Page 1

SIMATIC Ident

RFID systems

SIMATIC RF200

System Manual

07/2017

J31069

Introduction

1

Safety notes

2

System overview

3

Planning the RF200 system

4

Readers

5

Antennas

6

Transponder

7

System integration

8

System diagnostics

9

Appendix

A

-D0227-U001-A9-7619

Page 2

Siemens AG

Division Process Industries a

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ

Copyright © Siemens AG 2010 - 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

may

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

nd Drives

07/2017 Subject to change

Page 3

Table of contents

1 Introduction ........................................................................................................................................... 13

2 Safety notes .......................................................................................................................................... 15

3 System overview ................................................................................................................................... 19

4 Planning the RF200 system .................................................................................................................. 27

1.1 Abbreviations and naming conventions .................................................................................. 14

3.1 RFID components and their function ...................................................................................... 20

3.2 Overview of transponders ....................................................................................................... 23

4.1 Fundamentals of application planning .................................................................................... 27

4.1.1 Selection criteria for SIMATIC RF200 components ................................................................ 27

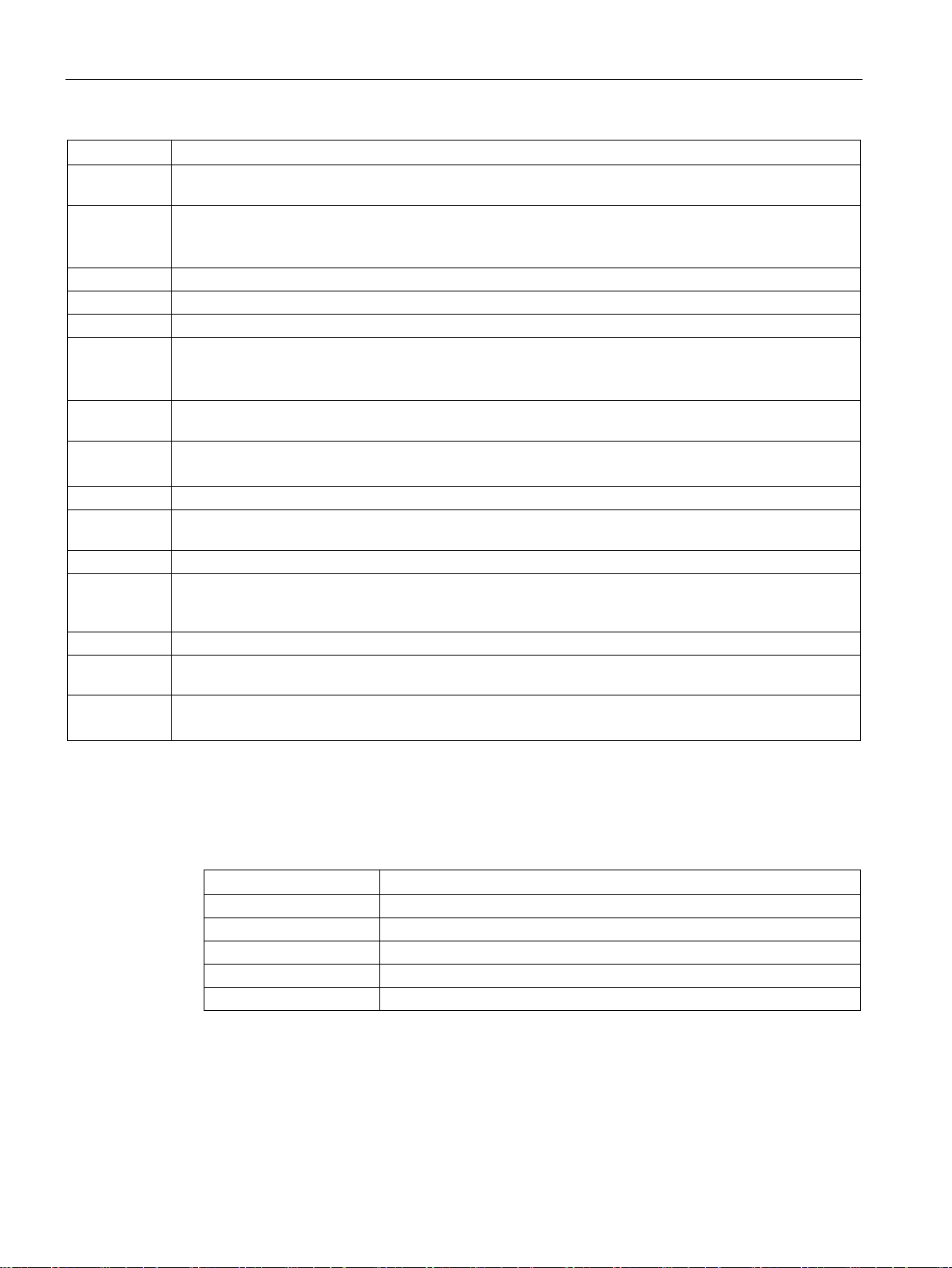

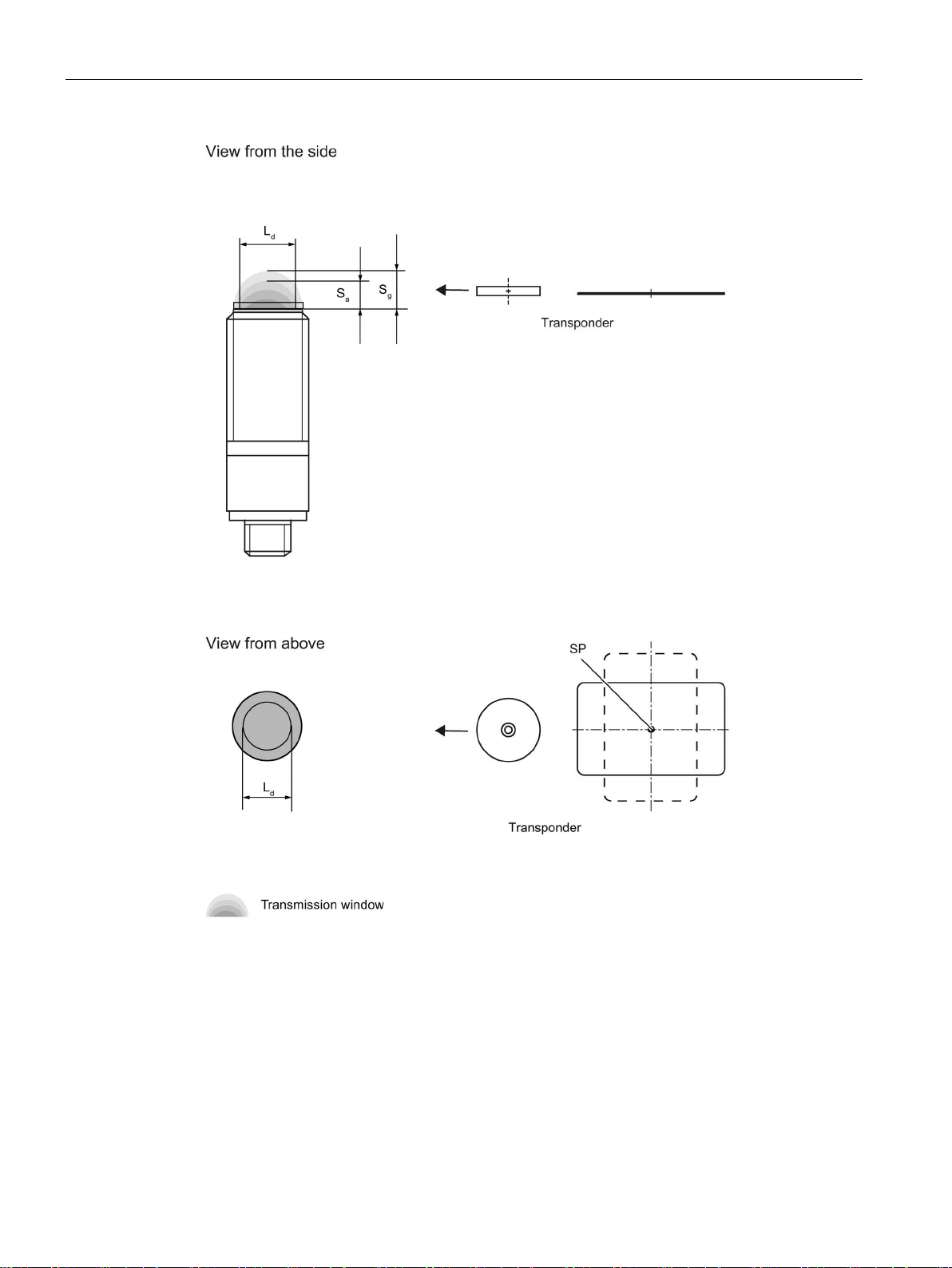

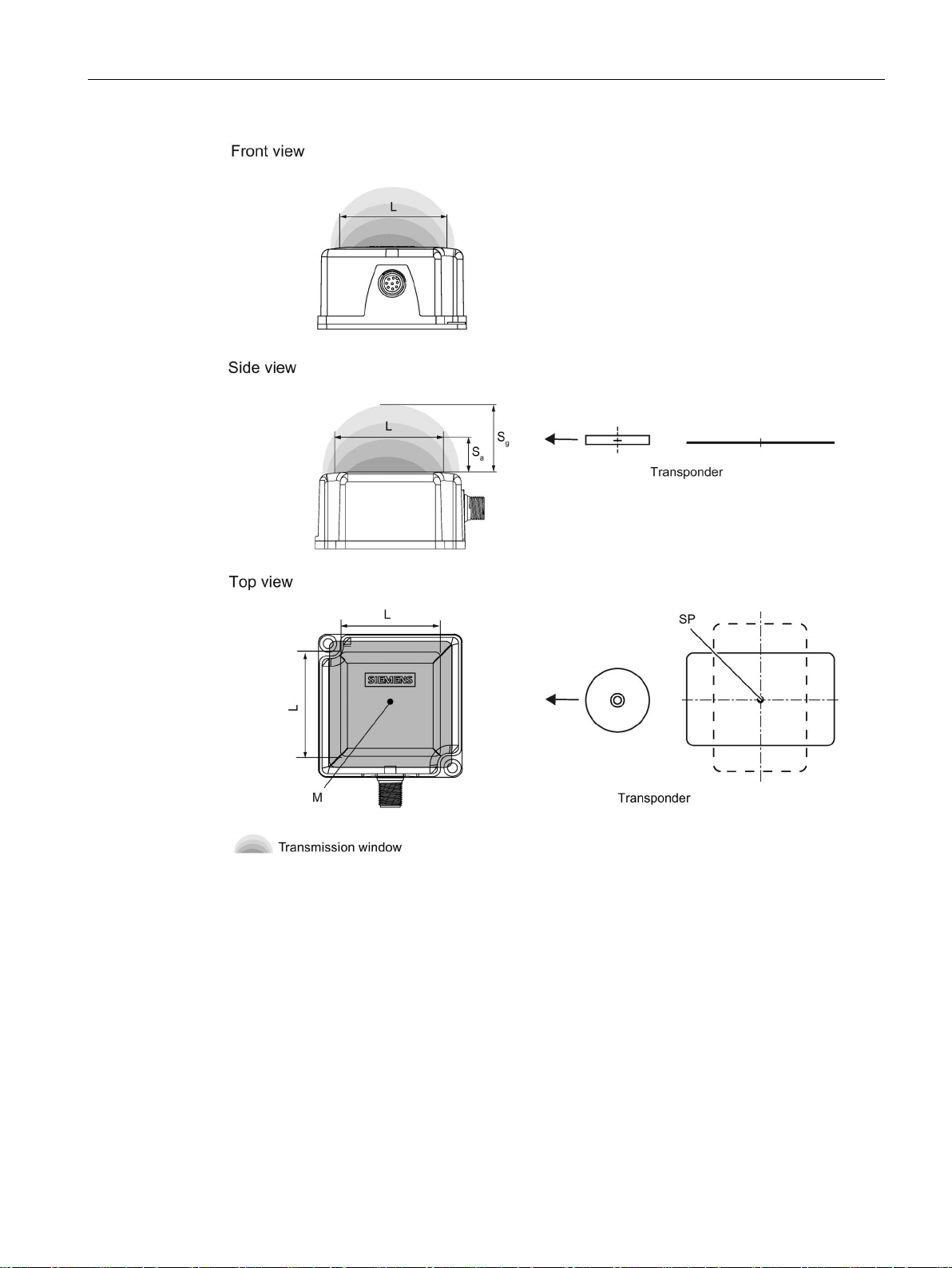

4.1.2 Transmission window and read/write distance ....................................................................... 27

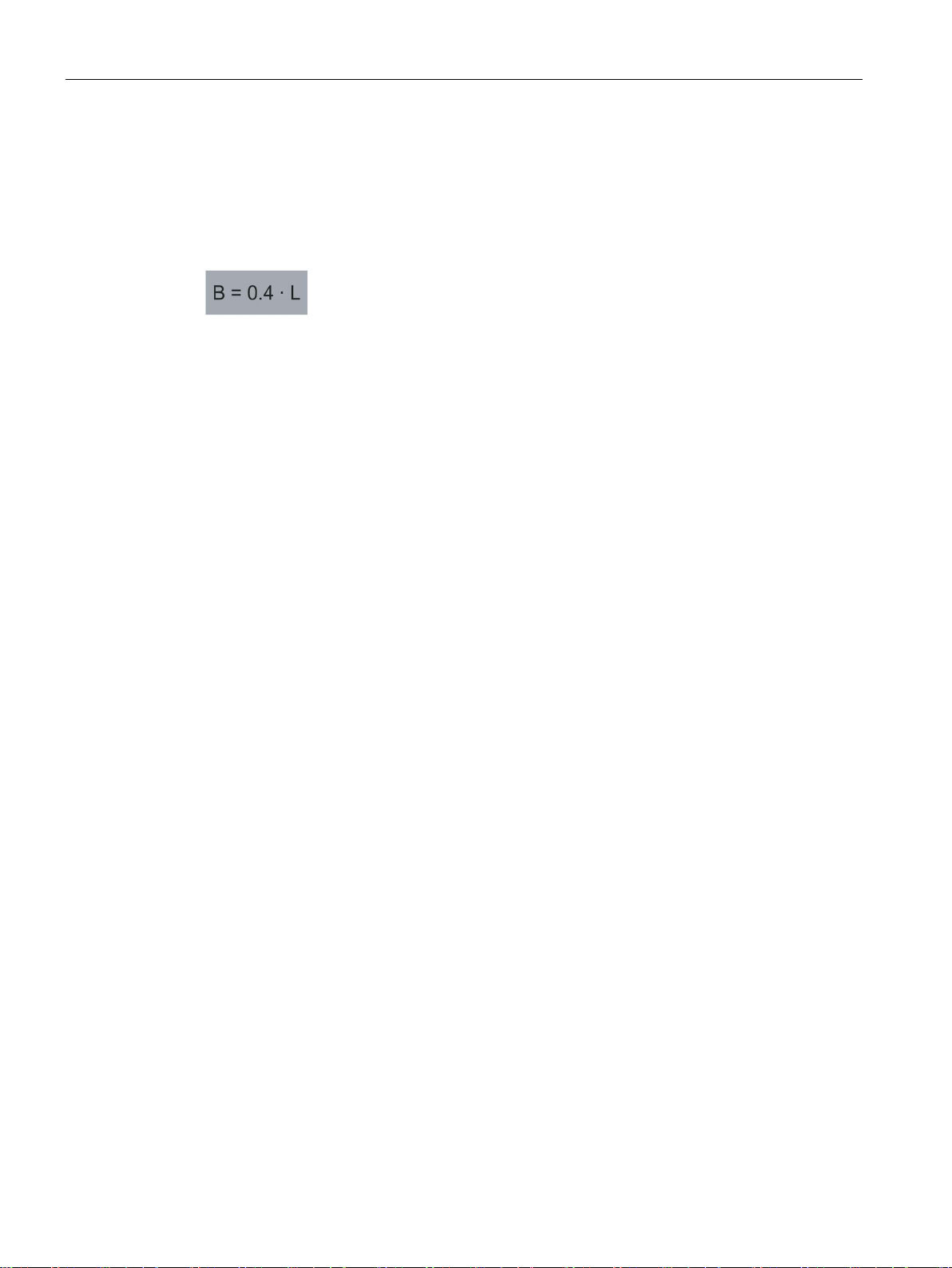

4.1.3 Width of the transmission window .......................................................................................... 30

4.1.4 Impact of secondary fields ...................................................................................................... 31

4.1.5 Permissible directions of motion of the transponder ............................................................... 34

4.1.6 Operation in static and dynamic mode ................................................................................... 35

4.1.7 Dwell time of the transponder ................................................................................................. 36

4.1.8 Communication between communication module, reader and transponder .......................... 37

4.2 Field data of transponders and readers .................................................................................. 38

4.2.1 Field data ................................................................................................................................ 39

4.2.2 Minimum clearances ............................................................................................................... 48

4.3 Installation guidelines.............................................................................................................. 50

4.3.1 Overview ................................................................................................................................. 50

4.3.2 Reduction of interference due to metal ................................................................................... 51

4.3.3 Effects of metal on different transponders and readers .......................................................... 53

4.3.4 Impact of metal on the transmission window .......................................................................... 54

4.3.4.1 RF210R ................................................................................................................................... 55

4.3.4.2 RF220R ................................................................................................................................... 58

4.3.4.3 RF240R ................................................................................................................................... 60

