Page 1

System Manual Edition 05/2005

RFID-SYSTEMS

SIMATIC RF 300

simatic sensors

Page 2

Page 3

SIMATIC

RFID systems

RF 300

System Manual

Introduction

Safety information

System overview

RF 300 system planning

Readers

Transponder/tags

Communication modules

1

2

3

4

5

6

7

Accessories

Appendix

8

A

Edition 05/2005

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring to property damage only have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Copyright Siemens AG . All rights reserved.

The distribution and duplication of this document or the utiliz ation and transmission of its

contents are not permitted without express written permission. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of a utility

model or design, are reserved.

Siemens AG

Automation and Drives

Postfach 4848, 90327 Nuremberg, Germany

Siemens Aktiengesellschaft --

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the

hardware and software described. Since variance cannot be precluded entirely, we cannot

guarantee full consistency. However, the information in this publication is reviewed

regularly and any necessary corrections are included in subsequent editions.

Siemens AG 2005

Technical data subject to change

Page 5

Table of contents

1 Introduction............................................................................................................................................. 1-1

1.1 Navigating in the system manual............................................................................................... 1-2

2 Safety information................................................................................................................................... 2-1

3 System overview..................................................................................................................................... 3-1

3.1 RFID systems............................................................................................................................. 3-1

3.2 RF 300 ....................................................................................................................................... 3-2

3.2.1 RF 300 application areas ........................................................................................................... 3-2

3.2.2 RFID components and their function ......................................................................................... 3-3

3.2.3 Technical data............................................................................................................................ 3-4

4 RF 300 system planning ......................................................................................................................... 4-1

4.1 Fundamentals of application planning .......................................................................................4-1

4.1.1 Transmission window and read/write distance .......................................................................... 4-2

4.1.2 Width of the transmission window.............................................................................................. 4-3

4.1.3 Impact of secondary fields ......................................................................................................... 4-3

4.1.4 Permissible directions of motion of the transponder.................................................................. 4-4

4.1.5 Operation in static and dynamic mode ...................................................................................... 4-5

4.1.6 Dwell time of the transponder .................................................................................................... 4-6

4.1.7 Communication between communication module, reader and transponder ............................. 4-7

4.1.8 Calculation example................................................................................................................... 4-9

4.2 Field data of transponders and readers................................................................................... 4-12

4.3 Impact of the data volume on the transponder speed with RF 310-R (IQ-Sense) .................. 4-13

4.4 Installation guidelines............................................................................................................... 4-14

4.4.1 Overview .................................................................................................................................. 4-14

4.4.2 Reduction of interference due to metal.................................................................................... 4-15

4.4.3 Effects of metal on different transponders and readers........................................................... 4-18

4.4.4 Impact on the transmission window by metal .......................................................................... 4-19

4.5 Chemical resistance of the transponders ................................................................................ 4-21

4.6 EMC Guidelines .............................................

4.6.1 Overview .................................................................................................................................. 4-26

4.6.2 Definition .................................................................................................................................. 4-27

4.6.3 Basic rules................................................................................................................................ 4-28

4.6.4 Propagation of electromagnetic interference ........................................................................... 4-29

4.6.5 Cabinet configuration ............................................................................................................... 4-32

4.6.6 Prevention of interference sources .......................................................................................... 4-35

4.6.7 Equipotential bonding .............................................................................................................. 4-36

4.6.8 Cable shielding......................................................................................................................... 4-37

.......................................................................... 4-26

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

iii

Page 6

Table of contents

5 Readers.................................................................................................................................................. 5-1

5.1 RF 310-R.................................................................................................................................... 5-2

5.1.1 Features ..................................................................................................................................... 5-2

5.1.2 Indicators.................................................................................................................................... 5-2

5.1.3 Transmission window................................................................................................................. 5-3

5.1.4 Metal-free area........................................................................................................................... 5-3

5.1.5 Minimum distance between several RF 310-R units ................................................................. 5-4

5.1.6 RF 310-R field data .................................................................................................................... 5-4

5.1.7 Pin assignment of the IQ-Sense interface .................................................................................5-5

5.1.8 Cable and connector pin assignment......................................................................................... 5-5

5.1.9 Technical data of the RF 310-R ................................................................................................. 5-6

5.1.10 FCC information ......................................................................................................................... 5-7

5.1.11 RF 310-R ordering data ............................................................................................................. 5-7

5.1.12 Dimension drawing..................................................................................................................... 5-8

6 Transponder/tags.................................................................................................................................... 6-1

6.1 RF 320-T .................................................................................................................................... 6-2

6.1.1 Features ..................................................................................................................................... 6-2

6.1.2 Metal-free area........................................................................................................................... 6-3

6.1.3 Field data.................................................................................................................................... 6-4

6.1.4 Technical data............................................................................................................................ 6-5

6.1.5 Ordering data ............................................................................................................................. 6-6

6.1.6 Dimension drawing..................................................................................................................... 6-6

6.2 RF 340-T .................................................................................................................................... 6-7

6.2.1 Features ..................................................................................................................................... 6-7

6.2.2 Metal-free area........................................................................................................................... 6-8

6.2.3 Field data.................................................................................................................................... 6-9

6.2.4 Technical data.......................................................................................................................... 6-10

6.2.5 Ordering data ............................................

............................................................................... 6-11

6.2.6 Dimension drawing................................................................................................................... 6-11

7 Communication modules ........................................................................................................................ 7-1

7.1 8xIQ-Sense ................................................................................................................................ 7-2

7.1.1 Features ..................................................................................................................................... 7-2

7.1.2 Indicators.................................................................................................................................... 7-3

7.1.3 Configuration.............................................................................................................................. 7-4

7.1.4 Addressing ................................................................................................................................. 7-5

7.1.5 Technical data............................................................................................................................ 7-7

7.1.6 Ordering data ............................................................................................................................. 7-7

8 Accessories ............................................................................................................................................ 8-1

8.1 MOBY software .......................................................................................................................... 8-1

A Appendix.................................................................................................................................................A-1

A.1 Certificates and approvals..........................................................................................................A-1

A.2 Service and support ...................................................................................................................A-3

A.3 Contact partners......................................................................................................................... A-3

A.4 Application consulting ................................................................................................................ A-4

A.5 Training ...................................................................................................................................... A-4

List of abbreviations.................................................................................................................... Glossary-1

Glossary ..................................................................................................................................... Glossary-1

Index

RF 300

iv System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 7

Table of contents

Tables

Table 4-1 Reduction of field data by metal (in %): Transponder and RF 310-R...................................... 4-20

Table 4-2 Interference sources: origin and effect .................................................................................... 4-30

Table 4-3 Causes of coupling paths......................................................................................................... 4-31

Table 5-1 RF 310-R indicators ................................................................................................................... 5-2

Table 5-2 RF 310-R pin assignment .......................................................................................................... 5-5

Table 5-3 Technical data of the RF 310-R ................................................................................................. 5-6

Table 6-1 Field data for transponder RF 320-T to reader RF 310-R ......................................................... 6-4

Table 6-2 Field data for transponder RF 320-T to RF 320-T ..................................................................... 6-4

Table 6-3 Technical data of the RF 320-T ................................................................................................. 6-5

Table 6-4 Field data for transponder RF 340-T to reader RF 310-R ......................................................... 6-9

Table 6-5 Transponder RF 340-T to transponder RF 340-T...................................................................... 6-9

Table 6-6 Technical data of the RF 340-T ............................................................................................... 6-10

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

v

Page 8

Table of contents

RF 300

vi System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 9

Introduction

Purpose of this document

This system manual contains all the information needed to plan and configure the system.

It is intended both for programming and testing/debugging personnel who commission the

system themselves and connect it with other units (automation systems, further

programming devices), as well as for service and maintenance personnel who install

expansions or carry out fault/error analyses.

Scope of validity of this document

This documentation is valid for all supplied variations of the SIMATIC RF 300 system and

describes the state of delivery as of May 2005.

