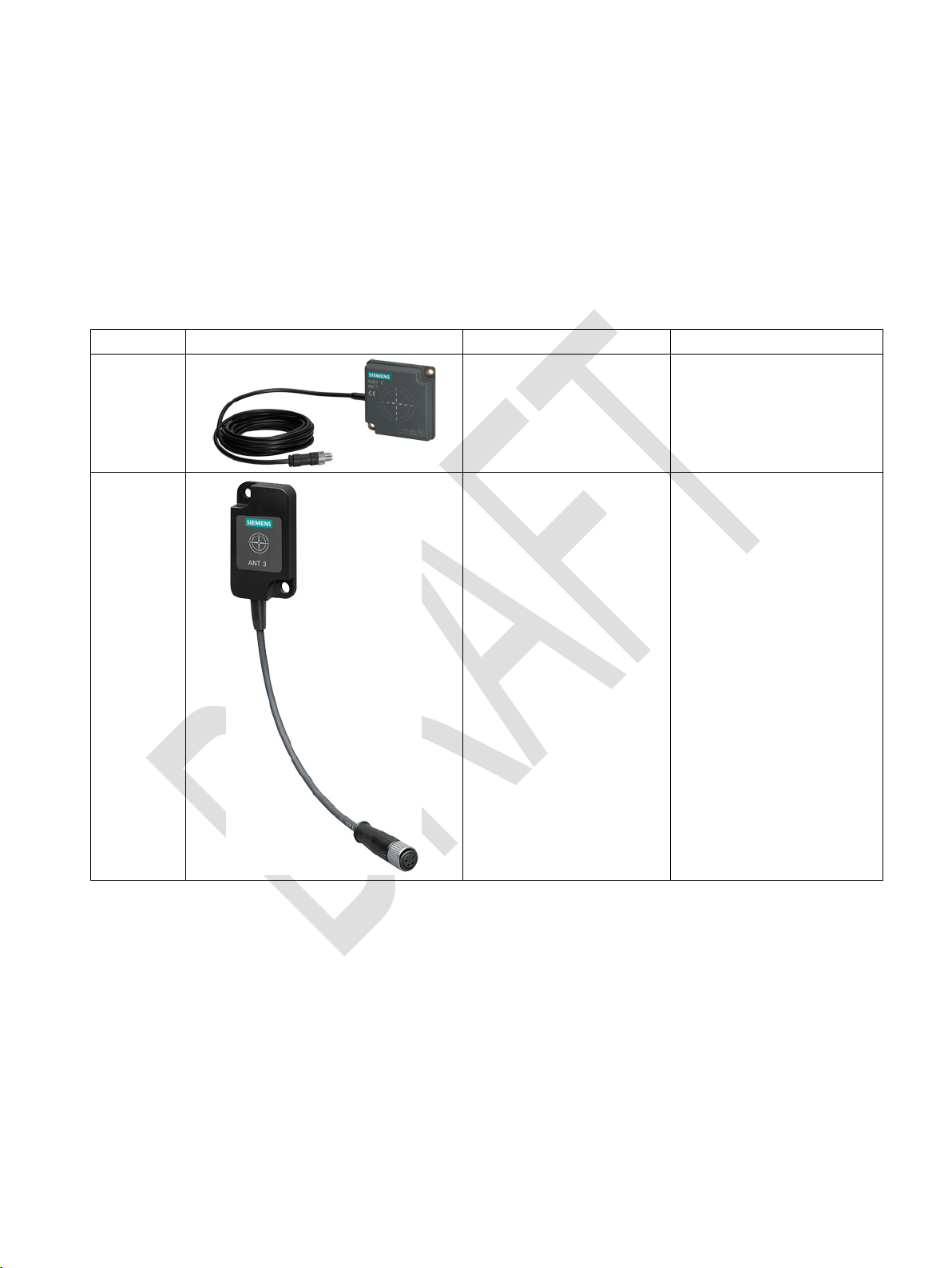

For the RF350R and RF350M readers, you can use the following plug-in antennas:

ANT 1

ANT 3

Up to 140 mm 75 x 75 x 20 mm

(L x W x H)

Up to 50 mm 50 x 75 x 10 mm

(L x W x H)

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

193

Page 2

Antennas

Antenna

Product photo

Limit distance Sg 1)

Dimensions

1)

2)

only released with RF350M und RF350R - second generation

6.1 Features

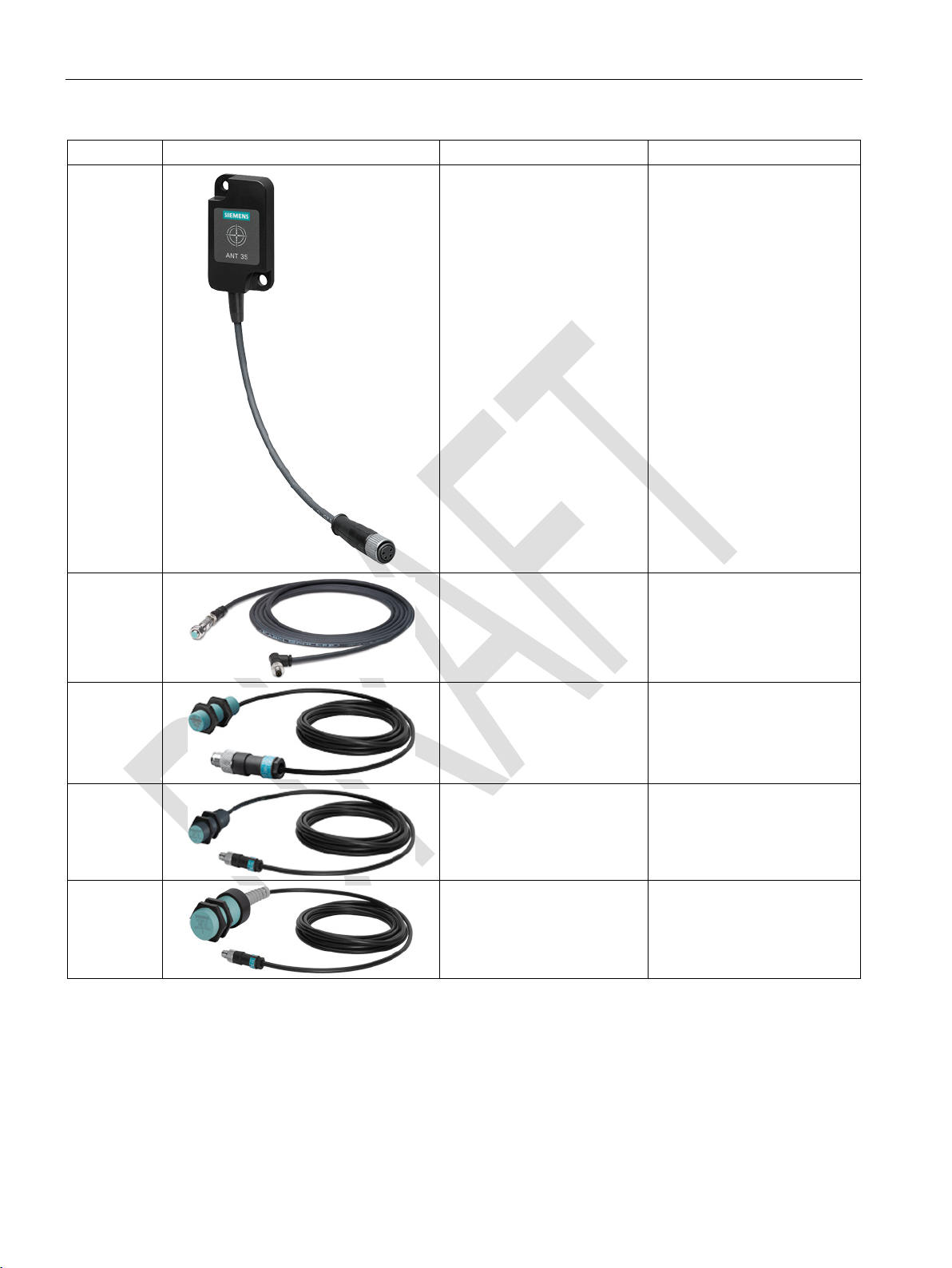

ANT 3S

ANT 8 2)

Up to 5 mm 50 × 28 × 10 mm

(L x W x H)

Up to 4 mm M8 x 1.0 x 39 mm

(∅ x thread x L)

ANT 12

ANT 18

ANT 30

Depending on the transponder used

Up to 16 mm M12 x 1.0 x 40 mm

(∅ x thread x L)

Up to 35 mm M18 x 1.0 x 55 mm

(Ø x thread x L)

Up to 55 mm M30 x 1.5 x 61 mm

(Ø x thread x L)

SIMATIC RF300

194 System Manual, 07/2016, C79000-G8976-C345-0x

Page 3

Antennas

Note

Use of the antennas in hazardous areas

The antennas ANT 1, ANT 12, ANT 18 and ANT 30 are approved for use in hazardous

locations. For more information, refer to the section "

(Page

ANT 1

ANT 3

ANT 3S

ANT 8

ANT 12

ANT 18

6.1 Features

Use of the reader in hazardous areas

149)".

The ANT 1 is an antenna in the mid performance range and can be used to the customer's

advantage in production and assembly lines due to its manageable housing shape. The

antenna dimensions make it possible to read/write large quantities of data dynamically

from/to the transponder during operation. The antenna cable can be connected at the reader

end.

The ANT 3 is designed for use in small assembly lines. The extremely compact design of the

antenna allows extremely accurate positioning. The antenna cable can be connected at the

reader end.

The ANT 3S is designed for use in small assembly lines. The extremely compact design of

the antenna allows extremely accurate positioning even with small transponders. The

antenna cable can be connected at the reader end.

The ANT 8 is primarily envisaged for tool identification applications. The extremely small

design of the antenna allows extremely accurate positioning. The antenna cable can be

connected at the reader end and screwed to the antenna.

The antenna ANT 8 has currently only been tested and released for use in conjunction with

the mobile reader RF350M and the reader RF350R - second generation.

The ANT 12 is primarily envisaged for tool identification applications. The very small size of

the antenna means that highly exact positioning is possible using the plastic nuts included in

the scope of delivery. The antenna cable can be connected at the reader end.

The ANT 18 is designed for use in small assembly lines. Due to its small, compact

construction, the antenna can be easily positioned for any application using two plastic nuts

(included in the package). The antenna cable can be connected at the reader end.

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

195

Page 4

Antennas

ANT 30

6.2

Ordering data

Article number

ANT 1

incl. integrated antenna cable 3 m

6GT2398-1CB00

incl. plug-in antenna cable 3 m

6GT2398-1CD40-0AX0

without antenna connecting cable

6GT2398-1CD50-0AX0

incl. plug-in antenna cable 3 m

6GT2398-1CD60-0AX0

without antenna connecting cable

6GT2398-1CF00

incl. plug-in antenna cable 3 m

6GT2398-1CF10

ANT 12

incl. plug-in antenna cable 3 m

6GT2398-1CC00

ANT 18

incl. plug-in antenna cable 3 m

6GT2398-1CA00

ANT 30

incl. plug-in antenna cable 3 m

6GT2398-1CD00

Article number

Antenna connecting cable

3 m

6GT2398-0AH30

6.3

Ensuring reliable data exchange

6.2 Ordering data

The ANT 30 is designed for use in small assembly lines. In comparison to ANT 18, the

maximum write/read distance is approximately 60 % larger. Due to its compact construction,

the antenna can be easily positioned for any application using two plastic nuts (included in

the package). The antenna cable can be connected at the reader end.

Table 6- 1 Ordering data for antennas

ANT 3 without antenna connecting cable 6GT2398-1CD30-0AX0

ANT 3S

ANT 8

Table 6- 2 Antenna accessories ordering data

The "center point" of the transponder must be situated within the transmission window.

SIMATIC RF300

196 System Manual, 07/2016, C79000-G8976-C345-0x

Page 5

Antennas

6.4

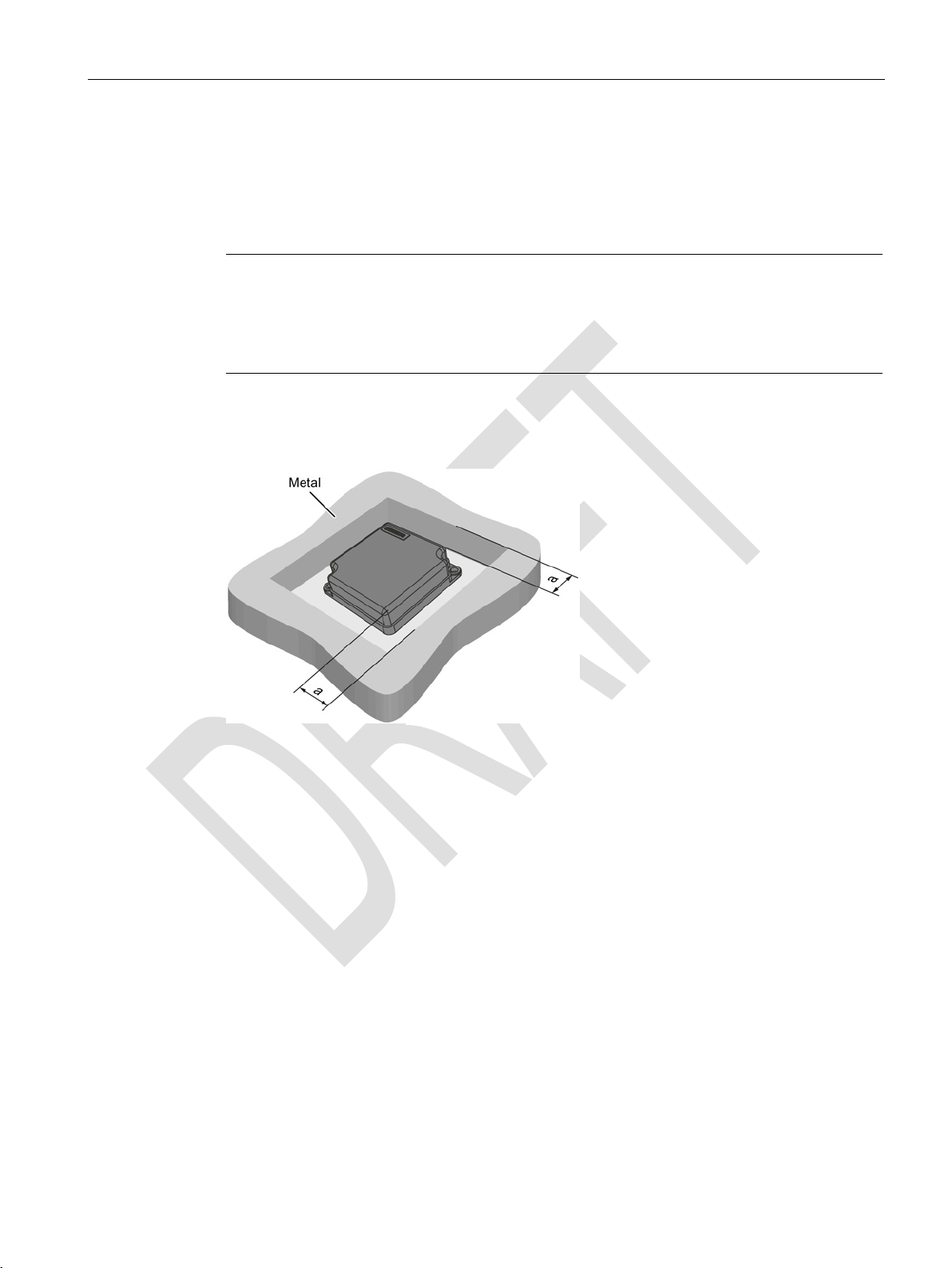

Metal-free area

Note

Reduction of range if the metal-free space is not maintained

At values lower than a and b, the field data changes significantly, resulting in a reduction in

the limit distance a

minimum distances (a and b) on/flush with the metal.