4.3.4.4 RF250R ................................................................................................................................... 63

4.3.4.5 RF260R ................................................................................................................................... 71

4.3.4.6 RF280R ................................................................................................................................... 74

4.3.4.7 RF290R ................................................................................................................................... 76

4.3.5 Installation and connection of 2 to 6 antennas with one RF290R reader ............................... 80

4.3.5.1 Installation options with the antenna splitter (2-4 antennas) .................................................. 80

4.3.5.2 Antenna installation ................................................................................................................. 84

4.3.5.3 Installation options with the antenna multiplexer (2-6 antennas) ........................................... 88

4.3.6 Chemical resistance of the reader and transponders ............................................................. 89

4.3.6.1 Readers .................................................................................................................................. 89

4.3.6.2 Transponder ............................................................................................................................ 93

4.4 Further information ................................................................................................................ 101

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

3

Page 4

Table of contents

5 Readers ............................................................................................................................................... 103

5.1 SIMATIC RF210R ................................................................................................................ 104

5.1.1 Features ............................................................................................................................... 104

5.1.2 RF210R ordering data ......................................................................................................... 104

5.1.3 Pin assignment RF210R with RS422 interface .................................................................... 105

5.1.4 LED operating display .......................................................................................................... 105

5.1.5 Minimum distance between RF210R readers ...................................................................... 106

5.1.6 Technical specifications of the RF210R reader ................................................................... 107

5.1.7 Approvals ............................................................................................................................. 108

5.1.8 Dimension drawing .............................................................................................................. 109

5.2 SIMATIC RF210M ................................................................................................................ 110

5.2.1 Features ............................................................................................................................... 110

5.2.2 Ordering data RF210M ........................................................................................................ 110

5.2.3 Installing the RF210M reader ............................................................................................... 111

5.2.4 Pin assignment RF210M with RS-422 interface .................................................................. 112

5.2.5 LED operating display .......................................................................................................... 112

5.2.6 Technical specifications of the RF210M reader ................................................................... 113

5.2.7 Approvals ............................................................................................................................. 114

5.2.8 Dimension drawing ..............................................................................................................