Conventions

The following terms/abbreviations are used synonymously in this document:

• Reader, read/write device, SLG

• Tag, transponder, mobile data memory, MDS

• Communication module, interface module, ASM

1

History

Previous editions of these operating instructions:

Edition Remarks

05/2005 First Edition

Declaration of conformity

The EC declaration of conformity and the corresponding documentation are made available

to authorities in accordance with the EC directives stated above. Your sales representative

can provide these on request.

Observance of installation guidelines

The installation guidelines and safety instructions given in this documentation must be

followed during commissioning and operation.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

1-1

Page 10

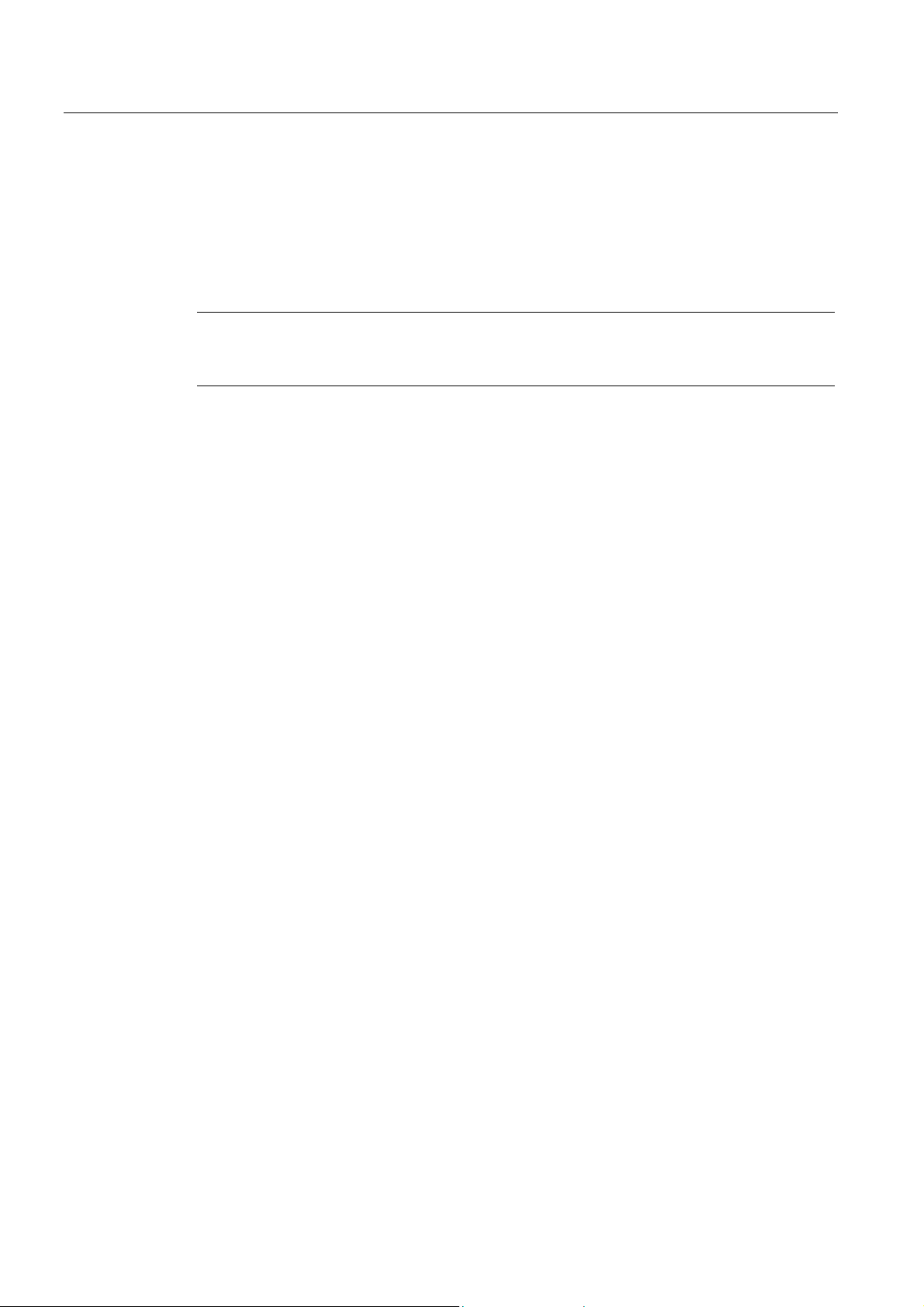

Introduction

1.1 Navigating in the system manual

1.1 1.1 Navigating in the system manual

Structure of contents Contents

Contents Organization of the documentation, including the index of pages and chapters

Introduction Purpose, layout and description of the important topics.

Safety information Refers to all the valid technical safety aspects which have to be adhered to while installing,

commissioning and operating the product/system and with reference to statutory

regulations.

System overview Overview of all RF identification systems, system overview of SIMATIC RF 300

RFID system planning Information about possible applications of SIMATIC RF 300, support for application

planning, tools for finding suitable SIMATIC RD 300 components.

Readers Description of readers which can be used for SIMATIC RF 300

Transponders Description of transponders which can be used for SIMATIC RF 300

Communication modules Description of communication modules used for SIMATIC RF 300