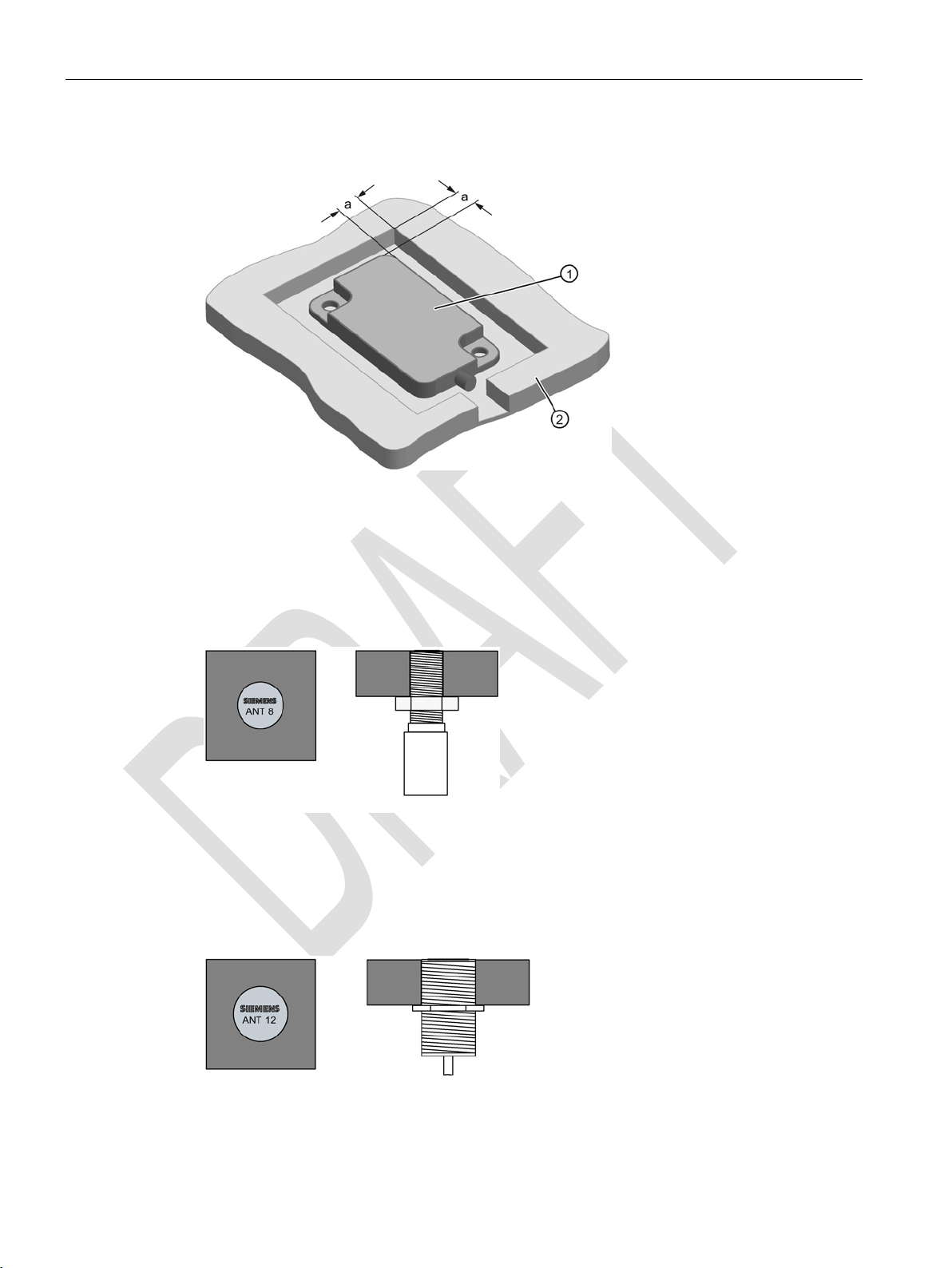

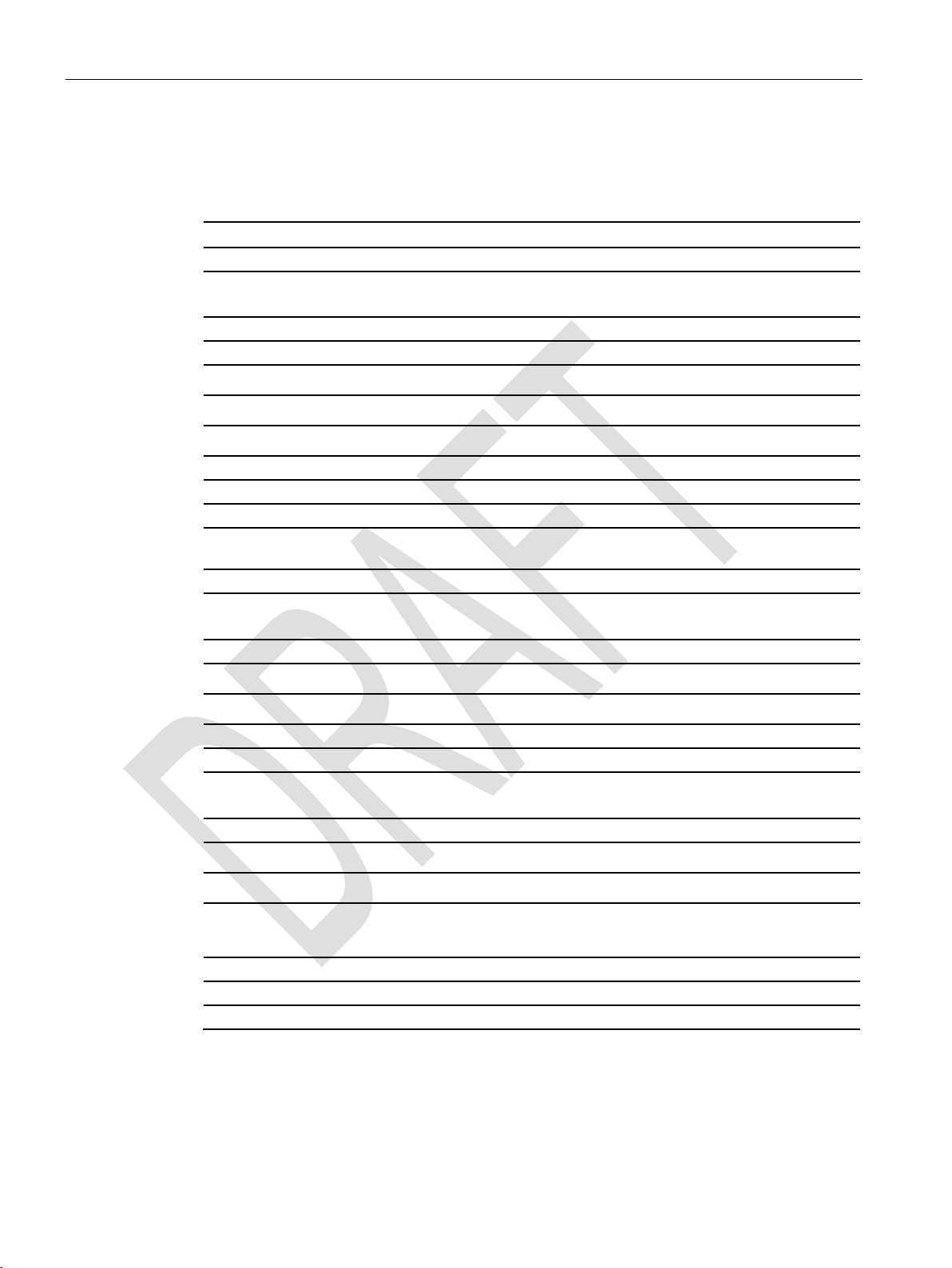

Metal-free space for flush-mounted installation of ANT 1

a =

40 mm

6.4 Metal-free area

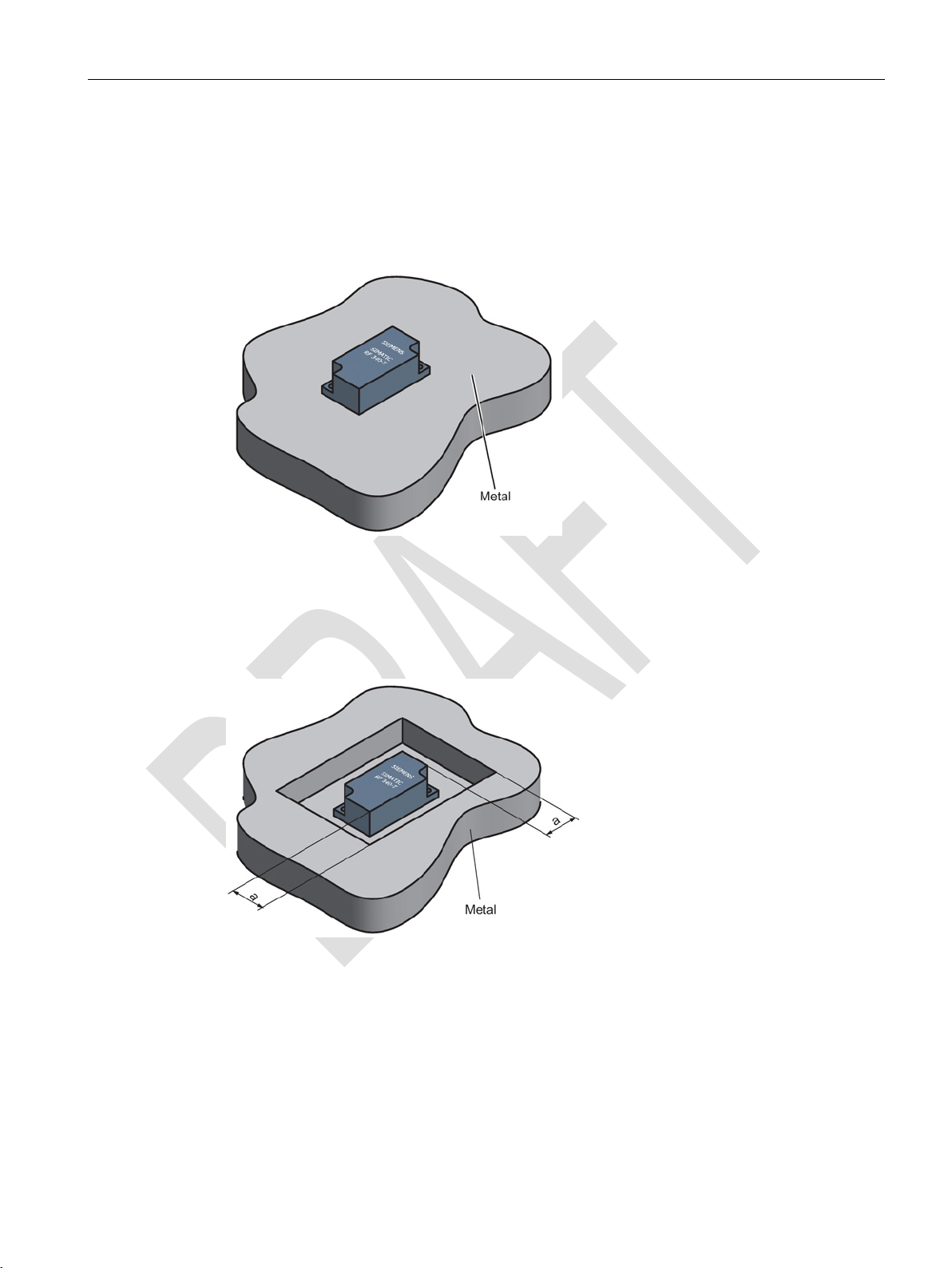

The antennas ANT 1, ANT 8, ANT 12, ANT 18 and ANT 30 can be flush-mounted in metal.

Please allow for a possible reduction in the field data values. During installation, maintain the

minimum distances (a and b) on/flush with the metal.

nd operating distance. Therefore, during installation, maintain the

Figure 6-1 ANT 1 flush-mounted in metal

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

197

Page 6

Antennas

Metal-free space for flush-mounted installation of ANT 3 and ANT 3S

①

ANT 3

②

Metal

a

= 10 mm

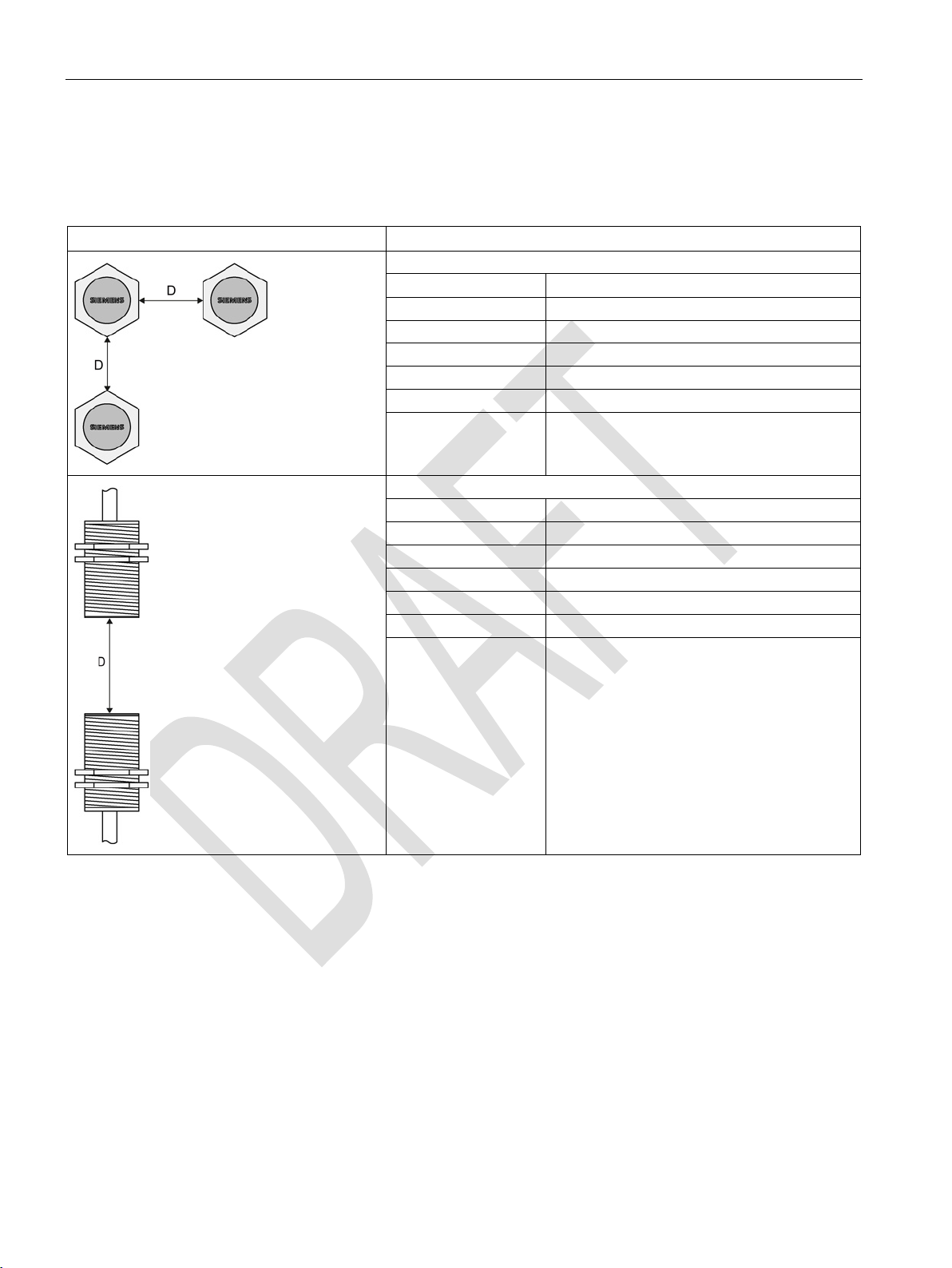

Flush-mounting of ANT 8

Flush-mounting of ANT 12

6.4 Metal-free area

Figure 6-2 ANT 3 and ANT 3S flush-mounted in metal

Figure 6-3 ANT 8 flush-mounted in metal

The ANT 8 can be flush-mounted in metal.

Figure 6-4 ANT 12 flush-mounted in metal

The ANT 12 can be flush-mounted in metal.

SIMATIC RF300

198 System Manual, 07/2016, C79000-G8976-C345-0x

Page 7

Antennas

Metal-free space for flush-mounted installation of ANT 18

a =

10 mm

b =

10 mm

Metal-free space for flush-mounted installation of ANT 30

a =

20 mm

b =

20 mm

6.4 Metal-free area

Figure 6-5 ANT 18 flush-mounted in metal

Figure 6-6 ANT 30 flush-mounted in metal

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

199

Page 8

Antennas

6.5

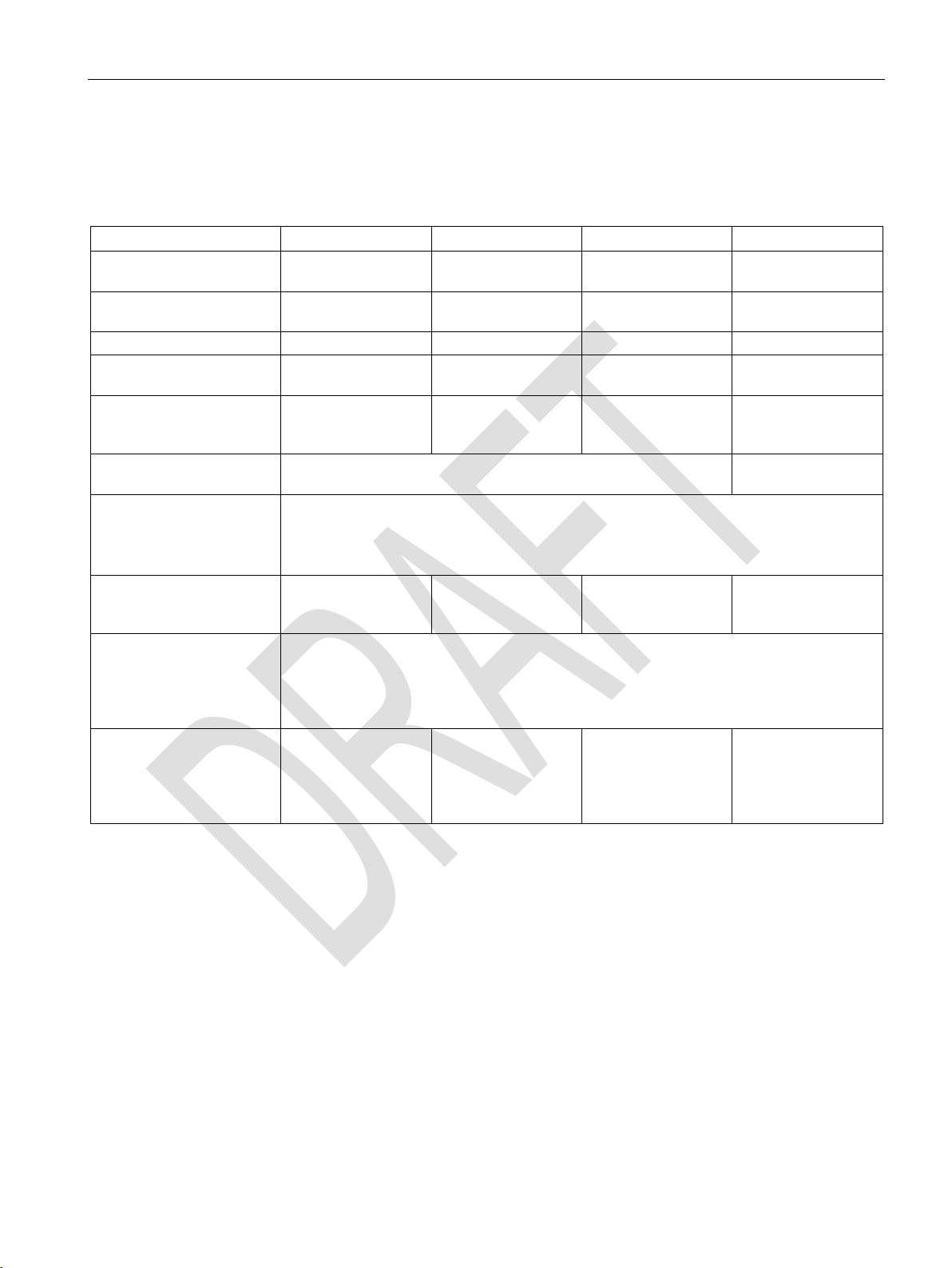

Minimum distance between antennas

Diagram (example)

Minimum distance [mm]

Antennas next to each other

ANT 3

D ≥ 80 mm

ANT 8

D ≥ 50 mm

ANT 12

D ≥ 70 mm

ANT 18

D ≥ 100 mm

Antennas face to face

ANT 1

D ≥ 500 mm

ANT 3

D ≥ 100 mm

ANT 3S

D ≥ 50 mm

ANT 8

D ≥ 50 mm

ANT 12

D ≥ 100 mm

ANT 18

D ≥ 100 mm

6.5 Minimum distance between antennas

Table 6- 3 Minimum distance between antennas

ANT 1 D ≥ 100 mm

ANT 3S D ≥ 20 mm

ANT 30 D ≥ 100 mm

ANT 30 D ≥ 200 mm

The reader electronics can be mounted directly alongside each other.