115

5.3 SIMATIC RF220R ................................................................................................................ 116

5.3.1 Features ............................................................................................................................... 116

5.3.2 RF220R ordering data ......................................................................................................... 116

5.3.3 RF220R pin assignment with RS422 interface .................................................................... 117

5.3.4 LED operating display .......................................................................................................... 117

5.3.5 Minimum distance between RF220R readers ...................................................................... 118

5.3.6 Technical specifications of the RF220R reader ................................................................... 119

5.3.7 Approvals ............................................................................................................................. 120

5.3.8 Dimension drawing .............................................................................................................. 121

5.4 SIMATIC RF240R ................................................................................................................ 122

5.4.1 Features ............................................................................................................................... 122

5.4.2 RF240R ordering data ......................................................................................................... 122

5.4.3 Pin assignment RF240R ...................................................................................................... 123

5.4.4 LED operating display .......................................................................................................... 123

5.4.5 Minimum distance between several RF240R readers ......................................................... 124

5.4.6 Technical specifications of the RF240R reader ................................................................... 125

5.4.7 Approvals ............................................................................................................................. 127

5.4.8 Dimension drawing

.............................................................................................................. 128

5.5 SIMATIC RF250R ................................................................................................................ 128

5.5.1 Features ............................................................................................................................... 128

5.5.2 Ordering data RF250R ......................................................................................................... 129

5.5.3 Pin assignment RF250R ...................................................................................................... 129

5.5.4 LED operating display .......................................................................................................... 129

5.5.5 Technical specifications of the RF250R reader ................................................................... 130

5.5.6 Approvals ............................................................................................................................. 131

5.5.7 Dimension drawing .............................................................................................................. 133

5.6 SIMATIC RF260R ................................................................................................................ 134

5.6.1 Features ............................................................................................................................... 134

5.6.2 Ordering data for RF260R ................................................................................................... 134

5.6.3 Pin assignment RF260R ...................................................................................................... 135

SIMATIC RF200

4 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 5

Table of contents

6 Antennas ............................................................................................................................................ 161

5.6.4 LED operating display ........................................................................................................... 135

5.6.5 Minimum distance between several RF260R ....................................................................... 136

5.6.6 Technical data of the RF260R reader................................................................................... 137

5.6.7 Approvals .............................................................................................................................. 138

5.6.8 Dimension drawing ............................................................................................................... 139

5.7 SIMATIC RF280R ................................................................................................................. 140

5.7.1 Features ................................................................................................................................ 140

5.7.2 Ordering data RF280R.......................................................................................................... 140

5.7.3 Pin assignment RF280R ....................................................................................................... 141

5.7.4 LED operating display ........................................................................................................... 141

5.7.5 Minimum distance between RF280R readers ...................................................................... 142

5.7.6 Technical specifications of the RF280R reader .................................................................... 143

5.7.7 Approvals .............................................................................................................................. 144

5.7.8 Dimension drawing ............................................................................................................... 146

5.8 SIMATIC RF290R ................................................................................................................. 147

5.8.1 Features ................................................................................................................................ 147

5.8.2 Ordering data RF290R.......................................................................................................... 147

5.8.3 Pin assignment RF290R ....................................................................................................... 149

5.8.4 LED operating display ........................................................................................................... 151

5.8.5 Installing the RF290R reader ................................................................................................ 152

5.8.5.1 Wall mounting ....................................................................................................................... 152

5.8.5.2 Installing on the S7-300 standard rail ................................................................................... 153

5.8.5.3 Installation on a DIN rail ........................................................................................................ 153

5.8.6 Technical specifications of the RF290R reader .................................................................... 155

5.8.7 Approvals .............................................................................................................................. 156

5.8.8 Note on the use of the RF290R as a replacement for SLG D10 / SLG D10S ...................... 158

5.8.9 Dimension drawing ............................................................................................................... 159

6.1 ANT 1 .................................................................................................................................... 161

6.1.1 Characteristics ...................................................................................................................... 161

6.1.2 Ordering data ........................................................................................................................ 161

6.1.3 Flush-mounted in metal ........................................................................................................ 162

6.1.4 Operating / limit distances .................................................................................................... 162

6.1.5 Minimum clearances ............................................................................................................. 163

6.1.6 Technical specifications ........................................................................................................ 164

6.1.7 Dimension drawing ............................................................................................................... 165

6.2 ANT 3 .................................................................................................................................... 166

6.2.1 Features ................................................................................................................................ 166

6.2.2 Ordering data ........................................................................................................................ 166

6.2.3 Mounting on/in metal............................................................................................................. 167

6.2.4 Operating / limit distances .................................................................................................... 168

6.2.5 Minimum spacing .................................................................................................................. 169

6.2.6 Technical data ....................................................................................................................... 170

6.2.7 Dimension drawing ............................................................................................................... 171

6.3 ANT 8 .................................................................................................................................... 172

6.3.1

Features ................................................................................................................................ 172

6.3.2 Ordering data ........................................................................................................................ 172

6.3.3 Transmission window............................................................................................................ 173

6.3.4 Flush-mounted in metal ........................................................................................................ 173

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

5

Page 6

Table of contents

6.3.5 Minimum spacing ................................................................................................................. 174

6.3.6 Technical data ...................................................................................................................... 175

6.3.7 Dimension drawing .............................................................................................................. 176

6.4 ANT 12 ................................................................................................................................. 177

6.4.1 Features ............................................................................................................................... 177

6.4.2 Ordering data ....................................................................................................................... 177

6.4.3 Transmission window ........................................................................................................... 178

6.4.4 Flush-mounted in metal ....................................................................................................... 178

6.4.5 Minimum spacing ................................................................................................................. 179

6.4.6 Technical data ...................................................................................................................... 180

6.4.7 Dimension drawing .............................................................................................................. 181

6.5 ANT 18 ................................................................................................................................. 182

6.5.1 Features ............................................................................................................................... 182

6.5.2 Ordering data ....................................................................................................................... 182

6.5.3 Transmission window ........................................................................................................... 183

6.5.4 Flush-mounted in metal ....................................................................................................... 183

6.5.5

Minimum spacing ................................................................................................................. 184

6.5.6 Technical data ...................................................................................................................... 185

6.5.7 Dimension drawing .............................................................................................................. 186

6.6 ANT 30 ................................................................................................................................. 187

6.6.1 Features ............................................................................................................................... 187

6.6.2 Ordering data ....................................................................................................................... 187

6.6.3 Transmission window ........................................................................................................... 188

6.6.4 Flush-mounted in metal ....................................................................................................... 189

6.6.5 Minimum spacing ................................................................................................................. 189

6.6.6 Technical data ...................................................................................................................... 190

6.6.7 Dimension drawing .............................................................................................................. 191

6.7 ANT D5 ................................................................................................................................ 192

6.7.1 Features ............................................................................................................................... 192

6.7.2 Ordering data ....................................................................................................................... 192

6.7.3 Transmission window ........................................................................................................... 193

6.7.4 Flush-mounted in metal ....................................................................................................... 194

6.7.5 Minimum spacing ................................................................................................................. 194

6.7.6 Technical data ......................................................................................................................

195

6.7.7 Dimension drawing .............................................................................................................. 197

6.8 ANT D6 ................................................................................................................................ 198

6.8.1 Features ............................................................................................................................... 198

6.8.2 Ordering data ....................................................................................................................... 198

6.8.3 Transmission window ........................................................................................................... 199

6.8.4 Metal-free area ..................................................................................................................... 200

6.8.5 Minimum spacing ................................................................................................................. 200

6.8.6 Technical data ...................................................................................................................... 201

6.8.7 Dimensional diagram ........................................................................................................... 202

6.9 ANT D10 .............................................................................................................................. 203

6.9.1 Features ............................................................................................................................... 203

6.9.2 Ordering data ....................................................................................................................... 203

6.9.3 Transmission window ........................................................................................................... 204

6.9.4 Metal-free area ..................................................................................................................... 205

6.9.5 Minimum spacing ................................................................................................................. 206

SIMATIC RF200

6 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 7

Table of contents

7 Transponder ....................................................................................................................................... 209

6.9.6 Technical data ....................................................................................................................... 206

6.9.7 Dimensional diagram ............................................................................................................ 208

7.1 Memory configuration of ISO the transponders .................................................................... 209

7.2 MDS D100 ............................................................................................................................ 210

7.2.1 Characteristics ...................................................................................................................... 210

7.2.2 Ordering data ........................................................................................................................ 210

7.2.3 Metal-free area ...................................................................................................................... 211

7.2.4 Technical data ....................................................................................................................... 212

7.2.5 Dimension drawing ............................................................................................................... 214

7.3 MDS D117 ............................................................................................................................ 215

7.3.1 Features ................................................................................................................................ 215

7.3.2 Ordering data ........................................................................................................................ 215