Accessories Products available in addition to SIMATIC RF 300

Appendix Service and support, contact partners, training centers

Error messages Overview of error messages

List of abbreviations List of all abbreviations used in the document

RF 300

1-2 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 11

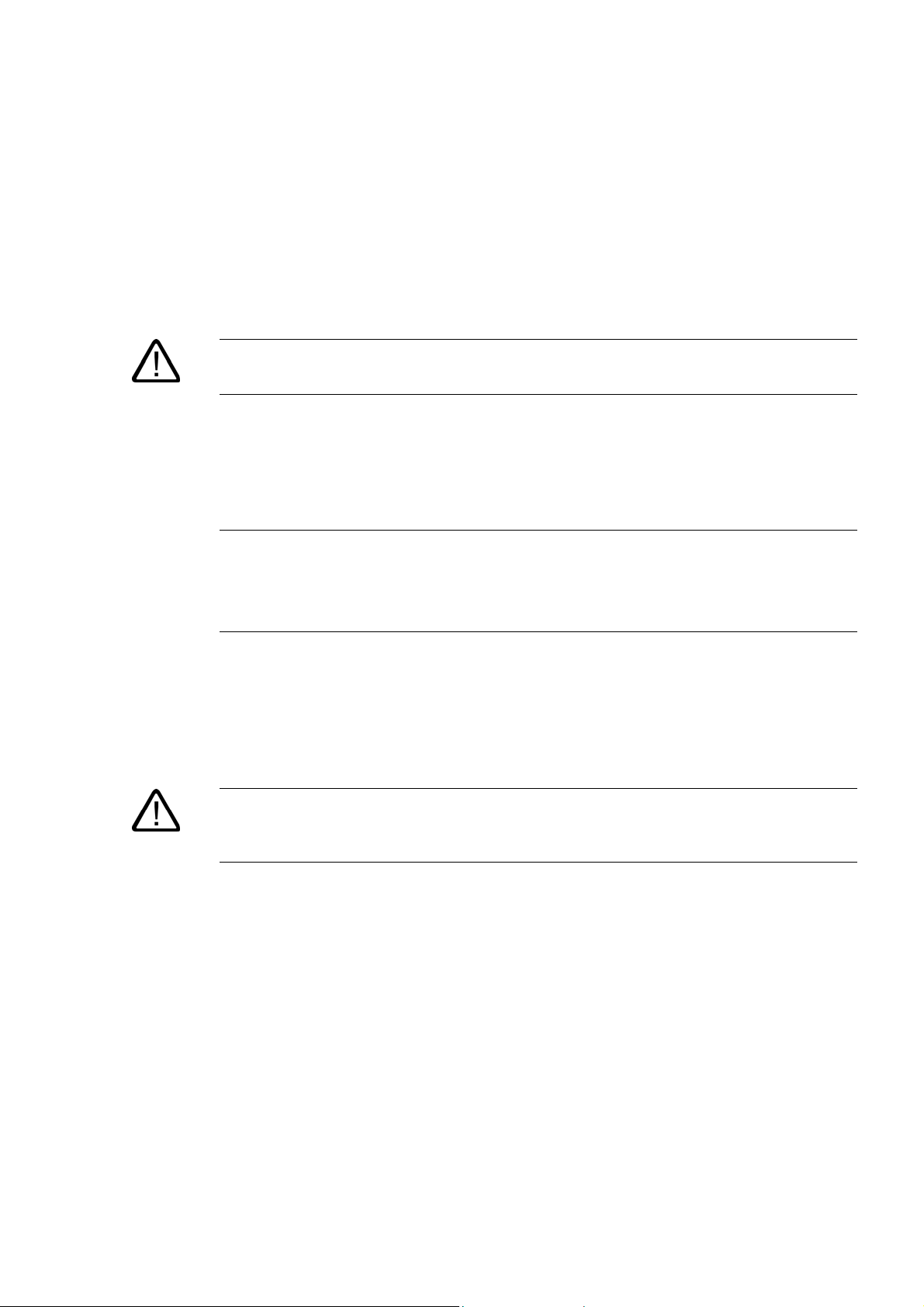

Safety information

Caution

Please observe the safety instructions on the back cover of this documentation.

SIMATIC RFID products comply with the salient safety specifications to IEC, VDE, EN, UL

and CSA. If you have questions about the admissibility of the installation in the designated

environment, please contact your service representative.

Repairs

Caution

Alterations to the devices are not permitted.

Failure to observe this requirement shall constitute a revocation of the radio equipment

approval, CE approval and manufacturer's warranty.

Repairs may only be carried out by authorized qualified personnel.

2

Warning

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or risk of personal injury to the user.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

2-1

Page 12

Safety information

System expansion

Only install system expansion devices designed for this device. If you install other upgrades,

you may damage the system or violate the safety requirements and regulations for radio

frequency interference suppression. Contact your technical support team or your sales outlet

to find out which system upgrades are suitable for installation.

Caution

If you cause system defects by installing or exchanging system expansion devices, the

warranty becomes void.

RF 300

2-2 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 13

System overview

3

3.1 3.1 RFID systems

RFID systems from Siemens control and optimize material flow. They identify reliably,

quickly and economically, are insensitive to contamination and store data directly on the

product.

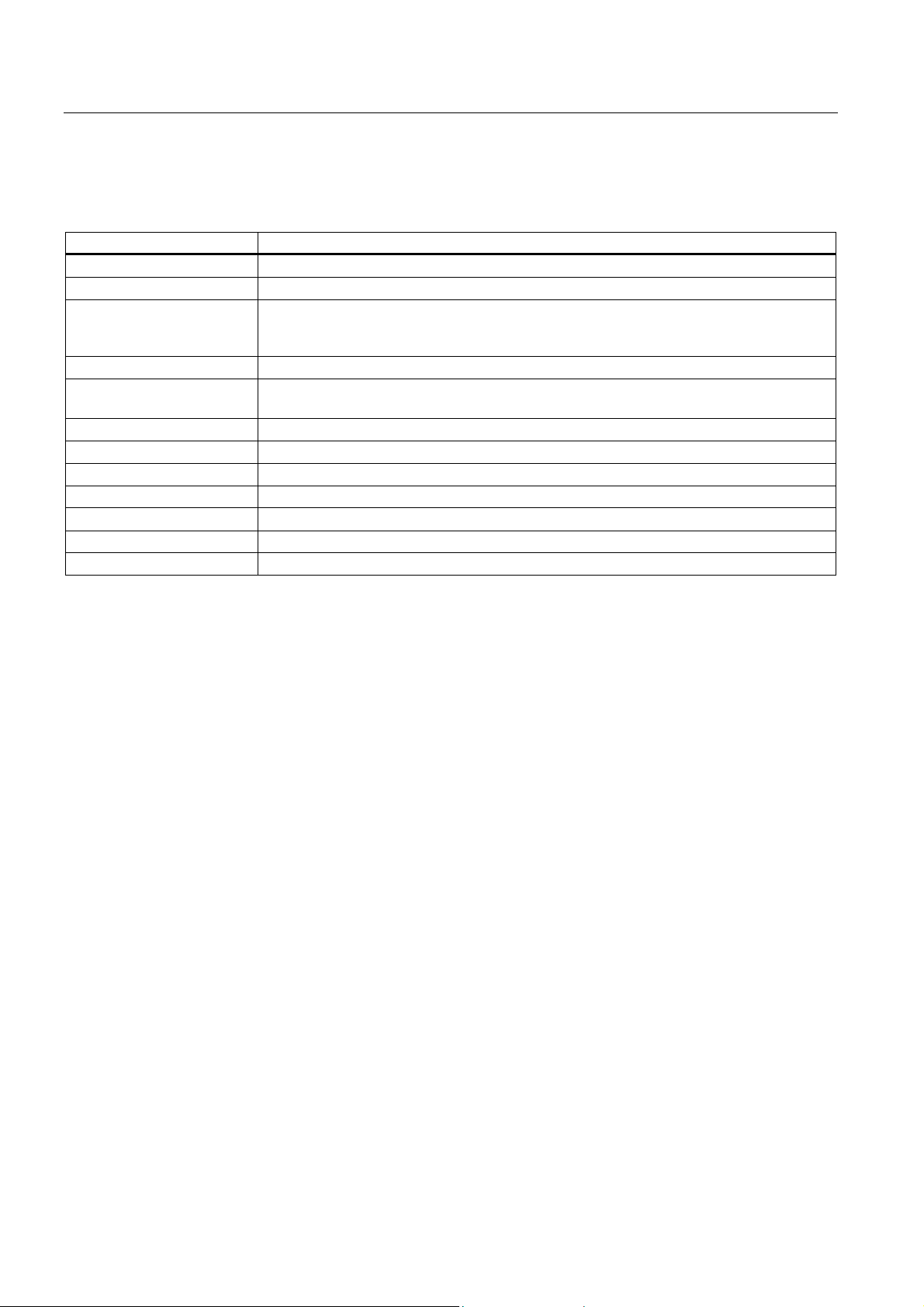

Identification system Frequency Max. range Max.

memory

RF 300 13.56 MHz 0.25 m 20 byte

EEPROM

64 KB

FRAM

MOBY F 125 kHz 0.4 m 192 byte

EEPROM

MOBY D 13.56 MHz 0.8 m 112 byte

EEPROM

MOBY E 13.56 MHz 0.1 m 752 byte

EEPROM

MOBY I 1.81 MHz 0.15 m 32 KB

FRAM

MOBY U 2.45 GHz 3.0 m 32 KB RAM 4800 + 85 °C or

Data

transfer rate

(typical) in

byte/s

3750 SLG: -25 °C

100 +130 °C Multitag capability

110 + 85 °C or

350 + 150 °C Battery-free data

1250 + 85 °C or

Max.

temperature

to +70 °C

MDS: -40 °C

to +85 °C

or

+ 220 °C

cyclic

+ 200 °C

+ 220 °C

cyclic

+ 220 °C

cyclic

Special features

IQ-Sense interface

available;

Battery-free data

memory

SmartLabels based

on ISO 15693

e.g. Tagit/Icode

memory

Battery-free data

memory

Frequency hopping

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

3-1

Page 14

System overview

3.2 RF 300

3.2 3.2 RF 300

SIMATIC RF 300 is an inductive identification system specially designed for use in industrial

production for the control and optimization of material flow. Thanks to its compact

components it is particularly suited to small assembly lines and conveyor systems with

restricted space for installation. The rugged components feature an attractive

price/performance ratio.