SIMATIC RF300

200 System Manual, 07/2016, C79000-G8976-C345-0x

Page 9

Antennas

6.6

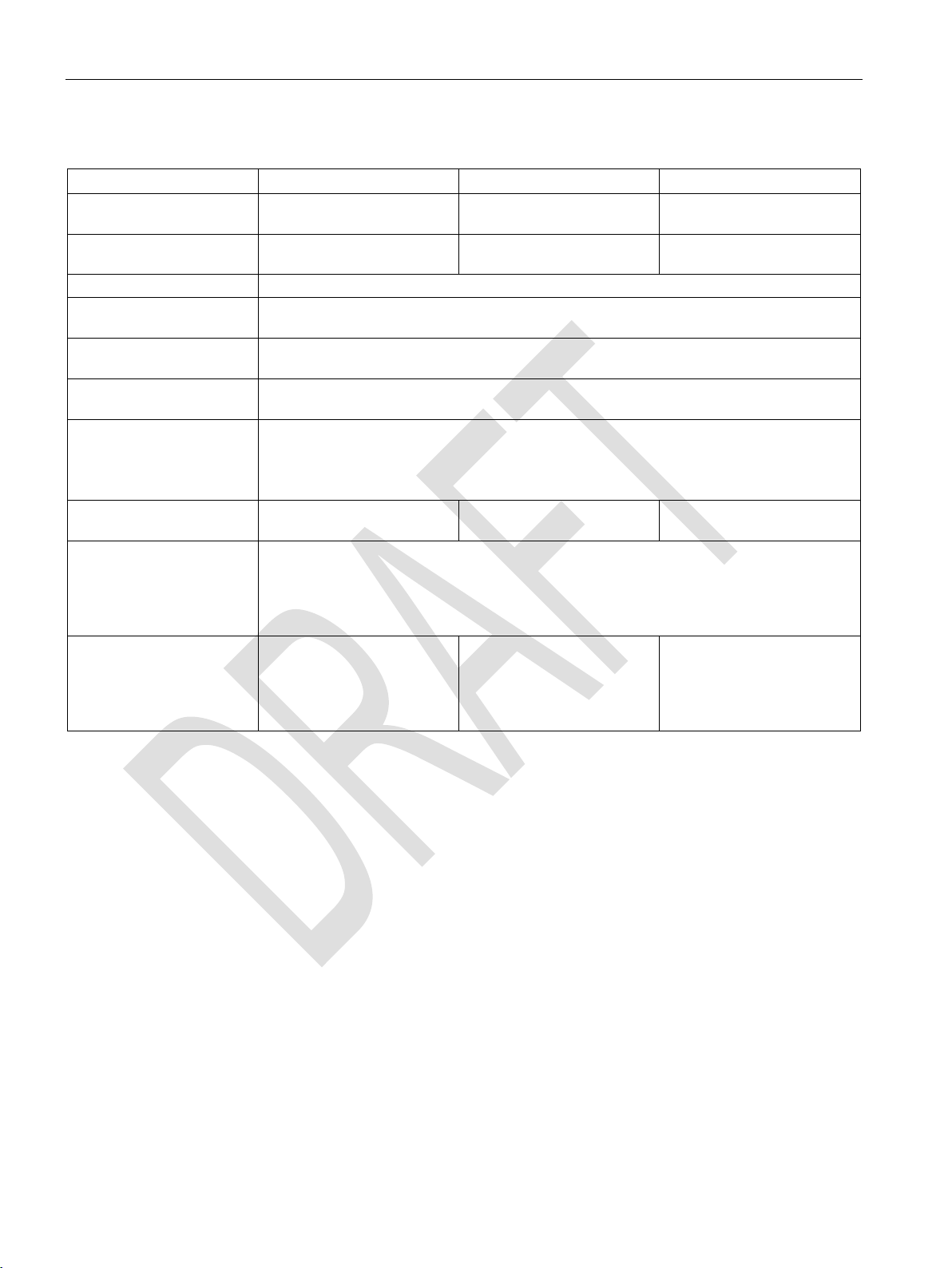

Technical specifications

ANT 1

ANT 3

ANT 3S

ANT 8

antenna ↔ transponder (Sg)

Color

Anthracite

Black

Black

silver-metallic

PA 12

PA6-V0

PA6-V0

side)

side

side

side)

60529

EN 60721-3-7, Class 7M2

20 g (3 to 50 Hz) 1)

M8 x 1.0 mm

1)

Warning: The values for shock and vibration are maximum values and must not be applied continuously.

6.6 Technical specifications

Table 6- 4 Technical specifications of the antennas ANT 1, ANT 3 , ANT 3S and ANT 8

Max. write/read distance

Housing dimensions 75 x 75 x 20 mm

Material Plastic

Plug connection M8, 4-pin;

Degree of protection to EN

Shock-resistant acc. to

EN 60721-3-7, Class 7M2

Vibration-resistant to

Attachment of the antenna 2 x M5 screws 2 x M4 screws 2 x M4 screws 2x stainless steel

Ambient temperature

• During operation

• During transportation

and storage

Weight, approx.

• without antenna cable

• with antenna cable

(3.0 m)

140 mm 50 mm 5 mm 4 mm

(L x W x H)

(pins on antenna

1)

50 g

• -25 ℃ ... +70 ℃

• -40 °C ... +85 °C

• --

• 225 g

50 x 28 x 10 mm

(L x W x H)

Plastic

M8, 4-pin;

socket on antenna

IP67 IP67 (front)

• 35 g

• 160 g

50 x 28 x 10 mm

(L x W x H)

Plastic

M8, 4-pin;

socket on antenna

• 35 g

• 160 g

M8 x 1.0 x 39 mm

(Ø x thread x L)

Stainless steel

M8, 4-pin;

(pins on antenna

nuts

• 10 g

• 140 g

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

201

Page 10

Antennas

ANT 12

ANT 18

ANT 30

antenna ↔ transponder (Sg)

Color

Pale turquoise

Crastin

(pins on antenna side)

60529

EN 60721-3-7, Class 7M2

20 g (3 to 50 Hz) 1)

M12 x 1.0 mm

M18 x 1.0 mm

M30 x 1.5 mm

1)

Warning: The values for shock and vibration are maximum values and must not be applied continuously.

6.6 Technical specifications

Table 6- 5 Technical specifications of the antennas ANT 12, ANT 18 and ANT 30

Max. write/read distance

Housing dimensions M12 x 1.0 x 40 mm

16 mm 35 mm 55 mm

M18 x 1.0 x 55 mm

(Ø x thread x L)

(Ø x thread x L)

Material Plastic

Plug connection M8, 4-pin;

Degree of protection to EN

Shock-resistant acc. to

EN 60721-3-7, Class 7M2

Vibration-resistant to

50 g

1)

Attachment of the antenna 2 plastic nuts

Ambient temperature

• During operation

• During transportation

• -25 ℃ to +70 ℃

• -40 ℃ to +85 ℃

IP67 (front)

2 plastic nuts

and storage

Approx. weight

• without antenna cable

• with antenna cable

• --

• 145 g

• --

• 130 g

(3.0 m)

M30 x 1.5 x 61 mm

(Ø x thread x L)

2 plastic nuts

• --

• 180 g

SIMATIC RF300

202 System Manual, 07/2016, C79000-G8976-C345-0x

Page 11

Antennas

6.7

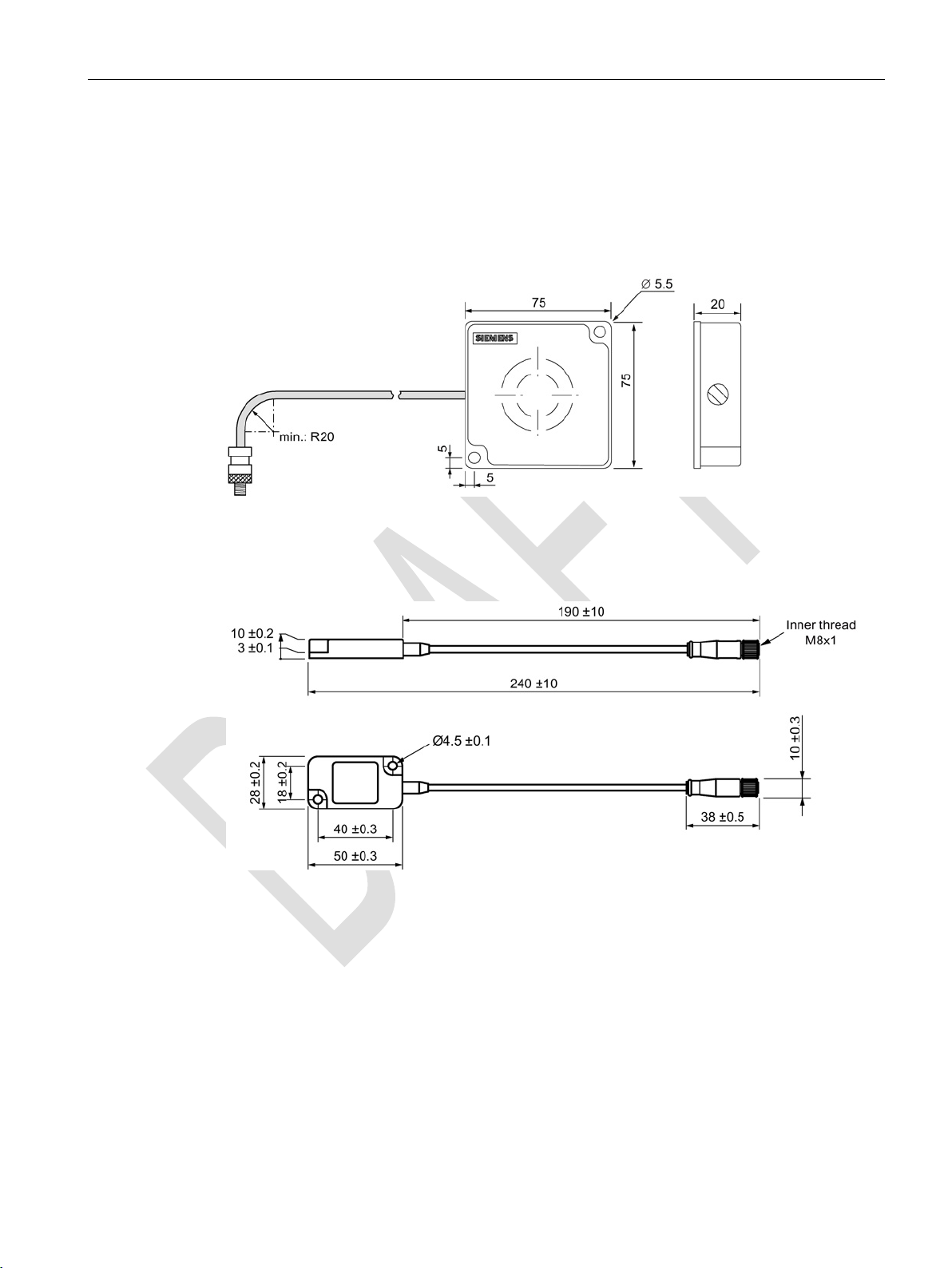

Dimensional drawings

ANT 1

ANT 3 / ANT 3S

6.7 Dimensional drawings

The cable length is 3 m. All dimensions are in mm.