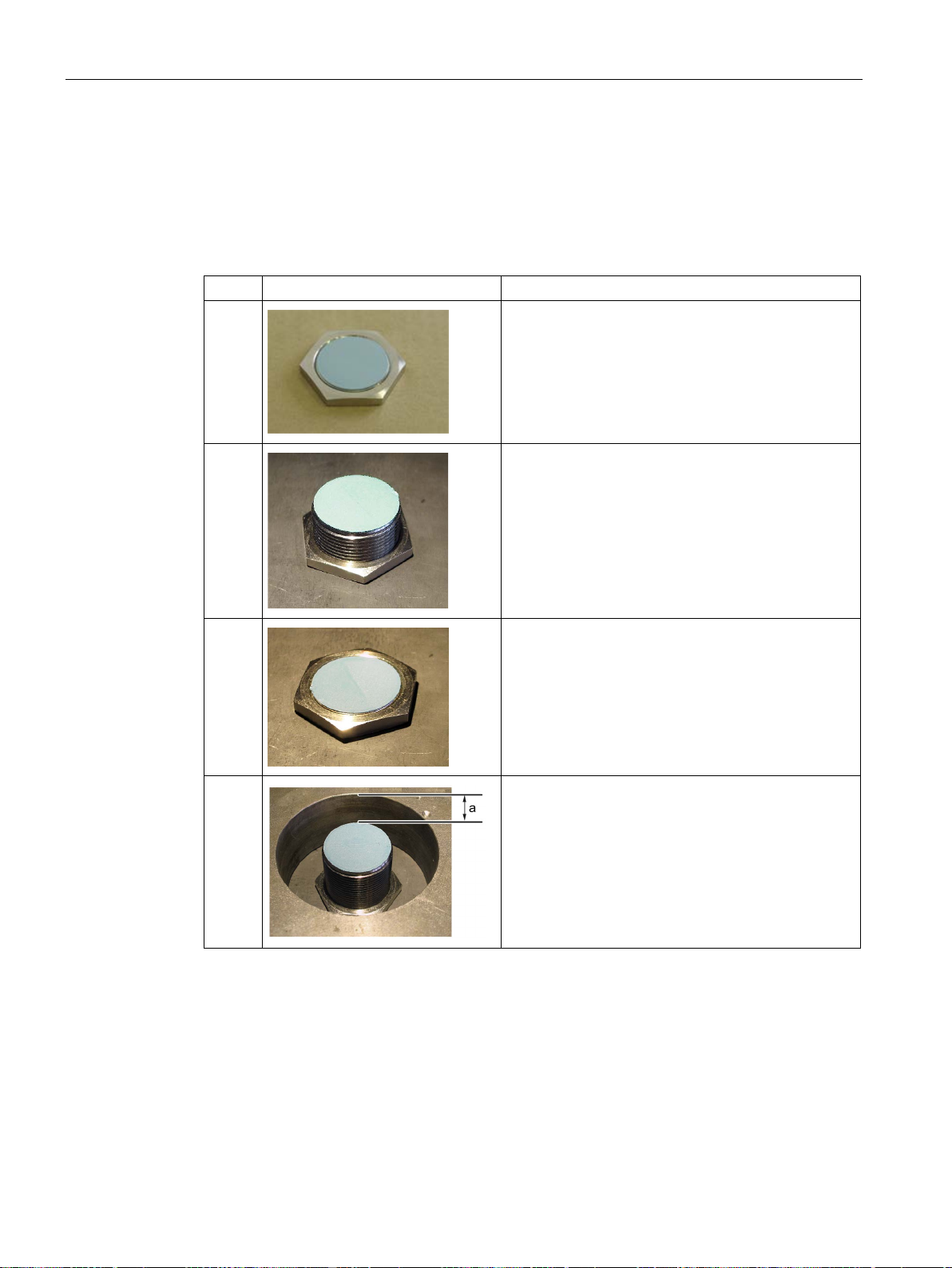

7.3.3 Mounting in metal .................................................................................................................. 215

7.3.4 Technical specifications ........................................................................................................ 216

7.3.5 Dimension drawing ............................................................................................................... 217

7.4 MDS D124 ............................................................................................................................ 218

7.4.1 Characteristics ...................................................................................................................... 218

7.4.2 Ordering data ........................................................................................................................ 218

7.4.3 Mounting on metal ................................................................................................................ 219

7.4.4

Technical specifications ........................................................................................................ 220

7.4.5 Use of the MDS D124 in hazardous area ............................................................................. 221

7.4.6 Dimension drawing ............................................................................................................... 223

7.5 MDS D126 ............................................................................................................................ 224

7.5.1 Characteristics ...................................................................................................................... 224

7.5.2 Ordering data ........................................................................................................................ 224

7.5.3 Mounting on metal ................................................................................................................ 225

7.5.4 Technical specifications ........................................................................................................ 226

7.5.5 Dimension drawing ............................................................................................................... 227

7.6 MDS D127 ............................................................................................................................ 228

7.6.1 Features ................................................................................................................................ 228

7.6.2 Ordering data ........................................................................................................................ 228