3.2.1 RF 300 application areas

SIMATIC RF 300 is used primarily for contactless identification of containers, pallets and

workpiece carriers in a closed production loop, i.e. the data carriers (transponders) remain in

the production chain and are not shipped out with the products. Thanks to the compact

enclosure dimensions of both the transponders and readers, SIMATIC RF 300 is particularly

suitable for (small) assembly lines where space is at a premium.

The main application areas of SIMATIC RF 300 are:

• Assembly and handling systems, assembly lines (identification of workpiece carriers)

• Production logistics (material flow control, identification of containers and other vessels)

• Parts identification (e.g. transponder is attached to product/pallet).

• Conveyor systems

RF 300

3-2 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 15

System overview

3.2 RF 300

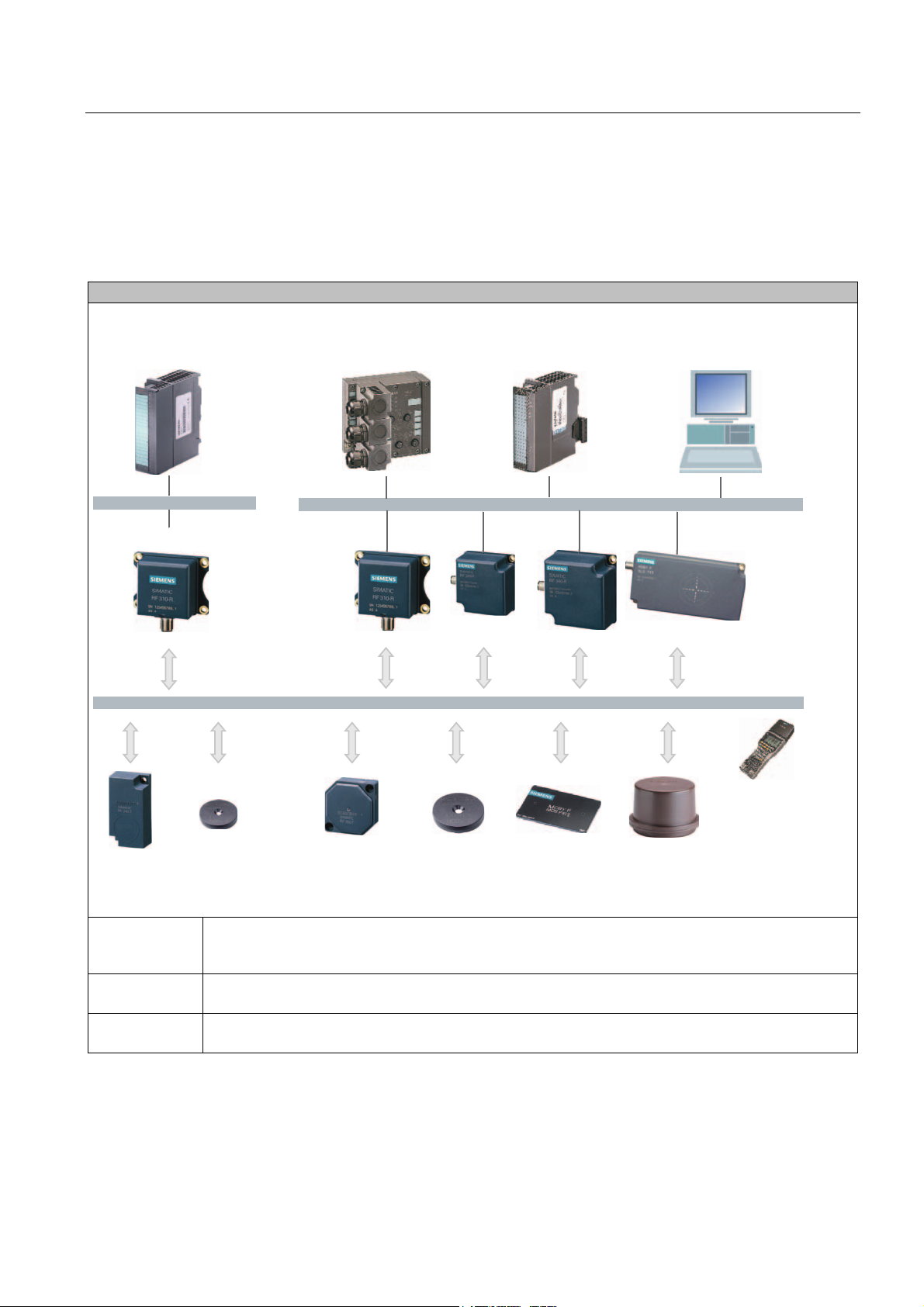

3.2.2 RFID components and their function

RF 300 system components

[,46HQVHIRU(70

RQ6ZLWK)&

$60IRU

352),%86'39

$60IRU

6,0$7,&6

3&LQWHUIDFHWKLUGSDUW\3/&

,46HQVHLQWHUIDFH

5)5

5)7

5)7

3RZHUDQGGDWDWUDQVPLVVLRQ0+]

5)7

6HULDODV\QFKURQRXVLQWHUIDFH5656

5)5

5)5

5)7

5)5

5)7

5)5

+DQG

WHUPLQDO

5)7

Communication

modules

Readers The reader ensures inductive communication, supplies power to the transponders, and handles the

Transponders Transponders (mobile data memories) are used, for example, in place of barcodes and can contain all

A communication module (interface module) is used to integrate the RF identification system in

PLC/automation systems. In the case of SIMATIC RF 300, the reader is connected to an S7 automation

system either via the 8xIQ-Sense module or an equivalent MOBY interface module (e.g. ASM 475).

connection to the various PLCs (e.g. SIMATIC S7).

product-specific data in addition to the product number.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

3-3

Page 16

System overview

3.2 RF 300

3.2.3 Technical data

RFID system RF 300

Type Inductive identification system for industrial

applications

Transmission frequency data/energy 13.56 MHz

Memory capacity 20 bytes up to 64 KB user memory (r/w)

4 bytes fixed code as serial number (ro)

Memory type EEPROM / FRAM

Write cycles EEPROM: > 100 000

FRAM: Unlimited

Read cycles Unlimited

Data management Byte-oriented access

Data transfer rate Transponder-Reader 3 KB/s

Read/write distance (system limit; depends on

reader and transponder)

Operating temperature Reader: -25°C to +70°C

Degree of protection Reader: IP 65

Can be connected to SIMATIC S7-300, Profibus DP V1,

Special features High noise immunity

Approvals ETS 300 330 (Europe)

Up to 250 mm

Transponder: -40°C to +85°C

and up to +220°C cyclic

Transponder: > IP 67

PC, third-party PLC

Compact components

Extensive diagnostic options

A reader with IQ-Sense interface

FCC Part 15 (USA), UL/CSA

CE

RF 300

3-4 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 17

RF 300 system planning

4.1 4.1 Fundamentals of application planning

Assess your application according to the following criteria, in order to choose the right

SIMATIC RF 300 components:

• Transmission distance (read/write distance)

• Tracking tolerances

• Static or dynamic data transfer

• Data volume to be transferred

• Speed in case of dynamic transfer

• Metal-free rooms for transponders and readers

• Ambient conditions such as relative humidity, temperature, chemical impacts, etc.

4

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-1

Page 18

RF 300 system planning

4.1 Fundamentals of application planning

4.1.1 Transmission window and read/write distance

The reader generates an inductive alternating field. The field is strongest near to the reader.

The strength of the field decreases in proportion to the distance from the reader. The

distribution of the field depends on the structure and geometry of the antennas in the reader

and transponder.

A prerequisite for the function of the transponder is a minimum field strength at the

transponder achieved at a distance S

from the reader. The picture below shows the

g

transmission window between transponder and reader:

7UDQVPLVVLRQ

ZLQGRZ

/'

5)[[5

6J

6

7UDQVSRQGHU

6LGHYLHZ

63

6,0$7,&

5)7

/6DPD[

/6DPLQ

5)7

7UDQVSRQGHU

3ODQYLHZ

Sa Operating distance between transponder and reader

Sg Limit distance (maximum clear distance between upper surface of the reader and the

transponder, at which the transmission can still function under normal conditions)

L Length of a transmission window

The length Ld is valid for the calculation. At Sa,min, the field length increases from Ld to Lmax.