Figure 6-7 Dimension drawing for ANT 1

Figure 6-8 Dimension drawing ANT 3 7 ANT 3S

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

203

Page 12

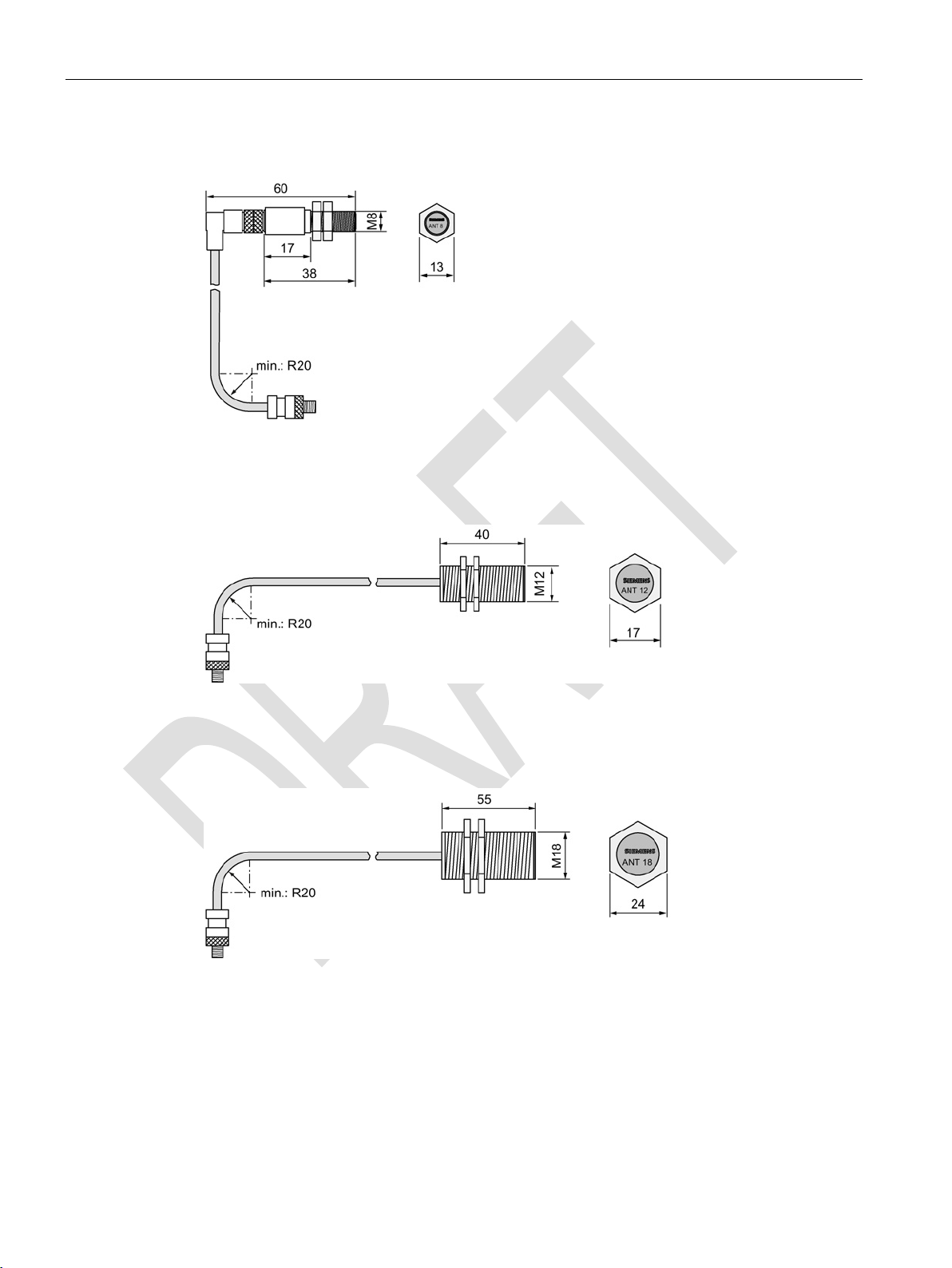

Antennas

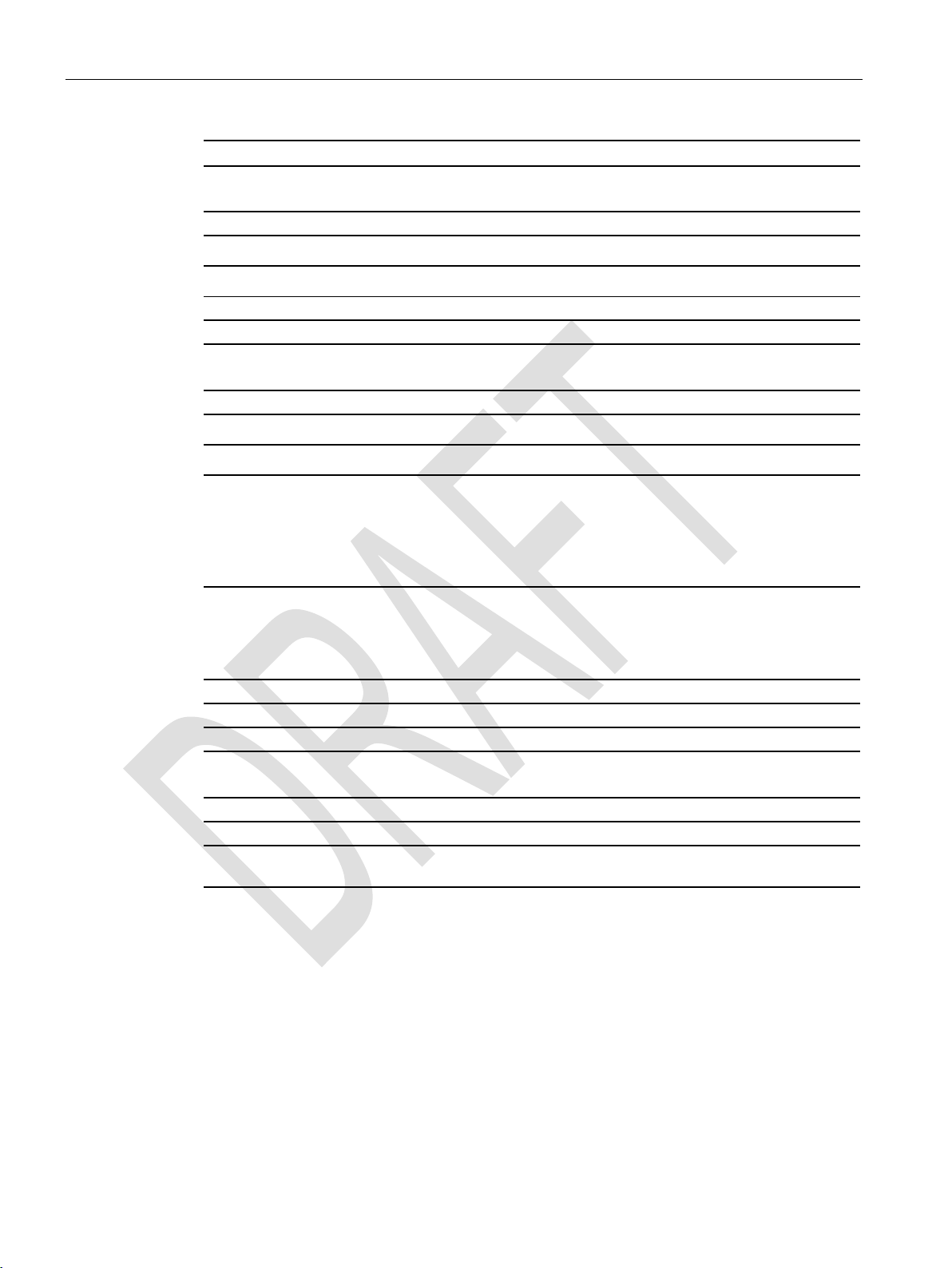

ANT 8

ANT 12

ANT 18

6.7 Dimensional drawings

Figure 6-9 Dimension drawing for ANT 8

Figure 6-10 Dimension drawing for ANT 12

Figure 6-11 Dimension drawing for ANT 18

SIMATIC RF300

204 System Manual, 07/2016, C79000-G8976-C345-0x

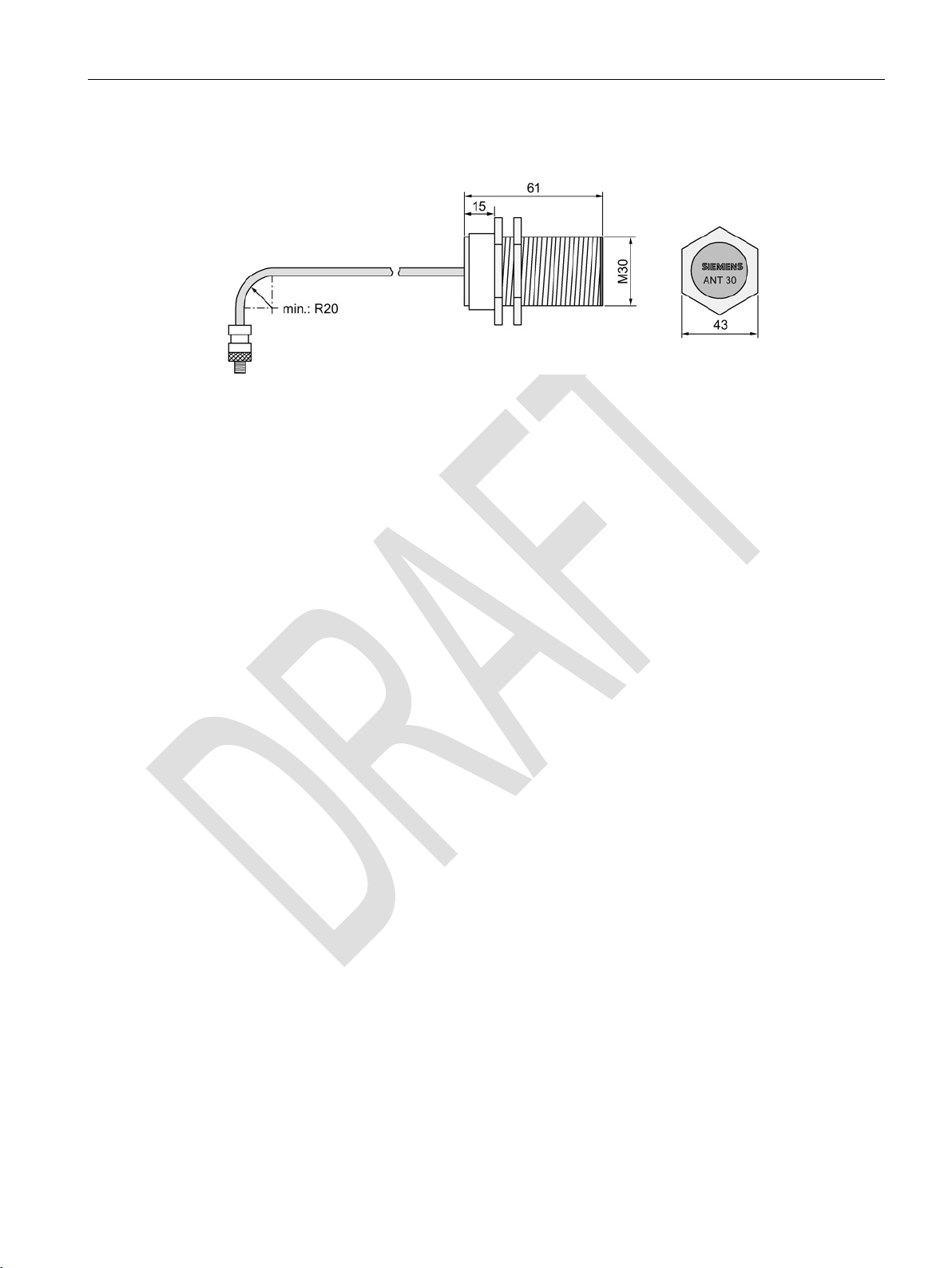

Page 13

Antennas

ANT 30

6.7 Dimensional drawings

Figure 6-12 Dimension drawing for ANT 30

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

205

Page 14

Antennas

6.7 Dimensional drawings

SIMATIC RF300

206 System Manual, 07/2016, C79000-G8976-C345-0x

Page 15

7

Features of the RF300 transponders

The RF300 transponders (RF3xxT) stand out particularly for their extremely fast data

exchange with the RF300 readers (RF3xxR). With the exception of the RF320T transponder,

all of the RF300 transponders have 8 to 64 KB of FRAM memory, which has an almost

unlimited capacity for reading and writing.

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

207

Page 16

RF300 transponder

7.1

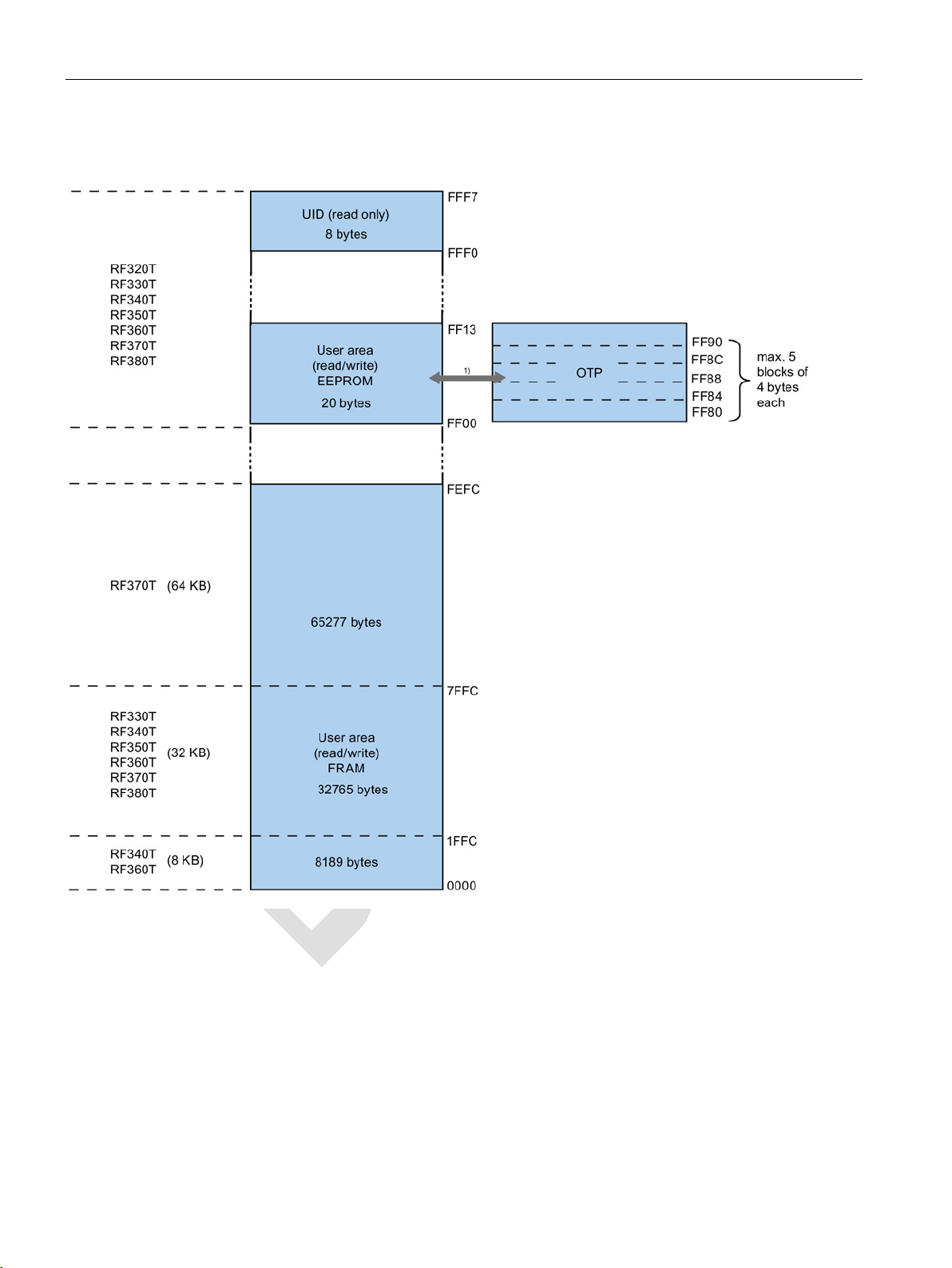

Memory configuration of the RF300 transponders

be modified (read only).

7.1 Memory configuration of the RF300 transponders

1)

Figure 7-1 Memory configuration of the RF300 transponders

SIMATIC RF300

208 System Manual, 07/2016, C79000-G8976-C345-0x

Physically identical memory When the OTP area is used, the corresponding user area (FF00-FF13) can no longer

Page 17

RF300 transponder

EEPROM area

Note

Write speed

The EEPROM user memory (address FF00

time for writing (approx. 11 ms/byte) than the high

applications with write functions, it is advisable to use FRAM transpond

RF340T, RF350T, RF360T, RF370T, RF380T).

FRAM area

OTP area

Note

Seamless use of the OTP area

When the OTP area is used, it must be ensured that the blocks are used starting from Block

0 consecutively.

Examples:

•

•

•

•

7.1 Memory configuration of the RF300 transponders

The memory configuration of an RF300 transponder always comprises an EEPROM that has

20 bytes for user data (read/write) and a 4-byte unique serial number (UID, read only). For

reasons of standardization, the UID is transferred as an 8 byte value through a read

command to address FFF0 with a length of 8. The unused 4 high bytes are filled with zeros.

-FF13, or FF80-FF90) requires significantly more

-speed FRAM memory. For time-critical

ers (e.g. RF330T,

Depending on the tag type, high-speed FRAM memory is available. (8 KB, 32 KB, 64 KB).

This area does not exist for the RF320T.

In the case of RF3xxT transponders with FRAM memory, the data carrier initialization

command (INIT) is only effective on this memory area but not on the EEPROM area (FF00FF13).

The EEPROM memory area (address FF00-FF13) can also be used as a so-called "OTP"

memory (One Time Programmable). The 5 block addresses FF80, FF84, FF88, FF8C and

FF90 are used for this purpose. A write command to this block address with a valid length (4,

8, 12, 16, 20 depending on the block address) protects the written data from subsequent

overwriting.

3 blocks (with write command), Block 0, 1, 2 (FF80, length = 12): valid

2 blocks (consecutive), Block 0 (FF80, length =4), Block 1 (FF84, length = 4): valid

2 blocks (consecutive), Block 0 (FF80, length =4), Block 2 (FF88, length = 4): Invalid

1 Block, Block 4 (FF90, length = 4): Invalid

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

209

Page 18

RF300 transponder

Note

Use of the OTP area is not reversible

If you use the OPT area, you cannot undo i

once.

7.1 Memory configuration of the RF300 transponders

t, because the OPT area can only be written to

SIMATIC RF300

210 System Manual, 07/2016, C79000-G8976-C345-0x

Page 19

RF300 transponder

7.2

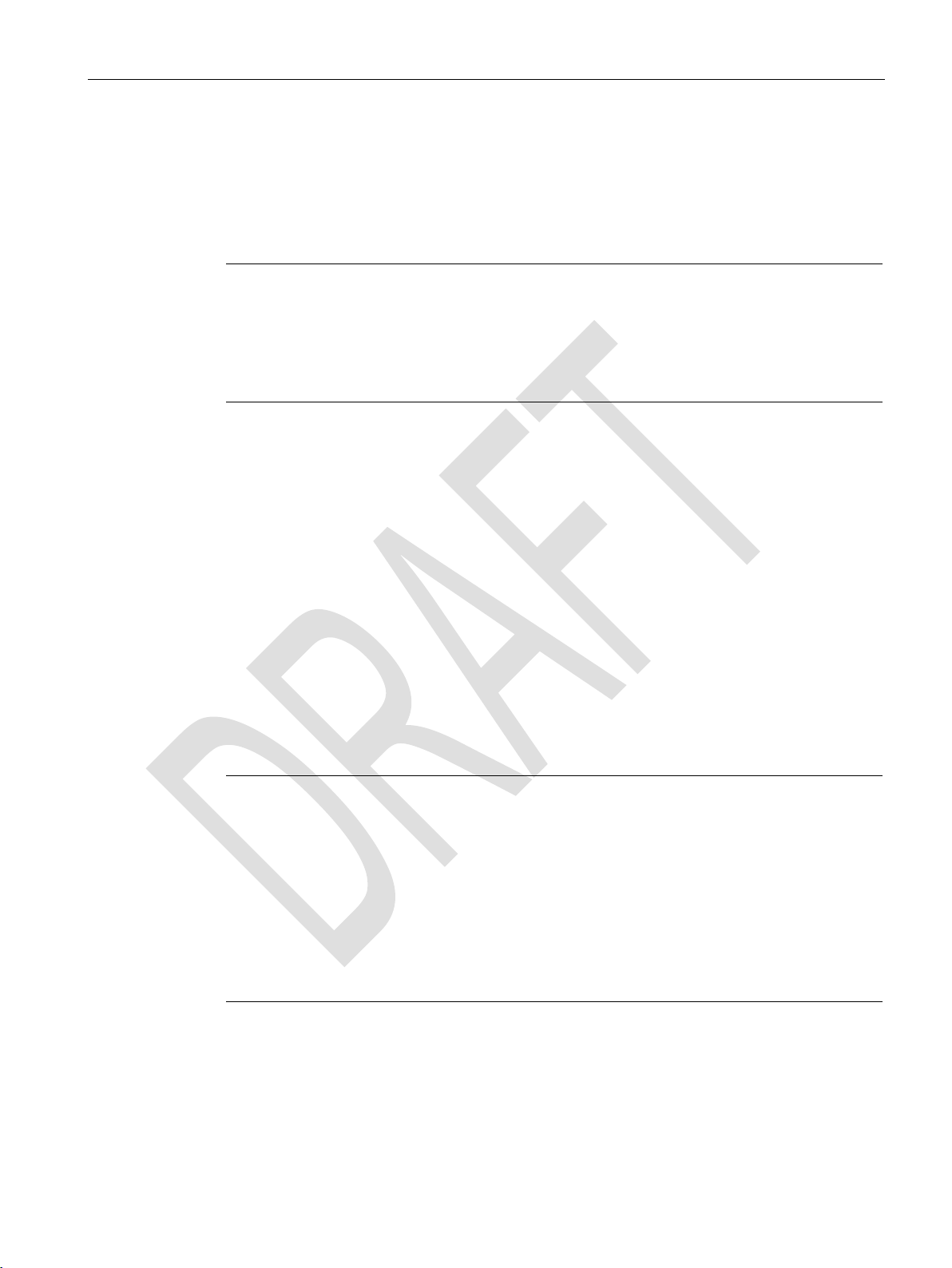

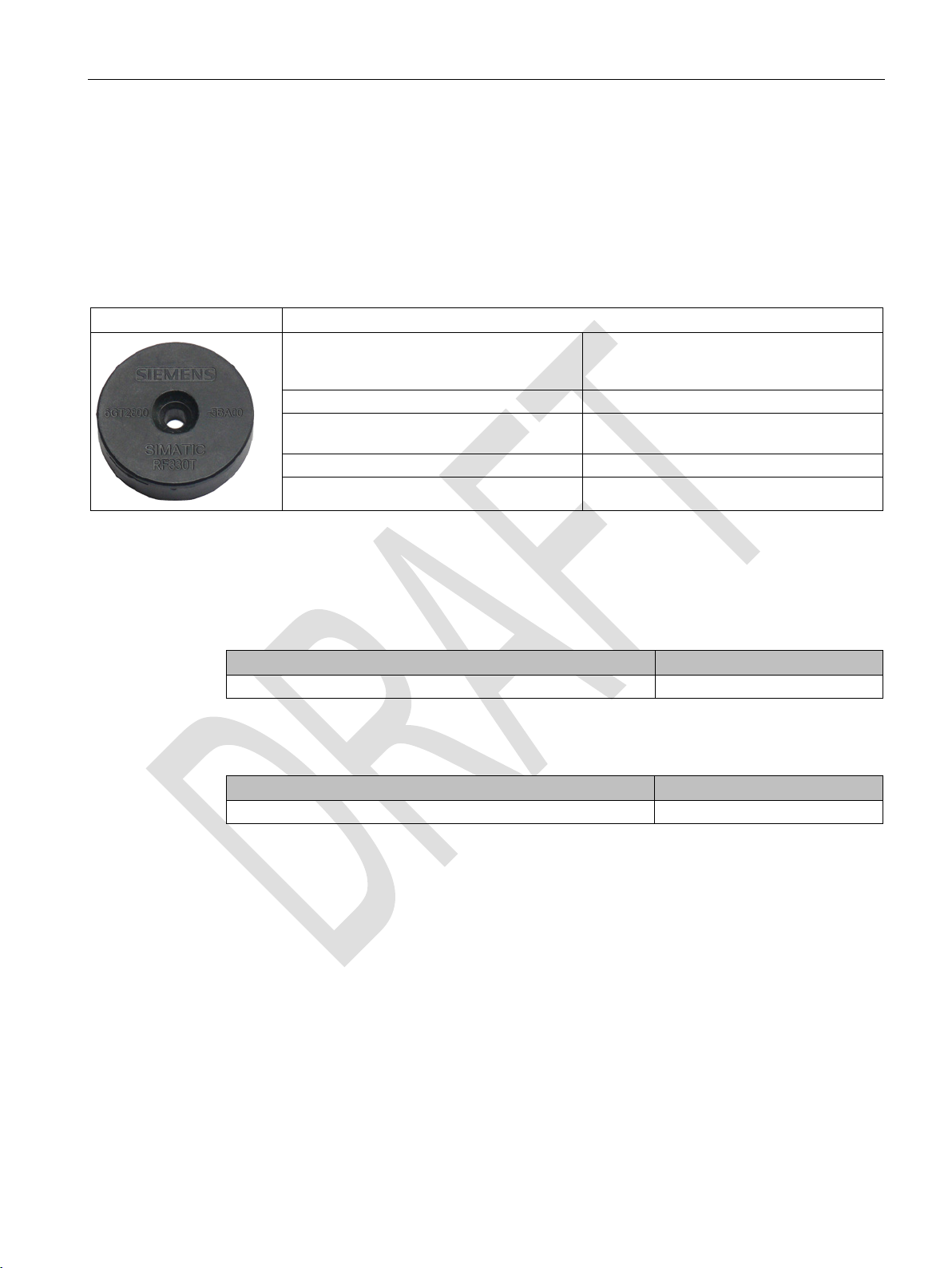

SIMATIC RF320T

7.2.1

Features

RF320T

Characteristics

industrial environments

Memory size

20 bytes of EEPROM user memory

(Page 49)