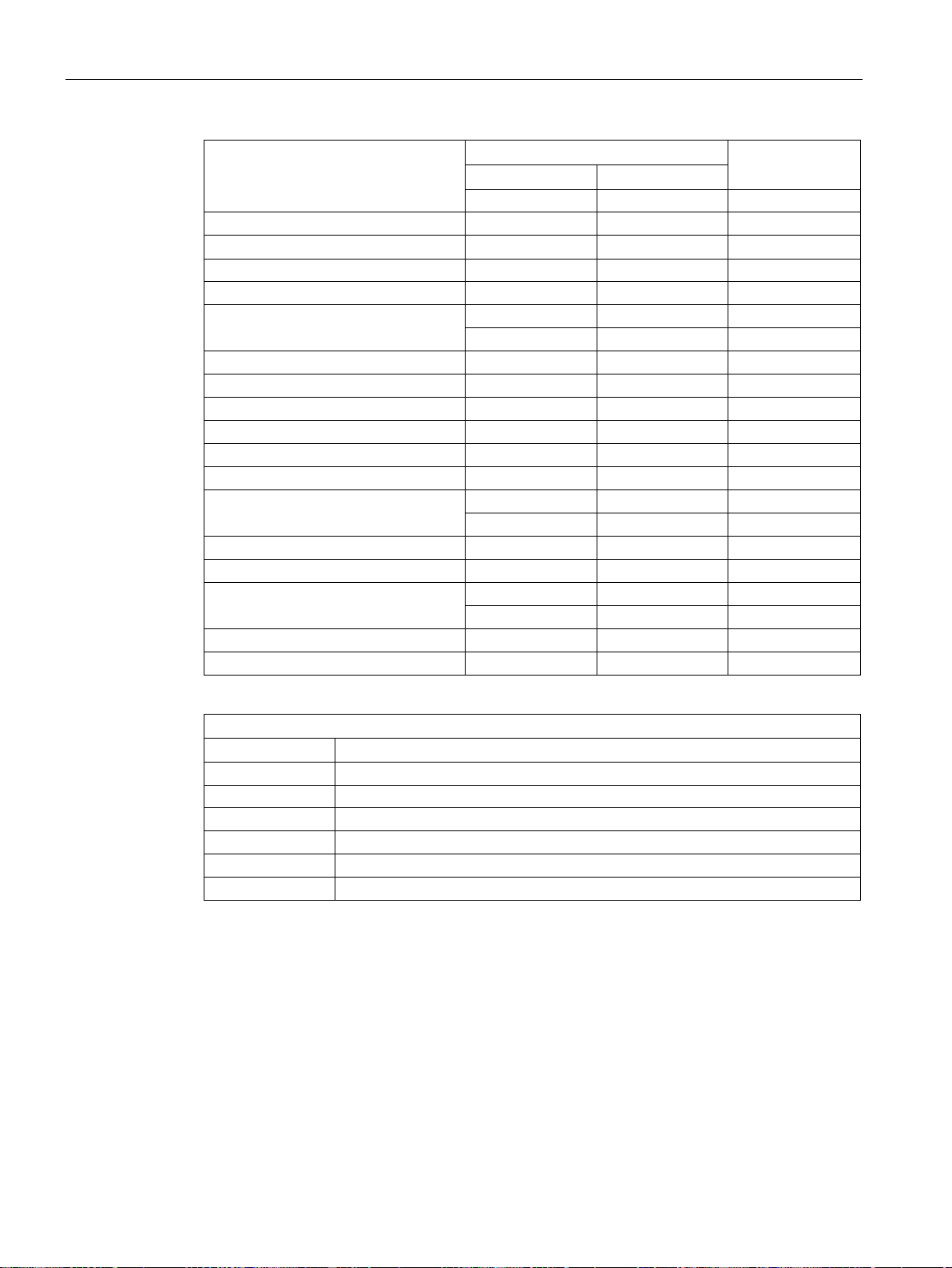

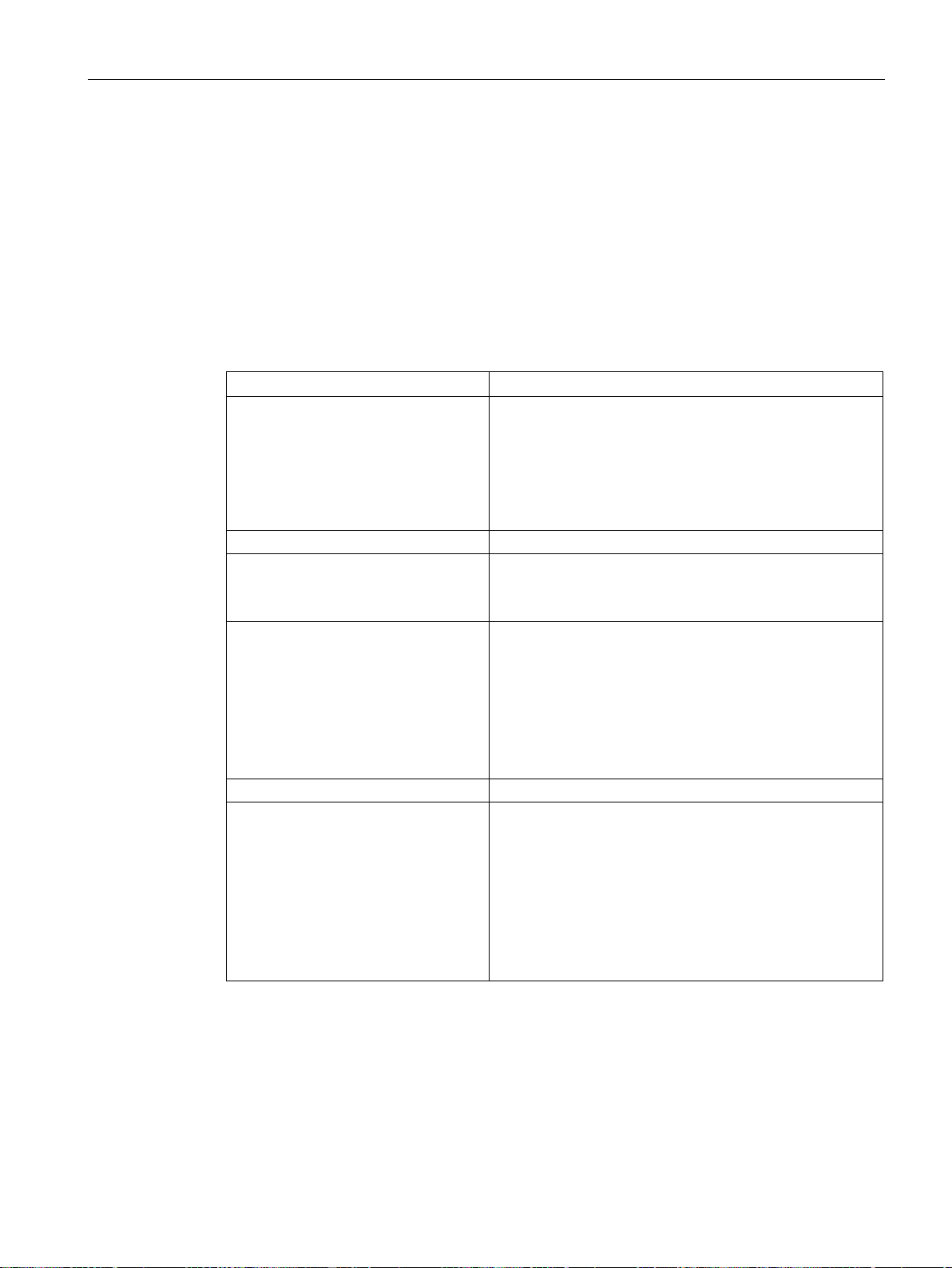

7.6.3 Mounting in metal .................................................................................................................. 229

7.6.4 Technical specifications ........................................................................................................ 230

7.6.5 Dimension drawing ............................................................................................................... 231

7.7 MDS D139 ............................................................................................................................ 232

7.7.1 Characteristics ...................................................................................................................... 232

7.7.2 Ordering data ........................................................................................................................

232

7.7.3 Metal-free area ...................................................................................................................... 233

7.7.4 Mounting in metal .................................................................................................................. 234

7.7.5 Cleaning the transponder ..................................................................................................... 234

7.7.6 Technical specifications ........................................................................................................ 235

7.7.7 Use of the MDS D139 in hazardous areas ........................................................................... 236

7.7.8 Dimension drawings .............................................................................................................. 238

7.8 MDS D160 ............................................................................................................................ 239

7.8.1 Characteristics ...................................................................................................................... 239

7.8.2 Ordering data ........................................................................................................................ 239

7.8.3 Mounting on metal ................................................................................................................ 240

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

7

Page 8

Table of contents

7.8.4 Technical specifications ....................................................................................................... 240

7.8.5 Dimension drawings ............................................................................................................. 242

7.9 MDS D165 ............................................................................................................................ 243

7.9.1 Features ............................................................................................................................... 243

7.9.2 Ordering data ....................................................................................................................... 243

7.9.3 Technical data ...................................................................................................................... 244

7.9.4 Dimension drawing .............................................................................................................. 245

7.10 MDS D200 ............................................................................................................................ 246

7.10.1 Features ............................................................................................................................... 246

7.10.2 Ordering data ....................................................................................................................... 246

7.10.3 Mounting on metal ............................................................................................................... 247

7.10.4 Technical data ...................................................................................................................... 248

7.10.5 Dimension drawing .............................................................................................................. 250

7.11 MDS D261 ............................................................................................................................ 250

7.11.1 Features ............................................................................................................................... 250

7.11.2 Ordering data ....................................................................................................................... 250

7.11.3 Technical data ......................................................................................................................

251

7.11.4 Dimension drawing .............................................................................................................. 252

7.12 MDS D324 ............................................................................................................................ 253

7.12.1 Characteristics ..................................................................................................................... 253

7.12.2 Ordering data ....................................................................................................................... 253

7.12.3 Mounting on metal ............................................................................................................... 254

7.12.4 Technical specifications ....................................................................................................... 255

7.12.5 Dimension drawing .............................................................................................................. 256

7.13 MDS D339 ............................................................................................................................ 257

7.13.1 Characteristics ..................................................................................................................... 257

7.13.2 Ordering data ....................................................................................................................... 257

7.13.3 Mounting on metal ............................................................................................................... 258

7.13.4 Mounting in metal ................................................................................................................. 259

7.13.5 Cleaning the transponder ..................................................................................................... 259

7.13.6 Technical specifications ....................................................................................................... 260

7.13.7 Use of the MDS D339 in hazardous areas .......................................................................... 261

7.13.8 Dimensional drawing ............................................................................................................ 263

7.14 MDS D400 ............................................................................................................................ 264

Features ............................................................................................................................... 264

7.14.1

7.14.2 Ordering data ....................................................................................................................... 264

7.14.3 Mounting on metal ............................................................................................................... 265

7.14.4 Technical specifications ....................................................................................................... 266

7.14.5 Dimension drawing .............................................................................................................. 268

7.15 MDS D421 ............................................................................................................................ 269

7.15.1 Characteristics ..................................................................................................................... 269

7.15.2 Ordering data ....................................................................................................................... 269

7.15.3 Mounting on metal ............................................................................................................... 270

7.15.4 Technical specifications ....................................................................................................... 272

7.15.5 Dimension drawing .............................................................................................................. 273

7.16 MDS D422 ............................................................................................................................ 274

7.16.1 Characteristics ..................................................................................................................... 274

7.16.2 Ordering data ....................................................................................................................... 274

SIMATIC RF200

8 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 9

Table of contents

7.16.3 Mounting in metal .................................................................................................................. 274

7.16.4 Technical specifications ........................................................................................................ 275

7.16.5 Dimension drawing ............................................................................................................... 276

7.17 MDS D423 ............................................................................................................................ 277

7.17.1 Characteristics ...................................................................................................................... 277

7.17.2 Ordering data ........................................................................................................................ 277

7.17.3 Mounting on metal ................................................................................................................ 277

7.17.4 Technical specifications ........................................................................................................ 279

7.17.5 Dimensional drawing............................................................................................................. 281

7.18 MDS D424 ............................................................................................................................ 281

7.18.1 Characteristics ...................................................................................................................... 281

7.18.2 Ordering data ........................................................................................................................ 282

7.18.3 Mounting on metal ................................................................................................................ 282

7.18.4 Technical specifications ........................................................................................................ 283

7.18.5 Dimension drawing ............................................................................................................... 285

7.19 MDS D425 ............................................................................................................................ 285

7.19.1 Characteristics ......................................................................................................................

285

7.19.2 Ordering data ........................................................................................................................ 286

7.19.3 Application example .............................................................................................................. 286

7.19.4 Technical specifications ........................................................................................................ 286

7.19.5 Dimension drawing ............................................................................................................... 288

7.20 MDS D426 ............................................................................................................................ 288

7.20.1 Characteristics ...................................................................................................................... 288

7.20.2 Mounting on metal ................................................................................................................ 289

7.20.3 Ordering data ........................................................................................................................ 290

7.20.4 Technical specifications ........................................................................................................ 290

7.20.5 Dimension drawing ............................................................................................................... 291

7.21 MDS D428 ............................................................................................................................ 292

7.21.1 Characteristics ...................................................................................................................... 292

7.21.2 Ordering data ........................................................................................................................ 292

7.21.3 Application example .............................................................................................................. 293

7.21.4 Technical specifications ........................................................................................................ 293

7.21.5 Dimension drawing ............................................................................................................... 295

7.22 MDS D460 ............................................................................................................................ 295

Characteristics ...................................................................................................................... 295

7.22.1

7.22.2 Ordering data ........................................................................................................................ 296

7.22.3 Mounting on metal ................................................................................................................ 296

7.22.4 Technical specifications ........................................................................................................ 297

7.22.5 Dimension drawings .............................................................................................................. 298

7.23 MDS D521 ............................................................................................................................ 299

7.23.1 Characteristics ...................................................................................................................... 299

7.23.2 Ordering data ........................................................................................................................ 299

7.23.3 Mounting on metal ................................................................................................................ 299

7.23.4 Technical specifications ........................................................................................................ 301

7.23.5 Dimension drawing ............................................................................................................... 303

7.24 MDS D522 ............................................................................................................................ 303

7.24.1 Characteristics ...................................................................................................................... 303

7.24.2 Ordering data ........................................................................................................................ 304

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

9

Page 10

Table of contents

8 System integration ............................................................................................................................... 325

9 System diagnostics .............................................................................................................................. 329

A Appendix ............................................................................................................................................. 335

7.24.3 Mounting in metal ................................................................................................................. 304

7.24.4 Technical specifications ....................................................................................................... 305

7.24.5 Dimension drawing .............................................................................................................. 306

7.25 MDS D522 special variant ................................................................................................... 307