SP Intersection of the axes of symmetry of the transponder

The active field for the transponder consists of a circle (cf. plan view).

6,(0(16

The transponder can be used as soon as the intersection (SP) of the transponder enters the

circle of the transmission window.

RF 300

4-2 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 19

RF 300 system planning

4.1 Fundamentals of application planning

From the diagram above, it can also be seen that operation is possible within the area

between Sa and Sg. The active operating area reduces as the distance increases, and

shrinks to a single point at distance Sg. Only static mode should thus be used in the area

between Sa and Sg.

4.1.2 Width of the transmission window

Determining the width of the transmission window

The following approximation formula can be used for practical applications:

0, 4BL=⋅

Figure 4-1 Formula: Width of the transmission window

B: Width of the transmission window

L: Length of the transmission window

Tracking tolerances

The width of the transmission window (B) is particularly important for the mechanical tracking

tolerance. The formula for the dwell time is valid without restriction when B is observed.

4.1.3 Impact of secondary fields

Secondary fields in the range from 0 to 20 mm always exist.

They should only be applied during planning in exceptional cases, however, since the

read/write distances are very limited. Exact details of the secondary field geometry cannot be

given, since these values depend heavily on the operating distance and the application.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-3

Page 20

RF 300 system planning

4.1 Fundamentals of application planning

4.1.4 Permissible directions of motion of the transponder

Active area and direction of motion of the transponder

The transponder and reader have no polarization axis, i.e. the transponder can come in from

any direction, be placed at any position, and cross the transmission window. The figure

below shows the active area for various directions of transponder motion:

/

RU

%

Figure 4-2 Active areas of the transponder for different directions of transponder motion

/

%

RU

%

/

RF 300

4-4 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 21

RF 300 system planning

4.1 Fundamentals of application planning

4.1.5 Operation in static and dynamic mode

Operation in static mode

If working in static mode, the transponder can be operated up to the limit distance (Sg). The

transponder must then be positioned exactly over the reader:

7UDQVSRQGHU

7UDQVPLVVLRQ

ZLQGRZ

5HDGHUV

Figure 4-3 Operation in static mode

Operation in dynamic mode

When working in dynamic mode, the transponder moves past the reader. The transponder

can be used as soon as the intersection (SP) of the transponder enters the circle of the

transmission window.

7UDQVPLVVLRQ

ZLQGRZ

6J

63

3ODQYLHZ

63

7UDQVSRQGHU

Figure 4-4 Operation in dynamic mode

7UDQVSRQGHU

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-5

Page 22

RF 300 system planning

4.1 Fundamentals of application planning

4.1.6 Dwell time of the transponder

The dwell time is the time in which the transponder dwells within the transmission window of

a reader. The reader can exchange data with the transponder during this time.

The dwell time is calculated thus:

0,8[ ]

Lm

⋅

t

=

K

[/]

vms

TPDR

tV: Dwell time of the transponder

L: Length of the transmission window

v

: Speed of the transponder (TPDR) in dynamic mode

TPDR

0,8: Constant factor used to compensate for temperature impacts and production tolerances

The dwell time can be of any duration in static mode. The dwell time must be sufficiently long

to allow communication with the transponder.

The dwell time is defined by the system environment in dynamic mode. The volume of data

to be transferred must be matched to the dwell time or vice versa.

In general:

tt≥

v

K

tV:: Dwell time of the data memory within the field of the reader

t

: Communication time between transponder and communication module

K

RF 300

4-6 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 23

RF 300 system planning

4.1 Fundamentals of application planning

4.1.7 Communication between communication module, reader and transponder

Communication with RF 310-R

Communication between the communication module (IQ Sense), RF 310-R reader and

transponders takes place in fixed telegram cycles. 3 cycles of approximately 3 ms are

always needed for the transfer of a read or write command. 1 or 2 bytes of user data can be

transferred with each of these commands. The acknowledgement transfer (status or read

data) takes place in 3 further cycles. Approximately 18 ms are thus needed for a complete

command acknowledgement sequence with up to 2 bytes of user data. The transponder

must be present within the field of the reader.

Calculation of the communication time for interference-free transfer

KWort

tKtn=+ ⋅

Calculation of the maximum amount of user data

v

tK

max

−

=

Wort

t

n

tK Communication time between communication module, RF 310-R (IQ-Sense) reader and

transponder

t

Dwell time

V

n Amount of user data in words (2 bytes)

n

Max. amount of user data in words (2 bytes) in dynamic mode

max

t

Transfer time for 1 word (2 bytes)

Word

K Constant (internal system time) This contains the time for power buildup on the transponder

and for command transfer

Note

If only 1 byte of user data is transferred, you still need to allow the time for 1 word.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-7

Page 24

RF 300 system planning

4.1 Fundamentals of application planning

Time constants K and t

K (ms) t

9 18 Read

9 27 Write (EEPROM area)

9 18 Write (FRAM area)

The table of time constants applies to every command. If a user command consists of

several subcommands, the above t

Word

(ms) Command

Word

formula must be applied to each subcommand.

K

RF 300

4-8 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 25

RF 300 system planning

4.1 Fundamentals of application planning

4.1.8 Calculation example

Task specification

A transport system moves pallets with transponders at a maximum velocity of V

TPDR

= 0.14

m/s. The following RFID components were chosen:

• 8xIQ-Sense module

• RF 310-R reader

• RF 340-T transponder

a) The designer of the plant is to be given mechanical specifications.

b) The programmer should be given the maximum number of words in dynamic mode.

Refer to the tables in the "Field data of transponders and readers" section for the technical

data.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-9

Page 26

RF 300 system planning

4.1 Fundamentals of application planning

Determine tolerance of pallet transport height

'LUHFWLRQRIPRWLRQ

7UDQVSRQGHU

+

5HDGHUV

VLGHYLHZ

+6

Figure 4-5 Tolerance of pallet transport height

Determine tolerance of pallet side transport

'LUHFWLRQRIPRWLRQRIWKHWUDQVSRQGHU

7UDQVSRQGHU

&HQWHUOLQHRIWUDQVSRQGHUDQGUHDGHU

5HDGHUV

7ROHUDQFHEDQGRIVLGHWUDQVSRUW

D

+PP

% ZLGWKRIWKHWUDQVPLVVLRQZLQGRZ

LQG\QDPLFPRGH

%

Figure 4-6 Tolerance of pallet side transport

Minimum distance from reader to reader

Refer to the field data of the reader for this value.

Minimum distance from transponder to transponder

Refer to the field data of the transponder for this value.

RF 300

4-10 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 27

RF 300 system planning

4.1 Fundamentals of application planning

Calculation of the maximum amount of user data in dynamic mode

Step Formula/calculation

1. Calculate dwell time of the

transponder

2. Calculate maximum user data (n

for reading

3. Calculate maximum user data (n

for writing

(FRAM area)

Refer to the "Field data of all transponders and readers" table for value L.

Value V

tsms

== = =

v

Take value tv from Step 1.

max)

Take values K and t

5HDG

Take value tv from Step 1.

max)

Take values K and t

6FKUHLEHQ

= 0.14m/s

TPDR

0,8 0,04 0, 8

Lm

⋅⋅

vms

TPDR

0,14 /

from Table "Time constants K and t

Word

v

t K ms ms

−−

Wort

tms

v

t K ms ms

−−

Wort

tms

228 9

==⇒=

from Table "Time constants K and t

Word

228 9

==⇒=

0,228 228

18

18

Word

12,17 12

12,17 12

n Words

max

Word

nWorte

max

".

".

Result

A maximum of 12 words can be read or written when passing the transponder.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-11

Page 28

RF 300 system planning

4.2 Field data of transponders and readers

4.2 4.2 Field data of transponders and readers

The following table shows the field data for all SIMATIC RF 300 components of transponders

and readers. It facilitates the correct selection of a transponder and reader.