Mounting on metal

Yes, with spacer

Degree of protection

IP67/IPx9K

7.2.2

Ordering data

Article number

RF320T

6GT2800-1CA00

Article number

Spacer

6GT2690-0AK00

7.2 SIMATIC RF320T

Area of application

Write/read range See section Field data of RF300 transponders

Table 7- 1 Ordering data RF320T

Table 7- 2 Ordering data for RF320T accessories

Identification tasks on small assembly lines in harsh

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

211

Page 20

RF300 transponder

7.2.3

Mounting on metal

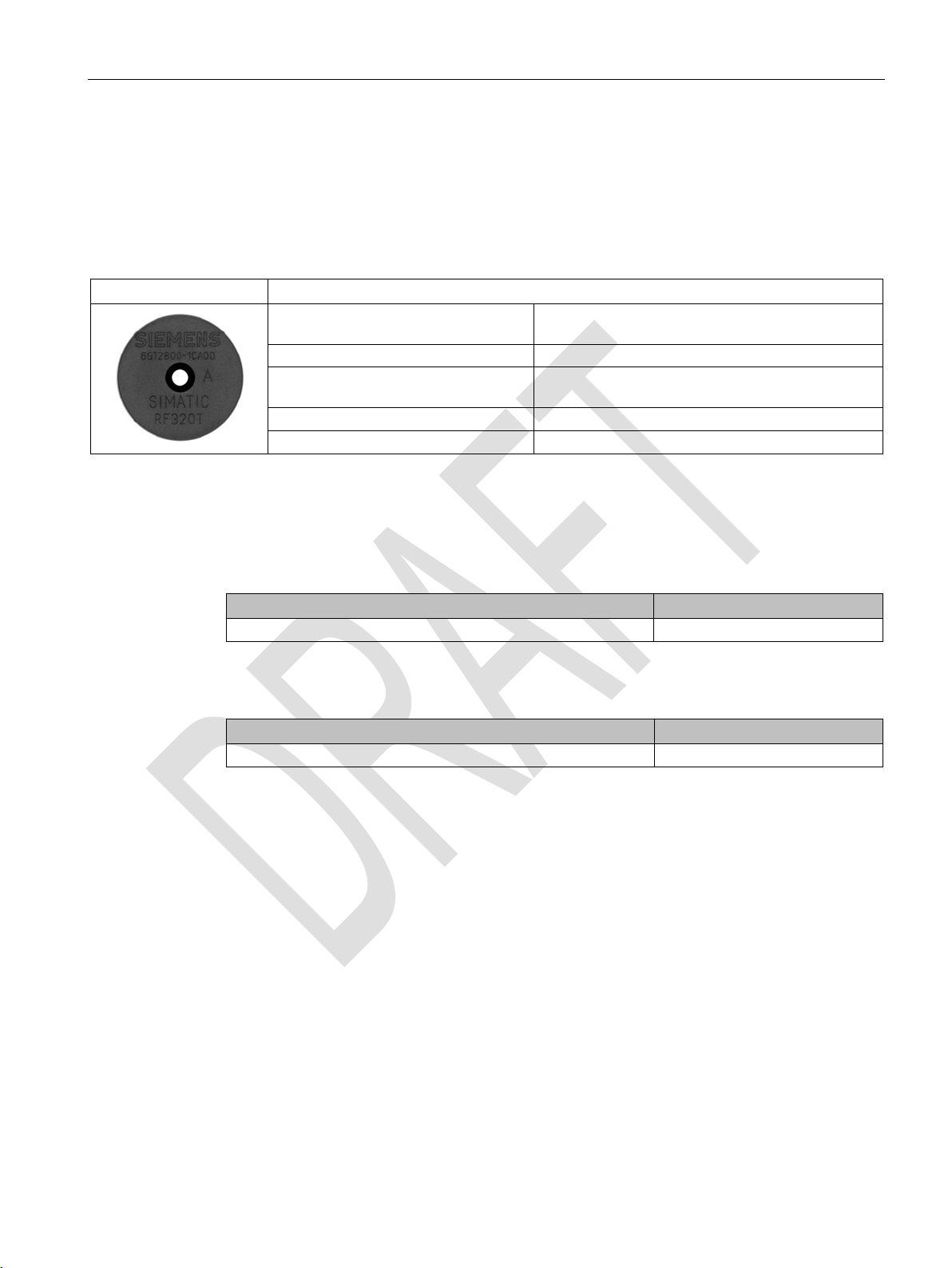

Mounting on metal

h

≥ 15 mm

Flush-mounting

h

≥ 15 mm

a

≥ 25 mm

7.2 SIMATIC RF320T

Figure 7-2 Mounting the MDS D124/D324/D424/D524/E624 and RF320T on metal with spacer

Figure 7-3 Flush-mounting of the MDS D124/D324/D424/D524/E624 and RF320T in metal with

spacer

SIMATIC RF300

212 System Manual, 07/2016, C79000-G8976-C345-0x

Page 21

RF300 transponder

Note

Going below the distances

If the distances (a and h) are not observed, a reduction of the field data results. It is possible

to mount the MDS with metal screws (M3 countersunk head screws). This has no tangible

impact on the range.

7.2.4

Technical data

6GT2800-1CA00

Product type designation

SIMATIC RF320T

Memory

blocks

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 105

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1800 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 20 mm

Power supply

Inductive, without battery

7.2 SIMATIC RF320T

Table 7- 3 Technical specifications for RF320T

Memory organization Byte-oriented, write protection possible in 4-byte

• UID • 4 bytes EEPROM

• User memory • 20 bytes EEPROM

• OPT memory • 20 bytes EEPROM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Black

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

213

Page 22

RF300 transponder

6GT2800-1CA00

Permitted ambient conditions

Ambient temperature

Shock-resistant to EN 60721-3-7, Class 7 M3

100 g 1)

Vibration-resistant to EN 60721-3-7, Class 7 M3

20 g 1)

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

27 x 4 mm

Weight

5 g

1)

2

) To prevent it loosening during operation, secure the screw with screw locking varnish.

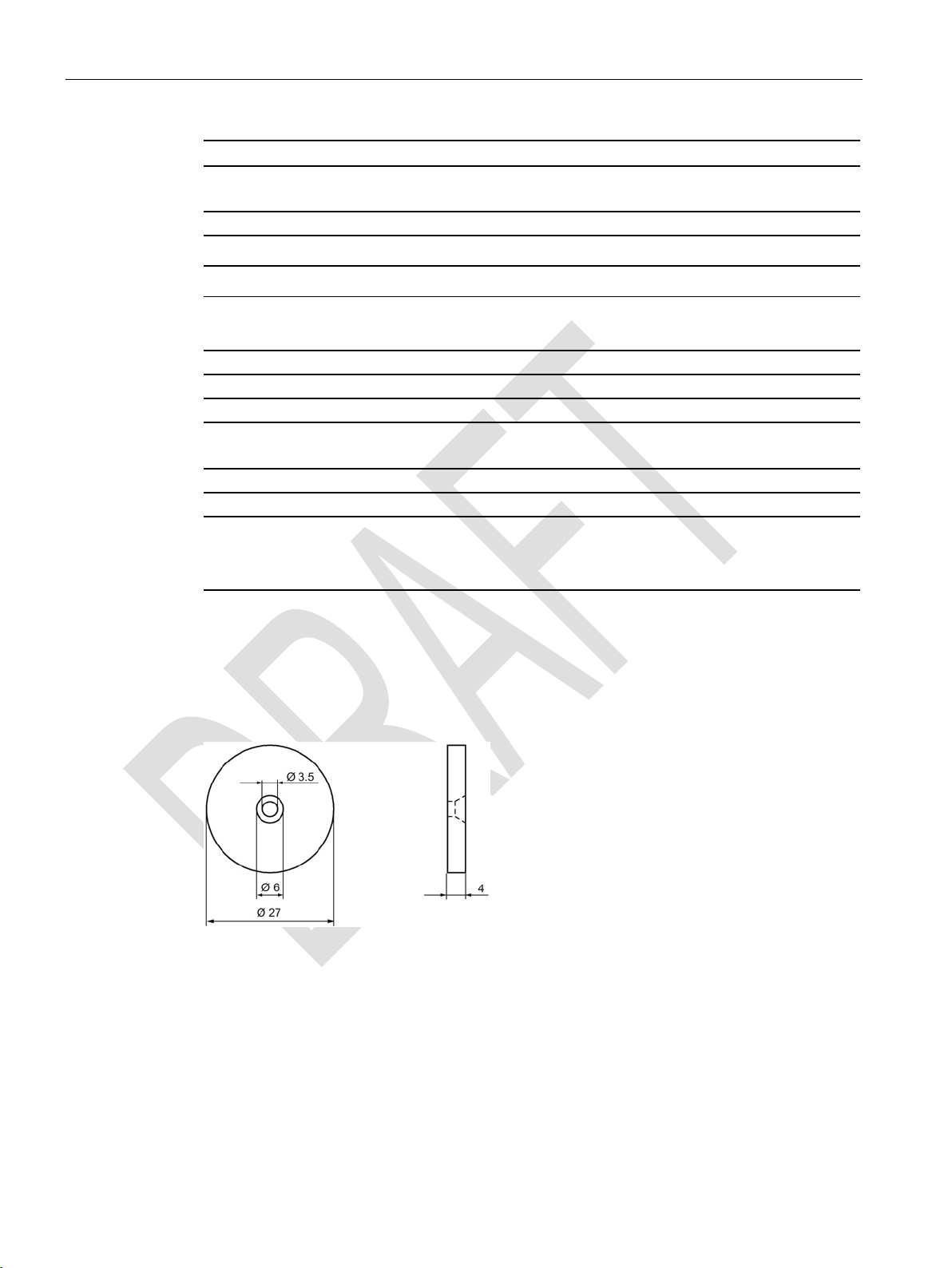

7.2.5

Dimension drawing

7.2 SIMATIC RF320T

• During operation • -25 to +125 ℃

• During transportation and storage • -40 to +140 ℃

Degree of protection to EN 60529

Type of mounting

The values for shock and vibration are maximum values and must not be applied continuously.

• IP67

• IPx9K

• 1 x M3 screw

≤ 1.0 Nm

• Glued

2)

Figure 7-4 RF320T dimension drawing

Dimensions in mm

SIMATIC RF300

214 System Manual, 07/2016, C79000-G8976-C345-0x

Page 23

RF300 transponder

7.3

SIMATIC RF330T

7.3.1

Features

RF330T

Characteristics

containers.

ers (Page 49)"

Mounting on metal

Yes flush mounted on/in metal

7.3.2

Ordering data

Article number

RF330T

6GT2800-5BA00

Article number

Fixing hood RF330T / MDS D423

6GT2690-0EA00

7.3 SIMATIC RF330T

Table 7- 4

Area of application

Memory size 32 KB EEPROM user memory

Write/read range See section "Field data of RF300 transpond-

Degree of protection IP68/IPx9K

Table 7- 5 Ordering data RF330T

Table 7- 6 Ordering data for RF330T accessories

In production automation for identification of

metallic workpiece holders, workpieces or

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

215

Page 24

RF300 transponder

7.3.3

Mounting on/in metal

Mounting of the RF330T on metal

Flush-mounting of RF330T in metal

a

≥ 10 mm

7.3 SIMATIC RF330T

Direct mounting of the RF330T on metal is permitted.

Figure 7-5 Mounting of the RF330T on metal

Figure 7-6 Mounting of the RF330T in metal with 10 mm clearance

SIMATIC RF300

216 System Manual, 07/2016, C79000-G8976-C345-0x

Page 25

RF300 transponder

Note

Reduction of the write/read range

Note that when the device is flush

mm, the write/read range is significantly reduced.

7.3.4

Technical specifications

6GT2800-5BA00

Product type designation

SIMATIC RF330T

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1200 years

7.3 SIMATIC RF330T

Figure 7-7 Mounting of the RF330T in metal without clearance

-mounted in metal without a surrounding clearance ≥ 10

Table 7- 7 RF330T technical specifications

Memory organization in bytes

• UID • 4 bytes EEPROM

• User memory • 8 KB FRAM

• OPT memory • 20 bytes EEPROM

Write cycles (at < 40 ℃) > 1014

Write/read distance (Sg) Dependent on the reader used, see section "Field

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

217

Page 26

RF300 transponder

6GT2800-5BA00

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

Shock-resistant to EN 60721-3-7, Class 7 M3

50 g 1)

Vibration-resistant to EN 60721-3-7, Class 7 M3

20 g 1)

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

30 x 8 mm

Weight

10 g

≤ 1.5 Nm

1)

2

) To prevent it loosening during operation, secure the screw with screw locking varnish.

7.3 SIMATIC RF330T

• Material • Plastic PPS

• Color • Black

• During operation • -25 to +85 ℃

• During transportation and storage • -40 to +100 ℃

Degree of protection to EN 60529

• IP68

2 hours, 2 m, 20 ℃

• IPx9K

°C

Pressure resistance

• Low pressure resistant

vacuum dryer: up to 20 mbar

• high pressure resistant (see degree of protec-

tion IPx9K)

Type of mounting 1 x M4 screw 2)

The values for shock and vibration are maximum values and must not be applied continuously.

SIMATIC RF300

218 System Manual, 07/2016, C79000-G8976-C345-0x

Page 27

RF300 transponder

7.3.5

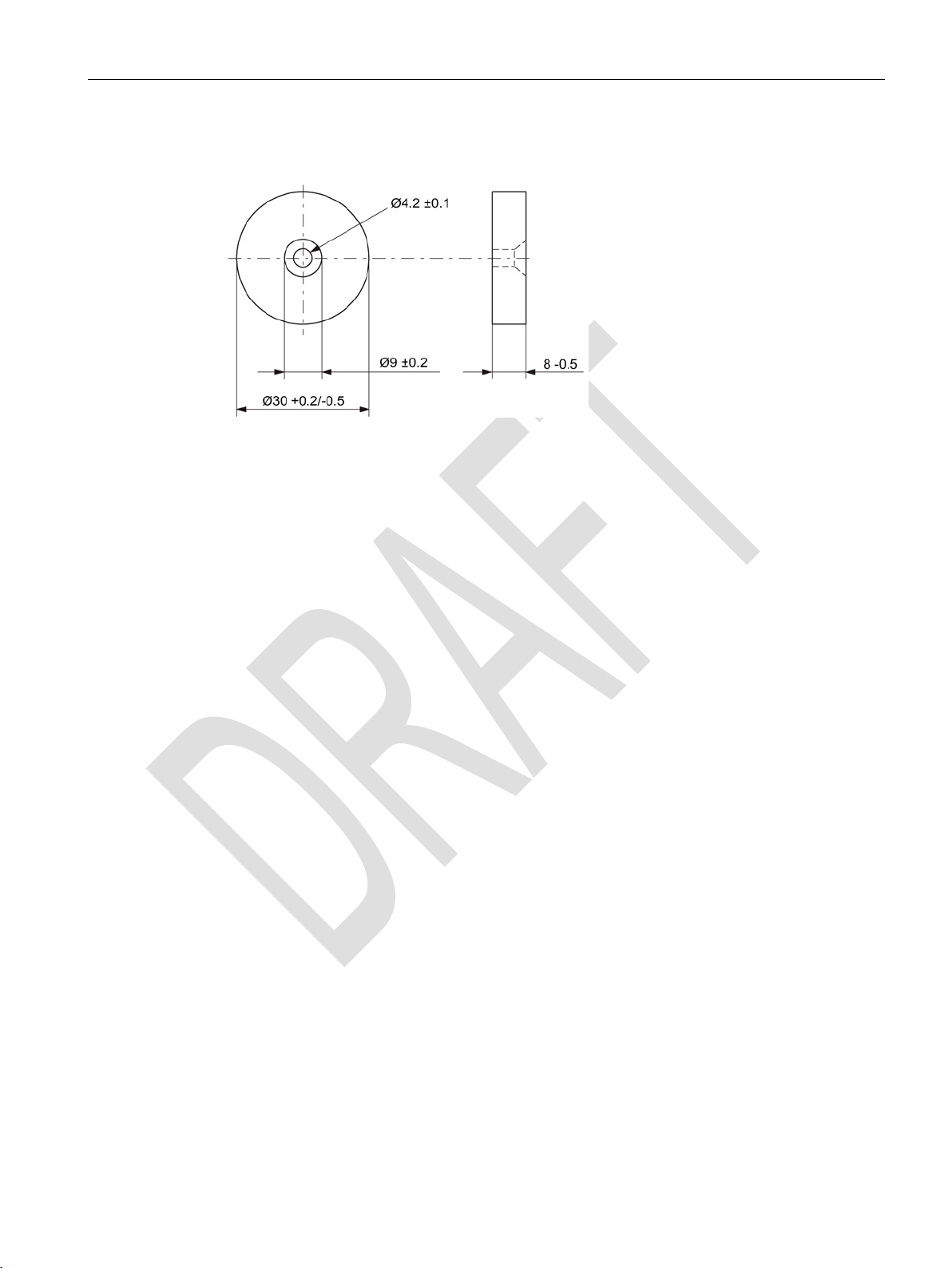

Dimension drawing

7.3 SIMATIC RF330T

Figure 7-8 RF330T dimension drawing

Dimensions in mm

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

219

Page 28

RF300 transponder

7.4

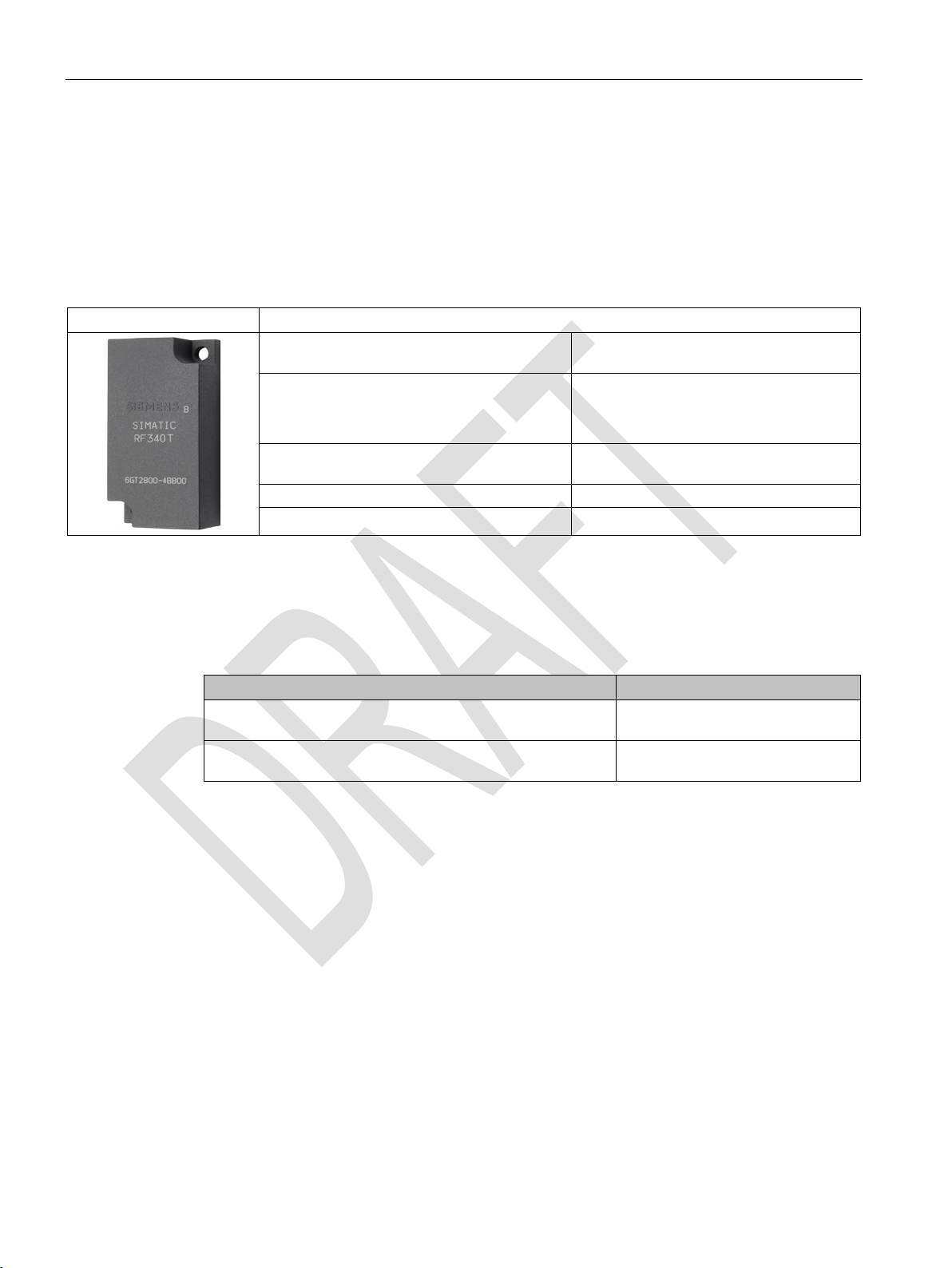

SIMATIC RF340T

7.4.1

Features

RF340T

Characteristics

in harsh industrial environments

sponders (Page 49)

Mounting on metal

Yes

7.4.2

Ordering data

Article number

8 KB FRAM user memory

32 KB FRAM user memory

7.4 SIMATIC RF340T

Table 7- 8

Area of application Identification tasks on small assembly lines

Memory size

Write/read range See section Field data of RF300 tran-

Degree of protection IP68/IPx9K

Table 7- 9 Ordering data RF340T

RF340T

RF340T

• 8 KB FRAM user memory

• 32 KB FRAM user memory

6GT2800-4BB00

6GT2800-5BB00

SIMATIC RF300

220 System Manual, 07/2016, C79000-G8976-C345-0x

Page 29

RF300 transponder

7.4.3

Mounting on metal

Mounting of RF340T on metal

Flush-mounting of RF340T in metal:

7.4 SIMATIC RF340T

Direct mounting of the RF340T on metal is permitted.