7.25.1 Characteristics ..................................................................................................................... 307

7.25.2 Ordering data ....................................................................................................................... 307

7.25.3 Mounting in metal ................................................................................................................. 308

7.25.4 Installation instructions ......................................................................................................... 308

7.25.5 Technical specifications ....................................................................................................... 310

7.25.6 Dimensional drawing ............................................................................................................ 311

7.26 MDS D524 ............................................................................................................................ 312

7.26.1 Characteristics ..................................................................................................................... 312

7.26.2 Ordering data ....................................................................................................................... 312

7.26.3 Mounting on metal ............................................................................................................... 313

7.26.4 Technical specifications ....................................................................................................... 314

7.26.5 Dimension drawing .............................................................................................................. 315

7.27 MDS D526

............................................................................................................................ 316

7.27.1 Characteristics ..................................................................................................................... 316

7.27.2 Ordering data ....................................................................................................................... 316

7.27.3 Mounting on metal ............................................................................................................... 317

7.27.4 Technical specifications ....................................................................................................... 318

7.27.5 Dimension drawing .............................................................................................................. 319

7.28 MDS D528 ............................................................................................................................ 320

7.28.1 Characteristics ..................................................................................................................... 320

7.28.2 Ordering data ....................................................................................................................... 320

7.28.3 Application example ............................................................................................................. 321

7.28.4 Technical specifications ....................................................................................................... 321

7.28.5 Dimension drawing .............................................................................................................. 323

9.1 Error codes of the RF200 readers ....................................................................................... 329

9.2 Diagnostics functions - STEP 7 ........................................................................................... 331

9.2.1 Reader diagnostics with "Reader Status" (SLG Status) ...................................................... 331

9.2.2 Transponder diagnostics with "Tag Status" (MDS Status) .................................................. 333

A.1 Certificates & approvals ....................................................................................................... 335

A.2 Accessories .......................................................................................................................... 337

A.2.1 Antenna splitter .................................................................................................................... 337

A.2.2 Antenna multiplexer SIMATIC RF260X ............................................................................... 339

A.2.2.1 Characteristics ..................................................................................................................... 339

A.2.2.2 Ordering data ....................................................................................................................... 339

A.2.2.3 Description ........................................................................................................................... 340

A.2.2.4 Principle of operation ........................................................................................................... 340

A.2.2.5 Connectors ........................................................................................................................... 341

A.2.2.6 Configuration ........................................................................................................................ 342

A.2.2.7 Parameterization .................................................................................................................. 342

A.2.2.8 RF260X commands ............................................................................................................. 344

SIMATIC RF200

10 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 11

Table of contents

Index................................................................................................................................................... 379

A.2.2.9 Technical specifications ........................................................................................................ 345

A.2.2.10 Dimensional drawing............................................................................................................. 346

A.2.3 Wide-range power supply unit for SIMATIC RF systems ..................................................... 347

A.2.3.1 Features ................................................................................................................................ 347

A.2.3.2 Scope of supply .................................................................................................................... 348

A.2.3.3 Ordering data ........................................................................................................................ 348

A.2.3.4 Safety Information ................................................................................................................. 348

A.2.3.5 Connecting ............................................................................................................................ 349

A.2.3.6 Technical specifications ........................................................................................................ 350

A.2.3.7 Pin assignment of DC outputs and mains connection .......................................................... 352

A.2.3.8 Dimension drawing ............................................................................................................... 353

A.2.3.9 Certificates and approvals .................................................................................................... 354

A.2.4 Transponder holders ............................................................................................................. 355

A.3 Connecting cable .................................................................................................................. 361

A.3.1 Reader RF2xxR (RS-422) with ASM 456 / RF160C / RF170C / RF180C / RF182C ........... 361

A.3.2 Reader RF2xxR (RS-422) with ASM 475 ............................................................................. 363

A.3.3 Reader RF2xxR (RS-422) with RF120C...............................................................................

364

A.3.4 Reader RF240R/RF260R/RF290R (RS232) with PC ........................................................... 364

A.3.5 Reader RF290R .................................................................................................................... 366

A.4 Ordering data ........................................................................................................................ 367

A.5 Service & Support ................................................................................................................. 377

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

11

Page 12

Table of contents

SIMATIC RF200

12 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 13

1

Introduction

Scope of validity of this document

Registered trademarks

Further information

SIMATIC RF200 is a compact RFID system in the SIMATIC RFID product family. The

product range comprises cost-efficient RF readers that are ideal for use in small assembly

lines or in intralogistics. SIMATIC RF200 RFID readers only support the RFID standard ISO

15693 and are therefore ideal for operation with the extensive range of ISO 15693

transponders.

The readers of the RF200 product family are available with the following interfaces:

● RS-422 for connecting to the communications modules

● RS-232 with a simple ASCII protocol for connection to PCs and third-party controllers

● IO-Link for connection to IO Link masters from Siemens and third-party controllers

Readers with an internal antenna have a particularly compact design

(RF210R/RF220R/RF240R/RF260R). RF250R and RF290R are designed for operation with

external antennas either to achieve longer distances or larger field sizes (RF290R with ANT

D5/D6/D10) or to allow installation where there is very little space (RF250R with ANT

3/8/12/18/30).

This documentation is valid for all variants of the SIMATIC RF200 system and describes the

devices shipped as of July 2015.

SIMATIC ®, SIMATIC RF ®, MOBY ®, RF MANAGER ® and SIMATIC Sensors ® are registered

trademarks of Siemens AG.

For additional information, refer to the manuals:

● Function manual "Ident profile and Ident blocks"

(https://support.industry.siemens.com/cs/us/en/view/106368029

● Function manual "FB 45" (https://support.industry.siemens.com/cs/ww/en/view/21738808)

)

● Operating instructions "RF200 IO-Link"

(https://support.industry.siemens.com/cs/ww/en/view/60641859

● System manual "MOBY D"

(https://support.industry.siemens.com/cs/ww/en/view/13628689

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

)

)

13

Page 14

Introduction

History

Output

Note

03/2011

First edition

RS-232 interface

09/2011

Expansion of the documentation with the device variant RF240R

1.1

Abbreviations and naming conventions

Abbreviations and naming conventions

Reader

Write/read device (SLG)

Transponder, tag

Data carrier, mobile data storage, (MDS)

Communications module (CM)

Interface module (ASM)

1.1 Abbreviations and naming conventions

● Operating instructions "RF310M"

(https://support.industry.siemens.com/cs/us/en/view/51812642

)

● Product information "RF200 command set"

(https://support.industry.siemens.com/cs/us/en/view/44864850

)

The following issues of the SIMATIC RF200 system manual have been published:

05/2011 Expansion of the documentation with the addition of the device variant RF260R with

03/2013 Expansion of the documentation with the device variant RF290R

09/2013 Expansion of the documentation by the following:

• The device variant RF250R

• The device variants RF240R and RF260R with ASCII interface

• Antennas ANT 8, ANT 12, ANT 18 and ANT 30

• Transponder

07/2015 Expansion of the documentation by the following:

• ANT 3 antennas

• MDS D5xx transponder

• Mobile reader RF210R

05/2017 Expansion of the documentation by the following:

• Device version RF280R

• Mobile Reader RF350M

The following terms/abbreviations are used synonymously in this document:

SIMATIC RF200

14 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 15

2

WARNING

Opening the device

NOTICE

Alterations not permitted

Installation instructions

NOTICE

Switch/fuse to disconnect the reader from the power supply

Operating temperature

CAUTION

Danger of burns

SIMATIC RFID products comply with the salient safety specifications acc. to IEC, VDE, EN,

UL and CSA. If you have questions about the permissibility of the installation in the planned

environment, please contact your service representative.

Do not open the device when when the power supply is on. Unauthorized opening of and

improper repairs to the device may result in substantial damage to equipment or risk of

personal injury to the user.

Alterations to the devices are not permitted.

Failure to observe this requirement shall constitute a revocation of the radio equipment

approval, CE approval and manufacturer's warranty.

Make sure that the readers can be disconnected from the power supply with a switch or a

fuse. The function of the switch or fuse must be clearly recognizable.

Note that some outer components of the reader are made of metal. Depending on the

environmental conditions temperatures can occur on the device that are higher than the

maximum permitted operating temperature.

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

15

Page 16

Safety notes

Repairs

WARNING

Repairs only by authorized qualified personnel

ng of

System expansions

NOTICE

Warranty conditions

Safety distances

CAUTION

Safety distance between reader/antenna and persons

Note

Safety distance with pacemakers

A safety distance between reader/antenna and persons with pacemakers is not necessary.

Repairs may only be carried out by authorized qualified personnel. Unauthorized openi

and improper repairs to the device may result in substantial damage to equipment or risk of

personal injury to the user.

Only install system expansions intended for this system. If you install other expansions, you

may damage the system or violate the safety requirements and regulations for radio

frequency interference suppression. Contact Technical Support or your local sales

department to find out which system expansions are suitable for installation.

If you cause system defects by installing or exchanging system expansion devices, the

warranty becomes void.

Note that for permanent exposure, the following safety distances must be adhered to:

• RF310R: ≥ 80 mm

• RF340R: ≥ 130 mm

• RF350R + ANT 1: ≥ 140 mm

• RF350R + ANT 3: ≥ 80 mm

• RF350R + ANT 12: ≥ 25 mm

• RF350R + ANT 18: ≥ 50 mm

• RF350R + ANT 30: ≥ 80 mm

• RF380R: ≥ 250 mm

• RF382R: ≥ 130 mm

SIMATIC RF200

16 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 17

Safety notes

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

Link: (http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

)

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity

).

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

17

Page 18

Safety notes

SIMATIC RF200

18 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 19

3

SIMATIC RF200 is an inductive identification system that is compatible with the ISO 15693

standard and was specially designed for use in industrial production for the control and

optimization of material flows.