All the technical data listed are typical data and are applicable for an ambient temperature of

between 0 C and +50 °C, a supply voltage of between 22 V and 27 V DC and a metal-free

environment. Tolerances of ±20 % are admissible due to production or temperature

conditions.

If the entire voltage range at the reader of 20 V DC to 30 V DC and/or the entire temperature

range of transponders and readers is used, the field data are subject to further tolerances.

Field data of all transponders and readers without interference from metal

RF 310-R reader RF 320-T transponder RF 340-T transponder

Length of the transmission window in mm (L) 30 mm 40 mm

Width of the transmission window in mm (W) 12 mm 16 mm

Working distance in mm (Sa) 0-12 mm 0-20 mm

Limit distance in mm (Sg) 18 mm 30 mm

• A maximum mean deviation of ±2 mm is possible in static mode (without affecting the

field data)

• This is reduced by approx. 15 % if the transponder enters the transmission window

laterally (see also "Transmission window" figure)

Minimum distance from transponder to transponder

Readers RF 320-T transponder RF 340-T transponder

RF 310-R > 100 mm 400 mm

Minimum distance from reader to reader

The minimum distance from RF 310-R to RF 310-R must be at least 400 mm.

Notice

Adherence to the values specified in the "Minimum distance from reader to reader" table is

essential. The inductive fields may be affected if the distance is smaller. In this case, the

data transfer time would increase unpredictably or a command would be aborted with an

error.

RF 300

4-12 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 29

RF 300 system planning

4.3 Impact of the data volume on the transponder speed with RF 310-R (IQ-Sense)

4.3 4.3 Impact of the data volume on the transponder speed with RF 310-R

(IQ-Sense)

The curves shown here show the relationship between the speed of the RF 320 and RF 340

transponders and the volume of data transferred.

90'6LQ

:ULWHWUDQVSRQGHU

5HDGWUDQVSRQGHU

Figure 4-7 Relationship between speed and data volume when using the RF 310-R (IQ-Sense)

1RRIE\WHVQ

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-13

Page 30

RF 300 system planning

4.4 Installation guidelines

4.4 4.4 Installation guidelines

4.4.1 Overview

The transponder and reader are inductive devices. Any type of metal, in particular iron and

ferromagnetic materials, in the vicinity of these devices will affect their operation. Some

points need to be considered during planning and installation if the values described in the

"Field data" section are to retain their validity:

• Minimum distance between two readers

• Minimum distance between two adjacent data memories

• Metal-free area for flush-mounting of readers and transponders in metal

• Mounting of several readers on metal frames or racks

The following sections describe the impact on the operation of the identification system when

mounted in the vicinity of metal.

RF 300

4-14 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 31

RF 300 system planning

4.4 Installation guidelines

4.4.2 Reduction of interference due to metal

Interference due to metal rack Problem

1RQPHWDOOLFVSDFHU

7UDQVSRQGHU

6D

5HDGHUV

7UDQVSRQGHU

6KHHW0HWDOUDFN

0HWDO

A metal rack is located above the

transmission window of the reader.

This affects the entire field. In

particular, the transmission window

between reader and transponder is

reduced.

Remedy:

The transmission window is no

longer affected if the transponder is

mounted differently.

5HD

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-15

Page 32

RF 300 system planning

4.4 Installation guidelines

Flush-mounting

Flush-mounting of transponders and readers Problem

1RQPHWDOOLFVSDFHU 6KHHW

0HWDO

5HDGHUV

0HWDO

PP

[!PP

5HD

DD

E

5HD

E

Flush-mounting of transponders and

readers is possible in principle.

However, the size of the

transmission window is significantly

reduced. The following measures

can be used to counteract the

reduction of the window:

Remedy:

Enlargement of the non-metallic

spacer below the transponder

and/or reader.

The transponder and/or reader are

10 to 20 mm higher than the metal

surround.

(The value x ≥ 100 mm is valid e.g.

for RF 310-R. It indicates that the

reader is no longer affected

significantly by the metal at a

distance of x ≥ 100 mm.)

Remedy:

Increase the non-metallic distance

a, b.

The following rule of thumb can be

used:

• Increase a, b by a factor of 2 to 3

over the values specified for

metal-free areas

• Increasing a, b has a greater

effect for readers or

transponders with a large limit

distance than for readers or

transponders with a small limit

distance.

RF 300

4-16 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 33

RF 300 system planning

4.4 Installation guidelines

Mounting of several readers on metal frames or racks

Any reader mounted on metal couples part of the field to the metal frame. There is normally

no interaction as long as the minimum distance D and metal-free areas a, b are maintained.

However, interaction may take place if an iron frame is positioned unfavorably. Longer data

transfer times or sporadic error messages at the communication module are the result.

Mounting of several readers on metal racks Problem: Interaction between readers

Remedy

Increase the distance D between the two readers.

5HDGHU

:ULWHU

'

5HDGHU

:ULWHU

5HDGHU

:ULWHU

5HDGHU

:ULWHU

Remedy

Introduce one or more iron struts in order to shortcircuit the stray fields.

UHDGHU

ZULWHU

1RQPHWDOOLF

VSDFHU

UHDGHU

ZULWHU

Remedy

Insert a non-metallic spacer of 20 to 40 millimeter

thickness between the reader and the iron frame. This

will significantly reduce the induction of stray fields on

the rack:

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-17

Page 34

RF 300 system planning

4.4 Installation guidelines

4.4.3 Effects of metal on different transponders and readers

Mounting different transponders on metal or flush-mounting

Not all transponders can be mounted directly on metal. For more information, please refer to

the descriptions of the individual transponders in the relevant sections.

The following section illustrates various possibilities for mounting, allowing for the effect of

metal on the particular transponder.

Transponders which can be mounted directly on metal

Any transponder whose operation is not affected by direct contact with metal can be mounted directly on metal.

Mounting of a transponder directly on

metal

0HWDO

D

E

0HWDO

Flush-mounting of a transponder in

metal

(a, b = required distance from metal)

RF 300

4-18 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 35

RF 300 system planning

4.4 Installation guidelines

Transponders which cannot be mounted directly on metal

Any transponder whose operation is interrupted by direct contact with metal cannot be mounted directly on metal. The

applicable minimum distance to metal must be maintained for the relevant transponder.

'DWDPHPRU\

K!PP

0HWDO

Mounting of a transponder on metal

with a non-metallic spacer

1RQPHWDO

'DWDPHPRU\

D!PP

0HWDO

1RQPHWDO

K!PP

4.4.4 Impact on the transmission window by metal

In general, the following points should be considered when mounting RFID components:

If the minimum guide values (a, h) are

not observed, a significant reduction of

the field data results. It is possible to

mount the transponder with metal

screws (M4 countersunk head

screws). This has no tangible impact

on the range.

• Direct mounting on metal is allowed only in the case of specially approved transponders.

• Flush-mounting of the components in metal reduces the field data; a test is

recommended in critical applications.

• When working inside the transmission window, it should be ensured that no metal rail (or

similar part) intersects the transmission field.

The metal rail would affect the field data.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-19

Page 36

RF 300 system planning

4.4 Installation guidelines

The impact of metal on the field data (Sg, Sa, L, B) is shown in tabular and graphical format in

this section. The values in the table describe the reduction of the field data in % with

reference to non-metal (100 % means no impact).

Reduction of field data: Transponder and Reader RF 310-R

Table 4-1 Reduction of field data by metal (in %): Transponder and RF 310-R

Transponder Reader RF 310-R

RF 320-T

Transponder without metal 100 95 80

Transponder on metal,

distance 20 mm

Flush-mounted in metal 80 70 60

RF 340-T

Transponder without metal 100 95 80

Transponder on metal, distance 20

mm

Flush-mounted in metal

distance 20 mm/

20 mm surround

without metal

100 80 70

100 95 80

90 85 70

on metal flush-mounted

in metal

(20 mm surround)

RF 300

4-20 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 37

RF 300 system planning

4.5 Chemical resistance of the transponders

4.5 4.5 Chemical resistance of the transponders

The following table provides an overview of the chemical resistance of the data memories

made of glass-fiber-reinforced epoxy resin (E624). The plastic housing has a notably high

resistance to chemicals used in automobiles (e.g.: oil, grease, diesel fuel, gasoline, etc,);

these are not specified separately.