Figure 7-9 Mounting of RF340T on metal

Figure 7-10 Flush-mounting of RF340T in metal

The standard value for a is ≥ 20 mm. At lower values, the field data change significantly,

resulting in a reduction in the range.

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

221

Page 30

RF300 transponder

7.4.4

Technical specifications

6GT2800-4BB00

Product type designation

SIMATIC RF340T

Memory

Memory organization

in bytes

Memory configuration

Read cycles (at < 40 ℃)

> 1010

Write cycles (at < 40 ℃)

> 1010

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1200 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock-resistant to EN 60721-3-7, Class 7 M3

50 g 1)

7.4 SIMATIC RF340T

Table 7- 10 Technical specifications for RF340T

• UID • 4 bytes EEPROM

• User memory • 8 KB FRAM

• OPT memory • 20 bytes EEPROM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PA 12

• Color • Anthracite

• During operation • -25 to +85 ℃

• During transportation and storage • -40 to +85 ℃

Degree of protection to EN 60529

Vibration-resistant to EN 60721-3-7, Class 7 M3 20 g 1)

Torsion and bending load Not permitted

• IP68

• IPx9K

SIMATIC RF300

222 System Manual, 07/2016, C79000-G8976-C345-0x

Page 31

RF300 transponder

6GT2800-4BB00

Design, dimensions and weight

Dimensions (L x W x H)

48 x 25 x 15 mm

Weight

25 g

≤ 1.0 Nm

1)

The values for shock and vibration are maximum values and must not be applied continuously.

7.4.5

Dimension drawing

7.4 SIMATIC RF340T

Type of mounting 2 x M3 screws

Figure 7-11 RF340T dimension drawing

Dimensions in mm

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

223

Page 32

RF300 transponder

7.5

SIMATIC RF350T

7.5.1

Features

RF350T

Characteristics

in harsh industrial environments

Memory size

32 KB FRAM user memory

sponders (Page 49)

Mounting on metal

Yes

Degree of protection

IP68

7.5.2

Ordering data

Article number

7.5.3

Mounting on metal

7.5 SIMATIC RF350T

Area of application Identification tasks on small assembly lines

Table 7- 11 Ordering data RF350T

• IP68

• Memory size: 32 KB FRAM (read/write) and 4 bytes EEPROM (read

only)

• Operating temperature: -25 °C to +85 °C

• Dimensions: 50 x 50 x 20 (L x W x H, in mm)

• incl. securing frame

Write/read range See section Field data of RF300 tran-

6GT2800-5BD00

SIMATIC RF300

224 System Manual, 07/2016, C79000-G8976-C345-0x

Direct mounting of the RF350T on metal is permitted.

Page 33

RF300 transponder

Mounting of RF350T on metal

Flush-mounting of RF350T in metal:

7.5 SIMATIC RF350T

Figure 7-12 Mounting of RF350T on metal

Figure 7-13 RF350T flush-mounted in metal

The standard value for a is ≥ 20 mm. At lower values, the field data change significantly,

resulting in a reduction in the range.

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

225

Page 34

RF300 transponder

7.5.4

Mounting options

Mounting with fixing frame

Dimensions of the fixing frame

7.5 SIMATIC RF350T

The RF350T transponder can be mounted as shown with the fixing frame:

Figure 7-14 Installation diagram

Figure 7-15 RF350T fixing frame

SIMATIC RF300

226 System Manual, 07/2016, C79000-G8976-C345-0x

Page 35

RF300 transponder

7.5.5

Technical data

6GT2800-5BD00

Product type designation

SIMATIC RF350T

Memory

Memory organization

in bytes

Memory configuration

Read cycles (at < 40 ℃)

> 1010

Write cycles (at < 40 ℃)

> 1010

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1200 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Degree of protection to EN 60529

IP68

Shock-resistant to EN 60721-3-7, Class 7 M3

50 g 1)

Vibration-resistant to EN 60721-3-7, Class 7 M3

20 g 1)

Torsion and bending load

Not permitted

7.5 SIMATIC RF350T

Table 7- 12 Technical specifications for RF350T

• UID • 4 bytes EEPROM

• User memory • 32 KB FRAM

• OPT memory • 20 bytes EEPROM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PA 12

• Color • Anthracite

• During operation • -25 to +85 ℃

• During transportation and storage • -40 to +85 ℃

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

227

Page 36

RF300 transponder

6GT2800-5BD00

Design, dimensions and weight

Dimensions (L x W x H)

50 x 50 x 20 mm

Weight

25 g

≤ 1.5 Nm

1)

The values for shock and vibration are maximum values and must not be applied continuously.

7.5.6

Dimension drawing

7.5 SIMATIC RF350T

Type of mounting 2 x M4 screws

Figure 7-16 RF350T dimension drawing

Dimensions in mm

SIMATIC RF300

228 System Manual, 07/2016, C79000-G8976-C345-0x

Page 37

RF300 transponder

7.6

SIMATIC RF360T

7.6.1

Features

RF360T

Characteristics

in harsh industrial environments

sponders (Page 49)

Degree of protection

IP67

7.6.2

Ordering data

Article number

8 KB FRAM user memory

32 KB FRAM user memory

Article number

(in conjunction with fixing pocket 6GT2190-0AB00)

(in conjunction with spacer 6GT2190-0AA00)

7.6.3

Mounting on metal

7.6 SIMATIC RF360T

Area of application Identification tasks on small assembly lines

Memory size

Write/read range see section Field data of RF300 tran-

Mounting on metal Yes, with spacer

Table 7- 13 Ordering data RF360T

RF360T

RF360T

Table 7- 14 Ordering data for RF360T accessories

• 8 KB FRAM user memory

• 32 KB FRAM user memory

6GT2800-4AC00

6GT2800-5AC00

Spacer

Fixing pocket

Direct mounting of the RF360T on metal is not allowed. A distance ≥ 20 mm is

recommended. This can be achieved using the spacer 6GT2190-0AA00 in combination with

the fixing pocket 6GT2190-0AB00.

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

6GT2190-0AA00

6GT2190-0AB00

229

Page 38

RF300 transponder

Mounting of RF360T on metal

Flush-mounting of RF360T in metal:

7.6 SIMATIC RF360T

Figure 7-17 Mounting of RF360T with spacer

The standard value for h is ≥ 20 mm.

Figure 7-18 Flush-mounting of RF360T with spacer

The standard value for a is ≥ 20 mm. At lower values, the field data change significantly,

resulting in a reduction in the range.

SIMATIC RF300

230 System Manual, 07/2016, C79000-G8976-C345-0x

Page 39

RF300 transponder

Dimensions of spacer and fixing pocket for RF360T

7.6 SIMATIC RF360T

Figure 7-19 Dimensions of spacer and fixing pocket for RF360T

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

231

Page 40

RF300 transponder

7.6.4

Technical data

6GT2800-4AC00

6GT2800-5AC00

Product type designation

SIMATIC RF360T

Memory

Memory organization

in bytes

Memory configuration

Read cycles (at < 40 ℃)

> 1010

Write cycles (at < 40 ℃)

> 1010

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1200 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 20 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Degree of protection to EN 60529

IP67

Shock-resistant to EN 60721-3-7, Class 7 M3

50 g

Vibration-resistant to EN 60721-3-7, Class 7 M3

20 g

Torsion and bending load

Not permitted

7.6 SIMATIC RF360T

Table 7- 15 Technical specifications for RF360T

• UID • 4 bytes EEPROM

• User memory • 8 KB FRAM

• OPT memory • 20 bytes EEPROM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Epoxy resin

• Color • Anthracite

• During operation • -25 to +75 ℃

• During transportation and storage • -40 to +85 ℃

SIMATIC RF300

232 System Manual, 07/2016, C79000-G8976-C345-0x

Page 41

RF300 transponder

6GT2800-4AC00

6GT2800-5AC00

Design, dimensions and weight

Dimensions (L x W x H)

86 x 55 x 2.5 mm

Weight

25 g

7.6.5

Dimension drawing

7.6 SIMATIC RF360T

Type of mounting

• 2 x M3 screws

≤ 1.0 Nm

• Fixing pocket (6GT2190-0AB00)

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

Figure 7-20 RF360T dimension drawing

Dimensions in mm

233

Page 42

RF300 transponder

7.7

SIMATIC RF370T

7.7.1

Features

RF370T

Characteristics

automotive industry

ers (Page 49)

Mounting on metal

Yes

Degree of protection

IP68/IPx9K

7.7.2

Ordering data

Article number

32 KB FRAM user memory

76 KB FRAM user memory

7.7 SIMATIC RF370T

The SIMATIC RF370T transponder is a passive (i.e. battery-free) data carrier in a square

type of construction.

Area of application Identification tasks on assembly lines in

harsh industrial environments, due to high

resistance to oils, lubricants and cleaning

agents, and suitable for larger ranges, e.g.

Memory size

Write/read range see section Field data of RF300 transpond-

Table 7- 16 Ordering data RF370T

RF370T

RF370T

• 32 KB FRAM user memory

• 64 KB FRAM user memory

6GT2800-5BE00

6GT2800-6BE00

SIMATIC RF300

234 System Manual, 07/2016, C79000-G8976-C345-0x

Page 43

RF300 transponder

7.7.3

Mounting on metal

Mounting of RF370T on metal

Flush-mounting of RF370T in metal:

7.7 SIMATIC RF370T

Direct mounting of the RF370T on metal is permitted.

Figure 7-21 Mounting of RF370T on metal

Figure 7-22 RF370T flush-mounted in metal

The standard value for a is ≥ 20 mm. At lower values, the field data change significantly,

resulting in a reduction in the range.

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

235

Page 44

RF300 transponder

7.7.4

Mounting instructions

Properties

Description

Type of installation

Screw fixing (two M5 screws)

7.7.5

Technical specifications

6GT2800-5BE00

6GT2800-6BE00

Product type designation

SIMATIC RF370T

Memory

Memory organization

in bytes

Memory configuration

Read cycles (at < 40 ℃)

> 1010

Write cycles (at < 40 ℃)

> 1010

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1200 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

7.7 SIMATIC RF370T

It is essential that you observe the instructions in the Section Installation guidelines

(Page 62).

Tightening torque < 1.2 Nm (at room temperature)

Table 7- 17 Technical specifications RF370T

• UID • 4 bytes EEPROM

• User memory • 32 or 64 KB FRAM

• OPT memory • 20 bytes EEPROM

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • Plastic PA 12

• Color • Anthracite

SIMATIC RF300

236 System Manual, 07/2016, C79000-G8976-C345-0x

Page 45

RF300 transponder

6GT2800-5BE00

6GT2800-6BE00

Permitted ambient conditions

Ambient temperature

Degree of protection to EN 60529

IPx9K

Shock-resistant to EN 60721-3-7, Class 7 M3

50 g 1)

Vibration-resistant to EN 60721-3-7, Class 7 M3

20 g 1)

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (L x W x H)

75 x 75 x 41 mm

Weight

200 g

≤ 1.5 Nm

1)

The values for shock and vibration are maximum values and must not be applied continuously.

7.7.6

Dimensional drawing

7.7 SIMATIC RF370T

• During operation • -25 to +85 ℃

• During transportation and storage • -40 to +85 ℃

Type of mounting 2 x M5 screws

Figure 7-23 RF370T dimension drawing

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

237

Page 46

RF300 transponder

7.8

SIMATIC RF380T

7.8.1

Features

SIMATIC RF380T transponder

Characteristics

Identification tasks in applications (e.g. automotive industry)

Memory size

32 KB FRAM user memory

Write/read range

see section "Field data of RF300 transponders (Page 49)"

Mounting on metal

Yes, flush-mounted in metal

Degree of protection

IP68

7.8.2

Ordering data

Article number

User memory 32 KB FRAM (read/write) and 4 bytes EEPROM

Article number

Holder (short version)

6GT2090-0QA00

Holder (long version)

6GT2090-0QA00-0AX3

Shrouding cover

6GT2090-0QB00

Universal holder

6GT2590-0QA00

7.8 SIMATIC RF380T

Dimensions in mm

The SIMATIC RF380T transponder is an extremely rugged and heat-resistant round data

carrier suitable e.g. for applications in the automotive industry.

Area of application

with cyclic high temperature stress > 85 °C and < 220 °C

Highly resistant to mineral oils, lubricants and cleaning

agents

Typical applications:

• Primer coat, electrolytic dip area, cataphoresis with the

associated drying furnaces

• Top coat area with drying furnaces

• Washing areas at temperatures > 85°C

• Other applications with higher temperatures

SIMATIC RF300

Table 7- 18 Ordering data RF380T

RF380T

Table 7- 19 Ordering data for RF380T

238 System Manual, 07/2016, C79000-G8976-C345-0x

6GT2800-5DA00

Page 47

RF300 transponder

7.8.3

Installation guidelines for RF380T

7.8.3.1

Mounting instructions

Note

Only use tag with original holder

You are strongly recommended to only use the tag with the original holder specified. Only

this holder guarantees that the data memory observes the listed values for shock, vib

and temperature. A protective cover is recommendable for applications in paint shops.

Data memory holder

Short version (6GT2 090-0QA00)

Long version (6GT2090-0QA00-0AX3)

Material: V2A sheet-steel with thickness 2.5 mm BI 2.5 DIN 59382 1.4541

7.8 SIMATIC RF380T

It is essential that you observe the instructions in the Section Installation guidelines

(Page 62

).

The following section only deals with features specific to the SIMATIC RF380T.

ration

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

239

Page 48

RF300 transponder

Assembly of data memory with holder

Scope of supply

7.8 SIMATIC RF380T

Figure 7-24 Assembly of tag with holder

The holder is provided with all mounting parts and a mounting diagram. Mounting screws for

securing the holder are not included. The mounting screws are of diameter M 10. The

minimum length is 25 mm. The optional cover can be used for the long and short versions of

the holder.