In contrast to SIMATIC RF300, SIMATIC RF200 is intended for RFID applications where

performance requirements are not very high, for example with regard to data volume,

transfer rate or diagnostics options. SIMATIC RF200 is characterized by particularly

favorable prices.

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

19

Page 20

System overview

3.1

RFID components and their function

RF200 system components

3.1 RFID components and their function

Figure 3-1 RF200 system overview

SIMATIC RF200

20 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 21

System overview

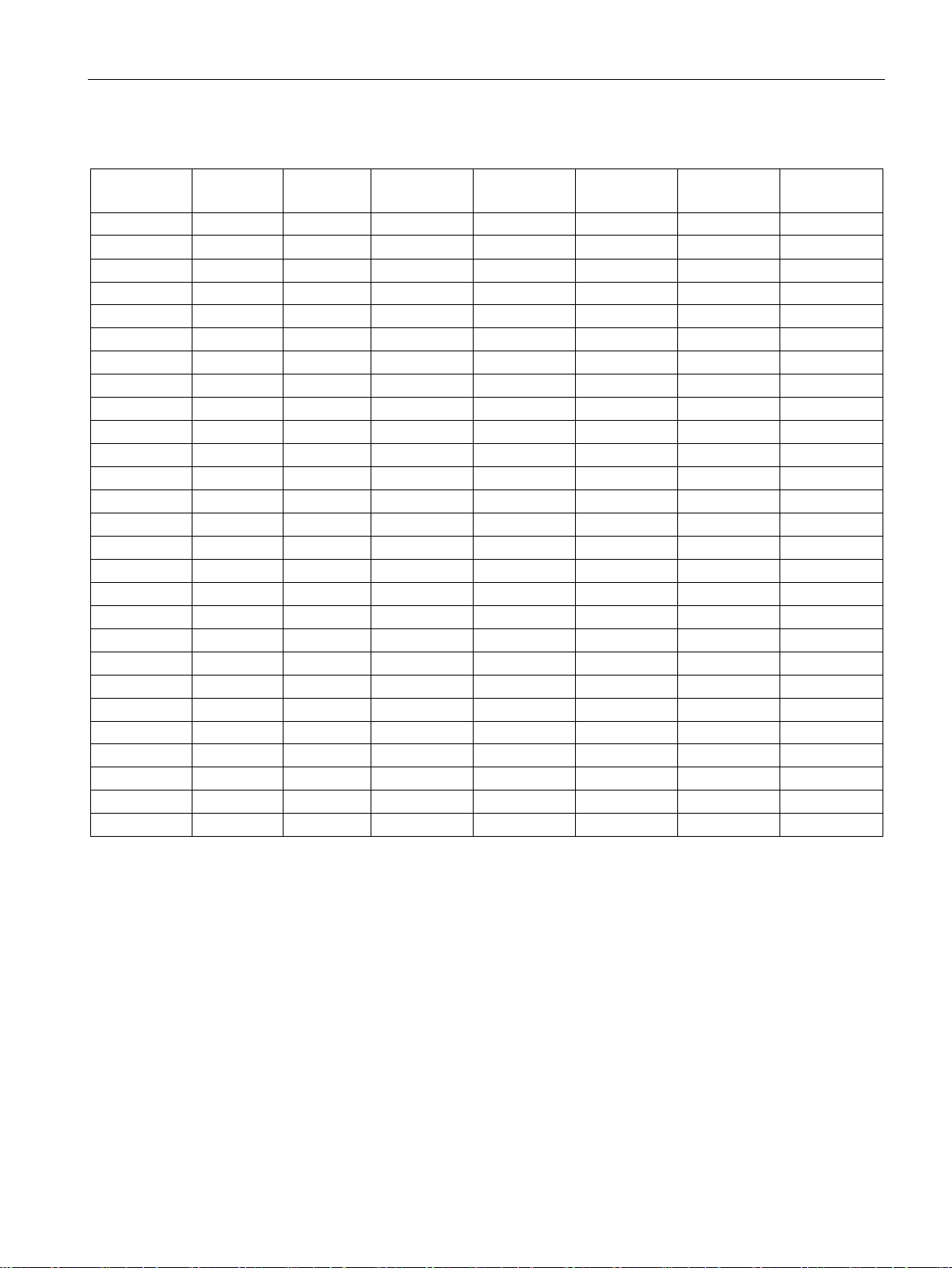

Transponder

RF210R/

RF210M

RF220R

RF240R

RF260R

RF280R

RF290R 4)

RF350M

MDS D100

-- ○ ✓ ✓ ✓ ✓ ✓

MDS D117

MDS D124

✓ ✓ ✓ ✓ ✓ ✓ ✓

MDS D126

-- ✓ ✓ ✓ ✓ ✓ ✓

MDS D127

✓

--

--

--

--

--

✓

MDS D139 1)

-- ○ ○ ✓ ✓ ✓ ✓

MDS D160 2)

✓ ✓ ✓ ✓ ✓ ✓ ✓

MDS D165

-- ○ ✓ ✓ ✓ ✓ ✓

MDS D200

-- ○ ✓ ✓ ✓ ✓ ✓

MDS D261

-- ○ ✓ ✓ ✓ ✓ ✓

MDS D324

✓ ✓ ✓ ✓ ✓ ✓ ✓

MDS D339

-- ○ ○ ✓ ✓ ✓ ✓

MDS D400

--

-- ✓ ✓ ✓ ✓

✓

MDS D421

✓ ○ --

--

--

--

✓

MDS D422

✓ ✓ ✓

--

--

--

✓

MDS D423

✓ ✓ ✓ ✓ ✓

--

✓

MDS D424

✓ ✓ ✓ ✓ ✓ ✓ ✓

MDS D425

✓ ✓ ✓

-- ✓ --

✓

MDS D426

-- ✓ ✓ ✓ ✓ ✓ ✓

MDS D428

✓ ✓ ✓ ✓ ✓

--

✓

MDS D460

MDS D521

✓ ○ --

--

--

--

✓

MDS D522 3)

✓ ✓ ✓

--

--

--

✓

MDS D524

✓ ✓ ✓ ✓ ✓ ✓ ✓

MDS D525

✓ ✓ ✓

-- ✓ --

--

MDS D526

-- ✓ ✓ ✓ ✓ ✓ ✓

MDS D528

✓ ✓ ✓ ✓ ✓

--

✓

1)

2)

3)

4)

5)

6)

Only in conjunction with RF350M for external antennas (6GT2803-1BA10)

✓

Combination possible

--

Combination not possible

○

Combination possible, but not recommended

3.1 RFID components and their function

Table 3- 1 Reader-transponder combination options, Part 1

○ -- -- -- -- -- ✓

✓ ✓ ✓ ✓ ✓ ○ / ✓ 5) ✓

6)

6)

6)

6)

6)

6)

only with the article number 6GT2600-0AA10

only with the article number 6GT2600-0AB10

The transponder MDS D522 special variant has the same compatibility as the transponder MDS D522.

in conjunction with ANT D5, D6 or D10

combination recommended only in conjunction with ANT D5.