RF 320-T transponder

Transponder RF 320-T is resistant to the substances specified in the following table.

Concentration 20°C 40°C 60°C

Allylchloride J

Formic acid 50 % J

100 % F

Ammonia gas J

Ammonia liquid, water-free j

Ammonium hydroxide 10 % J

Ethyl acrylate J

Ethyl glycol J

Gasoline, aroma-free J

Gasoline, containing benzol J

Benzoate (Na–, Ca.a.) J

Benzoic acid J

Benzol J

Benzenesulphonic acid J

Benzyl chloride j

Borax J

Boric acid J

Bromine, liquid j

Bromine, gas, dry j

Bromide (K–, Na.a.) J

Bromoform 100 % J

Bromine water j

Butadiene (1,3–) J

Butane gas J

Butanol j

Butyric acid 100 % F

Carbonate (ammonium,

Na.a.)

Chlorine, liquid j

Chlorine, gas, dry 100 % j

J

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-21

Page 38

RF 300 system planning

4.5 Chemical resistance of the transponders

Concentration 20°C 40°C 60°C

Chlorobenzene J

Chloride (ammonium, Na.a.) J

Chloroform j

Chlorophyl J

Chlorosulphonic acid 100 % j

Chlorine water (saturated

solution)

Chromate (K–, Na.a.) Up to 50 % J

Chromic acid Up to 30 % j

Chromosulphuric acid j

Citric acid J

Cyanamide J

Cyanide (K–, Na.a.) J

Dextrin (aqueous solution) J

Diethyl ether J

Diethylene glycol J

Dimethyl ether J

Dioxane j

Developer J

Acetic acid 100 % F

Ethanol J J

Fixer J

Fluoride (ammonium, K–,

Na.a.)

Hydrofluoric acid Up to 40 % J

Formaldehyde 50 % J

Formamide 100 % J

Glucon acid J

Glycerine J

Glycol J

Urine J

Uric acid J

Hydroxide (ammonium) 10 % J

Hydroxide (Na–, K–) 40 % J

Hydroxide (alkaline earth

metal)

Hypochlorite (K–, Na.a.) J

Iodide (K–, Na.a.) J

Silicic acid J

Cresol Up to 90 % j

Methanol 100 % J

Methylene chloride j

Lactic acid 100 % F

F

J

J

RF 300

4-22 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 39

RF 300 system planning

4.5 Chemical resistance of the transponders

Concentration 20°C 40°C 60°C

Mineral oils J

Nitrate (ammonium, K.a.) J

Nitroglycerine j

Oxalic acid J

Phenol 1 % J

Phosphate (ammonium,

Na.a.)

Phosphoric acid 50 % J

85 % J

Propanol J

Nitric acid 25 % j

Hydrochloric acid 10 % j

Brine j

Sulphur dioxide 100 % F

Carbon disulfide 100 % j

Sulphuric acid 40 % j

Sulphurous acid F

Soap solution J

Sulfate (ammonium, Na.a.) J

Sulfite (ammonium, Na.a.) j

Tar, aroma-free J

Turpentine J

Trichloroethylene j

Hydrogen peroxide 30 % J

Tartaric acid J

J

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-23

Page 40

RF 300 system planning

4.5 Chemical resistance of the transponders

RF 340-T transponder

The following table gives an overview of the chemical composition of the data memories

made from polyamide 12. The plastic housing has a notably high resistance to chemicals

used in automobiles (e.g.: oil, grease, diesel fuel, gasoline, etc,); these are not specified

separately.

Concentration 20°C 60 °C

Battery acid 30 F j

Ammonia gas J J

Ammonia, w. conc. J J

10 J J

Benzol J Y

Bleach solution (12.5% effective chlorine) F j

Butane, gas, liquid J J

Butyl acetate (acetic acid butyl ester) J J

n(n) J Y

Calcium chloride, w. J Y

Calcium nitrate, w. c.s. J Y

Chlorine j j

Chrome baths, tech. j j

Iron salts, w. c.s. J J

Acetic acid, w. 50 j j

Ethyl alcohol, w. undenaturated 96 J Y

50 J J

Formaldehyde, w. 30 Y j

10 J Y

Formalin Y j

Glycerine J J

Isopropanol J Y

Potassium hydroxide, w. 50 J J

Lysol F j

Magnesium salts, w. c.s. J J

Methyl alcohol, w. 50 J J

Lactic acid, w. 50 F j

10 Y F

Sodium carbonate, w. (soda) c.s. J J

Sodium chloride, w. c.s. J J

Sodium hydroxide J J

Nickel salts, w. c.s. J J

Nitrobenzol Y F

Phosphoric acid 10 f V

Propane J J

Mercury J J

Nitric acid 10 f j

RF 300

4-24 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 41

RF 300 system planning

4.5 Chemical resistance of the transponders

Concentration 20°C 60 °C

Hydrochloric acid 10 f j

Sulphur dioxide Low J J

Sulphuric acid 25 F j

10 Y j

Hydrogen sulphide Low J J

Carbon tetrachloride J J

Toluene J Y

Detergent High J J

Plasticizer J J

Abbreviations

J Resistant

Y Virtually resistant

F Partially resistant

f Less resistant

j Not resistant

w. Aqueous solution

c.s. Cold saturated

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-25

Page 42

RF 300 system planning

4.6 EMC Guidelines

4.6 4.6 EMC Guidelines

4.6.1 Overview

These EMC Guidelines answer the following questions:

• Why are EMC guidelines necessary?

• What types of external interference have an impact on the control system?

• How can interference be prevented?

• How can interference be eliminated?

• Which standards relate to EMC?

• Examples of interference-free plant design

The description is intended for "qualified personnel":

• Project engineers and planners who plan system configurations with RFID modules and

have to observe the necessary guidelines.

• Fitters and service engineers who install the connecting cables in accordance with this

description or who can rectify defects in this area in the event of interference.

Warning

Failure to observe notices drawn to the reader's attention can result in dangerous

conditions in the plant or the destruction of individual components or the entire plant.

RF 300

4-26 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 43

RF 300 system planning

4.6 EMC Guidelines

4.6.2 Definition

The increasing use of electrical and electronic devices is accompanied by:

• Increasing density of components

• Increasing power electronics

• Increasing switching rates

• Lower power consumption of components

The higher the degree of automation, the greater the risk of interaction between devices.

Electromagnetic compatibility (EMC) is the ability of an electrical or electronic device to

operate satisfactorily in an electromagnetic environment without affecting or interfering with

the environment over and above certain limits.

EMC can be broken down into three different areas:

• Intrinsic immunity to interference:

immunity to internal electrical disturbance

• Immunity to ambient interference:

immunity to external electromagnetic disturbance

• Degree of interference emission:

emission of interference and its effect on the electrical environment

All three areas are considered when testing an electrical device.

The RFID modules are tested for conformity with the limit values required by the CE and

BAPT guidelines. Since the RFID modules are merely components of an overall system, and

sources of interference can arise as a result of combining different components, certain

guidelines have to be followed when setting up a plant.

EMC measures usually consist of a complete package of measures, all of which need to be

implemented in order to ensure that the plant is immune to interference.

Note

The plant manufacturer is responsible for the observance of the EMC guidelines; the plant

operator is responsible for radio interference suppression in the overall plant.

All measures taken when setting up the plant prevent expensive retrospective modifications

and interference suppression measures.