SIMATIC RF300

240 System Manual, 07/2016, C79000-G8976-C345-0x

Page 49

RF300 transponder

Universal holder

7.8 SIMATIC RF380T

Figure 7-25 Universal holder 6GT2590-0QA00

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

241

Page 50

RF300 transponder

7.8.3.2

Metal-free area

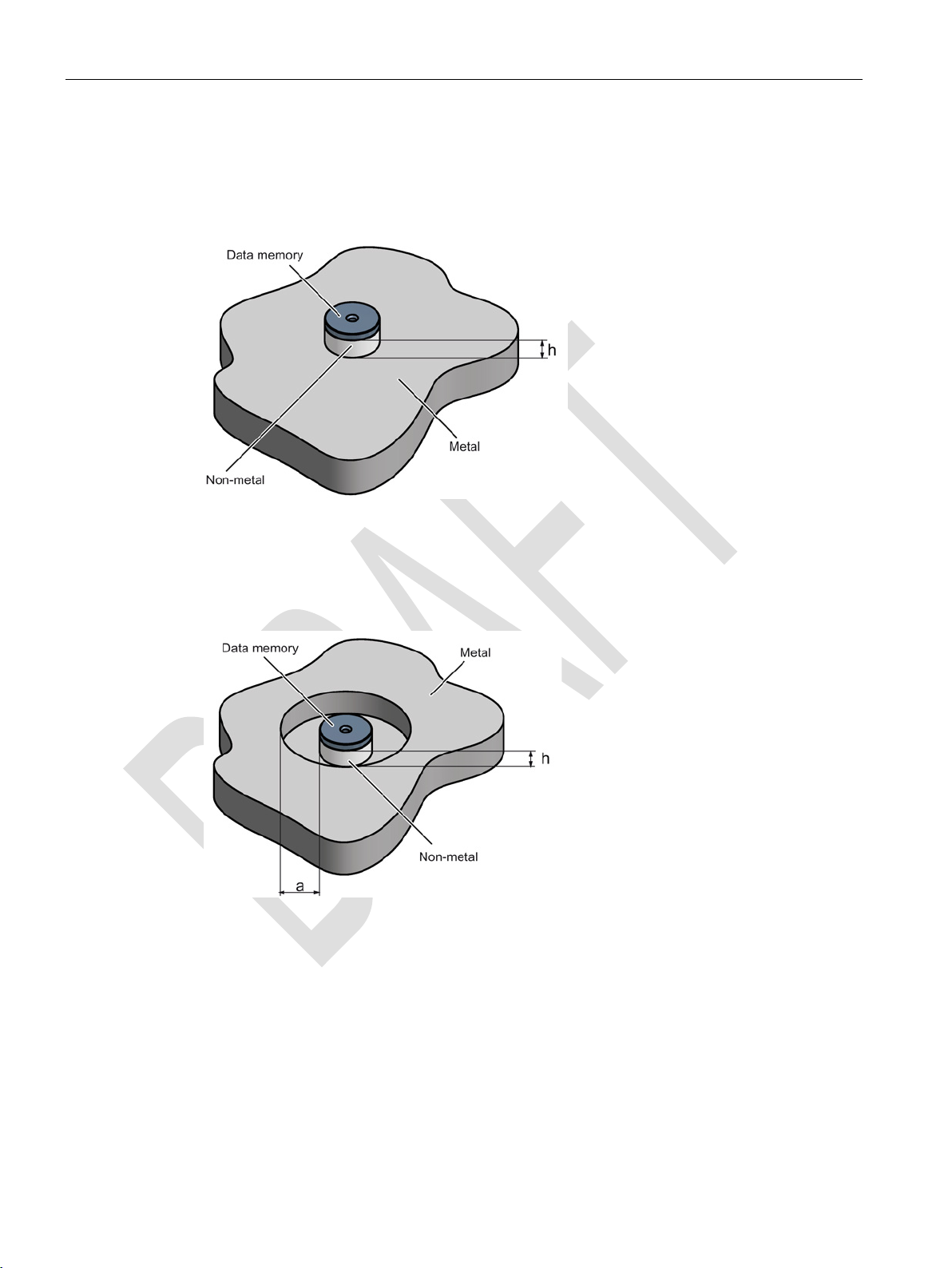

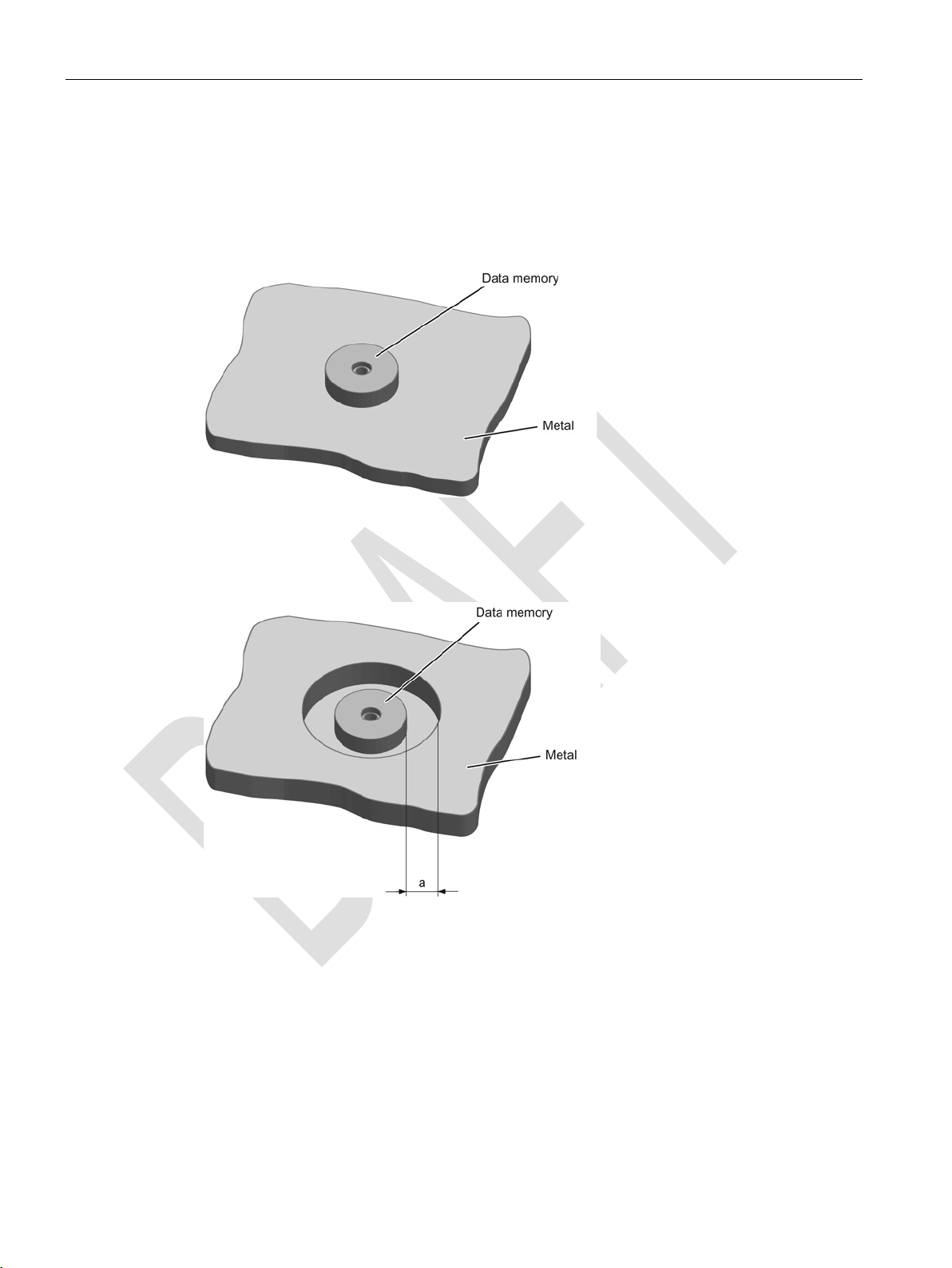

Mounting of RF380T on metal

Flush-mounting of RF380T in metal:

7.8 SIMATIC RF380T

Direct mounting of the RF380T on metal is permitted.

Figure 7-26 Mounting of RF380T on metal

Figure 7-27 RF380T flush-mounted in metal

The standard value for a is ≥ 40 mm. At lower values, the field data change significantly,

resulting in a reduction in the range.

SIMATIC RF300

242 System Manual, 07/2016, C79000-G8976-C345-0x

Page 51

RF300 transponder

7.8.4

Configuring instructions

7.8.4.1

Temperature dependence of the transmission window

7.8.4.2

Temperature response in cyclic operation

Note

Calculation of the temperature curves

Calculation of the temperatur

request by Siemens AG. Exact knowledge of the internal temperature facilitates

configuration for time

You can also carry out the calculation with the aid of the "SIMATIC RF T

Calculator" on the "Ident Systems Software & Documentation" DVD (refer to the section

"

Ambient temperatures > 110 °C

Note

Cancellation of warranty

The internal temperature of the data memory must not exceed the critical threshold of 110

°C. Each heating phase must be followed by a cooling phase. No warranty claims will

other

Tu (heating up)

Heating up

Tu (cooling down)

Cooling down

220 °C

0.5 h

25 °C

> 2 h

200 °C

1 h

25 °C

> 2 h

190 °C

1 h

25 °C

> 1 h 45 min

180 °C

2 h

25 °C

> 5 h

7.8 SIMATIC RF380T

The guidelines in the section "Planning the RF300 system" apply to configuration of heatresistant data memories, with the exception of the limit distance and field length at

temperatures above 85 °C. At temperatures above 85 °C, the length of the transmission

window is reduced by up to 10%.

At ambient temperatures (Tu) up to 110 °C, cyclic operation is not necessary, i.e. up to this

temperature, the transponder can be in constant operation.

e curves or of a temperature profile can be carried out on

-critical applications.

emperature

DVD "Ident Systems Software & Documentation" (Page 416)").

wise be accepted.

Some limit cycles are listed in the table below:

Table 7- 20 Limit cycles of data memory temperature

170 °C 2 h 25 °C > 4 h

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

243

Page 52

RF300 transponder

Ambient temperatures > 220°C

Note

Cancellation of warranty

The data memory must not be exposed to ambient temperatures > 220 °C. No warranty

claims will otherwise be accepted.

However, the mechanical stability is retained up to 230 °C!

Example of a cyclic sequence

Start of tag at initial point

Duration (min)

Ambient temperature (°C)

Electrolytic dip

20

30

Electrolytic dip dryer

60

200

Transport

60

25

PVC dryer

25

170

Transport

60

25

Filler dryer

60

160

Transport

60

25

Top coat dryer

60

120

Transport

60

25

Wax dryer

25

100

Transport

150

25

7.8 SIMATIC RF380T

The internal temperature of the tag follows an exponential function with which the internal

temperature and the operability of the tag can be calculated in advance. This is particularly

relevant to temperature-critical applications or those with a complex temperature profile.

Table 7- 21 Typical temperature profile of an application in the paint shop

SIMATIC RF300

244 System Manual, 07/2016, C79000-G8976-C345-0x

Page 53

RF300 transponder

The simulation results in the following:

7.8 SIMATIC RF380T

Figure 7-28 Graphic trend of temperature profile from above table

Following a simulation time of 36.5 hours, a total of 3 cycles were carried out, and an internal

temperature of 90 degrees Celsius was reached.

Figure 7-29 Complete temperature response due to simulation

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

245

Page 54

RF300 transponder

7.8.5

Use of the transponder in the Ex protection area

Document

Title

with type of protection "n"

(in parts)

Part 5: Explosion protection

ZLS SK 107.1

Central office of the states for safety; test components

Identification

-25°C to +70°C

Um=30Vdc

XXXYYYZZZ

[= serial number, is assigned during production]

TPS 09 ATEX 1 459 X

[= certificate number]

7.8.5.1

Use of the transponder in hazardous areas for gases

Temperature class delineation for gases

Ambient temperature range

Temperature class

-25 °C to +70 °C

T5

7.8 SIMATIC RF380T

The TÜV SÜD Automotive GmbH as approved test center as well as the TÜV SÜD Product

Service GmbH as certification center, identification number 0123, as per Article 9 of the

Directive of the European Council of 23 March 1994 (94/9/EC), has confirmed the

compliance with the essential health and safety requirements relating to the design and

construction of equipment and protective systems intended for use in hazardous areas as

per Annex II of the Directive. The essential health and safety requirements are satisfied in

accordance with the following standards:

Table 7- 22 Approvals

EN 60079-0: 2006

EN 60079-15: 2005 Electrical equipment for hazardous gas atmospheres -

DIN VDE 0848-5: 2001

Table 7- 23 The identification of the electrical equipment as an encapsulated unit

II 3G Ex nC IIB T5

Electrical equipment for hazardous gas atmospheres -

Part 0: General requirements

Part 15: Design, testing and identification of electrical equipment

Safety in electrical, magnetic and electromagnetic fields -

The equipment is assigned the following references:

"No use of the equipment in the vicinity of processes generating high charges"

The temperature class of the transponder for hazardous areas depends on the ambient

temperature range:

SIMATIC RF300

246 System Manual, 07/2016, C79000-G8976-C345-0x

Page 55

RF300 transponder

WARNING

Ignitions of gas-air mixtures

7.8.5.2

Installation and operating conditions for the hazardous area

7.8.6

Cleaning the mobile data memory

Note

Do not clean the transponder with mechanical tools, sand

cleaning methods result in damage to the transponder.

Clean the transponder only with the chemical cleansing agents listed in Chapter

resistance of the transponders

7.8.7

Technical specifications

6GT2800-5DA00

Product type designation

SIMATIC RF380T

Memory

Memory organization

in bytes

Memory configuration

7.8 SIMATIC RF380T

• When using the RF380T transponder, check that the temperature class is kept to in

conjunction with the requirements of the area of application.

If the temperature ranges are exceeded during use of the transponder, gas-air mixtures

may be ignited.

• The maximum transmit power of the transmitter used to operate the transponder must

not exceed 2 W.

If the transmit power id not kept to, gas-air mixtures may ignite.

a) Use of the equipment in the vicinity of processes generating high charges is not allowed.

b) The equipment must be mechanically protected when installed.

-blasting or pressure hose. These

Chemical

(Page 90).

Table 7- 24 RF380T technical specifications

• UID • 4 bytes EEPROM

• User memory • 32 KB FRAM

• OPT memory • 20 bytes EEPROM

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

247

Page 56

RF300 transponder

6GT2800-5DA00

Read cycles (at < 40 ℃)

> 1010

Write cycles (at < 40 ℃)

> 1010

Data retention time (at < 40 ℃)

> 10 years

data of RF300 transponders (Page 49)"

MTBF (Mean Time Between Failures)

1177 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Degree of protection to EN 60529

IP68

Shock-resistant to EN 60721-3-7, Class 7 M3

50 g

Vibration-resistant to EN 60721-3-7, Class 7 M3

5 g 2)

Torsion and bending load

Not permitted

Design, dimensions and weight

1)

2)

The values for shock and vibration are maximum values and must not be applied continuously.

7.8 SIMATIC RF380T

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PPS

• Color • Anthracite

• During operation • -25 to +110 ℃

• -25 … +220 ℃: cyclic operation possible

• During transportation and storage • -40 to +110 ℃

1)2)

Dimensions (Ø x H) 114 x 83 mm

Weight 900 g

Type of mounting Holder (must be ordered separately)

Applies only in conjunction with the original support

SIMATIC RF300

248 System Manual, 07/2016, C79000-G8976-C345-0x

Page 57

RF300 transponder

7.8.8

Dimensional drawing

7.8 SIMATIC RF380T

Figure 7-30 Dimension drawing RF380T

Dimensions in mm

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

249

Page 58

RF300 transponder

7.8 SIMATIC RF380T

SIMATIC RF300

250 System Manual, 07/2016, C79000-G8976-C345-0x

Page 59

8

Features of the ISO transponders

The transponders (MDS D) that are compatible with ISO 15693 represent a cost-effective

alternative to RF300 transponders. The performance that can be achieved with this

(transmission speed, memory size), however, is considerably less than with RF300

transponders.

You will find more information on transmission speeds in the section "Communication

between communications module, reader and transponder (Page 47)".

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

251

Page 60

ISO transponder

8.1

Memory configuration of ISO the transponders

8.1 Memory configuration of ISO the transponders

Figure 8-1 Memory configuration of ISO the transponders

SIMATIC RF300

252 System Manual, 07/2016, C79000-G8976-C345-0x

Page 61

ISO transponder

Memory areas

OTP area

Note

Exception Fujitsu chip (MDS D4xx and MDS D522)

The Fujitsu chip MB89R118 (MDS D4xx)

addresses have to be addressed: FF80 and FF88 with the length 8 and 16 bytes).

The Fujitsu chip MB89R112 (MDS D5xx) has 32 byte blocks and can therefore not be

addressed in the OTP area.

Note

Restriction to the use of the OTP

Observe the following restrictions when using OTP:

•

•

The Fujitsu chip MB89R112 (MDS D5xx) has 32 byte bl

addressed in the OTP area.

Note

Use of the OTP area is not reversible

If you use the OPT area, you cannot undo it, because the OPT area can only be written to

once.

8.1 Memory configuration of ISO the transponders

Depending on the manufacturer of the transponder chip, the memory configuration of an ISO

transponder consists of varying sizes of user memory.

The typical sizes are 112 bytes, 256 bytes, 992 bytes EEPROM or 2000 bytes FRAM. Each

ISO transponder chip has an 8-byte long unique serial number (UID, read only). This UID is

transferred as an 8 byte value through a read command to address FFF0 with a length of 8.

For the OTP area, a 16-byte address space is always reserved at the end of the memory

area. The blocks are divided up depending on the chip (see technical specifications). Note

that the corresponding addresses for the user data are therefore not available to the

application when the OTP area is used.

A total of 4 block addresses ("mapped" addresses) are provided:

● FF80

● FF84

● FF88

● FF8C

A write command to this block address with a valid length (4, 8, 12, 16 bytes depending on

the block address) protects the written data from subsequent overwriting.

has 8-byte blocks, which means that only 2 block

The OTP write/lock command can only be sent in static operation.

The OTP write/lock command can not be sent as a chained command.

ocks and can therefore not be

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

253

Page 62

ISO transponder

8.2

MDS D100

8.2.1

Characteristics

MDS D100

Characteristics

product identification.

Memory size

112 bytes of EEPROM user memory

(MDS D) (Page 52).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP68

8.2.2

Ordering data

Article number

MDS D100

6GT2600-0AD10

Article number

(in conjunction with fixing pocket 6GT2190-0AB00)

(in conjunction with spacer 6GT2190-0AA00)

(not suitable for fixing directly onto metal)

8.2.3

Metal-free area

8.2 MDS D100

Area of application From simple identification such as electronic

barcode replacement/supplementation, through

warehouse and distribution logistics, right up to

Write/read range See section Field data of ISO transponders

Table 8- 1 Ordering data for MDS D100

Table 8- 2 Ordering data for MDS D100 accessory

Spacer

Fixing pocket

Fixing pocket

6GT2190-0AA00

6GT2190-0AB00

6GT2390-0AA00

Direct mounting of the MDS D100 on metal is not allowed. A distance of ≥ 20 mm is

recommended. This can be achieved using the spacer 6GT2190-0AA00 in combination with

the fixing pocket 6GT2190-0AB00.

SIMATIC RF300

254 System Manual, 07/2016, C79000-G8976-C345-0x

Page 63

ISO transponder

Mounting on metal

h

≥ 20 mm

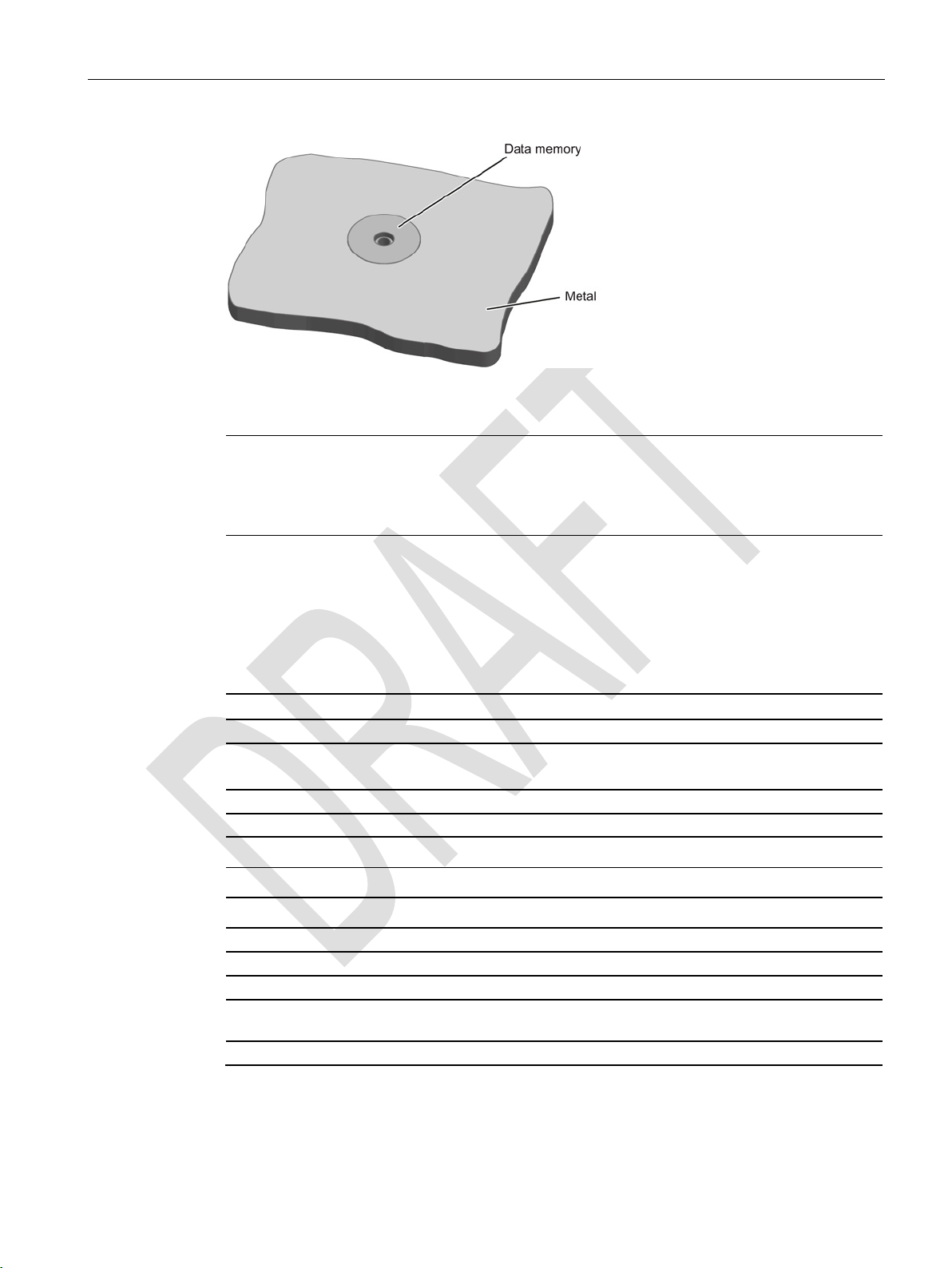

①

Data memory

②

Metal

③

Non-metal

8.2 MDS D100

Figure 8-2 Mounting of the MDS D100 on metal with spacer

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

255

Page 64

ISO transponder

Flush-mounting

a

≥ 20 mm

h

≥ 20 mm

①

Data memory

②

Metal

③

Non-metal

Note

If the minimum guide values (h or a) are not observed, a reduction of the field data results.