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

21

Page 22

System overview

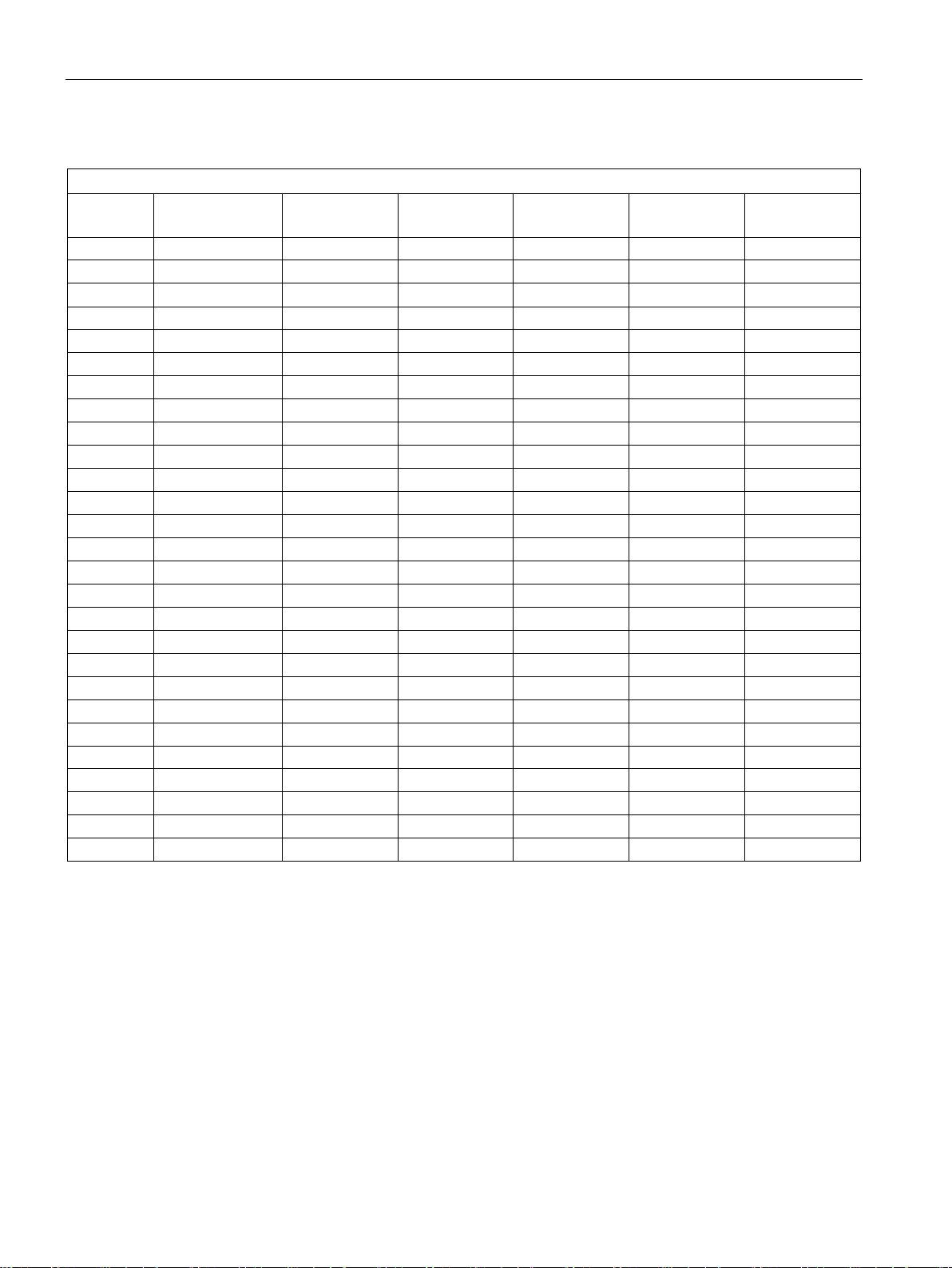

RF250R with

Transponder

ANT 1

ANT 3

ANT 8

ANT 12

ANT 18

ANT 30

MDS D100 ✓ ○

--

--

--

○

MDS D117

--

-- ✓ ✓

--

--

MDS D124

MDS D126 ✓ ✓

--

--

--

✓

MDS D127

--

-- ✓ ✓

--

--

MDS D139 ✓ ○

--

--

--

○

MDS D160 ✓ ✓

-- ✓ ✓

✓

MDS D165 ✓ ○

--

--

--

○

MDS D200 ✓ ○

--

--

--

○

MDS D261 ✓ ○

--

--

--

○

MDS D324 ✓ ✓

-- ○ ✓

✓

MDS D339 ✓ ○

--

--

--

○

MDS D400 ✓ ○

--

--

--

○

MDS D421

--

-- ✓ ✓ ✓ --

MDS D422

-- ✓ -- ✓ ✓

✓

MDS D423 ✓ ✓

--

-- ✓ ✓

MDS D424 ✓ ✓

--

-- ✓ ✓

MDS D425 ✓ ✓

-- ✓ ✓

✓

MDS D426 ✓ ✓

--

--

--

✓

MDS D428 ✓ ✓

-- ✓ ✓

✓

MDS D460 ✓ ✓

-- ✓ ✓

✓

MDS D521

MDS D522)

-- ✓ -- ✓ ✓

✓

MDS D524 ✓ ✓

--

-- ✓ ✓

MDS D525 ✓ ✓

-- ✓ ✓

✓

MDS D526 ✓ ✓

--

--

--

✓

MDS D528 ✓ ✓

-- ✓ ✓

✓

✓

Combination possible

--

Combination not possible

○

Combination possible, but not recommended

3.1 RFID components and their function

Table 3- 2 Reader-transponder combination options, Part 2

✓ ✓ -- -- ✓ ✓

-- -- ✓ ✓ ✓ --

SIMATIC RF200

22 System Manual, 07/2017, J31069-D0227-U001-A9-7619

Page 23

System overview

3.2

Overview of transponders

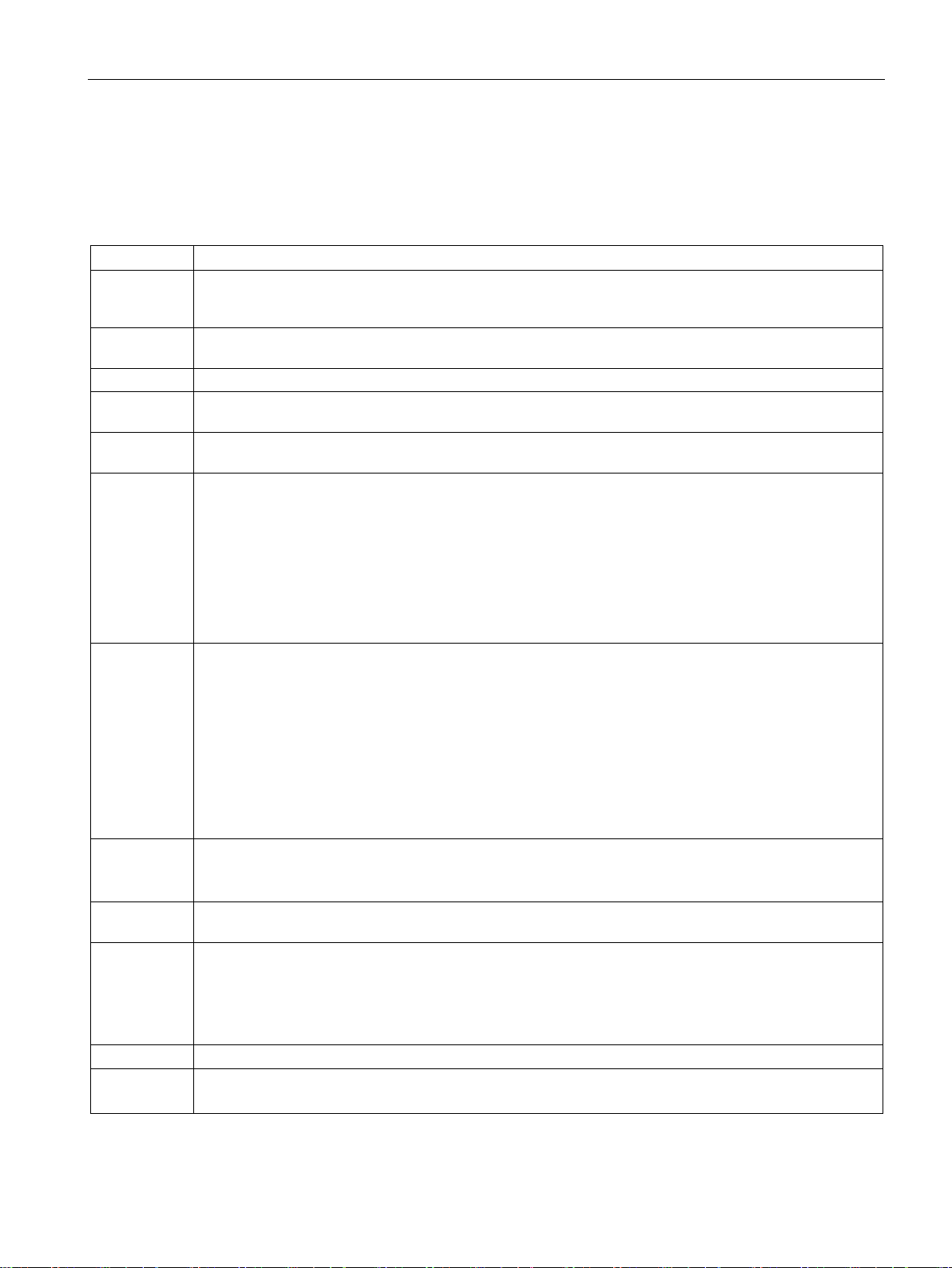

Overview of typical areas of application of ISO transponders for RF200

Transponder

Area of application

ranges are achieved in combination with the SIMATIC RF260R reader.

tool identification.

MDS D124

Application areas in factory automation (e.g. small paintshops to 180°C).

logistics; can also be deployed in harsh conditions.

identification.

and distribution logistics, right up to product identification

and distribution logistics, right up to product identification.

and distribution logistics, right up to product identification.

For typical areas of application, see "MDS D139".

3.2 Overview of transponders

MDS D100 From simple identification such as electronic barcode replacement or supplementation, through ware-

house and distribution logistics, right up to product identification. With this transponder, the maximum

MDS D117 Very compact data carrier that can be cemented into objects where precise positioning is necessary. e.g.

MDS D126 Compact and rugged ISO transponder; suitable for identification of transport units in production-related

MDS D127 Very compact data carrier that can be screwed into areas where precise positioning is necessary. e.g. tool

MDS D139 1) Applications in production automation with high temperature demands (up to +220 °C).

Typical application areas:

• Paintshops and their preparatory treatments

• Primer coat, electrolytic dip area, cataphoresis with the associated drying furnaces

• Top coat area with drying furnaces

• Washing areas at temperatures > 85 °C

• Other applications with higher temperatures

MDS D160 2) Typical applications are, for example:

• Rented work clothing

• Hotel laundry

• Surgical textiles

• Hospital clothing

• Dirt collection mats

• Clothing for nursing homes/hostels

• Assembly lines with very small workpiece holders

MDS D165 Smart label (self-adhesive label)

From simple identification such as electronic barcode replacement/supplementation, through warehouse

MDS D200 From simple identification such as electronic barcode replacement/supplementation, through warehouse

MDS D261 Smart label (self-adhesive label)

The design of the transponder (self-adhesive label) permits a variety of designs in order to ensure optimum dimensioning for the widest variety of applications.

From simple identification such as electronic barcode replacement/supplementation, through warehouse

MDS D324 Production and distribution logistics as well as in assembly and production lines

MDS D339 Applications in production automation with high temperature demands (up to +220 °C).

SIMATIC RF200

System Manual, 07/2017, J31069-D0227-U001-A9-7619

23

Page 24

System overview

Transponder

Area of application

tion logistics right through to product identification.

workpiece holders

MDS D422

Identification of metallic workpiece holders, workpieces or containers

MDS D424

Production and distribution logistics as well as in assembly and production lines

and workpiece holders

logistics; can also be deployed in harsh conditions