The salient national specifications and regulations must be observed. They are not covered

in this document.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-27

Page 44

RF 300 system planning

4.6 EMC Guidelines

4.6.3 Basic rules

It is often sufficient to follow a few elementary rules in order to ensure electromagnetic

compatiblity (EMC). The following rules must be observed when erecting a control cabinet:

Shielding by enclosure

• Protect the programmable logic controller against external interference by installing it in a

housing or enclosure. The housing or enclosure must be connected to the chassis

ground.

• Use metal plates to shield the programmable logic controller against electromagnetic

fields.

• Use metal connector housings to shield data conductors.

Laminar ground connection

• Bond all passive metal parts to chassis ground, ensuring large-area and low-HFimpedance contact.

• Establish a large-area connection between the passive metal parts and the central

grounding point.

• Don't forget to include the shielding bus in the chassis ground system. That means the

actual shielding busbars must be connected to ground by large-area contact.

• Aluminium parts are not suitable for ground connections.

Plan the cable installation

• Break the cabling down into cable groups and install these separately.

• Always route high-voltage and signal cables through separated ducts or in separate

bundles.

• Feed the cabling into the cabinet from one side only and, if possible, on one level only.

• Route the signal cables as close as possible to chassis surfaces.

• Twist the feed and return conductors of separately installed cables.

Shielding for the cables

• Shield the data cables and connect the shield at both ends.

• Shield the analog cables and connect the shield at one end, e.g. on the drive unit.

• Always apply large-area connections between the cable shields and the shielding bus at

the cabinet inlet and make the contact with clamps.

• Feed the connected shield through to the module without interruption.

• Use braided shields, not foil shields.

RF 300

4-28 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 45

RF 300 system planning

4.6 EMC Guidelines

Line and signal filter

• Use only line filters with metal housings

• Connect the filter housing to the cabinet chassis using a large-area low-HF-impedance

connection.

• Never fix the filter housing to a painted surface.

• Fix the filter at the control cabinet inlet or in the direction of the source.

4.6.4 Propagation of electromagnetic interference

Three components have to be present for interference to occur in a system:

• Interference source

• Coupling path

• Interference sink

,QWHUIHUHQFH

VRXUFH

GHYLFHHPLWWLQJ

LQWHUIHUHQFH

HJGULYHXQLW HJUHDGHU

Figure 4-8 Propagation of interference

&RXSOLQJSDWK

HJFRQQHFWLQJFDEOH

,QWHUIHUHQFHVLQN

GHYLFHDIIHFWHG

E\LQWHUIHUHQFH

If one of the components is missing, e.g. the coupling path between the interference source

and the interference sink, the interference sink is unaffected, even if the interference source

is transmitting a high level of noise.

The EMC measures are applied to all three components, in order to prevent malfunctions

due to interference. When setting up a plant, the manufacturer must take all possible

measures in order to prevent the occurrence of interference sources:

• Only devices fulfilling limit class A of VDE 0871 may be used in a plant.

• Interference suppression measures must be introduced on all interference-emitting

devices. This includes all coils and windings.

• The design of the cabinet must be such that mutual interference between individual

components is precluded or kept as small as possible.

• Measures must be taken to eliminate the impact of external interference.

Information and tips for plant design are given in the following sections.

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-29

Page 46

RF 300 system planning

4.6 EMC Guidelines

Interference sources

In order to achieve a high level of electromagnetic compatibility and thus a very low level of

disturbance in a plant, it is necessary to recognize the most frequent interference sources.

These must then be eliminated by appropriate measures.

Table 4-2 Interference sources: origin and effect

Interference source Interference results from Effect on the interference sink

Contacts System disturbances Contactors,

electronic valves

Power supply unit, switchedmode

High-frequency appliances Circuit Electromagnetic field

Transmitter

(e.g. service radio)

Ground or reference potential

difference

Operator Static charge Electrical discharge currents, electrical

Power cable Current flow Electrical and magnetic field, system

High-voltage cable Voltage difference Electrical field

Coils Magnetic field

Collector Electrical field Electrical motor

Winding Magnetic field

Contacts Electrical field Electric welding device

Transformer Magnetic field, system disturbance,

transient currents

Circuit Electrical and magnetic field, system

disturbance

Antenna Electromagnetic field

Voltage difference Transient currents

field

disturbance

RF 300

4-30 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 47

RF 300 system planning

4.6 EMC Guidelines

Coupling paths

A coupling path has to be present before the disturbance emitted by the interference source

can affect the system. There are four ways in which interference can be coupled in:

*DOYDQLFFRXSOLQJSDWK

,

1

7

(

5

)

(

5

(

1

&

(

6

2

8

5

&

(

&DSDFLWLYHFRXSOLQJSDWK

,QGXFWLYHFRXSOLQJSDWK

5DGLDWLRQFRXSOLQJ

5),'

$60RU

UHDGHU

ZULWHU

5),'

$60RU

UHDGHU

ZULWHU

5),'

$60RU

UHDGHU

ZULWHU

5),'

$60RU

UHDGHU

ZULWHU

,

1

7

(

5

)

(

5

(

1

&

(

6

,

1

.

Figure 4-9 Ways in which interference can be coupled in

When RFID modules are used, different components in the overall system can act as a

coupling path:

Table 4-3 Causes of coupling paths

Coupling path Invoked by

Conductors and cables

Control cabinet or

SIMATIC enclosure

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Incorrect or inappropriate installation

Missing or incorrectly connected shield

Inappropriate physical arrangement of cables

Missing or incorrectly wired equalizing conductor

Missing or incorrect earthing

Inappropriate physical arrangement

Components not mounted securely

Unfavorable cabinet configuration

4-31

Page 48

RF 300 system planning

4.6 EMC Guidelines

4.6.5 Cabinet configuration

The influence of the user in the configuration of an electromagnetically compatible plant

encompasses cabinet configuration, cable installation, ground connections and correct

shielding of cables.

Note

For information about electromagnetically compatible cabinet configuration, please consult

the installation guidelines for SIMATIC PLCs.

Shielding by enclosure

Magnetic and electrical fields and electromagnetic waves can be kept away from the

interference sink by using a metal enclosure. The easier the induced interference current can

flow, the greater the intrinsic weakening of the interference field. All enclosures and metal

panels in the cabinet should therefore be connected in a manner allowing good

conductance.

Figure 4-10 Shielding by enclosure

If the control cabinet panels are insulated from each other, a high-frequency-conducting

connection can be established using ribbon cables and high-frequency terminals or HF

conducting paste. The larger the area of the connection, the greater the high-frequency

conductivity. This is not possible using single-wire connections.

RF 300

4-32 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Page 49

RF 300 system planning

4.6 EMC Guidelines

Prevention of interference by optimum configuration

Good interference suppression can be achieved by installing SIMATIC PLCs on conducting

mounting plates (unpainted). When setting up the control cabinet, interference can be

prevented easily by observing certain guidelines. Power components (transformers, drive

units, load power supply units) should be arranged separately from the control components

(relay control unit, SIMATIC S7).

As a rule:

1. The effect of the interference decreases as the distance between the interference source

and interference sink increases.

2. The interference can be further decreased by installing grounded shielding plates.

3. The load connections and power cables should be installed separately from the signal

cables with a minimum clearance of 10 cm.

36

&&(8

'ULYH

6KLHOGSODWH

Figure 4-11 Prevention of interference by optimum configuration

RF 300

System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

4-33

Page 50

RF 300 system planning

4.6 EMC Guidelines

Filtering of the supply voltage

External interference from the mains can be prevented by installing line filters. Correct

installation is extremely important, in addition to appropriate dimensioning. It is essential that

the line filter is mounted directly at the cabinet inlet. As a result, interference is filtered

promptly at the inlet, and is not conducted through the cabinet.

&RUUHFW

/LQHILOWHU

,F

Figure 4-12 Filtering of the supply voltage

,QFRUUHFW

/LQHILOWHU

,F

,F LQWHUIHUHQFHFXUUHQW

RF 300

4-34 System Manual, 05/2005, (4)J31069 D0166-U001-A1-7618, --

Loading...

Loading...