8.2.4

Technical data

6GT2600-0AD10

Product type designation

SIMATIC MDS D100

Memory

Memory configuration

8.2 MDS D100

Figure 8-3 Flush-mounting of MDS D100 in metal with spacer

Table 8- 3 Technical specifications for MDS D100

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OPT memory • 16 bytes (EEPROM)

SIMATIC RF300

256 System Manual, 07/2016, C79000-G8976-C345-0x

Page 65

ISO transponder

6GT2600-0AD10

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 52)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 20 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock-resistant to EN 60721-3-7 class 7M3

ISO 10373 / ISO 7810 1)

Vibration-resistant to EN 60721-3-7, class 7M3

ISO 10373 / ISO 7810 1)

Torsion and bending load

ISO 10373/ISO 7816-1

Design, dimensions and weight

Dimensions (L x W x H)

85.6 x 54 x 0.9 mm

1)

The values for shock and vibration are maximum values and must not be applied continuously.

8.2 MDS D100

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PC

• Color • White/petrol

• During operation • -25 to +80 ℃

• During transportation and storage • -25 to +80 ℃

Degree of protection to EN 60529

• IP68

Weight 5 g

Type of mounting

• Fixing pocket

• Glued

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

257

Page 66

ISO transponder

8.2.5

Dimension drawing

Dimensions in mm

Dimensions for mounting holes

8.2 MDS D100

1)

Figure 8-4 MDS D100 dimension drawing

SIMATIC RF300

258 System Manual, 07/2016, C79000-G8976-C345-0x

Page 67

ISO transponder

8.3

MDS D117

8.3.1

Features

MDS D117

Characteristics

e.g. tool identification, workpiece holders etc..

(Page 52)."

Mounting in metal

Yes, flush-mounted in metal

ISO standard

ISO 15693

Degree of protection

IP68/IPx9K

8.3.2

Ordering data

Article number

Pack of 10

8.3 MDS D117

Area of application Very compact data carrier that can be cemented into

objects where precise positioning is necessary;

Table 8- 4 Ordering data for MDS D117

MDS D117

Memory size 112 bytes of EEPROM user memory

Write/read range See section "Field data of ISO transponders (MDS D)

6GT2600-0AG00

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

259

Page 68

ISO transponder

8.3.3

Mounting in metal

Flush-mounted in metal

①

Transponder

②

Metal

8.3.4

Technical specifications

6GT2600-0AG00

Product type designation

SIMATIC MDS D117

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 52)"

MTBF (Mean Time Between Failures)

228 years

8.3 MDS D117

Table 8- 5 Technical specifications for MDS D117

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OPT memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

SIMATIC RF300

260 System Manual, 07/2016, C79000-G8976-C345-0x

Page 69

ISO transponder

6GT2600-0AG00

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

2 hours, 2 bar, +20 °C

Shock-resistant to EN 60721-3-7 class 7M3

100 g 1)

Vibration-resistant to EN 60721-3-7, class 7M3

20 g 1)

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

4 x 5.2 mm

Weight

1 g

1)

The values for shock and vibration are maximum values and must not be applied continuously.

8.3.5

Dimension drawing

8.3 MDS D117

• Material • PPS

• Color • Black

• During operation • -25 to +85 ℃

• During transportation and storage • -40 to +125 ℃

Degree of protection to EN 60529 IP68

Type of mounting

Figure 8-5 Dimensions in mm

• Fixing pocket

• Glued

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

261

Page 70

ISO transponder

8.4

MDS D124

8.4.1

Characteristics

MDS D124

Characteristics

paintshops up to +180 °C)

Memory size

112 bytes of EEPROM user memory

(Page 52)".

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP68/IPx9K

8.4.2

Ordering data

Article number

MDS D124

6GT2600-0AC10

Article number

Spacer

6GT2690-0AK00

8.4 MDS D124

Area of application

Write/read range See section "Field data of ISO transponders (MDS D)

Table 8- 6 Ordering data for MDS D124

Table 8- 7 Ordering data for MDS D124 accessories

Application areas in production automation (e.g. small

SIMATIC RF300

262 System Manual, 07/2016, C79000-G8976-C345-0x

Page 71

ISO transponder

8.4.3

Mounting on metal

Mounting on metal

h

≥ 15 mm

Flush-mounting

h

≥ 15 mm

a

≥ 25 mm

8.4 MDS D124

Figure 8-6 Mounting the MDS D124/D324/D424/D524/E624 and RF320T on metal with spacer

Figure 8-7 Flush-mounting of the MDS D124/D324/D424/D524/E624 and RF320T in metal with

spacer

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

263

Page 72

ISO transponder

Note

Going below the distances

If the distances (a and h) are not observed, a reduction of the field data results. It i

to mount the MDS with metal screws (M3 countersunk head screws). This has no tangible

impact on the range.

8.4.4

Technical specifications

6GT2600-0AC10

Product type designation

SIMATIC MDS D124

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 52)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 15 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

8.4 MDS D124

s possible

Table 8- 8 Technical specifications for MDS D124

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OPT memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PPS

• Color • Black

• During operation • -25 to +180 ℃

• from +125 ℃: 20% reduction in the limit dis-

tance

• from +140 ℃: No processing possible

SIMATIC RF300

264 System Manual, 07/2016, C79000-G8976-C345-0x

Page 73

ISO transponder

6GT2600-0AC10

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

Shock-resistant to EN 60721-3-7 class 7M3

100 g 1)

Vibration-resistant to EN 60721-3-7, class 7M3

20 g 1)

Torsion and bending load

Not permitted

Design, dimensions and weight

Dimensions (Ø x H)

4 x 5.2 mm

Weight

5 g

1)

2

) To prevent it loosening during operation, secure the screw with screw locking varnish.

8.4.5

Use of the MDS D124 in hazardous area

8.4 MDS D124

• at +180 ℃: Tested up to 5000 hours or

3000 cycles

• During transportation and storage • -40 to +125 ℃

Degree of protection to EN 60529

Type of mounting

The values for shock and vibration are maximum values and must not be applied continuously.

• IP68

2 hours, 2 bar, +20 °C

• IPx9K

°C

• 1 x M3 screw

≤ 1 Nm

• Glued

• With spacer

2)

The mobile data memory MDS D124, device group II, category 1G or 1D may be installed

and operated in zones 0, 1 and 2 or in the zones 20, 21 and 22.

The following requirements of the 94/9/EC directive are met:

● EN 60079-0:2009

● EN 60079-11:2007

● EN 61241-11:2006

● EN 60079-26:2007

When used in hazardous areas, the MDS D124 must not be operated with field strengths > 5

A / m to avoid impermissible heating. This is not the case with readers from the SIMATIC RF

range (MOBY D, RF200 and RF300).

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

265

Page 74

ISO transponder

Identification

Ambient temperature range

Temperature class

Max. surface temperature

-25 ... +150 ℃

T3

T180

-25 ... +100 ℃

T4

T130

-25 ... +65 ℃

T5

T95

-25 ... +50 ℃

T6

T80

Note

Safety markings for hazardous areas

Since there is not enough space on the MDS D124 for the safety mark, this is supplied as a

label with the device.

This must be affixed immediately next to the MDS D124 so that the label clearly relates to

th

WARNING

Gefahr durch elektrostatische Entladungen

Potential electrostatic charging hazard

Danger potentiel de charges électrostatiques

8.4 MDS D124

II 1 G Ex ia IIC T3 to T6 Ga

or

II 1 D Ex ia IIIC T80 °C to T180 °C Da

TÜV 12 ATEX 084413 X

The temperature class or the maximum surface temperature depends on the maximum

ambient temperature. The relationship between temperature class (gas) or maximum surface

temperature (dust) can be found in the following table.

Table 8- 9 Ambient temperature

e device.

SIMATIC RF300

266 System Manual, 07/2016, C79000-G8976-C345-0x

Page 75

ISO transponder

Note

Installation and operating conditions for hazardous areas:

•

•

•

•

•

8.4.6

Dimension drawing

8.4 MDS D124

Use of the device in the vicinity of processes generating high charges is not allowed.

The device must be installed so that it is mechanically protected.

For applications requiring devices of category 1, the device must be mounted on a

grounded, conductive base.

It must only be cleaned with a damp cloth.

The device is suitable for use in atmospheres containing dust, however not for full

immersion in dust.

Figure 8-8 Dimension drawing of MDS D124

All dimensions in mm

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

267

Page 76

ISO transponder

8.5

MDS D126

8.5.1

Characteristics

MDS D126

Characteristics

related logistics; can also be deployed

in harsh conditions

Write/read range

See section Field data of ISO transponders (MDS D) (Page 52)

Mounting on metal

Yes, with spacer

ISO standard

ISO-15693

Degree of protection

IP68

8.5.2

Ordering data

Article number

MDS D126

6GT2600-0AE00

Article number

Spacer

6GT2690-0AL00

8.5 MDS D126

Area of application

Memory size 112 bytes of EEPROM user memory

Table 8- 10 Ordering data for MDS D126

Table 8- 11 Ordering data for MDS D126 accessories

Compact and rugged ISO transponder; suitable for identification of

transport units in production-

SIMATIC RF300

268 System Manual, 07/2016, C79000-G8976-C345-0x

Page 77

ISO transponder

8.5.3

Mounting on metal

Mounting on metal

h

≥ 25 mm

Flush-mounted in metal

h

≥ 25 mm

a

≥ 50 mm

8.5 MDS D126

Figure 8-9 Mounting the MDS D126 / D426 / D526 on metal with spacer

Figure 8-10 Flush installation of the MDS D126 / D426 / D526 in metal with spacer

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

269

Page 78

ISO transponder

8.5.4

Technical specifications

6GT2600-0AE00

Product type designation

SIMATIC MDS D126

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 52)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 25 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

2 hours, 2 bar, +20 °C

Shock-resistant to EN 60721-3-7 class 7M3

50 g 1)

Vibration-resistant to EN 60721-3-7, class 7M3

20 g 1)

8.5 MDS D126

Table 8- 12 Technical specifications for the MDS D126

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OPT memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PA6.6 GF

• Color • Black

• During operation • -25 to +85 ℃

• During transportation and storage • -40 to +100 ℃

Degree of protection to EN 60529 IP68

Torsion and bending load Not permitted

SIMATIC RF300

270 System Manual, 07/2016, C79000-G8976-C345-0x

Page 79

ISO transponder

6GT2600-0AE00

Design, dimensions and weight

Dimensions (Ø x H)

50 x 3.6 mm

Weight

13 g

1)

2

) To prevent it loosening during operation, secure the screw with screw locking varnish.

8.5.5

Dimension drawing

Dimensions in mm

8.5 MDS D126

Type of mounting

The values for shock and vibration are maximum values and must not be applied continuously.

• 1 x M4 screw

≤ 1 Nm

• Glued

2)

Figure 8-11 Dimension drawing of MDS D126

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

271

Page 80

ISO transponder

8.6

MDS D127

8.6.1

Features

MDS D127

Characteristics

e.g. tool identification, workpiece holders etc.

(Page 52)"

Mounting on metal

Yes, flush-mounted in metal

ISO standard

ISO 15693

8.6.2

Ordering data

Article number

(A screw-in aid is supplied with each pack)

8.6 MDS D127

Area of application

Memory size 112 bytes of EEPROM user memory

Write/read range See section "Field data of ISO transponders (MDS D)

Degree of protection IP68/IPx9K

Table 8- 13 Ordering data for MDS D127

MDS D127

Pack of 10

Very compact data carrier that can be screwed into

areas where precise positioning is necessary;

6GT2600-0AF00

SIMATIC RF300

272 System Manual, 07/2016, C79000-G8976-C345-0x

Page 81

ISO transponder

8.6.3

Mounting in metal

Flush-mounted in metal

①

Metal

②

Transponders

Note

Damage to the transponder due to improper mounting

To screw the MDS D127 into a suitable thread, use the supplied screw

damage to the MDS D127.

8.6 MDS D127

-in tool. This avoids

Figure 8-12 Screw-in aid for mounting the MDS D127

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

273

Page 82

ISO transponder

8.6.4

Technical specifications

6GT2600-0AF00

Product type designation

SIMATIC MDS D127

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 52)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 0 mm

Power supply

Inductive, without battery

Permitted ambient conditions

Ambient temperature

Shock-resistant to EN 60721-3-7 class 7M3

100 g 1)

Vibration-resistant to EN 60721-3-7, class 7M3

20 g 1)

8.6 MDS D127

Table 8- 14 Technical specifications for MDS D127

• UID • 8 bytes

• User memory • 112 bytes EEPROM

• OPT memory • 16 bytes (EEPROM)

Write/read distance (Sg) Dependent on the reader used, see section "Field

• Material • PA6

• Color • Black

• During operation • -25 to +100 ℃

• During transportation and storage • -40 to +125 ℃

Degree of protection to EN 60529

• IP68

2 hours, 2 bar, +20 °C

• IPx9K

steam jet: 150 mm; 10 to 15 l/min; 100 bar; 75

°C

Torsion and bending load Not permitted

SIMATIC RF300

274 System Manual, 07/2016, C79000-G8976-C345-0x

Page 83

ISO transponder

6GT2600-0AF00

Design, dimensions and weight

Dimensions (Ø x H)

M6 x 5.8 mm

Weight

1 g

1)

The values for shock and vibration are maximum values and must not be applied continuously.

8.6.5

Dimension drawing

8.6 MDS D127

Type of mounting

Figure 8-13 Dimensions in mm

• Glued

• 1 x M3 screw

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

275

Page 84

ISO transponder

8.7

MDS D139

8.7.1

Characteristics

MDS D139

Characteristics

(Page 52).

Mounting on metal

Yes, with spacer

ISO standard

ISO 15693

Degree of protection

IP68/IPx9K

Note

Compatibility with SIMATIC RF300 depending on the article number

The transponder MDS D139 with article numbe

SIMATIC RF300 system. The transponder MDS D139 with article number 6GT2600

is not compatible.

8.7 MDS D139

Area of application Applications in production logistics and in assembly

lines subject to high temperatures (up to +220 °C)

Typical application areas:

• Paintshops and their preparatory treatments)

• Primer coat, electrolytic dip area, cataphoresis

with the associated drying furnaces

• Top coat area with drying furnaces

Memory size 112 bytes of EEPROM user memory

Write/read range See section Field data of ISO transponders (MDS D)

• Washing areas at temperatures > 85 °C

• Other applications with higher temperatures

r 6GT2600-0AA10 is compatible with the

-0AA00

SIMATIC RF300

276 System Manual, 07/2016, C79000-G8976-C345-0x

Page 85

ISO transponder

8.7.2

Ordering data

Article number

MDS D139

6GT2600-0AA10

Article number

Spacer

6GT2690-0AA00

(Ø x H): 22 x 60 mm

(Ø x H): 22 x 47 mm

8.7.3

Mounting on metal

Mounting on metal

h

≥ 30 mm

8.7 MDS D139

Table 8- 15 Ordering data for MDS D139

Table 8- 16 Ordering data for MDS D139 accessory

Direct mounting of the MDS D139/D339 on metal is not allowed. A distance of ≥ 30 mm is

recommended. This can be achieved using spacers (see "Ordering data (Page 423)").

Quick change holder

Quick change holder

6GT2690-0AH00

6GT2690-0AH10

SIMATIC RF300

System Manual, 07/2016, C79000-G8976-C345-0x

Figure 8-14 Mounting the MDS D139/D339 on metal with spacer

277

Page 86

ISO transponder

Flush-mounting

h

≥ 30 mm

a

≥ 100 mm

Note

Going below the distances

If the distances (a and h) are not observed, a reduction of the field data results. It is possible

to mount the MDS

recommended that a test is performed in critical applications.

8.7.4

Cleaning the mobile data memory

Note

Do not clean the transponder with mechanical tools, sand

cleaning methods result in damage to the transponder.

Clean the transponder only with the chemical cleansing agents listed in Chapter

resistance of the transponders

8.7 MDS D139

It is possible to mount the MDS D139/D339 in metal. With large antennas, for example ANT

D5, this leads to a reduction of ranges.

Figure 8-15 Flush-mounting of the MDS D139/D339 in metal with spacer

with metal screws (M5). This has no tangible impact on the range. It is

-blasting or pressure hose. These

Chemical

(Page 90).

SIMATIC RF300

278 System Manual, 07/2016, C79000-G8976-C345-0x

Page 87

ISO transponder

8.7.5

Technical specifications

6GT2600-0AA10

Product type designation

SIMATIC MDS D139

Memory

Memory configuration

Read cycles (at < 40 ℃)

> 1014

Write cycles (at < 40 ℃)

> 106

Data retention time (at < 40 ℃)

> 10 years

data of ISO transponders (MDS D) (Page 52)"

MTBF (Mean Time Between Failures)

228 years

Mechanical specifications

Housing

Recommended distance to metal

≥ 30 mm

Power supply

Inductive, without battery